Patents

Literature

220results about How to "Enhanced Surface Acidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low carbon alkane dehydrogenation catalyst for alkene production and its preparation method and application

ActiveCN103769078AGood dispersionIncrease loadHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideActive component

The invention discloses a low carbon alkane dehydrogenation catalyst for alkene production and its preparation method and application. The catalyst uses Al2O3 (alumina) as a carrier, chromium as an active component, and an alkali metal as an assistant catalyst component, taking to the final catalyst weight as the base, the chromium oxide content is 10.0%-30.0%, the alkali metal oxide content is 0.5%-3.0%, and the rest is the alumina. The active component chromium is stepwise impregnated onto the alumina carrier before and after impregnation of the alkali metal assistant catalyst component. The low carbon alkane dehydrogenation catalyst for alkene production is used in dehydrogenation of propane to produce propylene. The low carbon alkane dehydrogenation catalyst for alkene production has high activity stability and propylene selectivity, and the preparation method is simple, and is suitable for industrial applications.

Owner:CHINA PETROLEUM & CHEM CORP +1

VOCs (volatile organic chemcials) catalytic combustion integral catalyst and preparation method thereof

ActiveCN106732585ATightly boundImprove anti-sintering performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationAir volumeAdhesive

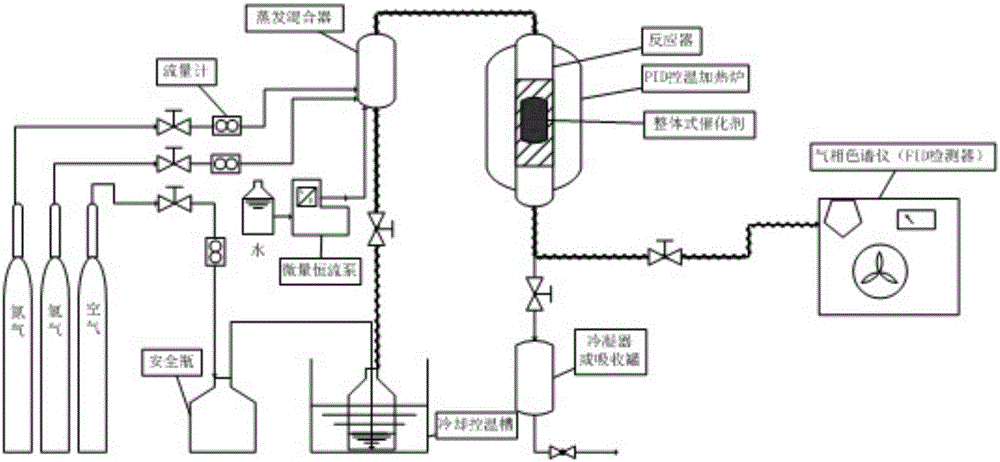

The invention provides a VOCs (volatile organic chemcials) catalytic combustion integral catalyst, and belongs to the technical field of catalysts. The VOCs catalytic combustion integral catalyst is prepared from the following raw materials in parts by mass: 82 to 87 parts of cordierite honeycomb ceramic carrier, 10 to 14 parts of gamma-Al2O3, 0.8 to 1.5 parts of oxide additive, and 0.01 to 0.05 part of active component Pd, wherein the gamma-Al2O3, the oxide additive and the active component Pd are used as coating layers. The invention also relates to a preparation method of the catalyst. The preparation method comprises the following steps of firstly, dispersing the Pd onto the special gamma-Al2O3 carrier, drying, and calcining, so as to obtain powder; adding an adhesive, a lubricant and water for preparing slurry, coating the cordierite honeycomb ceramic carrier with the slurry, drying and calcining, so as to obtain the catalyst. The catalyst has the characteristics that by using low-content noble metal Pd as the active component, the cost is low, the low-temperature ignition is quick, the anti-vulcanizing and anti-aging properties are realized, the catalyst is suitable for large air volume and high air speed, the dispersion property is good, the easiness in sintering is avoided, and the like; the catalyst is especially suitable for the catalyst combustion of sulfur-containing VOCs.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

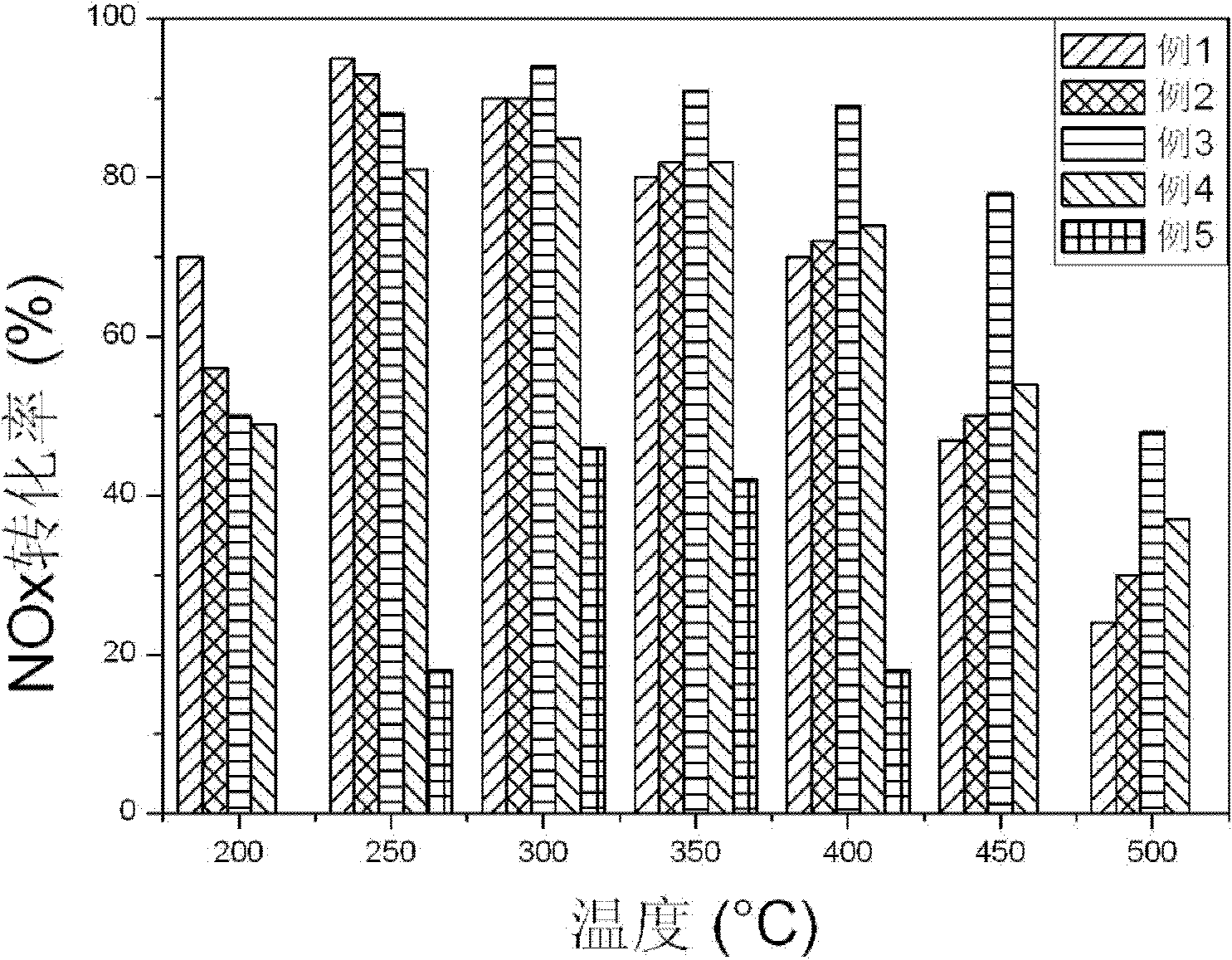

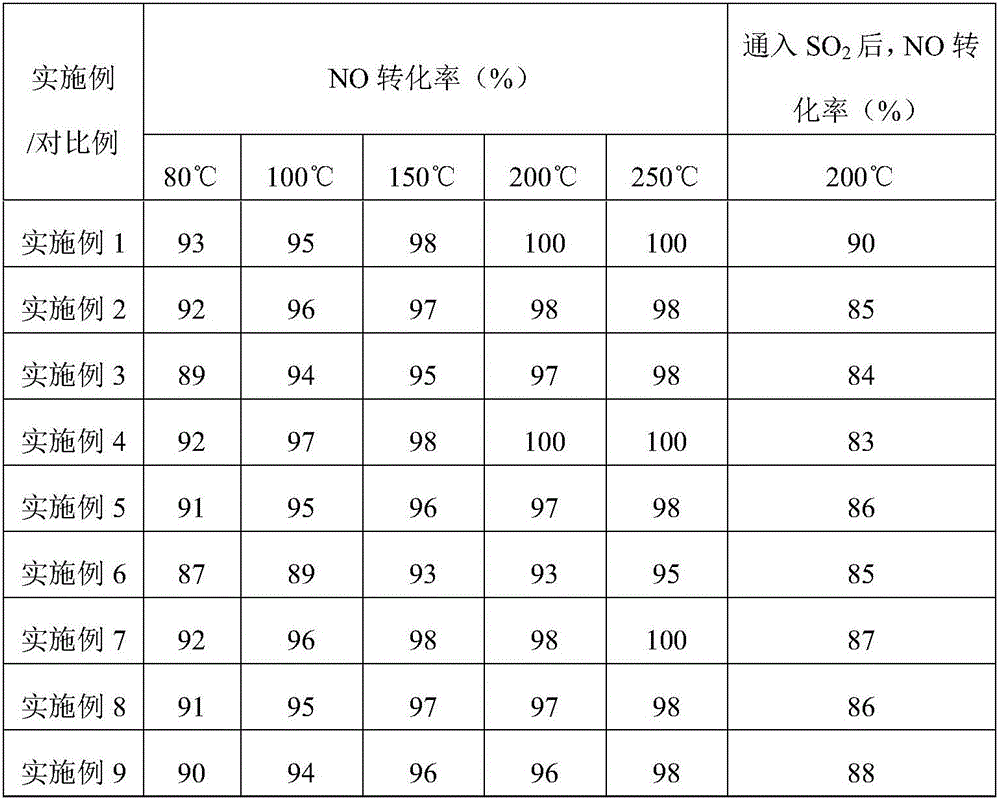

CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and preparation thereof

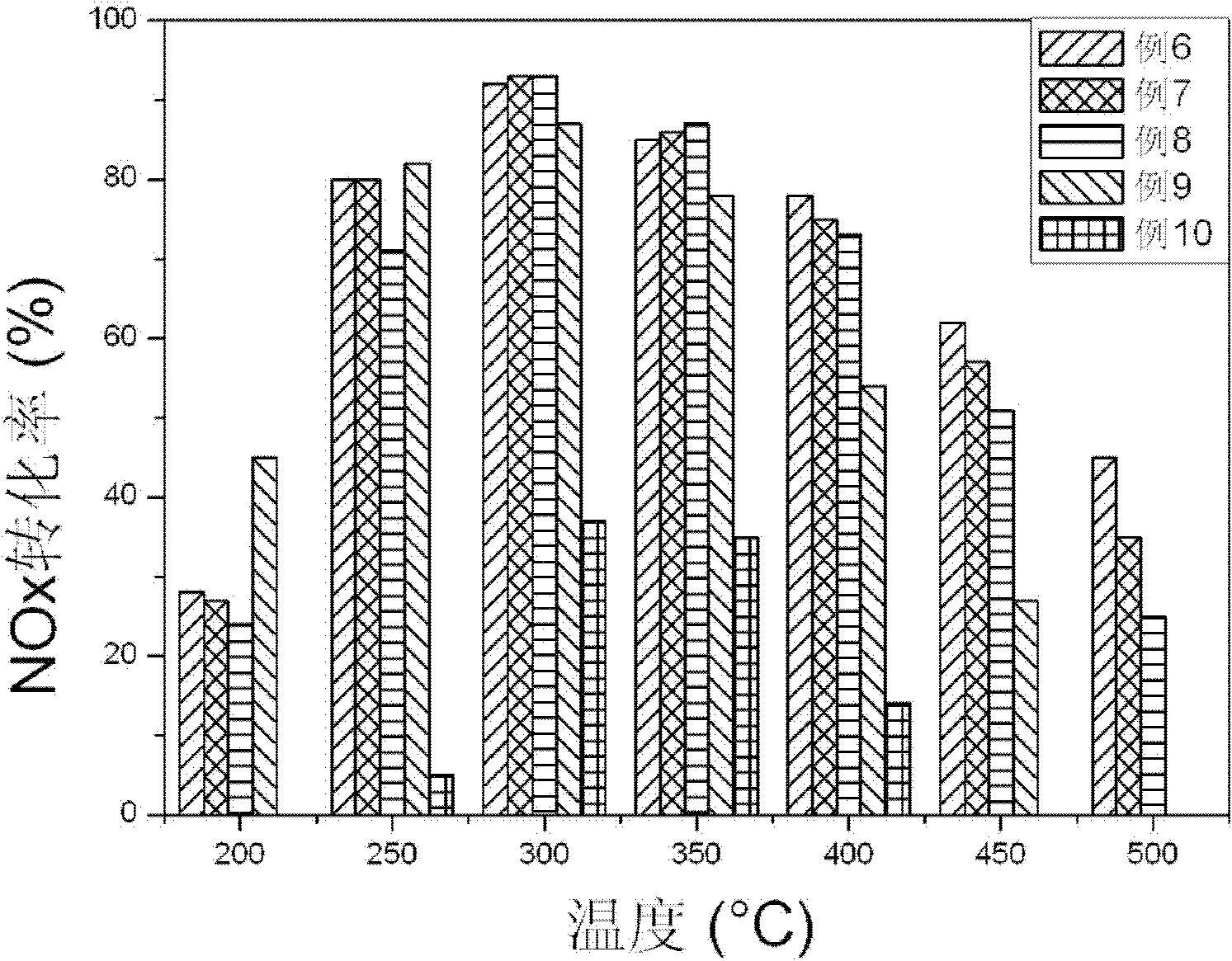

ActiveCN102240543AImprove anti-sulfur poisoning performanceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurWorking temperature

The invention discloses a CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and a preparation thereof and belongs to the field of nitric oxide post-processing purification. The catalyst has a three-layer structure, wherein cordierite honeycomb ceramic is used as a carrier; an active coating is loaded on the carrier; a modifying coating is loaded on the active coating; the cordierite carrier has a skeleton carrying function; the active coating of the catalyst mainly has a function of activating NOx and NH3; and the modifying coating mainly has functions of storing NH3, avoiding deep oxidation of NH3 on the surface of the catalyst when the catalyst is used at a high temperature and increasing the sulfur poisoning resistance of the catalyst. The preparation process of the catalyst is simple and can be easily industrialized. A working temperature window of the optimized catalyst can reach 250-450 DEG C, and denitration efficiency is above 80%. The catalyst has the significant advantage of being nontoxic and has excellent heat stability and excellent SO2 poisoning resisting property.

Owner:TSINGHUA UNIV +1

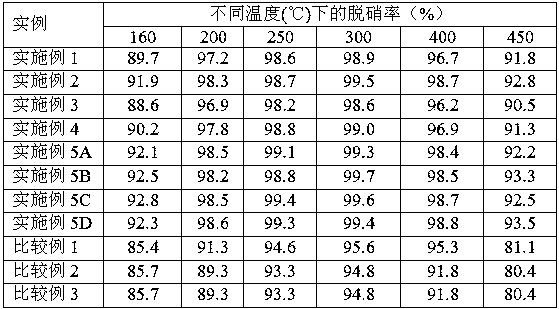

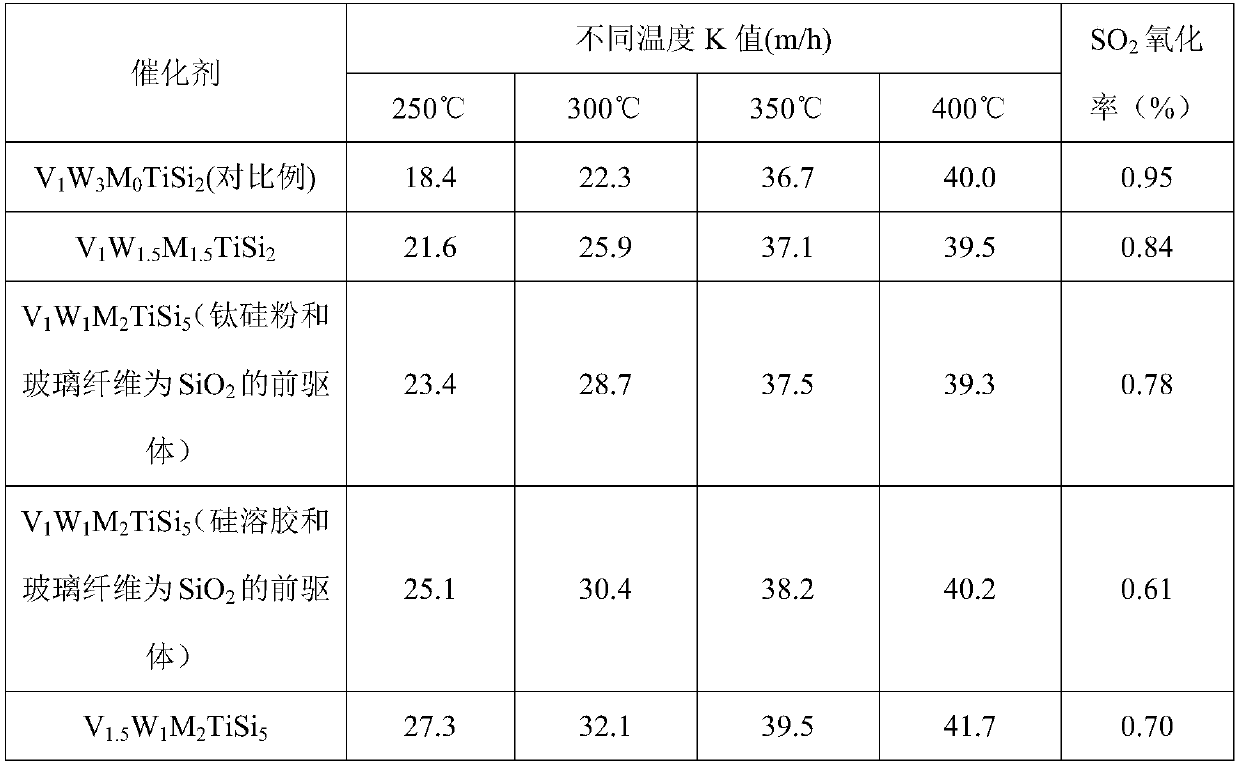

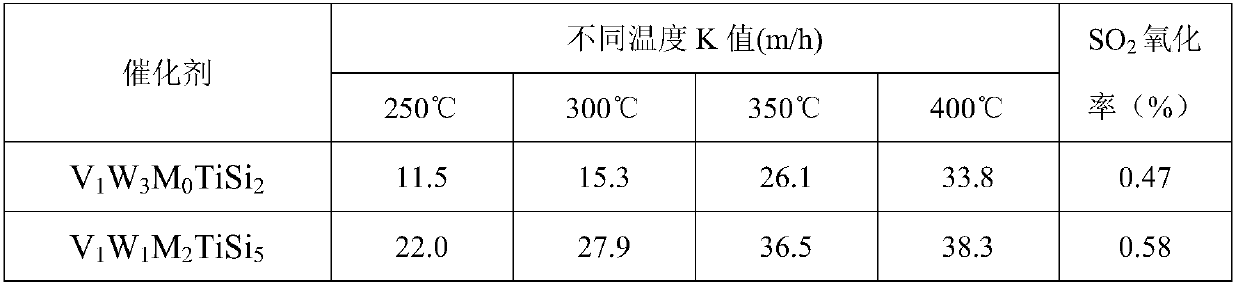

Low-temperature low-SO2-oxidation-rate honeycomb denitration catalyst and preparation method thereof

InactiveCN106807393AReduce oxidation rateLow temperature denitrification efficiency is highDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberHoneycomb

The invention discloses a low-temperature low-SO2-oxidation-rate honeycomb denitration catalyst and a preparation method thereof. The catalyst is prepared from, by mass, 1-5% of V2O5, 0.01-6% of WO3, 0.01-10% of MoO3, 0.01-0.5% of MgO, 3-6% of glass fibers, 66.5-95.96% of TiO2 and one or more of 0.01-1% of B2O3, 0.01-1% of F, 0.01-2% of P2O5, 0.01-1% of SnO2 and 0.01-1% of Sb2O3. Anatase type titanium dioxide serves as a carrier, V2O5 serves as an active center, and auxiliary agents including MgO, B2O3, F, SnO2, P2O5, Sb2O3 and the like are added to enhance synergistic effects among the active center, the auxiliary agents and the carrier to realize preparation of the low-temperature low-SO2-oxidation-rate honeycomb denitration catalyst. Compared with existing industrial V2O5-WO3-TiO2 catalysts, the denitration catalyst prepared according to the method has advantages of wide operating temperature window, high denitration efficiency, low SO2 oxidation rate, high water resistance, less proneness to hole blockage, long service life and the like and is especially suitable for low-temperature conditions (200-300 DEG C).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-temperature methanation catalyst for producing natural gas through coal and preparation method of catalyst

ActiveCN103706370AHigh mechanical strengthIncrease the areaCatalyst carriersGaseous fuelsAlkaline earth metalMethanation

The invention discloses a high-temperature-resistant methanation catalyst in a process of producing natural gas through coal. The high-temperature-resistant methanation catalyst comprises a carrier, an active component and assistants, wherein the carrier is a compound of CeO2, Al2O3 and ZrO2, the active component is Ni, the first assistant is one or two of alkaline earth metal oxides CaO and MgO, and the second assistant is one or two of transition metal oxides Cr2O3 and MnO. The high-temperature-resistant methanation catalyst disclosed by the invention has the advantages that the CeO2-Al2O3-ZrO2 compound oxide is used as the carrier to endow the catalyst with high mechanical strength, large specific surface area and heat resistance; the methanation activity of the catalyst is high and the thermal stability is strong; the alkaline earth metal oxide CaO and / or MgO are / is used as the first assistant to perfect the surface acidity of the carrier and inhibit carbon deposition of the catalyst; the Cr2O3 and / or MnO are / is used as the second assistant to beneficially improve the dispersibility of NiO particles and promote NiO reduction so as to improve the activity of the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND +1

Catalyst for purification of waste incineration flue gas and preparation method of catalyst

ActiveCN109126773AHigh catalytic activityImprove adsorption capacityGas treatmentDispersed particle separationCarbon nanotubePlatinum oxide

The invention discloses a catalyst for purification of waste incineration flue gas. The catalyst takes vanadium oxide, platinum oxide and tungsten oxide as active components, gamma-alumina, titanium oxide and carbon nanotubes as carriers and one or more of manganese oxide, iron oxide, copper oxide, tin oxide and cerium oxide as active aids. The catalyst has the functions of decomposing dioxin andchlorobenzene compounds and functions of denitration and sulfur resistance and still has excellent removal capacity for dioxin and NOx at lower temperature. The invention also discloses a preparationmethod of the catalyst for purification of waste incineration flue gas. The preparation method has the advantages of being simple to operate, convenient, controllable and suitable for mass industrialproduction.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

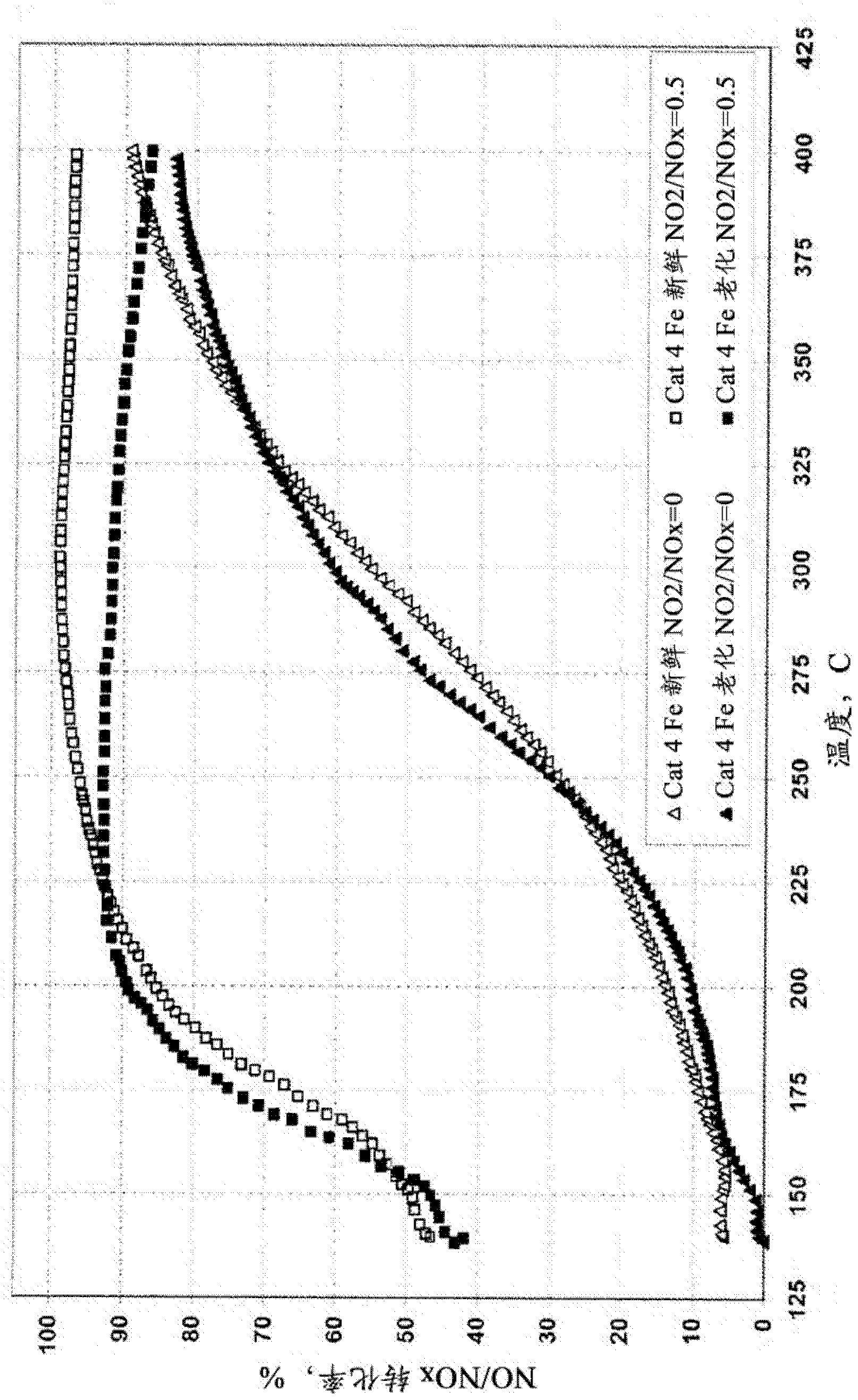

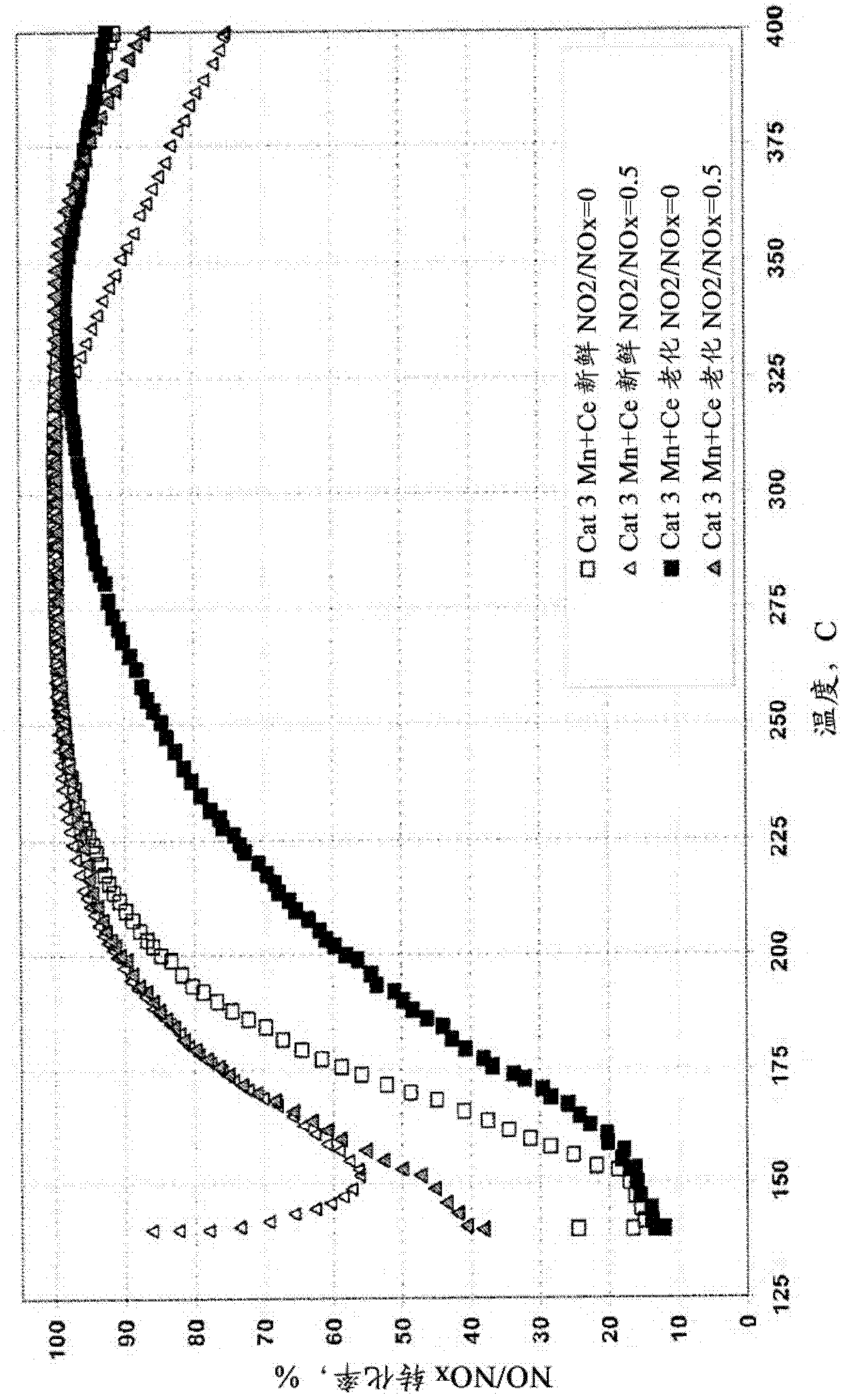

Ammonia scr catalyst and method of using the catalyst

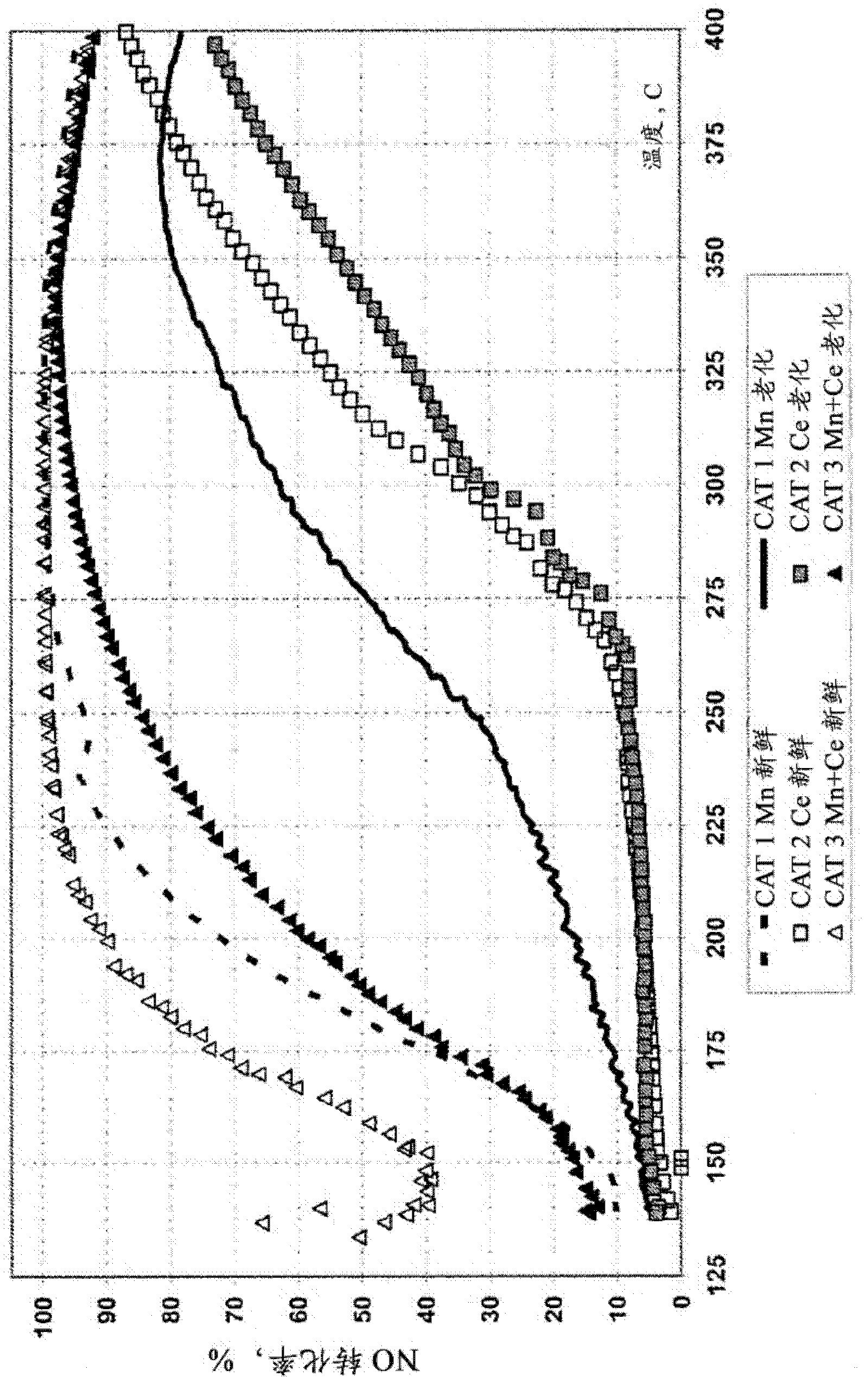

ActiveCN102612403ALow ignition temperatureEnhanced Surface AcidityMolecular sieve catalystsDispersed particle separationParticulatesNiobium

A DPF with an SCR catalyst and a method for selectively reducing nitrogen oxides with ammonia, filtering particulates, and reducing the ignition temperature of soot on a DPF are provided. The catalyst includes a first component of copper, chromium, cobalt, nickel, manganese, iron, niobium, or mixtures thereof, a second component of cerium, a lanthanide, a mixture of lanthanides, or mixtures thereof, and a component characterized by increased surface acidity. The catalyst may also include strontium as an additional second component. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia and oxidizes soot at low temperatures. The catalyst has high hydrothermal stability.

Owner:CATALYTIC SOLUTIONS INC

Method for preparing gasoline desulfurization adsorbent

ActiveCN102031141ASimple processLarge adsorption capacityOther chemical processesHydrocarbon oils refiningActivated carbonSorbent

The invention belongs to the technical field of gasoline desulfurization, and particularly relates to a method for preparing a gasoline desulfurization adsorbent. An activated carbon-based desulfurization adsorbent is obtained by loading active ingredients on activated and modified activated carbon serving as a carrier through impregnation, drying and roasting. The method is easy to operate, is low in investment, improves the capacity of adsorbing sulfide in gasoline by the adsorbent, particularly improves the adsorption on thiophene, dibenzothiophene and a tricyclic sulfur-containing compound, and has relatively small influence on the octane value of the gasoline.

Owner:临沂星火知识产权服务有限公司

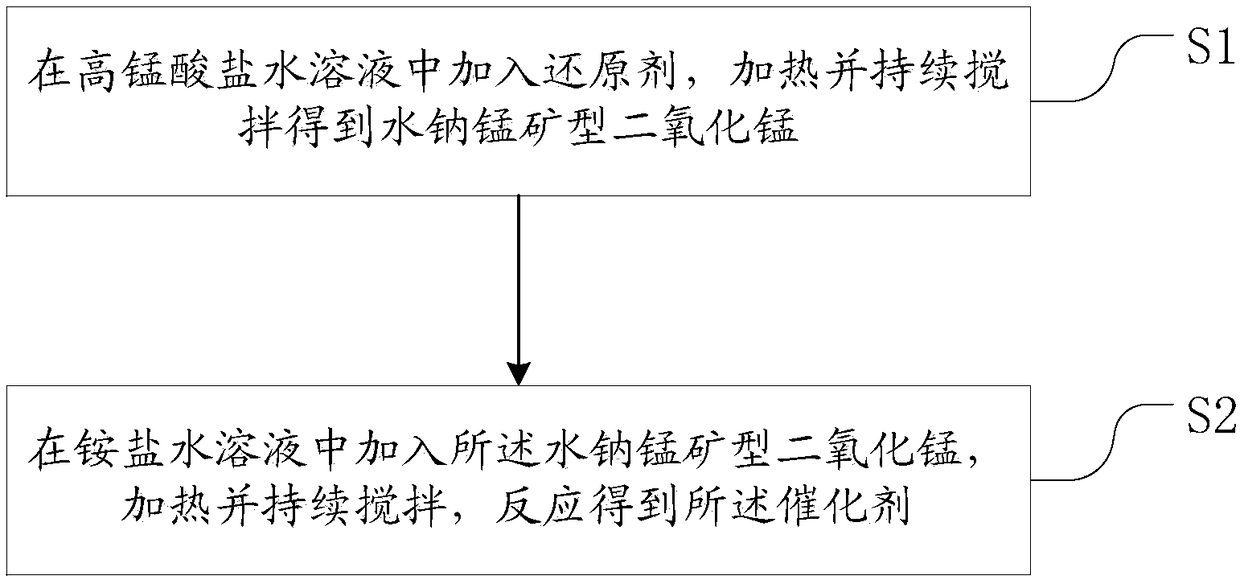

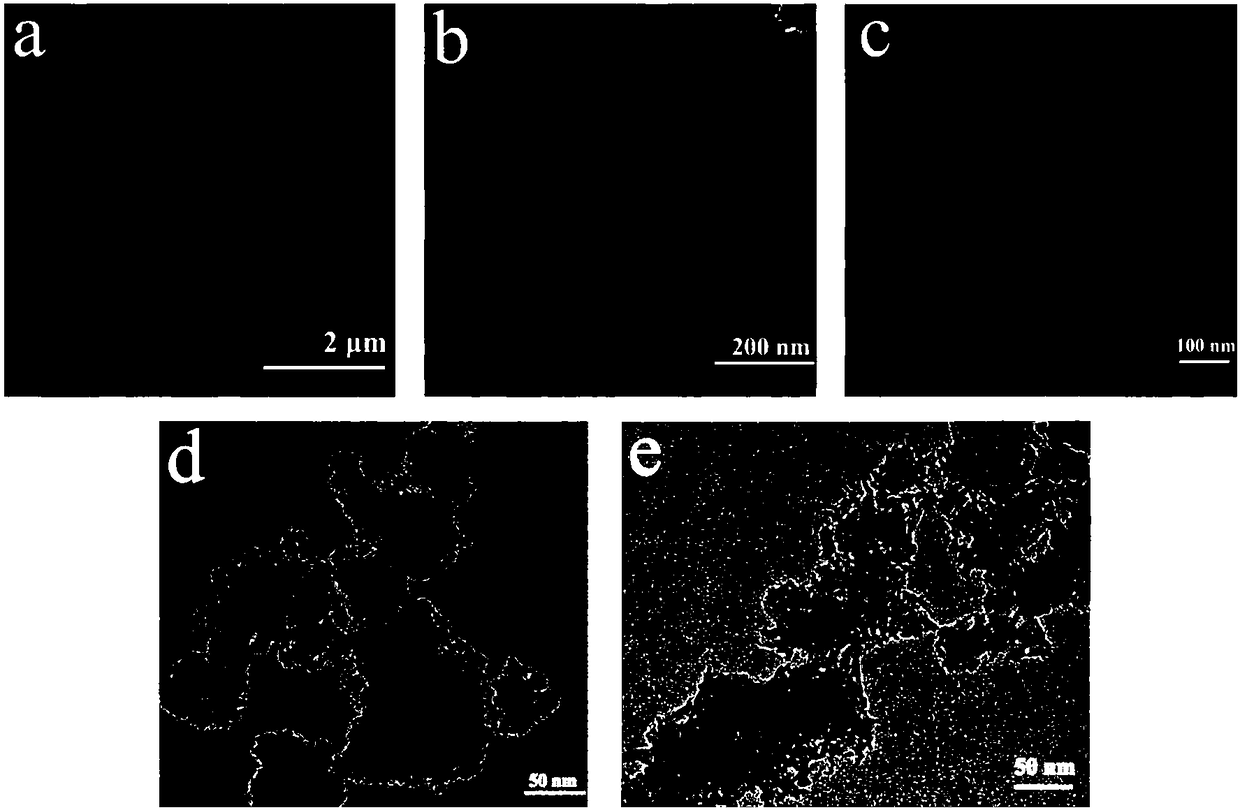

Preparation method of catalyst for ozone decomposition

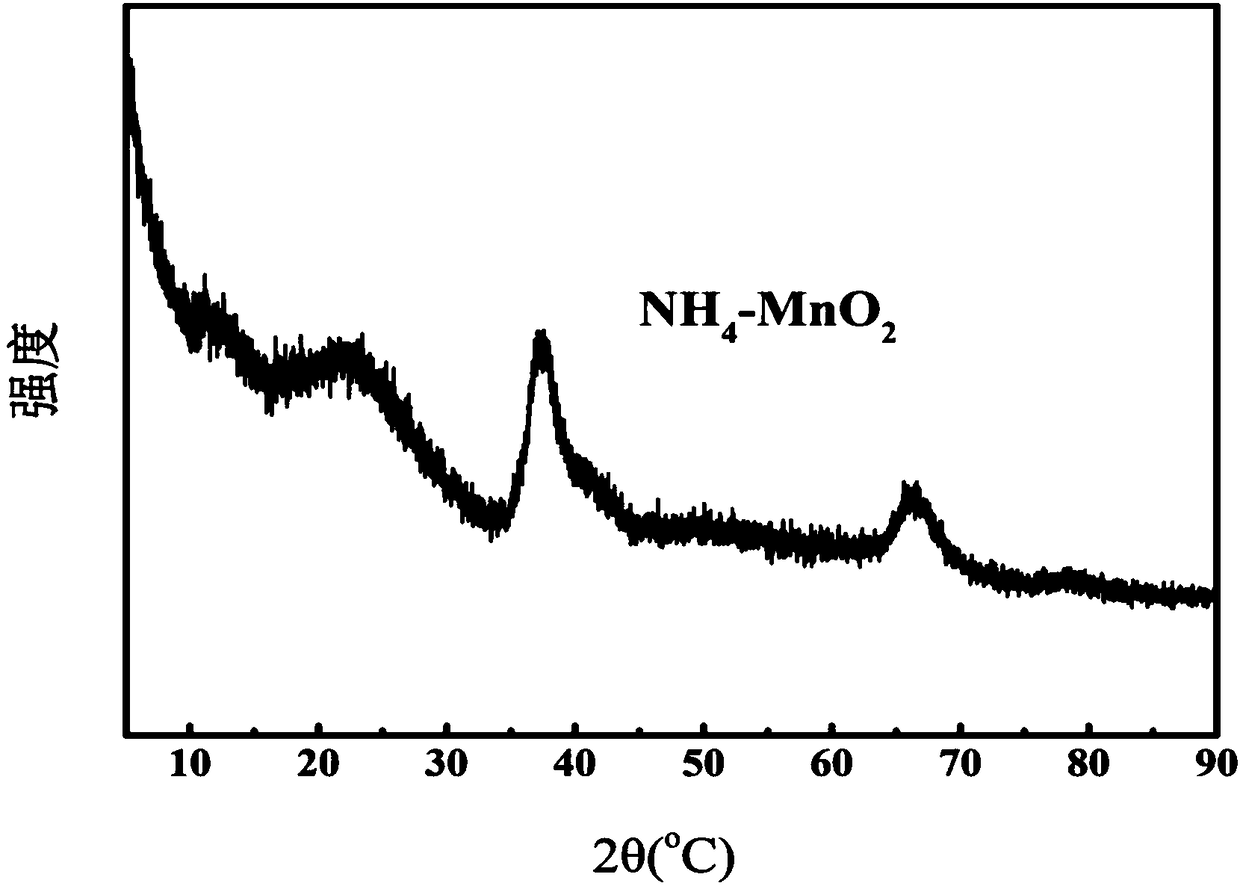

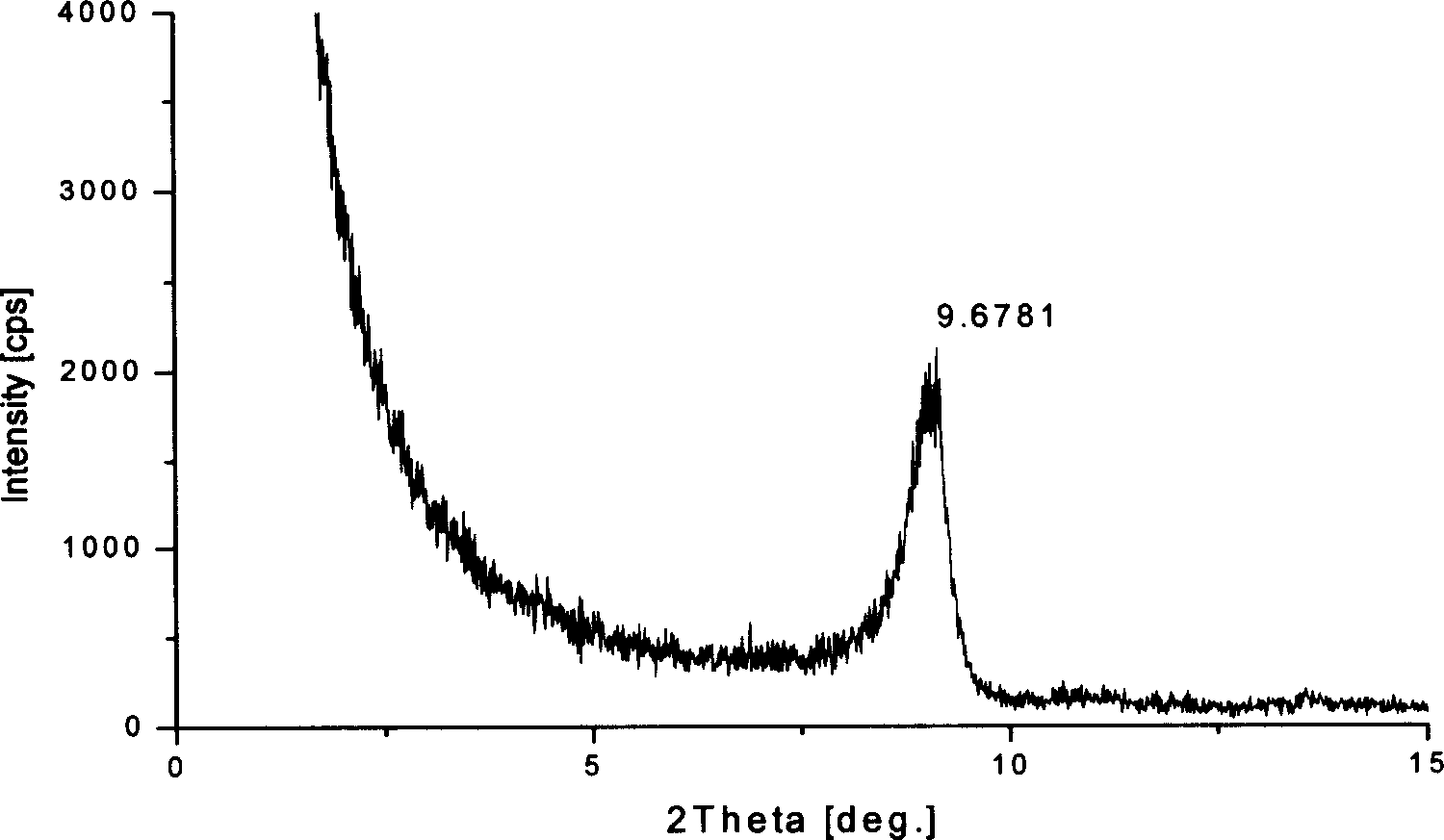

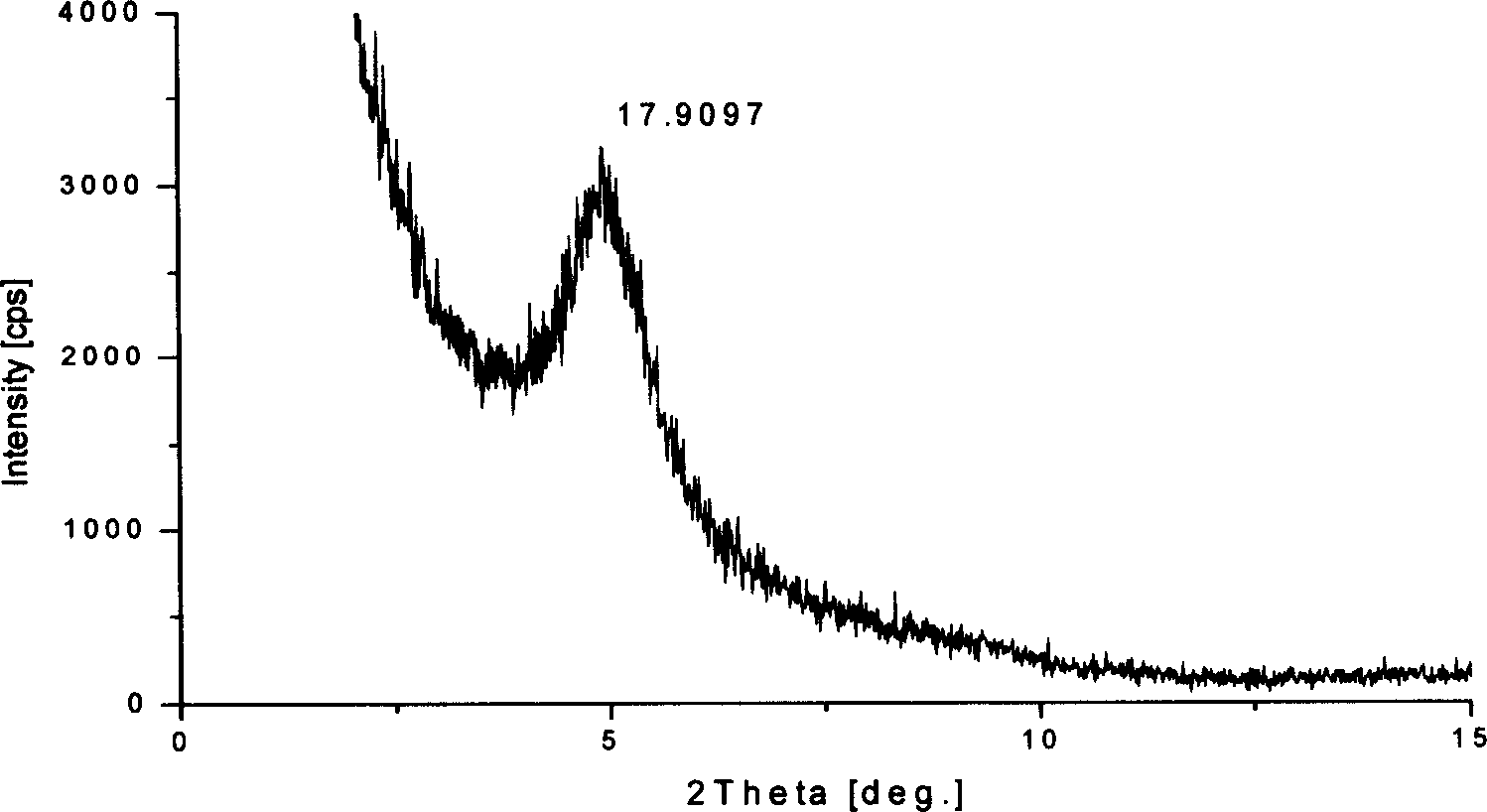

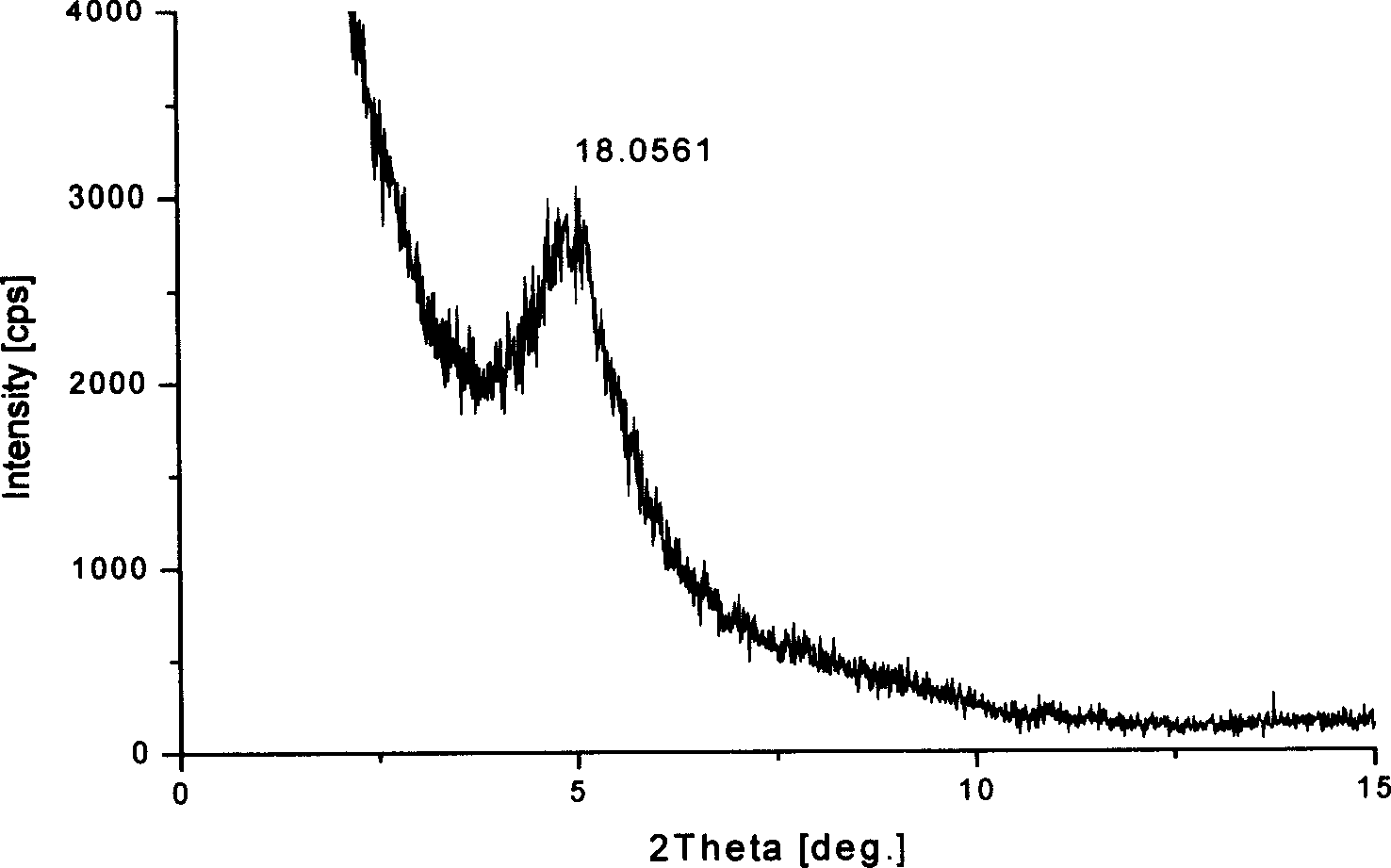

ActiveCN108579729ALarge specific surface areaEnhanced Surface AcidityGas treatmentDispersed particle separationBirnessiteDecomposition

The invention provides a preparation method of a catalyst for ozone decomposition. The preparation method comprises the following steps: S1, adding a reducing agent into permanganate water solution, heating, and continuously stirring to obtain birnessite manganese dioxide; and S2, adding the birnessite manganese dioxide into an ammonium salt water solution, heating and continuously stirring to obtain the catalyst.

Owner:TSINGHUA UNIV

Special tungsten-containing nano titanium dioxide for flue gas denitration catalyst and manufacturing method thereof

ActiveCN102416333AEnhanced Surface AcidityImprove denitrification activityPhysical/chemical process catalystsDispersed particle separationSulfate radicalsAmmonium paratungstate

The invention provides high-performance special tungsten-containing nano titanium dioxide for a flue gas denitration catalyst and a preparation method thereof. The nano titanium dioxide comprises the following ingredients by mass percentage: 85-96.2 percent of TiO2, 3-10 percent of WO3 and 0.8-5 percent of SO42-. The preparation method comprises: using metatitanic acid prepared in a sulfuric acidmethod as a raw material, adding a pore-forming agent, mixing, adding precursors of ammonium paratungstate and sulfate radical, mixing, and delivering the mixture to a rotary kiln for drying and roasting to obtain the nano titanium dioxide with a large specific surface and high surface acidity. Compared with the prior art, the invention has the following advantage that: (1) since the sulfuric acid is added, the surface acidity of TiO2 is significantly enhanced, and the denitration activity of the final catalyst is improved; (2) since the ammonium paratungstate is added into the metatitanic acid solution, the performance of titanium dioxide is improved, the process is simple, and the operation is facilitated; (3) the procedures are simple, the drying and roasting are completed in the rotary kiln, the number of devices is reduced, and the energy consumption is decreased; and (4) the specific surface area of the titanium dioxide is increased through the pore-forming agent, and the applied pore-forming agent is inexpensive and environmentally friendly.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

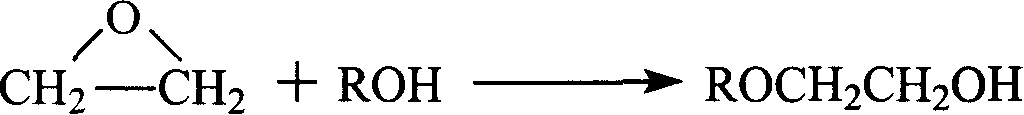

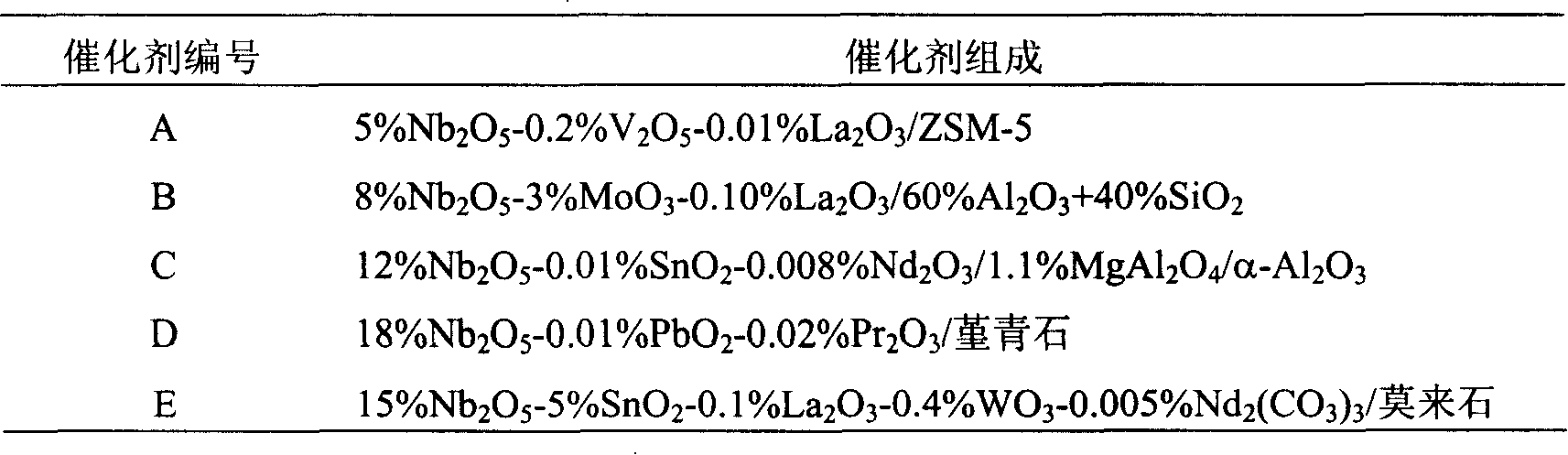

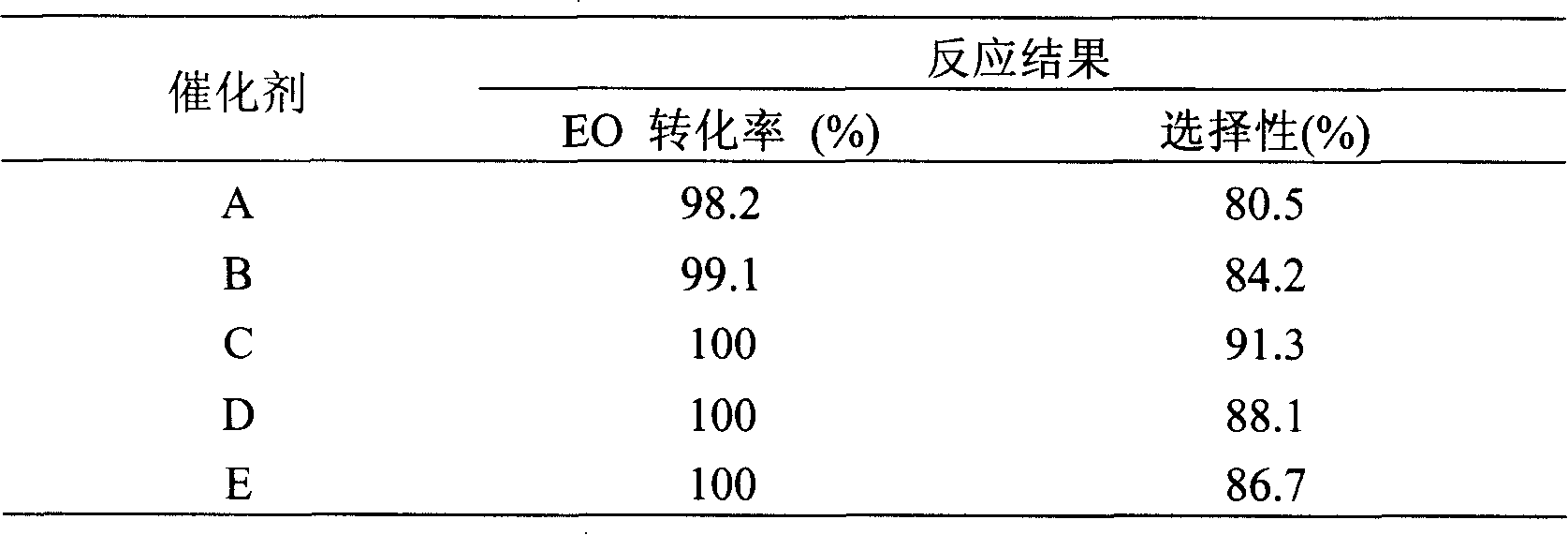

Method for preparing ethylene glycol ether

ActiveCN101190876AHigh activityReduced activityMolecular sieve catalystsEther preparation from oxiranesEpoxyEthylene oxide

The invention relates to a glycol ether preparation method, mainly solving the problems of the original technique that the target product, glycol ether, has low selectivity, high alcohol / epoxy ethane ratio (alcohol / alkyl ratio) and no concern on catalyst stability. The invention uses epoxy ethane and lower fatty alcohol as raw materials, adopts niobium oxide as a main activated component, and chooses at least one of elements or compounds of V, Mo, Sn, Pb, La, Pr, Nd as auxiliary agent to form catalyst, so as to prepare glycol ether under the reaction temperature of 100 to 300 DEG C, reaction pressure of 0.1 to 3.0MPa, alcohol / alkyl ratio of 1-5: 1, and reaction time of 30 minutes to 8.0 hours. The technical proposal can well solve the problem and can be used for the industrial production of the glycol ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inorganic clay compound material, its preparation and use

InactiveCN1736586AEfficient photocatalytic performanceWide wavelength response rangeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlcohol

The invention relates to inorganic clay composite and the method for preparation and the utility, belonging to the catalyst art. The material comprises rare-earth element, titanium oxide and clay, the rare-earth element being one or two from Ce, La, Nd, Pr, Yt, Eu and Er, the clay being montmorillonite, the mass ratio of every component being: montmorillonite 54- 90%, titanium oxide 8- 45%, and rare-earth oxide 0.1- 4.0%; and the technique contains the following steps: the mass ratio of material being: titanate 0.6- 1.8%, absolute ethyl alcohol 45- 90%, rare-earth salt 0.013- 0.08% clay 0.8- 1.8%, deionized water 3- 30% and glycerin 4- 35%, using titanate, absolute ethyl alcohol and glycerin solution to prepare titanium oxide sol, using rare-earth salt and absolute ethyl alcohol to prepare rare-earth solution, adding said sol and solution separately into the suspension of clay- absolute alcohol, mixing, aging, filter-pressing, drying in 60- 80Deg. C, and at last roasting 4- 10 hours to prepare the product. The material is added into coating as an additive. And the material has a high catalysis property and a short preparation process.

Owner:HEBEI UNIV OF TECH

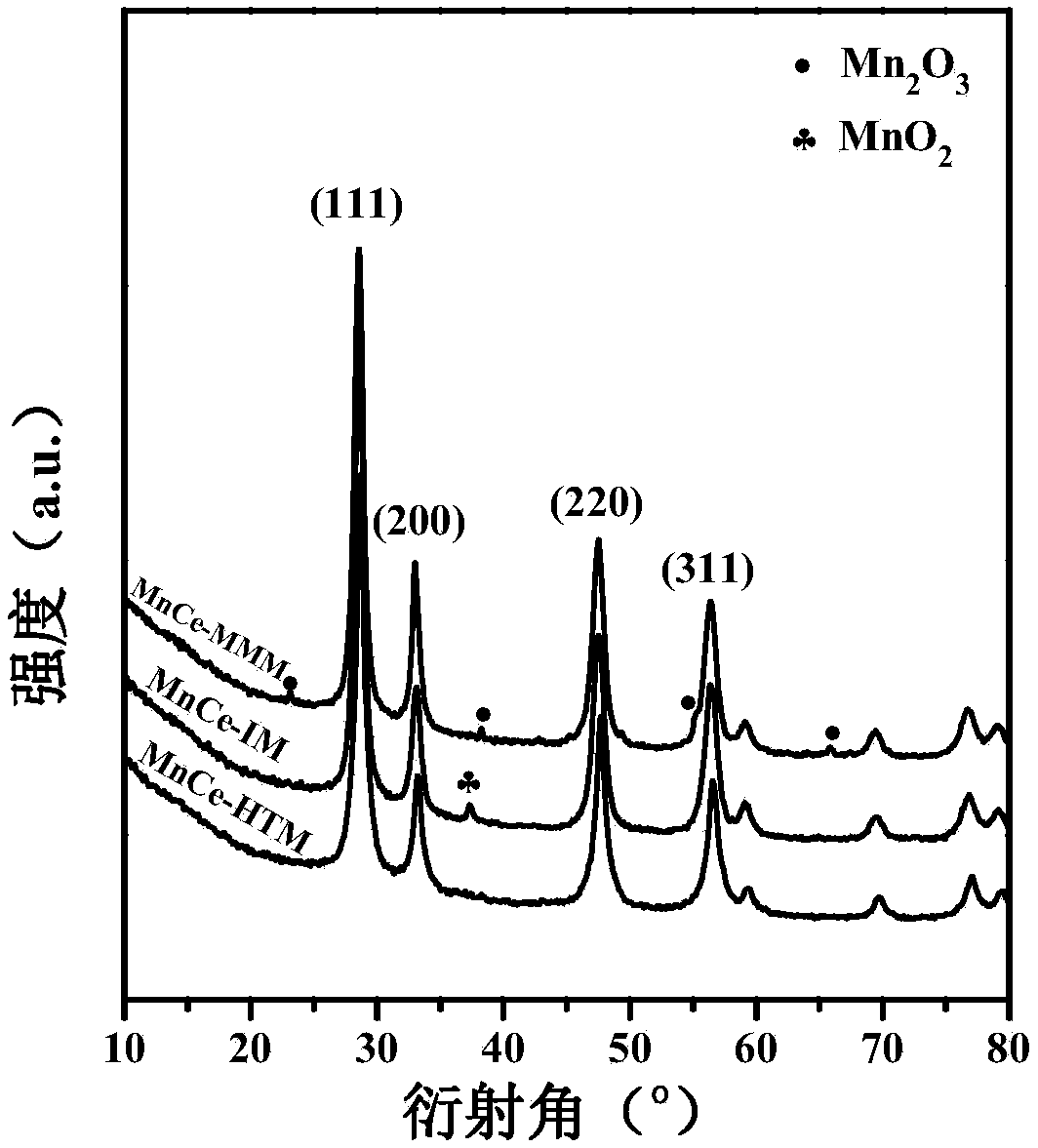

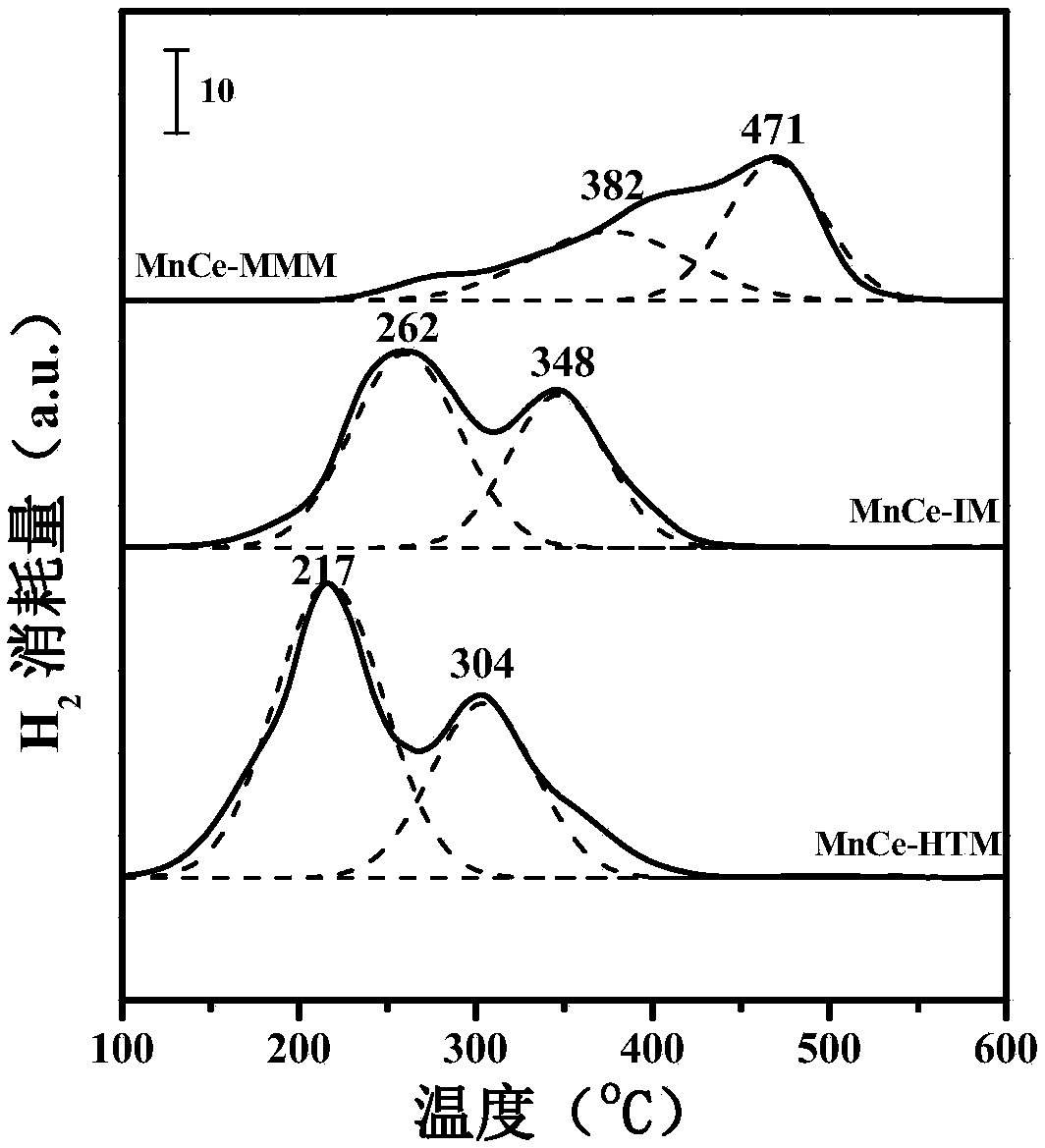

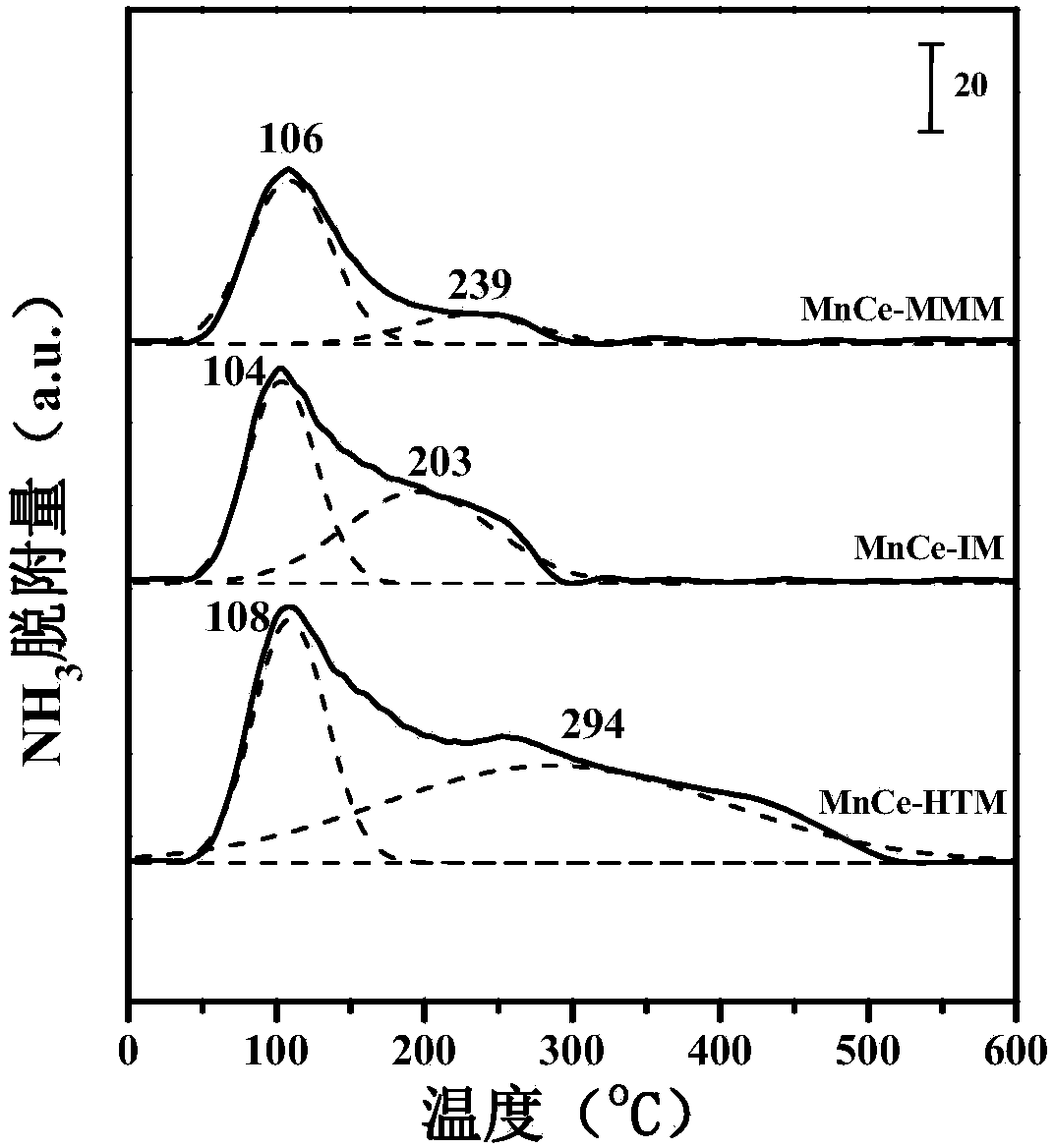

Preparation method for high-efficiency Ce1-xMnxO2-delta solid solution low-temperature denitration catalyst and application thereof

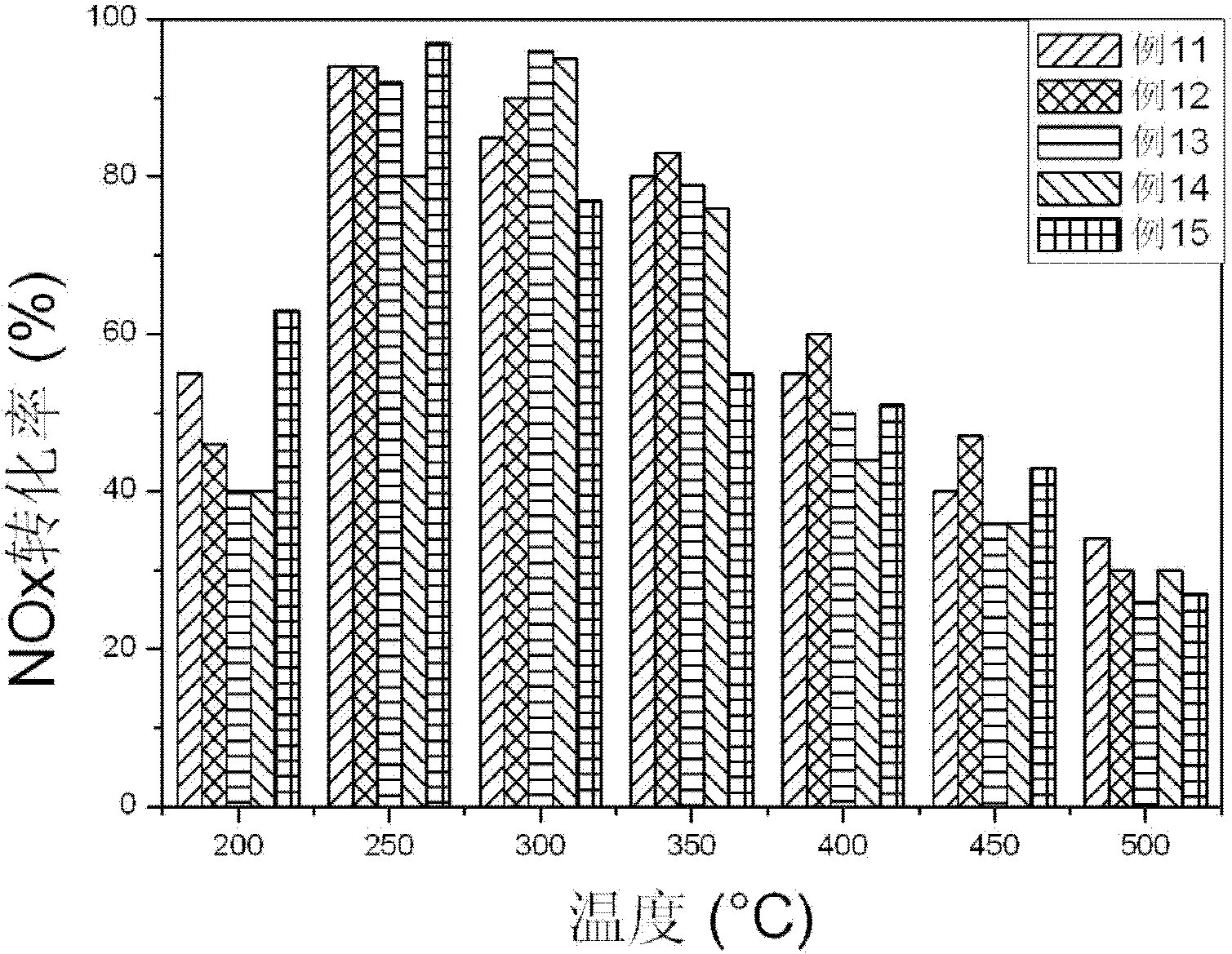

InactiveCN105214652AExcellent low temperature denitrification performanceImprove low temperature denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHigh pressureSolid solution

The invention provides a preparation method for a high-efficiency Ce1-xMnxO2-delta solid solution low-temperature denitration catalyst and an application thereof. The preparation method comprises the following steps: uniformly dissolving a certain amount of Mn(NO3)2 and Ce(NO3)3; slowly adding the mixture into a superfluous NaOH solution and completely depositing; transferring into a hydrothermal reaction kettle and performing high-temperature high-pressure reaction; and lastly, performing centrifuging and solid-liquid separation, and cleaning, drying and roasting the acquired solid phase matter, thereby acquiring the Ce1-xMnxO2-delta solid solution catalyst. The preparation method provided by the invention has the advantages that the prepared catalyst is excellent in denitration property and has high activity, high selectivity, wide operating temperature window and excellent water resistance; the required raw materials are rich in resources, cheap and easily acquired; the preparation process is simple and convenient; the energy consumption is low, the pollution is small and the environment is protected; and the catalyst is fit for mass production and has a wide industrial application prospect.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

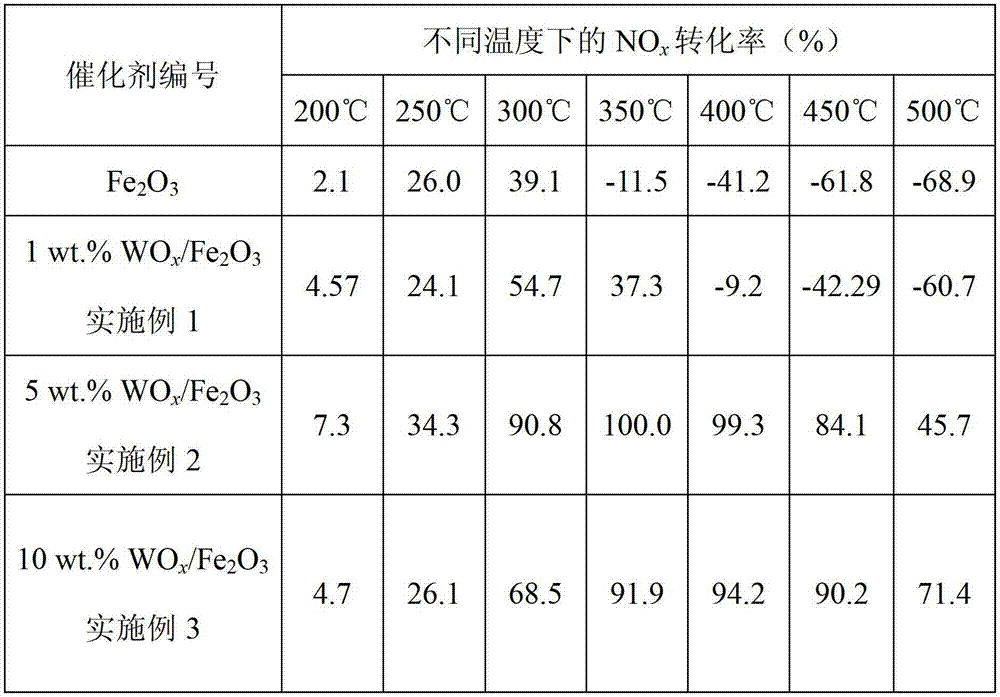

Tungsten oxide surface modified Fe2O3 catalyst as well as preparation method and application thereof

ActiveCN103170346AWide operating temperature windowImprove purification efficiencyNitrous oxide captureDispersed particle separationChemical compositionSurface modification

The invention relates to a tungsten oxide surface modified Fe2O3 catalyst comprising the following chemical compositions: WOx / Fe2O3(x=2-3), wherein the mass percent of WOx in the catalyst is 1-10 wt.%. The invention further discloses a method for preparing the catalyst. The NH3 selective catalytic reduction activity of surface non-modified Fe2O3 material into NOx (NH3-SCR) is extremely low, the operation temperature window is extremely narrow, and a large amount of N2O side product is generated, but the NH3-SCR catalyst activity and the N2 generation selectivity are remarkably improved after WOx surface modification. The tungsten oxide surface modified Fe2O3 catalyst as well the preparation method and the application thereof are suitable for catalytic elimination of stationary source and mobile source NOx.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

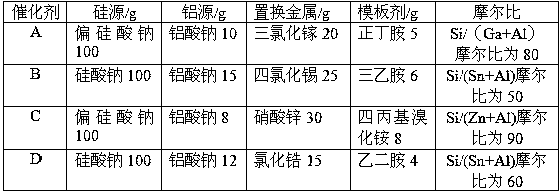

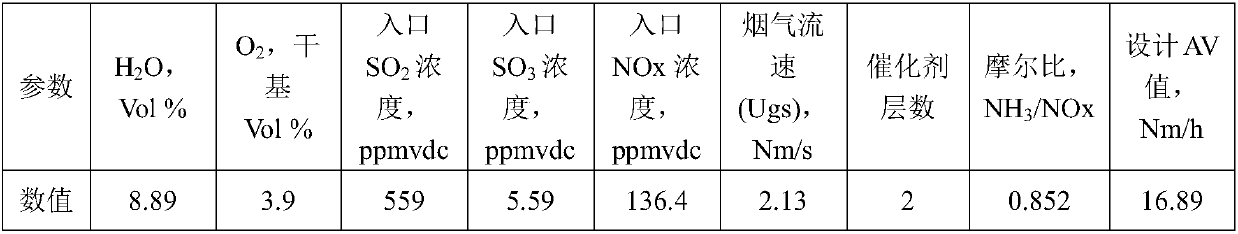

Composite Ti-Si-molecular sieve coating integral denitration catalyst and preparation method thereof

PendingCN108114742AStable mixFully dispersedMolecular sieve catalystsDispersed particle separationMolecular sieveActive component

The invention relates to a composite Ti-Si-molecular sieve coating integral denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) preparationof Ti-Si-molecular sieve composite sol; (2) preparation of Ti-Si-molecular sieve composite coating; and (3) loading of active components. The denitration catalyst is prepared by using the above method. The preparation method of the invention is simple in process and low in cost. The prepared denitration catalyst is adaptive to a wide active temperature range and has high denitration activity andstrong resistance to SO2 and H2O poisoning.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing dimethyl ether from methanol

ActiveCN101147860AHigh activityActivity unchangedCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAlcoholActive component

The present invention relates to a catalyst for preparing dimethyl ether by using methyl alcohol dehydration. Said catalyst is made up by using niobium oxide as main active component and selecting at least one kind of phosphorus or sulfur as adjuvant through a certain preparation process. Said catalyst not only has good activity, but also possesses good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wide-temperature denitration catalyst and preparation method thereof

ActiveCN108620058AImprove bindingImprove wear resistanceGas treatmentDispersed particle separationReaction temperatureBULK ACTIVE INGREDIENT

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

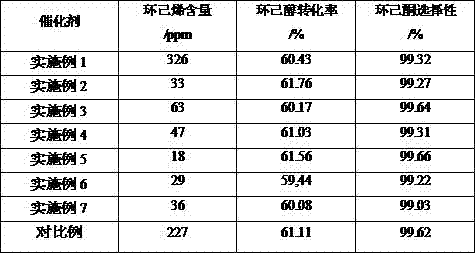

High-selective catalyst for dehydrogenating cyclohexanol to produce cyclohexanone and preparation method thereof

InactiveCN106890641AReduce contentHigh selectivityOrganic compound preparationPreparation by dehydrogenationCyclohexanoneCyclohexene

The invention belongs to the technical field of production of catalysts, and provides a catalyst for gas-phase-dehydrogenating cyclohexanol to produce cyclohexanone and a preparation method thereof. The catalyst can effectively reduce generation of a side product, cyclohexene. The catalyst is mainly composed of Cu2O / SiO2, wherein an active additive is added to improve acidic sites on the surface of the catalyst. The catalyst is prepared through a stepwise precipitating method, wherein the method includes the steps of washing, solid and liquid separation, drying, roasting and tabletting moulding. The catalyst is high in activity and selectivity, wherein the content of the cyclohexene in a product is 20-80 ppm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano titanium dioxide special for flue gas denitrifying catalyst and preparation method thereof

InactiveCN102489319AEnhanced Surface AcidityImprove denitrification activityPhysical/chemical process catalystsDispersed particle separationSulfate radicalsAmmonium sulfate

The invention provides a high-performance nano titanium dioxide special for flue gas denitrifying catalyst and a preparation method of the high-performance nano titanium dioxide. The nano titanium dioxide comprises 0.8 to 5% of sulfate ion and the balance of TiO2 by mass percent. The preparation method comprises the following steps: taking metatitanic acid which is prepared by a sulfuric acid method as raw material; adding pore-forming agent, stirring and adding a sulfate radical precursor; stirring, conveying mixture to a rotary kiln, and drying and calcining the mixture to obtain the nano titanium dioxide with relatively high specific surface area and relatively strong surface acidity. The preparation method has the advantages that: 1), after addition of the sulfate radical precursor, the acidity of the TiO2 surface can be improved greatly and the denitrifying activity of a final catalyst can be improved; 2), when ammonium sulfate is used, because the ammonium sulfate is non-acidic, the corrosion on a stirrer and the rotary kiln can be reduced, a requirement for equipment material is lowered, and the investment cost of the equipment is reduced; 3), the preparation method is simple, the drying and calcining processes are carried out in the rotary kiln, so that the equipment use is reduced and the energy consumption is lowered; and 4) the pore-forming agent can increase the specific surface area of the nano titanium dioxide, and is cheap and environment-friendly.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Attapulgite sewage treatment agent and preparation method thereof

InactiveCN106865655AGood dispersionGood suspensionWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionIron sulfateAluminium chloride

The invention discloses an attapulgite sewage treatment agent and a preparation method thereof, and relates to the technical field of attapulgite processing. The attapulgite sewage treatment agent is prepared from the following raw materials in parts by weight: 150 to 200 parts of attapulgite, 200 to 250 parts of hollow glass beads, 80 to 100 parts of deionized water, 20 to 25 parts of a sulfuric acid solution, 20 to 25 parts of cross-linked rectorite, 2 to 5 parts of ferric trichloride, 2 to 5 parts of ferrous sulfate, 2 to 5 parts of magnesium sulfate, 2 to 5 parts of polyacrylamide, 2 to 5 parts of aluminium chloride, 2 to 5 parts of polyferric sulfate, 2 to 5 parts of sodium hydroxide, 2 to 5 parts of sodium benzoate, 2 to 5 parts of corn starch, 2 to 5 parts of straw, 1 to 3 parts of cottonseed shell residue, 1 to 3 parts of modified diatomite, 1 to 3 parts of citric acid, 1 to 3 parts of aids and a proper amount of water. The attapulgite serves as the raw material and is subjected to modification treatment, so high dispersibility, high suspension property and good adsorption effect are achieved.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

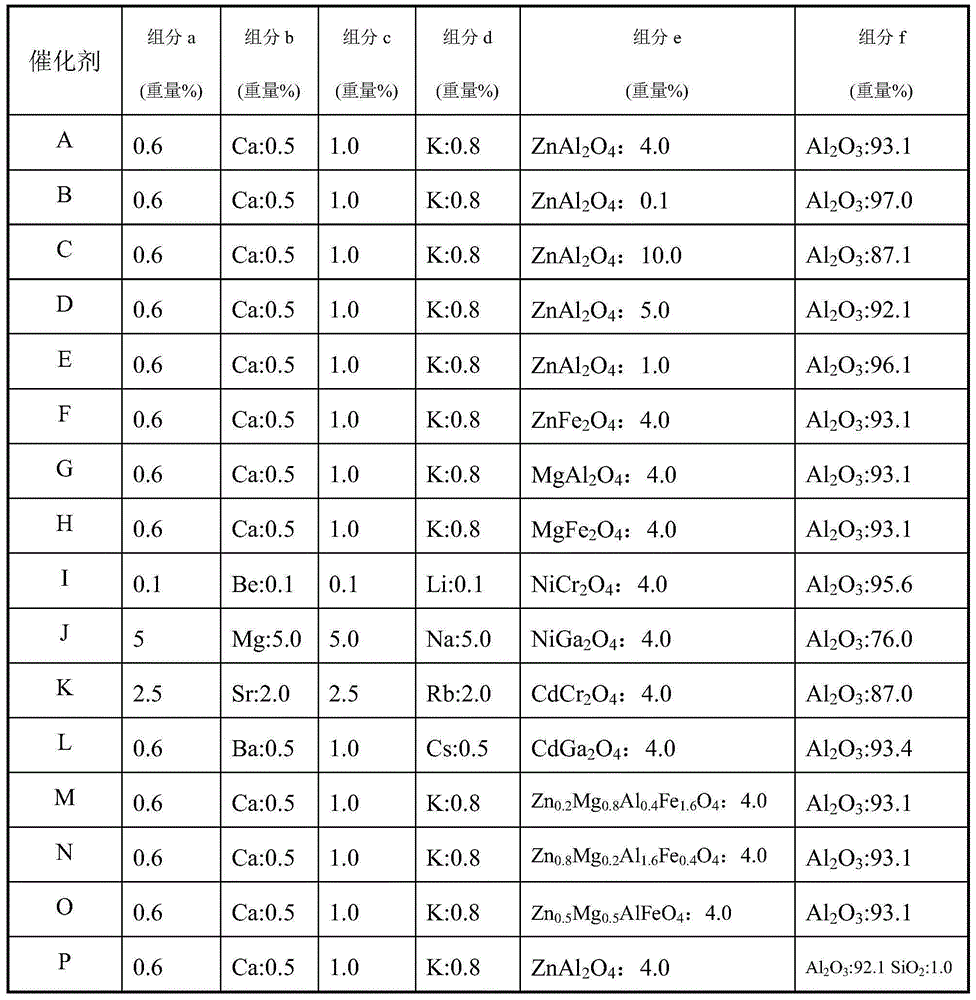

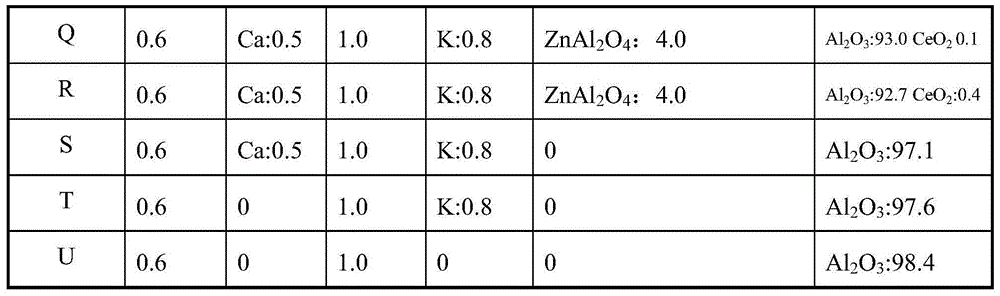

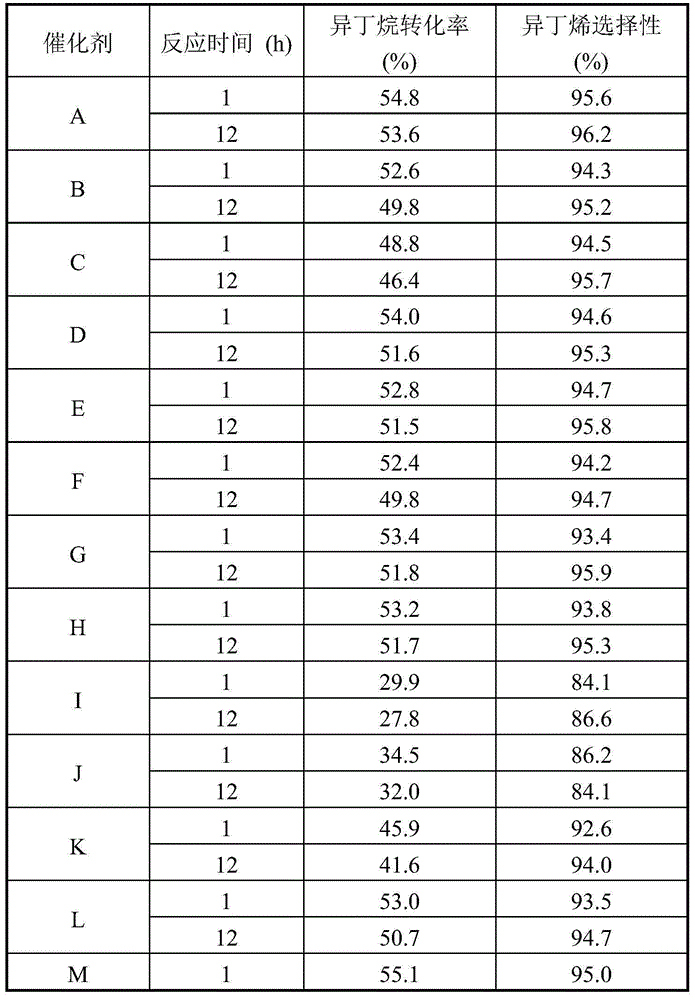

Catalyst for isobutane dehydrogenation production of isobutylene

ActiveCN106607021AEnhanced Surface AciditySlow down inactivationMetal/metal-oxides/metal-hydroxide catalystsDivalent metalLow activity

The invention relates to a catalyst for isobutane dehydrogenation production of isobutylene. The catalyst solves the problem that the dehydrogenation catalyst prepared by the prior art has low activity and poor stability. The catalyst provided by the invention comprises, by weight, a) 0.1 to 5 parts of Pt or an oxide thereof, b) 0.1 to 5 parts of an alkaline earth metal or an oxide thereof, c) 0.1 to 5 parts of Sn or an oxide thereof, d) 0.1 to 5 parts of an alkali metal or an oxide thereof, e) 0.1 to 10 parts of AB2O4 having a spinel structure, wherein A represents at least one divalent metal cation and B represents at least one trivalent metal cation, and f) 80 to 99 parts of a carrier Al2O3. The catalyst well solves the problem and can be used for isobutane dehydrogenation industrial production of isobutylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Denitrification catalyst and preparation method thereof

ActiveCN105879858AFine particleUniform particle size distributionGas treatmentHeterogenous catalyst chemical elementsNiobiumFiltration

The invention discloses a denitrification catalyst and a preparation method thereof. The preparation method of the denitrification catalyst comprises the following steps: (1) preparing a Nb-containing solution; (2) adding a TiOx to the Nb-containing solution and obtaining a mixture through impregnation; (3) drying, grinding and roasting the mixture to obtain a Nb2O5-TiO2 carrier; (4) adding the Nb2O5-TiO2 carrier to a Mg and Ce salt solution to obtain a carrier-containing solution; (5) adding a precipitant and a surfactant to the carrier-containing solution, and obtaining the catalyst through cooling, pumping filtration or centrifugation, washing, drying and roasting. The denitrification catalyst prepared with the method has higher catalysis efficiency and wider low-temperature activity temperature range.

Owner:CHINA BUILDING MATERIALS ACAD

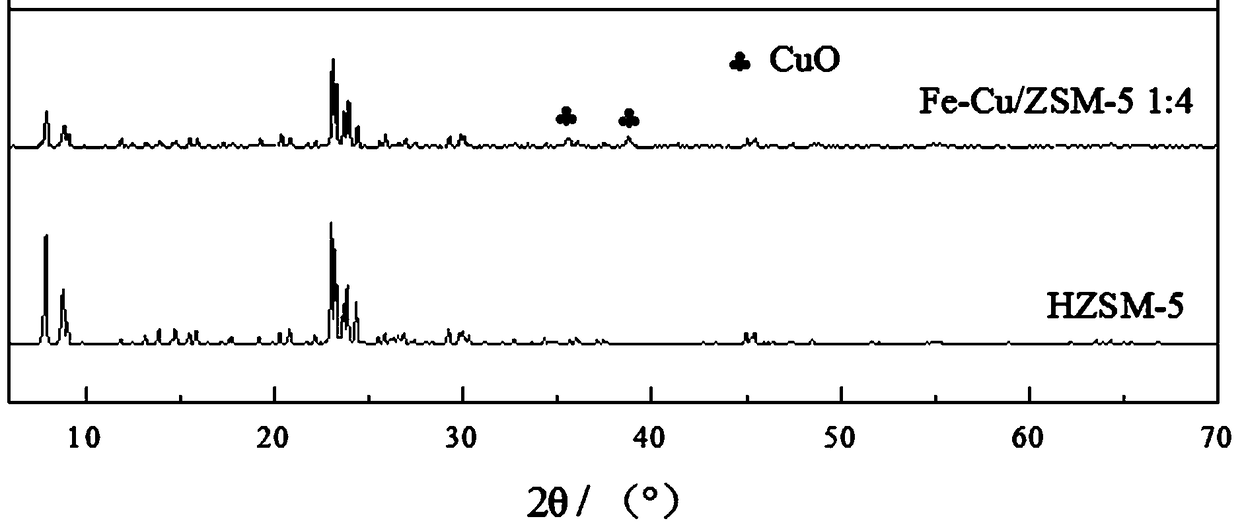

Preparation method of NH3-SCR flue gas desulfurization catalyst and catalyst thereof

InactiveCN108816274AImprove water and sulfur resistanceLarge specific surface areaGas treatmentMolecular sieve catalystsNitrateCopper nitrate

The invention relates to the technical field of the flue gas desulfurization catalyst, and specifically relates to a preparation method of an NH3-SCR flue gas desulfurization catalyst and the catalystthereof. The preparation method of the catalyst comprises the following steps: dispersing ZSM-5 zeolite carrier into a composite solution of ferric nitrate and copper nitrate, wherein the mole ratioof Fe atoms to Cu atoms in the composite solution is 1:4, the mass of the Fe element is 10% of the mass of the ZSM-5 carrier, and the dispersing method comprises stirring for 4-6h at 50-60 DEG C by adopting a magnetic stirrer, and ultrasonically oscillating for 40min; discarding supernatant after stratification of the dispersion system, drying a precipitate in an electric constant-temperature blast air oven, grinding the precipitate into powder after drying, then roasting in a muffle furnace, and repeatedly grinding into powder after roasting, thereby obtaining the flue gas desulfurization catalyst. The catalyst prepared with the method disclosed by the invention has a relatively wide active temperature window, and has the advantages of being low in price, environmentally-friendly and thelike.

Owner:HENAN UNIV OF SCI & TECH

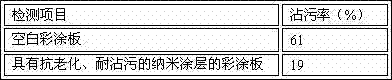

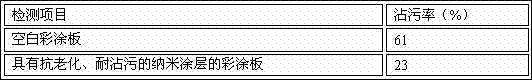

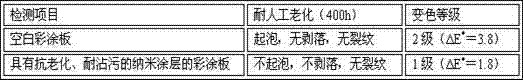

Nano-sol for forming anti-aging and stain-resistant nano-coating and preparation method and application thereof

The invention discloses nano-sol for forming an anti-aging and stain-resistant nano-coating and a preparation method thereof. The nano-sol for forming the anti-aging and stain-resistant nano-coating comprises the following components in percentage by weight: 0.1-10% of nano-TiO2 sol, 0.1-20% of sodium silicate, 0.1-5% of cerium oxide sol, 0-0.1% of colorant and the balance of water or mixed solution consisting of ethanol and water. The preparation method comprises the steps of firstly preparing the nano-TiO2 sol by adopting a sol-gel method, then preparing the Ce2O3 sol, then adding sodium silicate and the Ce2O3 sol into the nano-TiO2 sol, uniformly stirring, further adding the colorant, and finally adding the balance of water or the mixed solution consisting of ethanol and water to obtain the nano-sol for forming the anti-aging and stain-resistant nano-coating. The nano-coating which is used for a color-coated plate and obtained by coating has the properties of aging resistance, stain resistance, corrosion resistance and the like, and the service life of the color-coated plate can be prolonged.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

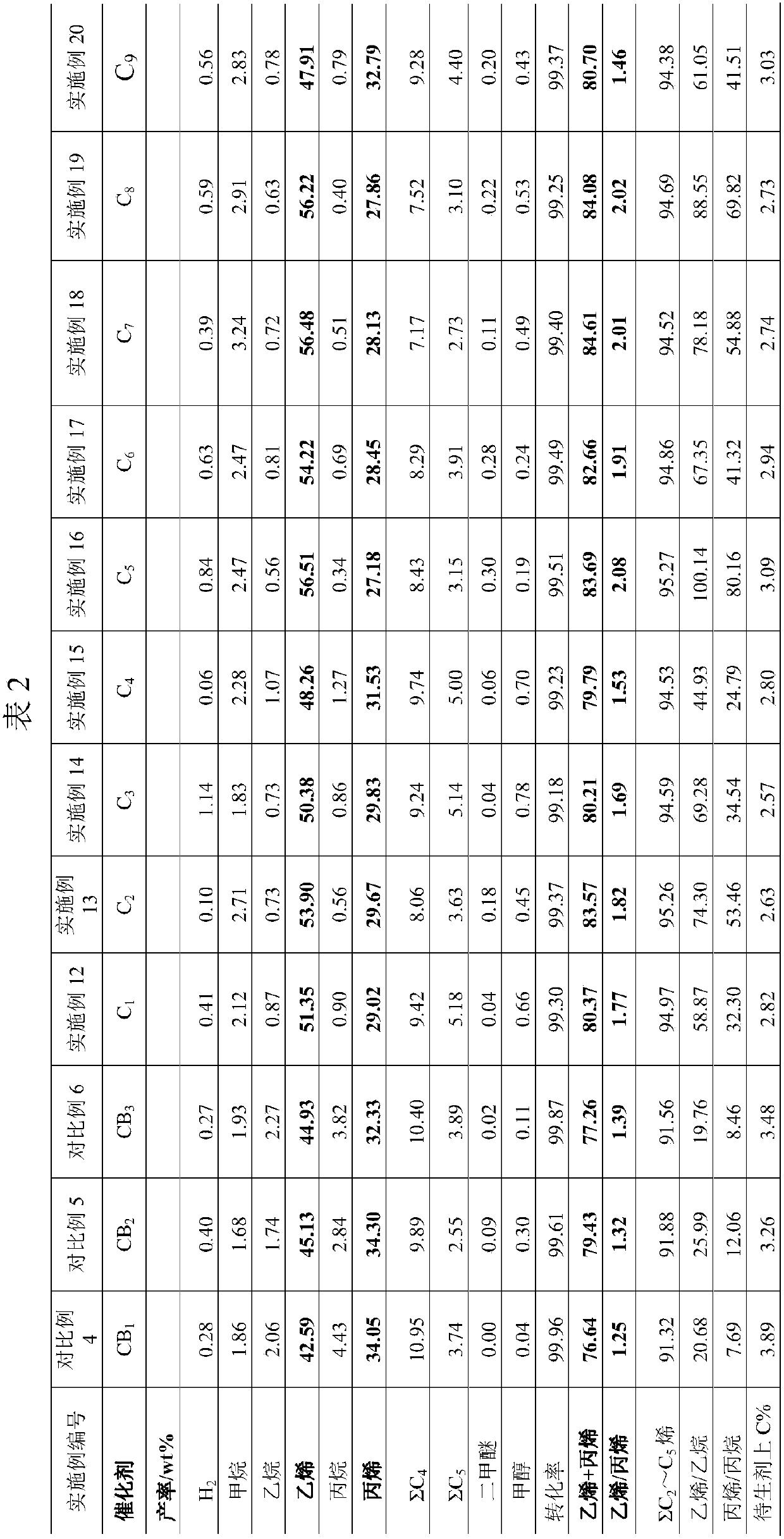

High-ethylene-selectivity catalyst for preparation of low carbon olefins from methanol

InactiveCN107626345AImprove catalytic performanceEnhanced Surface AcidityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveEthylene

The invention discloses a catalyst used for conversion of methanol for preparation of low carbon olefins (C2=-C4=). The catalyst is characterized by comprising, on a dry basis, 5 to 95 parts by weightof a modified silicoaluminophosphate (SAPO) molecular sieve, 4 to 50 parts by weight of an inorganic binder, 0.1 to 25 parts by weight of a Zn additive and 0.1 to 25 parts by weight of a phosphorus additive, and may optionally comprises 4 to 50 parts by weight of adhesion-free inorganic oxide or inorganic hydroxide and 1 to 60 parts by weight of clay, wherein the contents of the adhesion-free inorganic oxide or inorganic hydroxide, the inorganic binder, the Zn additive and the phosphorus additive are all calculated on in terms of oxide; and the Zn additive and the phosphorus additive do not contain Zn and P included in the modified silicoaluminophosphate (SAPO) molecular sieve. When the catalyst is applied to the process for preparation of low carbon olefins (C2=-C4=) through conversion of methanol, the catalyst can efficiently convert methanol into low carbon olefins (C2=-C4=), and in particular, the catalyst can greatly improve ethylene selectivity.

Owner:任丘市华北石油科林环保有限公司

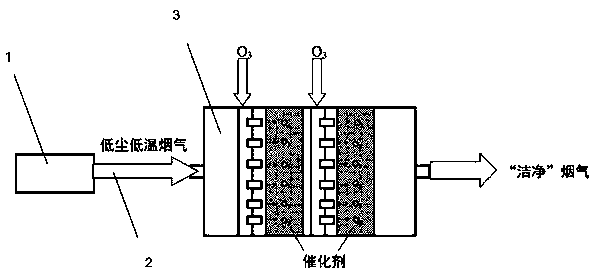

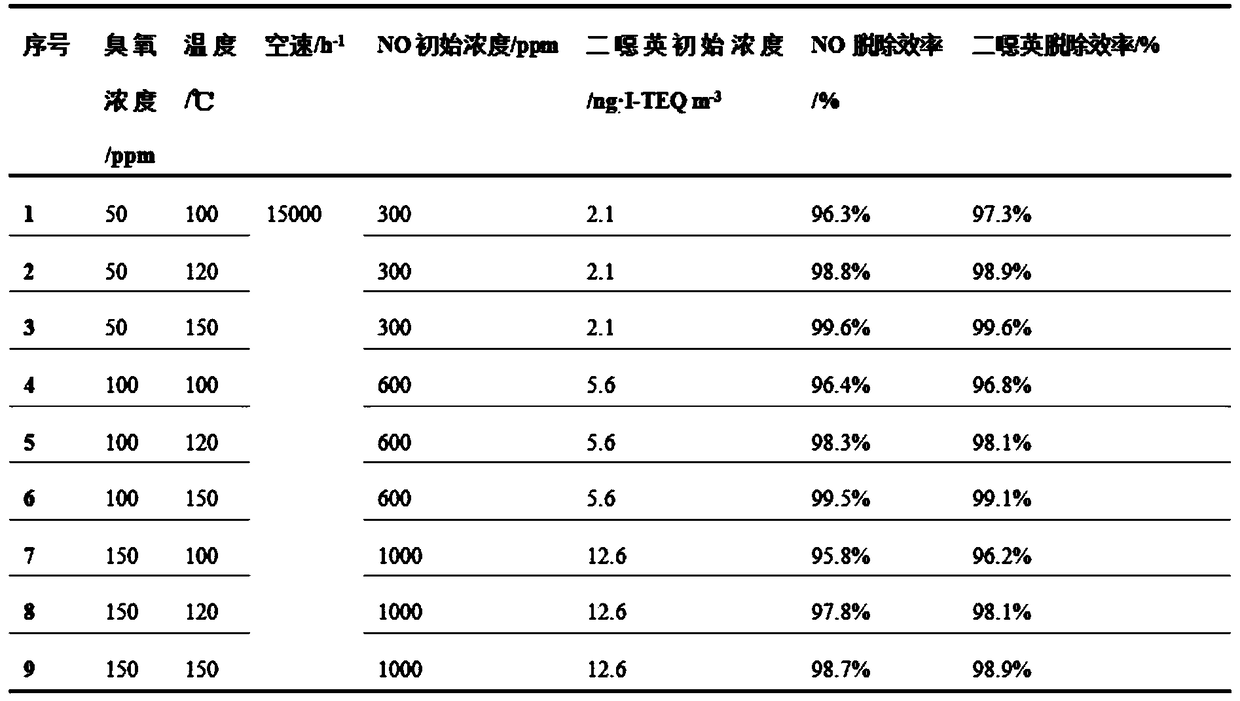

Catalyst used for removing dioxins and NO<x> in flue gas, and preparation method and applications thereof

ActiveCN108786788ASolving the problem of compound air pollutionStrong ozone decomposing abilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasActive component

The invention provides a catalyst used for removing dioxins and NO<x> in flue gas. TiO2 is taken as a carrier, an active component is dispersed on the surface of the carrier; the active component is composed of MnO<x> and CeO2. The invention also provides a preparation method of the catalyst used for removing dioxins and NO<x> in flue gas, and a method used for removing dioxins and NO<x> in flue gas with the catalyst. According to the method, flue gas is subjected to dust removing using a dust removing device, is conveyed into a device containing the catalyst through a pipeline, ozone is sprayed into the device through another pipeline provided with a plurality of small spray holes, flue gas, ozone, and the catalyst are mixed fully in the device, and after removing of dioxins and NO<x>, the flue gas is discharged. According to the method, ozone and the manganese containing catalyst are combined for cooperative removing of dioxins and NO<x>.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of high-acid-content carbon-based solid acid

InactiveCN102716767AExtend the industrial chainImprove efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsUltrasound - actionSolid acid

The invention relates to a preparation method of high-acid-content carbon-based solid acid, which comprises the steps of: firstly oxidizing coal tar pitch by using hydrogen peroxide under the effect of ultrasonic waves, using chloroacetic acid as chlorinating agent, introducing chlorine atoms in benzene ring structures of aromatic compounds through reaction and sulphonating the aromatic compounds to introduce more sulfonic acid groups, so as to increase carbon-based surface acid content, improve acid strength and enhance acid catalytic capability. Since the solid acid is prepared by introducing high-content sulfonic acid groups at more active sites which are provided by the chlorine atoms and can be substituted by the sulfonic acid groups and by fully using the characteristic that the major components, i.e. large ring aromatic compounds in the coal tar pitch are sulphonated, the esterification rate of ethanol and acetic acid esterification reaction can reach 87 percent, the esterification rate is not decreased after the solid acid is repetitively used for five times, the acid content of the solid acid is two times of the acid content of solid acid reported by open literature, and the solid acid has the characteristics of high acid content, acid and alkali resistance and high thermal stability.

Owner:TAIYUAN UNIV OF TECH

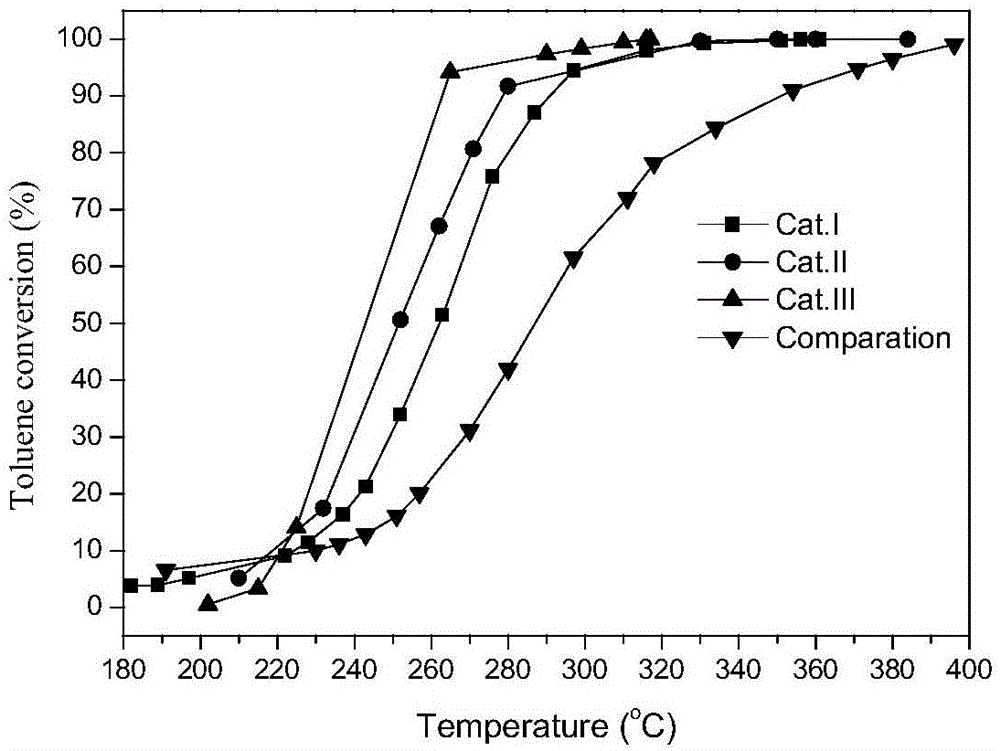

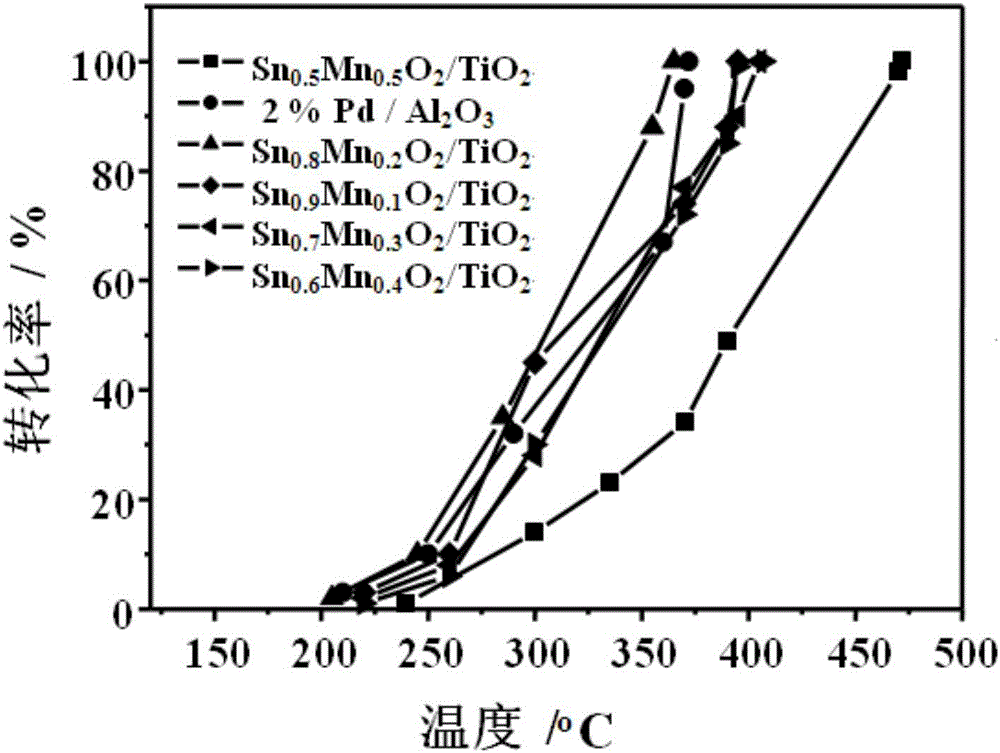

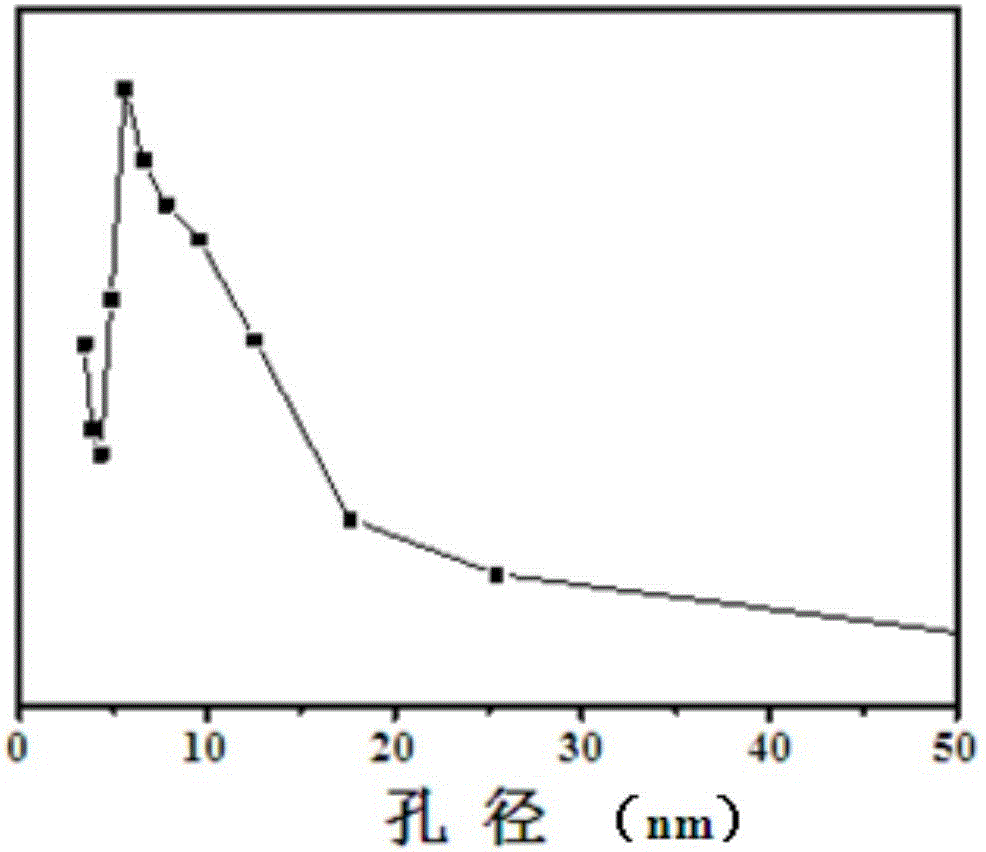

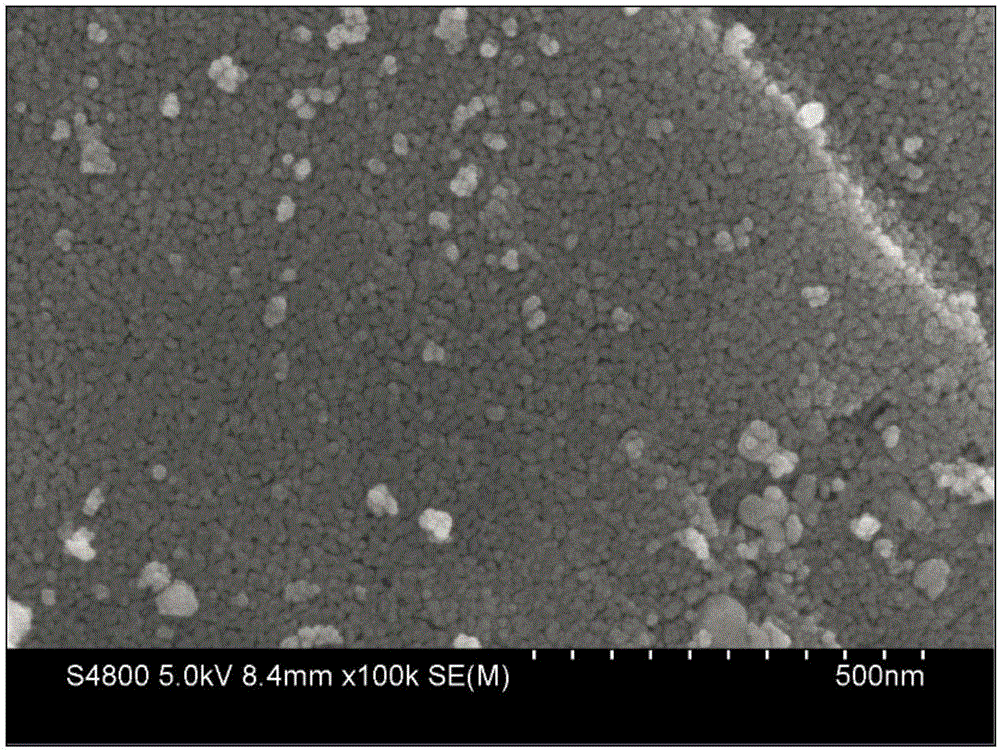

Composite non-precious metal oxide catalyst for catalytic combustion of toluene and preparation method and use thereof

ActiveCN106732539AElimination of tolueneLow costHeterogenous catalyst chemical elementsIncinerator apparatusExhaust gasToluene

The invention provides a composite non-precious metal oxide catalyst for catalytic combustion of toluene. The catalyst comprises TiO2 as a carrier and a composite non-precious metal oxide as an active component supported by TiO2. The composite non-precious metal oxide has a structural formula of Sn1-xMnxO2 and x is greater than or equal to 0.05 and less than or equal to 0.5. The catalyst comprises 10-30% by mass of the composite non-precious metal oxide. The invention also provides a preparation method of the composite non-precious metal oxide catalyst and a method for catalytic combustion of toluene through the composite non-precious metal oxide catalyst. The composite non-precious metal oxide catalyst can quickly and efficiently eliminate toluene in industrial exhaust gas.

Owner:XIAN ORIGIN CHEM TECH

Arsenic poisoning resistance and wide active temperature window integrated low-SO2-oxidation-ratio SCR (selective catalytic reduction) denitration catalyst and preparation method thereof

PendingCN108031466AImprove performanceSolve the strength problemGas treatmentHeterogenous catalyst chemical elementsActive componentArsenic poisoning

The invention discloses an arsenic poisoning resistance and wide active temperature window integrated low-SO2-oxidation-ratio SCR (selective catalytic reduction) denitration catalyst and a preparationmethod thereof. The catalyst is characterized by comprising, by weight, 0.5%-5% of V2O5, 0.5%-5% of WO3, 0.5%-15% of MoO3, 2%-20% of SiO2 and the balance TiO2, wherein V2O5, WO3, MoO3, TiO2 and SiO2are key components, and oxides with main components of TiO2 and SiO2 form a composite carrier of the catalyst. By adoption of a special modifying agent and a preparation method, the composite carrierenhances mutual action between active components and the carrier, a large specific surface area is provided, uniform dispersion level of the active component is improved, and a significant effect on catalyst performance improvement is achieved. Under the joint action of multiple factors, the catalyst has advantages of wide active temperature window, arsenic poisoning resistance and low SO2 oxidation ratio.

Owner:ZHEJIANG ZHENENG CATALYST TECH CO LTD +1

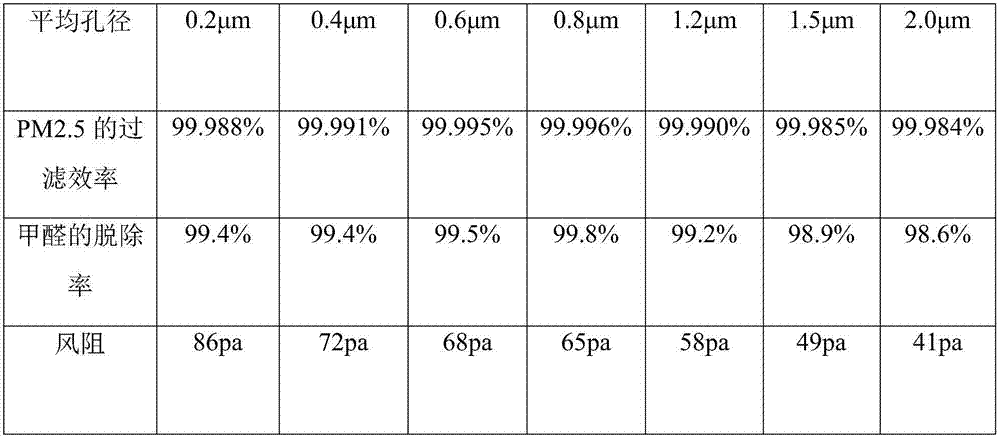

Novel composite filter net for air purifier and preparation method thereof

ActiveCN107308733AIncrease loadExtended service lifeGas treatmentDispersed particle filtrationAmmonium sulfideTungstate

The invention provides a novel composite filter net for an air purifier and a preparation method thereof. The novel composite filter net comprises a matrix layer, a transition layer and an active layer, the matrix layer is a stainless steel wire net after going through etching treatment, the transition layer is loaded on the surface of the matrix layer and is chosen from an aluminum oxide coating and a silicon dioxide coating or a composite coating of the two, and the active layer is arranged on the outermost layer of the composite filter net, loaded on the surface of the transition layer and composed of titanium dioxide, ammonium sulfide and bismuth tungstate. By the novel composite filter net, the problem that existing composite filter nets for the air purifier are high in filtering resistance and short in service life is solved, catalytic activity can be improved, and production cost is further lowered.

Owner:丁海军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com