Patents

Literature

30results about How to "Solve scour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

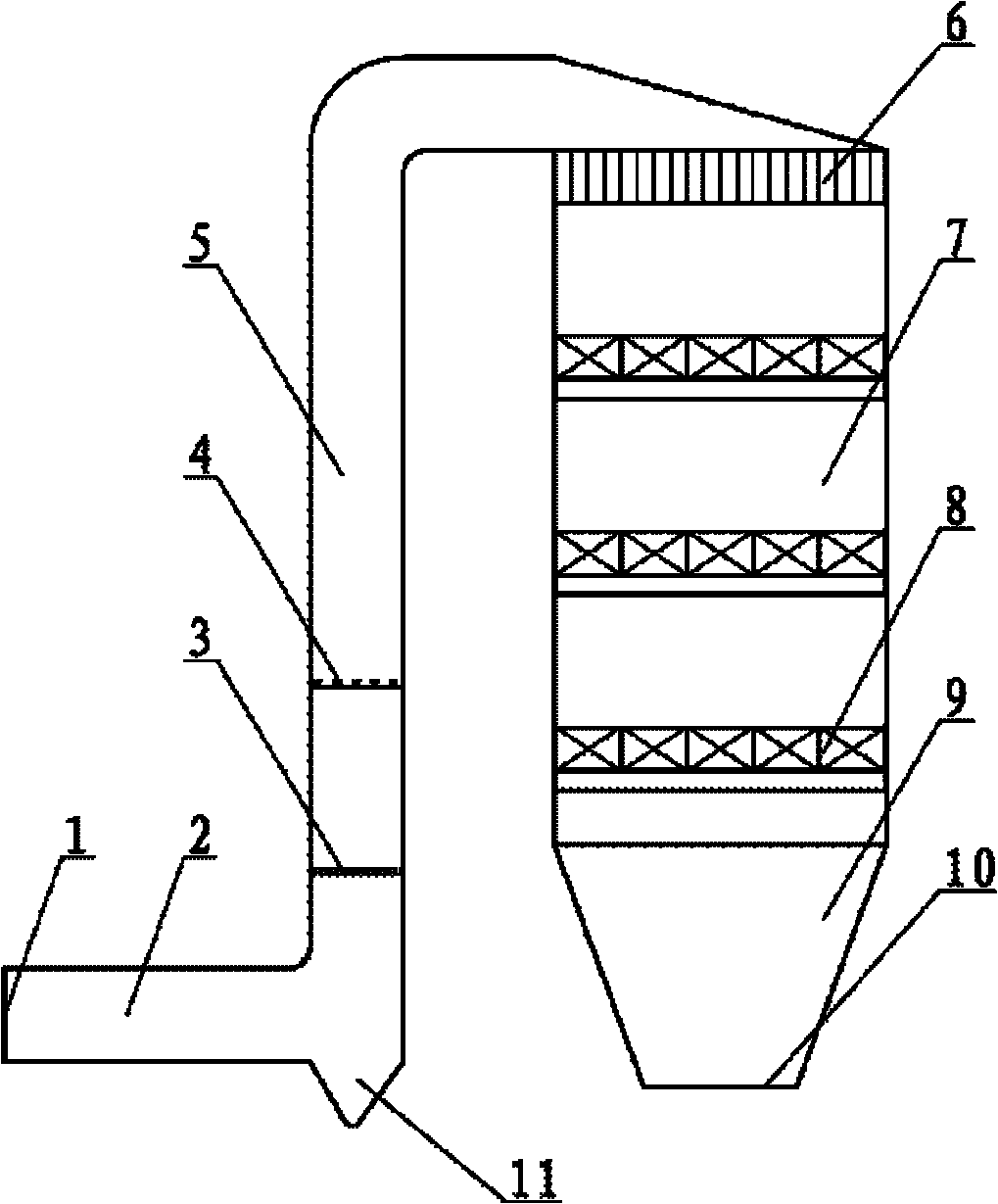

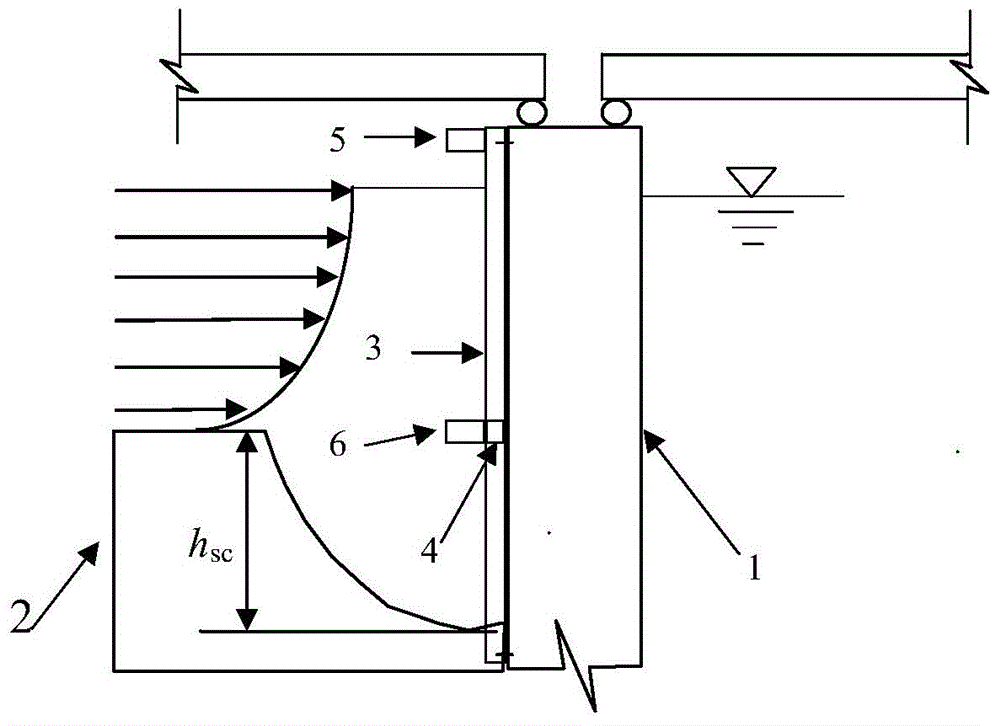

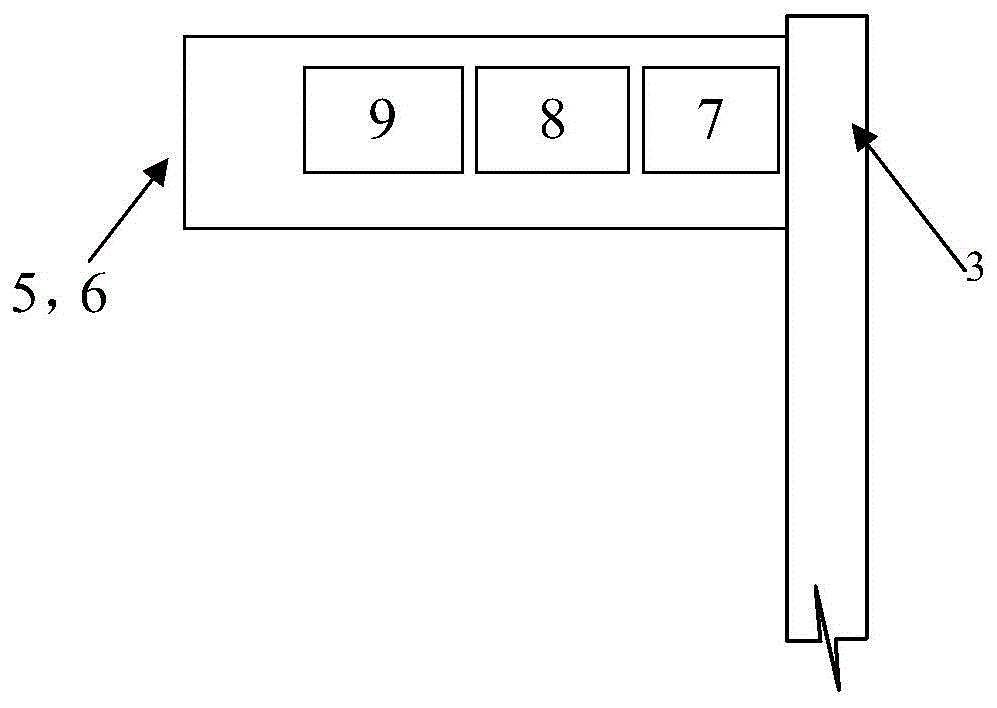

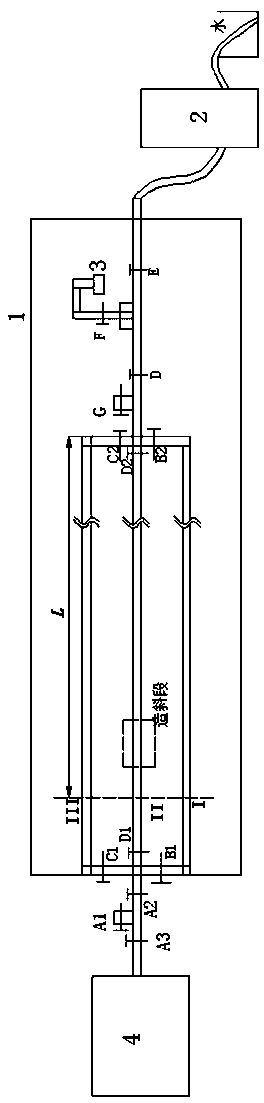

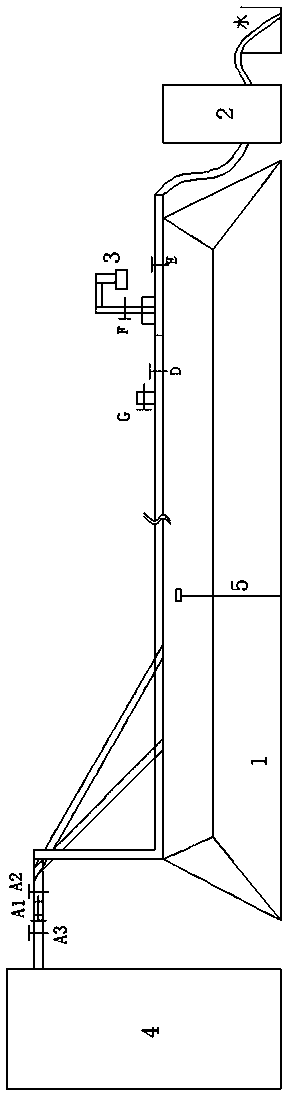

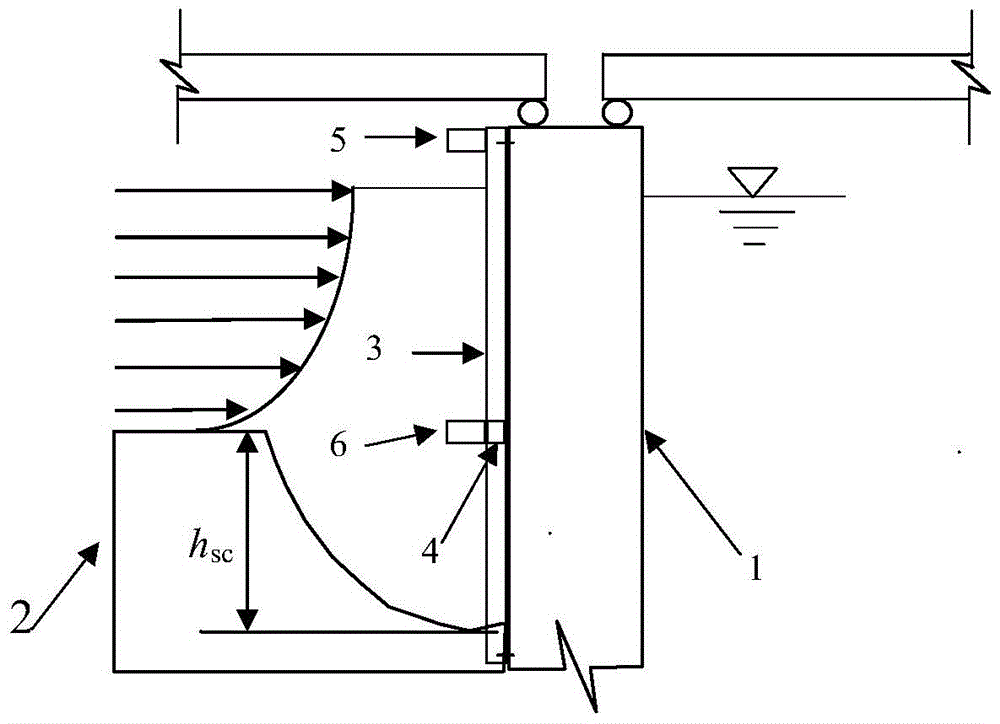

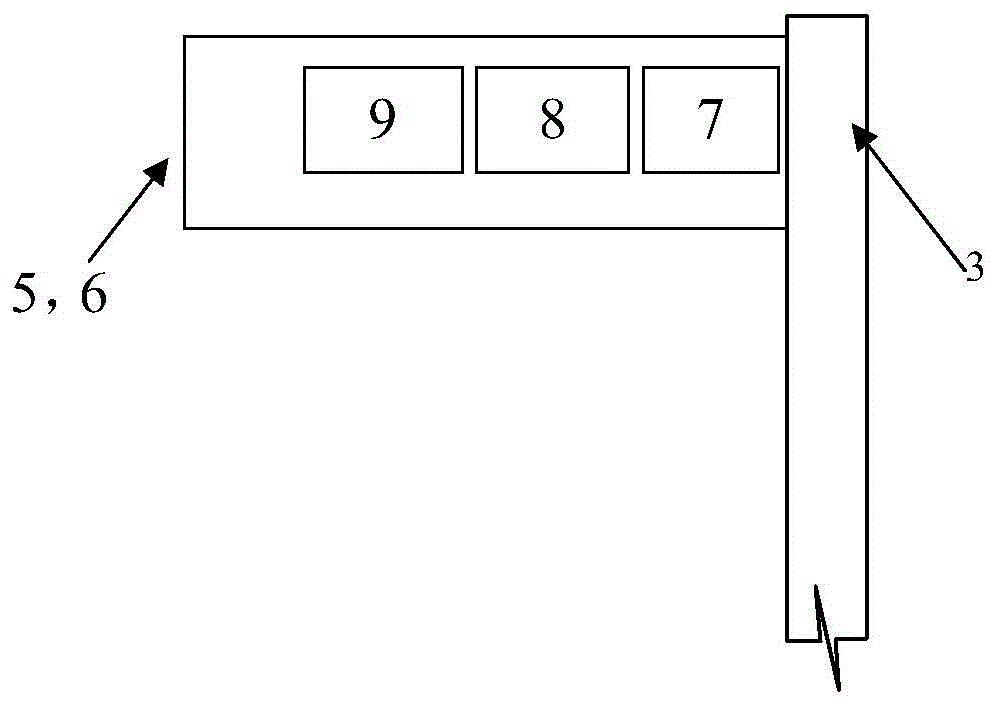

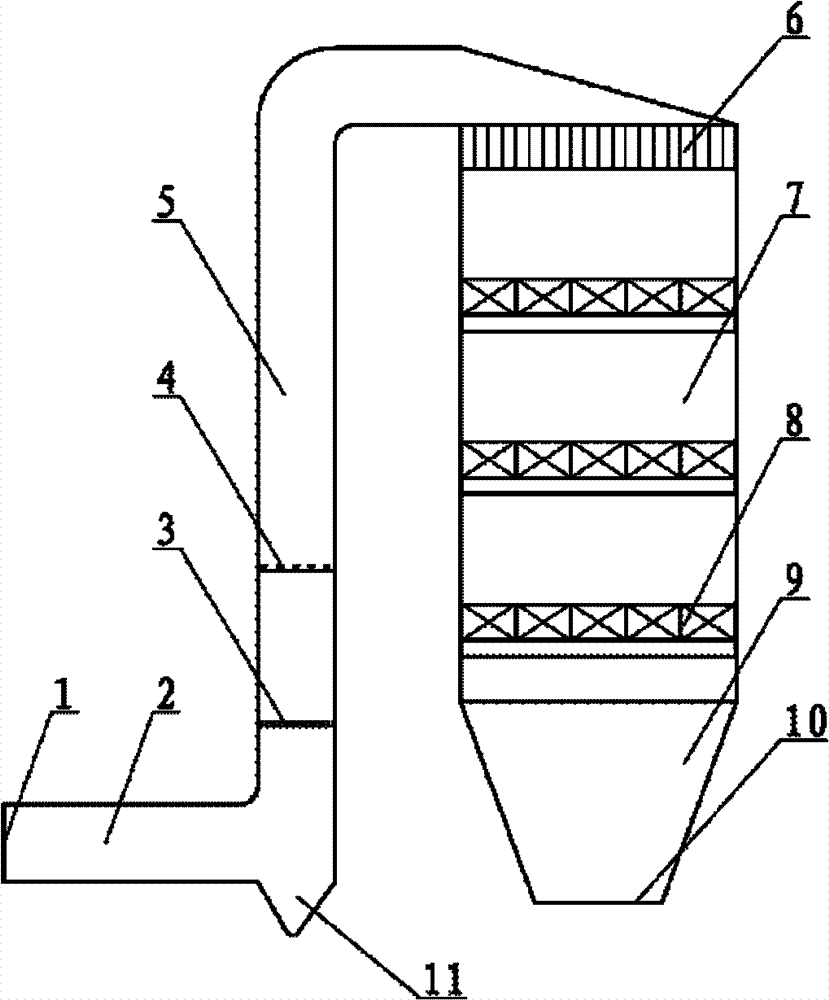

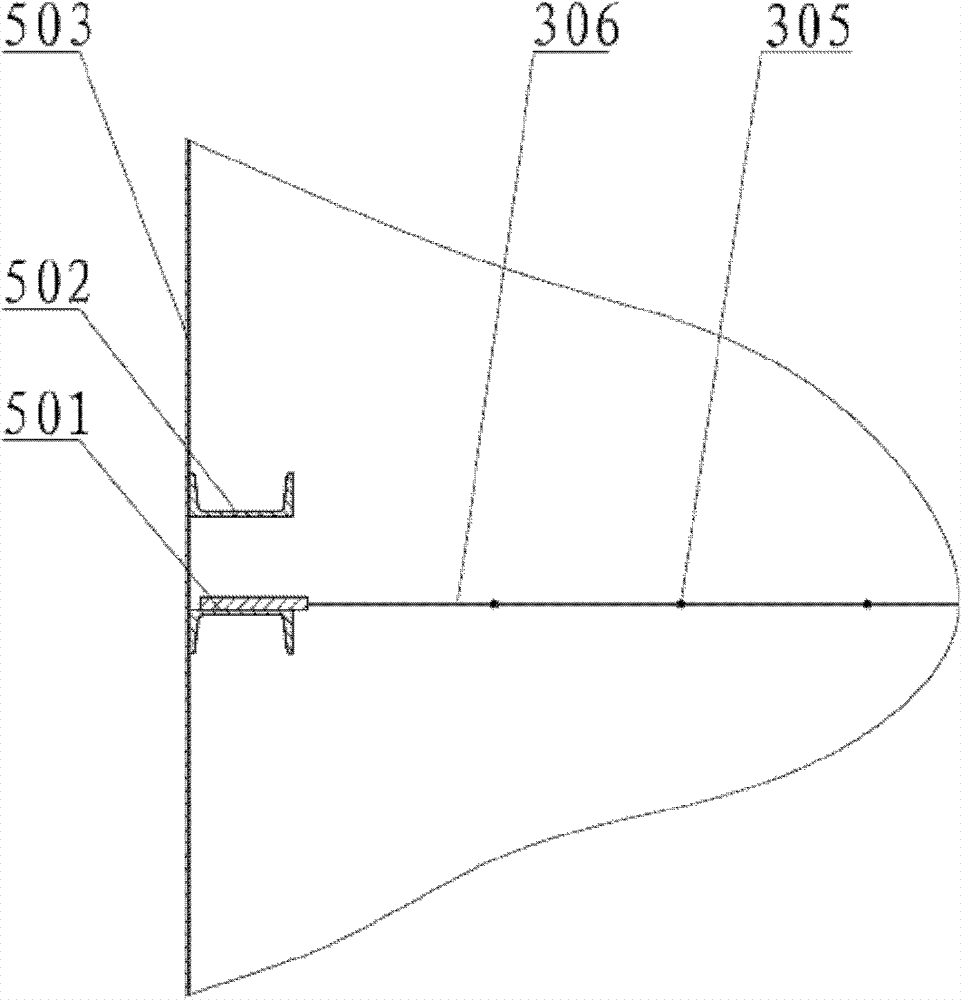

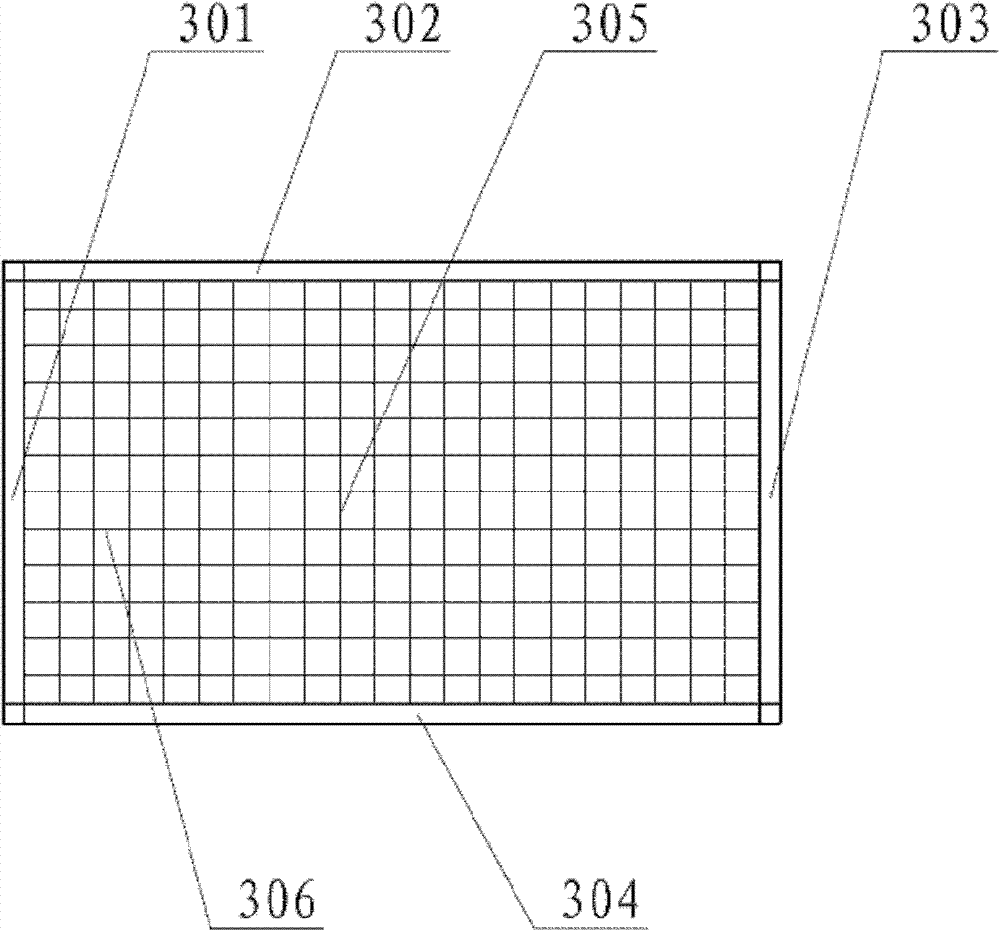

Smoke denitration device for preventing catalyst from being plugged by popcorn ash

InactiveCN102179156AAvoid destructionSolve scourDispersed particle filtrationLighting and heating apparatusGratingEngineering

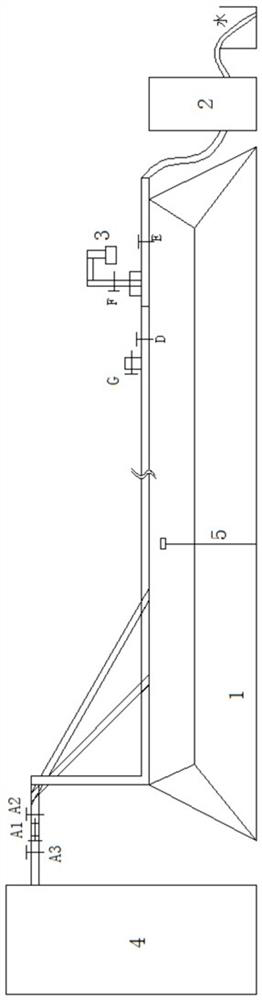

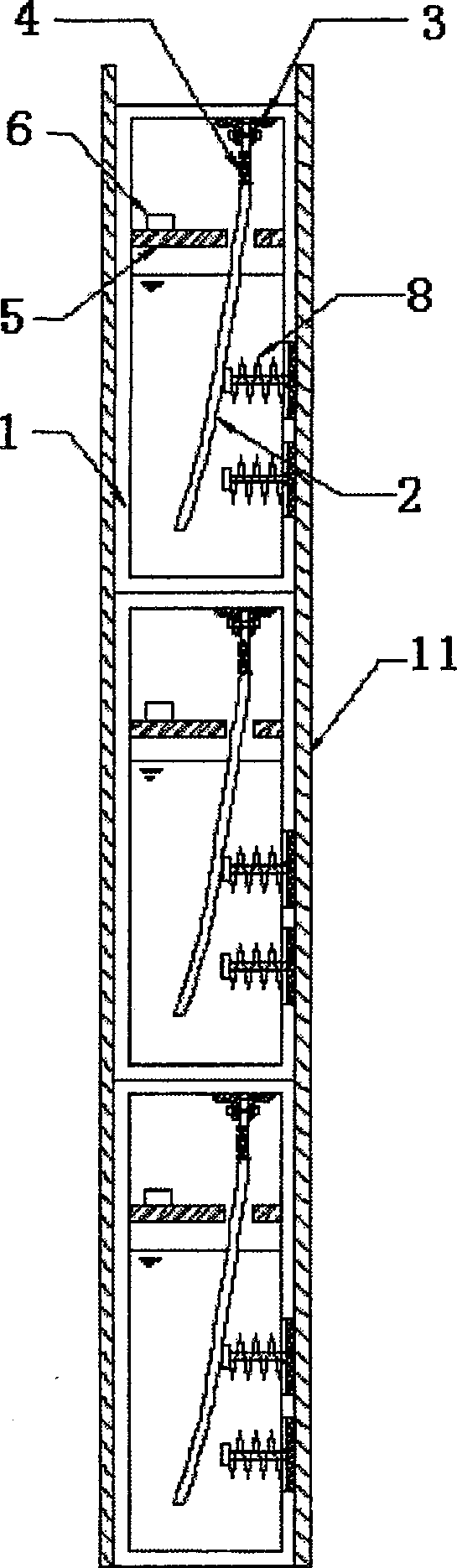

The invention discloses a smoke denitration device for preventing a catalyst from being plugged by popcorn ash. The device comprises a smoke inlet (1), a horizontal connecting flue (2), a vertical connecting flue (5), a denitration reactor (7), an outlet flue (9) and a smoke outlet (10) which are communicated in sequence, wherein an ammonia spraying grating (4) is arranged in the vertical connecting flue (5); and a rectifying device (6) and a plurality of layers of catalysts (8) are arranged in the denitration reactor (7) along the smoke flowing direction. The device provided by the inventionis characterized in that a metal screen (3) is arranged on the upstream of the ammonia spraying grating (4) in the vertical connecting flue (5). The smoke denitration device for preventing the catalyst from being plugged by the popcorn ash provided by the invention can be used for efficiently intercepting the 'popcorn ash' with a large grain size in the coal-fired smoke, separating the 'popcorn ash' from the smoke, and solving the problem that the catalyst is brushed and plugged by the 'popcorn ash'.

Owner:SOUTHEAST UNIV

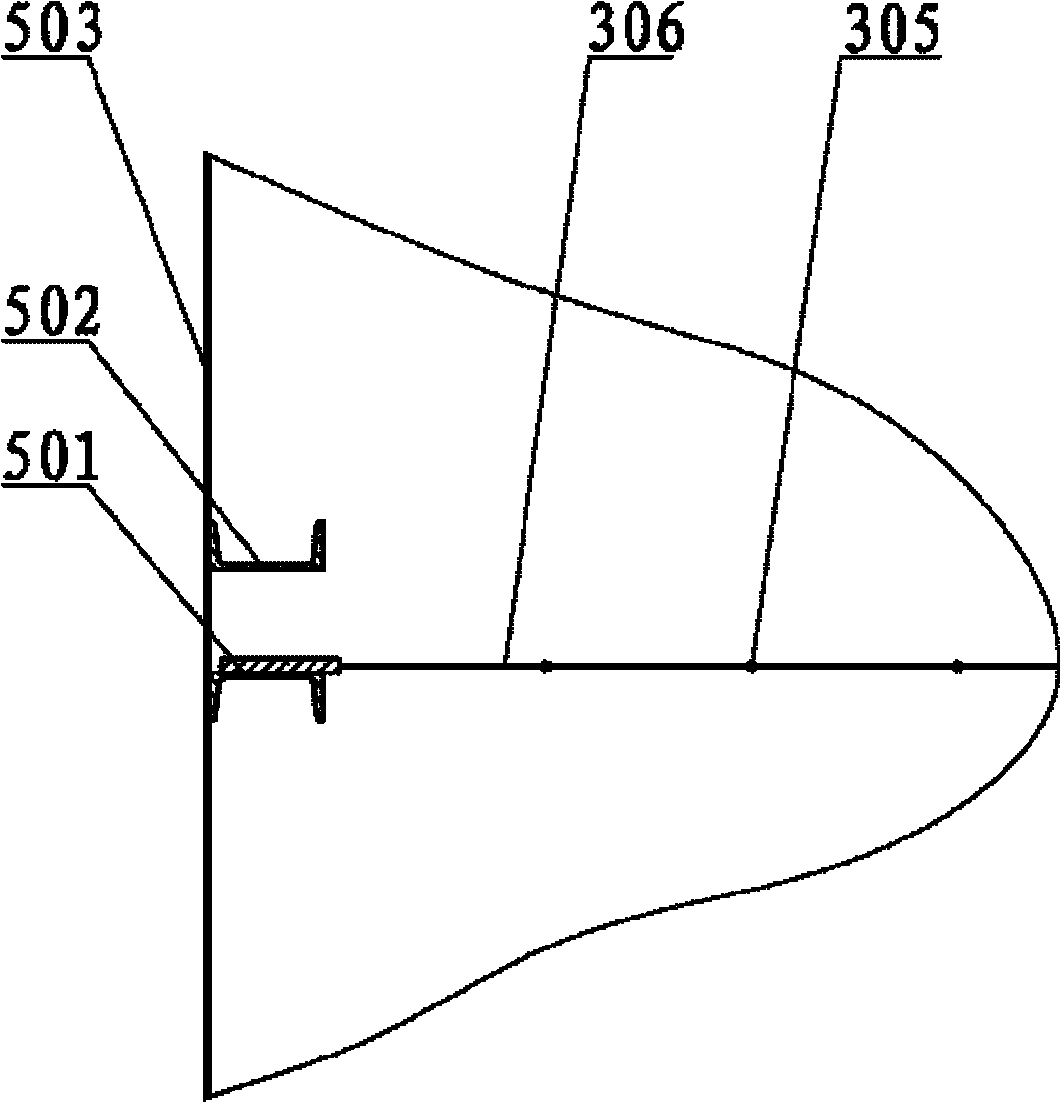

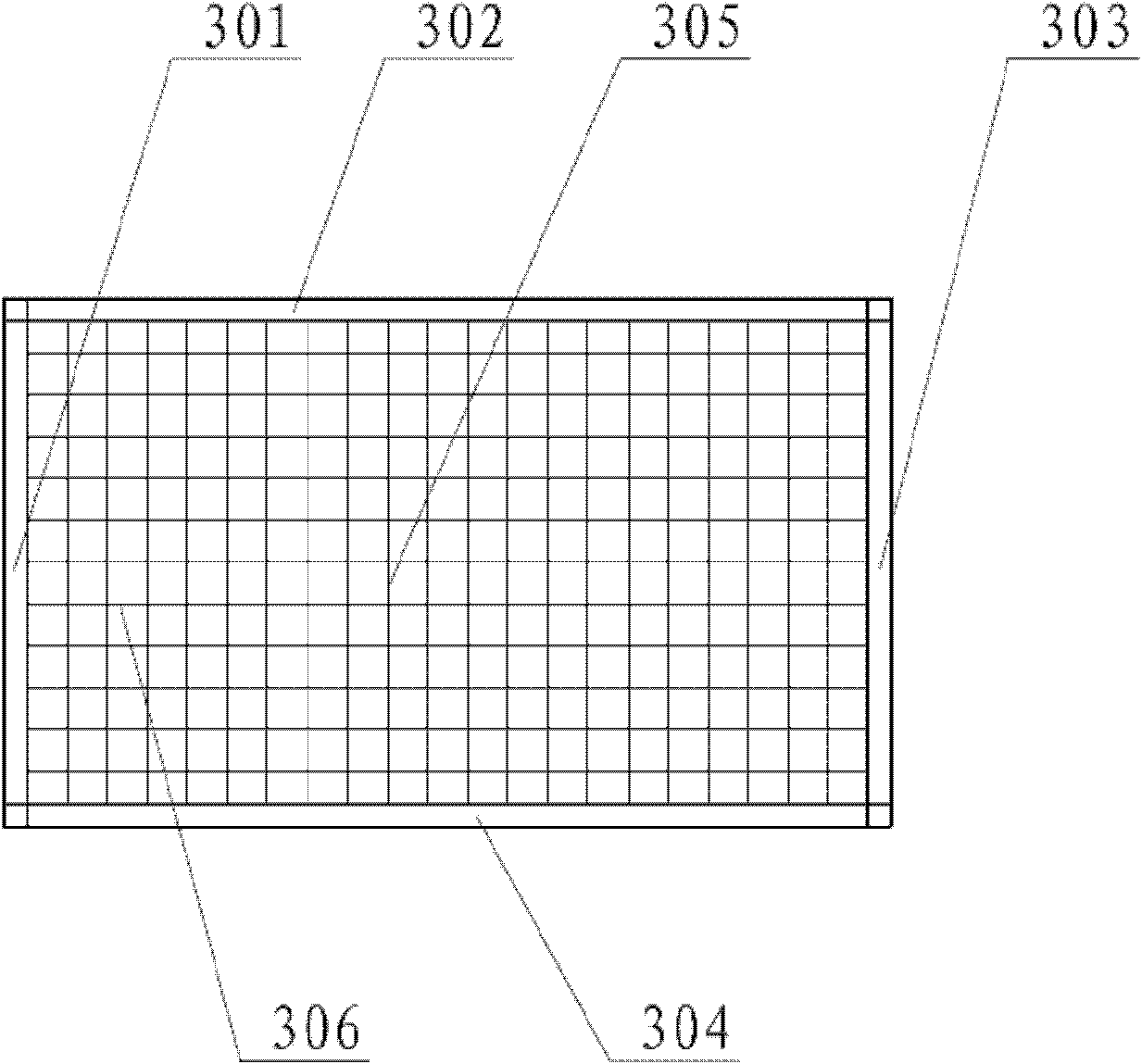

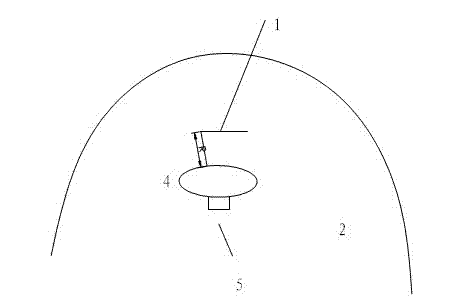

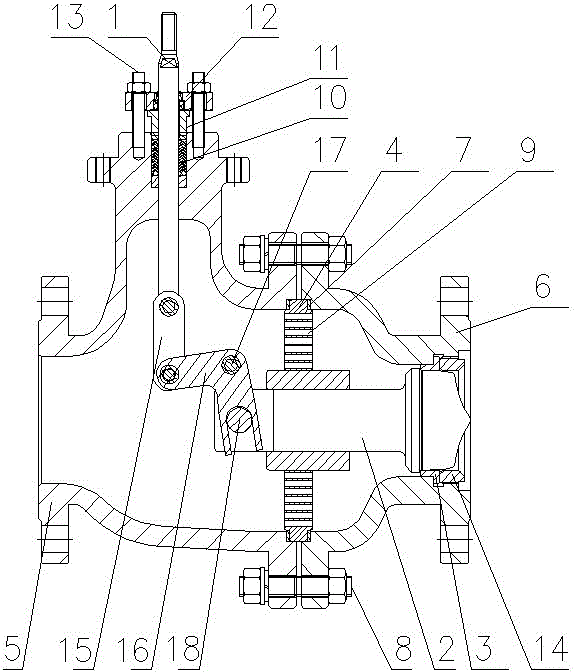

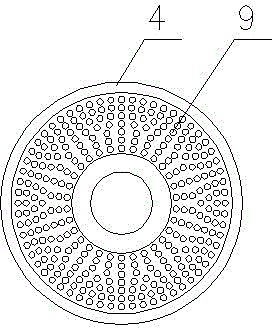

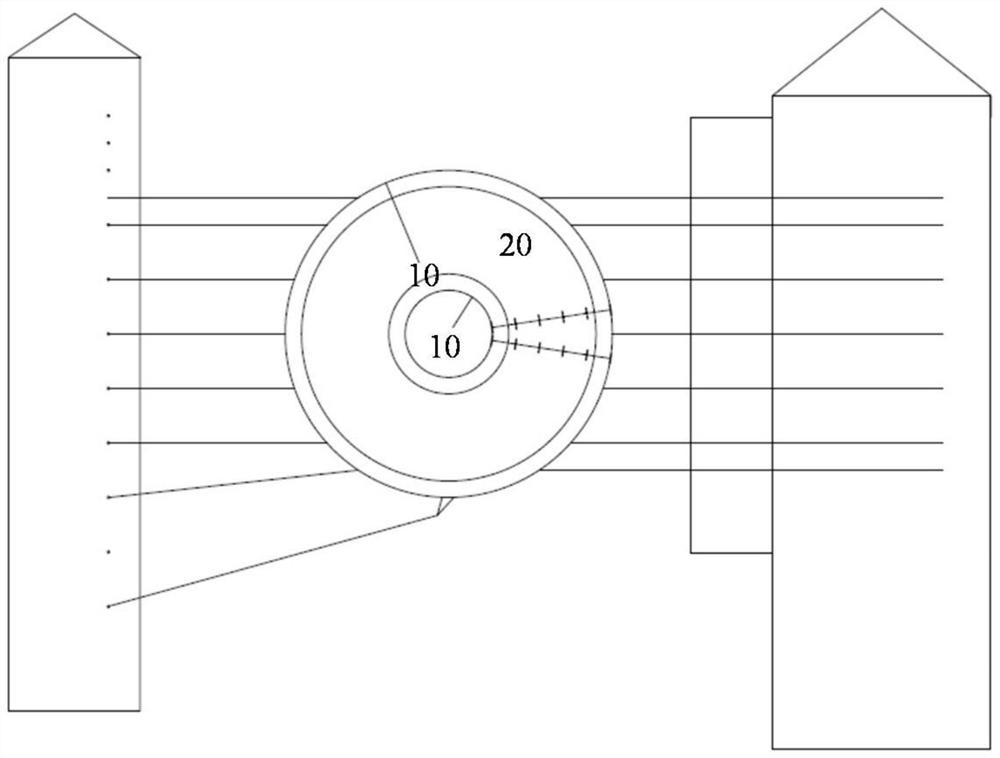

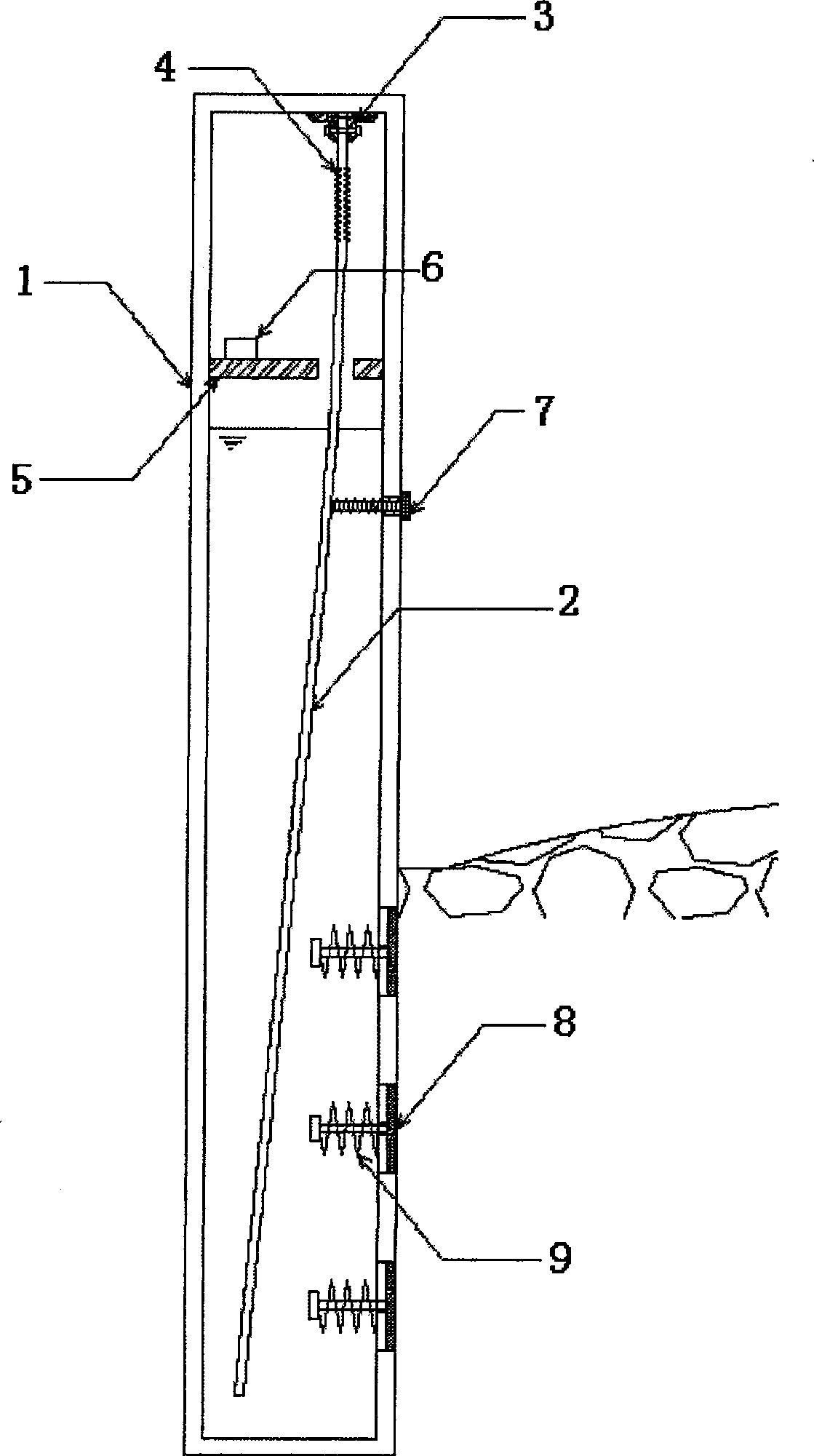

High durability optical fiber grating wash out sensor

InactiveCN101140176AIncreased durabilityHigh precisionUsing optical meansCoupling light guidesFiberCircular disc

The invention provides a high-durability fiber grating scouring sensor which comprises a metal shell and a measuring part arranged in the metal shell and connected with the metal shell, wherein the measuring part is composed of a FRP uniform strength beam and two fiber gratings stuck on the upper and lower surfaces of the FRP uniform strength beam, the leading-out wire of the fiber grating passes through the metal shell and is educed, the inner wall of the metal shell is provided with a metal baffle plate provided with a calcium carbide, the lower part of the metal shell is provided with a dowel bar, a prepressing small-rigidity spring is arranged between one end of the dowel bar and the inner wall of the metal shell, and the other end of the dowel bar is provided with a FRP disc. The scouring sensor has the advantages of the high precision, the convenient arrangement and the adjustable range and resolution, and is applied to the foundation soil scouring monitoring of health monitoring of civil engineering structure and the foundation soil scouring monitoring of structural test.

Owner:HARBIN INST OF TECH

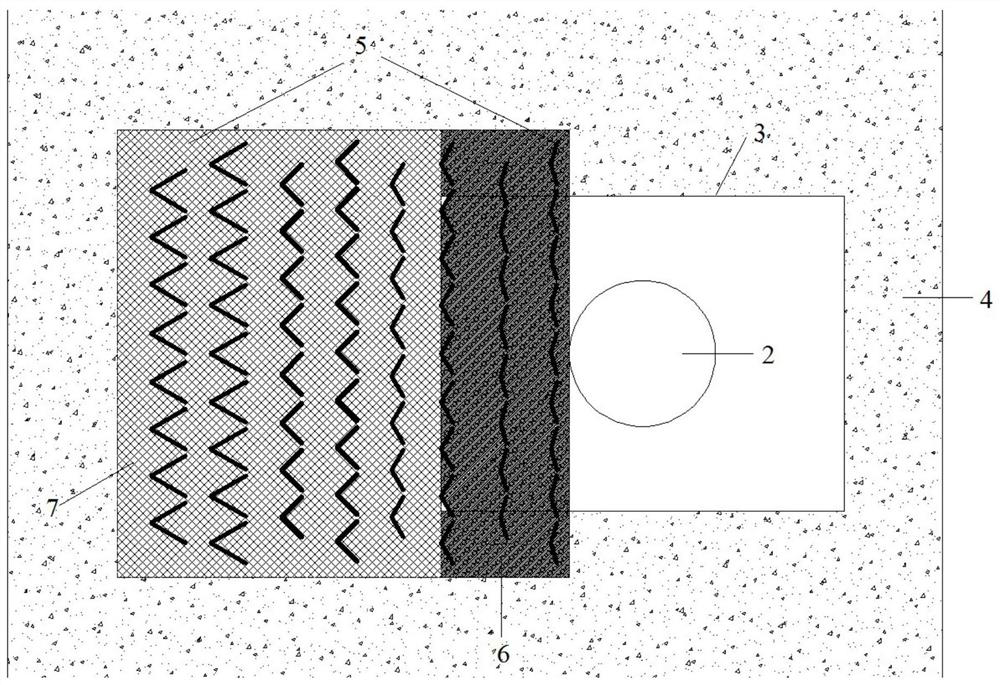

Anticorrosive and wear-resistant material for spraying zones of desulfurization towers

ActiveCN102343697AReduce construction difficultyLow costSynthetic resin layered productsDispersed particle separationFiller particleCorrosion prevention

The invention discloses an anticorrosive and wear-resistant material for the spraying zones of desulfurization towers. The material comprises an impermeable material, a reinforcing material and a wear-resistant material, wherein the impermeable material mainly comprises vinyl ester resin added with glass flakes; the reinforcing material mainly comprises vinyl ester resins, glass fiber cloth and glass fiber chopped strand mats; the wear-resistant material mainly comprises vinyl ester resin added with wear-resistant ceramic packing particles; and the wear-resistant ceramic packing particles can be divided into packing I, packing II and packing III mixed in certain proportion. The material disclosed by the invention has the advantages of low difficulty in construction, low cost, good anticorrosive effect, good wear-resistant performance, convenience in application and maintenance, and capability of effectively preventing the damage from an external force and an internal stress and resisting the corrosion of acid liquor or the erosion of flue gas, effectively resolving the problems of erosion, wear and damage of the wear-resistant material easily occurring in spraying zones of desulfurization towers, prolonging the service life of an anticorrosive layer, and greatly reducing the maintenance cost.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

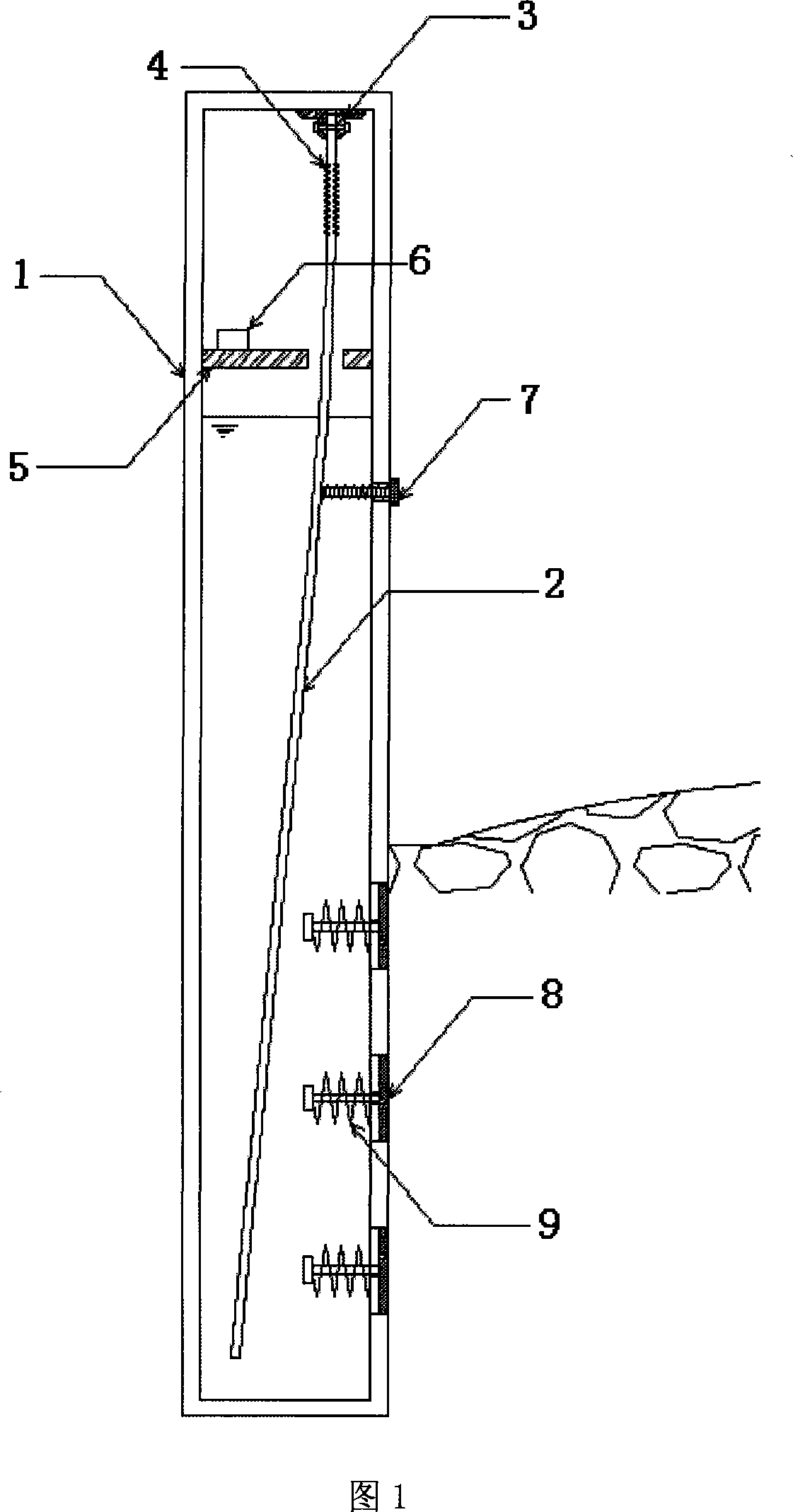

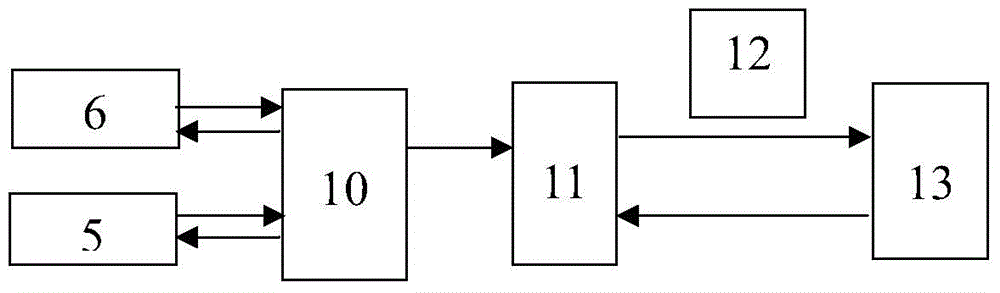

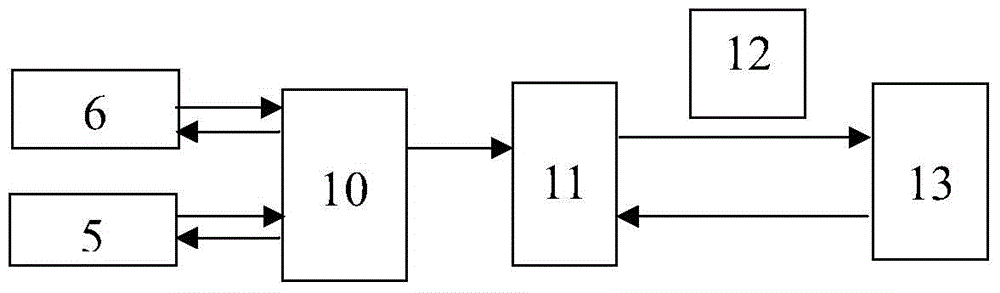

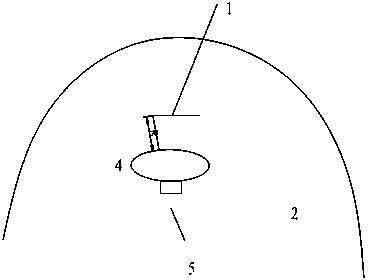

Micro-tremor measurement based bridge pier scour monitoring system and method

InactiveCN104457634ASolve scourUsing subsonic/sonic/ultrasonic vibration meansData processing systemMonitoring system

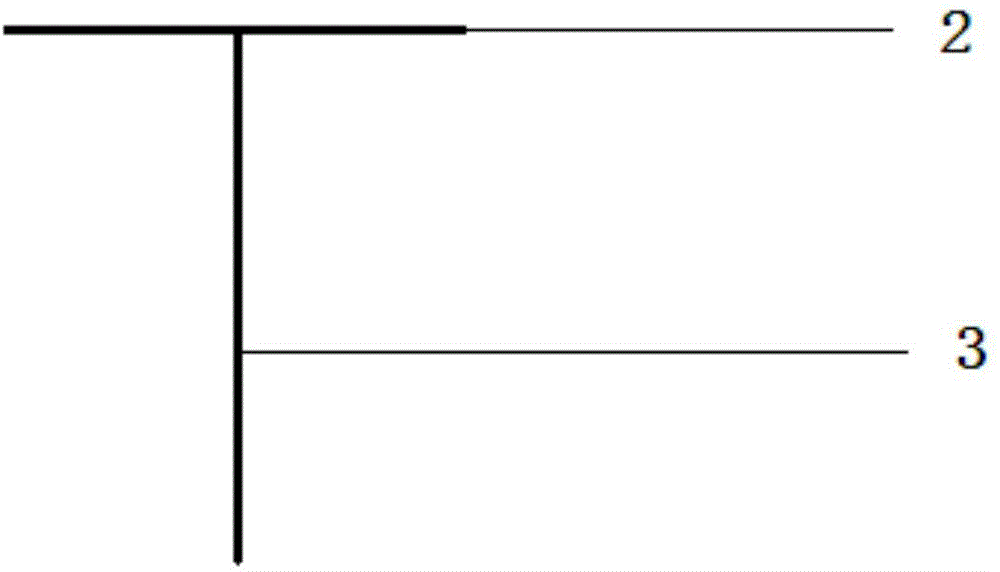

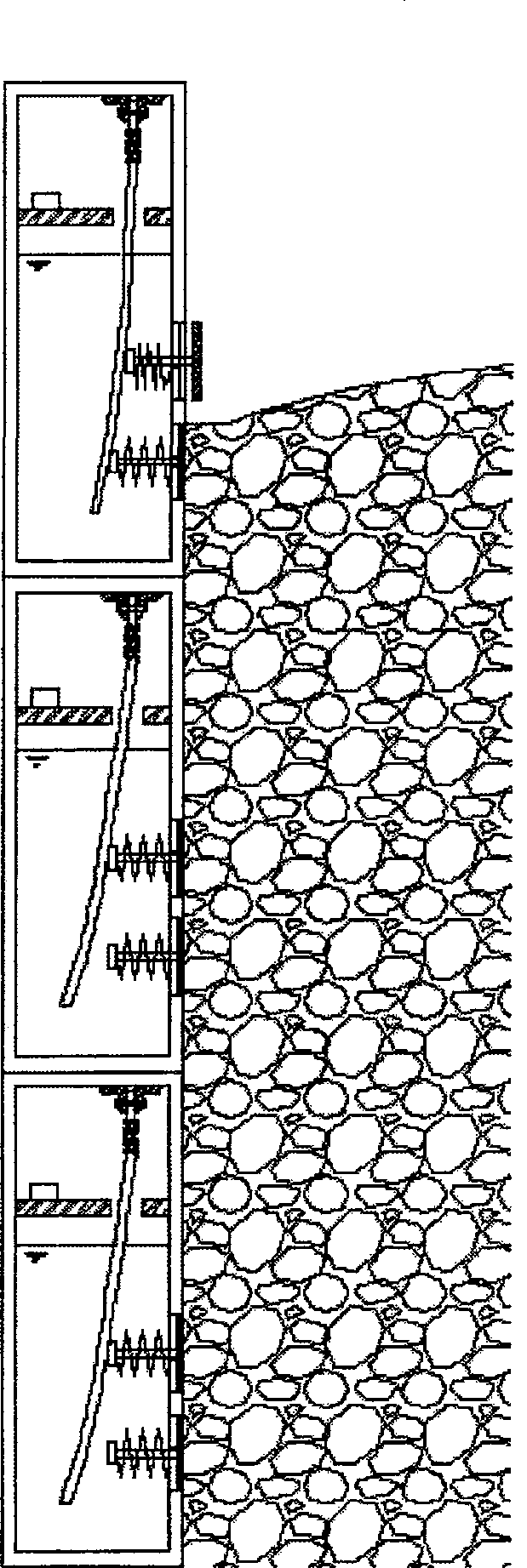

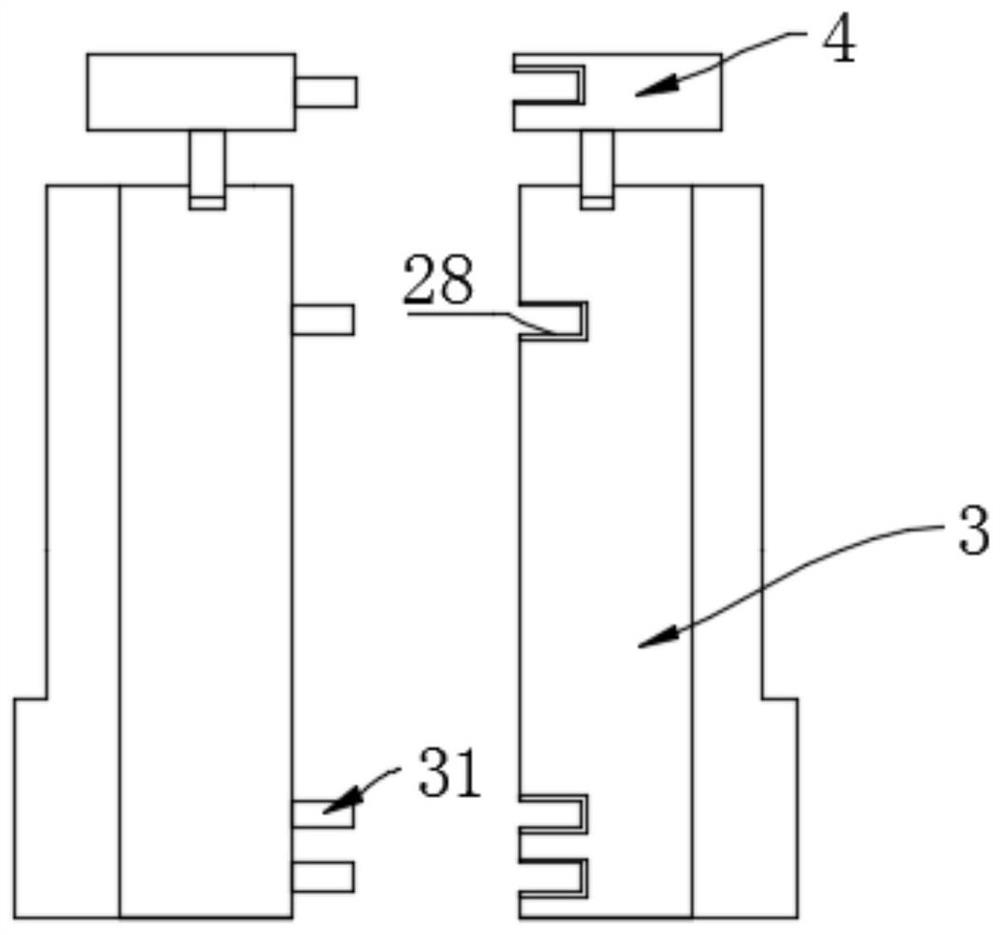

The invention discloses a micro-tremor measurement based bridge pier scour monitoring system. The micro-tremor measurement based bridge pier scour monitoring system comprises a fixed micro-seismograph probe installed at the top end of a bridge pier, a guide rail vertically installed on the upstream face of the bridge pier and provided with a portion under the water surface, a movable micro-seismograph probe vertically moving along the guide rail, a micro-seismograph mainframe receiving micro-tremor information detected by the fixed micro-seismograph probe and the movable micro-seismograph probe, and a data processing system for processing the micro-tremor information into bridge pier scour depth and early warning bridge pier scour. The micro-tremor information monitored by a micro-seismograph is processed into the bridge pier scour depth by the data processing system, early warning is performed on the bridge pier, and the micro-tremor measurement based bridge pier scour monitoring system is high in accuracy and long in service life. The invention further discloses a micro-tremor measurement based bridge pier scour monitoring method. The micro-tremor measurement based bridge pier scour monitoring method calculates the bridge pier scour depth based on the micro-tremor information, and a calculation result is accurate and reliable.

Owner:SOUTHWEST UNIV

Technology for welding carbon steel overlaying welding layer of tube plate of high pressure heat exchanger with low carbon steel tube in sealing way

The invention discloses a technology for welding a carbon steel overlaying welding layer of a tube plate of a high pressure heat exchanger with a low carbon steel tube in a sealing way, comprising the following technological processes, i.e. a step one of welding carbon steel on the tube plate of the high pressure heat exchanger in a submerged arc overlaying way, thermally treating the overlaying welding layer and the tube plate under the condition of passing 100% UT (Ultrasonic Test) and 100% MT (Magnetic Test) flow detection, and increasing the overlaying welding layer to the range of 6mm to 8mm in a machining way, wherein the groove structure of the tube plate is in the form of an aligned groove, the low carbon steel tube is aligned with the overlaying welding layer of the tube plate, and the sealing welding groove of the overlaying welding layer of the tube plate is chamfered at 2*45 degrees; a step two of preheating to 80 DEG to 100 DEG before welding, and welding the low carbon steel tube in the groove of the overlaying welding layer of the tube plate in a point way before welding as well, wherein the point welding enables the root part to be thoroughly welded without welding sticks; a step three of implementing sealing welding on the groove by adopting an automatic argon arc welding, implementing 100% PT (Penetration Test) flow detection on the welded junction after the completion of sealing welding, and eliminating surface defects of the welding line. According to the technology for welding the carbon steel overlaying welding layer of the tube plate of the high pressure heat exchanger with the low carbon steel tube in the sealing way, the surface of the welding line of the carbon steel subjected to the sealing welding is smooth and flat, and no needle-like air holes are formed in the near surface and the surface of the welding line; therefore, the long-term scour by supplied water can be completely withstood.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Anticorrosive material for smoke discharge and desulfurizing chimney

ActiveCN102585655AReduce construction difficultyLow costSynthetic resin layered productsAnti-corrosive paintsEpoxyInternal stress

The invention discloses an anticorrosive material for a smoke discharge and desulfurizing chimney, which comprises an anti-permeability material and an abrasion-resistant material, wherein the anti-permeability material mainly comprises EpigenXD modified epoxy resin added with glass flakes, and the abrasion-resistant material mainly comprises the EpigenXD modified epoxy resin added with abrasion-resistant white corundum filler particles. The abrasion-resistant white corundum filler particles are divided into fillers I and fillers II, and the fillers I and the fillers II are mixed according to a certain proportion. The anticorrosive material for the smoke discharge and desulfurizing chimney is small in construction difficulty, low in cost, good in anticorrosive effect, good in abrasion-resistant performance, capable of effectively preventing damage of external force and internal stress and resisting to corrosion of acid liquor or scour of smoke and convenient in use and maintenance. In addition, scour and abrasion damage which easily happen to the anticorrosive material of the smoke discharge and desulfurizing chimney are effectively avoided, service life of an anticorrosive layer is prolonged, and maintenance cost can be reduced to a large extent.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

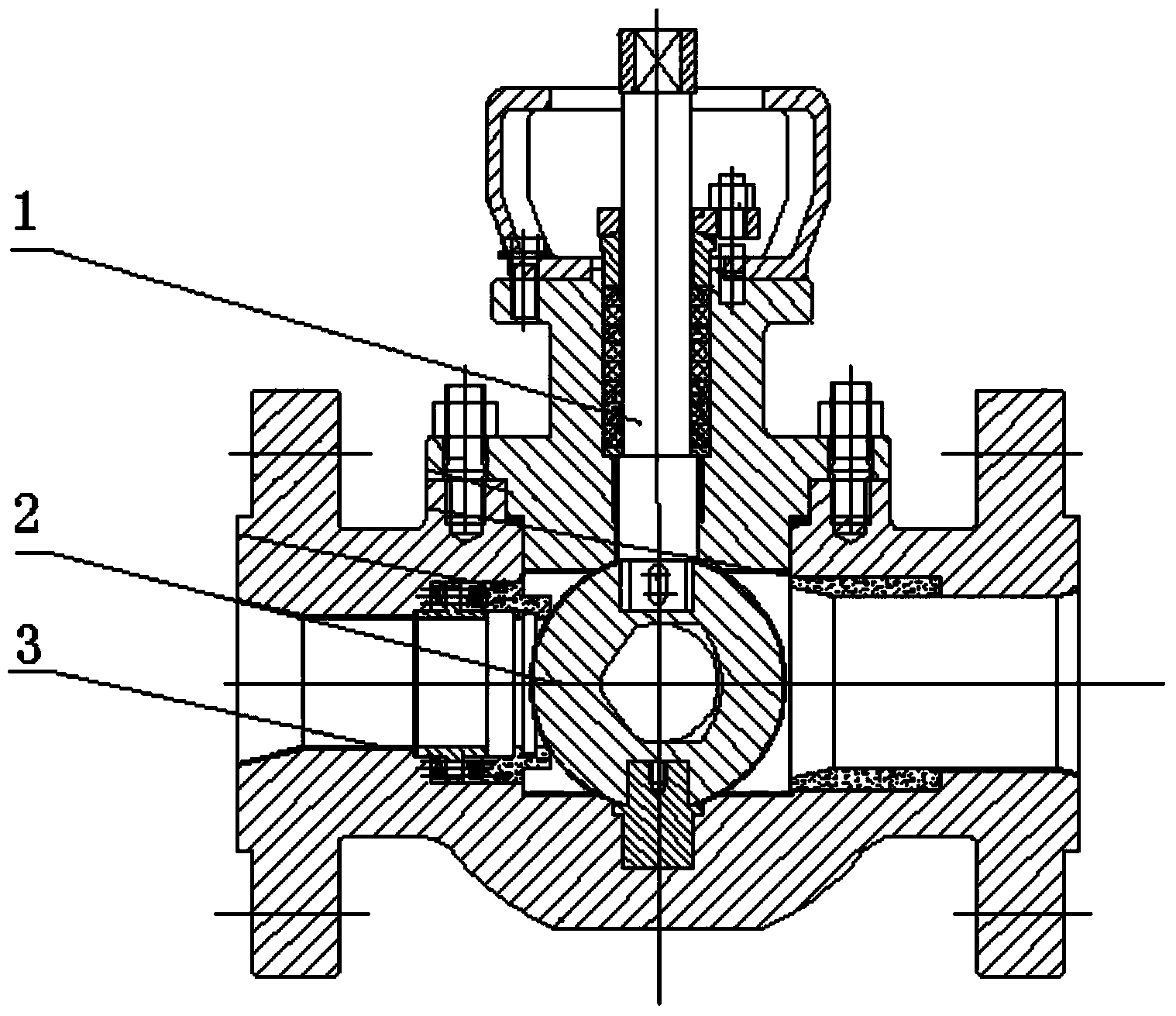

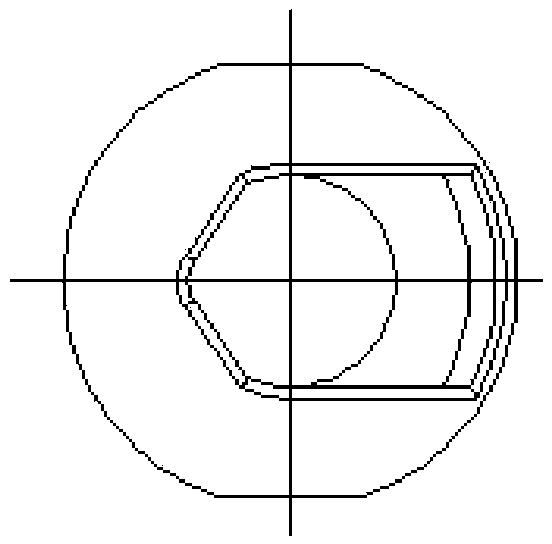

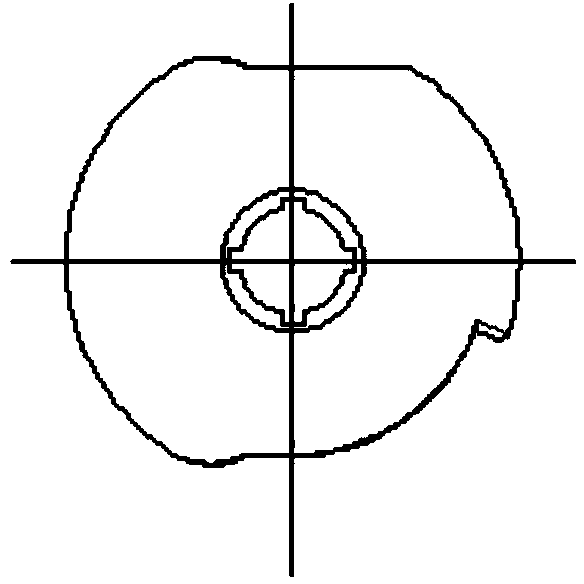

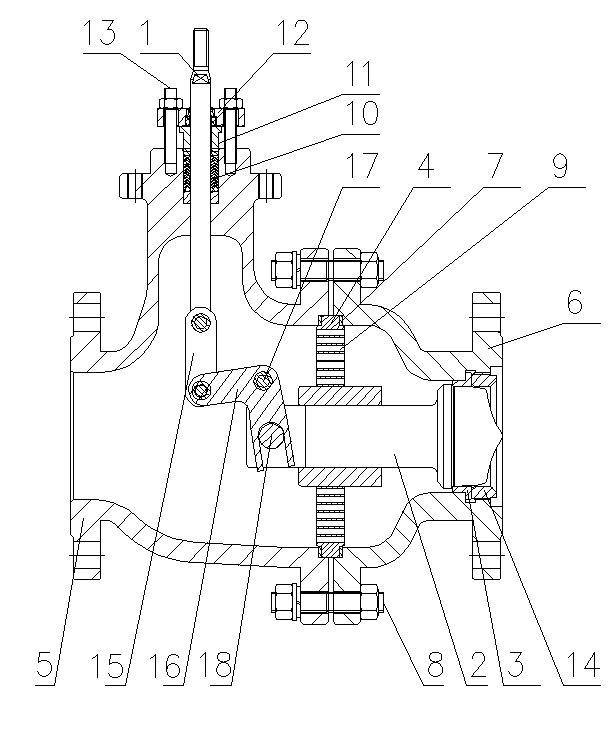

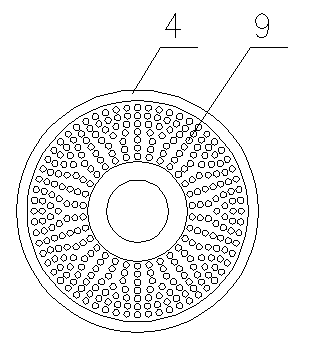

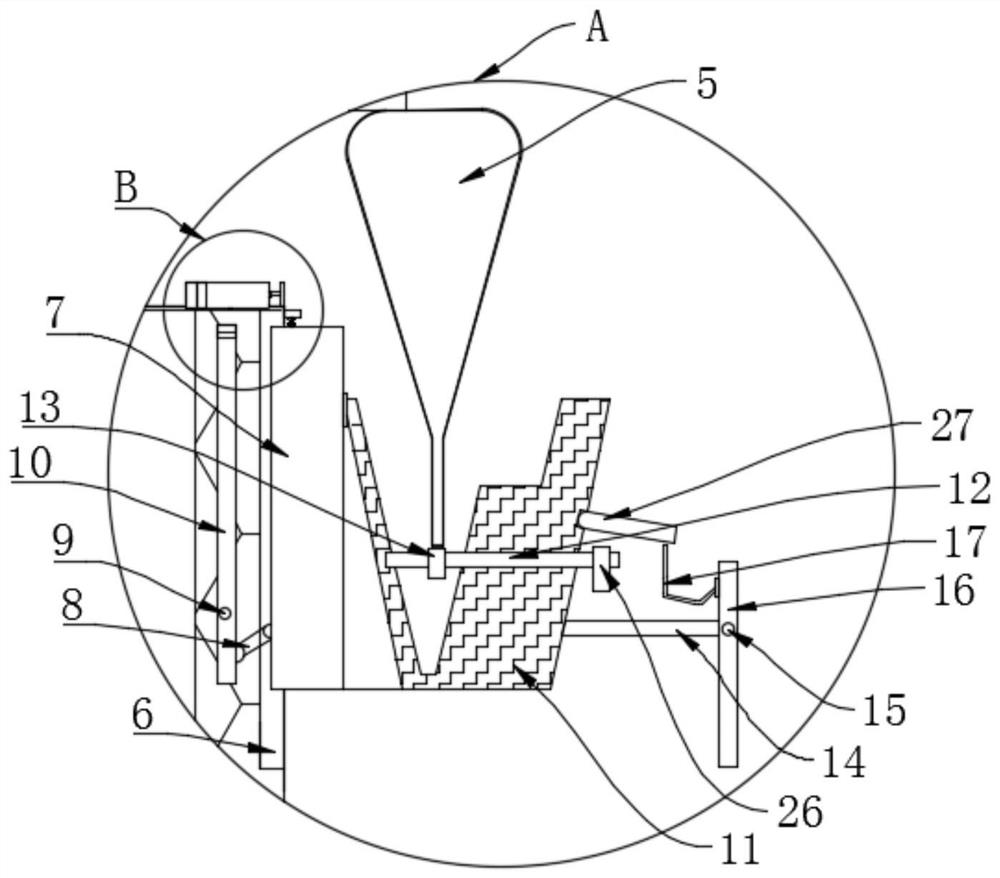

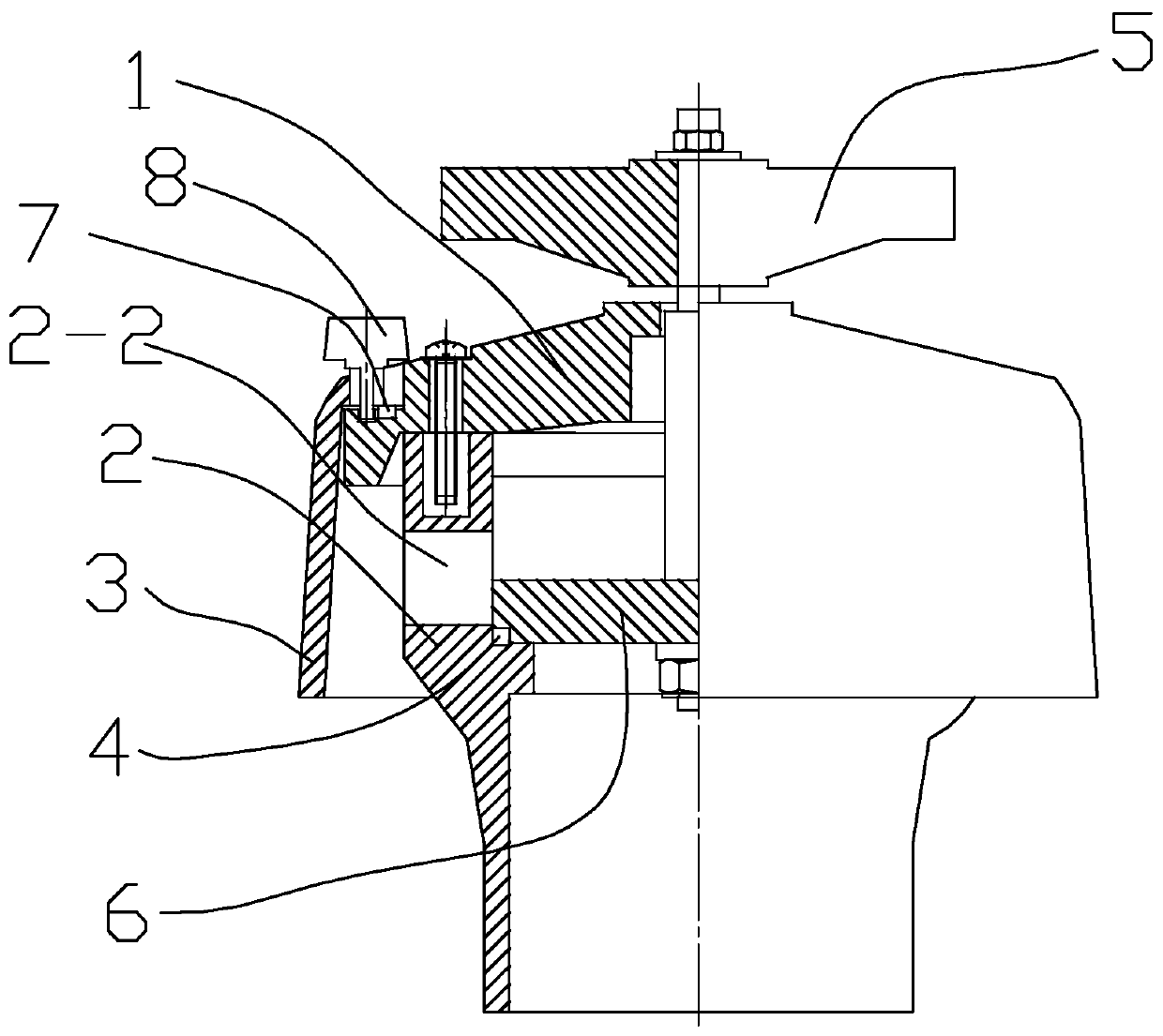

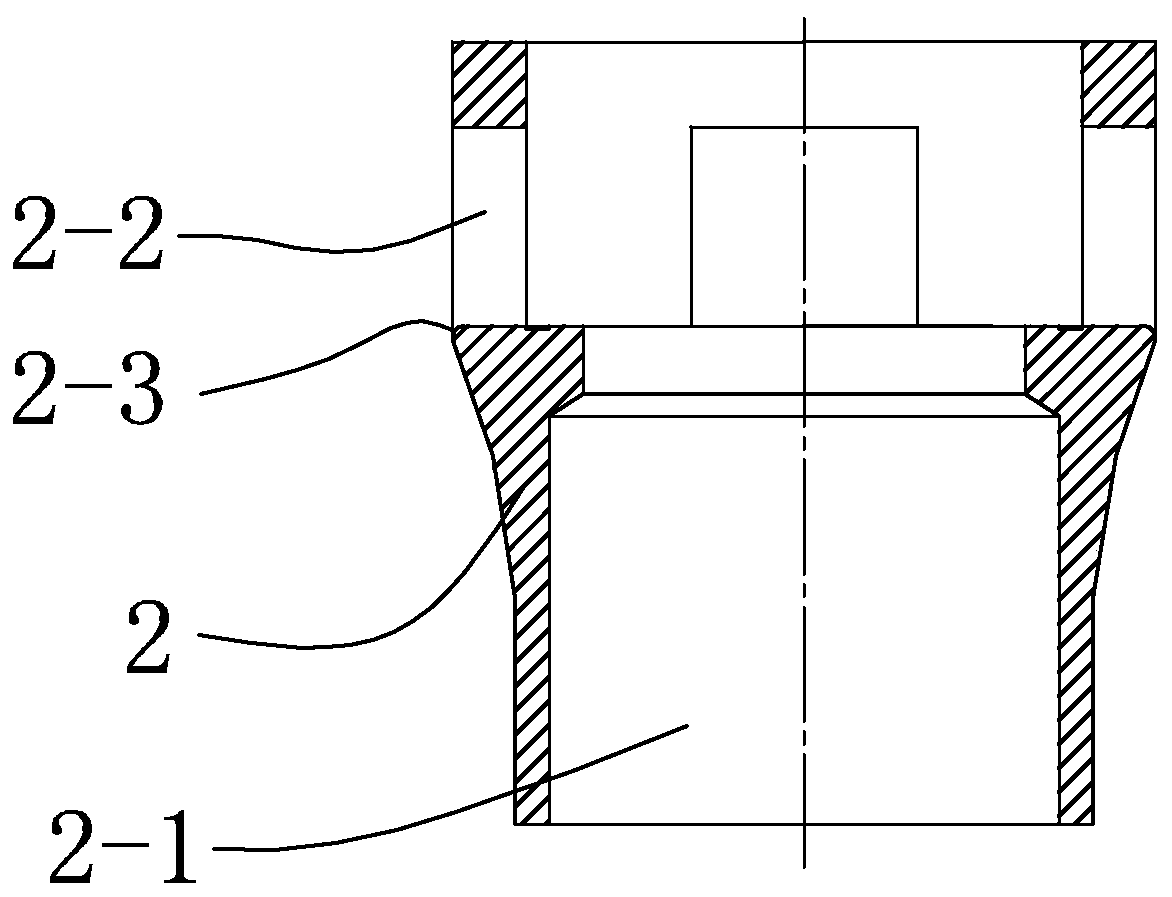

Novel regulating valve for coal slurry control

InactiveCN103672010AExtended service lifeSolve scourPlug valvesValve housingsEngineeringCoal chemical industry

The invention relates to a novel regulating valve for coal slurry control. The novel regulating valve comprises a main shaft (1), a valve body (3) and a valve element (2), and is characterized in that the upper end of the valve element (2) is connected with the main shaft (1), and the lower end of the valve element (2) is connected with a secondary shaft; the secondary shaft is installed on the valve body (3), a V-shaped window is arranged in the valve element (2), and the top end of the V-shaped window is a spherical surface. After trail, it is proved that through the adoption of the novel regulating valve, the problem of scouring of pulverized coal for a valve cavity and the valve element under a coal chemical industry working condition is solved, the service life of the regulating valve is effectively prolonged, and meanwhile the requirement for localization of the regulating valves for the coal chemical industry is met.

Owner:WUZHONG INSTR

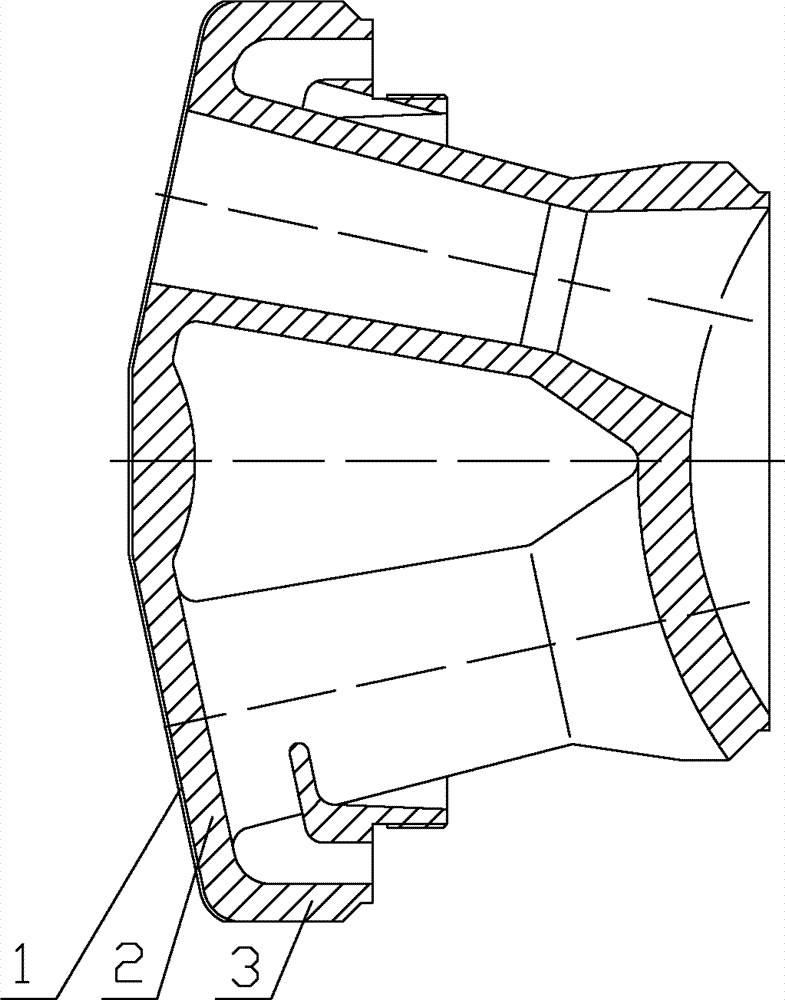

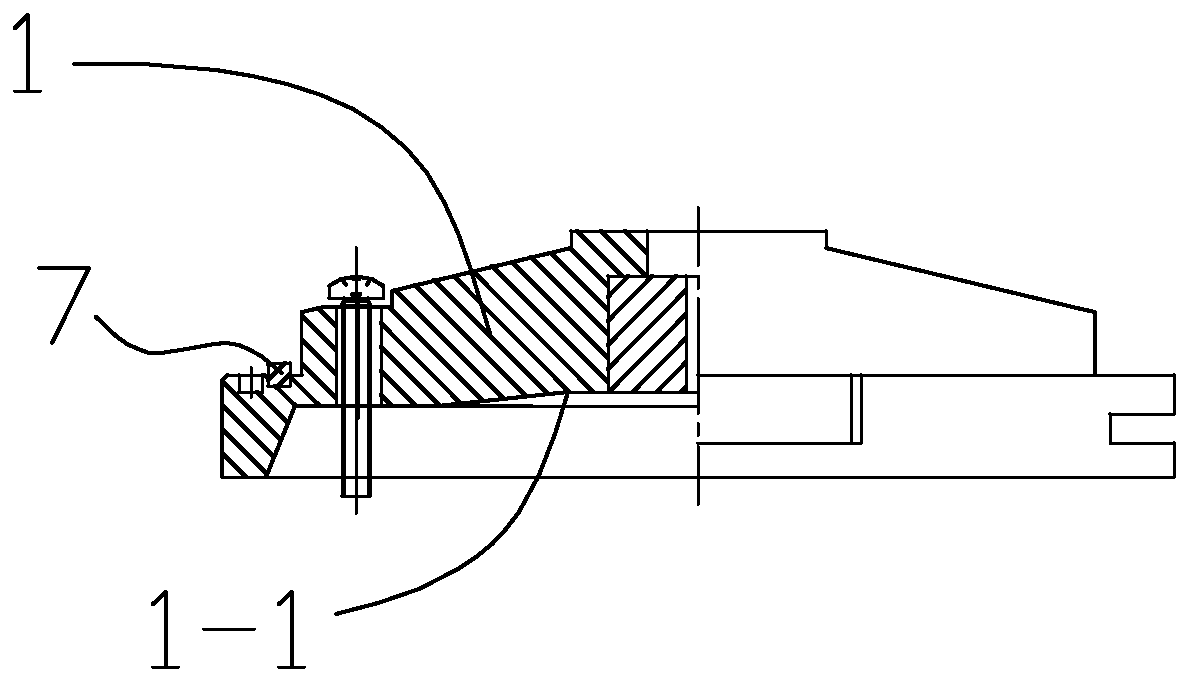

Axial flow type single-seat adjusting valve

InactiveCN103185145ASimple structureSmall flow resistance coefficientOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringValve seat

The invention discloses an axial flow type single-seat adjusting valve, and belongs to the field of valve production. The axial flow type single-seat adjusting valve comprises a valve body, a stuffing device assembly, a valve rod, a valve core, a valve seat and a guide plate, wherein the valve rod is arranged at a stuffing box of the valve body through the stuffing device assembly; the valve seat is arranged at a liquid inlet passage of the valve body; and the valve core and the guide plate are arranged in the valve body. The axial flow type single-seat adjusting valve is characterized in that the liquid inlet passage and a liquid outlet passage at two ends of the valve body are arranged coaxially; the valve rod is arranged on one side of the valve body close to the liquid outlet passage through the stuffing device assembly; the guide plate is fixed on one side close to the liquid inlet passage in the valve body; the base part of the valve core penetrates through the guide plate and is in transmission connection with the bottom of the valve rod through a transmission mechanism, and the movable end of the valve core is arranged at the liquid inlet passage of the valve body and matched with the valve seat. Compared with the prior art, the axial flow type single-seat adjusting valve has the advantages of high flow coefficient, stable flow rate and the like and has high popularization and application value.

Owner:山东益龙阀门有限责任公司

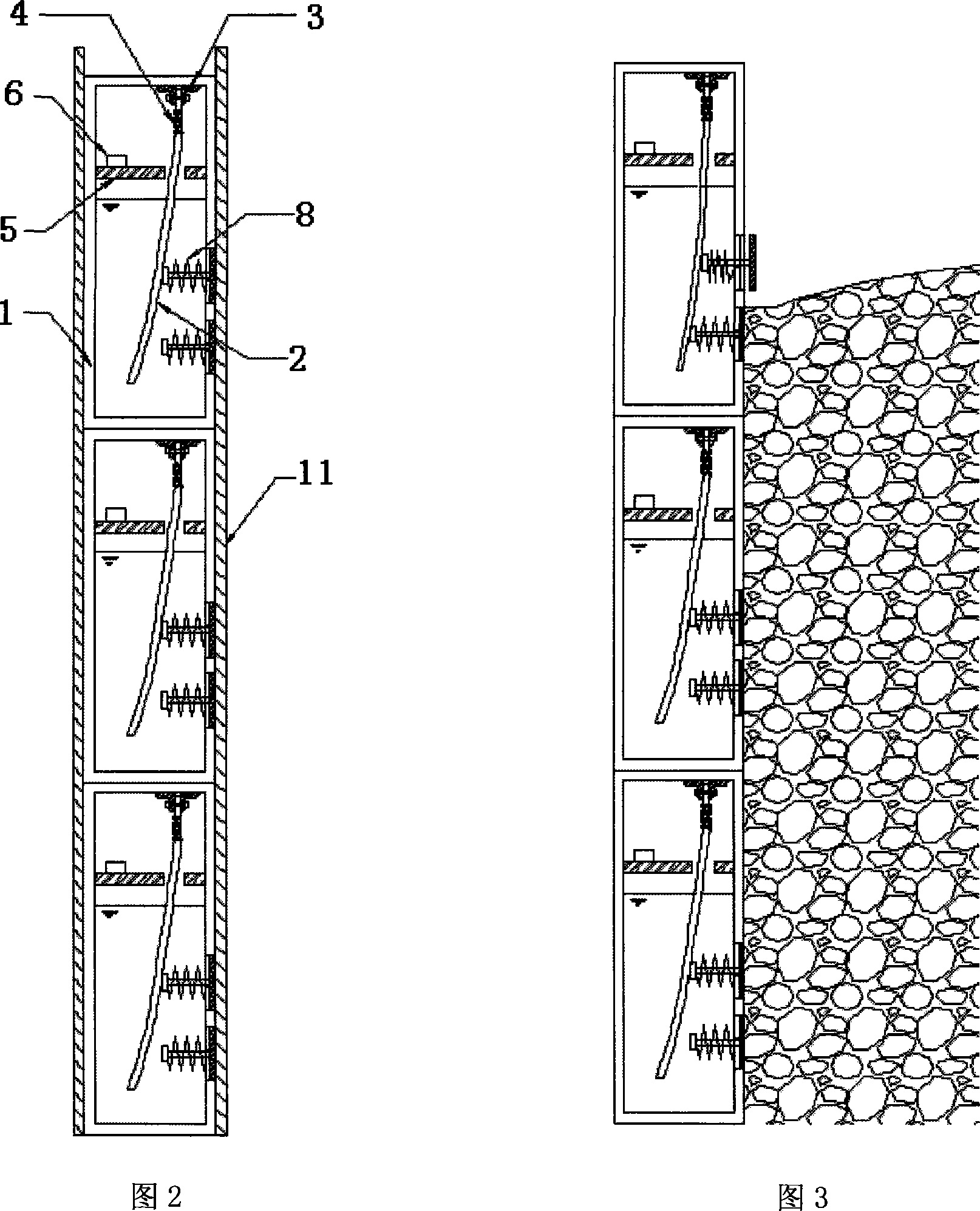

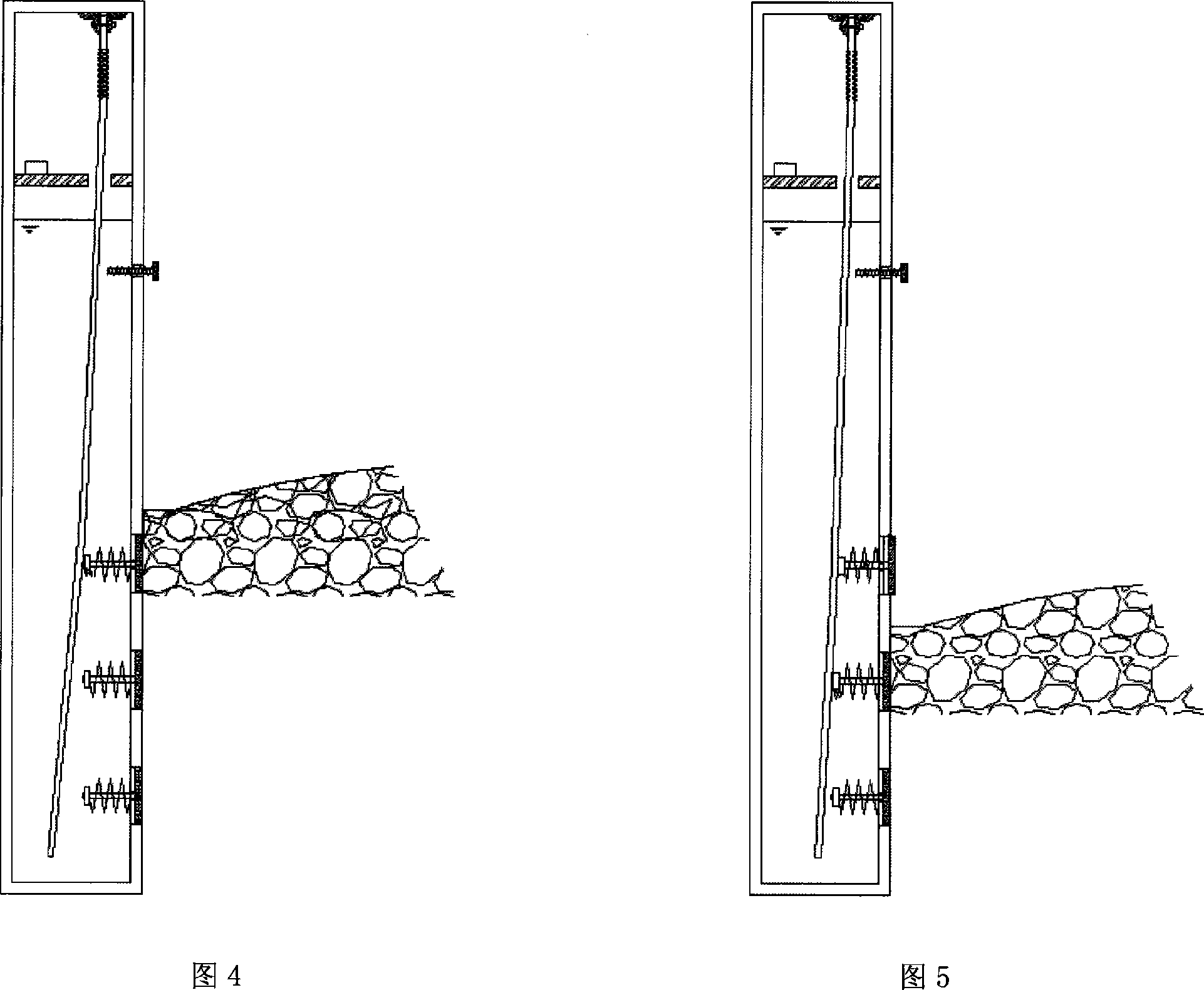

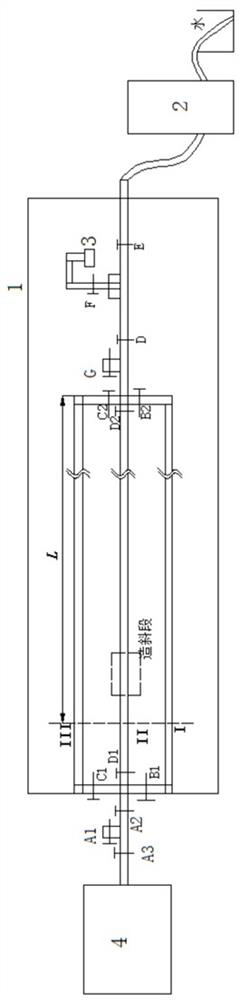

Simulation test device and method for multi-angle tilt drilling grouting technology for coal seam bottom plate under effect of pressure-bearing flowing water

ActiveCN109441441AEasy to observeOptimization of grouting processSealing/packingWater sourceOpen source

The invention discloses a simulation test device and method for a multi-angle tilt drilling grouting technology for a coal seam bottom plate under the effect of pressure-bearing flowing water. The simulation test device comprises a test rack, a pressure-bearing aquifer water source applying device, multi-angle drilling and different hole diameter fracture simulation devices and a grouting device;the test rack is used for bearing the multi-angle drilling and different hole diameter fracture simulation device; the multi-angle drilling and different hole diameter fracture simulation devices aredivided into multiple sets according to drilling angles and the sizes of fractures; the pressure-bearing aquifer water source applying device comprises a constant-pressure water pump, a water pressureadjusting valve, an open source fracture and sealed fracture control valve and a flowmeter; and the grouting device comprises a grouting machine, a safety valve, a slurry flushing valve, a grouting channel valve, a grouting hole selecting switch and a disassembly-free flushing valve. According to the simulation test device, simulation of a grouting process layout process, simulation of a dynamicprocess of slurry flowing to diffusion, simulation of drilling tilt angles to the slurry diffusion influence, and scenario simulation of precipitation and condensation mechanisms can be achieved.

Owner:NORTH CHINA INST OF SCI & TECH

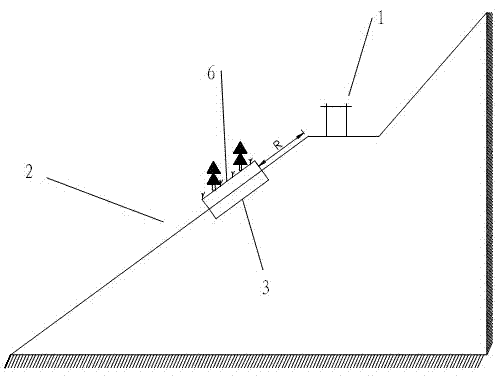

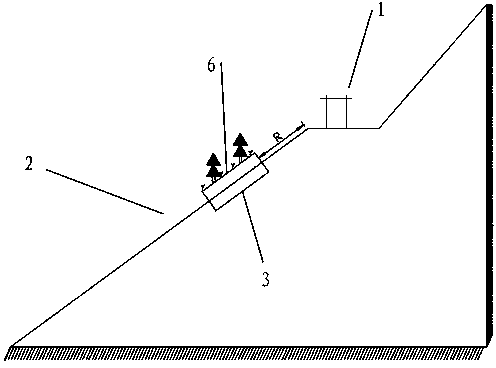

Method for greening discarded soil from mountainous transmission line pole tower foundation construction

ActiveCN102783330AReduce or avoid the impactSolve scourHorticultureSoil-working methodsEngineeringTower

A method for greening discarded soil from mountainous transmission line pole tower foundation construction comprises the following steps of: S1, selecting a lower side slope (2) of a pole tower foundation (shortened as a tower foundation) (1) as a discarded soil stacking position; S2, removing stones and all other impurities on a slope surface of the discarded soil stacking position, particularly removing growing plants so as to prevent an adverse slope after the plants on which soil is stacked die; S3, forming a gentle slope zone soil-covering layer (3) by the stacked discarded soil, wherein the thickens of the discarded soil gentle slope zone soil-covering layer is larger than 30cm but smaller than 200cm, the stacking gradient is determined on the basis of non-slipping of a saturated discarded soil side slope (3); S4, building a drainage ditch (4) along the edge of the discarded soil slope and building a reservoir (5) on the bottommost part of the drainage ditch so as to form an irrigation system; and S5, modifying the surface of a discarded soil gentle slope zone soil-covering layer which is not thicker than 25cm, fertilizing, and planting a mixed vegetation of shrubs and grass (6) on the gentle slope zone soil-covering layer by a vegetation belt slope protection method. The method for greening the discarded soil from the mountainous transmission line pole tower foundation construction is applicable to positions, where the discarded soil is nearby stacked, near a tower foundation during the mountainous tower foundation construction.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

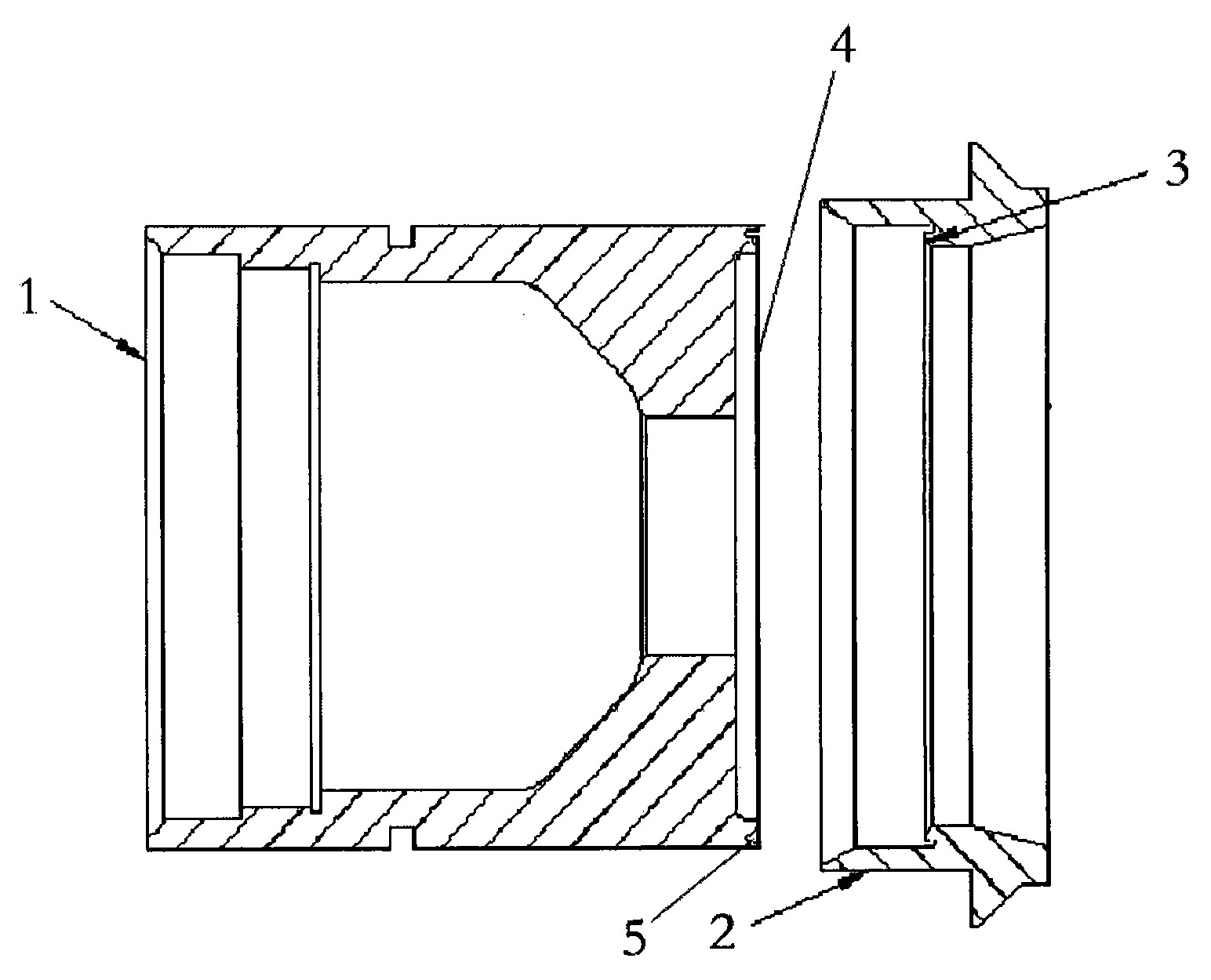

Anti-washing throttle valve sealing surface structure

The invention discloses an anti-washing throttle valve sealing surface structure. The anti-washing throttle valve sealing surface structure comprises a valve clack, a valve cage and a valve seat, wherein the valve cage and the valve seat are of an integrated structure; a sealing surface of the valve seat is arranged on an inner wall of the valve cage; the upper surface of the valve clack is a valve clack sealing surface and a shroud band is arranged at the circumference of the valve clack sealing surface to prevent fluid from washing. The flowing area is controlled according to the distance between the valve clack and the valve cage or the depth of inserting the valve clack into the valve cage; the valve is completely closed by the tight contact of the valve clack sealing surface and the sealing surface of the valve seat; the two sealing surfaces are made of anti-wearing alloys. The valve cage is arranged on the structure outside the valve clack so that impurities are prevented from being clamped in the sealing surfaces; the anti-washing shroud band of the valve clack sealing surface is designed in order to prevent the valve clack sealing surface from being washed by the fluid; the valve clack sealing surface is arranged in the anti-washing shroud band; meanwhile, the valve clack sealing surface does not have a washing angle so that the problems of sealing surface washing and impurity carrying are effectively solved.

Owner:ZHANGJIAKOU POWER GENERATION FACTORY OF DATANG INT POWER GENERATION

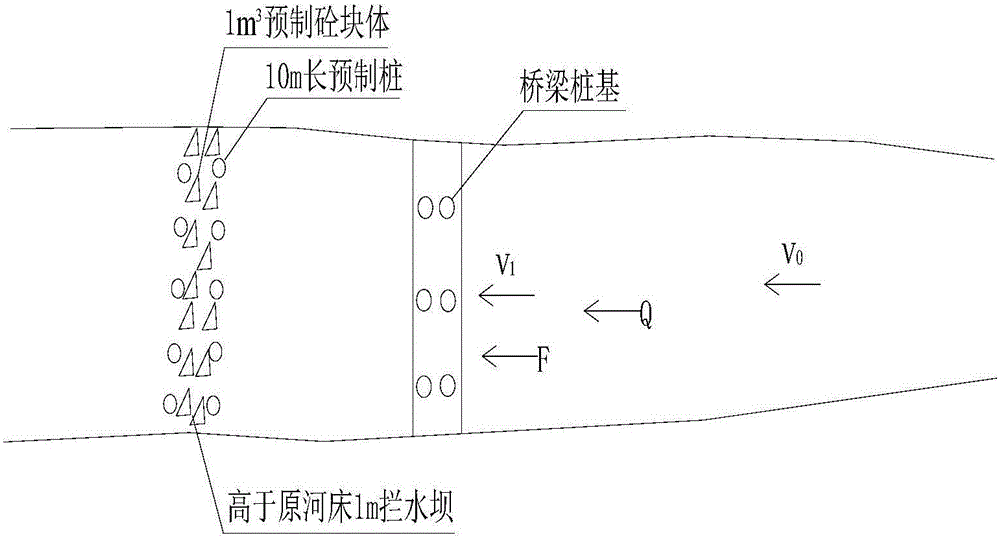

Construction method for preventing bridge foundation in mountain river from being scoured

The invention discloses a construction method for preventing and controlling the scour of bridge foundations in rivers in mountainous areas. The method specifically comprises: constructing a retaining dam on a river downstream of the bridge foundation to form a river energy-dissipating and speed-reducing pool. The construction method of the dam is as follows: drive at least one row of fixed piles in the riverbed along the section of the river, and the top of the piles is higher than the surface of the riverbed, and place a water retaining structure upstream or in the middle of the fixed piles to form a dam. Compared with the existing method for prevention and control of foundation erosion of bridges in mountainous rivers, the construction is simple, and only one dam needs to be constructed, and the cost is greatly reduced. Moreover, the setting of the dam can make the riverbed near the eroded bridge foundation back to silt, and gradually restore the embedding depth of the bridge foundation, thereby fundamentally solving the problem of bridge foundation scour.

Owner:SHANGHAI LANGZHAO HIGHWAY & RAILWAY MAINTENANCEENG TECH

A method and fixing device for planting mangroves on the windward surface of the coastal intertidal zone

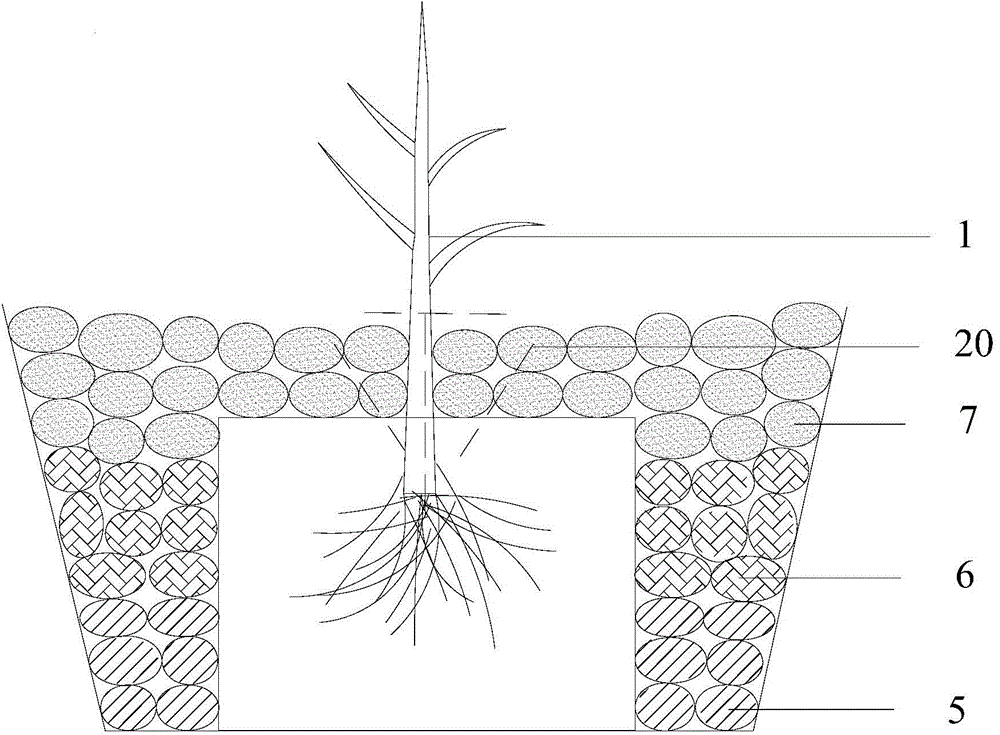

ActiveCN103988755BImprove survival rateImprove ventilationCultivating equipmentsForestryMangrove plantsOyster

The invention belongs to the technical field of mangrove forest planting, and provides a method for planting the mangrove forest in the coast intertidal zone stormward face and a fixing device. The method comprises the following steps that mangrove sapling planting caves are dug at the selected positions; the mangrove saplings are planted into the planting caves, three layers of maintaining sand bags are accumulated in sequence, and the caves are covered with silt or gravel or other sand grains to be tamped, wherein the first layer of maintaining sand bag is an organic fertilizer-gravel sand bag, the second layer of maintaining sand bag is a fresh oyster shell-sand-soil sand bag, and the third layer of maintaining sand bag is a gravel sand bag or a silt sand bag or a bag of other sand grains; the mangrove saplings are planted according to the method to form the mangrove forest in the area; the mangrove saplings are fixed through the fixing device; guard piles are arranged at the offshore end 2-5 meter away from the front end of the low water line. According to the method, the mangrove forest can be planted in intertidal zones with different bottom materials, the purpose of preventing stormy waves is achieved, and the mangrove forest survival rate is high.

Owner:SHENZHEN GREENJIUZHOU LANDSCAPING

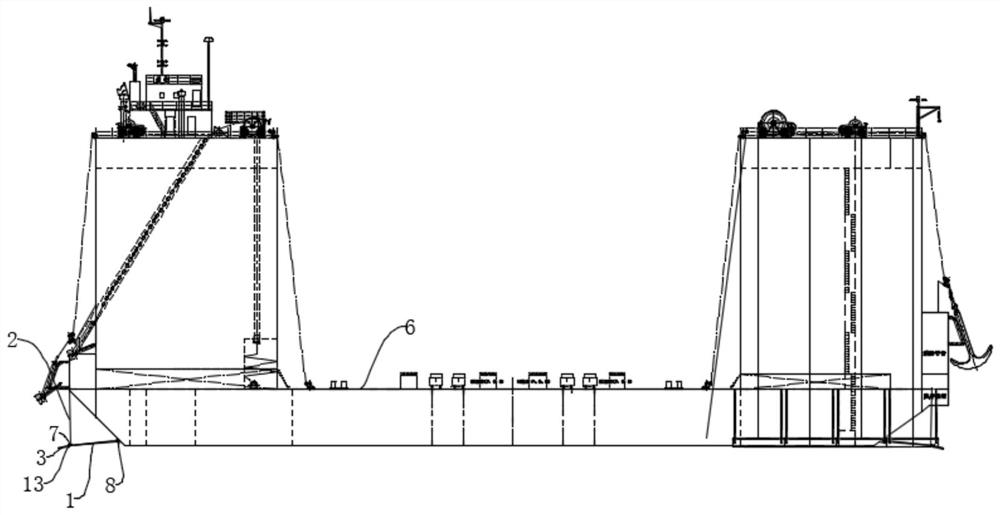

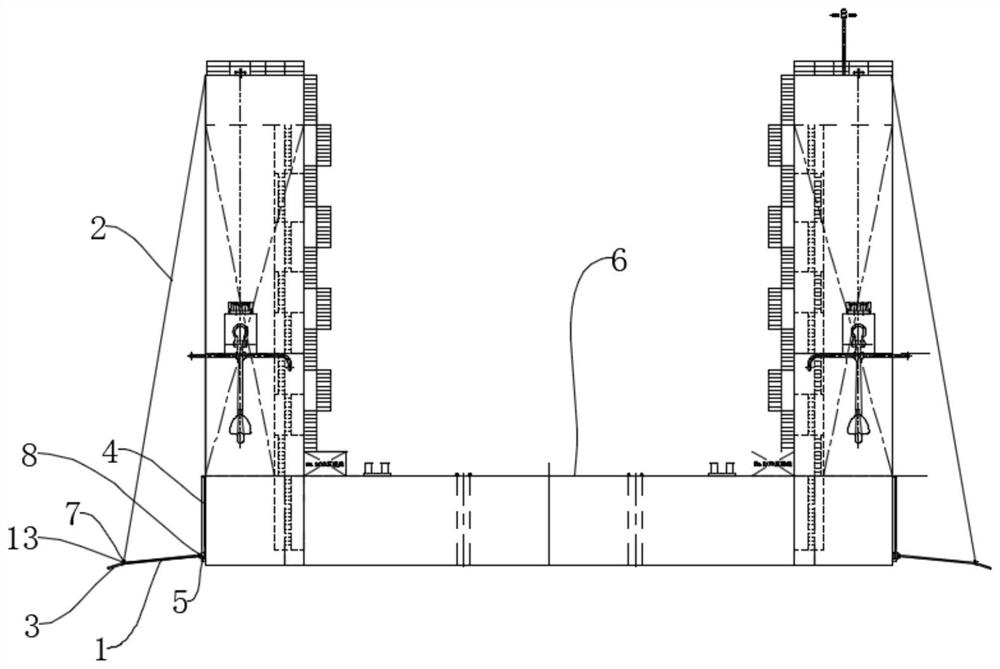

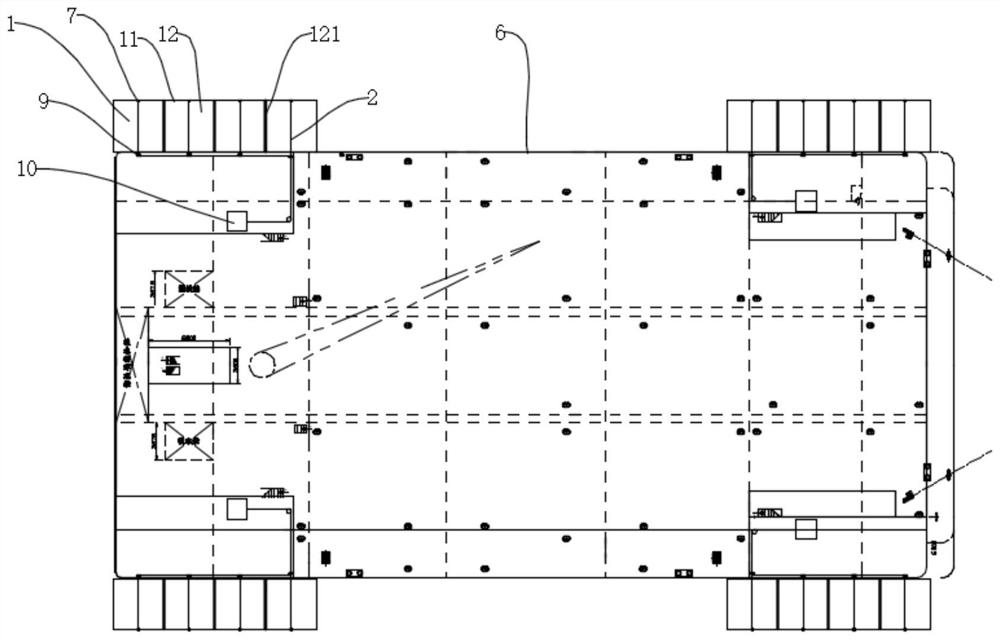

Protection device with movable protection plate for semi-submersible barge bottom-sitting construction and construction method

The invention relates to the technical field of hull protection, in particular to a protection device with a movable protection plate for semi-submersible barge bottom-sitting construction and a construction method. The protection device comprises a plurality of scour prevention plates, each scour prevention plate comprises a steel rib frame, each steel rib frame is formed by connecting a plurality of steel rib frame units, each mooring rope is connected with the corresponding steel rib frame unit, and a movable protection plate is hinged to the front edge of each scour prevention plate. A baffle used for limiting the rotating angle of the movable protection plate is further arranged on the anti-scouring plate, and the multiple mooring ropes are connected to a winch; the semi-submersible ship anti-scour protection device can conduct effective anti-scour protection on the periphery of a ship body, is simple in structure, convenient to obtain materials and low in manufacturing cost, canbe prefabricated and assembled in advance on land, can be rapidly assembled with the ship body, improves efficiency, has good anti-scour capacity, conducts re-protection on the front edge position ofan anti-scour plate, and further scouring of the foundation is effectively protected.

Owner:CCCC FIRST HARBOR ENG +1

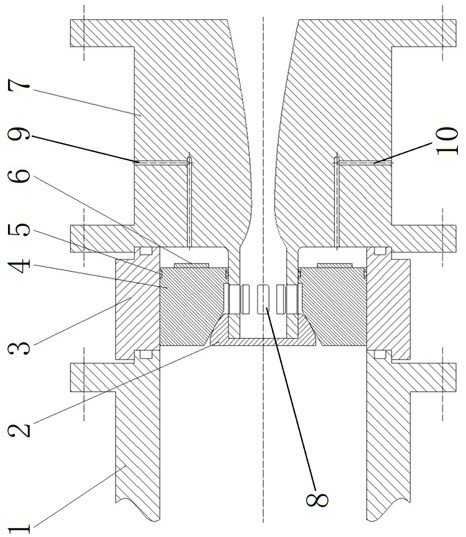

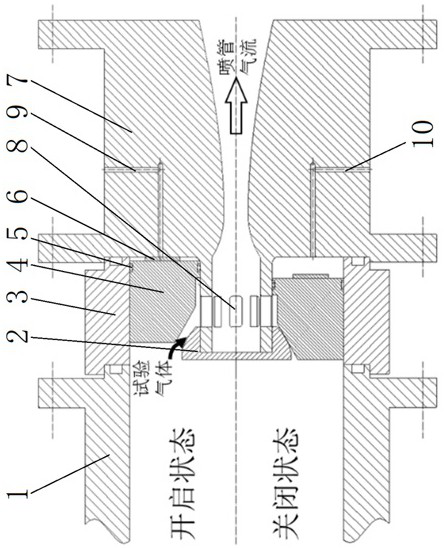

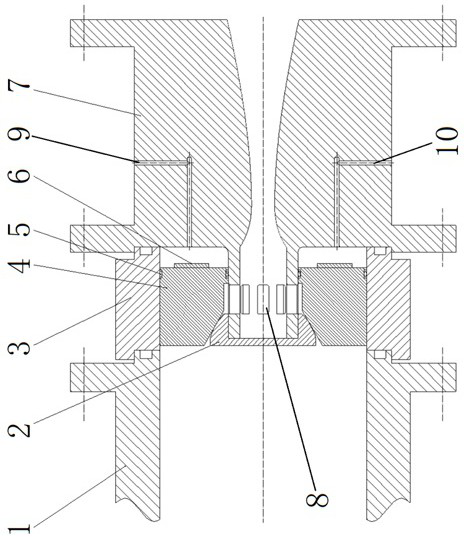

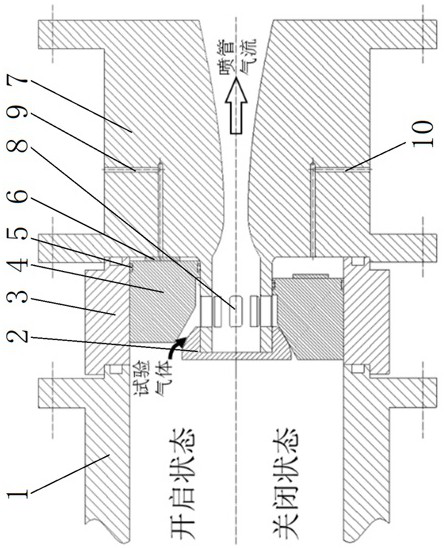

Diaphragm-free shock tunnel throat device and test method thereof

ActiveCN113916492AReduced risk of entering the shock tunnel throatAvoid the adverse effects of slag or petal dropAerodynamic testingPiston ringEngineering

The invention discloses a diaphragm-free shock tunnel throat device and a test method thereof. The throat device comprises a driven section, a piston supporting section and a throat section; a piston ring is arranged in the piston supporting section and moves front and back to form a moving cavity; and an air inlet through hole is formed in the round-tube-shaped air inlet cylinder protruding forwards from the throat section, an end socket is installed at the front end of the round-tube-shaped air inlet cylinder, the end socket and the piston ring form a ball head conical surface line sealing structure, and an inflation hole and a breathing hole which are communicated with the movable cavity are further formed in the throat section. During test, high-pressure test gas pushes the piston ring to move backwards, gas in a moving cavity is exhausted through a breathing hole, the piston ring impacts the front end face of the throat section, the piston ring and the spherical head conical surface line sealing structure of the sealing head lose efficacy, and the high-pressure test gas enters the shock tunnel throat through the gas inlet through hole. The throat device and the test method are simple and reliable, the test efficiency is high, and the damage to the test model and the test sensor on the test model is small.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Anticorrosive and wear-resistant material for spraying zones of desulfurization towers

ActiveCN102343697BReduce construction difficultyLow costSynthetic resin layered productsDispersed particle separationGlass fiberFlue gas

The invention discloses an anticorrosive and wear-resistant material for the spraying zones of desulfurization towers. The material comprises an impermeable material, a reinforcing material and a wear-resistant material, wherein the impermeable material mainly comprises vinyl ester resin added with glass flakes; the reinforcing material mainly comprises vinyl ester resins, glass fiber cloth and glass fiber chopped strand mats; the wear-resistant material mainly comprises vinyl ester resin added with wear-resistant ceramic packing particles; and the wear-resistant ceramic packing particles can be divided into packing I, packing II and packing III mixed in certain proportion. The material disclosed by the invention has the advantages of low difficulty in construction, low cost, good anticorrosive effect, good wear-resistant performance, convenience in application and maintenance, and capability of effectively preventing the damage from an external force and an internal stress and resisting the corrosion of acid liquor or the erosion of flue gas, effectively resolving the problems of erosion, wear and damage of the wear-resistant material easily occurring in spraying zones of desulfurization towers, prolonging the service life of an anticorrosive layer, and greatly reducing the maintenance cost.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

Axial flow type single-seat adjusting valve

InactiveCN103185145BSimple structureSmall flow resistance coefficientOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringVALVE PORT

Owner:山东益龙阀门有限责任公司

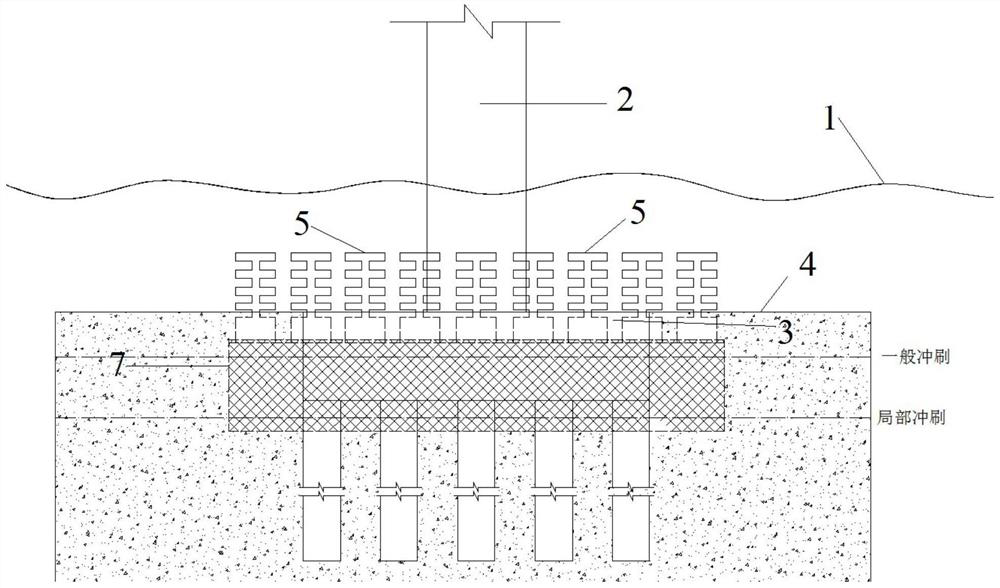

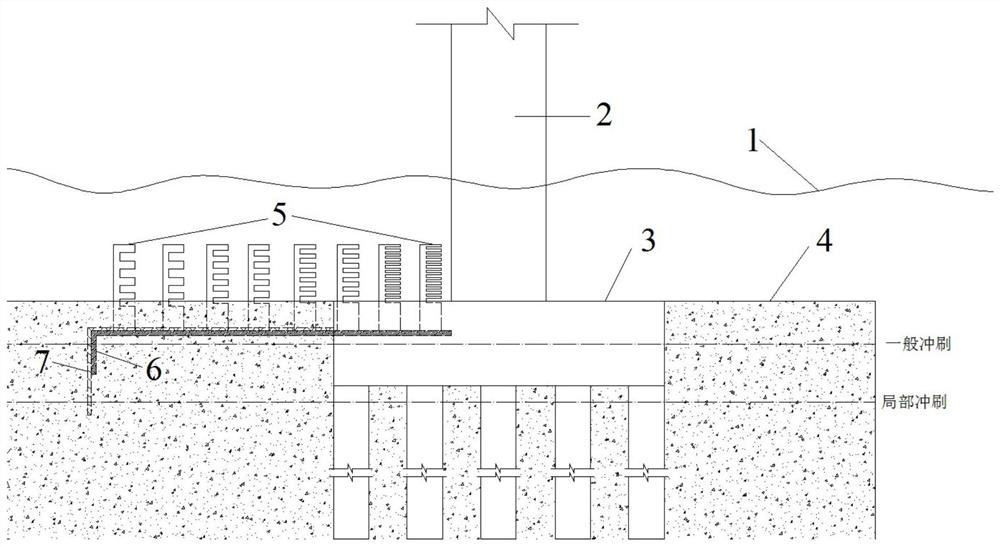

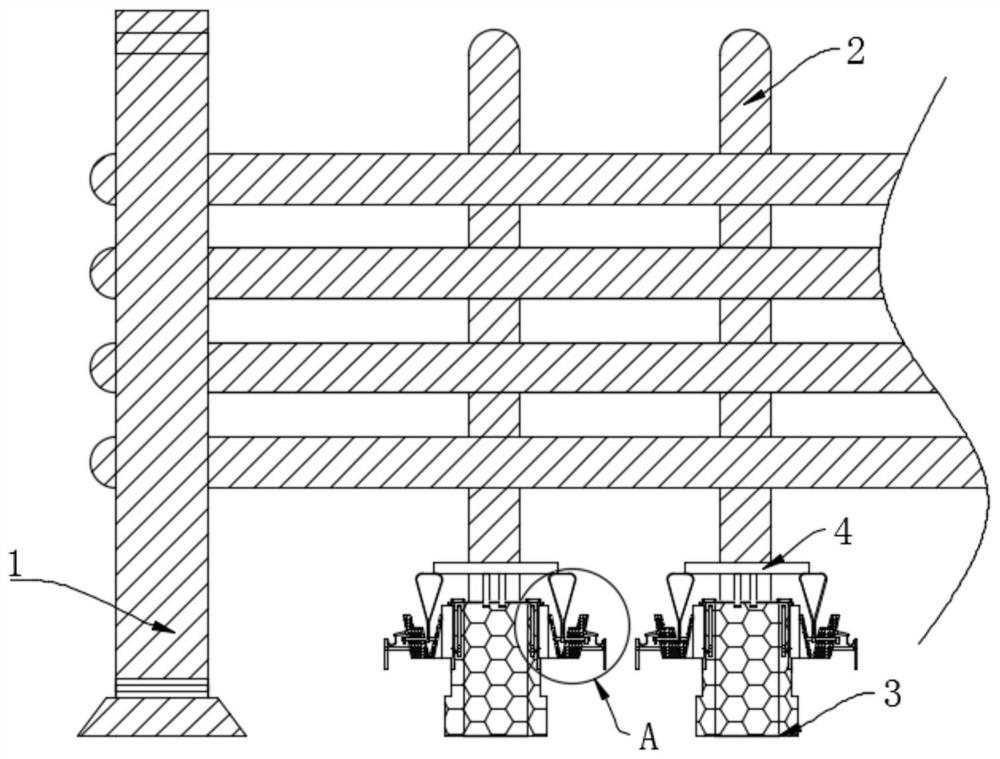

A comb tooth device for resisting erosion of pier column foundation of heavy-duty railway bridge

ActiveCN111424730BSolve scourBlocking from being lifted by the currentProtective foundationBridge structural detailsWater flowPier

The invention relates to a comb tooth device for resisting scour of a pier column foundation of a heavy-duty railway bridge, which belongs to the technical field of bridge reinforcement. Including comb teeth, L-shaped loading plate and diamond-shaped grid; the L-shaped loading plate is pre-embedded in the foundation and the river bed, and the rear end of the horizontal plate of the L-shaped loading plate is embedded in the foundation of the bridge pier column, which is embedded in the river bed The front end of the inner part is bent downwards to form a vertical plate; several comb teeth are arranged in layers and staggered on the upstream side of the pier and foundation washed by the water flow; Buried in the river bed; along the upstream direction towards the pier, the comb teeth of each layer are arranged in a staggered manner, the opening angle of the comb teeth gradually increases, and the spacing between the teeth gradually decreases. The invention effectively avoids the problem of bridge pier and foundation being eroded, and protects the river bed.

Owner:SHIJIAZHUANG TIEDAO UNIV

A kind of anticorrosion material used for exhaust gas desulfurization chimney

ActiveCN102585655BReduce construction difficultyLow costSynthetic resin layered productsAnti-corrosive paintsEpoxyCorrosion prevention

The invention discloses an anticorrosive material for a smoke discharge and desulfurizing chimney, which comprises an anti-permeability material and an abrasion-resistant material, wherein the anti-permeability material mainly comprises EpigenXD modified epoxy resin added with glass flakes, and the abrasion-resistant material mainly comprises the EpigenXD modified epoxy resin added with abrasion-resistant white corundum filler particles. The abrasion-resistant white corundum filler particles are divided into fillers I and fillers II, and the fillers I and the fillers II are mixed according to a certain proportion. The anticorrosive material for the smoke discharge and desulfurizing chimney is small in construction difficulty, low in cost, good in anticorrosive effect, good in abrasion-resistant performance, capable of effectively preventing damage of external force and internal stress and resisting to corrosion of acid liquor or scour of smoke and convenient in use and maintenance. In addition, scour and abrasion damage which easily happen to the anticorrosive material of the smoke discharge and desulfurizing chimney are effectively avoided, service life of an anticorrosive layer is prolonged, and maintenance cost can be reduced to a large extent.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

Method of backfilling and anti-scouring with flexible composite bagged sand

ActiveCN112144385BClosely connectedTightly boundBridge structural detailsFoundation engineeringSoil scienceStructural engineering

Owner:江苏在铭建设工程有限公司

Bridge pier scour monitoring system and monitoring method based on geopulsation measurement

InactiveCN104457634BSolve scourUsing subsonic/sonic/ultrasonic vibration meansData processing systemMonitoring system

The invention discloses a micro-tremor measurement based bridge pier scour monitoring system. The micro-tremor measurement based bridge pier scour monitoring system comprises a fixed micro-seismograph probe installed at the top end of a bridge pier, a guide rail vertically installed on the upstream face of the bridge pier and provided with a portion under the water surface, a movable micro-seismograph probe vertically moving along the guide rail, a micro-seismograph mainframe receiving micro-tremor information detected by the fixed micro-seismograph probe and the movable micro-seismograph probe, and a data processing system for processing the micro-tremor information into bridge pier scour depth and early warning bridge pier scour. The micro-tremor information monitored by a micro-seismograph is processed into the bridge pier scour depth by the data processing system, early warning is performed on the bridge pier, and the micro-tremor measurement based bridge pier scour monitoring system is high in accuracy and long in service life. The invention further discloses a micro-tremor measurement based bridge pier scour monitoring method. The micro-tremor measurement based bridge pier scour monitoring method calculates the bridge pier scour depth based on the micro-tremor information, and a calculation result is accurate and reliable.

Owner:SOUTHWEST UNIV

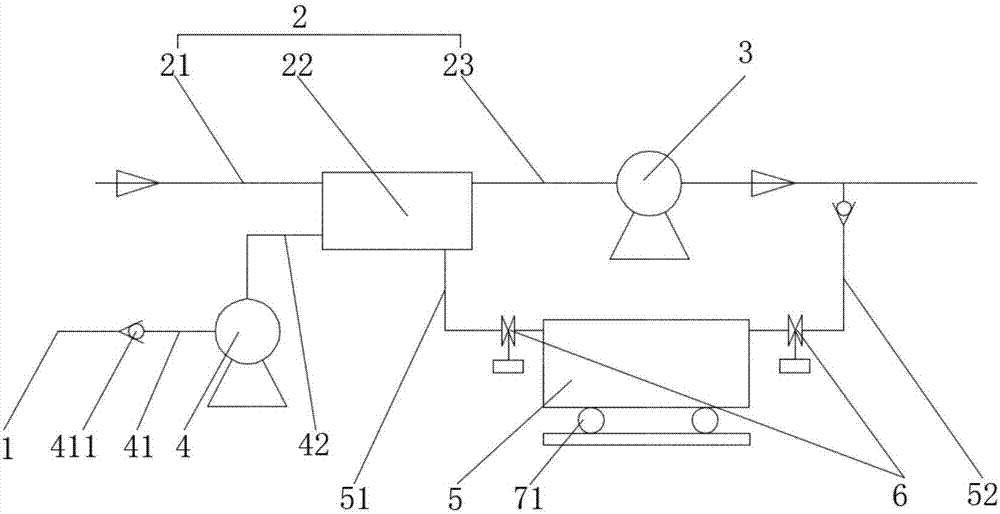

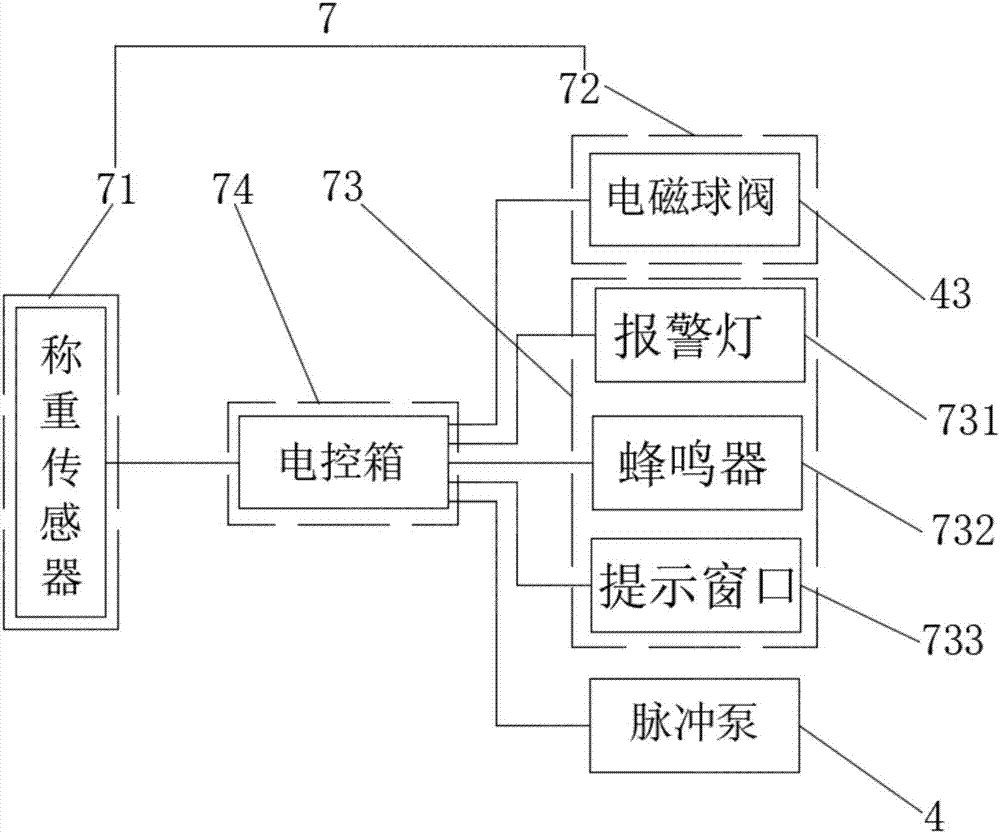

Sediment impulse cleaning system of slurry pipeline

PendingCN107952760ASolve scourExtended service lifePump componentsHollow article cleaningSlurry pipelineMechanical engineering

The invention provides a sediment impulse cleaning system of a slurry pipeline, which comprises a slurry feeding pipeline and a slurry discharging pipeline; the slurry discharging pipeline comprises afront end slurry discharging part, a sediment pipeline and a back end slurry discharging part which are linked in order and in series; the slurry discharging pump is mounted on the back end slurry discharging part, the slurry discharging pipeline is horizontal, and the section area of the sediment pipeline is more than the section area of the front end slurry discharging part; an impulse pump isfurther mounted between the slurry feeding pipeline and the sediment pipeline, and a fluid inlet pipe of the impulse pump is linked to the slurry feeding pipeline in series; a fluid outlet pipe of theimpulse pump is linked to the upstream of the sediment pipeline in series; the back end slurry discharging part is further linked with a sediment collecting box in parallel, and the upstream of the sediment collecting box is connected to the downstream of the sediment pipeline through a stone feeding pipe; the stone feeding pipe is located at the lower side of the back end slurry discharging part, the downstream of the sediment collecting box is linked with the downstream of the back end slurry discharging part through a recycling pipe. The cleaning system can clean the sediment box continuously without shutdown.

Owner:辽宁三三工业有限公司

A simulation test device and method for multi-angle inclined drilling and grouting process of coal seam floor under the action of pressure and dynamic water

ActiveCN109441441BEasy to observeOptimization of grouting processSealing/packingWater sourceSafety valve

The invention discloses a simulation test device and method for the multi-angle inclined drilling and grouting process of coal seam floor under the action of pressure dynamic water. Aperture crack simulation device and grouting device, wherein: the test bench is used to support multi-angle drilling and different aperture crack simulation devices; multi-angle drilling and different aperture crack simulation devices are divided into multiple groups according to the drilling angle and crack size; The water source application device for the confined aquifer includes a constant pressure water pump, water pressure regulating valve, control valve and flow meter for open and closed fissures; the grouting device includes a grouting machine, safety valve, grout flushing valve, grouting channel valve, grouting Orifice selector switch and no-disassembly flush valve. The device of the invention can realize the flow simulation of the grouting process layout, the dynamic process simulation from slurry flow to diffusion, the simulation of the effect of the inclination angle of the borehole on the slurry diffusion, and the scenario simulation of the precipitation and coagulation mechanism.

Owner:NORTH CHINA INST OF SCI & TECH

Method for greening discarded soil from mountainous transmission line pole tower foundation construction

ActiveCN102783330BReduce or avoid the impactSolve scourHorticultureSoil-working methodsEngineeringTower

A method for greening discarded soil from mountainous transmission line pole tower foundation construction comprises the following steps of: S1, selecting a lower side slope (2) of a pole tower foundation (shortened as a tower foundation) (1) as a discarded soil stacking position; S2, removing stones and all other impurities on a slope surface of the discarded soil stacking position, particularly removing growing plants so as to prevent an adverse slope after the plants on which soil is stacked die; S3, forming a gentle slope zone soil-covering layer (3) by the stacked discarded soil, wherein the thickens of the discarded soil gentle slope zone soil-covering layer is larger than 30cm but smaller than 200cm, the stacking gradient is determined on the basis of non-slipping of a saturated discarded soil side slope (3); S4, building a drainage ditch (4) along the edge of the discarded soil slope and building a reservoir (5) on the bottommost part of the drainage ditch so as to form an irrigation system; and S5, modifying the surface of a discarded soil gentle slope zone soil-covering layer which is not thicker than 25cm, fertilizing, and planting a mixed vegetation of shrubs and grass (6) on the gentle slope zone soil-covering layer by a vegetation belt slope protection method. The method for greening the discarded soil from the mountainous transmission line pole tower foundation construction is applicable to positions, where the discarded soil is nearby stacked, near a tower foundation during the mountainous tower foundation construction.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

High durability optical fiber grating wash out sensor

InactiveCN100538280CIncreased durabilityMonitor thickness changesUsing optical meansCoupling light guidesFiberCircular disc

The invention provides a high-durability fiber grating scour sensor. It includes a metal casing and a measuring part set in the metal casing and connected to the metal casing. The measuring part is composed of an FRP equal-strength beam and two fiber gratings attached to the upper and lower surfaces of the FRP equal-strength beam. The lead wire of the fiber grating passes through the metal The shell is drawn out. The inner wall of the metal shell is provided with a metal baffle, and calcium carbide is set on it. A dowel bar is set under the metal shell. The other end is provided with an FRP disc. The scour sensor has the advantages of high precision, convenient layout, adjustable range and resolution, etc., and is suitable for foundation soil scour monitoring of civil engineering structure health monitoring and foundation soil scour monitoring of structural tests.

Owner:HARBIN INST OF TECH

Bridge guardrail base shaping combined template

PendingCN112482230AAvoid enteringAvoid dilutionBridge structural detailsBridge erection/assemblySlide plateSlurry

The invention discloses a bridge guardrail base shaping combined template which comprises a fixing support, a plurality of guardrails are fixedly connected to the fixing support, two combined templateframes are fixedly connected to the side faces of the bottom ends of the guardrails in a sleeving mode, and baffles are fixedly connected to the two combined template frames respectively; wherein bolts are arranged on one combined template frame and one baffle, clamping grooves are formed in the other combined template frame and the other baffle, the clamping grooves are connected with the boltsin a clamped mode, a plurality of first water collecting tanks are fixedly connected to the two baffles, and feeding ports are formed in the two combined template frames. According to the bridge guardrail base shaping combined template, in rainy days, the gravity of rainwater is used for controlling a sliding plate to close the feeding ports, water can be prevented from entering the combined template frames through the feeding ports, the problem that slurry in the combined template frames is scoured by rainwater is solved, the slurry is prevented from being diluted by rainwater, and the shaping effect of the combined template frames is improved.

Owner:河南省第一公路工程有限公司 +1

Anti-corrosion method for oxygen lance nozzle and oxygen lance nozzle

InactiveCN102312041BImprove high temperature resistanceImprove anti-scourabilityLiquid surface applicatorsManufacturing convertersSlagThermal insulation

The invention discloses an anti-corrosion method for oxygen lance nozzles and an oxygen lance nozzle, belonging to the technical field of steel smelting in a converter. According to the invention, the technology of extrusion molding is employed, which enables crystal grains at a nozzle head face to arrange more compactly and enables the nozzle head face to have enhanced capacity of resisting erosion and immersion by slag and molten steel; an alloy heat insulation material is sprayed on the nozzle head face to form a thermal insulation layer, thereby enhancing heat insulation and radiation insulation functions of the nozzle head face, avoiding binding of copper and steel at a high temperature and enabling the oxygen lance nozzle to have better high temperature resistance performance. Therefore, the method provided in the invention enables the service life of the oxygen lance nozzle to be substantially prolonged and production cost to be reduced.

Owner:济南程信利冶金备件有限公司

A diaphragm-less shock tunnel throat device and its test method

ActiveCN113916492BReduced risk of entering the shock tunnel throatAvoid the adverse effects of slag or petal dropAerodynamic testingPiston ringEngineering

The invention discloses a diaphragm-less shock wave wind tunnel throat device and a test method thereof. The throat device includes a driven section, a piston supporting section and a throat section; a piston ring is arranged in the piston supporting section, and the piston ring moves back and forth to form a moving cavity; The air passage hole is equipped with a head at the front end, and the head and the piston ring form a ball head cone surface line sealing structure. There are also air-filling holes and breathing holes communicating with the moving cavity on the throat section. During the test, the high-pressure test gas pushes the piston ring to move backward, and the gas in the moving cavity is discharged through the breathing hole. The piston ring hits the front end of the throat section, and the sealing structure between the piston ring and the ball head cone of the head fails. The test gas enters the throat of the shock tunnel through the air inlet hole. The throat device and test method are simple, reliable, high in test efficiency, and have little damage to the test model and the test sensor on the test model.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Smoke denitration device for preventing catalyst from being plugged by popcorn ash

InactiveCN102179156BAvoid destructionSolve scourDispersed particle filtrationLighting and heating apparatusPolymer sciencePtru catalyst

Owner:SOUTHEAST UNIV

Counter-flow axial energy dissipation valve

PendingCN110159768ASimple structureLow costWatering devicesValve members for absorbing fluid energyBall valveFastener

The invention discloses a counter-flow axial energy dissipation valve, belongs to the technical field of valves, and aims at solving the problem that scouring is caused to a paddy field because a gatevalve or a ball valve is adopted for existing irrigation for the paddy field. The counter-flow axial energy dissipation valve comprises a valve cover, a valve body, a flow guide sleeve, a first sealing ring, a hand wheel, a valve plate and a second sealing ring, wherein a water inlet port and a water outlet port are formed in the valve body; the direction of the water inlet port in the valve bodyis vertical to the direction of the water outlet port; the valve plate is arranged at the water inlet port in the valve body, and the first sealing ring is arranged between the valve plate and the valve body; the valve cover is fixedly connected with the valve body; the hand wheel is connected with the valve cover through a screw rod, and due to the fixed connection of the screw rod and the valveplate, the valve plate is enabled to move in the direction of the water inlet port of the valve body; and the flow guide sleeve and the valve cover are sealed through the second sealing ring, and fixed together through a fastener, so that a water outlet direction is opposite to a water inlet direction. According to the counter-flow axial energy dissipation valve, the resistance of water is increased through the valve plate, so that the dynamic energy of water is reduced; and the dynamic energy of water is further reduced by enabling the water inlet direction to be opposite to the water outletdirection, so that the scouring of high-pressure water to the paddy field is avoided.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com