Aluminum alloy wire

A technology of aluminum alloy wires and wires, which is applied in the direction of metal/alloy conductors, conductors, conductive materials, etc., can solve the problems that aluminum wires cannot meet the needs of large-load transmission, and achieve simple and feasible preparation processes, excellent mechanical properties, high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An aluminum alloy wire, which is prepared from the following raw materials:

[0021] Germanium, tantalum, yttrium, rhenium, vanadium, molybdenum, zinc, manganese, chromium, titanium, aluminum, graphite, carbon fiber, nano-silica, bisphenol-A epoxy resin.

[0022] The preparation method of the above-mentioned aluminum alloy wire comprises the following steps:

[0023] 1) Put graphite into a crucible, place it in a muffle furnace for calcination, and under the protection of nitrogen, calcine at 700°C for 3 minutes, take it out, crush it into powder, and obtain material 1;

[0024] 2) Add material 1, carbon fiber and nano-silica to the high-speed mixer in turn, stir at 1000 rpm for 5 minutes, then preheat to 100°C, let stand for 5 minutes, and then immerse in bisphenol A epoxy resin, Pull it out in the form of strands through a shaping die and chop it to obtain modified carbon fiber; wherein, the mass ratio of material 1, carbon fiber, nano-silica and bisphenol A epoxy re...

Embodiment 2

[0028] An aluminum alloy wire, which is prepared from the following raw materials:

[0029] Germanium, tantalum, yttrium, rhenium, vanadium, molybdenum, zinc, manganese, chromium, titanium, aluminum, graphite, carbon fiber, nano-silica, bisphenol-A epoxy resin.

[0030] The preparation method of the above-mentioned aluminum alloy wire comprises the following steps:

[0031] 1) Put graphite into a crucible, place it in a muffle furnace for calcination, and under the protection of nitrogen, calcine at 800°C for 3 minutes, take it out, and crush it into powder to obtain material 1;

[0032] 2) Add material 1, carbon fiber and nano-silica to the high-speed mixer in turn, stir at 1000 rpm for 5 minutes, then preheat to 100°C, let stand for 5 minutes, and then immerse in bisphenol A epoxy resin, Pull it out in the form of strands through a shaping die and chop it to obtain modified carbon fiber; wherein, the mass ratio of material 1, carbon fiber, nano-silica and bisphenol A epoxy ...

Embodiment 3

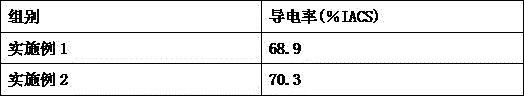

[0036] 1. Conductivity test:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com