Patents

Literature

161 results about "Removal procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

: the act or procedure of removing by or as if by cutting out; especially : surgical removal or resection.

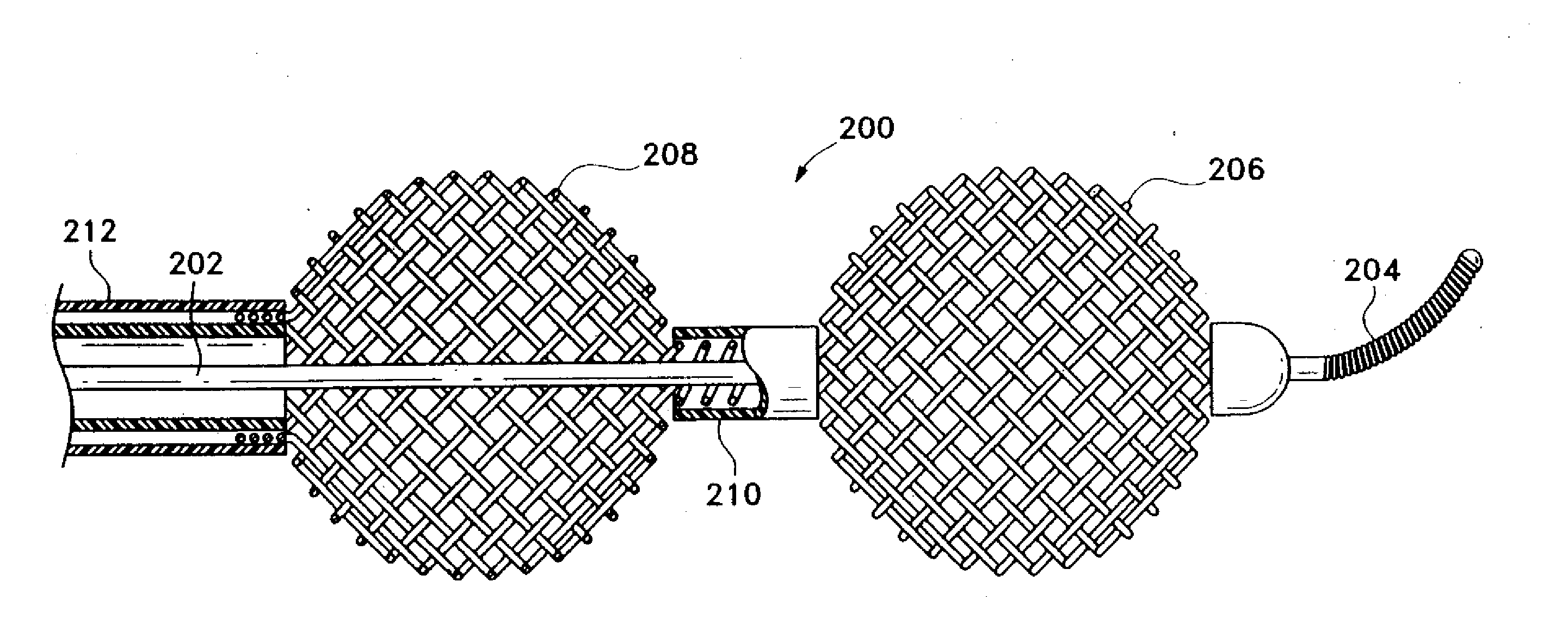

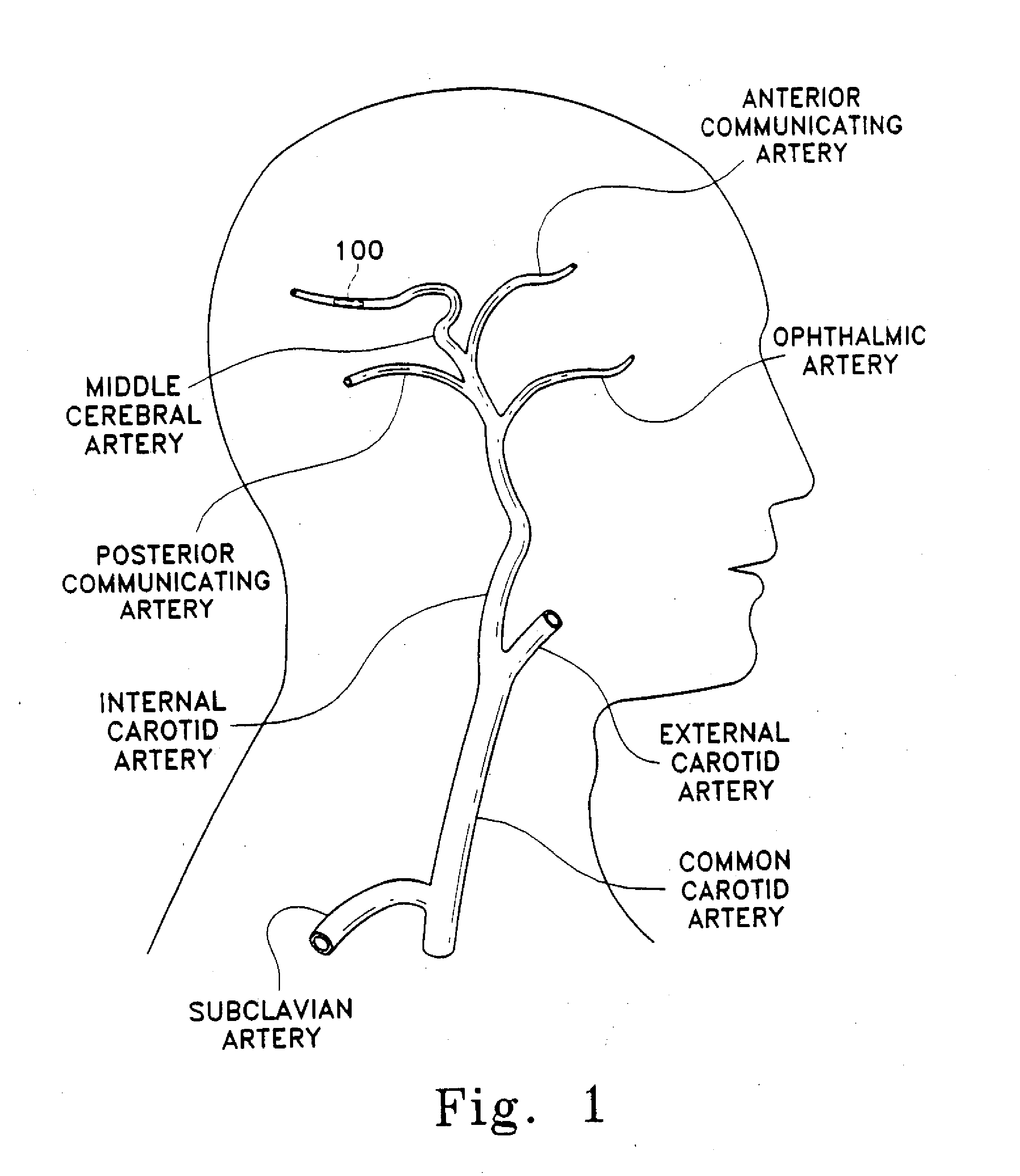

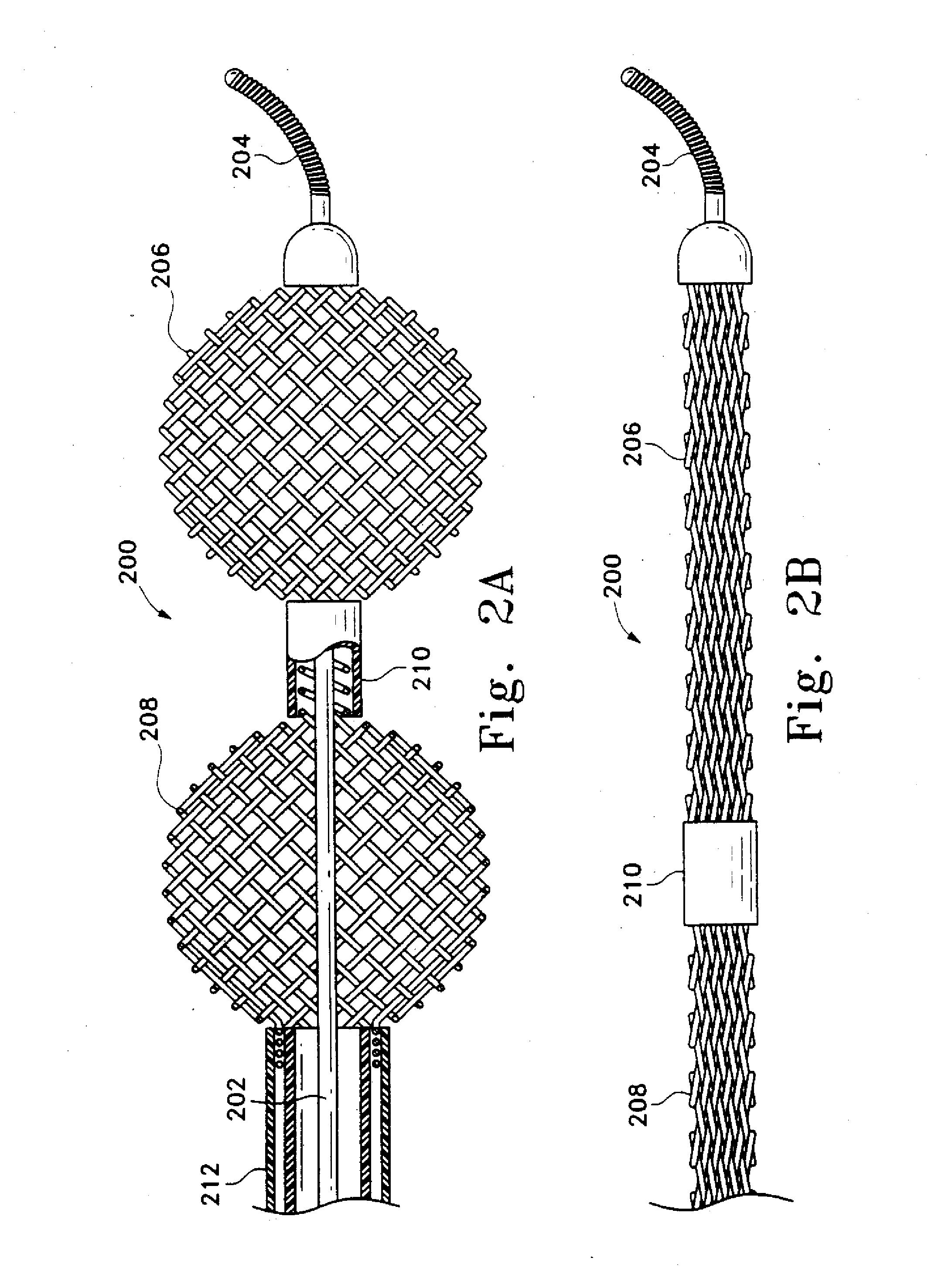

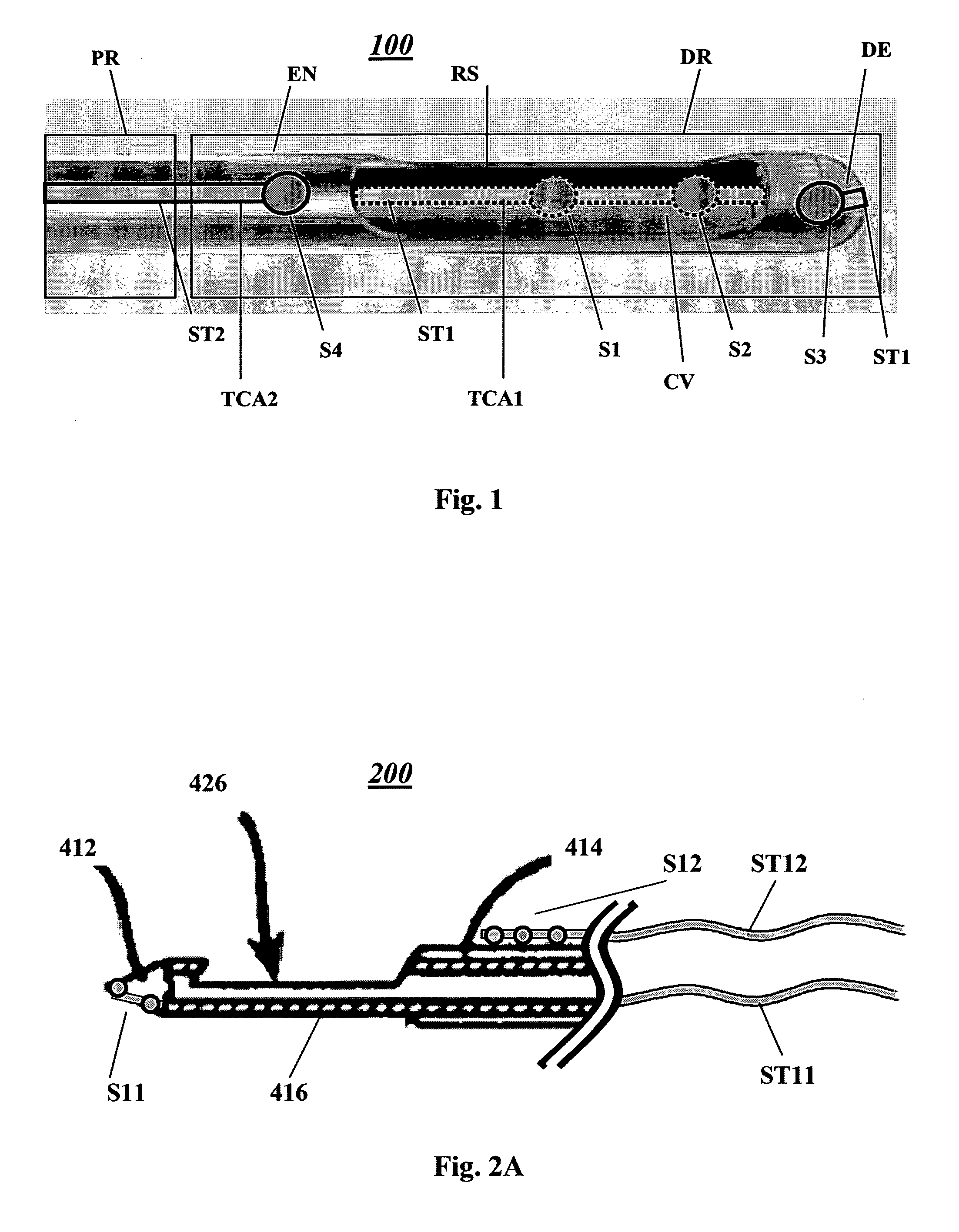

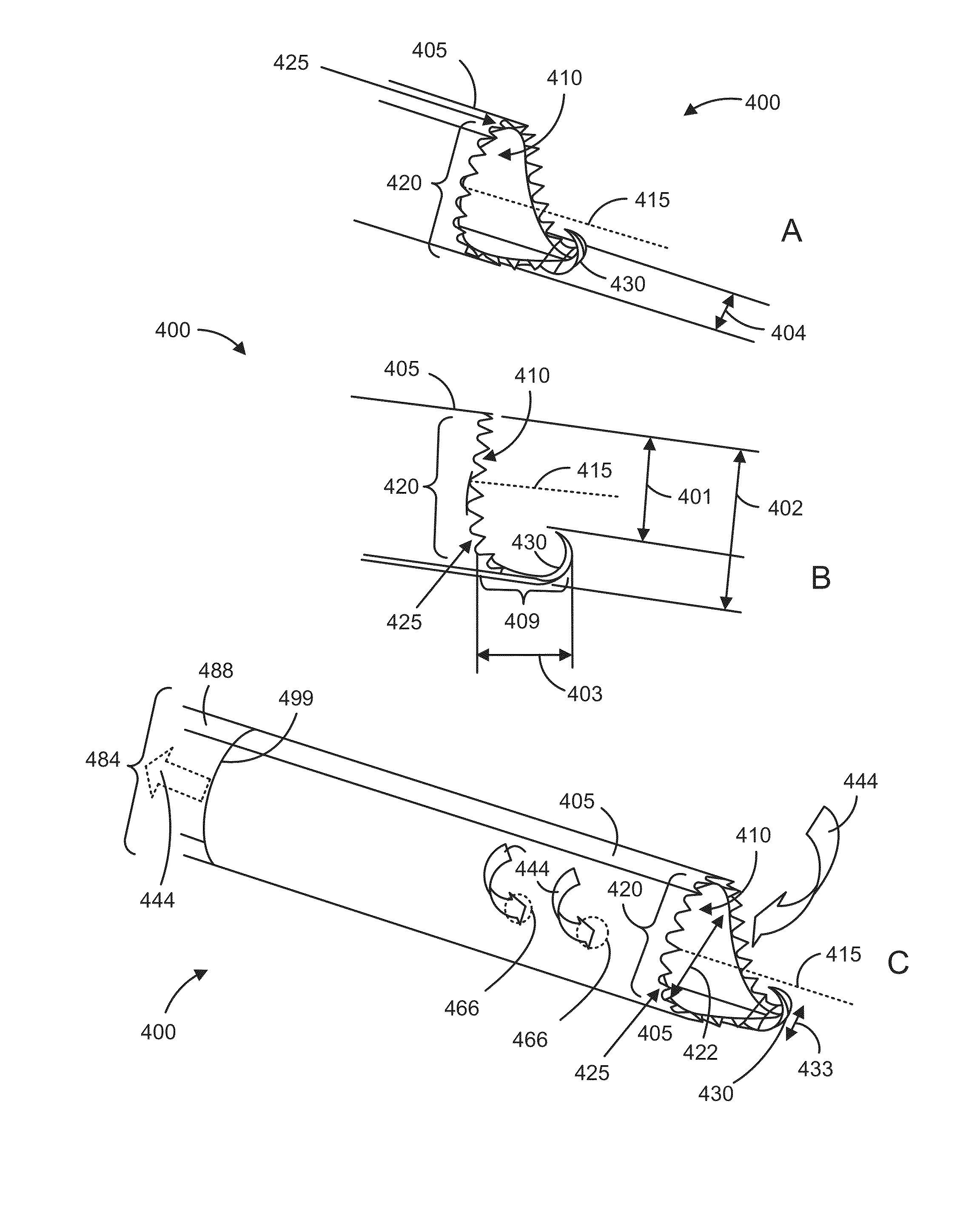

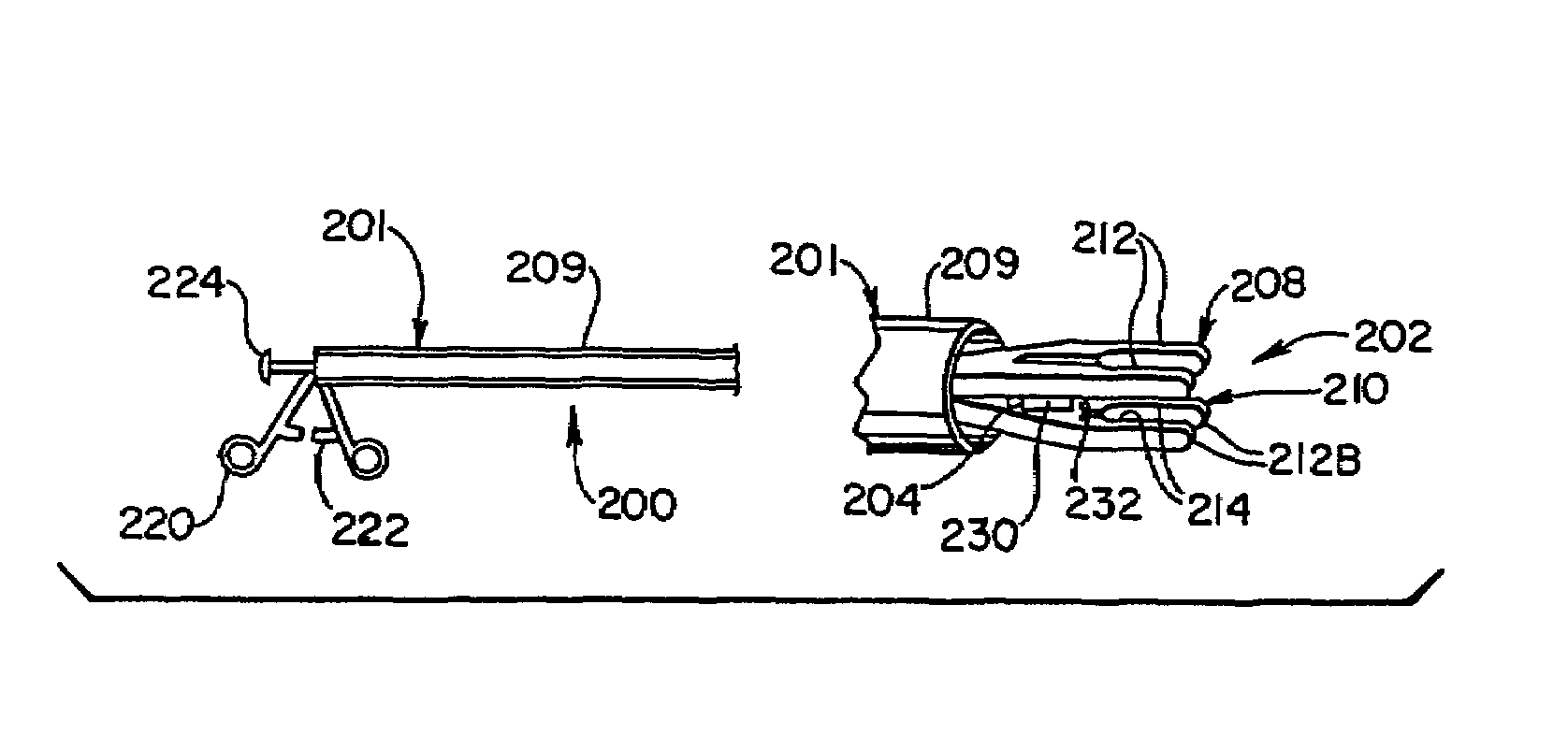

Medical clot treatment device with distal filter

This is a surgical device usually delivered through an intravascular catheter. It may be used in several ways. It may, for instance, be used to open a clear passageway adjacent thrombus to allow both blood and medication to bypass the clot. It may be used to pierce and to remove thrombus. These thrombus are often found in tortuous vasculature. The device includes several sections. The device has a core element, typically a core wire. Placed around the distal end of the core element is a collapsible but preferably self expanding proximal cage assembly and a distal filter, preferably a self-expanding cage assembly or other filter component. The various portions of those components are preferably radio-opaque. The proximal end of the proximal cage is typically is affixed to an actuator in such a way as to allow expansion of the cage after deployment. The proximal cage assembly may be used for collecting emboli or for displacing them to allow blood flow to resume, either with or without concurrent clot-dissolving drug treatment. The distal sector, whether a self-expanding cage or fan, is placed distally of the thrombus to collect portions of the thrombus which may loosen during the treatment or removal procedure.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

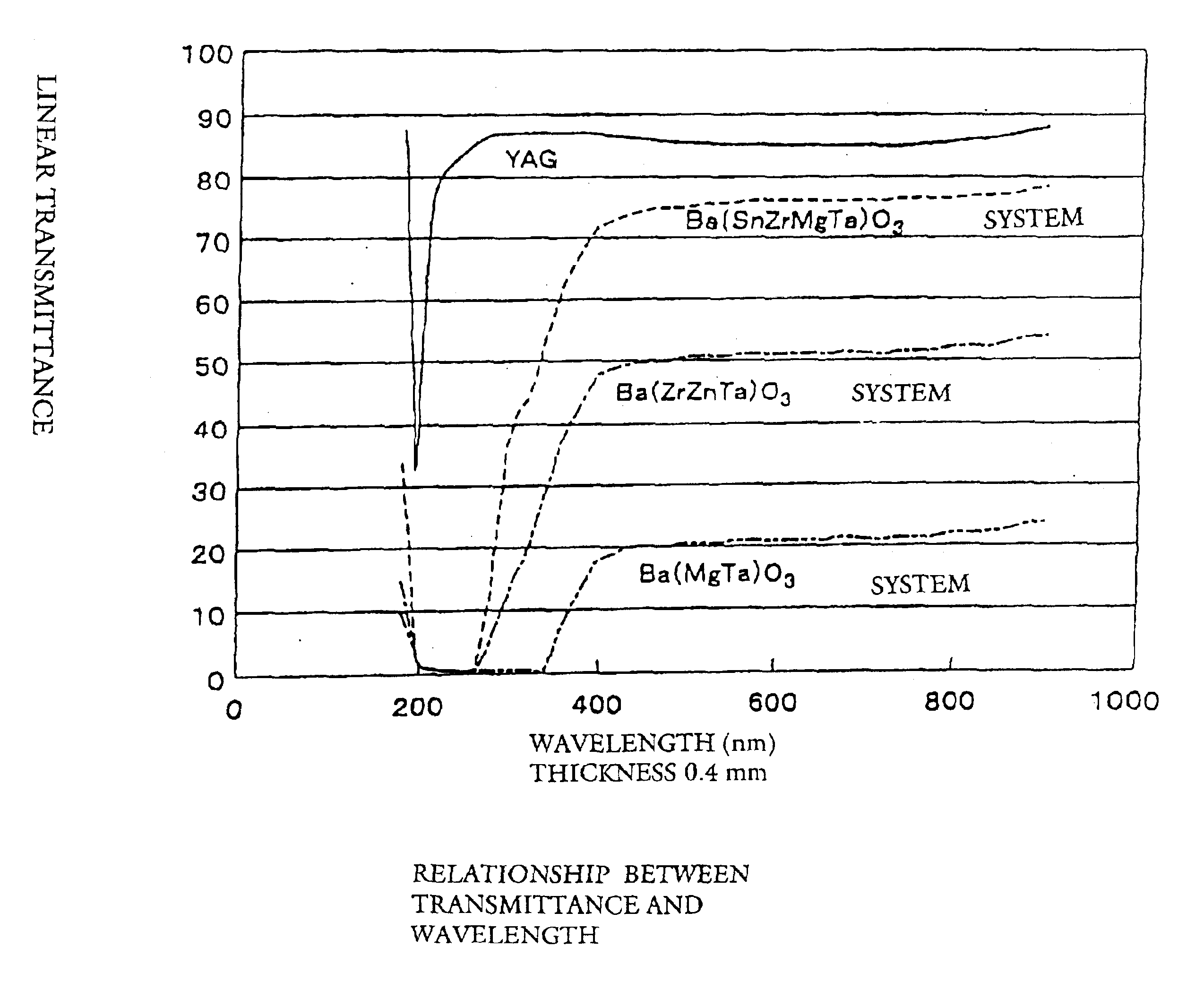

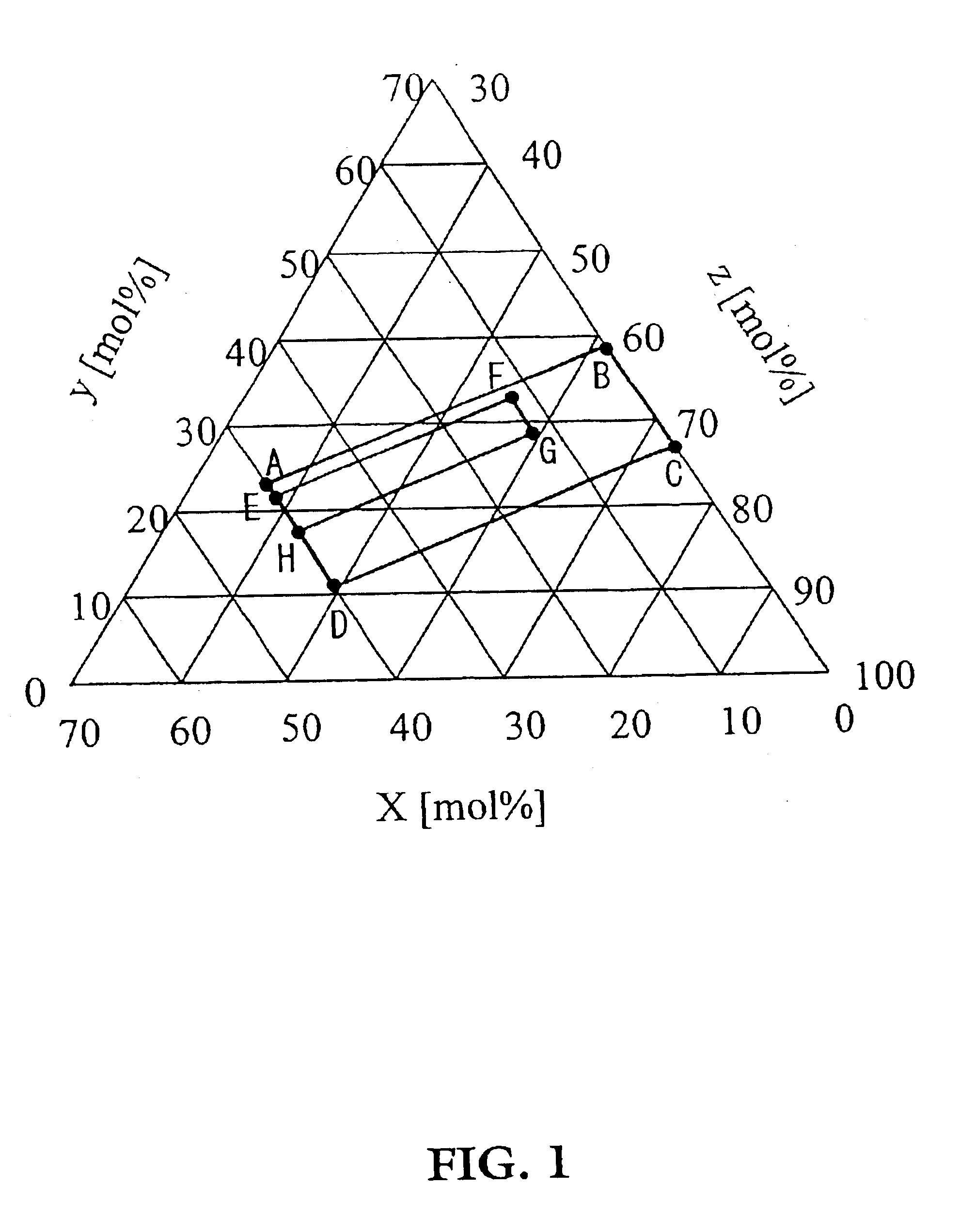

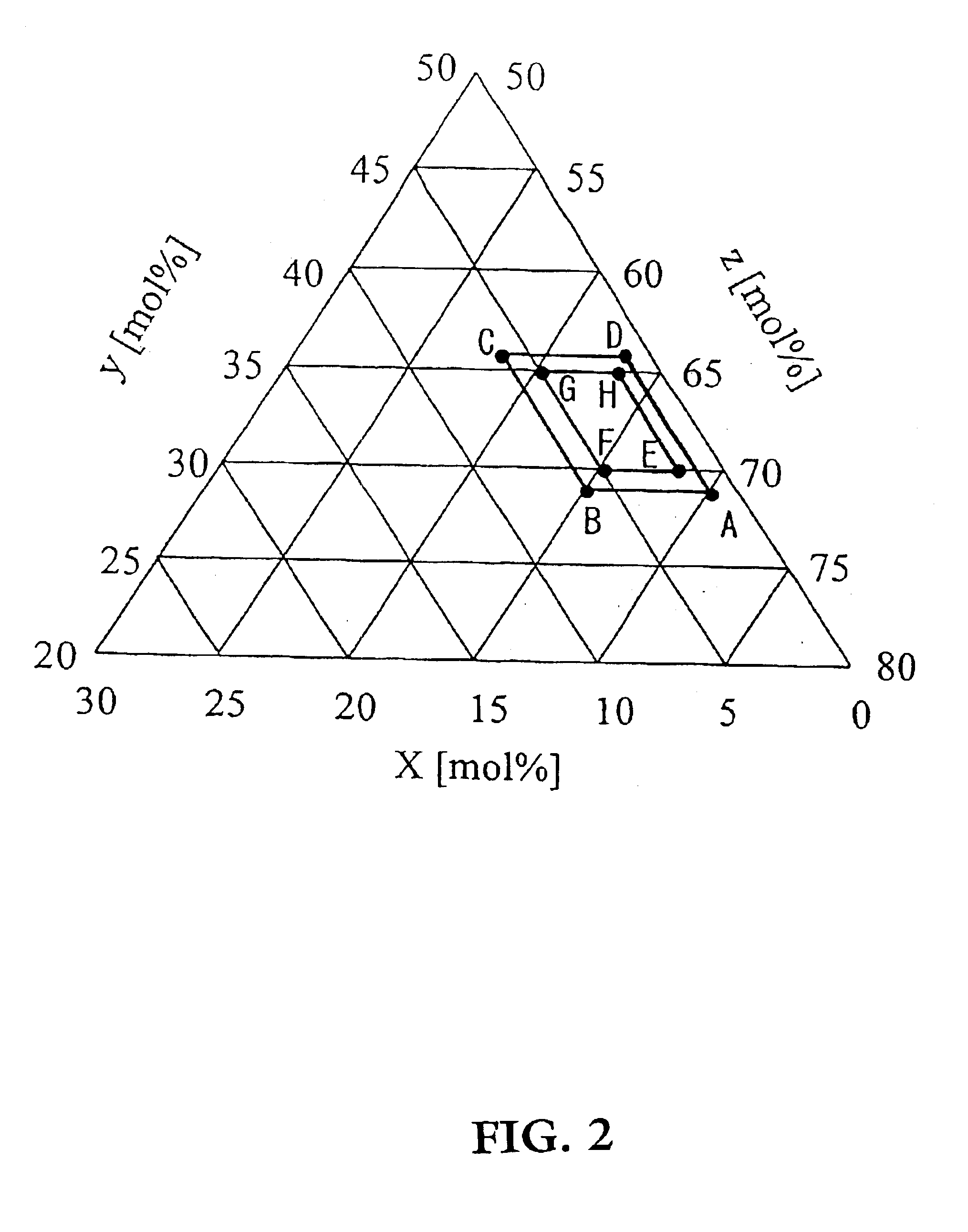

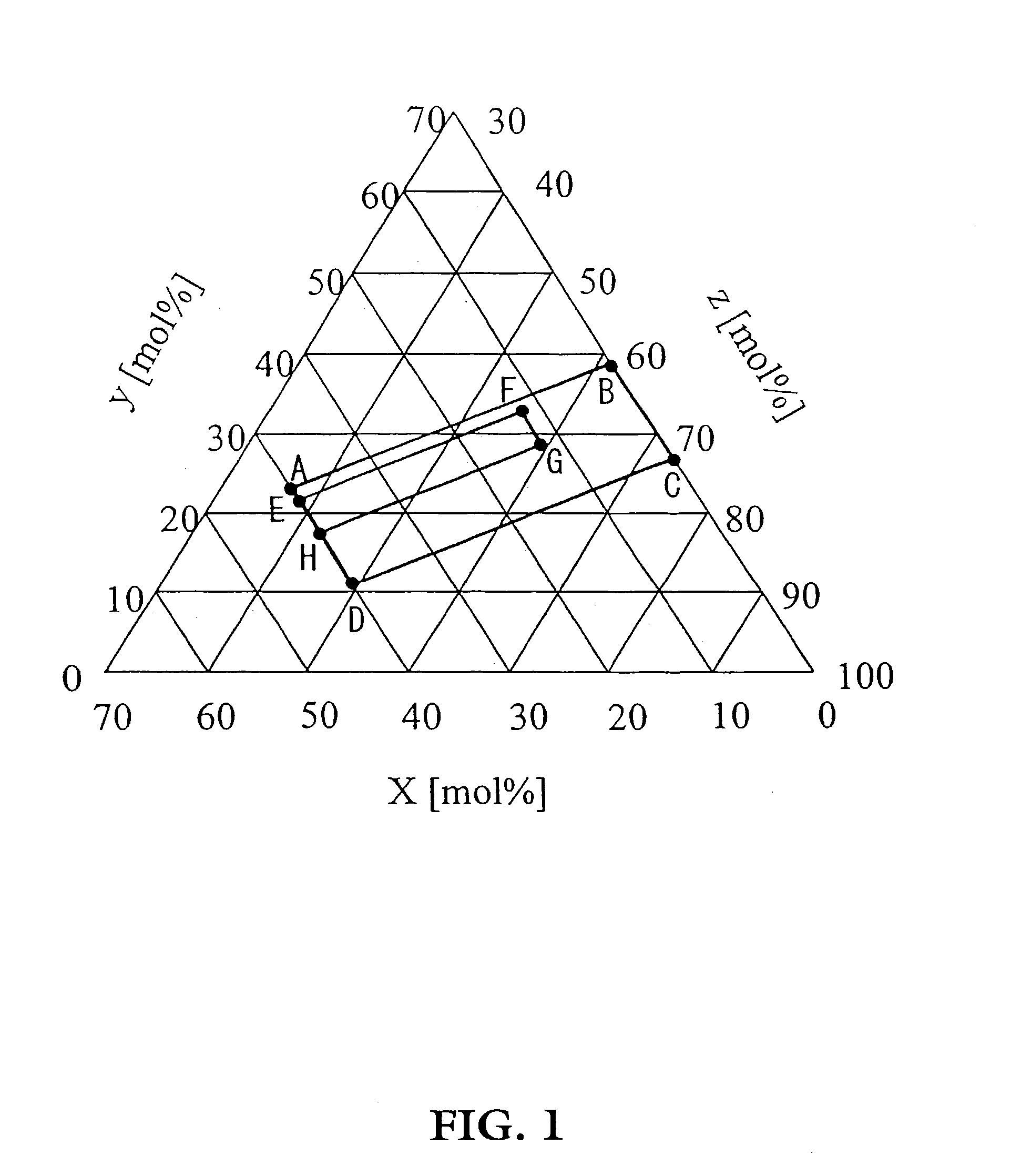

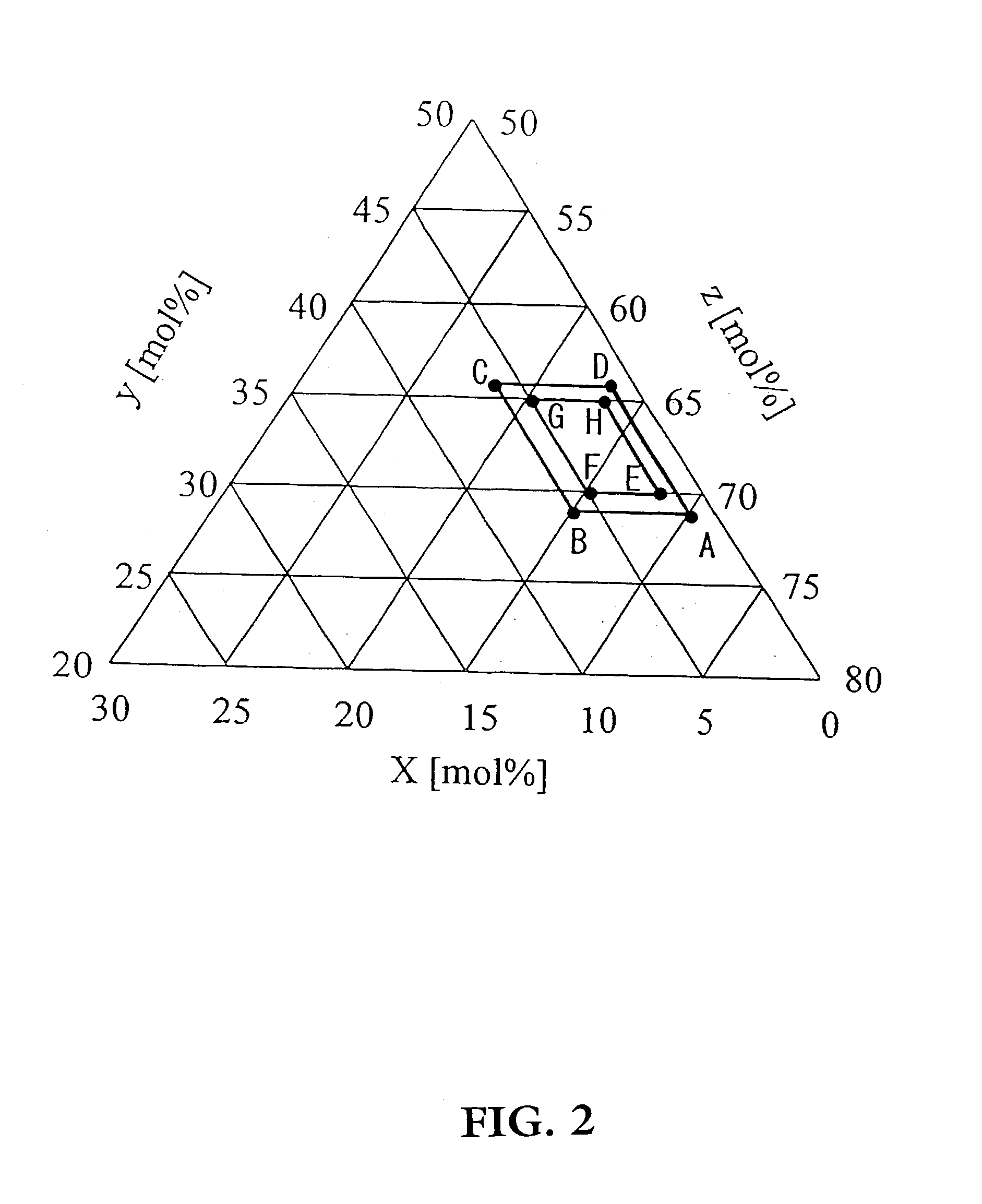

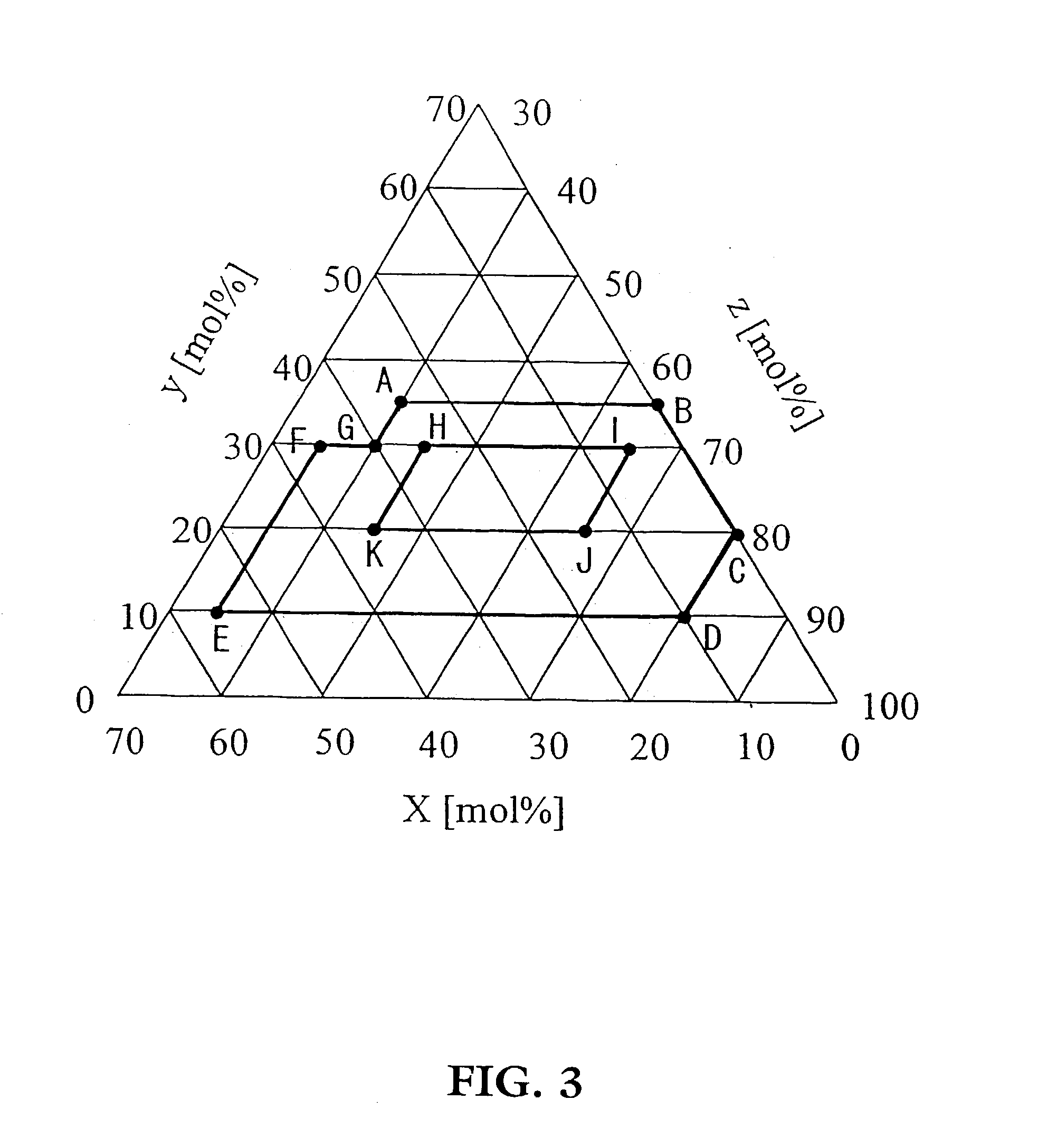

Transparent ceramic and method for production thereof, and optical element

InactiveUS6908872B2Induces no double refractionSmall sizeLamination ancillary operationsOther chemical processesRefractive indexTransparent ceramics

A ceramic material powder for a translucent ceramic is molded with a binder, and the resulting green compact is embedded in a ceramic powder having the same composition with the ceramic material powder. After removing the binder, the green compact embedded in the ceramic powder is fired in an atmosphere having an oxygen concentration higher than that in the removal procedure of the binder and thereby yields a translucent ceramic represented by Formula I: Ba{(SnuZr1-u)xMgyTaz}vOw, Formula II: Ba(ZrxMgyTaz)vOw or Formula III: Ba{(SnuZr1-u)xZntMg1-t)yNbz}vOw. The translucent ceramic has a refractive index of 1.9 or more and is paraelectric.

Owner:MURATA MFG CO LTD

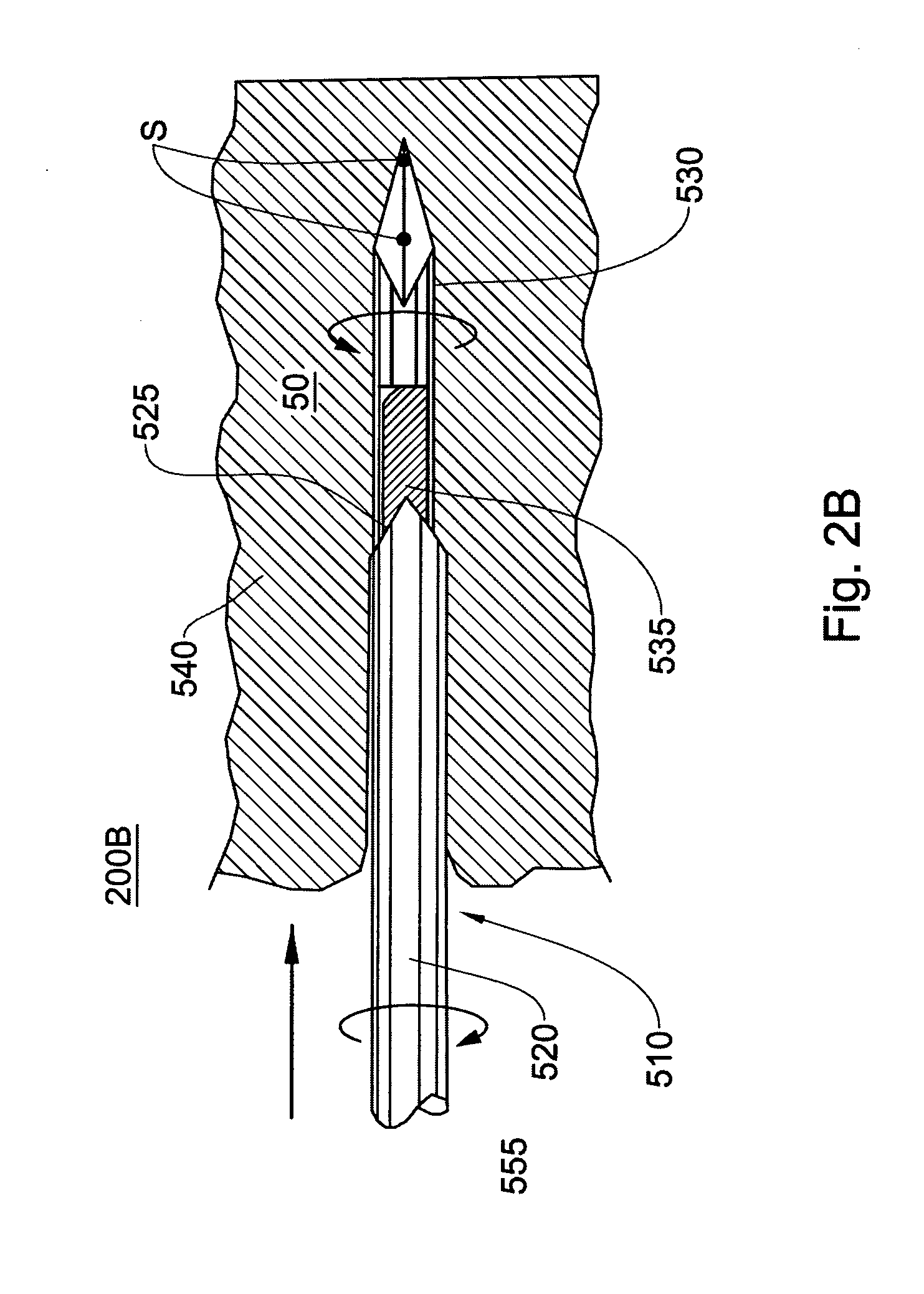

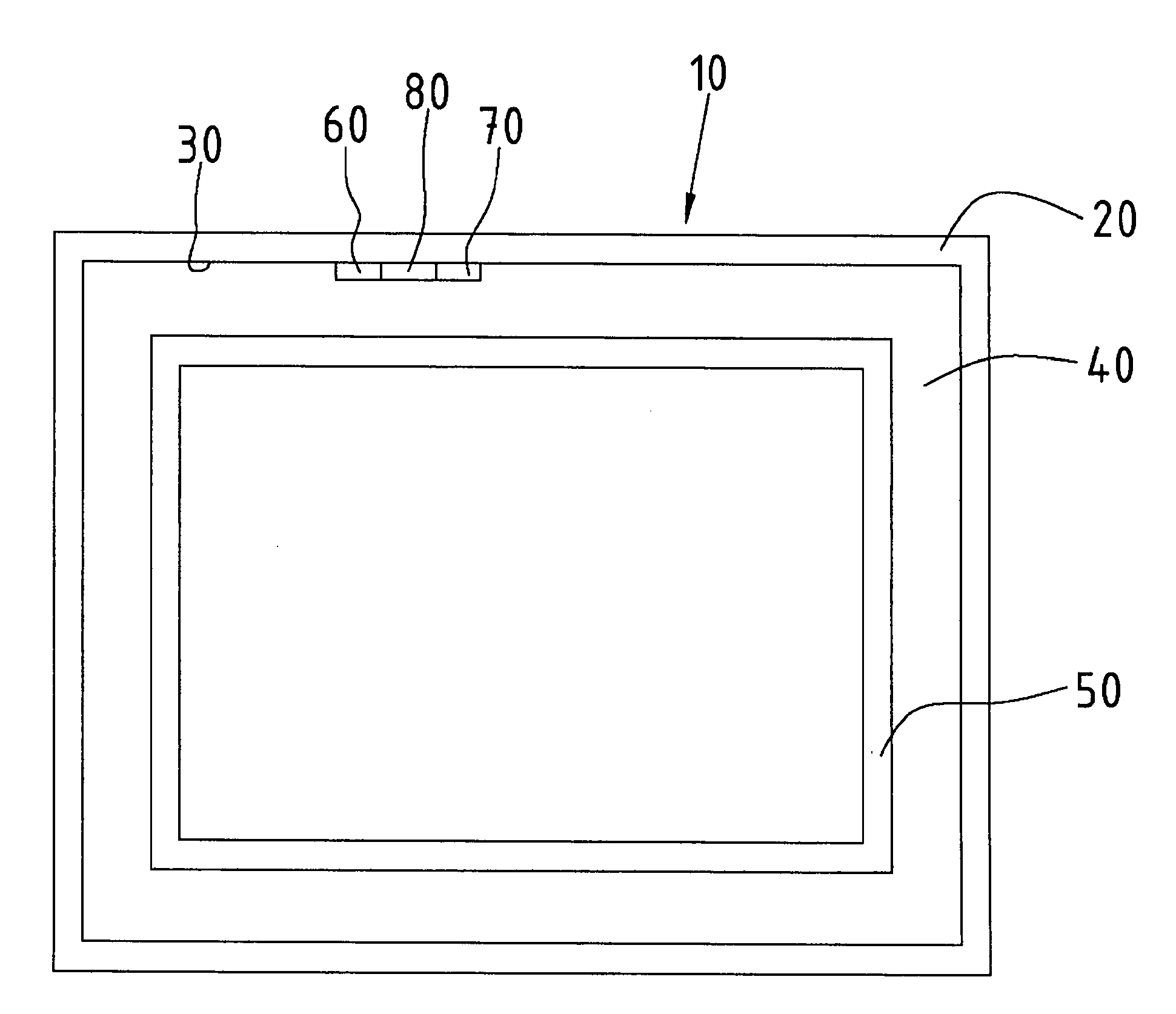

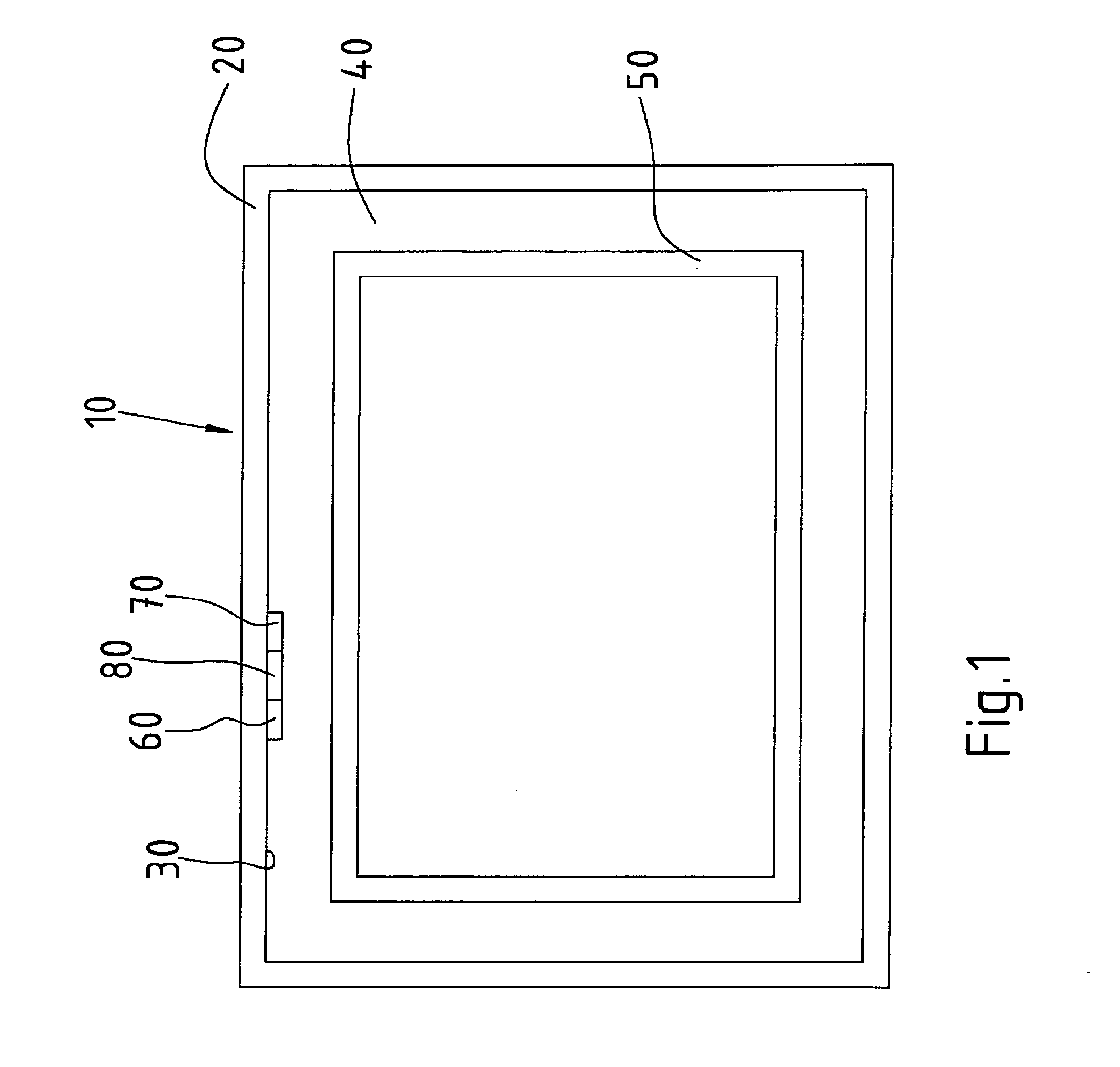

Surgical tool

ActiveUS20120123296A1Facilitate surgical procedureSimple and effective in-situ tissue characterizationSurgeryVaccination/ovulation diagnosticsProximal pointBiomedical engineering

A surgical tool for use in a tissue removal procedure from a subject is described. The surgical tool has proximal and distal regions and at least one sensor for sensing one or more predetermined conditions located at a distal region of the surgical tool. And a substantially flat signal transmission structure electrically connected with the at least one sensor and extending between the location at the distal region and the proximal region. The signal transmission structure is configured for providing impedance controlled signal transmission between the at least one sensor and the proximal region.

Owner:DUNE MEDICAL DEVICES

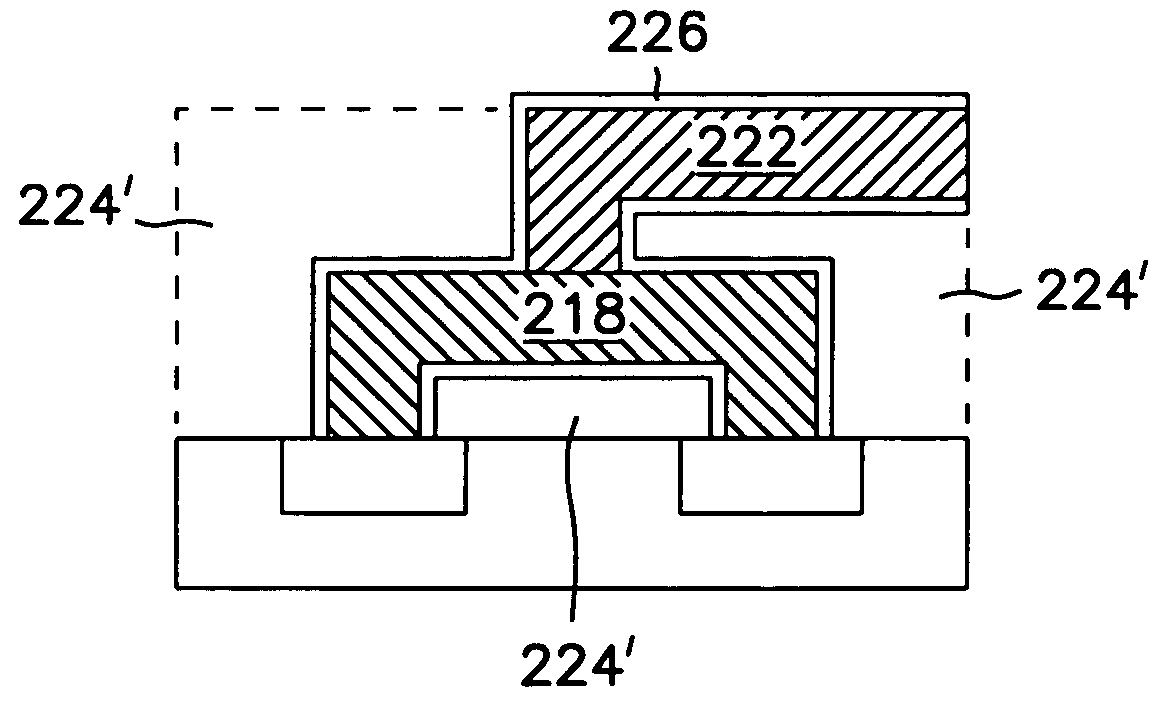

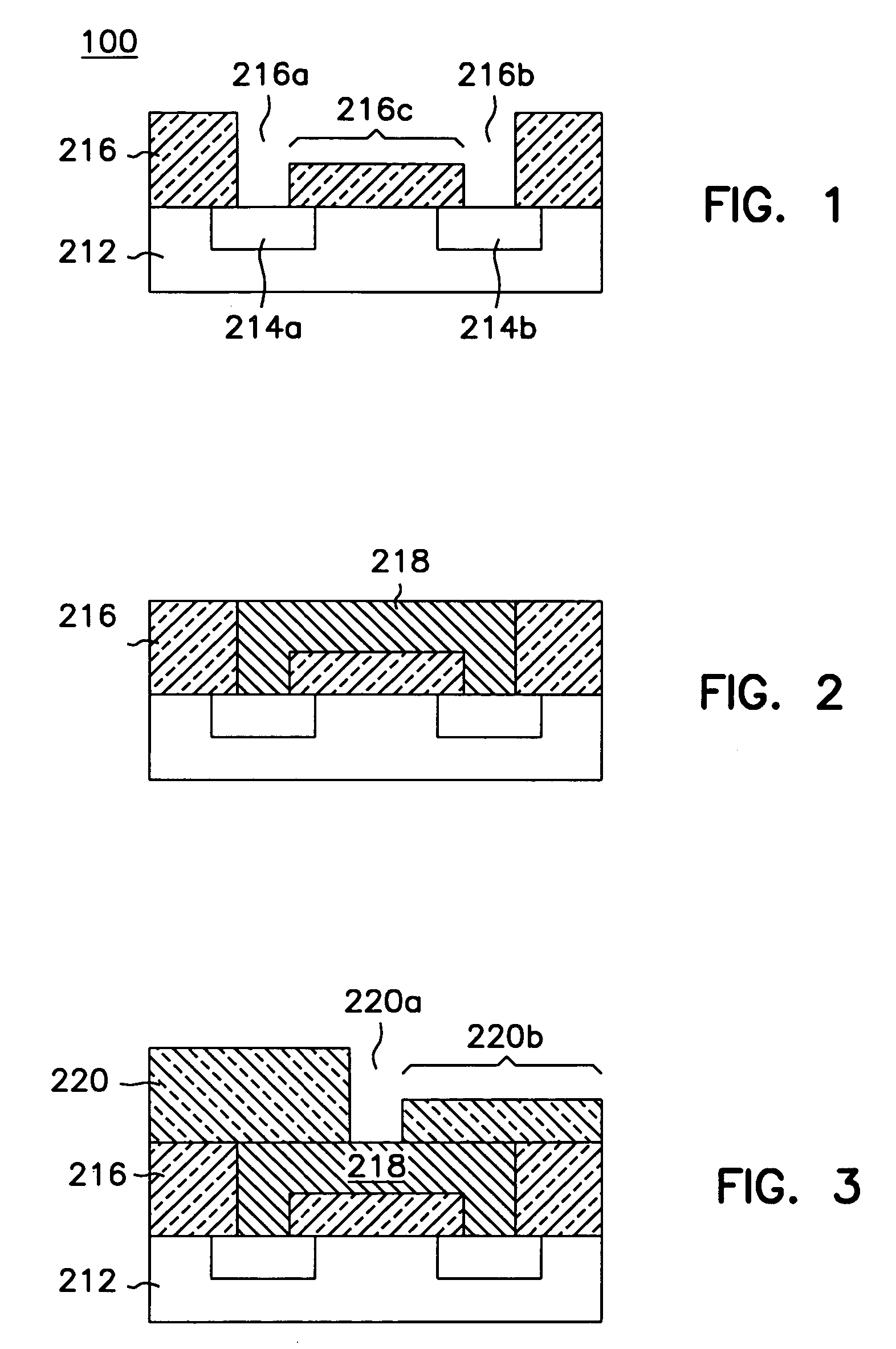

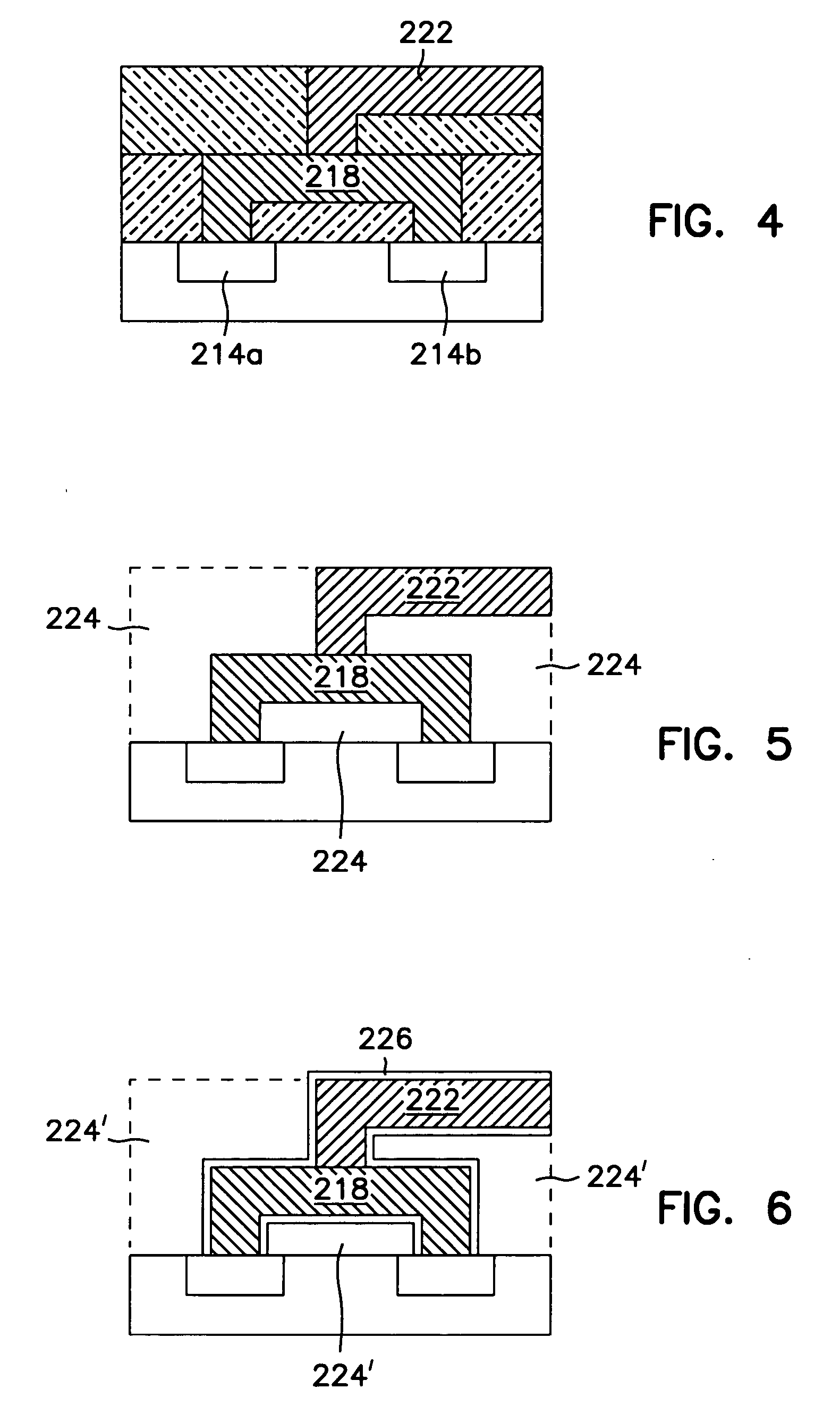

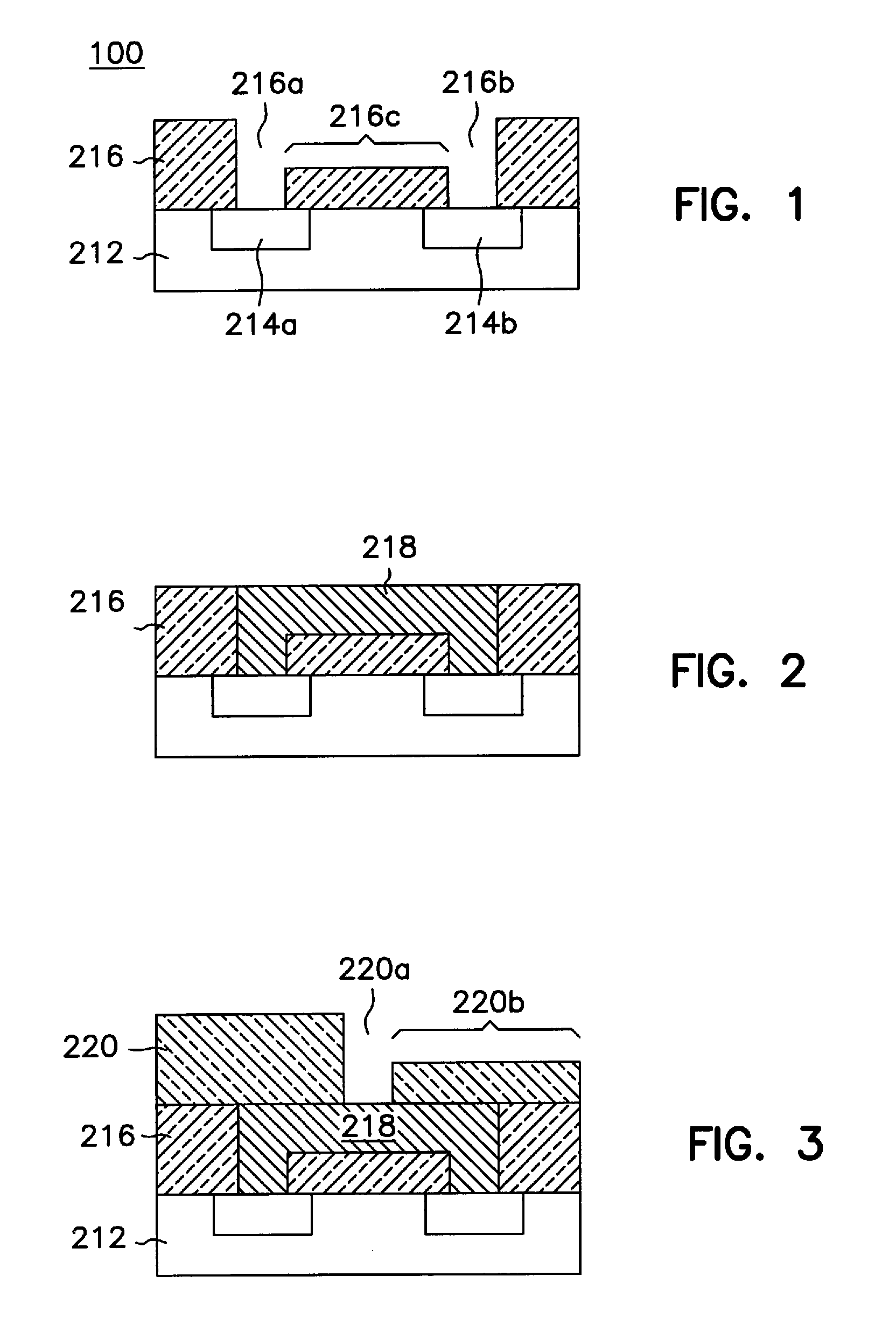

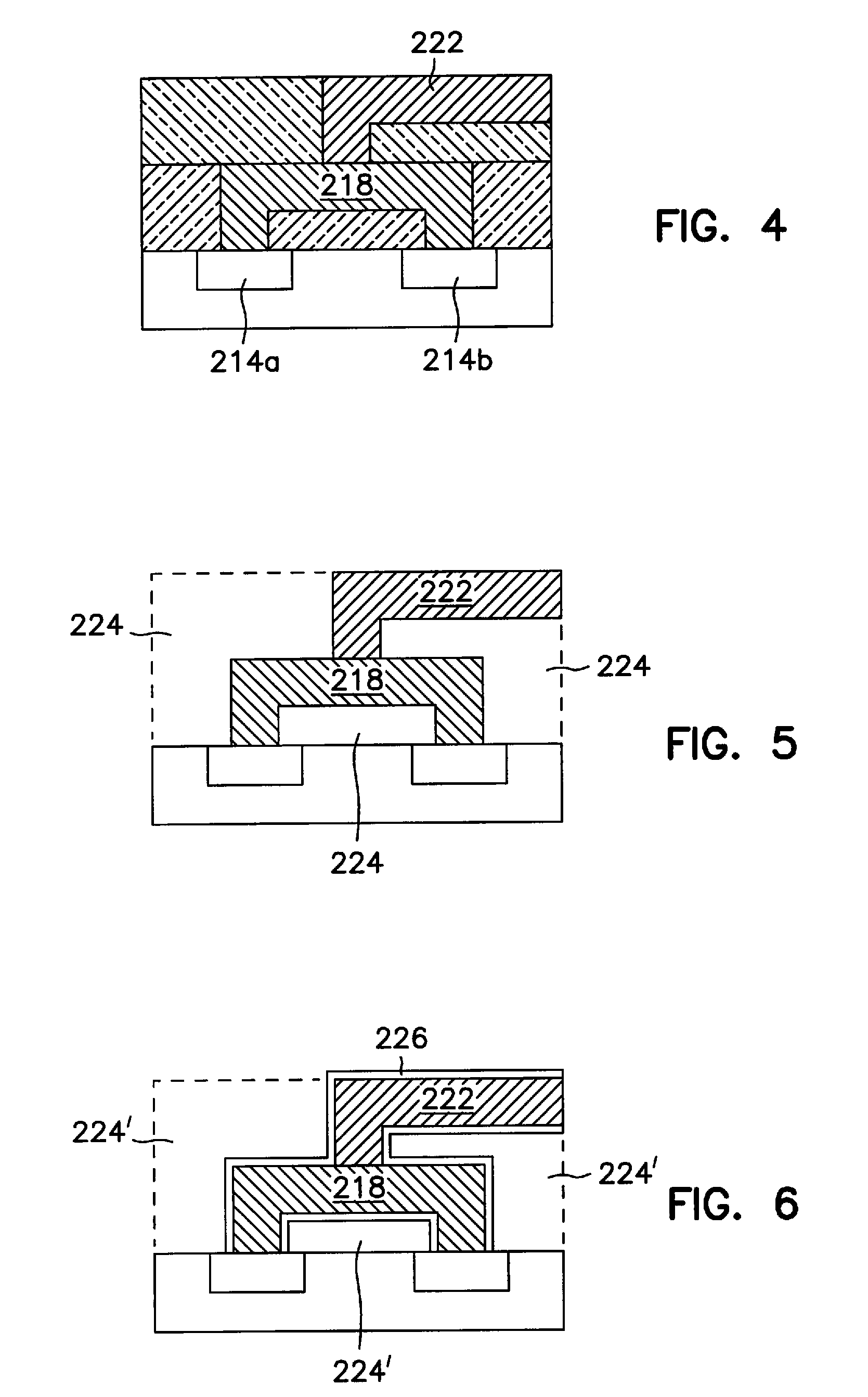

Methods for making integrated-circuit wiring from copper, silver, gold, and other metals

InactiveUS20050023697A1Semiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceDiffusion barrier

Integrated circuits include networks of electrical components that are typically wired, or interconnected, together with aluminum wires. In recent years, researchers have begun using copper in combination with diffusion barriers, rather than aluminum, to form the wires. Unfortunately, typical diffusion barriers add appreciable resistance to the wiring and require costly fabrication methods. Accordingly, the inventors devised one or more exemplary methods for making integrated-circuit wiring from materials, such as copper-, silver-, and gold-based metals. One exemplary method removes two or more masks in a single removal procedure, forms a low-resistance diffusion barrier on two or more wiring levels in a single formation procedure, and fills insulative material around and between two or more wiring levels in a single fill procedure. This and other embodiments hold the promise of simplifying fabrication of integrated-circuit wiring.

Owner:MICRON TECH INC

Anti-clogging device for a vacuum-assisted, tissue removal system

ActiveUS20150080896A1Easy to disassembleFacilitate entryDiagnosticsExcision instrumentsSolid componentEngineering

An anti-clogging device for a vacuum-assisted tissue removal system is provided. The device includes a tissue-separation chamber in a close proximity to (i) a cutting head operated by a physician and (ii) the physician for a filling and emptying by the physician during a tissue removal procedure, the cutting head and the tissue separation chamber in an operable communications with the suction assembly. The tissue separation chamber has an entry port in an operable communication with the cutting head for the entry of an excised tissue into the chamber, the excised tissue having a solid component and a liquid component; a baffle to separate the liquid component from the solid component; and, an exit port for the exit of liquid component out of the chamber. The tissue can include any tissue accessible through a small surgical opening, such as a nucleus pulposus tissue removed during a discectomy procedure.

Owner:DEPUY SYNTHES PROD INC

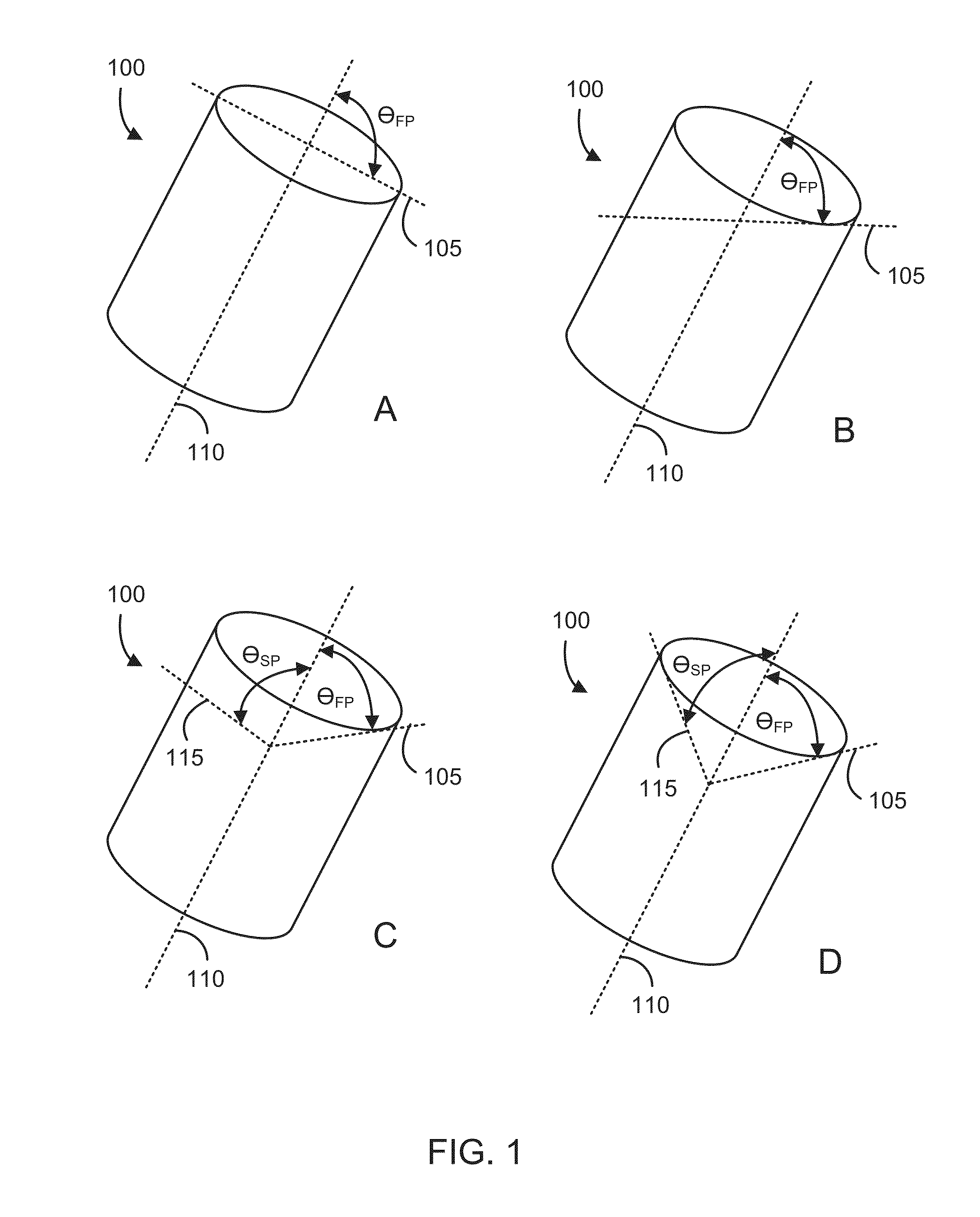

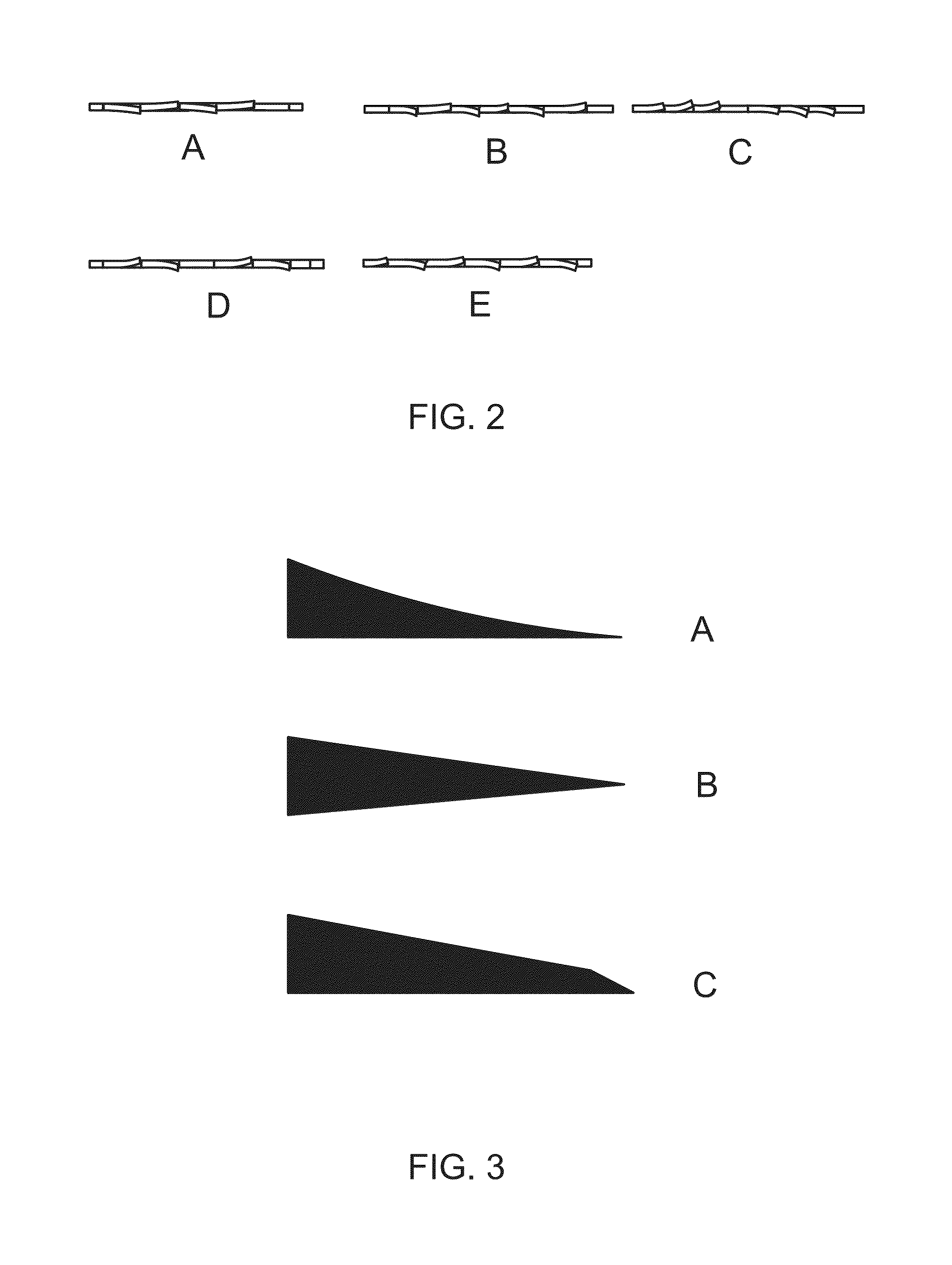

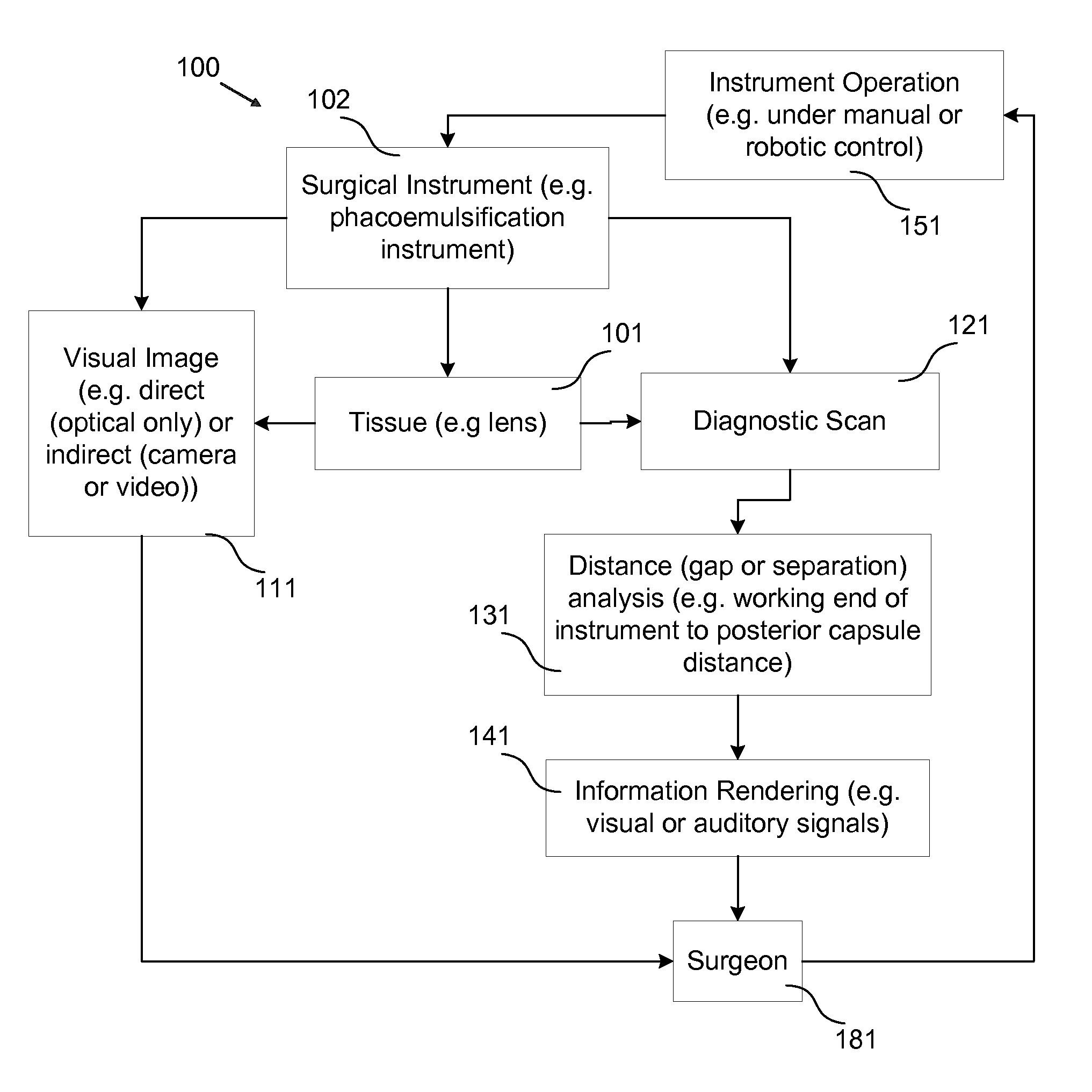

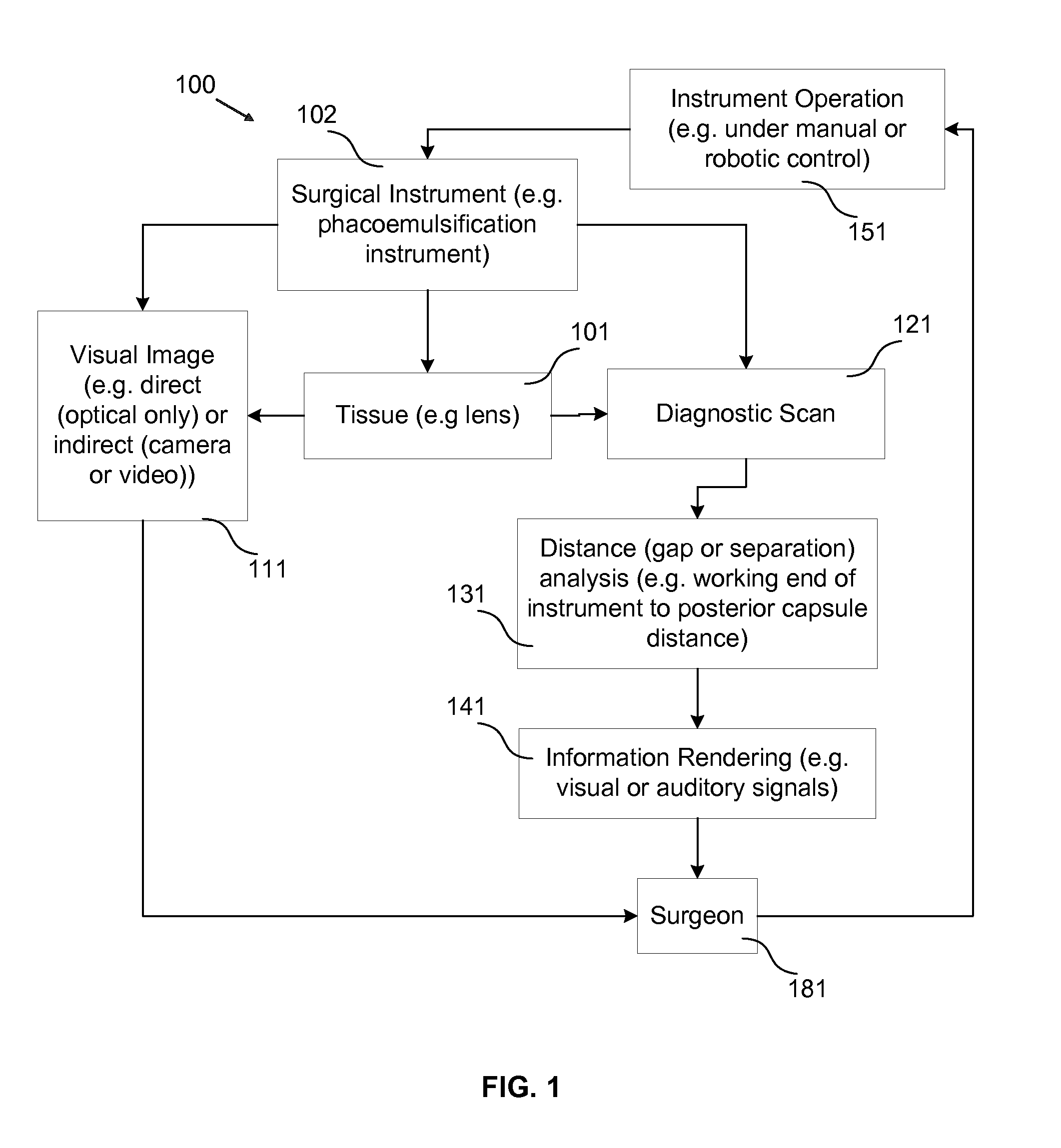

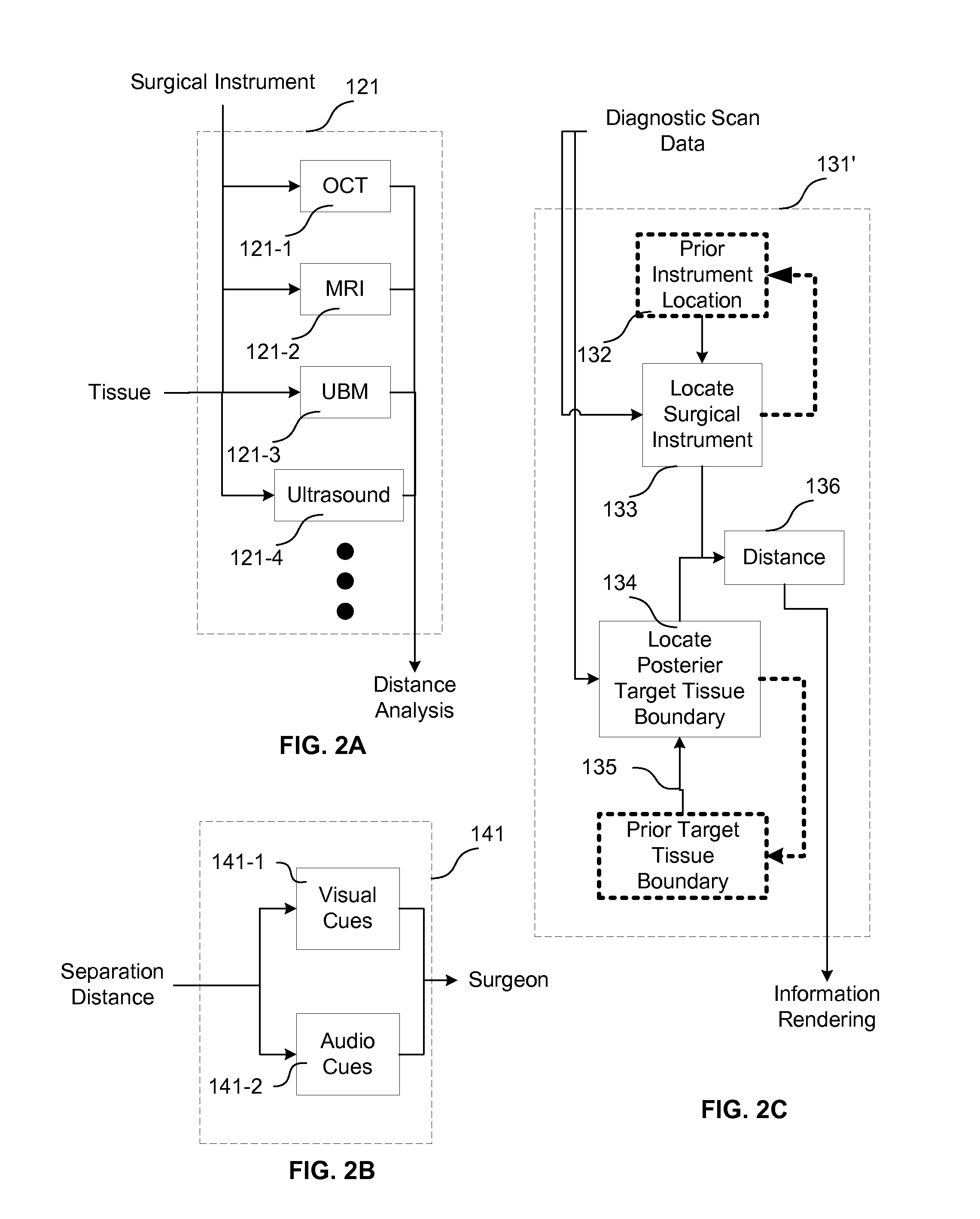

Surgical Procedures Using Instrument to Boundary Spacing Information Extracted from Real-Time Diagnostic Scan Data

InactiveUS20120022546A1Less riskAddressing slow performanceIncision instrumentsEye surgeryImage ViewSurgical department

Specific embodiments of the invention are directed to improved phacoemulsification procedures involving the use of processed non-visual three-dimensional data (i.e. diagnostic scan data) to provide a surgeon with additional guidance (i.e. more than that generally obtained from visual observation of the working area) concerning the distance separating a working end of a phacoemulsification instrument and the posterior portion of the capsule of the eye during surgical procedures involving the removal of the crystalline lens of an eye (e.g. a cataract removal procedure). Such separation (i.e. distance or gap) information may be used to aid the surgeon in cutting or scoring the lens to a desired depth while minimizing the risk of penetrating the posterior portion of the capsule with the working end of the instrument. Some embodiments provide for the visual and / or auditory conveyance of distance information to the surgeon wherein visual information may be conveyed by overlaying it with real visual images of actual surface features viewed by the surgeon. Additional embodiments provide for overlaying visual representations of selected three-dimensional structure information (e.g. depths of troughs cut into the lens) with the real surface feature images viewed by the surgeon.

Owner:VANTAGE SURGICAL SYST

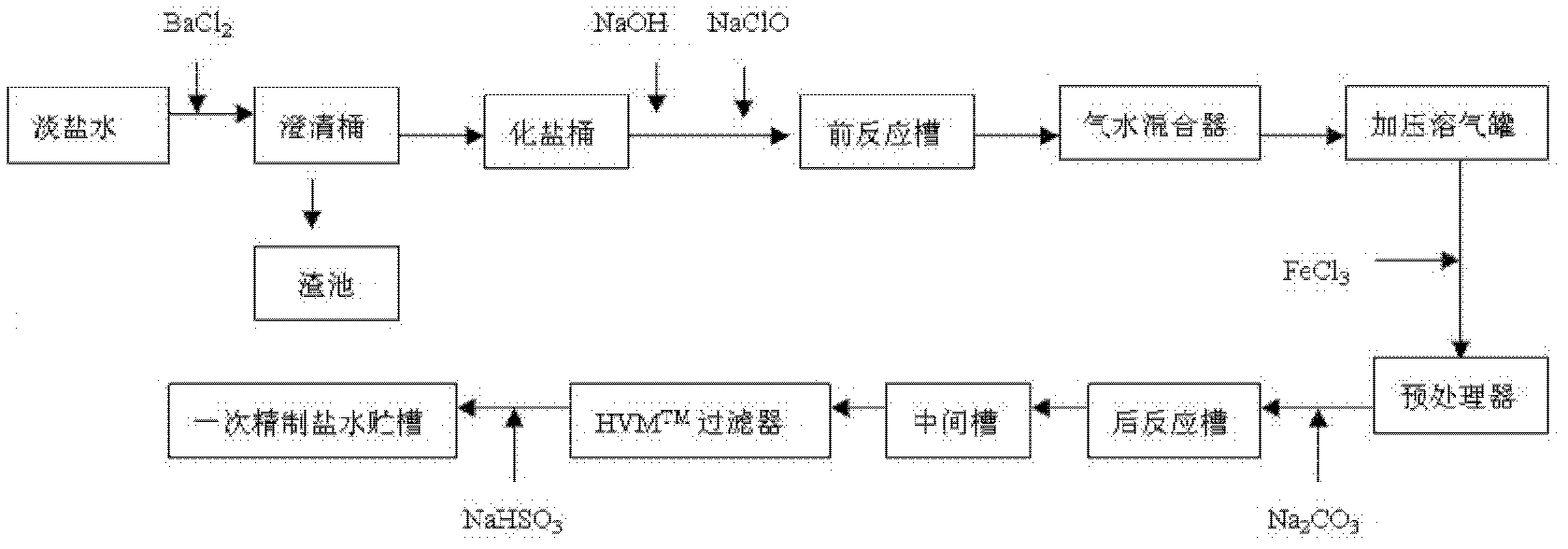

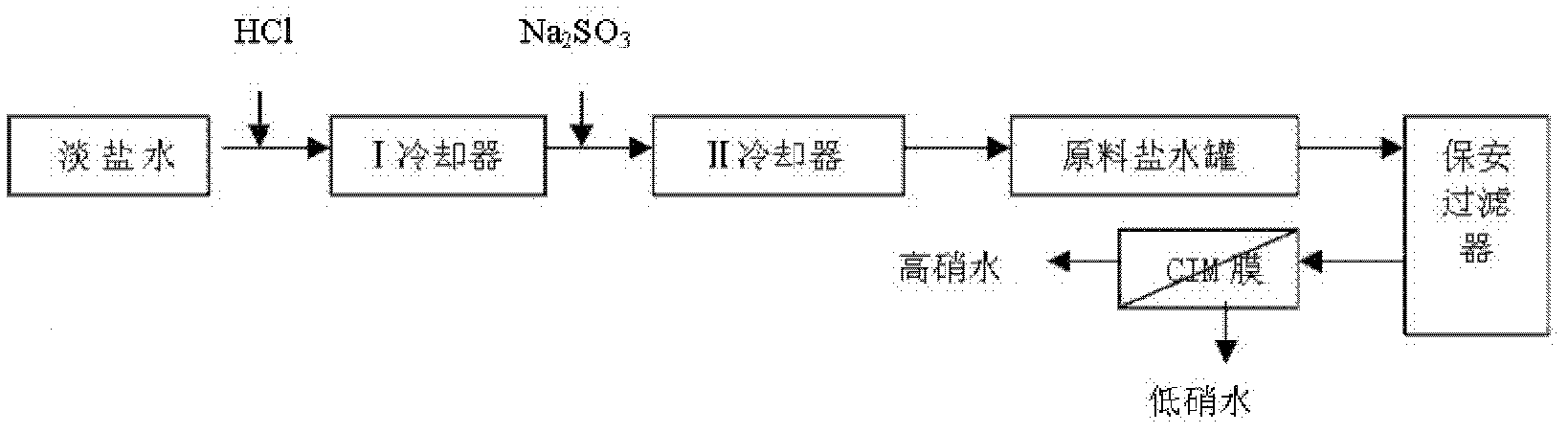

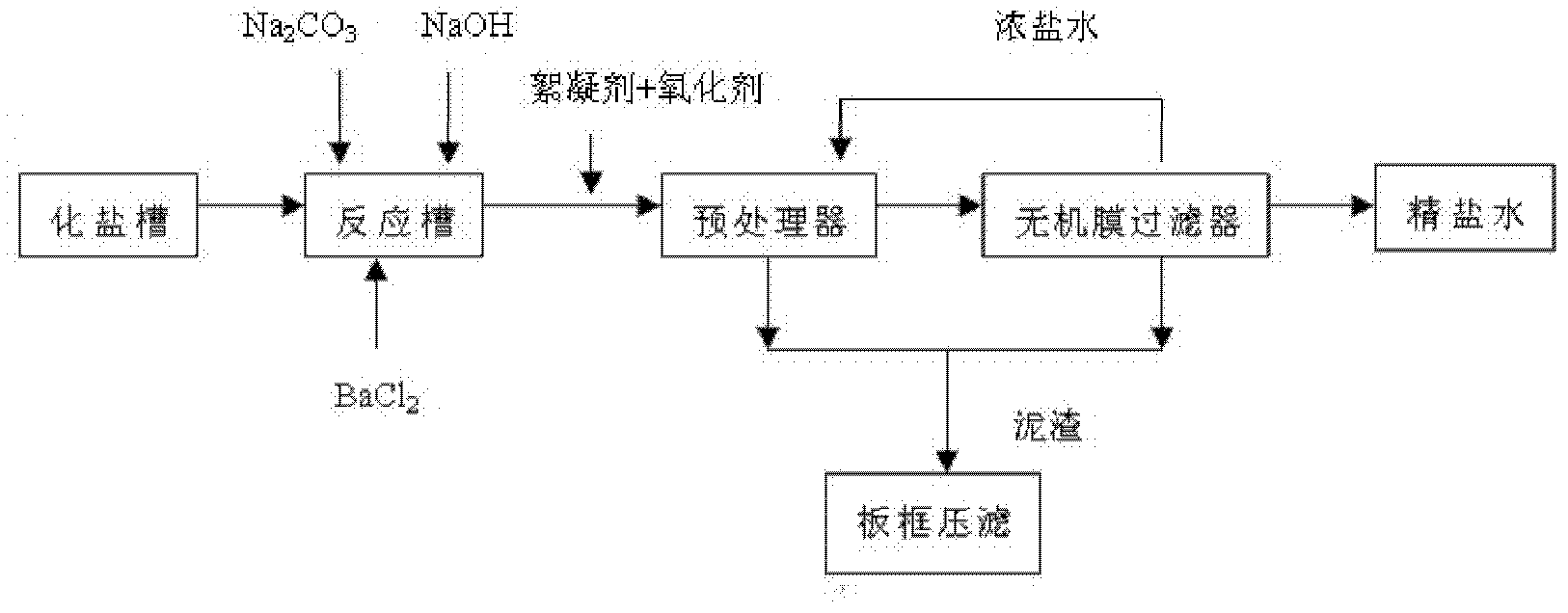

Double-membrane-method technology for refining brine and equipment for the same

ActiveCN102627300AAvoid secondary pollutionReduce manufacturing costAlkali metal halide purificationHigh concentrationUltrafiltration

The invention relates to double-membrane-method technology for refining brine and equipment for the same. After pretreatment, brine to be treated enters a filtration procedure to form high-concentration nitrate-containing water and refined brine; pretreatment refers to carrying out a removal procedure of calcium and magnesium ions, a removal procedure of ammonium, a reduction procedure and a pH adjusting procedure to the brine to be treated; the filtration procedure refers to the steps that: the pretreated brine is pumped to gas-stripping tubular type membrane module for ultrafiltration, thereby organic impurities, suspended matters and partial precipitates of the brine are intercepted; pressure raising is carried out to the brine which permeates a tubular type membrane, then the brine directly enters nanofiltration membrane module for nanofiltration; the brine which can not permeate the tubular type membrane returns the removal procedure of calcium and magnesium ions; and in a high pressure state, sulfate ions are intercepted by a nanofiltration membrane to form high-concentration nitrate-containing water, and chloride ions and sodium ions permeate smoothly the nanofiltration membrane to form refined brine. The technology in the invention is simple, low energy consumption, small land-occupation area, low investment and low production cost, a stable operation system, strong impact-resistance load capability and no secondary pollution.

Owner:CHINA PETROCHEMICAL CORP +3

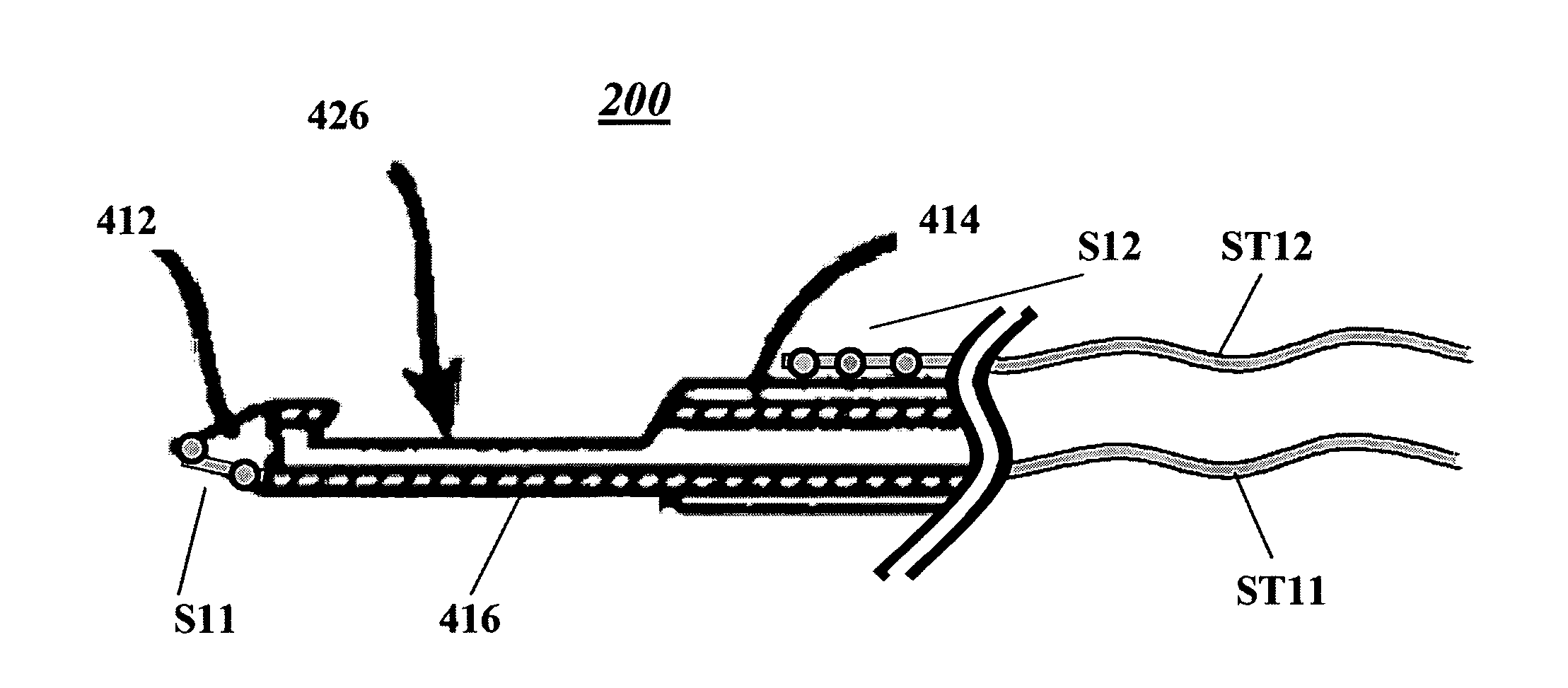

Apparatus and method for vein removal

A device and method for removing a generally cylindrical tissue structure such as a blood vessel from the body of a human or animal. The device includes a body portion having distal and proximal ends with at least one lumen extending longitudinally through the body portion. The lumen is sized to accommodate the vessel and at least one tool used in removing the vessel. Means is provided for isolating the vessel from the tools used in the removal procedure.

Owner:MAQUET CARDIOVASCULAR LLC

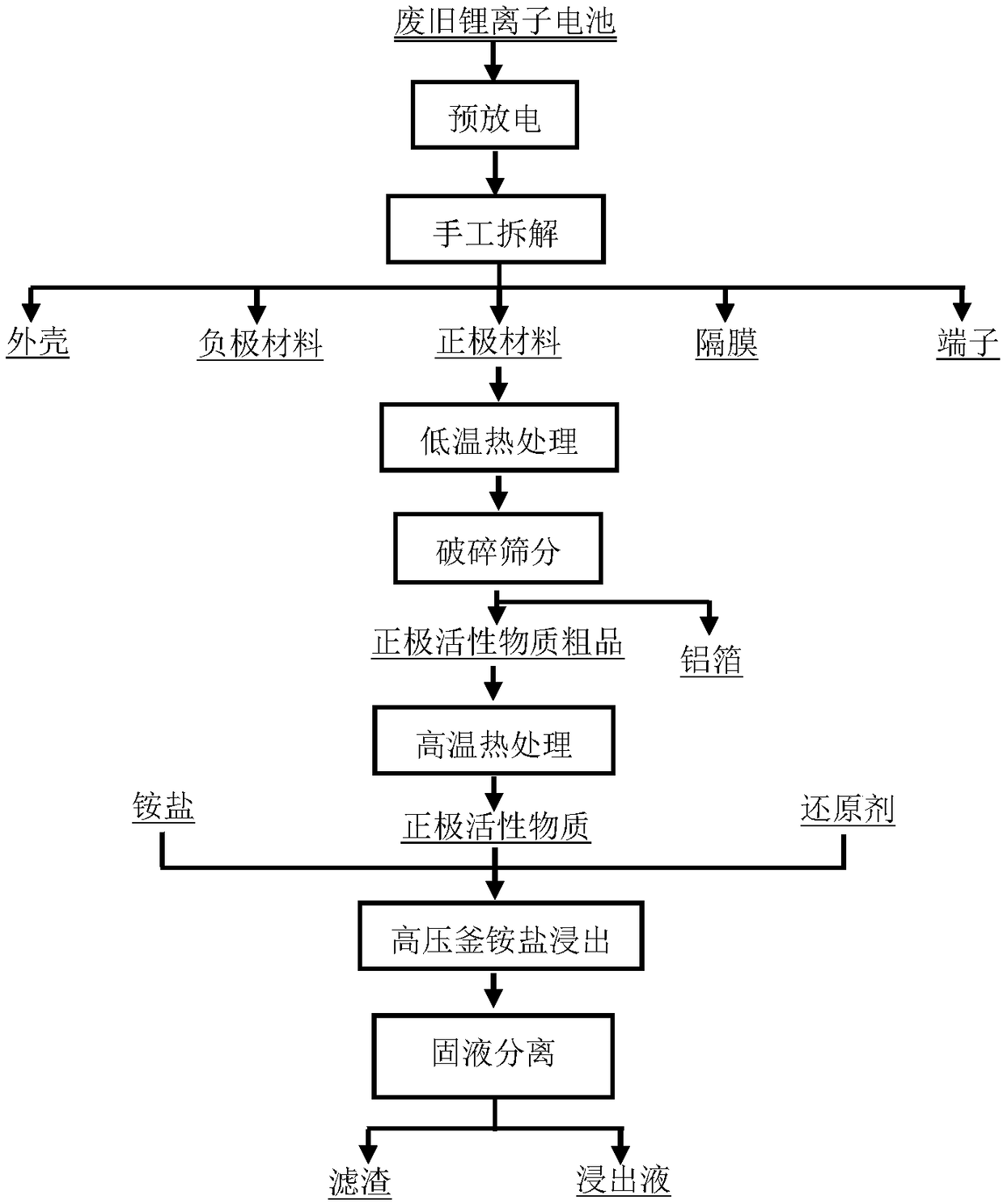

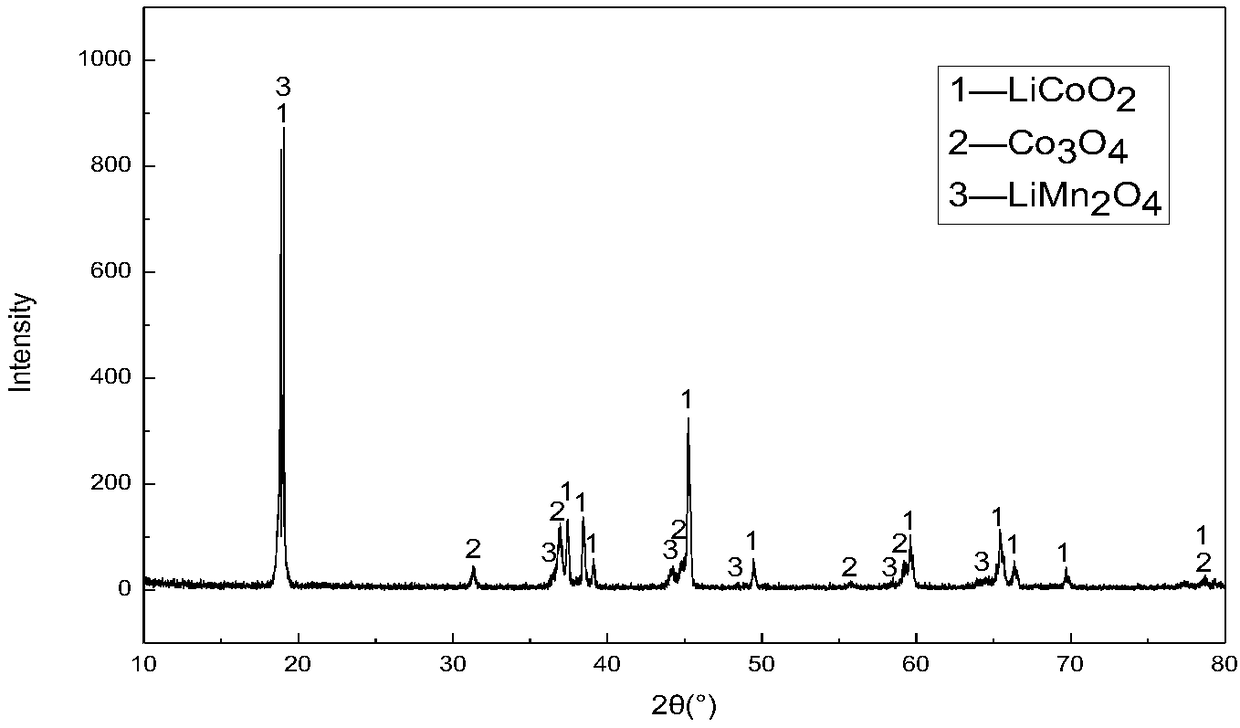

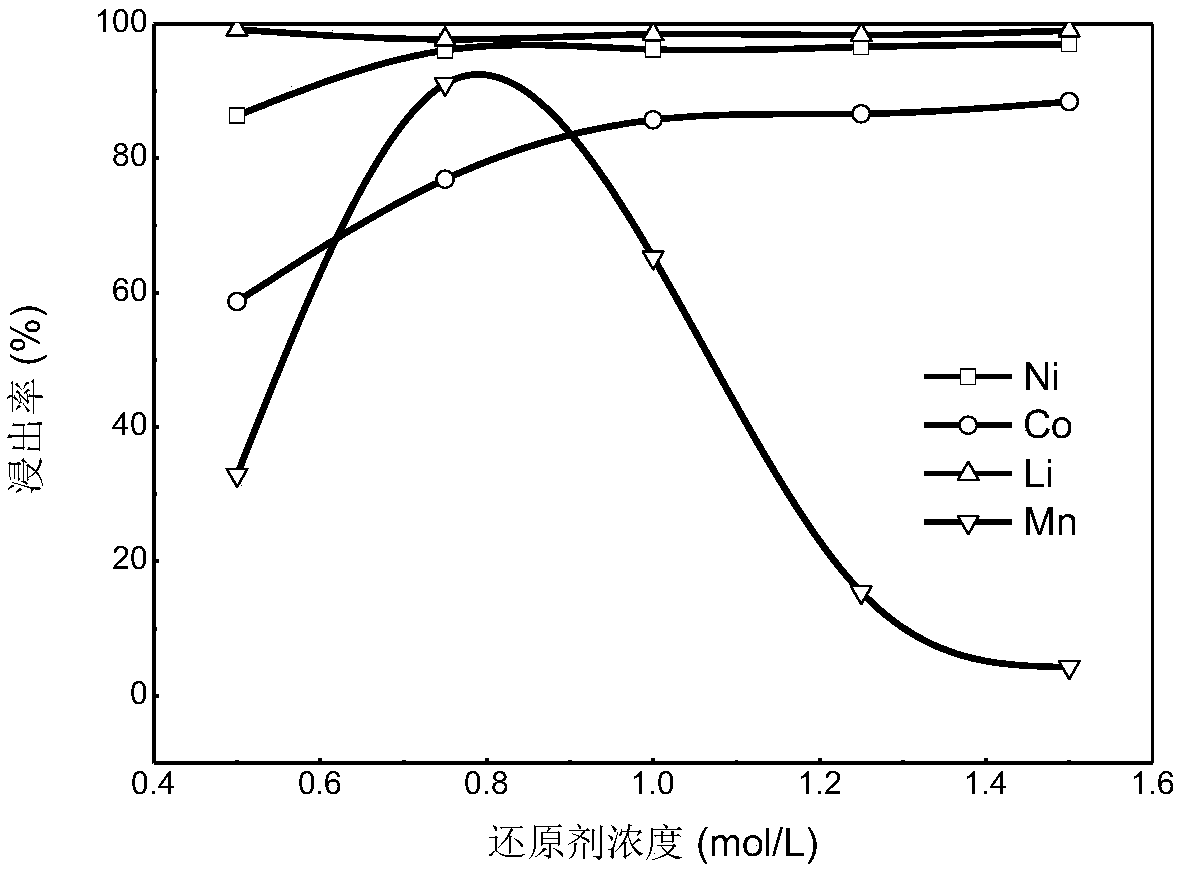

Method for leaching metals in anode material of waste lithium ion battery

InactiveCN108486376AImprove leaching rateHigh selectivityWaste accumulators reclaimingProcess efficiency improvementManganeseHigh pressure

The invention relates to a method for leaching metals in an anode material of a waste lithium ion battery. The method for leaching the metals in the anode material of the waste lithium ion battery comprises the steps that anode active substances are obtained after the waste lithium ion battery is pretreated, then the anode active substances are made to react with an ammonium salt solution containing a reducing agent, solid-liquid separation is conducted after the reaction, and thus, leachate and filter residues are obtained. According to the method, the process is simple, the metal leaching rate is high, and the metal selectivity is high; by controlling the type and quantity of the reducing agent used in the leaching process, selective leaching of the metals can be achieved, for instance,when the anode material contains metals such as Li, Co and Mn, the reducing agent is ammonium sulfite, the leaching rate of Mn is 90% when the concentration of the reducing agent is 0.75 mol / L, and the leaching rate of Mn is 4% when the concentration of the reducing agent is 1.5 mol / L; the impurity content of the leachate is low, so that the cost for the subsequent impurity removal procedure is low; and the leaching process is conducted in a high-pressure kettle, emission of poisonous gas is avoided in the operation process, and the operation environment is good.

Owner:CENT SOUTH UNIV

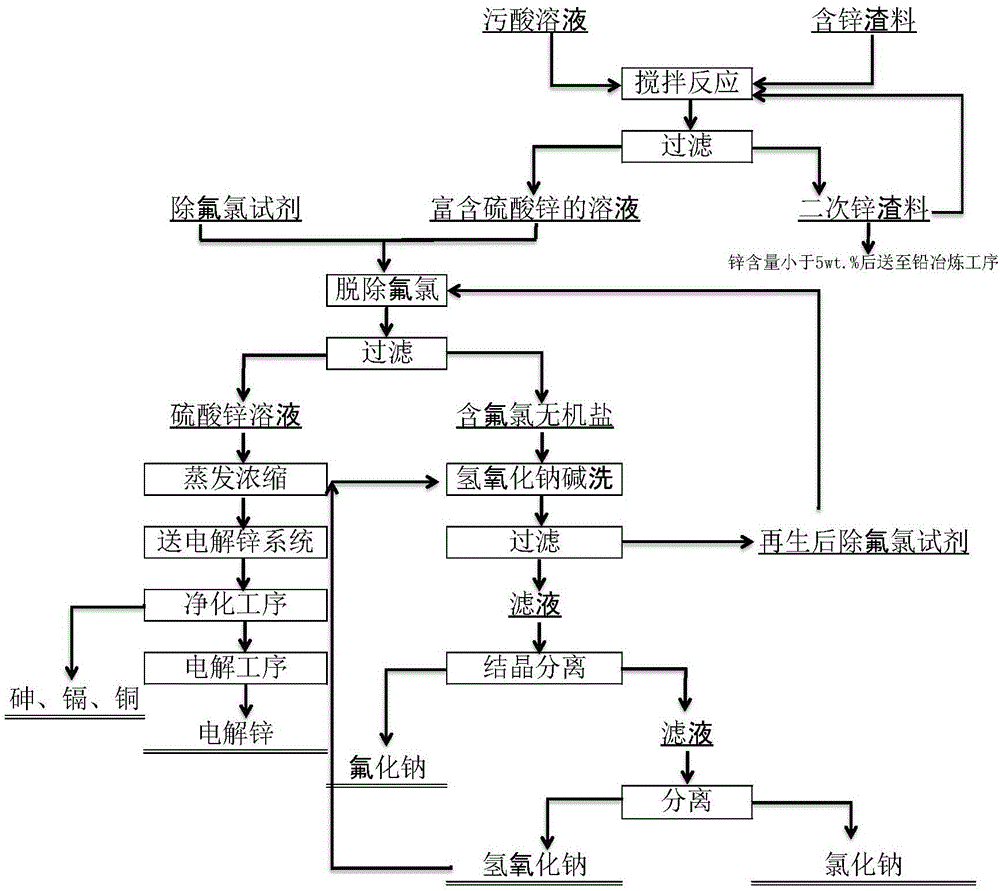

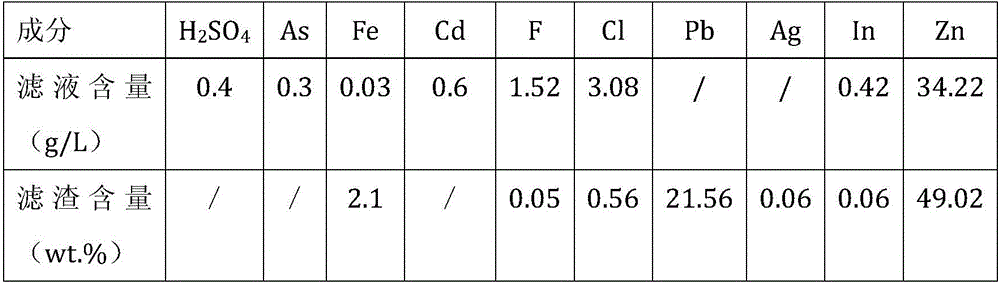

Comprehensive recycling method for non-ferrous metal metallurgy acidic wastewater and zinc-containing residues

ActiveCN105861844AEfficient separation and recoveryWon't break the balanceProcess efficiency improvementHydrometallurgyNon-ferrous extractive metallurgy

Disclosed is a comprehensive recycling method for non-ferrous metal metallurgy acidic wastewater and zinc-containing residues. The zinc-containing residues generated in the zinc smelting production process serve as an acidic wastewater neutralizer. Liquid obtained after neutralization is subjected to fluorine and chlorine removal and concentrated to meet the requirements for a zinc sulfate solution of a zinc system, and then directly enters the electrolytic zinc system. Valuable metal such as arsenic, cadmium and copper in the acidic wastewater is recycled through an impurity purification procedure of the zinc system. The zinc-containing residues are subjected to a neutralization step to be recycled and fed into a lead extraction procedure after being enriched with lead, silver and other metal. The filter residues with fluorine and chlorine removed are regenerated with a sodium hydroxide solution, the residues obtained after regeneration can be used for the fluorine and chlorine removal procedure repeatedly, and sodium fluoride, sodium chloride and sodium hydroxide in the liquid obtained after regeneration are separated and recycled through efficient evaporative crystallization. The comprehensive recycling method for non-ferrous metal metallurgy acidic wastewater and zinc-containing residues is based on an existing zinc hydrometallurgy system, the balance of original materials in the system is maintained, and an additional heavy metal impurity purification procedure is not added. The comprehensive recycling method for non-ferrous metal metallurgy acidic wastewater and zinc-containing residues is short in process, low in cost, high in valuable metal recycling rate, free of discharging of secondary waste residues and waste water and good in comprehensive economical benefit.

Owner:湖南麓云达环境科技有限公司

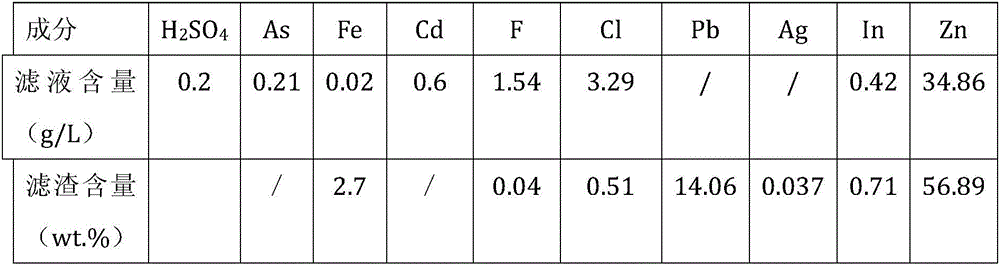

Construction method of steel reinforced concrete chimney

ActiveCN101225718ASignificant technical economySignificant social benefitsForms/shuttering/falseworksTowersSocial benefitsReinforced concrete

The invention discloses a construction method for reinforced concrete chimney, which comprises a foundation construction and a chimney cylinder construction; wherein the chimney cylinder construction comprises the steps: the steel bars are arranged on the cylinder wall along the direction of the chimney cylinder body; the firebrick lining is built along the inner circumference of the chimney; a displacement formwork is arranged at the outer circumference of the chimney cylinder body; the concrete is poured between the firebrick lining and the displacement formwork; when the intensity of the concrete is over 1.2N / mm<2>, the displacement formwork can be removed; the removable displacement formwork is displaced upwards; the steps are repeated until the chimney reaches the design height; the construction method for reinforced concrete chimney has the advantages that: the construction cost is low; the construction measure cost can be reduced greatly; an installation and removal procedure of the inner chimney formwork is reduced; the construction difficulty is reduced; the construction speed is improved and the construction cost is lowered; the construction period for displacement formwork construction is shortened by 30 percent than that of the slip-form construction in the same project, and the construction cost is reduced by 60 percent; thereby the construction method for reinforced concrete chimney has significant integrated technical economic and social benefits.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

Method for extracting valuable metal from cobalt metallurgical waste

InactiveCN107058745AHigh recovery rateShort processCalcium/strontium/barium sulfatesProcess efficiency improvementSlagManganese

The invention provides a method for extracting valuable metal from cobalt metallurgical waste. The method comprises the following steps of S1, calcium removal, S2, copper separation, S3, calcium and magnesium removal, and S4 zinc separation. The method has the beneficial effects that 1, impurity removal liquid generated by the impurity removal procedure of cobalt wet metallurgy P204 or the valuable metal in manganese-rich slag after the impurity removal liquid is precipitated can be sufficiently utilized; 2, the metal recovery rate of the method is high, the recovery rate of calcium can reach 85% or over, and the recovery rates of copper, cobalt, manganese and zinc can reach 90% or over; 3, the technological process of the method is short and only has four steps, and applied raw and auxiliary materials are easy to obtain and low in cost; and 4, the technological process does not involve high temperature or high pressure, reaction conditions are mild, and the number of potential safety hazards is small. Calcium sulfate generated through the method can serve as a raw material for production of cement, a small amount of generated calcium fluoride slag and a small amount of generated magnesium fluoride slag can be sent to a fluorination plant to serve as raw materials, and environmental friendliness is achieved.

Owner:青海快驴高新技术有限公司

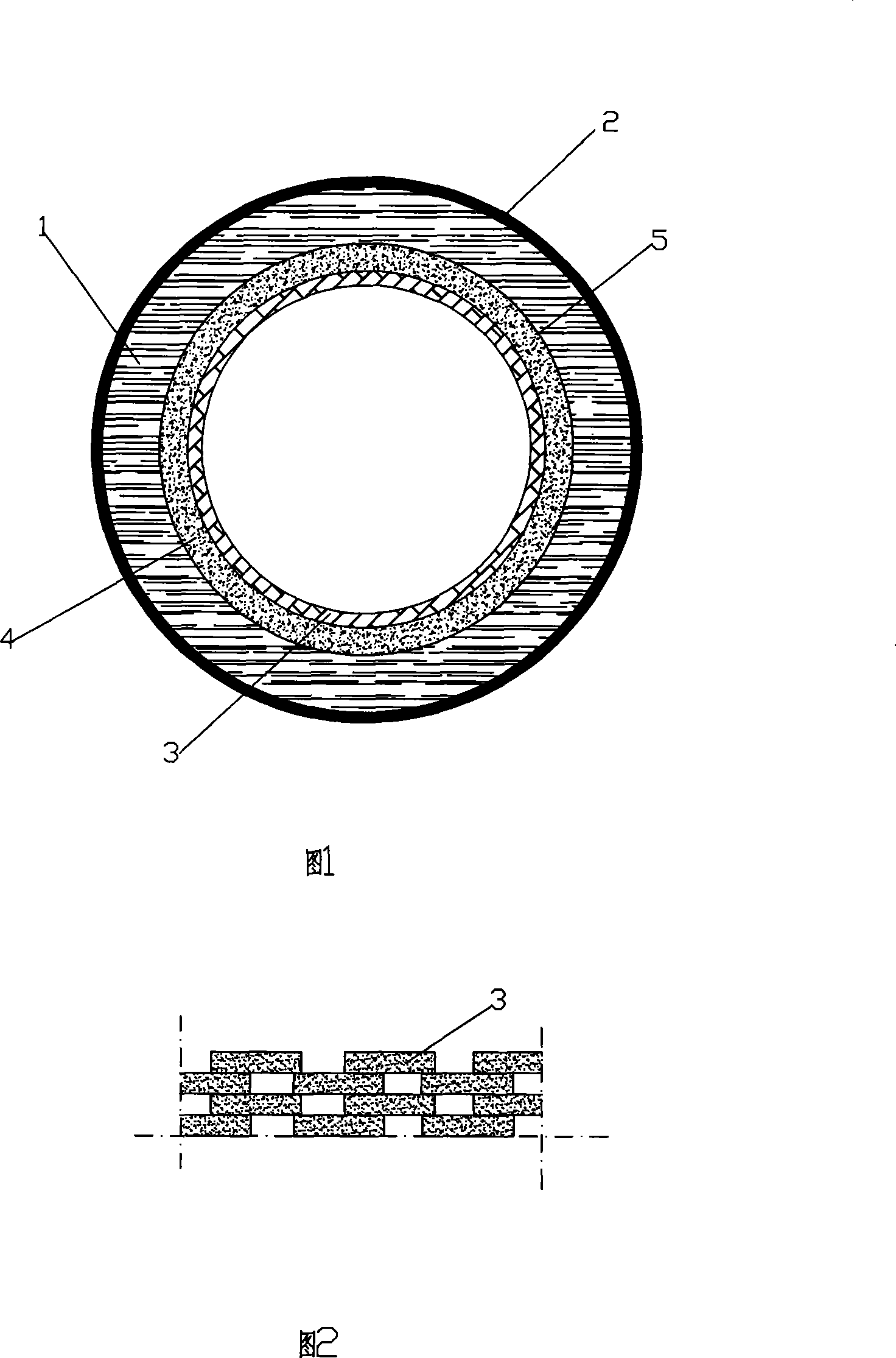

Method for making integrated circuits

InactiveUS20060246733A1Semiconductor/solid-state device manufacturingElectrical resistance and conductanceCopper-wiring

Integrated circuits, the key components in thousands of electronic and computer products, include interconnected networks of electrical components. The components are typically wired, or interconnected, together with aluminum wires. In recent years, researchers have begun using copper instead of aluminum to form integrated-circuit wiring, because copper offers lower electrical resistance and better reliability at smaller dimensions. However, copper typically requires use of a diffusion barrier to prevent it from contaminating other parts of an integrated circuit. Unfortunately, typical diffusion barrier materials add appreciable resistance to the copper wiring, and thus negate some advantages of using copper. Moreover, conventional methods of forming the copper wiring are costly and time consuming. Accordingly, the inventors devised one or more exemplary methods for making integrated-circuit wiring from materials, such as copper-, silver-, and gold-based metals. One exemplary method removes two or more masks in a single removal procedure, forms a low-resistance diffusion barrier on two or more wiring levels in a single formation procedure, and fills insulative material around and between two or more wiring levels in a single fill procedure. This and other embodiments hold the promise of simplifying fabrication of integrated-circuit wiring dramatically.

Owner:MICRON TECH INC

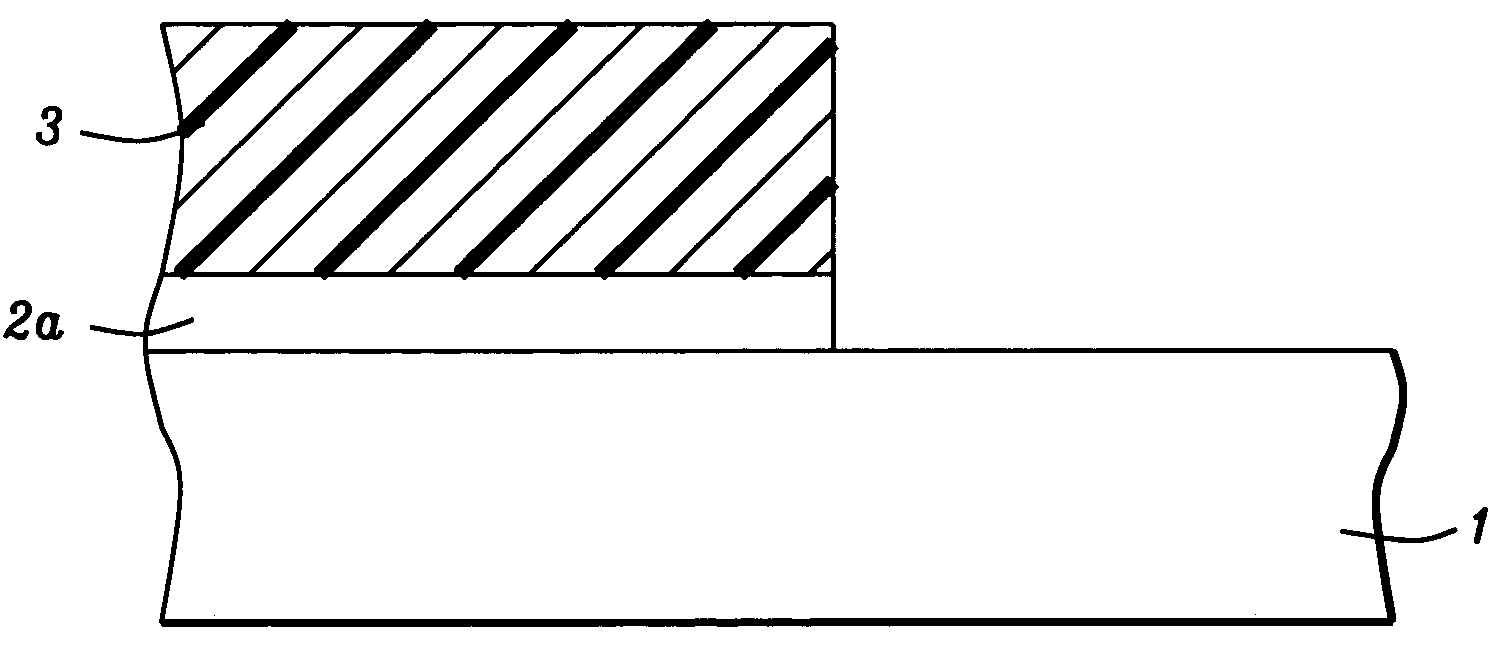

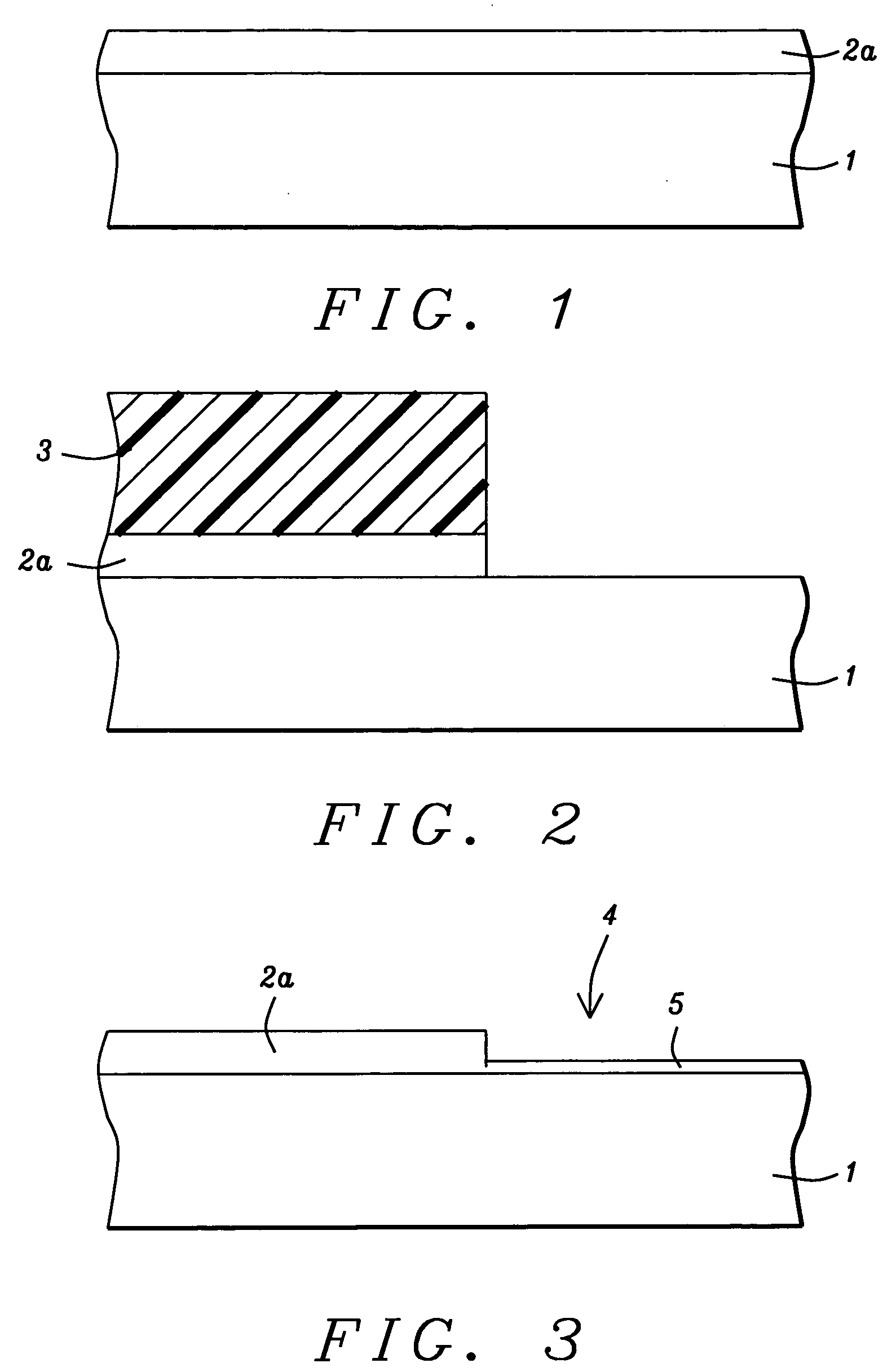

Transparent ceramic and method for production thereof, and optical element

InactiveUS20030181311A1Less variationInduces no double refractionLamination ancillary operationsOther chemical processesShell moldingRefractive index

A ceramic material powder for a translucent ceramic is molded with a binder, and the resulting green compact is embedded in a ceramic powder having the same composition with the ceramic material powder. After removing the binder, the green compact embedded in the ceramic powder is fired in an atmosphere having an oxygen concentration higher than that in the removal procedure of the binder and thereby yields a translucent ceramic represented by Formula I: Ba{(SnuZr1-u)xMgyTaz}vOw, Formula II: Ba(ZrxMgyTaz)vOw or Formula III: Ba{(SnuZr1-u)xZntMg1-t)yNbz}vOw. The translucent ceramic has a refractive index of 1.9 or more and is paraelectric.

Owner:MURATA MFG CO LTD

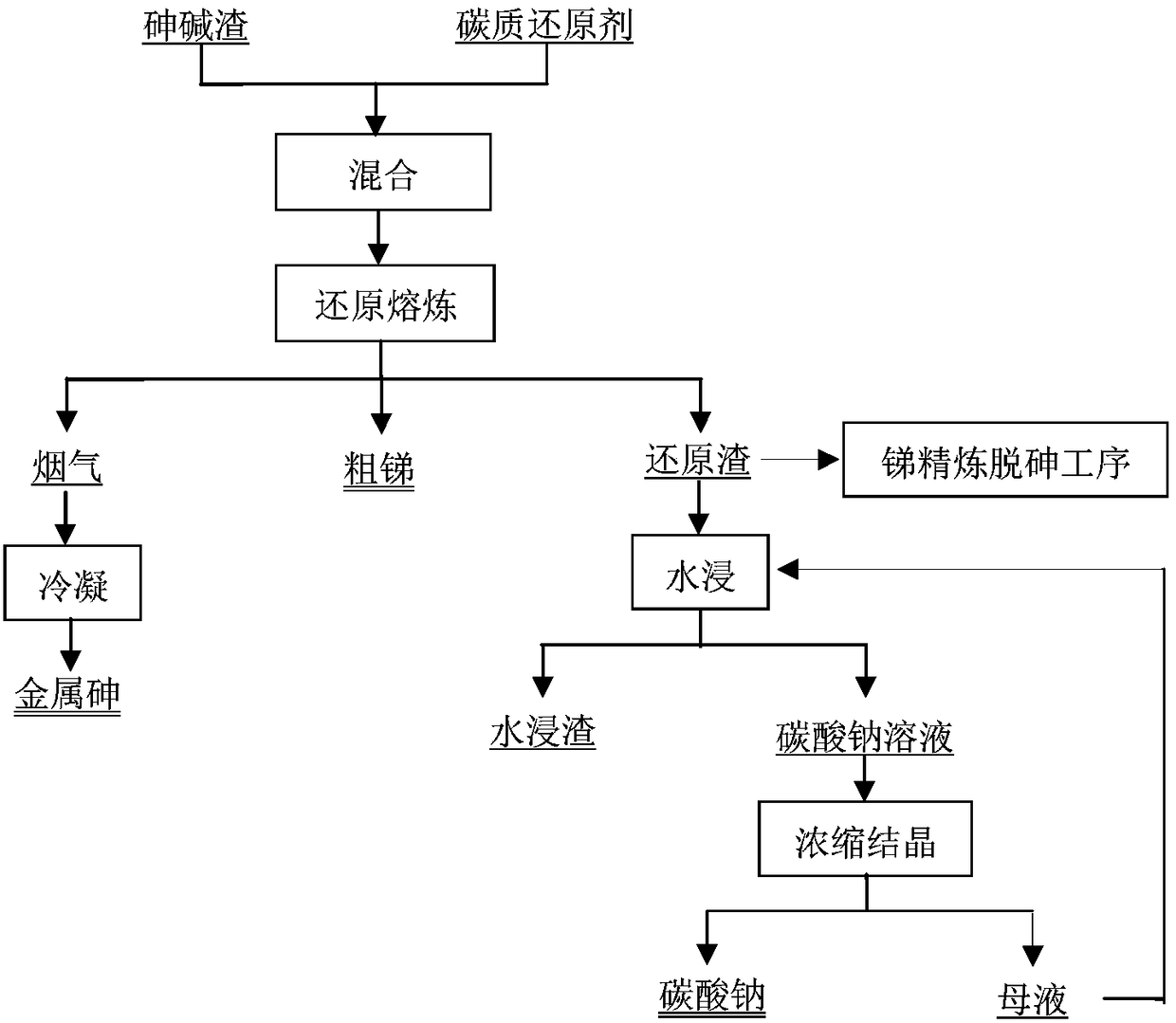

Arsenic-alkali slag reduction smelting treatment method

ActiveCN108220626ASolve disposal problemsSolve environmental problemsProcess efficiency improvementAlkali metal carbonatesSlagWater immersion

The invention discloses an arsenic-alkali slag reduction smelting treatment method. The method comprises the following steps: mixing arsenic-alkali slag and a carbon reducing agent and performing reduction smelting to obtain arsenic steam, crude antimony and reducing slag; after condensing the arsenic steam, obtaining a metal arsenic product, wherein a main component of the reducing slag is Na2CO3, can be directly used as an arsenic removal agent to be returned back to an antimony refining and arsenic removal procedure, and also can be subjected to a water immersion-concentration-crystallization technology to obtain an Na2CO3 crystal. According to the arsenic-alkali slag reduction smelting treatment method, metal arsenic and the crude antimony are prepared through one-step reduction; meanwhile, the Na2CO3 is regenerated; compared with an existing technology, a flow is simplified and the production cost is reduced; reduction, harmlessness and recycling of the arsenic are realized and the environment protection difficulty is solved; considerable economic benefits are generated and the arsenic-alkali slag reduction smelting treatment method is suitable for being industrially popularized.

Owner:湖南锐异资环科技有限公司

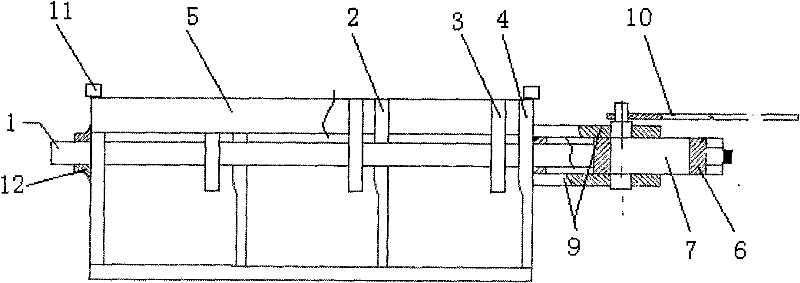

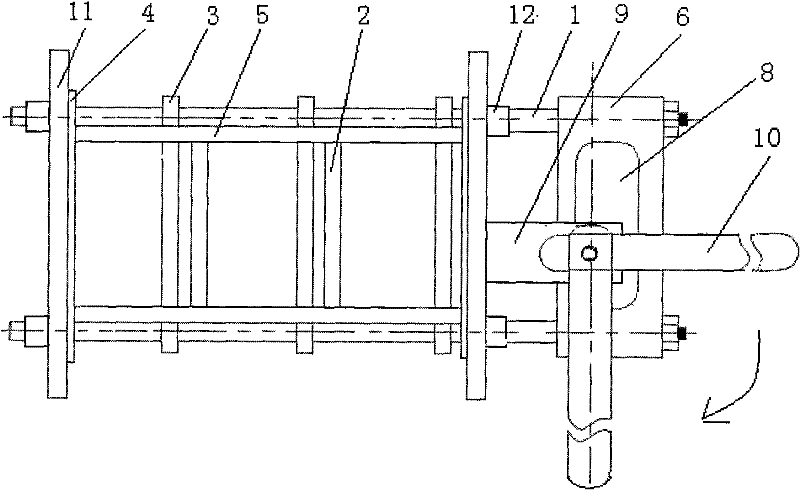

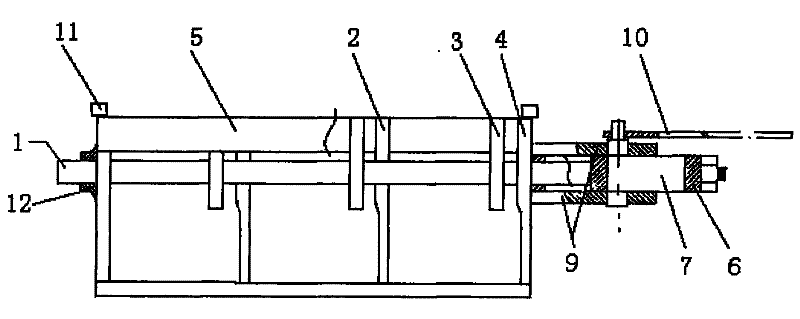

Welding device for lead acid battery electrodes

ActiveCN101745771AEasy to operateAccurate operationWelding/cutting auxillary devicesAuxillary welding devicesPush and pullElectrical battery

The present invention discloses a welding device for lead acid battery electrodes. The welding device consists of a welding unit box, a push-and-pull rod flexibly connected to the welding unit box and an assembly arranged outside the welding unit box. The push-and-pull rod is driven by the assembly to axially move. At least one grid plate is arranged in the welding unit box, the welding unit box is divided into two grids by the grid plate, an extruding plate is arranged in each grid, and the two sides of the extruding plate are fixedly connected with the push-and-pull rod. The present invention adopts the assembly module design thought that the push-and-pull rod is matched with an eccentric wheel. The electrodes are welded by being compressed in a compression ratio fitting with battery unit cells, so the operation of the electrode welding procedure is more convenient and accurate, and the production efficiency is improved. The effective compression of the electrodes by a compression ratio makes the groove removal procedure easier.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

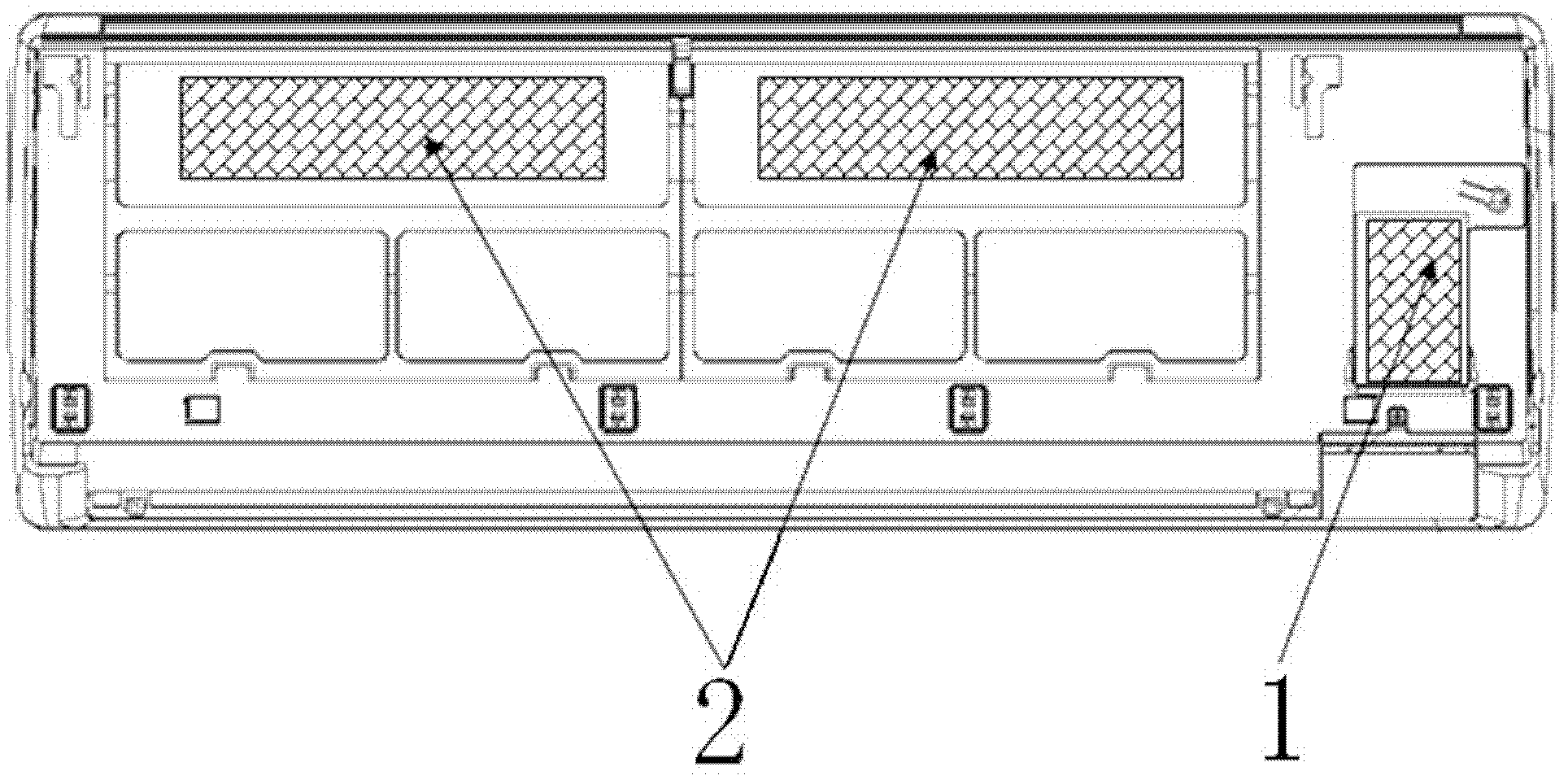

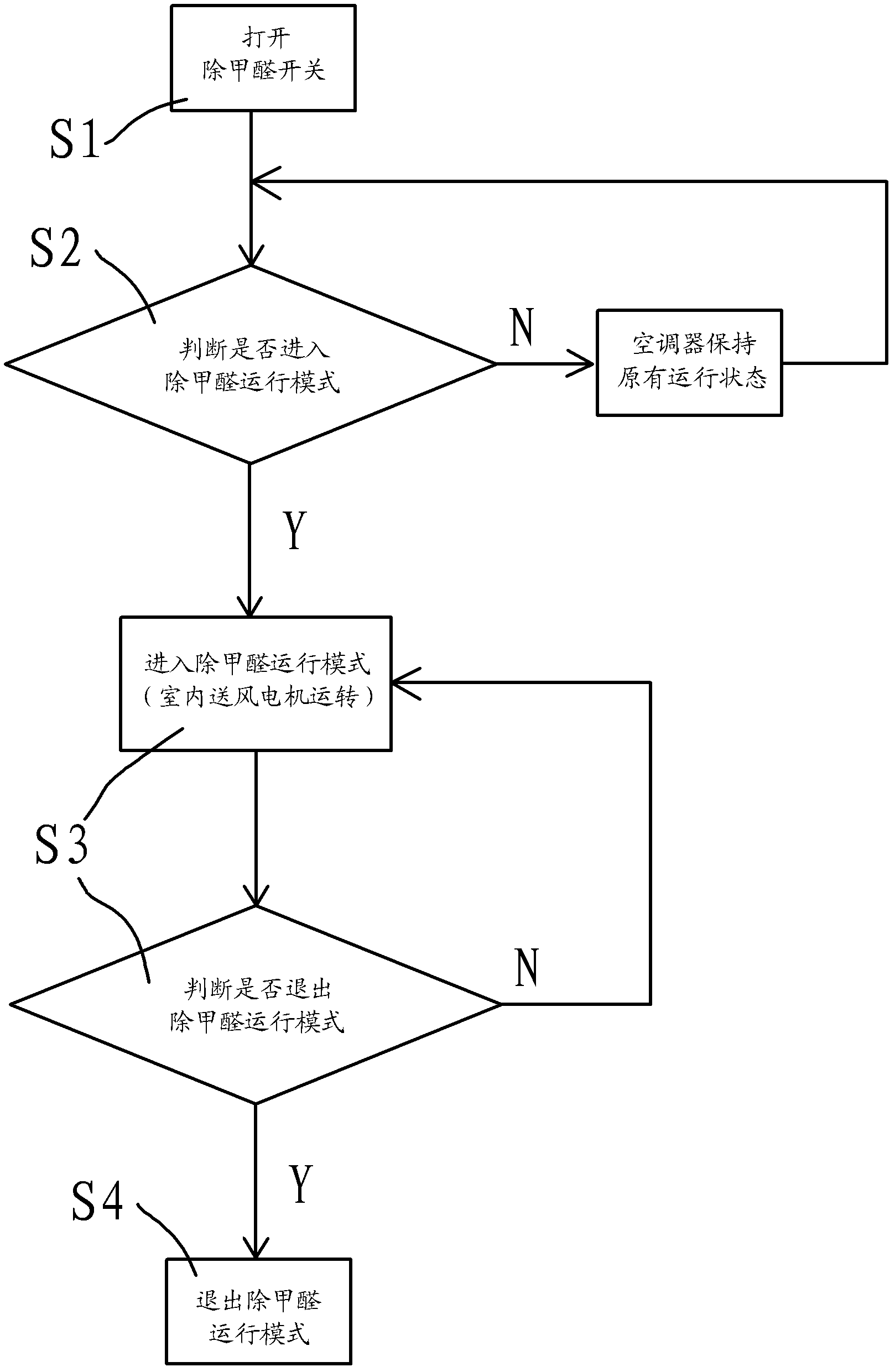

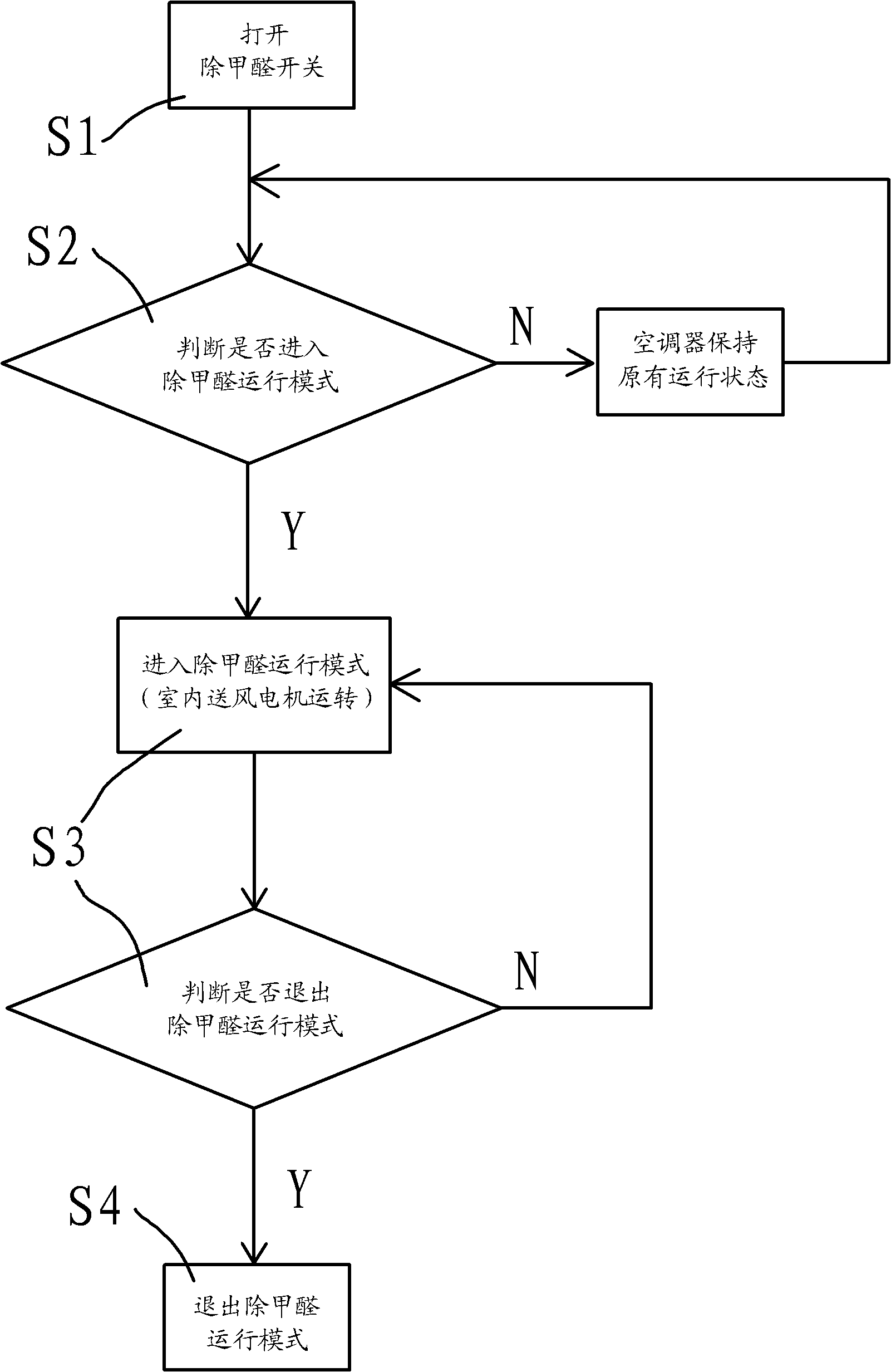

Air conditioner and method by utilizing air conditioner to remove formaldehyde

ActiveCN102367981AReduce the cost of removing formaldehydeQuality improvementSpace heating and ventilation safety systemsLighting and heating apparatusComputer moduleEngineering

The invention provides an air conditioner, which comprises a formaldehyde sensor, a formaldehyde detection control module and an air conditioner control module. The invention also provides a method by utilizing the air conditioner to remove formaldehyde, which comprises the following steps that: step 1, a formaldehyde-removal switch is powered on, and formaldehyde concentration is detected by the formaldehyde sensor in real time; step 2, in response to a formaldehyde concentration signal detected by the formaldehyde sensor, the formaldehyde detection control module judges whether a signal for entering a formaldehyde removal state is outputted; step 3, in response to the signal for entering the formaldehyde removal state, the air conditioner control module controls the air conditioner to enter a formaldehyde removal running mode to remove the formaldehyde until the formaldehyde detection control module outputs a signal for withdrawing the formaldehyde removal state; and step 4, in response to the signal for withdrawing the formaldehyde removal state, or the power off of the formaldehyde removal switch, the air conditioner control module controls the air conditioner to withdraw the formaldehyde removal running mode. Due to the adoption of the air conditioner and the method, the formaldehyde removal procedure can be simplified, and the cost can be reduced.

Owner:HEFEI HAIER AIR CONDITIONER

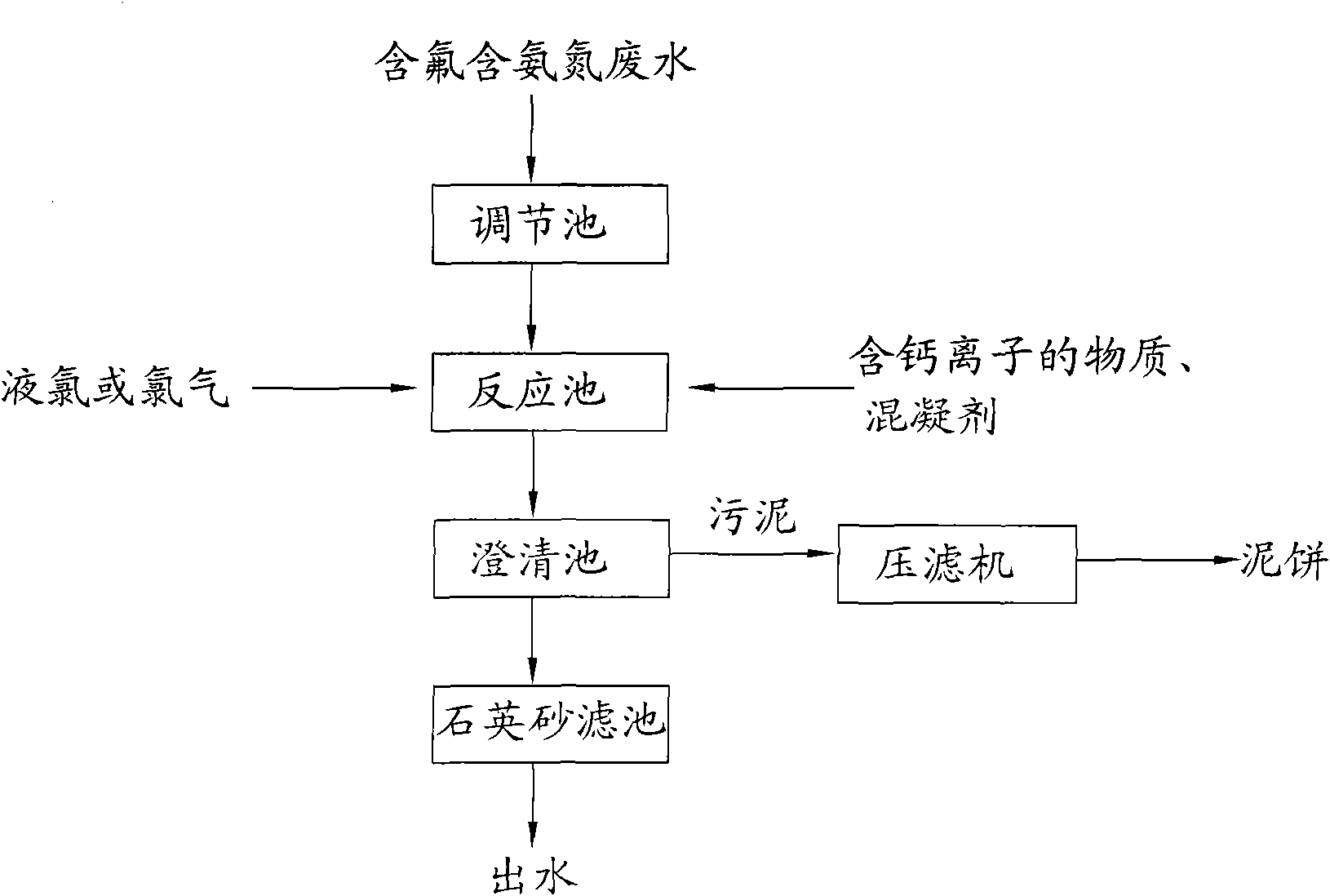

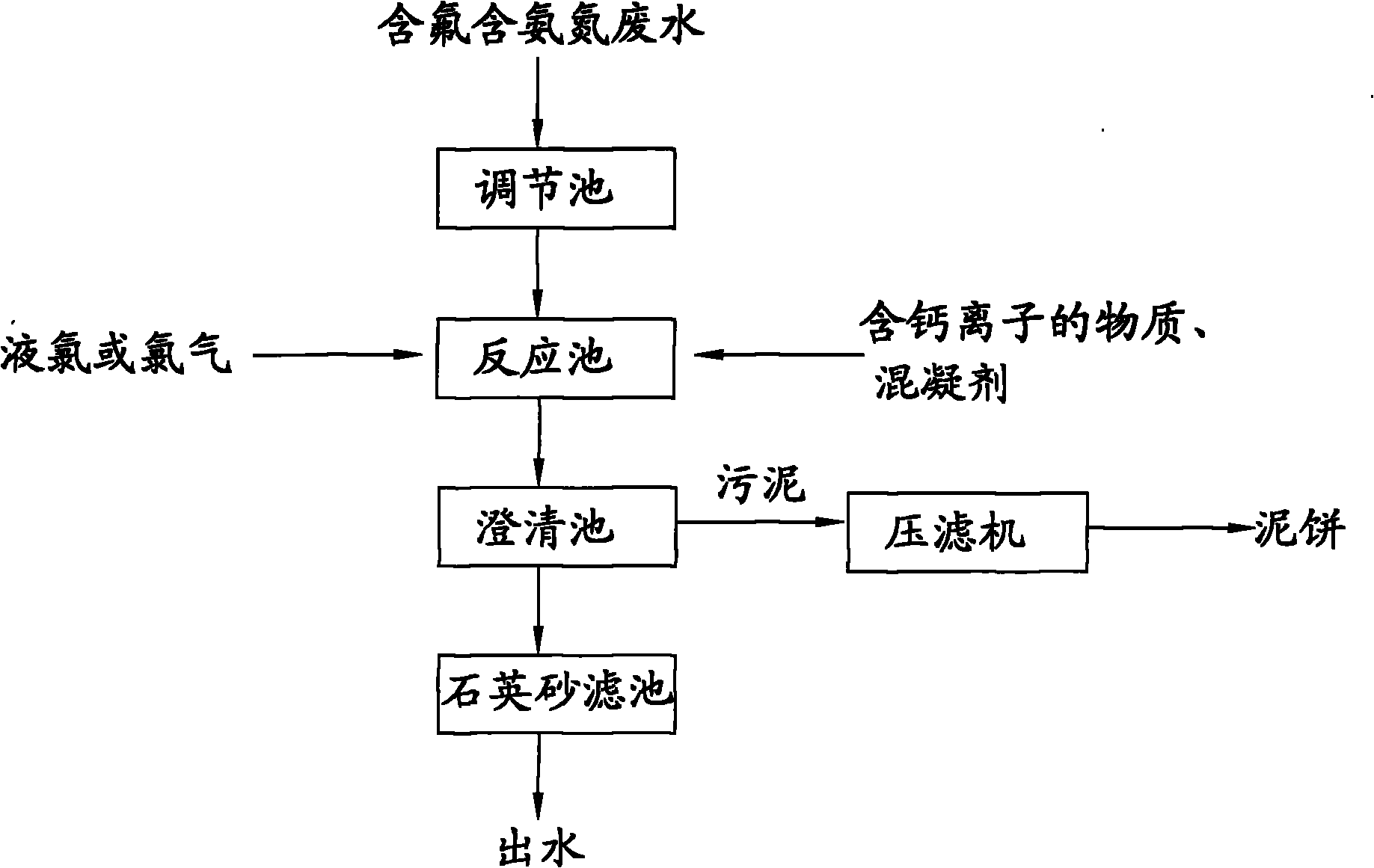

Method for treating fluorine-containing and ammonia nitrogen-containing waste water in electronic industry

ActiveCN102126799AReduce ammonia nitrogen contentTo achieve the treatment effectWater contaminantsMultistage water/sewage treatmentIon contentChemical reaction

The invention relates to a method for treating fluorine-containing and ammonia nitrogen-containing waste water in electronic industry. The method comprises an ammonia nitrogen removal procedure and a fluorine removal procedure, wherein the ammonia nitrogen removal procedure is as follows: Cl2 is added into waste water, wherein 7.6-8.0mg of Cl2 is added into every one liter of waste water containing 1mg of ammonia nitrogen, and the Cl2 is added in two batches; the addition amount for the first batch is 65-75%, and the addition amount for the second batch is the rest; after the first batch of Cl2 is added, alkali equivalent to the added Cl2 for the first batch is added to neutralize hydrochloric acid produced by the reaction of the Cl2 and ammonia nitrogen, and then, the second batch of Cl2 is added; and the fluorine removal procedure combines chemical reaction precipitation and coagulative precipitation separation. By firstly removing ammonia nitrogen and then removing fluorine, the invention achieves the advantages of stable and favorable treatment effect, high efficiency and high speed. The fluorine ion content and ammonia nitrogen content in the waste water treated by the invention are effectively reduced, and the waste water can be discharged or be subjected to further reclamation treatment to be reclaimed according to different environmental protection requirements.

Owner:WUXI DEPPEL WATER INVESTMENT

Shell-based memory read-write testing method

InactiveCN104598344AShorten test timeImprove test efficiencyDetecting faulty computer hardwareTest efficiencyOperational system

The invention discloses a shell-based memory read-write testing method and belongs to the field of memory tests. The method comprises the following specific steps of: 1, ensuring that a tested memory is based on a linux kernel operating system, installing a memtester tool and logging on a running program; 2, presetting program parameters; 3, selecting modes which include a default current mode, a timing mode and a circulation mode, wherein the timing mode and the circulation mode are mutually exclusive, so that only one of the timing mode and the circulation mode can be selected; 4, setting a test environment of the memtester tool under the mode, and starting a memtester single-thread or multithread parallel test; 5, after the test is finished, viewing a test result file in which a test result and a test time record are recorded, and eliminating temporary files created in a program run process. During a process of testing memory read-write, an auxiliary test program runs, so that a series of complicated test operations such as parameter modification, repeated thread starting and result treatment are omitted, the test application limitation is broken, and the test efficiency is greatly increased.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

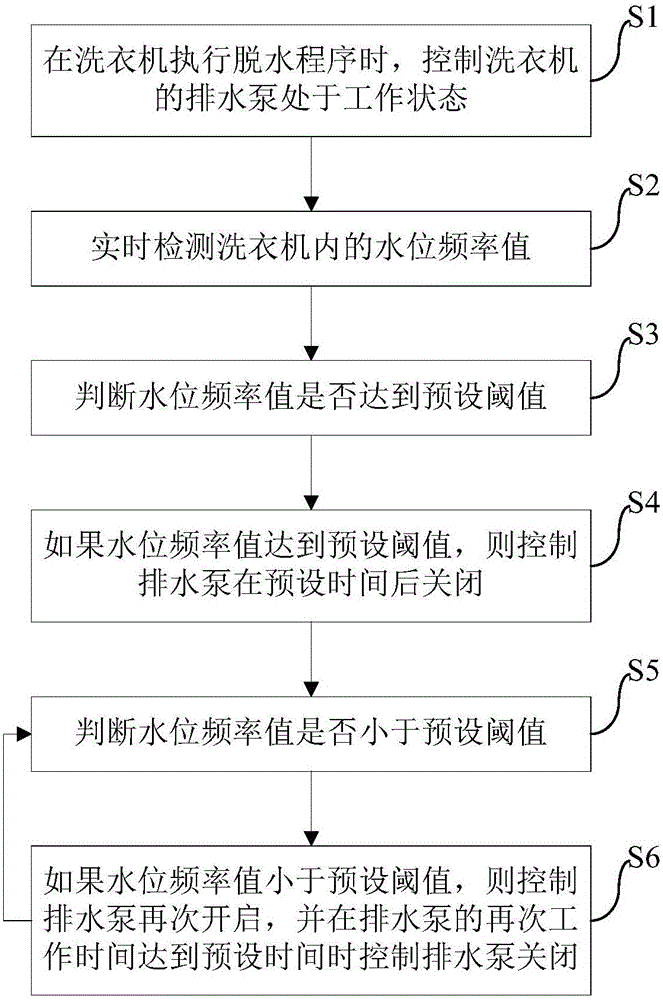

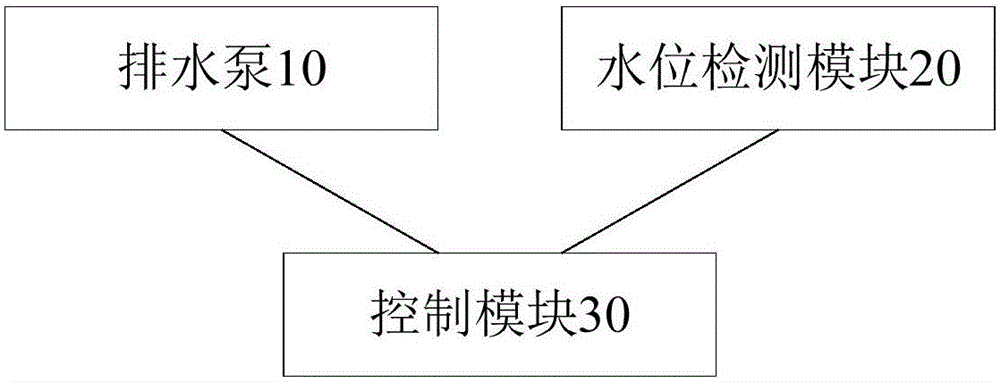

Water removal control method for washing machine and washing machine

ActiveCN105926236AExtended working hoursExtended service lifeOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention discloses a water removal control method for a washing machine and the washing machine. The method comprises the following steps: S1, a draining pump of the washing machine is controlled to be in a working state when the washing machine executes a water removal procedure; S2, a water level frequency value in the washing machine is detected in real time; S3, whether the water level frequency value reaches a preset threshold is judged; S4, if the water level frequency value reaches the preset threshold, the draining pump is controlled to stop after a preset time period; S5, whether the water level frequency value is smaller than the preset threshold is judged; S6, if the water level frequency value is smaller than the preset threshold, the draining pump is controlled to start again, when the working time of the draining pump reaches preset time again, the draining pump is controlled to stop, and operation returns to the step 5 for execution. According to the method, electricity can be saved, the service life of the draining pump is prolonged, meanwhile, the condition of noise production caused by too little water in the draining pump is improved, and the user experience is improved greatly.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

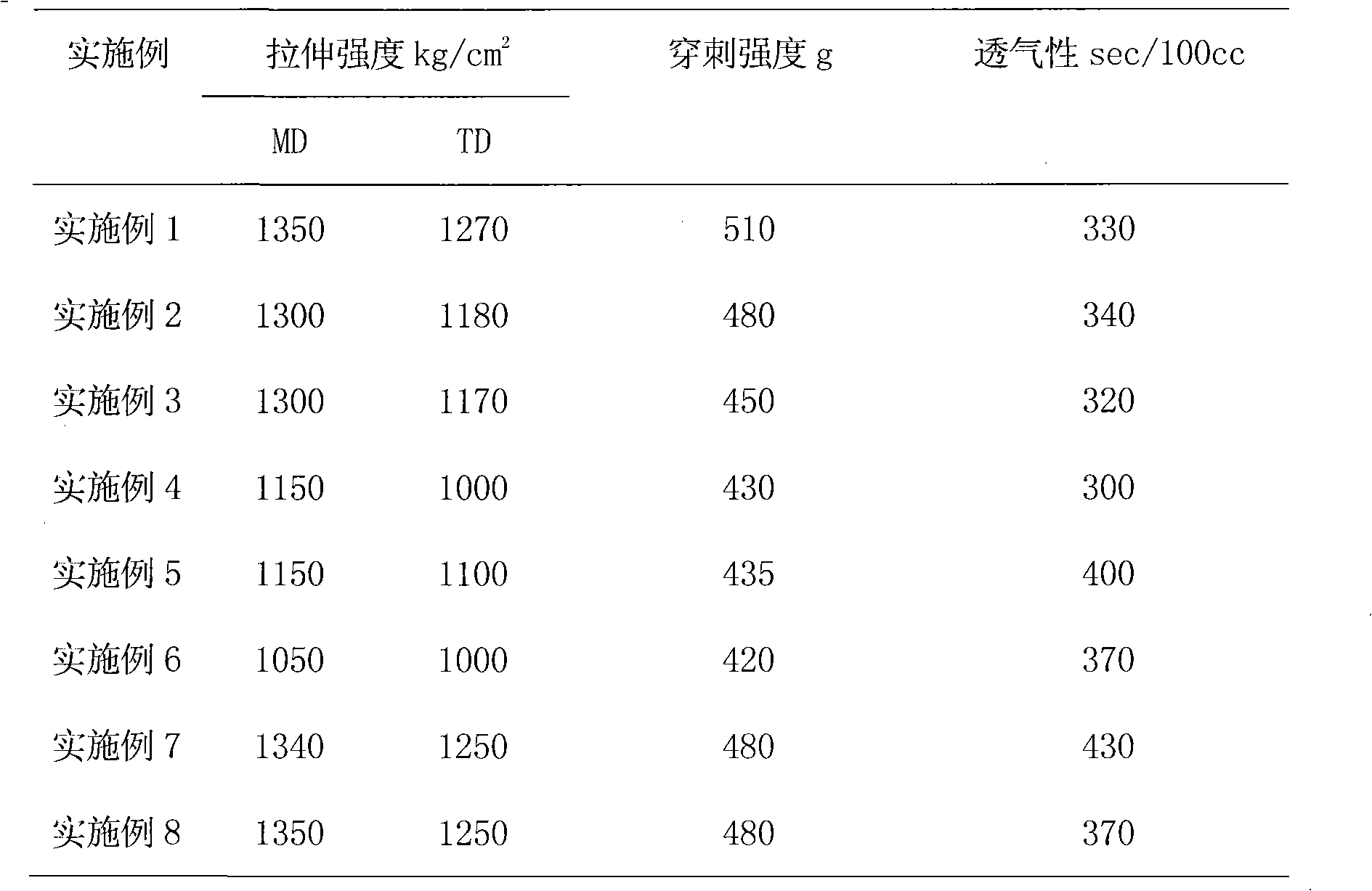

Method for preparing polyolefin microporous membrane through wet process

ActiveCN101781417ASolve the problems of low mechanical strength and poor uniformity of membrane poresImprove breathabilityCleaning using liquidsPolyolefinPolymer science

The invention discloses a method for preparing polyolefin microporous membrane through wet process, aiming at solving the problems of low mechanical strength and poor uniformity of the clearances of the membrane. The method takes polyolefine resin, nucleating agent and solvent as the materials to prepare polyolefin microporous membrane through polyolefine solution preparation procedure, extrusion and gel sheet forming procedure, drawing procedure, membrane forming and solvent removal procedure, drying procedure and heat treatment stereotyping procedure. The preparation technique is simple and the polyolefin microporous membrane prepared through the method can be used as medical dressing, clothes lining, various separation membranes, water treatment membrane as well as membranes for a super capacitor, a battery and the like.

Owner:德州东鸿制膜科技有限公司

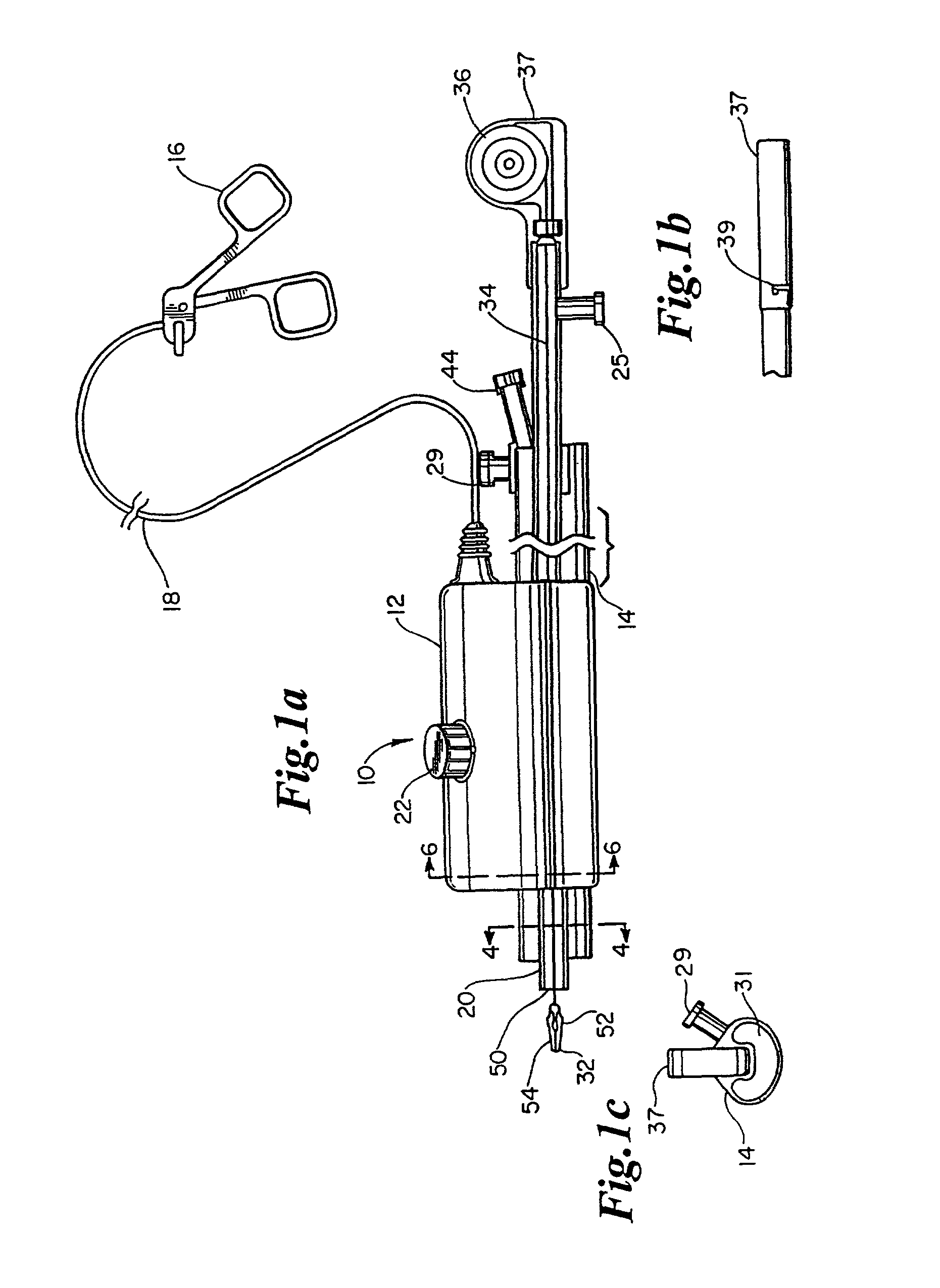

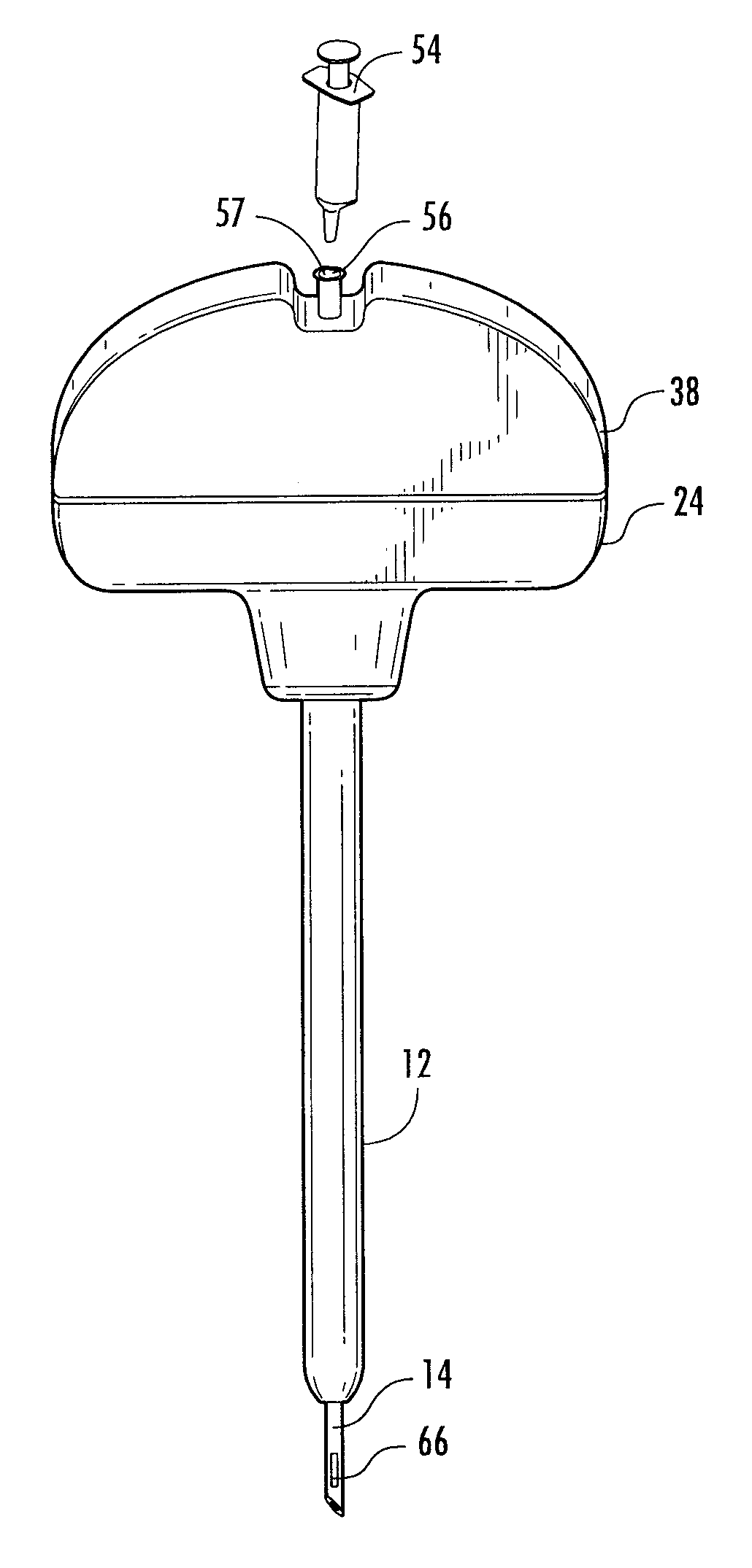

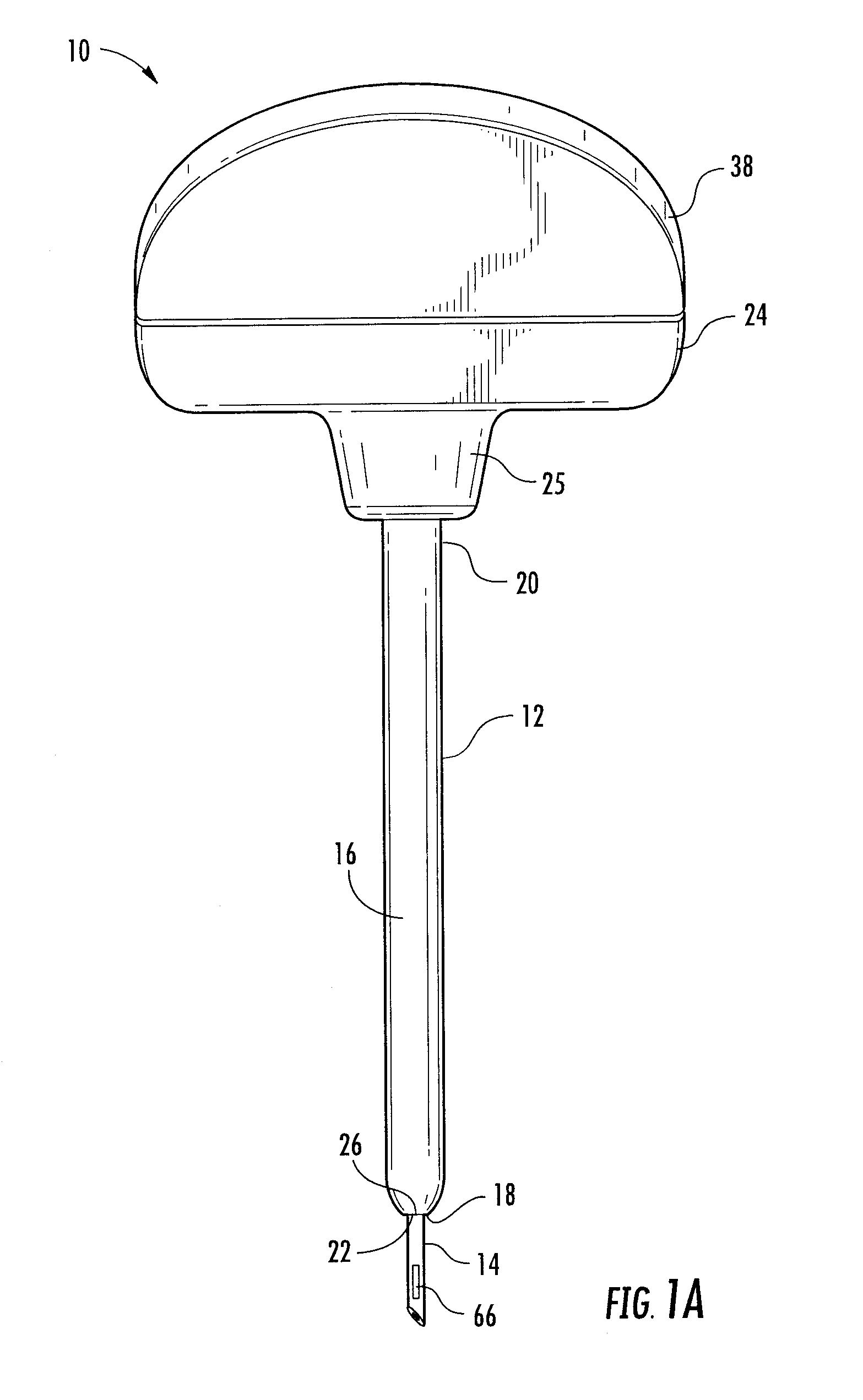

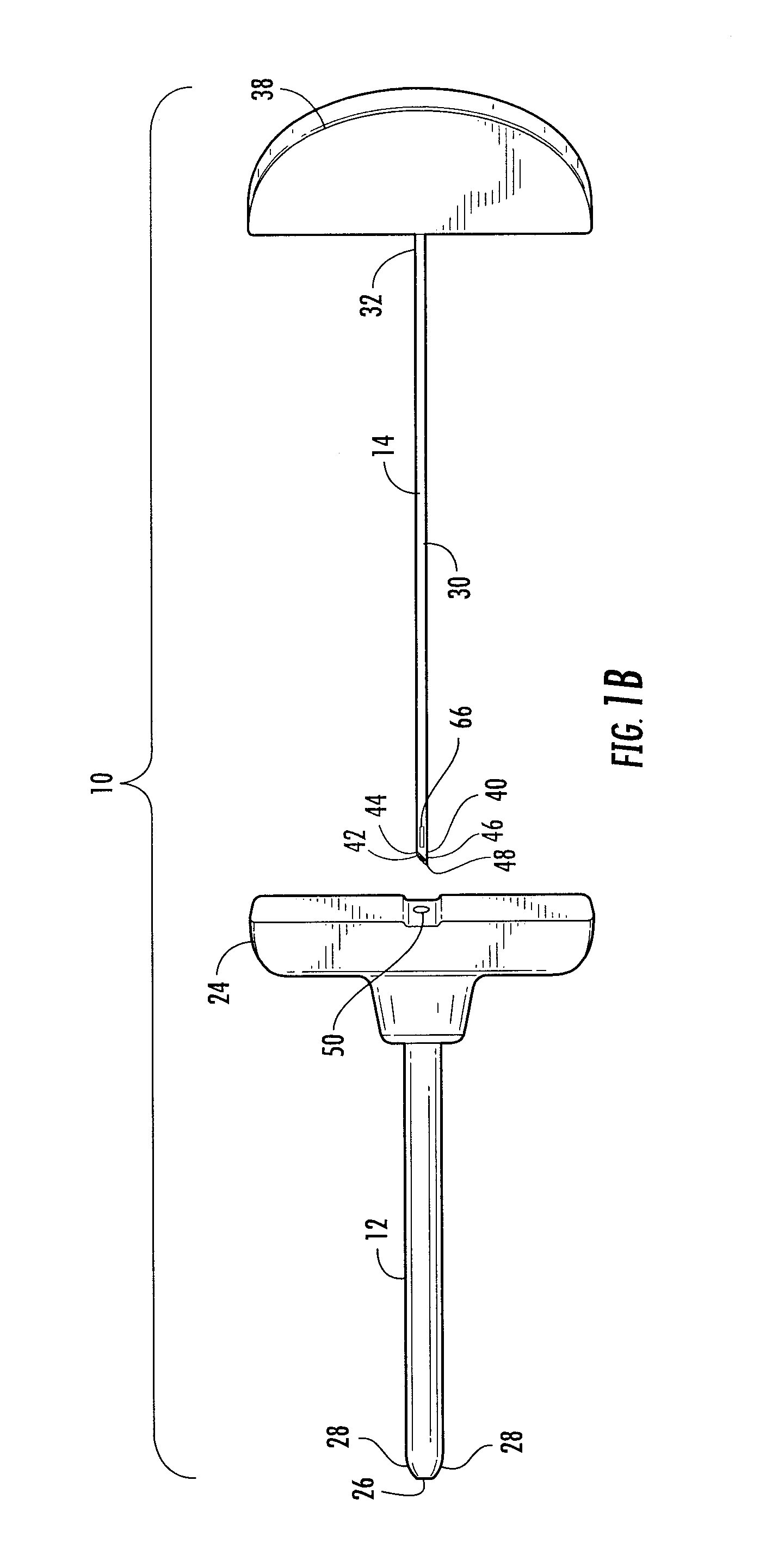

Instrument For Concurrent Injection Of Anesthesia And Removal Of Specimens From A Body

InactiveUS20130046200A1Relieve painUse of procedureSurgical needlesVaccination/ovulation diagnosticsBiopsy procedureBiopsy instruments

The instant invention describes a biopsy instrument which is useful in removal of tissue or fluid samples from a body, such as bone and soft tissue biopsy procedures. The biopsy instrument is an improvement over other biopsy needles currently in use in that the biopsy instrument according to the instant invention can be used to reduce the pain associated with specimen removal procedures. The biopsy instrument generally comprises an outer cannula and an inner medical probe member. The inner medical probe member is constructed and arranged to contain one or more fluid dispensing members for dispensing a fluid which are in fluid communication with a fluid dispensing device. In this arrangement, the user has the ability to continually inject fluids, such as anesthetizing agents, directly at or near the spot of specimen removal, without the need to remove the surgical instrument or use a separate fluid injecting needle.

Owner:INVENTIT

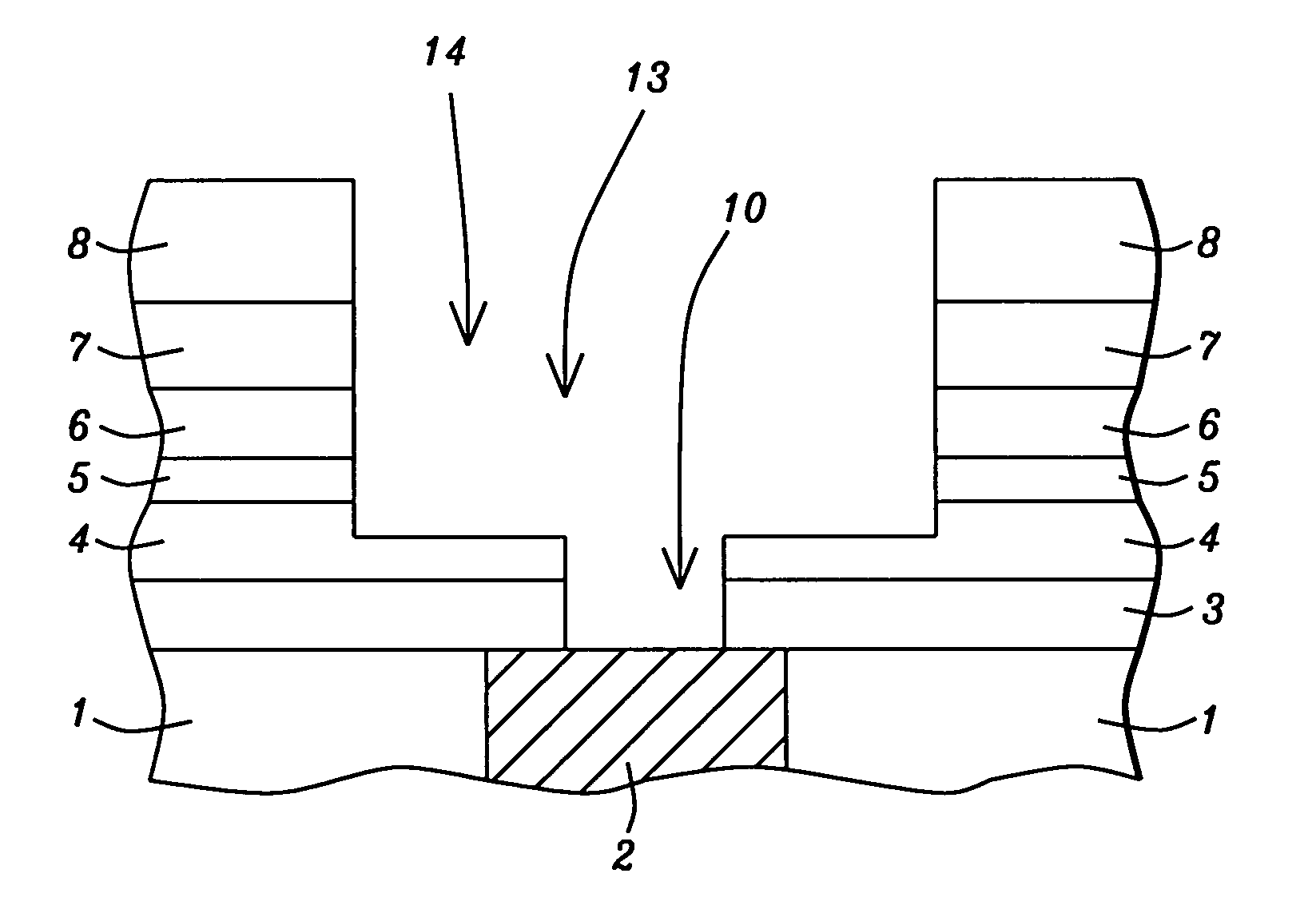

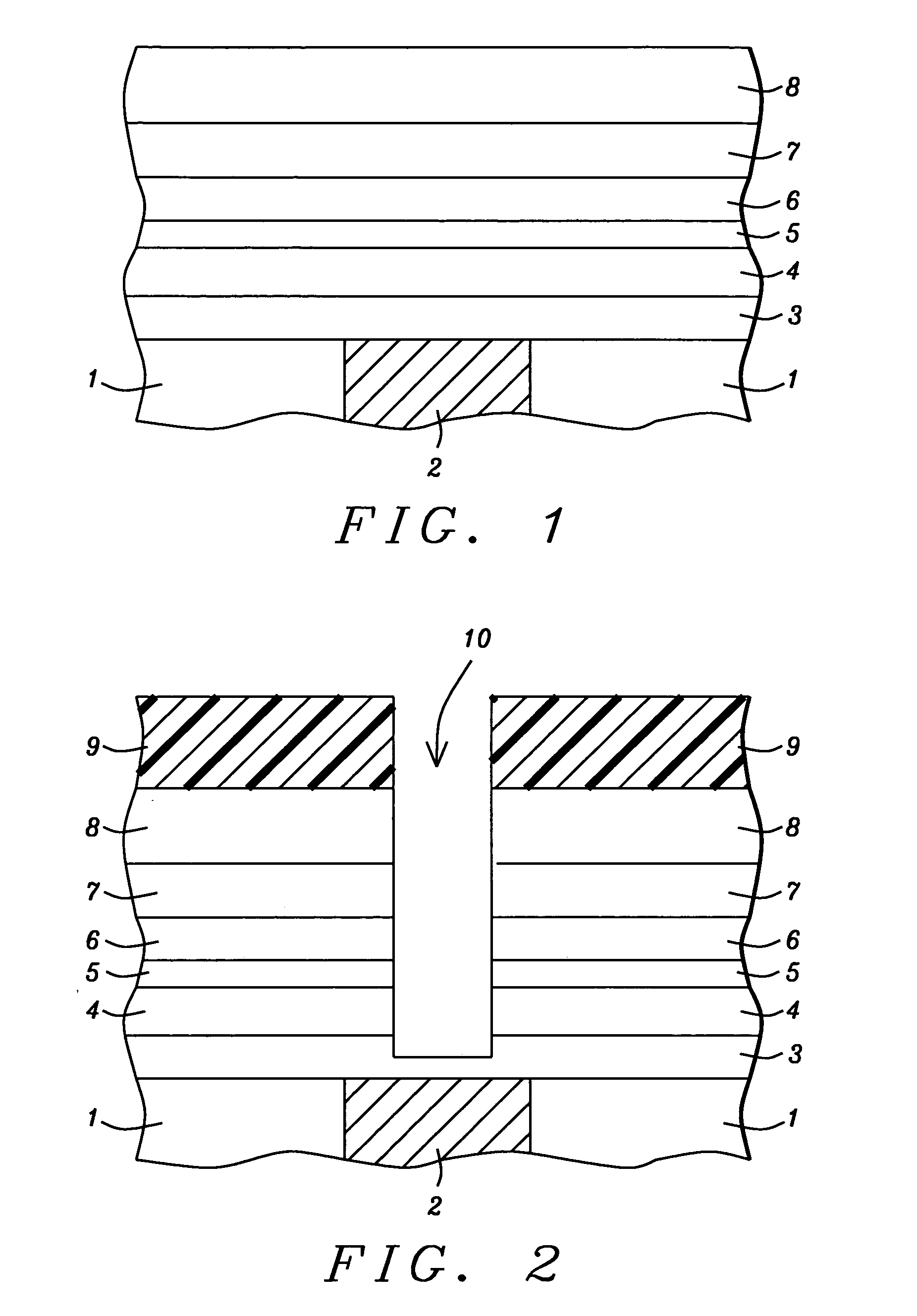

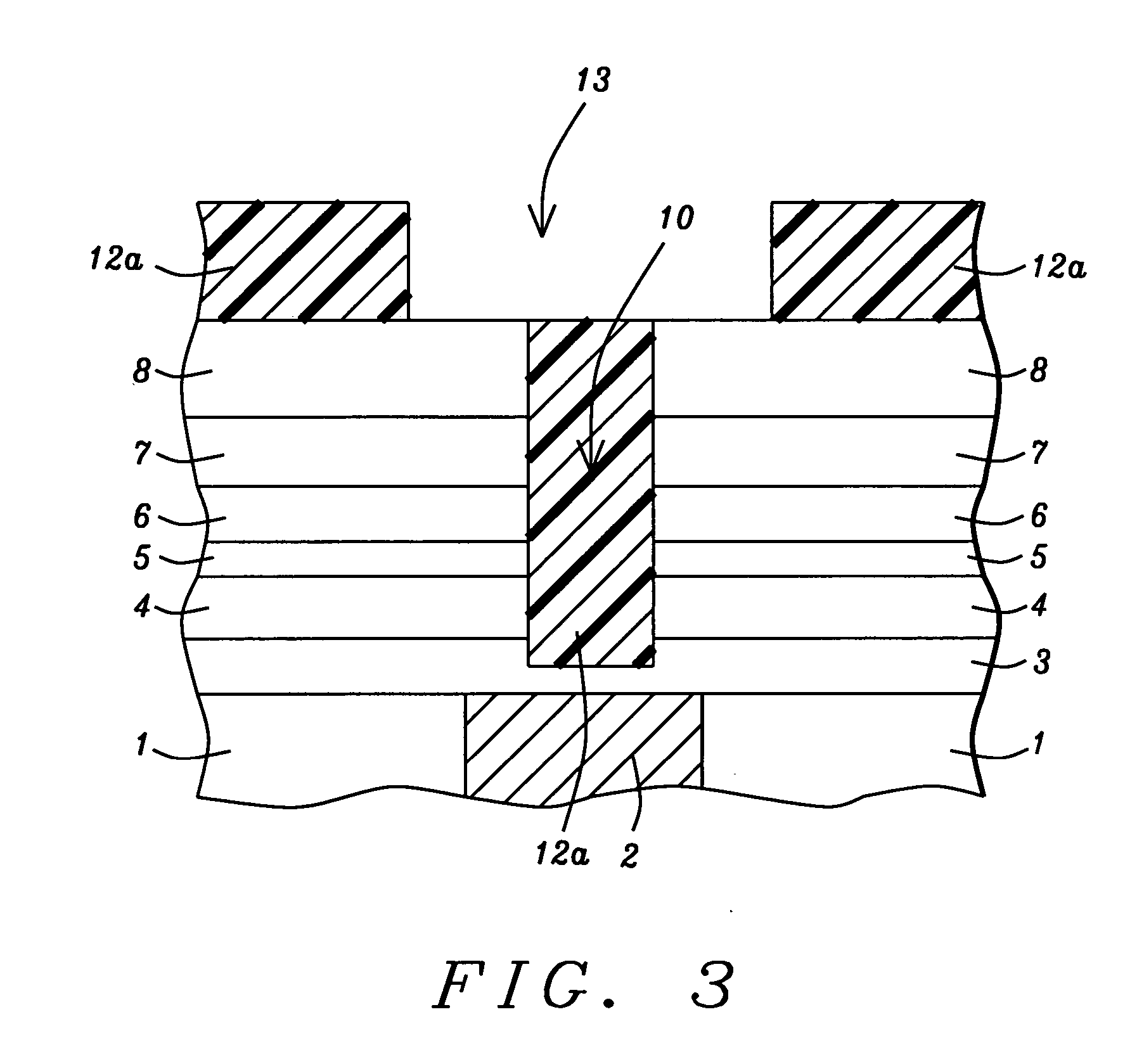

Two step trench definition procedure for formation of a dual damascene opening in a stack of insulator layers

InactiveUS20050215051A1Reduce riskReduce risk of damageSemiconductor/solid-state device manufacturingLayer removalPhotoresist

A process for defining a dual damascene opening in a stack of insulator layers to expose a portion of a top surface of an underlying conductive structure, has been developed. The process features a two step procedure for removal of insulator stop layers, wherein the stop layers are employed to allow selective dry etch procedures to be used for definition of both the via opening component and the trench shape component of the dual damascene opening. After definition of the via opening, terminating at the top surface of an underlying, first silicon nitride stop layer, a photoresist shape is used as an etch mask to allow a dry etch procedure to define a trench shape in a top portion of an insulator stack, with the dry etch procedure terminating at the top surface of an overlying second silicon nitride stop layer. The dry etch procedure also results in formation of a photoresist plug in the via hole, located on an underlying, first silicon nitride stop layer. The portion of the second silicon nitride stop layer exposed in the trench shape opening is next selectively removed via a first procedure of the two step, dry etch removal procedure, followed by removal of the trench shape defining photoresist shape and of the photoresist plug. Another dry etch procedure, the second step of the two step dry etch removal procedure, is next performed to selectively remove the portion of underlying, first silicon nitride stop layer exposed in the via opening, resulting in exposure of a portion of the top surface of the conductive structure. The two step, stop layer removal procedure reduces the level of insulator corner rounding at the top of the dual damascene opening, while also reducing damage to the top surface of the underlying conductive structure, exposed at the bottom of the dual damascene opening.

Owner:TAIWAN SEMICON MFG CO LTD

Method for removing phosphorus and extracting vanadium from high-calcium high-phosphorus vanadium slag

ActiveCN107164643AHigh phosphorus contentImprove qualityRecycling and recovery technologiesSlagSolid solution

The invention discloses a method for removing phosphorus and extracting vanadium from high-calcium high-phosphorus vanadium slag. The high-calcium high-phosphorus vanadium slag is broken and fine ground and is subject to leaching phosphorus removal treatment in a buffered solution or acid-deficient solution with the pH value ranging from 1.5 to 4.0, solid-solution separation is carried out, and phosphorus-contained filtrate and low-phosphorus vanadium slag are obtained; the low-phosphorus vanadium slag is dried and then subject to high-temperature roasting, and the high-temperature roasted low-phosphorus vanadium slag is subject to the water leaching working procedure, and a phosphorus-contained solution is obtained. The technical problems that the existing high-calcium high-phosphorus vanadium slag phosphorus removing and vanadium extracting process is large in phosphorus removing difficulty, poor in phosphorus removing effect, and high in phosphorus removing cost, in the phosphorus removing process, a large amount of vanadium is lost, the whole vanadium extracting technology process is complex, the impurity removal procedure difficulty is large, and the vanadium extracting cost is high are solved.

Owner:CHONGQING UNIV

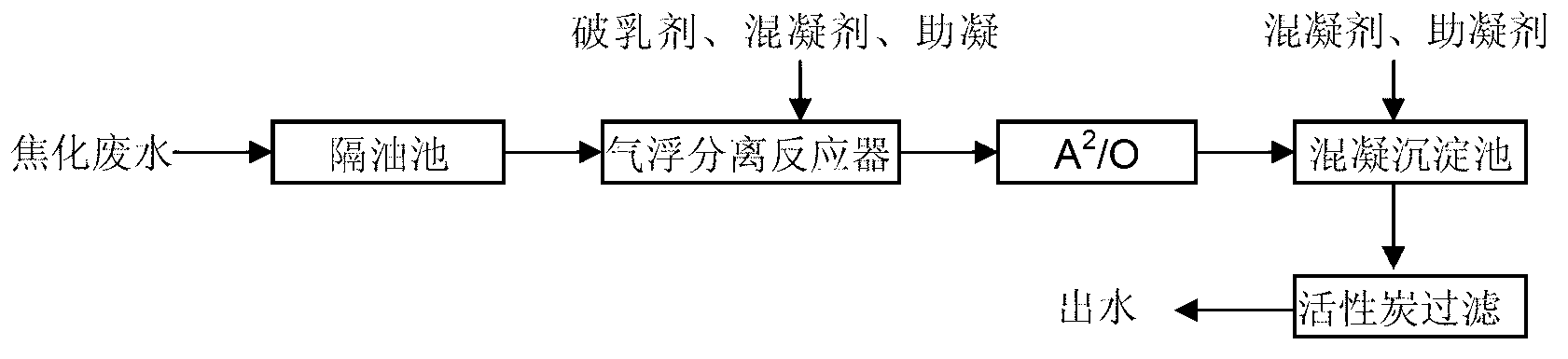

Treatment method for improving removal rate of benzo (a) pyrene in coking wastewater

InactiveCN103304095AImprove removal efficiencyMeet disposal discharge requirementsWater contaminantsMultistage water/sewage treatmentActivated carbon filtrationTurbidity

The invention relates to a treatment method for improving removal rate of benzo (a) pyrene in coking wastewater. The method is characterized by comprising the following steps of: (1) conveying the coking wastewater into an oil separation tank, and removing suspension oil in water; (2) conveying the wastewater from the oil separation tank into an air floatation reactor, adding a coagulant, a coagulant aid and a demulsifier into the air floatation separation reactor; (3) conveying the effluent of the air floatation separation reactor into an A2 / O biological treatment process; (4) conveying the effluent of the biological treatment process into a coagulation sedimentation basin, adding the coagulant and the coagulant aid into the coagulation sedimentation basin; (5) conveying the effluent of the coagulation sedimentation basin into an active carbon filtering basin. The method has the advantages that the air floatation and turbidity removal procedures are strengthened based on the distribution characteristics of the benzo (a) pyrene which mostly forms solid suspension or is dissolved in oil, removal of benzo (a) pyrene in coking wastewater is efficient, and the increasingly stringent wastewater treatment and discharge requirements are met.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method and device for accepting postal items

InactiveUS20100019024A1Easy to shipReduce in quantityApparatus for meter-controlled dispensingKitchen equipmentInteraction deviceComputer science

There is provided a method for receiving mailpieces in a container. An exemplary method comprises receiving a mailpiece in the container, storing the mailpiece in the container, and removing the mailpiece from the container. The exemplary method also comprises recording a removal procedure. The exemplary method additionally comprises storing and / or transmitting removal data about the removal procedure using an interaction device associated with the container, the interaction device comprising a transponder located in a Faraday cage.

Owner:DEUT POST AG

Tomato skin, seed and residue dehydration drying and dry method skin and seed separation and combination production method in tomato paste factory

The invention discloses a tomato skin, seed and residue dehydration drying and dry method skin and seed separation and combination production method in a tomato paste factory; the tomato skin, seed and residue obtained by pulping, peeling off and seed removal procedures in the tomato paste factory are used as raw materials, after wet skin, seed and residue are pre-dehydrated by adopting a squeezing method, a cocurrent rotary drum drier is adopted to dry the wet tomato skin, seed and residue with mixed skin and seed; and then a skin-seed rubbing dispersion device which is embedded between a material outlet of the drier and terminal dedusting equipment in series is adopted to separate the skin and seed; the separated skin is compressed to improve the density or high-pressure high-temperature disinfestation and sterilization is carried out to prepare into particles, and tomato seed crude oil and oil cakes are extracted from the separated seeds by adopting the equipment and technology in the existing vegetable oil plants, and the tomato seed crude oil is extracted only by degumming and deacidifying refining, in the way, the tomato skin, seed and residue can be processed in a large scale, so as to lead the comprehensive utilization of the tomato skin, seed and residue to realize industrial production; in addition, water does not need in the technology process, thereby greatly reducing the environmental protection of the tomato residue and completely eliminating the environment pollution of discharged waste water with high BOD and suspended matters in the technology of separating skin and seed with a wet process in the prior art; only degumming and deacidifying refining are carried out to the tomato seed crude oil, the decoloration and deodorization procedures in the deep refining are cancelled, so as to prevent oil rancidity, improve transparency and fully keep the commodity characteristics and nutritional components of the tomato seed oil.

Owner:XINJIANG TOMATIA TOMATO SCI & TECH DEV

Novel multi-gate formation procedure for gate oxide quality improvement

InactiveUS20050124160A1Layered productsSemiconductor/solid-state device manufacturingDevice materialGate insulator

A process for forming a semiconductor device with multiple gate insulator thicknesses, wherein exposed surfaces of a semiconductor substrate are protected during a photoresist stripping procedure, has been developed. After growth of an insulator layer on the entire surface of a semiconductor substrate portions of the insulator layer not covered by a photoresist masking shape are selectively removed. A two step photoresist removal procedure is then employed initiating with an ozone water cycle which partially removes the photoresist shape while forming a thin silicon oxide layer on the portions of bare semiconductor surface. A acid-hydrogen peroxide mixture (SPM), is then used to complete the photoresist removal procedure including removal of photoresist residues, with the thin silicon oxide layer formed during the ozone water cycle protecting the previously bare underlying semiconductor surface. An oxidation procedure is then performed allowing a first gate insulator layer to be formed incorporating the original insulator layer, and allowing a thinner, second gate insulator layer to be obtained, incorporating the thin silicon oxide layer.

Owner:TAIWAN SEMICON MFG CO LTD

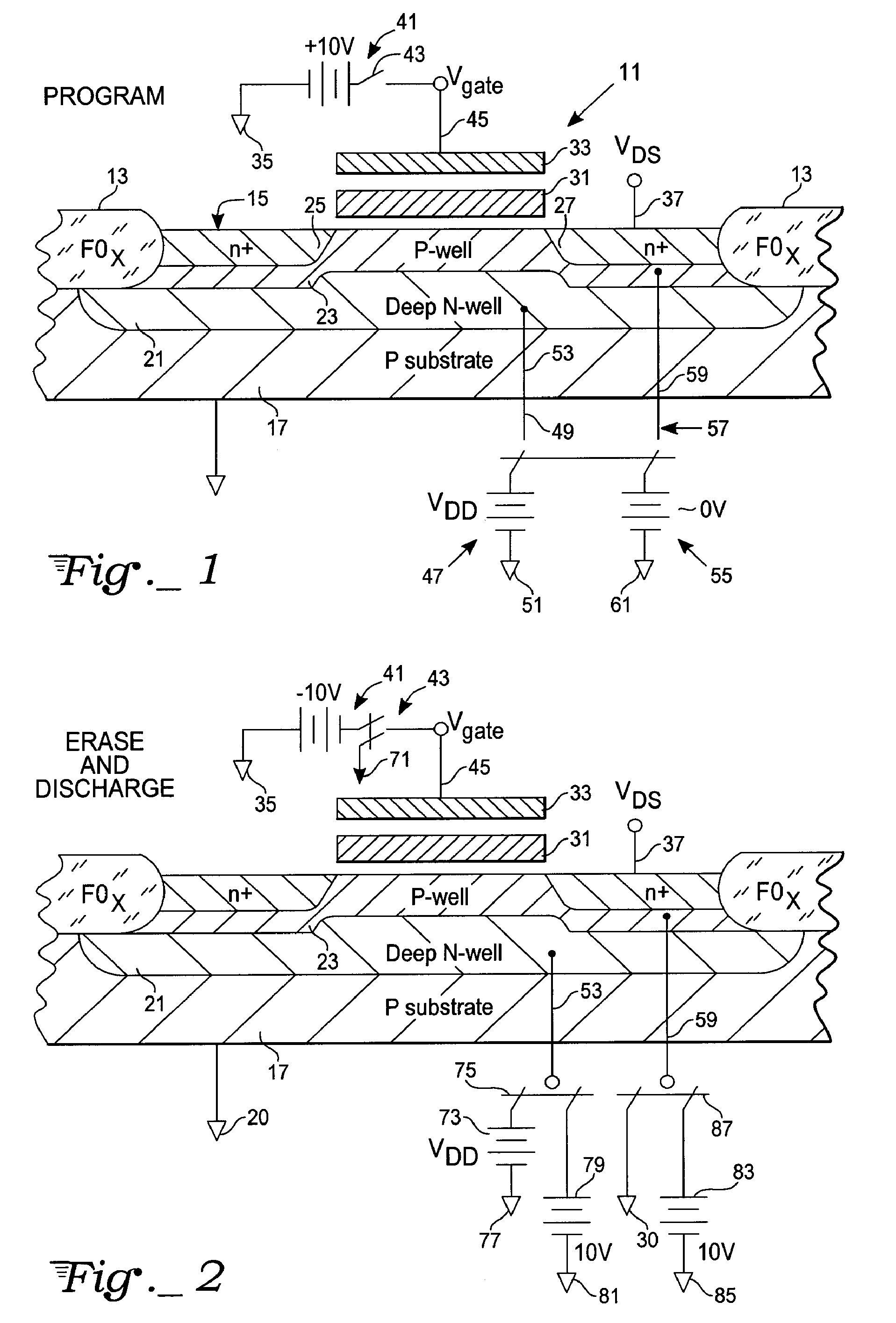

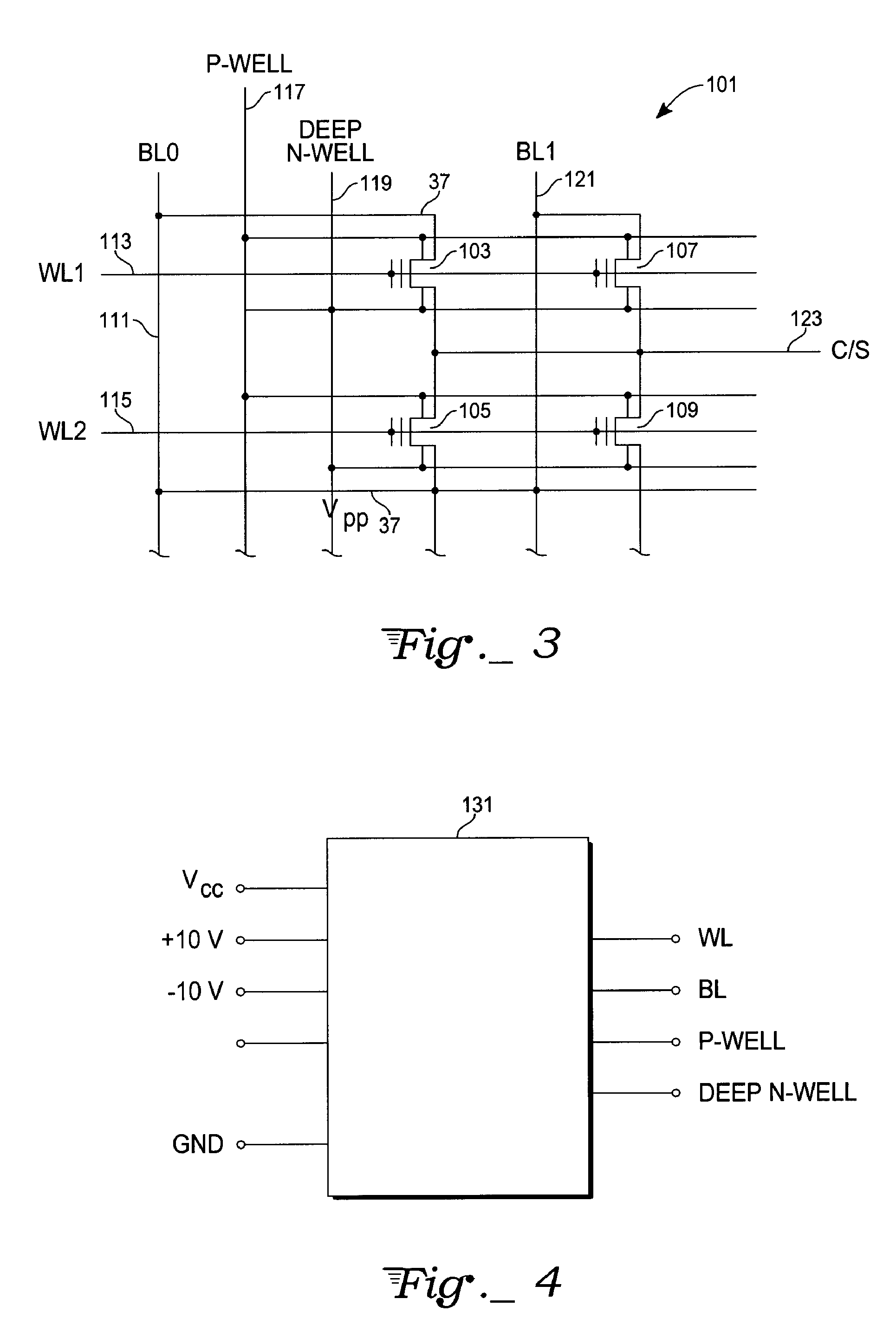

Channel discharging after erasing flash memory devices

A post-erase channel clearing procedure for double well, floating gate, non-volatile memory cells. The channel is cleared of charged particles coming from the floating gate after an erase operation in two steps. In the first step the charged particles are pushed into an upper substrate well below the floating gate but not allowed into a deeper well of opposite conductivity type relative to the upper well. After a brief time, T, the charged particles are pushed by a bias voltage into the deeper well from the upper well. This two step clearing procedure avoids device latchup that might occur otherwise.

Owner:ARTEMIS ACQUISITION

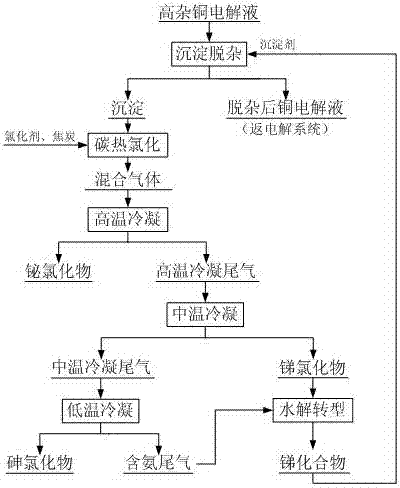

Method for carrying out precipitate impurity removal on copper electrolyte and carrying out chlorination regeneration on precipitant

ActiveCN107164785AEfficient removalHigh removal rateElectrolysis componentsPhotography auxillary processesElectrolysisHydrolysis

The invention discloses a method for carrying out precipitate impurity removal on a copper electrolyte and carrying out chlorination regeneration on a precipitant. The method comprises the following steps: adding an antimony compound in the copper electrolyte to remove co-precipitates containing arsenic, antimony and bismuth, then directly returning the copper electrolyte to an electrolysis system after the impurity removal, and comprehensively recovering the precipitates containing arsenic, antimony and bismuth by means of carbochlorination and gradient temperature-control condensation. The carbochlorination is carried out on the precipitates to obtain a mixed gas containing arsenic chlorides, antimony chlorides and bismuth chlorides under the action of coke and a chlorinating agent; high-temperature condensation is carried out on the mixed gas to obtain the bismuth chlorides and high-temperature condensation tail gas; medium-temperature condensation is carried out on the high-temperature condensation tail gas to obtain the antimony chlorides and medium-temperature condensation tail gas; low-temperature condensation is carried out on the medium-temperature condensation tail gas to obtain the arsenic chlorides and ammonia-containing tail gas; and the antimony chlorides and the ammonia-containing tail gas are slowly added in water, hydrolysis transformation is carried out on the antimony chlorides and the ammonia-containing tail gas to obtain the antimony compound, and the antimony compound is returned to a precipitate impurity removal procedure as the precipitant. The process method disclosed by the invention has the characteristics of being short in process flow, simple to operate, high in removal rate, free from the emission of 'three wastes', capable of repeatedly using the precipitant, low in cost and the like, and is suitable for large-scale industrial production.

Owner:JIANGXI UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com