Patents

Literature

139results about How to "Organic load reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated bioreactor and method of using the same for treatment of highly-concentrated organic wastewater

ActiveUS20120138527A1Increase concentrationIncrease alkalinityWater treatment parameter controlTreatment using aerobic processesRefluxPh monitors

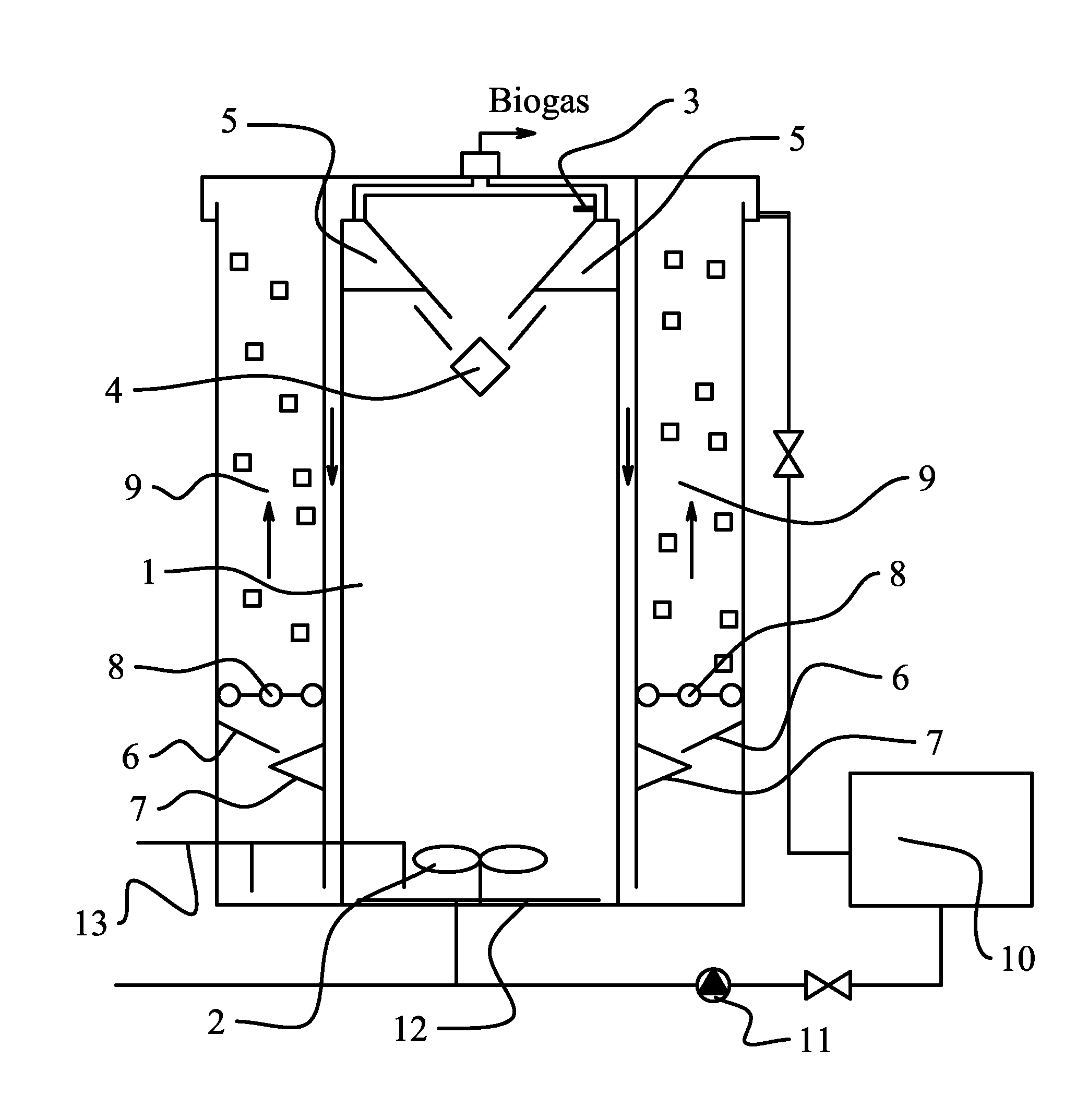

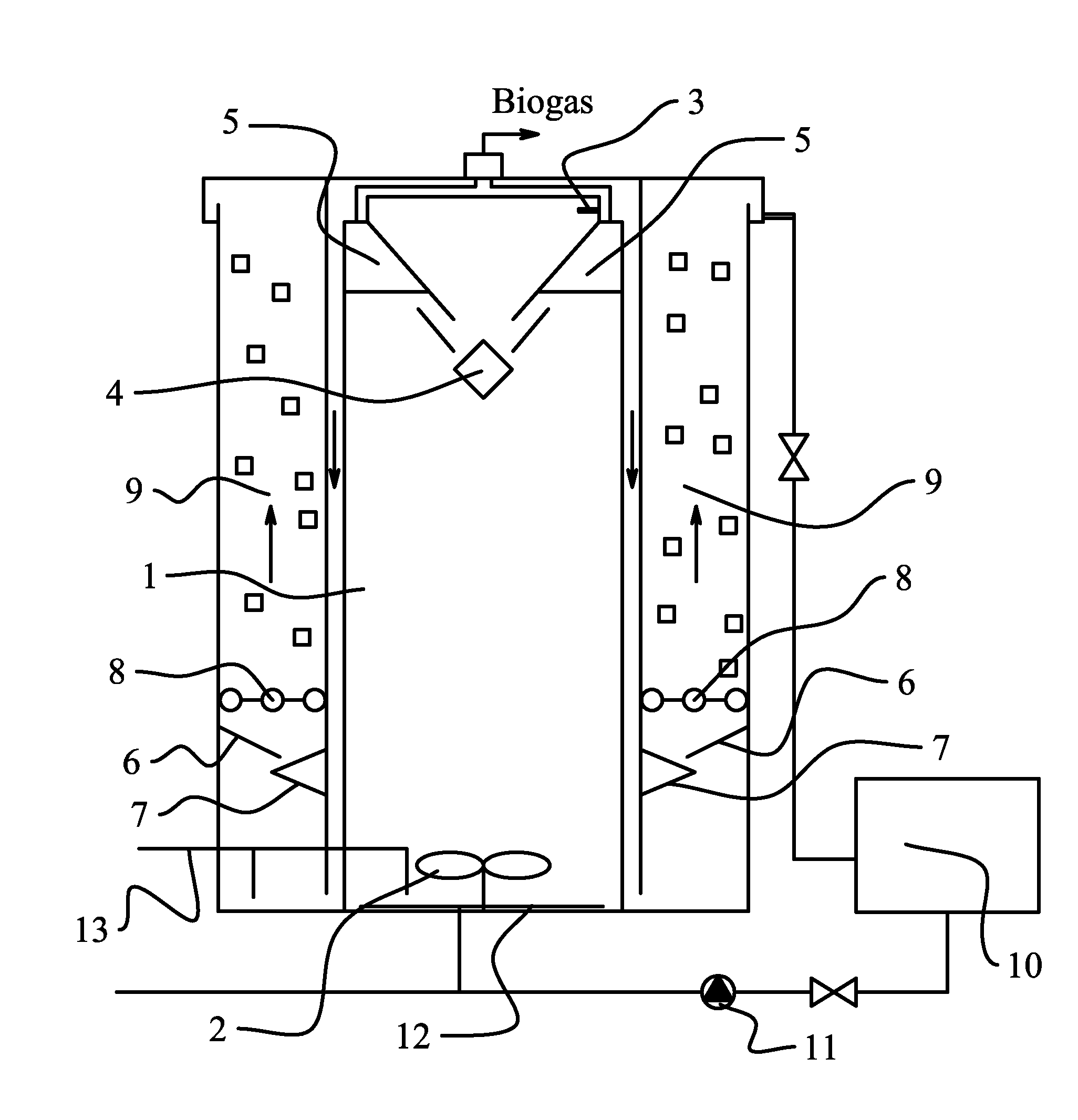

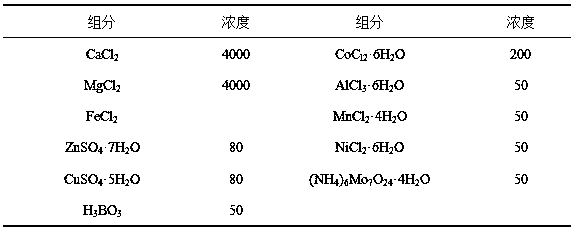

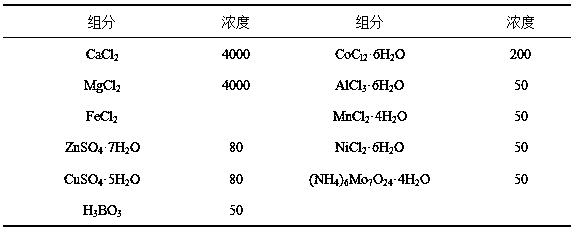

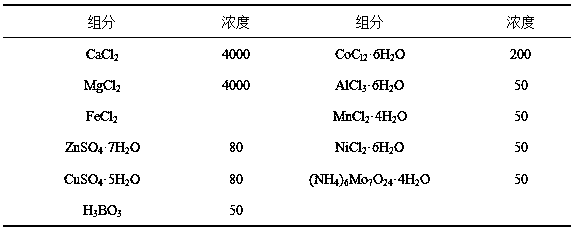

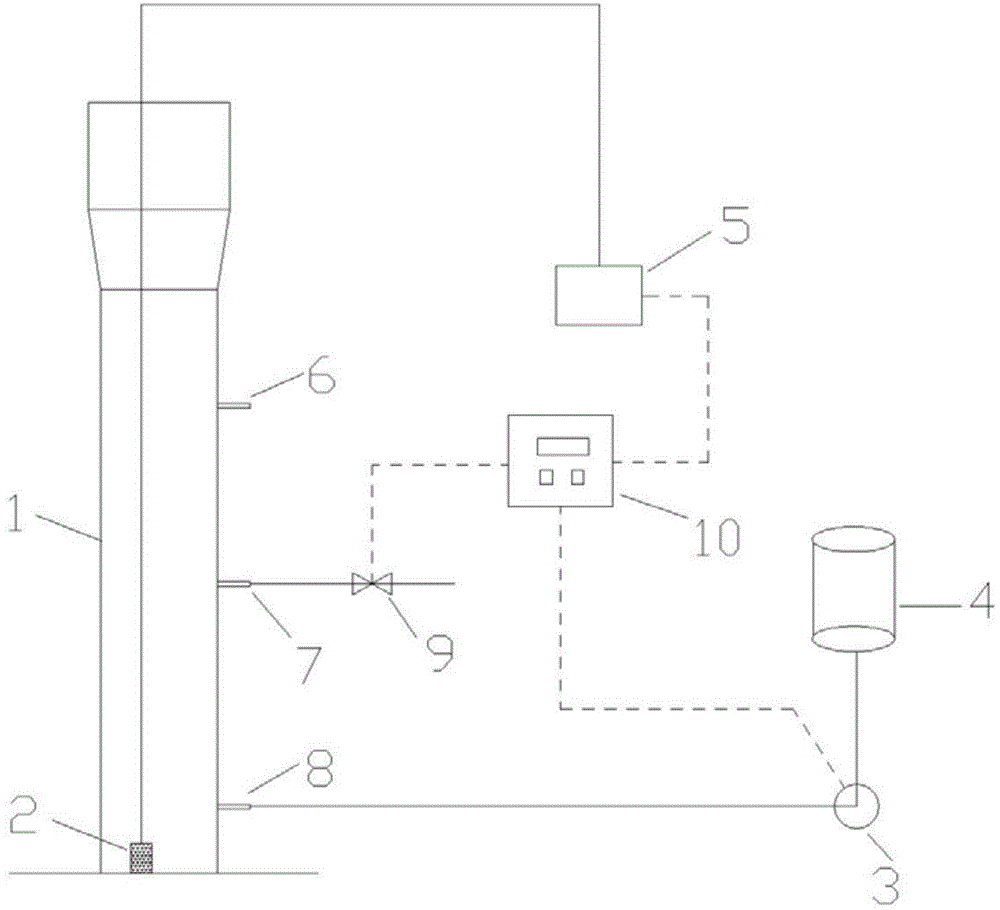

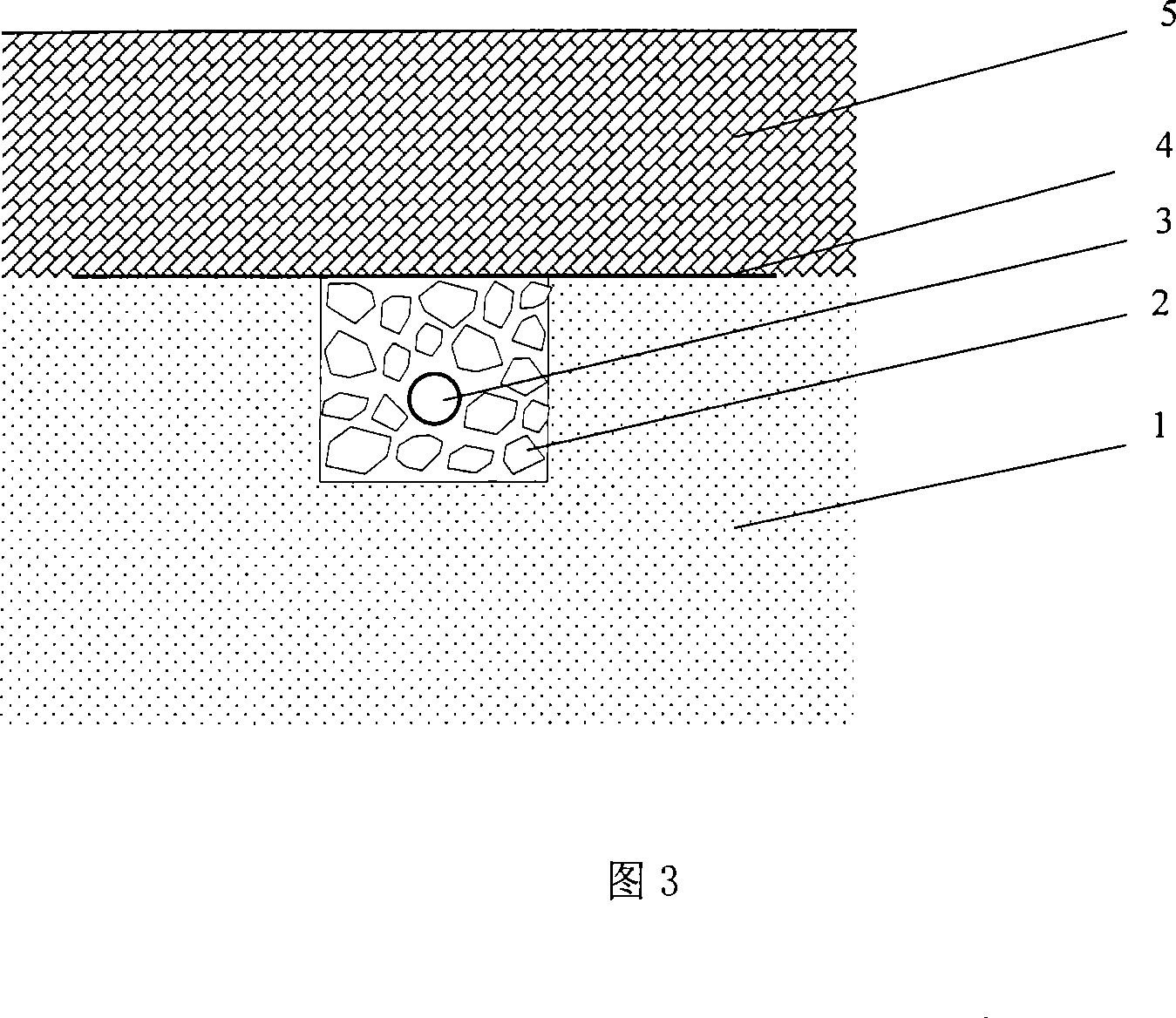

An integrated bioreactor and its applications as well as a method for treatment of highly-concentrated organic wastewater using the same. The integrated bioreactor with a concentric columnar structure includes an inner layer and an outer layer, in which the inner layer is an upflow anaerobic sludge blanket (UASB) and the outer layer is a moving bed biofilm reactor (MBBR). The effluent of the MBBR is recycled into UASB via a reflux pump mounted between a water tank and the integrated bioreactor. A water outlet of the UASB is arranged with an on-line pH monitor and a mechanical agitation device is arranged on the top of a bottom water distributor. The bioreactor is low in cost, features friendly maintenance, stable operation, and high degree of automation, and can be applied under low temperature.

Owner:NANJING UNIV

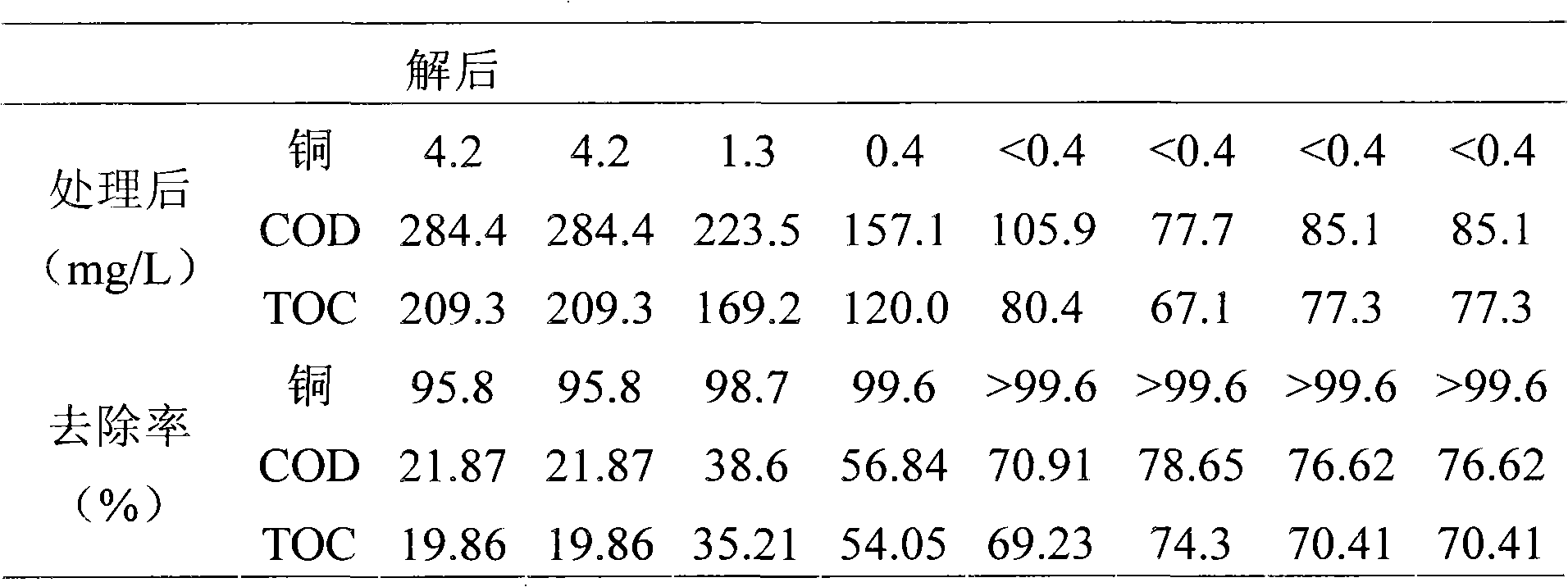

Method for processing heavy-metal complexed wastewater through Fenton reinforced iron-chip internal electrolysis process

InactiveCN102060355AReduce consumptionImprove biochemical propertiesWater/sewage treatmentElectrolysisWastewater

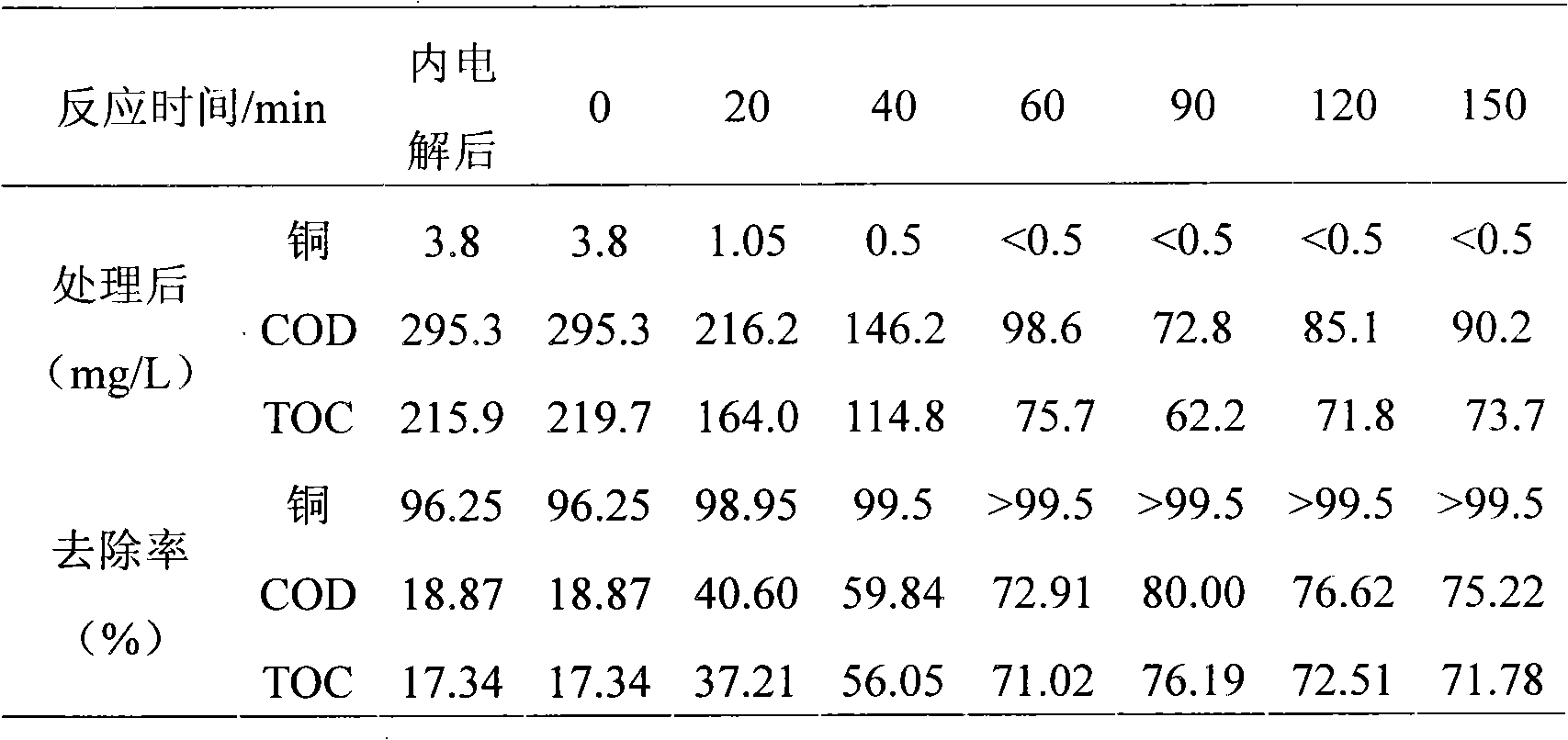

The invention discloses a method for processing heavy-metal complexed wastewater through a Fenton reinforced iron-chip internal electrolysis process. The method comprises the following steps of: filling an internal electrolysis filler into an iron-chip internal electrolysis reactor, then introducing the wastewater into the reactor after regulating the pH value of the wastewater to 1.5-3.5, adding a Na2SO4 solution, controlling dissolved oxygen to be not higher than 3.0mg / L, and controlling the flow speed of the introduced wastewater; then introducing the discharged water of the internal electrolysis reactor into a Fenton reactor, maintaining the ferrous concentration in the water to be 300-750mg / L, adding H2O2 according to the mass concentration ratio of H2O2 to Fe2+ of 2.0-7.0, and sufficiently reacting for 60-120 minutes under the condition of controlling the pH value to be 2.5-5.5; and regulating the pH value of the discharged water to 9.0-10.0, standing and settling, and separating mud from the water. According to the method disclosed by the invention, the operation is simple and convenient, the sewage biodegradability can be markedly improved, the difficulty and the organic load of subsequent processing are greatly reduced, and the cost is saved.

Owner:SOUTH CHINA UNIV OF TECH

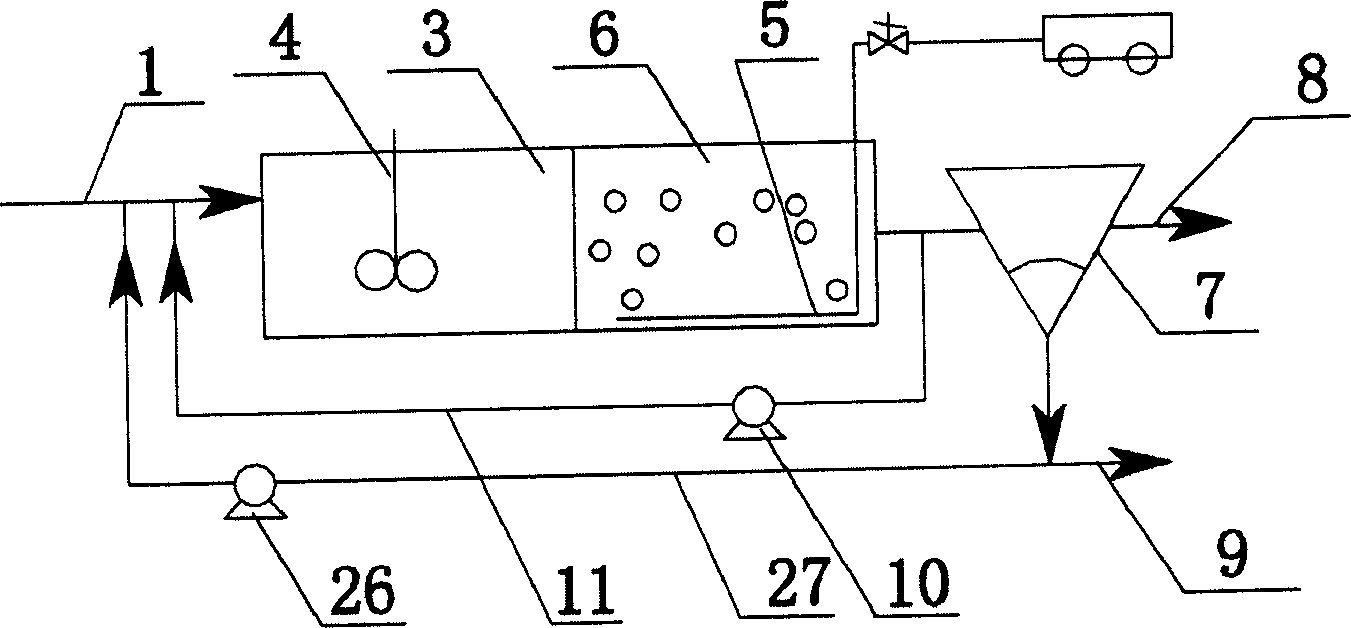

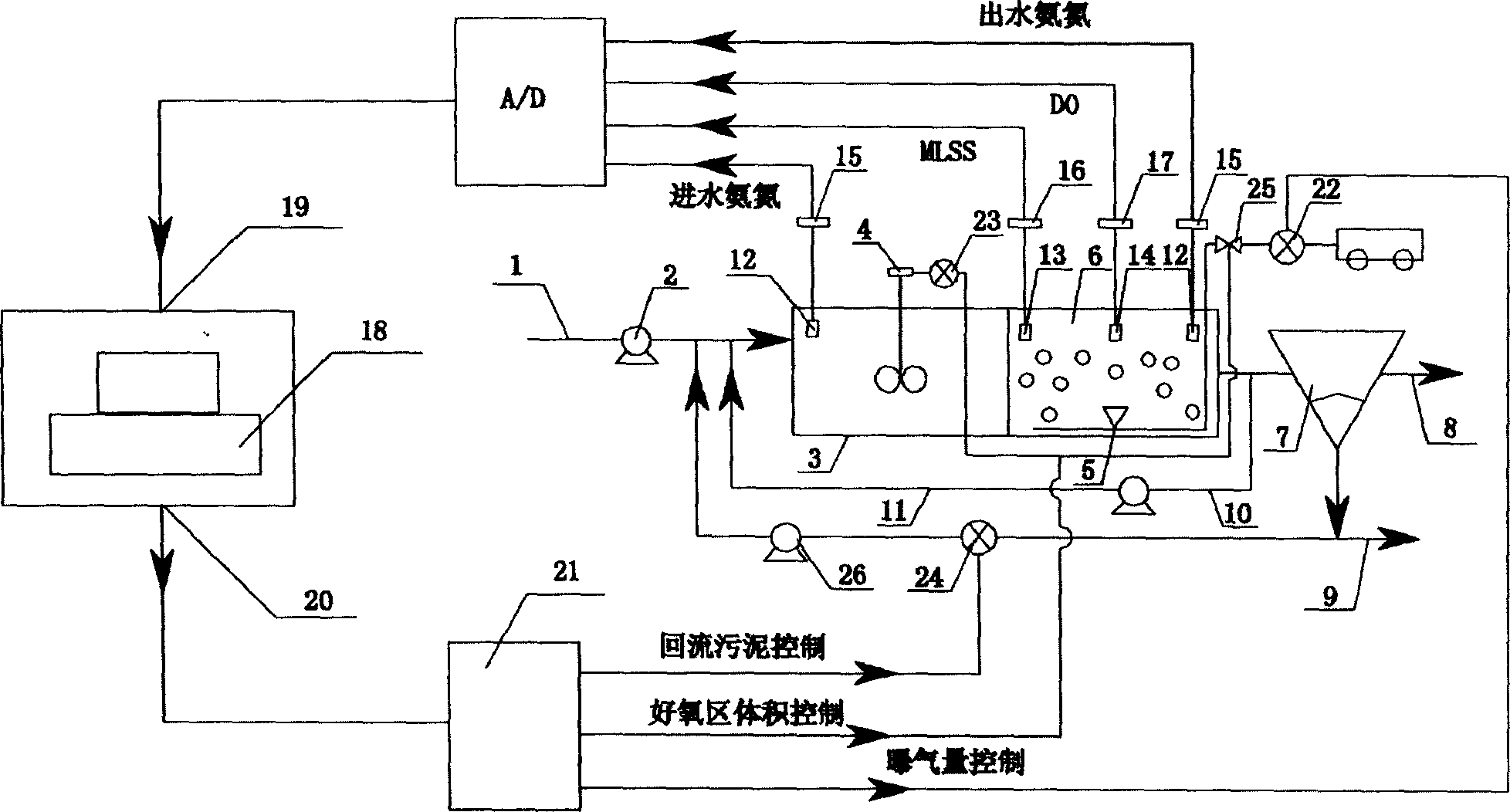

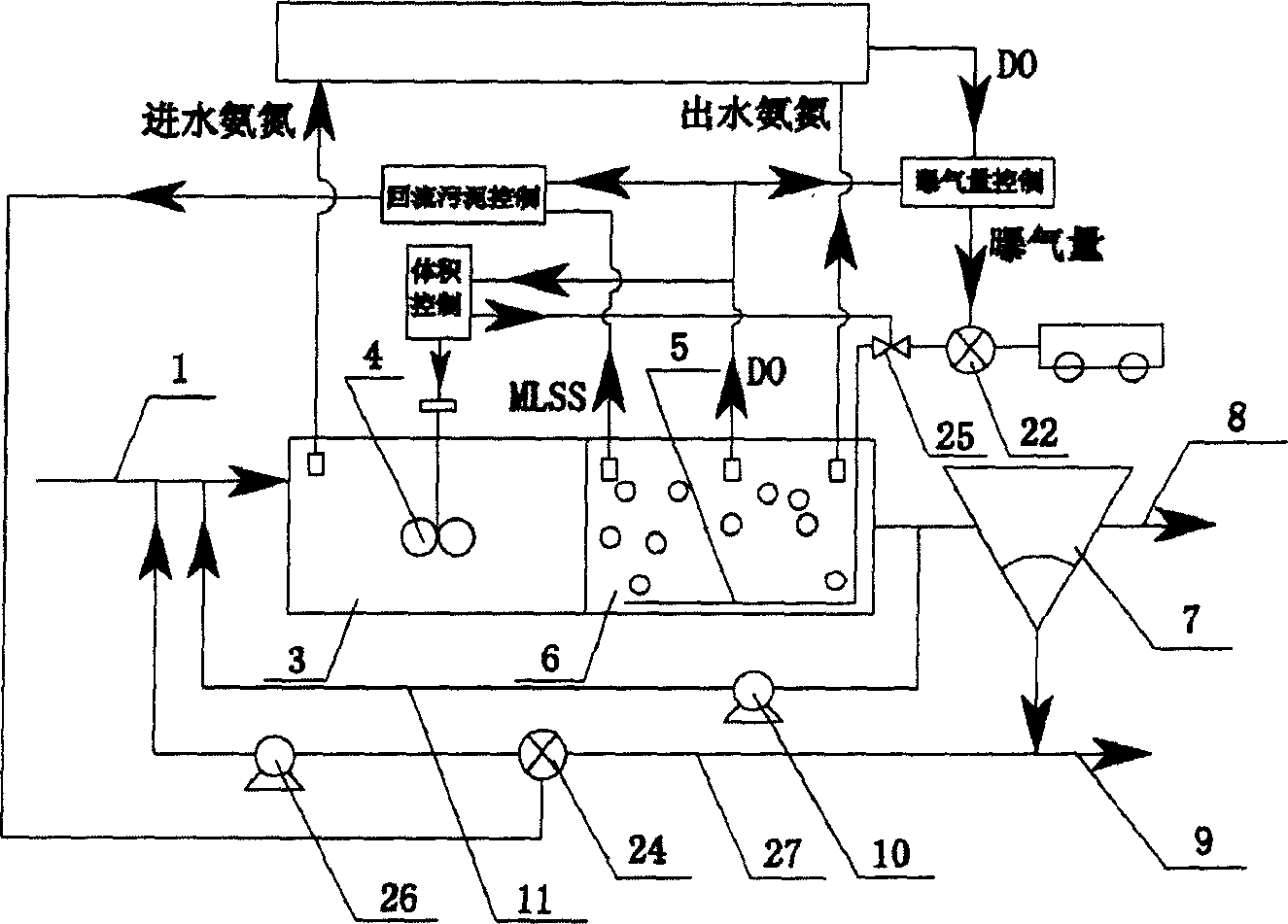

Adjusting method for A/O biological denitrification reactor and nitrification process, its on-line fuzzy controller and control thereof

InactiveCN1778714ASave dosing costOrganic load reductionControlling ratio of multiple fluid flowsChemical variable controlSludgeMarine engineering

Owner:姚宏

Totally-closed all-transparent intellectualized organic prawn ecological breeding device

ActiveCN104255632ASolve the accumulationRegulatory transparencyPisciculture and aquariaEnvironmental indexPrawn

The invention discloses a totally-closed all-transparent intellectualized organic prawn ecological breeding device and belongs to a product and a technical system for prawn aquiculture. The totally-closed all-transparent intellectualized organic prawn ecological breeding device solves various prawn farming industry faced difficulties and problems such as water quality oxygen deficit, bottom material oxygen deficit deterioration, bacterial and viral diseases, stress reaction, antibiotic residue, drug residue, difficult biophysical chemistry environmental index regulation, high death rate and low survival rate, achieves transition from a traditional prawn pond culture mode to a totally-closed all-transparent full-automatic factory-like intellectualized multilayer grading running water ecological breeding mode with low costs, timely and accurately adjusts water quality biophysical chemistry environmental indexes such as the water quality illumination, the light quality, the temperature, the salinity, the dissolved oxygen, the nutritive salt, the carbon dioxide, a PH (Potential of Hydrogen) value, the transparency, the ammonia nitrogen, the nitrite, the sulfuretted hydrogen, organic matters, bacterial phases, algal phases, insect phases, food organism varieties and the density and produces various aquatic products satisfying market requirements.

Owner:朱祖阳

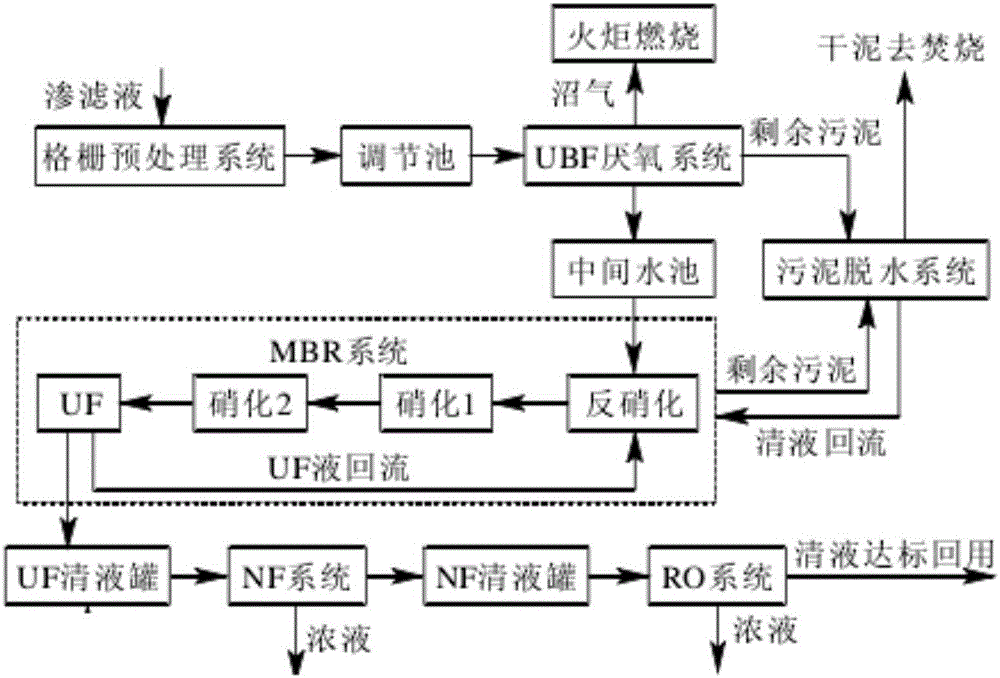

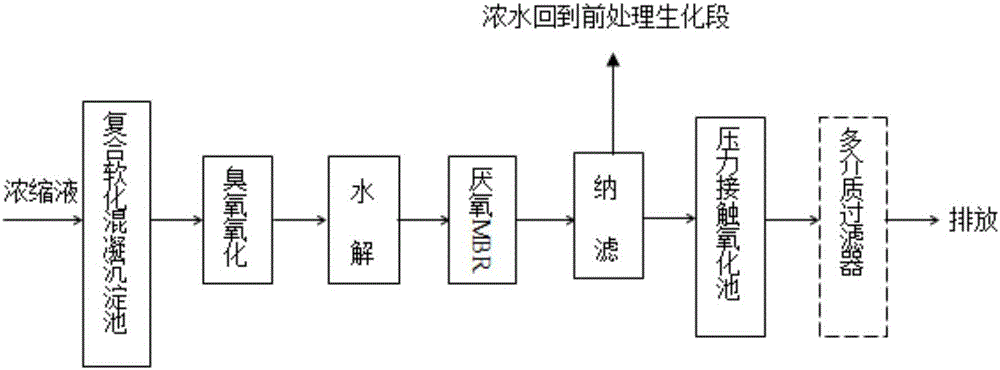

Treatment method of concentrated solution produced from landfill leachate by membrane method

ActiveCN106242163AImprove biodegradabilityReduce processing costsTreatment with anaerobic digestion processesMultistage water/sewage treatmentHigh concentrationFiltration

The invention discloses a treatment method of a concentrated solution produced from landfill leachate by a membrane method. The treatment method comprises the following steps of enabling the concentrated solution produced from the landfill leachate by the membrane method to sequentially pass through a composite softening coagulation and sedimentation pond, an ozone oxidation reactor, a hydrolyzing pond and an anaerobic MBR pond, and enabling effluent water from the anaerobic MBR pond to enter a nanofiltratoin system; enabling a permeation solution obtained through treatment of the effluent water in the nanofiltratoin system to be treated by a pressure contact oxidation reactor, and directly discharging the treated permeation solution, or after filtering the treated permeation solution by a multi-medium filter, discharging the filtered permeation solution; mixing a concentrated solution obtained after treatment by the nanofiltratoin system with the landfill leachate so as to obtain a mixed solution; and performing concentration treatment on the mixed solution by a biochemical method, an MBR method and the membrane method so as to obtain a concentrated solution, enabling the concentrated solution to enter the composite softening coagulation and sedimentation pond, and performing subsequent operations. The treatment method disclosed by the invention not only is suitable for treatment of the concentrated solution produced from the landfill leachate by membrane filtration, but also is suitable for treatment of other membrane concentrated solutions containing high concentration of organic compounds which are difficult to degrade.

Owner:江苏环保产业技术研究院股份公司

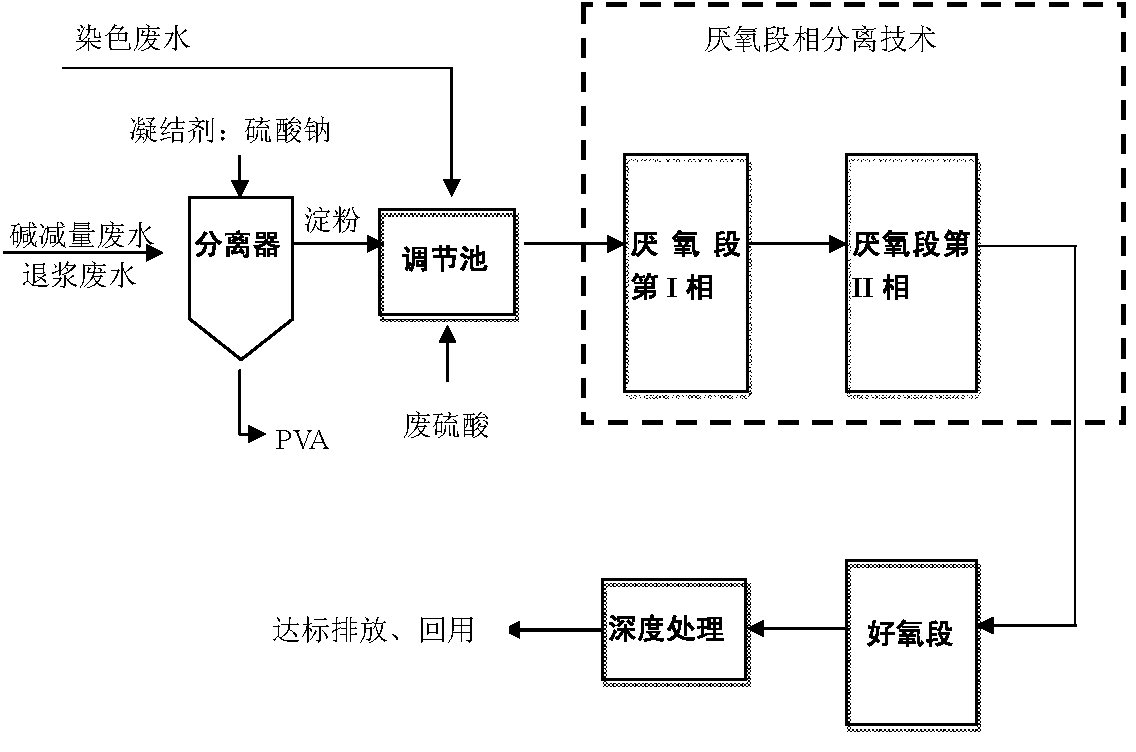

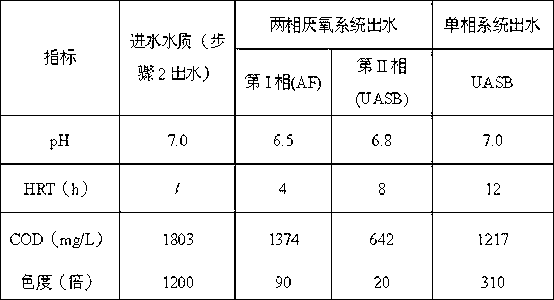

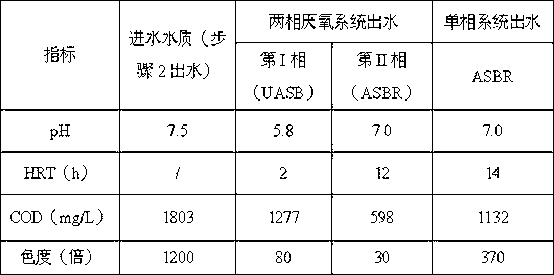

Printing and dyeing wastewater pretreatment method based on anoxic zone phase separation technology

ActiveCN103274524AImprove biodegradabilityEfficient removalWaste based fuelTreatment with anaerobic digestion processesChemical oxygen demandPretreatment method

The invention relates to a printing and dyeing wastewater pretreatment method based on an anoxic zone phase separation technology. According to the printing and dyeing wastewater pretreatment method, an anoxic zone is divided into a phase I and a phase II, namely a phase for hydrogen production and acid production through fermentation and a methanogenesis phase; an electron donor is provided by organic matters in the wastewater, and dye is effectively decolored in the phase I by using a sulfate reducing process and the reducing capacity of reduzate, namely the sulfide, therefore the biodegradability of the wastewater is improved; and the organic matters can be efficiently removed in the phase II. As an anoxic phase transformation technology in the printing and dyeing wastewater treatment course, the printing and dyeing wastewater pretreatment method is used for providing a two-phase anoxic system and carrying out pretreatment on the printing and dyeing wastewater; the chromaticity and the COD (Chemical Oxygen Demand) removal rates can be effectively increased, the biodegradability of the wastewater can be greatly improved, and the defects that a traditional anoxic process is instable in treatment effect, large in sludge yield and the like are overcome. The printing and dyeing wastewater pretreatment method can be used for effectively removing chromaticity and COD in the printing and dyeing wastewater, the removal rates of the chromaticity and the COD respectively reach more than 95 percent and 60 percent, and the organic loading to subsequent procedures is greatly reduced.

Owner:浙江一清环保工程有限公司

Method for preprocessing neopentyl glycol industrial wastewater by catalytic oxidation

InactiveCN101774675AHigh catalytic activityEfficient removalMolecular sieve catalystsNature of treatment waterMetal nitrateNitrate

The invention discloses a method for preprocessing neopentyl glycol industrial wastewater by catalytic oxidation. The invention is to remove formaldehyde and some organic matters from wastewater under a certain condition by adding a catalyst and 30wt% of hydrogen peroxide in the wastewater. The method for preparing the catalyst comprises the following steps: adding a porous inorganic oxide carrier in metal nitrate solution or acetate solution with mass fraction of 1.0-6.0% and mixing uniformly; dipping for a certain time; and drying and baking to obtain the catalyst. The removing rate of formaldehyde is above 89%, the removing rate of CODcr is above 50%, and preprocessed neopentyl glycol industrial wastewater can be processed thoroughly to meet emission standard by a common biological method.

Owner:UNIV OF JINAN

Method for treating ABS sewage

InactiveCN101186410AEffective contentEffective removal of contentMultistage water/sewage treatmentSustainable biological treatmentSocial benefitsFlocculation

The invention provides a disposal method for ABS sewage and adopts a comprehensive method that is the combination of physicochemical treatment and biochemical treatment. The sewage runs through a fine grid and enters a regulating pool. Air is pumped in the regulating pool to unify the water. Separation process of flocculation and sedimentation is adopted twice, which can effectively remove SS content in the ABS sewage and improve the biodegradability of the ABS sewage. The disposal method has the advantages of small investment, effective sewage disposal and better economic and social benefits.

Owner:FANGXIA ENTERPRISE INFORMATION CONSULTING WUJIANG

Water Treatment Apparatus and Water Treatment Method

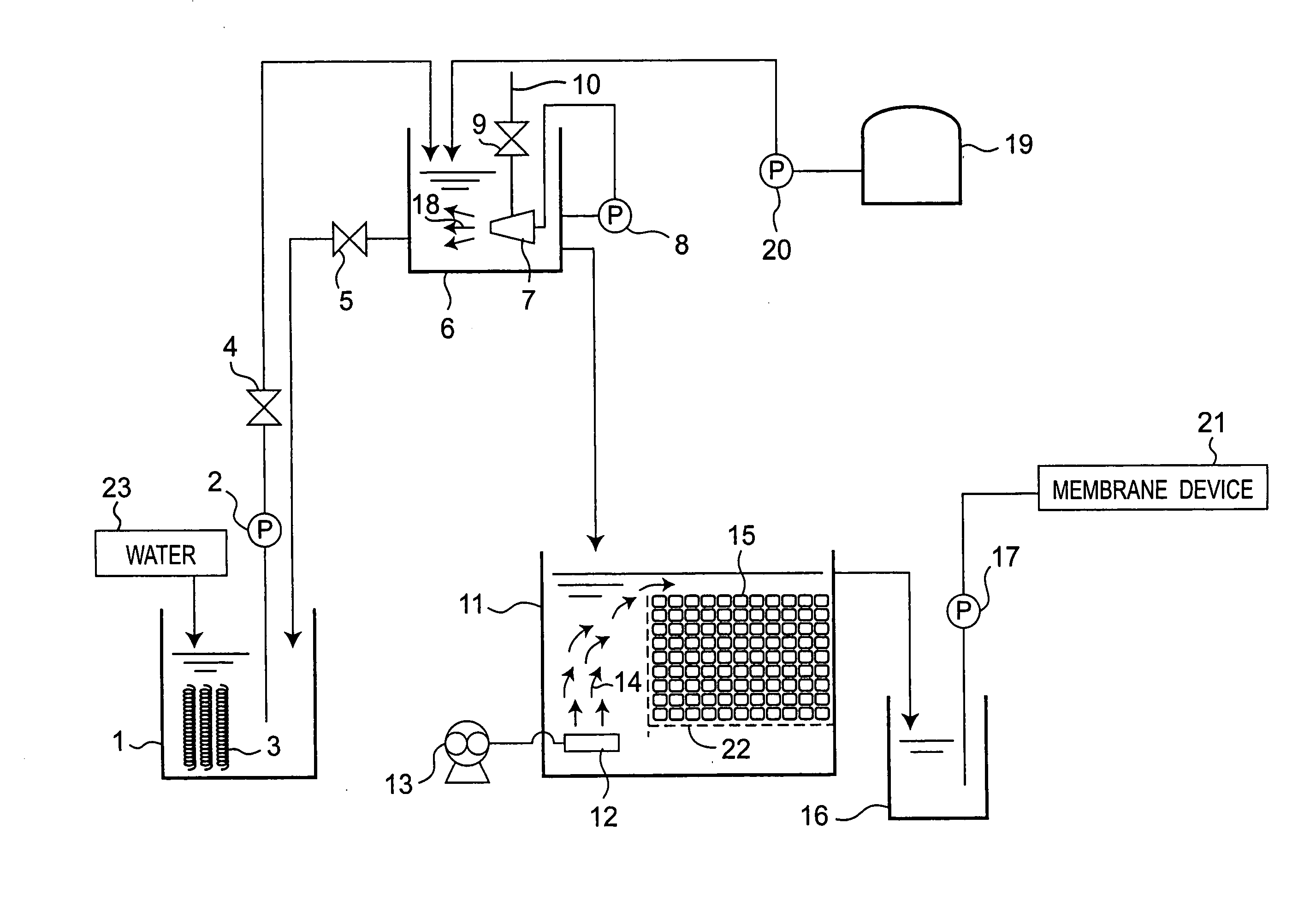

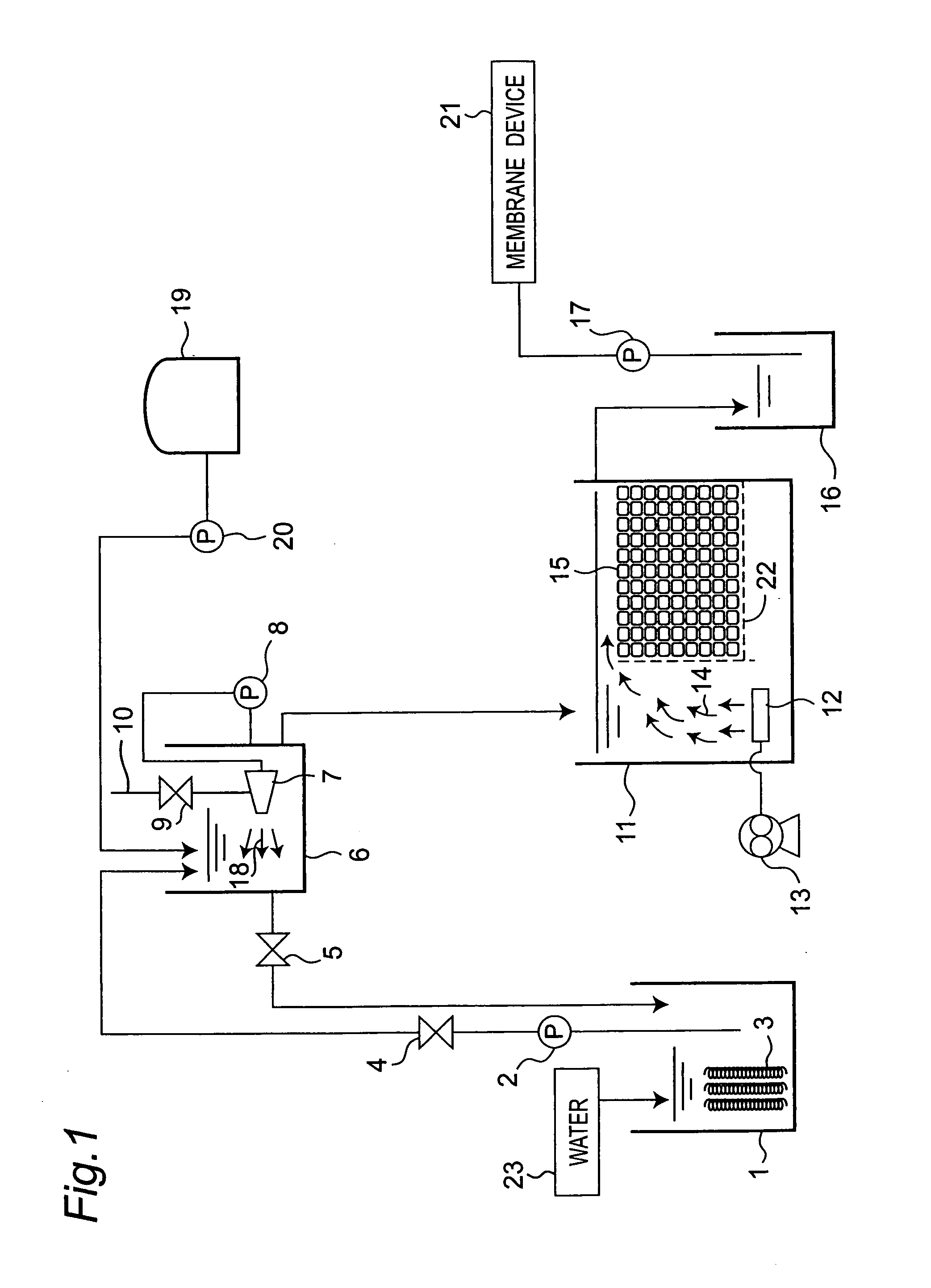

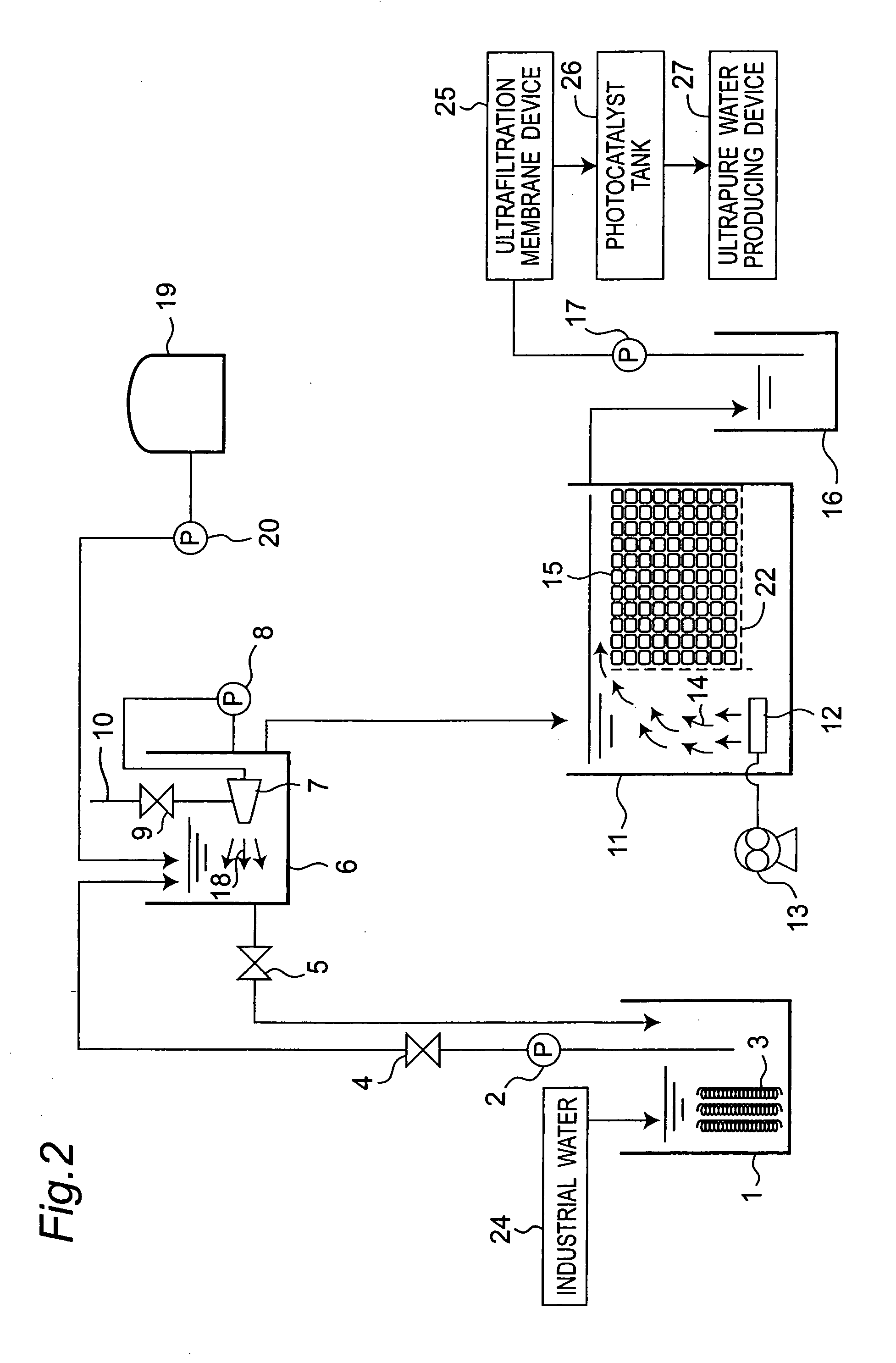

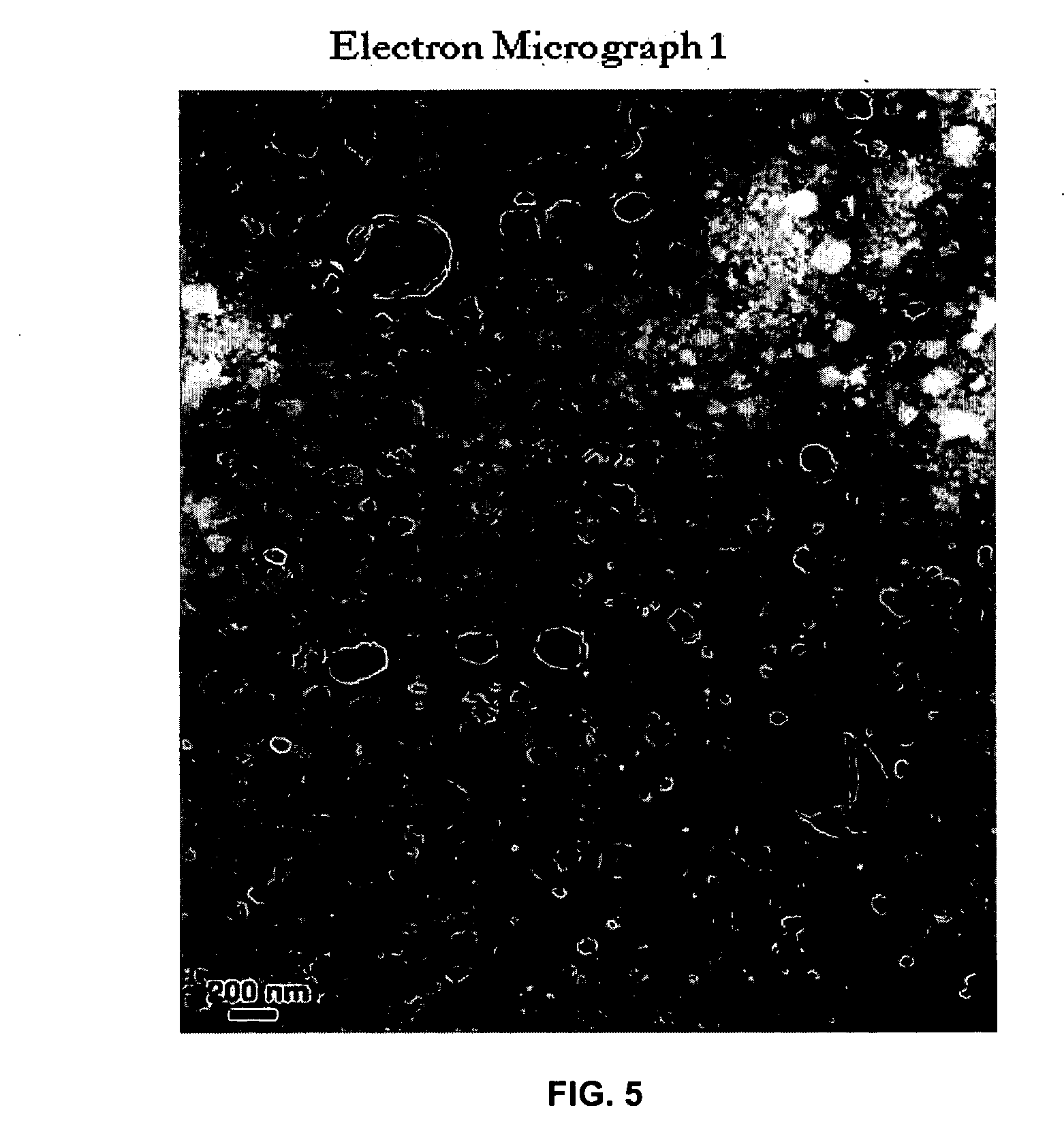

InactiveUS20090266763A1Organic load reductionHigh activityLiquid separation auxillary apparatusTreatment using aerobic processesMicro nanoAlcohol

Water (23) that contains micro-nano bubbles generated in a micro-nano bubble generation tank (6) is introduced and treated in a charcoal water tank (11) which is filled with a charcoal (15) and in which an air diffusing pipe (12) is placed and thereafter introduced and treated in a membrane device (21). Thus, activities of microorganisms propagating in the charcoal (15) are increased by the micro-nano bubbles, markedly increasing ability of decomposing organic matters in the water. Therefore, a clogging phenomenon due to the organic matters can be prevented by reducing organic loads on the membrane device (21). Moreover, a very small amount of alcohols or salts are added as a micro-nano bubble generation aid to the micro-nano bubble generation tank (6), improving an incidence rate of the micro-nano bubbles. In the case, since the alcohols and salts are easily decomposed by the charcoal water tank (11) and easily removed by the membrane device (21) in the subsequent stage, no bad influence is exerted on the membrane device (21).

Owner:SHARP KK

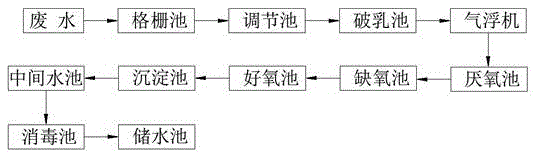

Machining wastewater treatment technology

ActiveCN105585218APurify waterLow costTreatment involving filtrationTreatment with aerobic and anaerobic processesWater qualityWastewater

The invention provides a machining wastewater treatment technology. The machining wastewater treatment technology comprises steps as follows: after wastewater passes through a grid pool and large-particle substances are intercepted, the wastewater enters a demulsification pool and is subjected to demulsification for phosphorous removal, then enters an air floatation machine for air floatation separation, enters an anaerobic pool, an anoxic pool and an aerobic pool sequentially for biochemical treatment, enters a sedimentation pool for solid-liquid separation and is finally filtered, sterilized and discharged when up to the standard. The machining wastewater treatment technology adopts a simple procedure and is low in operating cost, the operation is safe and reliable, and the water quality is stable and reaches the standard.

Owner:WUZHOU HUAHONG SEWAGE TREATMENT CO LTD

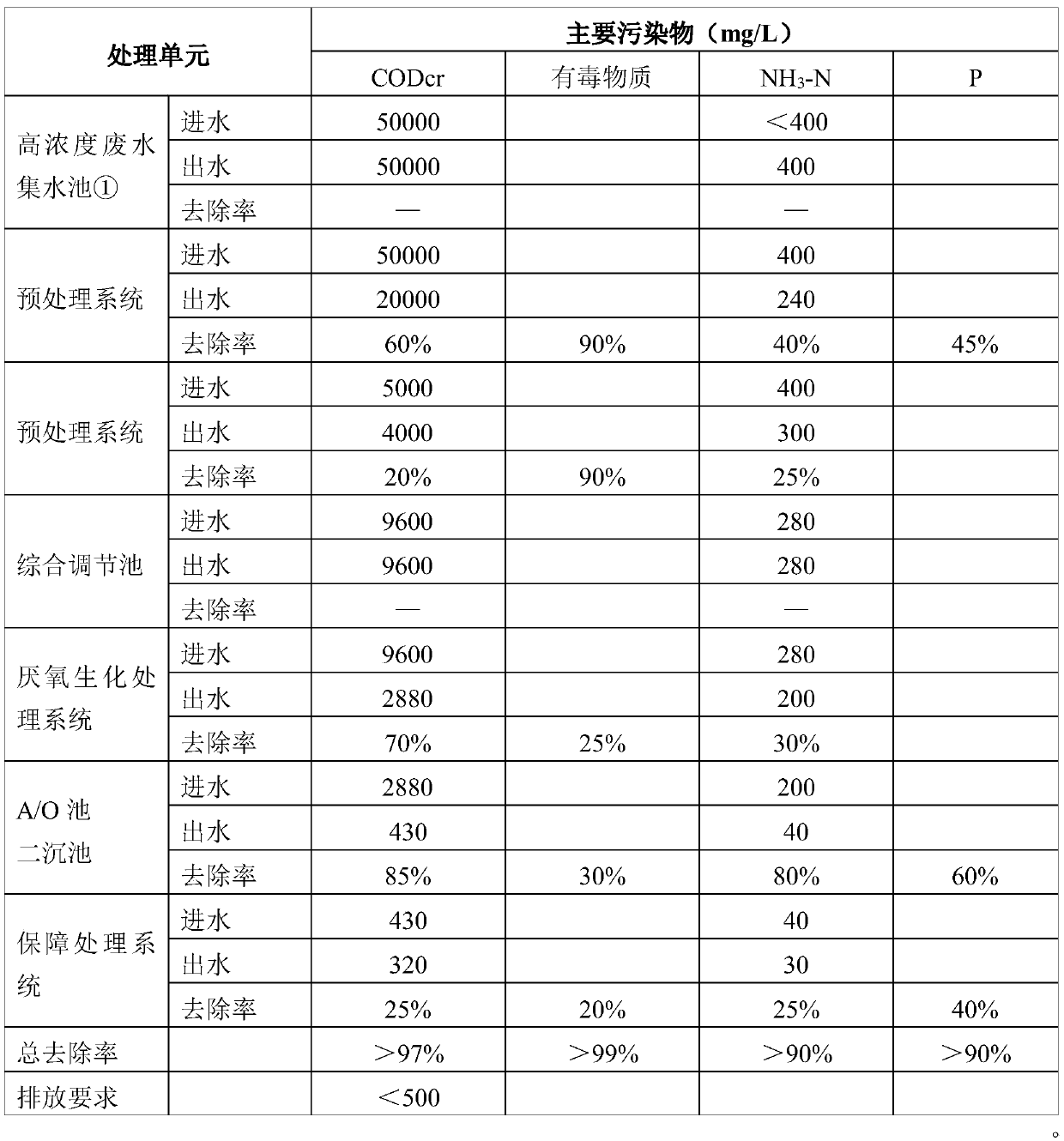

High concentration organic nitrogen waste water processing technology

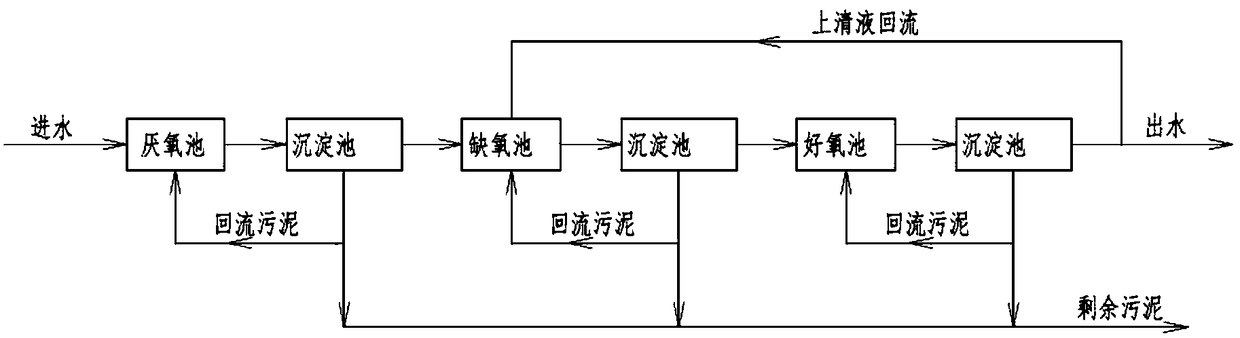

PendingCN109179656AReduce shockHelps control swellingWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationChemical oxygen demand

The invention discloses a high concentration organic nitrogen waste water processing technology. The high concentration organic nitrogen waste water processing technology is mainly used for processingof organic waste water high in raw water total nitrogen, is capable of realizing high efficiency low consumption removing of carbon and nitrogen with a denitrification unit used for supplying a partof carbon sources, the total nitrogen, ammonia nitrogen, and chemical oxygen demand of discharged water are capable of reaching discharge standards. The high concentration organic nitrogen waste waterprocessing technology comprises following steps: high concentration organic nitrogen waste water is introduced into an anaerobic pond; water discharged from the anaerobic pond is introduced into a first sedimentation basin; a supernatant discharged from the first sedimentation basin is introduced into an anoxic pool, a part of bottom sludge from the first sedimentation basin is discharged, and the other part of bottom sludge from the first sedimentation basin is recycled back into the anaerobic pond; water discharged from the anoxic pool is introduced into a second sedimentation basin; a supernatant from the second sedimentation basin is introduced into an aerobic tank, and bottom sludge from the second sedimentation basin is discharged; water discharged from the aerobic tank is introduced into a third sedimentation basin; after precipitation in the third sedimentation basin, bottom sludge is discharged, and an obtained supernatant is recycled back into the anoxic pool; after anoxic pool reaction, obtained water is introduced into the second sedimentation basin, and then is introduced into the aerobic tank, and after reaction, water from the aerobic tank is introduced into the third sedimentation basin, and then is discharged.

Owner:苏州德嘉环保工程有限公司

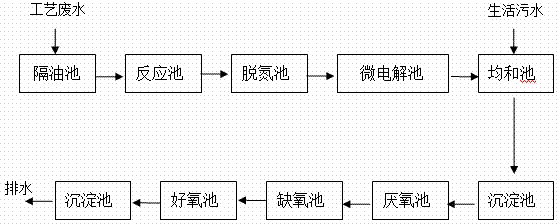

Coking wastewater treatment method

ActiveCN103936240AGuaranteed uptimeImprove biodegradabilityMultistage water/sewage treatmentVolatile phenolsChemical oxygen demand

The invention provides a coking wastewater treatment method. High-concentration coking wastewater with 7000-8000mg / L of COD (Chemical Oxygen Demand), 6000-6500mg / L of ammonia nitrogen, 800-900mg / L of volatile phenol and 100-200mg / L of cyanide is treated through the steps of: pretreatment; alkaline microelectrolysis; average value regulation; biological treatment; precipitation, drainage and the like. The method is high in efficiency for removing ammonia, phenol, cyanogen and suspended matters and stable in water quality of effluent.

Owner:SHANDONG SUNYON GRP

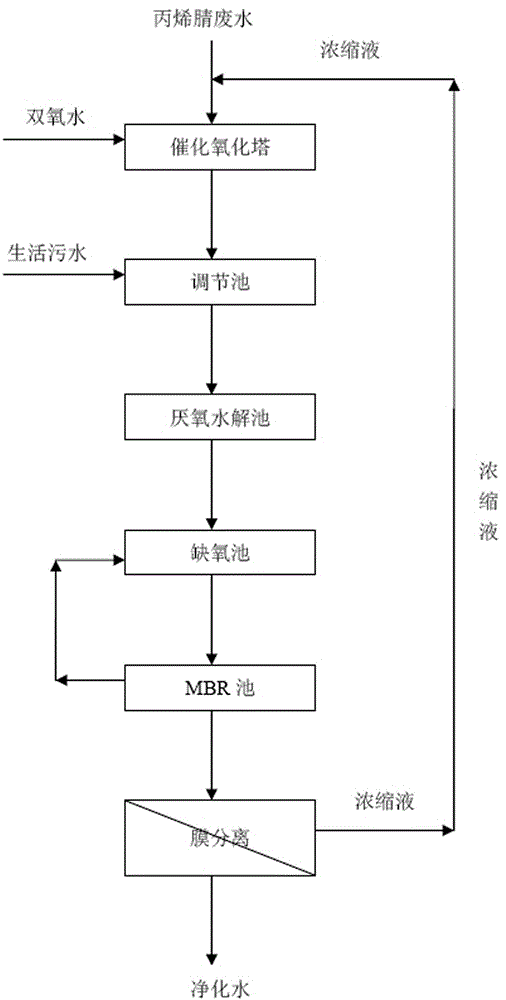

Efficient treatment combination process of acrylonitrile wastewater

ActiveCN105174644AReduce shockStable up-to-standard dischargeWater contaminantsMultistage water/sewage treatmentMicroorganismAcrylonitrile

The invention belongs to the field of chemical wastewater treatment of the petrochemical industry and particularly relates to an efficient treatment combination process of acrylonitrile wastewater. The combination process comprises: (1) acrylonitrile production wastewater enters a catalytic oxidation tower for catalytic hydrogen peroxide oxidation treatment; (2) water discharged form the catalytic oxidation tower and factory domestic sewage enter a biochemical treatment system after full mixing; the biochemical treatment system sequentially comprises an anaerobic hydrolysis tank, an anoxia tank and an MBR tank; (3) the biochemical treatment system adopts a membrane separation technique for treatment; partial concentrated solution flows back; the acrylonitrile production wastewater is wastewater produced by acrylonitrile device wastewater after four-effect evaporation and steam stripping; the temperature is 50 DEG C-80 DEG C; the hydraulic retention time in the catalytic oxidation tower is 30-120 min. According to the efficient treatment combination process of acrylonitrile wastewater, the microorganism poison inhibition effect of the biochemical treatment system microorganism can be reduced, the wastewater biodegradability is improved, the treatment load and the treatment cost of the catalytic oxidation tower are reduced, the denitrification effect is guaranteed, and the membrane service life is prolonged.

Owner:抚顺顺能化工有限公司

Method for preparing marsh gas through lignocellulose hydrolysate

ActiveCN110295201AImprove mass transfer efficiencyIncrease contactWaste based fuelFermentationCelluloseWater baths

The invention relates to a method for preparing marsh gas through a lignocellulose hydrolysate. The method comprises the following steps of acid production, wherein the lignocellulose hydrolysate is added into a reaction bottle with a stirring function, then an inoculum secondary sedimentation tank sludge is added according to a certain proportion, activated carbon is added, the mixture is evenlystirred and closely placed in a water bath heating device, and an air bag is connected to a reactor bottle plug and used for balancing the pressure of a reaction device; stirring is conducted on timeevery day, after 3 days, an acid production reaction stage is ended, and a fermentation solution with rich organic acid is obtained; methane production, wherein a, anaerobic granular sludge is subjected to domestication; b, the obtained acid production fermentation solution is taken out, subjected to centrifugal solid-liquid separation and diluted to the proper load, the pH is adjusted, and then the solution enters a methane production reactor; by controlling the mass loading rate, the aim of adjusting the system load is achieved, so that the methane production process is normally conducted; remaining sludge can be used as the inoculum and continues to be used for an acid production reaction in the later period through the hydrolysate; a water outlet of the methane production reactor is used for adjusting the load of materials entering a UASB, and the water is returned to an adjustment tank for recycling.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Moving bed biofilm reactor and its sewage treatment method

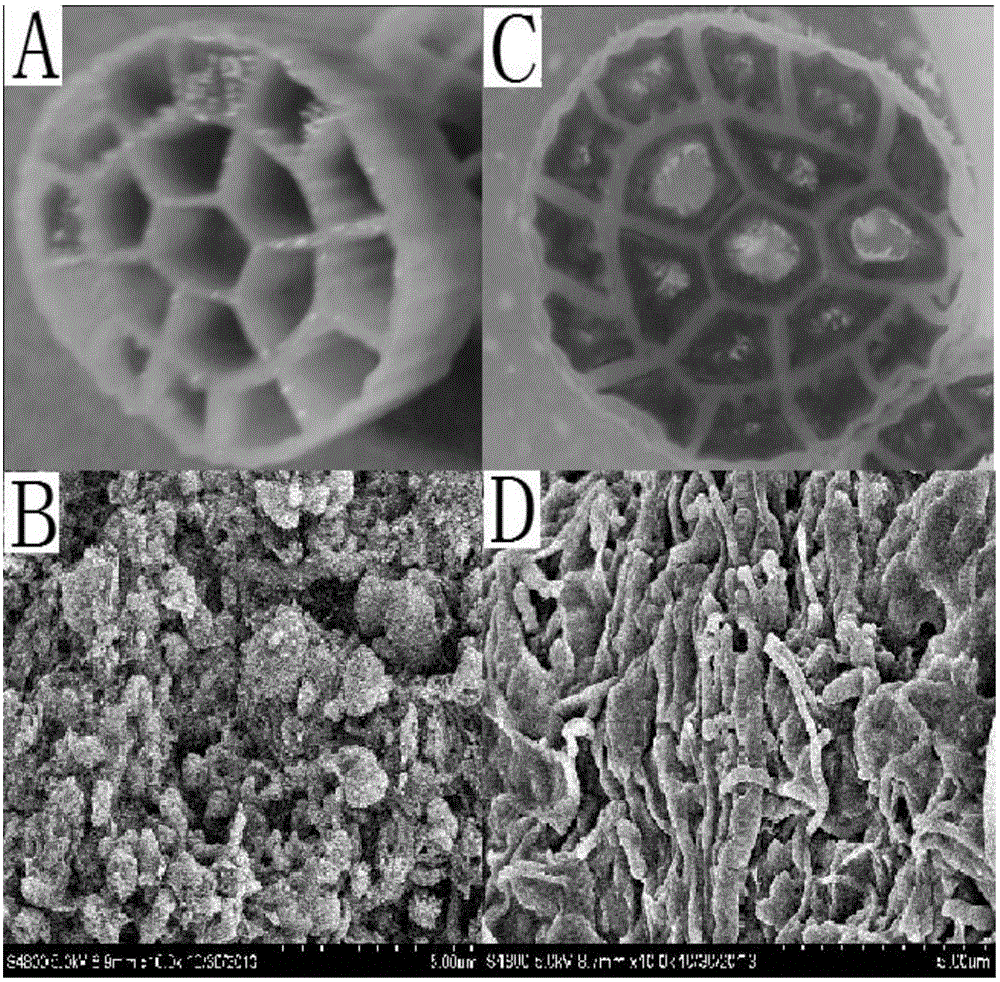

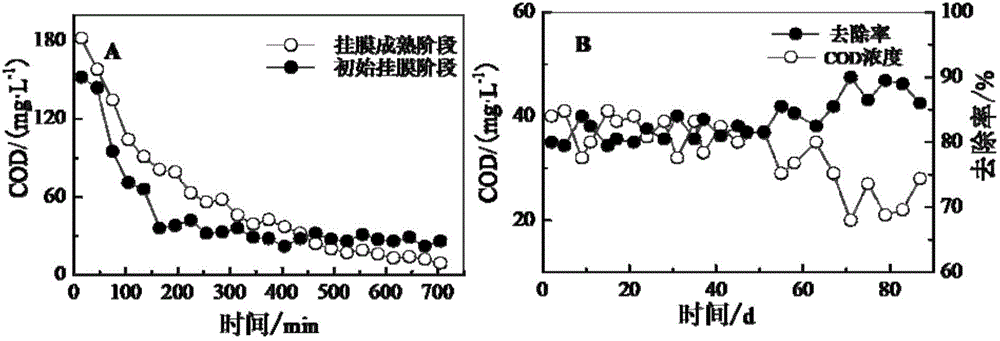

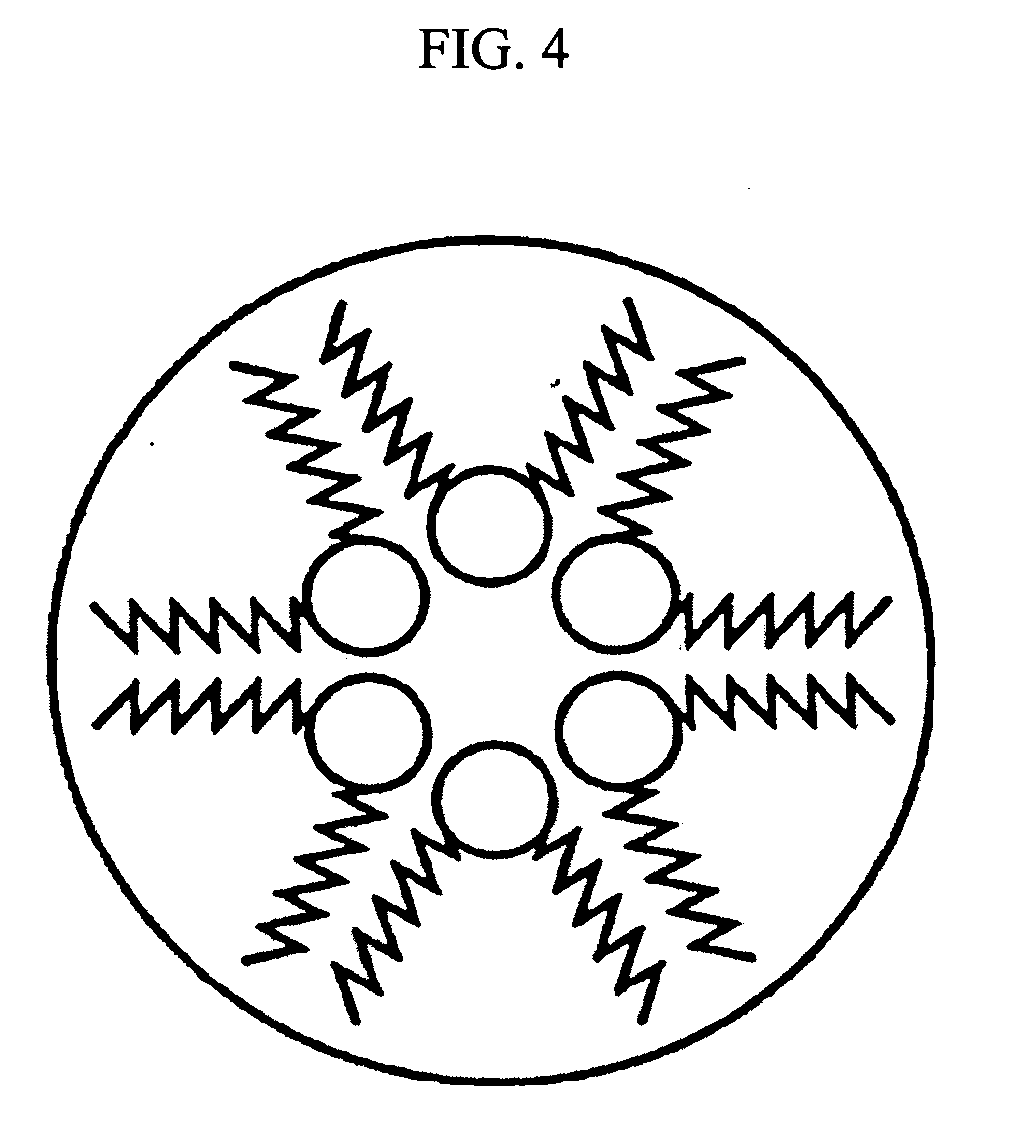

InactiveCN104150586AFully contactedReduce biological treatment costsTreatment using aerobic processesSustainable biological treatmentPeristaltic pumpAeration rate

The invention discloses a moving bed biofilm reactor and its sewage treatment method. The biofilm reactor comprises a tank body, an inlet water barrel, a peristaltic pump, an aeration sand head and an air aeration machine, the tank body is filled with a filler, the filler is a K3 filler, the diameter and the height of the K3 filler are 2.5cm and 1.1cm respectively, the material of the K3 filler is polypropylene, the filling rate of the filler in the tank body is 40%, and the reactor also comprises a time controller in order to control the on / off and the running time of the peristaltic pump, the air aeration machine and a water outlet solenoid valve. Compared with the prior art, the sewage treatment method disclosed in the invention has the advantages of realization of aerobic and anoxic environment in a same reactor, realization of a synchronous nitrification and denitrification process in a single reactor, organic load and aeration rate reduction, capital construction and operation cost reduction, and reaching of a good nitrogen removal effect.

Owner:安徽沛融环保技术有限公司

Technological process of back pouring percolate to speed stabilization of old landfill site

InactiveCN101020184AImprove uniformityImprove stabilitySolid waste disposalSewage drainingLitterWater quality

The present invention relates to the technological process of back pouring percolate to old landfill site for speeded stabilization and belongs to the field of environment protection technology. The technological process includes setting rain way guiding and draining facility in landfill site and sealing simply, and back pouring percolate through horizontal blind ditch with storage tank of polyethylene to speed the garbage stabilization. The technological process can speed the degradation of organic matter in the landfill site and makes it possible to omit special percolate treating facility.

Owner:TSINGHUA UNIV

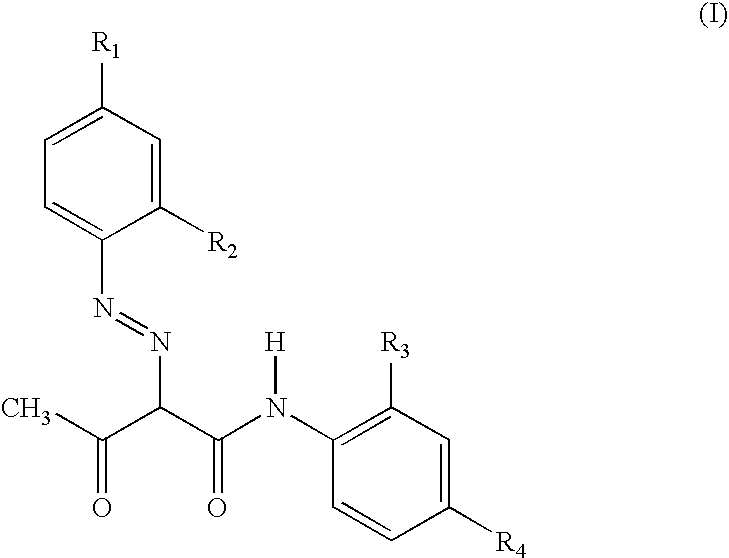

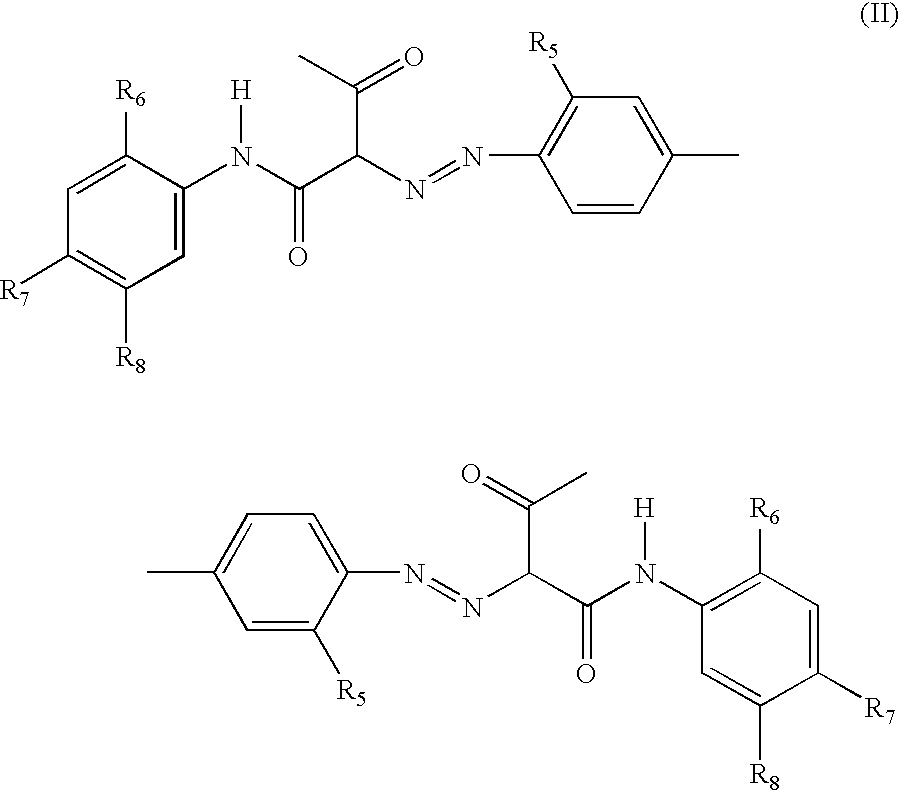

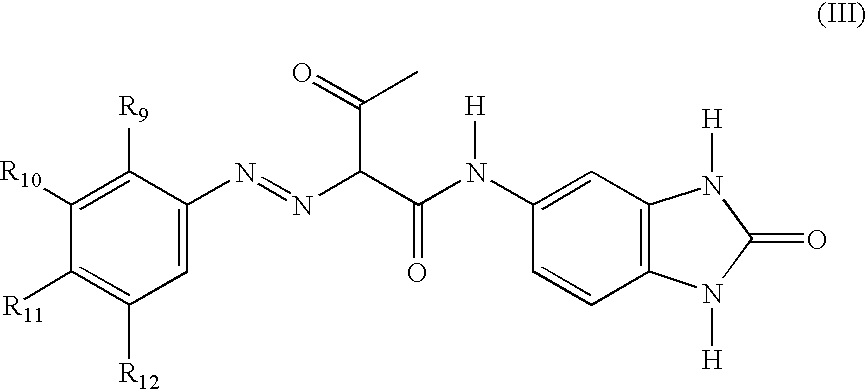

Color photographic materials with yellow minimum density colorants

InactiveUS7629112B1Increased sensitivityAcceptable reproductionPhotoprinting processesSilver halide emulsionsOrganic solventMinimum density

Silver halide color photographic elements having multiple color imaging layers contain a permanent, pre-formed yellow colorant that is present in an amount to provide a status M blue density greater than 0.003 per mg / m2. This colorant provides minimum density at lower cost and can be incorporated with minimal or no organic solvents and thus enable a reduced organic load that may lead to improved film physical properties.

Owner:EASTMAN KODAK CO

Wastewater treatment device and wastewater treatment technology

PendingCN108218117AIntelligent processingEasy and fast handlingMultistage water/sewage treatmentWater/sewage treatment by neutralisationFlocculationWater storage tank

The invention discloses a wastewater treatment device and a wastewater treatment technology. The wastewater treatment device comprises a water storage tank, a microbial water purification tank, a flocculation tank, an adsorption tank, an acid-base adjustment tank, a filter membrane, a water inlet pipe, 4 water pump and connecting pipe assemblies, four water pumps, a water outlet pipe and an intelligent controller, wherein the water storage tank, the microbial water purification tank, the flocculation tank, the adsorption tank and the acid-base adjustment tank are orderly connected through thewater pump and connecting pipe assemblies. Through reasonable matching and order adjustment of components such as the water storage tank, the microbial water purification tank, the flocculation tank,the adsorption tank, the acid-base adjustment tank, the filter membrane and the like, the wastewater treatment device has high treatment effect, low wastewater treatment cost and high treatment stability and treatment capacity.

Owner:广州市绿潮环保工程有限公司

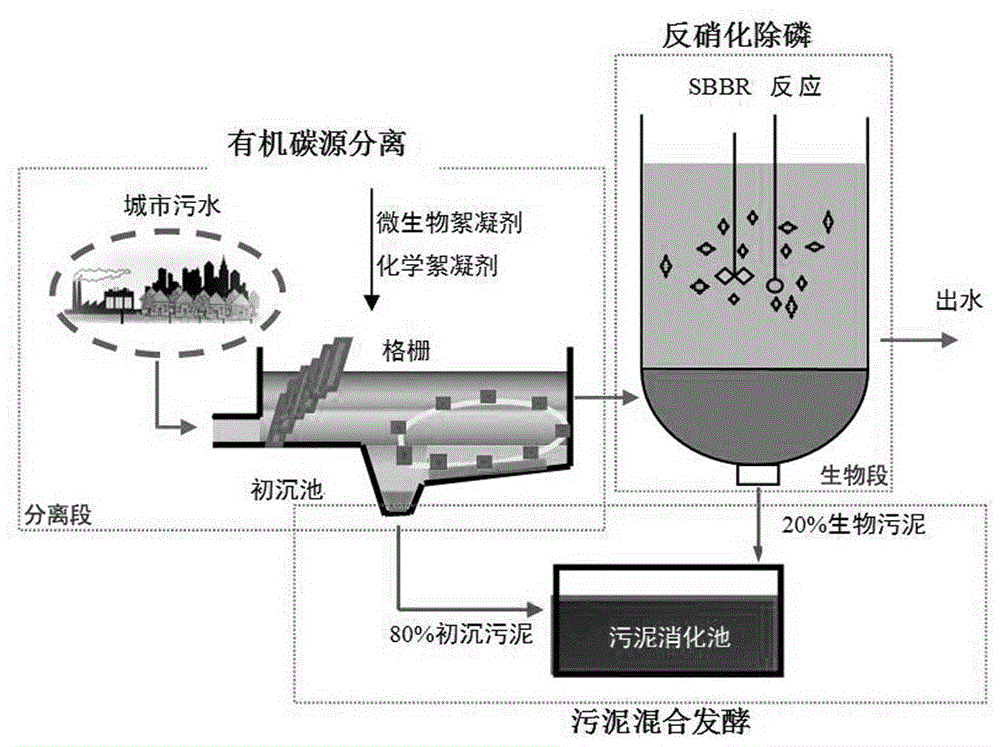

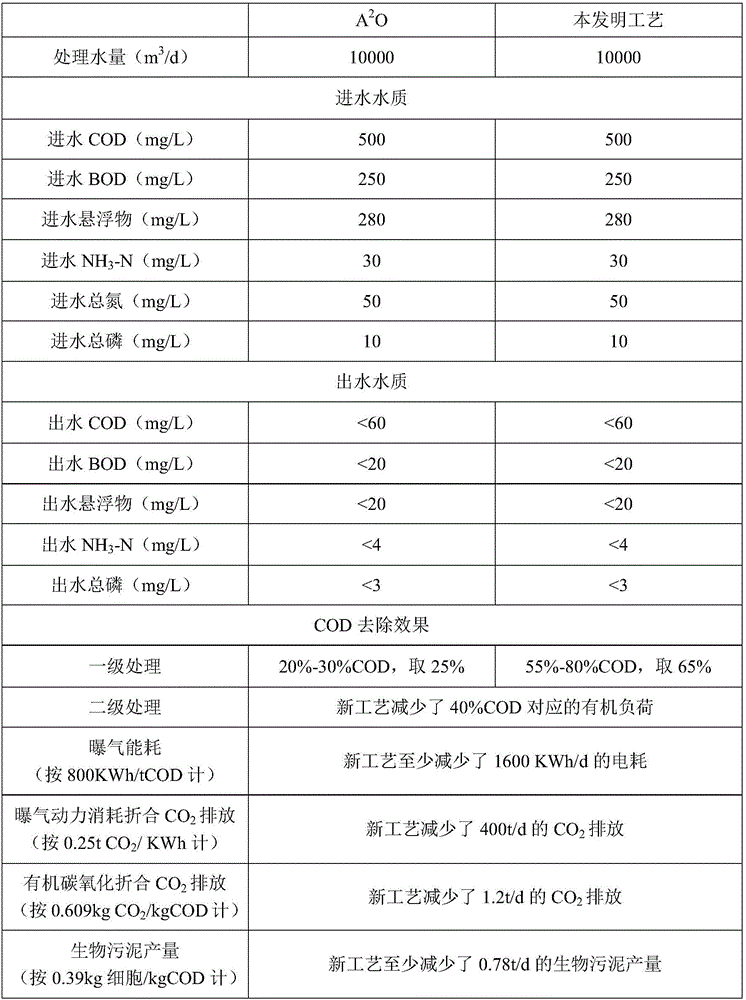

Process for efficient separation of organic carbon source in sewage and energy development and utilization

InactiveCN105776751AImprove sludge dewatering performanceOrganic load reductionTreatment involving filtrationWaste based fuelChemistryGreenhouse gas

The invention belongs to the field of sewage treatment and particularly provides a process for efficient separation of an organic carbon source in sewage and energy development and utilization. Most of suspended organic substances, colloid and parts of soluble organic carbon in raw water settle and are swept under the dual effects of a microbial flocculant and a macromolecular organic flocculant and are separated out of the sewage in the form of primary sludge, the primary sludge is mixed with biological sludge produced at a biological stage, anaerobic fermentation is performed to produce methane, and effluent at an organic carbon source separation stage is subjected to nitrogen and phosphorus removal at the biological stage. The process achieves organic carbon source separation before the biological stage, enables organic carbon to efficiently settle before the organic carbon enters cell walls, reduces the organic load at the biological stage, adopts a denitrifying phosphorus removal process to achieve the separation of the residual carbon source in the effluent and efficiency removal of ammonia, nitrogen and phosphorus, meanwhile achieves the multiple effects of reduction of aeration energy consumption, sludge output and greenhouse gas amount and the like, and has remarkable economic and environmental benefits.

Owner:TAIYUAN UNIV OF TECH

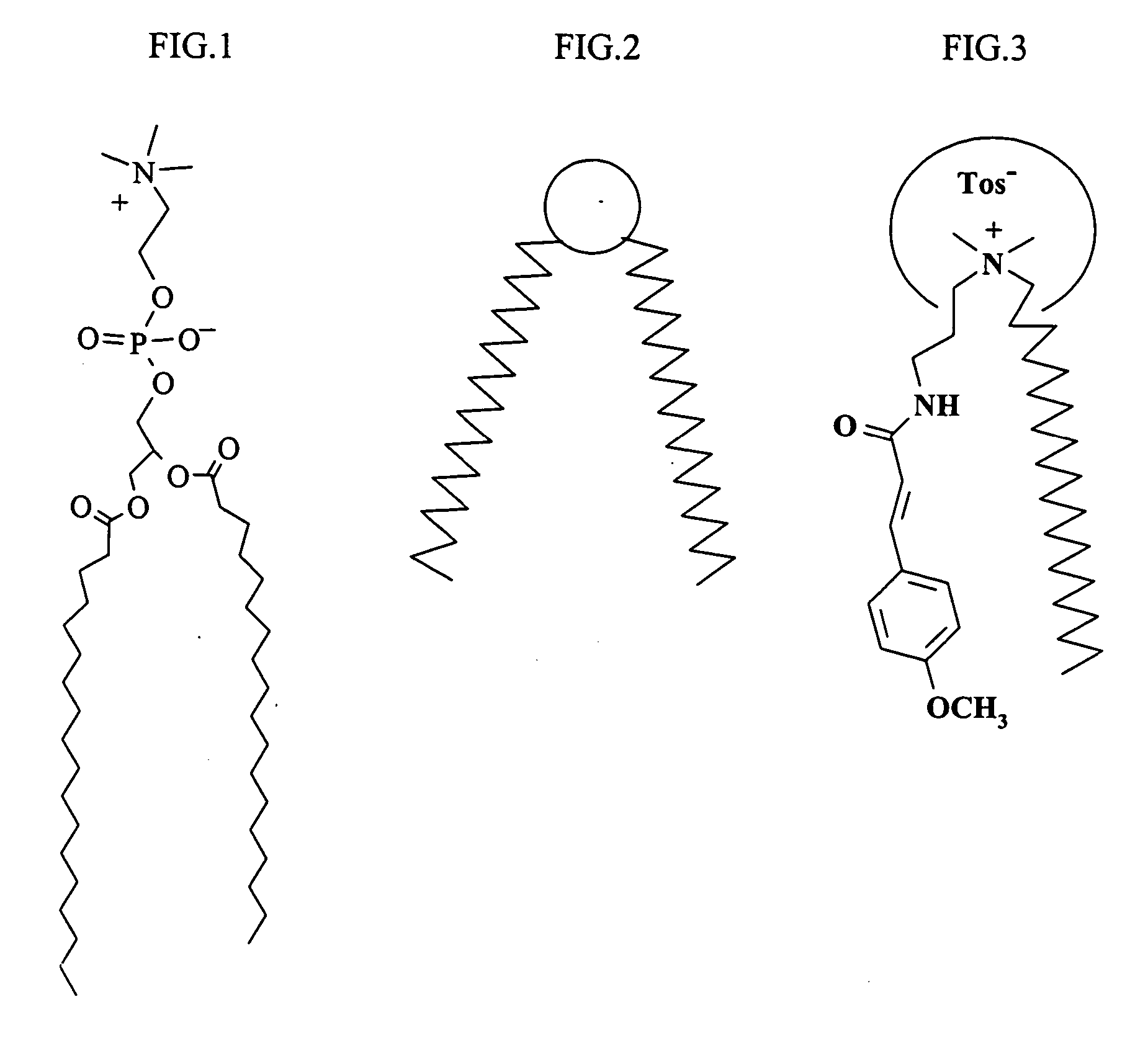

UV-absorbing lipid vesicles

InactiveUS20060067893A1Good curative effectProvide protectionOrganic active ingredientsCosmetic preparationsLipid formationUltraviolet

Highly effective vesicular compositions from UV-absorbing lipids are described in the present invention. Combination of UV-absorbing property and the vesicular delivery system results in higher levels of photoprotection to skin and hair. The vesicular compositions of the present invention are made from cationic UV-absorbing lipids of Formula I wherein, ArCO is selected from cinnamoyl, p-methoxy cinnamoyl, p-N,N-dimethylamino benzoyl and combinations thereof, R1 is selected from saturated or unsaturated alkyl group with carbons ranging from C10 to C22.

Owner:GALAXY SURFACTANTS

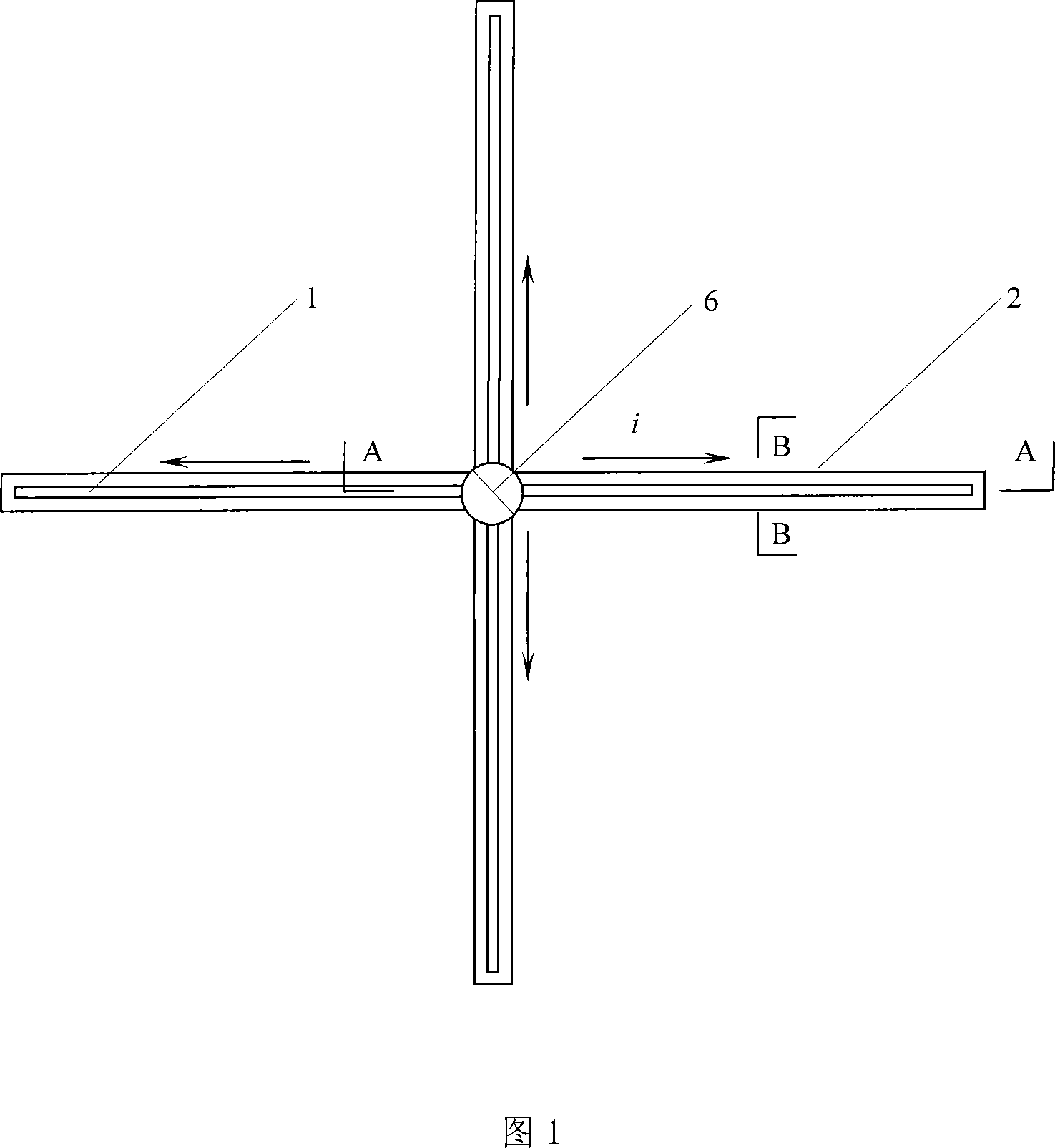

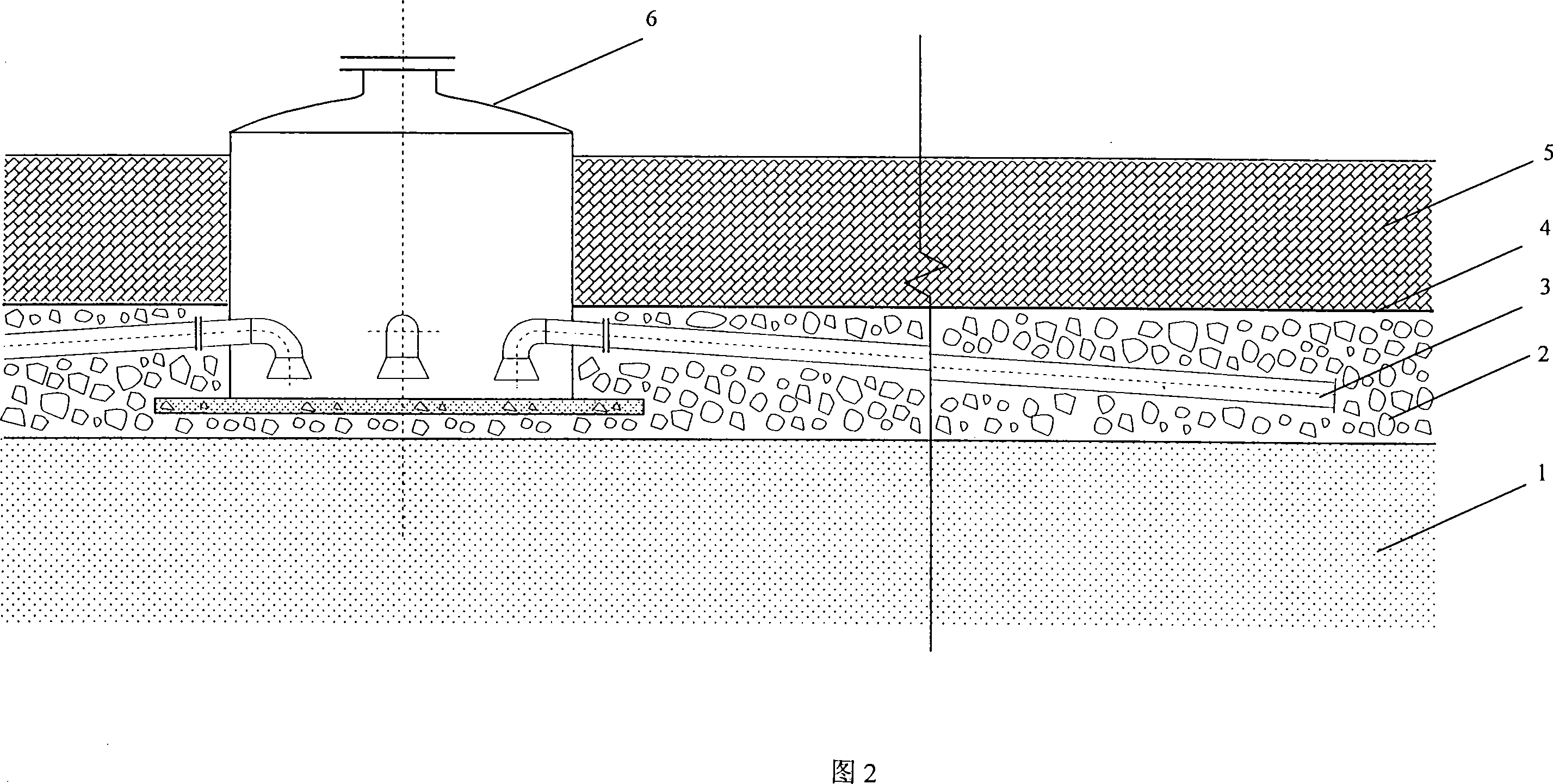

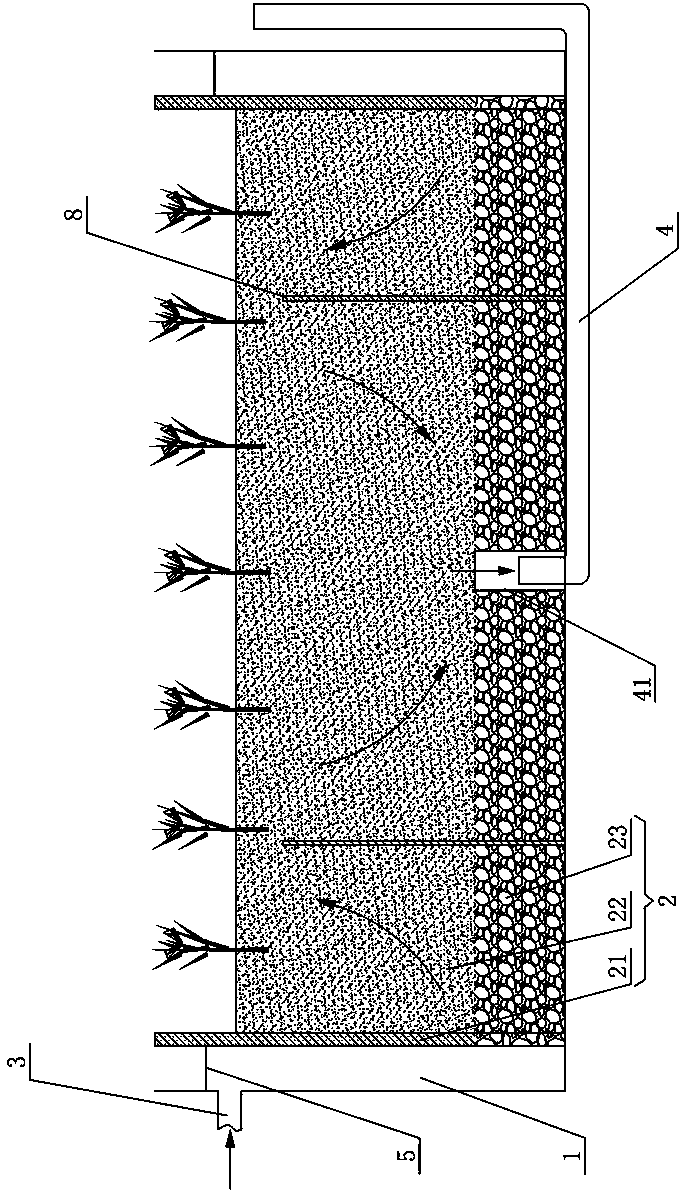

Three-dimensional radial inward artificial wetland sewage treatment system

InactiveCN104261565AOrganic load reductionReduce the chance of cloggingTreatment with anaerobic digestion processesMultistage water/sewage treatmentConstructed wetlandDraining tube

The invention discloses a three-dimensional radial inward artificial wetland sewage treatment system. The three-dimensional radial inward artificial wetland sewage treatment system comprises an annular anaerobic unit and an artificial wetland, wherein the inner ring of the annular anaerobic unit is vertically filled with the artificial wetland; a water inlet pipe for guiding sewage to flow to the annular anaerobic unit is mounted on the outer ring of the annular anaerobic unit; a seal cover is arranged on the top face of the annular anaerobic unit; a drainage pipe is mounted at the circle center of the bottom of the artificial wetland; the sewage permeates in the artificial wetland from the annular anaerobic unit, and flows in the drainage pipe for drainage to the circle center of the bottom of the annular anaerobic unit after being filtered through the artificial wetland. The system has the advantages of simple structure and blockage prevention, and the decontamination effect can be effectively improved.

Owner:HUNAN UNIV

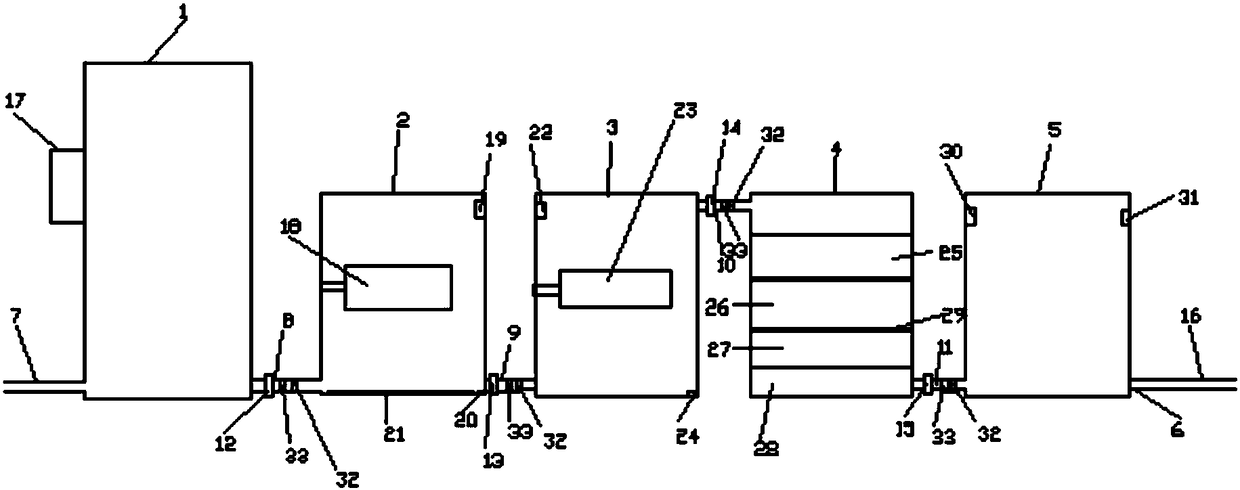

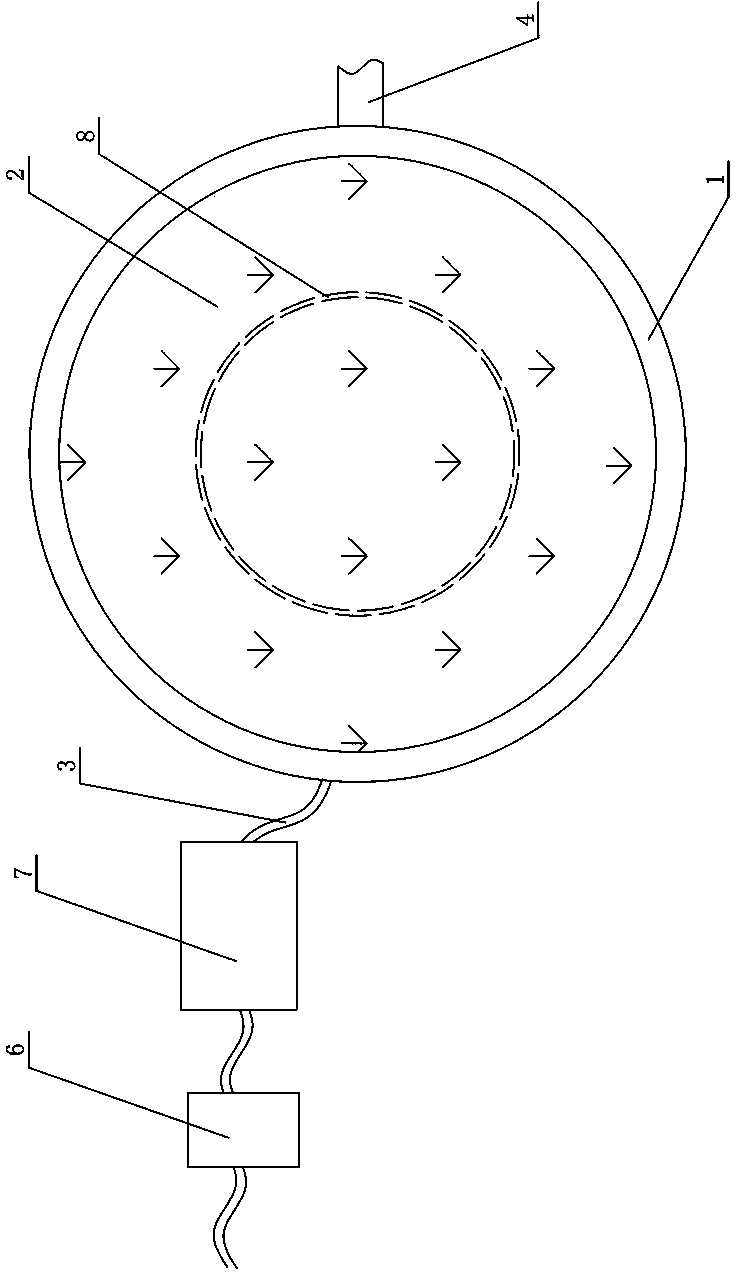

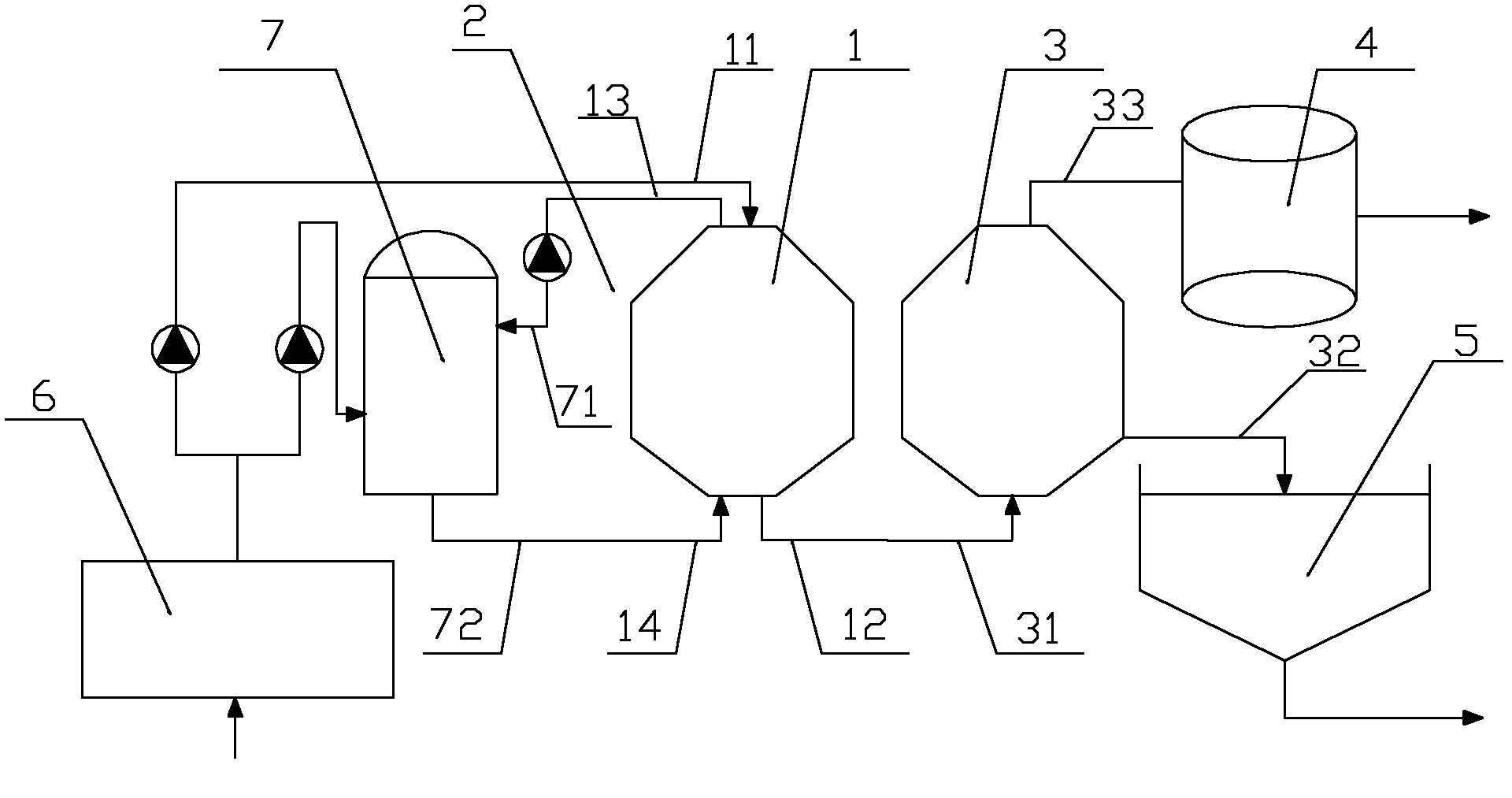

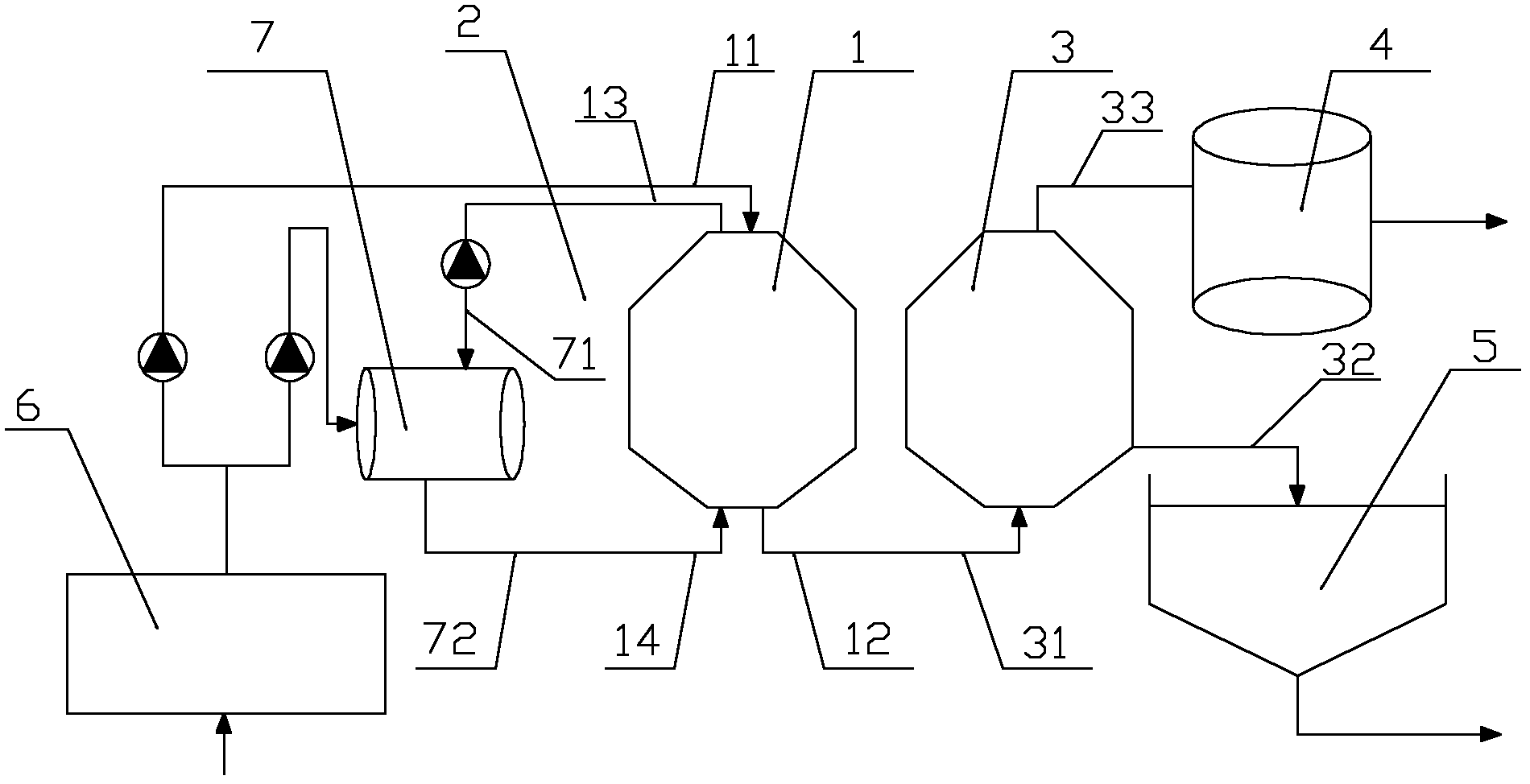

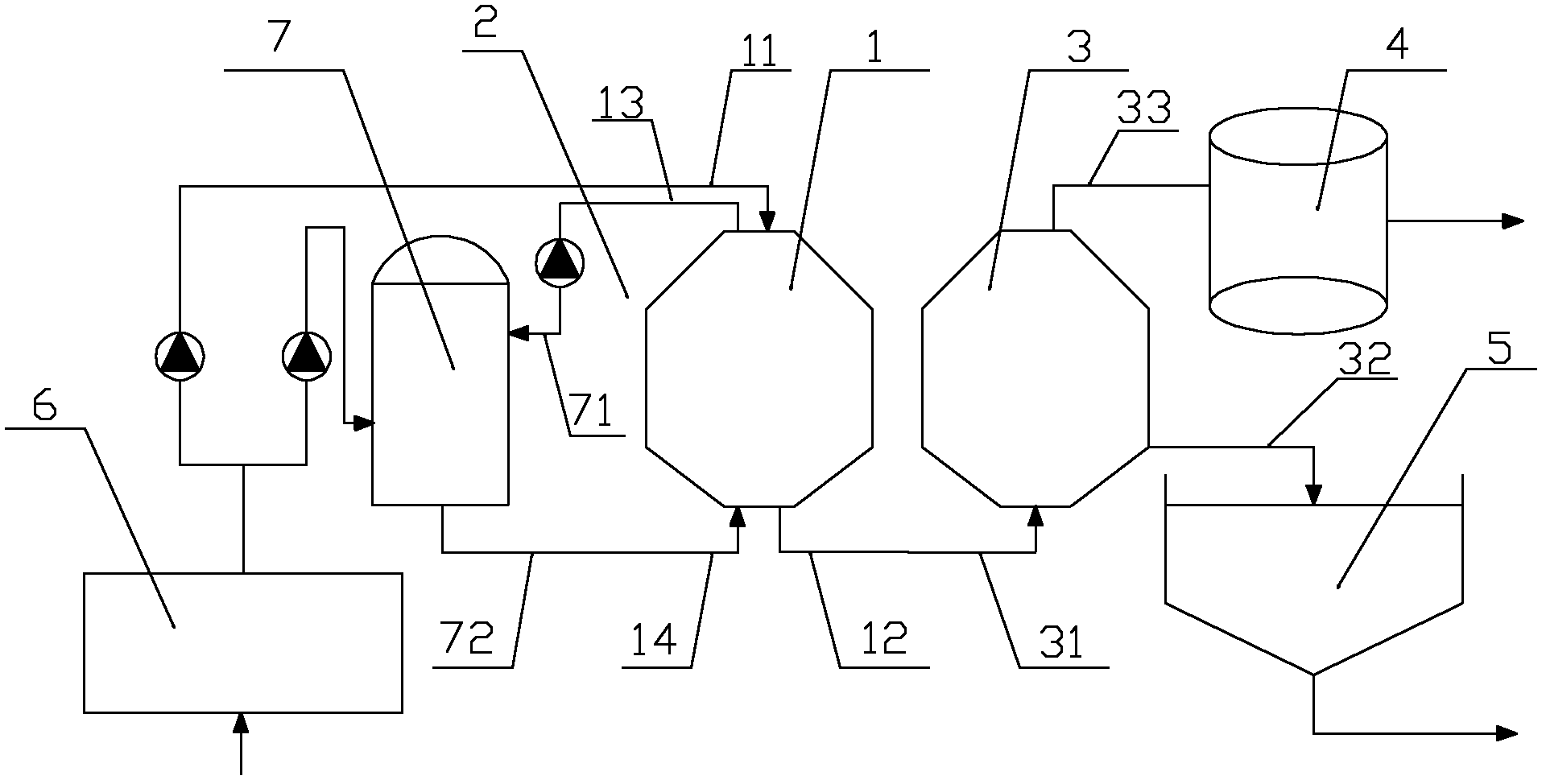

External circulation two-stage sludge anaerobic digestion system and application thereof

InactiveCN102583934AEfficient use ofHigh activityWaste based fuelBiological sludge treatmentRefluxOperational stability

The invention belongs to the field of recycling treatment of sludge and relates to an external circulation two-stage sludge anaerobic digestion system and an application thereof. The system comprises a primary high-temperature anaerobic digestion reactor (1), a circulating reflux system (2), a secondary medium-temperature anaerobic digestion reactor (3), a methane pool (4), a sludge collecting pool (5), a sludge mixing pool (6) and a pretreatment device (7), wherein the circulating reflux system (2) is arranged between the pretreatment device (7) and the primary high-temperature anaerobic digestion reactor (1). The system organically combines the technologies of performing two-stage anaerobic digestion, hydrolyzing organic matters at a high temperature, performing circulating reflux and the like, combines a physical enhanced treatment technology with a microbiological treatment technology, really realizes high-efficiency utilization of organic substrates, can exert highest activity of bacteria in two sections, and improves the operational stability of the whole system.

Owner:盐城同济环科固体废物处理处置有限公司 +2

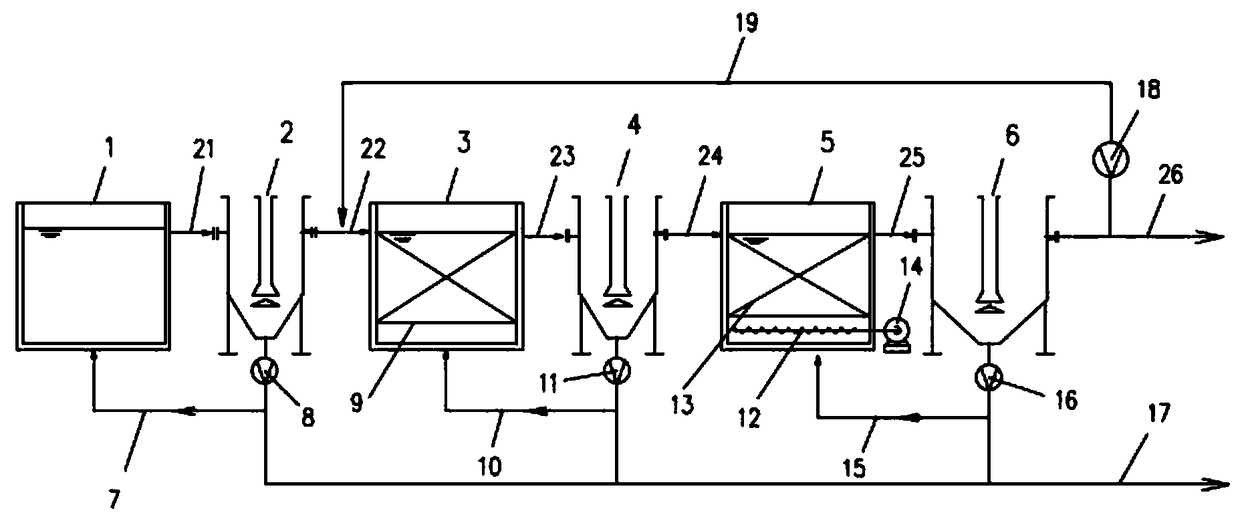

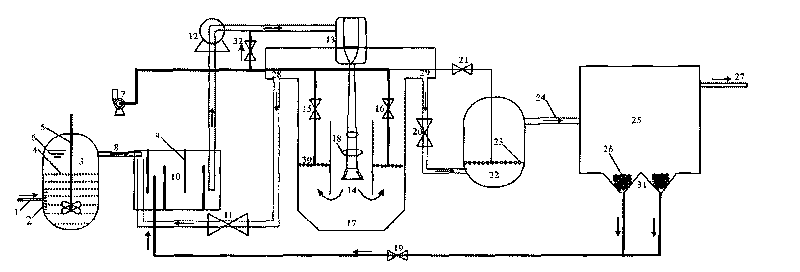

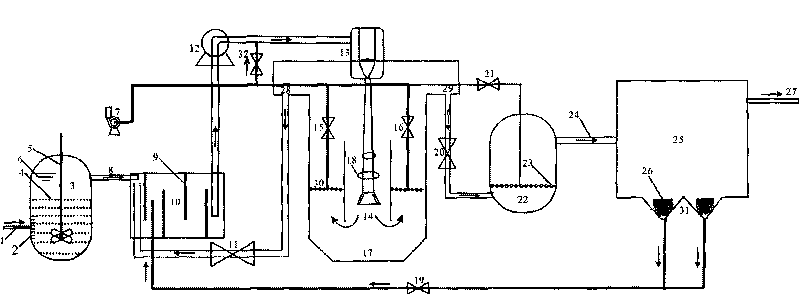

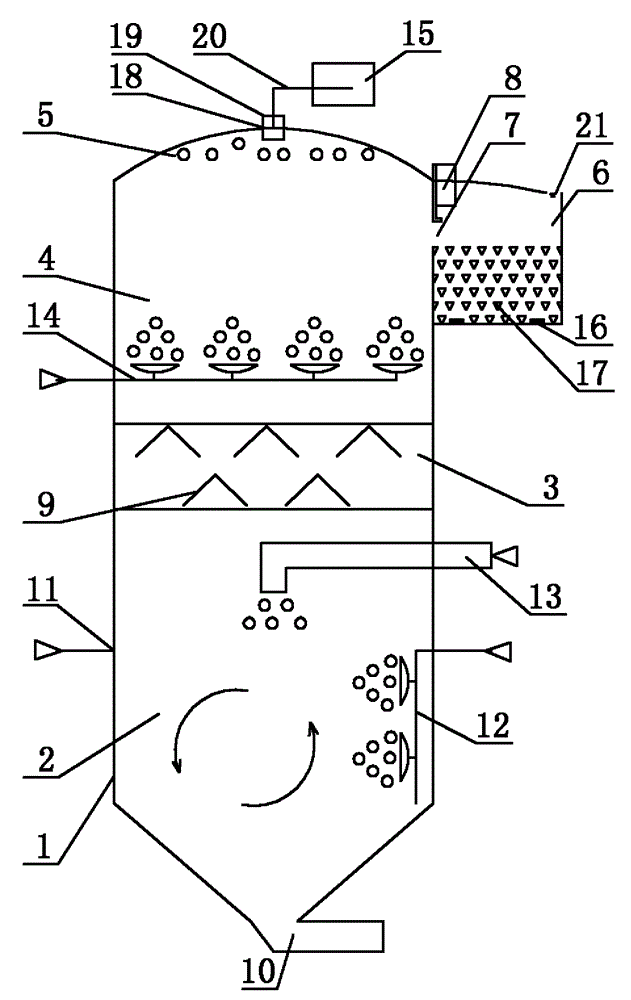

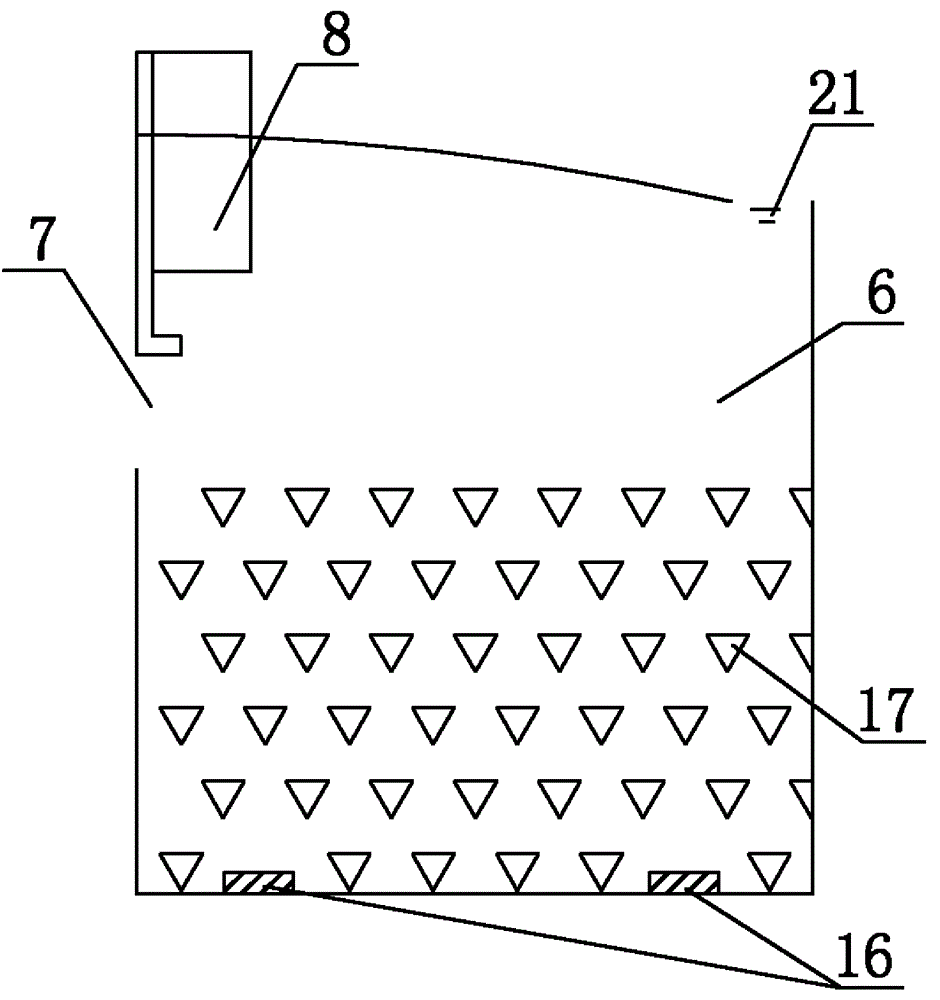

Efficient compound biological treatment device

ActiveCN101693580ALow running costReduce management costsMultistage water/sewage treatmentSustainable biological treatmentHigh concentrationMicro bubble

The invention discloses an efficient compound biological treatment device which comprises a centrifugal blower 7, a water inlet pipe 1, a water quality improving pool 3, a mixing pool 10, a biochemical pool 17, a degassing pool 22 and a settling pool 25. The water quality improving pool 3 and the mixing pool 10 containing a water distribution plate are additionally arranged in front of the biochemical pool 17 ; the biochemical pool 17 is connected with the degassing pool 22 by a water outlet trough 29; the degassing pool 22 is connected with the settling pool 25 by a pipeline 24; the biochemical pool 17 is internally and simultaneously provided with a jet device 13, and an aeration hose 30 and an ejetor air supply valve 32 that are connected with the centrifugal blower 7; the biochemical pool 17 is internally provided with two overflowing troughs, wherein one overflowing trough is a returning trough 28 with the yielding water entering the mixing pool 10 and being connected with the feed water; the other overflowing trough is a water reflowing trough 29 with the yielding water being connected with the degassing pool 22 so as to remove the micro-bubbles in the mud which enters the settling pool 25; and the mud in the settling pool 25 flows back to the mixing pool 10 and is homogenized with feed water. In the invention, the device has the advantages of reducing energy consumption, improving processing efficiency of high-concentration industrial wastewater and facilitating maintenance and management, and the like.

Owner:TONGJI UNIV +1

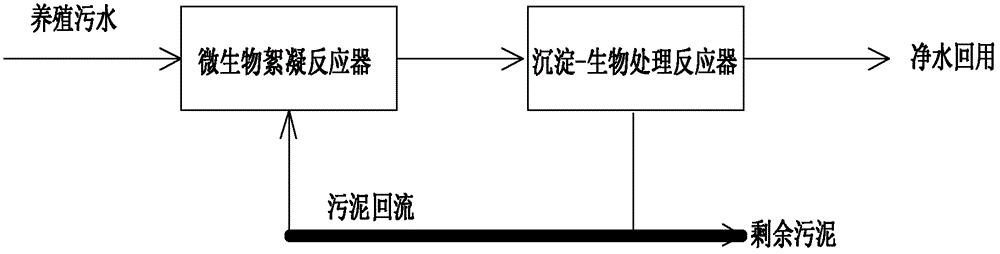

Process for treatment of high density aquaculture sewage

InactiveCN103058385AOrganic load reductionHigh specific surface areaTreatment using aerobic processesSustainable biological treatmentSewageOxygen supply

The invention relates to a process for treatment of high density aquaculture sewage. The process is characterized by: pumping high density aquaculture sewage into a microbial flocculation reactor, and adding a Bacillus subtilis seed bacterial solution subjected to activation culture, with the seed bacterial solution and the culture sewage being in a volume ratio of 1-3:100; disposing aeration equipment evenly at the bottom inside the reactor, and controlling the gas-water ratio at 2-2.5:1 and the dissolved oxygen at a concentration of 2-3mg / L; fully mixing the pumped sewage with the seed bacterial solution added therein for 0.8-1.2h under a blast aeration effect to produce biological flocculants decompose organic matters and proliferate microorganisms; leaving the mixed solution generated in the microbial flocculation reactor to flow through a sedimentation-biotreatment reactor, which relies on natural ventilation for oxygen supply and is filled with a suspending biological filter material at a filling rate of 25-30%; performing solid-liquid separation and biochemical reaction on the mixed solution in the sedimentation-biotreatment reactor; and subjecting the generated sediment, except for part of returned sludge, to centralized discharge, returning the sludge to the microbial flocculation reactor, and returning pure water to a culture pool.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Integral pretreatment device for leachate in waste incineration power plant

ActiveCN104150648ABiochemical improvementOrganic load reductionMultistage water/sewage treatmentElectrolysisPower station

The invention provides an integral pretreatment device for leachate in a waste incineration power plant. The device is arranged before rear-end biochemical treatment, has the characteristics of capability of efficiently degrading organic macromolecules, adjusting the carbon-nitrogen ratio and improving the biodegradability of the leachate, and is low in land cost due to small occupied area. The device comprises a shell and is characterized in that the shell is vertically arranged; an aeration dosing silt removal region, a mud-water separation region, an ammonia nitrogen blowoff region and a waste gas collection region are arranged in the shell in sequence from bottom to top; a mixed reaction cavity is formed in the top of one side of the shell; a water-passing hole is formed in the side wall, in the ammonia nitrogen blowoff region, at the upper part of the shell; the water-passing hole is communicated with the mixed reaction cavity in the outer side; an electrolysis and micro-electrolysis mixed reactor is arranged in the mixed reaction cavity; a doser is also arranged in the mixed reaction cavity; a three-phase separator is arranged in the mud-water separation region.

Owner:WUXI HUAGUANG BOILER

High concentration organic wastewater processing system

InactiveCN101195509AEfficient removalAvoid cloggingWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationFiltration

Provided is a treatment system for high concentrated organic wastewater, which comprises a flocculent sedimentation tank, a filter tank and a soil filtration device, wherein the soil filtration device comprises a casing made of anti-seep materials. The bottom portion inside the casing is a rinsing area, the end portion of the rinsing area is provided with a water outlet, and a bearing permeable stratum, a gravel stratum and a soil preparation stratum are sequentially arranged above the rinsing area. A separation layer is arranged between the gravel stratum and the soil preparation stratum, the middle upper portion of the soil preparation stratum is provided with a purifier in which a water giving-off pipe is disposed, and the filter tank is communicated with the water giving-off pipe via a water inflow device. The treatment system is capable of effectively removing the content of COD, BOD, SS and ammonia nitrogen in the water, is simple and convenient in operation and management, hard in being blocking up and small in accommodation area, and is adaptable to treatment systems for high concentrated organic wastewater of small and medium-sized food manufacturing enterprises.

Owner:HENAN AGRICULTURAL UNIVERSITY

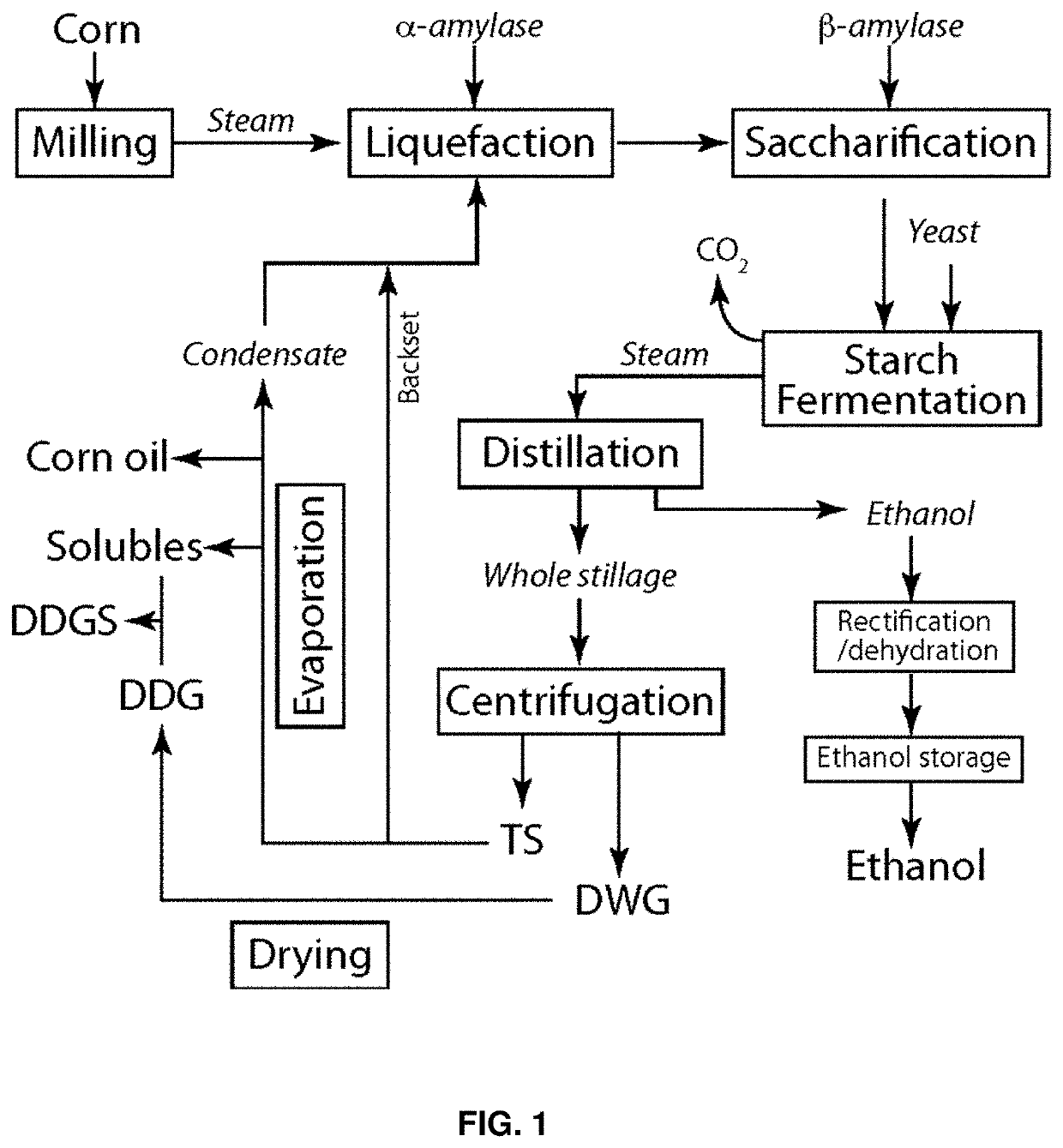

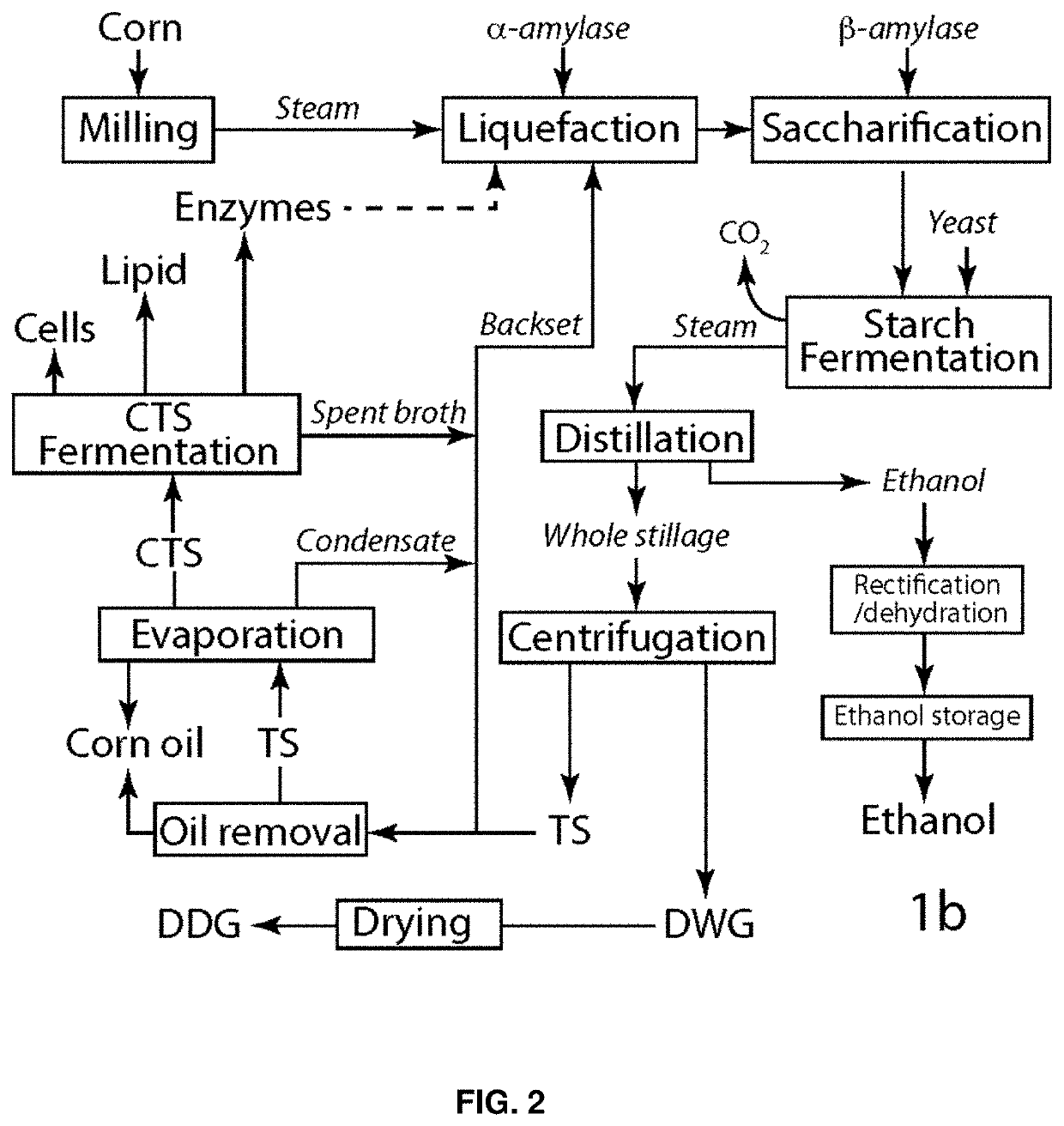

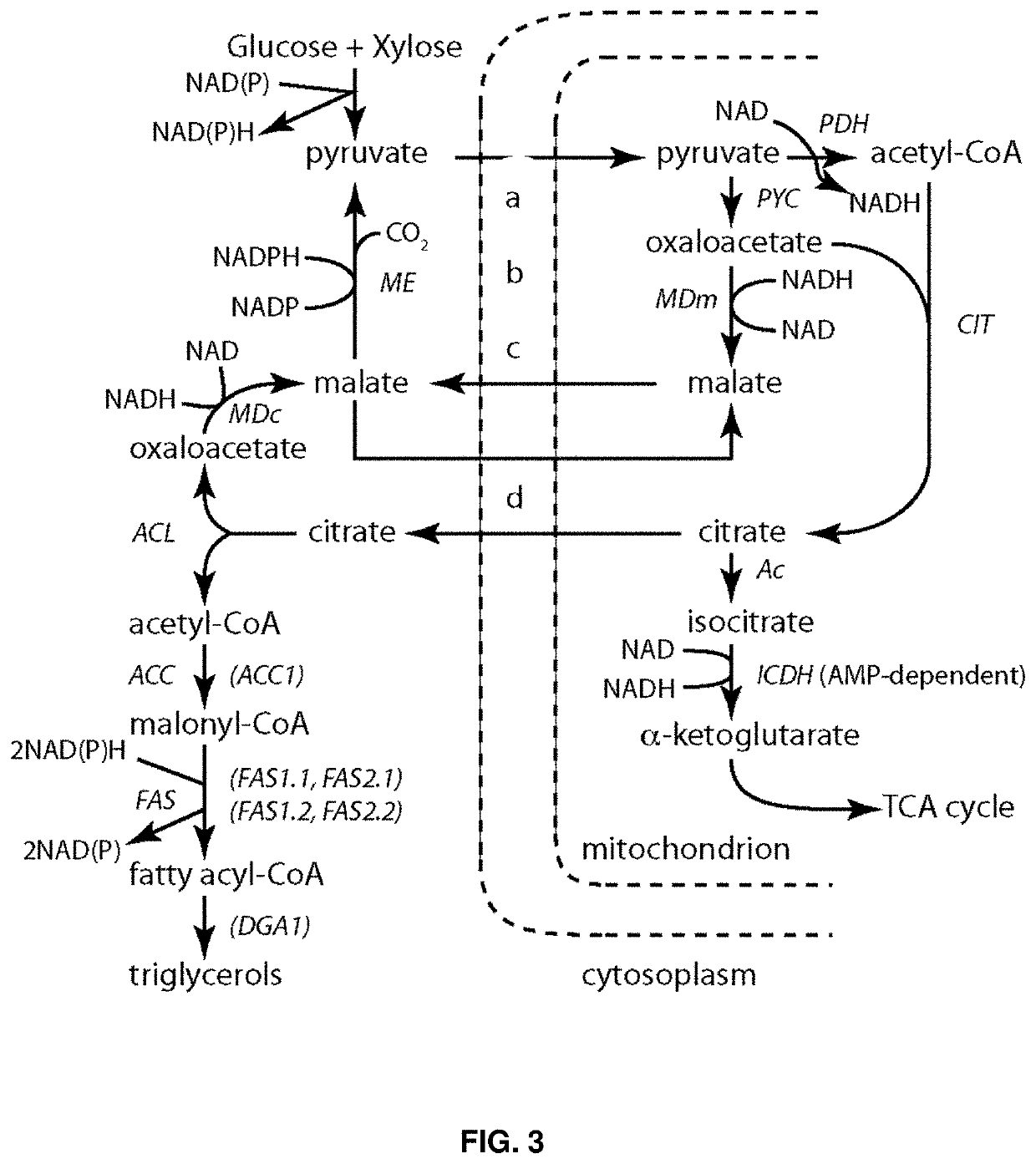

Compositions and methods for producing lipids and other biomaterials from grain ethanol stillage and stillage derivatives

ActiveUS10662448B2Conducive to liquefactionIncrease ratingsFungiMicrobiological testing/measurementPhospholipidAcyl CoA dehydrogenase

Lipogenic yeasts bioengineered to overexpress genes for lipid production, and methods of use thereof. The yeasts are modified to express, constitutively express, or overexpress an acetyl-CoA carboxylase, an alpha-amylase, an ATP citrate lyase, a diacylglycerol acyltransferase, a fatty acid synthase, a glycerol kinase, a 6-phosphogluconate dehydrogenase, a glycerol-3-phosphate dehydrogenase, a malic enzyme, a fatty acyl-CoA reductase, a delta-9 acyl-CoA desaturase, a glycerol-3-phosphate acyltransferase, a lysophosphatidate acyltransferase, a glucose-6-phosphate dehydrogenase, a beta-glucosidase, a hexose transporter, a glycerol transporter, a glycoside hydrolase enzyme, an auxiliary activity family 9 enzyme, or combinations thereof. The yeasts in some cases are also modified to reduce or ablate activity of certain proteins. The methods include cultivating the yeast to convert low value soluble organic stillage byproducts into lipids suitable for biodiesel production and other higher value uses.

Owner:XYLOME CORP

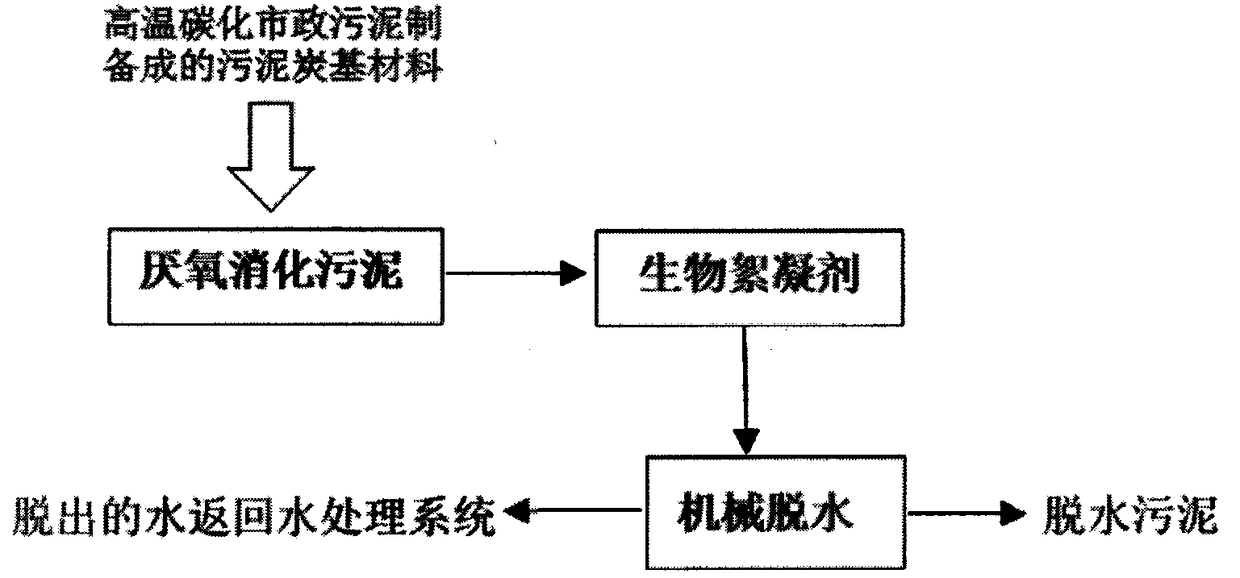

Anaerobic digestion sludge dewatering method

InactiveCN108358429AAchieve deep dehydrationImprove weight reduction effectSludge treatment by de-watering/drying/thickeningActivated carbonHigh concentration

The invention discloses an anaerobic digestion sludge dewatering method. By adopting the anaerobic digestion sludge dewatering method, secondary utilization can be performed on sludge, the sludge is prepared into a sludge activated carbon material firstly, sludge activated carbon and a biological flocculant are adopted for combined conditioning, and deep dewatering of the sludge or anaerobic digestion sludge is realized; by taking the sludge activated carbon as a skeleton structure substance, the floc structure strength of the sludge is strengthened through the hydrophobic interaction, viscousmacromolecular organic matters including humic acid and proteins and the like in a liquid phase of the anaerobic digestion sludge are removed synchronously, the filter performance of the sludge is improved, an organic load of subsequent reflux biochemical treatment is lowered; and then by further utilizing the biological flocculant for coagulation, sludge-water separation is promoted, and efficient deep dewatering of the anaerobic digestion sludge is realized. The dewatering method provided by the invention is an environment-friendly conditioning method and can improve the filtering and dewatering efficacy of the anaerobic digestion sludge specially aiming to the characteristics of small particles, high concentration of a dissolved microbial metabolite, poor filter performance and the like of the anaerobic digestion sludge.

Owner:北京环球中科水务科技股份有限公司

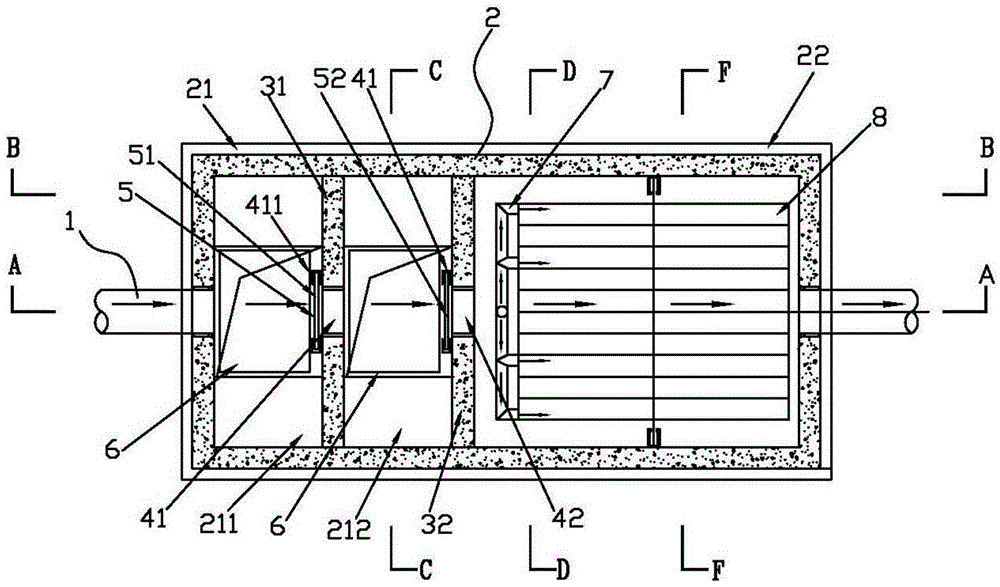

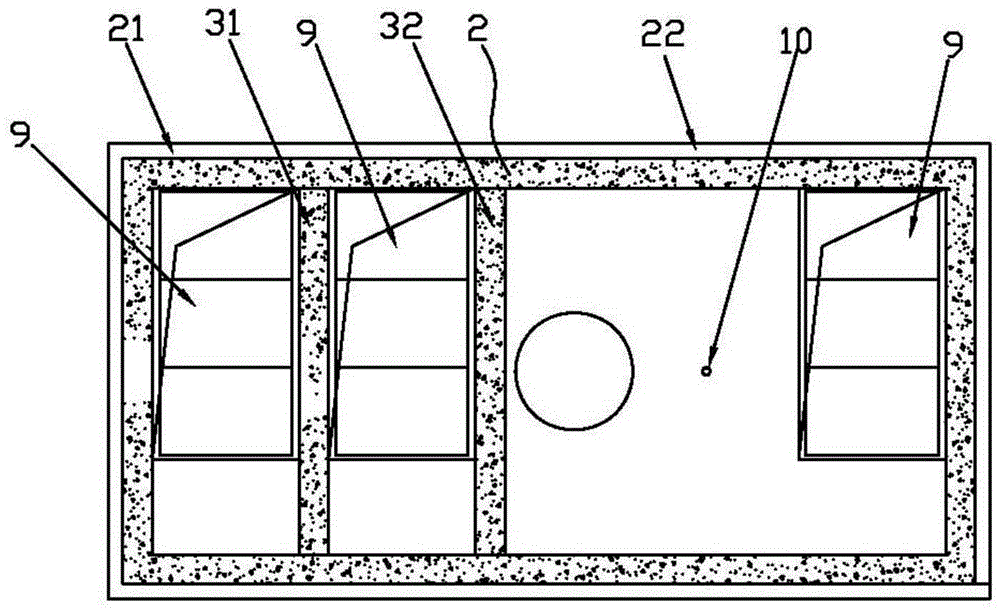

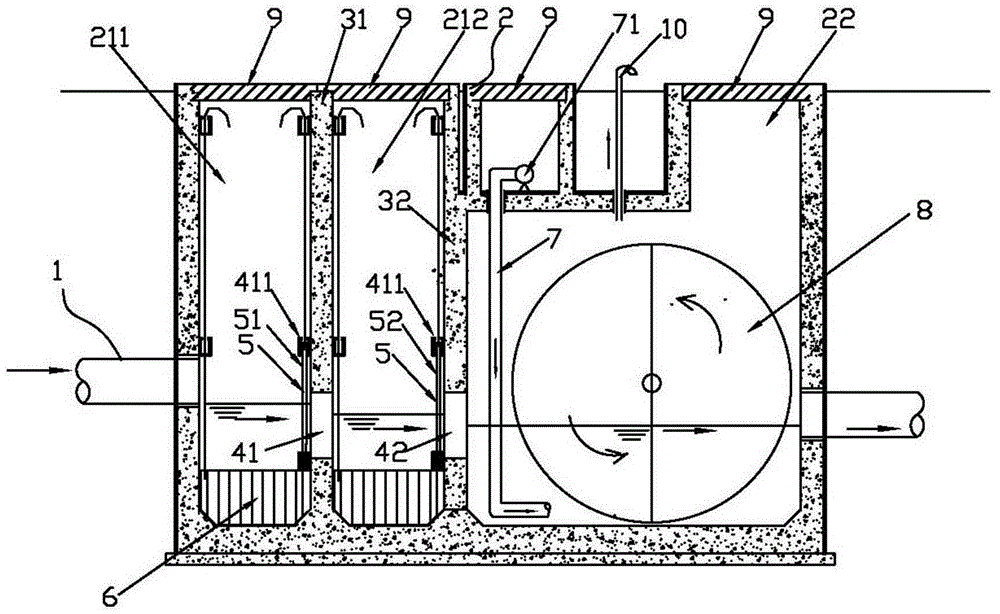

Sewage pretreatment device with slag-removal, coupling and air-driving biological rotating disc integrated structure

ActiveCN104671600ASmall footprintImprove B/C ratioMultistage water/sewage treatmentAtmospheric airSlag

The invention relates to a sewage pretreatment device with a slag-removal, coupling and air-driving biological rotating disc integrated structure. The sewage pretreatment device comprises a sewage draining pipeline and a sewage treatment pool. The sewage pretreatment device is characterized in that a partition wall I is arranged in the sewage treatment pool to divide the sewage treatment pool into a slag removal treatment pool and a biological treatment pool from front to back; a water passage I is arranged in the partition wall I, a grid is arranged at the water passage I, and the slag removal treatment pool is communicated with the biological treatment pool through the water passage I; an air-supplanting and oxygen-supplying pipeline and a biological rotating disc are arranged in the biological treatment pool, an air outlet of the air-supplanting and oxygen-supplying pipeline faces to the biological rotating disc, an air inlet of the air-supplanting and oxygen-supplying pipeline is communicated with atmosphere to generate atmospheric pressure difference to drive the biological rotating disc to rotate, and therefore, the biological rotating disc integrated structure with the slag removal, coupling and air driving functions is configured. The sewage pretreatment device is small in occupied area and can be used for effectively separating impurities in sewage and carrying out bio-enzyme catalysis.

Owner:广州市设计院集团有限公司

Sewage treatment process for recovering N-methyl pyrrolidone

InactiveCN110894125ASettling property without special requirementsReduce yieldFatty/oily/floating substances removal devicesWater treatment compoundsElectrolysisActivated carbon filtration

The invention discloses a sewage treatment process for recovering N-methyl pyrrolidone. The sewage treatment process comprises the following steps: pretreating high-concentration wastewater, wherein the pretreating sequentially comprises catalytic cracking, high-voltage pulse electrolysis and coagulating sedimentation; obtaining pretreated wastewater; carrying out biochemical treatment; sequentially carrying out mixing homogenization, anaerobic reaction, hydrolytic acidification and contact oxidation on the pretreated wastewater in the step (1); obtaining biochemical treatment water; ensuringtreatment; and sequentially carrying out precipitation reaction, multi-medium filtration and active carbon filtration on the biochemical treatment water in the step (2) to finish recovery. The methodhas the advantages of low process cost, high efficiency, good recovery effect and good wastewater treatment effect, and can be widely popularized and used.

Owner:镇江新纳环保材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com