Energy-saving type hot blast stove

A hot blast stove, energy-saving technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of non-compliance with energy saving and environmental protection, high flue gas discharge temperature, high heat loss from flue gas, and achieve extended use. Life, increase the heat exchange temperature difference, reduce the effect of the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

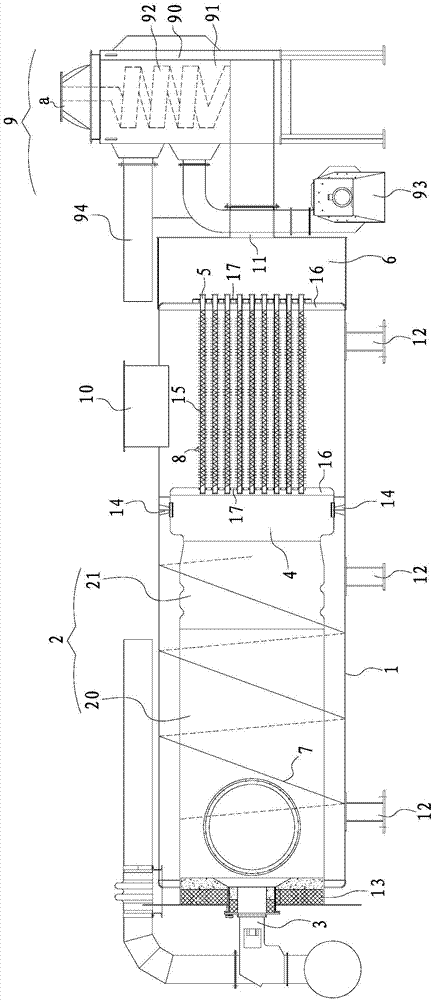

[0022] Such as figure 1 As shown, the energy-saving hot blast stove provided in this example includes a furnace body 1 extending along the horizontal direction, a combustion chamber 2 arranged in the furnace body 1, a burner 3 communicating with one end of the combustion chamber 2, and a The front smoke chamber 4 connected to the other end of the combustion chamber 2, the rear smoke chamber 6 connected to the front smoke chamber 4 through a plurality of heat exchange tubes 5, and the guide tube spirally wound on the outer periphery of the combustion chamber 2 along the length direction of the combustion chamber 2. flow plate 7 ; heat exchange fins 8 on the outer periphery of each heat exchange tube 5 ; and a combustion air preheating device 9 .

[0023] Specifically, the furnace body 1 has an air inlet 10, an exhaust port 11, and a smoke exhaust port 12. The air inlet 10 faces the heat exchange tube 5, and the smoke exhaust port 12 is arranged at the tail of the rear smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com