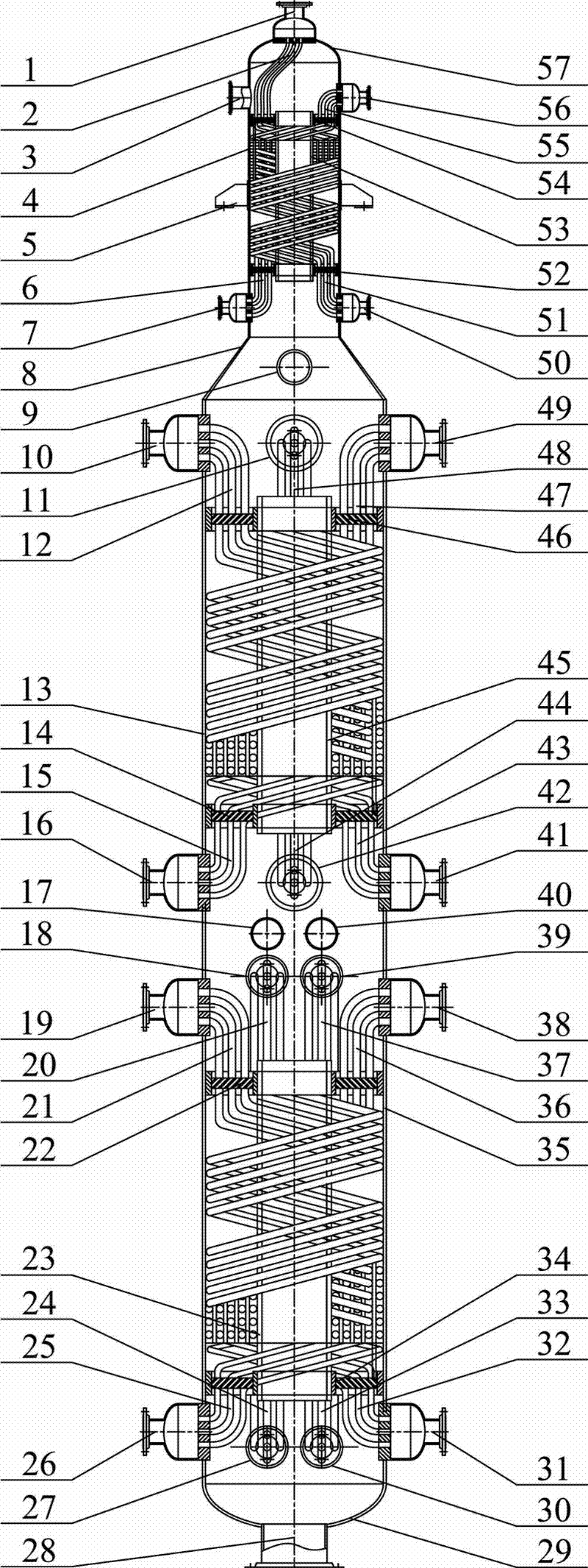

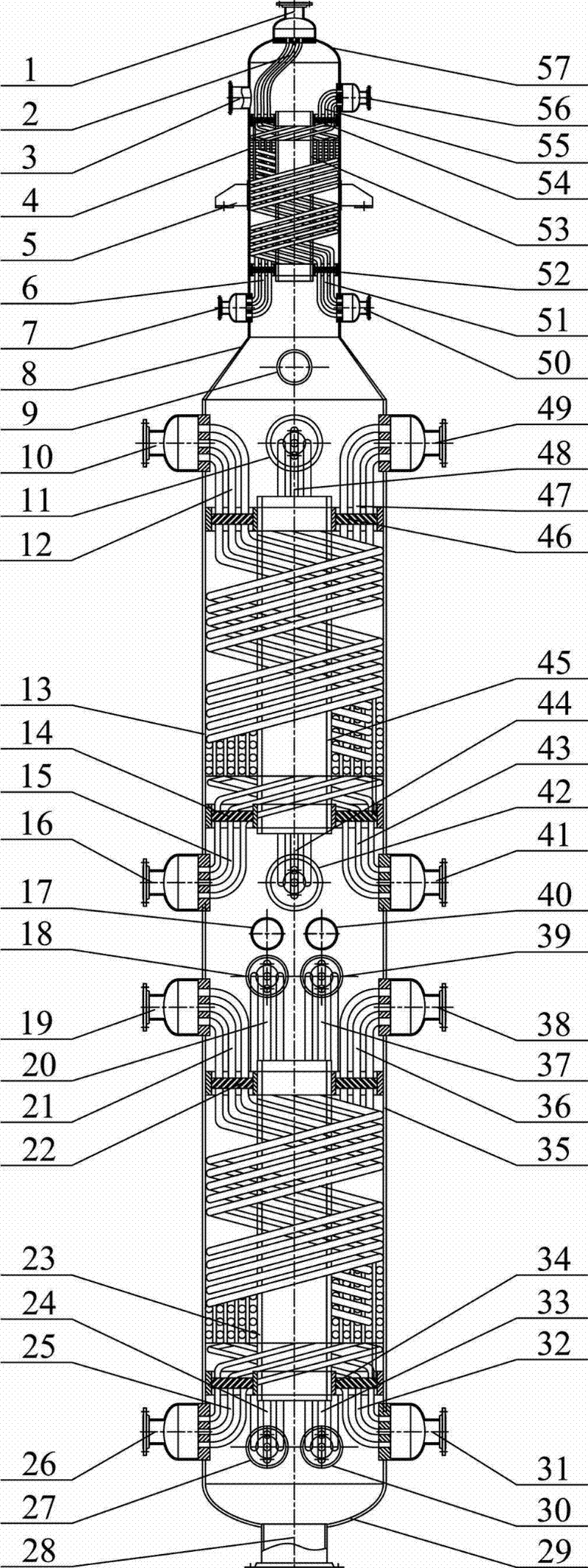

Multi-flow spiral winding tube type main heat exchange equipment with mixed refrigerant for low-temperature liquefaction of LNG (liquefied natural gas)

A mixed refrigerant and spiral winding technology, applied in liquefaction, indirect heat exchangers, heat exchanger types, etc., can solve problems such as low heat transfer efficiency, small temperature difference, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 36°C, 0.9MPa C4H separated from the mid-stage condensation of the mixed refrigerant compressor 10 — Different C 4 h 10 The mixed refrigerant enters the inlet 27 and is then distributed in C 4 h 10 — Different C 4 h 10 C 4 h 10 — Different C 4 h 10 、C 3 h 8 , N 2 —CH 4 —C 2 h 4 The mixed gas is supercooled, the temperature drops to -53°C, the pressure drops to 0.6MPa, and then flows to the outlet 18, and is throttled by the throttle valve installed between the outlet 18 and the inlet 17 to become a supercooled liquid. After throttling, the pressure drop to 0.3MPa, the temperature becomes -52.85°C, and then enters the cylinder 35 through the inlet 17, and the throttled C 3 h 8 , N 2 —CH 4 —C 2 h4 The mixed gas is mixed, and after mixing, it flows downward to cool the natural gas tube bundle 32, N 2 —CH 4 —C 2 h 4 Tube bundle 25, C 3 h 8 Tube bundle 33, C 4 h 10 — Different C 4 h 10 After the tube bundle 24, at 26°C and 0.3 MPa, it flows out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com