Patents

Literature

114results about How to "Conducive to liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

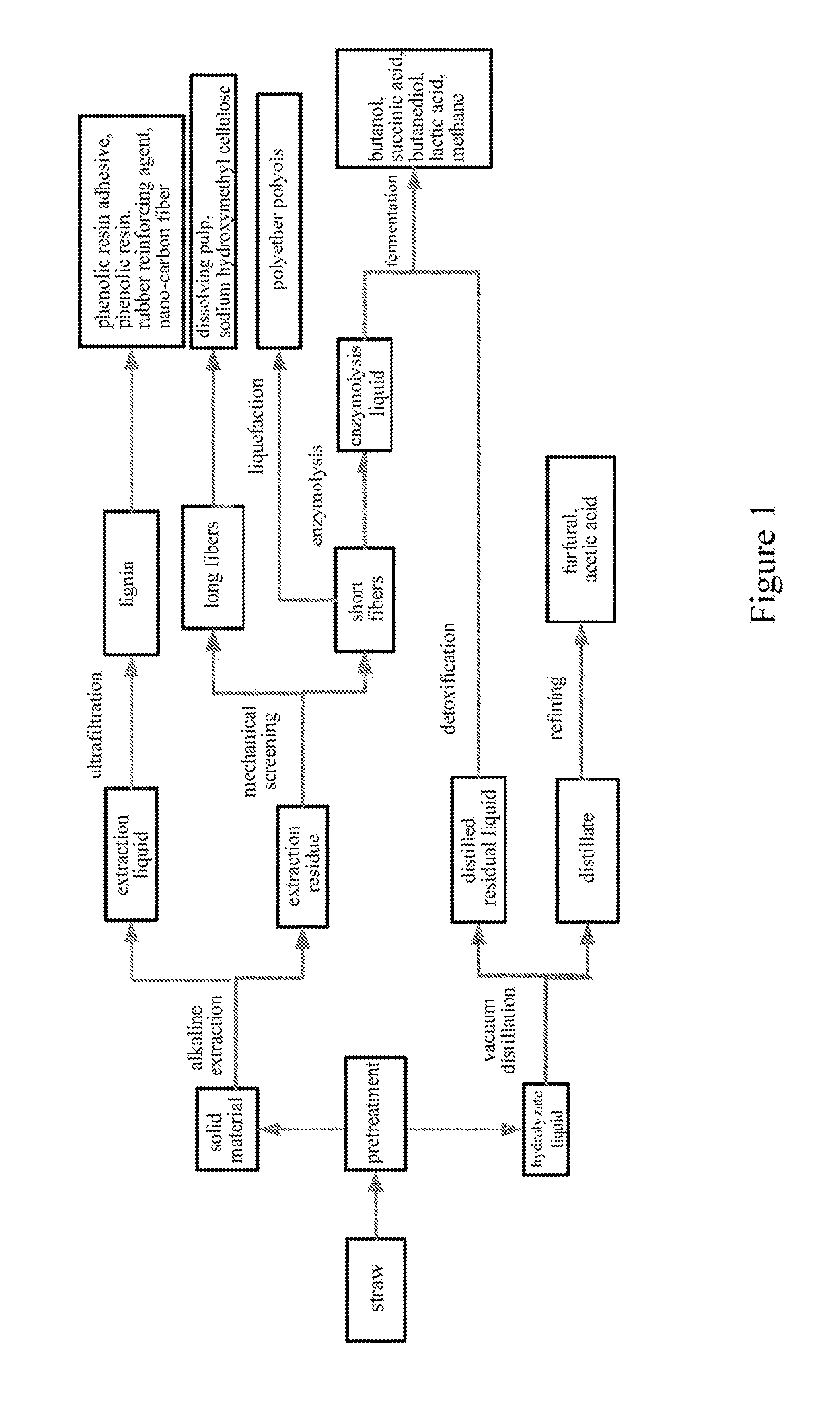

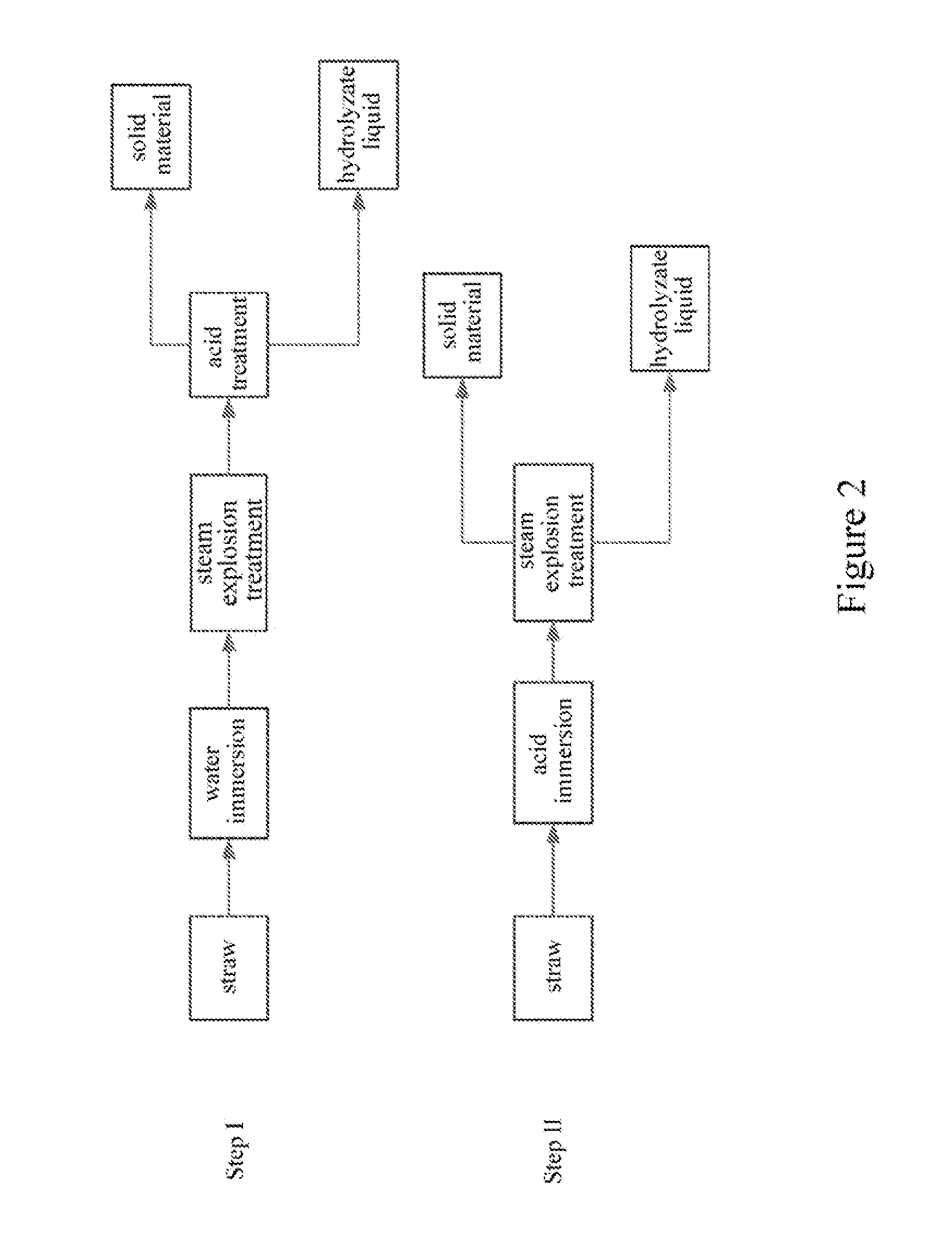

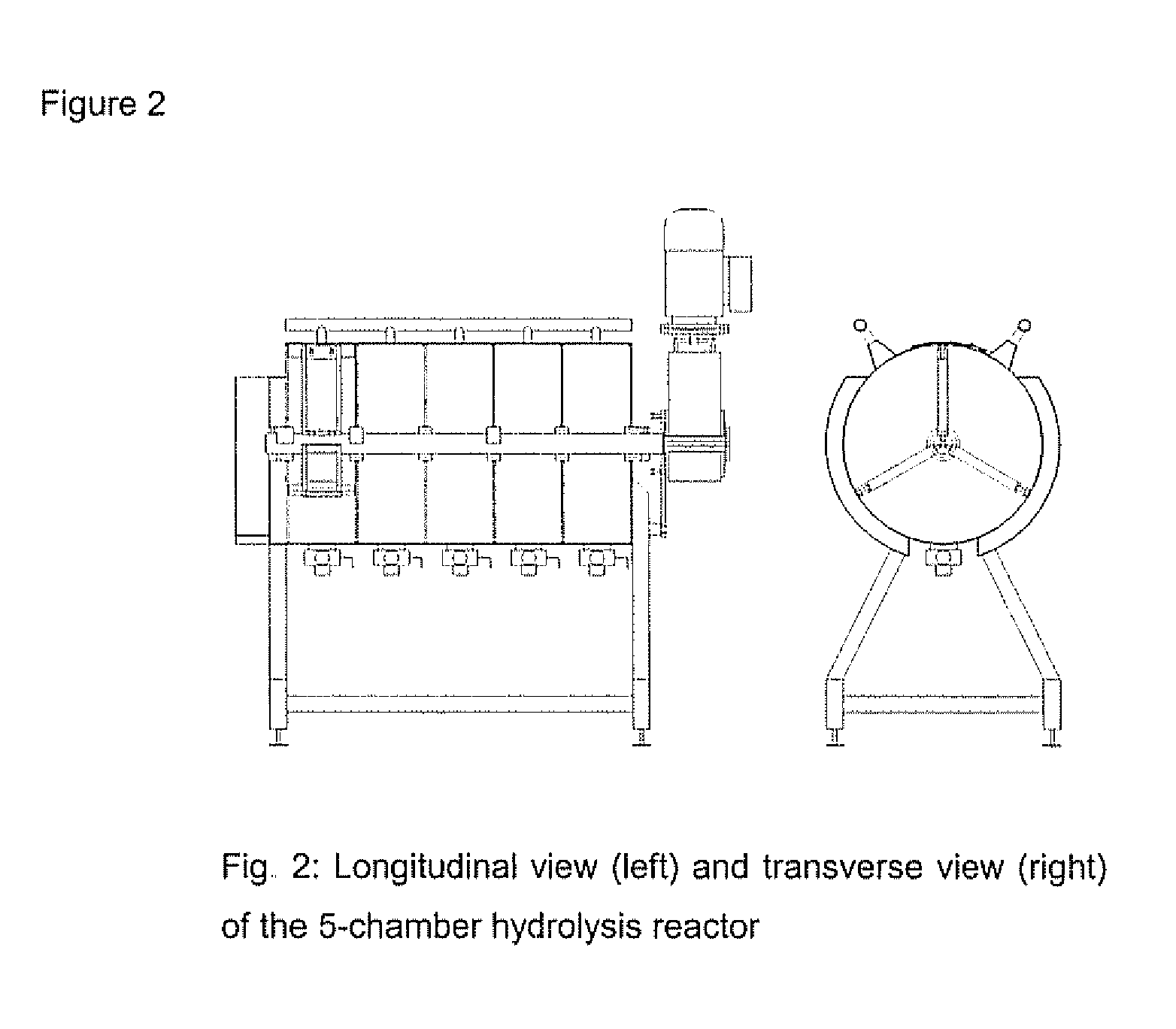

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

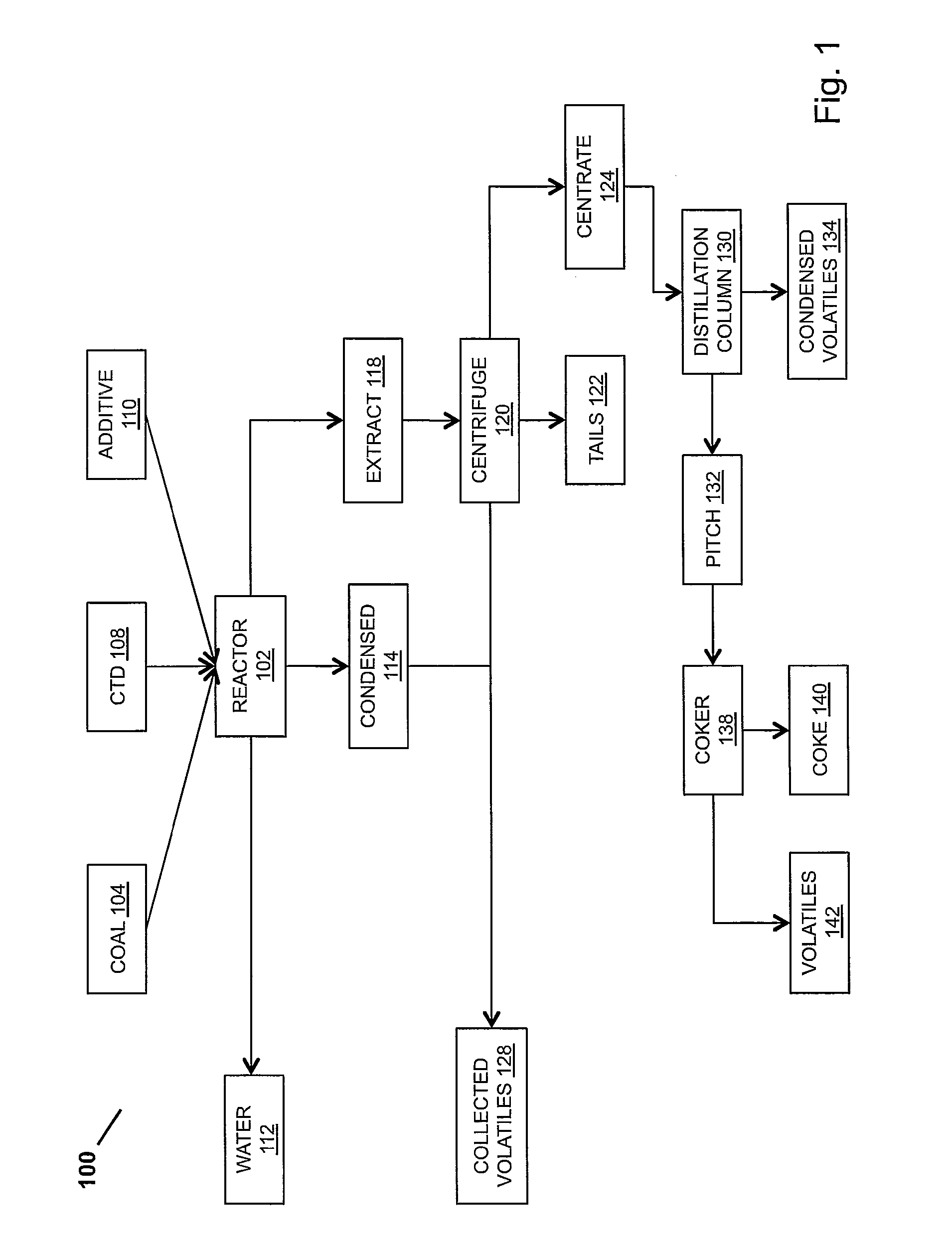

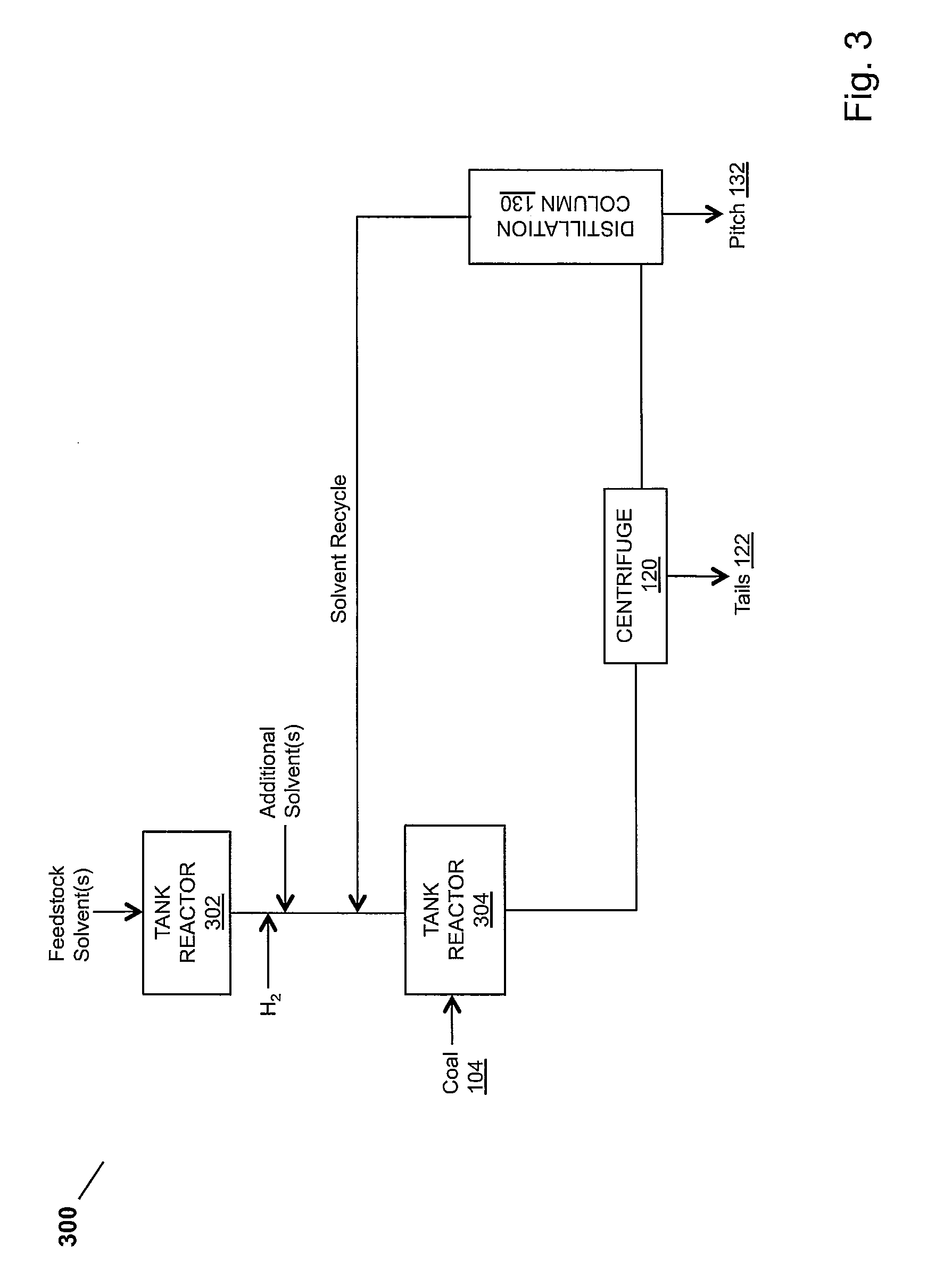

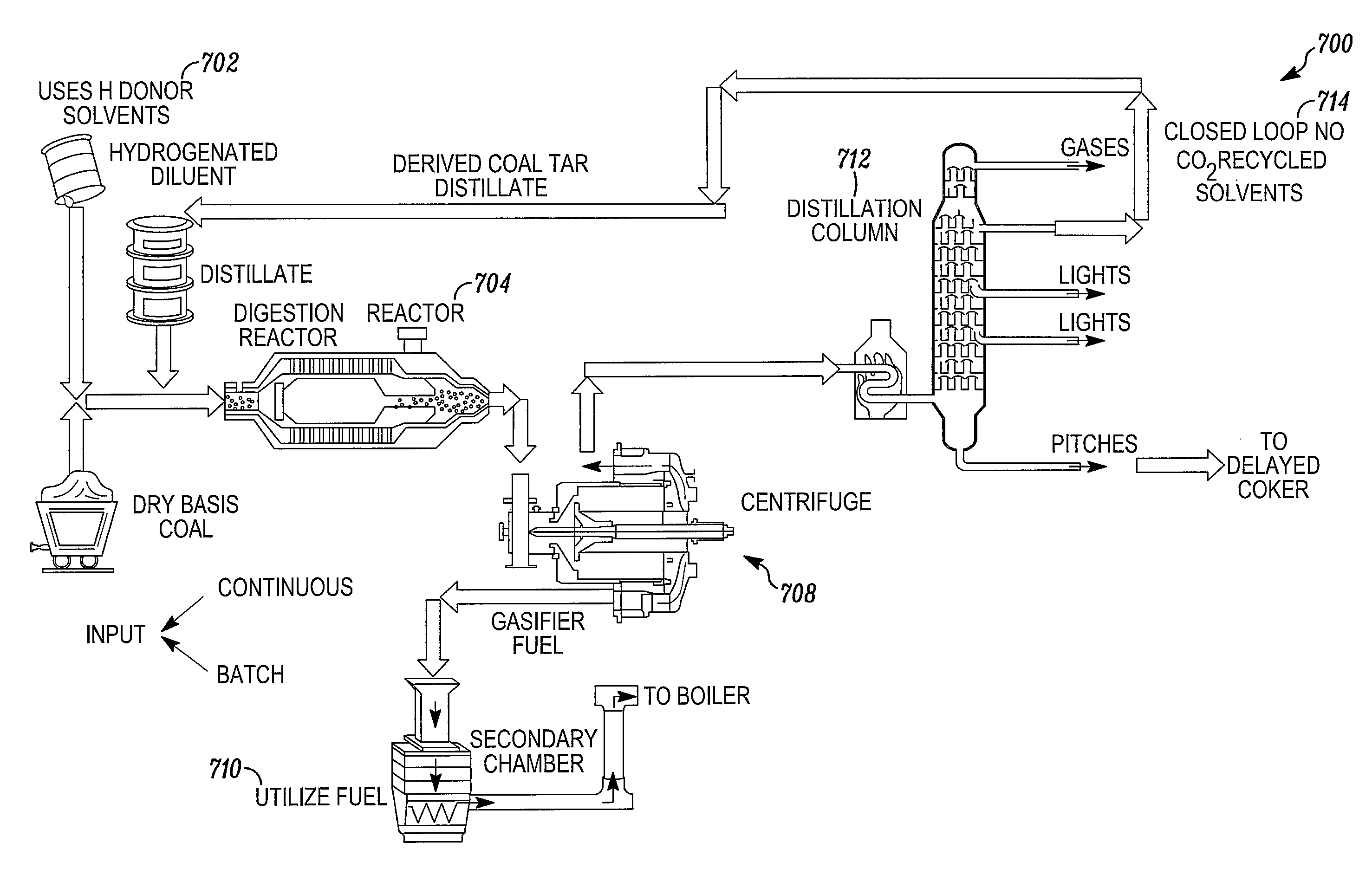

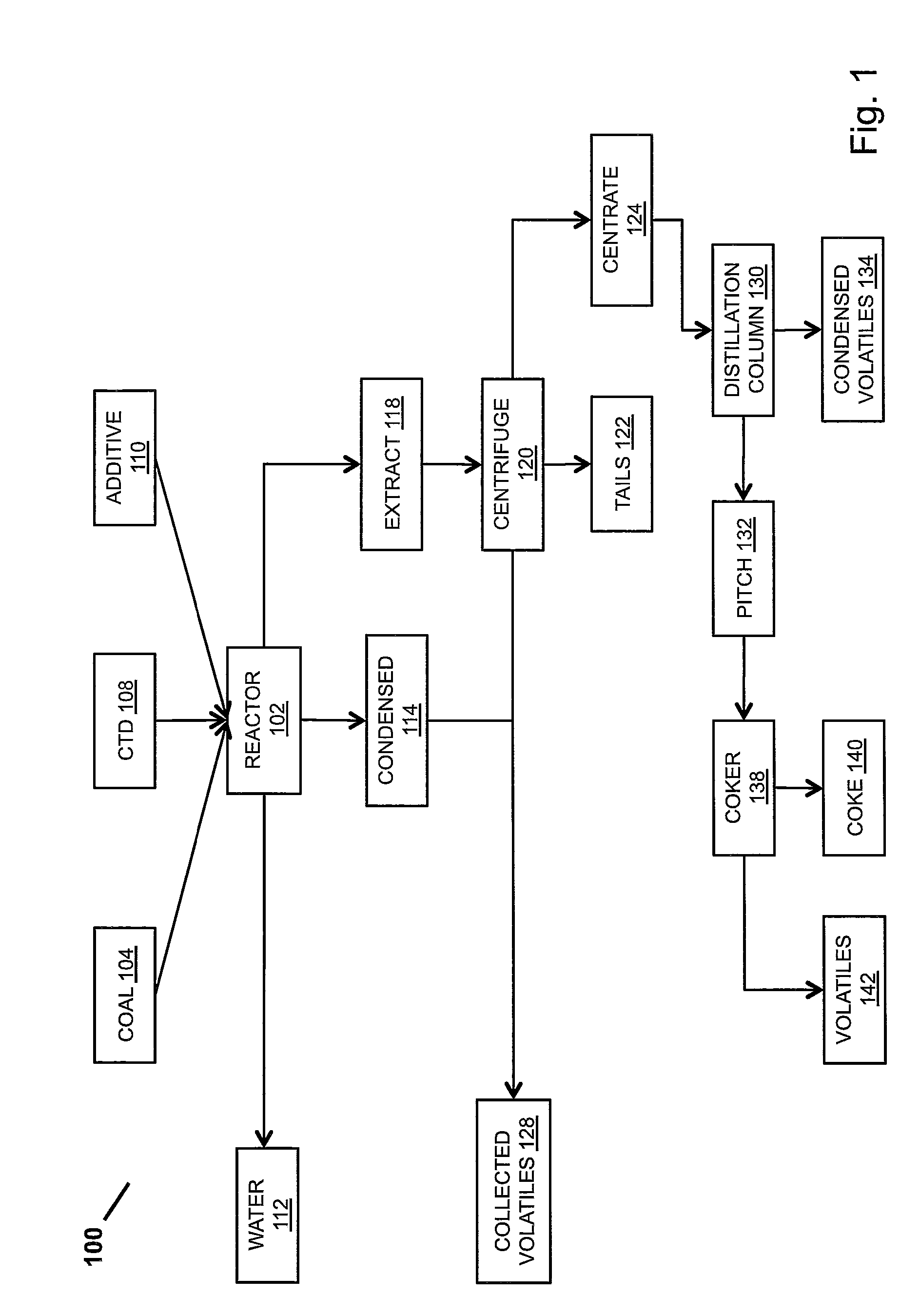

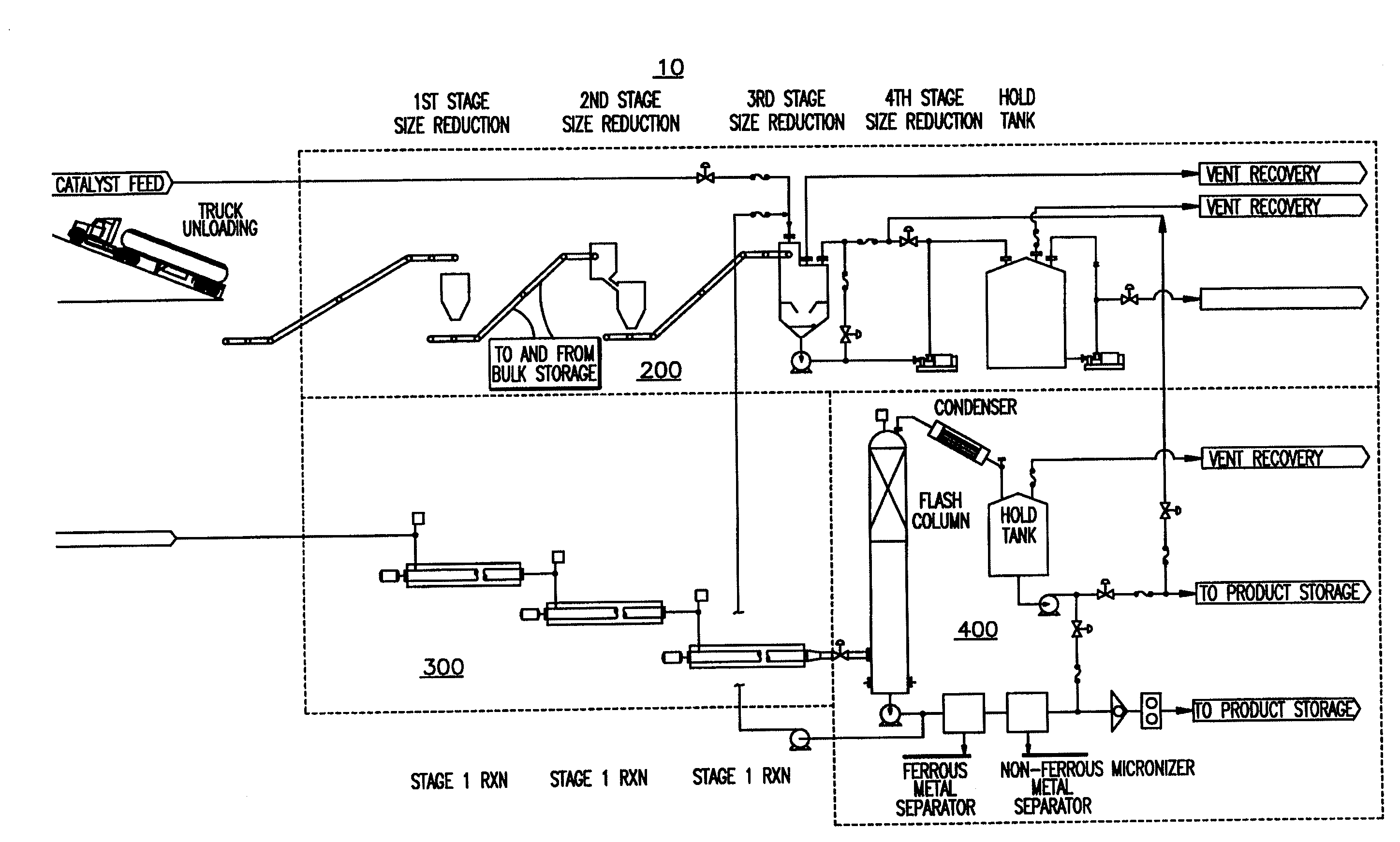

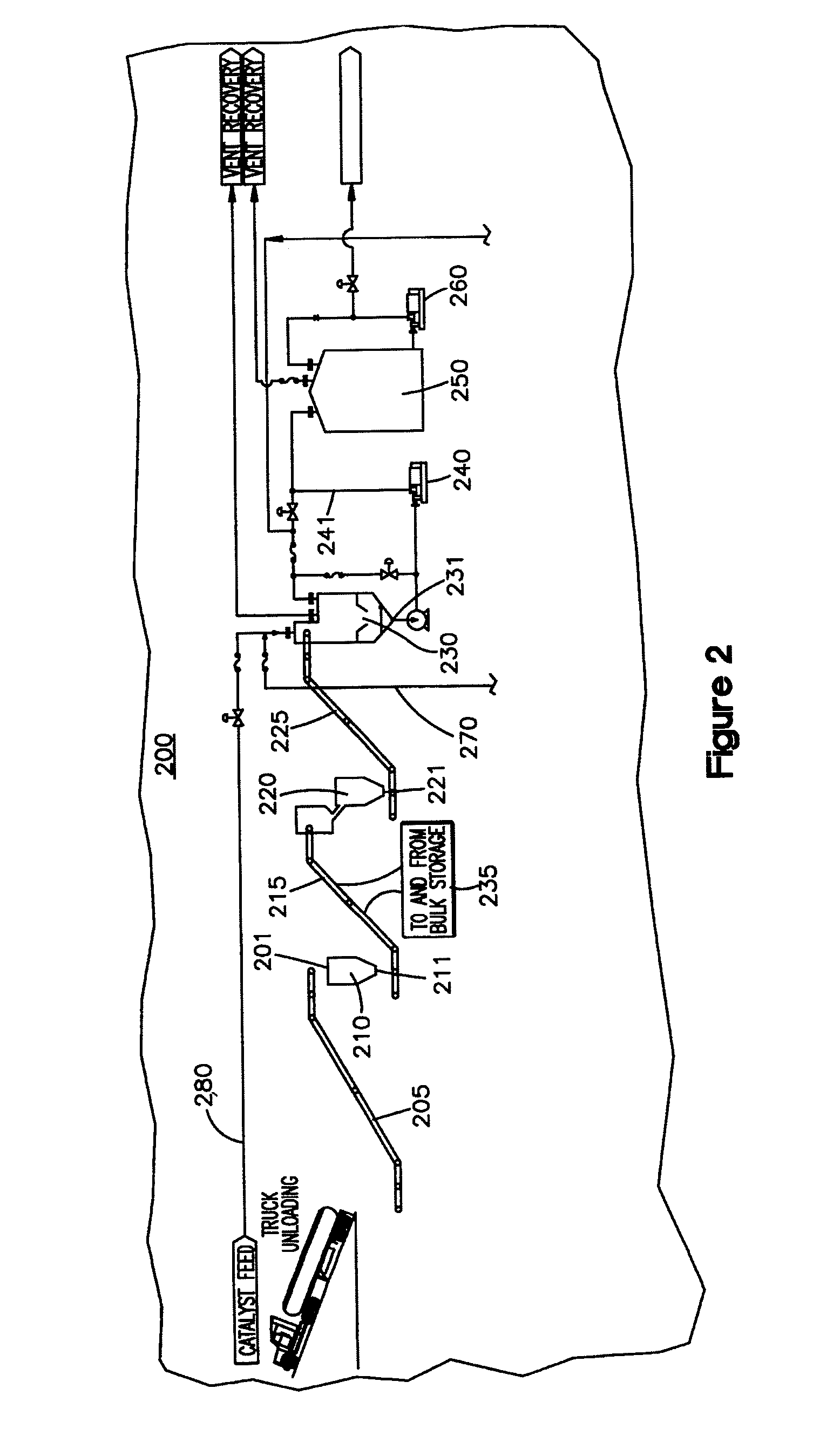

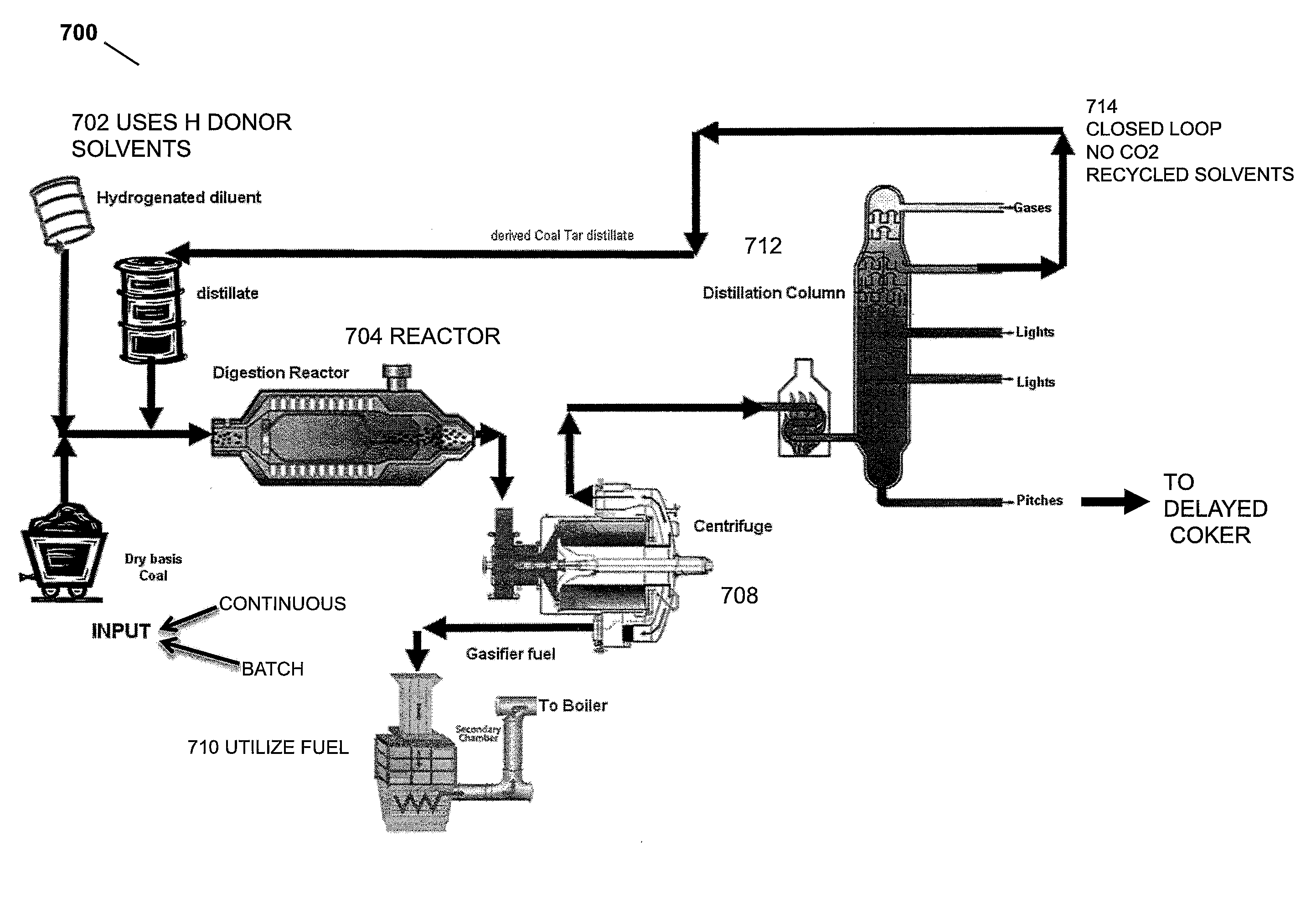

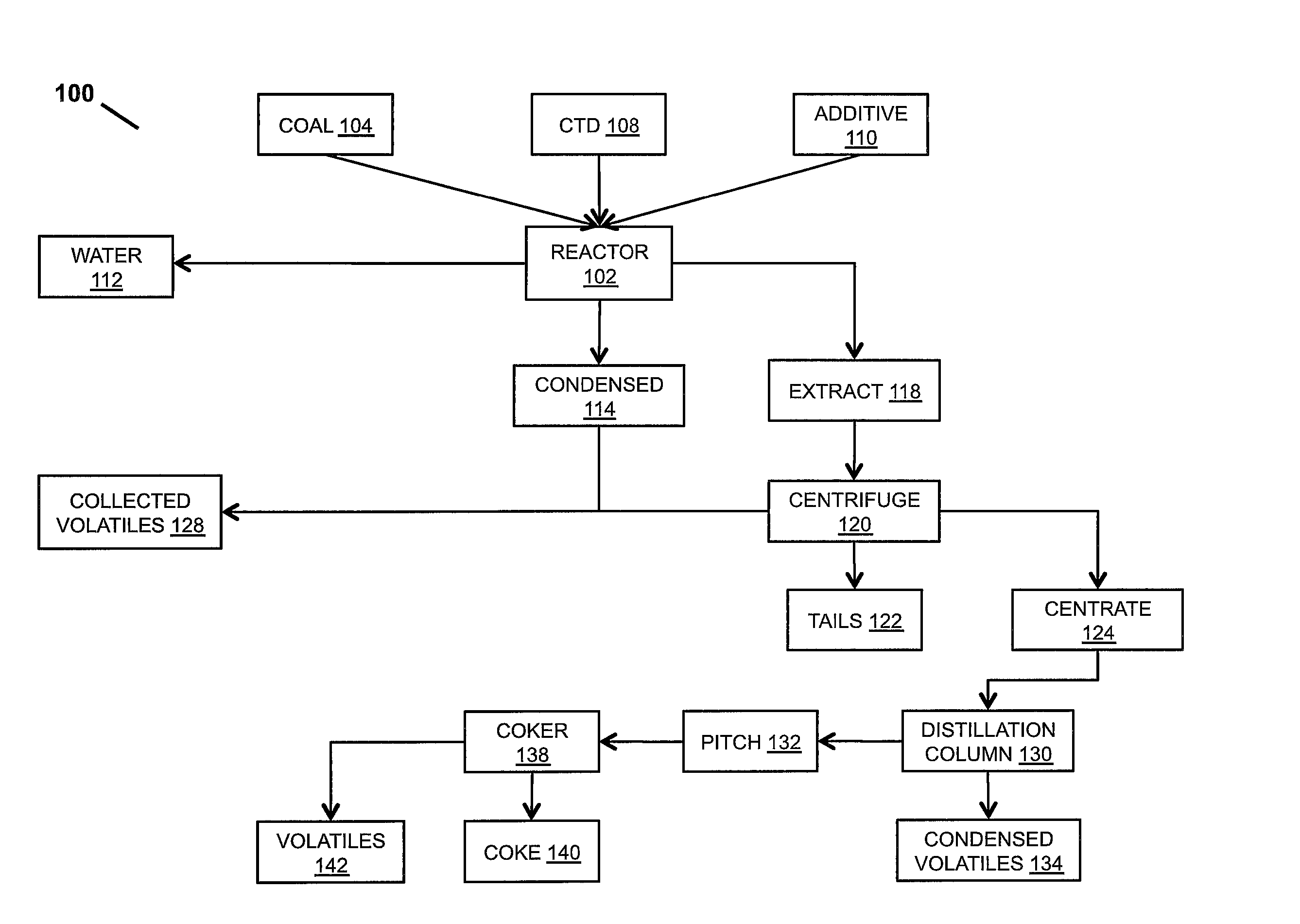

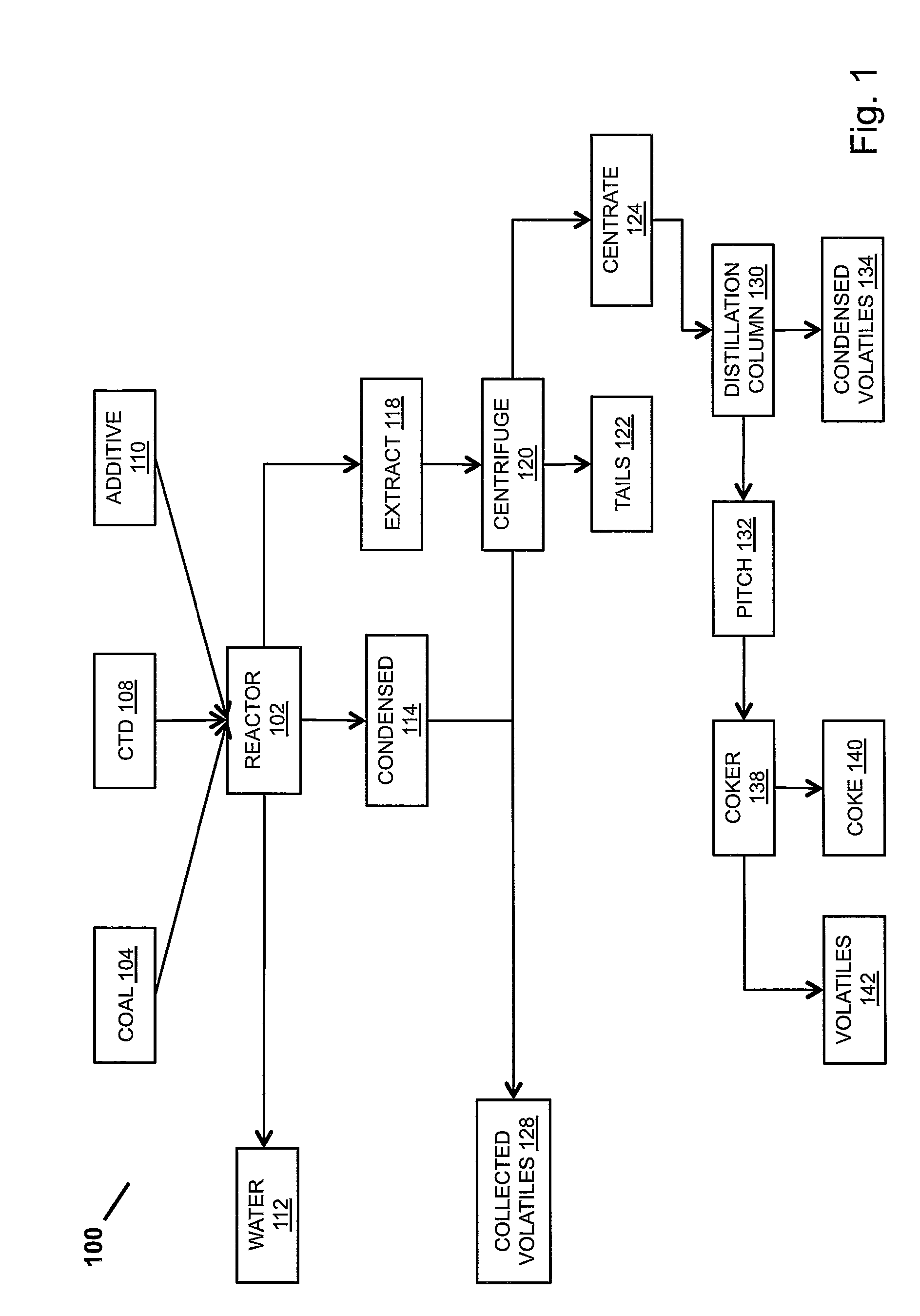

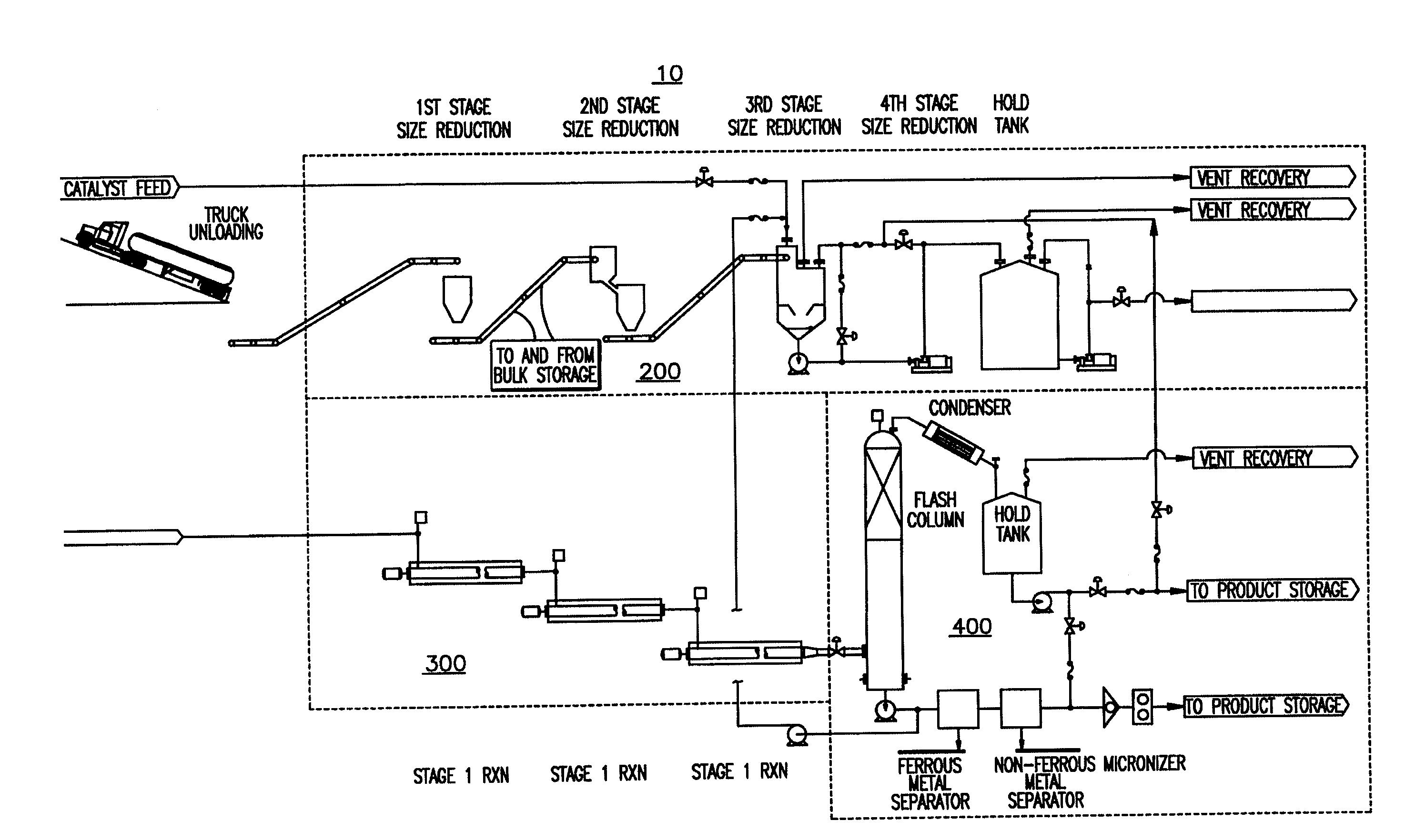

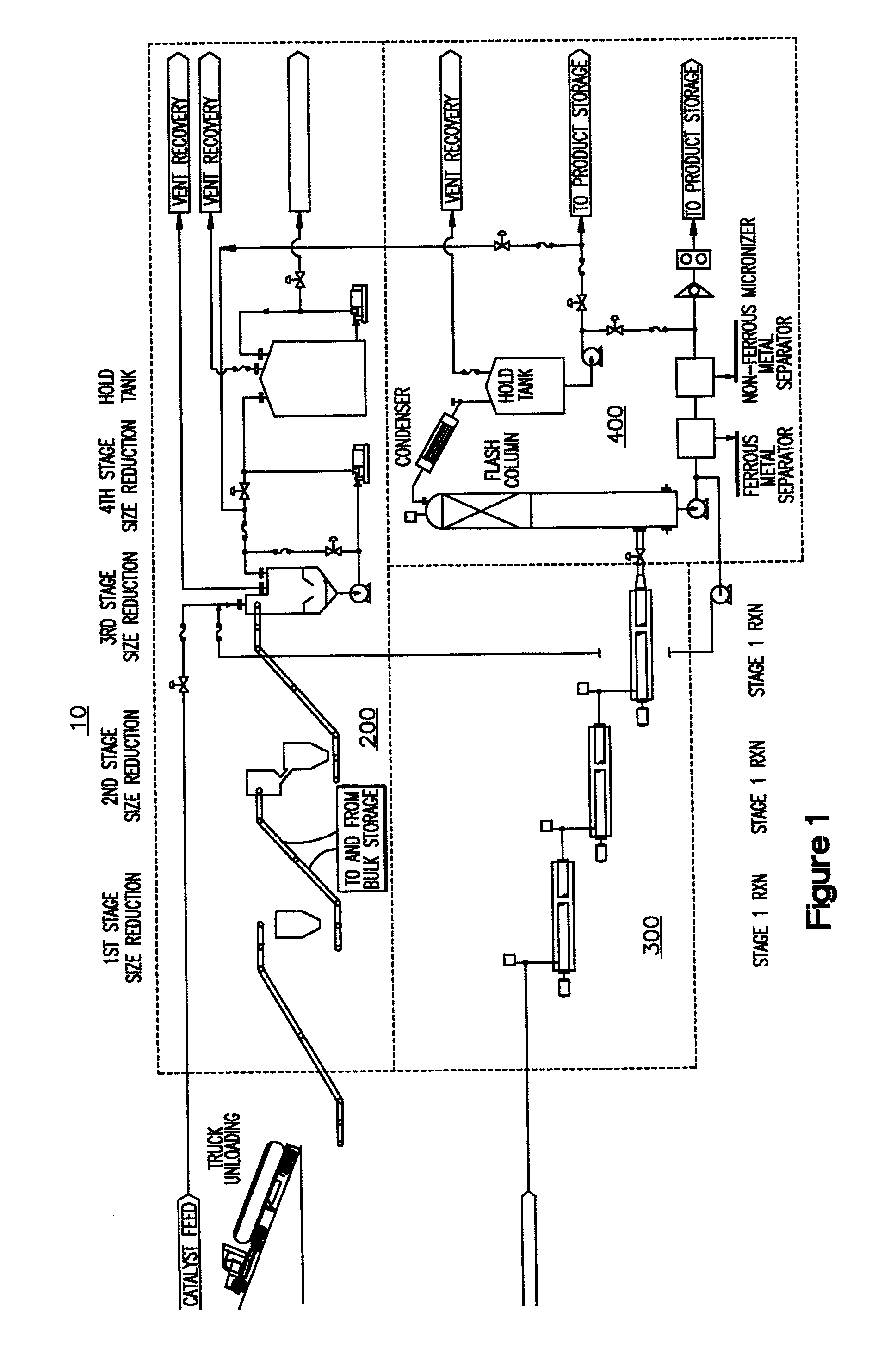

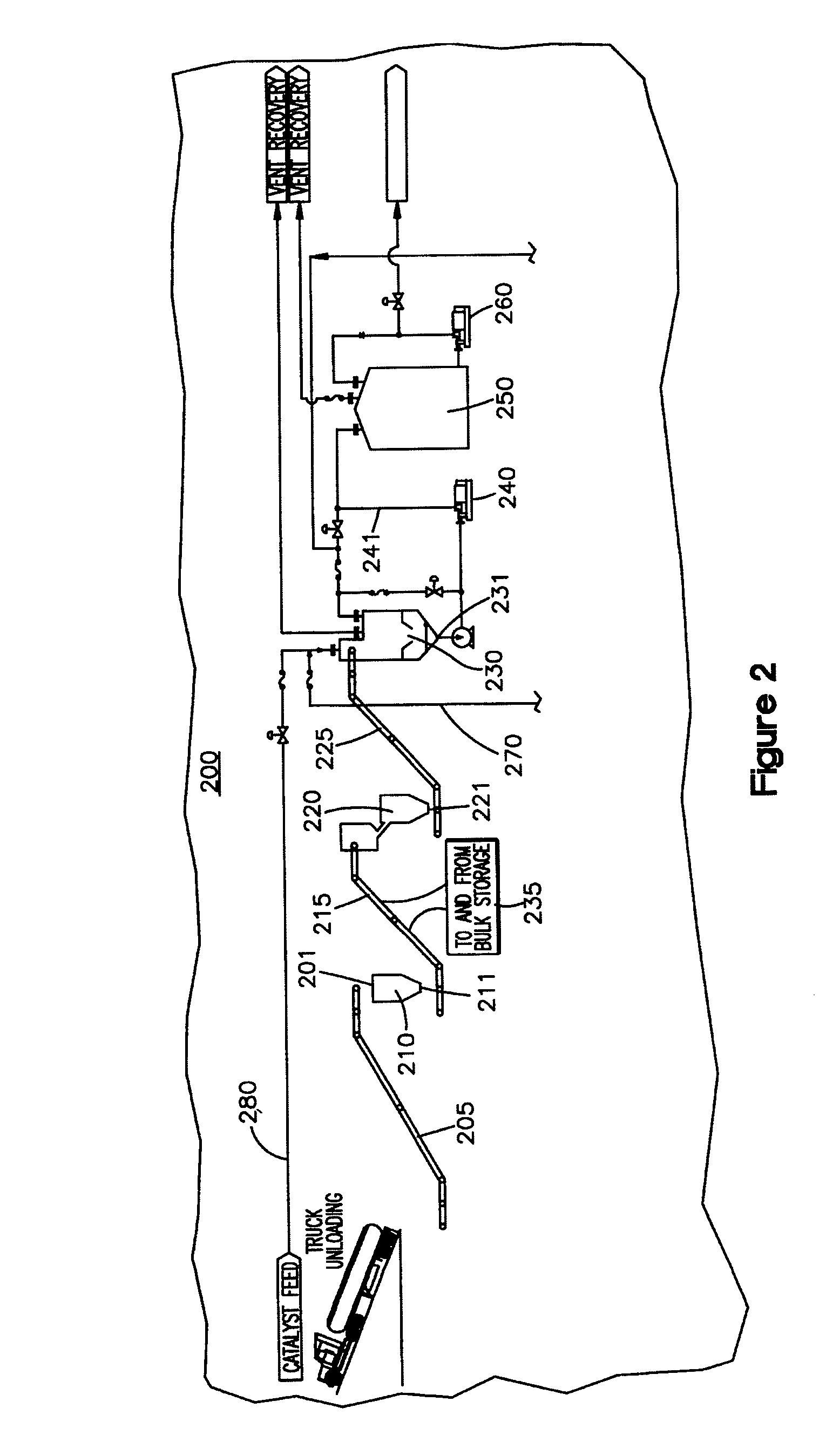

Modular Coal Liquefaction System

InactiveUS20120076703A1Low production costImprove solubilityOven incrustations prevention/removalLiquid hydrocarbon mixture productionTruck-trailerDownstream processing

The present disclosure provides methods and systems of a modular coal liquefaction system. A modular coal liquefaction system may include a reactor for exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, a heater that elevates the temperature of the slurry in the reactor to facilitate liquefying the coal and liberating a volatile matter, and a centrifuge that separates the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing, wherein the reactor, heater, and centrifuge are adapted to be modular. The system may further include a distillation column that distills the de-ashed coal extract to obtain a pitch. The system may further include a coker that cokes at least one of the de-ashed coal extract and the pitch to obtain a coke. The system may be adapted to be modularly disposed on a rail car. The system may be adapted to be modularly disposed on a semi-truck trailer.

Owner:WEST VIRGINIA UNIVERSITY

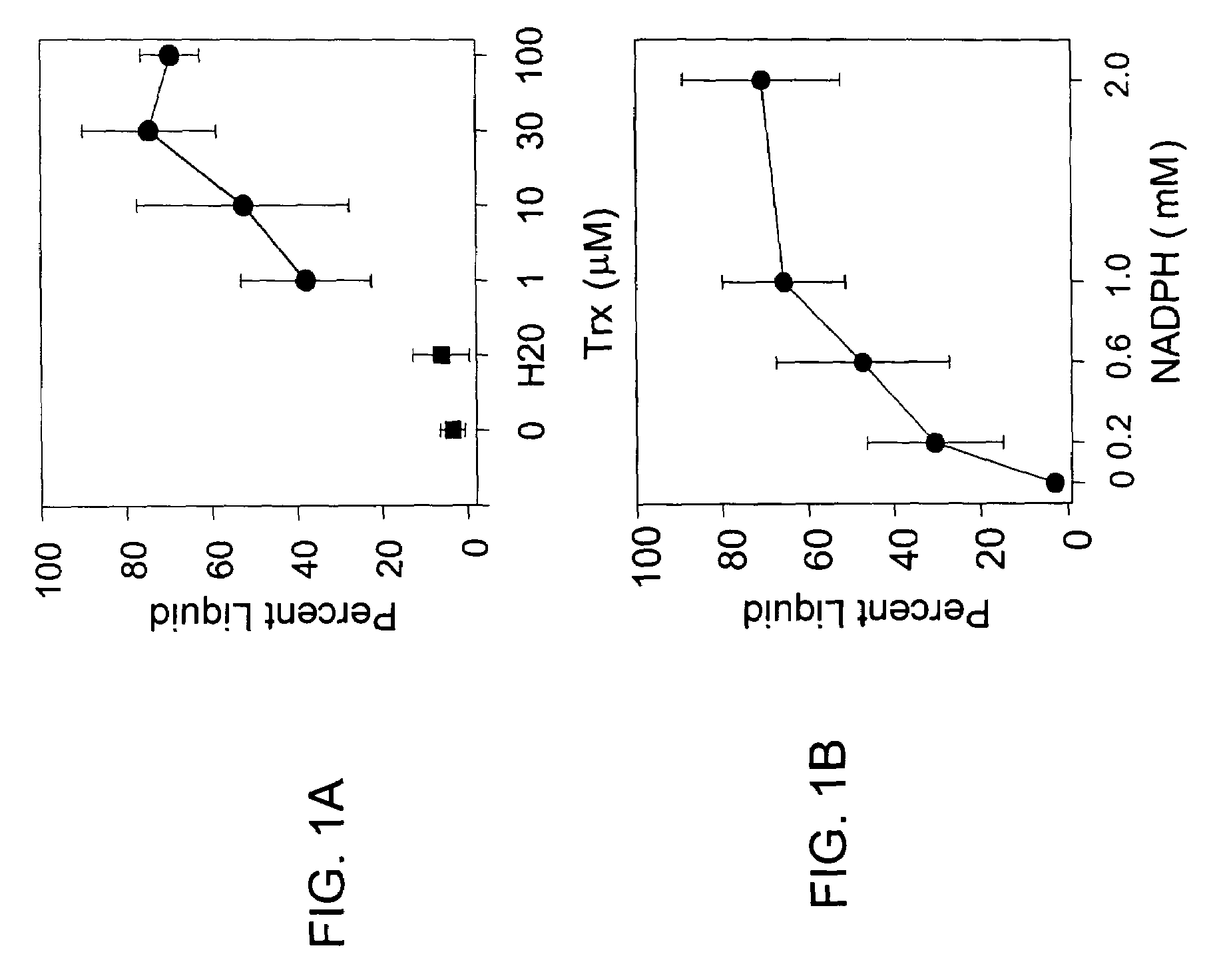

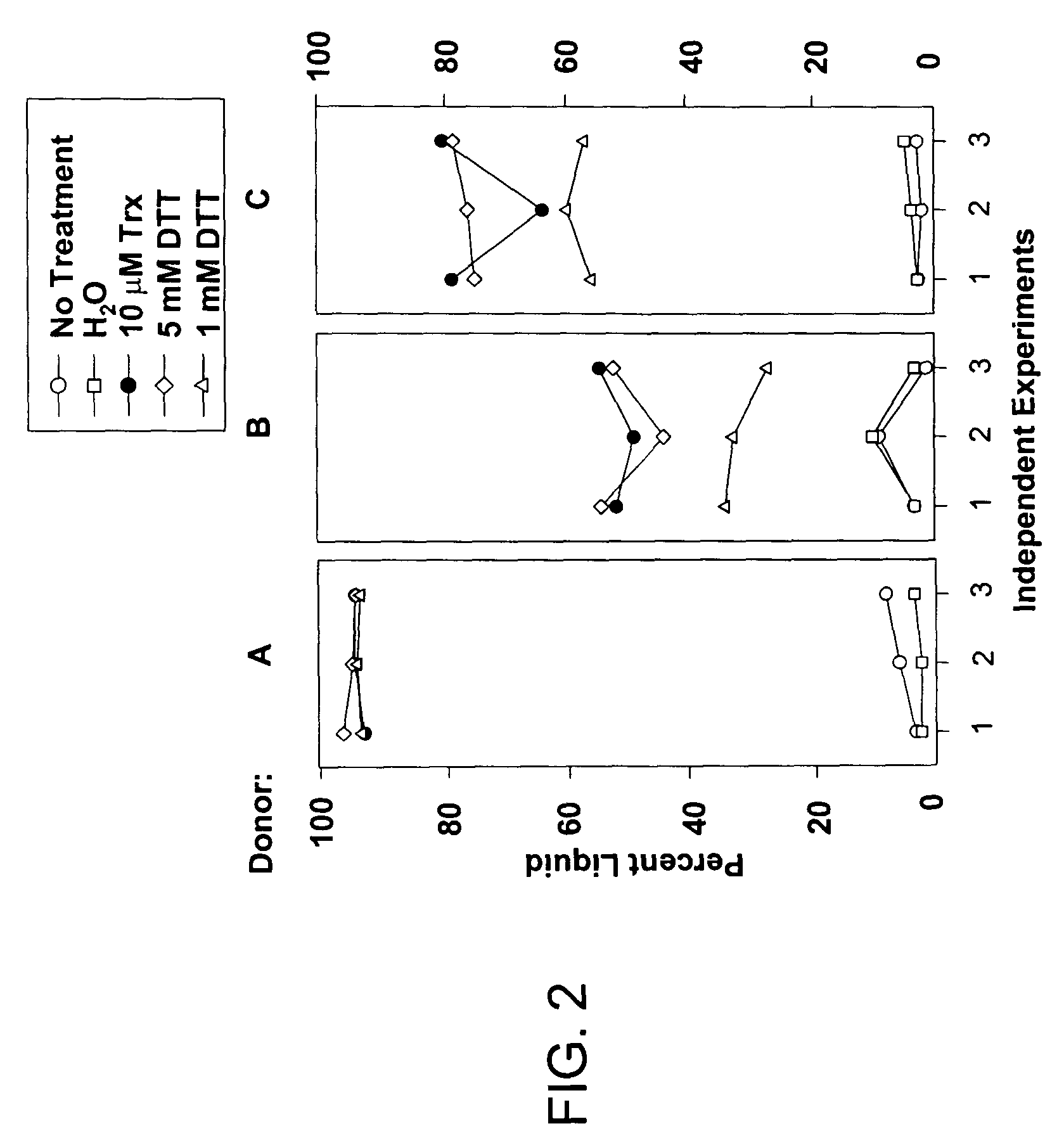

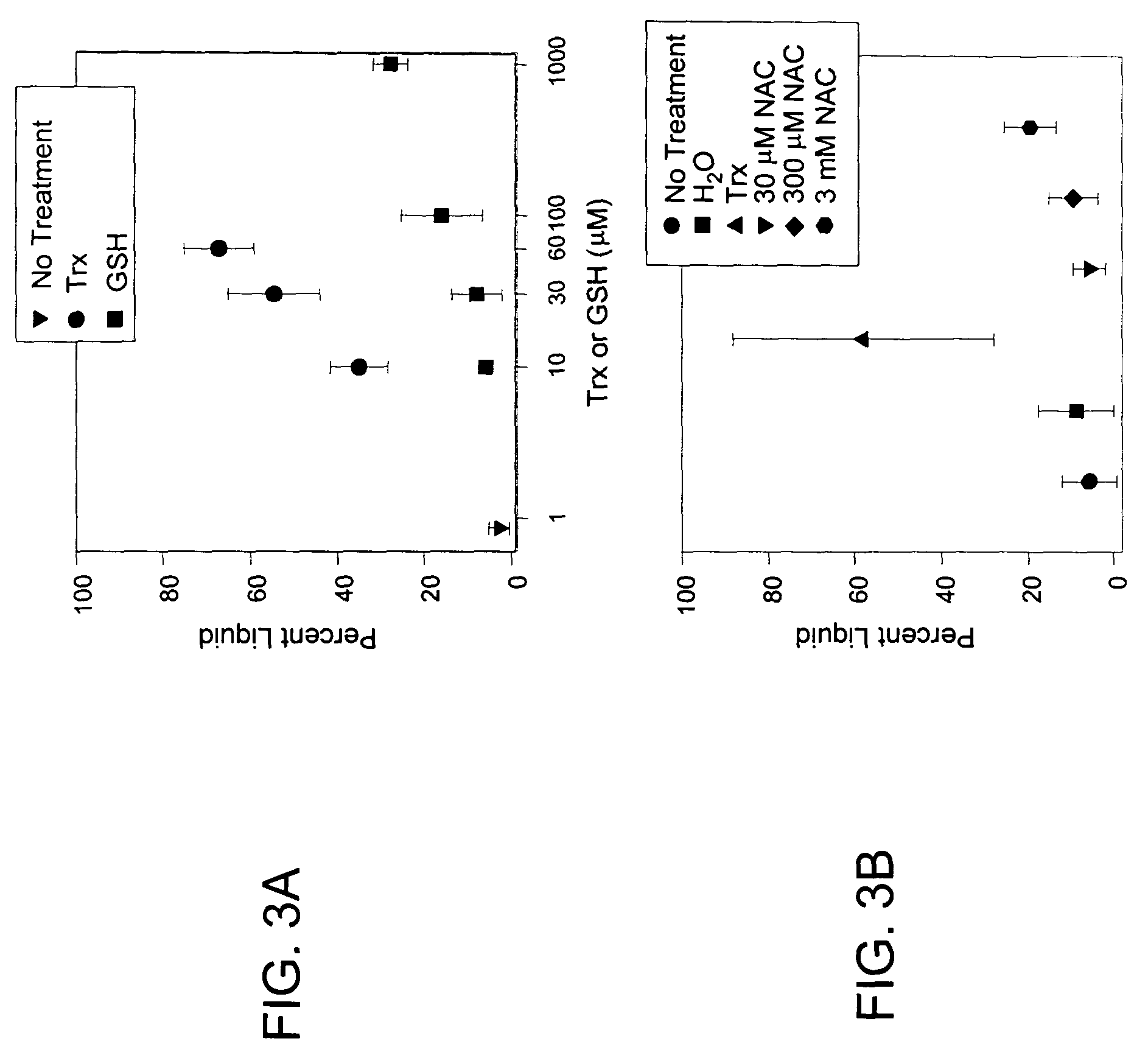

Product and process for liquefaction of mucus or sputum

ActiveUS7195766B2Conducive to liquefactionIncrease volumePowder deliveryOrganic active ingredientsReactive siteActive site

Owner:NAT JEWISH HEALTH

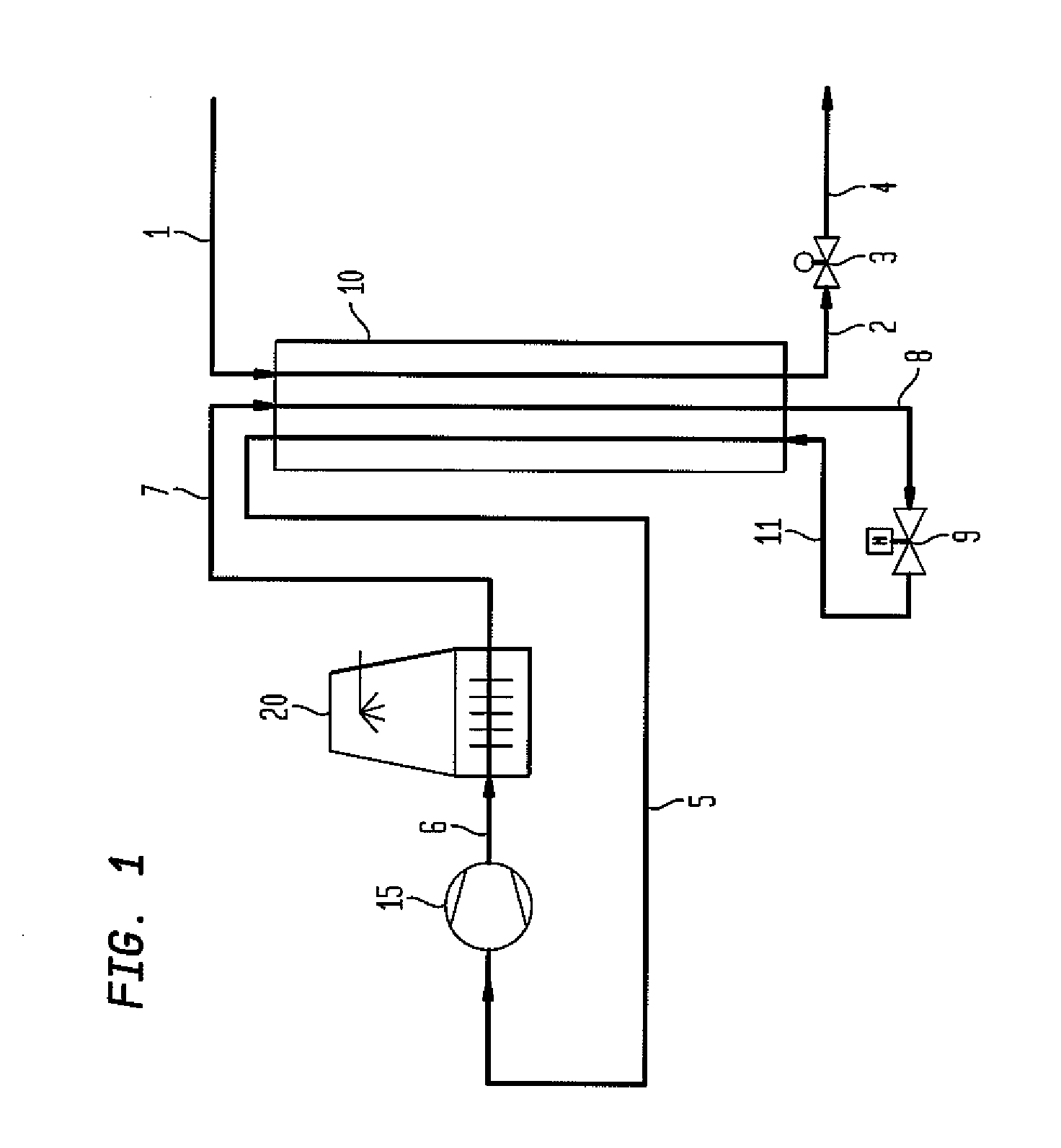

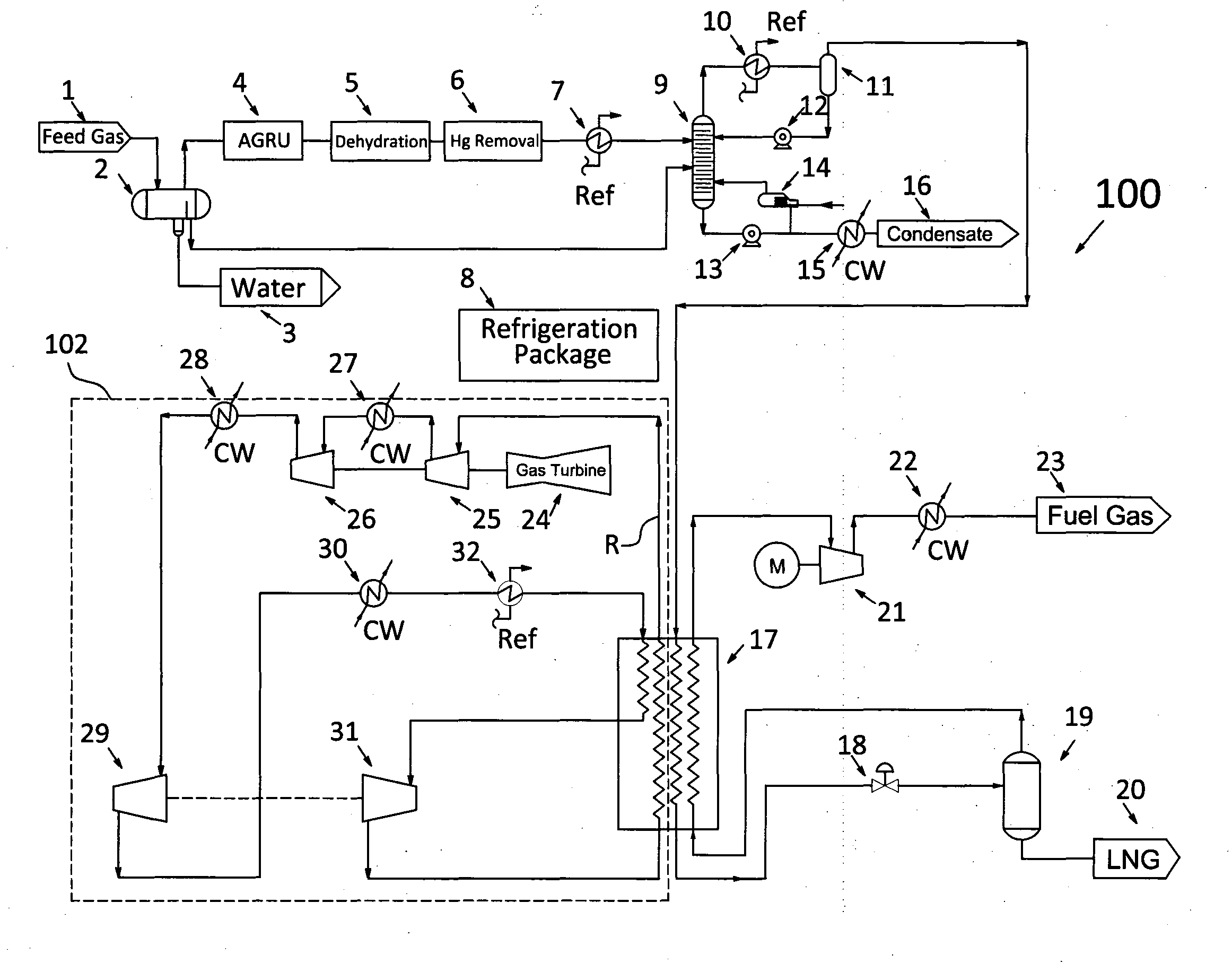

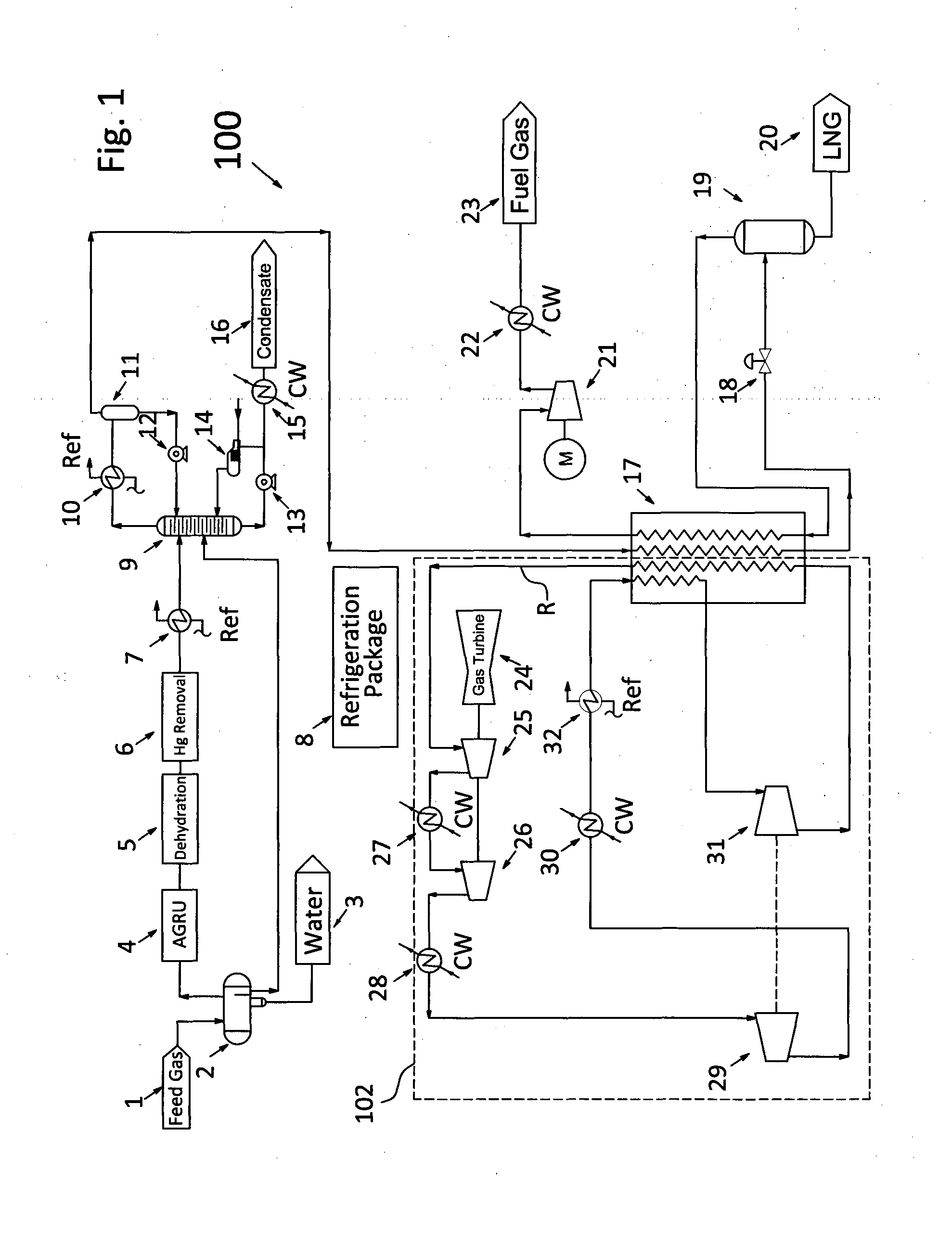

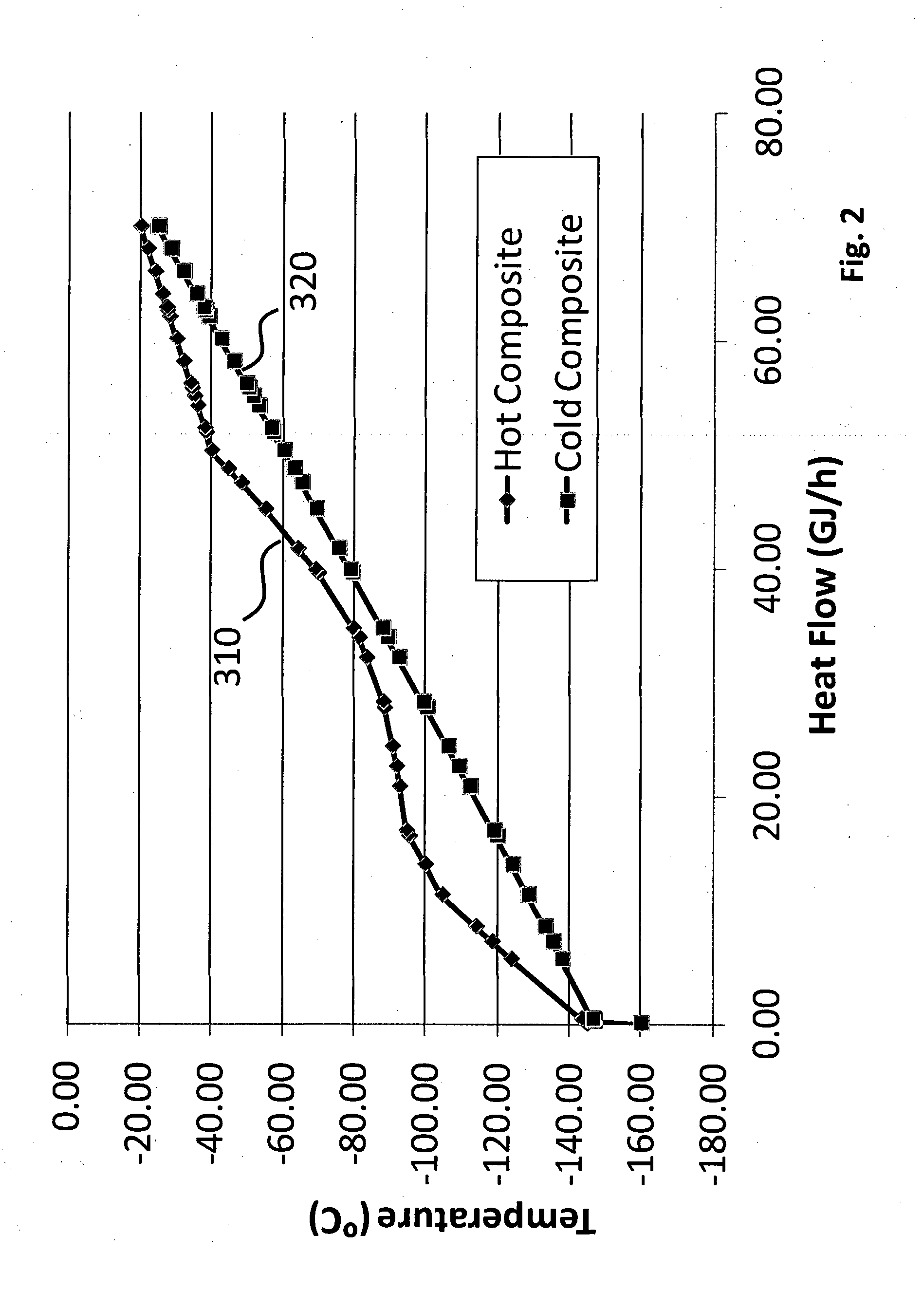

Closed cycle mixed refrigerant systems

InactiveUS20090071190A1Improve liquefaction efficiencyIncrease the number ofSolidificationLiquefactionEngineeringRefrigeration

The present invention provides for a process for providing cooling and controlling the refrigeration in a cooling loop used in the production of liquefied natural gas. A cooling loop in contact with a heat exchanger contains a refrigerant composition and by controlling the amount of a component in the refrigerant composition, the necessary level of cooling provided to the heat exchanger can be maintained.

Owner:LINDE NORTHA AMERICA

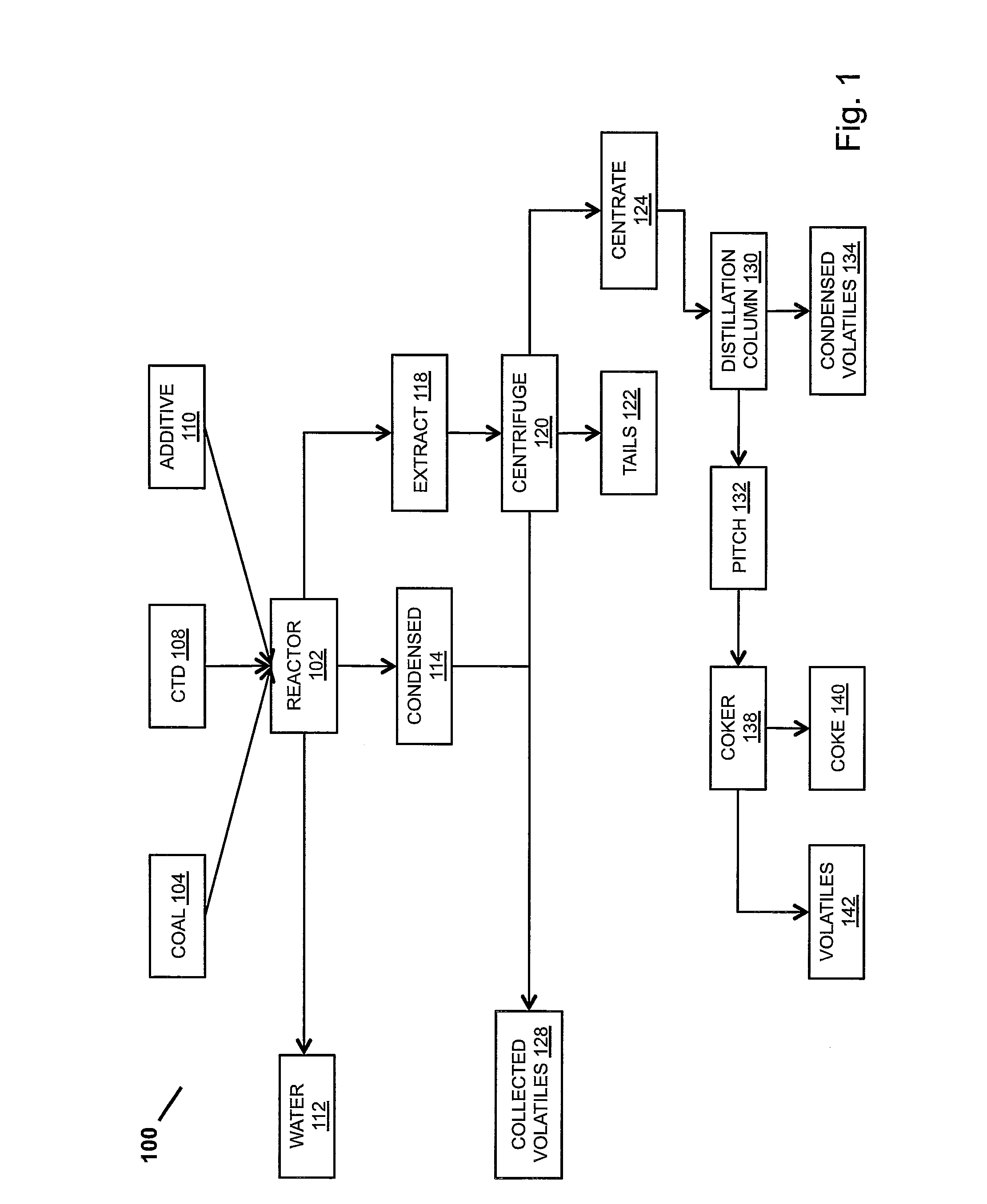

Hydrogenated Vegetable Oil in Coal Liquefaction

InactiveUS20120091042A1Low production costImprove solubilitySolid fuelsLiquid carbonaceous fuelsDownstream processingVegetable oil

The present disclosure provides methods and systems for coal liquefaction using a hydrogenated vegetable oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

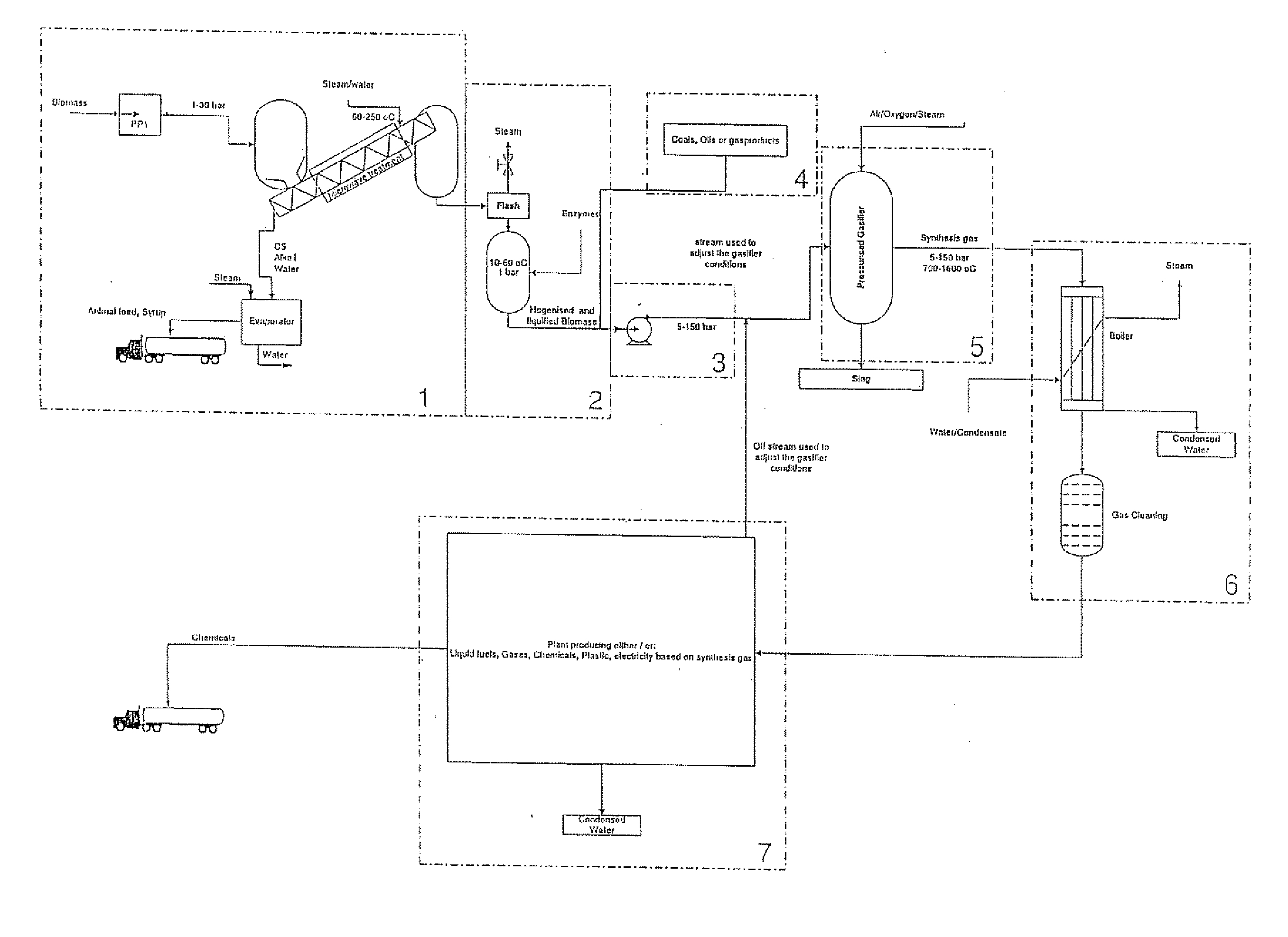

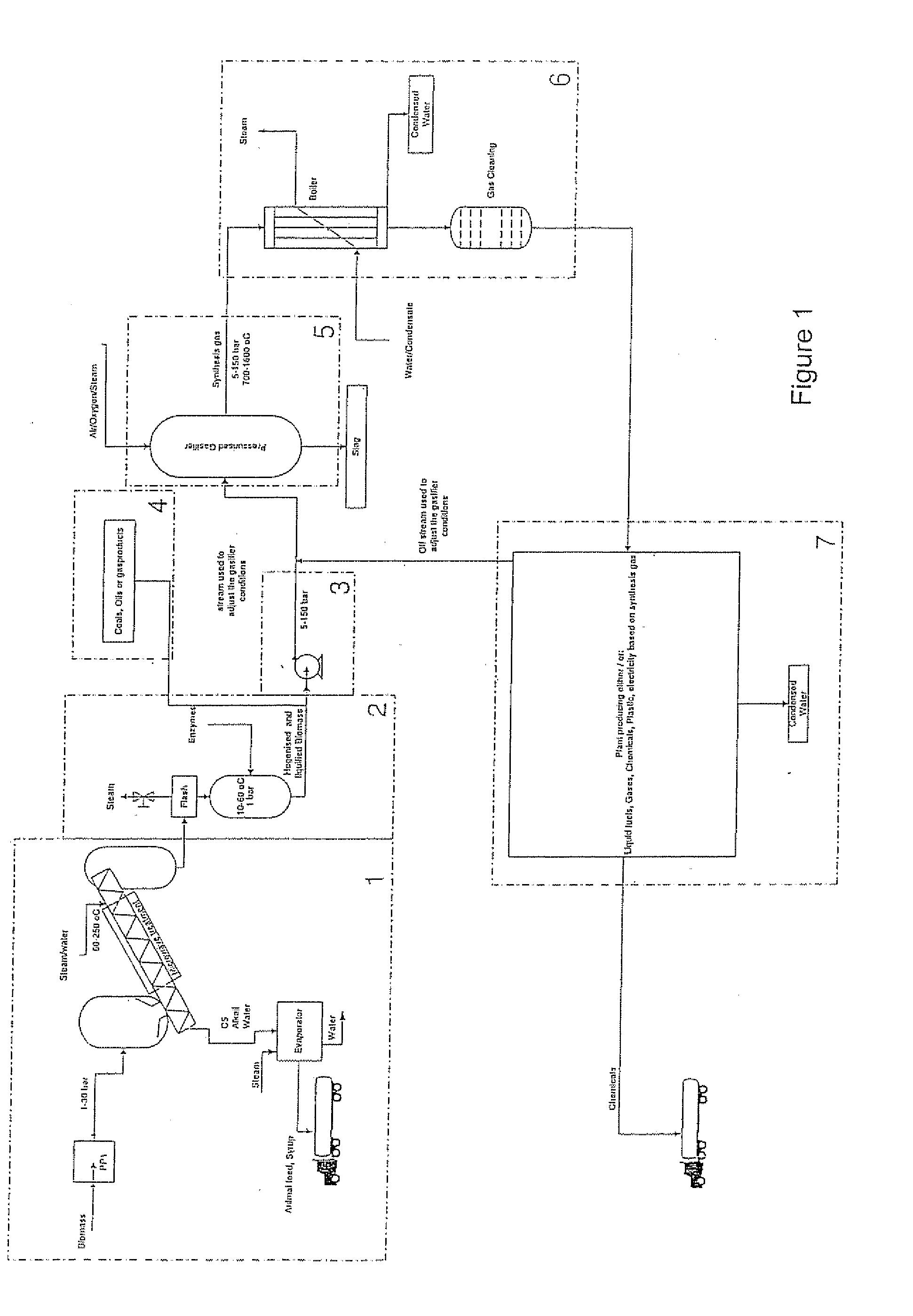

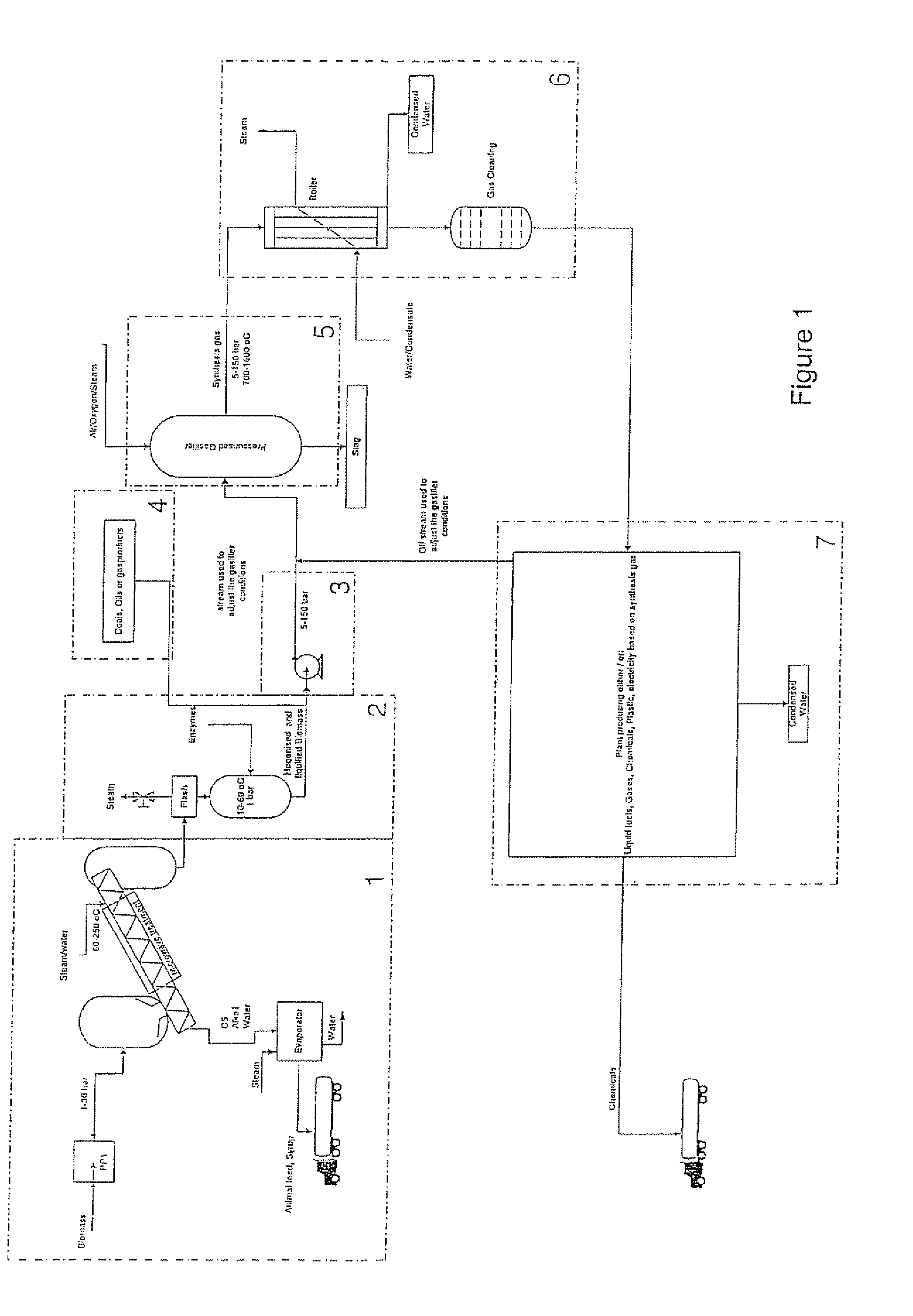

Method for Syngas-Production from Liquefied Biomass

The present invention relates to methods for syngas-production from biomass enabling the conversion of pre-treated biomasses having a high dry-matter content into electricity or oil-based products such as petrol, diesel, chemicals and plastics through the formation of syngas. The biomasses are converted into a biomass slurry having a suitable particle size and dry-matter content for optimal feeding and gasification in a pressurised gasifier.

Owner:DONG ENERGY POWER AS

Wood liquefier and method for preparing surfactant using liquidated wood

InactiveCN101396838AImprove liquefactionLow costTransportation and packagingWood treatment detailsEpoxyActive agent

The invention provides a preparation method for a wood liquefacient. A discarded PET bottle is crashed into powder, which is mixed with polylol and added with 0.01-0.5wt% of catalyst, and the mixture is stirred uniformly and heated to react, thus obtaining the wood liquefacient. The invention also relates to a method for preparing a surfactant by using the liquefacient to liquefying wood, which includes the steps: 0.5-10wt% of inorganic acid catalyst and glycerin are added into the mixture of the liquefacient and the wood meal of broad leaved forests or coniferous forests, which reacts by heating to obtain a coarse liquefied wood product; the product is cooled to room temperature, diluted in absolute ethyl alcohol or acetone and then filtered in vacuum to form the filtrate, which is subsequently decompressed and distilled so as to obtain refined liquefied wood; the sodium hydroxide solution of the fully dissolved liquefied wood is added with propylene oxide according to the mass morality of total hydroxide radical to propylene oxide being 1:3-10 for reaction, and then epoxy ethane is entered for end capping, after that, the pH value is adjusted to 7, then the liquefied wood polyethenoxy ether of the surfactant is obtained as the final product.

Owner:JIANGSU QIANGLIN BIO ENERGY

Process for liquefying natural gas and producing hydrocarbons

InactiveUS7451618B2Improve liquefaction efficiencySave energyHydrogenSolidificationLiquid productCold side

A process for the preparation of liquid hydrocarbons from a light hydrocarbonaceous feedstock in combination with a process for liquefying natural gas, which liquefaction process involves the steps of(a) passing the natural gas at liquefaction pressure through the product side of a main heat exchanger;(b) introducing cooled liquefied refrigerant at refrigerant pressure in the cold side of the main heat exchanger, allowing the cooled refrigerant to evaporate at the refrigerant pressure in the cold side of the main heat exchanger to obtain vaporous refrigerant at refrigerant pressure, and removing vaporous refrigerant from the cold side of the main heat exchanger;(c) removing the liquefied gas at liquefaction pressure from the product side of the main heat exchanger;(d) allowing the cooled liquefied gas to expand to a lower pressure to obtain expanded fluid;(e) supplying the expanded fluid to a separator vessel;(f) withdrawing from the bottom of the separator vessel a liquid product stream;(g) withdrawing from the top of the separator vessel a gaseous stream;(h) introducing the gaseous stream obtained in step (g) as feed and / or fuel in the process for the preparation of liquid hydrocarbons,which process for the preparation of hydrocarbons involves converting a light hydrocarbonaceous feedstock into synthesis gas, followed by catalytic conversion of the synthesis gas into liquid hydrocarbons.

Owner:SHELL OIL CO

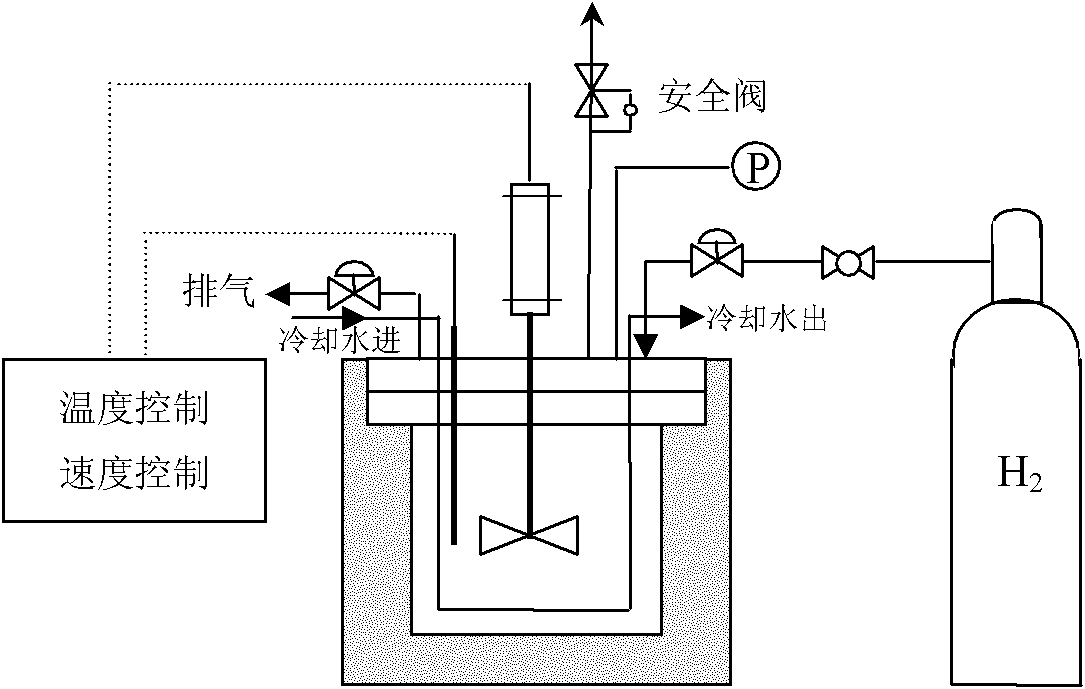

Method for preparing biological oil from algae biomass through direct catalytic liquefaction method

InactiveCN102002381AConducive to liquefactionIncrease liquefaction rateLiquid hydrocarbon mixture productionHydrogen atmosphereOxygen

The invention relates to a method for preparing biological oil from algae biomass through a direct catalytic liquefaction method, which is a hydrothermal method with algae biomass as a raw material. The method comprises pretreatment, catalytic liquefaction and separation, wherein the pretreatment comprises the steps of: soaking dried and crushed algae in 0.05-0.15mol / L alkali liquor or acid liquor for not less than 20h, pouring the soaking liquid and a modified natural mordenite catalyst into a pressure kettle, catalytically liquefying for not less than half an hour under the condition of agitation in an oxygen free and hydrogen atmosphere at 200-400 DEG C under 3-16MPa, cooling, reducing the temperature, relieving the pressure, separating the solid and the liquid, and dehydrating the liquid under reduced pressure to obtain biological oil. The algae liquefaction rate of the invention is high and reaches more than 82%; the grade of the oil product is high, and the heat value can reachmore than 30 MJ / kg; a water phase system is adopted, so that the invention has the advantages of environmental protection, low preparation cost, relatively mild reaction conditions and good market application prospects, saves energy and is simple and convenient for operation and easy for realization of large-scale production.

Owner:HEFEI UNIV OF TECH

System for the production of synthetic fuels

InactiveUS20080299021A1Assist in downsizingReduce charringLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionParticulatesMetal particle

A system and method for producing synthetic fuels are disclosed in which a slurry comprised of a particulate solid portion dispersed in a carrier liquid portion is provided. The solid portion comprises (i) a feedstock of carbon-containing polymeric materials that are substantially free of each of halogen, sulfur and nitrogen atoms, and contain about 5 to about 25 percent by weight water, and (ii) a catalytic amount of metal particles. The carrier liquid portion is a hydrocarbon / oxyhydrocarbon composition. The feedstock constitutes about 10 to about 60 weight percent of the slurry. The slurry is heated anaerobically to provide an elevated temperature of about 250° to about 455° C. and a pressure of about 20 to about 50 atmospheres that are maintained for a time period sufficient to provide a combustible liquid fuel at least 80 percent of which contains about 6 to about 21 carbon atoms per molecule.

Owner:CELLO ENERGY

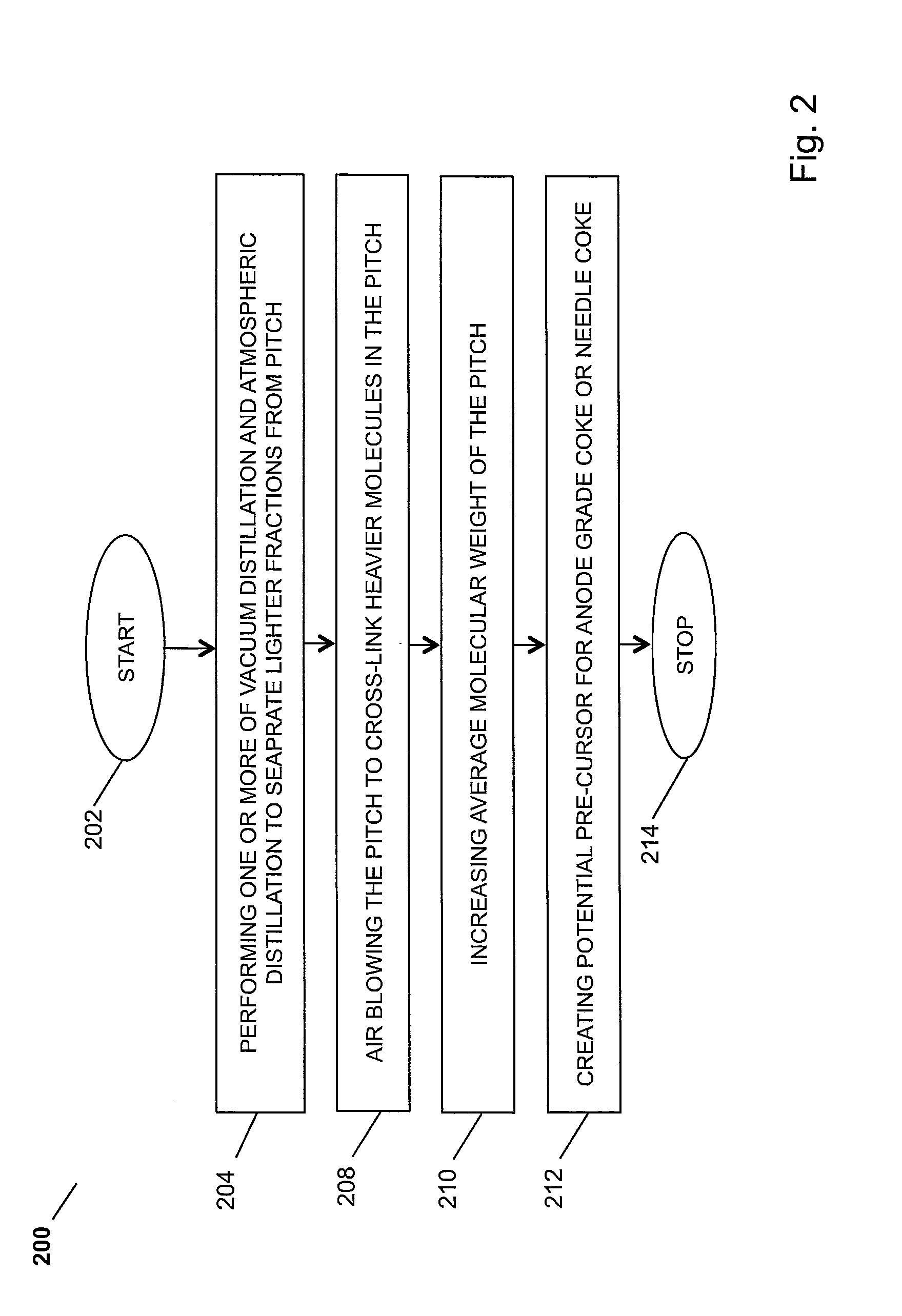

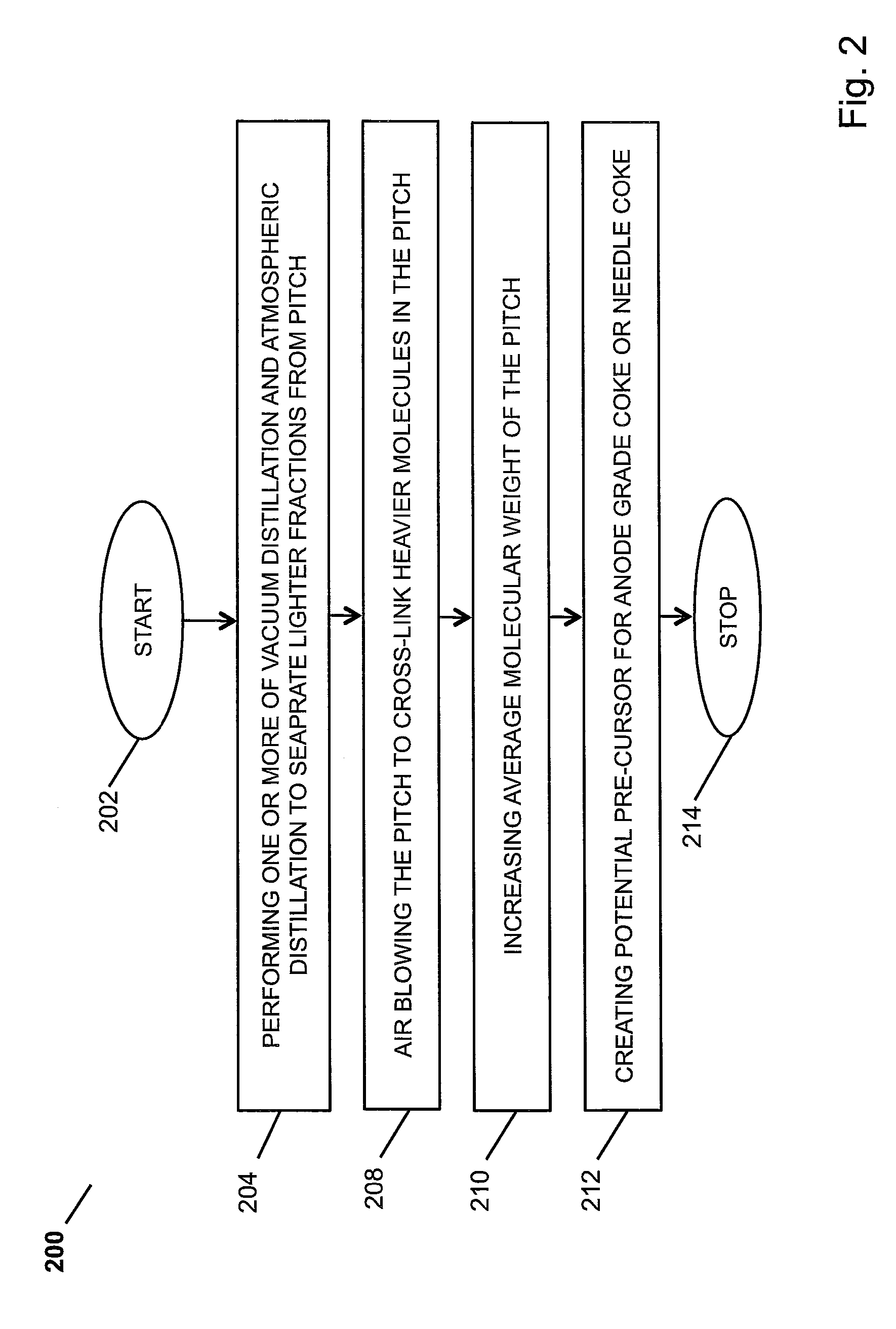

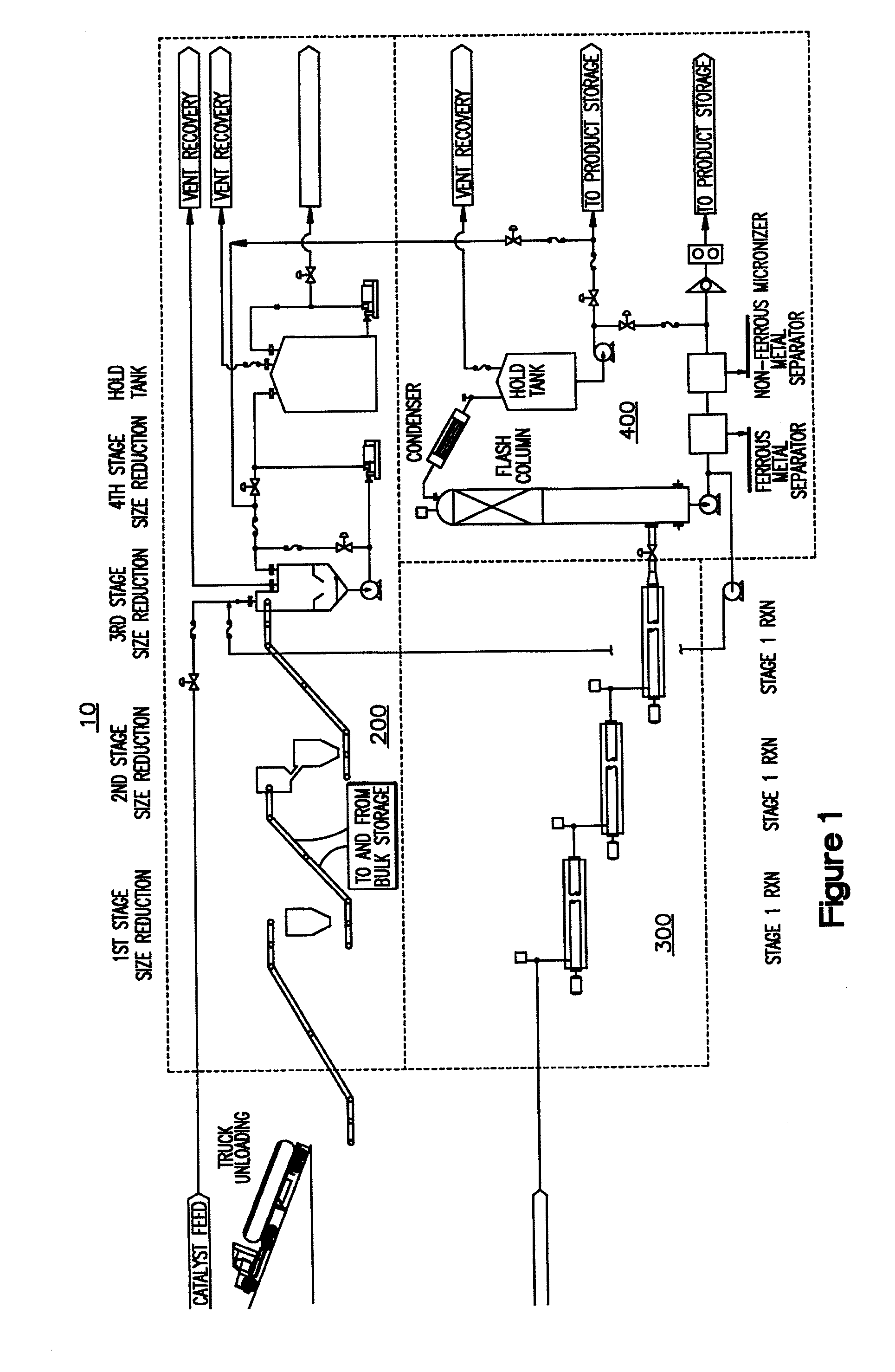

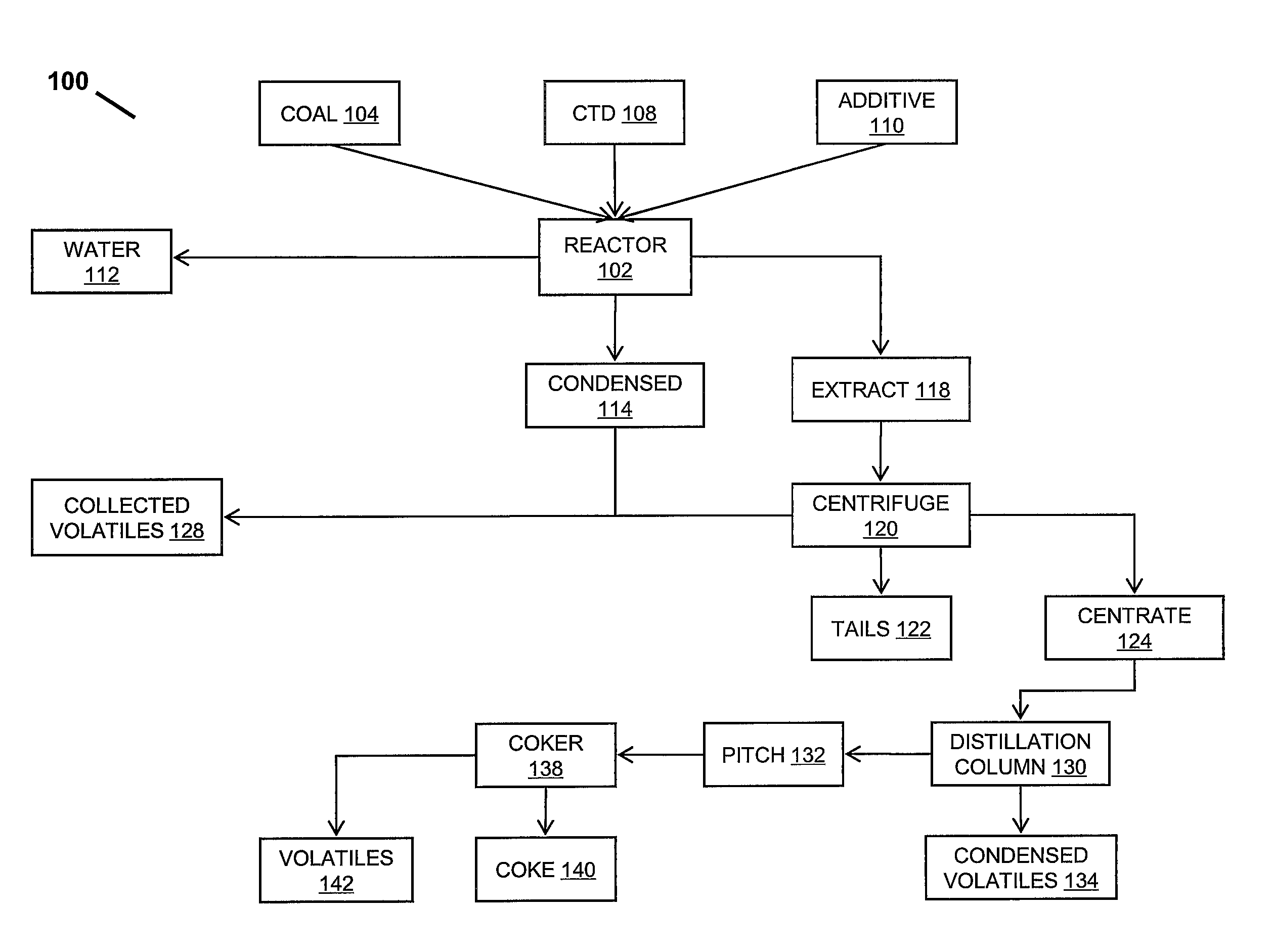

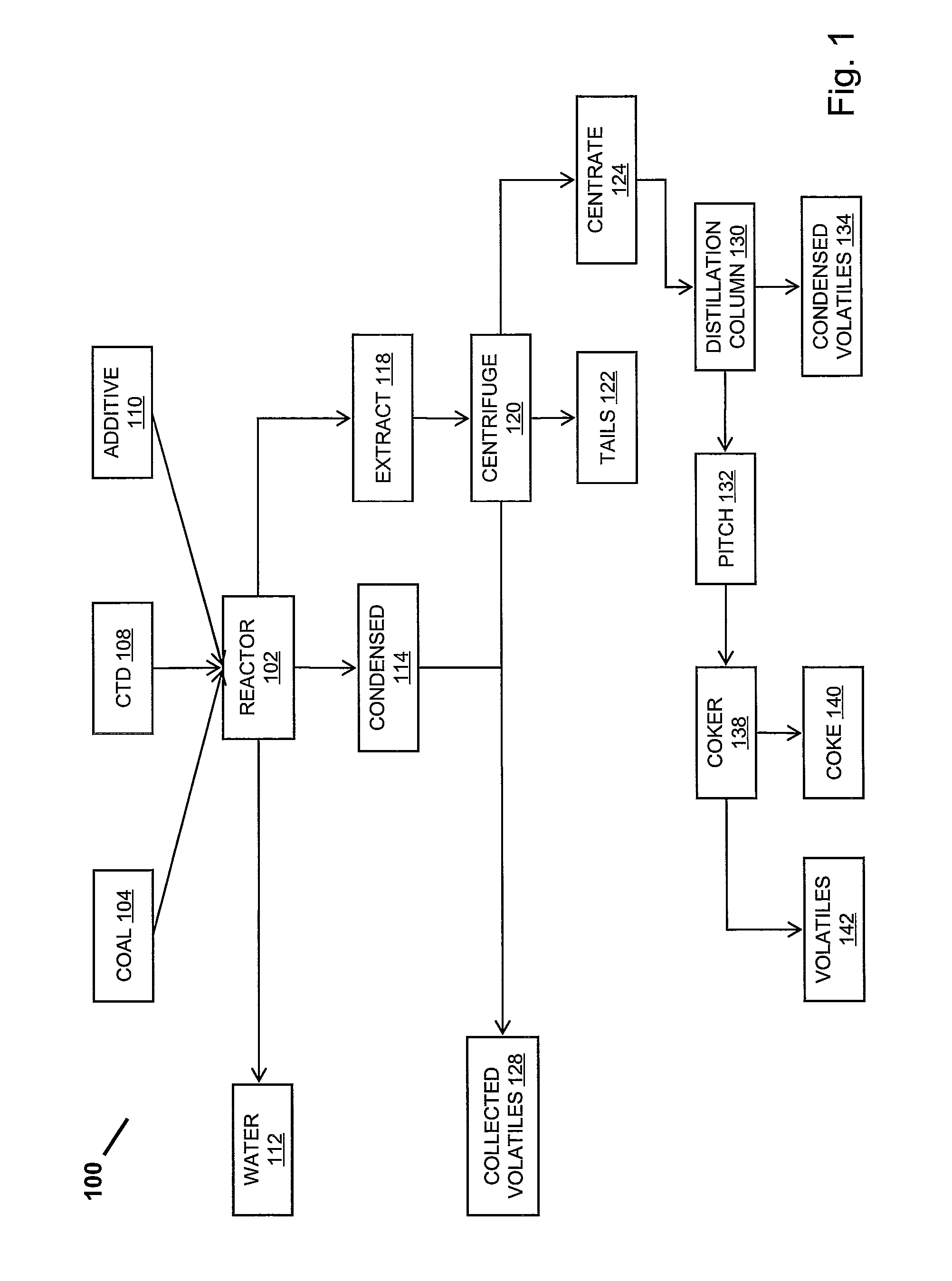

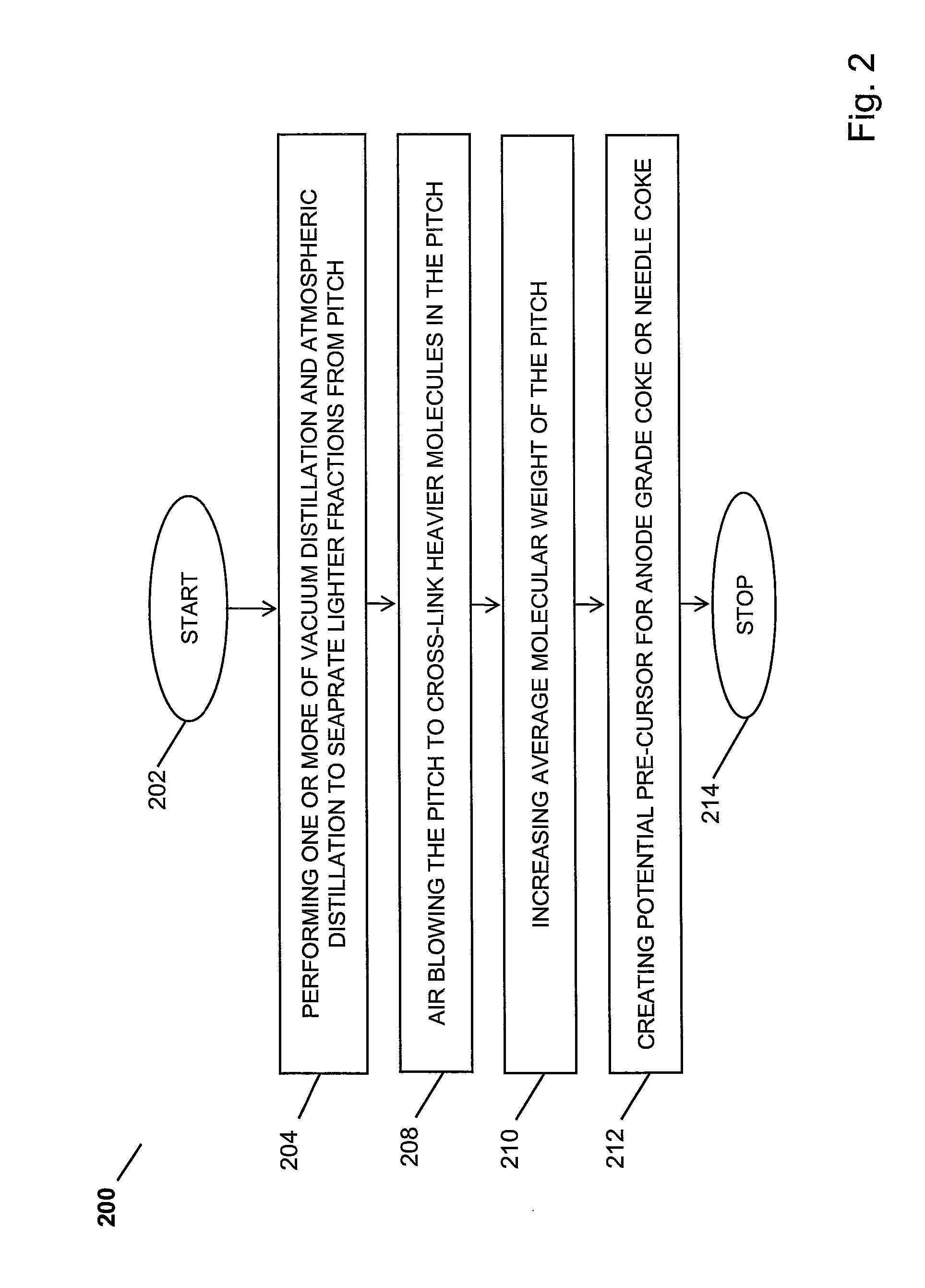

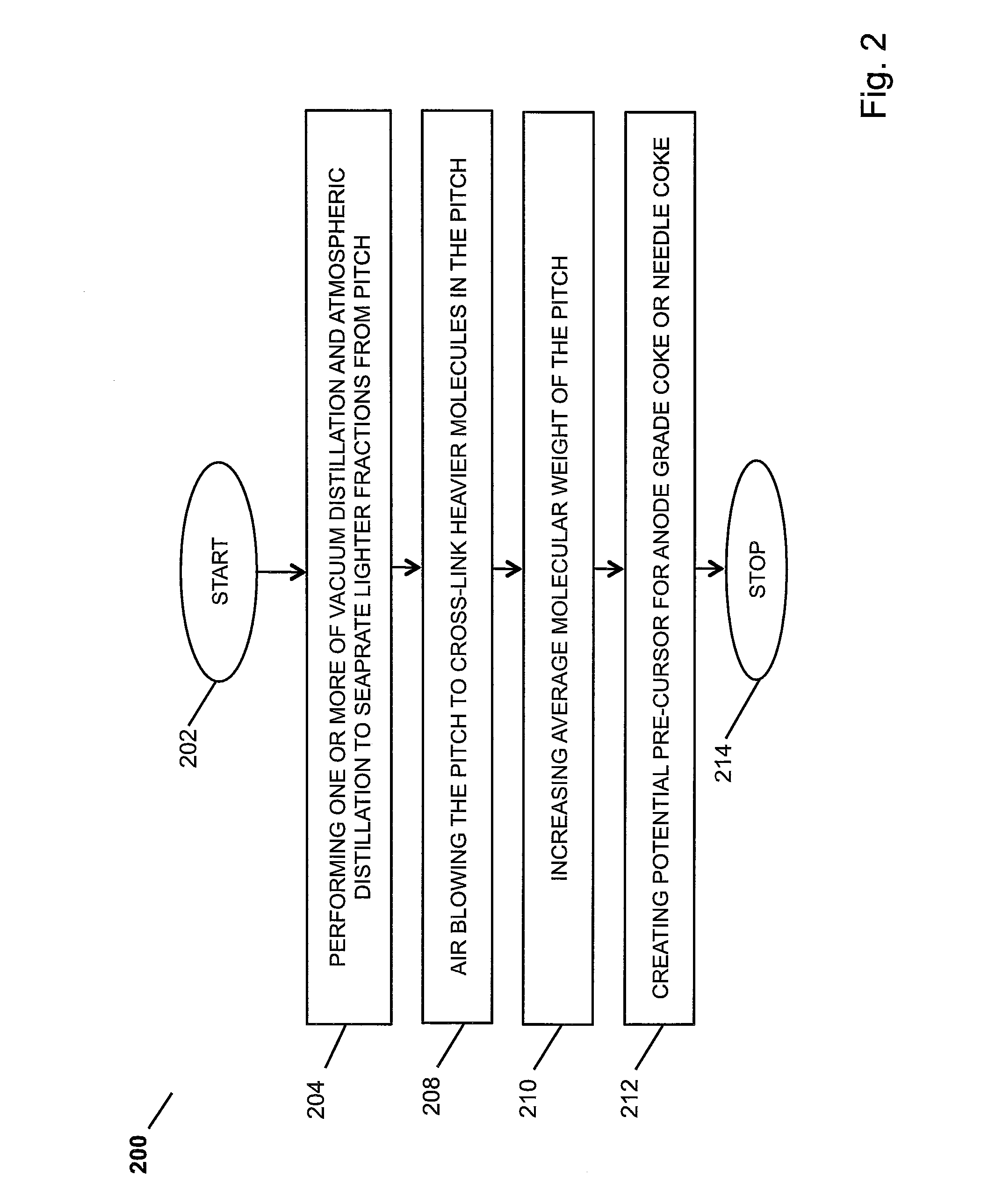

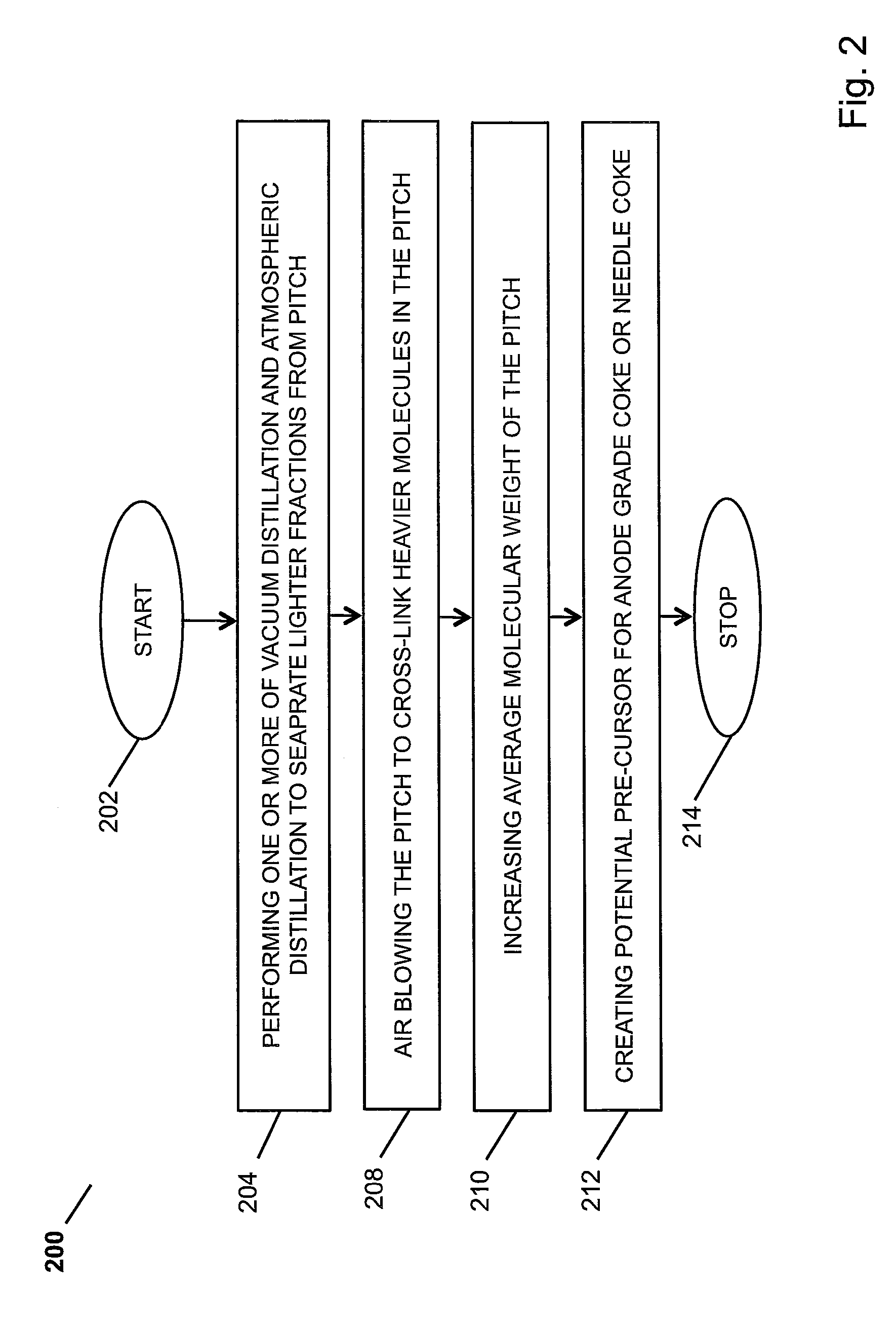

Coal Liquefaction System

ActiveUS20120082593A1Low production costImprove solubilityWorking-up pitch/asphalt/bitumen by distillationSolid fuelsVegetable oilDownstream processing

The present disclosure relates to a coal liquefaction system for utilizing a hydrogenated vegetable oil to liquefy coal. The system includes a reactor for exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, a heater that elevates the temperature of the slurry in the reactor to facilitate liquefying the coal and liberating a volatile matter, and a centrifuge that separates the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing. The system may also include a distillation column that distills the de-ashed coal extract to obtain a pitch. The system may also include a coker that cokes at least one of the de-ashed coal extract and the pitch to obtain a coke

Owner:WEST VIRGINIA UNIVERSITY

Cereal beverage manufacturing process

The invention relates to a cereal beverage manufacturing process which comprises the steps of raw material preparation, soaking, cleaning, crushing, gelatinizing, enzymolysis, saccharification, enzyme deactivation, auxiliary material blending, homogeneity, canning, sterilization and cooling, which are performed in sequence, the whole manufacturing process condition is strictly controlled, and the production parameters of all steps are monitored, and as a result, the quality of the cereal beverage is improved. Moreover, the whole manufacturing process is simple and clear, and provides a strong guarantee for the production of cereal beverage which is healthy, environment-friendly, safe, reliable and delicious; the produced finished product is rich in nutrition and complex in flavor, and more meets the high requirements of the modern people for greenness and healthiness.

Owner:江苏沃德铝业有限公司

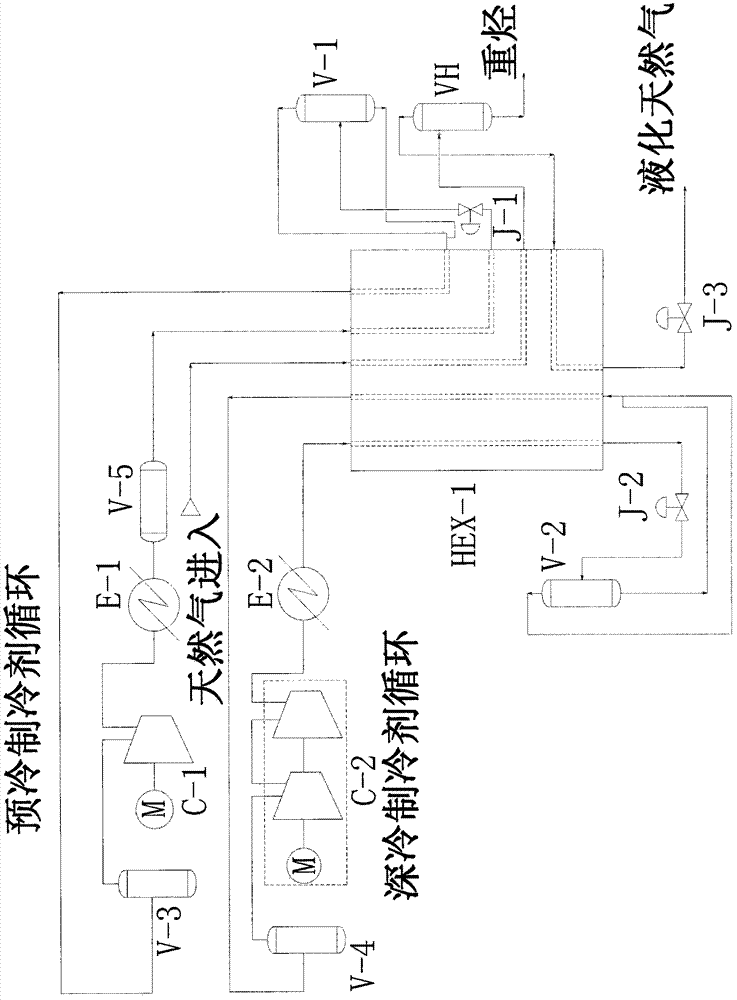

Method for producing liquefied natural gas by multi-component refrigerant double-stage compression

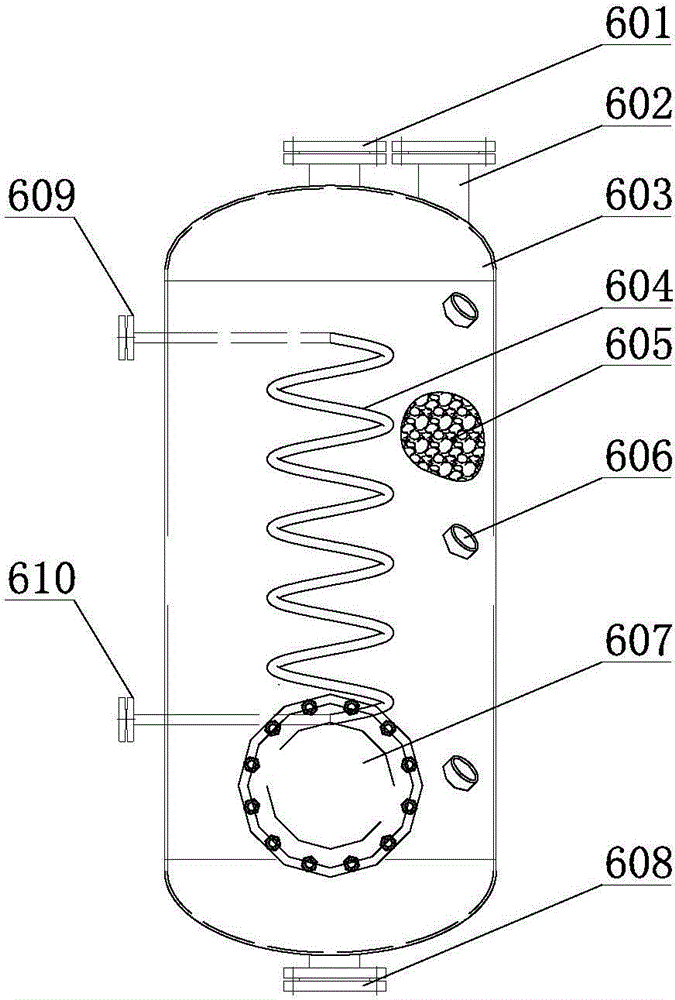

InactiveCN102954668AConducive to liquefactionAvoid complexitySolidificationLiquefactionBuffer tankEngineering

Provided is a method for producing liquefied natural gas by multi-component refrigerant two-stage compression. The method includes two multi-component refrigerant compression cycles, the refrigerant in a first cycle is called a pre-cooling refrigerant, the refrigerant in a second cycle is called a cryogenic refrigerant; the pre-cooling refrigerant returns to an ice chest after passing through a pre-cooling compressor, a cooler, a buffer tank, the ice chest, a throttle valve and a gas-liquid separation tank, and then returns to the pre-cooling compressor; the cryogenic refrigerant returns to the ice chest after passing through a cryogenic compressor, the cooler, the ice chest, the throttle valve and the gas-liquid separation tank, and then returns to the cryogenic compressor; and natural gas is cooled after heat transfer of the ice chest and the refrigerants and finally becomes the liquefied natural gas. The natural gas is liquefied by two independent multi-component refrigerant compression cycles, and composition and content of the two multi-component refrigerants are different, so that the method is wide in application range to raw material natural gas, high in operation flexibility and high in liquefying efficiency. Besides, the method is simple in liquefying process, low in investment cost, and is applicable to liquefied natural gas factories in various scales.

Owner:李志远

Pipeline Crude Oil in Coal Liquefaction

ActiveUS20120080358A1Low production costImprove solubilityWorking-up pitch/asphalt/bitumen by distillationSolid fuelsDownstream processingProcess engineering

The present disclosure provides methods and systems for coal liquefaction using a pipeline crude oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a pipeline crude oil to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

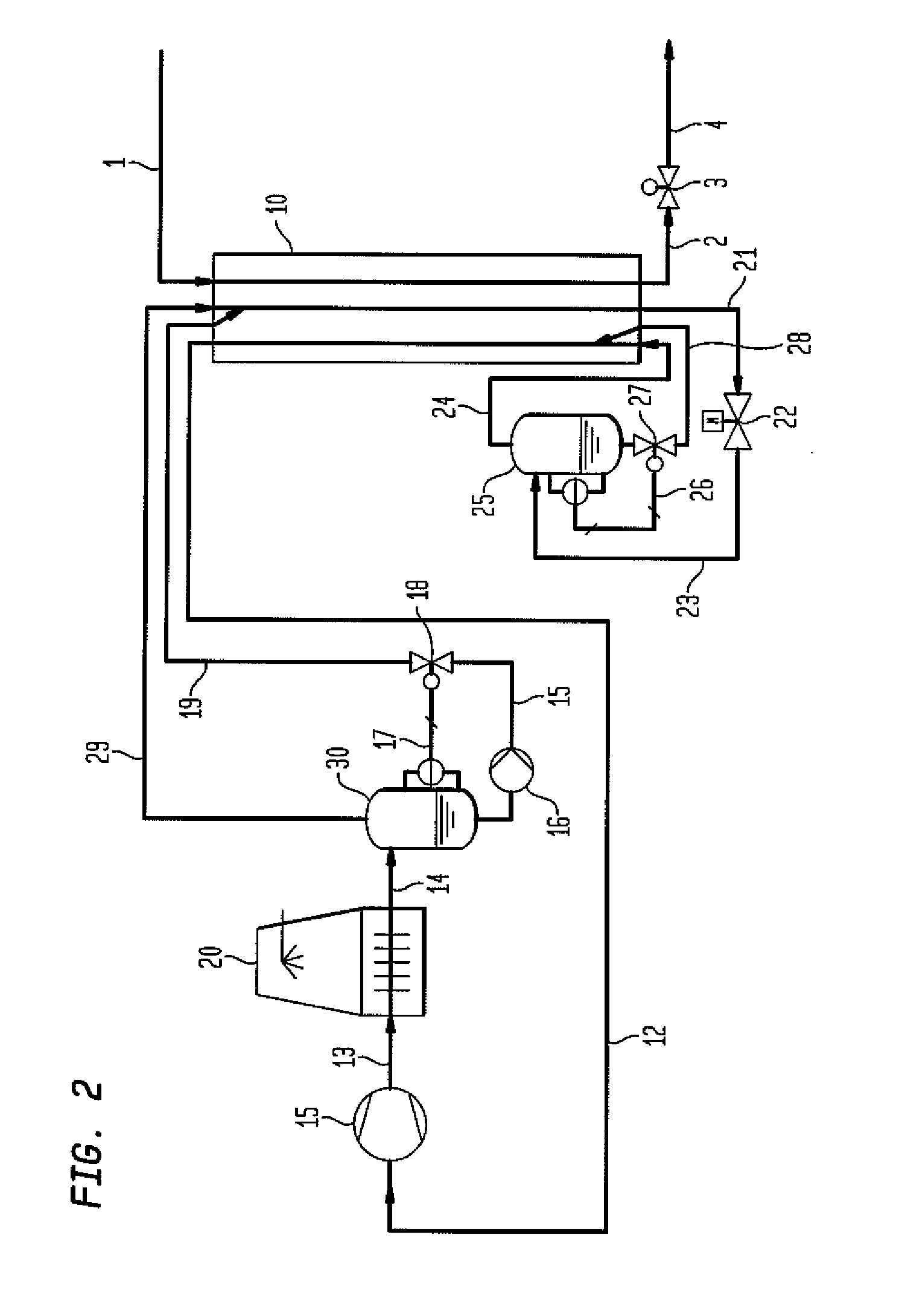

System and process for natural gas liquefaction

ActiveUS20140305160A1Increase ratingsConducive to liquefactionSolidificationLiquefactionEngineeringCooling capacity

Embodiments of the present invention provide a process for liquefaction of a natural gas. The process includes cooling the natural gas with a first refrigerant provided by a first cooling system and cooling the natural gas with a second refrigerant provided by a second cooling system. The second cooling system is a single phase cooling system. The first and second cooling systems operate independently from each other. The second refrigerant is cooled with the first refrigerant so that the cooling capacity of the second refrigerant and the second cooling system is increased.

Owner:KEPPEL OFFSHORE & MARINE TECH CENT PTE LTD

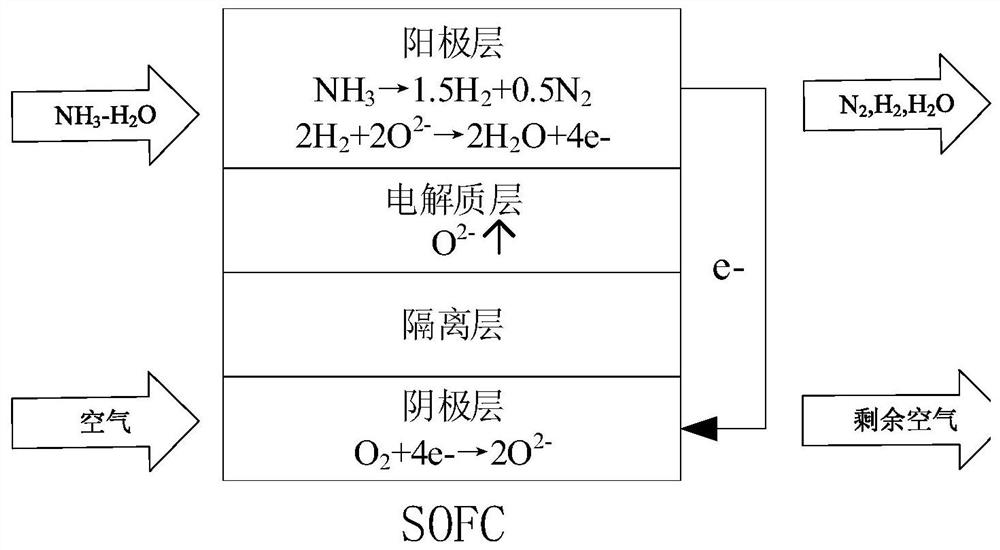

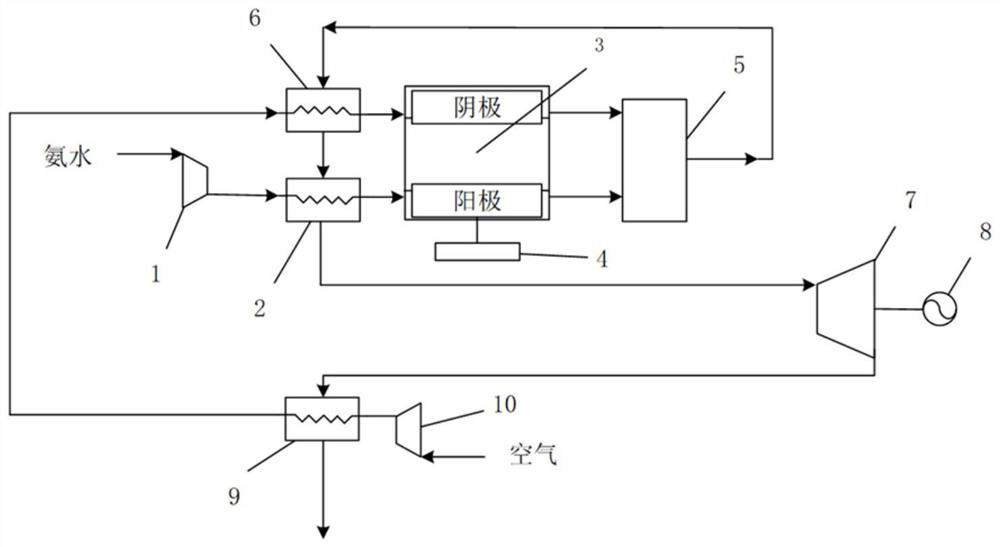

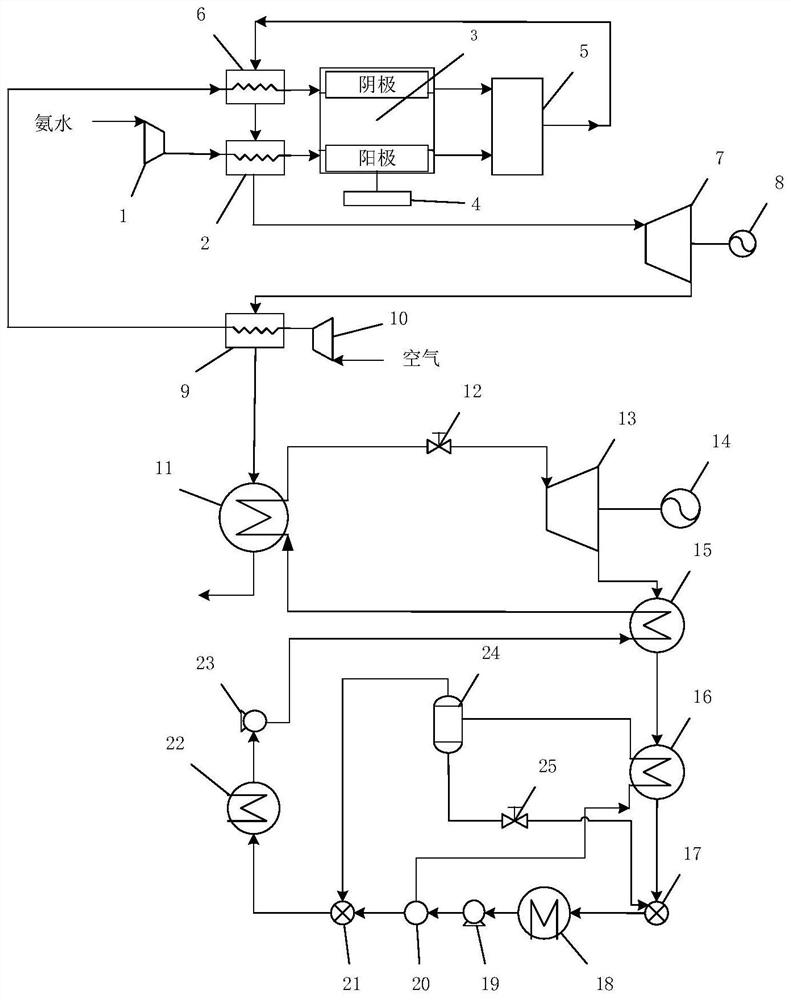

SOFC adopting ammonia water as fuel and cascade power generation system and operation method thereof

ActiveCN113540541AImprove power densityConducive to liquefactionFuel cell heat exchangeFinal product manufactureWater useEnvironmental engineering

The invention discloses an SOFC adopting ammonia water as fuel and a cascade power generation system and an operation method thereof. The SOFC adopting ammonia water as fuel comprises an anode layer, an electrolyte layer, an isolation layer and a cathode layer; compressed ammonia water is introduced into the anode; and the mass concentration range of the ammonia water is preferably 0.65-0.85, and the utilization rate of hydrogen generated by decomposition of ammonia gas in the SOFC is 75%. Ammonia is considered to be a novel and promising fuel in recent years besides traditional fuels such as hydrogen and natural gas in the aspect of SOFC fuels, and the ammonia fuel has the characteristics of no emission of carbon dioxide, high power density and easiness in liquefaction and transportation. In the invention, the ammonia water is used as the fuel of the SOFC, and compared with the currently used ammonia gas, the ammonia water used in the invention has the advantages of mature production process, relatively low toxicity, nonflammability, easiness in liquefaction and transportation and higher safety.

Owner:XI AN JIAOTONG UNIV

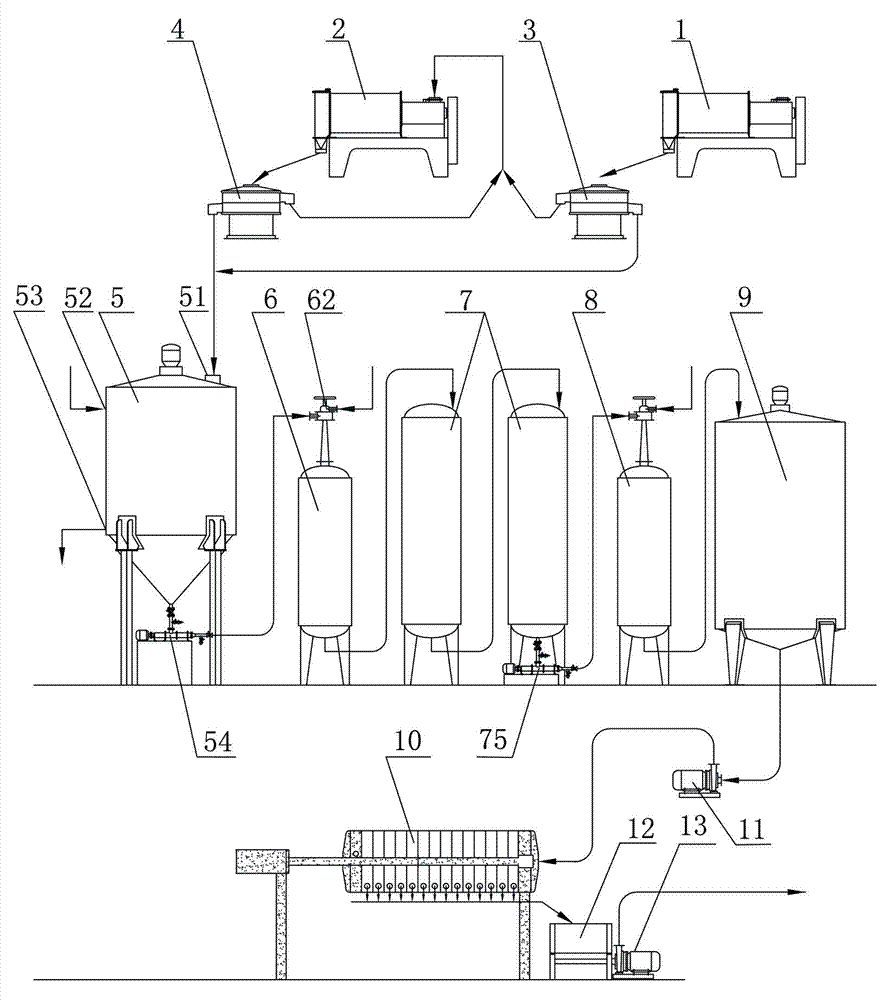

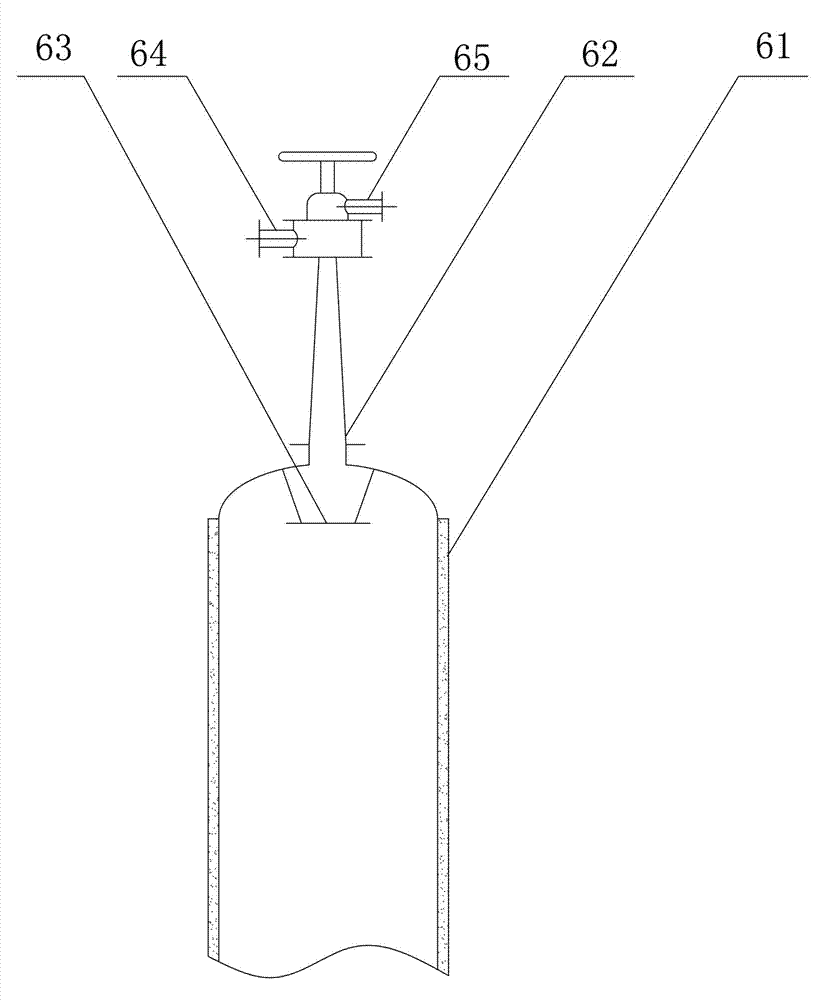

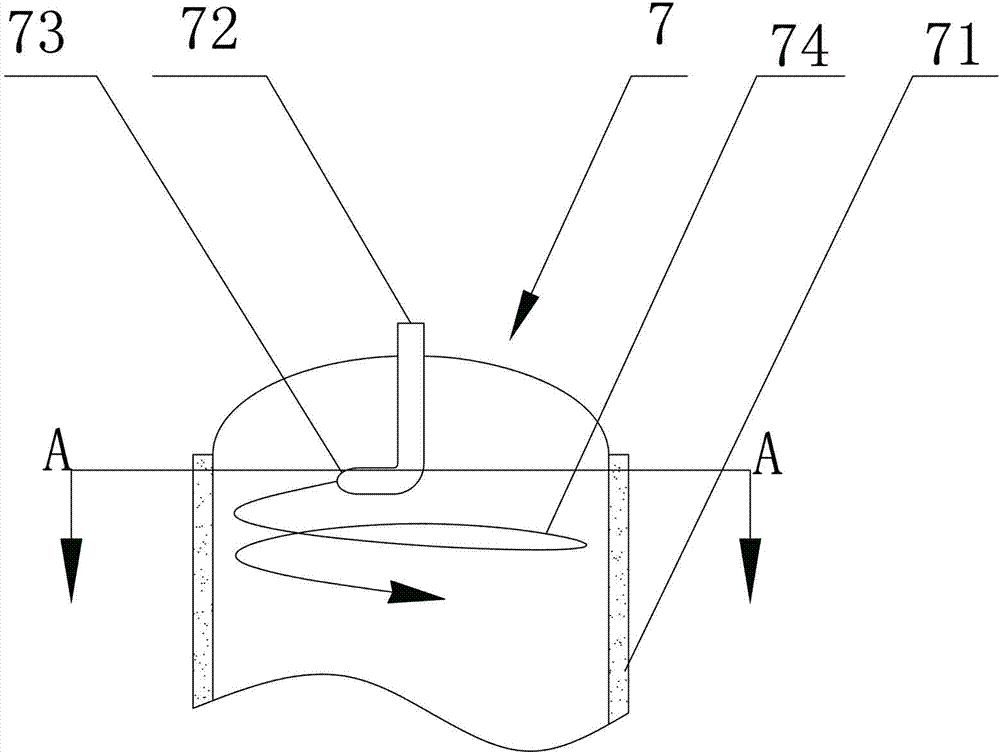

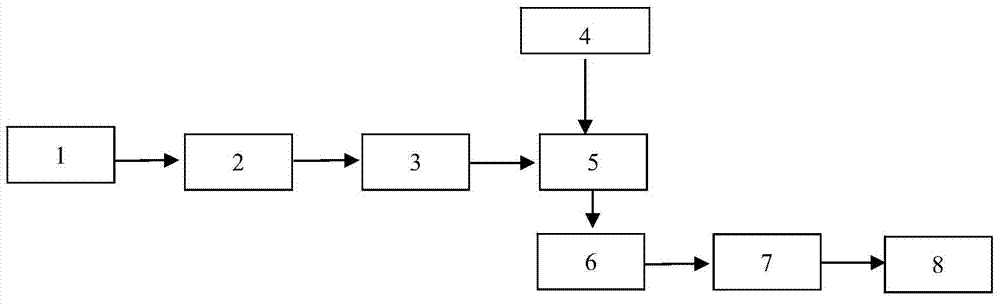

Liquefaction process and liquefaction equipment of glucose syrup

PendingCN104498560ALiquefaction process is simpleHigh extraction rateBioreactor/fermenter combinationsBiological substance pretreatmentsGlucose-Fructose SyrupWarm water

The invention provides a liquefaction process of glucose syrup. The liquefaction process mainly comprises the following steps: milling, size mixing, gelatinizing, sterilizing and filtering for separating, wherein the milling step comprises directly milling dry raw grains; the size mixing step comprises: firstly stirring and mixing warm water with fine grain powder for size mixing, soaking and stirring for 2-3 hours at a constant temperature condition, and adding a high temperature resistant liquefied enzyme preparation and a protein coagulant. The invention further provides liquefaction equipment of glucose syrup. The equipment comprises a primary flour mill, a primary classifying screen, a soaking tank, a jet tank for gelatinizing, at least two laminar flow tanks, a jet tank for sterilizing, a feed liquid temporary storage tank and a press filter which are serially connected in sequence. Therefore, the liquefaction process and liquefaction device of glucose syrup provided by the invention have the characteristics of simple process, high product extraction rate, reduced raw material waste, low cost, zero emission of wastewater and the like.

Owner:开封市四达农产品设备有限公司

Waste paper modified coated control release fertilizer and preparation method thereof

The invention relates to a waste paper modified coated control release fertilizer and a preparation method thereof. The preparation method comprises the following steps: first, adding waste paper or carton powder into a liquefier A to prepare a liquefied matter and modify; and then, uniformly mixing the modified liquefied matter and a curing agent C in a weight ratio of 1:1 as a coating material which is sprayed to the surfaces of fertilizer particles to be cured to films to obtain the coated control release fertilizer, wherein the coating material accounts for 2-8% of total weight of the fertilizer, the modified liquefied matter accounts for 0.5% of total weight of the fertilizer and the curing agent C accounts for 0.5% of total weight of the fertilizer. Compared with processing of common control release fertilizers, the fertilizer provided by the invention has the characteristics of few coating materials required, low production energy consumption, environment friendliness, production cost conservation and the like.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

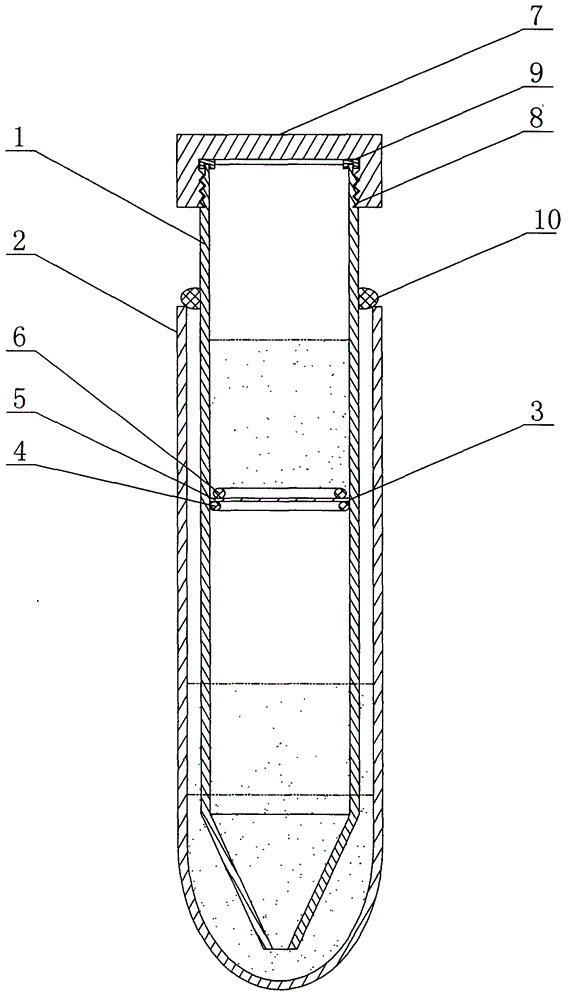

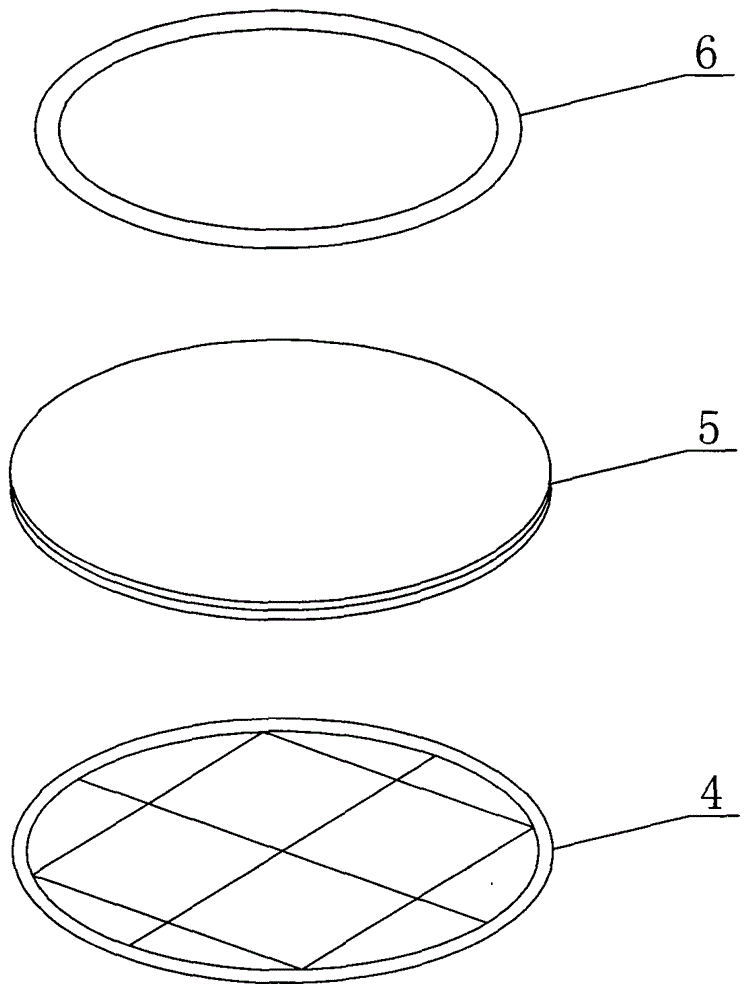

Double-tube vacuum film sperm separation method and separation device

InactiveCN104651224AEasy to separate and handleAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsLow speedDouble tube

The invention discloses a double-tube vacuum film sperm separation method and a separation device and mainly relates to the field of cytobiology. The separation device comprises an inner centrifugal tube and a centrifugal tube, wherein the lower part of the inner centrifugal tube is of a cone structure which is opened at the tip; a filter device is mounted in the inner centrifugal tube; an inner tube seal cover is arranged at the orifice at the top of the inner centrifugal tube. By using the device to separate a seminal fluid, a density gradient solution is prepared by adopting a classical density gradient sperm separation method and a sperm lotion and sperms are sequentially dropped onto the filter device, and the inner centrifugal tube after low-speed centrifugal treatment is taken out, so that the inner centrifugal tube a is separated from the centrifugal tube, and the residues in the centrifugal tube are part of alpha% density gradient solution and bottom spermatia. The method and device disclosed by the invention have the beneficial effects that whether the seminal fluid is liquefied or not, seminal plasma and sperms are thoroughly separated through a simple operation; the damage on sperms in the pre-treatment process of the seminal fluid is avoided; the success rate, the recovery rate and the quality of sperms are excellent.

Owner:张丽红

Production technology of starchiness raw material alcohol

InactiveCN102250964AReduce dosageImprove water absorptionBiofuelsMicroorganism based processesHigh densityAlcohol

The invention discloses a production technology of starchiness raw material alcohol. The technology is characterized in that: starchiness raw materials are liquefied and completely saccharified under a relatively high temperature; before fermentation, grain stillage and residual are separated, and the materials are washed; and saccharified liquid with a saccharide density of 25% by mass is fermented. According to the invention, high density mash fermentation is realized, fermentation time is reduced, amounts of total sugar and residual sugar are reduced, and discharging of COD, BOD and solids is reduced. With advantages such as high equipment utilization rate and low steam consumption, the production technology is suitable for the productions of alcohols produced from starchiness raw materials such as wheat, corn, rice, dried sweet potato and cassava.

Owner:HENAN TIANGUAN GRP

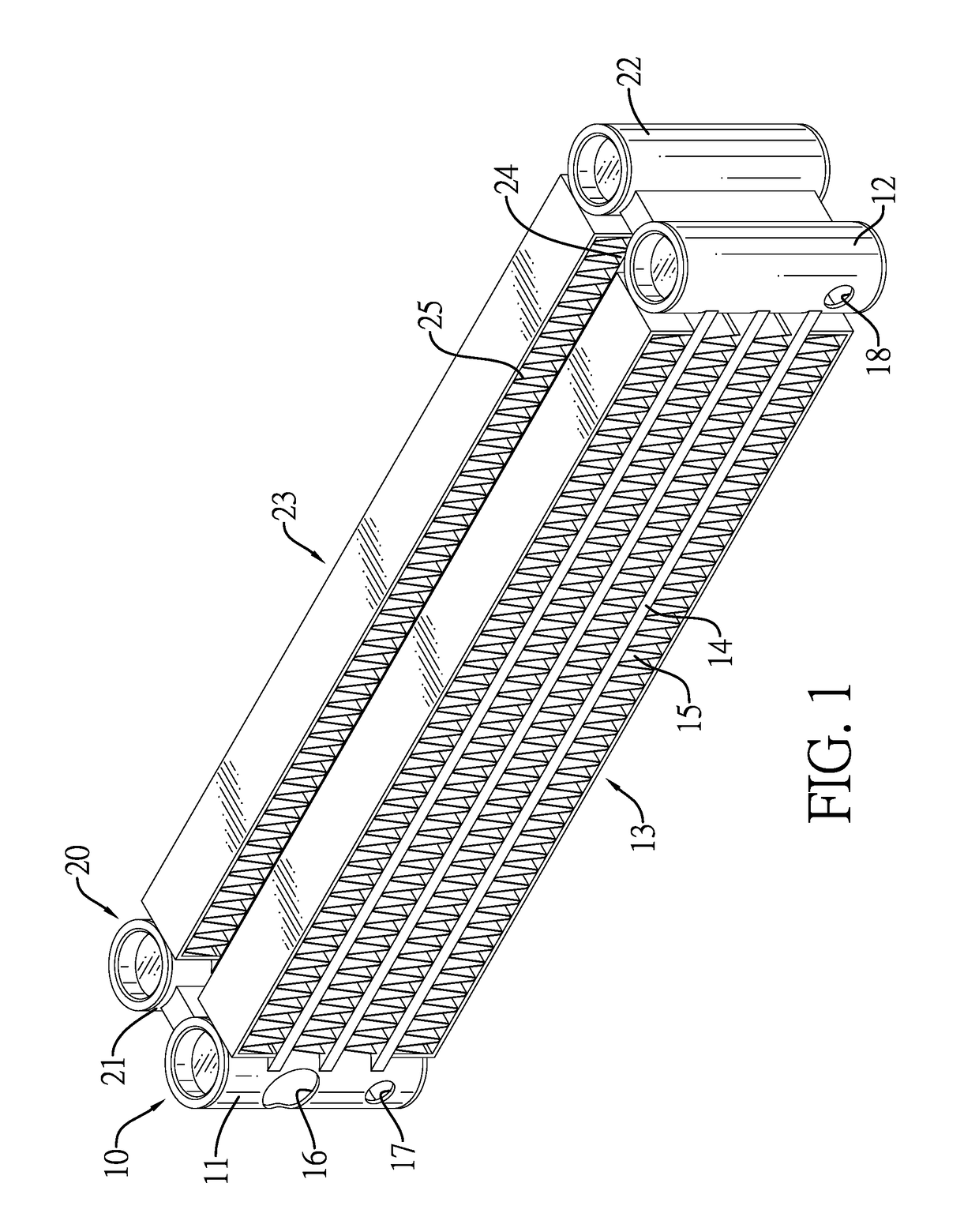

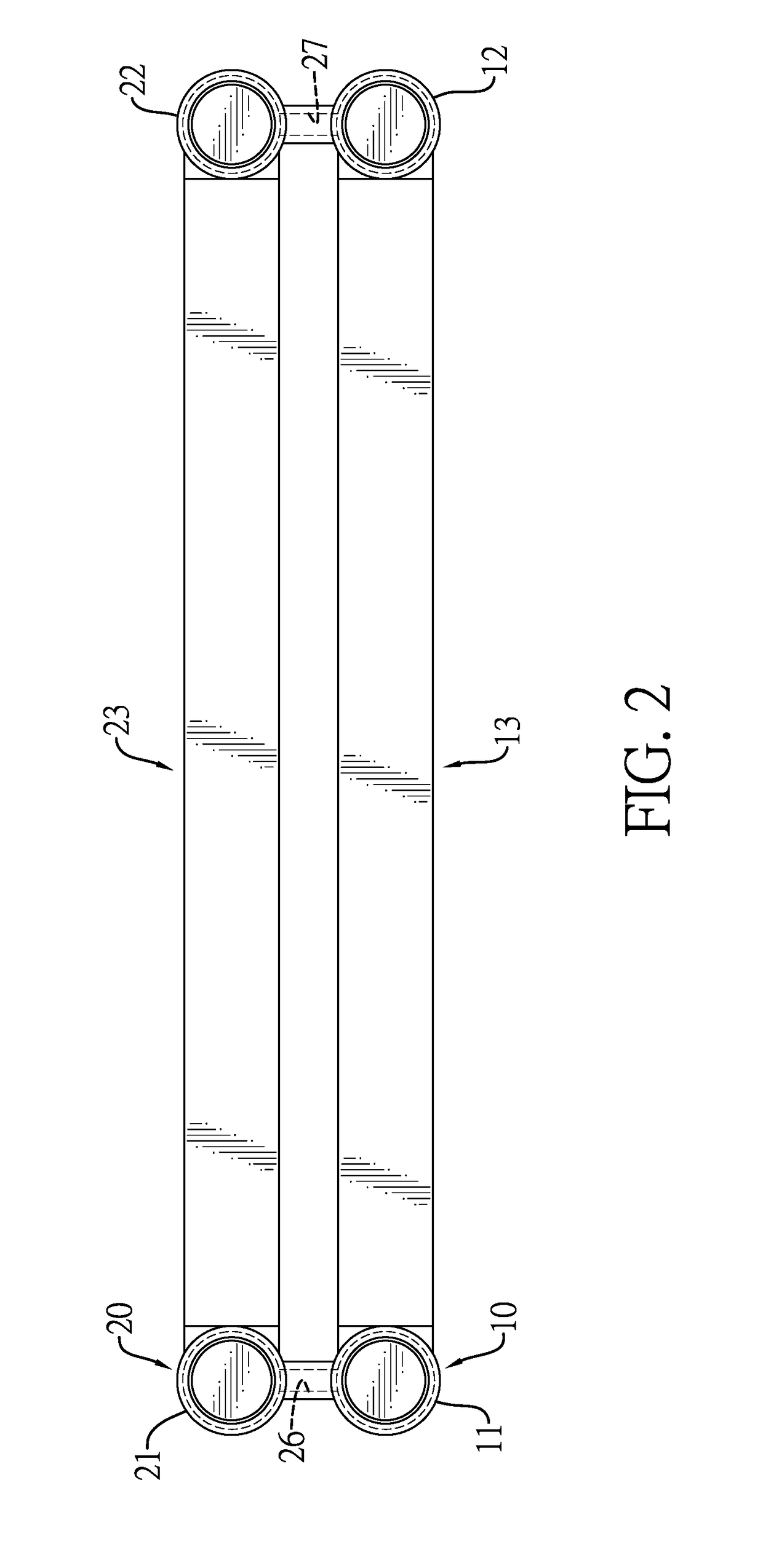

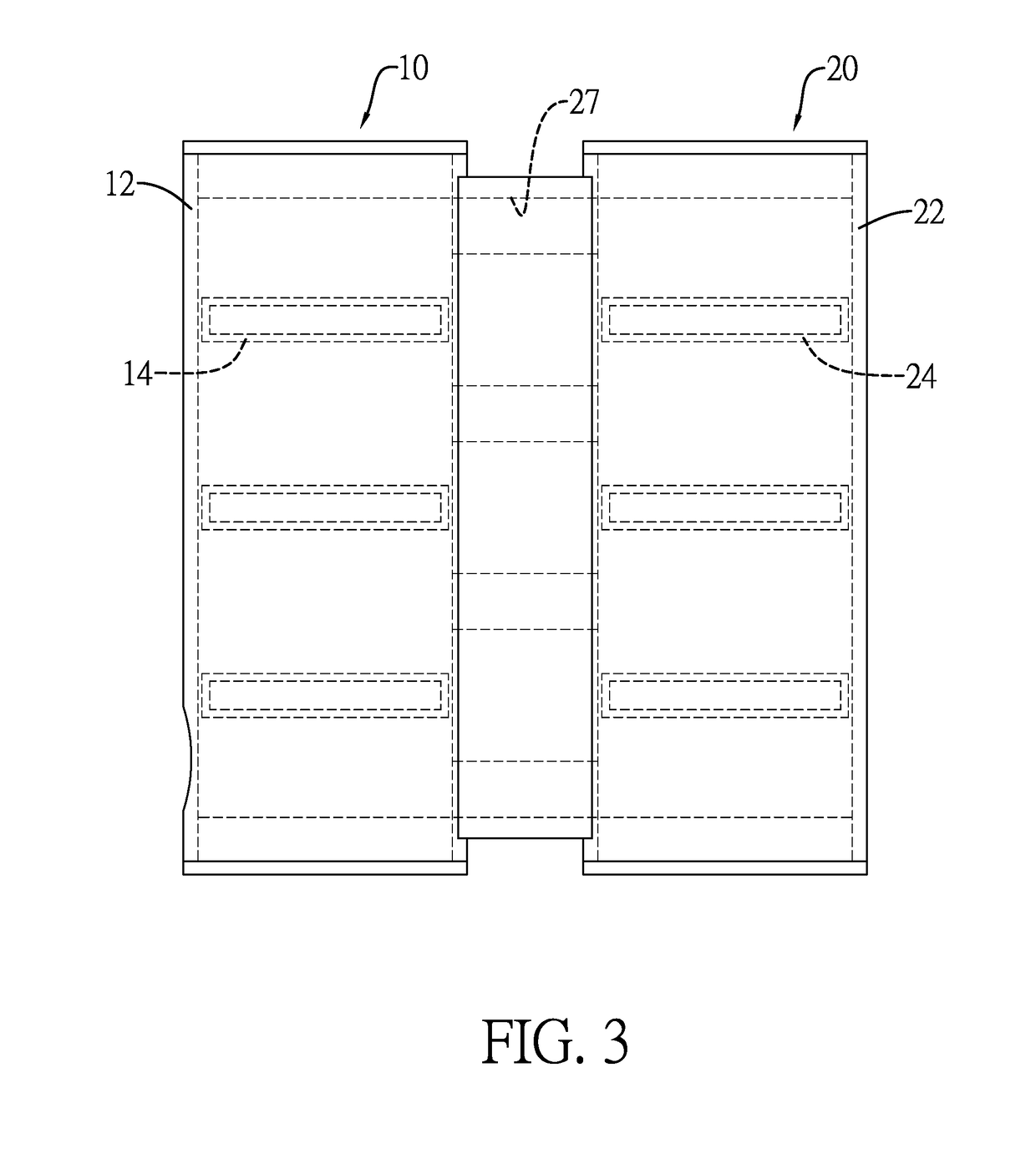

Parallel-connected condenser and cooling device using the same

InactiveUS20190078846A1Increase flow rateSatisfactory cooling performance of coolingSemiconductor/solid-state device detailsStationary conduit assembliesEvaporatorEngineering

A cooling device includes a parallel-connected condenser and an evaporator assembly. The parallel-connected condenser has a primary condenser assembly and at least one auxiliary condenser assembly. The evaporator assembly includes an evaporator, a coolant input pipe and a coolant output pipe. Two ends of the coolant input pipe are respectively connected to the evaporator and a first primary condenser tube. Two ends of the coolant output pipe are respectively connected to the evaporator and a second primary condenser tube for the parallel-connected condenser and the evaporator assembly to form a closed coolant circulation loop with coolant filled therein. By virtue of the primary condenser assembly and the auxiliary condenser assembly parallelly connected, gaseous coolant can be circulated through different paths and liquefied to effectively enhance cooling and liquefaction efficiency of coolant when the coolant is circulated through the cooling device.

Owner:MAN ZAI IND

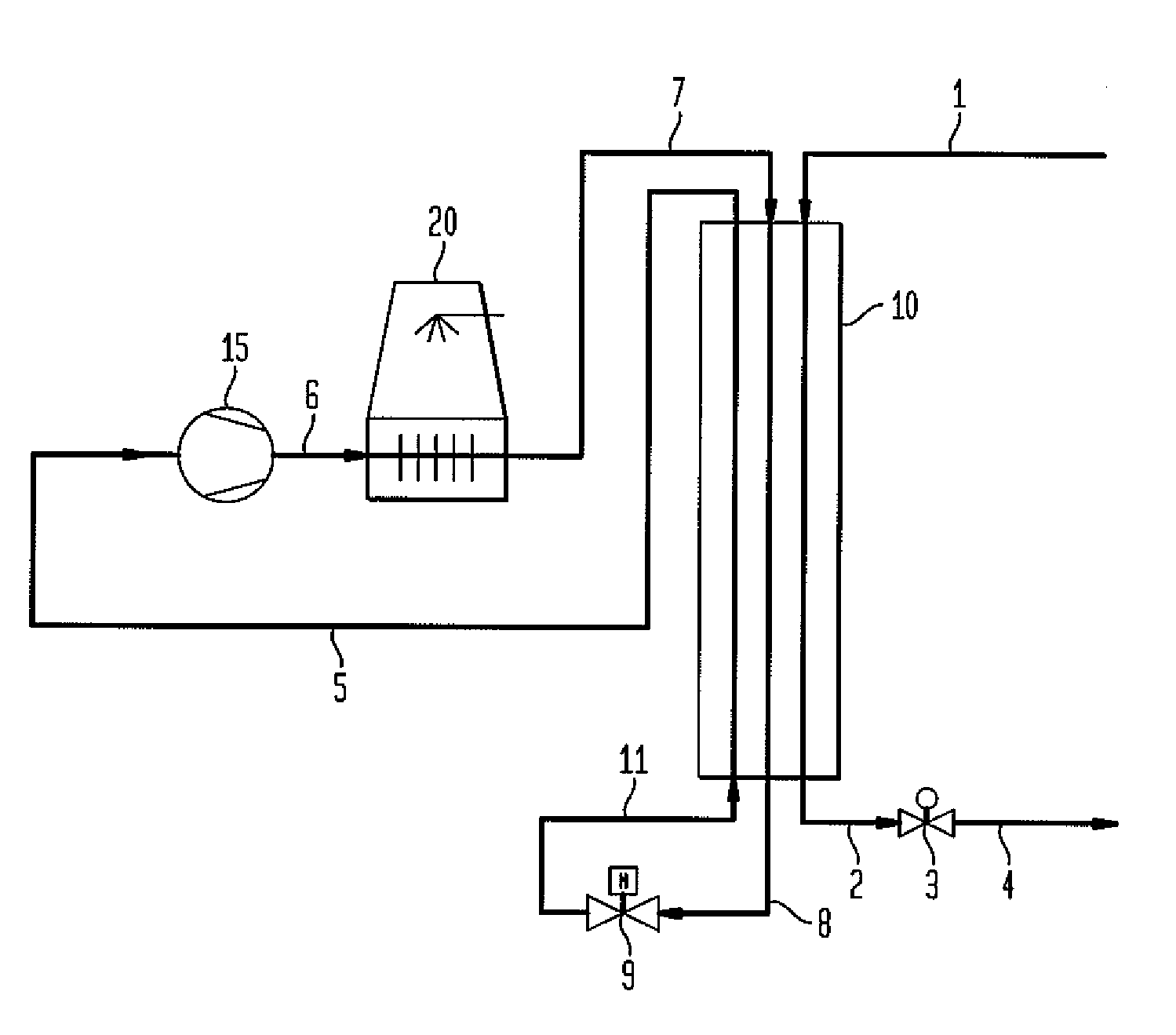

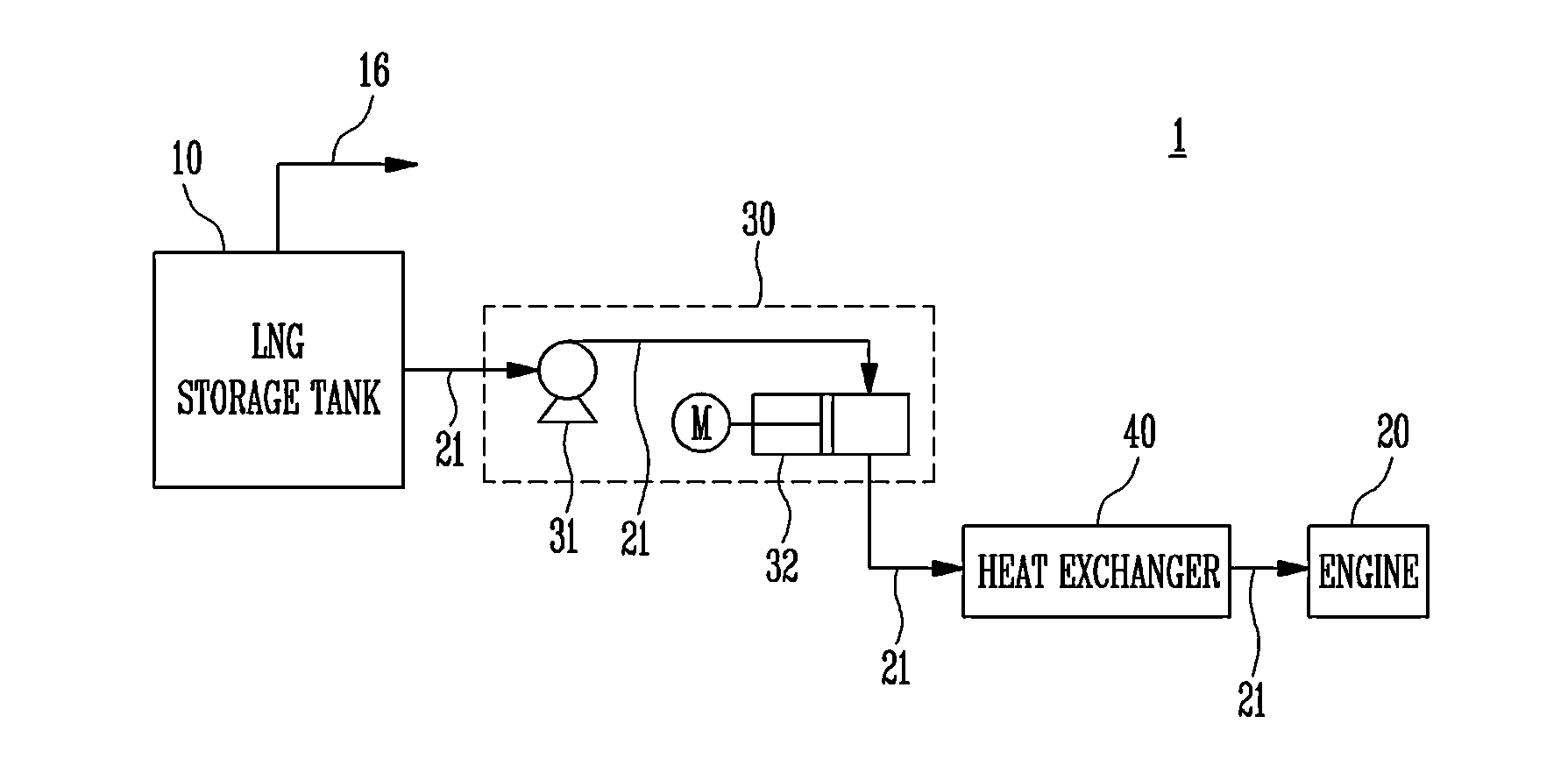

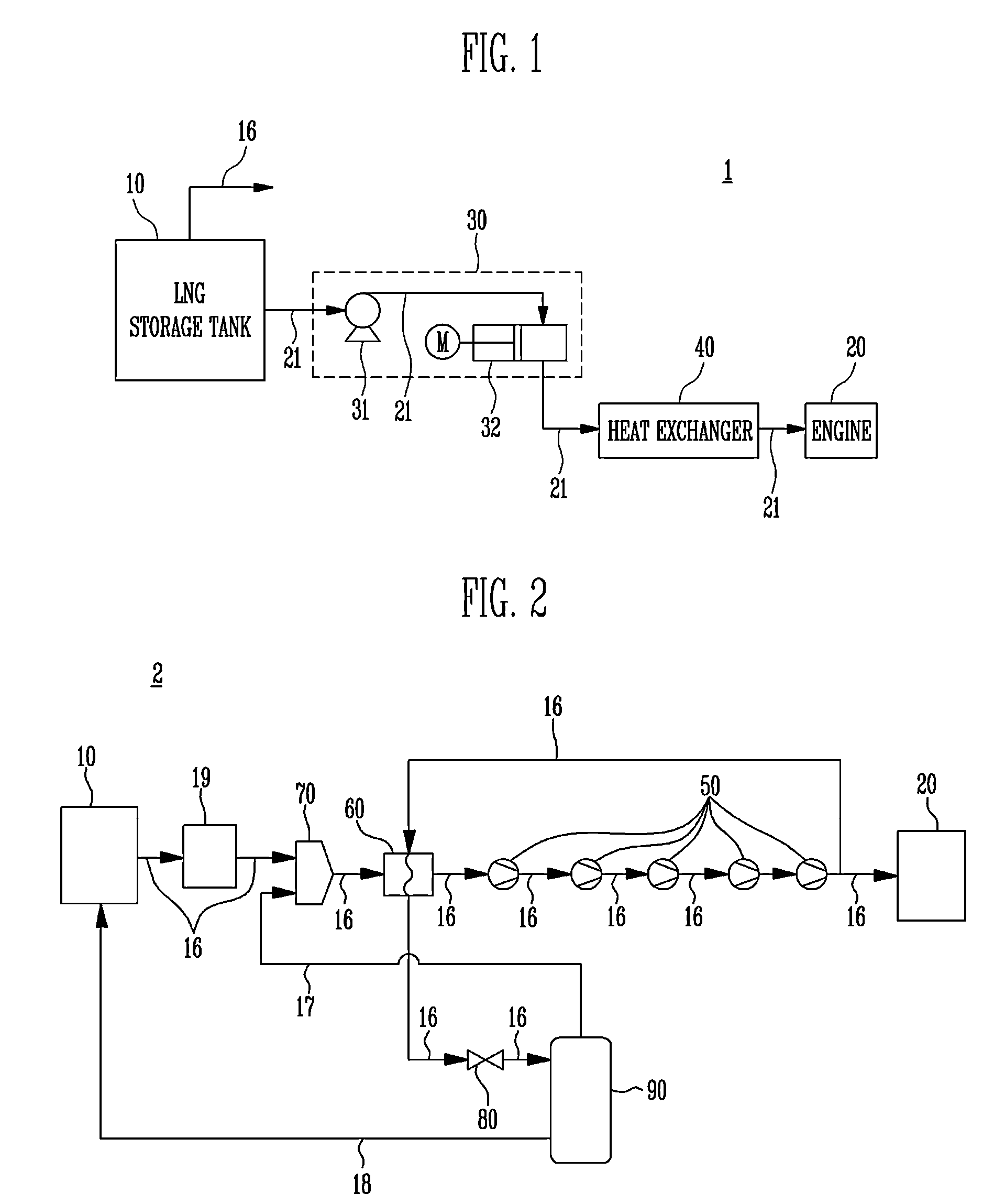

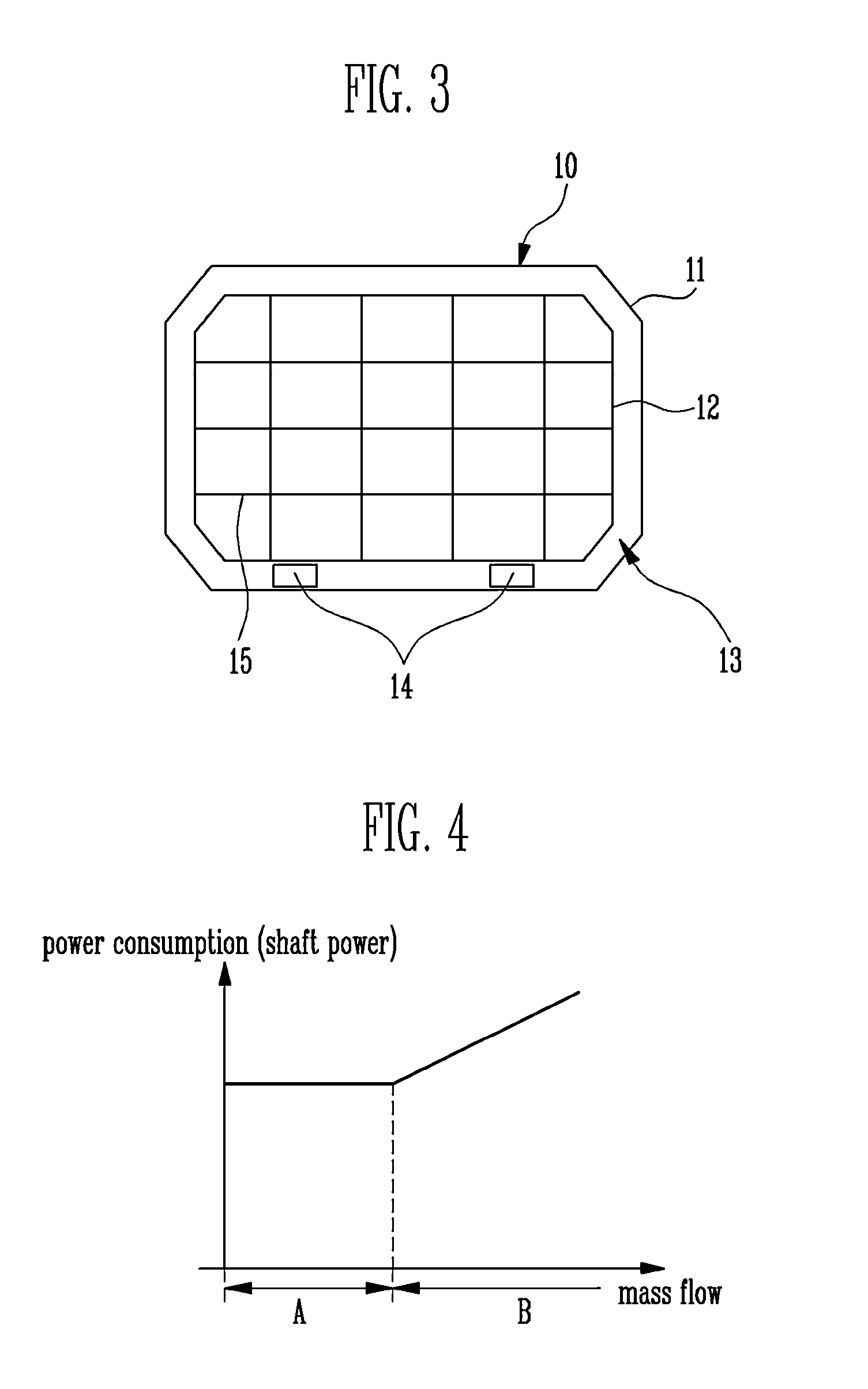

Liquefied gas treatment system

InactiveUS20140352330A1Conducive to liquefactionImproving reliquefaction efficiencySolidificationLiquefactionGas compressorFlash-gas

A liquefied gas treatment system according to an embodiment of the present invention includes a boil-off gas heat exchanger exchanging heat between boil-off gas, pressurized by a boil-off gas compressor and recovered along a boil-off gas supply line branching off upstream of a liquefied gas-consuming unit, and the boil-off gas supplied from a liquefied gas storage tank, wherein the boil-off gas heat exchanger cools the boil-off gas, recovered along the boil-off gas supply line, with the boil-off gas, supplied from the liquefied gas storage tank, or flash gas, supplied through a vapor recovery line.

Owner:HYUNDAI HEAVY IND CO LTD

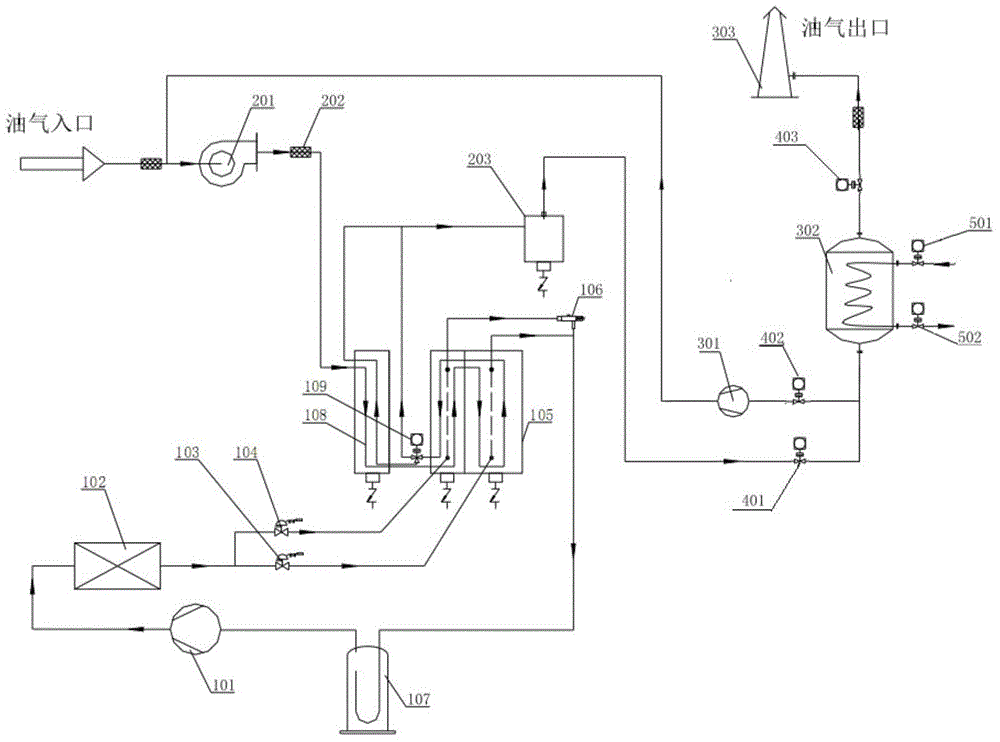

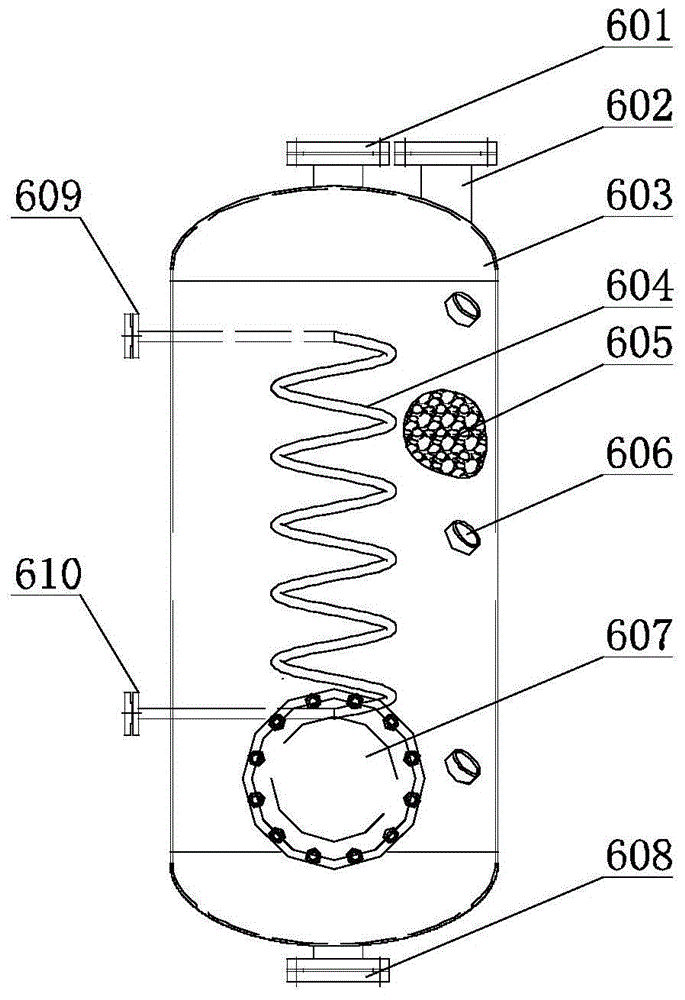

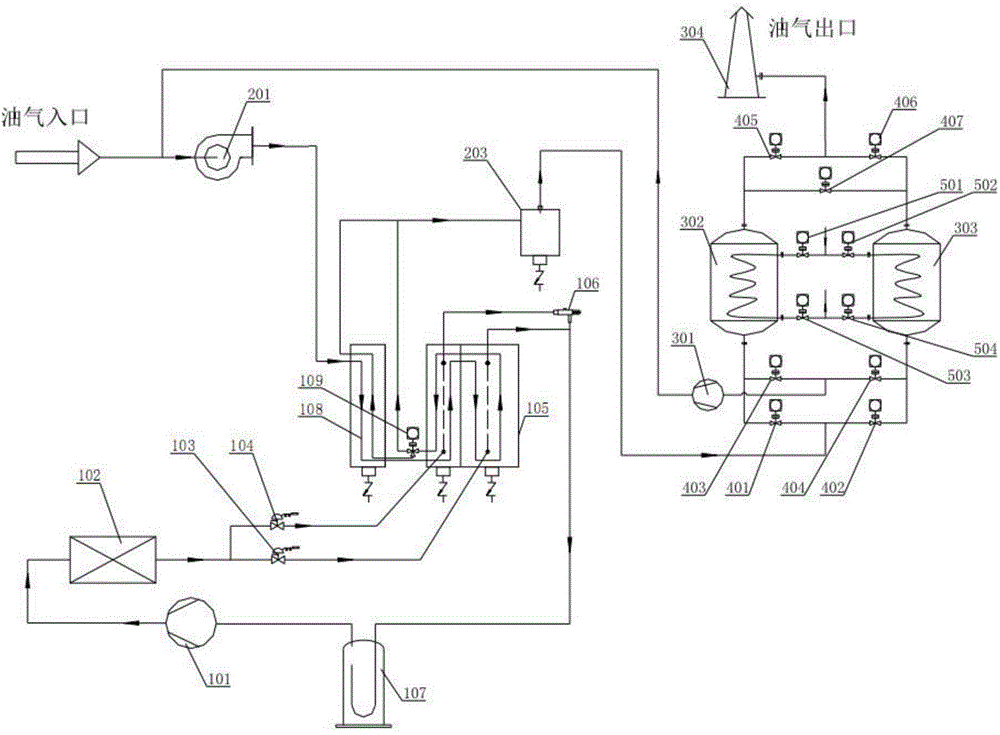

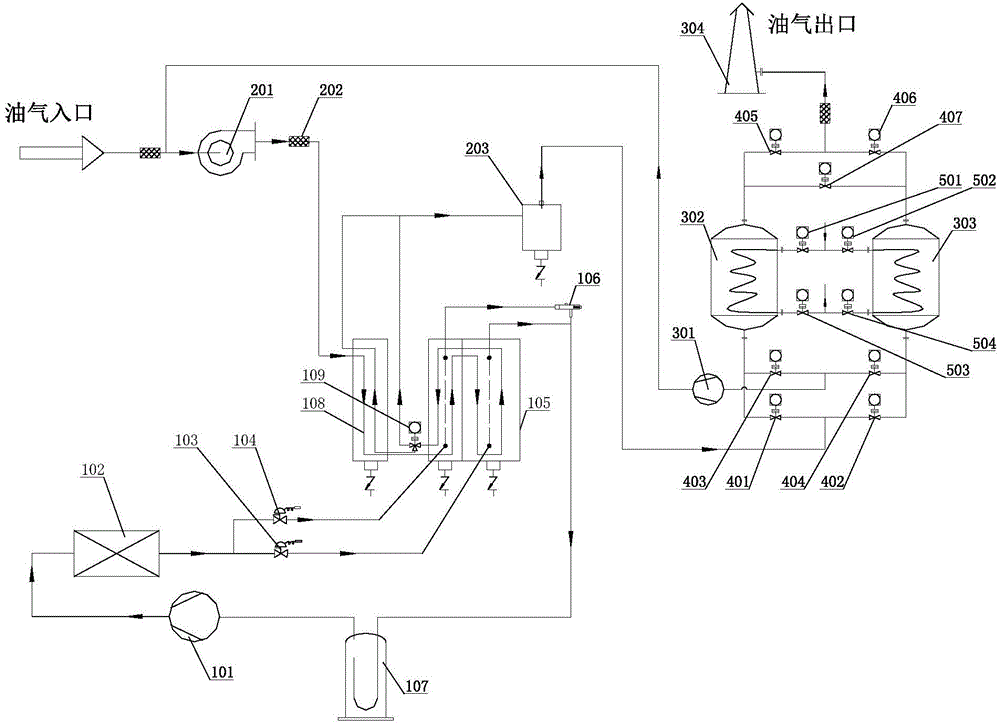

Adsorption recycling device and method for acrylonitrile gas

ActiveCN104826446AConducive to liquefactionActiveDispersed particle separationVapor condensationRecovery methodVapor–liquid separator

The invention discloses an adsorption recycling device and method for acrylonitrile gas. The adsorption recycling device comprises a condensation loop and a temperature-variable and pressure-variable adsorption loop, the condensation loop comprises a cold box heat exchanger, an antiexplosion refrigerating compressor, a throttling element, a condensing heat exchanger and a gas-liquid separator, and the temperature-variable and pressure-variable adsorption loop comprises a frequency-variable air pump, a return heat exchanger, a three-way switching valve, a cold box heat exchanger, a liquid-gush-preventive tank, a temperature-variable and pressure-variable adsorption device and an antiexplosion vacuum pump. Acrylonitrile gas is recycled and purified through the condensation loop and the temperature-variable and pressure-variable adsorption loop, concentration of acrylonitrile gas reaches milligram grade finally, and secondary pollution when a unit runs is eradicated completely.

Owner:NANJING DOULE REFRIGERATION EQUIP

Hydrogenated vegetable oil in coal liquefaction

InactiveUS8465561B2Low production costImprove solubilitySolid fuelsLiquid carbonaceous fuelsDownstream processingVegetable oil

The present disclosure provides methods and systems for coal liquefaction using a hydrogenated vegetable oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

Method for syngas-production from liquefied biomass

The present invention relates to methods for syngas-production from biomass enabling the conversion of pre-treated biomasses having a high dry-matter content into electricity or oil-based products such as petrol, diesel, chemicals and plastics through the formation of syngas. The biomasses are converted into a biomass slurry having a suitable particle size and dry-matter content for optimal feeding and gasification in a pressurised gasifier.

Owner:DONG ENERGY POWER AS

Piston type high-pressure feeding machine

The invention belongs to feeding equipment and in particular relates to a piston type high-pressure feeding machine. The machine comprises a cylinder, a piston type push rod in airtight fit with the inner wall of the machine and capable of linearly moving and an opening arranged on the front part of the cylinder. An end cover in fastened fit with the inner side wall of the cylinder is fixed on the front end of the cylinder. The opening is arranged on the end cover and communicated with the inner cavity of a mould. A power source is connected to the rear part of the piston type push rod. According to the piston type high-pressure feeding machine disclosed by the invention, the problems of incapability of rapid material feeding and manufacture influence of a polyurethane work-piece in the prior art can be solved; and the machine has the advantages of rational structural design, wide application range, convenient use and the like.

Owner:刘均平

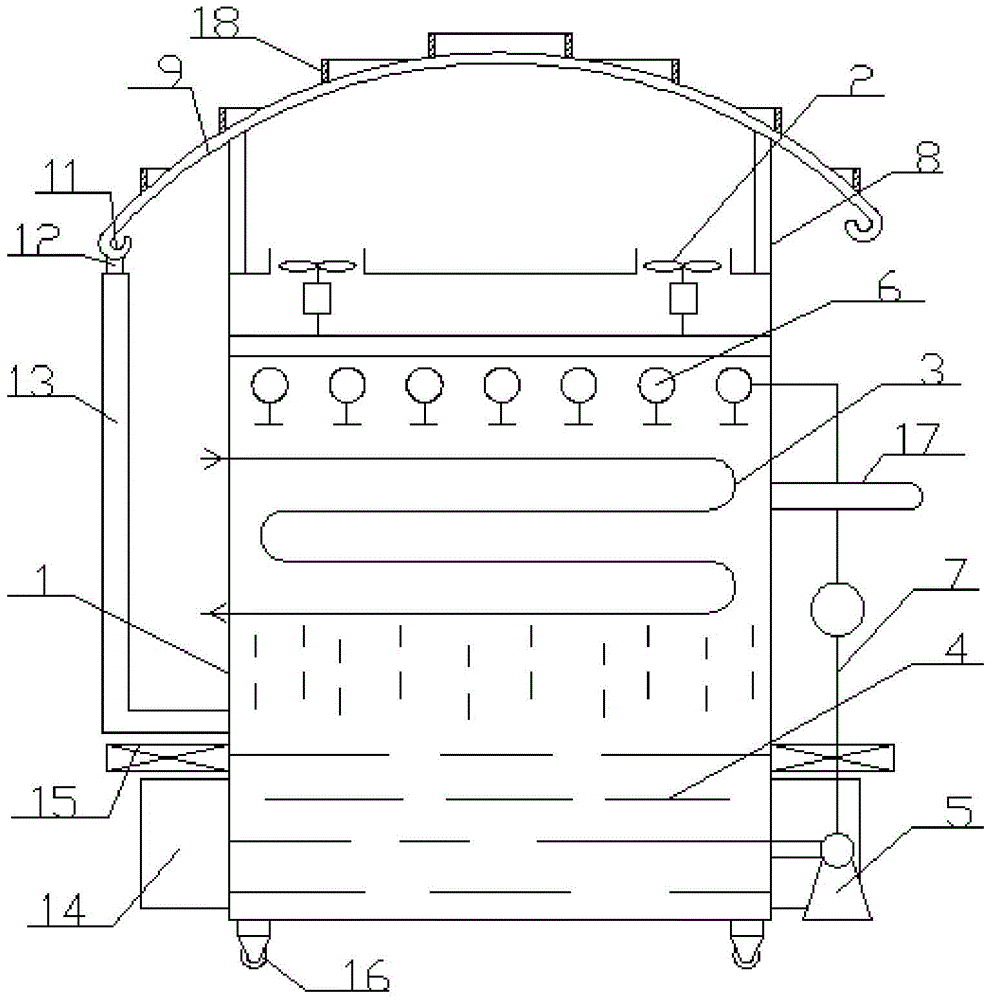

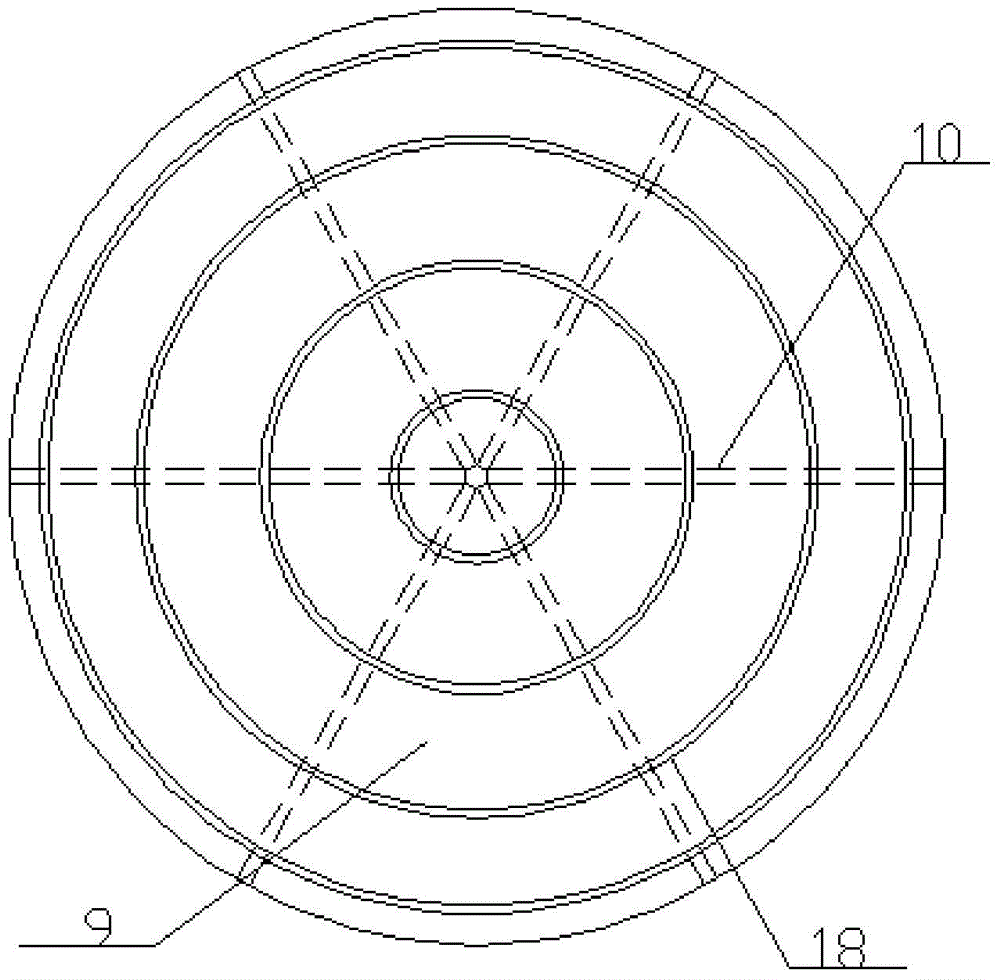

High-efficiency energy-saving evaporative condenser

InactiveCN104990426AImprove cooling effectConducive to liquefactionSteam/vapor condensersHeat exchanger casingsWater vaporWater resources

The invention discloses a high-efficiency energy-saving evaporative condenser and relates to the field of condensing equipment. According to the high-efficiency energy-saving evaporative condenser, a covering plate is installed at the top of a casing, so that water vapor exhausted from the casing can be absorbed fully; the absorbed water vapor is led to a water tank, so that the recovery and usage of water resources are realized, water resources are greatly saved; and the high-efficiency energy-saving evaporative condenser has excellent environmental protection property.

Owner:江苏进源压力容器有限公司

Device and method for recycling acrylonitrile gas

ActiveCN104826447AConducive to liquefactionAvoid secondary pollutionChemical industryDispersed particle separationRecovery methodRefrigeration compressor

The invention discloses a device and a method for recycling acrylonitrile gas. The device comprises a condensation loop and a temperature-variable and pressure-variable adsorption loop, the condensation loop comprises a cold box heat exchanger, a refrigerating compressor, a throttling element, a condensing heat exchanger and a gas-liquid separator, and the temperature-variable and pressure-variable adsorption loop comprises a frequency-variable air pump, a return heat exchanger, a three-way switching valve, a cold box heat exchanger, a liquid-gush-preventive tank, a temperature-variable and pressure-variable adsorption device and a vacuum pump. Acrylonitrile gas is recycled and purified through the condensation loop and the temperature-variable and pressure-variable adsorption loop, concentration of acrylonitrile gas reaches milligram grade finally, and secondary pollution when a unit runs is eradicated completely.

Owner:NANJING DOULE REFRIGERATION EQUIP

System for the production of synthetic fuels

InactiveUS20080295390A1Assist in downsizingReduce charringLiquid hydrocarbon mixtures productionLiquid carbonaceous fuelsParticulatesLiquid fuel

A system and method for producing synthetic fuels are disclosed in which a slurry comprised of a particulate solid portion and a carrier liquid portion is provided. The solid portion comprises (i) a feedstock of carbon-containing polymeric materials that are substantially free of each of halogen, sulfur and nitrogen atoms, and contain about 5 to about 25 percent by weight water, and (ii) a catalytic amount of metal particles. The carrier liquid portion is a hydrocarbon / oxyhydrocarbon composition. The feedstock constitutes about 10 to about 60 weight percent of the slurry. The slurry is heated anaerobically to provide an elevated temperature of about 250° to about 455° C. and a pressure of about 20 to about 50 atmospheres that are maintained for a time period sufficient to provide a combustible liquid fuel at least 80 percent of which contains about 6 to about 21 carbon atoms per molecule.

Owner:CELLO ENERGY

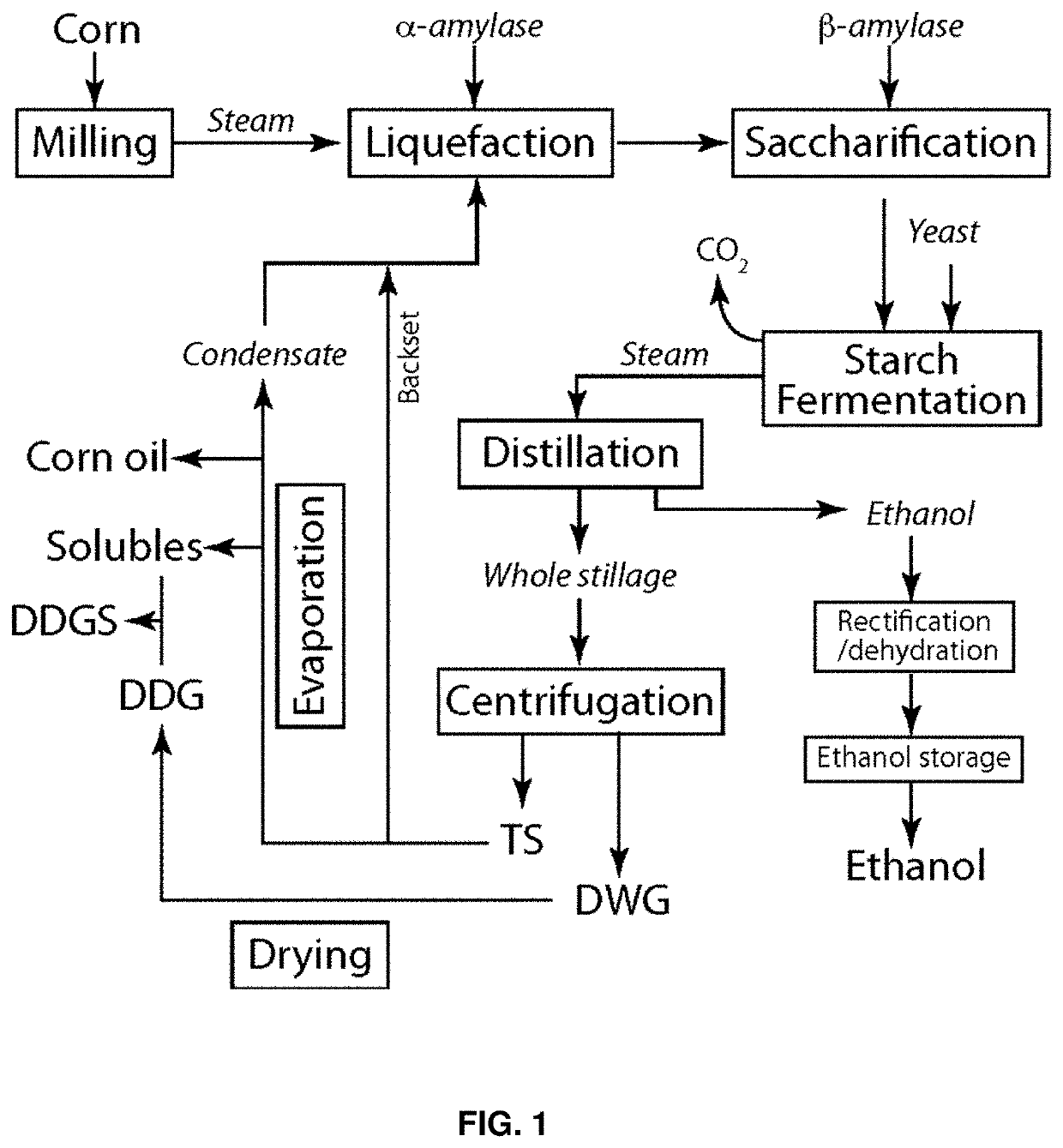

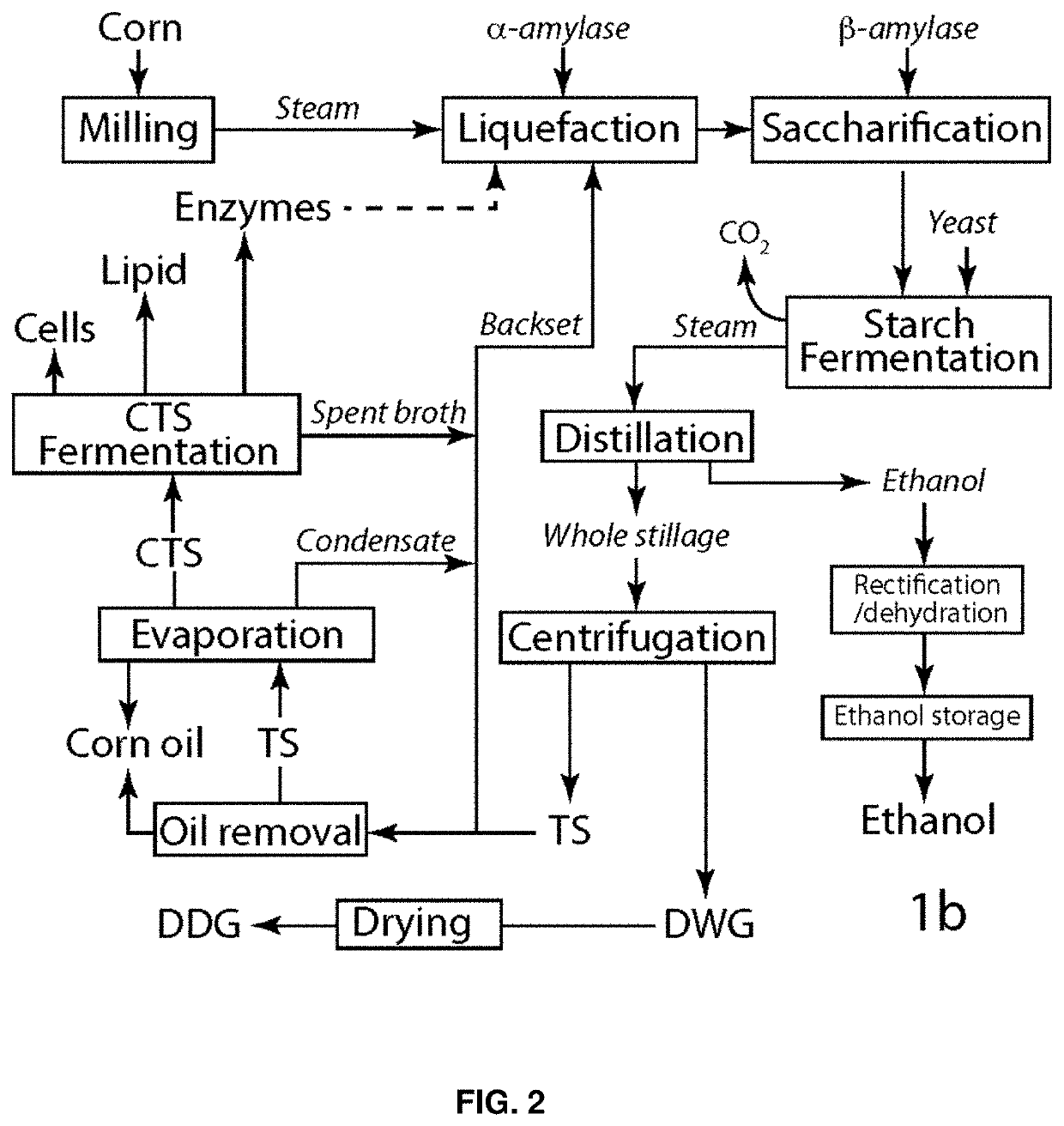

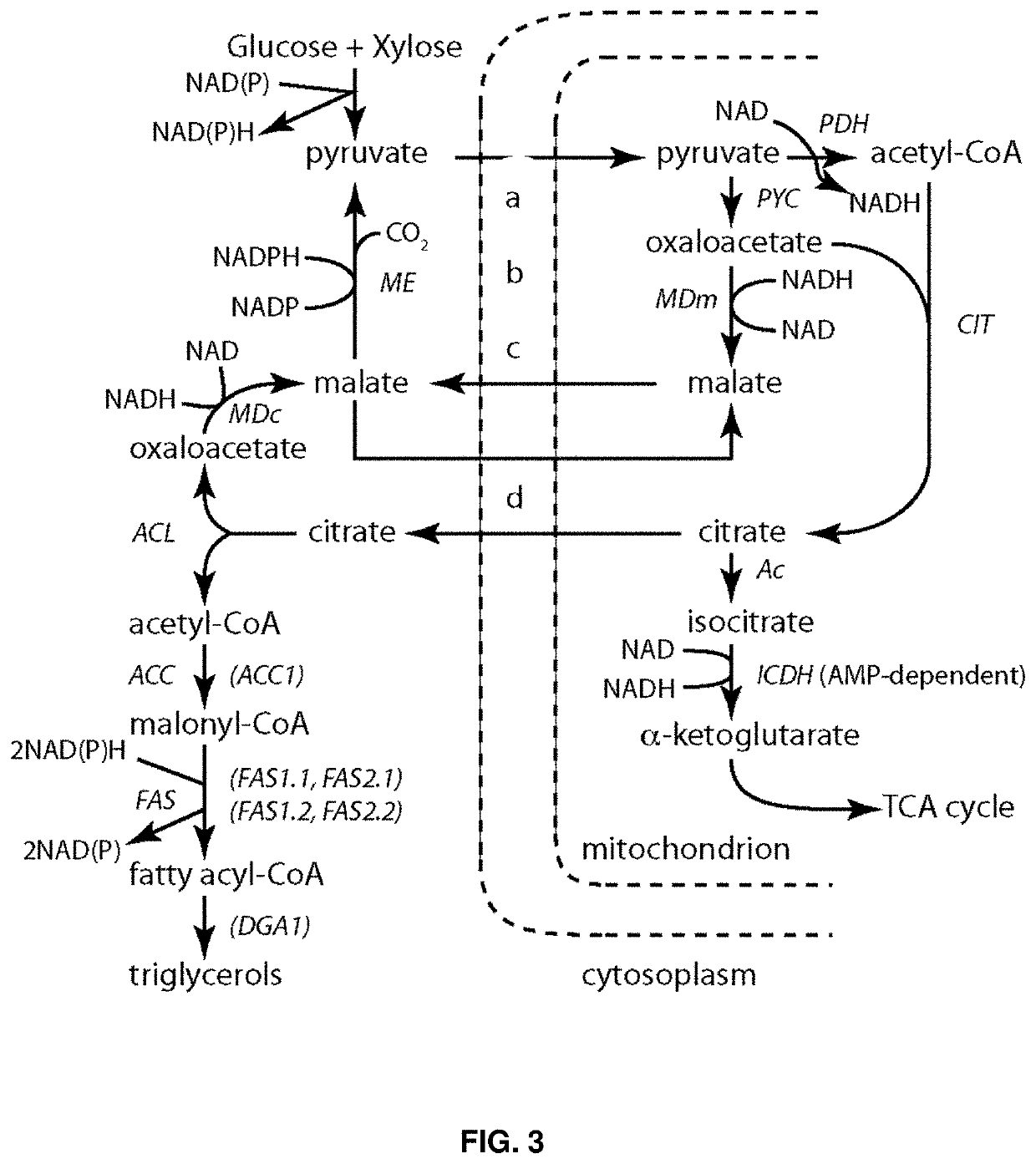

Compositions and methods for producing lipids and other biomaterials from grain ethanol stillage and stillage derivatives

ActiveUS10662448B2Conducive to liquefactionIncrease ratingsFungiMicrobiological testing/measurementPhospholipidAcyl CoA dehydrogenase

Lipogenic yeasts bioengineered to overexpress genes for lipid production, and methods of use thereof. The yeasts are modified to express, constitutively express, or overexpress an acetyl-CoA carboxylase, an alpha-amylase, an ATP citrate lyase, a diacylglycerol acyltransferase, a fatty acid synthase, a glycerol kinase, a 6-phosphogluconate dehydrogenase, a glycerol-3-phosphate dehydrogenase, a malic enzyme, a fatty acyl-CoA reductase, a delta-9 acyl-CoA desaturase, a glycerol-3-phosphate acyltransferase, a lysophosphatidate acyltransferase, a glucose-6-phosphate dehydrogenase, a beta-glucosidase, a hexose transporter, a glycerol transporter, a glycoside hydrolase enzyme, an auxiliary activity family 9 enzyme, or combinations thereof. The yeasts in some cases are also modified to reduce or ablate activity of certain proteins. The methods include cultivating the yeast to convert low value soluble organic stillage byproducts into lipids suitable for biodiesel production and other higher value uses.

Owner:XYLOME CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com