Wimble cap-shaped combusting device of oil heater

A fuel oil heater and burner technology, which is applied in the direction of evaporating liquid fuel burners, burners, combustion types, etc., can solve the problems of decreased thermal efficiency of heaters, unfavorable normal combustion of fuel oil, and deterioration of exhaust emissions, etc., and achieve economical improvement , Reduce the dead zone of the secondary combustion cylinder, and reduce the effect of starting blowdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

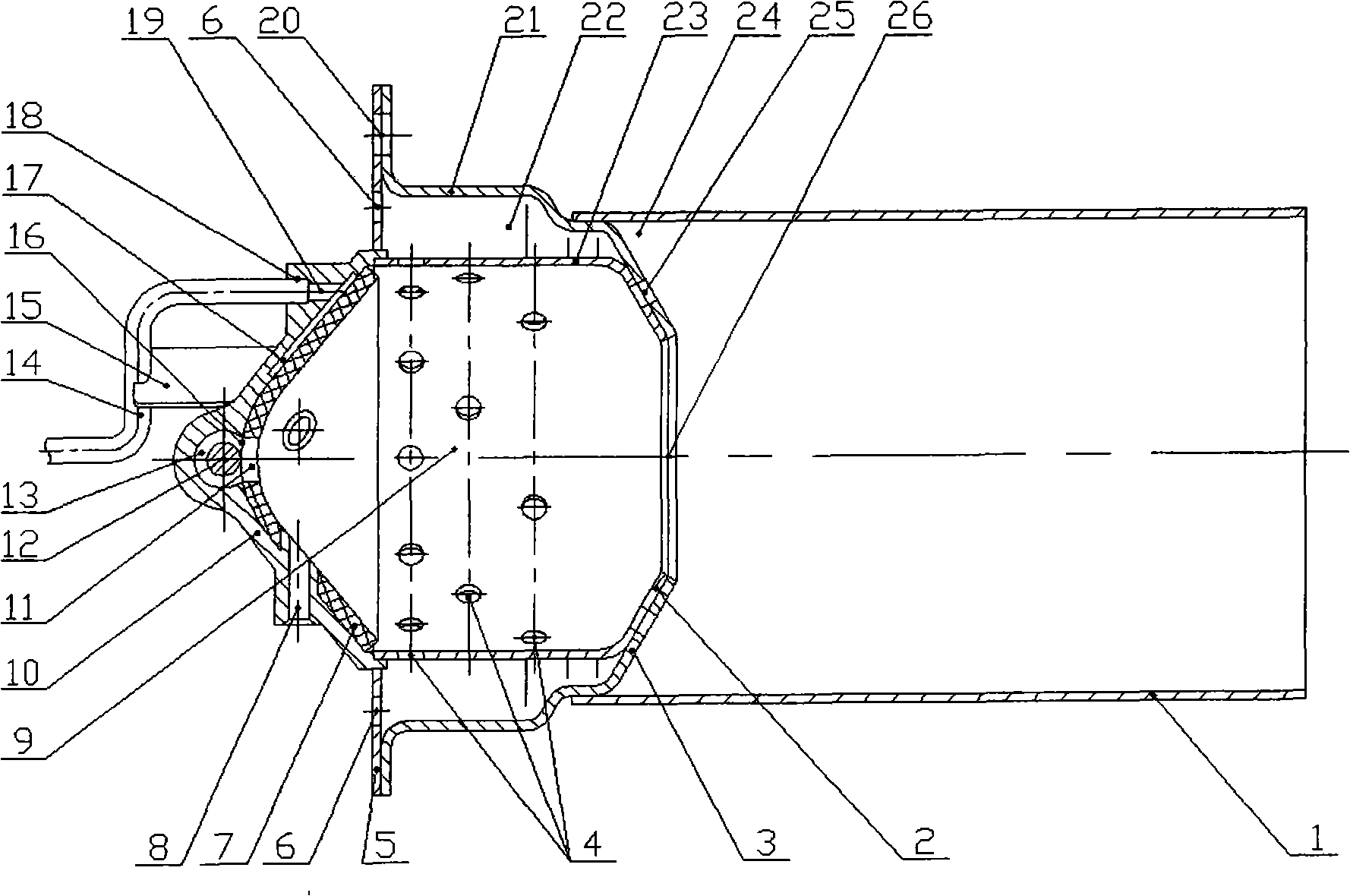

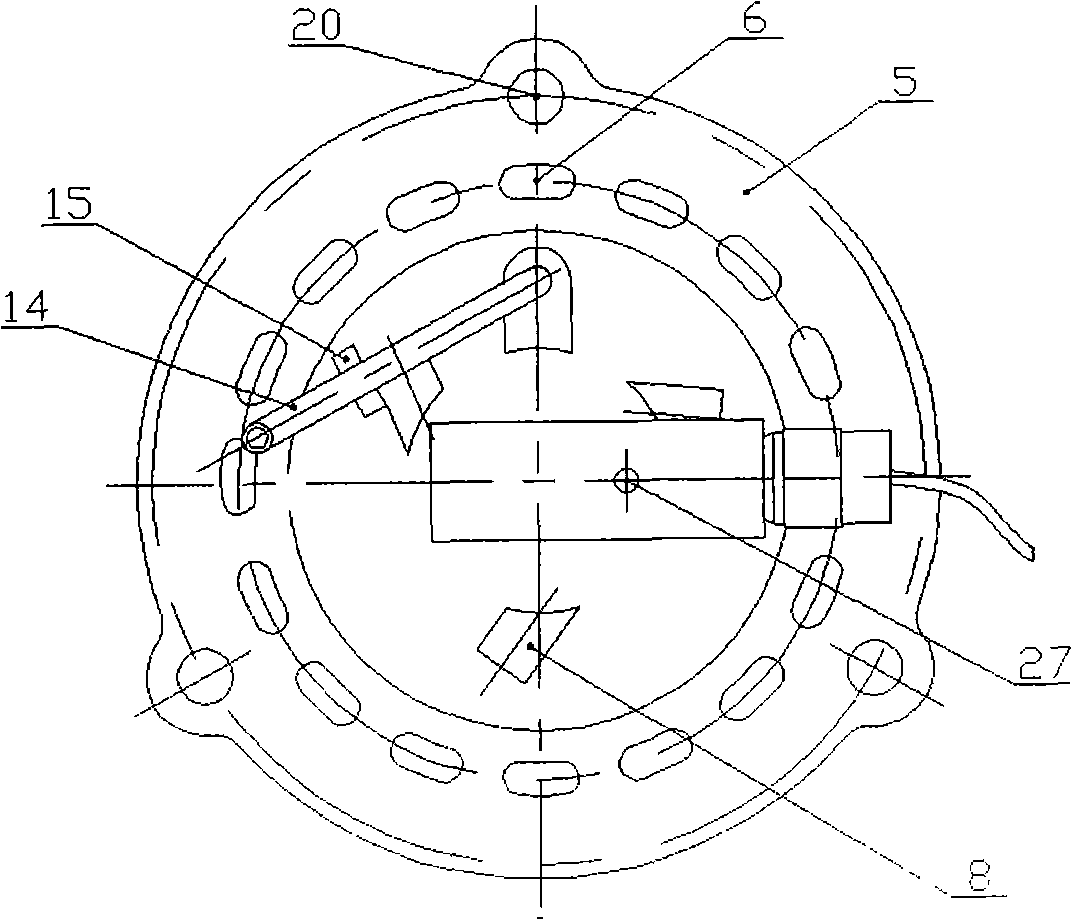

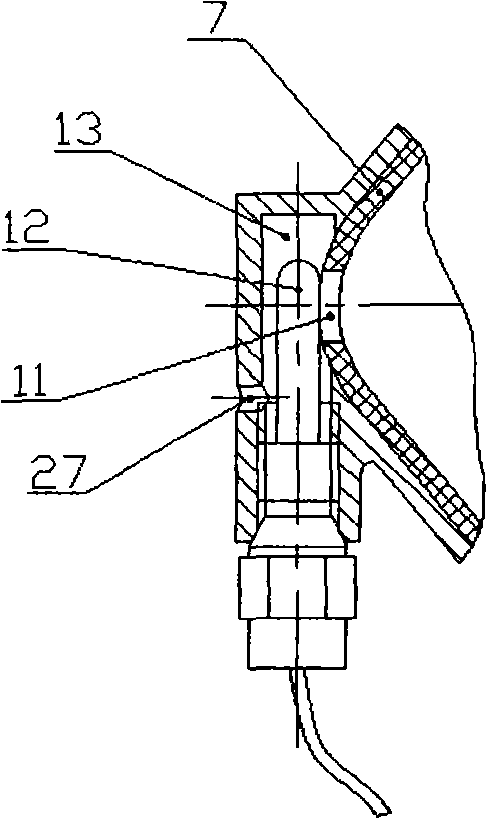

[0015] The structure of the cone-shaped burner of the fuel oil heater of the present invention is as figure 1 shown. Combustion chamber cover 10, oil suction cone liner 7, primary combustion tube 23, secondary combustion tube 1, air intake guide tube 21, air intake splitter 5, fuel pipe 14 and glow plug 12 are included. The front end of the primary combustion tube 23 is inserted into the positioning seam of the combustion chamber cover 10 end, and the welding is firm. There are 4 to 12 bypass holes 25 which can reduce the flow dead zone 24 in the secondary combustion cylinder 1 distributed on the conical flanging flange 2 at the rear end of the primary combustion cylinder 23 . There are 2 to 5 circles of air intake holes 4 distributed in the circumferential direction on the cylinder wall of the primary combustion cylinder 23 . The tapered flange 3 at the rear end of the air intake guide tube 21 is spot-welded with the tapered flange 2 at the tail end (flame outflow end) of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com