A split air-air heat exchange unit with a humidification section

An air heat exchange, split-type technology, applied in heating methods, air humidification systems, lighting and heating equipment, etc., can solve the problems of low enthalpy value, insufficient utilization of air energy, and insufficient utilization of air energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

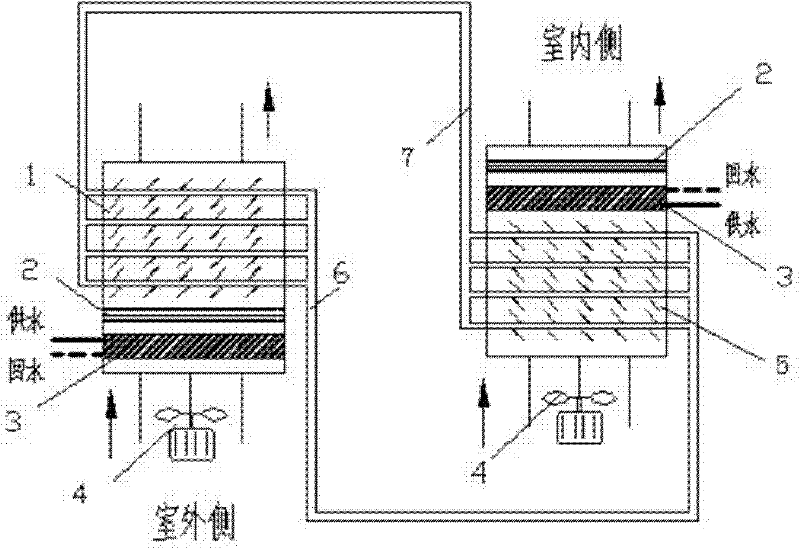

[0017] Example 1: A thermosiphon split air-to-air heat exchanger (without pump) with a humidification section using a natural cold source to cool down the computer room

[0018] Such as figure 1 As shown, a thermosiphon split air-to-air heat exchanger with a humidification section, the heat exchanger is a thermosiphon split heat exchanger without a pump. The condenser and the evaporator are connected together through the gas collecting pipe and the liquid collecting pipe. When installing, ensure that the height of the evaporator is lower than the condenser. Return to the evaporator through the height difference. Condenser, evaporator, gas collection pipe and liquid collection pipe form a closed space, after sealing, vacuumize, and then fill the inside with 30% low boiling point phase change medium. Based on the evaporator, the air duct is fixedly connected at the air inlet and outlet of the evaporator to form a closed indoor air duct. The inlet and outlet of the air duct com...

Embodiment 2

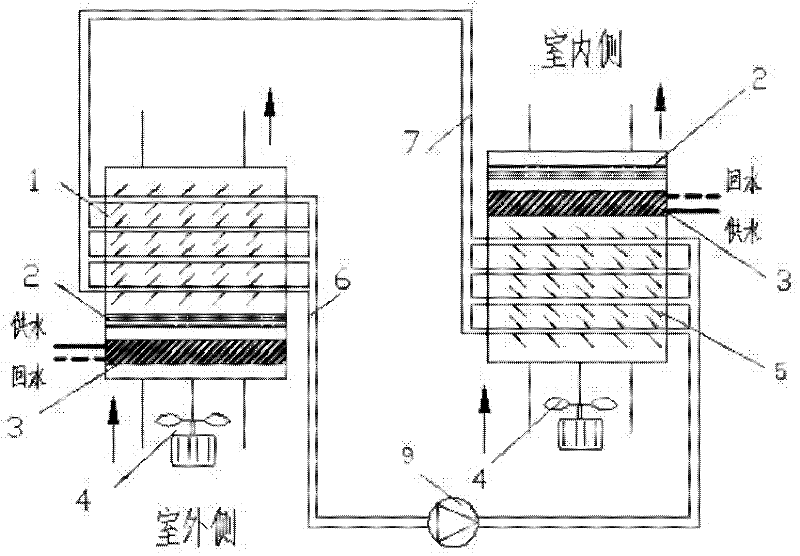

[0019] Embodiment 2: A thermosiphon split air-to-air heat exchanger (with a liquid pump) with a humidification section using a natural cold source to cool down the machine room

[0020] Such as figure 2 As shown, a thermosiphon split air-to-air heat exchanger with a humidification section, the heat exchanger is equipped with a liquid pump, the condenser and the evaporator are connected together through the gas collection pipe and the liquid collection pipe, and the liquid collection pipe A liquid pump is installed on the top, and through external force, it can overcome the problem that the height of the condenser must be higher than that of the evaporator. Its working mode is the same as that of the first embodiment.

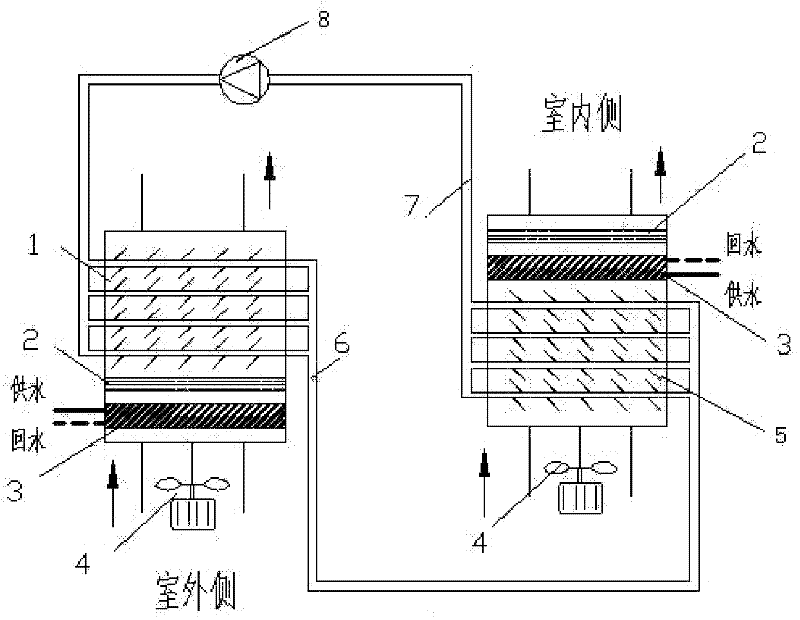

[0021] attached image 3 : Embodiment Three—Using natural cold source to carry out the thermosiphon type split air-air heat exchanger (with air pump) with humidification section for the machine room to cool down

[0022] Such as image 3 As shown, a thermos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com