Patents

Literature

191results about How to "Large heat transfer temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

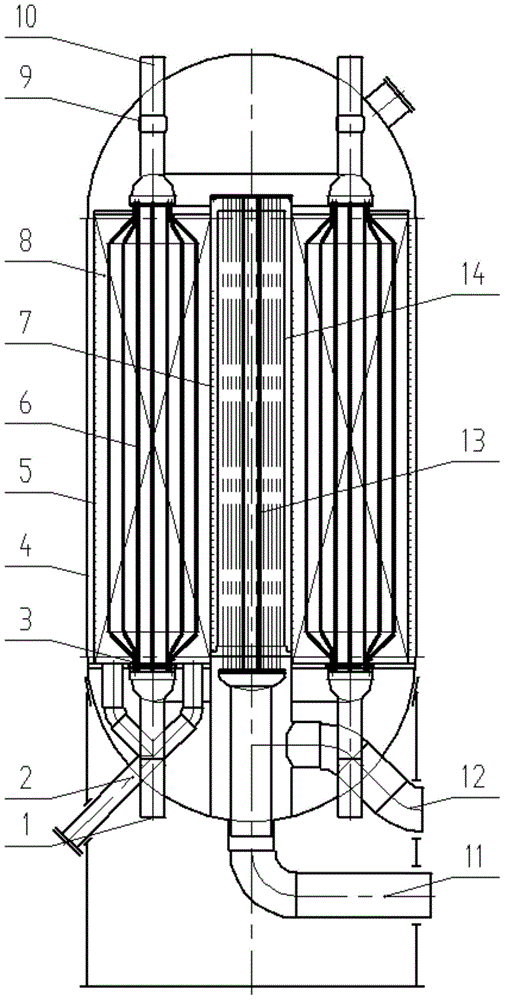

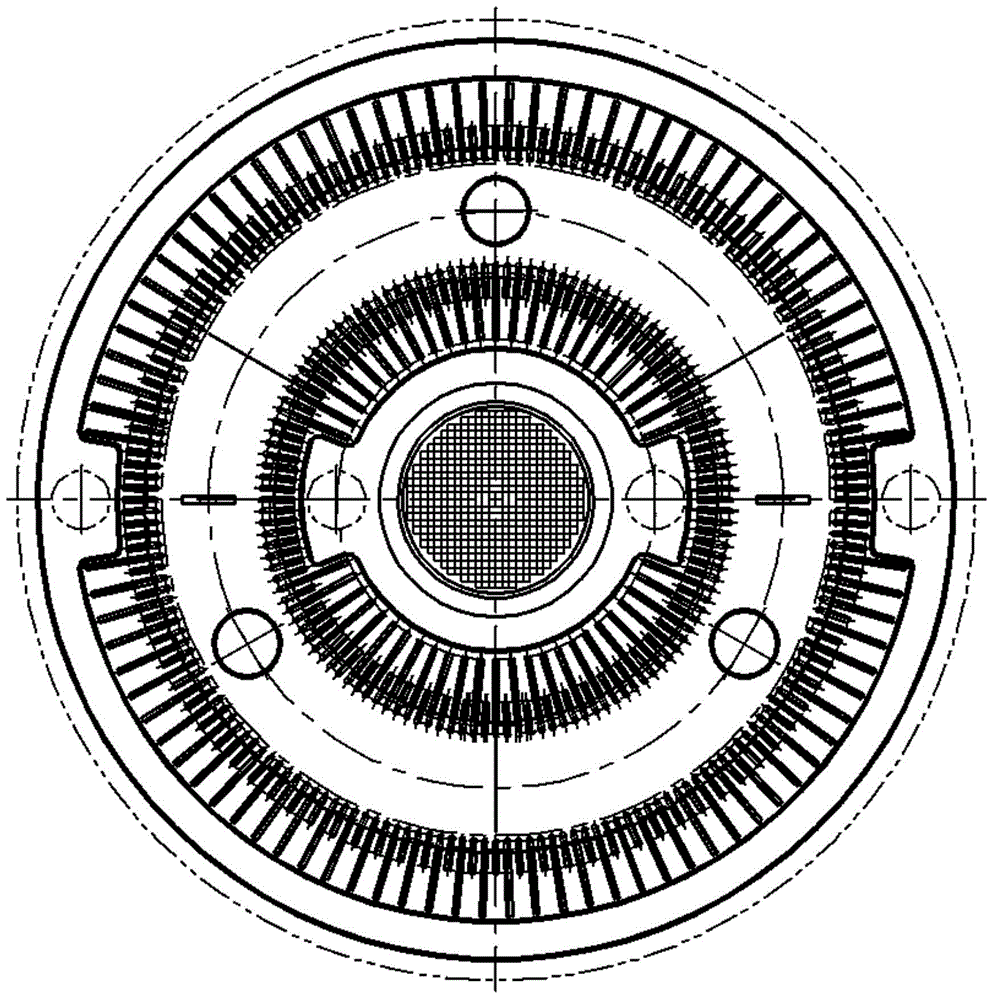

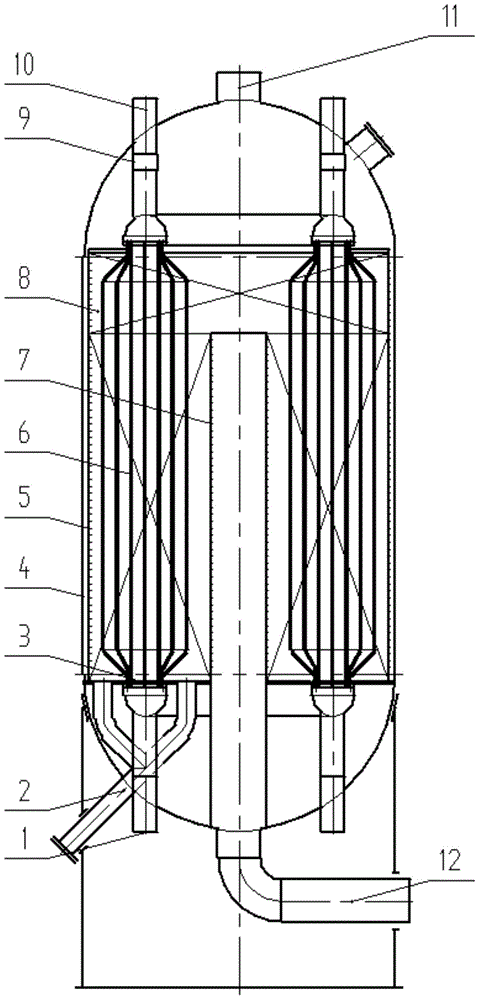

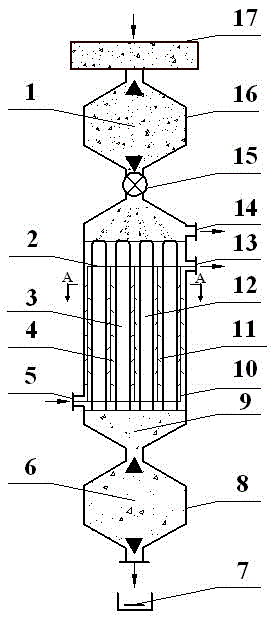

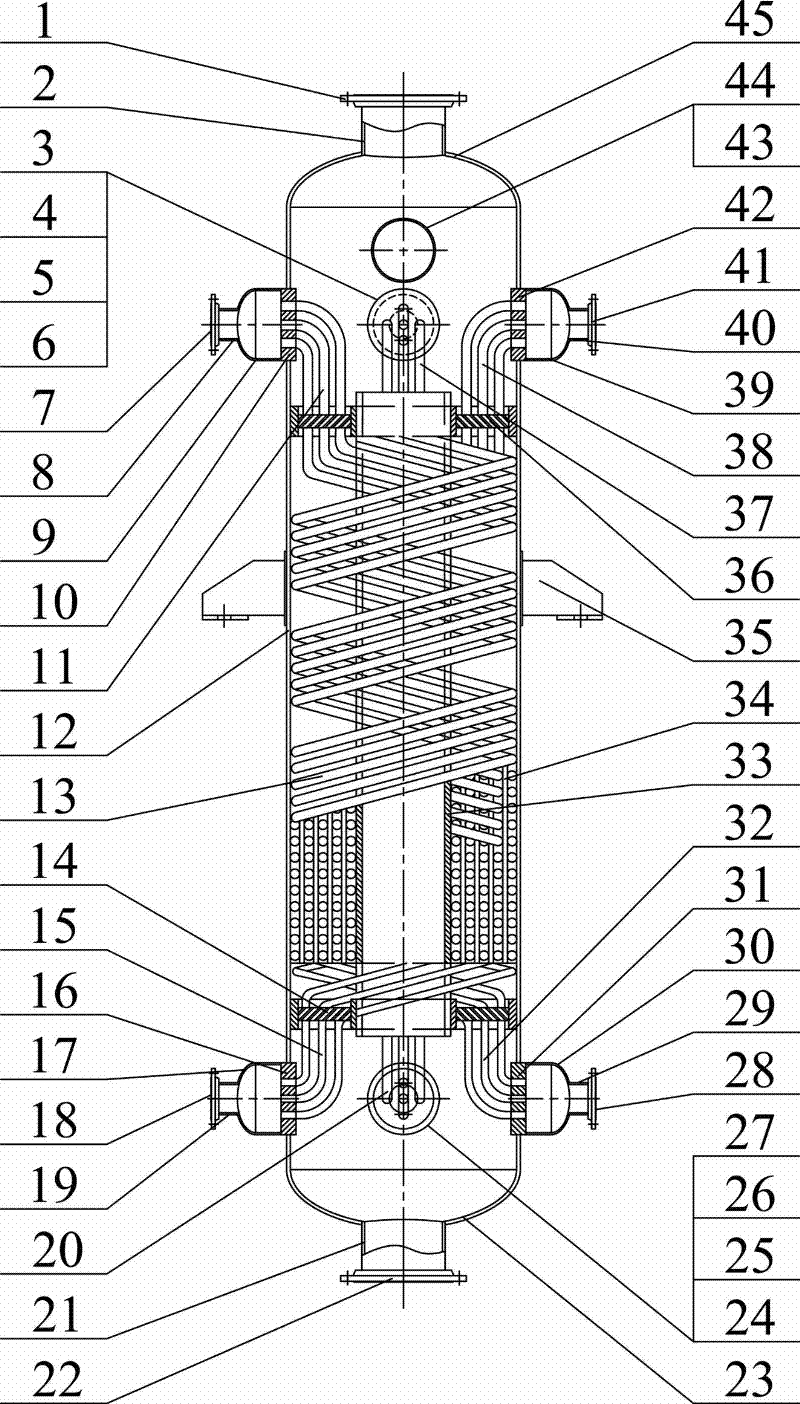

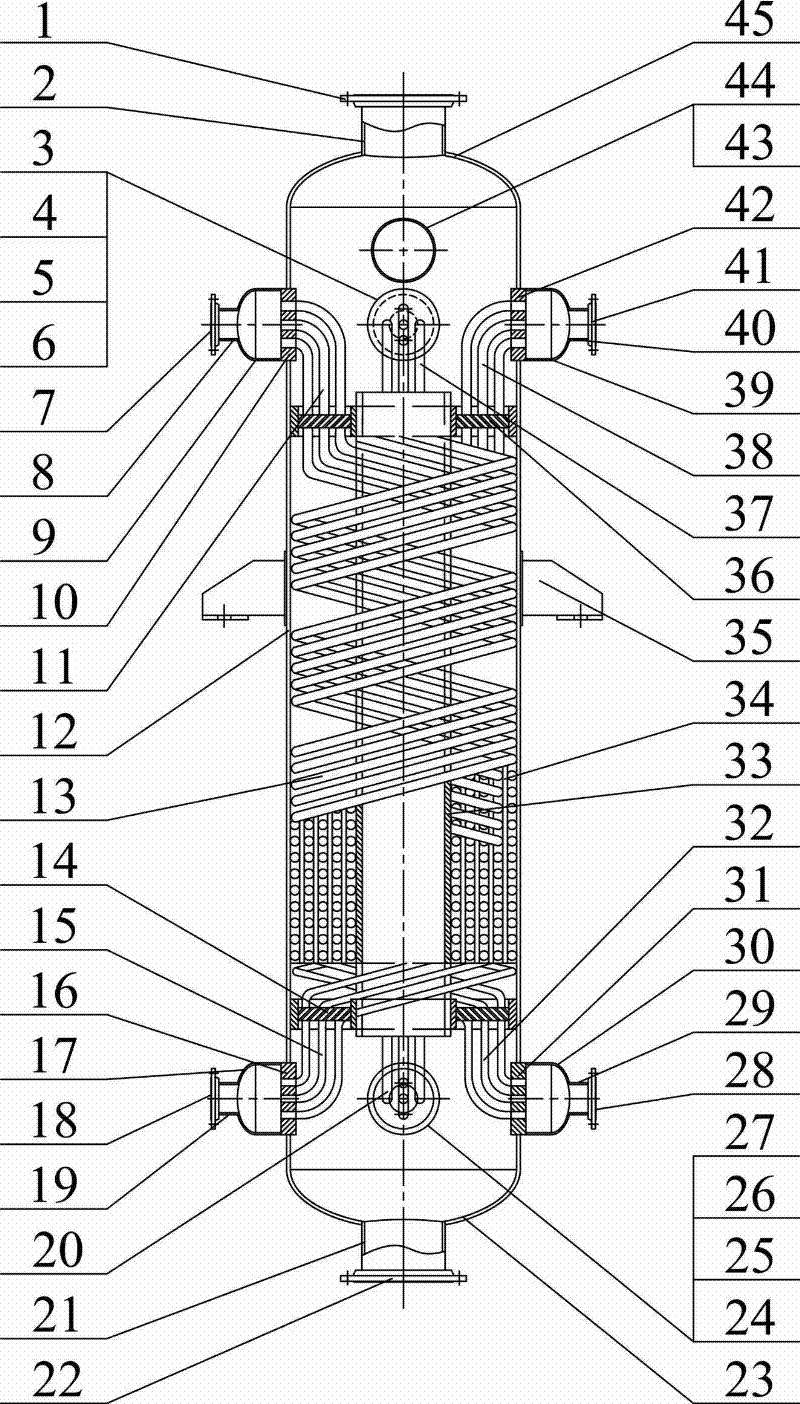

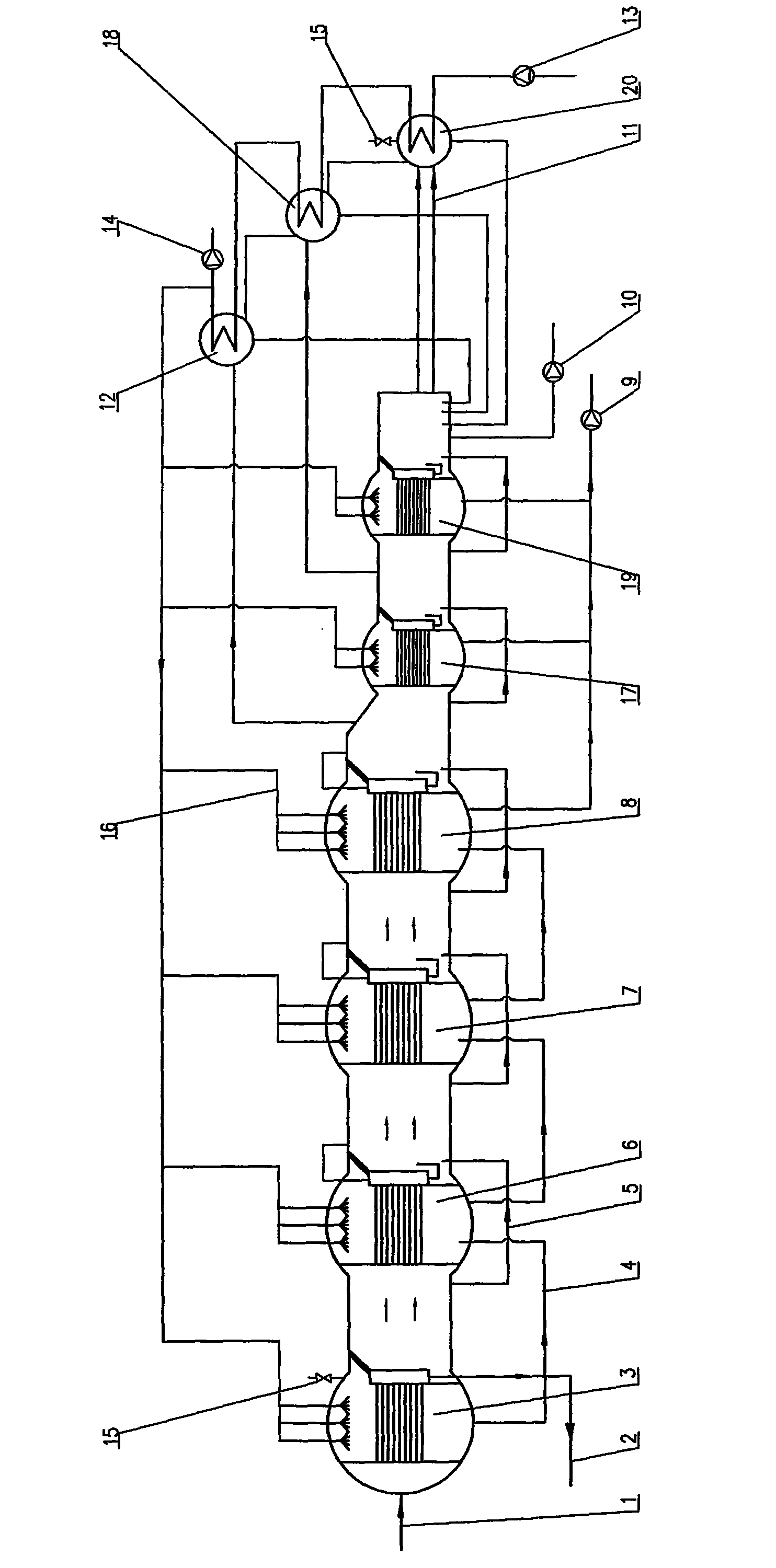

Pipe-bundle-builtin isothermal-shift reactor

ActiveCN105457563AFrom burningExtend your lifeHydrogenChemical/physical processesEngineeringHigh heat

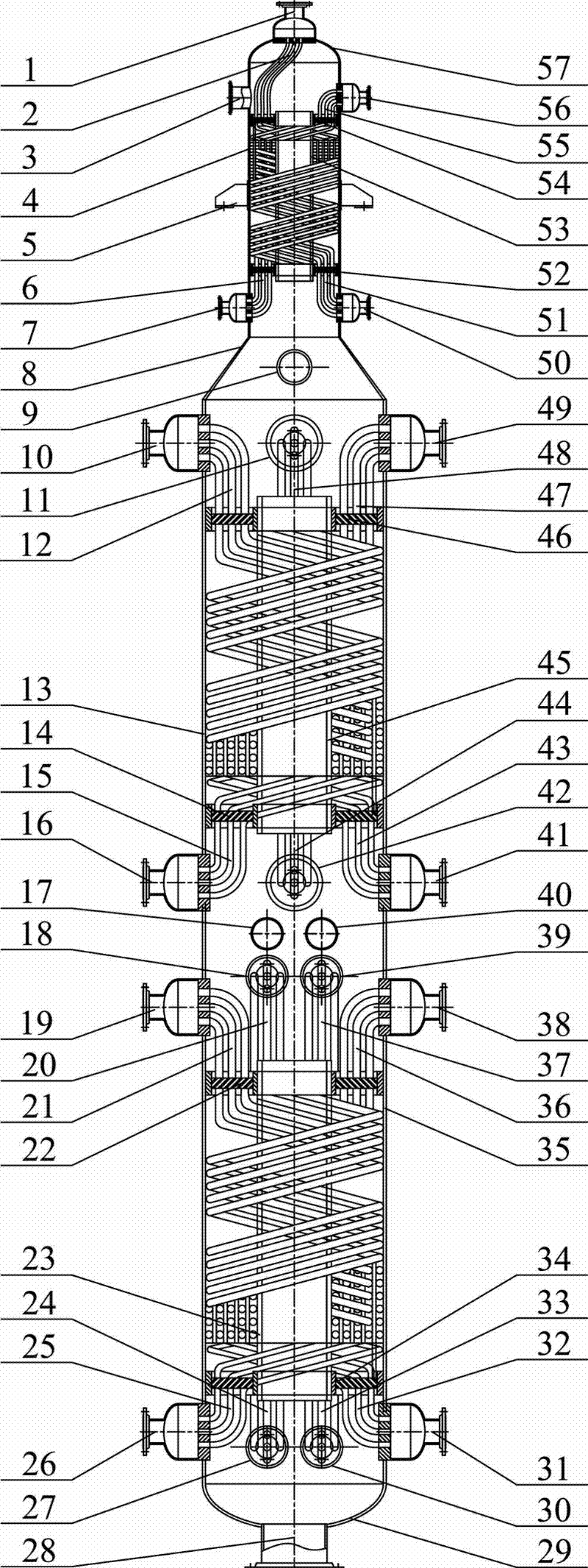

The invention relates to a pipe-bundle-builtin isothermal-shift reactor. According to the pipe-bundle-builtin isothermal-shift reactor, axial annular pipe bundles, which are builtin and are uniformly distributed in a catalyst bed layer along circumferential direction, are adopted to shift out heat of reaction, so as to realize isothermal shift; and a central pipe bundle which is built in a central pipe is adopted to preheat raw material gas entering the reactor, so as to realize the builtin of a gas-gas heat exchanger. The isothermal-shift reactor comprises a pressure-bearing shell, a catalyst basket, the axial annular pipe bundles, the central pipe and the central pipe bundle; and the axial annular pipe bundles consist of upper and lower annular pipe boxes, upper and lower annular pipe sheets and heat exchange tubes. According to the pipe-bundle-builtin isothermal-shift reactor, due to builtin pipe bundles, the manufacturing cost of equipment is effectively reduced; due to an end-part bent structure for the heat exchange tubes, the size of the pipe sheets is effectively reduced; due to a heat insulating layer laid between the pipe sheets and the high-temperature catalyst bed layer, the contact between pipe end weld spots and a bed layer high-temperature area is effectively isolated, the probability of leakage is lowered, and the reliability of equipment is improved; and the pipe-bundle-builtin isothermal-shift reactor is compact in structure, low in manufacturing cost, relatively easy in maintenance, high in reliability, complete in function and high in applicability.

Owner:CHANGZHENG ENG

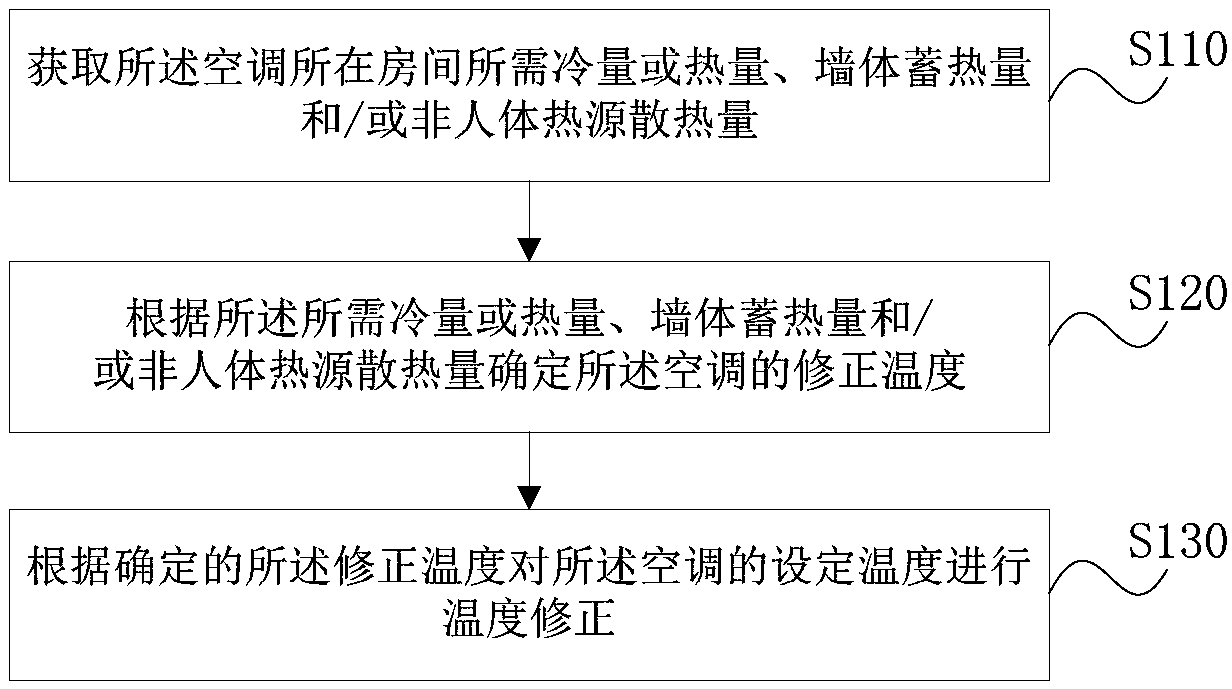

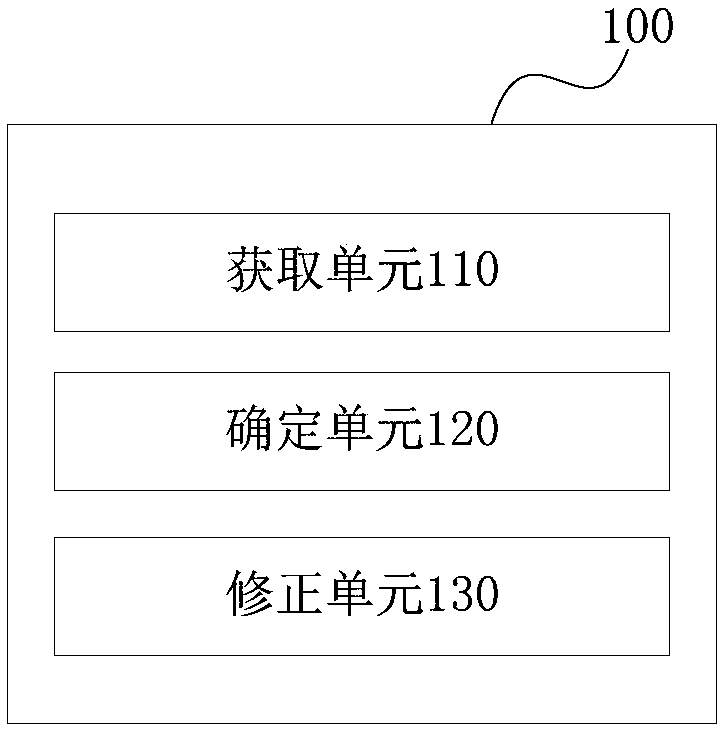

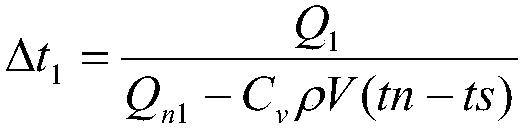

Temperature correction method, device, storage medium of air conditioner and air conditioner

ActiveCN108679788AGuaranteed comfort requirementsPrecise temperature controlMechanical apparatusTemperature controlEngineering

The invention provides a temperature correction method, device, storage medium of an air conditioner and an air conditioner. The method comprises following steps: obtaining a required cooling quantityor heat quantity, wall heat storage capacity, and / or non-human body heat source heat dissipation capacity in a room where the air conditioner is located; determining the corrected temperature of theair conditioner according to the required cooling quantity or heat quantity, wall heat storage capacity, and / or non-human body heat source heat dissipation capacity; performing temperature correctionof the set temperature of the air conditioner according to the determined corrected temperature. The solution provided by the invention can realize the temperature control of the air conditioner and respond to the fluctuation of the external temperature in time, and can perform temperature compensation according to the need, so that the temperature control of the air conditioner is more precise, and the user is provided with a more comfortable indoor environment.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

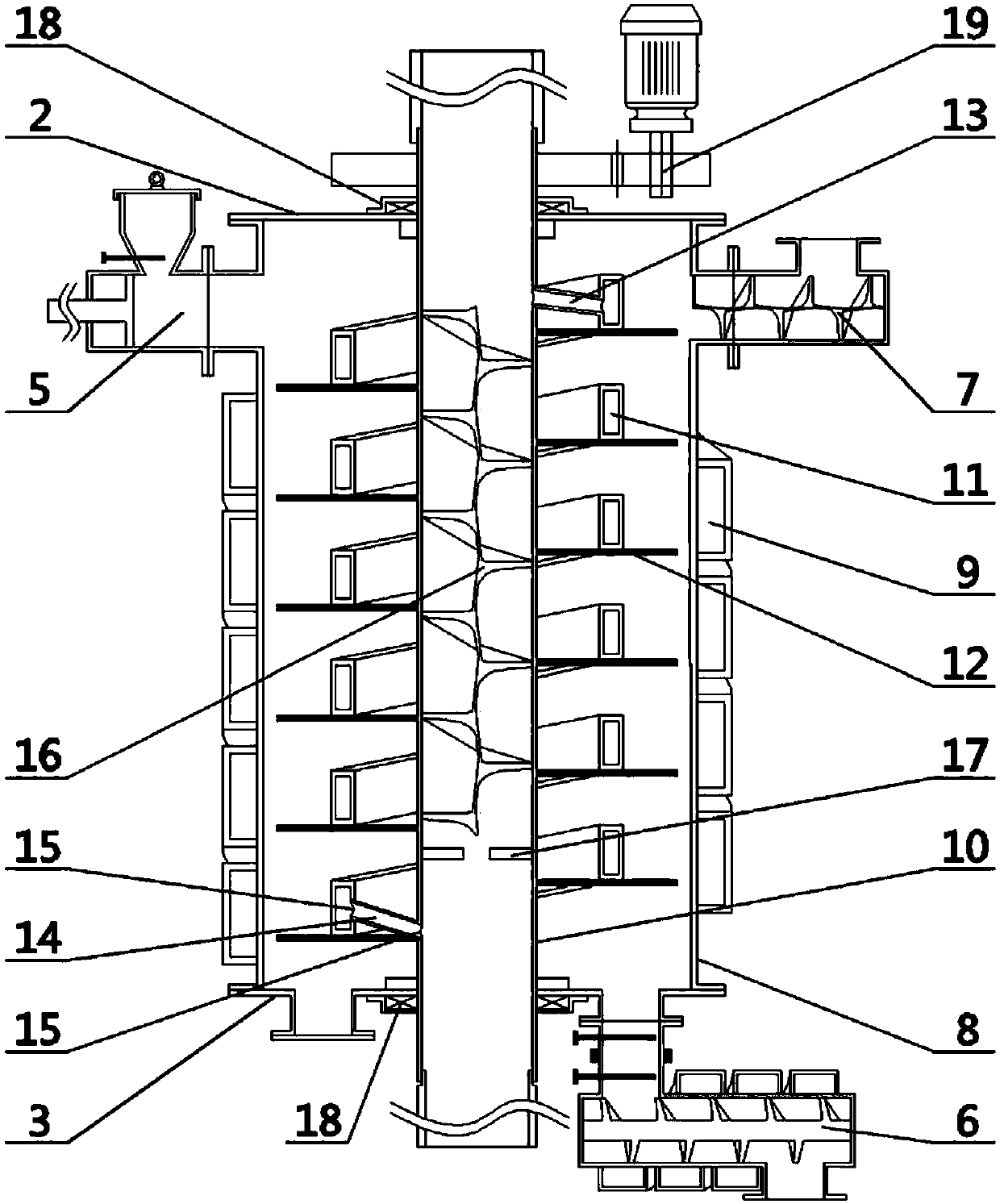

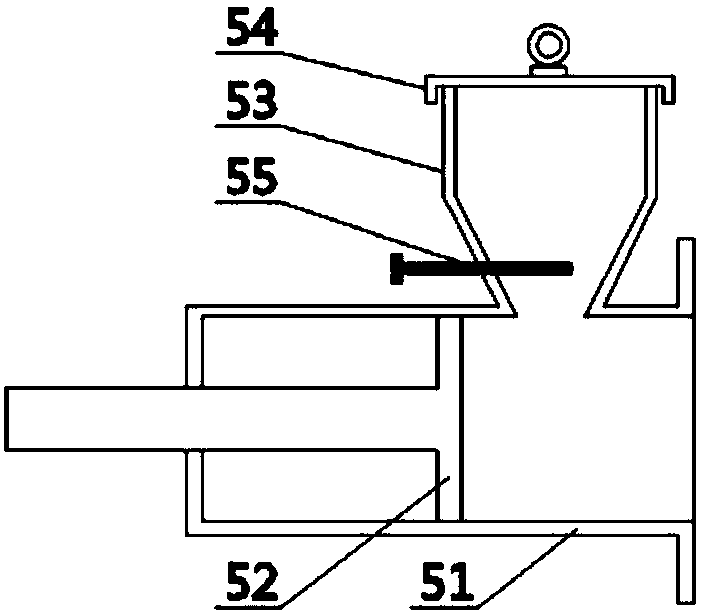

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

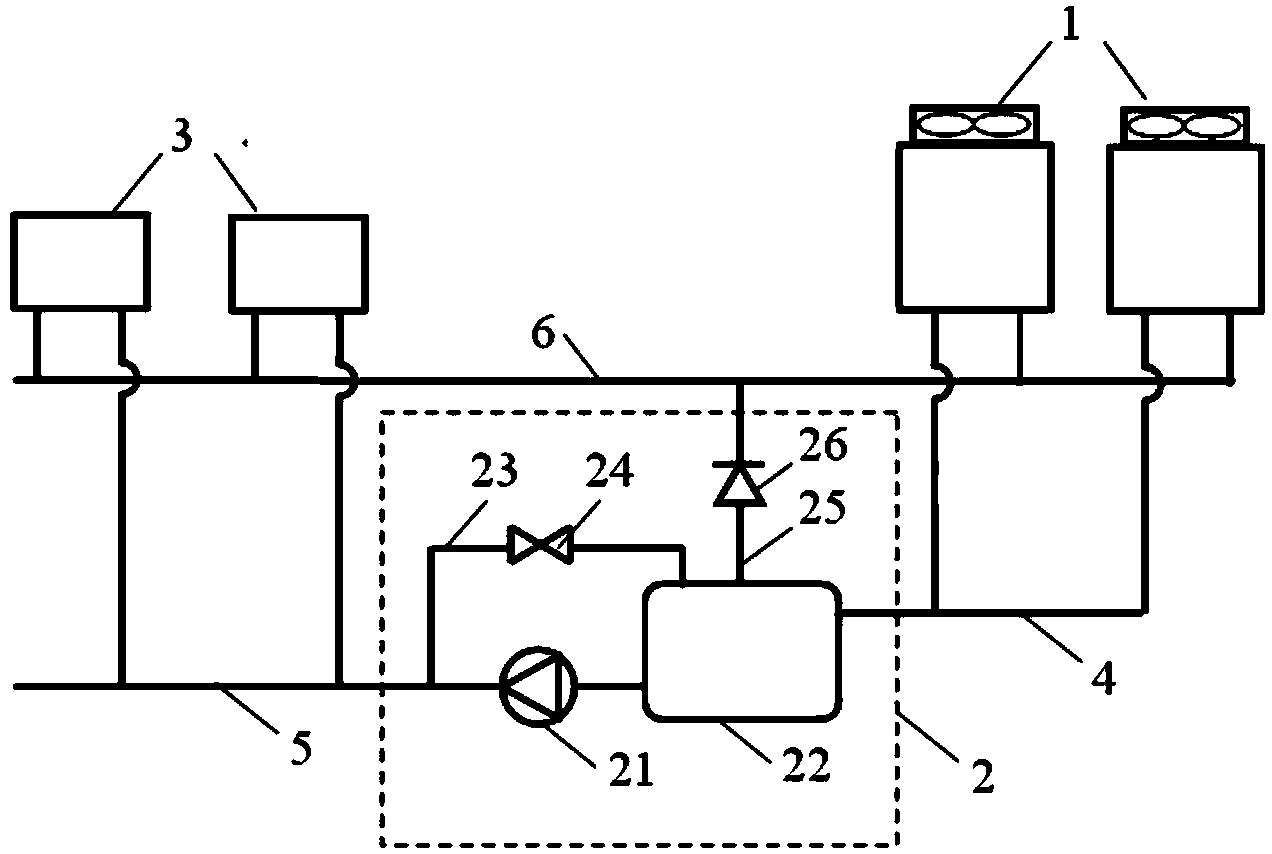

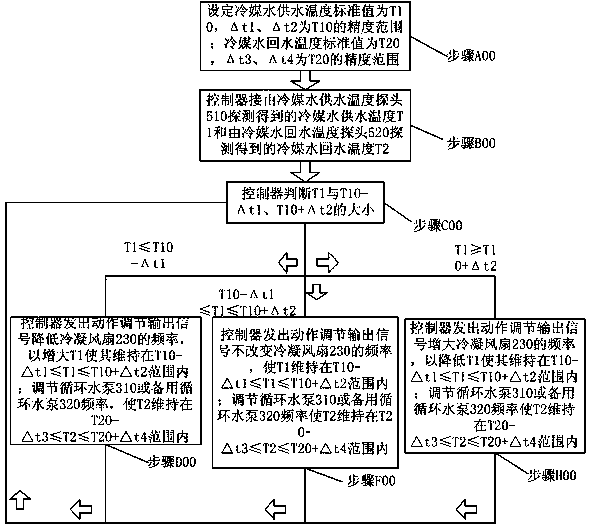

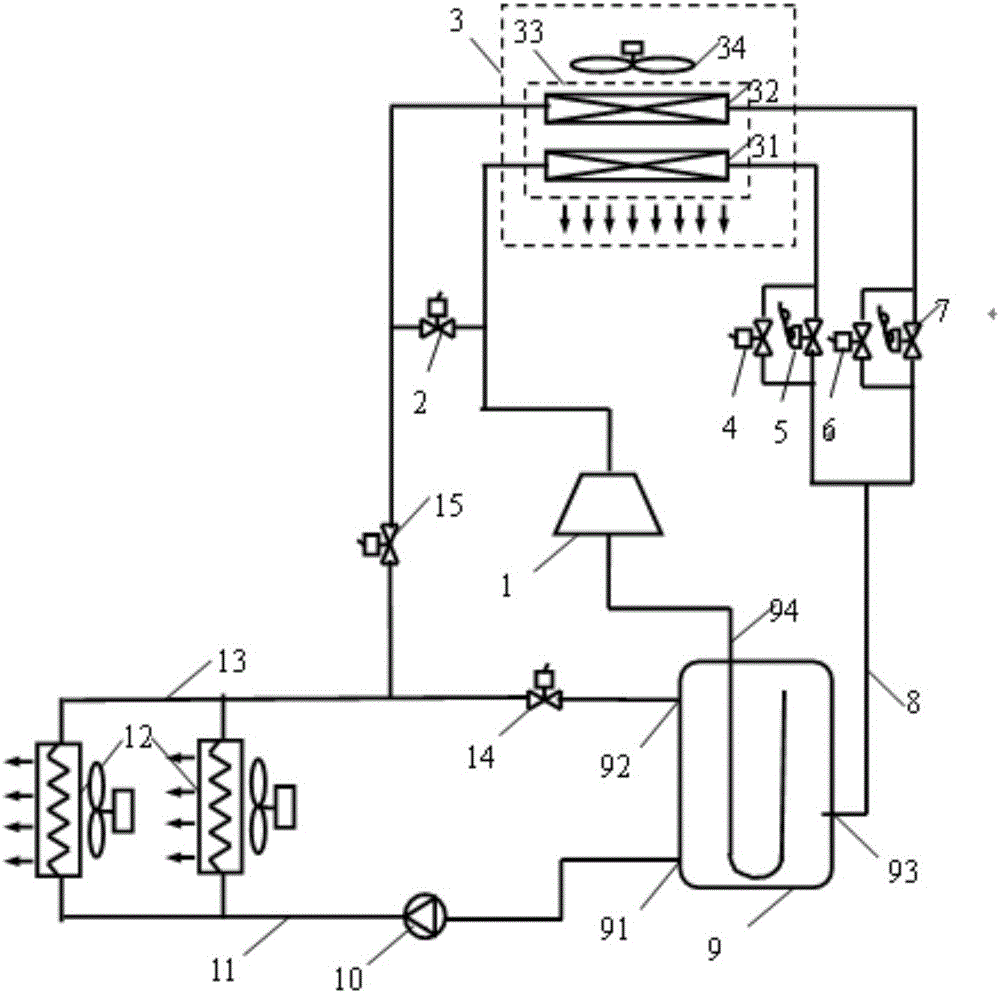

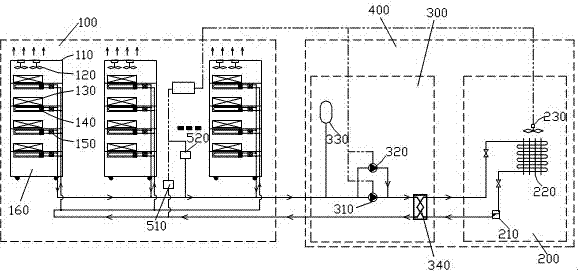

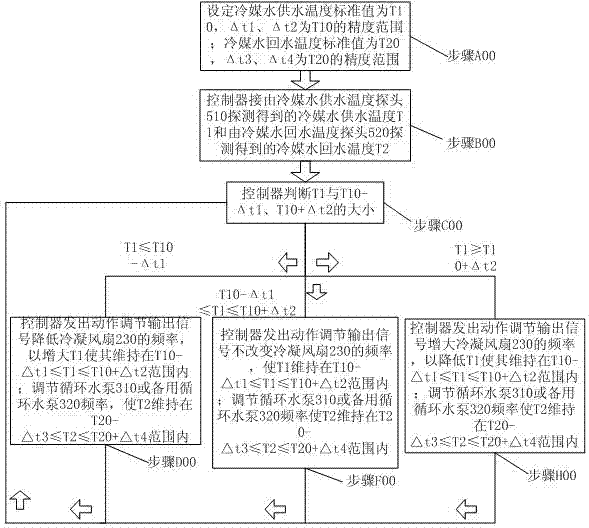

Control method for combined refrigerating multi-split air conditioner system

InactiveCN104266314ALarge working temperature zoneEasy to increase capacityMechanical apparatusSpace heating and ventilation safety systemsIndoor airTransition season

The invention discloses a control method for a combined refrigerating multi-split air conditioner system. The multi-split air conditioner system is characterized in that two or more outdoor combined refrigerating modules are arranged the outdoor side to form a cold source system of the multi-split air conditioner system, each outdoor combined refrigerating module is composed of a first refrigerant vapor compression and refrigeration circulating loop and a second refrigerant circulating loop, one or more direct evaporation type indoor air cooler modules are arranged at the indoor side, and a refrigerant storing and conveying unit is connected with the part between each outdoor combined refrigerating module and the corresponding indoor air cooler module to form a closed circulating system through a liquid collecting tube, a main liquid supply tube and a main air return tube. According to the control method for the combined refrigerating multi-split air conditioner system, the number of the indoor and outdoor modules is decided according to the designed thermal load of an air conditioner, and the control method precisely regulates the refrigerating capacity to meet the heat control needs of round-the-clock running data machine rooms and electronic equipment; the control method for the combined refrigerating multi-split air conditioner system is capable of making the maximum use of the natural cold source of the day and night, transition season and winter so as to realize the great energy conservation and emission reduction of the air conditioner system.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

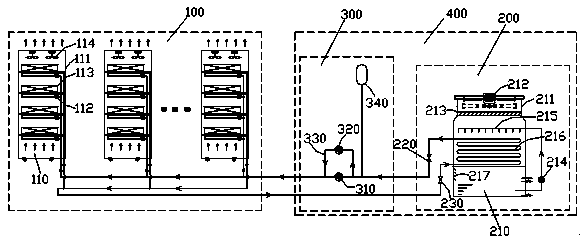

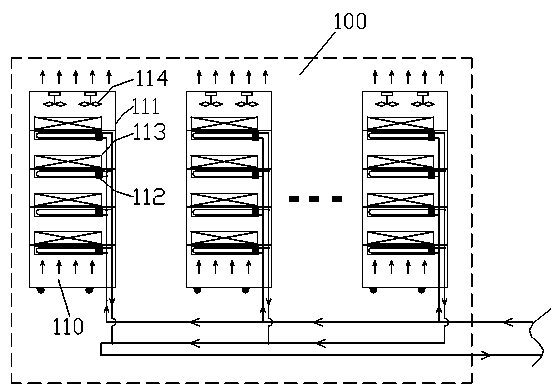

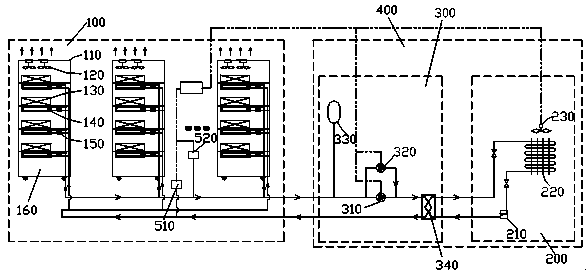

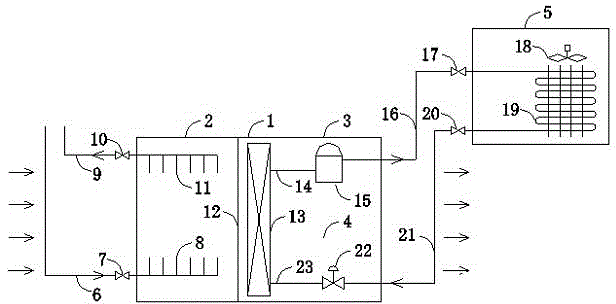

Primary water loop heat pipe radiation system for cabinet server

InactiveCN104235981AFree from pollutionImprove cleanlinessLighting and heating apparatusAir conditioning systemsCold airFree cooling

The invention discloses a primary water loop heat pipe radiation system for a cabinet server. The system comprises a machine room unit, a cooling unit and a cyclic power unit, wherein the machine room unit is connected with the cyclic power unit, and is connected with the cooling unit; the cyclic power unit is connected with the cooling unit; refrigerant water is powered by the cyclic power unit to enter the machine room unit to cool the machine room unit after being subjected to the evaporative heat absorption cooling of an outdoor air natural cooling source and spray water of the cooling unit. According to the system, a method of shortening the cold air delivery distance of a cabinet and accurately supplying air is adopted, so that the problems of local overheating and existence of hot spots of a server are solved on the basis of fully utilizing the natural cooling source and not increasing the power consumption; meanwhile, the introduction of outdoor air is avoided, so that influence on the cleanliness and the humidity of air in a machine room is eliminated; the whole system is simple in design and less in investment, the system has the characteristics of no power requirements and noise running noise in the machine room, and the aims of energy saving, synergy, safety and reliability of the data machine room are fulfilled.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

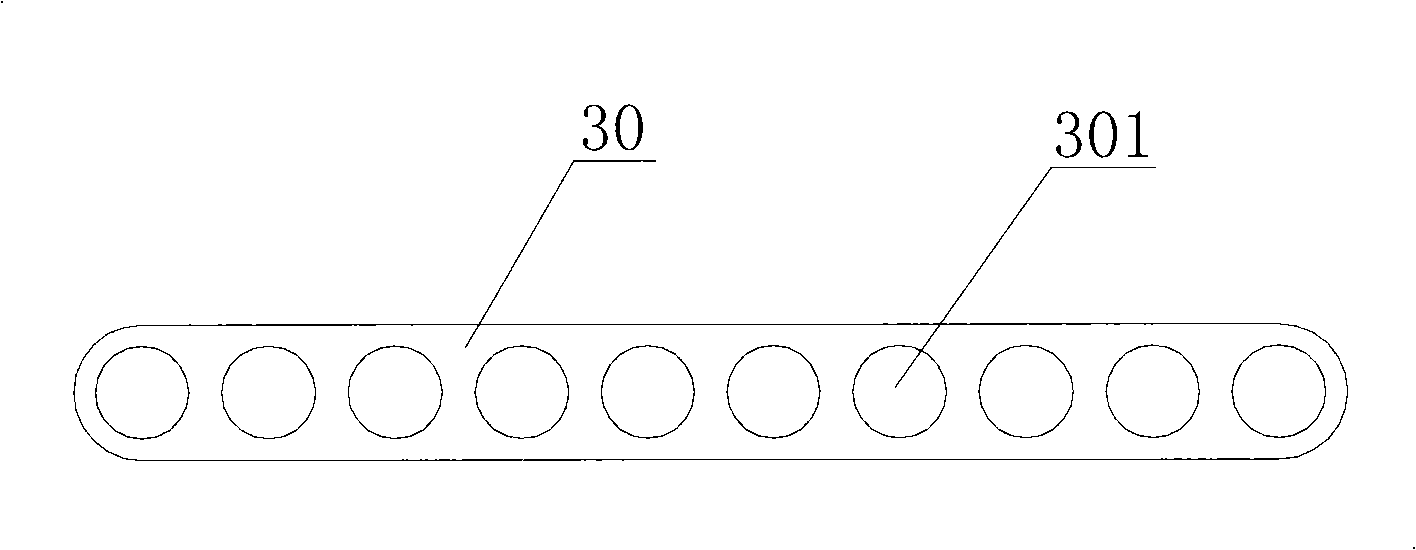

Condenser

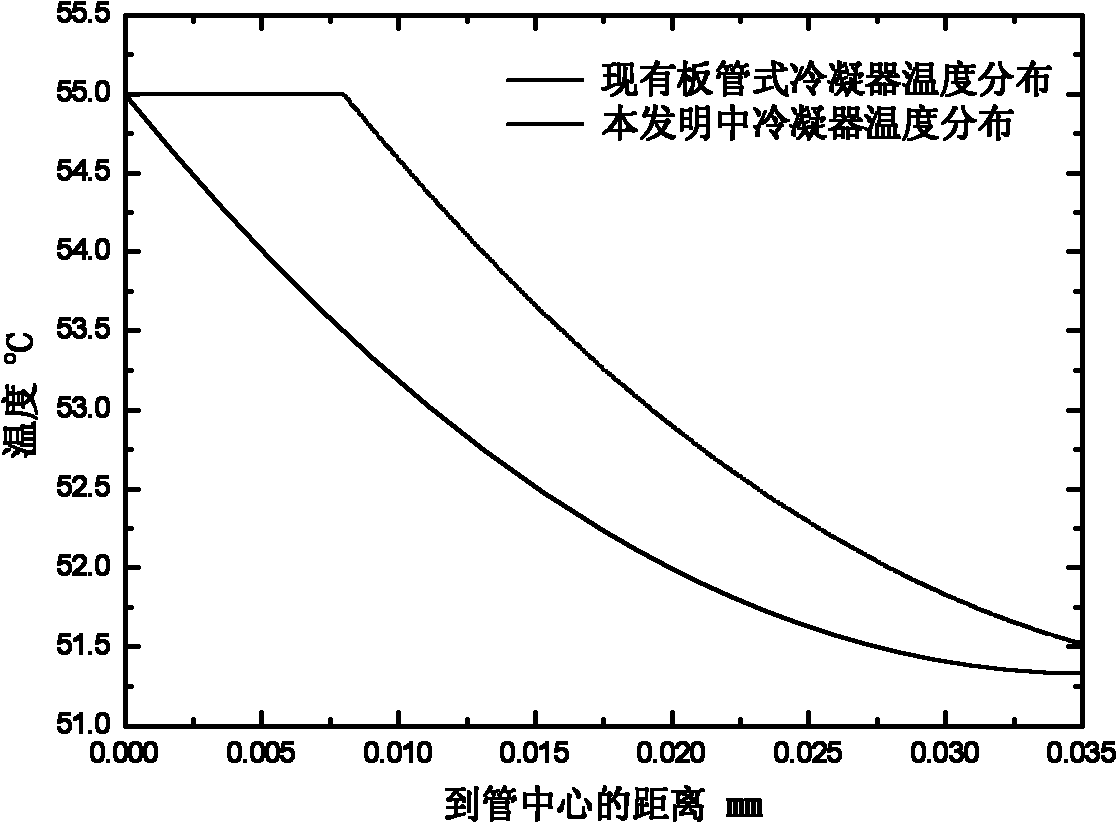

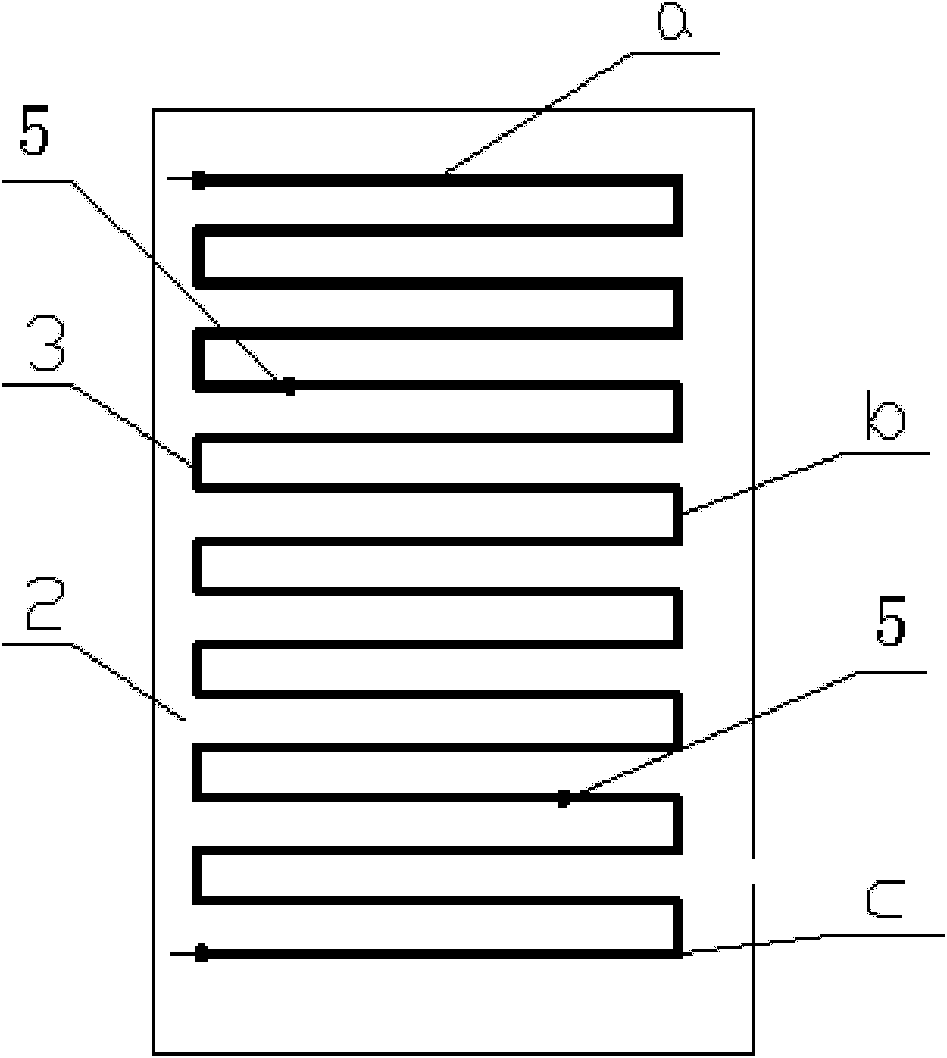

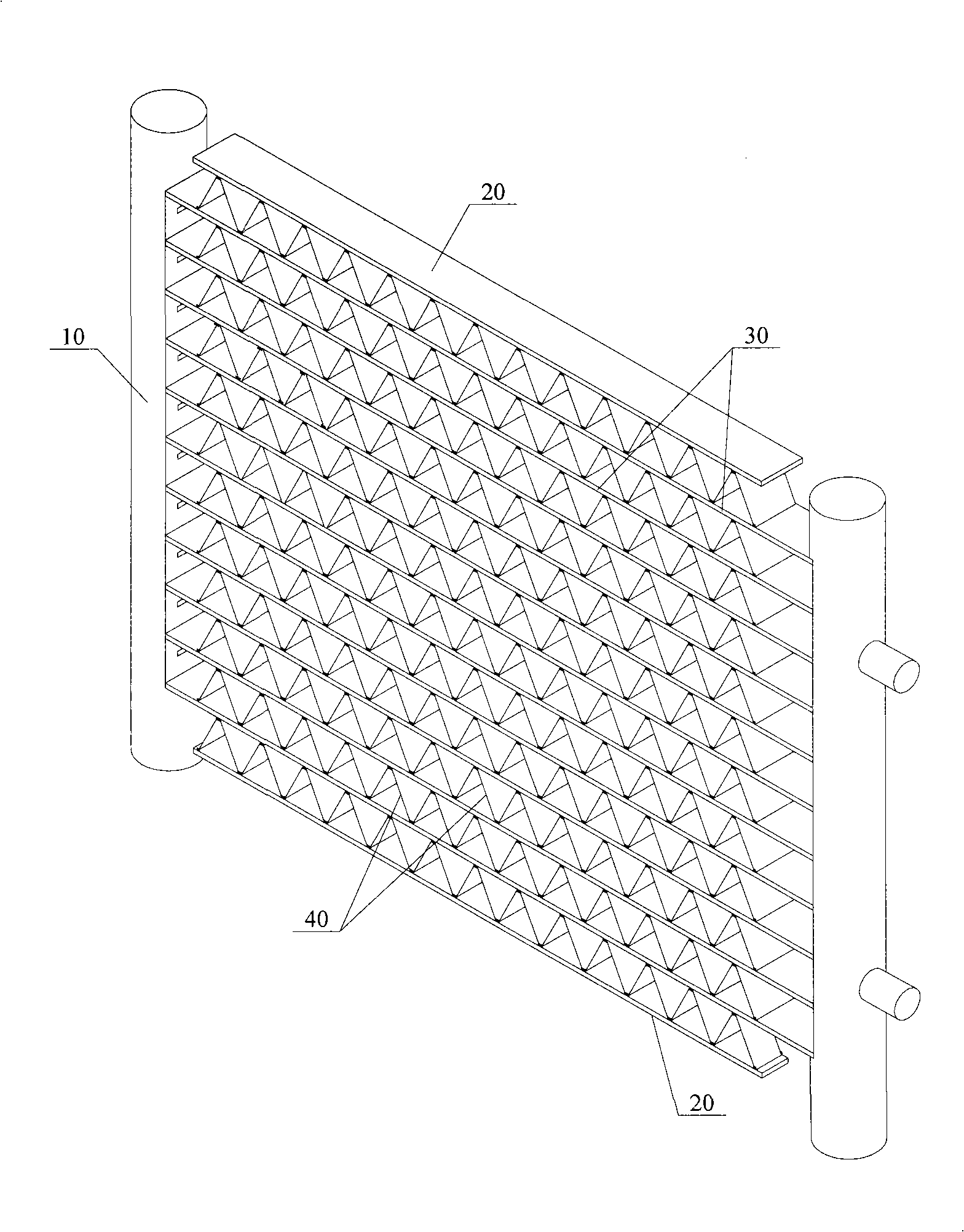

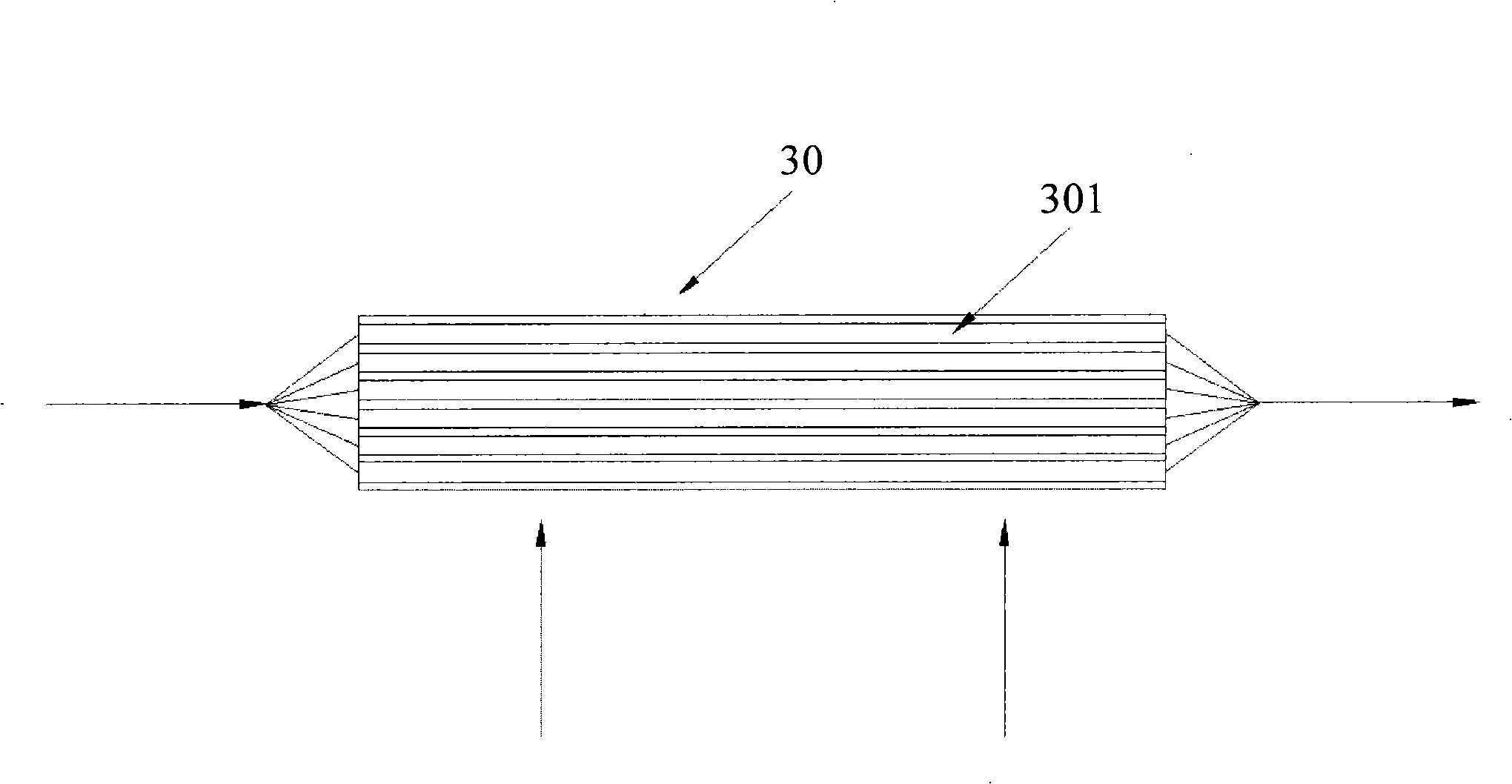

InactiveCN102052807AIncrease temperatureImprove the overall heat transfer coefficientThermal insulationEvaporators/condensersFlow resistivityMaterial consumption

The invention discloses a condenser which is composed of a porous micro through heat exchange flat tube, a corresponding connecting header and a heat dissipation back plate arranged at one side of the heat exchange flat tube. In the invention, the structure is compact, the heat exchange efficiency is high, the aluminum flat tube is adopted, thus the condenser is more advantageous than the existing copper heat exchange tube in the aspect of economical efficiency, and the condenser is suitable for the fields such as refrigeration, chemical engineering, energy source, heat exchange and the like. The condenser is characterized in that on the one hand, since the porous micro channel flat tube structure is adopted, the coefficient of heat transfer in the tube is improved, and simultaneously the flow resistance of a refrigerant in the tube is reduced; and on the other hand, the contact type of the condenser and the side wall of the heat dissipation back plate is surface contact, so that contact thermal resistance is reduced, the average temperature of the side wall of the heat dissipation back plate is improved, and the heat exchange between the side wall of the back plate and the ambient air is strengthened, namely the condensing effect is strengthened, thus, when the lengths of pipes are the same, the quantity of the condenser can be increased, or when the heat exchange quantities are the same, the length of the pipes can be reduced, therefore the condenser is more compact, simultaneously the material consumption is reduced, and the condenser has a certain advantage in the aspect of economical efficiency.

Owner:XI AN JIAOTONG UNIV

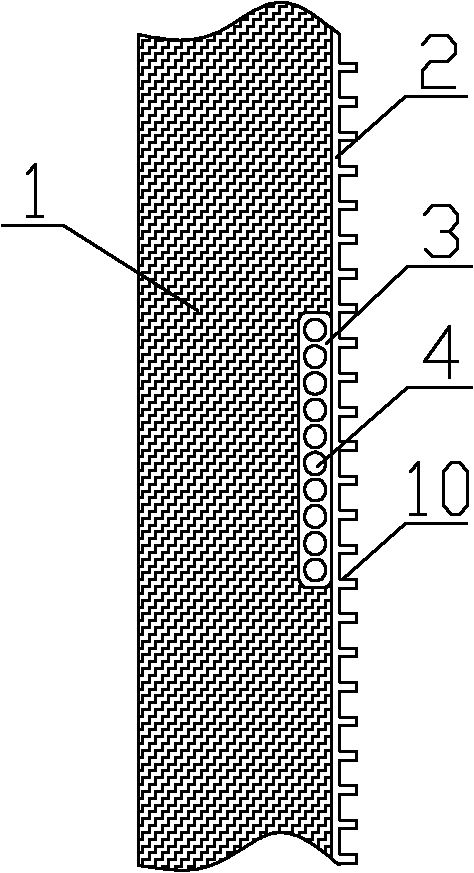

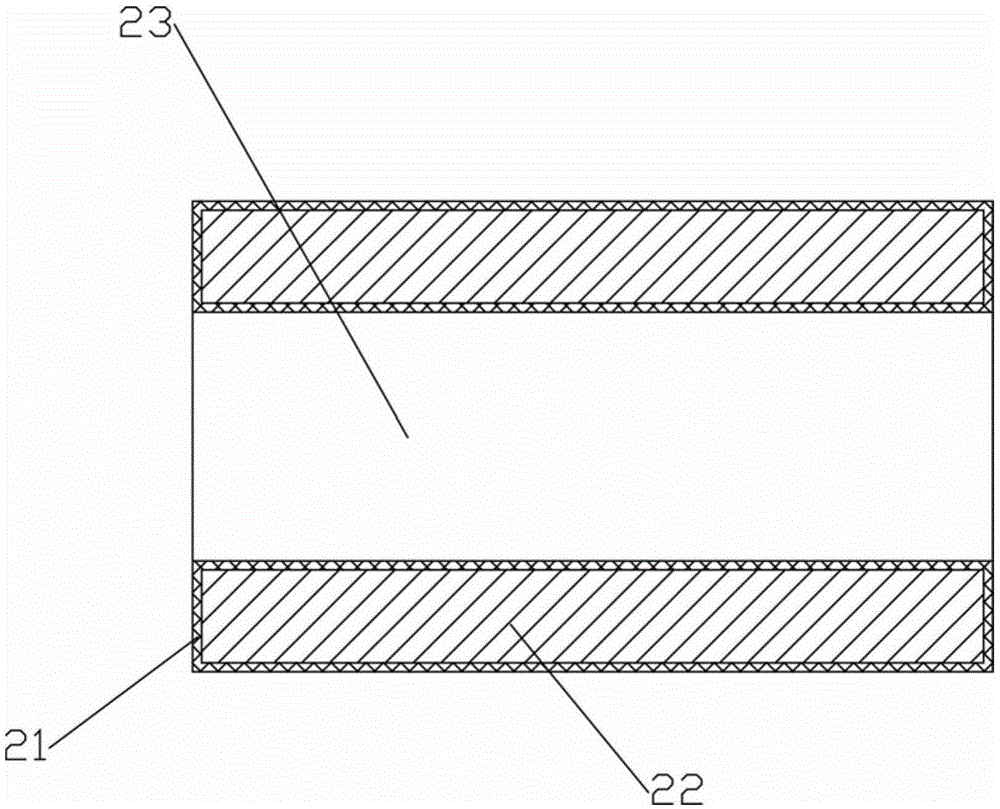

Flat pipe and heat exchanger

InactiveCN101526322AGive full play to the heat transfer performanceUniform stateStationary conduit assembliesTubular elementsPlate heat exchangerHeat transmission

The invention relates to the technical field of heat exchanger, in particular to a flat pipe which comprises not less than two through holes which extend along the lengthwise direction of the flat pipe. The through holes are arranged side by side along the width direction of the flat pipe. Two ends of the flat pipe along the width direction respectively form an external air influx entrance end and an external air outflux end. The section sizes of the through holes are reduced gradually along the direction from the external air influx entrance end of the flat pipe to the external air outflux end of the flat pipe. The through hole near the external air influx entrance end of the flat pipe has larger section size, larger heat transmission temperature difference, large heat exchange volume and larger mass flow. The through hole near the external air outflux end of the flat pipe has smaller section size, lower heat transmission temperature difference, less heat exchange volume and less mass flow. The invention brings the heat exchange performance of the flat pipe into play completely and improves the heat exchange efficiency of the heat exchanger further. The invention also provides a heat exchanger.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD

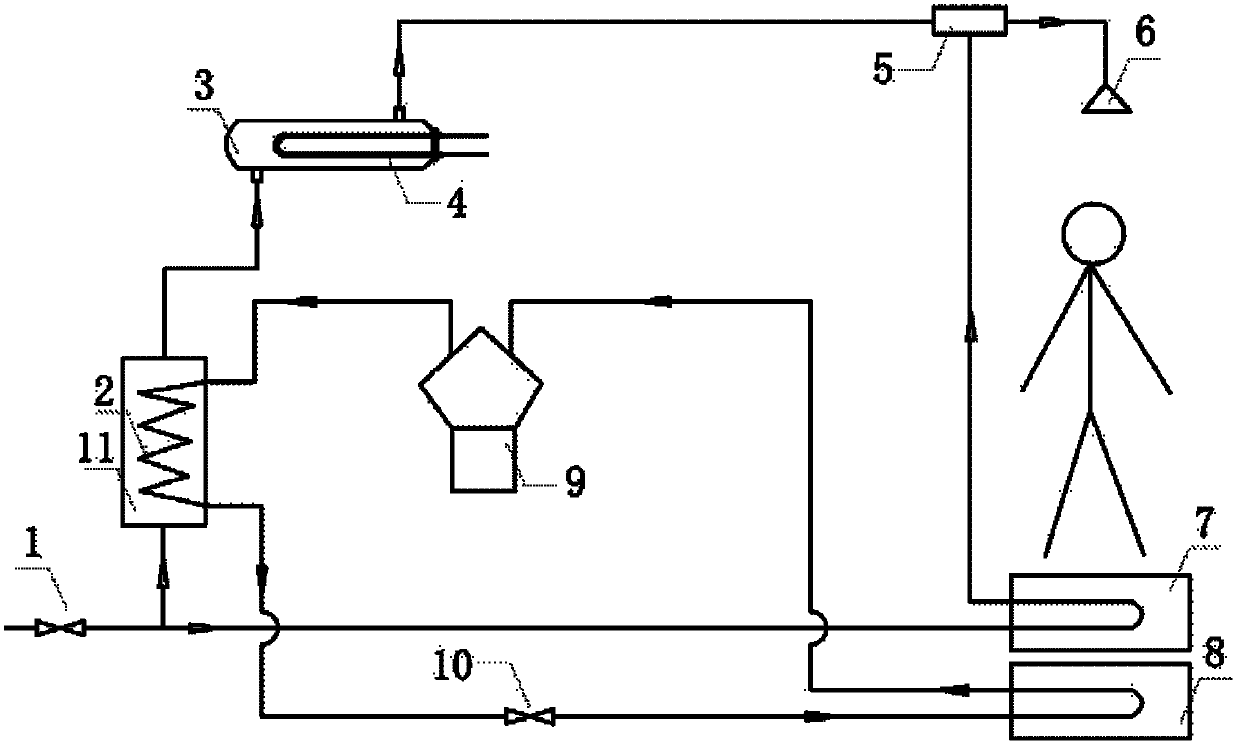

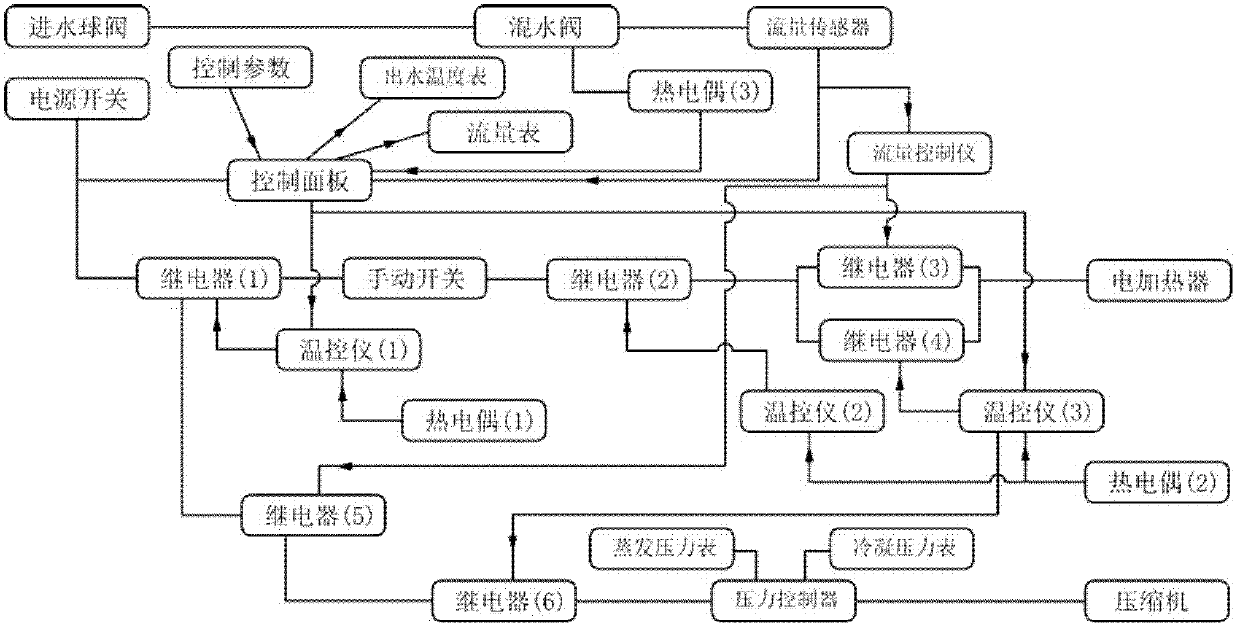

Quick heating type heat pump water heater for recovering shower waste heat

ActiveCN102607170AShorten the timeIncrease power and efficiencyFluid heatersHeat pumpsEvaporatorHeat pump water heater

A quick heating type heat pump water heater for recovering shower waste heat is composed of a condenser, an evaporator, a throttling device, a compressor, a heat regenerator, a preheater, a primary water tank, an auxiliary water tank, a water mixing controller, a spraying device and a valve. The heat regenerator and the evaporator are installed under the feet of a shower person, the spraying device is arranged above the head and communicated with the water mixing controller, the preheater is arranged in the auxiliary water tank, the condenser is arranged in the primary water tank, the water outlet end of the auxiliary water tank is connected with an inlet of the water mixing controller, and the water inlet end of the auxiliary water tank is connected with a water outlet pipe of the primary water tank. One end of the valve is connected with tap water, the other end of the valve is respectively connected with a water inlet pipe of the primary water tank and a water inlet pipe of the heat regenerator, and the water outlet end of the heat regenerator is communicated with the water mixing controller. The condenser, the throttling device, the evaporator and the compressor form a closed loop, an outlet of the condenser is connected with an inlet of the throttling device, an outlet of the throttling device is connected with an inlet of the evaporator, an outlet of the evaporator is connected with an inlet of the compressor, and an outlet of the compressor is connected with an inlet of the condenser.

Owner:佛山市三角洲电器科技有限公司 +1

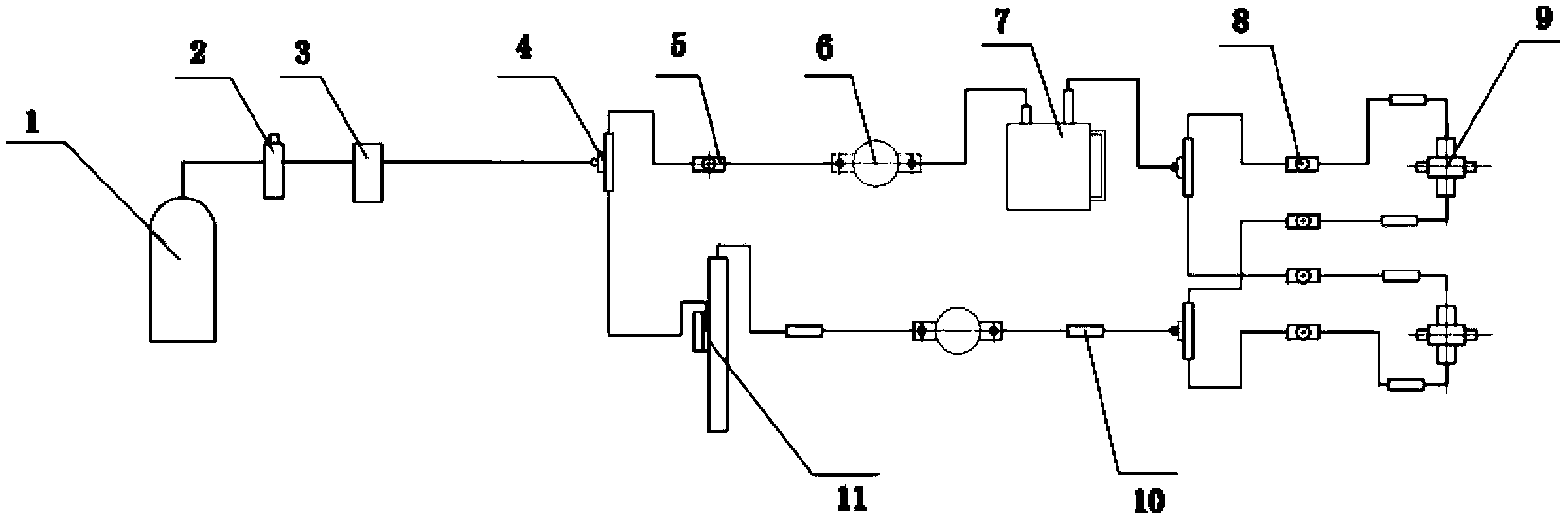

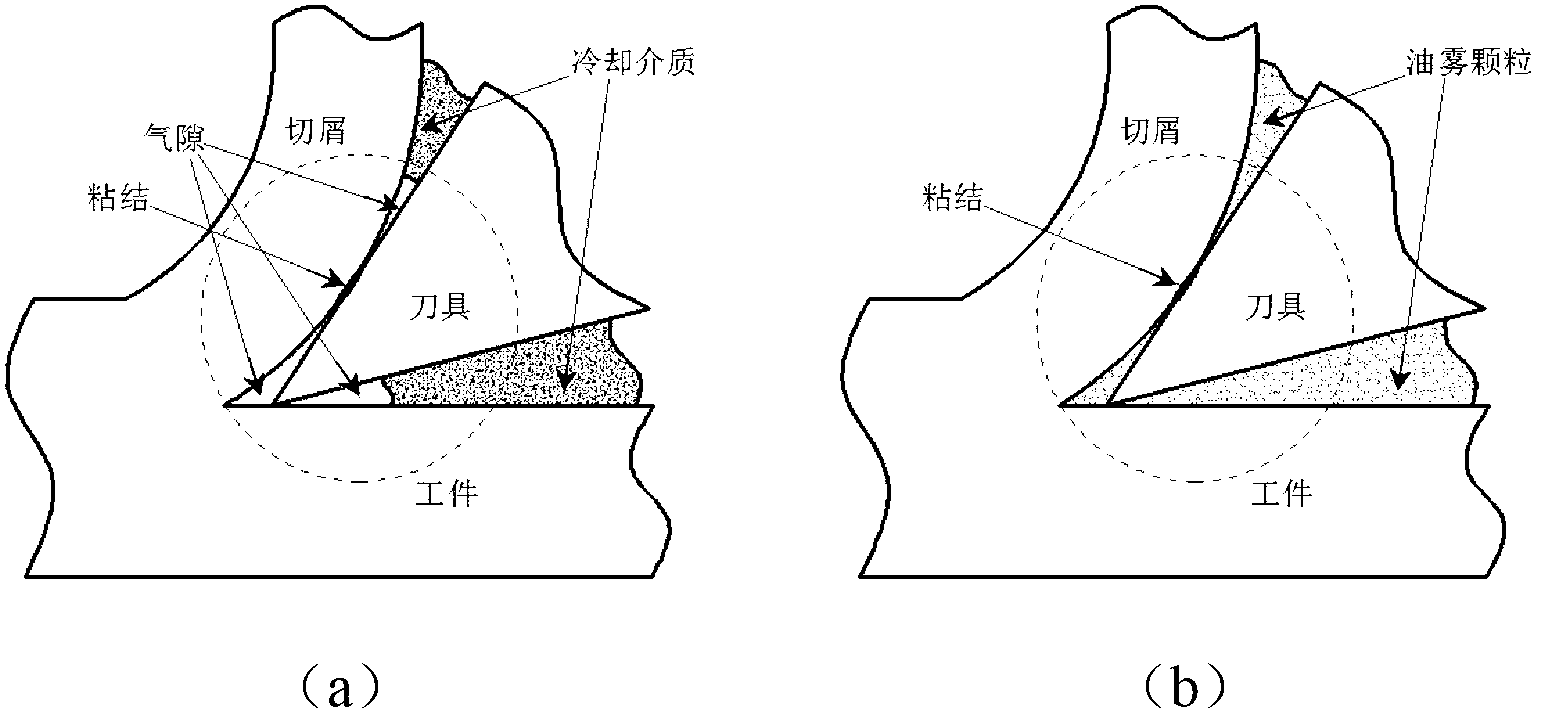

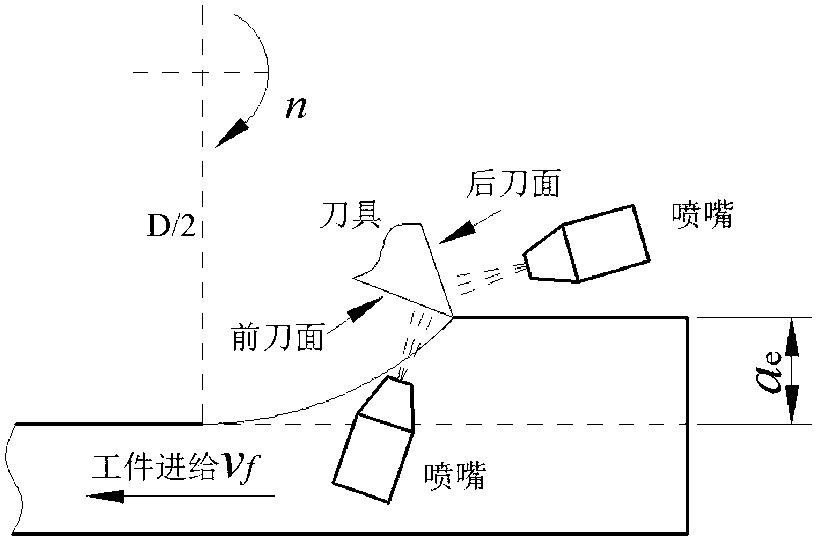

Method and device for forming high-pressure and low-temperature jet flow by cutting coolant

ActiveCN103286629AIncreased durabilityReduce cutting temperatureMaintainance and safety accessoriesJet flowSpray nozzle

The method discloses a method and device for forming high-pressure and low-temperature jet flow by cutting coolant. The method includes that compressed air stored inside an air storage tank is filtered and dried and connected to a tee joint through a hose to divide an output pipe into two branches, air in one branch is cooled by a cooling device to become low-temperature high-pressure air, and inputted into an air inlet end of a pneumatic spray nozzle after being connected with one or more than one tee joint, the air in the other branch is inputted into a well-sealed cutting fluid storage container after pressure in the air is regulated by a pressure regulating valve, the cutting fluid is pressed out, and connected into liquid inlet ends of a plurality of pneumatic spray nozzles after passing one or more than one tee joint prior through the hose, the air and the liquid are mixed outside a jet nozzle to produce high-speed jet flow. By the method, usage amount of cooling lubricating liquid is reduced, cooling and lubricating functions of fluid medium are fully performed, cutting temperature is greatly lowered, and tool durability is conspicuously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Control method of combined type air-conditioning system with natural cooling function

ActiveCN106051969ALarge working temperature zoneAvoid single-run compression refrigerationMechanical apparatusSpace heating and ventilation safety systemsData centerTransition season

The invention discloses a control method of a combined type air-conditioning system with a natural cooling function. The control method of the combined type air-conditioning system with the natural cooling function is characterized in that the system comprises a compressor module, an air-cooling heat exchange module, a multifunctional liquid storage device, a liquid pump, an air treatment module and control valves, wherein the air-cooling heat exchange module is composed of a heat exchanger assembly and a cooling fan; and the control method comprises the step that the three different work modes including a compression refrigeration work mode, a compression refrigeration and natural cooling coordinated operation combined refrigeration work mode and the natural cooling work mode are achieved by operating the control valves to change the flowing path of refrigeration media. According to the control method of the combined type air-conditioning system with the natural cooling function, fuzzy control is used for adjusting the refrigeration capacity, natural cooling is used for replacing compression refrigeration in low-temperature or transition seasons, natural cold resources are efficiently utilized, the control method is particularly suitable for control over the work environments of data centers, high-performance computers, communication base stations and power electronic equipment, and the energy consumption and operating cost of the air-conditioning system are greatly reduced.

Owner:HEFEI UNIV OF TECH

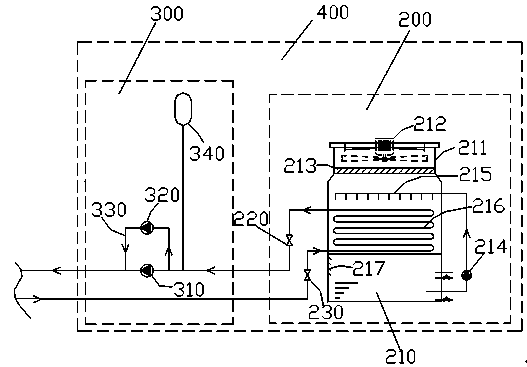

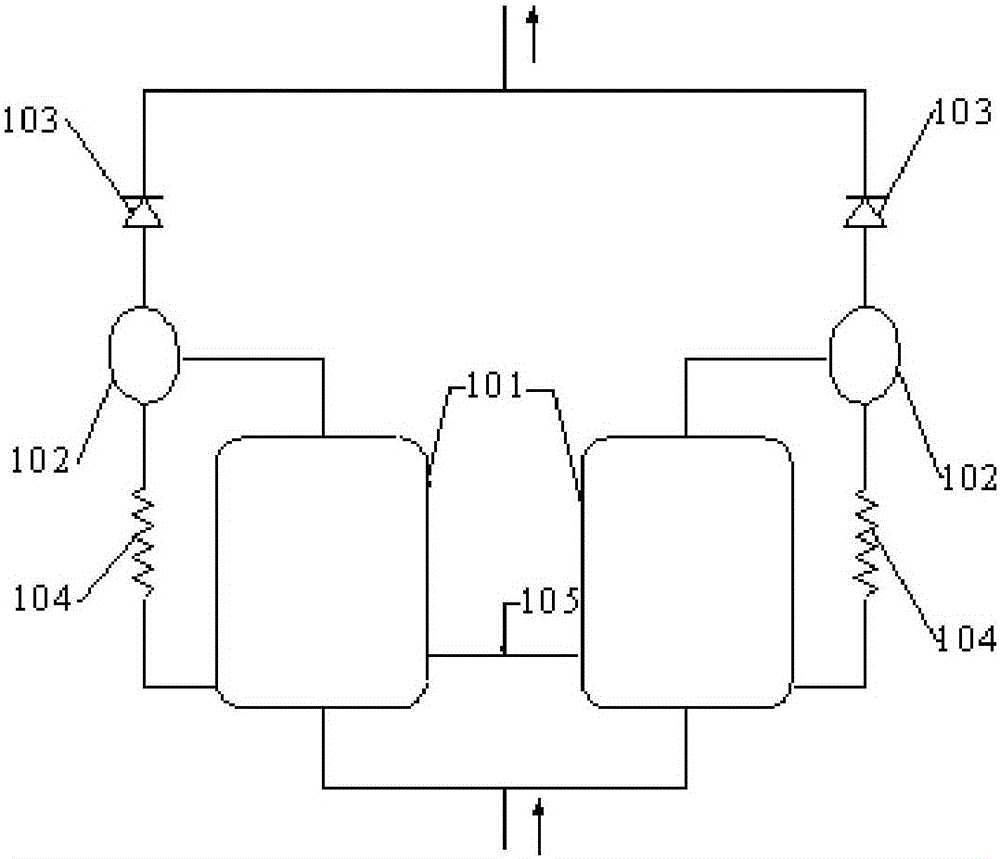

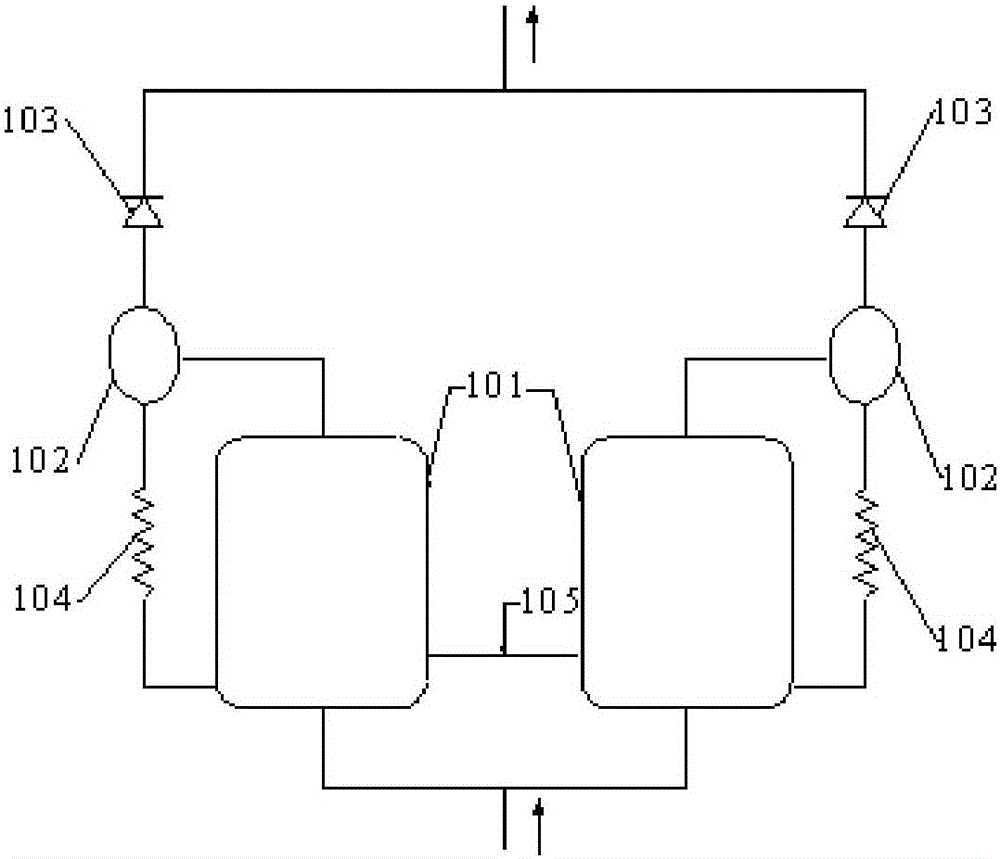

Control method for heat pipe secondary refrigerant loop server cabinet cooling system

ActiveCN104270930ASolve localized overheating and existing hot spotsLarge heat transfer temperature differenceDigital data processing detailsEfficient regulation technologiesEngineeringWater supply

The invention discloses a control method for a heat pipe secondary refrigerant loop server cabinet cooling system. The system comprises one or more heat pipe radiators, a server cabinet, a water supply branch pipe, a water return branch pipe, a machine room water supply main pipe, a machine room water return main pipe, an automatic water replenishing constant pressure device, a circulating water pump, a standby water pump, a heat exchange device, an outdoor refrigerant return connecting pipe, an outdoor air outflow connecting pipe, a refrigerant valve, an air valve, an air-cooled condenser and a control system. Natural cooling energy-saving measures are adopted in the air-cooled condenser. By the adoption of the control method, a server can be directly cooled, and the problems that a server cabinet is partially too hot and hot spots exist are solved; meanwhile, the natural cooling measures are utilized, the heat exchange temperature difference is large, efficiency is high, and the system has the advantages of being simple, reliable and low in power consumption and noise and meets the ideas of energy saving and environment friendliness.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

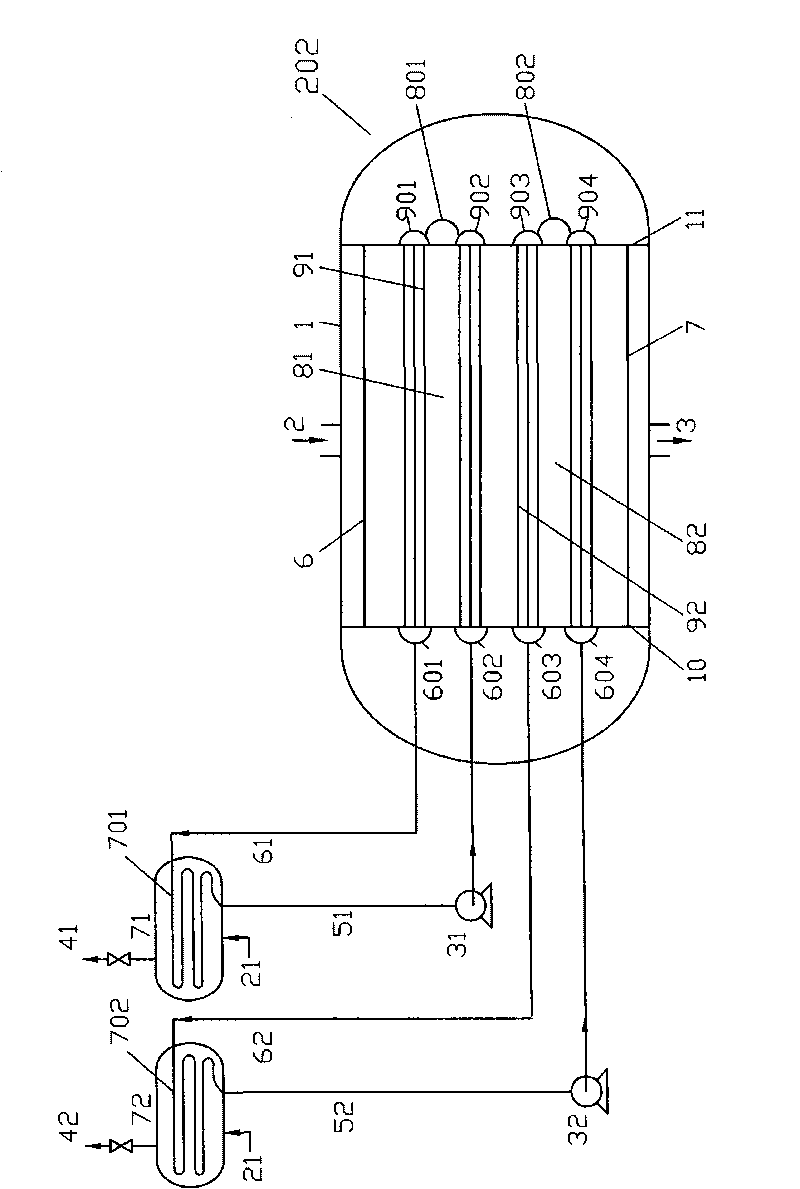

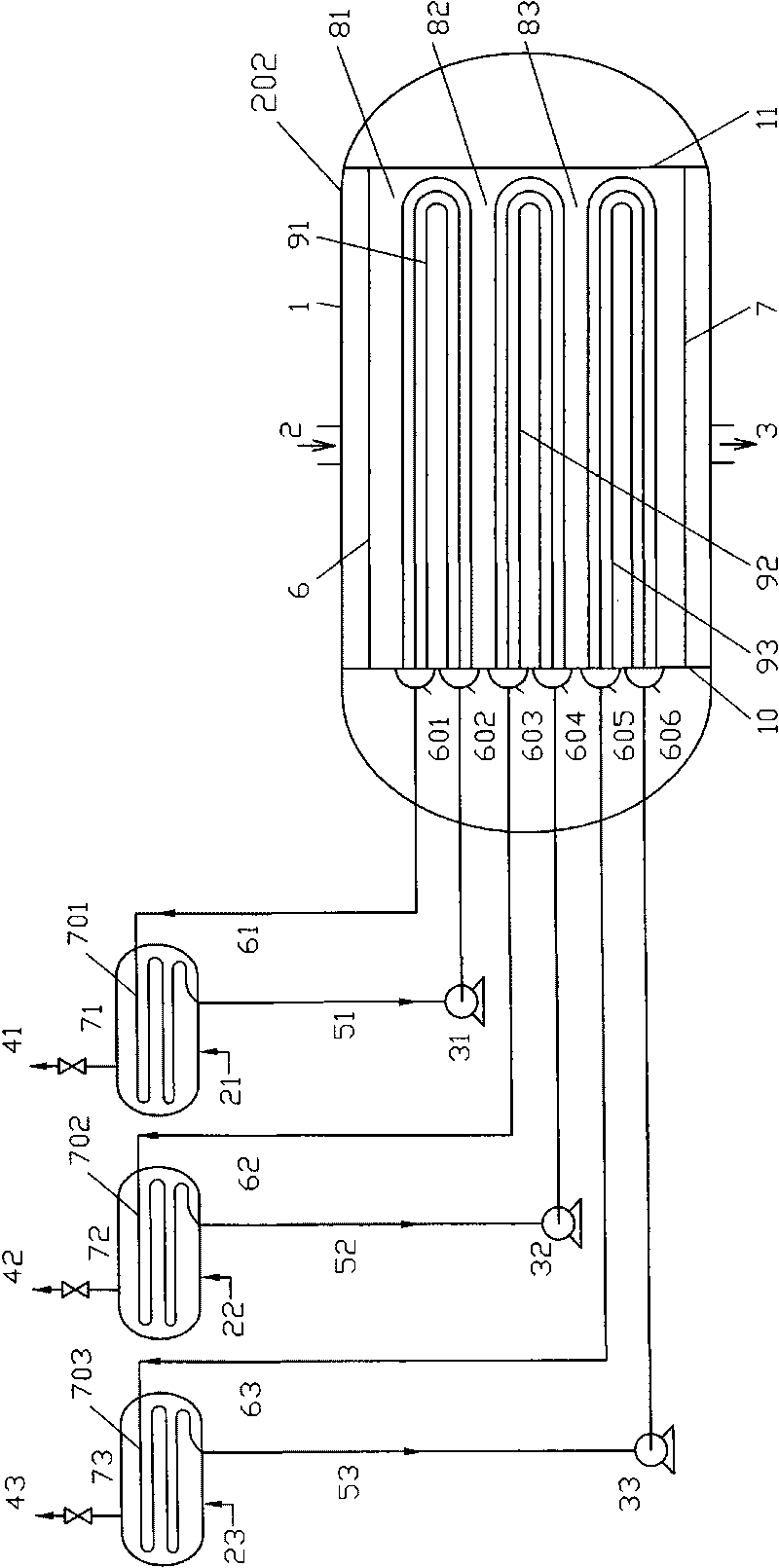

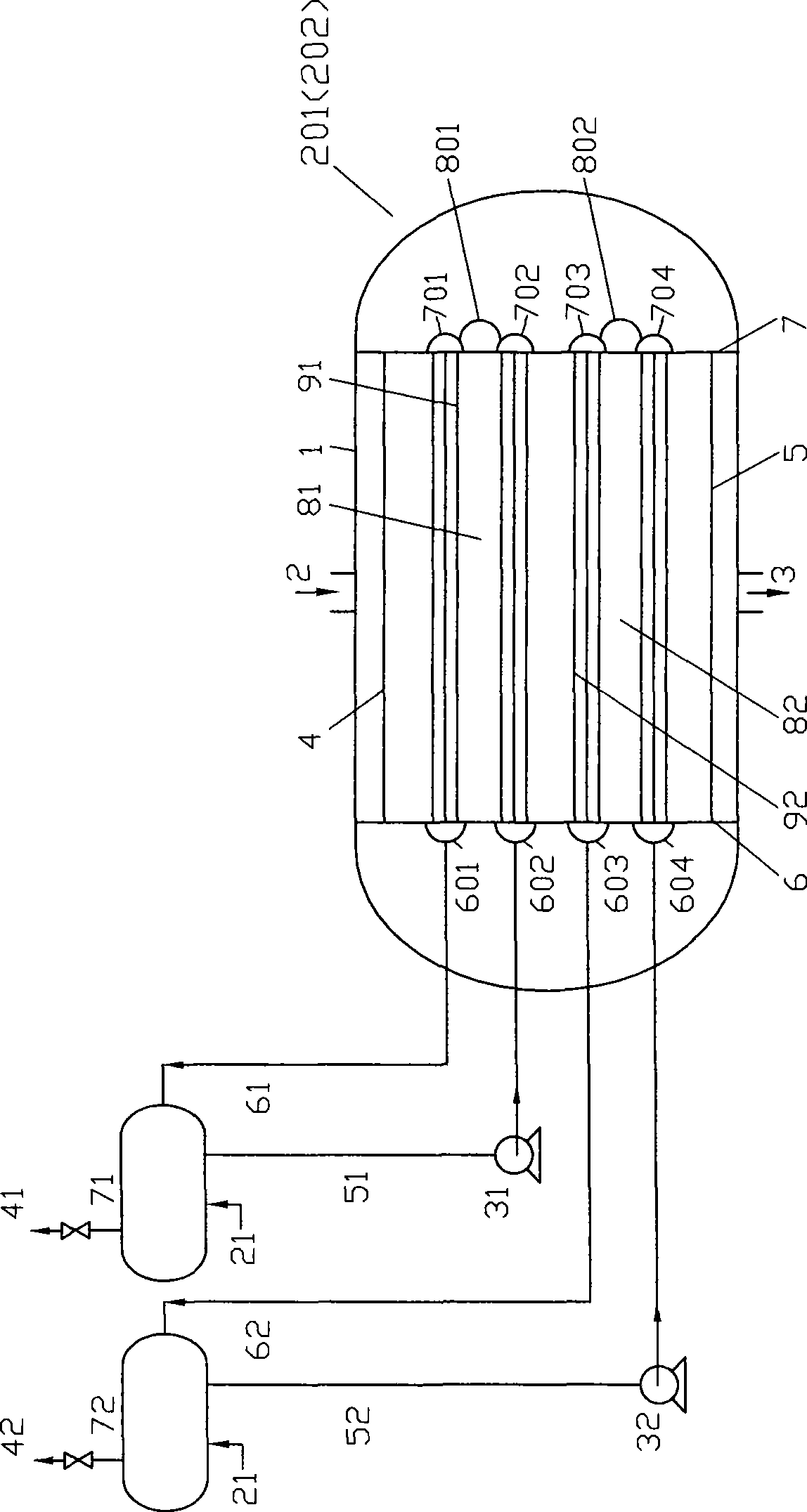

Method and equipment for preparing hydrocarbon by methyl alcohol or/ and dimethyl ether

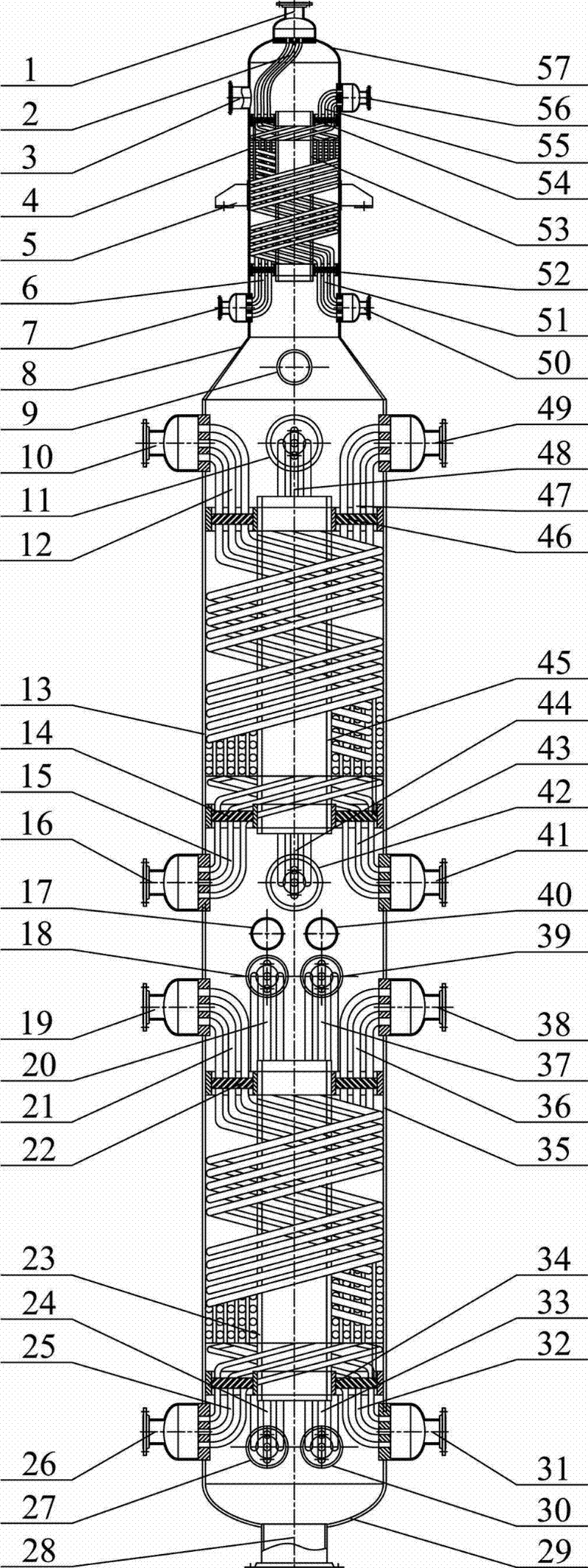

ActiveCN101723775AImprove heat transfer abilityRelease more heat of reactionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAlcoholFixed bed

The invention discloses a method and equipment for preparing hydrocarbon by methyl alcohol or / and dimethyl ether. The invention is mainly characterized in that raw material gases, such as methyl alcohol or / and dimethyl ether and the like pass through fixed bed reaction composition equipment for catalysis to generate hydrocarbon, wherein the fixed bed reaction combination equipment is at least provided with two reaction zones, and each reaction zone is provided with a heat exchange tube set capable of independently adjusting heat exchange medium temperature; after reaction gases separate target product hydrocarbon and water by heat exchange and cooling, expect that less chillout recycle gas is mixed with raw material gas, reaction for generating target product hydrocarbon is carried out.The invention has the beneficial effects of small catalyst layer temperature difference, low recycle ratio, high synthetic ratio, small investment, high output, energy saving and consumption reduction.

Owner:杭州林达化工技术工程有限公司

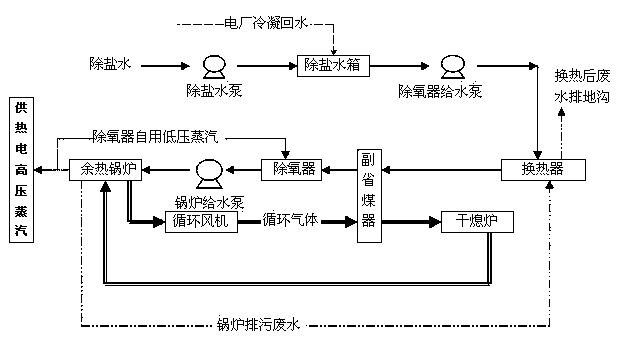

Residual heat recovery system of sewage water of coke dry quenching boiler

InactiveCN103388817ALarge heat transfer temperature differenceImprove heat recovery effectLiquid degasificationBoiler blowdownEngineering

The invention relates to a residual heat recovery system of sewage water of a coke dry quenching boiler. The system is characterized in that a sewage water heat exchanger is additionally arranged, desalting water which is delivered to an auxiliary coal saver by a water feed pump of a deaerator is used as a cooling medium to exchange heat with the sewage water nearby, and then the heat-exchanged desalting water is delivered to the deaerator to be deaerated. The system has the advantages that the problem of quantity distribution of water entering the heat exchanger and the auxiliary coal saver is avoided, and the operation and the control are convenient; the temperature of the desalting water entering the heat exchanger is minimum, the heat exchange temperature difference is high, and the heat recovery effect is good; the temperature of air at an inlet of the coke dry quenching boiler is controlled to 115 DEG C to 135 DEG C, and the temperature of actual running is controlled to about 125 DEG C and has a space of 10 DEG C from the maximum temperature, so the adjusting capability is high; and in addition, the quantity of circulating air is higher, so the temperature of the water entering the auxiliary coal saver is raised by about 8 DEG C in comparison with the temperature of the previous arrangement, the effect on the temperature of circulating air is little, and the running parameters of a coke dry quenching groove and the boiler are controlled within the specified range.

Owner:广西华锐工程设计有限公司

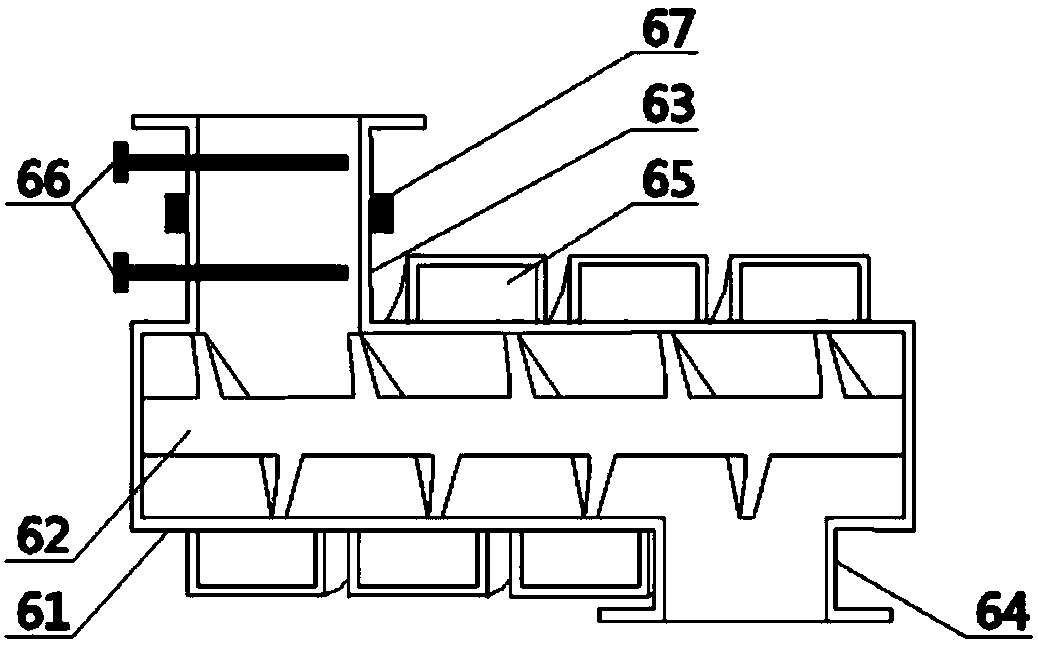

Coal thermolysis device for heat-carrying gas

InactiveCN102911677AHigh thermal conductivityLarge heat transfer temperature differenceHydrocarbon from carbon oxidesGaseous fuelsHeat transmissionProcess engineering

The invention provides a coal thermolysis device for heat-carrying gas. The coal thermolysis device is formed by correspondingly fastening two metal plates in which a plurality of semicircular concave grooves are arranged according to the concave grooves, wherein the plurality of semicircular concave grooves are combined to form a plurality of heat-carrying gas heat transmission pipes; the heat transmission pipes are sequentially communicated with a small vertical pipe, a transverse pipe, a main pipe, a heat-carrying gas inlet and a heat-carrying gas outlet, so as to form a heat-carrying gas heat transmission system. According to the coal thermolysis device, the heat-carrying can be used for directly drying the coal in a destructive distillation chamber through a metal heat intromission pipe, so as to achieve normal-pressure or destructive distillation; and the coal thermolysis device has the characteristics of being fast in transmission rate, high in heat utilization rate, simple in structure and low in cost.

Owner:TAIYUAN UNIV OF TECH

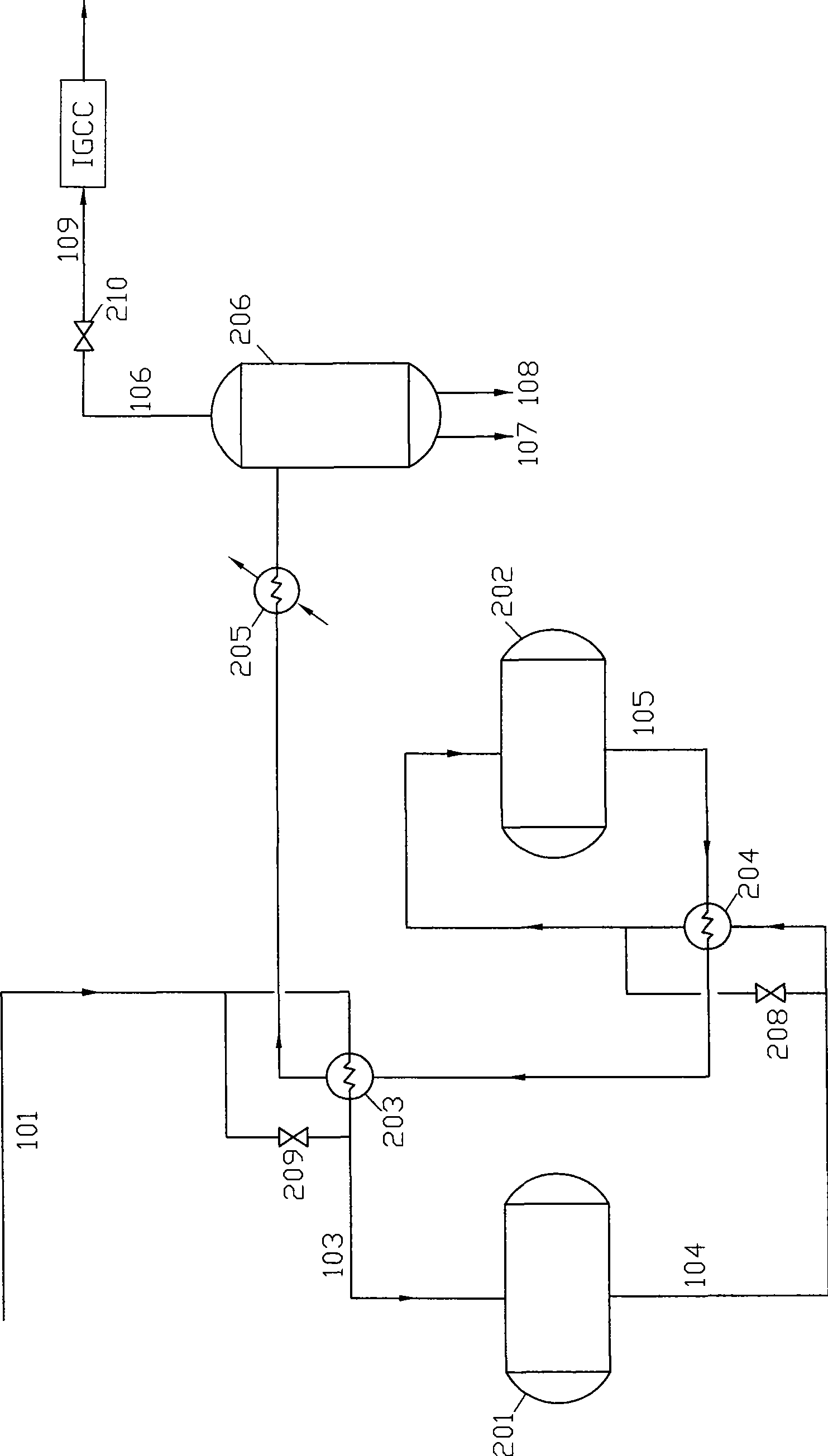

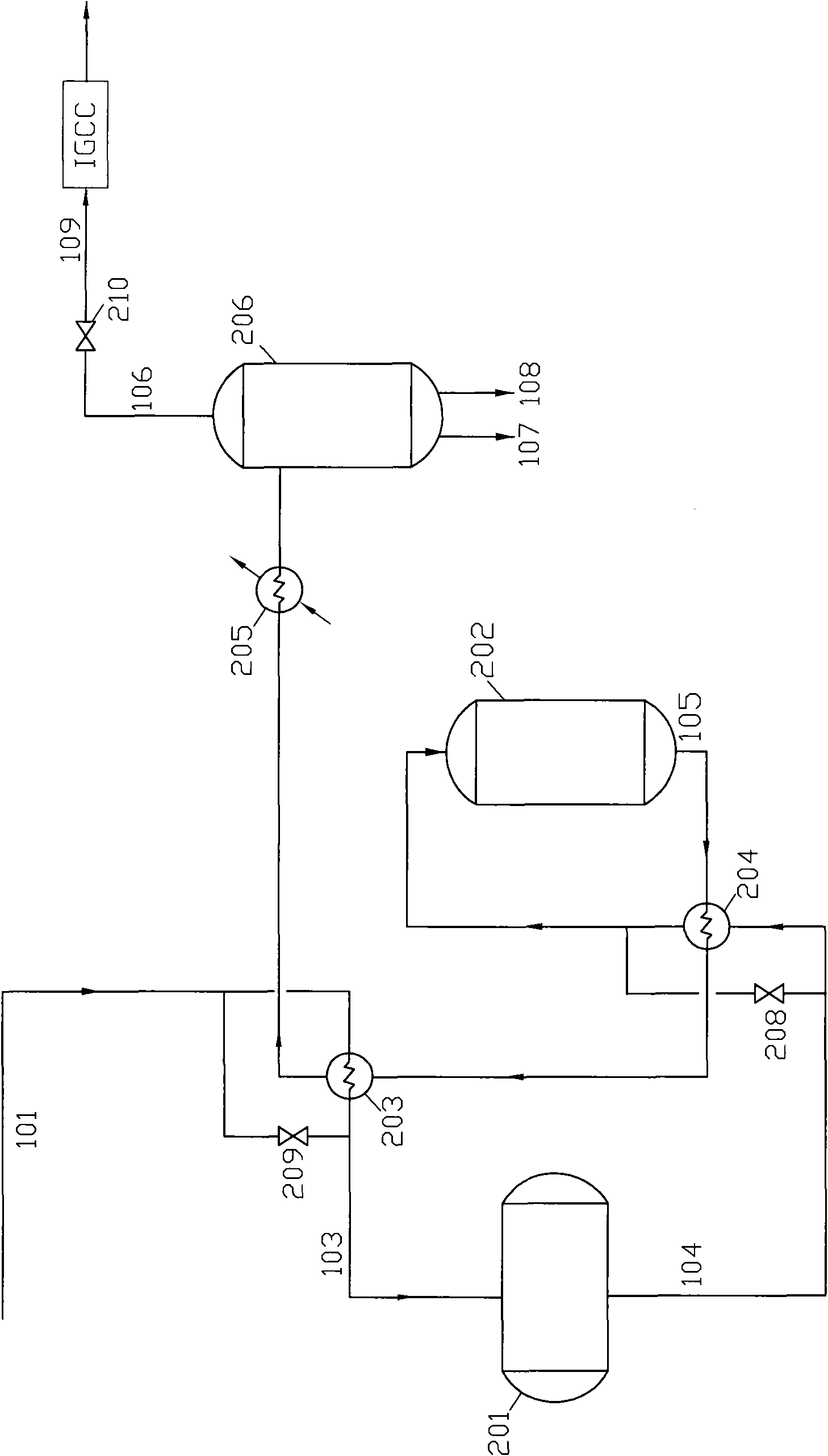

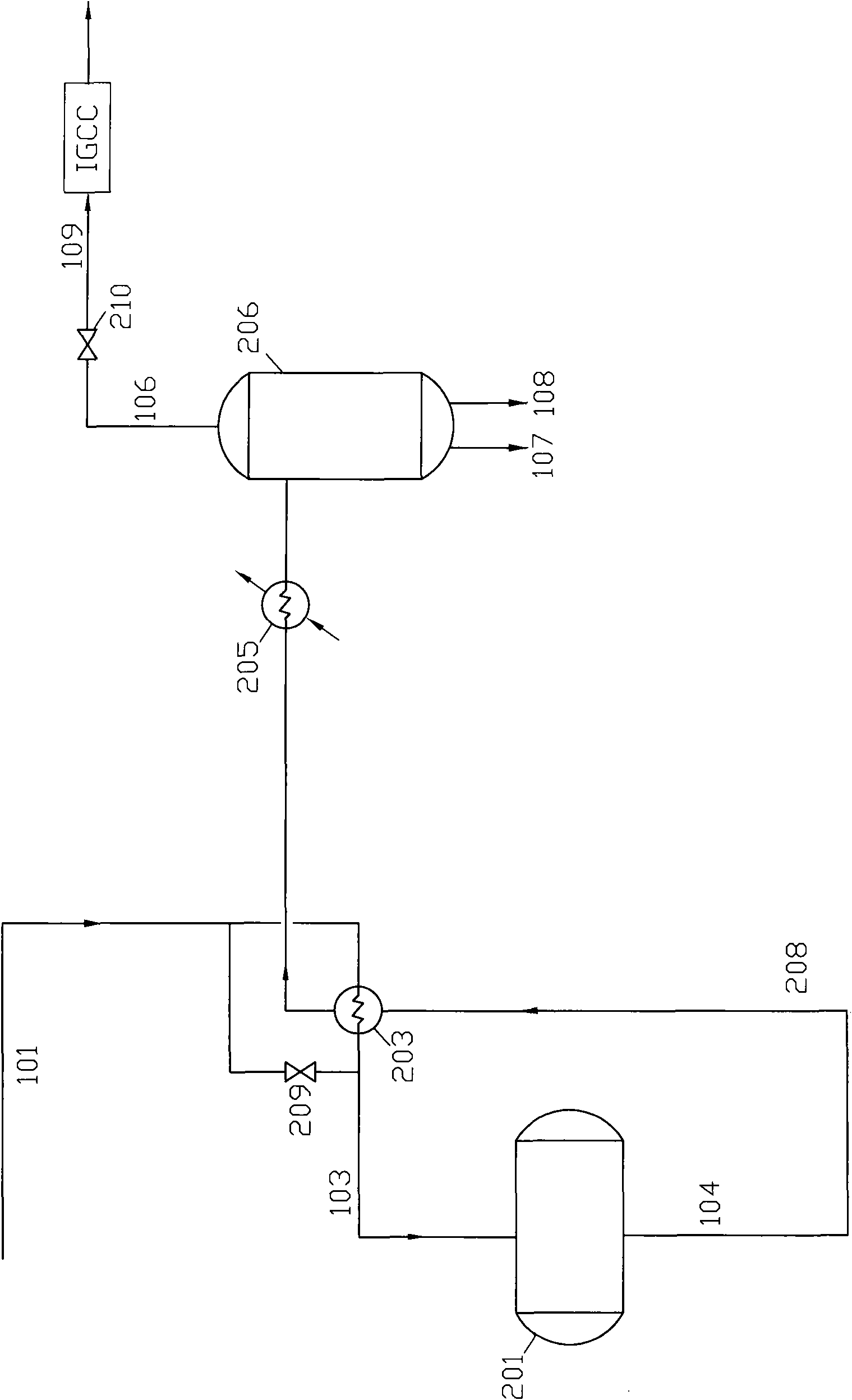

Method and equipment for producing hydrocarbon with synthetic gas

ActiveCN101519336AHigh methanol contentQuick responseOrganic compound preparationHydroxy compound preparationTowerIntegrated gasification combined cycle

The invention discloses a method for producing hydrocarbon with synthetic gas, which comprises essentially the steps as follows: methanol synthetic reaction of the pressurized synthetic gas is implemented in a methanol synthetic reactor, reaction gas is not separated after being output from a reaction tower and enters a methanol dehydrating reactor under the same pressure level so as to implement the methanol dehydrating reaction and generate the hydrocarbon product, the final reaction gas is cooled and separated so as to generate the hydrocarbon product, water and unreacted synthetic gas, and the separated synthetic gas is either discharged for gas-steam integrated gasification combined cycle (IGCC) or taken as recycled synthetic gas and mixed with the raw material synthetic gas in further methanol synthesis, methanol dehydration and product separation besides little discharge.

Owner:杭州林达化工技术工程有限公司

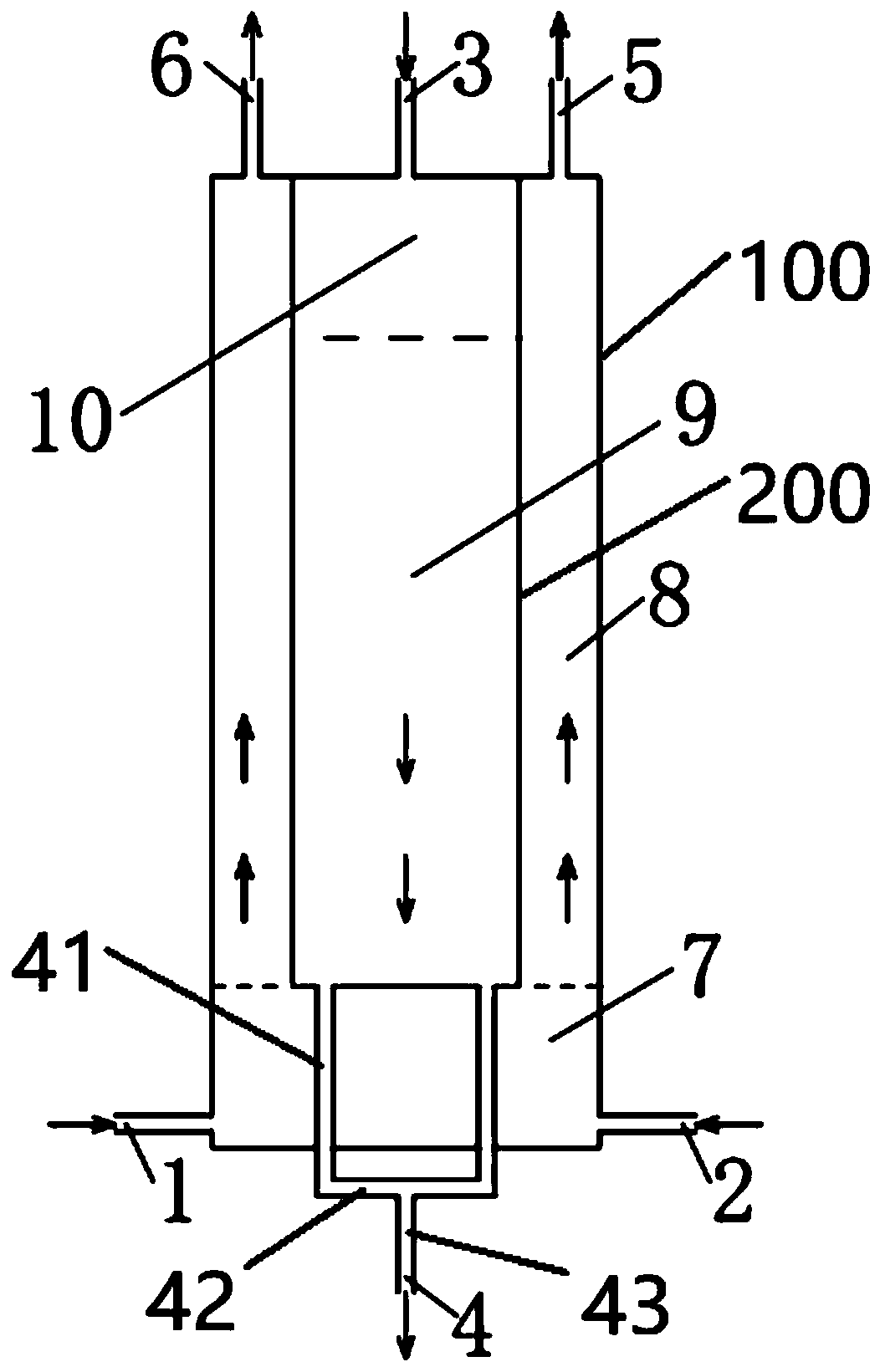

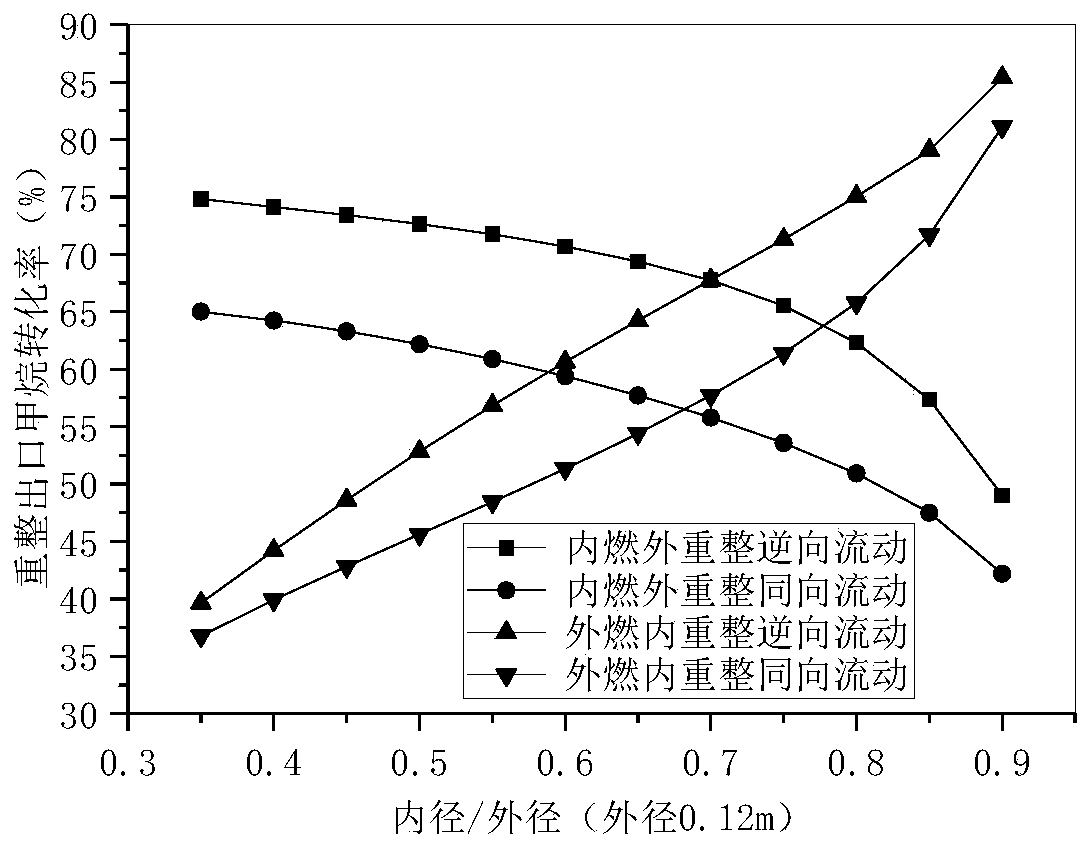

Efficient reformer for autothermal reforming of methane

The invention discloses an efficient reformer for autothermal reforming of methane. The efficient reformer for autothermal reforming of methane comprises an external cylinder body and an internal cylinder body; the external cylinder body and the internal cylinder body are concentrically arranged cylinders; an annular space between the external cylinder body and the internal cylinder body comprisesa combustion chamber and a combustion buffering chamber, wherein the combustion chamber is formed in the upper part and used for supplying heat to combustion, and the combustion buffering chamber isformed in the lower part; and the cylindrical space in the internal cylinder body comprises a reforming buffering chamber and a reforming chamber, wherein the reforming buffering chamber is formed inthe upper part, and the reforming chamber is formed in the lower part of the reforming buffering chamber and used for hydrogen production by reforming. As an external combustion chamber of a reactor has a small section, and a reforming chamber of the reactor has a big section, the heat transfer resistance from the combustion chamber to the reforming chamber is reduced, the staying time of reforming gas in the reforming chamber is also increased, and the strong heat of combustion is sufficiently absorbed; moreover, compared with a common internal combustion and external reforming form, the efficient reformer for autothermal reforming of methane, disclosed by the invention, has the advantages that the heat exchanging areas of the combustion chamber and the reforming chamber are also increased, and the heat exchanging efficiency is made higher.

Owner:XI AN JIAOTONG UNIV

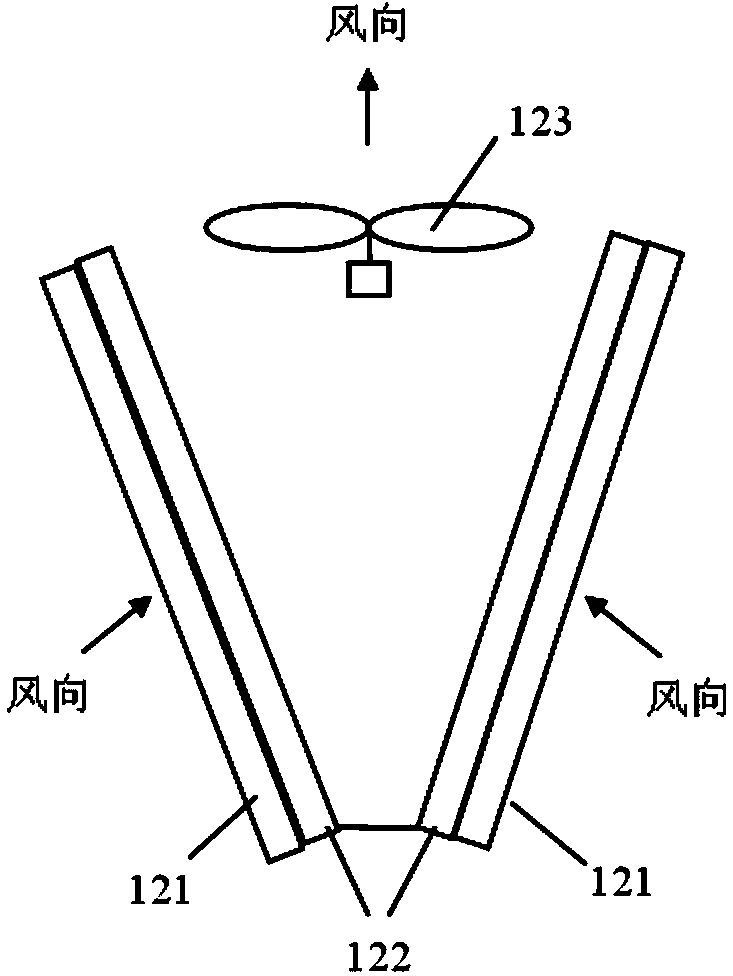

Compound air conditioning system with natural cooling function

ActiveCN106016534ALarge working temperature zoneAvoid single-run compression refrigerationMechanical apparatusSpace heating and ventilation safety systemsData centerEngineering

The invention discloses a compound air conditioning system with a natural cooling function. The system is characterized by comprising a compressor module, an air cooling heat exchange module consisting of a heat exchanger module and a cooling fan, a multifunctional liquid accumulator, a liquid pump, an air treatment module and control valves; and a control valve is operated to change a flow path of a refrigerating medium to realize the following three different working modes: a compression refrigeration working mode, a compound refrigeration working mode of coordinated operation of compression refrigeration and natural cooling and a natural cooling working mode. The system adjusts the refrigerating capacity by using fuzzy control, applies natural cooling to replace compression refrigeration in low-temperature or transition seasons, efficiently uses a natural cold source, is particularly suitable for working environment control of a data center, a high-performance computer, a communication base station and power electronic equipment, and substantially reduces the energy consumption and the operation cost.

Owner:HEFEI UNIV OF TECH

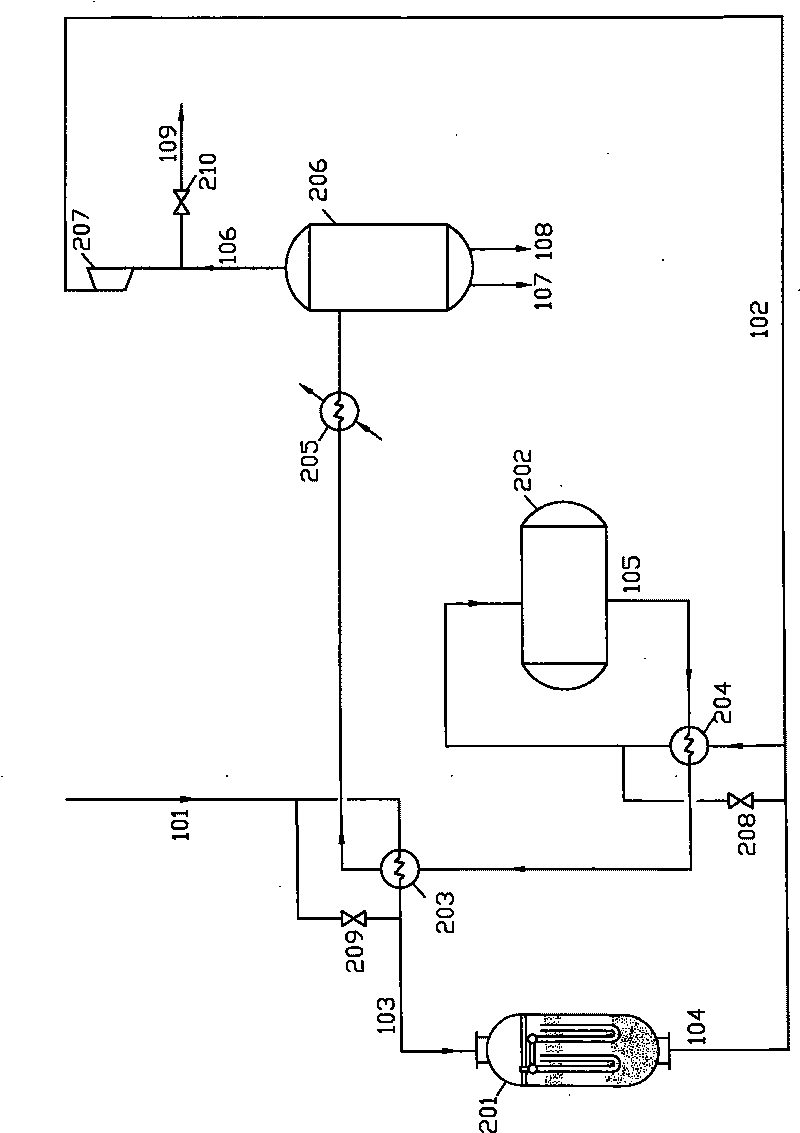

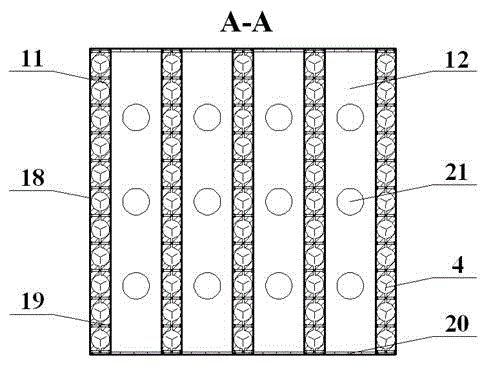

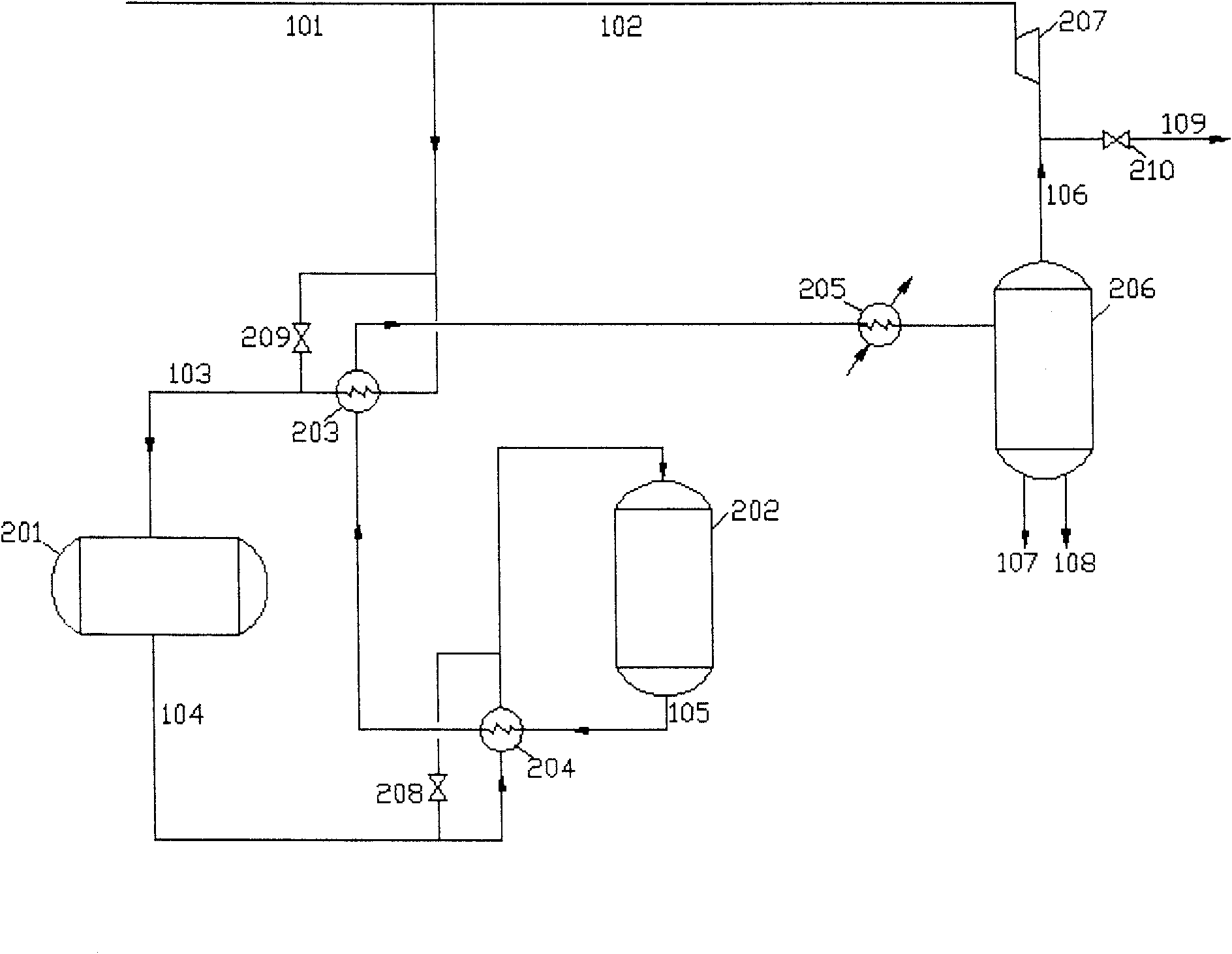

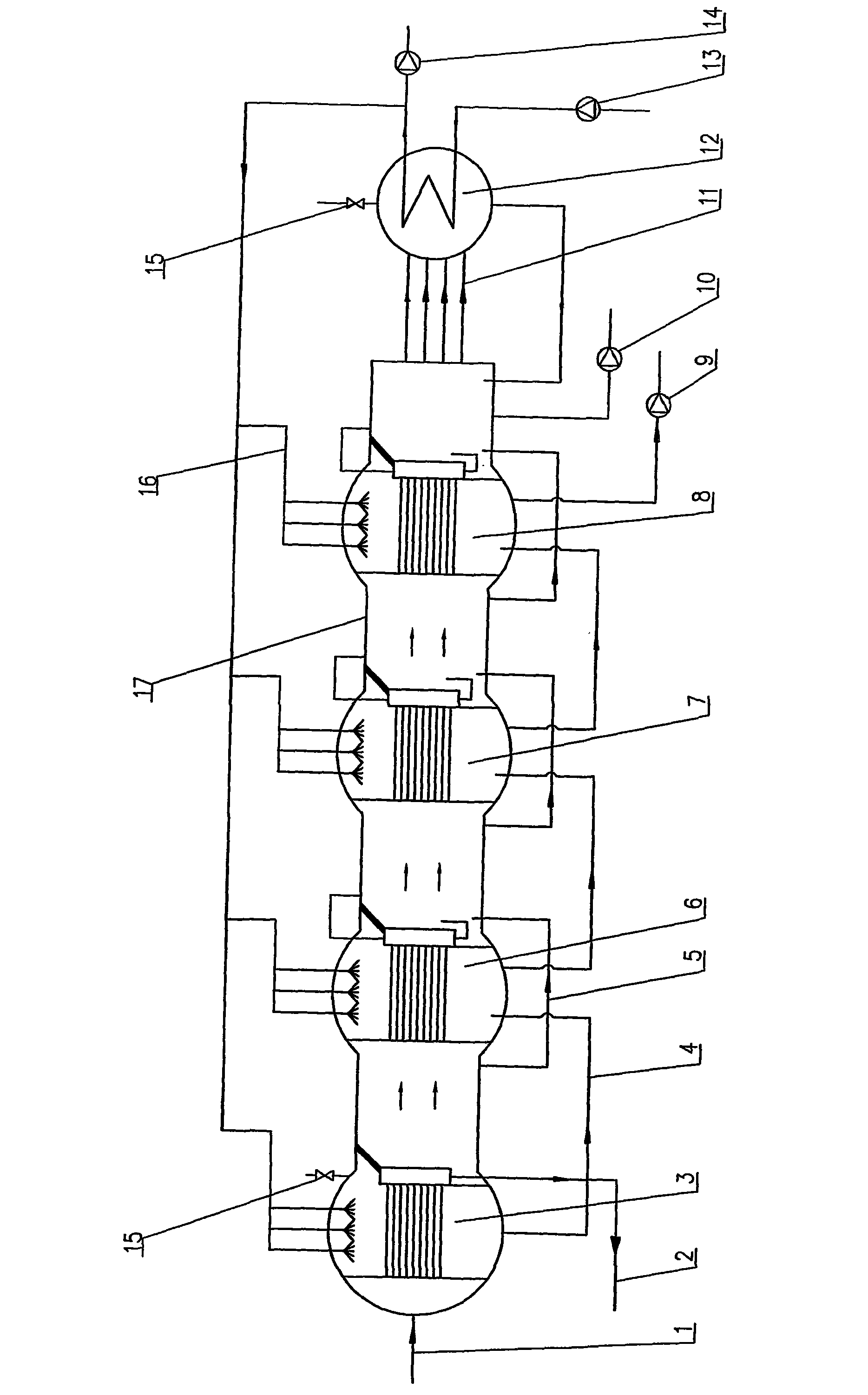

Method and device for producing hydrocarbon by Fishcer-Tropsch reaction of synthesis gas

InactiveCN101560406AQuick responseLarge heat transfer temperature differenceLiquid hydrocarbon mixture recoveryMolecular sieveSyngas

The invention relates to a method for producing hydrocarbon by Fishcer-Tropsch reaction of synthesis gas, comprising the following steps: firstly, under the pressurizing, the synthesis gas containing hydrogen and carbon monoxide carries out Fishcer-Tropsch synthetic reaction in a Fishcer-Tropsch synthetic reactor 201 which has at least two zones capable of independently adjusting vaporizing temperature of cooling medium and preferably adopts a water cooling heat exchanging pipe set with the front-low rear-high temperature; tower reaction gas is cooled and separated or enters a hydrocarbon modifying reactor 202 with molecular sieve to carry out hydrocarbon modification, final reaction gas is cooled to separate hydrocarbon, water and unreacted synthesis gas, the separated synthesis gas is discharged to gas / steam for integral circulation generating (IGCC), or the separated synthesis gas is used as circulation synthesis gas to be mixed with the synthesis gas of raw materials except a little discharged separated synthesis gas, and the Fishcer-Tropsch reaction and product separation are carried out again.

Owner:杭州林达化工科技有限公司

Three-stream spiral wound type heat exchange equipment for secondary refrigeration and low-temperature liquefaction of LNG (liquefied natural gas)

The invention belongs to the technical field of low-temperature natural gas liquefaction, and relates to LNG (liquefied natural gas) secondary low-temperature liquefaction equipment and the technique of refrigeration by mixed refrigerant. C2H4 refrigerant and N2-CH4 mixed refrigerant steam of 0.3MPa and -130 DEG C from an LNG three-level outlet are used for cooling and liquefying natural gas of 5.8MPa and -53 DEG C in a three-stream spiral wound type heat exchanger, so that LNG can conveniently enter a three-level undercooling stage. The three-stream spiral wound type heat exchanger for secondary liquefaction is used for undercooling the C2H4 refrigerant first, the undercooled C2H4 refrigerant is throttled to a shell side to be mixed with the N2-CH4 to cool a -53-DEG C LNG pipeline, a N2-CH4 precooling tube bundle and a C2H4 undercooling tube bundle, so that undercooling of the C2H4 and precooling of the N2-CH4 and liquefaction of natural gas are realized. The equipment is compact in structure and high in heat exchange efficiency, and can be used for the field of phase-variable low-temperature heat exchange of gas at temperature ranging from -53 DEG C to -120 DEG C, the problem of LNG secondary low-temperature liquefaction is solved, and low-temperature heat exchanging efficiency of an LNG system can be improved.

Owner:张周卫

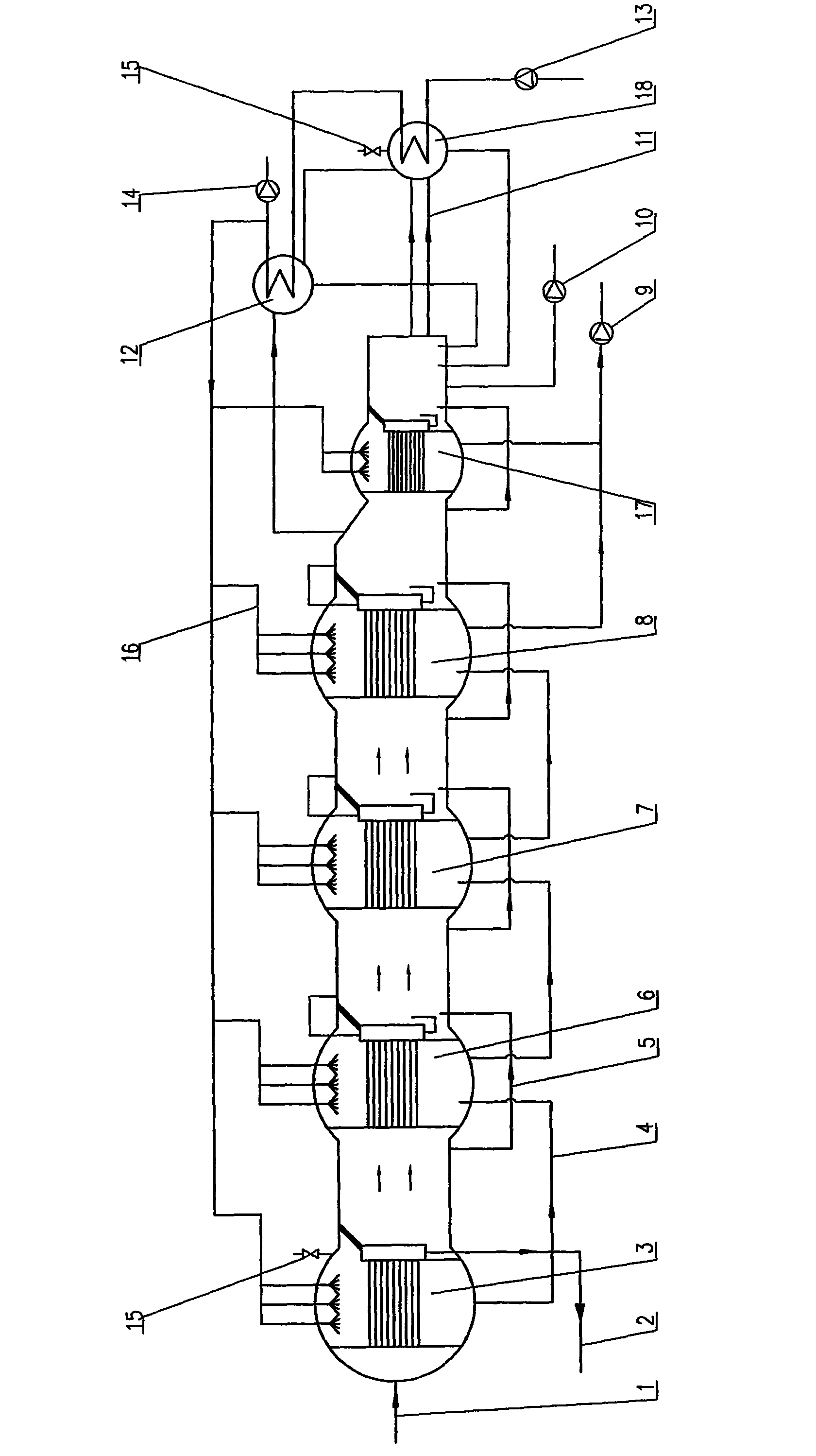

Multi-flow spiral winding tube type main heat exchange equipment with mixed refrigerant for low-temperature liquefaction of LNG (liquefied natural gas)

InactiveCN102564056AReduce volumeImprove heat transfer efficiencySolidificationLiquefactionThree stageEngineering

The invention belongs to the technical field of low-temperature liquefaction of natural gas, and relates to multi-flow spiral winding tube type main heat exchange equipment with mixed refrigerant for low-temperature liquefaction of LNG (liquefied natural gas) and refrigerating technology of mixed refrigerant. Natural gas at the temperature of 36 DEG C and pressure of 6.1MPa is gradually cooled to the temperature of minus 164 DEG C and is overcooled by the aid of mixed refrigerant consisting of N2, CH4, C2H4, C3H8, C4H10 and isomerized C4H10 via a three-stage refrigerating process, the N2, the CH4, the C2H4, the C3H8, the C4H10 and the isomerized C4H10 are gradually overcooled by a multi-flow spiral winding type heat exchanger and are respectively throttled, a natural gas tube bundle and a mixed refrigerant tube bundle are pre-cooled, and purposes of primary precooling of the natural gas, secondary liquefaction of the natural gas and tertiary overcooling of the natural gas are achieved. The multi-flow spiral winding tube type main heat exchange equipment is compact in structure and high in heat exchange efficiency, and can be used for the field of phase-change low-temperature heat exchange of gas at the temperature ranging from 36 DEG C to minus 164 DEG C, technical difficult problems in terms of low-temperature liquefaction of the LNG are solved, and low-temperature heat exchange efficiency of an LNG system is improved.

Owner:张周卫

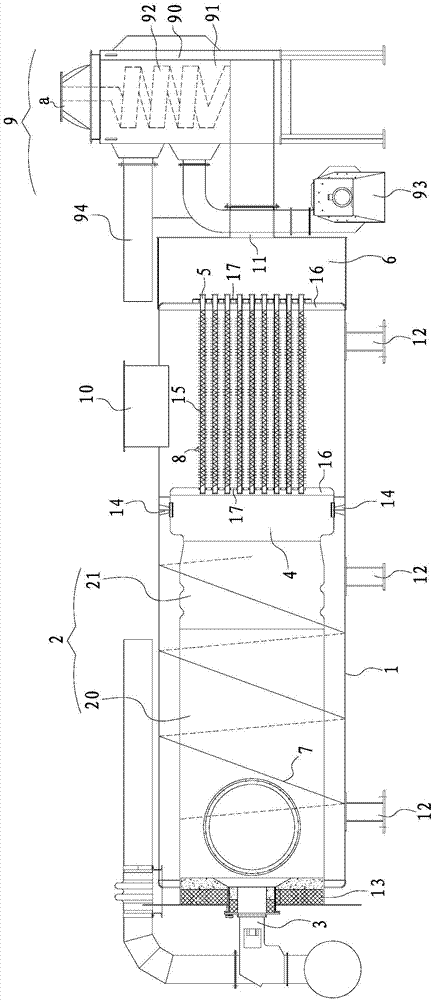

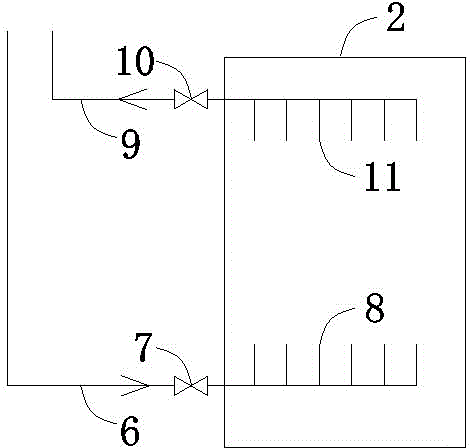

Multi-effect distillation seawater desalinating device of multi-stage type condenser

ActiveCN101648733ALow costIncrease heat transfer areaGeneral water supply conservationSeawater treatmentComing outDesalination

The invention relates to a multi-effect distillation seawater desalinating device of a multi-section type condenser, belonging to the technical field of seawater desalinization. The device comprises an evaporator, a condenser, a working steam inlet (1), a working steam condensate water outlet (2), a concentrated seawater connecting pipe (4), a condensed fresh water connecting pipe (5), a concentrated seawater draining pump (9), a fresh water draining pump (10), a secondary steam inlet condensing pipe (11), a seawater inlet (13), a cooling seawater draining port (14) and a seawater inlet branchpipe (16). The invention is characterized in that the condenser is divided into N sections from section 1 to section N, and seawater enters in the multi-section type condenser from the section N to the section 1 which are connected in series; on the basis of an original M-effect evaporator, an N-1-effect evaporator which corresponds to the N-section condenser is additionally arranged on the evaporator; secondary steam coming out of the original M-effect evaporator is divided into two paths and enters the 1-effect condenser and the M+1-effect evaporator in parallel, and so forth,, the secondary steam coming out of the M+N-1-effect evaporator enters the N-effect condenser finally. On the premise of not increasing the quantity of inlet seawater of unit water making quantity, the invention can increase the total temperature difference of the first evaporator and the last evaporator.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

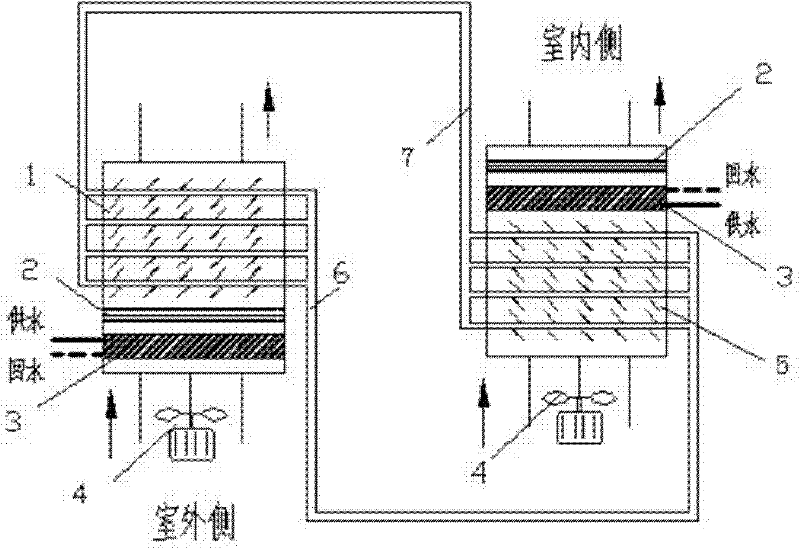

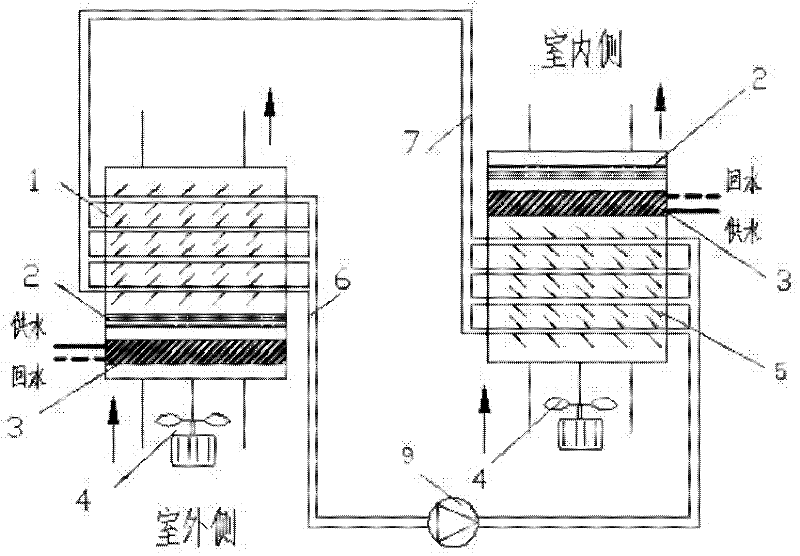

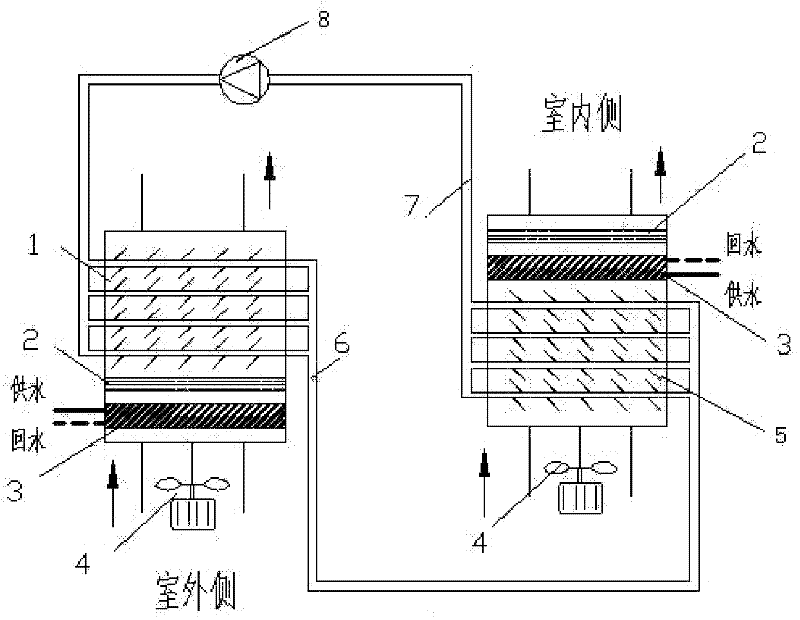

A split air-air heat exchange unit with a humidification section

InactiveCN102287880ALarge heat transfer temperature differenceImprove comfortLighting and heating apparatusFree-cooling systemsIndoor airRelative humidity

A split-type air-air heat exchange unit with a humidification section relates to a device used in an air-conditioning system to reduce temperature by using a natural cold source, and belongs to the technical field of heat exchange of heat devices. On the basis of the existing split air-air heat exchange unit, the present invention adds an air humidification section at the outdoor air inlet and indoor air outlet, so that the outdoor low-temperature air first flows through the humidification section for humidification, and the humidity is increased through humidification After the temperature is lowered, heat exchange is performed. Compared with the heat exchange equipment without the low-temperature air humidification section, the heat exchange temperature difference on both sides of the air heat exchanger is enlarged, the heat exchange amount is increased, and the heat exchange efficiency is improved. In addition, an air humidification section is added at the indoor air outlet, which can humidify the air as needed, control the relative humidity of the air within the required range, prevent static electricity, and improve the comfort of the air environment.

Owner:BEIJING UNIV OF TECH

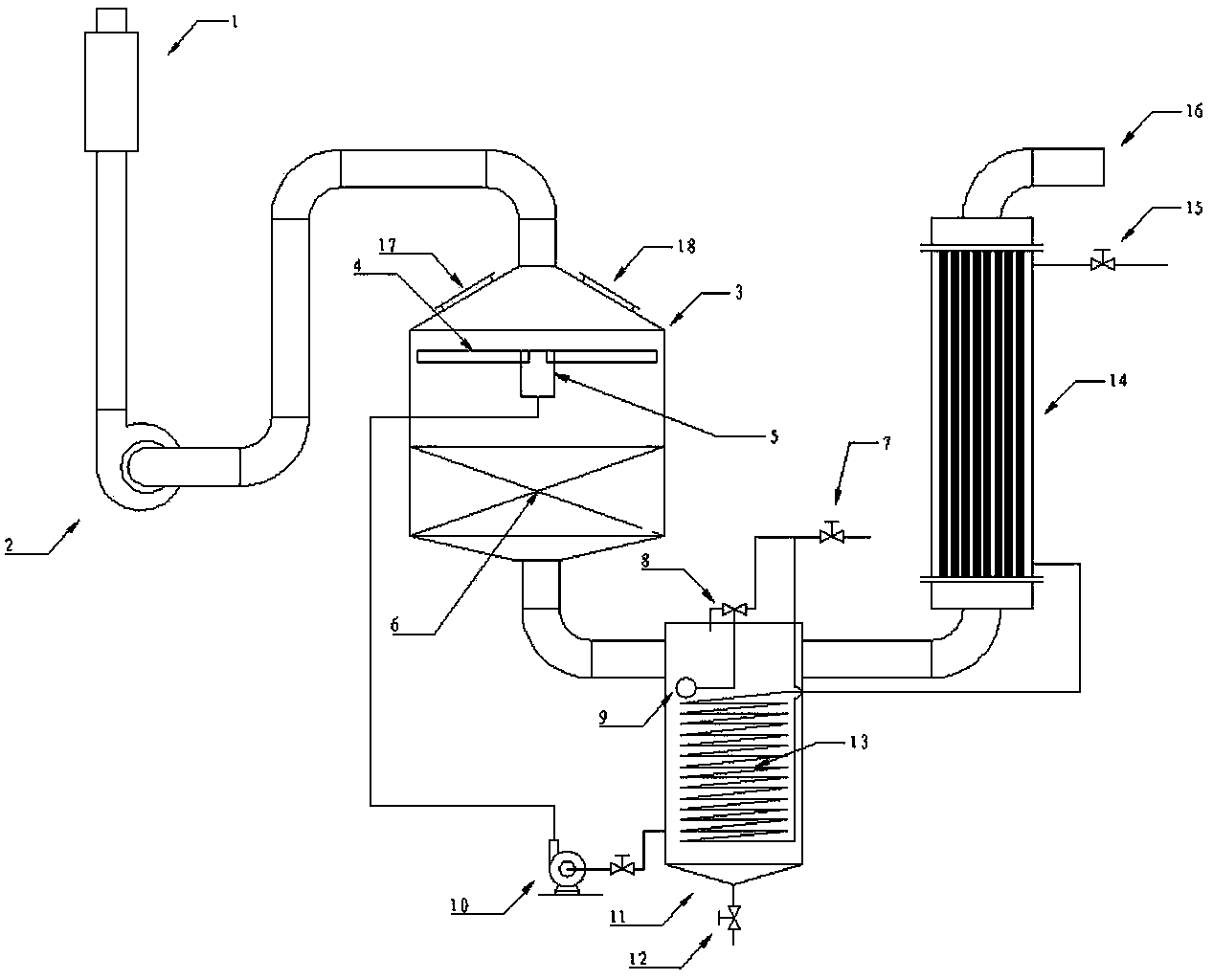

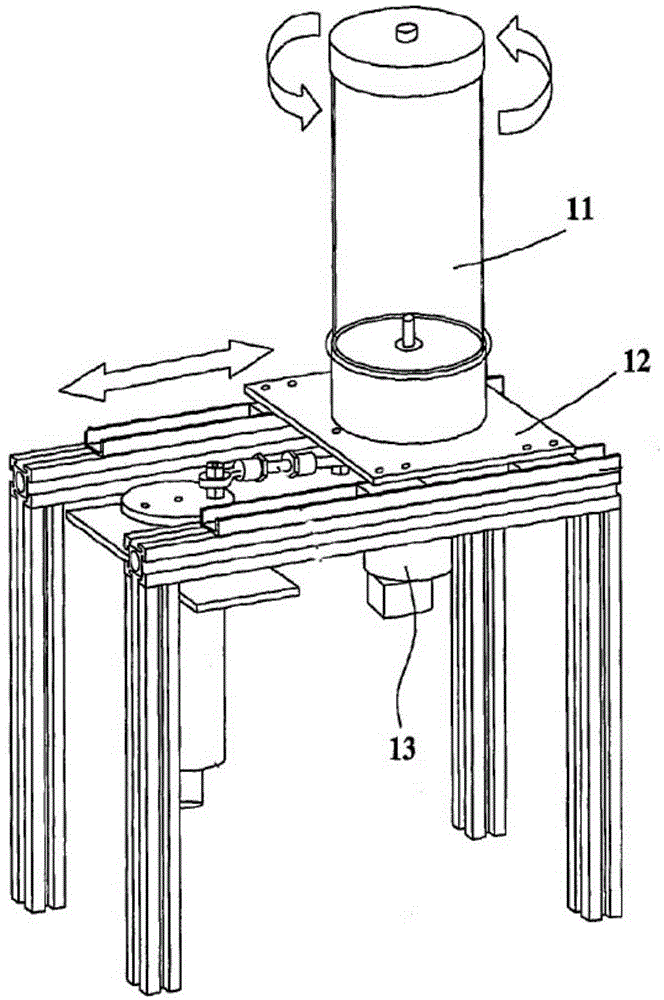

Waste gas processing and heat efficient recycling device

ActiveCN103900403AMechanism is simple and reliableLow running costStationary tubular conduit assembliesTrickle coolersShell and tube heat exchangerPlate heat exchanger

The invention discloses a waste gas processing and heat efficient recycling device. An upper tube pass of a shell-and-tube heat exchanger is connected with a waste gas inlet pipe, a lower tube pass of the shell-and-tube heat exchanger is connected with a water tank inlet, a water tank outlet is connected with a bottom inlet of a spraying tower, a top outlet of the spraying tower is connected with a waste gas outlet pipe, the spraying tower is of a sealed structure, a padding layer is arranged in the spraying tower, a water distribution pipe and a rotary drum are arranged on the padding layer, holes are formed in the water distribution pipe, and the water distribution pipe sprays water through the holes to drive the rotary drum and the water distribution pipe to revolve. A water tank is communicated with the water distribution pipe through a water pump, a coiled pipe is arranged in the water tank, the inlet of the coiled pipe is connected with a water inlet valve, the outlet of the coiled pipe is connected with a lower shell pass of the shell-and-tube heat exchanger, and an upper shell pass of the shell-and-tube heat exchanger is connected with a water outlet valve. The waste gas processing and heat efficient recycling device is simple and reliable in structure, low in operation cost, and particularly suitable for recycling the waste heat of tail gas containing pollutants, achieves both environmentally friendly processing and energy recycling, and obtains a large amount of hot water through heat exchange, thereby being high in practicability and broad in market prospect.

Owner:JIANGSU GELAN ENVIRONMENTAL TECH CO LTD

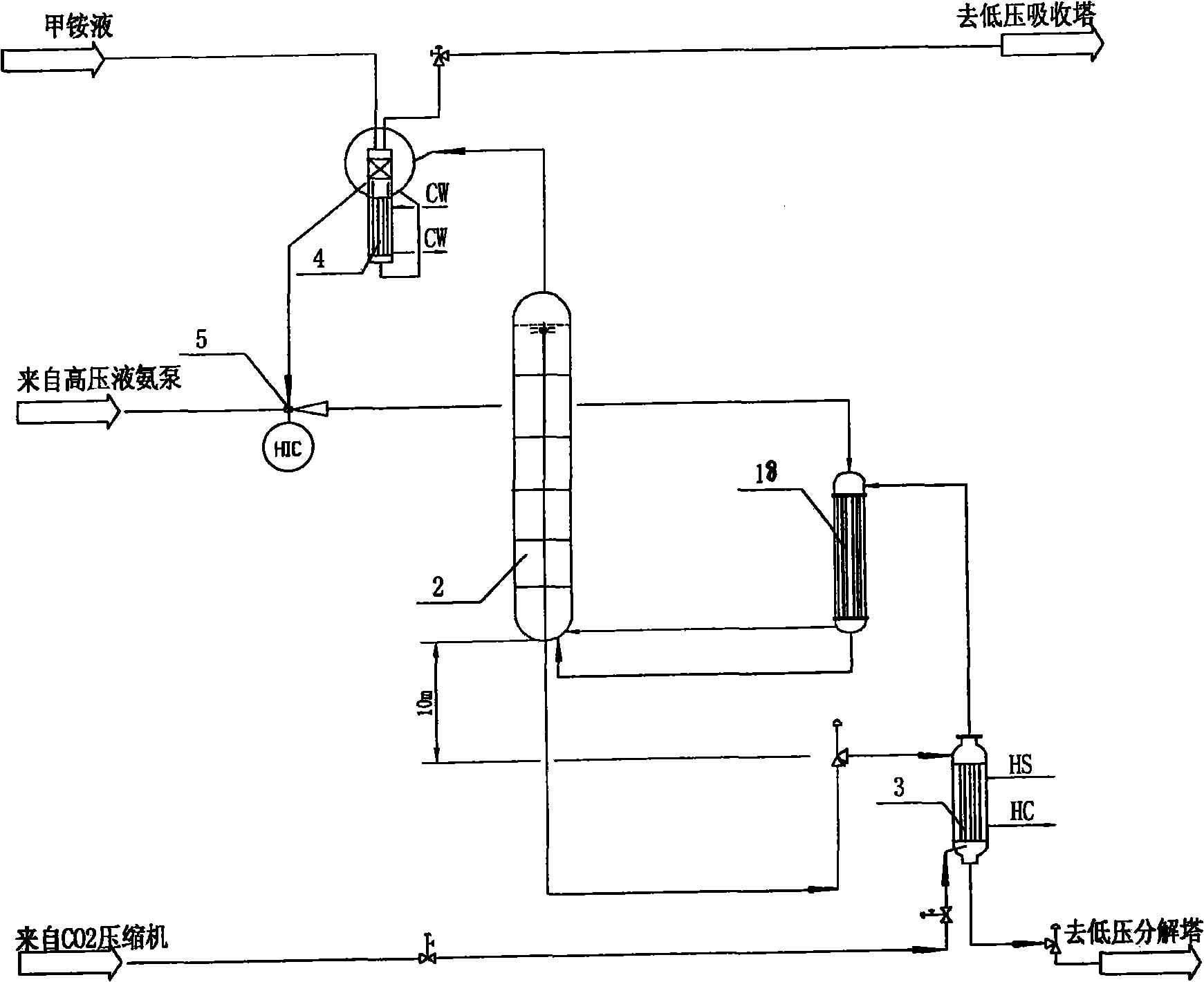

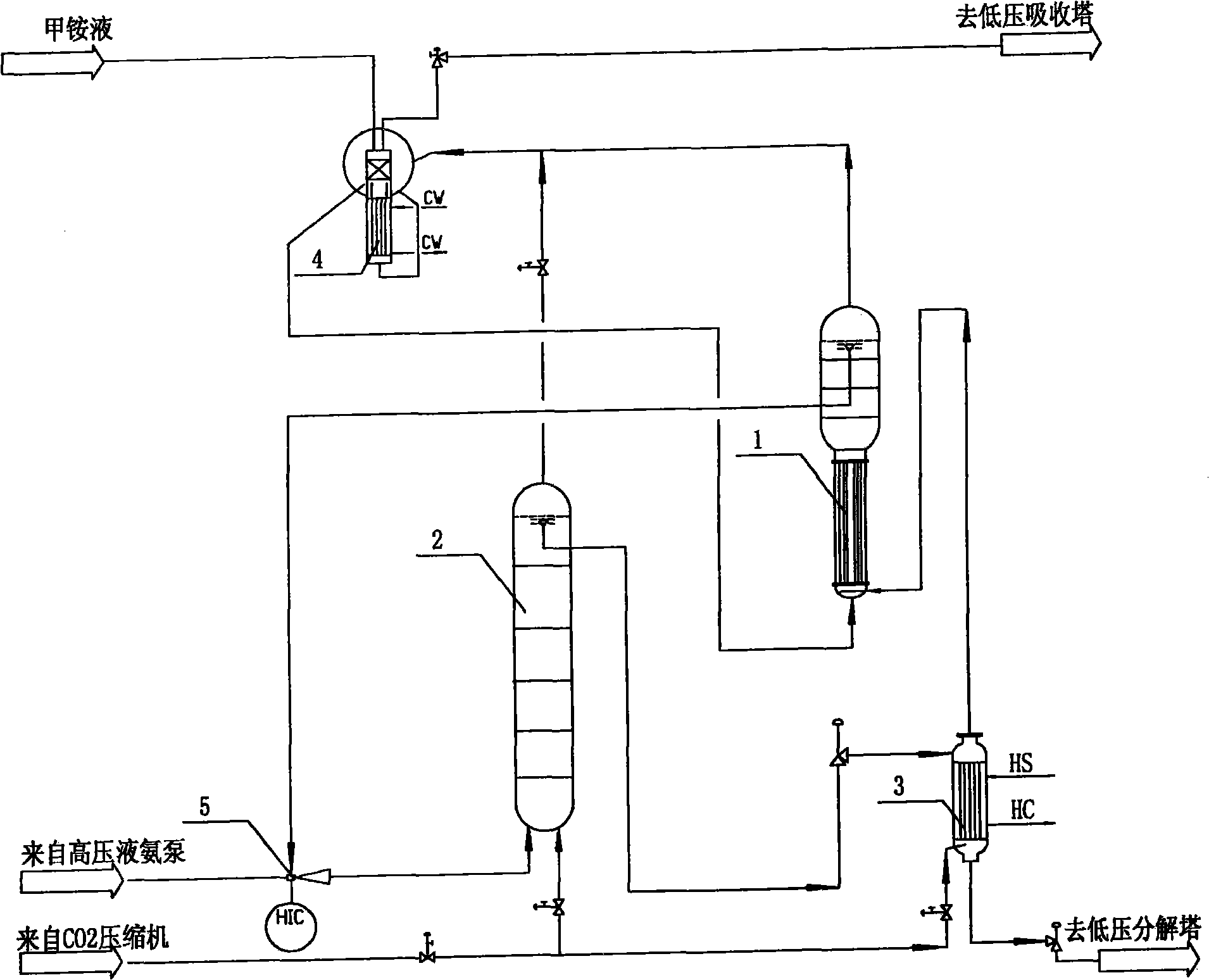

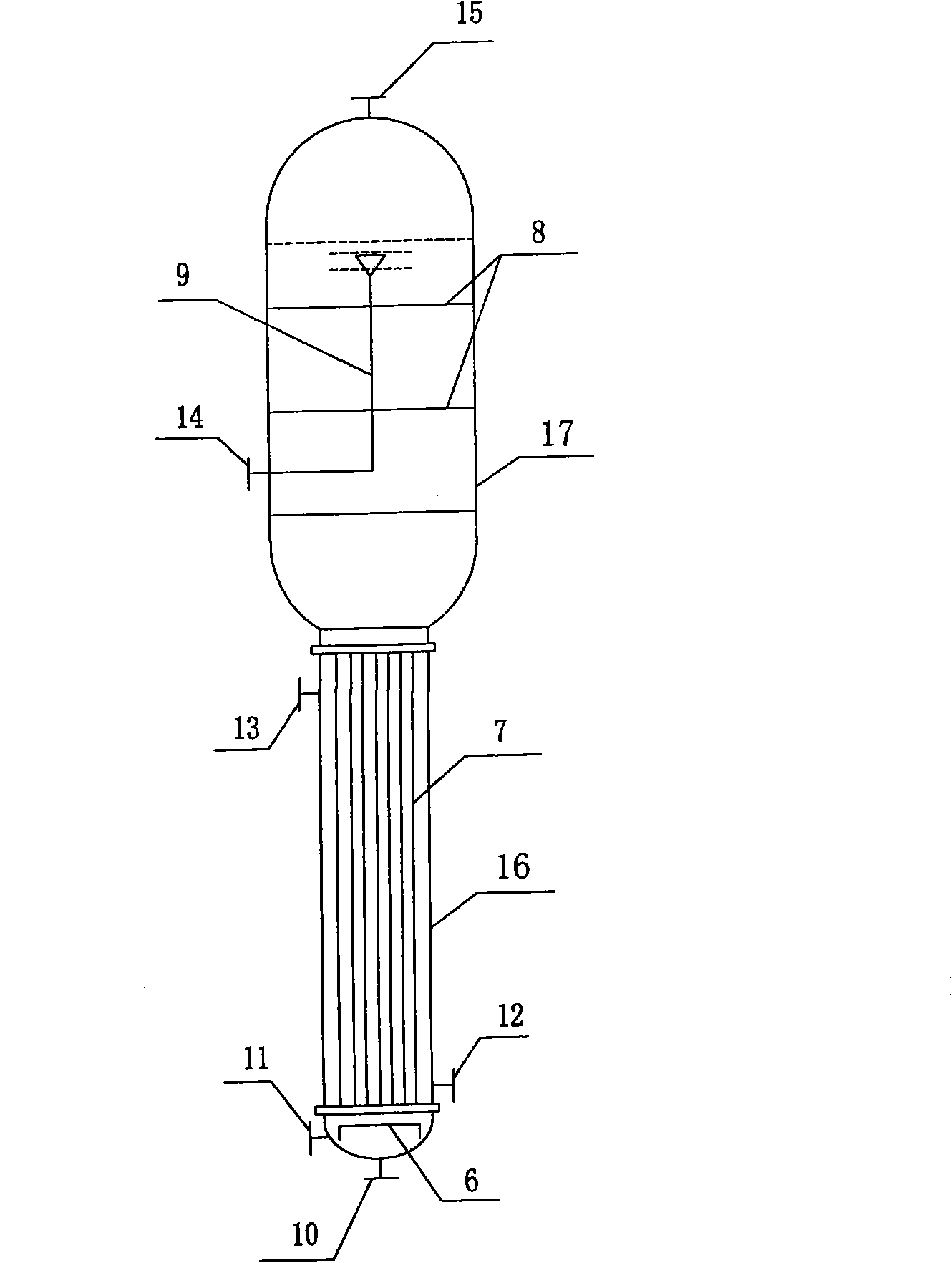

Urea production process of high-efficiency condensation, low-mounting height CO2 air stripping method and high-voltage lamp type full condensation reactor

ActiveCN101492398AProcess modification is simpleLess investmentUrea derivatives preparationOrganic compound preparationChemistryUrea

The invention discloses a CO2-stripping process for urea with efficient condensation and low installation height and a high pressure tube condensation reactor. Problems of a traditional urea process are solved, including high civil construction framework, high device investment and hard operation, management and maintenance. With the specific high pressure tube condenser adopted, gas and liquid are separated, unreacted gas in the high pressure tube condensation reactor is directly sent to a scrubber, and simultaneously reacted liquid is sent to a synthesizing tower by a high pressure ejector. Compared with the traditional urea civil construction framework, the height of the framework of the process is lowered by 20-25m. The process has the advantages of simple modification, energy-saving property, lowered energy consumption, lowered investment, convenient operation and convenient maintenance and overhauling.

Owner:WUHUAN ENG

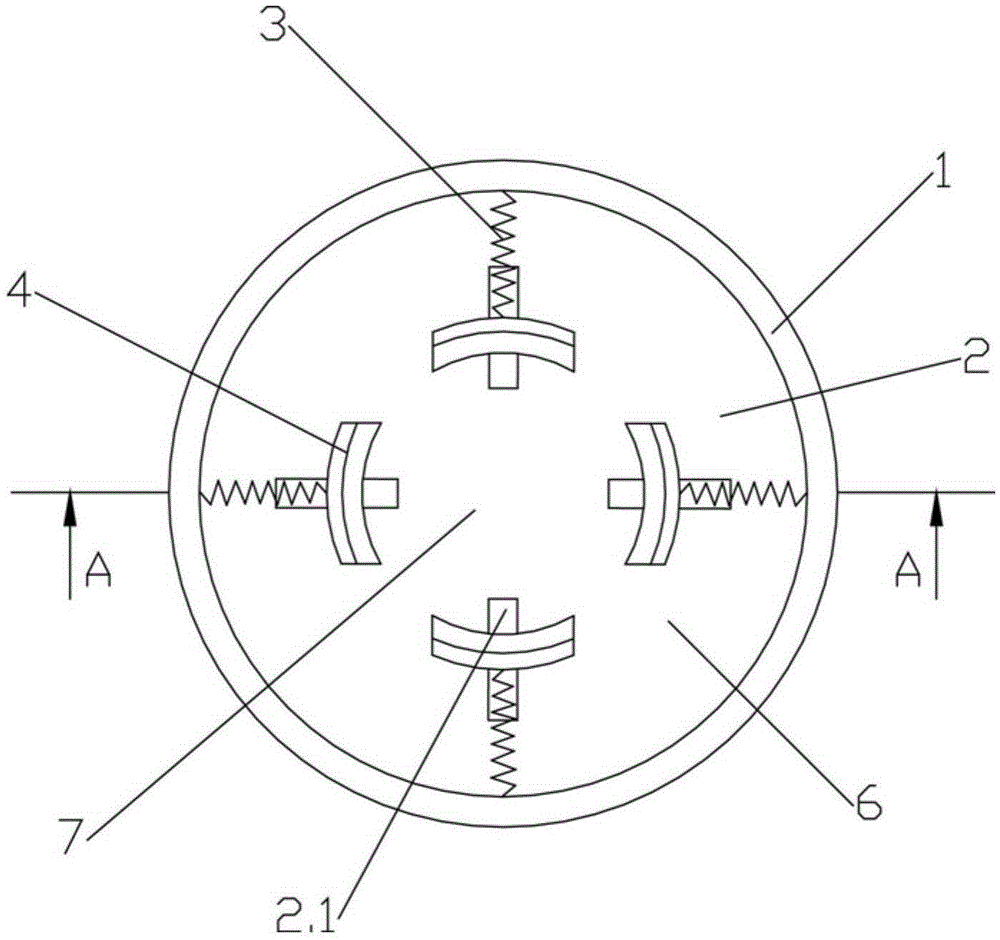

Beverage quick-cooling device

InactiveCN105241177ASimple structureReduce volumeDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention relates to the technical field of refrigeration, and discloses a beverage quick-cooling device. The beverage quick-cooling device comprises a barrel, a base plate is arranged at the lower end of the barrel, and a containing cavity with an opening in the upper end is formed; a plurality of elastic pieces with the stretching direction pointing to the center of the containing cavity are arranged on the inner lateral wall of the barrel, a clamping plate is connected to each elastic piece, and a cooling cavity used for containing a product to be cooled is defined by the clamping plate; and a medium cavity is formed in each clamping plate, and refrigerating media are stored in the medium cavities. According to the beverage quick-cooling device, the problem of potential safety hazards caused by contact between the refrigerating media and the product to be cooled in the prior art is solved, the beverage quick-cooling device is simple in structure, small in size and suitable for home use, and can be suitable for to-be-cooled products with outer packages in multiple sizes.

Owner:HEFEI HUALING CO LTD +1

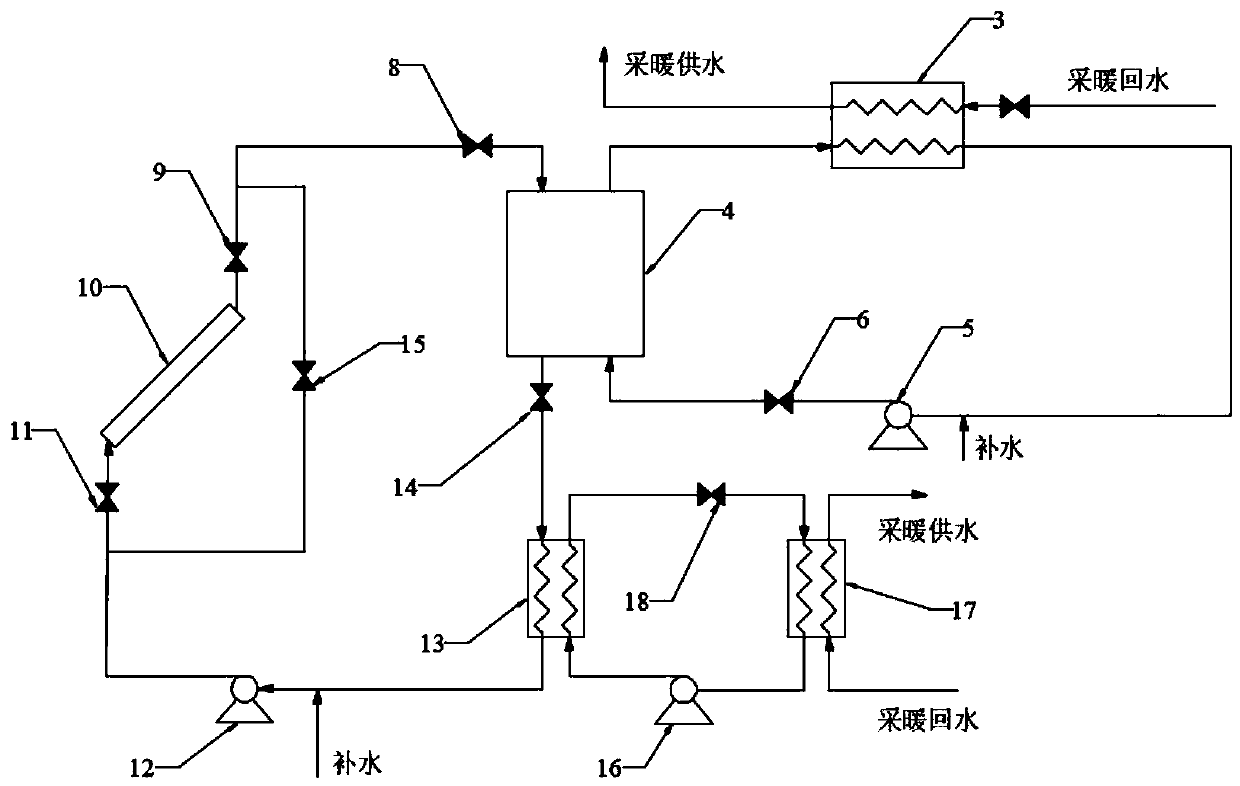

Solar energy-water source heat pump combined heat-supply system

PendingCN111023231AIncrease profitLower inlet fluid temperatureSolar heating energyCentral heating with accumulated heatWater source heat pumpThermodynamics

The invention aims to provide a solar energy-water source heat pump combined heat-supply system which comprises a phase change heat storage module; the phase change heat storage module, an evaporatorand a solar heat collector form a loop in sequence, and the evaporator and a condenser form a loop; valves for controlling the connection and disconnection of pipelines are arranged on the connectingpipelines of all the loops. The problems that a conventional solar heat-supply system is not continuous in heat supply, and the energy storage utilization rate of a phase change heat storage device islow are solved.

Owner:思安新能源股份有限公司

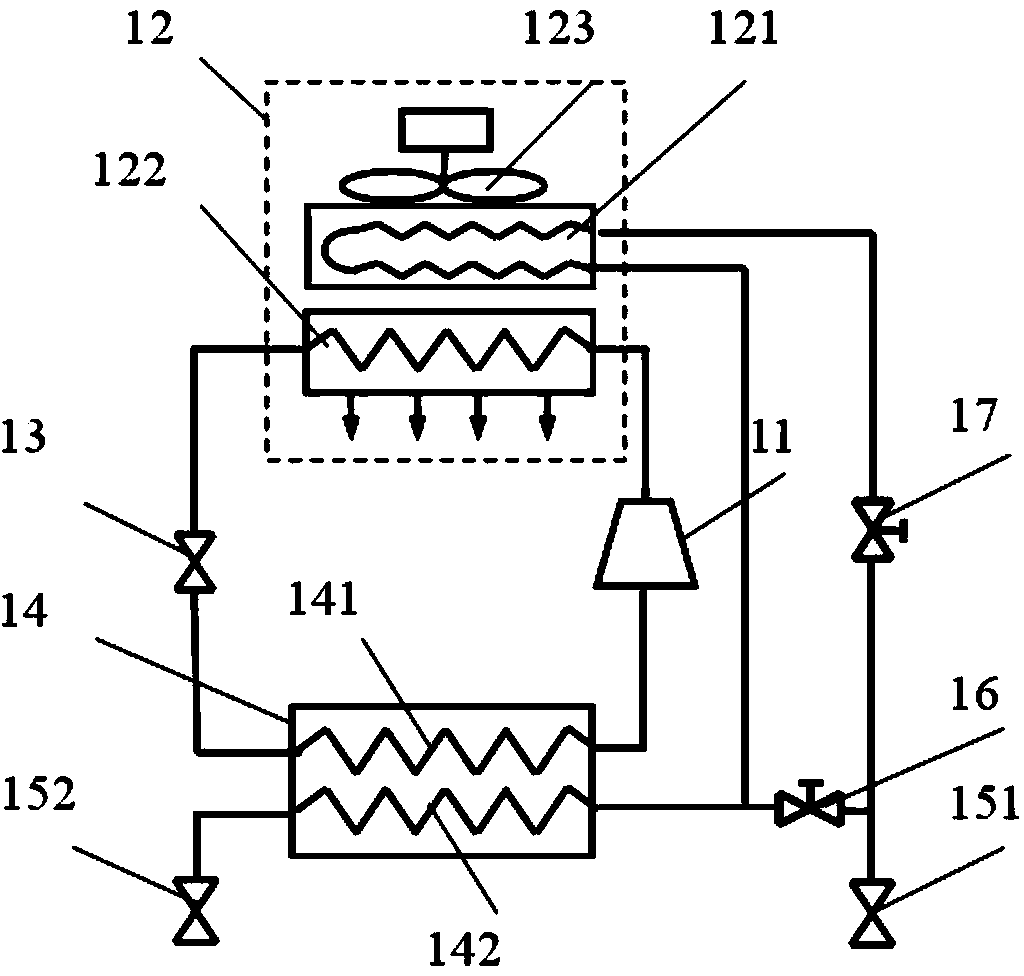

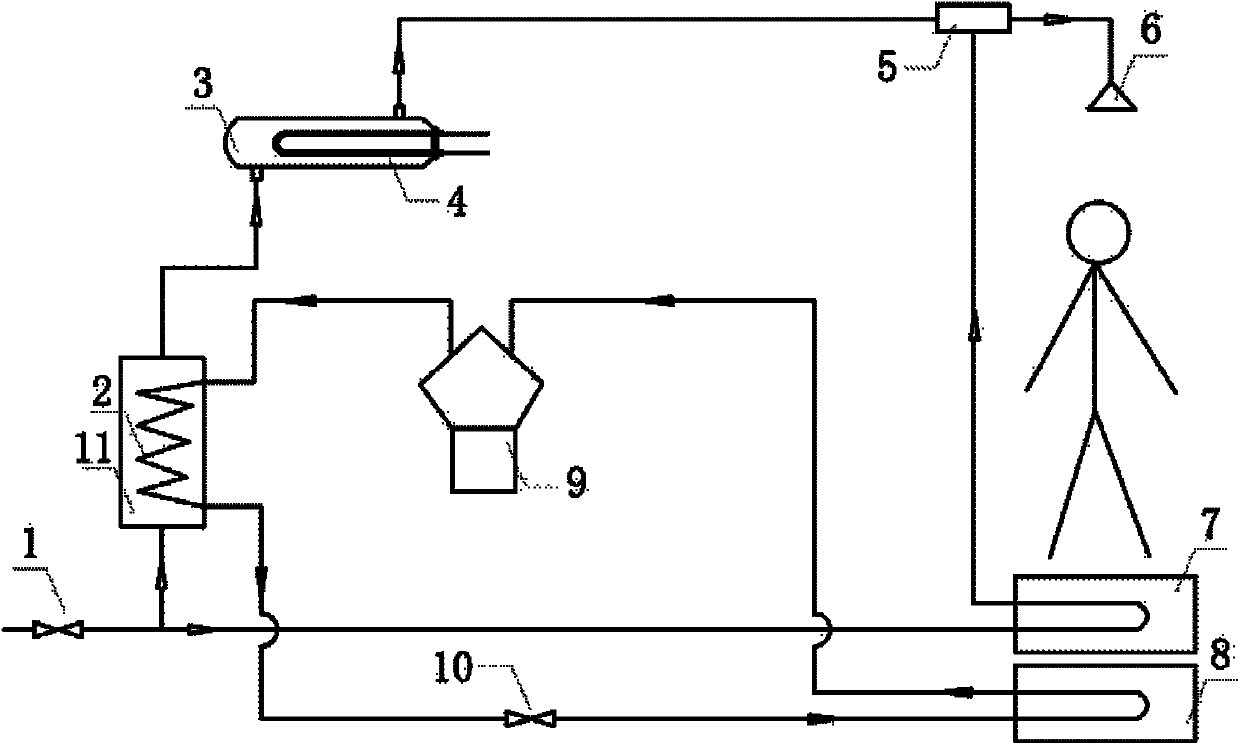

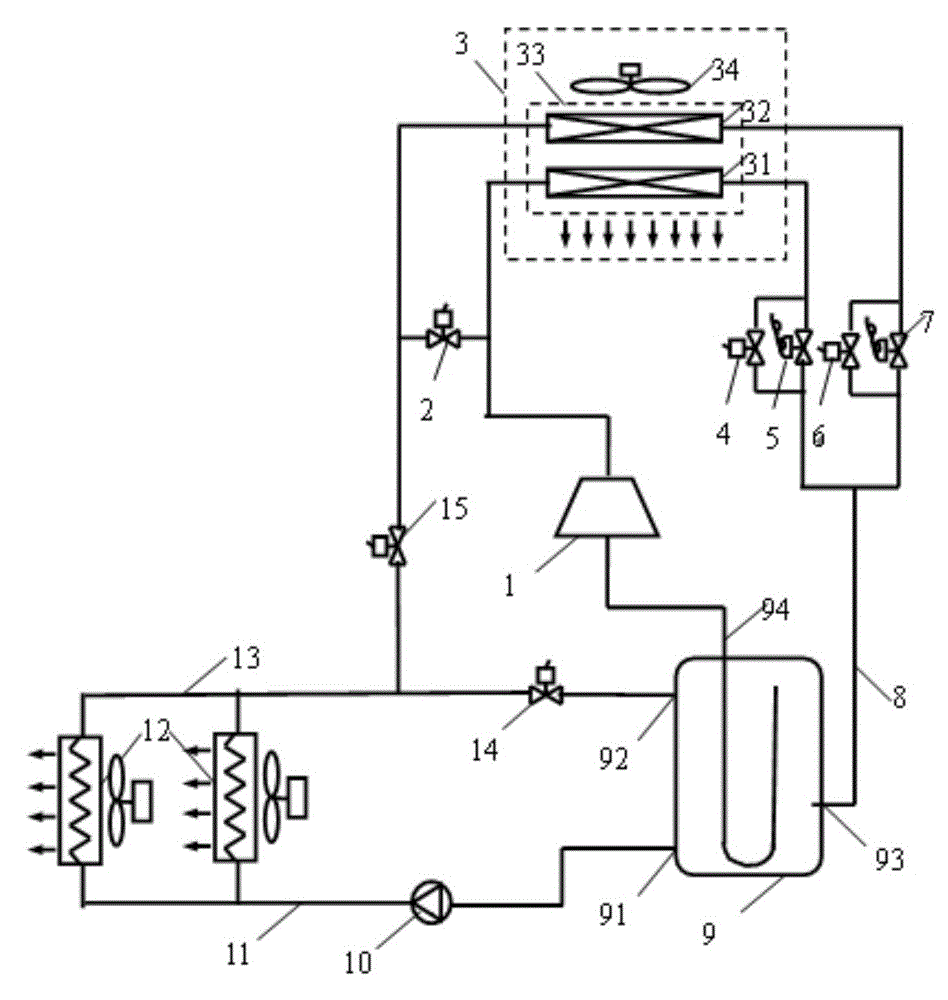

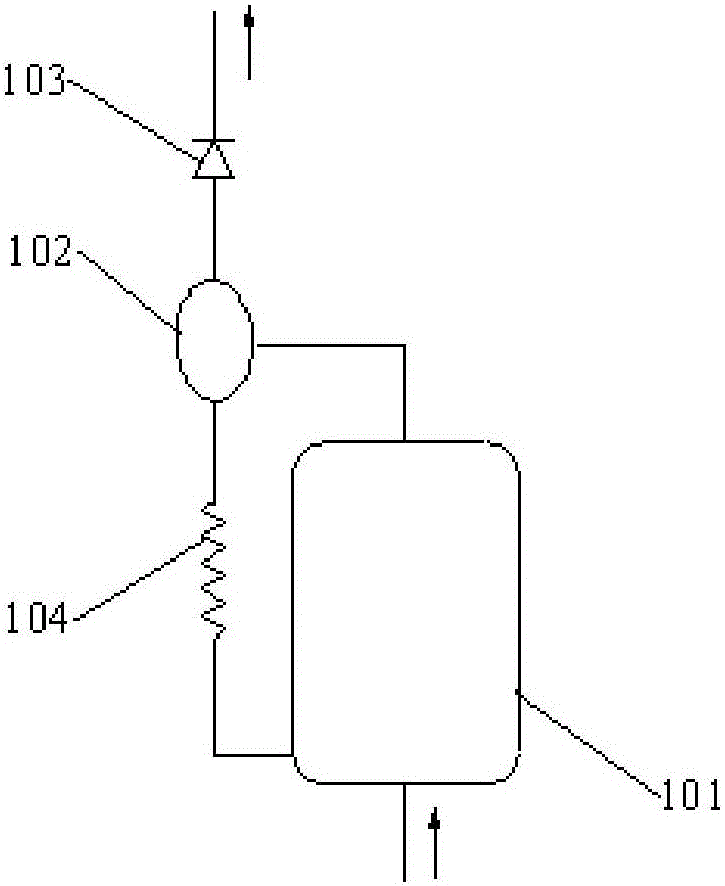

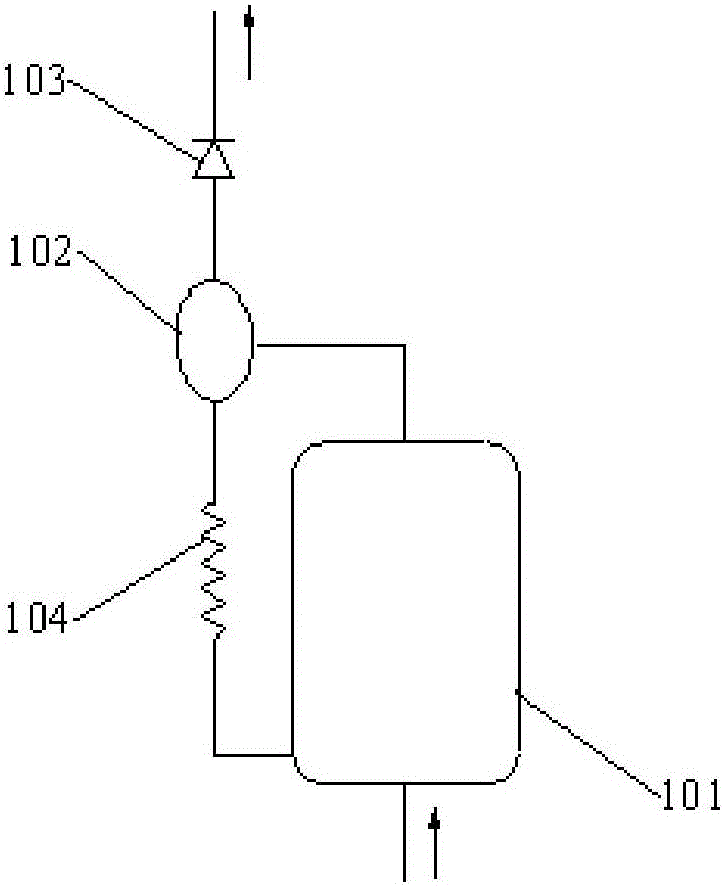

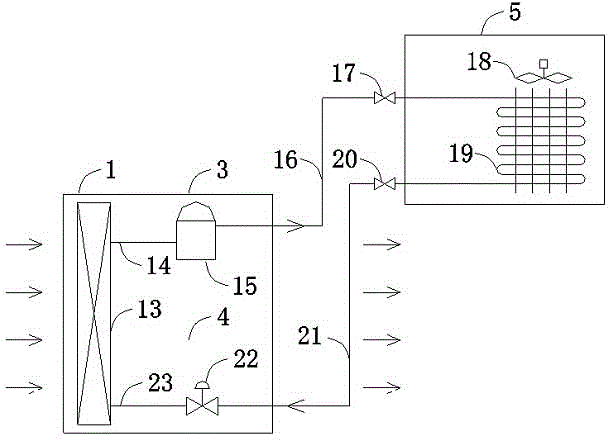

Cooling system of heat-pipe external-circulation type secondary coolant loop server cabinet

ActiveCN104244681AEnables direct coolingAchieve energy saving and efficiencyMechanical apparatusSpace heating and ventilation safety systemsNuclear engineeringControl system

The invention discloses a cooling system of a heat-pipe external-circulation type secondary coolant loop server cabinet. The cooling system comprises more than one heat-pipe cooler, the server cabinet, a water supply branch pipe, a water return branch pipe, a machine room water supply trunk pipe, a machine room water return trunk pipe, an automatic water replenishing and pressure fixing device, a circulating water pump, a reserve pump, heat exchange devices, an outdoor liquid return connecting pipe, an outdoor air outlet connecting pipe, a liquid valve, an air valve, an air cooling condenser and a control system. The air cooling condenser adopts natural-cooling and energy-saving measures. The servers can be directly cooled, and the problems of local overheat and heat points of the server cabinet are solved. Meanwhile, by means of the natural-cooling measures, heat-exchange temperature is high in difference and efficiency, and the cooling system has the advantages of simplicity, reliability and low power consumption and noise and meets the concept of energy conservation and environment friendliness.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

Energy-saving type hot blast stove

InactiveCN104729081AExtended service lifeLarge heat transfer temperature differenceCombustion processAir heatersCombustion chamberThermodynamics

The invention discloses an energy-saving type hot blast stove comprising a stove body, a burning chamber, a burner communicated with one end of the burning chamber, a front smoke chamber communicated with the other end of the burning chamber and a rear smoke chamber communicated with the front smoke chamber through multiple heat exchange pipes. The stove body is provided with an intake port, an exhaust port and a smoke vent. The intake port is opposite to the heat exchange pipes. The smoke vent is formed in the tail portion of the rear smoke chamber. The hot blast stove further comprises a deflector, heat exchange fins and a combustion air preheating device, wherein the deflector is spirally wound around the outer circumference of the burning chamber in the length direction of the burning chamber, the heat exchange fins are arranged on the peripheries of all the heat exchange pipes, and the combustion air preheating device is communicated with the smoke vent, absorbs waste heat of discharged smoke and preheats gas fed into the burner. According to the energy-saving type hot blast stove, because gas to be heated and smoke flow are arranged in a pure countercurrent mode, the heat exchange temperature difference is increased, and the heat exchange area is reduced; due to the deflector, a flushing dead corner is avoided, and the service life is prolonged; due to the combustion air preheating device, the hot blast stove saves energy and is environmentally friendly.

Owner:JIANGNAN BOILERS & PRESSURE VESSELS ZHANGJIAGANG

Double-effect type server radiating device combining liquid cooling and compressor air cooling systems

InactiveCN104703452ASmall cleanlinessLow humidityCooling/ventilation/heating modificationsAir cooling systemEnergy conservation

The invention discloses a double-effect type server radiating device combining liquid cooling and compressor air cooling systems. The device comprises a main radiating device and an auxiliary radiating device which are assembled into the same frame and separated through a hole plate; the main radiating device exchanges heat with a liquid cooling radiating device which is in direct contact with a server; the auxiliary radiating device is used for absorbing afterheat which is not absorbed by the main radiating device;, wherein the auxiliary radiating device is a compressor air cooling system. According to the device, a server is directly cooled through the main radiating device, so that the problem of local overheat and hot point of the server can be solved; meanwhile, the auxiliary radiating device is used for absorbing the afterheat which is directly cooled by the main radiating device and is not absorbed; the device has the characteristics of being simple, reliable, low in power consumption, and small in noise, and meetings the concept of energy conservation and environmental protection.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

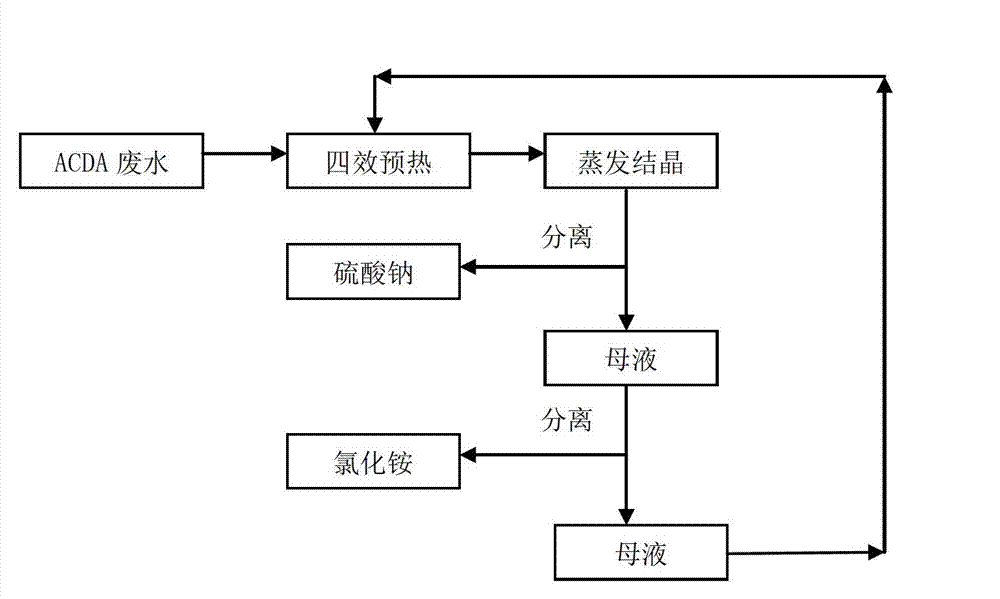

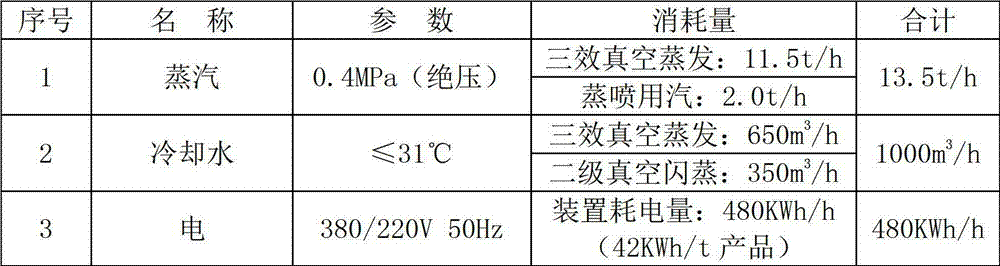

ADCA (Azodicarbonamide) foaming agent liquid waste disposal process

InactiveCN103043841ALow fluid resistanceReduce running power consumptionMultistage water/sewage treatmentAmmonium halidesLiquid wasteWastewater

The invention relates to an ADCA (Azodicarbonamide) foaming agent waste liquor treatment process which comprises the following steps of: preheating waste liquor to 40-60 DEG C; treating the waste liquor in a vacuum crystallizer under the condition that the temperature is 45-130 DEG C and the vacuum degree is 0-0.1 MPa; separating out sodium sulfate; reducing the temperature of a mother solution obtained after the sodium sulfate is separated to 35-40 DEG C, and crystallizing under the condition that the vacuum degree is 0.080-0.085 MPa; and separating out ammonium chloride. The ADCA foaming agent waste liquor treatment process provided by the invention can recover the sodium sulfate and the ammonium chloride under the precondition of zero sewage discharge and can greatly reduce the treatment cost of waste water.

Owner:ZAOZHUANG ZHONGKE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com