Patents

Literature

120results about How to "Improve the effect of grafting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood-plastic formwork for construction engineering

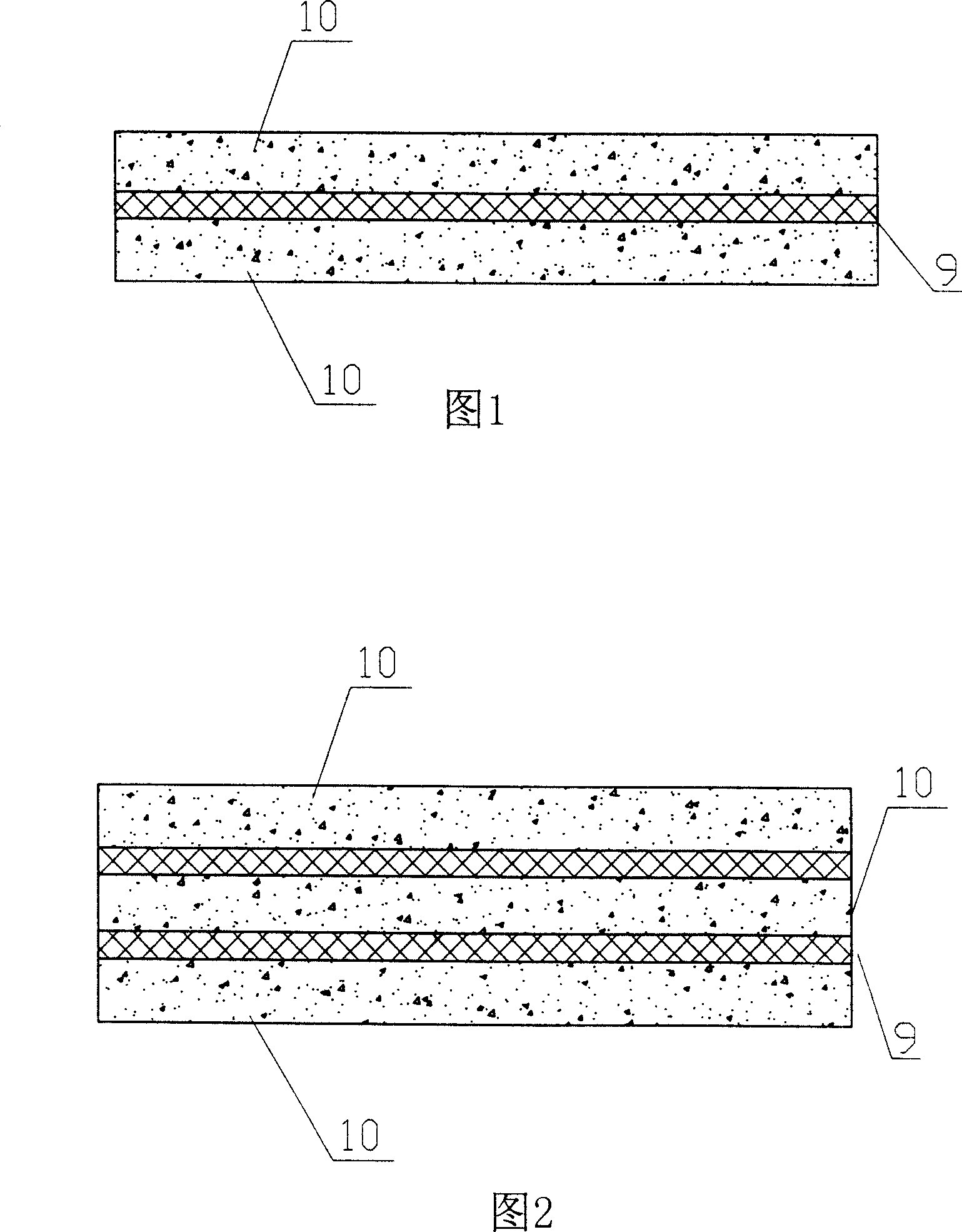

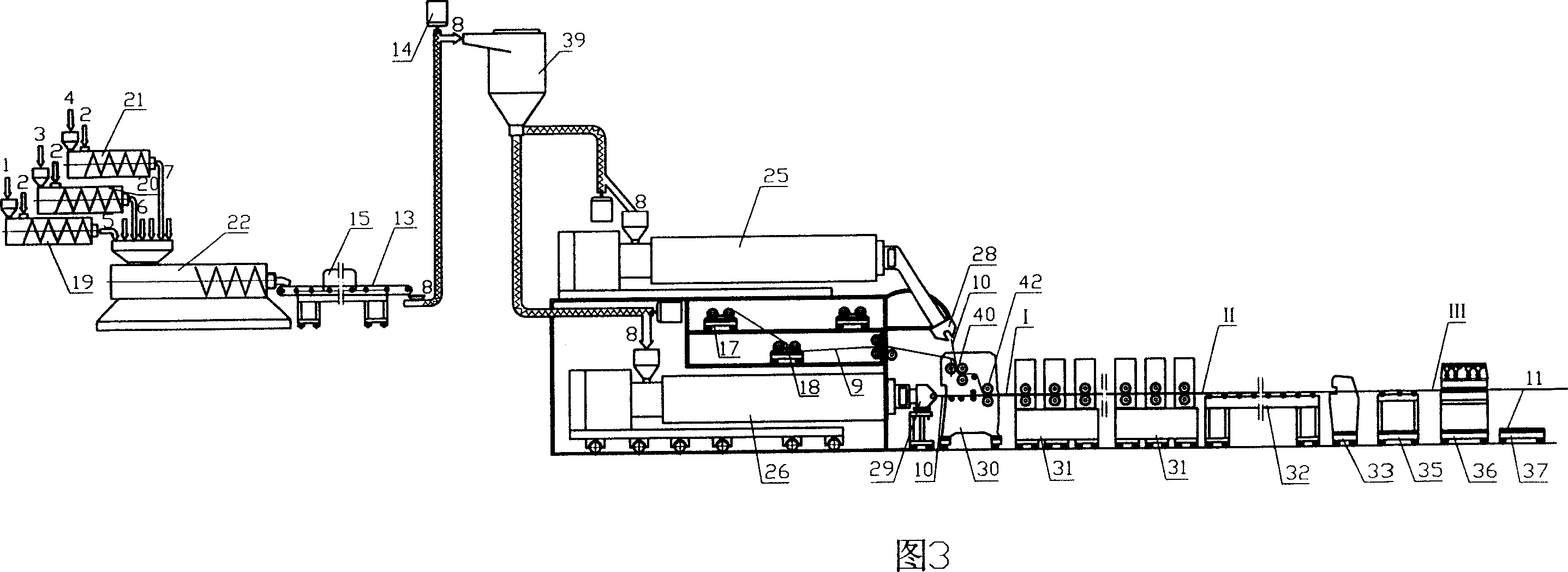

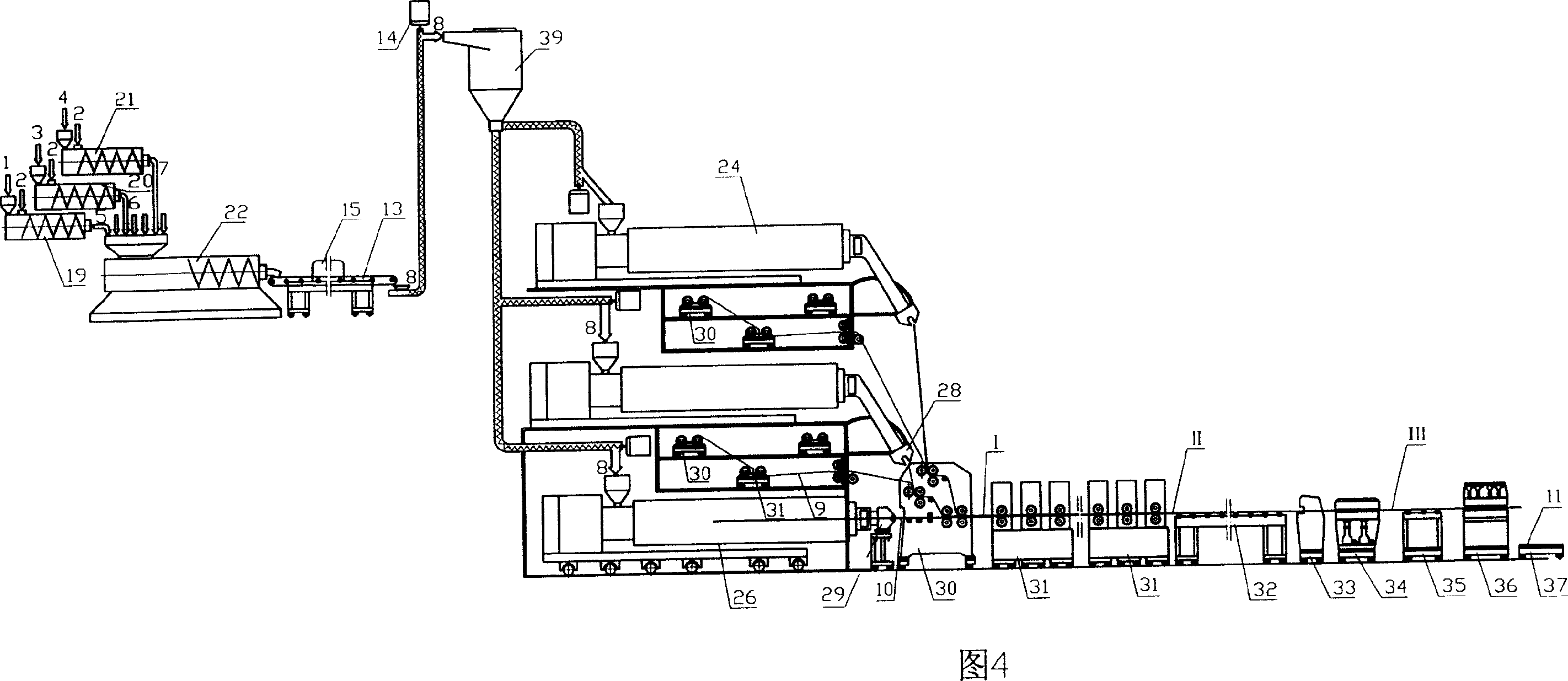

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

High-viscosity modified asphalt material and preparation method thereof

InactiveCN110041720AReduce manufacturing costOptimizing the distribution of ingredientsBuilding insulationsBituminous materialsWaste rubber

The invention discloses a high-viscosity modified asphalt material. The asphalt material is prepared from the following raw materials in parts by mass: 100 parts of matrix asphalt, 4-7 parts of a thermoplastic elastomer, 4-10 parts of waste rubber powder or an ethylene-vinyl acetate copolymer, 1-3 parts of a plasticizer, 2-4 parts of thermoplastic resin, 3-5 parts of a solubilizer, 0.2-2 parts ofa stabilizer, 0.5-1.5 parts of a chemical modifier and 0.2-0.7 part of polypropylene glycol. Through the high-viscosity modified asphalt material, the storage stability of high-viscosity modified asphalt is improved; meanwhile, high-temperature viscosity of the high-viscosity modified asphalt is reduced; when the high-viscosity modified asphalt material is applied to mixing of asphalt mixture, themixing temperature is low; the high-viscosity modified asphalt material is easy to construct, low in cost and simple in preparation method.

Owner:无锡市城市道桥科技有限公司

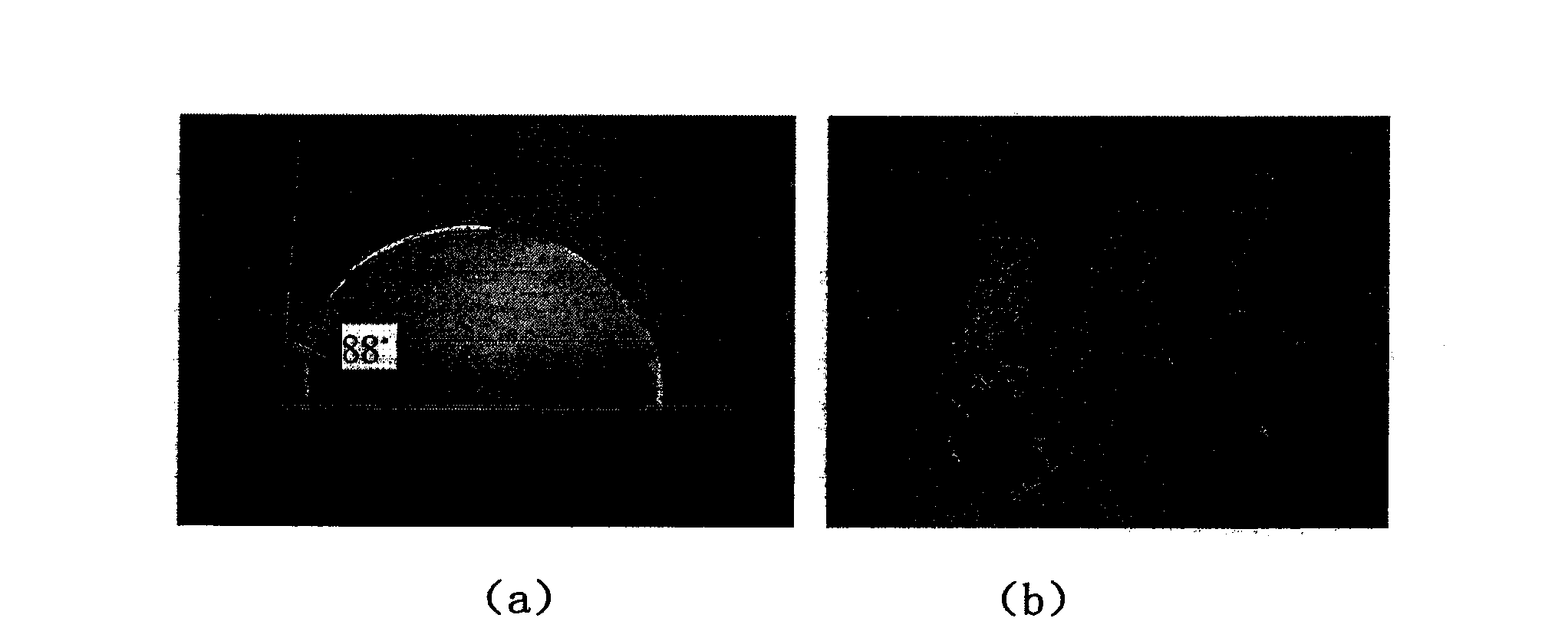

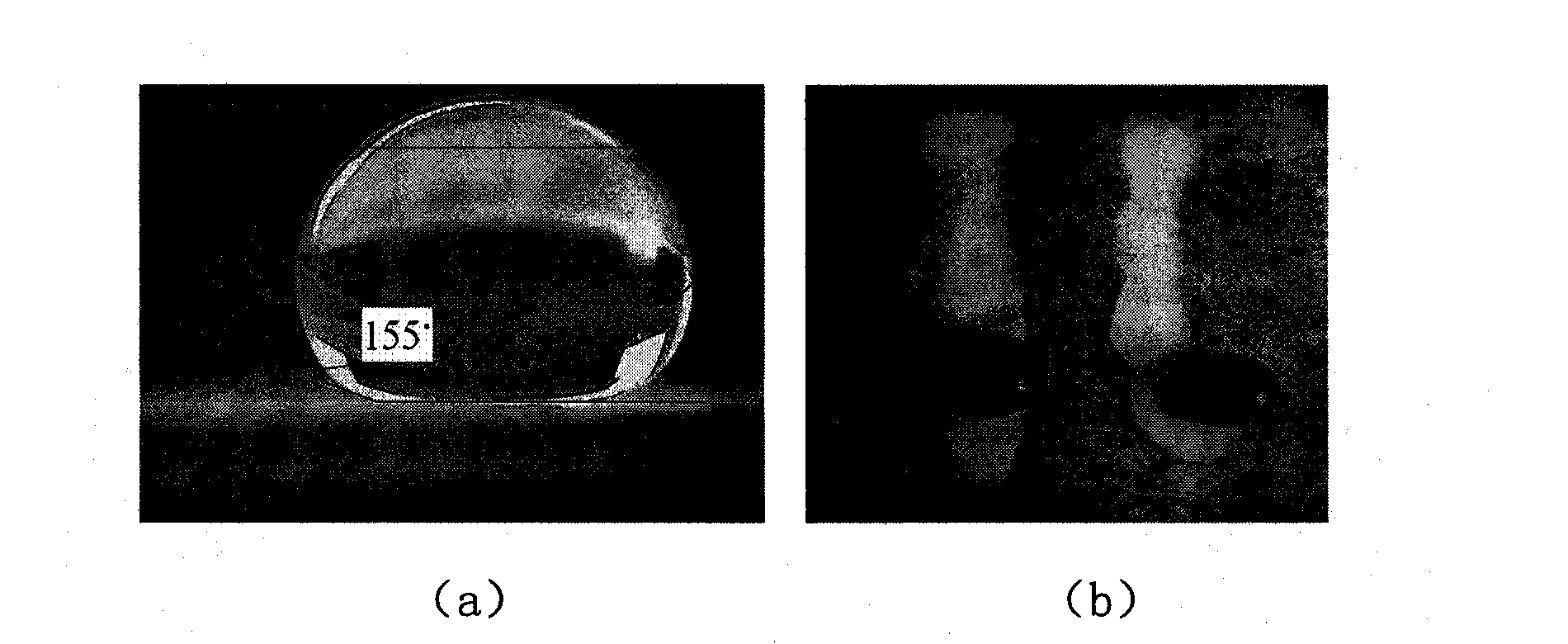

Method for preparing pollution preventing self-cleaning polyvinylidene fluoride (PVDF) film and product thereof

InactiveCN101649065AImprove the effect of graftingDoes not affect light transmissionAlcoholPolyvinylidene difluoride

The invention relates to a method for preparing a pollution preventing self-cleaning polyvinylidene fluoride (PVDF) film and a product thereof. The method comprises the following processes: (1) PVDF film preparation; and (2) PVDF film processing with alkali liquor, including an alkali-water solution processing process and an alkali-alcohol solution processing process, wherein the alkali-water solution processing process comprises the following steps: soaking the PVDF film in alkali-water solution with the mass concentration of 20-40 percent; processing at 60-80 DEG C for 2-3 hours and then taking out to wash with water; drying and obtaining the PVDF film; the alkali-alcohol solution processing process comprises the following steps: soaking the PVDF film in alkali-alcohol solution with themass concentration of 2-10 percent; processing at 25-40 DEG C for 3-5 minutes and then taking the film out; washing with water and drying; soaking the PVDF film in proper solution to react at 25-60 DEG C for 3-10 minutes; then taking out and fully washing with water; drying and then obtaining the PVDF film; (3) decorating the surface of the PVDF film by organosilane and preparing the pollution preventing self-cleaning polyvinylidene fluoride film. The pollution preventing self-cleaning PVDF film product is prepared by the method.

Owner:TIANJIN POLYTECHNIC UNIV

Treatment method for improving operating characteristics of nano-zinc oxide

ActiveCN107312362AOptimal treatment processImprove usage characteristicsPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsZno nanoparticlesNano zinc oxide

The invention discloses a treatment method for improving operating characteristics of nano-zinc oxide. The treatment method comprises the following steps of soaking modification treatment and deposition modification treatment. The prepared modified nano-zinc oxide has good dispersing characteristics, an agglomeration phenomenon is not likely to occur, the strength, corrosion resistance and temperature resistance of the nano-zinc oxide are very well improved, the compatibility with organic components are better, a filling usage effect is good, and the nano-zinc oxide has a popularization and usage value.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

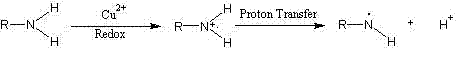

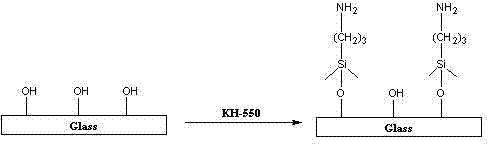

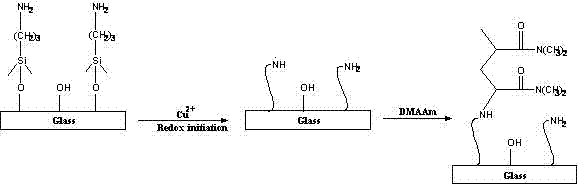

A method of grafting polymer on glass surface

The invention belongs to the technical field of glass surface modification, and relates to a glass surface grafting method, especially to a method for grafting polymer chains on the surface of glass through free radical polymerization initiated by redox. According to the invention, glass flake processed by a silane coupling agent is added into a monomer aqueous solution containing a few CuSO4 to react for 3-4 hours at the temperature of 80 DEG C, so as to obtain a glass flake sample with the polymer chains being fixed on the surface. The operation technology provided by the invention is simple; the grafting effect is obvious; raw materials used are products sold in the market, can be used without complex purification process, and are low in price and easily available; water is used as a reaction medium, thus avoiding complex solvent recovery process in the later period, reducing cost and minimizing the pollution to the environment; and grafted sheet glass or glass fiber products can be applied to reinforce the bond property between resins and glass in composite materials, and has an extensive industrial application prospect.

Owner:溧阳常大技术转移中心有限公司

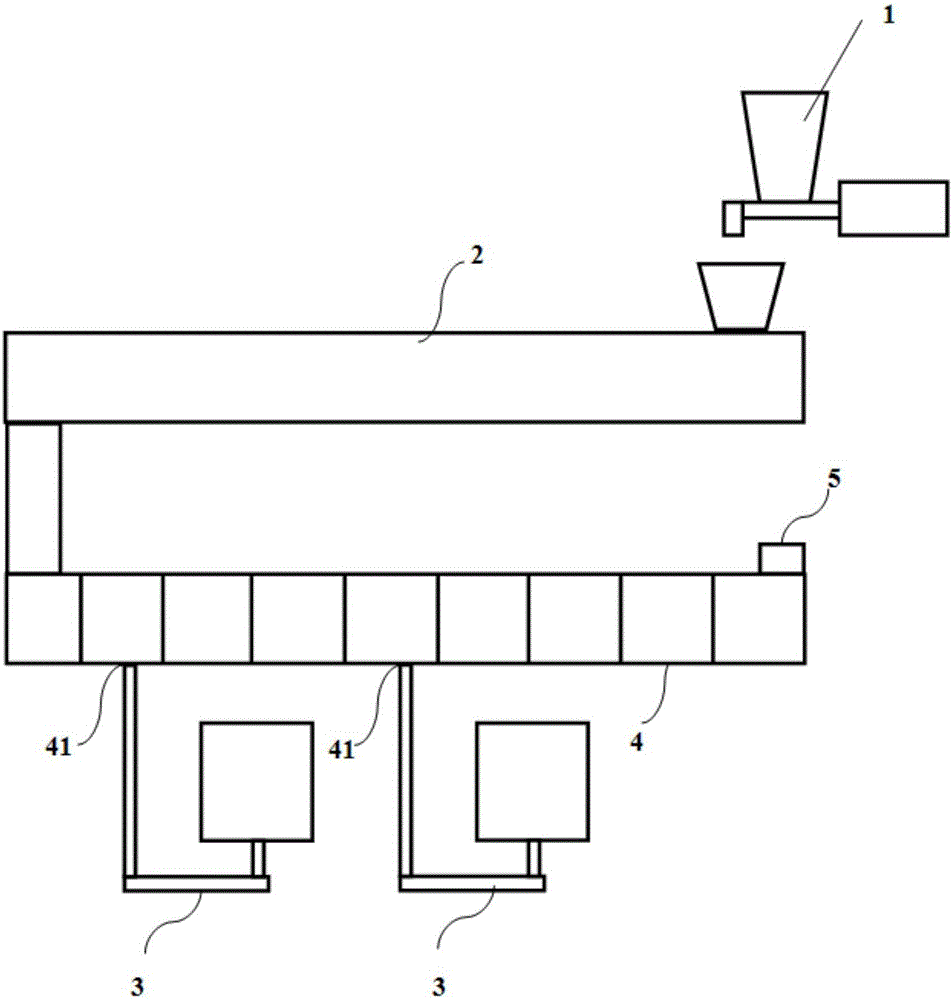

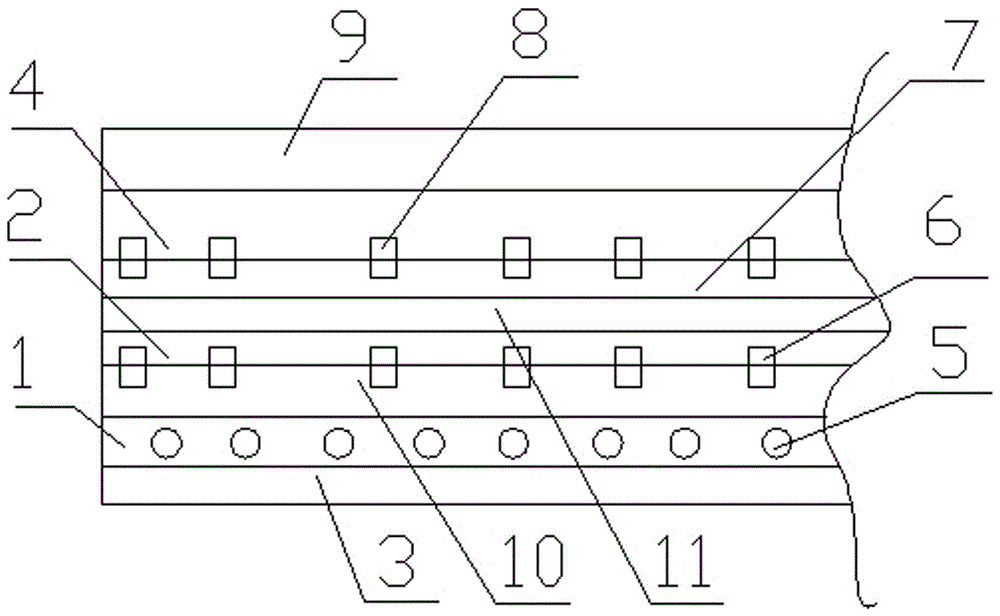

Grafting reaction device and use method thereof

The invention discloses a grafting reaction device and a use method thereof. The grafting reaction device comprises a weightlessness feeding device, a single-screw melting device, an aid adding device, a twin-screw grafting reaction device and a vacuum devolatilization device. The use method comprises steps as follows: 1) a premix is added to the single-screw melting device by the weightlessness feeding device; 2) the single-screw melting device plasticizes and melts the premix into polymer melt and introduces the polymer melt into the twin-screw grafting reaction device; 3) the aid adding device adds aids to one or two heating zones of the twin-screw grafting reaction device; a graft polymer is formed through a grafting reaction in the twin-screw grafting reaction device and then introduced into the vacuum devolatilization device; 4) a solvent and non-reacted grafting aids are removed from the vacuum devolatilization device, and a finished product is obtained. The reaction device can effectively reduce crosslinked byproducts in the melting graft process of the polymer.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Composite denaturation cornstarch emulsion and preparation method thereof

The present invention relates to the preparation method for composite modified corn starch emulsion, which belongs to the adhesive technology field. The raw materials comprise 25 to 35 shares of corn starch, 65 to 75 shares of inorganic acid, 0.5 to 1.3 shares of peroxide initiator, and 5 to 7 weight shares of copolymerization monomer. The corn starch is acid-splitted and oxidized to generate relatively-low viscosity primary acidolysis oxidation corn starch emulsion with a certain degree of oxidation. Then the acidolysis oxidation corn starch emulsion and the acrylamide experiences graft copolymerization to generate composite modified corn starch emulsion. Compared with the raw materials used in the tradition method, such as the synthetic resin waterborne polymer- isocyanate wood adhesive and the environmentally-friendly urea-formaldehyde resin adhesive, natural macromolecule material corn starch is used to replace the synthetic resin, significantly reducing the cost and truly realizing the green wood adhesive. The present invention has the advantages of unique design, standardized process, easy operation, easily-obtained equipment, no pollution, easy implementation, low cost and so on. After promotion, the present invention can be of enormous environmental benefits as well as social and economic benefits.

Owner:BEIHUA UNIV

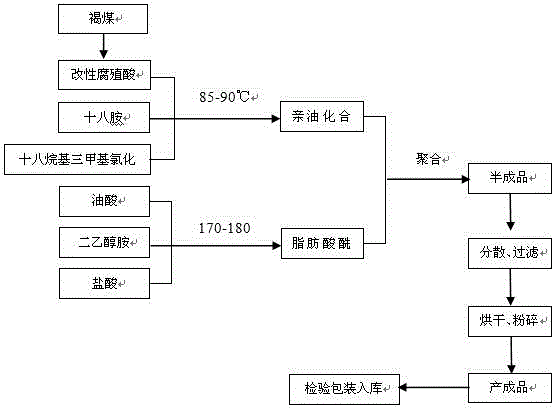

Filtrate reducer for oil-based drilling fluids and production method thereof

InactiveCN105586017AImprove lipophilicityDoes not affect high temperature resistanceDrilling compositionFiltrationCarbon chain

The invention provides a filtrate reducer for oil-based drilling fluids and a production method thereof. The production method is characterized in that humic acid undergoes surface modification and the humic acid is grafted with an alkyl group of long carbon chain, and a product which has oleophylic emulsifying property and ammonium salt undergo polymerization so as to obtain the required product. The production method comprises the following concrete operations: stirring a certain amount of brown coal, caustic soda and water and reacting for a period of time, and extracting a humic acid solution; preparing grafted humic acid from the obtained humic acid solution and octadecylamine and octadecyl trimethyl ammonium chloride; preparing fatty acid amide from oleic acid, diethanolamine and concentrated hydrochloric acid; and preparing humic acid acetamide, dispersing, filtering and drying to obtain a finished product. According to the method, humic acid is modified to be grafted with the alkyl group of long carbon chain, and then the humic acid filtrate reducer has remarkable lipophilicity, can be dissolved or dispersed in oil and can be directly used in water-in-oil drilling fluids. Humic acid and amine are combined firmly, and high temperature resistance is strong. The product has a certain emulsification capability and good filtration reduction effects. The production method is simple, and the environment is not polluted.

Owner:TIANJIN TIANCHENG TUOYUAN TECH DEV

High-efficient sewage purification material

InactiveCN107890853APromote degradationRealize secondary useWater/sewage treatment by irradiationOther chemical processesFiberActivated carbon

The invention discloses a high-efficient sewage purification material. The material comprises, by mass, 100 parts of modified straw fiber, 15-30 parts of modified bentonite, 5-12 parts of nano filler,5-16 parts of activated carbon and 10-28 parts of polyving akohol. According to the high-efficient sewage purification material, the modified straw fiber which is adopted as a main body, polyving akohol which is mainly adopted as an adhesive and a compatilizer, the composite nano filler, the modified bentonite and the activated carbon are used for preparing the purification material; the nano filler and the activated carbon are inorganic materials. According to the high-efficient sewage purification material, a water purification material is obtained through organic-inorganic composite preparation, and the water purification material is mainly used for purifying heavy metals in water; the modified straw fiber is adopted as a matrix, combined with the water purification material to obtaina high-tech water purification material, and the high-efficiency sewage purification material is more environmentally friendly.

Owner:成都尊华荣域科技有限公司

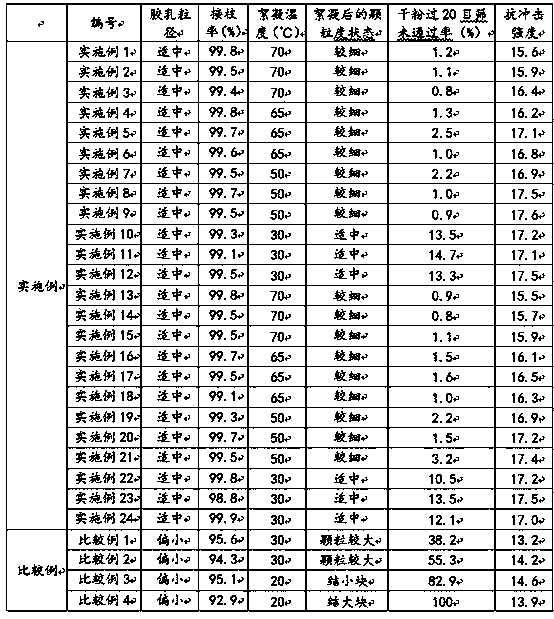

PVC (polyvinyl chloride) impact modifier opaque high-impact-resistance MBS and preparation method thereof

The invention discloses PVC (polyvinyl chloride) impact modifier opaque high-impact-resistance MBS and a preparation method thereof, and relates to the technical field of PVC auxiliary production andpreparation, the PVC (polyvinyl chloride) impact modifier opaque high-impact-resistance MBS is prepared from the following components in parts by mass: 80-95% of a core layer structure, 4-20% of a shell layer structure and 0.001-0.05% of a protective colloid; the core layer structure is a lightly cross-linked butadiene and styrene polymer, the butadiene content is 95-100%, the styrene content is 0-5%, the shell layer structure is one or a copolymer of two or three of styrene, acrylate and methyl methacrylate, the styrene content is 0-5%, the acrylate content is 0-2%, and the methyl methacrylate content is 13-20%; the protective colloid includes one or a compound of two or three of polyvinyl alcohol, gelatin and hydroxypropyl methylcellulose. According to the invention, the problems that anexisting MBS product is low in impact strength and difficult in agglomeration or difficult to spray in a post-treatment process are solved.

Owner:SHANDONG DONGLIN NEW MATERIALS CO LTD

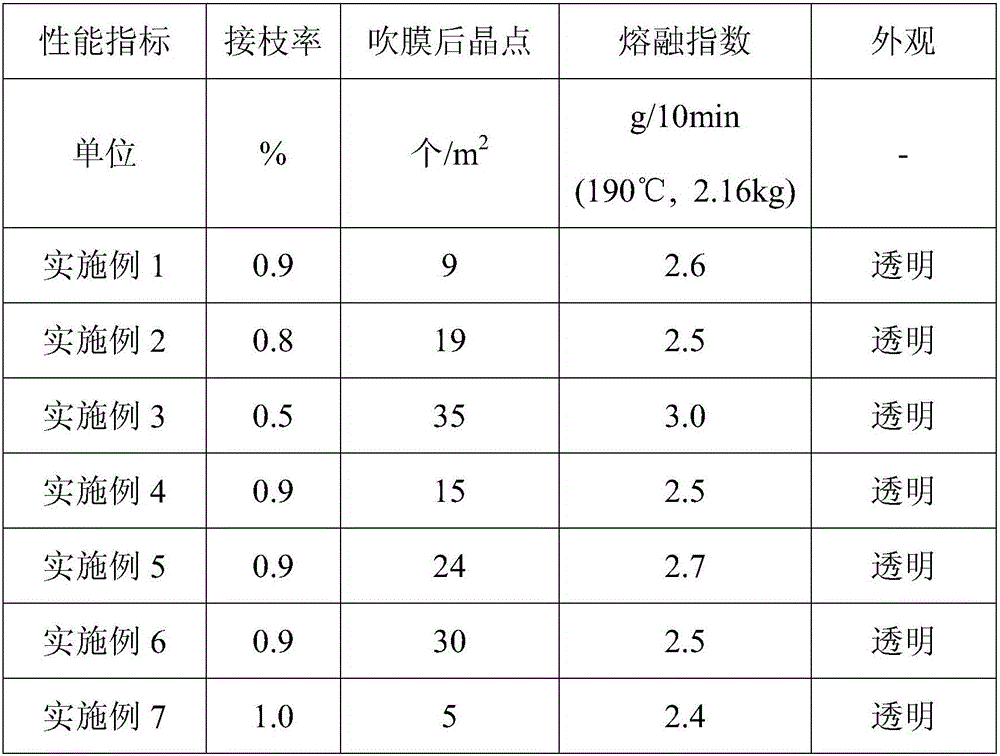

Environment-friendly degradable packaging bag and preparation method thereof

PendingCN113121964ADegradable realizationImprove the effect of graftingBio-packagingPolymer scienceCross linker

The invention relates to the technical field of environment-friendly degradable packaging equipment, and provides an environment-friendly degradable packaging bag and a preparation method thereof. The degradable packaging bag comprises following raw materials by weight: 5 to 10 parts of polylactic acid (PLA); 60 to 70 parts of poly(butylene adipate / terephthalate) (PBAT); 25-30 parts of corn starch; and 0.1 to 0.3 part of a cross-linking agent. The preparation method further comprises the following steps: 1, drying prepared materials; 2, stirring and mixing; 3, hot melting and drying; 4, performing film blowing forming; 5, cutting and making bags. According to the degradable packaging bag, the defects in the prior art are overcome, the design is reasonable, the structure is compact, the problems that an existing degradable packaging bag is complex and tedious in manufacturing process, contains non-degradable materials and is poor in degradable effect are solved, all the adopted raw materials are degradable; by adding the cross-linking agent, the compatibility effect of all the raw materials is improved, and product performance is improved. A simple preparation process is adopted, the processing is simple, and the packaging material can be widely applied to disposable packaging of supermarkets or shops.

Owner:WUXI JHT HOMEWARES CO LTD

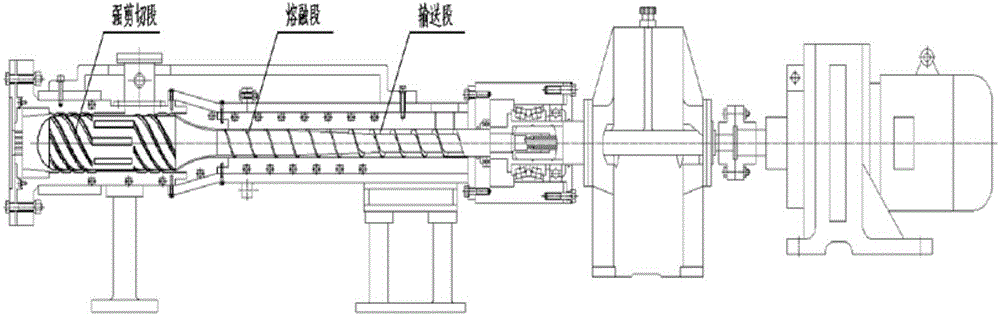

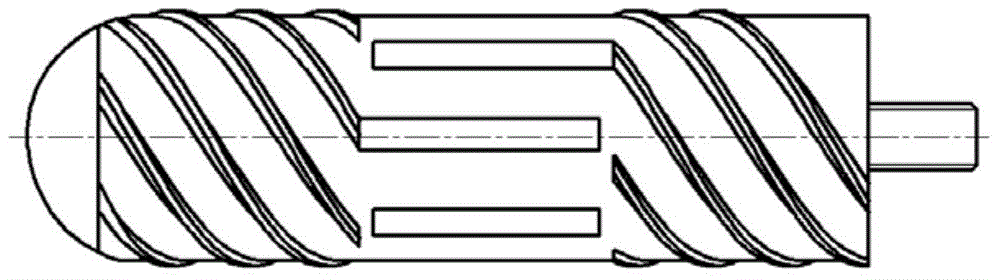

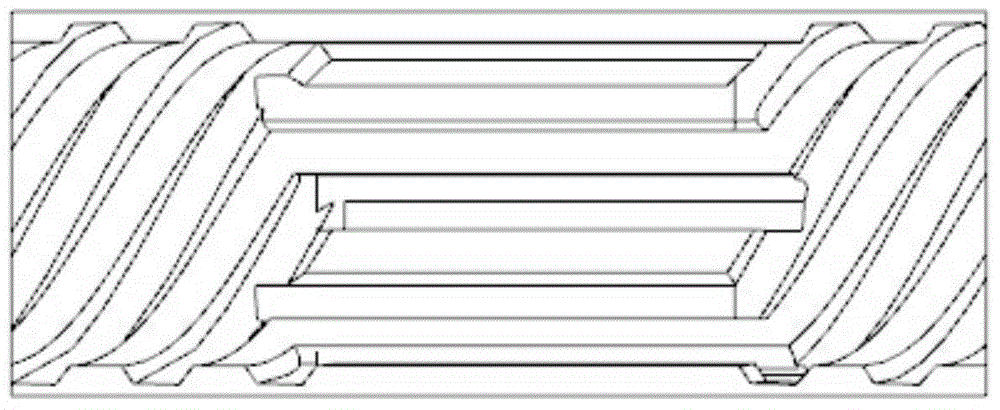

Screw and charging barrel structure for strong-shearing-force chemical reactor

ActiveCN104890215AIncrease shear forceRealize the graft copolymerization reactionMolten stateChemical reactor

The invention discloses a screw and charging barrel structure for a strong-shearing-force chemical reactor. According to the structure, a strong shearing section is communicated with the back end surface of a melting section, and a screw in the strong shearing section rotates in a charging barrel to form a strong shearing and conveying structure; screw edges of the screw in the strong shearing section and screw grooves in the charging barrel adopt a combined structure of a screw structure and a linear structure; the thread number of both the screw edges of the screw and the screw grooves in the charging barrel is 5; the rise angles of the screw edges of the screw and the screw grooves in the charging barrel are 40 degrees; when the width of the screw edges of the screw and the screw grooves in the charging barrel is 10, the height of the screw edges of the screw is 4.5 mm, and the depth of the screw grooves in the charging barrel is 2 mm; the rotating directions of the screw edges of the screw and the screw grooves in the charging barrel are opposite. The screw edges of the screw in the strong shearing section and the screw grooves in the charging barrel adopt a screw and linear combined structure, so that the shearing performance of the chemical reactor on molten state high polymer material is improved by 100%.

Owner:焦作市禹通塑料科技有限公司

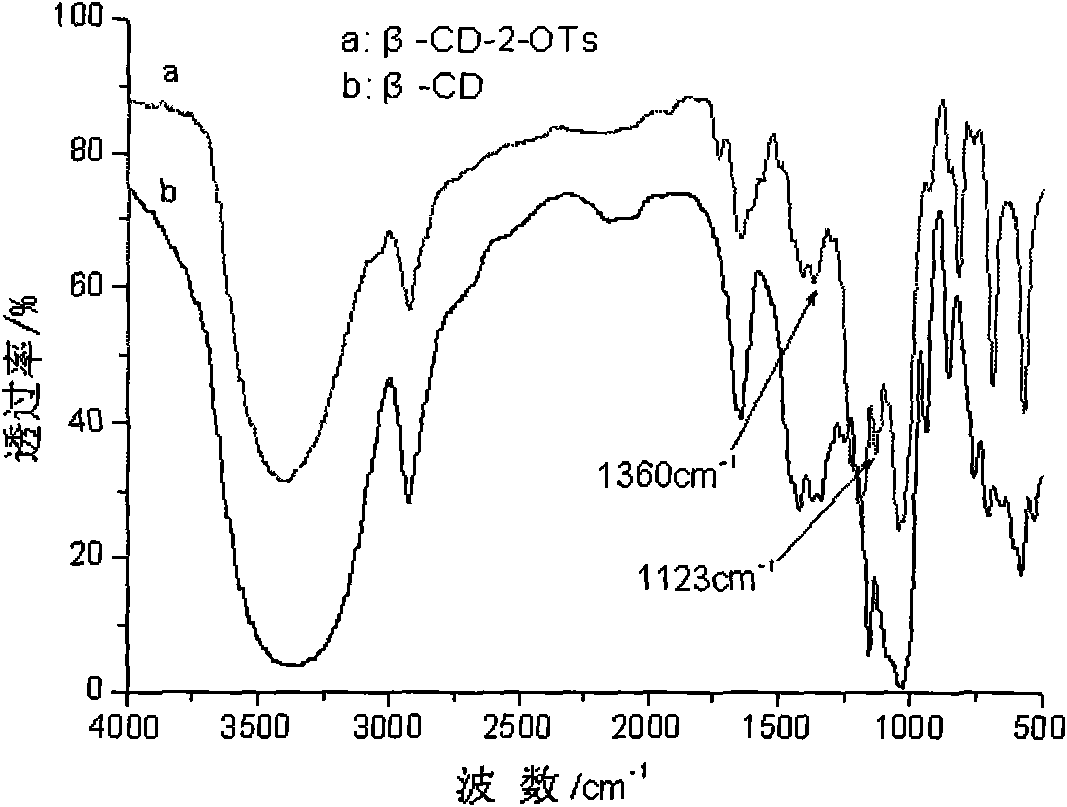

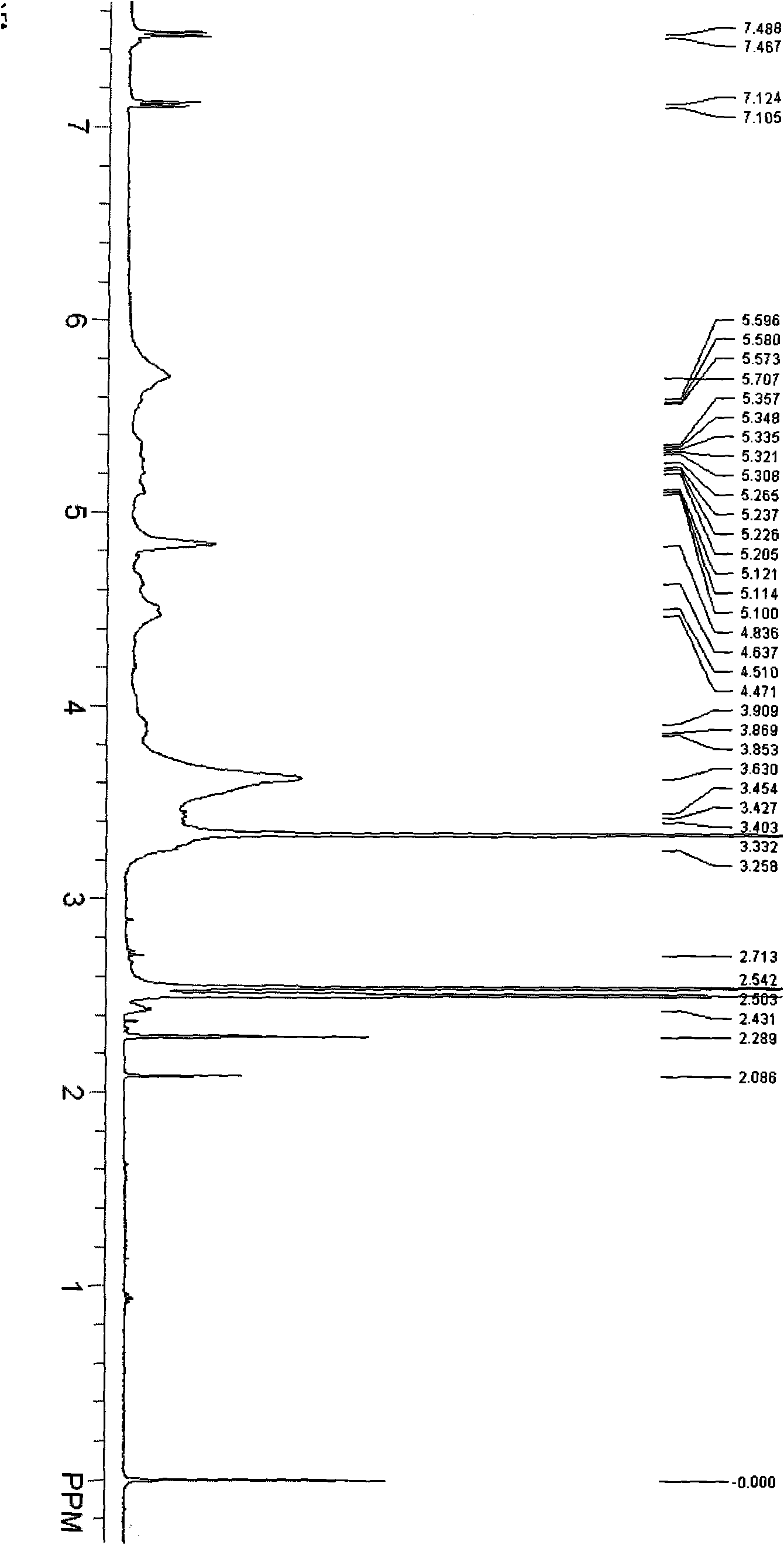

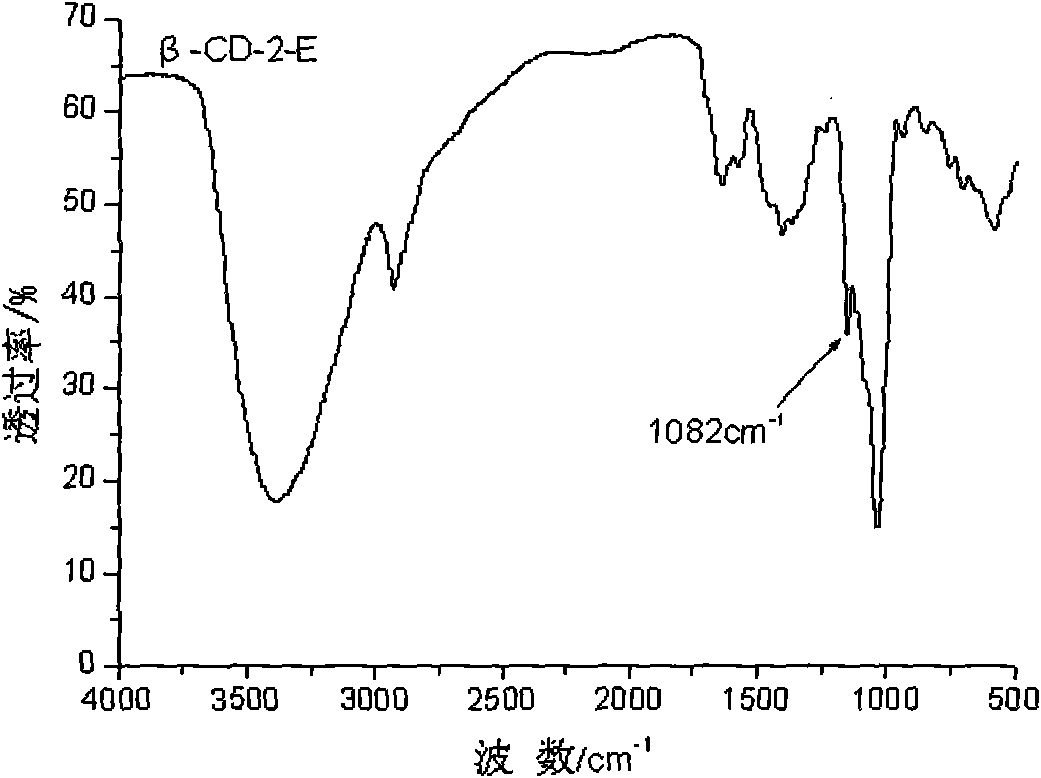

Preparation method of cyclodextrin derivatives capable of grafting silk fabric

InactiveCN101671402AImprove the effect of graftingAnimal fibresEthylenediamineCyclodextrin derivative

The invention relates to a preparation method of cyclodextrin derivatives capable of grafting silk fabric, which comprises the following steps: (1) dissolving beta-CD into NaOH water solution, addingdropwise paratoluensulfonyl chloride, and stirring for reaction; (2) uniformly mixing ethylene diamine and beta-CD-2-OTs in a container for reaction for 5h at the temperature of 65-75 DEG C, filteringand dispersing the mixture in an acetone solution, and separating products out; and (3) dissolving the products into N,N'-dimethyl formamide, adding dropwise 2,3-dibromopropionyl chloride at the temperature of 0-5 DEG C for reaction, and using acetone for depositing and filtering. The preparation method of the invention is simple, the yield is 70.39-85.90%, and the method has better grafting effect on real silk fabric.

Owner:DONGHUA UNIV

Antibacterial treatment method for natural silk fabric surface

InactiveCN103334300ANot easy to fall offUniform antibacterial layer on the surfaceAnimal fibresAnti bacterialGraft reaction

The invention relates to an antibacterial treatment method for a natural silk fabric surface. The method includes: adopting silicon dioxide loaded nano-silver as an antibacterial agent, leaving it and a coupling agent to undergo a high temperature reaction, and then letting the reaction product react with a silk fabric. The method employs a chemical grafting method to link the antibacterial agent with a silk fiber surface by the coupling agent so as to form a washable antibacterial functional layer. SEM analysis show that the antibacterial layer on the natural silk fabric surface is uniform, and the grafting effect is good.

Owner:TAIYUAN UNIV OF TECH

Polypropylene/polystyrene alloy and preparation method thereof

InactiveCN105037656ALow reaction temperatureInhibit degradationBulk chemical productionChemistryPolypropylene

The invention provides a preparation method of polypropylene / polystyrene alloy. The preparation method comprises the following steps: 1, weighing, by weight, 50-90 parts of polypropylene, 10-50 parts of polystyrene, 1-5 parts of acrylate monomers with polyfunctional groups, 0.1-0.5 part of antioxygen and 0.01-0.5 part of initiating agent; 2, adding the acrylate monomers with polyfunctional groups, the antioxygen and the initiating agent into organic solvent, conducting premixing, obtaining a premixed solution, and then mixing the premixed solution, the polypropylene and the polystyrene for obtaining a mixture; 3, adding the mixture into a screw extruder, introducing supercritical carbon dioxide at 1 / 5-1 / 3 position of a screw of the screw extruder, conducting melt extrusion, and obtaining the polypropylene / polystyrene alloy. According to the method, the supercritical carbon dioxide is introduced into the screw, the reaction temperature is lowered substantially, the reaction capacity between the polypropylene and the polystyrene is improved greatly, more polypropylene grafted polystyrene is formed in situ, and therefore the consistency between the polypropylene and polystyrene is improved remarkably. The invention further provides the polypropylene / polystyrene alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation and application of casein-carboxymethyl chitosan glycosylation nanoparticles

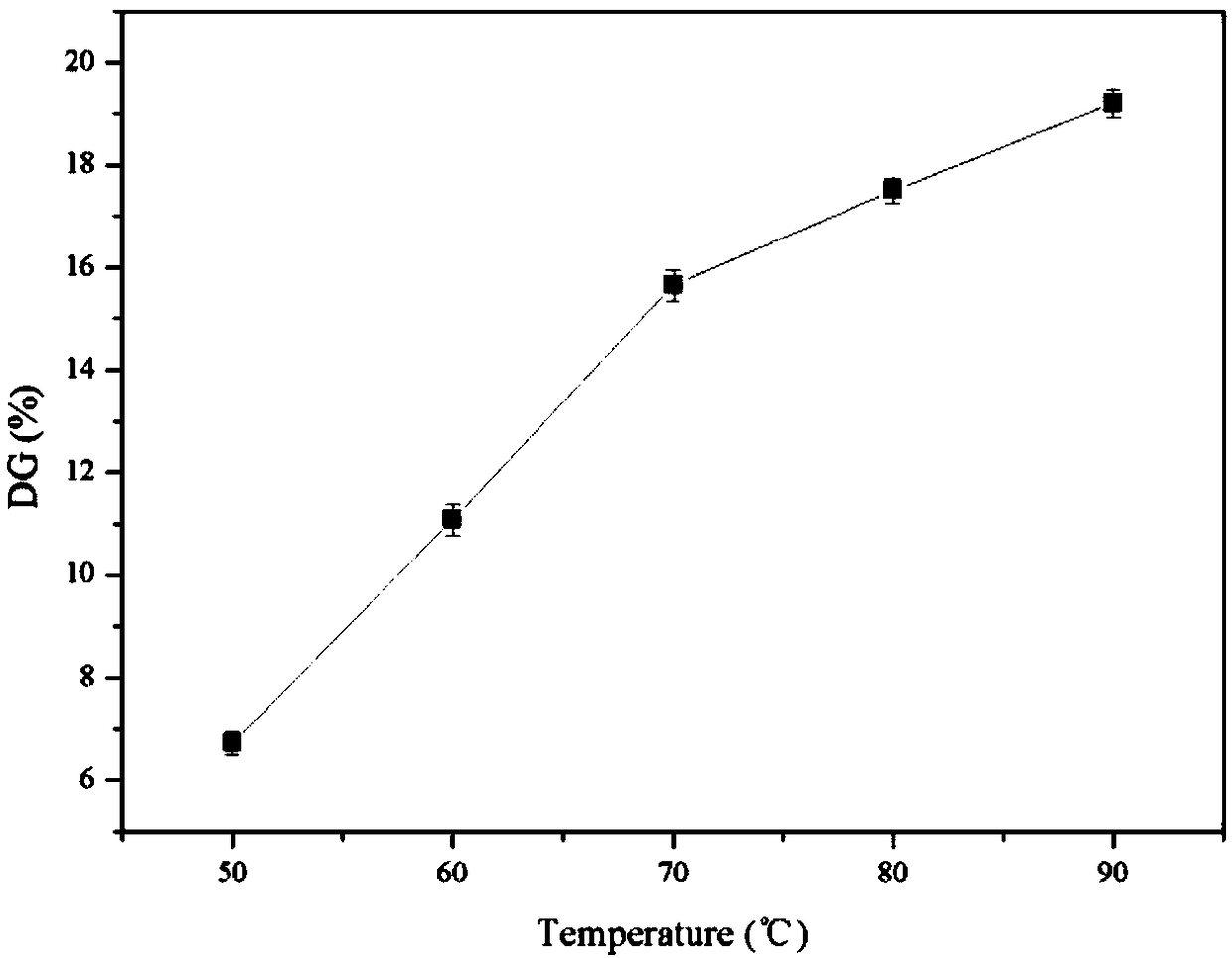

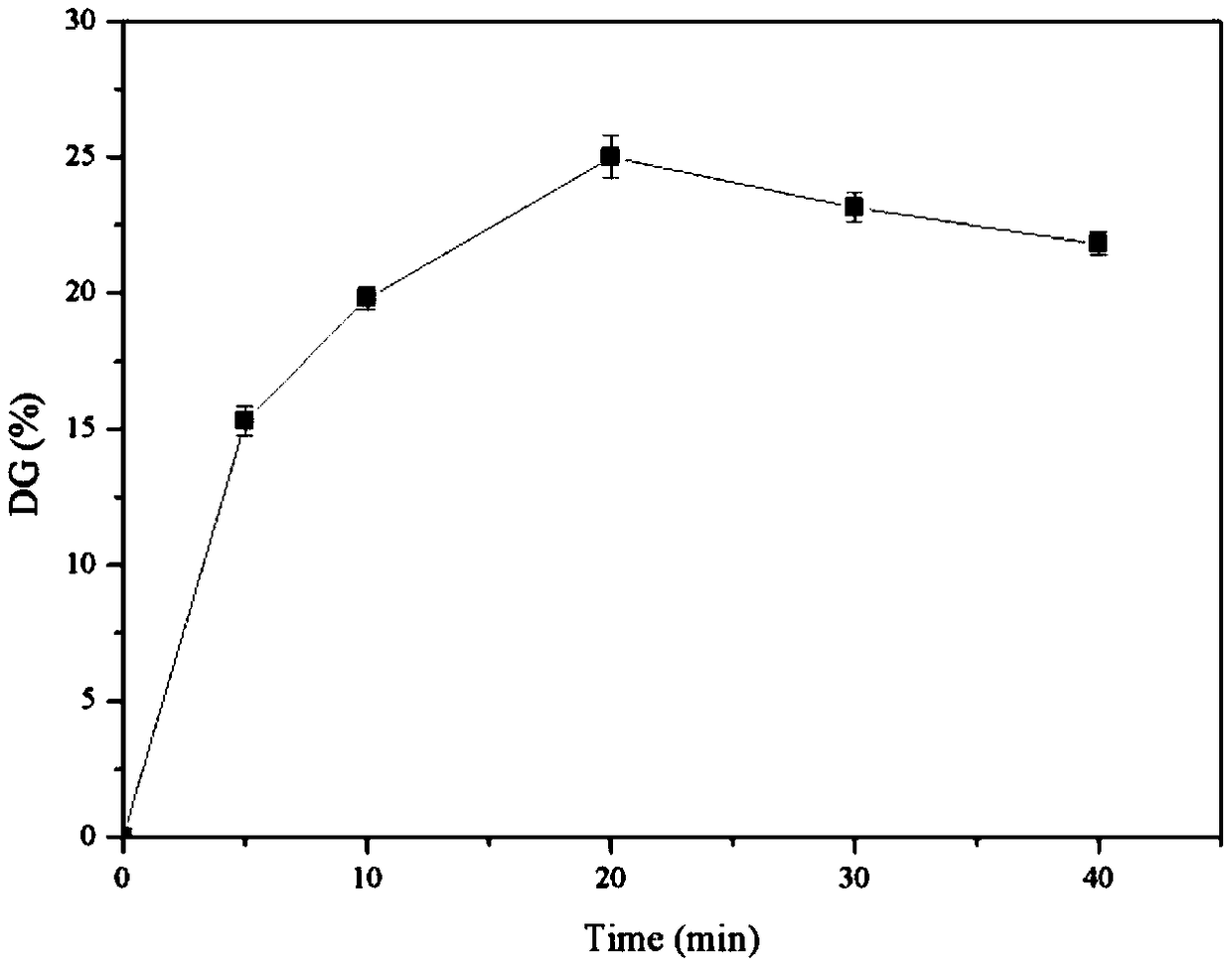

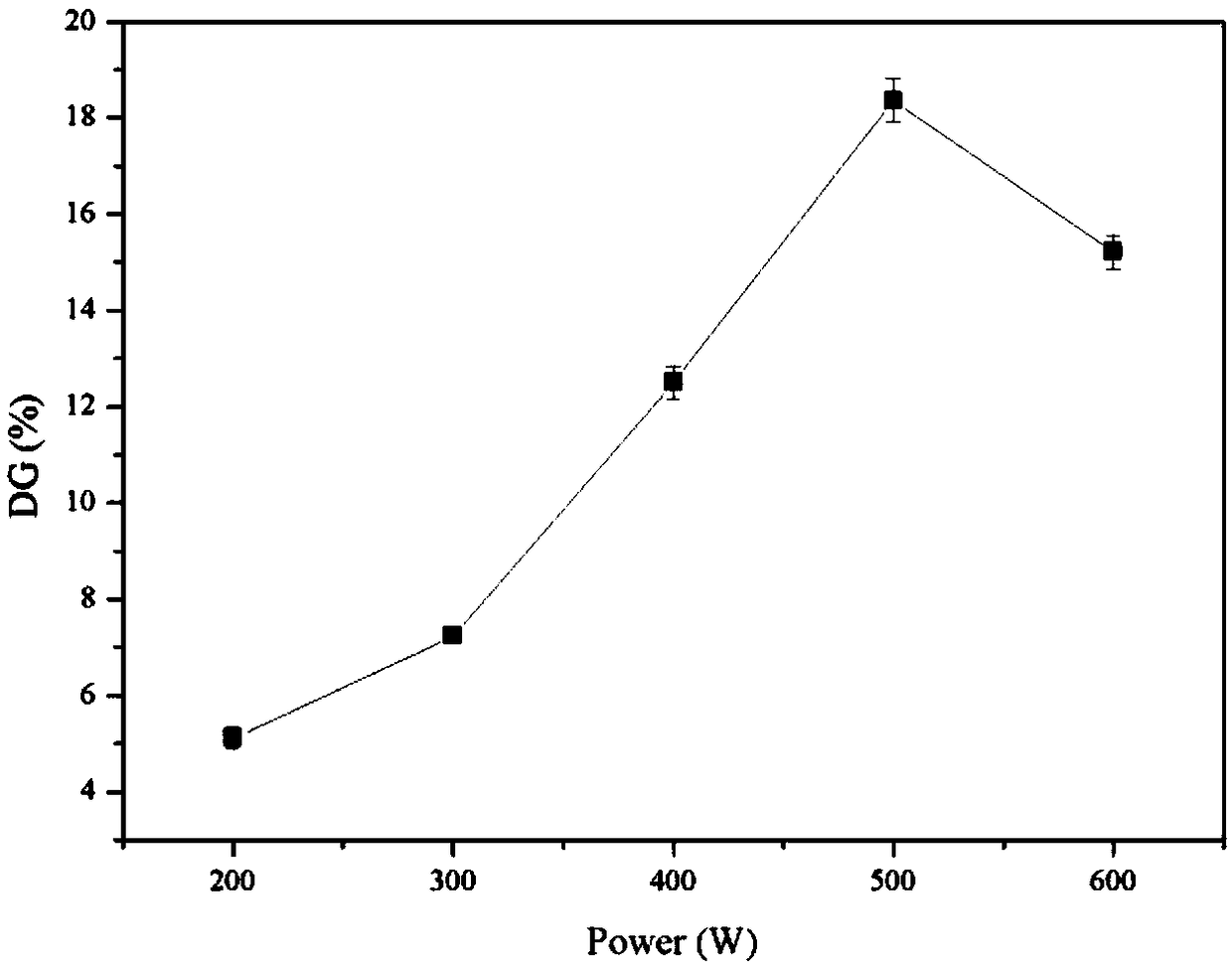

PendingCN109480291AIncrease the degree of graftingImprove thermal stabilityFood ingredientsFood shapingMicrowaveNanoparticle

The invention relates to a novel composite glycosylation modifying method. Casein and carboxymethyl chitosan are used as raw materials, and a copolymer high in grafting degree and good in heat stability is prepared, is applied to encapsulating of EGCG, and aims to improve the stability and slow release properties of EGCG. The specific method comprises the following steps of firstly performing polysaccharide graft modification on casein by a microwave wet method, then performing dry-method modification on primary wet-method products to obtain glycosylation products of which the grafting rate is80.5%, and loading and encapsulating the EGCG by a homogenizing method to obtain a ternary compound. The largest encapsulating rate of the compound on the EGCG is 79.68%, the reducing rate of resisting oxidation of the EGCG can be notably delayed during heat treatment and shelf life, the EGCG is slowly released in intestine and stomach liquid, the phenomenon of sudden release is effectively avoided, and the novel composite glycosylation modifying method can be widely applied to trade of foods, health-care products and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Preparation method of glycosylated silybum marianum protein isolate

InactiveCN105837668ASimple processImprove the effect of graftingPeptide preparation methodsPlant peptidesProtein isolateCentrifugation

A preparation method of glycosylated silybum marianum protein isolate. The invention relates to a preparation method of protein. The method includes the following steps: (A) dissolving silybum marianum protein isolate in deionized water according to the mass concentration of 1.2 g / 100 ml; (B) regulating the pH to 11 of the solution by a 0.1 mol / L NaOH solution, heating the solution to 50 DEG C with magnetic stirring for 30 min, and cooling the solution at room temperature; (C) adding saccharide according to proportion, stirring the liquid for 30 min and regulating the pH of the system with a 0.1 mol / L HCl solution until precipitate is generated; (D) magnetically stirring the mixture for 30 min, performing centrifugation, removing the supernatant, and freeze-drying the precipitate to obtain a freeze-dried powder of a mixture of silybum marianum protein and saccharide; and (E) drying the freeze-dried powder in a dryer filled with saturated KI solution, performing a reaction to obtain a product which is the glycosylated silybum marianum protein composite. The preparation method is simple in operations and mild in conditions, and has significant grafting effects of protein and the saccharide, improves additional value of silybum marianum protein, improves comprehensive utilization rate of resources and reduces waste.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

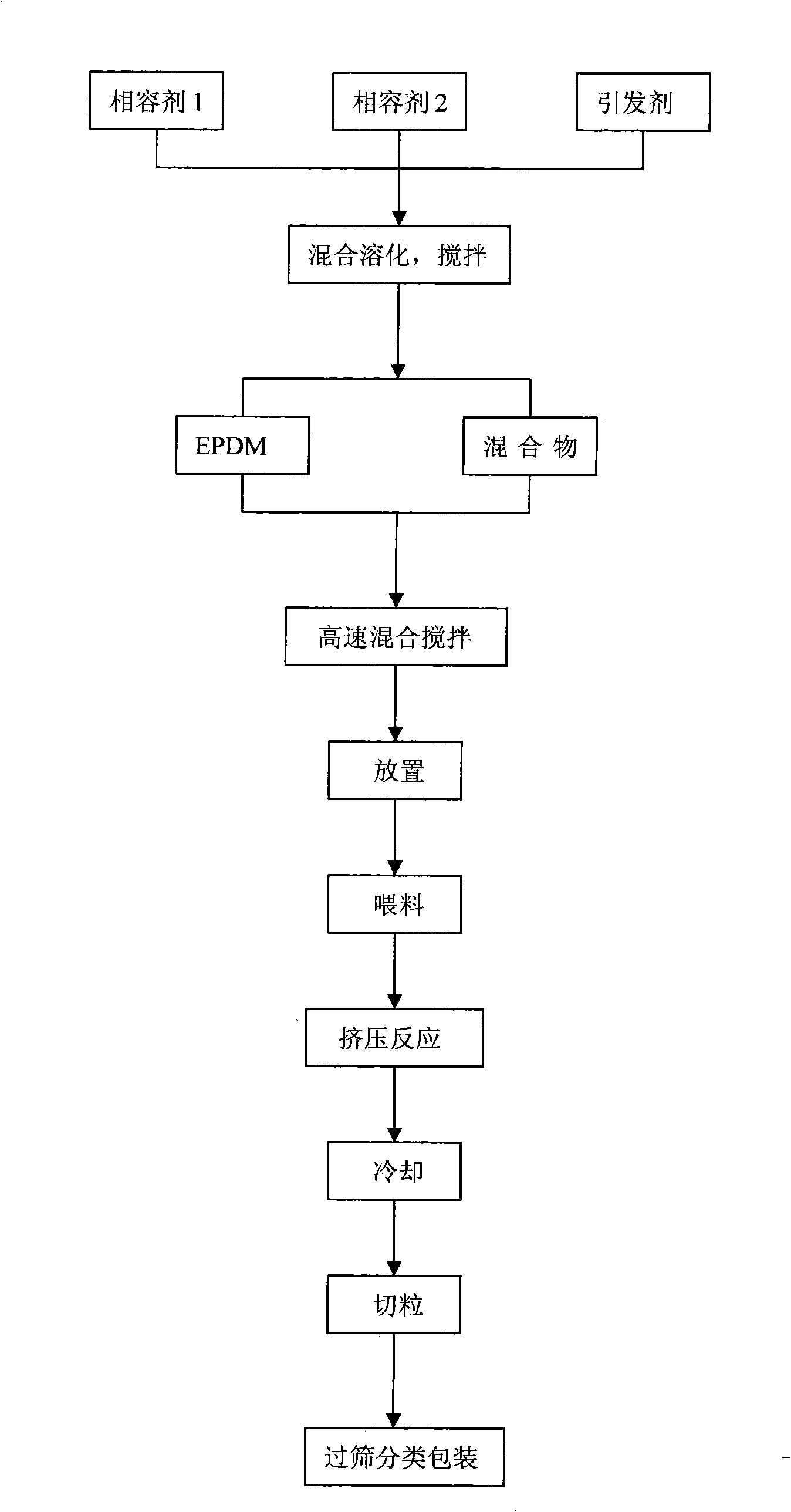

Components proportions of nylon plastics flexibilizer and production process thereof

InactiveCN101302274AGood grafting effectImproved elasticity and reaction compatibilityChemistryEPDM elastomer

A nylon plastics toughening agent comprises ethylene propylene diene methylene (EPDM), compatilizer 1, compatilizer 2 and initiator. The toughening agent is characterized in that the proportion of each component is as follows: 99,050 to 100,050g of EPDM, 1,899 to 901g of compatilizer, 2,319 to 321g of compatilizer and 29 to 31g of initiator. The manufacturing technique of the toughening agent is as follows: the weight of each component is measured; other components except EPDM are placed in a container so as to be dissolved through stirring; the obtained mixture and EPDM are mixed and stirred at a high speed to obtain a blend; the blend is fed into an extruder after deposited for one minute so as to carry out extruding reaction; meanwhile, pressure and the temperature of each temperature zone are controlled to obtain a linear toughening agent; then, the nylon plastics toughening agent is obtained through cooling, granulating and packaging. The nylon plastics toughening agent is specially developed for toughening nylon products, and has excellent graft effect; moreover, the toughening agent can greatly improve the compatibility, the interface affinity and the mechanical property of nylon plastics.

Owner:PINGDINGSHAN HUABANG ENG PLASTIC

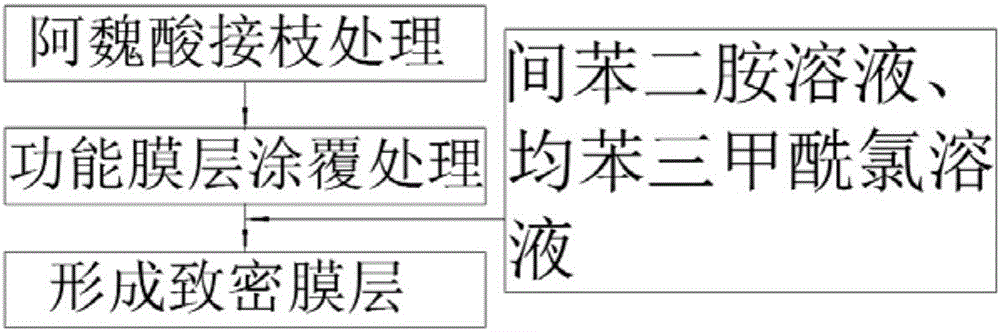

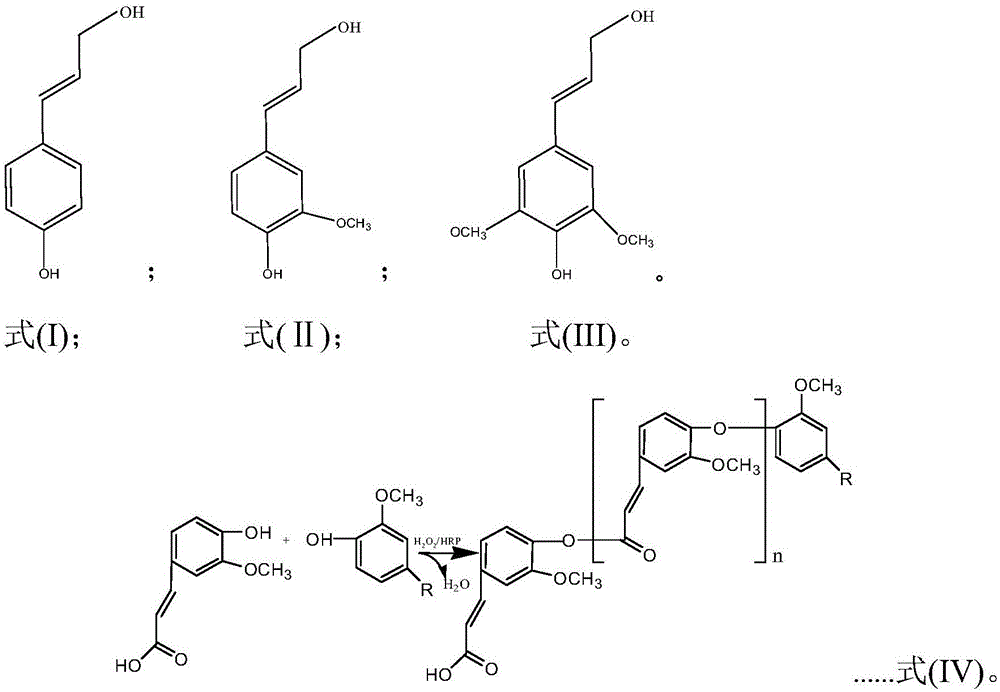

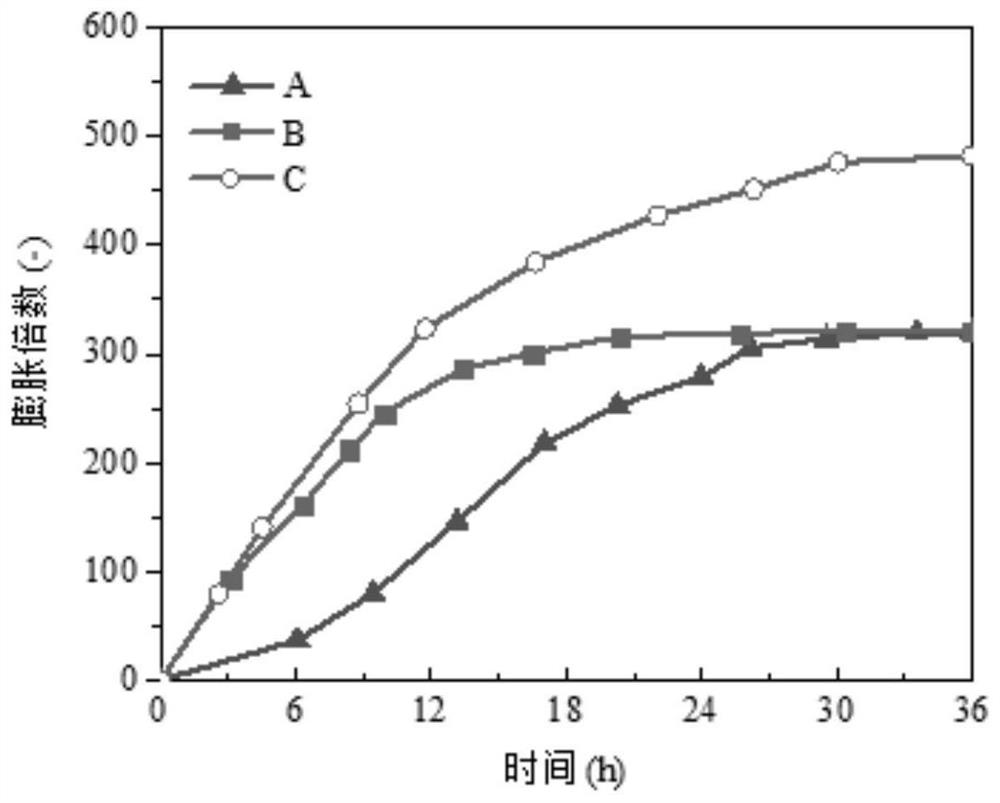

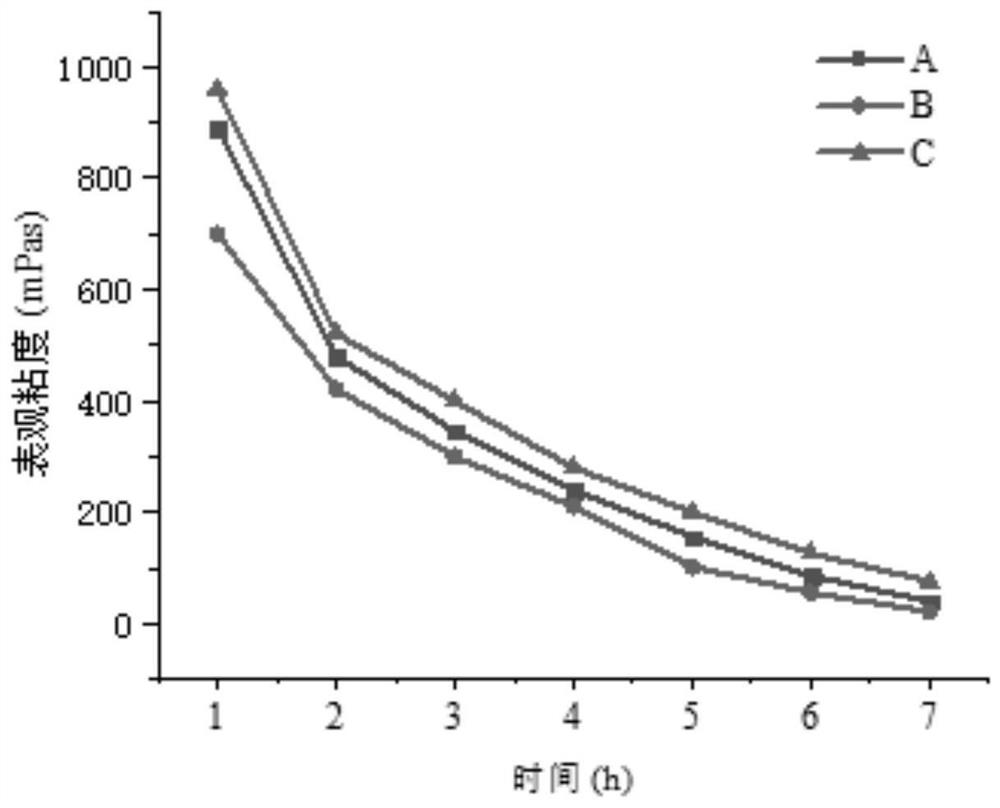

Biological pollution-resistant reverse osmosis membrane and preparation method thereof

ActiveCN106669439AImprove anti-biological pollution abilityGood pollution effectMembranesReverse osmosisReverse osmosisFerulic acid

The invention relates to the technical field of a reverse osmosis membrane, and in particular relates to a biological pollution-resistant reverse osmosis membrane and a preparation method thereof. The biological pollution-resistant reverse osmosis membrane comprises a supporting membrane layer, and an anti-pollution membrane layer and a compact membrane layer which are successively combined outwards from one surface of the supporting membrane layer; and the anti-pollution membrane layer is formed by lignin grafted by ferulic acid. The biological pollution-resistant reverse osmosis membrane can effectively inhibit the growth of microorganisms on the surface of the membrane, the biological pollution resistance of the membrane is improved, and the reverse osmosis membrane has no adverse influence on the health of the human body and the environment while still keeping high water flux and high desalting rate and can be widely applied to the field of water treatment.

Owner:恩泰环保科技(常州)有限公司

High-strength high-water-absorption degradable plugging agent and preparation method thereof

The invention relates to a high-strength high-water-absorption degradable plugging agent and a preparation method thereof. The plugging agent is prepared from the following raw materials: an alkenyl monomer, a hydrophilic auxiliary agent, modified starch, a cross-linking agent, an initiator, an inorganic reinforcing agent, a degradation auxiliary agent and a degradation activator, wherein based onthe total mass of the raw materials, the content of the alkenyl monomer is 15-30%, the content of the hydrophilic additive is 10-30%, the content of the modified starch is 20-45%, the content of thecross-linking agent is 0.05-1.5%, the content of the initiator is 1.5-2%, and the content of the inorganic reinforcing agent is 2-5%. According to the invention, the high-strength high-water-absorption degradable plugging agent contains a plurality of hydrophilic groups, so that the plugging agent is high in water absorption rate and elasticity, is flexible gel, has deformability, can be squeezedinto a leakage channel to be compacted, is high in pressure bearing strength, contains high-temperature-resistant alpha-amylase, is subjected to degradation reaction at high temperature to destroy a plugging agent framework, is slowly liquefied, is free of residues and is free of pollution to stratums.

Owner:PETROCHINA CO LTD +2

Heavy metal ion porous adsorbent as well as preparation method and application thereof

ActiveCN107446096AControl Aperture SizeLow densityOther chemical processesWater contaminantsSorbentAdsorption effect

The invention provides a heavy metal ion porous adsorbent as well as a preparation method and application thereof. The preparation method of the heavy metal ion porous adsorbent comprises the following steps: (1) dropwise adding a dispersion phase containing an initiator and an electrolyte into a continuous phase containing ethyl glycidyl acrylate, divynyl benzene and an emulsifier, thus obtaining concentrated emulsion; (2) carrying out polymerization reaction on the concentrated emulsion, and washing and drying a polymerization reaction product, thus obtaining a porous polymer; (3) carrying grafting reaction on polyacrylic acid and the porous polymer under the existence of a catalyst, thus obtaining the heavy metal ion porous adsorbent. The heavy metal ion porous adsorbent provided by the invention has good adsorption effect on various heavy metal ions.

Owner:CRRC TANGSHAN CO LTD

Natural plant fiber modifying agent and surface modifying method of natural plant fibers

InactiveCN105113250ALow costImprove modification efficiencyDry-cleaning apparatus for textilesVegetal fibresPlant fibreSurface-active agents

The invention discloses a natural plant fiber modifying agent. The natural plant fiber modifying agent comprises, by weight, 2-5 parts of surfactant, 5-10 parts of bridging agent and 780-800 parts of solvent. A surface modifying method of natural plant fibers comprises the following steps that firstly, the natural plant fibers are soaked into a cleaning agent to be cleaned to remove impurities, water is used for cleaning, and drying is conducted; secondly, the natural plant fibers dried in the first step are soaked into the natural plant fiber modifying agent and bathed in water for 10-20 min at the temperature of 70-90 DEG C, the natural plant fibers are taken out, standing and natural drying are conducted, and surface-modified natural plant fibers are obtained. According to natural plant fiber strengthened polymer composite materials processed through the natural plant fiber modifying agent and the modifying method, the tensile strength is increased by more than 20%, and the impact strength is increased by more than 15%.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

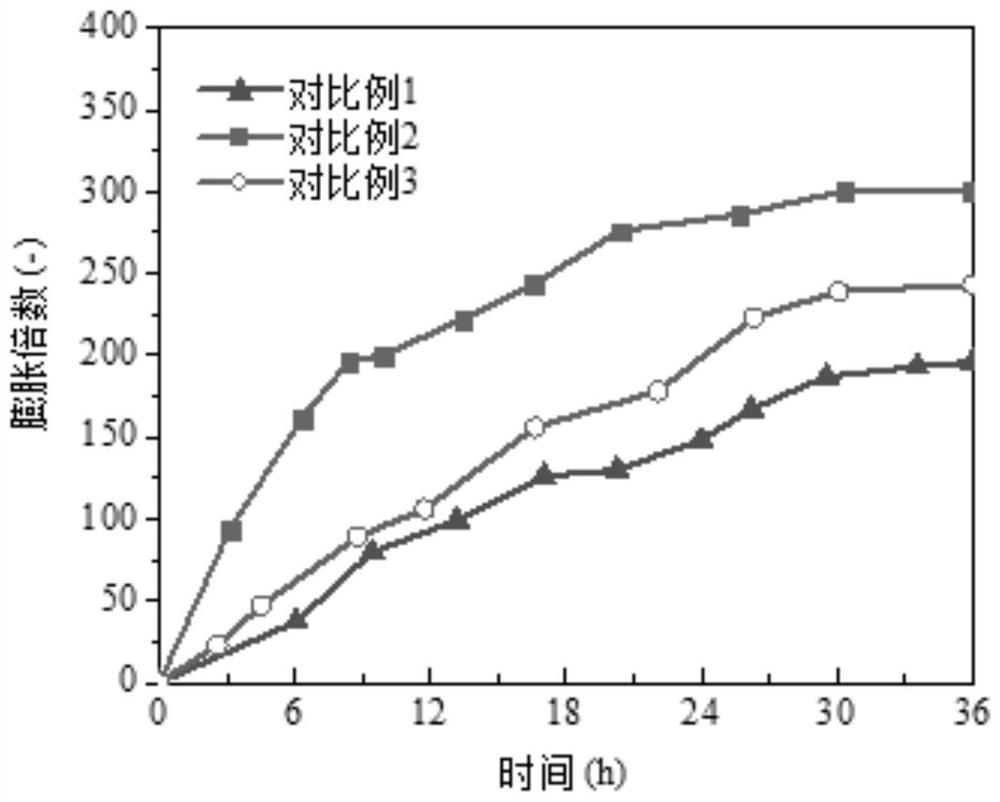

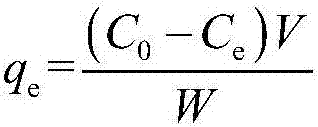

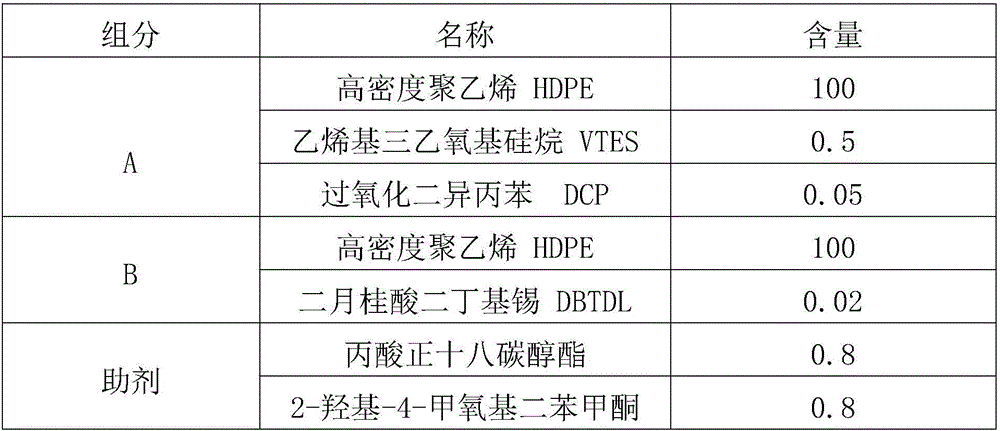

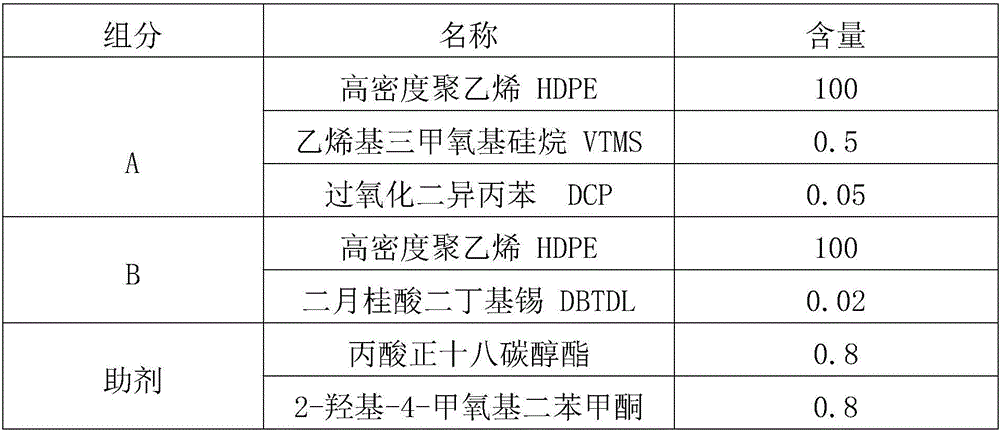

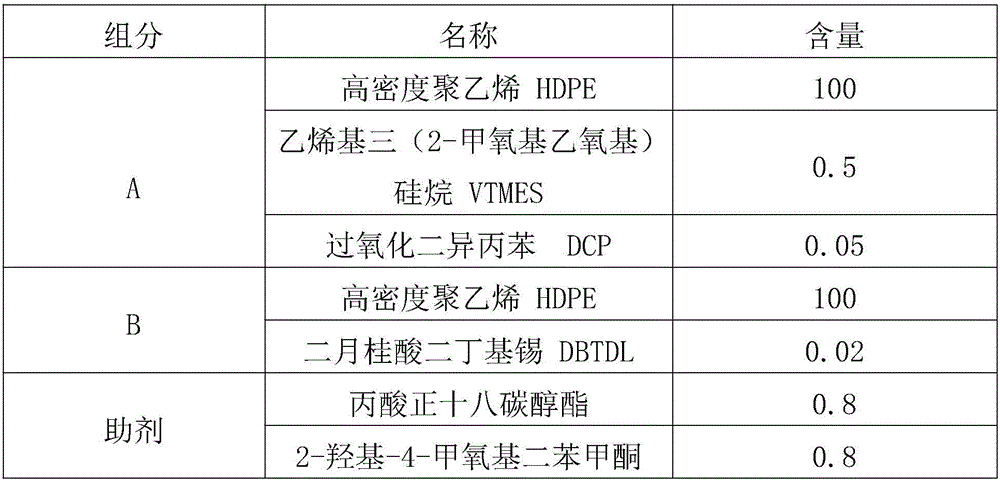

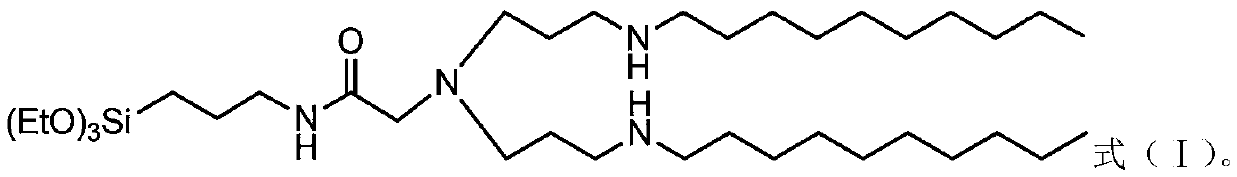

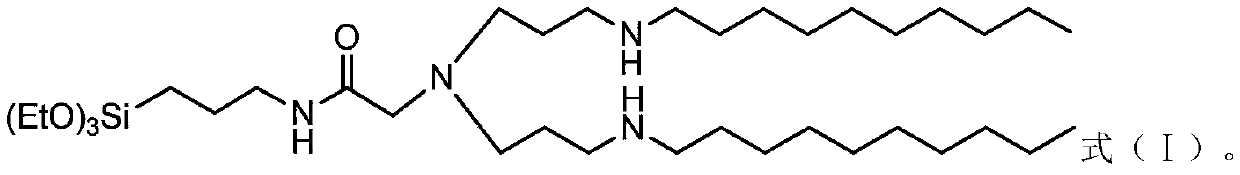

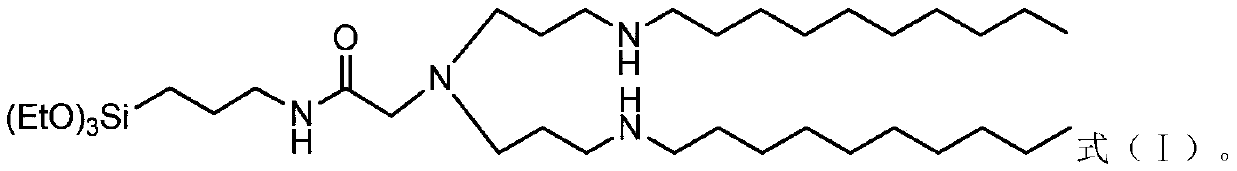

High-strength polyethylene tube for communication and preparation method thereof

The invention discloses a high-strength polyethylene tube for communication, wherein a component A comprises 100 parts of high-density polyethylene, 0.5-3.0 parts of silane and 0.05-0.15 part of dicumyl peroxide; a component B comprises 100 parts of high-density polyethylene and 0.02-1 part of dibutyltin dilaurate; and an additive component C comprises 0.5-1.5 parts of antioxidant and 0.6-0.8 part of benzophenone ultraviolet absorbent. The formula of the polyethylene tube for communication is improved by a mode of silane cross-linked with polyethylene, the strength of the tube is improved, and the tube has the advantages of rigid texture, better toughness and better environmental resistance.

Owner:WUJIANG JIATONG OPTICAL FIBER CO LTD

Finishing method of long-acting washable antibacterial fabric

ActiveCN110453492AHas antibacterial activityStable structureGroup 4/14 element organic compoundsPhysical treatmentGraft reactionBiocompatibility Testing

The invention discloses a finishing method of a long-acting washable antibacterial fabric, and belongs to the field of textile engineering. The method comprises the steps that (1) a stable antibacterial siliceous body is prepared from organic-inorganic composite lipid with an antibacterial property; (2) a fabric is treated by a plasma treatment device and then soaked in an antibacterial siliceousbody solution for a grafting reaction; (3) the fabric subjected to the grafting reaction is washed with water and dried. By means of the method, after the fabric is subjected to surface grafting modification, the fastness and durability of fabric adsorption particles are improved, and the finished fabric belongs to a non-dissolution-out antibacterial fabric and is good in biocompatibility, ecologically friendly and excellent in washability.

Owner:揭西县合祥织造有限公司

Fishing net thread use quality improvement processing process

InactiveCN107641955AImprove the effect of modified treatmentImprove physical and chemical propertiesPhysical treatmentFibre typesPhosphoric acidEngineering

The invention discloses a fishing net thread use quality improvement processing process. The process includes steps: (1) cleaning and deoiling treatment; (2) phosphoric acid solution soaking treatment; (3) treating fluid A soaking treatment; (4) ultraviolet irradiation treatment; (5) treating fluid B soaking treatment; (6) flushing and drying treatment. By special processing of fishing net threads, under joint actions in each step, the grafting effect of the fishing net threads is evidently improved, utilization characteristics of the fishing net threads are improved, and the finally treaded fishing net threads are high in coating compatibility, corrosion resistance, strength and comprehensive quality, thereby being high in popularization and utilization value.

Owner:CHAOHU JUNYE FISHING TACKLE CO LTD

Scratch-resistant PP plastic and preparation method thereof

The invention discloses a scratch-resistant PP plastic and a preparation method thereof, the scratch-resistant PP plastic is obtained by co-extrusion granulation of a composite filler and polypropylene resin, and the composite filler is obtained by mixing a modified filler and carboxylated polypropylene micro wax powder according to a weight ratio, ball milling and drying. Carboxylated polypropylene micro wax powder is grafted on the surface of the modified filler, so that the dispersion effect of the modified filler in polypropylene and the combination effect of the modified filler and a polypropylene material are improved. In the preparation process of the modified filler, a compound of nano hydrotalcite and nano silicon dioxide is mixed with a nano graphene dispersion liquid, and then heating and ultrasonic reaction are performed, so that a layer of graphene is grafted and fixed on the surface of the compound of nano hydrotalcite and nano silicon dioxide, on one hand, the surface friction coefficient of the plastic is reduced, and on the other hand, hydrotalcite sheet layers and nano silicon dioxide exposed when the surface of the plastic is scratched can be reduced, and obviousscratches are avoided.

Owner:蔡美英

Device for automatically grafting nursery stock

The invention relates to a device for automatically grafting a nursery stock. The device comprises a nursery stock grafting fixing layer, of which the upper and lower portions are respectively provided with an upper binding layer and a lower biding layer, and an upper grafting medicament layer and a lower grafting medicament layer are respectively arranged on the upper portion of the upper binding layer and the lower portion of the lower biding layer. An adhesive binding layer and an air filtering layer are respectively arranged on the upper portion of the upper grafting medicament layer and the lower portion of the lower grafting medicament layer, and a back water-proof layer is arranged on the lower portion of the air filtering layer. A plurality of upper grafting binding ropes are connected between the upper grafting medicament layer and the upper binding layer, a plurality of lower grafting binding ropes are connected between the lower grafting medicament layer and the lower binding layer, and a plurality of grafting air vents are arranged in the internal of the air filtering layer. The device effectively improves nursery stock grafting effect, and employs such a special structure to enhance nursery stock grafting effect, and increase nursery stock grafting survival rate. The device can be used as needed.

Owner:界首市鑫诺家庭农场

Preparation method of farm-oriented water retaining agent using waste paper craps as raw materials

The invention discloses a preparation method of a farm-oriented water retaining agent using waste paper craps as raw materials. By using the waste paper craps as raw materials, the recycle of the domestic waste is realized and the pollution to the environment is reduced; at the same time, the paper craps which are rich in vitamin can be biologically degraded, so that the further pollution to the soil is prevented. According to the preparation method, the water retaining agent is produced via microwave radiation, so that the progress of the chemical reaction is greatly accelerated and the reaction time is shortened. The main synthesis principle of a cellulose water retaining agent is to trigger polymerization by free radicals, and the specific progress comprises the steps of enabling cellulose macromolecules to generate free radicals and then reacting with monomers to form grafted copolymers. By using the microwave radiation triggering method, the progress of the chemical reaction can be accelerated and relatively good grafting effect can be achieved in relatively short time.

Owner:WEST ANHUI UNIV

Method for initiating graft polymer through ultraviolet induction on surface of glass

The invention relates to a method for initiating a graft polymer through ultraviolet induction on the surface of glass, belonging to the technical field of surface modification of the glass. The method comprises the following steps of: uniformly coating a prepared reaction solution on the surface of the glass treated by a silane coupling agent, and placing the glass in an ultraviolet light curing machine to irradiate the glass for 3min, thereby obtaining a sheet glass sample, the surface of which is fixed with a polymer chain. The method has the advantages that an operating technology is simple, the grafting effect is obvious, and raw materials used are commercially available, can be used without needing to be subjected to a complex purification process and are low in cost and easily obtained; graft polymerization is initiated through ultraviolet induction, the operation is simple, the reaction time is short, and the environmental pollution is low; and the method can be used for the reinforcement of adhesive property between resin in a reinforced material and the glass and the modification of the surface character of the glass and has wide industrial application prospect.

Owner:CHANGZHOU UNIV

Ethylene-vinyl acetate copolymer-polystyrene resin and preparation method thereof

The invention discloses ethylene-vinyl acetate copolymer-polystyrene resin and a preparation method thereof. The method comprises the following steps of: pre-irradiating an ethylene-vinyl acetate copolymer with beta rays or gamma rays, adding the pre-irradiated ethylene-vinyl acetate copolymer, a functional monomer, a dispersant, an emulsifier, a nucleating agent and a homopolymerization inhibitor into a reactor, and undergoing a suspension graft polymerization reaction; and filtering a suspension grafting product, washing and drying to obtain the ethylene-vinyl acetate copolymer-polystyrene resin. The pre-irradiated ethylene-vinyl acetate copolymer is used for generating a large molecular peroxide for serving as an initiator, so that side reactions such as homopolymerization of a monomer caused by a small molecular initiator, crosslinking of the ethylene-vinyl acetate copolymer and the like are avoided; through the suspension graft polymerization reaction, the grafting rate mass percentage is up to 80.2 percent, and a good grafting effect is achieved; the grafting product has the technical properties of high strength, high flexibility and impact resistance; and the ethylene-vinyl acetate copolymer-polystyrene resin has the characteristics of an ethylene-vinyl acetate copolymer and polystyrene.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com