Patents

Literature

621results about How to "Improve dust resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

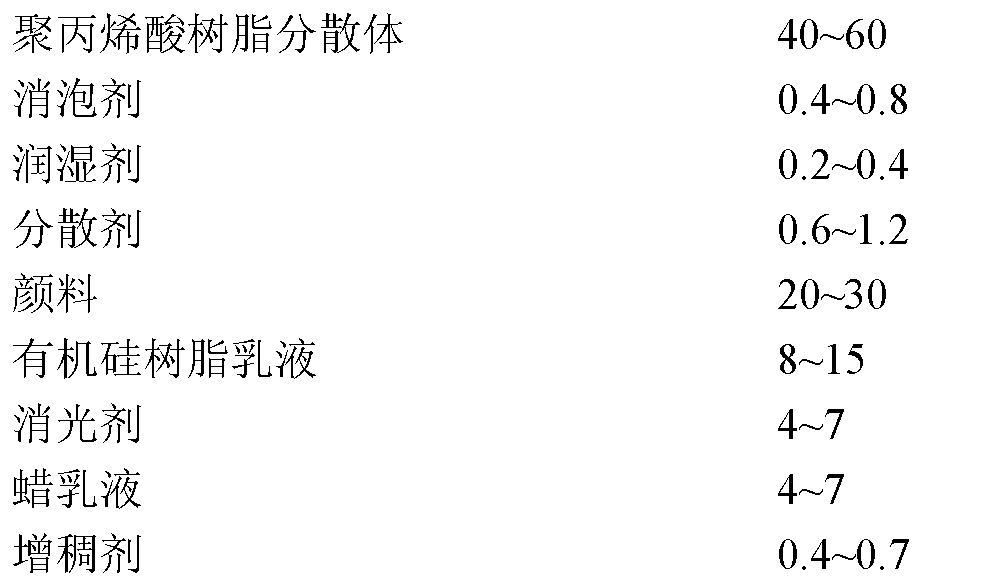

Dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance and preparation thereof

InactiveCN102516858AImprove scratch resistanceImprove friction resistancePolyurea/polyurethane coatingsWaxChemistry

The invention discloses a dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance, and a preparation method thereof. The dual-component aqueous polyurethane paint with scrawling resistance and pasting resistance is prepared by using aqueous hydroxy-containing polyacrylic resin dispersion and fatty group polyisocyanate as main film forming substances, adding organosilicon resin emulsion, deionized water, antifoaming agent, wetting agent, dispersant, pigment, dulling agent, wax emulsion and thickening agent and carrying out high speed disperse. The paint has characteristics of high crosslinking density, low surface tension, strong permeability resistance, good scratch resistance, substantial scrawling resistance and pasting resistance, excellent performances of low VOC content, high hardness, good weatherability, brushing resistance and chemical resistance, and is suitable for application fields of municipal public facility, building paint and terrace paint coating, etc.

Owner:CENT SOUTH UNIV +1

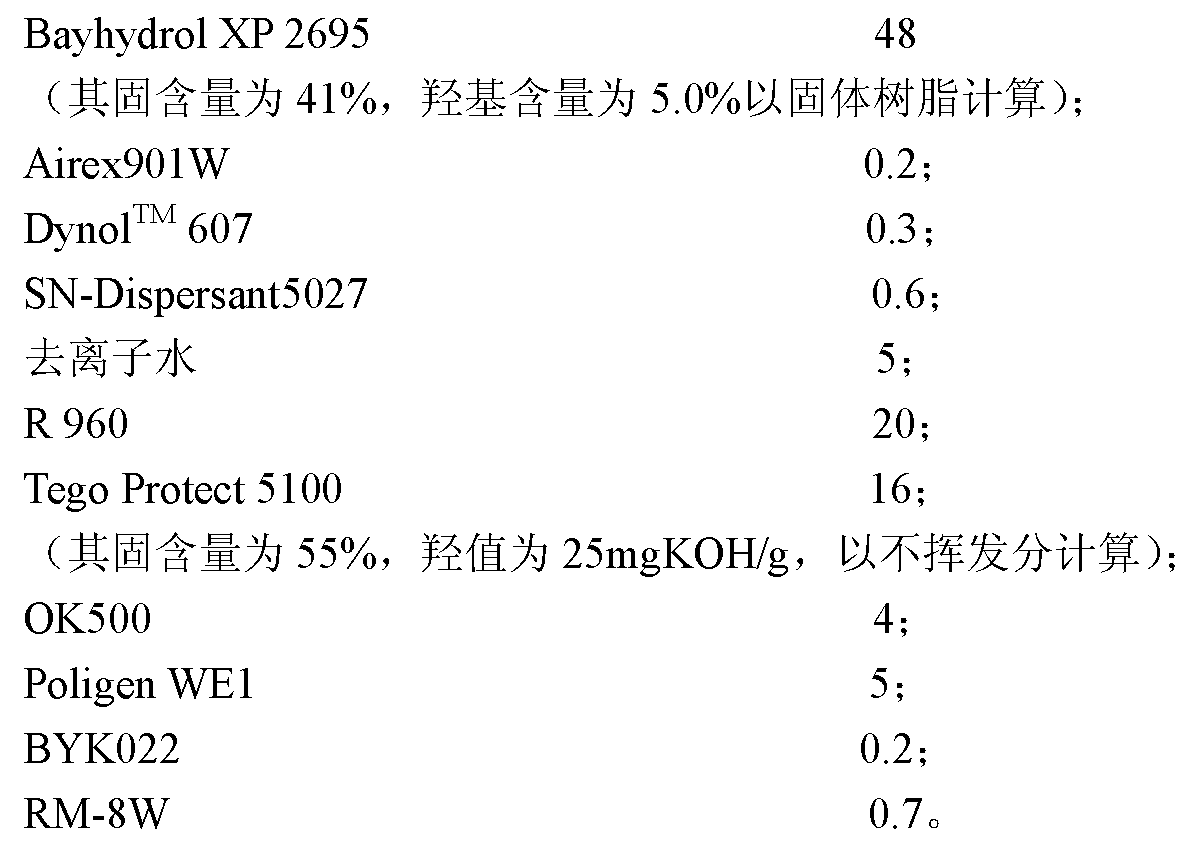

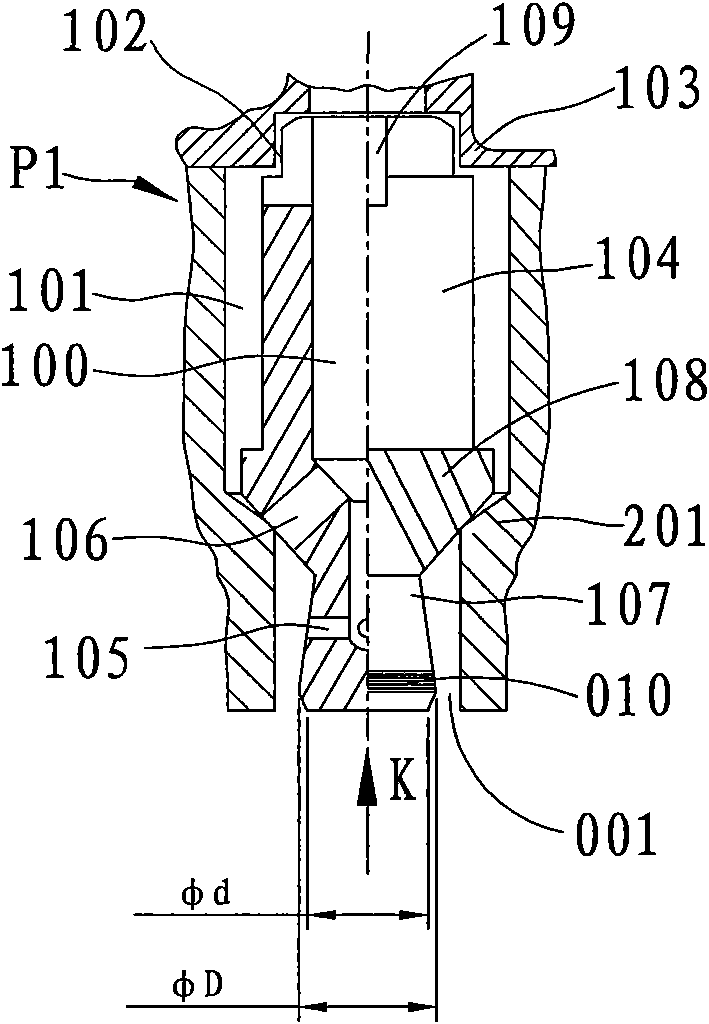

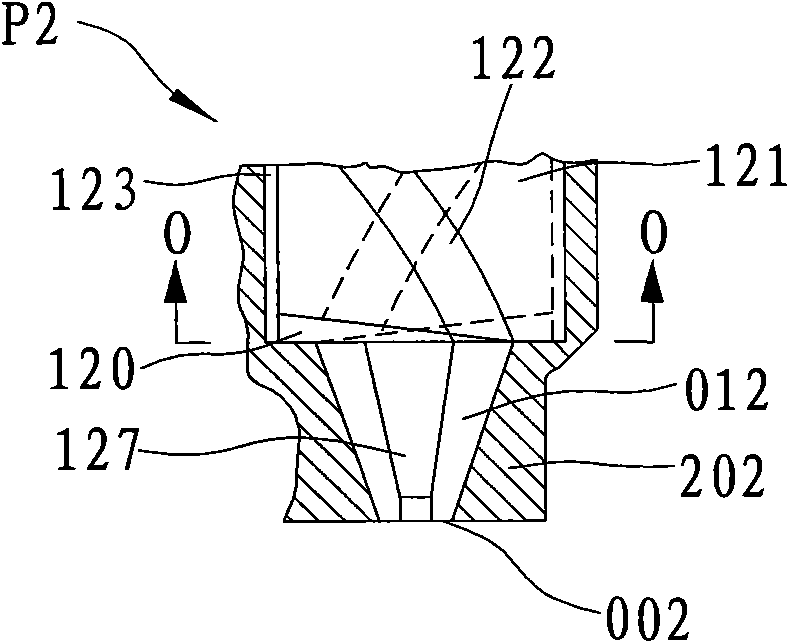

Rotary annular-seam spray nozzle and spraying device thereof

InactiveCN102039228AEasy ultra-fine atomizationUltra-fine atomization promotionSpray nozzlesLiquid spraying apparatusSpray nozzleFineness

The invention discloses a rotary annular-seam spray nozzle comprising a core seat, a rotary core and a rotary annular-seam spray hole, wherein a core cavity is arranged in the core seat, an inlet and an outlet which are communicated with the core cavity are arranged on the core seat, a core seat inlet is communicated with a pressure flow source, the rotary core can be sleeved into the core cavity in positioning and rotating modes and is concentric with the core cavity, a rotation-promoting flow path is arranged on the rotary core or / and the wall of the core cavity in order to mutually rotate the rotary core and the core cavity by using flow power, one end of the rotary core is penetrated into the core seat outlet, and the penetrating end forms the rotary annular-seam spray hole with the inner wall of the core seat outlet. The cross section of the spray hole of the rotary annular-seam spray nozzle is an annular seam, the annular seam and a diameter can be set to respectively and conveniently control the fineness and the flow of pressure spray and make liquid drop sizes more evenly and finely distributed. The rotary annular-seam spray nozzle has a self-cleaning function, is not easy to block and is in a self-closing dust-resisting type; the rotary annular-seam spray nozzle is arranged on a spray head body or the core seat of the rotary annular-seam spray nozzle is connected with the spray head body, the spray head body is communicated with the pressure flow source, and therefore, the spray device with the rotary annular-seam spray nozzle can be formed.

Owner:韩铁夫

Wax-containing composition for leather and its product surface coating

ActiveCN1611560AGood miscibilityHigh affinityLiquid surface applicatorsCoatingsSolubilityCarbon chain

The invention relates to a kind of waxy combination for surface coating of leather and its products, which is mainly composed with wax, high molecular polymer cream, long carbon-chain fatty alcohol, fatty amide, surface-active agent, and water, but its components doesn't contain organic solvent, water solubility organic alcohol, and mineral oil. Use fatty amide as cosolvent of coating combination system; fatty amide has fine intersolubility with wax, fatty alcohol, high molecular polymer, and other solid constituents; so it can improve stability of coating combination system, can guarantee continuation and compactness of coating film, and also can avoid the disadvantages of containing mineral oil and low molecular water solubility alcohol in the components. When using for surface coating of leather and its products, it has natural gloss, excellent abilities of water-resistant, antidusting, drying proof, and wet proof, and fine frictional property. So it has convenient usage that is safe, and can decline pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

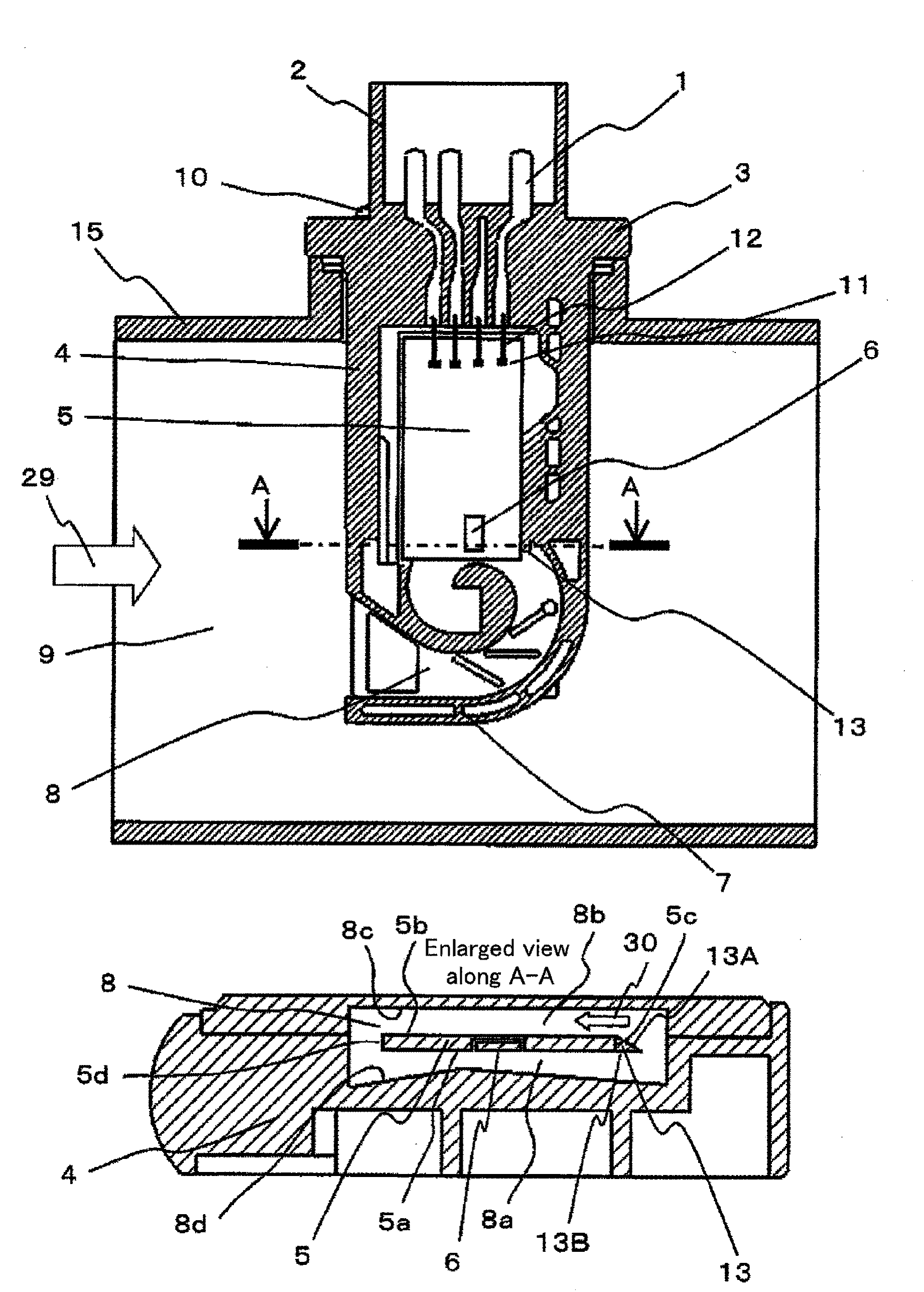

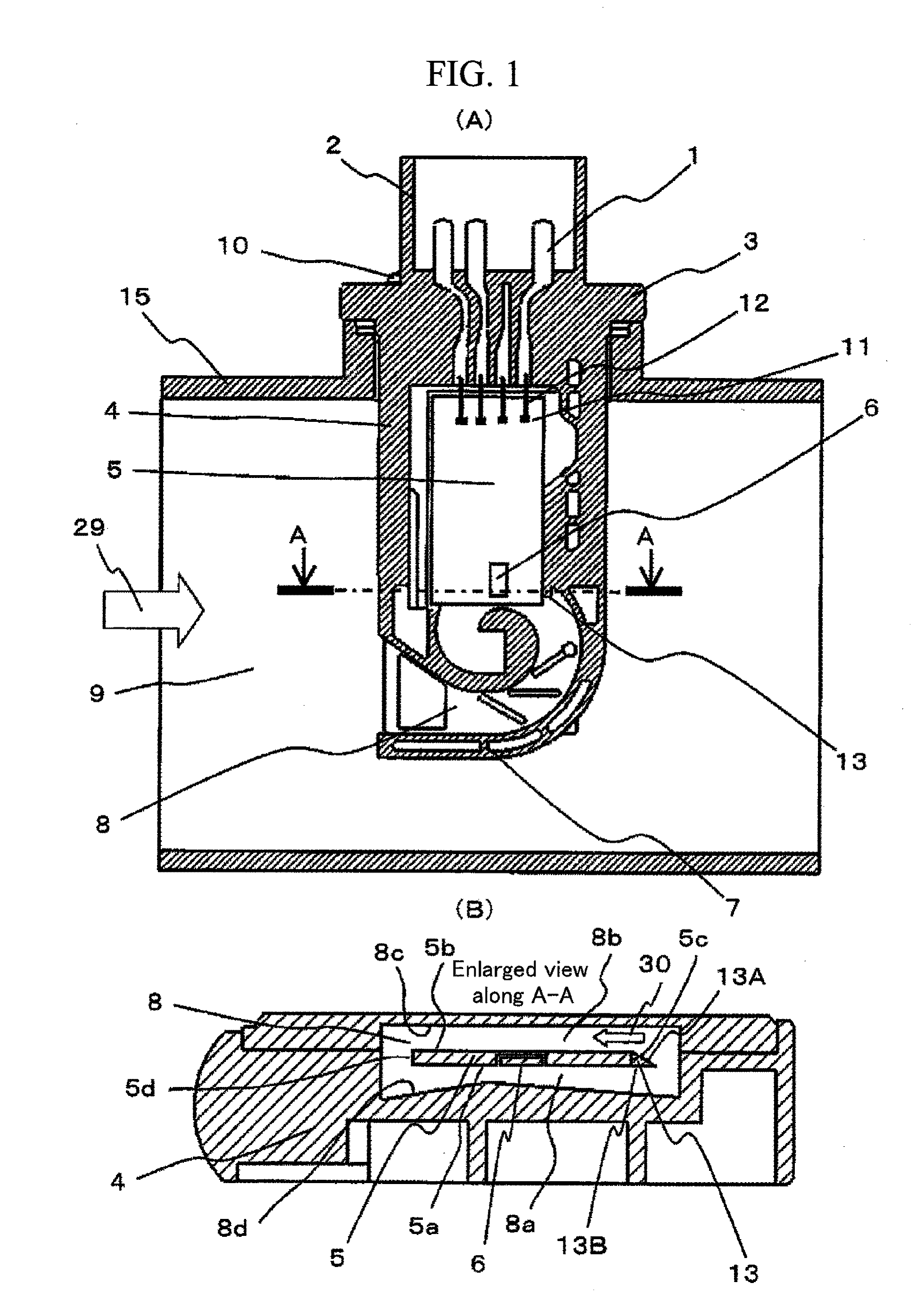

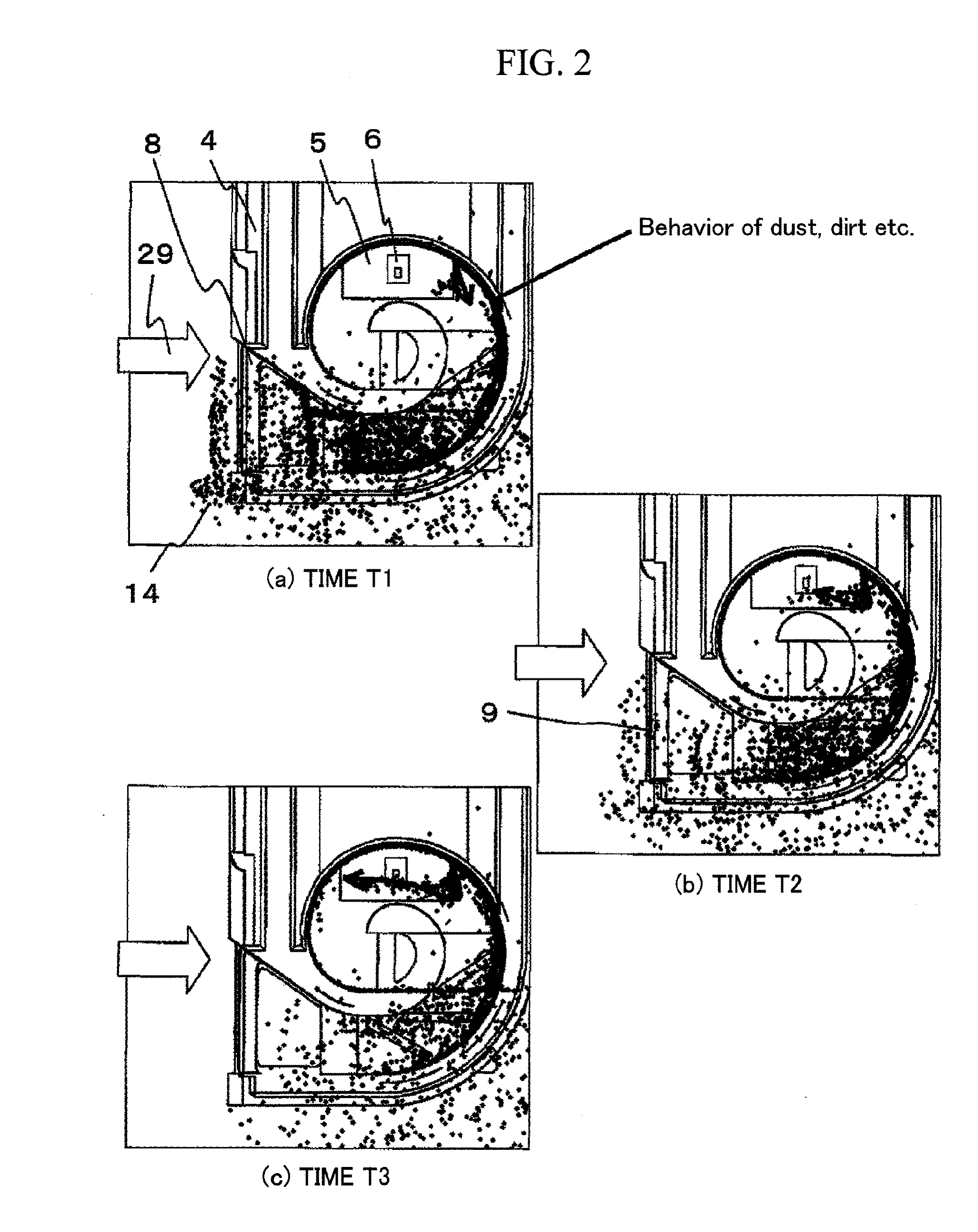

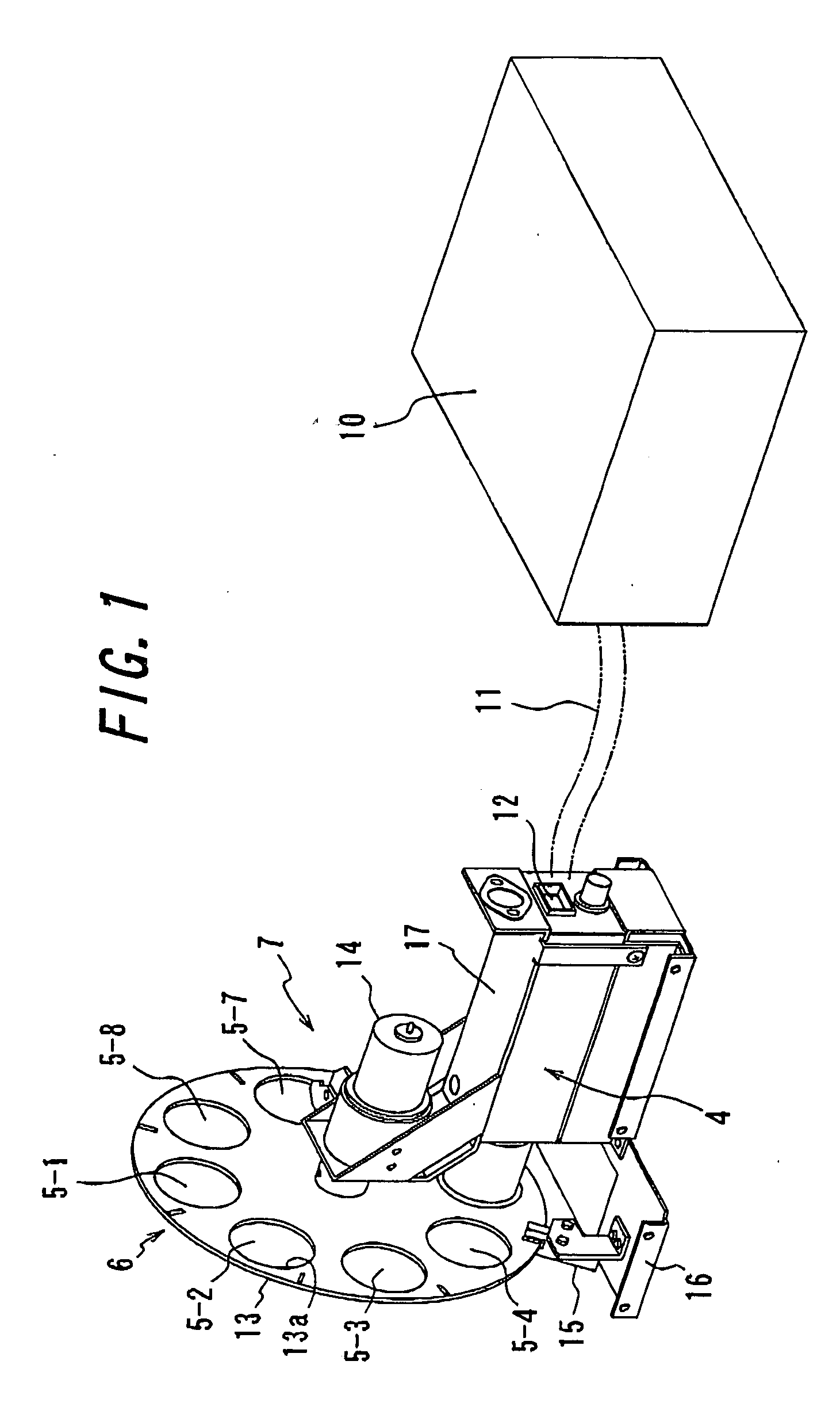

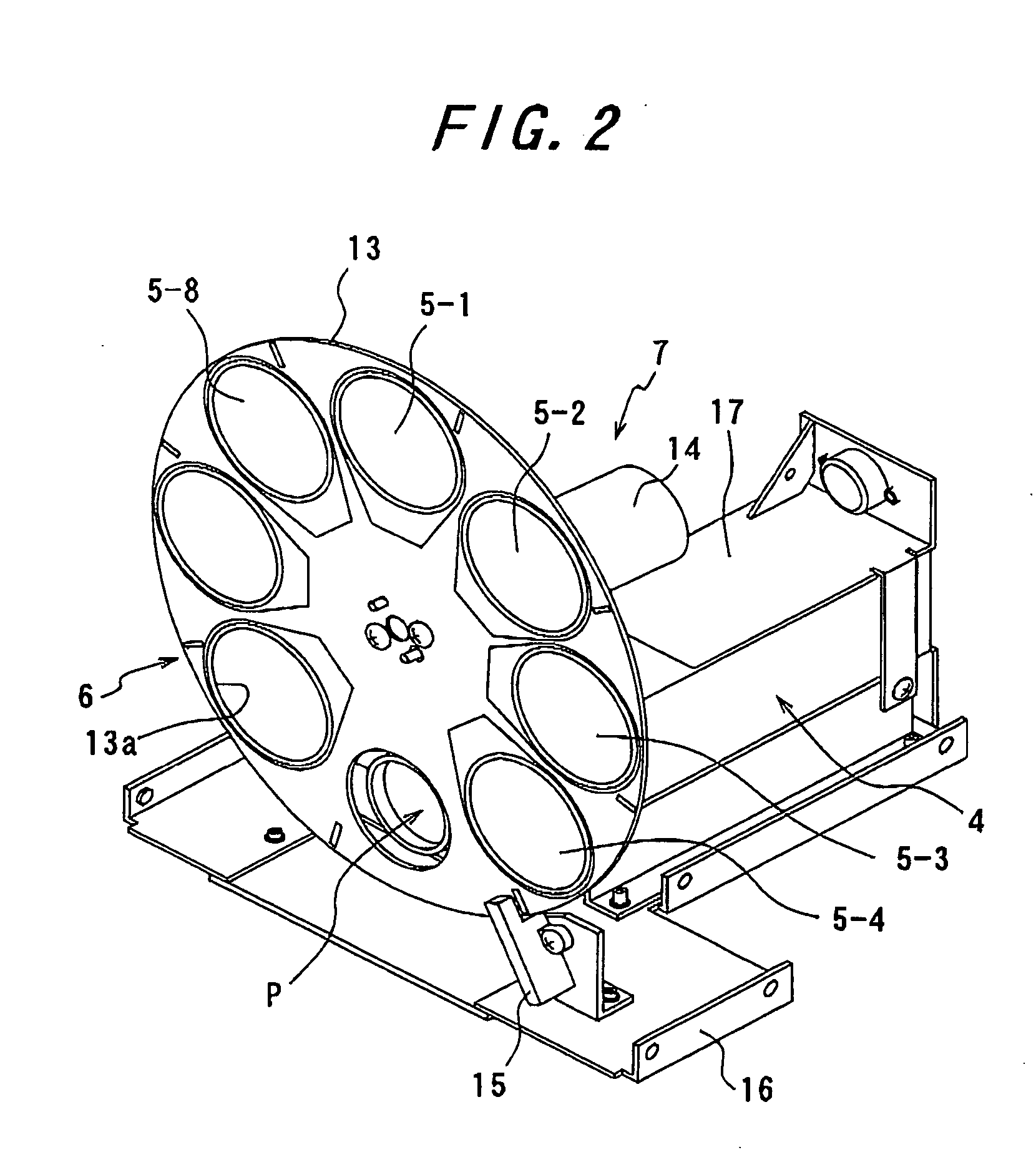

Air Flow Measuring Instrument

InactiveUS20090126477A1Improve dust resistanceImprove reliabilityVolume/mass flow by thermal effectsVolume flow proportion measurementMeasuring instrumentEngineering

An air flow measuring instrument, comprising: an auxiliary passage 8 arranged inside a main passage through which fluid flows, a tabular member 5 on which a pattern of a heating resistor for measuring an air flow is provided on one face 5a, the tabular member being disposed inside the auxiliary passage so that the one face 5a on which the heating resistor pattern of the tabular member is provided is disposed along a flow of fluid inside the auxiliary passage 8, a heating resistor pattern-side fluid passage 8a portion formed so that the fluid flows between the face 5a and a passage-forming surface 8d of the auxiliary passage, and a back-surface 8b side fluid passage portion formed so that fluid flows between a face 5b on a side opposite to the face of the tabular member and the passage-forming surface of the auxiliary passage. Guidance portion 13 guiding dust that collides against the end portion to back-surface side fluid passage portion 8b side is provided on upstream-side end of tabular member.

Owner:HITACHI LTD

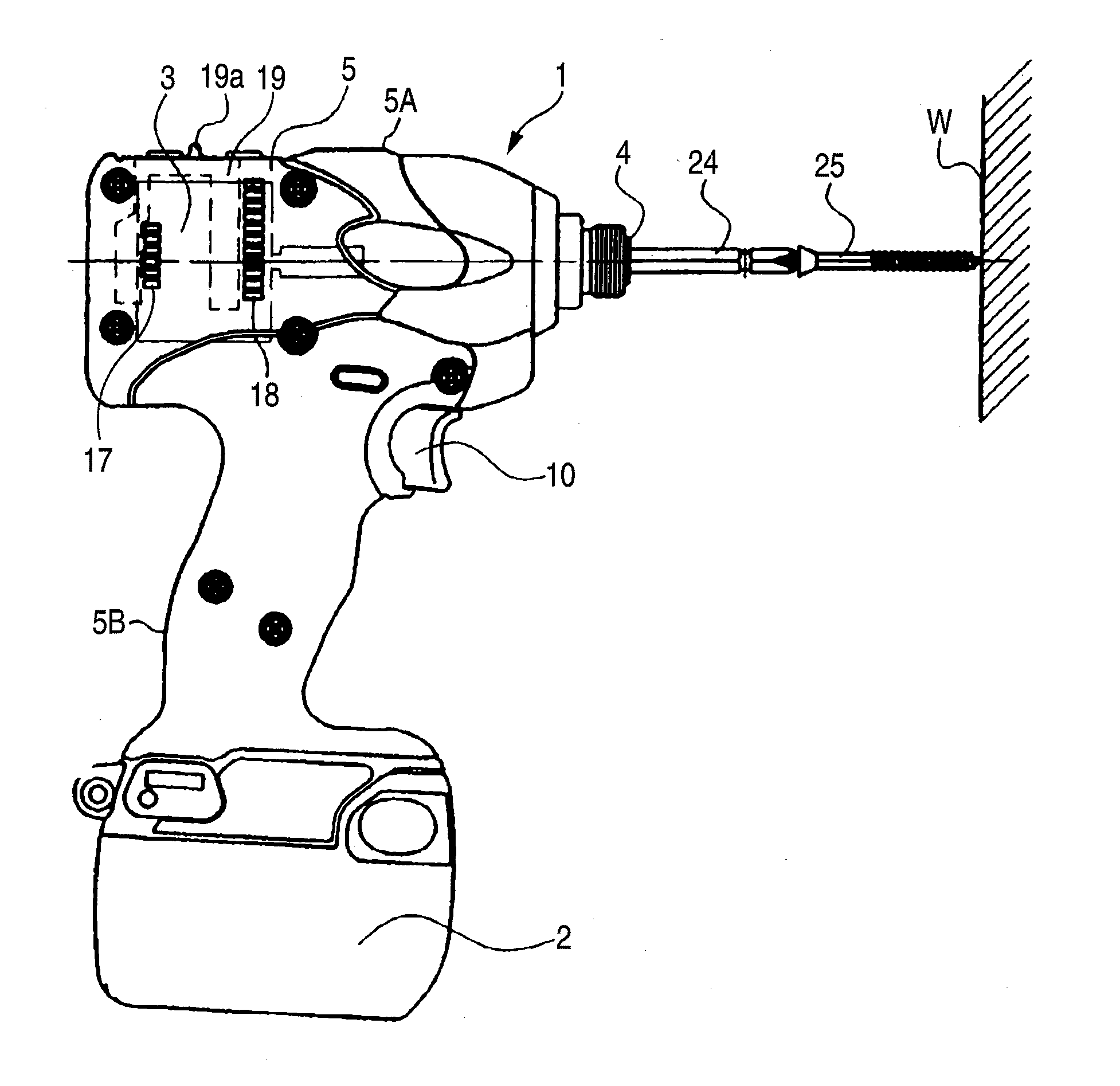

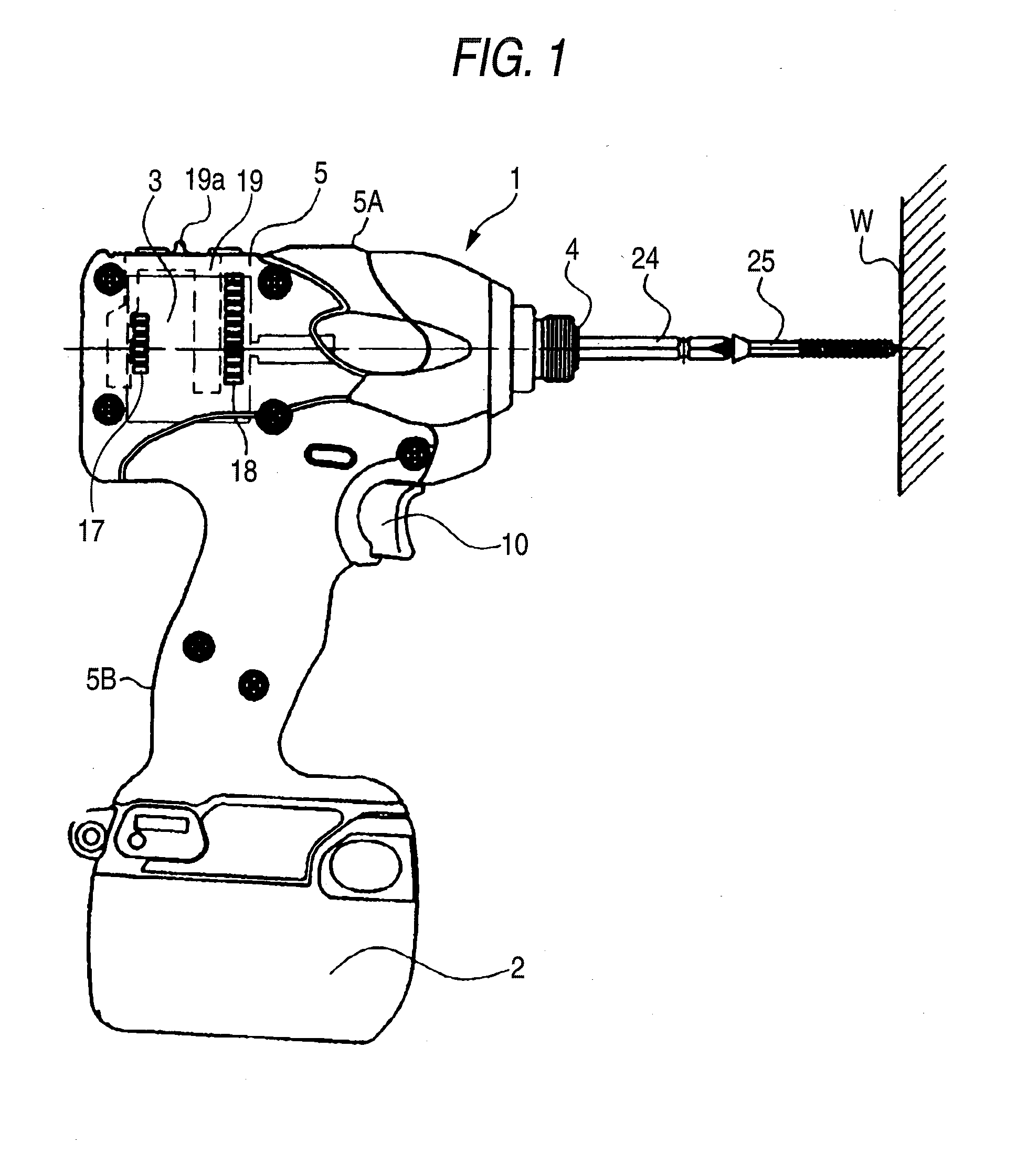

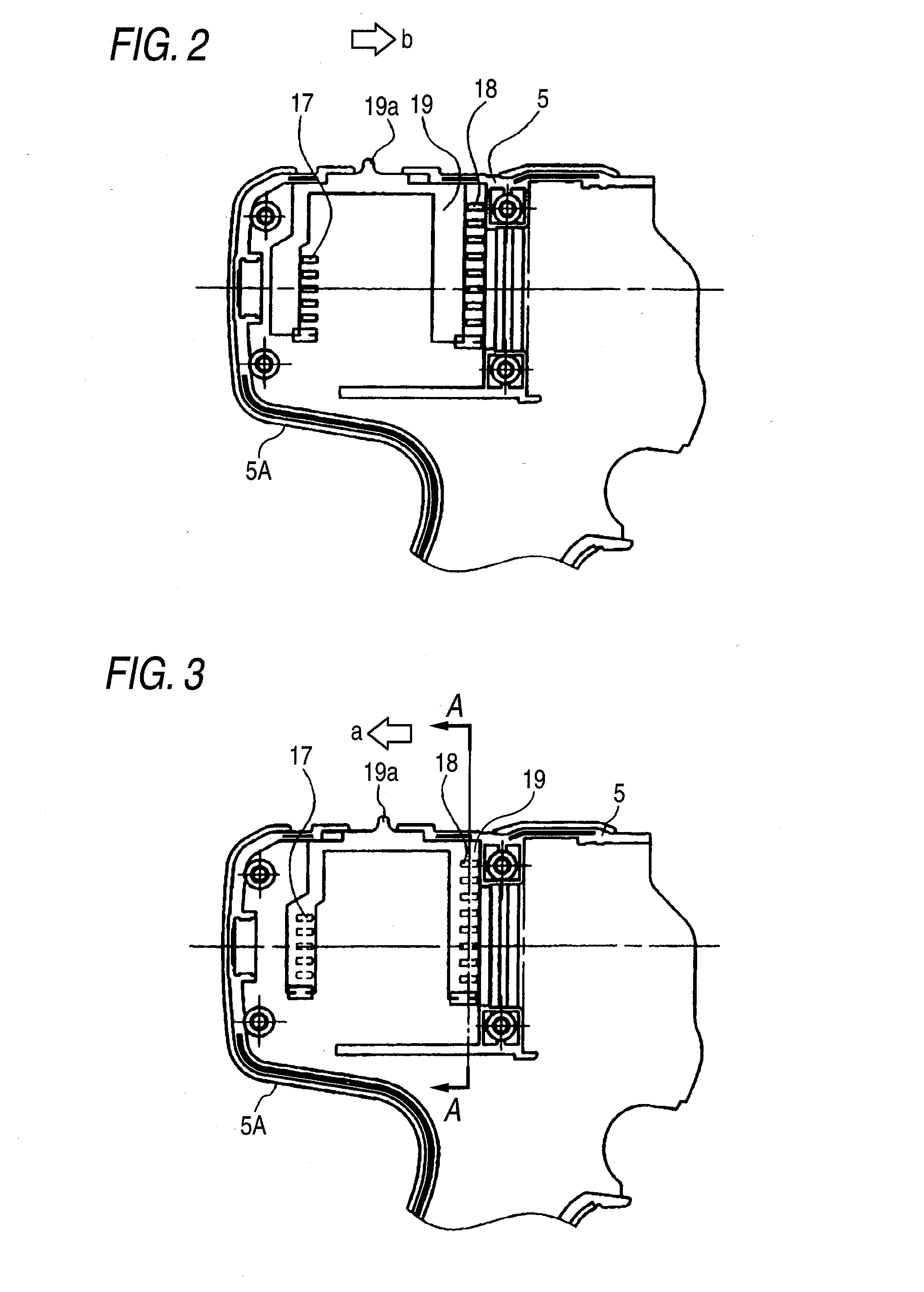

Electric tool

InactiveUS20080302551A1Easily identifiableImprove cooling effectDrilling rodsConstructionsPower toolTipped tool

According to an aspect of the present invention, there is provided an electric tool including: a housing; a motor that is housed in the housing; a tip tool; a rotation transmission mechanism that transmits a rotation of the motor to the tip tool; an air inlet that is disposed on the housing to introduce a cooling air for cooling the motor from an outside of the housing; an air outlet that is disposed to discharge the cooling air; and a cover that is slidable along an inner wall or an outer wall of the housing and that is movable in a first position where the air inlet and the air outlet are opened and a second position where the air inlet and the air outlet are closed.

Owner:HITACHI KOKI CO LTD

Multifunctional three layers combined antifog film of polythene for shed

ActiveCN101003720AInhibition and mitigation of diseaseIncrease light intensityOther chemical processesClimate change adaptationAgricultural engineeringCo extrusion

This invention relates to a three-layer multifunctional anti-fogging film of polyethylene. The film has three layers, with the thickness ratio of 3:4:3. All the three layers are based on polyethylene, and the anti-fogging agent is added in the innermost layer. The film is molded by co-extrusion blowing, has good anti-fogging performance and low cost, and can inhibit crop diseases, increase crop illumination intensity, improve crop quality, and increase crop yield.

Owner:白山市喜丰塑业有限公司

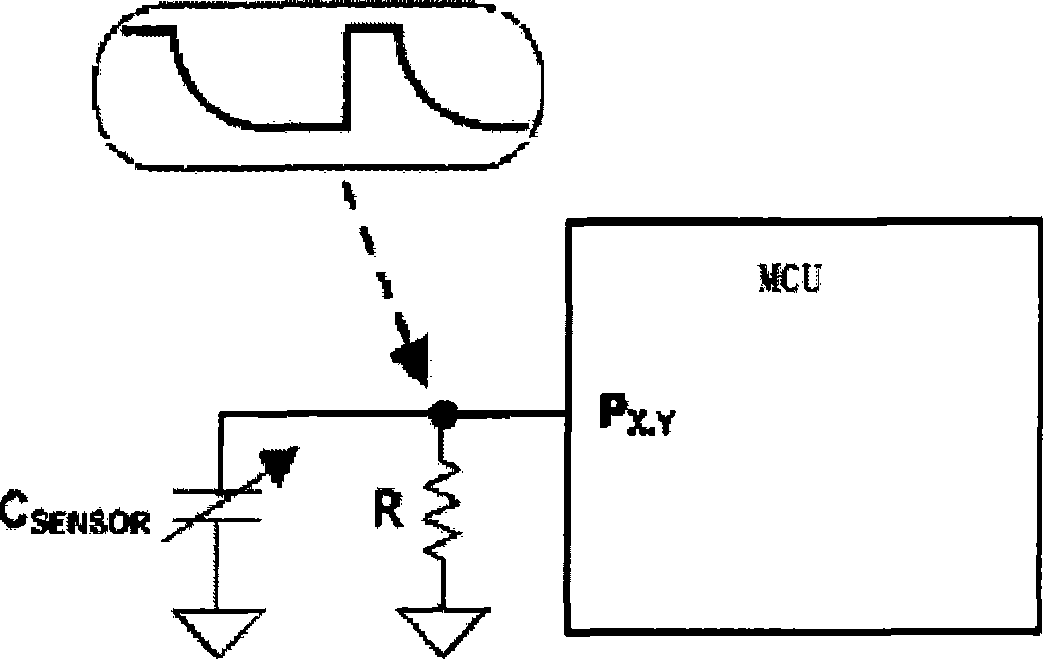

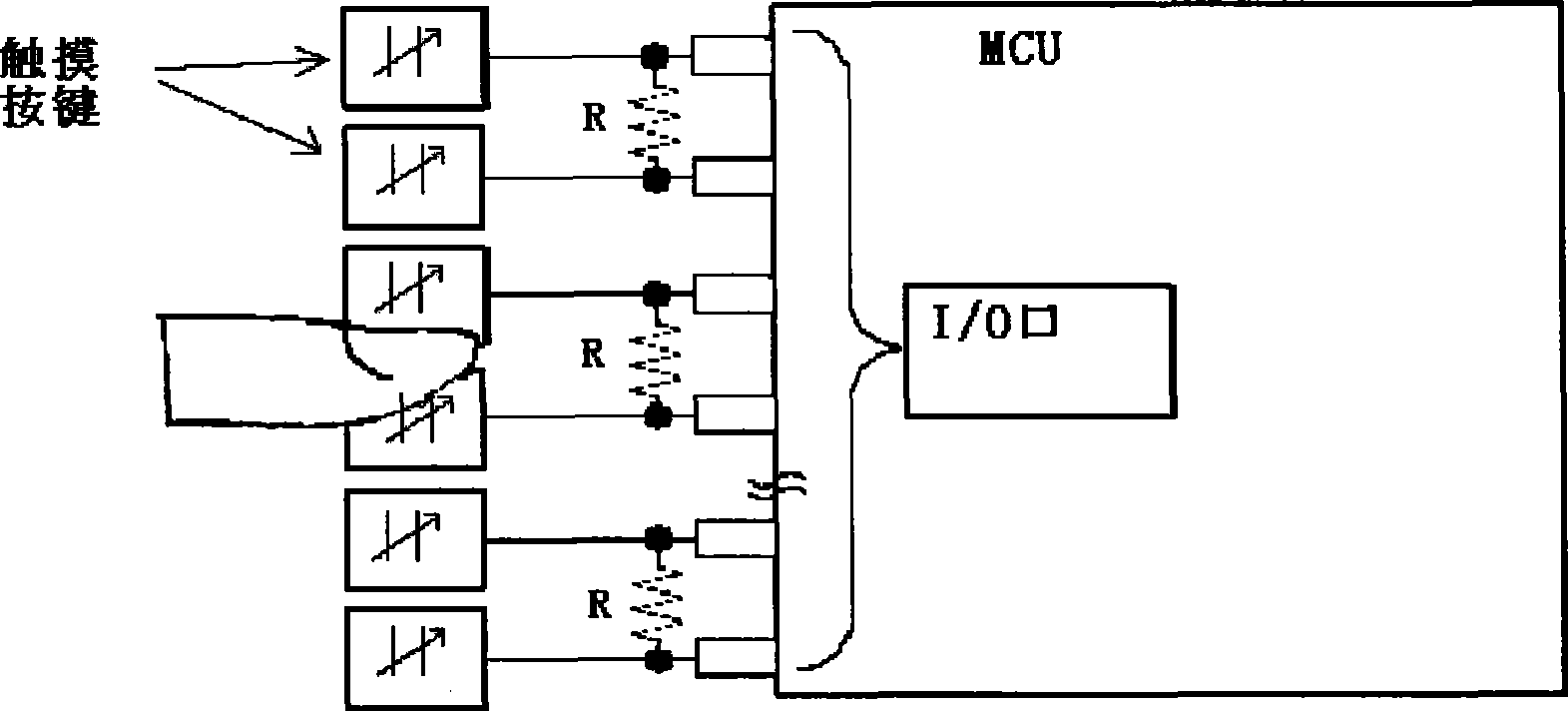

Capacitor induction type touch press-key based on MCU and measuring method for touch press-key capacitance

InactiveCN101499793AImprove dust resistanceLow costResistance/reactance/impedenceElectronic switchingCapacitanceKey pressing

The invention relates to a capacitive sensitive type touch key based on MCU and a measuring method for the capacitance of the touch key. The touch keys are distributed on a PCB printed circuit and are respectively connected with an I / O end of the MCU and one end of a resistor R and the other end of the resistor R is connected with the ground. The invention has the advantages that (1) the capacitance touch sensitive technology is adopted to design the touch keys, the cost is low and the special sensor is not needed; (2) the power consumption is lower; (3) the sensitive type light touch can realize the output of the signals; (4) the realizing mode can be diverse and can realize positioning of precision; (5) the touch key can replace various mechanical keys, switches and proximity detectors; (6) the structure is simple and the wear resistance is good; and (7) as the traditional key is not used, the touch sensitive key can adopt a whole seamless panel, the dust prevention effect is excellent and the reliability of the product is improved.

Owner:LIERDA SCI & TECH GRP

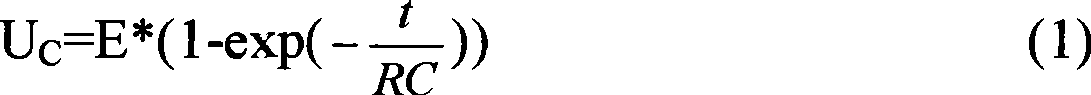

Flame-retardant encapsulating material and preparation method thereof

The invention relates to the field of encapsulation of electronic component, in particular relates to a flame-retardant encapsulating material applicable to electronic and electric product and a preparation method of the flame-retardant encapsulating material, solving the problems of the prior art that the fire-proofing and flame retardant performance is poor, and relatively high flame-retardant rating cannot be obtained. The material comprises a component A and a component B; in percentage by weight, the component A comprises base stock bisphenol-A epoxy resin, fire retardant, diluent diethylene glycol dibenzoate, flexibilizer dioctyl phthalate, pigment, organic silicon defoaming agent and filler silica micropowder; the component B comprises curing agent phthalic anhydride or methyl tetrahydrophthalic anhydride, curing agent eleostearate anhydride, and accelerator 2, 4, 6-tri(dimethylamino methyl) phenol; before the flame-retardant encapsulating material is used, the component A is pre-heated in an oven and then uniformly agitated in an up-to-bottom way; and the component A and the component B are uniformly mixed, so as to obtain flame-retardant encapsulating material; and then the encapsulating can be carried out. The flame-retardant encapsulating material provided by the invention is mainly applicable to insulating packaging of various electronic components such as power engine, rail transit, war industry, spaceflight, car and power.

Owner:大连宝津科技发展有限公司 +1

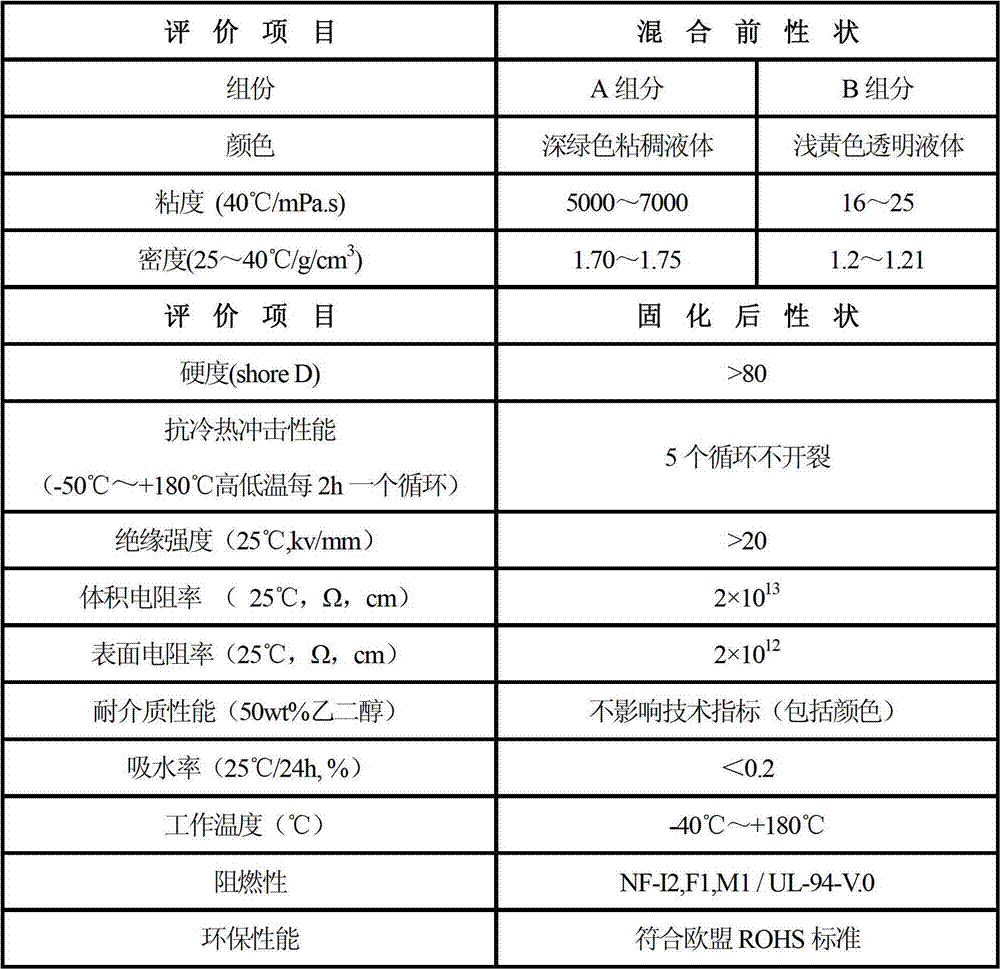

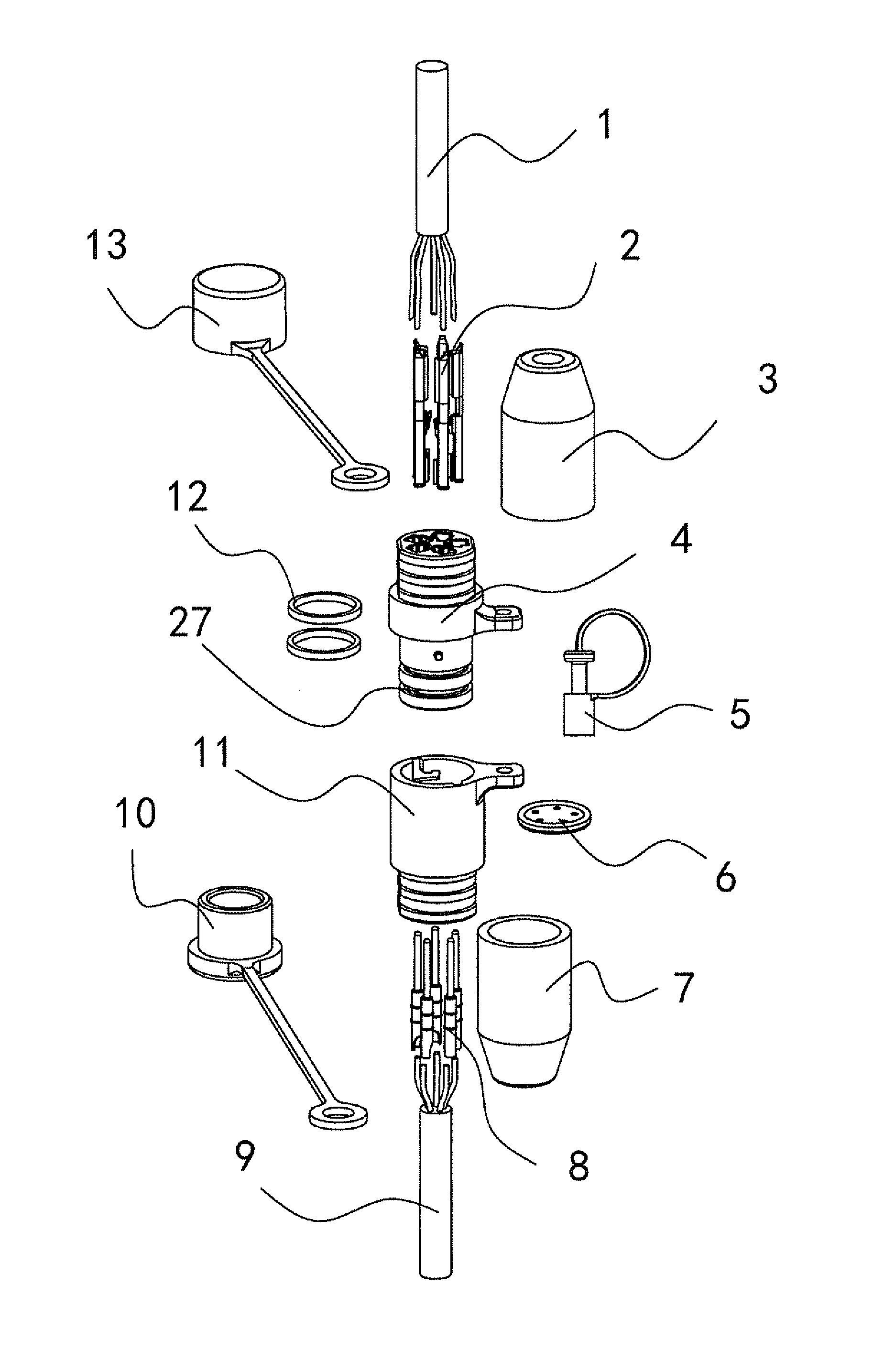

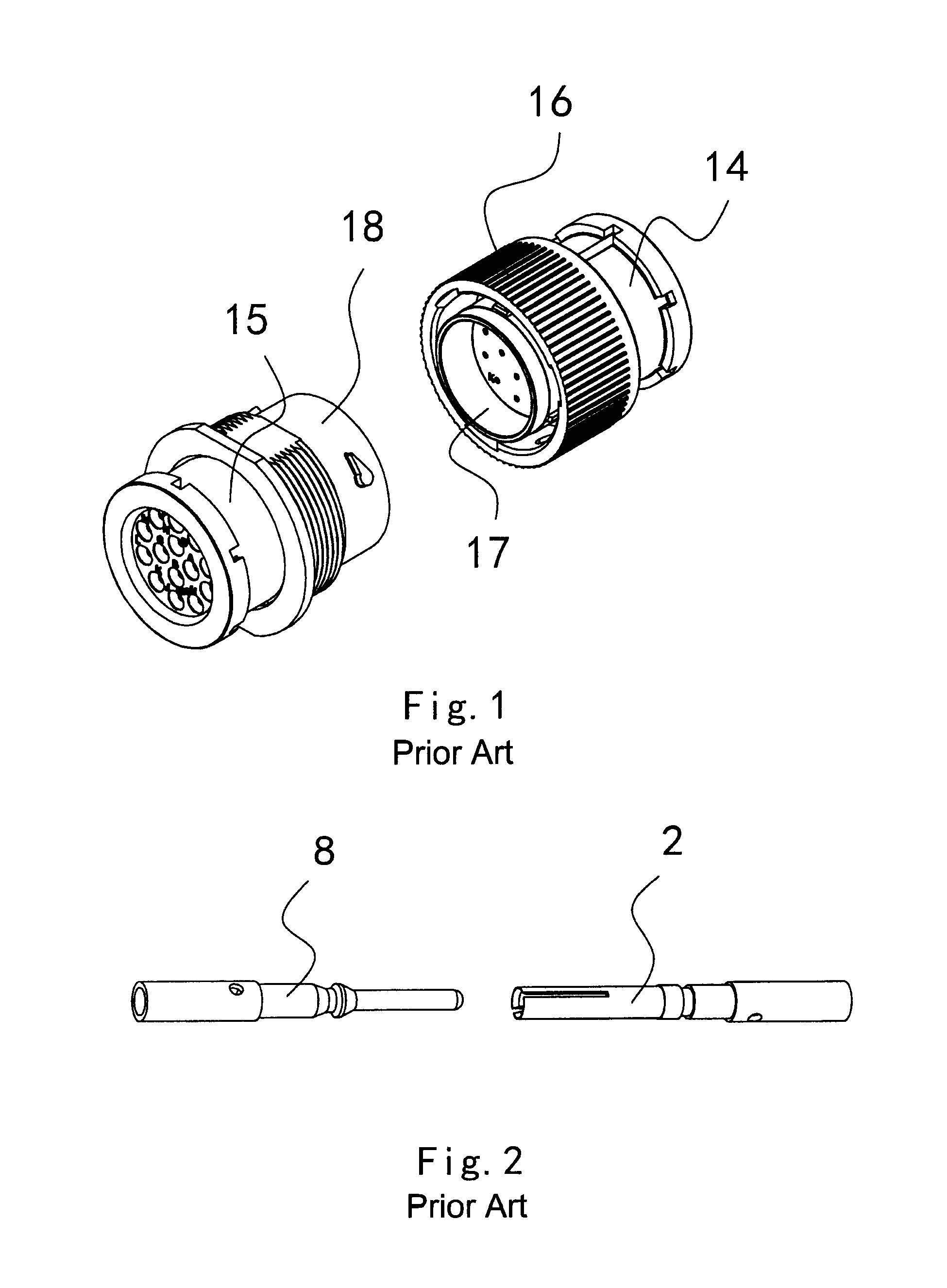

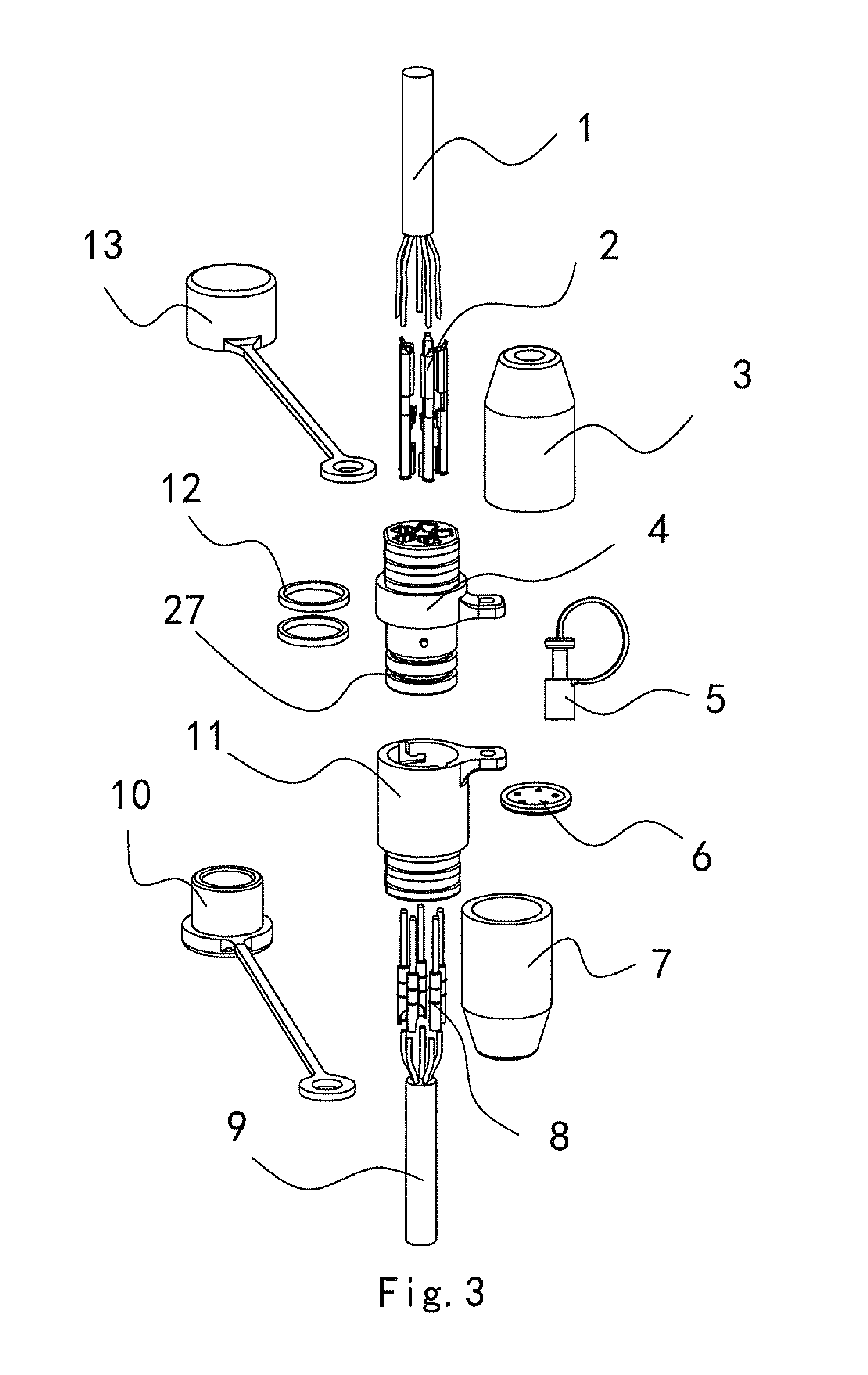

Quick connecting type outdoor waterproof electric coupler

InactiveCN101882719AImprove reliabilityGuaranteed electrical conductivityCoupling contact membersCouplings bases/casesButt jointEngineering

Owner:LEOCO SUZHOU PRECISE IND

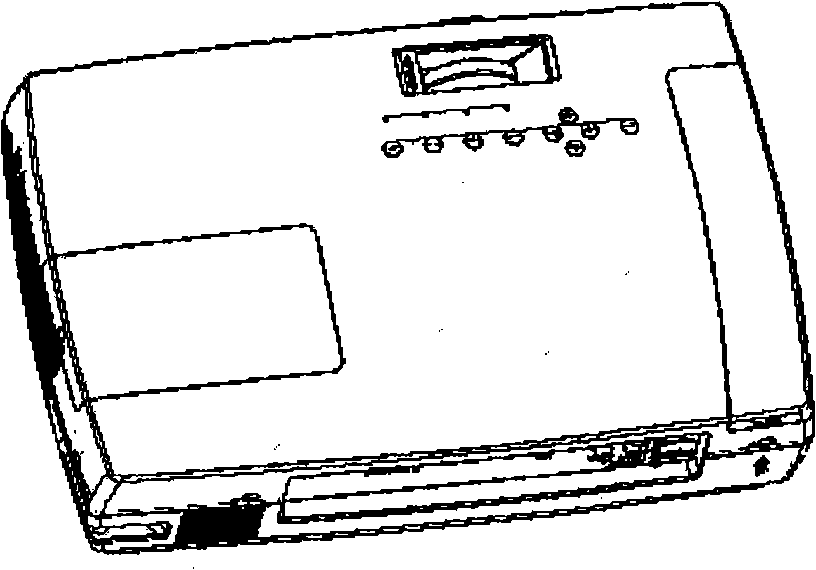

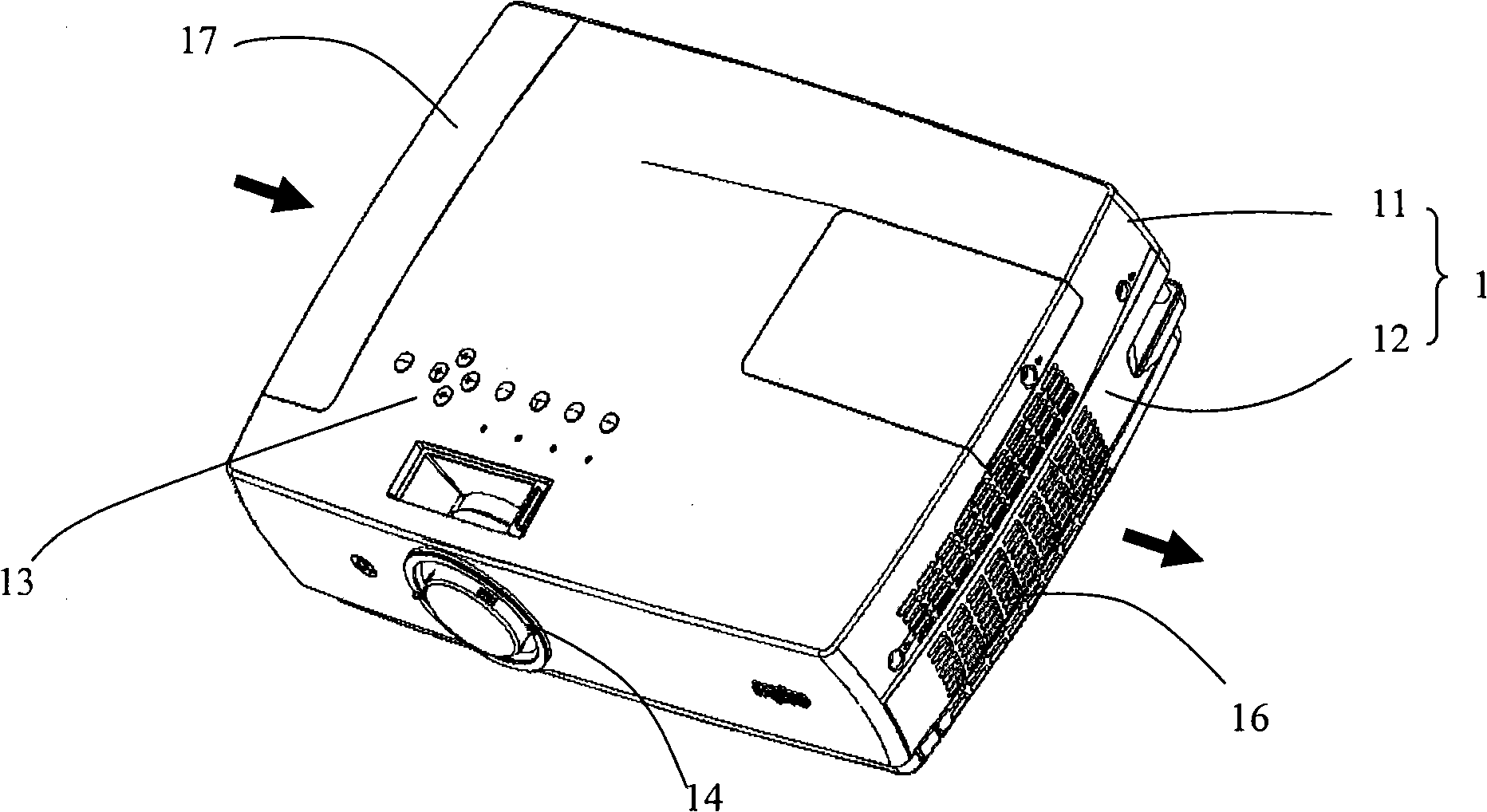

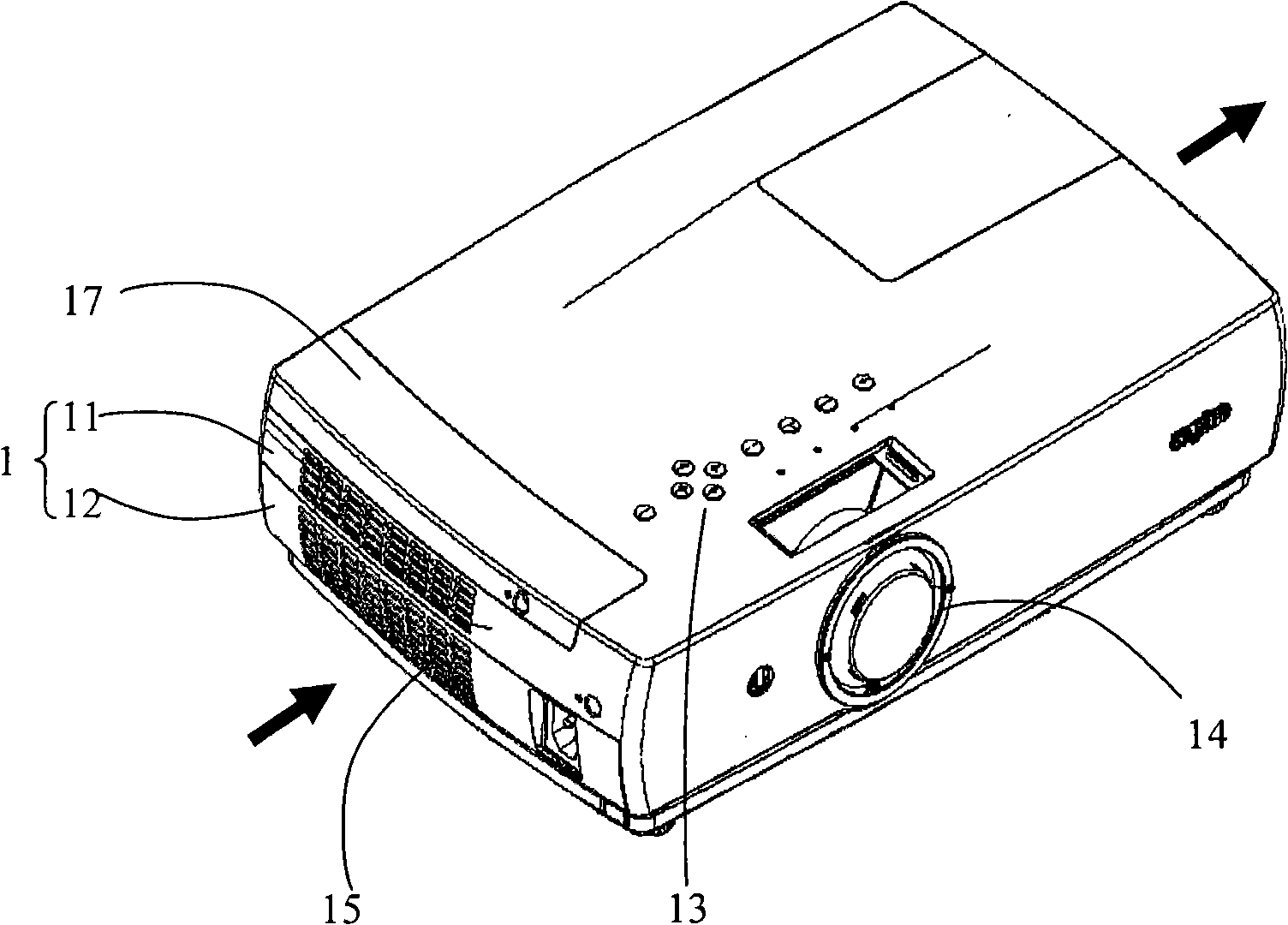

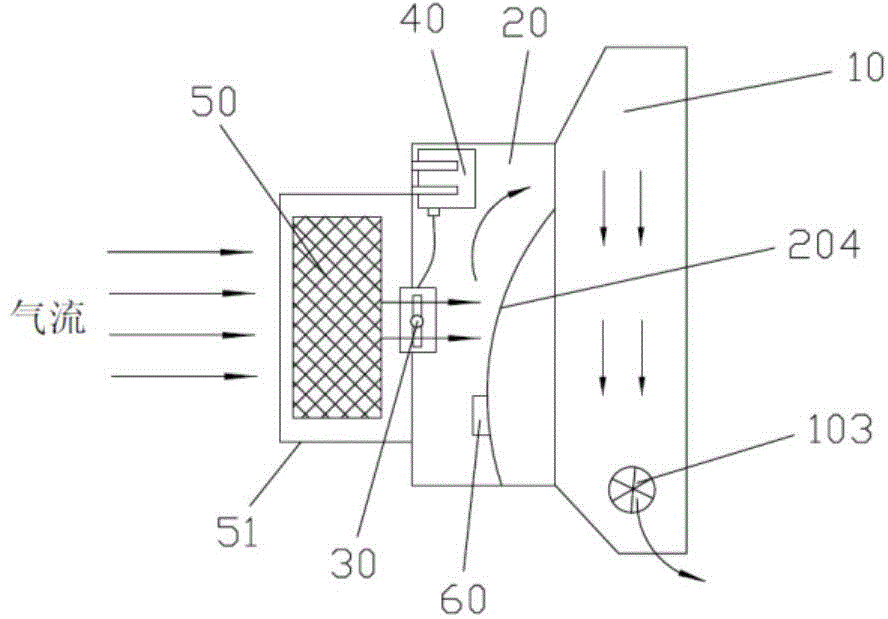

Cooling system and projecting apparatus adopting same

ActiveCN101576706AAvoid enteringImprove dust resistanceProjectorsCooling/ventilation/heating modificationsWaste managementAir channel

The invention provides a cooling system and a projecting apparatus adopting the same. The projecting apparatus comprises a shell and also comprises optical components, a lamp bulb assembly and a power supply component which are arranged in the shell. The cooling system comprises an air inlet, an air outlet, a dust preventing component, a cooling air channel, a lamp bulb component air-cooling unit, a power supply air-cooling unit and an exhauster; the air inlet and the air outlet are respectively arranged at two opposite narrower sides of the shell; the dust preventing component is arranged in the shell and clings to the air inlet; the cooling air channel clings to the dust preventing component and is internally provided with a plurality of fans and air guiding pipes which correspond to the fans, wherein the air guiding pipes lead to all the optical components; the lamp bulb component air-cooling unit and the power supply air-cooling unit collect the air-cooled exhausted air at the air outlet; and the exhauster is arranged in the shell and near to the air outlet and discharges the collected exhausted air out of the shell. When the dust is prevented, heating components in the projecting device are fully cooled, and local hot air accumulation is avoided.

Owner:SANYO TECH CENT SHENZHEN +1

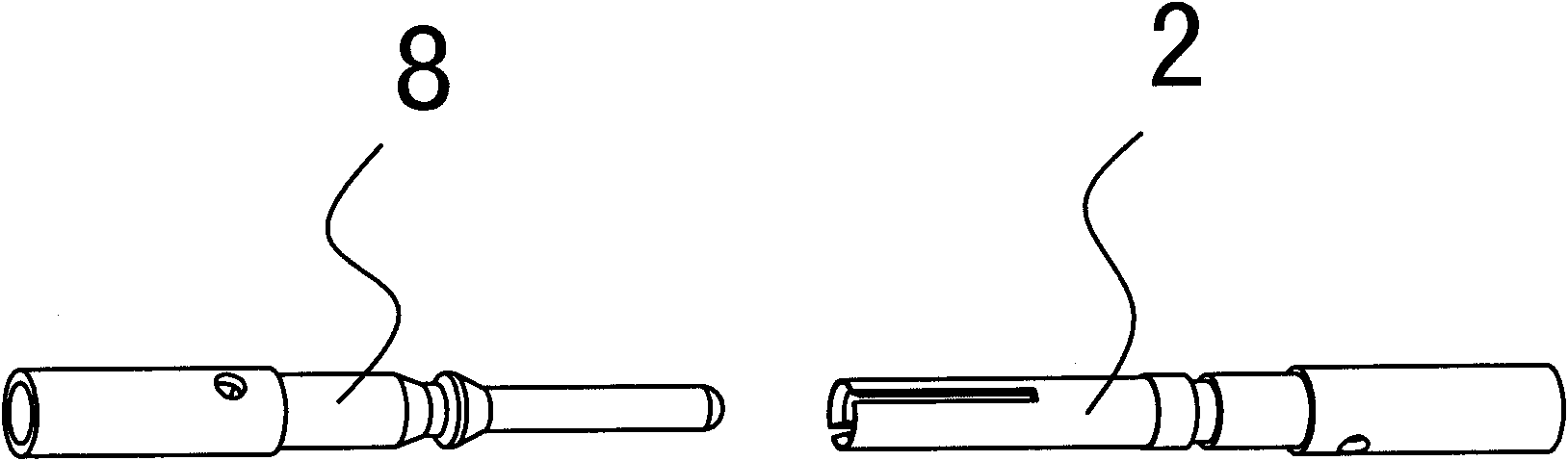

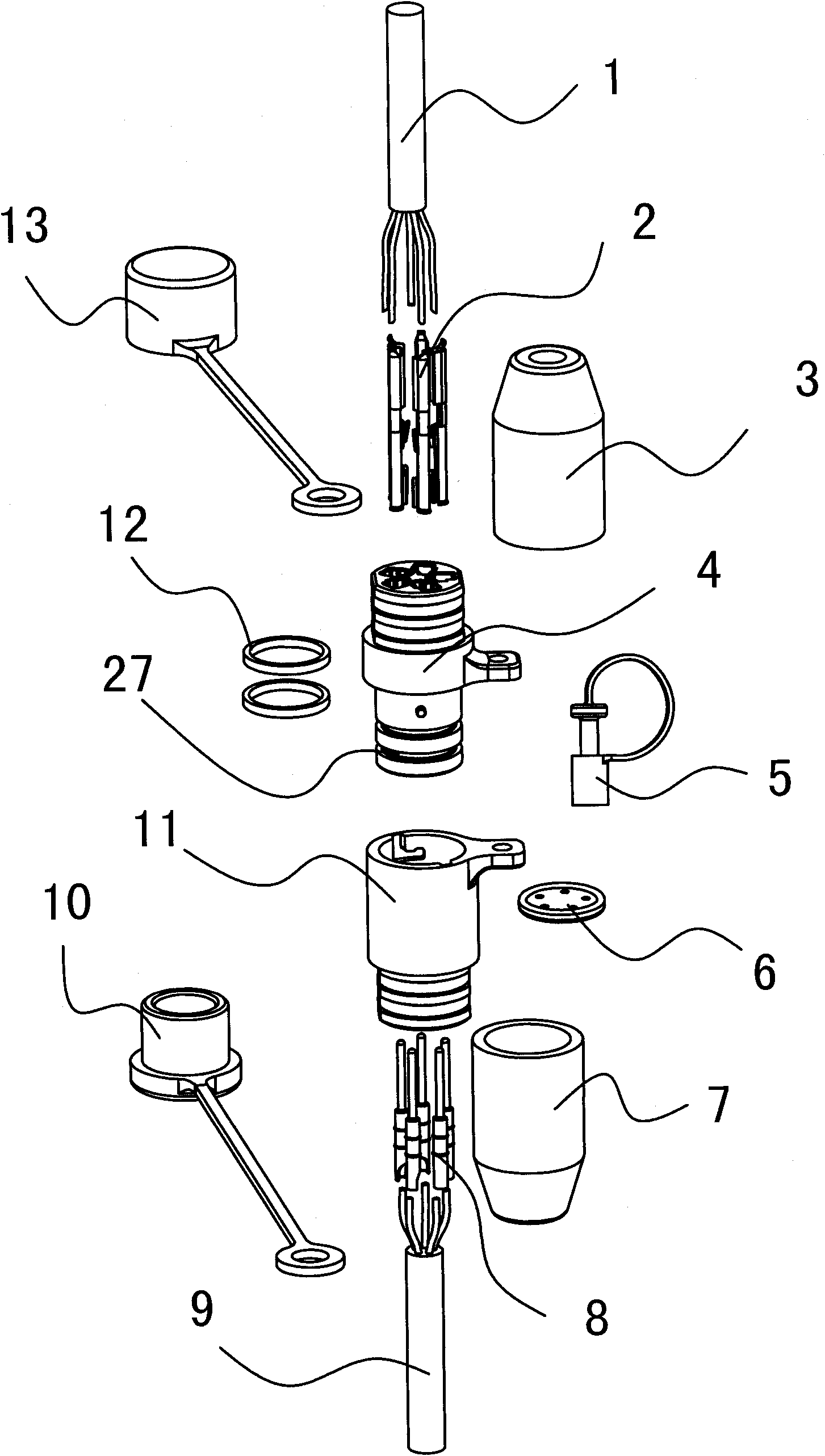

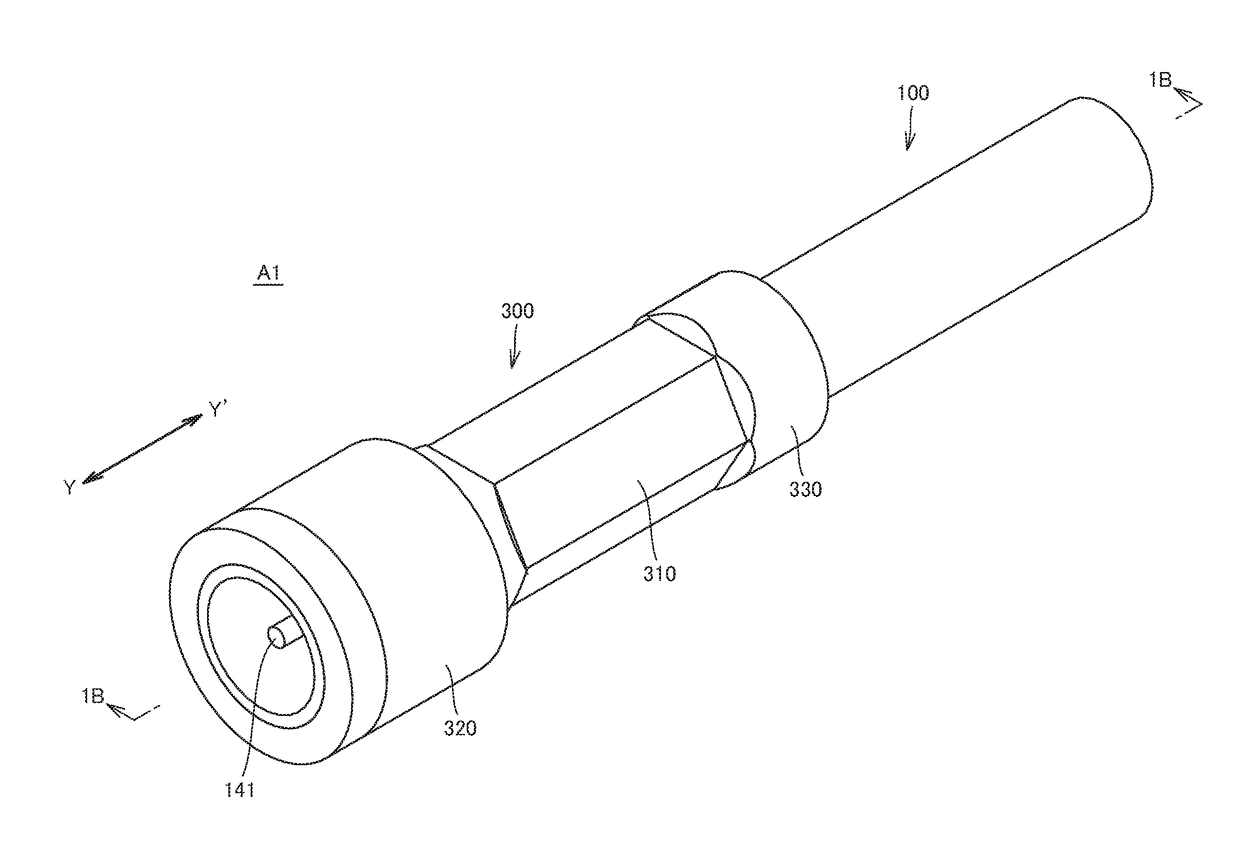

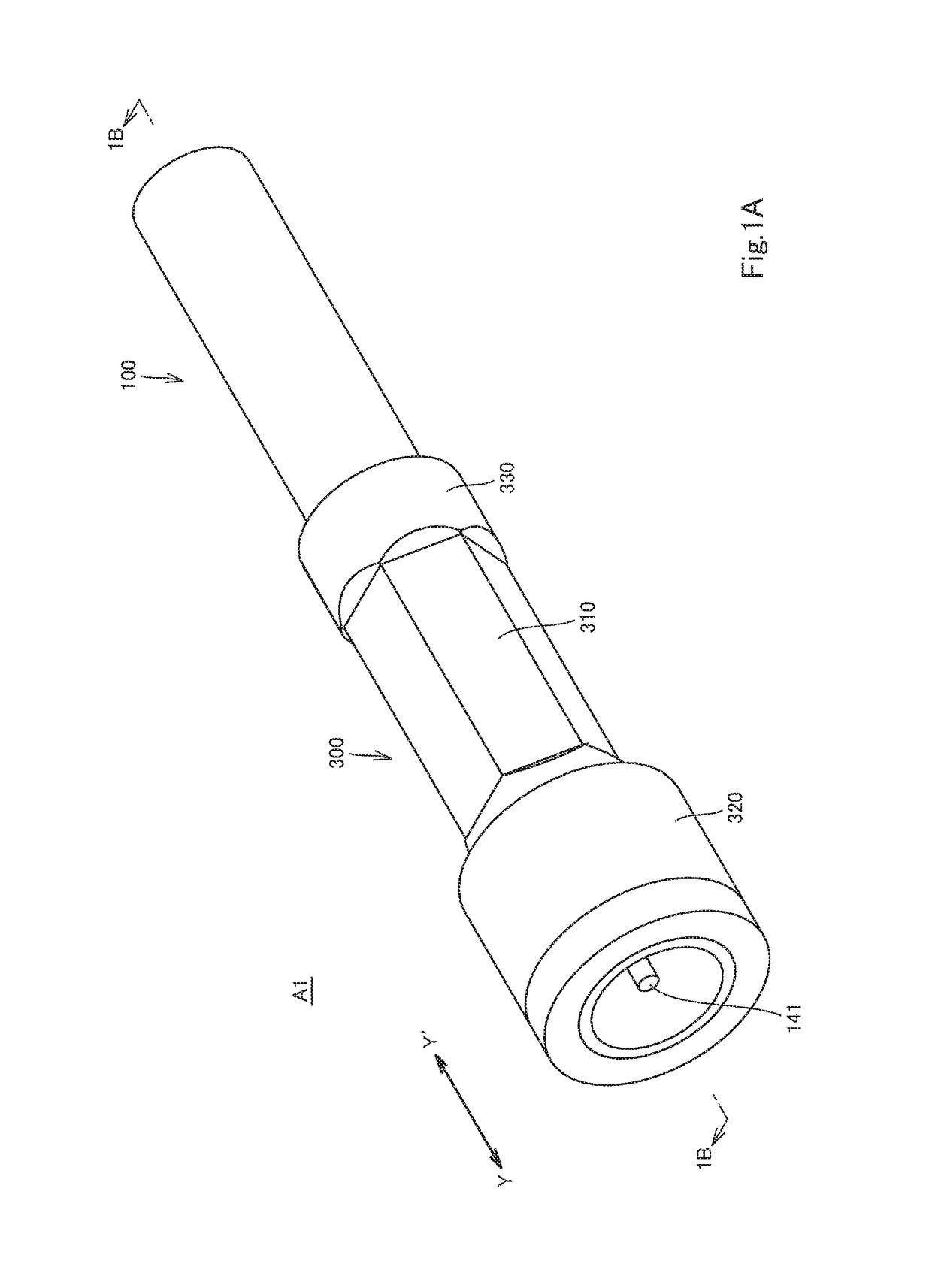

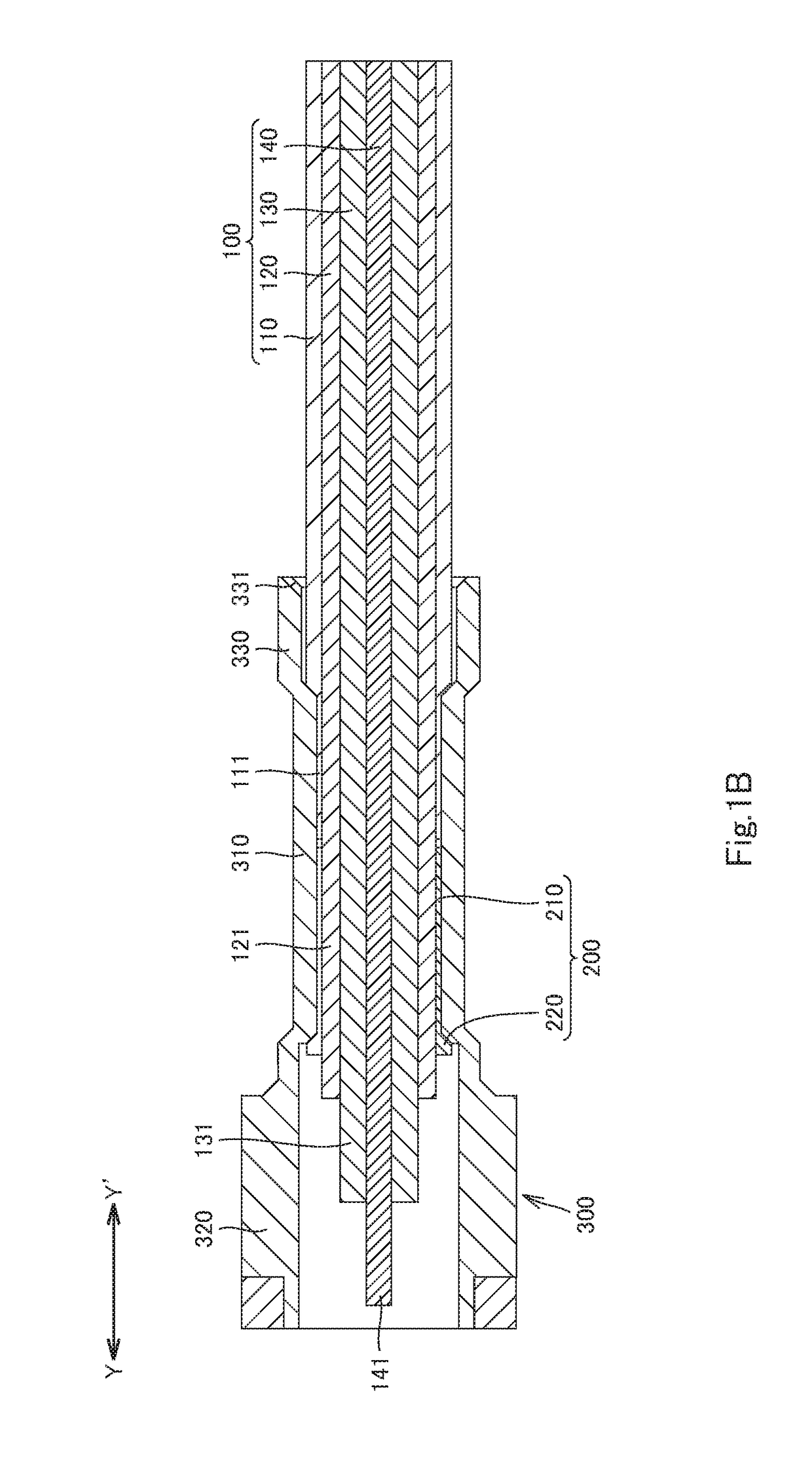

Cable assembly, connector, and method for manufacturing cable assembly

ActiveUS20170110838A1Reduce loadImprove dust resistanceCoaxial cables/analogue cablesContact member manufacturingElectrical conductorEngineering

A cable assembly including a cable, a metal clamp, and a tuboid metal case. The cable includes a outer insulator and a outer conductor thereinside. The outer conductor includes a protruding portion protruding to one side in the first direction from an end portion of the outer insulator on the one side in the first direction. The clamp holds the protruding portion and includes an end portion on the other side in the first direction. The metal case includes a swaged portion, which houses at least the end portion of the outer insulator and the end portion of the clamp. Swaged from outside, the swaged portion is in pressure contact with and fixed to at least the end portion of the outer insulator and the end portion of the clamp so that the end portion of the outer insulator is elastically deformed and the end portion of the clamp is plastically deformed.

Owner:HOSIDEN CORP

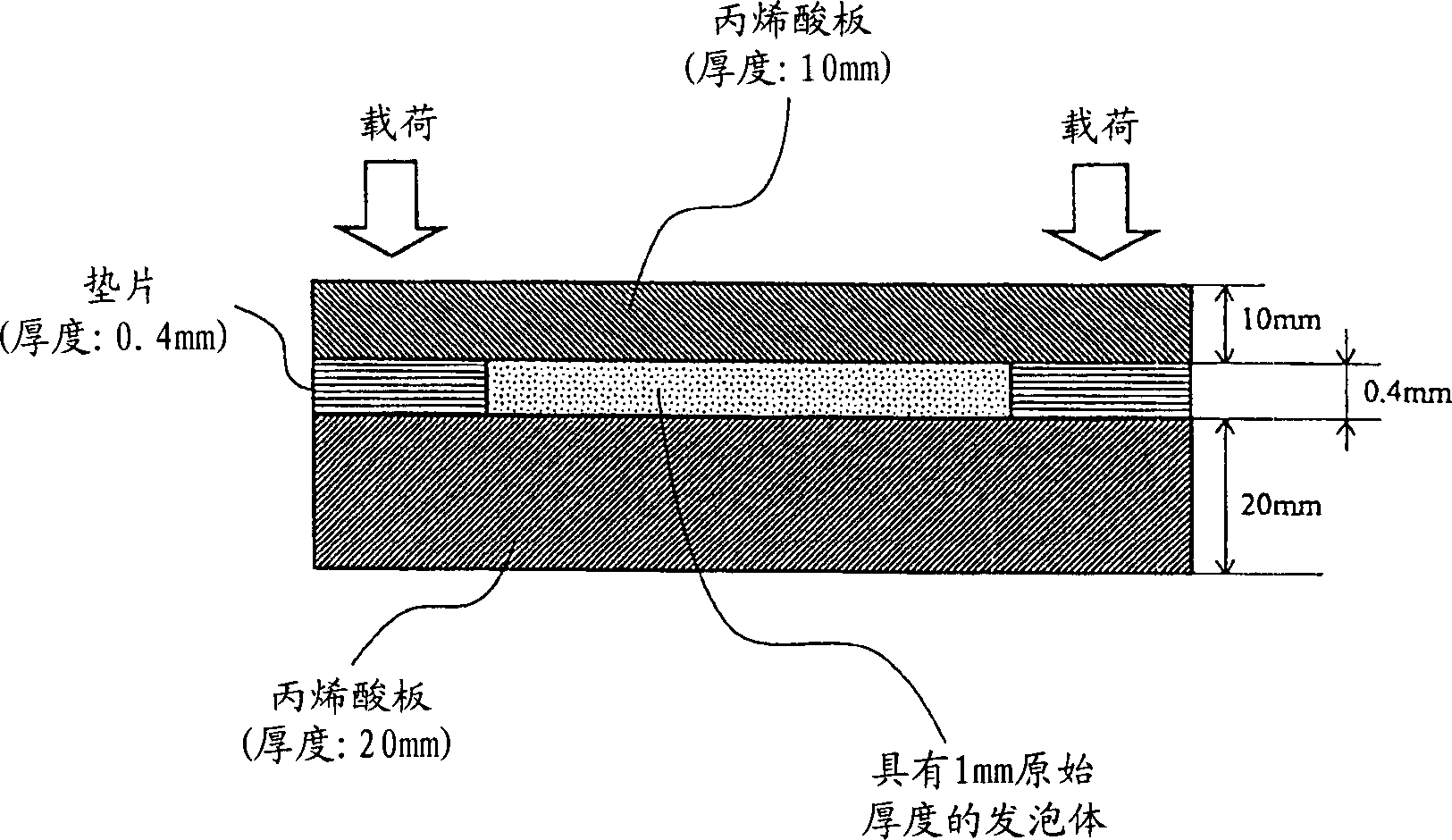

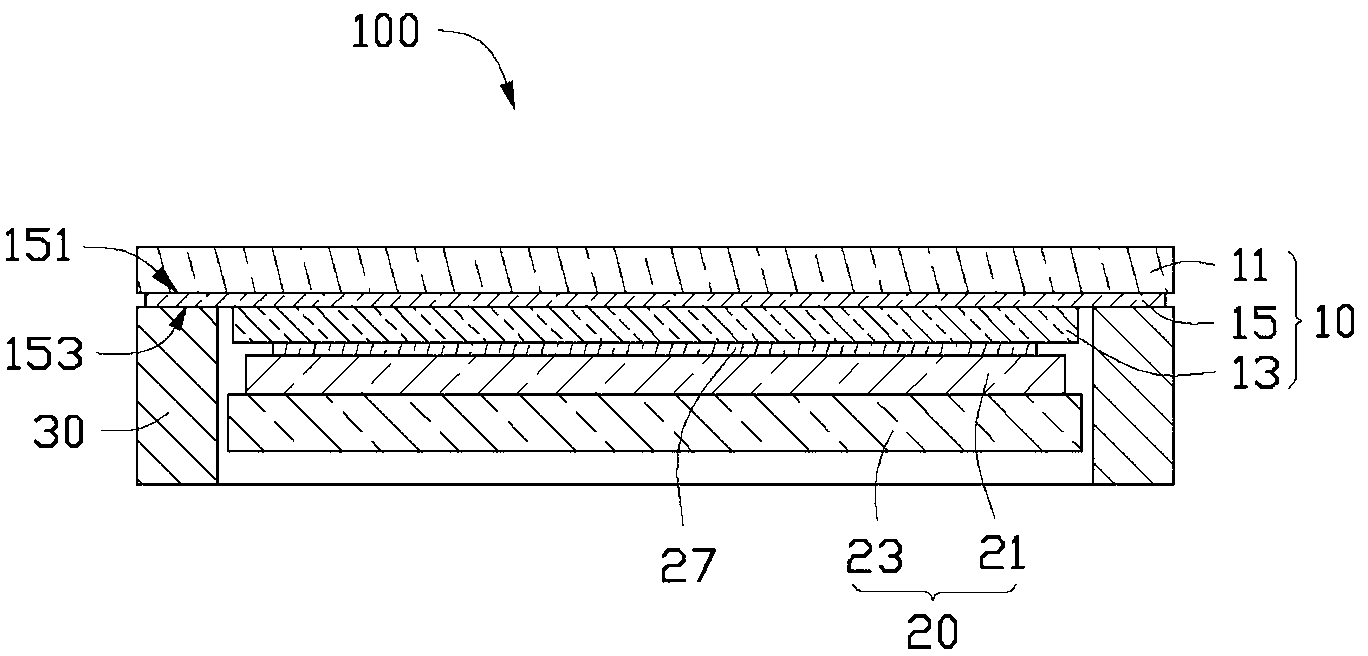

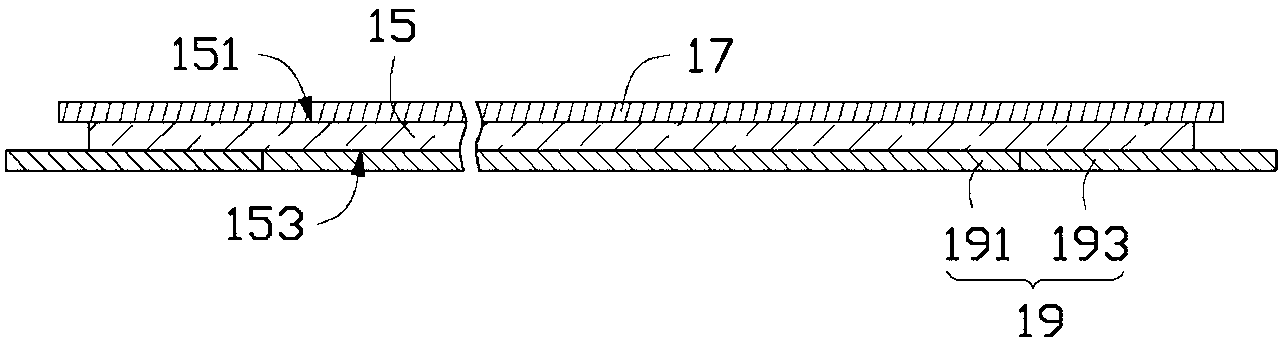

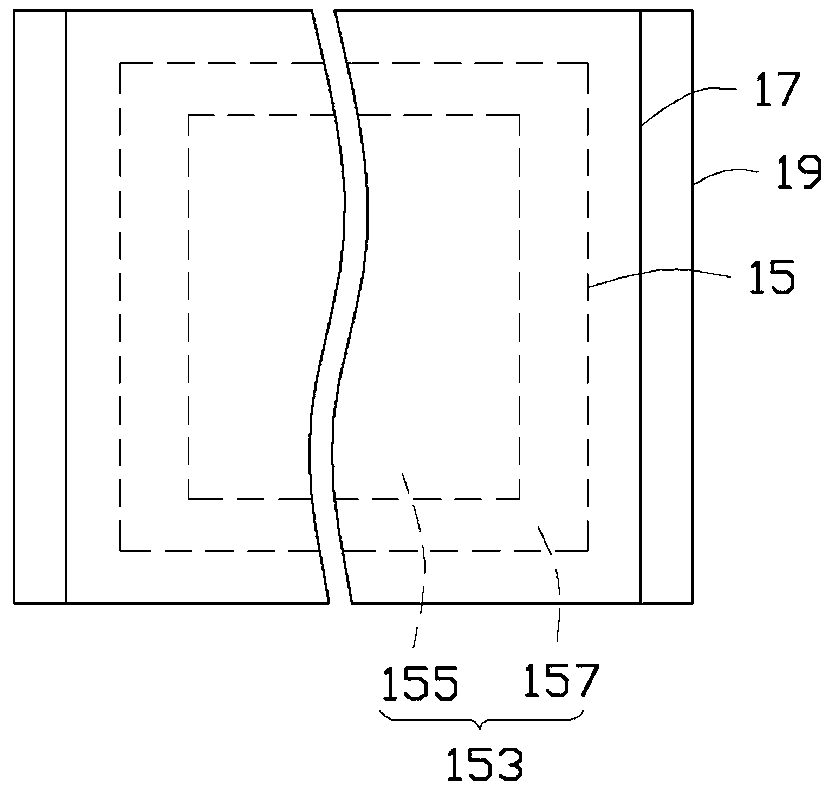

Foamed dustproof material and dustproof structure using foamed dustproof material

ActiveCN1618918AImprove dust resistanceGood flexibilityContact surface shape/structureOther chemical processesPolymer sciencePolymer chemistry

A foamed dustproof material which comprises a foamed body, wherein the foamed body has an average cell diameter of from 10 to 90 mu m, a load against repulsion upon compressing to 50% of from 0.1 to 3.0 N / cm<2>, and an apparent density of from 0.01 to 0.10 g / cm<3>. <IMAGE>

Owner:NITTO DENKO CORP

Inorganic-organic hybrid super-hydrophilic self-cleaning coating and production method thereof

ActiveCN104629617AImprove self-cleaning functionImprove adhesionCoatingsWeather resistanceDisplay device

The invention discloses an inorganic-organic hybrid super-hydrophilic self-cleaning coating and a production method thereof. The inorganic-organic hybrid super-hydrophilic self-cleaning coating is prepared from the following raw materials in percentage by weight: 60-90% of a solvent, 5-20% of a compound binder, 3-10% of a curing agent and 1-10% of a functional material. By adopting an inorganic-organic hybrid process, the inorganic-organic hybrid super-hydrophilic self-cleaning coating which is excellent in various performances such as hydrophilicity, dust resistance, pollution prevention, mildew resistance, weather resistance and durability is prepared. The coating is coated on the surface of a base material to form a concave-convex film of a micro-nano structure, so that the surface of the base material obtains the functions of hydrophilicity, dust resistance, pollution prevention, self-cleaning property and the like. The coating disclosed by the invention is suitable for large-area construction, has the advantages of high film forming hardness, high self-cleaning property, good wear resistance and good durability, and can be applied to surfaces of building external walls, glass, tiles, marbles, artificial stones, plastic, aluminum sheets, displays, walls and the like.

Owner:NANJING MISURFACE NEW MATERIAL TECH

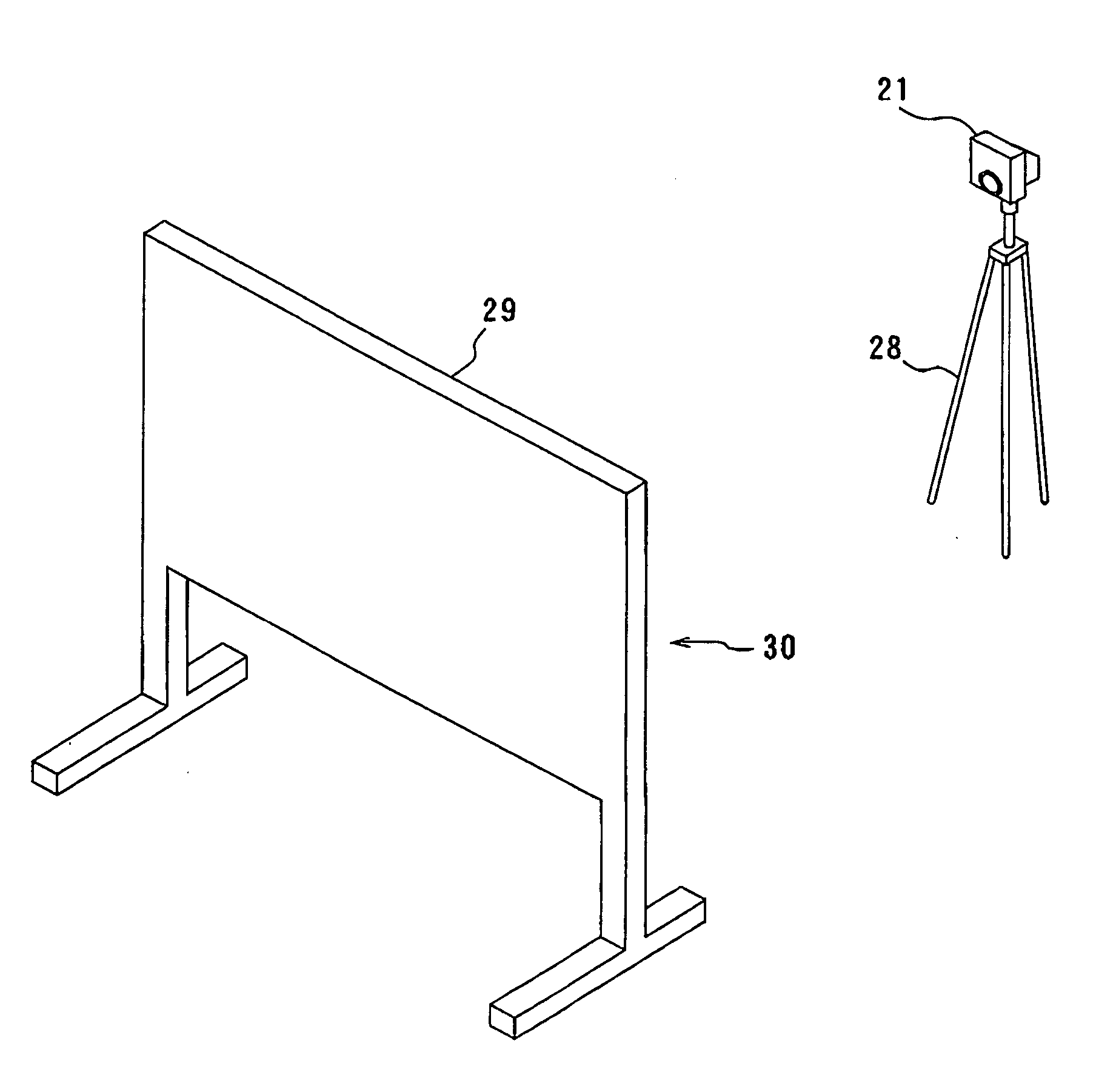

Calibration camera device and calibration system

InactiveUS20050225640A1Improve dust resistanceEasy to optimizeTelevision system detailsColor television detailsColor correctionLight filter

A calibration camera device for geometrical correction or color correction, including a camera mechanism containing a lens, a near-infrared light cutting filter and an imaging element, an optical filter mechanism with three through eight optical filters which is provided in front of the lens, a filter switching mechanism to select any one from among the optical filters and dispose the selected one optical filter at a photometric point, an external cover having an opening formed in front of the lens and covering the optical filter mechanism, the filter switching mechanism and the camera mechanism, an dustproof transparent member to be attached to the opening of said external cover, and a controller which includes an image storing part to store an image captured by the imaging element and a correction information generating part to generate correction data on the image.

Owner:OLYMPUS CORP

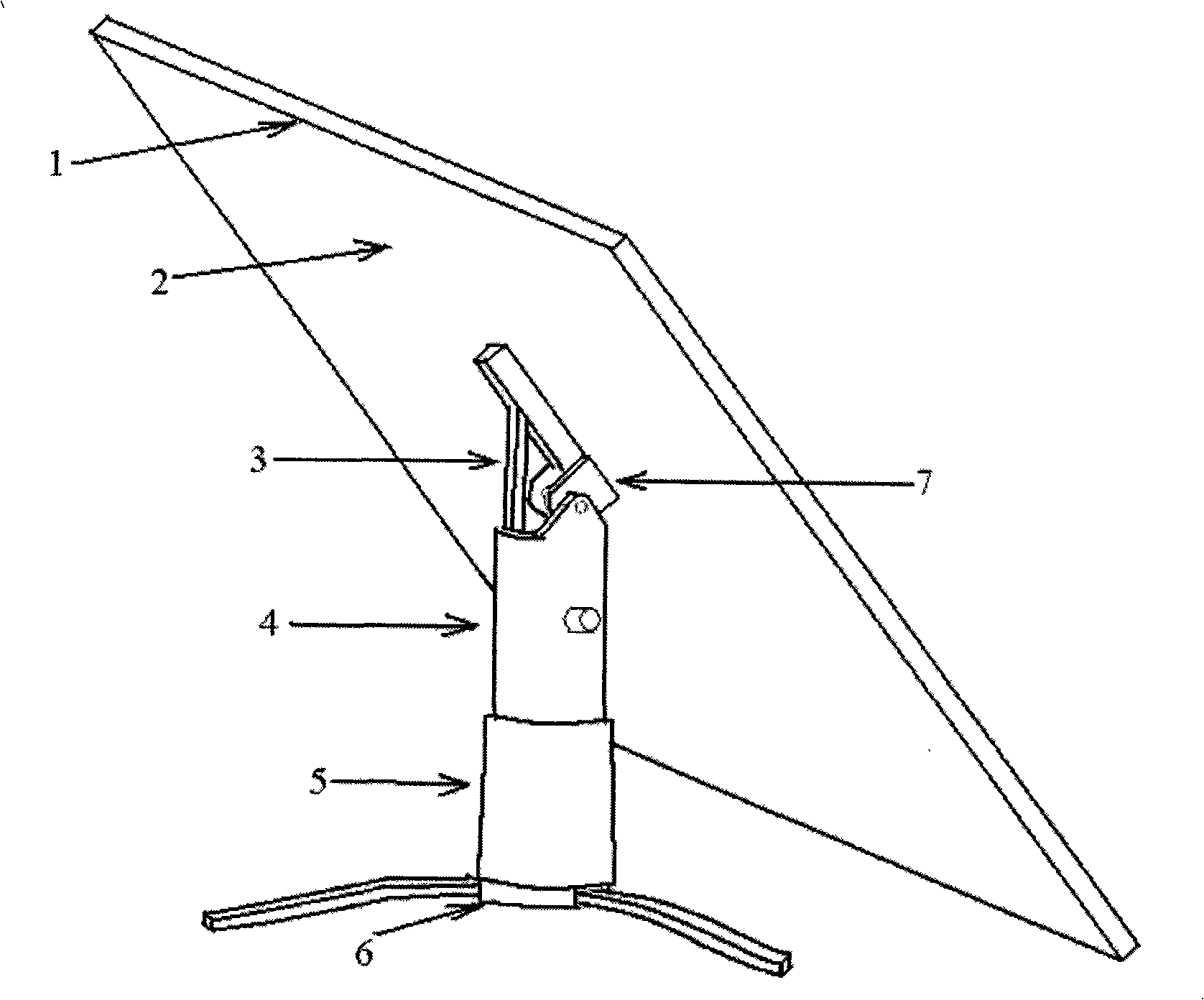

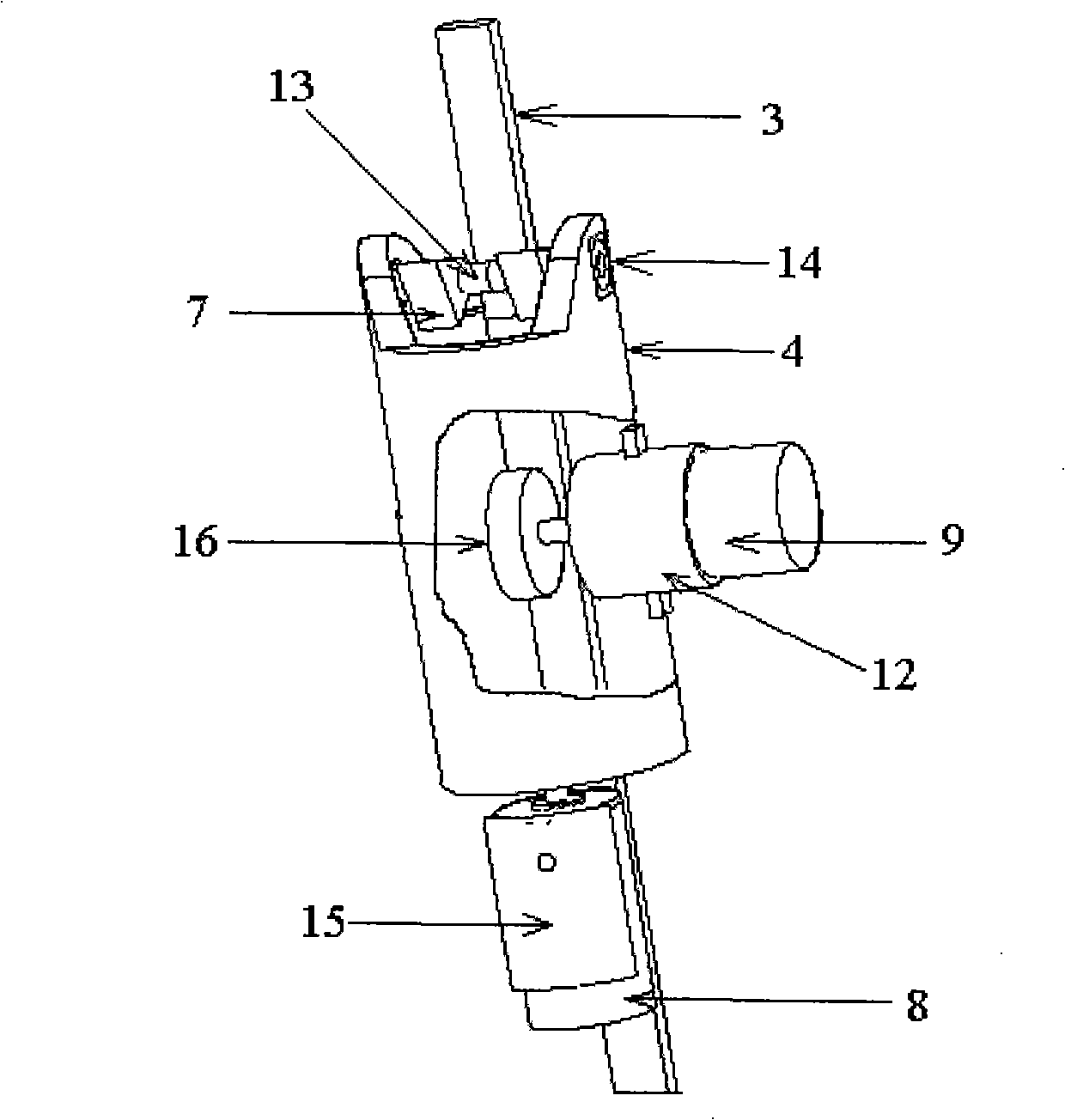

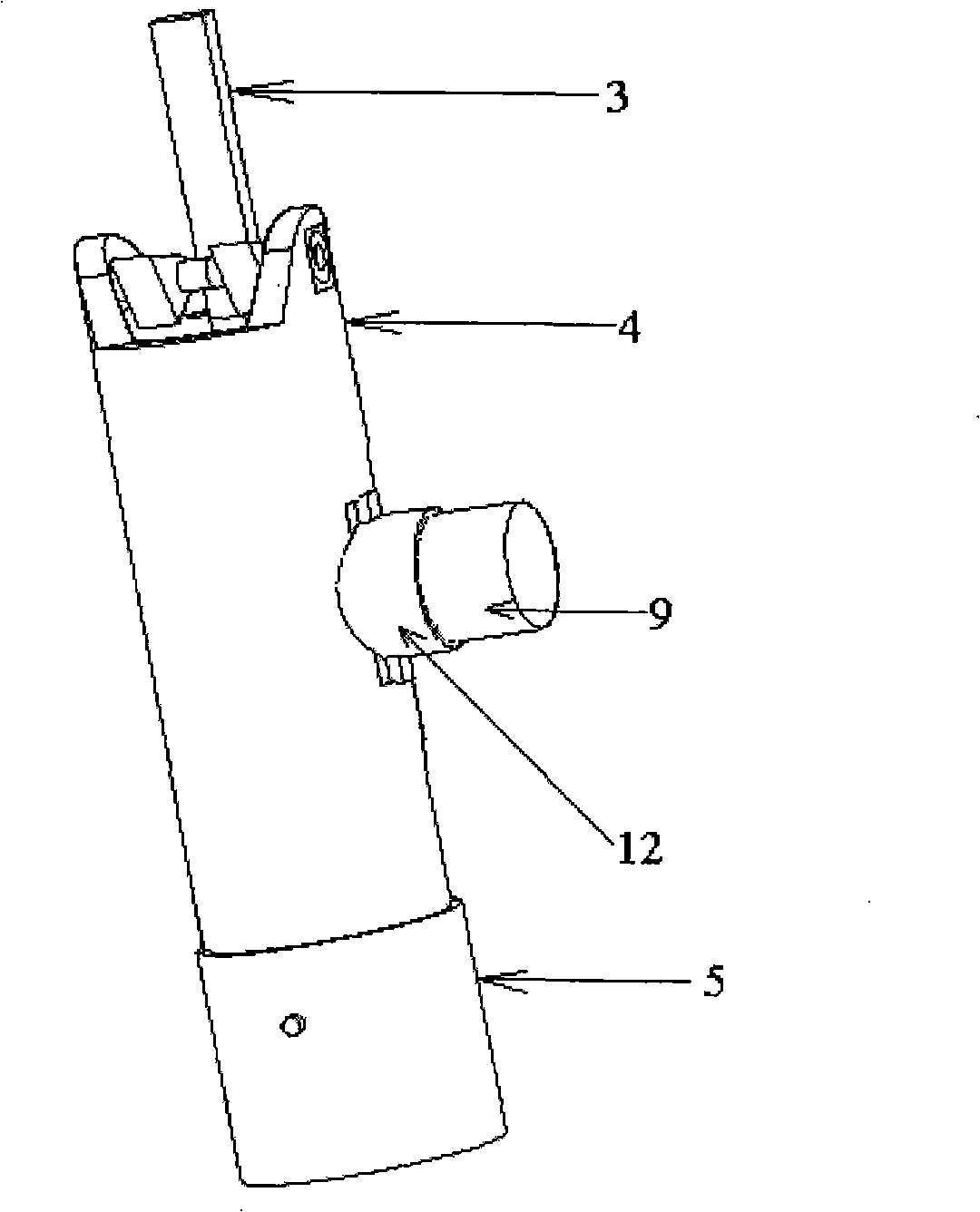

Sunflower type sun tracking device

InactiveCN101403927ARealize all-round trackingValid acceptanceControl using feedbackGear driveEngineering

The invention belongs to the field of solar equipment, in particular relates to a solar tracking unit for a solar panel. A running track of an idler wheel or a sliding block is arranged at the back of the solar panel; a supporting frame of the solar panel is arranged in the center of the back of the solar panel and connected with an upper vertical rotating shaft; a supporting bar that can move vertically is arranged in the upper vertical rotating shaft, and one end of the upper vertical rotating shaft is inserted in the running track of the idler wheel or the sliding block by the idler wheel or the sliding block; an electric motor is respectively arranged in the upper vertical rotating shaft and a lower vertical rotating shaft and respectively drives the supporting bar that can move vertically to move up and down and drives the up vertical rotating shaft to rotate by the transmission of gears, so as to realize the luffing movement and horizontal revolution movement of the unit; a photosensor element is arranged on the solar panel and can control the operation of the electric motor by a control circuit, so as to track the sun. Therefore, the unit of the invention can track the sun in all dimensions and receive the sunlight more effectively; and the unit has the advantages of compact mechanical structure, flexible rotation, good dustproof property, etc.

Owner:CECEP SOLAR ENERGY TECH

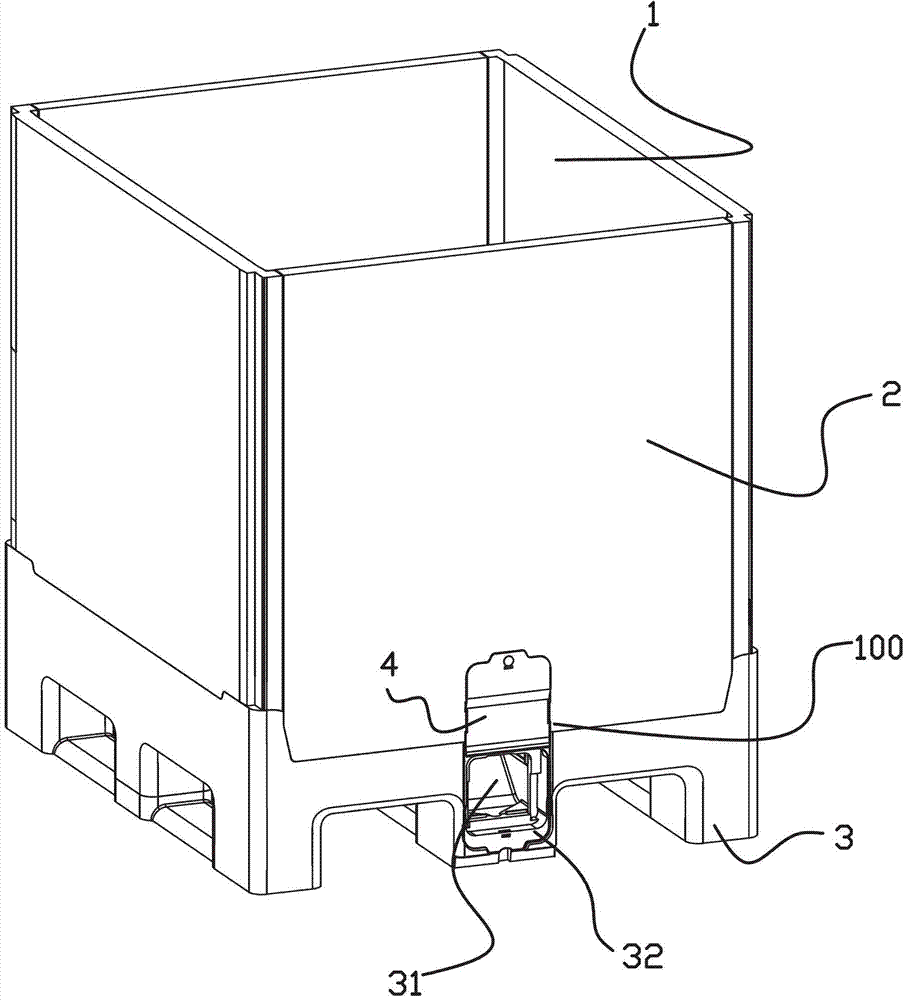

Cover device and container for covering built-in valve mounting passage opening in composite type midsize bulk container

ActiveCN102785829ASimple structureEasy to operateLarge containersNon-removalbe lids/coversIntermediate bulk containerEngineering

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

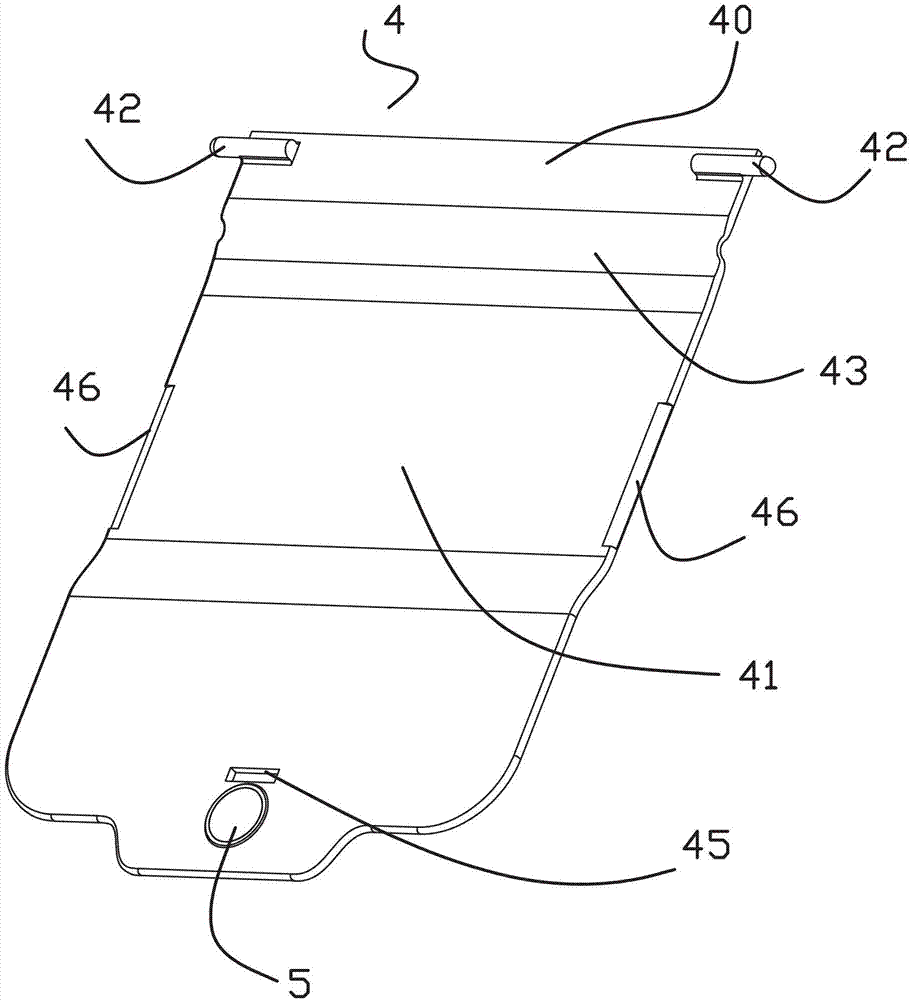

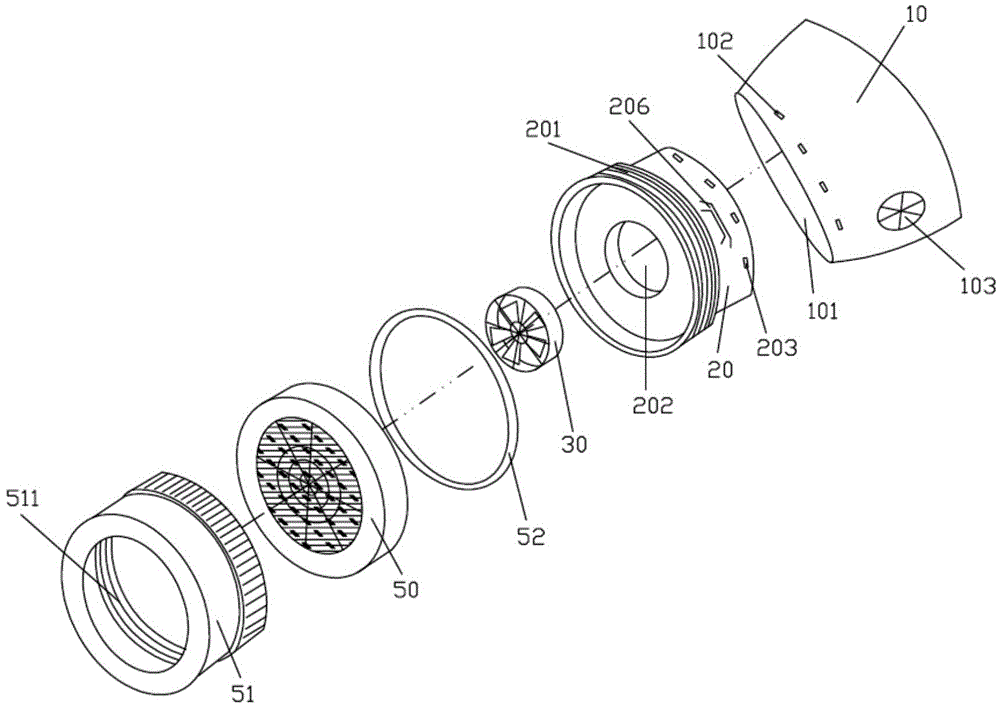

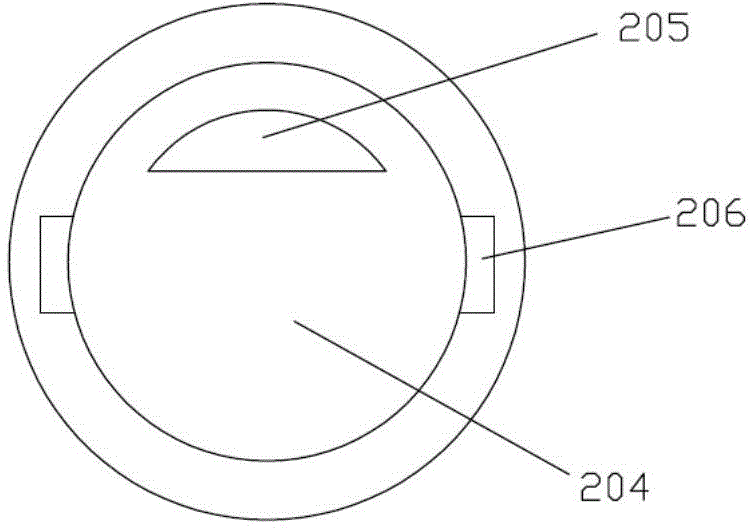

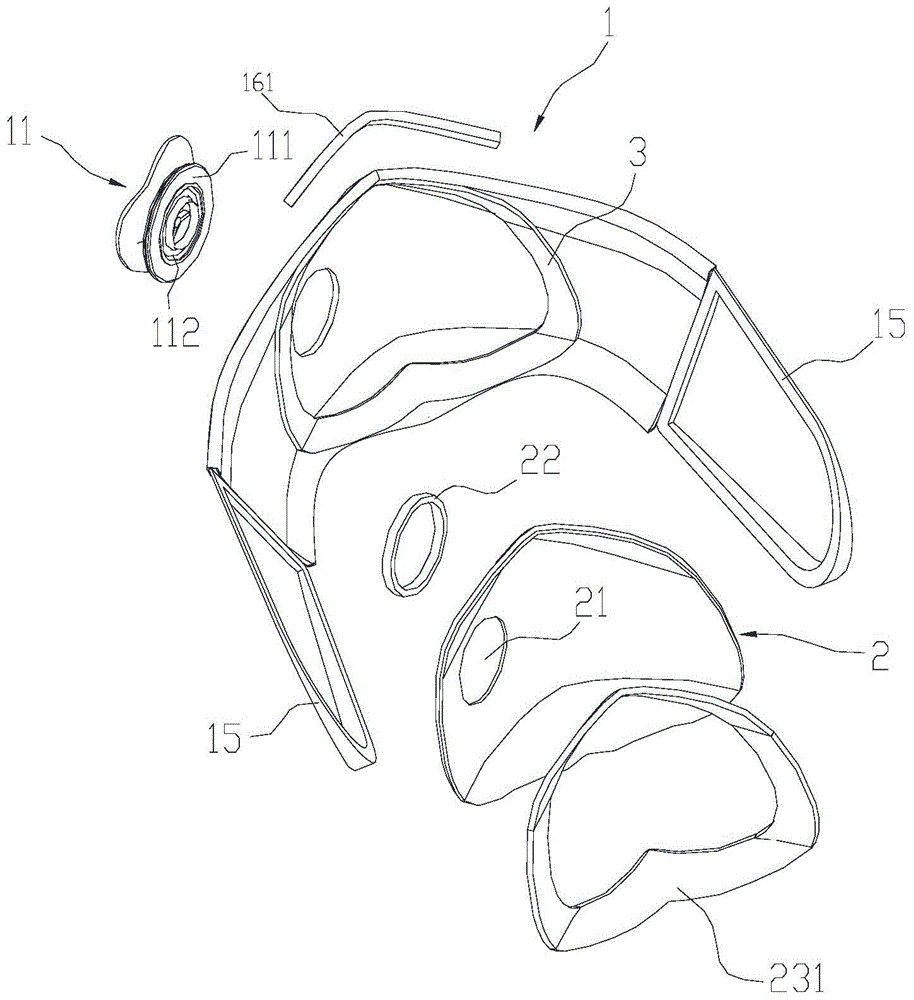

Electric air supply respirator

InactiveCN104587617AImprove dustproof effectImprove dust resistanceBreathing filtersFire rescueExhaust valveRespirator

The invention provides an electric air supply respirator. The electric air supply respirator comprises a respirator body, a shell, a fan, a filter tank and a power supply, wherein an end face of the respirator body is provided with a casing hole; the lower edge face of the respirator body is provided with at least one one-way exhaust valve; an end face of the shell is provided with an air inlet; the other end of the shell is provided with a flow guide plate; the flow guide plate and the shell form at least one air outlet; the air outlet is positioned in the upper side of a nose of a user. The electric air supply respirator has a good dust-proof effect, air in the respirator is fresh, and the user breathes smoothly without feeling stuffy.

Owner:SHENZHEN SELEN SCI & TECH CO LTD +1

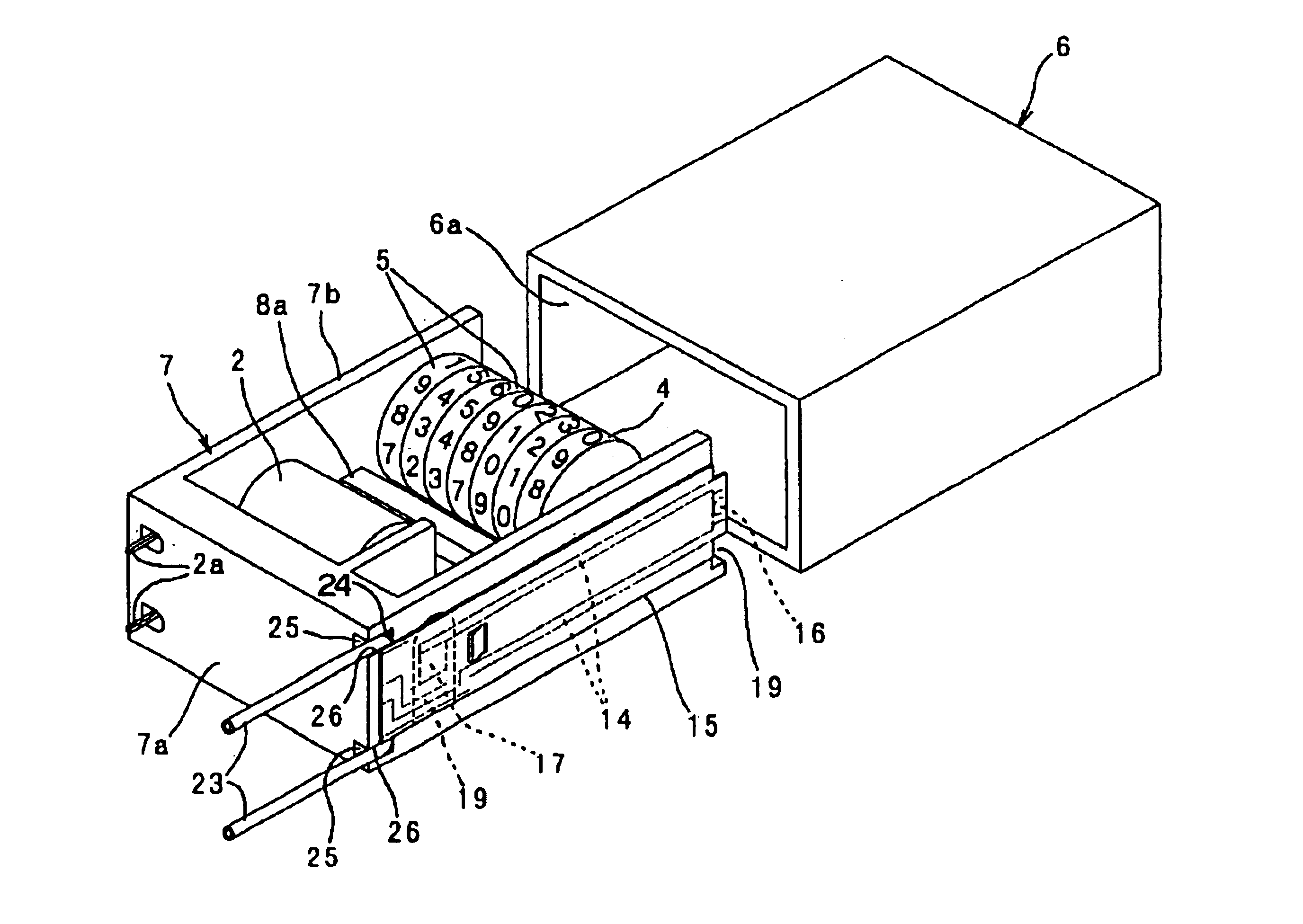

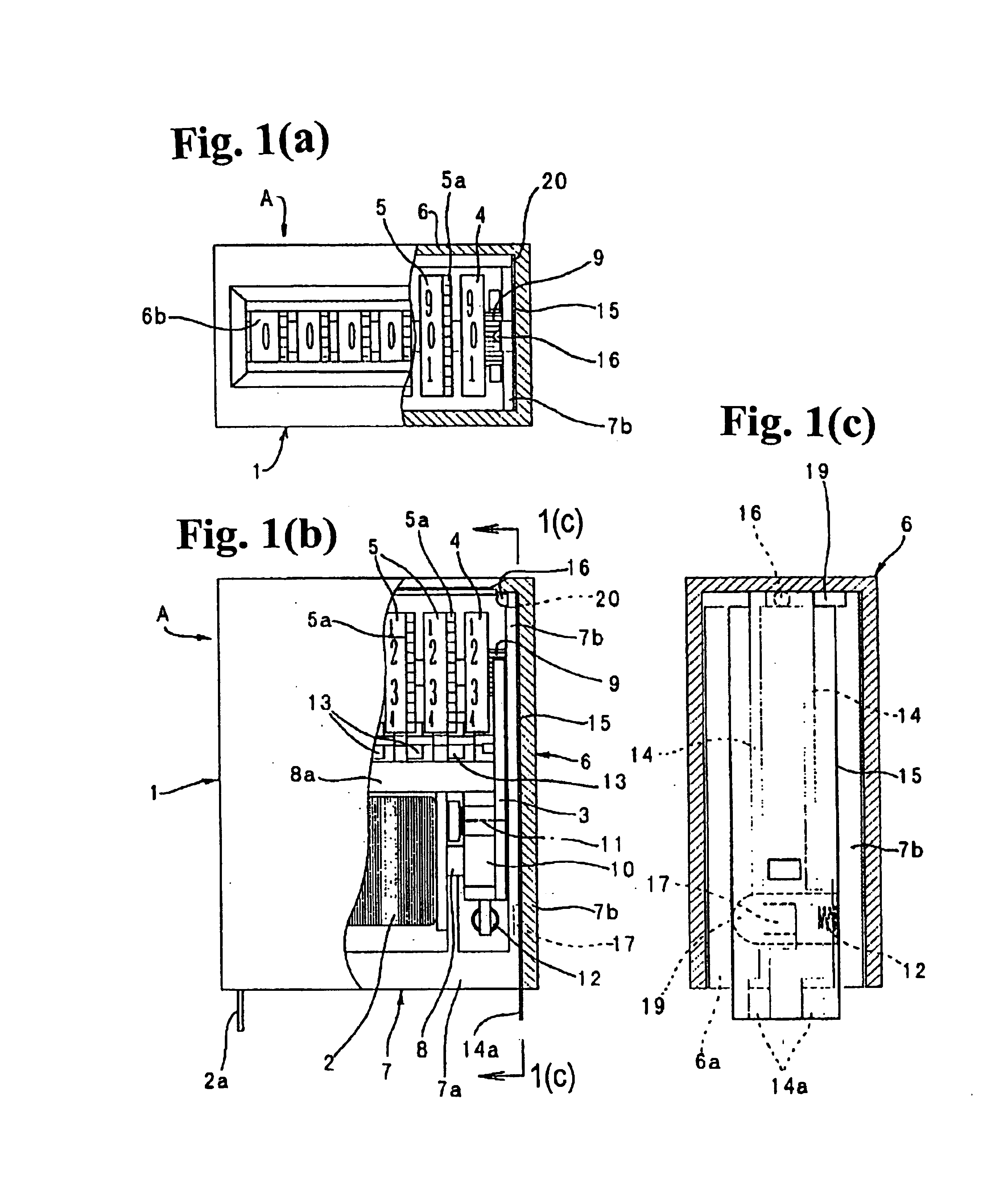

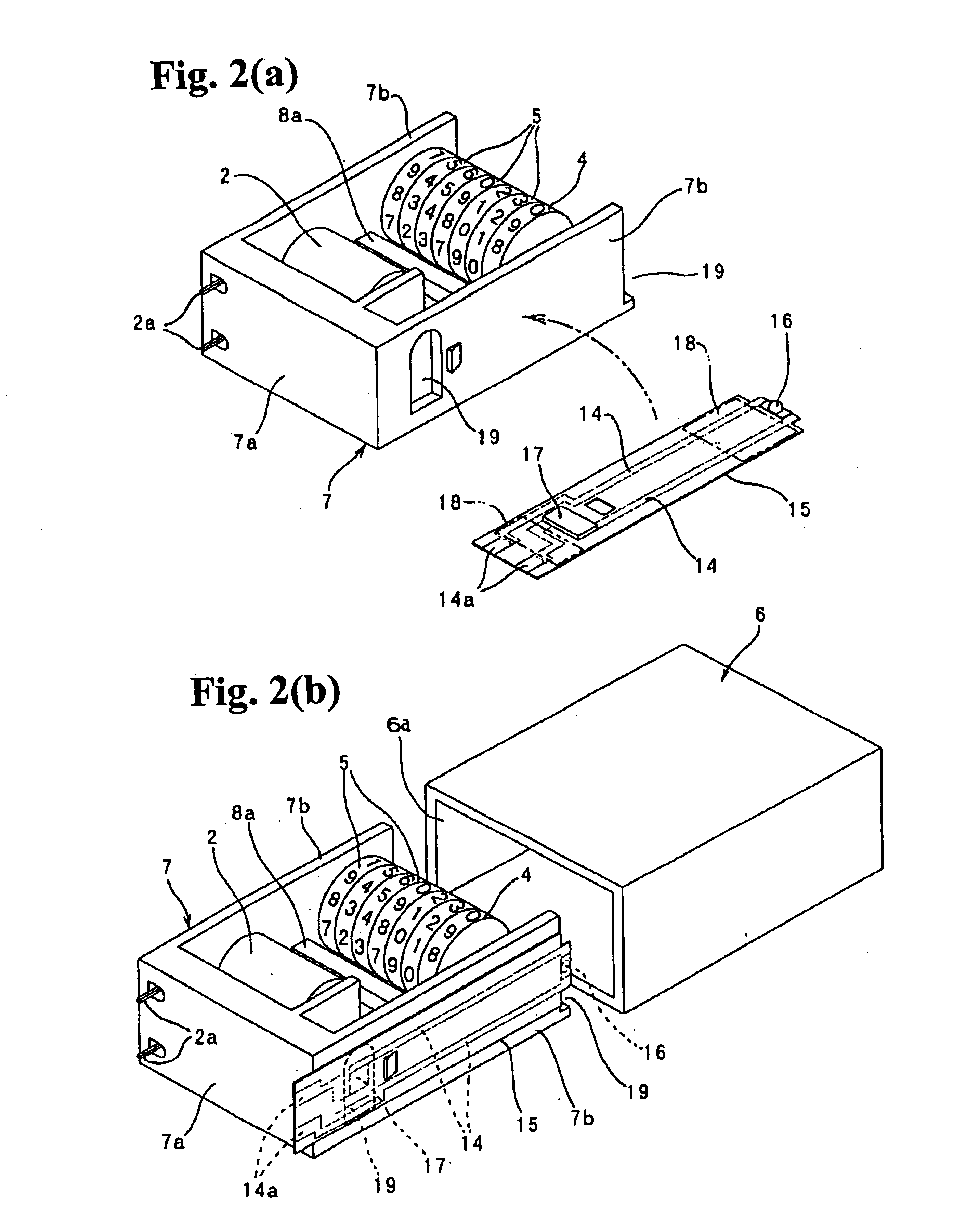

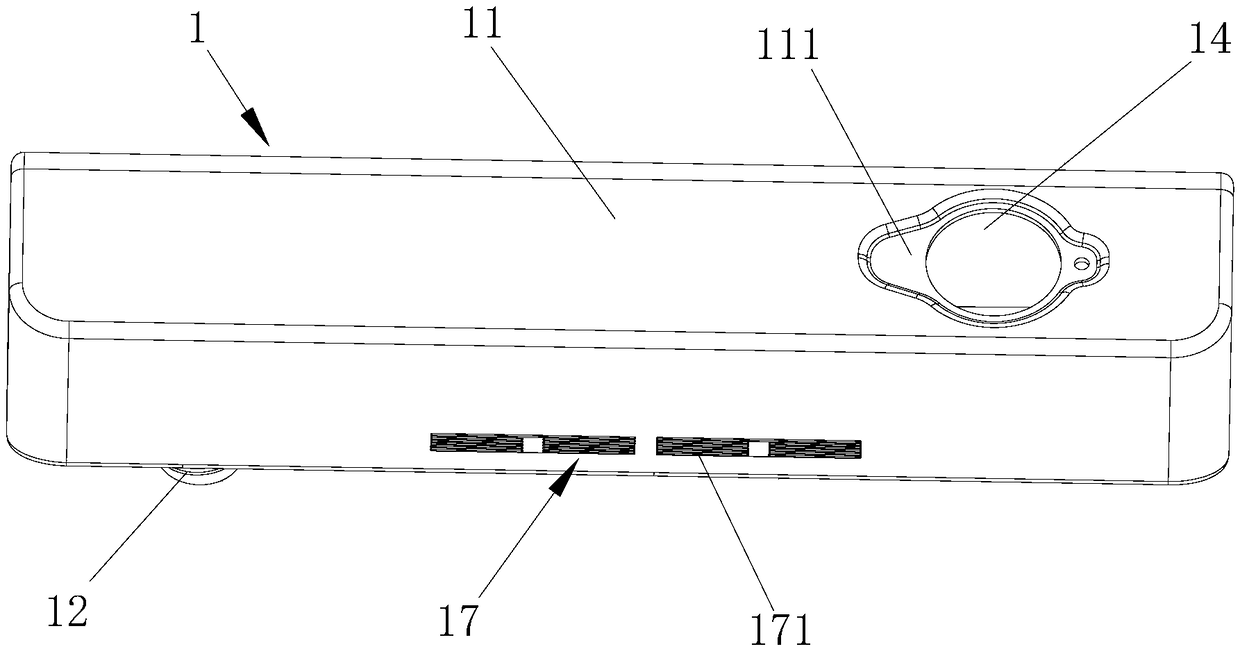

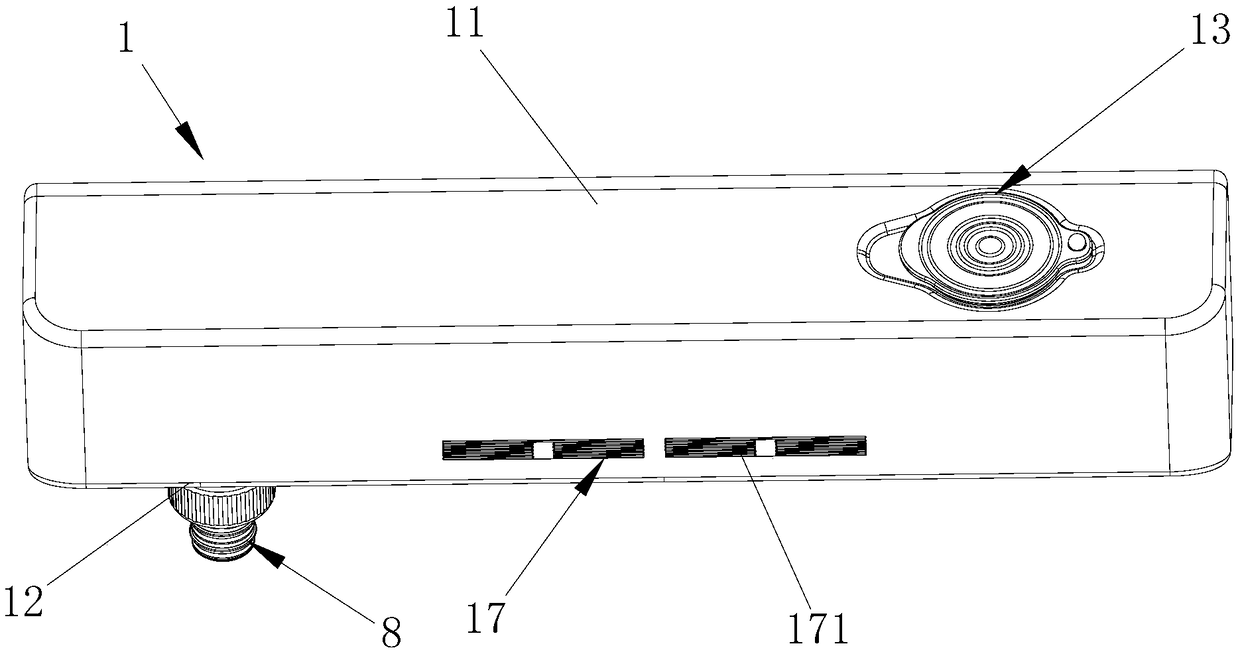

Electromagnetic counter with built-in illumination device

ActiveUS6859510B1Easy to installMinimal maintenanceMagnetic property measurementsCounting mechanisms/objectsMagnetizationConfined space

An electromagnetic counter includes a case, an electromagnet, an anchor rotatable through magnetization and demagnetization of the electromagnet, and number wheels rotated by a predetermined angle according to the rotation of the anchor. A flexible board with a light emitting diode is disposed in a confined space in the case for illuminating the number wheels.

Owner:CONTEX +1

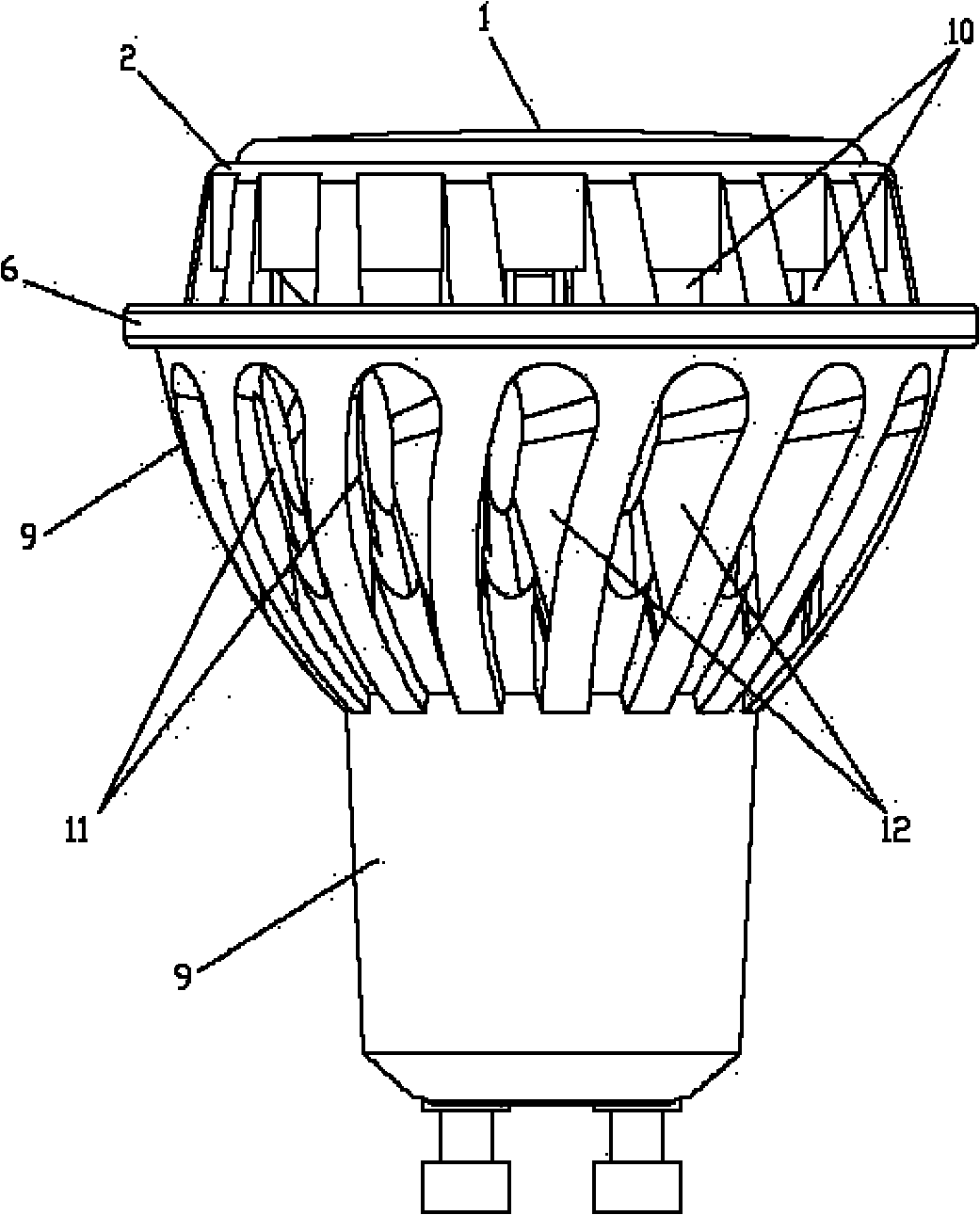

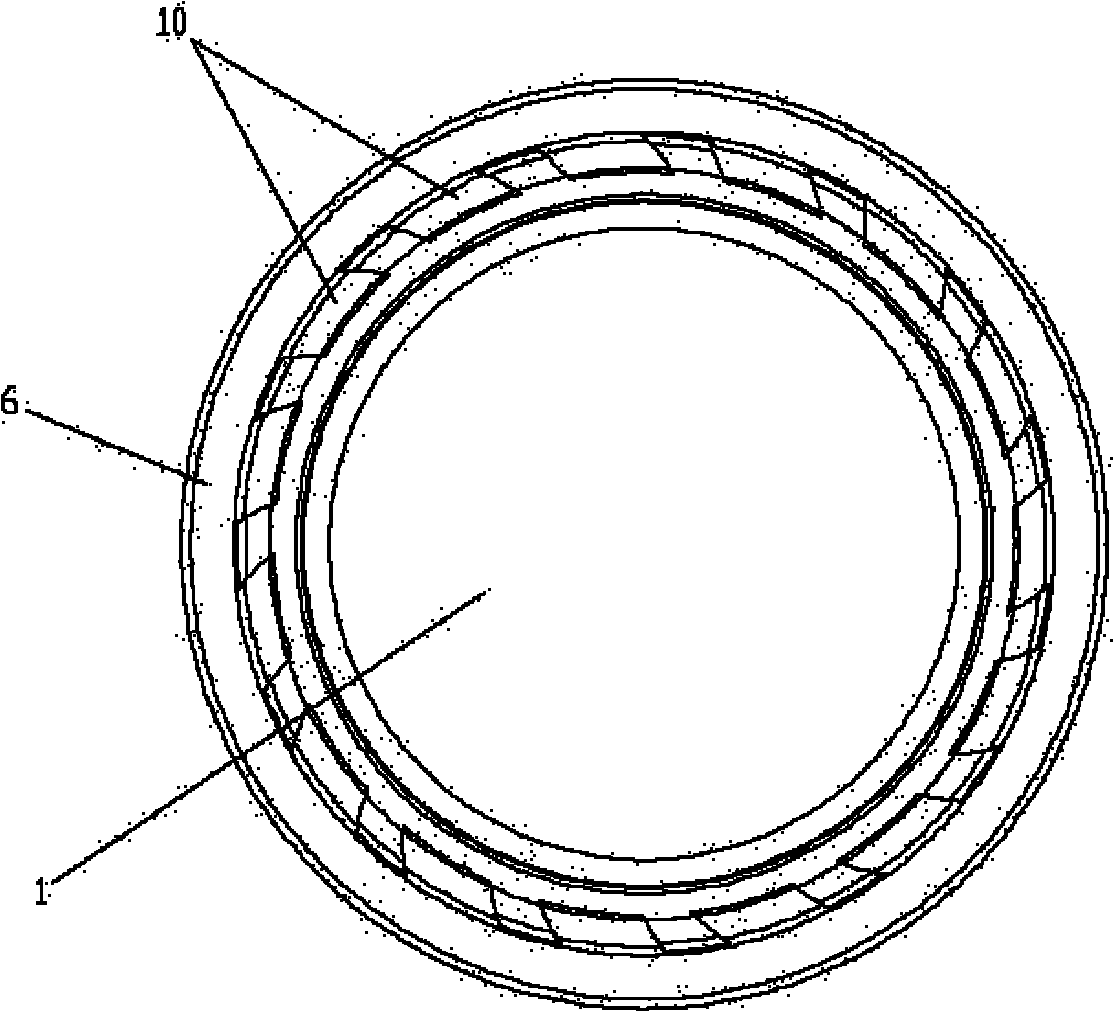

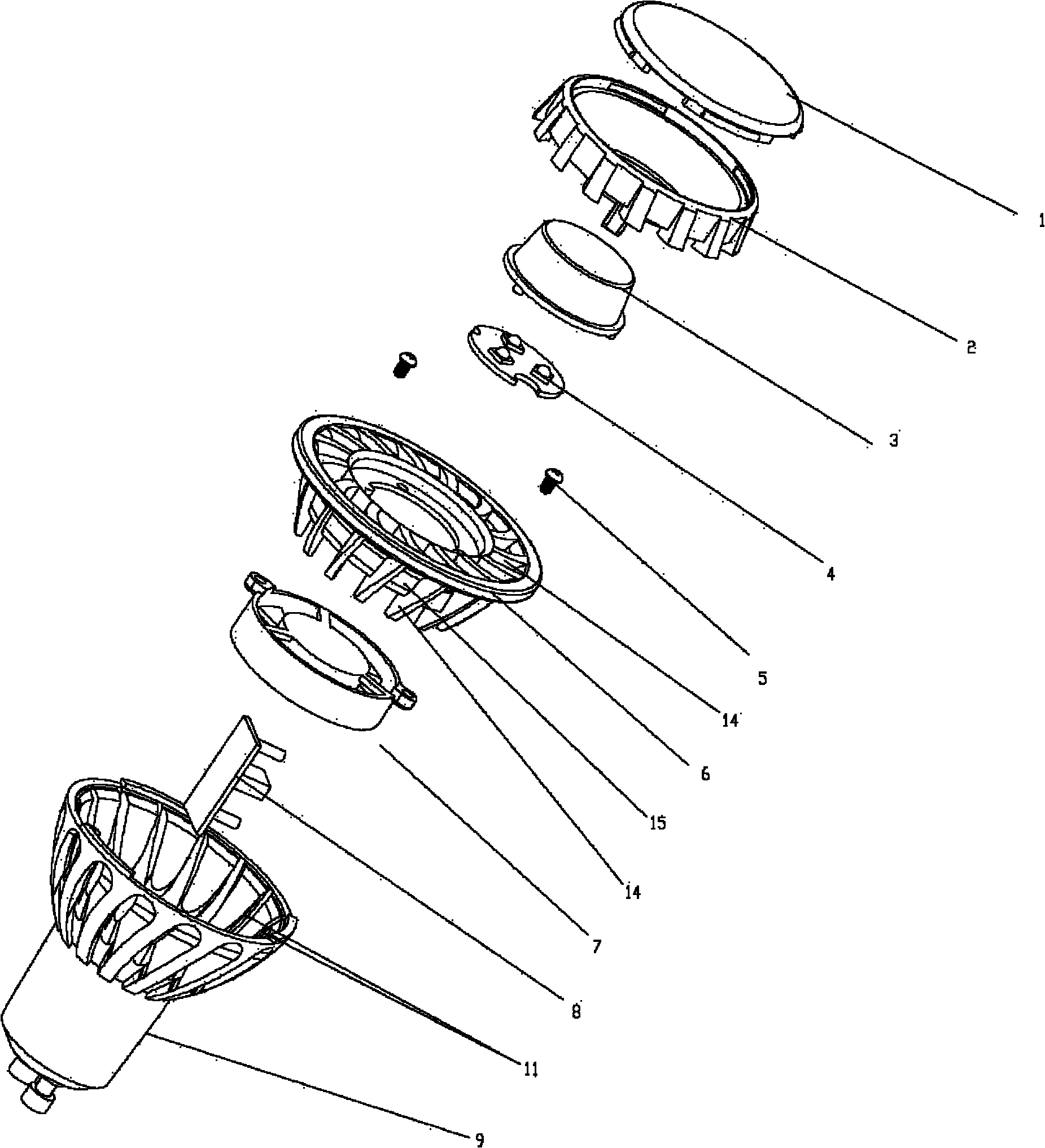

LED bulb with fan and lamp

InactiveCN102121612AImprove cooling effectImprove dust resistancePoint-like light sourceLighting heating/cooling arrangementsEngineeringTroffer

The invention relates to an LED bulb with a fan and a lamp, which belongs to the field of LED illumination. The lamp comprises a heat radiation shell, a bulb shell, an LED lamp body as well as a micro fan and a power supply which are arranged in the interior, wherein an assembly gap is arranged between the heat radiation shell and the bulb shell, and the assembly gap is matched with the heat radiation shell and the bulb shell to form an S-shaped air path for air ventilation, which increases the contact area of air flows with the bulb, particularly with the heat radiation shell and ensures that the bulb and the lamp have good heat radiation; and meanwhile, a first ventilation hole is arranged on the side wall of a groove, which ensures that the bulb has good dustproof effect, and the service life of the bulb and the lamp is prolonged.

Owner:CIVILIGHT SHENZHEN SEMICON LIGHTING

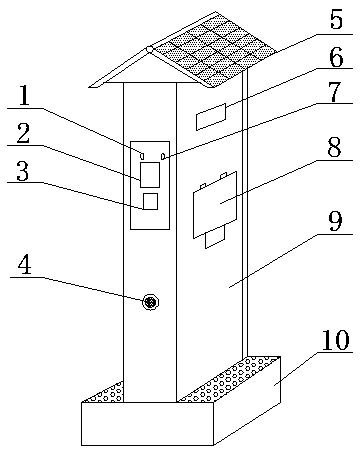

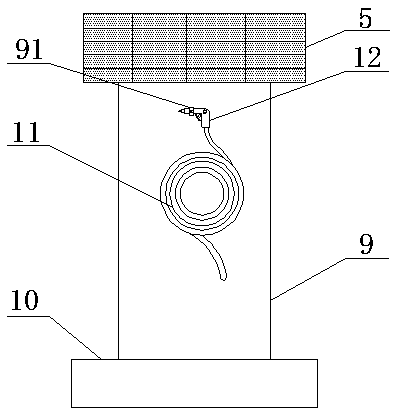

Multifunctional new energy automobile charging pile

InactiveCN105515134ACompact structureExtended service lifeCircuit monitoring/indicationDifferent batteries chargingPower storageWater pipe

The invention belongs to the technical field of new energy equipment application, and discloses a multifunctional new energy automobile charging pile. The multifunctional new energy automobile charging pile comprises a base and a pile body arranged at the top end of the base. A charging socket opening is formed in the side wall of the pile body, and a lamp tube is arranged at the top end of the charging socket opening. Solar cell panels are arranged at the top end of the pile body, and an alarm is arranged on the side wall of the pile body. An IC card reading unit is arranged on one side of the alarm, and an operation panel is arranged on one side of the IC card reading unit. A charging indicator lamp is arranged on one side of the operation panel, and a fault indicator lamp is arranged on one side of the charging indicator lamp. A water pipe is arranged on the side wall of the pile body, and one end of the water pipe is connected with a water gun head. The solar cell panels are arranged at the top end of the multifunctional new energy automobile charging pile to charge backup power storage devices in the charging pile; besides, the solar cell panels at the top end of the charging pile have the good effect of keeping out rain, and thus the service life is long.

Owner:刘志运

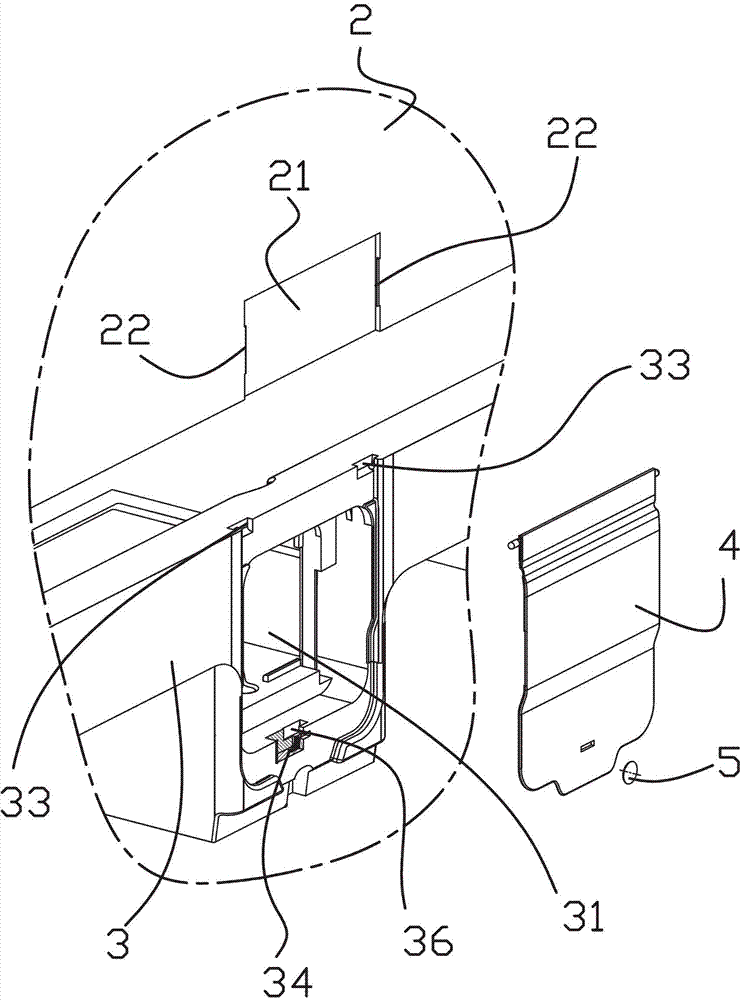

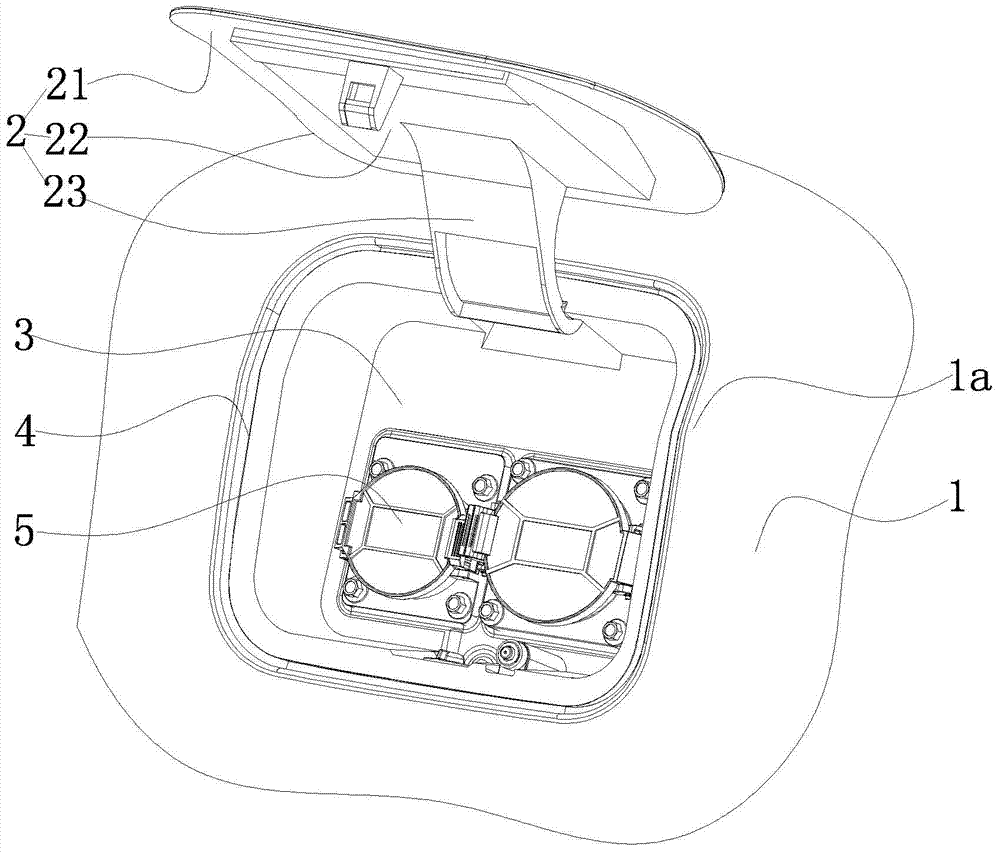

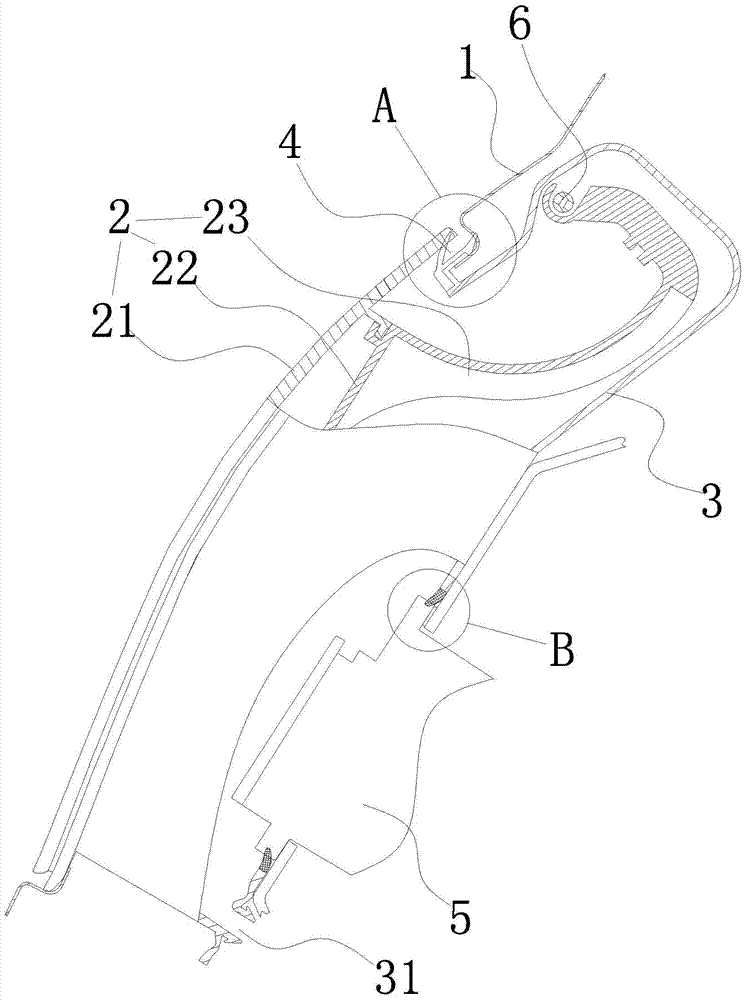

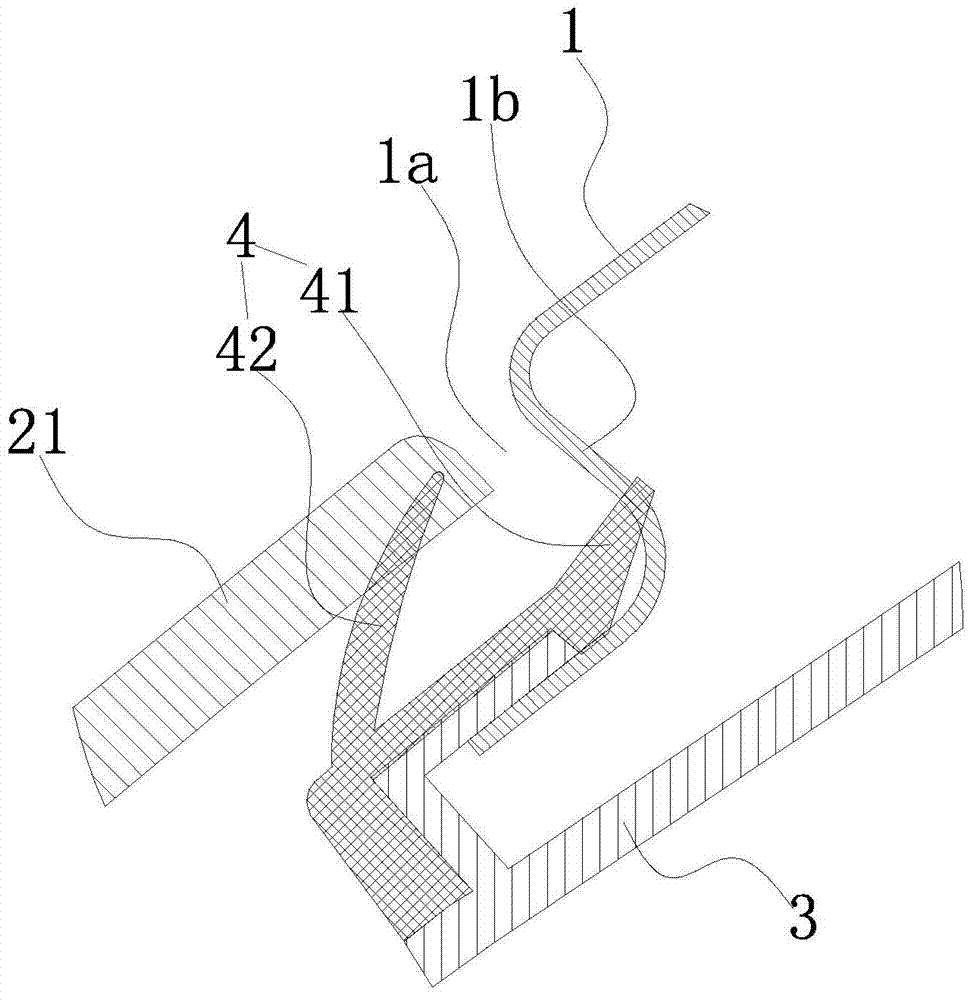

Waterproof and dustproof charging port structure assembly of automobile

ActiveCN104709364AAffect normal useImprove sealingCharging stationsSuperstructure subunitsEngineeringElectrical and Electronics engineering

The invention discloses a waterproof and dustproof charging port structure assembly of an automobile, and aims to provide a charging port structure assembly which has good waterproof and dustproof effects and can effectively solve the problems that in long-term running of an automobile, water enters a charging port assembly, and normal use of a charging port is influenced. The charging port structure assembly comprises a charging base arranged on an automobile body, a charging operation port formed in a sidewall outer plate of the automobile body, a charging port box arranged in the charging operation port and a charging port cover hinged to the charging port box through a rotating shaft. A receding notch corresponding to the charging base is formed in the bottom surface of the charging port box, an annular inner sealing element is arranged on the edge of the receding notch, the charging base penetrates through the receding notch, and the inner edge of the annular inner sealing element abuts upon the side face of the charging base. An annular baffle extending to the inner side of the automobile body is arranged on the edge of the charging operation port. An annular outer sealing element is arranged on the edge of the opening of the charging port box.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Electronic device provided with touch screen and assembling method thereof

InactiveCN103324250AShorten the timeAvoid inaccurate stickersDigital data processing detailsInput/output processes for data processingCentral regionComputer science

The invention provides an electronic device which comprises a touch screen and a frame. The touch screen comprises a protective layer, a sensing layer and a first optical transparent adhesive layer. The first optical transparent adhesive layer comprises a first surface and a second surface which are arranged in a back-to-back mode. The protective layer adheres to the first surface. The second surface comprises a central region and a peripheral region. The sensing layer adheres to the central region, and the frame adheres to the peripheral region. The electronic device has good dustproof effect, and assembly is simple. The invention further relates to an assembling method of the electronic device.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

Dust-raise preventing spray covering bonding agent on surface of unit train and preparation method thereof

ActiveCN101851473ALow costNo special requirementsOther chemical processesStarch adhesivesSodium benzoateChemistry

The invention discloses a dust-raise preventing spray covering bonding agent on the surface of a unit train and a preparation method thereof. The bonding agent comprises sodium carboxymethylcellulose, pre-gelatinized starch, sodium benzoate and water. The preparation method comprises the following steps of: pre-adding the tap water into a stirring pot at the normal temperature, and adding and stirring the sodium carboxymethylcellulose, the pre-gelatinized starch and the sodium benzoate respectively until the sodium carboxymethylcellulose, the pre-gelatinized starch and the sodium benzoate are completely dissolved to obtain the finished product. The bonding agent has the advantages of low cost, production process finished at the normal temperature, no special requirement, simple and convenient process, long storage time, independent components and solution thereof without any toxic or side effect and corrosiveness, no secondary pollution and remarkable dustproof effect.

Owner:SCI INST HOHHOT ADMINISTRATION OF RAILWAY

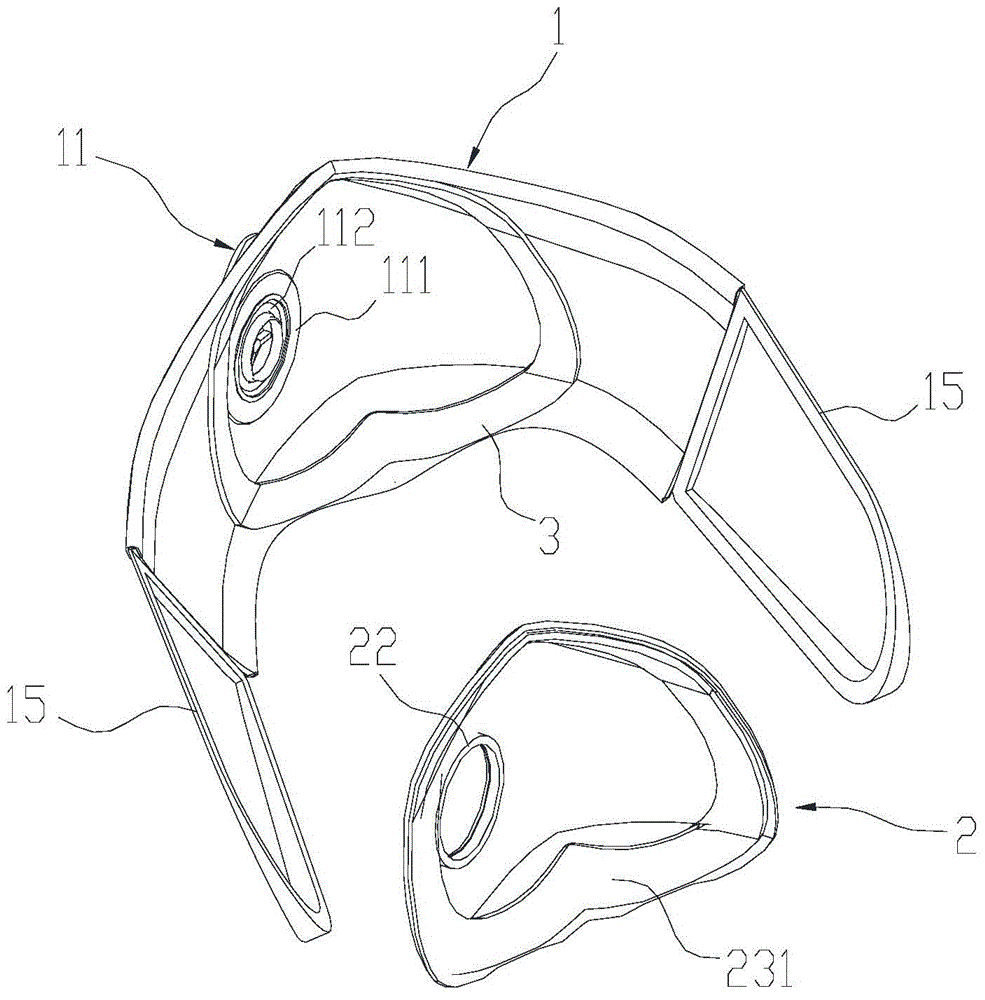

Respirator with novel breather valve

ActiveCN104147719AImprove dust resistanceReduce wasteRespiratory apparatusInterference fitUltrasonic welding

The invention discloses a respirator with a novel breather valve. The respirator comprises an outer respirator body and a filtering inner respirator body which is detachably connected to the inner side of the outer respirator body in an attachment mode, the breather valve is fixed at the lower portion of the outer respirator body, and a groove is formed in the end, located on the inner side of the respirator, of the breather valve. A hole is formed in the position, corresponding to a valve body, of the filtering inner respirator body, a plastic sleeve is fixedly connected to the peripheral edge of the hole with an ultrasonic welding technology, and the plastic sleeve is clamped in the groove of the breather valve in an interference fit mode. The respirator is divided into the outer respirator body and the filtering inner respirator body; after the respirator is used, the filtering inner respirator body can be abandoned, and the outer respirator body can be left; by means of split structural design, material waste can be reduced, and the environmental requirement is met; meanwhile, the plastic sleeve is fastened on the valve body in a sealed and sleeved mode, it can be guaranteed that the good dust prevention effect of the respirator is achieved, and the combination immobility of the filtering inner respirator body and the outer respirator body is strengthened.

Owner:GUANGZHOU BIOFIL AIR PURIFICATION MATERIAL CO LTD

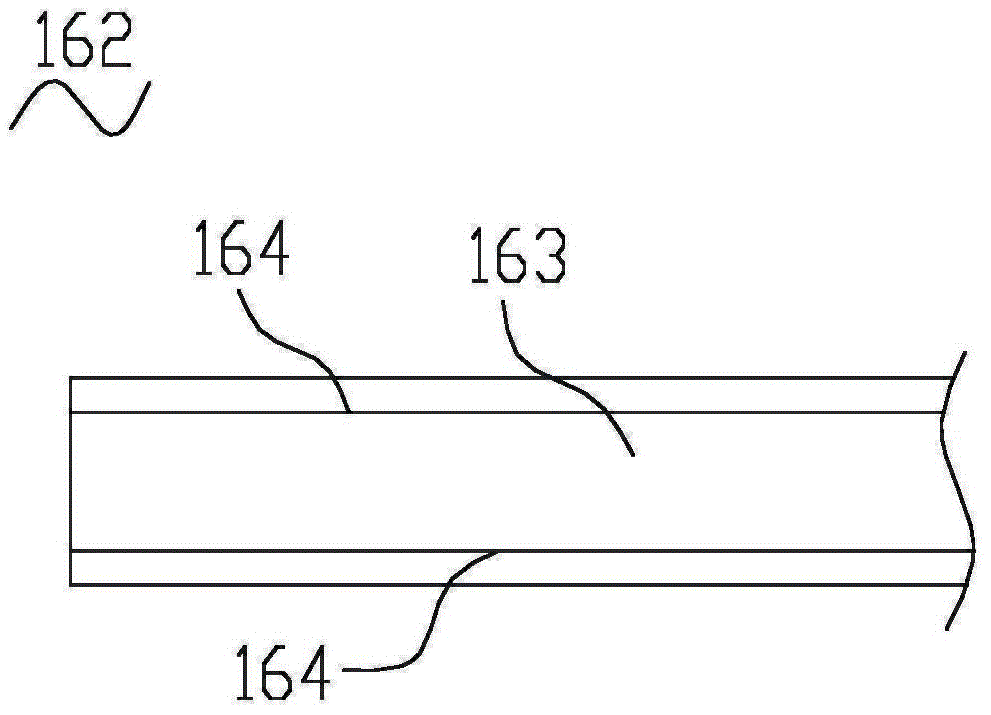

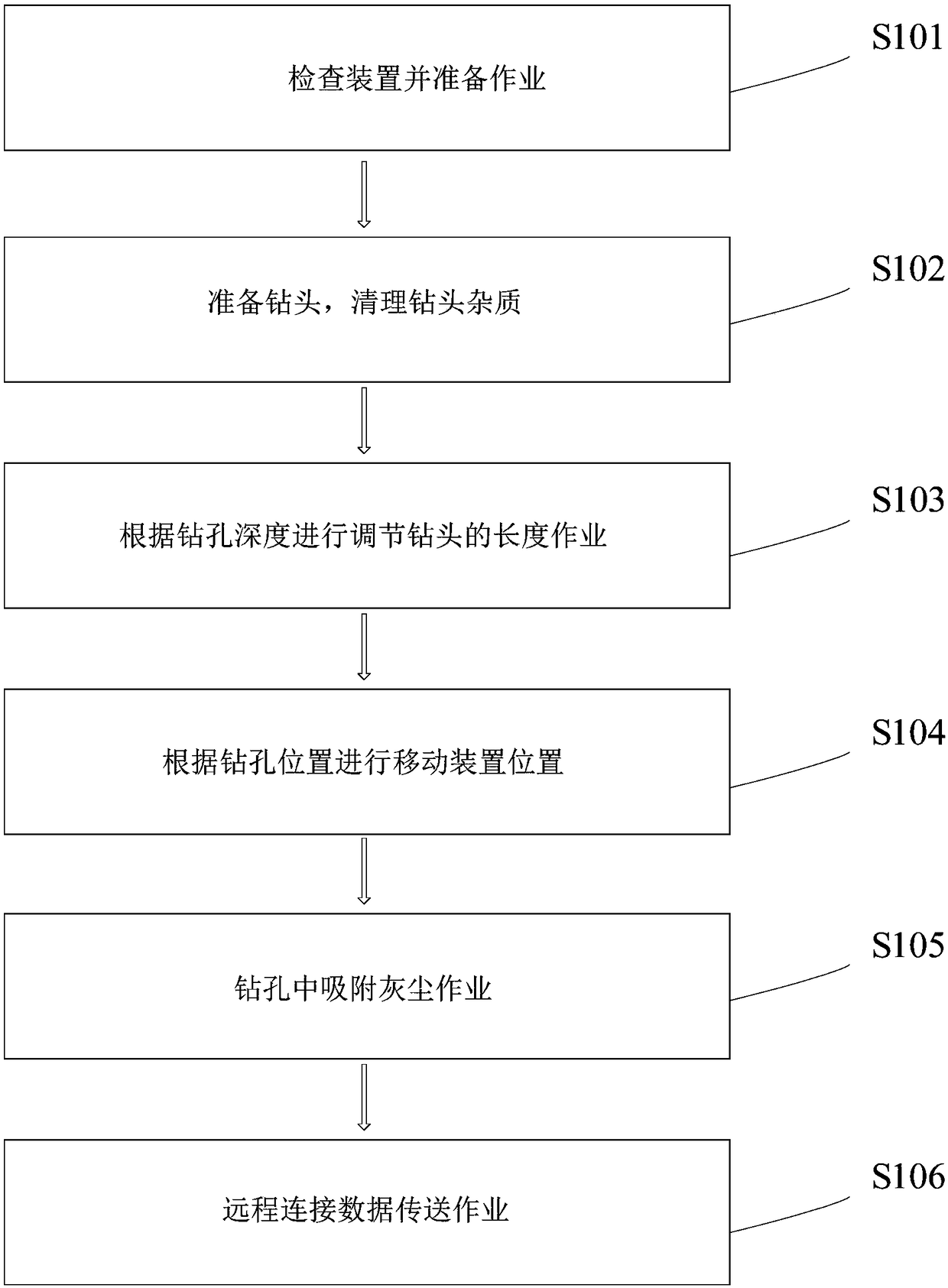

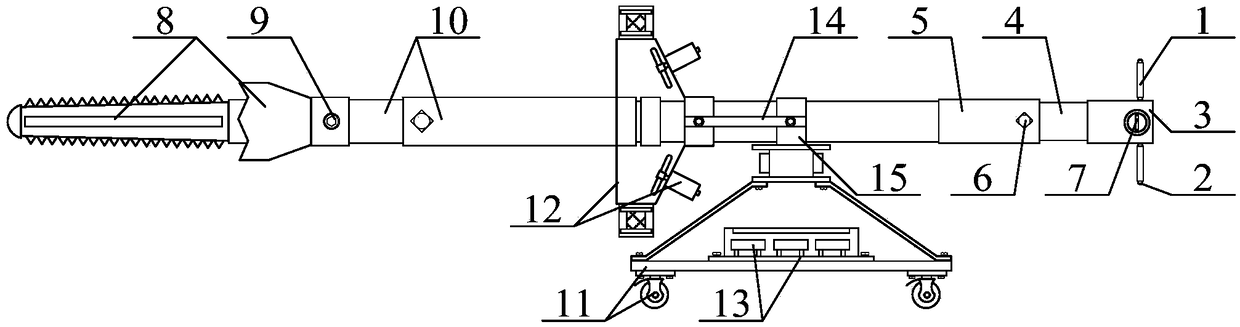

While-drilling testing method and device for coal seam gas parameters

ActiveCN109403865AImprove protectionAvoiding the Problem of Damage to Tapered BitsEarth drilling toolsSurveySlagRemote data transmission

The invention provides a while-drilling testing method and device for coal seam gas parameters. The while-drilling testingdevice comprises a hand-holdingsleeve, a hand-holdingrod, a connecting casing,a butting shaft, a connecting pipe, fastening bolts, a strip-shaped port iron pin, a removable hard coal seam assisted drilling bit structure, fixed hexagon socket bolts, a drilling extension rod structure with the adjustable length, an auxiliary moving supporting transport frame, a during-drilling dust auxiliary adsorptionsplash-preventing shield structure, a heat dissipating shield structure capable of conducting remote data transmission, a connecting plate and a fixing casing. According to thewhile-drilling testing method and device for the coal seam gas parameters, drilling teeth, a flow-guiding groove, a connection liner pipe and a drill bit body are arranged, coal slag produced during drilling through a cone-shaped bit can be discharged in time through the flow-guiding groove, and the problem of drilled hole blocking is avoided; through the drilling teeth, good auxiliary drilling work can be achieved, and influence of a hard coal seam on deep drilling is avoided; and final reaming operation can be conducted through the drill bit body, and it is ensured that drilling work is conducted smoothly.

Owner:NORTH CHINA INST OF SCI & TECH

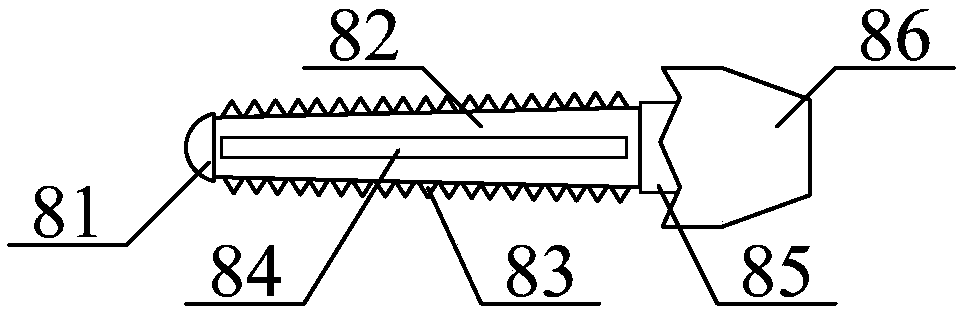

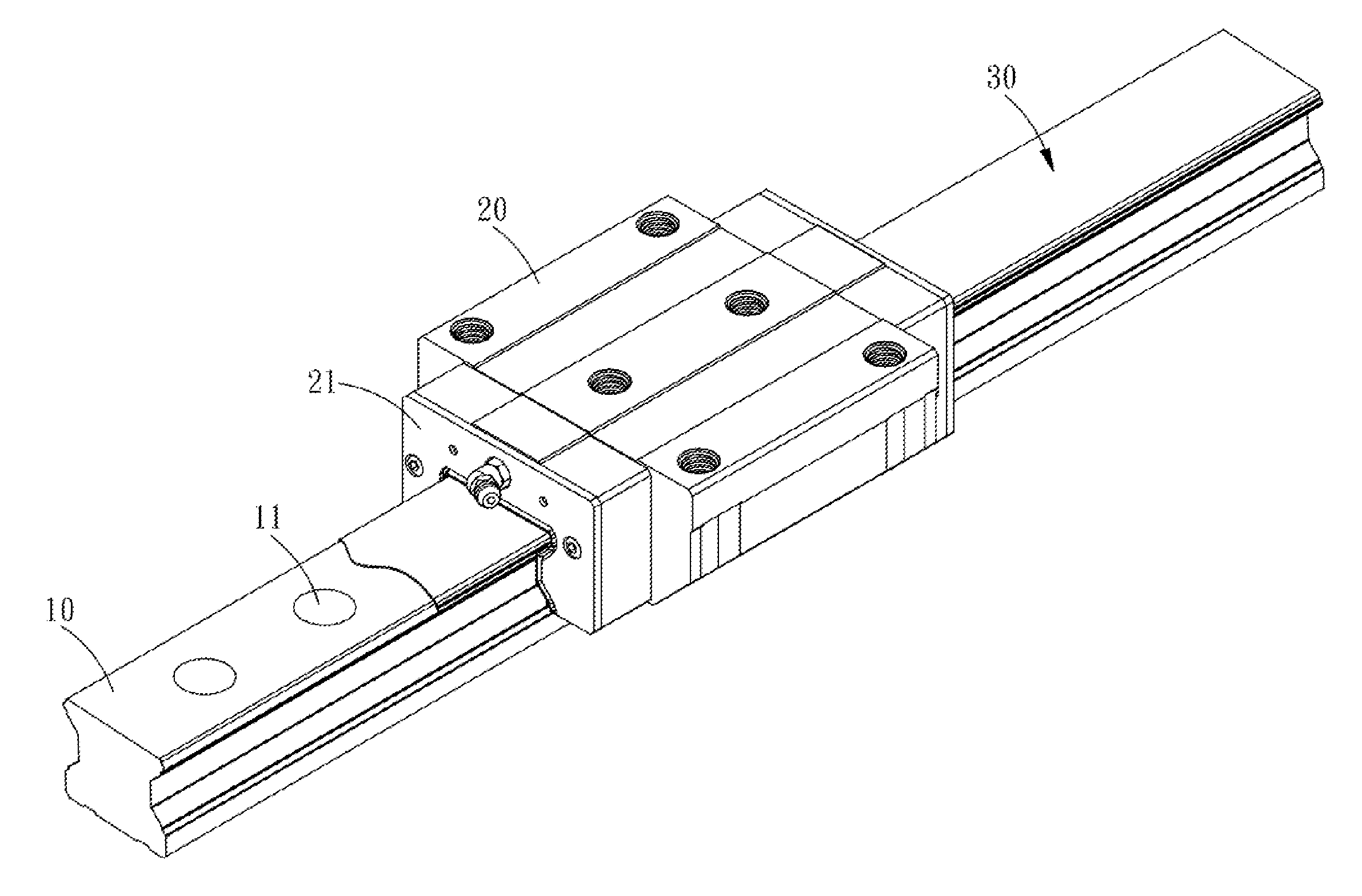

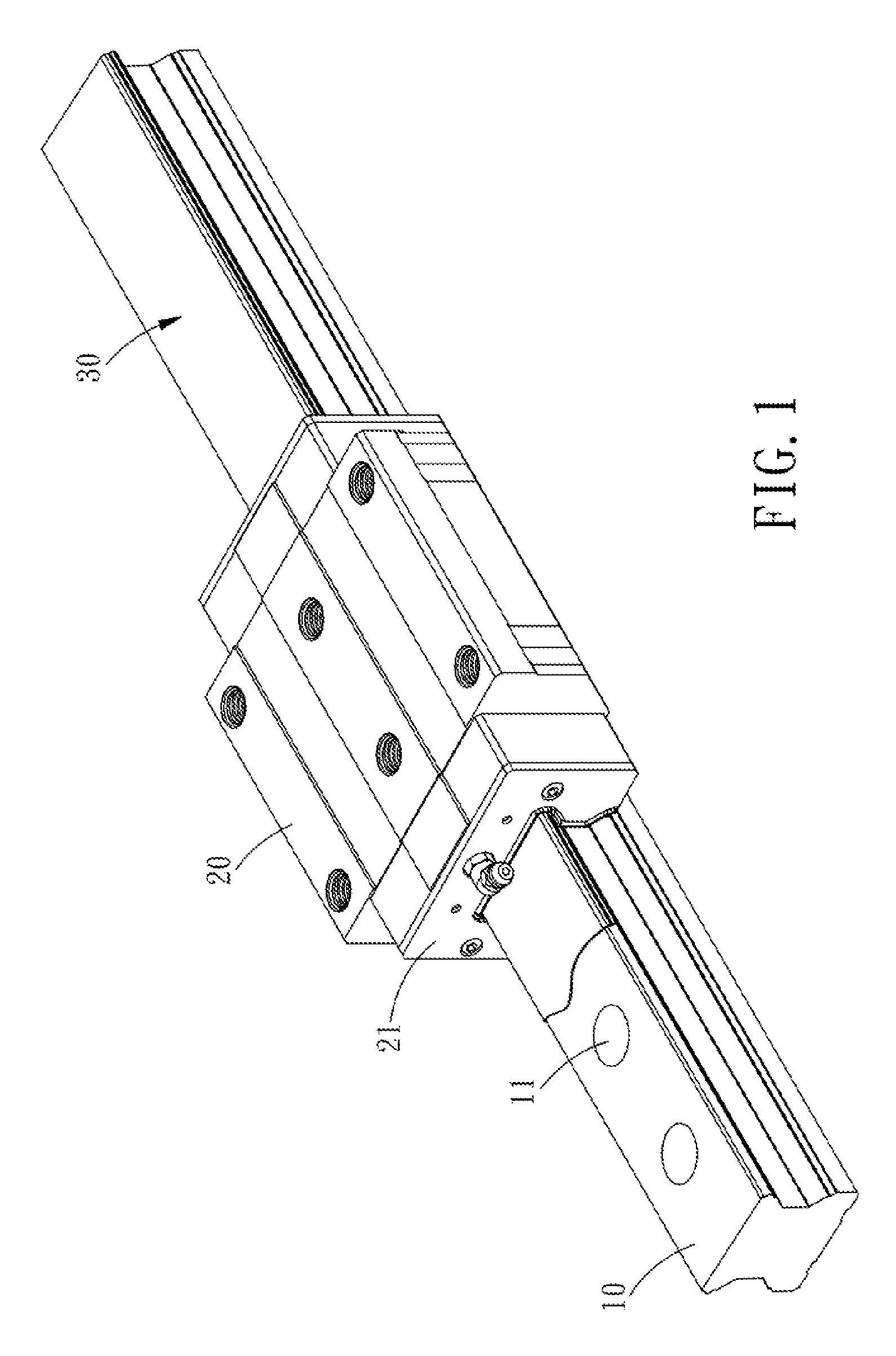

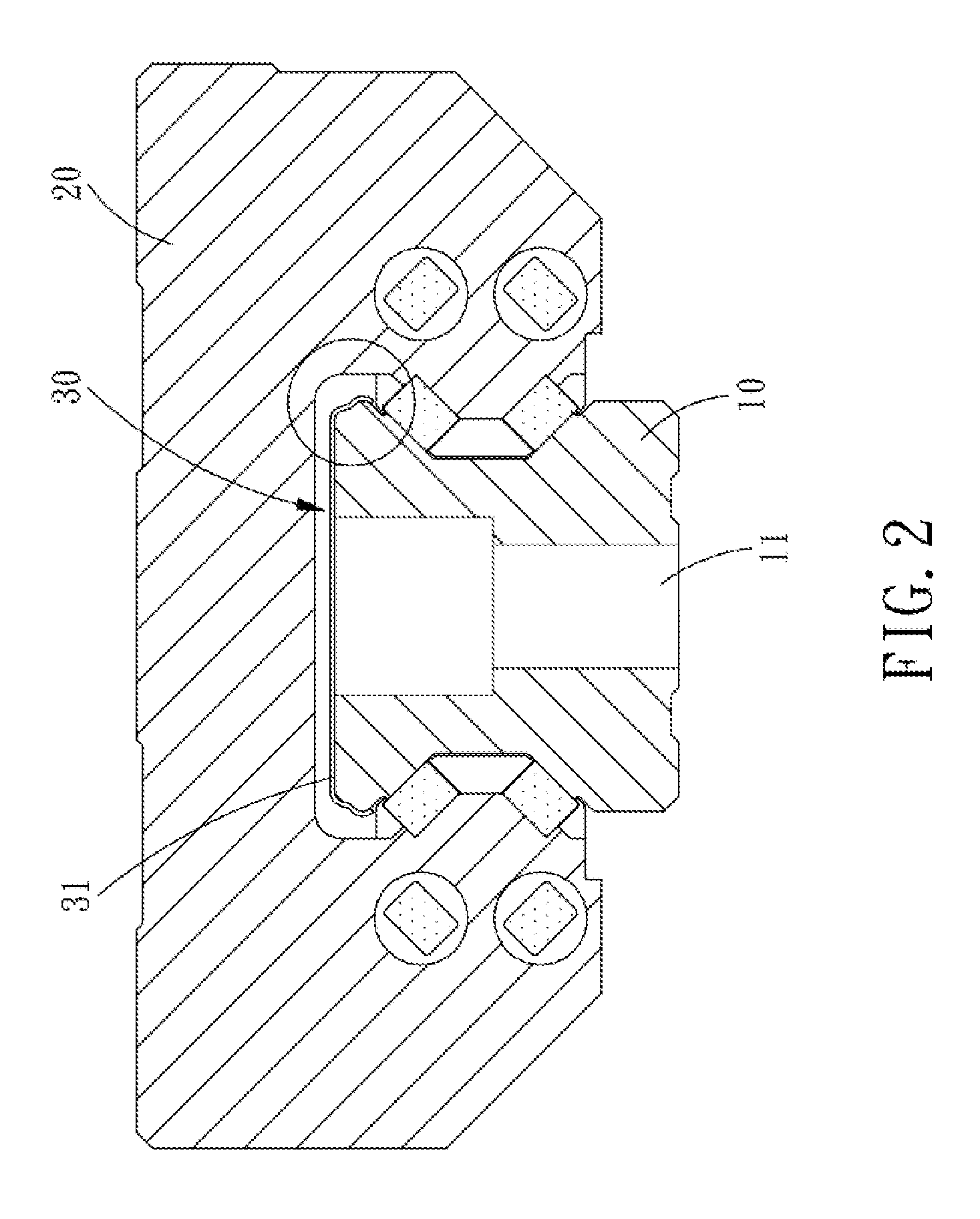

Cover Strip for a Linear Guide Rail

InactiveUS20090290818A1Improve dust resistanceImprove accuracyLinear bearingsBearing componentsFlangeRidge

A cover strip for a linear guide rail, wherein a slide block is slidably disposed on the guide rail, a cover strip covers an upper surface of the guide rail, each of two sides of the guide rail extend outwards to form an extending surface with large slope, and each extending surface extends downward to form a flange, two sides of the central portion of the cover strip are provided with extending portions, and each extending portion extends downwards to form an engaging portion, the structures extending from two sides of the cover strip are configured in the shape of the corresponding structures of the guide rail, and a free end of each engaging portion extends downward to cover the ridge of each flange in such a manner that the cover strip can be positioned on the guide rail assuredly and stably.

Owner:HIWIN TECH

Wall skin cleaning device for building construction and use method thereof

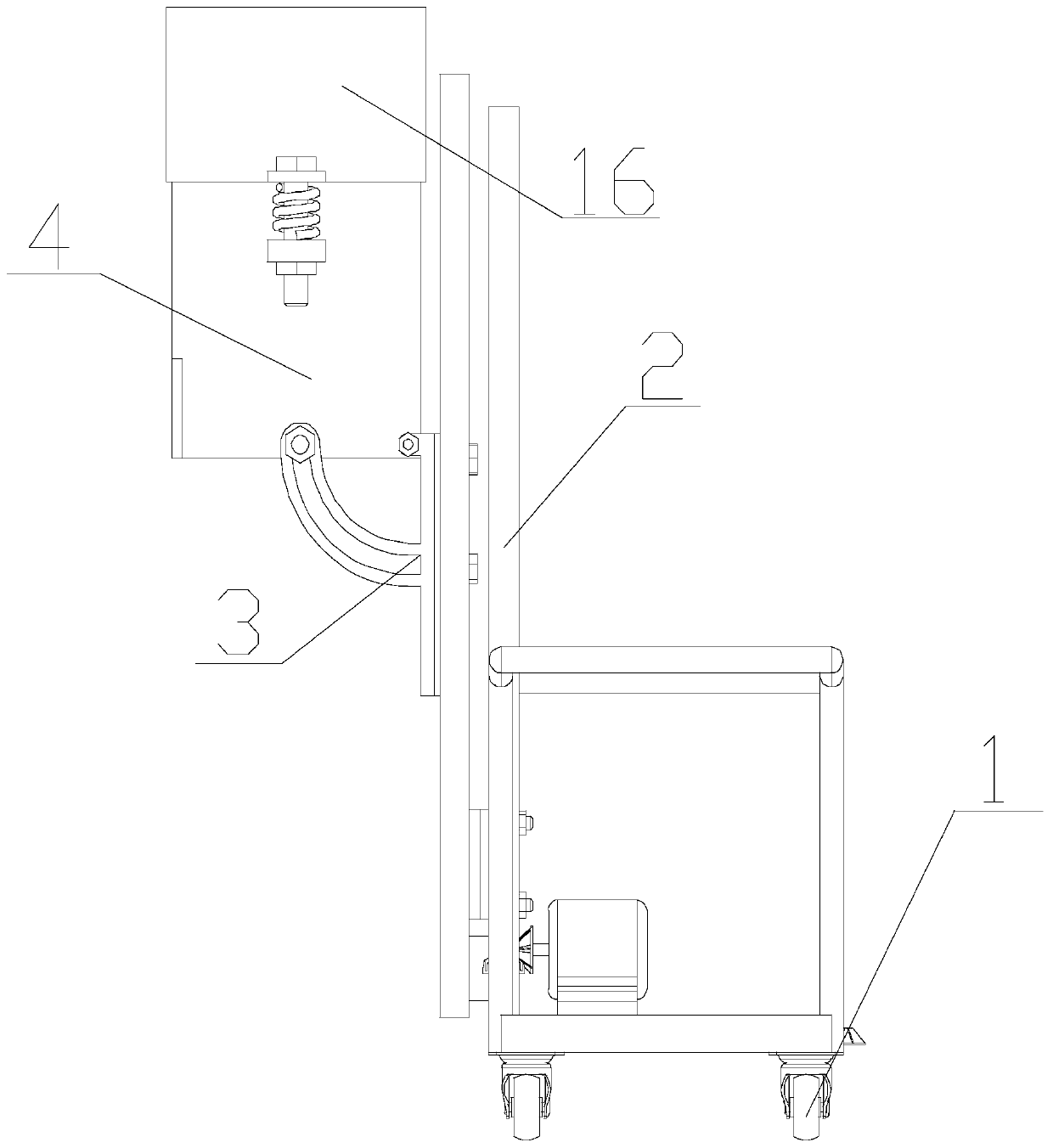

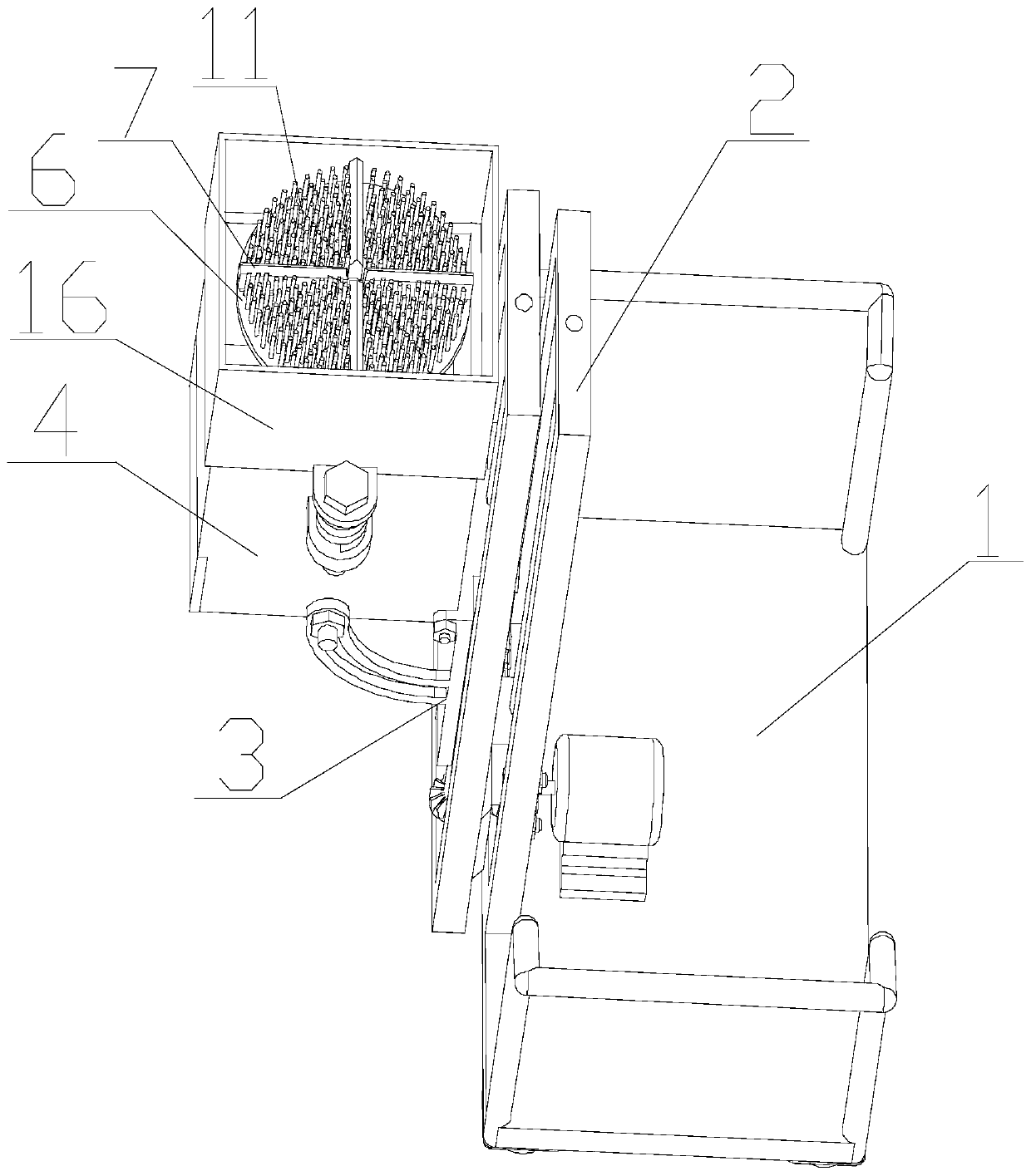

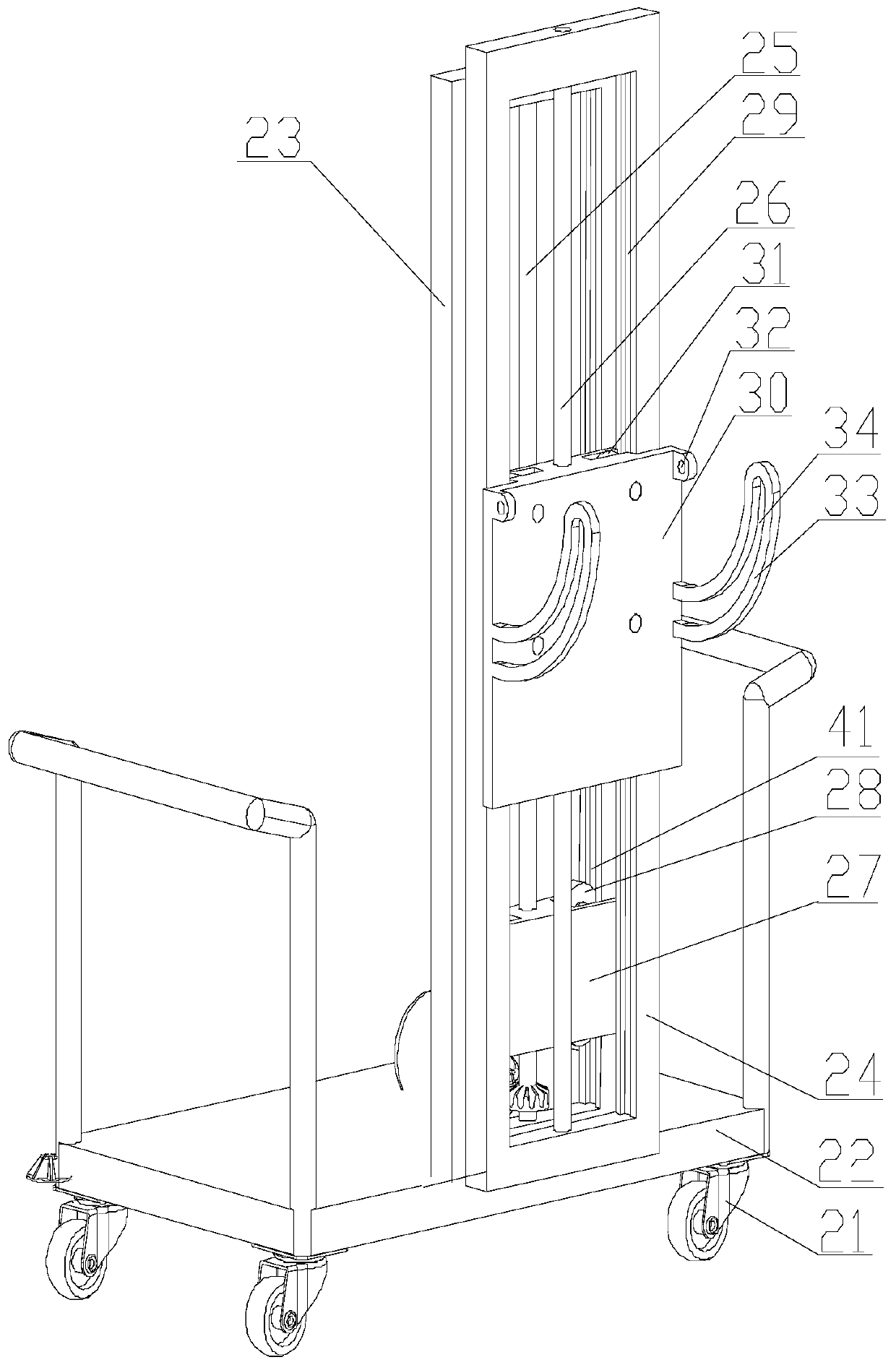

PendingCN111376159AImprove cleaning efficiencyEasy to useBuilding repairsGrinding machinesConstruction engineeringStructural engineering

The invention discloses a wall skin cleaning device for building construction. The wall skin cleaning device for building construction includes a walking device, a lifting device, a turning device, amounting frame, a power device, a cleaning disc, and a cleaning blade; the lifting device is installed on the walking device, and the walking device can drive the lifting device to move; the turning device is installed on the lifting device, and the lifting device can drive the turning device to move up and down; the mounting frame is mounted on the turning device, and the turning device can rotate the mounting frame; the power device is fixedly installed on the mounting frame; the cleaning disc is connected to the power device, and the power device can drive the cleaning disc to rotate; and the cleaning blade is mounted on the cleaning disc, and the cleaning blade can move along the axis of the cleaning disc. The cleaning efficiency of the wall skin cleaning device for building construction is high; and through the cleaning blade which is arranged in a floating manner, the wall skin cleaning device for building construction can adapt to the cleaning of uneven wall surfaces.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

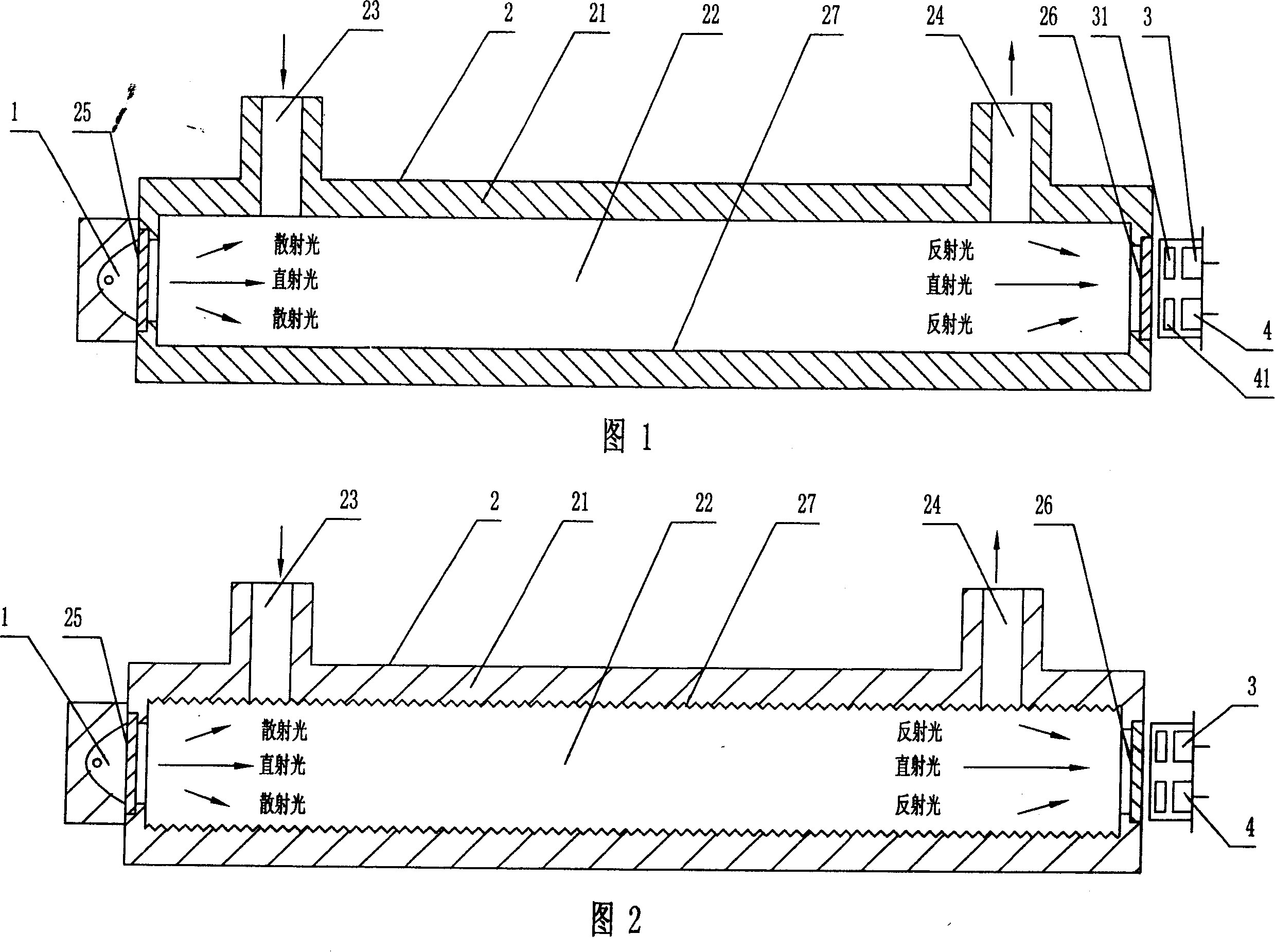

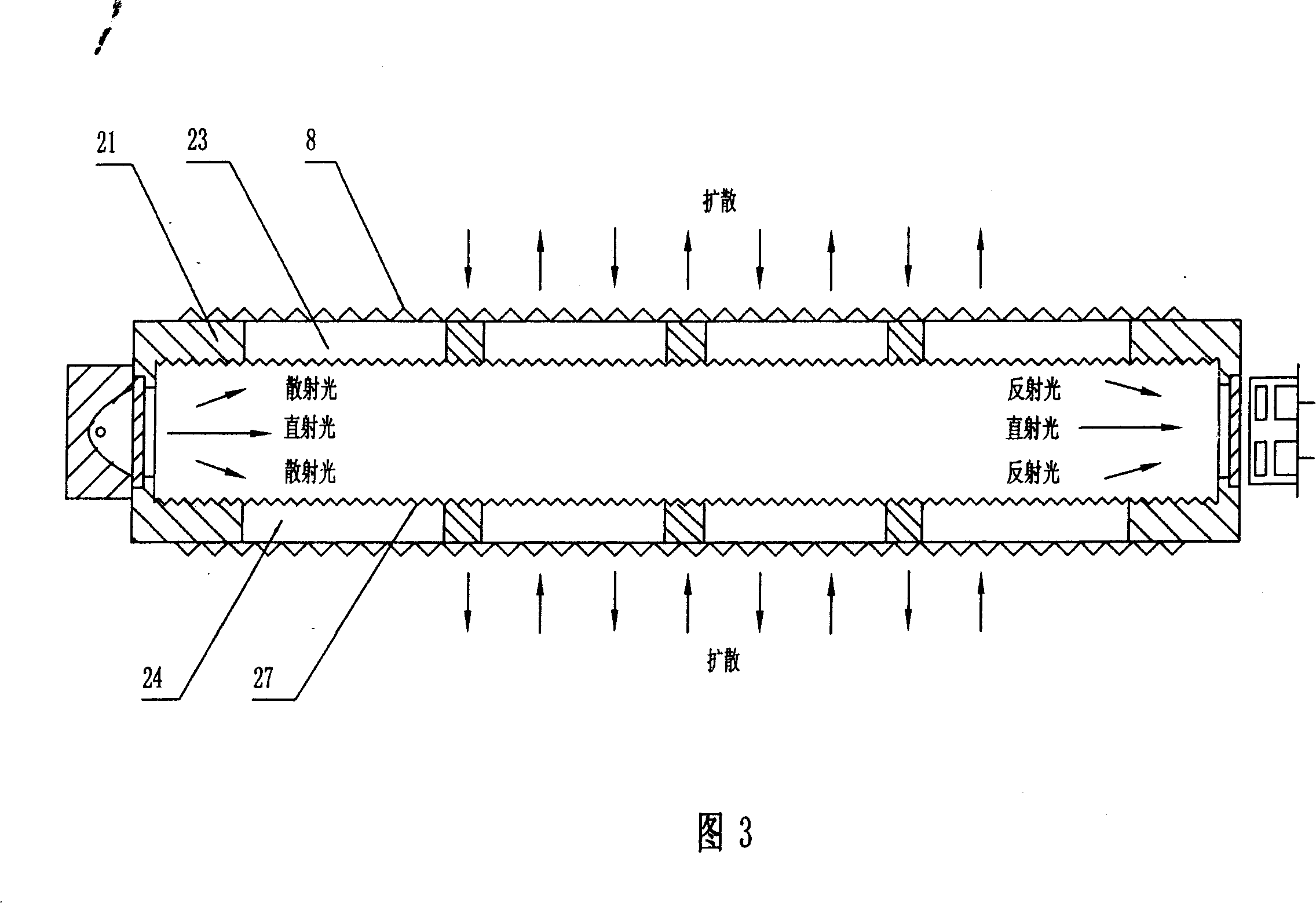

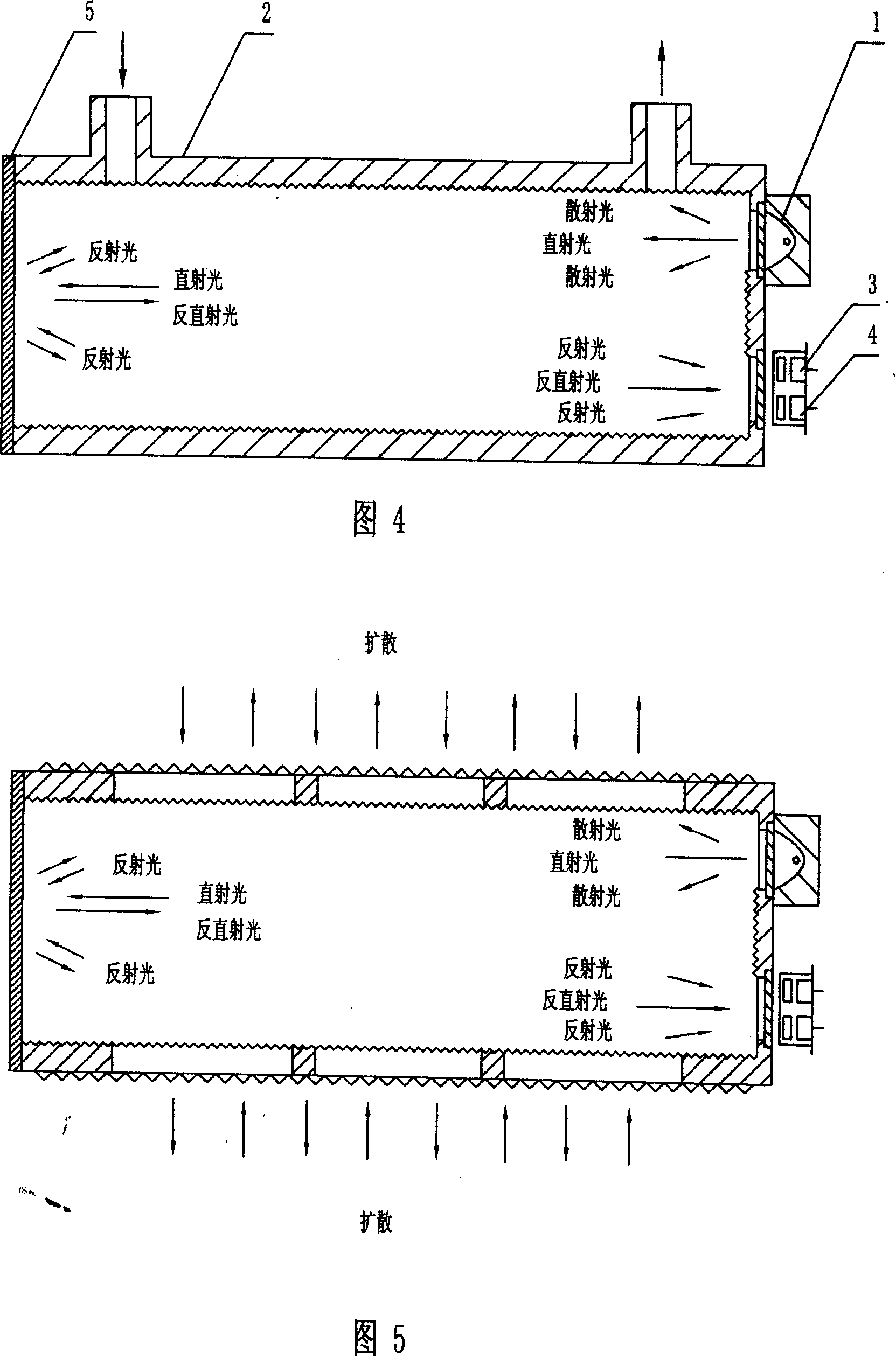

Gas sampling room

ActiveCN101153832AImprove dust resistanceImprove interferenceWithdrawing sample devicesMaterial analysis by optical meansGas analysisCavity wall

The invention discloses a gas-sampling chamber which is applied in infrared gas analysis instrument (or sensor) field, is capable of reducing the affect of dust and water vapour on measurement accuracy furthermost so as to improve measurement accuracy. The chamber structure comprises a cavity body which is provided with an opening that allows an inner cavity to be communicated with the outside and a window that beam can permeate, and is characterized in that the inner cavity of the sampling chamber is also provided with a device that is capable of blocking the reflection of beams, which can be realized by making the inner cavity wall more rough, making the inner cavity wall with material that absorbs infrared light intensely, painting substance that absorbs infrared light on the inner wall surface or arranging a reflected light blocking ring that can block reflected light from entering the infrared detector in the sampling chamber cavity body. Then the rate of the reflected light reaching the infrared detector is approximate to zero, thereby improving the anti-dust capability and the anti-water vapour interference capability of the infrared gas analysis instrument (or sensor).

Owner:SHENZHEN WINPOWER TECH CO LTD

External liquid storage box and household appliance

PendingCN108978132AEasy to storeGood dustproof performanceTableware washing/rinsing machine detailsOther washing machinesExternal LiquidEngineering

The invention discloses an external liquid storage box and a household appliance. The external liquid storage box comprises an internally hollow box body for accommodating liquid and also comprises abreathable unit which balances the air pressure inside the hollow box body with that of the outside. The breathable unit comprises an opening and a sealing cover mounted on the opening, one side surface of the sealing cover facing the opening is provided with a ventilation structure, and the ventilation structure communicates with the inside and the outside of the box body through the opening. Thepresent invention also provides the household appliance which is provided with a communication unit that is quickly connected to an external accessory, and the communication unit is mated with and connected to the external liquid storage box. According to the household appliance of the invention, an external detachable liquid storage box assembly manner is employed, so the maintenance of the liquid storage box is simple and convenient, a phenomenon that a clogging problem and the like cannot be solved is effectively avoided, the structure is simple, the disassembly is convenient, and replacement and cleaning are facilitated.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

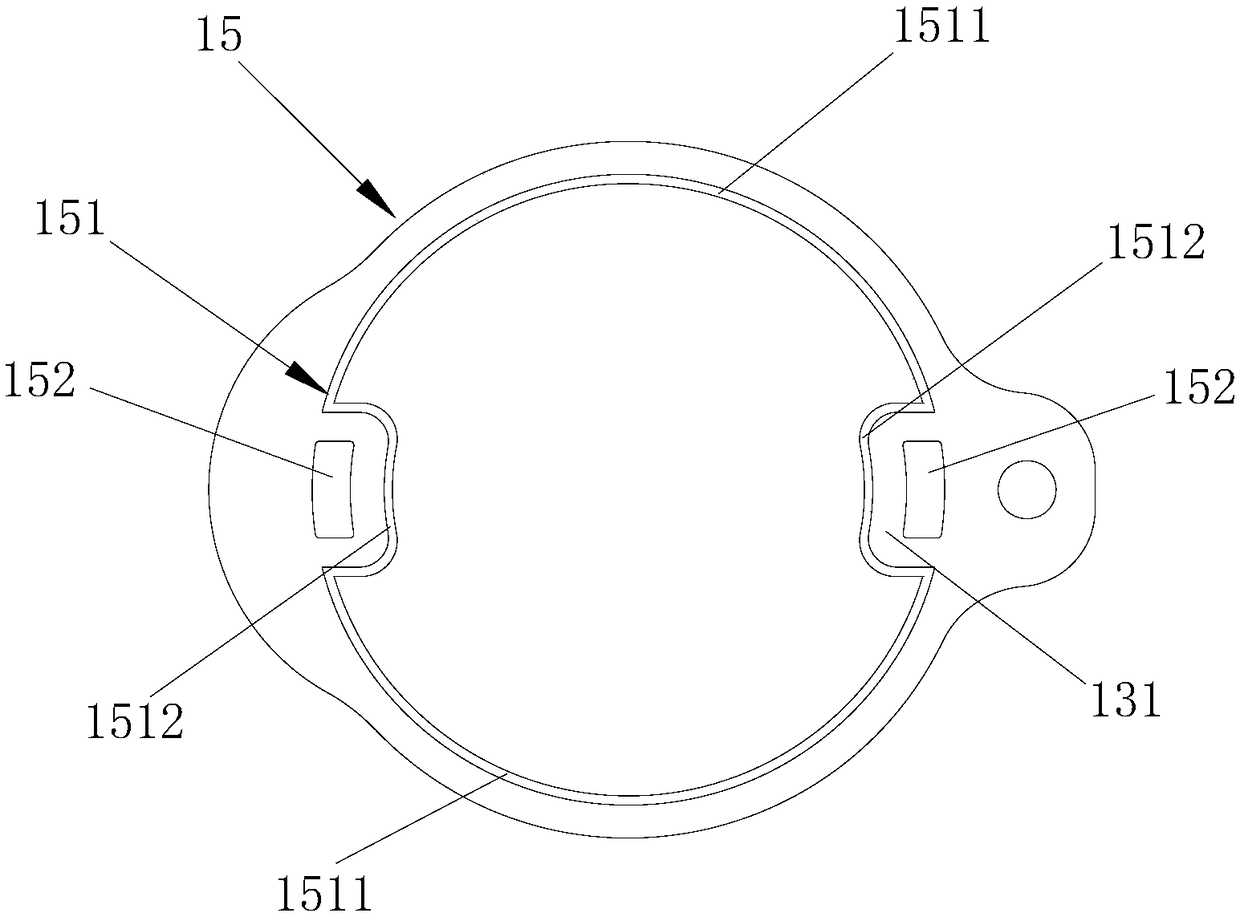

Quick-connection outdoor waterproof electrical connector

InactiveUS8016603B1Improve fitImprove dust resistanceCouplings bases/casesElectricityElectrical connector

A quick-connection outdoor waterproof electrical connector is provided, having the following features: All of the male terminals and the female terminals are all positioned in a peripheral direction with the same diameter; the female terminal is provided at its connection portion with a “U-shaped” structure; for the internal wall of the cylindrical hole and the external edge of the cylindrical plug, one is provided with an “L-shaped” guide slot and the other with a convex guide pole, with the cylindrical hole being provided at its bottom with an end-plane waterproof washer.

Owner:LEOCO SUZHOU PRECISE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com