Quick connecting type outdoor waterproof electric coupler

An electrical connector, outdoor technology, applied in the direction of connection, connecting device parts, circuits, etc., can solve the problems of poor contact, decreased terminal reliability, metal fatigue of shrapnel, etc., to achieve convenient outdoor construction and operation, and ensure electrical conductivity. effect, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

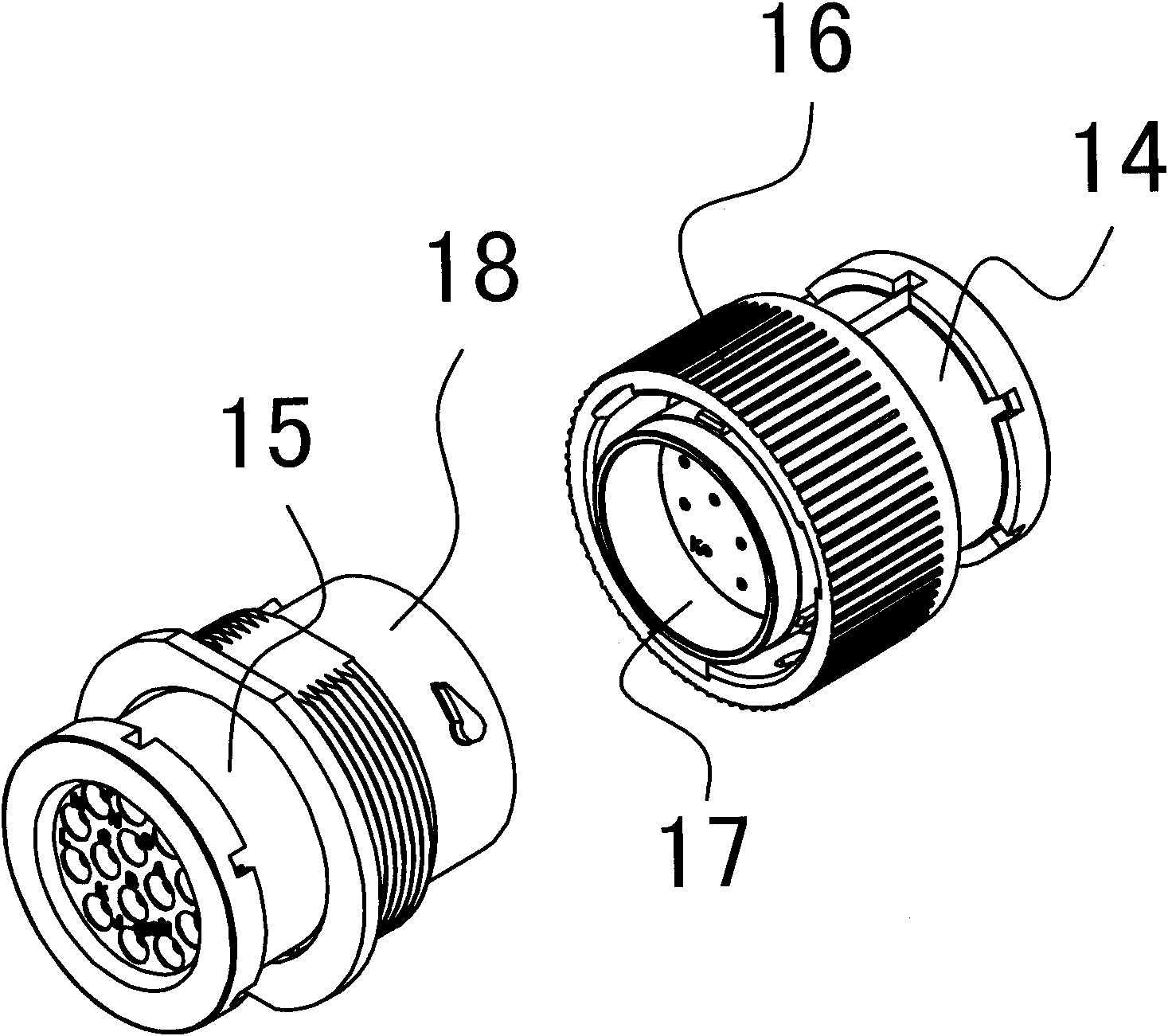

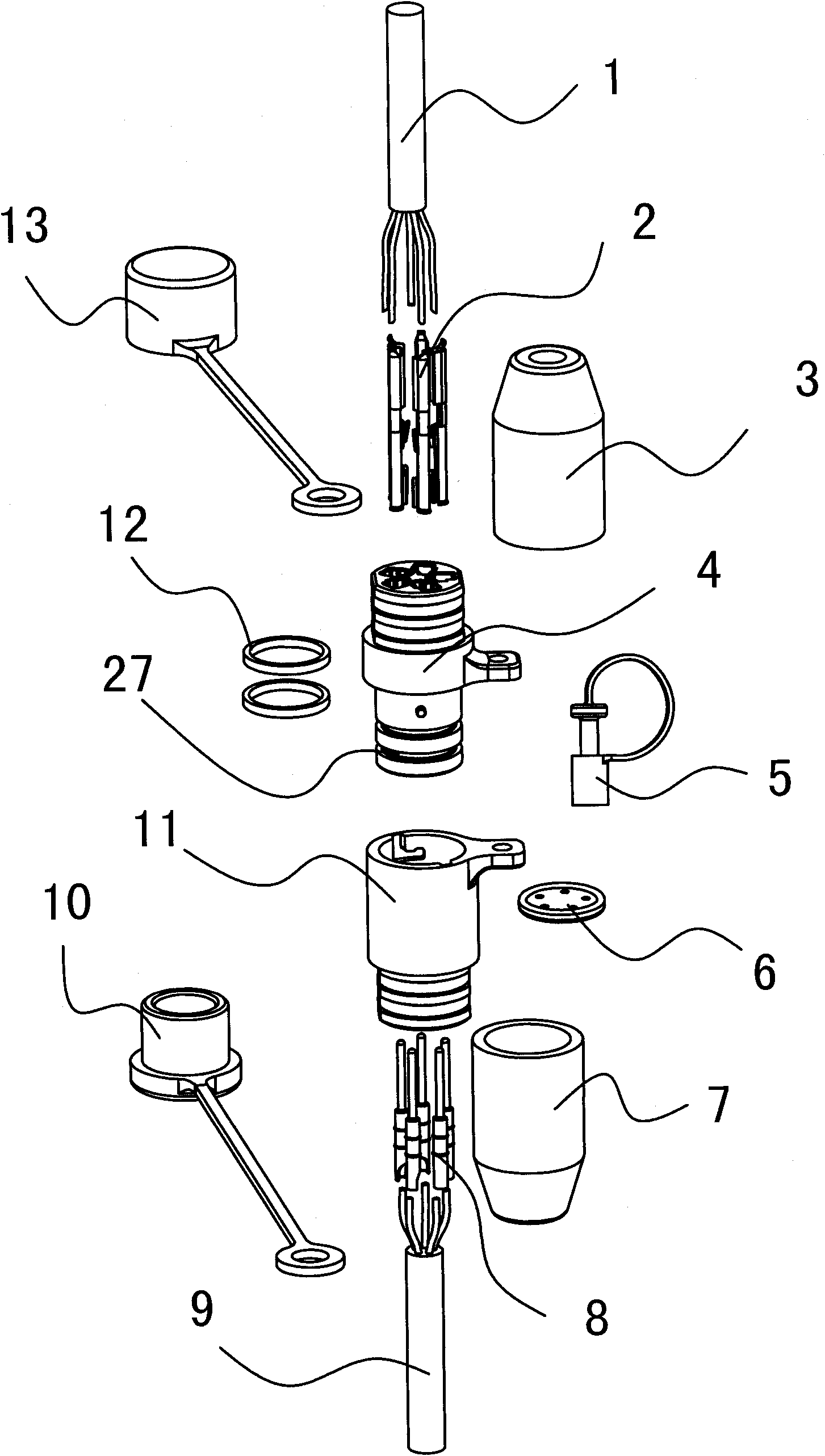

[0053] Example: a quick-connect outdoor waterproof electrical connector

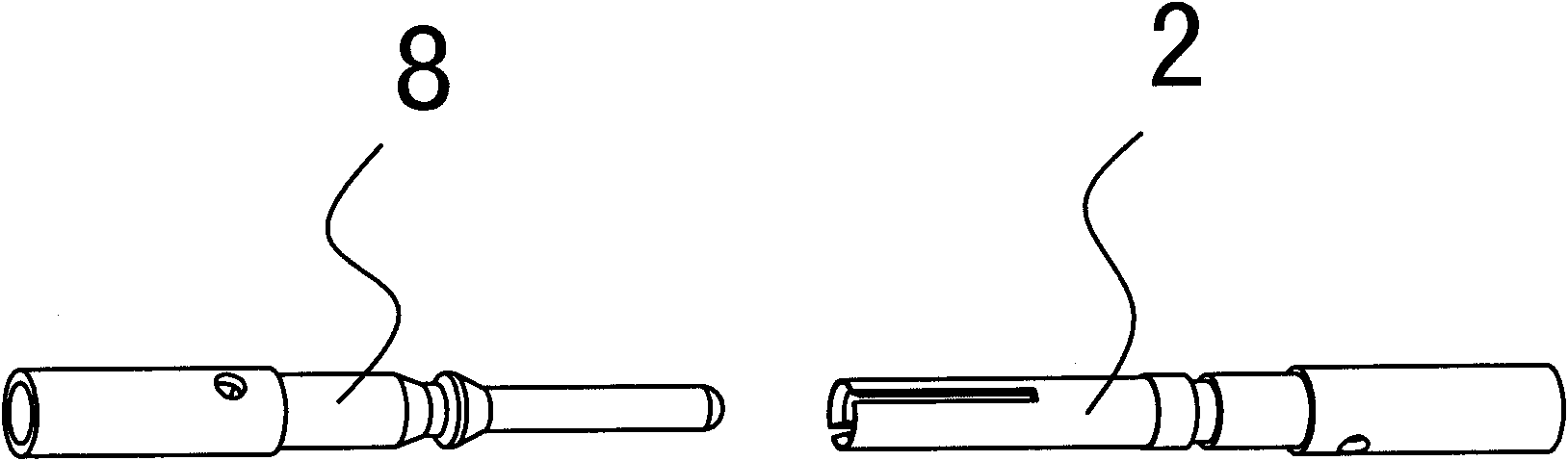

[0054] Such as Figure 3 ~ Figure 23 As shown, the quick-connect outdoor waterproof electrical connector includes a male connector 14 and a female connector 15 (see Figure 8-10 ). The connecting end of the male seat connector 14 is concavely provided with a cylindrical hole 17 for connecting (see Figure 12 ), a strip-shaped male terminal 8 is arranged parallel to the axial direction in the cylindrical hole 17, the head of the strip-shaped male terminal 8 is suspended in the cylindrical hole 17, and the root is fixed in the body of the male seat connector 14. The male seat joint 14 is composed of a male outer mold 7 and a male rubber core 11 (see image 3 and Figure 10 ). The female joint 15 is composed of a female outer mold 3 and a female rubber core 4 (see image 3 and Figure 10 ), the connecting end of the female base joint 15 is convexly provided with a cylindrical plug 18 that is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com