Patents

Literature

138results about How to "Low starting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrofining catalyst and preparation method thereof

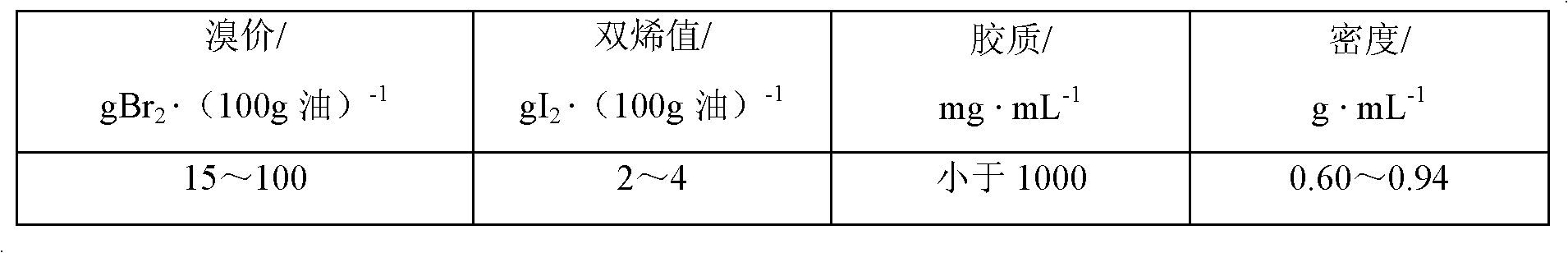

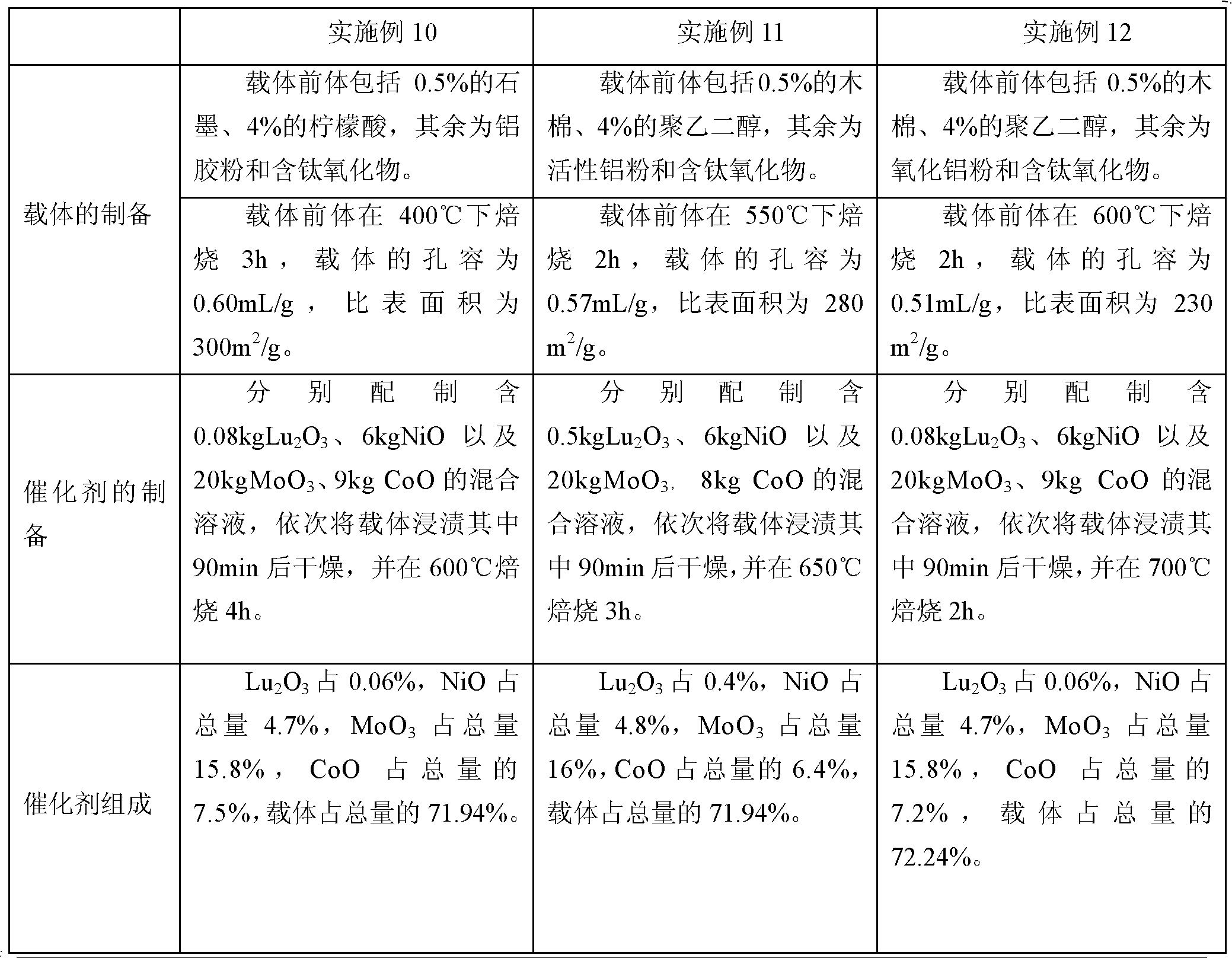

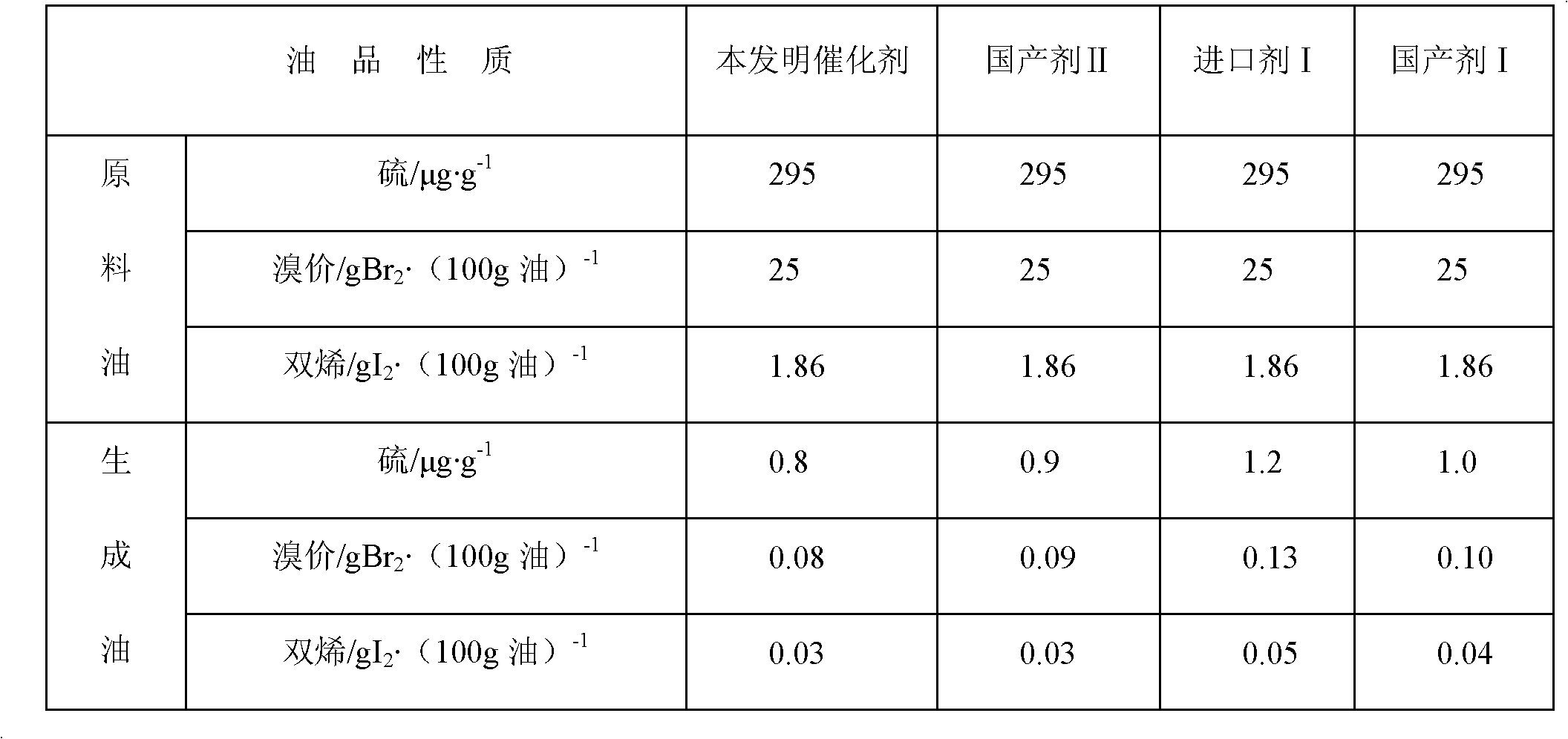

ActiveCN102861593ALarge hole volumeLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemical industryRare-earth element

The invention discloses a hydrofining catalyst and a preparation method thereof, belonging to the field of catalysts used in the petroleum-chemical industry. The hydrofining catalyst disclosed herein comprises a carrier, an active component and an auxiliary agent, wherein the carrier is Ti-modified gamma-alumina, the active component comprises oxides of Mo, Co and Ni, and the auxiliary agent comprises oxides of rare earth. The catalyst is characterized in that: based on 100% of the total weight of the catalyst, Co (measured in CaO) in the active component accounts for 2.0-7.5% of the total weight of the catalyst, Mo (measured in MoO3) in the active component accounts for 4.0-18.0% of the total weight of the catalyst, Ni (measured in NiO) in the active component accounts for 0.2-5.0% of the total weight of the catalyst, the auxiliary agent accounts for 0.05-1.0% of the total weight of the catalyst, and the balance consists of the carrier. According to the invention, the catalyst prepared by the formula and the method disclosed in the invention can carry out hydrogenation on saturated monoolefine while the catalyst is used for carrying out hydrodesulfurization on oils, can be suitable for technical requirements of heavy oriention, changeable sulphur content, and high air speed of hydrogenation liquid for pyrolysis gasoline two-stage hydrogenated raw materials, and simultaneously, the catalyst has the advantages of low activation temperature and low loss of aromatics in the hydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP

Catalyst for decomposing nitrous oxide and preparation method of catalyst

InactiveCN104437499AHigh activityIncreased reactive sitesNitrous oxide captureDispersed particle separationReaction temperatureAdipic acid

The invention discloses a catalyst for decomposing nitrous oxide and a preparation method of the catalyst. The catalyst is prepared by the deposition precipitation method. The method comprises the processes of preparing a deposit, washing, forming a deposit, activating through the catalyst, etc.; the catalyst comprises active ingredients, a carrier which is zirconium oxide, and additives, wherein the active ingredients include one or more than two of Co, Ni, Fe and Mn; the additives include one or more of cerium oxide, lanthanum oxide and barium oxide. A catalyst activity experiment shows that nitrous oxide can be completely catalytically decomposed into nitrogen and oxygen at the temperature ranging from 450 to 700 DEG C; therefore, the activation temperature is low, and the T50 (reaction temperature under conversion rate of 50%) is about 350 DEG C. The catalyst is high in activity and outstanding in heat resistance, has a wide operation window, and enables the concentration of nitrous oxide in industrial waste gas to be greatly reduced, and therefore, the environmental pollution is decreased; the catalyst is particularly suitable for N2O removal of a nitric plant and an adipic acid plant.

Owner:LANZHOU TIANYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Catalyst for preparing 2-methyl furan through gas phase hydrogenation of furfural and preparation method thereof

InactiveCN101961652AHigh activityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranGas phase

The invention discloses a catalyst for preparing 2-methyl furan through gas phase hydrogenation of furfural and a preparation method thereof. The catalyst consists of the following components in percentage by weight: 45 to 60 percent of copper oxide CuO, 30 to 40 percent of chromic oxide CR2O3, 1 to 10 percent of alumina Al2O3 and 1 to 5 percent of silicon oxide SiO2, and is prepared by a coprecipitation method. The catalyst has the characteristics of low activation temperature, long service life, and high selectivity of the 2-methyl furan, and can be used for industrial production of the 2-methyl furan through gas phase hydrogenation of the furfural.

Owner:LAIAN XUNNENG CATALYST

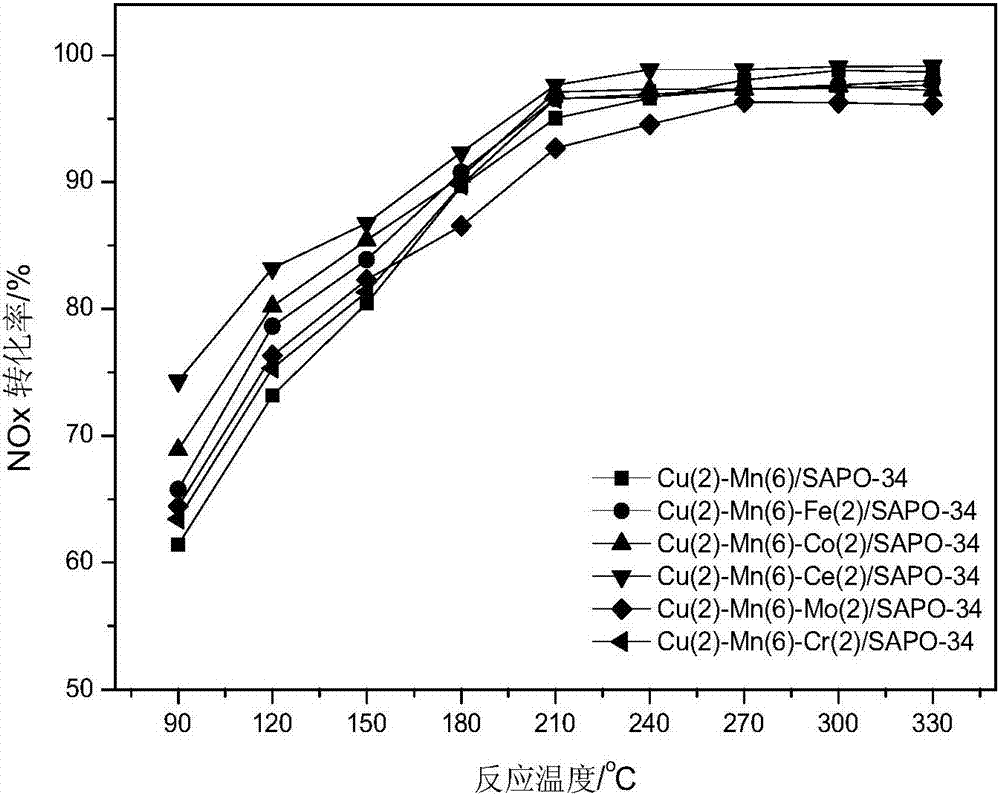

MnMe/molecular sieve series catalysts and preparation and application thereof

InactiveCN101992116ALower operating temperatureReduce energy costsMolecular sieve catalystsDispersed particle separationAlkaline earth metalRare earth

The invention relates to MnMe / molecular sieve series catalysts and preparation and application thereof. The catalysts of the invention comprise a carrier, a main active component and an auxiliary active component, wherein the carrier is selected from an MFI structural molecular sieve, a Y molecular sieve and a beta molecular sieve; the main active component is the oxides of metal Mn; and the auxiliary active component Me is selected from one or the combination of two or more oxides of transition metal or rare earth metal or alkaline earth. The preparation method comprises the following steps: respectively dissolving the metal salts of the metal Mn and the metal Me in water, putting the molecular sieve carrier into the water solution, soaking, drying to obtain the catalyst precursors, and then calcinating to obtain the catalysts. The catalysts of the invention have low operating temperature, can reduce the energy consumption and the investment cost, have very low activating temperature, can have very high activity in a wide temperature range, and also have certain sulfur-resisting and water-resisting capacities.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

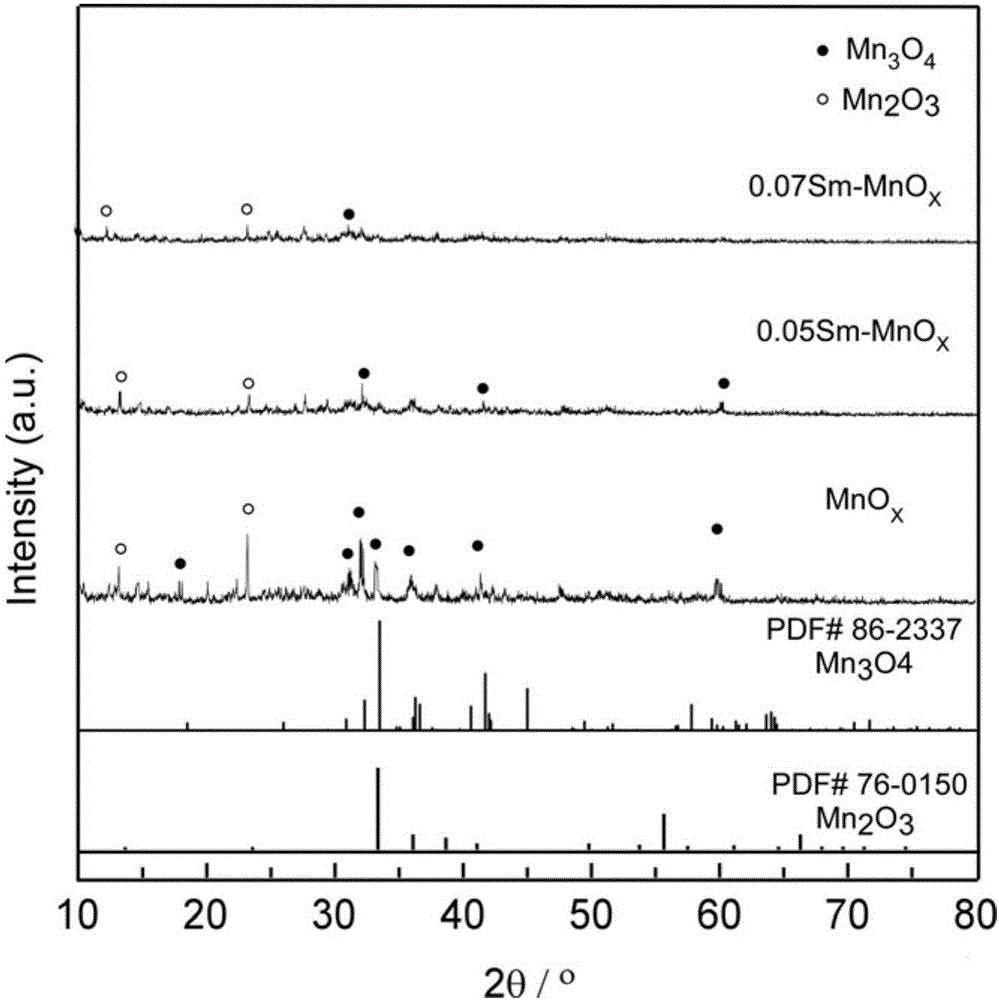

Samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as preparation method and application thereof

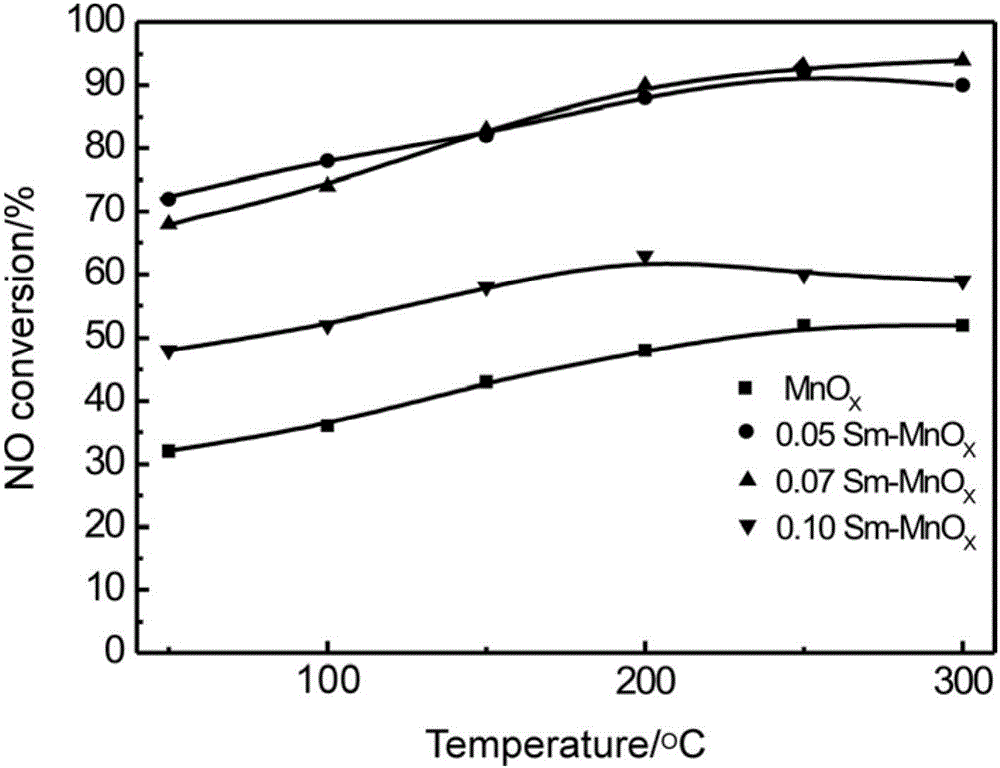

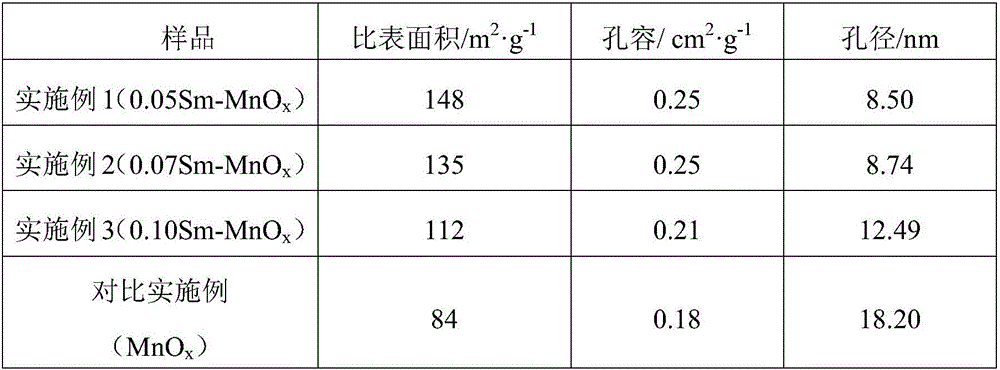

InactiveCN106268787ALarge specific surface areaSmall particle sizeHeterogenous catalyst chemical elementsDispersed particle separationDispersityMischmetal

The invention relates to a samarium-doped MnOx low-temperature SCR (Selective Catalytic Reduction) catalyst as well as a preparation method and application thereof. A proper amount of rare-earth metal samarium is doped into a manganese-based catalyst to obtain the samarium-doped MnOx low-temperature SCR catalyst; compared with a single manganese-based catalyst, the specific surface area of the catalyst is enlarged and the grain diameter of MnOx is reduced; the dispersity of manganese oxide in the catalyst is improved, and reaction activity of the MnOx at low temperature is effectively facilitated; an SCR denitration activity temperature window is expanded, and a modification effect on an MnOx catalyst is very good; the samarium-doped MnOx low-temperature SCR catalyst has relatively high catalytic activity at the low temperature.

Owner:WUHAN UNIV OF TECH

Steel plate used for hot stamping forming, forming process of hot stamping and hot-stamped component

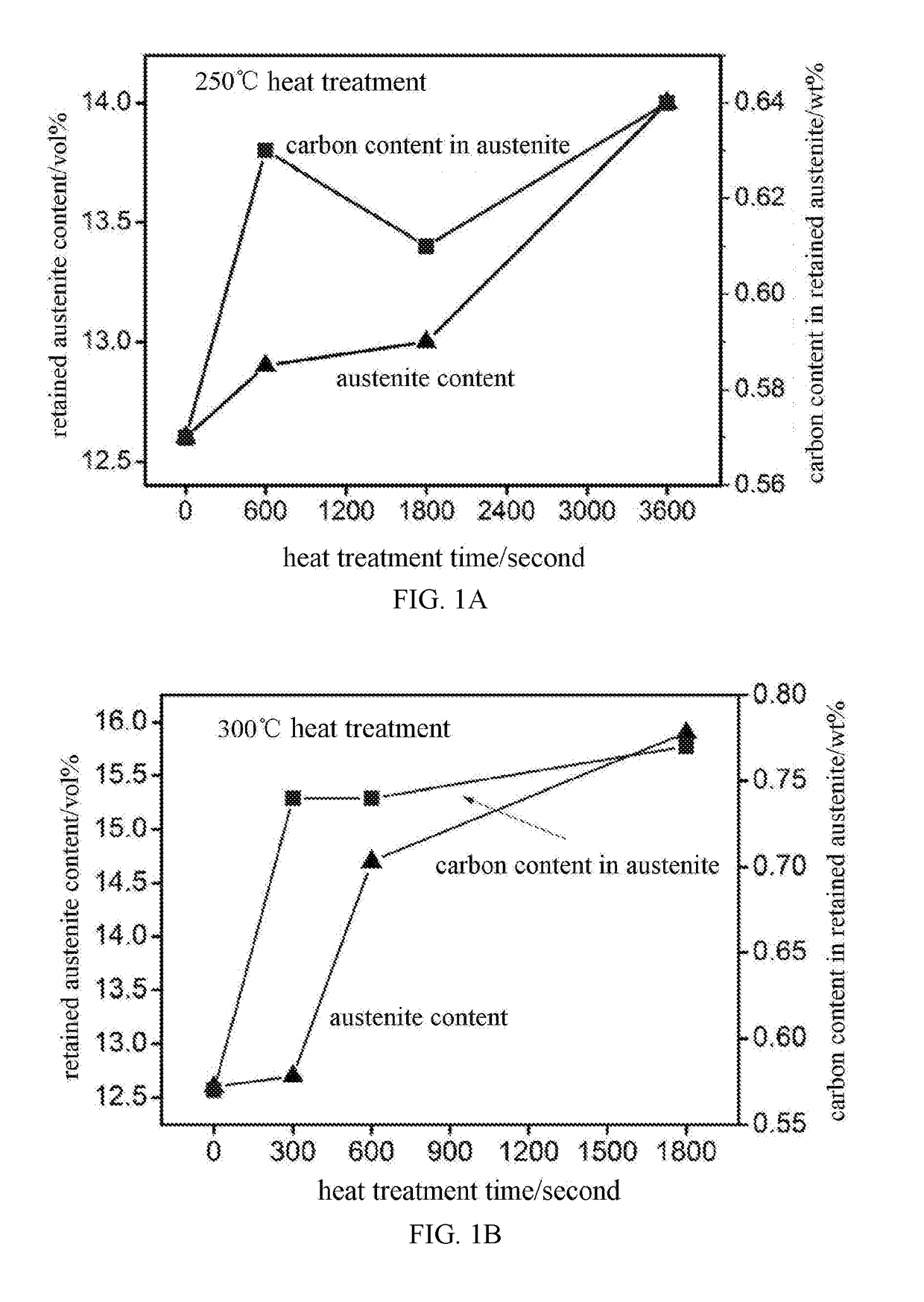

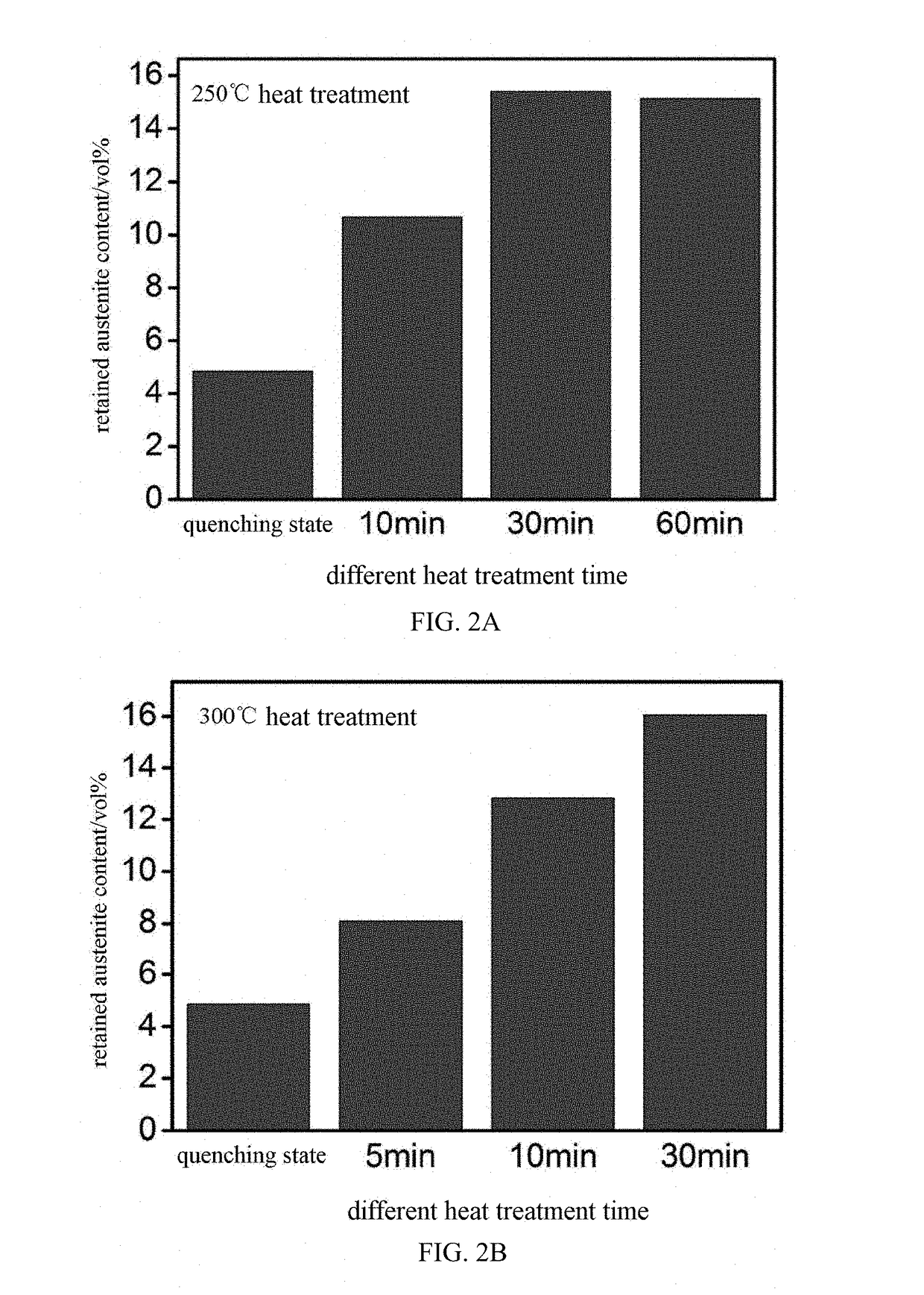

ActiveUS20180030567A1Low austenizingGood temperature controlShaping toolsFurnace typesAlloy elementHot stamping

A steel sheet used for hot stamping includes, by weight percent, 0.18˜0.42% of C, 4˜8.5% of Mn and 0.8˜3.0% of Si+Al with the balance being Fe and unavoidable impurities. The alloy elements of the steel sheet enable the actual measured value of the martensitic transformation start temperature after hot stamping to be ≦280° C. The method for manufacturing the component includes: heating the material to 700˜850° C. and then stamping; cooling it to the temperature that is 150˜260° C. below the martensitic transformation start temperature by cooling in a die, cooling by air, water, or other methods; heating the component to a temperature ranging from 160 to 450° C. and maintaining the temperature for 1 to 100000 seconds for heat treatment, and then cooling the component to room temperature. The formed component has a yield strength of ≧1200 MPa, a tensile strength of ≧1600 MPa and a total elongation of ≧10%.

Owner:EASYFORMING STEEL TECH CO LTD

Cerium supported medium temperature SCR (selective catalytic reduction) catalyst and preparation method thereof

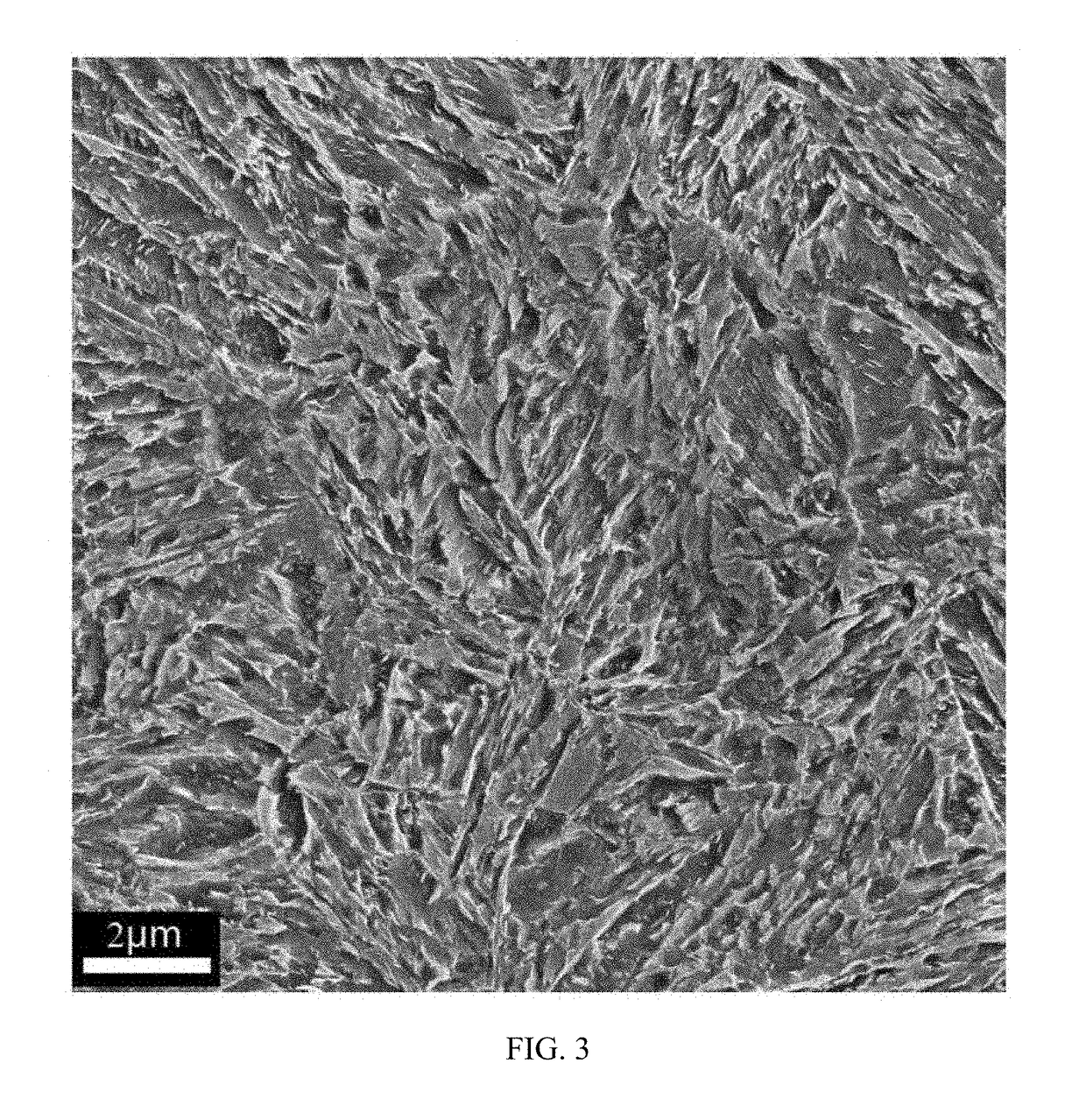

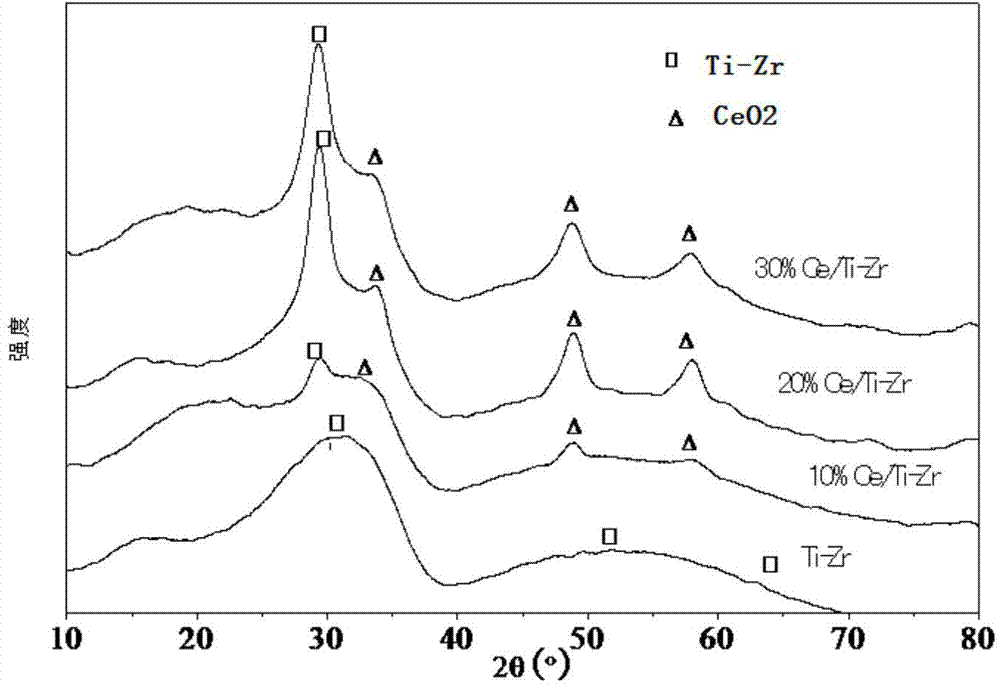

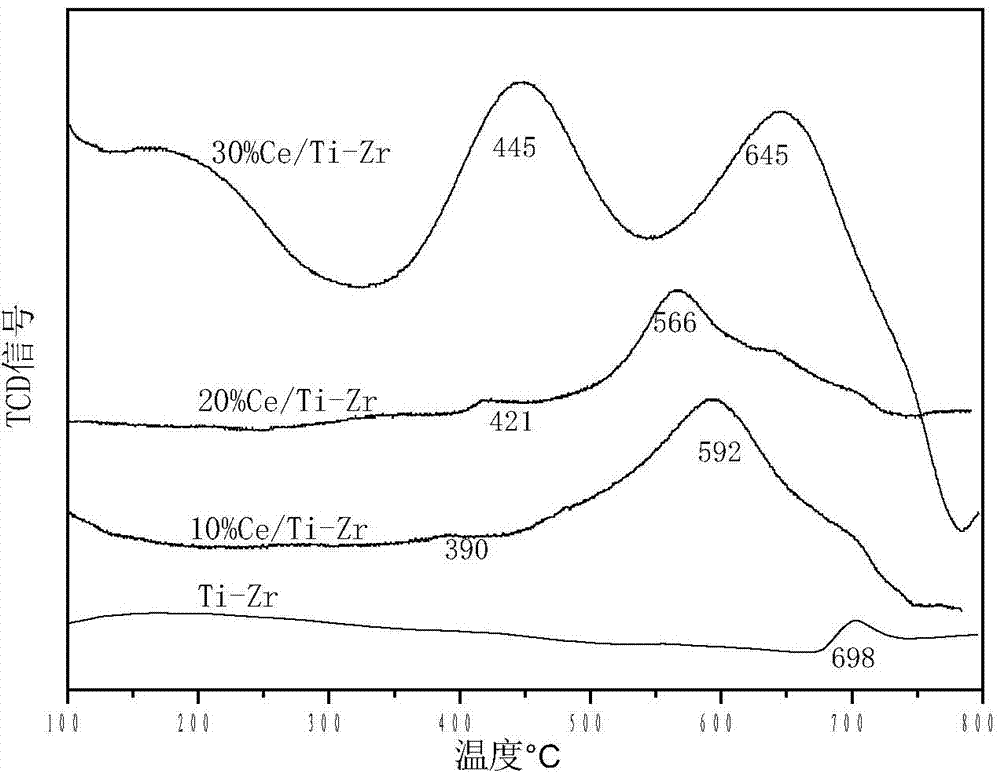

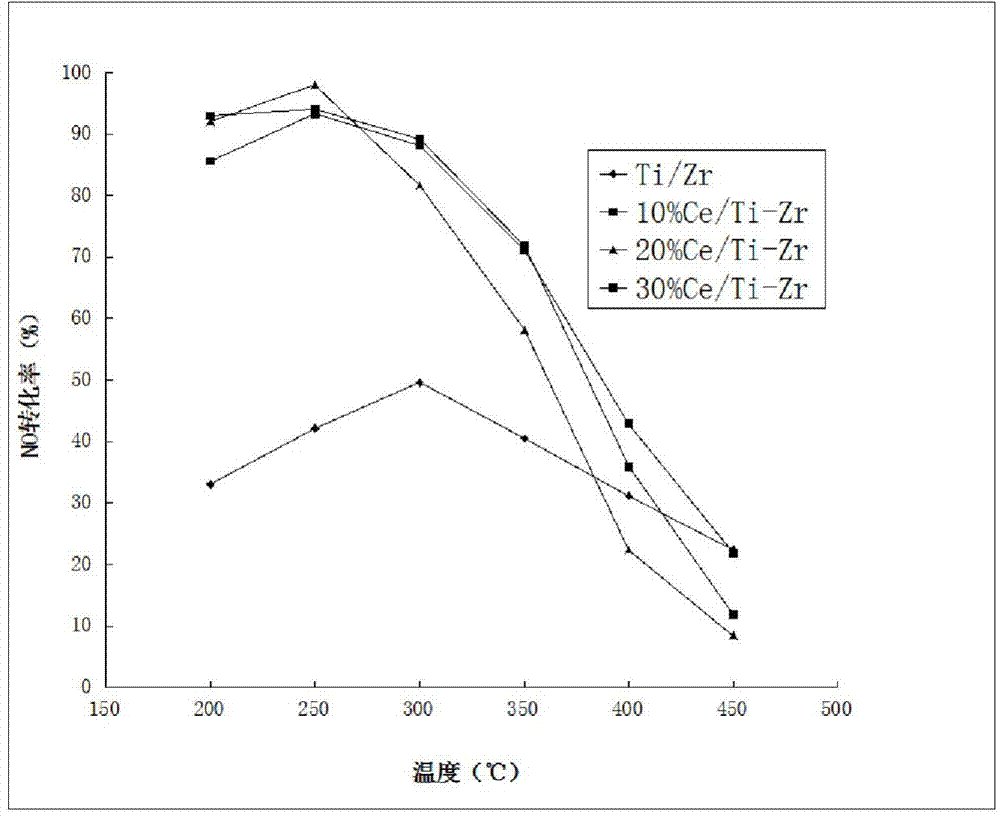

InactiveCN104258840ALower the temperature of the denitrification reactionImprove denitrification efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHeat resistanceTitanium zirconium

The invention discloses a cerium supported medium temperature SCR (selective catalytic reduction) catalyst. Titanium zirconium oxide is taken as a supporter, and cerium oxide is taken as an active ingredient, wherein a ratio of cerium to titanium to zirconium in the catalyst is (0.1-0.3):1:1. The invention also discloses a preparation method of the cerium supported medium temperature SCR catalyst. Compared with a single titanium zirconium composite oxide catalyst, the cerium supported medium temperature SCR catalyst has the advantages that as CeO2 is taken as the active ingredient, a catalyst denitration reaction temperature is lowered, denitration efficiency and heat resistance are obviously improved, an SCR activity temperature window is expanded, and a good modification effect on a TiO2-ZrO2 catalyst is achieved.

Owner:SOUTHEAST UNIV

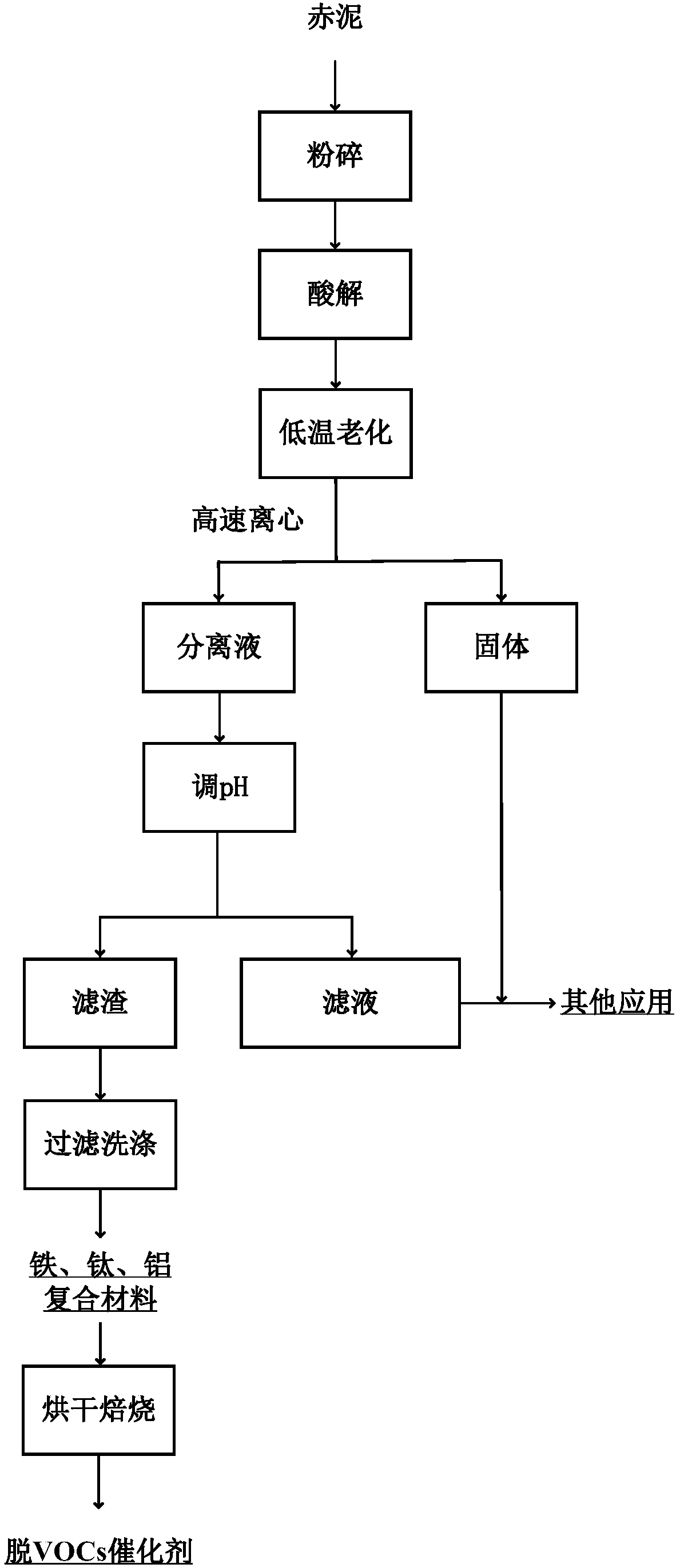

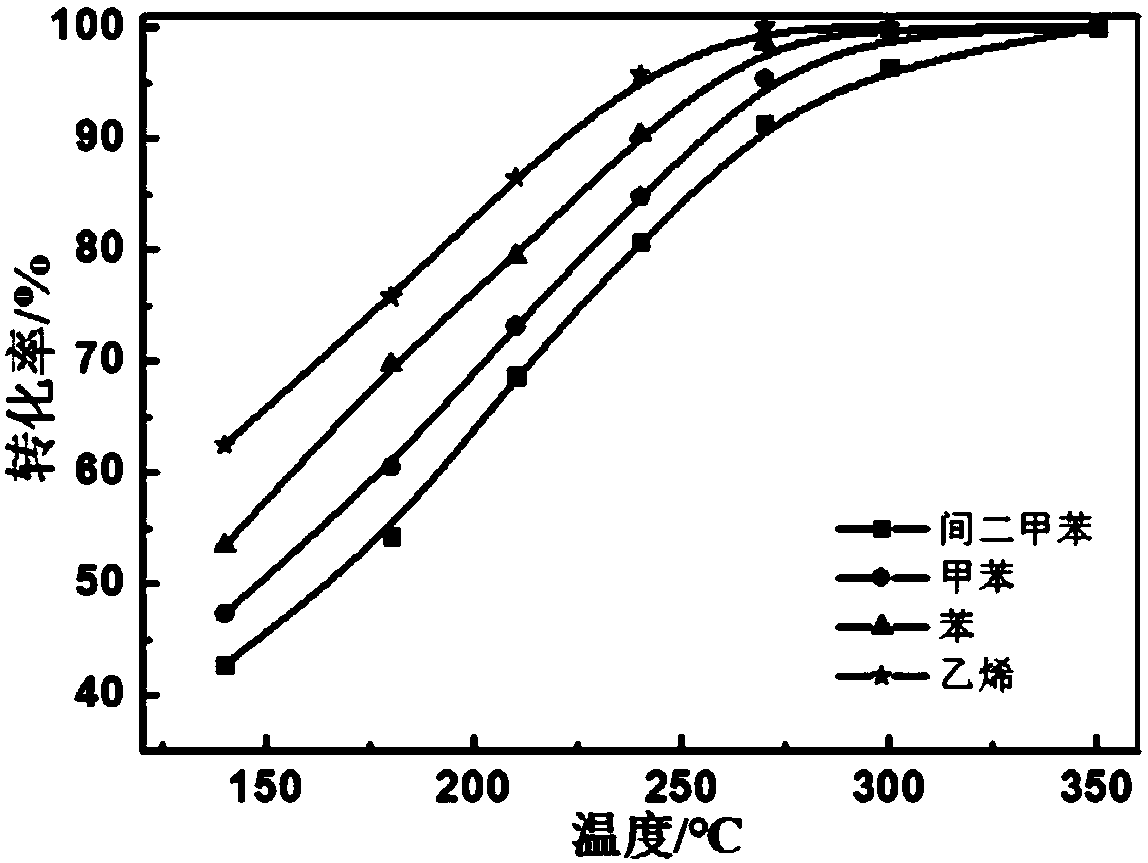

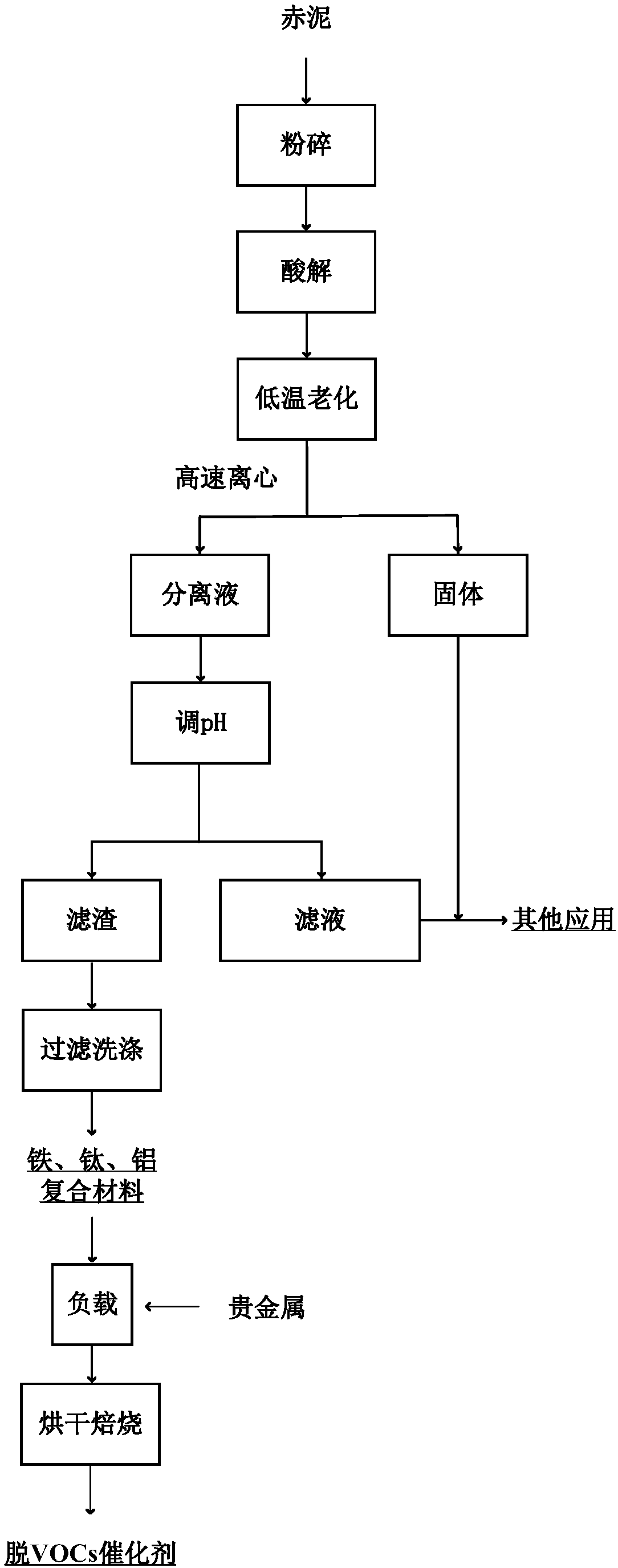

Catalyst prepared from red mud for removing volatile organic compound and preparation method of catalyst

ActiveCN108043404ARealize high-value utilizationReduce usageHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystEngineering

The invention provides a catalyst prepared from red mud for removing a volatile organic compound and a preparation method of the catalyst. The method comprises the following steps that 1, acid is added in the red mud, acidolysis leaching is conducted, first slurry is obtained after acidolysis, the first slurry is acidic, the first slurry is subjected to ageing, solid-liquid separation is conducted, and then a solid and separation liquid are obtained; 2, the pH of the separation liquid in step 1 is adjusted to be larger than or equal to 8.5, second slurry is obtained, the second slurry is subjected to solid-liquid separation to take a solid, and the obtained solid is an iron, titanium and aluminum composite precursor; 3, the iron, titanium and aluminum composite precursor obtained in step 2is calcined to obtain an iron, titanium and aluminum catalyst. In step 3, the iron, titanium and aluminum composite precursor serves as a carrier, noble metal is loaded on the iron, titanium and aluminum composite precursor, and a noble metal / iron, titanium and aluminum catalyst can be obtained. According to the preparation method, the steps are simple, high-value utilization of the red mud is achieved, and a wide industrial application prospect is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

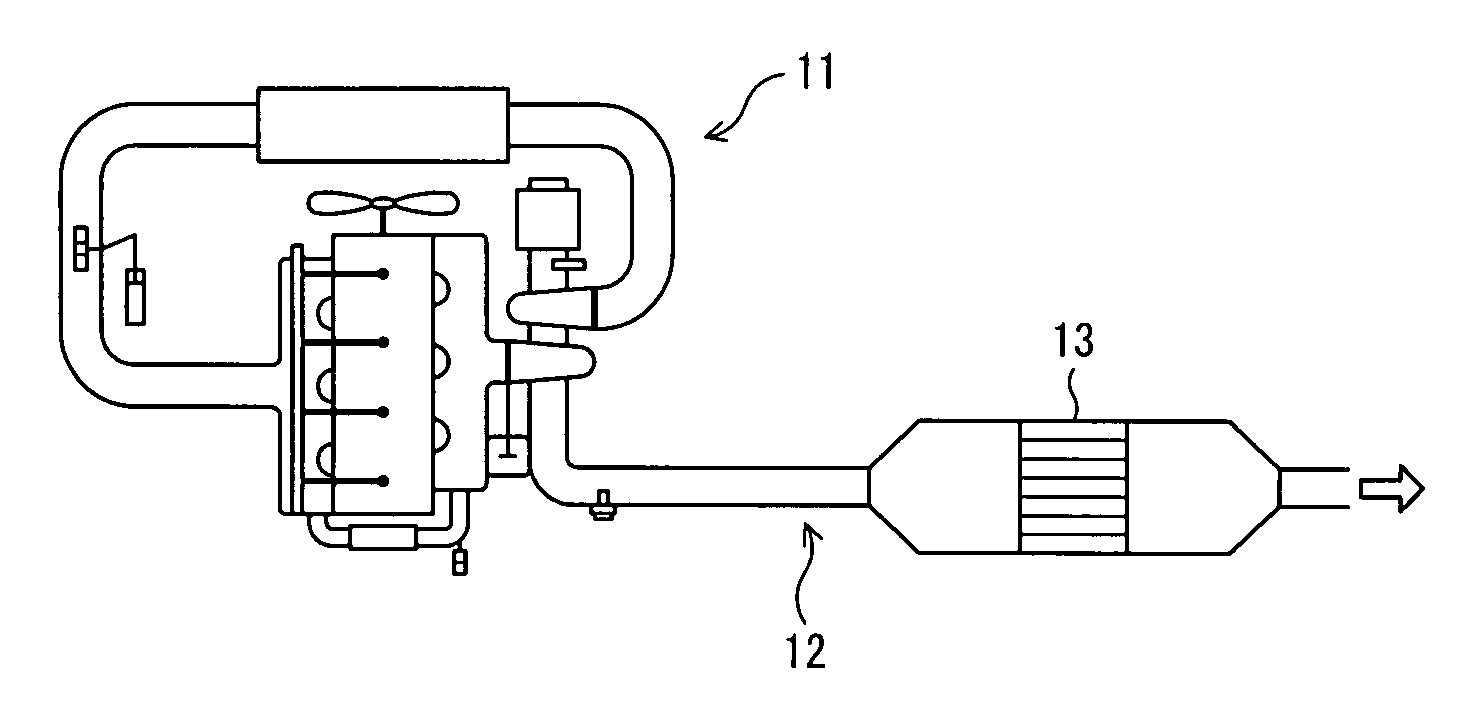

Diesel particulate filter and exhaust emission control system

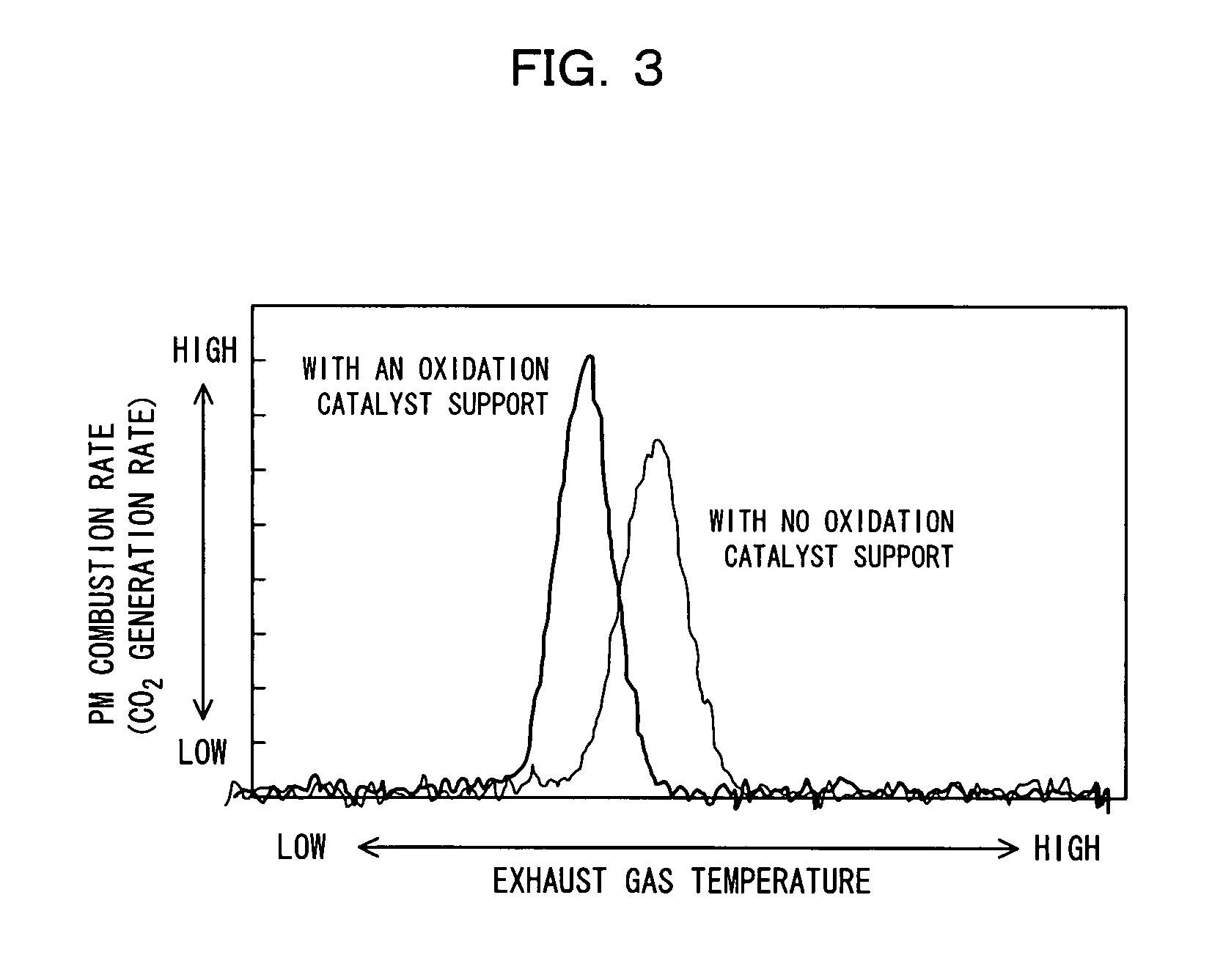

InactiveUS20070196246A1Low starting temperatureCombination devicesGas treatmentCombustionControl system

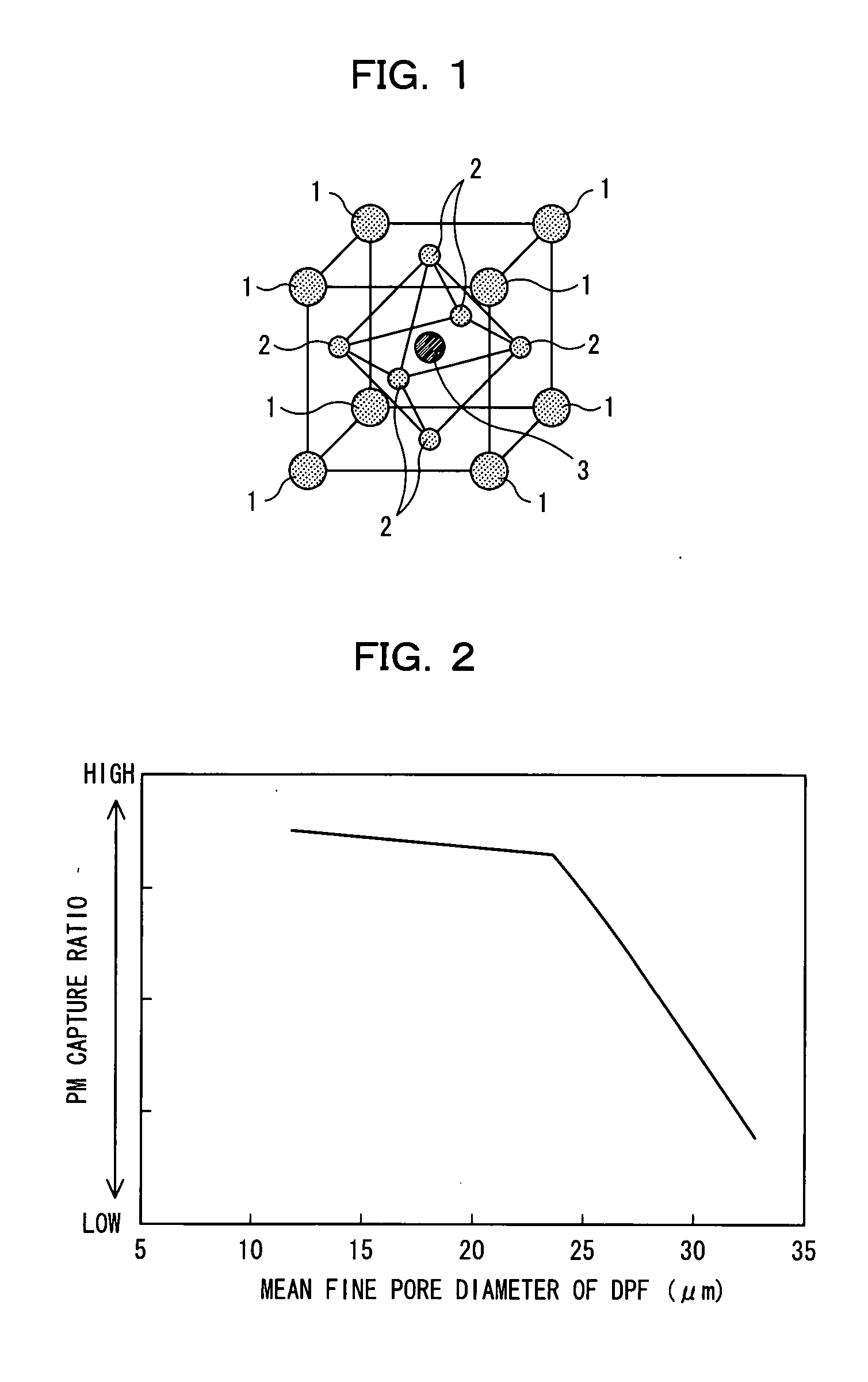

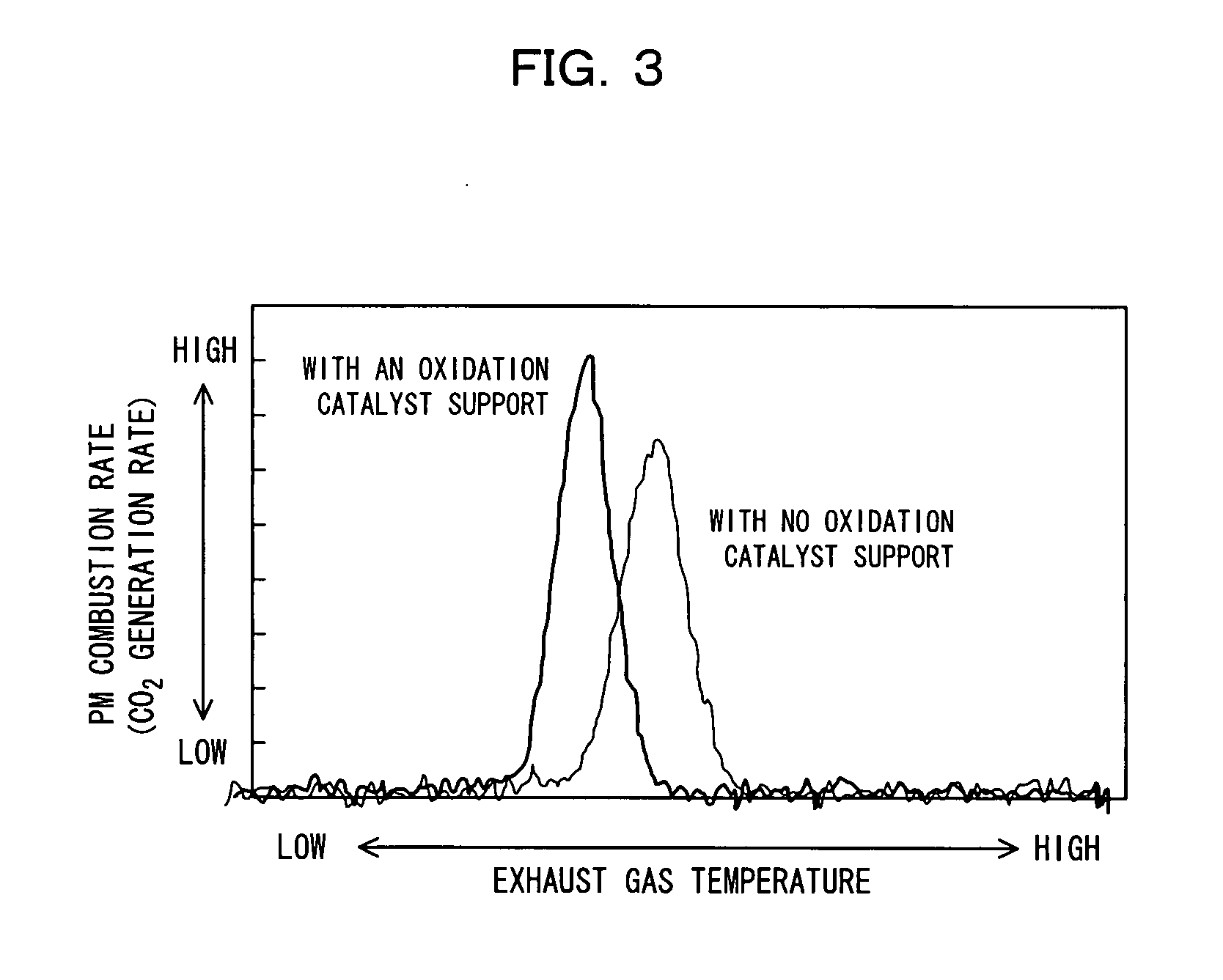

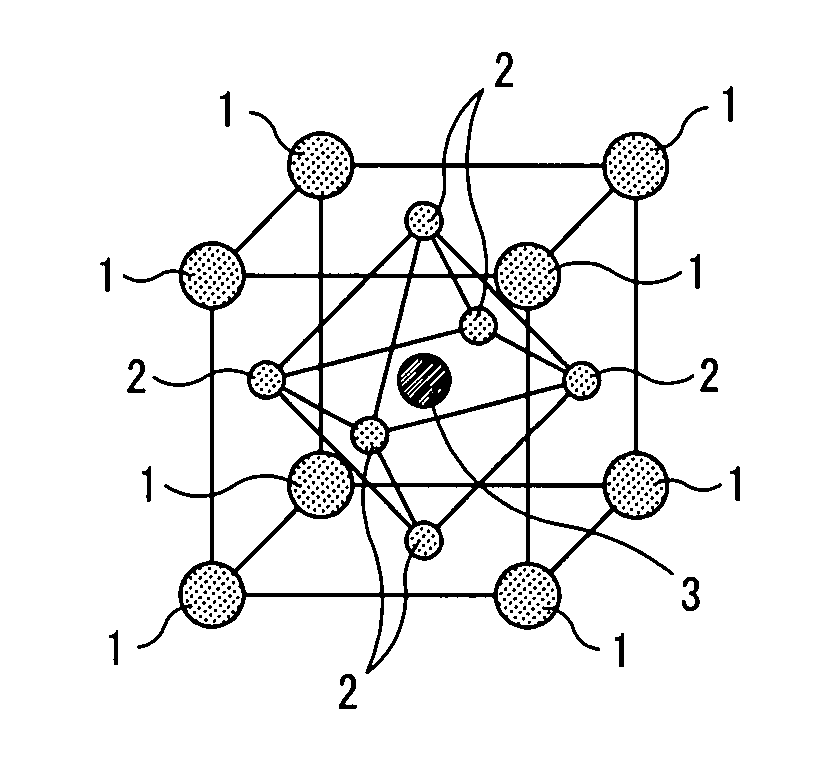

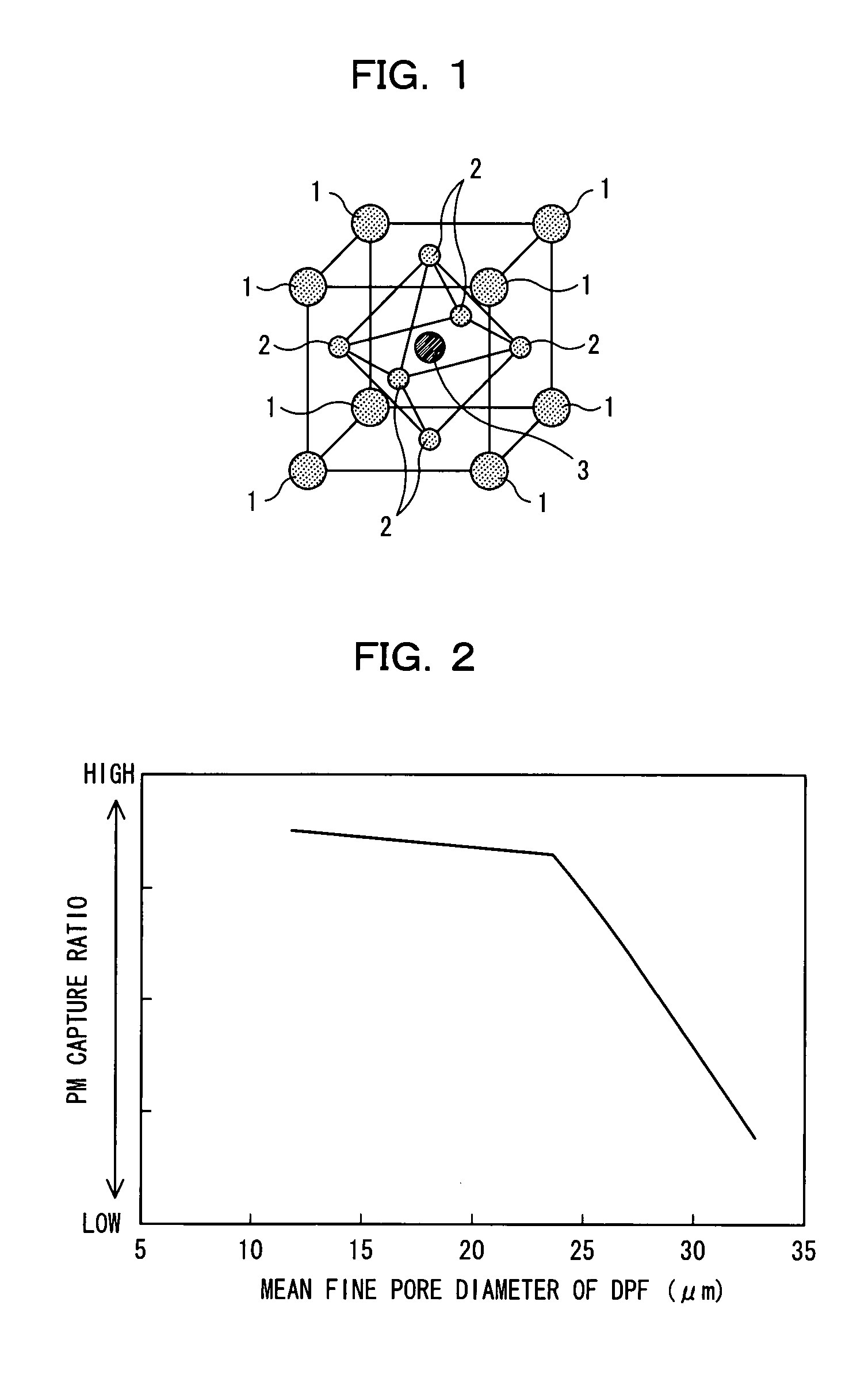

To provide a diesel particulate filter that can lower the PM combustion start temperature and use material containing Si for a carrier. The carrier which has a filter function is allowed to support a perovskite type complex oxide expressed by formula (1): La1−xBaxMnyFe1−yO3 (1) (where 0<x<0.7 and 0≦y≦1).

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Diesel particulate filter and exhaust emission control system

Diesel particulate filter that can lower the particulate matter (PM) combustion start temperature and use material containing silicon (Si) for a carrier. The carrier, which has a filter function, is allowed to support a perovskite-type complex oxide expressed by formula (1) as follows, wherein 0<x<0.7 and 0≦y≦1: formula (1)=La1-xBaxMnyFe1-yO3.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

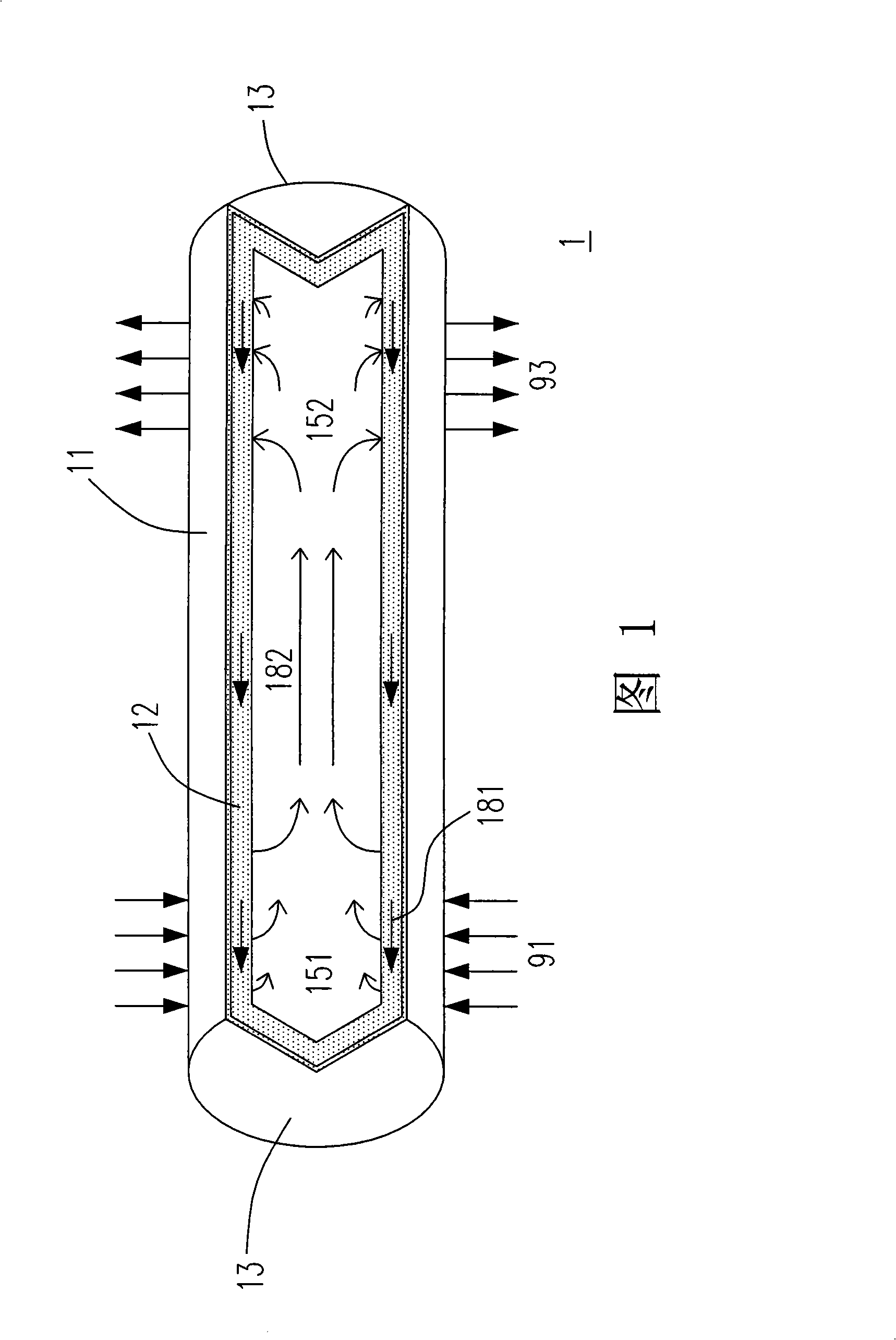

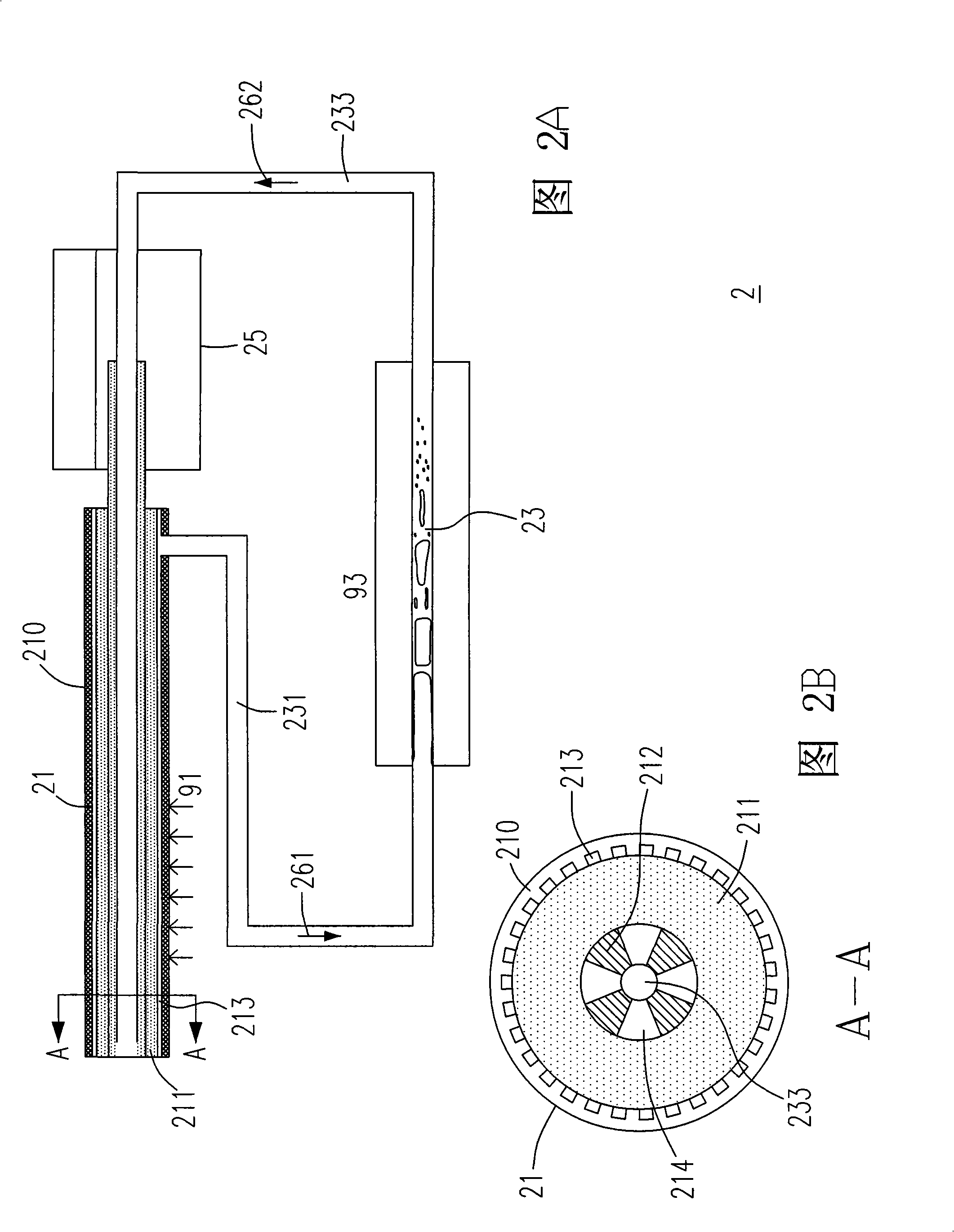

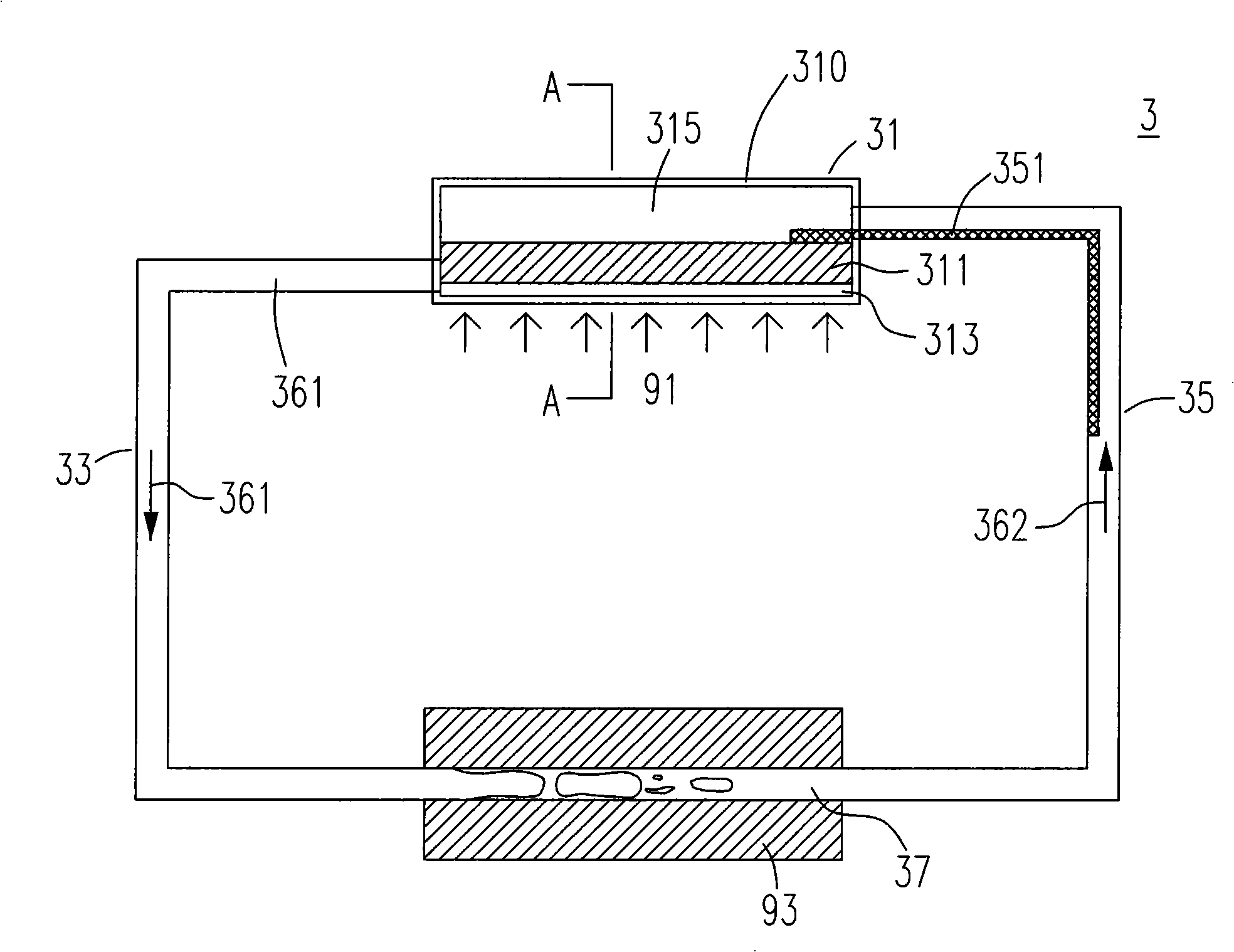

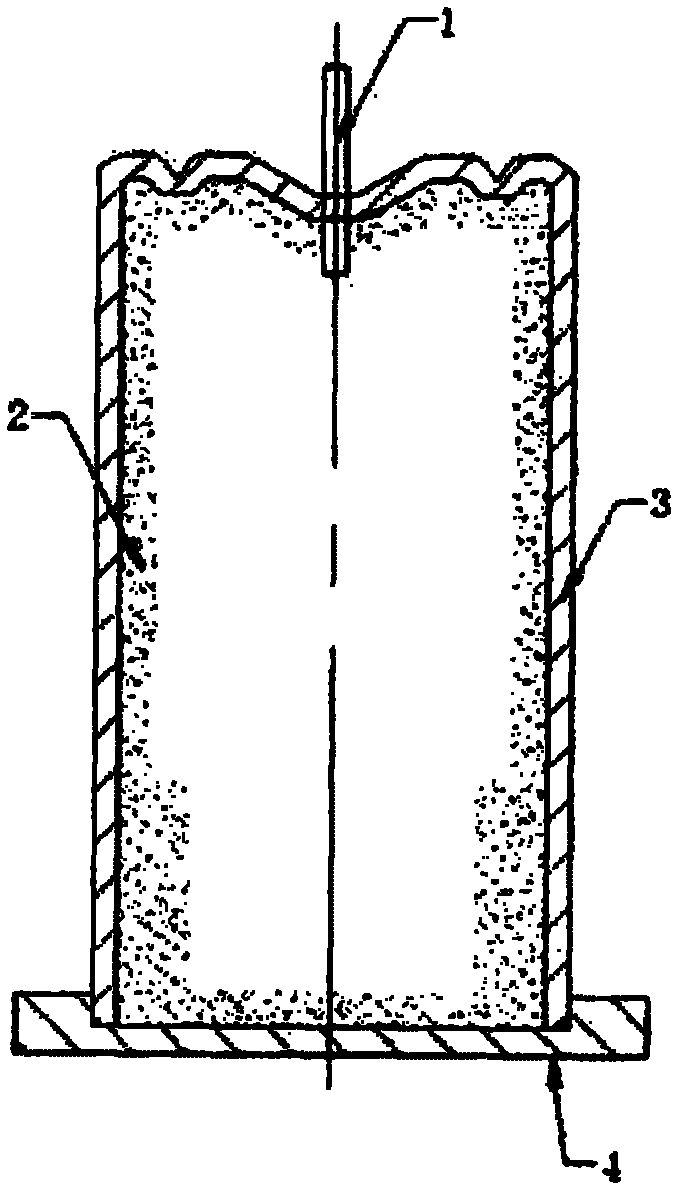

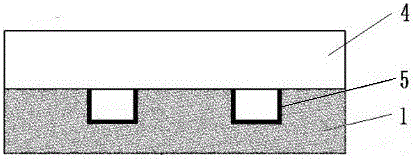

Flat type evaporator radiation system

InactiveCN101311662ALow starting temperatureIndirect heat exchangersCooling/ventilation/heating modificationsHeat conductingEngineering

The invention discloses a heat dissipation system which is used for increasing the efficiency of traditional heat conducting pipes, promoting the efficient utilization of space and reducing the temperature in starting the heat conducting pipe. The heat dissipation system comprises an evaporator, a steam channel, a condensing area and a condensate channel; wherein, one end of the steam channel is connected with the evaporator and the steam channel is used for conveying the steam from the evaporator; the other end of the condensate channel is connected with the condensing area which is used for condensing the stream into the condensate, and the condensate channel is connected with the condensing area and the evaporator and one of the condensing area and the evaporator is provided with a capillary structure; the condensate channel and the steam channel are connected with the condensing area by the evaporator; the condensate returns to the evaporator by the condensate channel and transforms into other steam by an outer heat source in the evaporator.

Owner:IND TECH RES INST

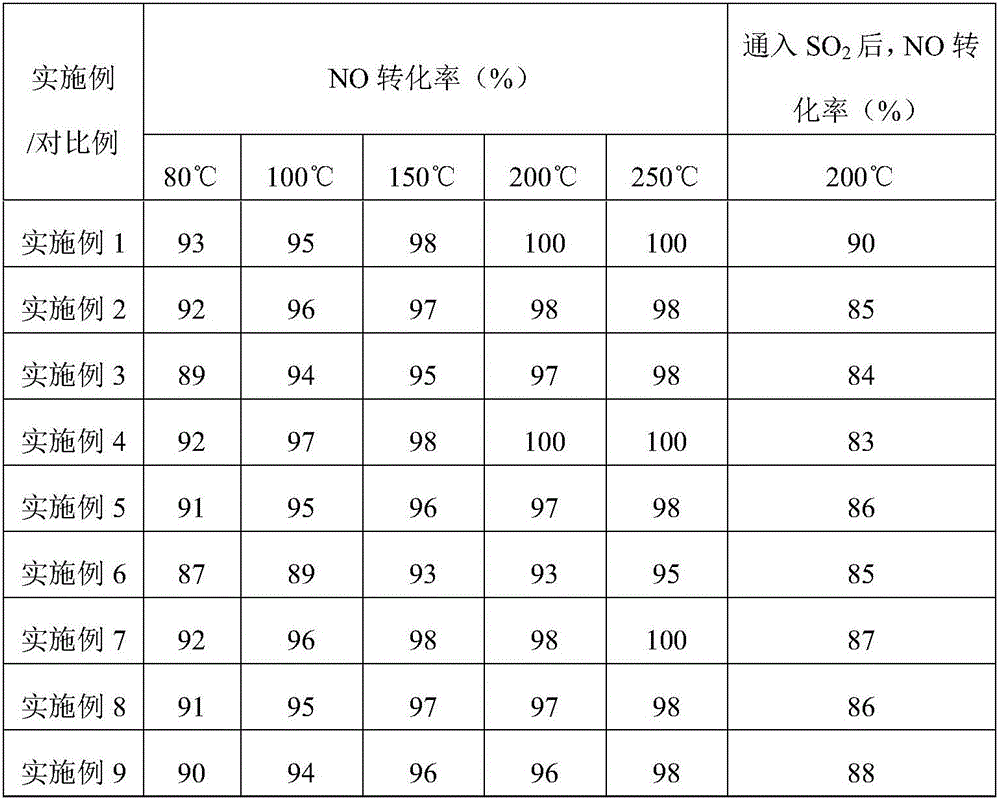

Cu-Mn bimetallic composite type low-temperature denitration catalyst and preparation method thereof

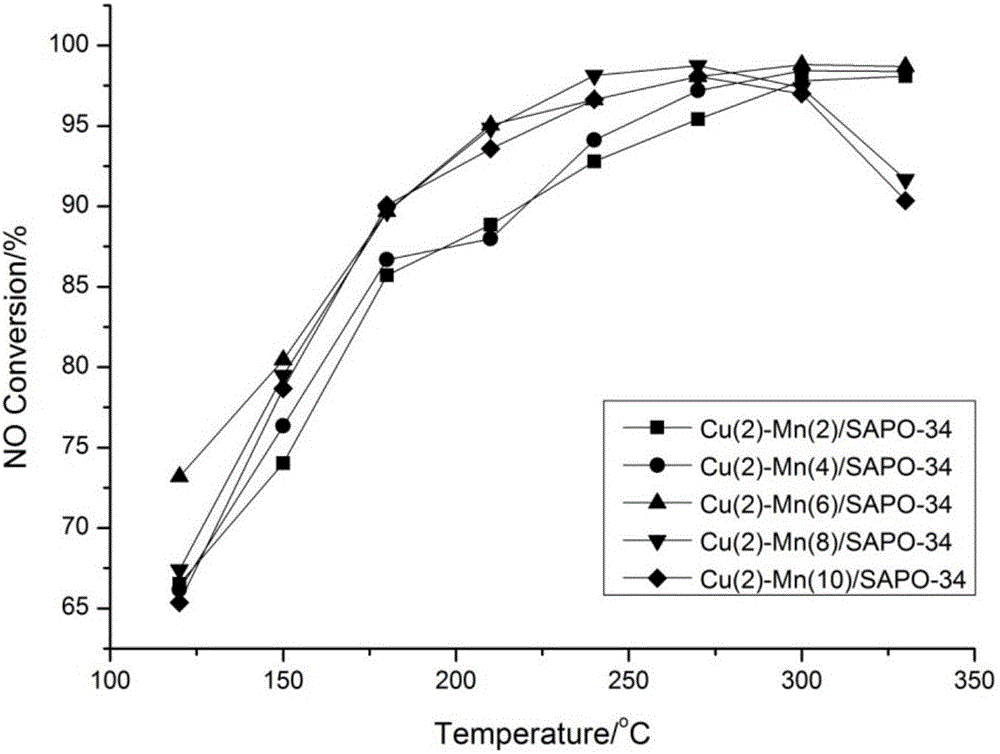

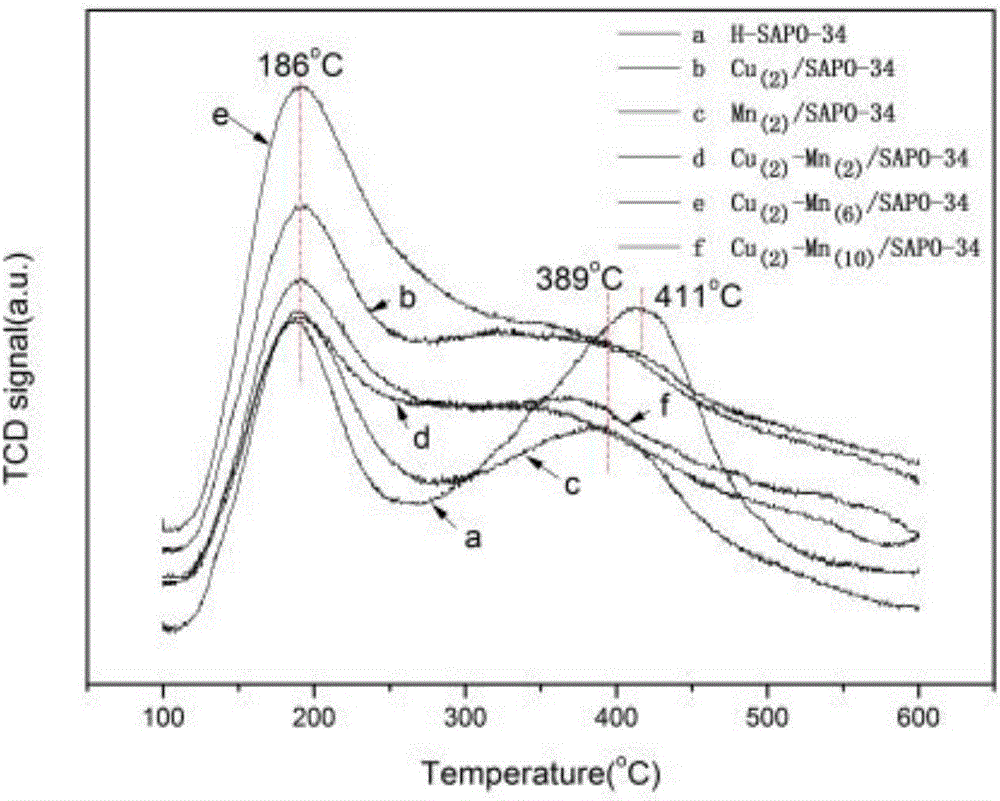

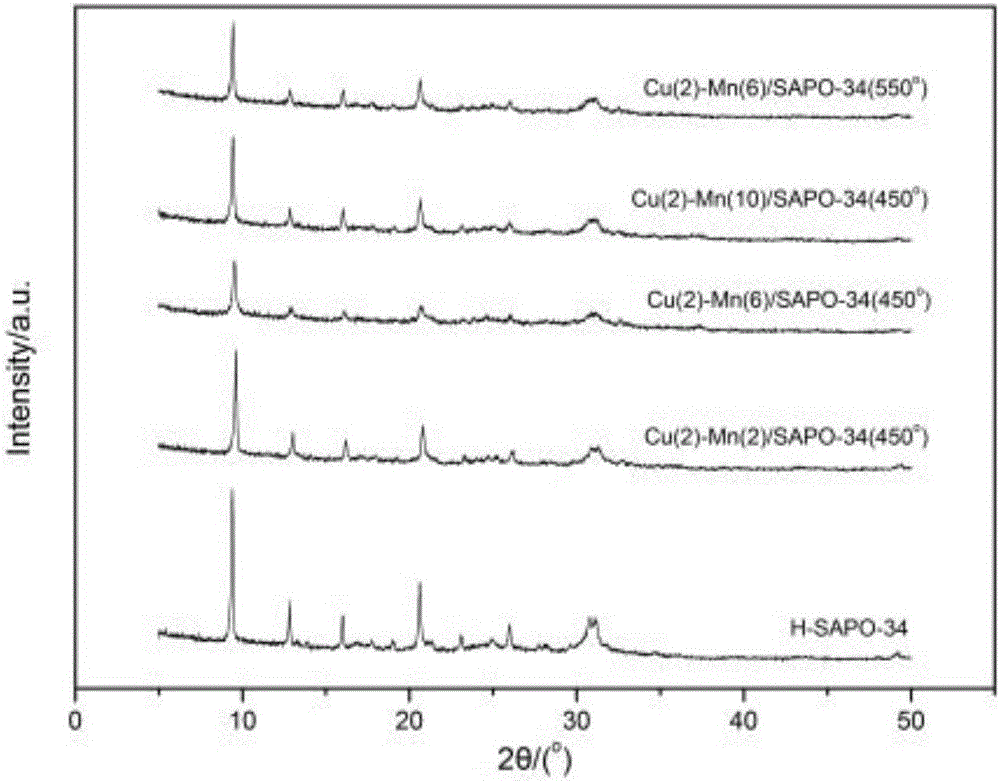

InactiveCN105854932ALow starting temperatureLower the temperature of the denitrification reactionMolecular sieve catalystsMolecular sieveActive component

The invention discloses a Cu-Mn bimetallic composite type low-temperature denitration catalyst and a preparation method thereof. The catalyst is prepared by using an immersion method. A chabasite molecular sieve H-SAPO-34 is taken as a carrier, and active components are composite oxides of transition metals Cu and Mn, wherein the weight percentages of the active components Cu and Mn are 2% to 10% respectively. According to the SCR catalyst disclosed by the invention, compared with a Cu-based or Mn-based catalyst of a single component, the denitration efficiency and heat stability of the catalyst are improved obviously by using a bimetallic synergistic effect, and the active temperature window of the catalyst is effectively widened; at the temperature of 180-350 DEG C, the conversion rate of NO can reach 90% or more.

Owner:SOUTHEAST UNIV

Amino compound-supported composite denitration catalyst, and preparation method and application thereof

ActiveCN107213917AImprove denitrification efficiencyHigh selectivityGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsInorganic saltsNitrogen

The invention relates to an amino compound-supported composite denitration catalyst, and a preparation method and an application thereof. The catalyst is prepared from 50-90 wt% of a carrier, 5-25 wt% of metal oxide and 5-25 wt% of an amino compound. The method comprises the following steps: weighing the carrier and a metal inorganic salt precursor, impregnating the carrier in an aqueous solution of a metal inorganic salt through an isopyknic impregnation technology, stirring the obtained solution, drying the stirred solution, introducing nitrogen, calcining the dried solution, weighing and dissolving the amino compound, impregnating the obtained calcined solid sample in the aqueous solution of the amino compound, and standing and drying the obtained solution to obtain the composite denitration catalyst. A fixed bed reactor is filled with the prepared composite catalyst, and normal pressure smoke is introduced and is denitrated. The catalyst has the characteristics of good economic property, energy saving, environmental protection, high denitration efficiency, and realization of repeated use of the recovered support amino compound, and is extremely suitable for the field of low temperature denitration of fixed sources.

Owner:EAST CHINA UNIV OF SCI & TECH

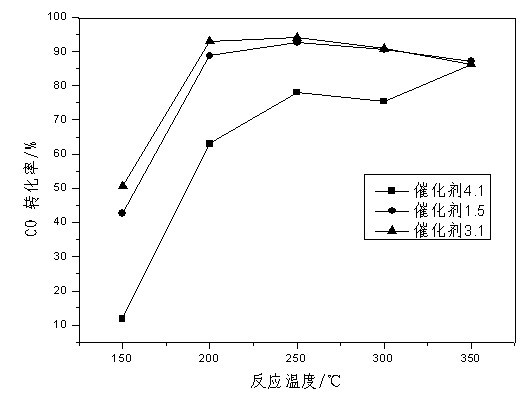

Cu-based low-temperature water gas conversion catalyst under hydrogen rich reformed gas and preparation method thereof

InactiveCN102091617AImprove low temperature catalytic activityLow starting temperatureHydrogenCombustible gas catalytic treatmentHydrogenReaction temperature

The invention relates to a low-temperature water gas conversion catalyst under hydrogen rich reformed gas and a preparation method thereof, and belongs to the technical field of water gas conversion processes and catalysts. The active ingredient in the catalyst is Cu, the carrier is monoclinic phase ZrO2, and the auxiliary agent is one or more of acidic oxide and rare earth oxide. During preparation, the carrier is prepared by using a hydrothermal method, and then the active ingredient is carried by using a co-precipitation method. Compared with other copper-based conversion catalysts, the catalyst prepared by the method has high water gas conversion catalysis activity, and particularly the low-temperature water gas conversion activity of the catalyst is remarkably improved. For example, the catalyst with 25 percent of CuO can achieve the CO conversion rate of 53 percent at the temperature of 150 DEG C, and the CO conversion rate at the reaction temperature of 200 to 300 DEG C is over 90 percent.

Owner:FUZHOU UNIV

Lead carbon compound material as well as preparation method and application thereof

InactiveCN105990578AAchieve homogeneous mixingControllable specific surface areaElectrode manufacturing processesCarbideSaline solutions

The invention discloses a lead carbon compound material as well as a preparation method and application thereof. The preparation method comprises the following steps of: adding alginic acid or alginate into a lead saline solution, thereby preparing lead alginate; carbonizing the lead alginate in a carbide furnace at a high temperature, thereby preparing a lead carbon compound material with a three-dimensional cellular structure and specific area of 1-3000m<3> / g; uniformly mixing lead with carbon, wherein the total content of lead and carbon is not less than 70% and the mass ratio of lead to carbon is (0.6-1.5):1. The lead carbon compound material can be used for further preparing anode and cathode materials of a lead carbon battery.

Owner:厦门百美特生物材料科技有限公司

Denitrification catalyst and preparation method thereof

ActiveCN105879858AFine particleUniform particle size distributionGas treatmentHeterogenous catalyst chemical elementsNiobiumFiltration

The invention discloses a denitrification catalyst and a preparation method thereof. The preparation method of the denitrification catalyst comprises the following steps: (1) preparing a Nb-containing solution; (2) adding a TiOx to the Nb-containing solution and obtaining a mixture through impregnation; (3) drying, grinding and roasting the mixture to obtain a Nb2O5-TiO2 carrier; (4) adding the Nb2O5-TiO2 carrier to a Mg and Ce salt solution to obtain a carrier-containing solution; (5) adding a precipitant and a surfactant to the carrier-containing solution, and obtaining the catalyst through cooling, pumping filtration or centrifugation, washing, drying and roasting. The denitrification catalyst prepared with the method has higher catalysis efficiency and wider low-temperature activity temperature range.

Owner:CHINA BUILDING MATERIALS ACAD

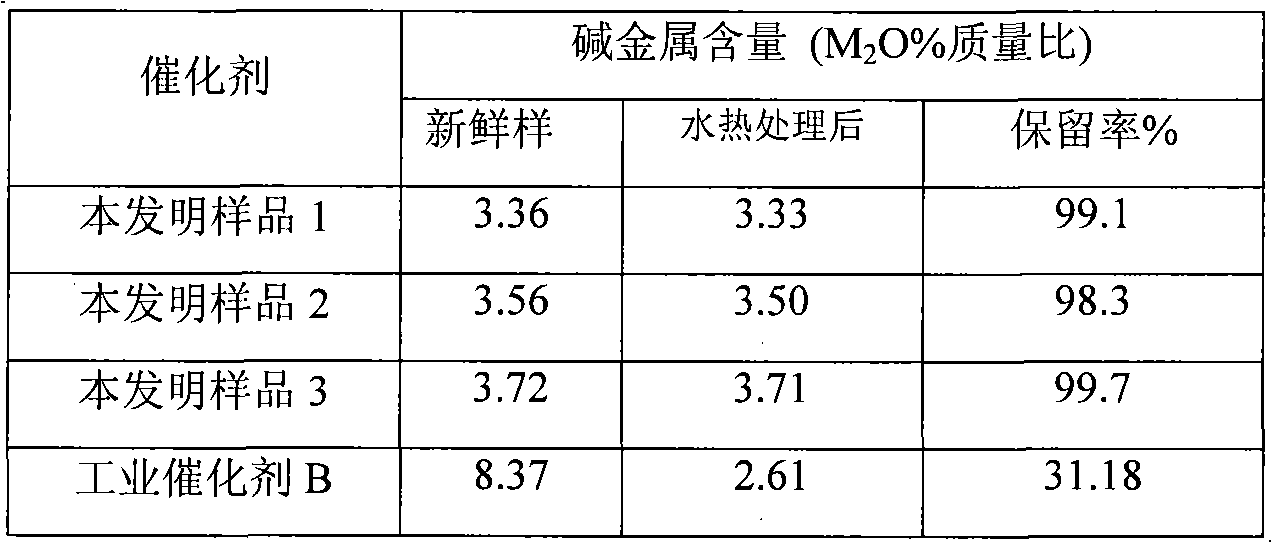

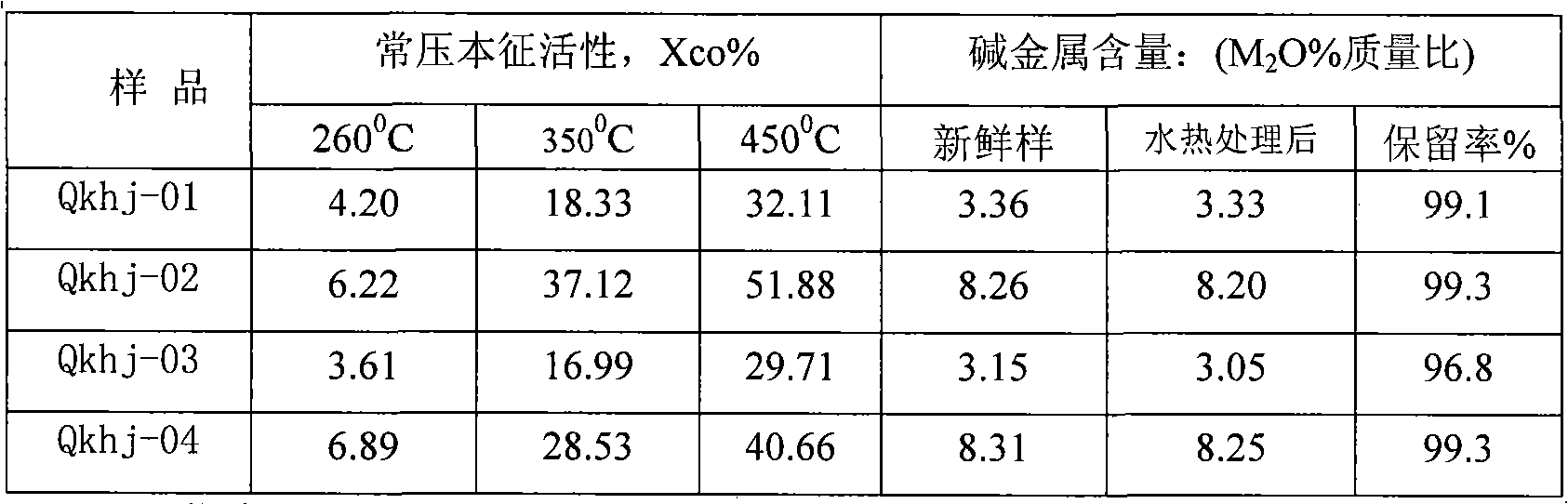

High voltage sulphur resistant translation catalyst of CO and preparation method thereof

ActiveCN101318137AHigh retention rateActivity hasMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideHigh pressure

The invention discloses a carbon monoxide high pressure sulfur-tolerant shift catalyst, comprising a catalyst active component, an alkali metal activated assistant and a carrier, which is characterized in that the alkali metal activated assistant is an alkali metal mineralizer. The alkali metal mineralizer is an albite, a potash feldspar, a sodium nepheline or / and a kalsilite, wherein, the sodium nepheline or / and a kalsilite is preferable. An alkali metal oxide accounts for 0.1 to 15 percent of the total weight of the catalyst. The invention also provides the preparation method of the catalyst. The operation technology is simple and the catalyst can be prepared by kneading, extruding and calcining. The prepared catalyst has low light-off temperature. Under the conditions of high pressure, high temperature and high water-gas ratio, the alkali metal has little drain rate or even no drain and has high strength and strength stability.

Owner:青岛联信催化材料有限公司

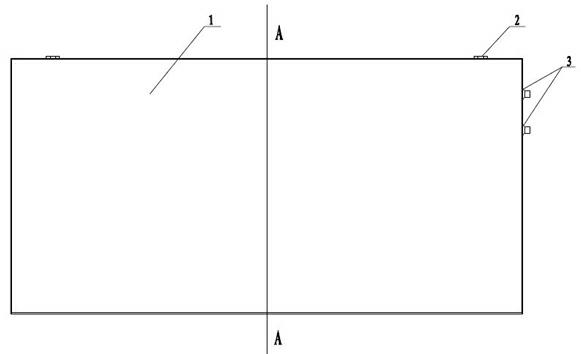

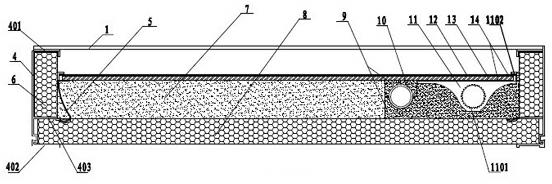

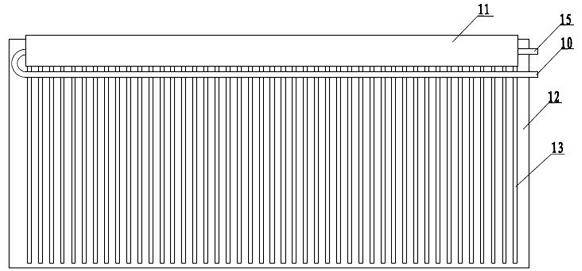

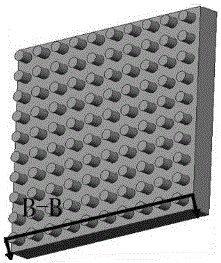

Balcony type microporous superconducting flat-plate solar thermal collector

InactiveCN102141307ASimple structureReasonable designSolar heating energySolar heat devicesCollector deviceEngineering

The invention relates to a balcony type microporous superconducting flat-plate solar thermal collector, and belongs to the technical field of flat-plate solar thermal collectors. The balcony type microporous superconducting flat-plate solar thermal collector comprises a frame, a transparent cover board arranged on the surface of the frame, and a heat insulating layer arranged inside the frame, wherein a heat absorption board core is arranged between the transparent cover board and the heat insulating layer; the heat absorption board core comprises a hollow flow passage pipe; the hollow wall of the flow passage pipe is provided with a rack for increasing a heat absorption area; and one or more microporous superconducting aluminum strips are inserted on the flow passage pipe; one or more superconducting liquid passages, the inner walls of which are provided with dentate structures, are arranged in the microporous superconducting aluminum strips; and the surface of the microporous superconducting aluminum strip is provided with a heat absorption layer. The thermal collector is convenient to install, the production cost is low, the thermal collecting efficiency is high and the freezing-proof effect is good.

Owner:黄山创鑫企业管理咨询有限公司

Vanadium-series loading type high-temperature SCR catalyst and preparation method thereof

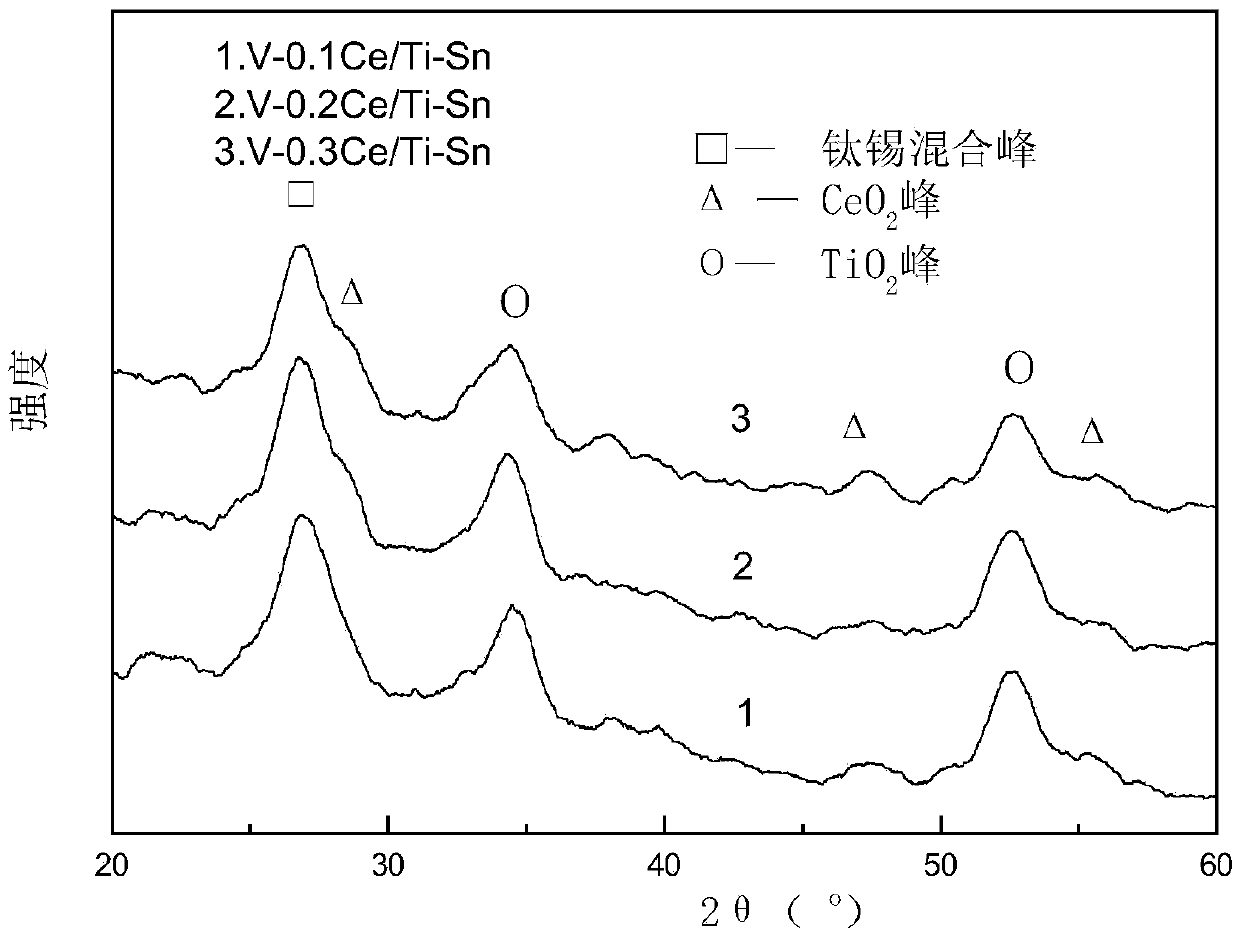

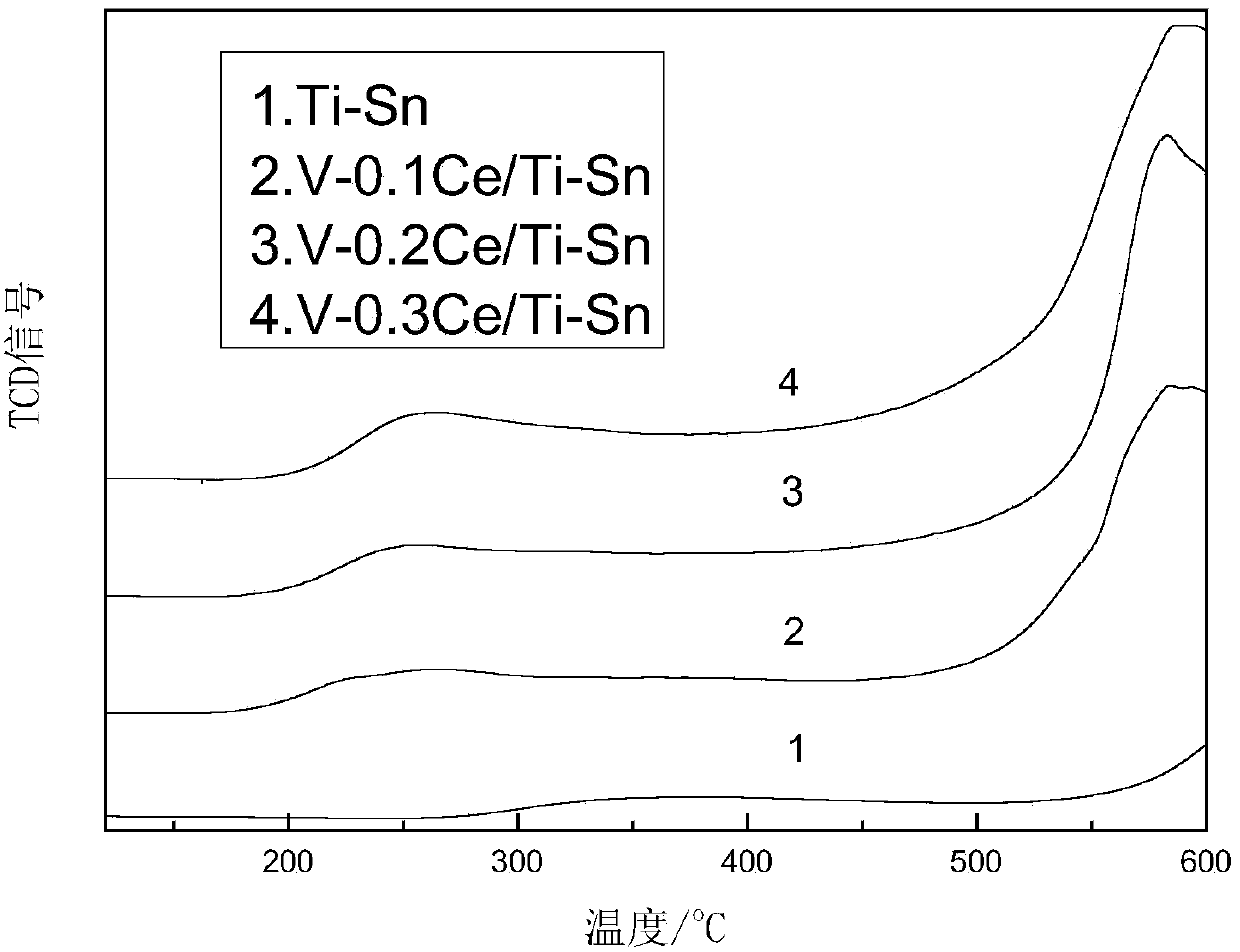

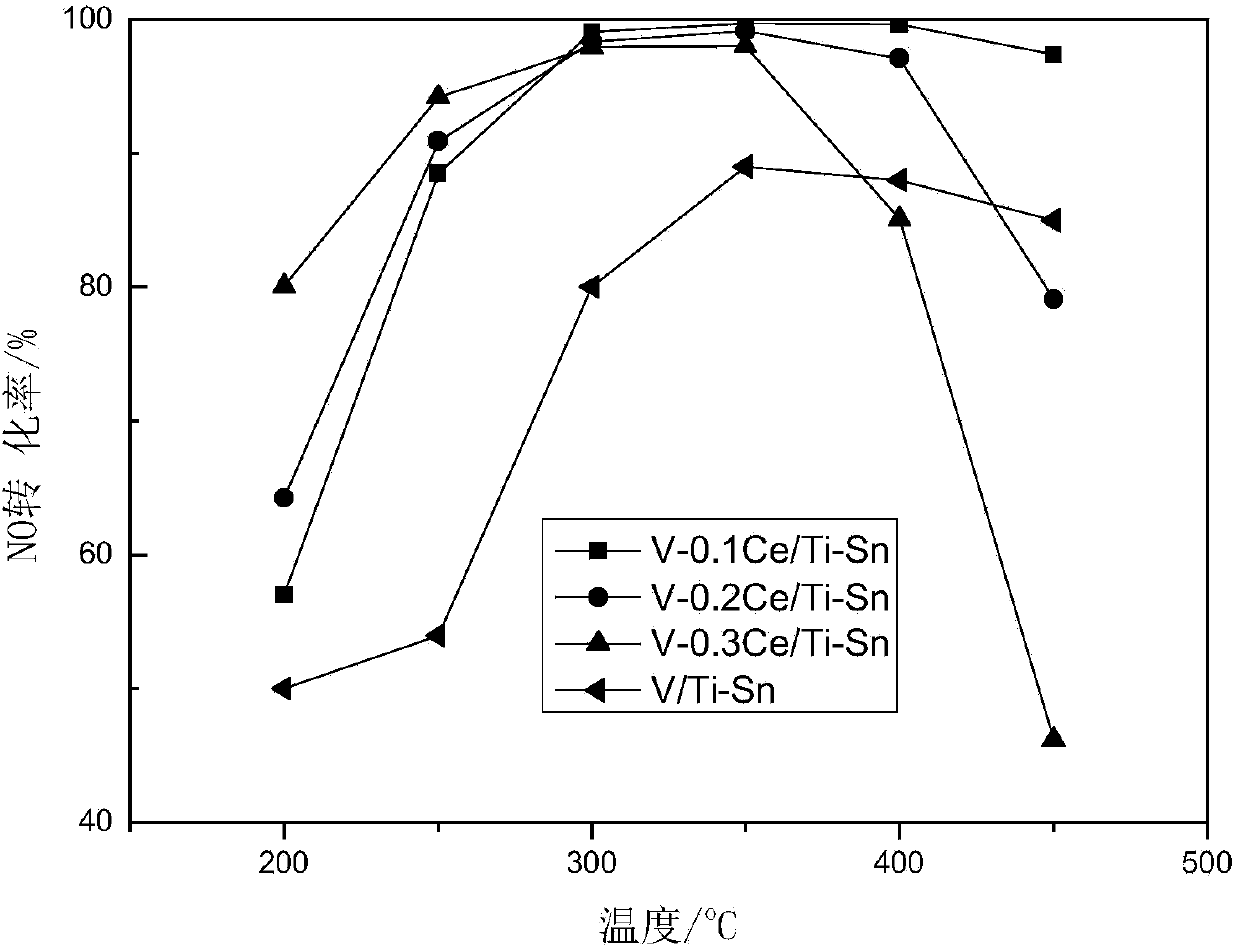

InactiveCN104209115AImprove heat resistanceLow reduction temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHeat resistanceActive component

The invention discloses a vanadium-series loading type high-temperature SCR catalyst. The vanadium-series loading type high-temperature SCR catalyst takes a titanium tin oxide as a carrier, takes an oxide of vanadium as an active component and takes an oxide of cerium as a cocatalyst, wherein the mol ratio of cerium to titanium to tin in the catalyst is (0.1-0.3) to 1 to 1; and the mass of the oxide of vanadium accounts for 1% of the whole mass of the catalyst. The invention further discloses a preparation method of the catalyst. Compared with a single vanadium-based catalyst, the vanadium-series loading type high-temperature SCR catalyst has the advantages that CeO2 is added, so that the heat resistance of the catalyst is improved; the reduction temperature of the catalyst is reduced and the denitration efficiency is improved; a selective catalytic reduction denitration active temperature window is widened; and the modification effect on a V2O5 / TiO2-SnO2 catalyst is very good.

Owner:SOUTHEAST UNIV

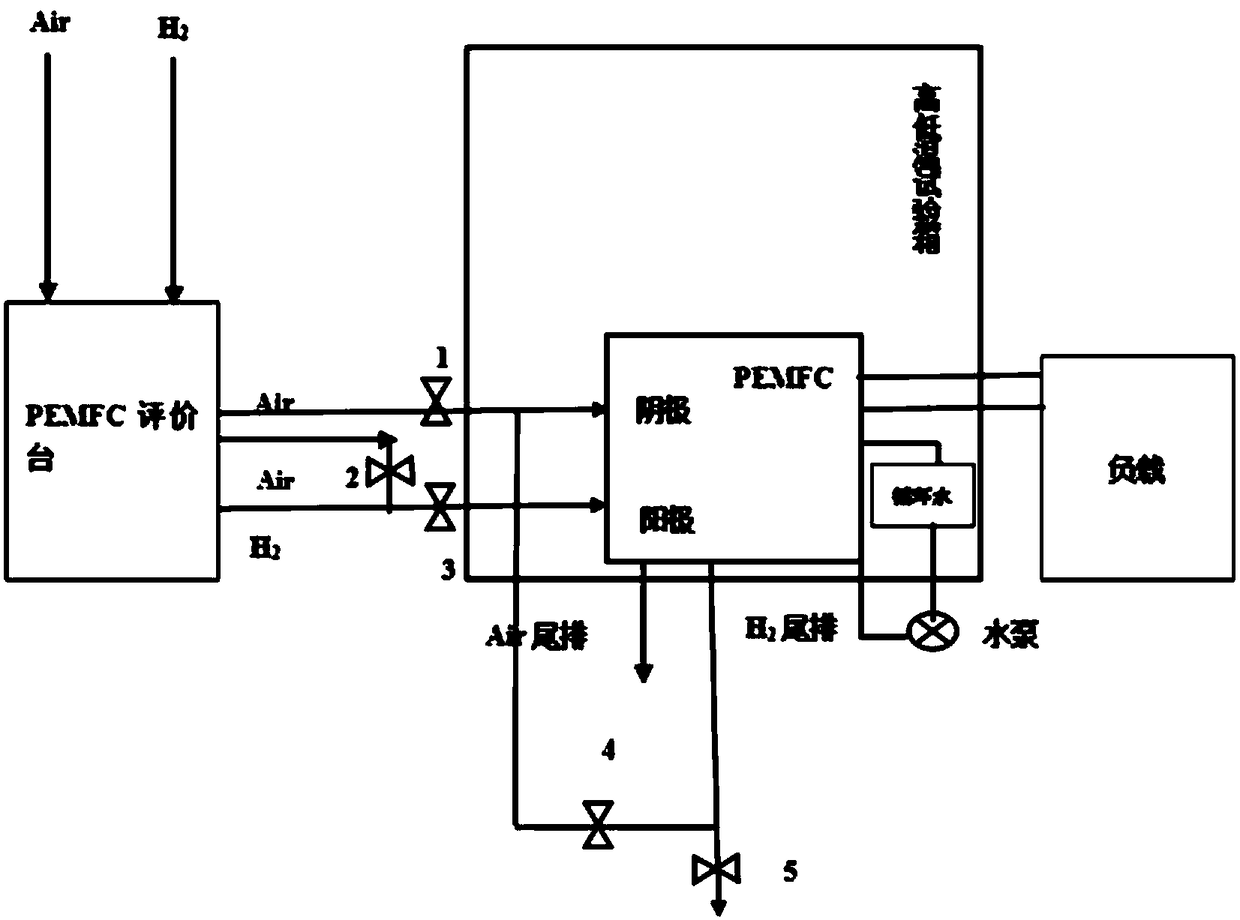

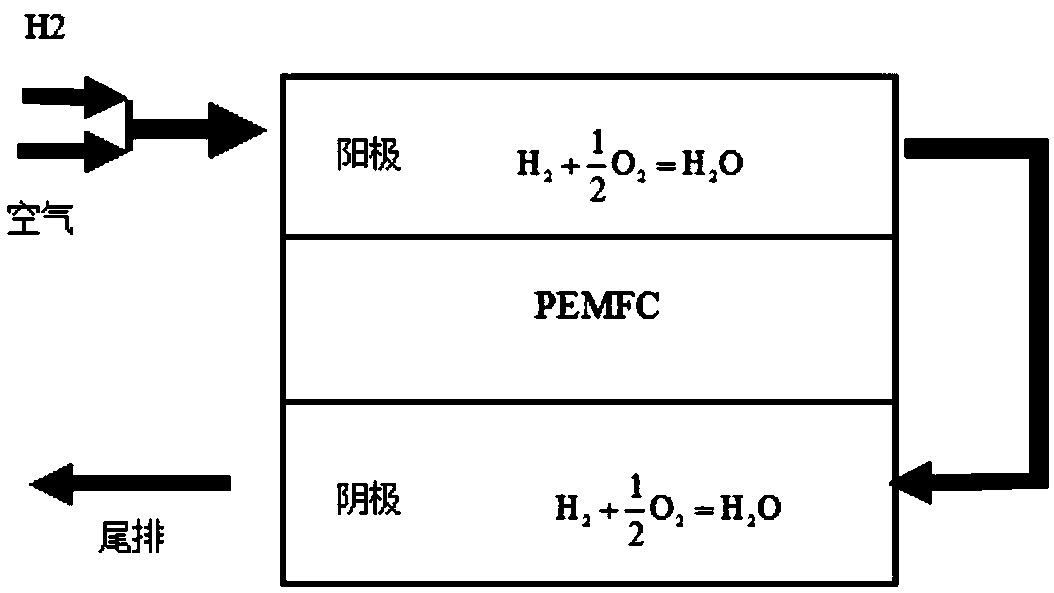

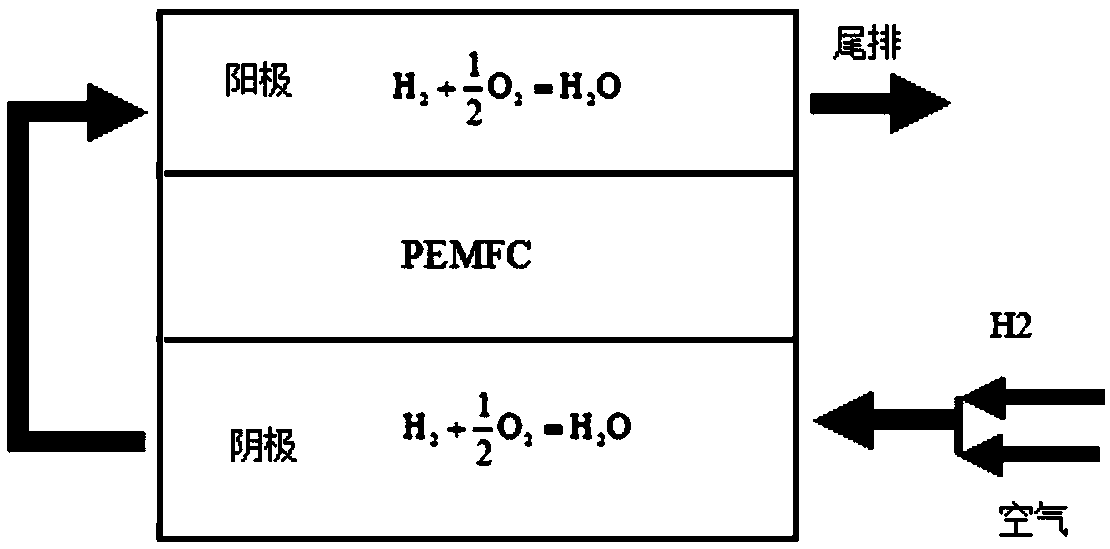

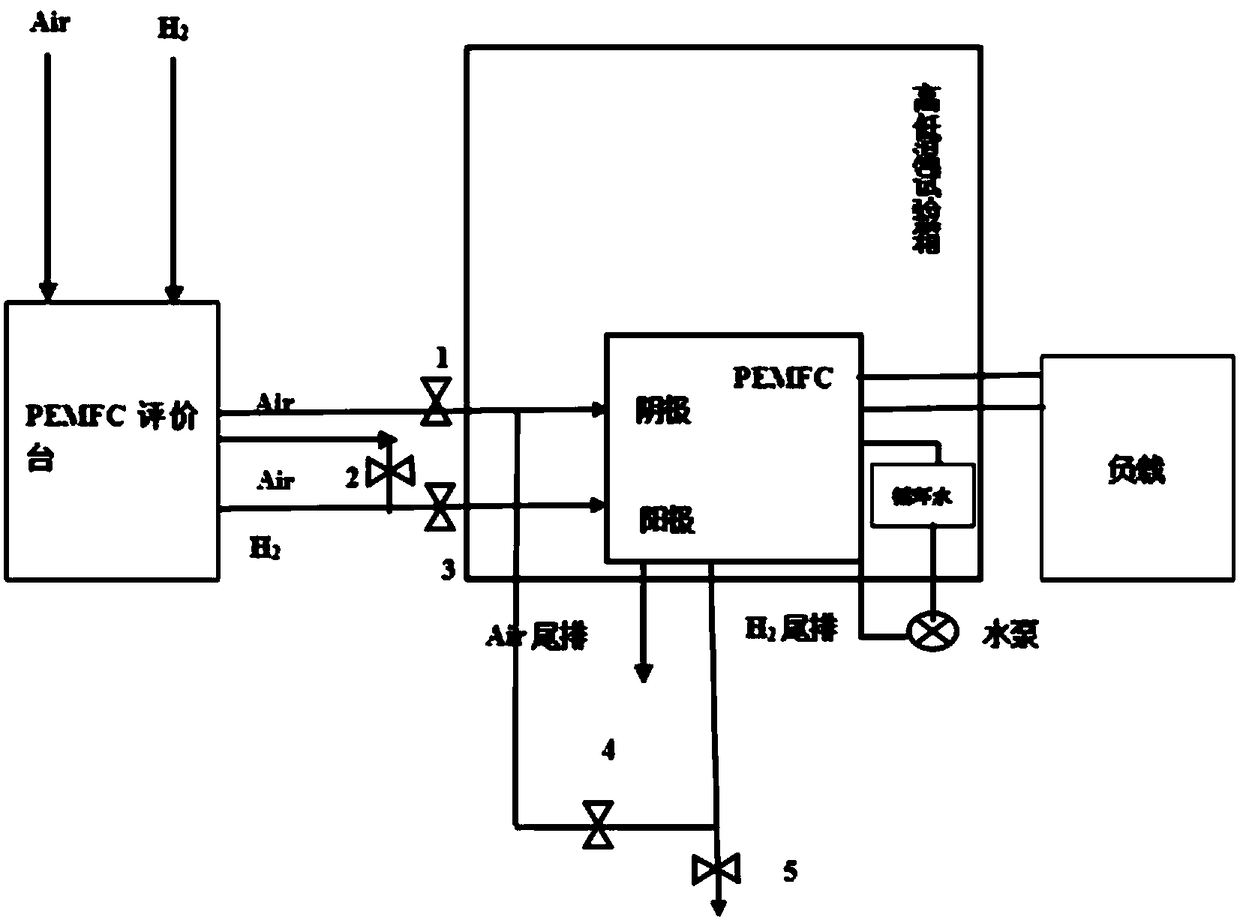

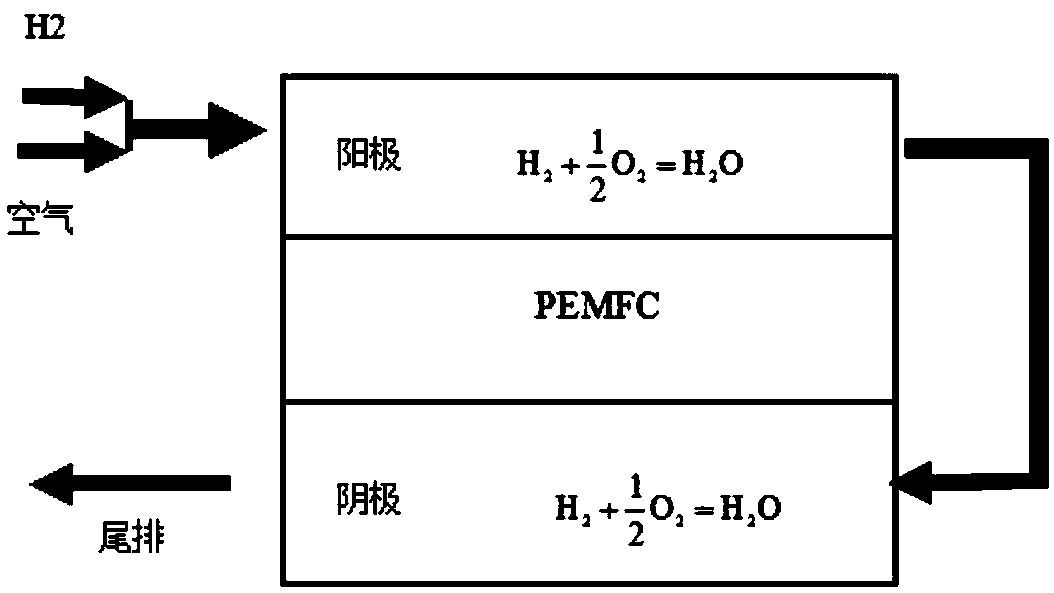

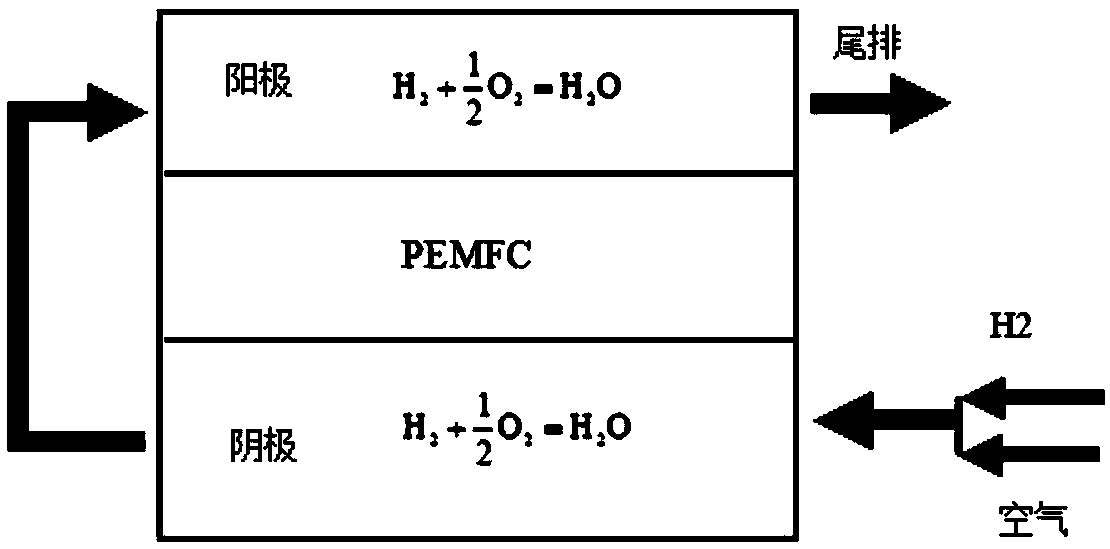

Method for starting proton exchange membrane fuel cell under low-temperature state

ActiveCN108711630AIncrease profitImprove utilization efficiencyFuel cell heat exchangeStart timeElectrical battery

The invention relates to a method for starting a proton exchange membrane fuel cell under a low-temperature state. A mixed gas is introduced to a positive electrode for catalytic pre-heating, a tail gas of the positive electrode is introduced to a negative electrode, so that the mixed gas which does not react generates catalytic reaction in the negative electrode, and the effect of simultaneouslyrising temperatures of the negative electrode and the positive electrode is achieved. The method is improved on the basis of a traditional catalytic cold-starting method, the negative electrode and the positive electrode can simultaneously generate catalytic reaction, heat is provided for the cell, low-temperature starting at -45 DEG C even a lower temperature range can be achieved, fuel can be fully utilized, the starting power consumption of the cell is reduced, and the low-temperature starting time is greatly reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Waste heat recovery for condensing type anti-corrosive gas/oil-fired boiler

ActiveCN102410550AReduce pollutionAchieve energy saving and emission reductionCorrosion preventionIndirect heat exchangersThermal energyWater vapor

The invention discloses a waste heat recovery for condensing type anti-corrosive gas / oil-fired boiler, which can effectively recover the physical heat of boiler flue; not only lots of sensible heat is recovered, but also the latent heat of vaporization discharged by condensation of water vapor. The structure is as follows: a common heat tube heat exchanger body and a solution spraying device are included. The heat tube heat exchanger body is used for transferring the heat from the flue side to the other side by the shock transmission of the heat tube, so as to heat the air or water; the solution sprayed by the sprayer is uniformly distributed in the heat exchange tube on the flue side and on the inner wall of the heat exchanger, so as to remove the corrosion from the weakly acidic solution formed by condensation of water vapor in the flue of the boiler.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

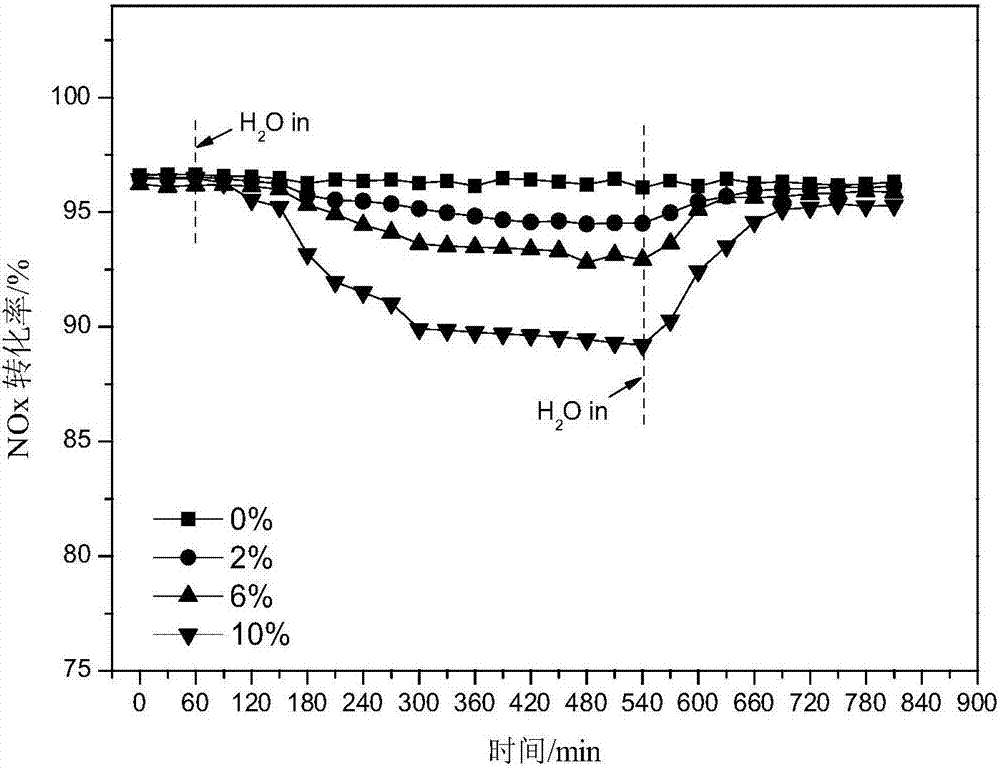

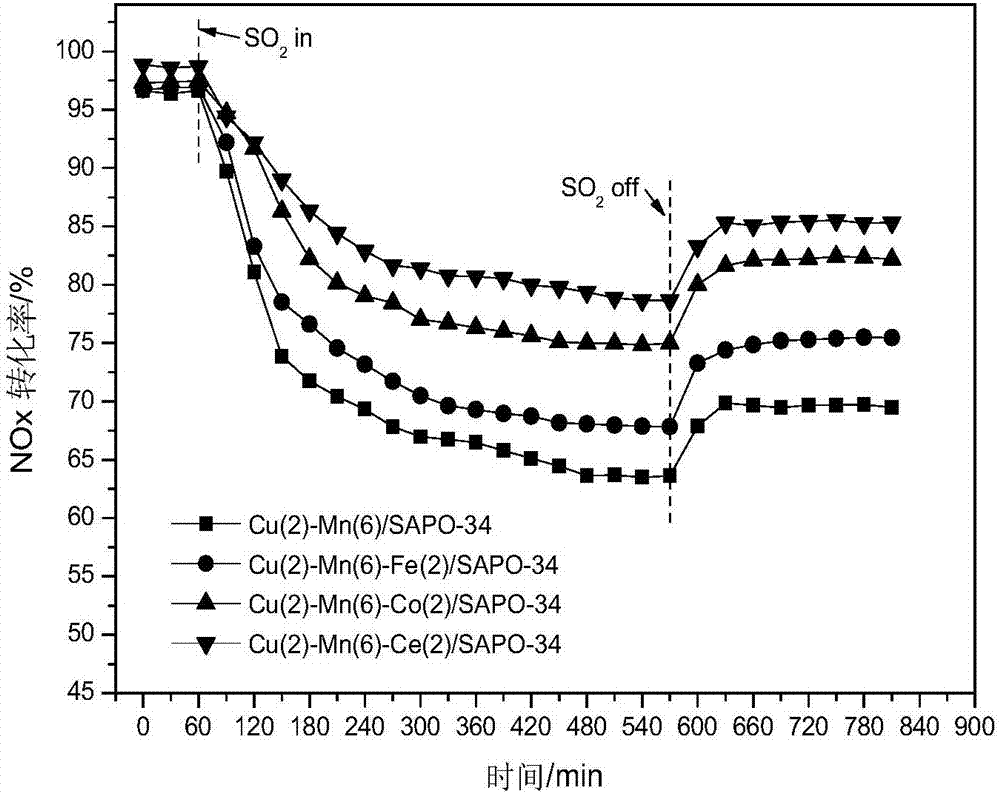

Sulfur-resistant and water-resistant low-temperature denitration composite molecular sieve catalyst and preparation method thereof

ActiveCN107185588ALow starting temperatureLower the temperature of the denitrification reactionGas treatmentMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a sulfur-resistant and water-resistant low-temperature denitration composite molecular sieve catalyst and a preparation method thereof. The catalyst is prepared by an impregnation method, a chabasite molecular sieve H-SAPO-34 serves as a support, an active component is a composite oxide of transition metal Cu and Mn, an additive is one of Ce, Fe, Co, Mo and Cr, the supported weight of a copper element and a manganese element in the active component is 2%-10% in weight percentage, and the supported weight of additive is 1-10% in weight percentage. Compared with a Cu or Mn-based catalyst of a single component, the denitration composite molecular sieve catalyst remarkably improves denitration efficiency and heat stability by the aid of multi-metal synergistic effect, an active temperature window of the catalyst is effectively widened, and the catalyst has good sulfur resistance.

Owner:SOUTHEAST UNIV

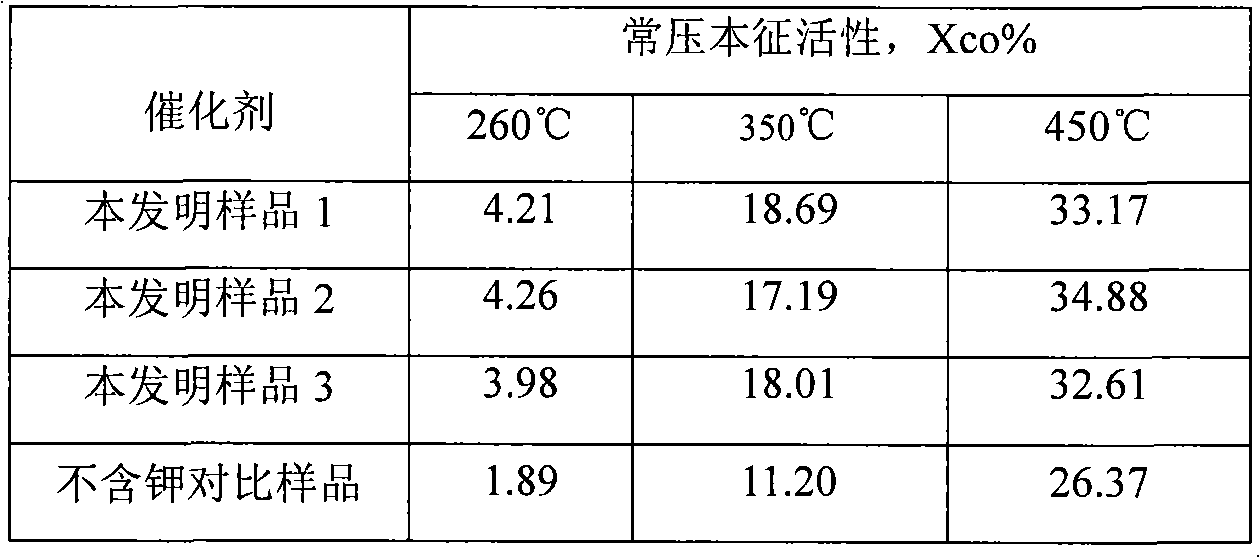

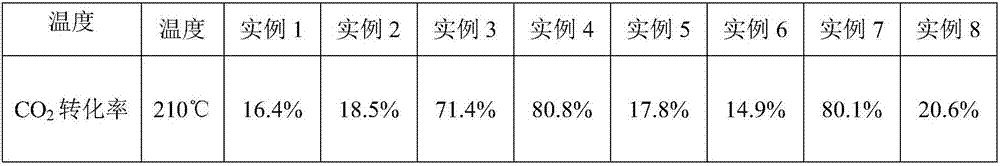

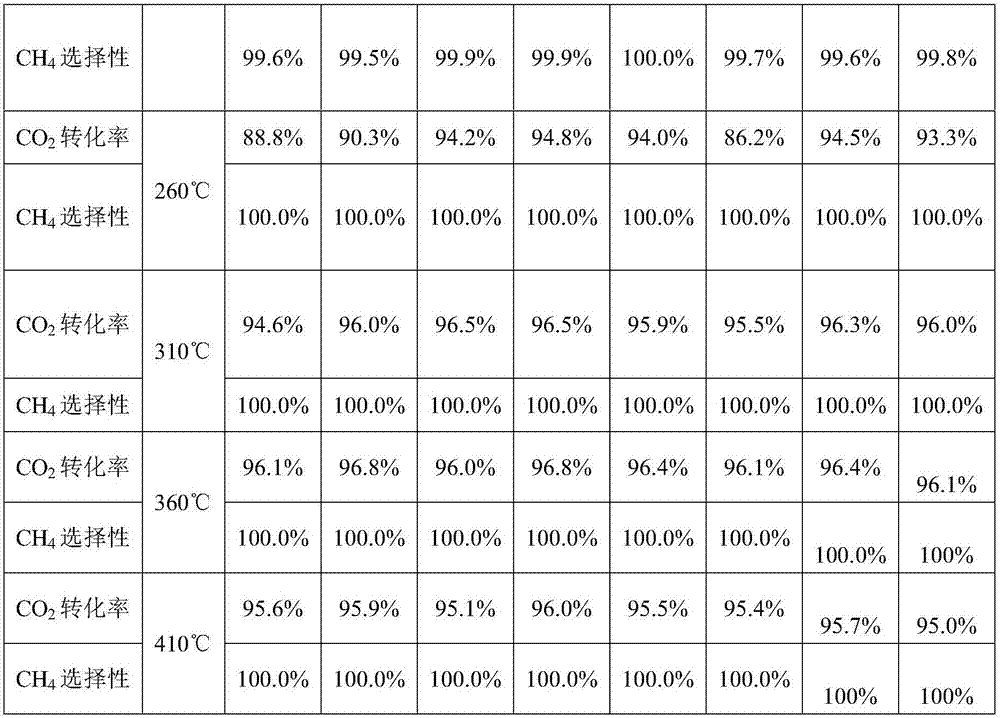

Low temperature high activity carbon dioxide methanation catalyst and preparation method thereof

ActiveCN107376925ALow starting temperatureStrong interactionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationHydrolysis

The invention provides a low temperature high activity carbon dioxide methanation catalyst and a preparation method thereof. CO(NH2)2 is used to replace NaOH and Na2CO3 to avoid the introduction of Na <+> ions. CO(NH2)2 slowly carries out hydrolysis at a temperature of 90 to 120 DEG C to generate OH<-> and CO2<-> for precipitation so that uniform precipitate [Ni<1-x><2+>Al<x><3+>(OH)<2>]<x+>(CO3)<x / 2><2-> is generated. The precipitate is subjected to centrifugation, filtering, washing, drying, and burning to obtain a nickel-aluminum hydrotalcite catalyst precursor; and then potassium carbonate and calcium aluminate cement are added to carry out wet milling, kneading, flattening, and moulding to prepare a finished methanation catalyst. The preparation method has the advantages of simple technology, low cost, high catalyst strength, and long service life of catalyst. The methanation catalyst is activated at a temperature about 150 to 250 DEG C. When the temperature reaches 260 to 400 DEG C, the CO2 conversion rate can reach 90% or more, and the CH4 selectivity is close to 100%. The hydrothermal stability of the catalyst is good.

Owner:CHINA HUANENG GRP CO LTD +1

Method for preparing synthetic natural gas low-ruthenium methanation catalyst

InactiveCN103464148ALow starting temperatureLarge specific surface areaGaseous fuelsCatalyst activation/preparationPtru catalystMethanation

The invention discloses a method for preparing a synthetic natural gas low-ruthenium methanation catalyst, and belongs to the field of catalysts and fine chemical engineering. According to the method, gamma-type aluminum oxide is infiltrated by the solution of soluble titanium compounds, dried and roasted to obtain composite support TiO2 / Al2o3, and is then impregnated in the solution of soluble ruthenium compounds in an equivalent-volume impregnation mode, the obtained impregnant is dried and roasted to obtain the synthetic natural gas low-ruthenium methanation catalyst, and the carrying capacity of Ru is 0.3-2.0% by weight. The prepared Ru / TiO2-Al2O3 catalyst gets a good result in a CO methanation reaction evaluation. The synthetic natural gas low-ruthenium methanation catalyst has big specific surface area, is high in catalytic activity,low in sensibility to poisons, good in stability, low in starting temperature, simple in preparation process, feasible economically and used for the inlet of a synthetic natural gas one-stage methanator, can reduce synthetic natural gas preheating temperature, and reduces heat energy consumption.

Owner:大连瑞克科技股份有限公司

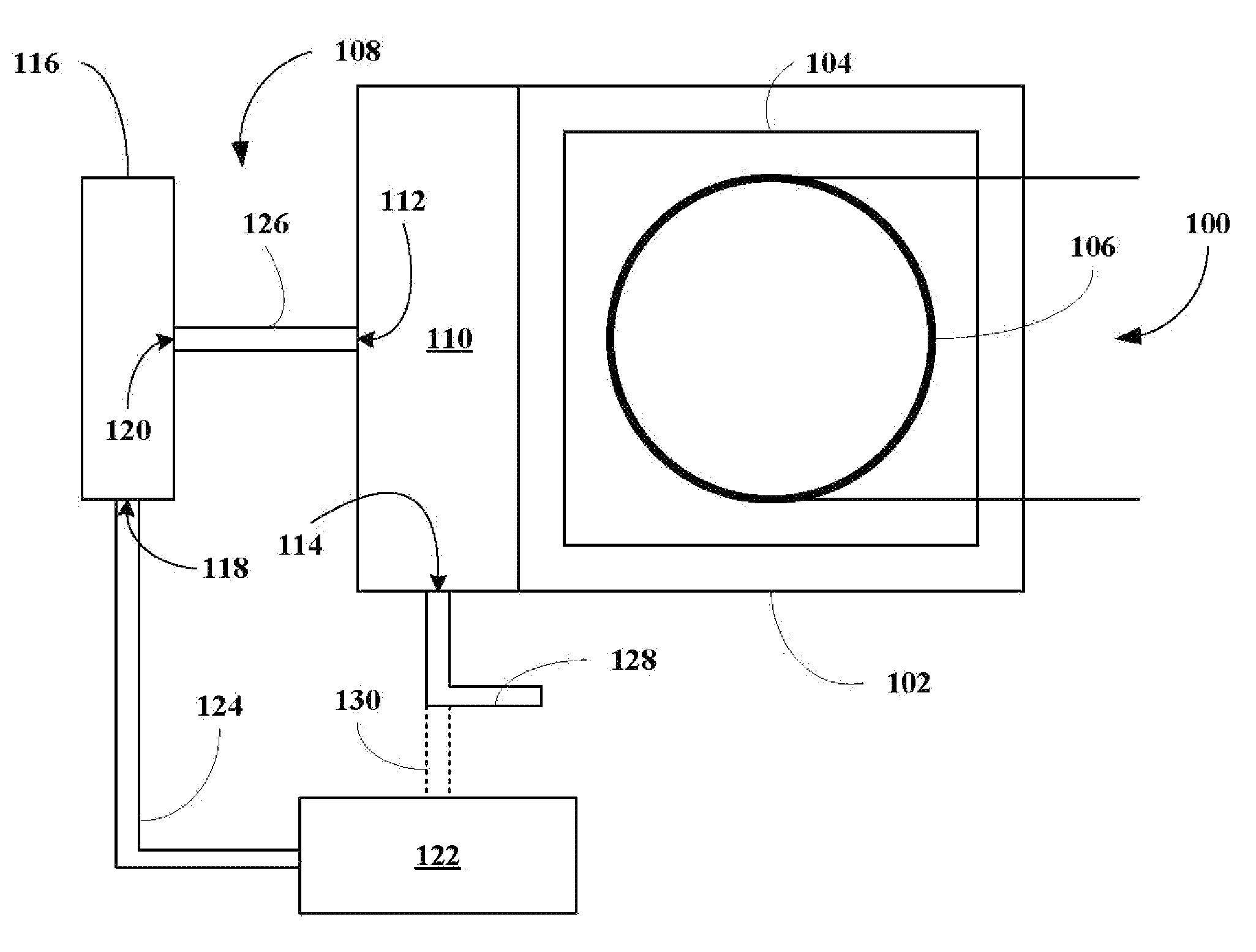

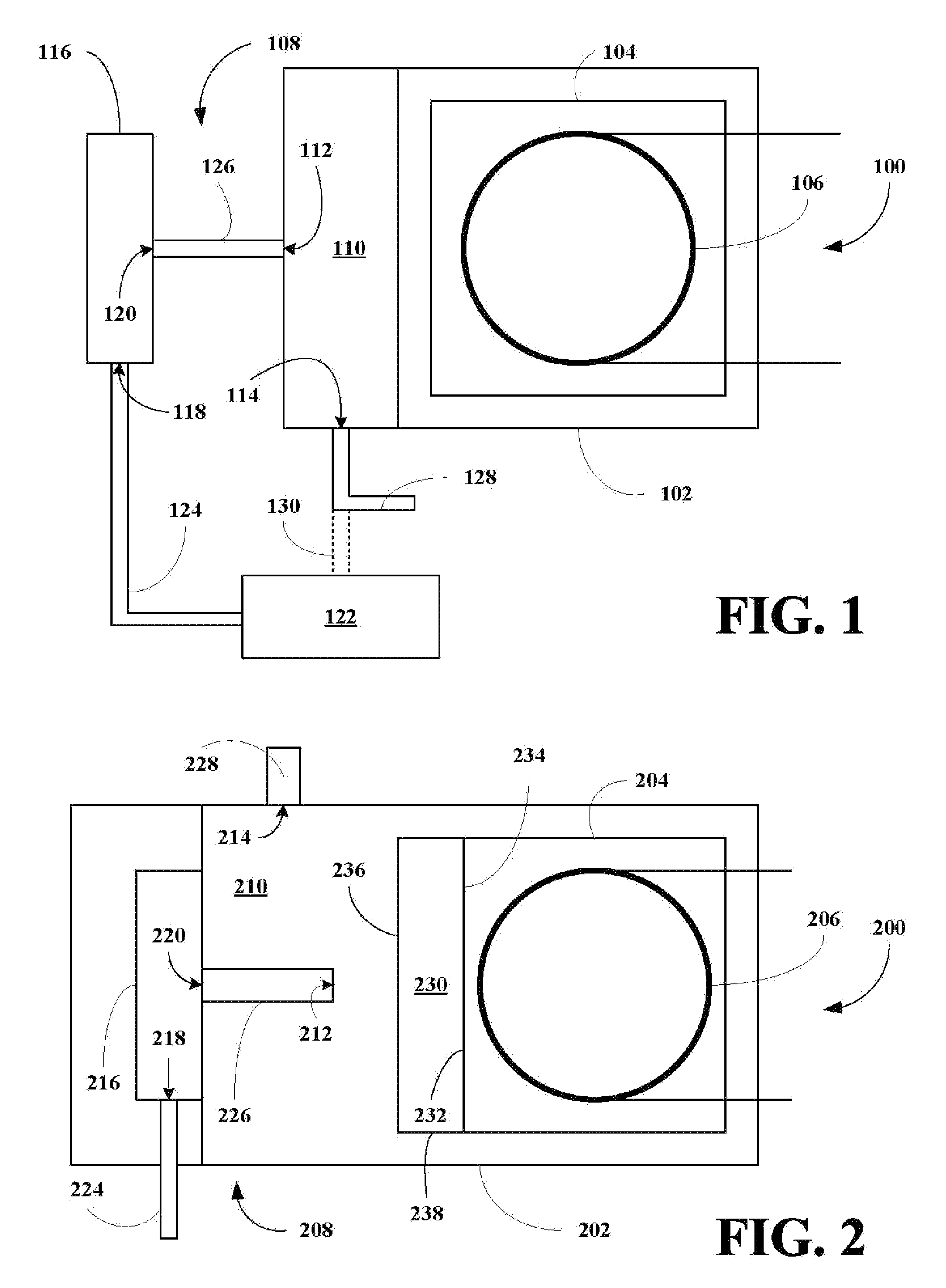

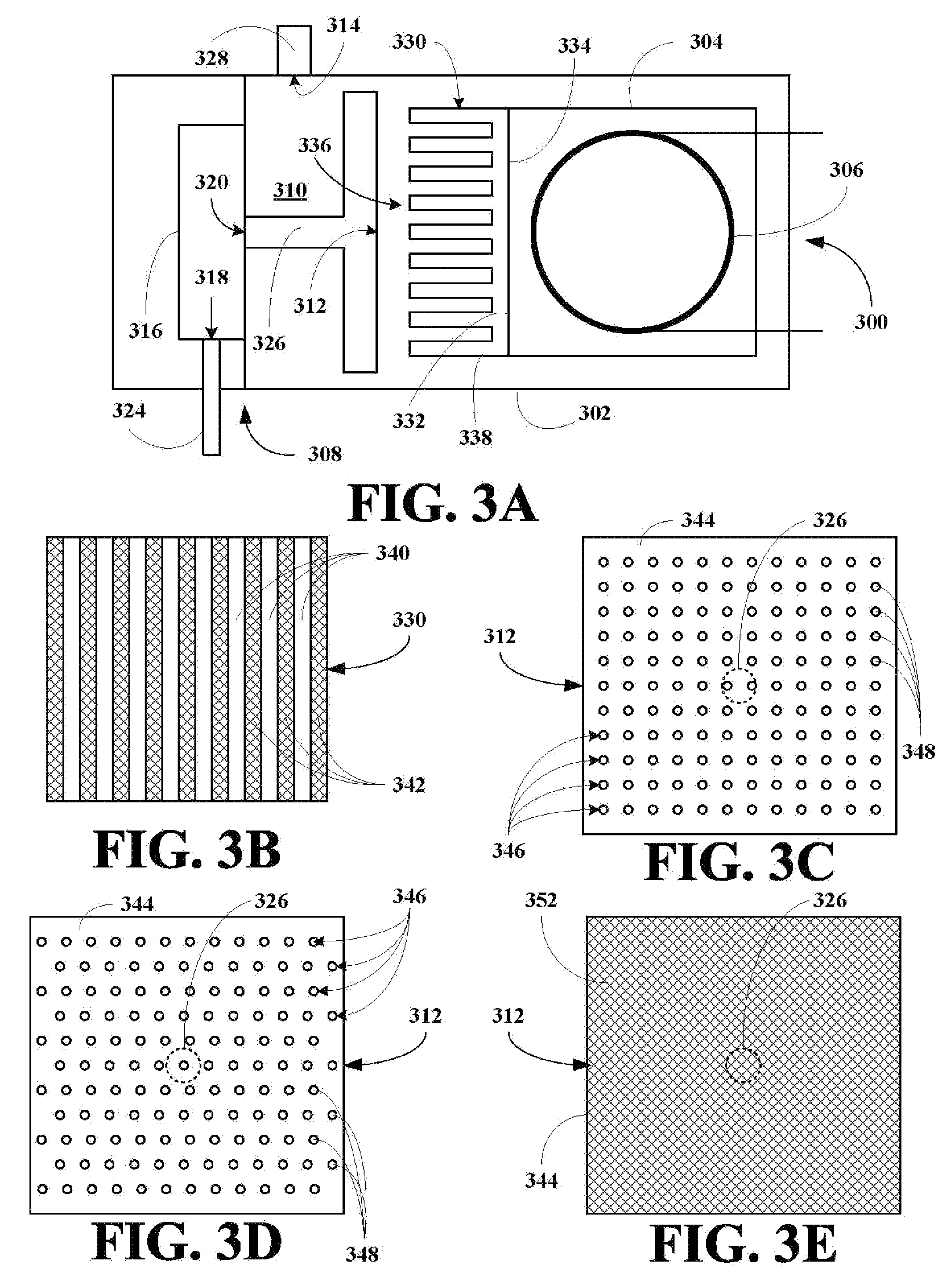

Cooling apparatus for microwave chromatography

InactiveUS7908901B2Low starting temperatureShorten cycle timeComponent separationMicrowaveEngineering

A cooling apparatus for a radiant energy heated oven is disclosed, where the cooling apparatus cools the oven by directing a flow of coolant through a chamber in thermal communication with the oven resulting in sub-ambient cooling, sub-ambient holds, and in chromatography instruments, higher sample throughput by reducing cycle time or column cool down time.

Owner:PETROLEUM ANALYZER COMPANY

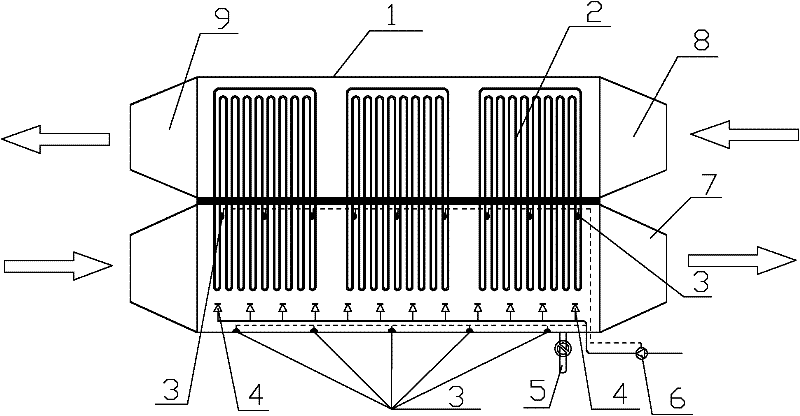

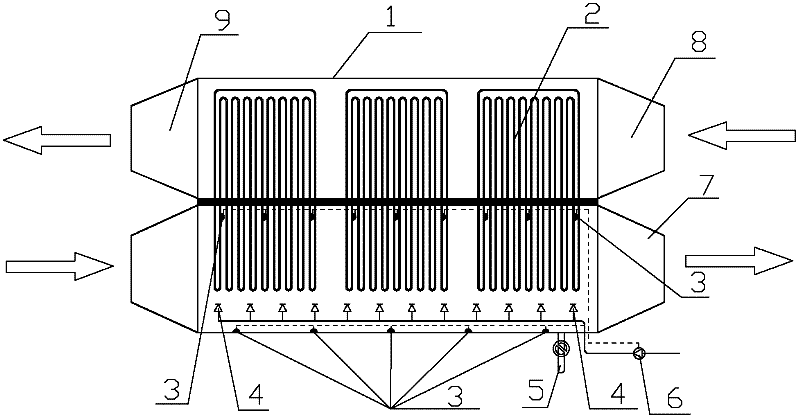

Device for starting a proton exchange membrane fuel cell at low temperature

ActiveCN108832158AIncrease profitImprove utilization efficiencyFuel cell heat exchangeReactant parameters controlStart up timeProton exchange membrane fuel cell

The invention relates to a device for starting a proton exchange membrane fuel cell at a temperature below zero degree, wherein a mixed gas is catalytically preheated at an anode, and tail gas of theanode is introduced into a cathode, so that an unreacted mixed gas is catalytically reacted at the cathode, and the effect of simultaneous heating of the cathode and the anode is realized. The invention is improved on the traditional catalytic cold start device, the cathode and the anode can simultaneously generate catalytic reaction and provide heat to the battery, which can realize low temperature start-up in the temperature range equal to -45 DEG C or below, fuel is fully utilized, the battery start-up power consumption is reduced and the low temperature start-up time is greatly reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

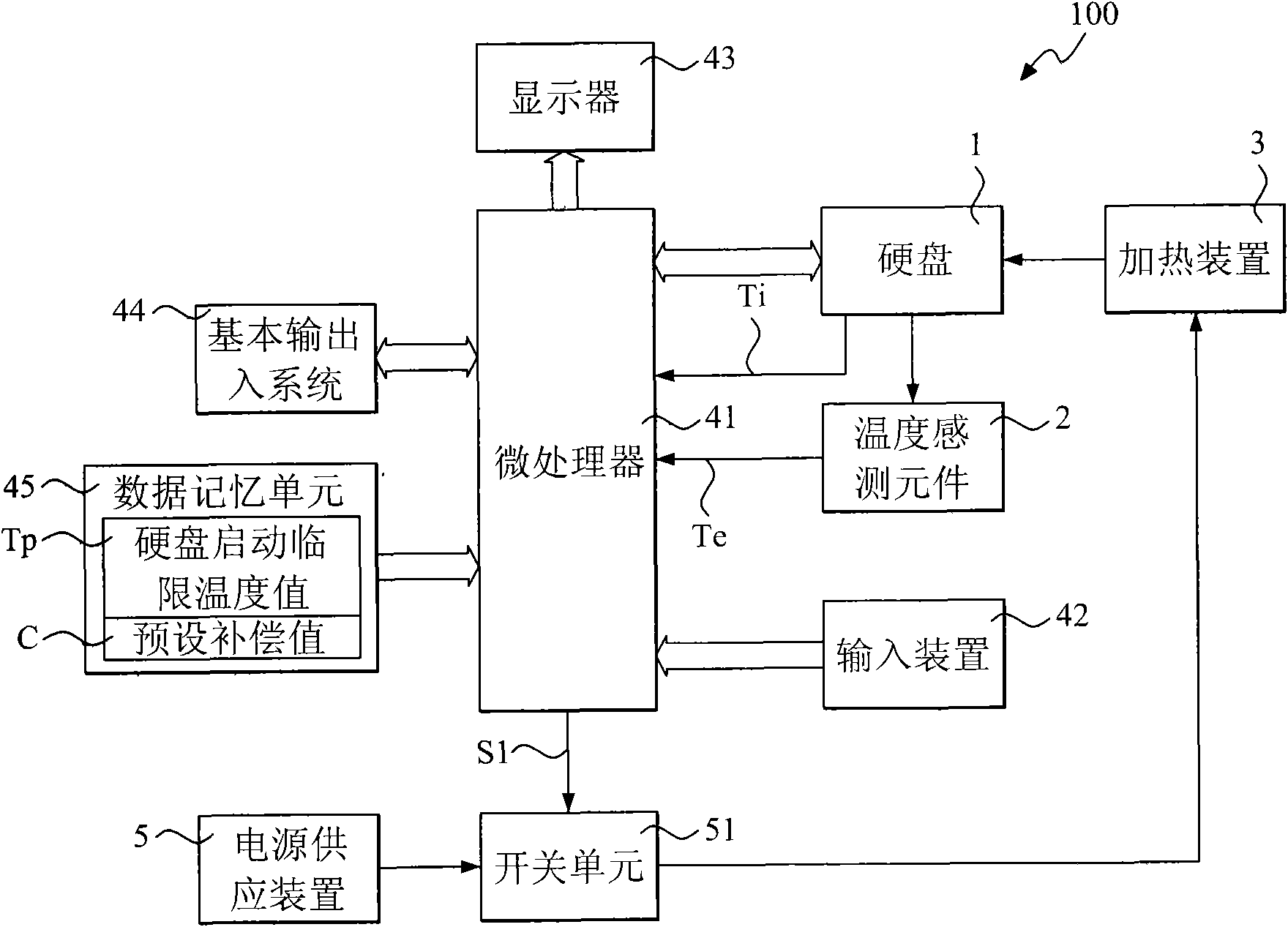

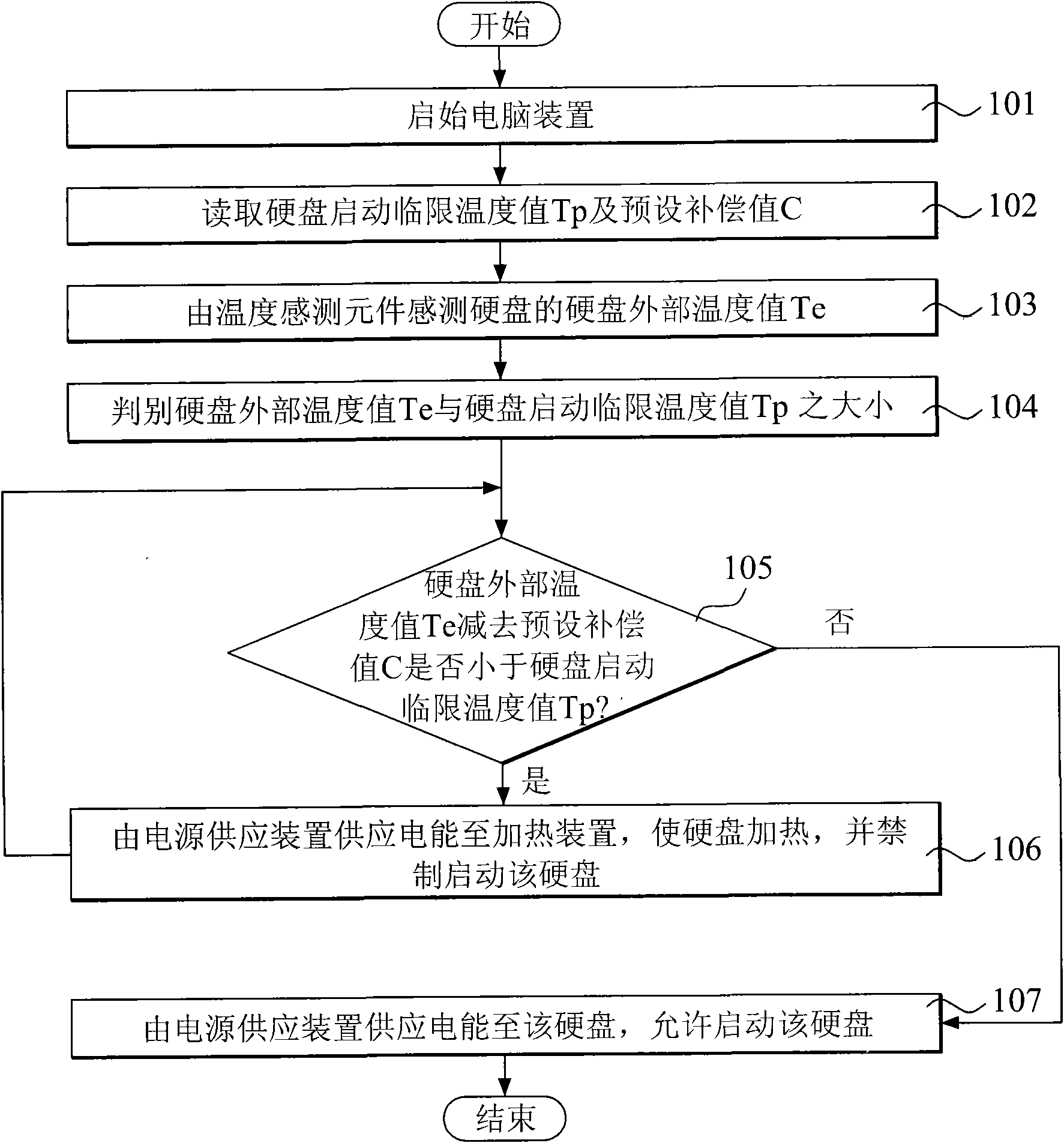

Hard disk preheating method of computer device

InactiveCN101661315ALow starting temperatureAvoid damageDigital data processing detailsError detection/correctionData memoryThreshold temperature

The invention relates to a hard disk preheating method of a computer device. Preset positions outside the computer device are provided with a temperature sensing element and a heating device. The temperature sensing element is utilized to sense an external temperature value of a hard disk, and the external temperature value of the hard disk is compared with a start threshold temperature value in adata memory unit of the computer device, and the start threshold temperature value is corrected by a preset compensation value stored in the data memory unit. When a result obtained by subtracting the preset compensation value from the external temperature value of the hard disk is smaller than the start threshold temperature value, the hard disk is prohibited to start, and after the hard disk isheated by the heating device to reach the start threshold temperature value of the hard disk, the hard disk is started so as to avoid the damage of the hard disk because of too low temperature in thehard disk when the hard disk is started.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Preparation method and application of efficient catalyst used for organic sulfur hydrogenation conversion

ActiveCN107486223AImprove uniformityImprove anti-coking performanceDispersed particle separationGaseous fuelsEfficient catalystCalcination

A preparation method of an efficient catalyst used for organic sulfur hydrogenation conversion comprises: reacting a mixed solution of TiCl4 and AlCl3 with an ammonia-water solution in a microwave-heated reactor, performing ageing and spray drying, and performing microwave calcination to obtain catalyst carrier powder; mixing a mixed solution of ammonium paramolybdate and soluble first active auxiliary agent salt with the carrier powder, performing impregnating in supersonic wave and performing drying, and calcinating the obtained product in a microwave calcinator to obtain a semi-finished catalyst powder; mixing a mixed solution of ammonium paramolybdate, the soluble first active auxiliary agent salt, and soluble second active auxiliary agent salt with the semi-finished catalyst powder, performing impregnating in supersonic wave, and calcinating the obtained product to obtain finished catalyst powder; and uniformly mixing the finished catalyst powder, a binder, a pore forming agent and water, and performing extrusion moulding, drying and calcination to obtain the finished catalyst used for organic sulfur hydrogenation. The catalyst is high in conversion rate and long in life.

Owner:江苏天东新材料科技有限公司

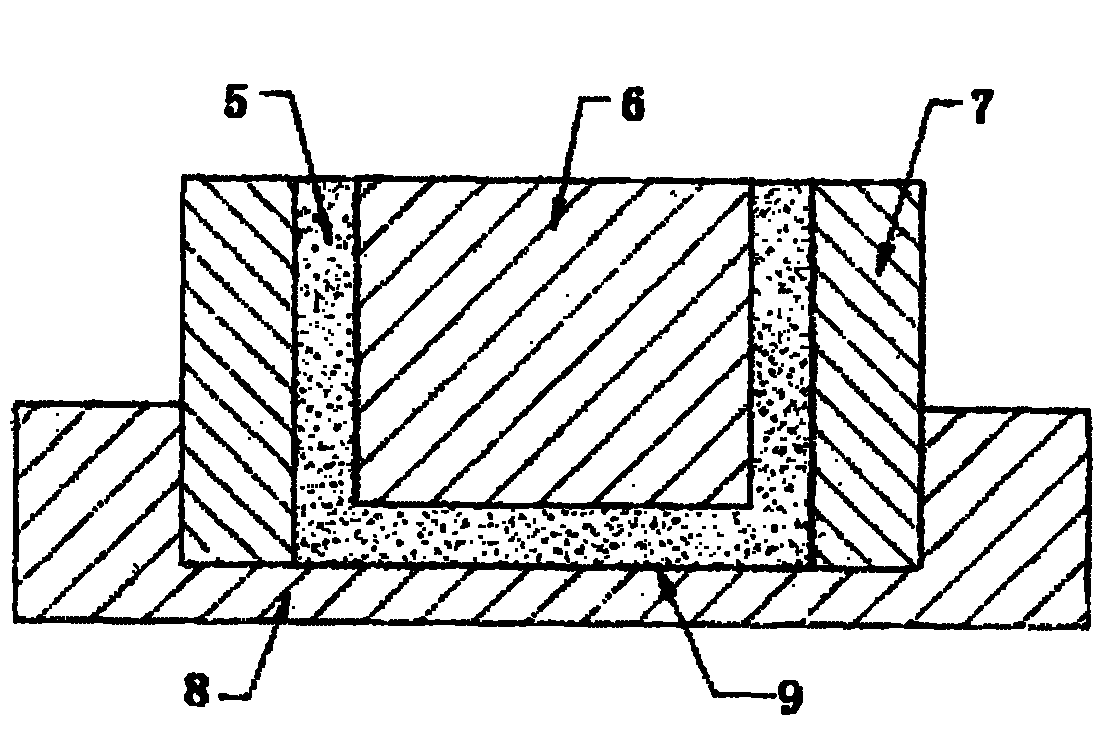

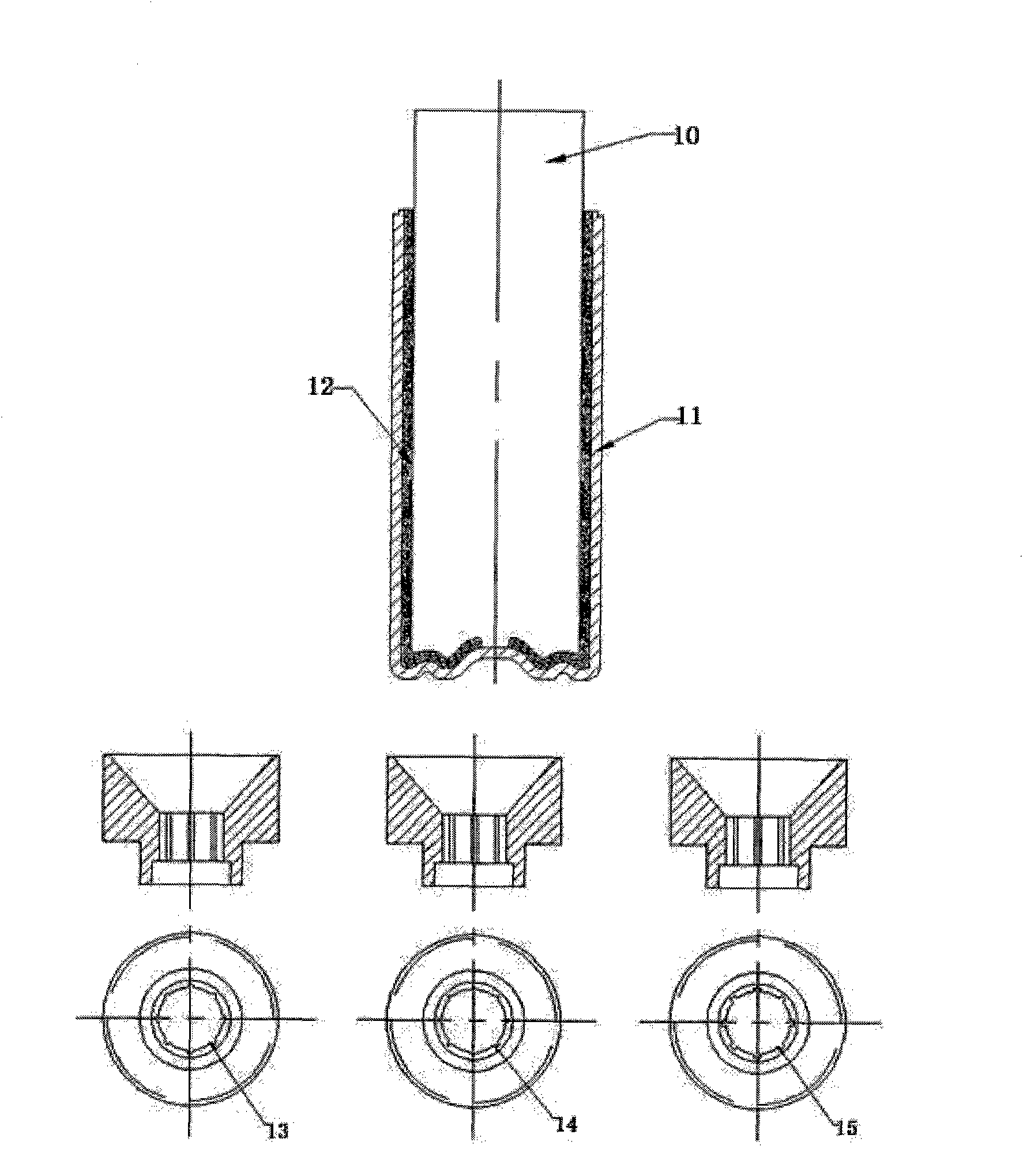

Manufacturing method of thermal column

ActiveCN101846472AGuarantee normal workReduce thermal resistanceIndirect heat exchangersIntegrated circuitBackflow

The invention provides a structure of a heat transfer element, i.e. thermal column and a manufacturing method thereof. Stamping or extrusion is utilized to prepare pure copper metal barrel and a base plate; the inner cavity of the thermal column is provided with various capillary structures, such as sintered copper powder, copper nets, grooves and the like; after being sintered, the capillary structures are assembled to cause capillary tissues in the cavity to be fully communicated, and the thermal column is obtained by welding, injection and vacuum degassing. The invention can effectively solve the problem of working medium backflow and blockade in the processes of liquid heat transfer medium evaporation and condensation phase change so as to greatly improve heat transfer performance; asthe heat radiation core element, the thermal column can satisfy the operating requirements on high heat dissipation power and light weight of computer microprocessors, large-power LED illumination and integrated circuit radiators.

Owner:嘉善恒杰热管科技有限公司

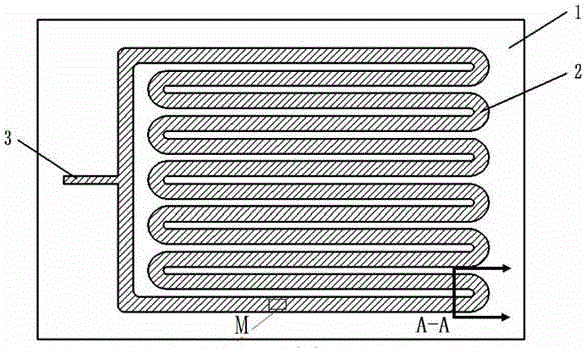

Silicon-based micro pulse heat pipe with micro/nano composite structures

InactiveCN106643243ASpeed up evaporationIncrease evaporation areaIndirect heat exchangersCooling/ventilation/heating modificationsEvaporationCarbon nanotube

The invention relates to a pulse heat pipe, in particular to a silicon-based micro pulse heat pipe with micro / nano composite structures. The micro pulse heat pipe is formed by bonding a semiconductor silicon wafer and a heat-resisting borosilicate glass piece which are in a pair. Vacuum pumping / liquid injecting holes are machined in the borosilicate glass piece. The vacuum pumping / liquid injecting holes correspond to the positions of the top ends of vacuum pumping / liquid injecting micro slots in the semiconductor silicon wafer. Multiple micro slots are etched in the semiconductor silicon wafer, and the surfaces of the micro slots are the micro / nano composite structures formed by carbon nano pipe bundles. According to the silicon-based micro pulse heat pipe with the micro / nano composite structures, the defects that an evaporation section of a common micro pulse heat pipe is likely to be burnt out, the starting temperature is too high, and the starting time is too long are overcome; and the purposes of improving the heat pipe cooling temperature control performance and improving the heat load bearing capability can be achieved by changing the channel section size of the pulse heat pipe, changing the shape of the micro slot surface carbon nano pipe bundles and the like.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com