Patents

Literature

168results about How to "Improve liquefaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

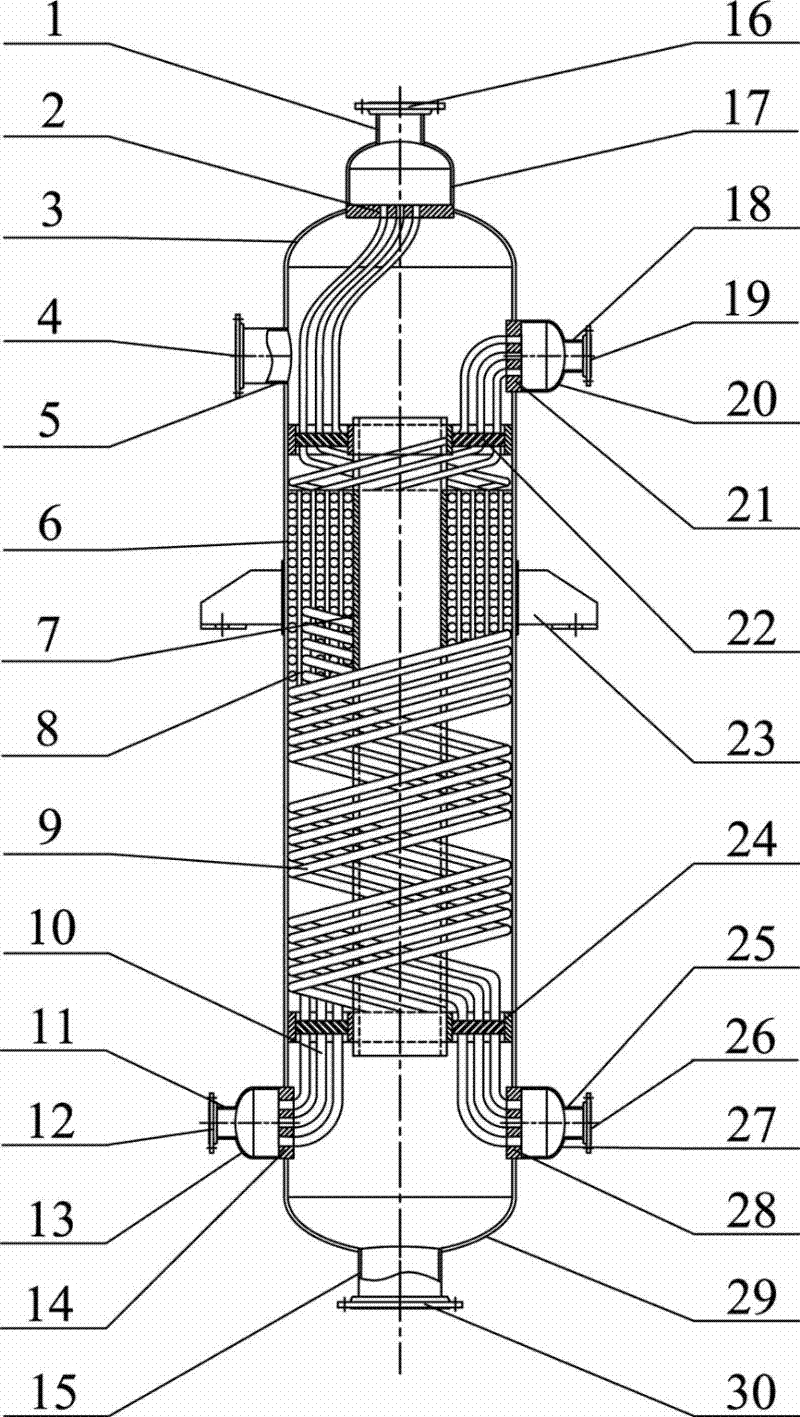

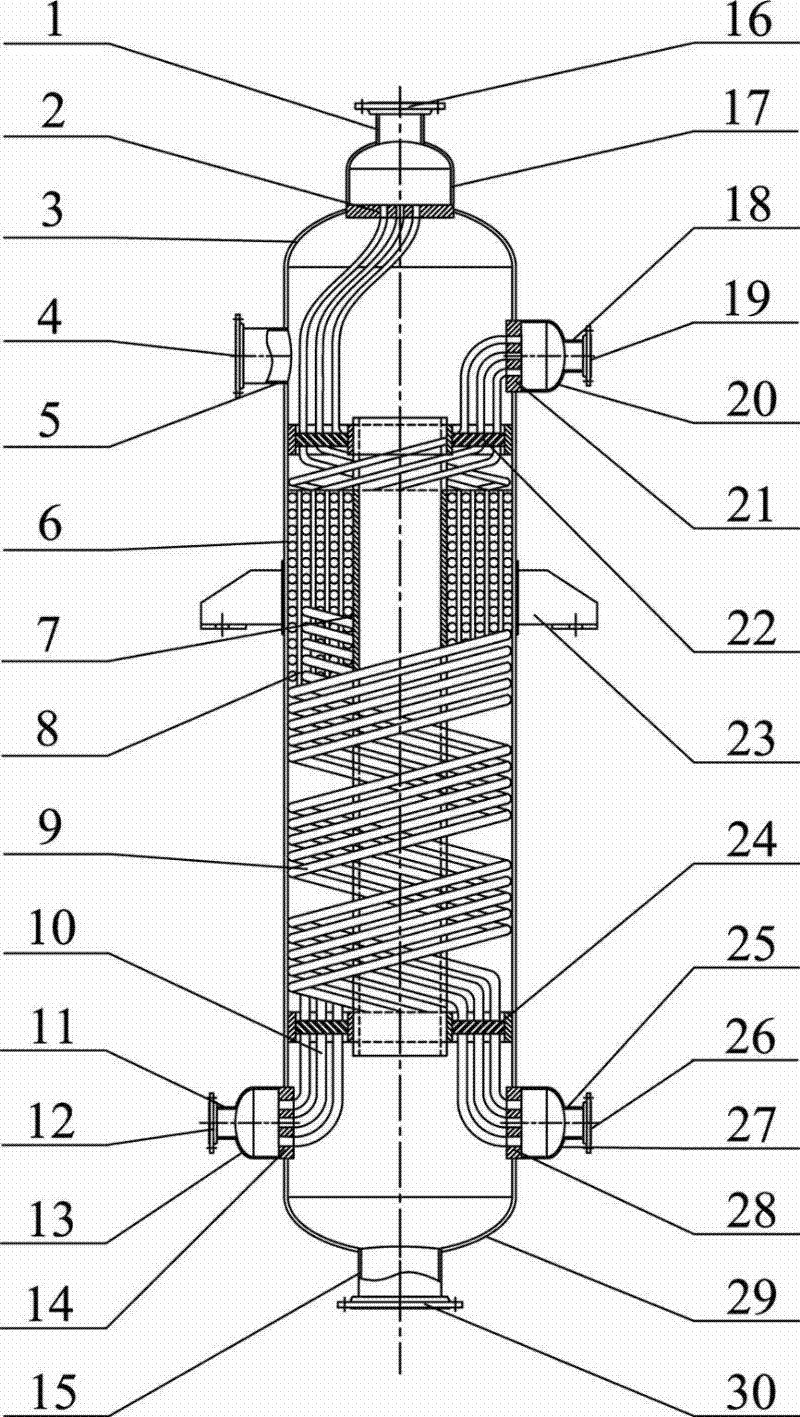

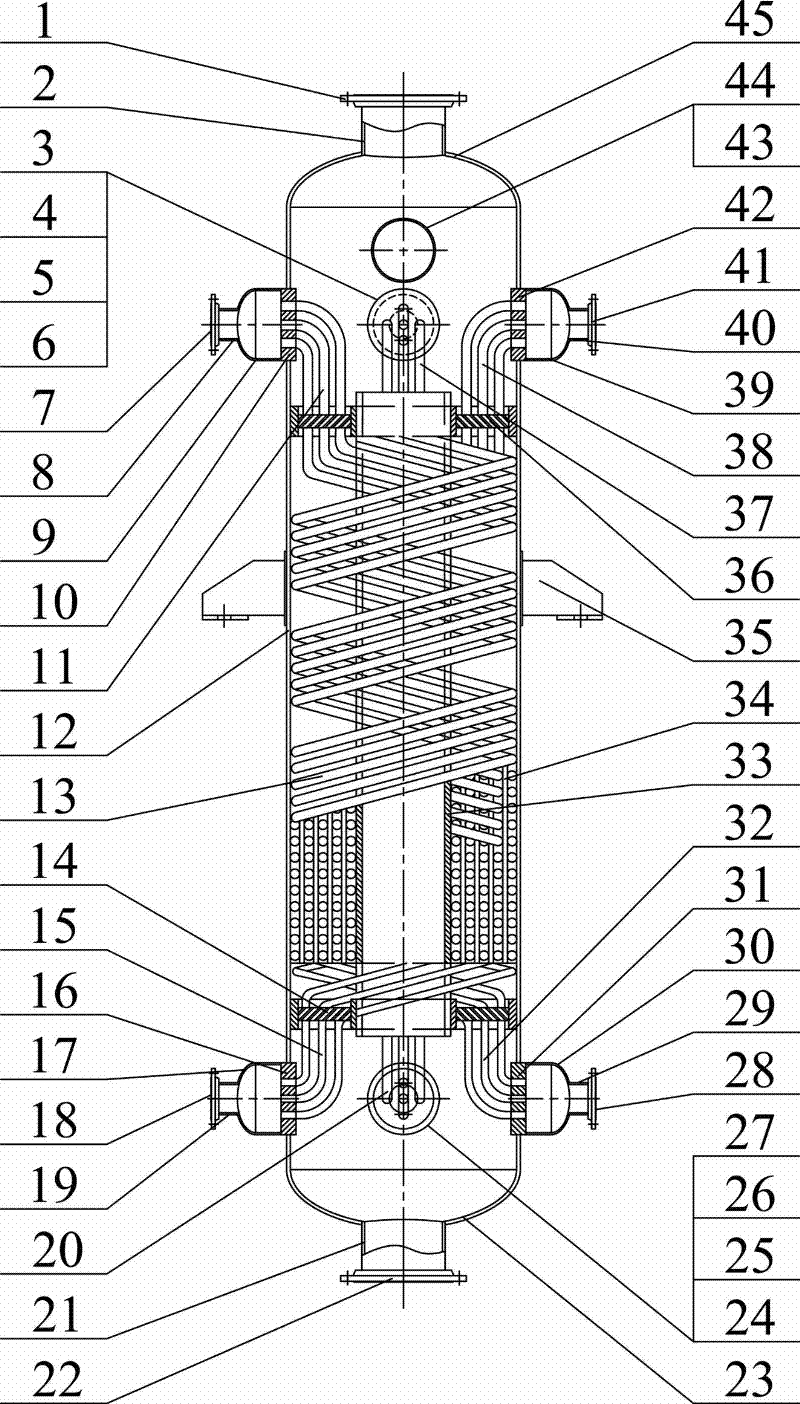

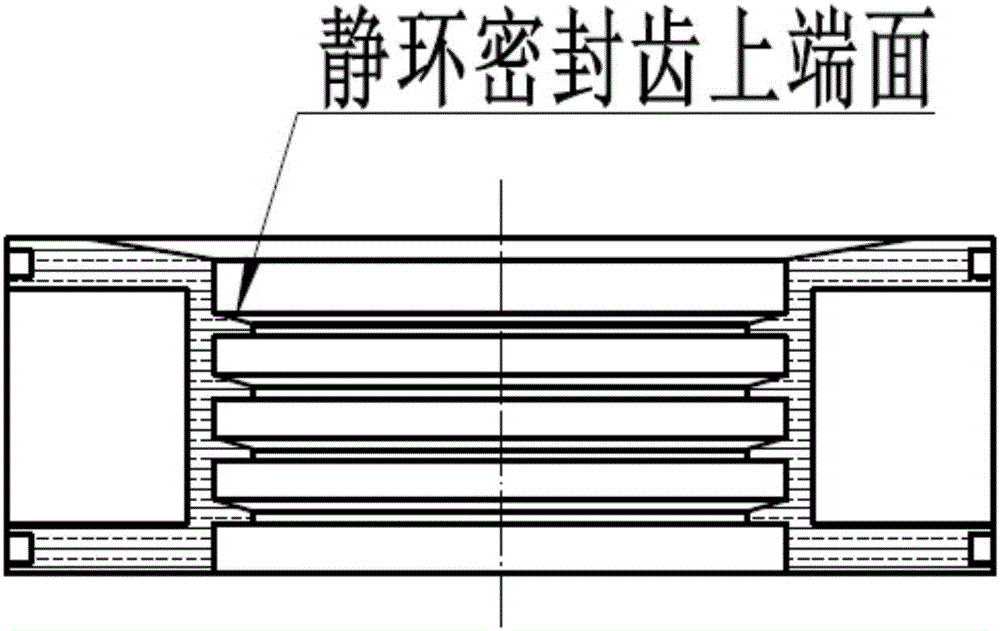

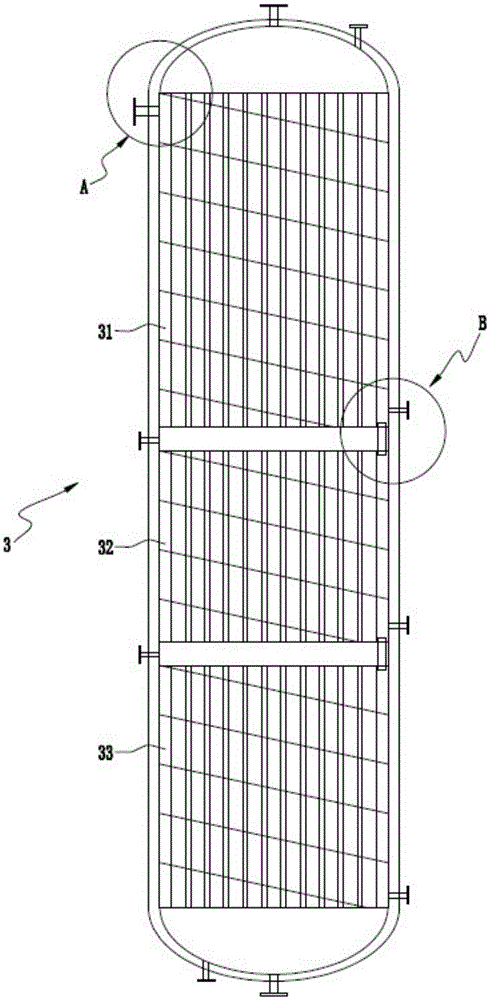

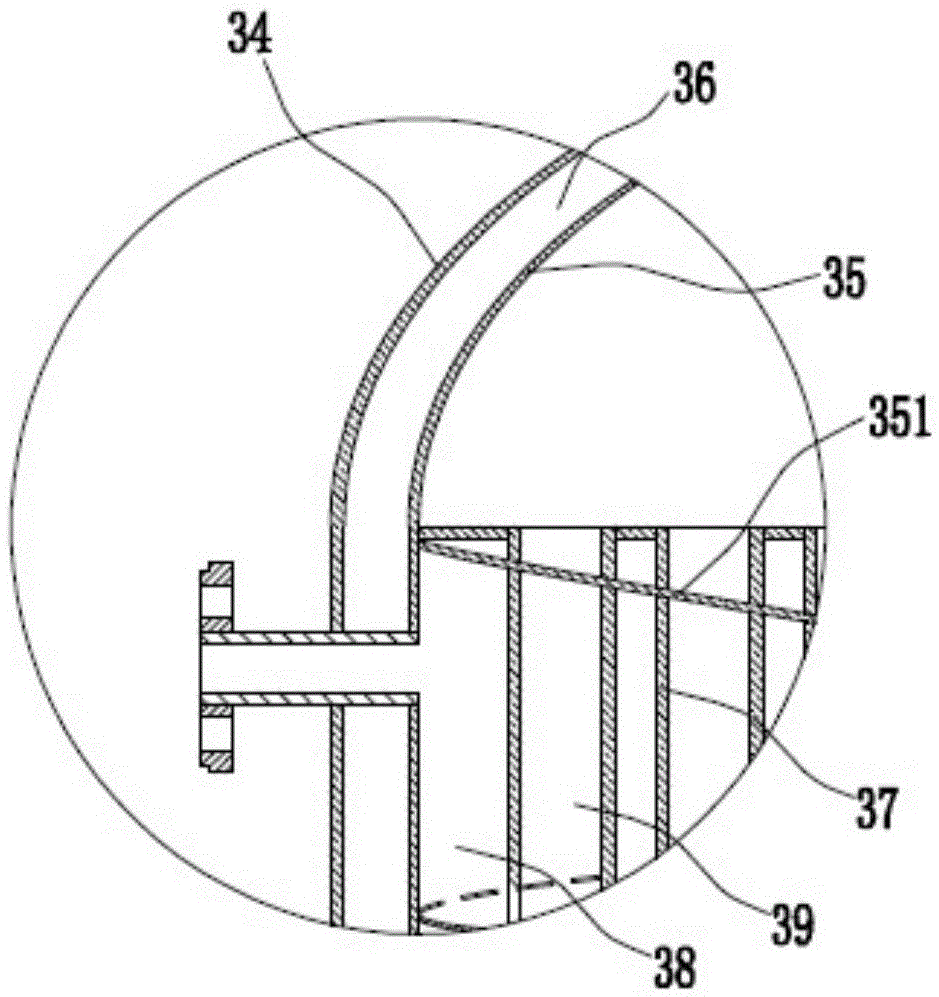

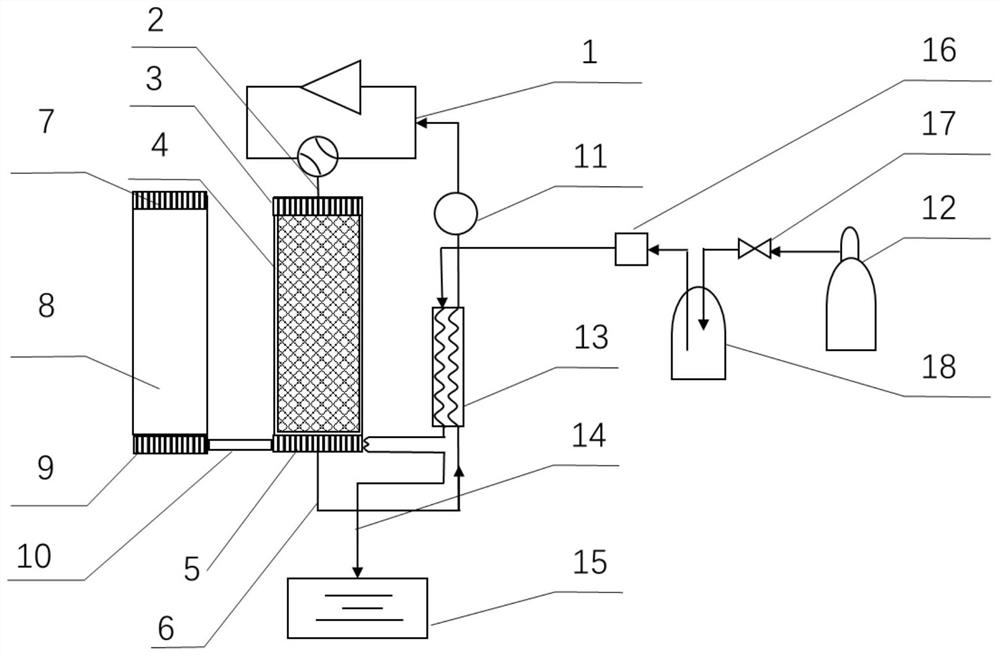

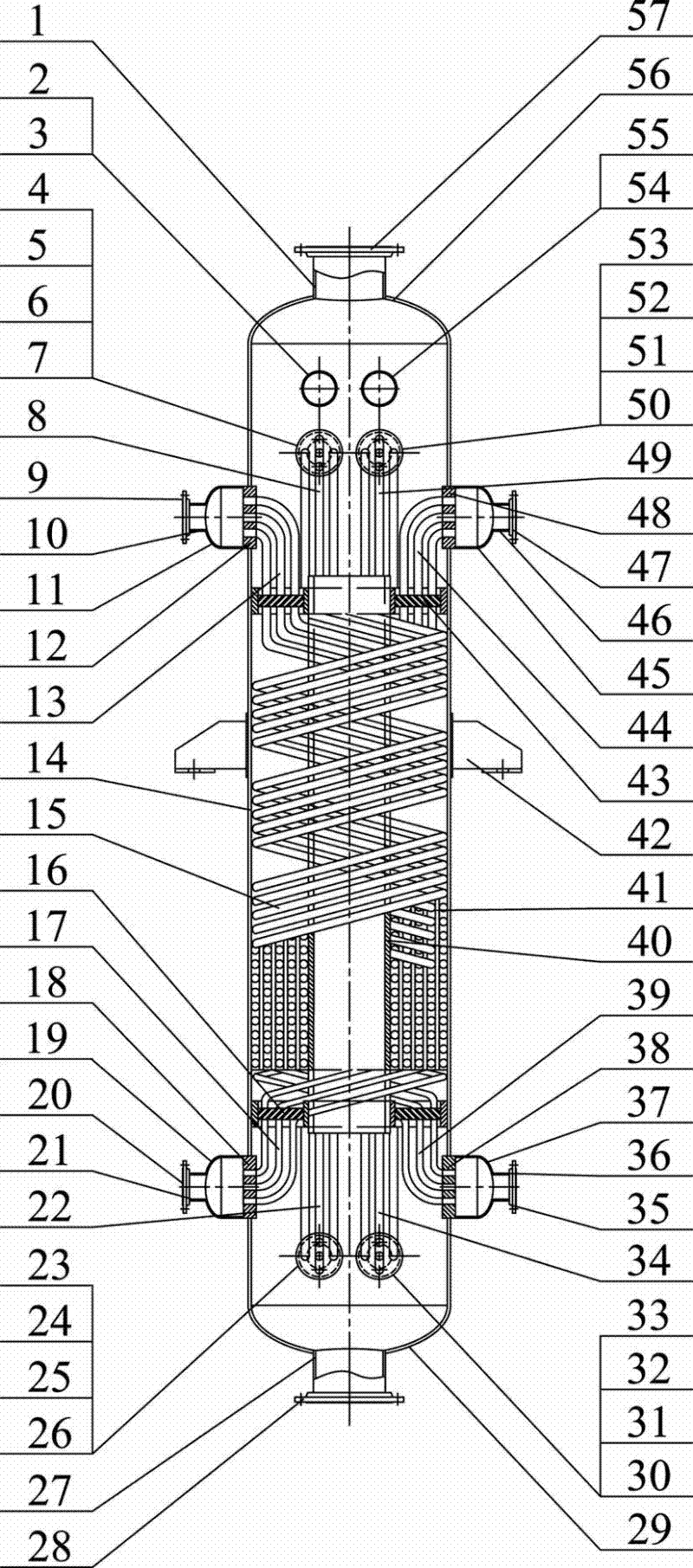

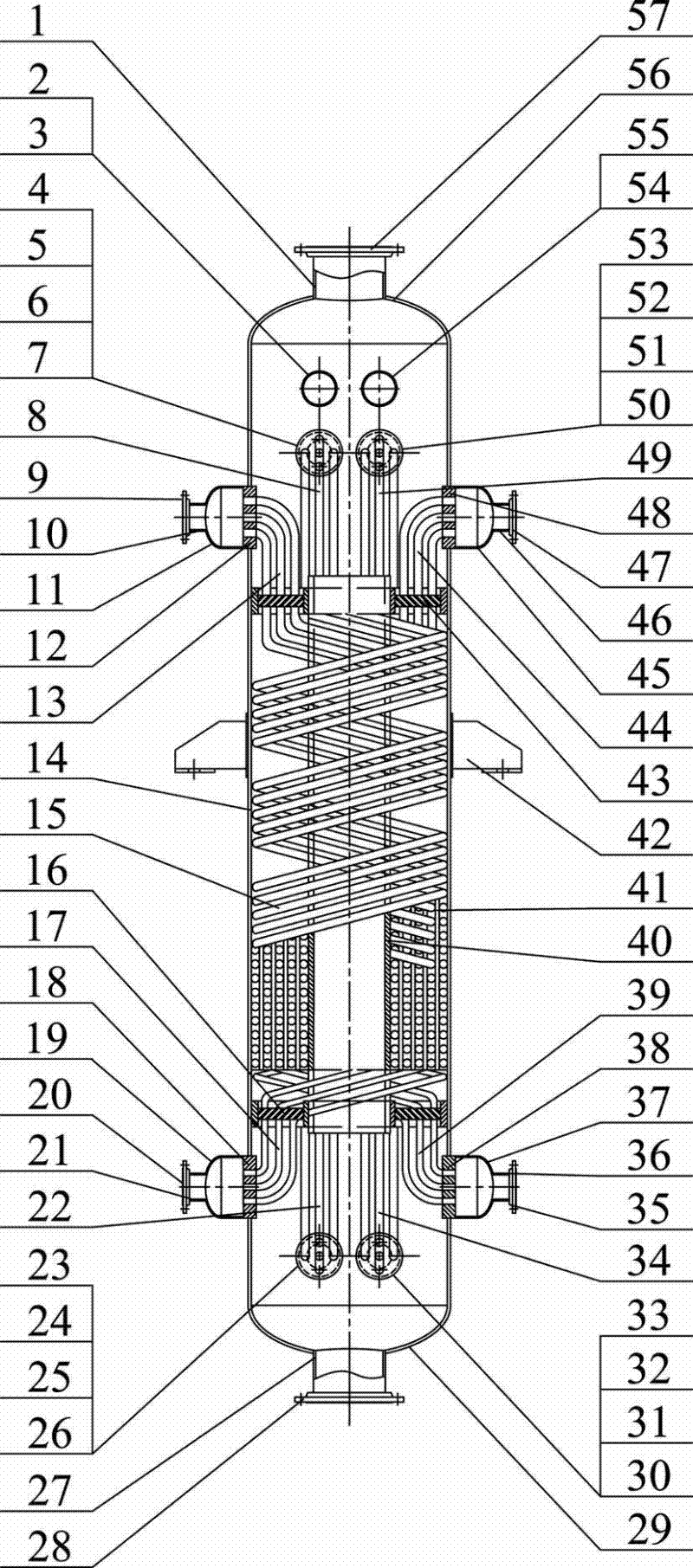

Liquefied natural gas (LNG) low temperature liquefied three-level refrigeration spiral wound tube type heat exchanger

InactiveCN102538387AWith self-tightening adjustment functionReduce volumeSolidificationLiquefactionThree levelSpiral wound

The invention belongs to the field of natural gas low temperature liquefied technology, and relates to a liquefied natural gas (LNG) three-level low temperature liquefied process device and a mixed refrigerant refrigeration technology, which cools 6.0MPa, -120DEG C natural gas into -164DEG C to be liquefied in two-steam spiral wound tube type heat exchanger by applying a certain proportion of non-azeotropic N2-CH4 mixed refrigerant, thereby being convenient for LNG to be stored in a surpercooling mode and being convenient to transport. The non-azeotropic N2-CH4 mixed refrigerant is firstly precooled and liquefied by a three-level refrigerant spiral wound tube type heat exchanger, and is throttled to a shell pass after being liquefied to cool a LNG tube bundle and a N2-CH4 mixed refrigerant precooling tube bundle from a secondary outlet in -120DEG C, thereby leading natural gas and precoolded refrigerant in the tube pass to be liquefied, and achieving the purpose of precooling mixed refrigerant before throttling and liquefying nature gas at low temperature. The LNG three-level low temperature liquefied process device is compact in structure and high in heat exchange efficiency, can be used to exchange heat for mixed gas with low-temperature phase transition, solves the difficult problem of LNG three-level low temperature technology, and increases low temperature heat exchange efficiency of a LNG system.

Owner:张周卫

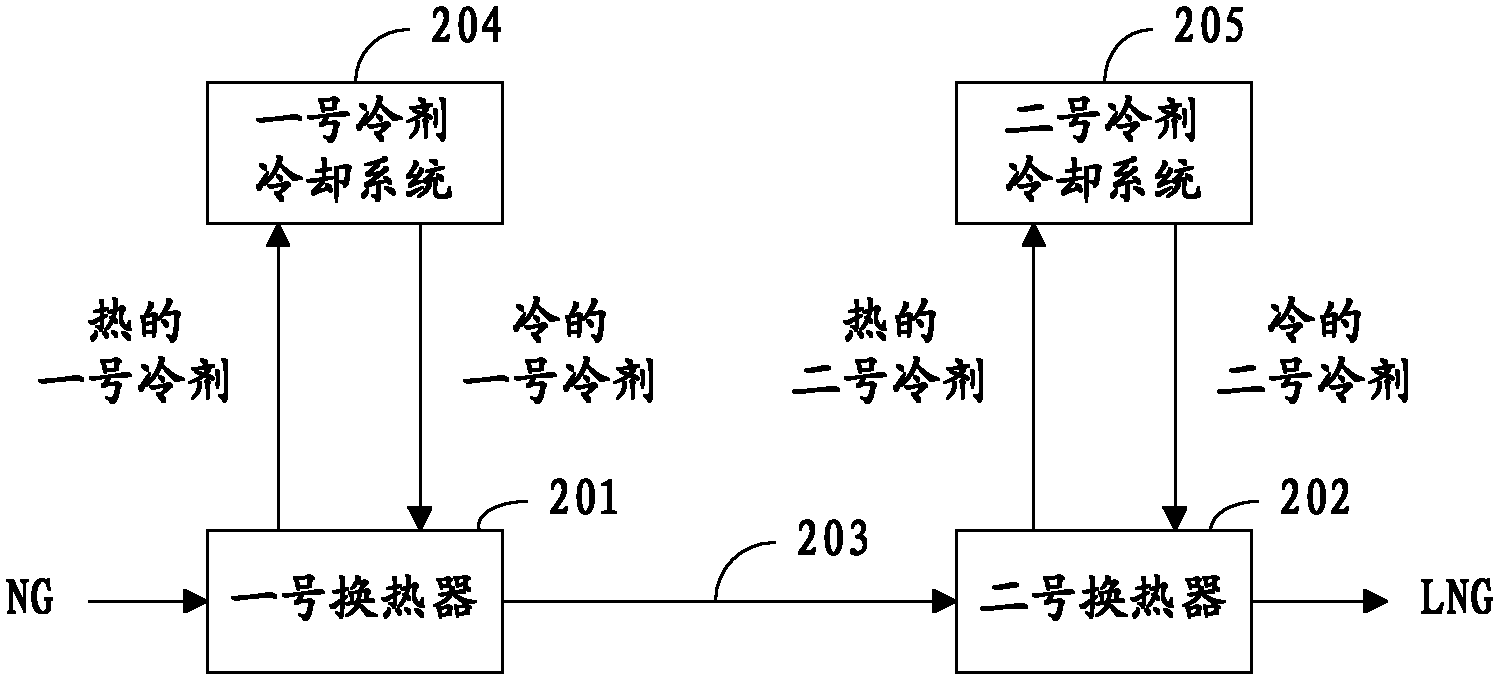

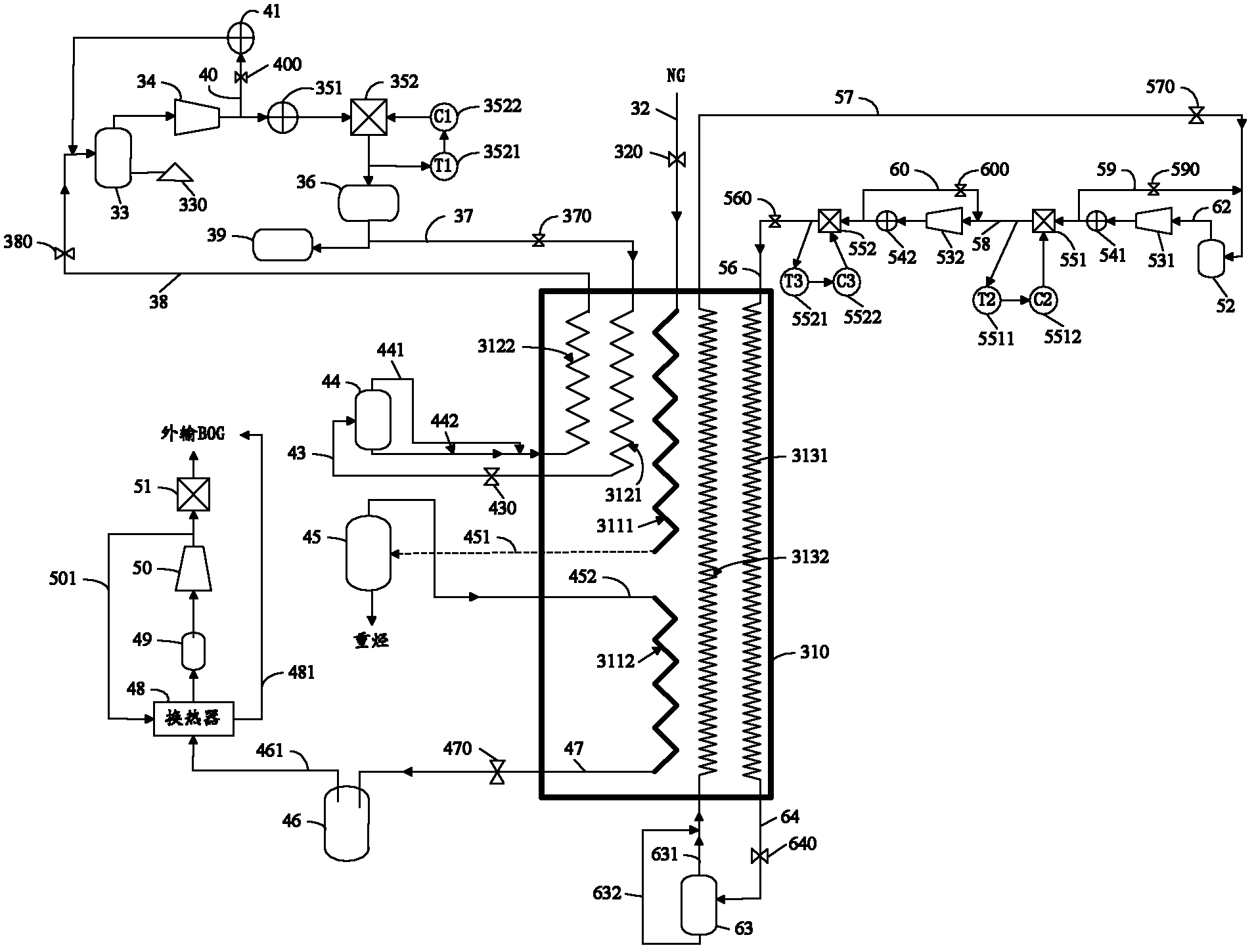

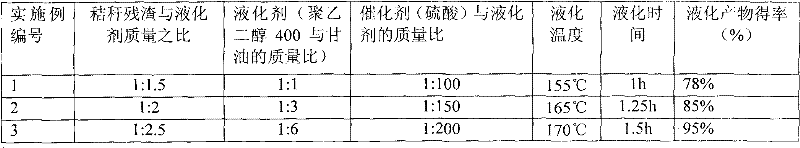

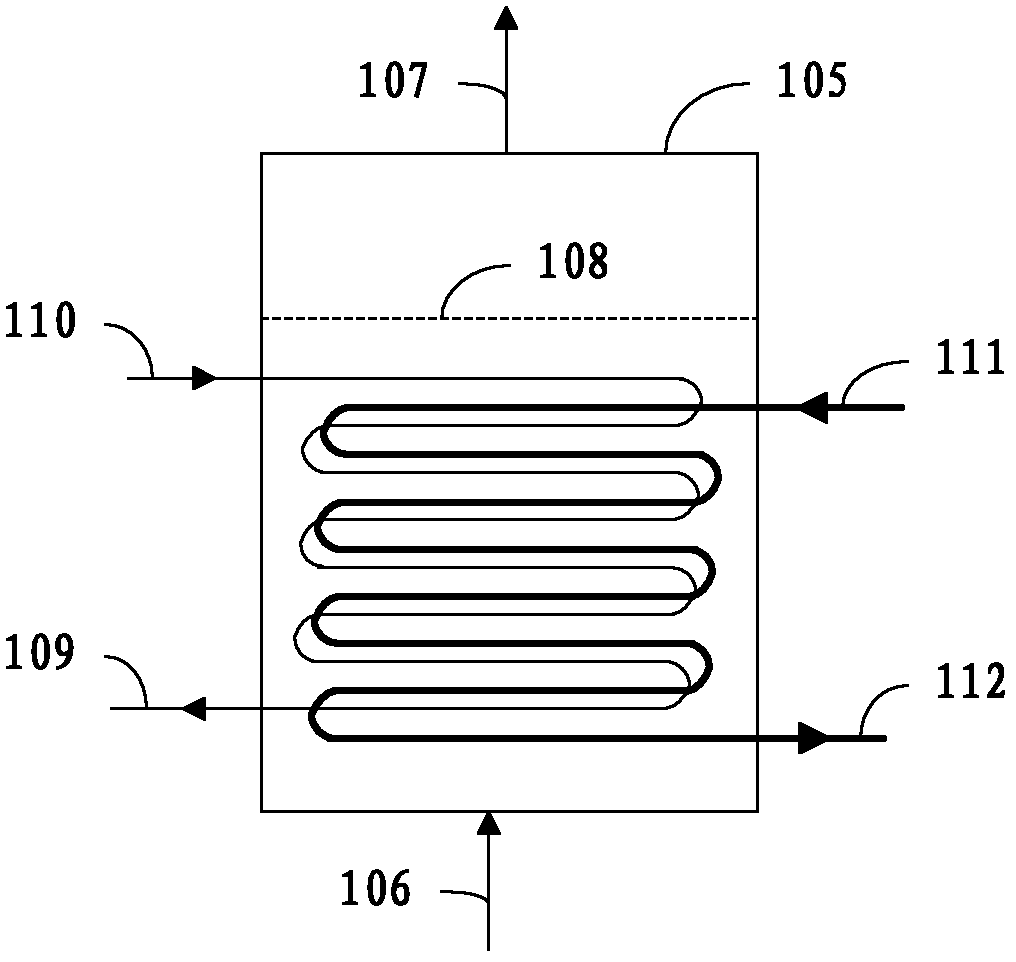

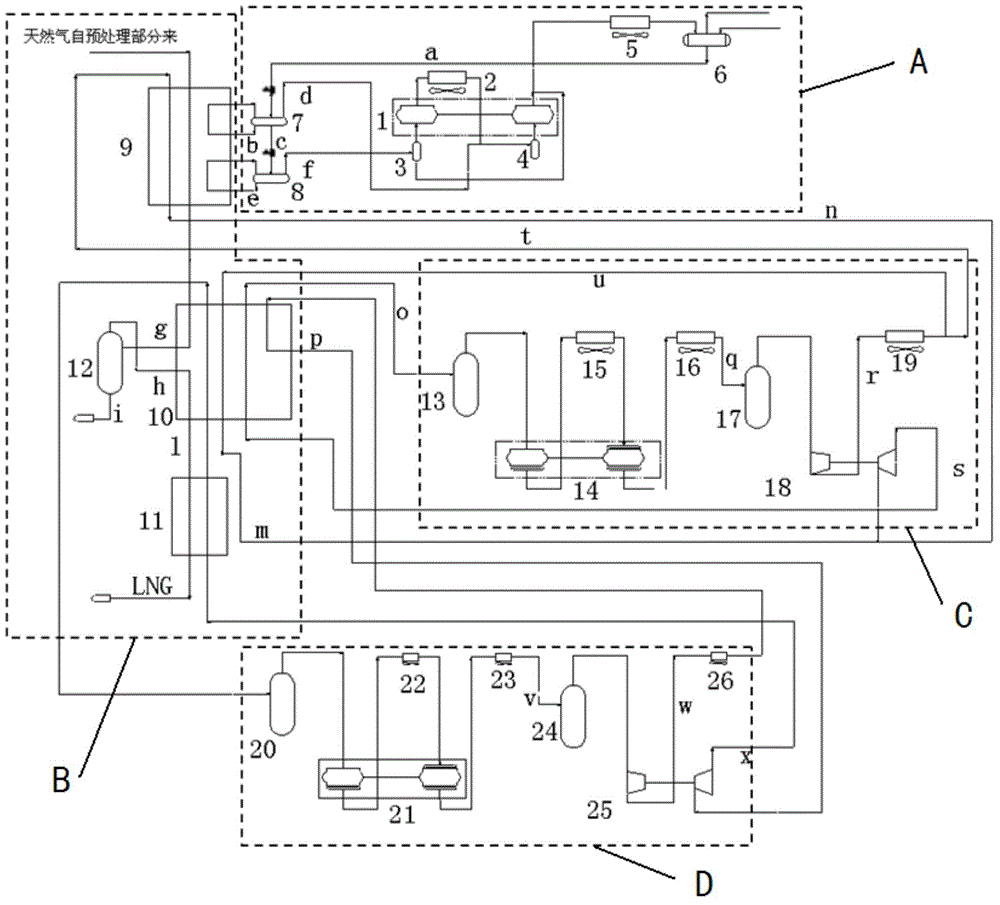

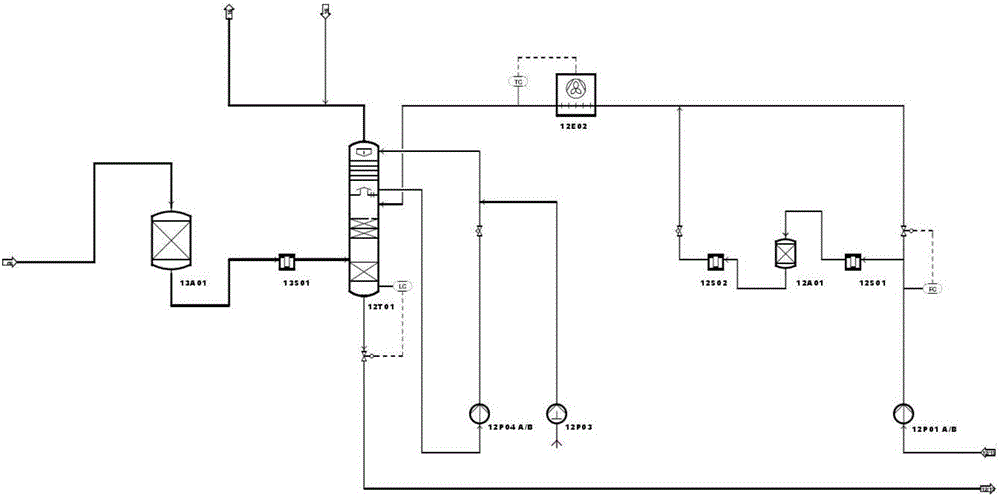

Liquefaction system and method for NG (Natural Gas)

ActiveCN103075868AImprove utilization efficiencyImprove cooling efficiencySolidificationLiquefactionEngineeringHigh pressure

The invention relates to a liquefaction system and a liquefaction method for NG (Natural Gas). The system comprises a cold box, a supply pipe for supplying the NG to the cold box, a No.1 refrigerant liquefaction subsystem, a No.2 refrigerant liquefaction subsystem, a No.1 refrigerant cooling subsystem, a No.2 refrigerant cooling subsystem, a heavy hydrocarbon separation tank which is used for conducting gas-liquid separation to liquid heavy hydrocarbon and gas light hydrocarbon, and an LNG (Liquefied Natural Gas) storage tank which is used for storing LNG obtained through liquefaction, wherein the cold box comprises an NG precooling passage which is connected with the heavy hydrocarbon separation tank and is used for supplying the NG; an NG deep cooling passage which is connected with the LNG storage tank and is used for supplying the gas light hydrocarbon; a No.1 refrigerant precooling passage and a No.2 refrigerant precooling passage which are used for respectively supplying and cooling high-pressure No.1 refrigerant and high-pressure No.2 refrigerant which are respectively supplied by the No.1 refrigerant liquefaction subsystem the No.2 refrigerant liquefaction subsystem, and are used for respectively supplying the cooled high-pressure No.1 refrigerant and the cooled high-pressure No.2 refrigerant to the No.1 refrigerant cooling subsystem and the No.2 refrigerant cooling subsystem; and a No.1 refrigerant cooling passage and a No.2 refrigerant cooling passage which are used for respectively supplying low-temperature No.1 refrigerant and low-temperature No.2 refrigerant which are respectively supplied by the No.1 refrigerant cooling subsystem and the No.2 refrigerant cooling subsystem to cool the NG, high-temperature No.1 refrigerant and high-temperature No.2 refrigerant. By adopting the technical scheme, the complexity and the energy consumption of the system can be reduced.

Owner:PETROCHINA CO LTD +1

Straw liquefied coating liquid and preparation method and application thereof

ActiveCN105016874AAvoid negative effectsAccelerate the speed of in situ reactionFertilizer mixturesPolyolControl release

The invention discloses methods for a straw liquefied coating liquid and a coated controlled-release fertilizer. The preparation method of the coating liquid comprises the steps: mixing straw, a liquefying agent, an acidic catalyst and a surfactant, carrying out a reaction, and removing a residue in the reaction system, to obtain a filtrate which is a straw liquefied product; and then carrying out a mixing reaction of the straw liquefied product with polyether polyol, an alkaline catalyst and an auxiliary agent, and thus obtaining the straw liquefied coating liquid. The preparation method of the coated controlled-release fertilizer comprises the steps: preheating fertilizer granules, then simultaneously atomizing the straw liquefied coating liquid and a curing agent onto the surface of the fertilizer granules, to obtain the straw liquefied coated controlled-release fertilizer. The coated controlled-release fertilizer provided by the invention utilizes compounding of heteropolyacid and inorganic acid to catalyze liquefaction of a straw powder; while the alkaline catalyst in the straw liquefied coating liquid is used for acid-alkali adjustment of the straw liquefied product, the in-situ reaction speed is accelerated, and thus the controlled-release characteristic of the coated controlled-release fertilizer is improved.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

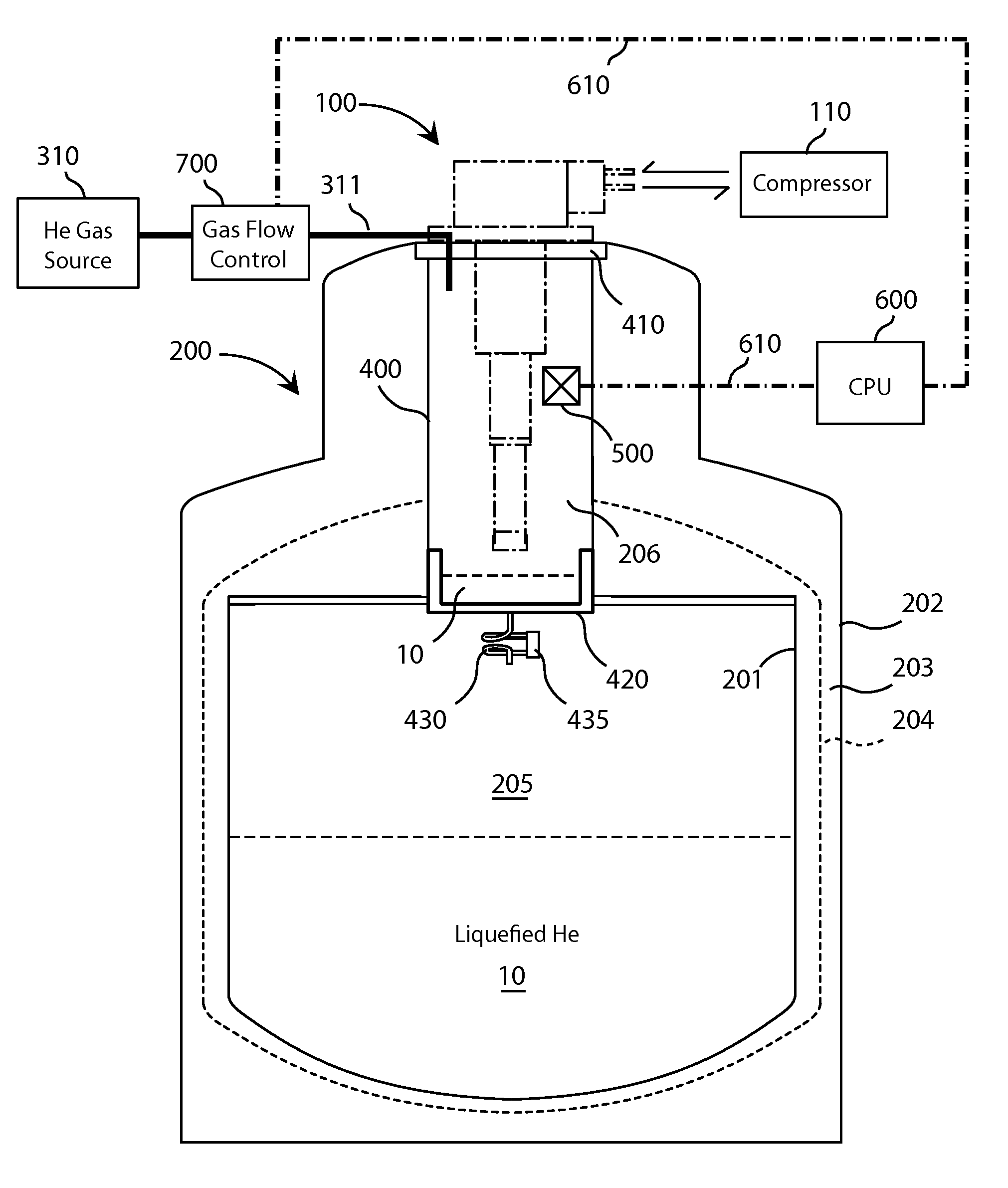

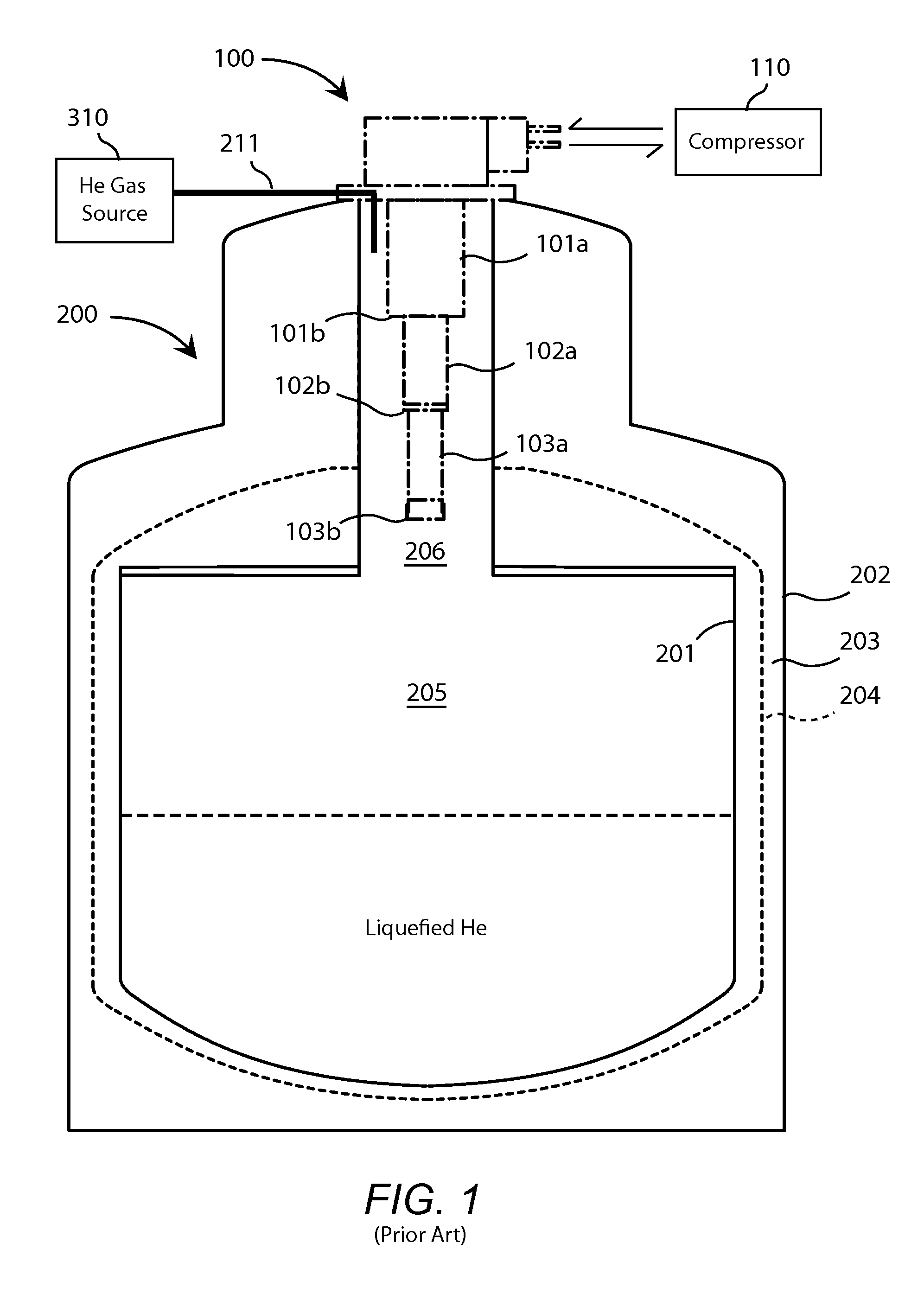

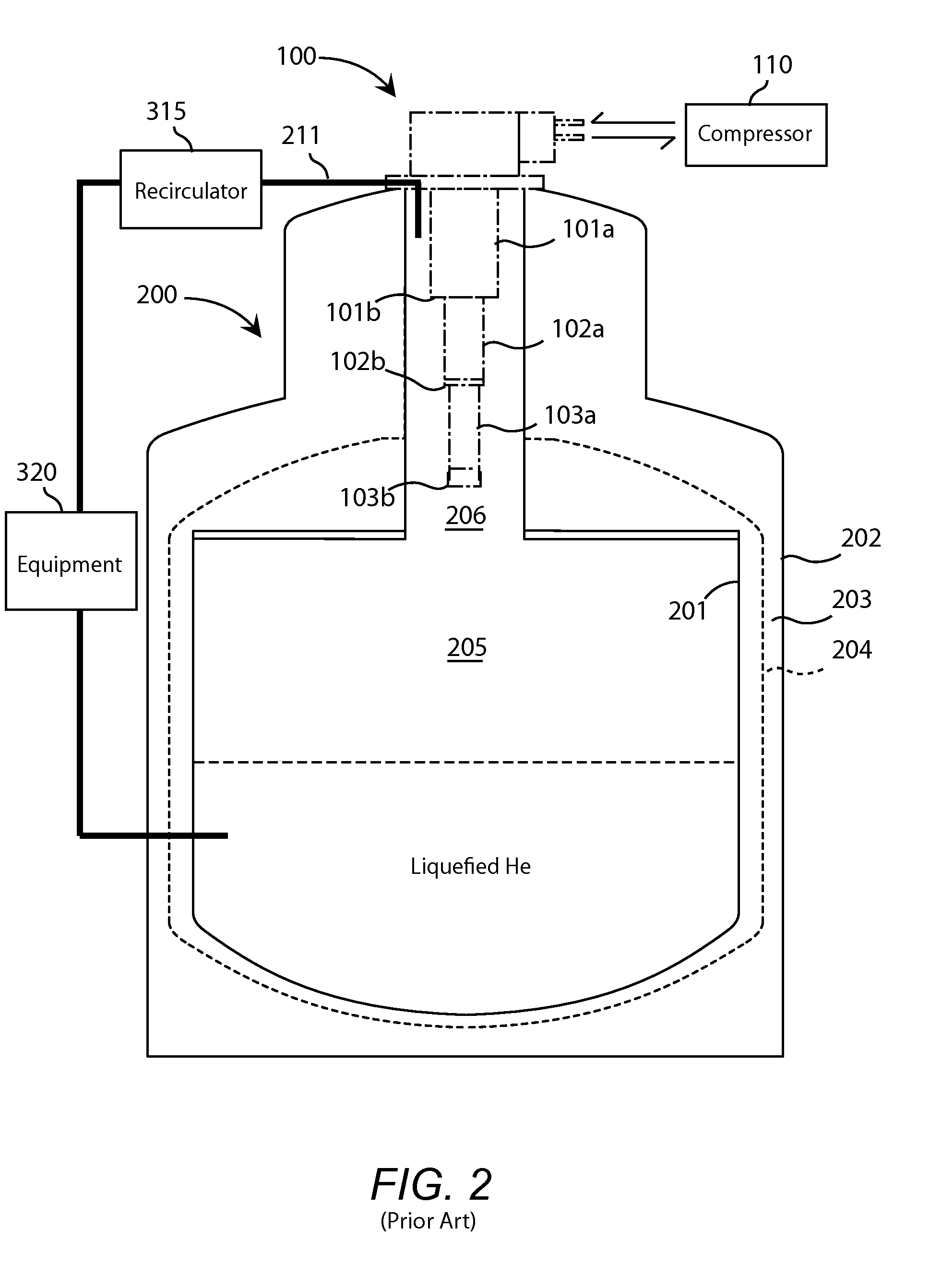

Liquefier with pressure-controlled liquefaction chamber

ActiveUS20130014517A1Improve liquefaction efficiencyIncrease cooling powerVessel mounting detailsSolidificationCounter flowEngineering

A liquefier includes a Dewar having a storage portion and a neck portion extending therefrom. A hermetically isolated liquefaction chamber is disposed within the neck of the Dewar. One or more control components including a temperature and pressure sensor are coupled to a CPU and disposed within the liquefaction chamber for dynamic control of liquefaction conditions. A gas flow control is coupled to the CPU for regulating an input gas flow into the liquefaction chamber. A volume surrounding the liquefaction chamber may be adapted to provide a counter-flow heat exchange. These and other features provide improved liquefaction efficiency among other benefits.

Owner:QUANTUM DESIGN

Preparation method of syrup special for moon cake

The invention relates to the field of starch sugar manufacturing, in particular to a preparation method of syrup special for moon cake. According to the method, corn starch is taken as the raw material, and the syrup is prepared through the steps such as size mixing, enzyme immersion, liquefaction, saccharification, glucoside conversion, decolorization, filtering, ion exchange, concentration, blending and the like. The prepared syrup comprises 20-25% of maltobiose, 12-17% of maltotriose, 15-20% of maltotetraose, 8-12% of tetrasaccharide-above, 3-5% of oligoisomaltose, 25-30% of fructose, and less than 3% of glucose. The syrup special for moon cake produced through the method is sucrose-free; the sweetness is slightly lower than that of the sucrose; the sweet taste is mild and pure, cool and refreshing; and the syrup is provided with a sweet flavor peculiar to honey, and has the advantages that the oil return property is obvious, the moisture retention property is good, the starch retrogradation is prohibited, the shelf life and the quality guarantee period of products are effectively prolonged, and the like.

Owner:BAOLINGBAO BIOLOGY

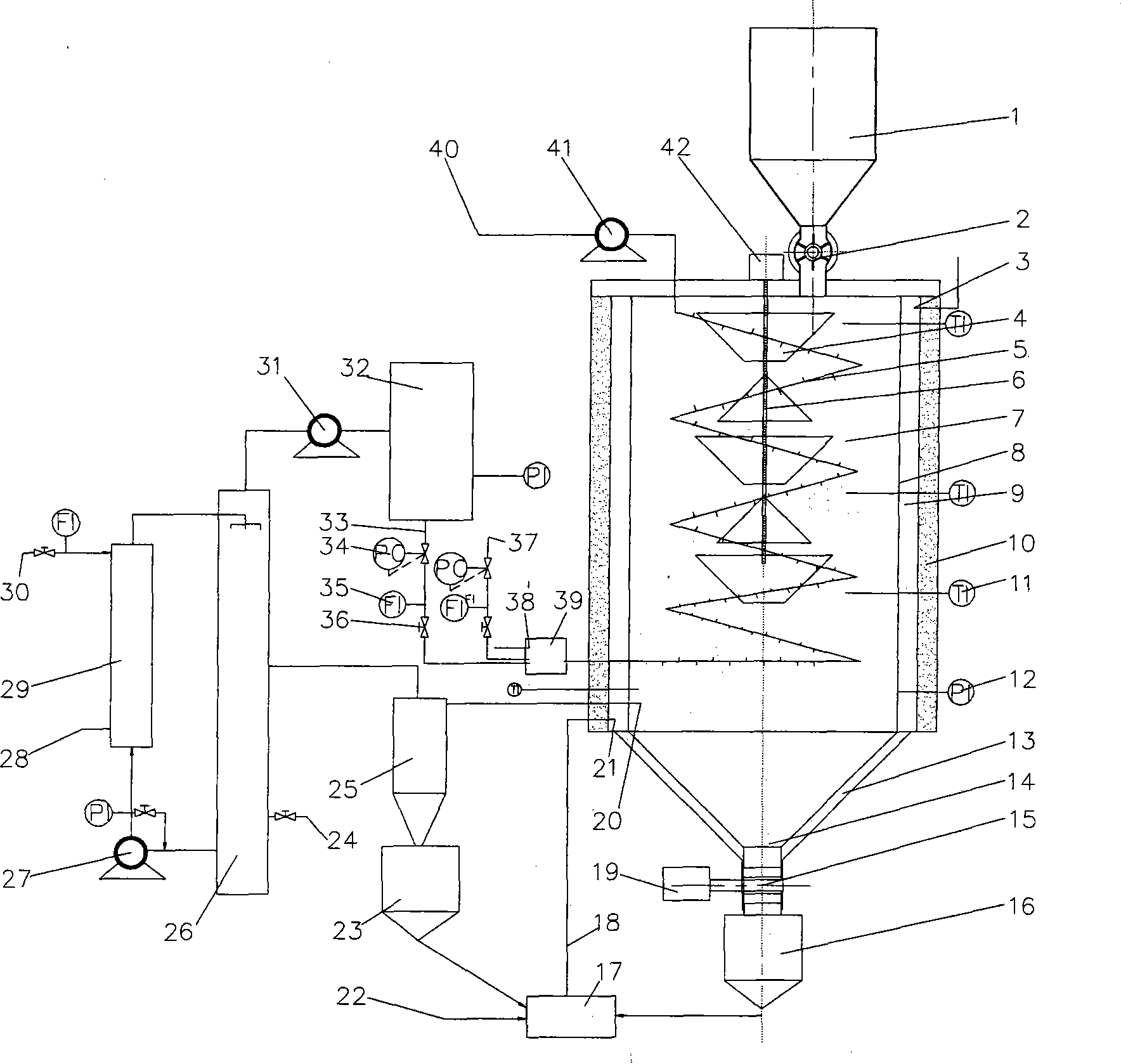

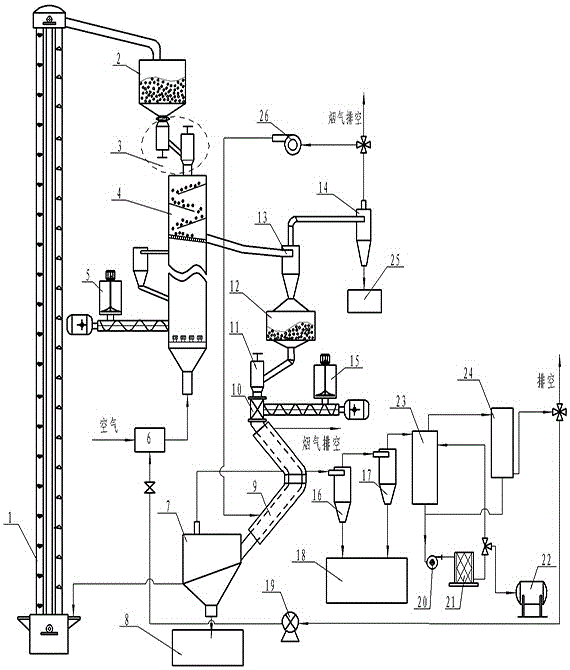

Internal combustion heating moving-bed type biomass pyrolysis liquefying apparatus

InactiveCN101376814AIncrease profitReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionBiomassPyrolysis

The invention discloses an internal combustion heating movable-bed biomass-pyrolysis liquefaction device which includes a reactor (7); the inside of the reactor is provided with an internal combustion pipeline (5); both the inlet and the outlet of the internal combustion pipeline (5) are arranged outside the reactor (7); a hopper (1) is arranged above the reactor (7); a blanking control valve (2) is arranged on the hopper (1); a rotary shaft (6) is arranged in the center of the reactor (7); conical hoppers (4) are arranged on the rotary shaft (6); conical material dividing umbrellas are arranged between the conical hoppers (4); the material inlet of the hopper (1) is arranged above the conical hoppers (4); a pyrolysis gas outlet (20) is arranged on the reactor (7); the bottom part of the reactor (7) is provided with a slag discharge opening (14); a cyclone separator (23) is connected on the gas pipeline of the pyrolysis gas outlet (20); the flue gas outlet of the cyclone separator (23) is connected into a condenser (26); an oil outlet and an outlet for non-condensable gas are arranged on the condenser (26); the outlet for non-condensable gas is connected to a gas buffer tank (28) through a draught fan. The biomass-pyrolysis liquefaction device reduces the liquefaction cost of bio-oil, has a simple structure and a low processing and manufacture cost as well as is simply and conveniently operated, managed and maintained.

Owner:HEFEI UNIV OF TECH

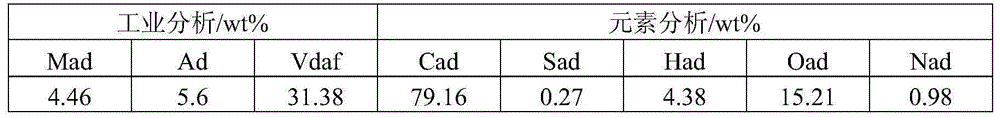

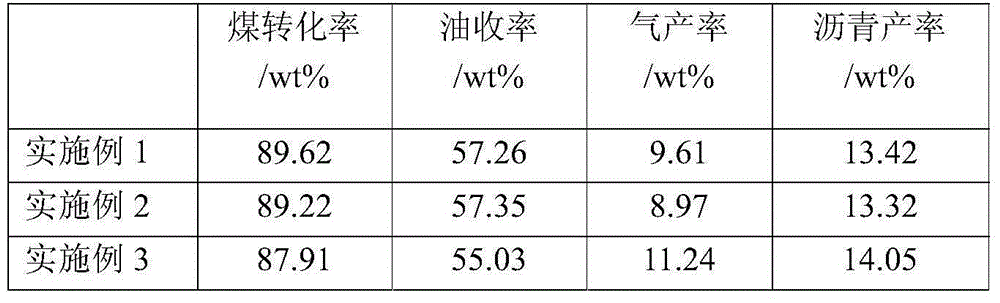

Iron-based catalyst and preparation method thereof

InactiveCN105013505AGood dispersionImprove stabilityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsCatalytic pyrolysisActive phase

The present invention provides an iron-based catalyst and a preparation method thereof. The catalyst comprises an active ingredient, a structure additive and a catalyst carrier, the active ingredient comprises FeOOH, the structure additive includes MnO (OH) 2, the MnO (OH) 2 is added to separate and disperse the FeOOH for ultimate formation of the FeOOH with very small size. The FeOOH with smaller particle size is combined easily with S for conversion into an active phase Fe1-xS. The iron-based catalyst can be nearestly and rapidly reacted with coal, catalytic pyrolysis and hydrogenation of coal macromolecules can be promoted, and the efficiency of coal liquefaction is improved. The iron-based catalyst has better dispersion and stability, as well as higher activity of direct coal liquefaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

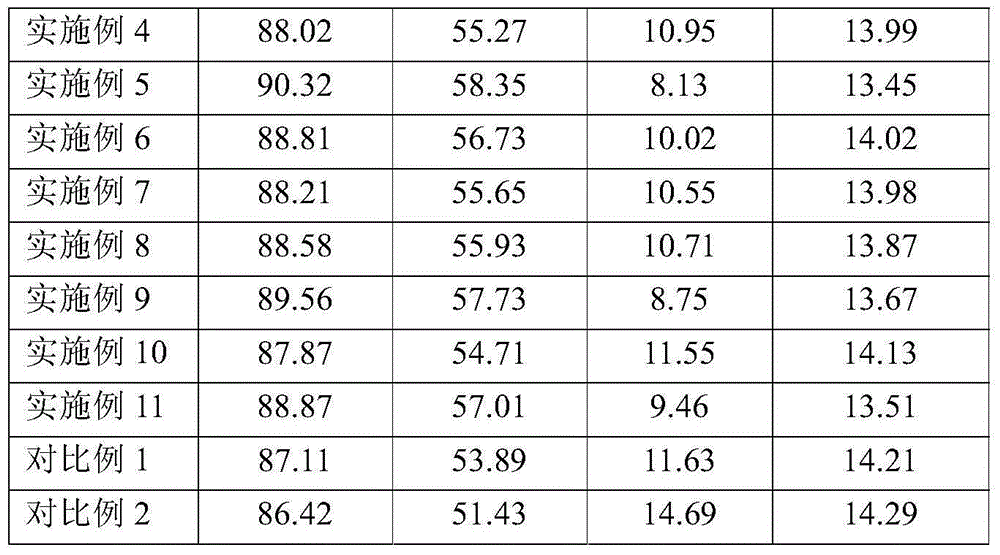

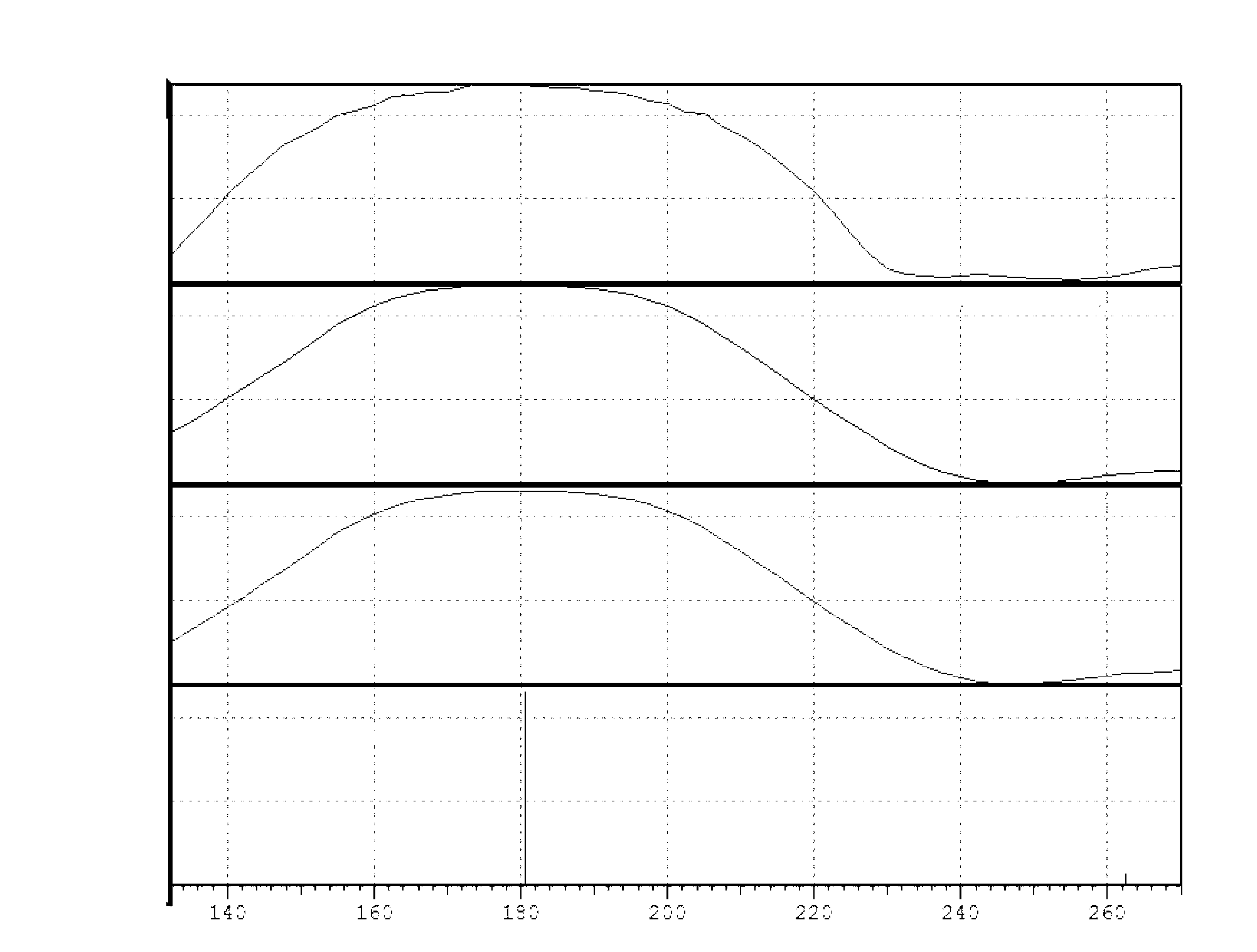

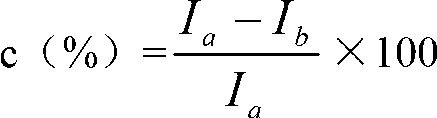

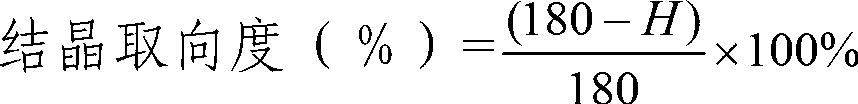

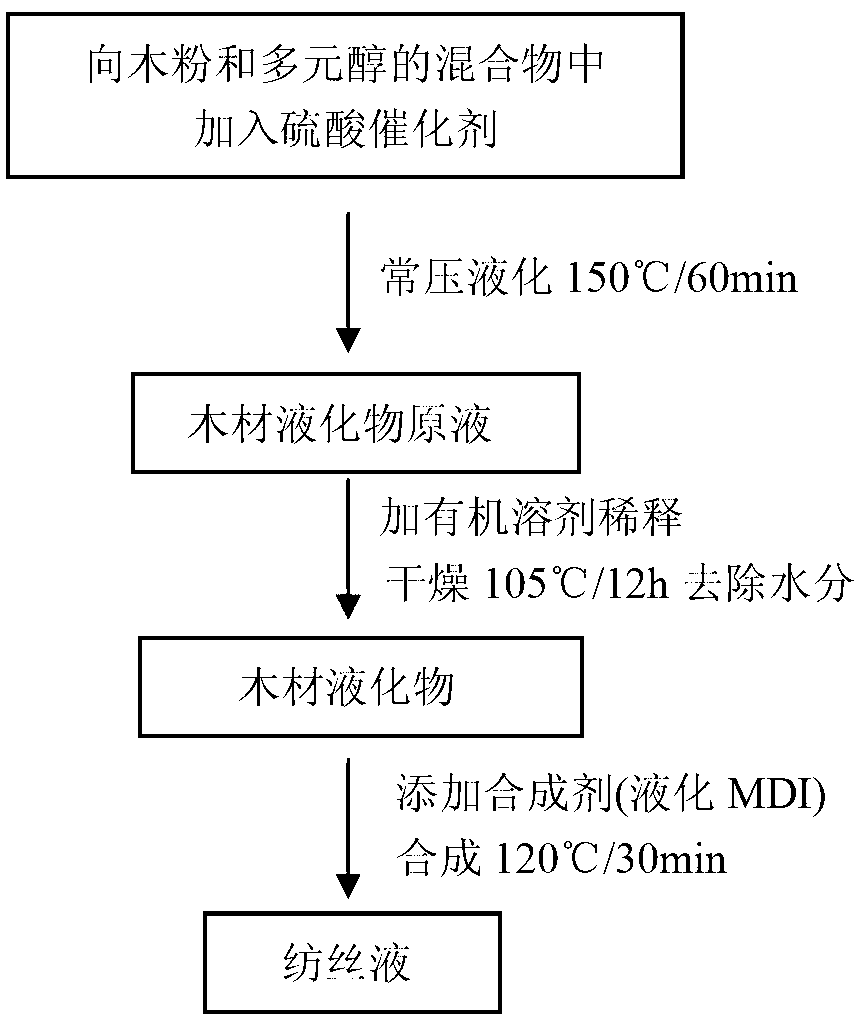

Wood carbon fiber precursor and preparation method thereof

InactiveCN103014920ALiquefaction effectHas a swelling effectFibre chemical featuresWet spinning methodsFiberCarbon fibers

The invention relates to a wood carbon fiber precursor and a preparation method of the carbon fiber precursor. The preparation method comprises the following steps: (1) adding phenol into wood, and liquefying the wood by using sulfuric acid as a catalyst to obtain a liquefied wood product; (2) mixing the liquefied wood product and a synthesizing agent, reacting, and spinning to obtain an initial fiber; and (3) curing the initial fiber to obtain the wood carbon fiber precursor. The preparation method is high in liquefying efficiency and low in residue rate; preparation of a spinning solution and a spinning process are carried out at the same time, the carbon fiber precursor can be prepared more easily; and compared with the prior art, the prepared wood carbon fiber precursor has obviously superior quality indexes of crystallinity and orientation degree and has a wider application prospect and a higher economic value.

Owner:BEIJING FORESTRY UNIVERSITY

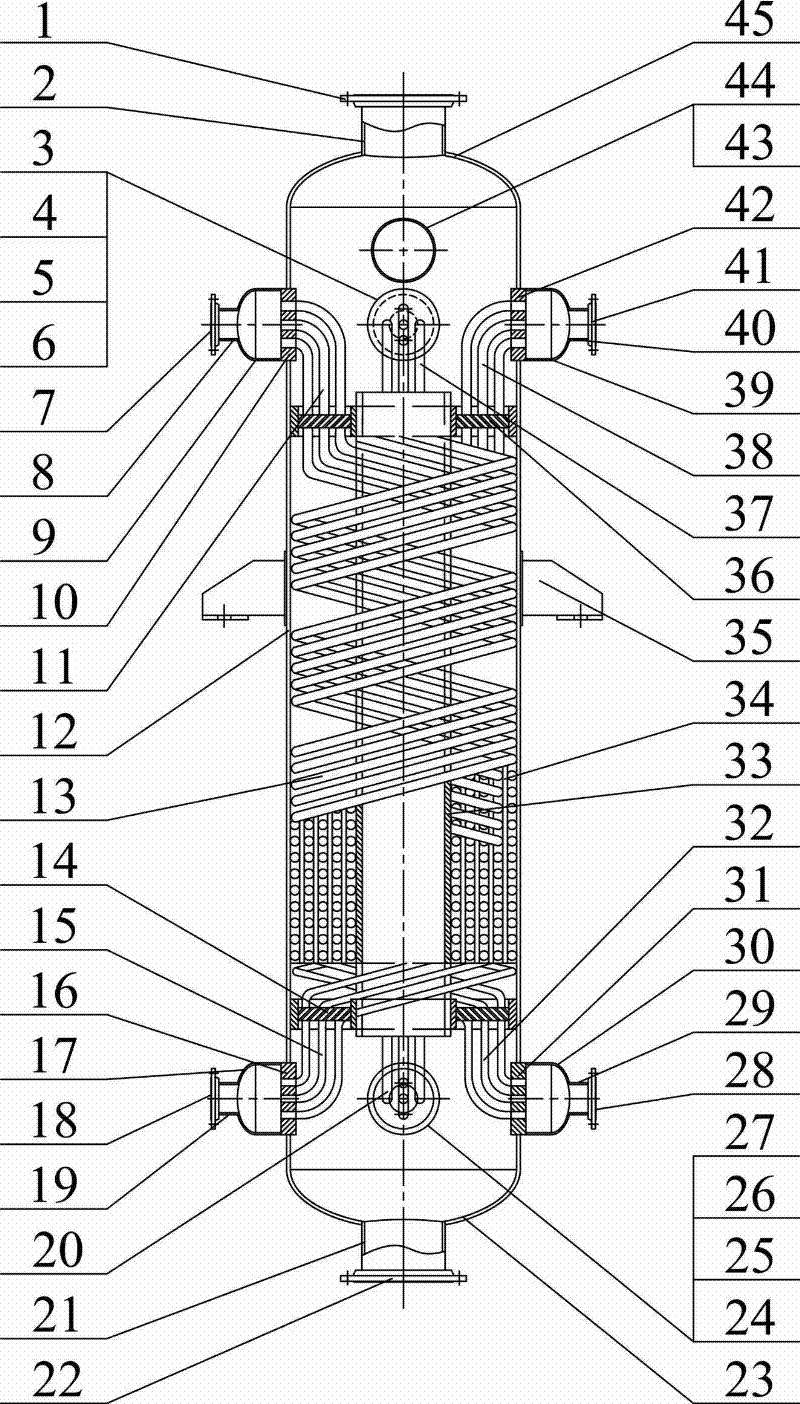

Three-stream spiral wound type heat exchange equipment for secondary refrigeration and low-temperature liquefaction of LNG (liquefied natural gas)

The invention belongs to the technical field of low-temperature natural gas liquefaction, and relates to LNG (liquefied natural gas) secondary low-temperature liquefaction equipment and the technique of refrigeration by mixed refrigerant. C2H4 refrigerant and N2-CH4 mixed refrigerant steam of 0.3MPa and -130 DEG C from an LNG three-level outlet are used for cooling and liquefying natural gas of 5.8MPa and -53 DEG C in a three-stream spiral wound type heat exchanger, so that LNG can conveniently enter a three-level undercooling stage. The three-stream spiral wound type heat exchanger for secondary liquefaction is used for undercooling the C2H4 refrigerant first, the undercooled C2H4 refrigerant is throttled to a shell side to be mixed with the N2-CH4 to cool a -53-DEG C LNG pipeline, a N2-CH4 precooling tube bundle and a C2H4 undercooling tube bundle, so that undercooling of the C2H4 and precooling of the N2-CH4 and liquefaction of natural gas are realized. The equipment is compact in structure and high in heat exchange efficiency, and can be used for the field of phase-variable low-temperature heat exchange of gas at temperature ranging from -53 DEG C to -120 DEG C, the problem of LNG secondary low-temperature liquefaction is solved, and low-temperature heat exchanging efficiency of an LNG system can be improved.

Owner:张周卫

Method for liquefying wood

InactiveCN101032820AMild conditions for liquefactionLow residue rateWood treatment detailsPolymer scienceCarbon fibers

The timber liquefying method is to mixing timber with solvent in the presence of acid catalyst and under timber liquefying condition, with the timber accounting for not less than 30 wt% of the 1 wt% concentration water solution of NaOH as the extractant. The present invention has mild timber liquefying condition, reduced solvent consumption, greatly reduced liquefied residue rate, environment friendship and other advantages. The timber liquefying product is used for preparing adhesive, foamed polyurethane plastic, molded phenolic plastic and other polymer material.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

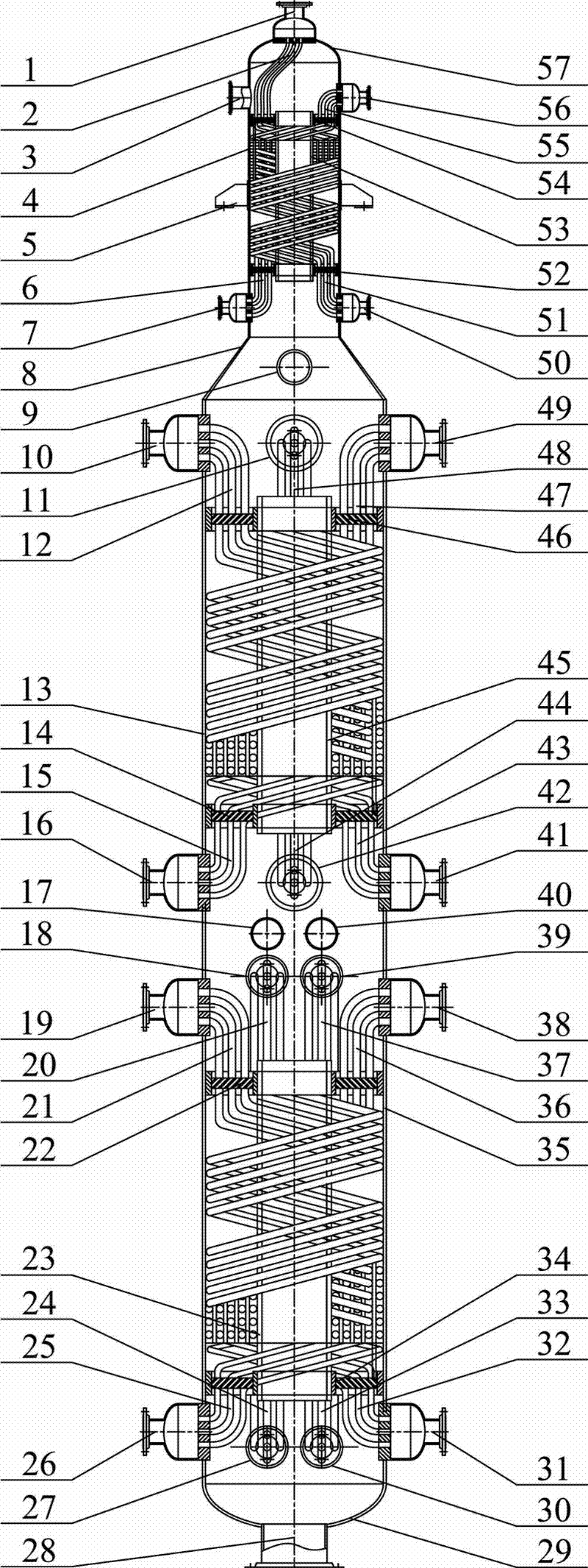

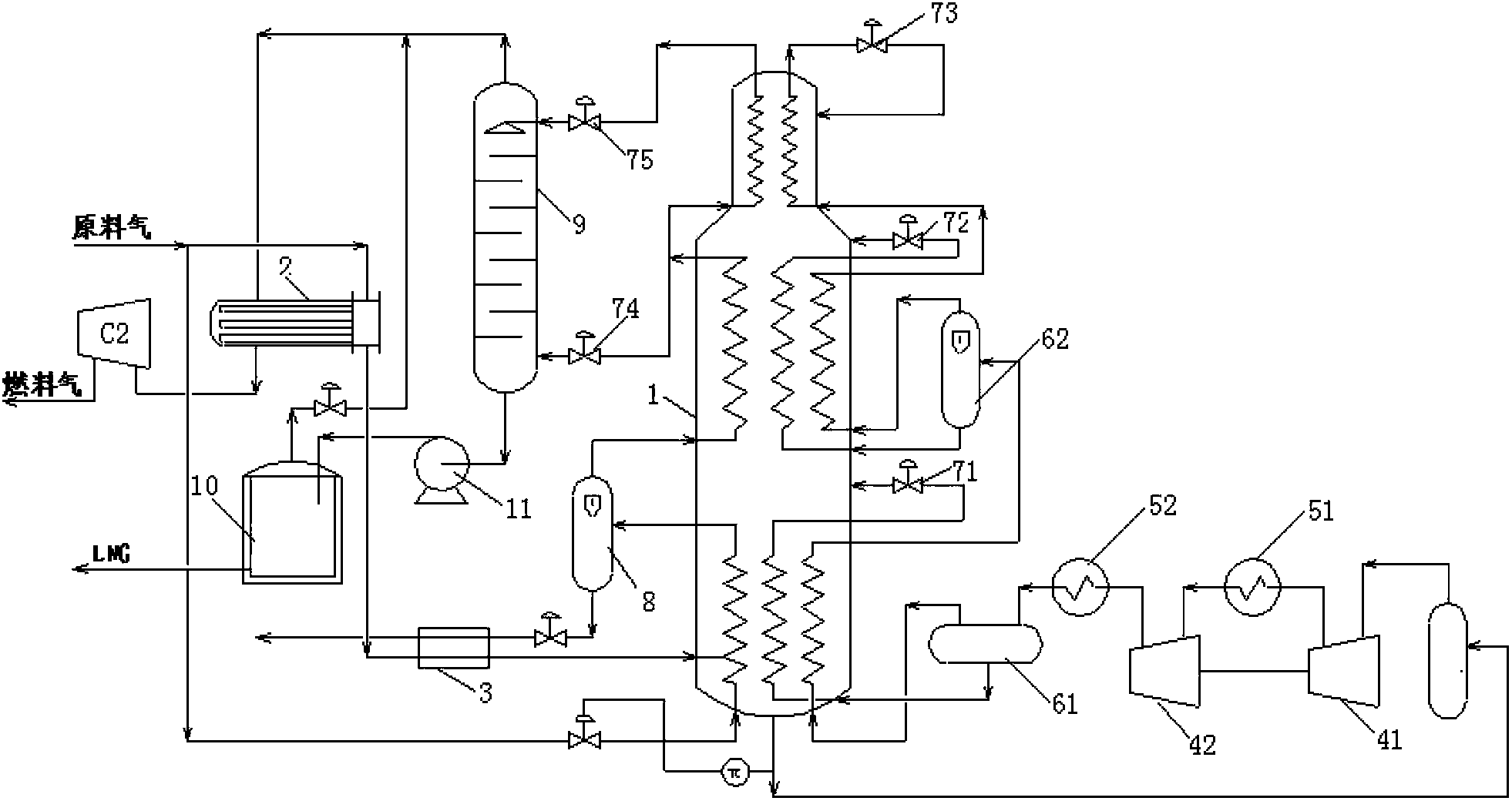

Multi-flow spiral winding tube type main heat exchange equipment with mixed refrigerant for low-temperature liquefaction of LNG (liquefied natural gas)

InactiveCN102564056AReduce volumeImprove heat transfer efficiencySolidificationLiquefactionThree stageEngineering

The invention belongs to the technical field of low-temperature liquefaction of natural gas, and relates to multi-flow spiral winding tube type main heat exchange equipment with mixed refrigerant for low-temperature liquefaction of LNG (liquefied natural gas) and refrigerating technology of mixed refrigerant. Natural gas at the temperature of 36 DEG C and pressure of 6.1MPa is gradually cooled to the temperature of minus 164 DEG C and is overcooled by the aid of mixed refrigerant consisting of N2, CH4, C2H4, C3H8, C4H10 and isomerized C4H10 via a three-stage refrigerating process, the N2, the CH4, the C2H4, the C3H8, the C4H10 and the isomerized C4H10 are gradually overcooled by a multi-flow spiral winding type heat exchanger and are respectively throttled, a natural gas tube bundle and a mixed refrigerant tube bundle are pre-cooled, and purposes of primary precooling of the natural gas, secondary liquefaction of the natural gas and tertiary overcooling of the natural gas are achieved. The multi-flow spiral winding tube type main heat exchange equipment is compact in structure and high in heat exchange efficiency, and can be used for the field of phase-change low-temperature heat exchange of gas at the temperature ranging from 36 DEG C to minus 164 DEG C, technical difficult problems in terms of low-temperature liquefaction of the LNG are solved, and low-temperature heat exchange efficiency of an LNG system is improved.

Owner:张周卫

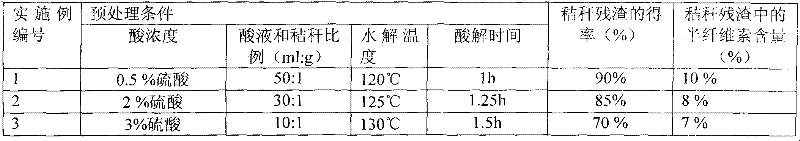

Method for preparing plant-based polyether polyol by straw liquefaction

The invention discloses a method for preparing plant-based polyether polyol by straw liquefaction. The method comprises the following steps: adding a liquefacient and a catalyst into acid-hydrolytic straw residues, reacting at 155 DEG C-170 DEG C for 1 h-1.5 h, wherein the mass ratio of the straw residue and the liquefacient is 1:1.5-1:2.5; after the reaction, adjusting the pH of the liquefied product to 6-7, filtering to remove residues in the liquefied product so as to obtain liquid which is the plant-based polyether polyol. According to the invention, straws are subject to acid treatment, which increases the accessibility of the liquefacient, cellulose and lignin, removes hemicellulose in the straws, facilitates the condition control of the liquefaction reaction, and improves the liquefaction efficiency and the quality of the liquefaction product.

Owner:李翠花

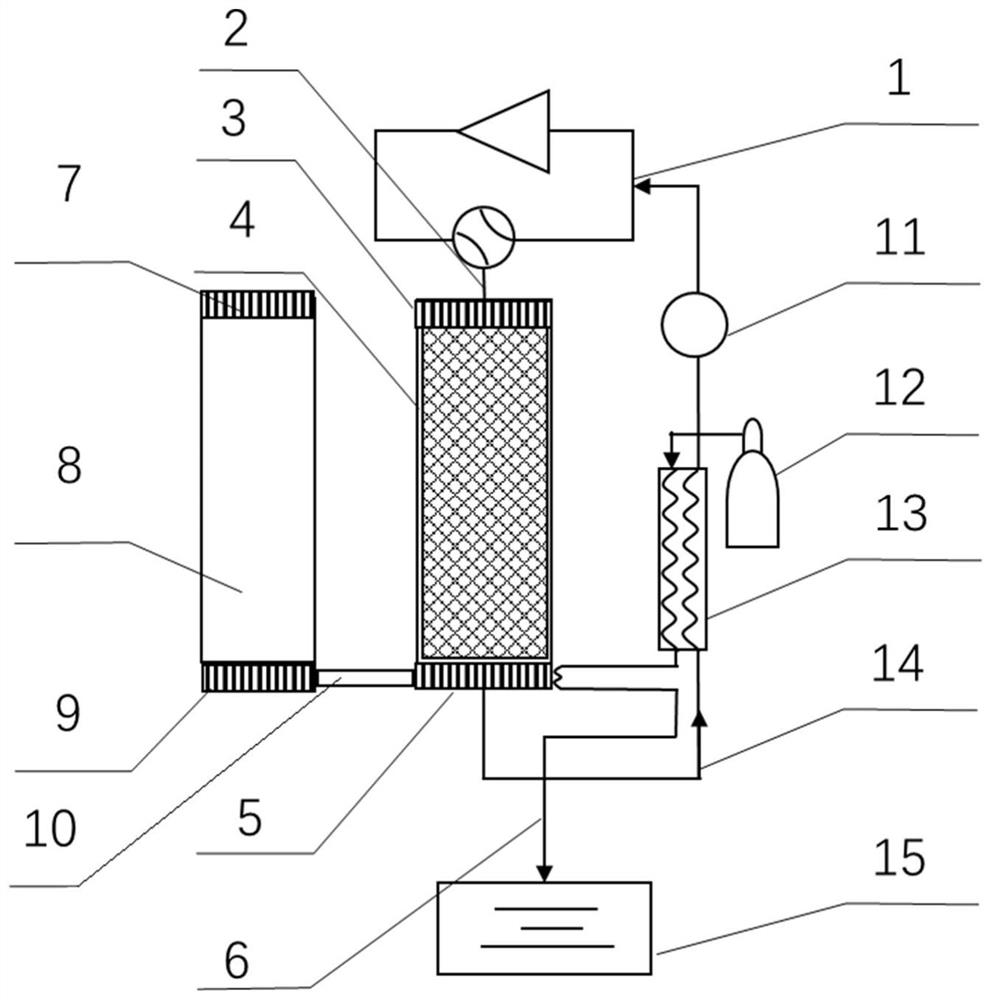

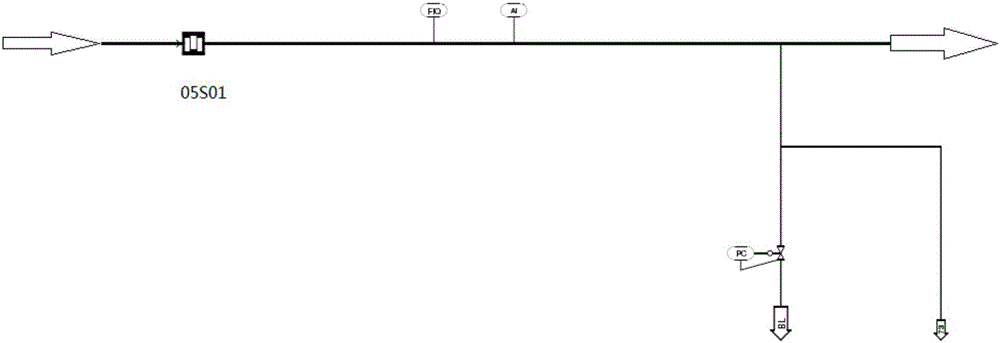

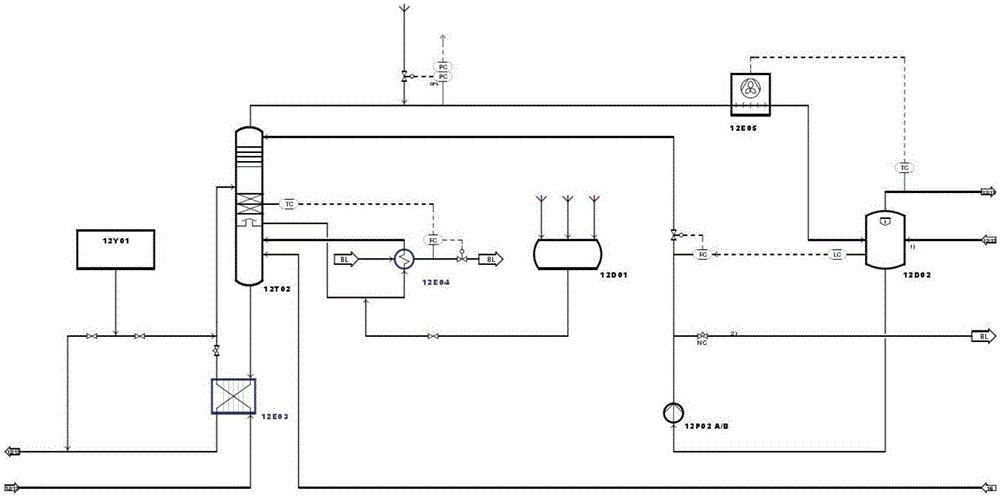

Method for producing liquefied natural gas by multi-component refrigerant double-stage compression

InactiveCN102954668AConducive to liquefactionAvoid complexitySolidificationLiquefactionBuffer tankEngineering

Provided is a method for producing liquefied natural gas by multi-component refrigerant two-stage compression. The method includes two multi-component refrigerant compression cycles, the refrigerant in a first cycle is called a pre-cooling refrigerant, the refrigerant in a second cycle is called a cryogenic refrigerant; the pre-cooling refrigerant returns to an ice chest after passing through a pre-cooling compressor, a cooler, a buffer tank, the ice chest, a throttle valve and a gas-liquid separation tank, and then returns to the pre-cooling compressor; the cryogenic refrigerant returns to the ice chest after passing through a cryogenic compressor, the cooler, the ice chest, the throttle valve and the gas-liquid separation tank, and then returns to the cryogenic compressor; and natural gas is cooled after heat transfer of the ice chest and the refrigerants and finally becomes the liquefied natural gas. The natural gas is liquefied by two independent multi-component refrigerant compression cycles, and composition and content of the two multi-component refrigerants are different, so that the method is wide in application range to raw material natural gas, high in operation flexibility and high in liquefying efficiency. Besides, the method is simple in liquefying process, low in investment cost, and is applicable to liquefied natural gas factories in various scales.

Owner:李志远

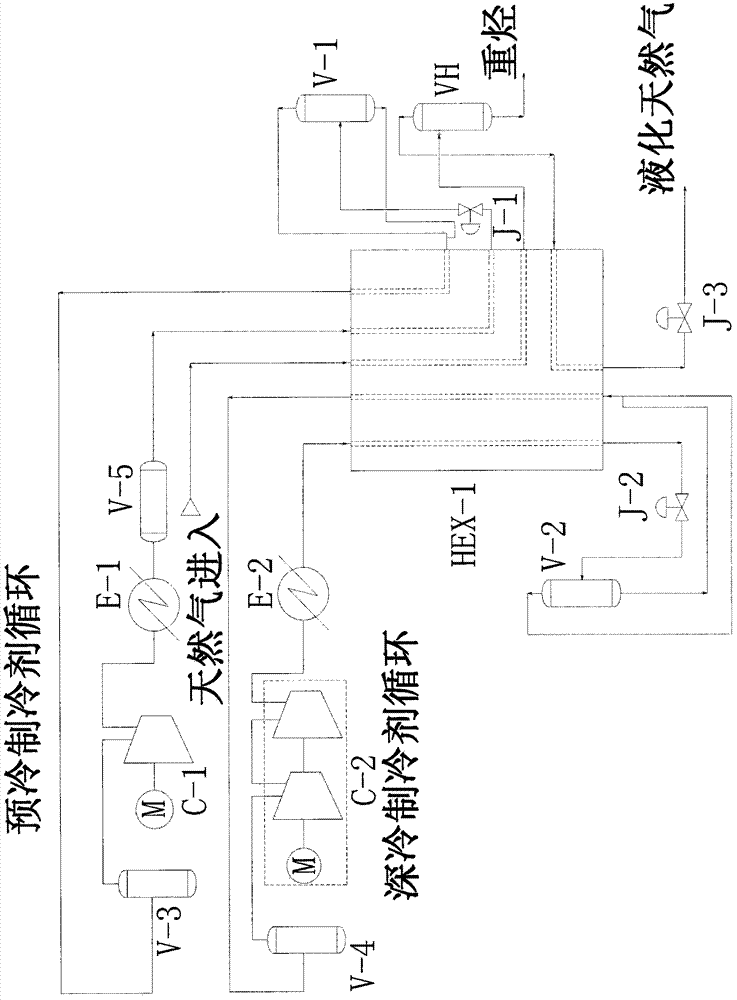

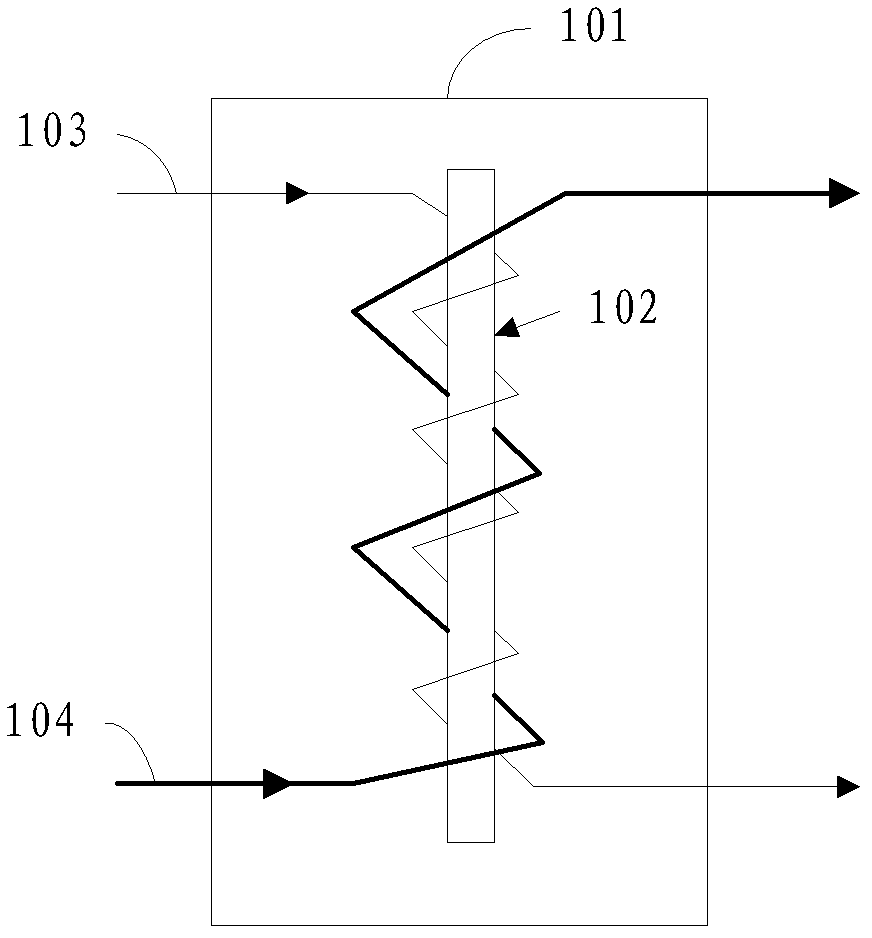

Staggered maze cooling reaction still magnetic liquid sealing device

InactiveCN106402402ASolution to short lifeIncrease contact areaEngine sealsOrganic solventMagnetic liquids

The invention discloses a staggered maze cooling reaction still magnetic liquid sealing device and belongs to the field of mechanical engineering sealing. The problem that when existing magnetic liquid sealing devices are used on reaction stills, due to the fact that organic solvent vapor in the reaction stills has a corrosion function on magnetic liquid, the sealing devices are short in service life and prone to losing efficacy is solved. The device is composed of a magnetic liquid sealing assembly, a movable ring (17), a fixed ring (2) and a positioning ring (5). The fixed ring (2) is low in temperature and good in thermal conductivity, a groove is formed in an inner circle of the movable ring (17), and the movable ring (17) is poor in thermal conductivity, so that the fixed ring and the movable ring form a staggered maze, and liquefying of the organic solvent vapor is facilitated. The upper end face of the fixed ring (2) and the upper end faces of sealing teeth of the fixed ring (2) are inclined faces inclining towards a rotation shaft (15), and thus the liquefied organic solvent vapor flows downwards advantageously. The temperature of fixed ring cooling liquid is 11-15 DEG C lower than that of pole shoe cooling liquid, and liquefying of the organic solvent vapor on a pole shoe is reduced advantageously. The problem that the sealing devices are short in service life due to corrosion of organic solvent vapor to magnetic liquid is successfully solved.

Owner:BEIJING JIAOTONG UNIV

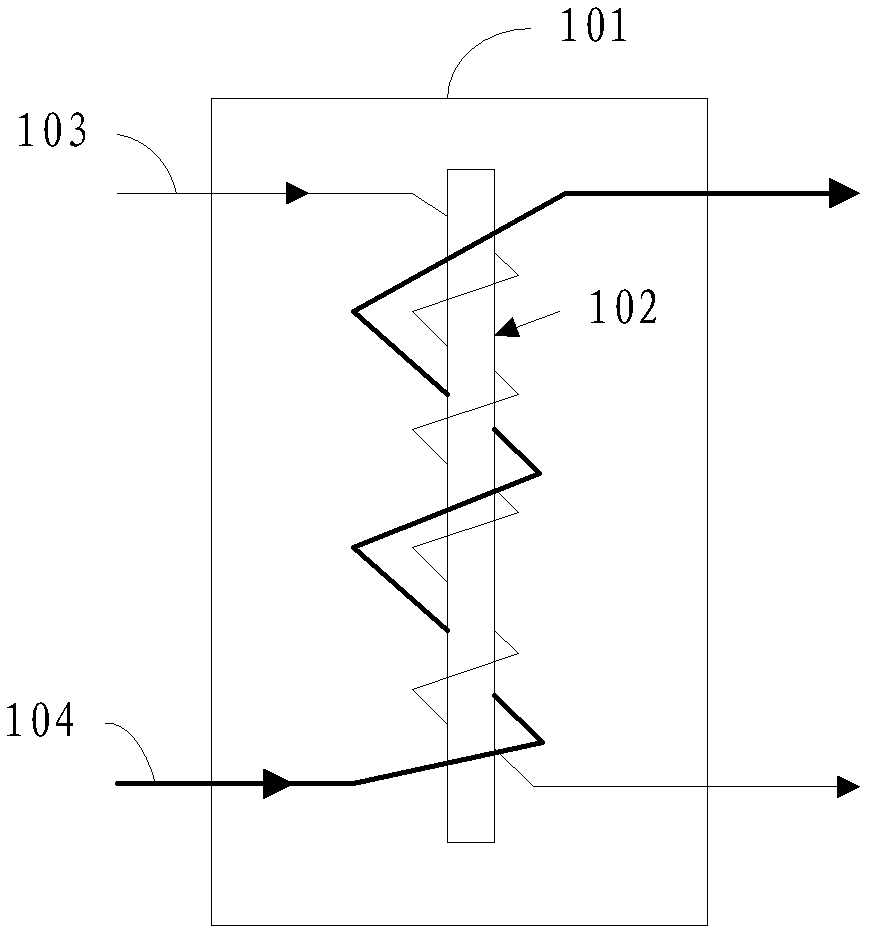

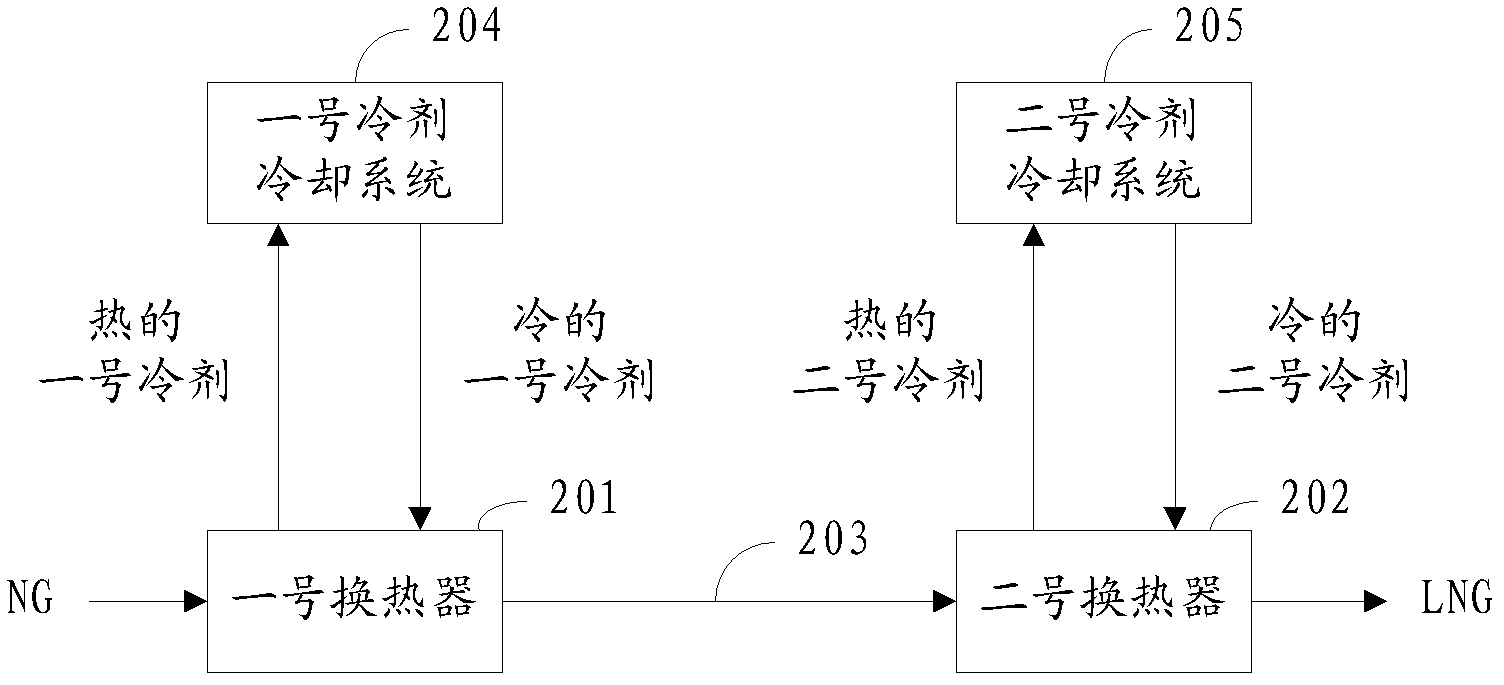

Dual-refrigerant liquefaction system and method for NG (Natural Gas)

ActiveCN103075869AImprove cooling efficiencyReduce volumeSolidificationLiquefactionCooling channelEngineering

The invention relates to a dual-refrigerant liquefaction system and a dual-refrigerant liquefaction method for NG (Natural Gas). The system comprises a cold box for liquefying the NG, an NG supply pipe, a No.1 refrigerant external treatment subsystem, a No.2 refrigerant external treatment subsystem, a No.1 refrigerant cooling subsystem, a No.2 refrigerant cooling subsystem, a heavy hydrocarbon separation tank which is used for realizing gas-liquid separation of heavy hydrocarbon and light hydrocarbon, and a denitrification tank, wherein the cold box comprises an NG precooling passage which is used for cooling liquid heavy hydrocarbon components and gas light hydrocarbon components obtained through cooling; an NG deep cooling passage which is used for liquefying the gas light hydrocarbon components; a No.1 refrigerant precooling passage which is used for cooling high-pressure normal-temperature No.1 refrigerant; a No.2 refrigerant first section precooling passage and a No.2 refrigerant second section precooling passage which are used for cooling No.2 refrigerant; a No.1 refrigerant cooling passage which is used for cooling the NG, the high-pressure normal-temperature No.1 refrigerant and high-pressure normal-temperature No.2 refrigerant by using low-pressure low-temperature No.1 refrigerant; and a No.2 refrigerant cooling passage which is used for cooling the light hydrocarbon components and the No.2 refrigerant by using low-pressure low-temperature No.2 refrigerant. By adopting the technical scheme, the complexity and the energy consumption of the system can be reduced.

Owner:PETROCHINA CO LTD +1

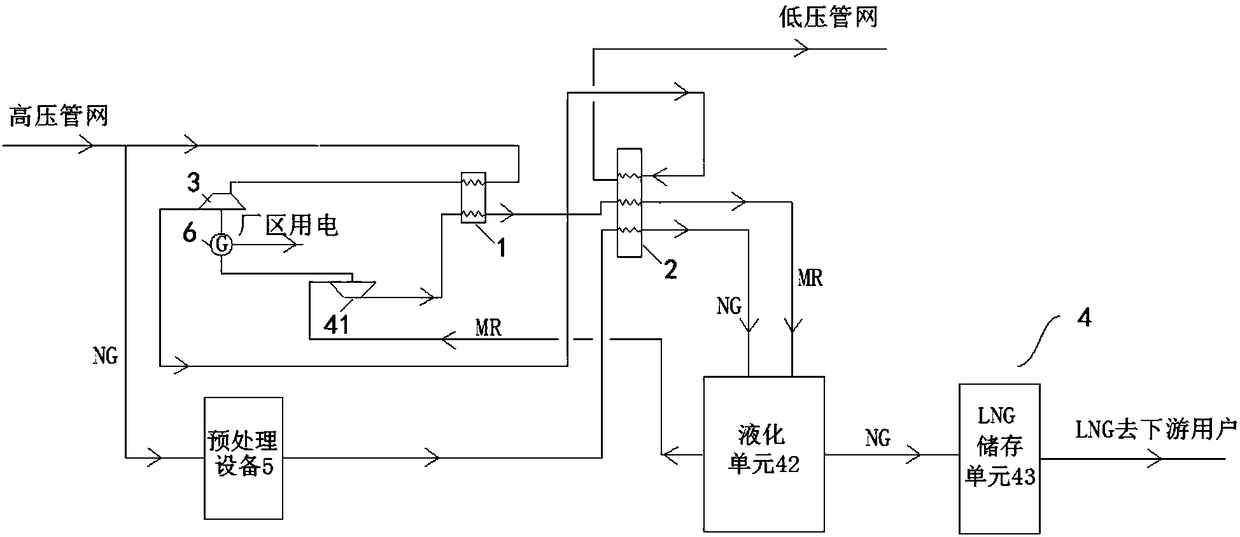

Comprehensive utilization device and method for pipeline natural gas pressure energy cold energy

ActiveCN108386719AReduce energy consumptionAvoid preprocessingPipeline systemsEngineeringProcess engineering

The invention relates to a comprehensive utilization device and method for pipeline natural gas pressure energy cold energy. The device comprises a first cold energy recycling system, a second cold energy recycling system, an expanding system, a liquefying system, a pre-treatment device and a power generating system; a refrigerant inlet / outlet of the first cold energy recycling system is connectedwith a high-pressure pipe network and the input end of the expanding system correspondingly, and a hot medium inlet / outlet is connected with a refrigerating agent outlet of the liquefying system anda first hot medium inlet of the second cold energy recycling system correspondingly; a first hot medium outlet of the second cold energy recycling system is connected with a refrigerating agent inletof the liquefying system, and a second hot medium inlet / outlet is connected with the input end of the pre-treatment device and the input end of the liquefying system correspondingly; a refrigerant inlet / outlet is connected with the output end of the expanding system and a low-pressure pipe network correspondingly; the power output end of the expanding system is connected with the power generatingsystem; the input end of the pre-treatment device is connected with the high-pressure pipe network; and the LNG output end of the liquefying system is connected with a downstream user. The comprehensive utilization device and method for the pipeline natural gas pressure energy cold energy can be widely applied in the natural gas energy utilizing field.

Owner:CNOOC GAS & POWER GRP

Skid-mounted natural gas liquefaction device

ActiveCN104880023AEasy to transportEasy to installSolidificationLiquefactionProcess engineeringPre cooling

The invention relates to a skid-mounted natural gas liquefaction device, which is characterized by comprising a pre-cooling system skid, a cold box skid, a liquefaction system skid and an overcooling system skid, wherein the pre-cooling system skid is connected with the cold box skid through a pipeline; the cold box skid is connected with the liquefaction system skid and the overcooling system skid through a pipeline respectively, the pre-cooling system skid is formed by independently assembling equipment and a pipeline of a pre-cooling circulation system, the cold box skid is formed by independently assembling equipment and a pipeline of a natural gas liquefaction system, the liquefaction system skid is formed by independently assembling equipment and a pipeline of a liquefied gas expansion cooling system, the overcooling system skid is formed by independently assembling equipment and a pipeline of an overcooling air expansion cooling system, and then each independent skid is assembled into the whole set of skid-mounted device. Therefore, the skid-mounted device is convenient to transport and mount, and can be widely applied to natural gas liquefaction production processes of offshore and onshore small gas fields.

Owner:CHINA NAT OFFSHORE OIL CORP +2

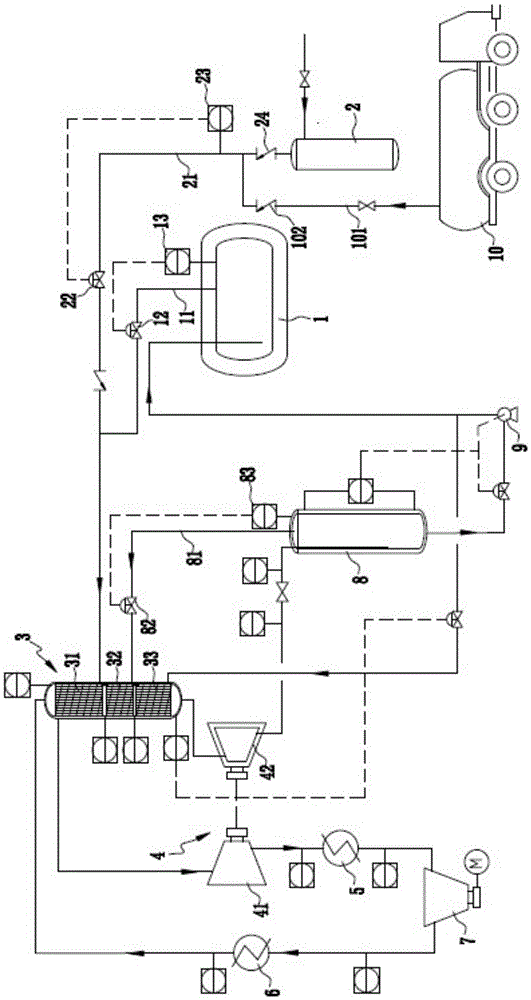

System and method for compression, liquefaction and recovery of BOG in LNG filling station

ActiveCN105627694AImprove liquefaction efficiencyTake advantage ofSolidificationLiquefactionHeat lossesProcess engineering

The invention relates to the technical field of overall station recovery for BOG generated by liquefied natural gas in LNG filling stations due to heat-loss gasification, specifically relates to a system and a method for compression, liquefaction and recovery of BOG in an LNG filling station, and particularly relates to an optimization design in a re-liquefaction system. According to the invention, a first-stage compressor and a vacuum heat-insulation three-in-one heat exchanger are driven by a heat-insulation expander; and the system and the method have the characteristics of being investment-saving, low in running expense, short in process flow, convenient for equipment skidding, and the like, and is quite suitable for being popularized in the LNG filling station.

Owner:JIANGSU DUBLE ENG

Method for liquefying surplus solid residue in fermentation of cellulosic ethanol

ActiveCN103740397ALow liquefaction temperatureReduce energy consumptionLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionLiquid productSulfide

The invention discloses a method for liquefying surplus solid residue in the enzymolysis saccharification and ethanol fermentation by adopting lignocellulose as a raw material. The method is characterized in that the solid residue is liquefied in a high-pressure vessel in the presence of a catalyst and an organic solvent, wherein the organic solvent is absolute ethyl alcohol, anhydrous propyl alcohol or absolute butanol, and the catalyst is aluminum chloride, aluminum sulfide and zinc sulfide. The catalyst which is specially selected by an inventor is added in the method, so that the liquefying temperature is effectively lowered, the liquefying rate of the fermented solid residue and the residue degrading degree can be improved, and more liquid products with smaller molecular weight can be generated. The method can be widely used for liquefying the residue produced by fermenting the biomass fuel ethanol and lignocellulose-rich biomass raw material and has the advantages of low liquefying temperature, simplicity in process, high efficiency and the like, and the raw materials are easily obtained.

Owner:SHANDONG UNIV

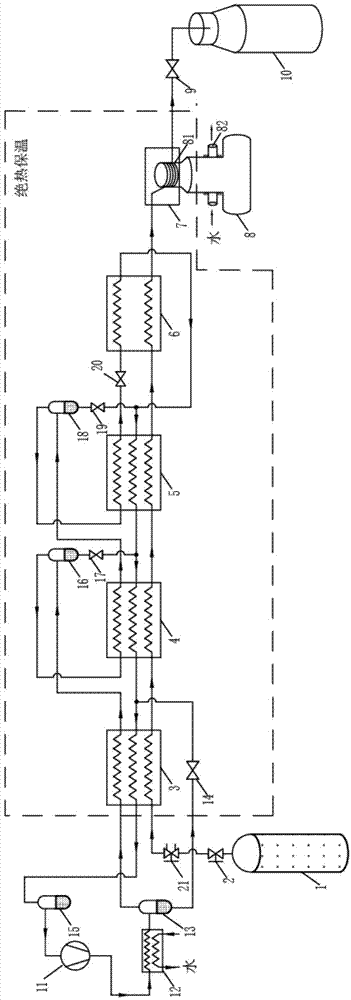

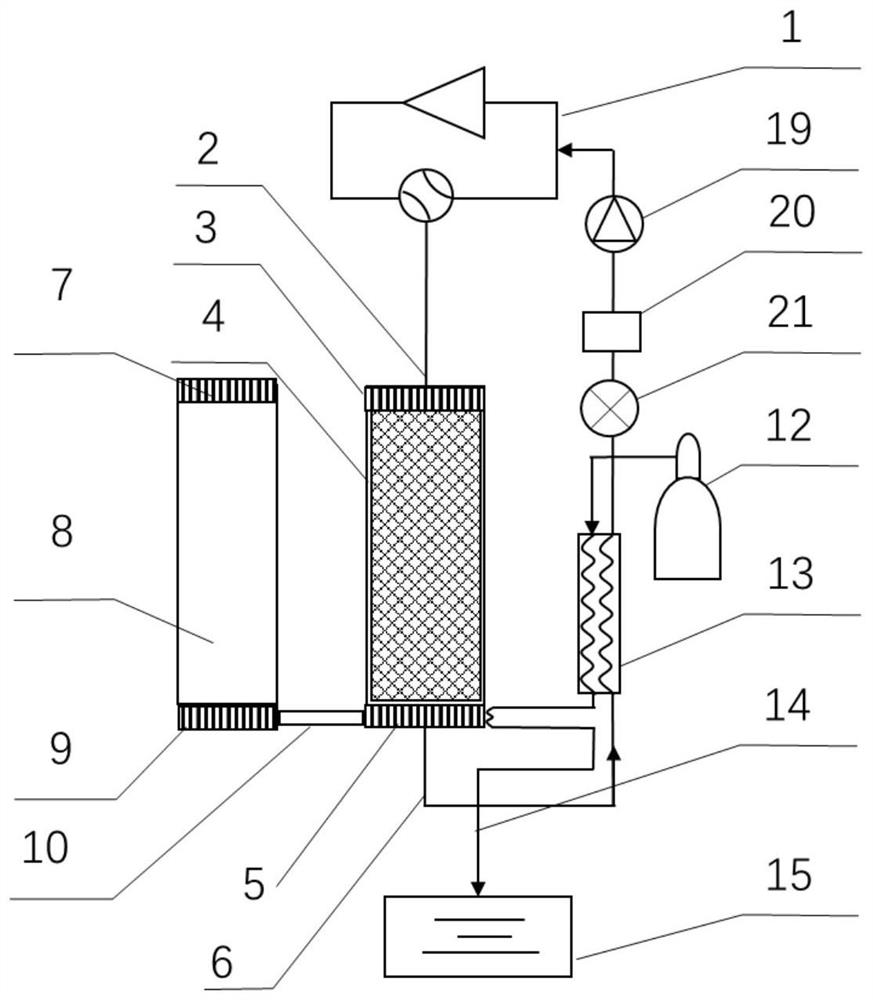

Natural gas liquefaction system with combination of auto-cascade refrigeration system and pulse tube refrigerator

ActiveCN104729233AImprove cooling efficiencyImprove liquefaction efficiencySolidificationLiquefactionLiquefied natural gasEngineering

The invention relates to a natural gas liquefaction system with combination of an auto-cascade refrigeration system and a pulse tube refrigerator. A gas source output end is sequentially connected with a first-stage heat exchanger, a second-stage heat exchanger and a third-stage heat exchanger in an auto-cascade refrigeration cycle through a pressure stabilizing valve and a flow adjusting valve, so that heat exchange is carried out between a gas source and a mixed refrigerant in the first-stage, second-stage and third-stage heat exchangers for first-time cooling, second-time cooling and second-time cooling; the gaseous state natural gas output end of the third-stage heat exchanger is connected with an evaporator, so that heat exchange is carried out between the gaseous state natural gas and the refrigerant in the evaporator for fourth-time cooling. The gaseous state natural gas output end of the evaporator is wound around a cold head of the pulse tube refrigerator in a natural gas condensation box, so that heat exchange is carried out between the gaseous state natural gas and the working medium helium in the cold head in the pulse tube refrigerator in the natural gas condensation box, and the gaseous state natural gas is condensed into liquefied natural gas. The pipe output end wound around the cold head of the pulse tube refrigerator is connected with a storage device through a restricting element, so that the liquefied natural gas is depressurized after flowing through the restricting element and then flows into the storage device to be stored.

Owner:江苏热声机电科技有限公司

Unconventional gas liquefaction system based on spiral wound heat exchanger

ActiveCN103542692AAvoid easy cloggingEfficiency of large liquefactionSolidificationLiquefactionPre coolingPlate fin heat exchanger

The invention discloses an unconventional gas liquefaction system based on a spiral wound heat exchanger. The liquefaction system comprises the spiral wound heat exchanger, a fuel gas heat exchanger, a heavy hydrocarbon heat exchanger and a mixed refrigerant circulation mechanism. The mixed refrigerant circulation mechanism comprises a primary mixed refrigerant compressor and a primary mixed refrigerant compressor cooler, wherein the primary mixed refrigerant compressor and the primary mixed refrigerant compressor cooler are sequentially connected. The fuel gas heat exchanger, the heavy hydrocarbon heat exchanger and a pre-cooling section of the spiral wound heat exchanger are sequentially communicated with one another, and an outlet of the pre-cooling section of the spiral wound heat exchanger is communicated with the heavy hydrocarbon heat exchanger. A qualified component outlet of the heavy hydrocarbon heat exchanger is communicated with a liquefaction section of the spiral wound heat exchanger, an outlet of the liquefaction section of the spiral wound heat exchanger is communicated with a low-temperature rectifying tower and a super-cooling section of the spiral wound heat exchanger, an outlet of the super-cooling section of the spiral wound heat exchanger is communicated with the low-temperature rectifying tower, and the bottom portion of the low-temperature rectifying tower is communicated with an LNG storage tank. The spiral wound heat exchanger is adopted as a main heat exchanger and has the advantages of being firm in structure, allowing a runner not to be easily blocked, being less in leakage point and allowing large-temperature-difference heat transmission in comparison with a louvered fin heat exchanger.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Polyfoam using plant fiber as material and its preparation method

The invention relates to a polyfoam using plant fiber as material wherein its preparation method comprises reacting liquefied plant fiber with methyl aldehyde, creating bakelite an and foaming, the process for preparing liquefied plant fiber includes pre-treating through ultraviolet radiation and gamma-ray irradiation, then liquefied plant fiber is obtained by oxybenzene dissolving method.

Owner:SUN YAT SEN UNIV

Efficient liquefaction system of regenerative refrigerator adopting direct currents

PendingCN112097422AReduce heat transfer resistanceClose contactFluid circulation arrangementSuperheatersProcess engineeringMechanical engineering

The invention relates to an efficient liquefaction system of a regenerative refrigerator adopting direct currents. The efficient liquefaction system comprises a regenerative refrigerating module and aliquefaction module. The regenerative refrigerating module comprises a regenerative refrigerator unit and a direct-current external circulation unit. The regenerative refrigerator unit comprises a compression device, a heat regenerator hot end heat exchanger, a heat regenerator, a heat regenerator cold end heat exchanger, an expansion mechanism cold end heat exchanger, an expansion mechanism andan expansion mechanism hot end heat exchanger which are connected in sequence. Compared with the prior art, the heat exchange heat resistance is smaller, the efficient liquefaction system is particularly suitable for a compact GM refrigerator with excellent refrigerating performance, due to the fact that the heat regenerator is arranged in an air cylinder and an air gap inevitably exists between the heat regenerator and the air cylinder, only a liquefied working medium flow channel can be wound around the outer side of the air cylinder, and large air gap heat resistance exists with heat exchange of the heat regenerator; and the direct currents led out from the interior are in close contact with regenerative filler and alternating currents, so that almost no heat exchange temperature difference exists, and the heat resistance can be effectively reduced.

Owner:TONGJI UNIV

Coalbed methane liquefaction process

ActiveCN105865145AShorten the liquefaction processSimple processSolidificationLiquefactionRefrigerantPre cooling

The invention discloses a coalbed methane liquefaction process. A feeding unit, a mercury removing unit, a CO2 removing unit, a drying unit, a liquefaction unit, a refrigerant circulation unit, a refrigerant supplementing unit, a storage unit, a storage tank return gas compression unit, a hot oil unit and a torch unit are included. The feeding unit is sequentially connected with the mercury removing unit, the CO2 removing unit, the drying unit, the liquefaction unit and the storage unit; the liquefaction unit is pre-cooled, liquefied and supercooled through the refrigerant circulation unit; refrigerants are supplemented to the refrigerant circulation unit through the refrigerant supplementing unit; and the storage tank return gas compression unit is connected with the storage unit.

Owner:JINCHENG HUAGANG GAS CO LTD

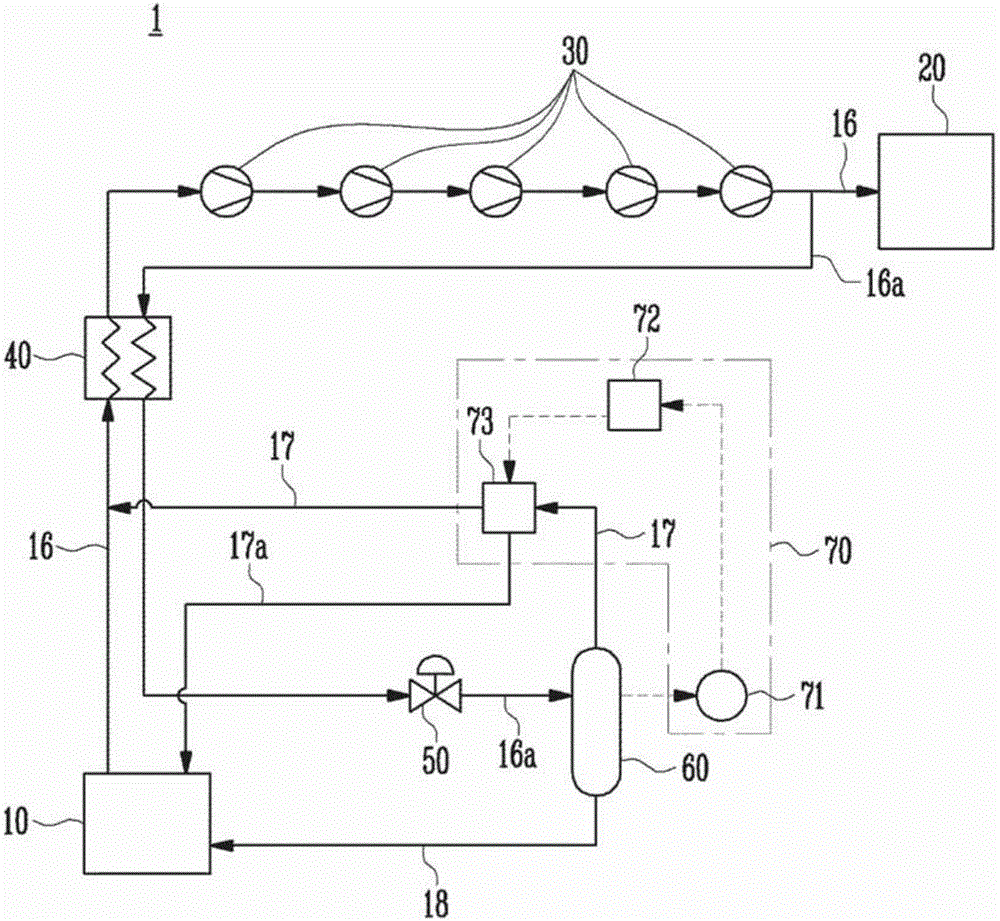

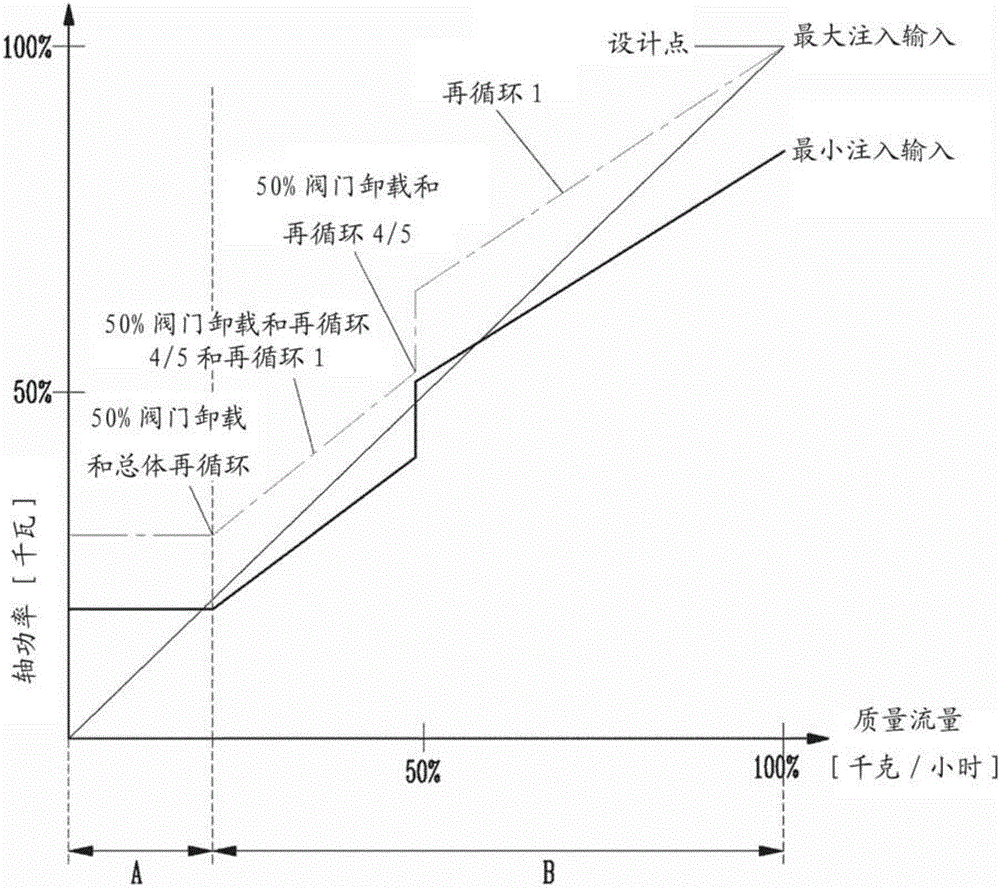

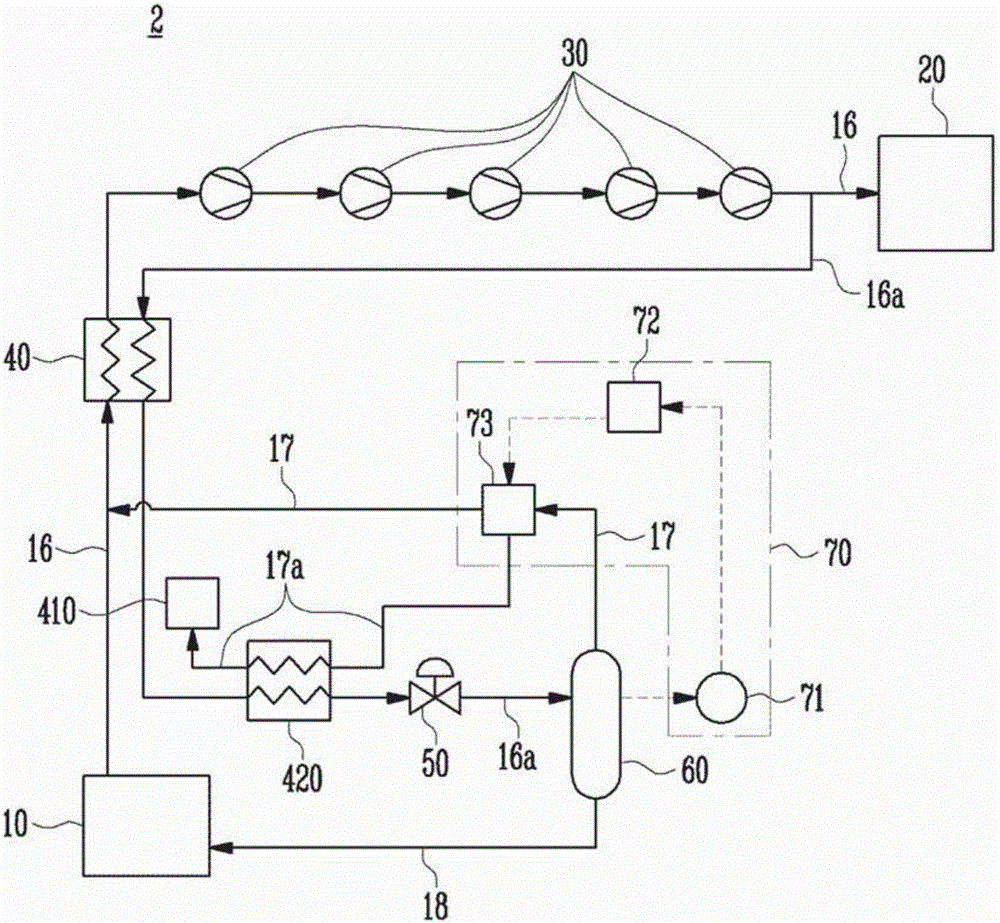

Liquefied gas treatment system

ActiveCN106537023AImprove reliquefaction efficiencyAvoid wastingSolidificationLiquefactionGas compressorFlash-gas

The present invention relates to a liquefied gas treatment system in which a nitrogen control unit controls the content of nitrogen in a boil-off gas or a flash gas when nitrogen components of the flash gas are greater than or equal to a preset value. The efficiency of a boil-off gas compressor can be improved and the system can be stabilized by means of the nitrogen control unit.

Owner:HYUNDAI HEAVY IND CO LTD

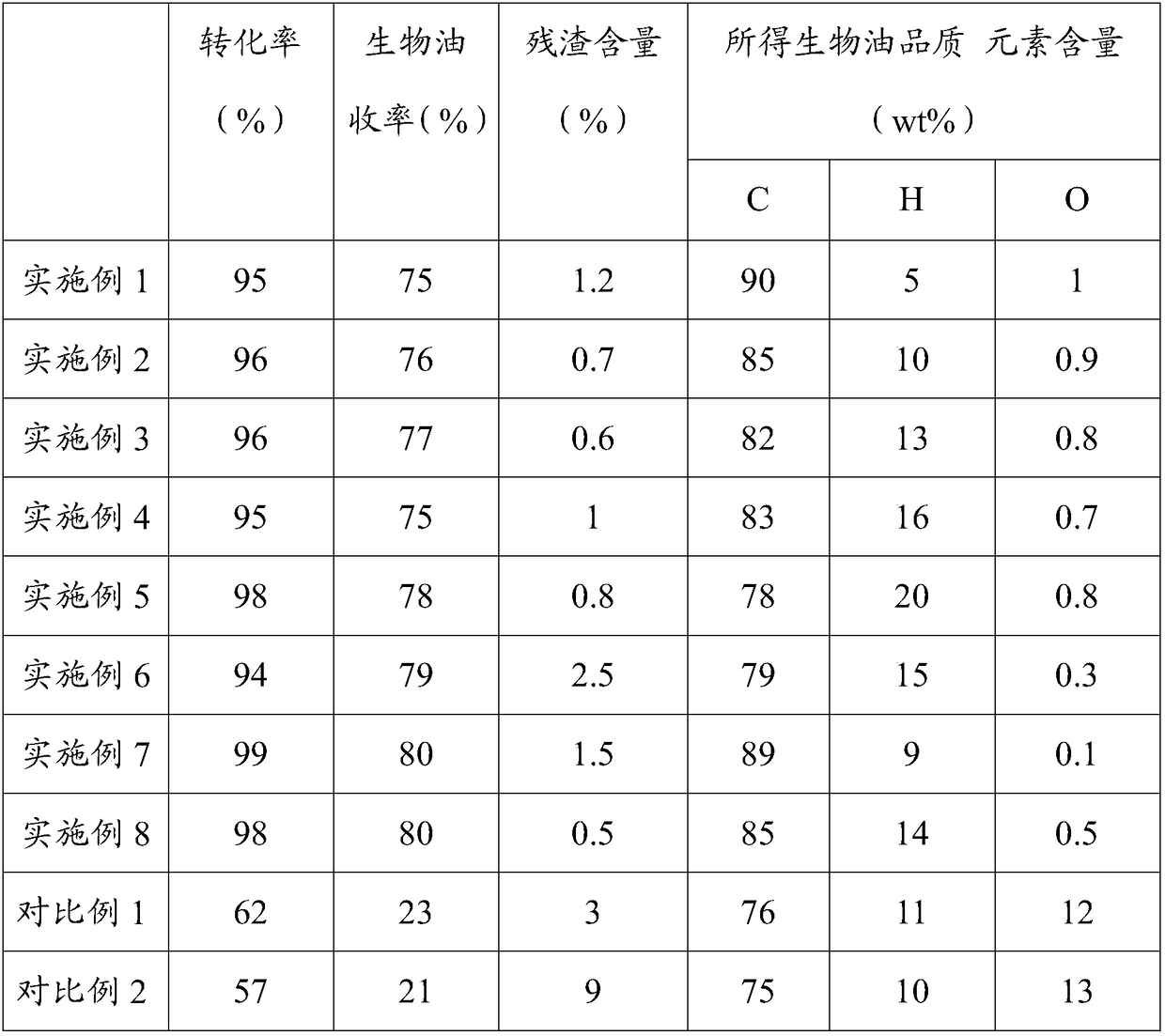

Multi-grade liquefying technology of coal and biomass

ActiveCN108285808ARealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionSolventBiomass

The invention relates to the technical field of clean energy, and specifically provides a multi-grade liquefying technology of coal and biomass. The technology is characterized in that the coal and the biomass raw materials are processed by crushing, compressing and crushing again, then the sizing is prepared, so that biomass diesel oil which is high in solid content and can be stably conveyed through a pump can be obtained; high-viscosity waste oil which cannot be used as a coal and biomass liquefying solvent in the prior art can be utilized. According to the technology, coal and biomass canbe liquefied under high pressure and high temperature in the existence of proper volume of water; the liquefying product is sequentially subjected to primary cracking, hydrogenation reaction and deepcracking and hydrogenation reaction under the effects of resisting hydrogen and a first catalyst and a second catalyst, so that the coal and the biomass can be converted into biomass oil, and the biomass oil can be refined; the conversion rate of the biomass and the coal is up to 95-99%; the yield of the biomass oil is up to 70-80%; and moreover, the residue content is less than 2.5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Novel down pipe pyrolysis liquefying system in ceramic heat storage ball cyclic heating mode

ActiveCN105861019AAvoid jammingControl flowDirect heating destructive distillationBiofuelsCombustionHeat carrier

The invention relates to a novel down pipe pyrolysis liquefying system in a ceramic heat storage ball cyclic heating mode, and belongs to the technical field of renewable energy source utilization. The novel down pipe pyrolysis liquefying system is characterized by comprising a double-barreled heat carrier elevator, a first heat carrier storage bin, a cyclic fluid bed type heat carrier heater, a gas and solid separator, a second heat carrier storage bin, a V-shaped casing pipe reactor and a heat carrier separator which are in sequential cyclic connection. The upper portion of the double-barreled heat carrier elevator is connected with the first heater carrier storage bin through a pipeline, the upper portion of the cyclic fluid bed type heat carrier heater is connected with the gas and solid separator through a pipeline, a first biomass feeding device is connected to the lower portion of the cyclic fluid bed type heat carrier heater, a second biomass feeding device is connected to the upper portion of the V-shaped casing pipe reactor, and the bottom of the heat carrier heater is connected with a gas mixing controller through a pipeline. An angle-adjustable baffle is arranged in the heat carrier heater. The combustion heat of the cyclic fluid bed type heat carrier heater and the waste heat of high-temperature flue gas can be fully utilized, and the novel down pipe pyrolysis liquefying system is high in biomass pyrolysis liquefying efficiency, low in cost and stable in operation.

Owner:SHANDONG UNIV OF TECH

Preparation method of wood liquefied product spinning solution

InactiveCN103304765AIncrease profitIncrease elasticityMonocomponent polyurethanes artificial filamentCarbon fibersFossil fuel

The invention provides a preparation method of a wood liquefied product spinning solution. The preparation method comprises the following steps of: mixing a solid-state wood biomass material which is difficult to dissolve with a polyhydric alcohol; liquefying a mixture into a solubilized wood material with reaction activity under an acidic catalysis condition; and adding a synthesizing agent to react under a certain condition to generate a spinning solution capable of being drew. According to the preparation method, the defects in a wood fiber material preparation technology are overcome and the utilization rate of the material is improved; the spinning solution is used for spinning a carbon fiber precursor so that the dependence on fossil fuel resources by a carbon fiber industry is relieved, the whole comprehensive utilization performance of wood is improved, and the additional values of the biomass material including the wood are greatly improved. Compared with an existing wood liquefaction technology, the preparation method disclosed by the invention has the characteristics of high liquefaction efficiency, low liquefaction temperature, no toxin and no harm, environmental friendliness, low fusion and spinning temperature range and the like, and spinning is easy and convenient to control.

Owner:BEIJING FORESTRY UNIVERSITY

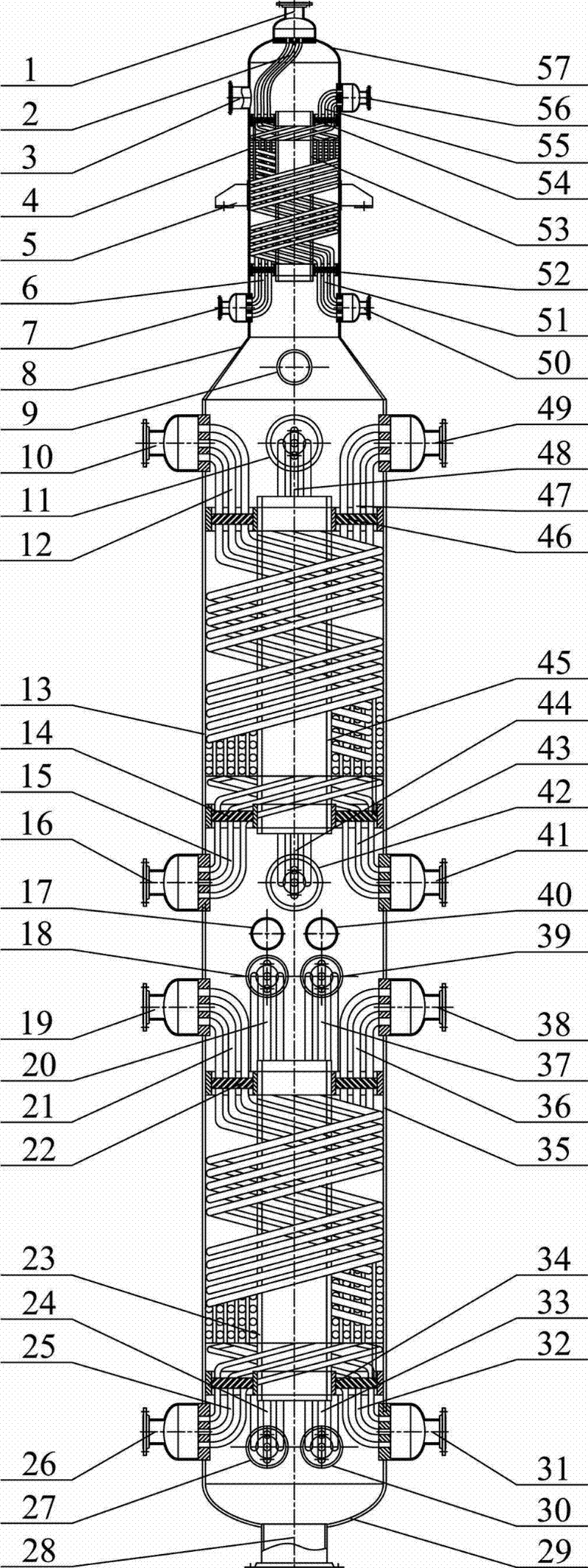

Liquefied natural gas (LNG) low-temperature liquefied primary refrigerating four-stream spiral twined pipe type heat exchange equipment

The invention belongs to the technical field of liquefied natural gas (LNG) low-temperature liquefaction, and relates to LNG primary low-temperature refrigerating equipment and a mixed refrigerant refrigerating technology. Natural gas at the temperature of 36 DEG C and under the pressure of 6.1MPa is cooled so as to enter a secondary pre-cooling stage at the temperature of 53 DEG C below zero in a four-stream spiral twined pipe type heat exchanger by using a refrigerant of C3H8 and C4H10-iso-C4H10 and an N2-CH4-C2H4 mixed gas under the pressure of 0.3MPa and at the temperature of 63 DEG C below zero at an LNG secondary outlet; and the C3H8 and the C4H10-iso-C4H10 are sub-cooled by using the twined pipe type heat exchanger, throttled to a shell pass and mixed with the N2-CH4-C2H4 to pre-cool a natural gas pipe bundle, an N2-CH4-C2H4 pipe bundle, a sub-cooling C3H8 pipe bundle and a C4H10-iso-C4H10 pipe bundle, so that the aims of primary natural gas pre-cooling, N2-CH4-C2H4 mixed gas pre-cooling and sub-cooling before the C3H8 and the C4H10-iso-C4H10 are throttled are fulfilled. The equipment has a compact structure and high heat exchange efficiency, can be applied in the field of phase change low-temperature heat exchange of gas zones at the temperature of between 36 DEG C and 53 DEG C below zero, solves the technical problem of primary refrigeration of LNG, and improves the low-temperature heat exchange efficiency of an LNG system.

Owner:张周卫

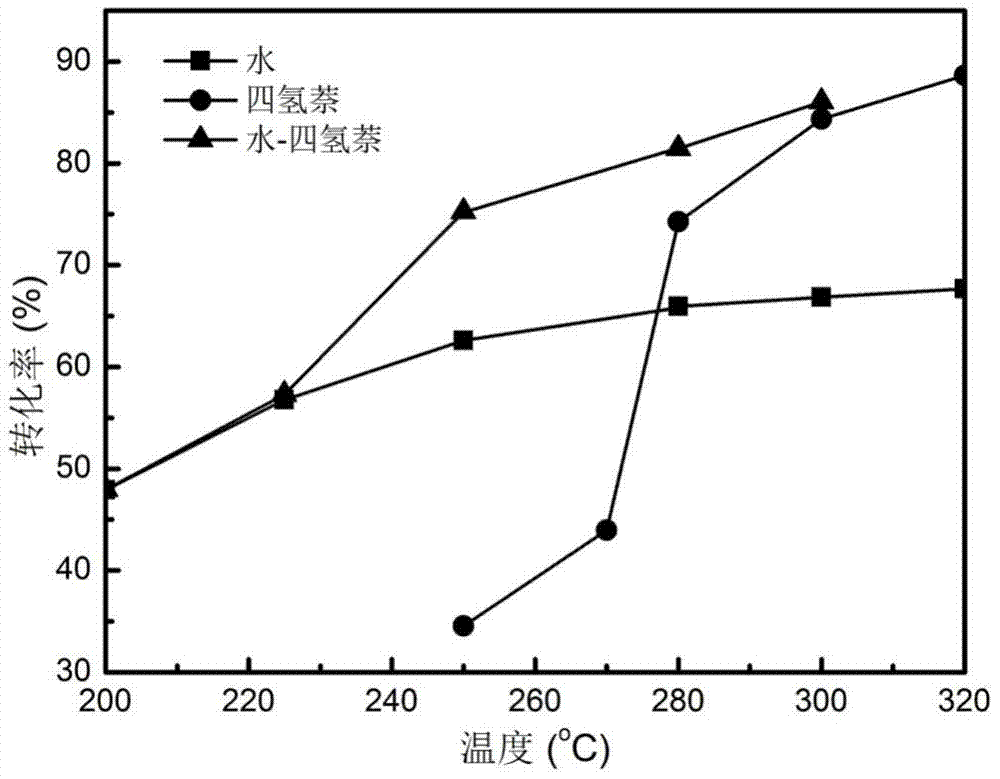

Method for efficiently preparing biological oil by liquefying with water-hydrogen donor mixed solvent

InactiveCN104327875AEfficient use ofBroaden and diversifyLiquid hydrocarbon mixture productionHydrocarbon oils treatmentLiquid productHydrogen

The invention discloses a method for efficiently preparing biological oil by liquefying with a water-hydrogen donor mixed solvent. The method comprises the following steps: simultaneously adding sundried, crushed, sieved and dried bagasse and a tetrahydronaphthalene mixed solvent into a reaction kettle, stirring at 200-320 DEG C and liquefying for 0.5-1.5 hours under the anaerobic condition; cooling the reaction kettle body and releasing pressure of the reaction kettle body after the reaction is ended, opening the kettle, pouring solid and liquid products out of the reaction kettle, and carrying out low-pressure suction filtration to separate the liquid product from residue; successively washing the reaction kettle and the filtration residue by dichloromethane and acetone for a plurality of times, and successively carrying out reduced pressure distillation on dichloromethane washing liquid and acetone washing liquid at 30 DEG C and 70 DEG C to evaporate solvent and water in the product so as to obtain bagasse biological oil. By virtue of the method of preparing the biological oil by carrying out alkaline leaching pretreatment on the bagasse with a low-concentration alkali solution and liquefying with the water-tetrahydronaphthalene mixed solvent, the bagasse liquefying efficiency comprising the bagasse conversation rate and the biological oil yield is greatly improved; the conversation rate reaches over 98%; the biological oil yield reaches over 40%.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com