Patents

Literature

1154results about How to "Guaranteed electrical conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

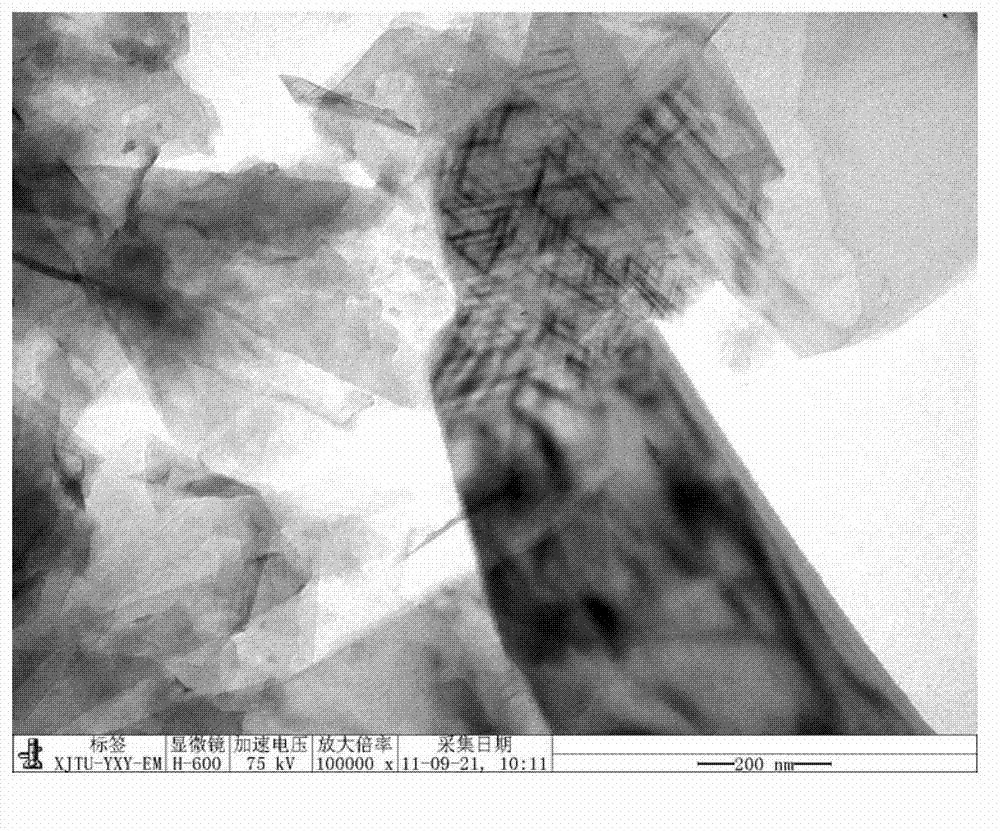

Li-ion secondary battery cathode material preparation method with nuclear shell structure

ActiveCN101752547AGuaranteed electrical conductivityImproving the performance of electrochemical lithium intercalation reactionElectrode manufacturing processesCarbon layerSolvent

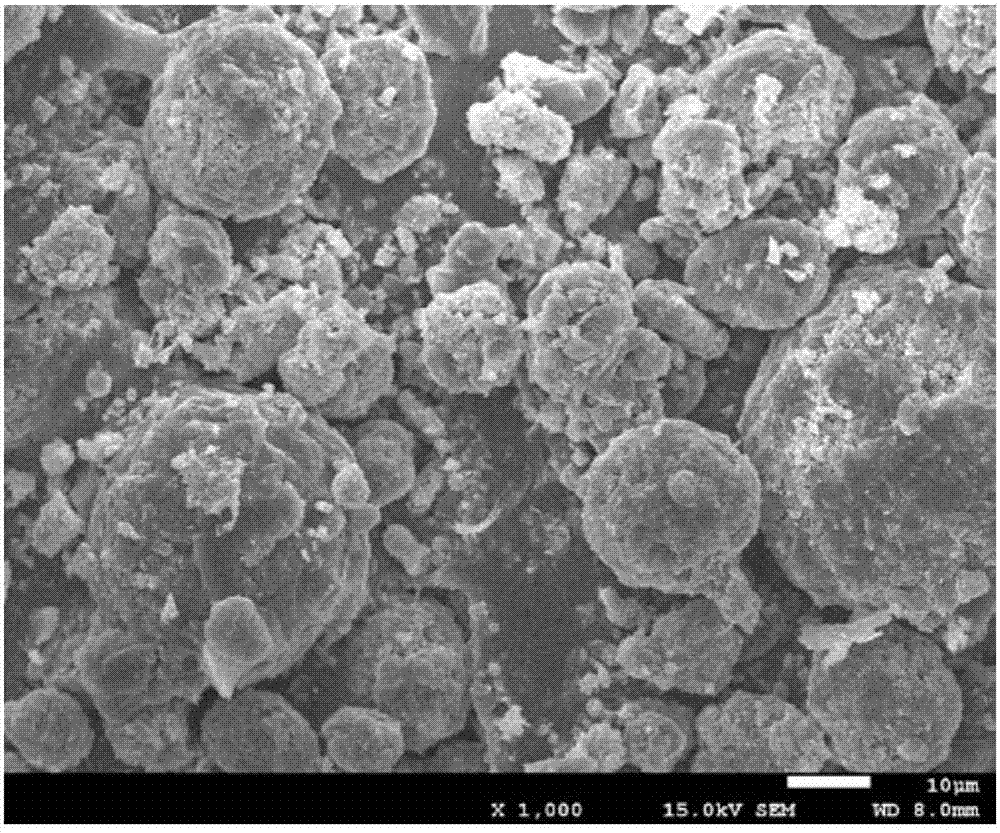

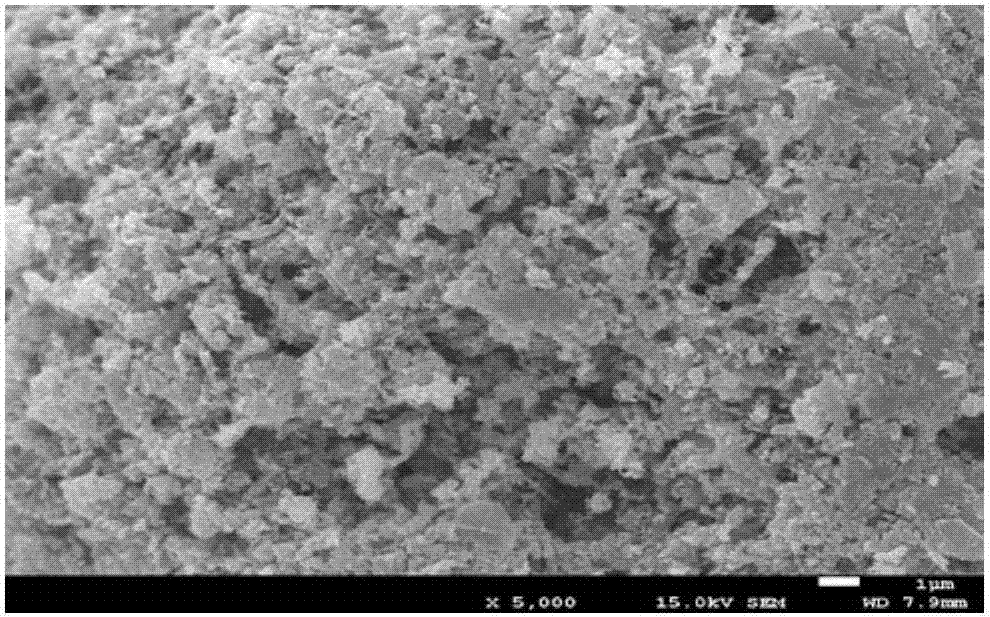

The invention relates to a Li-ion secondary battery cathode material preparation method with a nuclear shell structure; the preparation method is characterized in that: SiO, asphalt and graphite are weighted and are added in solvent for carrying out stirring; drying is carried out; the solvent is extracted out to obtain precursors which are uniformly distributed; the precursors are arranged in a high-temperature furnace, high-temperature sintering is carried out at inert atmosphere, the temperature is reduced to room temperature, so as to obtain the Li-ion secondary battery cathode material preparation method with the nuclear shell structure; meanwhile, the SiO, the asphalt and the graphite are chosen as initial raw material, so as to prepare the Si-SiO2-C electrode material with the nuclear shell structure, when the volume of the buffering Si material is expanded, the electricity-conducting capacity of the electrode material is ensured and the electro-chemical Li-embedded reaction property of the electrode material is improved; the asphalt is used as a carbon source, while reducing the product cost, the material is coated; a regular carbon layer structure is set up in the material body and on the surface, so as to improve the electricity-conducting performance of the material; the method has simple process and is suitable for large-scale industrial production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

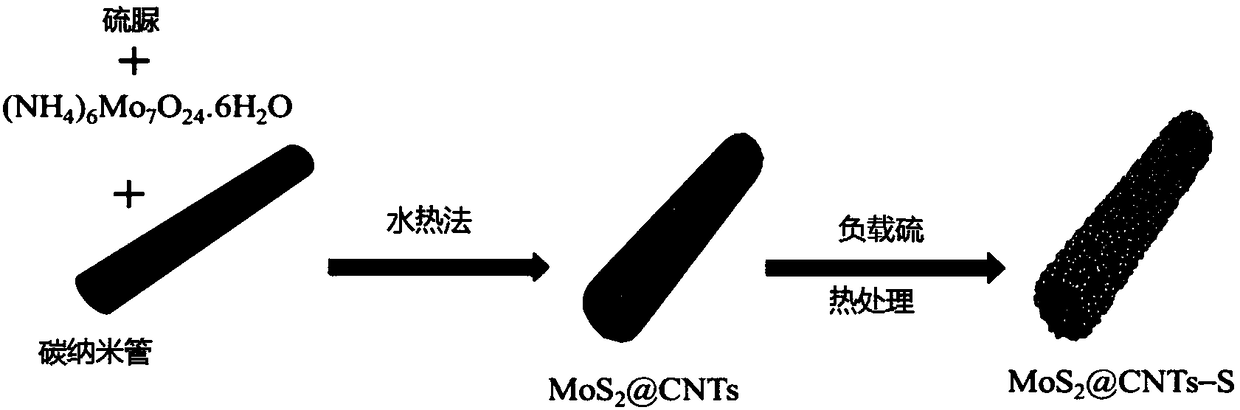

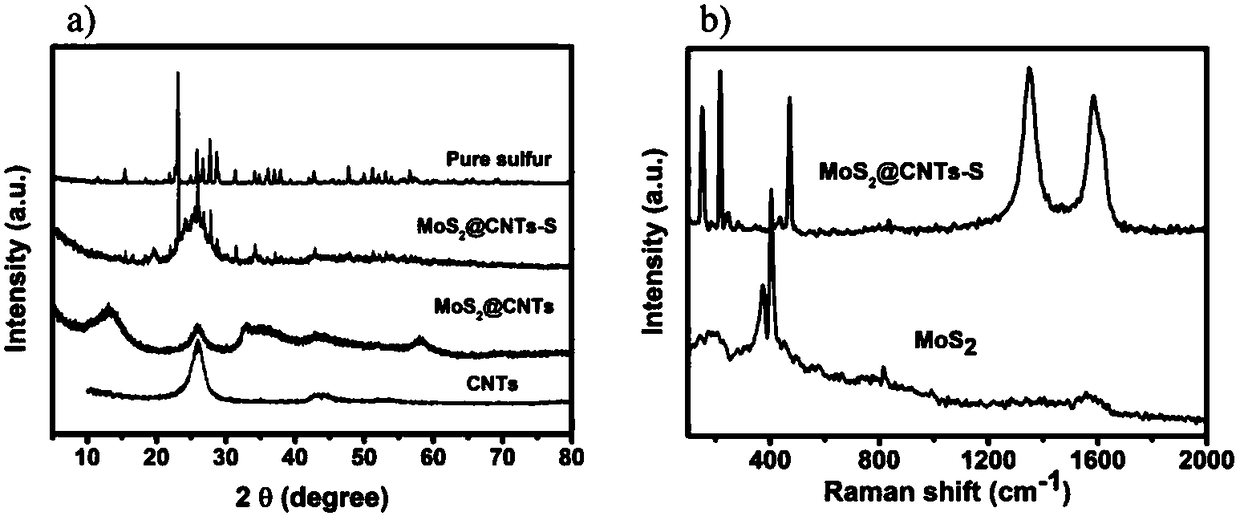

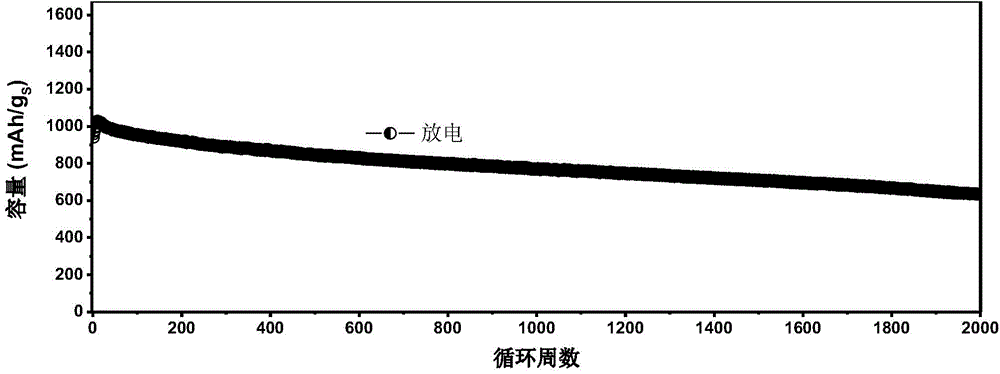

Lithium sulfur battery positive electrode material and preparation method thereof

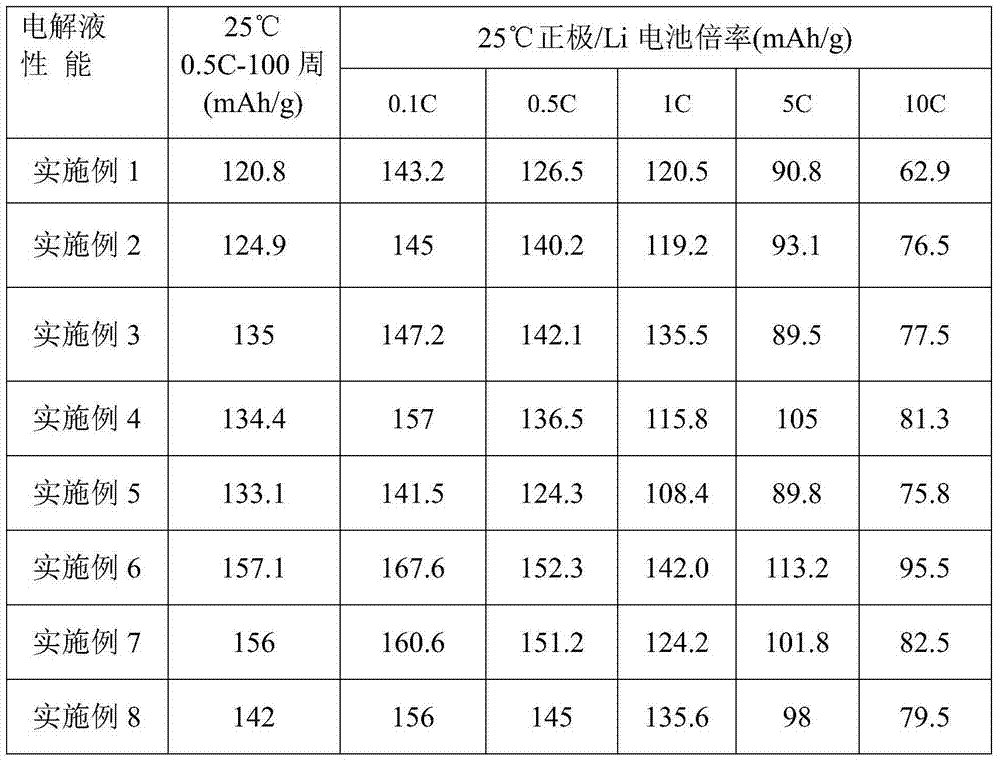

InactiveCN108232164AFacilitate the transfer of electronsImprove charge and discharge propertiesPositive electrodesLi-accumulatorsChemistryHigh rate

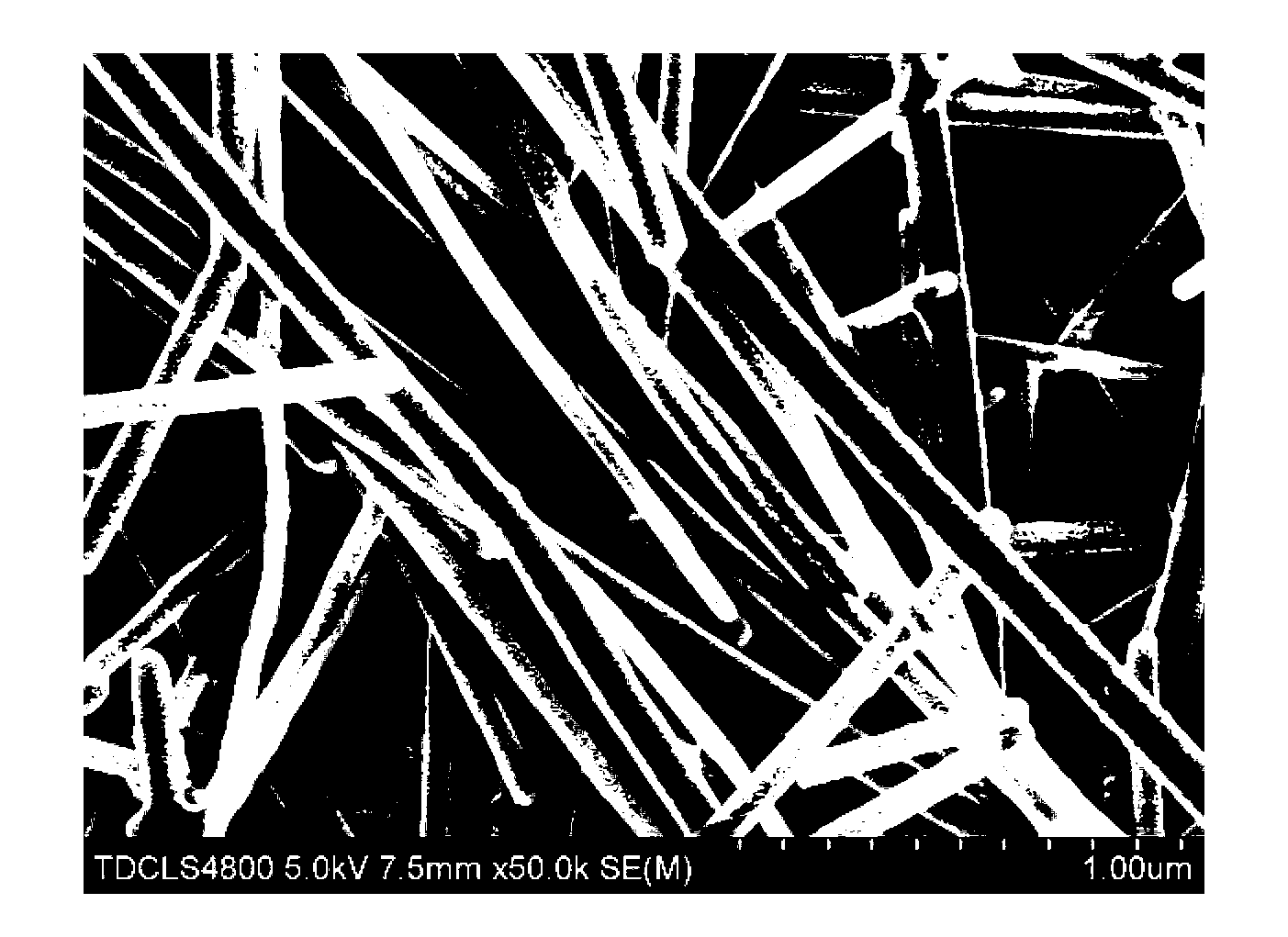

The invention belongs to the field of lithium sulfur battery material, and in particular, relates to a lithium sulfur battery positive electrode material including a host material and elemental sulfurloaded on the host material; the host material includes carbon nanotubes and a transition metal sulfide compounded on the carbon nanotubes. The invention also discloses a preparation method and an application of the positive electrode material. According to the lithium sulfur battery positive electrode material, a strategy of adding the transition metal sulfide is adopted for reducing a back-and-forth shuttling effect; secondly, the carbon nanotubes are added to prevent the collapse of an electrode structure; the positive electrode material has excellent electrochemical performance, and is applied to a lithium sulfur battery to show high initial discharge capacity, high coulombic efficiency and high rate performance.

Owner:CENT SOUTH UNIV

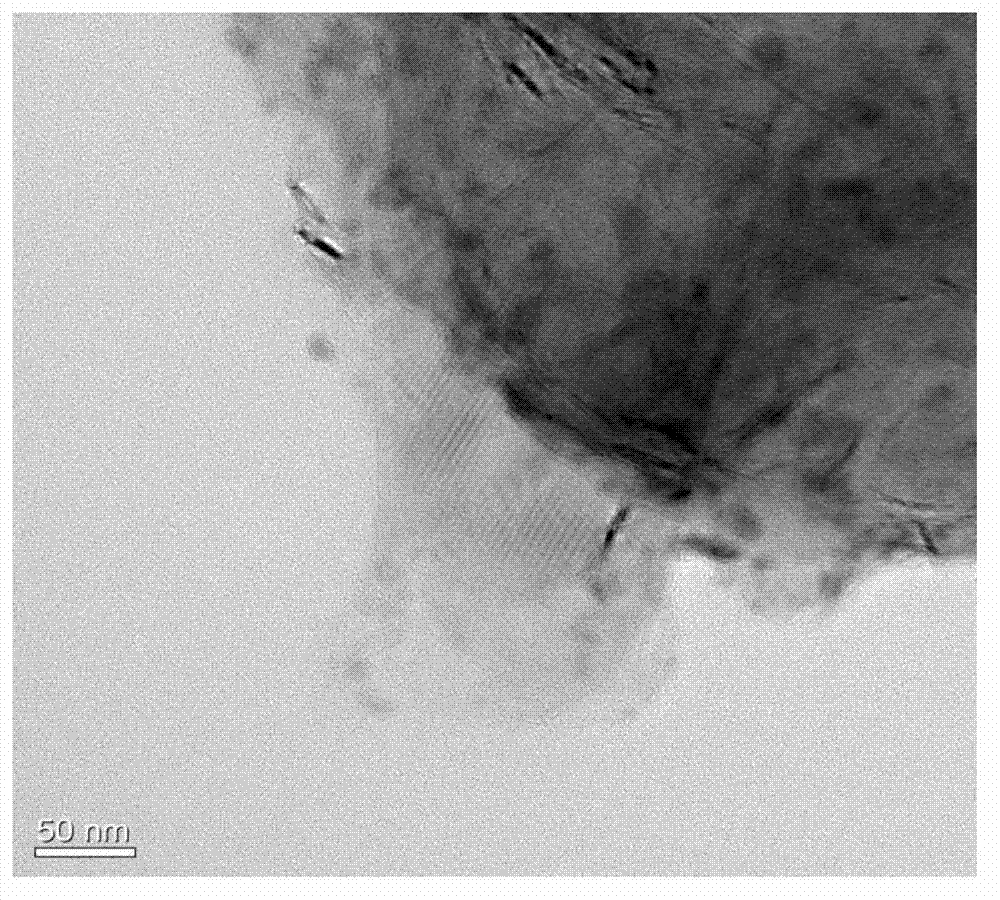

Lithium ion battery negative electrode active material, preparation method thereof, negative electrode and battery

ActiveCN107293700AImprove conductivityImprove structural stabilityCell electrodesSecondary cellsCarbon layerCarbon composites

The invention provides a lithium ion battery negative electrode active material. The lithium ion battery negative electrode active material has a three-layer composite structure and comprises an inner core, an intermediate layer and an outermost layer, wherein the inner core is silicon carbon composite particles, the intermediate layer is a porous carbon layer, and the outermost layer is a compact carbon layer. The invention also provides a preparation method of the lithium ion battery negative electrode active material, a negative electrode comprising the negative electrode active material and a battery. By the lithium ion battery negative electrode active material, the technical problems that the volume of nanometer silicon particles in the silicon carbon negative electrode lithium ion battery in the prior art is expanded and the electrical conductivity is reduced are solved, meanwhile, an electrolyte can be effectively isolated by the compact carbon layer of the prepared negative electrode material, the electrolyte invasion is prevented, and the initial efficiency and the cycle property of the battery are improved.

Owner:BYD CO LTD

Recovery method of positive active material in lithium ion battery waste material

InactiveCN103794832AHigh charge and discharge capacityImprove charge and discharge efficiencyWaste accumulators reclaimingBattery recyclingElectrochemistryLithium electrode

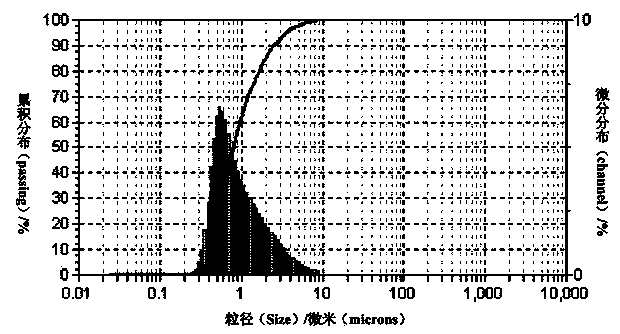

The invention provides a recovery method of a positive active material in a lithium ion battery waste material. The method includes the following steps: S1, heat treatment of the waste material is performed at 350-500DEG C in inert gas or reducing gas atmosphere; S2, powder product obtained in the step S1 is sintered at 600-800DEG C in the inert gas or reducing gas atmosphere; and the positive active material is obtained by recovery; the positive active material is one or multiple substance selected from lithium phosphate, lithium silicate or a vanadium material of lithium. The positive active material obtained by recovery is high in charge and discharge capacity, and high in charge and discharge efficiency, the obtained positive active material is even in particle size distribution, and complete in crystal structure, the technical process of the recovery method is simple, the requirement on equipment is low, the process is easy to control, at the same time, the recovery process may not cause a negative impact on the active material, physical and chemical properties and electrochemical activity of the active material may not be affected, the recovery and reuse of the positive active material raw material can be realized, the cost can be saved, and the recovery method has environmental-friendly benefits.

Owner:BYD CO LTD

Method for preparing nano-silver particle and nano-silver wire mixed conductive ink

The invention discloses a method for preparing nano-silver particle and nano-silver wire mixed conductive ink. In the method, nano-silver particles and nano-silver wires are uniformly dispersed in a solvent. In the prepared nano-silver mixed conductive ink, the mass percentage of the nano-silver particles is 6-10 percent of the total mass of the conductive ink, and the mass percentage of the nano-silver wires is 2-5 percent of the total mass of the conductive ink. The solvent is a mixed solution which comprises the components by volume percentage of 40-50 percent of ethanol, 50-60 percent of ethylene glycol and 5-10 percent of glycerin. The mixed conductive ink has low content of silver, low cost and high electrical conductivity and is specially suitable for printing ways such as intaglio printing, letterpress printing and the like.

Owner:TIANJIN UNIV

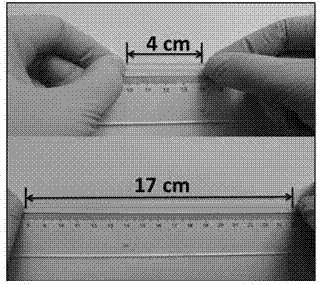

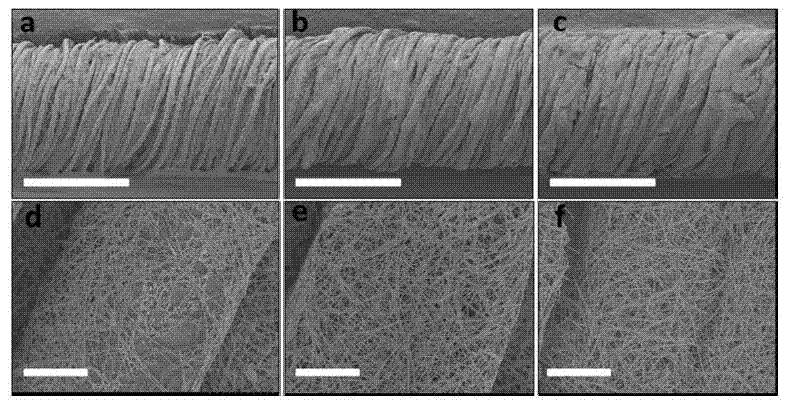

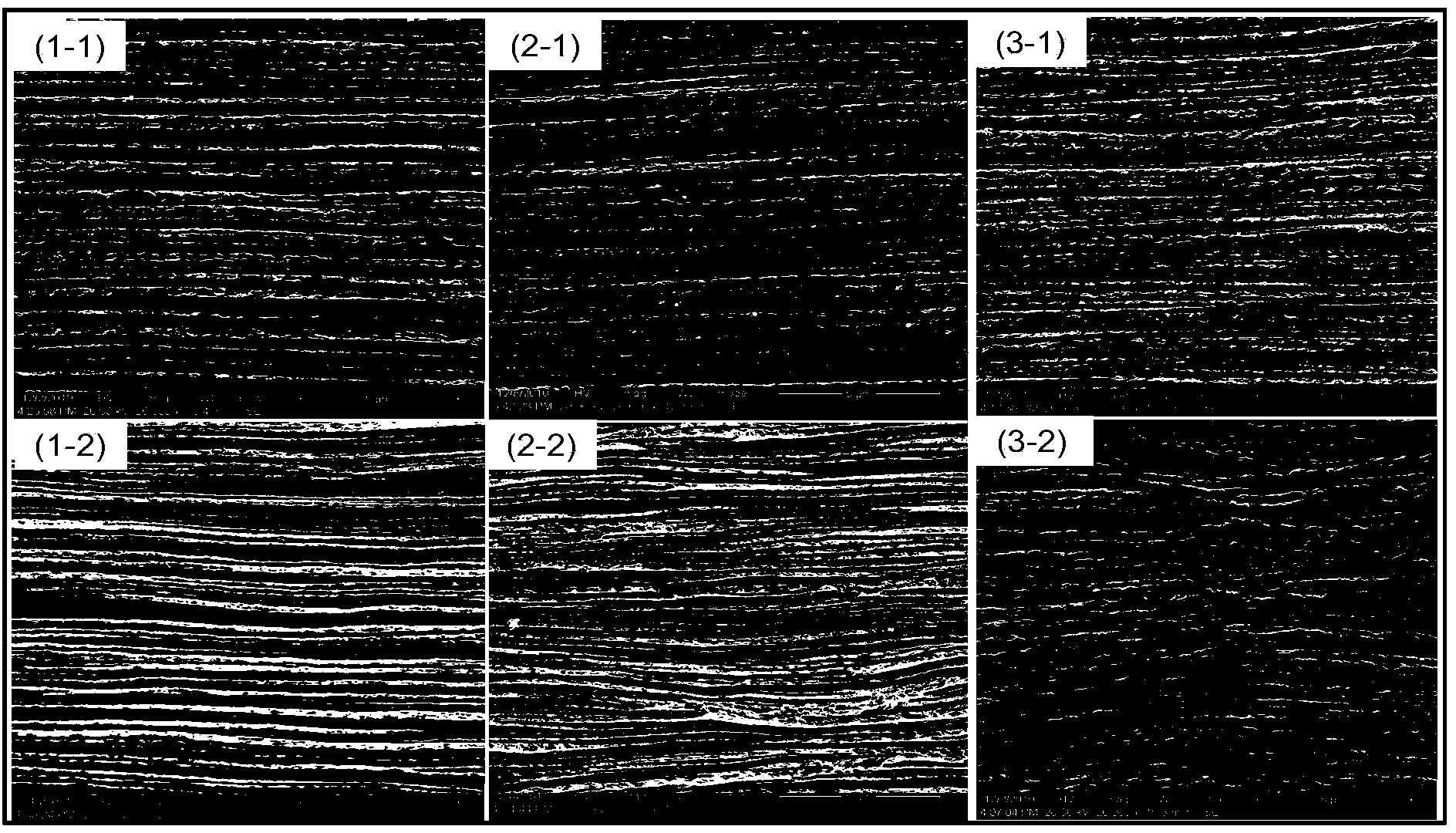

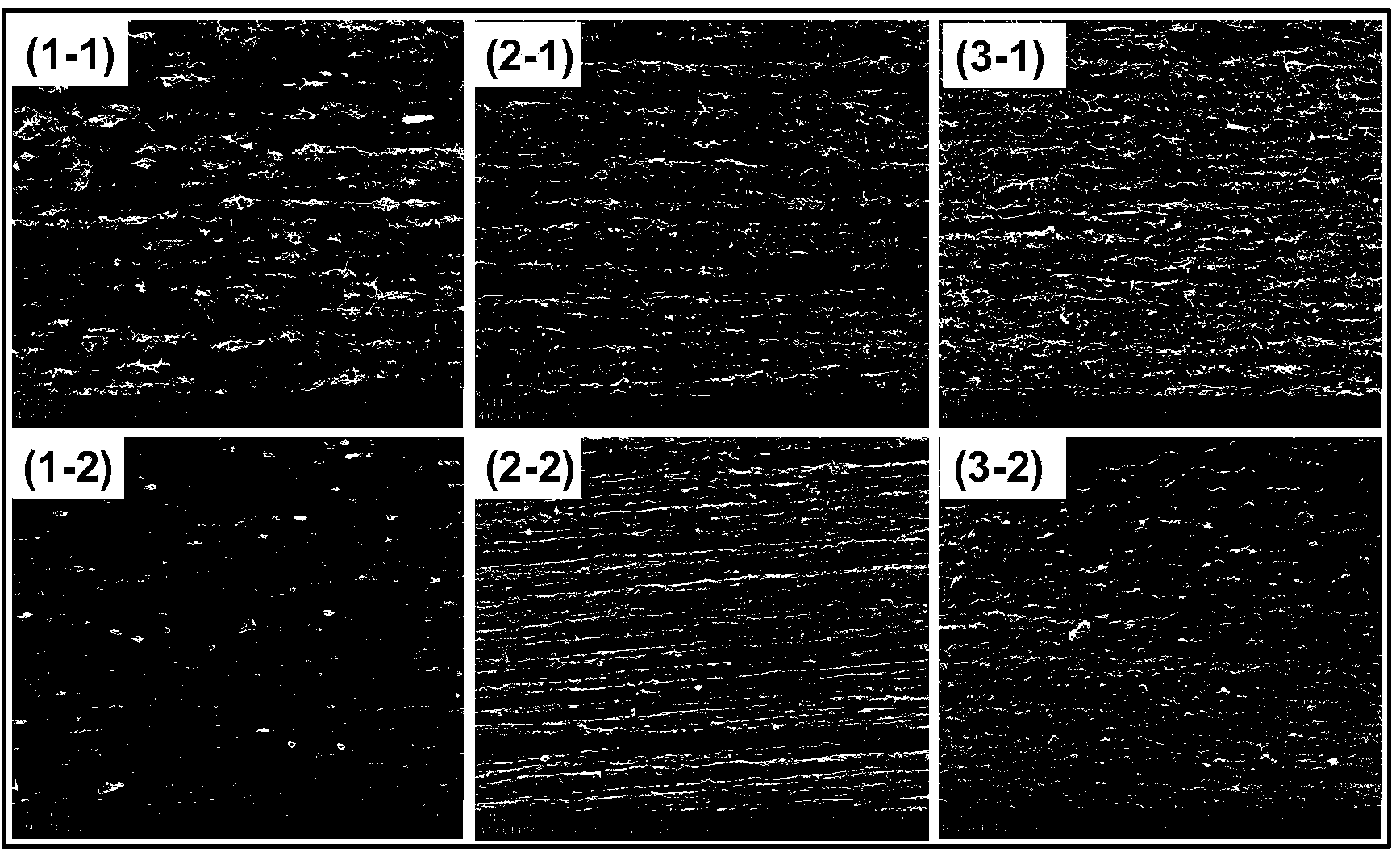

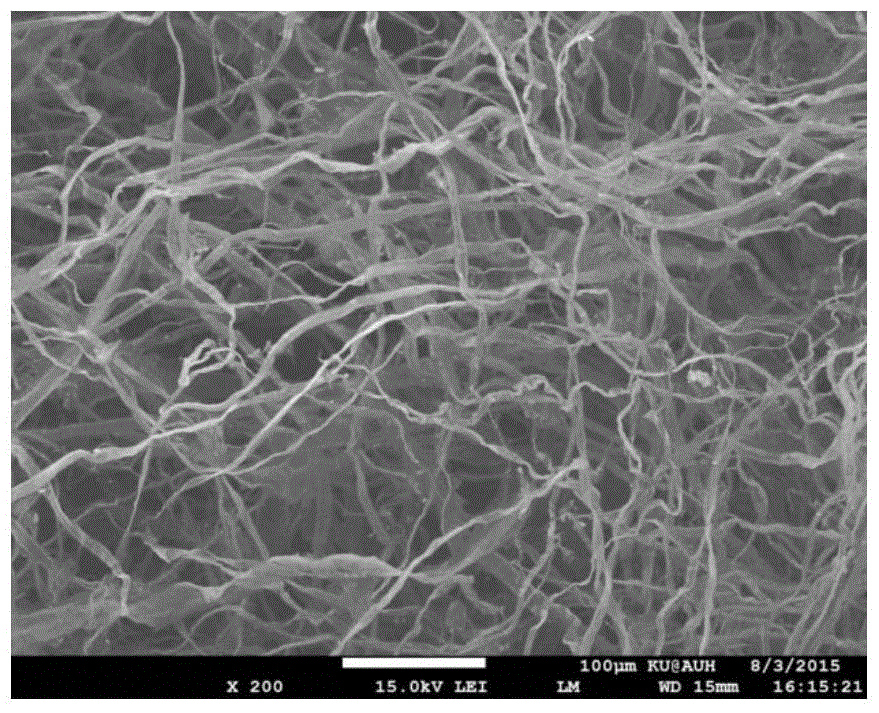

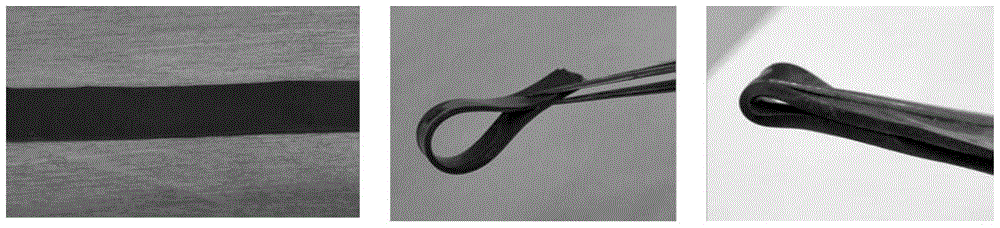

High-elasticity conductive fiber and preparation method thereof

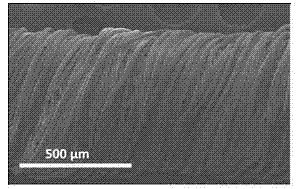

The invention relates to a high-elasticity conductive fiber and a preparation method thereof. The preparation method includes that firstly, elastic yarns are subjected to preprocessing, secondly, a metal nanowire dispersion liquid is used for impregnating and coating the preprocessed elastic yarns and metal nanowires can be adsorbed to the surface of the elastic yarns, and thirdly, the elastic yarns with the metal nanowires adsorbed to the surface are subjected to hydrogen plasma processing or thermal processing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

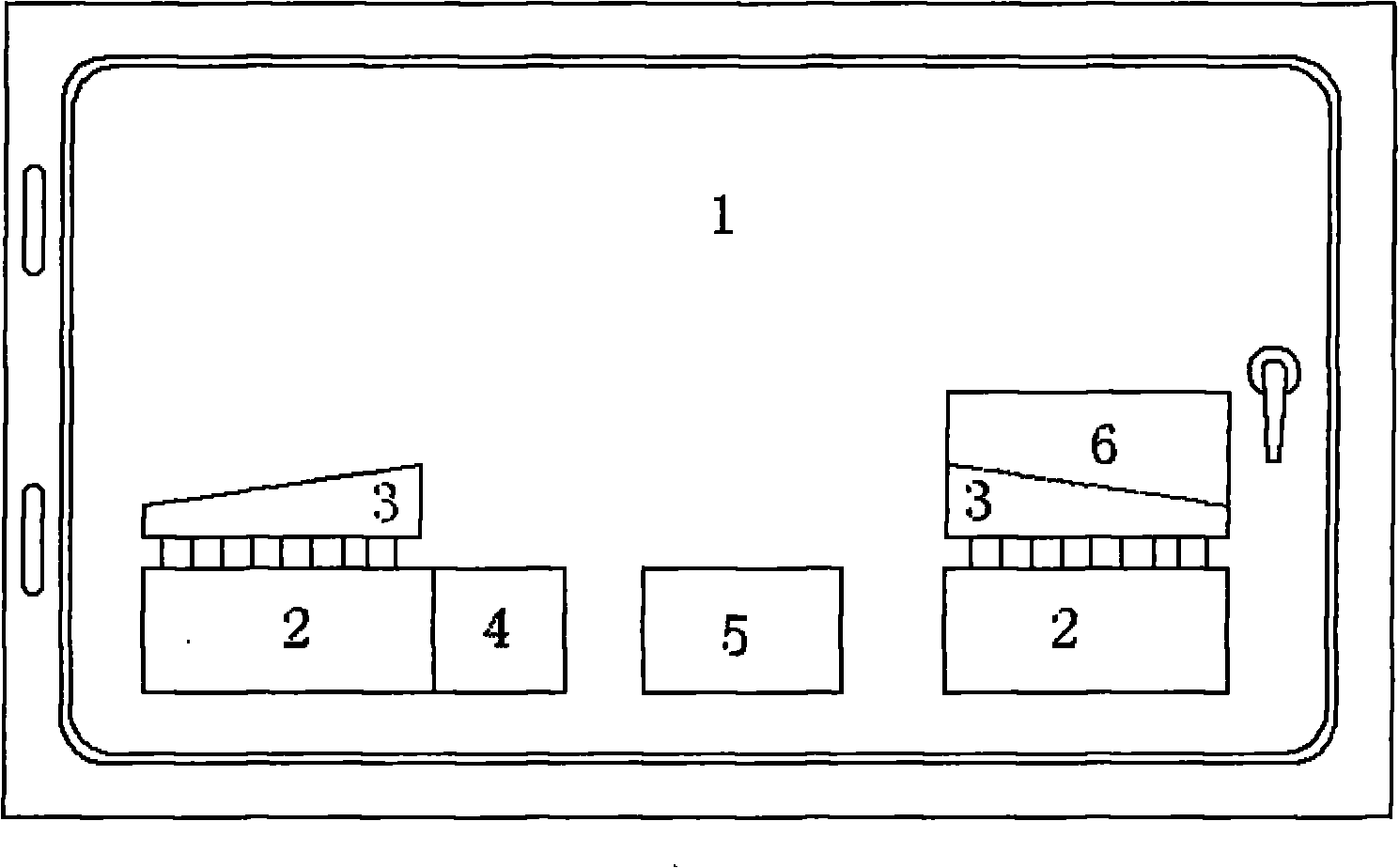

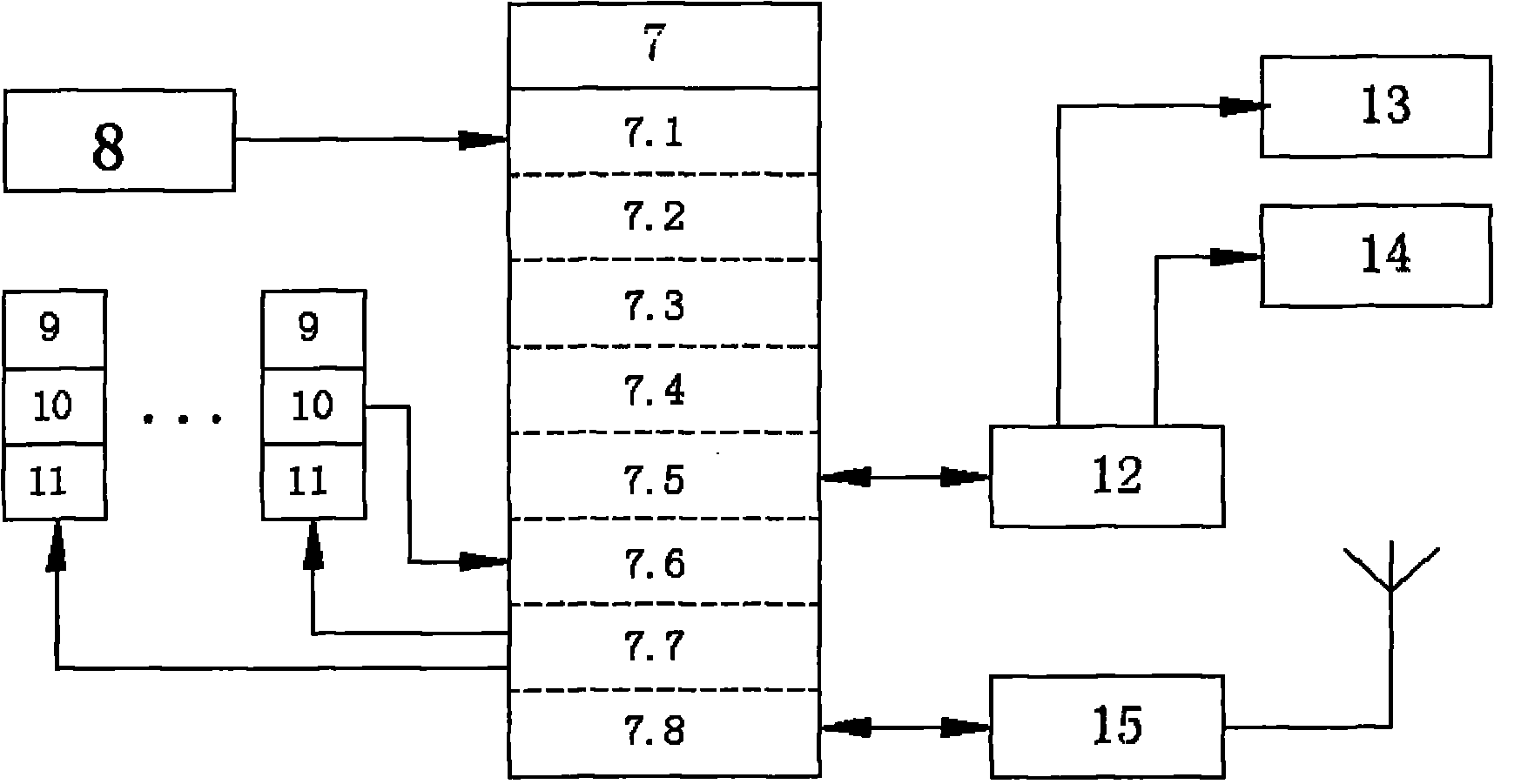

System for monitoring photovoltaic battery pack string

InactiveCN102109578AReduce usageGuaranteed electrical conductivityElectric devicesCurrent/voltage measurementMicrocontrollerEngineering

The invention relates to a system for monitoring a photovoltaic battery pack string and belongs to the field of running and management of a photovoltaic power generation system. In a photovoltaic power station, photovoltaic battery packs are connected in series and then are connected with a header box according to specific conditions, photovoltaic battery pack strings are connected in parallel, and the header box is connected with a grid-connected inverter. When the typical problems of connection, dust accumulation, component obsolescence difference and the like in a photovoltaic battery occur, the efficiency of the photovoltaic power generation system is influenced, and a monitoring system is needed to be arranged in the header box to monitor the photovoltaic battery pack string. The monitoring system can effectively manage the photovoltaic power station by acquiring photovoltaic pack string parameters, and combining other system parameters of the power station to realize autodiagnosis and effectively identify the problem of the power station. The system comprises a singlechip system, a power supply circuit, a voltage detection circuit, a current detection circuit, an intelligent communication interface circuit, an electrical meter chip and the like. In the system, a large-scale integrated circuit is used, and the system has a small volume, is low in energy consumption, has high reliability, and realizes the capacity of continuously monitoring the photovoltaic pack string in the life of the photovoltaic power generation system when assembled in the photovoltaic header box.

Owner:叶明宝

Method for preparing colorful film for protecting solar cell thin grid line metal electrode by adopting mask

InactiveCN101834230ANot easily oxidizedGuaranteed electrical conductivityFinal product manufactureSemiconductor devicesButt jointMetal electrodes

The invention relates to a method for preparing a colorful film for protecting a solar cell thin grid line metal electrode by adopting a mask. In the method, after a solar cell is prepared, a mask is utilized to cover a main grid line metal electrode on the front surface of the solar cell, a film is coated on the area which is not covered by the mask for the second time, and a dielectric layer for protecting the thin grid line metal electrode is prepared to form a structure comprising the dielectric layer, the thin grid line metal electrode and a passivation layer. The method can protect the thin grid line metal electrode against easy oxidation, and the main grid line metal electrode can be normally connected by welding rods. The passivation effect of the front surface can be enhanced through optimizing the passivation layer; the reflectivity of the front surface of the solar cell can be reduced and color regulation can be realized through regulating the dielectric layer; and characters, figures, graphics and the like can be displayed on the front surface of the solar cell through changing a mask pattern. In addition, the secondary film coating method is convenient to be in butt joint with the traditional crystalline silicon solar cell preparation process and is easy for industrialization.

Owner:SUN YAT SEN UNIV

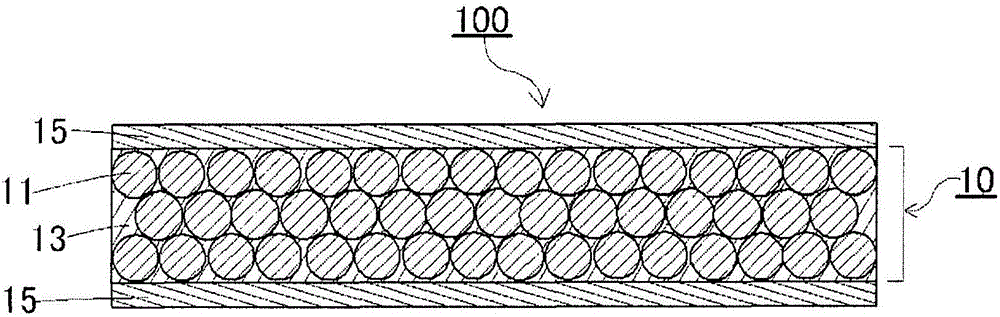

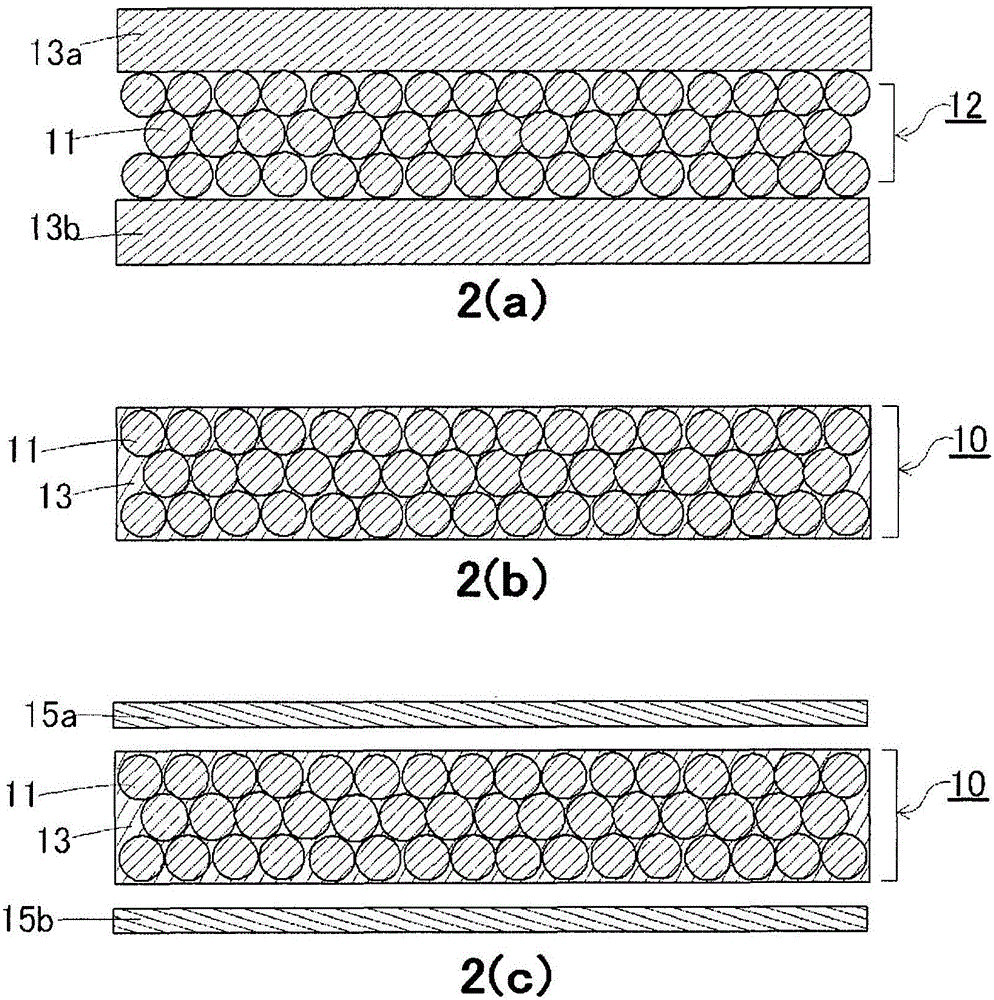

Prepreg and method for producing same

ActiveCN105164192AImprove conductivityImprove impact resistanceSynthetic resin layered productsLaminationFiberEpoxy

The invention provides a prepreg comprising: a primary prepreg composed of reinforcing fibers and a resin composition (I) impregnating the interior of a reinforcing fiber layer formed from these fibers; and a surface layer composed of a resin composition (II) formed on one or both sides of the primary prepreg; wherein the resin composition (I) is an epoxy resin composition [B} containing at least an epoxy resin and a thermoplastic resin, and the resin composition (II) is an epoxy resin composition [A] containing at least an epoxy resin and conductive particles.

Owner:TEIJIN LTD

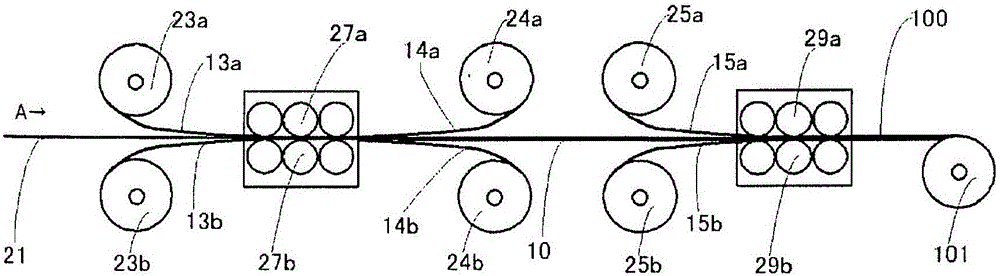

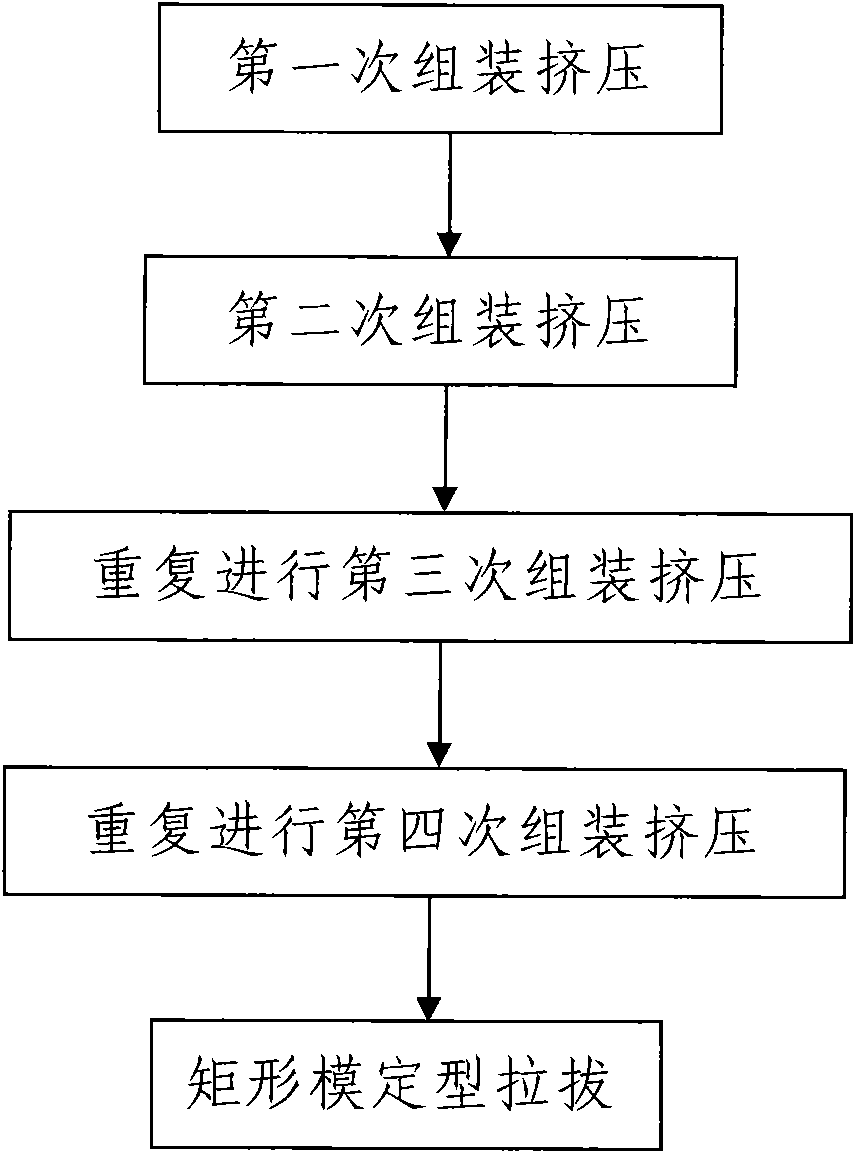

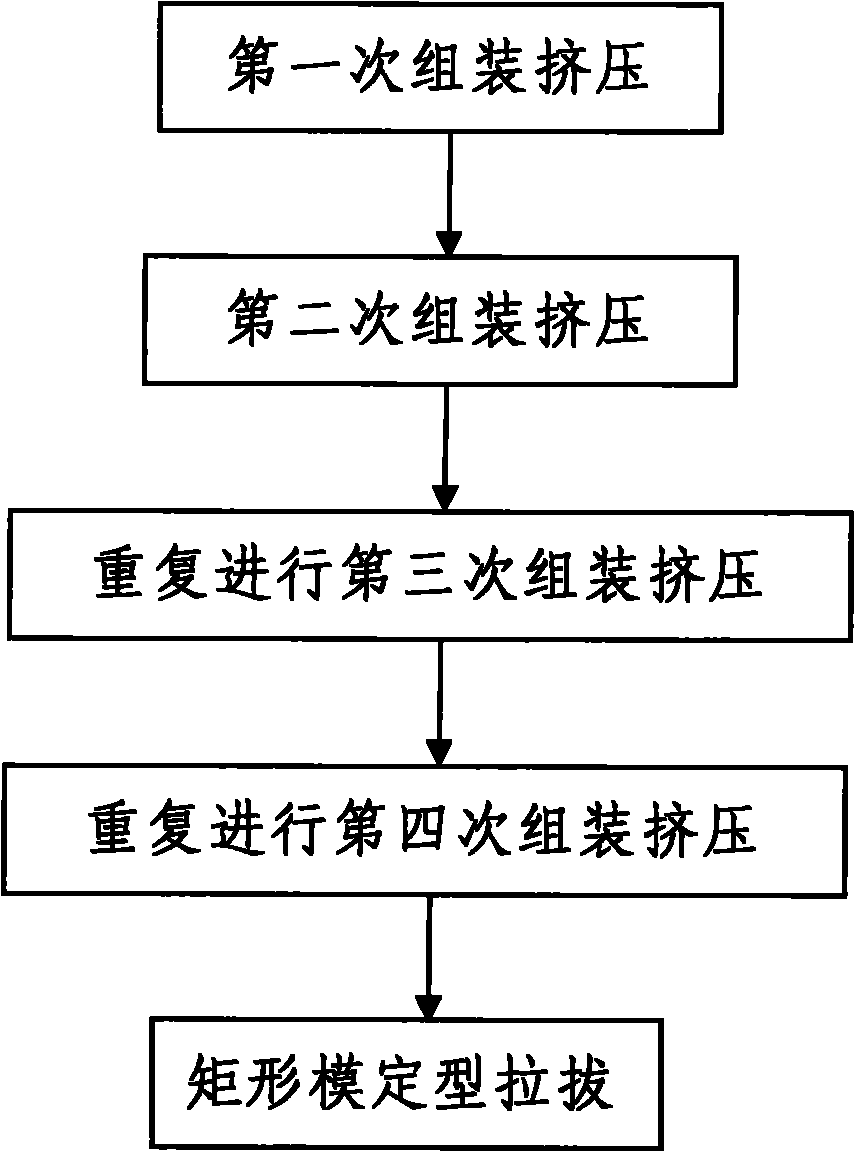

Preparation method of Cu-Nb multi-core composite wire with rectangular cross-section

InactiveCN101872660AThe process steps are simpleShort processSuperconductors/hyperconductorsManufacturing extensible conductors/cablesL&D processExtrusion

The invention discloses a preparation method of a Cu-Nb multi-core composite wire with the rectangular cross-section, which comprises the following steps: firstly, carrying out first extrusion assembly and drawing for a single pure Nb rod and a first outer oxygen-free copper sheathing; secondly, carrying out second extrusion assembly and obtaining a first Cu-Nb multi-core composite filament; secondly, according to the extrusion assembly method and related process parameters in the step 2, repeatedly carrying out third extrusion assembly; thirdly, according to the extrusion assembly method and related process parameters in the step 2, repeatedly carrying out fourth extrusion assembly; and finally, setting and drawing by a rectangular mold. The invention has simple process step, short process, high production efficiency, low preparation cost and good use effect, and the produced Cu-Nb multi-core composite wire has superior performance; and the invention is suitable for mass production, can better control the dimensional accuracy of the rectangular cross-section, and can machine any size and length of hundred-million-magnitude-order Cu-Nb multi-core composite wires with the rectangular cross-section.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

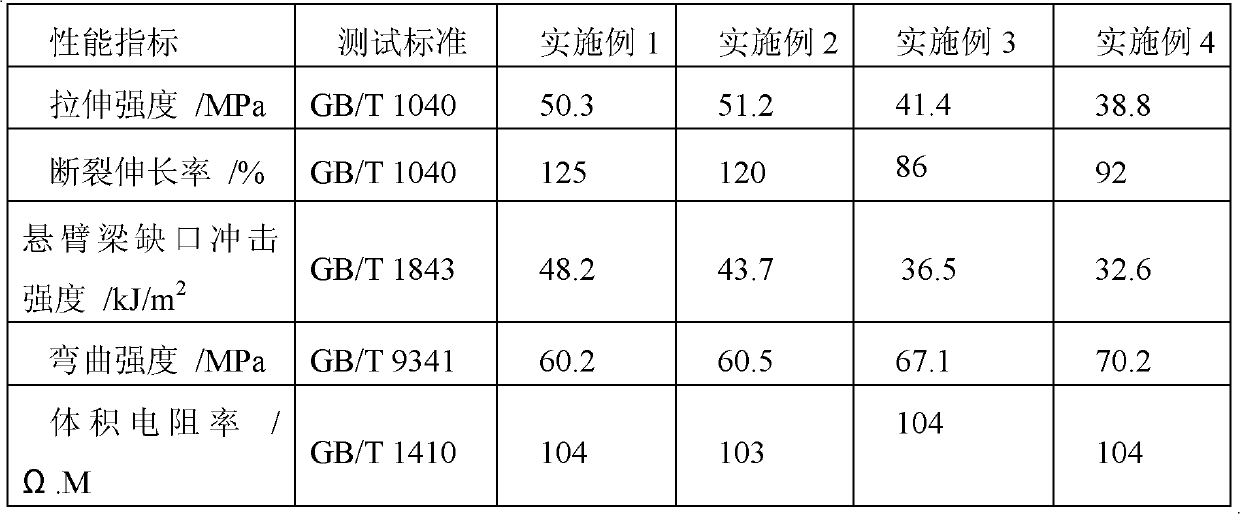

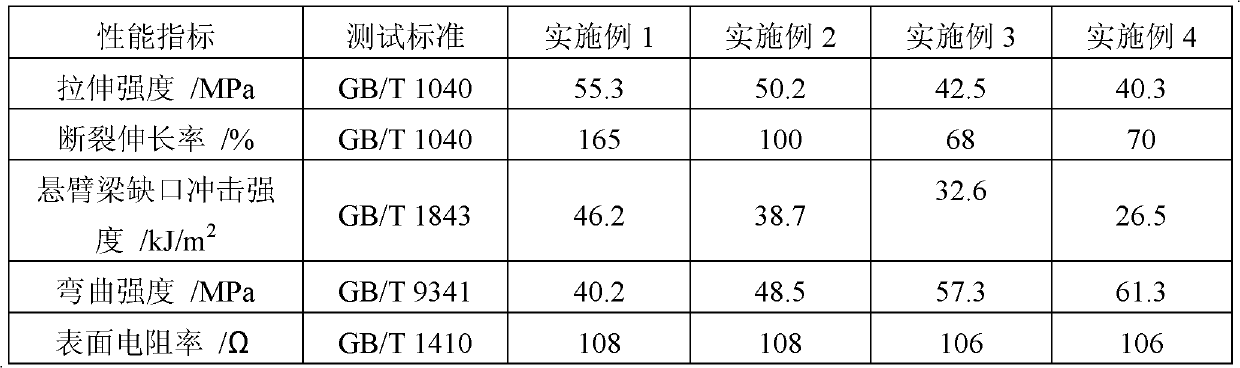

Toughened conducting material and preparation method for toughened conducting material

ActiveCN102585348AImprove conductivityGood dispersionNon-conductive material with dispersed conductive materialPolymer compositesPolypropylene

The invention belongs to the technical field of polymer composites and discloses a toughened conducting material and a preparation method for the toughened conducting material. The toughened conducting material disclosed by the invention comprises the following components in parts by weight: 40-70 parts of polypropylene, 5-15 parts of polyethylene, 5-20 parts of ethylene-octene copolymer, 0-20 parts of calcium carbonate, 2-5 parts of compatilizer, 0.1-0.5 parts of coupling agent, 2-25 parts of conducting packing and 0.1-0.5 parts of antioxygen. The preparation method for the toughened conducting material disclosed by the invention comprises the following steps of: weighing 40-70 parts of polypropylene, 5-15 parts of polyethylene, 5-20 parts of ethylene-octene copolymer, 0-20 parts of calcium carbonate, 2-5 parts of compatilizer, 0.1-0.5 parts of coupling agent, 2-25 parts of conducting packing and 0.1-0.5 parts of antioxygen; mixing in a high-speed mixing machine for 5 minutes; then taking out; performing extruding granulation in a twin-screw extruder to prepare the toughened conducting material, wherein the temperature of the extruder is set to be 175-215 DEG C. The material disclosed by the invention can be widely applied to the field of automobiles, electrical and electronic equipment, industrial machinery and the like.

Owner:HEFEI GENIUS NEW MATERIALS

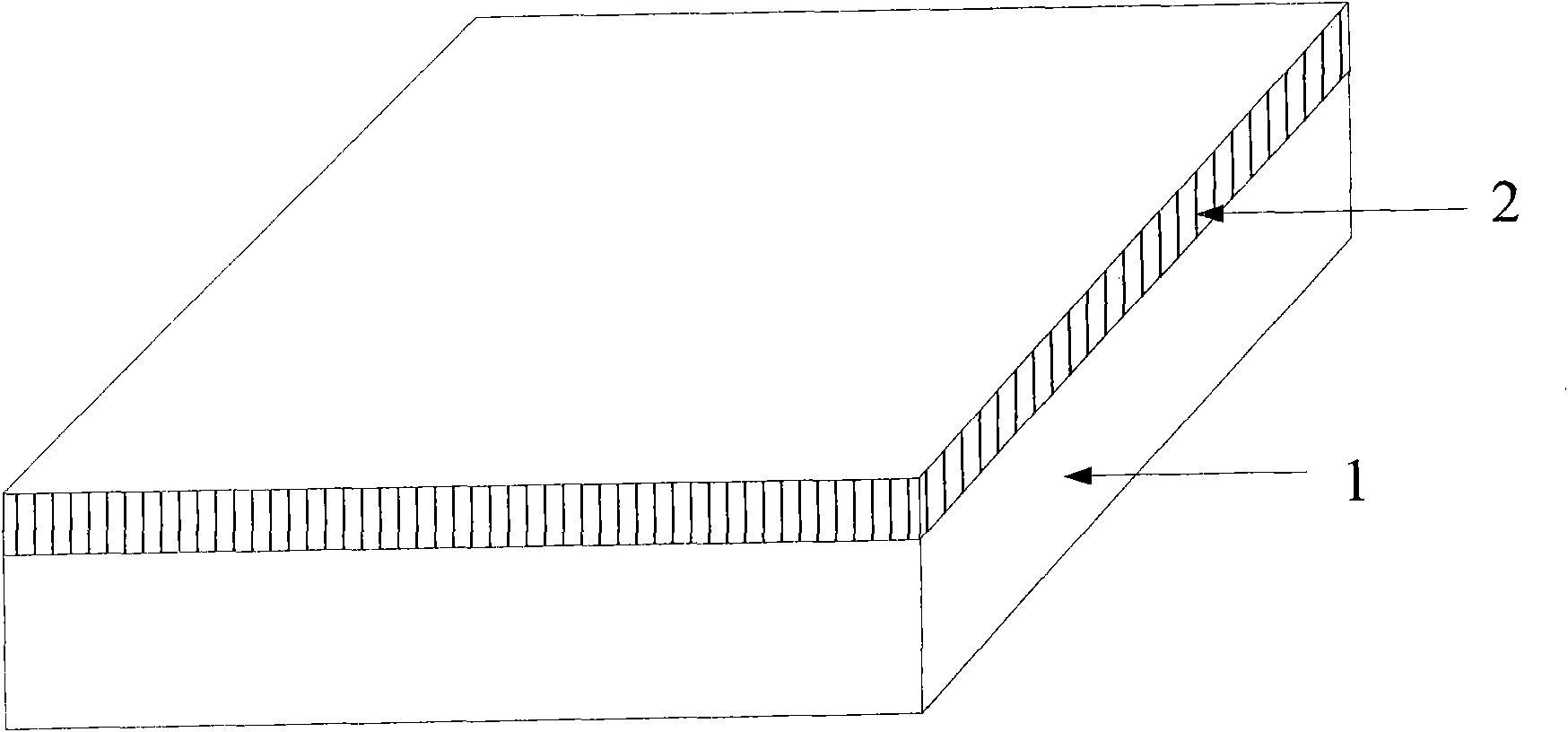

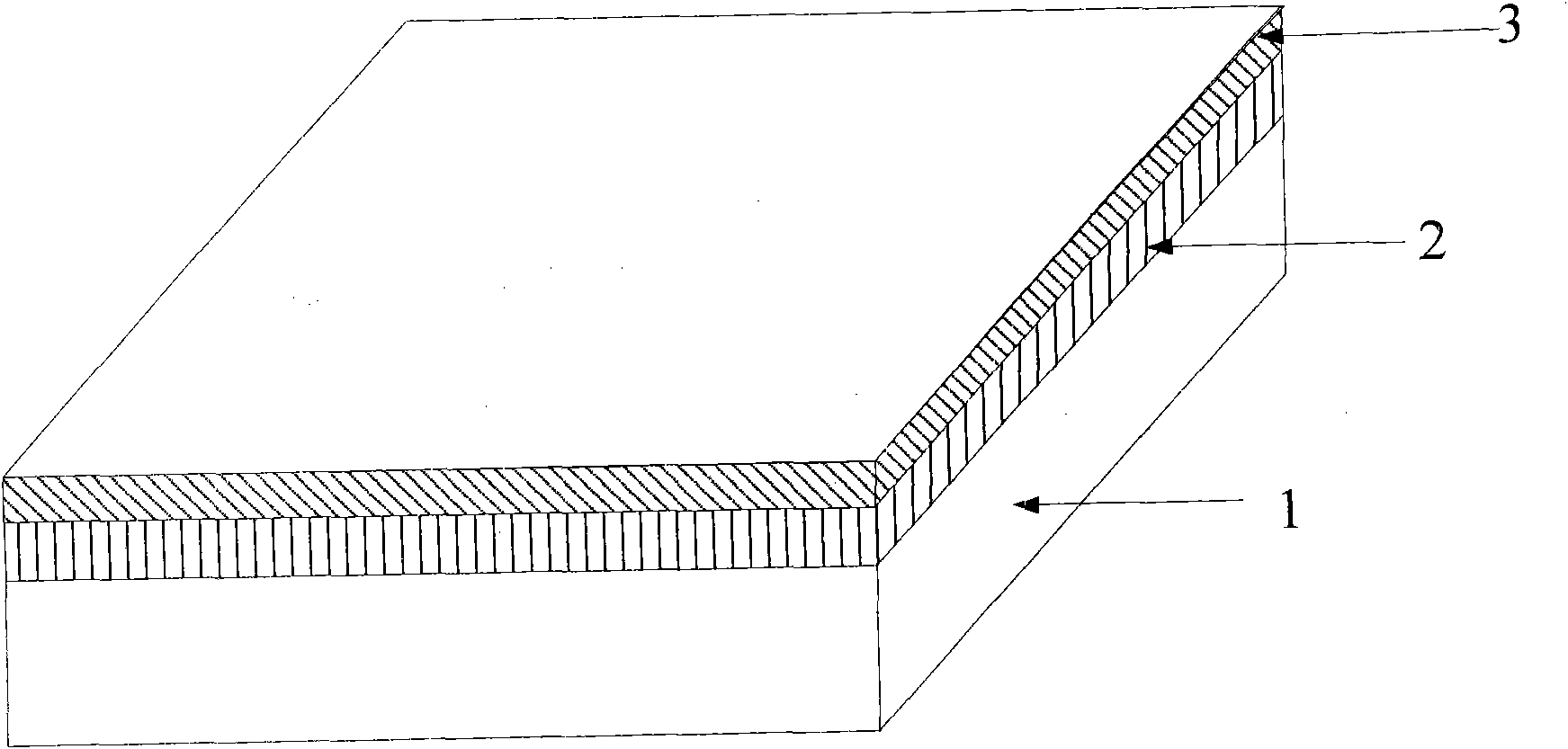

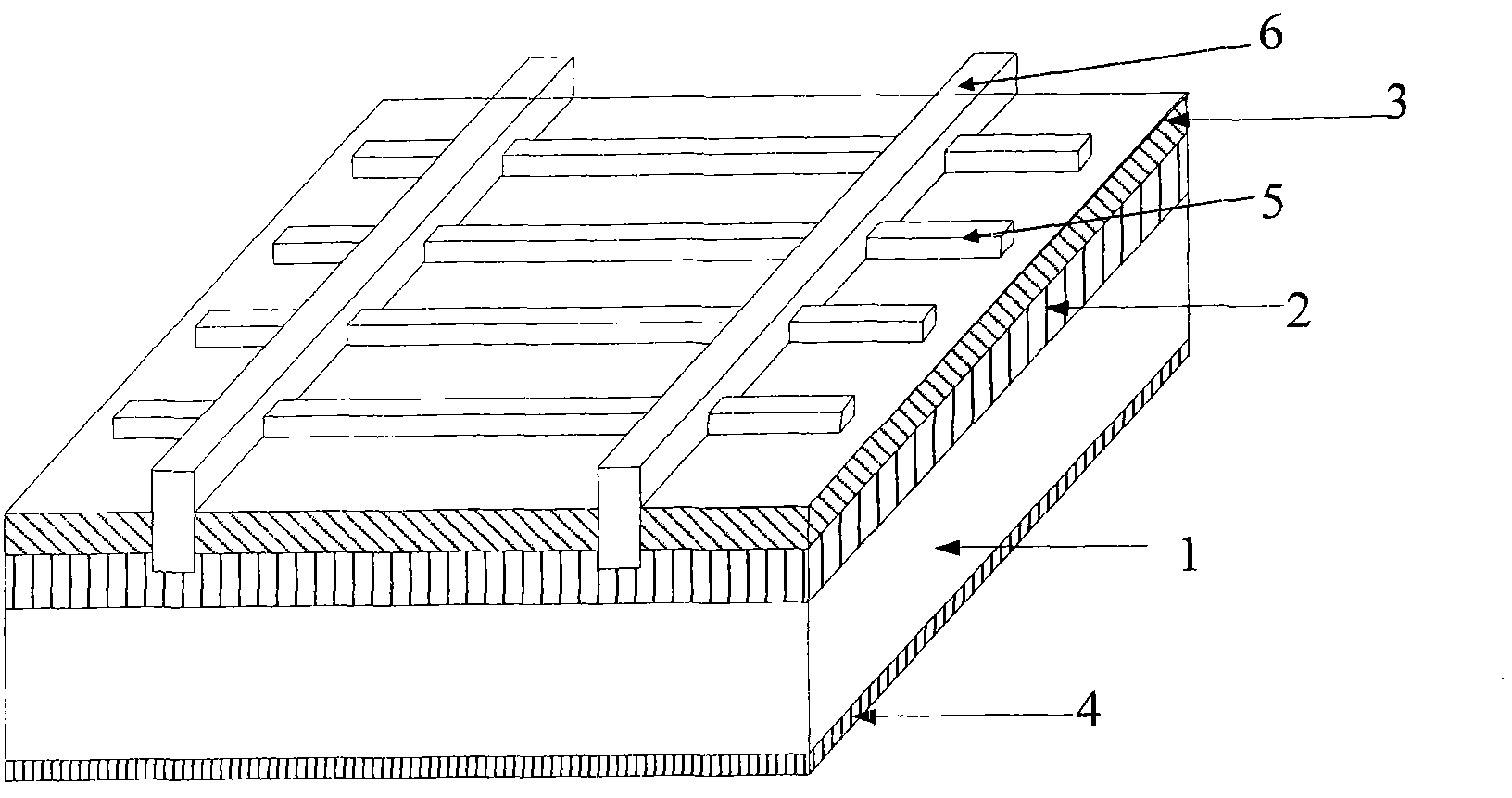

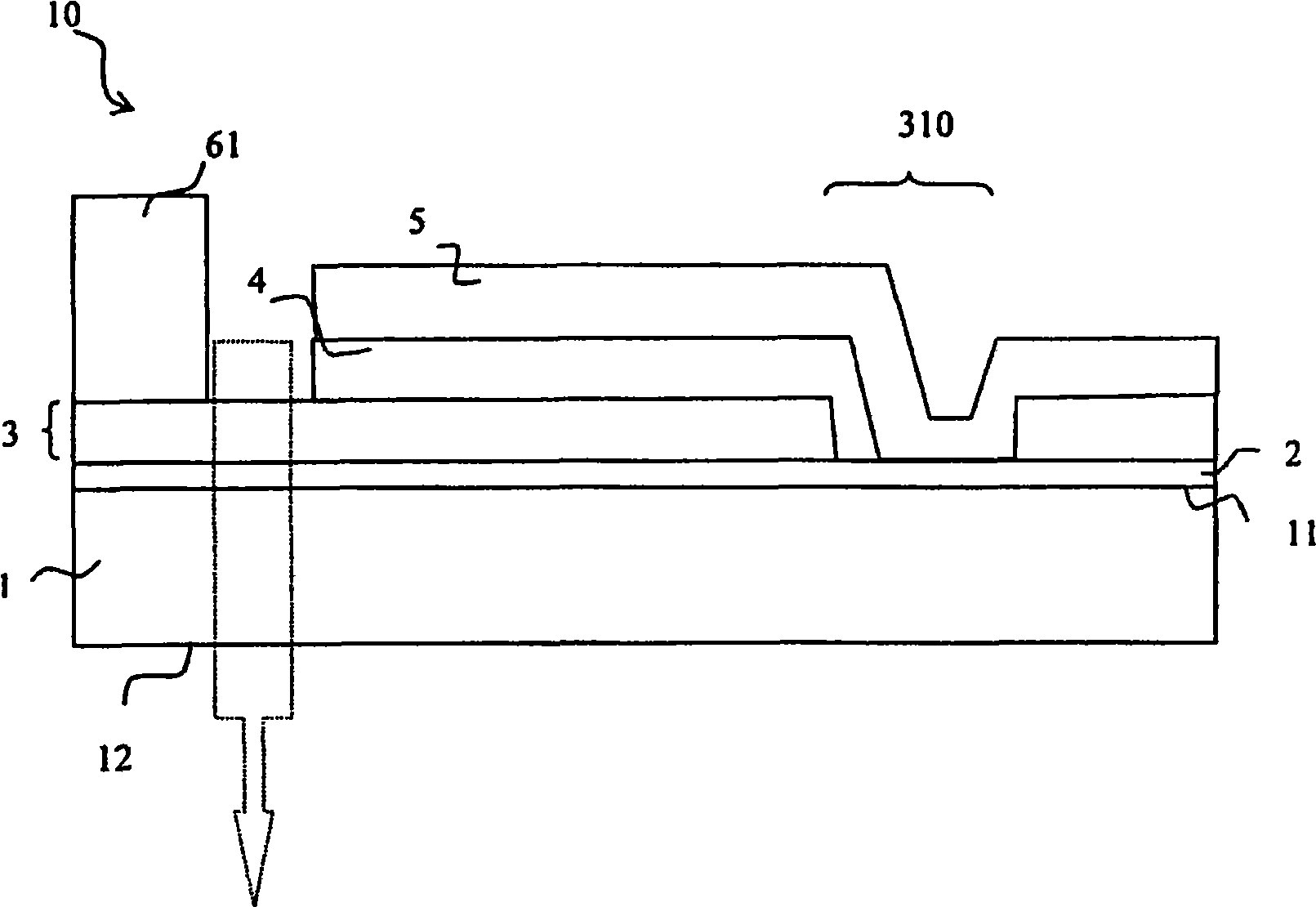

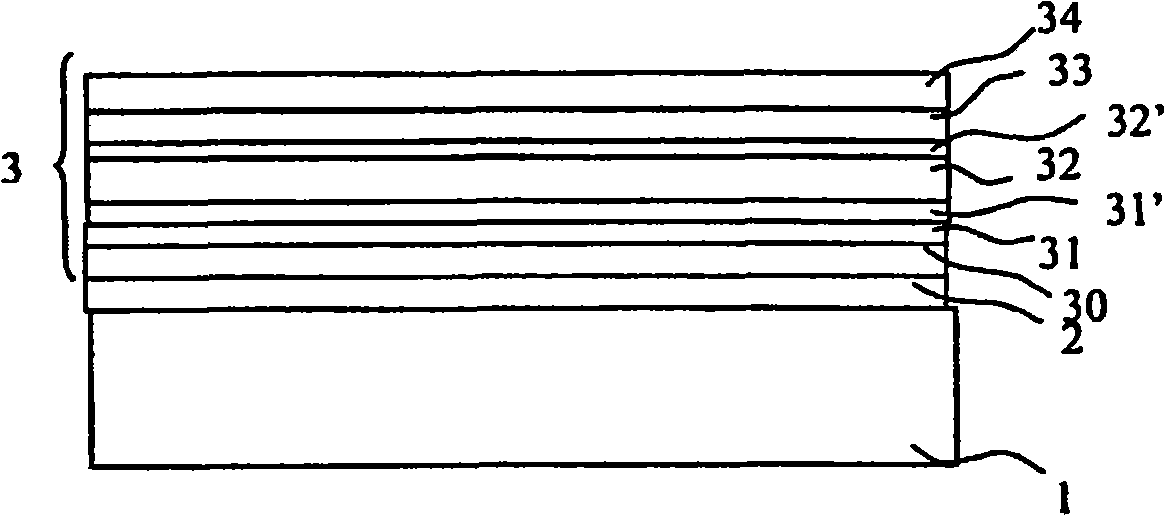

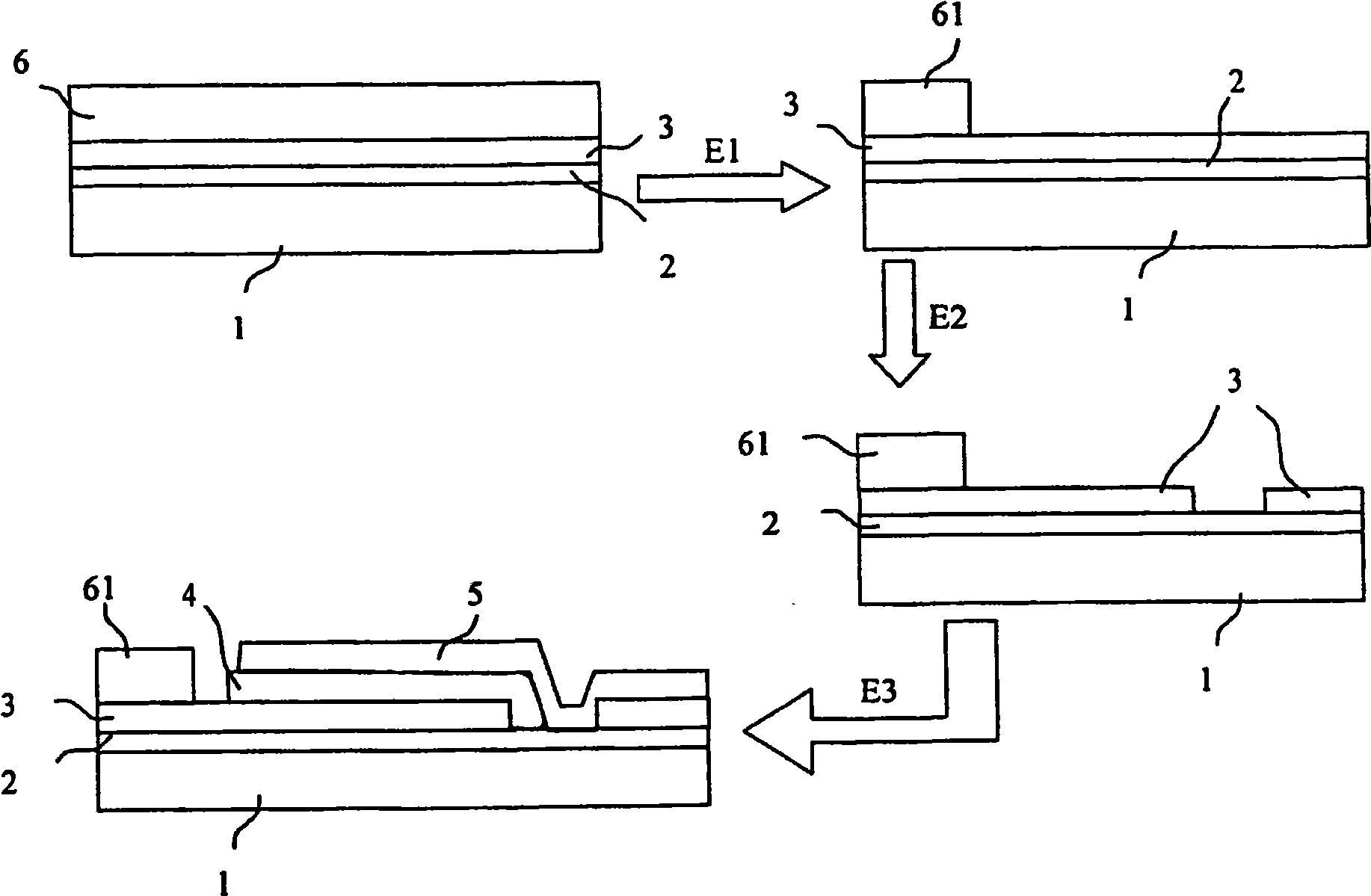

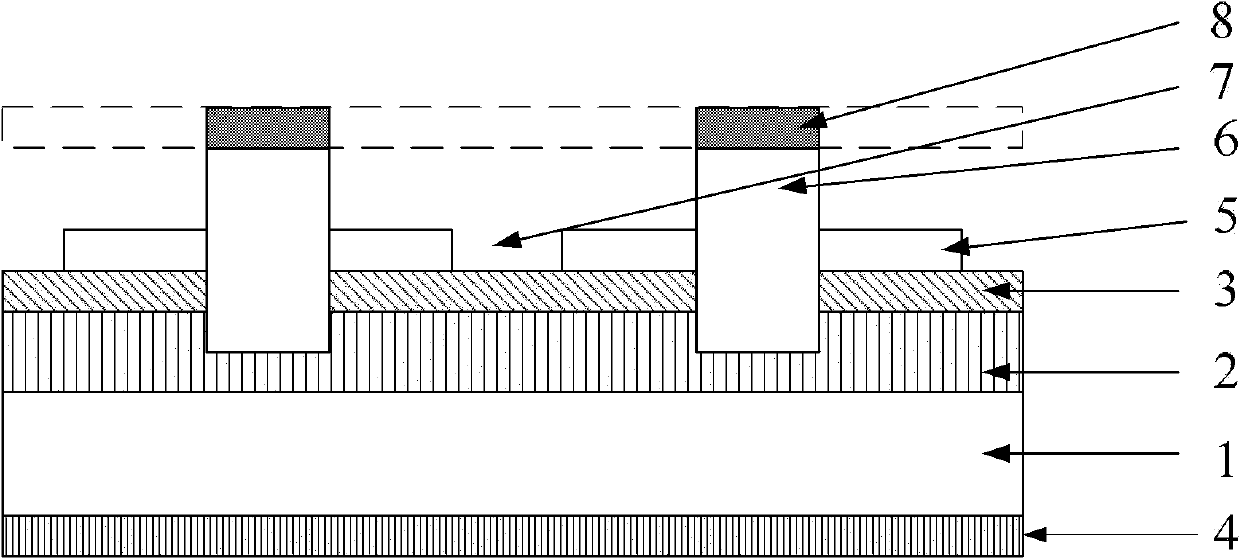

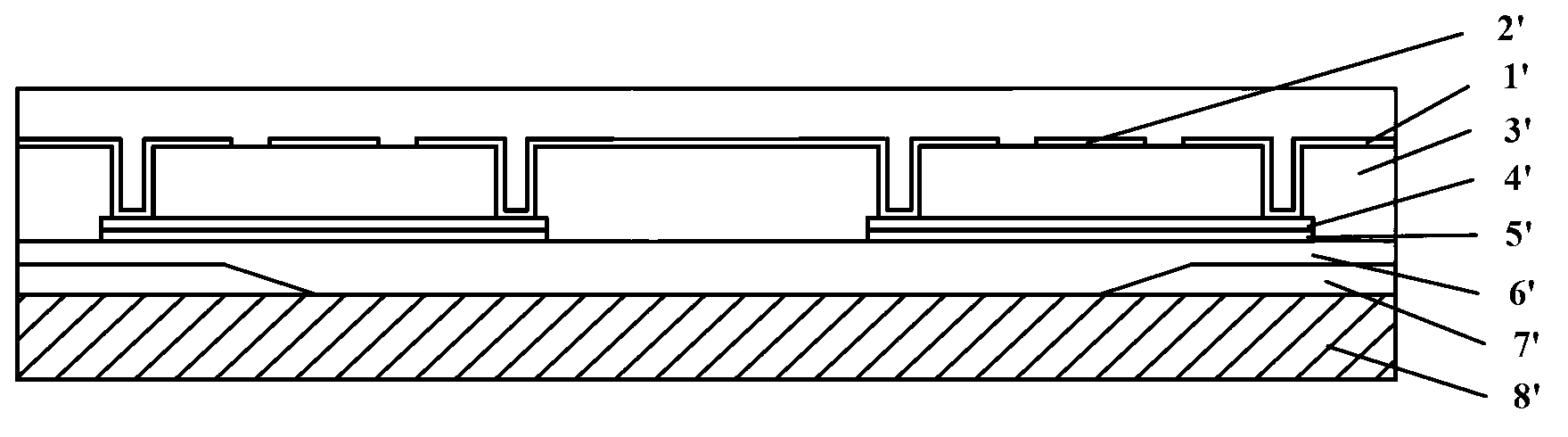

Substrate for an organic light-emitting device, use and process for manufacturing this substrate, and organic light-emitting device

InactiveCN101536608AFree from pollutionGuaranteed electrical conductivityElectroluminescent light sourcesSolid-state devicesOrganic light emitting deviceWork function

The invention relates to a substrate (1) for an organic light-emitting device (10), especially a transparent glass substrate, comprising, on a first main face (11), a lower electrode coating (3), the electrode coating (3) consisting of a thin-film multilayer comprising, in succession, at least: a contact layer (31) based on a metal oxide and / or metal nitride; a metallic functional layer (32) having an intrinsic electrical conductivity property; and an overlayer (34) based on a metal oxide and / or metal nitride, especially for matching the work function of said electrode coating, said substrate including a bottom layer (2), said bottom layer (2) covering said main face (11).

Owner:SAINT-GOBAIN GLASS FRANCE

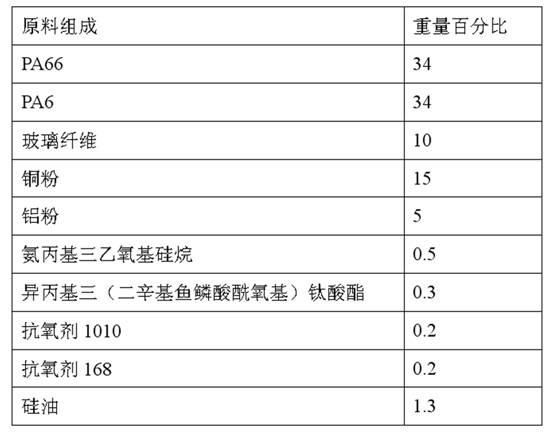

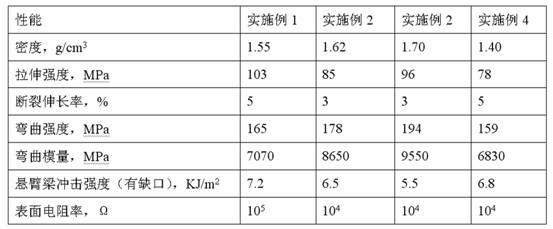

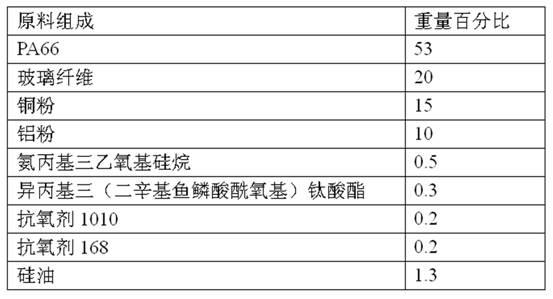

Enhanced conductive nylon material and preparation method thereof

InactiveCN101955653AGood dispersionEvenly dispersedNon-conductive material with dispersed conductive materialGlass fiberNylon material

The invention relates to an enhanced conductive nylon material and a preparation method thereof. The enhanced conductive nylon material comprises the following raw materials in percentage by weight: 40 to 70 percent of nylon, 10 to 40 percent of glass fibers, 10 to 40 percent of metal powder, 0.1 to 5 percent of coupling agent, 0.1 to 0.5 percent of antioxidant and 0.5 to 5 percent of silicone oil. The invention provides a method for thermoplastic conductive plastics by attaching the metal powder to the glass fibers twice and mixing the glass fibers, the metal powder and plastics for pelleting by utilizing the characteristics of easy machining and dispersion of the glass fibers in the plastics, and the prepared thermoplastic conductive plastics have the characteristics of simple and convenient production process, uniform dispersion of the metal powder, small addition amount, controlled conductivity and smooth surfaces of products.

Owner:NANJING HONGRUI PLASTIC PROD

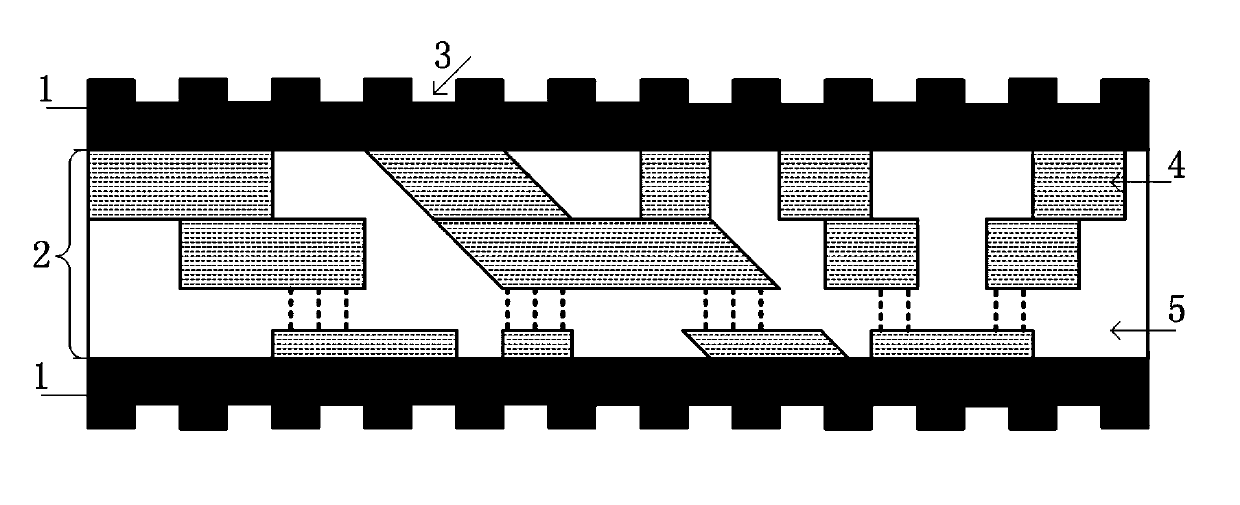

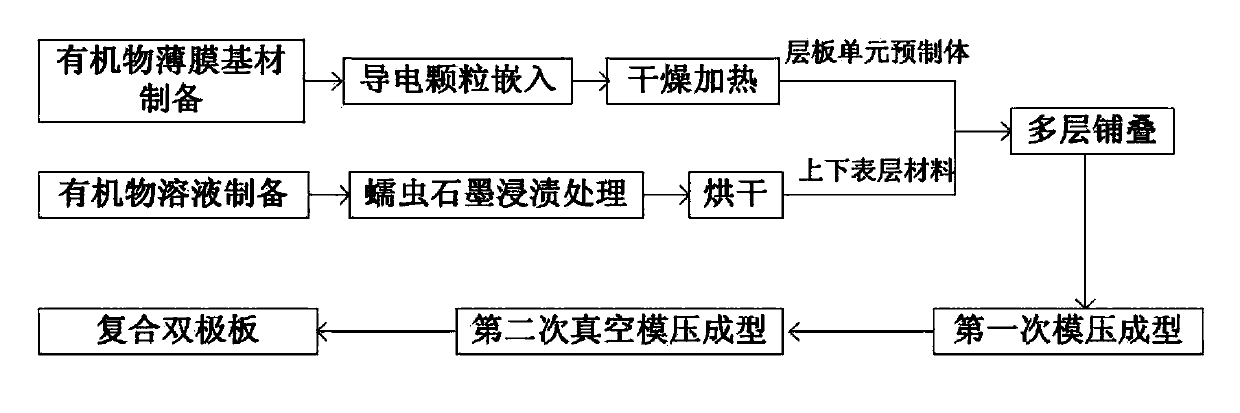

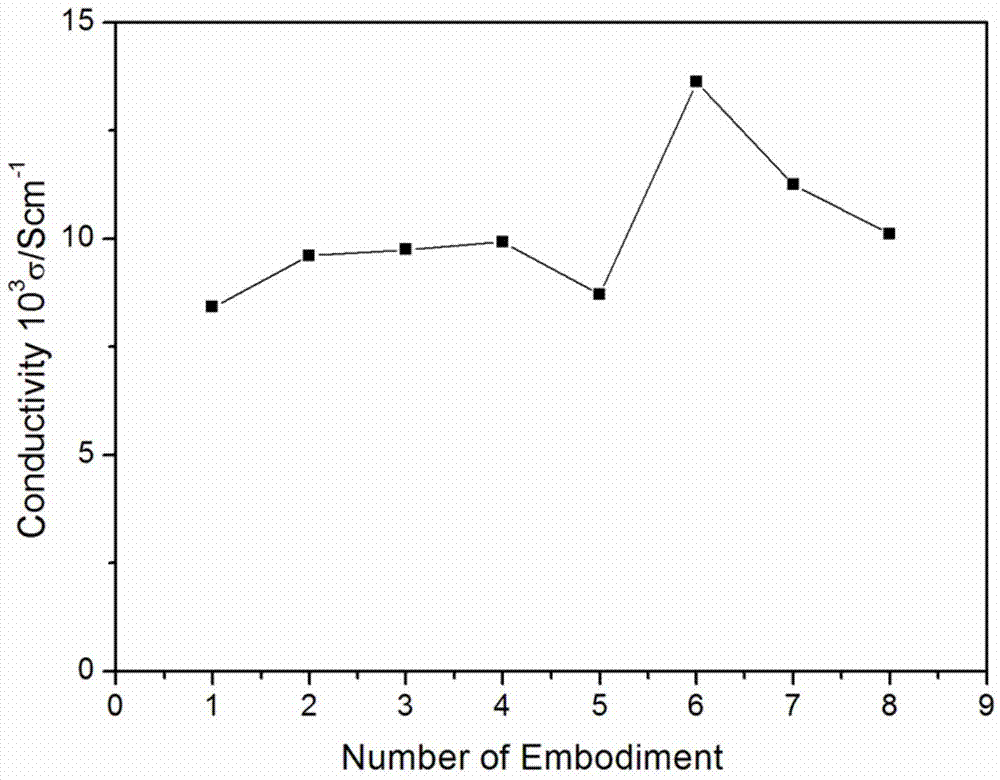

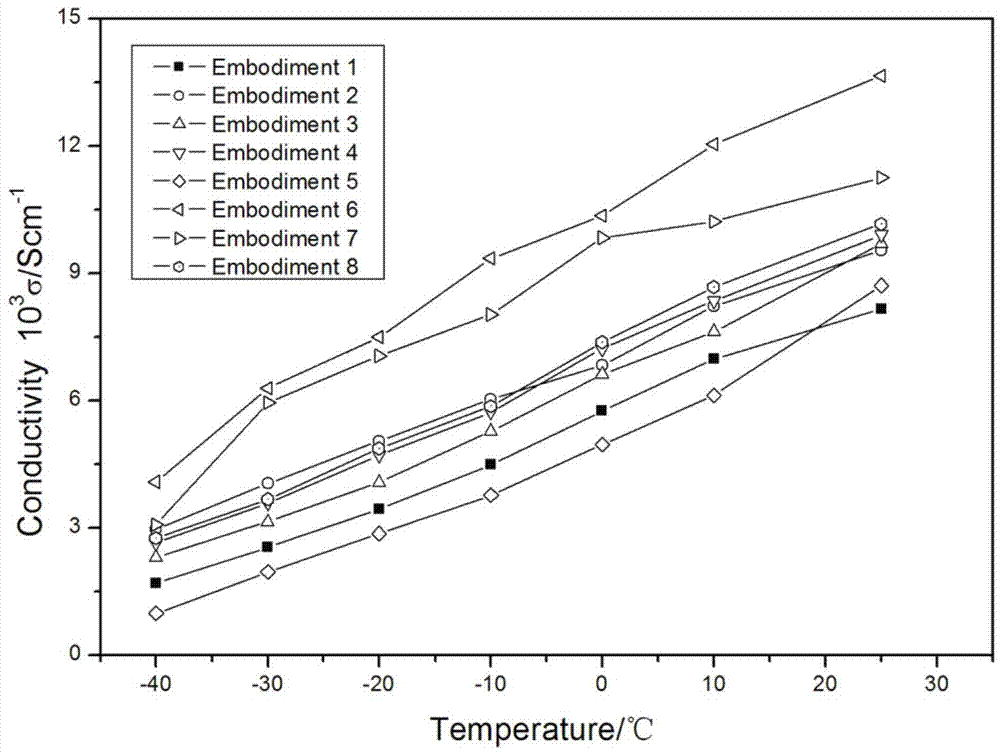

Composite bipolar plate for PEM (proton exchange membrane) fuel battery and preparation method thereof

ActiveCN103746131AGood effectImprove air tightnessFinal product manufactureCell electrodesSurface layerProton

The invention discloses a composite bipolar plate for a PEM (proton exchange membrane) fuel battery and a preparation method thereof. The bipolar plate comprises an upper and lower surface layers prepared by using vermicular graphite as a base material, and a plurality of laminated plate unit preforms prepared by embedding conductive particles in organic substance films, wherein every two adjacent laminated plate unit preforms are provided with one or a plurality of conductive particle overlay areas to form one or a plurality of zigzag conductive paths. The preparation method comprises the following steps: sequentially laying the lower surface layer material, the laminated plate unit preforms and the lower surface layer material in a die, and carrying out die pressing twice to obtain the bipolar plate for a PEM fuel battery. The method enhances the production efficiency of the composite bipolar plate for a PEM fuel battery, and lowers the manufacturing cost; and the composite bipolar plate has the advantages of high bending strength, favorable conductivity and favorable air tightness.

Owner:CHINA THREE GORGES UNIV

Low-temperature electrolyte of lithium iron phosphate battery

InactiveCN103500850AEasy to buyFair priceSecondary cellsOrganic electrolytesLithium vanadium phosphate batteryLithium iron phosphate

The invention relates to a low-temperature electrolyte of a lithium iron phosphate battery. The low-temperature electrolyte includes the following solvents of, by volume, 30%-45% of carbonic ester solvent, 50%-65% of carboxylic ester solvent and 4%-10% of additive. The solvents contain solute lithium, the lithium is LiPF6 or a combination of the LiPF6 and LiBF4, and the concentration of the lithium is 0.8-1.4mol / L. The low-temperature electrolyte is a nonaqueous electrolyte, through optimization of kinds and proportioning combination of the solvents of the electrolyte, low-viscosity carbonic ester and low-melting-point carboxylic ester are selected and used, the freezing point at low temperature is lowered, and low-temperature conductivity is increased. According to the low-temperature electrolyte, the lithium of the electrolyte is optimized, the low-temperature additive is selected preferably, normal-temperature circulation ratio performance of the electrolyte is maintained, and meanwhile, the low-temperature capacity retention ratio of the lithium iron phosphate battery and the ratio performance of the lithium iron phosphate battery are improved. The commercial application requirements of the electrolyte can be met, the low-temperature performance of the electrolyte is improved particularly, and therefore the electrolyte is suitable for aerospace and plateau alpine environment.

Owner:SHANDONG UNIV

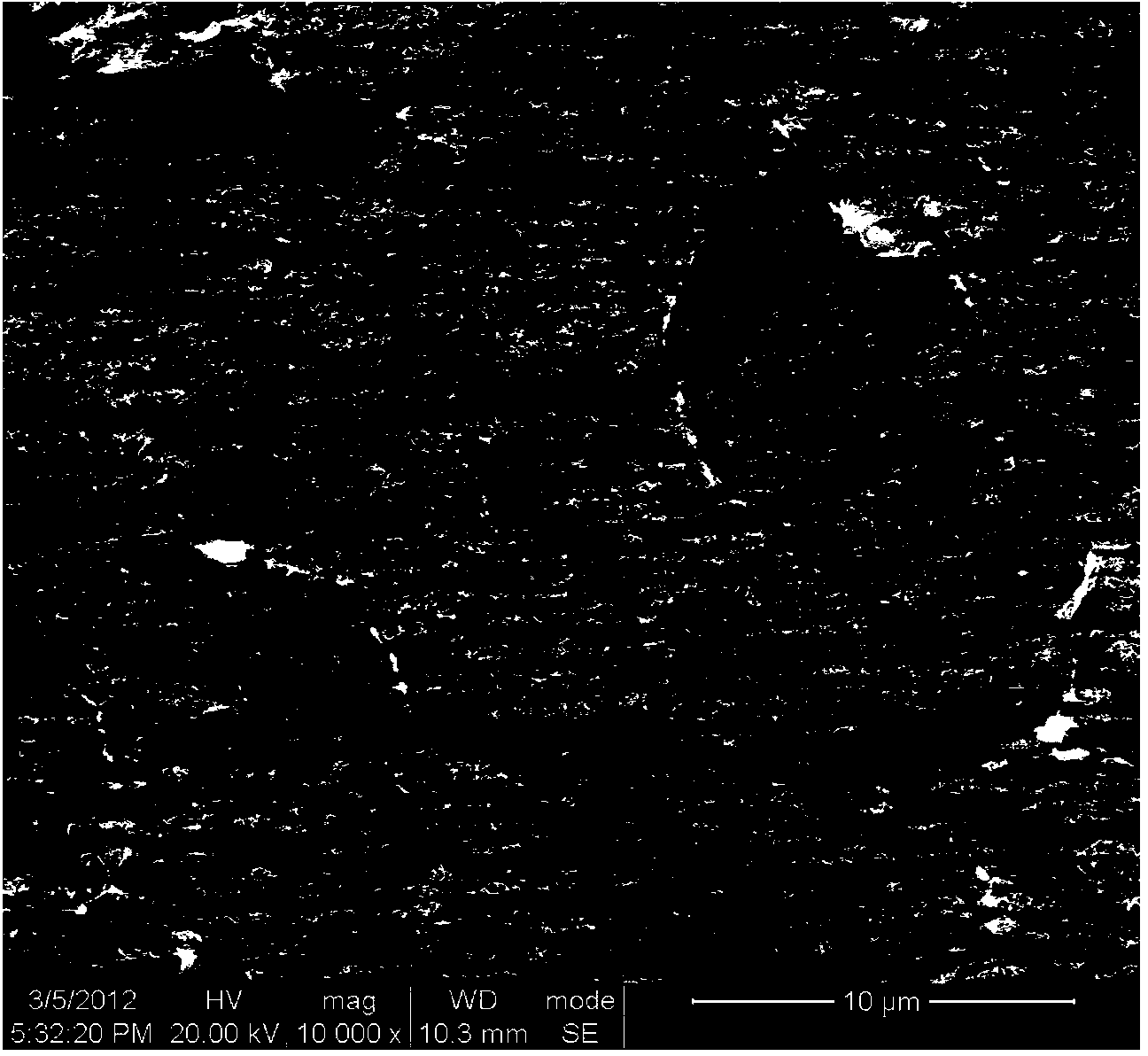

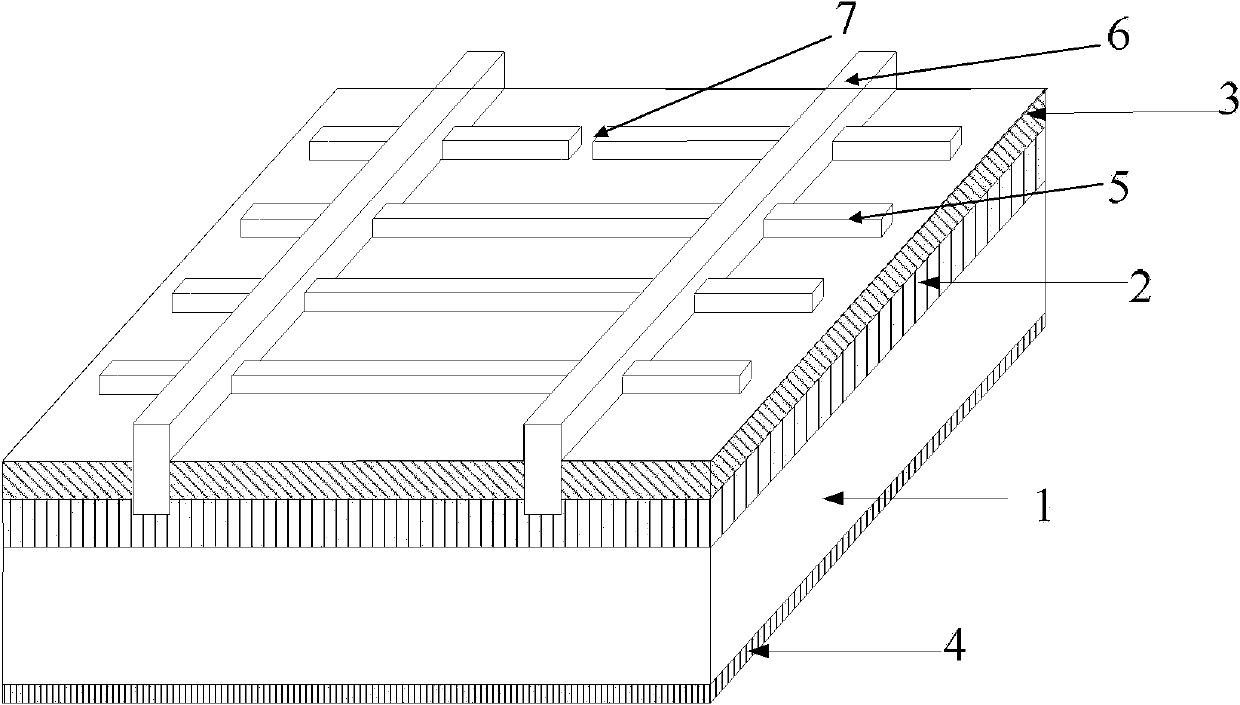

Electrode current collector material of lithium ion battery and preparation method thereof

InactiveCN101958418AGuaranteed electrical conductivityGood chemical propertiesElectrode carriers/collectorsCarbon layerInternal resistance

The invention provides an electrode current collector material of a lithium ion battery and a method for preparing the material. The method comprises the following steps of: coating a carbon layer on the surface of a copper foil or an aluminum foil, wherein the thickness of the coated carbon layer is 0.003-0.015mm; and depositing the carbon layer on the surface of the copper foil or the aluminum foil by utilizing a physical vapor deposition method, and then carrying out thermal treatment. While ensuring the conductive property of the material as a current collector, the material improves the chemical property of easy oxidization of the foil in the working process of the battery, enhances the corrosion resisting property of the foil, and can effectively prevent a metal dendritic crystal produced by the lithium ion battery in the working process due to reaction, increase the safety performance of the battery, reduce the internal resistance of the battery and effectively prolong the service life of the battery. The process has the advantages of low temperature, less distortion and damage on the material, low energy consumption, less pollution and lower cost.

Owner:CHANGDE LYRUN MATERIAL

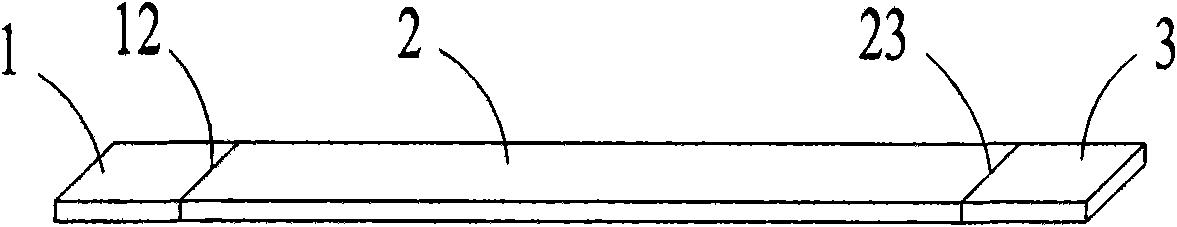

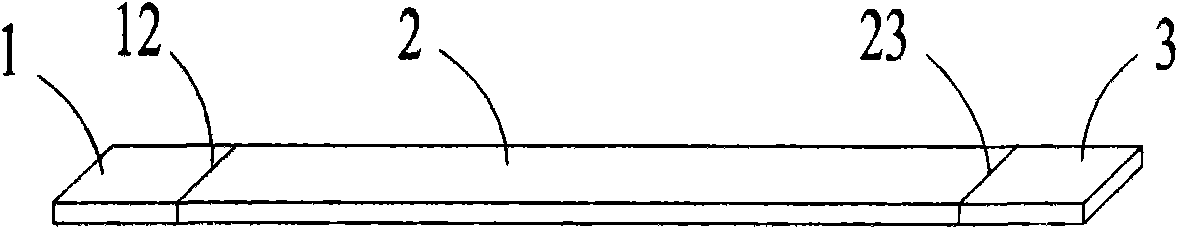

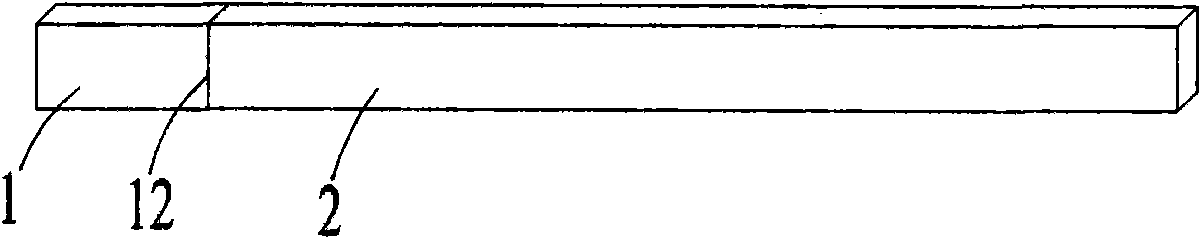

Conductive connecting sheet with side composite metal structure and production method thereof

ActiveCN102035080AReduce contact resistanceHigh recycling valueContact member manufacturingSingle bars/rods/wires/strips conductorsMetal stripsLap joint

A conductive connecting sheet with a side composite metal structure comprises at least two foreign metal sheets. Each metal sheet comprises at least one copper metal sheet or nickel metal sheet, and the rest is a metal sheet at the price lower than the price of copper and nickel. Each metal sheet is arranged along the length direction of the conductive connecting sheet. The adjacent metal sheets are combined closely on an end face, and lap joint does not exist among the adjacent metal sheets. The production method comprises the following steps that: in the at least two metal strips, the adjacent metal strips are firmly combined on the adjacent side to form a side composite board strip by side composite technology; and the produced board strip is subjected to rolling and process annealing treatment to produce a final board strip with thickness the same as that of the conductive connecting sheet, and then is punched and formed along the transverse direction. The invention makes the bestof the advantages of combination of the side composite metal board strips, can ideally meet the requirement of the overall high-conductivity and the transition welding component, prevent the negativeeffect of the traditional lap joint and obviously save scarce metal and improve the waste recovery value.

Owner:徐卓辉 +1

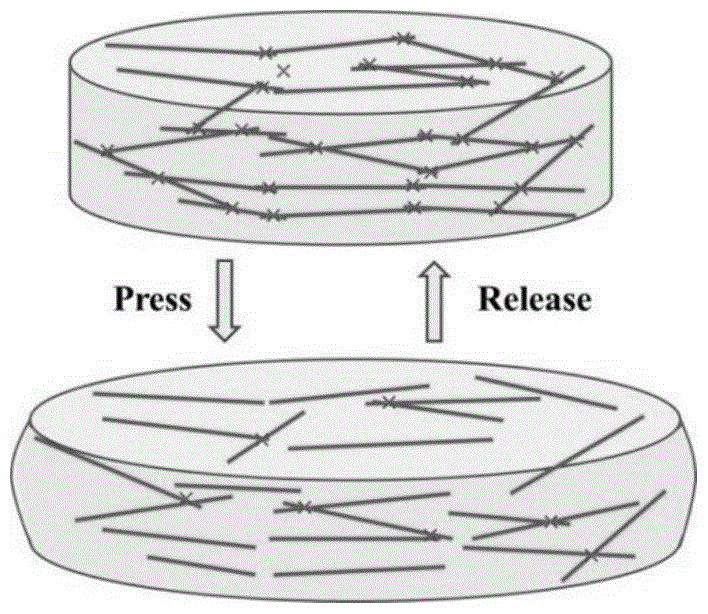

Composite hydrogel, preparation method and application thereof

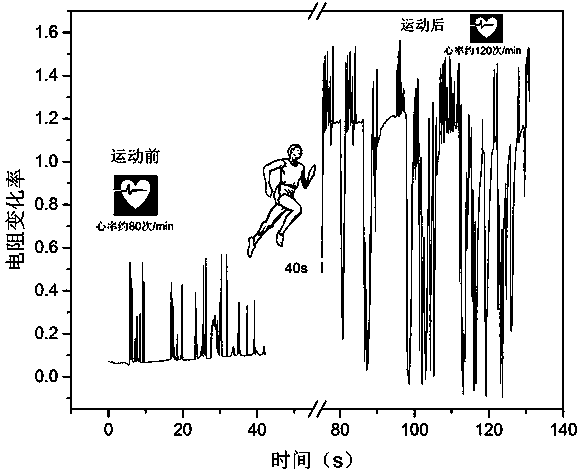

ActiveCN109251449AEnsure mechanical stabilityGuaranteed electrical conductivitySensorsMeasuring/recording heart/pulse rateCross-linkPolypyrrole

The invention discloses a composite hydrogel, a preparation method and application thereof. The preparation method includes: firstly, blending polyvinyl alcohol (PVA), sodium carboxymethyl cellulose (CMC) and monomer pyrrole (Py), and then taking glutaraldehyde as the cross-linking agent to prepare CMC and Py embedded polyvinyl alcohol single-network hydrogel under an acidic condition, then at a low temperature, soaking the obtained single-network hydrogel in an FeCl3 solution of appropriate concentration to obtain polypyrrole / sodium carboxymethyl cellulose-Fe<3+> / polyvinyl alcohol (PPy / CMC-Fe<3+> / PVA) double-network composite hydrogel. By applying the composite hydrogel to a strain sensing patch, finally a composite hydrogel strain sensing patch with high mechanical strength, elasticity,conductivity and strain sensitivity can be obtained. The invention opens up a new way for in-situ synthesis of polypyrrole in hydrogel, and provides a new idea and new method for application of a hydrogel strain sensor in wearable field.

Owner:TAIYUAN UNIV OF TECH

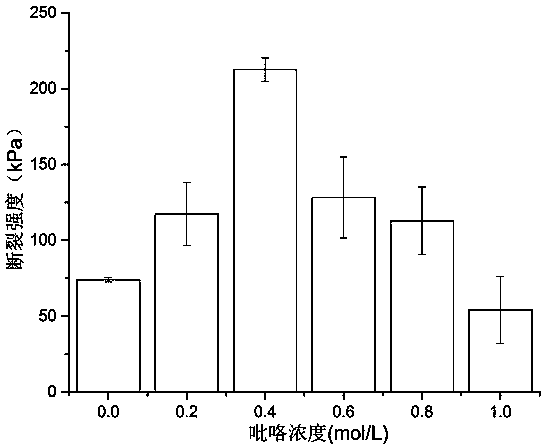

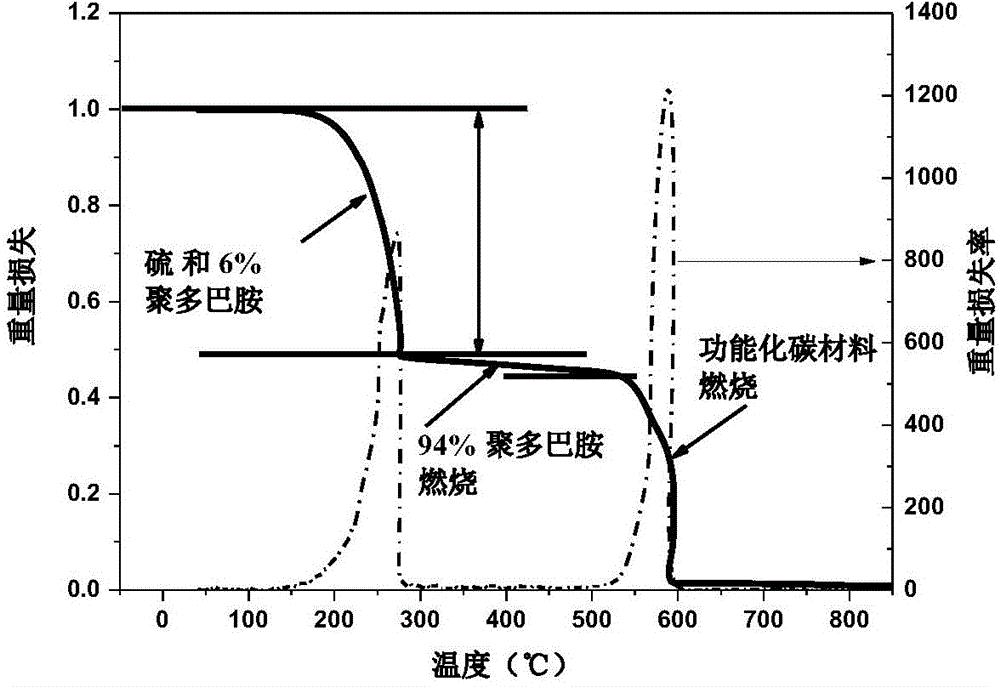

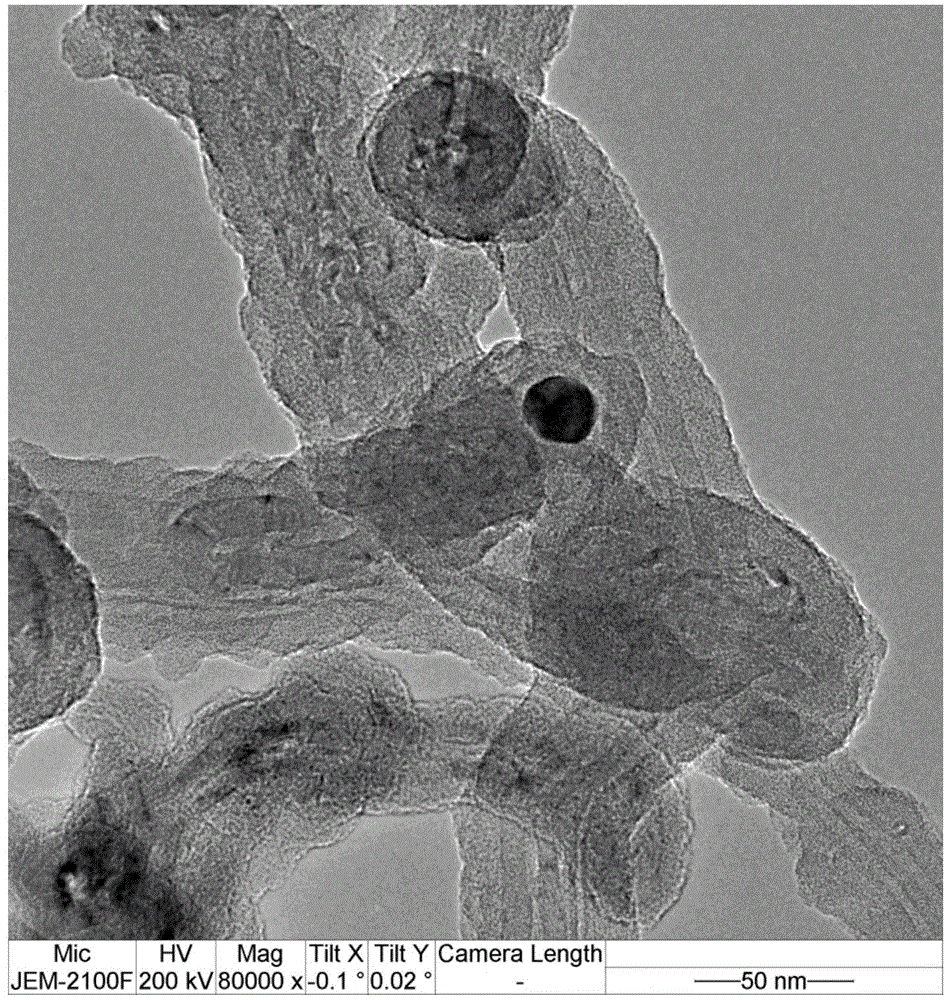

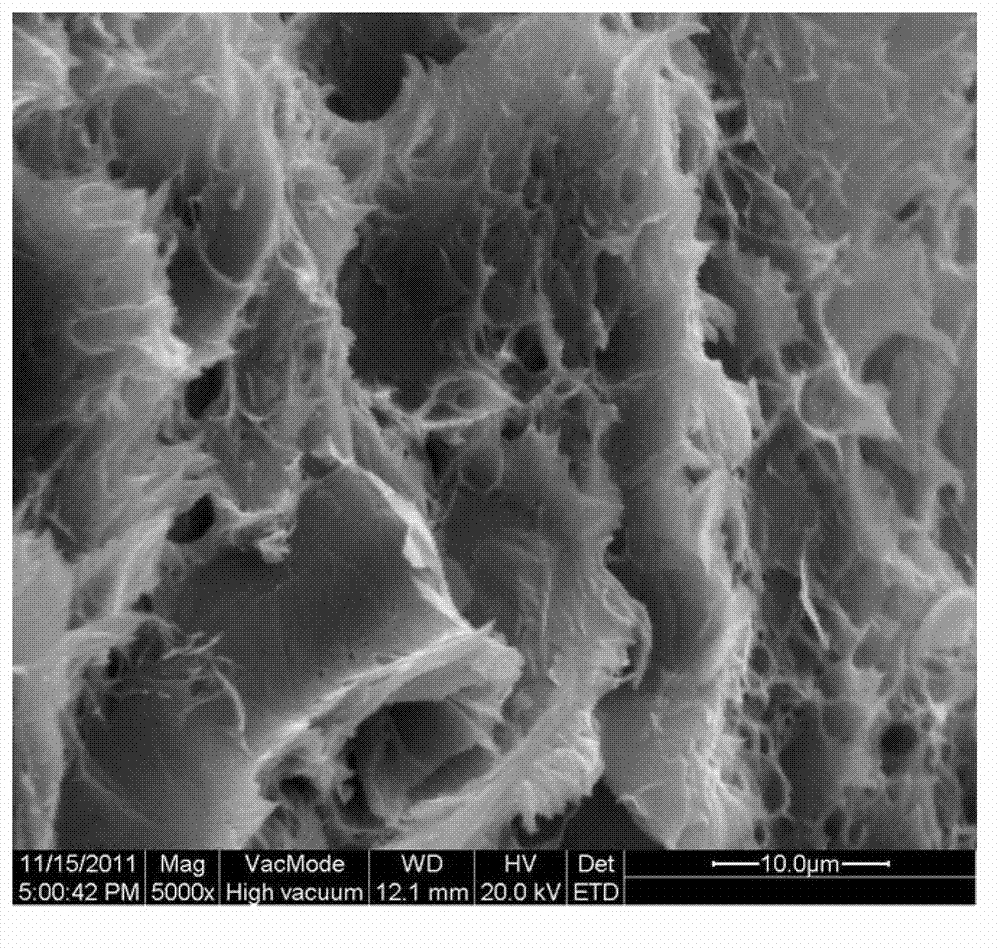

Anode material of lithium-sulfur battery, lithium-sulfur battery and method for preparing anode material

ActiveCN104617327AGuaranteed conductivityGood structural stabilityCell electrodesLi-accumulatorsCarboxylationDopamine hcl

The invention relates to an anode material of a lithium-sulfur battery, the lithium-sulfur battery and a method for preparing the anode material, and belongs to the field of battery materials. The center of the anode material is made of a functionalized carbon nano-material, the middle interlayer is made from sulfur, and the outer layer adopts a polydopamine film, wherein the functionalization method is hydroxylation or carboxylation. The preparation method comprises the following steps: dissolving the carbon nano-material in an alkaline or acid liquid to obtain the functionalized carbon nano-material; adding the functionalized carbon nano-material in a sulfur water solution, stirring, dropwise adding diluted acid to the solution, and obtaining the functionalized carbon nano-material coated with sulfur on the outer side; adding the functionalized carbon nano-material coated with sulfur on the outer side in a tris(hydroxymethyl) methane buffer solution, and performing a polymerization reaction to a dopamine hydrochloride solution, so as to obtain the anode material. The invention further relates to the lithium-sulfur battery using the anode material. The battery can further comprise a polyethylene diaphragm modified by polydopamine. The anode material can inhibit the shuttle flying effect and the structural damage caused by volume expansion; and the lithium-sulfur battery is good in cycle performance and capacity retention ratio.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

PVC (Polyvinyl Chloride)/graphite alkene antistatic composite material and preparation method thereof

The invention discloses a PVC (Polyvinyl Chloride) / graphite alkene antistatic composite material. The PVC graphite alkene antistatic composite material is prepared by the following ingredients in percentage by weight: 2-20% of a shock resistance modifying agent, 0.5-10% of an electric conductive filler, 2-20% of a processing agent and the balance of matrix resin. In addition, the invention also provides a preparation method of the PVC / graphite alkene antistatic composite material. Due to the adoption of the preparation method, the PVC has the antistatic property, and the enhancing and toughening are realized at the same time; and the surface resistivity of the prepared PVC / graphite alkene antistatic composite material is 104-108 omega, the volume resistivity is not more than 108 omega / cm, the tensile strength is not less than 50MPa, the impact strength is not less than 5kJ / m<2>, the elongation at break is not less than 75%, and the antistatic requirements on GB / T20105-2006 and MT164-2007 and MT165-2007 in the colliery industry are met.

Owner:XIAN UNIV OF SCI & TECH

Polymer material with continuously-alternating layer structure and preparation method for same

ActiveCN103481393ASimple operation processReduce manufacturing costPolymer scienceInjection moulding

The invention discloses a preparation method for a polymer material with a continuously-alternating layer structure. The preparation method comprises the following steps of step 1, premixing 30-70 parts of first resin or a first resin compound and 70-30 parts of second resin or a second resin compound, adding the premix in a double-screw extruder, performing melt blending and extrusion at a temperature of 100-300 DEG C, cooling, and slicing to obtain blend grains; and step 2, performing high-speed thin-wall injection forming on the obtained blend grains at an injection temperature of 100-300 DEG C and an injection speed of 50-1200 mm / s, so as to obtain the polymer material with a continuously-alternating layer structure. The preparation method disclosed by the invention is simple in the whole operation process, low in production cost, suitable for large-scale industrialized production, capable of regulating and controlling the thickness of the continuously-alternating layer structure by adjusting the component proportioning ratio of the blend, and suitable for various blend systems.

Owner:SICHUAN UNIV

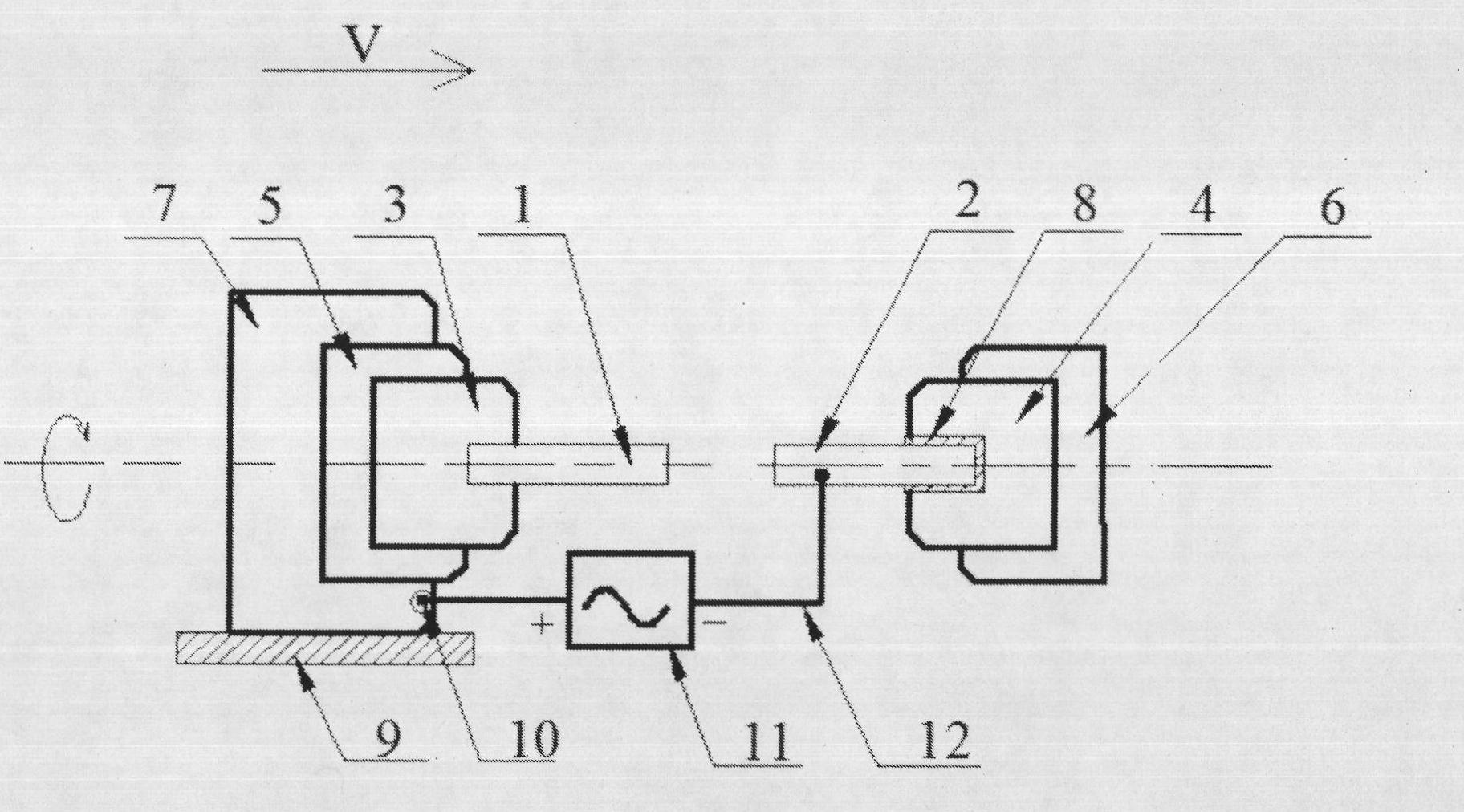

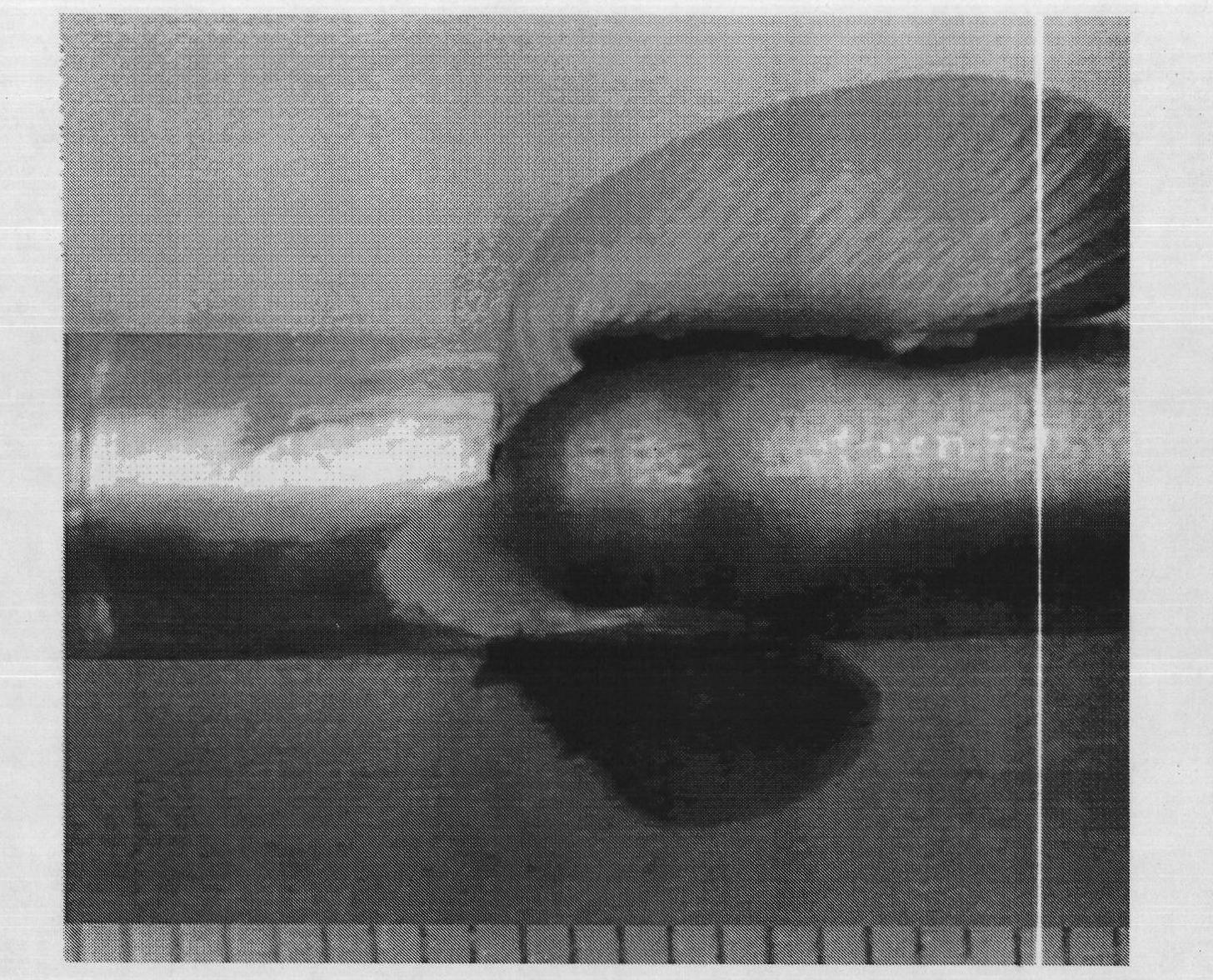

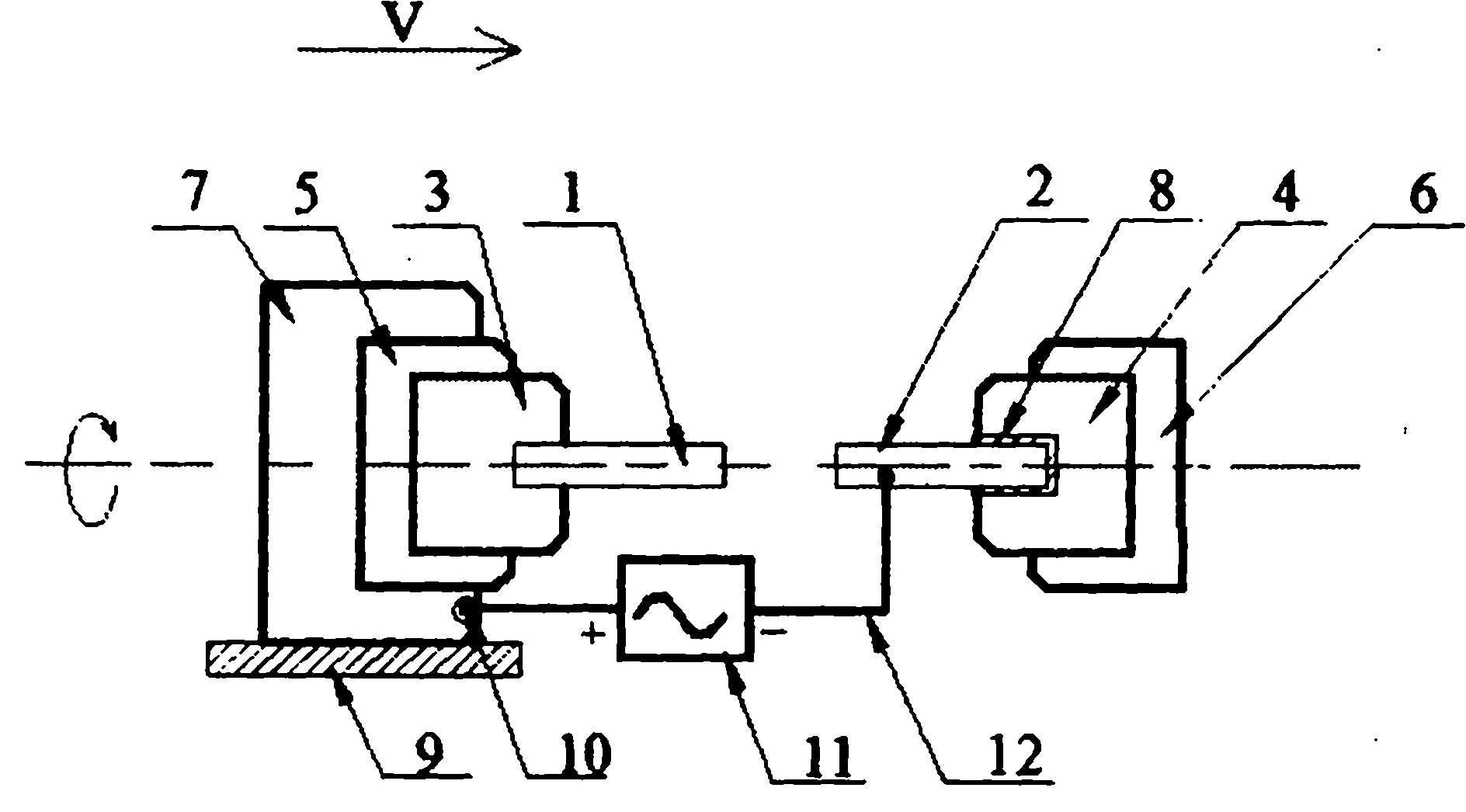

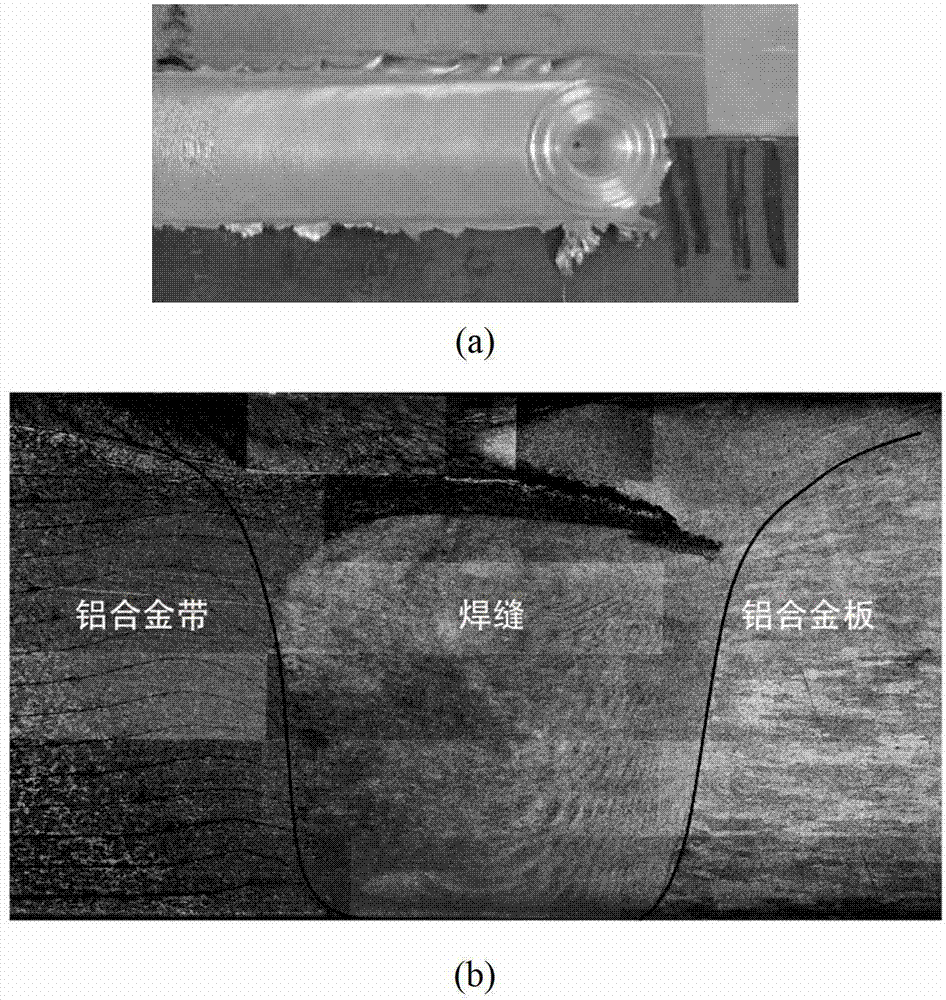

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853AGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

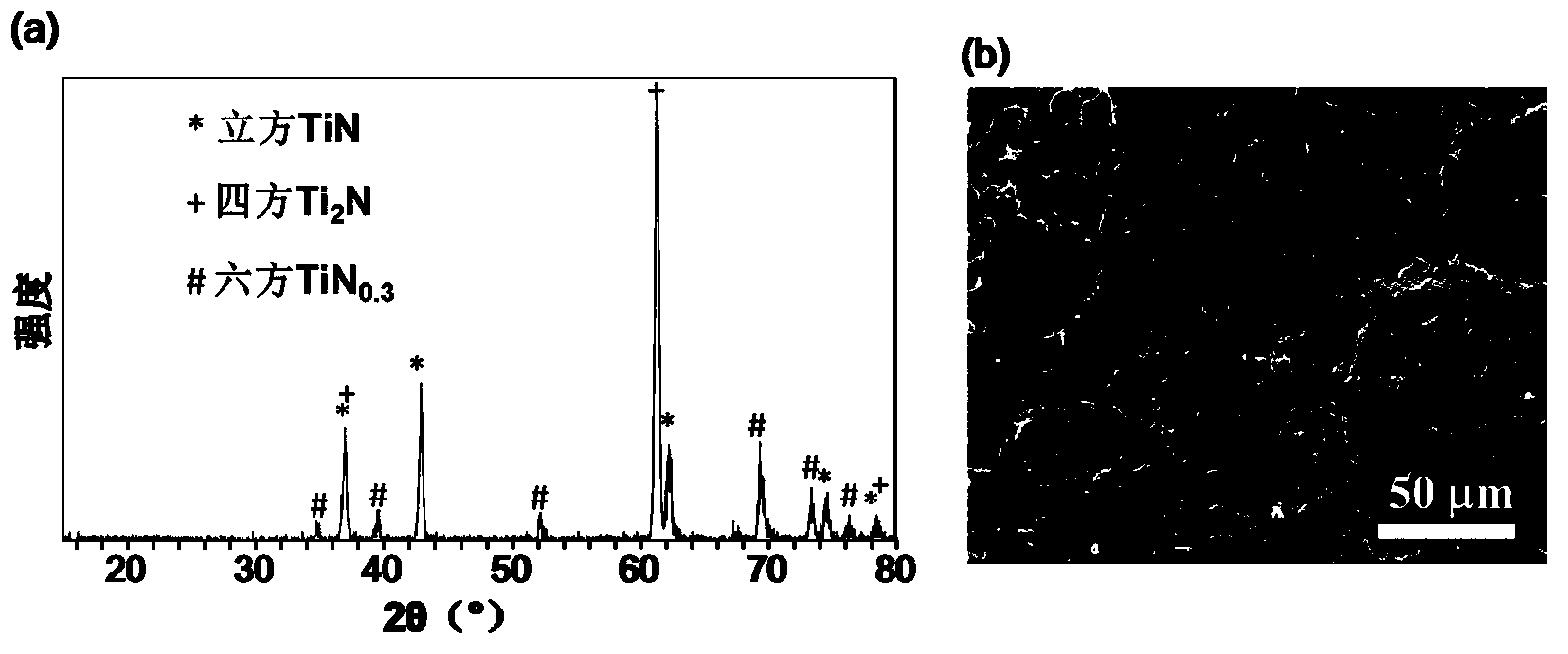

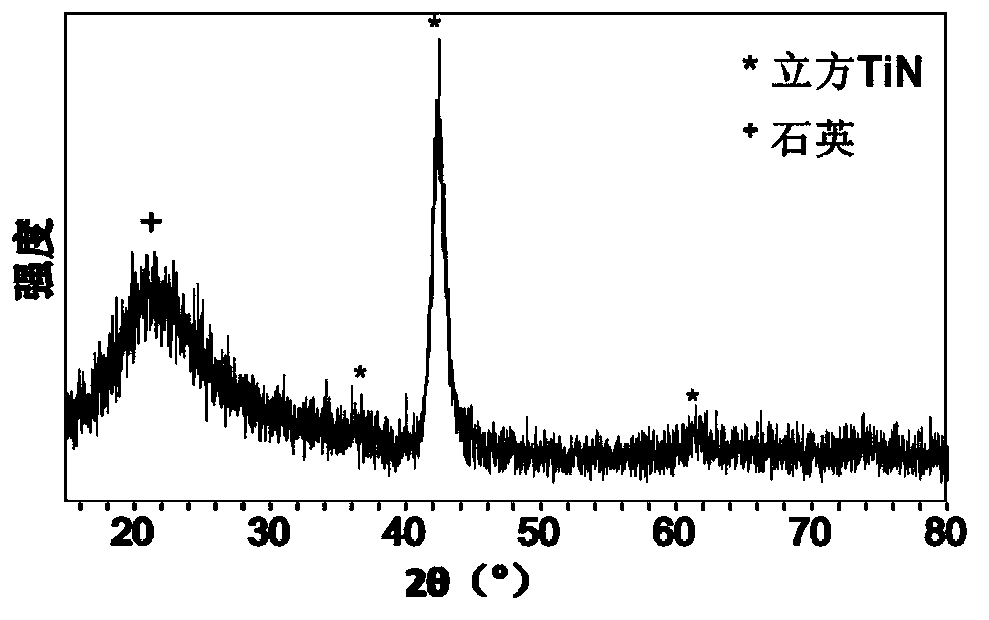

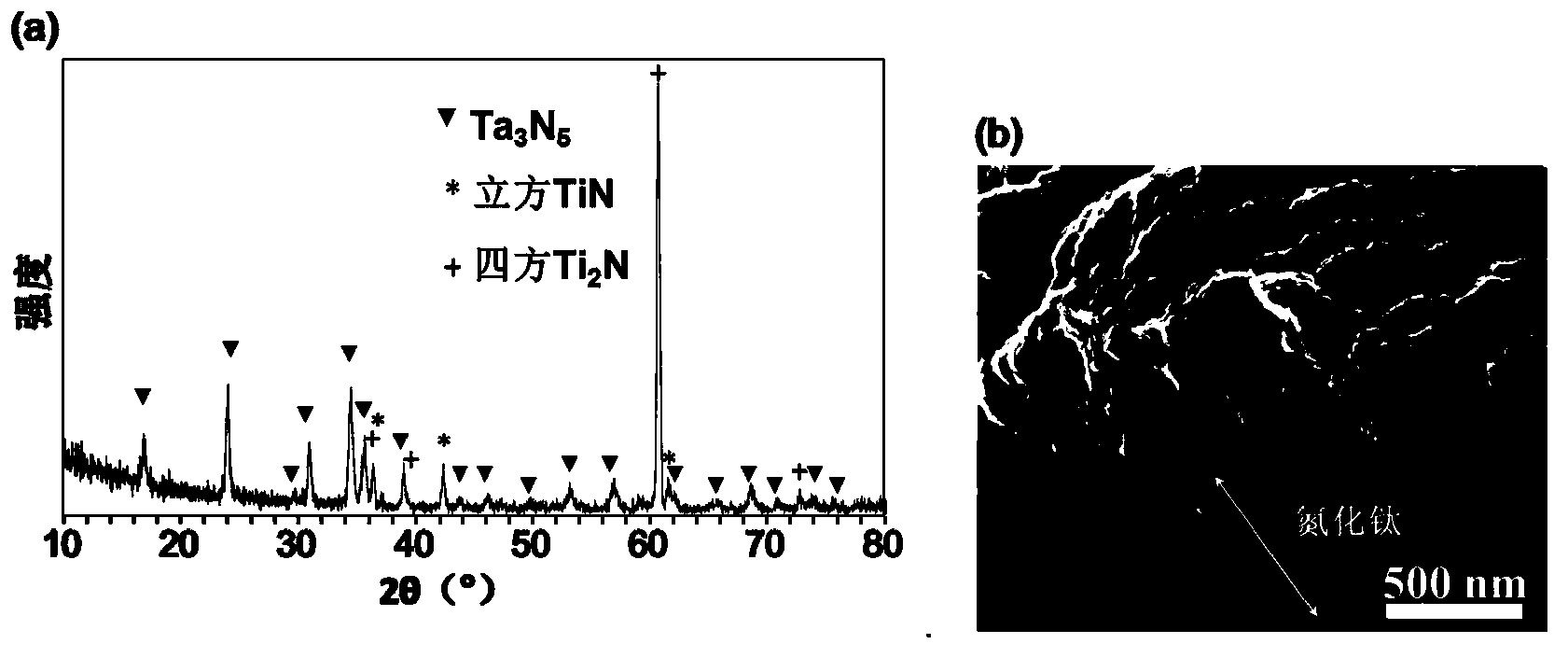

Photoelectrode using metal nitride as conductive substrate and preparation method thereof

The invention discloses a photoelectrode and a preparation method thereof. A metal nitride substrate serves as a current collection body and is tightly contacted with a photoactive layer which is a non-complete oxide semiconductor with or without the decoration of a promoter, so that the photoelectrochemical photoelectrode is formed. The preparation method comprises the following steps of: firstly, preparing the conductive metal nitride substrate, wherein the lowest sheet resistance of the conductive metal nitride substrate is 1.8 ohm per square, the electrical resistivity is 0.16 mohm per centimeter, the conductive metal nitride substrate is superior to commercial FTO and ITO; and secondarily, depositing or coating the semiconductor or a precursor containing a semiconductor metal constituent, performing high-temperature processing in an inert atmosphere or a hydride atmosphere of the semiconductor nonmetal constituent. The metal nitride substrate can keep conductivity after being subjected to high-temperature processing in the inert or hydride atmosphere (such as to 900 DEG C in ammonia gas), and is applicable for high-temperature preparation process of a non-all oxide semiconductor photoelectrode, and the whole photoelectrode preparation process is easy to industrialize. The photoelectrode can be used for application such as water decomposition, hydrogen preparation and carbon dioxide conversion by means of solar energy in photoelectrochemistry.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

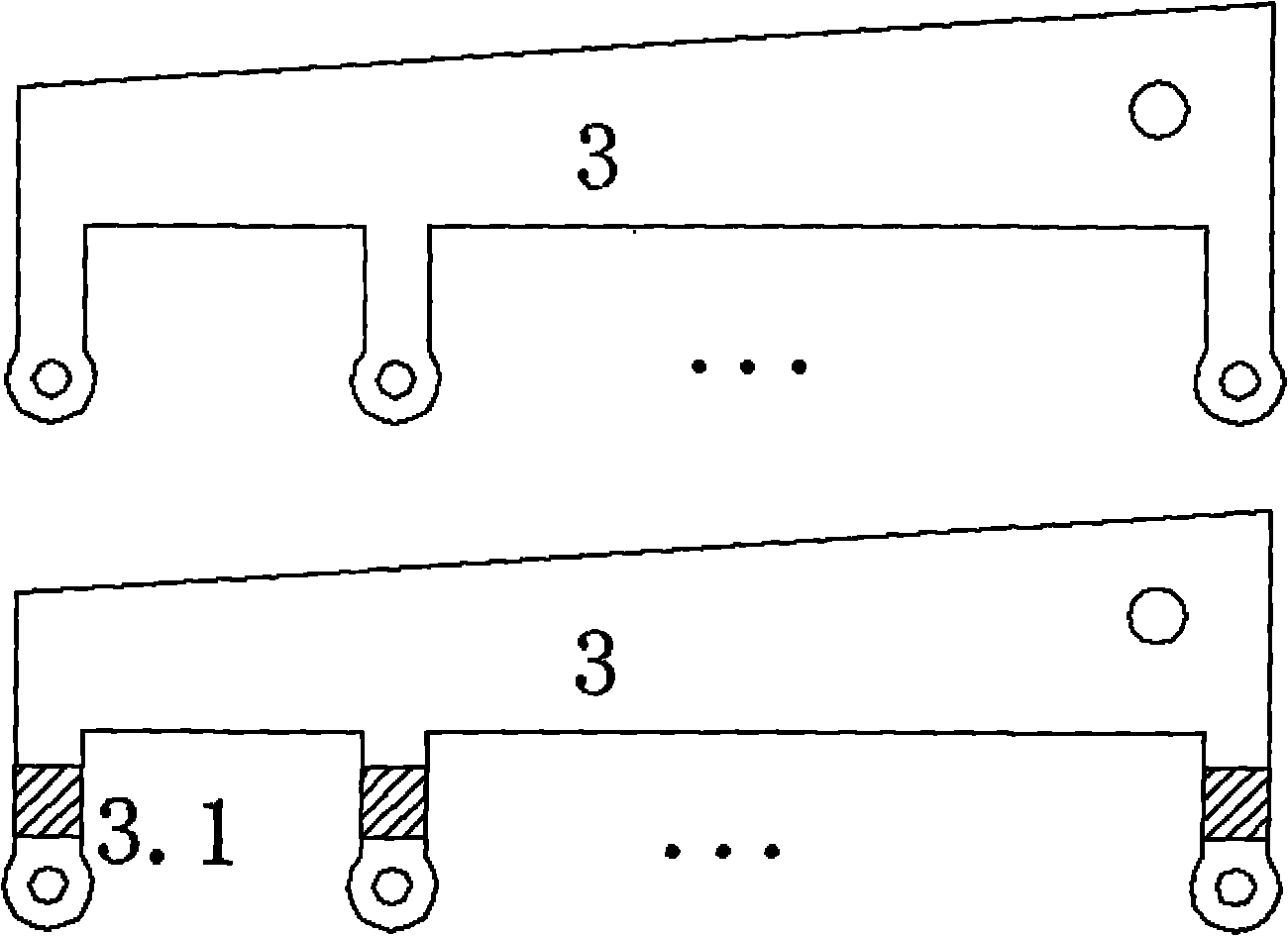

Welding method for multi-layer metal strip

ActiveCN102873454AQuality improvementGuaranteed electrical conductivityNon-electric welding apparatusMetal stripsControllability

The invention relates to a welding method for a multi-layer metal strip. The method is characterized by comprising the following steps of: stacking the multi-layer metal strip to be welded to reach the required thickness, and aligning the multi-layer metal strip with the weld of another stacked multi-layer metal strip or metal plate; fixing a welding guiding plate of which the thickness is the same as that of the multi-layer metal strip to be welded at the starting end of a weld joint along the welding direction; selecting a stirring head, wherein the diameter of a shaft shoulder of the stirring head is 2 to 3 times the plate thickness, the length of a stirring needle on the stirring head is 0.05 to 0.2mm less than the plate thickness, and the press amount of the shaft shoulder is 0.1 to 0.3mm; and selecting rotation speed and welding speed according to a welding material, and welding. The method is energy-saving and environment-friendly, an operation process is greatly simplified, and production efficiency is improved; the quality of a joint is improved, the conductivity of the joint is ensured, and production cost is reduced; controllability is high, and industrial application is easy to implement; and the obtained joint has a compact structure, does not have any pore or crack and is slightly deformed, the operation process is simple, the production period is short, efficiency is high, and the production cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

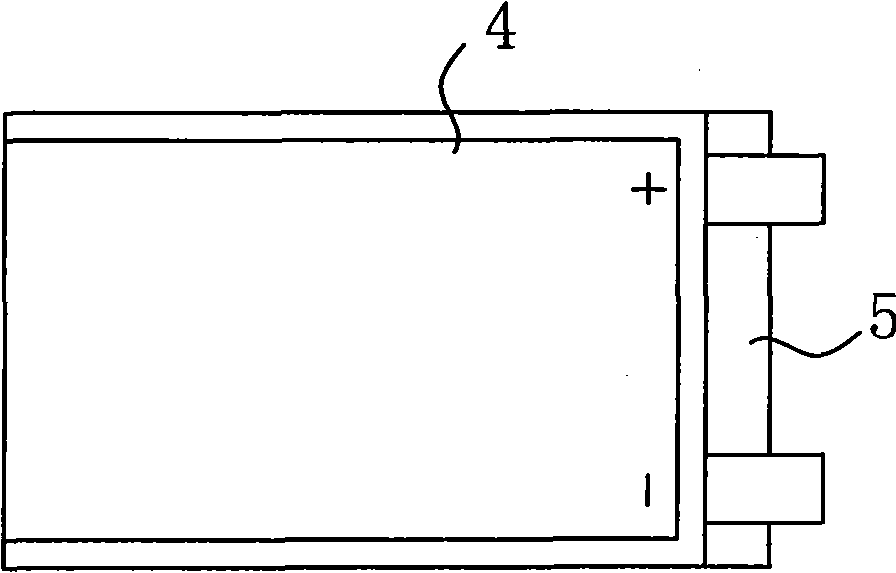

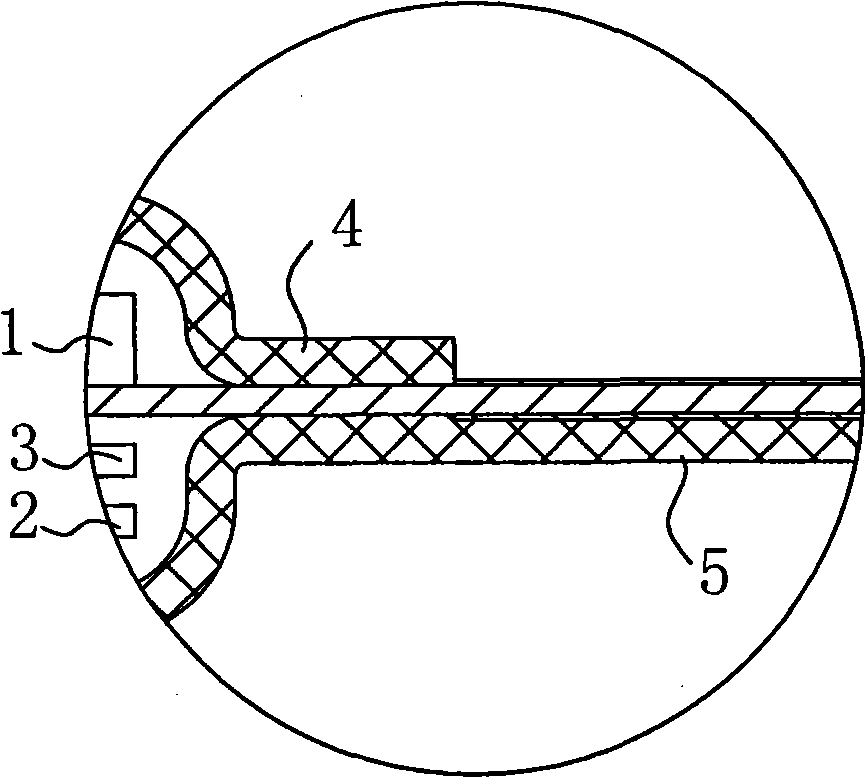

Ultrathin lithium-manganese polymer battery and processing method thereof

ActiveCN101867059AIncrease profitGood molding effectFinal product manufactureElectrode carriers/collectorsManganesePolypropylene

The invention discloses an ultrathin lithium-manganese polymer battery and a processing method thereof, belonging to the technology of lithium and manganese batteries. The technical scheme is that the ultrathin lithium-manganese polymer battery comprises an anode, a cathode, a diaphragm and an external packaging film. The anode consists of current collector aluminum foil, manganese dioxide, a conductive agent and a binder, the thickness of the anode is 0.03-0.2 mm, and the lead of the anode is formed in such a way that the extending part of the current collector aluminum foil outside the external packaging film is compounded with polypropylene or polyethylene. The cathode consists of a metal lithium sheet and a nickel strap or a copper strap or a steel strap, and the lead of the cathode is formed in such a way that the extending part of the nickel strap or the copper strap or the steel strap outside the external packaging film is compounded with polypropylene or polyethylene. The integral thickness of the battery is 0.3-0.5 mm. The processing method comprises the following steps of: (1) preparing the anode; (2) preparing the cathode; and (3) laminating and combining for molding. The invention solves the technical problem of great thickness of a traditional polymer battery, and has important significance for the generalization of various active identification cards.

Owner:深圳市超壹新能源科技有限公司

Crystalline silicon solar cell with low series resistor and preparation method thereof

InactiveCN102169909AImprove conductivityGuaranteed power outputFinal product manufactureOther printing apparatusGratingTransparent conducting film

The invention relates to a crystalline silicon solar cell with low series resistor, which comprises a p-n node; a passivation layer, a thin grating metal electrode and a main grating metal electrode are arranged on the front surface of the p-n node, and a back electric field and a back electrode are arranged on the back surface of the p-n node; the thin grating metal electrode, the main grating metal electrode, the back electric field and the back electrode are communicated with the p-n node; and a transparent conducting film is arranged on the full or partial area of the front surface of the crystalline silicon solar cell. The solar cell has a structure having the transparent conducting film, the metal electrodes and the passivation layer, wherein the transparent conducting film can be used for connecting breaking gates so as to reduce the power loss of the breaking gates; the film can reduce the series resistor on the front surface of the cell and enhance the conducting capability of the cell; simultaneously, the crystalline silicon solar cell can play a role in protecting the metal electrode on the front surface of the cell and prevent the metal electrode from oxidizing; and the reflectivity and the color of the crystalline silicon solar cell can be further controlled by adjusting and controlling the transparent conducting film. The invention further discloses a preparation method of the crystalline silicon solar cell.

Owner:SUN YAT SEN UNIV

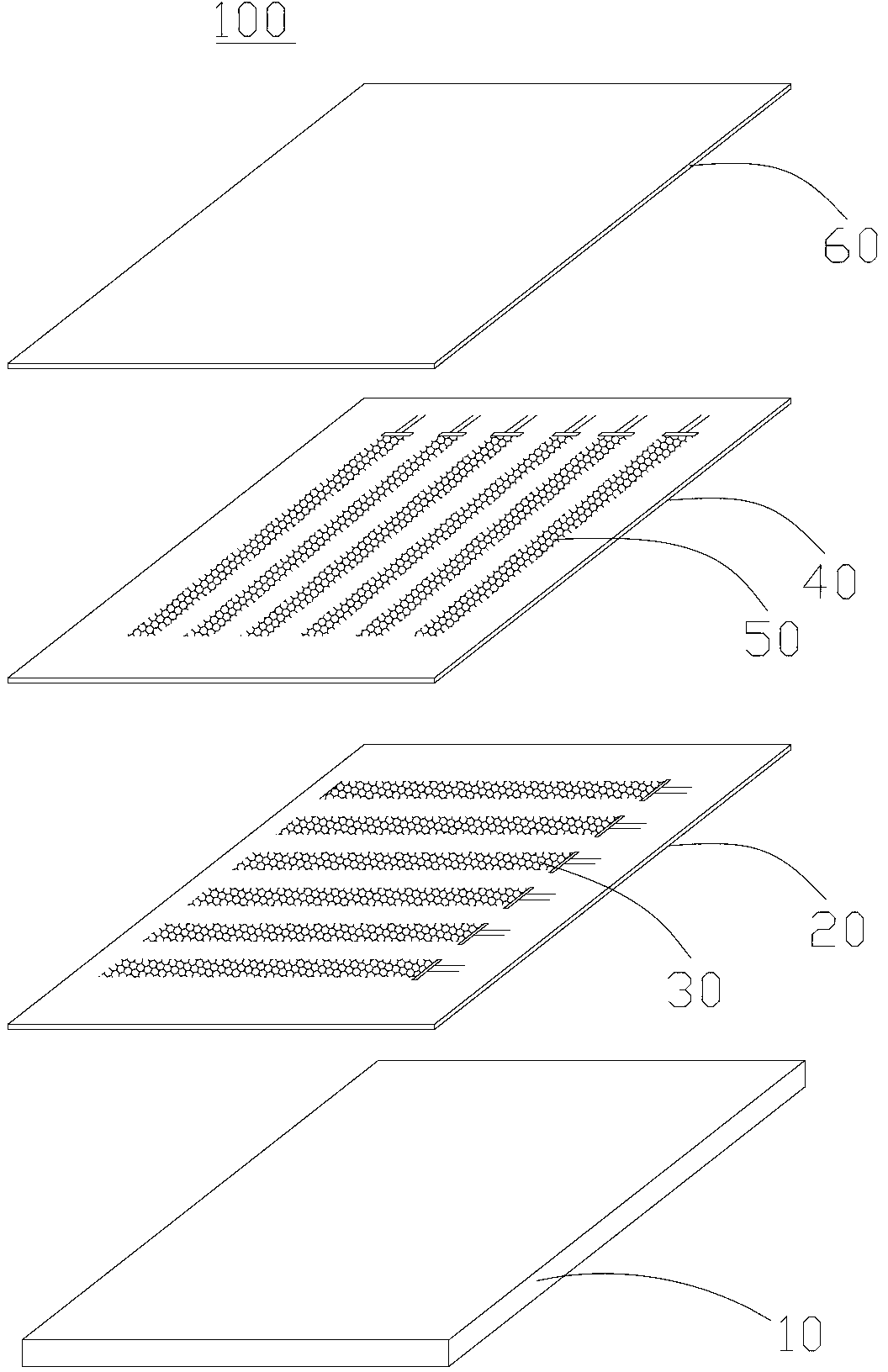

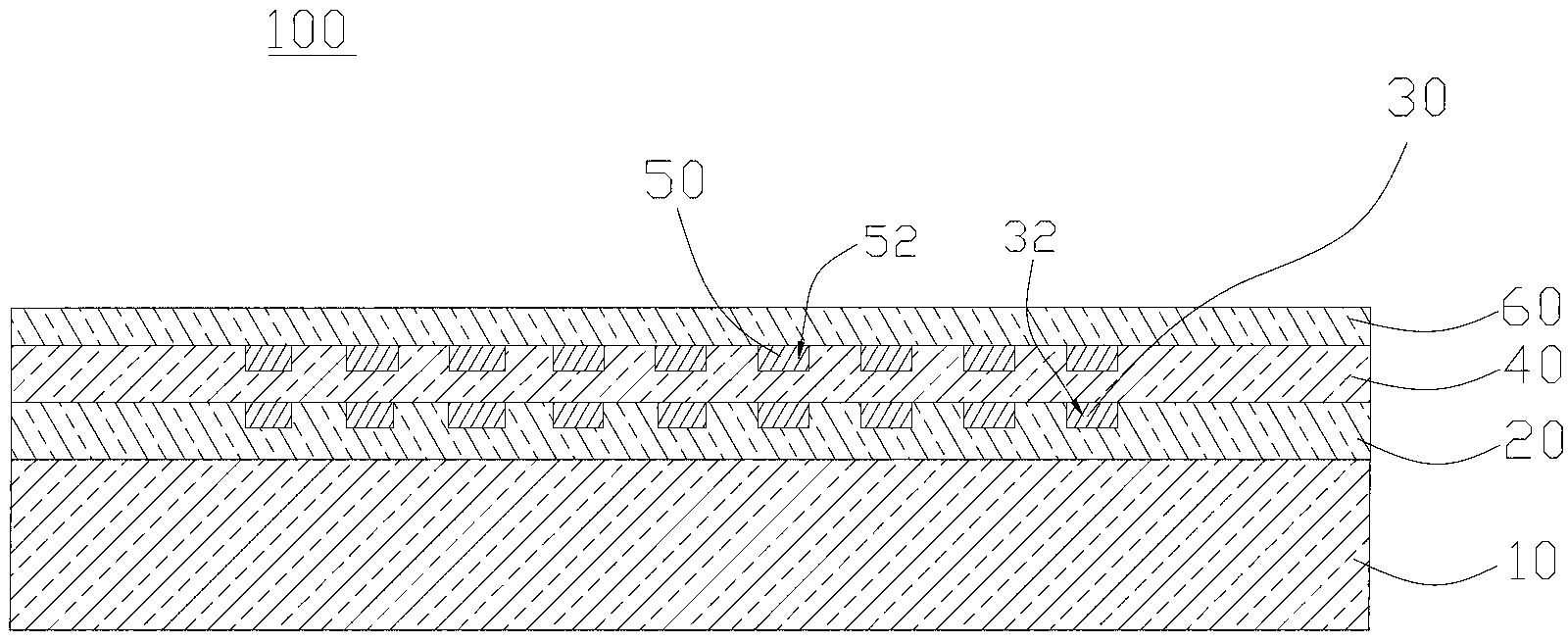

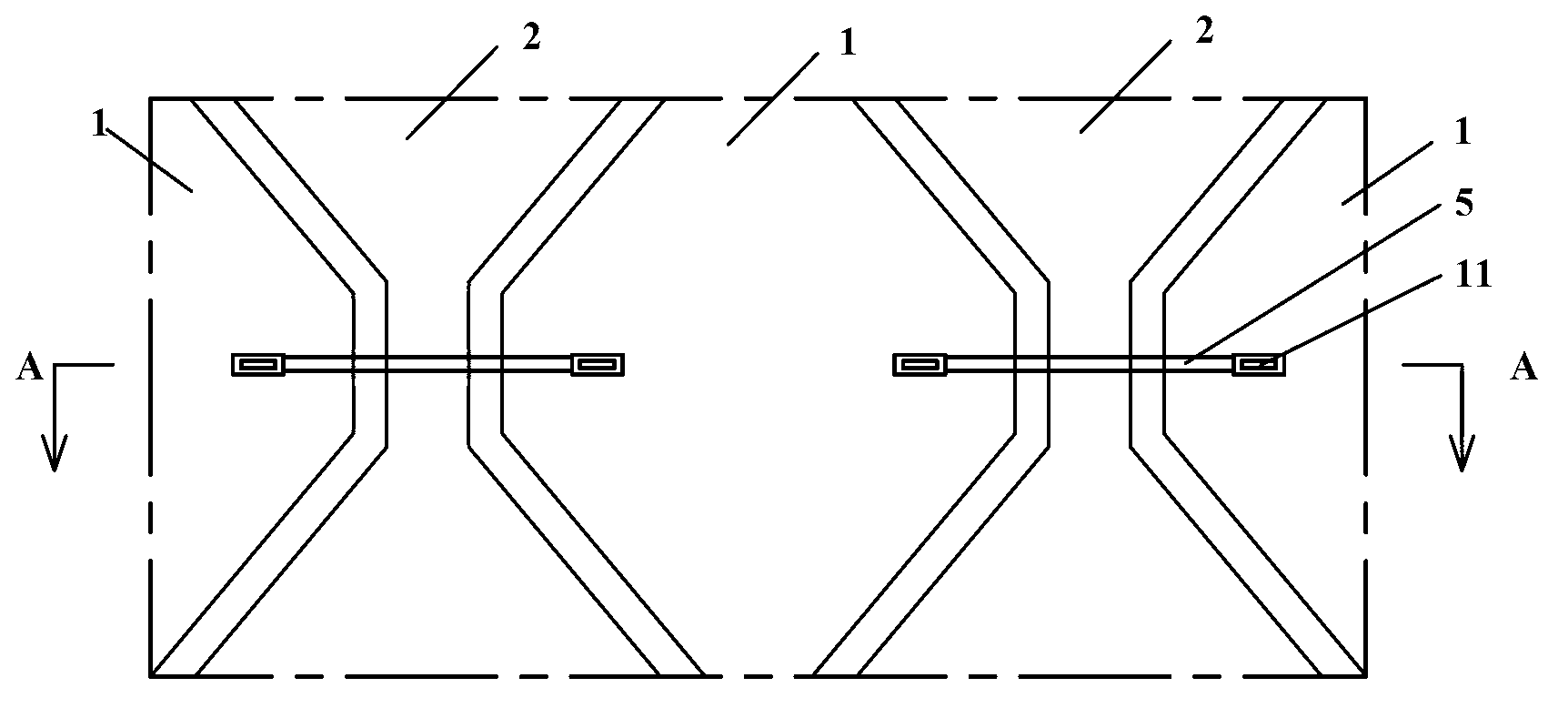

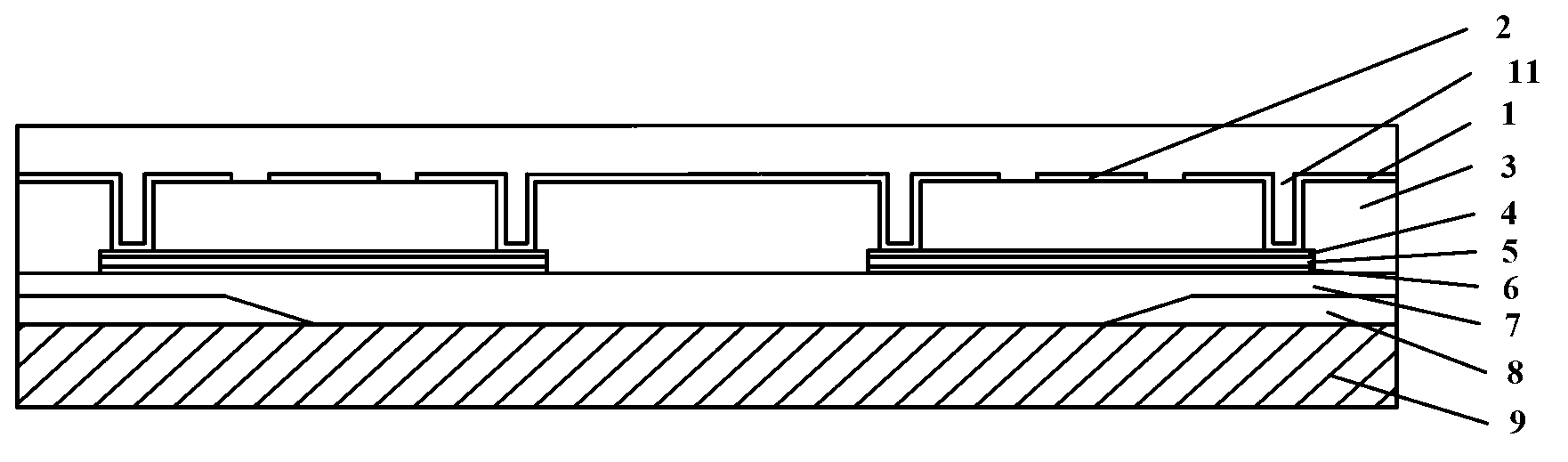

Double-layer touch screen and preparation method for same

ActiveCN103218081AGuaranteed light transmittanceGuaranteed electrical conductivityDetails for portable computersInput/output processes for data processingIndium tin oxideTransmittance

The invention discloses a double-layer touch screen, which comprises transparent cover plate glass, a first transparent impressing adhesive layer, a first conductive layer, a second transparent impressing adhesive layer, a second conductive layer and an anti-reflection layer, wherein the first conductive layer is embedded in the first transparent impressing adhesive layer, and comprises a plurality of first bus-bars, and the first bus-bars extend along a first direction, and are formed by intersecting conductive silk threads; and the second conductive layer is embedded in the first transparent impressing adhesive layer, and comprises a plurality of second bus-bars, and the second bus-bars extend along a second direction, and are formed by intersecting conductive silk threads. Compared with the conventional touch screen, the double-layer touch screen has the advantages that indium tin oxide (ITO) is replaced by the first and second conductive layers formed by a conductive material filled in a first groove and a second groove, an additional etching technology is not required by such a process, the light transmittance and the electrical conductivity are ensured, and meanwhile, the material cost is lower, so that the cost can be lowered. The invention also discloses a preparation method for the double-layer touch screen.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Touch screen, electronic equipment including same and method for manufacturing same

InactiveCN102799311AGuaranteed conductivityAvoid Oxide ResistanceElectronic switchingInput/output processes for data processingOrganic matterMetal

The invention relates to the technical field of touch screens, and in particular relates to a touch screen, electronic equipment including the same and a method for manufacturing the same. The touch screen comprises driving electrode layers, a transparent polymerization organic matter layer and a metal bridge, wherein the metal bridge is used for conducting two adjacent driving electrode layers; and a protective layer for covering the metal bridge and preventing oxidization of the metal bridge is arranged between the driving electrode layers and the metal bridge. According to the touch screen provided in the invention, as the protective layer covers the metal bridge, the metal bridge is not subjected to an oxidation reaction due to the contact of the metal bridge and a transparent polymerization organic matter, thus the conductivity of the metal bridge is effectively guaranteed, the impedance of an oxidation layer is avoided from increasing, and the yield of the touch screen is improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

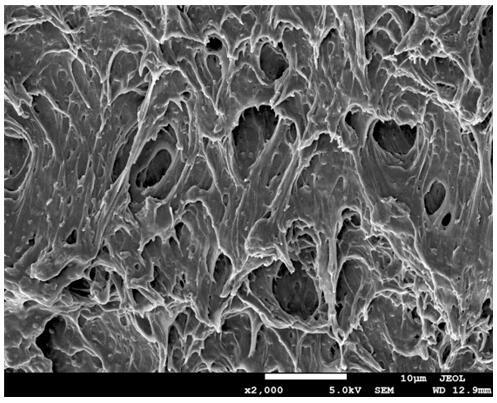

Preparation method of cellulose-based flexible stress-strain sensitive material

InactiveCN105675182AImprove conductivityGuaranteed electrical conductivityForce measurementCelluloseStructural health monitoring

The invention provides a preparation method of a cellulose-based flexible stress-strain sensitive material. The preparation method comprises the steps of: 1) adding cellulose into water and mixing uniformly to form a 0.2-5wt% aqueous solution, and freeze-drying the aqueous solution to prepare a cellulose aerogel; 2) subjecting the cellulose aerogel prepared in the step 1) to pyrolysis processing at high temperature of 600-1000 DEG C for 0.5 to 5 hours under the protection of vacuum or inert atmosphere to prepare a carbon gel; 3) and pouring PDMS resin in the carbon gel, and carrying out vacuum defoamation, thereby the flexible stress-strain sensitive material with high sensitivity is obtained after resin is solidified. The preparation method has the advantages of rich, chip and renewable raw materials, simple and controllable preparation process, and wide strain range and high sensitivity of the prepared stress-strain sensitive material; and the preparation method has good application prospect in aspects of structural health monitoring, electronic skin, biological medicine, wearable electronic product and the like.

Owner:CHONGQING UNIV

Antistatic material, preparation method and applications of antistatic material

The invention belongs to the technical field of polymer composites and discloses an antistatic material, a preparation method and applications of the antistatic material. The antistatic material disclosed by the invention comprises the following components in parts by weight: 40-70 parts of polypropylene, 3-10 parts of polyethylene, 3-10 parts of elastomer, 10-30 parts of talcum powder, 1-2 parts of compatilizer, 0.1-0.5 parts of coupling agent, 1-20 parts of conductive filler and 0.1-0.5 parts of antioxygen. The preparation method for the antistatic material disclosed by the invention comprises the following steps of: weighing 40-70 parts of polypropylene, 3-10 parts of polyethylene, 3-10 parts of elastomer, 10-30 parts of talcum powder, 1-2 parts of compatilizer, 0.1-0.5 parts of coupling agent, 1-20 parts of conductive filler and 0.1-0.5 parts of antioxygen; mixing in a high-speed mixing machine for 5 minutes; then taking out; performing extruding granulation in a twin-screw extruder to prepare the antistatic material, wherein the temperature of the extruder is set to be 175-215 DEG C. The method disclosed by the invention is simple in operation, is easy for industrial production realization and is capable of meeting the requirements of high strength and antistatic behavior of automotive materials.

Owner:HEFEI GENIUS NEW MATERIALS

Popular searches

Simple process Suitable for large-scale industrial production Reduce Shuttle Effect Excellent electrochemical performance Improve initial discharge capacity Improve Coulombic efficiency Improved magnification performance Increase the rate of electron transfer Good charge and discharge performance Shorten migration distance

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com