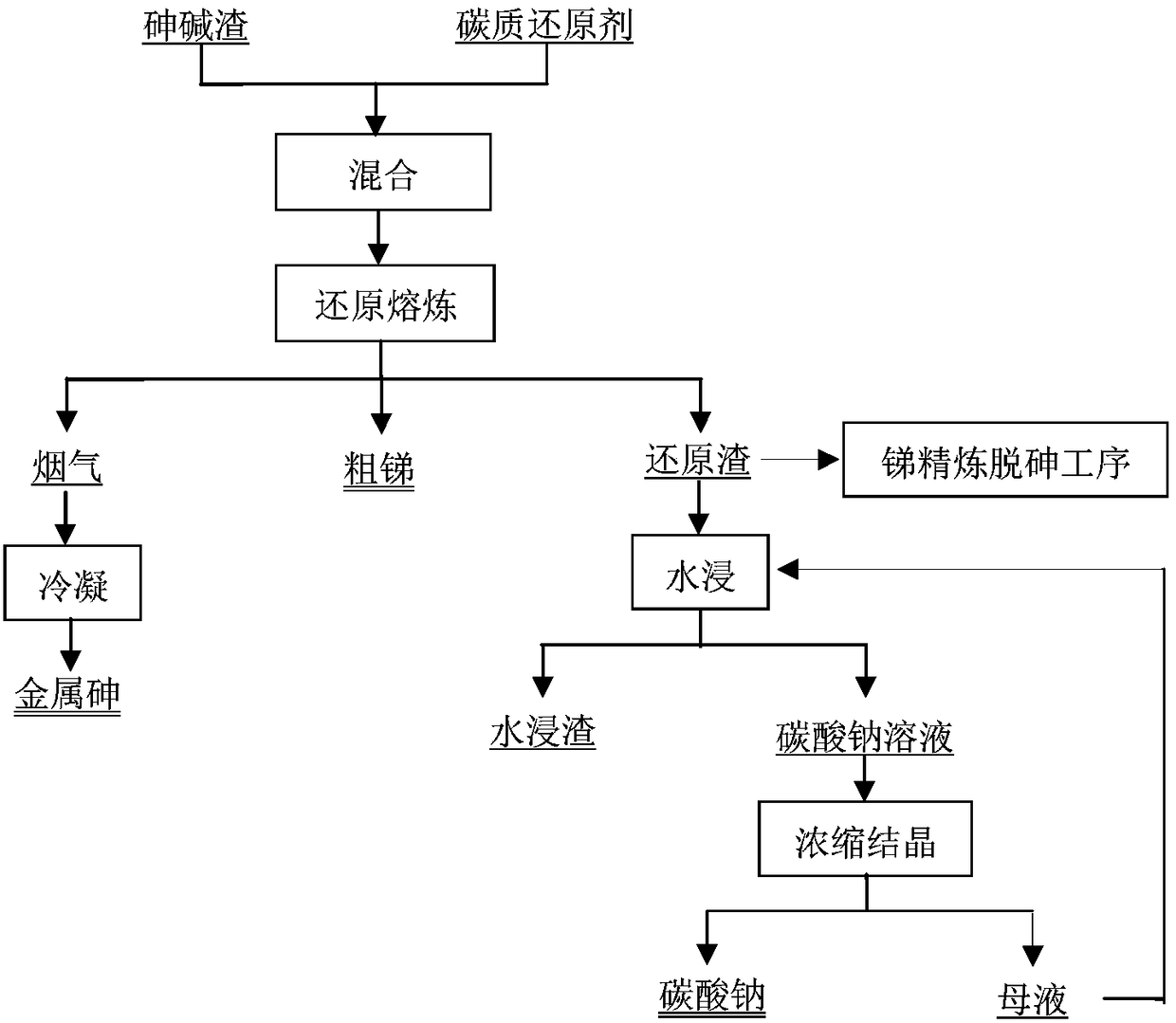

Arsenic-alkali slag reduction smelting treatment method

A treatment method and technology for arsenic-alkali slag, applied in chemical instruments and methods, alkali metal compounds, alkali metal carbonates, etc., can solve the problems of long process, difficult safe disposal of arsenic, difficult separation of arsenic and antimony, etc., and achieve environmental protection. problems, solving the effect of arsenic dispersion and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The arsenic-alkali slag produced by an antimony smelter is used as the raw material, and the chemical composition of the raw material is: As9.68%, Sb26.2%, Pb5.85%, Na22.88%. Take 100kg of the arsenic-alkali slag and carbon powder and mix them evenly at a mass ratio of 100:12, then send them to the reduction smelting furnace, raise the temperature to 1100°C and keep the reduction environment for 3 hours, then stop heating, and discharge the slag from the bottom of the reduction furnace twice to obtain crude Antimony and reducing slag, metal arsenic is taken out from the condensation chamber, the purity is >99% after testing, and the recovery rates of antimony and lead are both greater than 98%. The reduced slag is leached with hot water, the leaching temperature is controlled at 80°C, the leaching time is 2 hours, and the stirring speed is 500rpm. 2 CO 3 solution, which was concentrated and crystallized to obtain Na2 CO 3 The crystal and crystallization mother liquor ...

Embodiment 2

[0036] The arsenic-alkali slag produced by an antimony smelter is used as the raw material, and the chemical composition of the raw material is: As9.68%, Sb26.2%, Pb5.85%, Na22.88%. Take 100kg of the arsenic-alkali slag and carbon powder and mix them uniformly according to the mass ratio of 100:16, then send them to the reduction smelting furnace, close the reduction furnace, use a vacuum pump to evacuate, when the vacuum degree is less than 500Pa, start to heat up to 950°C and maintain the reduction environment for 1.5 hours Stop heating, discharge the slag twice from the bottom part of the reduction furnace to obtain crude antimony and reduced slag respectively, take out the metal arsenic from the condensation chamber, the purity is >99% after testing, the recovery rate of both antimony and lead is greater than 98%, and the reduced slag is used as the desulfurization slag. The arsenic agent is returned to the antimony refining and arsenic removal process.

Embodiment 3

[0038] The arsenic-alkali slag produced by an antimony smelter is used as the raw material, and the chemical composition of the raw material is: As9.68%, Sb26.2%, Pb5.85%, Na22.88%. Take 100kg of the arsenic-alkali slag and carbon powder and mix them evenly at a mass ratio of 100:10, then send them to the reduction smelting furnace, close the reduction furnace, use a vacuum pump to evacuate, and when the vacuum degree is less than 50Pa, start to heat up to 800°C and maintain the reduction environment for 3 hours. Heating was stopped, and the slag was discharged twice from the bottom part of the reduction furnace to obtain crude antimony and reduced slag respectively. The metal arsenic was taken out from the condensation chamber, and the purity was detected to be >99%, and the recovery rates of both antimony and lead were greater than 98%. The solid ratio is 5:1, stirring and leaching at room temperature for 0.5h, and the filtered solution is evaporated by a three-effect evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com