Patents

Literature

52results about How to "Improve water and sulfur resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

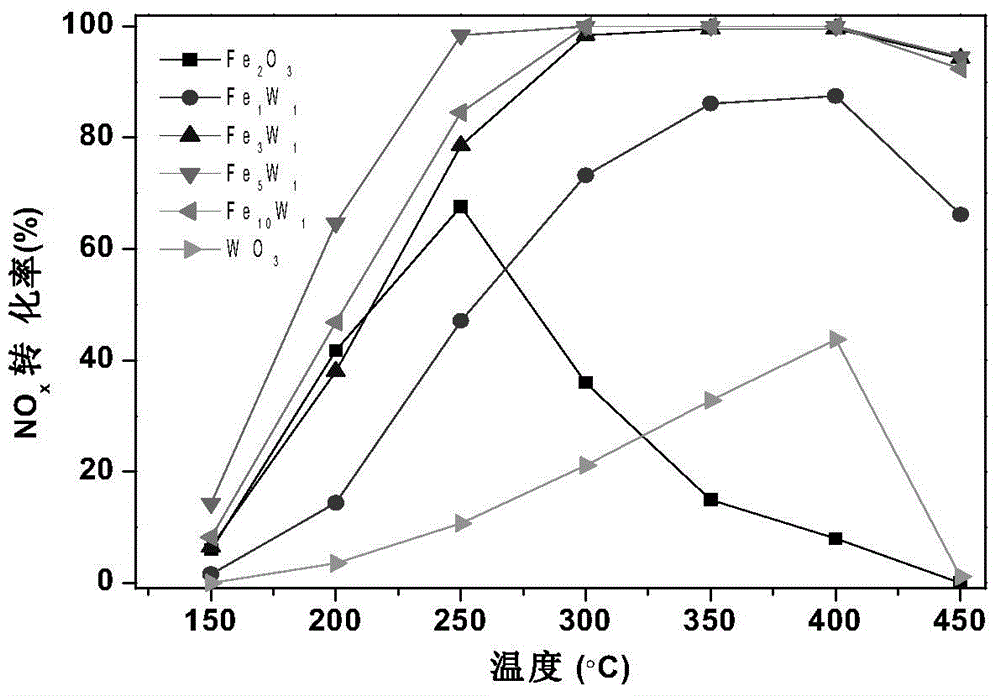

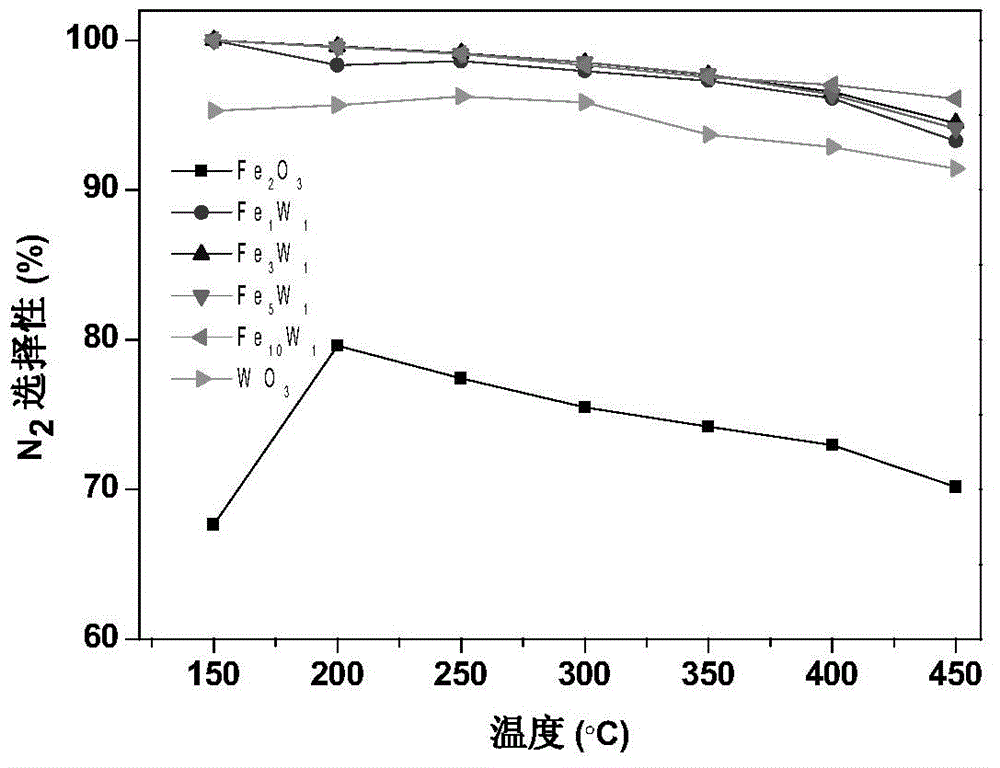

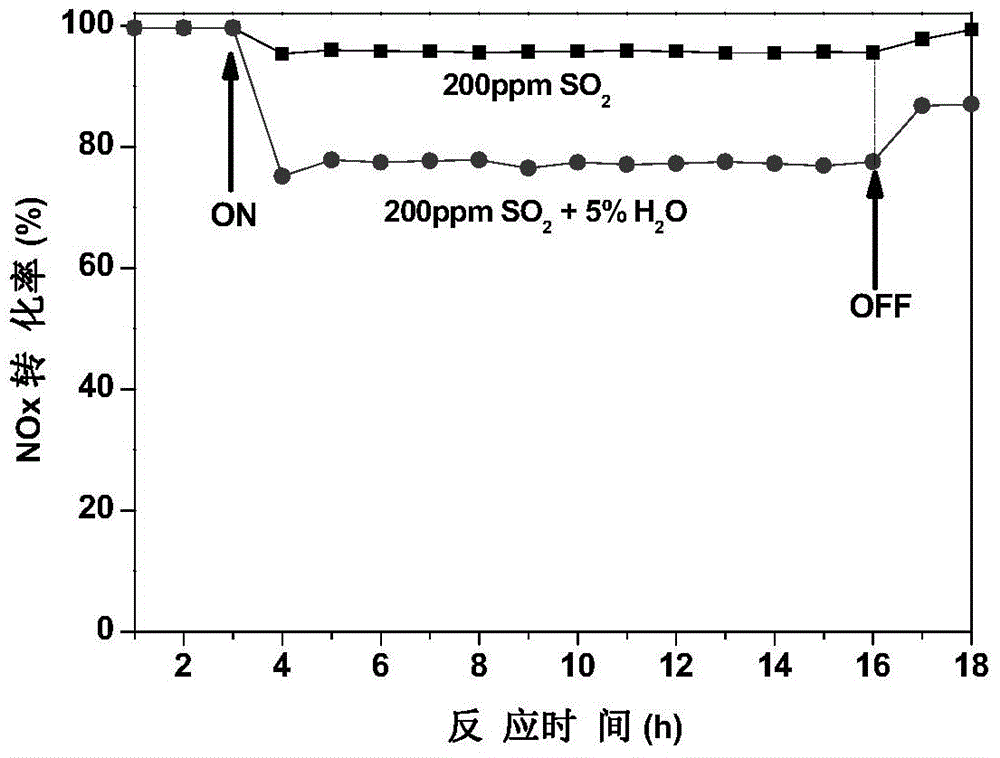

Novel iron-tungsten composite oxide denitration catalyst and preparation and application thereof

ActiveCN104941655AHigh catalytic activityImprove water and sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationHigh activity

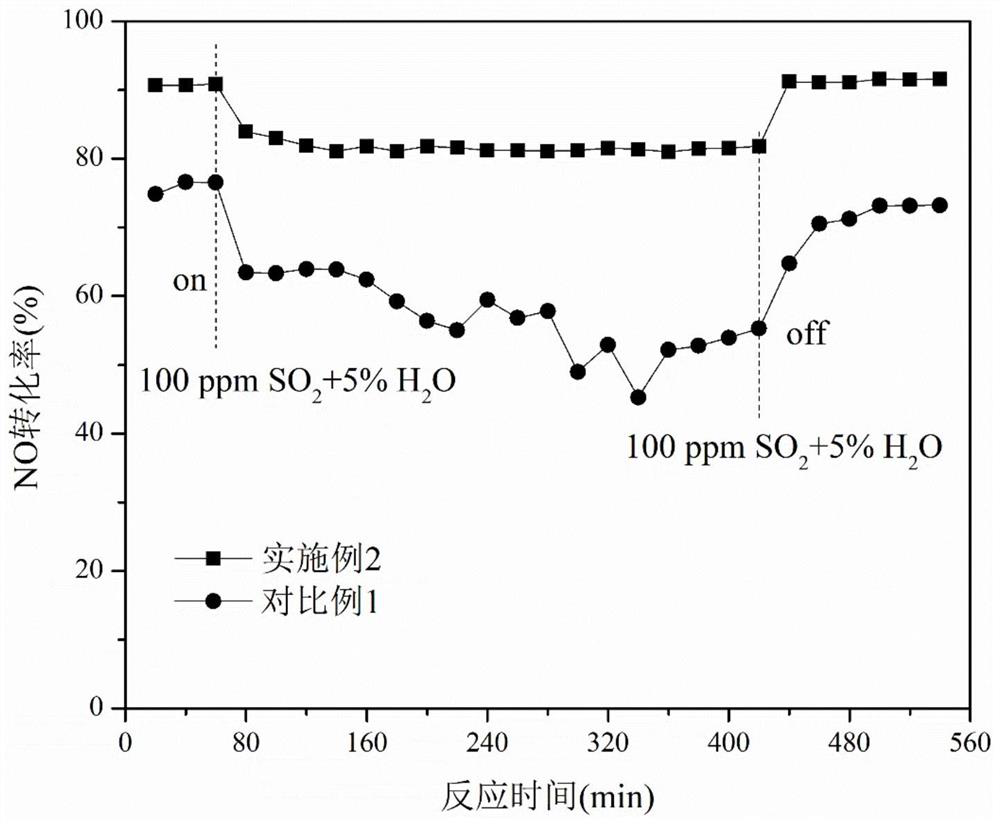

The invention discloses a novel iron-tungsten composite oxide denitration catalyst and its preparation and application and belongs to the technical field of environmental science and technology. The preparation comprises the following steps: respectively dissolving ferric salt and tungsten salt in deionized water, uniformly mixing, adding the mixture into an ammonia solution, stirring, carrying out suction filtration, drying and roasting. The preparation has the following advantages: oxides of iron and tungsten are uniformly mixed by a coprecipitation method; synergism of the two components guarantees the catalyst has high NOx conversion rate and wide temperature window; selectivity of N2 is higher than 90% in the overall temperature window; and the catalyst still has a very high activity in the presence of 200ppm SO2 and 5% H2O. The catalyst provided by the invention has a good catalytic activity and excellent water resistance and sulfur tolerance, and can be applied in efficient purification of NOx in a stationary source flue gas and diesel exhaust.

Owner:TSINGHUA UNIV

Composite carrier type SCR denitration catalyst capable of simultaneously removing nitrate and mercury, and preparation method thereof

InactiveCN105597732ALarge specific surface areaGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention discloses a composite carrier type SCR denitration catalyst capable of simultaneously removing nitrate and mercury, and a preparation method thereof. The catalyst comprises, by mass, 0.2 to 1.2% of V2O5 and 1.0 to 10% of WO3, with the balance being a TiO2-Ce2 composite oxide carrier. The nanometer TiO2-Ce2 composite oxide carrier has a higher specific surface area, enables active components to be better dispersed and has good water resistance and sulfur resistance; through interaction between the active components and the carrier, activity of the catalyst is further improved, and the catalyst has strong HgO oxidation activity in absence of HCl or under the condition of low HCl; and the catalyst simultaneously completes catalytic reduction of NOx and catalytic oxidation of HgO without additional installation of flue gas purifying facilities of a coal-fired power plant, thereby realizeing simultaneous controlling of NOx and HgO.

Owner:HUNAN UNIV

Preparation method of NH3-SCR flue gas desulfurization catalyst and catalyst thereof

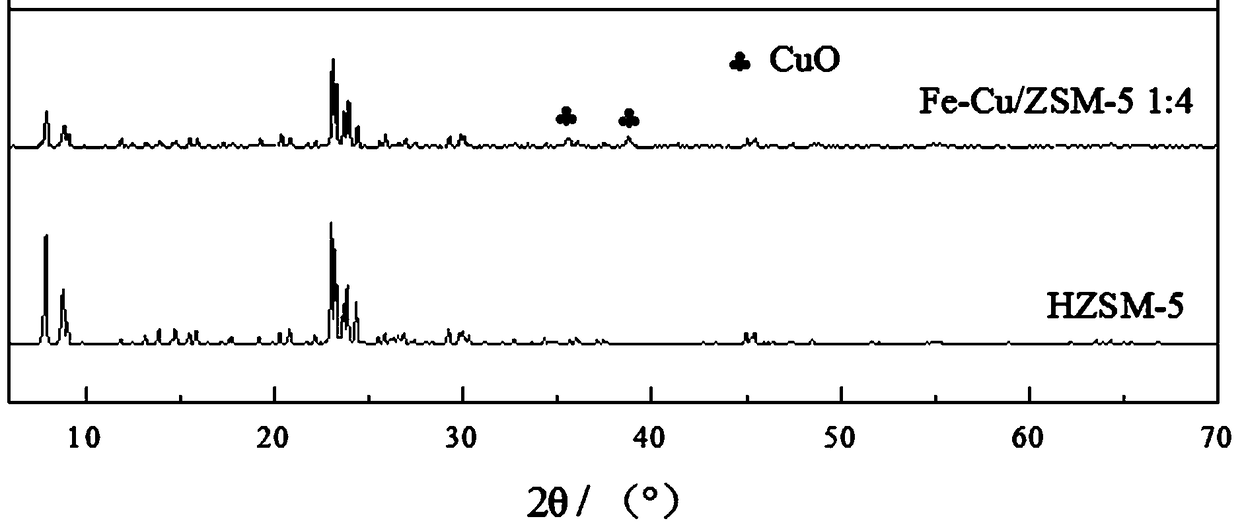

InactiveCN108816274AImprove water and sulfur resistanceLarge specific surface areaGas treatmentMolecular sieve catalystsNitrateCopper nitrate

The invention relates to the technical field of the flue gas desulfurization catalyst, and specifically relates to a preparation method of an NH3-SCR flue gas desulfurization catalyst and the catalystthereof. The preparation method of the catalyst comprises the following steps: dispersing ZSM-5 zeolite carrier into a composite solution of ferric nitrate and copper nitrate, wherein the mole ratioof Fe atoms to Cu atoms in the composite solution is 1:4, the mass of the Fe element is 10% of the mass of the ZSM-5 carrier, and the dispersing method comprises stirring for 4-6h at 50-60 DEG C by adopting a magnetic stirrer, and ultrasonically oscillating for 40min; discarding supernatant after stratification of the dispersion system, drying a precipitate in an electric constant-temperature blast air oven, grinding the precipitate into powder after drying, then roasting in a muffle furnace, and repeatedly grinding into powder after roasting, thereby obtaining the flue gas desulfurization catalyst. The catalyst prepared with the method disclosed by the invention has a relatively wide active temperature window, and has the advantages of being low in price, environmentally-friendly and thelike.

Owner:HENAN UNIV OF SCI & TECH

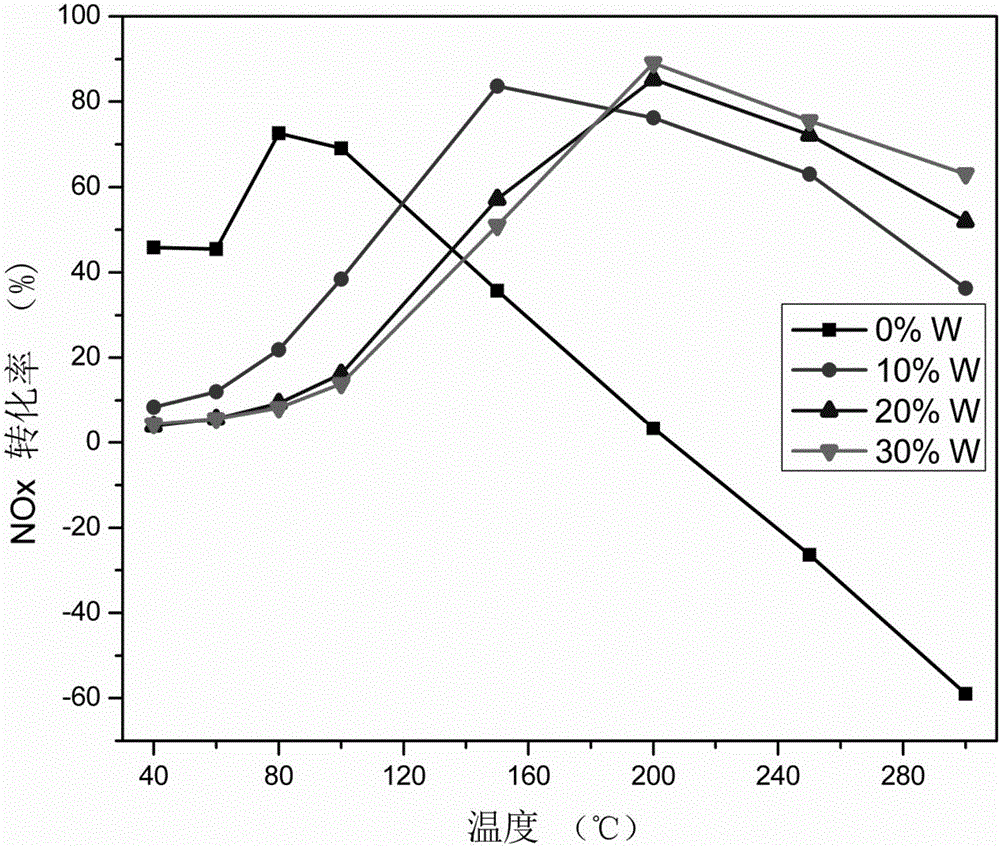

Low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN106492790AIncrease oxygen storageImprove water and sulfur resistanceHeterogenous catalyst chemical elementsDispersed particle separationCerium nitrateTungstate

The invention provides a low-temperature SCR denitration catalyst and a preparation method thereof. The catalyst can be used for a low-temperature nitric oxide selectivity catalytic reduction reaction. The catalyst adopts manganese, cerium, vanadium and tungsten oxides as active components and adopts a coal ash and nanometer titania mixture as a compound carrier. The preparation method of the catalyst comprises the steps that coal ash is subjected to washing, drying and acid-pickling and then mixed with the nanometer titania into a quantity of deionized water, and stirring and drying are performed to obtain the composite carrier. The manganese nitrate, cerium nitrate, ammonium metavanadate and ammonium tungstate are dissolved into deionized water, the prepared composite carrier is added, and stirring, standing, drying, grinding, calcination, roasting and other processes are performed to prepare the finished catalyst. The needed raw materials are cheap and easy to obtain, the cost is obviously lowered, and the denitration performance under the low temperature condition is good.

Owner:HEBEI UNIV OF TECH

Denitration and dioxin removal composite catalyst and preparation method

ActiveCN108837830AImprove denitrification performanceImprove water and sulfur resistanceGas treatmentHeterogenous catalyst chemical elementsSulfurFlue gas

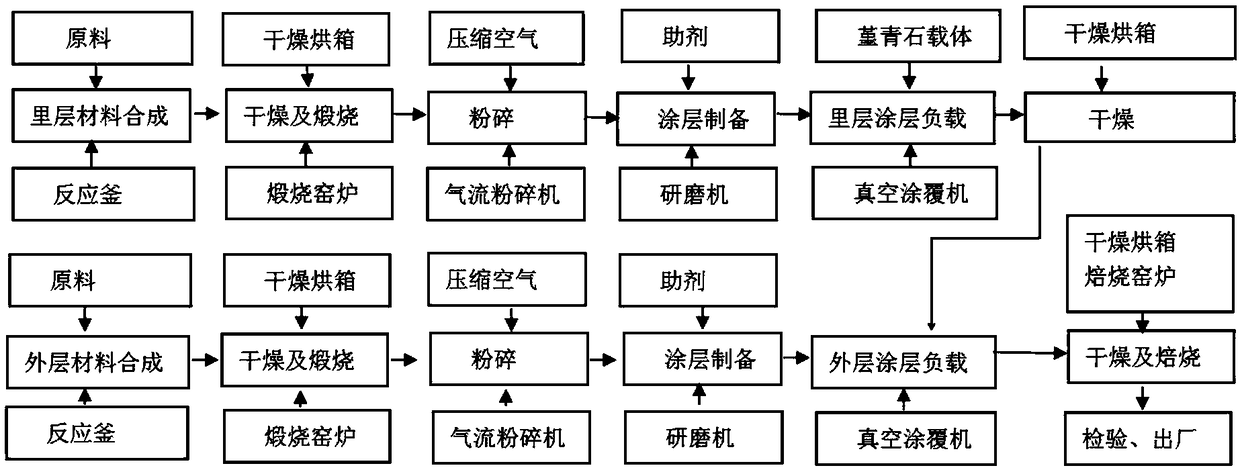

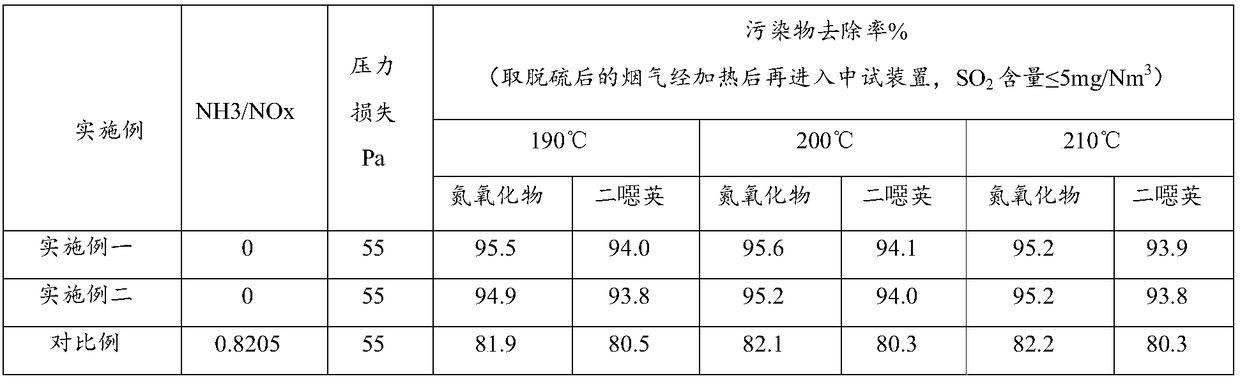

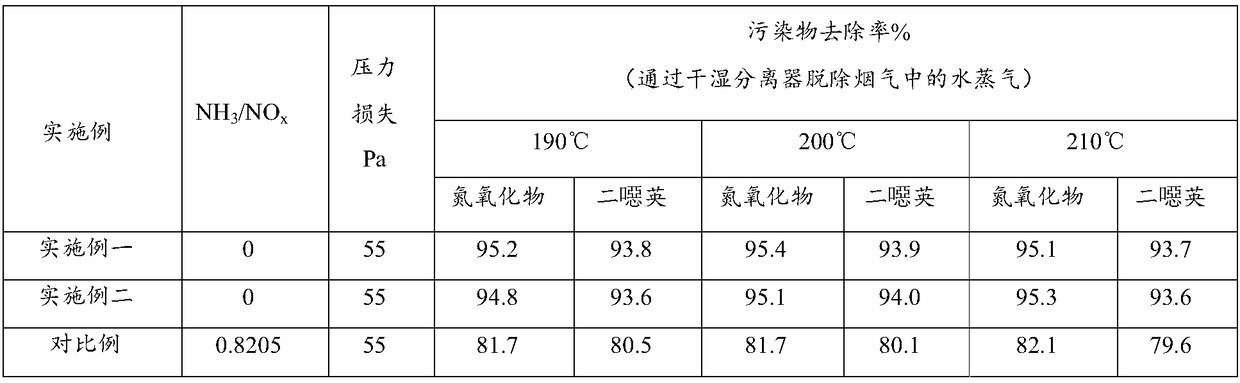

The invention discloses a denitration and dioxin removal composite catalyst applied to flue gas of a steel sintering machine and a preparation method thereof. The flue gas contains CO; the catalyst comprises a carrier, and a dioxin removing inner layer and a denitrating outer layer which are sequentially loaded onto the carrier, wherein the dioxin removing inner layer comprises a first active substance for removing dioxin; the denitrating outer layer comprises a second active substance for removing nitrogen oxide; the CO in the flue gas reacts with the second active substance and can be used as a reducing agent for removing the nitrogen oxide. The denitration and dioxin removal composite rear earth-based catalyst prepared by the preparation method provided by the invention, has greatly improved denitration performance and water and sulfur resistance under a low-temperature working condition of the steel sintering machine; the CO in the flue gas is used as the reducing agent, and NH3 isnot required to be sprayed, so that the operating cost is reduced; efficient selectivity for dioxin removal is achieved.

Owner:江苏浩日朗环保科技有限公司

Method for preparing wide-working-temperature denitration catalyst with metatitanic acid as raw material

ActiveCN106076316AWide operating temperatureImprove denitrification efficiencyHeterogenous catalyst chemical elementsDispersed particle separationWorking temperatureCerium

The invention discloses a method for preparing a wide-working-temperature denitration catalyst with metatitanic acid as the raw material. The method specifically includes the following steps that firstly, metatitanic acid is added into water for pulping, ammonium salt is added into the pulp and dispersed, the pH value is regulated to be 3-6 with ammonium hydroxide, cerium and tungsten precursors are added, the pH value is regulated to be 6-10 by adding ammonium hydroxide, and after filtering, drying and roasting, CeO2-WO3 / TiO2 powder is prepared; b, a vanadium precursor is dissolved in an oxalic acid aqueous solution, the CeO2-WO3 / TiO2 powder is added, stirring is carried out, and after drying and roasting, the V2O5-CeO2-WO3 / TiO2 catalyst is prepared. Compared with an existing industrial V2O5-WO3 / TiO2 catalyst, the denitration catalyst prepared through the method has the advantages of being wide in working temperature, high in denitration efficiency, high in water resistance and SO2 resistance and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sulfur-resistant and water-resistant low-temperature denitration composite molecular sieve catalyst and preparation method thereof

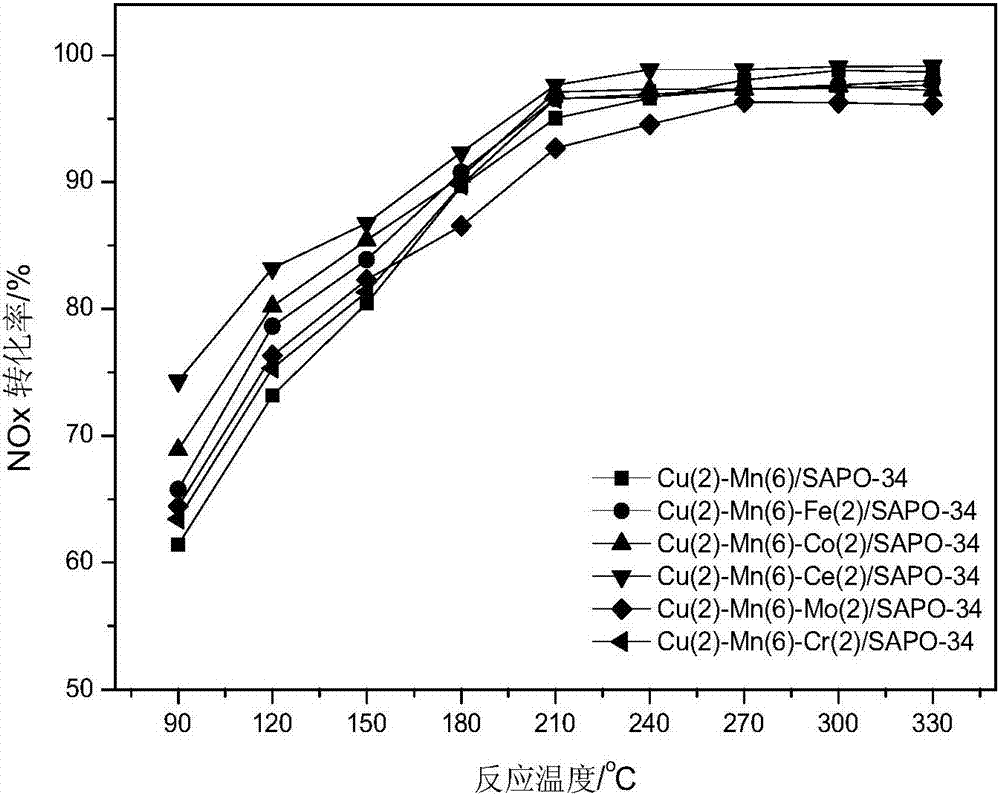

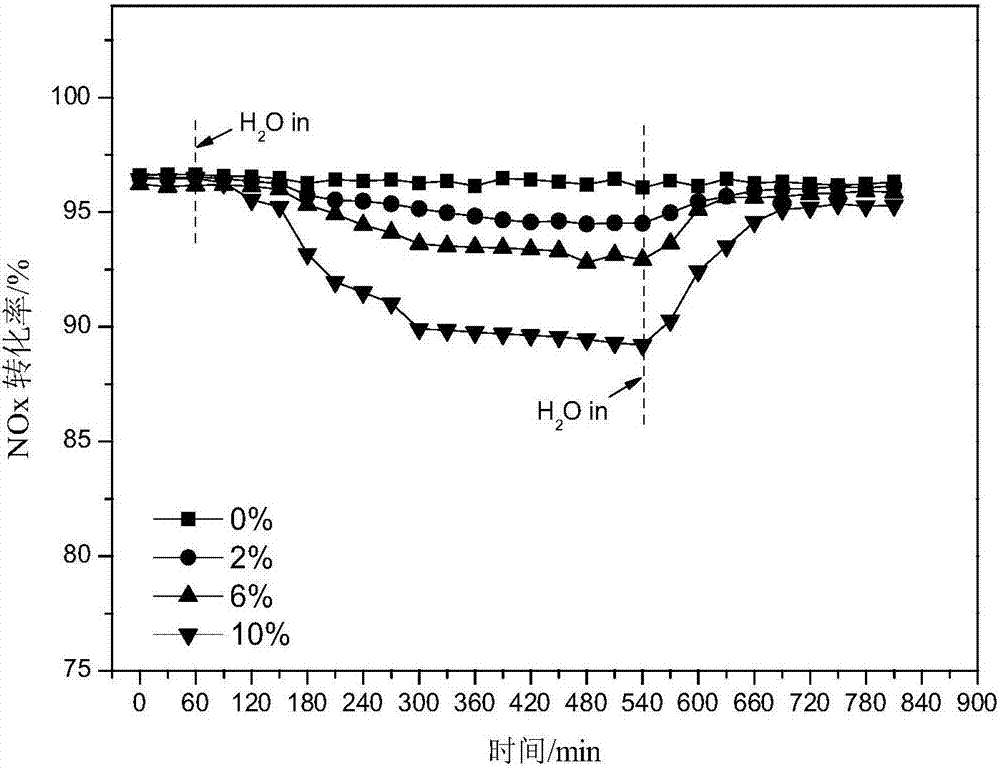

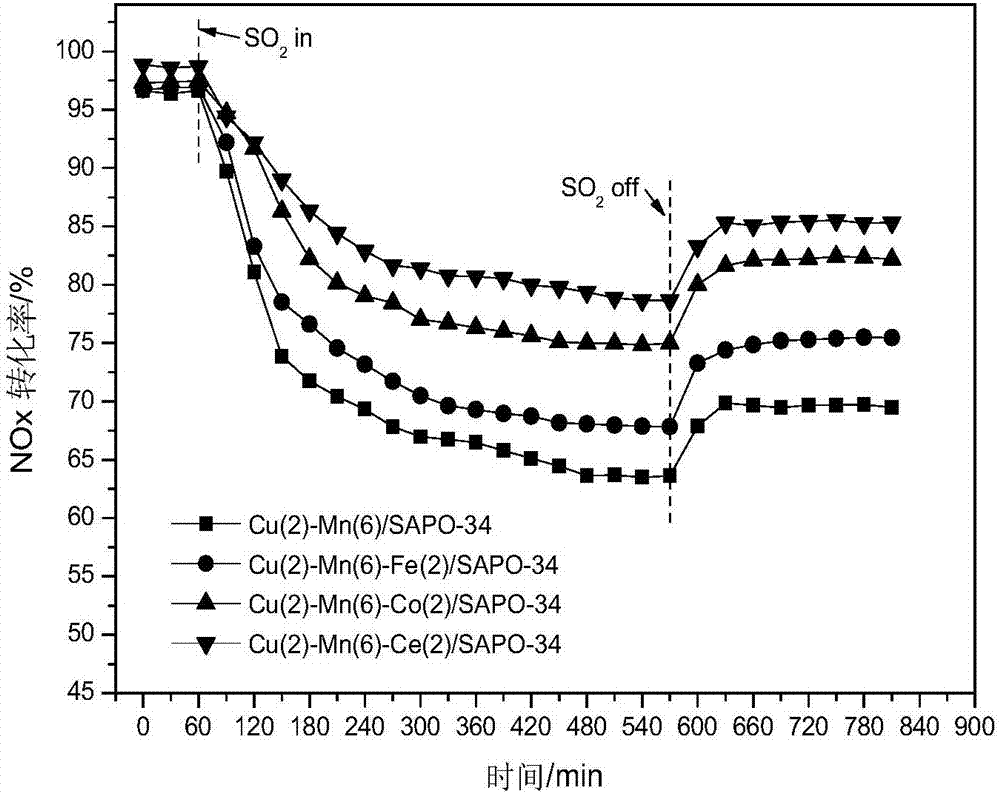

ActiveCN107185588ALow starting temperatureLower the temperature of the denitrification reactionGas treatmentMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a sulfur-resistant and water-resistant low-temperature denitration composite molecular sieve catalyst and a preparation method thereof. The catalyst is prepared by an impregnation method, a chabasite molecular sieve H-SAPO-34 serves as a support, an active component is a composite oxide of transition metal Cu and Mn, an additive is one of Ce, Fe, Co, Mo and Cr, the supported weight of a copper element and a manganese element in the active component is 2%-10% in weight percentage, and the supported weight of additive is 1-10% in weight percentage. Compared with a Cu or Mn-based catalyst of a single component, the denitration composite molecular sieve catalyst remarkably improves denitration efficiency and heat stability by the aid of multi-metal synergistic effect, an active temperature window of the catalyst is effectively widened, and the catalyst has good sulfur resistance.

Owner:SOUTHEAST UNIV

Iron-modified low-temperature denitration SCR catalyst and preparation method thereof

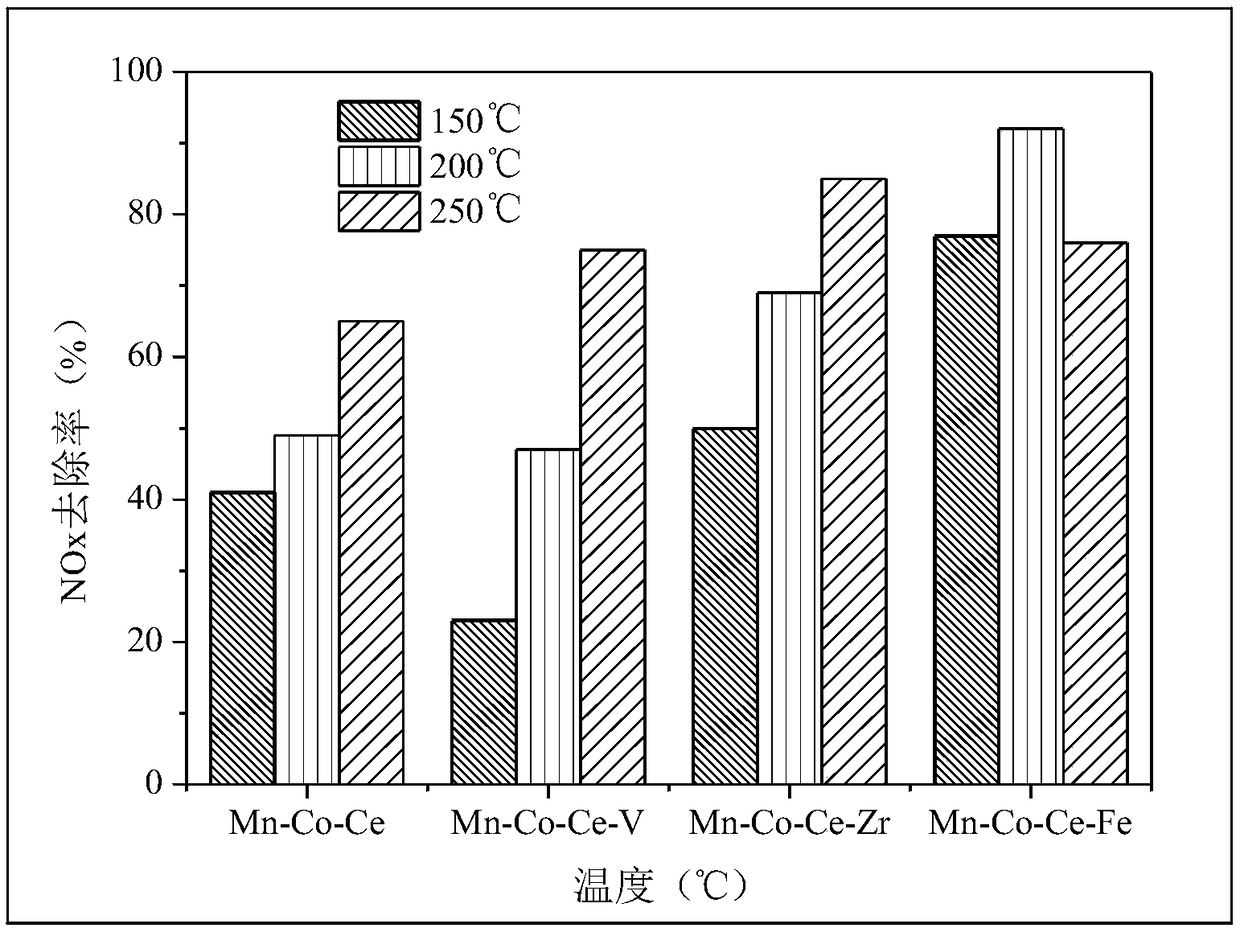

InactiveCN108993528AImprove water and sulfur resistanceLarge specific surface areaHeterogenous catalyst chemical elementsDispersed particle separationEnvironmental resistanceReaction temperature

The invention relates to the field of the environmental protection technology and SCR catalysts, in particular to an iron-modified low-temperature denitration SCR catalyst, a preparation method thereof and the application thereof to flue gas treatment. The iron-modified low-temperature denitration SCR catalyst is a MnCoCeFe oxide catalyst, and is prepared through loading modification and sulfationtreatment by using titanium dioxide and a 100-200 mesh porous silica gel sphere as a composite carrier, wherein the loading modification is achieved by modifying the composite carrier by using manganese salt, iron salt, cerium salt and cobalt salt as metal element precursors; the sulfation treatment is achieved by impregnating the composite carrier obtained after the loading modification with a sulfuric acid solution. By the preparation method, the sulfur resistance and the water resistance of a Mn-based catalyst can be improved, the reaction temperature window can be widened, and the activity and the stability of the catalyst can be improved at the same time. The catalyst can be popularized, and is applicable to various SCR technologies so as to meet the urgent needs for flue gas denitrification catalysts in China.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Low-temperature denitration catalyst and preparation method thereof

InactiveCN106732758AHigh low temperature activityImprove sulfur resistanceMolecular sieve catalystsMolecular sieveHigh concentration

The invention discloses a low-temperature denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: by taking honeycombed ceramic as a substrate, firstly, coating the substrate with an Al2O3 coating in a soaking manner, secondly, coating the substrate with a TiO2-molecular sieve coating in the soaking manner, and finally loading active components of Mn, Cu, Ce and Sn in the soaking manner. According to the low-temperature denitration catalyst disclosed by the invention, based on the honeycombed ceramic substrate, the percentage of the Al2O3 coating is 1-10wt%, the percentage of the TiO2-molecular sieve coating is 1-10wt%, and the mass ratio of TiO2 to a molecular sieve ranges from (10:1) to (1:1); the percentage of the active component Mn is 1-10wt%, the percentage of Cu is 0.5-5wt%, the percentage of Sn is 0.1-1wt%, and the percentage of Ce is 1-10wt%. The preparation method disclosed by the invention is simple in preparation process, and the prepared catalyst contains fume of SO2 and H2O of high concentration, and is good in low-temperature denitration activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

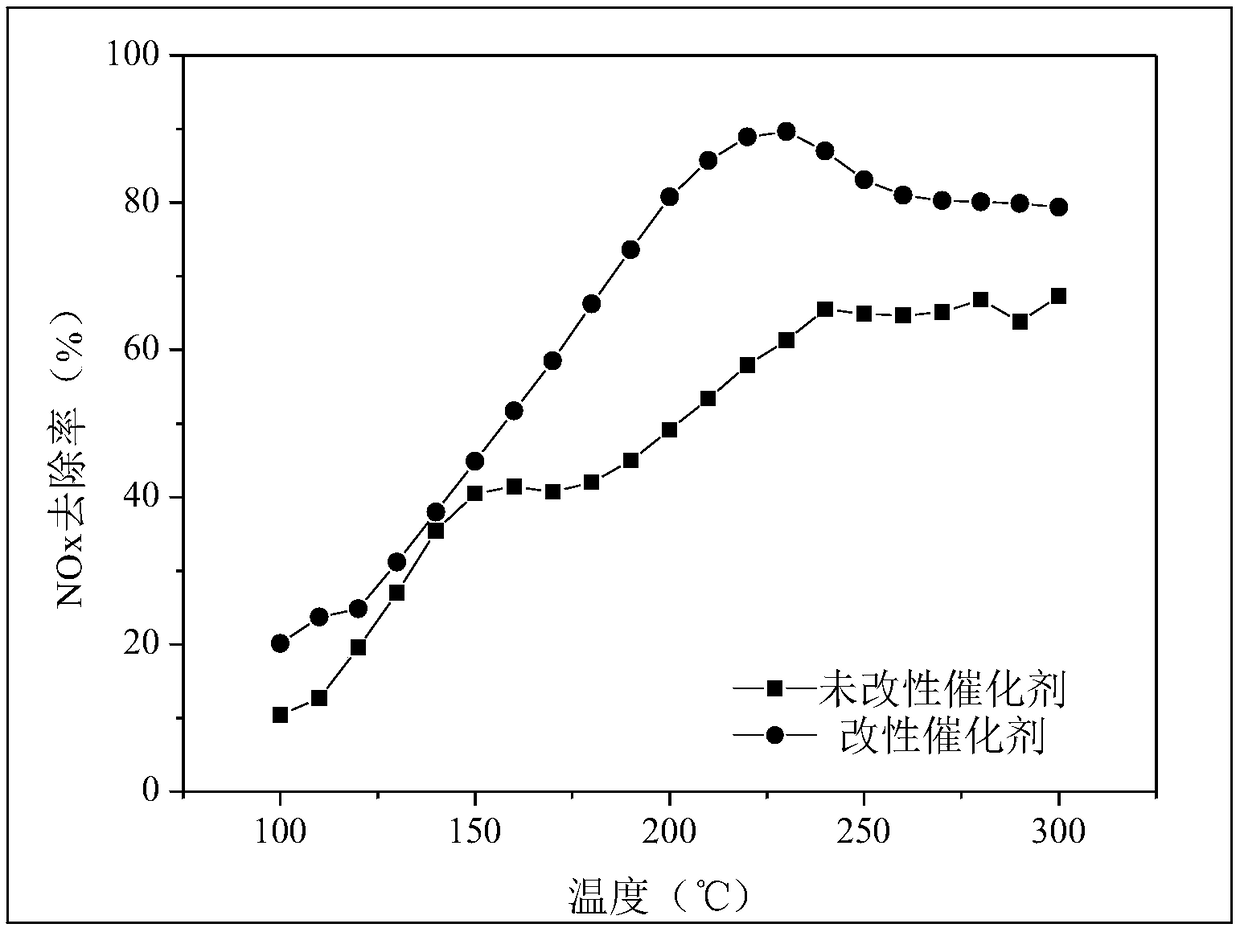

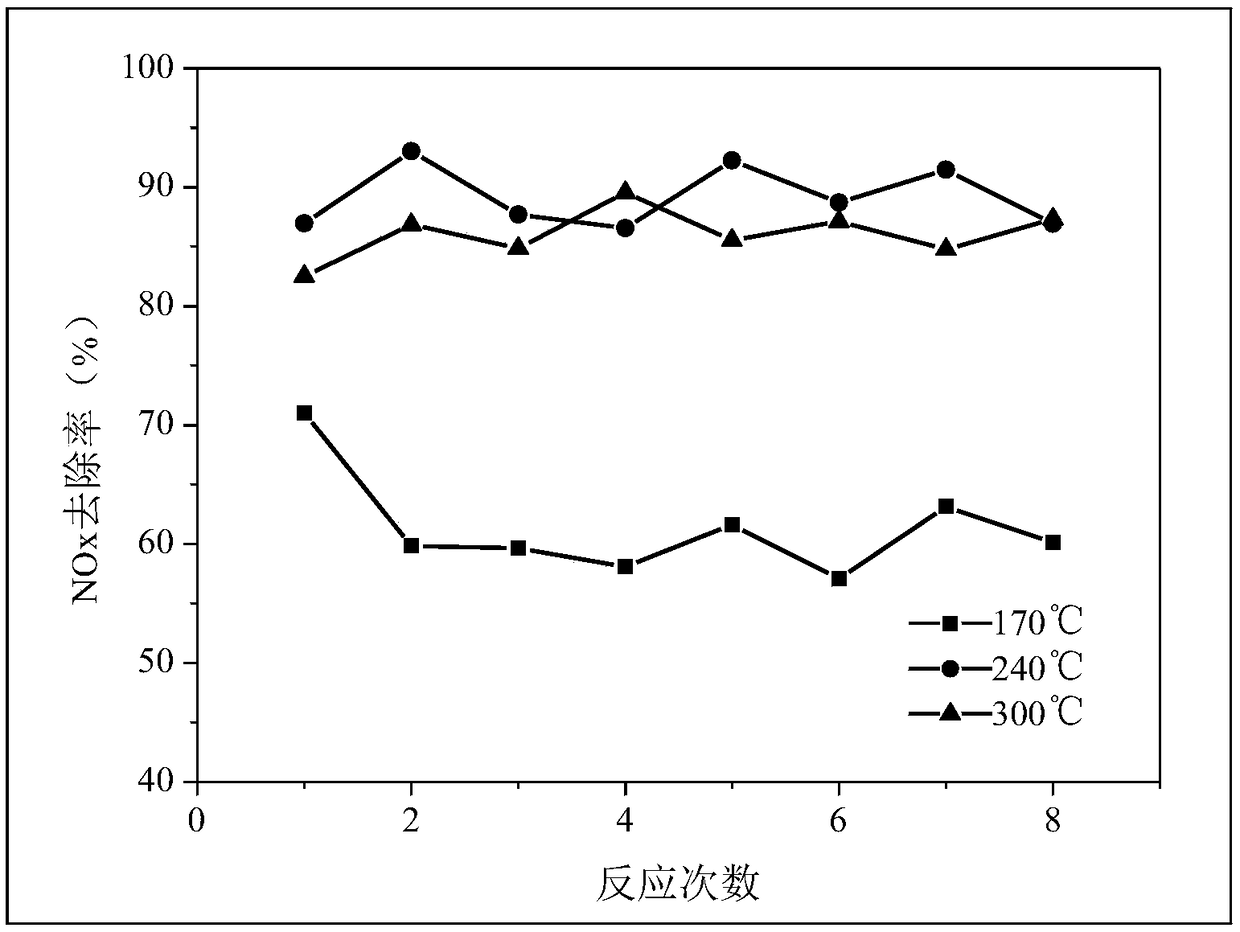

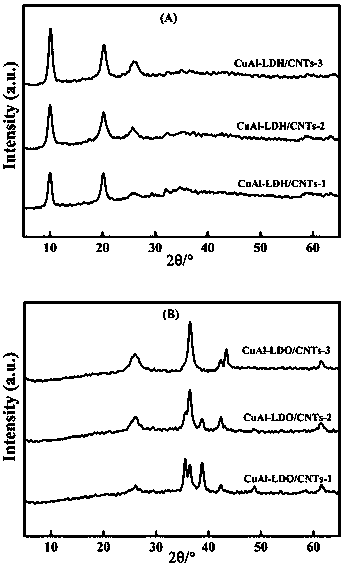

Carbon nanotube doped copper-aluminum compound metal oxide denitration catalyst as well as preparation method and application thereof

ActiveCN108906050AEnhance water and sulfur resistanceSlow down the effect of poisonGas treatmentDispersed particle separationChemistryCarbon nanotube

The invention discloses a carbon nanotube doped copper-aluminum compound metal oxide denitration catalyst as well as a preparation method and application thereof and belongs to the technical field ofpollution control. The carbon nanotube doped copper-aluminum compound metal oxide denitration catalyst (CuAl-LDO / CNTs) is prepared by dropwise adding an aluminum nitrate and copper nitrate mixed solution and an NaOH alkaline solution into a dispersion solution mixed with modified carbon nanotubes, controlling the synthesis pH value within the range of 4.50-5.50, and carrying out hydrothermal crystallization, suction filtration washing and drying to prepare a carbon nanotube doped CuAl hydrotalcite precursor (CuAl-LDH / CNTs); and then, roasting the carbon nanotube doped CuAl hydrotalcite precursor at a nitrogen atmosphere. Denitration activity test and sulfur resistance evaluation prove that the catalyst CuAl-LDO / CNTs has high NH3-SCR activity and N2 selectivity as well as strong water and sulfur resistance in a low-temperature region (180-300 DEG C).

Owner:TAIYUAN UNIV OF TECH

High-efficiency denitration catalyst and preparation process thereof

InactiveCN106311212AReduce secondary pollutionEvenly dispersedGas treatmentHeterogenous catalyst chemical elementsAfter treatmentSulfur

The invention discloses a high-efficiency denitration catalyst and a preparation process thereof. The catalyst is a cerium bismuth aluminum composite oxide, wherein based on the molar ratio of metal elements, the molar ratio of cerium to aluminum is 0.1-1.0, and the molar ratio of bismuth to aluminum is 0.1-1.0. The catalyst is prepared by utilizing a treatment process of integrating a homogeneous co-precipitation method and a hydrothermal method, after-treatment is performed by utilizing the technical means of azeotropic distillation, and solid solution can be formed when the cerium and bismuth oxides are positioned in a highly dispersed state in the metal compound oxide. The high-efficiency denitration catalyst prepared by the invention can achieve excellent denitration activity, reaction stability, water resistance and sulfur tolerance in a temperature range of 200-400 DEG C.

Owner:王欧庭

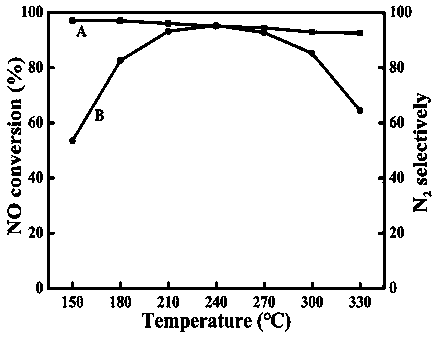

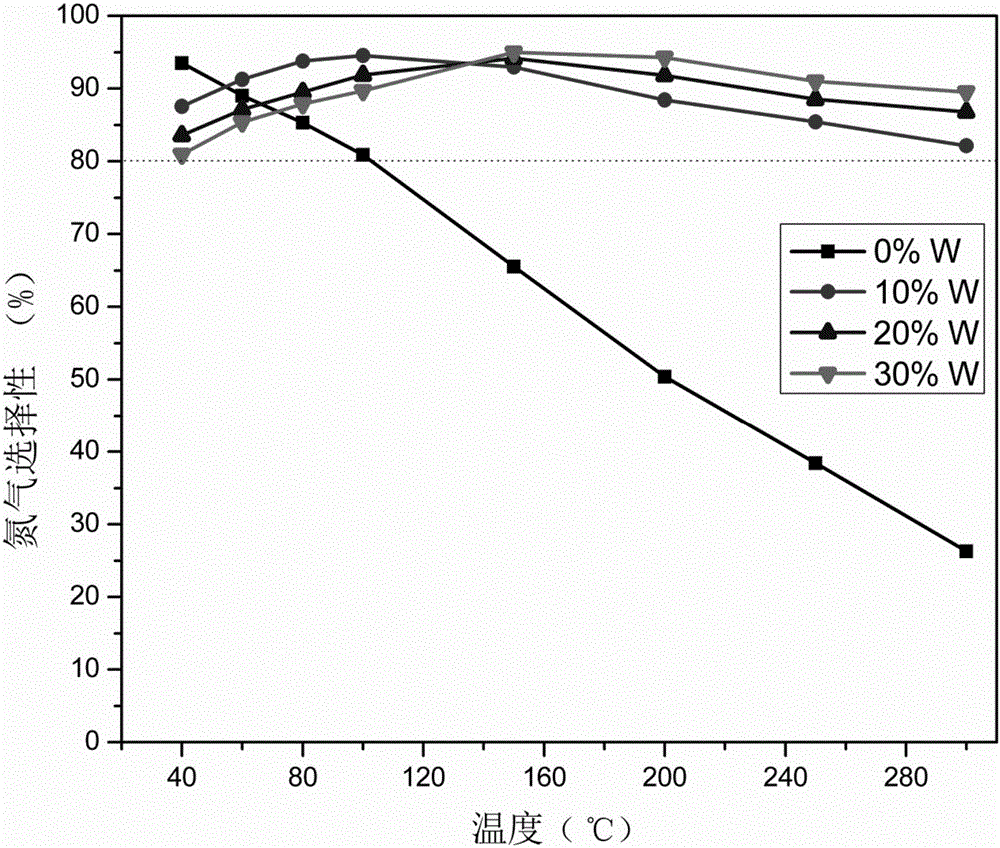

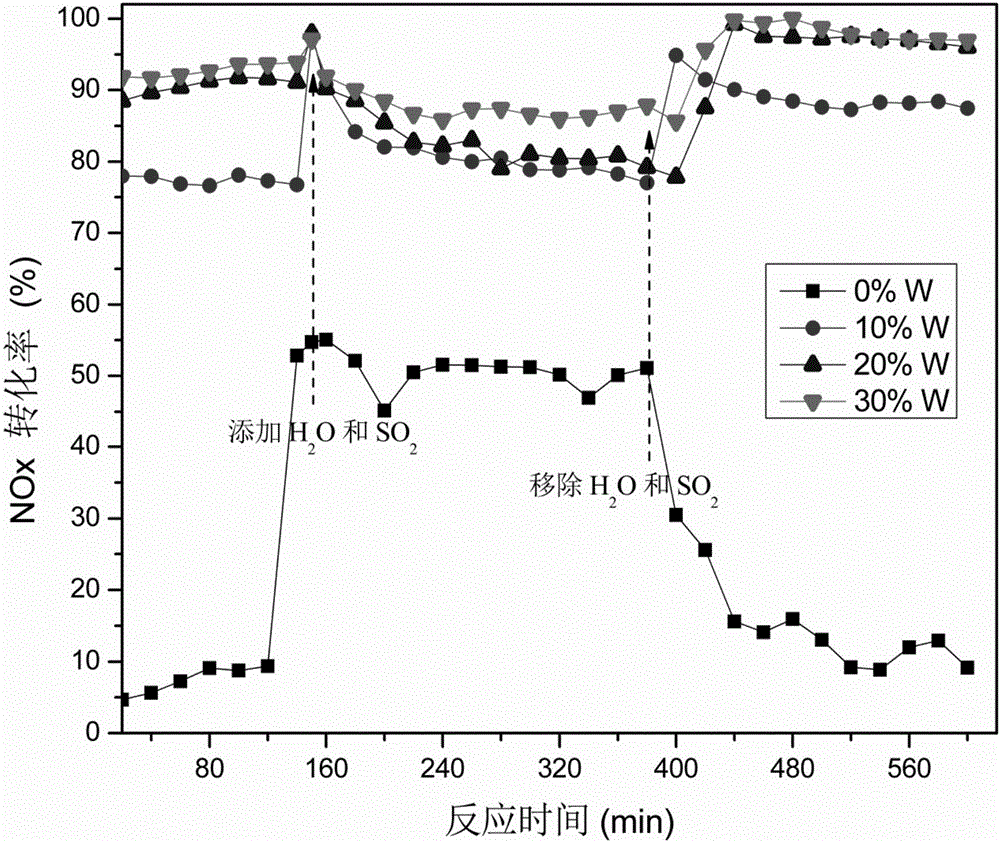

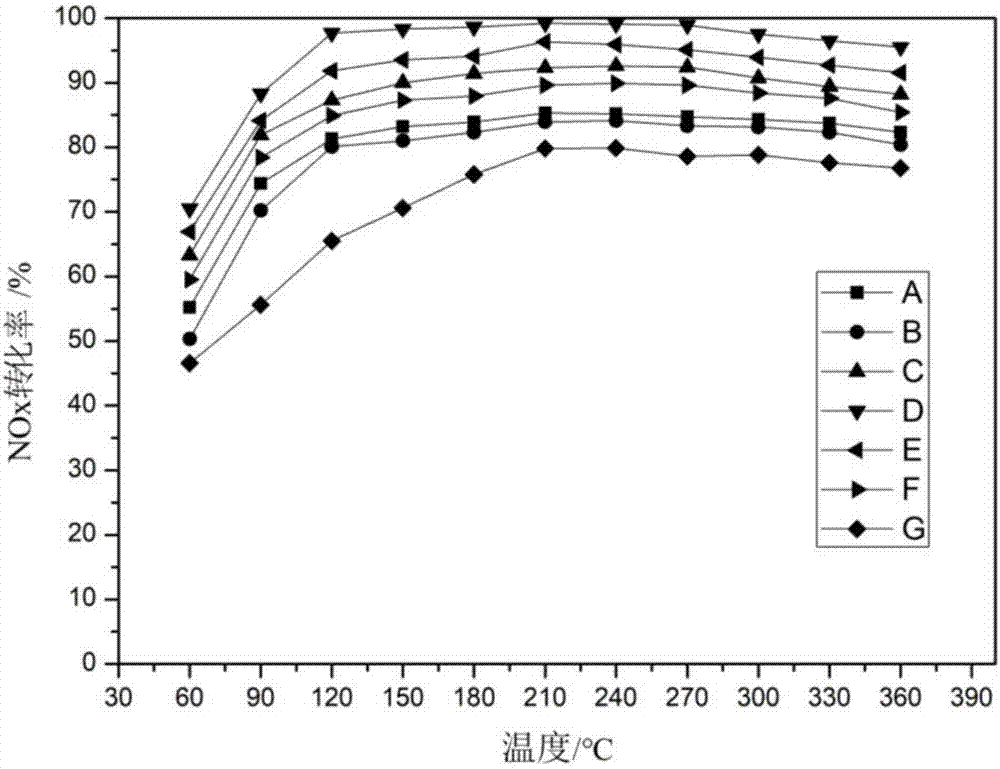

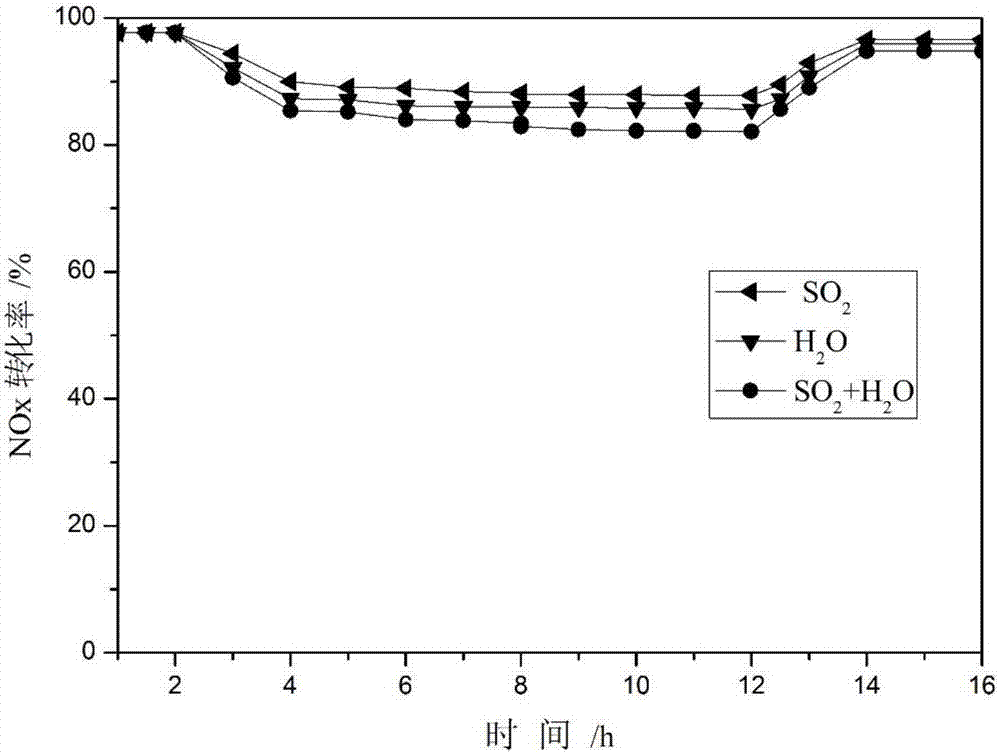

Denitration catalyst containing tungsten-tin-manganese-cerium composite oxide as well as preparation and application of denitration catalyst

ActiveCN105944713AHigh selectivityImprove toleranceGas treatmentHeterogenous catalyst chemical elementsNon toxicityCerium

A denitration catalyst containing a tungsten-tin-manganese-cerium composite oxide contains active components including WO3, MnO2, SnO2 and CeO2; the chemical formula of the catalyst is WxSn0.1Mn0.4Ce0.5Oy, wherein x is equal to the quotient obtained by dividing W by the sum of Sn, Mn and Ce, and x is equal to 0.1, 0.2 or 0.3. The invention also provides a preparation method of the denitration catalyst containing the tungsten-tin-manganese-cerium composite oxide, and the prepared denitration catalyst containing the tungsten-tin-manganese-cerium composite oxide can be used for removing NOx contained in flue gas in a fixed stationary source and motor vehicle exhaust. Compared with the prior art, the denitration catalyst has the advantages of non-toxicity, high activity, high selectivity, high SO2 tolerability and the like; the NOx conversion rate is increased and the nitrogen selectivity of the catalyst is improved through mutual synergistic effect of four elements including W, Sn, Mn and Ce and mutual influence of oxidation-reduction properties of the four elements; the denitration catalyst containing the tungsten-tin-manganese-cerium composite oxide has better activity and selectivity in the test range from 120 DE GC to 300 DEG C and has higher tolerability to SO2 and H2O.

Owner:TSINGHUA UNIV

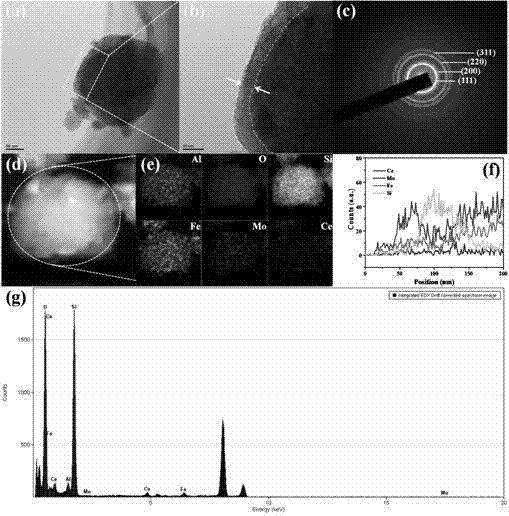

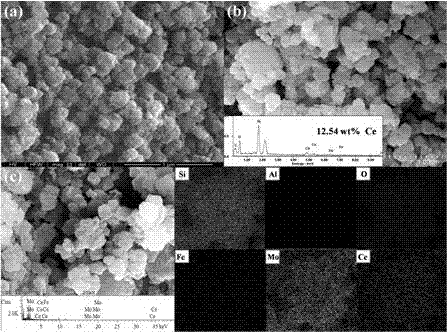

Core-shell catalyst for denitration of FCC regeneration flue gas and preparation method of core-shell catalyst

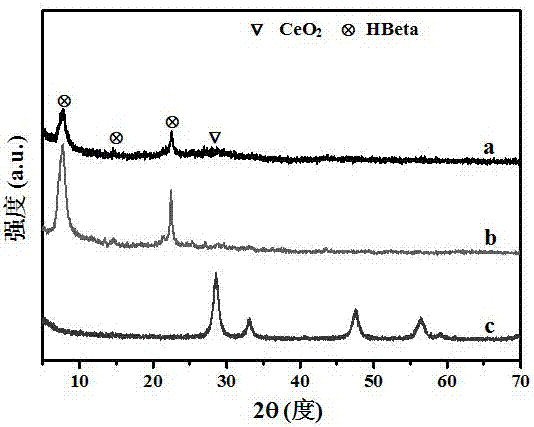

InactiveCN107029782AImprove thermal stabilityHigh catalytic activityMaterial nanotechnologyGas treatmentSynthesis methodsWater resistant

The invention relates to the field of preparation of catalysts and particularly provides a MoFe / Beta@CeO2 core-shell catalyst which is used for FCC regeneration flue gas desulfurization and denitration, has high catalytic activity and is water-resistant and sulphur-resistant. The catalyst is the core-shell catalyst, with MoFe / Beta as a core structure and a CeO2 film as a shell structure. Further, a preparation method of MoFe / Beta comprises steps as follows: firstly, small-grain H-Beta molecular sieves with the average particle size being 100 nm are prepared; the molecular sieves are taken as carriers, active components Mo and Fe are subjected to equivalent-volume impregnation, then subjected to ultrasonic dispersion, aired at the room temperature and baked, and MoFe / Beta is prepared; MoFe / Beta is taken as the carriers and coated with CeO2 films with a self-assembly method, and the MoFe / Beta@CeO2 core-shell catalyst is prepared. The prepared MoFe / Beta@CeO2 core-shell catalyst has higher thermal stability, catalytic activity, low-temperature activity, water resistance and sulfur resistance, and the synthesis method is simple and has better application prospects.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Loaded tourmaline rare earth compound selective denitration catalyst

InactiveCN106975513AImprove protectionReduce manufacturing costGas treatmentMolecular sieve catalystsRare-earth elementCerium

The invention relates to a loaded tourmaline rare earth compound selective denitration catalyst which comprises a carrier, an auxiliary agent and an active ingredient. The carrier is SBA-15, the auxiliary agent is tourmaline and the active ingredient is manganese-cerium-samarium compound oxide; the catalyst comprises the following components based on 100% of total mass of the materials of the catalyst: 36.0-54.0% of the active ingredient, 0.1-1.0% of tourmaline and the balance of an SBA-15 carrier. The waterproof sulfur-resisting property of the catalyst is improved by means of rare earth elements such as cerium and samarium; the activity of the catalyst is improved by means of excellent physical and chemical properties of far infrared radiation and spontaneous polarization of the tourmaline; the dispersibility of the active ingredient of the catalyst is improved by means of the SBA-15 carrier and the contact area of the catalyst and smoke is enlarged, and a catalytic reaction is performed better.

Owner:HEBEI UNIV OF TECH

Environment-friendly iron-antimony composite oxide denitration catalyst and preparation method thereof

ActiveCN106466607AHarm reductionSimple production processGas treatmentDispersed particle separationComposite oxideCoprecipitation

The invention discloses an environment-friendly iron-antimony composite oxide catalyst. A combined treatment process of a homogeneous coprecipitation process and a hydrothermal process is employed during preparation of the catalyst; the technical means of azeotropic distillation is used for post-treatment; and the oxide of iron and the oxide of antimony in the metal composite oxide can form a solid solution, and in terms of the mol ratio of metallic elements, a mol ratio of iron to antimony is 0.5 to 2.0. The catalyst prepared in the invention shows excellent denitration activity, N2 selectivity, reaction stability, water resistance and sulfur tolerance in a range of 200 to 400 DEG C.

Owner:江苏盛勤环境工程有限公司

Iron-copper composite molecular sieve based honeycomb type denitration catalyst and preparation method thereof

InactiveCN107626342AEvenly dispersedImprove water and sulfur resistanceMolecular sieve catalystsDispersed particle separationIon exchangeMolybdenum trioxide

Belonging to the field of air pollution control technology and environment-friendly catalytic material technology, the invention in particular relates to an iron-copper composite molecular sieve basedhoneycomb type denitration catalyst and a preparation method thereof. The iron-copper composite molecular sieve based honeycomb type denitration catalyst utilizes the synergistic effect of an iron copper loaded molecular sieve-titanium dioxide carrier and tungsten trioxide / molybdenum trioxide to improve the denitration activity and water and sulfur poisoning resistance of the honeycomb type denitration catalyst, has relatively low consumption of high cost molecular sieve carrier, and is an environment-friendly denitration catalyst with controllable cost. According to the invention, the molecular sieve iron-copper metal loading and catalyst mixing are completed synchronously, the process is simplified, the production efficiency is improved, and the production cost is lowered. Pseudo-boehmite is added in the mixing process, can balance the acidity produced by ion exchange of the molecular sieve, also can utilize the easy peptization characteristic to improve the mechanical strength of the honeycomb type denitration catalyst finally.

Owner:VALIANT CO LTD

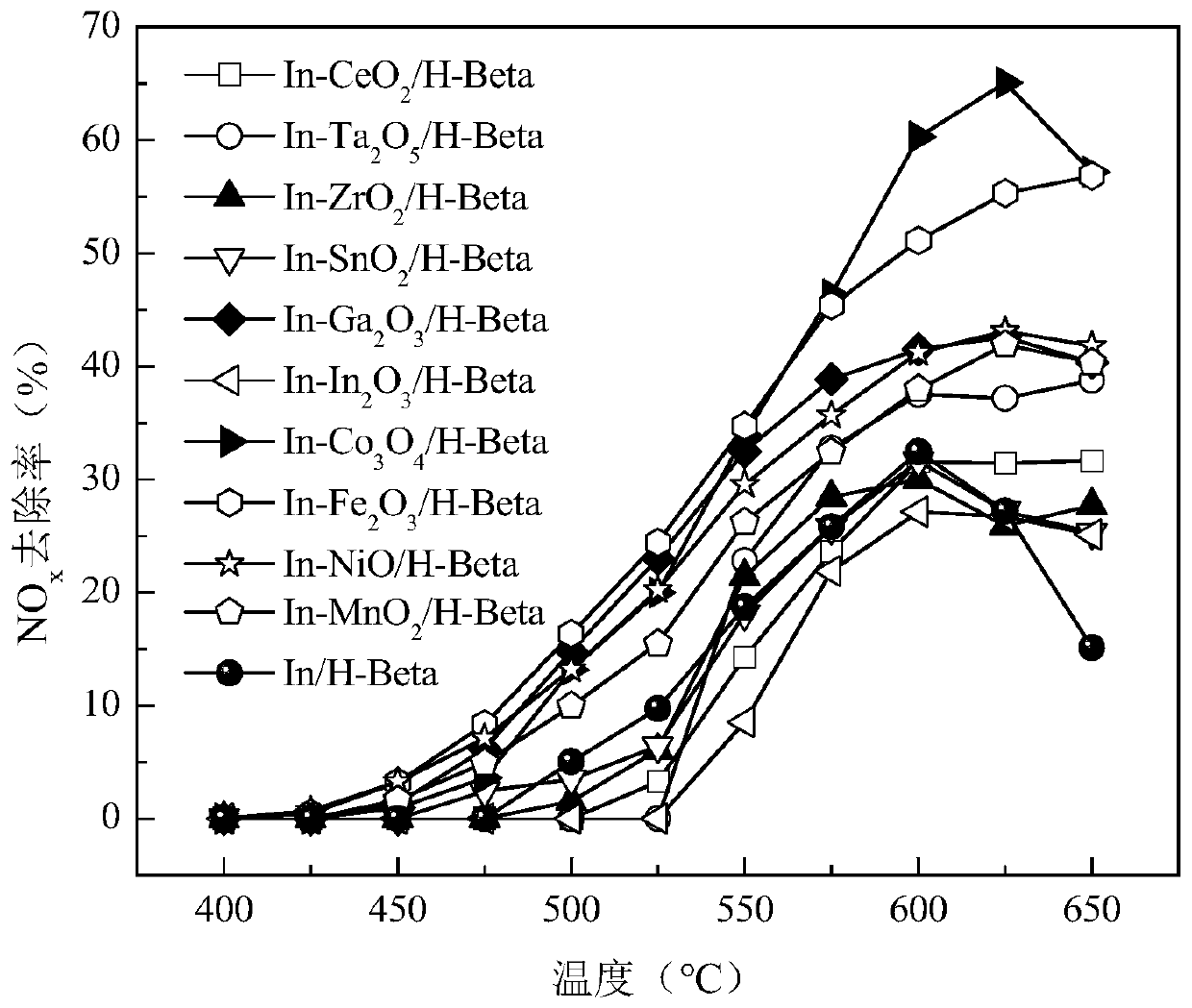

Co-In/Hbeta catalyst and preparation method and application thereof

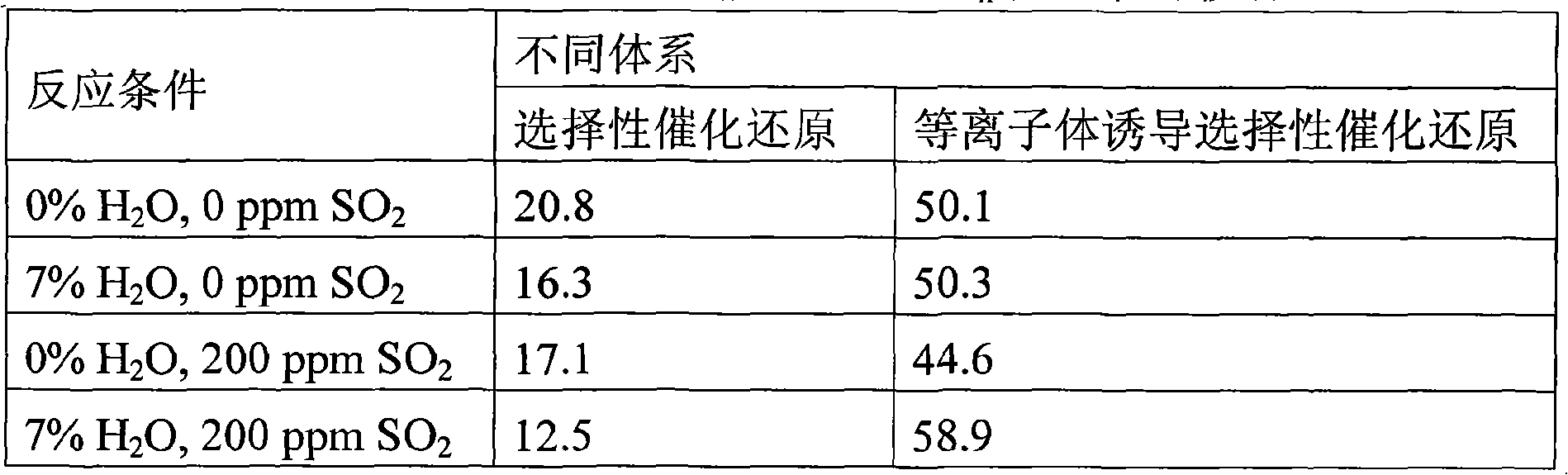

InactiveCN101664693AHigh output pulse powerHigh pulse leading edgeMolecular sieve catalystsDispersed particle separationDielectricIndium

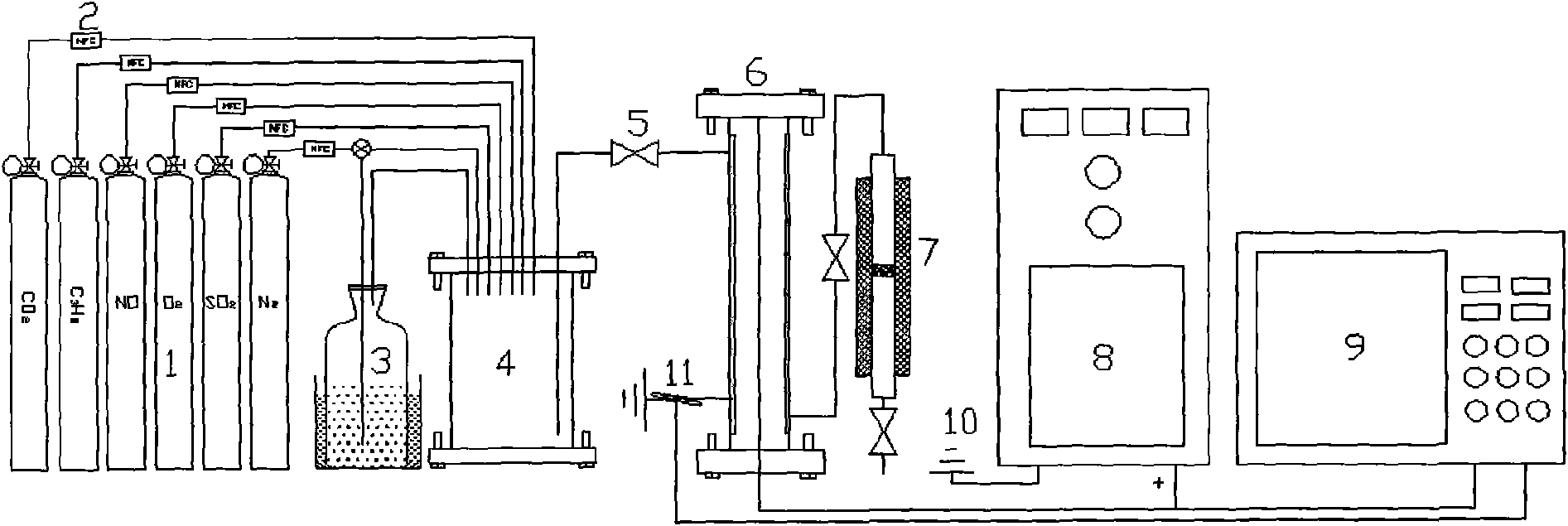

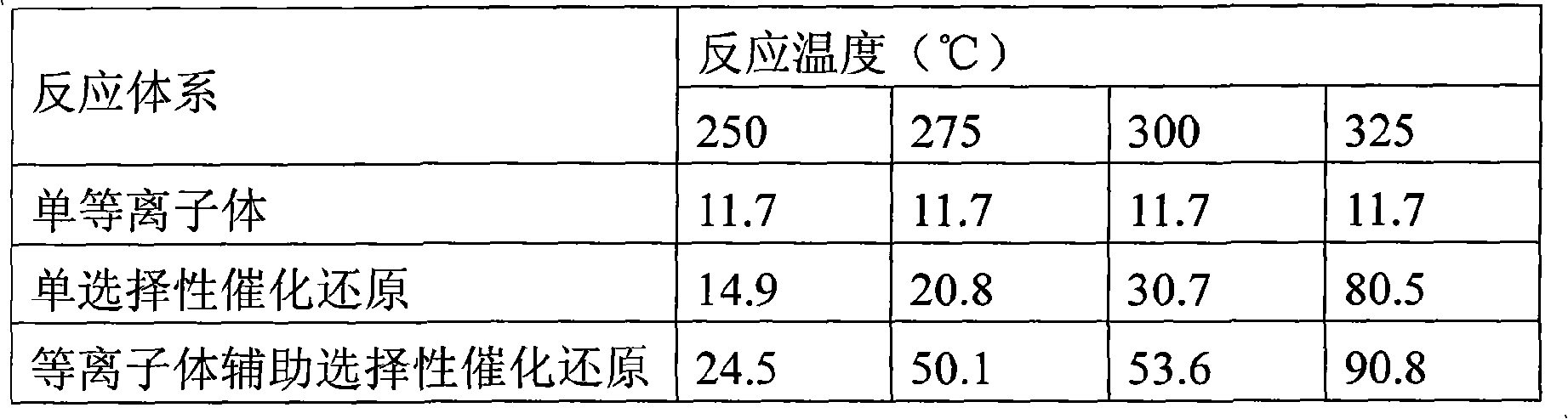

The invention discloses a Co-In / Hbeta catalyst and a preparation method and an application thereof for the synergetic catalysis and purification of nitrogen oxides in coal-fired flue gas. The catalystadopts Co and In as active components to load on H-beta molecular sieve with the silica-alumina ratio of 10-50 and the weight percentages of Co and In loaded on the H-beta molecular sieve are both 1-5%. The invention adopts dielectric barrier plasma to induce light hydrocarbon to perform selective catalyctic reduction of nitrogen oxides so as to increase the removal rate of nitrogen oxides, reduce the activity temperature and increase the water resistance and sulfur resistance of the catalyst.

Owner:ZHEJIANG UNIV

Plate-type sulfur-resistant water-resistant low-temperature SCR denitration catalyst and preparation method thereof

ActiveCN113019358AImprove water and sulfur resistanceHigh porosityDispersed particle separationCatalyst activation/preparationPtru catalystCerium

The invention belongs to the technical field of preparation of SCR denitration catalysts, and particularly relates to a plate-type sulfur-resistant water-resistant low-temperature SCR denitration catalyst and a preparation method thereof. According to the catalyst, anatase type nano titanium dioxide serves as a carrier, vanadium pentoxide is loaded on the surface of the carrier to serve as an active component, molybdenum trioxide or tungsten trioxide serves as a cocatalyst, and modified metal elements such as tin or cerium are added to improve the activity and sulfur and water poisoning resistance of the low-temperature SCR denitration catalyst. The catalyst comprises the components: 75-90% of titanium dioxide, 1.5-8.0% of vanadium pentoxide, 3.0-10.0% of molybdenum trioxide or tungsten trioxide and 0-1.0% of tin oxide or cerium oxide, and is obtained by mixing, dipping, extruding and granulating, coating and forming and roasting by a dipping method. The preparation method has the characteristics that the preparation conditions and process are simple, the raw materials are easy to obtain, industrial production can be realized and the like, the obtained catalyst has relatively high low-temperature denitration activity, the denitration activity can reach 80-99% in a range of 100-420 DEG C, and the catalyst has relatively good water resistance and sulfur resistance.

Owner:SHANXI PULI ENVIRONMENT ENG CO LTD

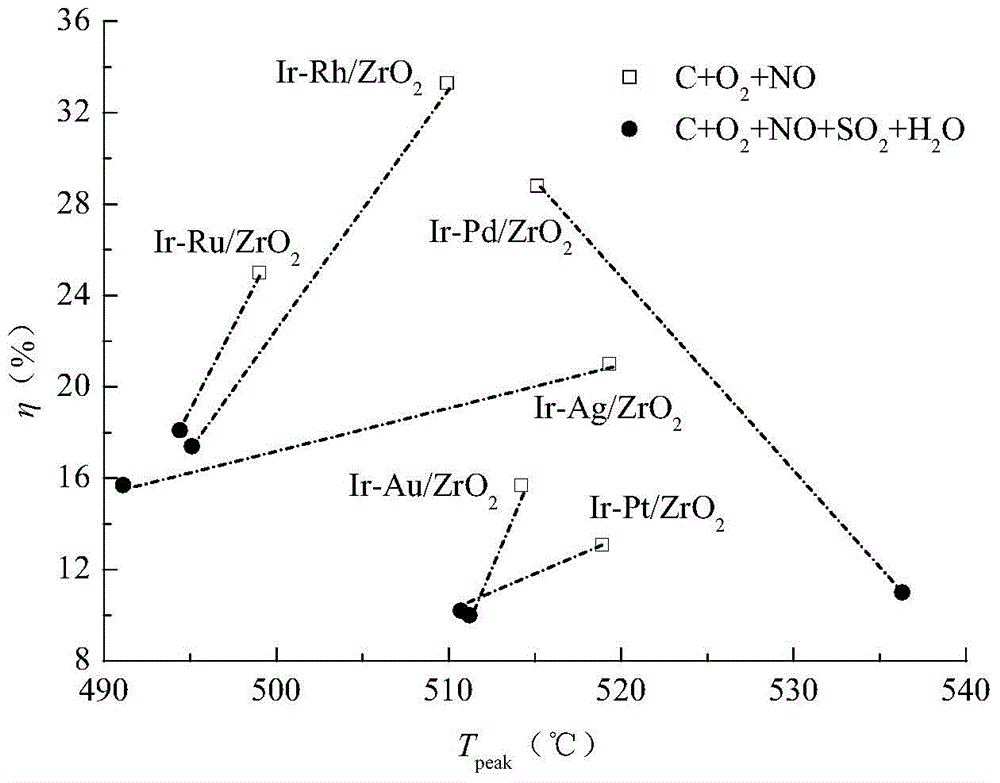

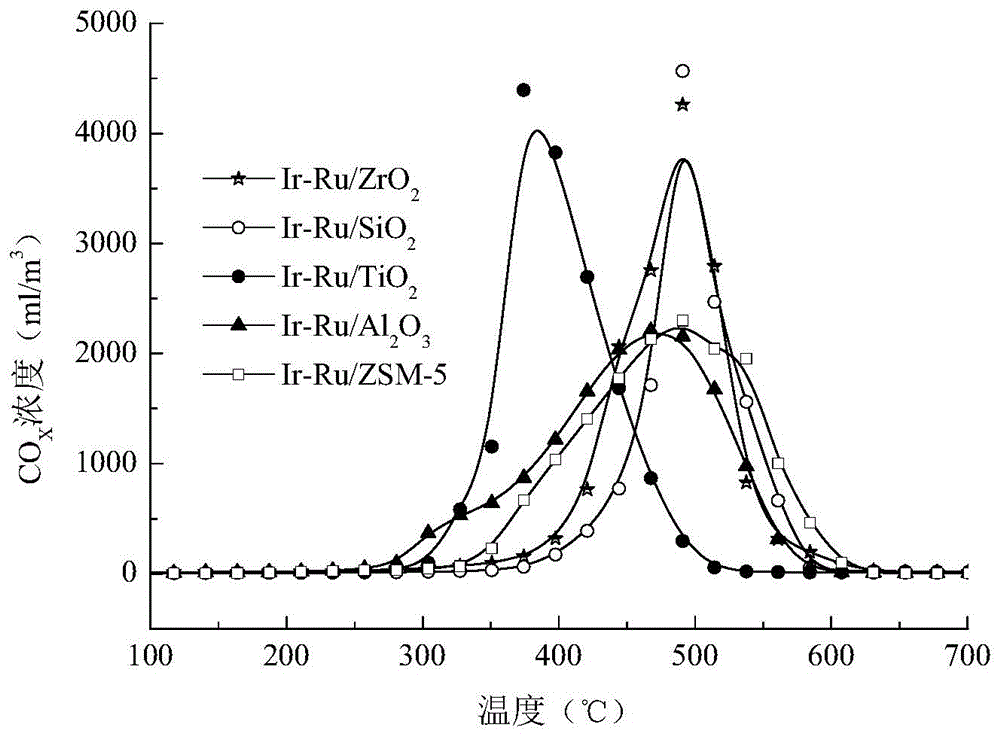

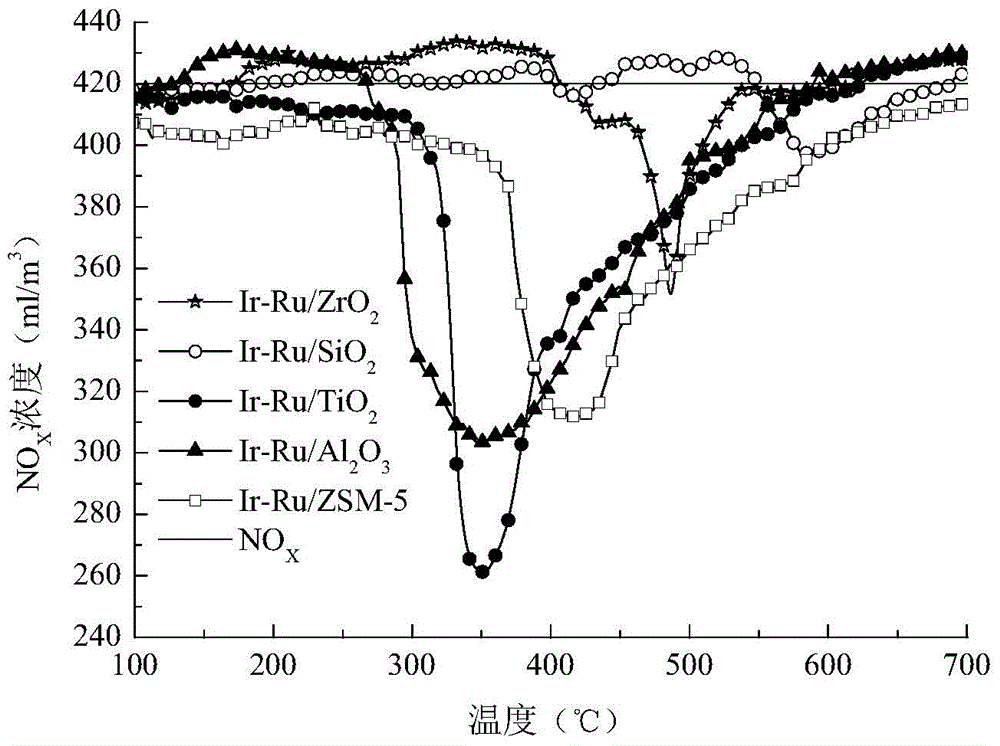

Catalyst for concurrently and efficiently removing soot and NOx under oxygen-enriched, sulfur-containing and water-containing conditions, and preparation method thereof

InactiveCN104368339AGuaranteed removal rateImprove water and sulfur resistanceMolecular sieve catalystsDispersed particle separationSootSulfur containing

The present invention provides a catalyst for concurrently and efficiently removing soot and NOx under oxygen-enriched, sulfur-containing and water-containing conditions, and a preparation method thereof. According to the catalyst, two noble metals are loaded on a certain carrier according to a certain ratio and a certain loading sequence. According to the present invention, with the catalyst, soot and NOx can be concurrently removed under the oxygen-enriched condition, the soot oxidation temperature can be substantially reduced and the high NOx removing rate can be maintained under the oxygen-enriched, sulfur-containing and water-containing condition; and the catalyst has characteristics of high sulfur resistance and high water resistance, and is diesel vehicle tail gas pollutant purification material having the high application value.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Sulfur-resistant and water-resistant manganese low-temperature denitration catalyst and preparation method thereof

InactiveCN111659364AImprove sulfur resistanceSolution areaDispersed particle separationPerfluorocarbons/hydrofluorocarbons capturePtru catalystPhysical chemistry

The invention discloses a sulfur-resistant and water-resistant manganese low-temperature denitration catalyst and a preparation method thereof, and relates to the technical field of catalyst preparation. The catalyst comprises a sulfur-resistant auxiliary agent, an active component and a hydrophobic substance, and a carrier of the catalyst is a titanium dioxide nanotube synthesized by using a waste SCR catalyst as a raw material through a hydrothermal method. A titanium dioxide nanotube precursor is prepared from the waste SCR low-temperature denitration catalyst through a closed hydrothermalreaction, and is used as a raw material for preparing the honeycomb low-temperature denitration catalyst, and the prepared manganese-based low-temperature denitration catalyst with high sulfur resistance, water resistance and low cost has the following advantages: the production cost is greatly reduced, the sulfur resistance and water resistance are enhanced, and the denitration efficiency is obviously higher than that of the low-temperature denitration catalyst applied in the industry at present. The resource saving is easily achieved, the resource reutilization is improved, the problems of low specific surface area and small pore volume of the existing titanium dioxide are solved, and the industrial application and promotion of the manganese-based low-temperature denitration catalyst areachieved.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

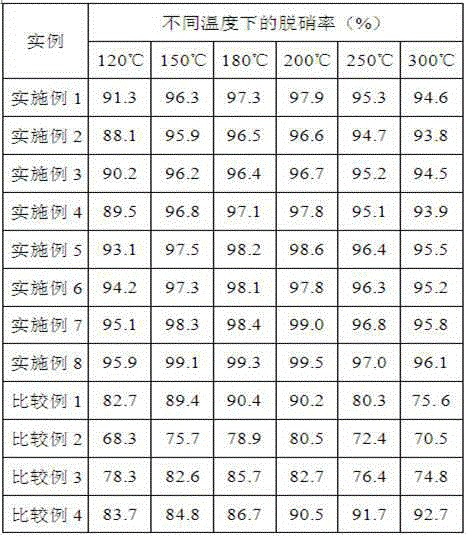

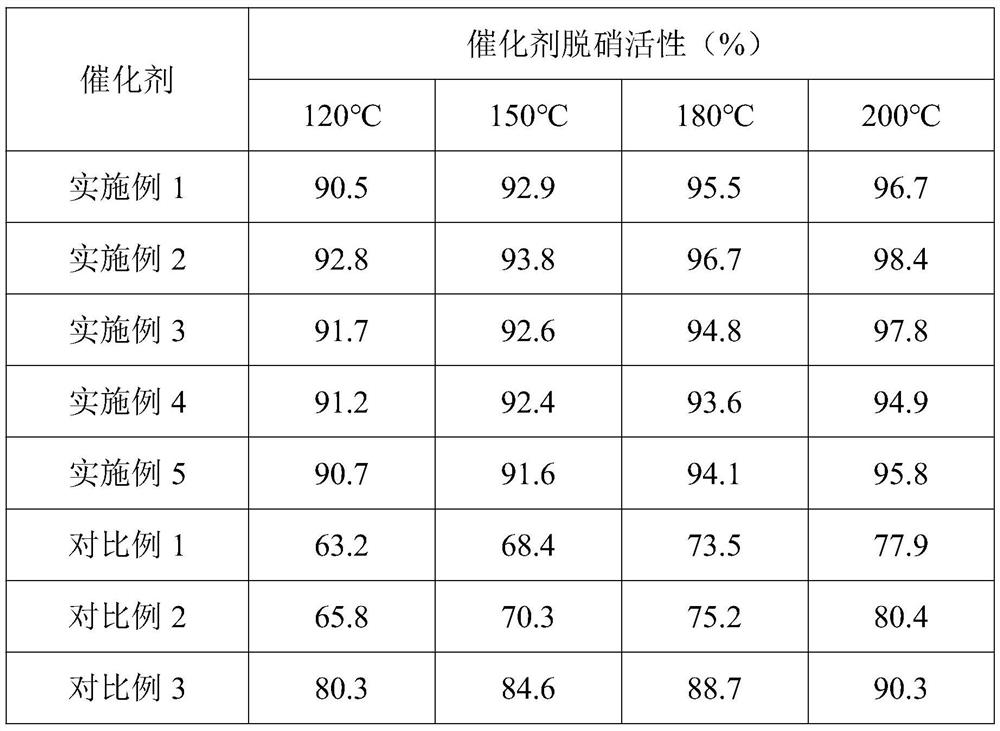

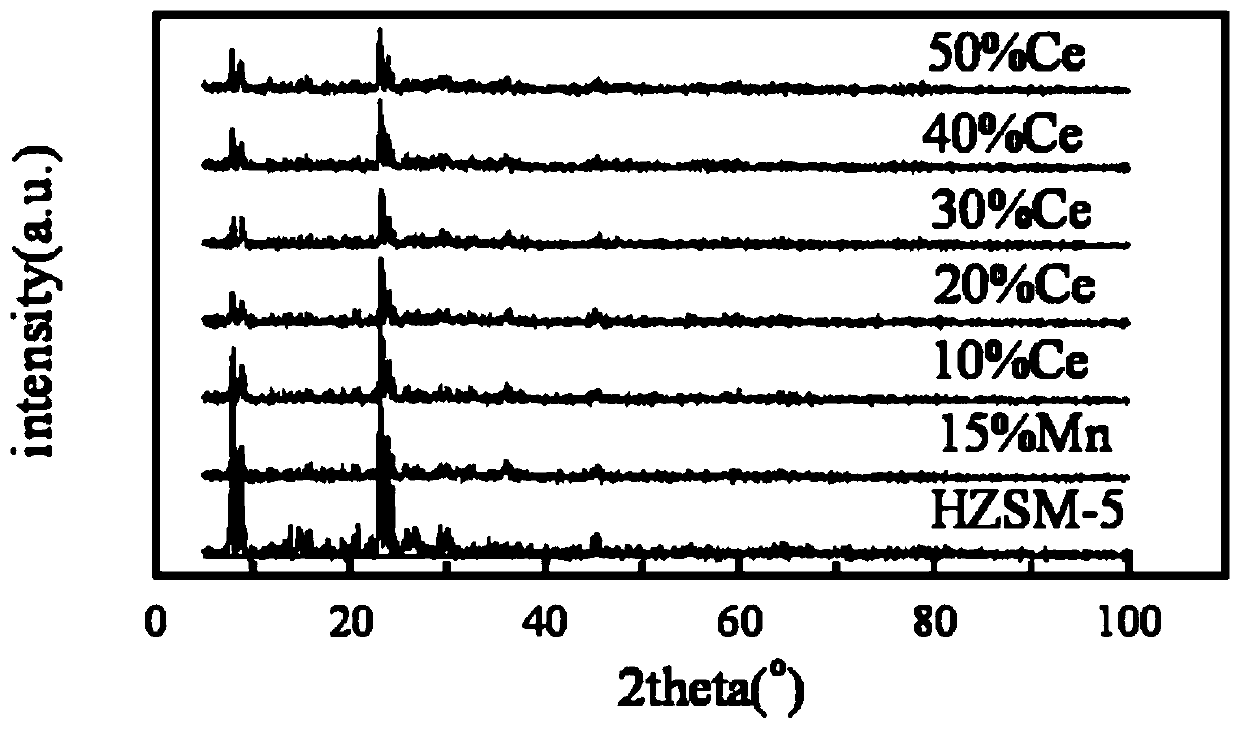

Molecular sieve loaded modified manganese-based catalyst used for diesel car tail gas denitration, and preparation method and applications thereof

InactiveCN109954514ALow costSimple and fast operationGas treatmentInternal combustion piston enginesMass ratioCerium

The invention relates to a molecular sieve loaded modified manganese-based catalyst used for diesel car tail gas denitration, and a preparation method and applications thereof. According to the catalyst, HZSM-5 molecular sieve is taken as a carrier, manganese oxides (MnO<x>) is taken as a main active component, cerium dioxide (CeO2) is taken as an auxiliary agent, equivalent-volume impregnation method is adopted to prepare a finished product; the mass ratio of the carrier, the active component, and the auxiliary agent is controlled to be 100: (10-16.5) : (1.5-7.5); the catalytic efficiency ofthe molecular sieve loaded modified manganese-based catalyst in catalytic purifying of nitrogen oxides (NO<x>) at 120 to 250 DEG C is higher than 85%; the active temperature window is wide; high activity and high selectivity at a low temperature zone are achieved; sulfur resistance and water resistance are excellent; the molecular sieve loaded modified manganese-based catalyst is friendly to the environment; cost is low; operation is convenient; and the molecular sieve loaded modified manganese-based catalyst can be widely used for diesel car tail gas denitration.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

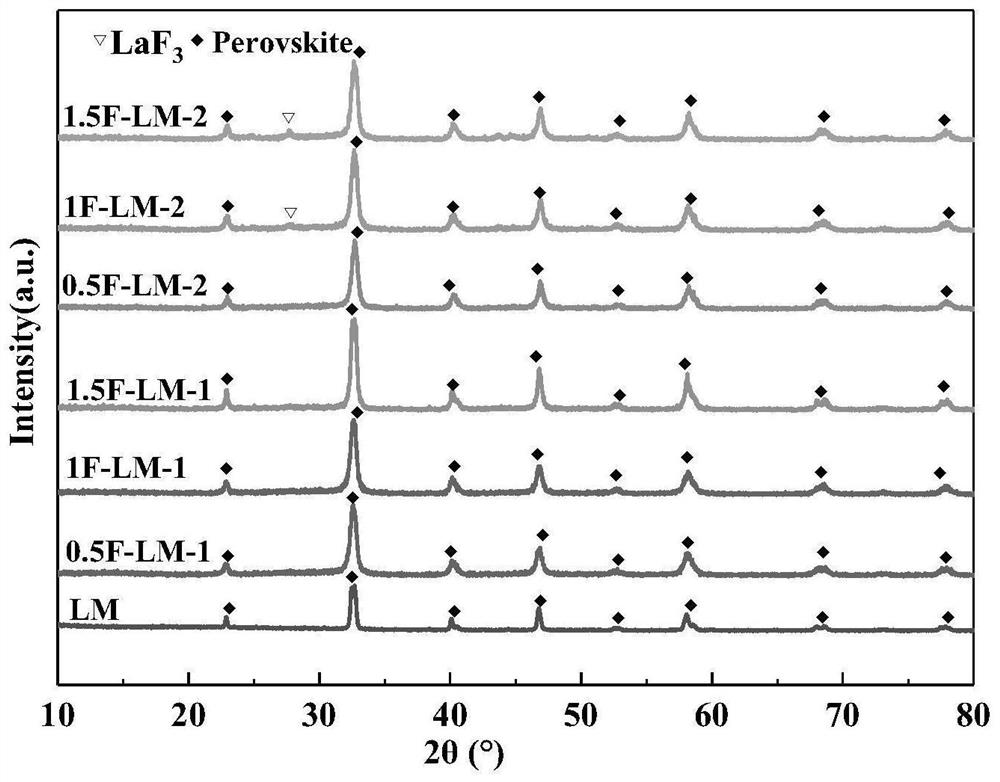

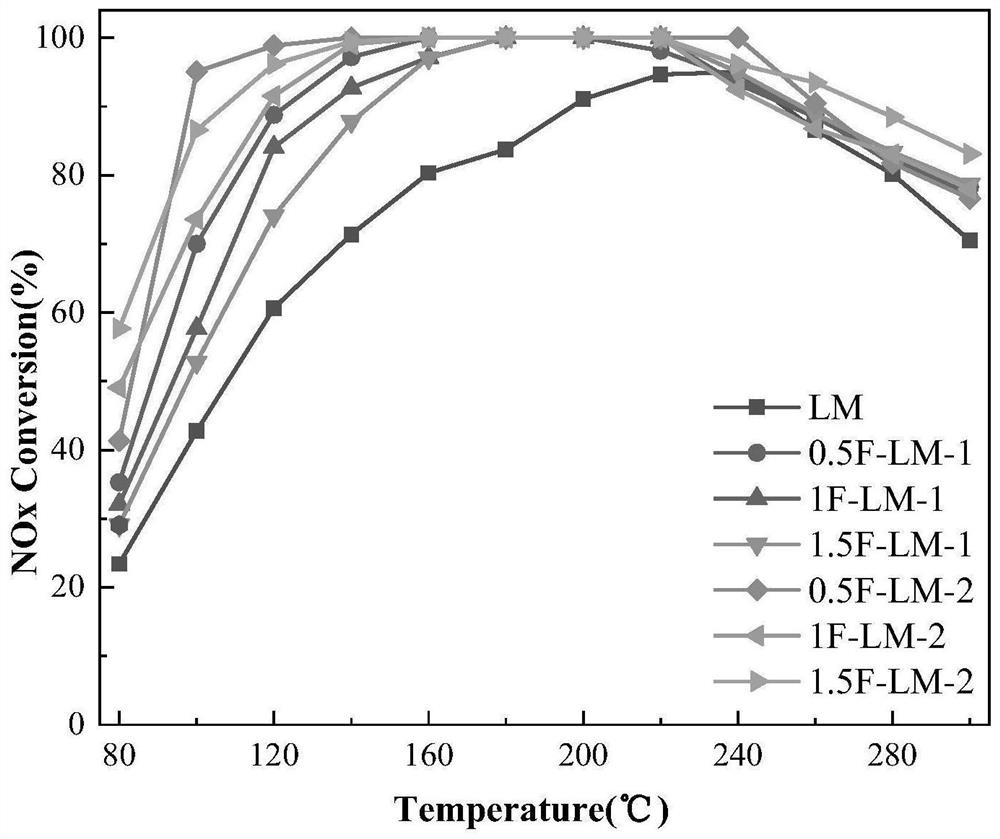

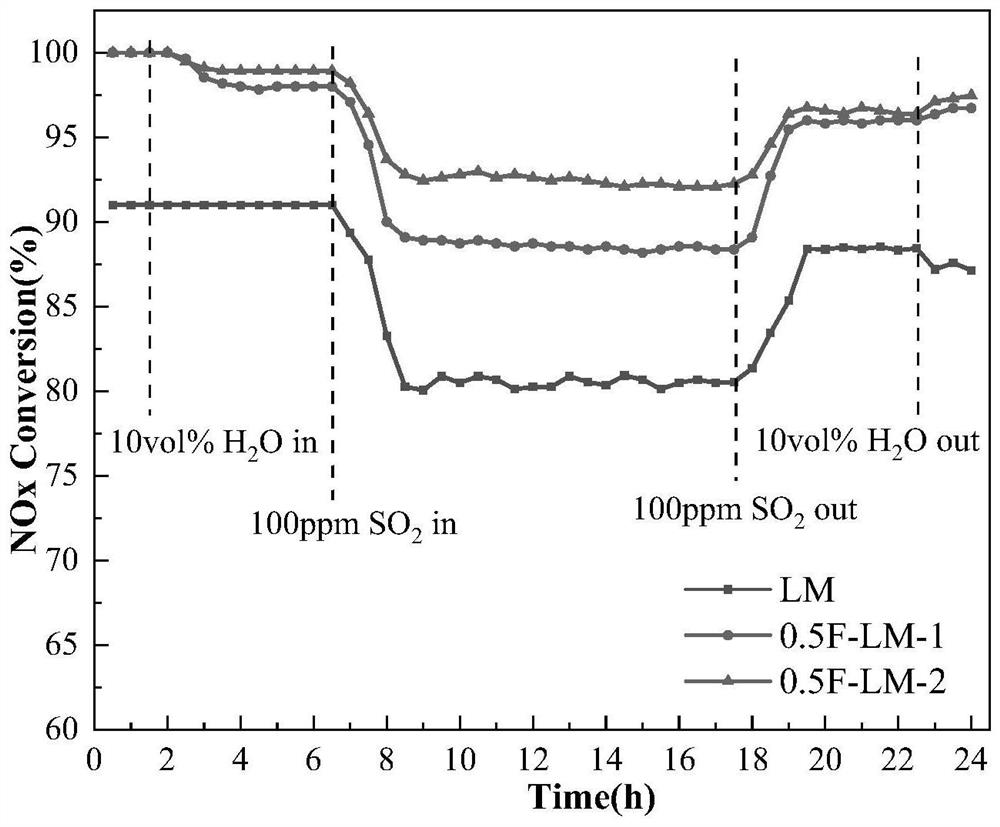

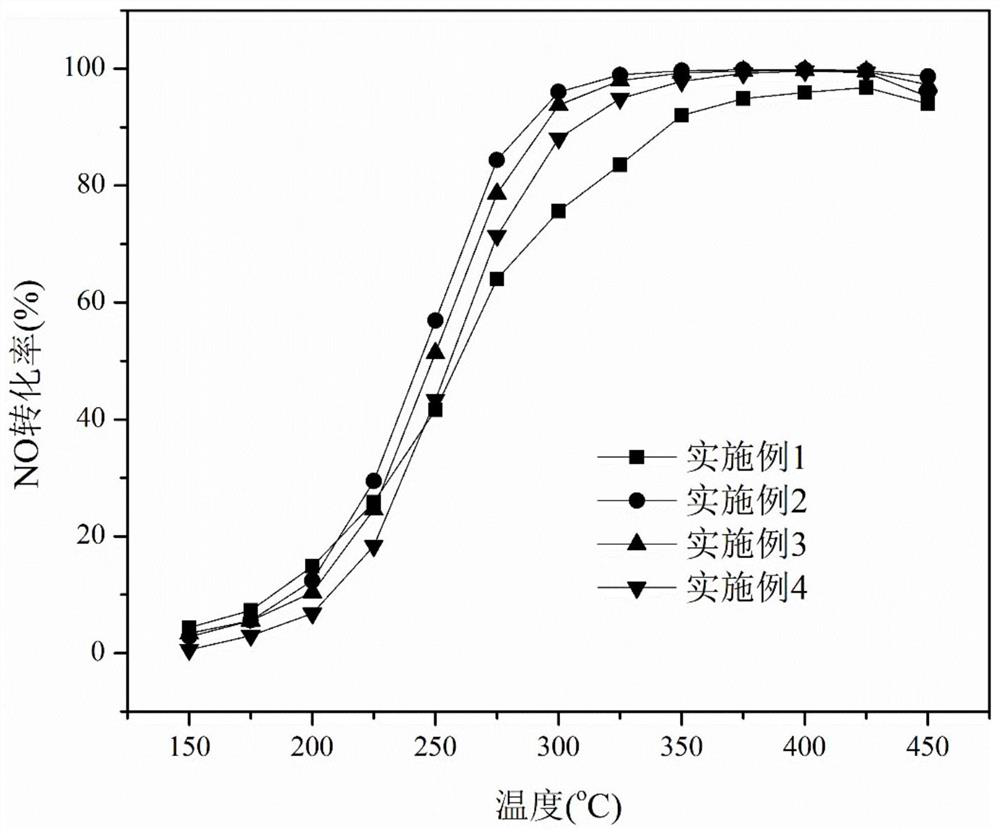

Fluorine modified lanthanum manganese composite oxide SCR denitration catalyst and preparation method thereof

InactiveCN113198495AHas a perovskite structureWide temperature window for SCR denitrification activityPhysical/chemical process catalystsDispersed particle separationPtru catalystManganate

The invention discloses a fluorine modified lanthanum manganese composite oxide SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of denitration catalysts. The technical problem to be solved by the invention is that the current manganese-based catalyst is poor in sulfur resistance and water resistance. The catalyst is prepared from a fluorine element and LaMnO3 according to a certain weight ratio, the fluorine element is uniformly distributed on the surface of LaMnO3, and the preparation method comprises the following steps: synthesizing LaMnO3 by using lanthanum nitrate, manganese nitrate and anhydrous citric acid as raw materials and adopting a citric acid sol-gel method, and then preparing the fluorine-modified lanthanum manganate catalyst by adopting a mechanical mixing method or an impregnation method. The SCR denitration active temperature window is wide, meanwhile, the good sulfur resistance and water resistance are achieved, the preparation process is simple, the requirement for equipment is low, the used raw materials are common chemical reagents, the source is wide, the price is low, the raw materials are easy to obtain, and industrial production is easy.

Owner:SICHUAN UNIV

Wear-resistant catalyst and preparation method thereof

ActiveCN110975905AEfficient removalImprove permeabilityDispersed particle separationCatalyst activation/preparationCarbide siliconNano silicon

The invention discloses a wear-resistant catalyst and a preparation method thereof. The catalyst takes mesoporous SiC microspheres as a carrier and a manganese copper oxide as an active component, andthe method comprises the steps: firstly, fully mixing pseudo-boehmite and nano silicon carbide powder, and performing spray drying forming to obtain a mixed microsphere carrier; then carrying out chemical etching processing on the microspheres by using a processing agent under a hydrothermal condition to obtain the mesoporous SiC microspheres; and finally, sequentially adding a copper salt and amanganese salt, and uniformly mixing to obtain the catalyst disclosed by the invention. According to the present invention, the catalyst carrier is the mesoporous silicon carbide microspheres, the mesoporous structure with the uniform pore size is beneficial for a reactant to achieve active sites so as to improve the activity and the stability of the catalyst, and the preparation method enhances the dispersity of the active components Mn and Cu and improves the activity of the catalyst.

Owner:WANHUA CHEM GRP CO LTD

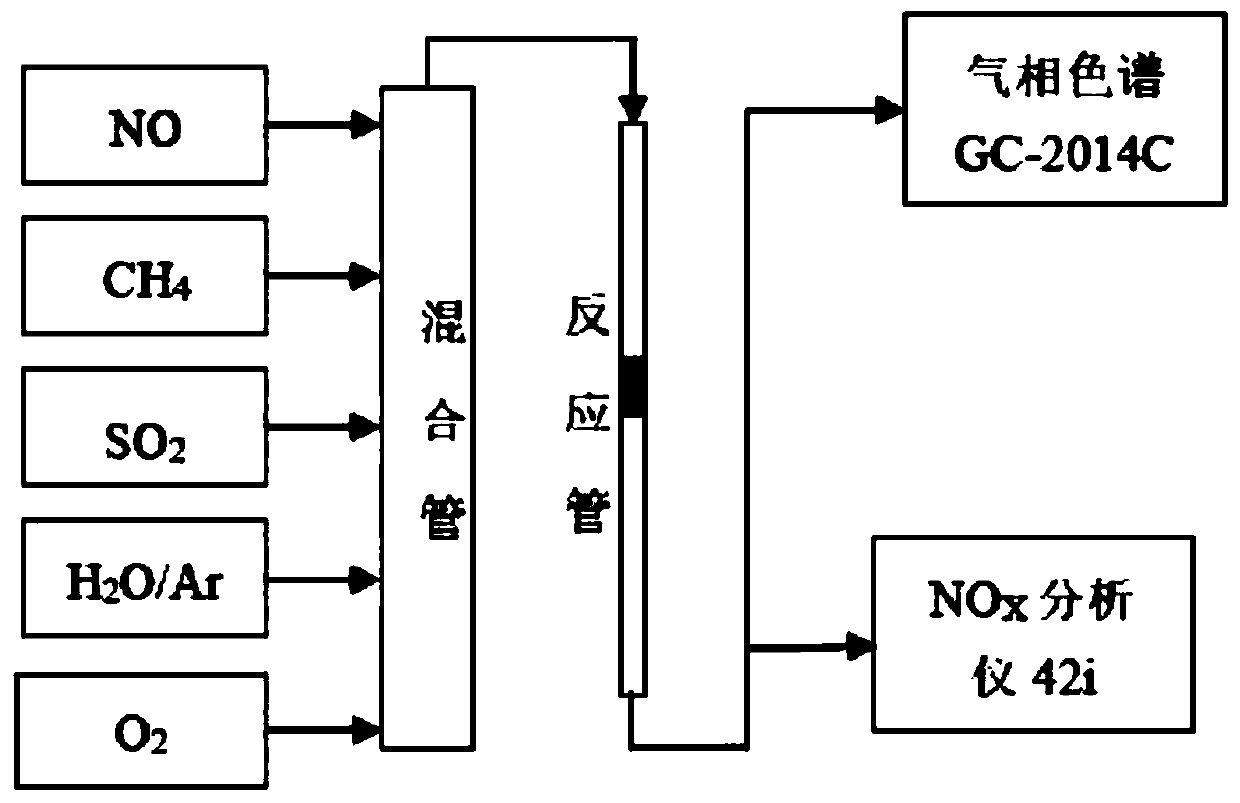

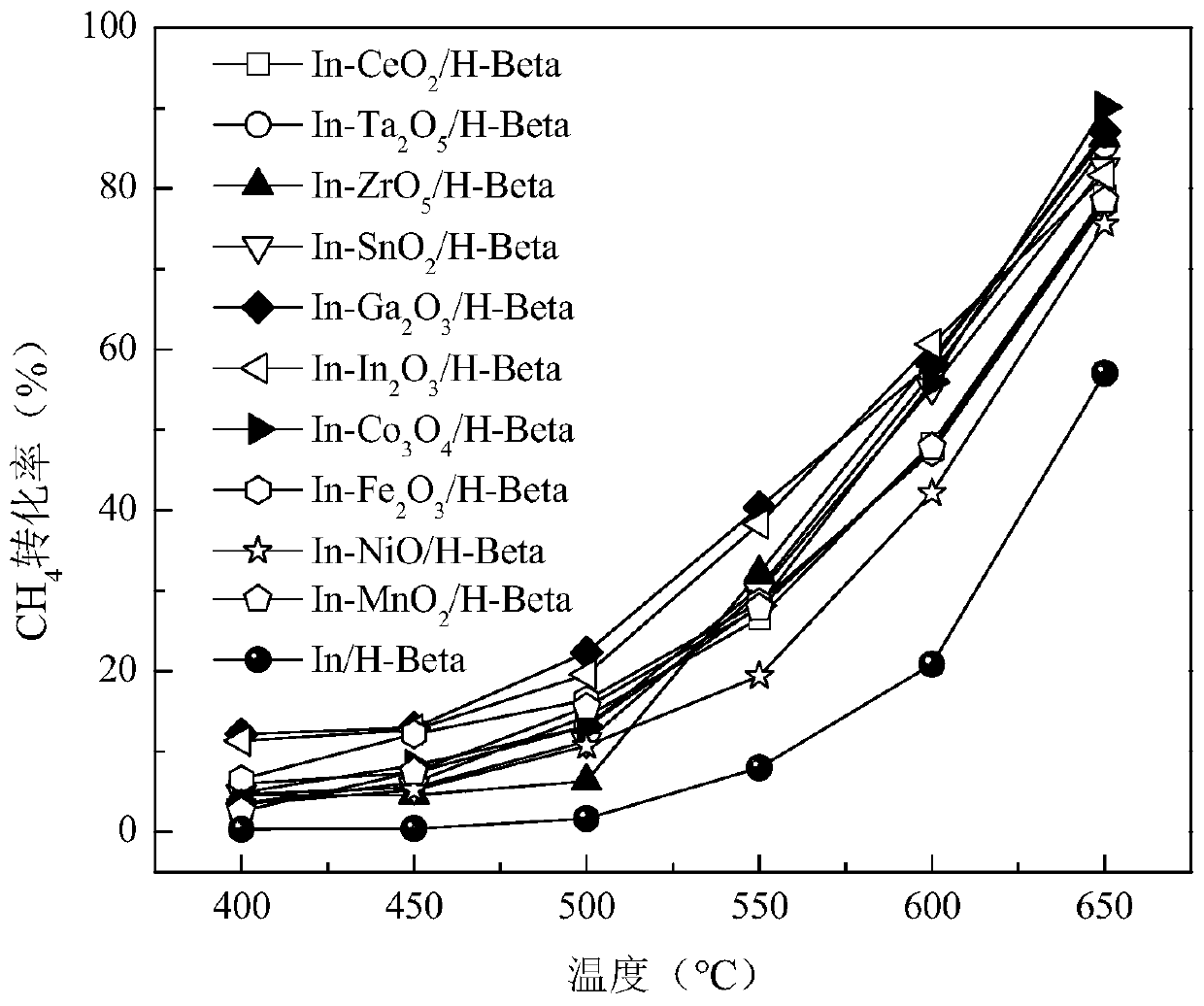

CH4-SCR denitration catalyst and preparation method thereof and waste gas denitration method

ActiveCN111097498AImprove water and sulfur resistanceImprove denitrification rateMethane captureMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a CH4-SCR denitration catalyst and a preparation method thereof and a waste gas denitration method. The CH4-SCR denitration catalyst is prepared from the following components:an H-Beta molecular sieve carrier, indium and a metal oxide, the indium is loaded on the H-Beta molecular sieve carrier, and the metal oxide is selected from the combination of Co3O4 and at least oneof Ga2O3, Fe2O3, NiO and CeO2. Due to the addition of the metal oxide formed by combining at least one of Ga2O3, Fe2O3, NiO and CeO2 with Co3O4, the sulfur resistance and water resistance of the catalyst are remarkably improved, and the denitration rate of the catalyst can be increased.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

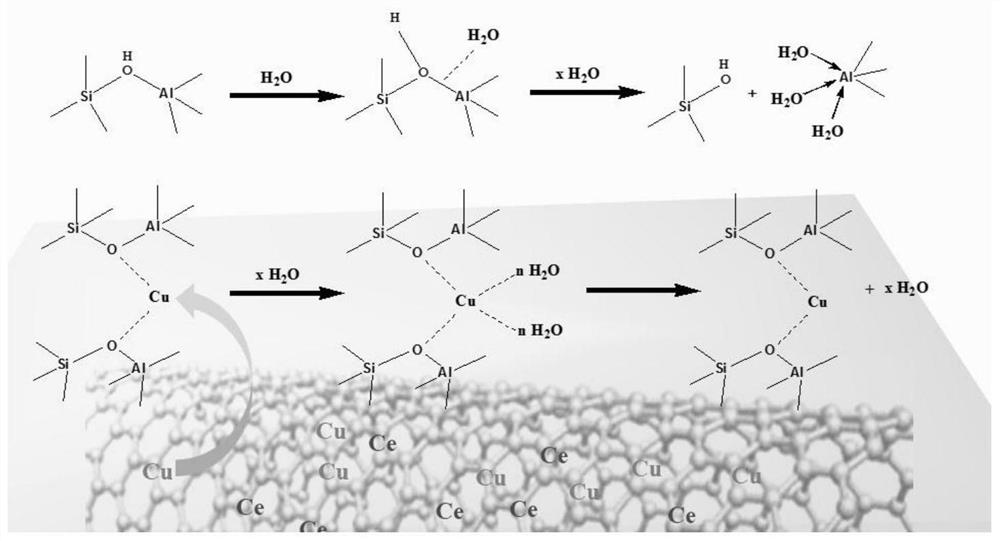

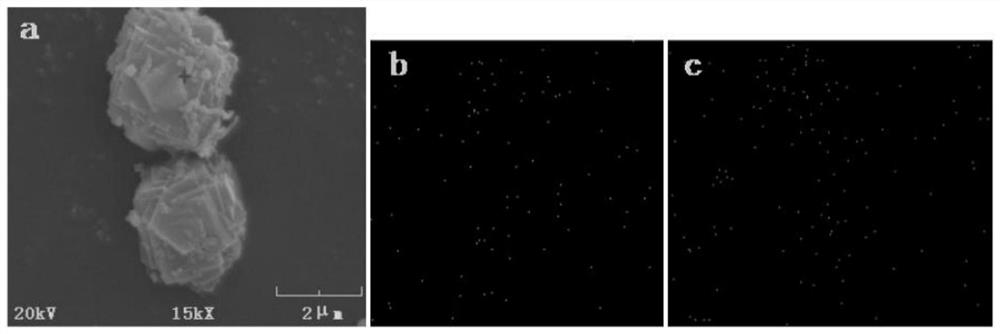

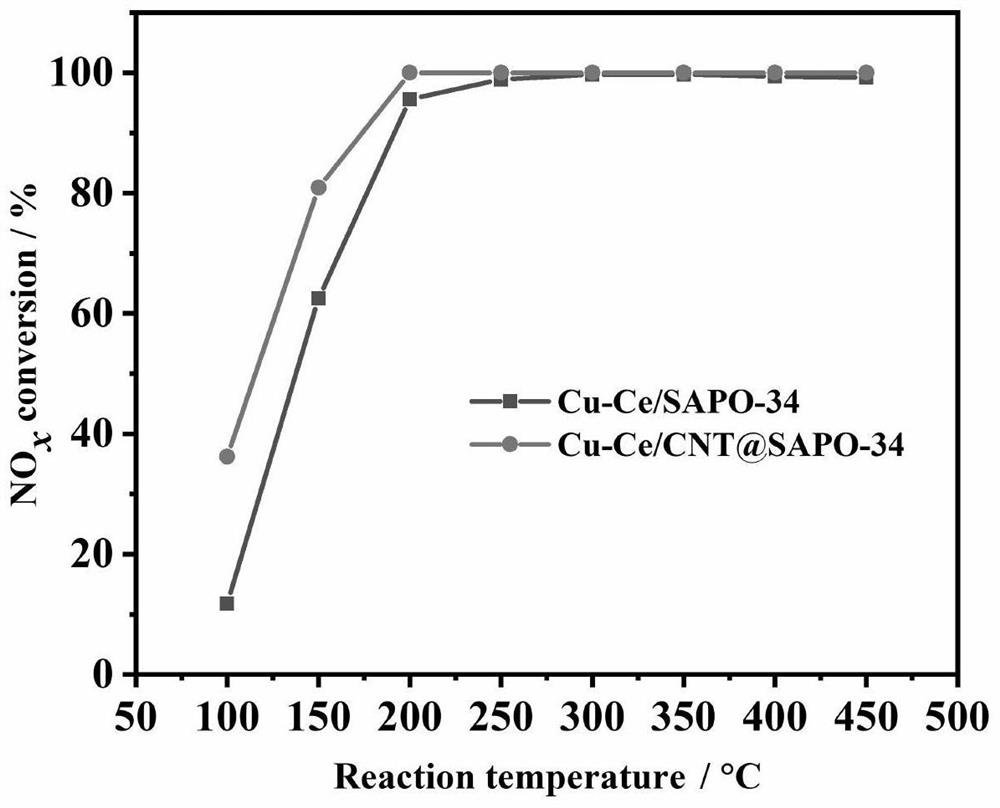

Synthesis method of copper-cerium co-doped CNT-coated SAPO-34 composite denitration catalyst

PendingCN112774725AImprove stabilityGood water and sulfur resistanceMolecular sieve catalystsDispersed particle separationPtru catalystSilicic acid

The invention relates to a synthesis method of a copper-cerium co-doped CNT-coated SAPO-34 composite denitration catalyst. The invention belongs to the field of denitration catalyst preparation. The invention aims to solve the technical problems of poor thermal stability, water resistance and sulfur resistance and low active component loading capacity of an existing NH3-SCR catalyst for a diesel vehicle. The method comprises the following steps: step 1, loading active components Cu and Ce on a carbon nanotube by using an impregnation method to obtain a mixed solution; 2, taking aluminum isopropoxide, phosphoric acid, tetraethyl orthosilicate and diethylamine as an aluminum source, a phosphorus source, a silicon source and a template agent to obtain sol; and 3, adding the mixed solution into the sol, conducting stirring, carrying out ultrasonic treatment, conducting crystallizing, carrying out suction filtration, conducting washing, conducting drying, and conducting roasting in an N2 atmosphere to obtain the copper-cerium co-doped CNT-coated SAPO-34 composite structure catalyst. The catalyst provided by the invention has good stability, water resistance and sulfur resistance. When the temperature is higher than 200 DEG C, the conversion rate of NOx can reach 100%. Meanwhile, the active components are high in loading capacity and good in dispersity, and the effects of high reactant adsorbability and good low-temperature stability are achieved.

Owner:QIQIHAR UNIVERSITY

Low-temperature cerium-based sulfur-resistant and water-resistant denitration catalyst and preparation method thereof

ActiveCN112547099AAvoid the problem of heating up the flue gas when the temperature is lowAvoid heating upGas treatmentPhysical/chemical process catalystsMANGANESE ACETATEPtru catalyst

The invention relates to a low-temperature cerium-based sulfur-resistant water-resistant denitration catalyst and a preparation method thereof, the denitration catalyst comprises a carrier, an activecomponent precursor and an auxiliary agent, and the mass ratio of the carrier to the active component precursor to the auxiliary agent is 50-100: 60-120: 1-2; wherein the active component precursor comprises a component A, a component B and cerium oxide, and the mass ratio of the component A to the cerium oxide to the component B is (1-5): (1-3): (2-5); wherein the component A and the component Bare respectively selected from one of manganese acetate, zirconium acetate, ferric nitrate, nickel nitrate and chromium nitrate; and cerium oxide in the active component precursor is subjected to sulfation treatment; and a mixture of the raw materials is subjected to extrusion molding, and then carrying out drying and roasting so as to obtain the cerium-based sulfur-resistant water-tolerant denitration catalyst. The denitration catalyst provided by the invention has significantly improved sulfur resistance and water resistance, avoids the problem that flue gas needs to be heated due to low flue gas temperature, saves a large amount of resources and cost, and is relatively simple in preparation process and easy to realize large-scale mass production.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Sulfur-resistant and water-resistant manganese-based low-temperature denitration catalyst as well as preparation method and application thereof

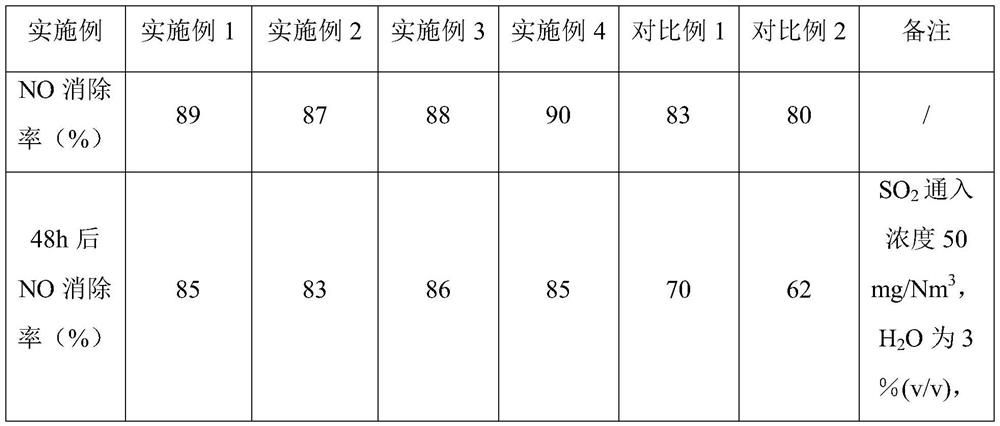

ActiveCN112547129AImprove water and sulfur resistanceHigh low temperature activityNitrous oxide captureGas treatmentPtru catalystFlue gas

The invention relates to a sulfur-resistant and water-resistant manganese-based low-temperature denitration catalyst as well as a preparation method and an application thereof, the sulfur-resistant and water-resistant manganese-based low-temperature denitration catalyst comprises a main active component, an auxiliary agent, a carrier and a forming auxiliary agent, the main active component is OMS2, and the auxiliary agent is vanadium oxide, transition metal oxide and rare earth metal oxide; the catalyst powder is prepared by dipping and modifying carrier powder, then performing a hydrothermalmethod, and molding by an extrusion method. The obtained monolithic honeycomb catalyst is easy to produce, small in resistance, high in low-temperature activity and good in sulfur resistance and waterresistance, the NOx conversion rate of the denitration catalyst prepared by the method is kept at 85% or above within 48 hours under the conditions of 80-180 DEG C, 0-100 mg / Nm3SO2 and 2%-5% H2O, andthe denitration catalyst is suitable for removing NOx in flue gas of industries such as steel, cement and coking and the like.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Denitration catalyst and preparation method thereof

ActiveCN109453758AImprove adsorption capacityAvoid reunionGas treatmentHeterogenous catalyst chemical elementsDeposition precipitationHalloysite

The invention discloses a denitration catalyst and a preparation method thereof. The method includes the steps: halloysite nano-tube purification; halloysite nano-tube surface modification; active component loading. The catalyst is prepared by the aid of a technological means combining a deposition precipitation method and a sol-gel method, and the catalyst takes a mesoporous CeO2 modified halloysite nano-tube as a carrier and takes magnesium vanadium oxide as an active component. The catalyst has higher specific surface area and can have high catalytic activity and reaction stability within the range of 250-450 oC and is high in SO2 poisoning resistance.

Owner:FUJIAN UNIV OF TECH

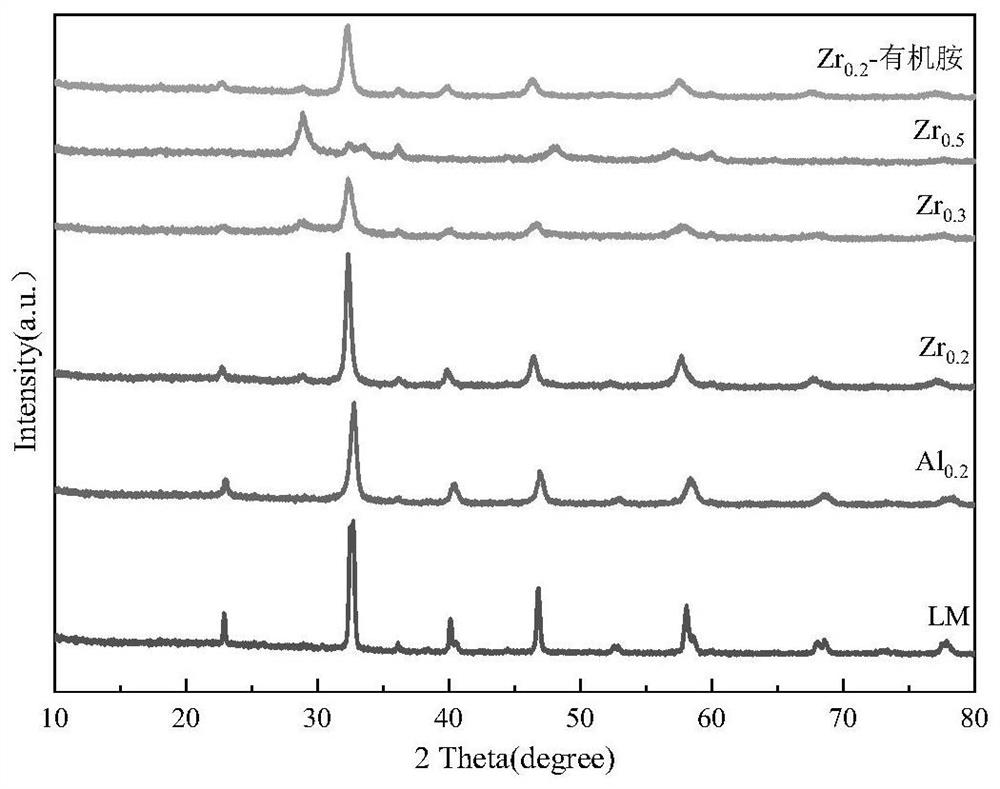

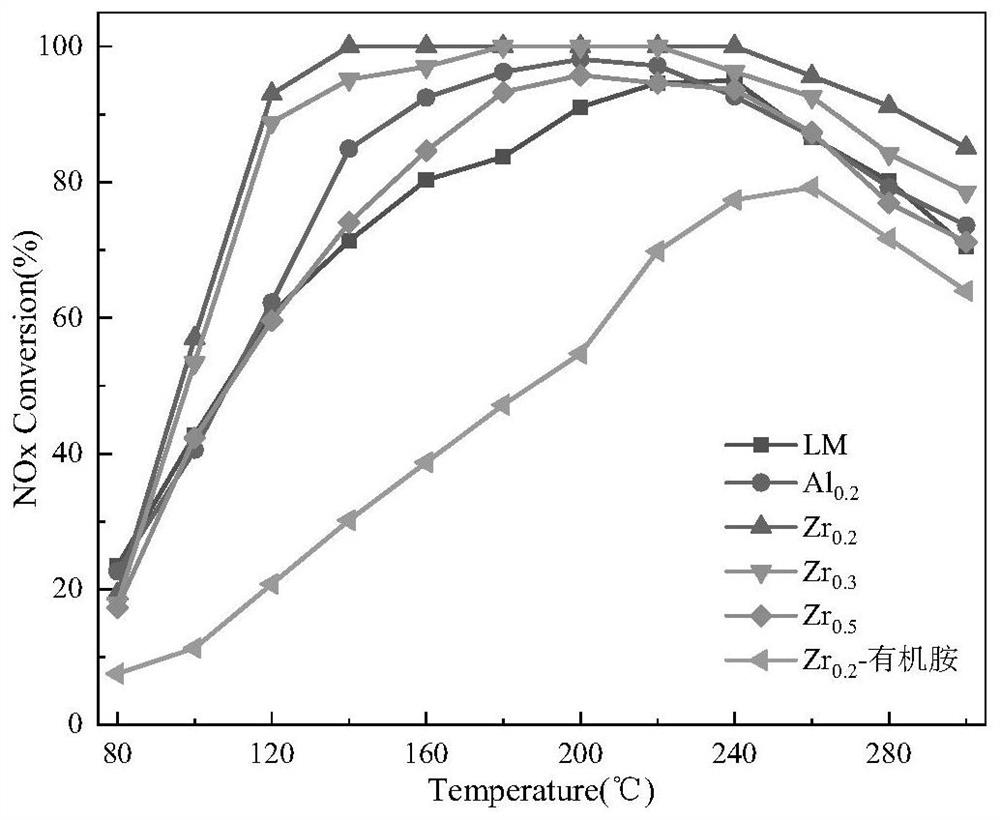

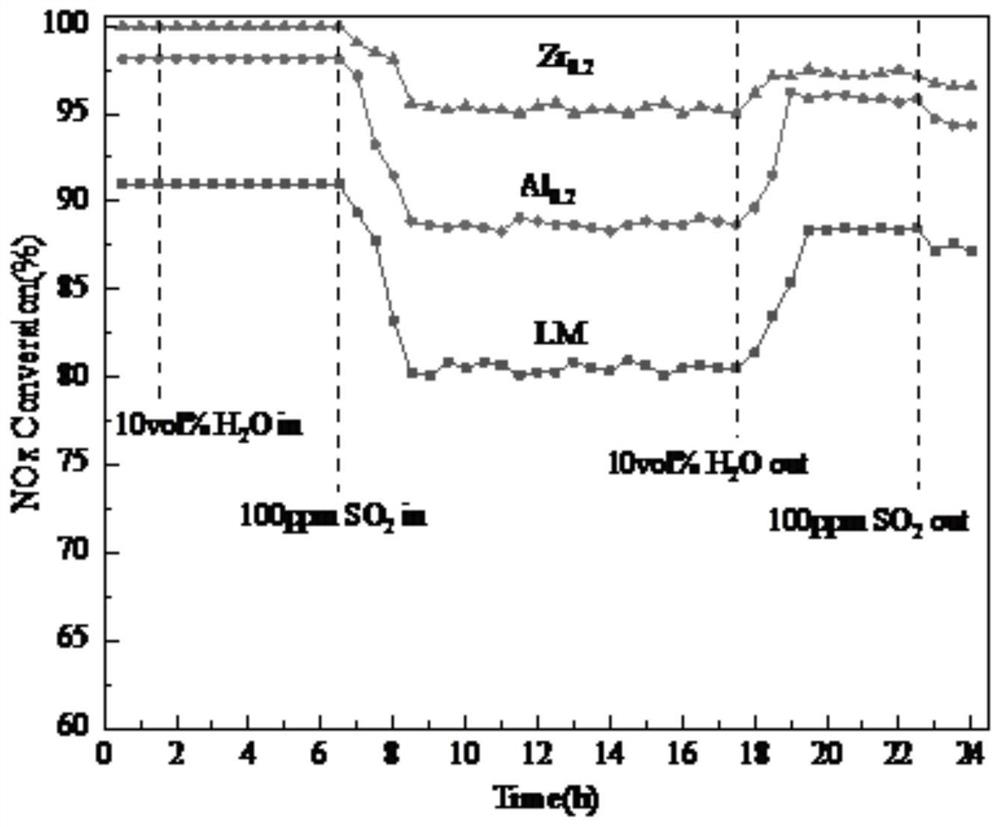

Zirconium-doped lanthanum-manganese-based SCR denitration catalyst and preparation method thereof

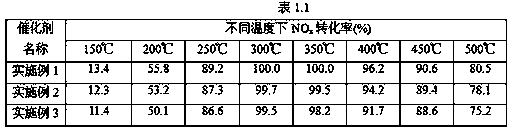

ActiveCN112958077AWide active temperature windowImprove water and sulfur resistanceNitrous oxide captureGas treatmentPtru catalystNitrogen oxides

The invention discloses a zirconium-doped lanthanum-manganese-based SCR denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a precursor; (2) conducting alkalinity adjustment; (3) preparing gel; and (4) conducting aging, calcining and forming. The catalyst is prepared by one-step synthesis through a citric acid sol-gel method, has a perovskite structure, is wide in SCR denitration activity temperature window, can keep excellent SCR denitration activity in the wide temperature window of 120-280 DEG C, has the nitrogen oxide removal rate of 90% or above, and maintains the nitrogen oxide removal rate of 100% at 140-240 DEG C, and in addition, the sulfur resistance and water resistance of the catalyst can be effectively improved, and the removal rate of nitrogen oxides can be kept to be 95% or above under the test condition.

Owner:SICHUAN UNIV

Sulfating modified iron-tungsten-titanium SCR (selective catalytic reduction) denitration catalyst as well as preparation method and application thereof

PendingCN114146713AImprove water and sulfur resistanceGood water and sulfur resistanceGas treatmentPhysical/chemical process catalystsHydration reactionPtru catalyst

The invention discloses a sulfation-modified iron-tungsten-titanium SCR (selective catalytic reduction) denitration catalyst as well as a preparation method and application thereof. According to the preparation method, ferric nitrate or ferric nitrate nonahydrate, ammonium tungstate and tetrabutyl titanate are used as raw materials, iron-tungsten-titanium is prepared through a sol-gel method and a high-temperature calcination method, and thiourea is added in the sol process to prepare the sulfated iron-tungsten-titanium catalyst. The catalyst has relatively strong oxidation-reduction capability and more acidic sites, has relatively strong adsorption capability on NO, and can keep the denitration efficiency of 90% or above within a reaction temperature interval of 240-460 DEG C, so that the denitration efficiency is effectively improved. The preparation method disclosed by the invention is simple, and the prepared catalyst is relatively fine in particle, good in dispersity and relatively good in medium-high temperature catalytic activity.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com