Patents

Literature

2454results about How to "Speed up evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

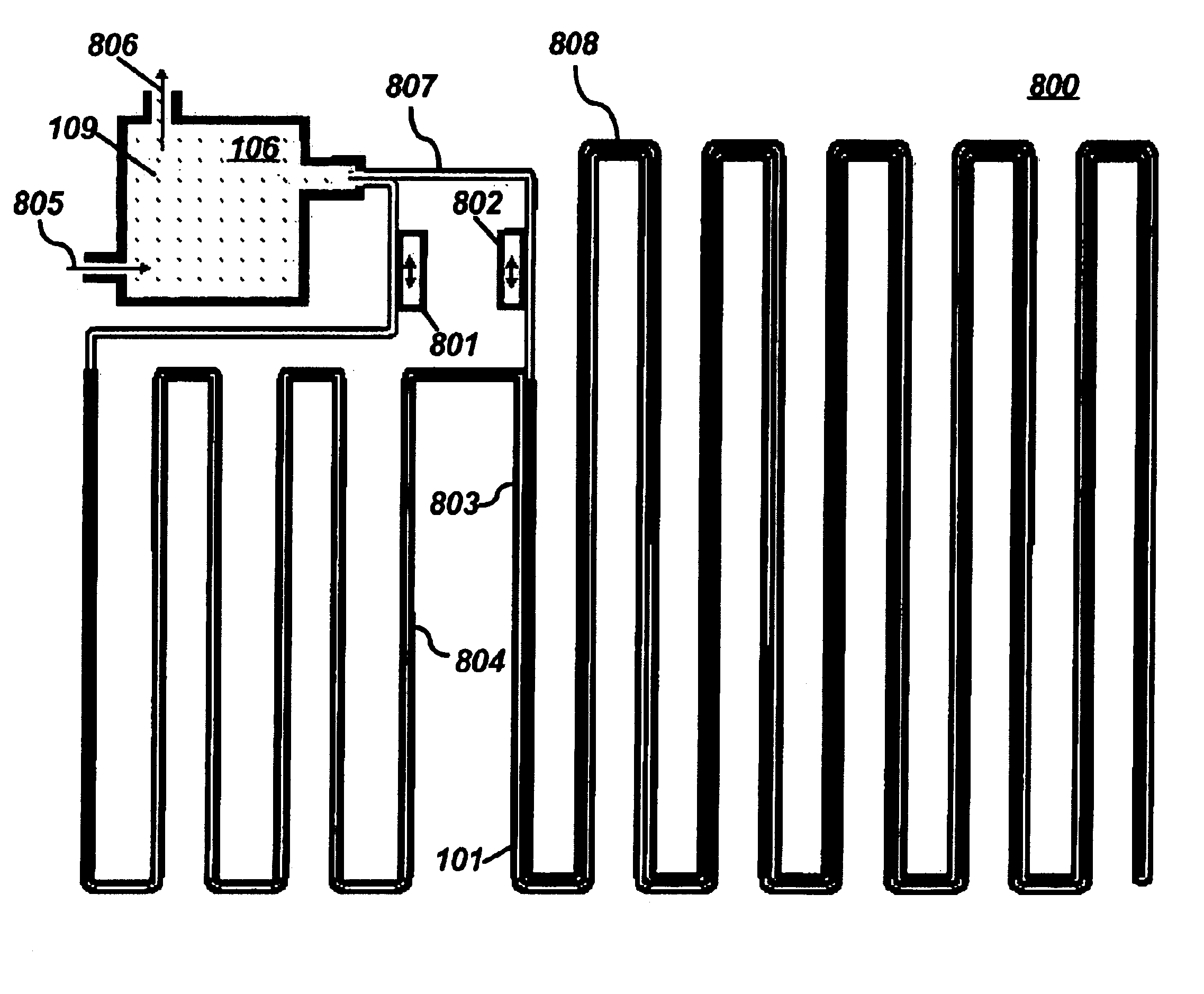

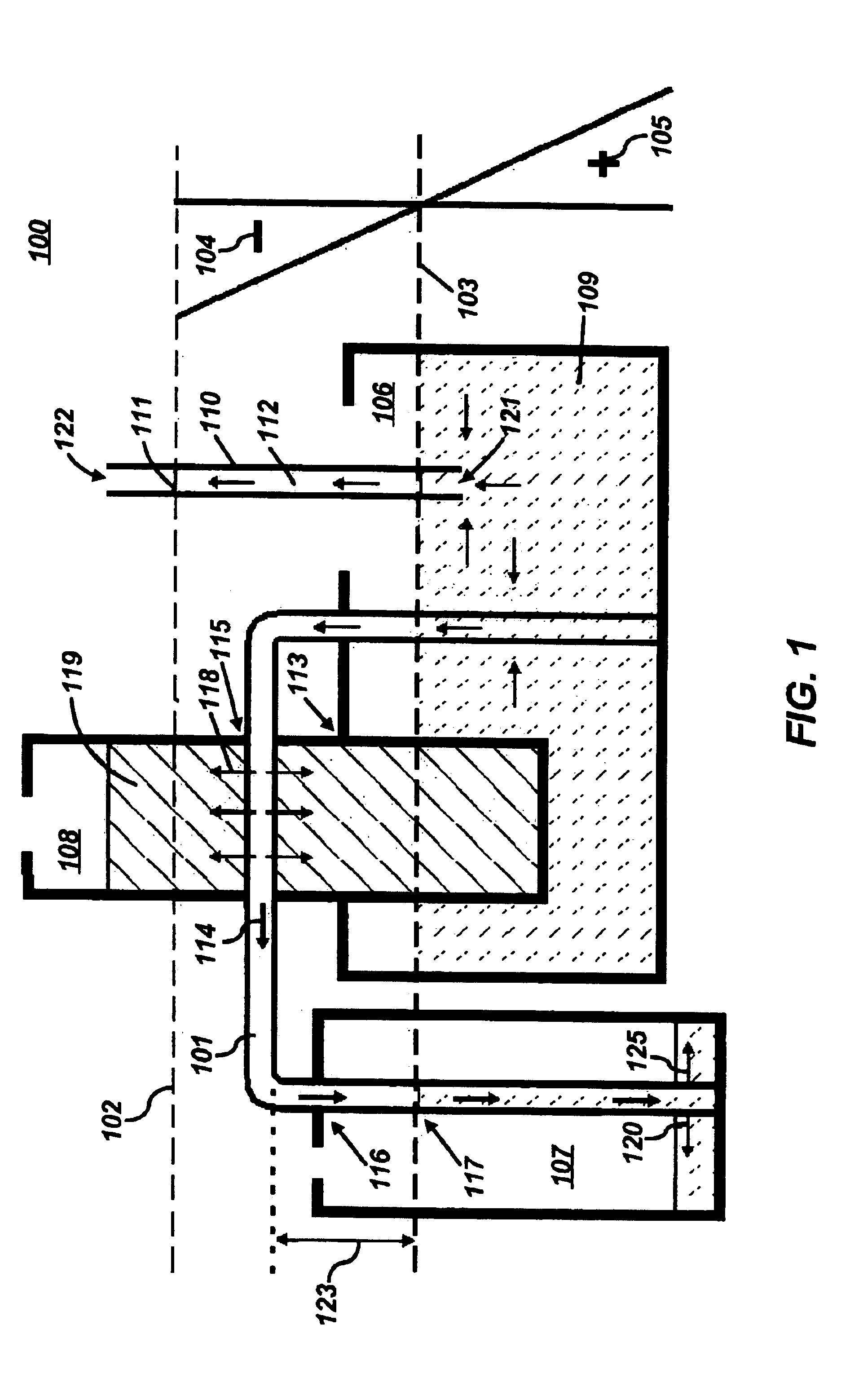

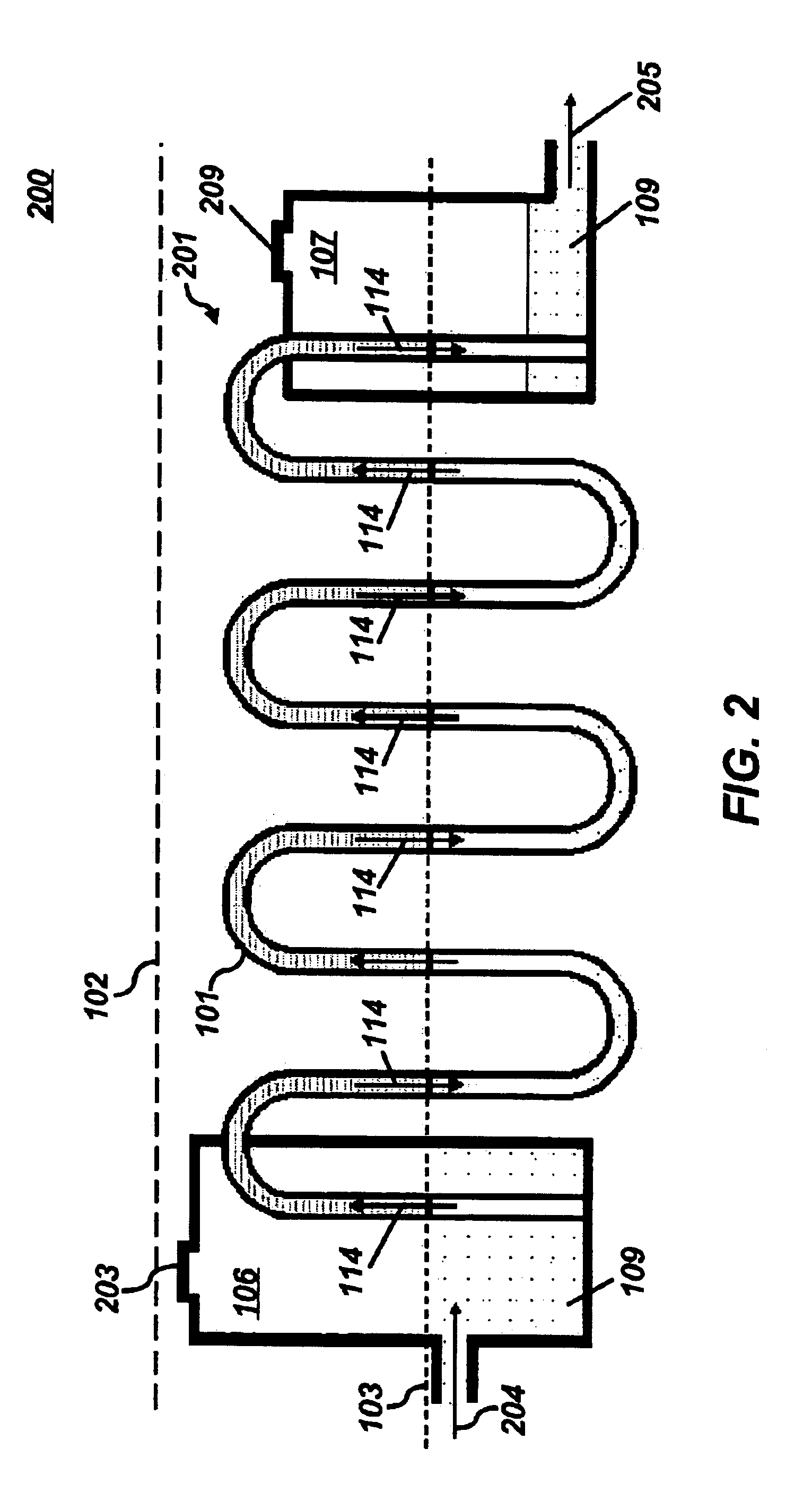

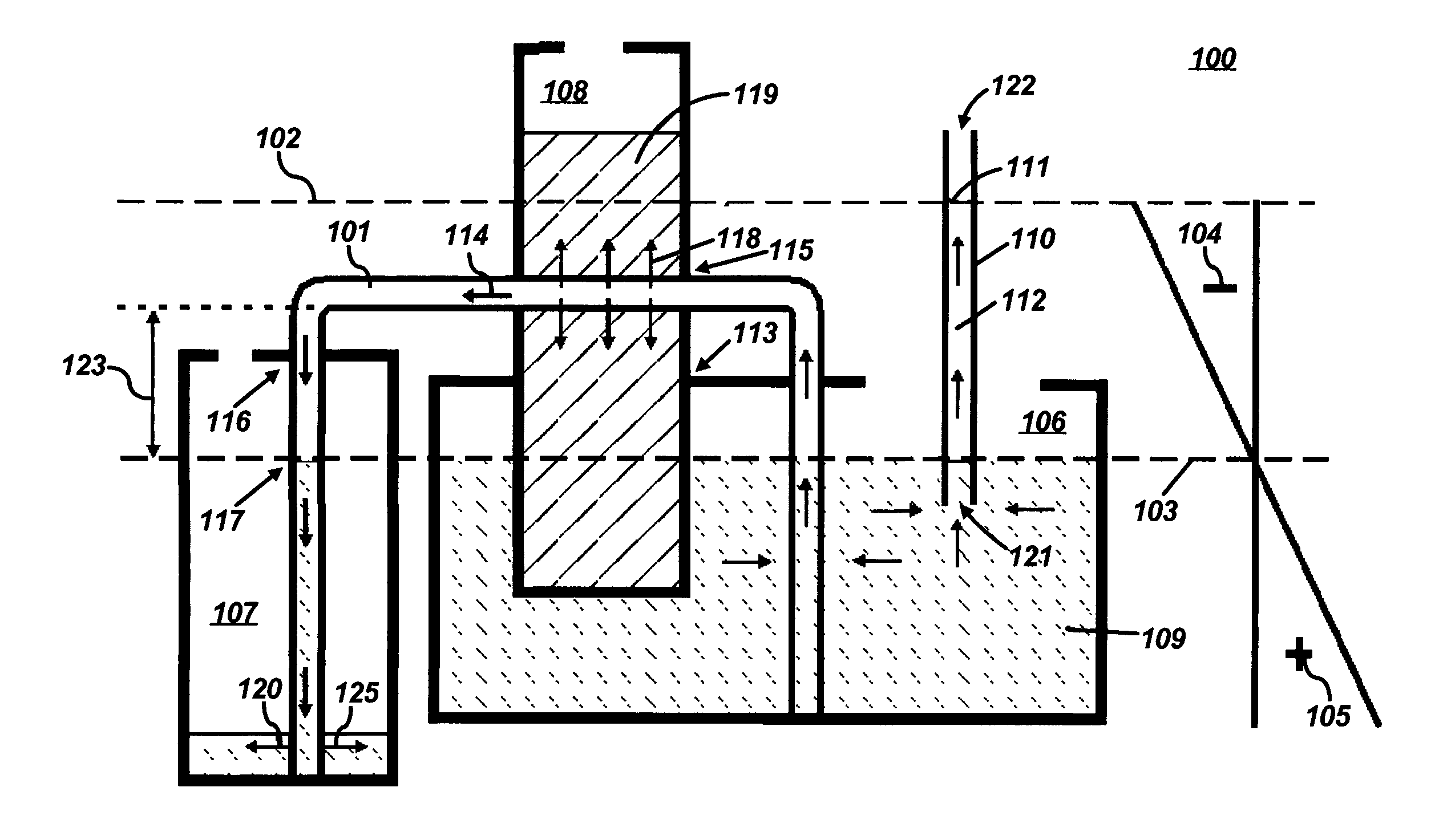

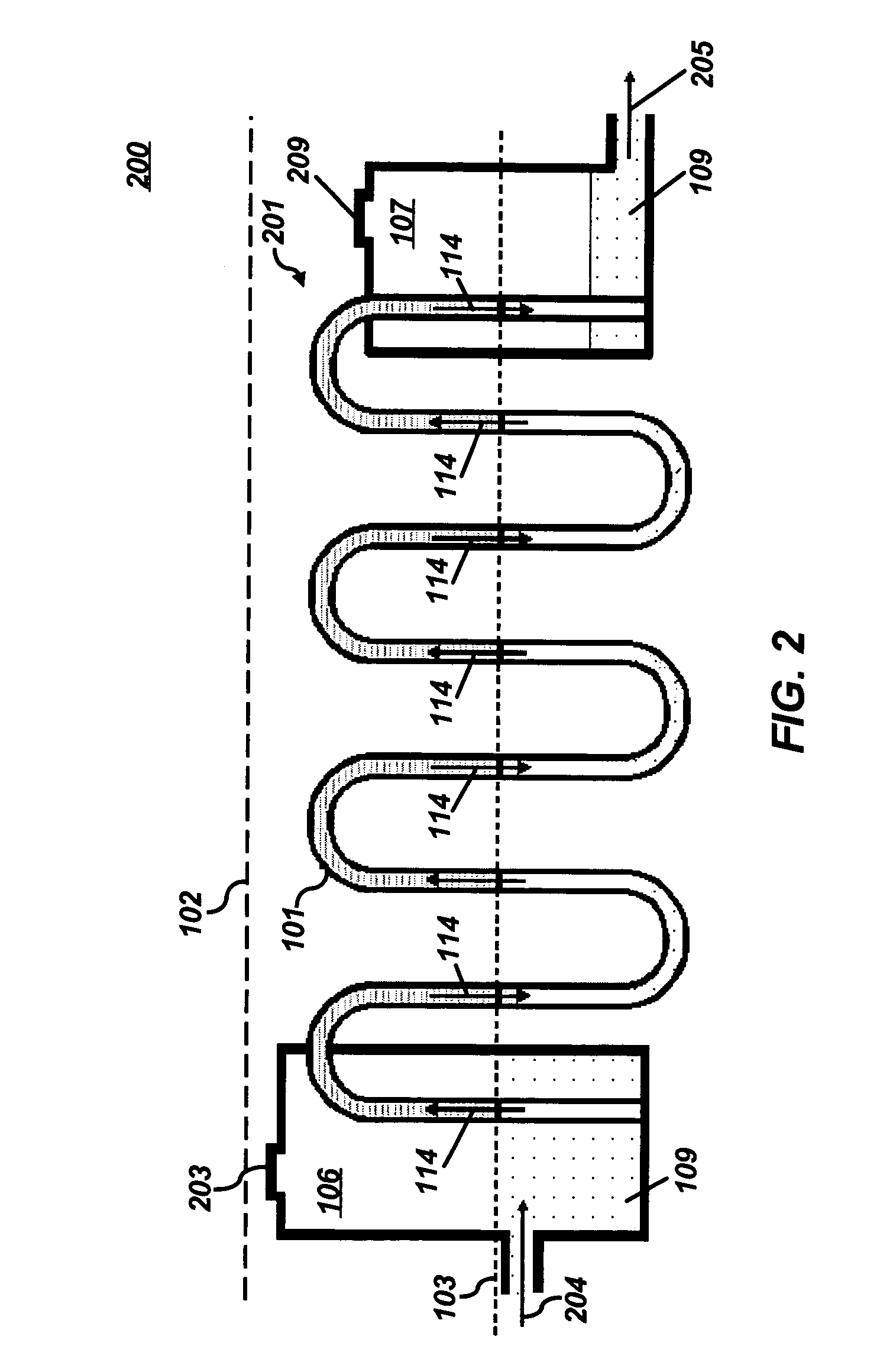

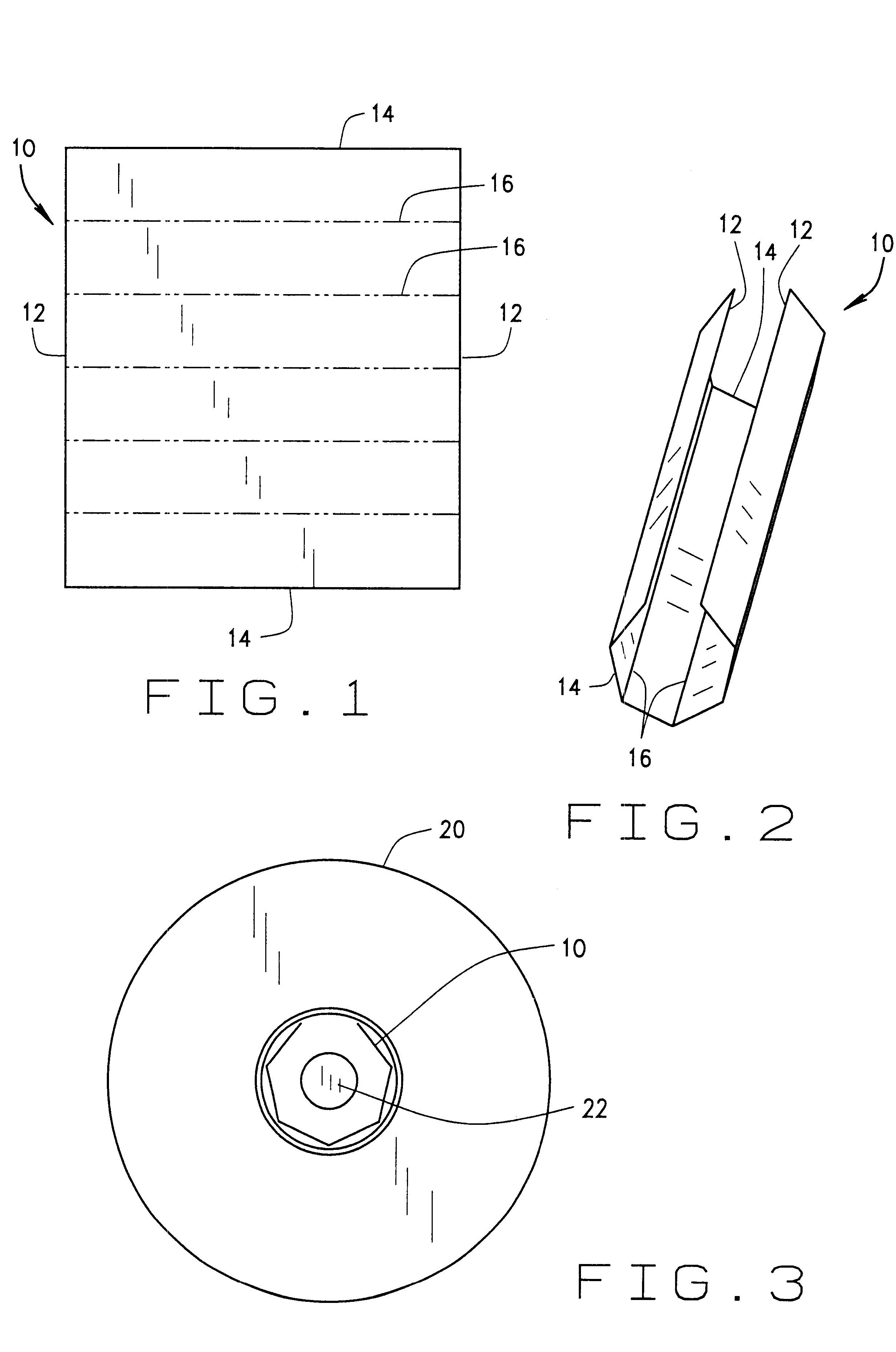

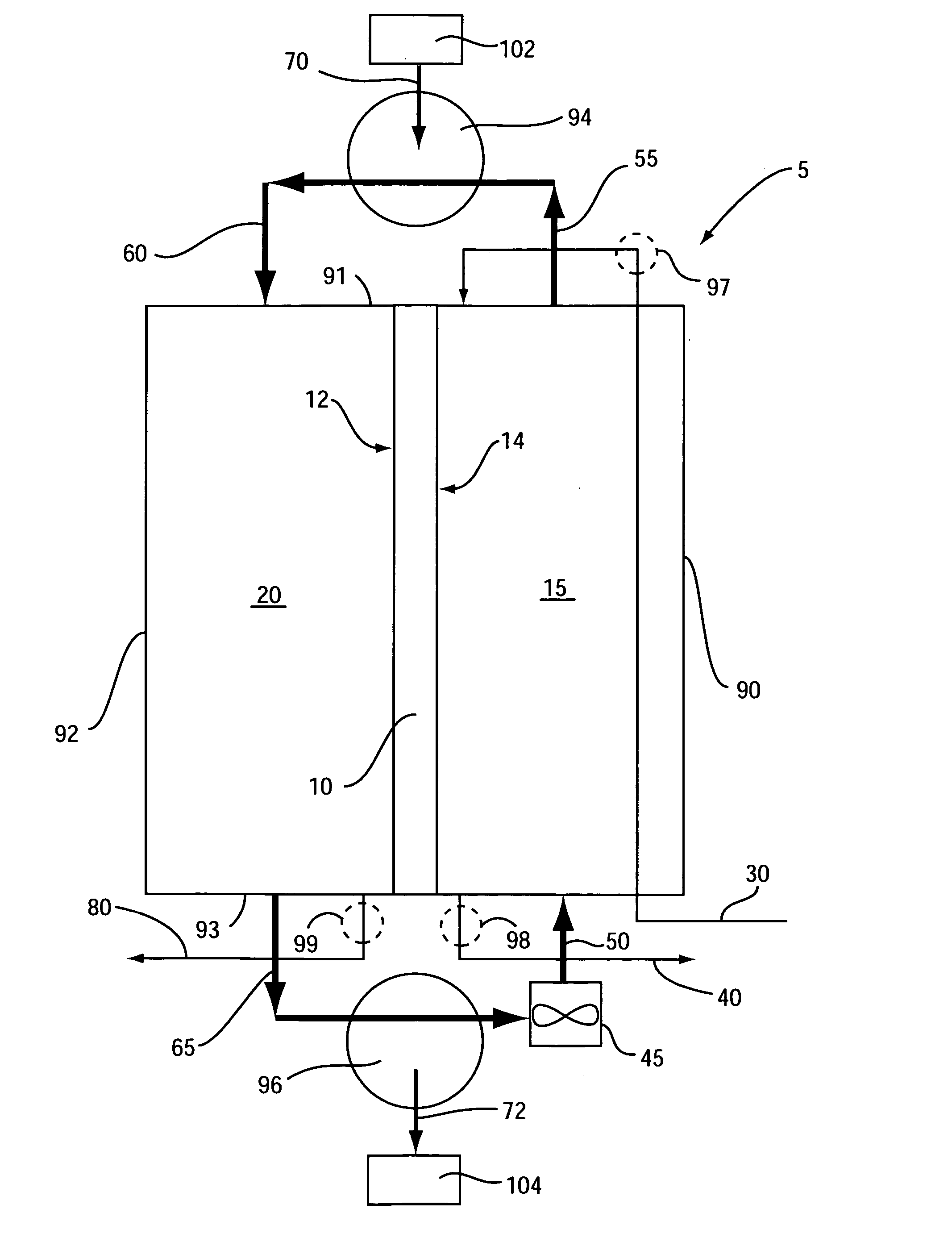

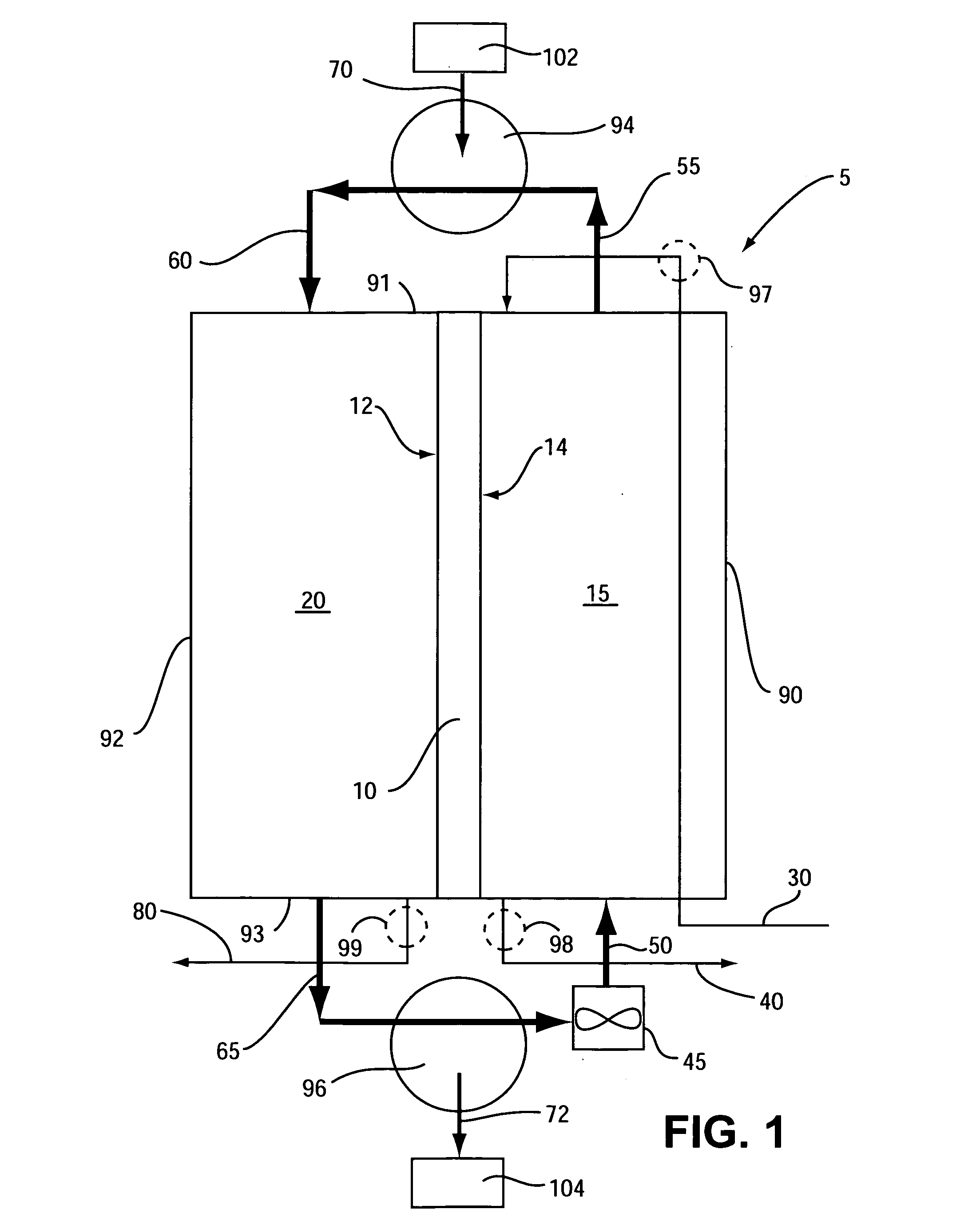

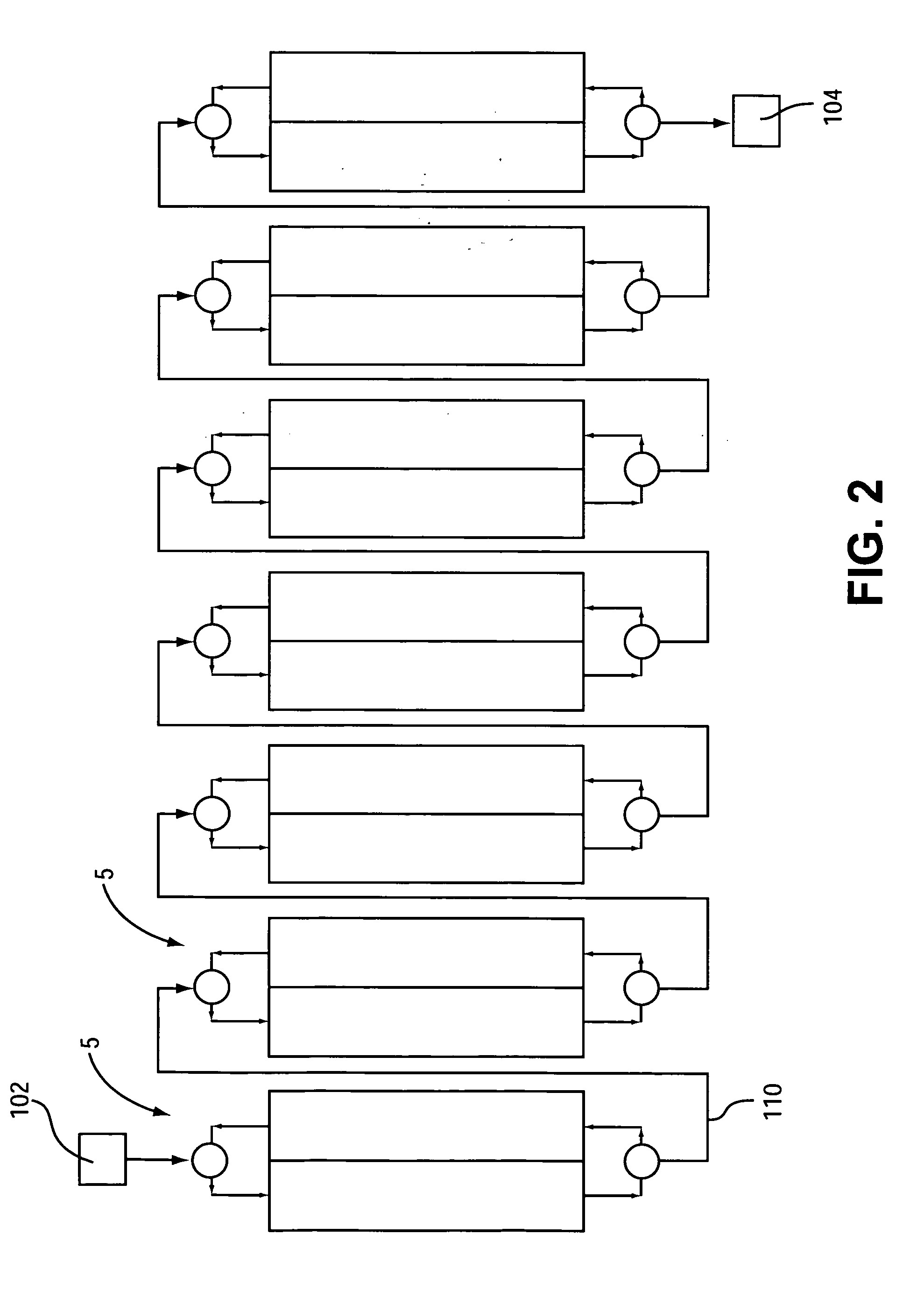

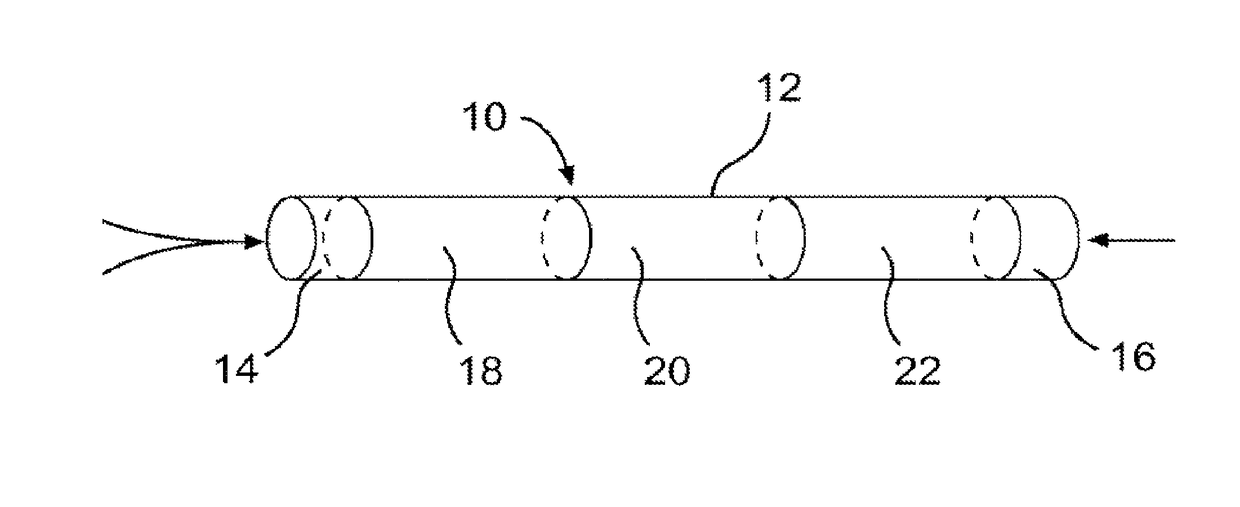

Irrigation and drainage based on hydrodynamic unsaturated fluid flow

InactiveUS6918404B2Improve the level ofHigh porosityPipeline systemsMachines/enginesEnvironmental engineeringPorous microstructure

Irrigation and drainage systems are disclosed, including a saturated zone and at least one pipe in communication with the saturated zone. The pipe(s) can be configured to comprise a tubarc porous microstructure for conducting water from the saturated zone to an unsaturated zone in order to drain the water from the saturated zone. The water can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the water to be harnessed for irrigation or drainage through the hydrodynamic movement of the water from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

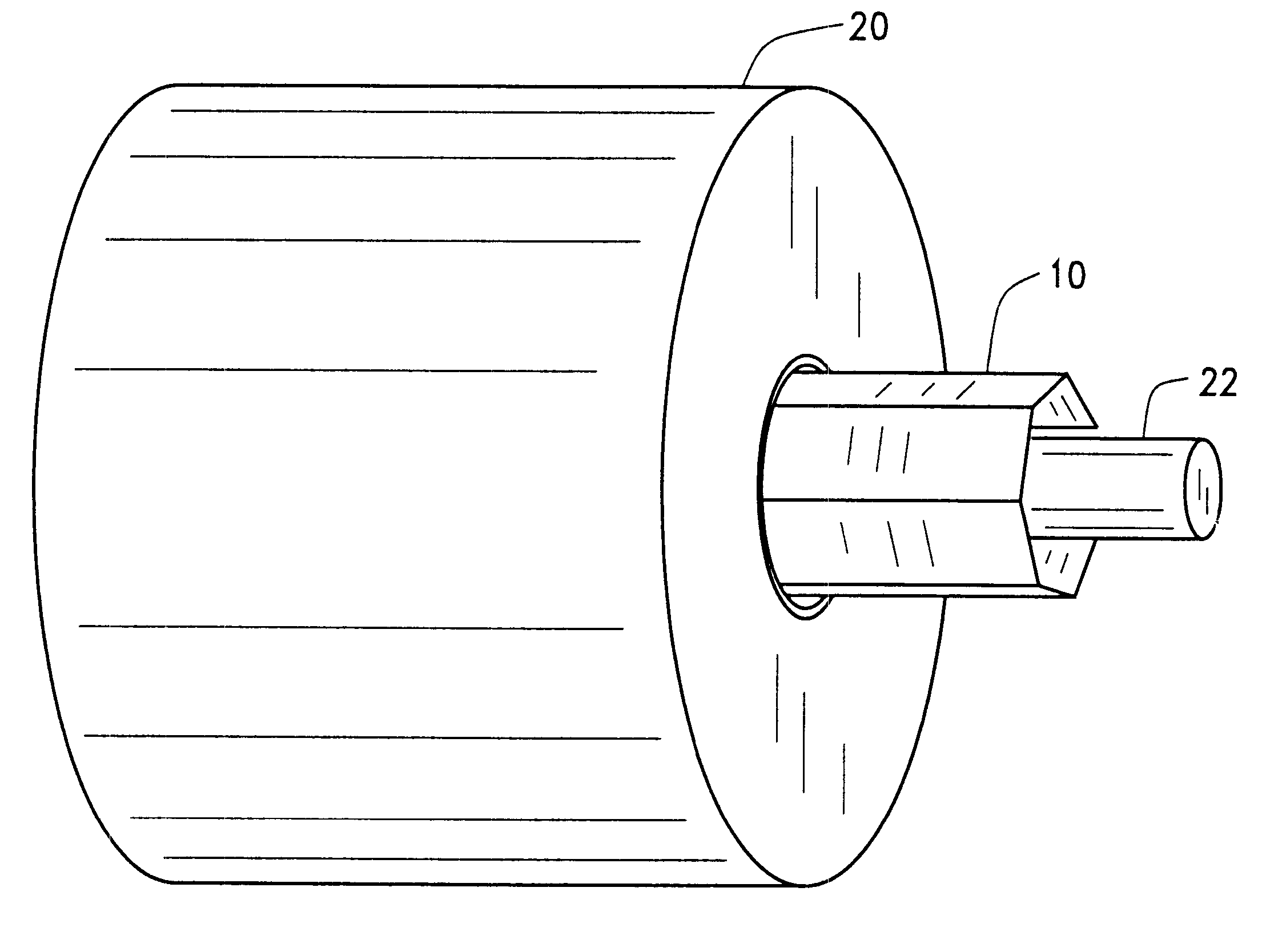

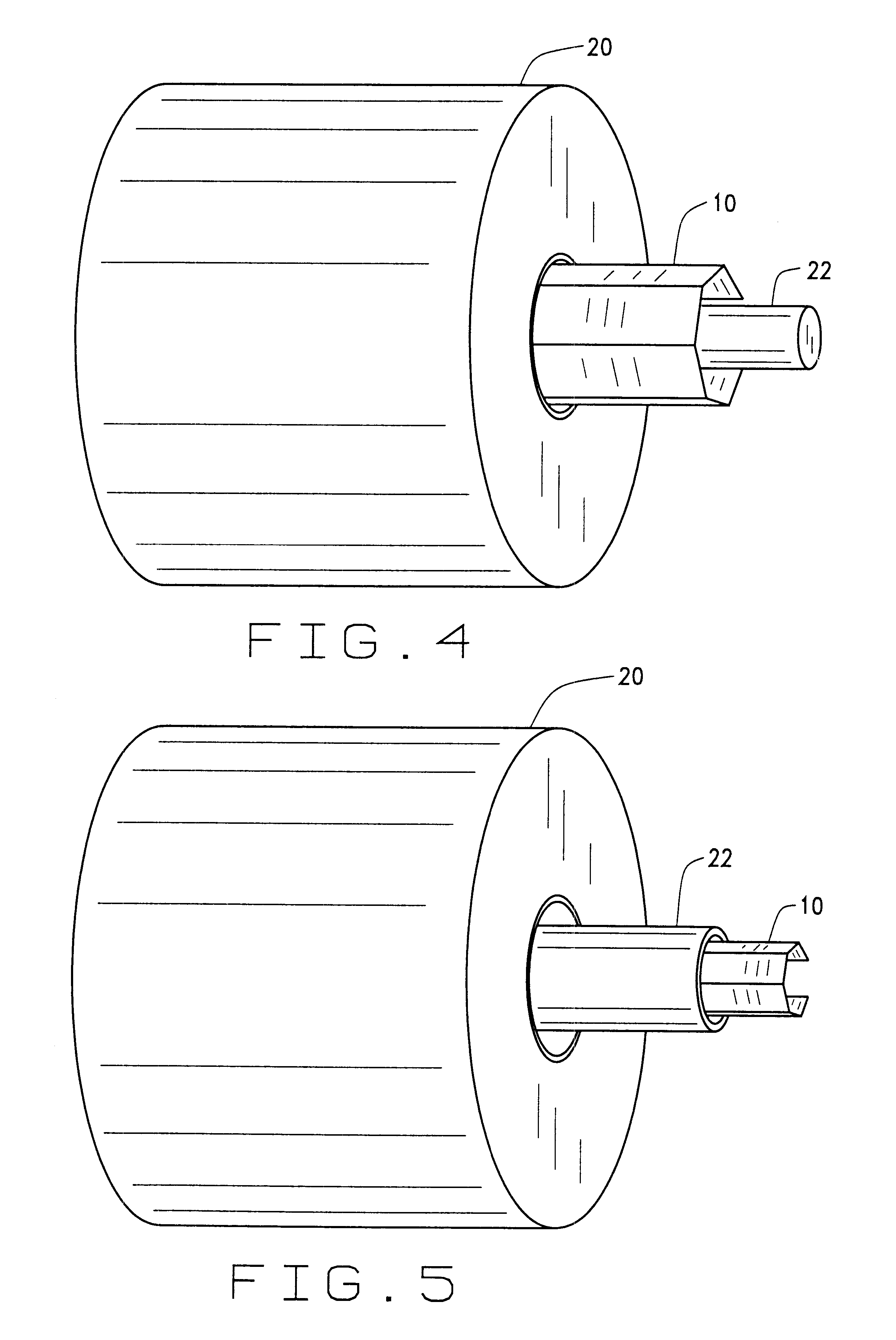

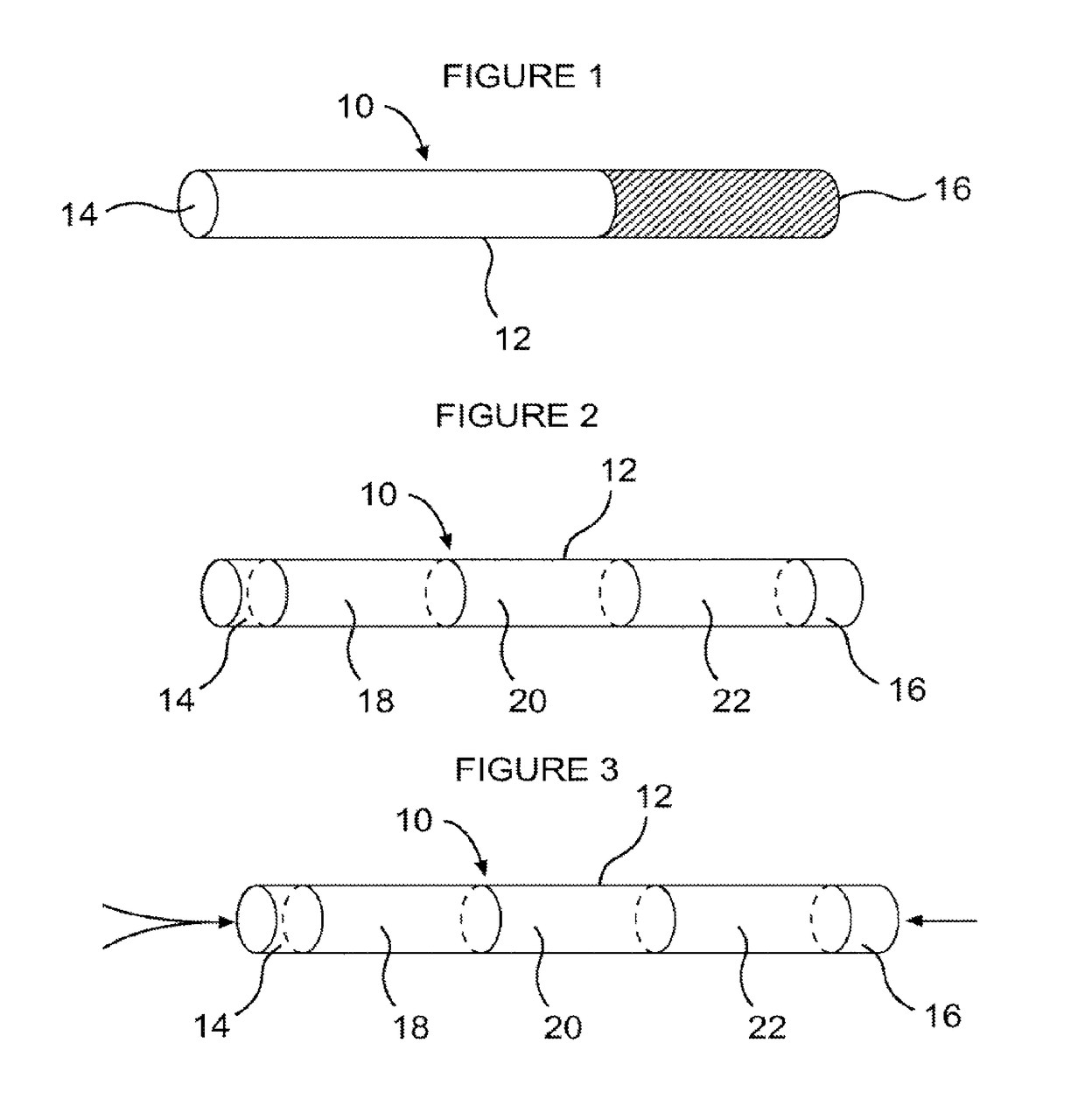

Ink refill and recharging system

InactiveUS7066586B2Improve reliabilityPrecise deliveryPipeline systemsPrintingEngineeringPrint-through

Ink refill systems are disclosed. In general, an ink source comprising a saturated zone and a tubarc porous microstructure for conducting ink from the saturated zone to an unsaturated zone are provided. The ink can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the ink to be harnessed for ink writing and / or printing through the unsaturated hydrodynamic flow of the ink from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

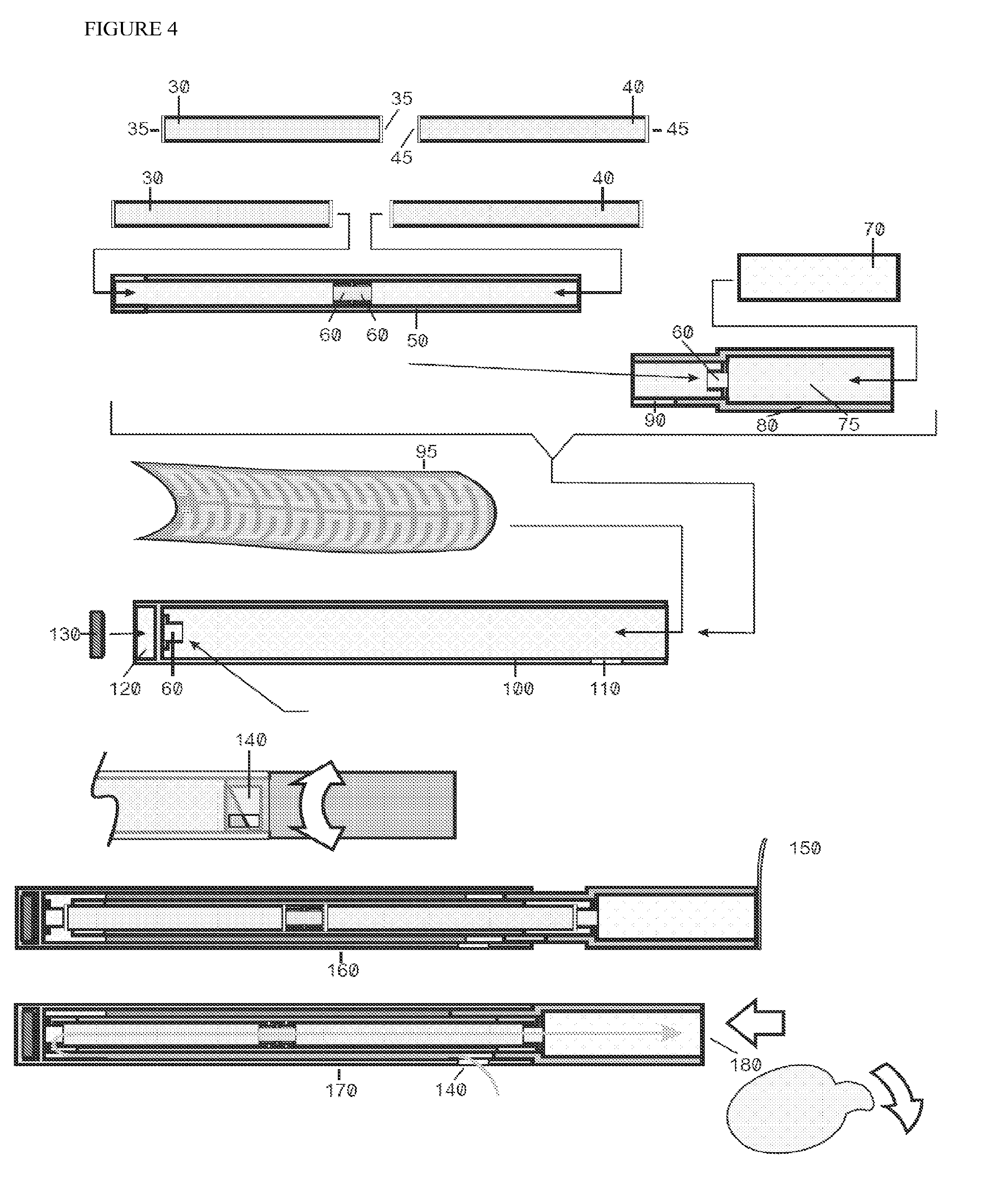

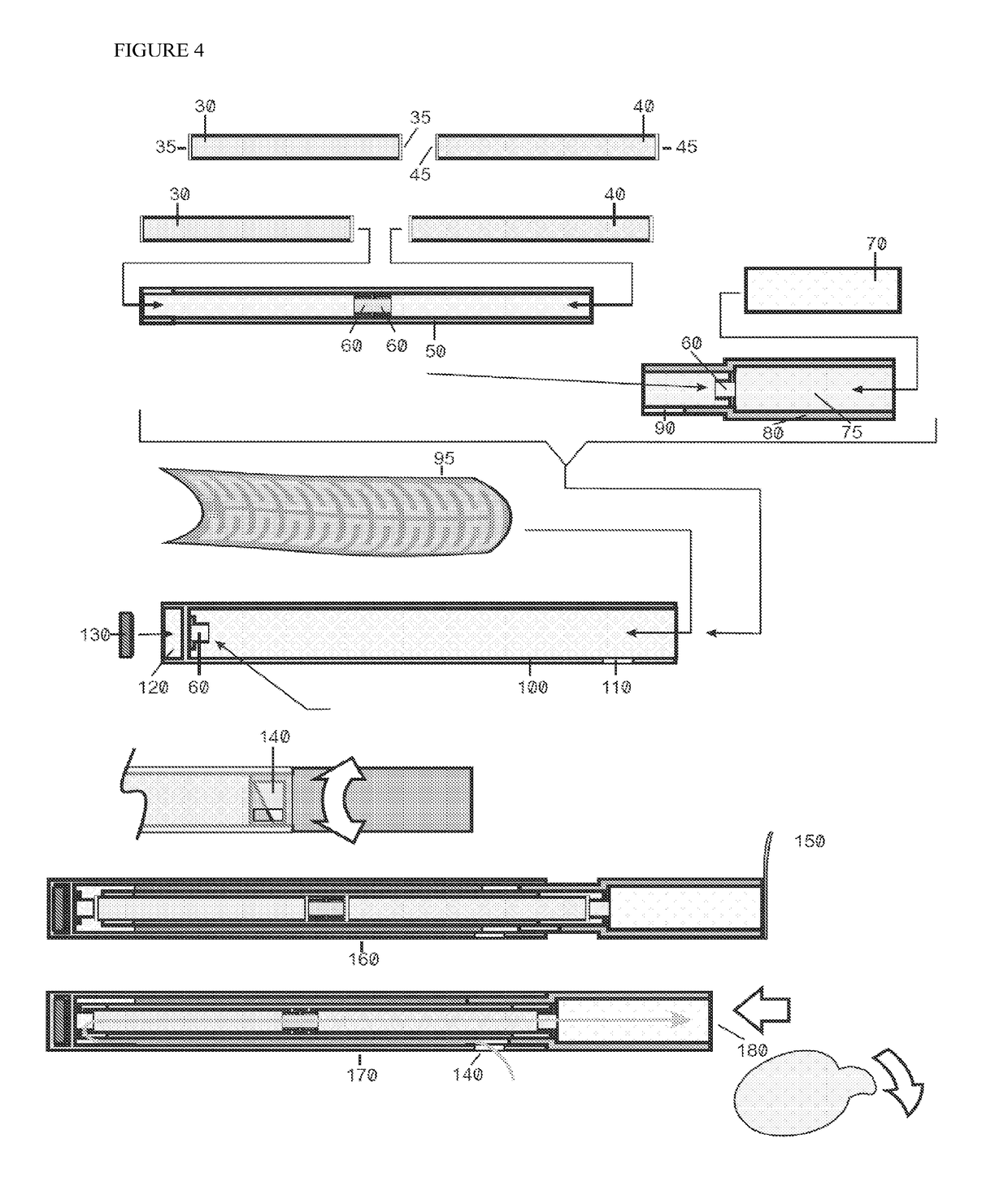

Improved device and method for delivery of a medicament

ActiveUS20120255567A1Easy to useImprove the situationOrganic active ingredientsPowder deliveryDiseaseTherapeutic effect

The disclosure relates to an improved method of enhancing nicotine concentrations in a gaseous carrier. The methods are adaptable to the delivery of nicotine for therapeutic effect in various diseases, in particular nicotine for tobacco product use cessation, substitution and / or harm reduction. The disclosure further relates various devices and device design principles for practicing these methods.

Owner:PHILIP MORRIS PROD SA

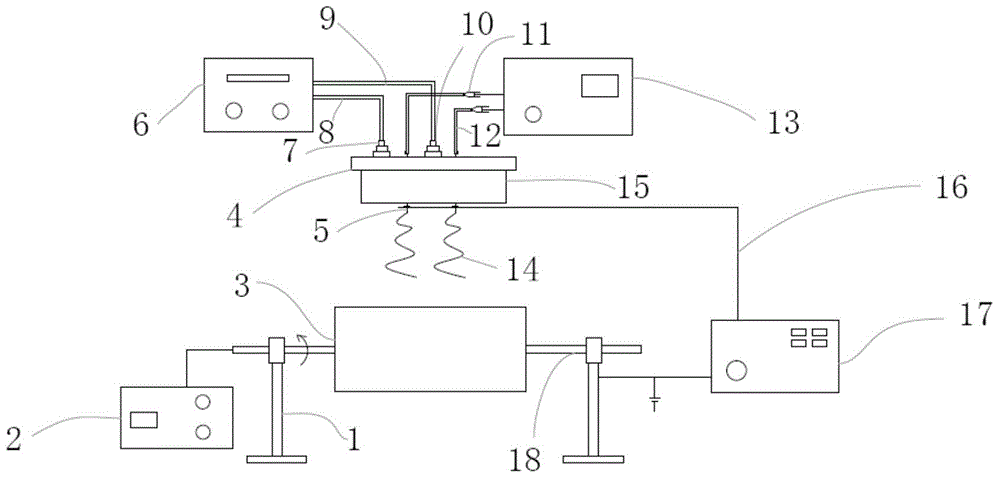

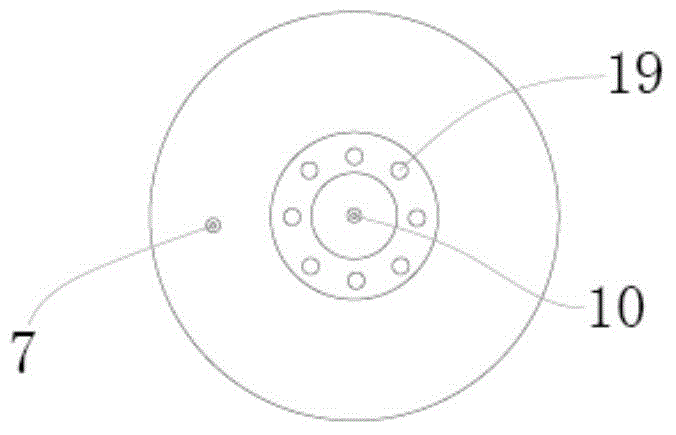

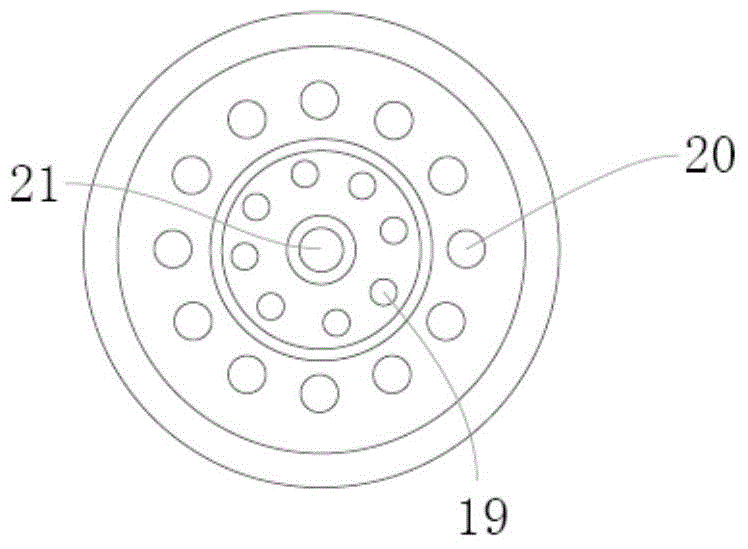

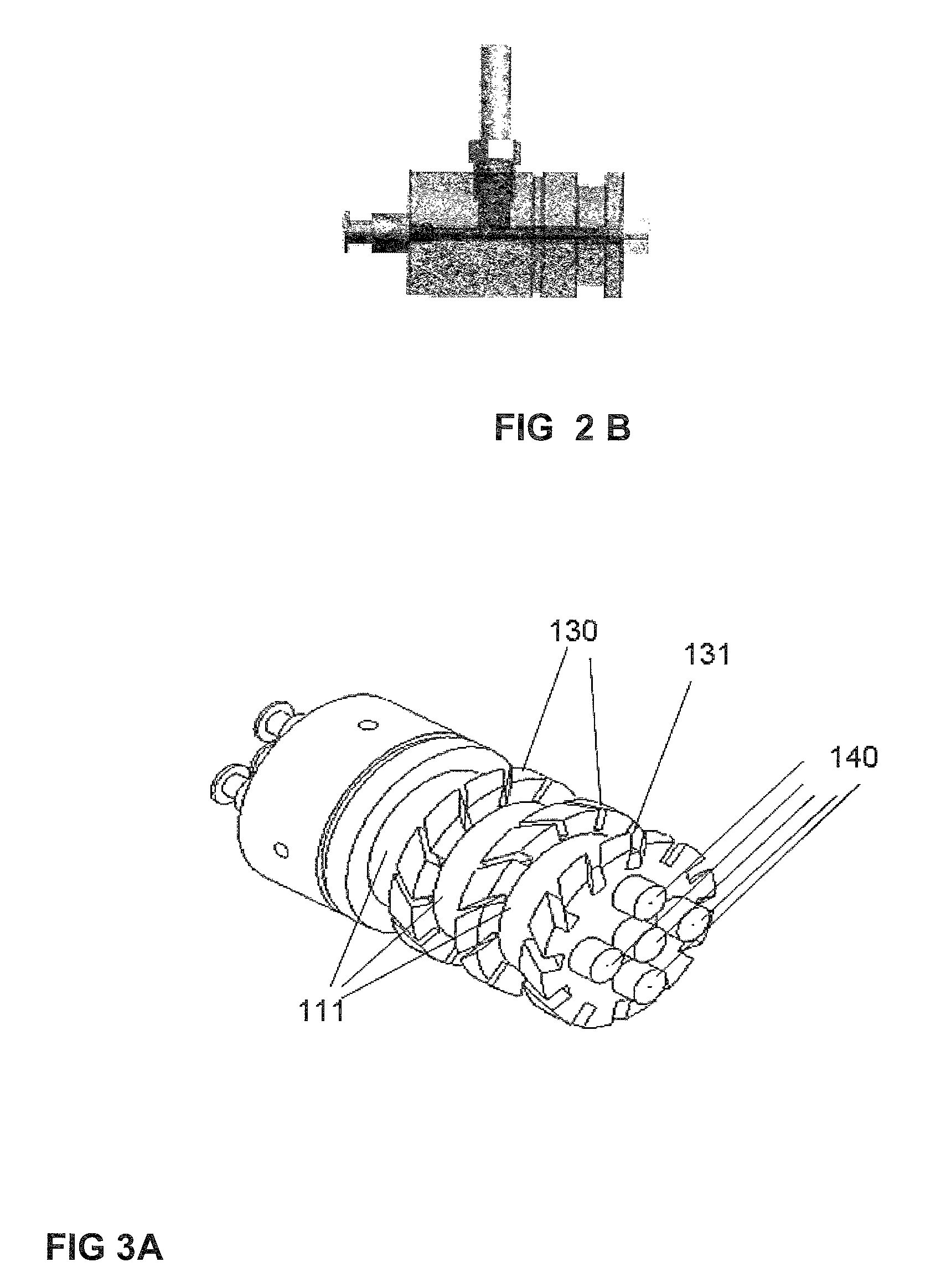

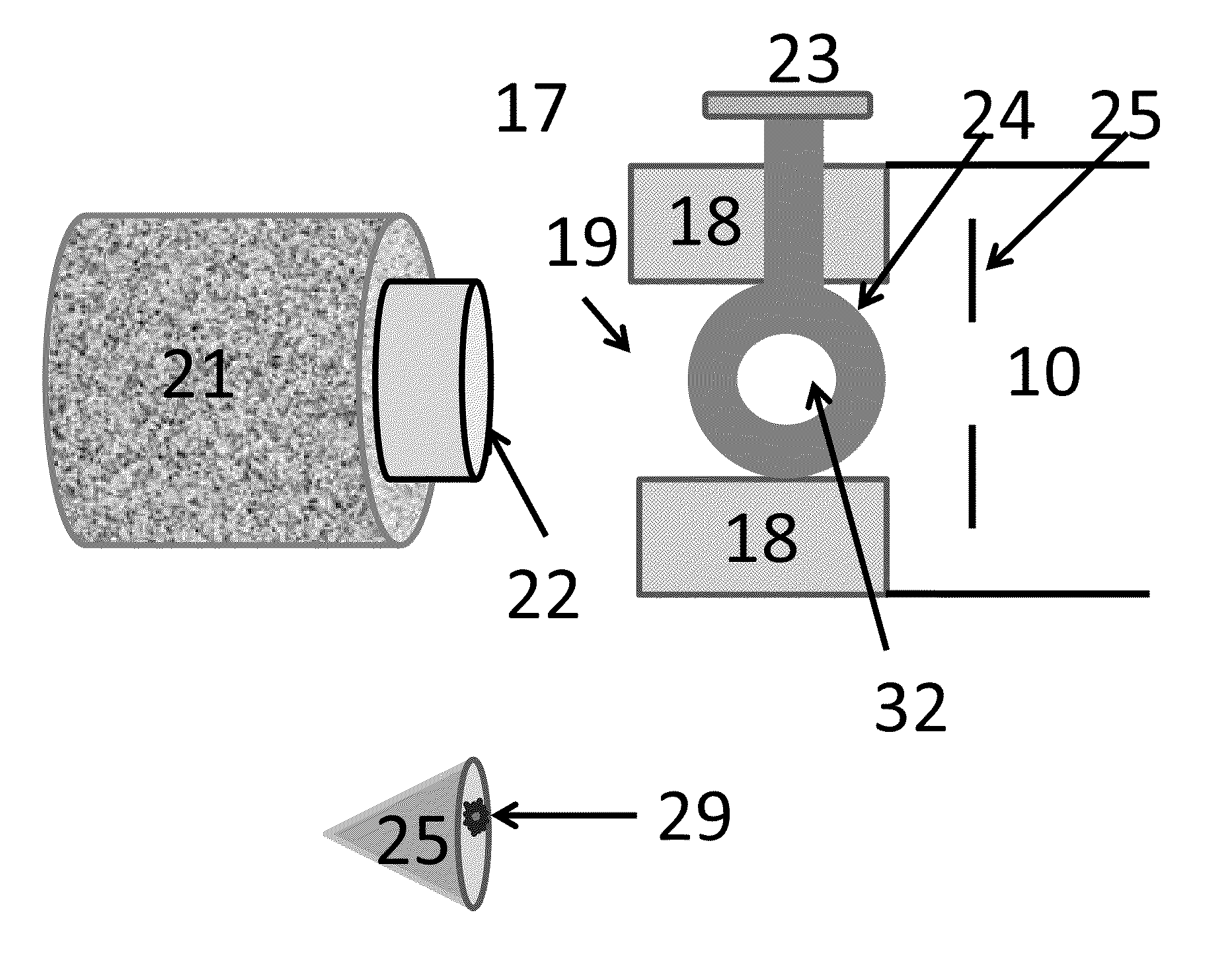

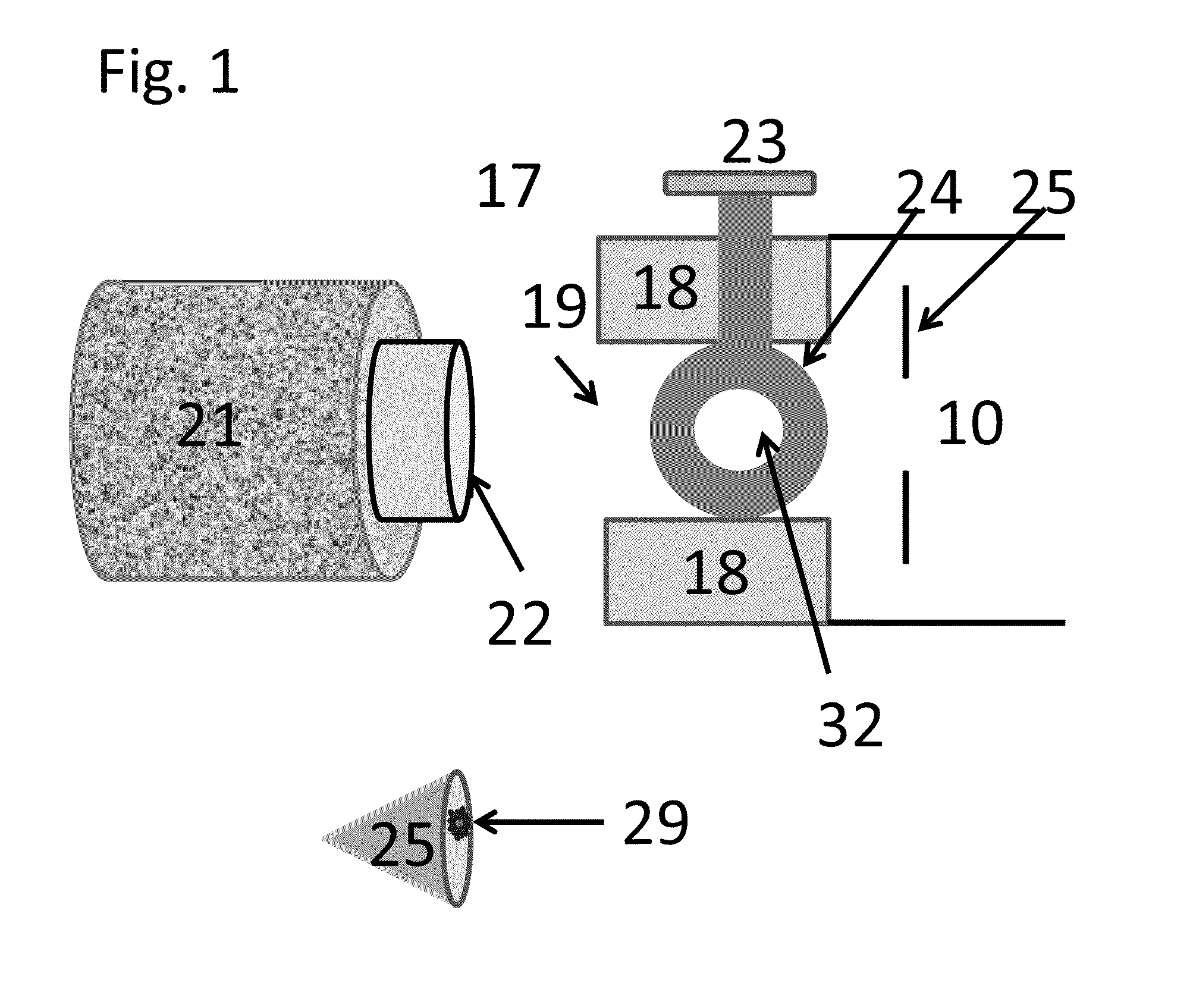

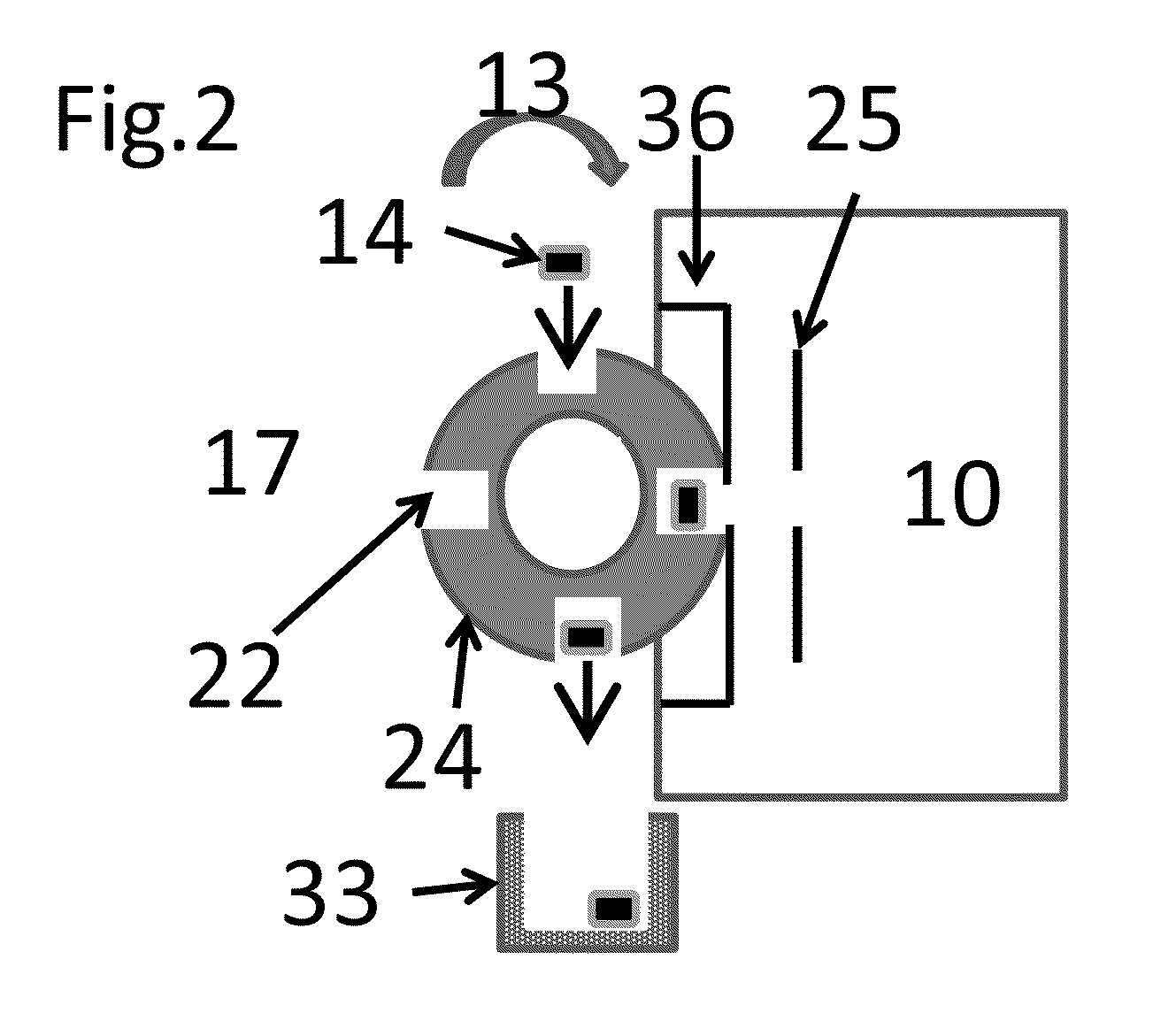

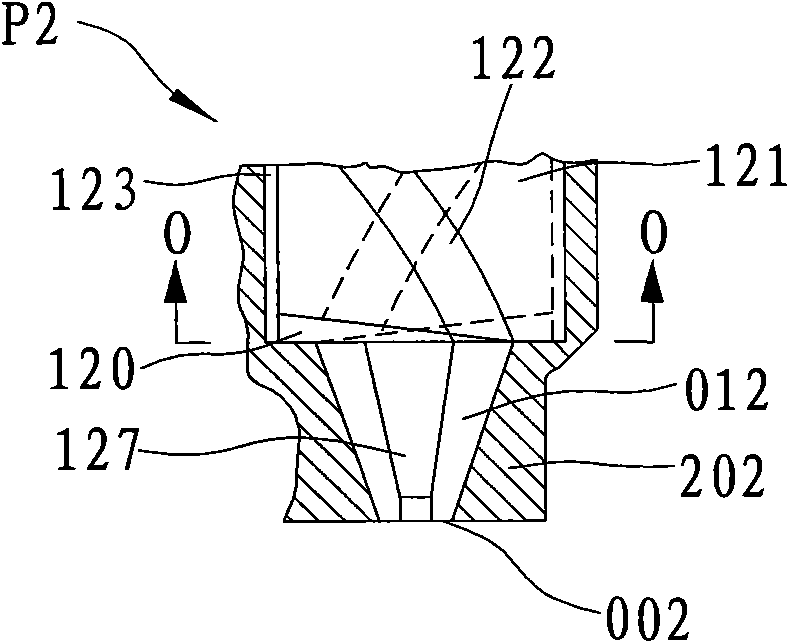

Air jet assisting multi-needle electrostatic spinning device and method for preparing nanofiber net through air jet assisting multi-needle electrostatic spinning device

InactiveCN104862788ASpeed up evaporationFaster curing and running speedFilament/thread formingNon-woven fabricsInjectorAirflow

The invention discloses an air jet assisting multi-needle electrostatic spinning device which comprises a spinneret plate with the air jet assisting function. Multiple metal needles are arranged on the spinneret plate. The head ends of all the metal needles are connected in series through a wire. The wire is connected with the positive electrode of a direct-current high-pressure generator. The tail end of each metal needle is connected with an injector through a liquid guide pipe. The injector is driven through a micro-injection pump. A receiving device is arranged below the spinneret plate and connected with the negative electrode of the direct-current high-pressure generator. By the adoption of the air jet assisting multi-needle electrostatic spinning device, the spinneret plate with the multiple needles serves as a spinning module, on the basis, the air jet assisting function is added to increase the volatilizing speed of a spinning solvent, accelerate jet flow solidification and increase the operation speed, so that the yield of unit time of nanofibers is increased, the fibers are stretched to a certain degree through jet air flow, and the nanofibers with the smaller diameter can be acquired.

Owner:XI'AN POLYTECHNIC UNIVERSITY

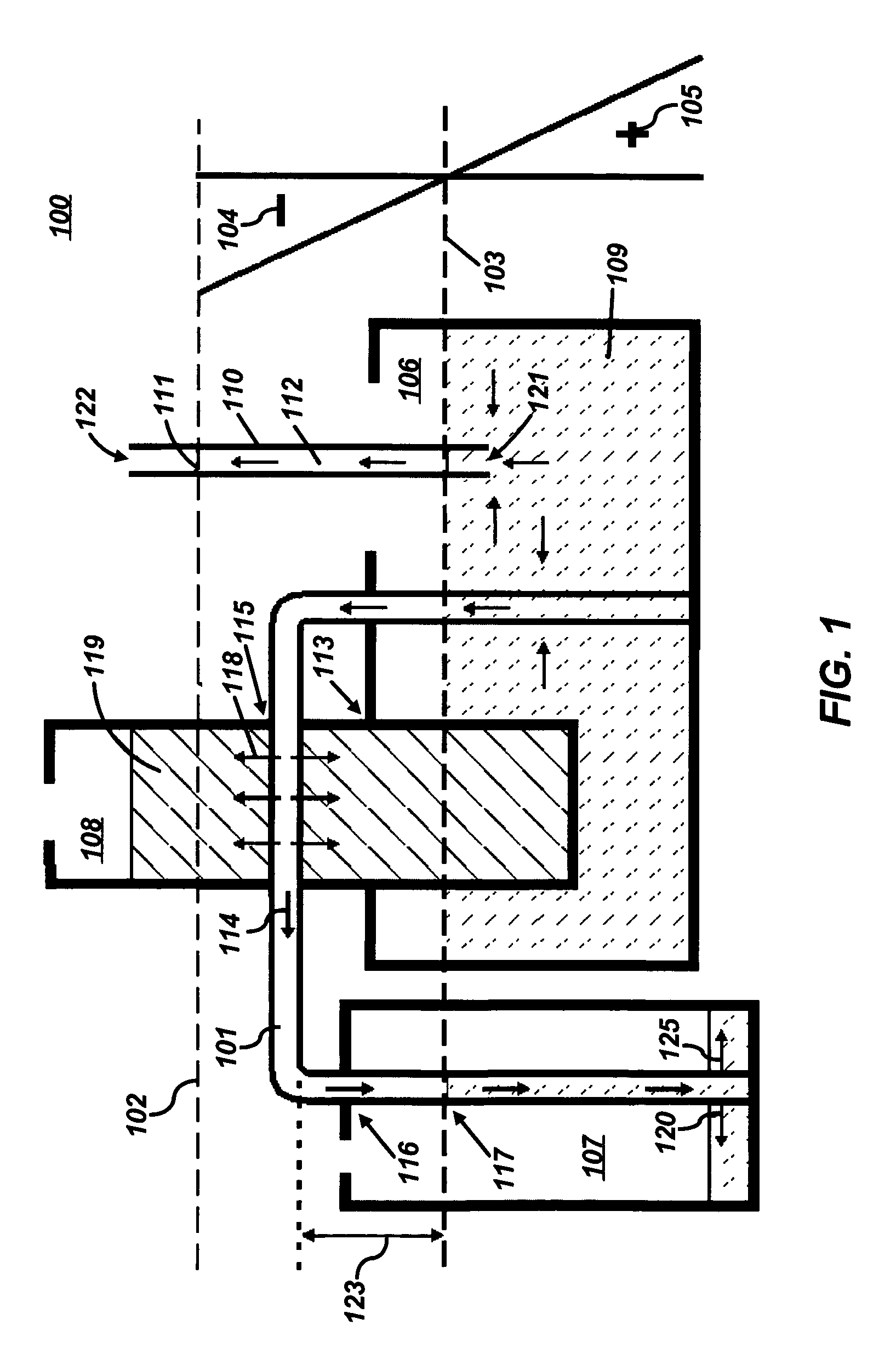

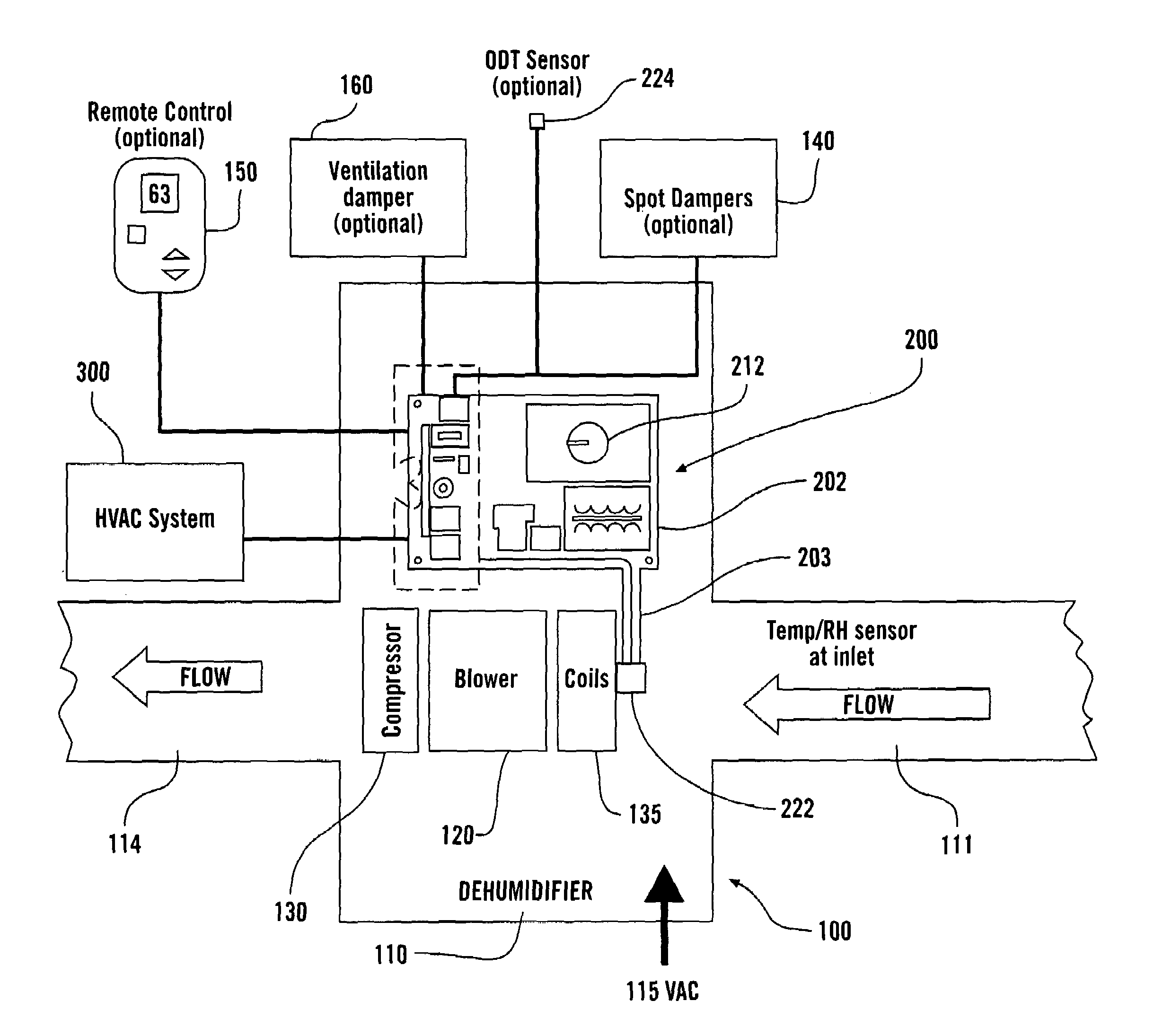

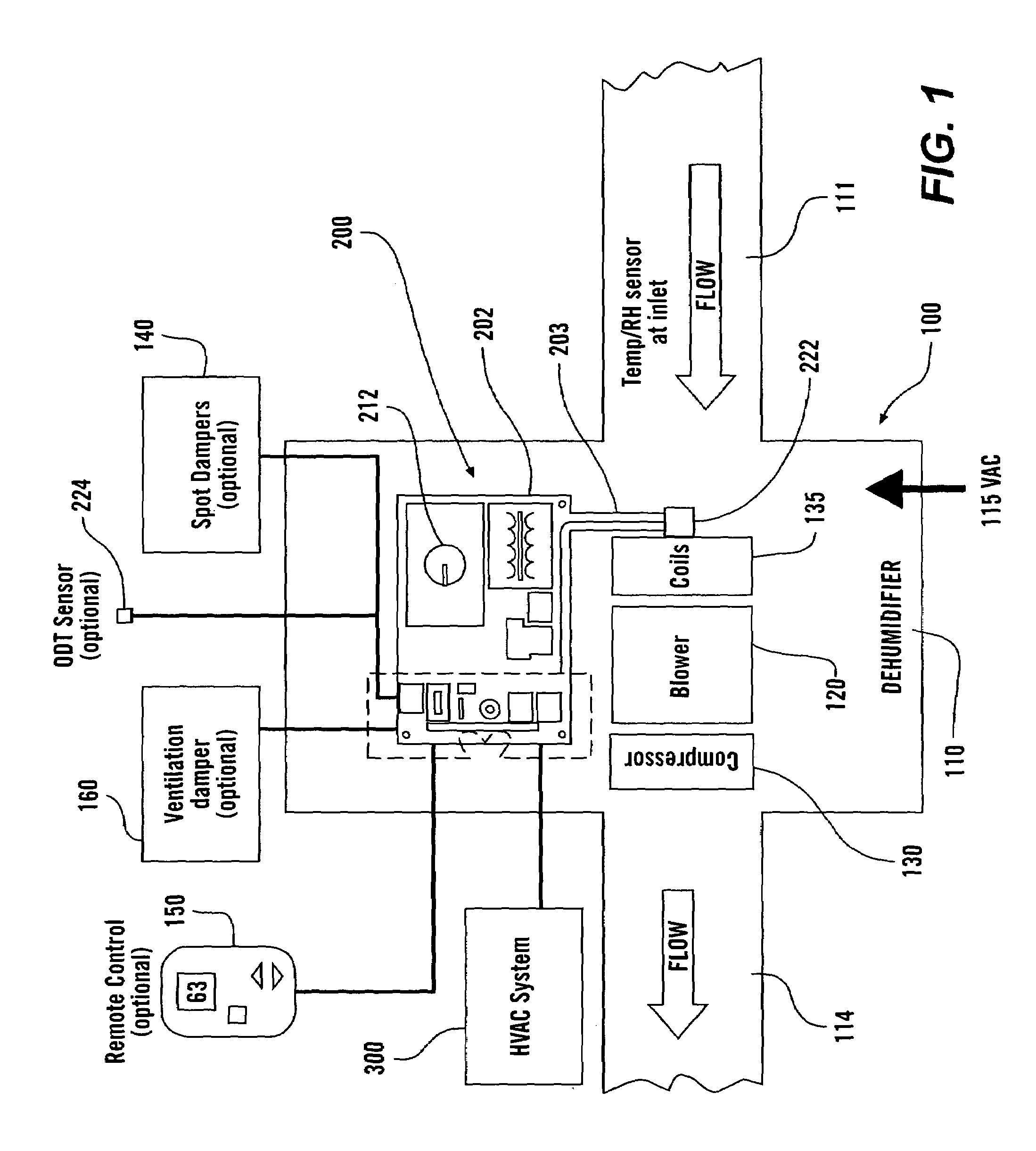

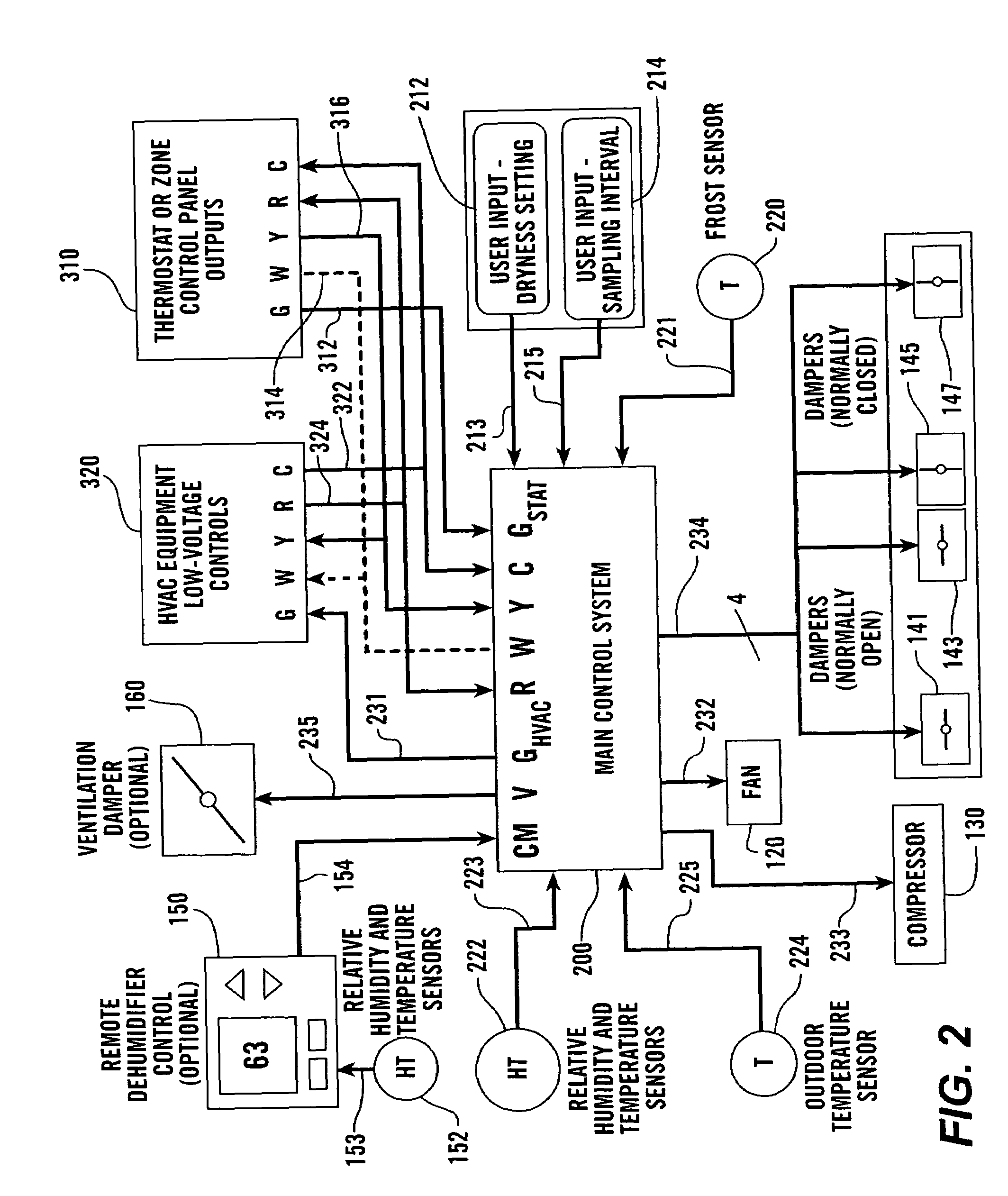

Systems and methods for whole-house dehumidification based on dew point measurements

ActiveUS7574871B2Speed up evaporationEfficient dehumidificationMechanical apparatusControlling ratio of multiple fluid flowsInterior spaceEngineering

A dehumidifier system is connected to an interior space of a building through supply and return ducts, either directly and / or through an HVAC system. Controllable dampers can be used to select how the dehumidifier system is connected to the interior space and the HVAC system. The dehumidifier determines the dew point of the ambient air from temperature and relative humidity measurements taken at location(s) of relative humidity and temperature sensors. Based on the determined dew point, the dehumidifier system determines whether to operate. The temperature and relative humidity sensors can be located in the interior space or within the dehumidifier, where they project into the air stream flowing through the dehumidifier. The dehumidifier system operates in response in part to blower calls to the HVAC system and controls the HVAC system and a ventilation system to distribute the dehumidified air and outside air throughout the building.

Owner:RES PRODS

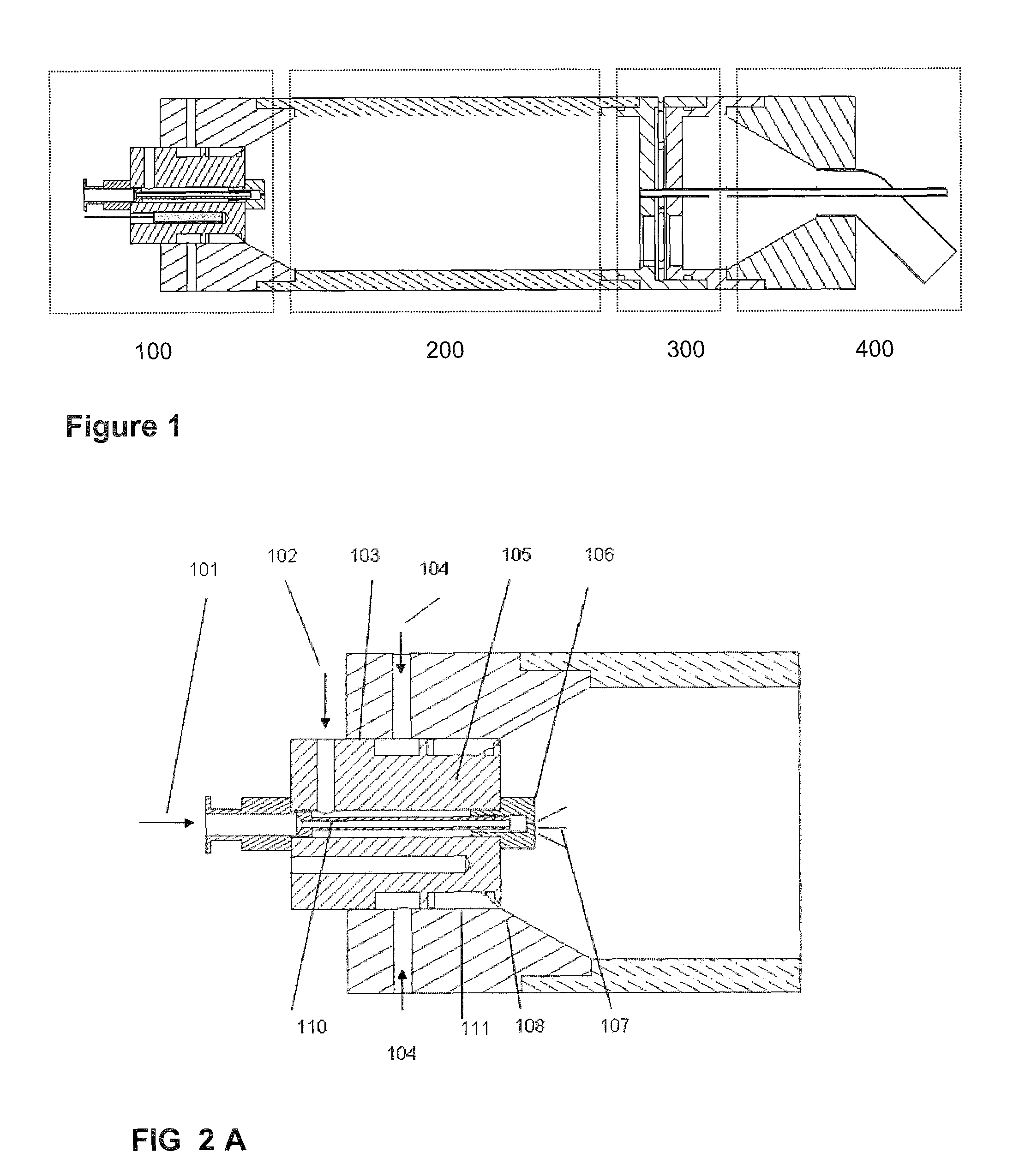

Aerosol processing and inhalation method and system for high dose rate aerosol drug delivery

ActiveUS7802569B2Risk minimizationIncrease dose rateRespiratorsDispersed particle separationCounter flowSolvent vapor

Owner:KAER BIOTHERAPEUTICS CORP

Prescented and custom scented card insert

InactiveUS6575383B2Better friendlinessThicken fragranceSpraying apparatusDe-icing equipmentsPaper towelEngineering

A pre-scented or custom scented card insert designed to fit into any existing toilet paper or paper towel holder. The insert allows consumers to choose a scent additive to freshen their bathroom, kitchens or any other place where these products are used, as well as to scent the toilet paper or paper towel rolls. The insert can be replaced easily to refresh the roll, or additional inserts can be added to create a stronger fragrance impact.

Owner:ORLANDI INC

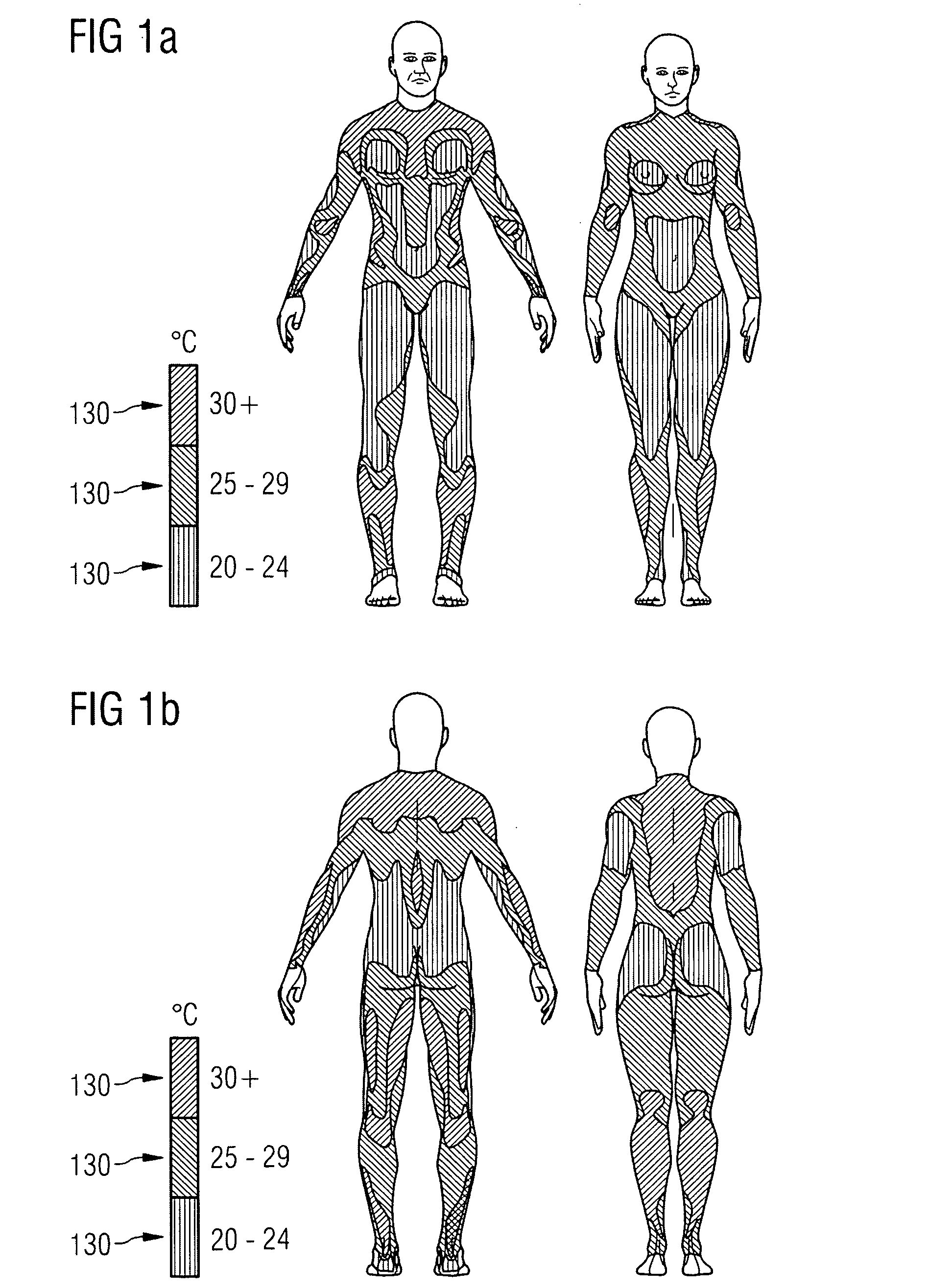

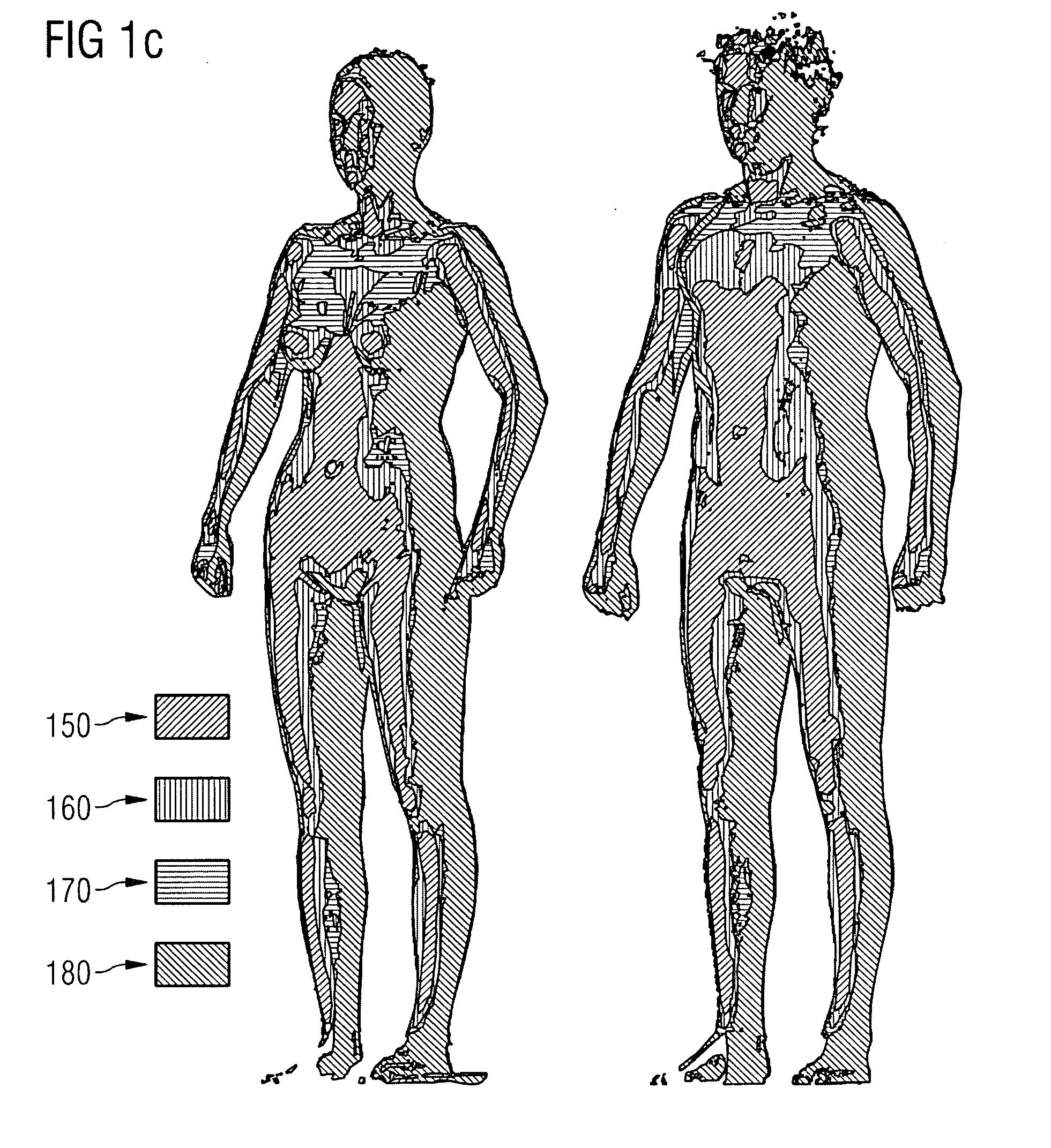

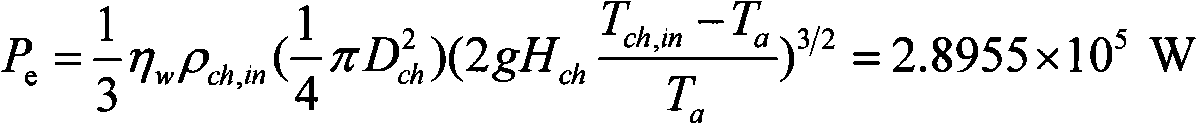

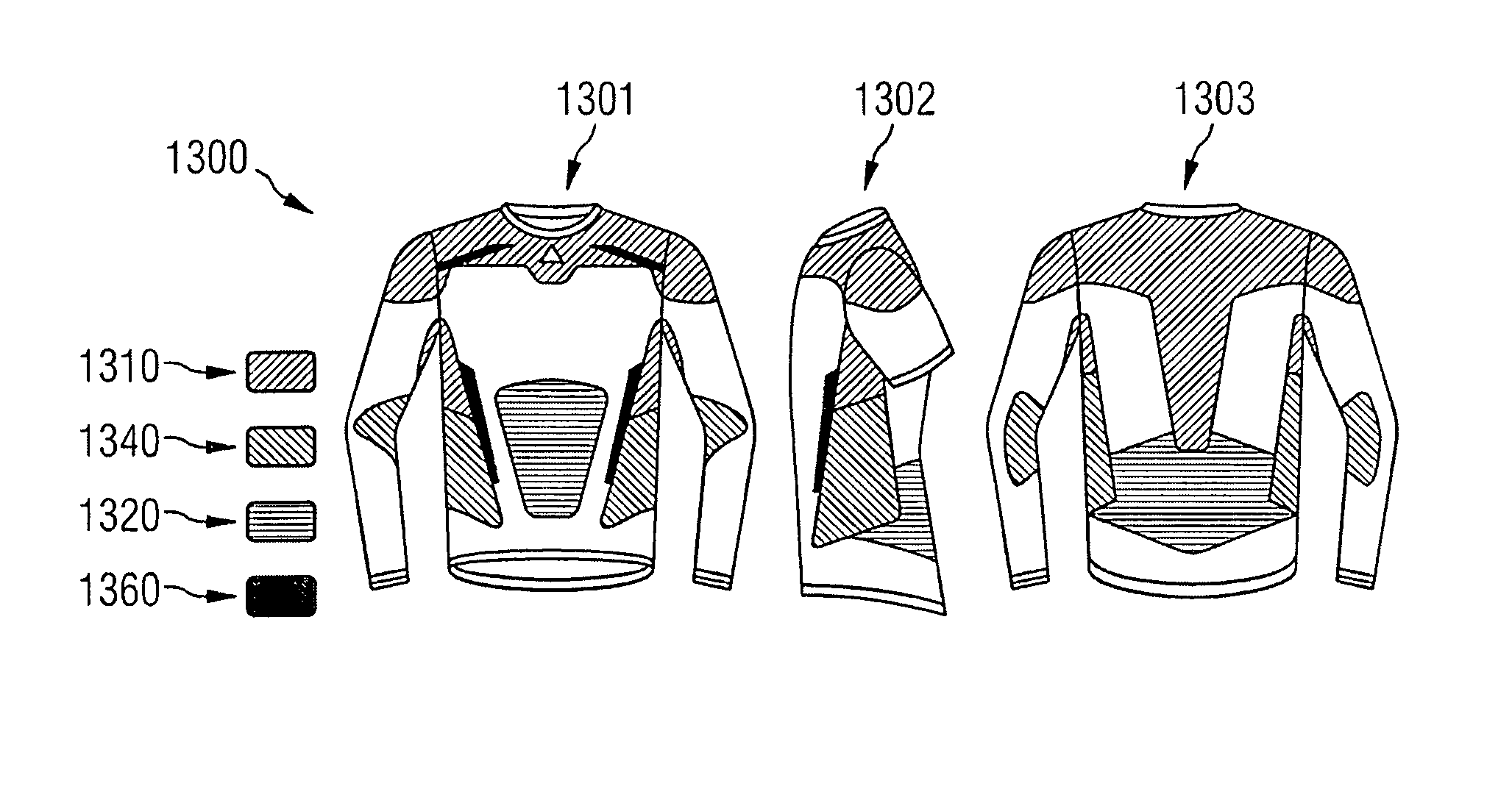

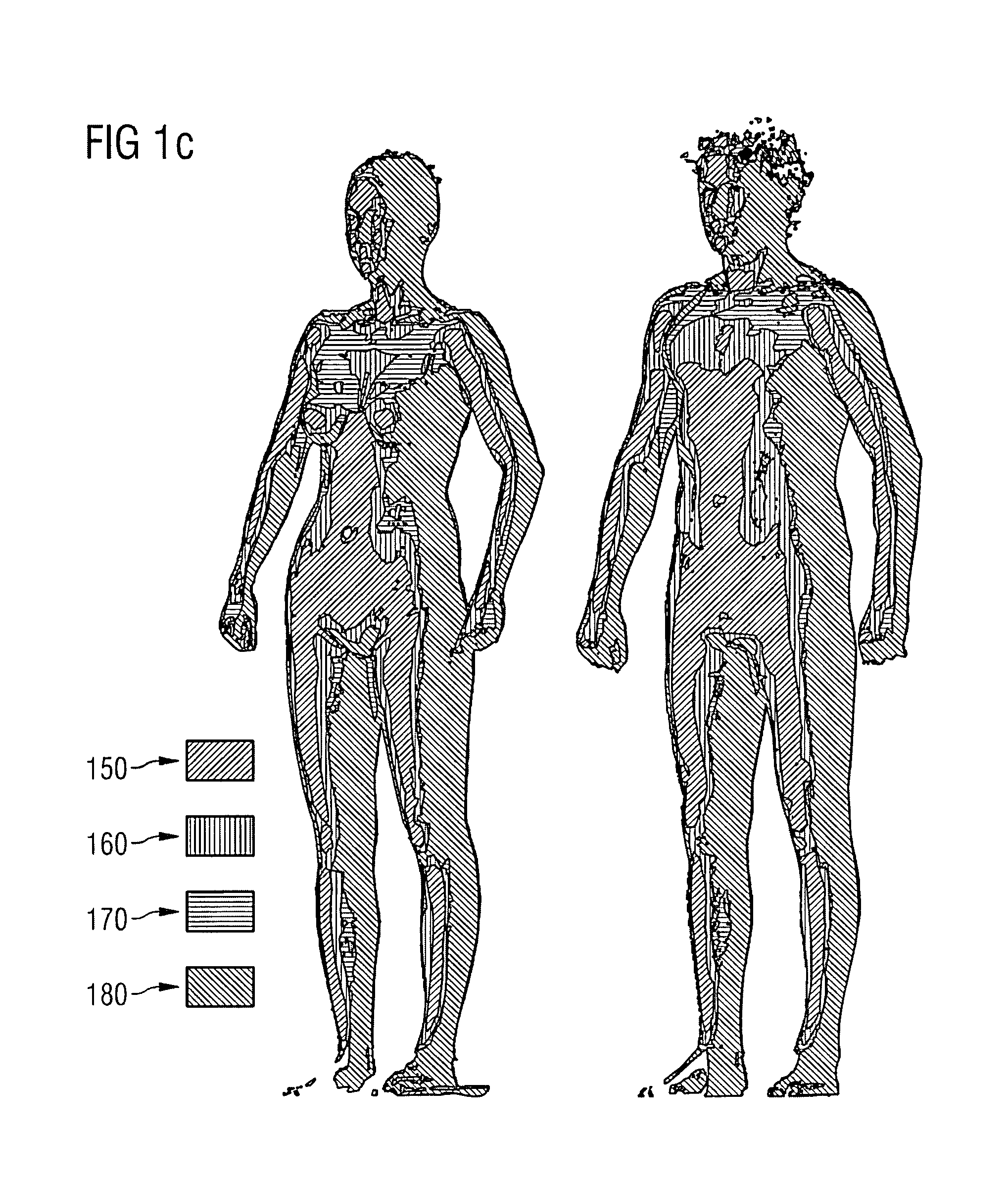

Apparel

ActiveUS20110099680A1High sweat productionLow skin temperatureGarment special featuresTrousersEngineeringMoisture

An aspect of the invention relates to a garment which comprises at least a first zone and a second zone. The first zone of the garment is arranged in the spine area and comprises a higher degree of air permeability than the second zone. The second zone of the garment is arranged below the breast area and in the area of the lumbar vertebrae and comprises a higher degree of moisture wicking than the first zone.

Owner:ADIDAS

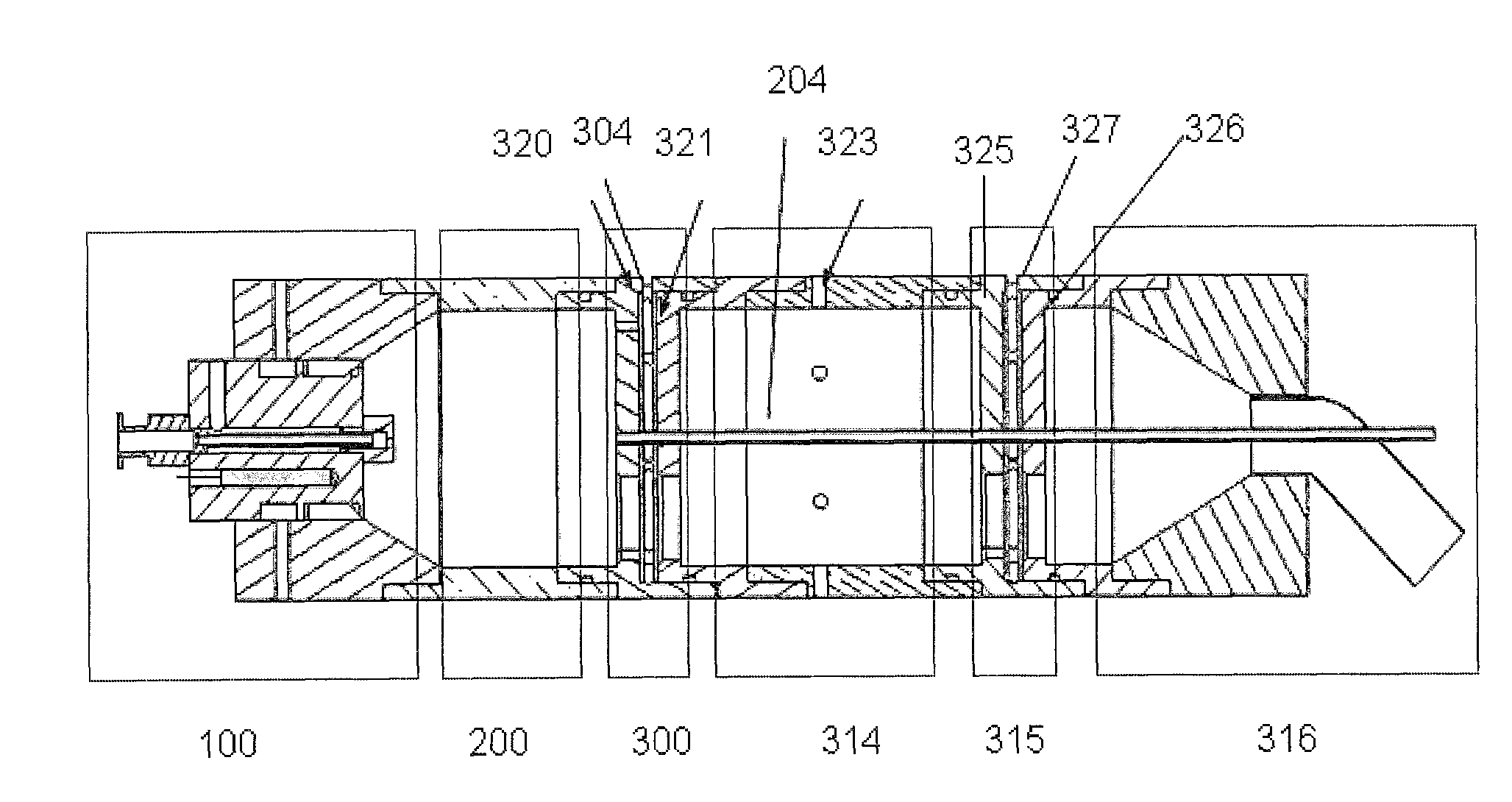

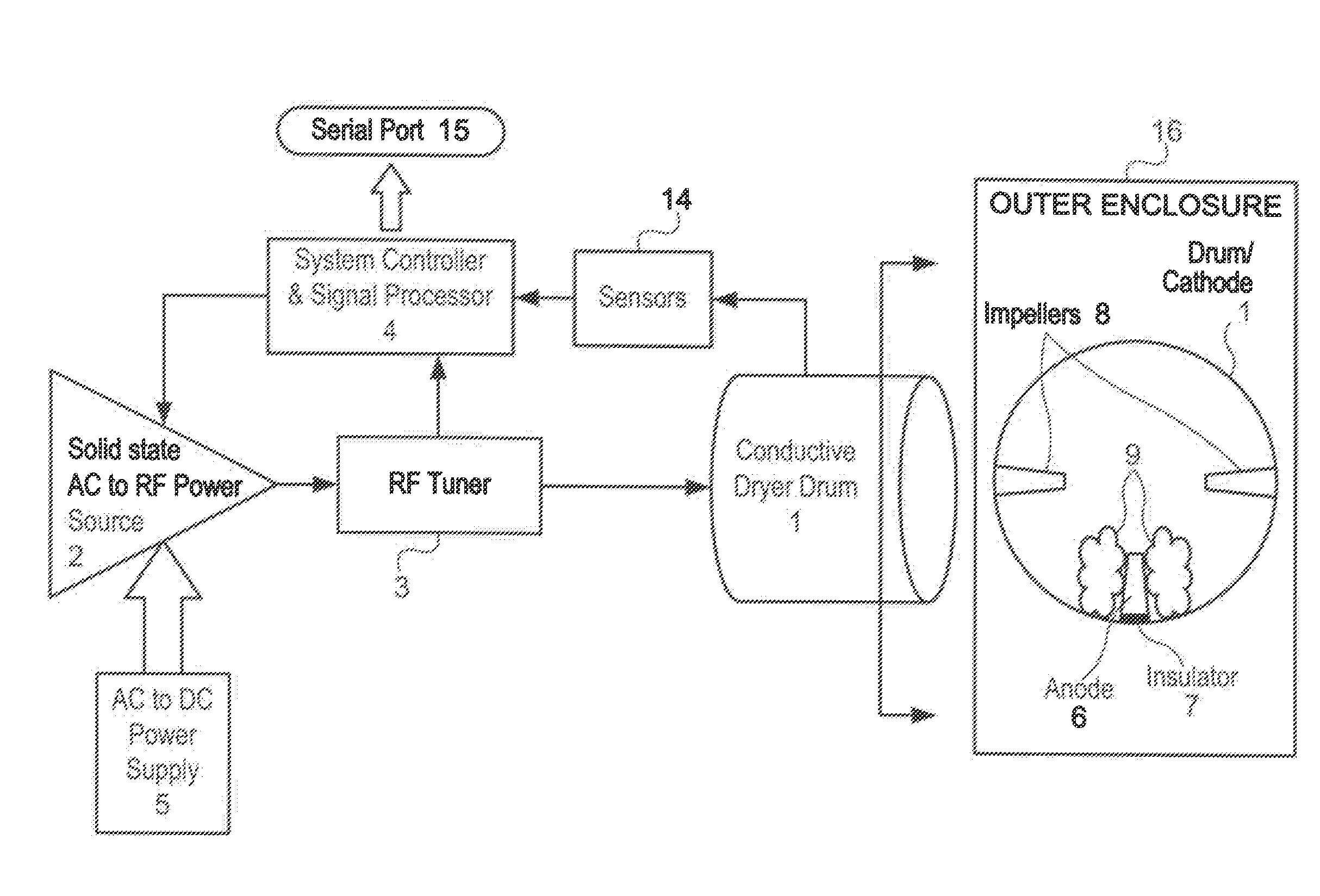

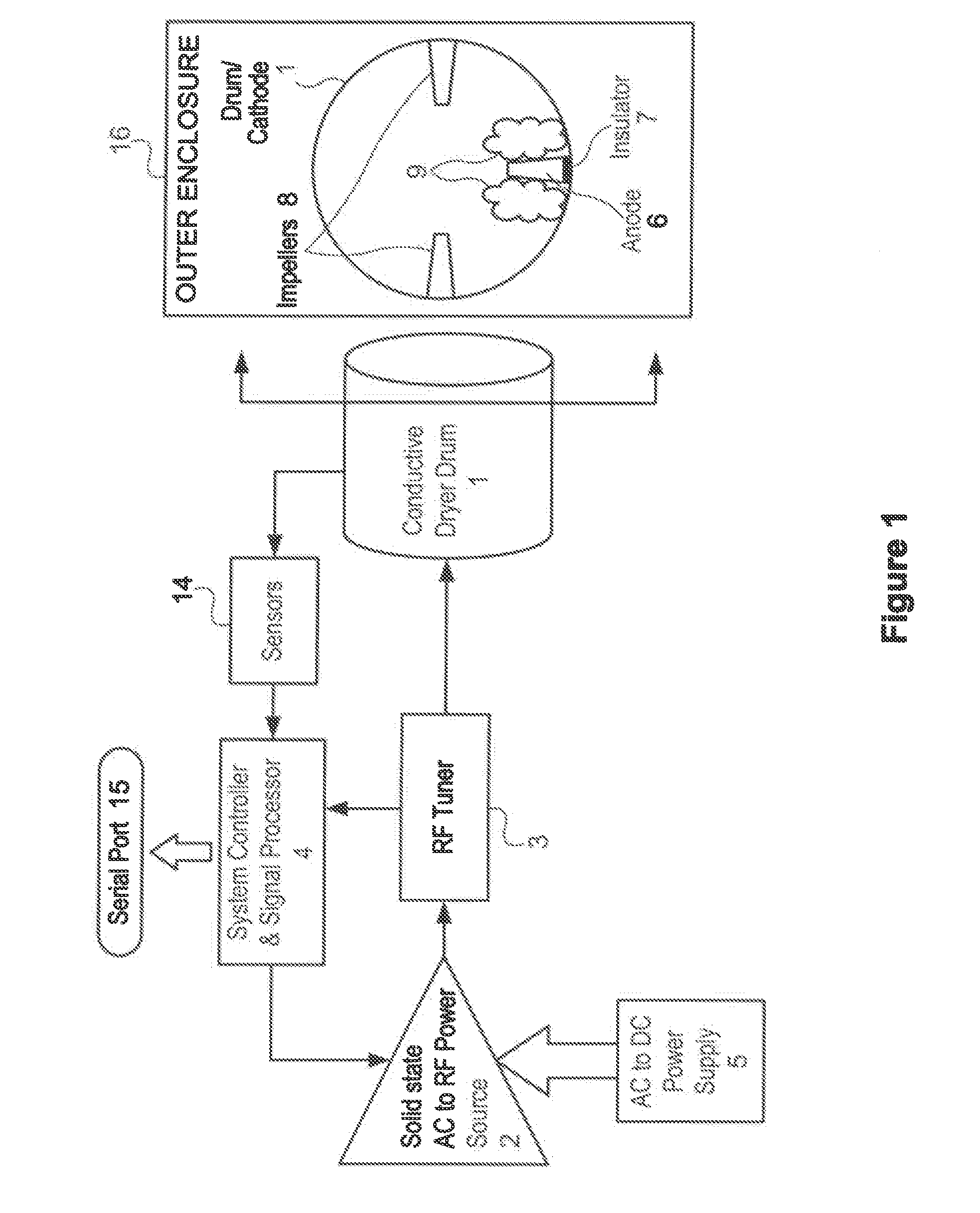

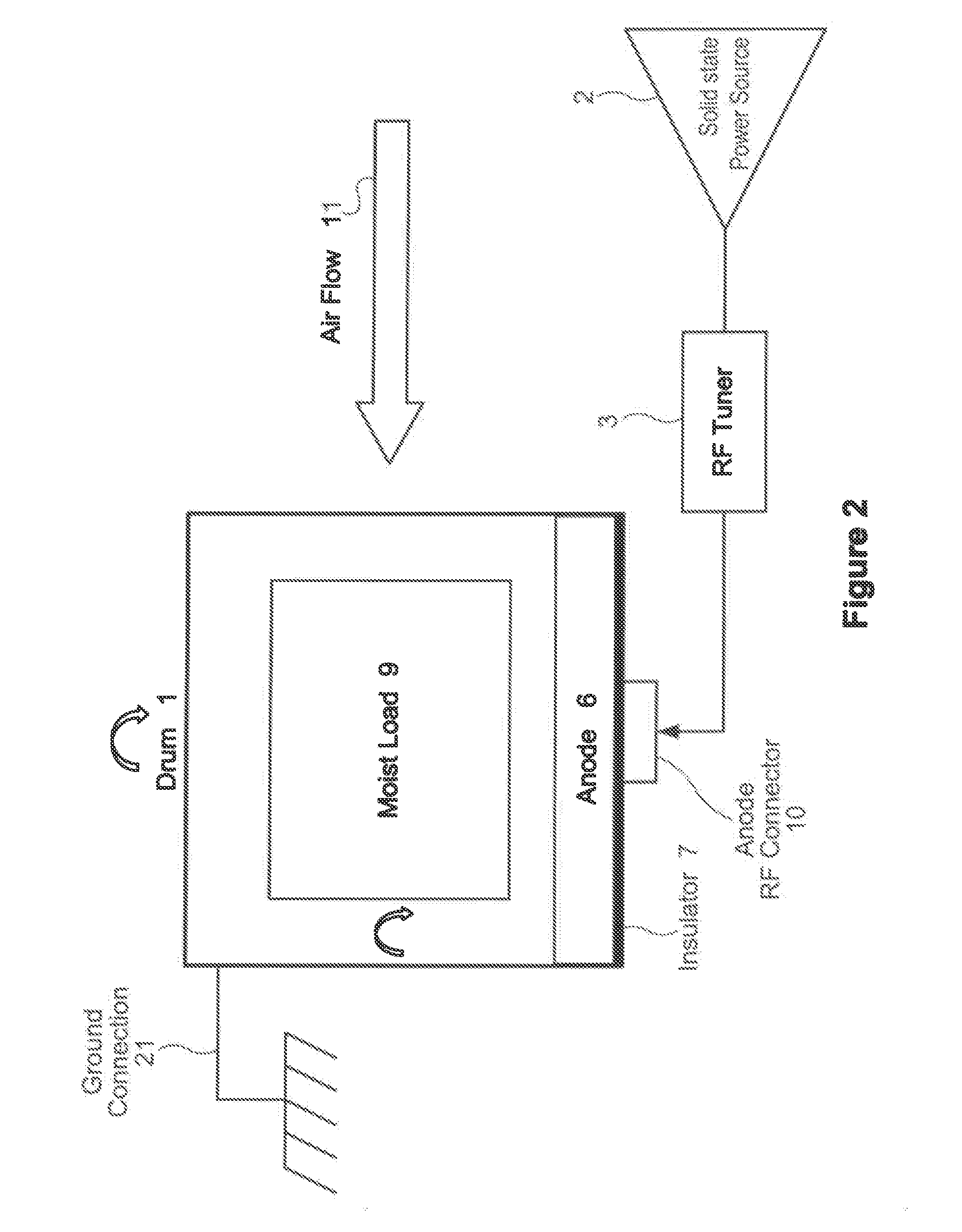

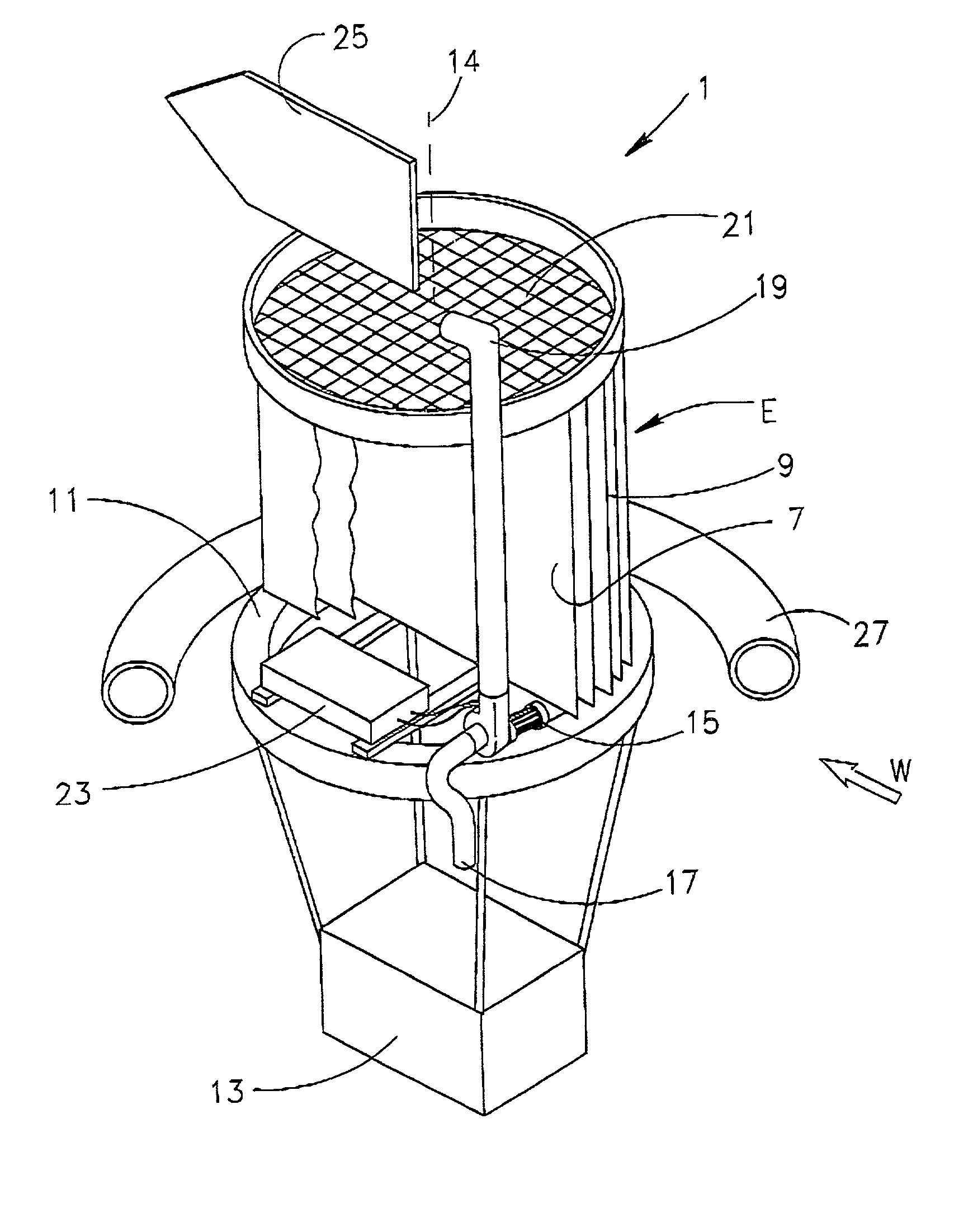

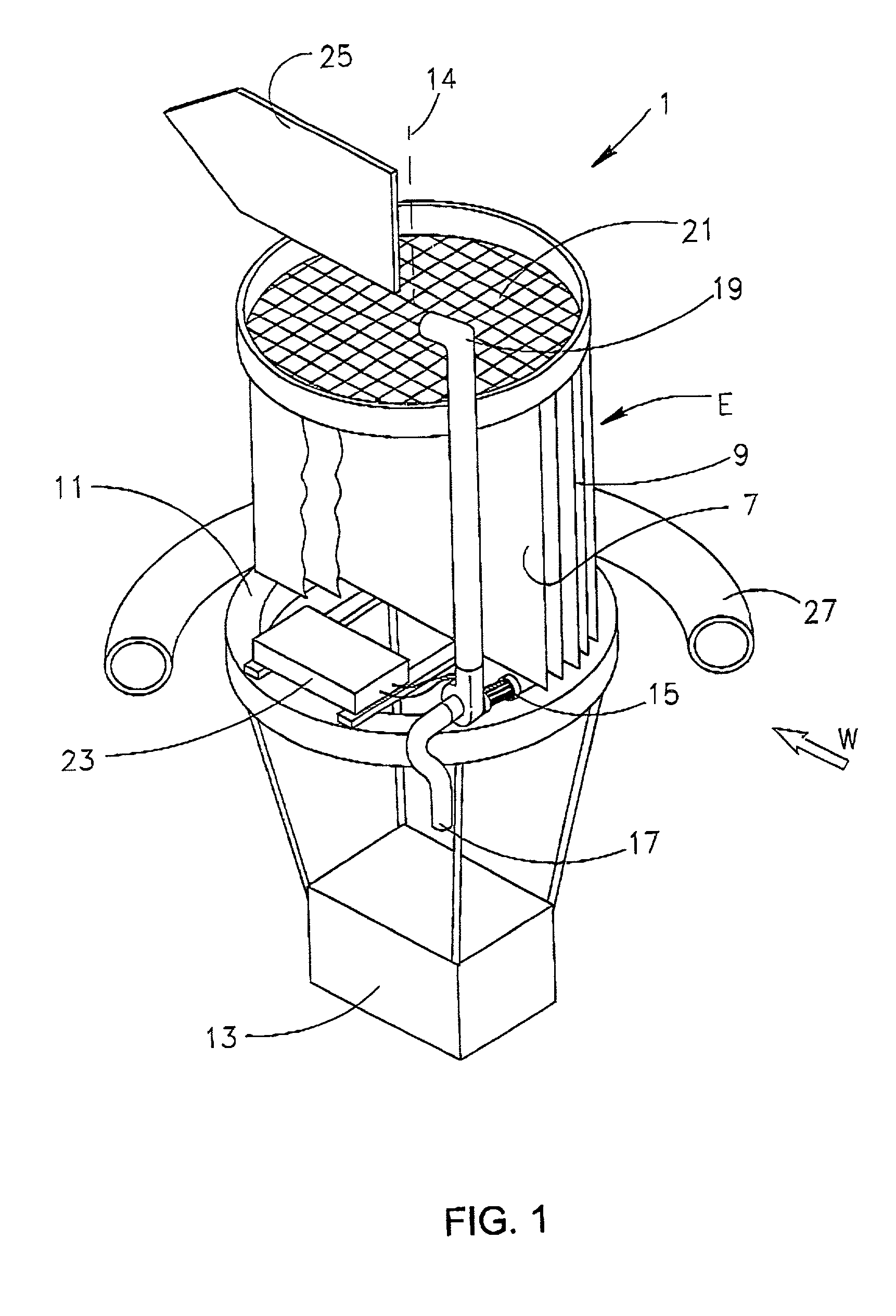

Dielectric dryer drum

ActiveUS20140325865A1Sufficient heat energyAvoid problemsDrying solid materials with heatDrying machines with non-progressive movementsDielectricEngineering

Methods and apparatus for heating an object 9 that includes an absorbed medium. A method embodiment comprises: placing the object 9 including the medium into an enclosure 16; initiating a heating process by subjecting the object 9 and medium to a capacitive AC electrical field generated by an RF power source 2 at a single low frequency; controlling the heating process by taking real time measurements; and making real time adjustments to the RF power source 2 in response to the real time measurements. The object 9 substantially absorbs the medium in a first “cool” state, and therefore has a maximum weight in the first “cool” state. The object 9 is substantially free from the medium in a second “heated” state, due to substantial release of the medium from the object 9. The released medium is evaporated during the heating process. The heating process is completed when the object 9 is substantially transitioned into the second “heated” state. The method further comprises causing an air flow 11 inside the enclosure 16 to carry away evaporated medium out of the enclosure 16.

Owner:LG ELECTRONICS INC

Processing process of woven fabric with one-way quick moisture conducting composite structure

The invention discloses a processing process of a woven fabric with a one-way quick moisture conducting composite structure. The process comprises a design process and a weaving process, wherein the design process comprises the steps of: establishing a one-way quick moisture conducting model and designing an organization structure; and the weaving process comprises the steps of: selecting and weaving warp and yarn raw materials by the moisture conducting principle of the established fabric moisture conducting model. The invention can be used for designing and weaving the woven fabric with a one-way quick moisture conducting composite structure, and moisture conducting and quick drying series functional fabrics are a great trend of the future consumer market and have wide development prospect.

Owner:杭州新天元织造有限公司

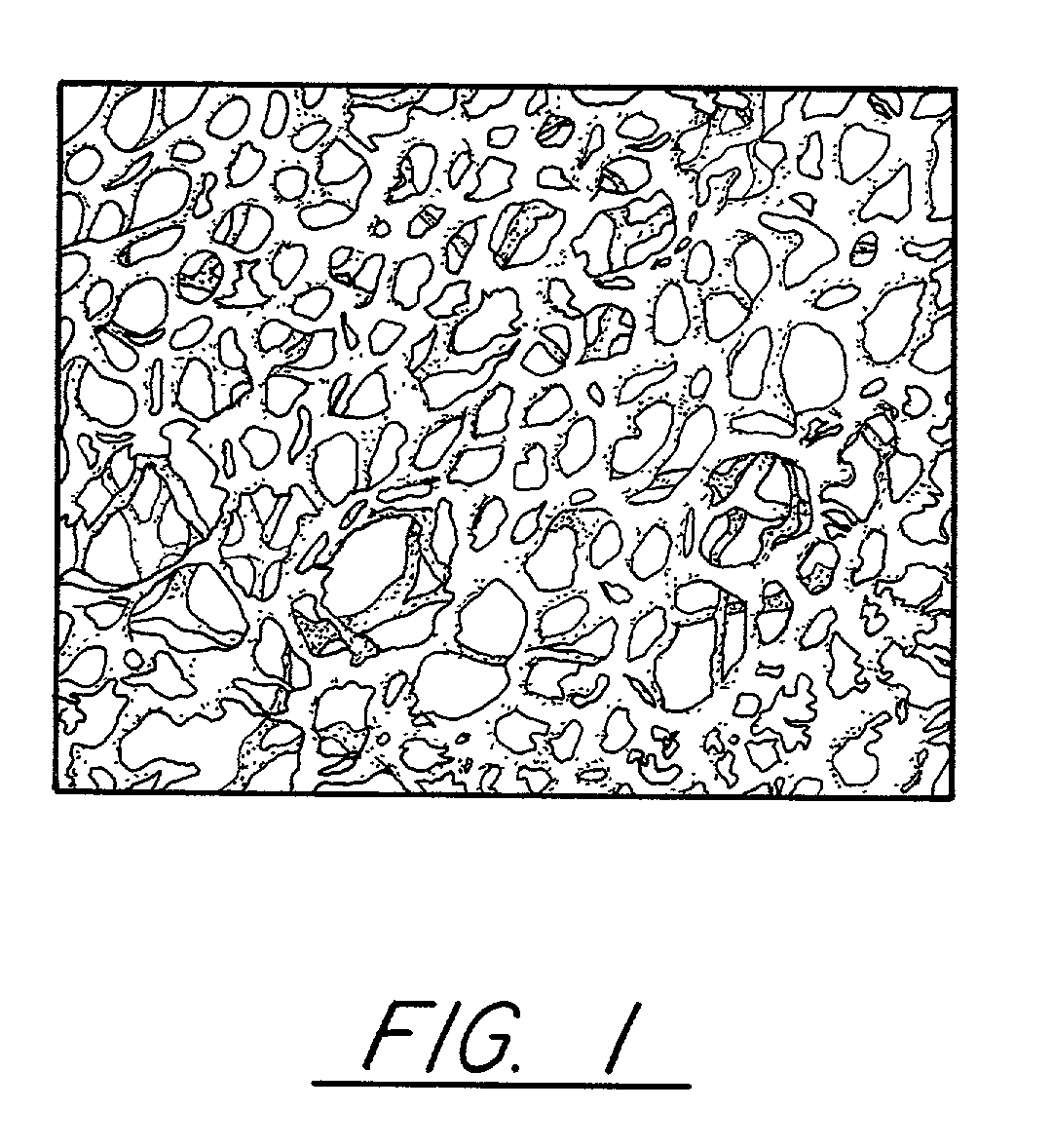

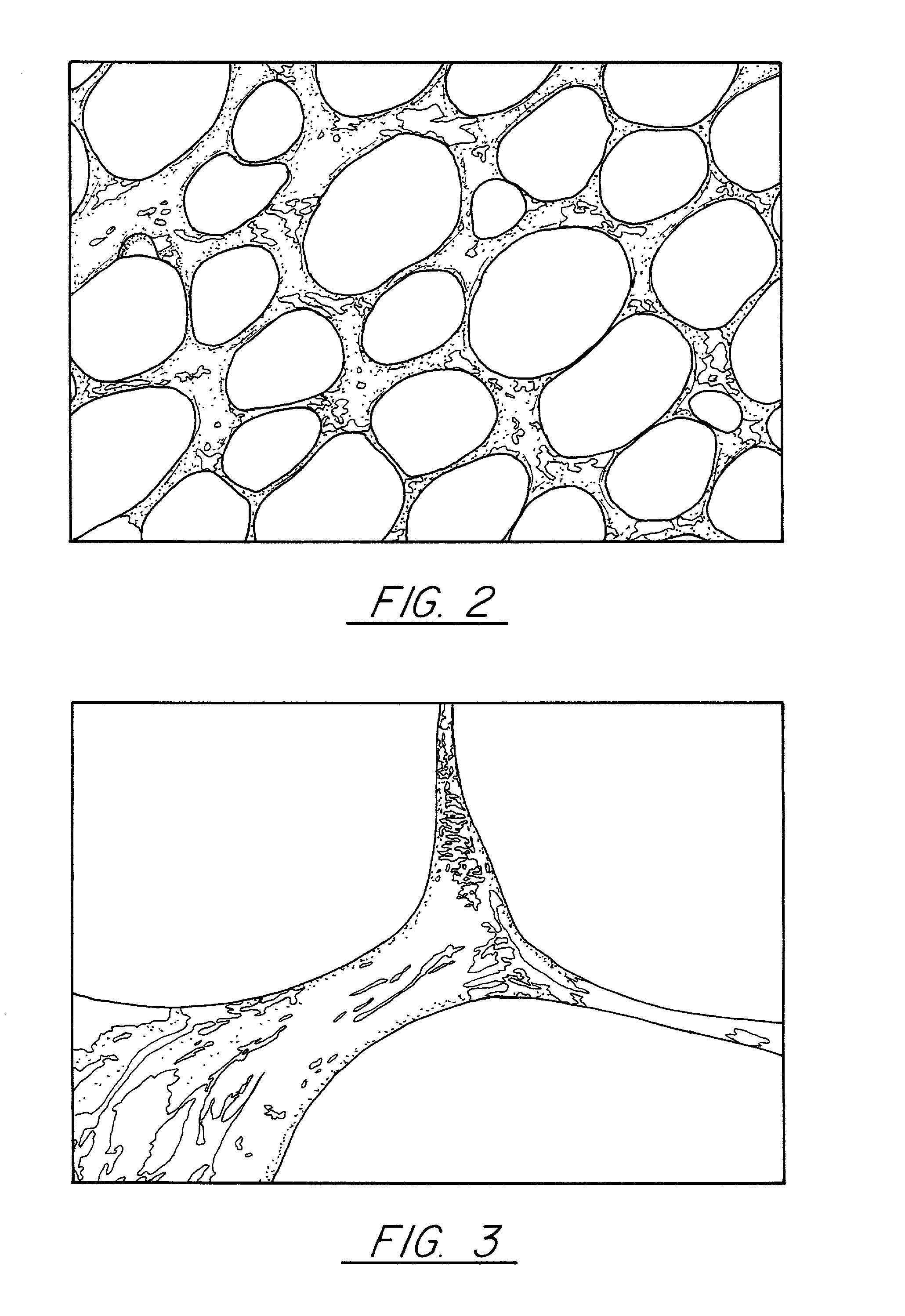

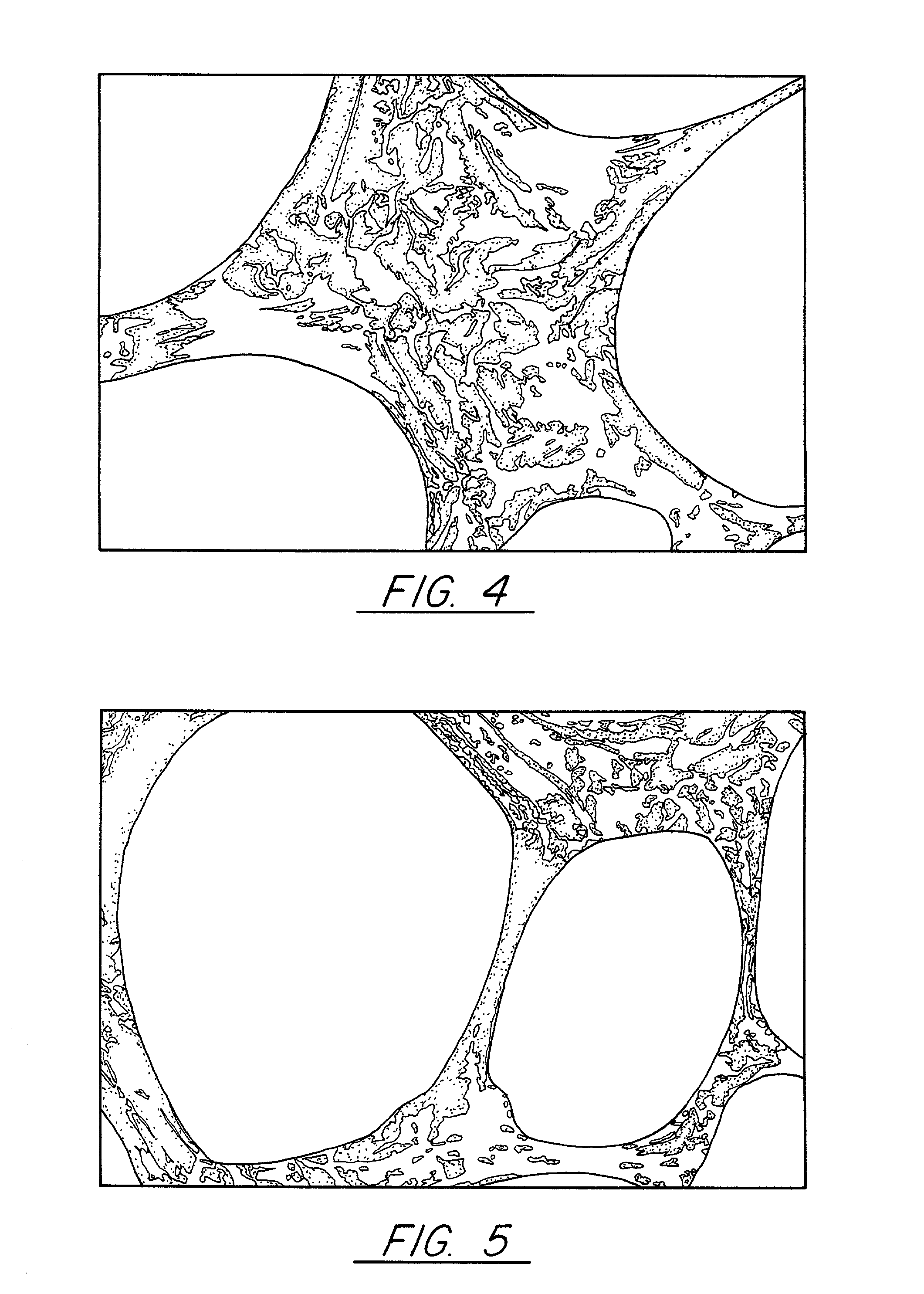

Pitch-based carbon foam and composites and use thereof

InactiveUS7070755B2Speed up evaporationImprove cooling effectCarbon compoundsHeat storage plantsX-rayVolumetric Mass Density

A thermally conductive carbon foam is provided, normally having a thermal conductivity of at least 40 W / m·K. The carbon foam usually has a specific thermal conductivity, defined as the thermal conductivity divided by the density, of at least about 75 W·cm3 / m·° K·gm. The foam also has a high specific surface area, typically at least about 6,000 m2 / m3. The foam is characterized by an x-ray diffraction pattern having “doublet” 100 and 101 peaks characterized by a relative peak split factor no greater than about 0.470. The foam is graphitic and exhibits substantially isotropic thermal conductivity. The foam comprises substantially ellipsoidal pores and the mean pore diameter of such pores is preferably no greater than about 340 microns. Other materials, such as phase change materials, can be impregnated in the pores in order to impart beneficial thermal properties to the foam. Heat exchange devices and evaporatively cooled heat sinks utilizing the foams are also disclosed.

Owner:UT BATTELLE LLC

Method and apparatus for simultaneous heat and mass transfer utilizing a carrier-gas at various absolute pressures

ActiveUS20050121304A1Improve energy efficiencyLow operating costSpace heating and ventilationDistillation regulation/controlMass transferEngineering

A method, system, and apparatuses for simultaneous heat and mass transfer utilizing a carrier-gas at various absolute pressures are described. A method may include: thermally coupling at least two continuous contacting apparatuses together; varying the pressure between the at least two continuous contacting apparatuses; allowing heat removed from the first continuous contacting apparatus to be the heat delivered to the second continuous contacting apparatus. A system may include: at least two continuous contacting apparatuses thermally coupled together and operating at different absolute pressures. A continuous contacting apparatus may include: an evaporation chamber and a dew-formation chamber both operating at an absolute pressure in a vacuum range. A continuous contacting vapor recompression apparatus may include: an evaporation chamber operating at a first absolute pressure; and a dew-formation chamber operating at a second absolute pressure higher than the first absolute pressure.

Owner:ARIZONA STATE UNIVERSITY

Fragrancing system and method

InactiveUS7377493B2Reduce pressureSpeed up evaporationCarburetting airFlow mixersQuiescent stateEngineering

System and method for emanating fragrance vapor into a region. Fragrance liquid within a receptacle exhibits a liquid phase-vapor phase interface surface when in a quiescent state. Utilizing sub-pressure generators such as fan driven systems, the pressure above the interface is lowered to promote the escape of vapor molecules for dissemination into the atmosphere. The surface area of the fragrance fluid may be increased through the use of a bubbling technique to derive an effective area permitting a larger vapor molecule escape.

Owner:INNOVATIVE PROD MANAGEMENT

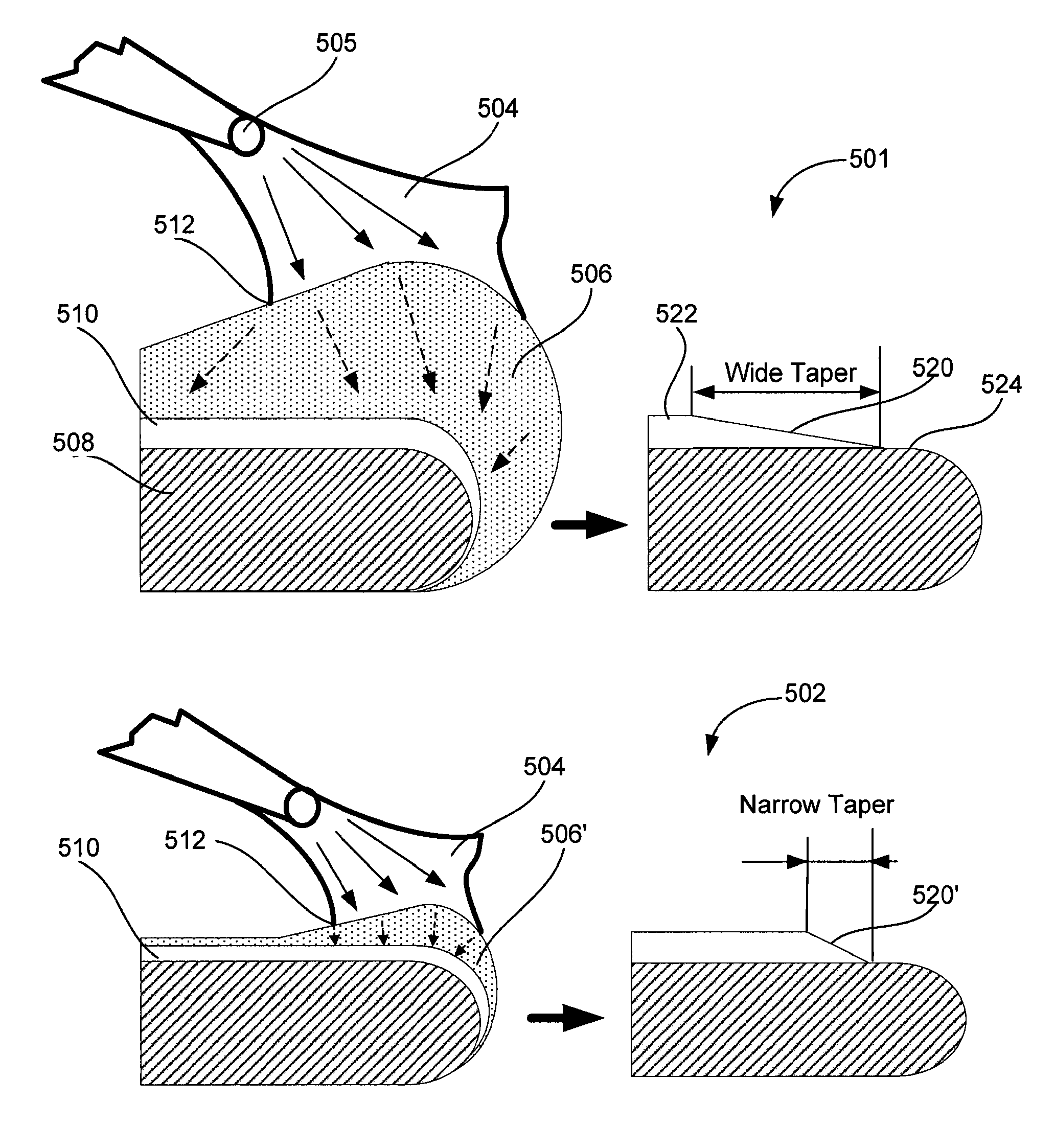

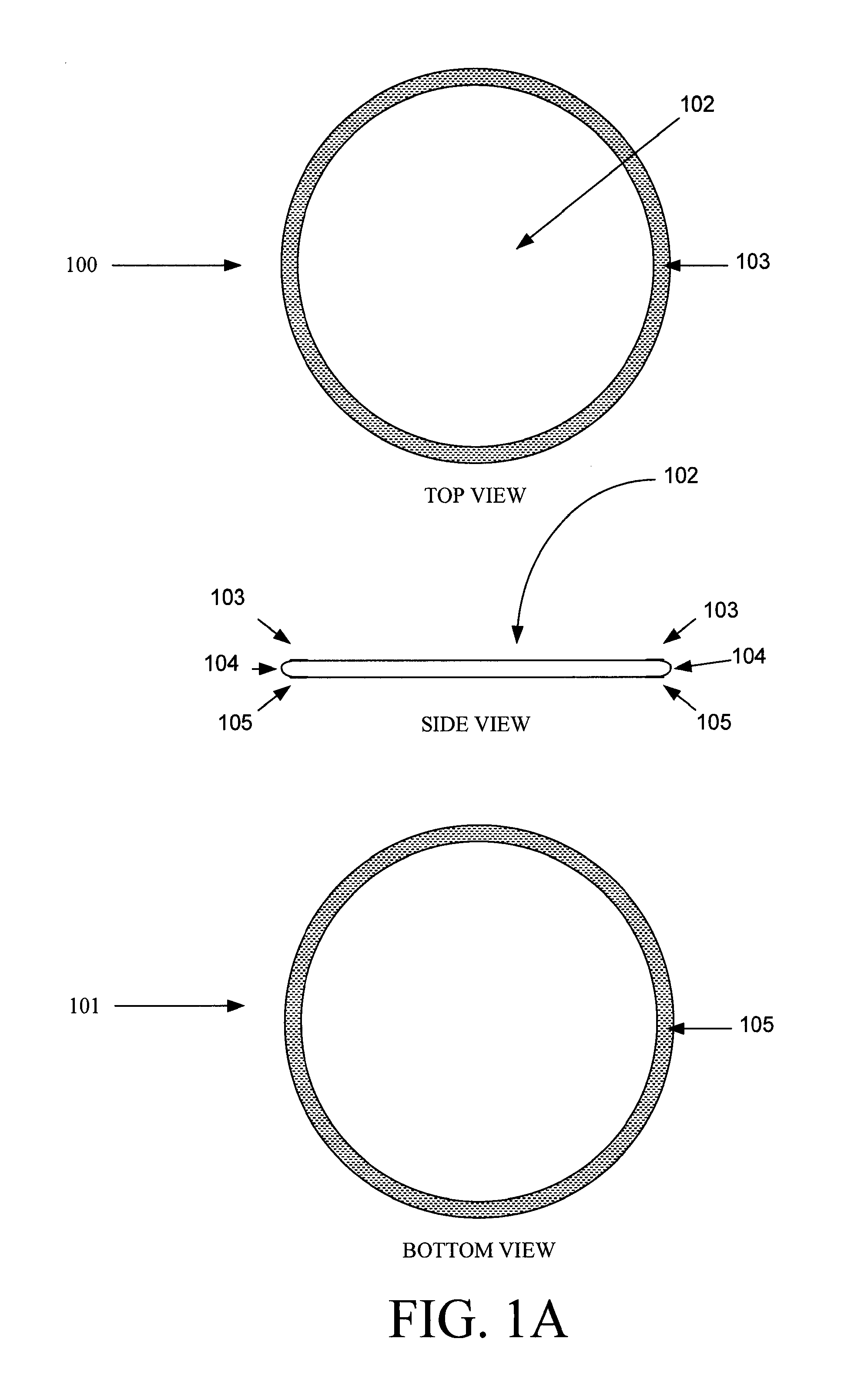

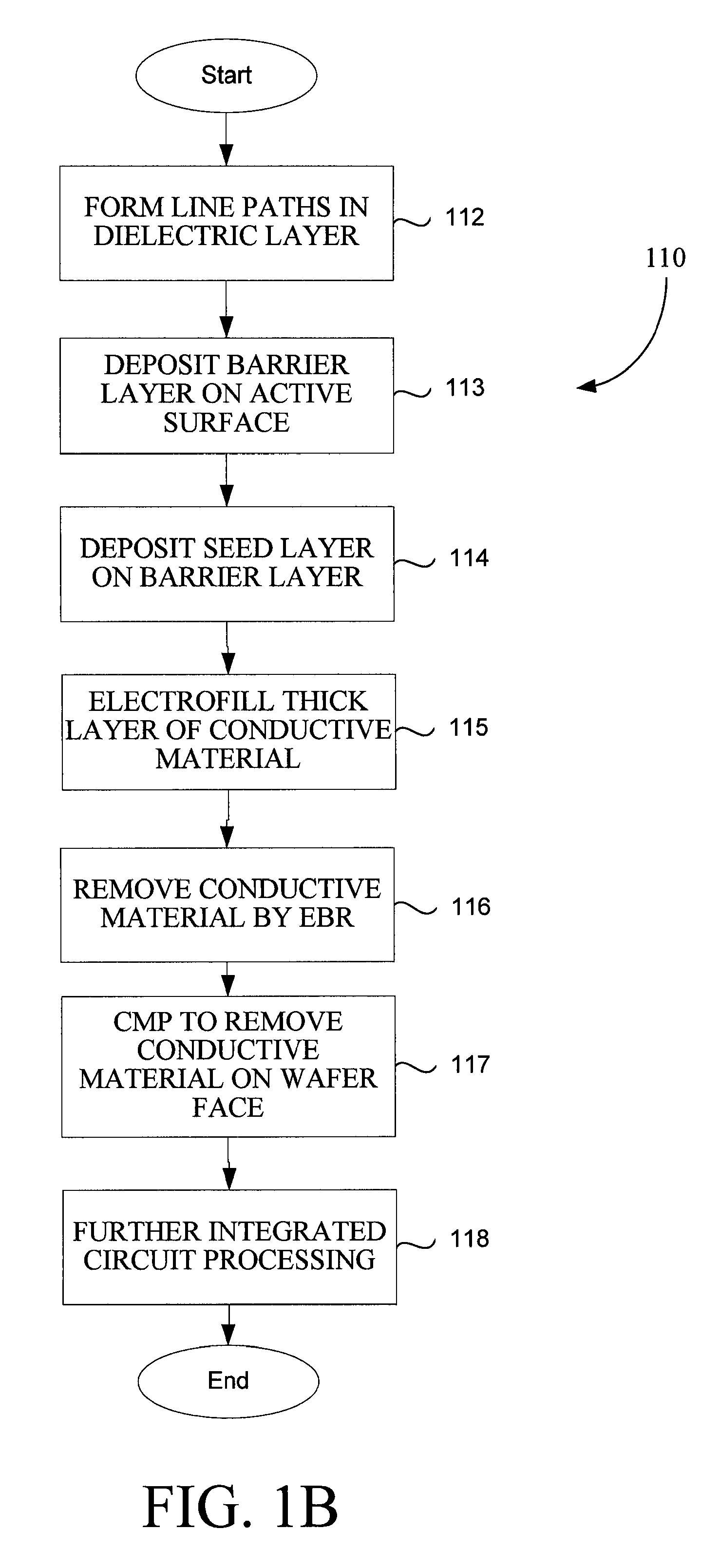

Apparatus and method for edge bevel removal of copper from silicon wafers

ActiveUS20100055924A1Facilitated DiffusionIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingLiquid layerThin layer

Chemical etching methods and associated modules for performing the removal of metal from the edge bevel region of a semiconductor wafer are described. The methods and systems provide the thin layer of pre-rinsing liquid before applying etchant at the edge bevel region of the wafer. The etchant is less diluted and diffuses faster through a thinned layer of rinsing liquid. An edge bevel removal embodiment involving that is particularly effective at reducing process time, narrowing the metal taper and allowing for subsequent chemical mechanical polishing, is disclosed.

Owner:NOVELLUS SYSTEMS

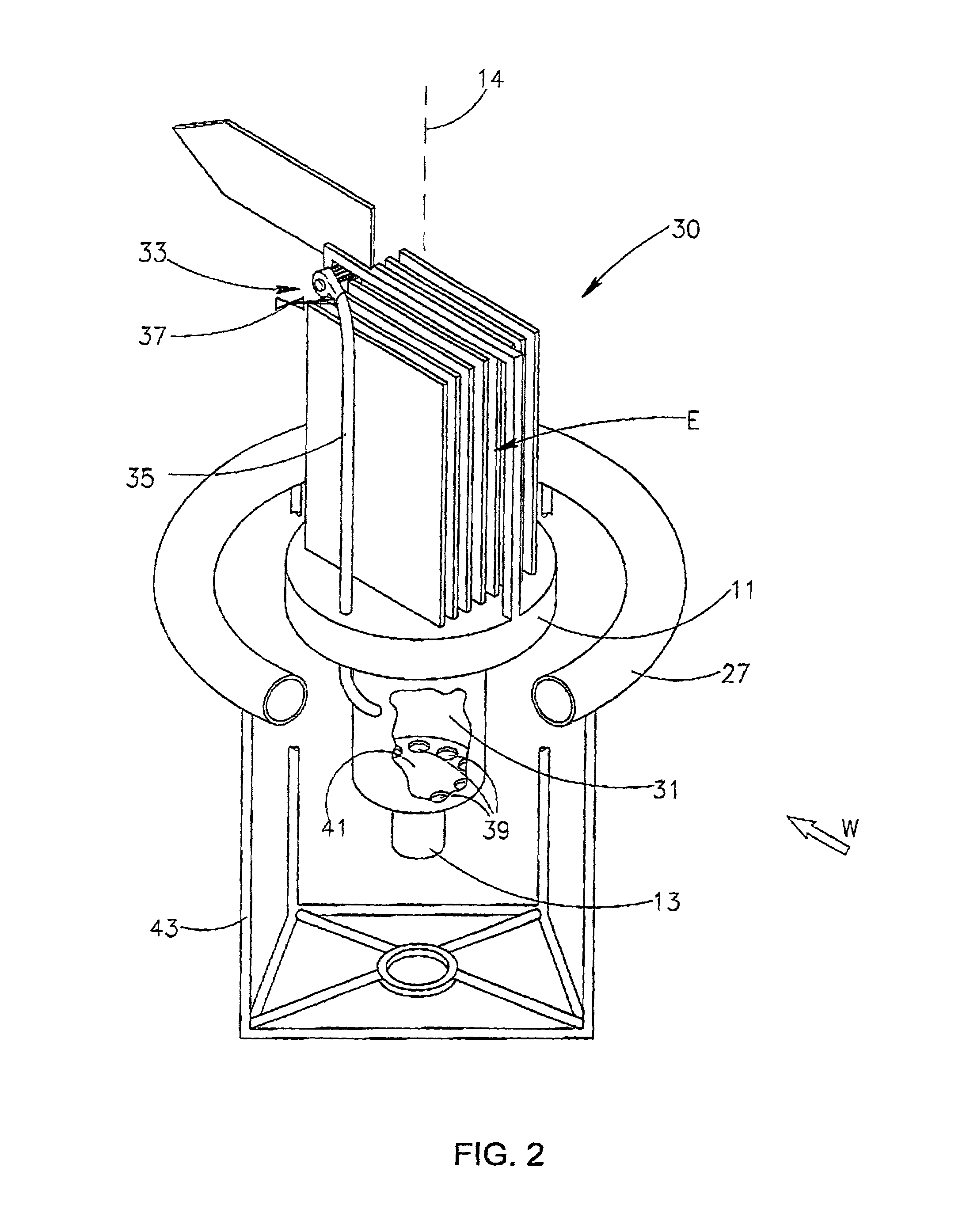

Evaporation device

InactiveUS7166188B2Increase evaporation rateIncrease surface areaDrying solid materials with heatGeneral water supply conservationEvaporationChemistry

An evaporation device for increasing evaporation from a surface of a body of liquid, comprises at least one evaporation element having at least one evaporation surface wettable by the liquid and at least partially exposable to wind when wetted, so as to allow evaporation of the liquid from the evaporation surfaces whereby the total evaporation area of the surface of the body of liquid is increased.

Owner:B G NEGEV TECH & APPL LTD +1

Stage method for improving uniform expansion effect of granular fruits and vegetables during microwave spouted drying

The invention discloses a stage method for improving the uniform expansion effect of granular fruits and vegetables during microwave spouted drying, which belongs to the technical field of the processing of fruit and vegetable foods. The method mainly comprises the steps of: performing selection, washing, dicing, enzyme killing by blanching, and color protection treatment on fruit and vegetable raw materials; placing the pretreated fruit and vegetable cubes into a microwave spouted drying bed; setting the microwave power and the air inlet heating temperature; then performing the combined drying of stage hot air drying and microwave drying; and controlling different spouted air intakes at different drying stages, wherein the uniform expansion effect of products is improved during the quick microwave drying. The method has the advantages that the method ensures that the granular fruits and vegetables are evenly heated in a microwave field through a hot air and microwave spouted drying stage method, has quick moisture evaporation, ensures that the fruits and vegetables have porous structures after the drying, effectively improves the expansion degree of the products, also improves the expansion effect of the products and ensures the uniform expansion of the products while the granular fruits and vegetables are quickly dried, and has the characteristics of good preservation of nutrient content and good qualities of color luster, sense and the like.

Owner:JIANGNAN UNIV +1

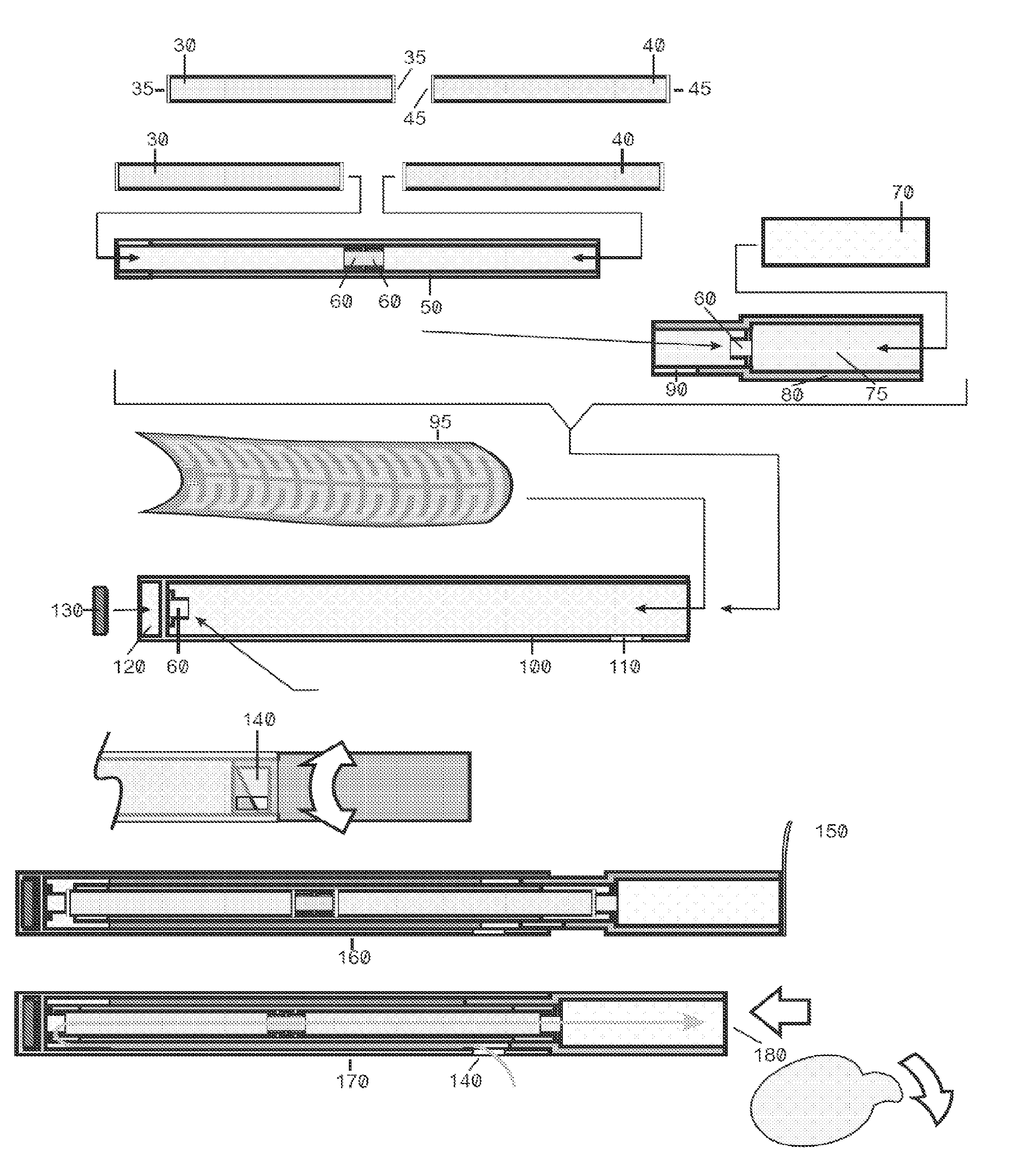

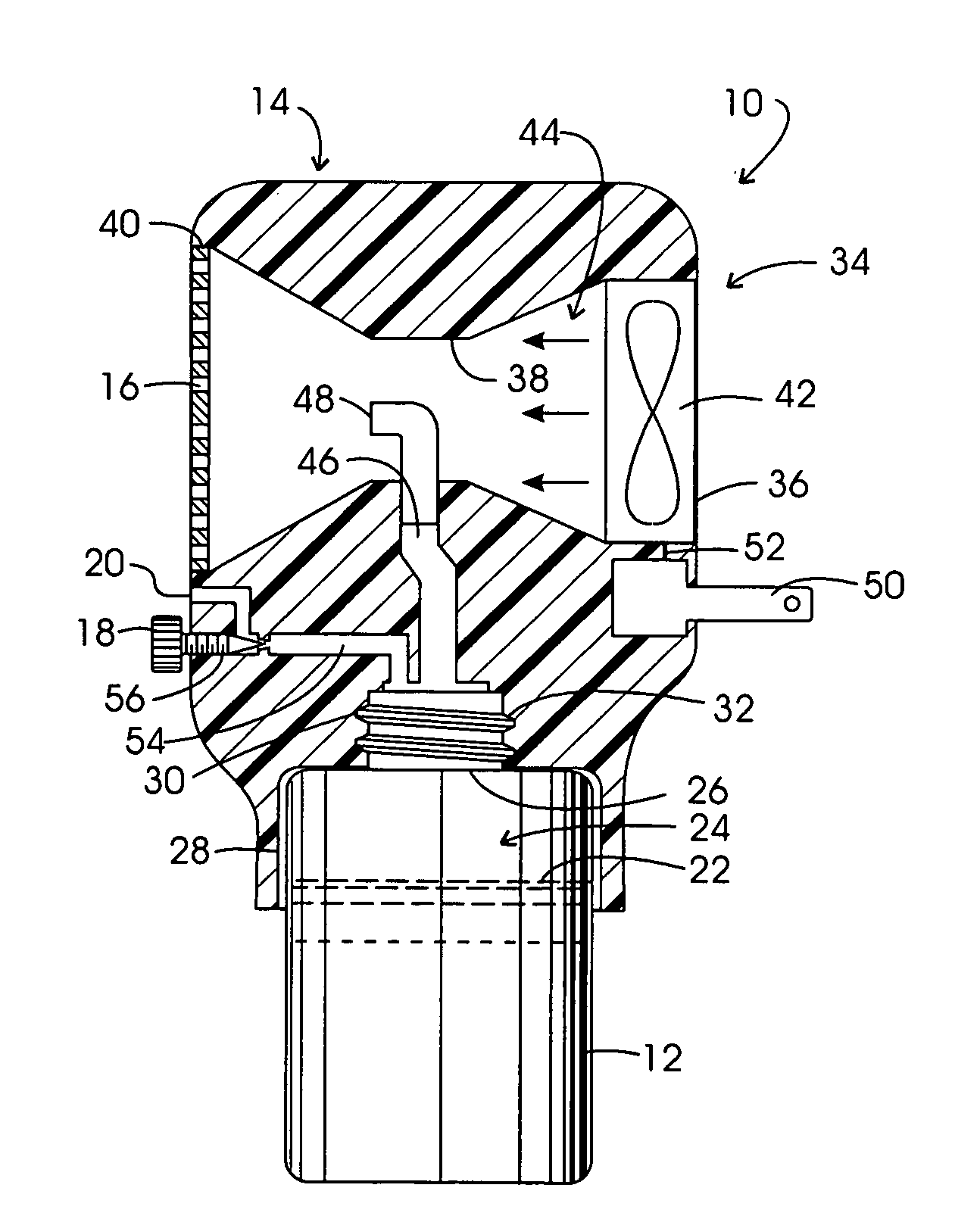

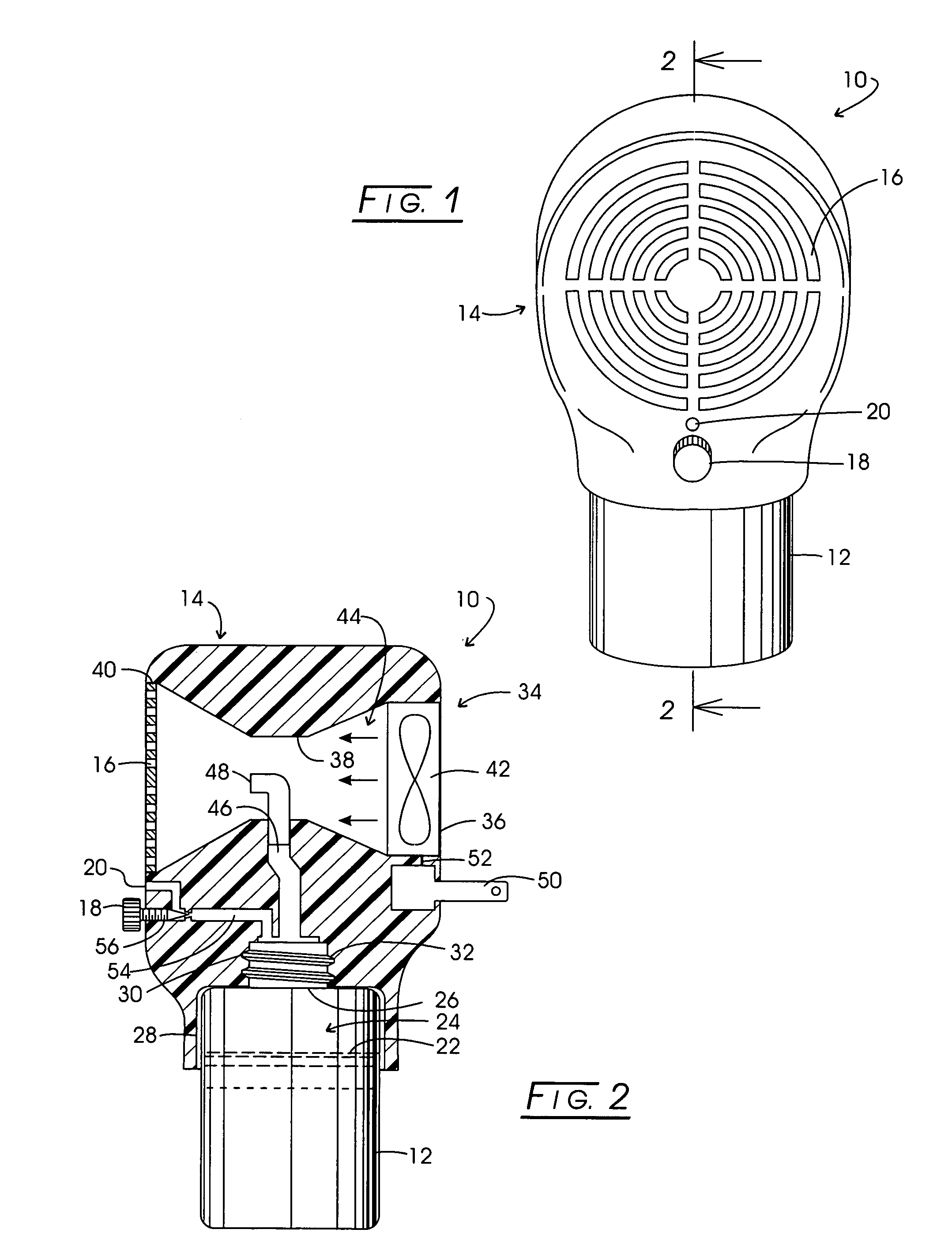

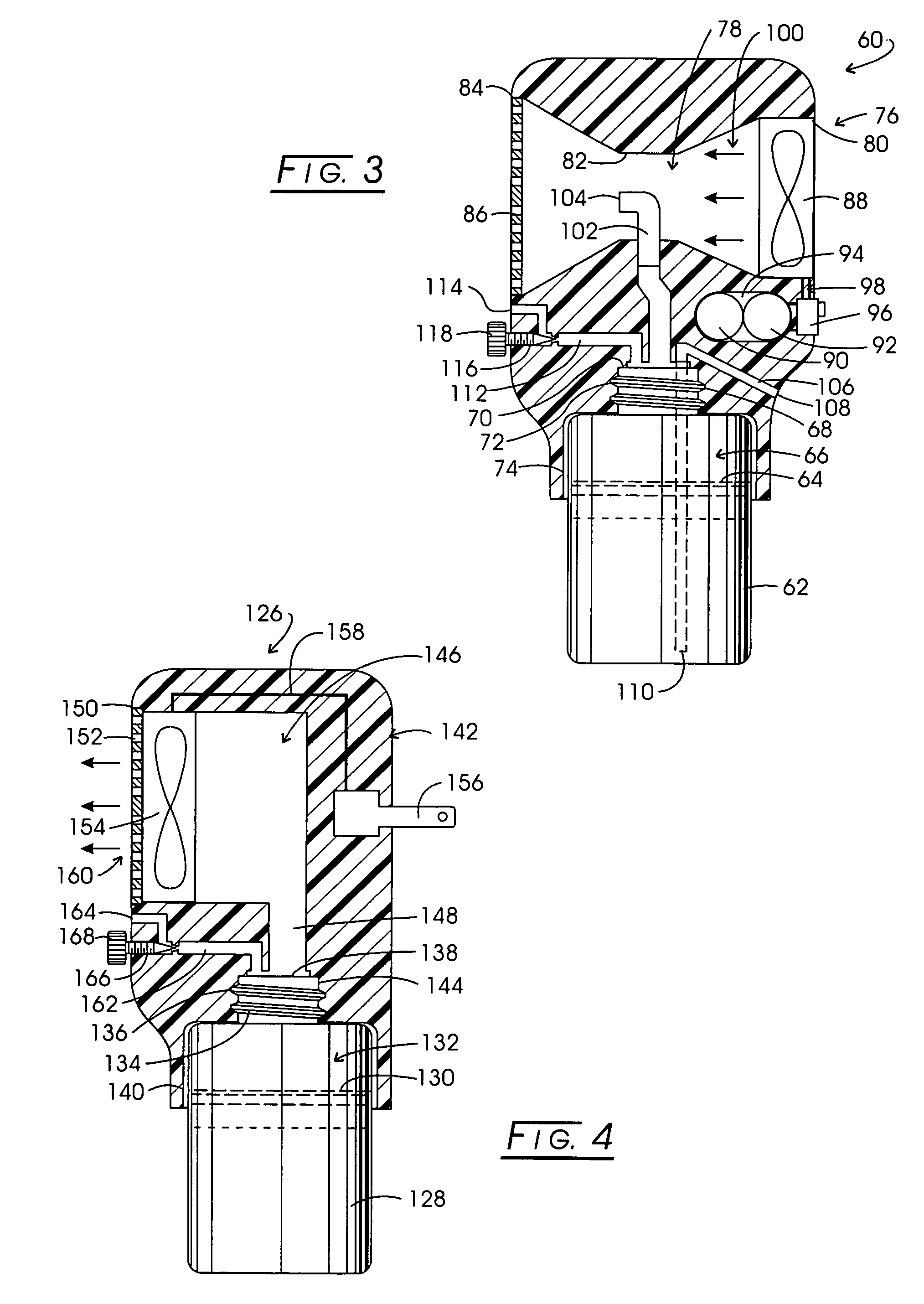

Device and method for delivery of a medicament

ActiveUS9974743B2Easy to useImprove the situationPowder deliveryOrganic active ingredientsDiseaseTherapeutic effect

The disclosure relates to an improved method of enhancing nicotine concentrations in a gaseous carrier. The methods are adaptable to the delivery of nicotine for therapeutic effect in various diseases, in particular nicotine for tobacco product use cessation, substitution and / or harm reduction. The disclosure further relates various devices and device design principles for practicing these methods.

Owner:PHILIP MORRIS PROD SA

System and Methods for Ionizing Compounds using Matrix-assistance for Mass Spectometry and Ion Mobility Spectometry

ActiveUS20130306856A1Facilitated ionizationLow costSamples introduction/extractionMaterial analysis by electric/magnetic meansVacuum assistedGas phase

An ionization method for use with mass spectrometry or ion mobility spectrometry is a small molecule compound(s) as a matrix into which is incorporated analyte. The matrix has attributes of sublimation or evaporation when placed in vacuum at or near room temperature and produces both positive and negative charges. Placing the sample into a region of sub-atmospheric pressure, the region being in fluid communication with the vacuum of the mass spectrometer or ion mobility spectrometer, produces gas-phase ions of the analyte for mass-to-charge or drift-time analysis without use of a laser, high voltage, particle bombardment, or a heated ion transfer region. This matrix and vacuum assisted ionization process can operate from atmosphere or vacuum and produces ions from large (e.g. proteins) and small molecules (e.g. drugs) with charge states similar to those observed in electrospray ionization.

Owner:MSTM LLC

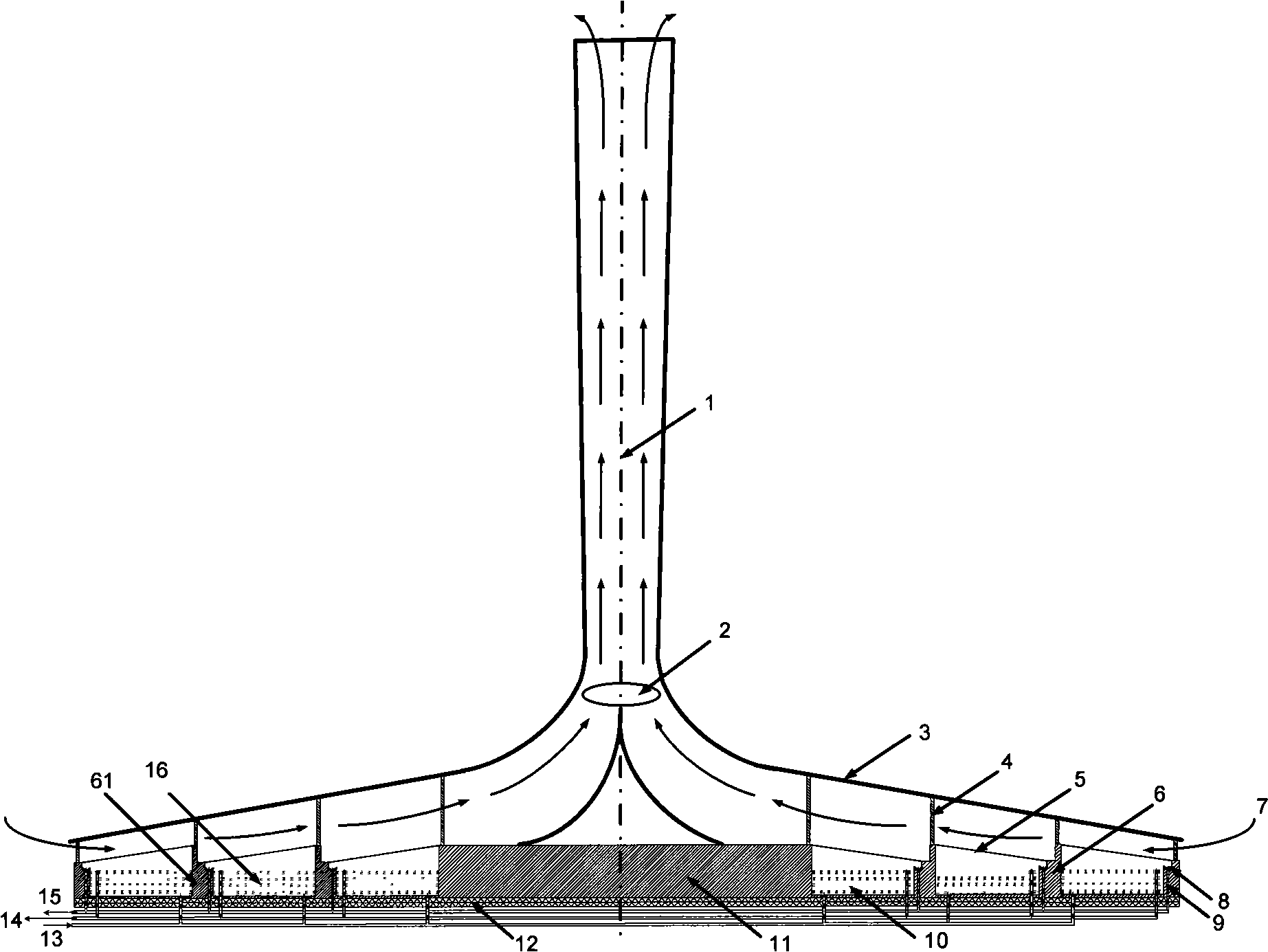

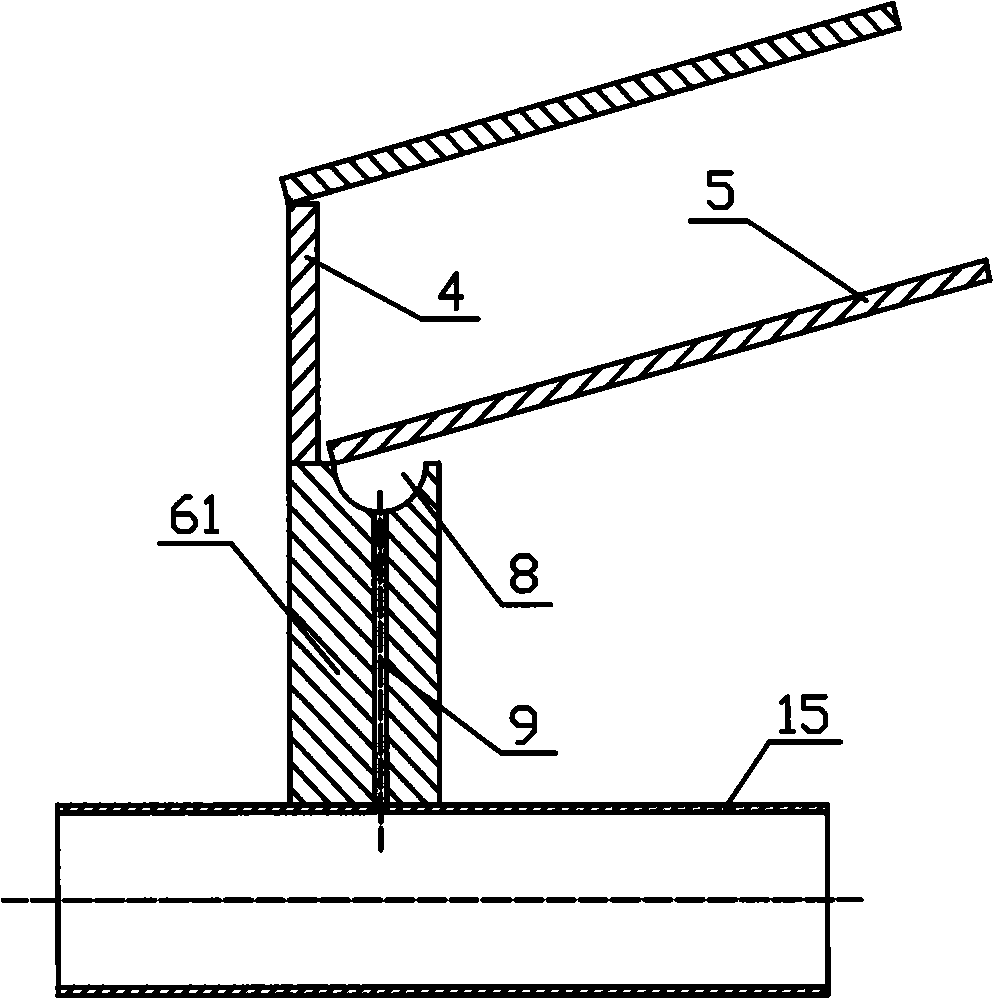

Chimney generation and desalination device by solar

InactiveCN101358578ASpeed up evaporationIncrease productionGeneral water supply conservationSeawater treatmentTurbo generatorSeawater

A device which utilizes the solar energy to carry out chimney generating and seawater desalting relates to the technical field of utilizing the solar energy to carry out generating and seawater desalting. The invention includes a solar chimney, a transparent heat collecting shed, a solar distilling pool and a turbine generator set. The transparent heat collecting shed is covered on a supporting group; the turbine generator set is arranged in the solar chimney arranged at the connection location of the solar chimney and the transparent heat collecting shed; the solar distilling pool and a rock heat accumulating layer are arranged at the lower side of the transparent heat collecting shed; a transparent cover plate is obliquely arranged at the upper end of the solar distilling pool; the lower end of the solar distilling pool is respectively connected with a seawater input pipe, a brine output pipe and a fresh water output pipe. The device of the invention improves the comprehensive operating factor of the solar energy, improves the comprehensive operating factor of land resource and simultaneously reduces the cost of each product such as power, heat accumulating amount, fresh water in another way.

Owner:HOHAI UNIV

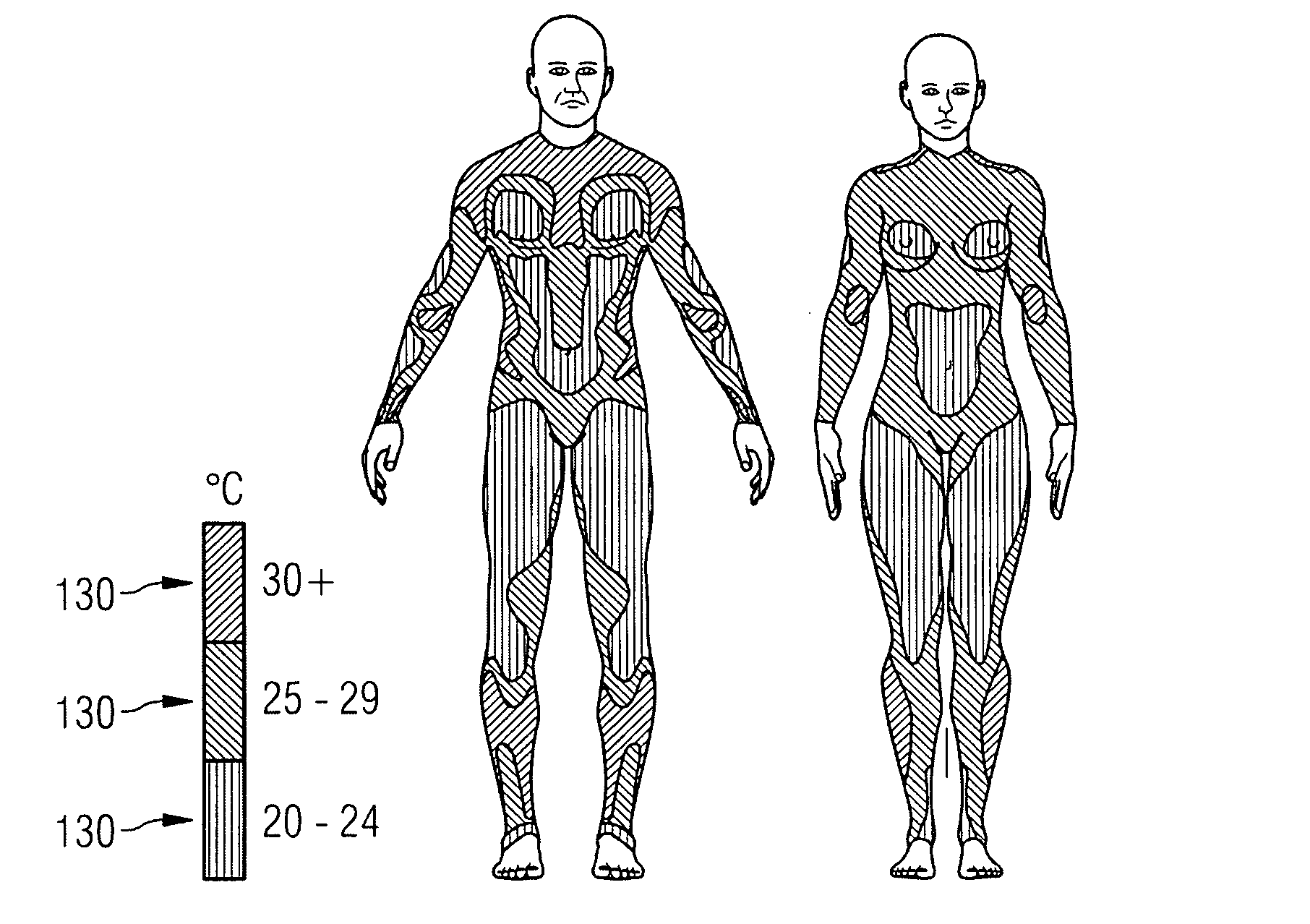

Apparel

ActiveUS8910313B2Easy to transportEasy to adjustGarment special featuresTrousersLumbar vertebraeEngineering

An aspect of the invention relates to a garment which comprises at least a first zone and a second zone. The first zone of the garment is arranged in the spine area and comprises a higher degree of air permeability than the second zone. The second zone of the garment is arranged below the breast area and in the area of the lumbar vertebrae and comprises a higher degree of moisture wicking than the first zone.

Owner:ADIDAS

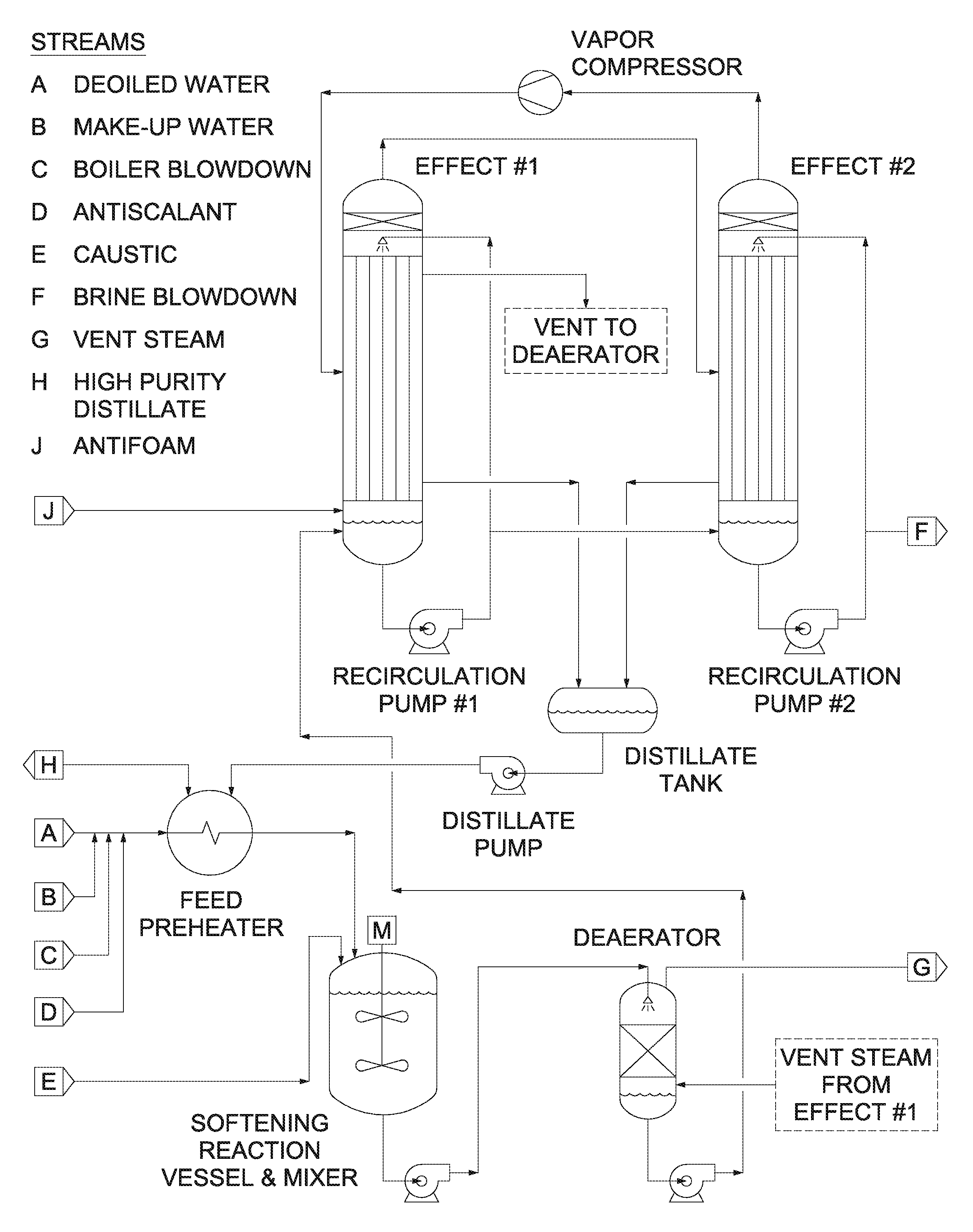

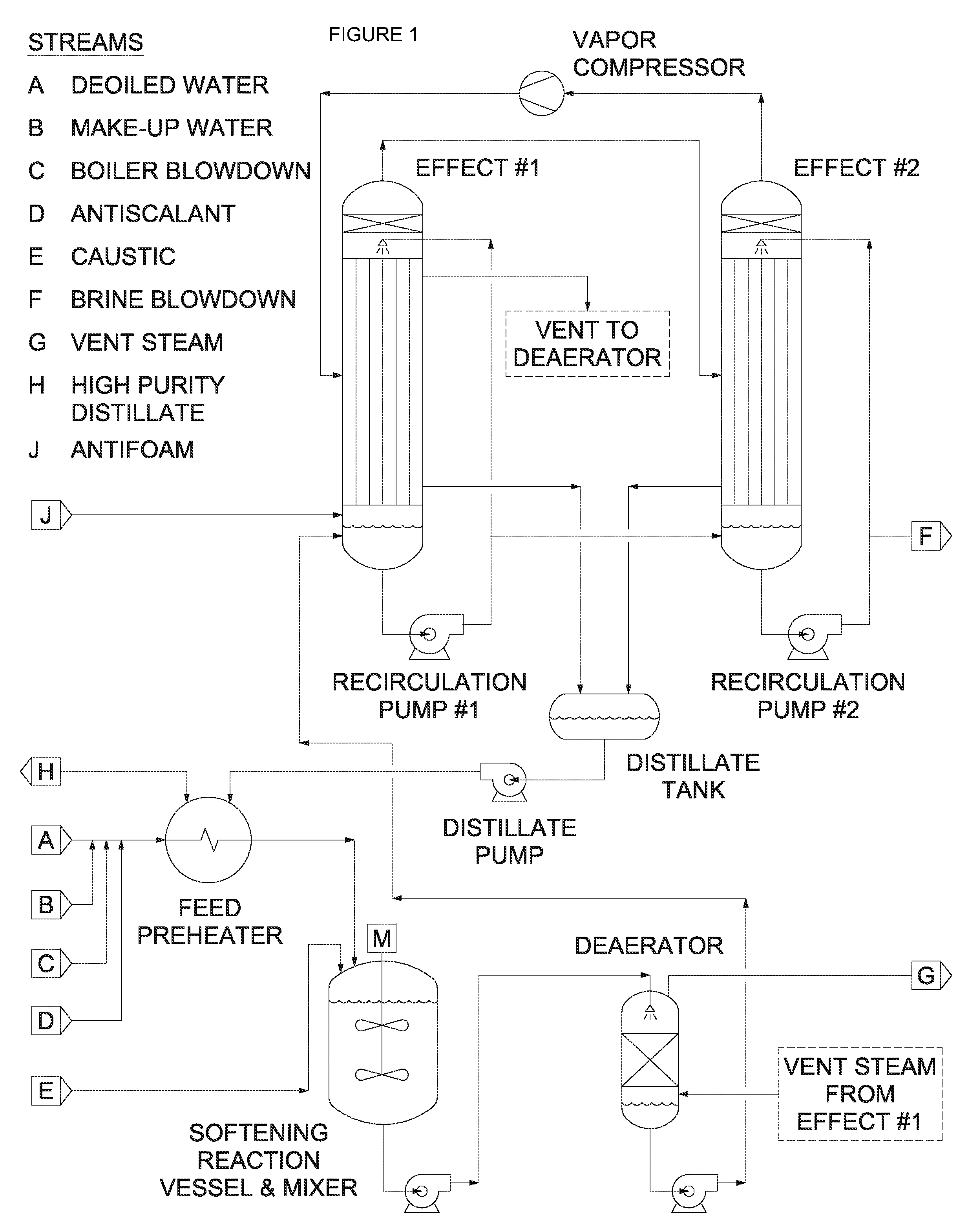

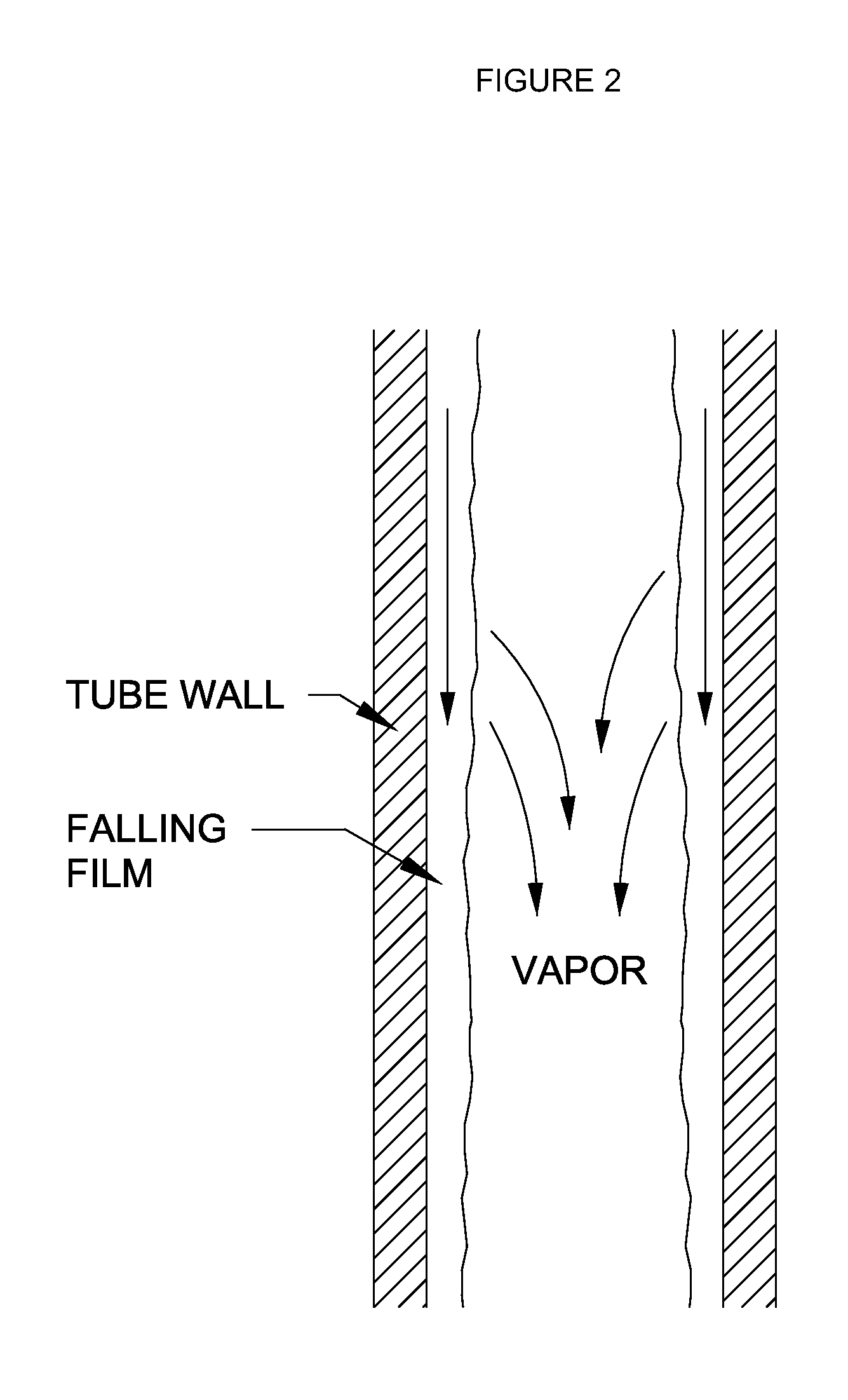

Method for recycling deoiled water using counterflow falling-film evaporators

ActiveUS20120145386A1High speedReduce chemical consumption requirementFatty/oily/floating substances removal devicesEvaporation with vapour compressionWater useSaline water

We provide an evaporator technology for treatment of produced water that may be deoiled water. Systems described herein utilize a vertical tube heat exchanger bundle where the brine is distributed in a falling film along the inside of the tube wall. Condensing steam causes a portion of the deoiled water to evaporate; this water vapor travels upward in a counterflow direction relative to the deoiled water. This evaporator technology provides several design advantages over the conventional vertical tube co-current flow evaporators (where the vapor flows downward with the falling film). These advantages include a minimal total installed cost (TIC) as well as offering optimal design features for water chemistry management.

Owner:AQUATECH INT LLC

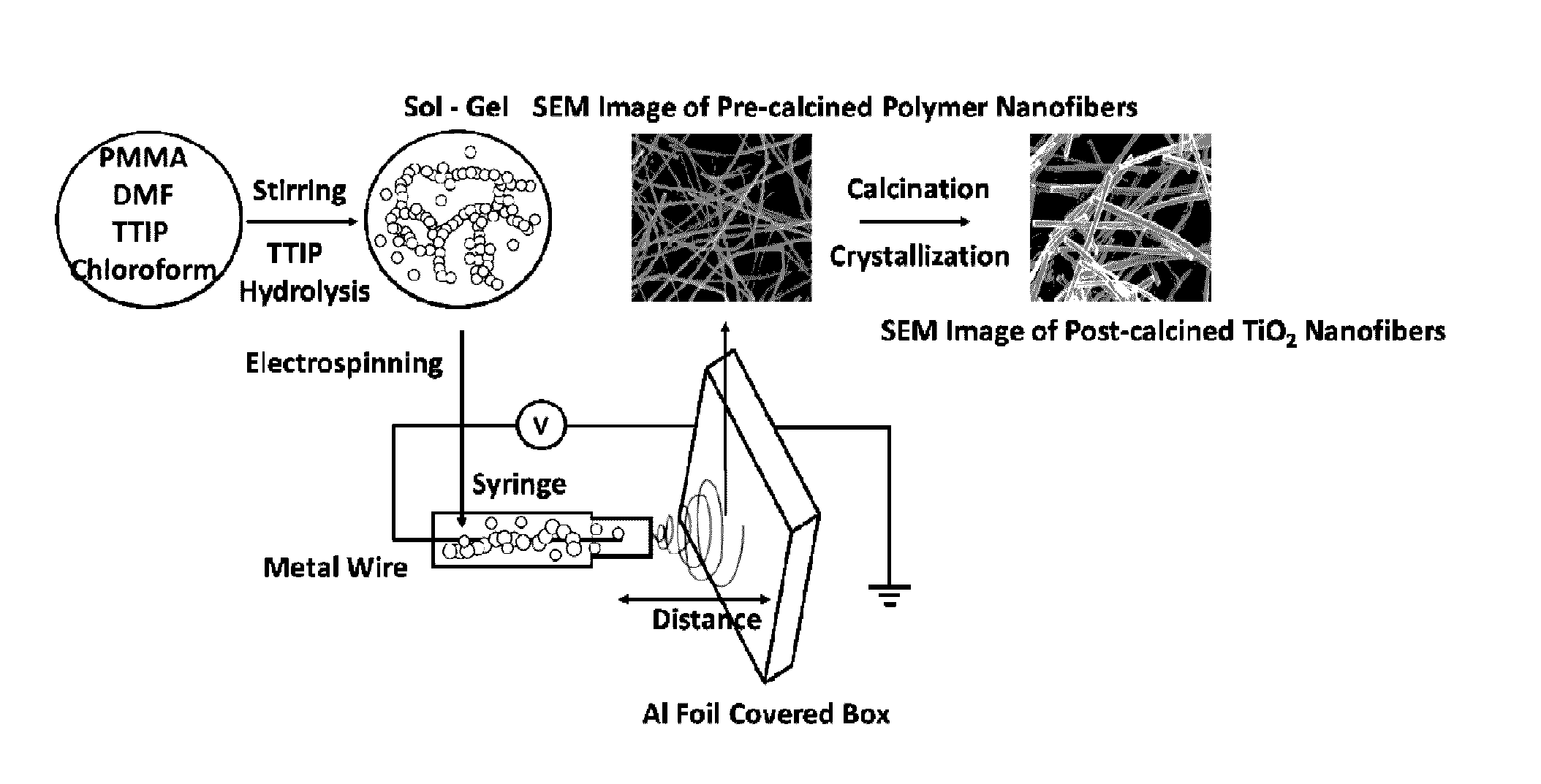

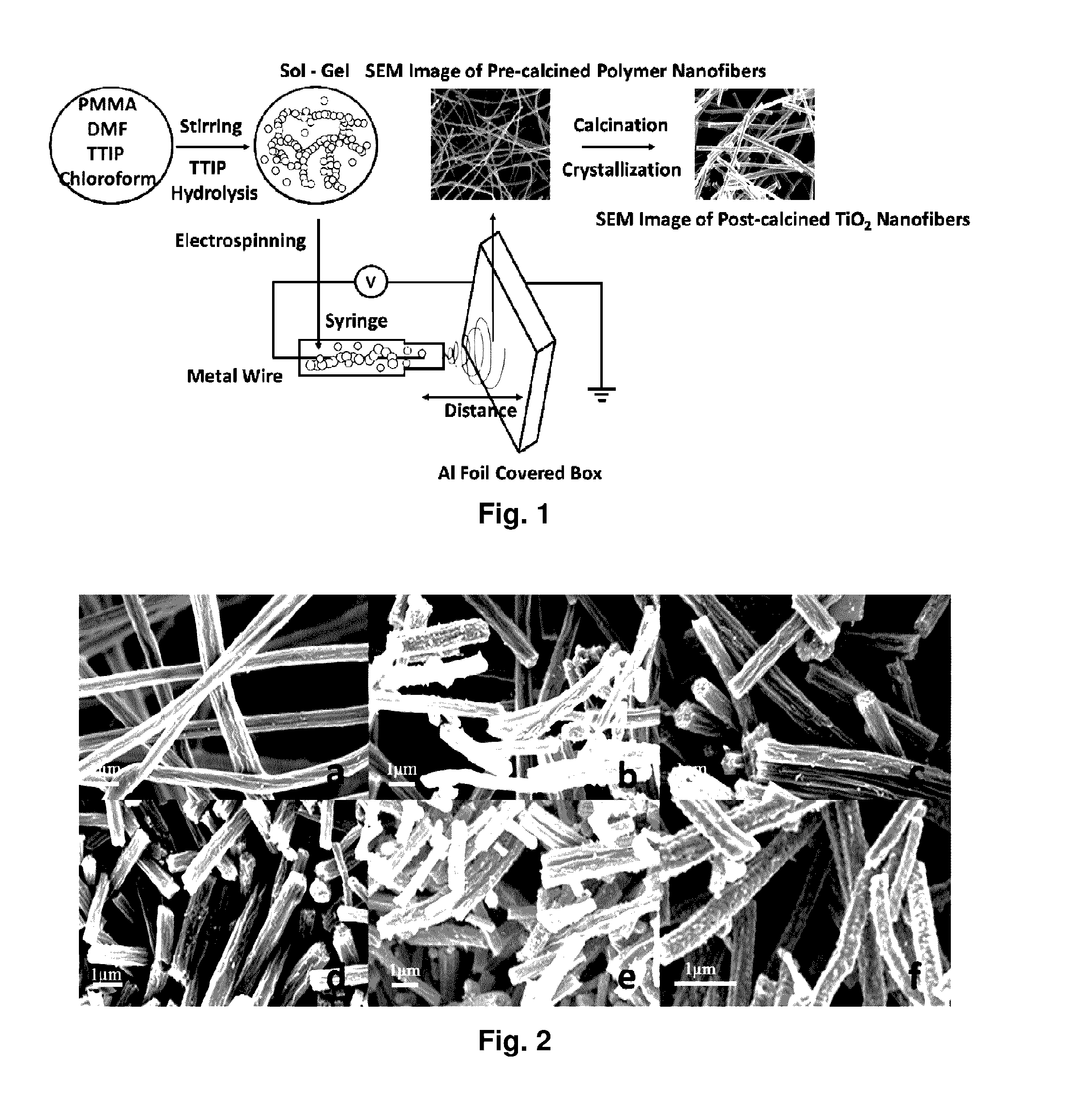

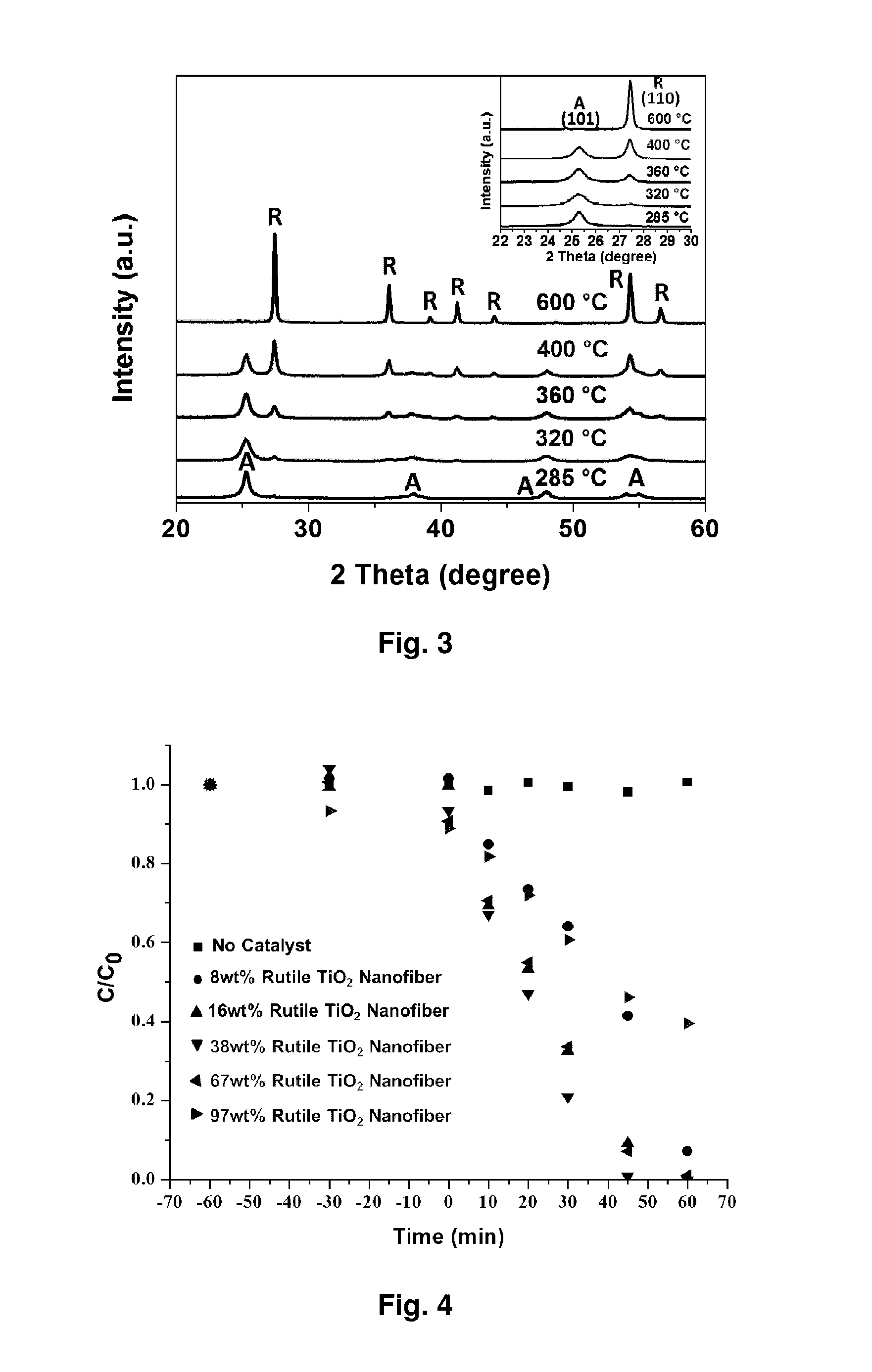

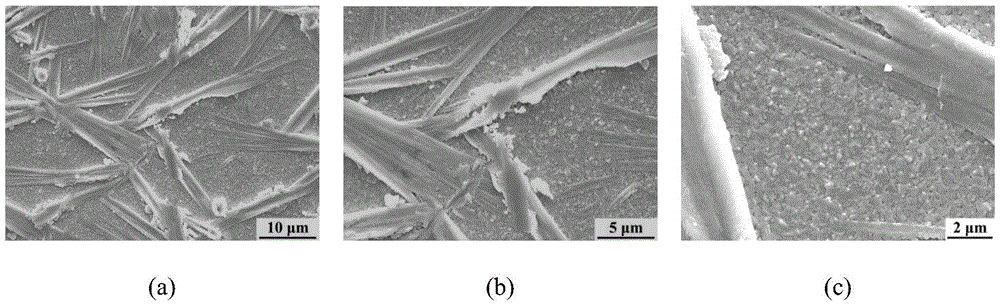

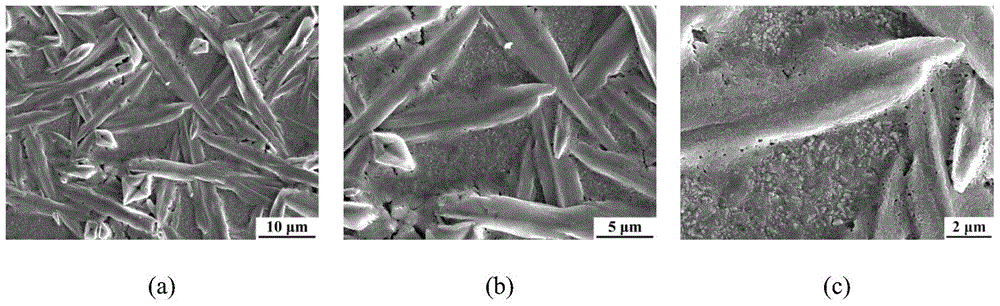

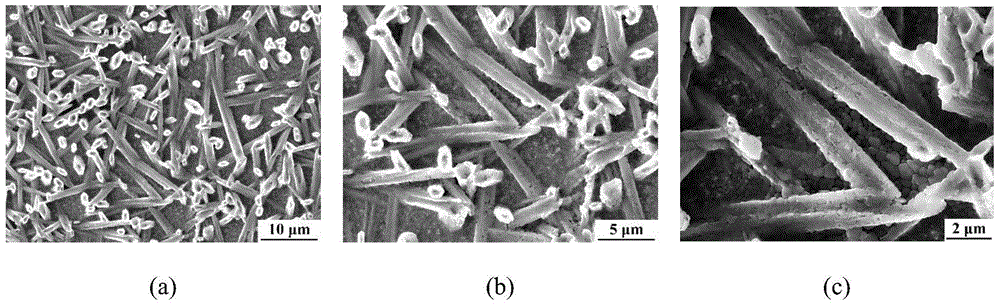

Metal oxide nanofibrous materials for photodegradation of environmental toxins

ActiveUS20170056873A1Rapid and inexpensiveAccelerated photodegradationWater/sewage treatment by irradiationWater treatment compoundsFiberRutile

Mixed-phase TiO2 nanofibers prepared via a sol-gel technique followed by electrospinning and calcination are provided as photocatalysts. The calcination temperature is adjusted to control the rutile phase fraction in TiO2 nanofibers relative to the anatase phase. Post-calcined TiO2 nanofibers composed of 38 wt % rutile and 62 wt % anatase exhibited the highest initial rate constant of UV photocatalysis. This can be attributed to the combined influences of the fibers' specific surface areas and their phase compositions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

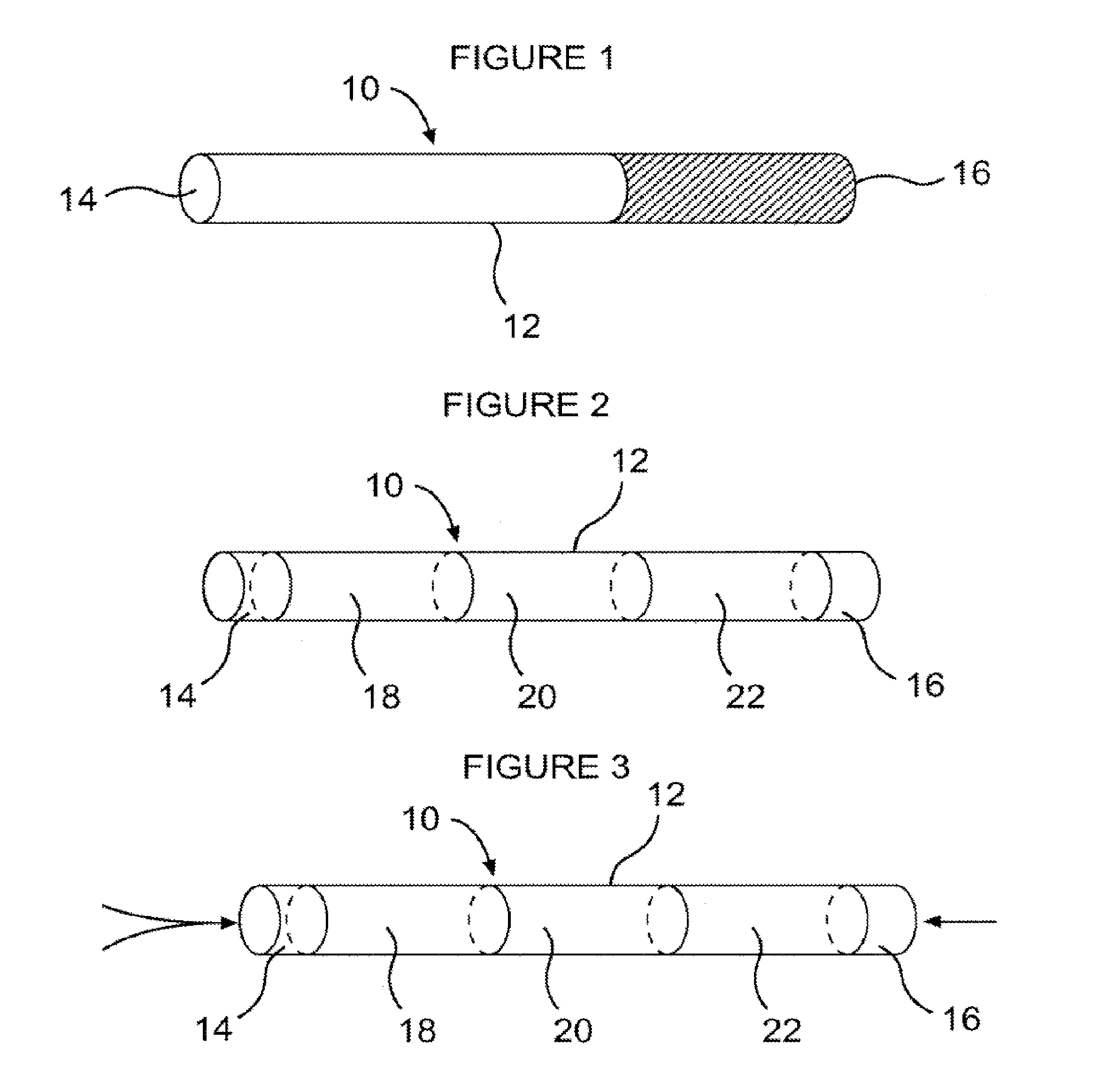

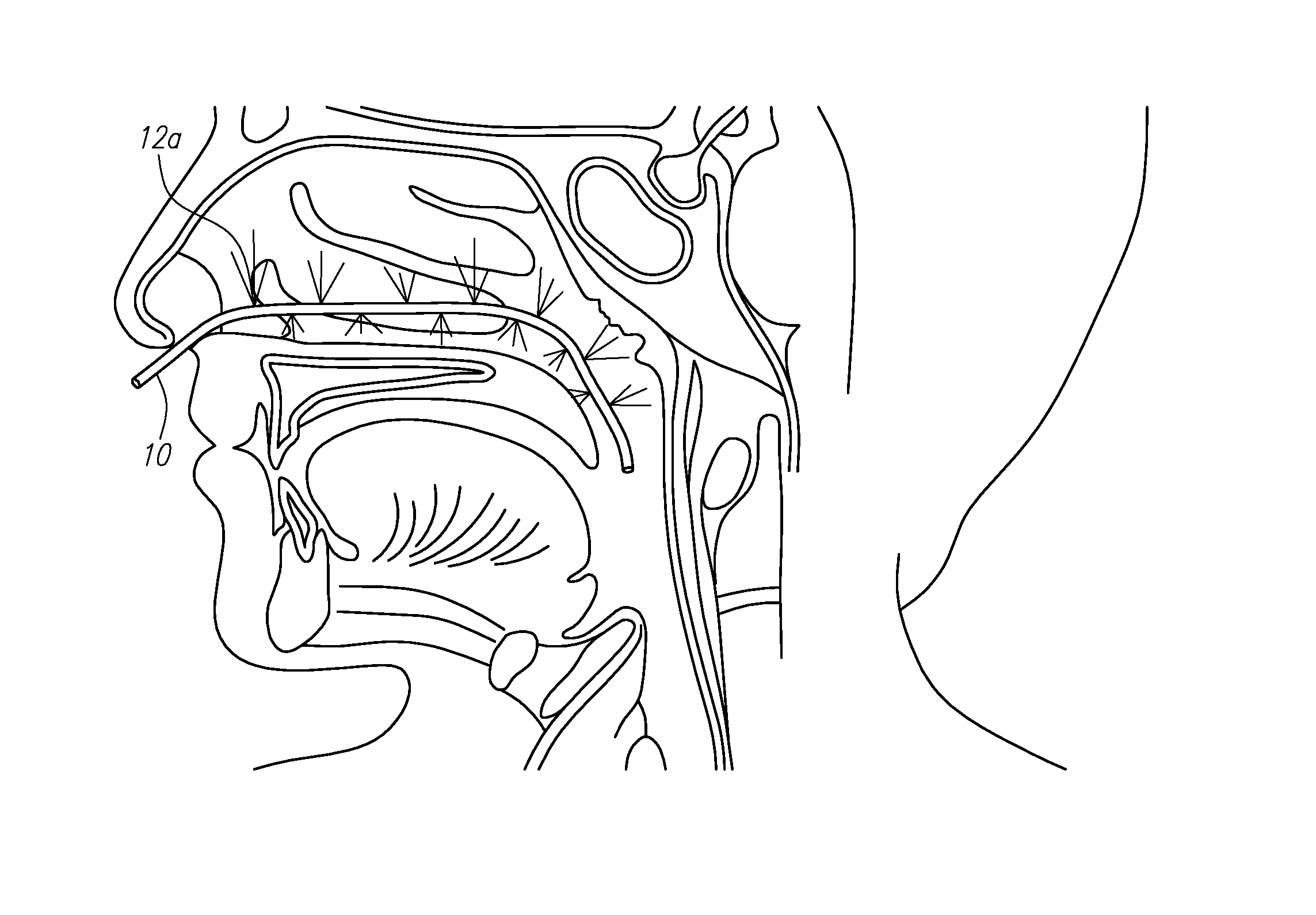

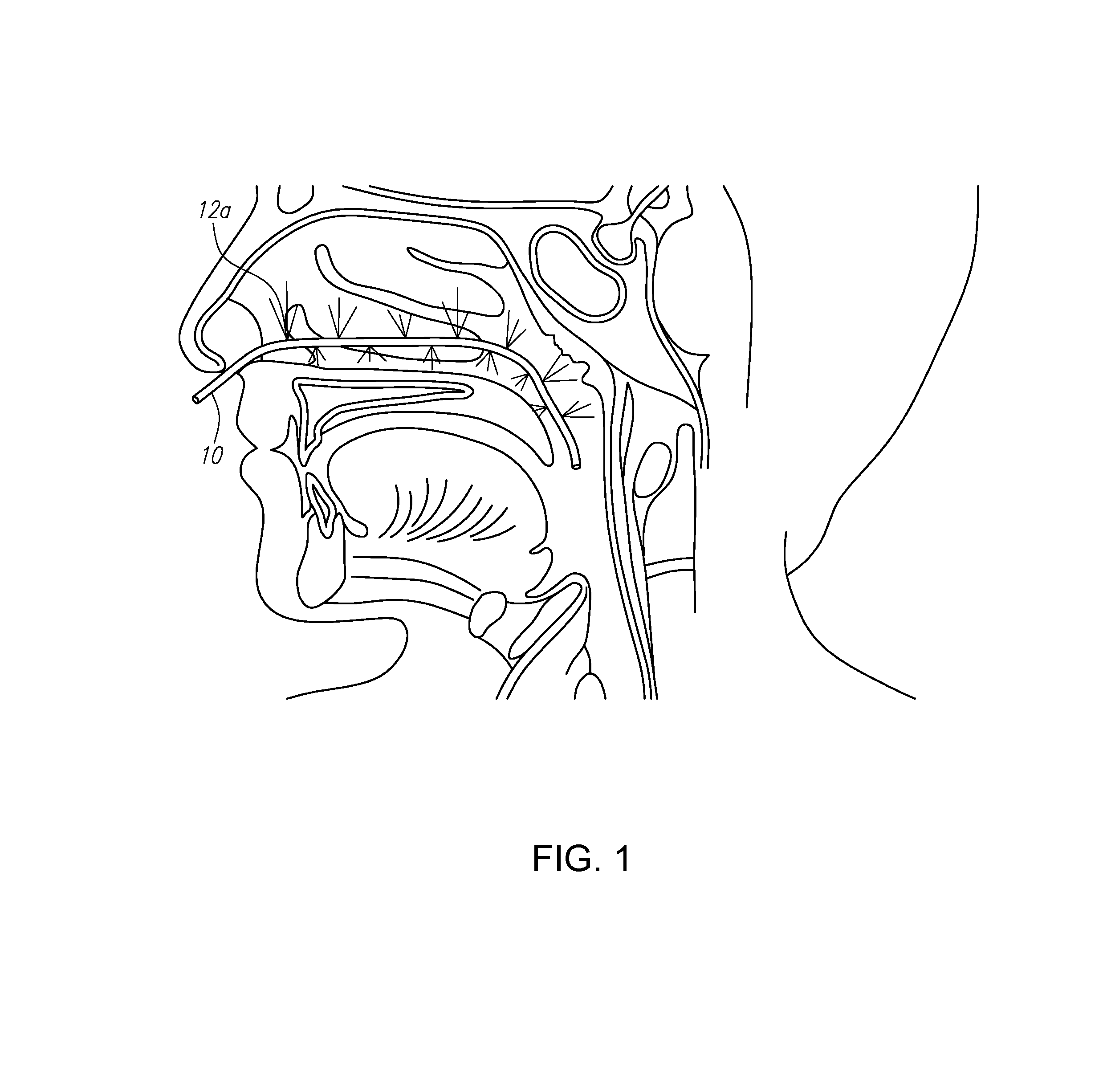

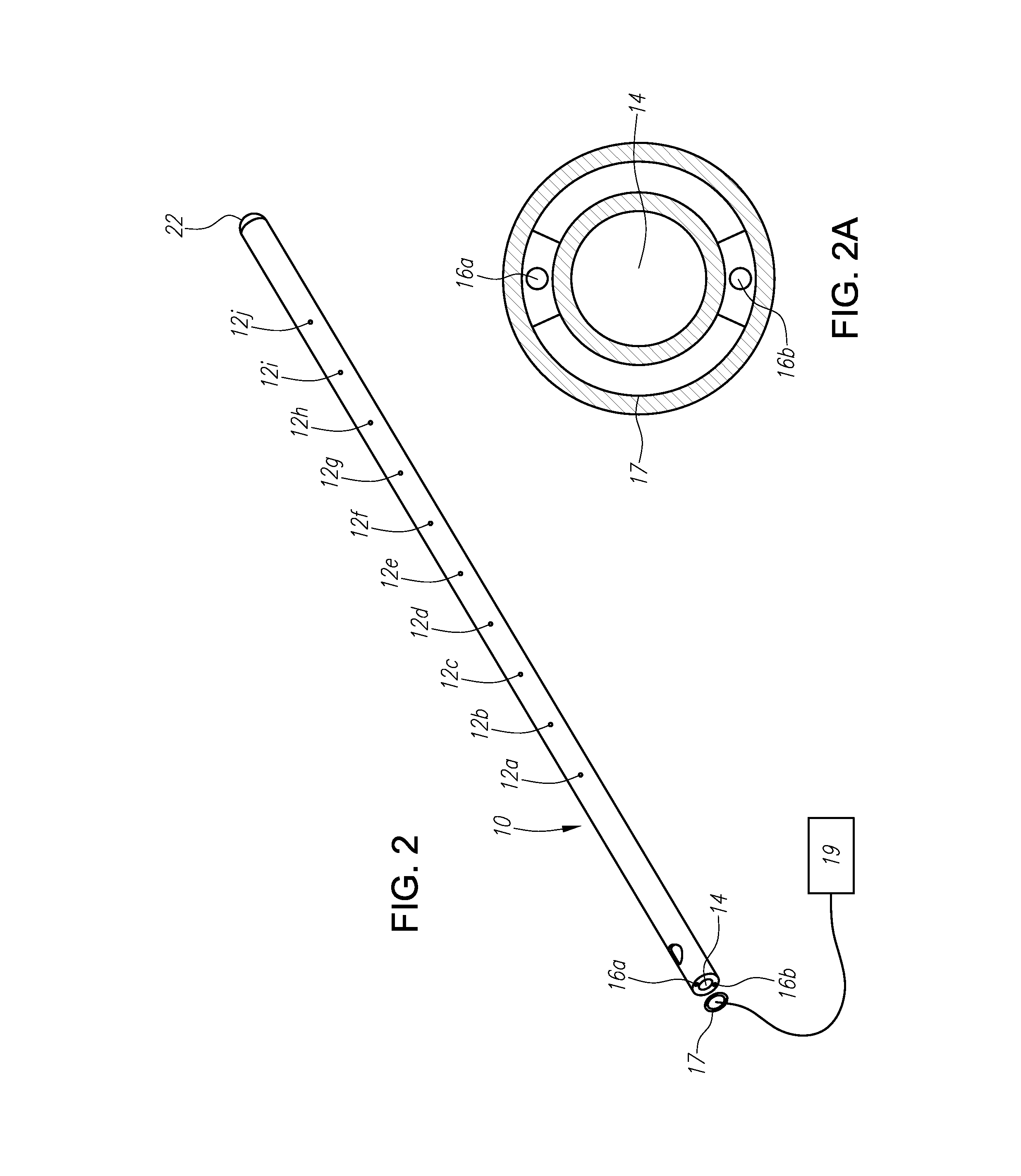

Methods and devices for non-invasive cerebral and systemic cooling alternating liquid mist/gas for induction and gas for maintenance

ActiveUS20130073015A1Minimize neurologic deficitMaximize coolingHalogenated hydrocarbon active ingredientsTracheal tubesNostrilNasal cavity

Methods for cerebral and systemic cooling via a patient's nasopharyngeal cavity are described. In one method, a cooling assembly is inserted into a nasal cavity through a patient's nostril. A substantially dry gas is delivered through a lumen of the catheter onto the surface of the patient's nasal cavity. Evaporative heat loss cools the patient's nasal cavity. If additional cooling is needed, a liquid coolant is delivered through a separated lumen of the catheter. The liquid coolant is nebulized at a plurality of delivery ports on the distal end of the catheter and is delivered onto the surface of the patient's nasal cavity in combination with the dry gas. The dry gas enhances evaporation of the nebulized coolant and additional cooling is provided from the evaporative heat loss of the liquid coolant.

Owner:BRAINCOOL

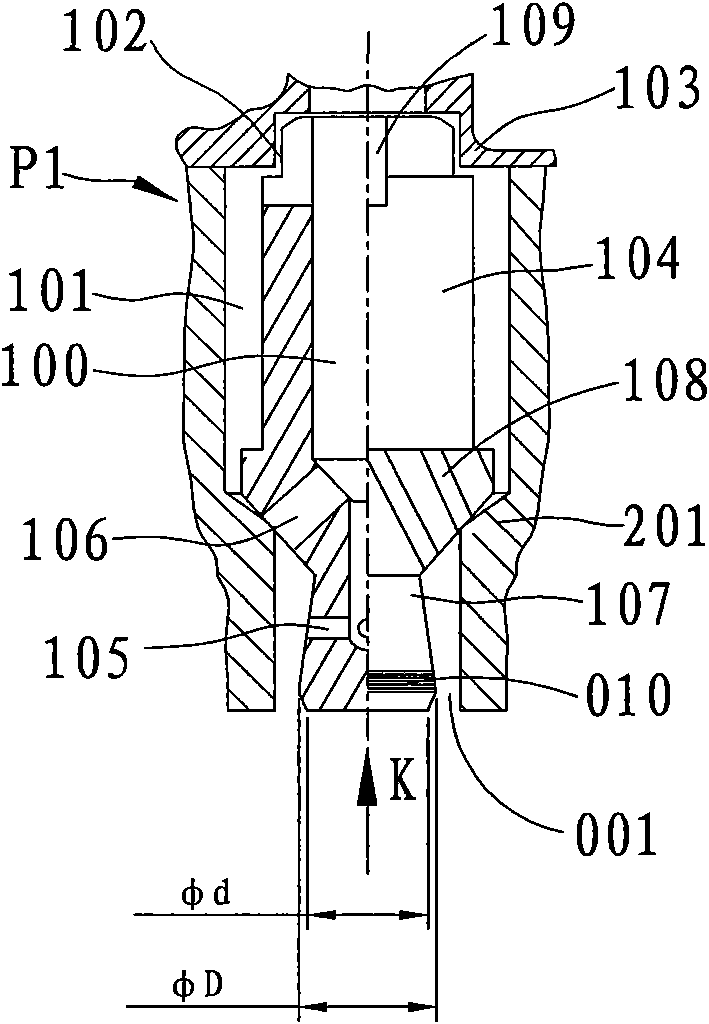

Rotary annular-seam spray nozzle and spraying device thereof

InactiveCN102039228AEasy ultra-fine atomizationUltra-fine atomization promotionSpray nozzlesLiquid spraying apparatusSpray nozzleFineness

The invention discloses a rotary annular-seam spray nozzle comprising a core seat, a rotary core and a rotary annular-seam spray hole, wherein a core cavity is arranged in the core seat, an inlet and an outlet which are communicated with the core cavity are arranged on the core seat, a core seat inlet is communicated with a pressure flow source, the rotary core can be sleeved into the core cavity in positioning and rotating modes and is concentric with the core cavity, a rotation-promoting flow path is arranged on the rotary core or / and the wall of the core cavity in order to mutually rotate the rotary core and the core cavity by using flow power, one end of the rotary core is penetrated into the core seat outlet, and the penetrating end forms the rotary annular-seam spray hole with the inner wall of the core seat outlet. The cross section of the spray hole of the rotary annular-seam spray nozzle is an annular seam, the annular seam and a diameter can be set to respectively and conveniently control the fineness and the flow of pressure spray and make liquid drop sizes more evenly and finely distributed. The rotary annular-seam spray nozzle has a self-cleaning function, is not easy to block and is in a self-closing dust-resisting type; the rotary annular-seam spray nozzle is arranged on a spray head body or the core seat of the rotary annular-seam spray nozzle is connected with the spray head body, the spray head body is communicated with the pressure flow source, and therefore, the spray device with the rotary annular-seam spray nozzle can be formed.

Owner:韩铁夫

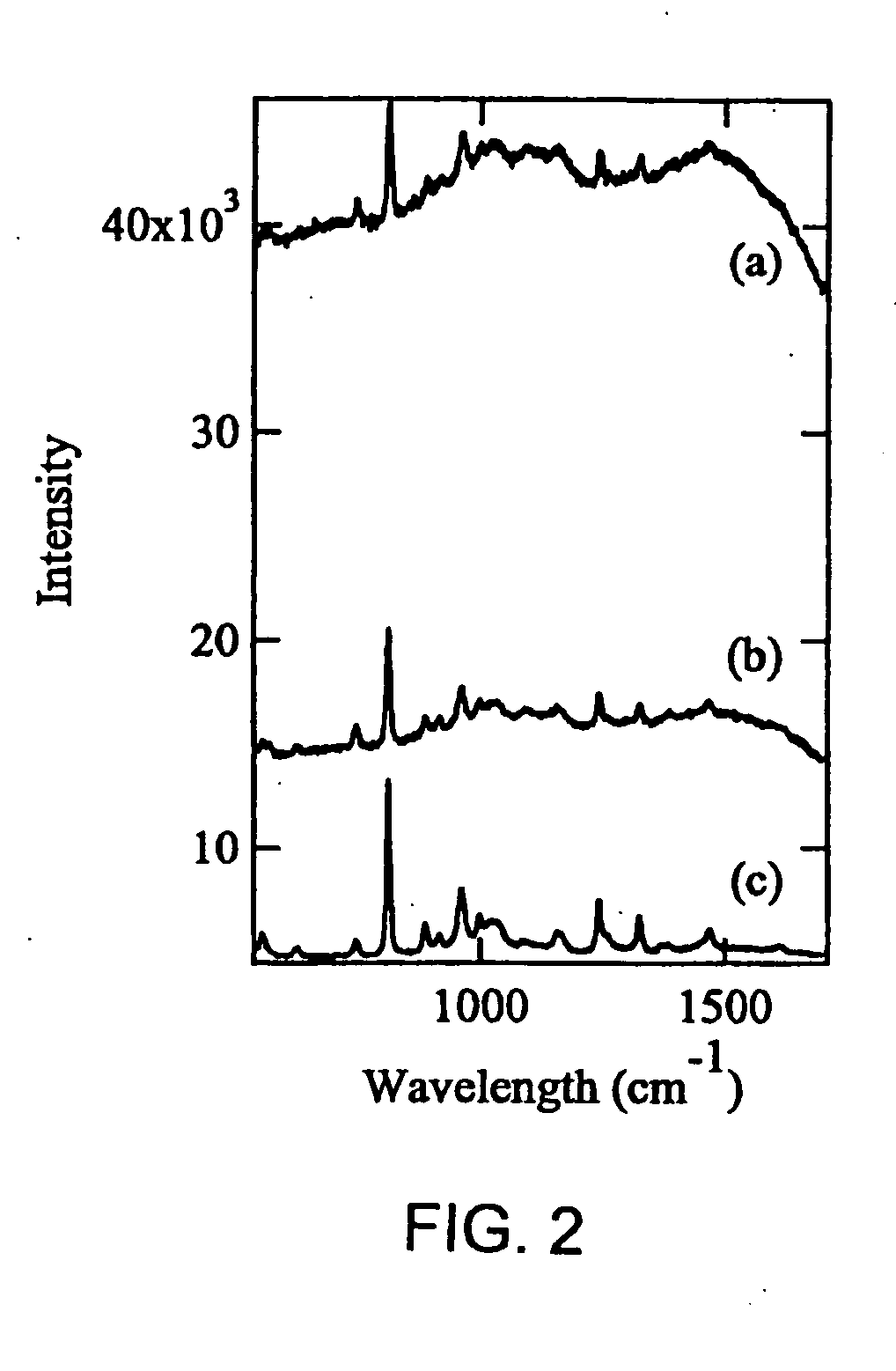

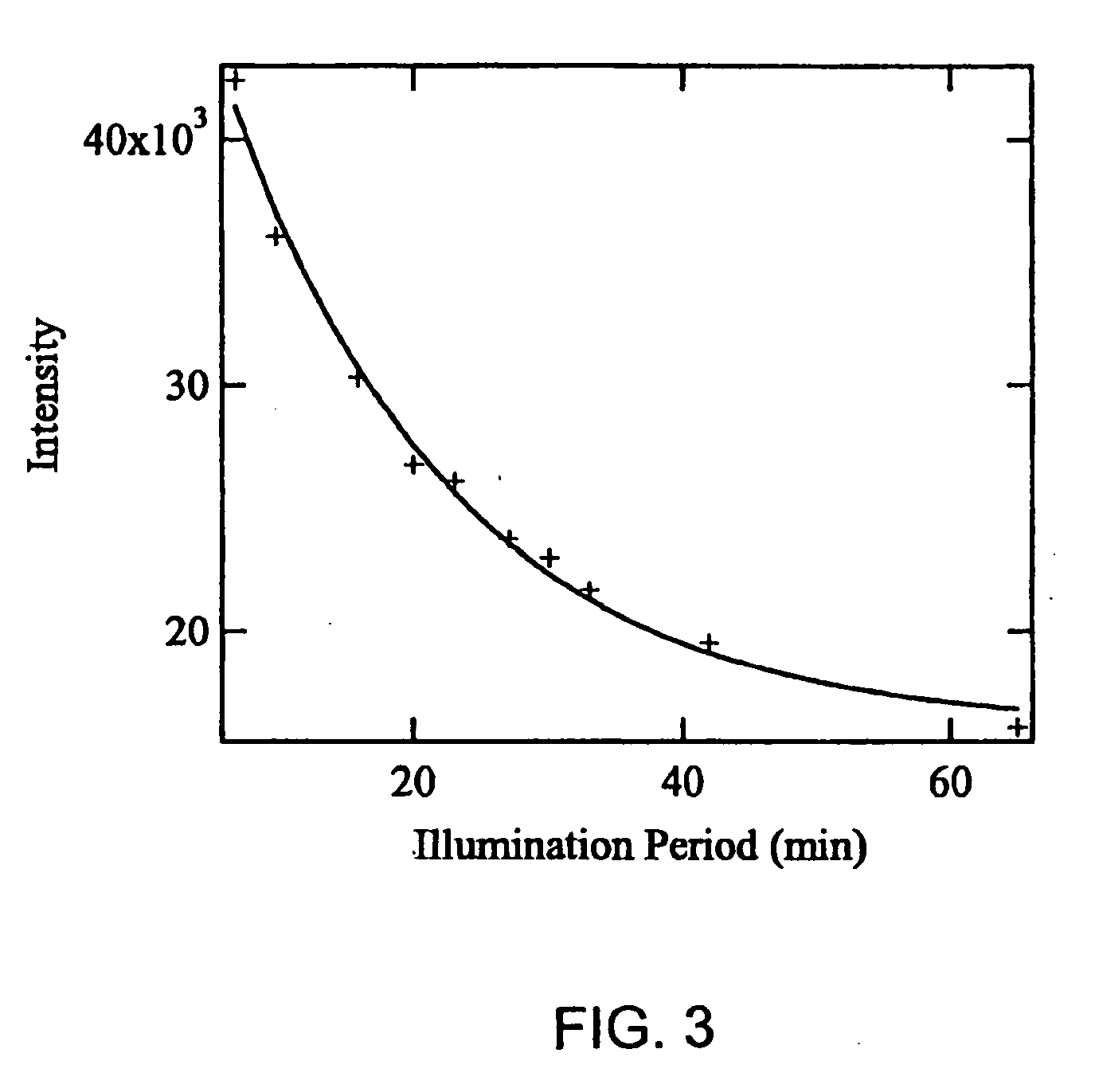

Process and apparatus for segregation and testing by spectral analysis of solid deposits derived from liquid mixtures

InactiveUS20050275837A1Limiting and controlling spreadAvoid spreadingMaterial nanotechnologyRadiation pyrometrySolubilitySpectroscopy

Micro-droplets of liquid confining organic molecules of interest are dried on selected planar solvo-phobic substrates under conditions facilitating segregated precipitation of the larger, less soluable analytes toward edge portions of the deposit. Micro-spectrometer imaging using white light and FTIR false color can identify points of interest, and the same optics generally directed perpendicularly to the substrates selectively captures normal Raman spectra from selected points in the deposit. The spectra are manipulated using various data techniques to extract reliable information concerning analytes present at pico-Molar levels. The selected spots can also be subjected to FTIR spectroscopy followed by MALDI mass spectroscopy to obtain a variety of information from the identical specimen.

Owner:PURDUE RES FOUND INC

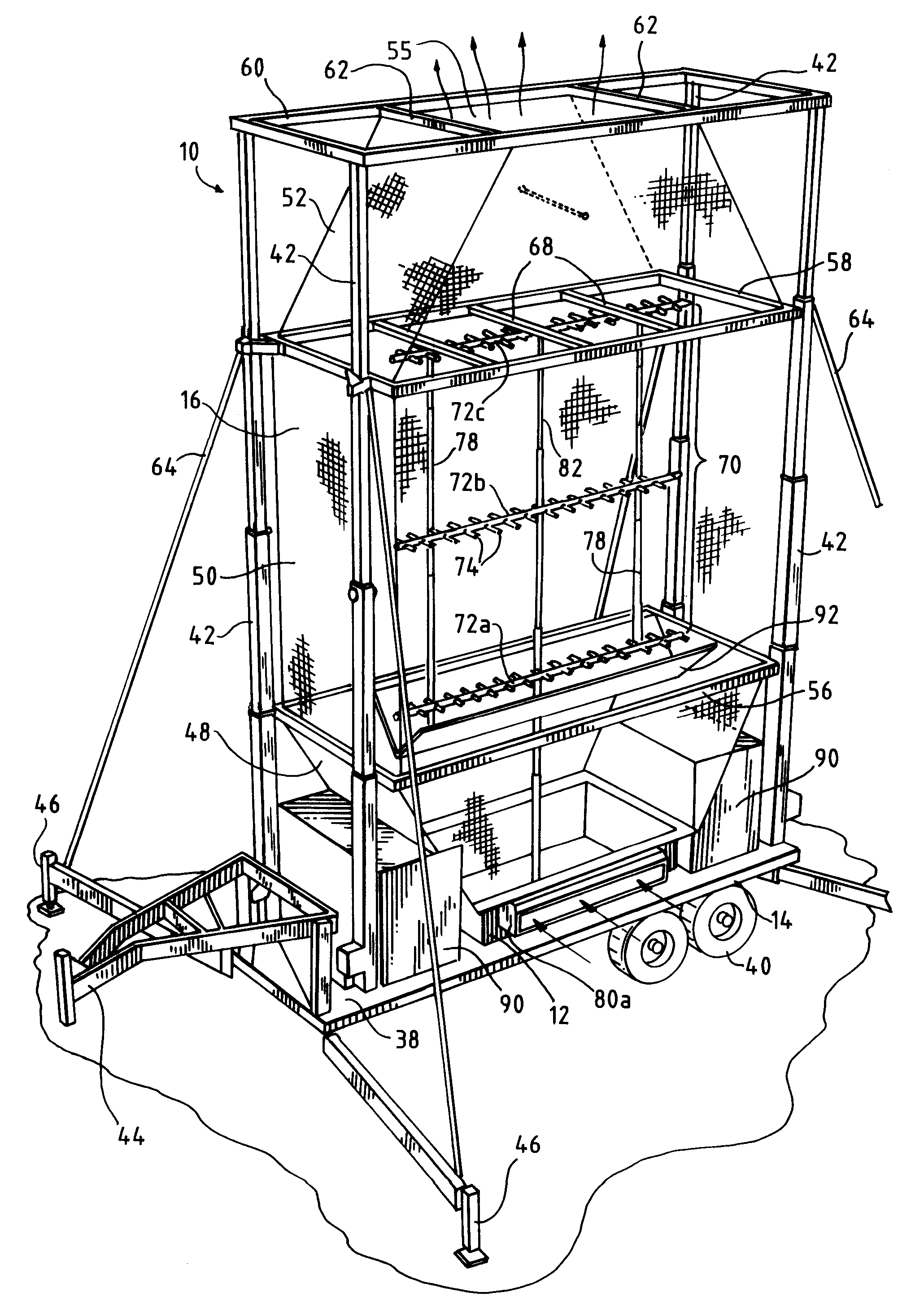

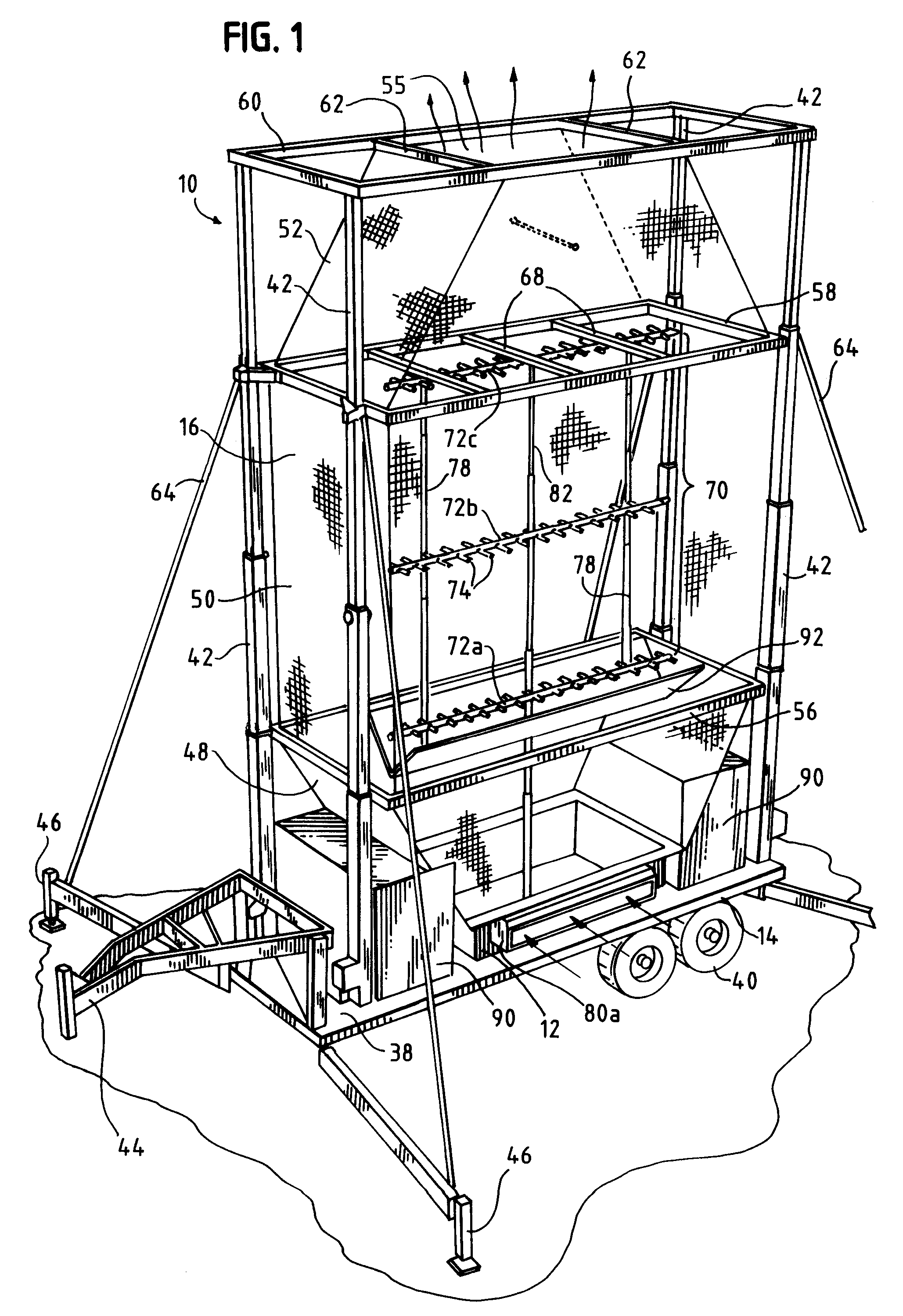

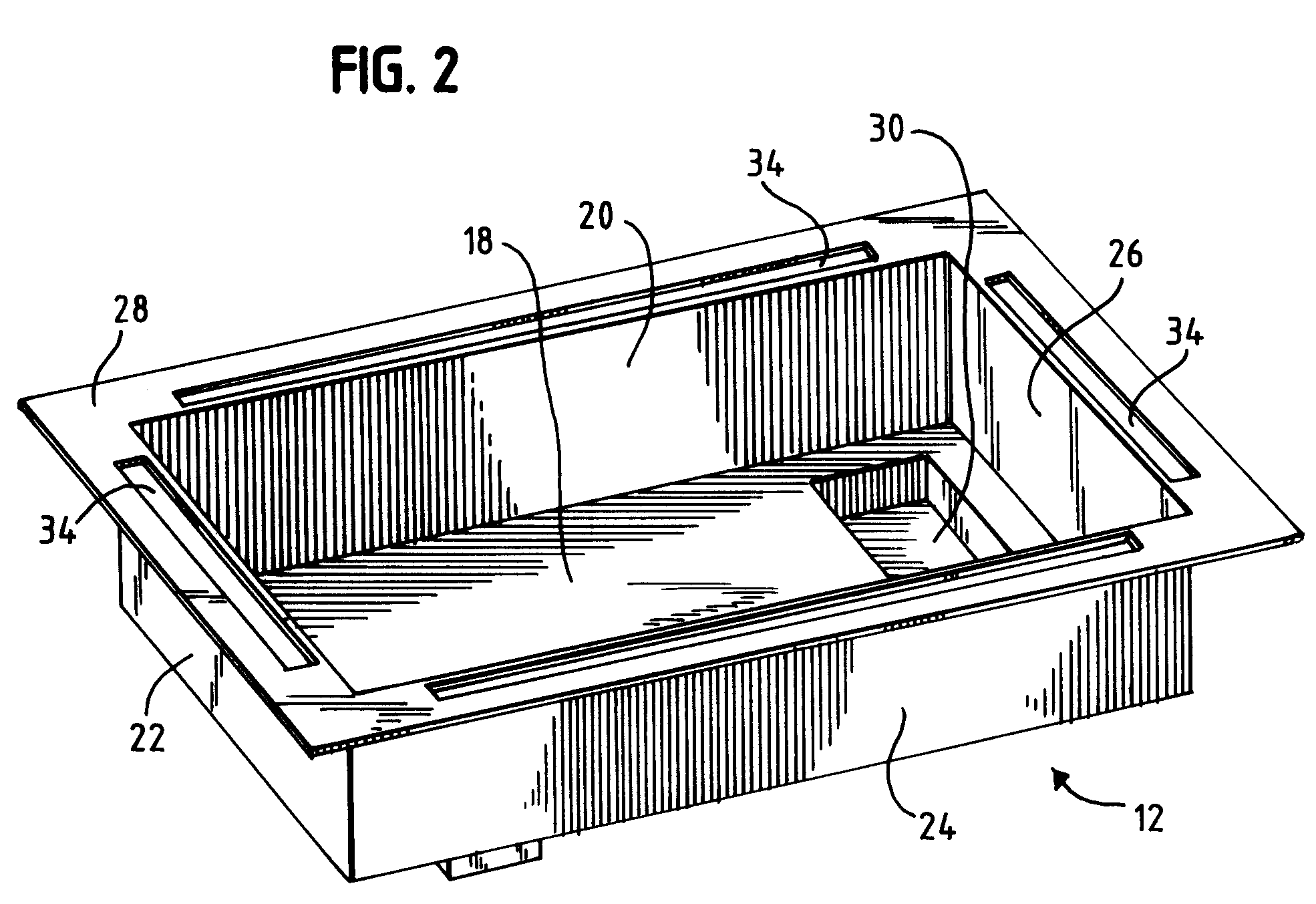

Portable evaporation chamber

InactiveUS7722739B2Speed up evaporationImprove stabilityMechanical conveying coke ovensEvaporator accessoriesZero temperatureWastewater

A self-contained evaporation system for use in disposing of excess water from oil and gas drilling operations is provided. The system includes a water holding tank in which the wastewater is preheated, an evaporation chamber mounted over the holding tank and having an open top, a nozzle system located within the chamber for producing a fine liquid mist, and fans disposed within the chamber for producing an air flow that carries the mist out the open top of the chamber. The system can be set up and taken down by one person in an hour or less, can be used with pond or tank operations, and is capable of operating in high winds and sub-zero temperatures. The system can be carried and mounted on a trailer for easy transport to and from various drilling sites.

Owner:EVAPORITE SYST

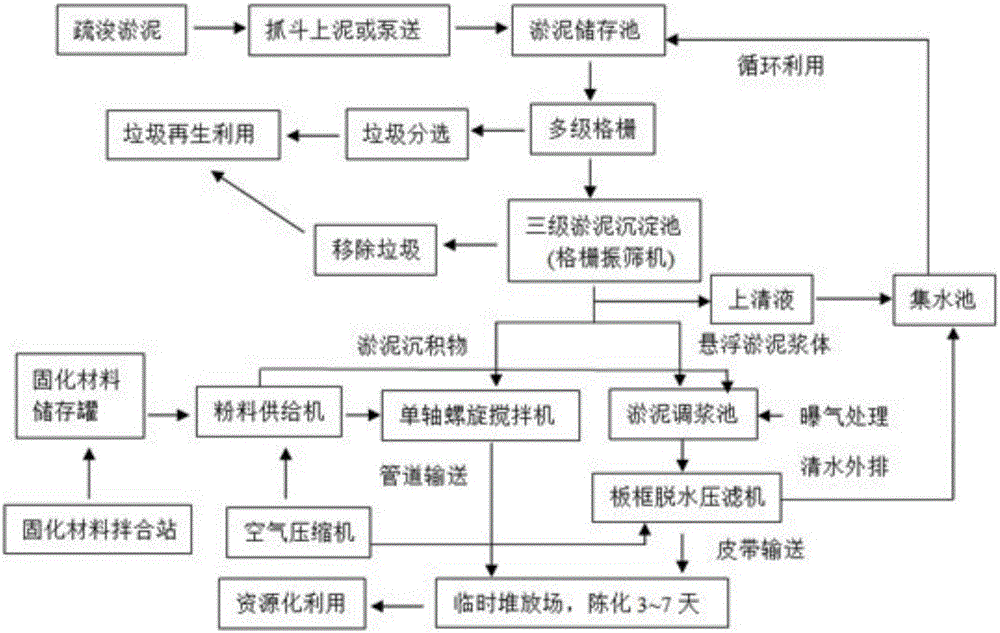

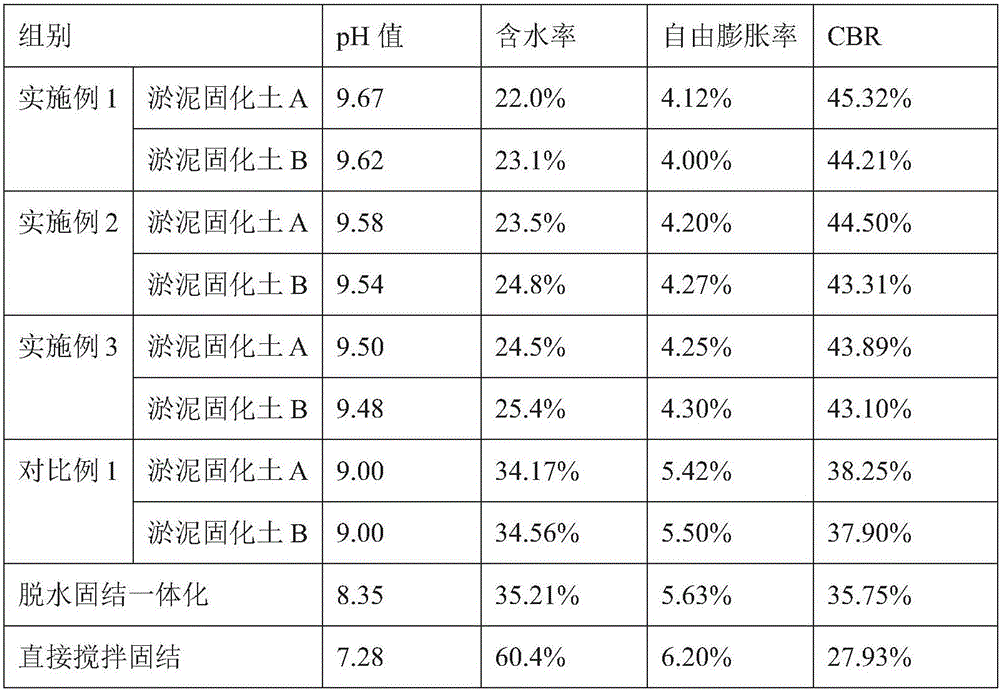

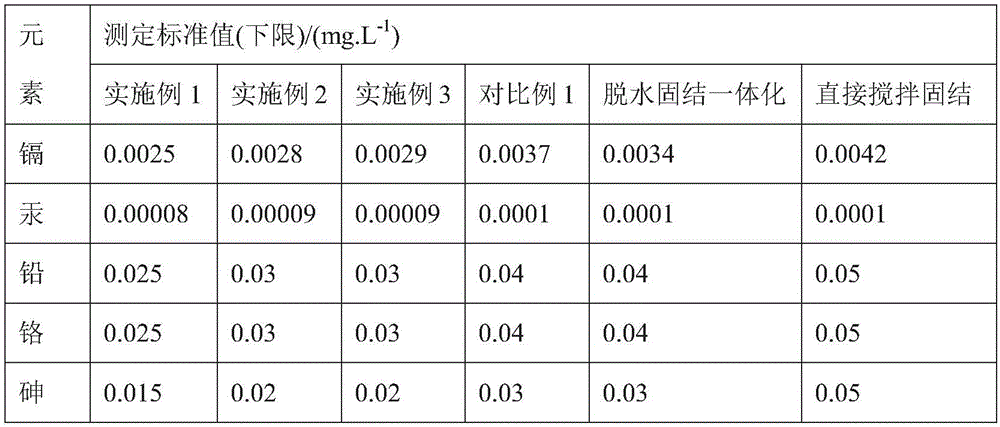

Sludge treatment process

The invention belongs to the field of environmental protection, and in particular relates to a sludge treatment process. The sludge treatment process comprises the following steps: 1) impurity removal: use multi-stage grille to filter out the garbage in the sludge; 2) pretreatment: utilize the three-stage sludge settling tank to pretreat the sludge to obtain the first, second, and The sludge in the three-stage sludge settling tank, the sludge slurry and the supernatant after being settled in the three-stage sludge settling tank; 3) solidification treatment: respectively adopt mixing solidification and dehydration solidification methods for the first, second, and third-stage sludge sedimentation The silt and silt slurry in the pond are dehydrated and solidified to obtain silt-solidified soils A and B; 4) stacking and aging: transport the silt-solidified soils A and B to a temporary storage yard and age them for 3 to 7 days to complete the treatment. The sludge treatment process of the present invention can simultaneously process particles and sludge with high viscosity and low water content, as well as sludge slurry with fine particles, organic matter and high water content, and is especially suitable for river courses with complex components, wide particle distribution, and large water content differences silt.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

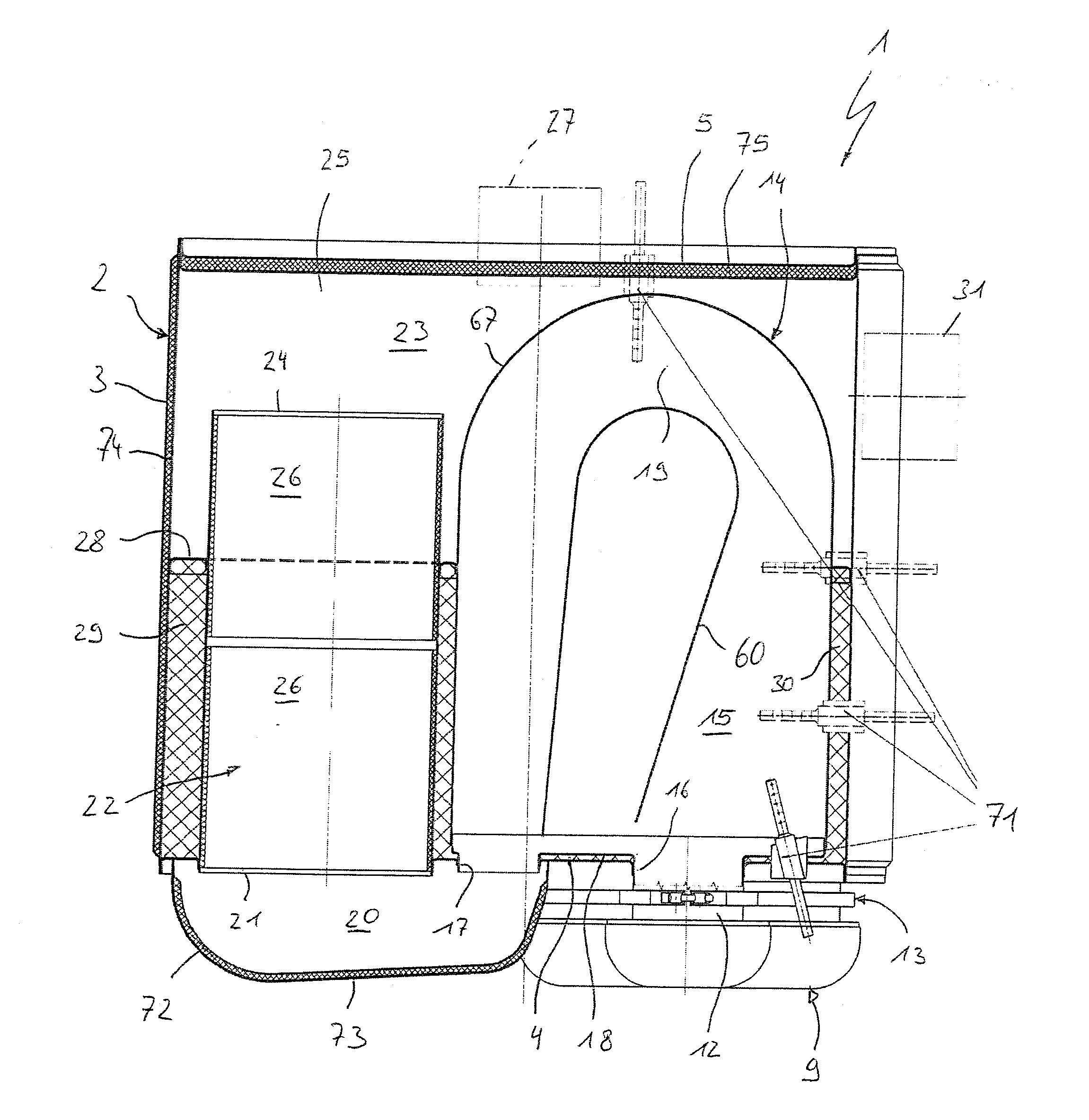

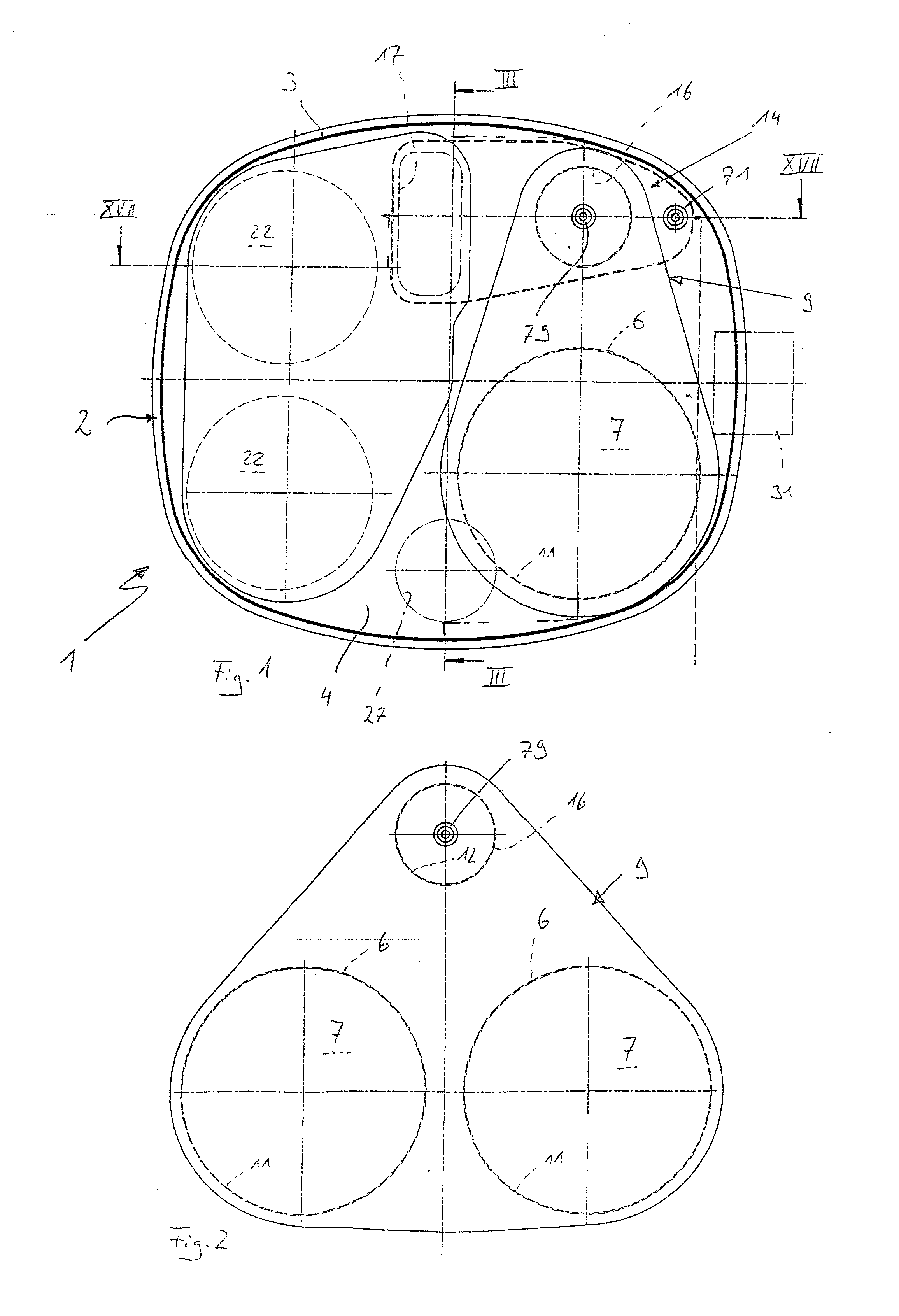

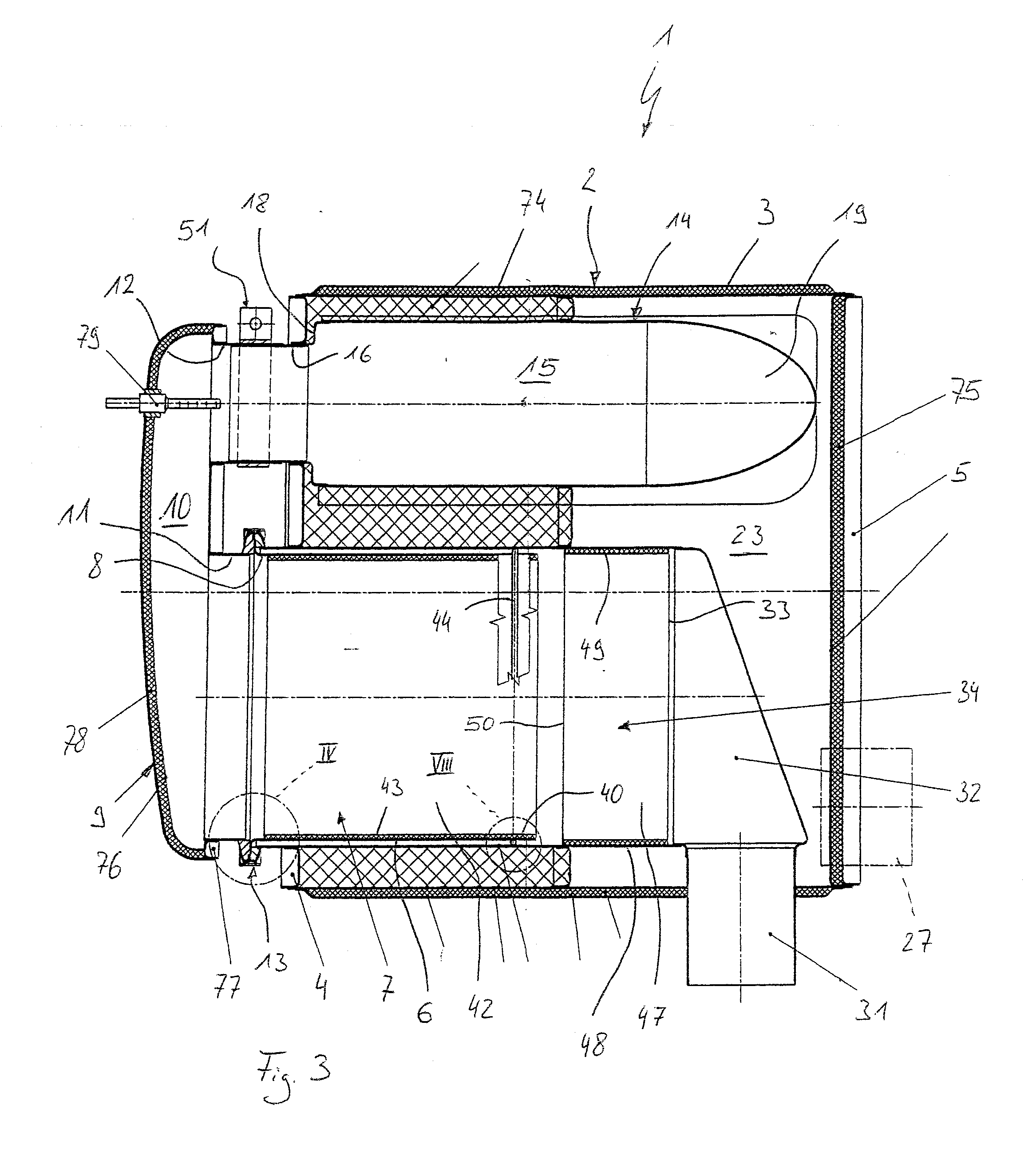

Exhaust gas-treating device

ActiveUS20100242451A1Improve homogenizationSpeed up evaporationInternal combustion piston enginesSilencing apparatusInterior spaceExhaust fumes

An exhaust gas-treating device (1) for an exhaust system of an internal combustion engine, especially of a motor vehicle, is provided with a housing (2), which has a jacket (3) extending circumferentially on the side and at least one bottom (4). The homogenization of the exhaust gas flow is improved with a mixing housing (14), which is arranged in the interior space (23) of the housing (2) and which has a mixing chamber (15). An inlet (16) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15). An outlet (17) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15).

Owner:VOLVO LASTVAGNAR AB +1

Method for preparing perovskite thin film in perovskite solar cell via solution air extraction and ventilation method

ActiveCN105702871AIncrease supersaturationSpeed up evaporationSolid-state devicesSemiconductor/solid-state device manufacturingSolvent moleculePerovskite solar cell

The invention provides a method for preparing a perovskite thin film in a perovskite solar cell via a solution air extraction and ventilation method. The method comprises the following steps: a perovskite liquid film coated on a surface of a base body is subjected to air extracting and drying operation in an environment where the partial pressure of the solvent is lower than 99% saturated vapor pressure of the solvent at current temperature; during drying processes or after the perovskite liquid film is completely dries, a gas which does not react chemically with a perovskite is let in, and therefore a process that the solvent is evaporated or solvent molecules leave the environment can be accelerated via solvent molecule concentration dilution. Heterogeneous nucleation and growth of the surface of the base body can be realized via control over drying process conditions, and therefore a uniform and compact perovskite thin film can be formed. The method can be used for accelerating liquid film drying processes, making solvent steam molecules leave a surface of the thin film quickly, and obtaining the uniform-structured and compact perovskite thin film; thus current leakage caused by perovskite thin film loopholes can be prevented and the method can help make high-efficiency solar cells; the method is advantaged by simple operation, easy-to-implement property, low cost, high repetition accuracy, convenience for industrialization and the like.

Owner:杨冠军

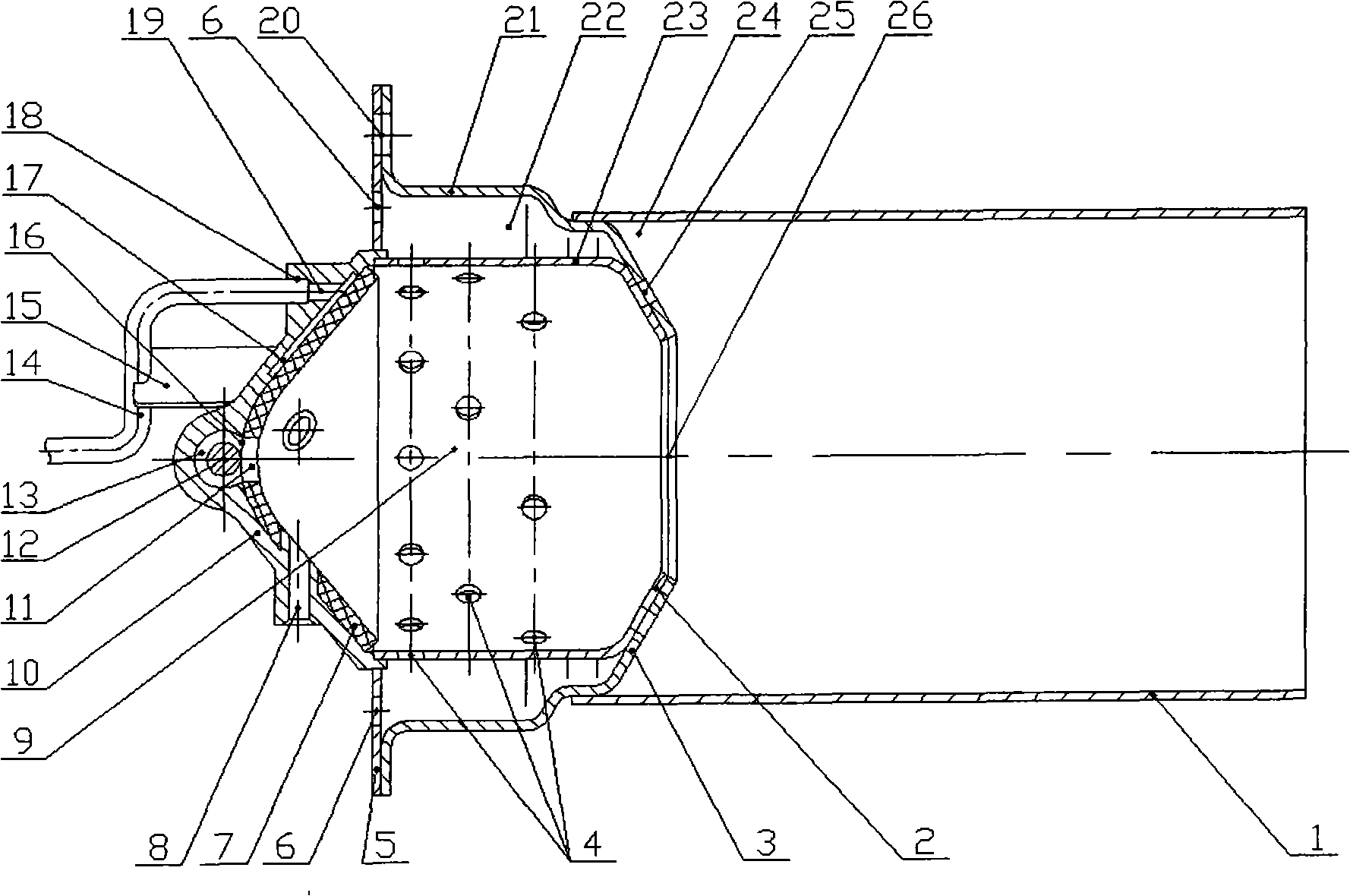

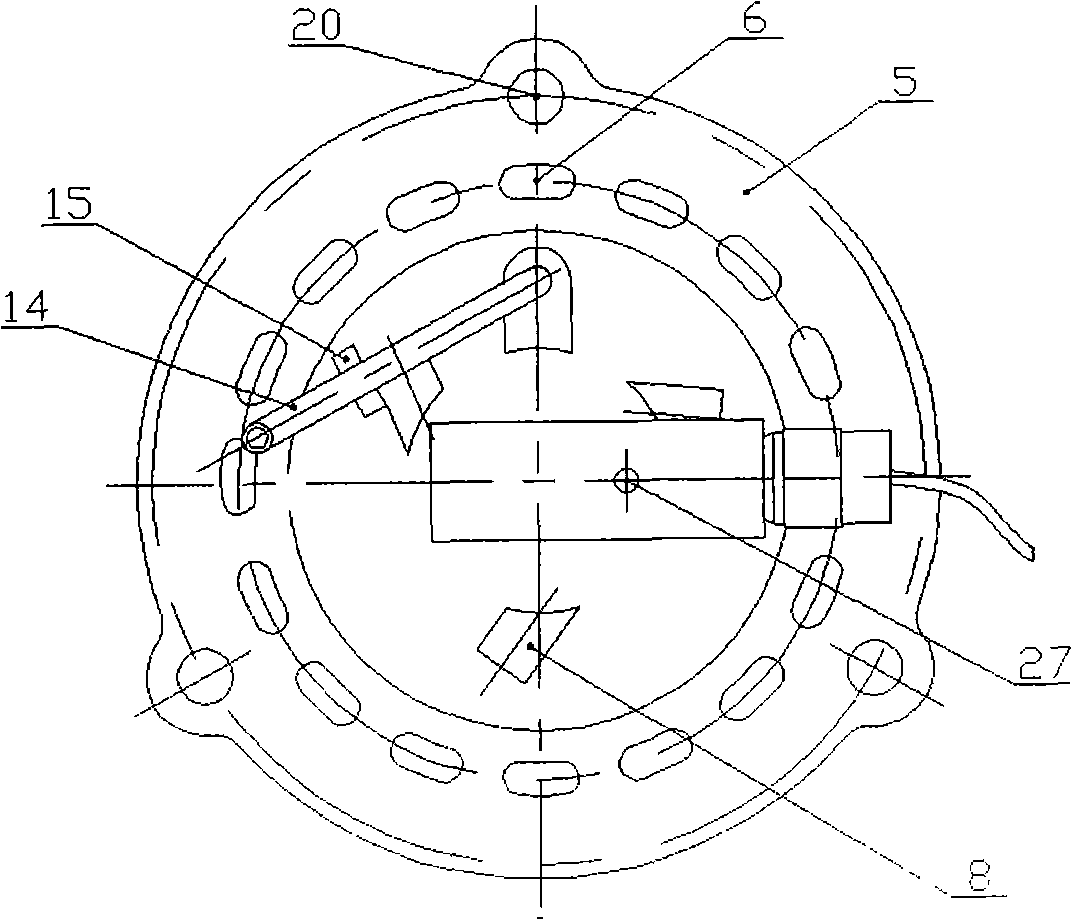

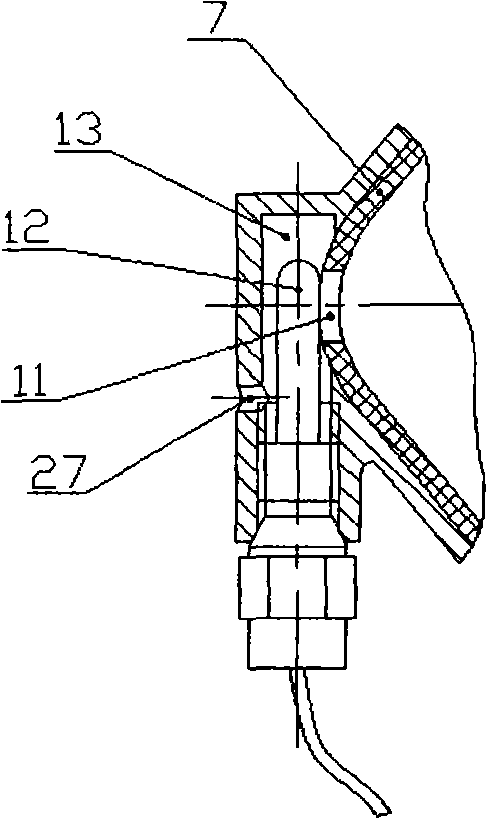

Wimble cap-shaped combusting device of oil heater

InactiveCN101280922AEasy to moveReduce flowLiquid fuel evaporation burnersCombustorCombustion chamber

The present invention provides a wimble cover shaped combustor of fuel heater comprising a combustion chamber cover, a oil suction wimble liner, a primary combustion barrel, a secondary combustion barrel, an air inlet guide barrel, an air inlet split stream slice, a fuel oil tube and a glow plug; the oil suction wimble liner is applied on the combustion chamber cover internal surface, an oil groove is arranged between the both; the primary combustion barrel is connected to the combustion chamber cover, and the air inlet guide barrel is arranged at outer portion of the primary combustion barrel, and air inlet holes are arranged circumferentially on the barrel wall of the primary combustion barrel; the primary combustion barrel is connected to the back end of the air inlet guide barrel to form a conical contraction hole; the front end of the air inlet guide barrel connects to the air inlet split stream slice which is provided with air split stream holes; the secondary combustion barrel connect is connected to the back end of the air inlet guide barrel; the combustion chamber cover has a conical shape, a fuel oil tube connected onto, a glow plug arranged on top, and tangential air holes are arranged circumferentially on the combustion chamber cover. The invention provides credible, rapid ignition start, uneasily generates carbon deposition, has high combustion efficiency and economical efficiency improved by more than 6%.

Owner:河北宏业永盛汽车加热器股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com