Anode material of lithium-sulfur battery, lithium-sulfur battery and method for preparing anode material

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, battery components, etc., can solve the problem of insufficient suppression, achieve the effects of avoiding direct contact, inhibiting the shuttle effect, and increasing the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

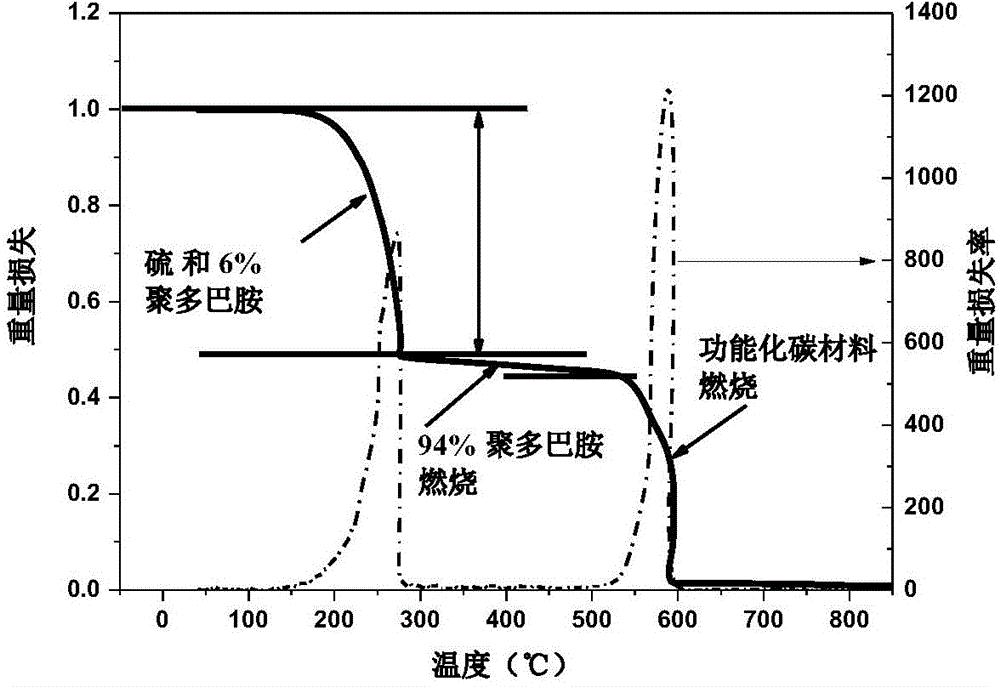

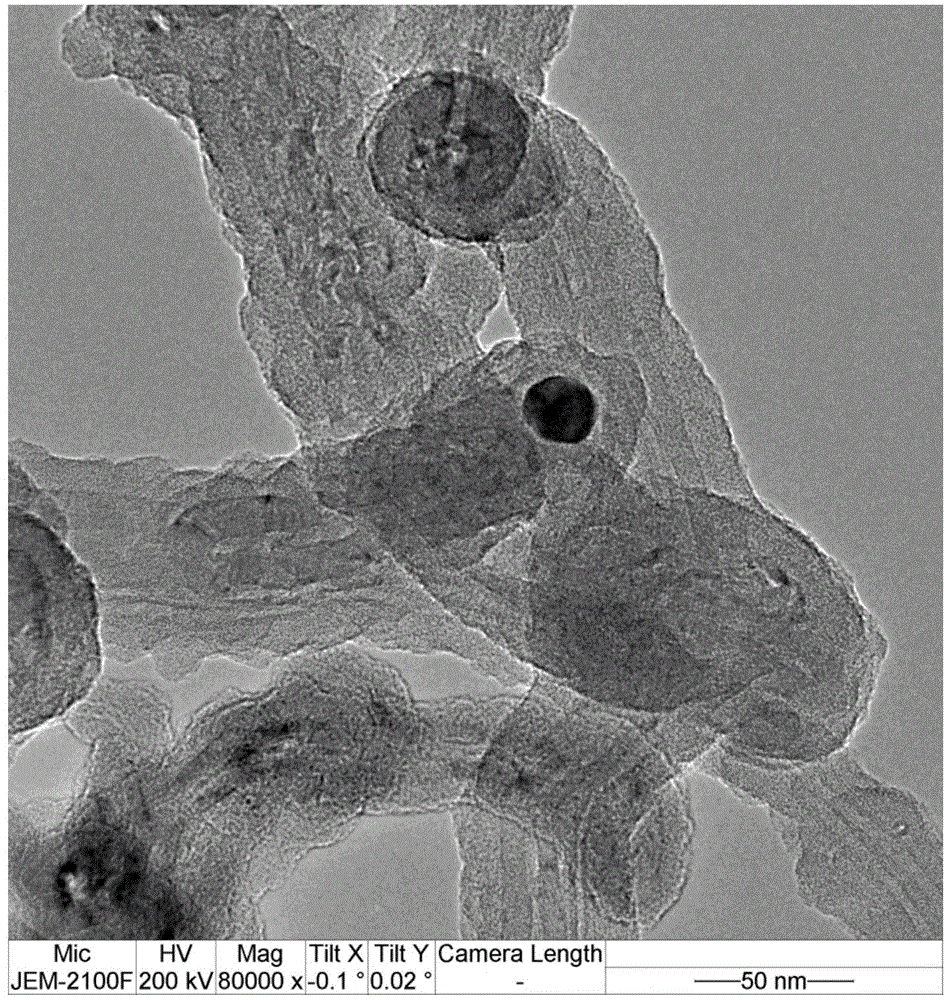

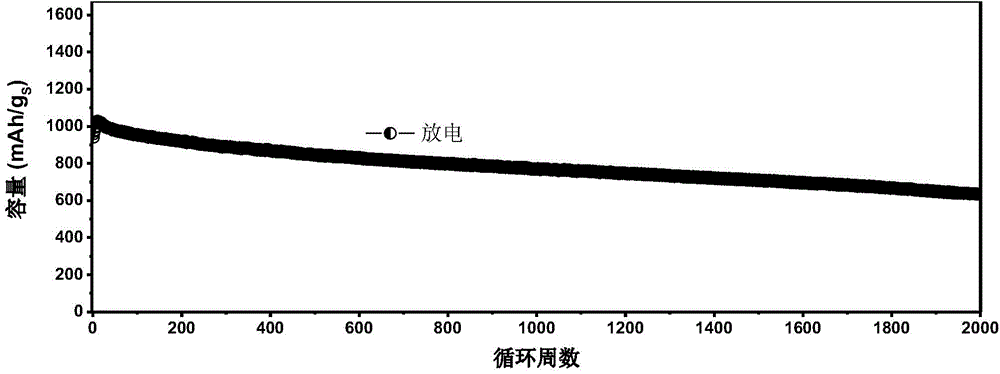

[0075] Dissolve 2.0g of carbon nanotubes in 80mL of aqueous solution containing 6.0g of sodium hydroxide, and conduct a hydrothermal reaction at 180°C for 3 hours in a closed environment to obtain reaction product 1. After centrifuging, the reaction product 1 is separated to obtain a precipitate, and washed with water to pH If it is neutral, a functionalized carbon nanomaterial is obtained. Add 2 g of functionalized carbon nanomaterials into 0.08 mol of sodium thiosulfate aqueous solution, stir well to obtain a mixed solution, add 0.2 mol / L dilute hydrochloric acid dropwise at a rate of 20 μL / min to the mixed solution at 20 ° C, and the dropwise addition ends After reacting at 20°C for 12 hours, the reaction product 2 was obtained. The reaction product 2 was centrifuged and separated to obtain a precipitate, washed with water until the pH was neutral, and dried to obtain a functionalized carbon nanomaterial coated with sulfur on the outside. Add 2 g of functionalized carbon na...

Embodiment 2

[0086] Dissolve 2.0g of carbon nanospheres in 80mL of aqueous solution containing 6.0g of sodium hydroxide, and conduct a hydrothermal reaction at 180°C for 3 hours in a closed environment to obtain reaction product 1. After centrifuging, the reaction product 1 is separated to obtain a precipitate, and washed with water to pH If it is neutral, a functionalized carbon nanomaterial is obtained. Add 2 g of functionalized carbon nanomaterials into 0.08 mol of sodium thiosulfate aqueous solution, stir well to obtain a mixed solution, add 0.2 mol / L dilute hydrochloric acid dropwise at a rate of 20 μL / min to the mixed solution at 20 ° C, and the dropwise addition ends After reacting at 20°C for 12 hours, the reaction product 2 was obtained. The reaction product 2 was centrifuged and separated to obtain a precipitate, washed with water until the pH was neutral, and dried to obtain a functionalized carbon nanomaterial coated with sulfur on the outside. Add 2 g of functionalized carbon ...

Embodiment 3

[0097] Dissolve 2.0g of graphene in 80mL of aqueous solution containing 6.0g of sodium hydroxide, conduct a hydrothermal reaction in a closed environment at 180°C for 3 hours to obtain reaction product 1, centrifuge reaction product 1 and separate to obtain a precipitate, wash with water until the pH is Neutral to obtain functionalized carbon nanomaterials. Add 2 g of functionalized carbon nanomaterials into 0.08 mol of sodium thiosulfate aqueous solution, stir well to obtain a mixed solution, add 0.2 mol / L dilute hydrochloric acid dropwise at a rate of 20 μL / min to the mixed solution at 20 ° C, and the dropwise addition ends After reacting at 20°C for 12 hours, the reaction product 2 was obtained. The reaction product 2 was centrifuged and separated to obtain a precipitate, washed with water until the pH was neutral, and dried to obtain a functionalized carbon nanomaterial coated with sulfur on the outside. Add 2 g of functionalized carbon nanomaterials coated with sulfur on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Capacity retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com