Patents

Literature

5938 results about "Nitrogen oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen Oxide. Definition - What does Nitrogen Oxide mean? Nitrogen oxide is a common term for mono-nitrogen oxides viz. nitric oxide (NO) and nitrogen dioxide (NO 2). Its chemical formula is (NOx). It is formed when nitrogen (N 2) comes in contact or reacts with oxygen (O 2).

Low Temperature Deposition of Silicon-Containing Films

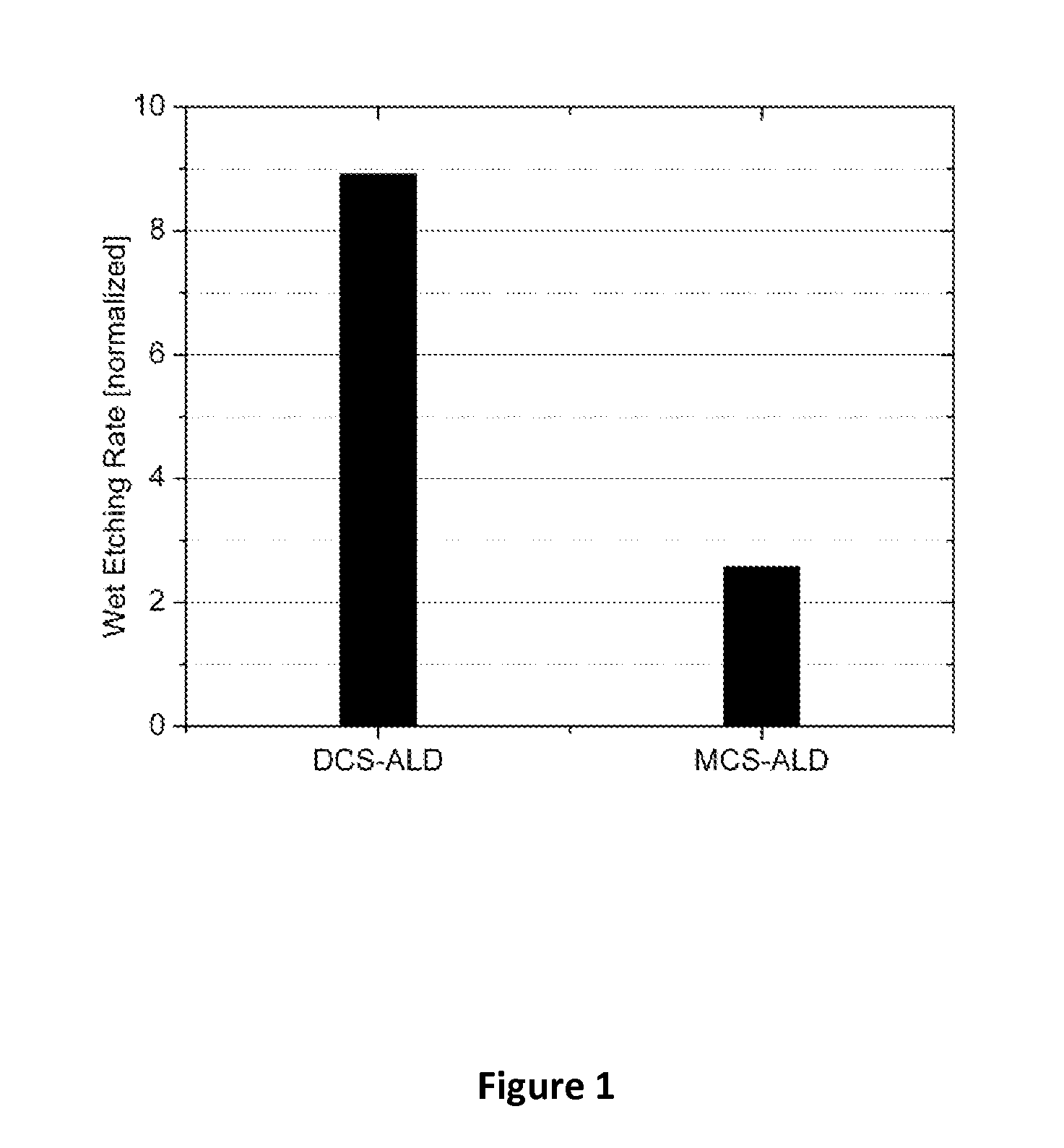

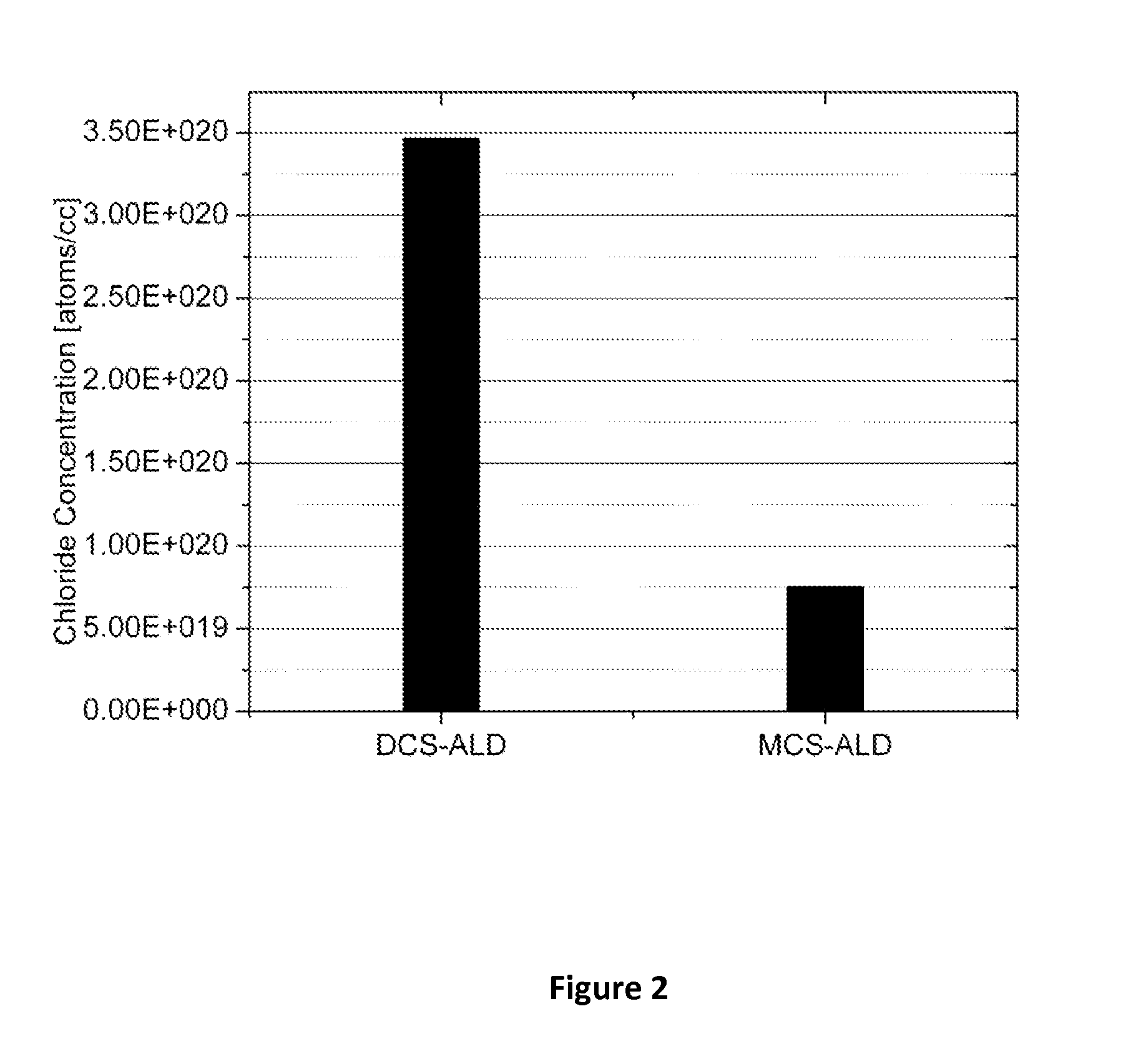

ActiveUS20100304047A1Low deposition temperatureSemiconductor/solid-state device manufacturingSpecial surfacesLow temperature depositionDeposition temperature

This invention discloses the method of forming silicon nitride, silicon oxynitride, silicon oxide, carbon-doped silicon nitride, carbon-doped silicon oxide and carbon-doped oxynitride films at low deposition temperatures. The silicon containing precursors used for the deposition are monochlorosilane (MCS) and monochloroalkylsilanes. The method is preferably carried out by using plasma enhanced atomic layer deposition, plasma enhanced chemical vapor deposition, and plasma enhanced cyclic chemical vapor deposition.

Owner:TOKYO ELECTRON LTD +1

Method of self-cleaning of carbon-based film

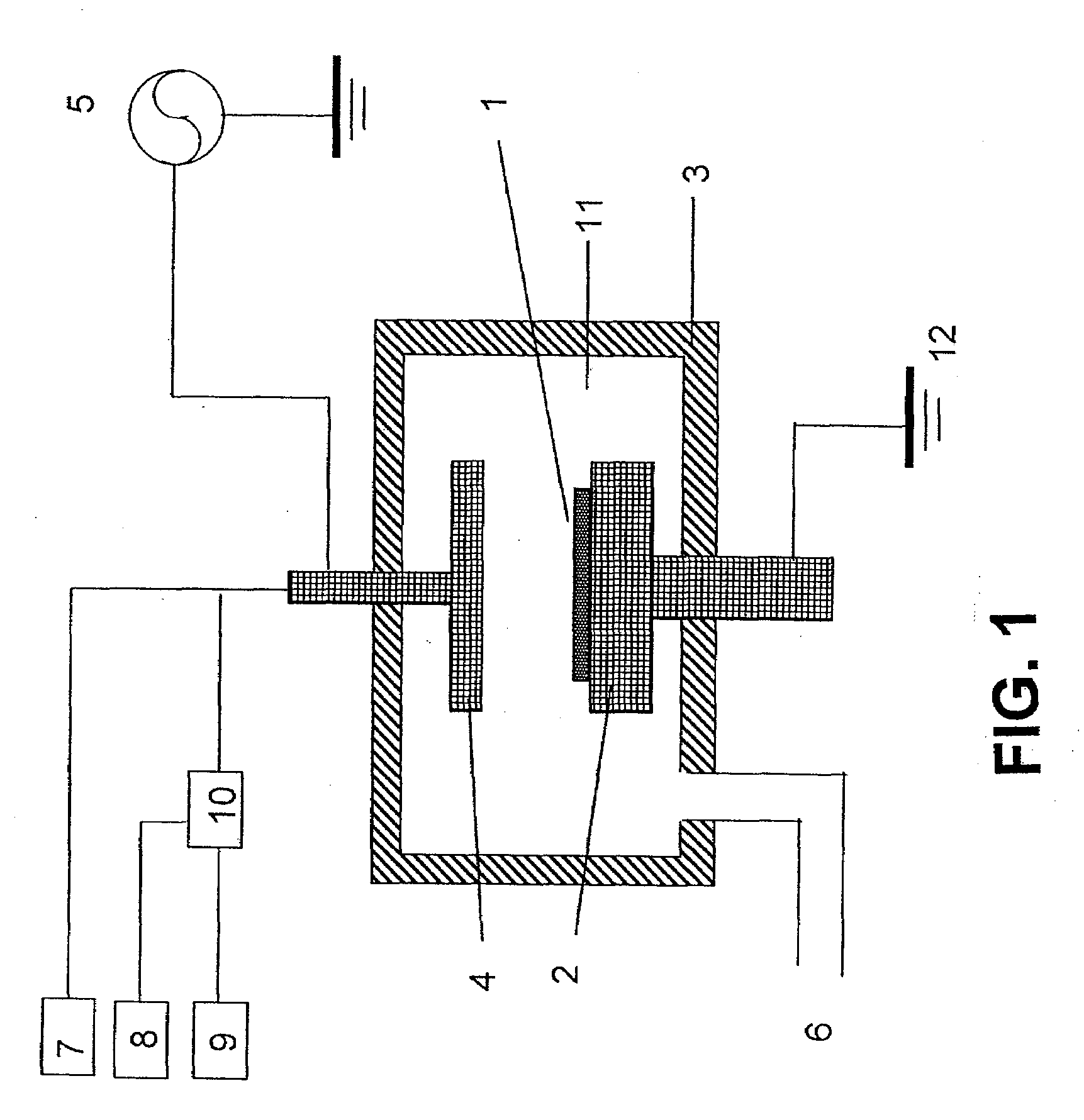

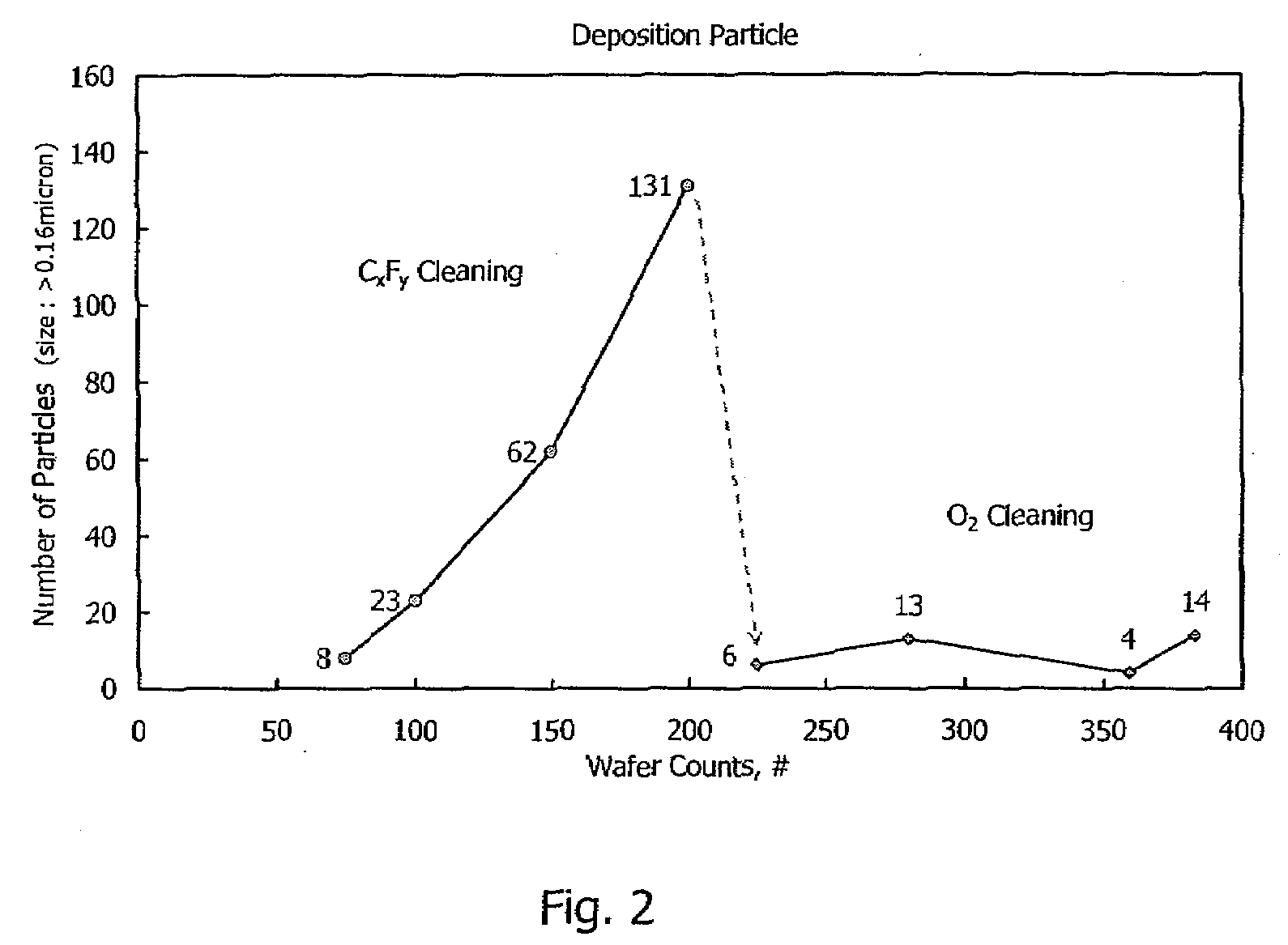

InactiveUS20070248767A1Hollow article cleaningVacuum evaporation coatingNitrogen oxidePlasma reactor

A method of self-cleaning a plasma reactor upon depositing a carbon-based film on a substrate a pre-selected number of times, includes: (i) exciting oxygen gas and / or nitrogen oxide gas to generate a plasma; and (ii) exposing to the plasma a carbon-based film accumulated on an upper electrode provided in the reactor and a carbon-based film accumulated on an inner wall of the reactor.

Owner:ASM JAPAN

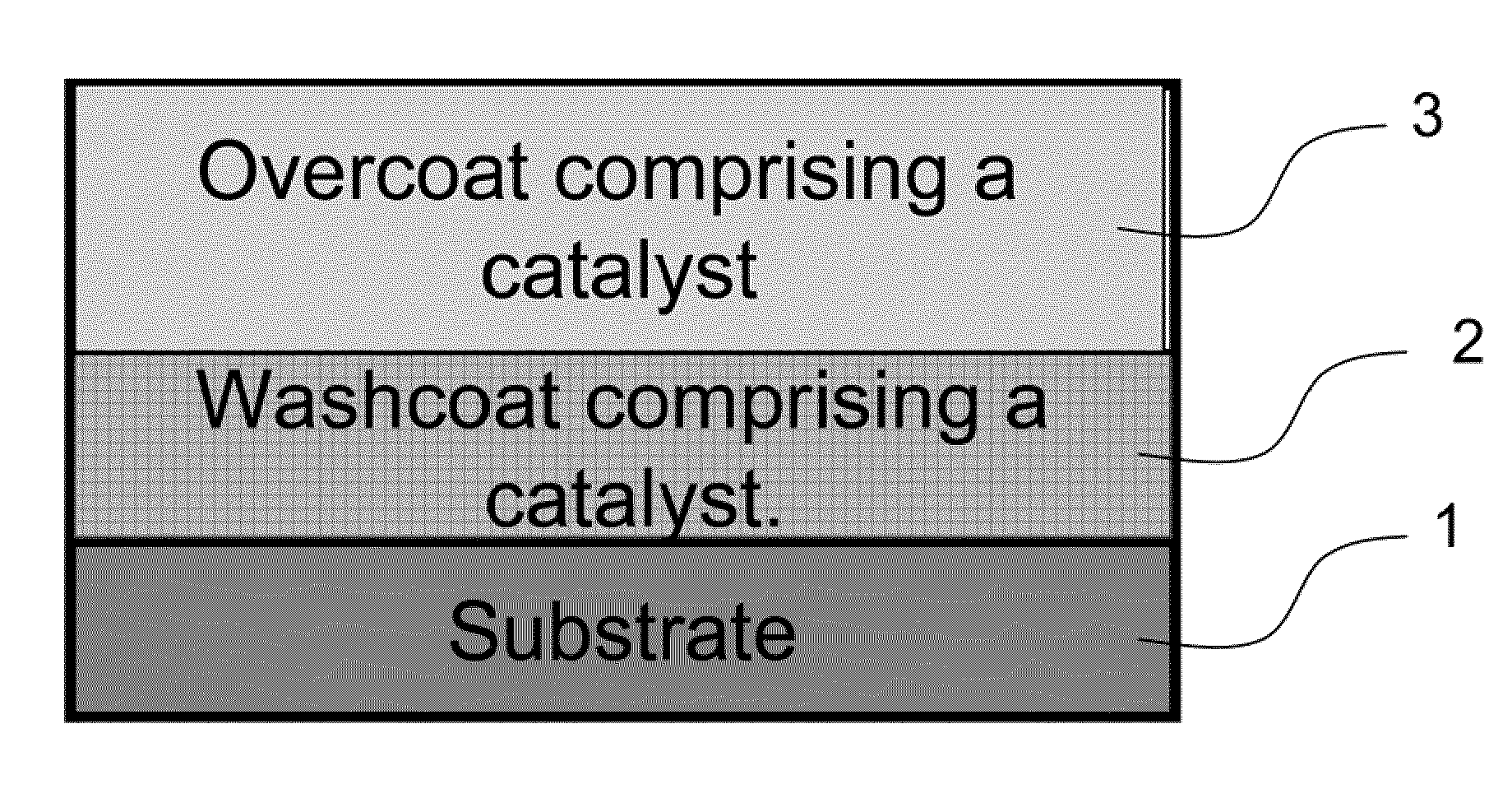

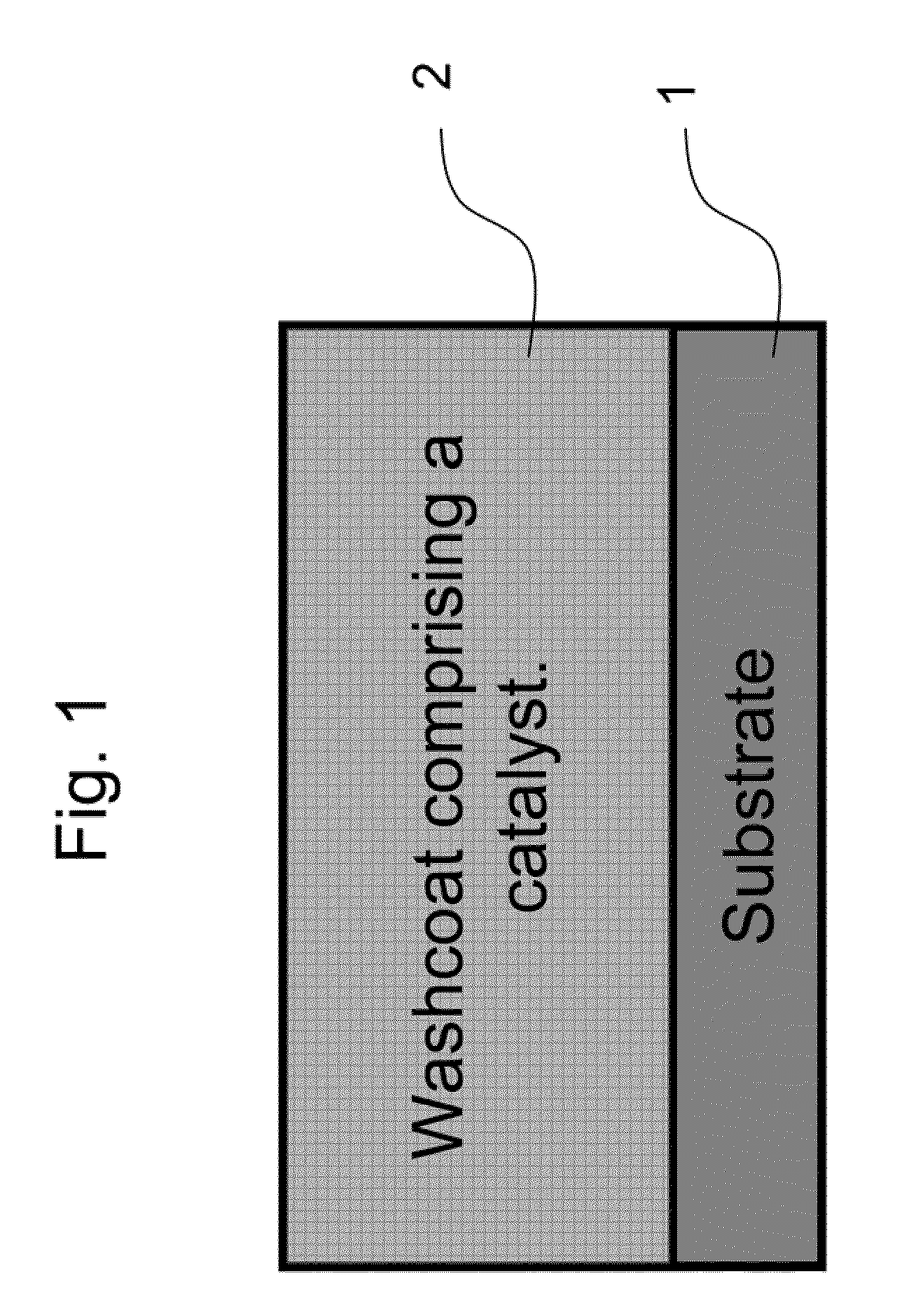

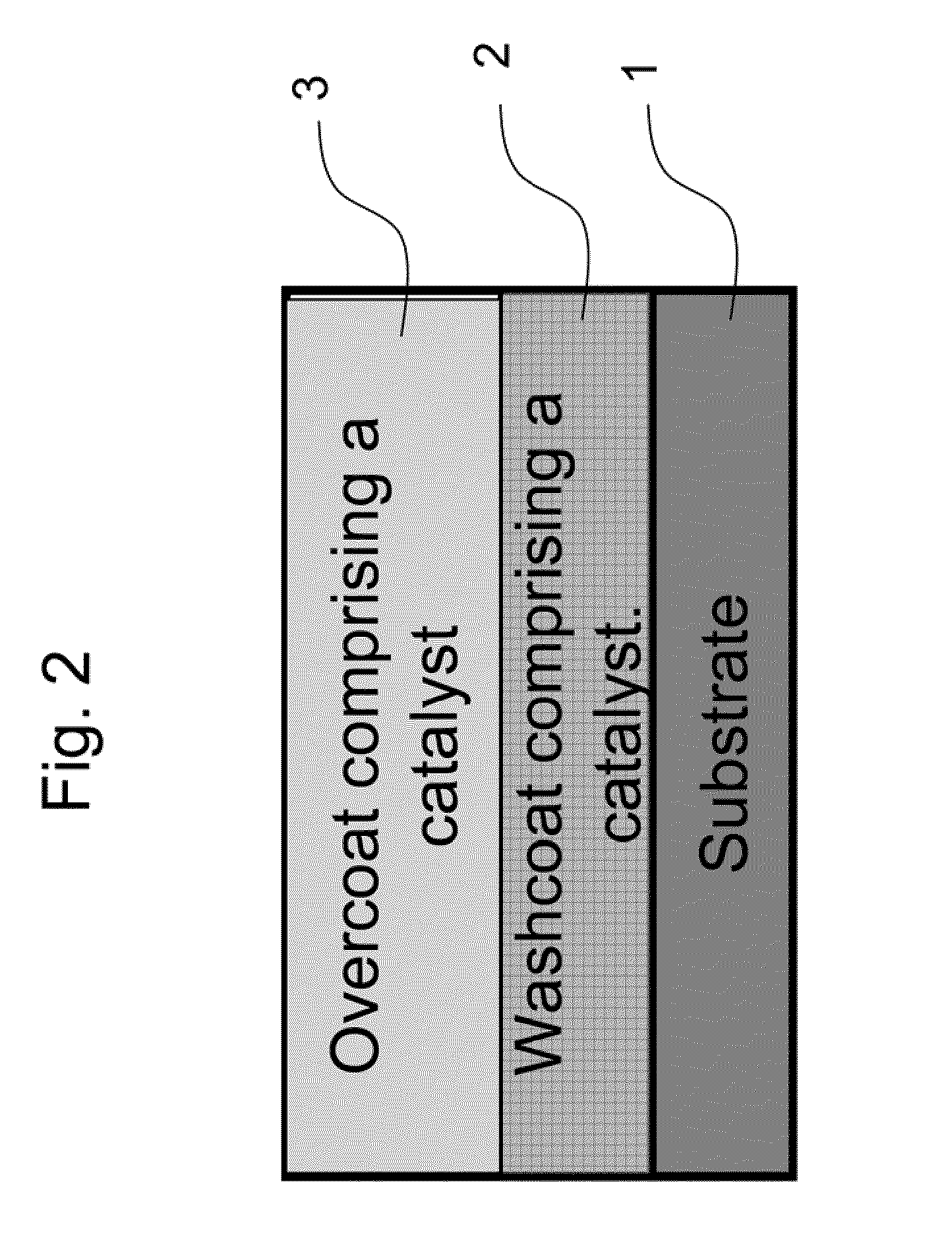

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS20080045405A1Nitrous oxide captureMolecular sieve catalystsExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

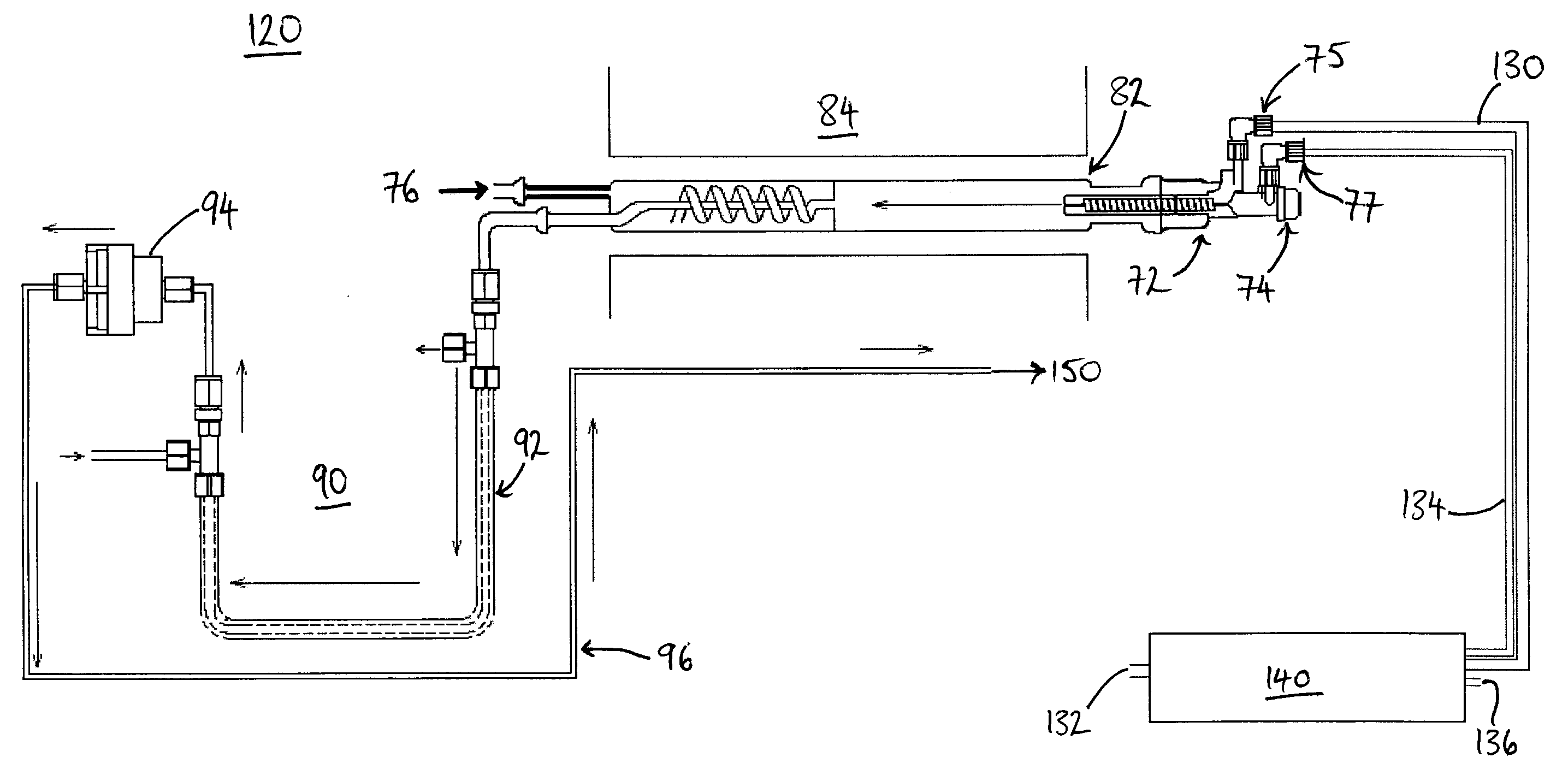

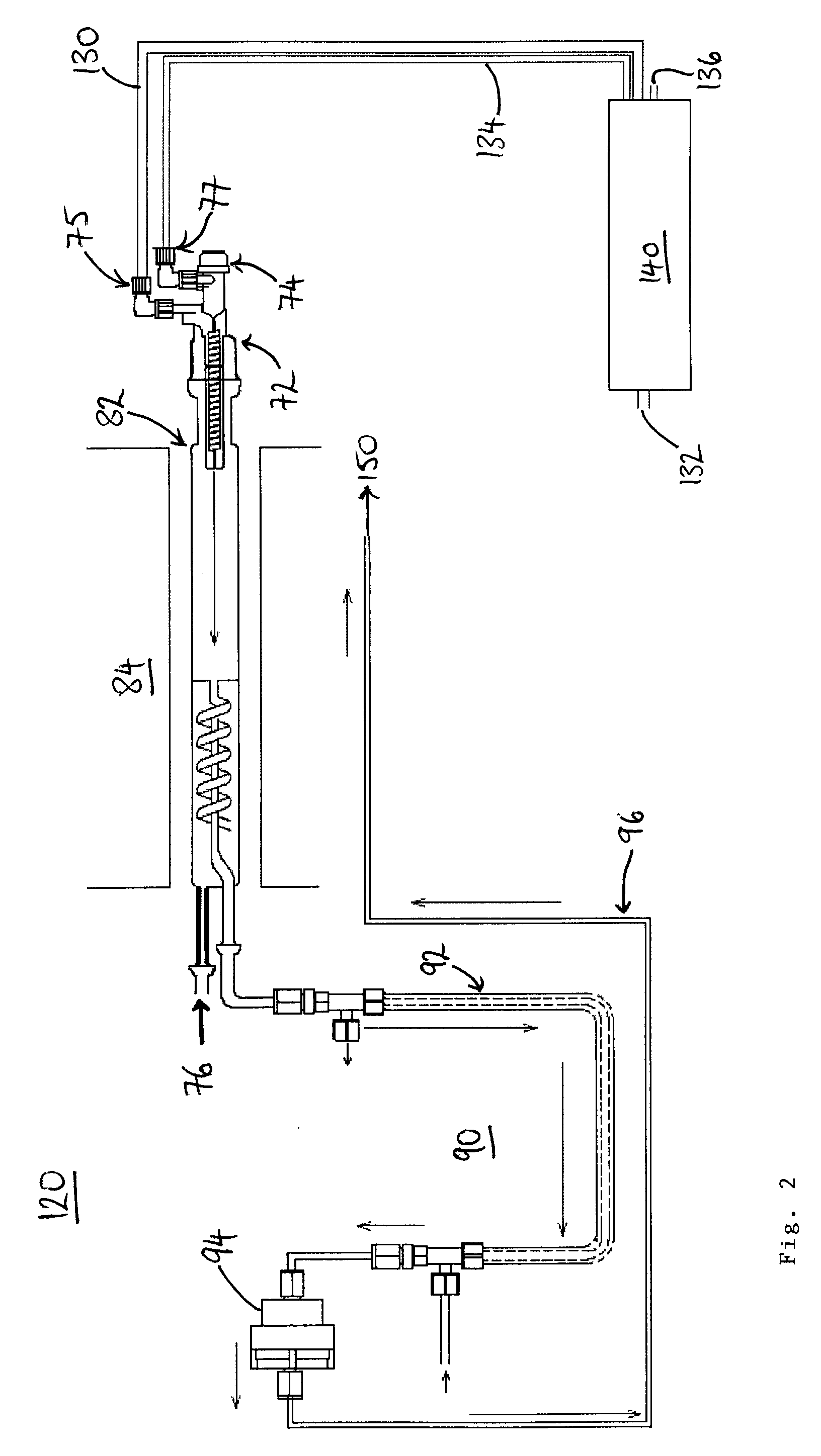

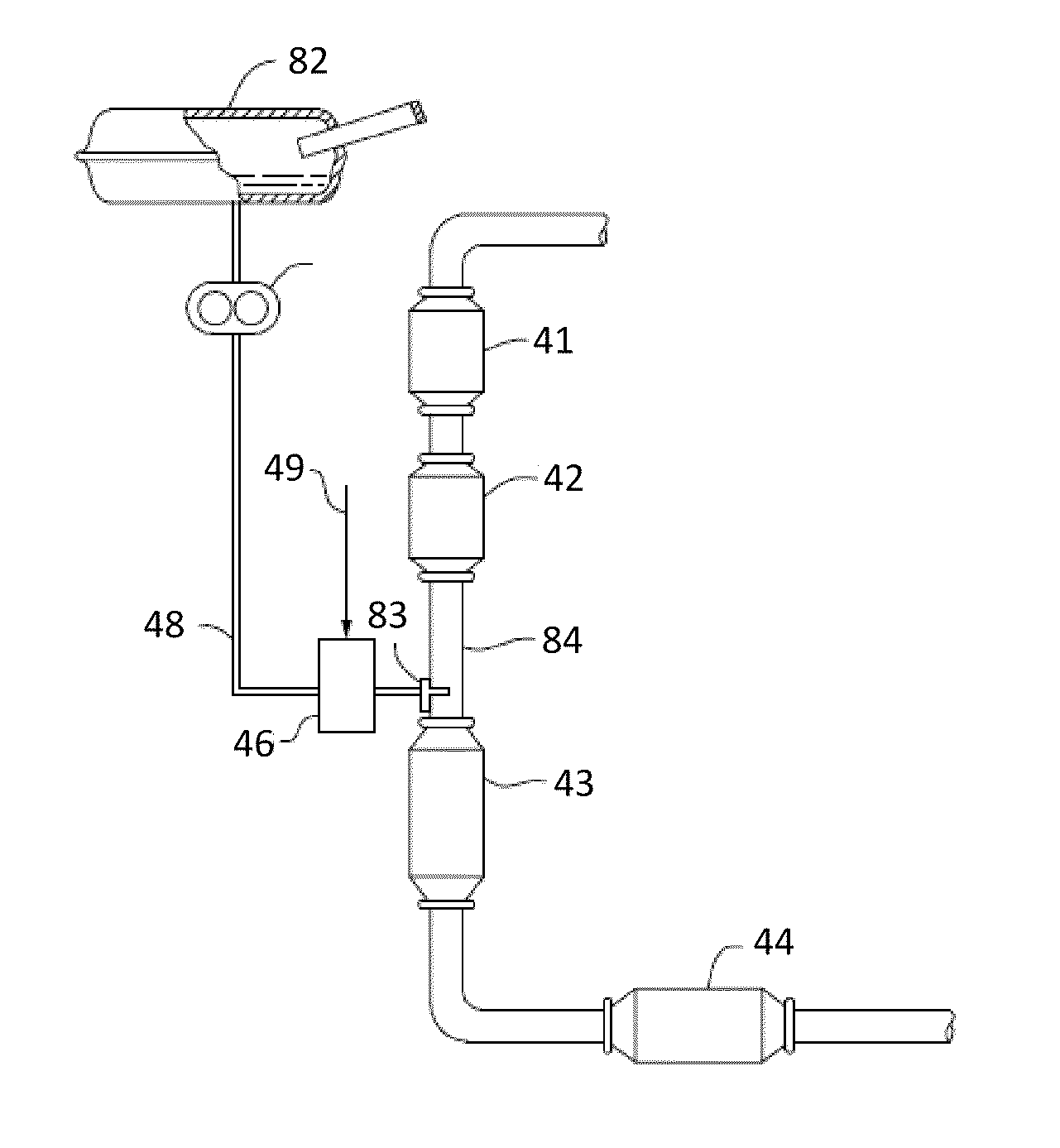

Apparatus and method for generating nitrogen oxides

InactiveUS20080176335A1Possible to useIncrease productionChemical analysis using combustionNitrogen compoundsCombustion chamberWorking temperature

A combustion analyzer apparatus and method for combustion analysing a sample, the analyzer comprising a combustion chamber (82) for receiving a sample for combustion therein to form combustion products, and a fluid supply apparatus for supplying fluid(s) into the chamber. The fluid supply apparatus (130-140) comprises a nitrogen oxides (NOx) generating apparatus (140,190,210,240) and is arranged to supply NOx into the combustion chamber. A yield of sulphur dioxide in the combustion products may thereby be improved. The NOx generating apparatus may be operated at a raised working temperature. The NOx generating apparatus may be provided by an ozonator with a supply of nitrogen and oxygen. A Venturi tube arrangement (246) may draw the generated NOx into a (carrier or oxygen) gas line to the combustion chamber. Ozone may be supplied to the combustion products to convert nitrogen monoxide therein to nitrogen dioxide. The NOx and ozone may be supplied by a single device (210,240).

Owner:THERMO ELECTRON MFG

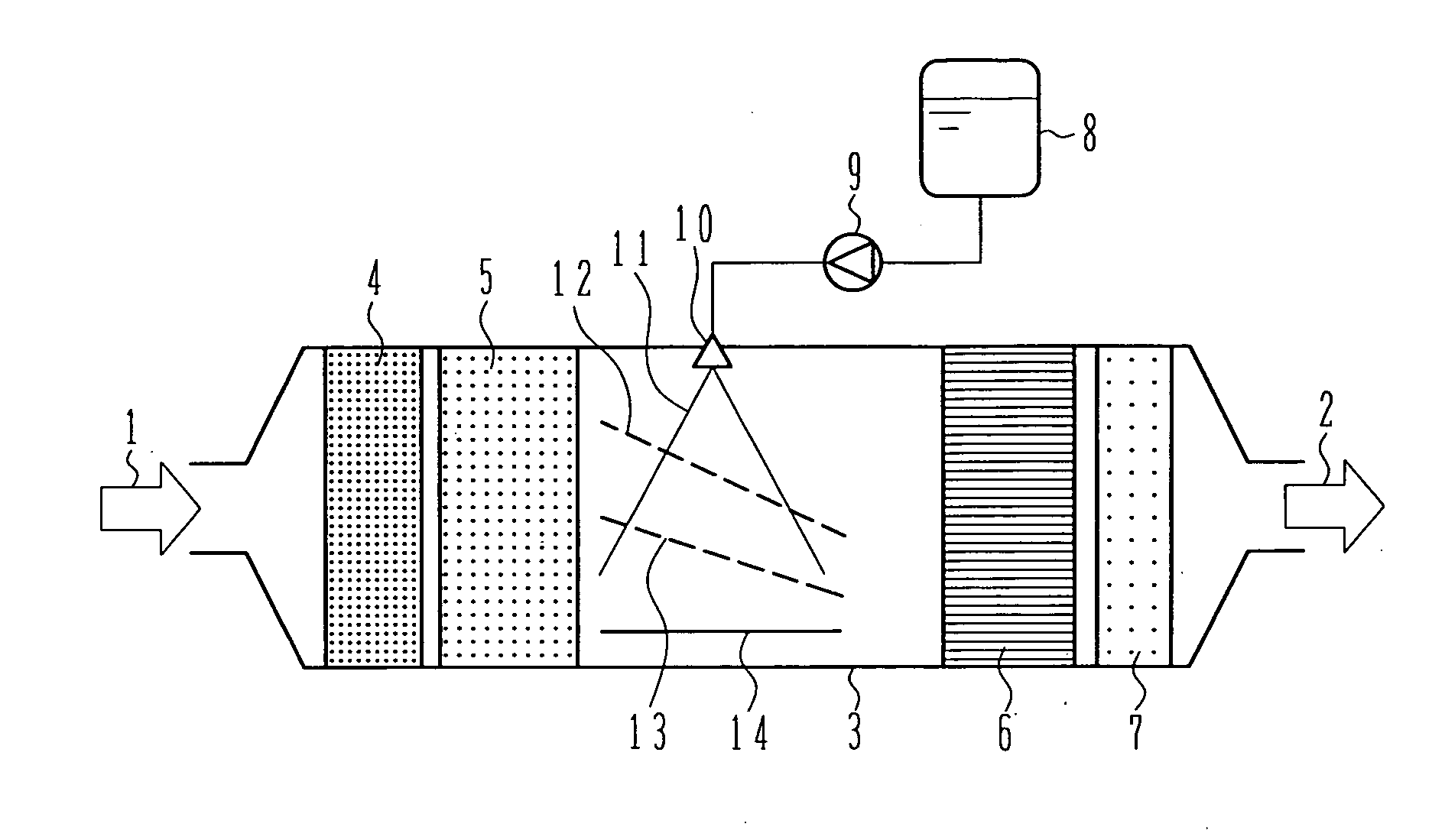

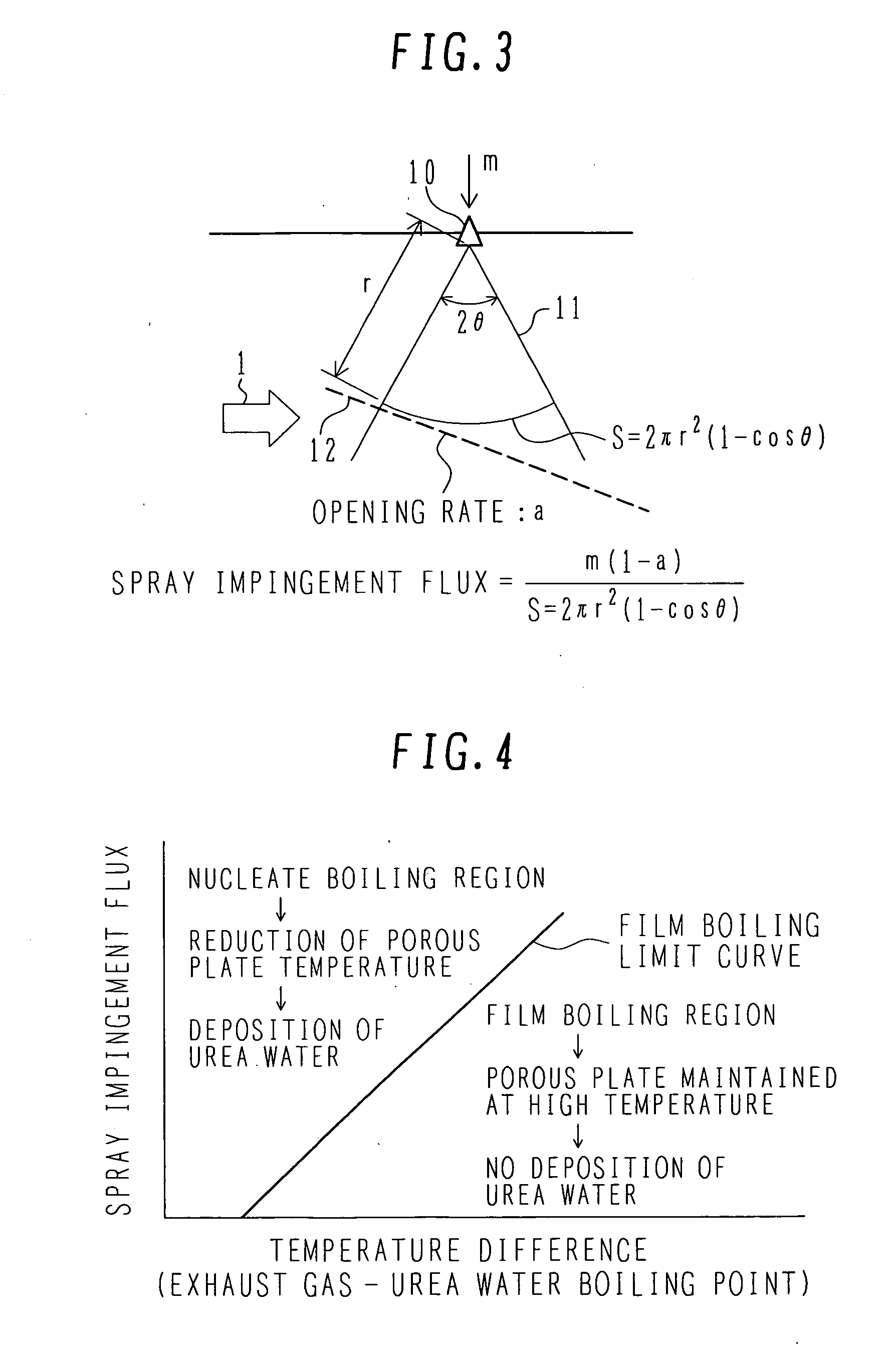

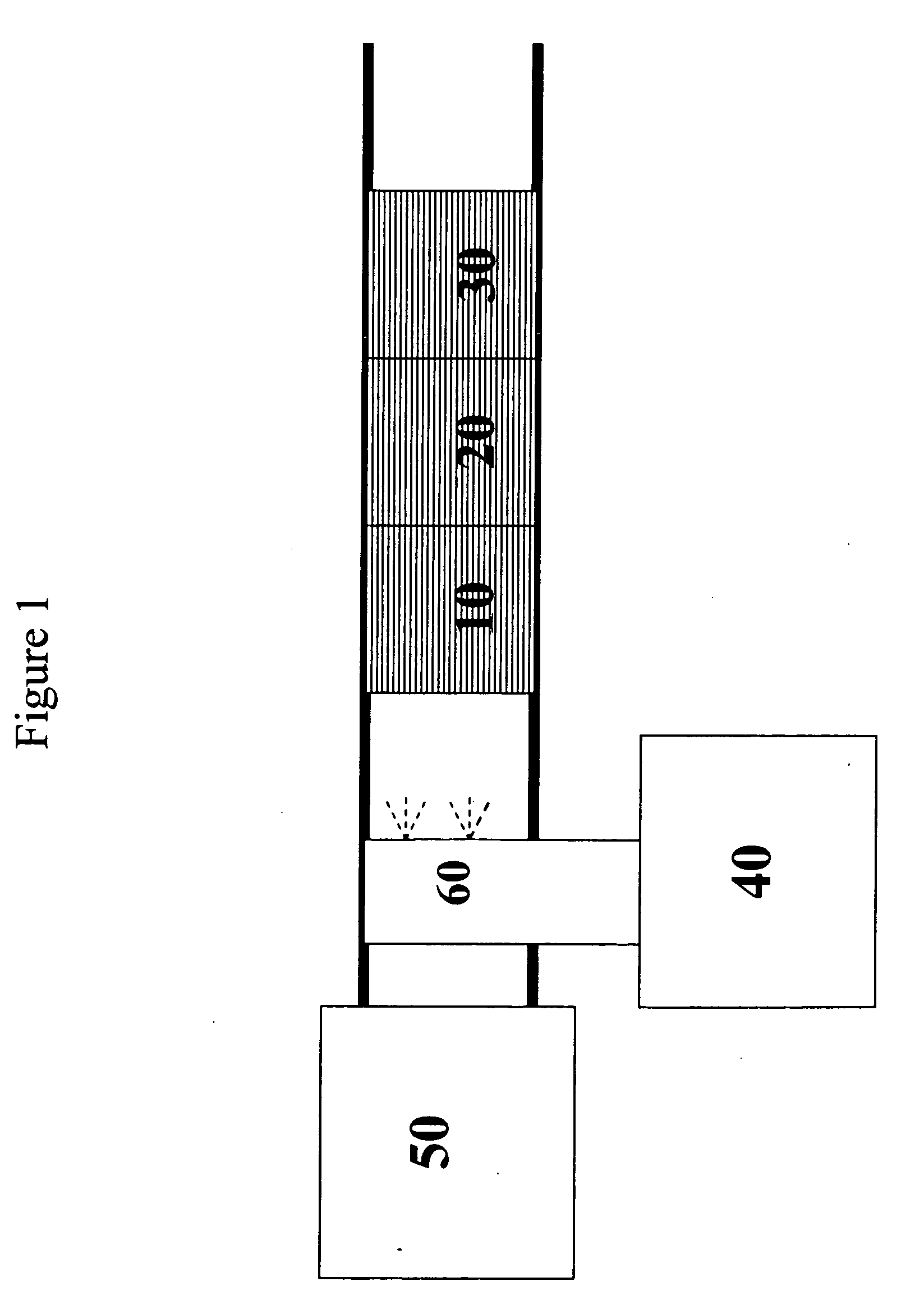

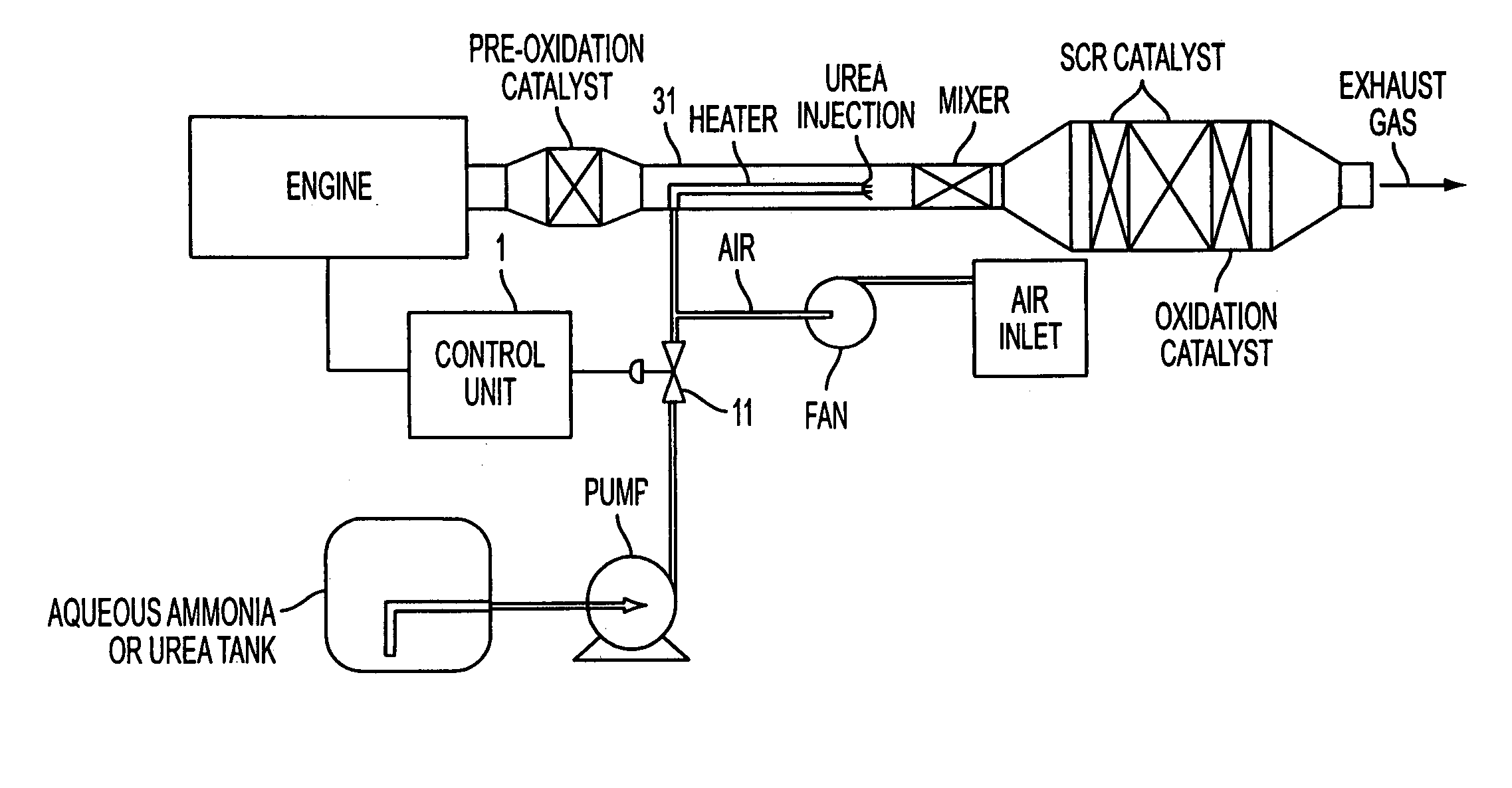

Exhaust aftertreatment system using urea water

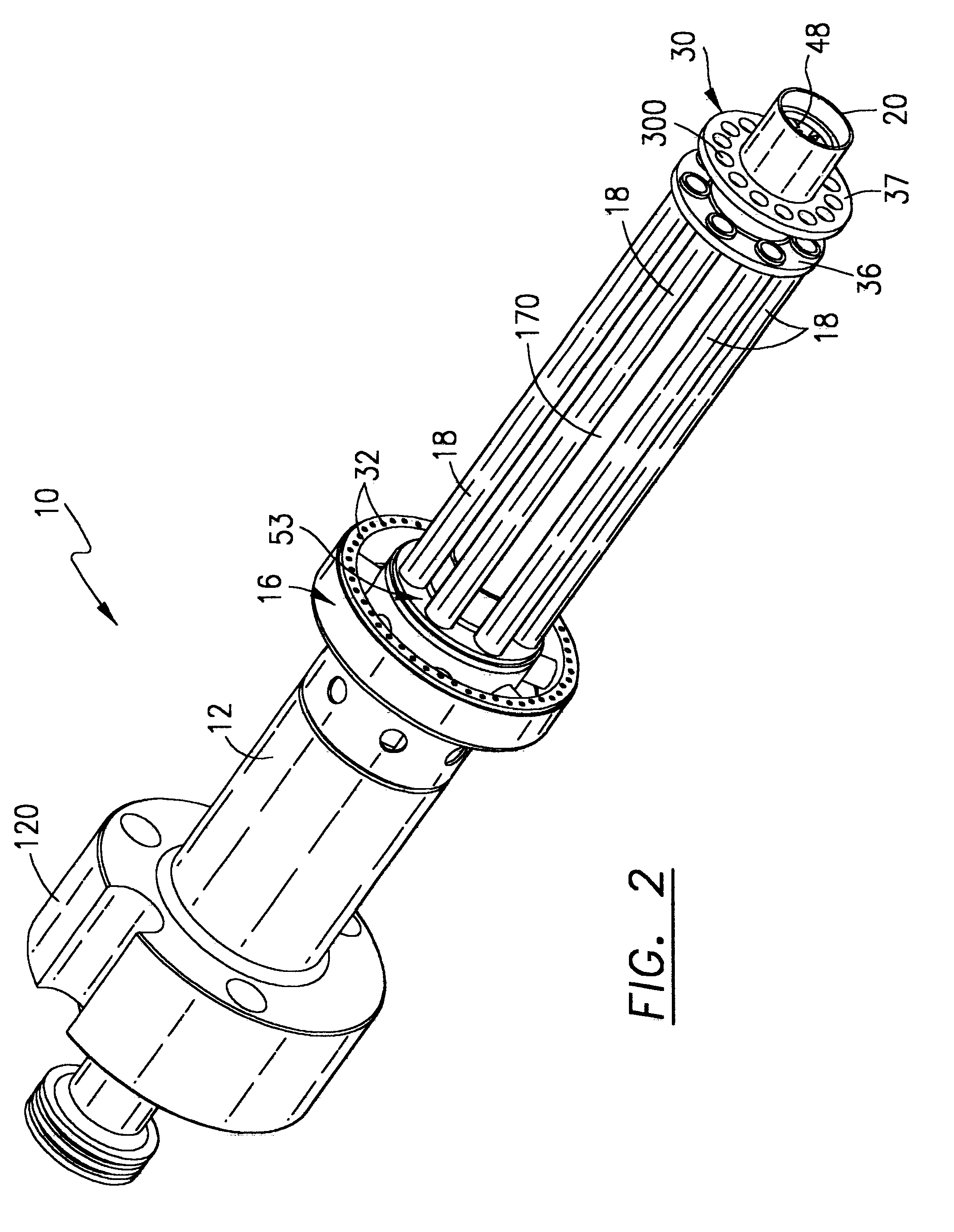

InactiveUS20070036694A1Avoid depositionReduced responseCombination devicesInternal combustion piston enginesHandling systemMultiple stages

An exhaust aftertreatment system comprises an injector for injecting urea water into an exhaust duct, and a denitration catalyst disposed downstream of the injector with respect to a flow of exhaust gas. The exhaust aftertreatment system reduces nitrogen oxides in the exhaust gas by the denitration catalyst while using ammonia produced from the urea water injected from the injector. The urea water is injected along a direction of the flow of the exhaust gas within the exhaust duct, and a porous plate is disposed in multiple stages in a space of the exhaust duct such that droplets of the injected urea water impinge against the porous plate before reaching a wall surface of the exhaust duct. A surface of the porous plate subjected to the impingement of the droplets is arranged to face downstream with respect to the flow of the exhaust gas. Deposition of the urea water is prevented by causing film boiling when the droplets impinge against the porous plate, and the urea water reflected by the porous plate is uniformly dispersed into the exhaust gas. Thus, the urea water is uniformly dispersed into the exhaust gas without increasing a pressure loss of the exhaust gas. The urea water is prevented from depositing on the wall surface and producing a precipitate in the form of a solid.

Owner:HITACHI HIGH-TECH CORP +2

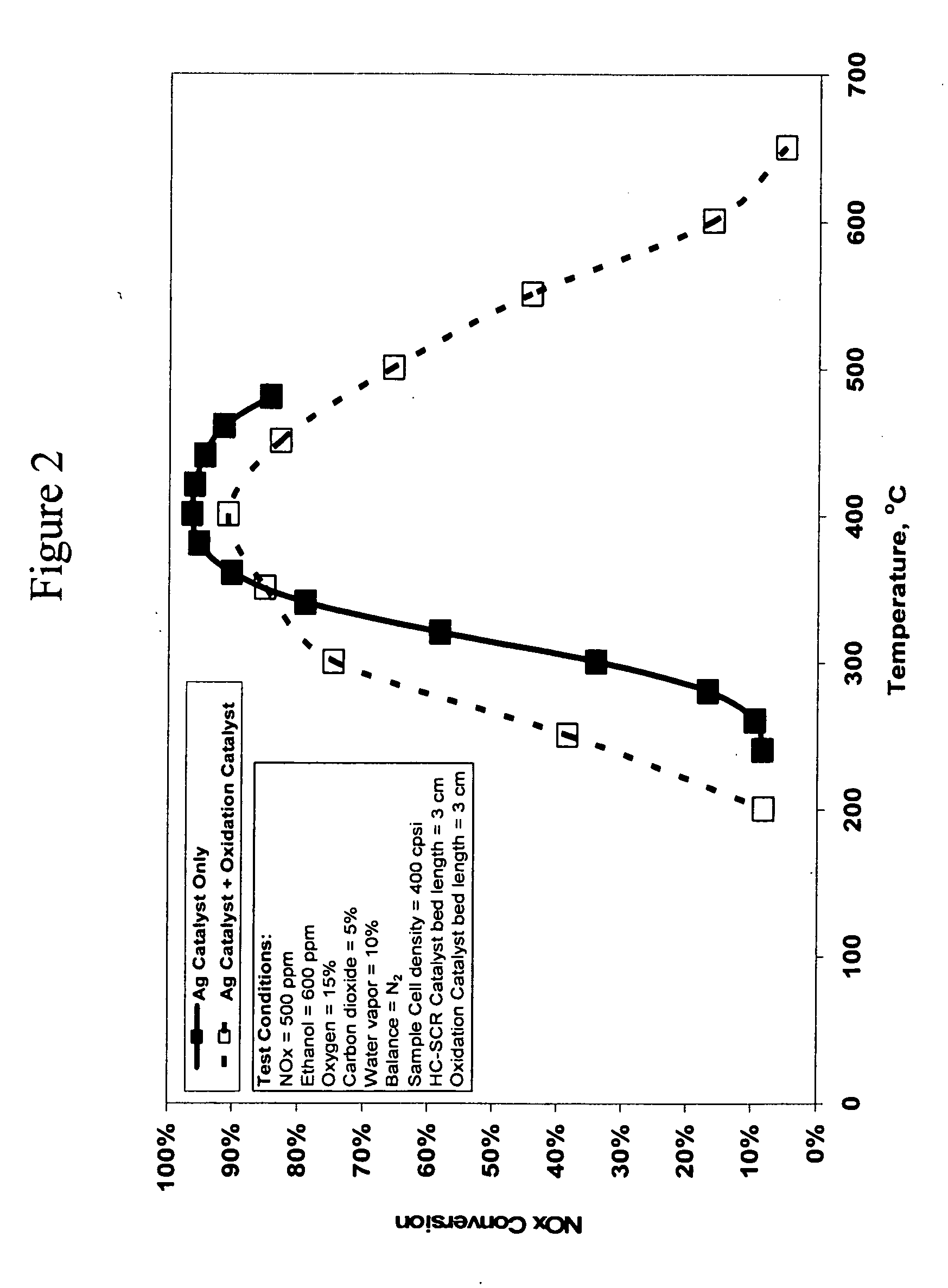

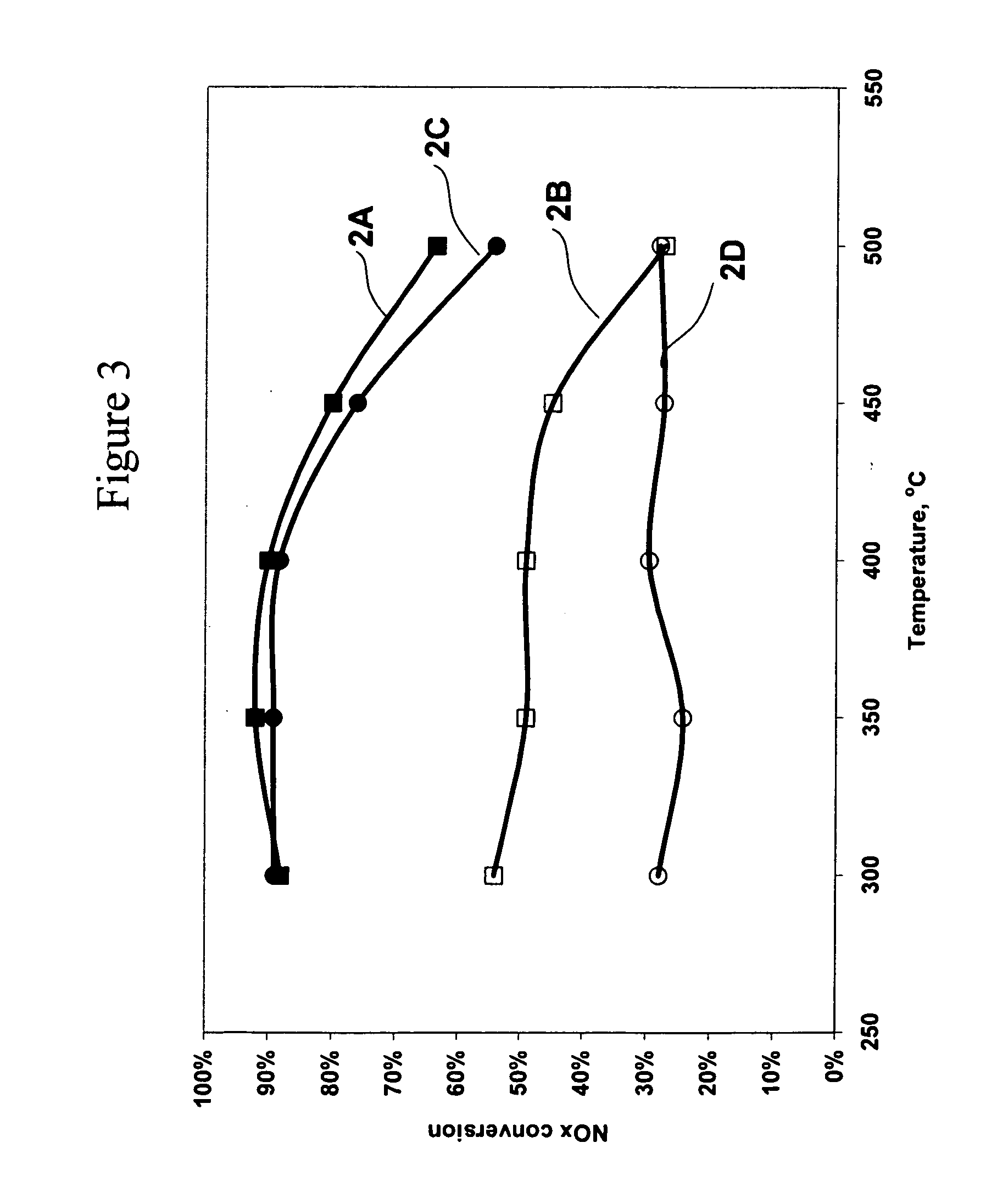

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

Zero Platinum Group Metal Catalysts

Owner:ECS HLDG +1

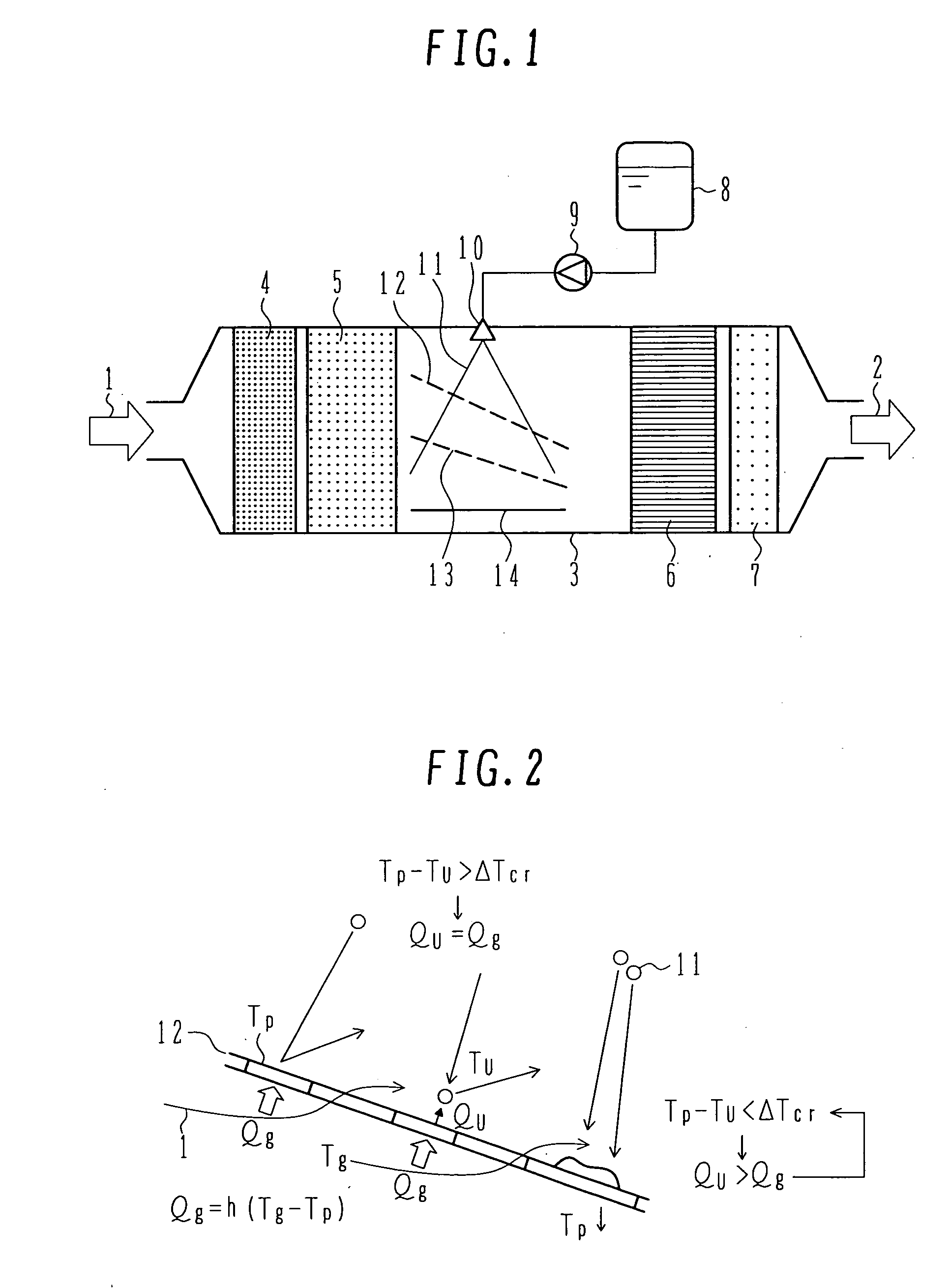

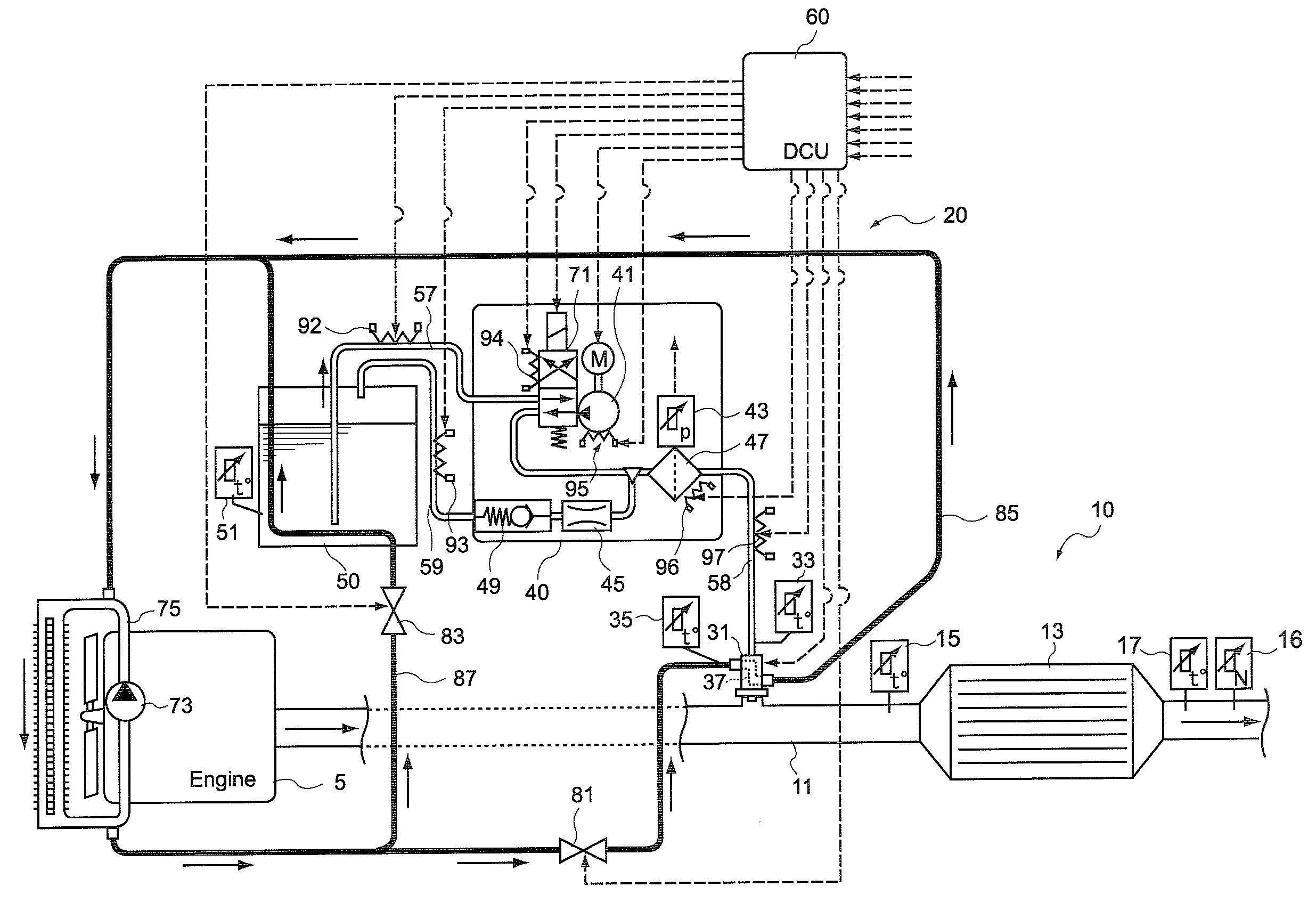

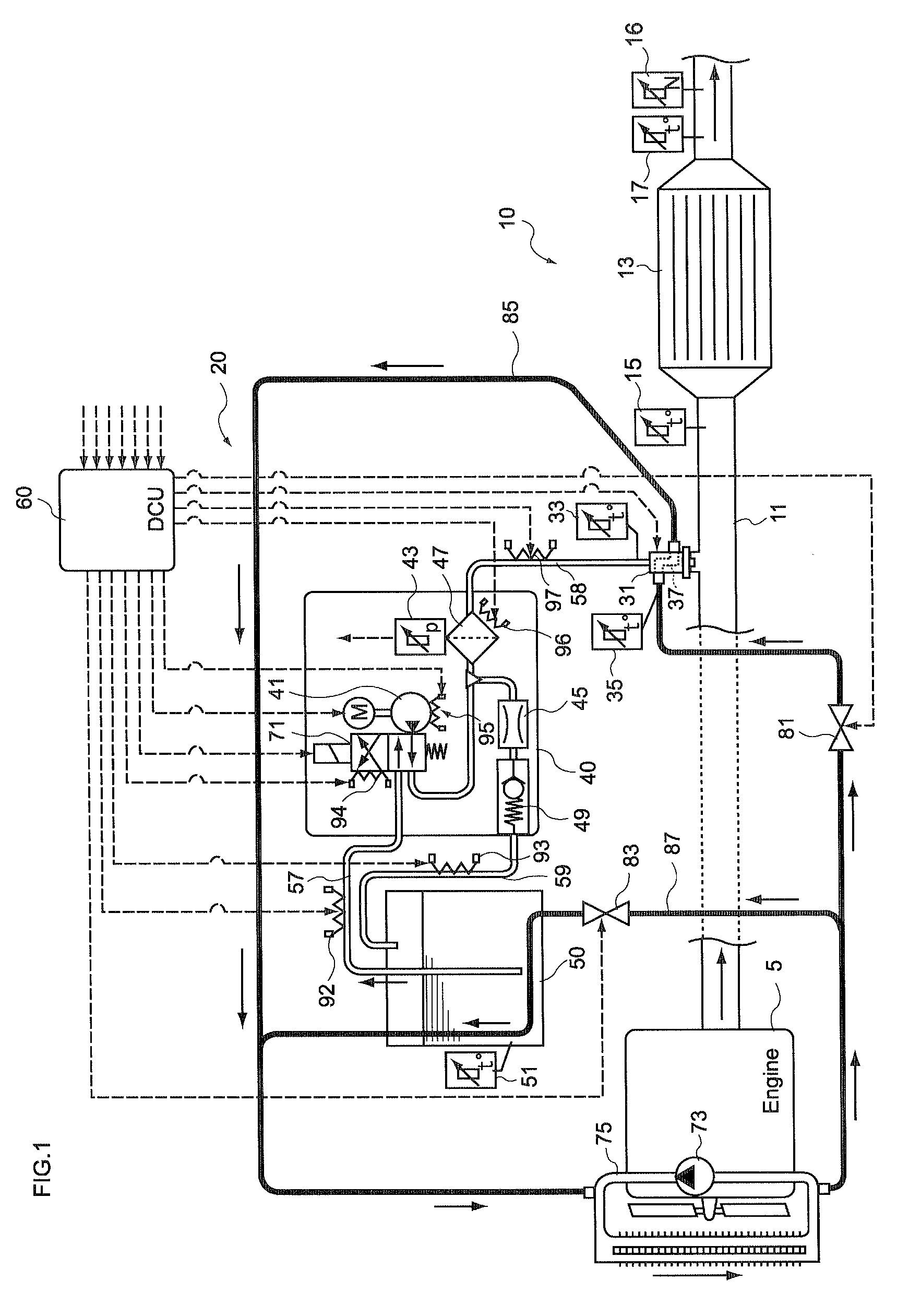

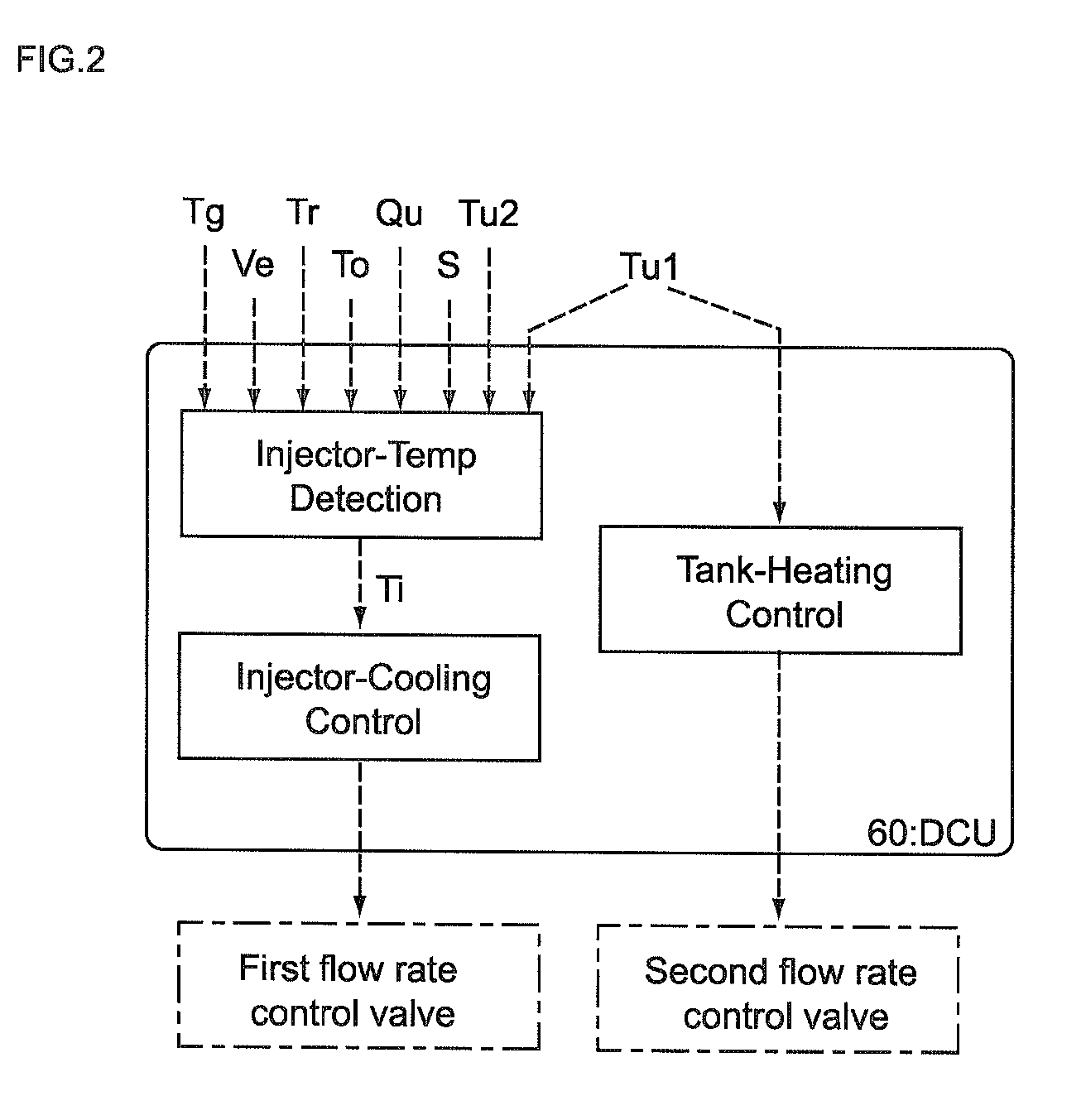

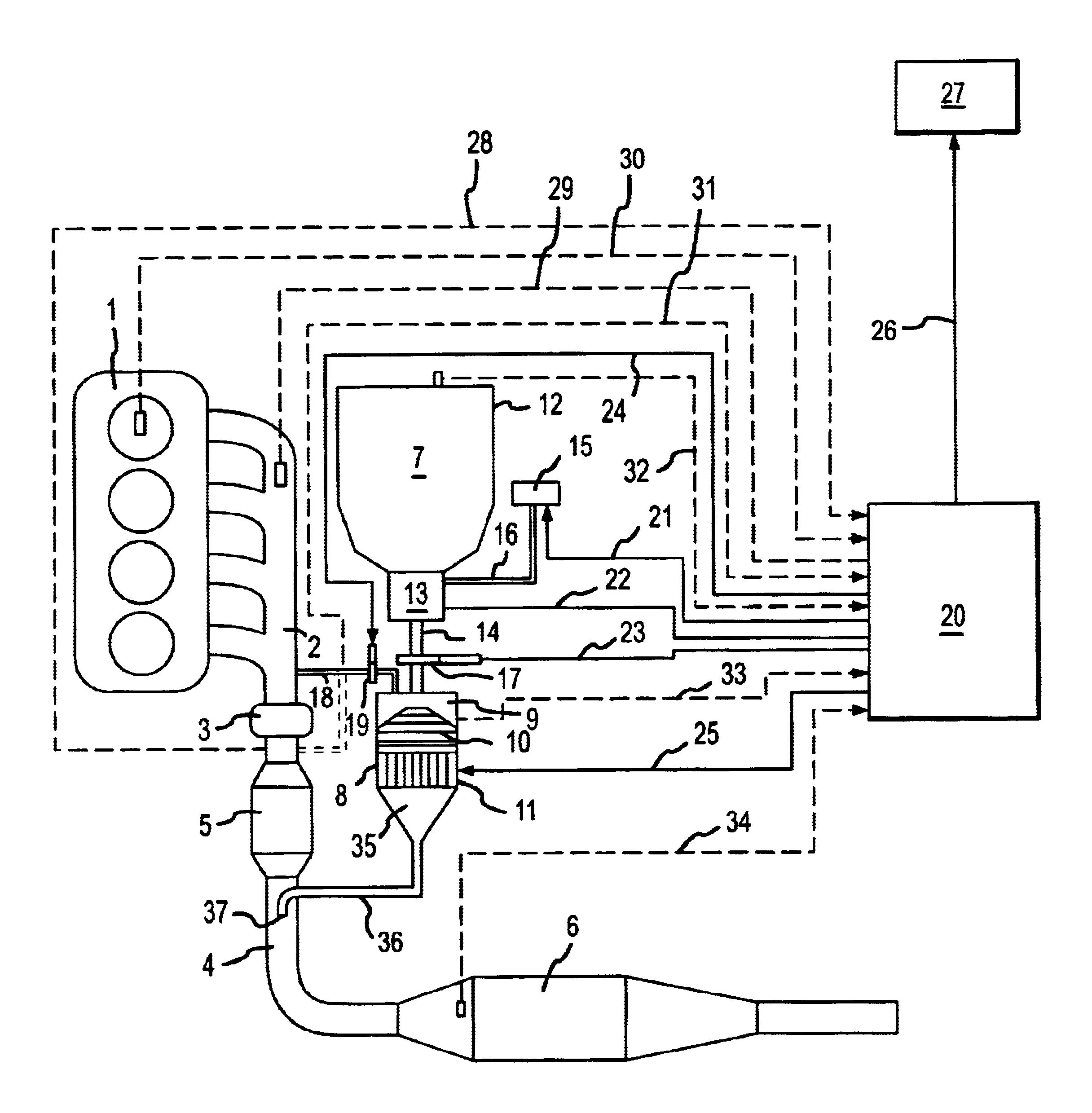

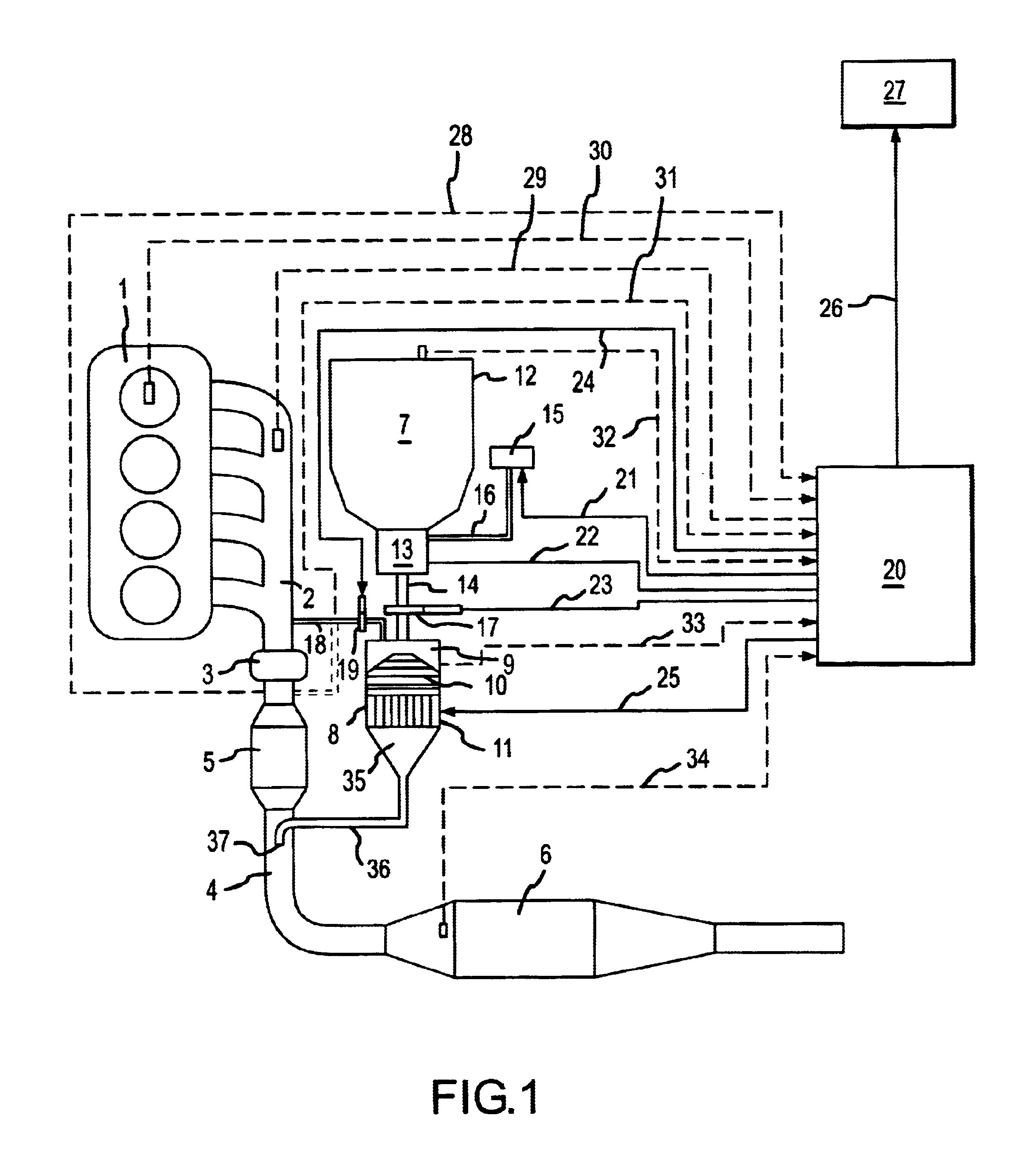

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

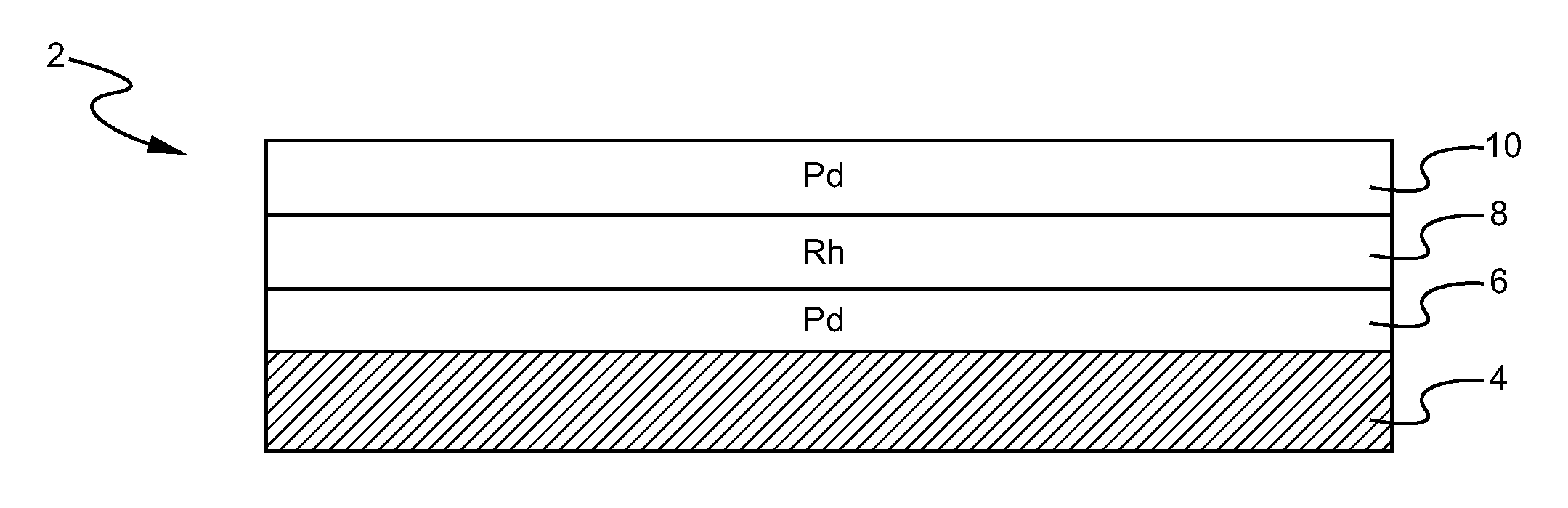

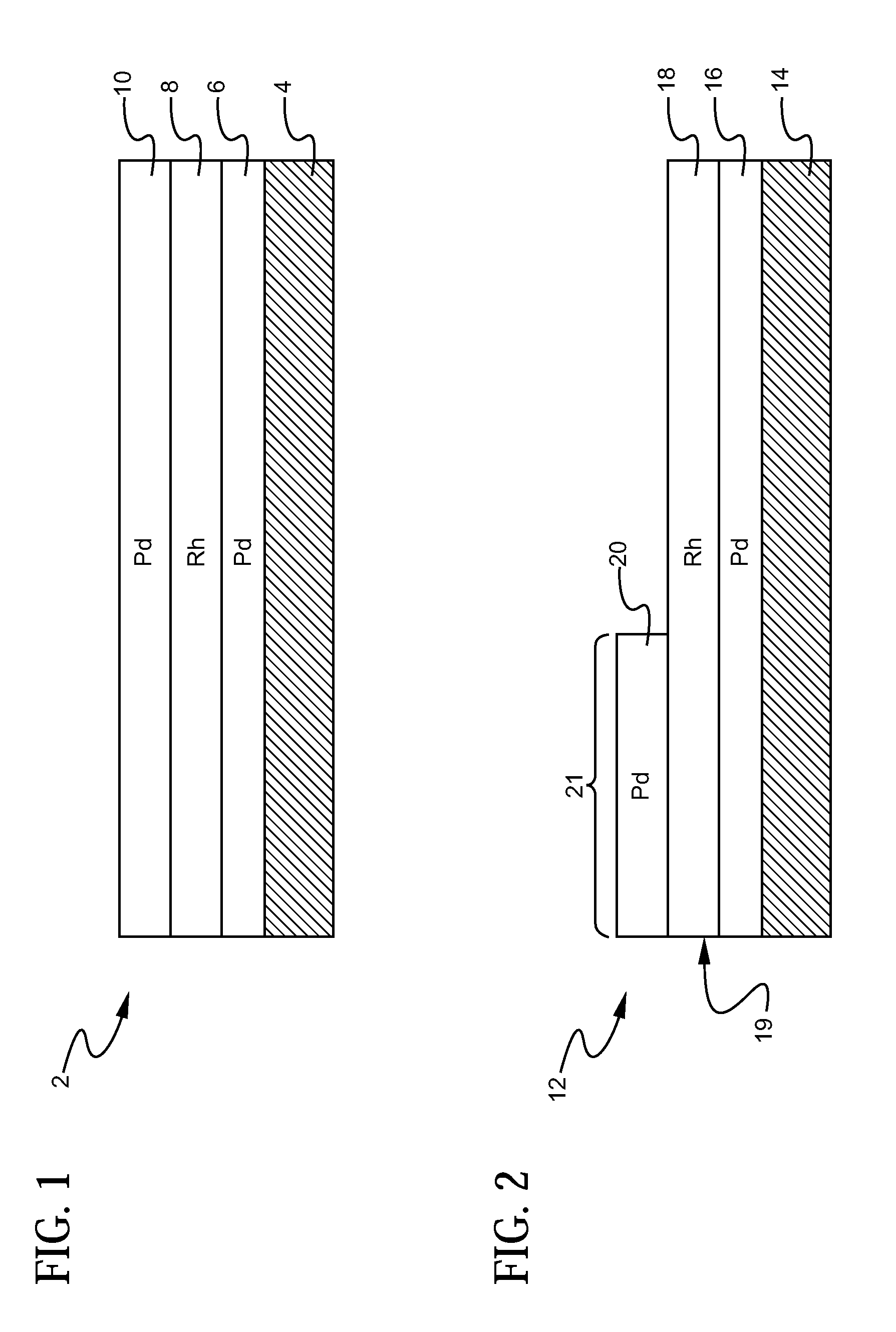

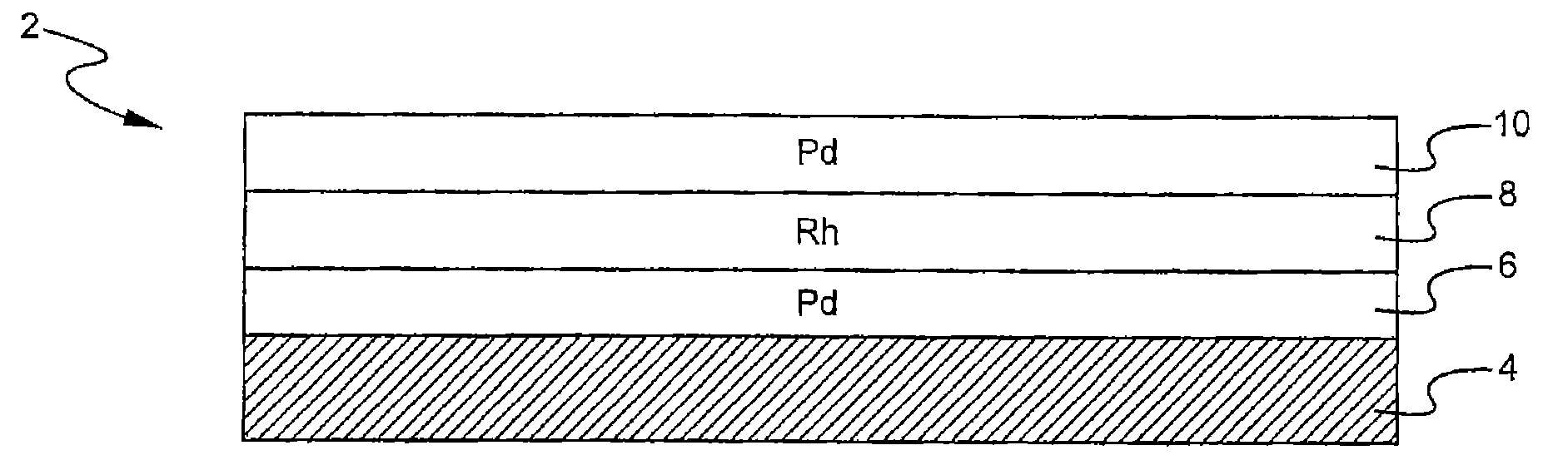

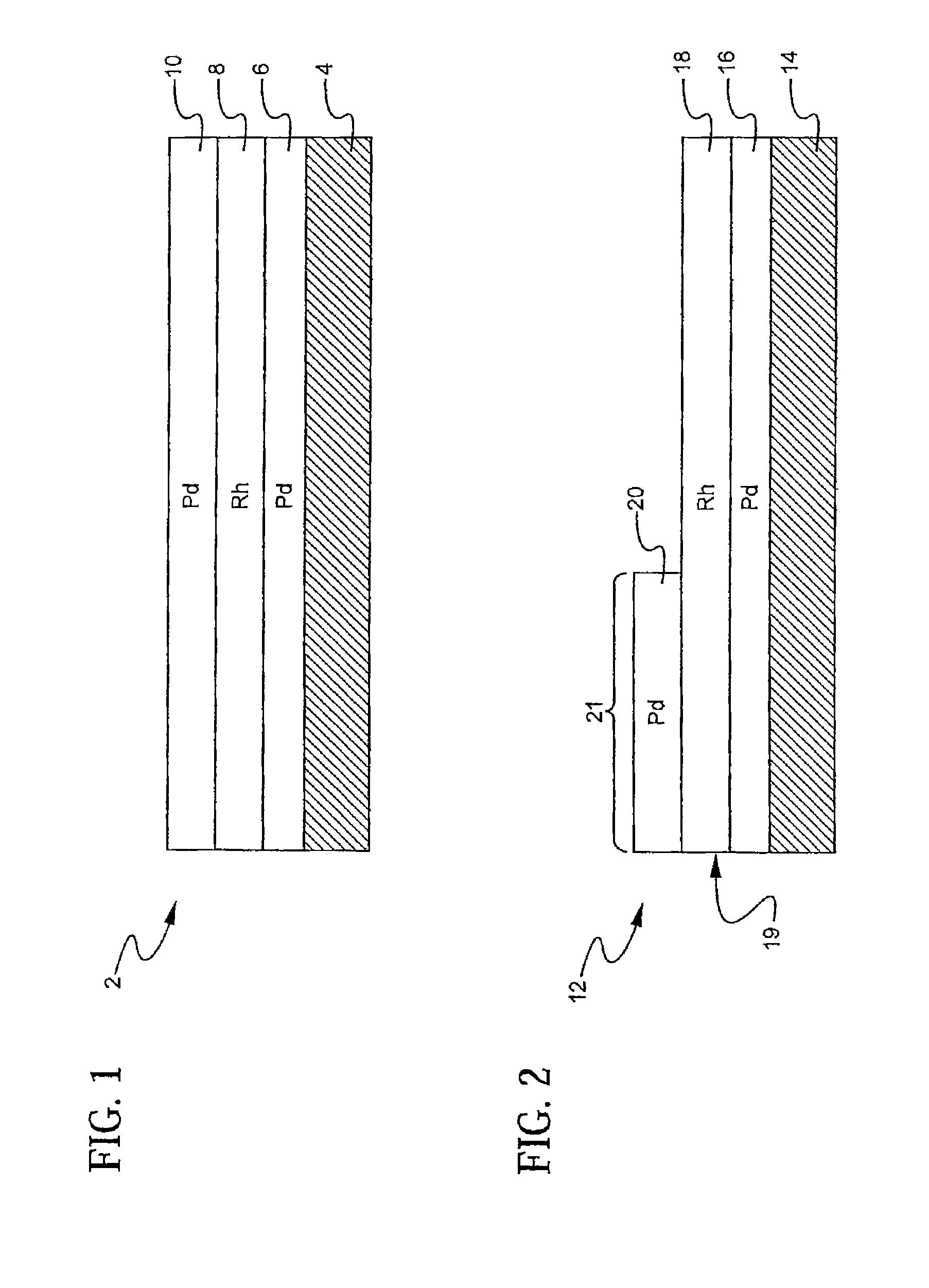

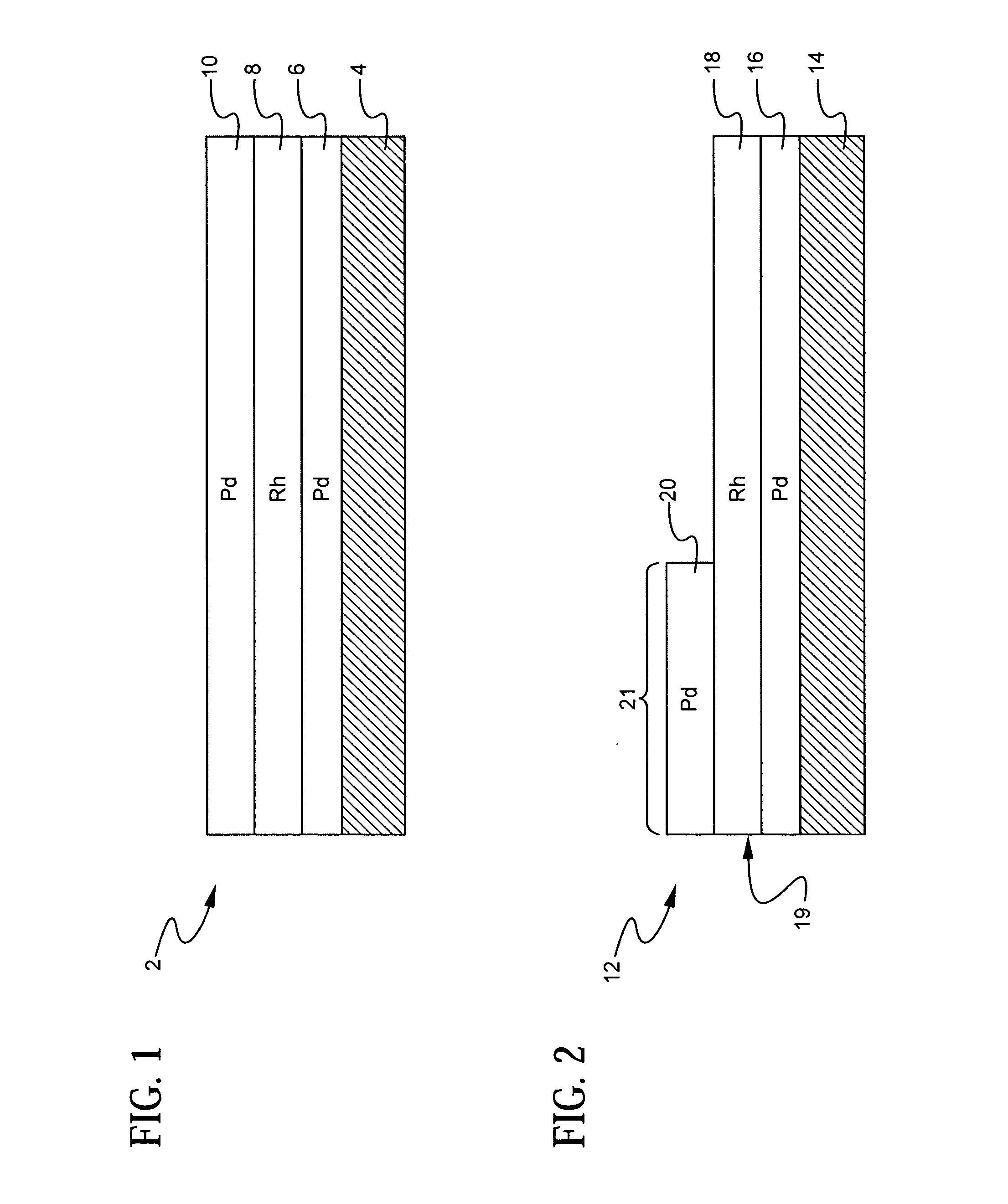

Layered catalyst composite

A layered, three-way conversion catalyst having the capability of simultaneously catalyzing the oxidation of hydrocarbons and carbon monoxide and the reduction of nitrogen oxides is disclosed. In one or more embodiments, the catalyst comprises three layers in conjunction with a carrier: a first layer deposited on the carrier and comprising palladium deposited on a refractory metal oxide and an oxygen storage component; a second layer deposited on the first layer and comprising rhodium deposited on a refractory metal oxide and an oxygen storage component; and a third layer deposited on the second layer and comprising palladium deposited on a refractory metal oxide.

Owner:BASF CATALYSTS LLC

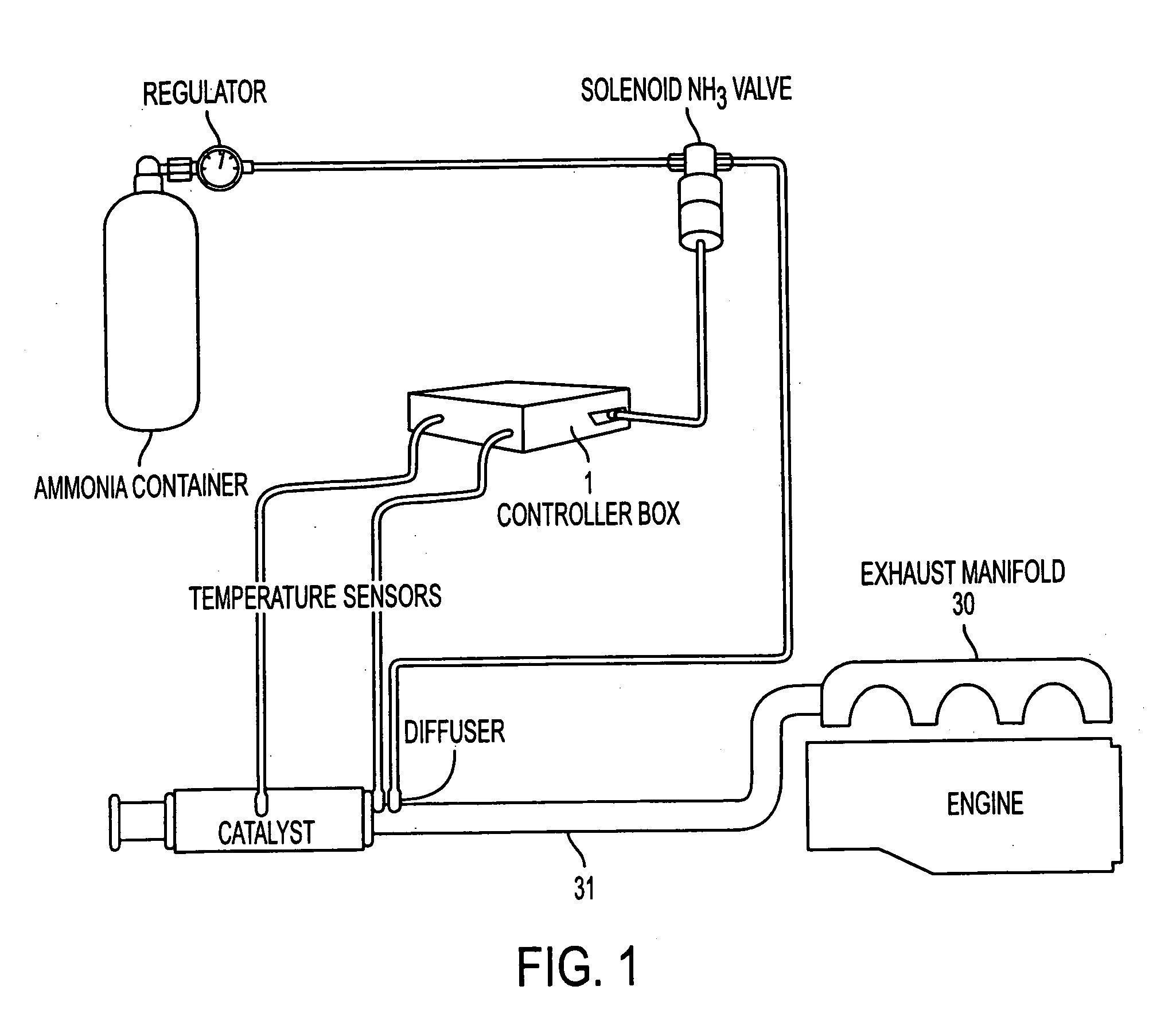

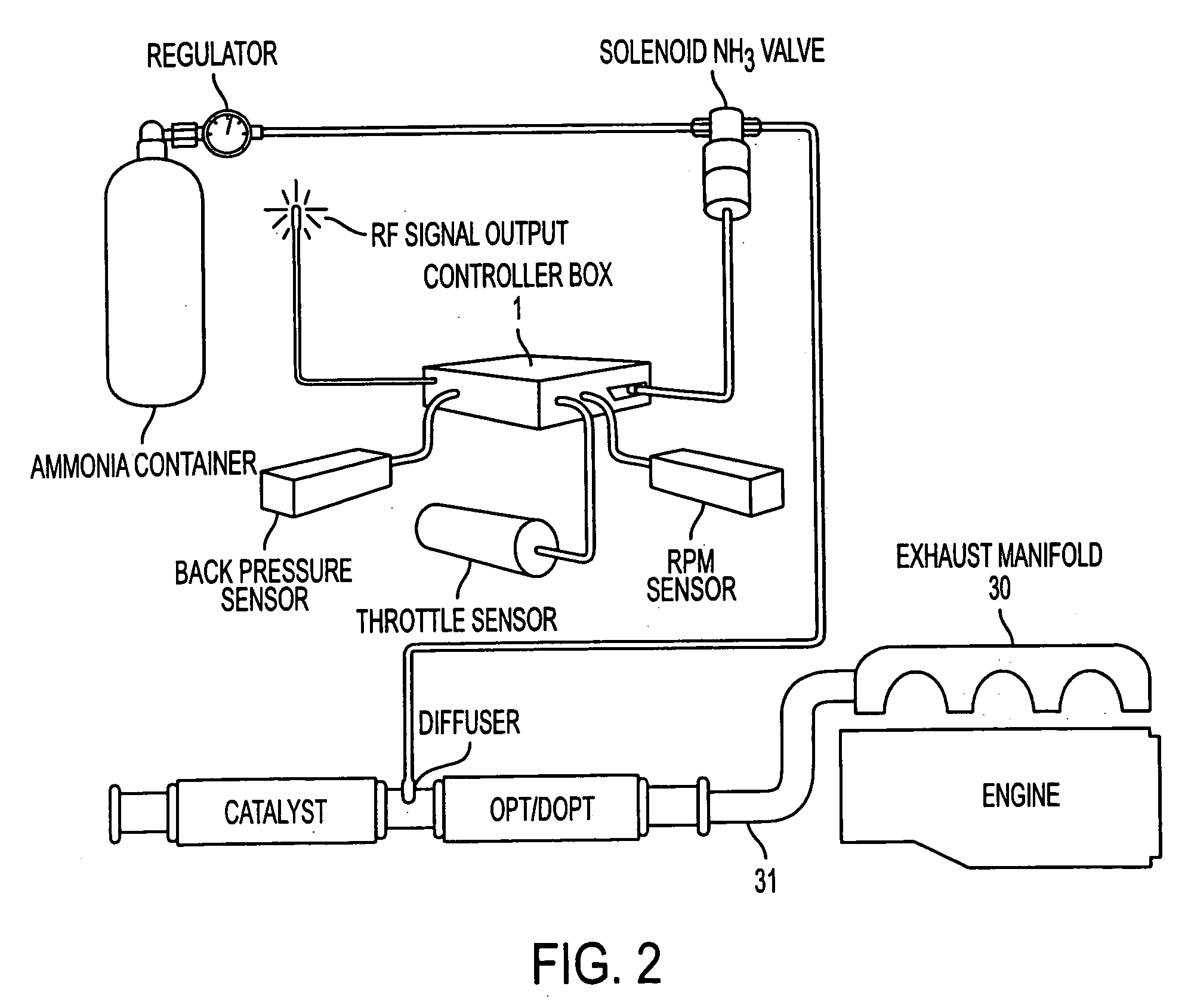

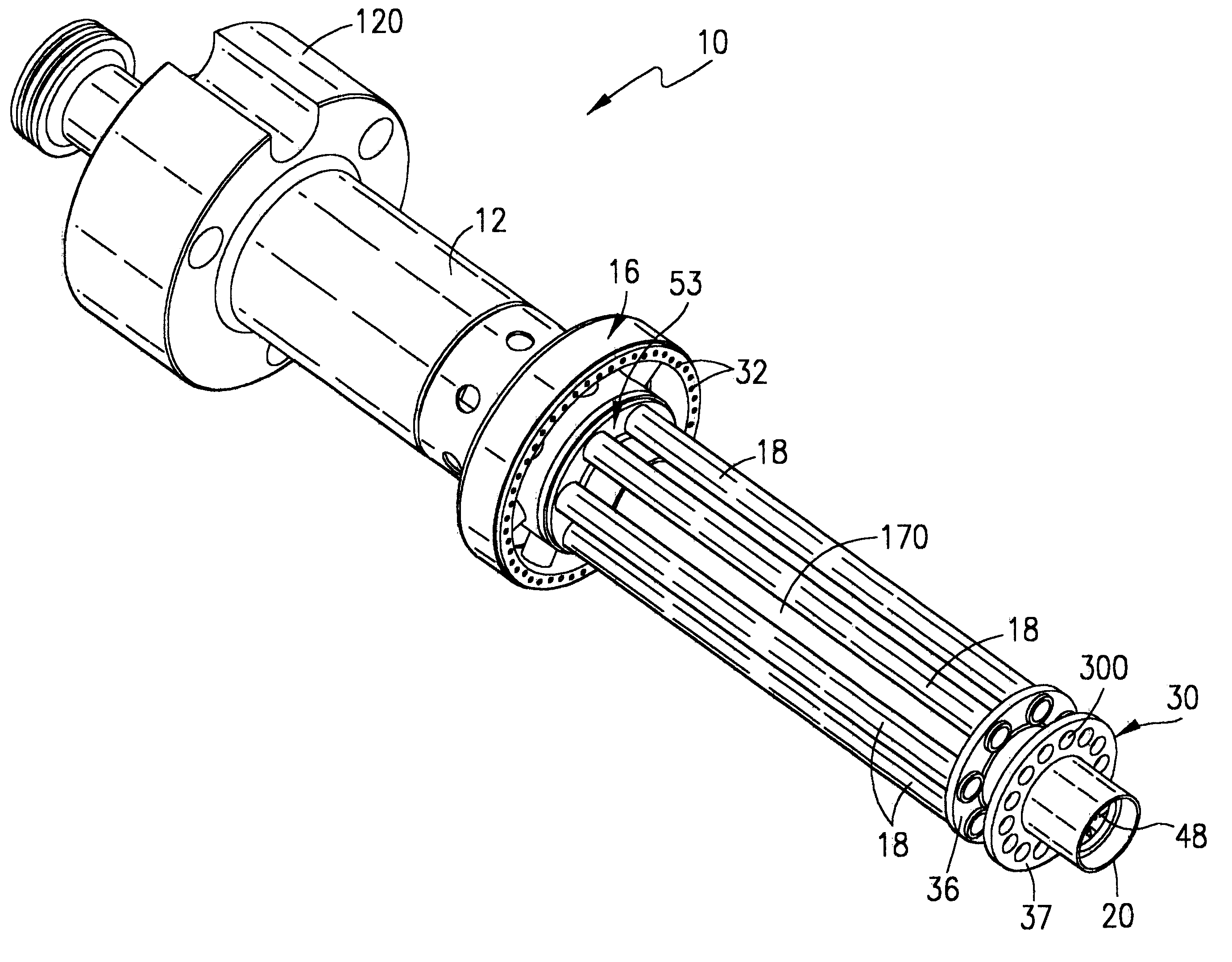

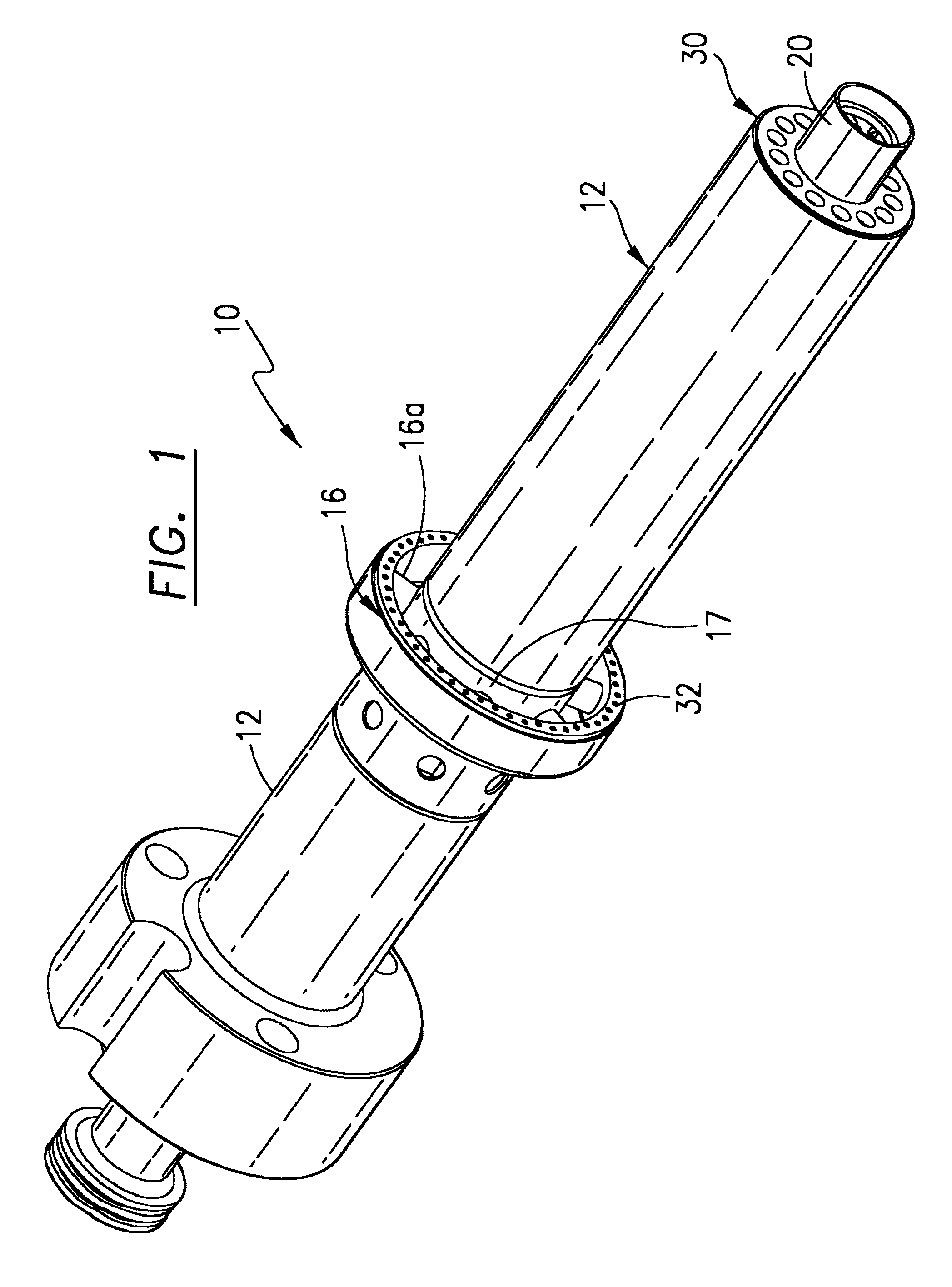

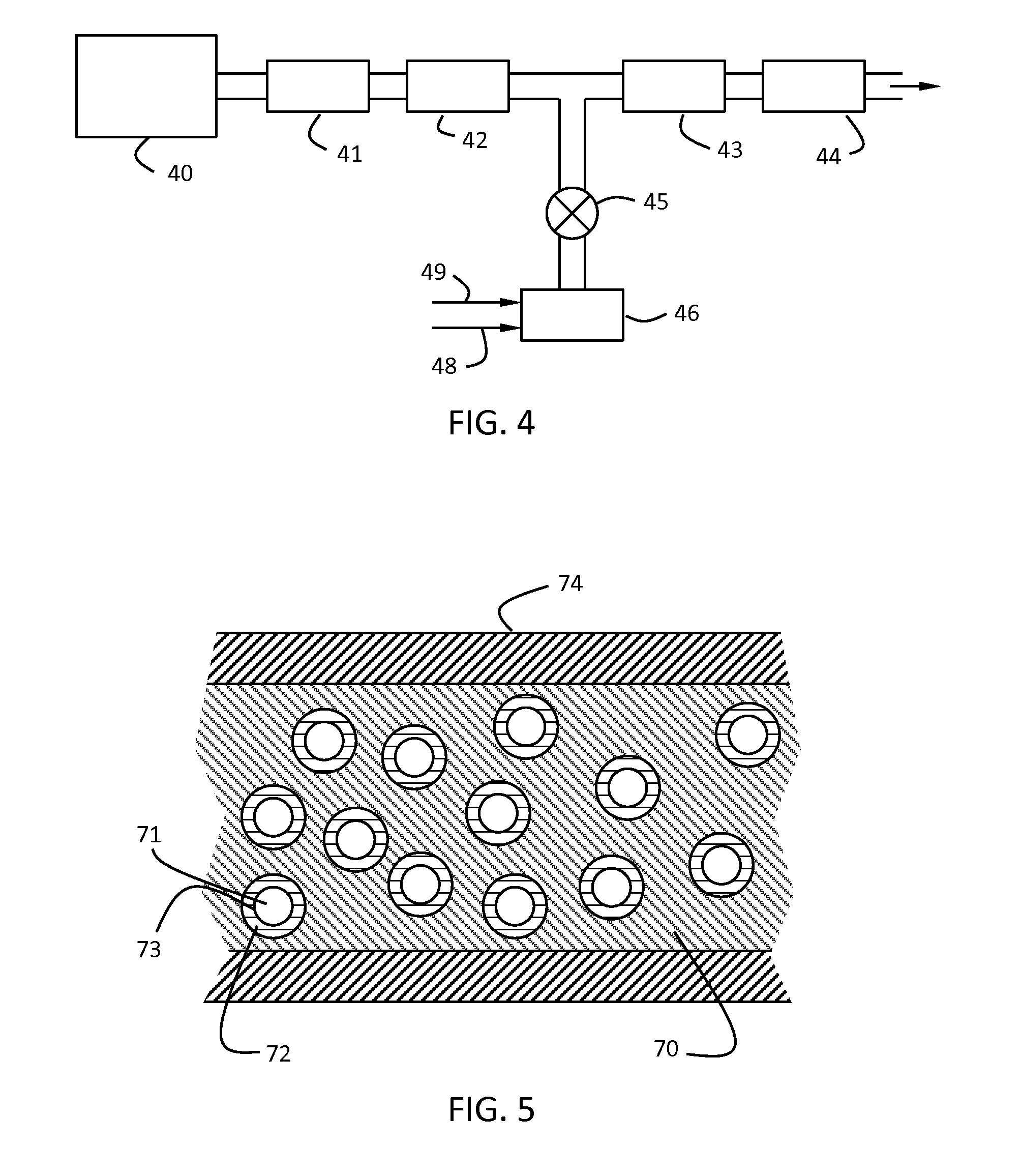

Emission control system

InactiveUS7065958B2Emission reductionEfficientlyInternal combustion piston enginesFlow mixersNitrogen oxidesControl system

A method and apparatus to reduce the emissions of an exhaust stream is provided. One feature of the present invention includes a control unit for metering a reagent into the exhaust stream. The control unit adjusts a quantity of the reagent to be metered into the exhaust stream. One embodiment of the present invention concerns a method of removing nitrogen oxides in exhaust gases from a diesel engine by introducing ammonia into the exhaust stream. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:EXTENGINE TRANSPORT SYST

Layered catalyst composite

A layered, three-way conversion catalyst having the capability of simultaneously catalyzing the oxidation of hydrocarbons and carbon monoxide and the reduction of nitrogen oxides is disclosed. In one or more embodiments, the catalyst comprises three layers in conjunction with a carrier: a first layer deposited on the carrier and comprising palladium deposited on a refractory metal oxide and an oxygen storage component; a second layer deposited on the first layer and comprising rhodium deposited on a refractory metal oxide and an oxygen storage component; and a third layer deposited on the second layer and comprising palladium deposited on a refractory metal oxide.

Owner:BASF CATALYSTS LLC

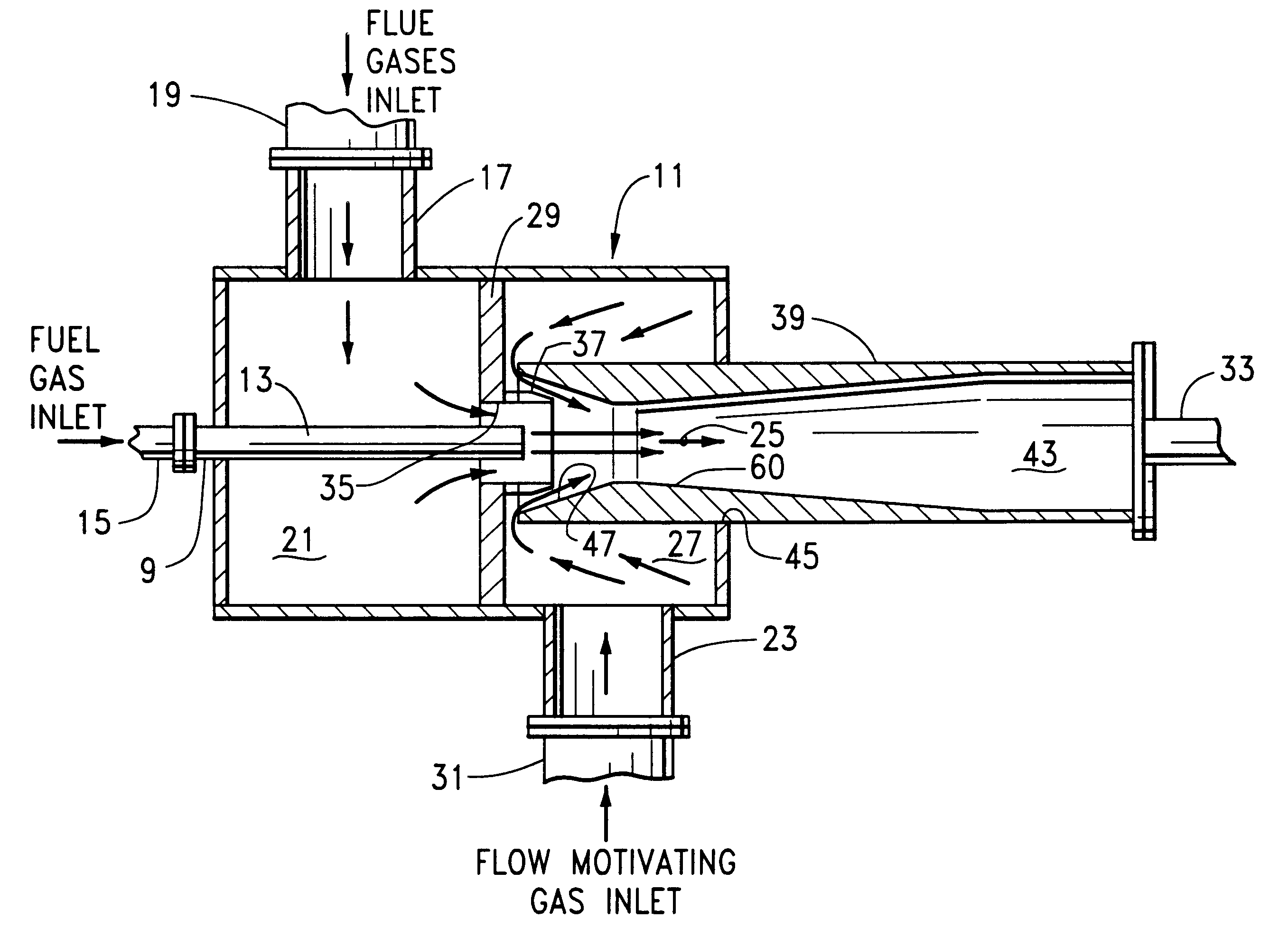

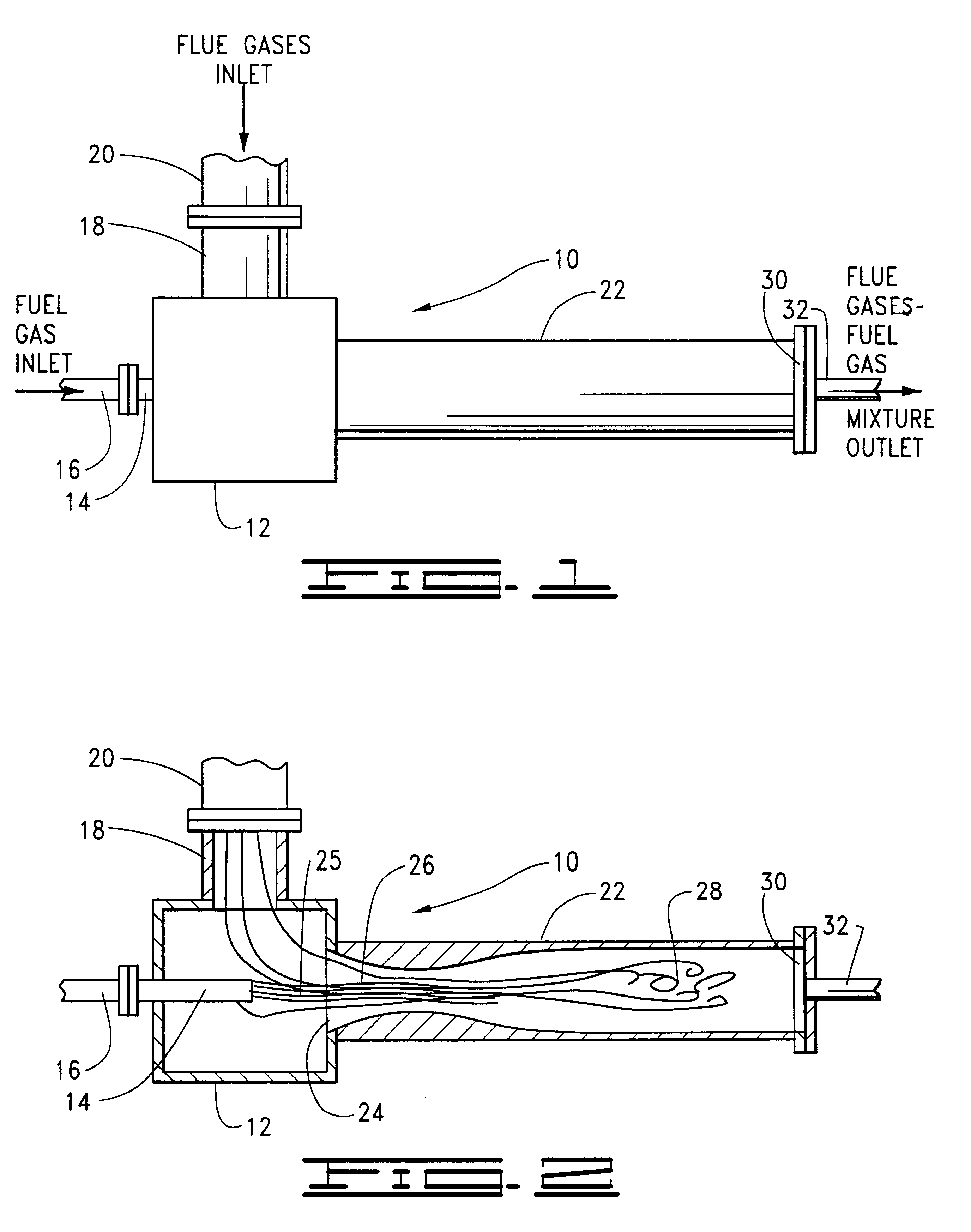

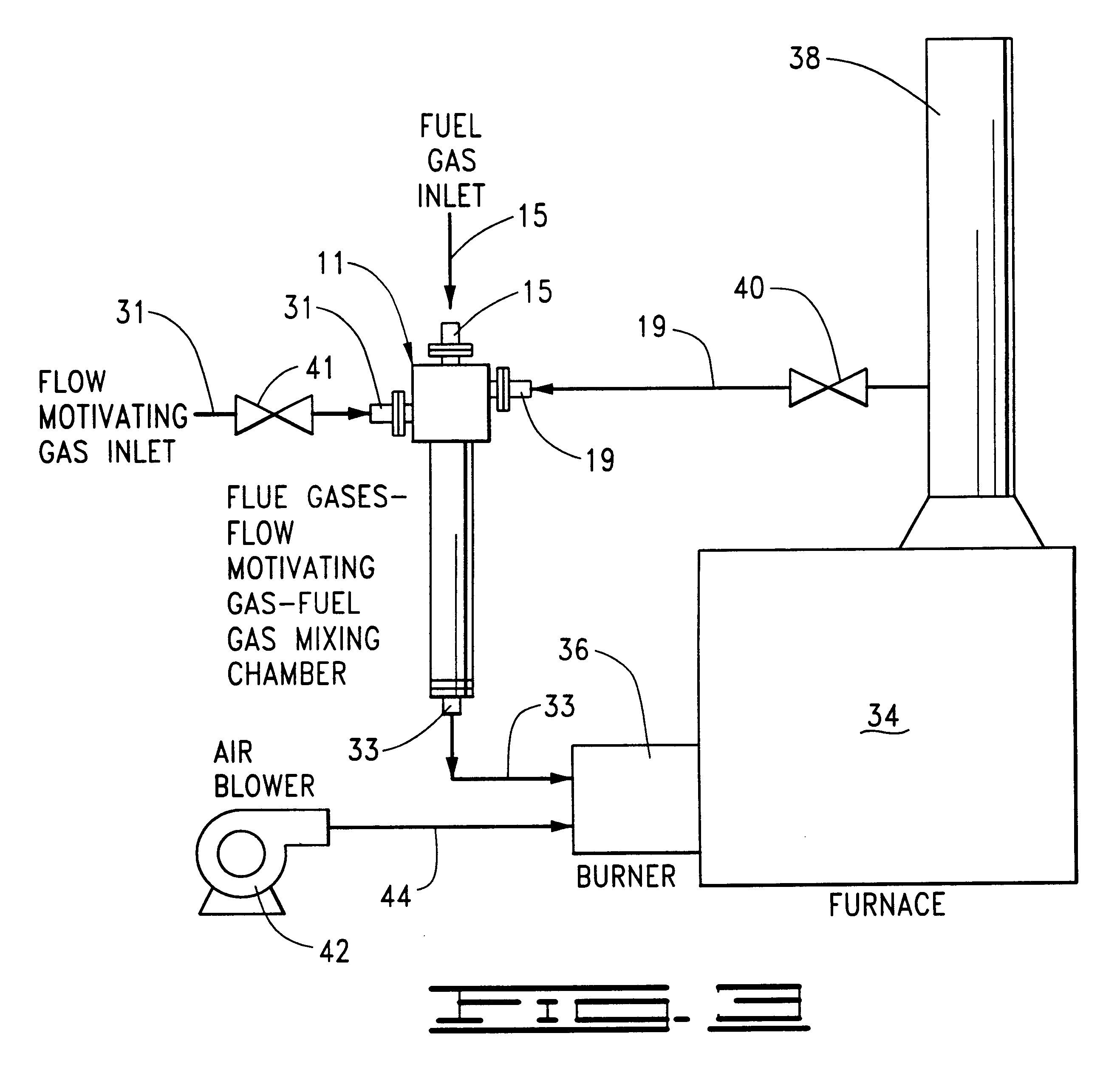

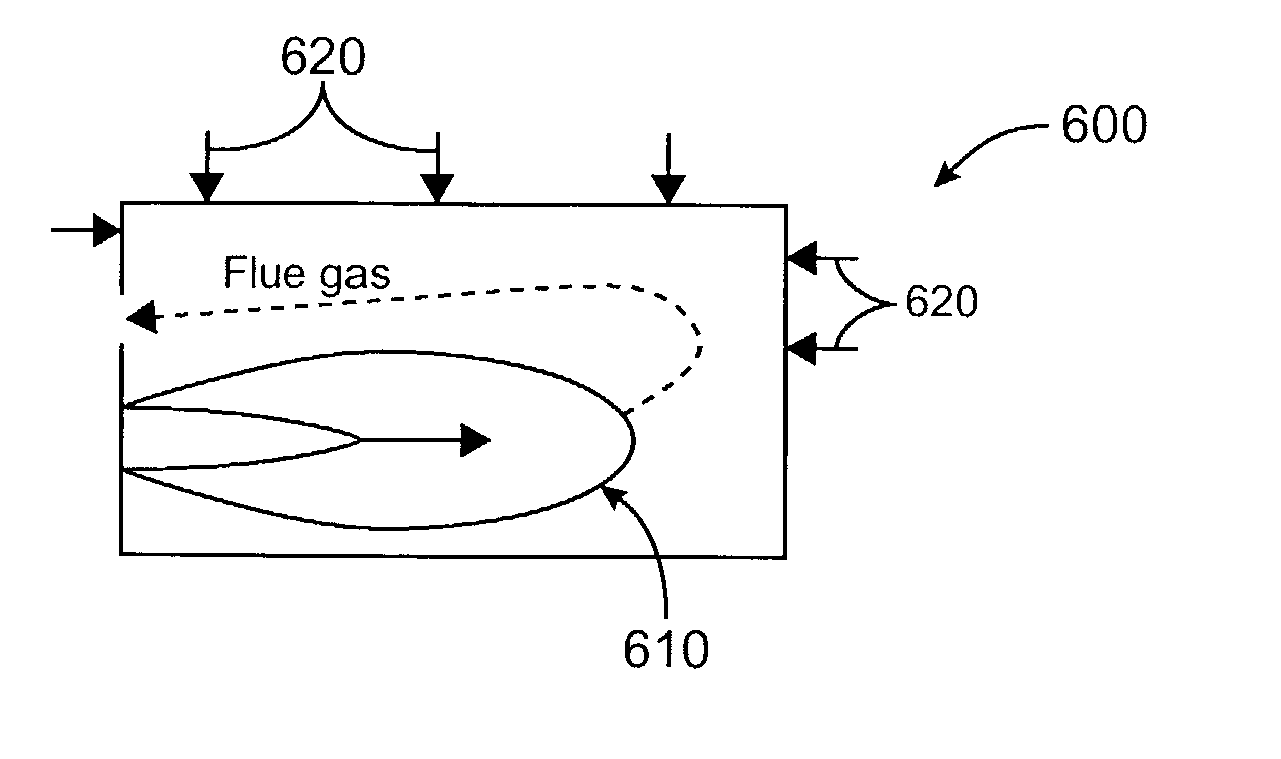

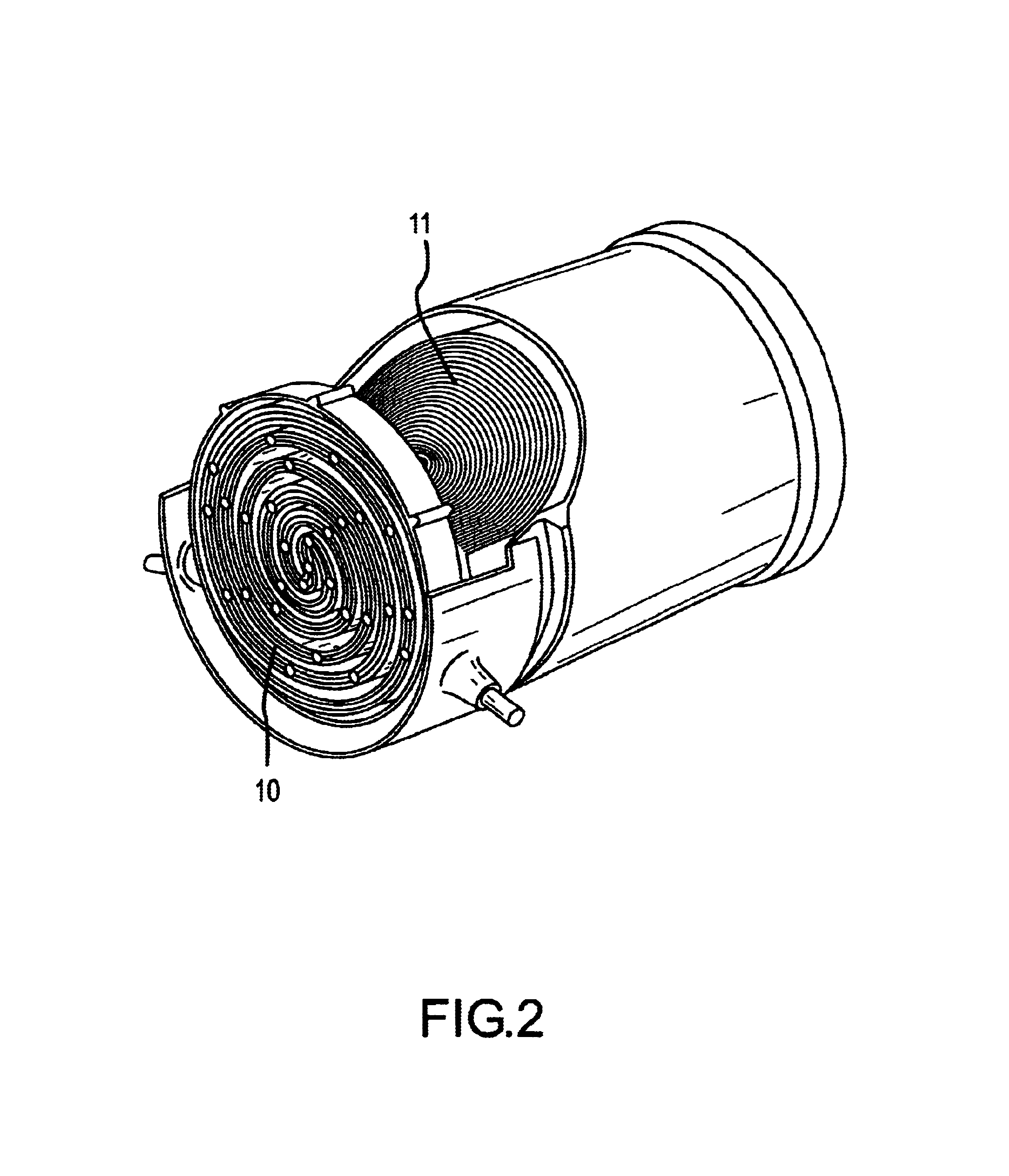

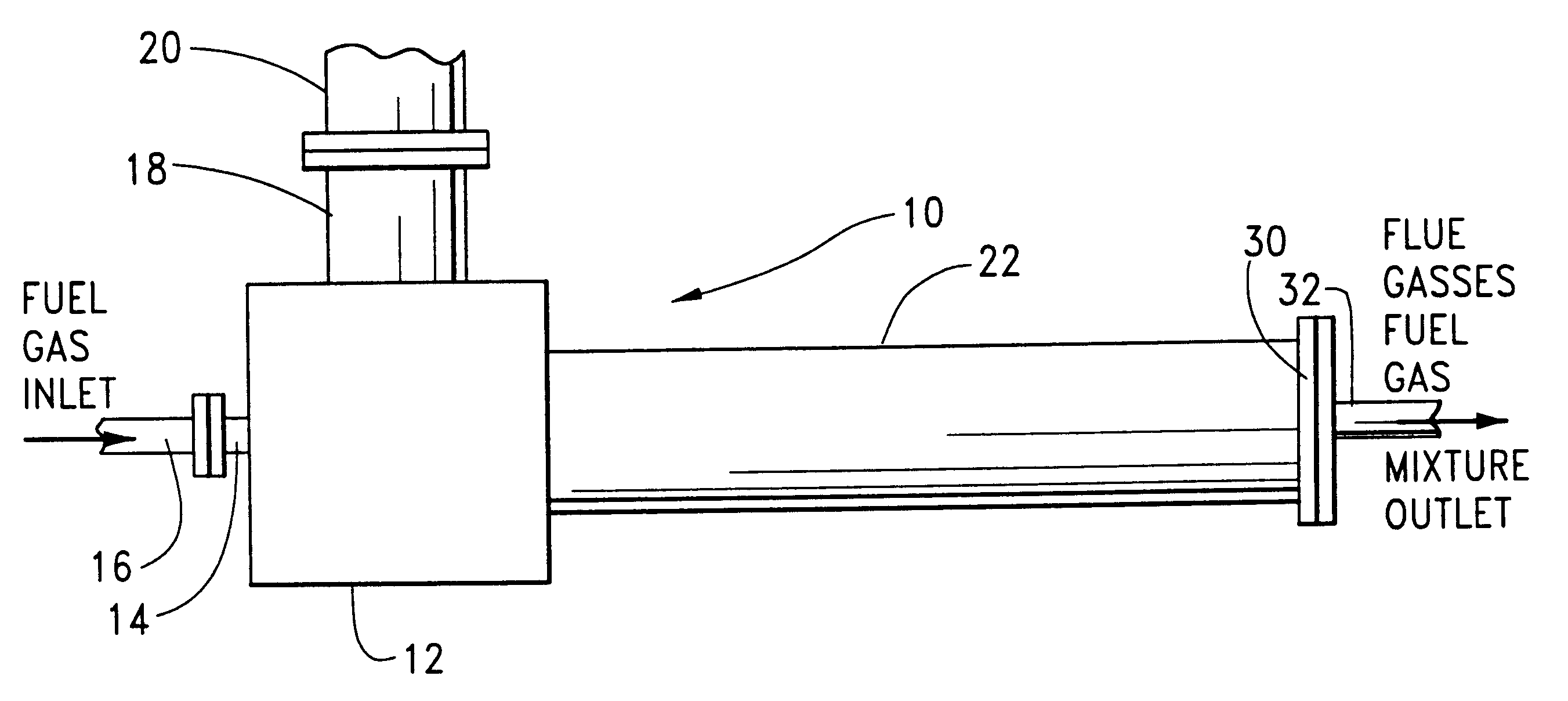

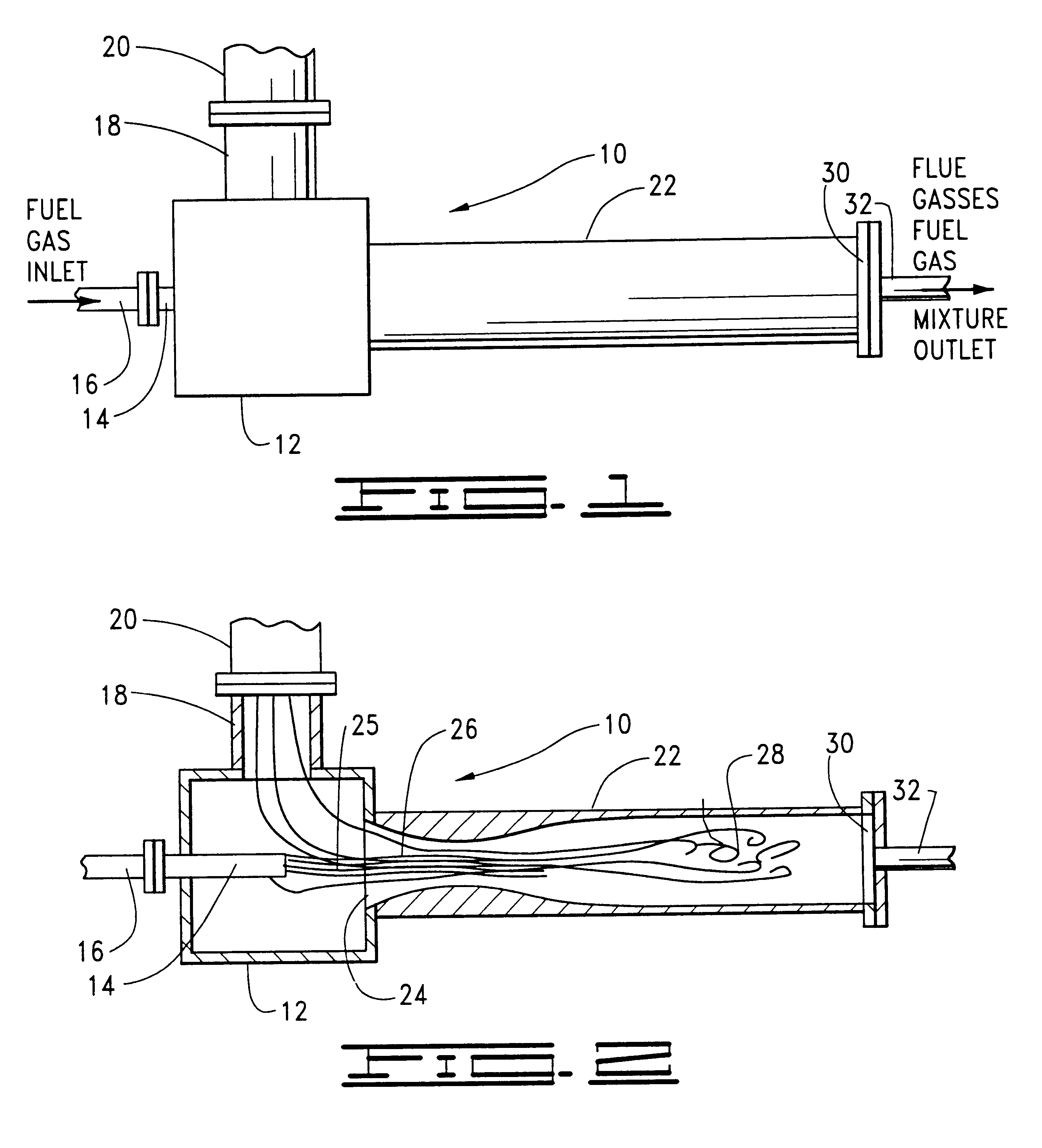

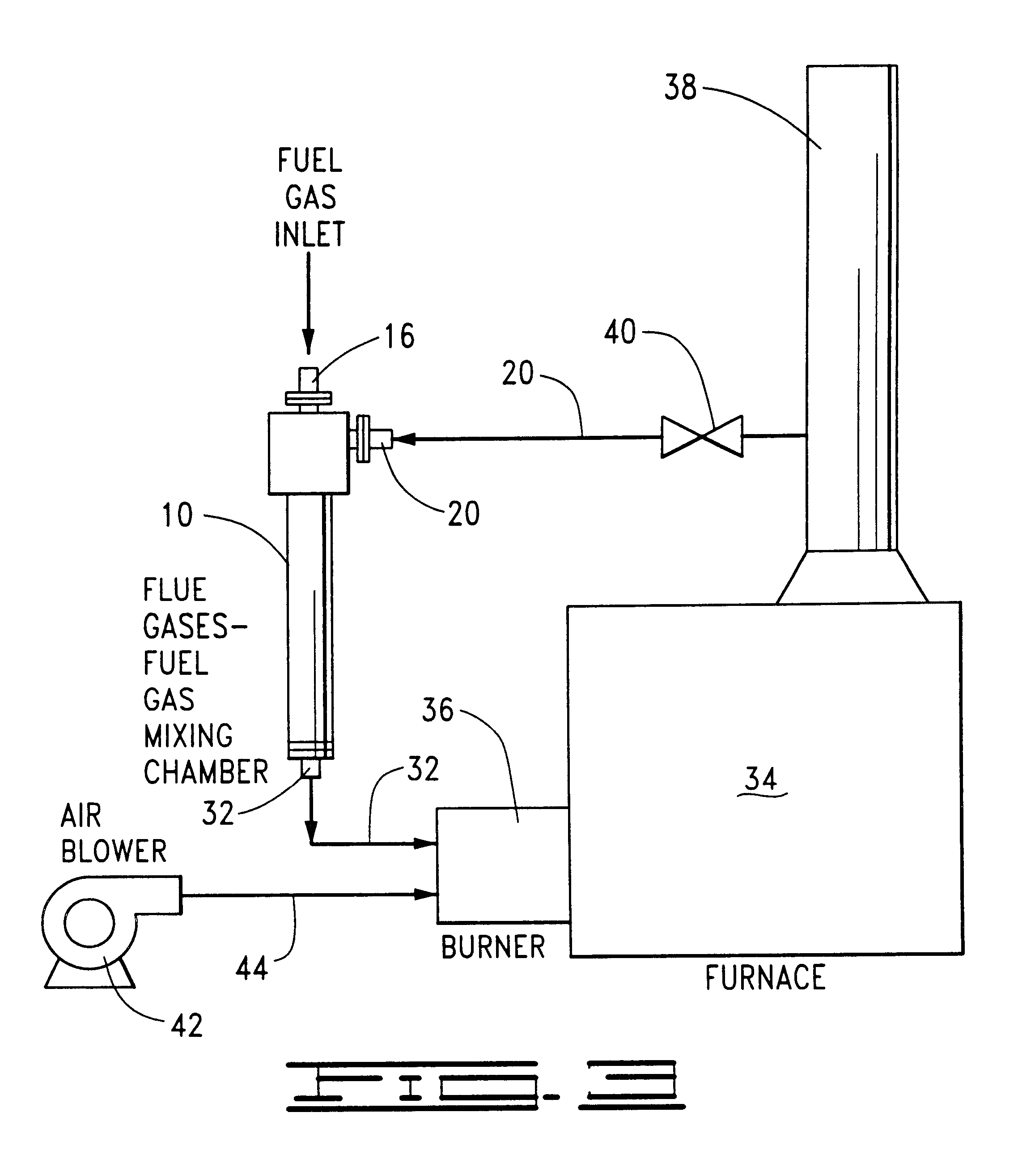

Fuel dilution methods and apparatus for NOx reduction

Methods and apparatus for reducing the content of nitrogen oxides in the flue gases produced by the combustion of fuel gas and combustion air introduced into a burner connected to a furnace are provided. The methods basically comprise the steps of conducting the combustion air to the burner, providing a chamber outside of the burner and furnace for mixing flue gases from the furnace with the fuel gas, discharging the fuel gas in the form of a fuel jet into the mixing chamber so that flue gases from the furnace are drawn into the chamber and mixed with and dilute the fuel gas therein and conducting the resulting mixture of flue gases and fuel gas to the burner wherein the mixture is combined with the combustion air and burned in the furnace.

Owner:JOHN ZINK CO LLC

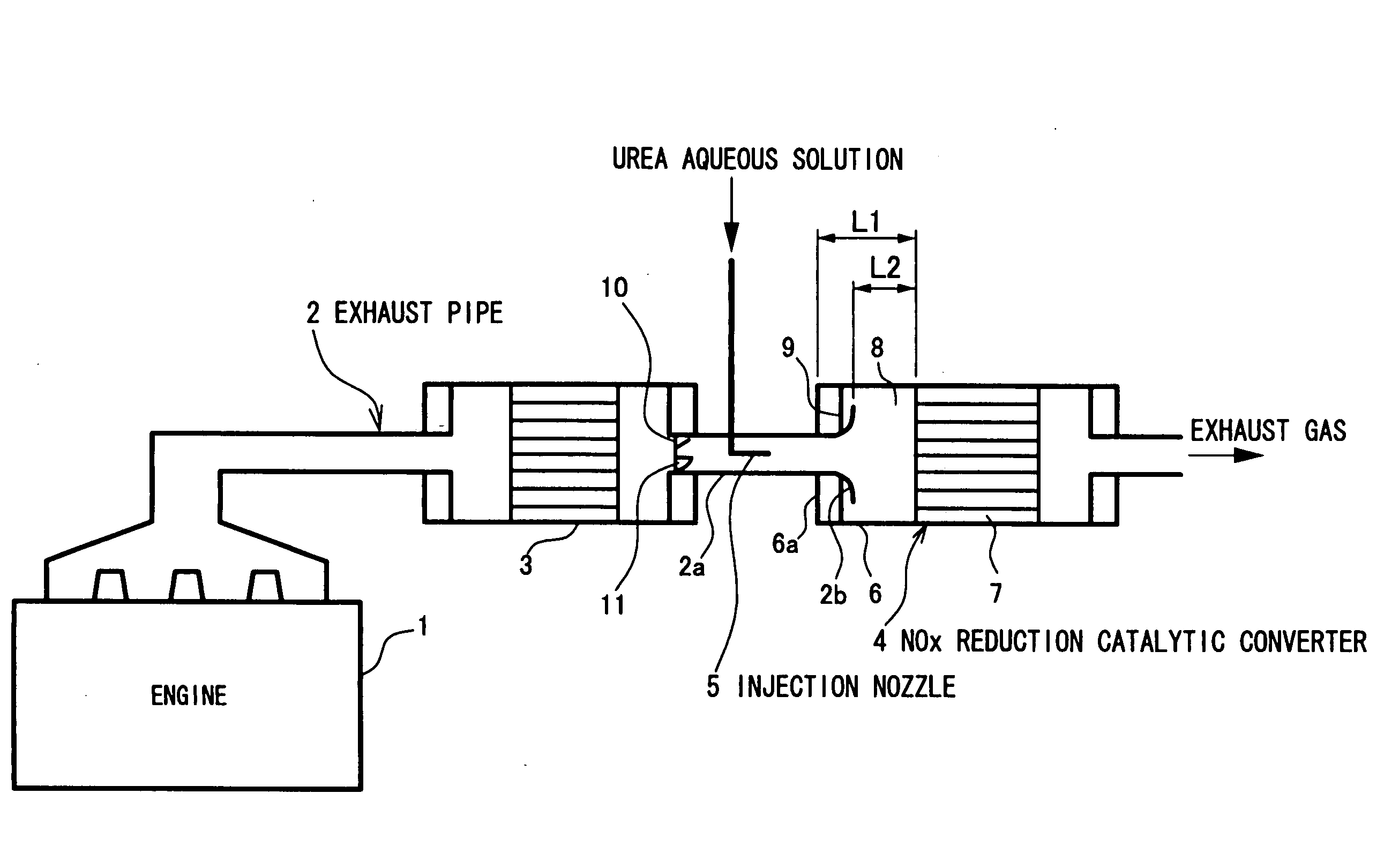

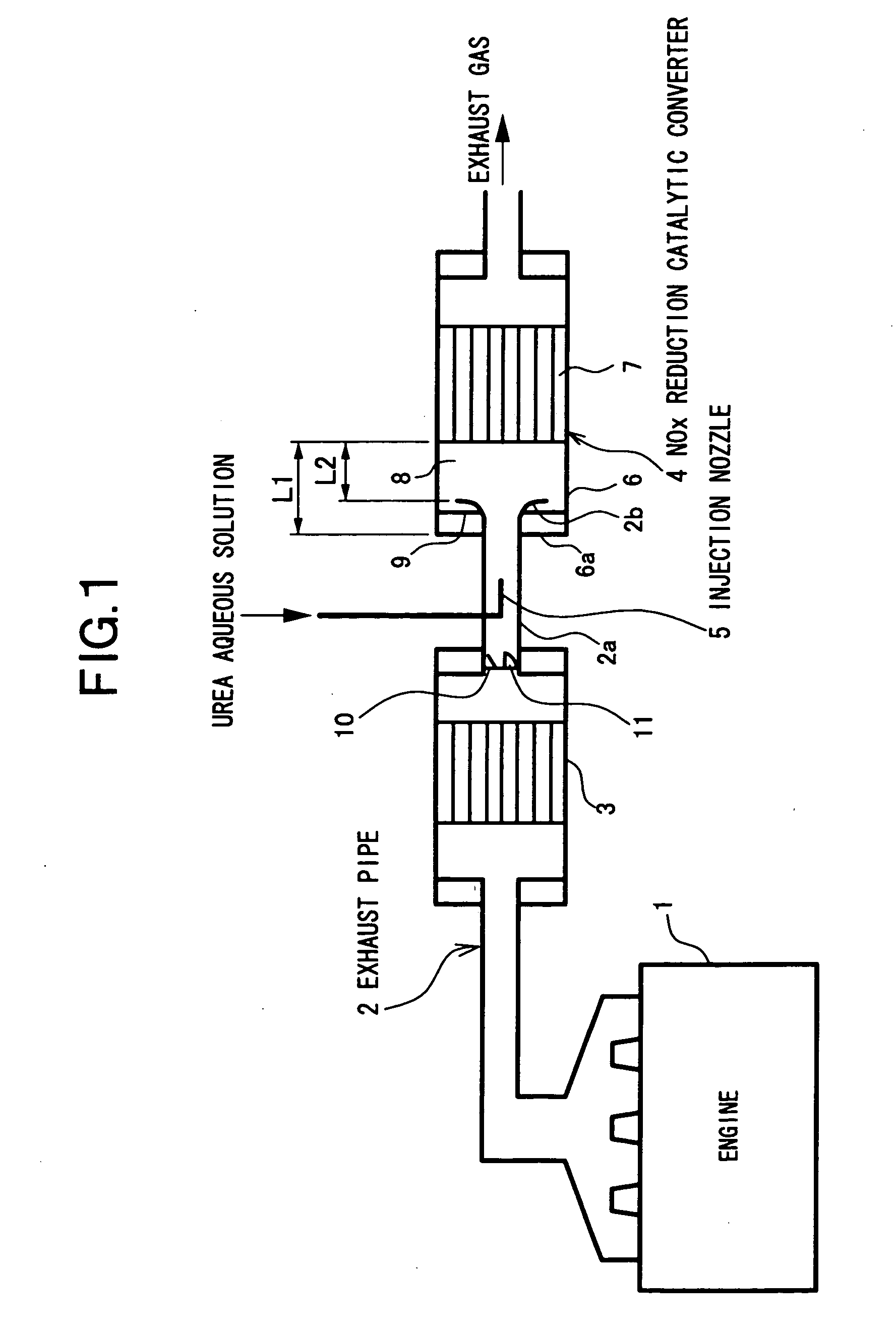

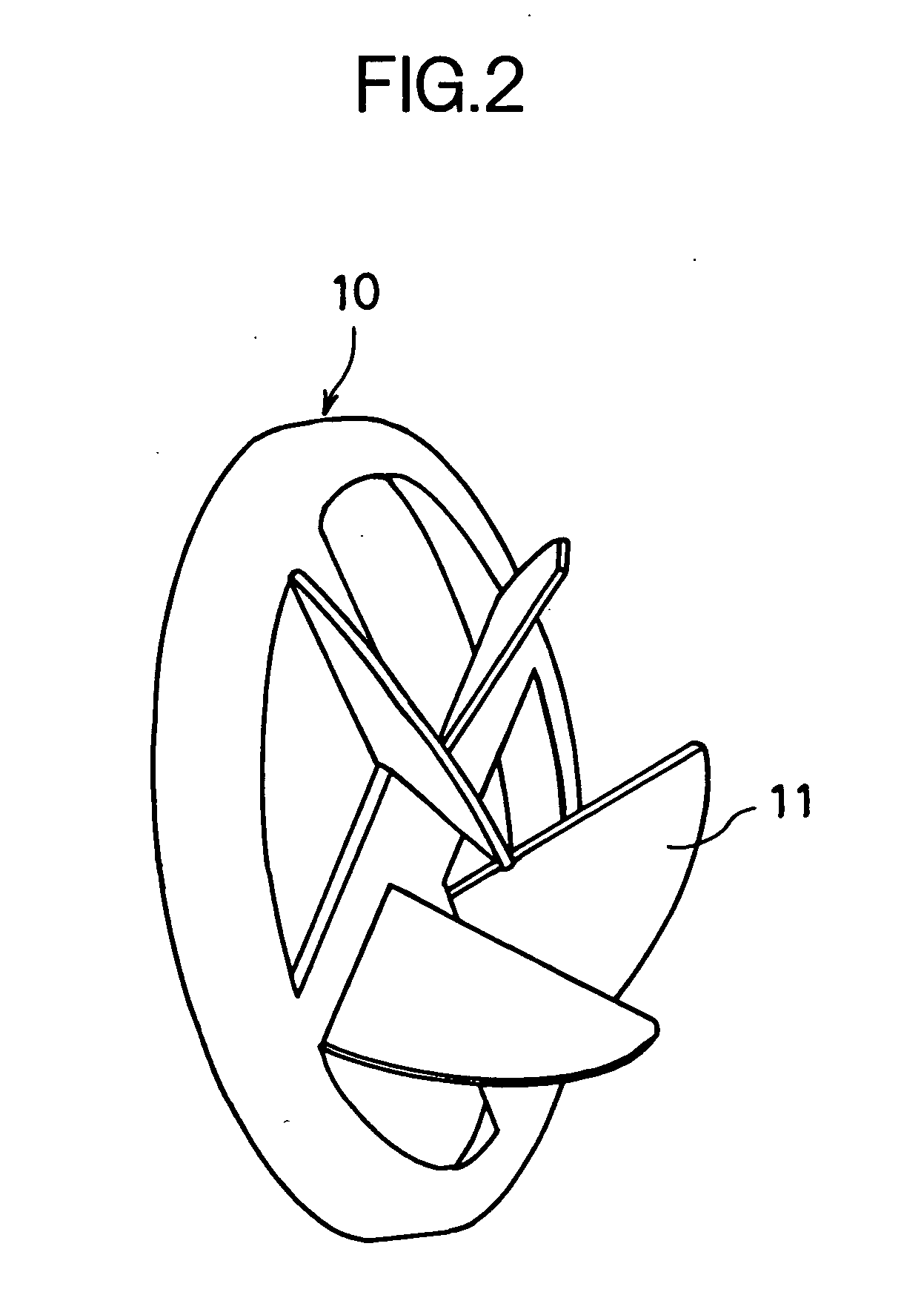

Exhaust emission purifying apparatus for engine

ActiveUS20070101703A1Easy to produceEasily swirling flowInternal combustion piston enginesFlow mixersNitrogen oxidesExhaust fumes

An exhaust emission purifying apparatus has a NOx reduction catalytic converter in an exhaust passage of an engine, for purifying nitrogen oxides in the exhaust gas by reduction with urea aqueous solution; an injection nozzle injecting the urea solution toward an exhaust upstream side of the converter in the exhaust passage; and fins disposed on an exhaust upstream side of an injection position of the urea solution in the injection nozzle, for generating a spiral swirling flow of the gas swirling about a center corresponding to the central axis of an exhaust pipe. The swirling flow generated in the exhaust gas prior to the injection-supply of the urea aqueous solution promotes mixing of the solution with the gas to thereby promote the hydrolysis of the urea solution. And the exhaust gas and ammonia generated from the urea solution are uniformly mixed together.

Owner:TOKYO ROKI +2

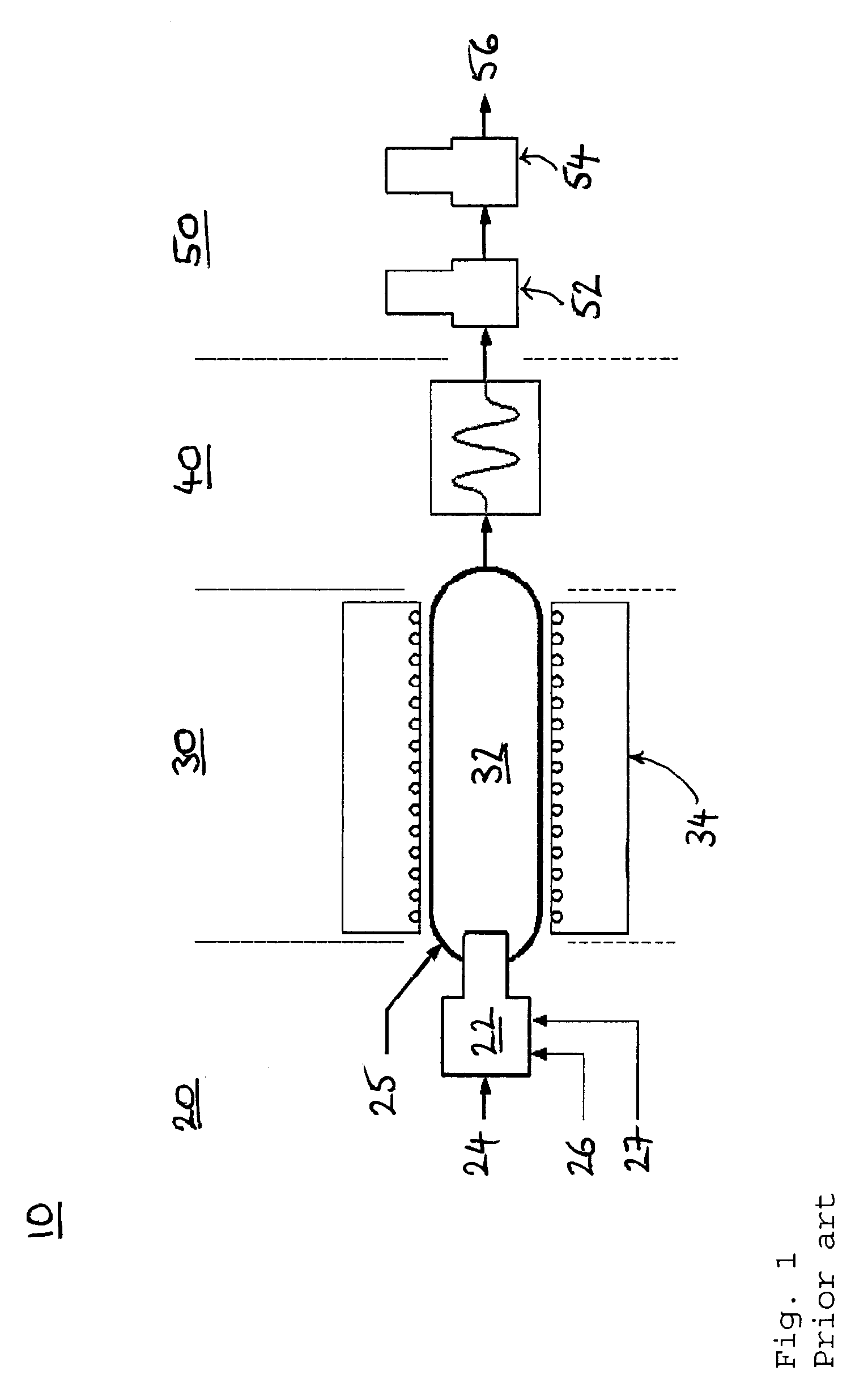

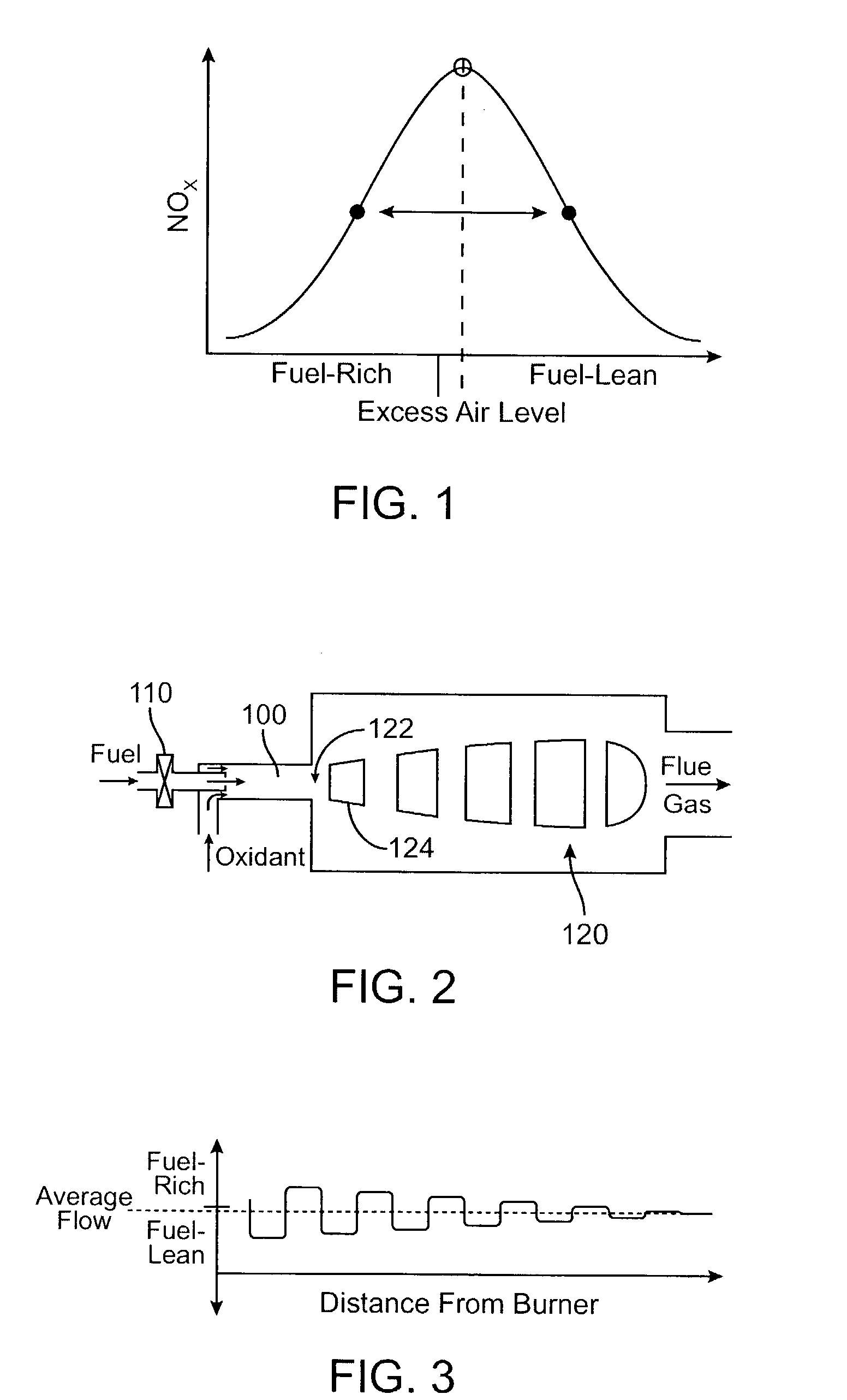

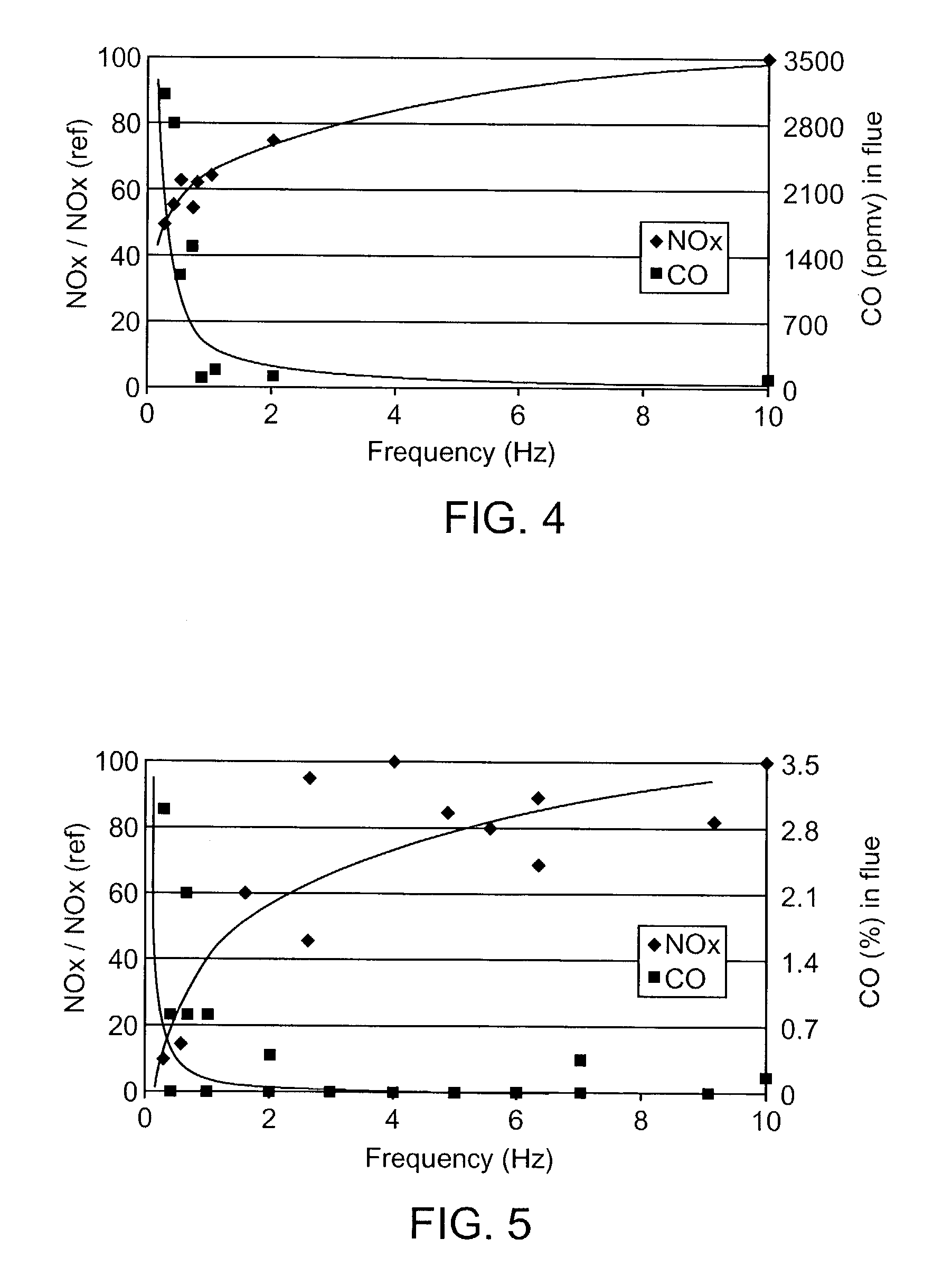

Process and apparatus of combustion for reduction of nitrogen oxide emissions

InactiveUS20030134241A1Special fuel supply arrangementsIndirect carbon-dioxide mitigationNitrogen oxidesControl system

A combustion control system allows the dramatic reduction of NOx emission levels from industrial combustion processes without having recourse to expensive flue gas clean up methods. The system combines the technique of oscillating combustion with an adapted system for post combustion burn out of the excess of CO resulting from the low-NOx combustion zone. A process for fuel combustion includes generating an oscillating combustion zone by oscillating at least one of the fuel flow and the oxidant flow to achieve a reduced nitrogen oxide emission, selecting oscillating parameters and furnace operating parameters to maximize nitrogen oxide reduction efficiency to the detriment of carbon monoxide production, and combusting carbon monoxide downstream of the oscillating combustion zone by injecting a post combustion oxidant.

Owner:MARIN OVIDIU +3

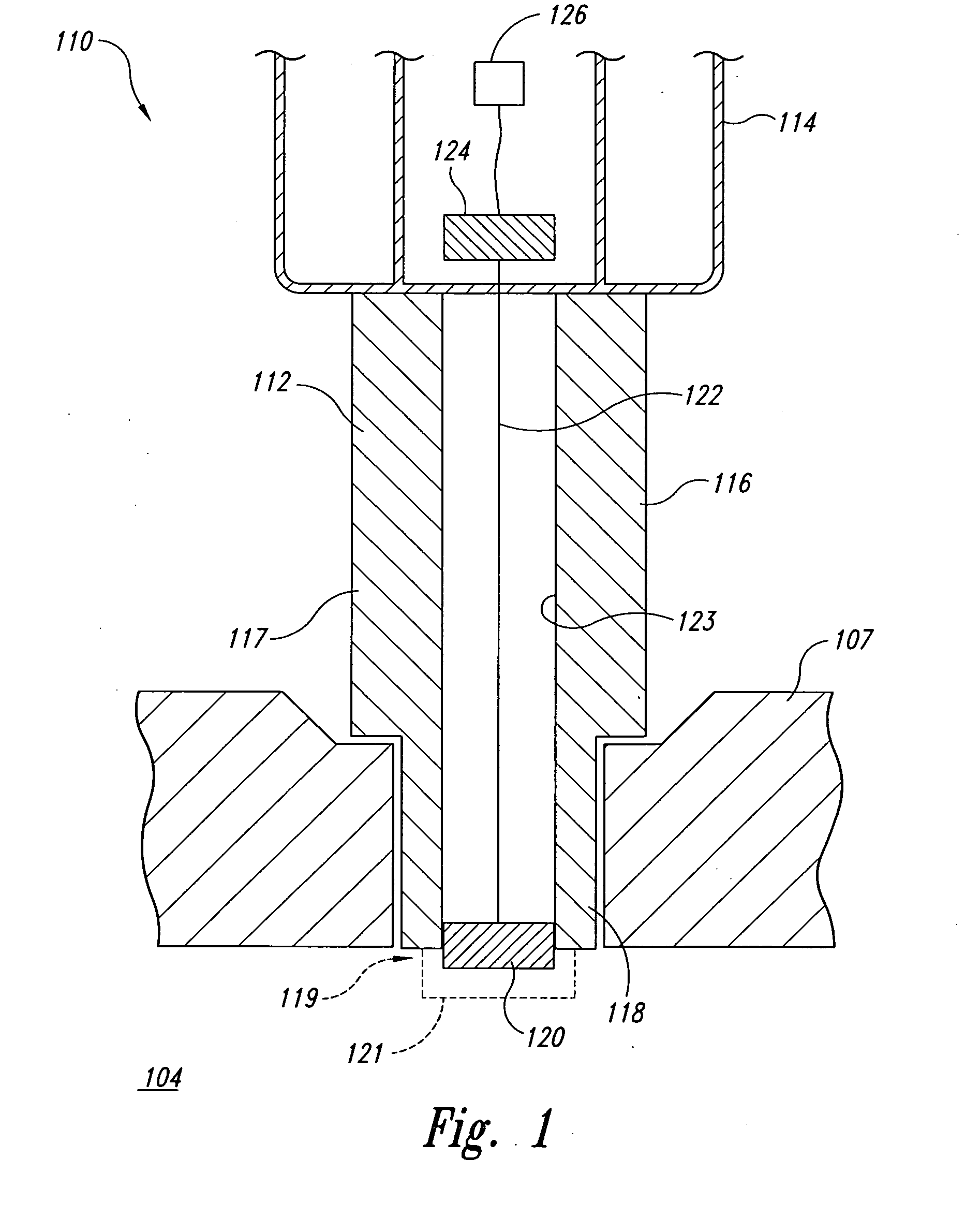

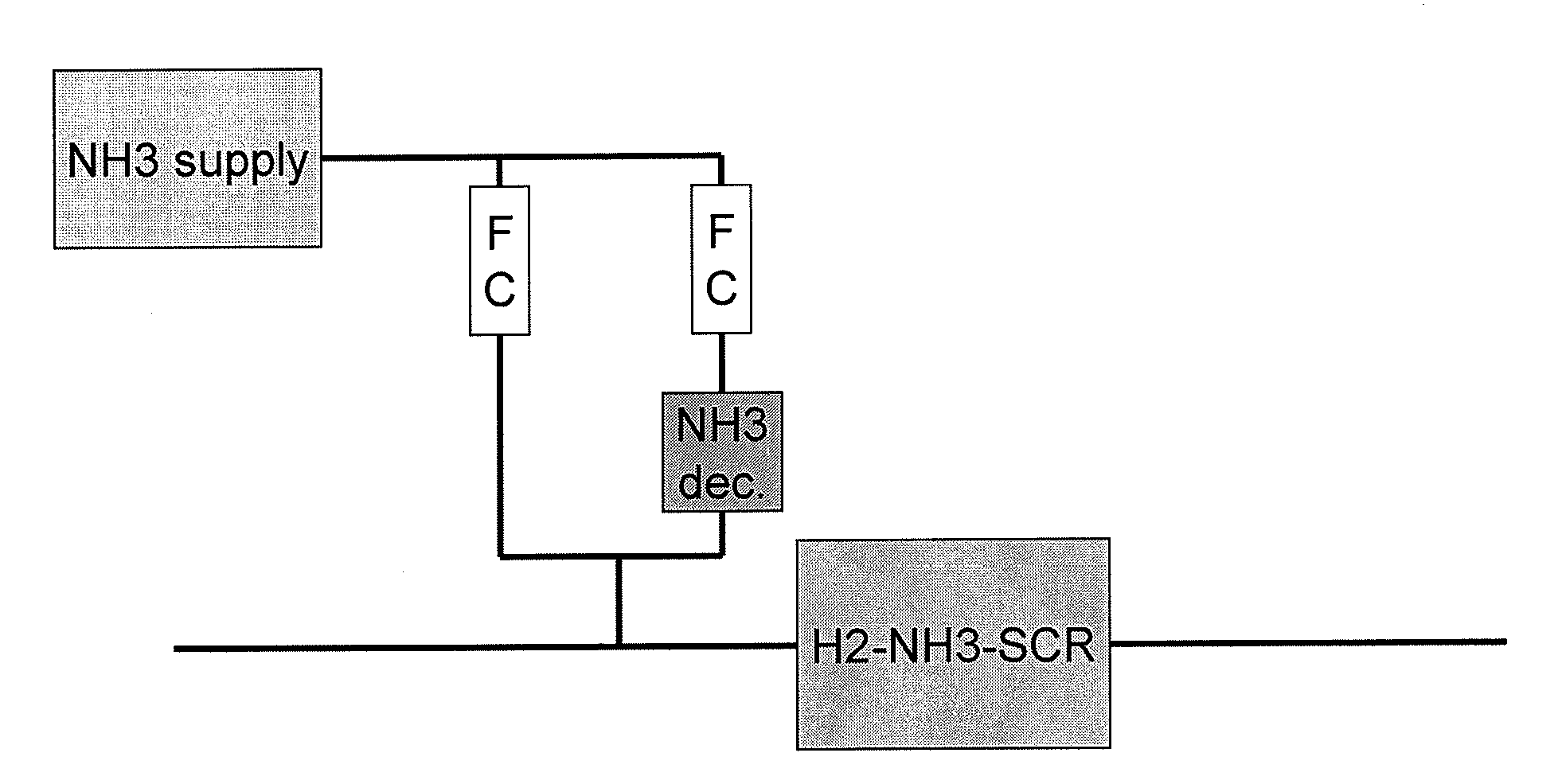

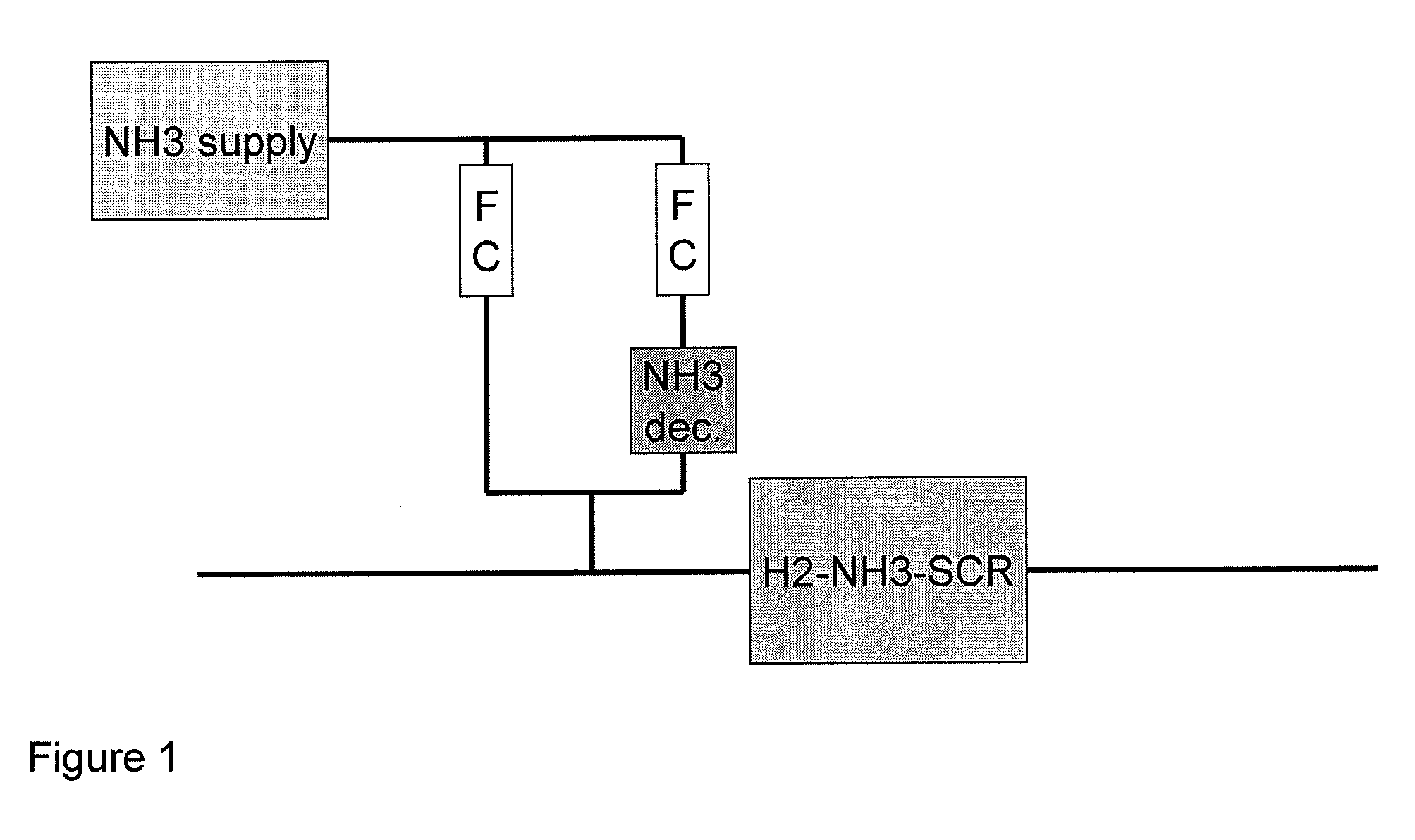

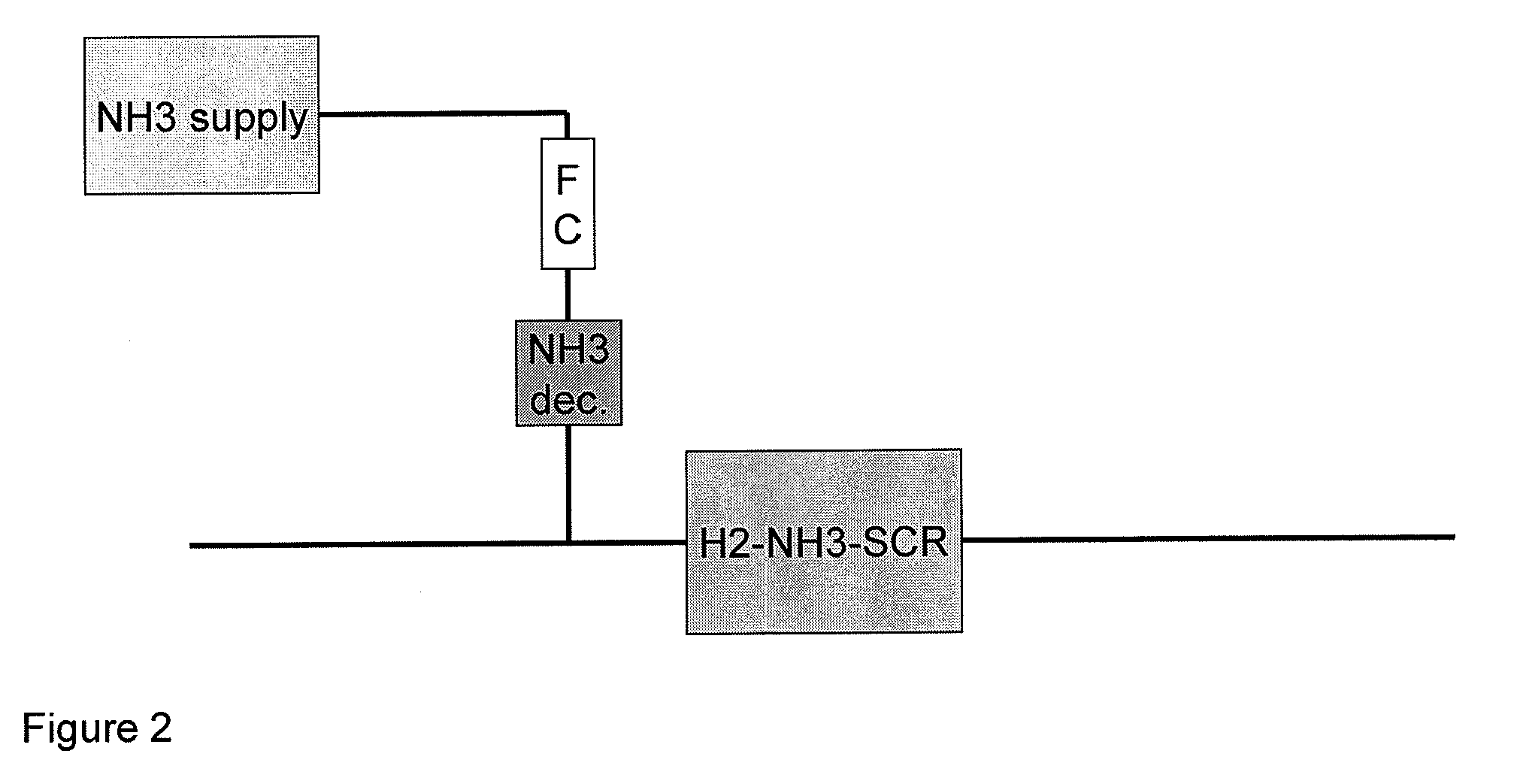

Method and apparatus for producing ammonia (NH3)

InactiveUS6928807B2High activityNitrogen compoundsInternal combustion piston enginesHydrolysisRapid thermal processing

A method is provided for producing ammonia (NH3) and introducing the produced ammonia (NH3) into an exhaust gas stream as a reduction means for selectively catalytically reducing nitrogen oxides contained in the exhaust gas stream, which is an exhaust stream generated by the combustion process of a motor, a gas turbine, or a burner. The method comprises feeding dry urea from a supply container in a controlled amount to reactor and subjecting the dry urea in the reactor to a sufficiently rapid thermal treatment such that a gas mixture comprising the reaction products of ammonia (NH3) and isocyanic acid (HCNO) is created. Also, the method comprises immediately catalytically treating the thus produced gas mixture in the presence of water such that the isocyanic acid (HCNO) resulting from the rapid thermal treatment is converted, via quantitative hydrolysis treatment, into ammonia (NH3) and carbon dioxide (CO2).

Owner:MAN NUTZFAHRZEUGE AG

Fuel dilution methods and apparatus for NOx reduction

InactiveUS6383461B1Reduce contentAdd additional massCombination devicesNitrogen compoundsCombustorFlue gas

Methods and apparatus for reducing the content of nitrogen oxides in the flue gases produced by the combustion of fuel gas and combustion air introduced into a burner connected to a furnace are provided. The methods basically comprise the steps of conducting the combustion air to the burner, providing a chamber outside of the burner and furnace for mixing flue gases from the furnace with the fuel gas, discharging the fuel gas in the form of a fuel jet into the mixing chamber so that flue gases from the furnace are drawn into the chamber and mixed with and dilute the fuel gas therein and conducting the resulting mixture of flue gases and fuel gas to the burner wherein the mixture is combined with the combustion air and burned in the furnace.

Owner:JOHN ZINK CO LLC

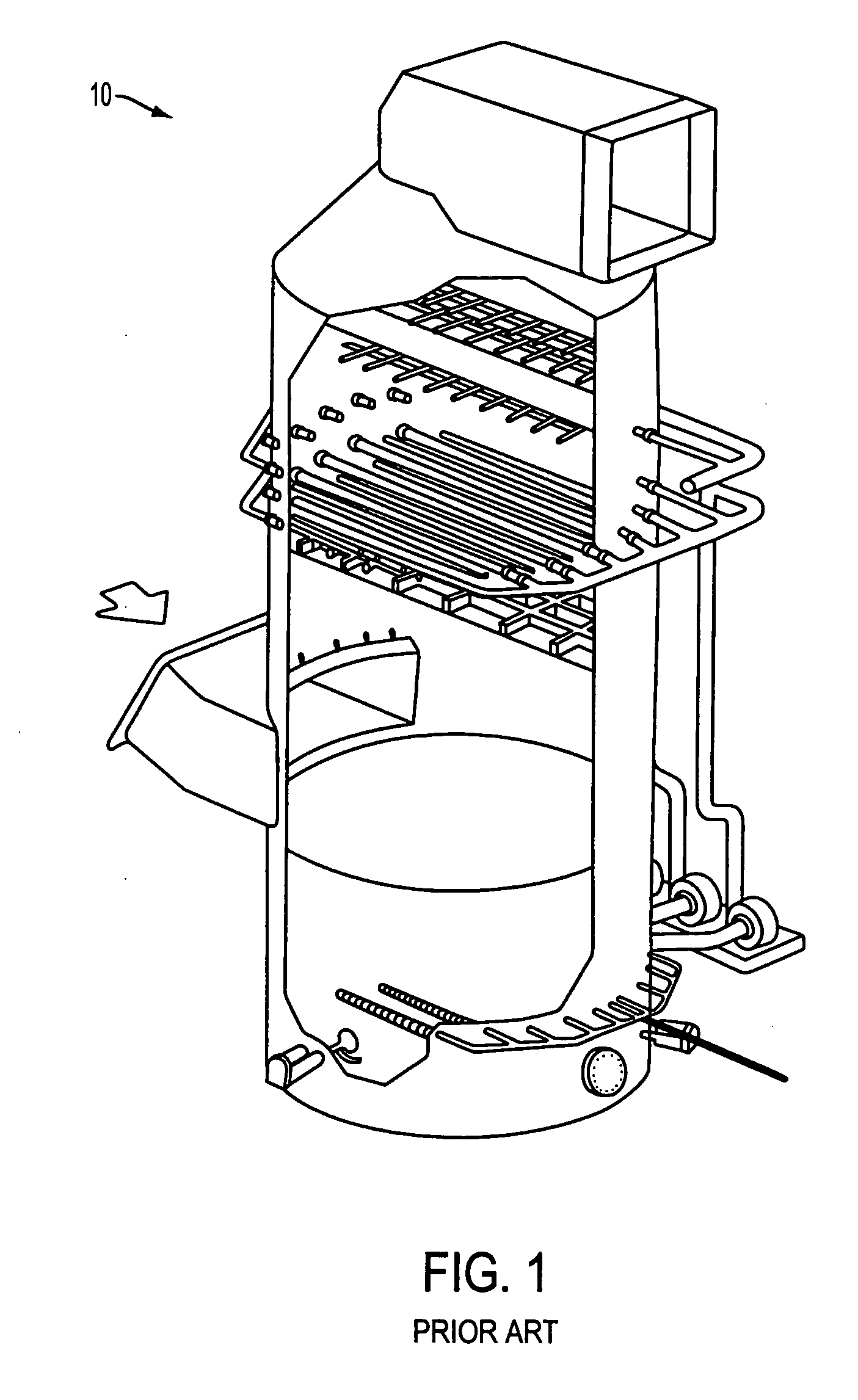

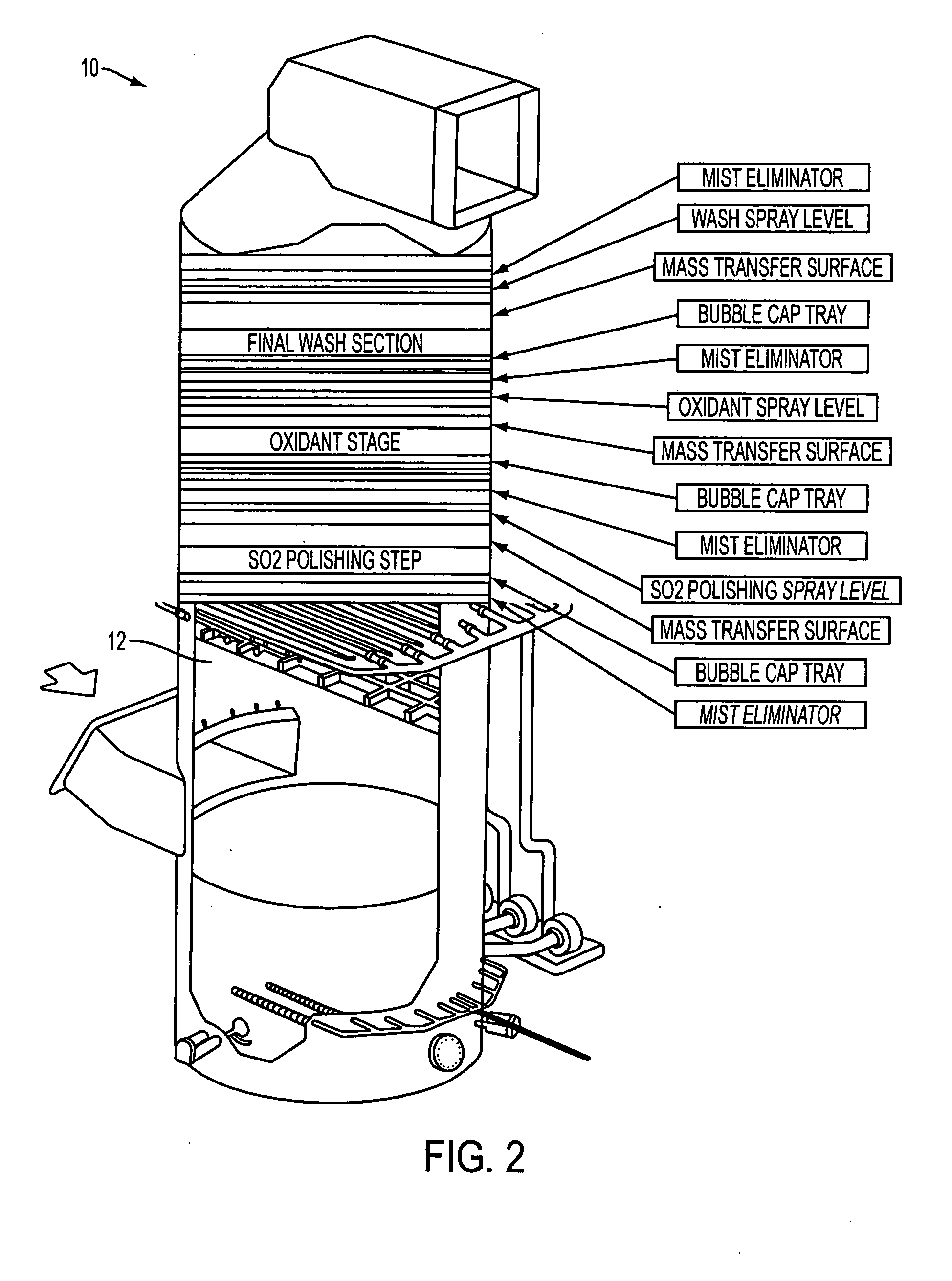

Removal of Hg, NOx, and SOx with using oxidants and staged gas/liquid contact

InactiveUS20050214187A1Simple methodHigh removal rateGas treatmentNitrogen compoundsNitrogen oxidesSorbent

A method of scrubbing mercury compounds and nitrogen oxides from a gas stream employing a scrubbing operation. The method involves the contact of the stream which contains mercury, SOx and NOx compounds with a sorbent to remove at least a portion of the latter compounds. This results in a partially cleaned stream. The method further involves contacting the latter stream with an oxidant to oxidize and remove substantially all residual nitrogen oxides, mercury and mercury compounds remaining in the stream.

Owner:AIRBORNE IND MINERALS INC CA

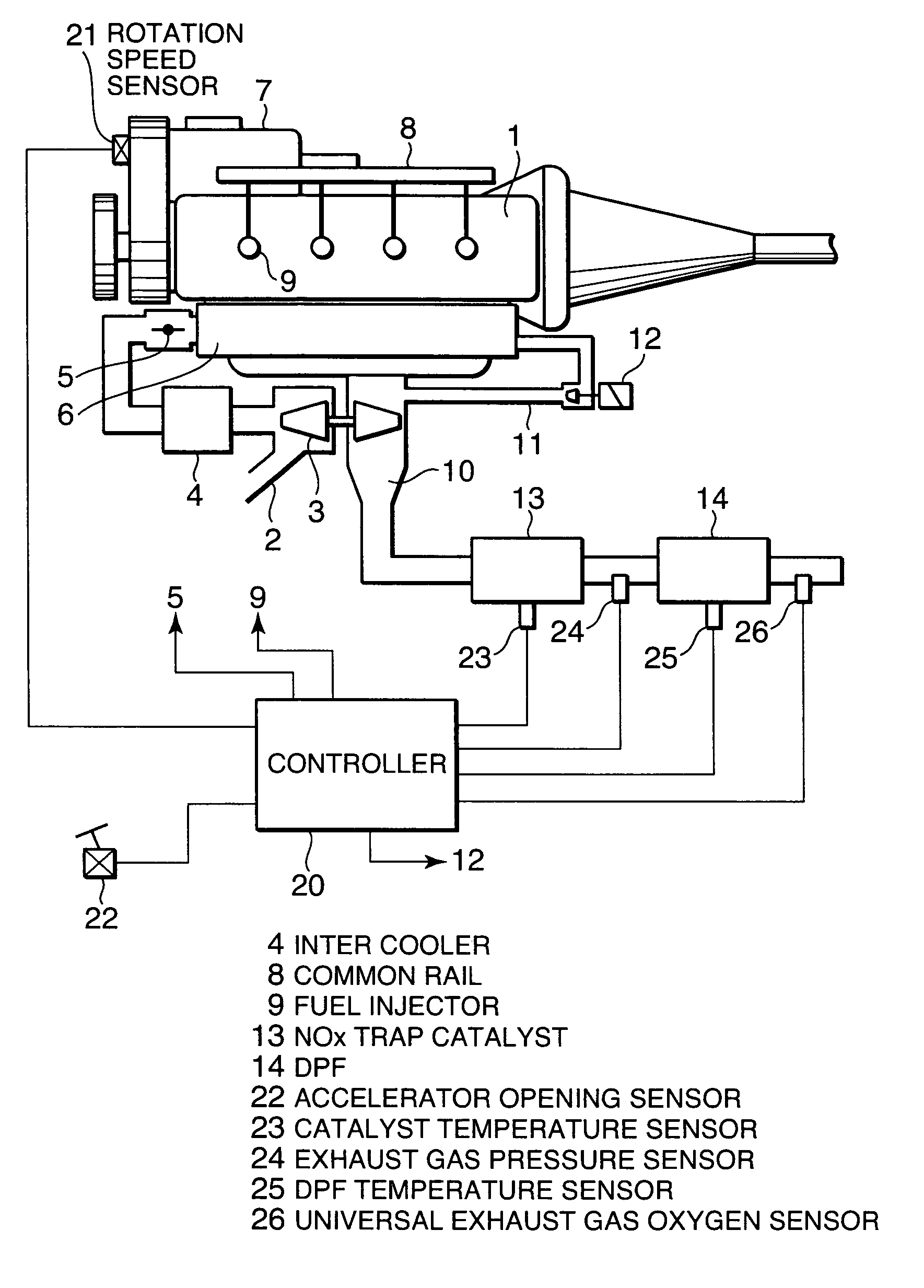

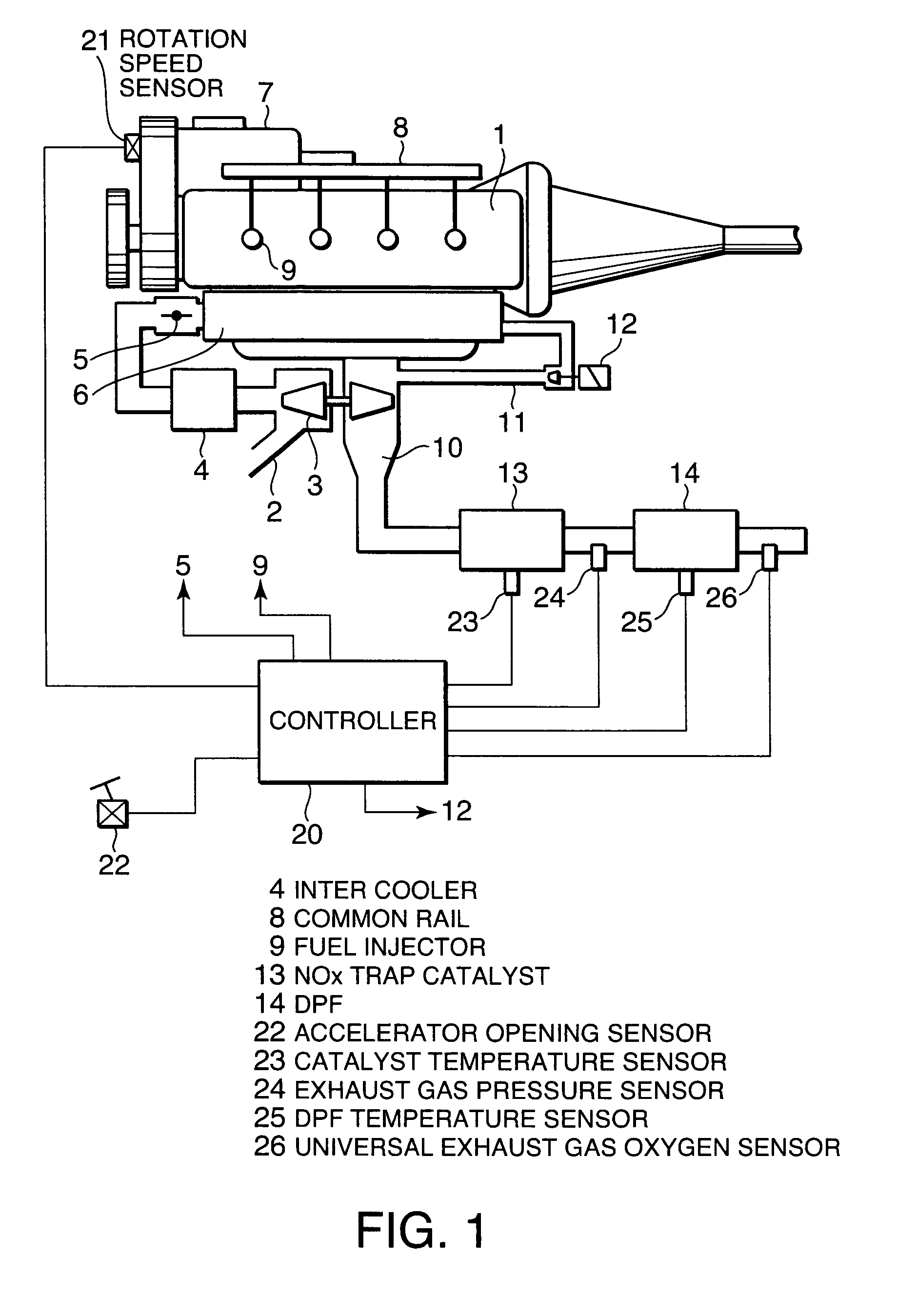

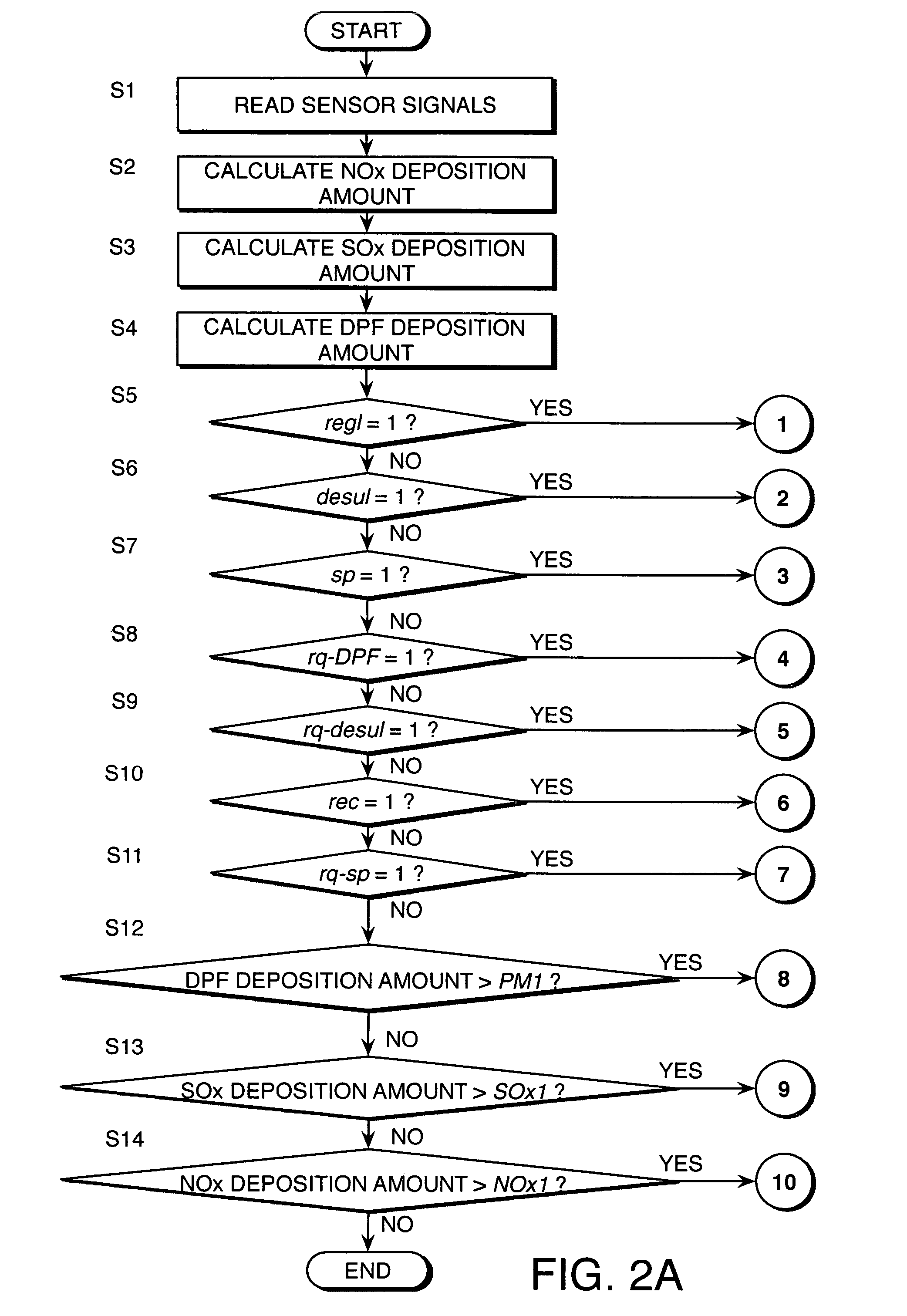

Exhaust gas purification control of diesel engine

InactiveUS7631493B2Reduce the amount of solutionCombination devicesElectrical controlNitrogen oxidesExhaust fumes

A diesel particulate filter (14) which traps particulate matter and a NOx trap catalyst (13) which traps nitrogen oxides are installed in series in an exhaust passage (10) of a diesel engine (1). A controller (21) calculates a particulate matter deposition amount in the diesel particulate filter (14) (S4). The controller (21), when the particulate matter deposition amount exceeds a first predetermined amount (PM2), prevents sharp increase of the particulate matter deposition amount by prohibiting rich spike where the oxygen concentration of the exhaust gas is controlled to a value corresponding to a rich air-fuel ratio in order to regenerate the NOx trap catalyst (13) (S301, S302, S306), and prevents the particulate matter deposition amount of the diesel particulate filter (14) from reaching a limit.

Owner:NISSAN MOTOR CO LTD

Full ring fuel distribution system for a gas turbine combustor

InactiveUS6282904B1Convenient lightingEnhancing quality and integrityBurnersContinuous combustion chamberCombustion chamberCombustor

A fuel nozzle system for use in a combustor utilized in a combustion turbine for reducing nitrogen oxides and other pollutants including an annular fuel distribution manifold separately mounted away from a diffusion nozzle, said annular manifold having a plurality of fuel emitting passages or holes disposed along the downstream side of the manifold, said manifold being mounted in a position away from the diffuser nozzle body to allow air to stream around the manifold on all sides allowing for a thorough mixture of fuel and air around the annular manifold for better premixing in the combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

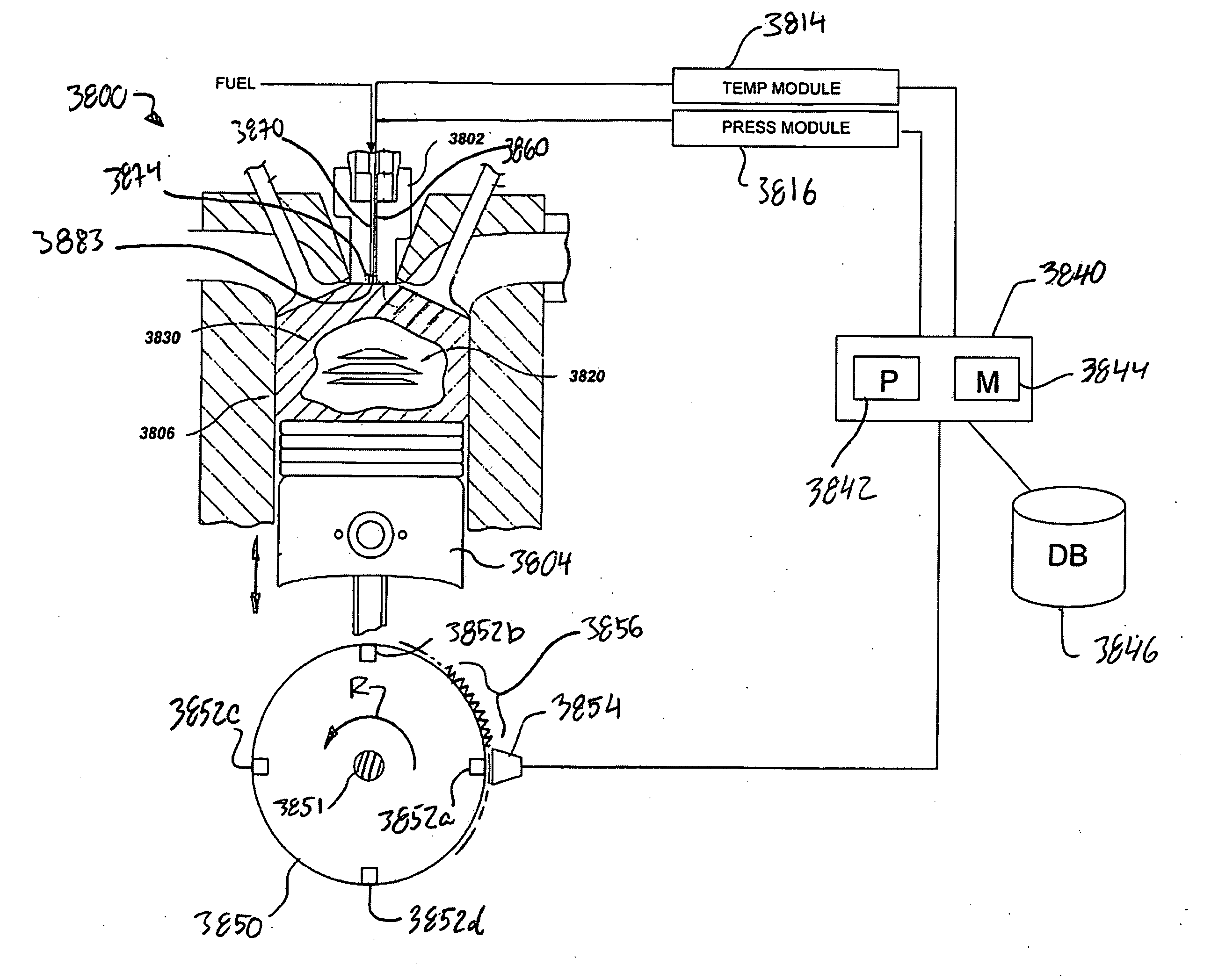

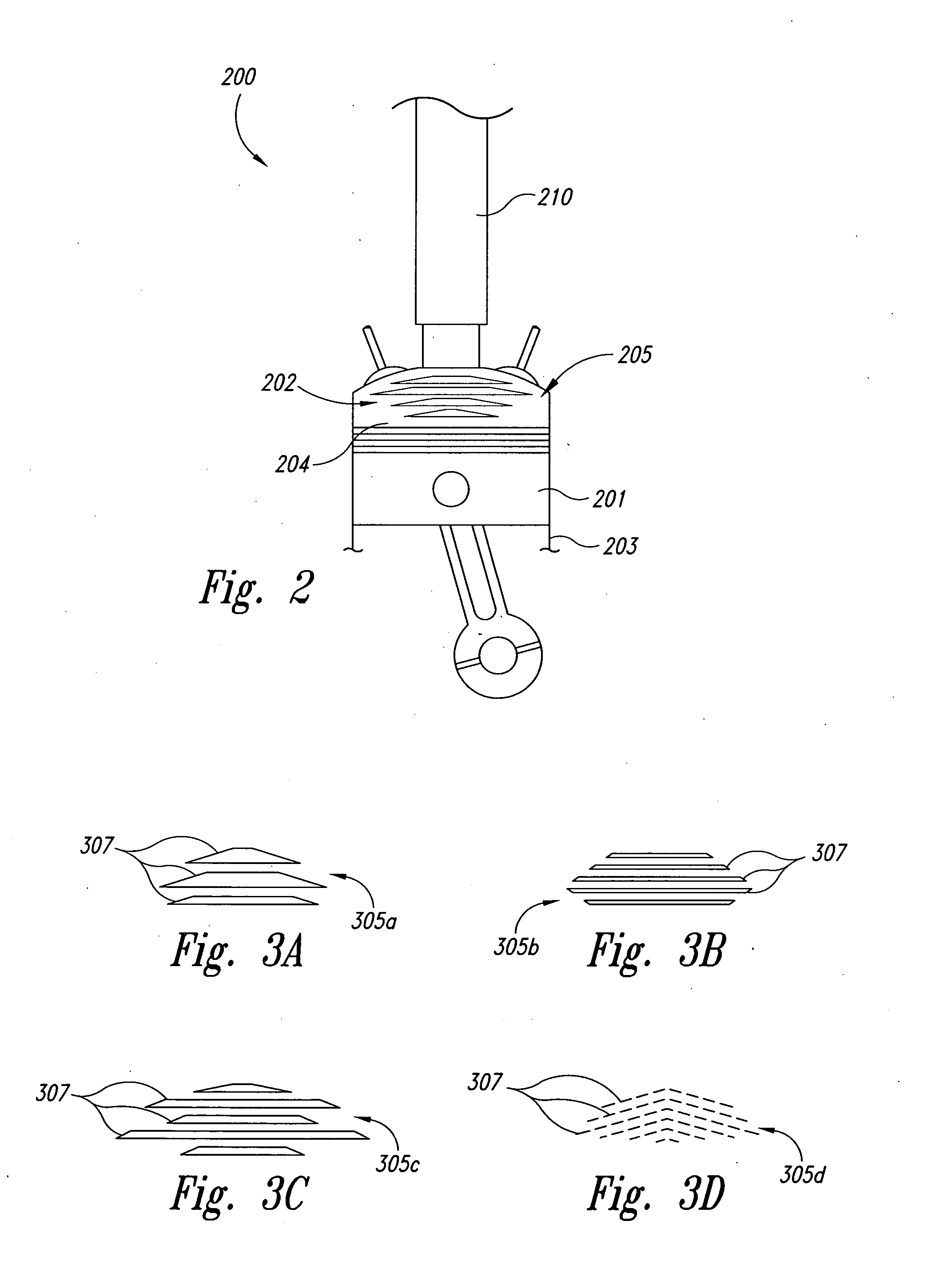

Methods and systems for reducing the formation of oxides of nitrogen during combustion in engines

The present disclosure is directed to various embodiments of systems and methods for reducing the production of harmful emissions in combustion engines. One method includes correlating combustion chamber temperature to acceleration of a power train component, such as a crankshaft. Once the relationship between acceleration / deceleration of the component and combustion temperature are known, an engine control module can be configured to adjust combustion parameters to reduce combustion temperature when acceleration data indicates peak combustion temperature is approaching a harmful level, such as a level conducive to the formation of undesirable oxides of nitrogen. Various embodiments of the methods and systems disclosed herein can employ injectors with integrated igniters providing efficient injection, ignition, and complete combustion of various types of fuels.

Owner:ADVANCED GREEN INNOVATIONS LLC +1

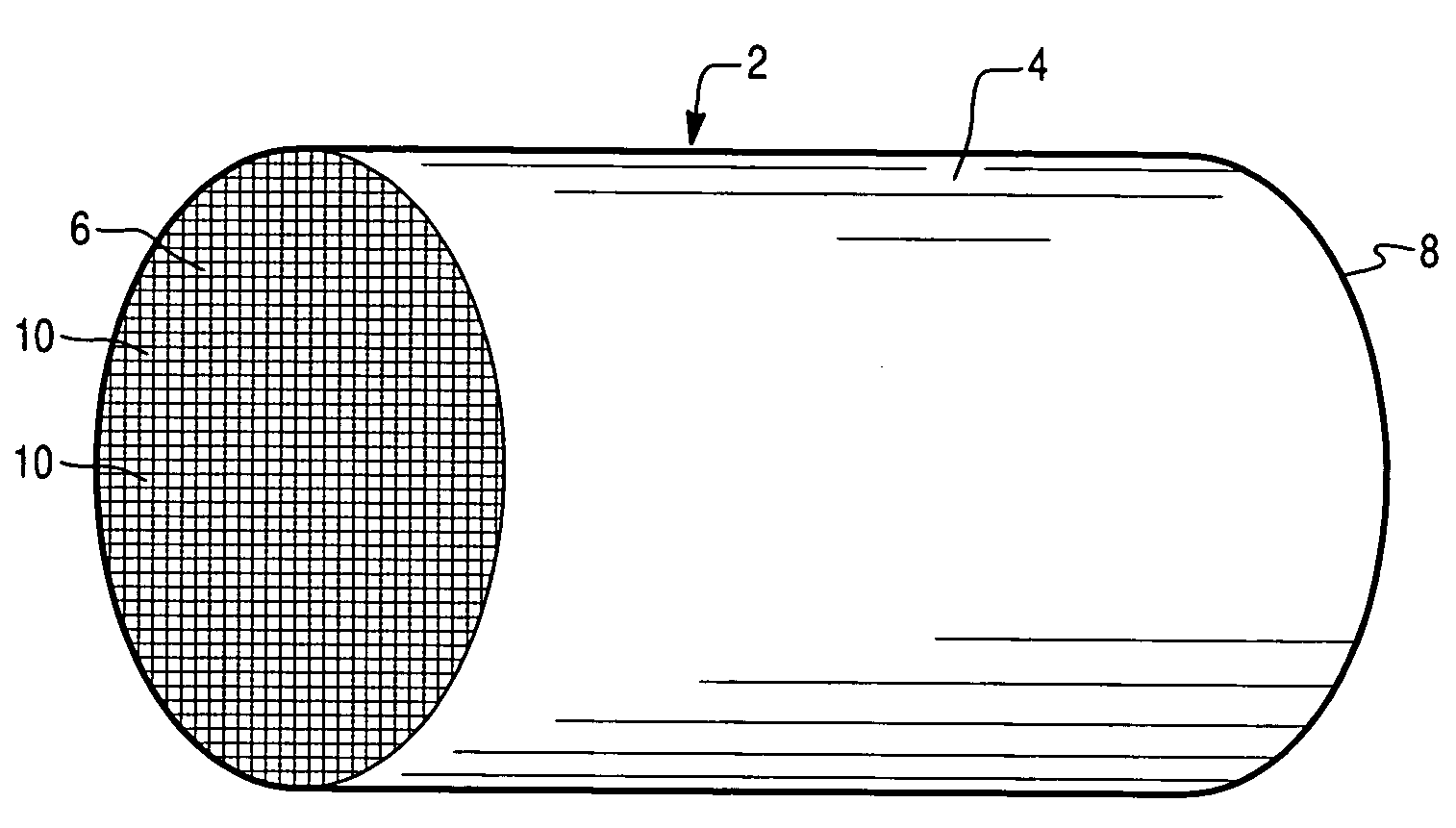

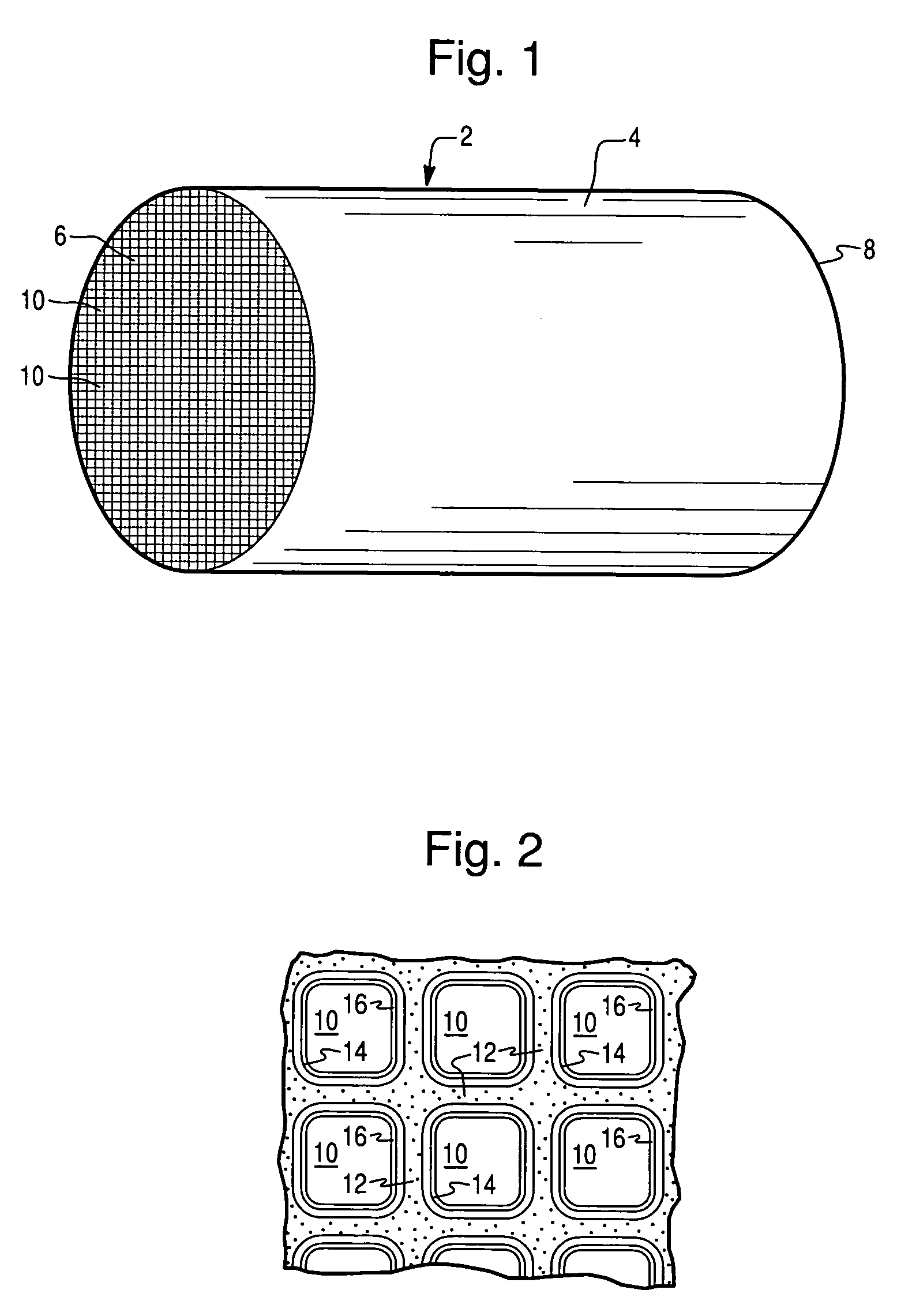

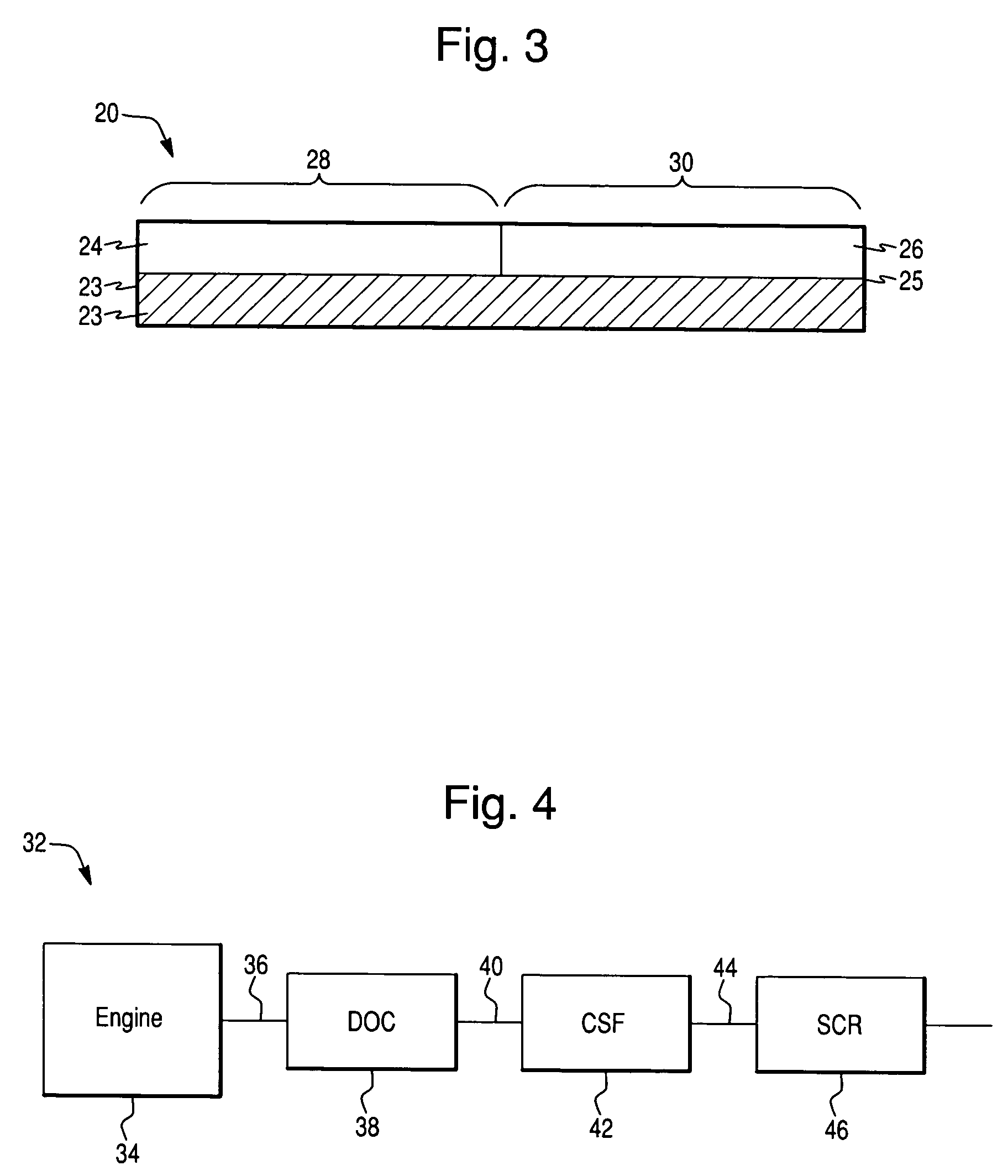

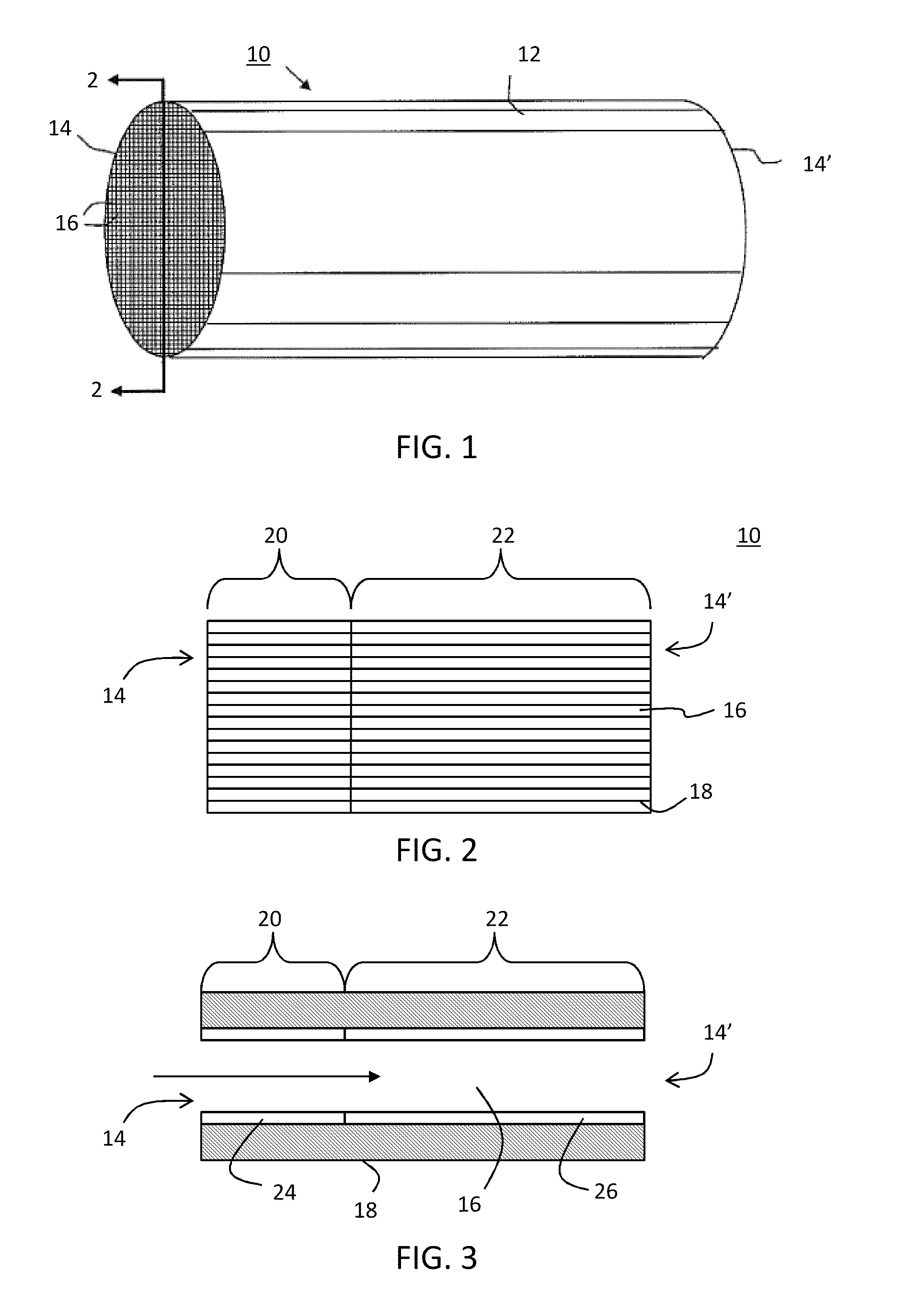

Emission Treatment Catalysts, Systems and Methods

ActiveUS20090288402A1Easy to controlNitrogen compoundsInternal combustion piston enginesNitrogen oxideTreatment system

Zoned diesel oxidation catalysts containing a higher precious metal loading in the inlet zone that the outlet zone and an equal or shorter length inlet zone are described. Emission treatment systems and methods of remediating nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons using zoned diesel oxidation catalysts are also described.

Owner:BASF CORP

Ammonia scr catalyst and method of using the catalyst

ActiveUS20090304566A1Enhanced Surface AcidityCombination devicesOrganic chemistryParticulatesNiobium

A DPF with an SCR catalyst and a method for selectively reducing nitrogen oxides with ammonia, filtering particulates, and reducing the ignition temperature of soot on a DPF are provided. The catalyst includes a first component of copper, chromium, cobalt, nickel, manganese, iron, niobium, or mixtures thereof, a second component of cerium, a lanthanide, a mixture of lanthanides, or mixtures thereof, and a component characterized by increased surface acidity. The catalyst may also include strontium as an additional second component. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia and oxidizes soot at low temperatures. The catalyst has high hydrothermal stability.

Owner:CATALYTIC SOLUTIONS INC

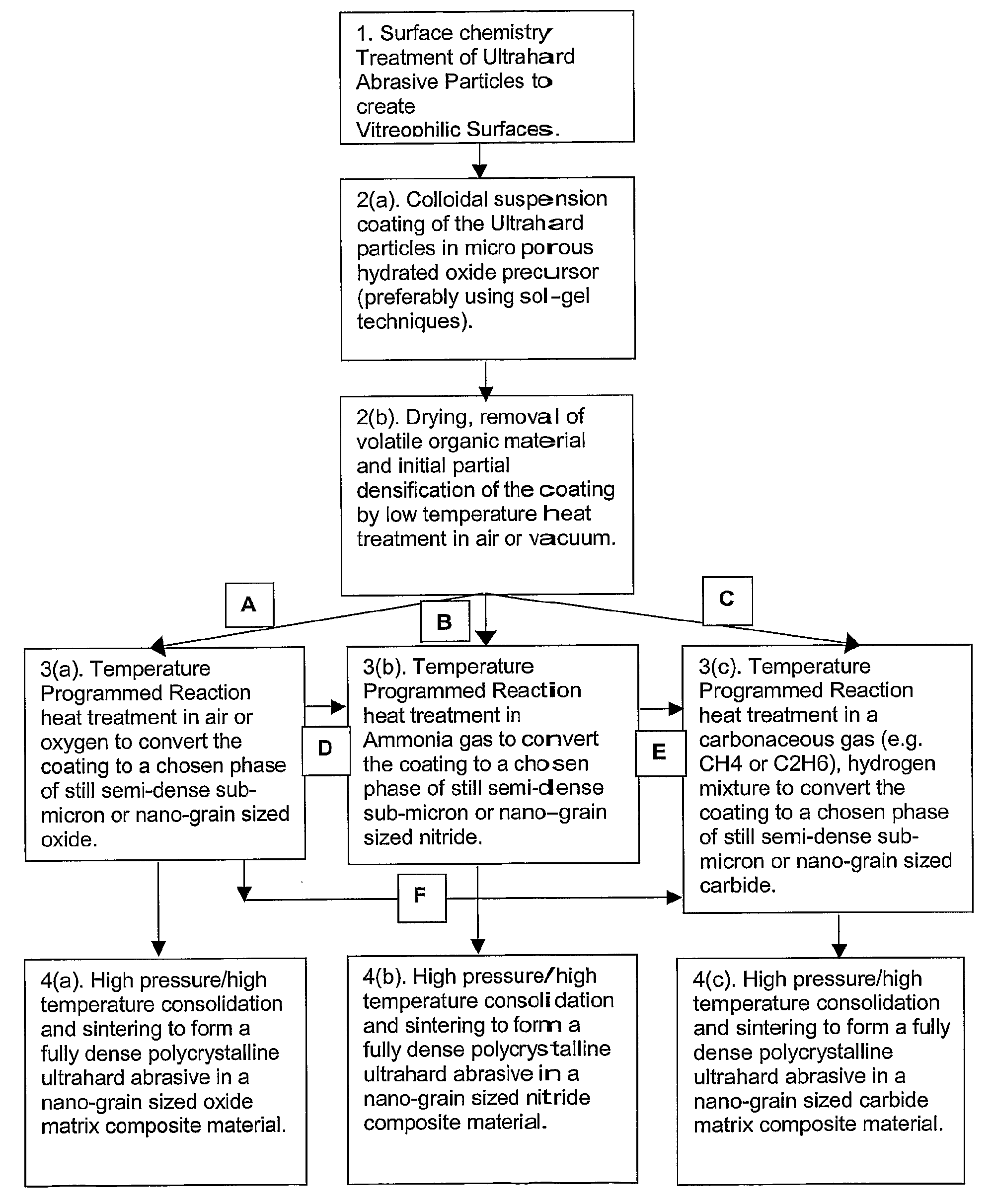

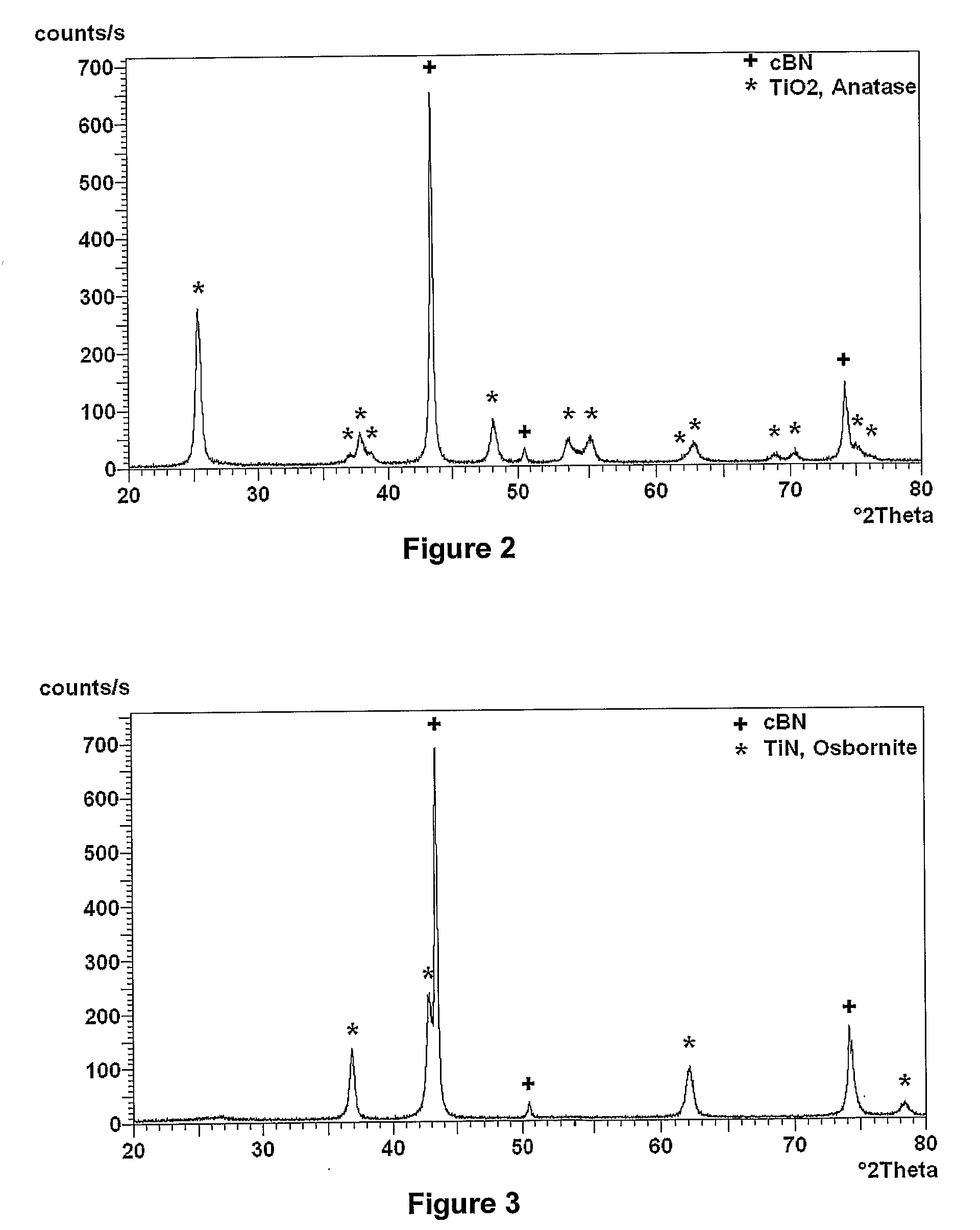

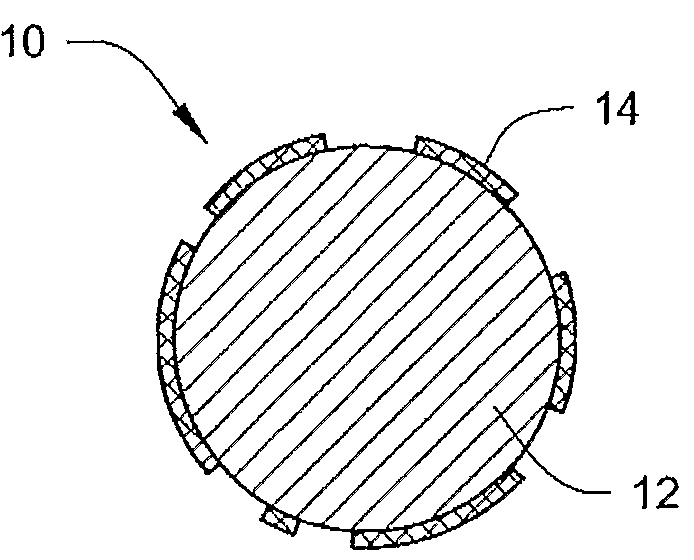

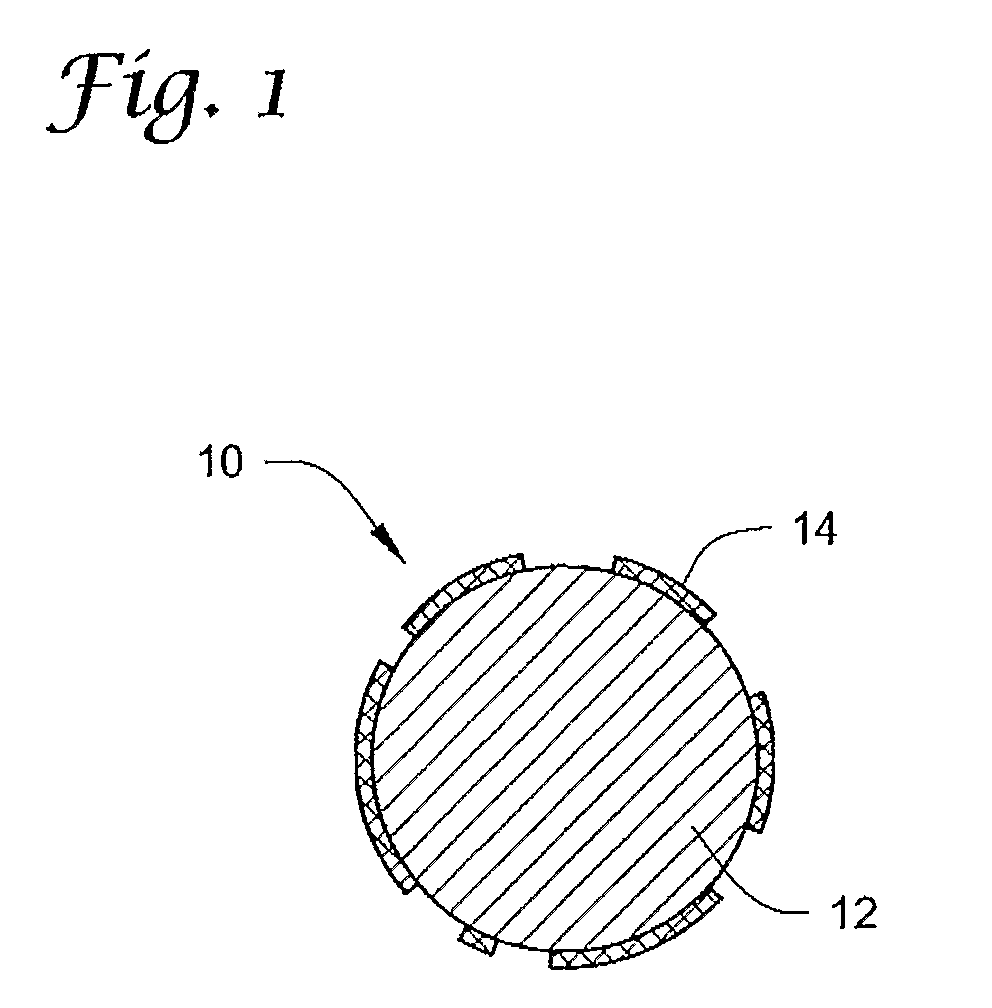

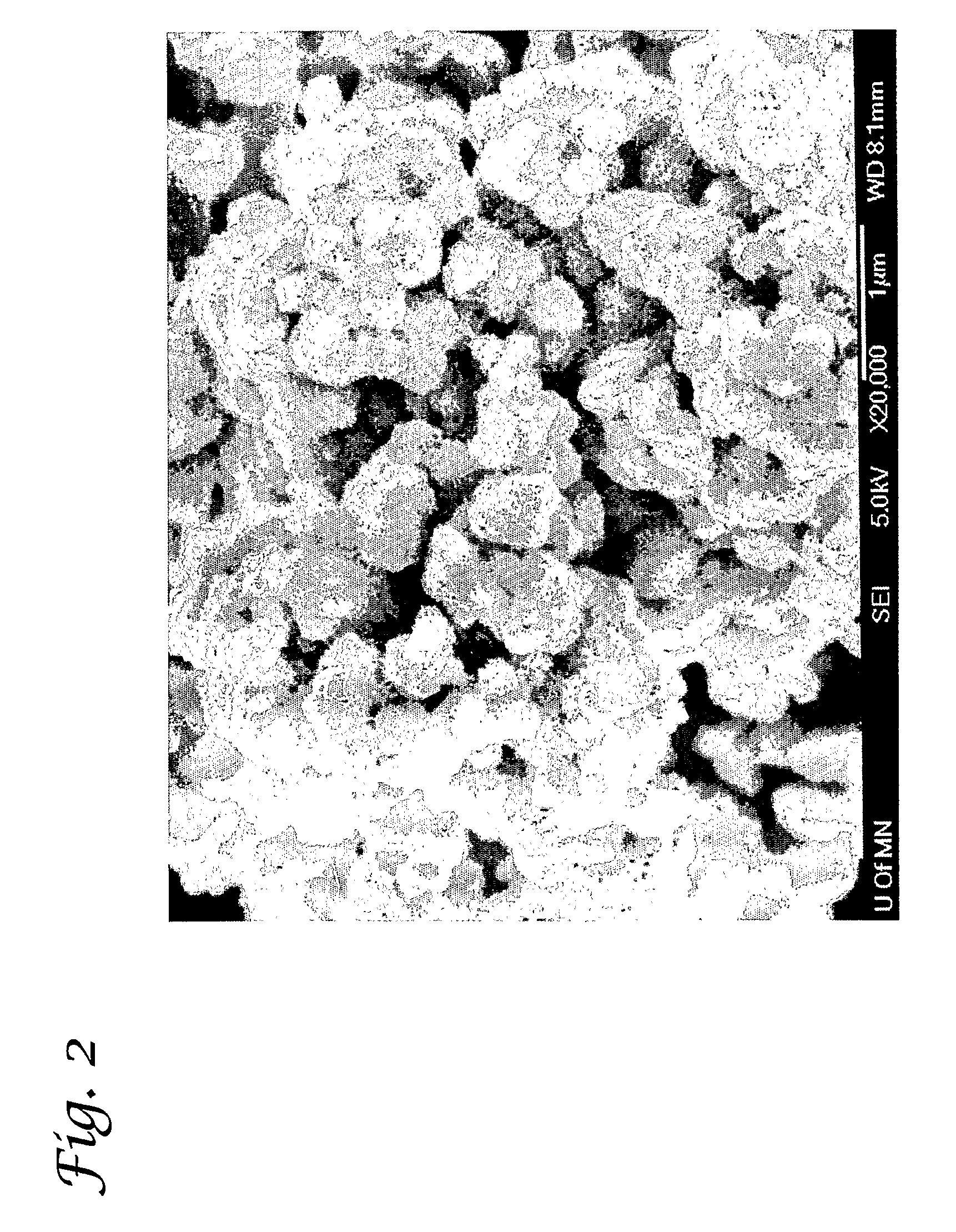

Polycrystalline Abrasive Materials and Method of Manufacture

ActiveUS20080115424A1Reduce the temperatureNanostructure manufactureOther chemical processesNitrogen oxidesNano size

A method of manufacturing polycrystalline abrasive elements consisting of micron, sub-micron or nano-sized ultrahard abrasives dispersed in micron, sub-micron or nano-sized matrix materials. A plurality of ultrahard abrasive particles having vitreophilic surfaces are coated with a matrix precursor material and then treated to render them suitable for sintering. The matrix precursor material can be converted to an oxide, nitride, carbide, oxynitride, oxycarbide, or carbonitride, or an elemental form thereof. The coated ultrahard abrasive particles are consolidated and sintcred at a pressure and temperature at which they are crystallographically or thermodynamically stable.

Owner:ELEMENT SIX TRADE MARKS LTD +2

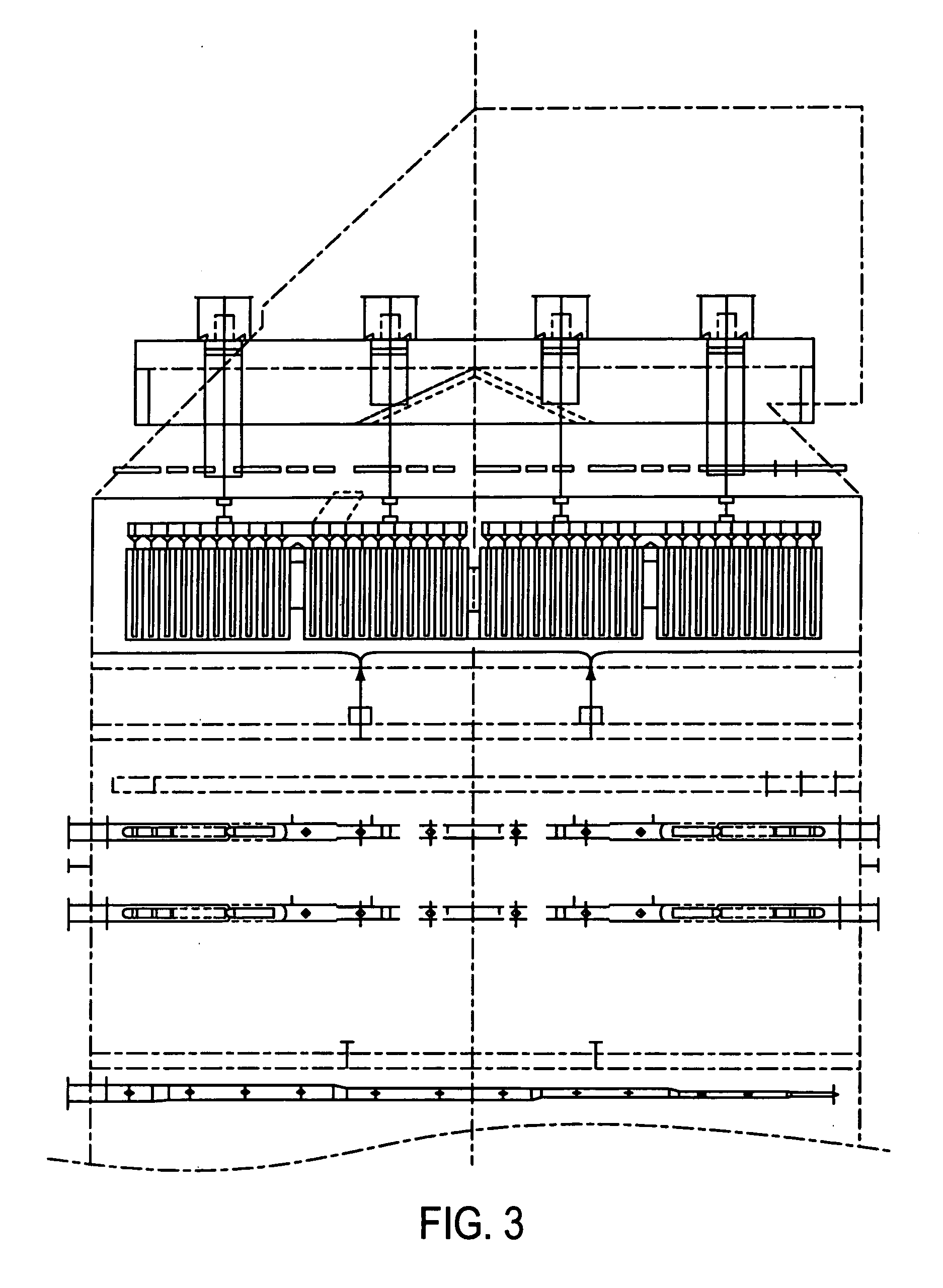

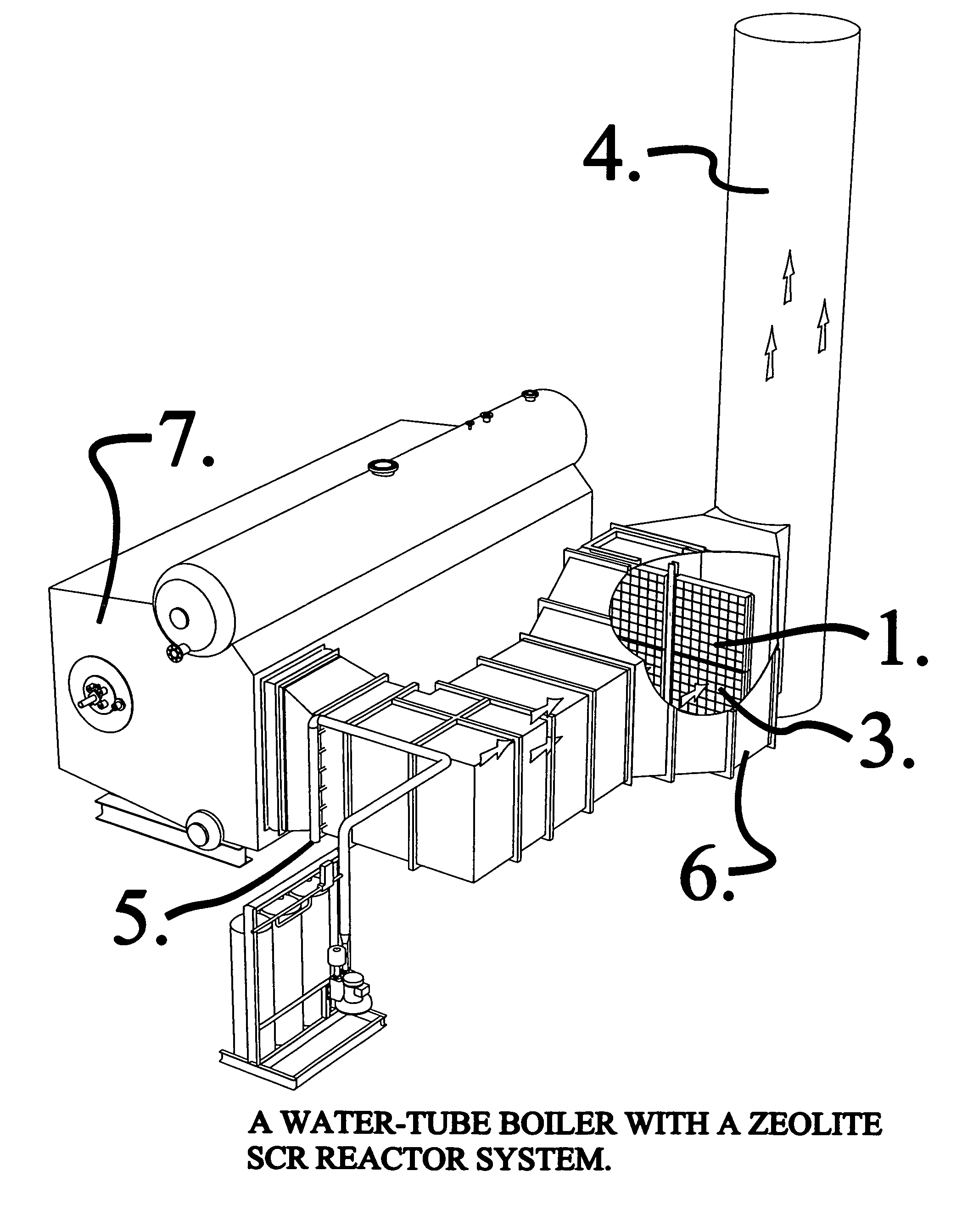

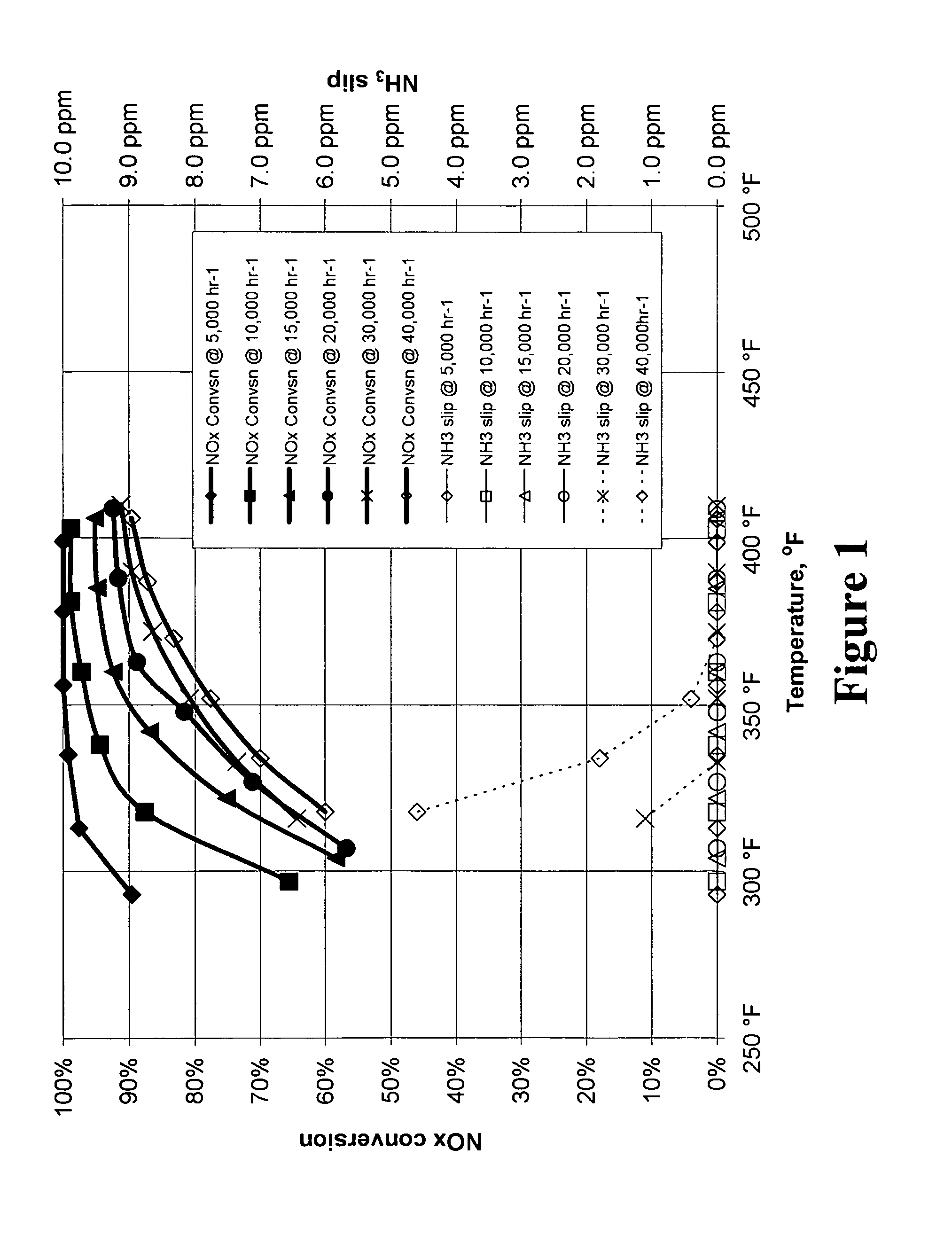

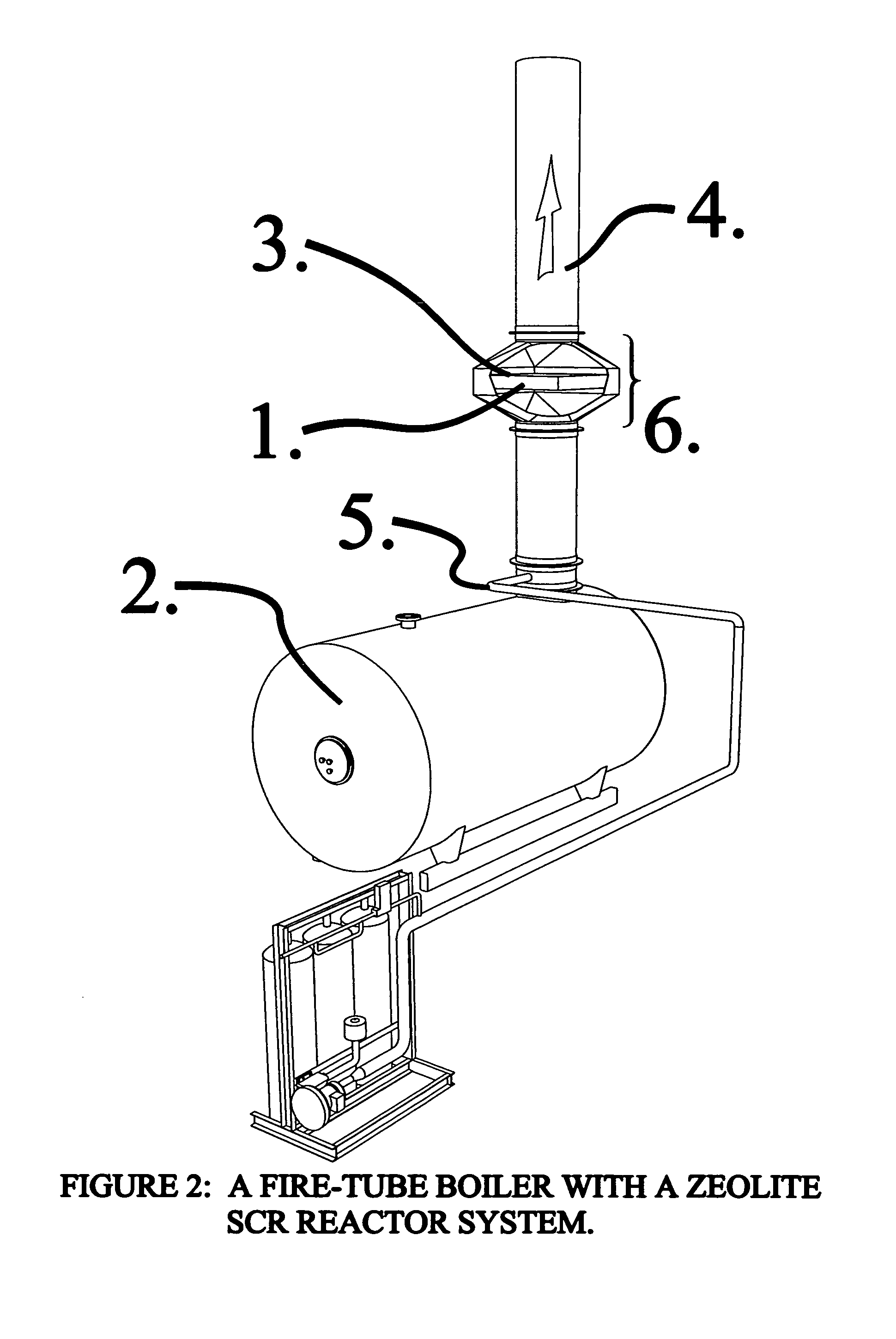

Reactor system for reducing NOx emissions from boilers

ActiveUS7943097B2Low costEasy maintenanceCombination devicesNitrogen compoundsCombustorReactor system

A zeolite based SCR catalyst for NOx reduction using a reducing agent for treating exhaust streams from industrial and commercial boilers is provided. The reactor system has a zeolite based catalyst arranged in catalyst cassettes in a modular fashion where the reactor containing the zeolite based SCR catalyst cassettes is placed in a perpendicular direction to the exhaust exiting the industrial and / or commercial boiler. The catalyst selectively reduces nitrogen oxides to nitrogen with a reducing agent at low to medium temperatures. The reactor results in high NOx conversions and very low ammonia slip and is active for a wide range of boiler firing conditions. Boilers with low NOx and / or ultra low NOx burners can be replaced with a standard conventional burner for overall emissions reduction performance, efficiency improvements and energy savings. Boilers with low NOx and ultra low NOx burners can also be fitted with this zeolite based SCR catalyst reactor for additional NOx reductions and energy savings.

Owner:CATALYTIC SOLUTIONS INC

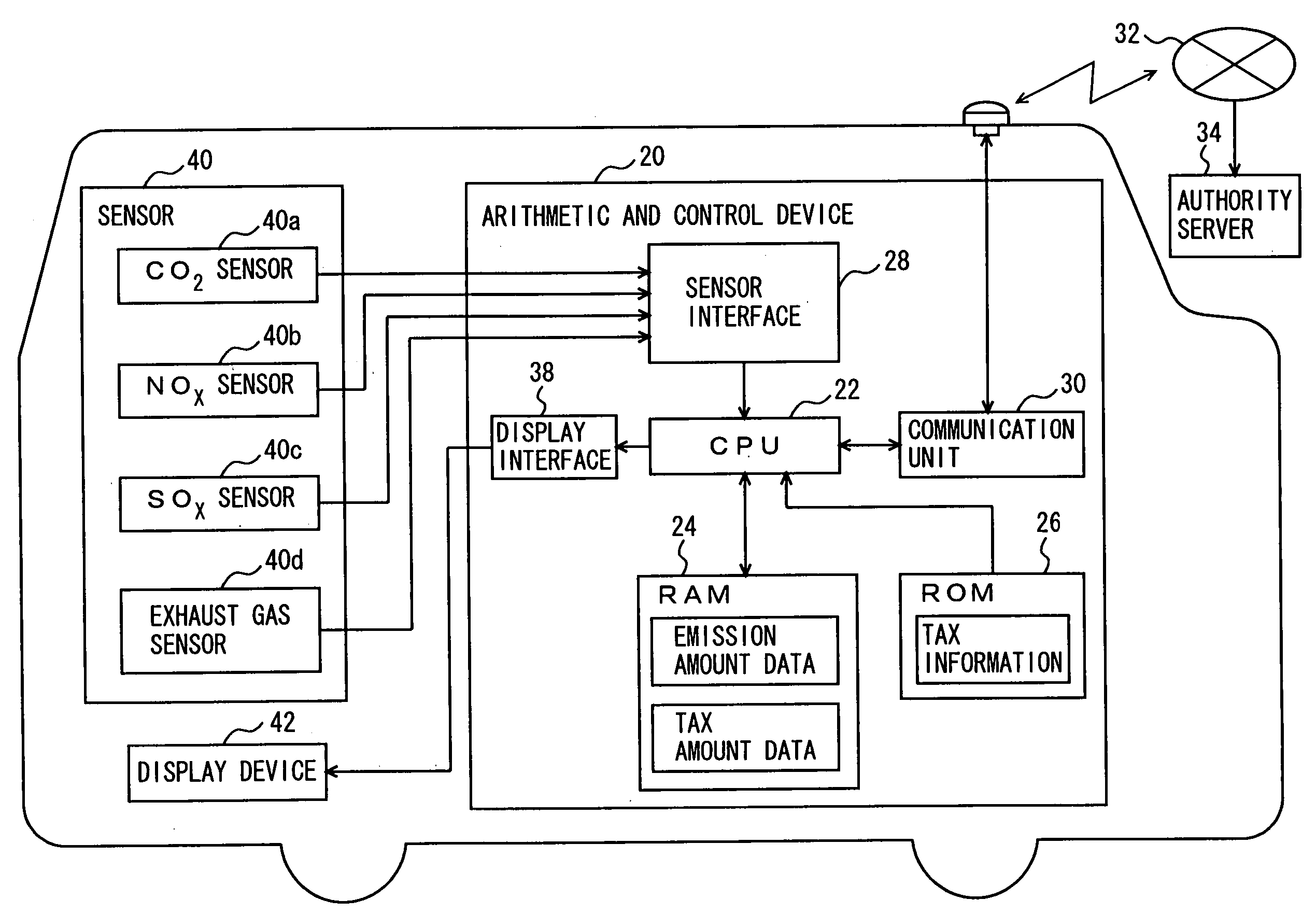

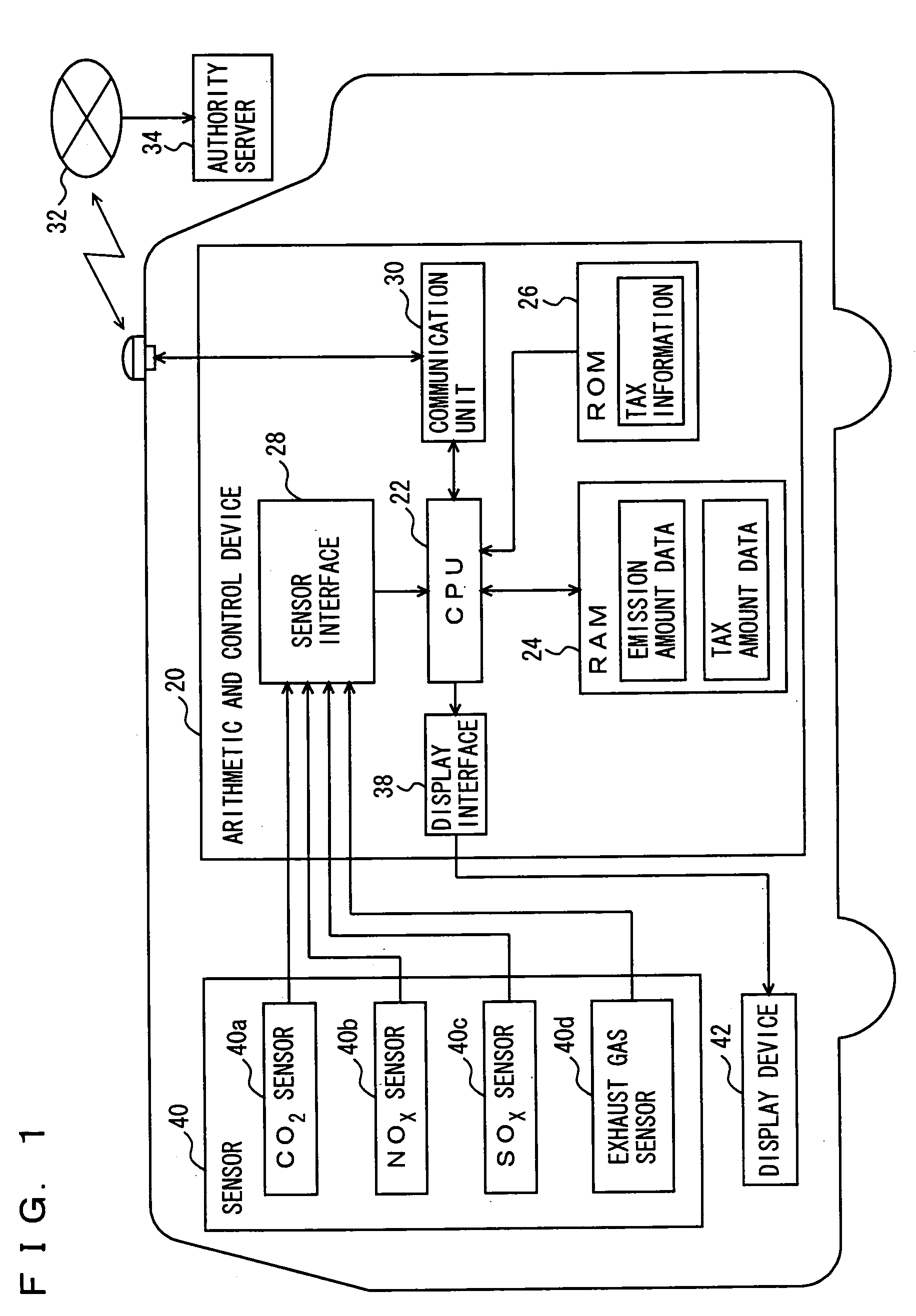

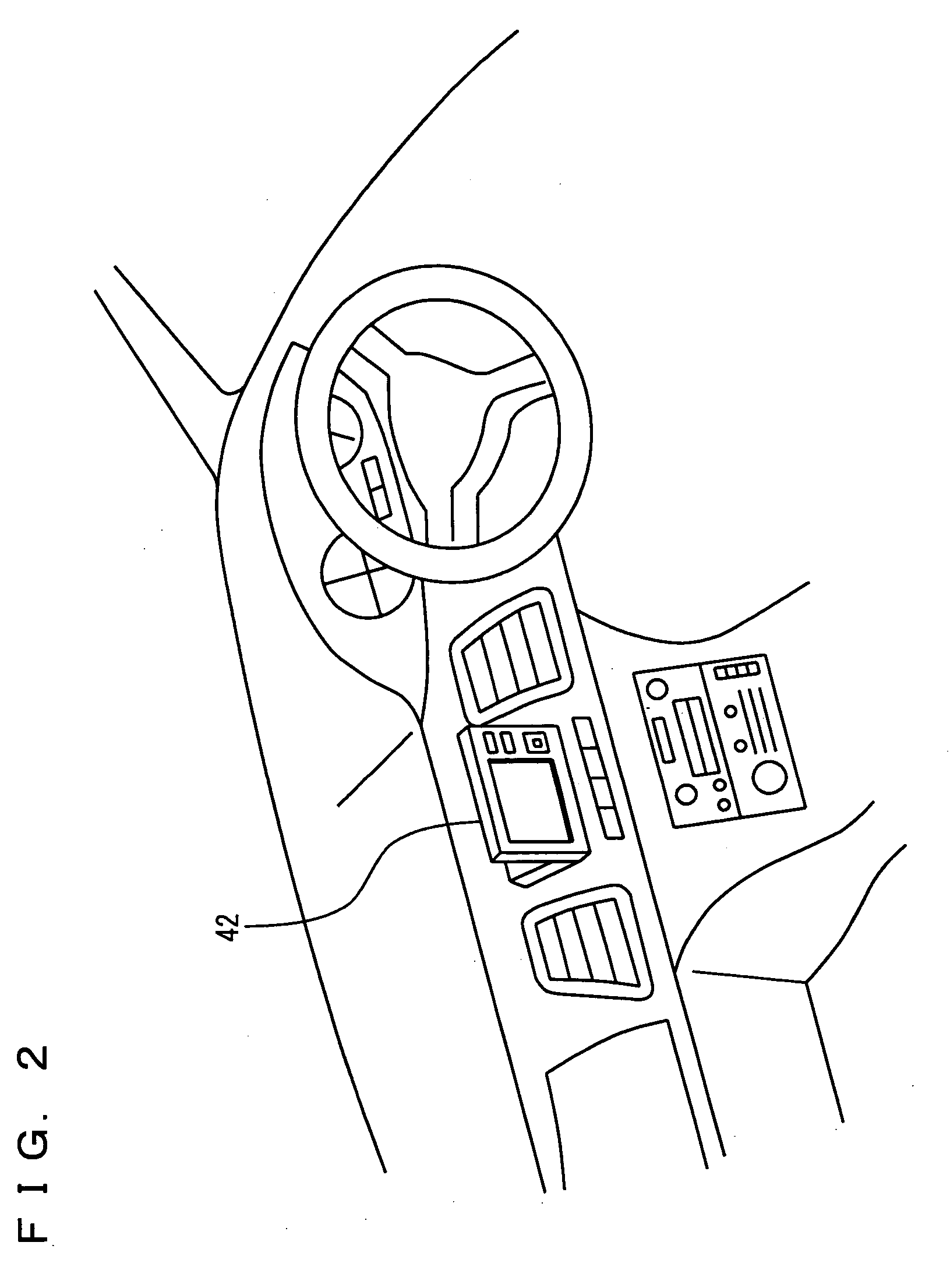

Emission amount report device, system for charge for exhaust gas from vehicle, management unit and inspection device making up the system

InactiveUS20050173523A1Sure easyIncrease volumeTicket-issuing apparatusInternal combustion piston enginesHydrocotyle bowlesioidesHazardous substance

For improving driver's awareness about emissions and promoting environmental protection, an emission amount notifying device is provided. When such a taxation system becomes effective that a tax is imposed in accordance with an amount of one or more kinds of harmful substances, which include a carbon dioxide, nitrogen oxides, sulphur oxides and hydrocarbons emitted from a vehicle, a sensor determines the emission amounts of respective harmful substances, and a CPU obtains the amount of tax corresponding to the determined emission amounts from a ROM storing tax information related to the tax amounts corresponding to respective displacements, and displays the obtained tax amount on a display device. Further, the CPU sends the information relating to the determined emission amount to a server of authorities from a communication unit for performing tax payment procedures.

Owner:SUMITOMO ELECTRIC IND LTD

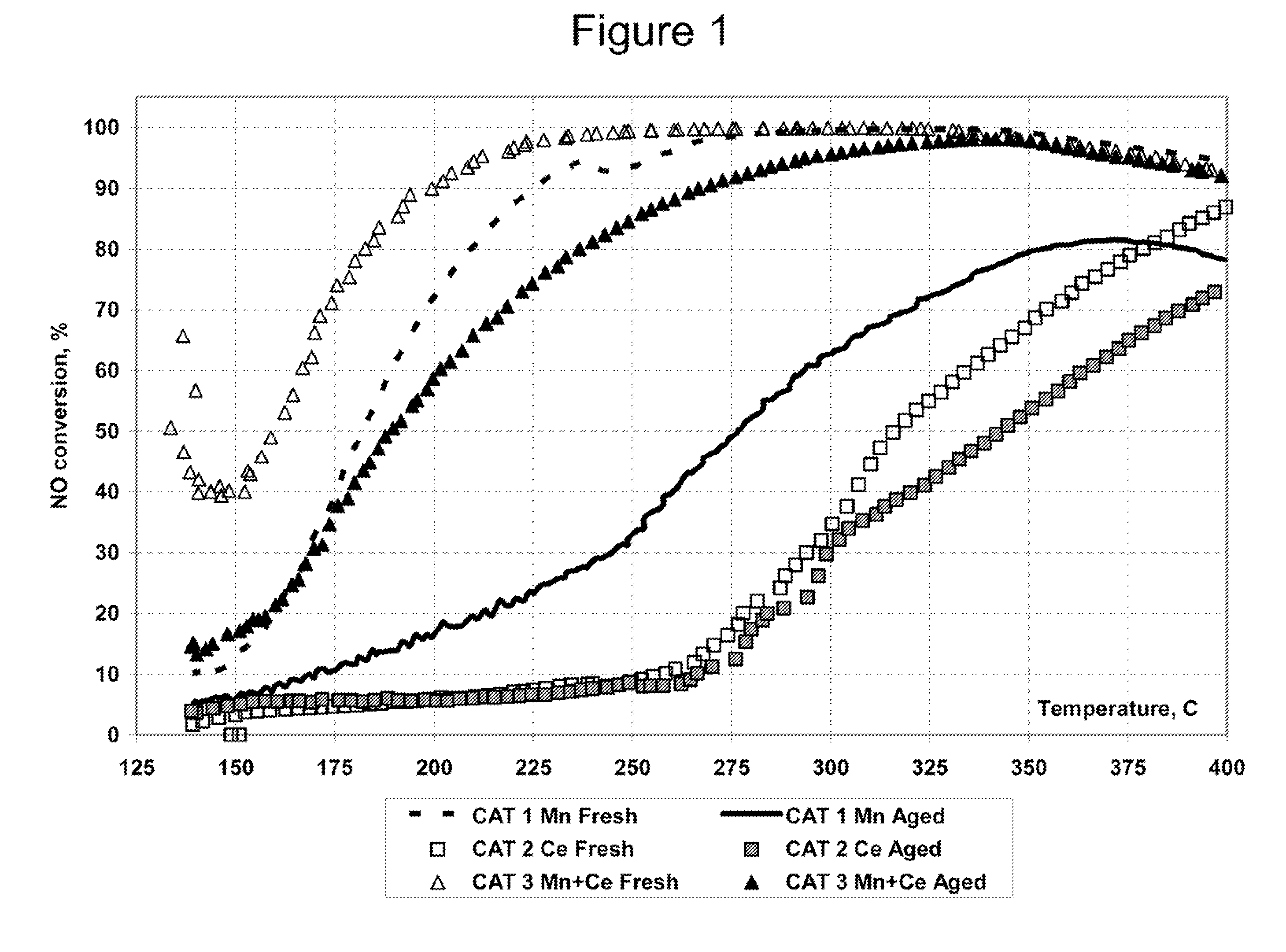

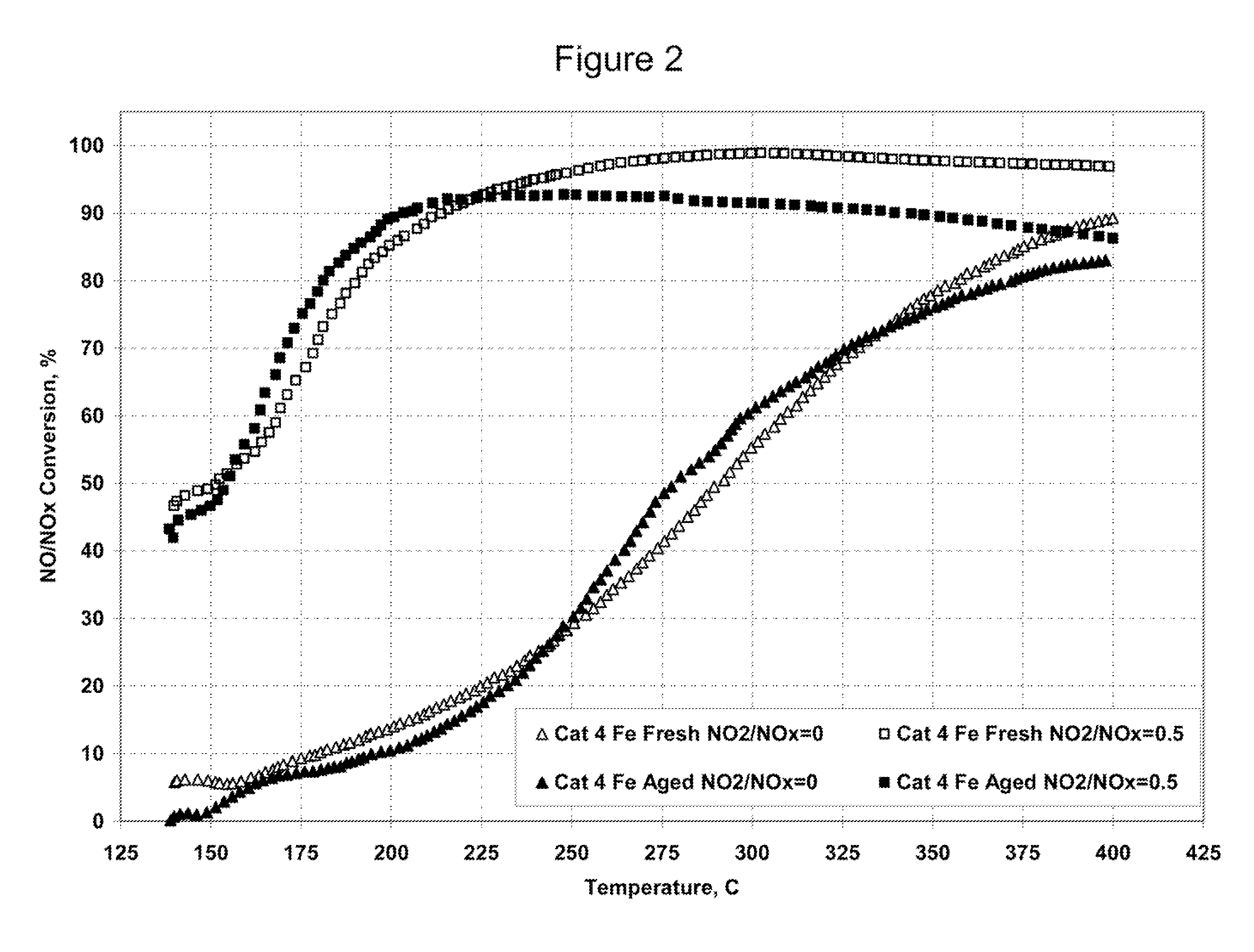

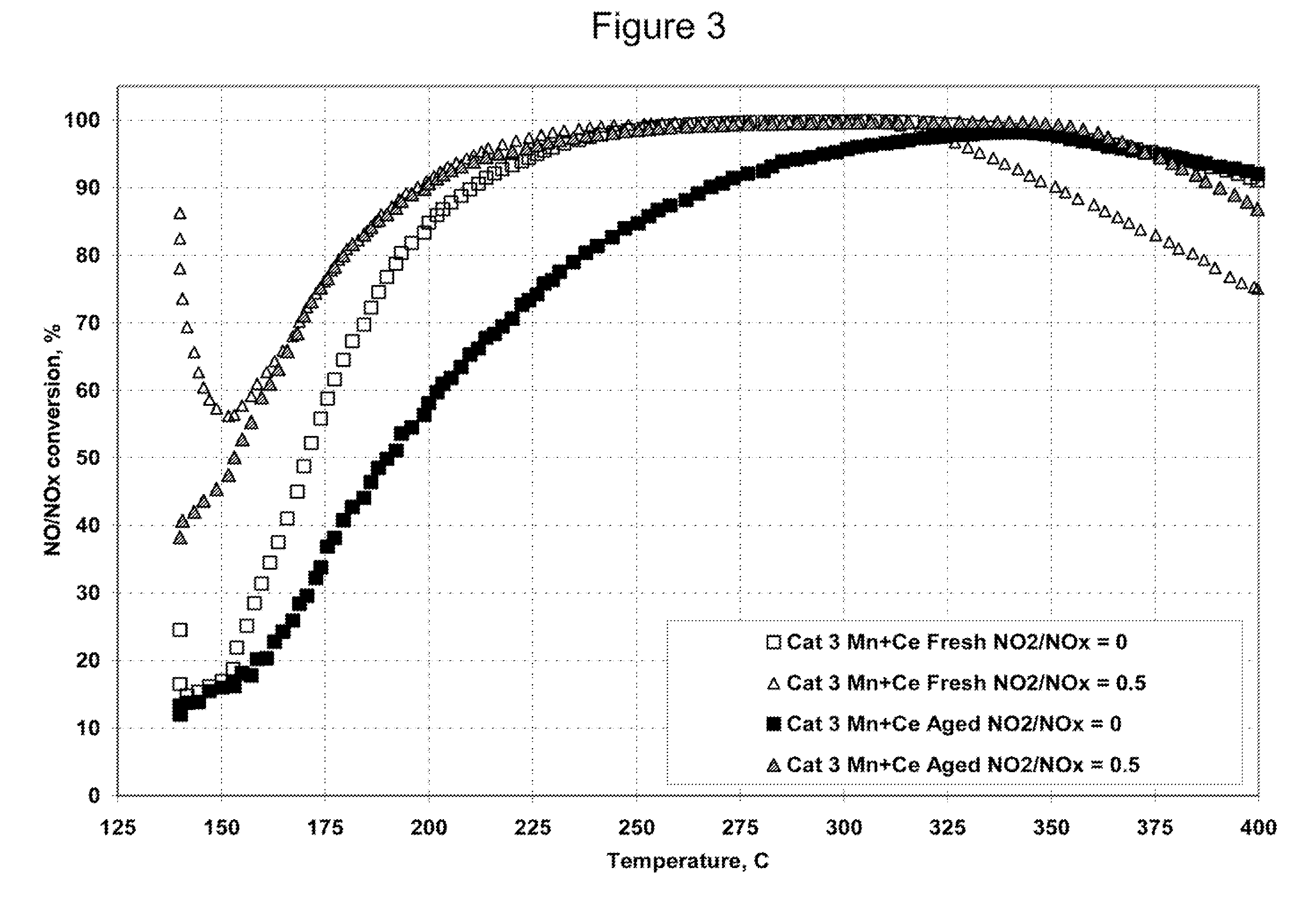

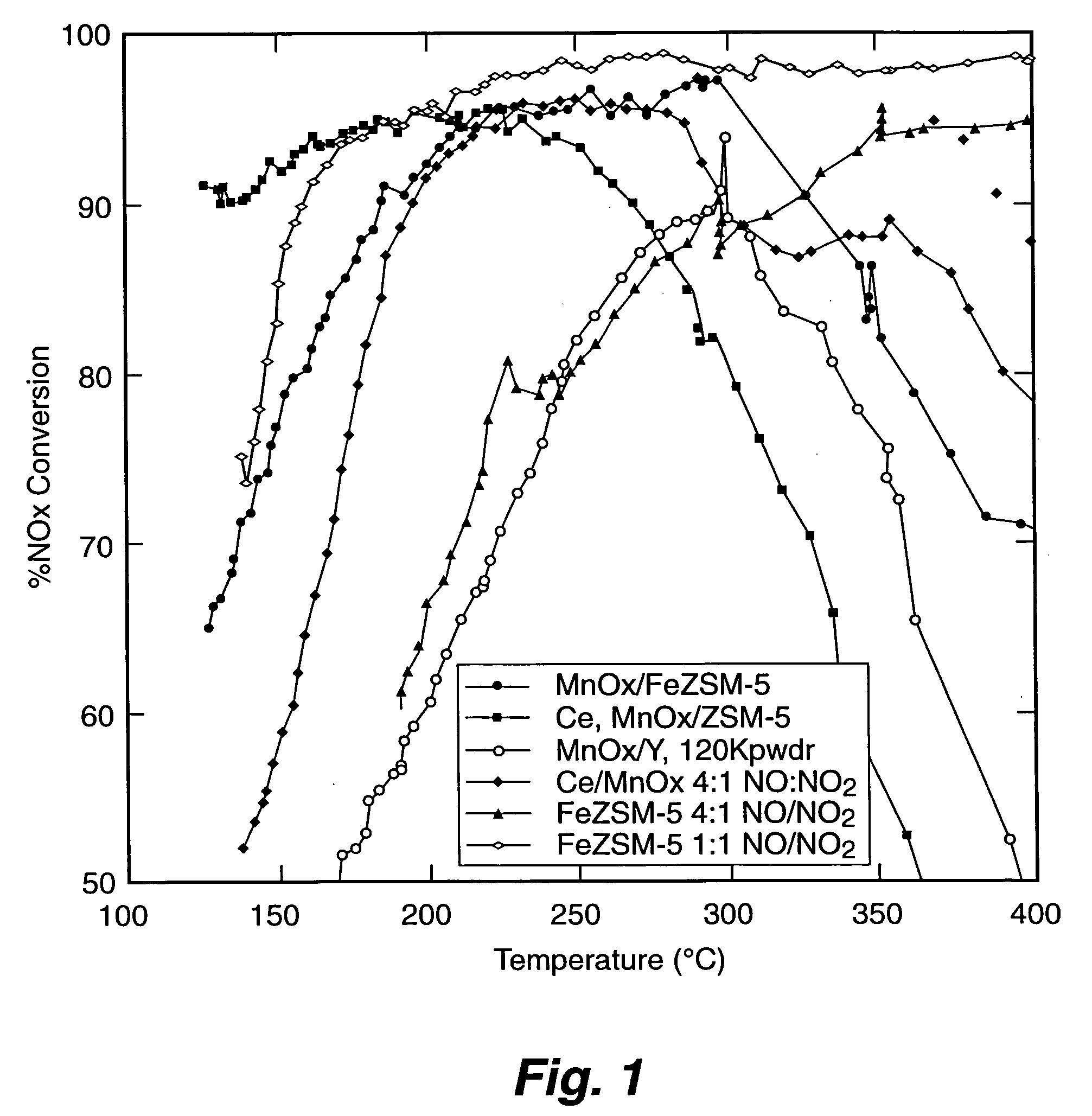

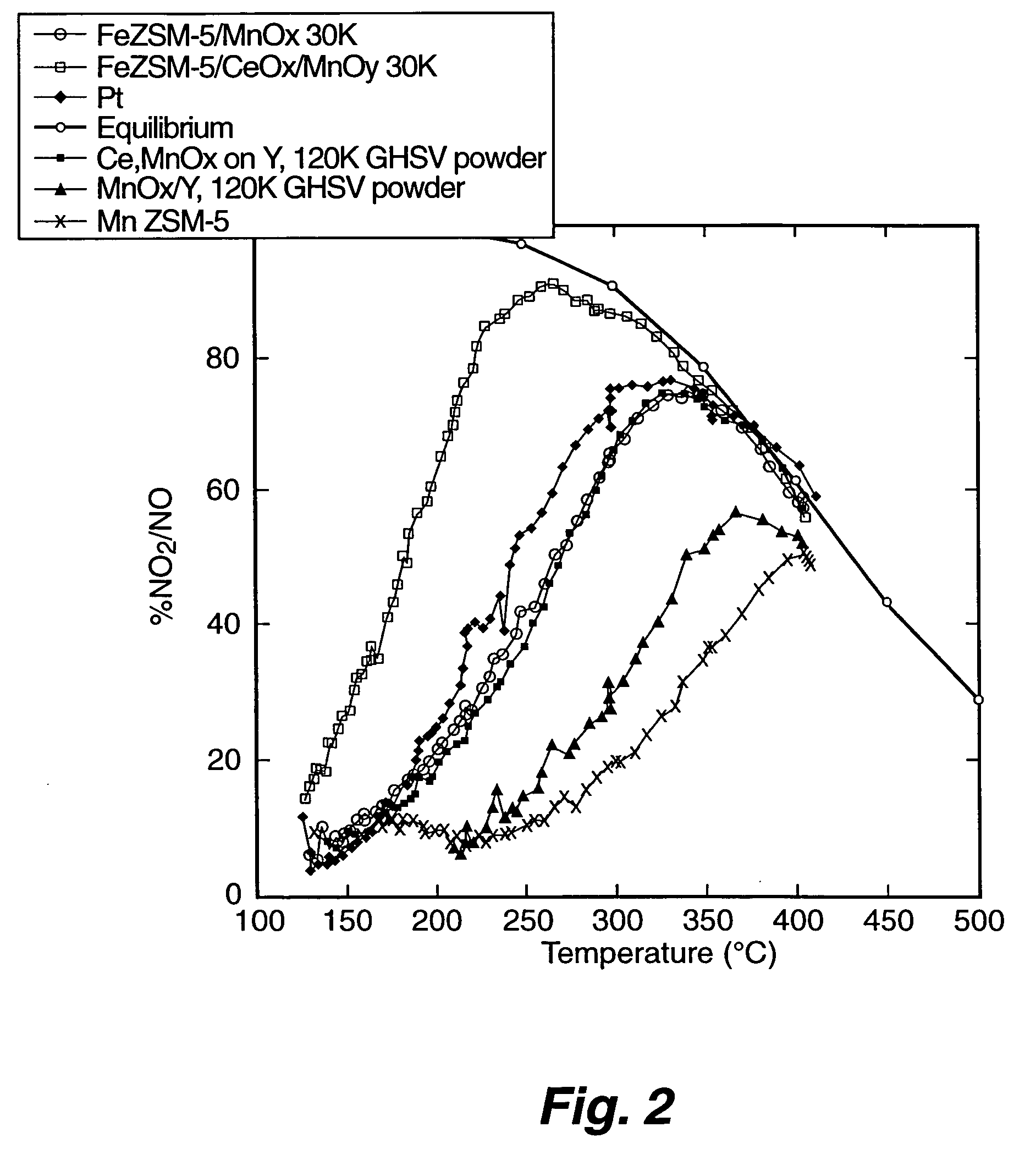

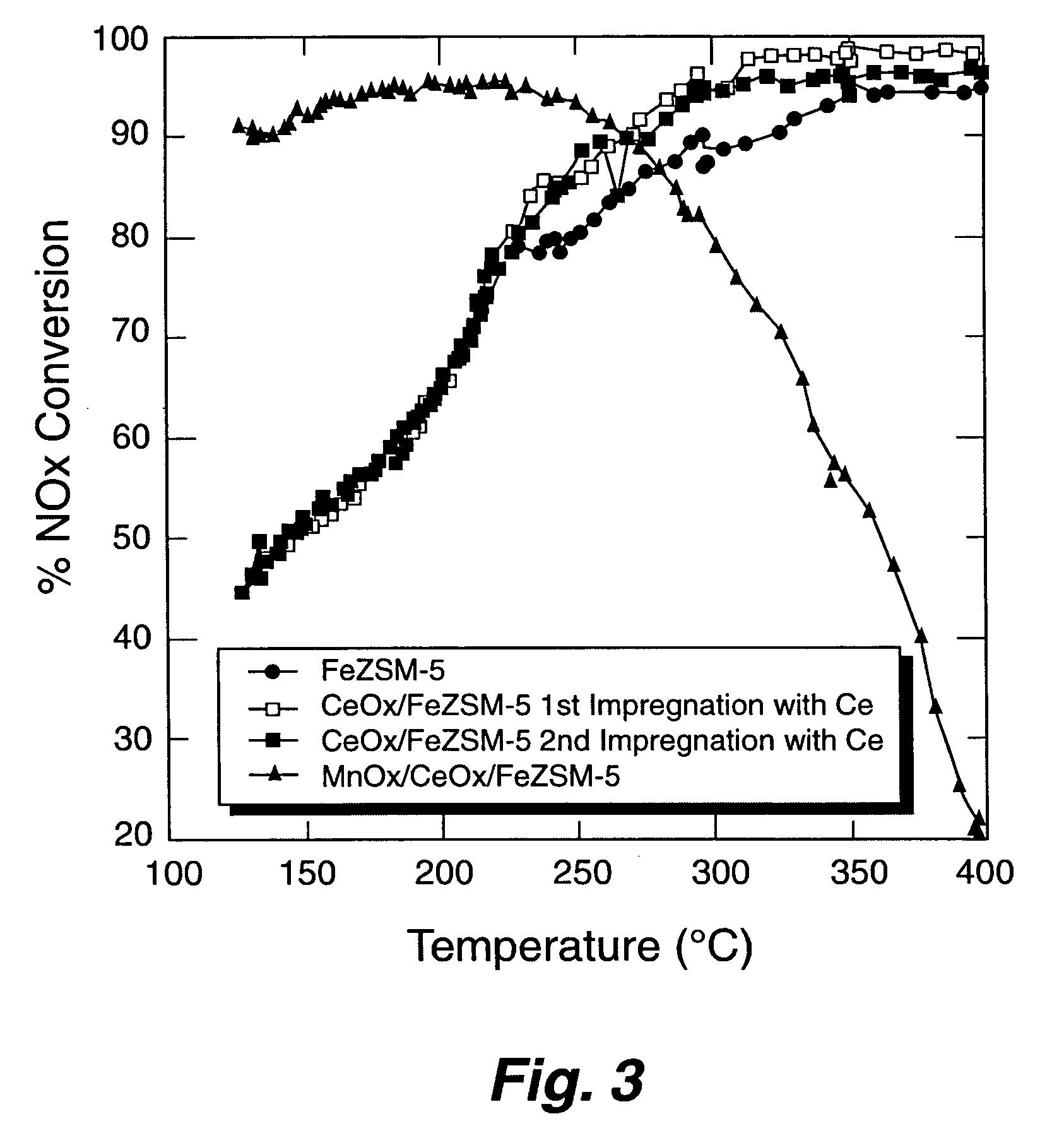

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

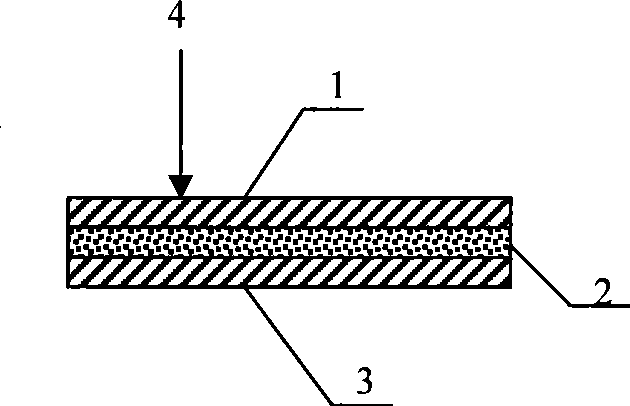

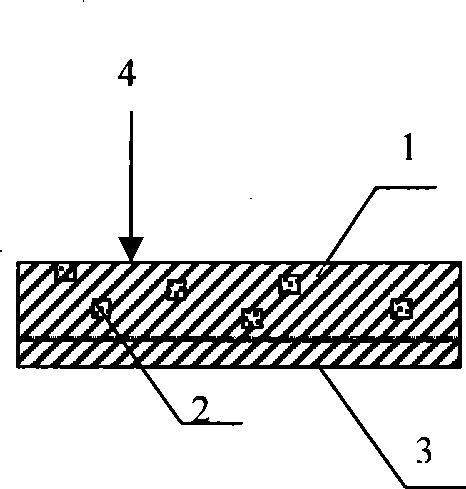

Functional filter felt for eliminating harmful constituents of fume, preparation method and application method thereof

ActiveCN101518718AExtended service lifePrevent penetrationPhysical/chemical process catalystsDispersed particle separationNonwoven fabricHigh heat

The invention pertains to the technical field of fume purification. The provided functional filter felt for eliminating harmful constituents of fume can realize the desulfurization or denitration of fume when removing dust; the filter felt is made from fiber materials and a functional catalyst in a compound manner; when purifying the harmful constituents of fume, the filter felt filters the dusts in the fume with nonwoven fabrics made from high temperature-resistant fiber material and carries out a catalytic reaction to eliminate nitrogen oxides (NOX) and / or sulfur oxides (SOX) through the functional catalyst contained in the filter felt. The provided filter felt is applicable to fume dedusting devices, fume desulfurization devices and fume denitration devices in power plants, metallurgical plants and chemical plants, in particular to the manufacturing of bag type fume filter. Compared with the prior art, the invention simplifies the fume purifying processes, improves processing efficiency, effectively saves the investment and reduces operational expenses, thus being suitable for the modification of the existing fume dedusting device.

Owner:CHINESE TEXTILE ACAD

Layered catalyst composite

A layered, three-way conversion catalyst having the capability of simultaneously catalyzing the oxidation of hydrocarbons and carbon monoxide and the reduction of nitrogen oxides is disclosed. In one or more embodiments, the catalyst comprises three layers in conjunction with a carrier: a first layer deposited on the carrier and comprising palladium deposited on a refractory metal oxide and an oxygen storage component; a second layer deposited on the first layer and comprising rhodium deposited on a refractory metal oxide and an oxygen storage component; and a third layer deposited on the second layer and comprising palladium deposited on a refractory metal oxide.

Owner:BASF CATALYSTS LLC

Process and catalyst system for SCR of NOx

ActiveUS8062617B2Improve performanceNo tendency toward deactivationCombination devicesNitrogen compoundsNitrogen oxidesFerric

Process for reducing nitrogen oxides to nitrogen in an exhaust gas comprising passing the exhaust gas in the presence of a reducing agent through a catalyst system comprising at least two catalyst beds, in which a first catalyst bed is an iron-beta-zeolite and a second catalyst bed downstream is silver supported on alumina.

Owner:UMICORE AG & CO KG

Air Pollutant Removal Using Magnetic Sorbent Particles

InactiveUS20080307960A1Inexpensive to produce and useSimply and inexpensively convertingGas treatmentOther chemical processesChemistryAir pollutants

Absorbent magnetic particles are used to remove air pollutants. The adsorbent magnetic particles can adsorb various air pollutants, including nitrogen oxides, sulfur oxides, and mercury, and may be regenerated for reuse.

Owner:RGT UNIV OF MINNESOTA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com