Smoke denitration device for preventing catalyst from being plugged by popcorn ash

A catalyst and popcorn technology, applied in chemical instruments and methods, dispersed particle filtration, lighting and heating equipment, etc., can solve problems such as blockage of effective flow cross-section, damage to screen mesh structure, high hardness, etc., to prevent damage, solve The effect of flushing and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

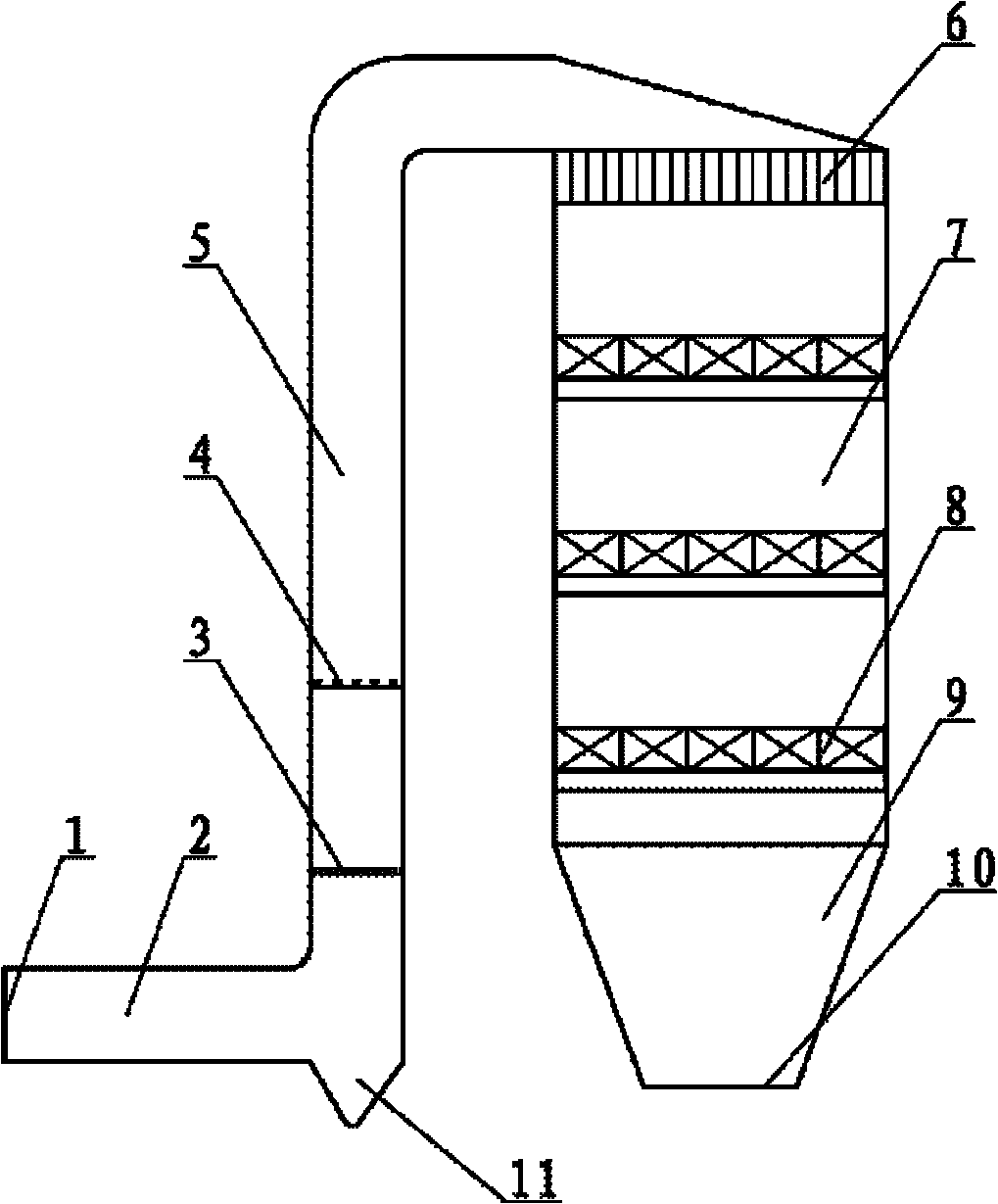

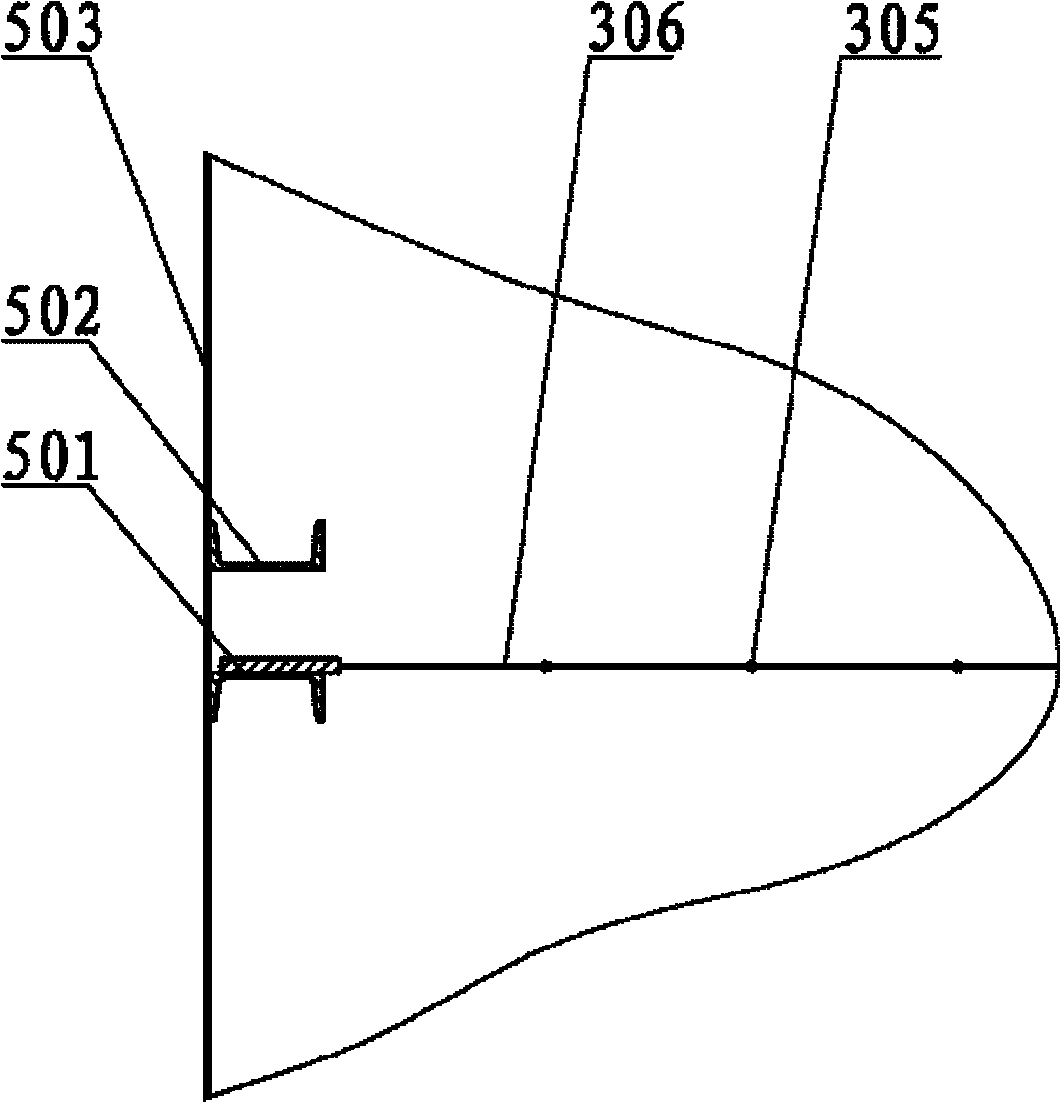

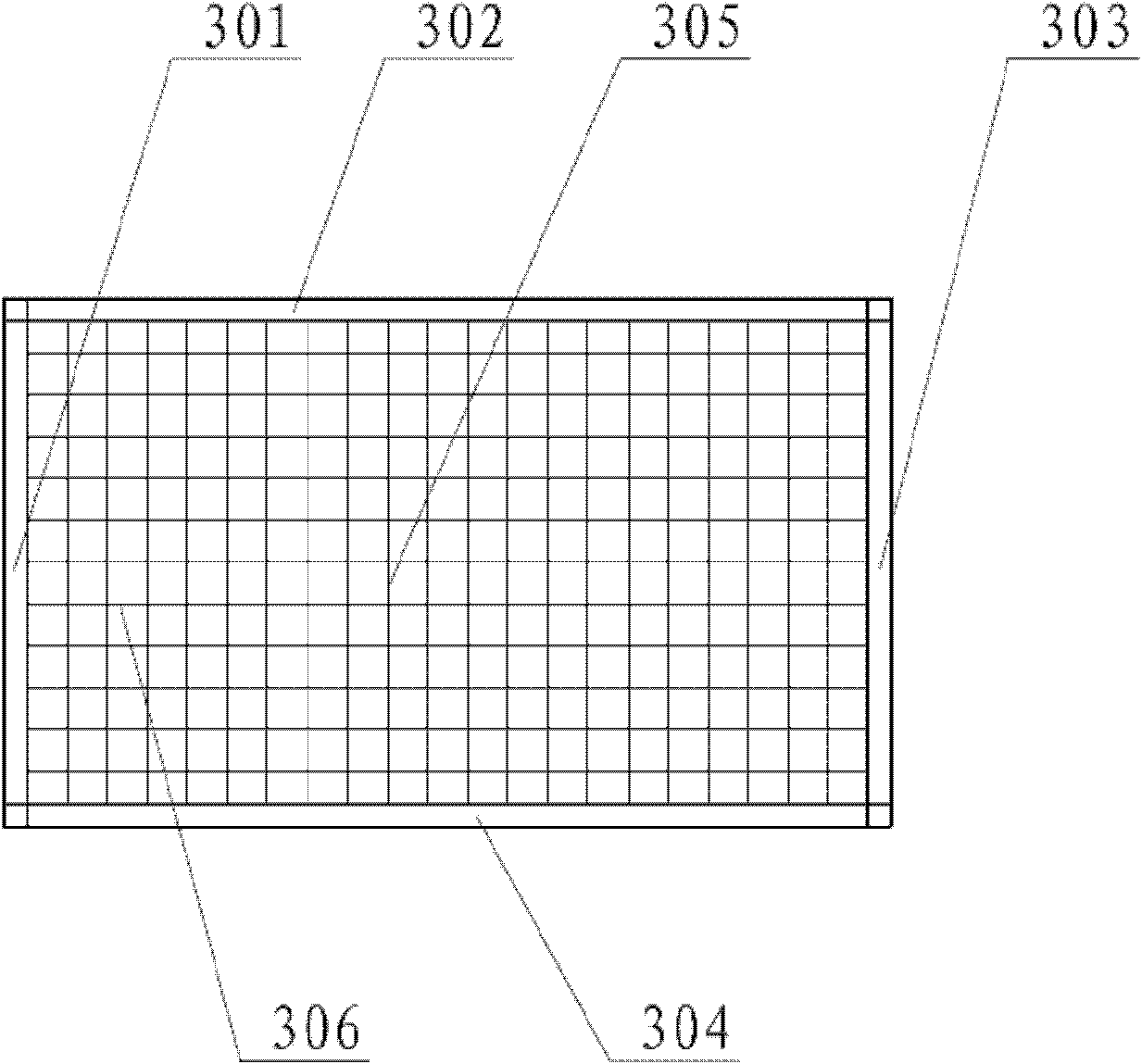

[0022] see Figure 1~4 As shown, the flue gas denitrification device for preventing popcorn ash from clogging the catalyst includes flue gas inlet 1 connected in sequence, horizontal section connecting flue 2, vertical section connecting flue 5, denitrification reactor 7, outlet flue 9 and flue gas The gas outlet 10, wherein the ammonia injection grid 4 is arranged in the flue 5 connecting the vertical section, the rectification device 6 and several layers of catalysts 8 are arranged in the denitrification reactor 7, and the metal screen 3 is also arranged in the flue 5 connecting the vertical section , an ash hopper 11 is provided at the junction of the connecting flue 2 of the horizontal section and the connecting flue 5 of the vertical section.

[0023] During operation, the flue gas to be treated enters the connecting flue 2 of the horizontal section from the flue gas inlet 1, and then turns into the connecting flue 5 of the vertical section. Wherein the popcorn ash with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com