Lightweight porous MXene-based composite film electromagnetic shielding material and preparation method thereof

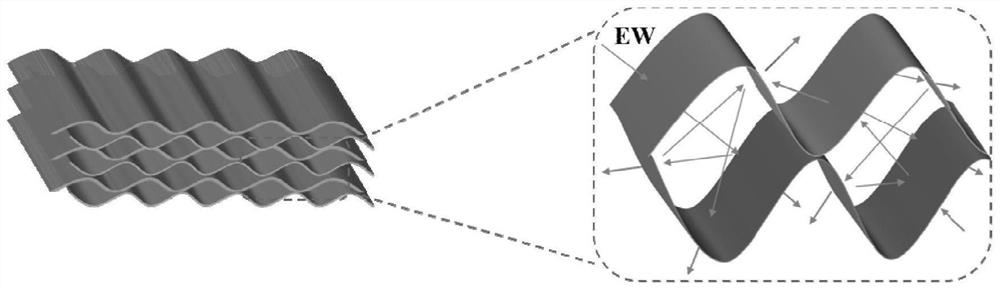

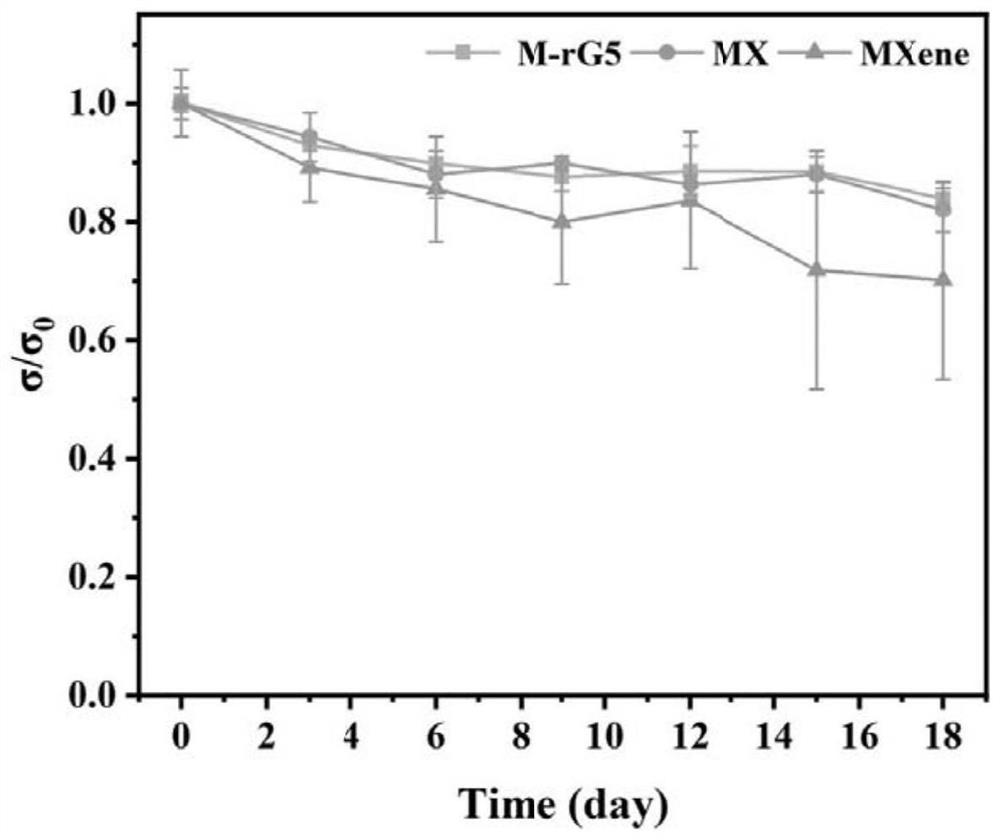

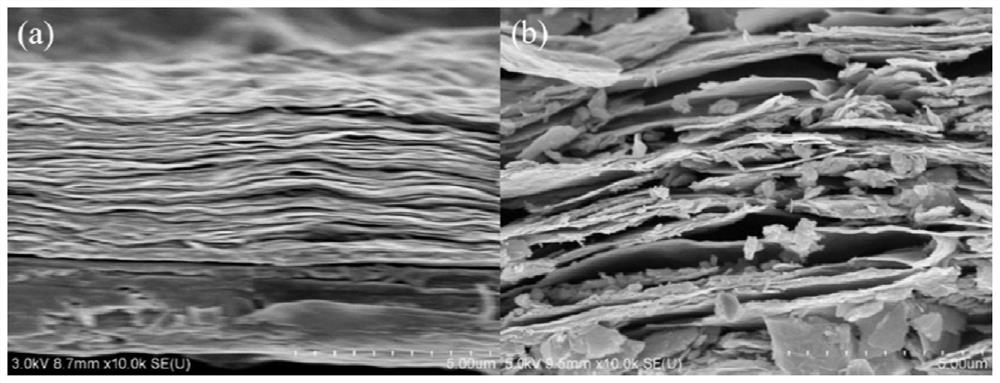

A technology of electromagnetic shielding material and composite film, which can be applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of MXene conductivity and stability, uneven pore structure, etc., to achieve multiple scattering/reflection effects increase, simple operation , the effect of improving the absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of MXene / GO dispersion:

[0040] Preparation of MXene: Dissolve 2gLiF in a hydrochloric acid solution prepared by 10mL water and 30mL concentrated hydrochloric acid by magnetic stirring in a polytetrafluoroethylene beaker, then add 2g400 mesh aluminum carbon titanium oxide (Ti 3 AlC 2 , MAX) powder, the reactor was placed in a 35°C water bath and continuously stirred for 24 hours, and then washed with absolute ethanol and ultrapure water by ultrasonication and centrifugation several times to remove residual impurities. The obtained MXene dispersion was freeze-dried for later use.

[0041] Preparation of graphene oxide (GO): Add 4g of 325 mesh flake graphite, 480mL of concentrated sulfuric acid and 54mL of concentrated phosphoric acid into a 1000mL three-neck flask, mechanically stir for 30min, then slowly add 24g of potassium permanganate, continue to stir at a constant speed, and put in a water bath at 50°C for 12h. After the reaction was completed, t...

Embodiment 2

[0047] (1) Preparation of MXene / GO dispersion:

[0048] Take 126mg of MXene and dissolve it in an appropriate amount of ultrapure water. After ultrasonic and magnetic stirring, the MXene is uniformly dispersed, and then add 4.7mL of 50% polyethyleneimine aqueous solution. After 1.5h11000 r / min high-speed centrifugation, remove the lower layer of sediment, and then continue to add ultrapure water to disperse evenly. After repeating 4 times, add 25mL ultrapure water, and then add 2mL 7mg / mL graphene oxide dispersion evenly dispersed by ultrasonic stirring , mixed evenly under magnetic stirring, and named it M-G10 dispersion.

[0049] (2) Preparation of lightweight porous MXene-based composite films

[0050] Preparation of MXene / GO film: Take 5mL of the MXene / GO dispersion obtained in step (1), drop-coat it on a polyethylene terephthalate (PET) sheet leveled by a leveler, and vacuum it in a vacuum oven. Drying at a vacuum of -0.08MPa and a temperature of 50°C. After drying for ...

Embodiment 3

[0053] (1) Preparation of MXene / GO dispersion:

[0054] Take 119mg of MXene and dissolve it in an appropriate amount of ultrapure water. After ultrasonic and magnetic stirring, the MXene is dispersed evenly. Then add 4.5mL of 50% polyethyleneimine aqueous solution. After 1.5h11000 r / min high-speed centrifugation, remove the lower layer of sediment, and then continue to add ultrapure water to disperse evenly. After repeating 4 times, add 24mL ultrapure water, and then add 3mL7mg / mL graphene oxide dispersion uniformly dispersed by ultrasonic stirring. Mix evenly under magnetic stirring, and name it M-G15 dispersion liquid.

[0055] (2) Preparation of lightweight porous MXene-based composite films

[0056] Preparation of MXene / GO film: Get 5ml of the MXene / GO dispersion obtained in step (1), drop-coat it on a polyethylene terephthalate (PET) sheet leveled by a leveler, and vacuum it in a vacuum oven. Drying, the vacuum degree is -0.08MPa, and the temperature is 50°C. After dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com