Sludge fermentation enhanced short-cut denitrification-anaerobic ammonia oxidation nitrogen removal and phosphorus recovery device and method

A short-range denitrification and anammox technology, applied in the field of low C/N ratio and high nitrogen wastewater treatment, to reduce carbon source competition, ensure stable operation, and reduce design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

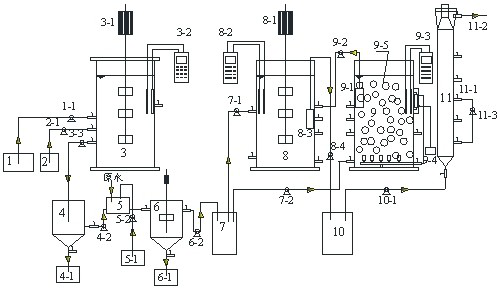

[0029] Such as figure 1 As shown, a sludge fermentation enhanced short-range denitrification-ANAMMOX denitrification and phosphorus recovery device, including sludge anaerobic fermentation reactor 3, the outlet of anaerobic fermentation reactor 3 is connected with sedimentation tank I4, and sedimentation The outlet of pool Ⅰ4 is connected with the phosphorus recovery system, and the outlet of the phosphorus recovery system is connected with the intermediate water tank Ⅰ7. The outlet is connected to the short-range denitrification system through pipelines, the outlet of the denitrification system is connected to the intermediate water tank Ⅱ10, and the outlet of the intermediate water tank Ⅱ10 is connected to the anaerobic ammonium oxidation system. Fermentation acid production treatment, mud water separation, mixed with high nitrogen wastewater in the mixing tube and dosing agent II to form blue iron ore, mud water separation in the sedimentation tank to realize the recovery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com