Rotary annular-seam spray nozzle and spraying device thereof

A technology of spray nozzle and rotating ring, which is applied in the field of rotating annular seam spray nozzle and its spray device, and spray device, which can solve the problem of difficult balance between spray flow rate and fine atomization, and achieve the effect of not being easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

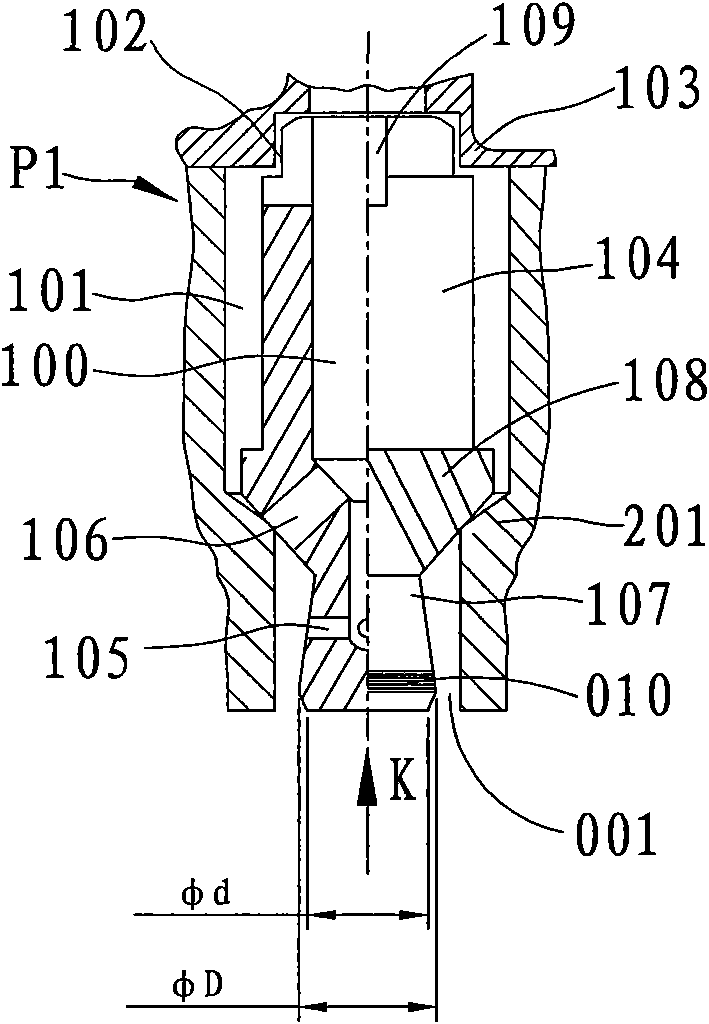

[0050] Such as Picture 1-1 As shown, a rotary annular spray nozzle p1 includes a core seat 201 , a rotary core 104 , a rotary annular spray hole 001 and a core seat cover 103 . The core seat 201 is provided with a core chamber 101, and the core seat 201 is provided with an inlet and an outlet communicating with the core chamber 101, and the inlet of the core seat 201 is connected to a pressure flow source; the two ends are small and the middle is a large stepped cylindrical rotary core 104 uses the round hole 104 of the core chamber of the core base and the round hole 102 of the core base cover 103 as bearings at both ends, and the three are concentric, and the rotating core 104 can float and rotate in the stepped circular hole core cavity 101; The head end of the big cylinder of the core is shrunk into a conical annulus and a small cylinder or a small conical column. The outer circumference of the column head 107 can be a smooth surface. The core column head 107 is located i...

Embodiment 2

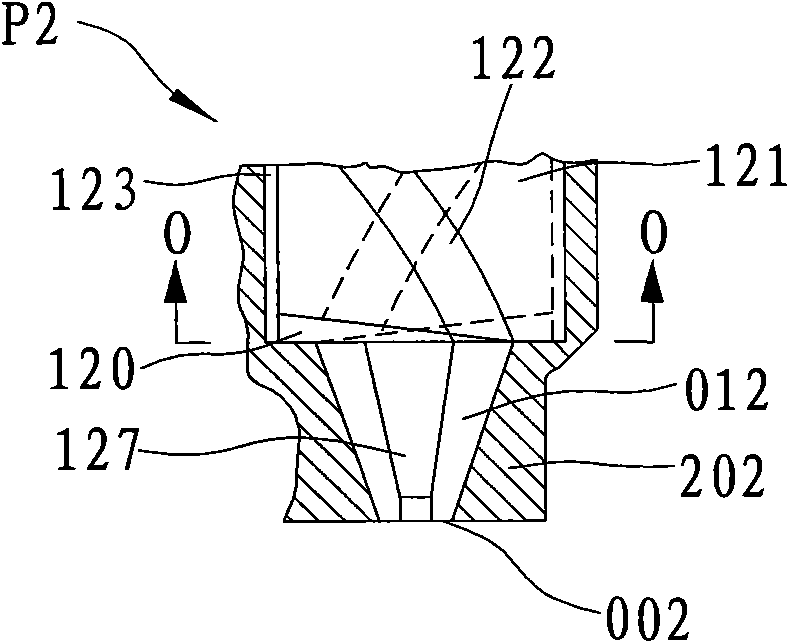

[0054] Such as Figure 1-2 As shown, a solid column rotary core spray nozzle p2. A core chamber 123 is provided in the center of the core seat 202, and a rotating core 121 that can float and rotate is provided in the round hole of the core chamber. The front end of the large cylindrical section of the rotary core 121 shrinks into a small cylindrical or small conical core column head 127. The core column head 127 is located in the inverted tapered nozzle hole at the exit of the core cavity to form an annular slot nozzle hole 012, and the inlet of the annular slot nozzle hole 012 The gap is greater than the exit gap, the outlet of the annular nozzle hole 012 is the annular nozzle 002, and the diversion groove 122 exits at the end ring surface 128 where the large cylinder and the core column head 127 are handed over (such as Figure 1-2A As shown) and communicate with the annular nozzle hole 012, the end ring surface 128 leans against the ring step of the shrinkage hole of the c...

Embodiment 3

[0056] Such as Figure 1-3 As shown, a multi-rotary core combined spray nozzle p3 with a shared core seat. It includes a seat body 135 , a core seat 203 , and rotating cores 131 , 130 , 111 . The core seat 203 is screwed on the seat body 135, and at least three outer peripheral core cavities 133, 138 and a central rotary core cavity 139 are provided on the core seat 203, and the rotatable core cavities 133, 138 are rotatably nested Stepped cylindrical rotary cores 131, 111. In this embodiment, the stepped cylindrical rotary core 131 has a stepped cylindrical shape with small two ends and an annular shoulder in the middle. The spiral tooth or the spiral groove 132, the front end of the rotary core 131 shrinks into a cylindrical core column head, and the core column head is inserted into the outlet of the rotary core cavity 133 to form an annular slot nozzle hole and its nozzle 003 whose inner annular gap is larger than the outer annular gap; Cylindrical rotary core 111 is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com