Screw and charging barrel structure for strong-shearing-force chemical reactor

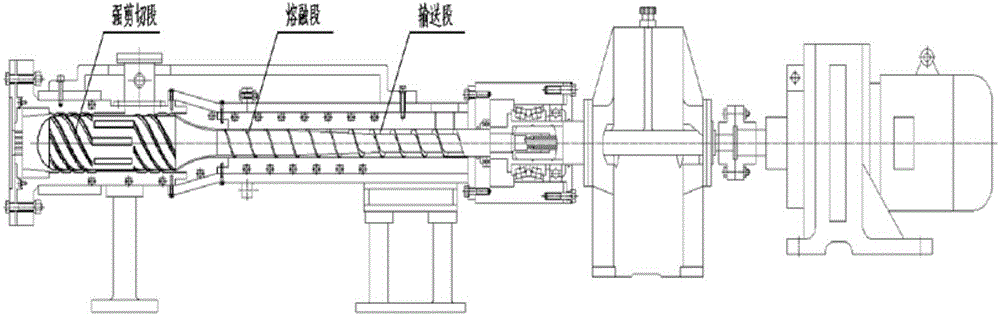

A chemical reactor and strong shearing technology, applied in the field of screw and barrel structure, can solve the problems of insufficient graft copolymerization reaction, insufficient screw shear force, low extrusion efficiency, etc., and achieve good chain breaking and grafting effect, increased shear force, and improved shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

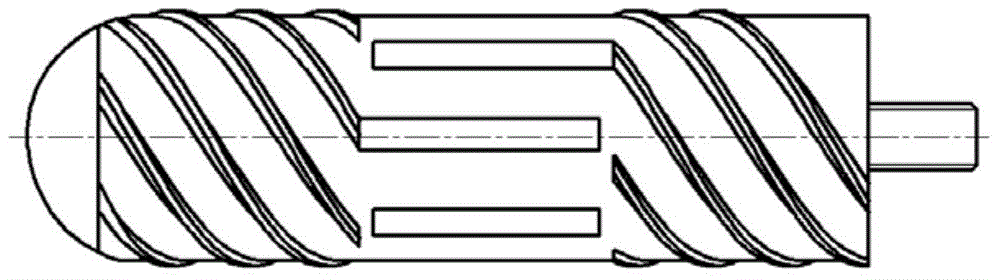

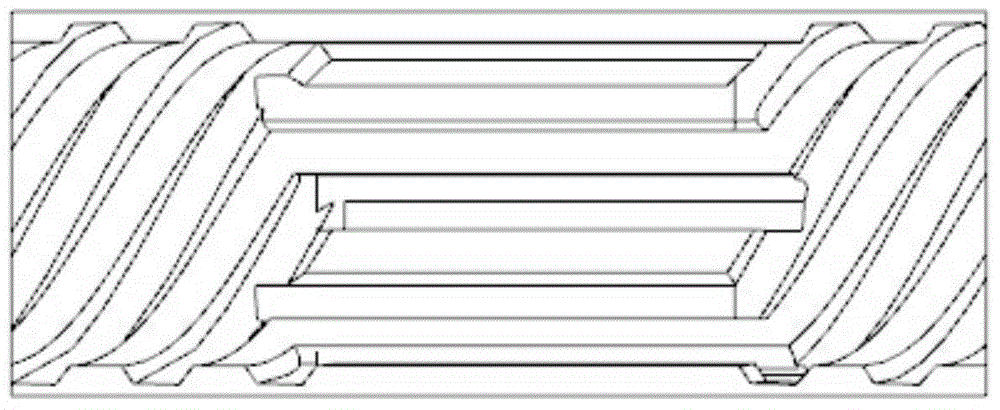

[0043] The thread distribution form of the screw and the barrel of the strong shearing part is arranged in the form of helix-straight-helix. The length of the screw is l=270mm, the diameter D=90mm, and the aspect ratio is 3.

[0044] The length ratio of each section of the screw: helix: straight line: helix = 1:1:1; the number of helix heads in the helical part is 3, the length-to-diameter ratio is 1, right-handed, and the helix rise angle is 50°; the number of helix heads in the straight part is 3. Evenly distributed, with an aspect ratio of 1.

[0045] The length of the barrel is l=270, the diameter D=92mm, and the aspect ratio is 3.

[0046] The length ratio of each section of the barrel is spiral: straight line: spiral = 1:1:1; the number of screw groove heads in the spiral part is 3, the length-to-diameter ratio is 1, left-handed, and the screw edge rise angle is 50°; the number of screw edge heads in the straight line part is 5. Evenly distributed, with an aspect ratio...

Embodiment 2

[0058] The thread distribution form of the screw and the barrel of the strong shearing part is arranged in the form of helix-straight-helix. The length of the screw is l=270mm, the diameter D=90mm, and the aspect ratio is 3.

[0059] The length ratio of each section of the screw: helix: straight line: helix = 1:1:1; the length-to-diameter ratio of the helix part is 1, right-handed, and the helix angle is 50°; The edge sections are selected as trapezoidal shape.

[0060] The length of the barrel is l=270, the diameter D=92mm, and the aspect ratio is 3.

[0061] The length ratio of each section of the barrel is helix: straight line: helix = 1:1:1; The edge sections are selected as trapezoidal shape.

[0062] The number of heads of the screw flight and the barrel groove is combined in the form of 3 heads, 4 heads and 5 heads in order to carry out the combination experiment.

[0063] The motor power is 22Kw, and the speed is 600 rpm.

[0064] Raw materials: High-density polye...

Embodiment 3

[0073] The thread distribution form of the screw and the barrel of the strong shearing part is arranged in the form of helix-straight-helix. The length of the screw is l=270mm, the diameter D=90mm, and the aspect ratio is 3.

[0074] Among them, the length ratio of each section of the screw: helix: straight line: helix = 1:1:1; the number of helix heads in the helical part is 5, the length-to-diameter ratio is 1, and right-handed; the number of helix heads in the straight part is 5, uniformly distributed, long The diameter ratio is 1; the cross-section shape of the spiral rib is trapezoidal Image 6 .

[0075] The length of the barrel is l=270, the diameter D=92mm, and the aspect ratio is 3.

[0076] Among them, the length ratio of each section of the barrel is spiral: straight line: spiral = 1:1:1, the number of screw groove heads in the spiral part is 5, the length-to-diameter ratio is 1, and left-handed; the number of screw edge heads in the straight line part is 5, unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com