Silicon-based micro pulse heat pipe with micro/nano composite structures

A composite structure and pulsating heat pipe technology, which is applied in cooling/ventilation/heating transformation, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of uneven micro pulsating heat pipe start-up state, dry-out temperature, etc., and achieve load-bearing improvement The ability of heat load and cooling temperature control performance, the effect of improving cooling efficiency and enhancing heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

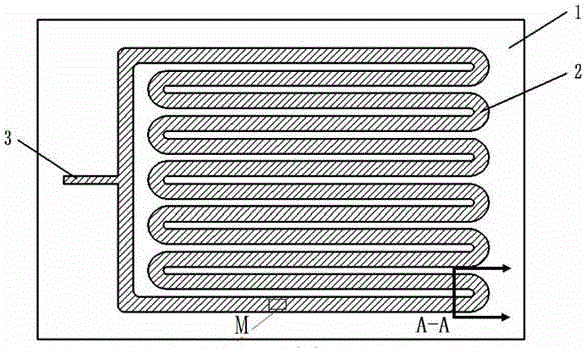

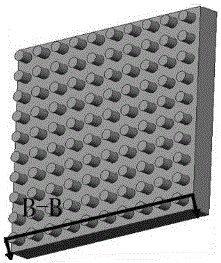

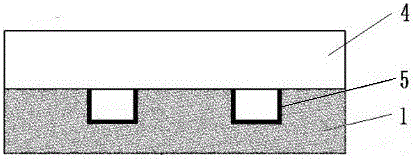

[0027] Embodiment 1: as Figure 1~Figure 6 As shown, the silicon-based micro pulsating heat pipe with a micro / nano composite structure is formed by bonding a pair of semiconductor silicon wafers 1 and heat-resistant borosilicate glass wafers 4 . The surface of the silicon wafer 1 in contact with the borosilicate glass wafer 4 is etched with a microchannel 2 with a rectangular cross-section by plasma dry etching technology; the surface of the microchannel 2 is covered with a layer of carbon nanotubes by the silicon-based surface carbon nanotube array growth technology. tube 7, thereby forming a micro / nano composite structure surface 5 with a micro-rib 6 composite structure; the borosilicate glass sheet 4 is processed with a vacuum / liquid injection hole 8; the vacuum / liquid injection hole 8 and the vacuum / liquid injection The top positions of the microchannels 3 are corresponding. Fill 50% volume fraction of FC-72 from the vacuum / injection hole 8.

[0028] Figure 1~Figure 4 ...

Embodiment 2

[0030] Embodiment 2: as Figure 1~Figure 4 , Figure 5 and Figure 7 As shown, with embodiment 1, the difference is that the micro-rib composite structure and Figure 6 There are certain differences in . The cross-sectional shape and depth of the microchannel are the same as in Example 1, Figure 7 The micro-rib height, diameter and longitudinal / transverse spacing of the carbon nanotube array in the micro-rib composite structure are all the same as Figure 6 Same, but the carbon nanotube bundles are arranged in a forked row.

[0031] Similarly, if Figure 7 The silicon-based micro-pulsating heat pipe with micro-nano composite structure inherits the liquid-absorbing core function of the traditional heat pipe, and enhances the wetting and re-wetting effect of the working fluid in the tube, effectively enhancing the heat transfer and temperature control ability.

Embodiment 3

[0032]Embodiment 3: Same as embodiment 1 and embodiment 2, the cross-sectional shape and depth of the micro-channel of the micro-nano composite structure silicon-based micro-pulsation heat pipe are the same as in embodiment 1, except that the surface of the micro-channel is as follows: Figure 8 . Figure 8 The medium-micro-nano composite structure is a microcavity 9 of a carbon nanotube array, wherein the shape, height, arrangement and density of the microcavity 9 are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com