Patents

Literature

243results about How to "Optimal treatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

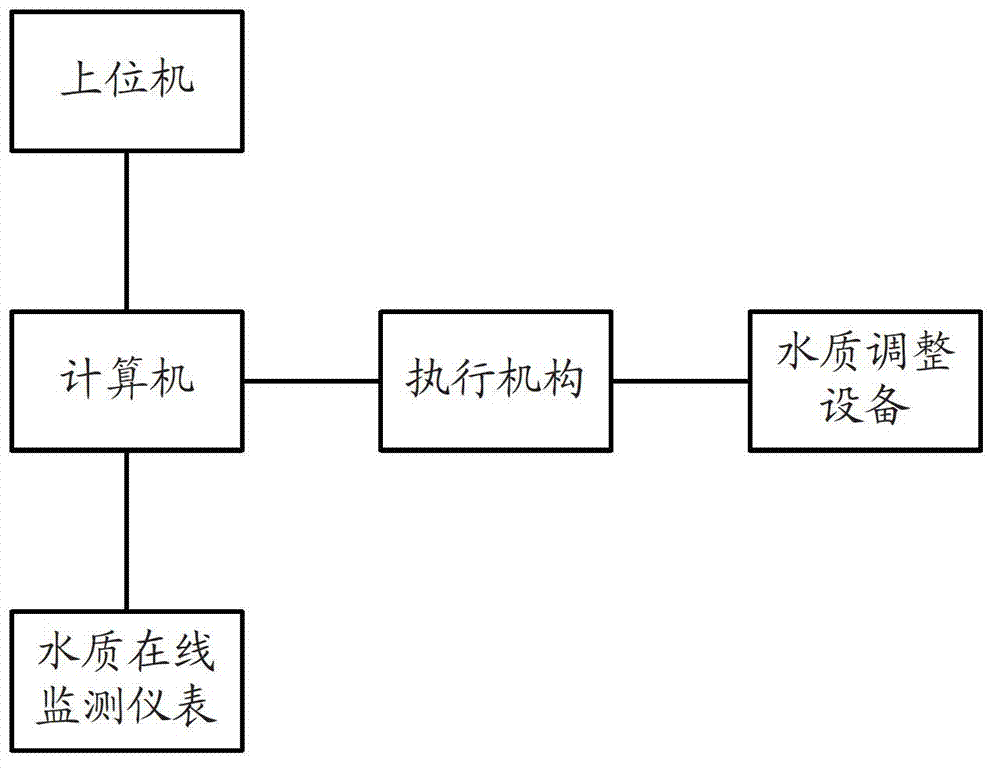

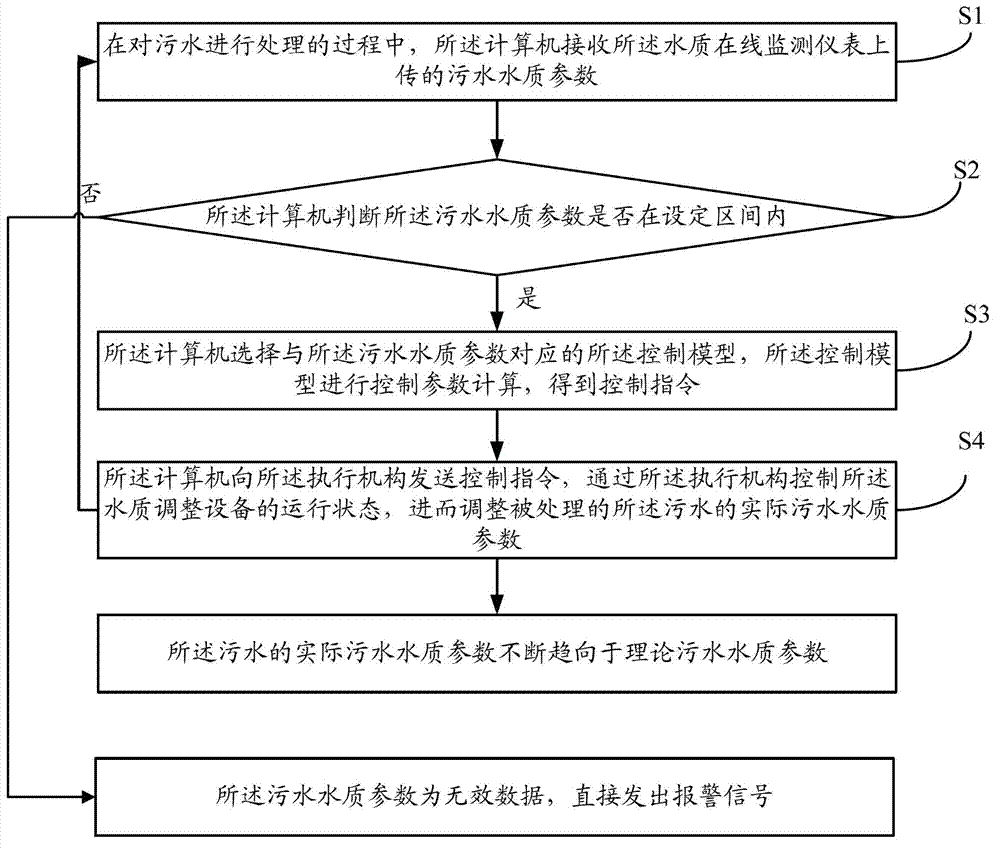

Sewage treatment process optimization and energy-saving control system and method

ActiveCN102902257AEffective regulationOptimal treatment processTreatment using aerobic processesSustainable biological treatmentProcess optimizationControl signal

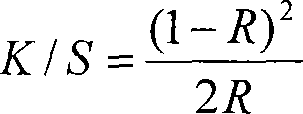

The invention provides a sewage treatment process optimization and energy-saving control system and a sewage treatment process optimization and energy-saving control method. The sewage treatment process optimization and energy-saving control system comprises a computer, an upper computer, an executing mechanism, more than one on-line monitoring instrument and more than one piece of water quality adjusting equipment, wherein the more than one on-line monitoring instrument is used for acquiring a water quality parameter of treated sewage; and the more than one piece of water quality adjusting equipment is used for adjusting the water quality parameter of the sewage. By acquiring sewage treatment field data, performing simulation treatment on the field data through a simulation model and calculating through a control model, a control signal is obtained to control the operation state of the water quality adjusting equipment so as to form a feed forward-feedback-control model calculation-execution artificial intelligent closed-loop control loop; and the water quality parameter which meets the process requirements can be calculated, and accurate control is performed on the parameter of the sewage water quality process, so that a sewage treatment process optimization and energy-saving effect is achieved.

Owner:W STARTECH BEIJING ENVIRONMENTAL TECH

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Normal-pressure low-temperature plasma preprocessing technique of textile for digital inking printing

InactiveCN101100808AImprove clarityImprove color vibrancyUltrasonic/sonic fibre treatmentDyeing processEngineeringPre treatment

The invention relates to fabric plasma surface modification processing technology used in dye ink digital inking printing. The fabric is processed inking printing by dye ink in the digital inking printing machine after processing by impulse normal pressure air low temperature plasma, then baking to form the finished product. Compared with the traditional preprocessing technology, the invention has the advantages of fast, convenient, saving water and energy, low cost, no social effects of pollution, suiting for industrialization continuous production etc.

Owner:JIANGNAN UNIV

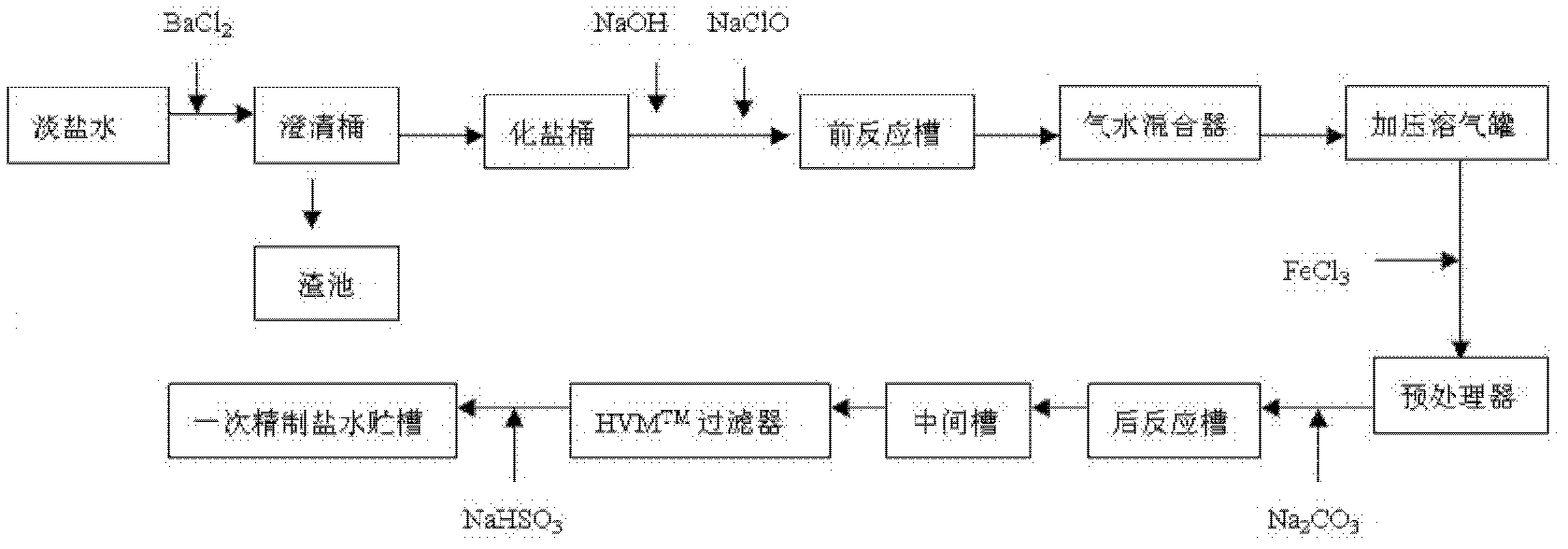

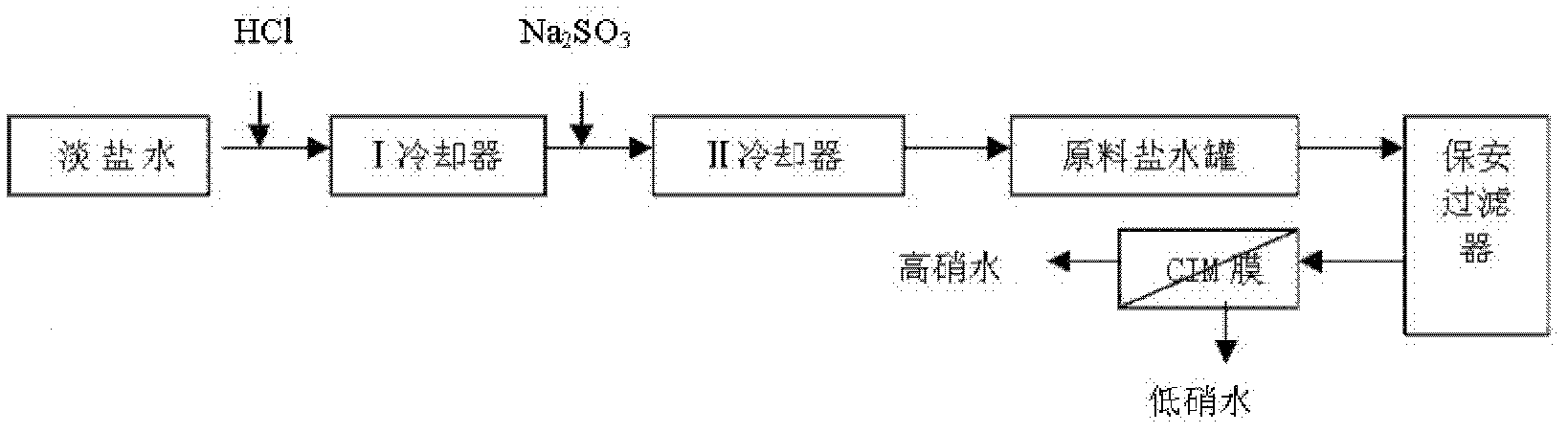

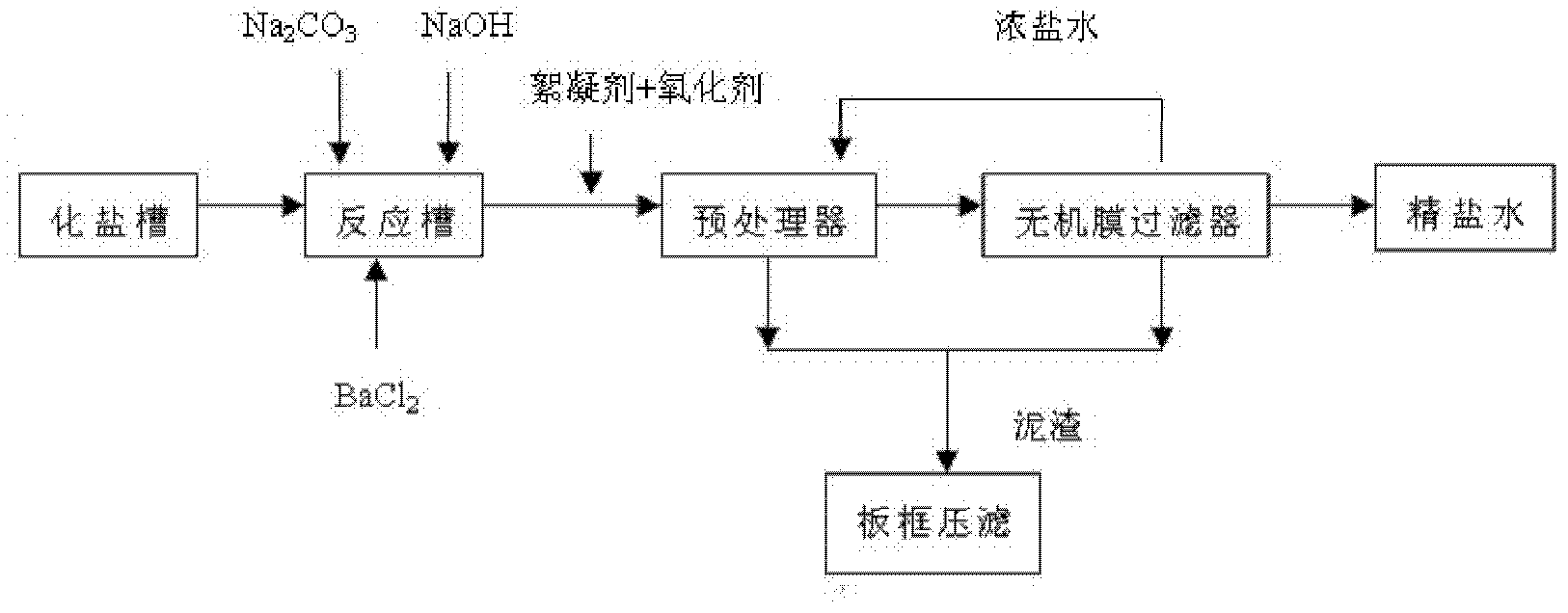

Double-membrane-method technology for refining brine and equipment for the same

ActiveCN102627300AAvoid secondary pollutionReduce manufacturing costAlkali metal halide purificationHigh concentrationUltrafiltration

The invention relates to double-membrane-method technology for refining brine and equipment for the same. After pretreatment, brine to be treated enters a filtration procedure to form high-concentration nitrate-containing water and refined brine; pretreatment refers to carrying out a removal procedure of calcium and magnesium ions, a removal procedure of ammonium, a reduction procedure and a pH adjusting procedure to the brine to be treated; the filtration procedure refers to the steps that: the pretreated brine is pumped to gas-stripping tubular type membrane module for ultrafiltration, thereby organic impurities, suspended matters and partial precipitates of the brine are intercepted; pressure raising is carried out to the brine which permeates a tubular type membrane, then the brine directly enters nanofiltration membrane module for nanofiltration; the brine which can not permeate the tubular type membrane returns the removal procedure of calcium and magnesium ions; and in a high pressure state, sulfate ions are intercepted by a nanofiltration membrane to form high-concentration nitrate-containing water, and chloride ions and sodium ions permeate smoothly the nanofiltration membrane to form refined brine. The technology in the invention is simple, low energy consumption, small land-occupation area, low investment and low production cost, a stable operation system, strong impact-resistance load capability and no secondary pollution.

Owner:CHINA PETROCHEMICAL CORP +3

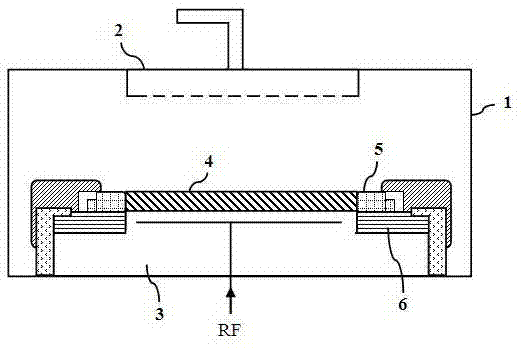

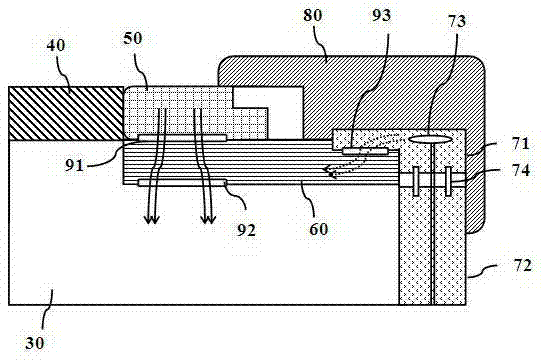

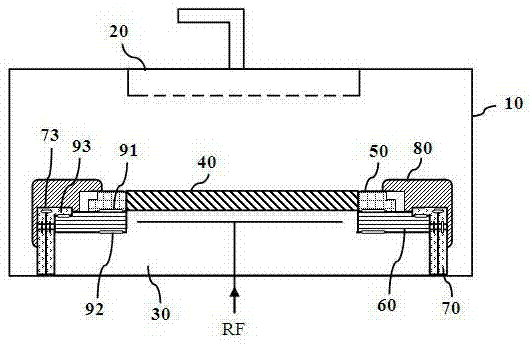

Temperature adjustment device and method of focusing ring

ActiveCN106920725AOptimal treatment processRealize the function of grounding conductionParticle separator tubesSemiconductor/solid-state device manufacturingWorking temperatureEngineering

The invention provides a temperature adjustment device and method of a focusing ring. Energy is radiated onto the focusing ring by plasma and is downwards transferred to a base by a first thermal conduction pad, an insulation ring and a second thermal conduction pad, the first thermal conduction pad is in contact with a lower surface of the focusing ring, the insulation ring is in contact with a lower surface of the first thermal conduction pad, the second thermal conduction pad is in contact with a lower surface of the insulation ring, the base is in contact with the second thermal conduction pad, cooling and temperature reduction are performed by a cooling system arranged at the base, a heater which is arranged in a shielding ring is started to generate a controllable external heating source, the shielding ring is connected with the ground, energy of the external heating source is transferred to the focusing ring by the shielding ring, a third thermal conduction pad, an insulation ring and the first thermal conduction ring, the third thermal conduction pad is in contact with the shielding ring, the insulation ring is in contact with the third thermal conduction pad, and controllable temperature rise is performed on the focusing ring. By providing a good heat conduction cooling path and by combining a heating mode of a controllable parameter, fine control on a working temperature of the focusing ring is achieved, the focusing ring is tunable during etching, so that the process demand is satisfied.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

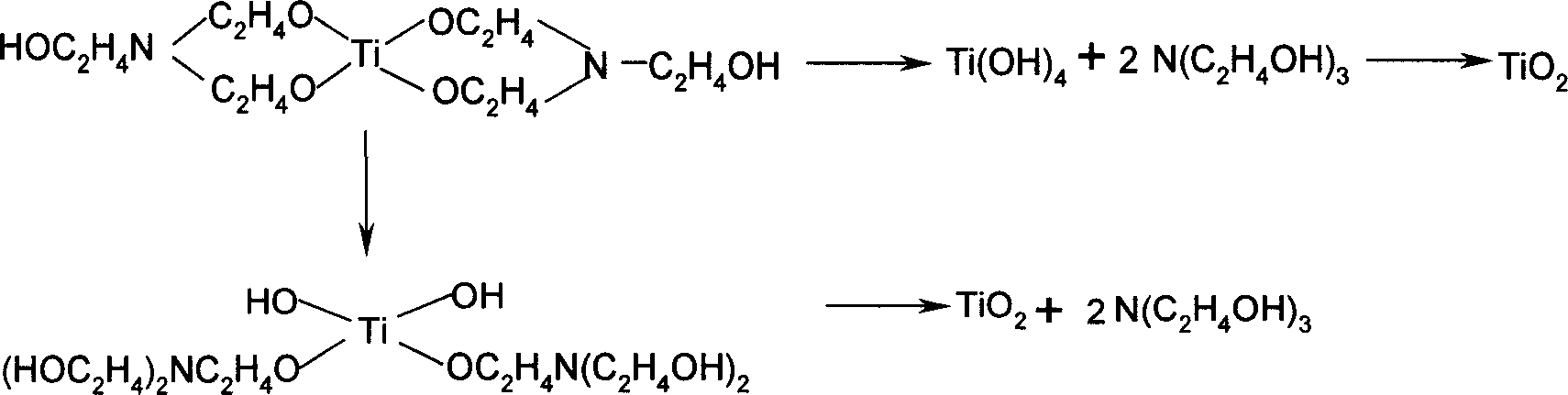

Method for in-situ generating inorganic nanoparticles in textile

InactiveCN1807750AImprove the protective effectOptimal treatment processFibre treatmentLiquid/gas/vapor textile treatmentUltravioletInorganic nanoparticles

This invention discloses a method for producing inorganic nanometer particle in original position in the textiles. First preparing the transparent solution that can produce inorganic nanometer particle TiO2,SiO2, immersing the textile, then through ultrasonic, hot water and whisking method to use the original position compound technology to produce the inorganic nanometer particle TiO2,SiO2 in the original position in the textile, which improves the dispersed and adhesive force of the nanometer particle in the textile to endow the textile with ultra-violet proof and antibiotic capability.

Owner:ZHEJIANG SCI-TECH UNIV

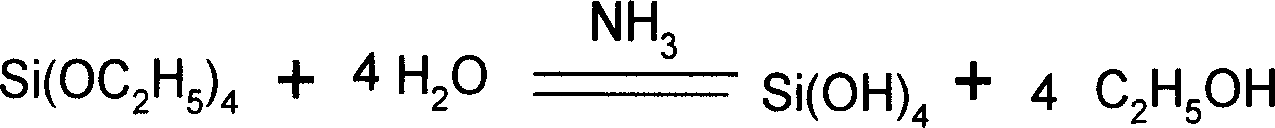

Method of treating magnesium alloy work-piece surface

InactiveCN101016627AProtectiveDecorativeMetallic material coating processesElectrolysisChemical transformation

The invention discloses a surface disposing method of electron alloys work piece, which is characterized by the following: including work piece fore treatment, chemical transformation treatment, drying treatment and washing treatment of each interprocess; dipping electron alloys work piece into inverting liquid of main filming matter and assistance filming matter as chemical transformation treatment; setting main filming matter as one or several zircon salt, manganic salt, molybdate and tungstate and so on transient metal salt; converting to Na2MoO4.2H2O content with density at 5-150g / L; setting the assistance filming matter as one or several nitrate and sulfate of lithium, sodium and potassium alkali metal; converting to LiNO3 content with density at 0.5-20g / L and pH value of inverting liquid at 2-6; controlling the disposing temperature at 10-90 deg.c and disposing time at 5-30 min. This surface film possesses properties of protection and decoration.

Owner:CHONGQING UNIV

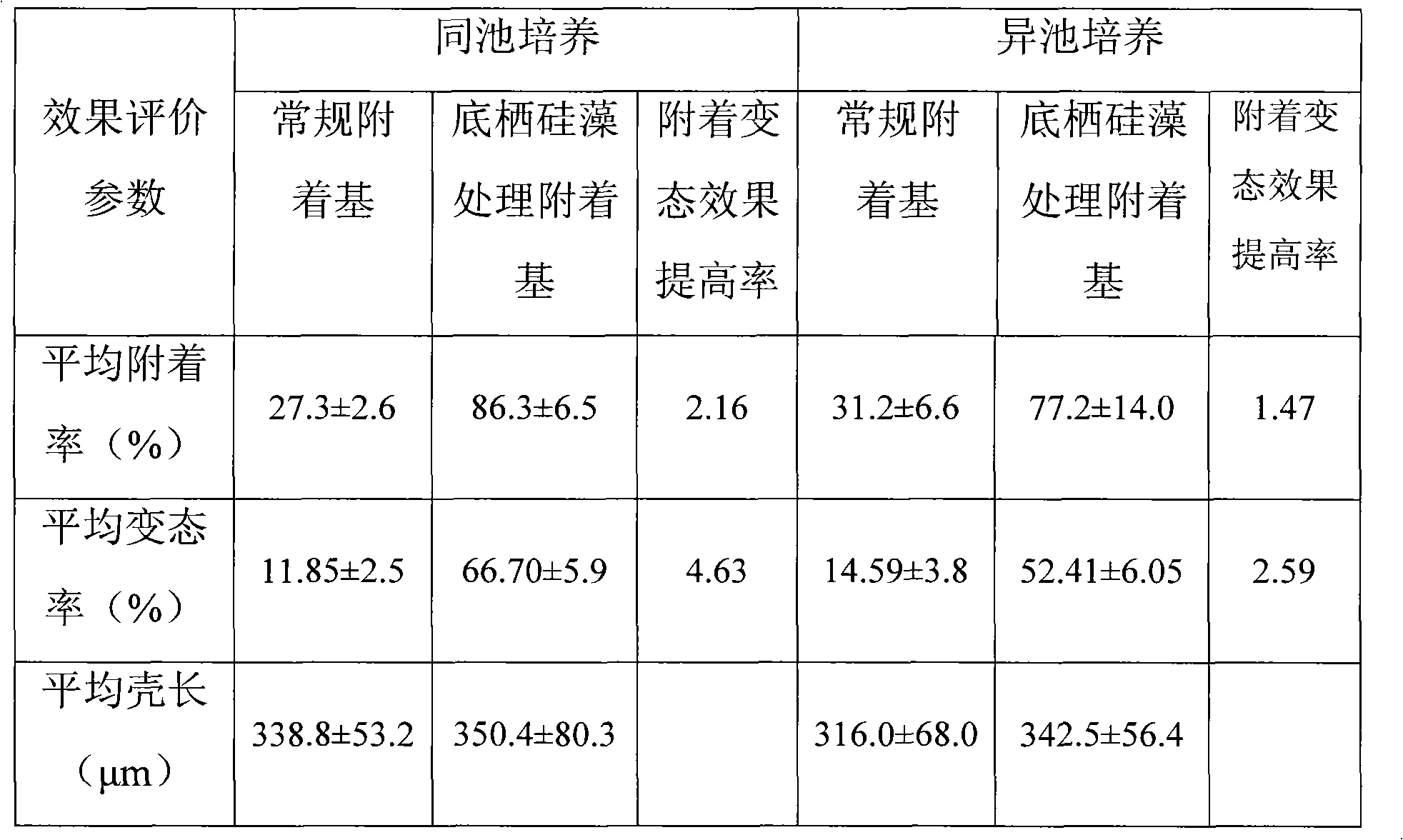

Ecological treatment and seedling attaching method of shellfish attaching bases

ActiveCN101675732AEasy to operateOptimal treatment processClimate change adaptationPisciculture and aquariaAfter treatmentLate stage

The invention relates to a treatment method of middle-late stage attaching bases in shellfish seedling breeding, in particular to a method for treating the attaching bases (mesh sheets, red palm ropesand the like) of shellfish (scallops, mussels, arca inflata reeves and the like) by using the benthic diatom film method, thereby greatly improving the larval attaching rate and the metamorphosis rate. The method has convenient operation and can treat a large number of attaching bases. The treatment method and the attaching bases after treatment have no pollution and are safe and environment-friendly; more importantly, the seedling attaching effect is significantly better than the attaching bases treated by using the traditional method.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

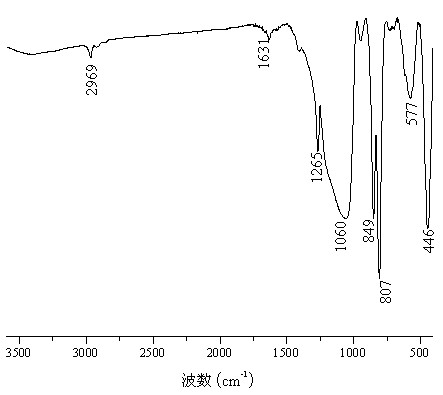

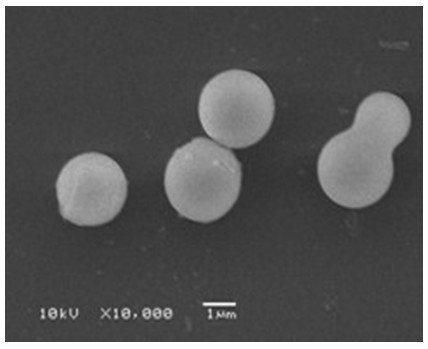

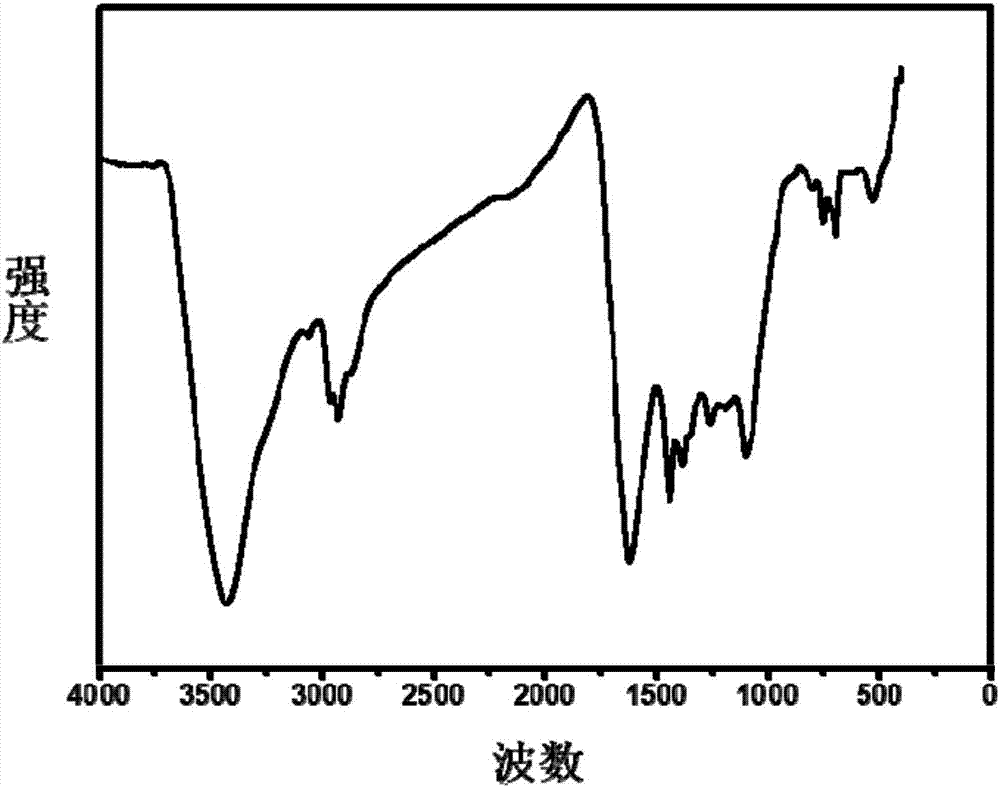

Synthesizing method for organic silicon micro-balls with performances of super hydrophobicity and high temperature resistant

The invention discloses a synthesizing method for organic silicon micro-balls with performances of super hydrophobicity and high temperature resistant, which relates to the synthesizing method of organic silicon. The synthesizing method for the organic silicon micro-balls comprises the following steps: firstly hydrolyzing n-silicate ester of which the structural formula is Si(ORn)4 (n is the number of carbon atom), and then forming a spherical pre-polymer after polycondensation; adding alkylchlorosilane of which the structural formula is Cl2Si(Rn)2 (n is the number of carbon atoms) or alkoxy silane of which the structural formula is (Rn)2Si(ORn)2 (n is the number of carbon atoms), so as to obtain the organic silicon micro-balls of which surfaces are fully provided with alkyls after copolycondensation. The obtained micro-balls have good dispersibility, and have characteristics of super hydrophobicity and high temperature resistant and the range of particle diameter is within 0.5-10 microns. The organic silicon micro-balls are simple in production technology, free form pollution during the production process and convenient for post-treatment technology, and can be widely applied to rubber, plastic and adhesive, so as to improve the temperature resistant performance of basis materials. The organic silicon micro-balls also can be applied to coating and self-prepared hydrophobic self-cleaned coating.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

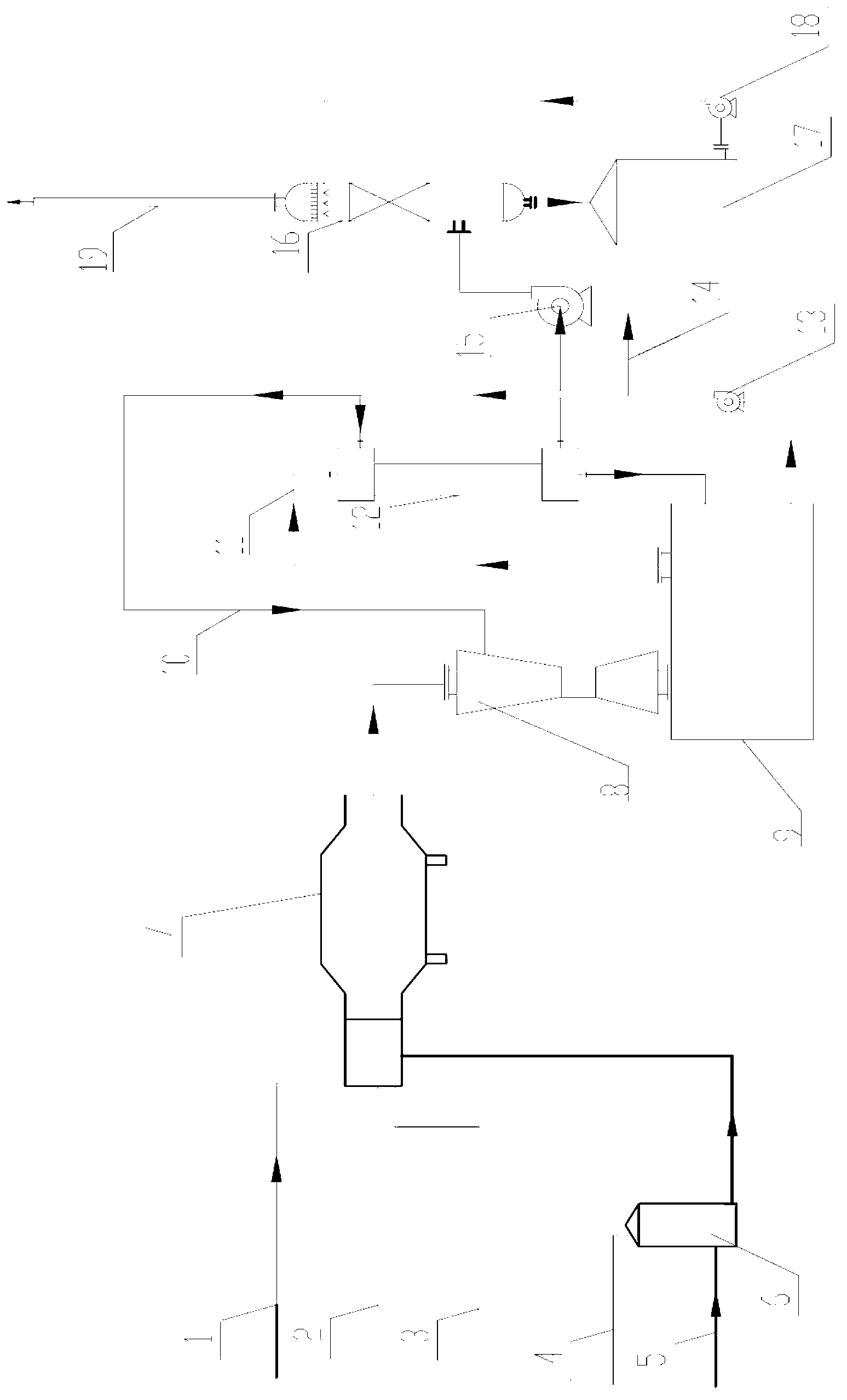

Negative-pressure incineration disposal system and negative-pressure incineration disposal method for fluorine-containing organic waste liquid and exhaust gas

ActiveCN103292332AExtend your lifeImprove conversion rateFluorine/hydrogen-fluorideIncinerator apparatusCombustion chamberDecomposition

The invention provides a negative-pressure incineration disposal system and a negative-pressure incineration disposal method for fluorine-containing organic waste liquid and exhaust gas. The negative-pressure incineration disposal system comprises an incinerator, a fluorine-containing organic waste liquid and exhaust gas supply system, a fuel supply system, a negative-pressure air supply system, a flue gas chilling and HF (hydrogen fluoride) recycling system and an alkali cleaning system. The negative-pressure incineration disposal method includes respectively and simultaneously feeding the fluorine-containing waste liquid and exhaust gas into combustion chambers of the incinerator; enabling the fluorine-containing waste liquid and exhaust gas to carry out high-temperature decomposition reaction at the 1100-1200 DEG C reaction temperature of the inside of the incinerator, under the -50Pa pressure of the inside of the incinerator and in the presence of oxygen; filling H<2> or CH<4> into the incinerator to promote redundant organic fluorine to be converted into inorganic hydrogen fluoride so as to guarantee that all the organic fluorine is converted into inorganic hydrogen fluoride ultimately; treating reaction products discharged from the combustion chambers of the incinerator and then discharging the treated reaction products into the atmosphere via a chimney. The negative-pressure incineration disposal system and the negative-pressure incineration disposal method have the advantages that the parameter adjustment quantity and parameter adjustment links are reduced, operation is facilitated, and long-period stable production running can be maintained.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

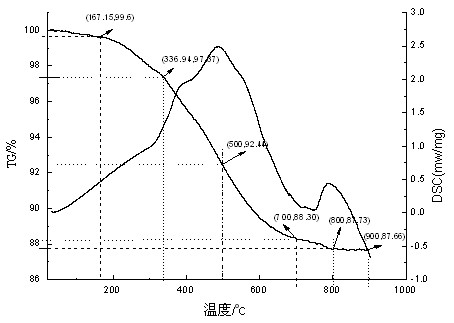

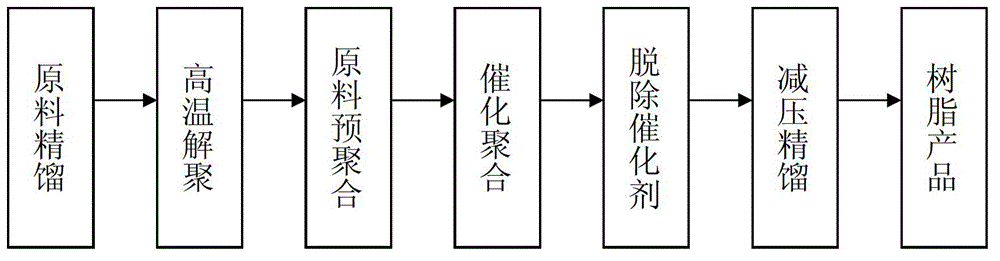

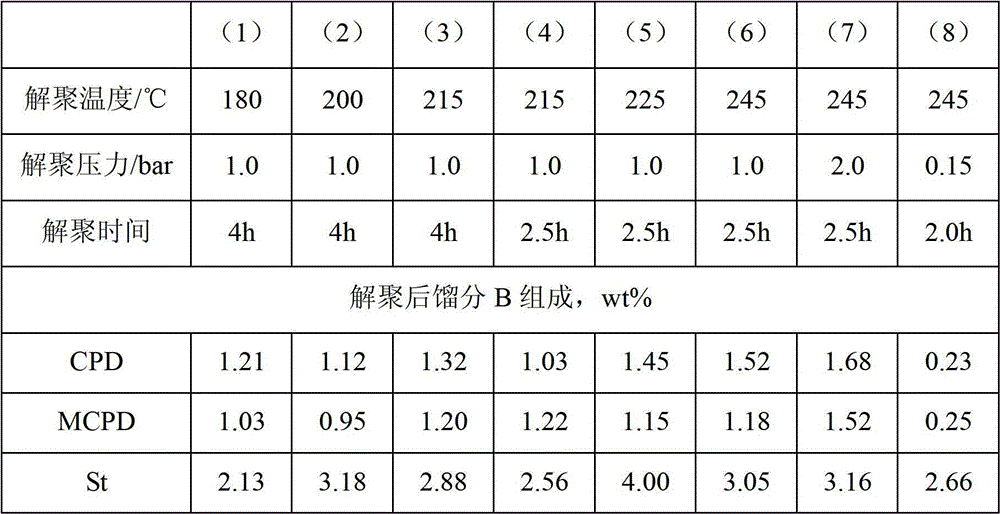

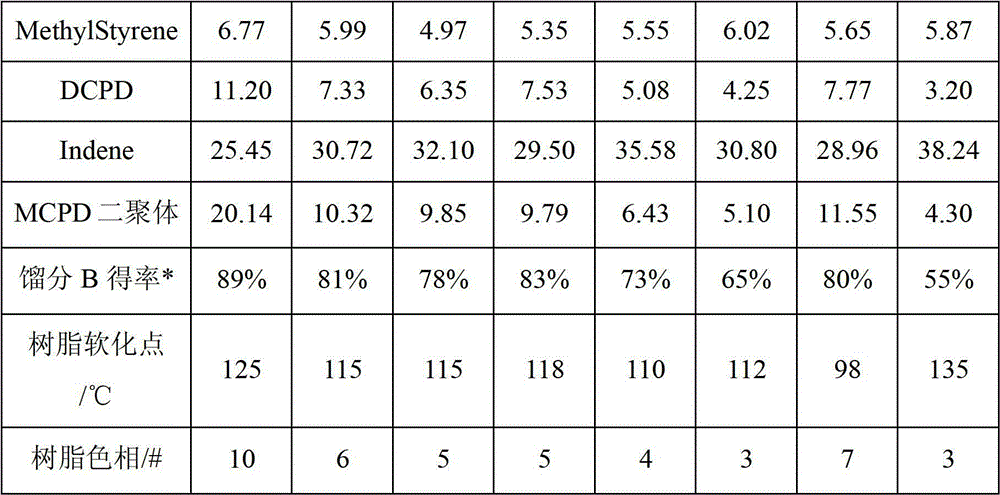

Method for preparing cold-polymerized indene resin with high softening point and light color

The invention relates to a method for preparing a cold-polymerized indene resin with high softening point and light color. The method comprises a step of intercepting a fraction A having a boiling point of 180 to 230 DEG C from a C9 fraction which is a byproduct of ethene pyrolysis; a step of getting a fraction B through removing most DCPD, DMCPD, CPD-MCPD dimers by depolymerizing in a depolymerization reactor at atmospheric pressure; a step of getting a fraction C through pre-polymerizing the fraction B by a Friedel-Crafts catalyst at room temperature; a step of getting a polymerization solution by polymerizing at 10 to 45 DEG C in which the fraction C is used as raw materials and boron trifluoride ether or gas boron trifluoride is used as a catalyst; a step of getting a resin solution through removing the catalyst by using a mixture of calcium hydrate and methanol or ethanol; and a step of getting the cold-polymerized indene resin through removing a solvent by distillation under a reduced pressure. The method is simple in technology and mild in reaction condition, and the prepared indene resin has high softening point and light color, and is applicable in the fields of high-grade paint, printing ink, printing, etc.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

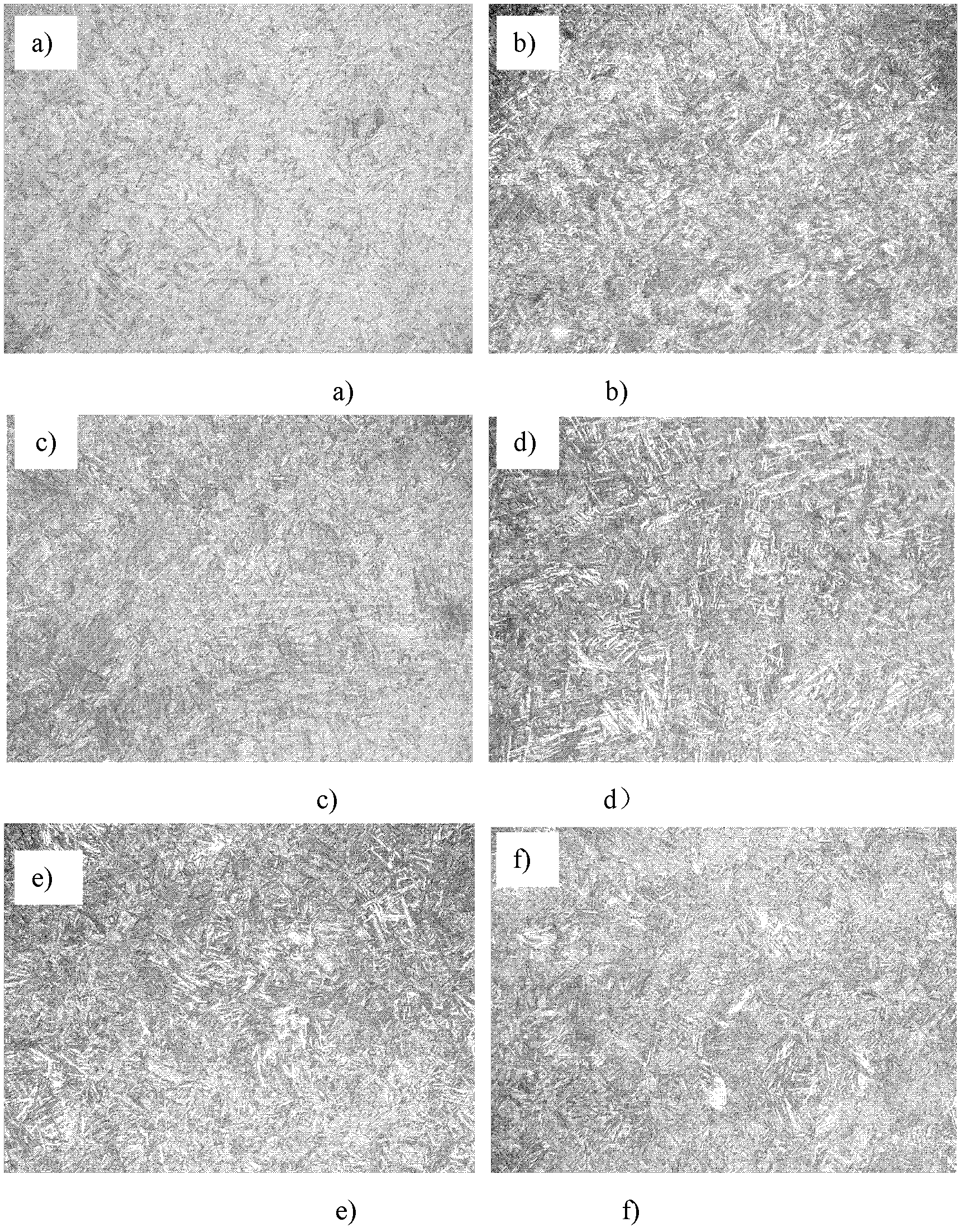

Thermal treatment process for TC4 titanium alloy forging

The invention discloses a thermal treatment process for a TC4 titanium alloy forging. The traditional common annealing treatment process is improved, and the thermal treatment process comprises the steps of carrying out solution treatment at the temperature about 50 DEG C lower than a phase transformation point of the TC4 titanium alloy forging, wherein water cooling is used as a cooling way; after finishing solution treatment, annealing at 760-780 DEG C; and after annealing and air cooling, additionally carrying out aging treatment at 530+ / -10 DEG C for at least 6h. By using the thermal treatment process, the problems of excessive primary alpha phases, unqualified high-temperature durability and excessively-low room-temperature strength in the integration of the traditional common annealing thermal treatment process for the TC4 titanium alloy forging are effectively solved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

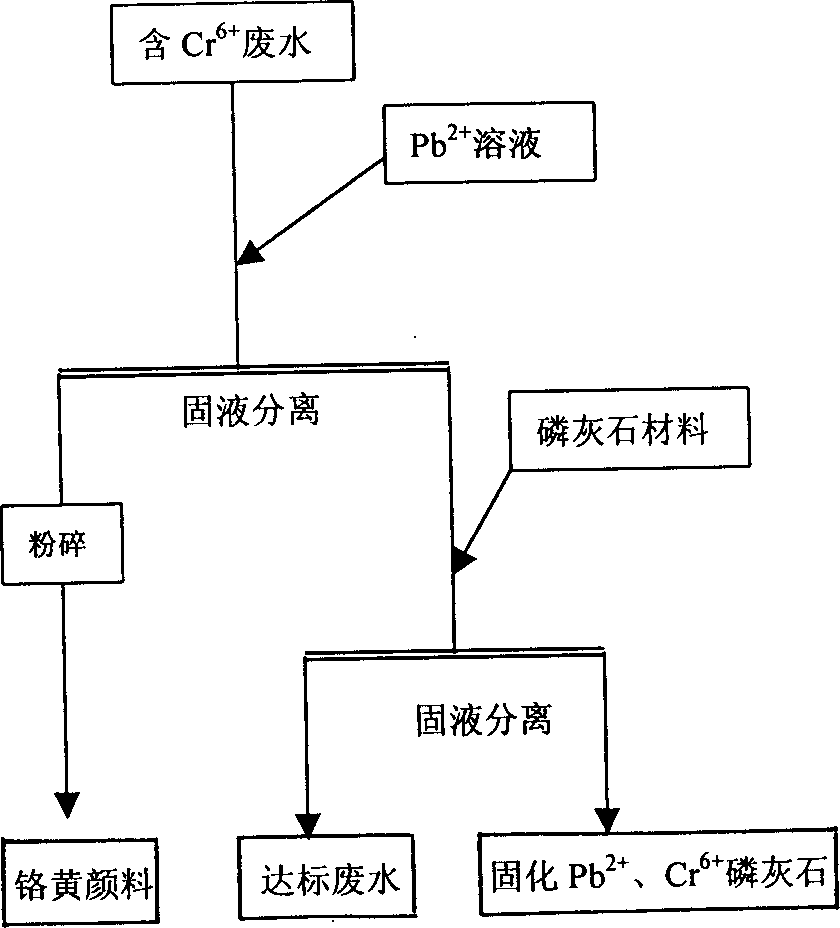

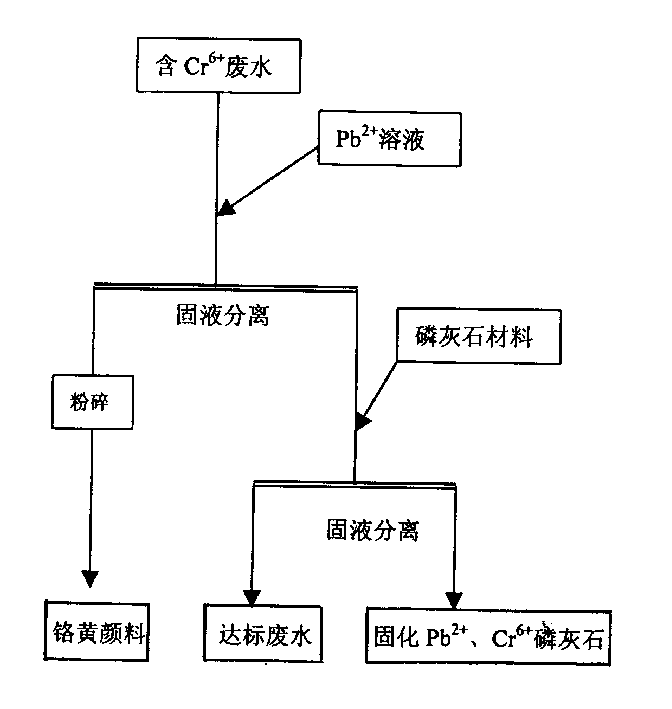

Process for recovering chrome yellow from chrome containing sewage

InactiveCN1373094AAvoid secondary pollutionOptimal treatment processPigmenting treatmentChromates/bichromatesWastewaterSewage

A process for recovering chrome yellow from the Cr-containing waste water and removing metallic ions includes adding the solution containing Pb (2+) ions to said waste water to generate PbCrO4 precipitate and reduce the Cr (6+) concentration to lower than 0.5 mg / L, solid-liquid separation, drying the solid, cooling, pulverizing to obtain chrome yellow powder, adding francolite to the liquid to adsorb Cr (6+) and Pb (2+) ions, solid-liquid separation, and draining the liquid.

Owner:WUHAN CHEM COLLEGE

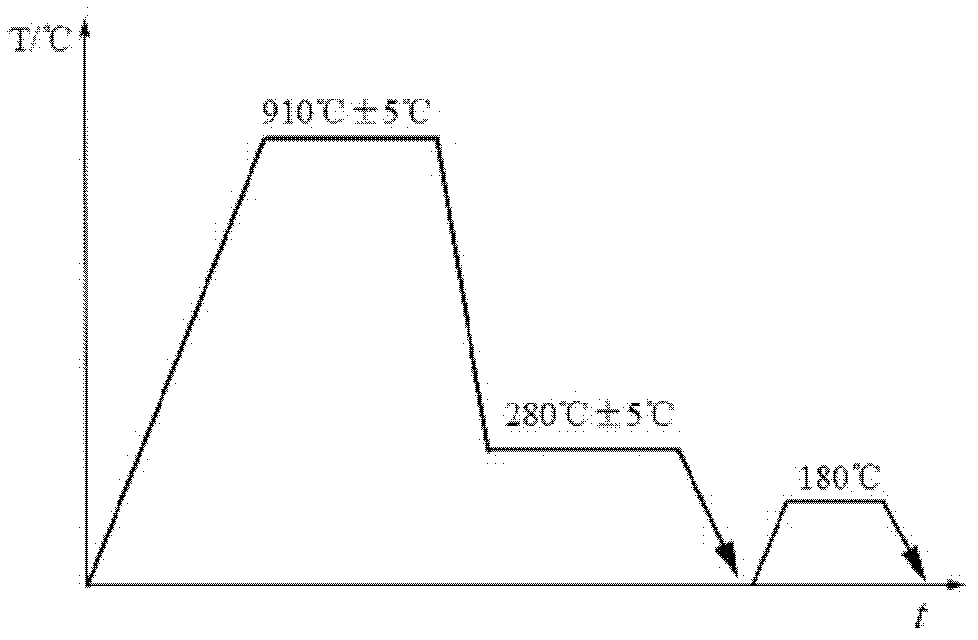

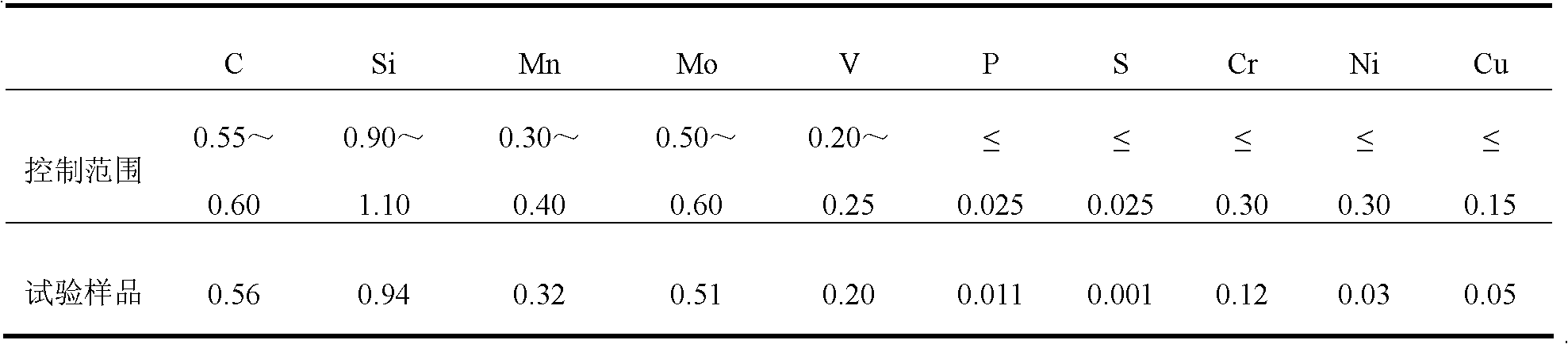

Isothermal quenching method of bearing steel G55SiMoV

The invention discloses an isothermal quenching method of bearing steel G55SiMoV. The isothermal quenching method is characterized in that bainitic bearing steel G55SiMoV is subjected to isothermal quenching and a quenched microstructure is a bainite / martensite mixed microstructure. The isothermal quenching method comprises the following steps of 1, keeping a sample at an austenitizing temperature of 890 to 920 DEG C for 20 to 30 minutes, 2, carrying out quenching in a medium containing KNO3 and NaNO2, 3, cooling to a temperature of 270 to 290 DEG C and keeping the temperature for 15 to 45 minutes, and 4, cooling gradually to a temperature of 170 to 190 DEG C and carrying out tempering thermal insulation for 1 to 2 hours, wherein the steel G55SiMoV treated by the above steps has a lower bainite / martensite mixed microstructure and the content of lower bainite is in a range of 15 to 25%. A workpiece treated by the isothermal quenching method has the advantages of small deformation, good size stability, generation of a surface stress state, difficult generation of grinding cracks, and high impact toughness and fracture toughness. Therefore, the isothermal quenching method can improve steel performances greatly.

Owner:董吉广

Environmentally friendly multifunctional metal cleaning agent

The invention relates to environmentally friendly multifunctional metal cleaning agent, especially applicable to cleaning of metal workpieces of bearing, tractor, automobile, construction machine, aviation machine, textile machine and chemical machine. The environmentally friendly multifunctional metal cleaning agent provided by the invention can effectively remove oil on non-ferrous metal and ferrous metal, is antirust and has no pollution to the environment. The invention is prepared by the following raw materials: 0.5-2% of peregal, 1-10% of 6501, 1-5% of triethanolamine oleate, 1-10% of sodium nitrite, 1-10% of triethanolamine, 5-8% of triethanolamine, 10-12% of C8-9 alkylphenol polyoxyethylene ether, 8-10% of C12 fatty alcohol-polyoxyethylene ether, 6-9% of 12 fatty alcohol-polyoxyethylene ether, 8-10% of polyether and 50-70% of water.

Owner:黄远婕

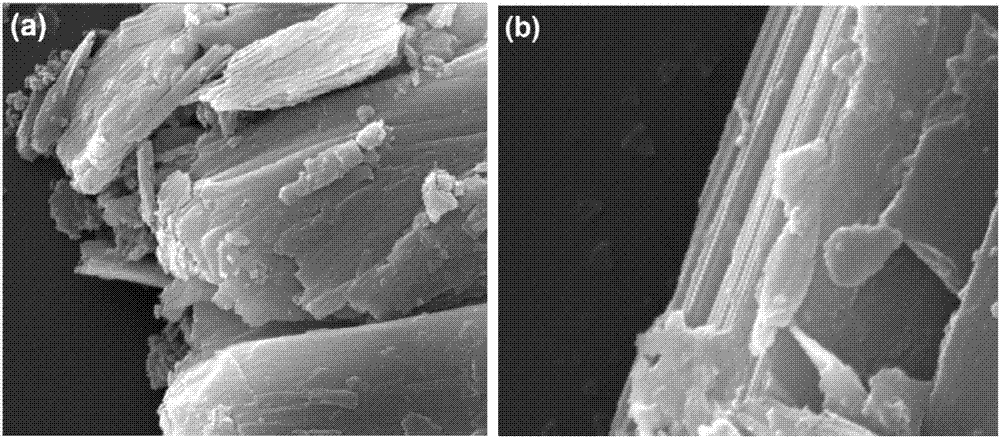

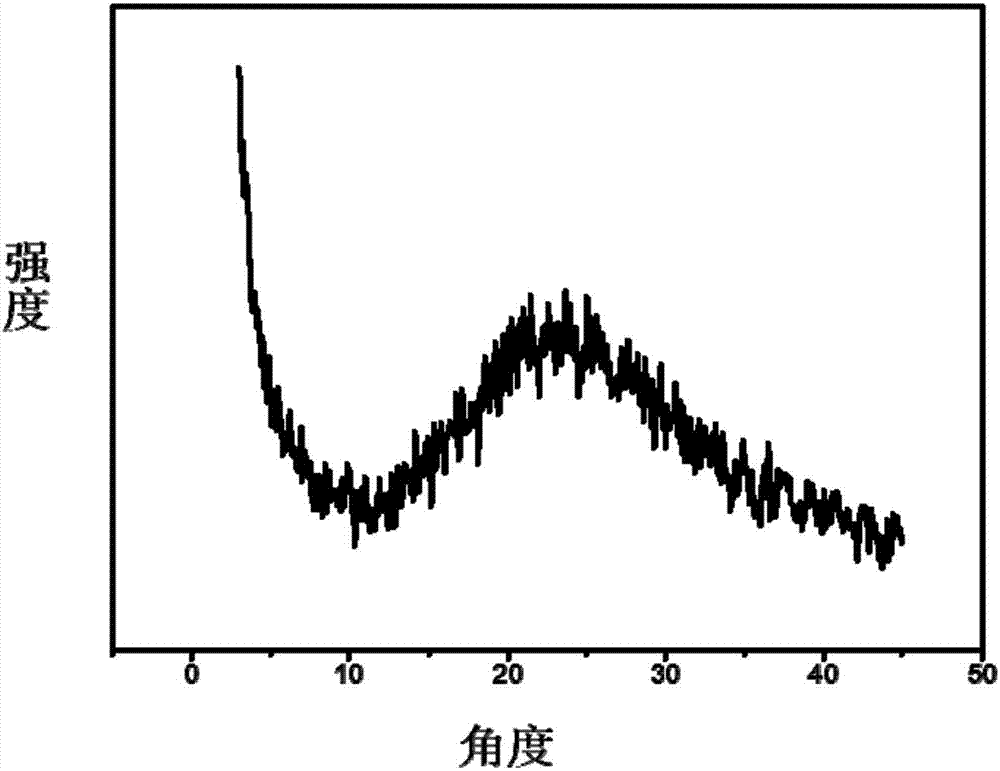

Beta-graphdiyne and synthesis method and application thereof in field of energy storage

ActiveCN106865526AImprove stabilityEasy to manufactureHybrid capacitor electrodesCell electrodesOrganic synthesisSynthesis methods

The invention discloses a beta-graphdiyne and a synthesis method and application thereof in the field of energy storage, and belongs to the field of organic synthesis. The synthesis method of the beta-graphdiyne provided by the invention comprises the following steps: using 3-(dibromomethenyl)-1,4-pentadiine as a reaction monomer, and undergoing an Sonogashira coupling reaction under the action of a catalyst and a solvent and the protection of an inert gas at a temperature of 60 to 150 DEG C to obtain beta-graphdiyne, wherein the catalyst is a mixture of a palladium catalyst and a Cu (I) salt with a molar ratio of (1 to 10) to (1 to 1), and the solvent is a mixed solvent of a conventional solvent and an organic amine solvent; and the molar ratio of the reaction monomer to the palladium catalyst is (1 to 0.05) to (1 to 0.2). The synthesis method of the beta-graphdiyne provided by the invention has the advantages that raw materials are cheap and easy to obtain, the process is simple, the cost is relatively low, and the yield is relatively high, and can be used for realizing industrial production.

Owner:SICHUAN UNIV

Treatment method for improving operating characteristics of nano-zinc oxide

ActiveCN107312362AOptimal treatment processImprove usage characteristicsPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsZno nanoparticlesNano zinc oxide

The invention discloses a treatment method for improving operating characteristics of nano-zinc oxide. The treatment method comprises the following steps of soaking modification treatment and deposition modification treatment. The prepared modified nano-zinc oxide has good dispersing characteristics, an agglomeration phenomenon is not likely to occur, the strength, corrosion resistance and temperature resistance of the nano-zinc oxide are very well improved, the compatibility with organic components are better, a filling usage effect is good, and the nano-zinc oxide has a popularization and usage value.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

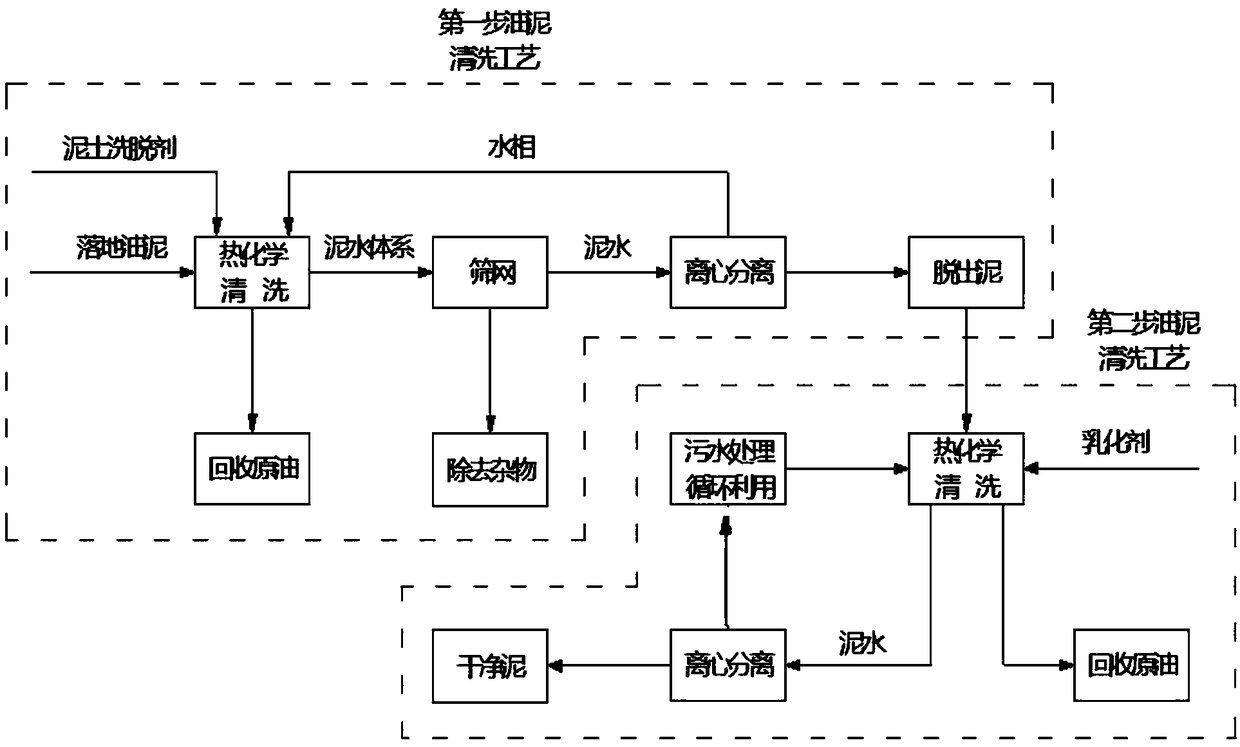

Oil sludge cleaning agent and method for treating oil sludge by using oil sludge cleaning agent

ActiveCN108059313AImprove cleaning effectLow raw material costSludge treatmentLiquid hydrocarbon mixture productionLimoneneChemistry

The invention discloses an oil sludge cleaning agent which is prepared from a soil detergent and an emulsifier. The soil detergent is prepared from the following raw material components: sodium sulfate, limonene, organic acid, trimethylene-based di(octadecyl dimethyl ammonium chloride) and water; the emulsifier is prepared from raw material components of fatty alcohol-polyoxyethylene ether, hydroxyethyl ethylenediamine, sodium carbonate and rhamnolipid. An oil sludge cleaning method comprises the following steps: Step I, adding the oil sludge cleaning agent into oil sludge to be treated for primary thermochemical cleaning, then stewing to enable a mixed system to be divided into three layers: the upper layer being cleaned crude oil, the middle layer being a water layer and the lower layerbeing a sludge and water system, performing centrifugal separation on the sludge and water system after the sludge and water system is filtered, and collecting centrifugated sludge; Step II, mixing the collected sludge with clean water, adding the emulsifier for secondary thermochemical cleaning, and then performing centrifugal separation, thus obtaining clean sludge. According to the oil sludge cleaning agent cooperating with the oil sludge cleaning method, a brand-new technical solution for twice thermochemical cleaning is adopted, so that the oil sludge cleaning efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

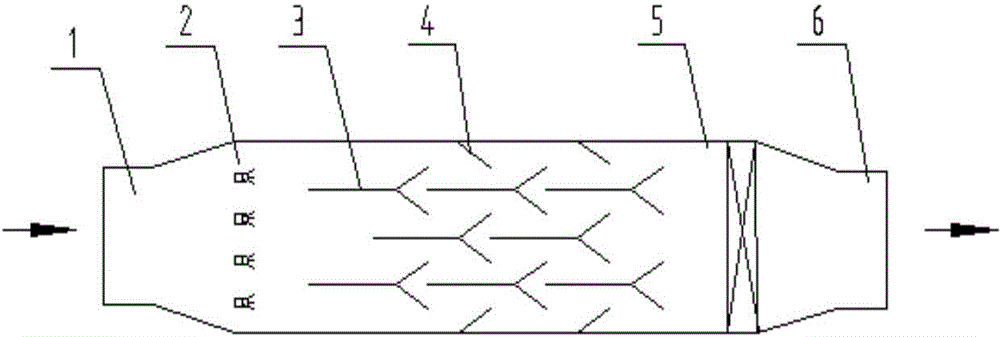

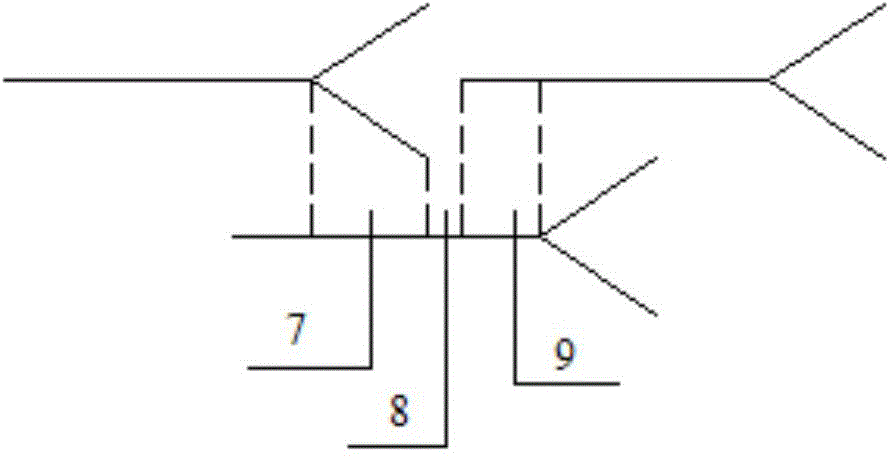

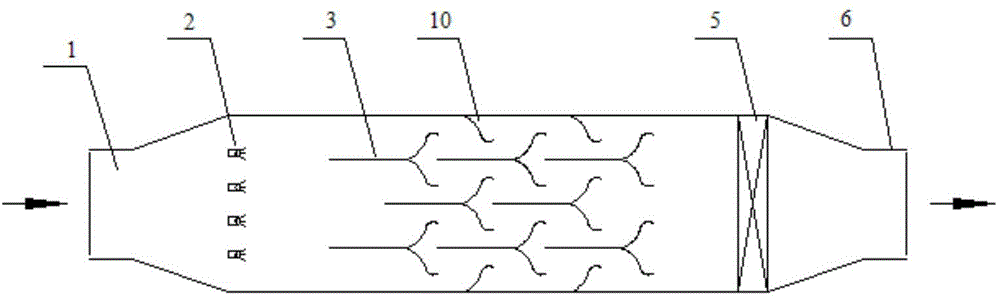

Passive plate type wet dust and mist removal device and treatment technology thereof

ActiveCN104667687ASave spaceEfficient removalCombination devicesUsing liquid separation agentSmall dropletFuel oil

The invention relates to a passive plate type wet dust and mist removal device and a treatment technology thereof. The device comprises a shell, wherein a smoke inlet channel and a smoke outlet channel are formed at two ends of the shell; an atomizing nozzle, a venturi air guide channel and a demister are sequentially arranged in the shell; the atomization nozzle is adjacent to the smoke inlet channel; the demister is connected with the smoke outlet channel; dust and mist removal treatment can be carried out through the passive plate type wet dust and mist removal device. The passive plate type wet dust and mist removal device is simple in structure arrangement, low in running resistance, and high in safety and reliability; an optimized treatment technology is adopted, so that the running is fast, and the cost is low; small particles such as small droplets, fine dust particles and aerosol in smoke can be effectively removed; and especially compared with a wet electric dust removal device and technology capable of reaching the same purification effect, the dust and mist removal device and the technology provided by the invention are free of an electrical element; the energy consumption is reduced; the economic cost is greatly reduced; and the wet dust and mist removal device is convenient to mount and is suitable for application in the field of smoke purification, dust removal and mist removal of related industries such as fire coal, fuel oil and gas thermal power plants, metallurgy, chemical engineering, and solid waste (garbage) treatment.

Owner:BEIJING ZHONGNENG NUOTAI ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

Low-temperature plasma treating process for pigment ink digital injection stamping fabric

InactiveCN101113567AClear patternBright colorUltrasonic/sonic fibre treatmentDyeing processTextile printerWater saving

The invention relates to a plasma body treatment technology of a textile used for colorant ink digital ink jet printing under low temperature, pertaining to fabric printing technical field. The invention is characterized in that the textile is put into a reaction chamber of a processor to be treated by low temperature plasma: the procedure is that: the non-collective air is flowed in, pressure adjusted, then discharged; the colorant ink is jetted and printed to textile treated by low-temperature plasma through a jet-printing machine, thus, the finished products are acquired after the textile being baked. The invention uses non-polymerized gas and low temperature plasma to modify the surface of the textile to improve moisture absorption and hydrophilicity of the modified textile, thus avoiding the problem of bleeding and too light color caused by fabric jet printing directly. The technology is characterized by rapidness, simplicity, water saving, energy conversation, harmlessness and environmental protective, etc.

Owner:JIANGNAN UNIV

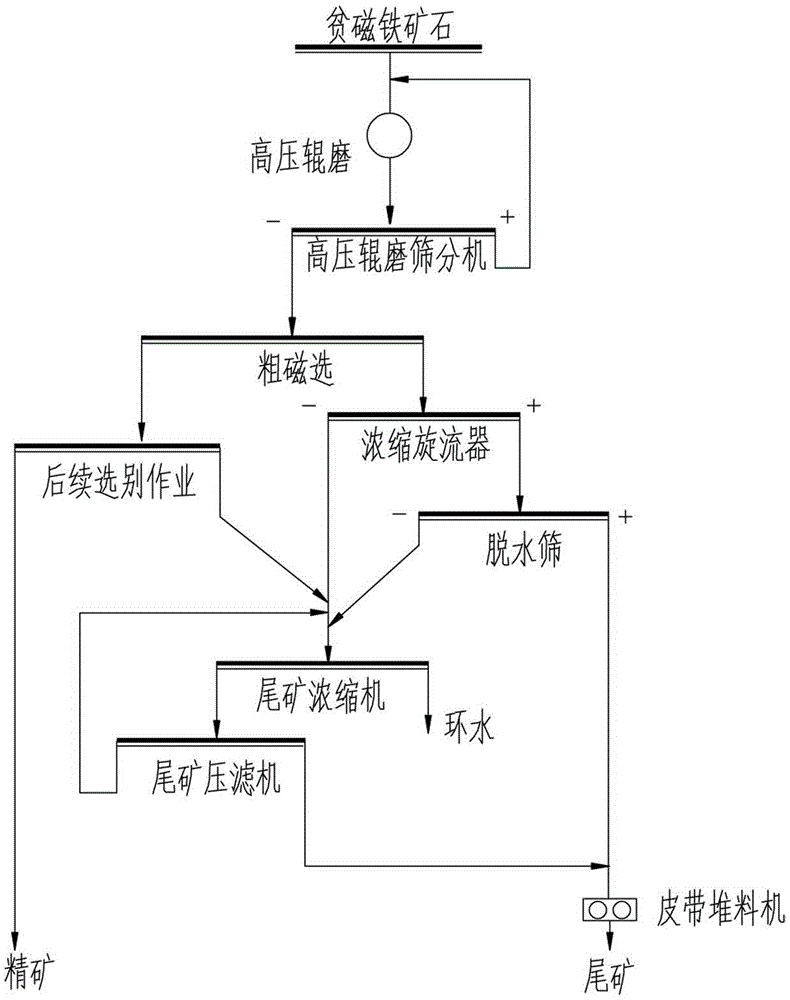

Tailing treatment process in poor magnetic iron ore beneficiation process

InactiveCN105233975AReduce processingReduce investment and footprintSolid separationMechanical material recoveryMagnetic separatorChemistry

The invention relates to a tailing treatment process in a poor magnetic iron ore beneficiation process. The tailing treatment process comprises the following steps: a poor magnetic iron ore is fed in a high-pressure grinding roller and a screening machine for a closed-circuit grinding operation; a screened product of the screening machine is fed to a roughing magnetic separator; and a concentrate thereof is fed to a subsequent operation. The tailing treatment process is characterized by further comprising the following steps: a tailing of the roughing magnetic separator is fed to a concentration cyclone; a underflow product of the concentration cyclone is fed to a tailing dehydration sieve; an overflow product of the concentration cyclone, a screened product of the dehydration sieve and a tailing in a subsequent separation operation are all fed to a tailing concentrator for a concentration operation; a underflow product of the tailing concentrator is fed to a tailing press filter for filtration; and an unscreened product of the dehydration sieve and a filter cake of the tailing press filter are fed to a tailing dry discharge belt conveyer for conveying to a tailing storage yard or a tailing pond for storage. The tailing treatment process has the following advantages: the dry discharge treatment is performed for a thick-particle tailing in nearly one half of the separation process, and the rest tailing is concentrated and filtered to realize the tailing dry discharge, so that the tailing treatment process in the poor magnetic iron ore beneficiation process is comprehensively optimized.

Owner:ANSTEEL GRP MINING CO LTD

Preparation and purification method for plant linoleic acid

InactiveCN1605618ASimple processShort cycleFatty acids production/refiningPurification methodsBoiling point

The plant linolic acid preparing and purifying process includes the following steps: stoving and crushing paper mulberry fruit and sieving to obtain paper mulberry fruit powder; preparing supercritical CO2 extracting system and feeding paper mulberry fruit powder to supercritical CO2 extracting system; extracting to obtain paper mulberry fruit oil; preparing system and feeding material; regulating rotation speed, flow rate and vacuum degree, and distilling to eliminate low boiling point component; distilling in molecular distillatory at certain temperature, vacuum degree and rotor speed to obtain coarse linolic acid; and distilling in molecular distillatory at regulated temperature, vacuum degree and rotor speed to obtain refined linolic acid. The product has linolic acid content of 78-82 5 and the process has yield of 36-41 %.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

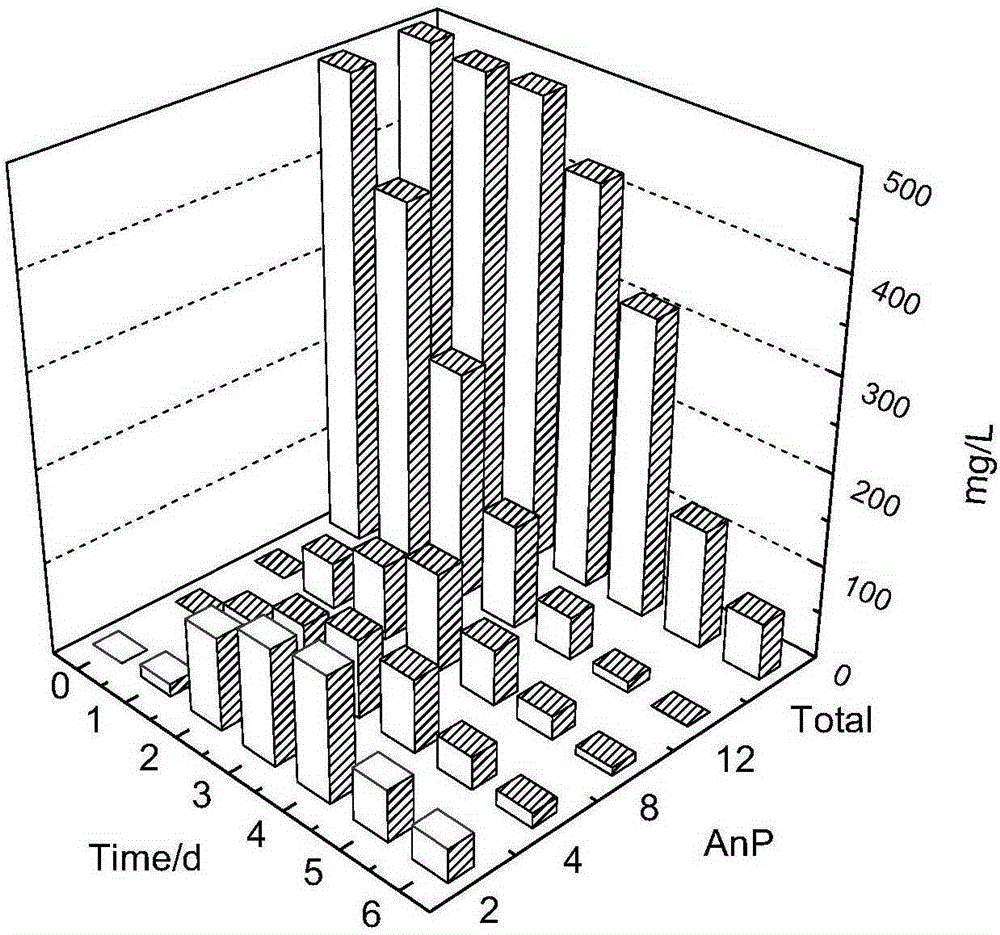

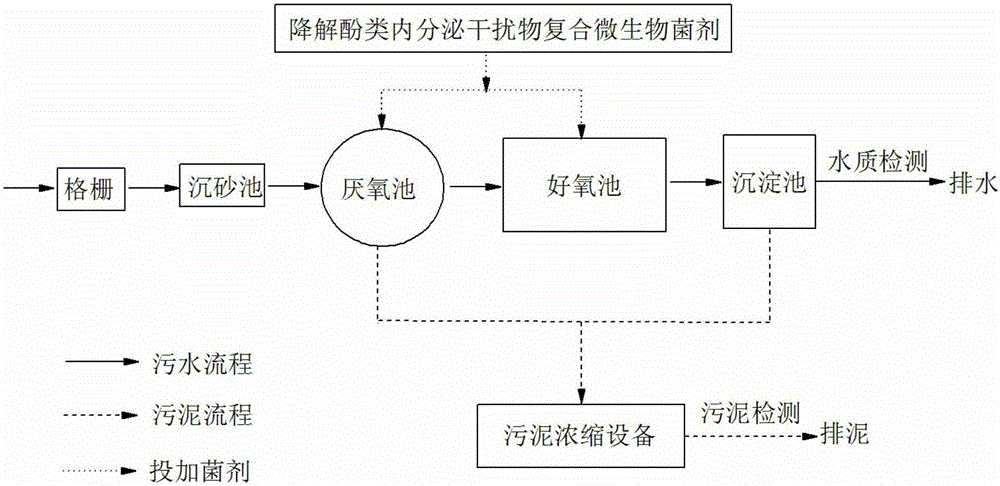

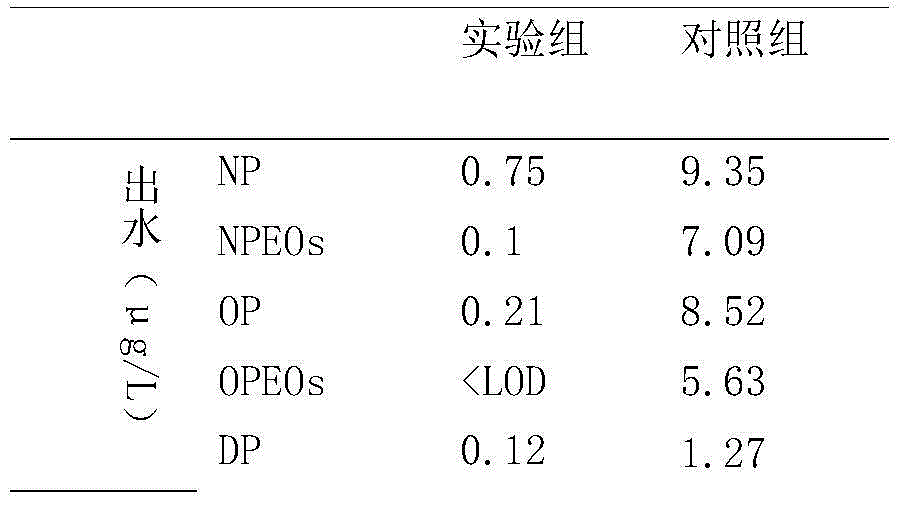

Compound microbial preparation for degrading phenol endocrine disrupter and preparation method

ActiveCN105219684ASimple processOptimal treatment processBacteriaWater contaminantsBacillus licheniformisHigh concentration

The invention relates to a compound microbial preparation for degrading phenol endocrine disrupter and a preparation method, and relates to microorganism projects and sewage and waste water treatment processes. The compound microbial preparation comprises Klebsiella sp., azospirillum lipoferum, rhodococcuserythropolis and bacillus licheniformis. The microbial content of Klebsiella sp. accounts for 30%-50% of the total microbial content. The microbial content of azospirillum lipoferum accounts for 30%-50% of the total microbial content. The microbial content of rhodococcuserythropolis accounts for 10%-30% of the total microbial content. The microbial content of bacillus licheniformis accounts for 10%-30% of the total microbial content. The compound microbial preparation is fed into an anaerobic tank and an aerobic tank, and the sewage and waste water treatment processes are enhanced. The compound microbial flora can tolerate the high-concentration phenol endocrine disrupter which is used as organic matter needed in growth for being fully utilized and degraded, the sewage and waste water treatment processes are optimized, the secondary pollution of output water and sludge is reduced, and the safety of sludge landfill and agricultural utilization is improved.

Owner:ANHUI QINGMING ENVIRONMENTAL PROTECTION TECH CO LTD

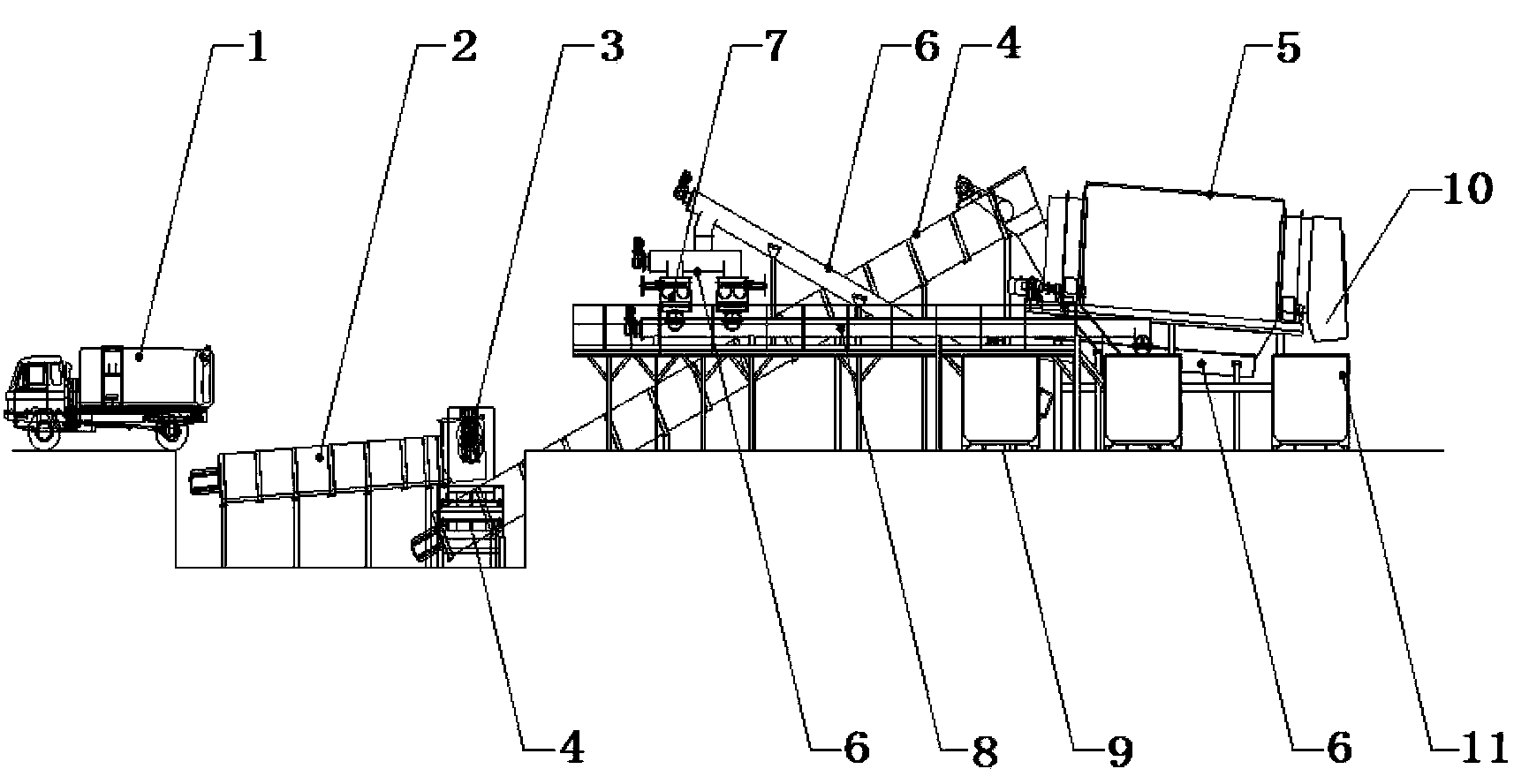

Food waste composting pre-treatment method

ActiveCN103804035AReduce oil and salt contentMeet composting process requirementsBio-organic fraction processingClimate change adaptationFiltrationMaterial distribution

The present invention relates to a food waste composting pre-treatment method, which comprises that: 1) food waste is fed, wherein food waste is poured onto a chain plate bag-breaking conveying integration machine through a special food waste transporter; 2) a roller bag-breaking device is arranged on the head section of the chain plate bag-breaking conveying integration machine to cut a big bag in materials so as to carry out preliminary bag breaking; 3) the food waste being subjected to preliminary solid-liquid separation and bag breaking is conveyed to a drum sieve through a chain belt conveyor to carry out screening; 4) the undersize material enters a pressing dewatering device through a screw conveyor; 5) the pressed and dewatered food waste is conveyed to a uniform material distribution garbage bin through the screw conveyor; and 6) the oversize material is discharged into a compressible garbage bin through the oversize material outlet of the drum sieve. The food waste composting pre-treatment method is mainly used for carrying out bag breaking, water filtration, screening and pressing dewatering on food waste so as to meet composting process requirements and improve composting effect.

Owner:BMEI

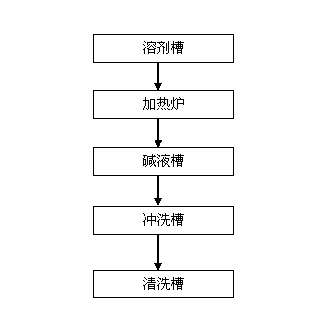

Sintered filter core cleaning device and method

InactiveCN103908840AOptimal treatment processGood regeneration effectFilter regenerationSolventMegasonic cleaning

The invention discloses a sintered filter core cleaning device and method. The device includes a solvent tank, a heating furnace, an alkali liquor tank, a swashing tank and a cleaning tank. The method comprises soaking, baking, alkali cleaning, high-pressure water cleaning, ultrasonic cleaning and high-pressure water cleaning. On a principle of not destroying a sintered filter core material and structure, and aiming at defects and weaknesses existing in a conventional sintered filter core cleaning device, improvement and reinforcement are carried out; and through optimization of a control method of the conventional device, the whole device has good regeneration effect, the filter core off-line cleaning period is prolonged, the off-line backwashing frequency is reduced, the service life of a filter core and equipment are improved, and the production cost is reduced.

Owner:DALIAN KANGSAIPU TECH DEV

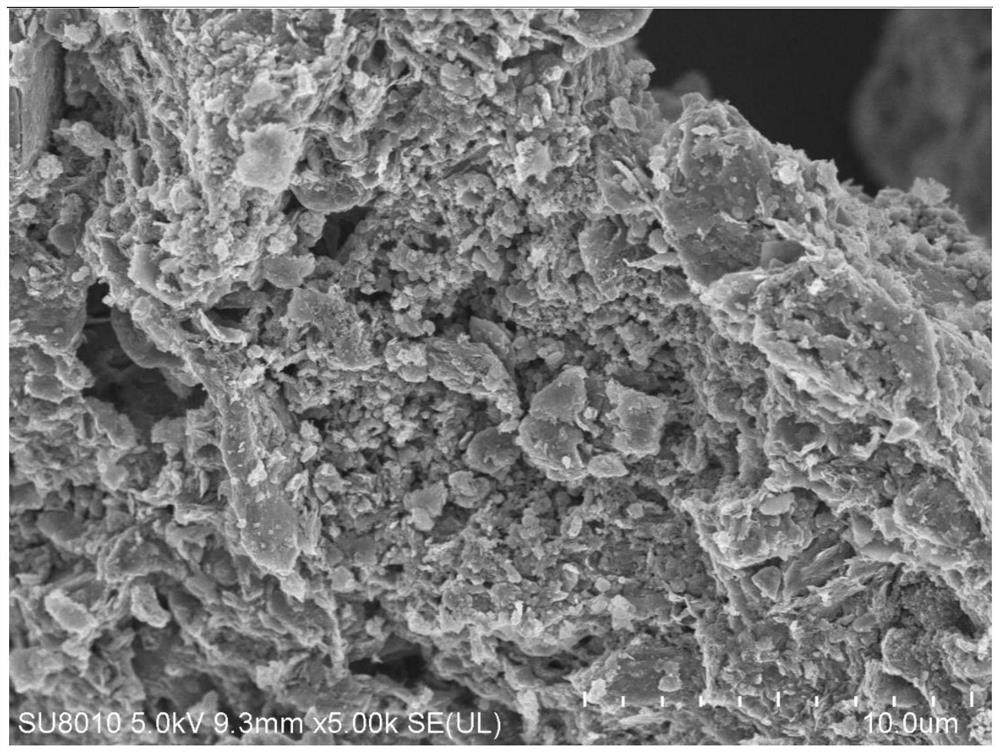

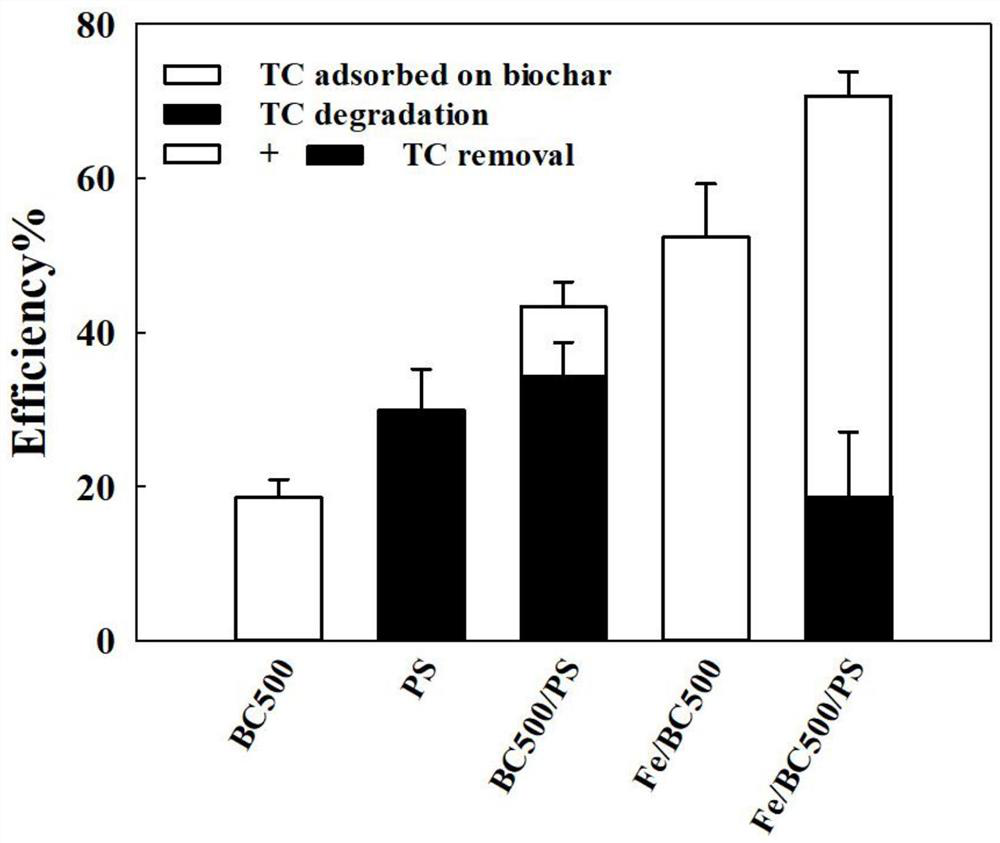

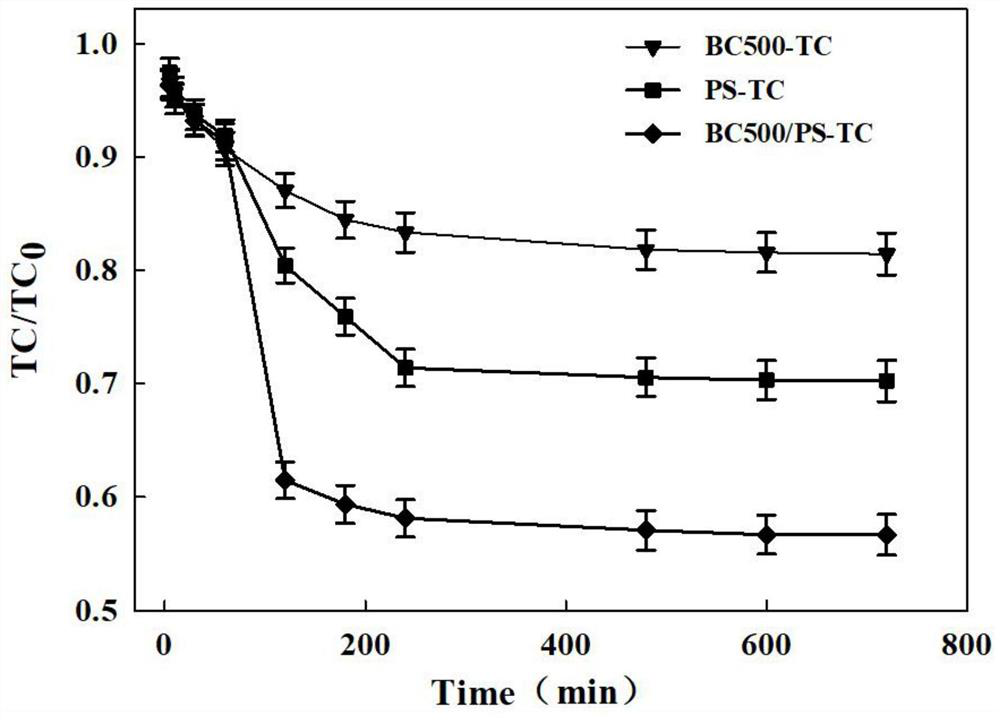

Method for activating persulfate with sludge-based biochar and synergistically removing tetracycline in water

InactiveCN111939874AOptimal treatment processEfficient removalOther chemical processesWater contaminantsSludgeBiochar

The invention discloses a method for activating persulfate with sludge-based biochar and synergistically removing tetracycline in water. The method comprises the following steps: adding 15-35mg of sludge-based charcoal and 20mL of persulfate with the concentration of 270-330mg / L into 50mL of a tetracycline solution with the concentration of 120mg / L. According to the method, the tetracycline in thewastewater is efficiently removed while the sludge resource utilization is realized, the problems of secondary water environment pollution and the like caused by metal ions or complexes of the metalions are solved to a great extent, and the method has important significance for optimizing a sewage treatment process and realizing energy conservation and emission reduction. The specific surface area of the sludge-based biochar cultured from the excess sludge at high temperature is large and is 39.719 m<2 > / g, and the sludge-based biochar can be used as an excellent adsorption material due to more attachment sites on the surface and a large pore size area.

Owner:XUZHOU UNIV OF TECH

Method for in-situ generating ultrafine silver particles in textile

InactiveCN1804203ASmall particle sizeGood dispersionFibre treatmentTextile fiberElectromagnetic radiation

The disclosed preparation method for ultramicro Ag+ in textile comprises: adsorbing Sn2+ on textile fiber surface to reduce the silver and realize the connection between silver and fiber; with the assistant of ultrasonic wave, dipping the treated textile into the ethanol-water solution of with dissolved AgNO3 to let silver grow on fiber surface at room temperature. This invention improves the dispersion and adhesion force of Ag+ in textile with simple process to enhance its prevention against electromagnetic radiation, thermal conduction and antibacterial property greatly.

Owner:ZHEJIANG SCI-TECH UNIV

Treatment method for waste water with high chloride ion content in polysilicon production

InactiveCN102351362AImprove qualityOptimal treatment processWater contaminantsMultistage water/sewage treatmentIon contentEvaporation

The invention relates to a treatment method for waste water with high chloride ion content in polysilicon production. The treatment method comprises steps of: A. pretreating the waste water with high chloride ion content aggregated in the pool to obtain a sodium chloride solution with a clarification degree and a pH reaching standards and deposition; B. concentrating the sodium chloride solution to obtain 40-50% sodium chloride concentrate and 50-60% reuse water and filtering the deposition; C. carrying out evaporation crystallization on the sodium chloride solution to obtain a sodium chloride solid-liquid mixture; D. filtering and drying the sodium chloride solid-liquid mixture containing crystals to obtain high purity sodium chloride salt. The invention employs a technology containing aconcentration before an evaporation to change waste into valuables, reuse and save water resource as possible and produce high quality solid sodium chloride salt; besides a relative cost, steam amount and electric energy are reduced and saved.

Owner:天威四川硅业有限责任公司

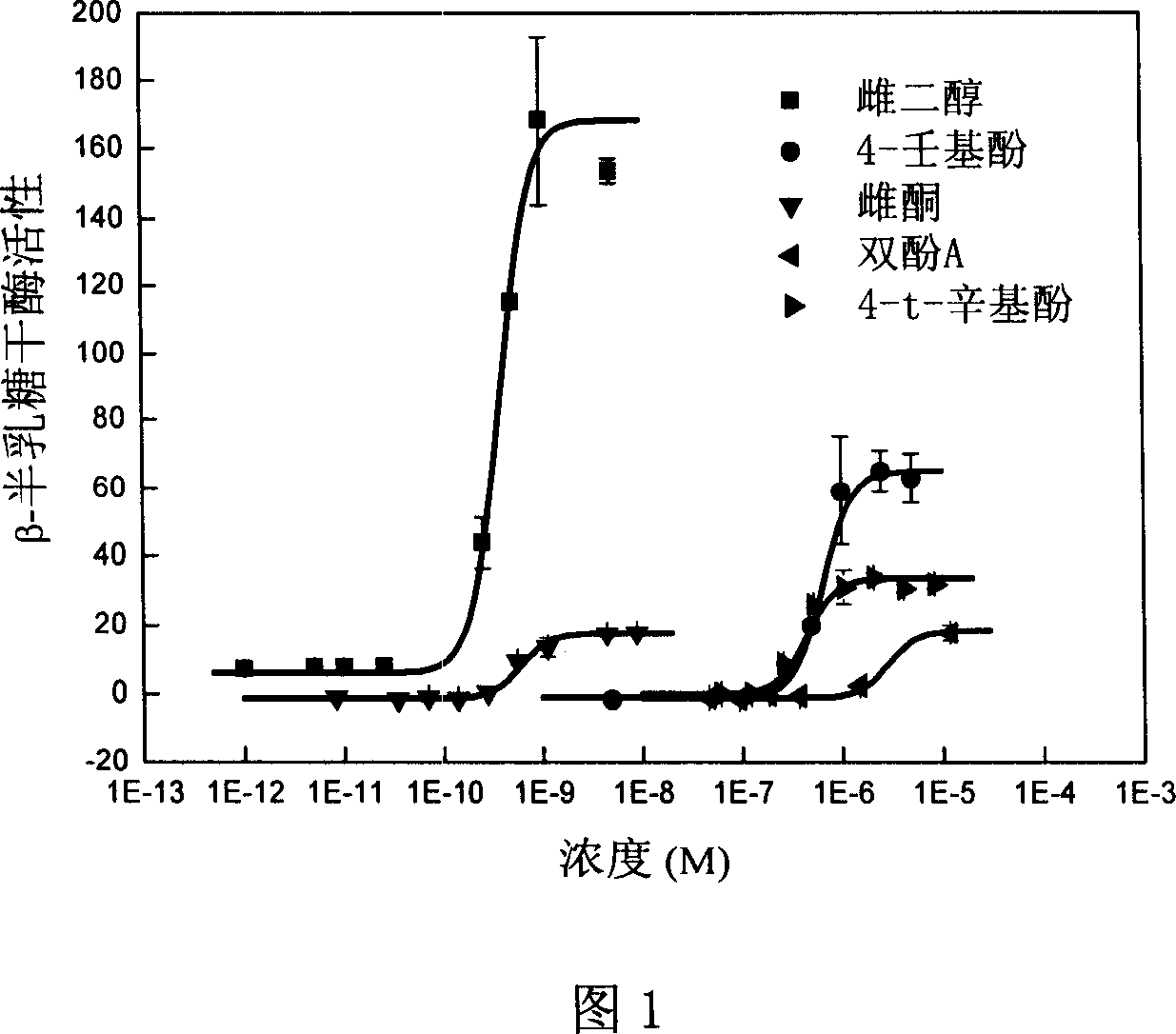

Method for investigating estrogen active constribution material in sewage

InactiveCN101000330AEliminate interferenceLong test timeComponent separationMicrobiological testing/measurementGas liquid chromatographicGas phase

The invention relates to a method used to detect estrogen activity contribution matter in sewage. It includes the following steps: extracting estrogen activity matter form the sewage sample by solid phase column extractor; using methanol, dichloroethanes, normal hexane purging, and silica gel chromatographic column to classify into polarity, moderate and weak polarity three components; using recombination gene yeast bioassay method to measure the estrogen activity; taking out the maximum component to analyze its kind and density by gas phase color photography-mass spectrum on line. This method can fast effectively detect the main estrogen activity contribution matter in the sewage, supply foundation and support for sewerage treatment technology improvement.

Owner:TSINGHUA UNIV

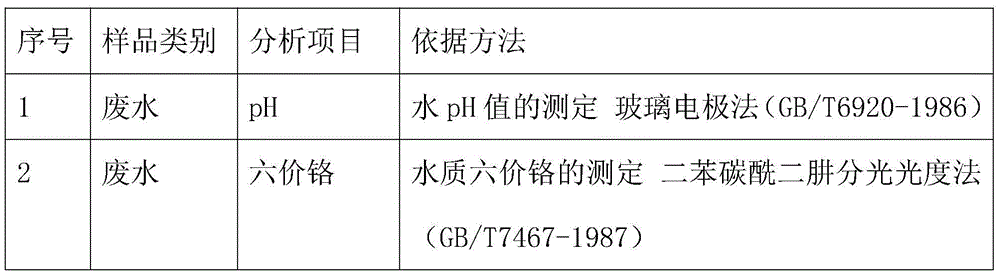

Processing technology of electroplating wastewater

ActiveCN105523663AOptimal treatment processFew stepsWater treatment parameter controlWater treatment compoundsCyanideFerrous salts

The invention discloses a processing technology of electroplating wastewater; the processing technology comprises the following steps: step 1, collecting chromium-containing electroplating wastewater and cyanide-containing electroplating wastewater; step 2, reducing chromic acid in the chromium-containing electroplating wastewater by virtue of cyanide in the cyanide-containing electroplating wastewater, to obtain comprehensive electroplating wastewater; step 3, adding an alkaline solution into the comprehensive electroplating wastewater, and adjusting the pH value of the comprehensive electroplating wastewater to 7-8, to obtain a primary precipitate; step 4, filtering the primary precipitate to obtain a supernatant; step 5, adding a ferrous salt solution and hydrogen peroxide into the supernatant, and respectively carrying out reaction to remove the remaining chromic acid and cyanide; step 6, adding the alkaline solution again, and adjusting the pH value of the supernatant to 9-10, to obtain a secondary precipitate; and step 7, removing the secondary precipitate. The processing technology is optimized, the purification efficiency is improved, the investment cost is reduced, the resource waste is saved, and the effects of treatment of wastes with wastes and resource utilization are realized.

Owner:XIAMEN TONGLIYUAN ELECTRIC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com