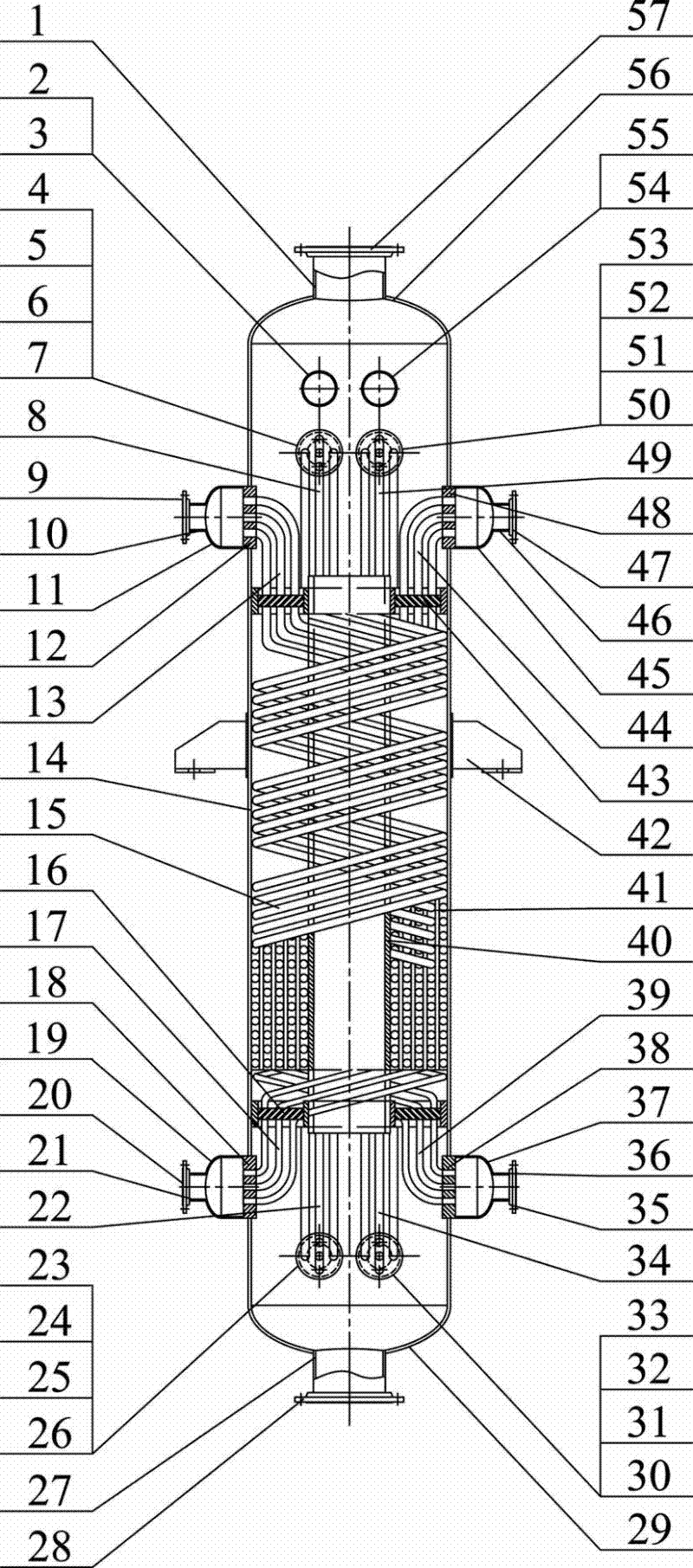

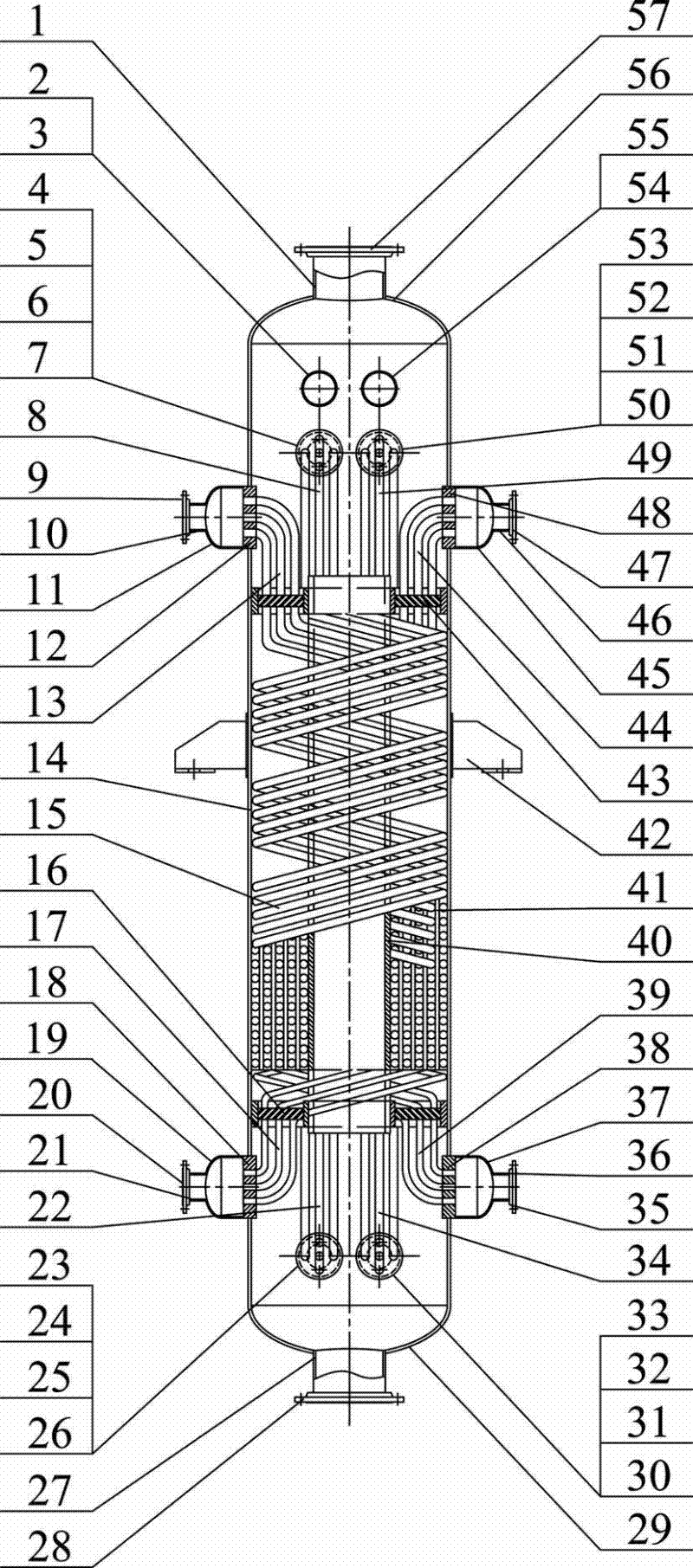

Liquefied natural gas (LNG) low-temperature liquefied primary refrigerating four-stream spiral twined pipe type heat exchange equipment

A technology of spiral winding and tubular heat exchange, which is applied in the field of LNG low-temperature liquefaction primary refrigeration four-stream spiral winding tubular heat exchange equipment, which can solve the problem of heat exchanger scrapping, processing and manufacturing, inconvenient on-site installation and transportation, and complete sets of process equipment. Discontinuation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 36°C, 0.9MPa C4H separated from the mid-stage condensation of the mixed refrigerant compressor 10 — Different C 4 h 10 The mixed refrigerant enters the tube box 25 and is distributed in the tube box 25 at C 4 h 10 — Different C 4 h 10 C 3 h 8 、C 4 h 10 — Different C 4 h 10 , The -63°C, 0.3MPa N that enters the shell from the connecting pipe 1 2 —CH 4 —C 2 h 4 The mixed gas is supercooled, the temperature drops to -53°C, the pressure drops to 0.6MPa, and then flows to the pipe box 6, and the throttle valve installed between the connecting pipe 5 and the connecting pipe 2 is throttled into a supercooled liquid, and the pressure after throttling down to 0.3MPa, the temperature becomes -52.85°C, and then enters the cylinder 14 through the connecting pipe 2, and the throttled C 3 h 8 , N entering the shell from the connecting pipe 1 2 —CH 4 —C 2 h 4 The mixed gas is mixed, and after mixing, it flows downward to cool the natural gas tube bundle 39, N 2 —C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com