Patents

Literature

1062 results about "Smoke flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

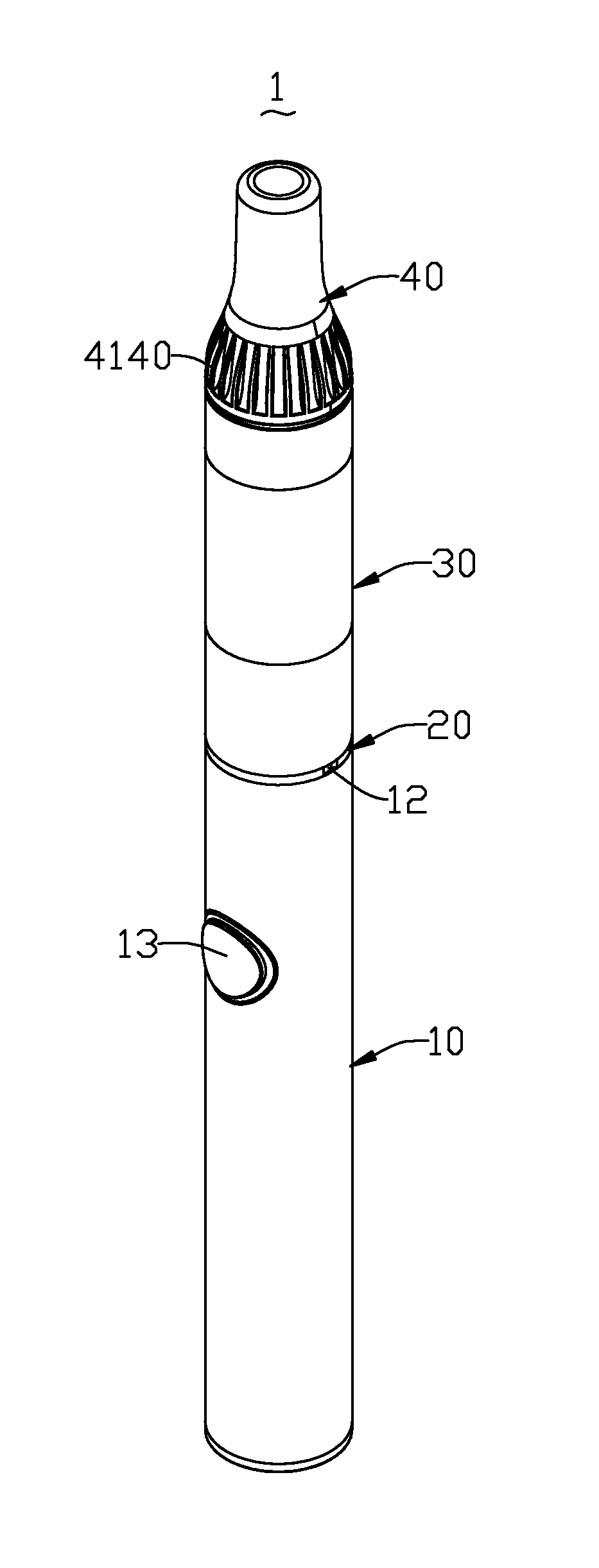

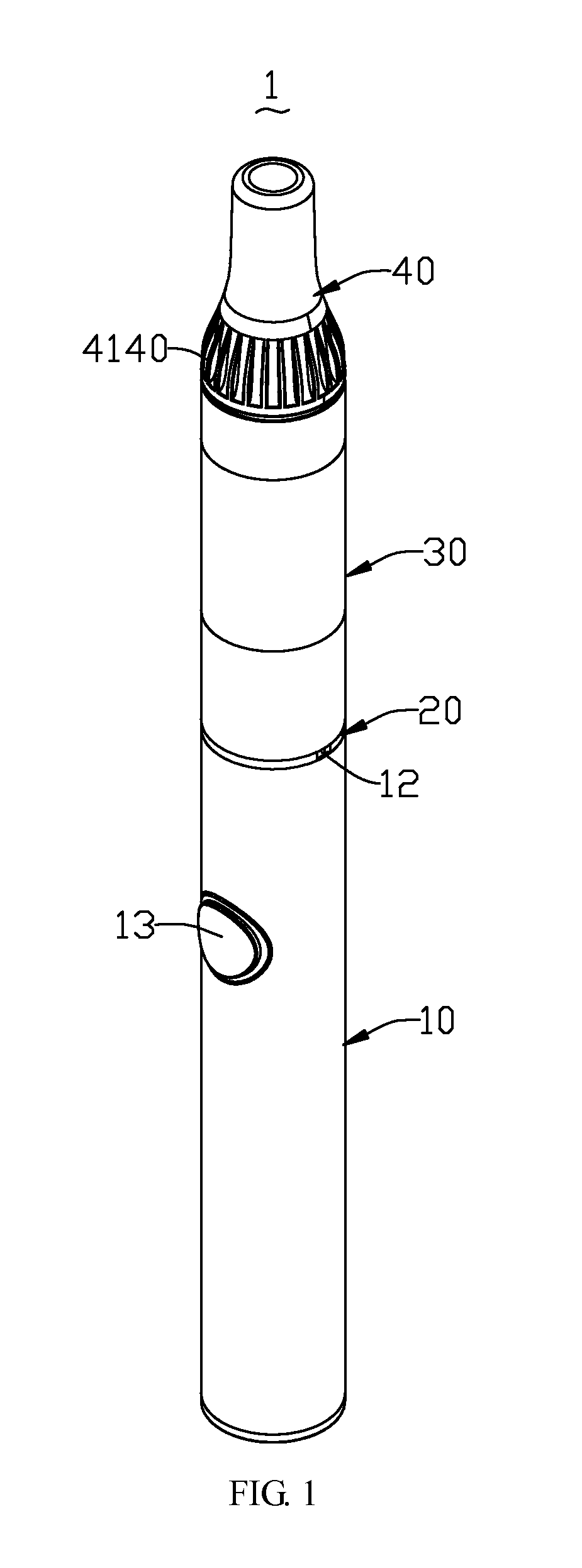

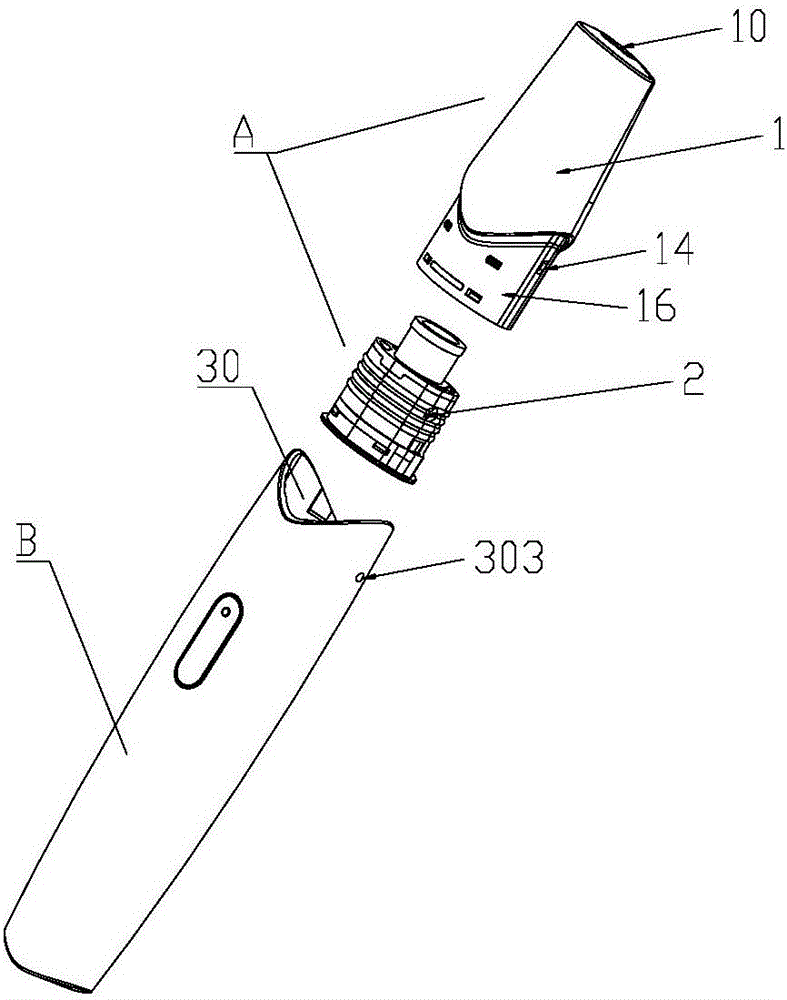

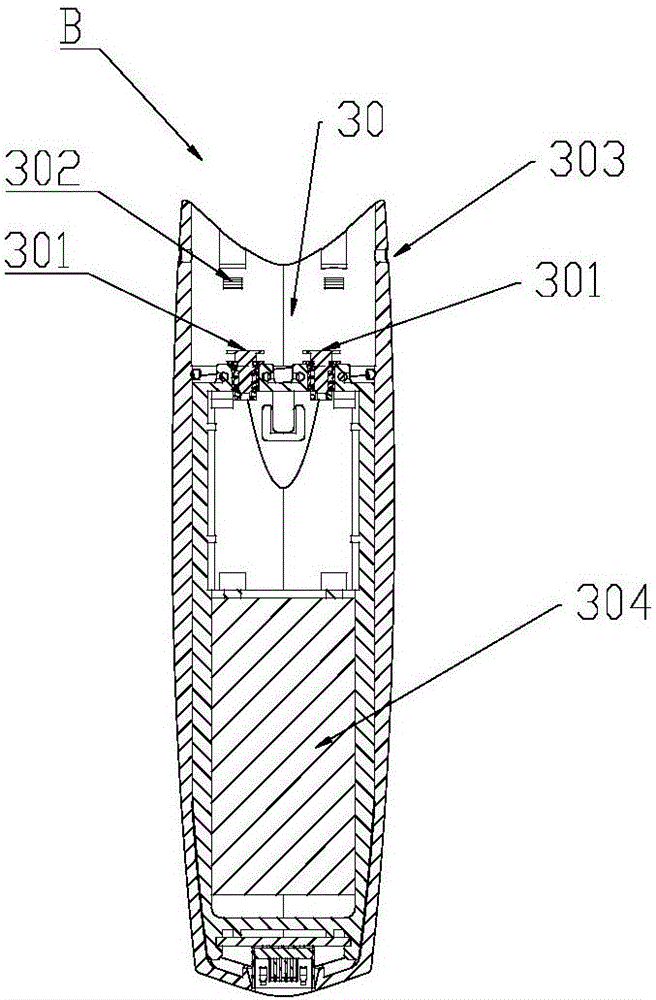

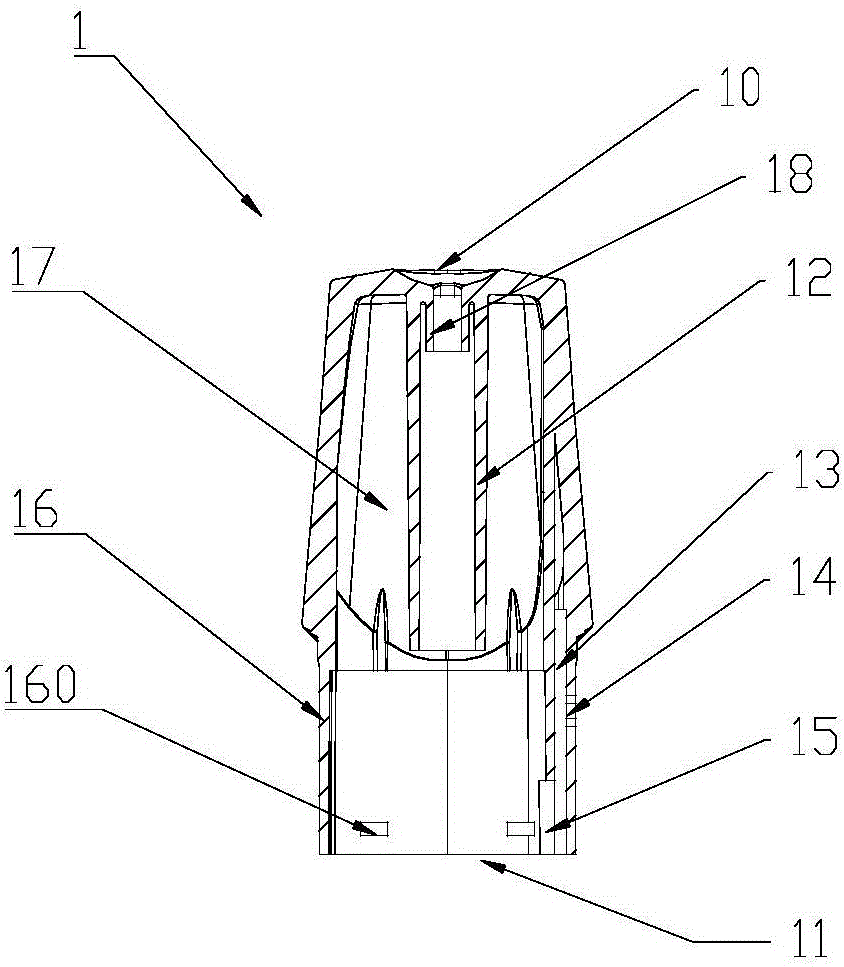

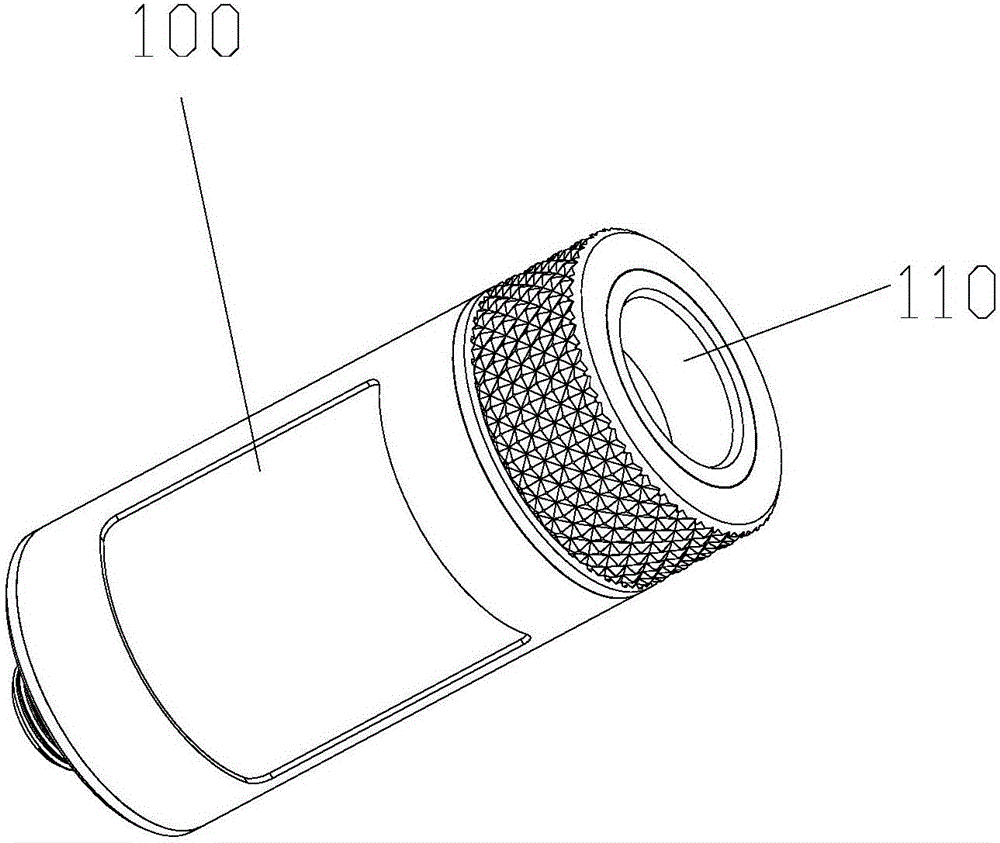

Cartridge for electronic cigarette

The present disclosure relates to a cartridge for an electronic cigarette. The cartridge includes a cartridge body defining a smoke channel for smoke flowing therethrough and a reservoir chamber surrounding the smoke channel for storing liquid solution, the reservoir chamber comprising an opening which communicates the interior of the reservoir chamber with the exterior of the reservoir chamber; and a sealing member secured to the cartridge body, the sealing member comprising a first sealing portion for sealing the opening

Owner:SHENZHEN SMOORE TECH LTD

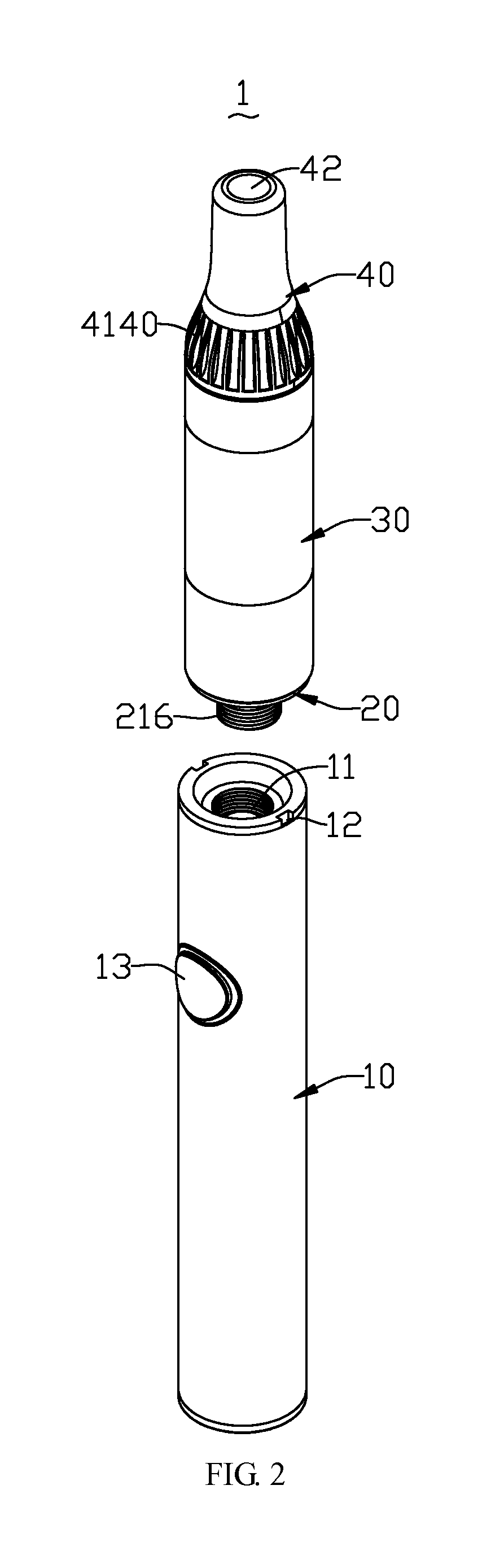

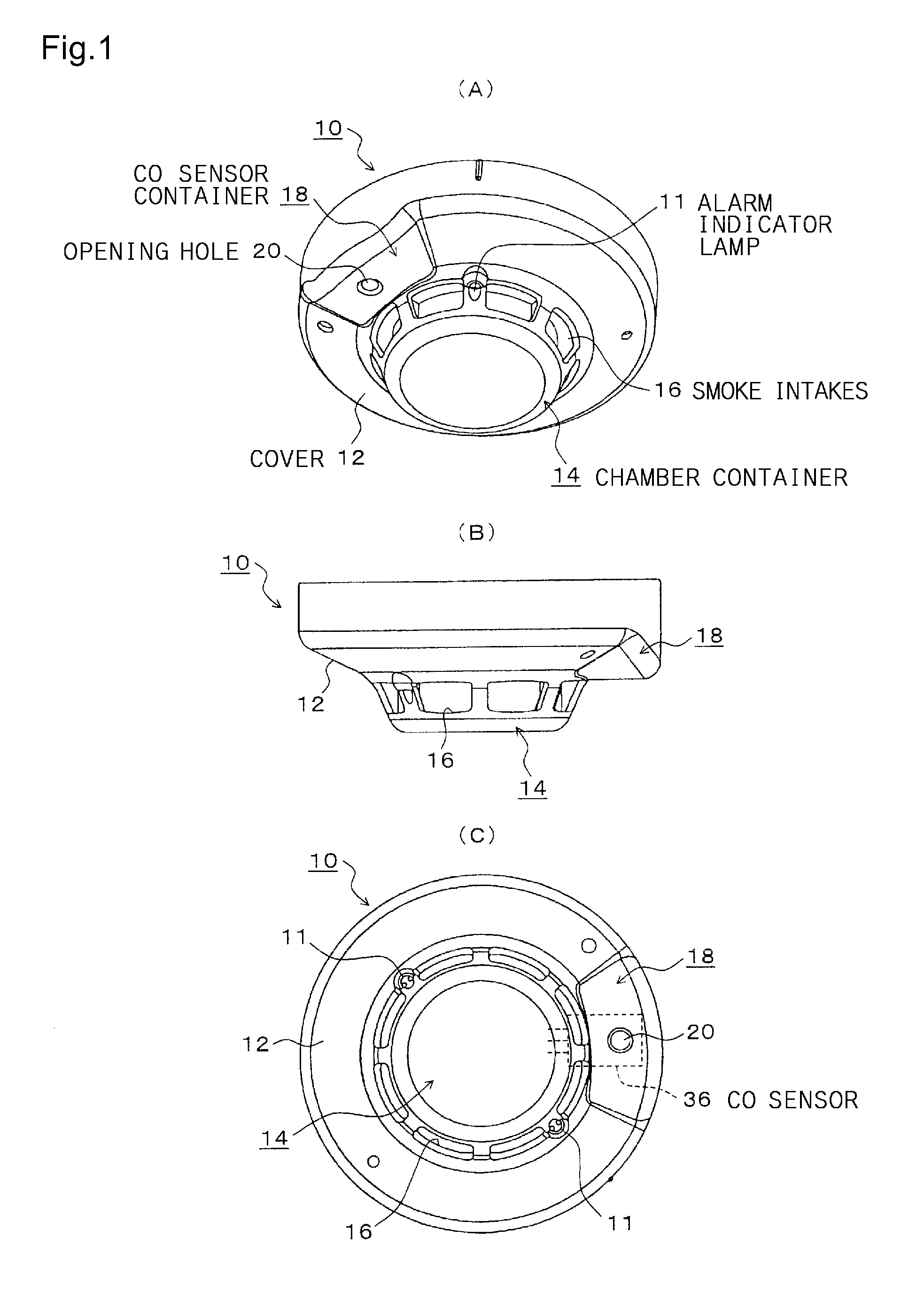

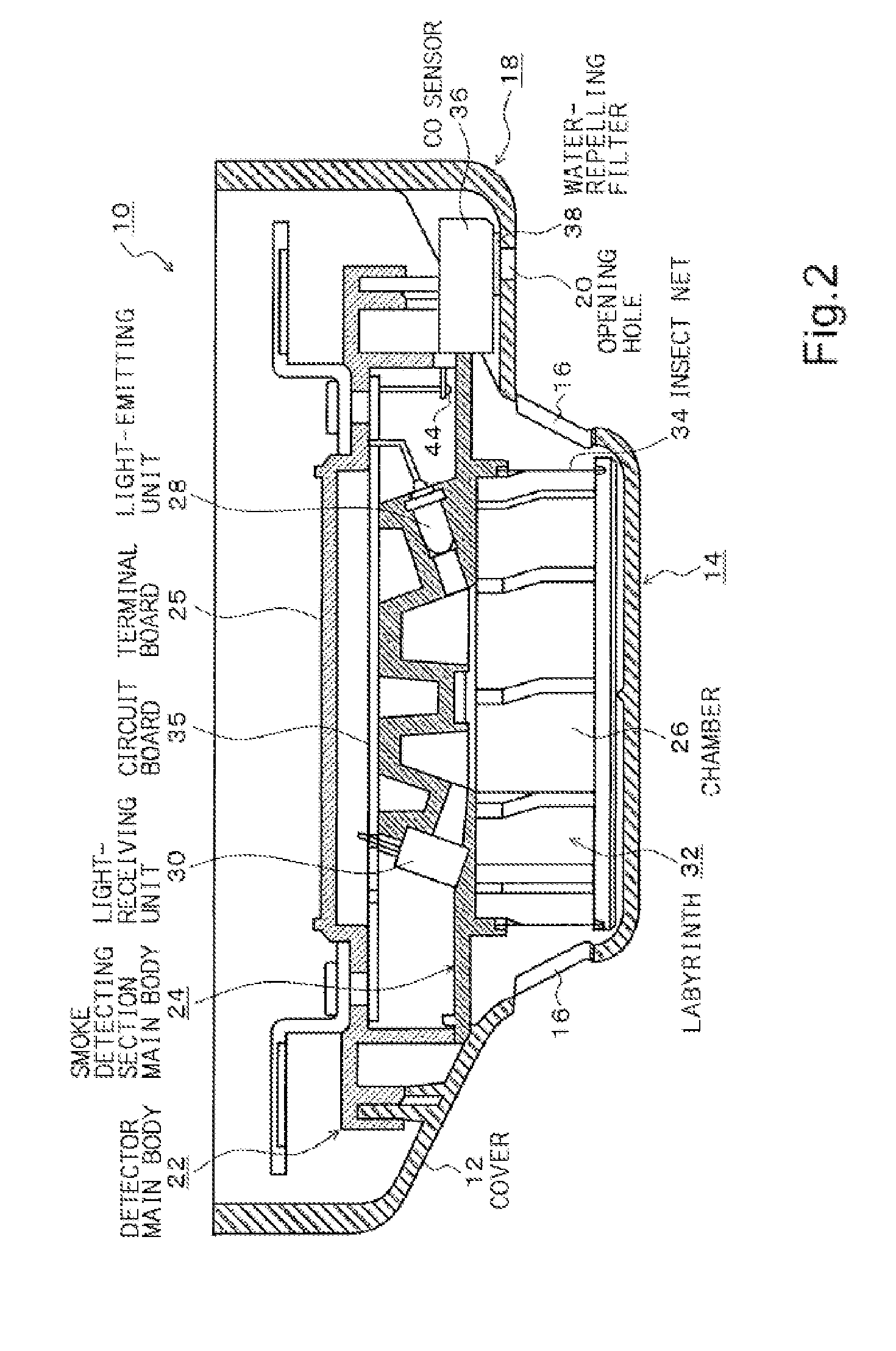

Detector

ActiveUS20130008787A1Minimize adverse effectsReduce advantageMaterial analysis by electric/magnetic meansFire alarm electric actuationElectrochemical gas sensorEngineering

A detector includes a smoke detecting section that includes a light-receiving unit at a position at which the light-receiving unit does not directly receive light emitted by a light-emitting unit in a chamber in which a labyrinth for preventing light from directly entering from the outside and an insect net covering the rim of the labyrinth are provided, the light-receiving unit receiving light scattered by smoke flowing into the chamber. An opening hole is formed open in the surface of the cover receiving hot air current, of the detector. In the cover behind the opening hole, an electrochemical gas sensor is placed to bring gas generated by a fire through the opening hole into contact with an electrolyte solution to detect the gas by an electrode.

Owner:HOCHIKI CORP

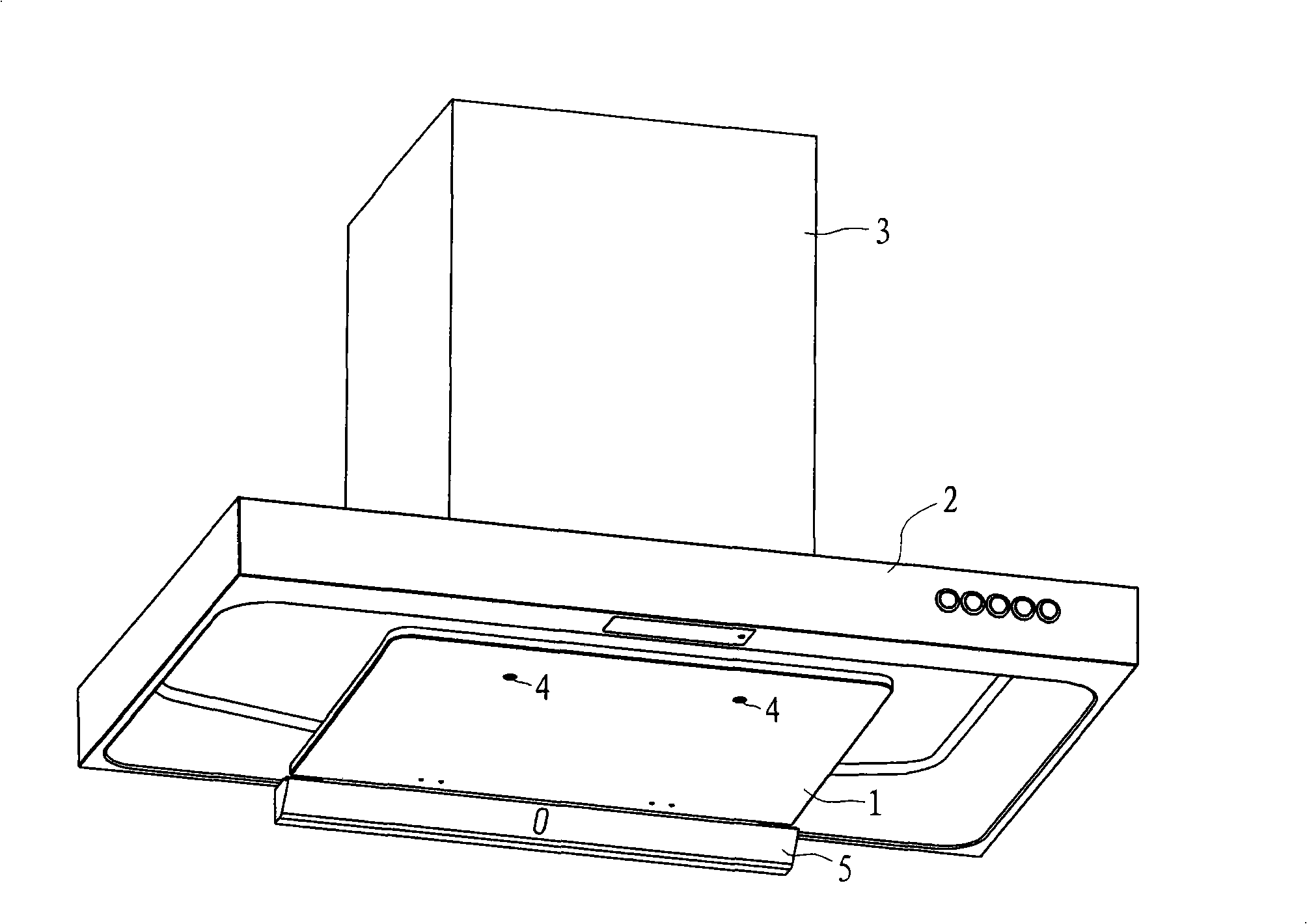

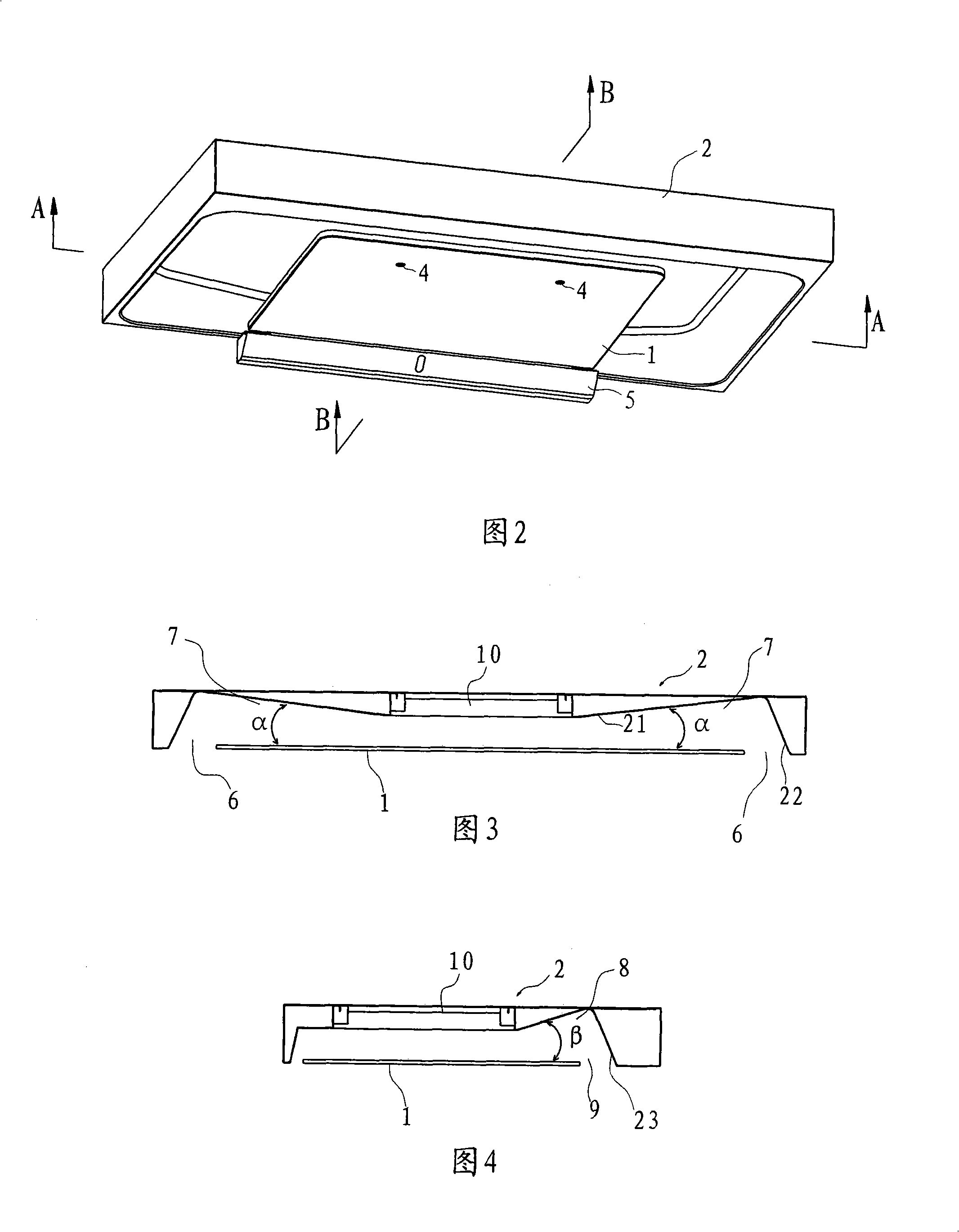

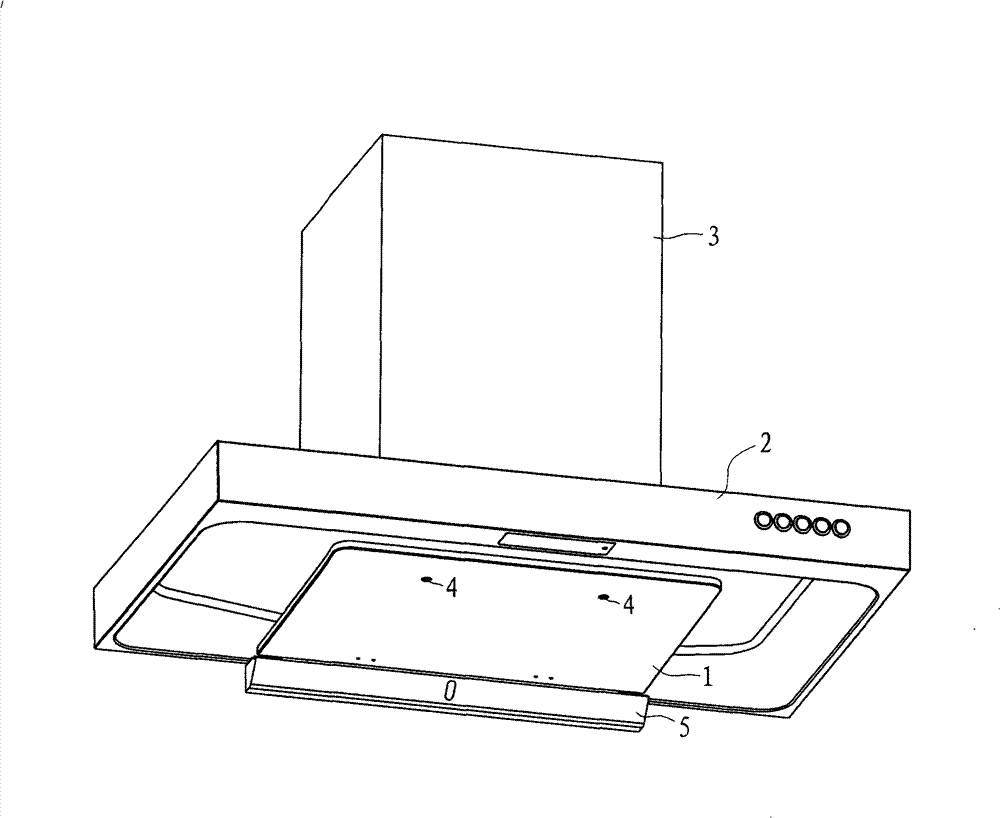

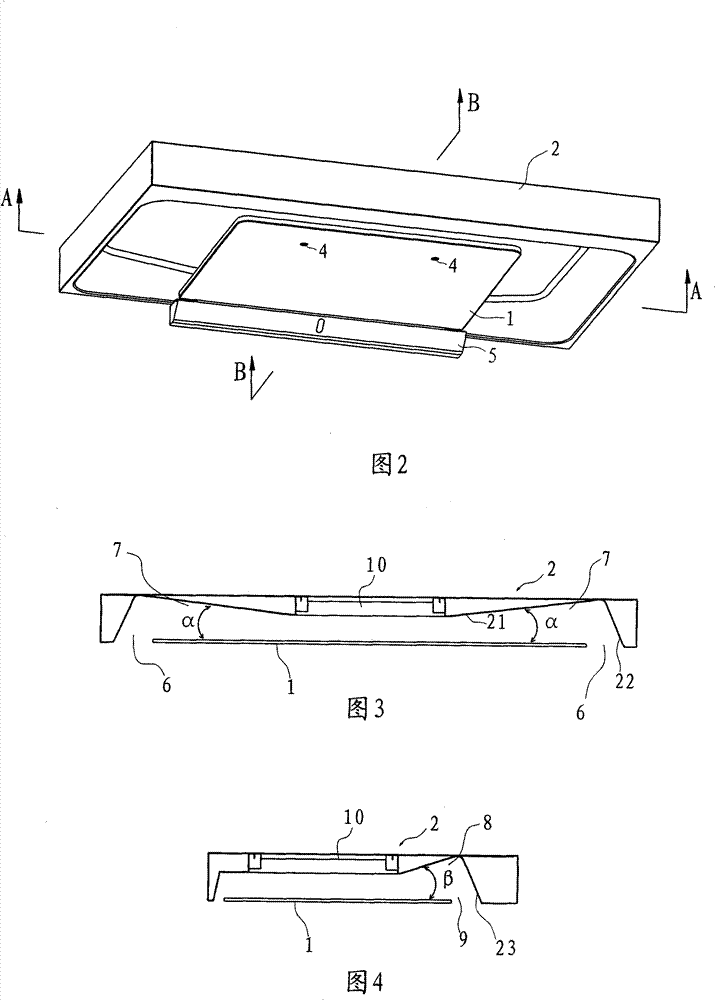

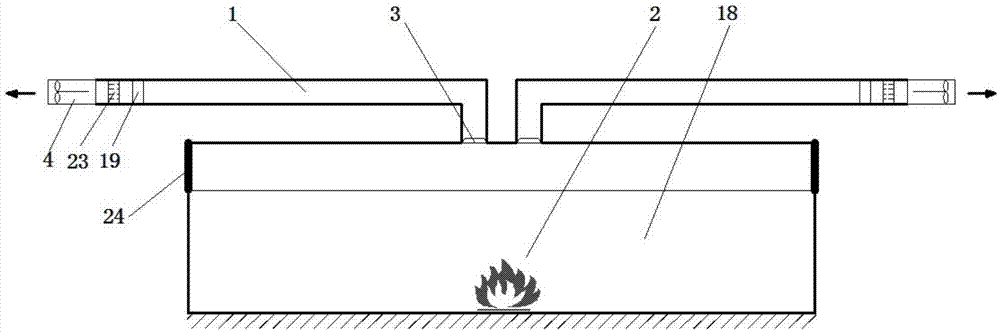

Range hood with smoke deflector

ActiveCN101514823ASpeed up the flowNo streamingDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

A range hood with a smoke deflector, comprises a body, a smoke collecting cover and the smoke deflector, wherein an air inlet is arranged on the smoke collecting cover, the smoke deflector faces to the air inlet and be in the predetermined distance from the smoke collecting cover, thus a oil smoke channel through which the oil smoke can pass is formed between the smoke deflector and the smoke collecting cover, the range hood is characterized in that the distance between the smoke deflector corresponding to the oil smoke channel and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet. Compared with the prior art, the invention has the advantages: the smoke deflector is used for forming the wall-attachment effect, the oil smoke flow uniformly without series flow, the distance between the smoke deflector and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet, so that the Venturi effect is formed conveniently, thus accelerating the sucking of smoke by the blower fan.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

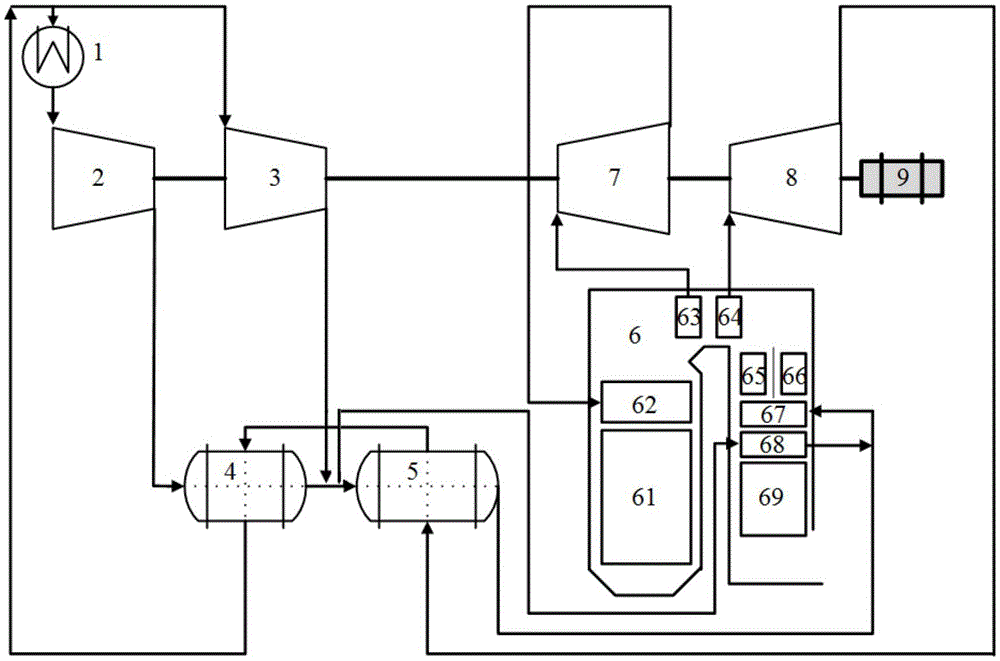

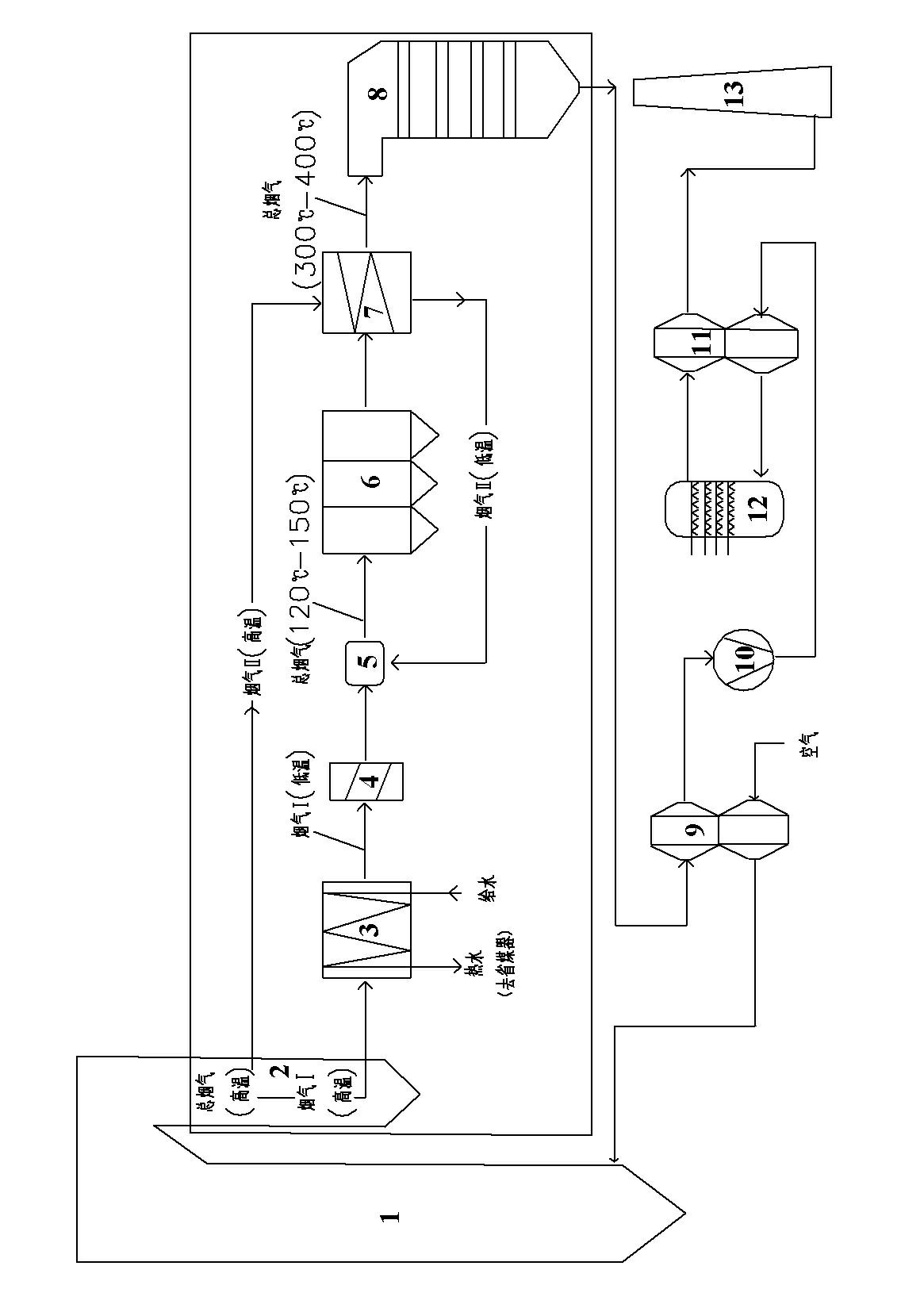

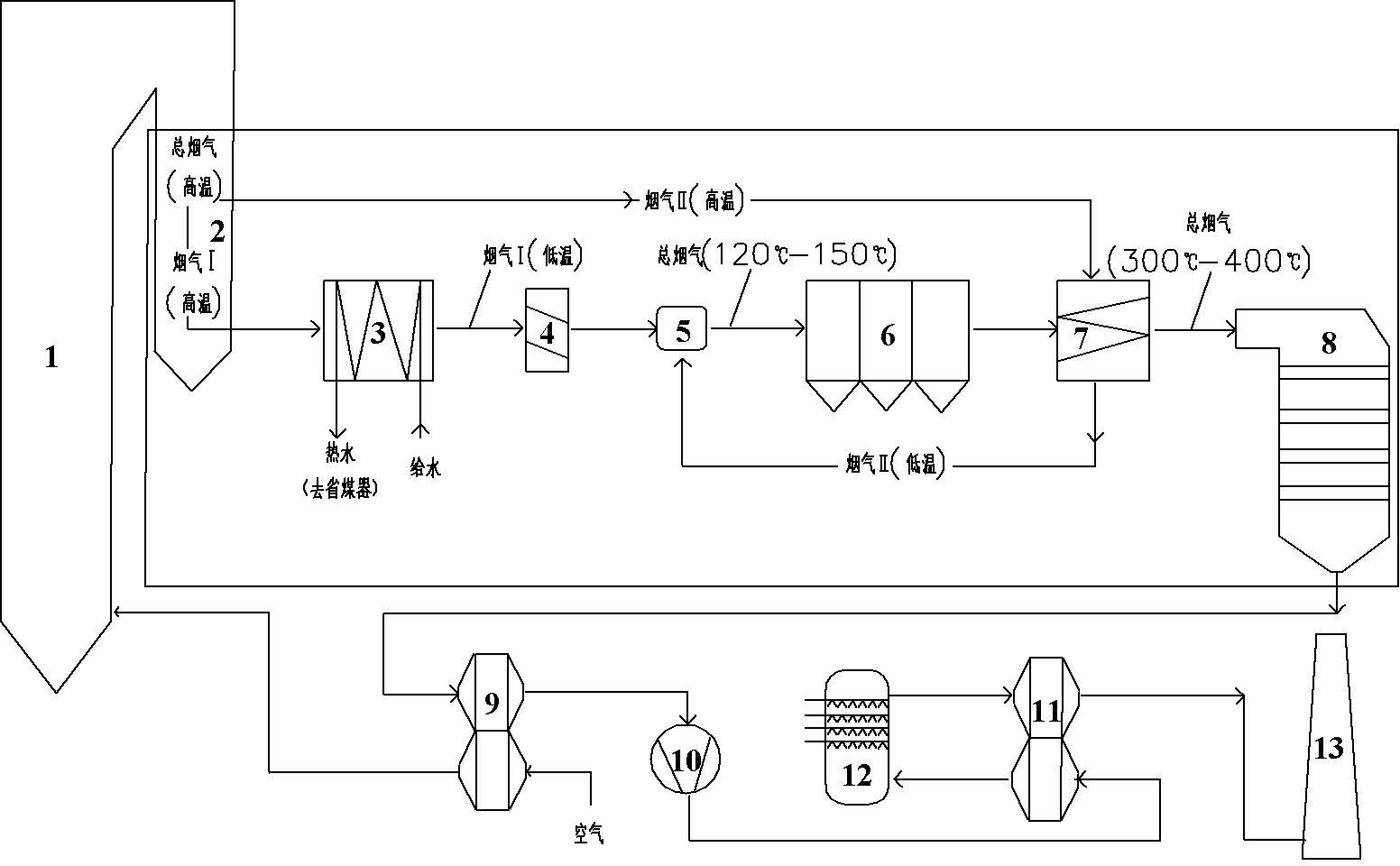

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

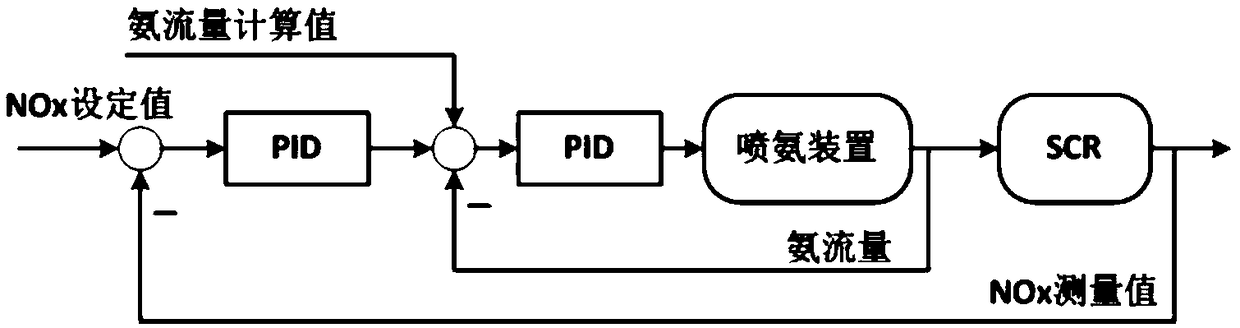

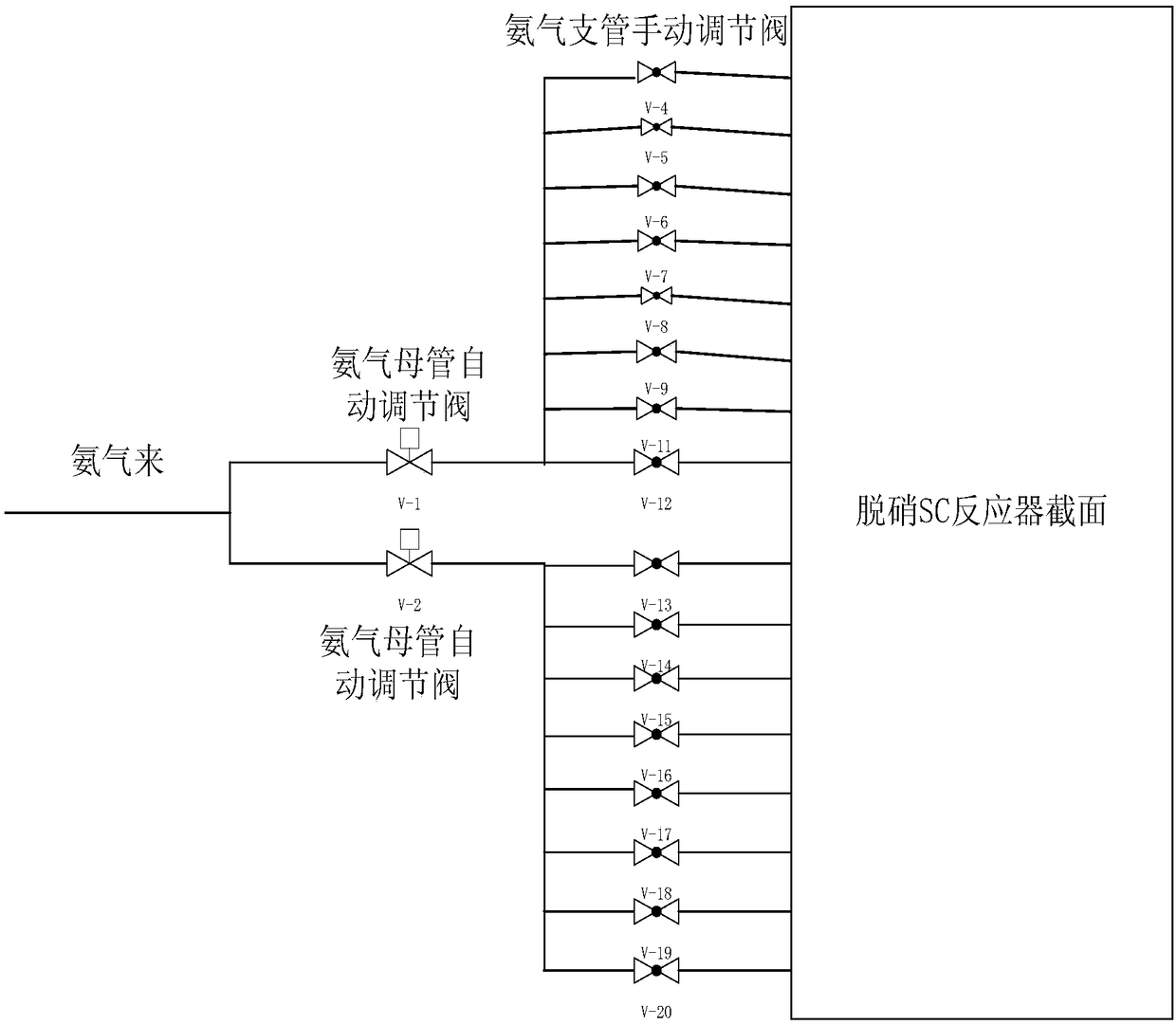

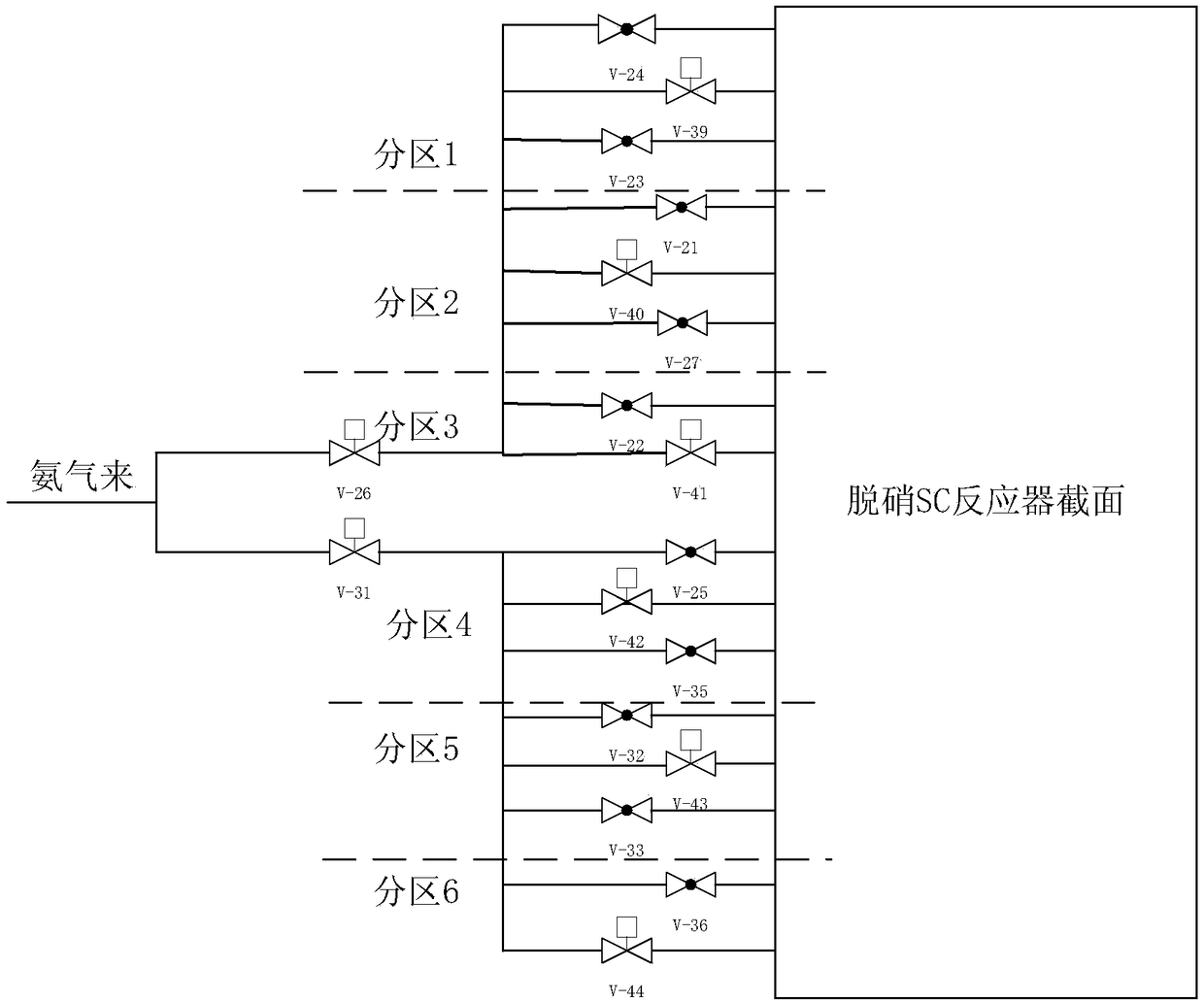

SCR denitration intelligent ammonia spraying optimization method and system based on zone control and advanced control

PendingCN108664006AStable up-to-standard dischargeStable emissionsDispersed particle separationTotal factory controlAuto regulationNitrogen oxide

The invention discloses an SCR denitration intelligent ammonia spraying optimization method and system based on zone control and advanced control. The method comprises the steps that 1, based on running data, an inlet oxynitride concentration model is established; the model and currently collected running data are utilized to obtain a predicted value of the concentration of inlet oxynitride; 2, ammonia spraying amount under a current working condition is calculated according to the predicted value to be sent to an SCR denitration system as a feed-forward signal; 3, a deviation between a measured value of the concentration of outlet oxynitride and a set value is solved and then input into a self-adaptive PID controller to obtain an ammonia spraying amount feedback control signal and send the signal to the SCR denitration system; 4, the SCR denitration system controls the ammonia spraying amount of an SCR denitration reactor according to the ammonia spraying amount feed-forward signal and the ammonia spraying amount feedback control signal; the SCR denitration reactor is divided into a plurality of zones, and the SCR denitration system adjusts an automatic adjusting valve of each zone according to the smoke oxynitride concentration and smoke flow rate of the corresponding zone to control the ammonia spraying amount of the corresponding zone.

Owner:DATANG ENVIRONMENT IND GRP

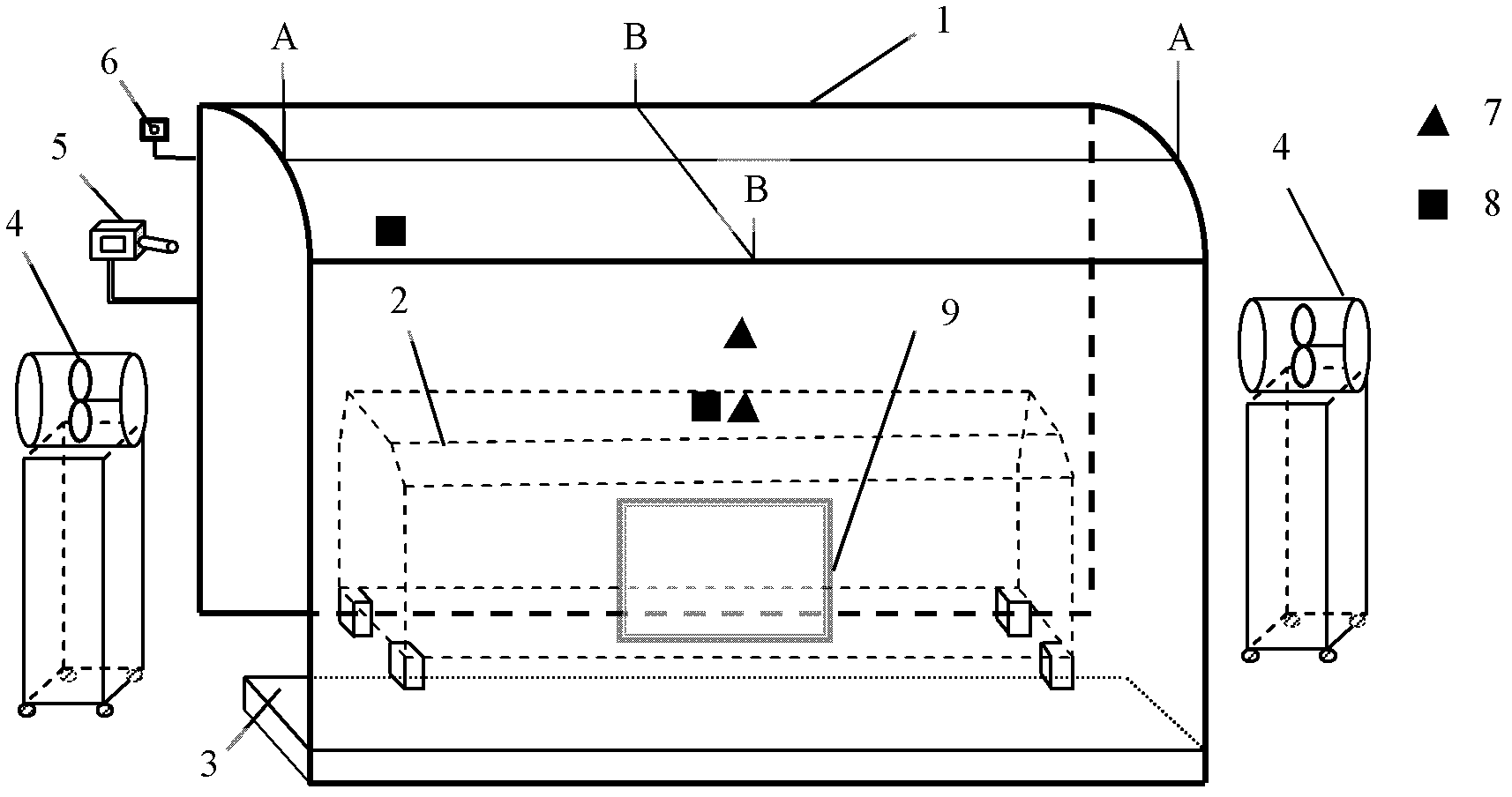

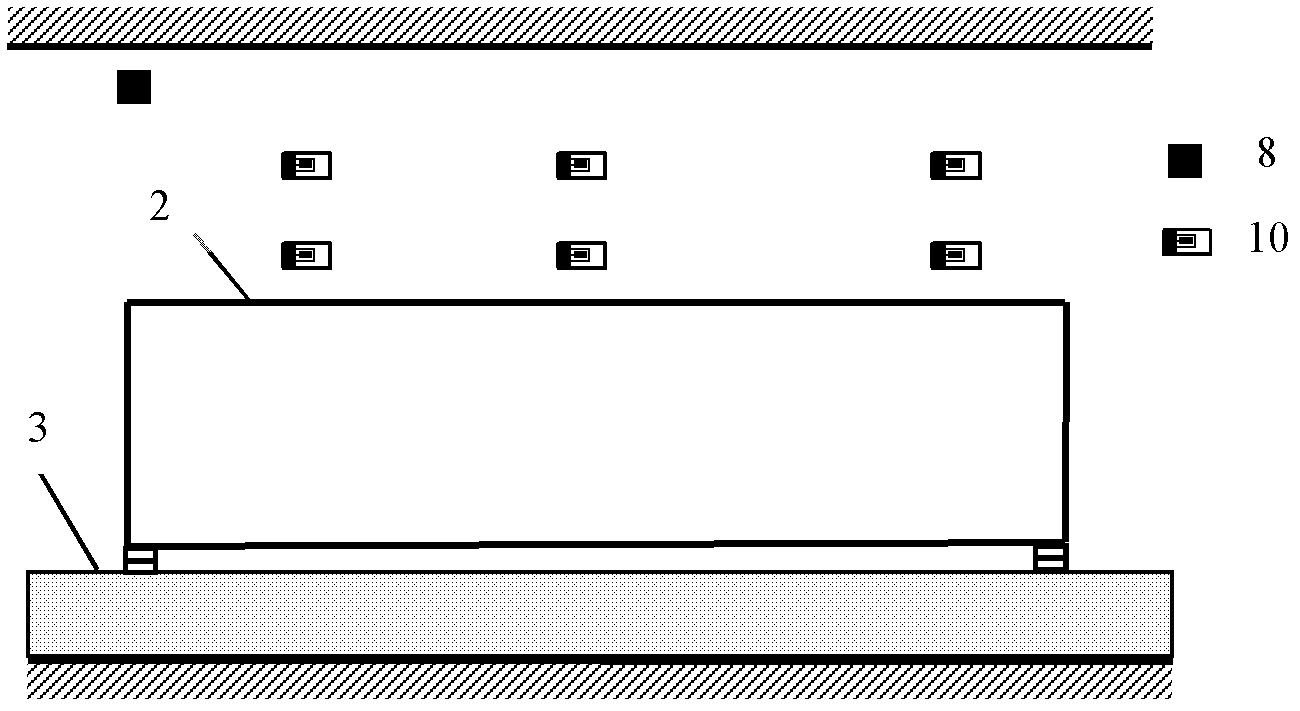

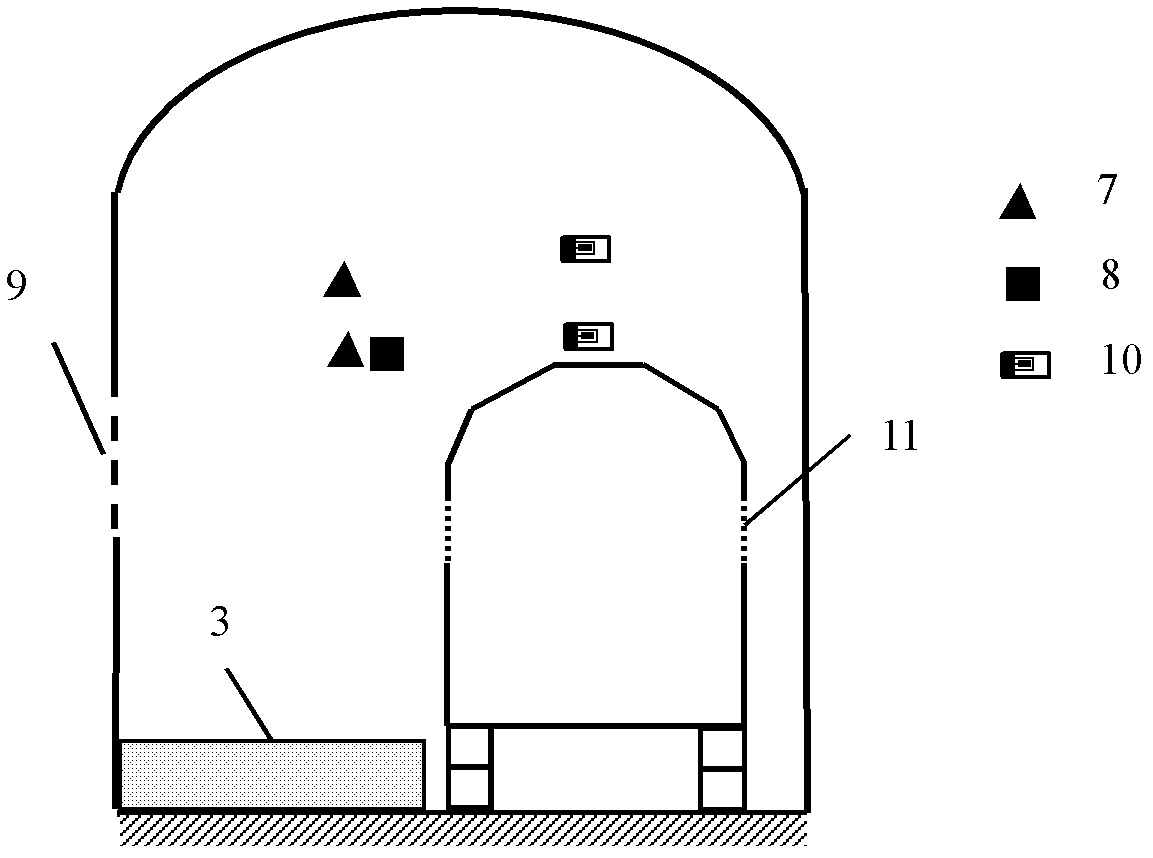

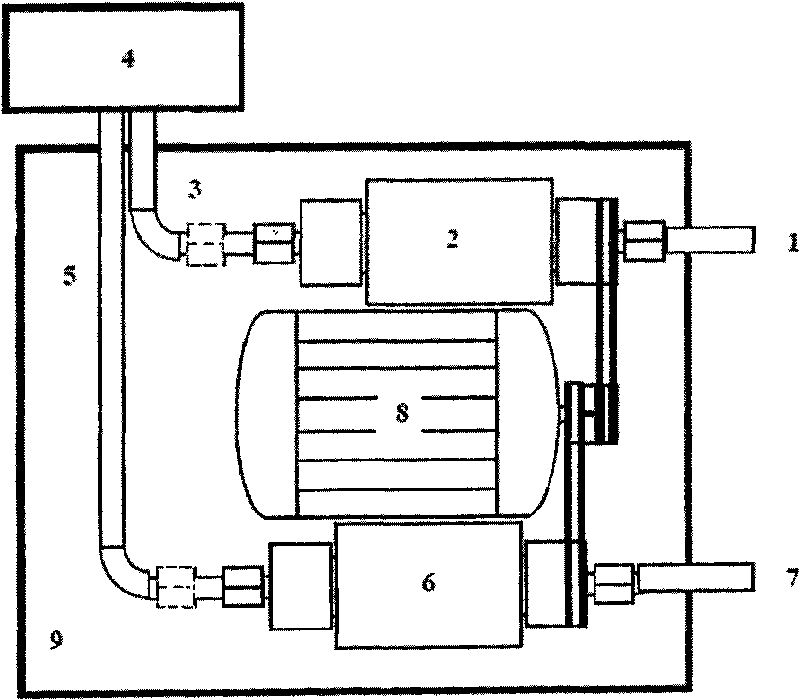

Fire simulation experiment system for railway tunnel rescue station

InactiveCN102306459ARealize measurementReal-time recording and objective reflection of heat insulation protection effectCosmonautic condition simulationsSimulatorsRailway tunnelBody compartment

The invention provides a fire simulation experiment system for a rail tunnel rescue station. The system comprises a simulation tunnel, a simulation rescue station platform, a simulation railway train, a smoke exhaust system, a fire monitoring system, a fire suppression system and a fire parameter measurement system. By the experiment system, the research of a series of basic theory problems and engineering practice problems of fire development, smoke flow, fire monitoring and suppression and the like generated when the fire of the tunnel rescue station is positioned on the top of a carriage, inside the carriage and at the bottom of the carriage can be comprehensively carried out. By the system, a whole set of solution is provided for the research on the effectiveness of a fire monitoring and suppression technology and a smoke control technology under the condition of different longitudinal wind speeds and the evolution law of characteristic parameters such as a temperature field, a poisonous and harmful gas concentration field, thermal radiation and the like in the scene that a train in an extra-long railway tunnel is stopped at the rescue station in the fire process.

Owner:UNIV OF SCI & TECH OF CHINA

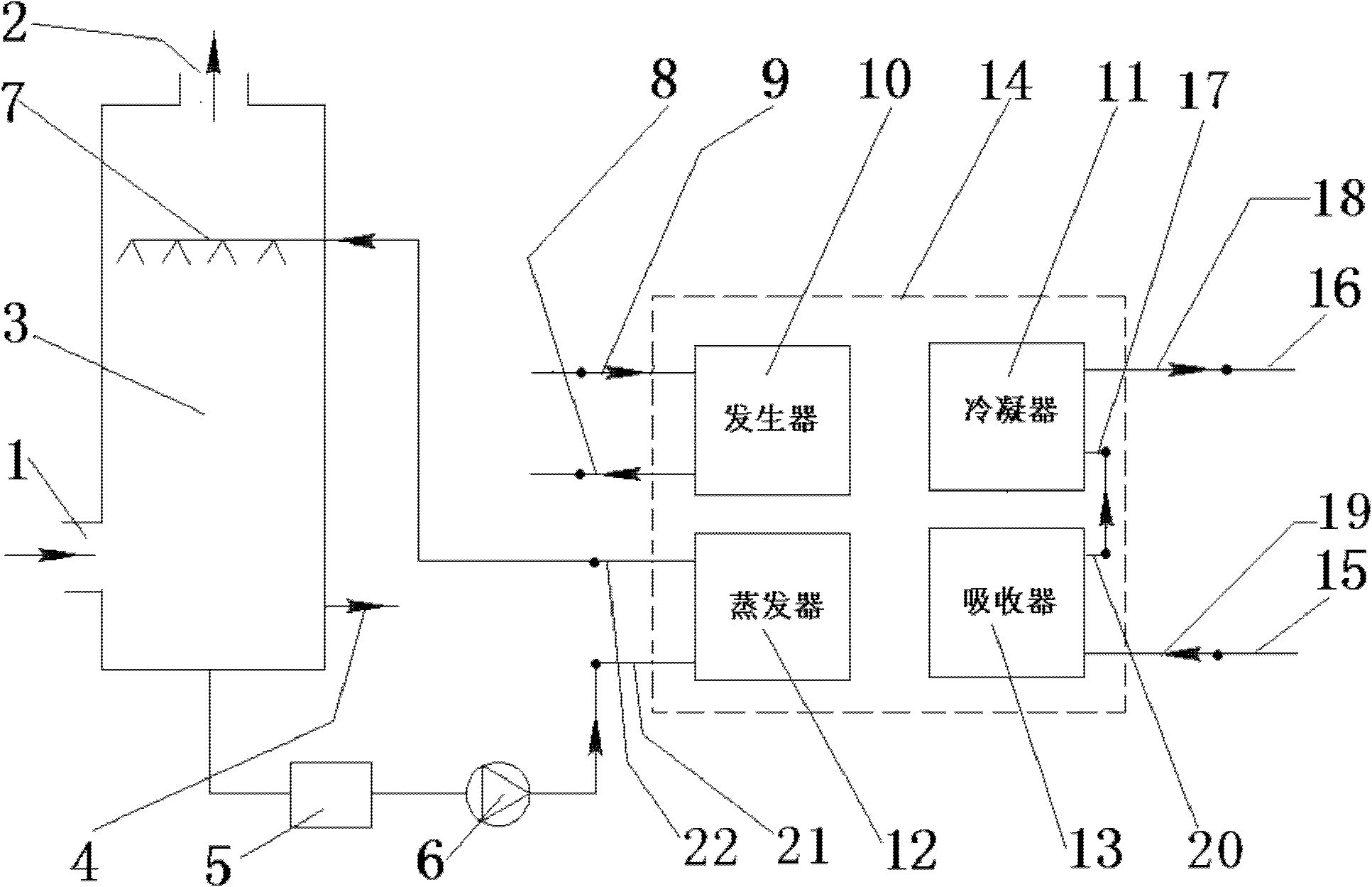

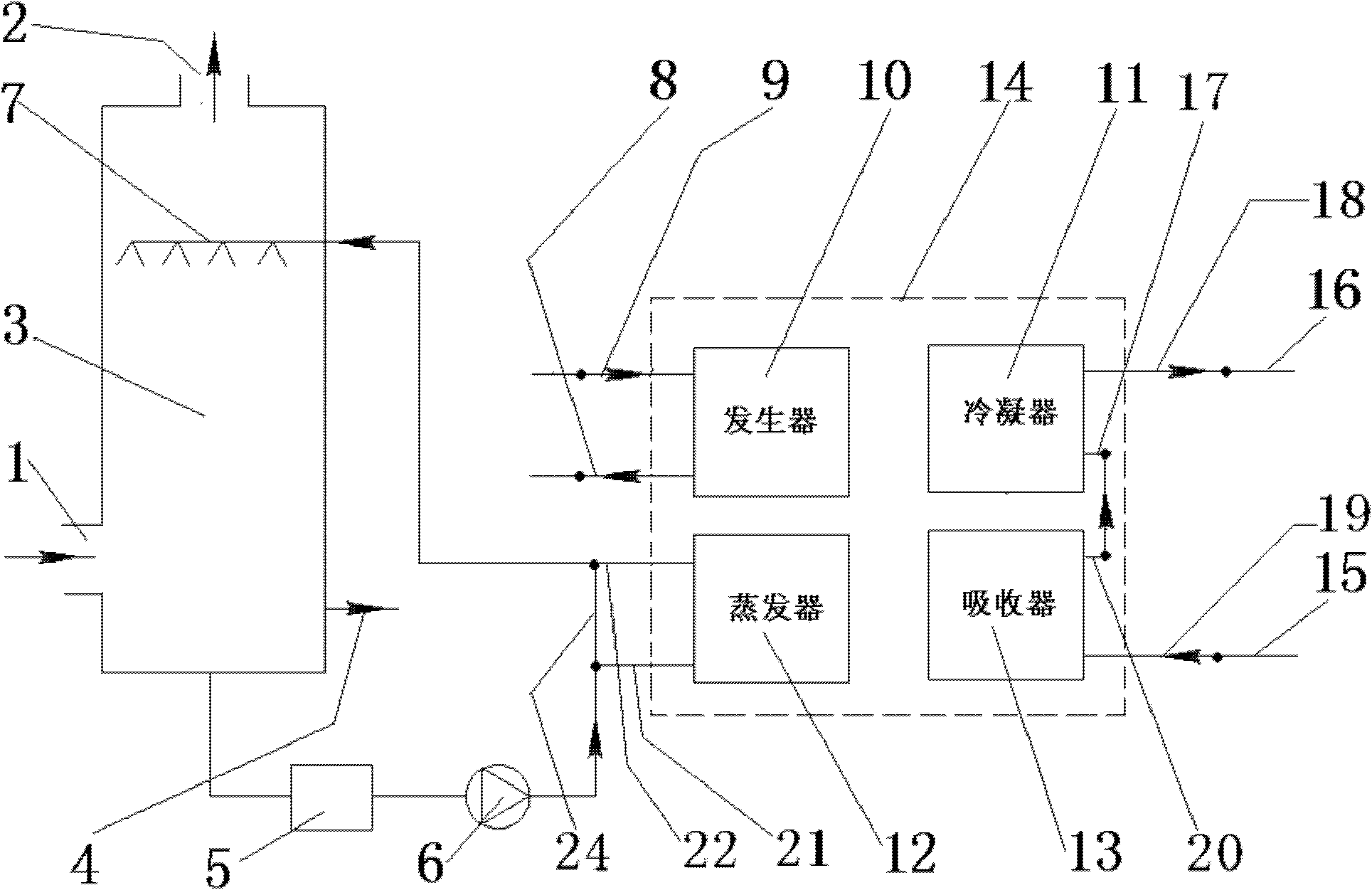

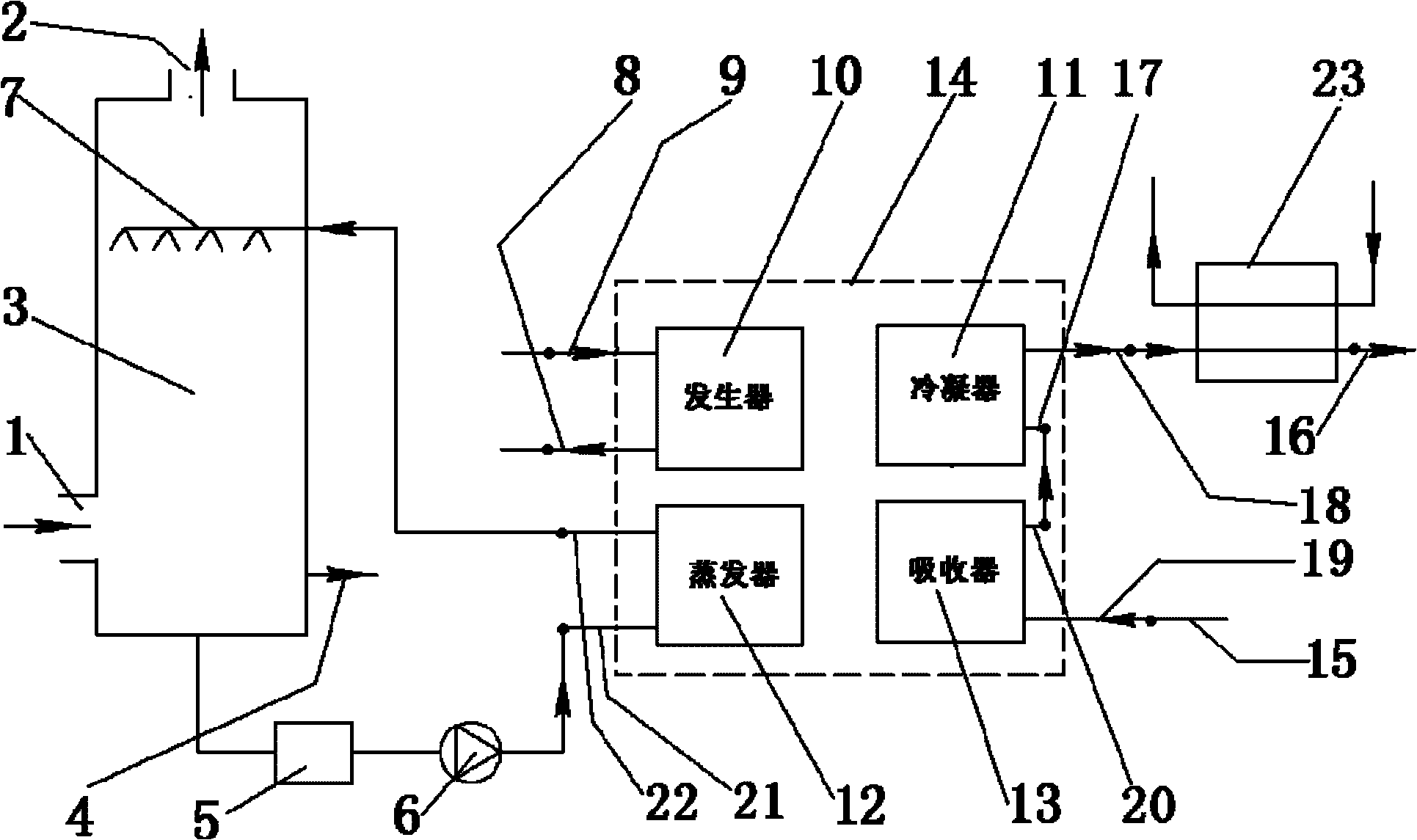

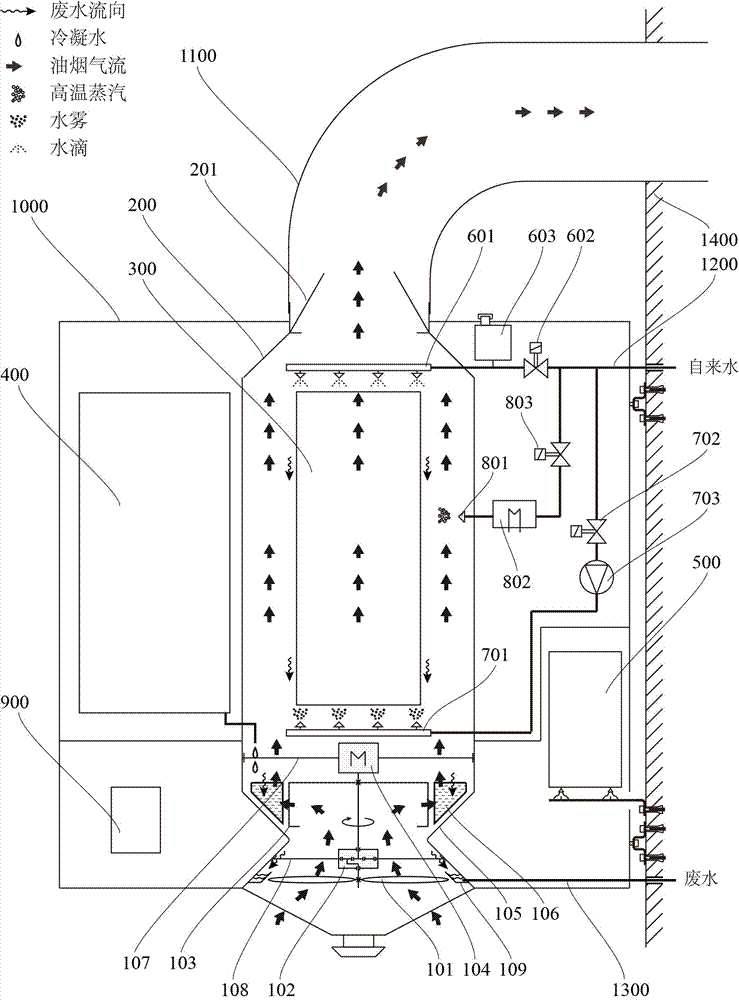

Concentrated heat supply system for reclaiming smoke afterheat by absorption heat pump

ActiveCN102242946AImprove energy efficiencyIncrease return water temperatureHeat recovery systemsTrickle coolersNet returnWater quality

The invention belongs to the technical field of energy sources, and relates to a concentrated heat supply system for reclaiming smoke afterheat by an absorption heat pump. The system is used for reclaiming smoke afterheat of natural gas and water. The system is composed of a smoke flue, the absorption heat pump, a spray device, a water quality processing device and a circular water pump; smoke flows in the smoke flue from bottom to top; circular water is ejected by the spray device to form atomized drops for directly contacting with the smoke to exchange heat and is introduced to an evaporator of the absorption heat pump by the water pump after being processed by the water quality processing device after flowing out from the smoke flue; hot net returned water is sequentially introduced toan absorber and a condenser of the absorption heat pump; the circular water absorbing heat of the smoke and the hot net returned water are subjected to heat exchange in the absorption heat pump to reach the needed temperature and then are returned to a hot net. The smoke and the water are in direct contact for heat exchange in the invention; the heat of the circular water heated by the smoke is extracted from the absorption heat pump to raise the temperature of the returned water of the heat supply system; thus the total energy utilization rate of the concentrated heat supply system is increased; and the effects of cleaning the smoke and protecting the environment are achieved.

Owner:TSINGHUA UNIV +1

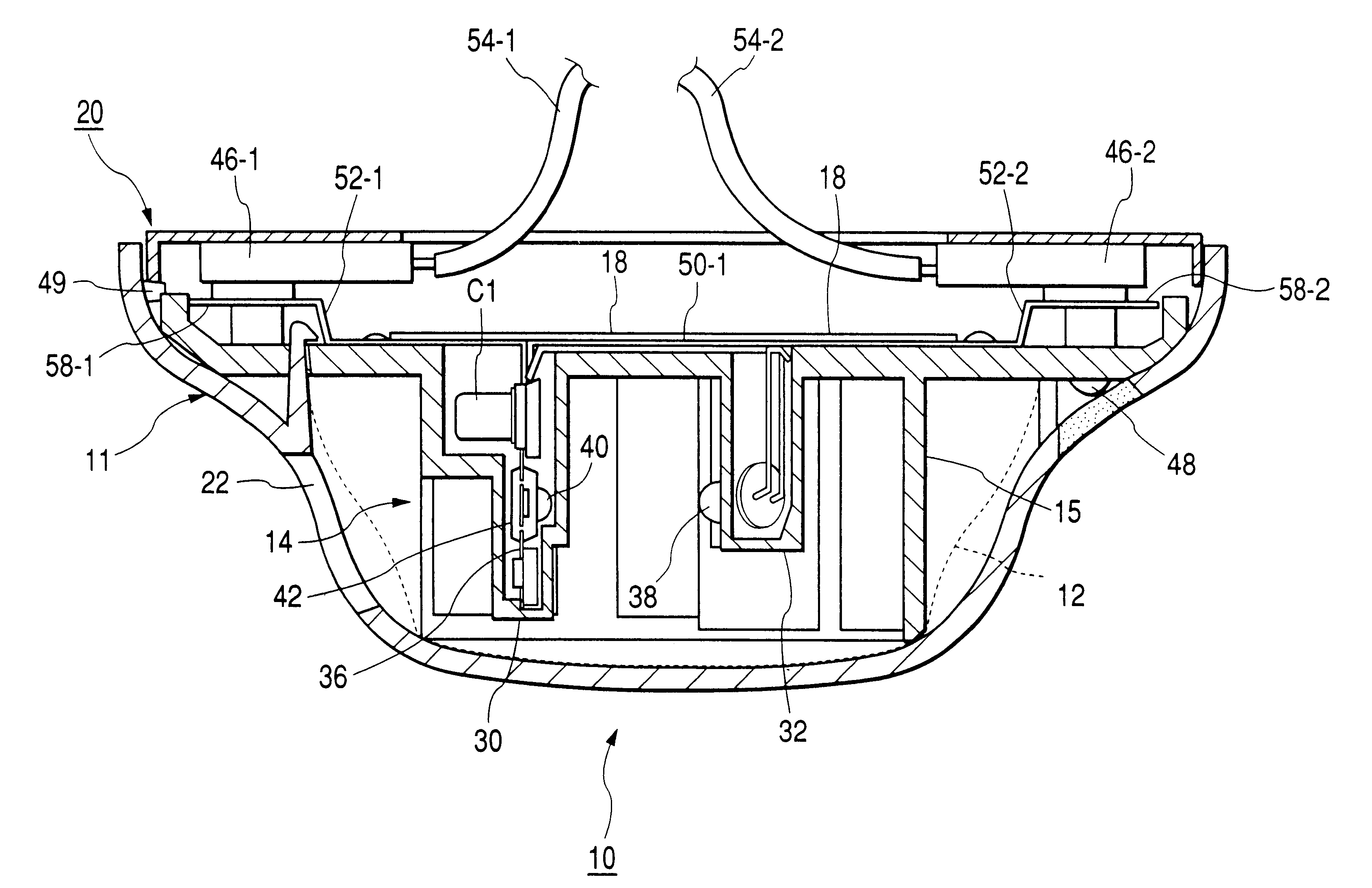

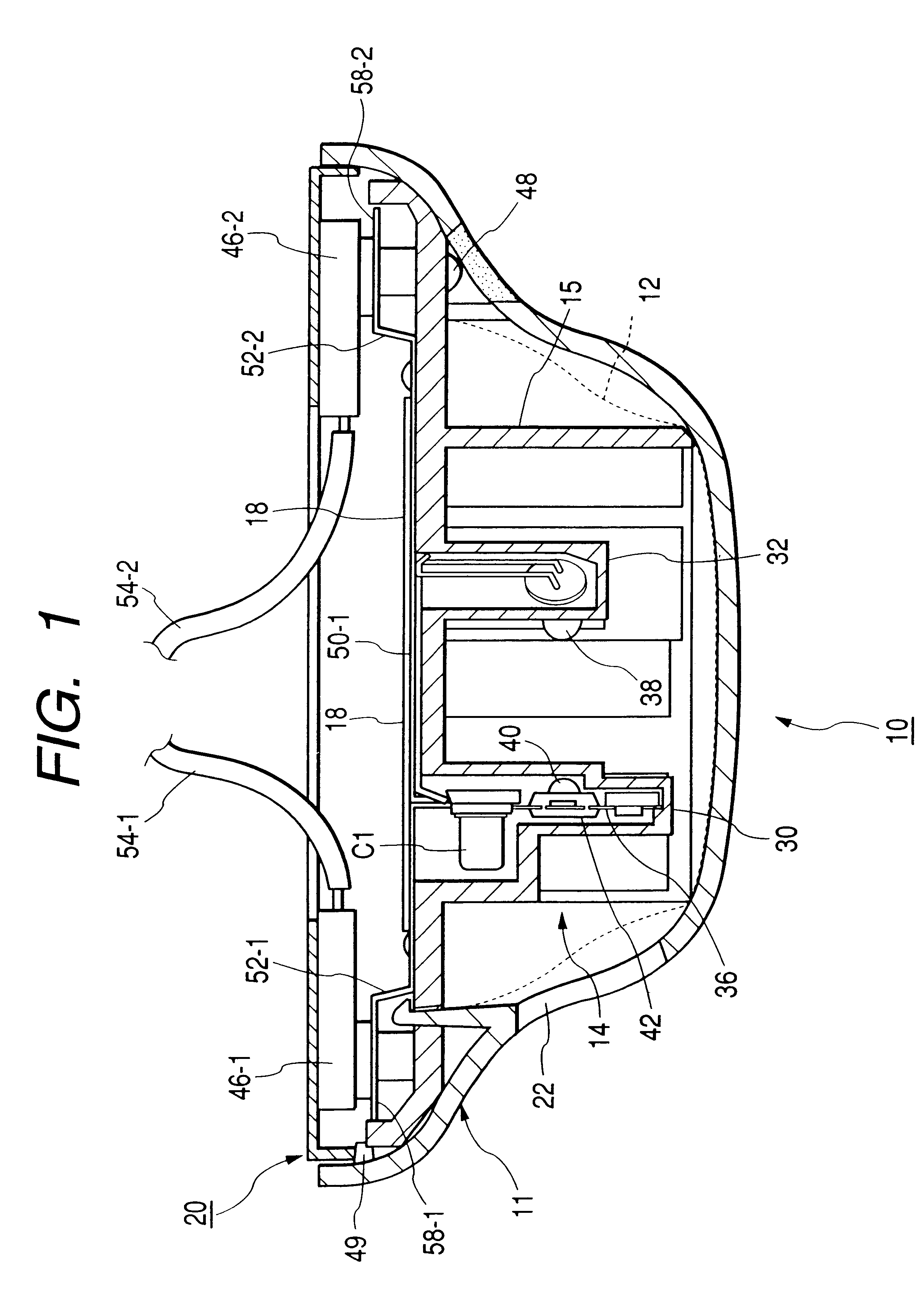

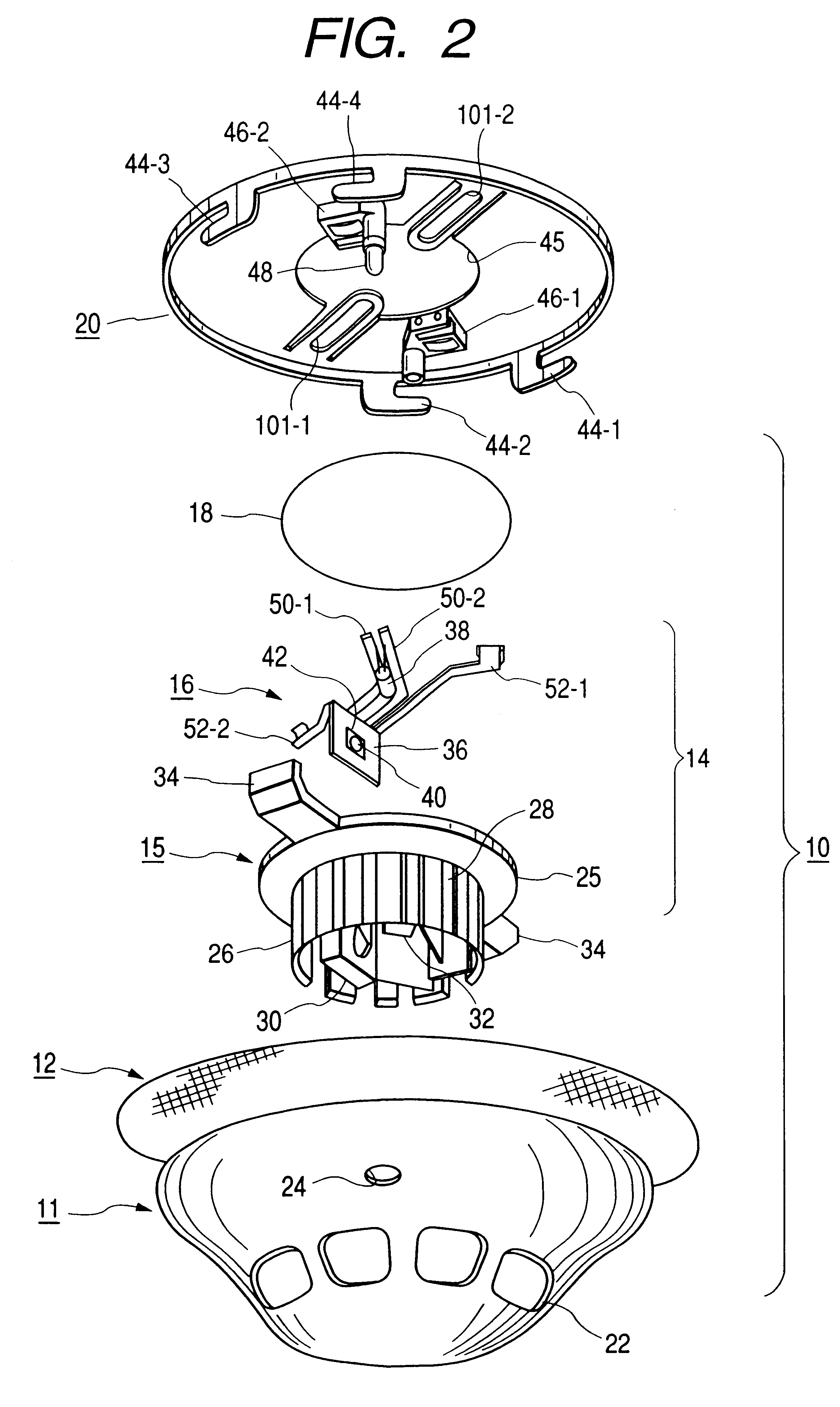

Photoelectric smoke detector, and smoke detection section assembly

InactiveUS6288647B1Investigating moving fluids/granular solidsScattering properties measurementsSmoke detectorsEngineering

A photoelectric smoke detector includes a smoke detecting section defining a smoke detecting space, a light emission section holder having a light-emission element disposed in the smoke detecting section, and a light receiving section holder having a light-receiving element disposed in the smoke detecting section. The light-receiving element receives light which has been emitted from the light-emission element and is scattered by smoke flowing in the smoke detecting space. A hybrid circuit board has an integrated circuit mounted thereon and is housed in the light receiving section holder. The integrated circuit including the light-receiving element and at least a received-light signal amplifying circuit. The hybrid circuit board is arranged so that the light-receiving surface of the light-receiving element is directed toward the smoke detecting space.

Owner:HOCHIKI CORP

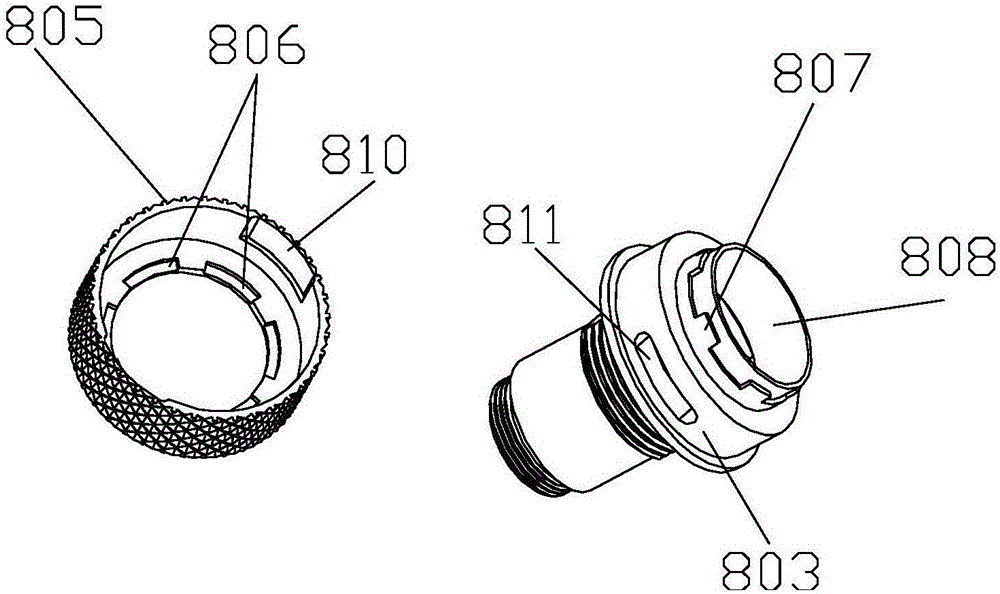

Water spray-resistant electronic cigarette

Owner:HUIZHOU HAPPY VAPING TECH LTD

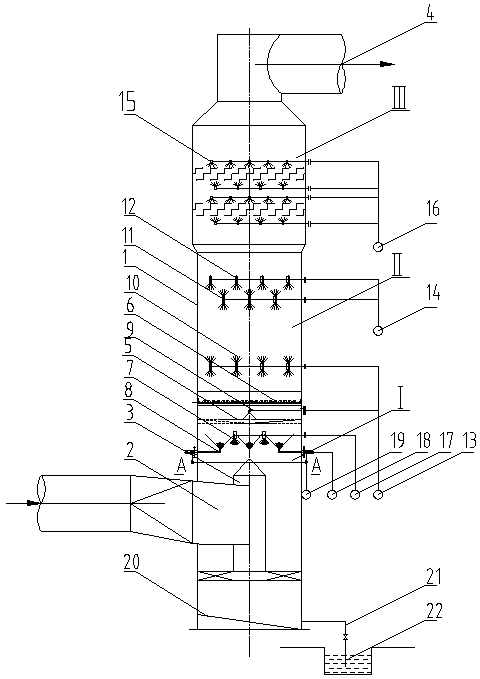

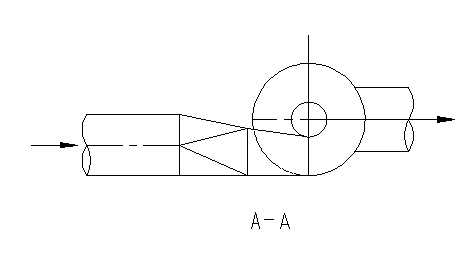

Efficient wet-type variable flow fog-spraying sprinkling dust-removing purification device

ActiveCN103316553AUniform rotary contactMake full use of the mass transfer efficiency of block purificationUsing liquid separation agentSuspended particlesParticulates

The invention relates to an efficient wet-type variable flow fog-spraying sprinkling dust-removing purification device comprising a washing tower, wherein the lower end of the washing tower is provided with a smoke inlet tangent with the washing tower; a center steady flow column is arranged in the middle of the lower end of the washing tower to form an annular channel with the washing tower; a fog condensation trapping area, a sprinkling washing area and a dehydration demisting area are arranged above the steady flow column from bottom to top; a variable flow jet intercepting layer is arranged between the fog condensation trapping area and the sprinkling washing area; a smoke outlet is formed in the upper end of the washing tower. According to the efficient wet-type variable flow fog-spraying sprinkling dust-removing purification device, the variable flow jet intercepting layer is additionally arranged in the washing tower so that rotary flow direction jet flow and plug flow transformation are implemented in the smoke flow direction sequentially, fogdrop groups of different fine particle sizes or the fogdrop groups of an absorbent are poured into the fog condensation trapping area to form a high-density fog group fog field taking suspended particles as a core, and the fog group fog field can be efficiently condensed and intercepted by the variable flow jet intercepting layer to improve the classification purification efficiency of particulate matters with the particle size being less than 40 microns so as to improve the total dust-removing purification efficiency of sprinkling the washing tower under the condition of low energy consumption.

Owner:JIANGSU BOJI SPRAYING SYST HLDG CO LTD

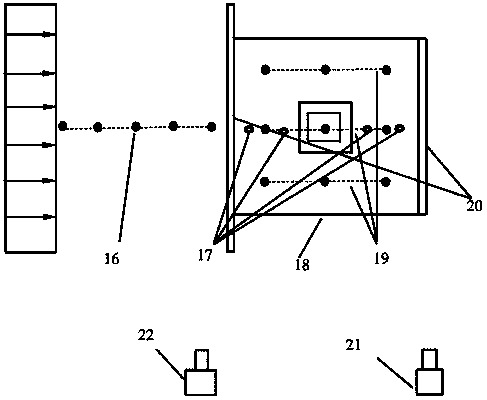

Device for removing fine particles by combining sound wave agglomeration and conventional dedusting

InactiveCN103736356AEfficient removalAuxillary pretreatmentElectrostatic separationInhalable particlesSound sources

The invention discloses a device for removing fine particles by combining sound wave agglomeration and conventional dedusting. The device mainly comprises a smoke pipeline, sound sources and a conventional deduster, wherein the acoustic agglomeration and the conventional dedusting technology are combined to agglomerate and remove fine inhalable particles in smoke; and the device has a specific structure that line sound sources and area sound sources are arranged around or adjacent to two faces of the smoke pipeline, the length of a sound source covering face along a smoke flowing direction is bound to meet the condition that the smoke moves for 2-5s in a sound field, and the tail of the smoke pipeline is provided with the conventional deduster. The smoke flows through the smoke pipeline provided with the sound sources, the fine inhalable particles in the smoke are in the sound field, various mechanisms of sound agglomeration promote small particles to be adsorbed to large particles or promote the small particles to be agglomerated into large particles, and then, the fine inhalable particles can be effectively removed through the conventional deduster.

Owner:SOUTHEAST UNIV

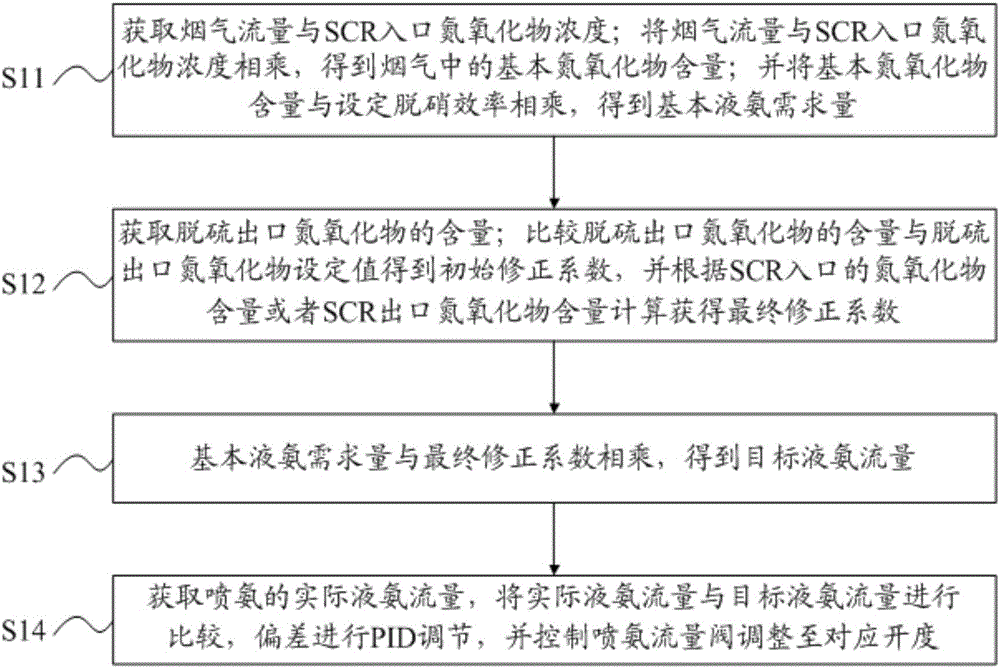

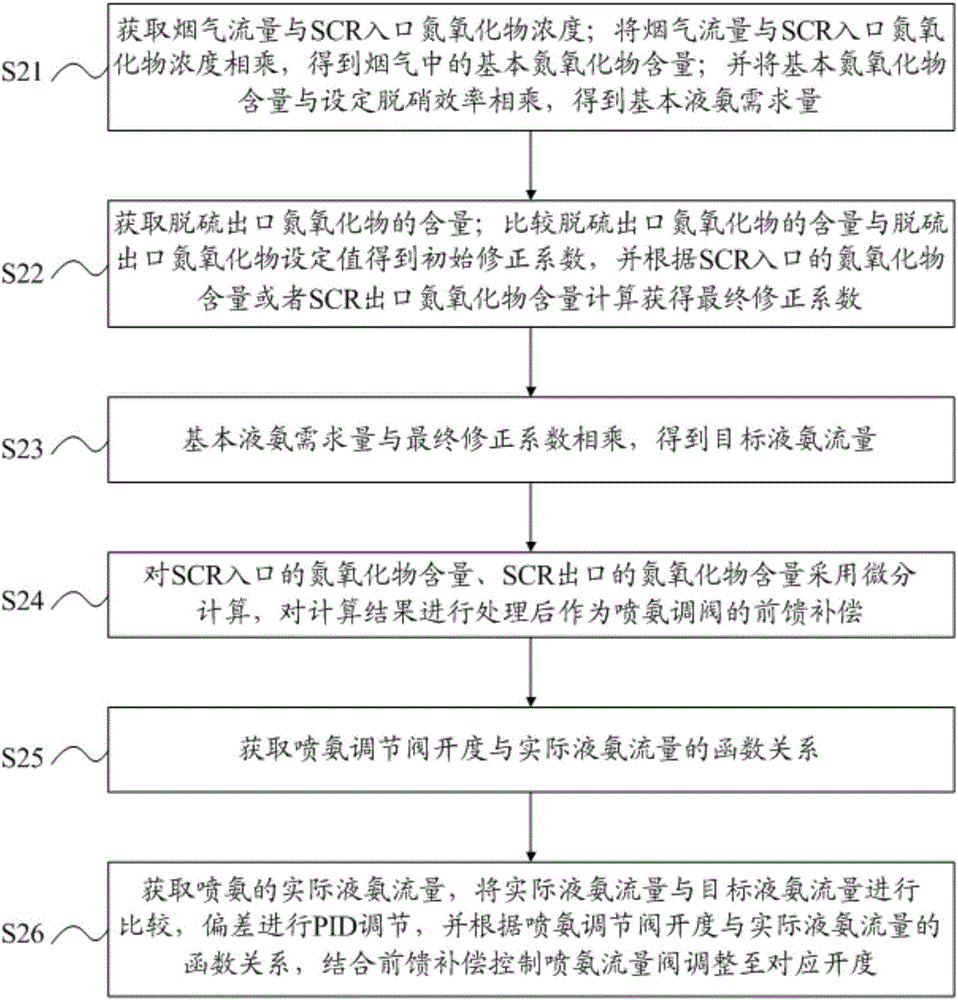

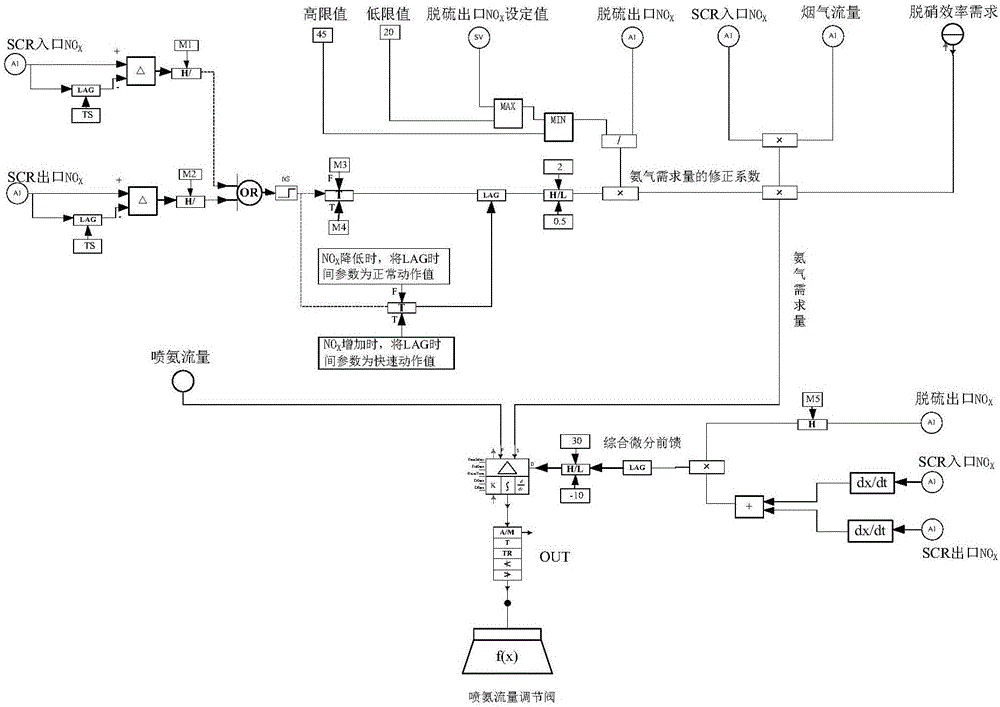

Automatic control method and system of thermal-power-unit SCR denitration ammonia spraying

ActiveCN106582284AImprove securityImprove economyGas treatmentDispersed particle separationAutomatic controlControl objective

The invention discloses an automatic control method of thermal-power-unit SCR denitration ammonia spraying. The automatic control method includes the steps that the smoke flow and SCR-inlet-nitric-oxide concentration are obtained; the smoke flow is multiplied by the SCR-inlet-nitric-oxide concentration, and the basic-nitric-oxide content in smoke is obtained; the basic-nitric-oxide content is multiplied by the set denitration efficiency, and the basic-liquid-ammonia demanded quantity is obtained; the denitration-outlet-nitric-oxide content is obtained, the denitration-outlet-nitric-oxide content is compared with a denitration-outlet-nitric-oxide set value, an initial correction factor is obtained, a final correction factor is obtained in cooperation with further correction, and the liquid-ammonia demanded quantity is corrected. As the denitration-outlet-nitric-oxide set value is introduced, the denitration-outlet-nitric-oxide concentration serves as a final control target, the control target is specific, physical inspection and operation intervention intensity of operational persons are reduced, and the operational persons are liberated out of busy working. The invention also discloses an automatic control system of thermal-power-unit SCR denitration ammonia spraying.

Owner:HENAN CHINA RESOURCES POWER GUCHENG

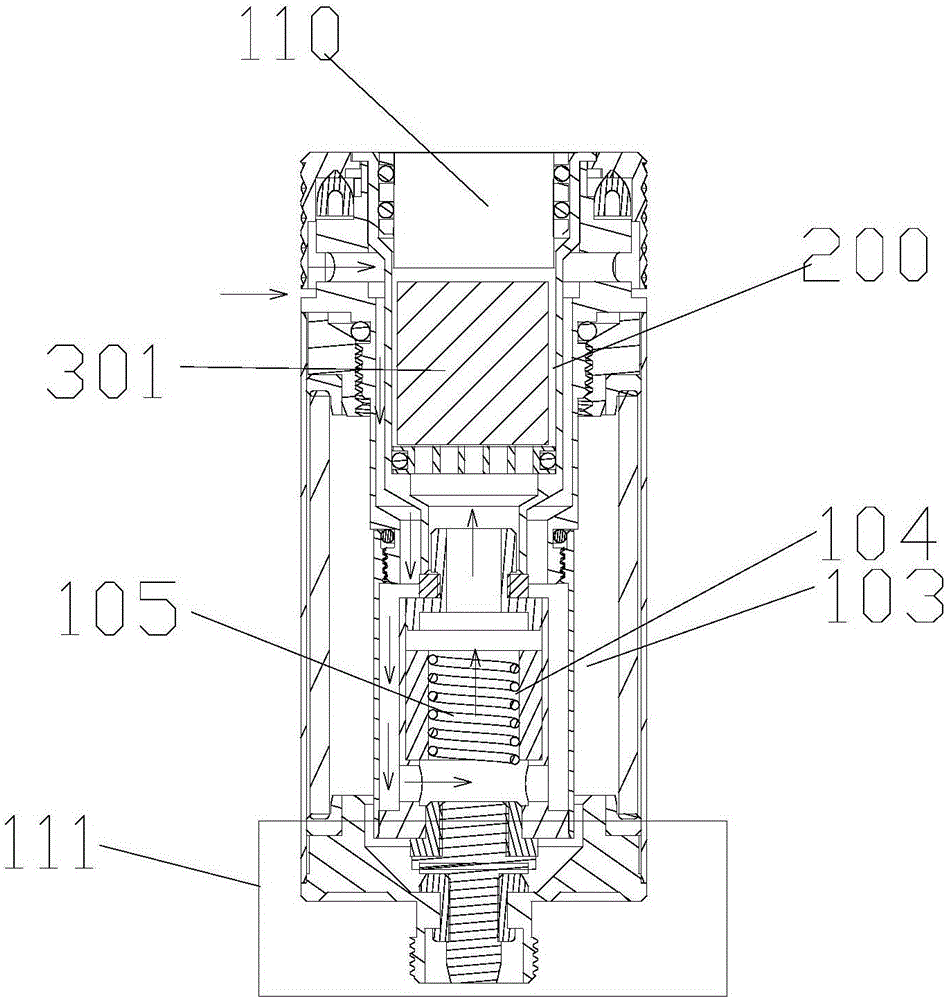

Atomizer kit

The invention provides an atomizer kit which comprises an atomizer body, wherein a receiving chamber, an oil storage chamber, an atomizing chamber and a heating assembly are arranged in the atomizer body; the atomizer body is coordinated with a suction nozzle assembly to form an atomizer; the receiving chamber is used for accommodating tobaccos and is used as a first smoke channel; the heating assembly is used for atomizing tobacco tar in the oil storage chamber to form smoke; the smoke formed by atomization in the atomizing chamber is used for heating the tobaccos in the receiving chamber to form mixed smoke, so that the mixed smoke flows to the suction nozzle assembly through the first smoke channel when a user smokes. The atomizer kit provided by the invention does not require an additional electric heating device for baking the tobaccos, can uniformly heat and fully steam out aroma of the tobaccos in the receiving chamber, and can generate a large amount of smoke, thereby solving the problem that many harmful substances are generated due to easy carbonization when the tobaccos are baked by the electric heating device in the prior art.

Owner:HUIZHOU KIMREE TECH

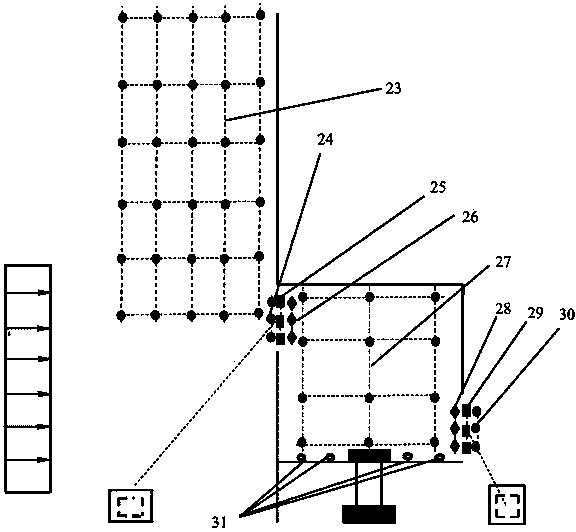

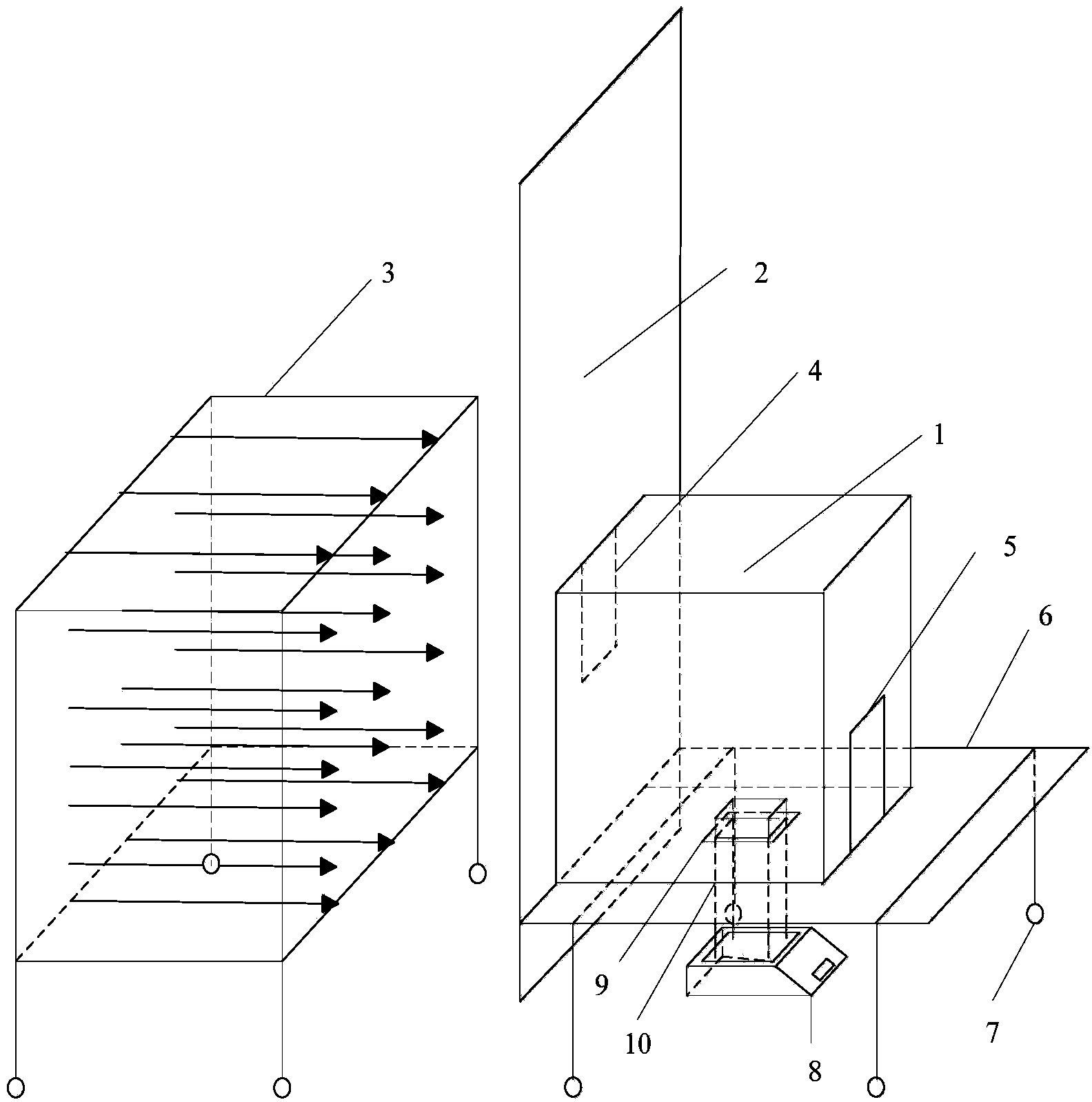

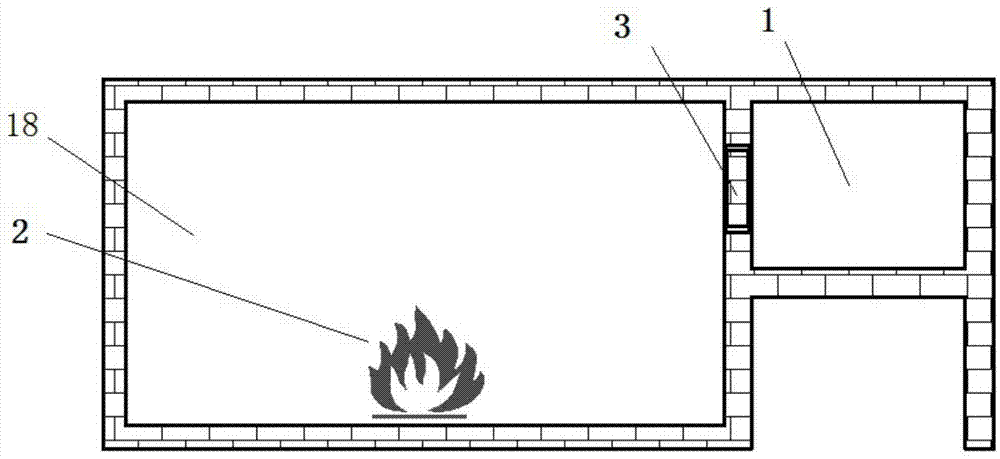

Chamber fire simulation experiment device under action of external wind

The invention provides a chamber fire simulation experiment device under the action of external wind. The device can simulate chamber fire combustion conditions in a laboratory under the action of the external wind and can be used for researching chamber fire development and windowsill overflow rules under the action of the external wind. The chamber fire simulation experiment device under the action of the external wind comprises an experiment table body, an outer vertical face, an external wind system and a matched measurement and control system. The device is designed according to a medium-size model proportion of 1:3 and is the first experimental device carrying out comprehensive and systematic study on the heat release rate, smoke flowing, temperature distribution, smoke compositions, the air supplement speed, thermal radiation flux, flame forms, sill overflowing and the like of a chamber fire under the action of the external wind. On the basis of previous experimental bases, the defects that a full-scale experiment is high in cost and a numerical simulation tool is not precise enough are overcome, repeatability of the experiment is guaranteed, and the device has great application value and important guiding significance in conducting laboratory scientific research and influences of actual external wind on the chamber fire.

Owner:UNIV OF SCI & TECH OF CHINA

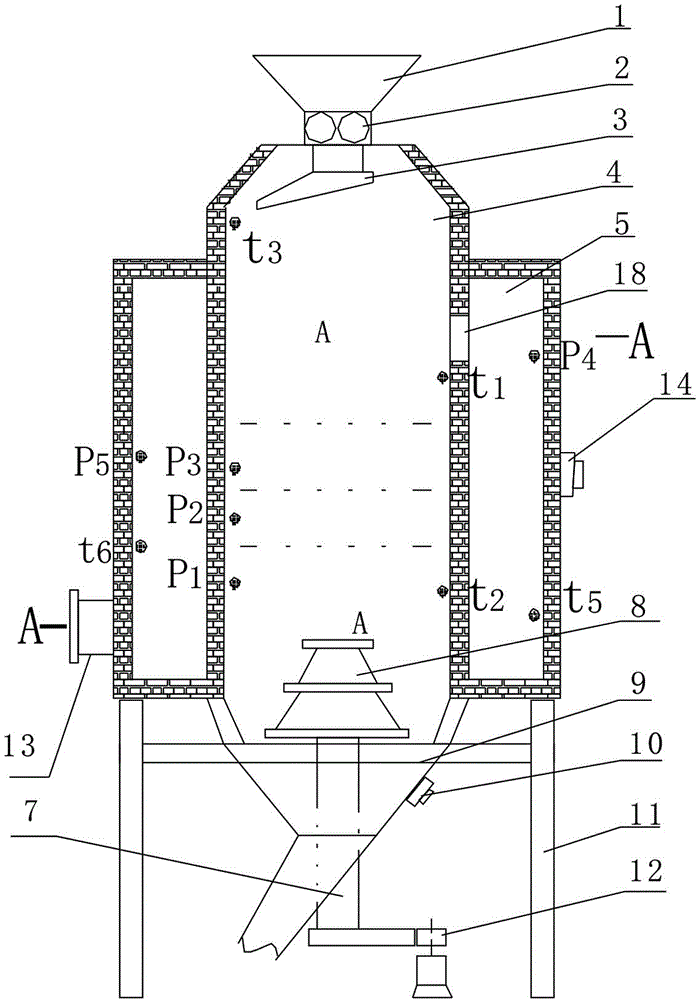

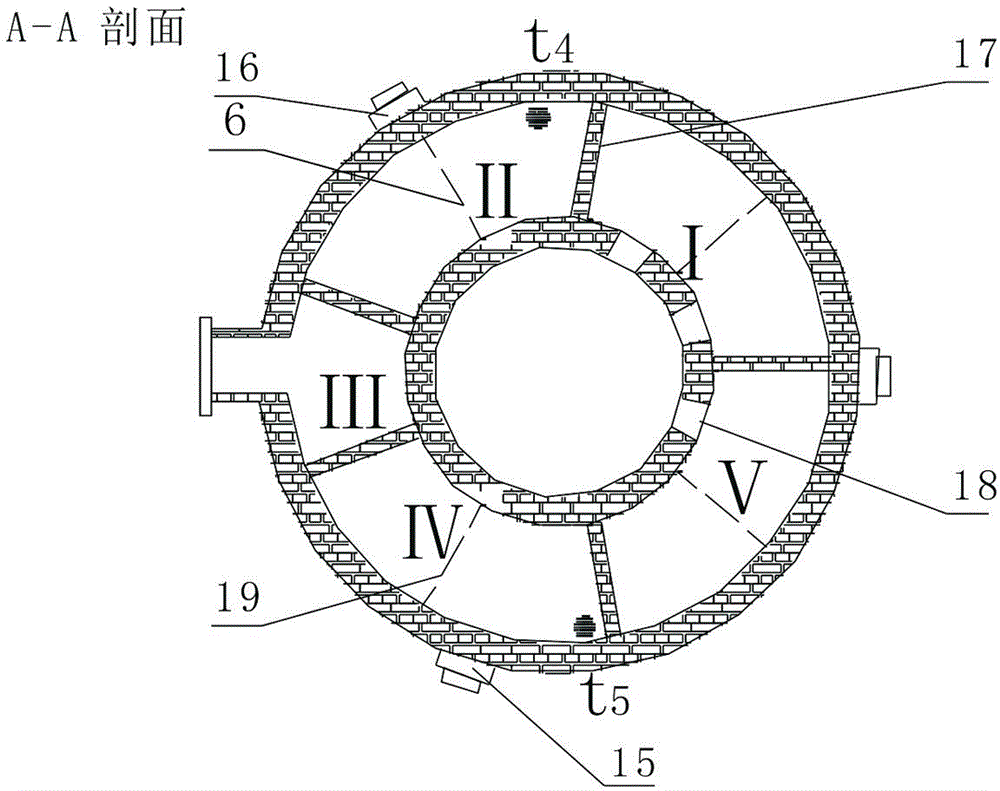

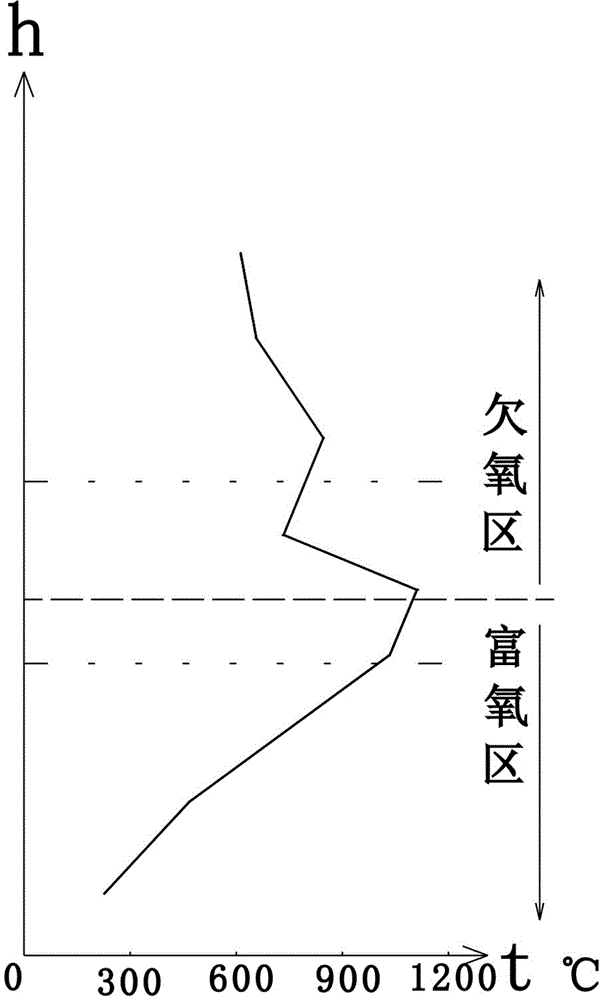

Household garbage pyrolysis combustion furnace and operation process thereof

The invention provides a household garbage pyrolysis combustion furnace which is a vertical sleeve furnace. A furnace body is composed of a cylindrical pyrolysis gasification hearth and a secondary combustion chamber surrounding the hearth. Five isolation walls are arranged in the secondary combustion chamber. The secondary combustion chamber is divided into a secondary combustion hearth I, a secondary combustion hearth II, a secondary combustion hearth III, a secondary combustion hearth IV and a secondary combustion hearth V. The secondary combustion hearth III corresponds to a smoke outlet. The secondary combustion hearth I, the secondary combustion hearth II, the secondary combustion hearth IV and the secondary combustion hearth V are each internally provided with a lattice wall. Each lattice wall is provided with a plurality of smoke flowing through holes with unequal diameters. The outer side in the secondary combustion chamber is further provided with three secondary wind supply systems. The inner side wall of the secondary combustion hearth I and the inner side wall of the secondary combustion hearth V are each provided with a pyrolysis smoke outlet. The smoke flowing state is a layer flow state and a turbulent flow state which are implemented many times to participate in and interfere with secondary wind appropriately, a stable platform is provided for energy conversion of smoke discharged by the pyrolysis gasification process stage and decomposition and purification of harmful substance, and thus the quality index of waste treatment of the discharged smoke is increased greatly.

Owner:YICHANG JIUTIAN ENVIRONMENTAL SCI & TECH

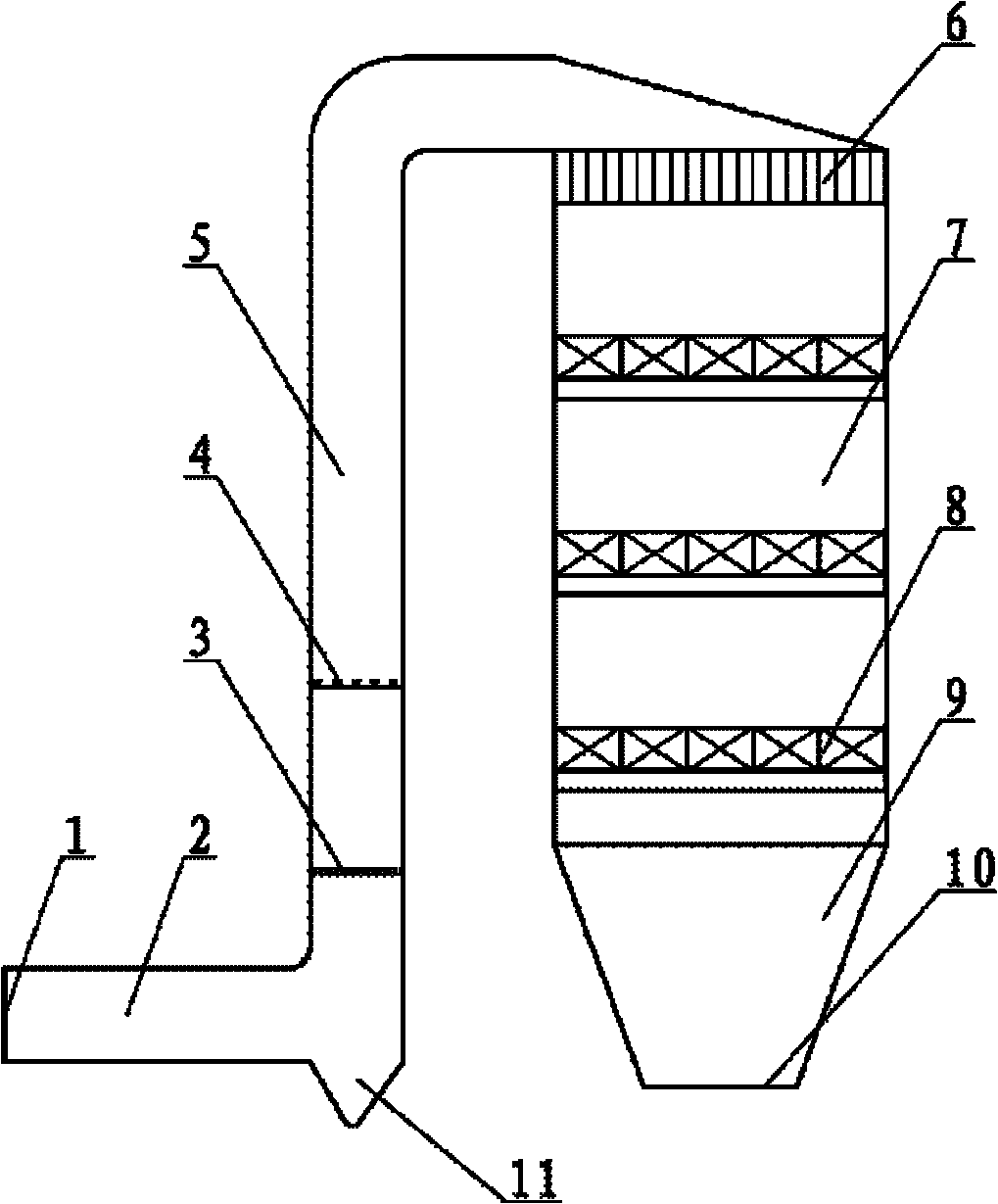

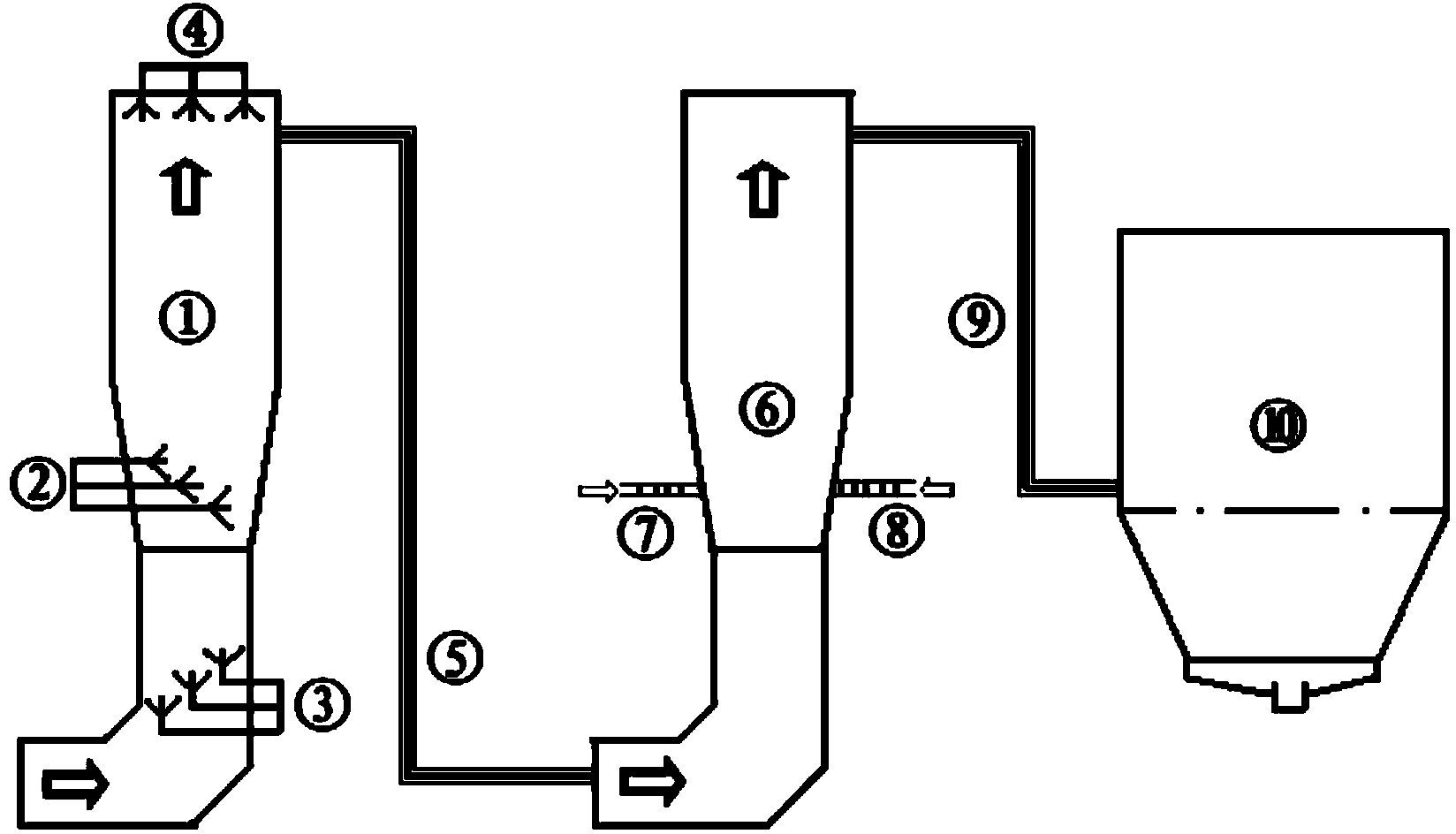

Smoke denitration device for preventing catalyst from being plugged by popcorn ash

InactiveCN102179156AAvoid destructionSolve scourDispersed particle filtrationLighting and heating apparatusGratingEngineering

The invention discloses a smoke denitration device for preventing a catalyst from being plugged by popcorn ash. The device comprises a smoke inlet (1), a horizontal connecting flue (2), a vertical connecting flue (5), a denitration reactor (7), an outlet flue (9) and a smoke outlet (10) which are communicated in sequence, wherein an ammonia spraying grating (4) is arranged in the vertical connecting flue (5); and a rectifying device (6) and a plurality of layers of catalysts (8) are arranged in the denitration reactor (7) along the smoke flowing direction. The device provided by the inventionis characterized in that a metal screen (3) is arranged on the upstream of the ammonia spraying grating (4) in the vertical connecting flue (5). The smoke denitration device for preventing the catalyst from being plugged by the popcorn ash provided by the invention can be used for efficiently intercepting the 'popcorn ash' with a large grain size in the coal-fired smoke, separating the 'popcorn ash' from the smoke, and solving the problem that the catalyst is brushed and plugged by the 'popcorn ash'.

Owner:SOUTHEAST UNIV

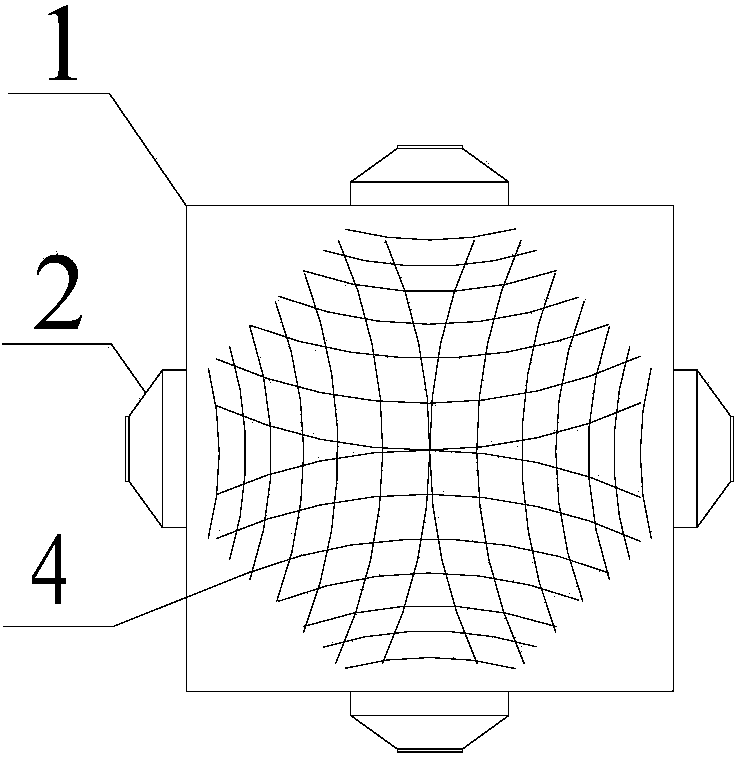

Range hood with smoke deflector

ActiveCN101514823BSpeed up the flowNo streamingDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

A range hood with a smoke deflector, comprises a body, a smoke collecting cover and the smoke deflector, wherein an air inlet is arranged on the smoke collecting cover, the smoke deflector faces to the air inlet and be in the predetermined distance from the smoke collecting cover, thus a oil smoke channel through which the oil smoke can pass is formed between the smoke deflector and the smoke collecting cover, the range hood is characterized in that the distance between the smoke deflector corresponding to the oil smoke channel and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet. Compared with the prior art, the invention has the advantages: the smoke deflector is used for forming the wall-attachment effect, the oil smoke flow uniformly without series flow, the distance between the smoke deflector and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet, so that the Venturieffect is formed conveniently, thus accelerating the sucking of smoke by the blower fan.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

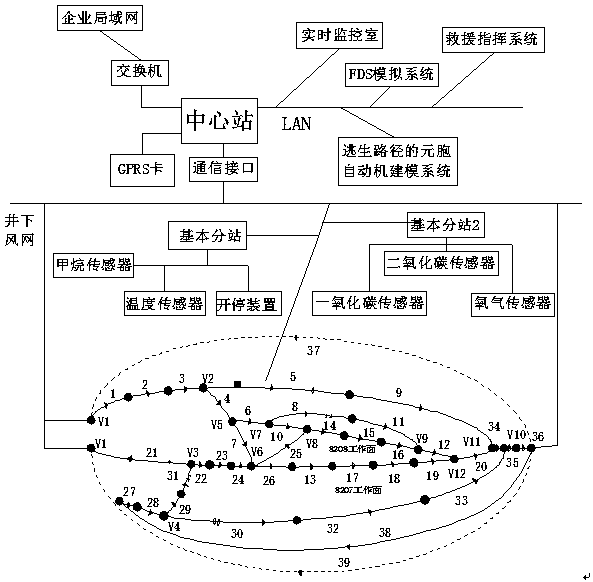

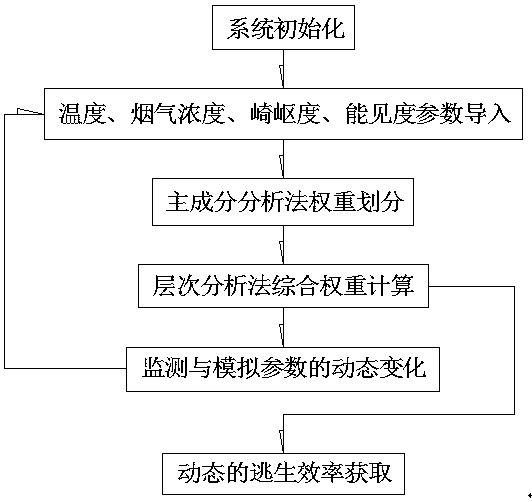

Mine fire escape route cellular automaton optimizing and guiding method

ActiveCN108154265AImprove escape efficiencySolve the problem of psychological panic and self-helpForecastingResourcesPhysical modelEngineering

The invention discloses a mine fire escape route cellular automaton optimizing and guiding method, and belongs to mine fire safe escape methods. An underground monitoring subsystem, a smoke plume migration simulation subsystem, an escape route selection subsystem and a rescue and escape command guiding subsystem are included, and the monitoring system is composed of a ground central station and various underground sensors and monitors temperature, gas and flue gas parameters in real time; the smoke plume migration simulation system simulates dynamic evolution rules of underground fire smoke through FDS software; the escape route selection subsystem applies a cellular automaton for building a mathematical physical model under the mine ventilation network structure actual condition, dynamically quantizes the complex roadway environment and the smoke pollution range, calculates the escape efficiency and determines the best escape route; the rescue and escape command guiding subsystem provides guidance for underground escape persons on the basis of the escape route calculation result, and the best escape route is fed back to underground workers by means of an upper computer and an underground voice alarm system, the escape efficiency is comprehensively improved, and casualties are reduced to the maximum extent.

Owner:CHINA UNIV OF MINING & TECH

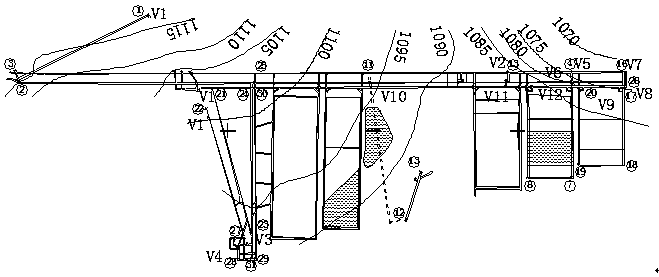

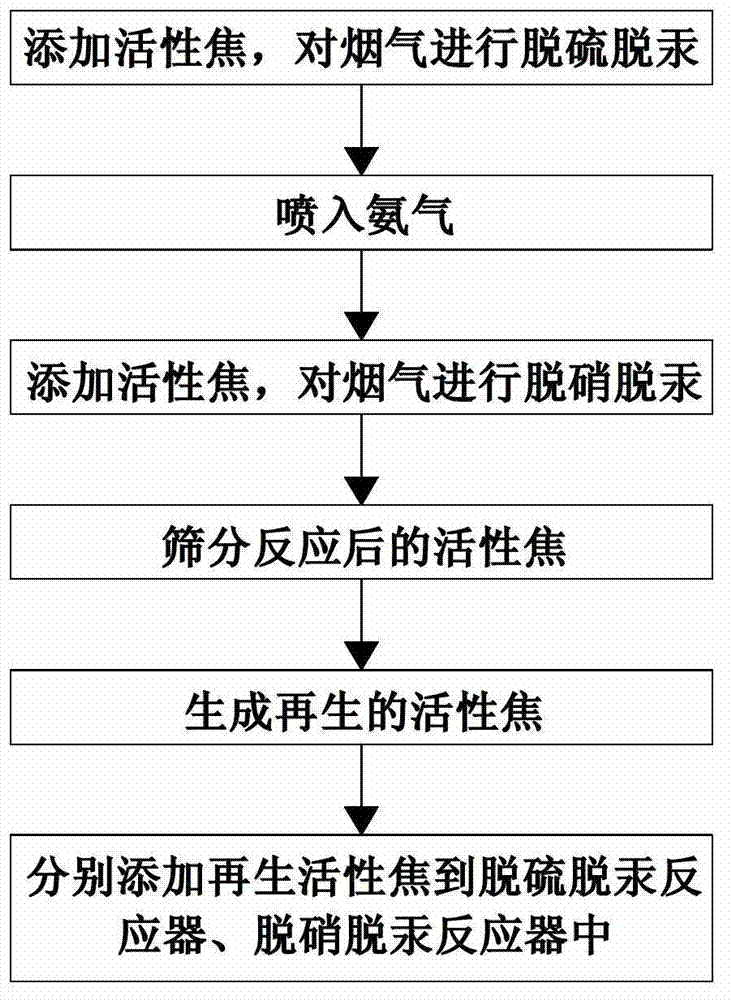

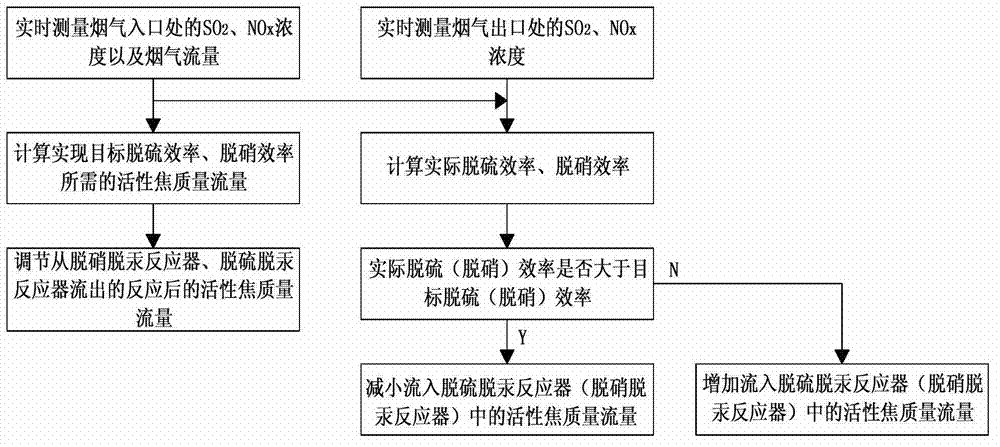

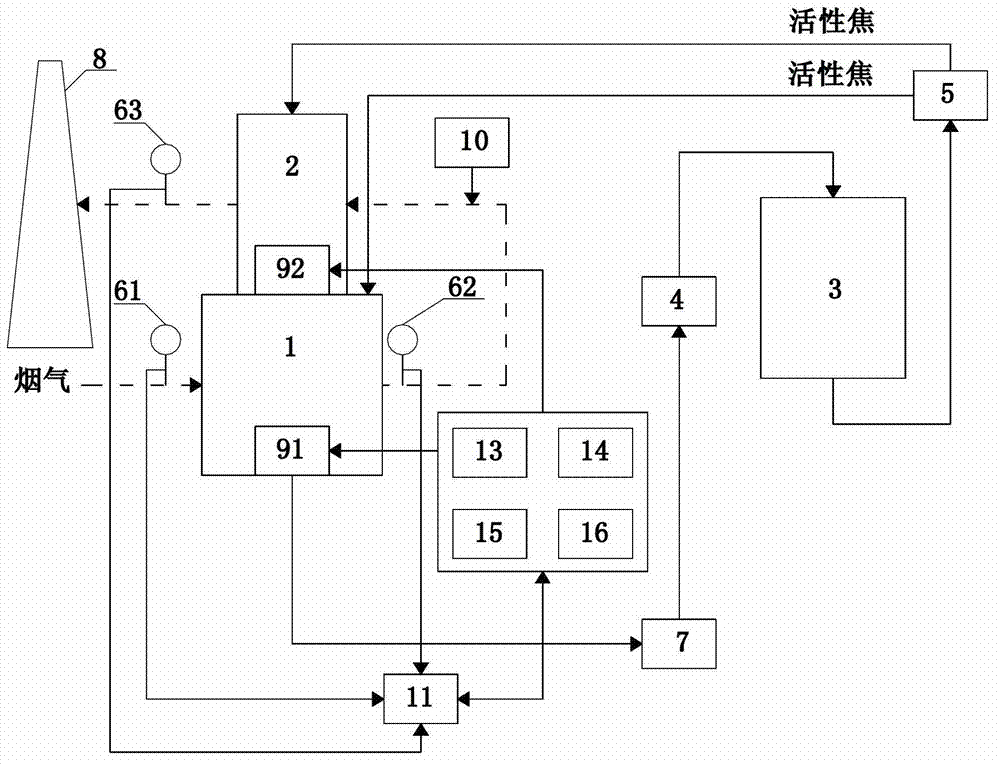

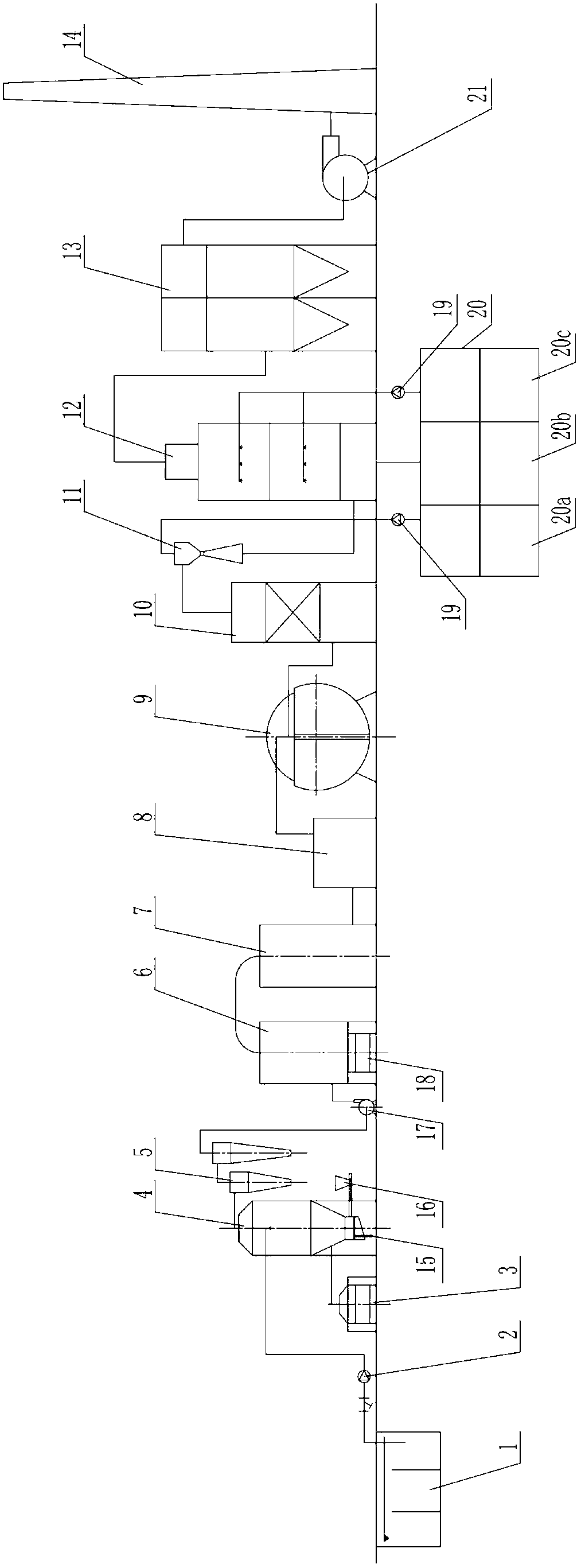

Method and system for jointly desulfuration, denitration and demercuration by activated coke of moving bed

ActiveCN102728217ARealize automatic controlAdapt to changes in pollutant concentration in real timeDispersed particle separationCokeProcess engineering

The invention dislocates a method and a system for jointly desulfuration denitration and demercuration by activated coke of a moving bed. The method comprises the following steps of: S1, adding activated coke to a desulfuration demercuration reactor and a denitration demercuration reactor respectively, carrying out desulfuration, denitration and demercuration on smoke, and respectively measuring the SO2 and NOx concentrations and the smoke flow at a smoke inlet; S2, calculating the mass flow of the activated coke required for realizing the target desulfuration and denitration efficiency, and adjusting the real-time mass flow of the flowed and reacted activated coke; S3, sieving out the dust attached by the reacted activated coke and the carbon power generated by self-abrasion; S4, charging the sieved activated coke into an activated coke regenerating reactor to be reacted to obtain regenerated activated coke; and S5, adding the regenerated activated coke into the desulfuration demercuration reactor and the denitration demercuration reactor respectively, and carrying out the circulation of desulfuration, denitration and demercuration. The method can be used for timely adjusting the inflow and outflow mass flow of the activated coke of the desulfuration demercuration reactor and the denitration demercuration reactor, and removing mercury in the smoke.

Owner:CHINA HUADIAN ENG +1

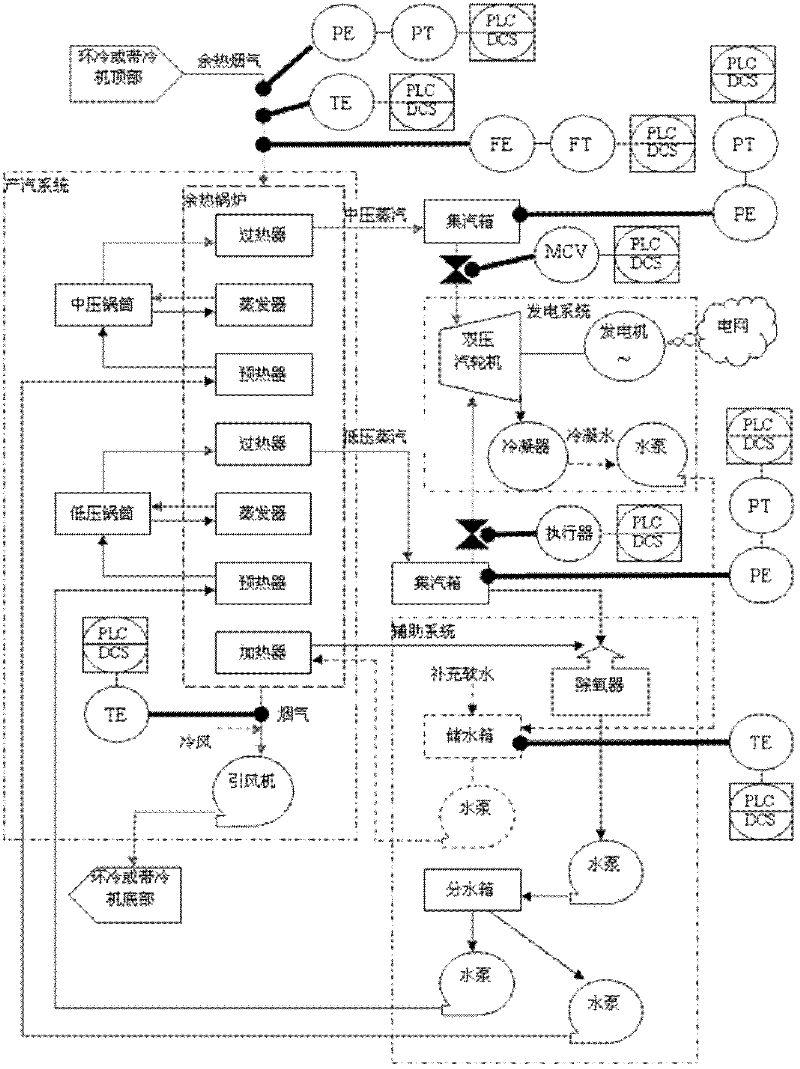

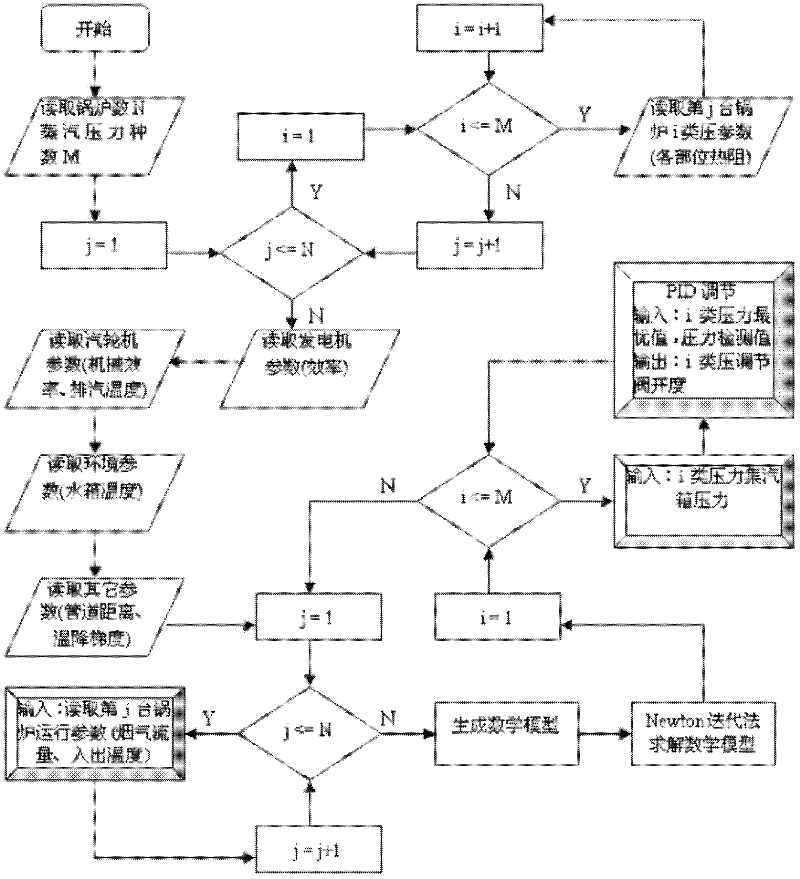

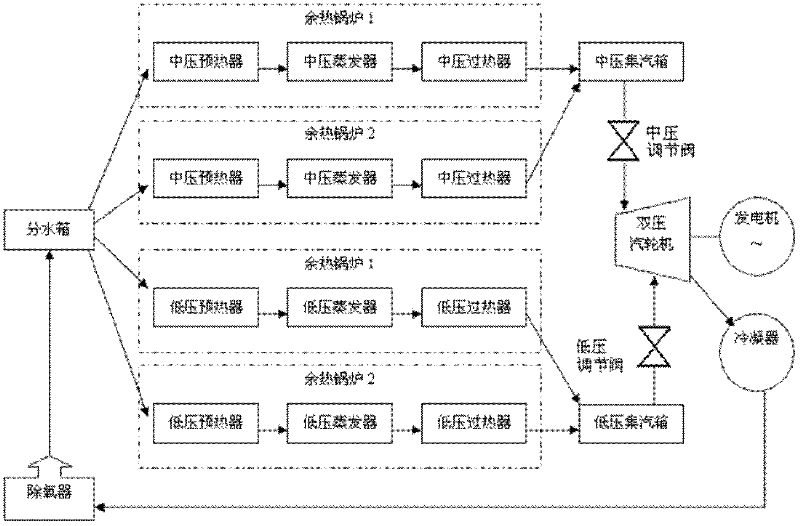

Optimizing control method for sintering waste heat power generation system

ActiveCN102385356AEasy to controlIncreasing energy efficiencySteam engine plantsOptimal controlEngineering

The invention relates to an optimizing control method for a sintering waste heat power generation system; the optimizing control method is characterized in that when parameters of a waste heat boiler and a steam turbine and the smoke flow and the inlet / outlet temperature of the waste heat boiler are constant, the power generation capacity of the steam turbine is only related to the pressure of middle pressure steam and low pressure steam which are output by the waste heat boiler, and the power generation capacity of the steam turbine is maximized by controlling the pressure of middle pressure steam and low pressure steam which are output by the waste heat boiler. Compared with the prior art, the optimizing control method has the beneficial effects: (1). the optimum control on a waste heat recycling system can be realized; and when external conditions change, the real-time automatic tracking is carried out and the optimal pressure value is adjusted; (2). the optimizing control method not only can be used for carrying out optimum control on the sintering waste heat power generation system put into operation, but also can be used for checking the design of the sintering waste heat power generation system and optimizing the design, thereby obtaining parameters such as the optimal outlet temperature of a preheater of the waste heat boiler, the optimal temperature of an evaporator, the optimal outlet temperature of a superheater, the optimal flow of the middle pressure steam and the low pressure steam, and the like and selecting the appropriate steam turbine.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

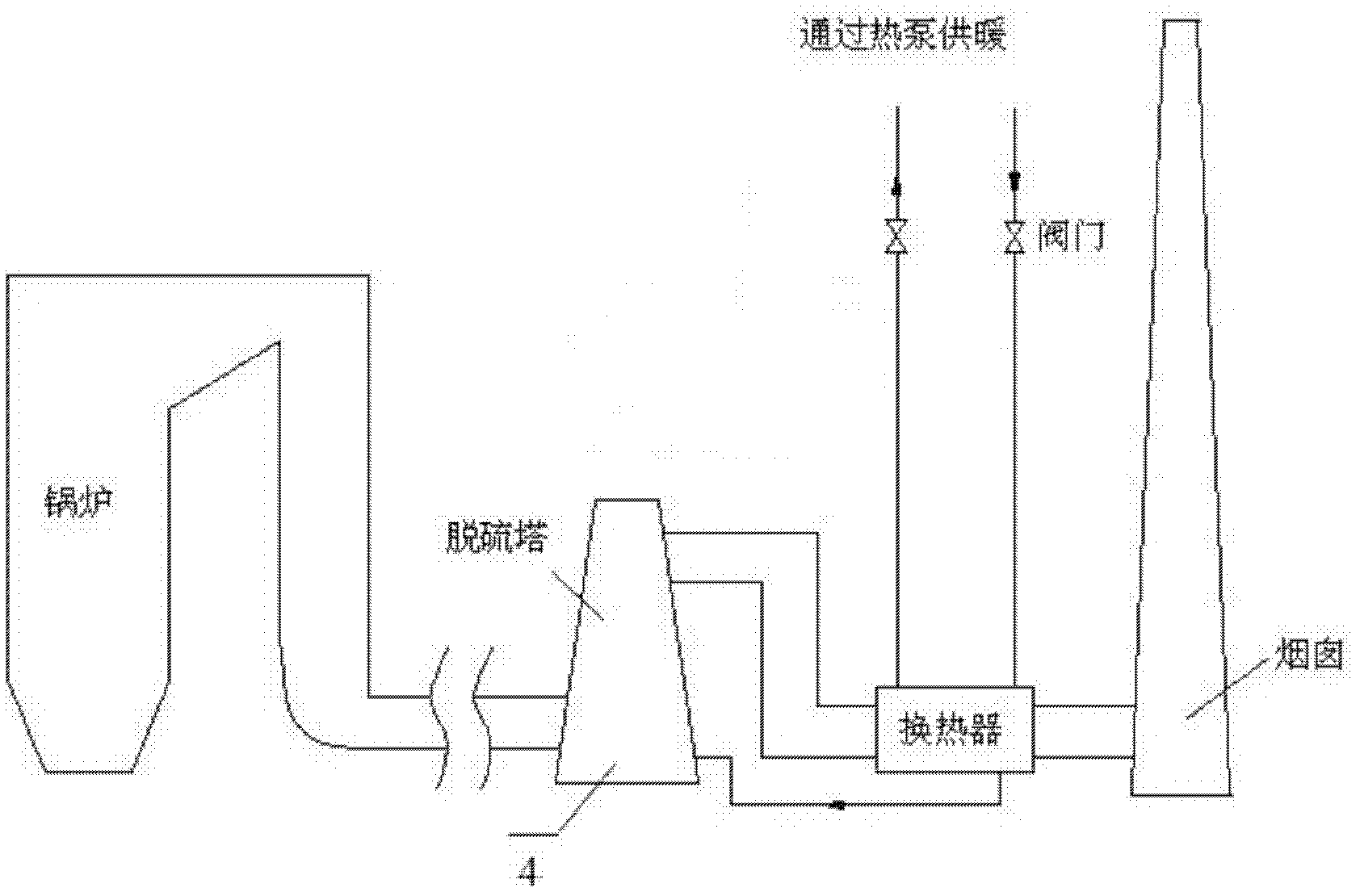

Smoke water condensing and waste heat recovering device

ActiveCN102519068AReduce volumeLow costHeat exchange apparatusHot-water central heatingWater vaporProcess engineering

A smoke water condensing and waste heat recovering device is provided. A propene polymer (PP) (or polytetrafluoroethylene (PTFE)) heat exchanger is arranged at the top of a desulfurizer or in a smoke duct of the desulfurizer to aim at solving the problems that smoke temperature at a desulfuration outlet is generally from 50 DEG C to 60 DEG C, and low temperature corrosion exists. After smoke flows by the heat exchanger to be cooled, water steam in the smoke condenses, and is recovered and sent back to a desulfuration system; heat released by the smoke and vaporized latent heat released by the steam are used by a heat pump to continuously increase temperature and supply heating. The smoke water condensing and waste heat recovering device aims at solving the problem of low temperature corrosion of the tail smoke of desulfuration, adopts the heat exchanger made of corrosion-resistant materials, recovers waste heat and smoke condensate water, and has a positive effect for energy saving and consumption reduction of a power plant.

Owner:XI AN JIAOTONG UNIV

Smoke denitration method and device

ActiveCN104258701AReduce consumptionThorough responseDispersed particle separationNitrogen oxideOrganic chemistry

The invention provides a smoke denitration method. The smoke denitration method comprises the following steps: carrying out oxidation reaction on to-be-denitrated smoke and a denitration oxidant; carrying out absorption reaction on the smoke subjected to the oxidation reaction when the smoke flowing through an absorbent and finishing the denitration of the smoke. According to the method provided by the invention, oxidation reaction and absorption reaction are sequentially carried out on the to-be-denitrated smoke; in the process of oxidation reaction, NO, a main component difficult to dissolve in water in NOx in the smoke is converted to high-valence nitrogen oxides easy to dissolve in water, such as NO2; then in the process of absorption reaction, the high-valence nitrogen oxides, such as NO2 react with water and an alkaline absorbent to finish the denitration process. The method provided by the invention ensures that oxidation reaction and absorption reaction are fully carried out, the denitration efficiency is improved, and the consumption of materials, such as a the denitration oxidant and the absorbent is reduced.

Owner:FUJIAN LONGKING +1

System and method for incineration treatment of saliferous waste residue, saliferous waste water and stink waste gas

The invention discloses a system and a method for incineration treatment of saliferous waste residue, saliferous waste water and stink waste gas and relates to the technical field of unharmful resourceful treatment of industrial three wastes. The system and the method aim at resolving the problem that the existing three water treatment method is large in device investment, high in treatment cost, salt cannot be separated to obtain purified salt, and no device can be used for treating the three wastes simultaneously. The system for treatment comprises a pretreating chamber, a incineration device, a waste heat recycling device and a tail gas purifying device which are sequentially connected. The upper portion of the pretreating chamber is connected with a waste liquid injection port, the lower portion of the pretreating chamber is connected with a waste slag input port, and a salt discharge port is arranged at the bottom end of the pretreating chamber. The incineration device comprises a main combustion chamber and a post-combustion chamber which are sequentially connected in the smoke flowing direction. The method for treatment includes a. pretreating: delivering waste liquid, high temperature smoke and waste residue into the pretreating chamber to be combusted; b. high temperature incineration: placing the gasified waste liquid and the stink waste gas into the incineration device to be incinerated; c. waste heat recycling; and d. tail gas purification. The system and the method are especially suitable for treatment of industrial three wastes.

Owner:季栋梁

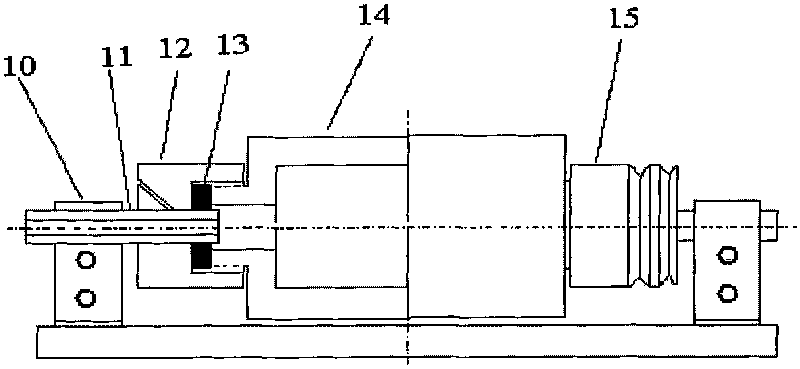

Device for simulating absorption of mainstream smoke by human oral cavity in smoking process

ActiveCN101718645AQuality reflectionHighly integratedPreparing sample for investigationHuman bodyEngineering

The invention discloses a device for simulating the absorption of mainstream smoke by human oral cavity in the smoking process, which is characterized by comprising a cigarette clamping and holding device, a rotating roller type device for simulating the absorption of inhaled smoke by human oral cavity, a single-channel smoke absorbing machine, a rotating roller type device for simulating the absorption of exhaled smoke by human oral cavity, a stepless speed-regulating electric motor, a power transmitting mechanism and a smoke outlet. The device for simulating the absorption of mainstream smoke by human oral cavity in the smoking process is arranged in an integral constant-temperature cover and can be used for more accurately simulating the cigarette smoking by human body and the biophysical and biochemical mainstream smoke flowing process in the human oral cavity so as to be convenient for studying more deeply and accurately the mainstream smoke flowing process in the human body.

Owner:CHINA TOBACCO HUNAN INDAL CORP

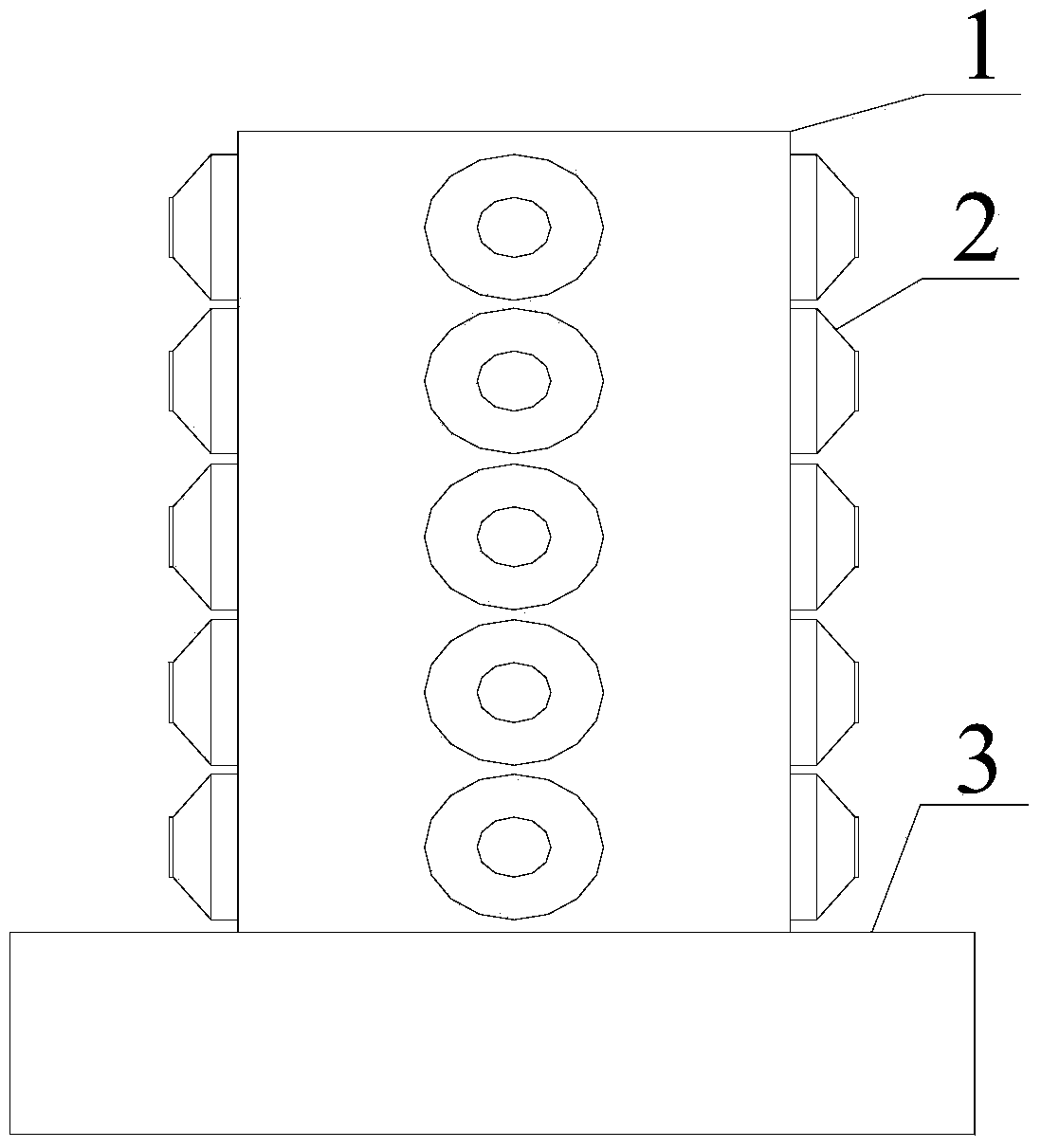

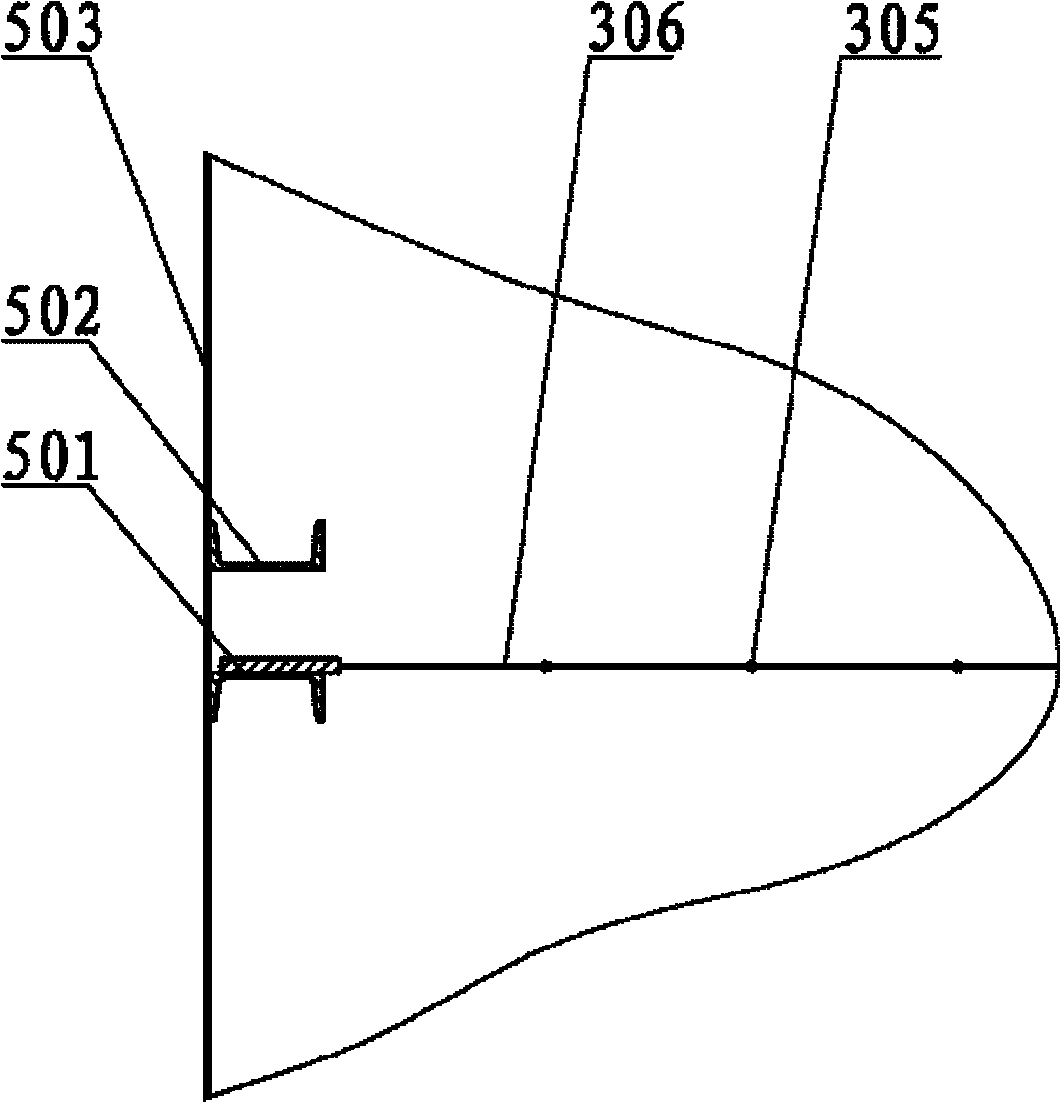

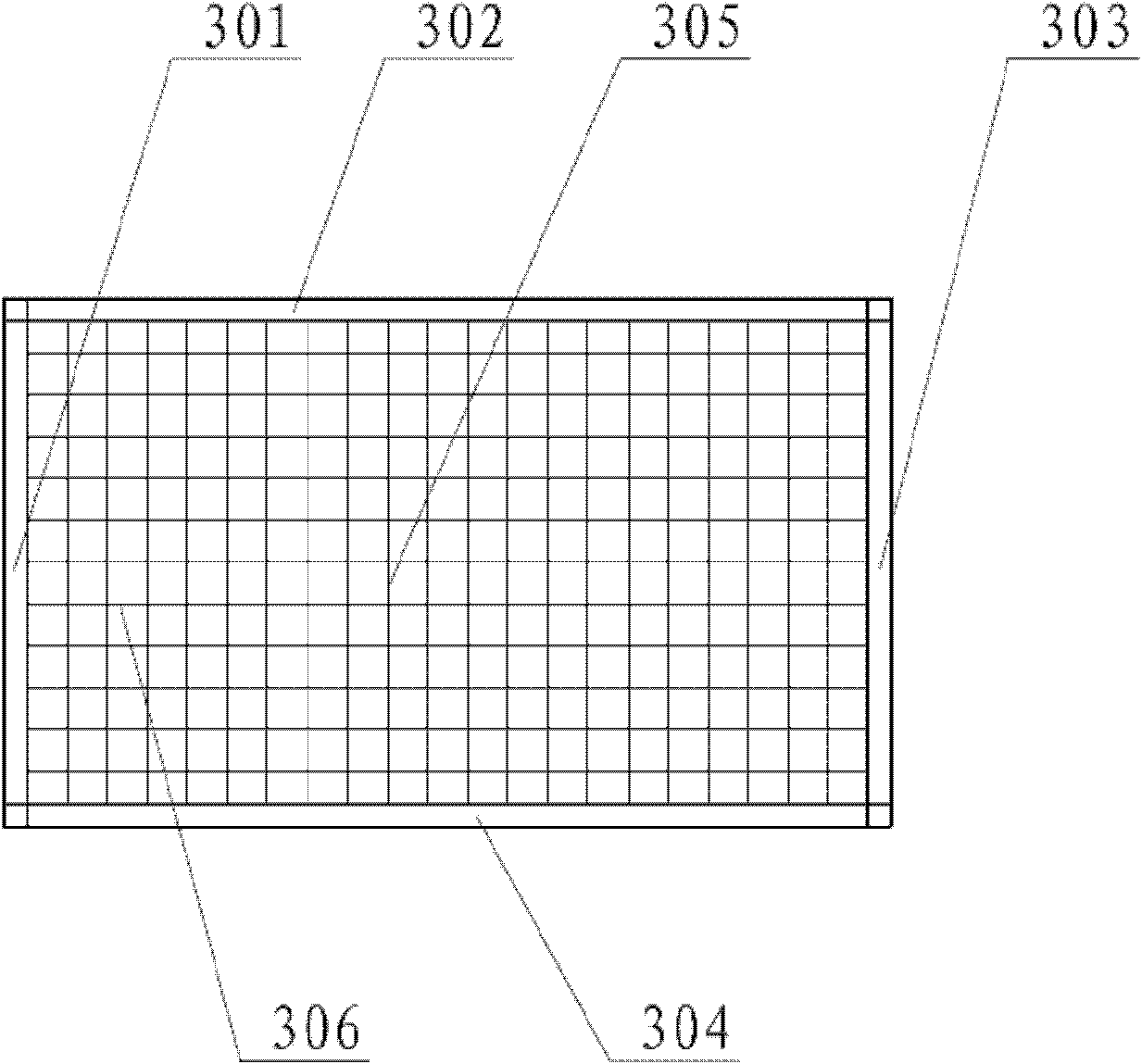

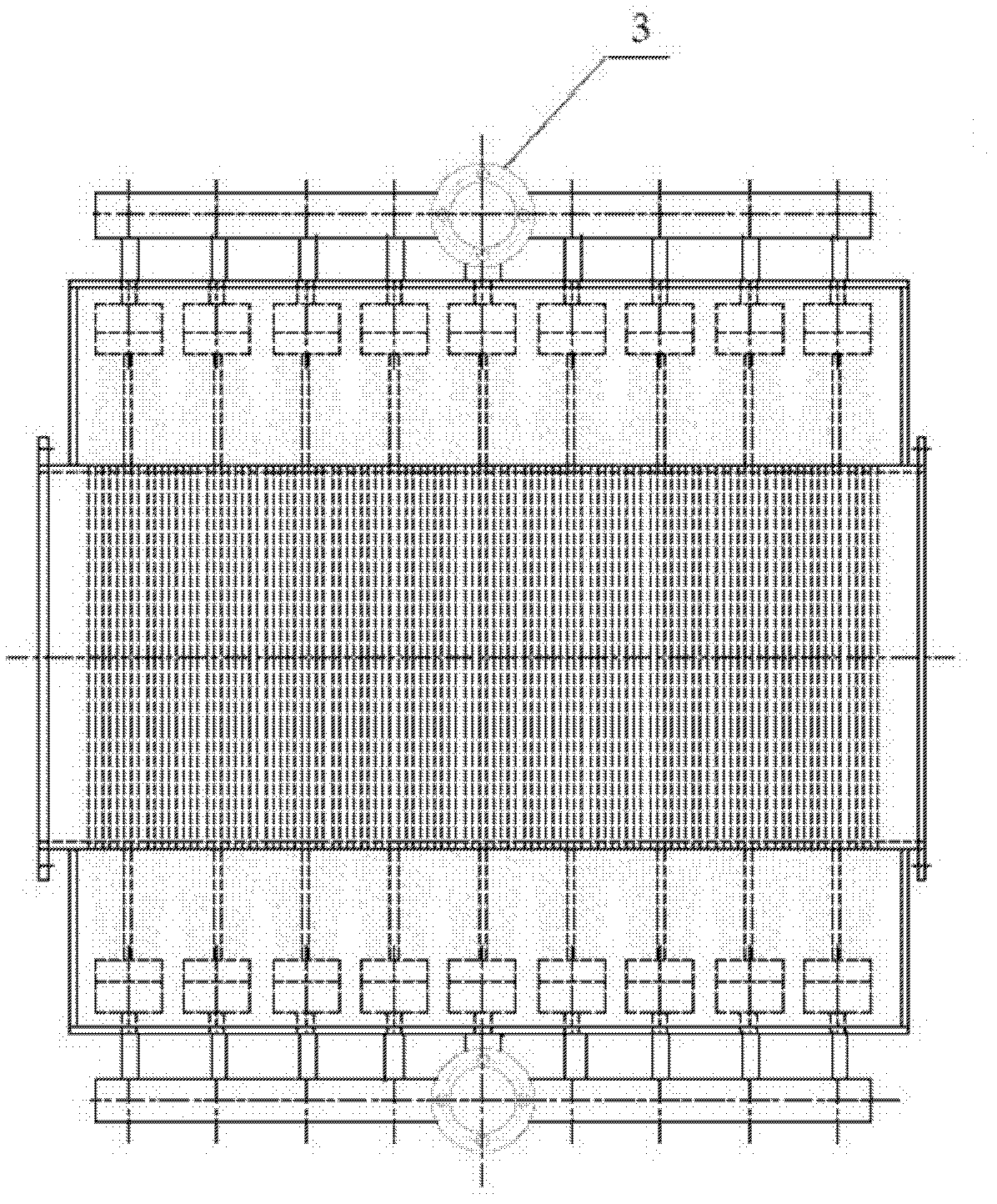

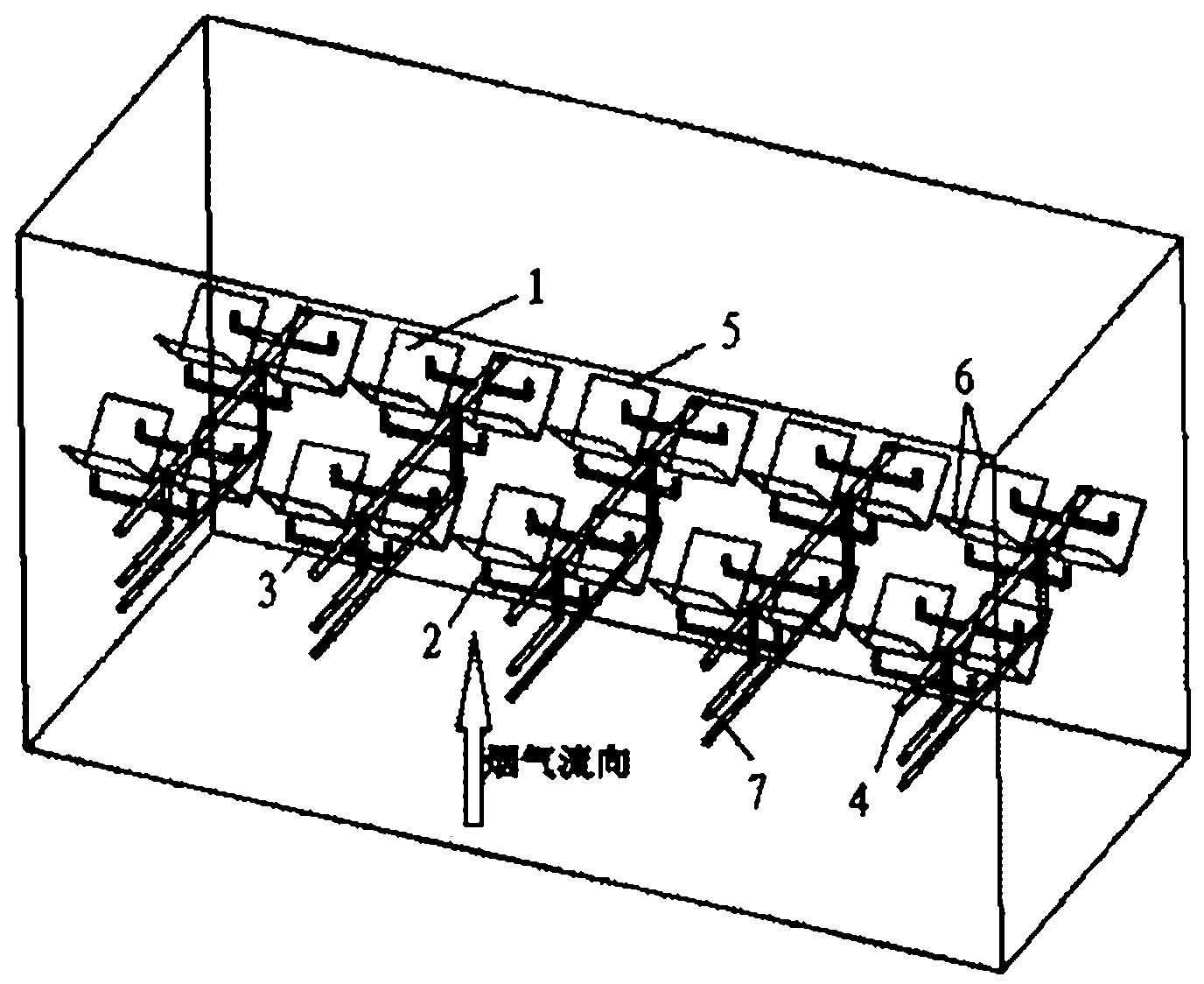

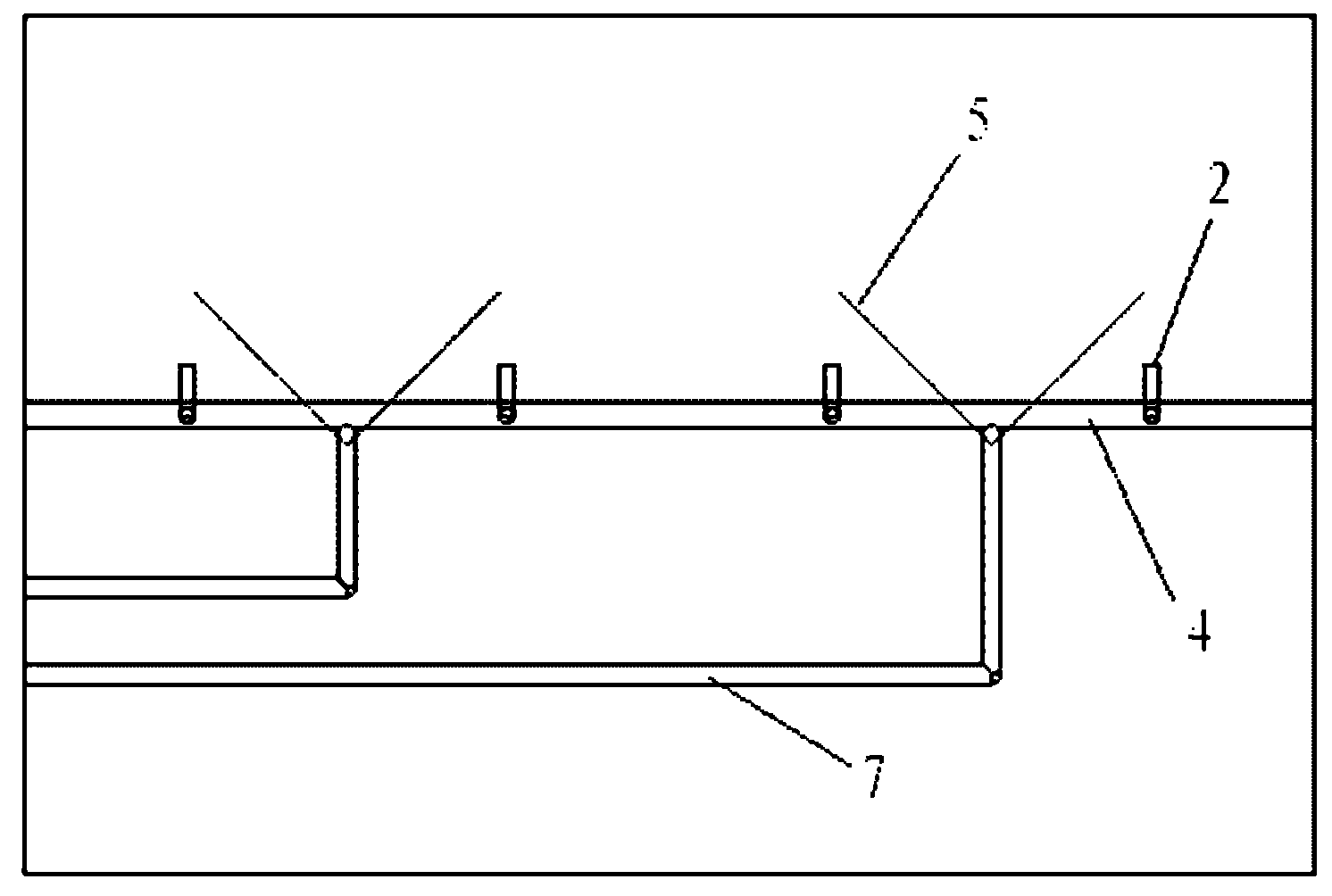

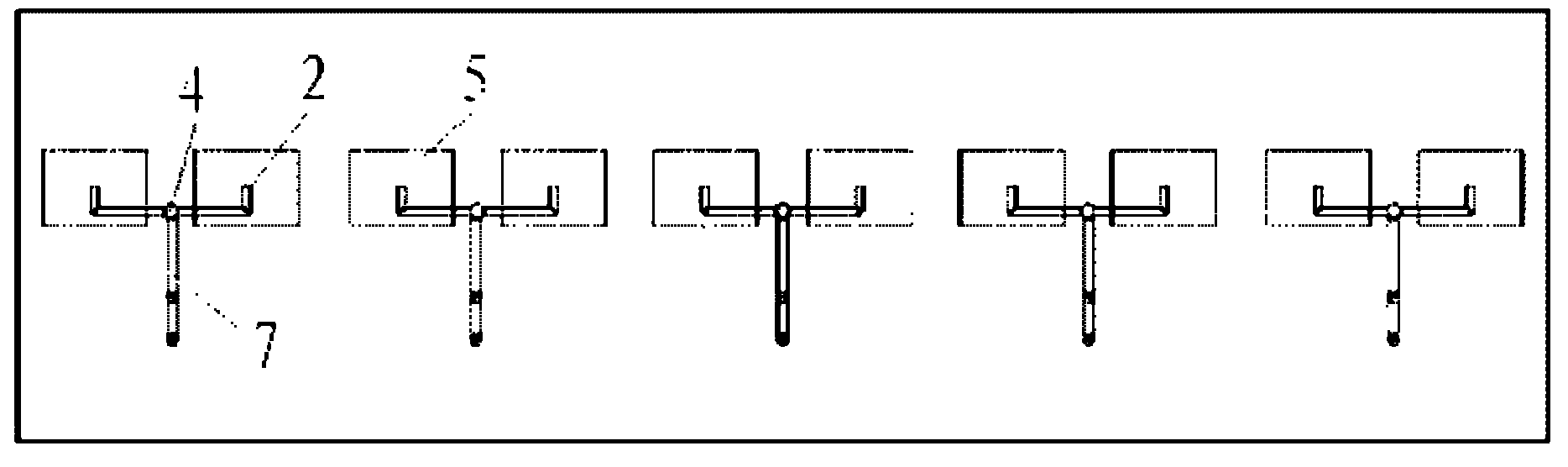

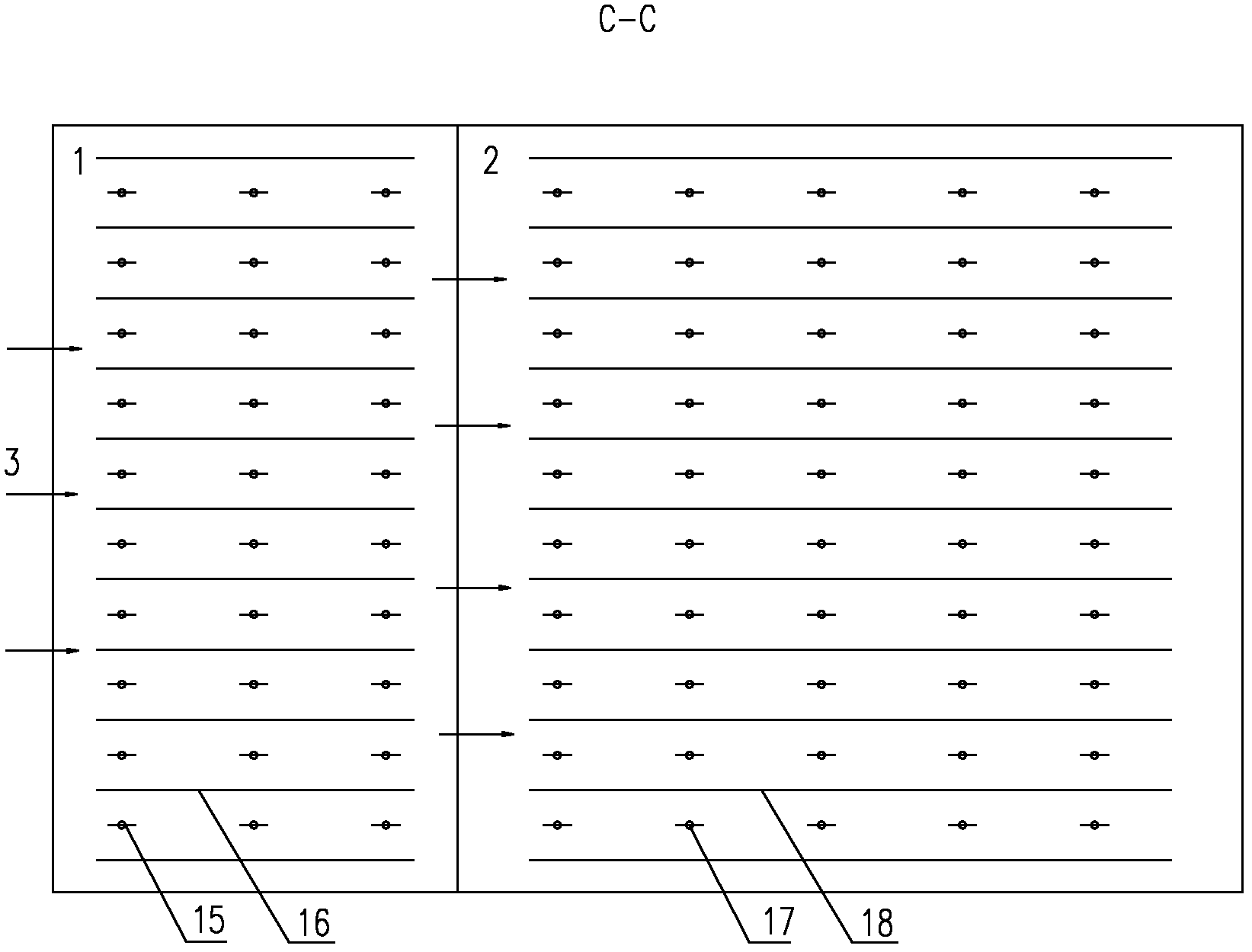

V-type ammonia spraying and mixing system for SCR (Selective Catalytic Reduction) smoke denitrification device

ActiveCN102626585ASimple structurePromotes even distributionDispersed particle separationEngineeringStatic mixer

The invention discloses a V-type ammonia spraying and mixing system for an SCR (Selective Catalytic Reduction) smoke denitrification device. The V-type ammonia spraying and mixing system comprises static mixers, ammonia spraying branch pipes with nozzles at end parts and ammonia spraying header pipes communicated with the ammonia spraying branch pipes; each static mixer is formed by arraying a plurality of mixing units, each mixing unit is composed of two blades distributed in a V shape, and an included angle between each blade and a smoke flow is 30-60 degrees; and a nozzle opposite to each blade is arranged below the blade, and a distance between each nozzle and each blade is 0.2-1 time that of the height of the corresponding mixing unit. The V-type ammonia spraying and mixing system disclosed by the invention has the advantages of fewer nozzles and simplified ammonia spraying device; symmetric reverse vortexes can be formed with strong vortex mixing, so that a mixing process is strengthened to make ammonia distribute uniformly, and meanwhile, a distance required for achieving the goal of homogenizing the ammonia is shortened, so that the denitrification efficiency is enhanced; and the caused pressure drop is lower and the energy utilization efficiency is high.

Owner:ZHEJIANG UNIV

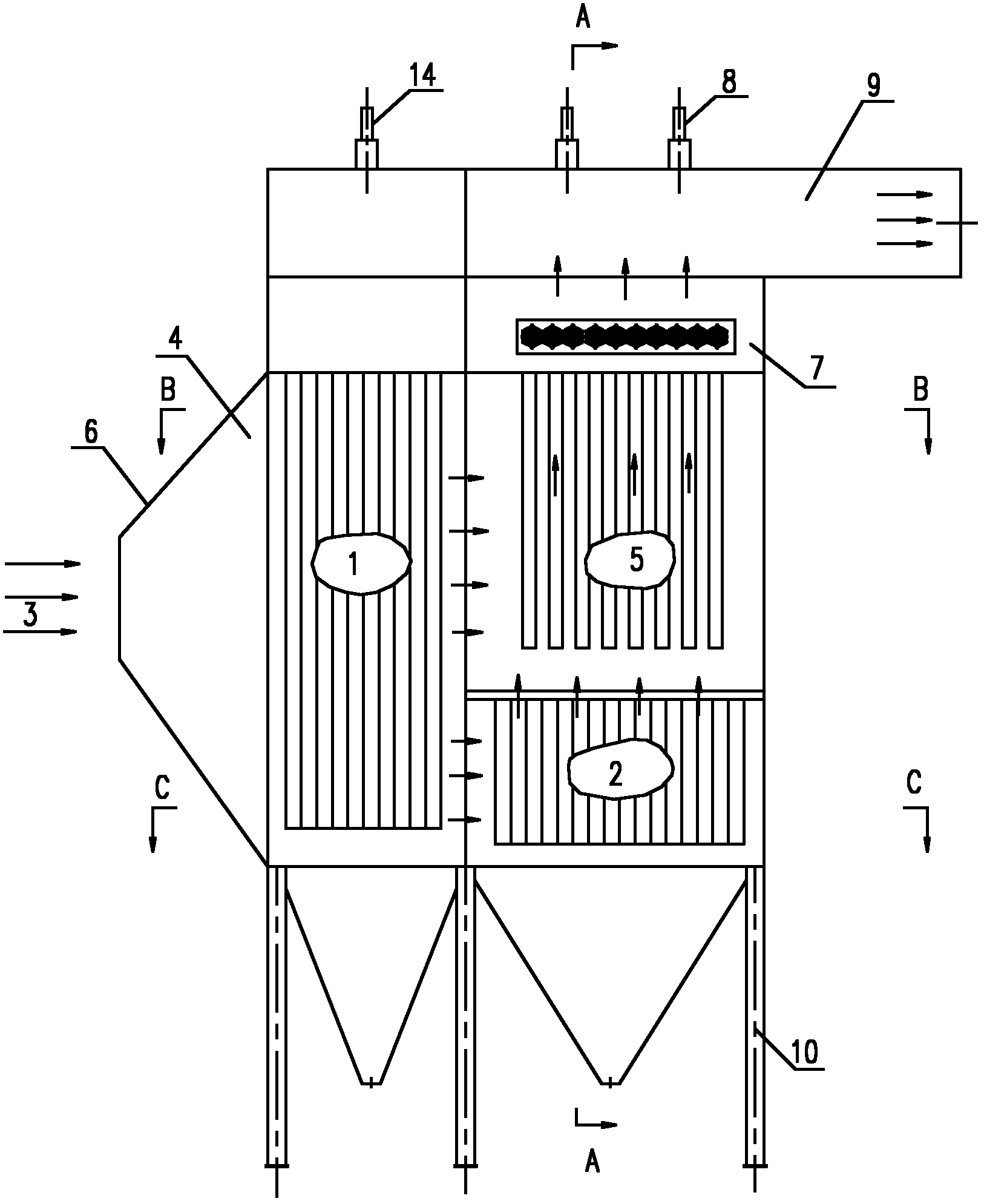

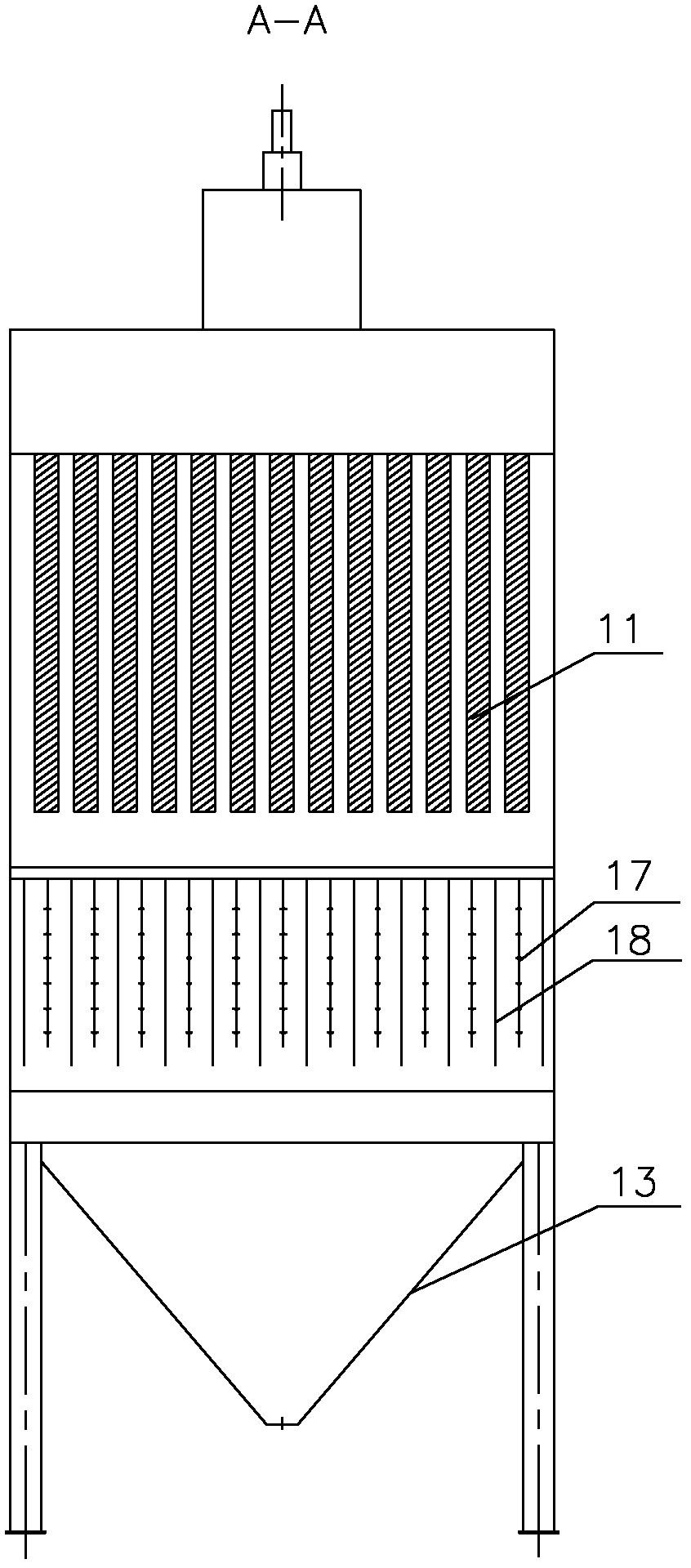

Electric-bag composite dust collector

ActiveCN102327724AIncrease the filtration speedReduce processingCombination devicesEngineeringDust emission

The invention discloses an electric-bag composite dust collector. The electric-bag composite dust collector comprises a composite dust collecting region in a housing, wherein the composite dust collecting region comprises an electric bag dust collecting region and a first electric field dust collecting region; the electric bag dust collecting region comprises a filter bag region and a second electric field dust collecting region; a filter bag dust collecting device is arranged in the filter bag region, and located on the upper end of the electric bag dust collecting region; an electric field dust collecting device is arranged in the second electric field dust collecting region, which is communicated with the filter bag region and located on the lower end of the electric bag dust collecting region; and an electric field dust collecting device is arranged in the first electric field dust collecting region, which is communicated with the electric bag dust collecting region and located onthe front end of the electric bag dust collecting region. In the electric-bag composite dust collector provided by the invention, the second electric field dust collecting region is arranged on the lower end of the electric bag dust collecting region, so that the dust can be recharged when a portion of smoke flows from the first electric field dust collecting region to the second electric field dust collecting region, thereby enhancing the dust charging strength. Additionally, the second electric field dust collecting region can effectively collect dust dropping from the filter bag region when the dust is removed, thereby reducing secondary dust emission, prolonging dust removal period, prolonging the service life of the filter bag, reducing the whole dust removing resistance, and improving the overall performance of the dust collector.

Owner:FUJIAN LONGKING

Kitchen ventilator comprising refrigeration air conditioner

InactiveCN107300200AEasy to clean by handEasy to cleanDomestic stoves or rangesLighting and heating apparatusRefrigerationFlue

The invention discloses a kitchen ventilator comprising a refrigeration air conditioner. The kitchen ventilator comprises an air intake assembly, a main oil flue, a condenser, a radiator, a compressor, a spray device, an atomization device, a steam generator, a program control device and a case, wherein non-stick coatings are arranged on the surfaces of the condenser and the radiator; the air intake assembly comprises two stages of fans and a lampblack filter element; the condenser is arranged at the center of the main oil flue; the spray device and the atomization device are arranged at the upper part and the lower part of the condenser separately; the radiator and the compressor are arranged outside the main oil flue; the compressor is arranged on a bracket of a kitchen wall through a vibration isolator; and the wall on which the case is arranged is provided with a running water outlet pipe and a waste water return pipe. The condenser is boldly arranged in a path through which smoke flow passes, the favorable condition that water is in a kitchen is fully utilized and the problem that smoke particles are attached to fins of the condenser is solved by using multiple means. The scheme is simple and efficient, the kitchen ventilator has the refrigerating capacity, is safe, reliable, low in work noise and simple to dismantle and clean.

Owner:向英特

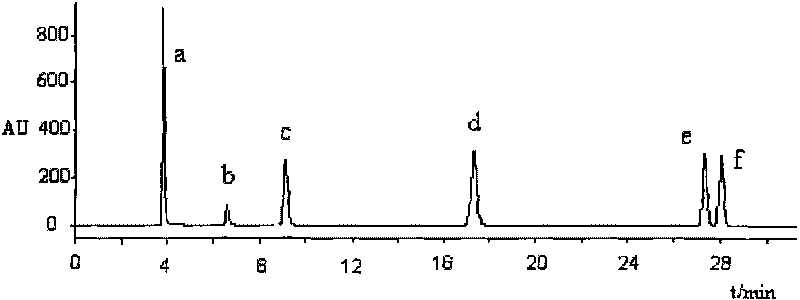

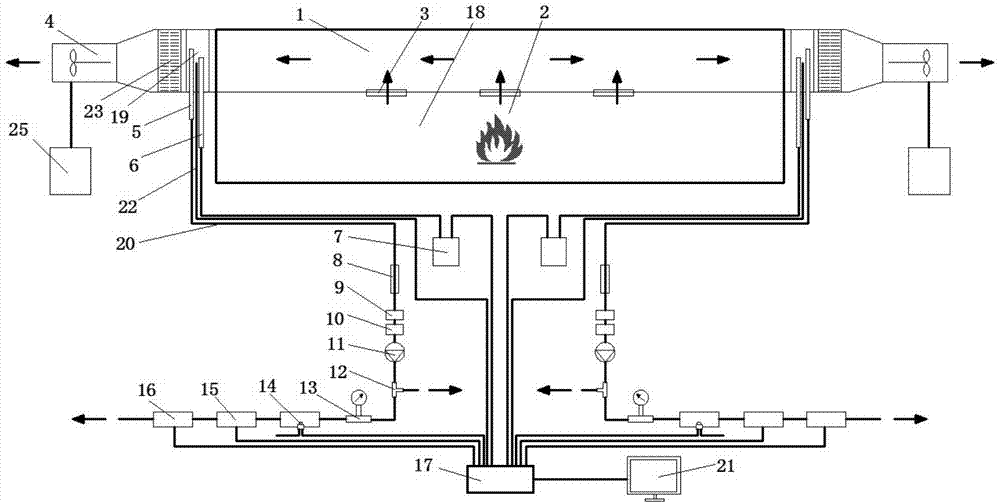

Multichannel parallel heat release rate test system and test method

InactiveCN104764769AHigh trafficReduce loadMaterial heat developmentCombustion chamberCollection system

The invention discloses a multichannel parallel heat release rate test system and test method, and aims at providing a system and a test method for accurate calorimetric measurement of a fire disaster with large burning area and high heat release rate through a multichannel parallel mode. The test system comprises a combustor, a data acquisition unit, a data processor and a plurality of test units; each test unit comprises a smoke collection system, a smoke flow measuring system and a smoke sampling system, and the smoke collection system comprises a smoke discharge pipeline, a damping screen, a sampling section and a smoke discharge blower; the smoke flow measuring system comprises a bidirectional pitot tube, a differential pressure transducer and a thermocouple; the smoke sampling system comprises a smoke sampling pipe, a condenser, a smoke filter, a drying device, a sampling pump, a rotor flow meter, an oxygen sensor, a CO2 sensor and a CO sensor; and the smoke discharge pipelines in the test units are connected in parallel. The multichannel parallel heat release rate test system and the test method, provided by the invention, can be used for testing the heat release rate of a tunnel fire disaster, and also can be used for testing the heat release rates of fire disasters of automobiles and trains.

Owner:TIANJIN UNIV OF COMMERCE

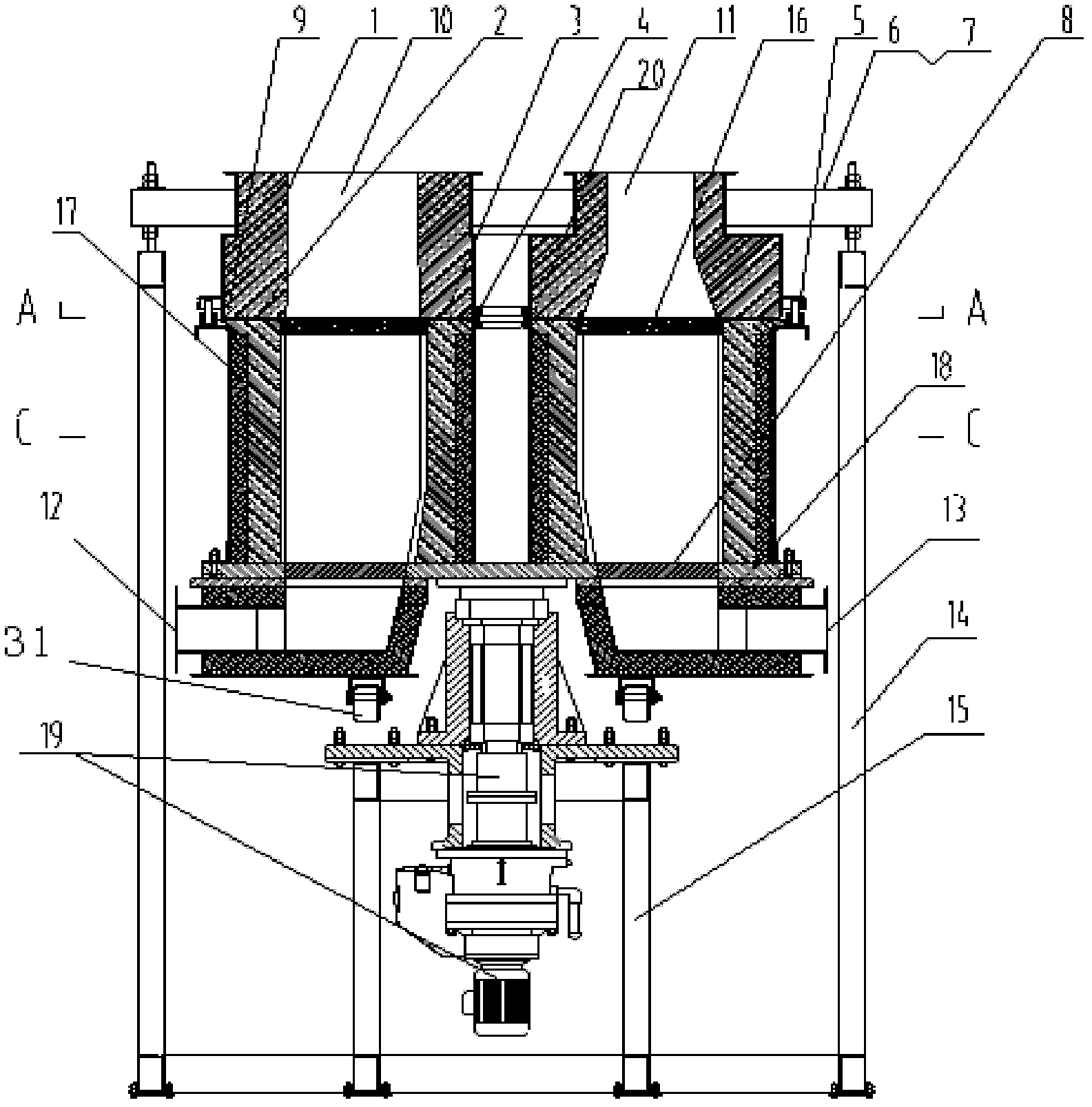

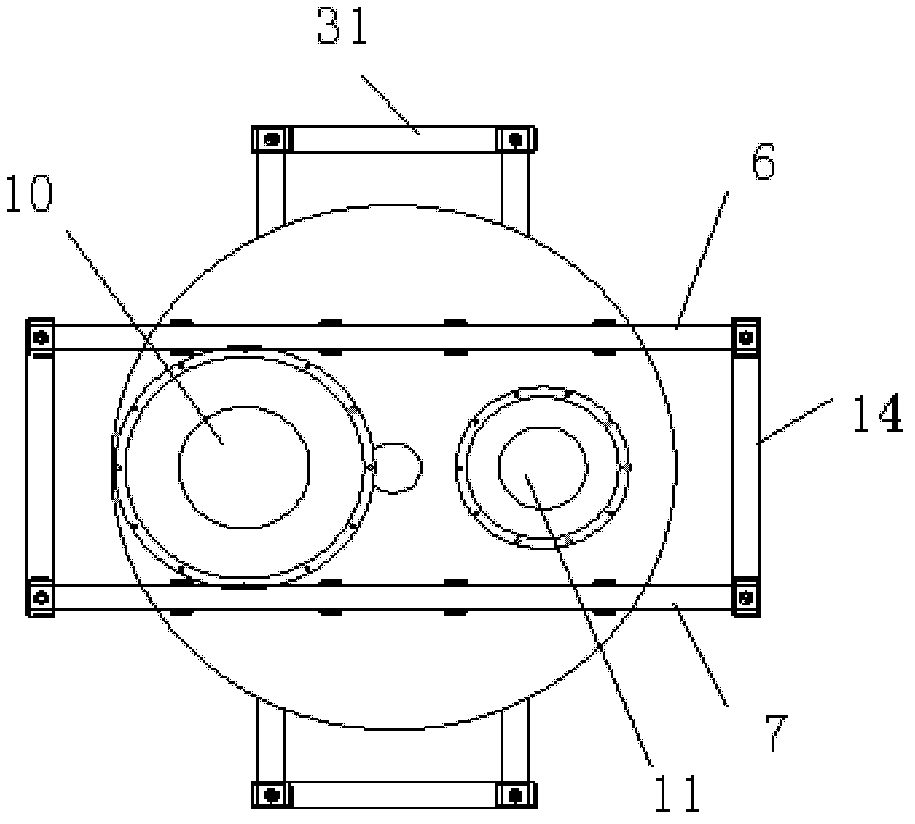

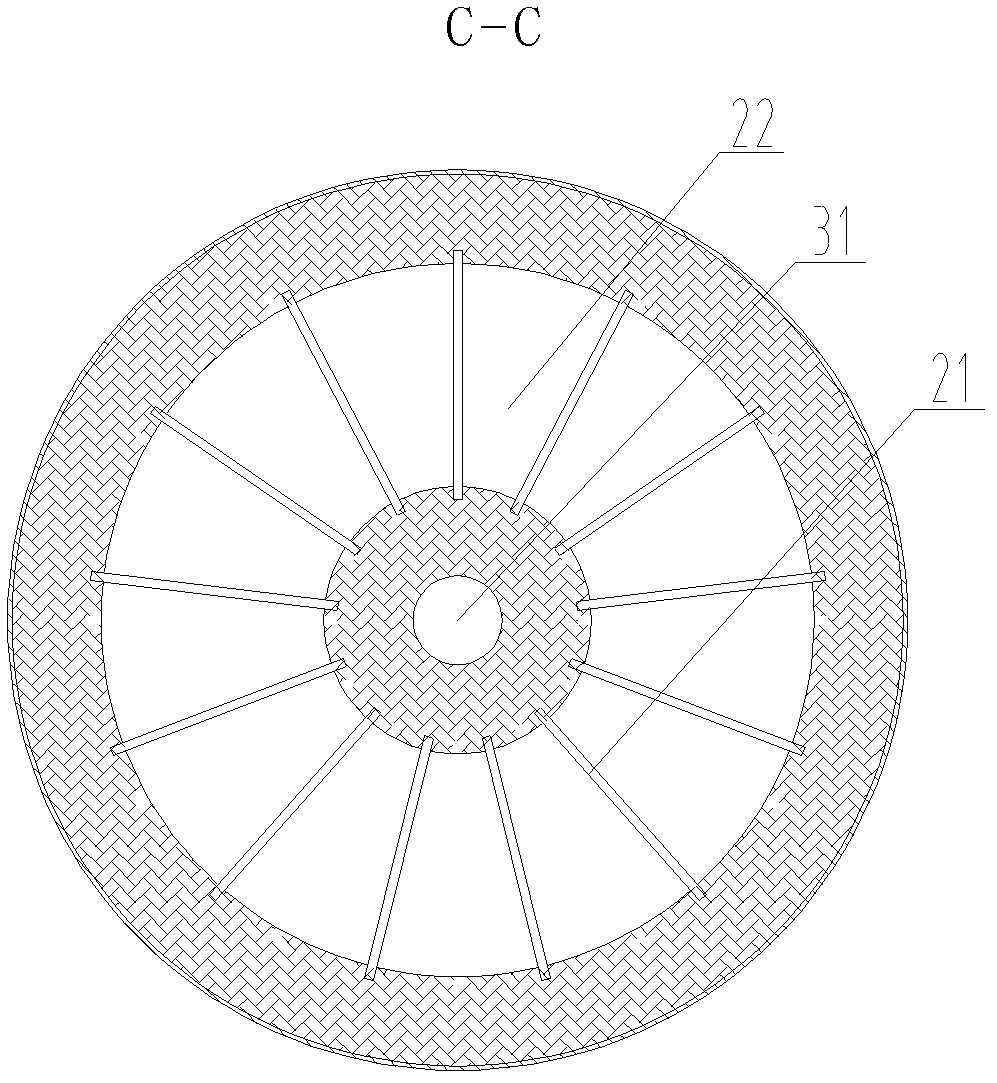

Continuous heat accumulating type heat exchanger

ActiveCN102645116AAchieve alternate flowRealize continuous hot air supplyCombustion processIndirect carbon-dioxide mitigationFurnace temperatureInsulation layer

The invention discloses a continuous heat accumulating type heat exchanger. A groove (28) and an air hole (27) are arranged on a supporting plate (8), a plurality of channels are arranged in an annular hollow device (22), and heat accumulators are filled in the plurality of channels. A ceramic covering plate (16) with holes is arranged at the upper portion of a cylinder body (17) which is installed on a power transmission device (19). A high-temperature air cap (1) is in butt-joint with the ceramic covering plate (16) with holes, a sealing device is arranged between the high-temperature air cap (1) and the ceramic covering plate (16) with holes, a low-temperature air cap (18) is in butt-joint with the supporting plate (8), and a sealing structure is arranged between the low-temperature air cap (18) and the supporting plate (8). Smoke flows in from an inlet (10), flows through the heat accumulators, and then is exhausted out from an outlet (12), and air flows in from an inlet (13), flows through the heat accumulators, and then is exhausted out from an outlet (11). The high-temperature air cap (1) and the low-temperature air cap (18) are static. A motor and a transmission device drive the cylinder body (17) to rotate at the constant speed, and insulation layers (20) are arranged both inside and outside the motor, the transmission device and the cylinder body (17). The continuous heat accumulating type heat exchanger is small in fluctuation of furnace temperature, furnace pressure and preheated air temperature.

Owner:CENT SOUTH UNIV

Dedusting and denitration system for thermal power plant fire coal smoke

ActiveCN102309918AImprove catalytic performanceExtend your lifeDispersed particle separationAir preheaterSilicon-controlled rectifier

The invention provides a dedusting and denitration system for thermal power plant fire coal smoke, which lowers denitration cost while ensuring that the system efficiently denitrate. The dedusting and denitration system is characterized in that heat exchangers comprise a heat exchanger I and a heat exchanger II; a coal economizer is provided with two smoke outlets, wherein one smoke outlet is ledto the high-temperature inlet of the heat exchanger I, and the other smoke outlet is led to the high-temperature inlet of the heat exchanger II; the high-temperature outlet of the heat exchanger I isconnected with the inlet of a smoke flow regulation valve; the outlet of the smoke flow regulation valve is connected with one inlet of a smoke mixer; the high-temperature outlet of the heat exchanger II is connected with the other inlet of the smoke mixer; the outlet of the smoke mixer is connected with the inlet of an efficient dust remover; the outlet of the efficient dust remover is connectedwith the low-temperature inlet of the heat exchanger II; the low-temperature outlet of the heat exchanger II is connected with the inlet of an SCR (Silicon Controlled Rectifier) reactor; the outlet of the SCR reactor is connected with an air preheater; and the low-temperature inlet to the low-temperature outlet of the heat exchanger I is low-temperature liquid.

Owner:WUXI HUAGUANG BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com