Patents

Literature

44 results about "Flying shuttle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The flying shuttle was one of the key developments in the industrialization of weaving during the early Industrial Revolution. It allowed a single weaver to weave much wider fabrics, and it could be mechanized, allowing for automatic machine looms. The flying shuttle, which was patented by John Kay (1704–c. 1779) in 1733, greatly sped up the previous hand process and halved the labour force. Where a broad-cloth loom previously required a weaver on each side, it could now be worked by a single operator. Until this point the textile industry had required four spinners to service one weaver. Kay's innovation, in wide use by the 1750s, greatly increased this disparity.

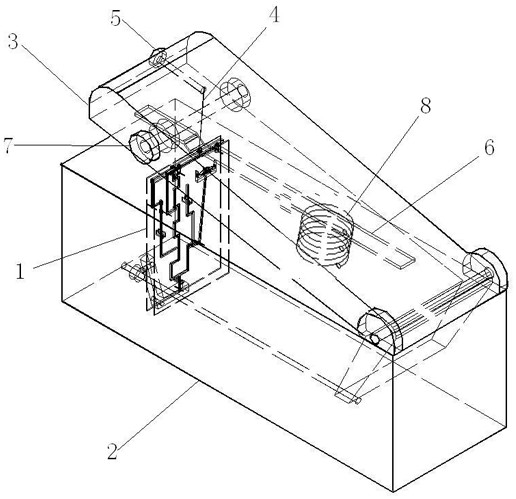

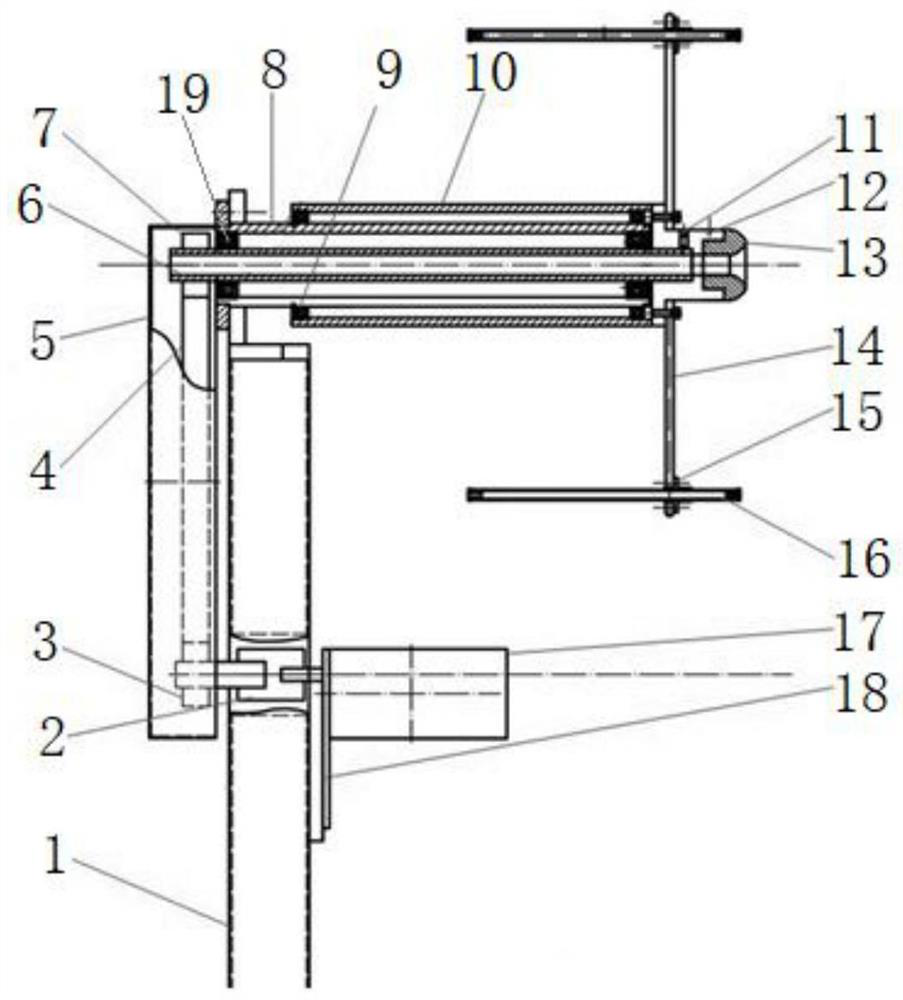

Single-line flying shuttle system

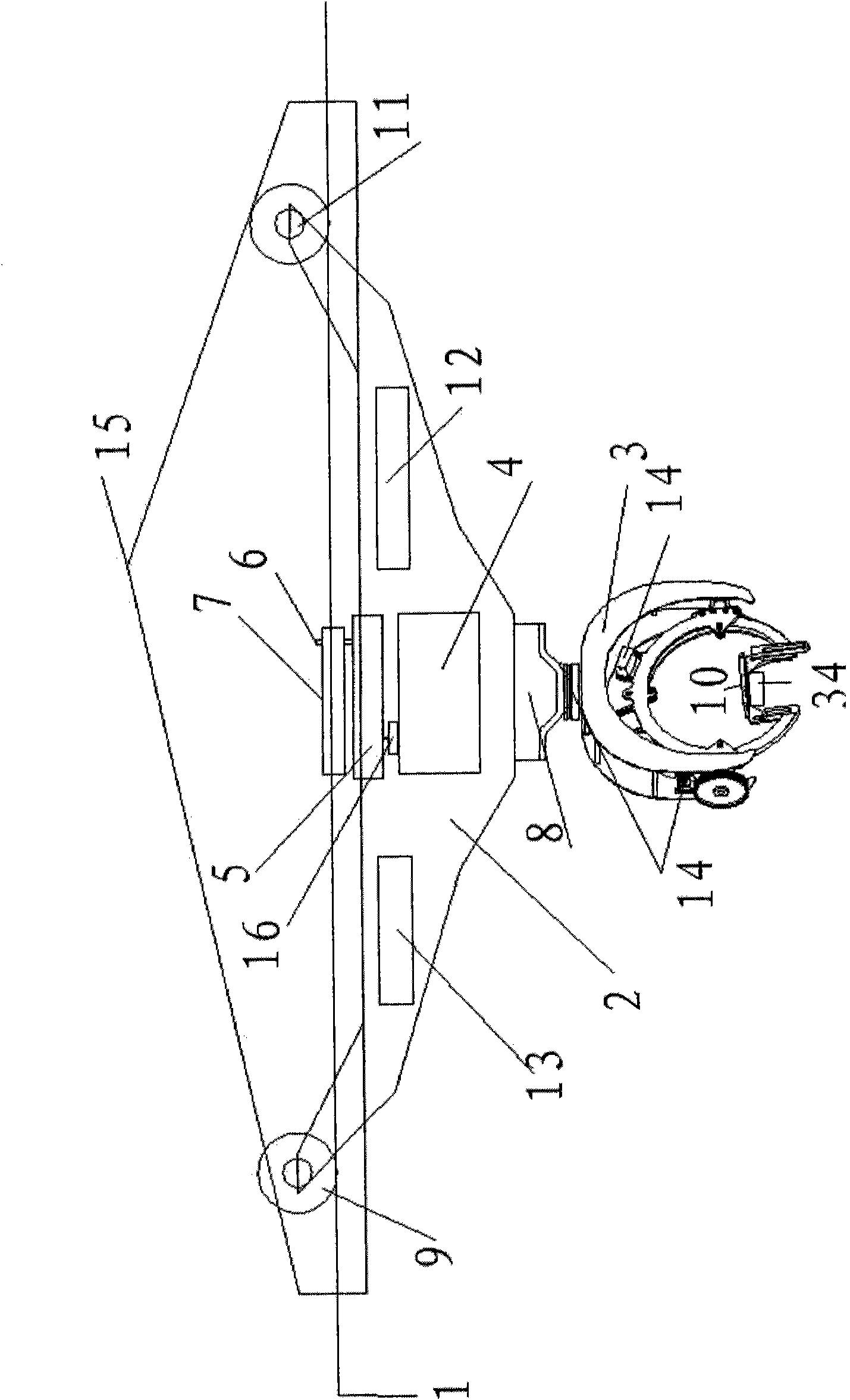

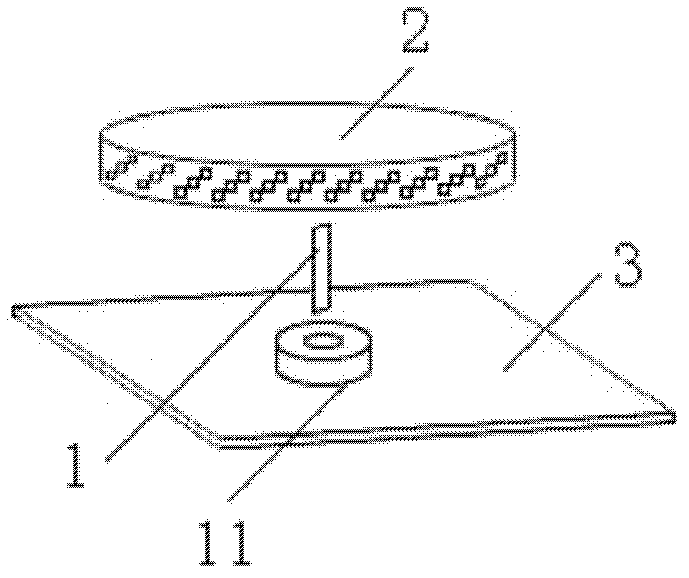

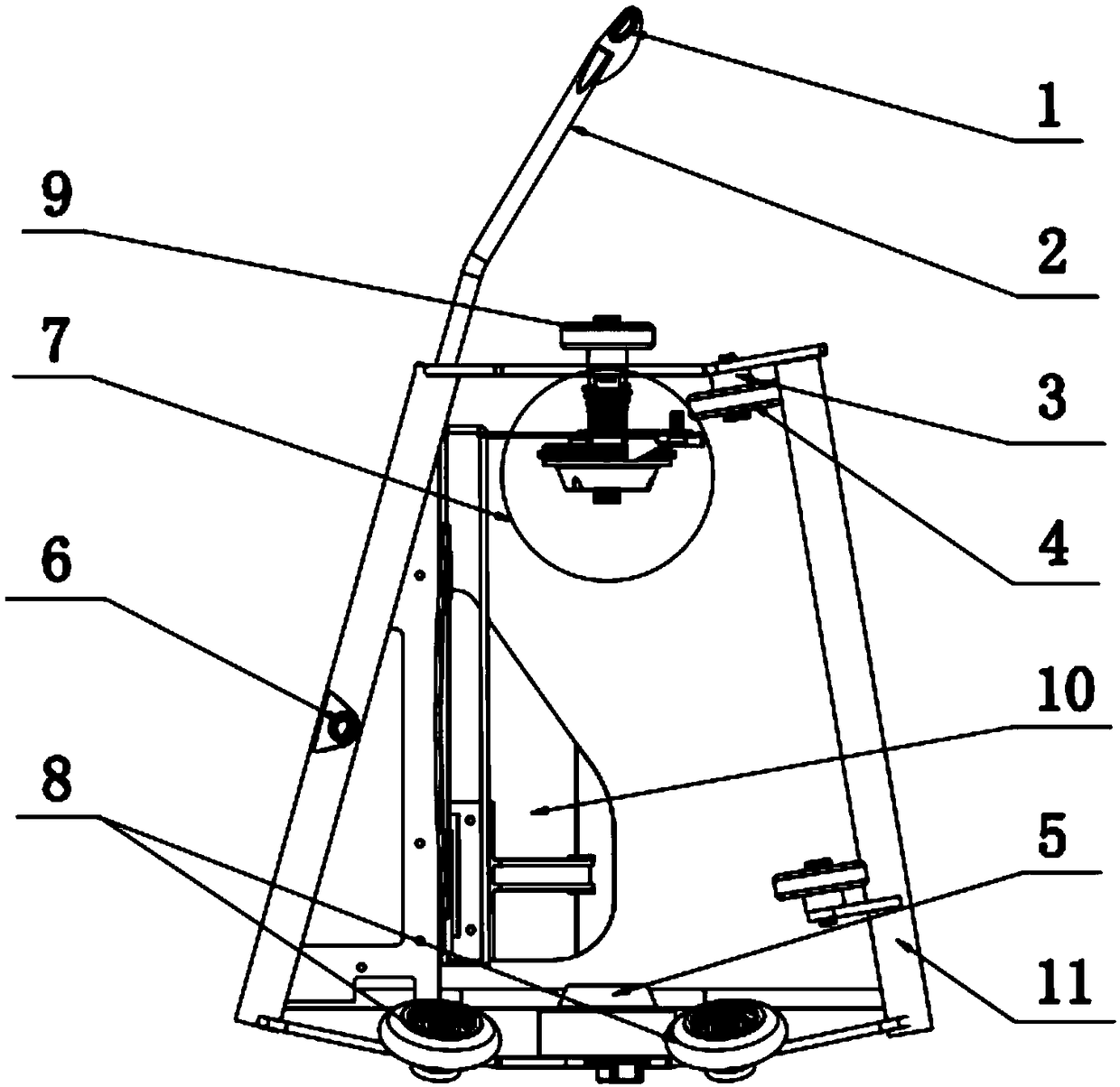

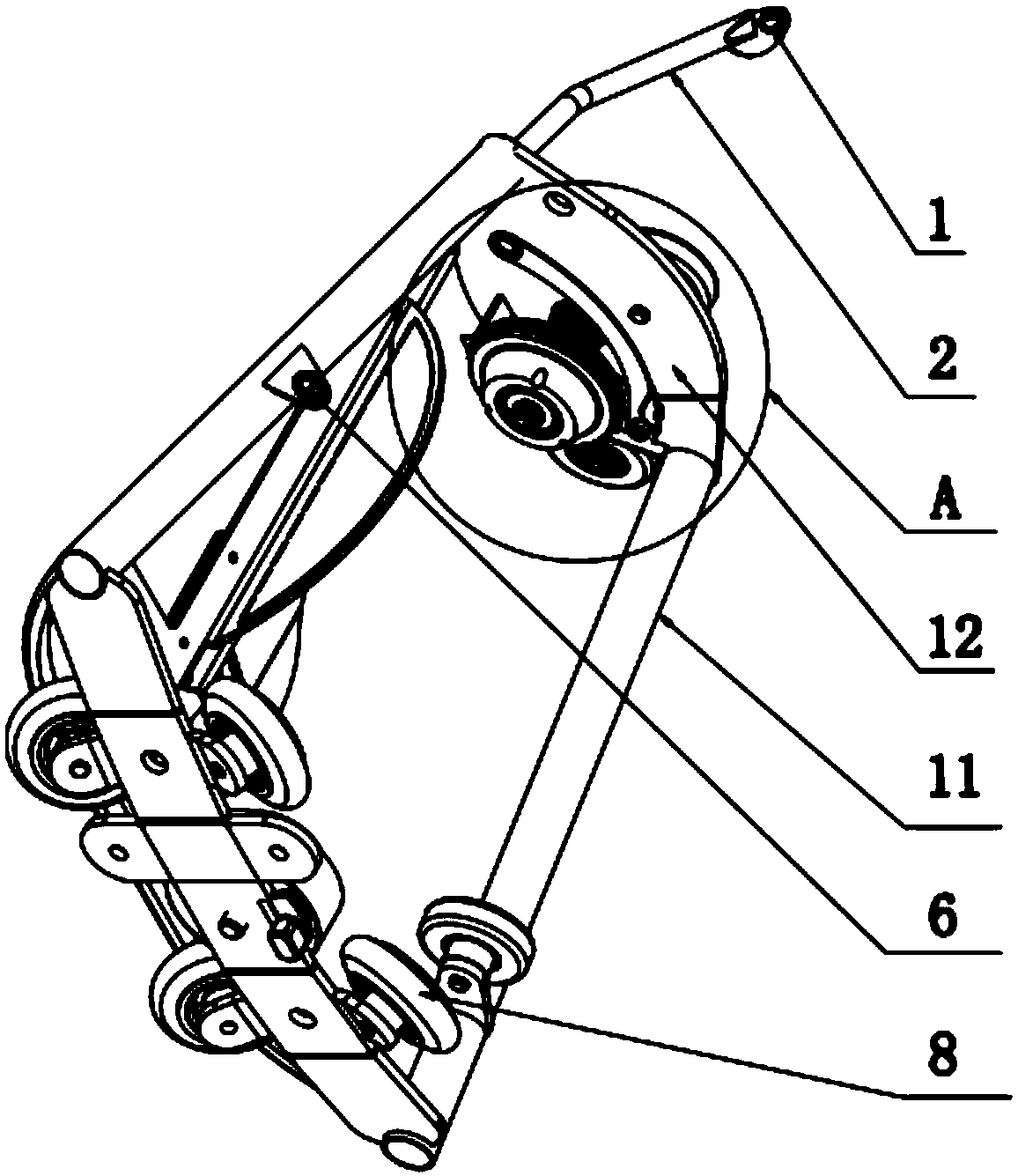

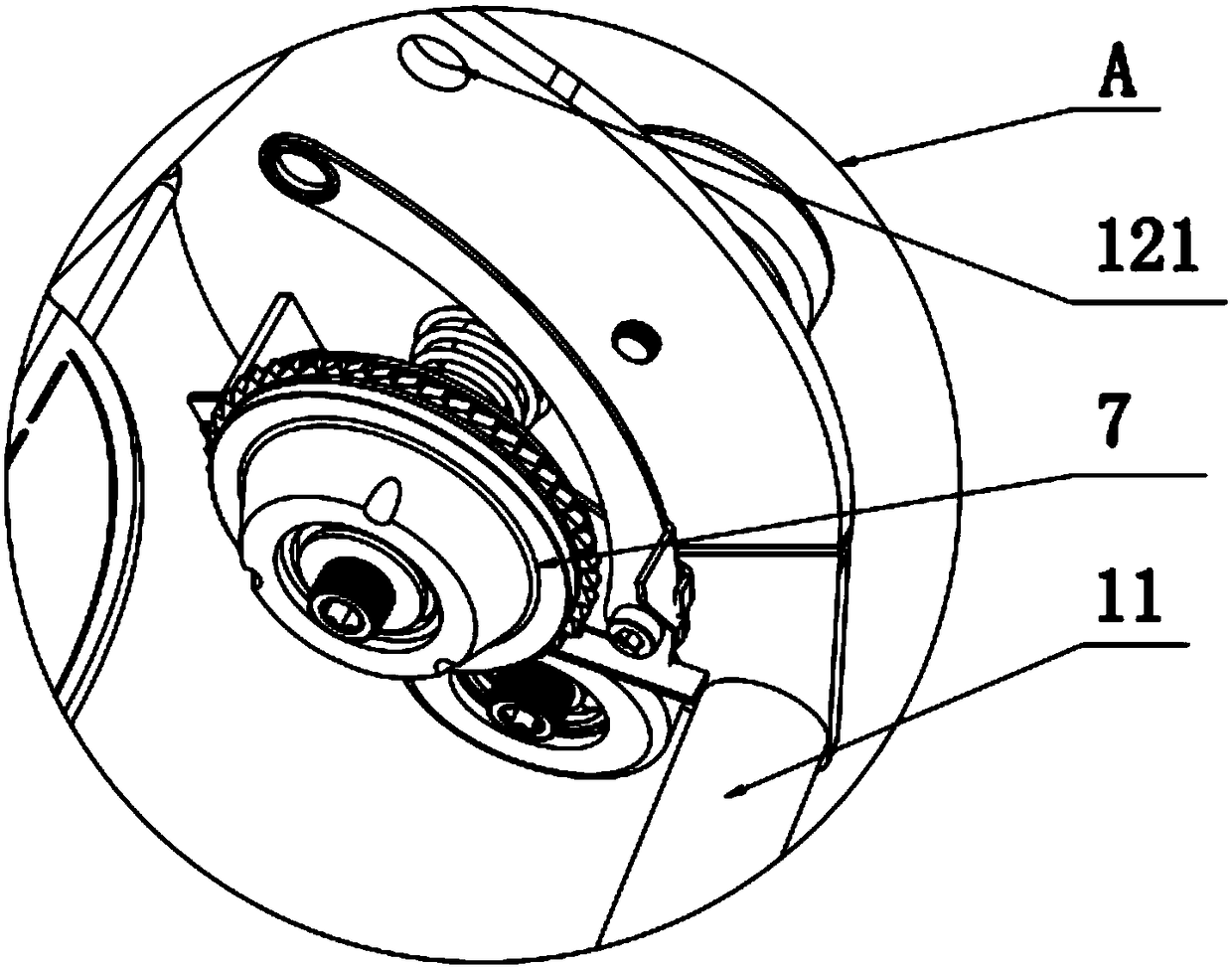

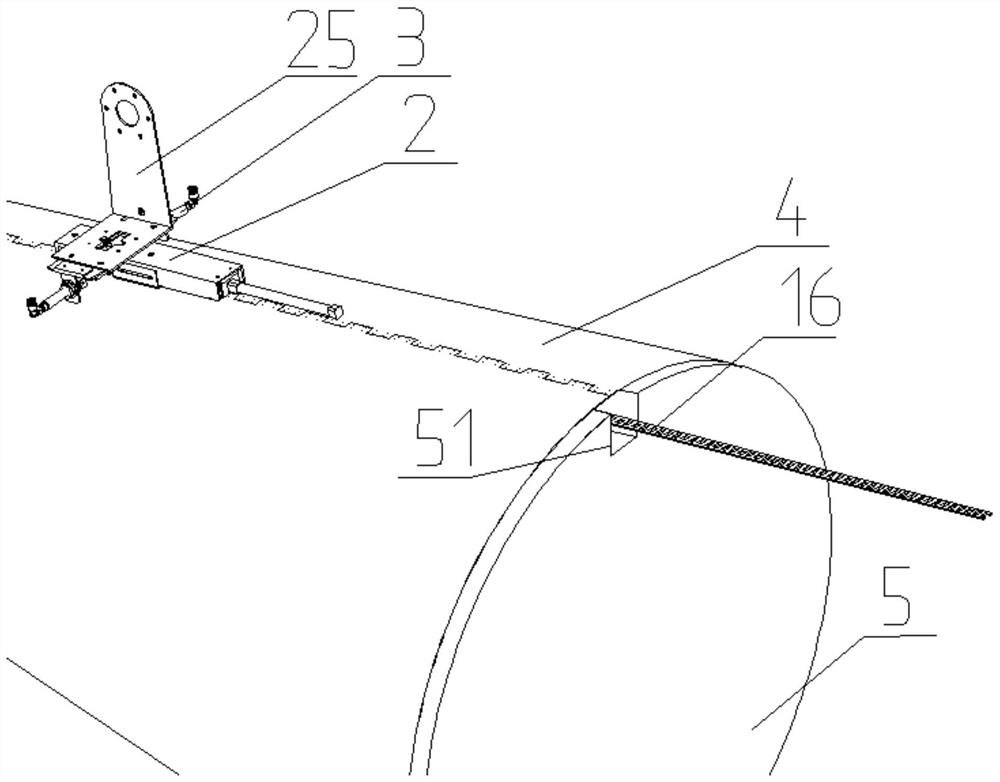

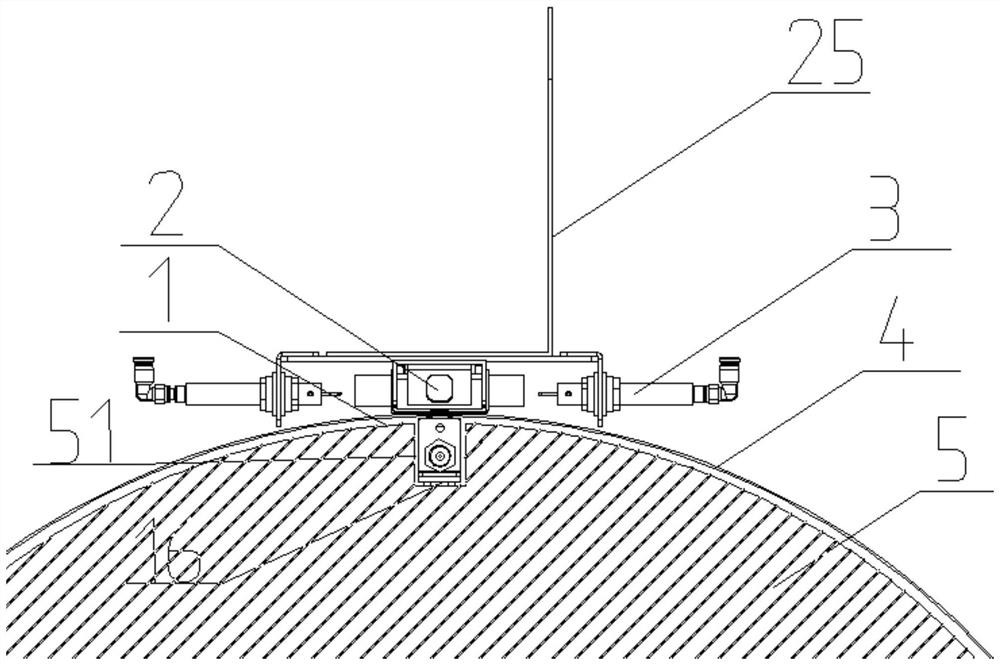

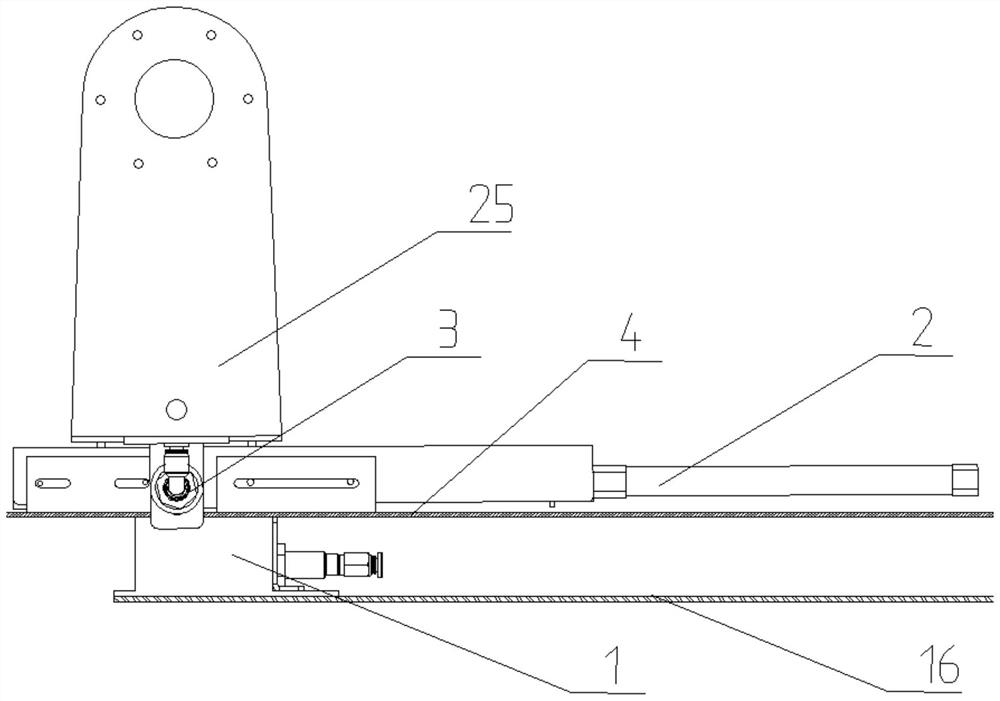

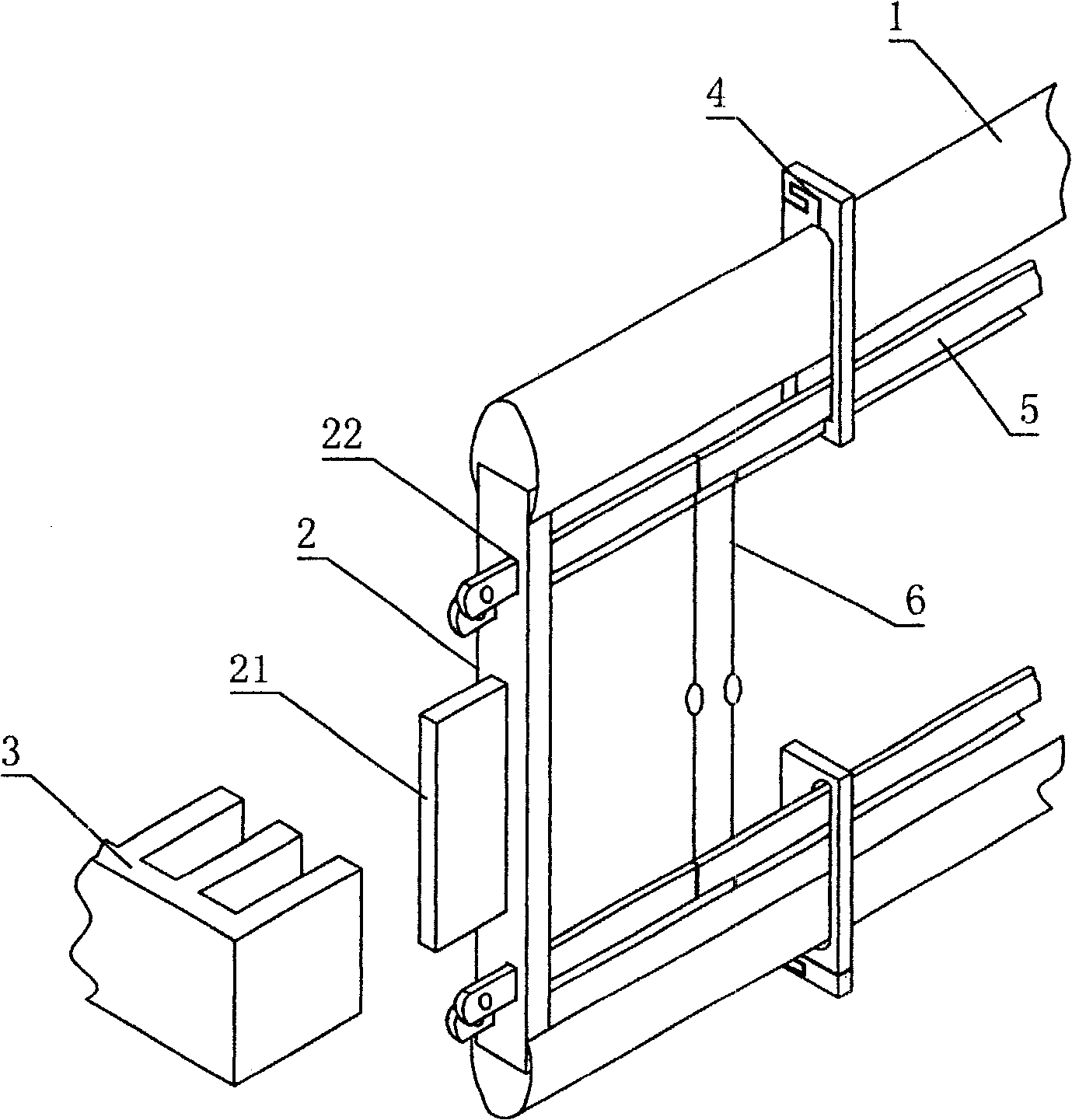

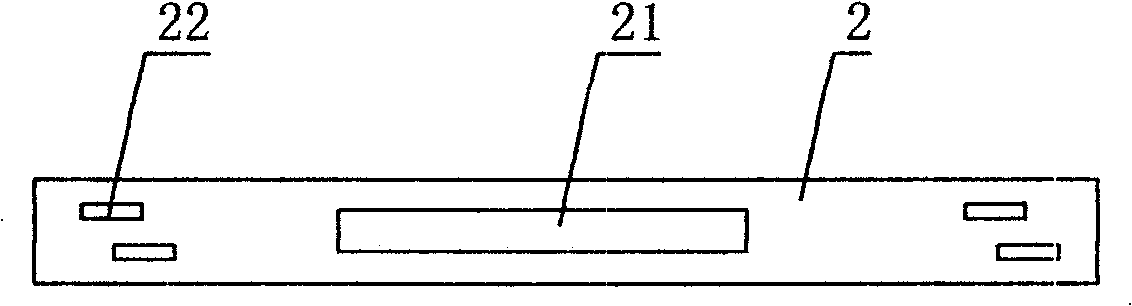

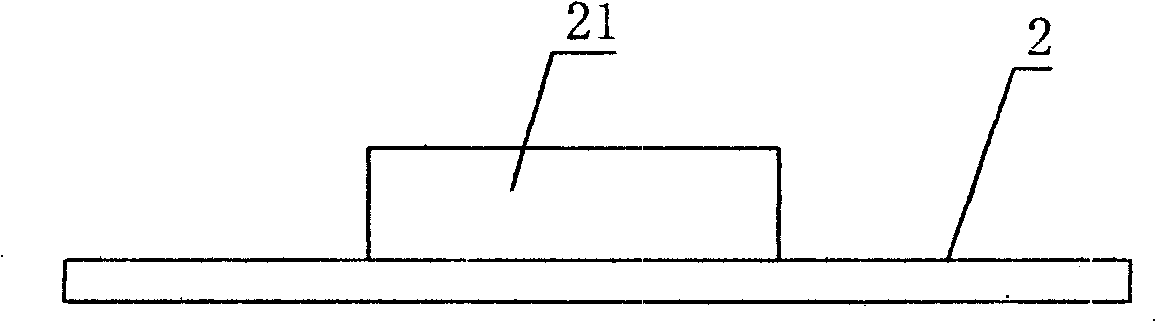

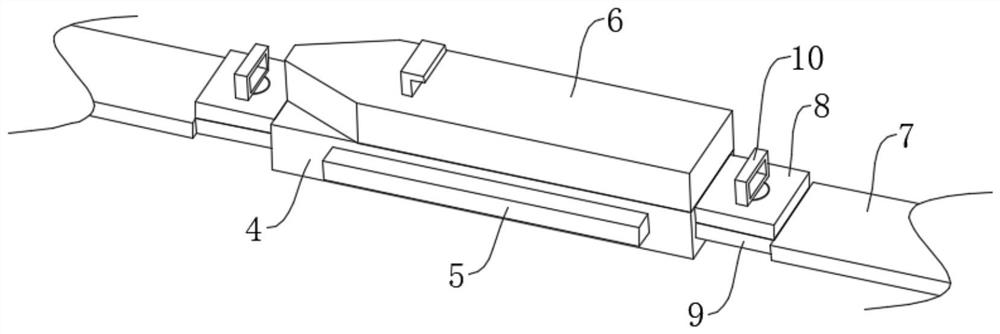

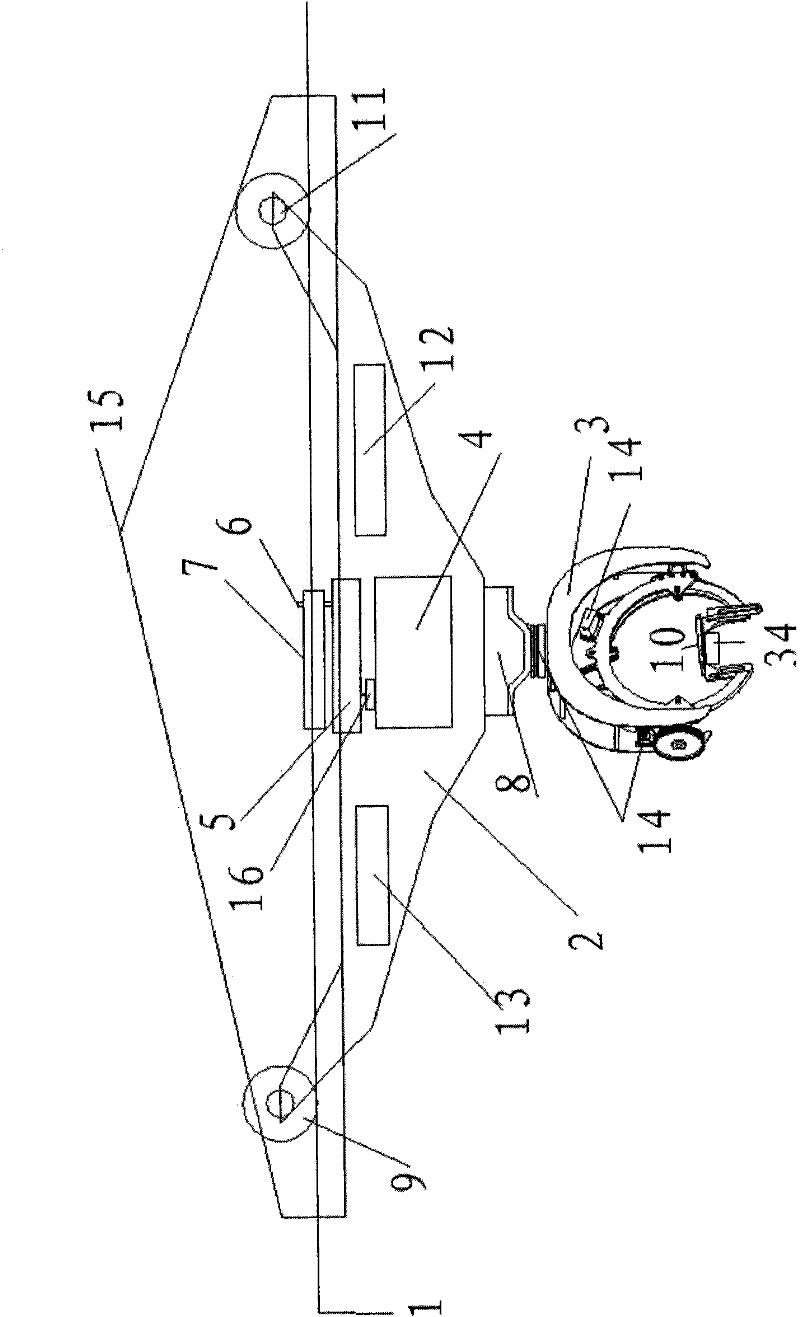

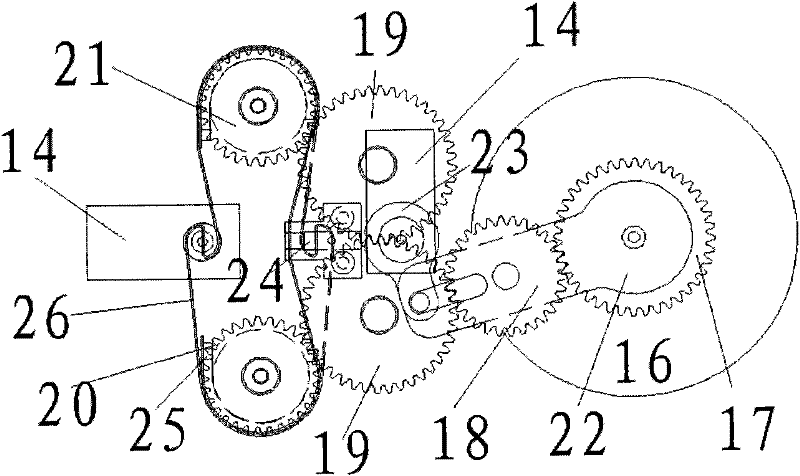

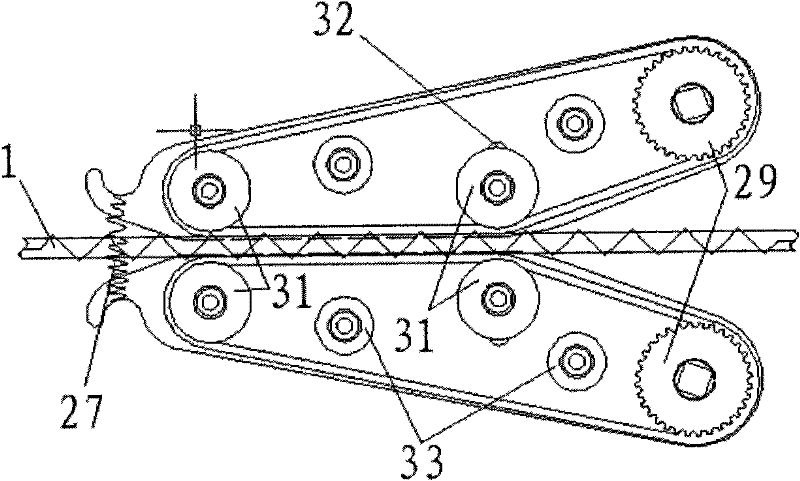

ActiveCN101848320AReduce weightTelevision system detailsColor television detailsLinear motionFlying shuttle

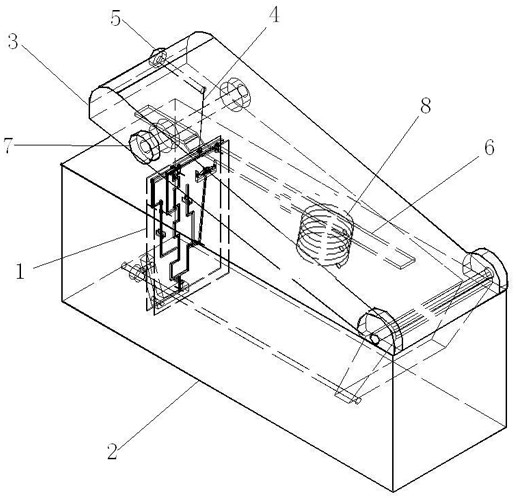

The invention discloses a single-line flying shuttle system and relates to a special shooting technology in the film and television industry, in particular to a single-line system for air motion shooting. The system realizes motion control of azimuth, rolling and pitching on a shooting holder hung and carried on a vehicle body in motion by adopting a single lead as a guide rail and leading the vehicle body to carry power and run along the guide rail. The invention adopts a lightweight design and reduces weight as much as possible on the premise of ensuring function; meanwhile, when the linear motion of a flying shuttle is designed, a soft limit is set for enabling a cameraman to concentrate on artistic creation without fearing the safety problem of running of a flying shuttle during creation; and the holder carried by the flying shuttle has the function of stabilizing a camera and enables a shot image to be more stable.

Owner:必威易悠孚(北京)影视技术有限公司

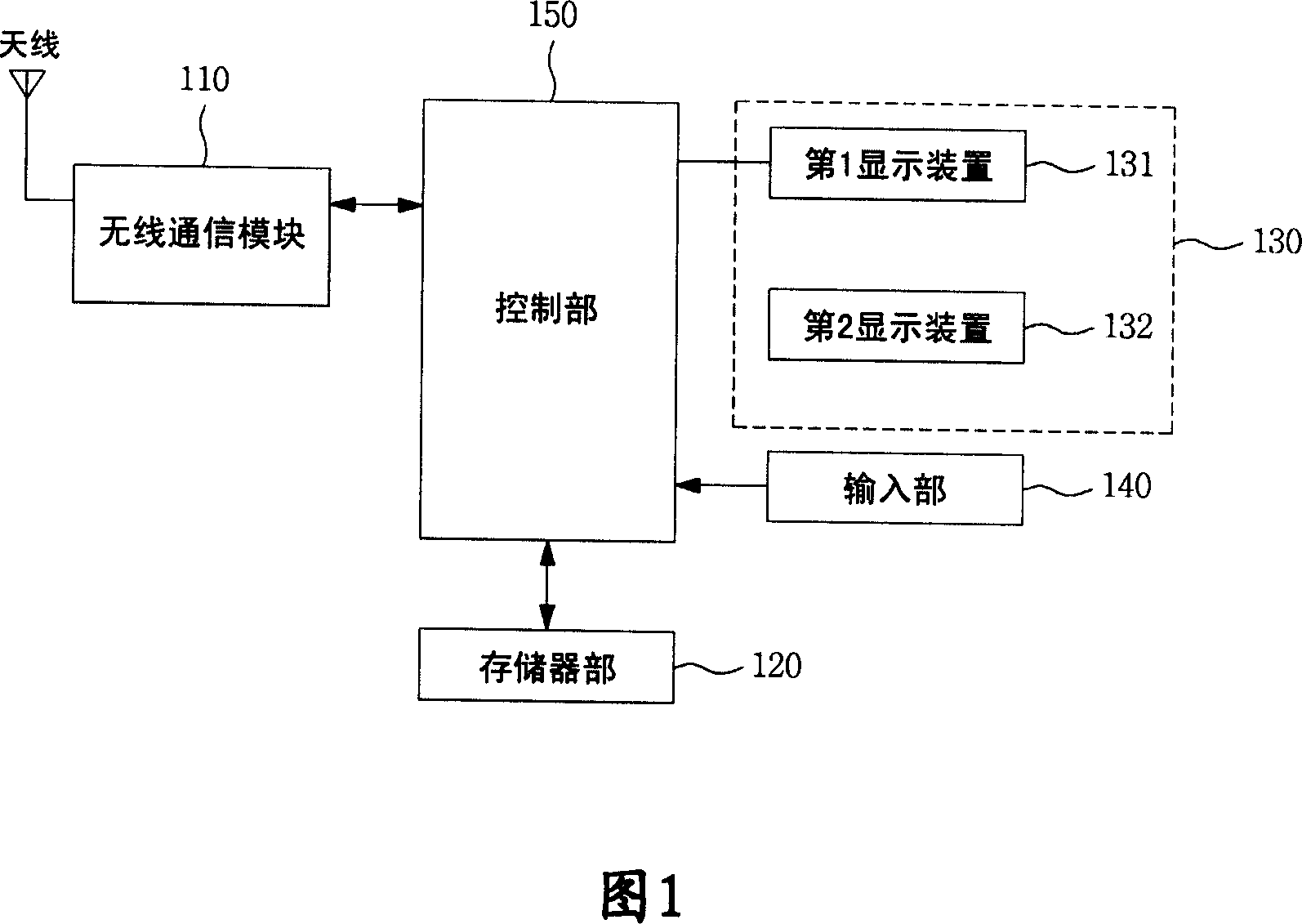

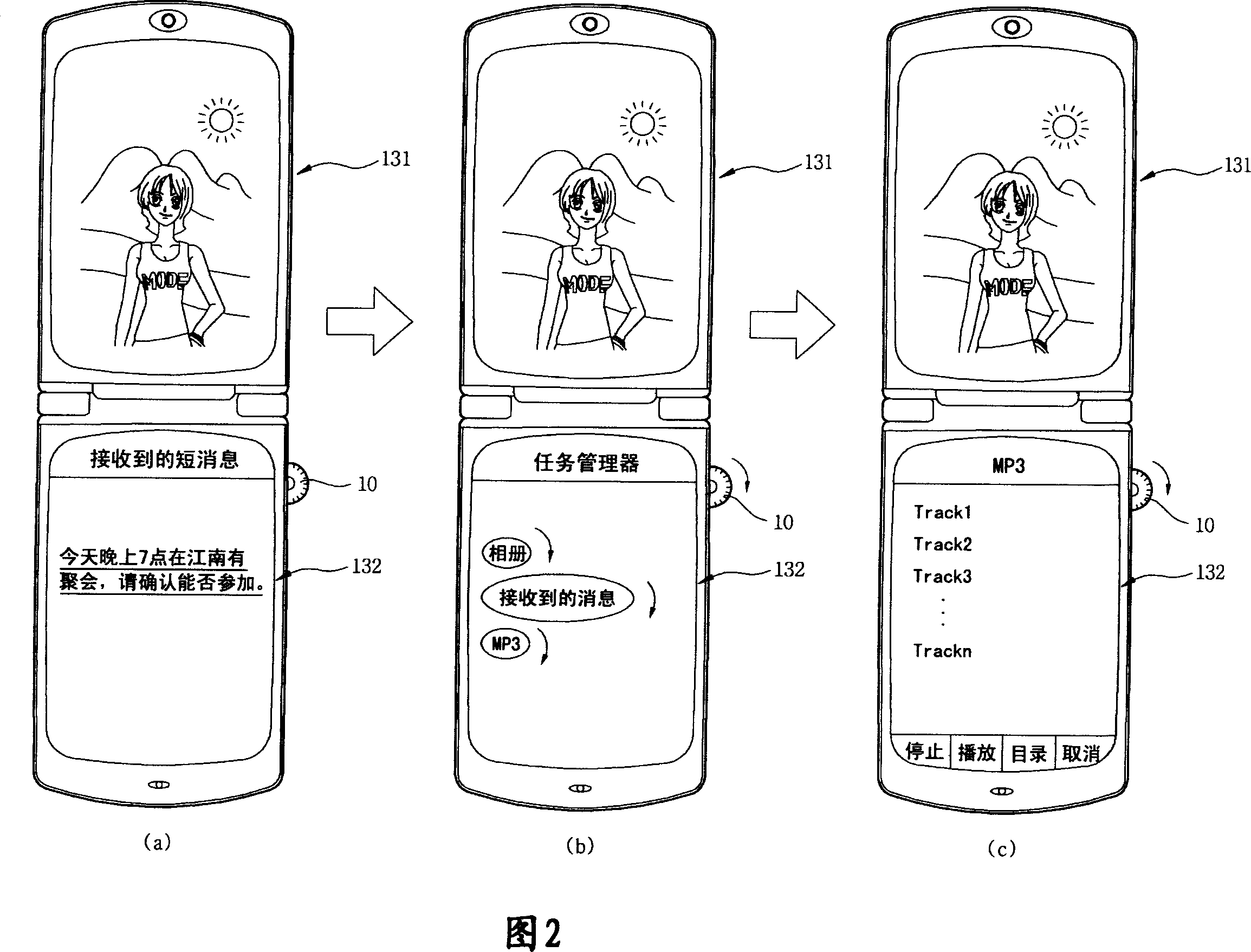

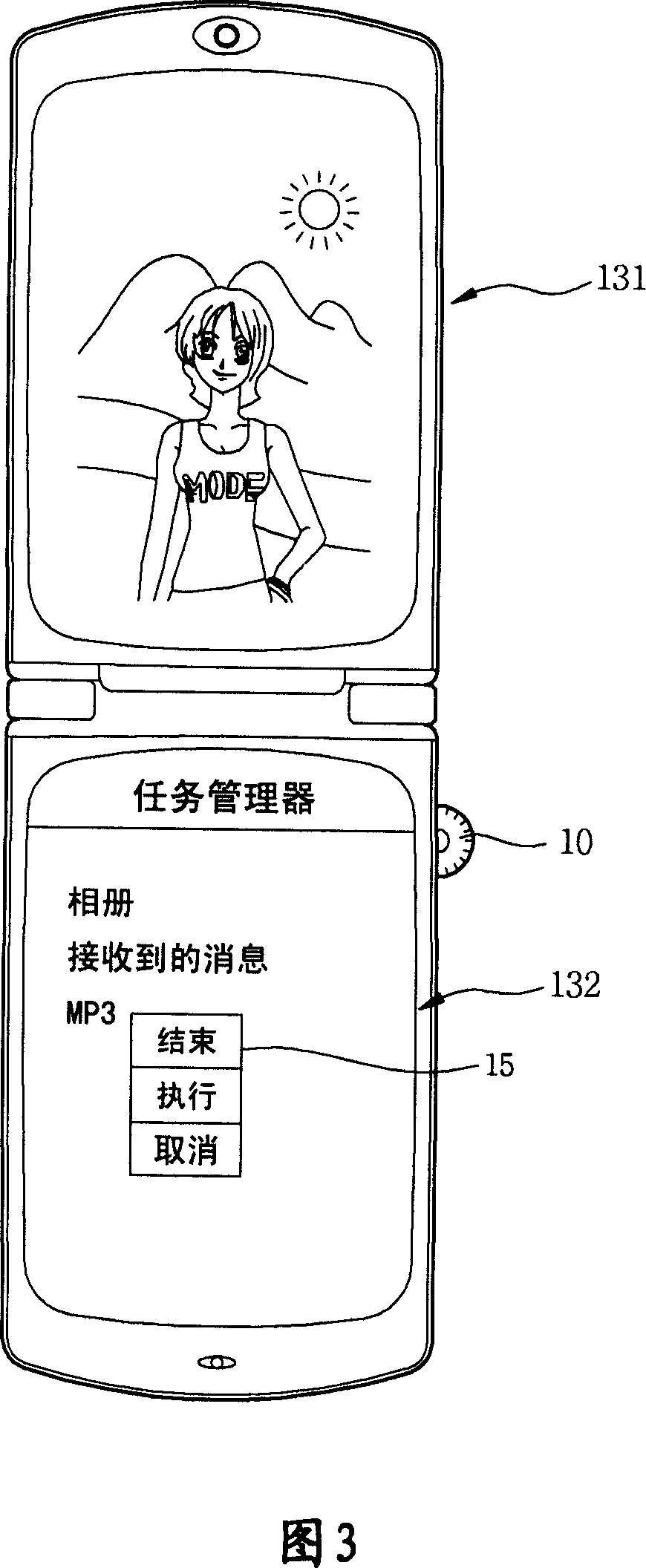

Mobile communication terminal and task manager indication method using the same

InactiveCN1941974APromote conversionRadio/inductive link selection arrangementsTelephone set constructionsFlying shuttleDisplay device

The present invention relates to a mobile communication terminal and task manager indication method using the same. The mobile communication terminal of the present invention includes following parts: a memory part for storing the information of plurality of menus; a display part including plurality of display devices for displaying the executing status for the plurality of menus in the memory part; an input part for making the task manager execute action; a control part for executing the plurality of menus stored in the memory part and controlling the action of the task manager based on the input operation of the input part. The present invention is characterized in that: the input part is one or more of the flying shuttle knob, flying shuttle or side key. According to the present invention, the menu in the current execution can be easily affirmed by providing the task manager. Furthermore, one of the menu catalog in the current execution provided by the selectable task manager can be selected by supplying plurality of display devices, and the image conversion operation for corresponding menu can be executed easily.

Owner:INSPUR LG DIGITAL MOBILE COMMUNICATIONS CO LTD

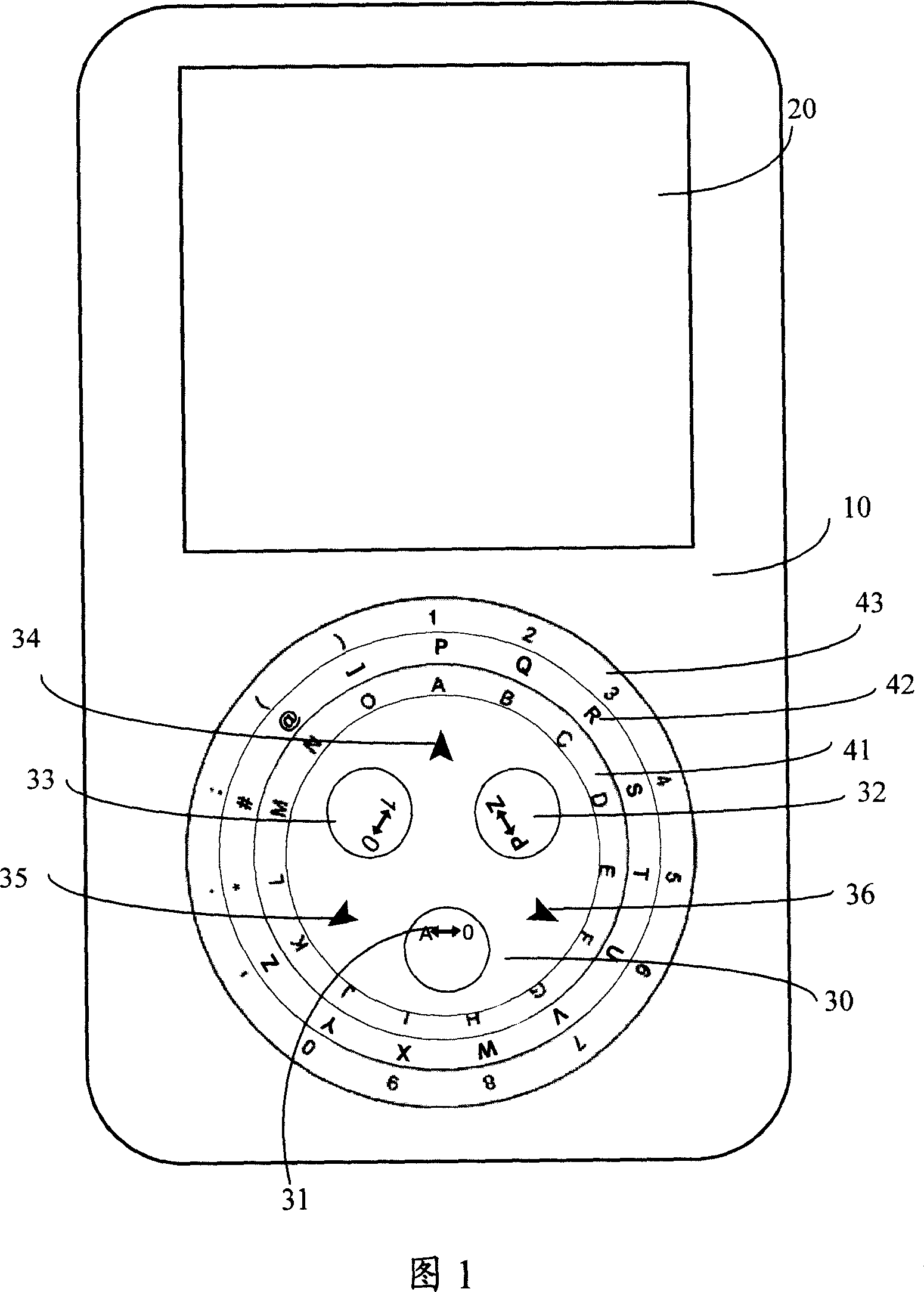

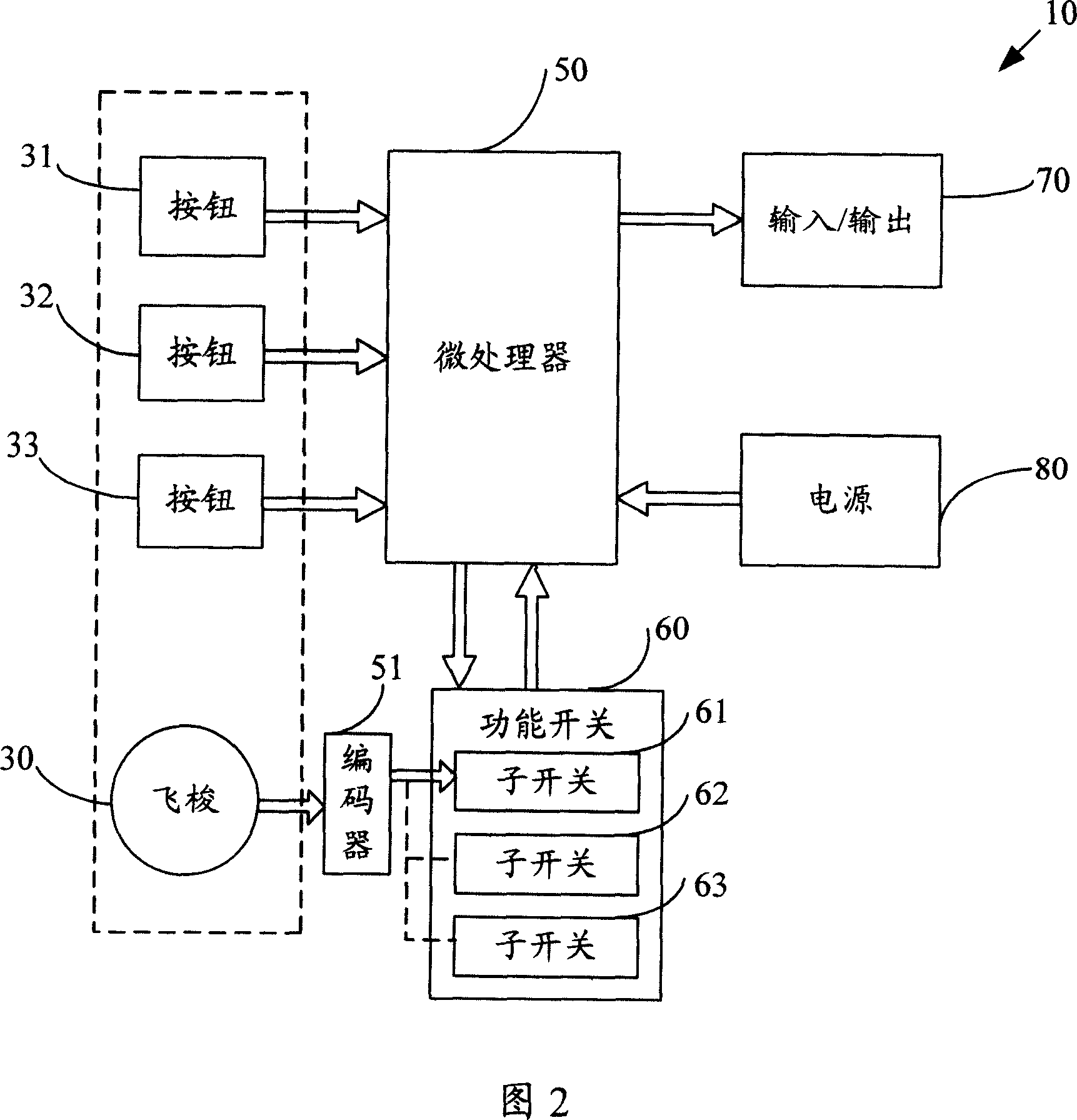

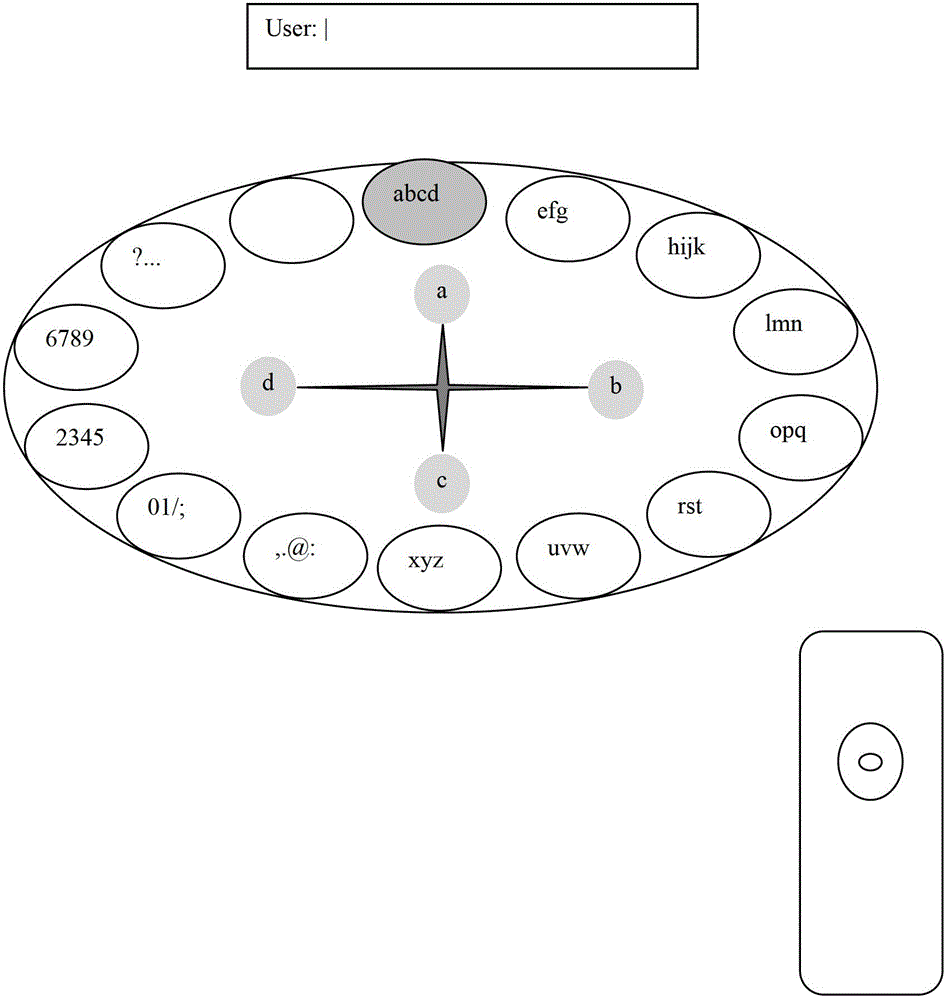

Electronic installation with character input fly shuttle

InactiveCN1991707ASmall sizeReduce the numberInput/output processes for data processingComputer graphics (images)Flying shuttle

The invention provides an electric device that includes a display screen, a character input fly shuttle, and the fly shuttle has several rotation positions, at least two buttons are mounted on the fly shuttle, there are several character circles same as the button number besides the fly shuttle, and every button corresponds with a character circle, and every character circle has several characters corresponding with the rotation positions of fly shuttle. Press the button, choose the corresponding character circle, and turn the fly shuttle to a rotation position, and input the character corresponding with the rotation position. Using the electric device provided by the invention, the keyboard is not needed, so it can reduce the volume, and convenient for input characters.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

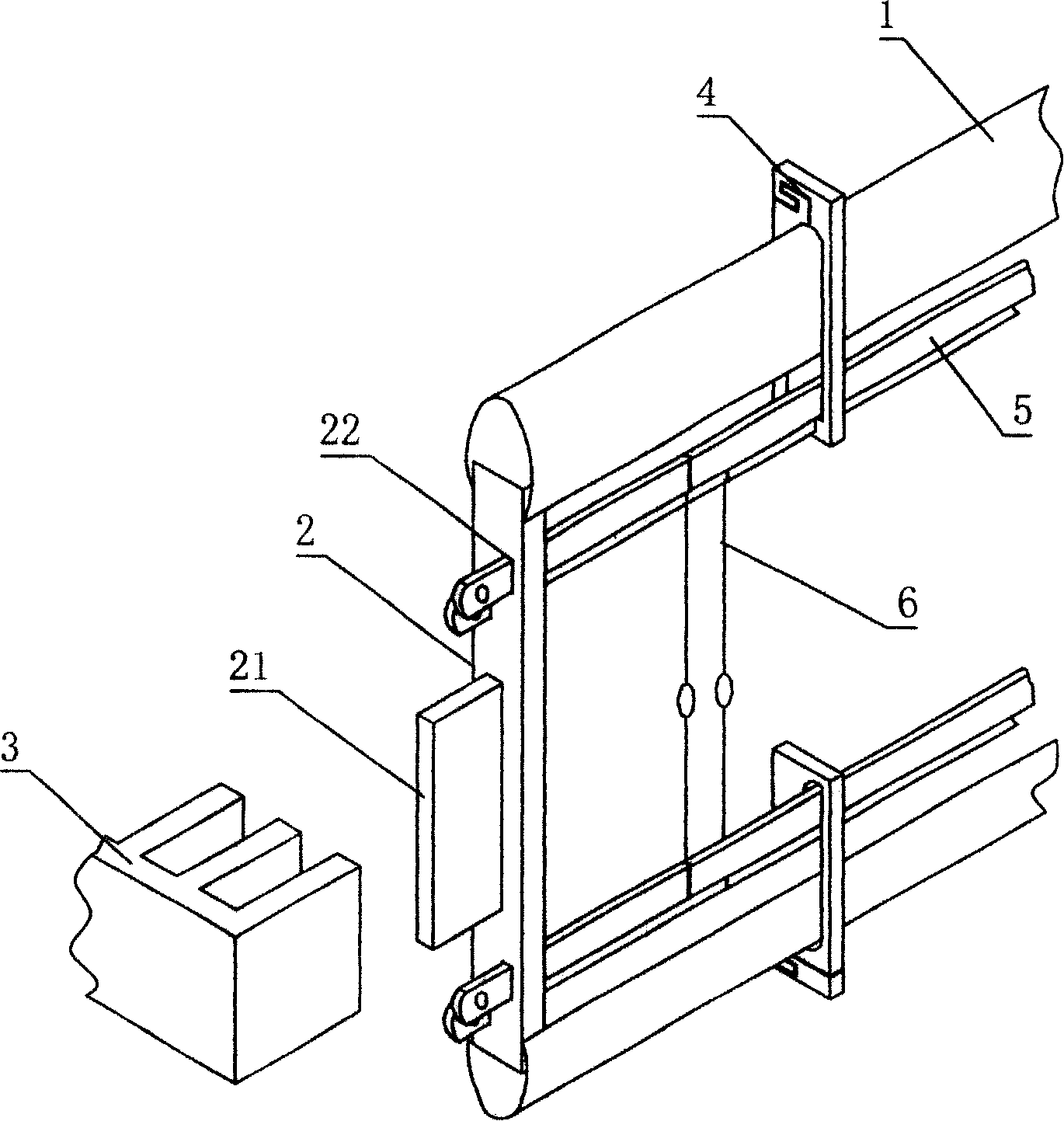

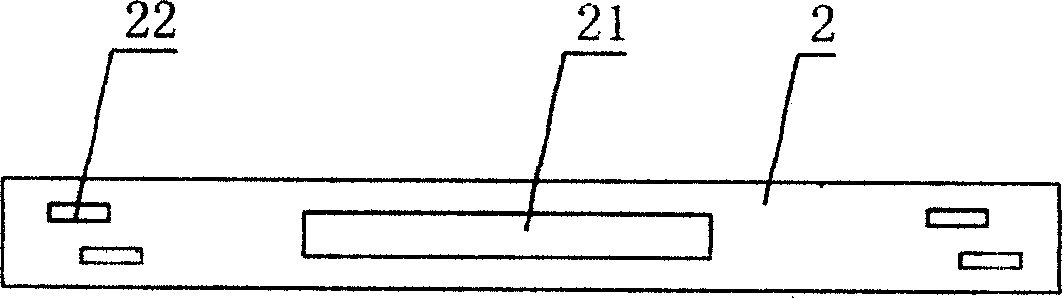

Fly-shuttle loom harness frame position limiter

InactiveCN101173414AGood for up and down movementReduce distanceAuxillary apparatusHealdsYarnFlying shuttle

The invention discloses a heald frame limit device for shuttle loom, comprising a plurality of heald frames, which is characterized in that: two heald transverse heads are respectively arranged at two ends of a heald frame; an upper row and a lower row of location perforations are arranged on the heald transverse heads of the heald frame for a heald bar to pass through; a plurality of heald yarns pass through the heald bar; the heald bar is fixed on the heald frame via a heald clip; a slider is arranged on each heald transverse head of the heald frame; a limited block is arranged at each end of the heald frame, and a lifting track corresponding to the slider and capability of controlling the sliding of the slider is arranged on the limited block. The invention has the advantages that the shaking of the heald frames in the weaving process is effectively solved and the distance between heald frames is greatly reduced, so that friction between warp and heald yarn or other loom elements in the weaving process is avoided and the end breaking is reduced.

Owner:丁宏利

Sulfur-carbon compound and preparation method therefor, and electrode material and lithium-sulfur battery containing sulfur-carbon compound

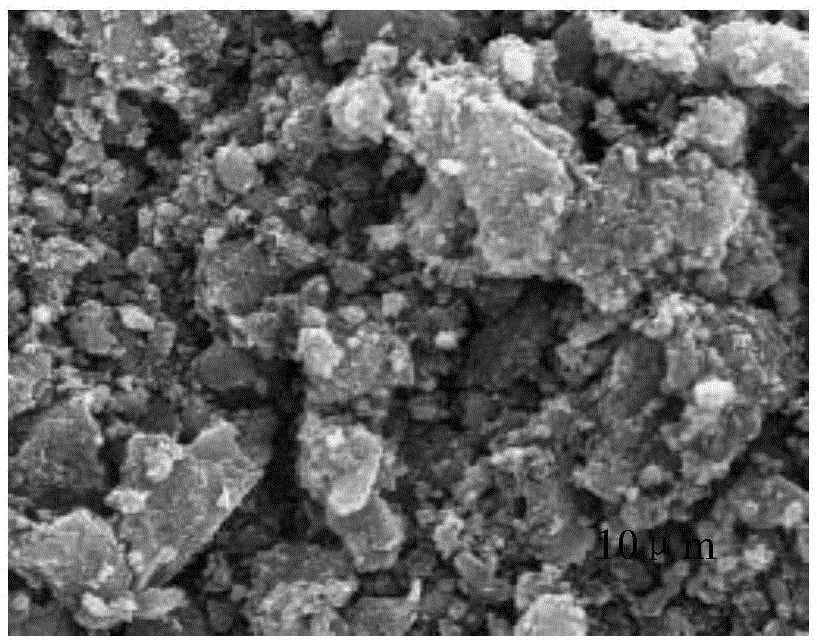

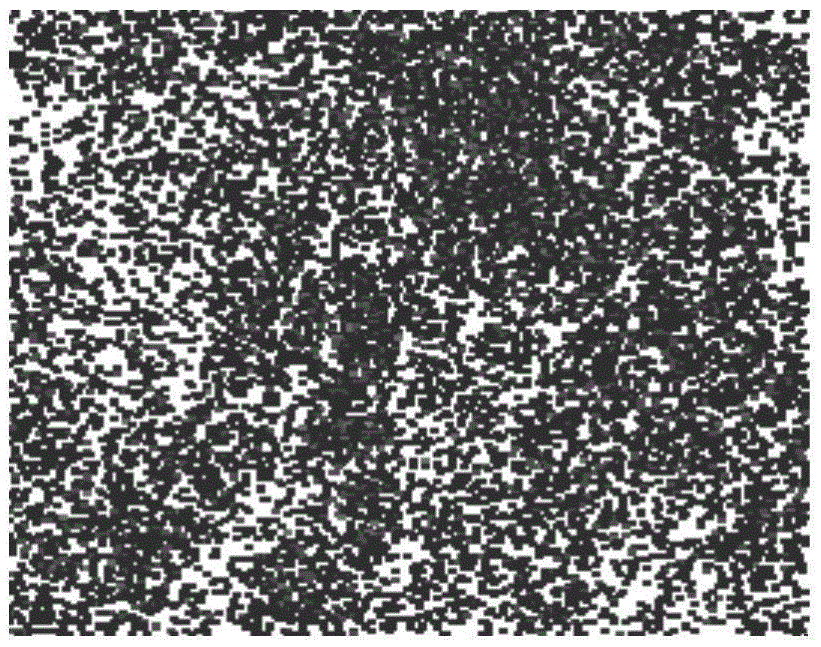

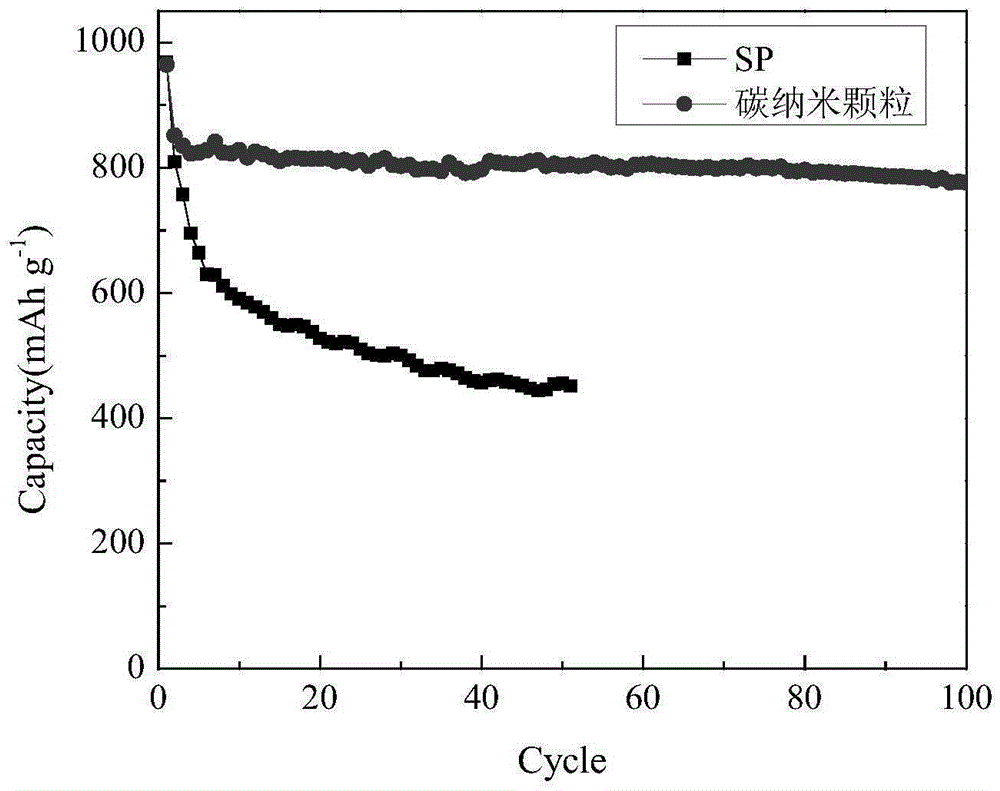

InactiveCN105552345ASmall apertureStop the "Shuttle Effect"Material nanotechnologyCell electrodesElectrochemical responseFlying shuttle

The invention relates to the technical field of a lithium ion battery, and particularly to a sulfur-carbon compound for a lithium-sulfur battery. The sulfur-carbon compound comprises carbon nanoparticles, sulfur loaded in the carbon nanoparticles and silicon dioxide template existing in the carbon nanoparticles in a residual manner, wherein the content of sulfur accounts for 40-70% of the content of the sulfur-carbon compound based on mass percent; and the content of the silicon dioxide template accounts for 0.3-3% of the content of the sulfur-carbon compound based on mass percent. The residual silicon dioxide template in the sulfur-carbon compound is dispersed in the carbon nanoparticles so as to reduce the aperture of the carbon nanoparticles; therefore, the carbon nanoparticles have a relatively high capture capability for polysulfide lithium that is an intermediate product of an electrochemical reaction in use; meanwhile, the residual silicon dioxide template can effectively prevent a flying shuttle effect of polysulfide lithium; and the invention also relates to a preparation method for the sulfur-carbon compound, and an electrode material and the lithium-sulfur battery containing the sulfur-carbon compound.

Owner:MCNAIR TECH +2

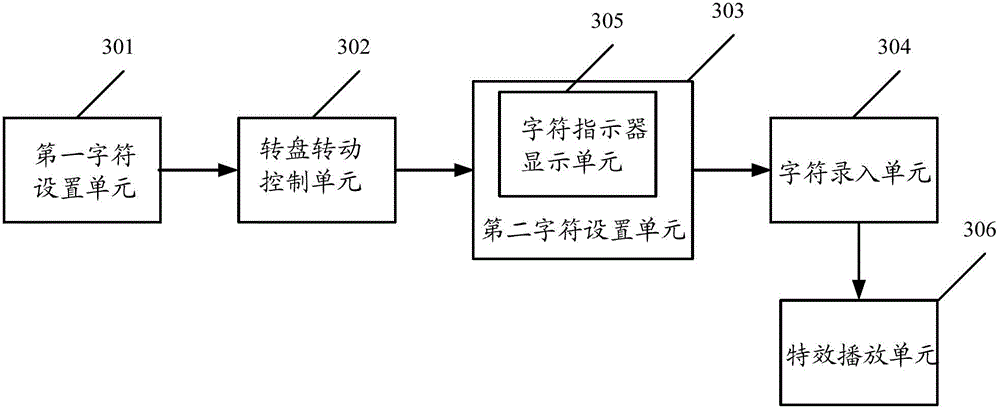

Character input method and character input device

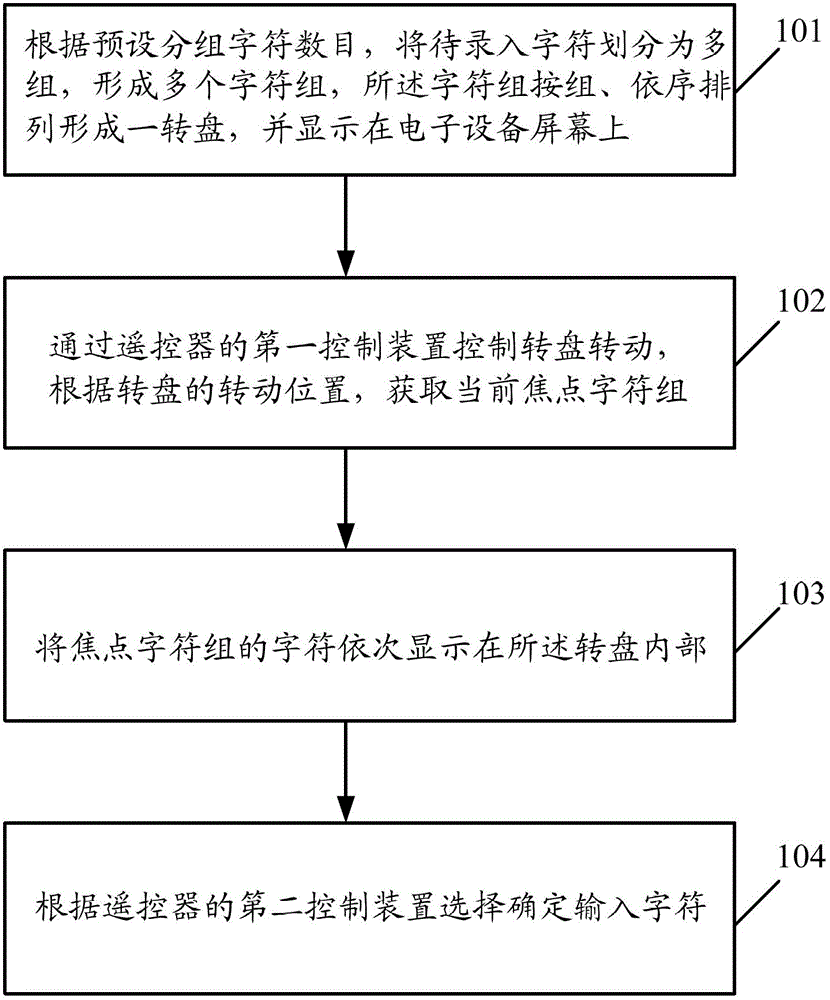

InactiveCN102946568AImprove experienceReduce fatigueSelective content distributionFlying shuttleSpecial design

The embodiment of the invention provides a character input method which comprises the following steps: characters to be typed-in are divided according to the preset number of characters in each set into multiple sets to form multiple character sets, and the character sets are sequentially arranged according to sets to form a turntable and displayed on an electronic equipment screen; the turntable is controlled by a first control device of a remote controller to rotate, and the current focus character set is obtained according to the rotating position of the turntable; the characters of the focus character set are sequentially displayed in the interior of the turntable; and the input character is selected and determined according to a second control device of the remote controller. According to the invention, when a special design of a fly shuttle and a character input interaction device is utilized, an effect of inputting the character faster is achieved, the feeling of fatigue caused by inputting is reduced, the user experience of inputting texts on a computer is improved, and information and transaction processing are promoted.

Owner:TCL CORPORATION

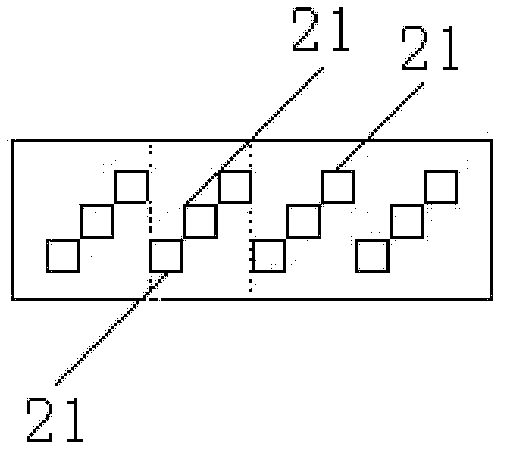

Photoelectric flying shuttle control system and signal processing method and electronic equipment thereof

The invention is suitable for the technical field of electronic control and provides a photoelectric flying shuttle control system and a signal processing method and electronic equipment thereof. The photoelectric flying shuttle control system comprises an electrooptical conversion device, a photoelectric conversion device, a flying shuttle turnplate and a signal processing device, wherein the photoelectric conversion device is arranged opposite to the electrooptical conversion device and is used for receiving optical signals sent out by the electrooptical conversion device in sequence; the flying shuttle turnplate is supported by a rotating shaft; the side wall of the flying shuttle turnplate is located between the electrooptical conversion device and the photoelectric conversion device; the signal processing device is used for processing electrical signals output by the photoelectric conversion device into control instructions and sending the control instructions; and the side wall of the flying shuttle turnplate is provided with a plurality of through holes for the optical signals to pass through. Thus, the flying shuttle turnplate rotates smoothly and has good hand feeling and low noise. The whole photoelectric flying shuttle control system has a simple structure and low cost.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Template sewing machine for down jackets

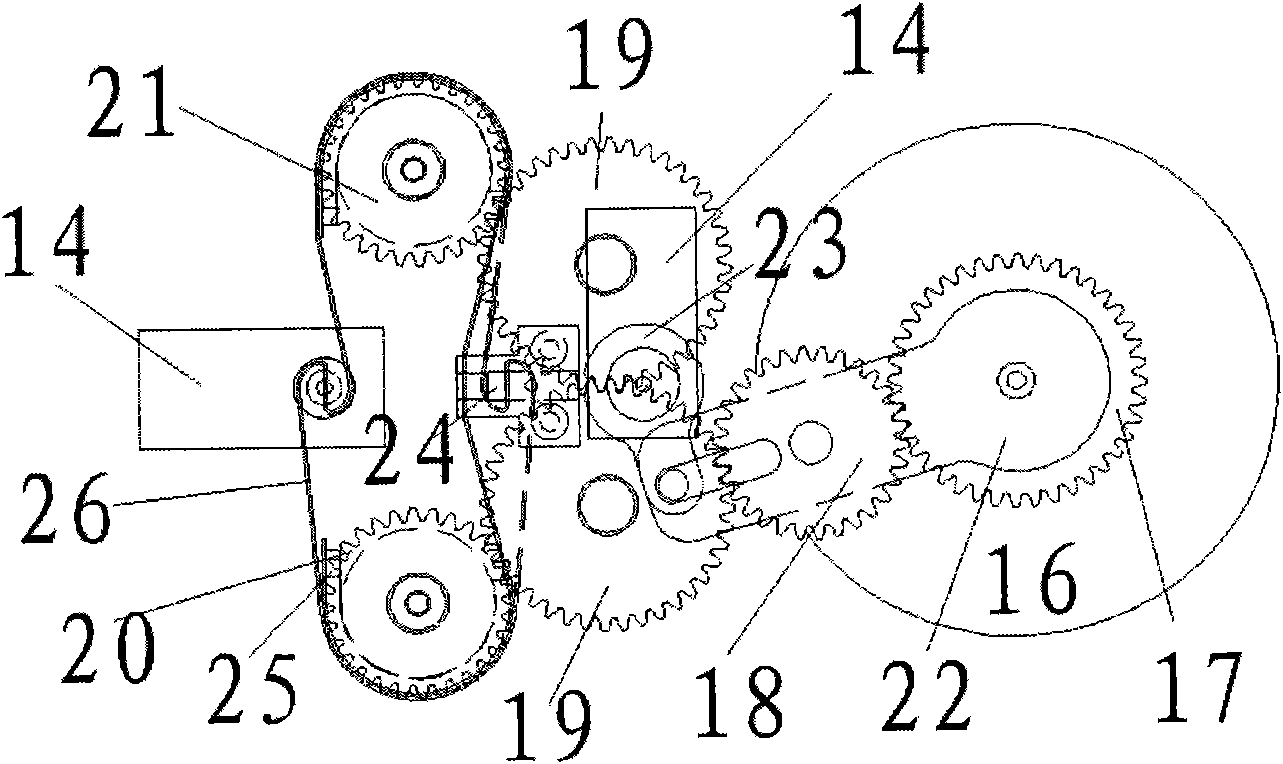

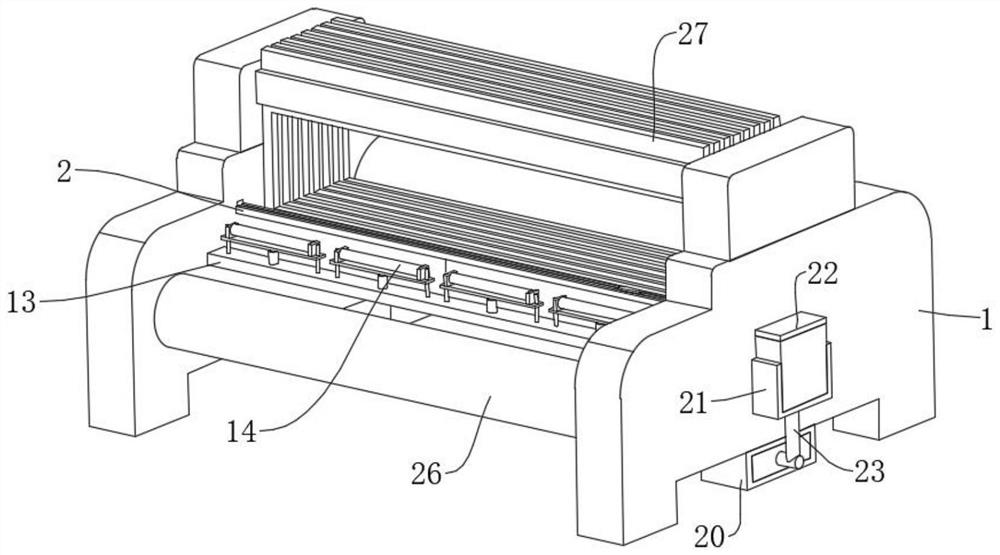

ActiveCN113718433AOvercome the disadvantages of inconvenient sewing tubular fabricsAvoid uneven distributionWork-feeding meansNeedle barsFlying shuttleGear wheel

The invention relates to the technical field of template sewing machines, and discloses a template sewing machine for down jackets. The template sewing machine for the down jackets comprises a power module, a first dowel bar and a second dowel bar, wherein the end part of the first dowel bar is provided with a threading device; the end part of the second dowel bar is provided with a flying shuttle; the threading device and the flying shuttle cooperate with each other to complete cloth sewing; the power module is provided with a matching rod; the matching rod is provided with a matching wheel; and the second dowel bar is sleeved with a cloth roller. The power module, the first dowel bar and the second dowel bar are matched with each other, and transmission of a fixed proportion is formed through an internal gear, so that the threading device and the flying shuttle are matched with each other, and uniform sewing is facilitated; and the cloth roller is arranged, cylindrical cloth is connected to the cloth roller in a sleeving mode, and the cloth roller is rolled to drive the cloth to rotate, so that sewing of the cloth by one circle is completed, the defect that common sewing equipment is inconvenient to sew the cylindrical cloth is overcome, and uneven distribution of the down jackets is prevented.

Owner:ANHUI GUIGU E COMMERCE

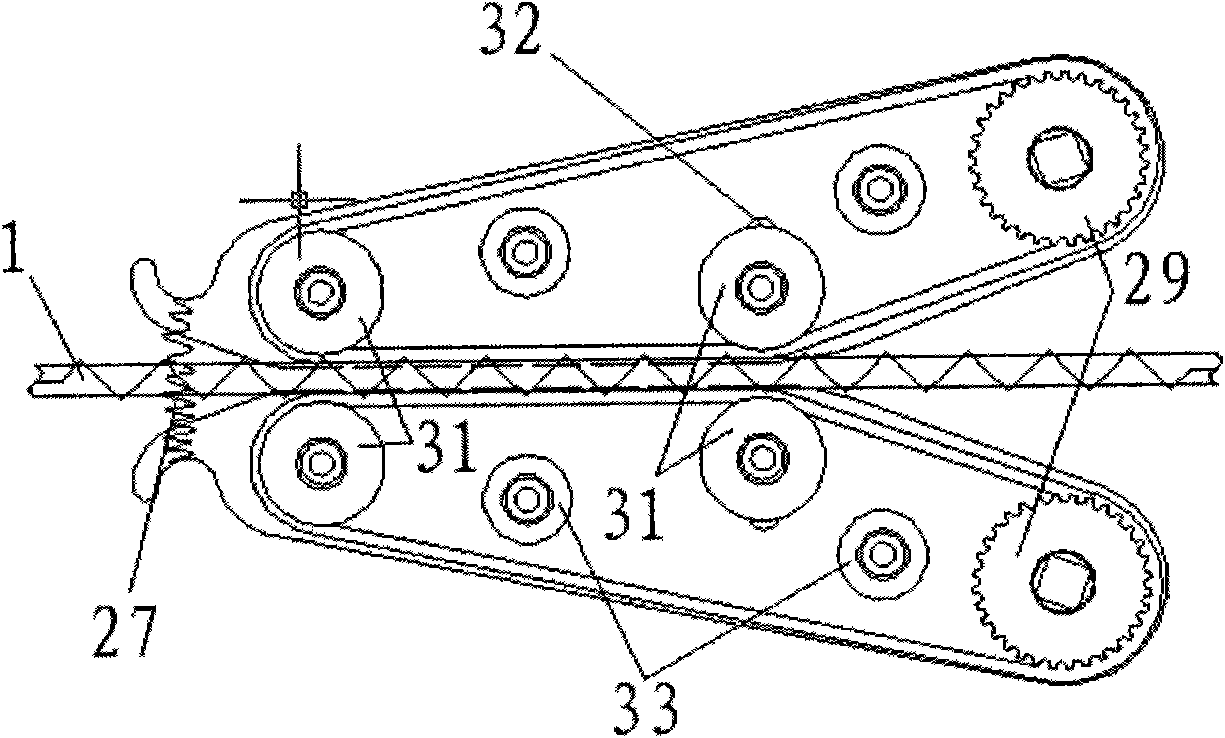

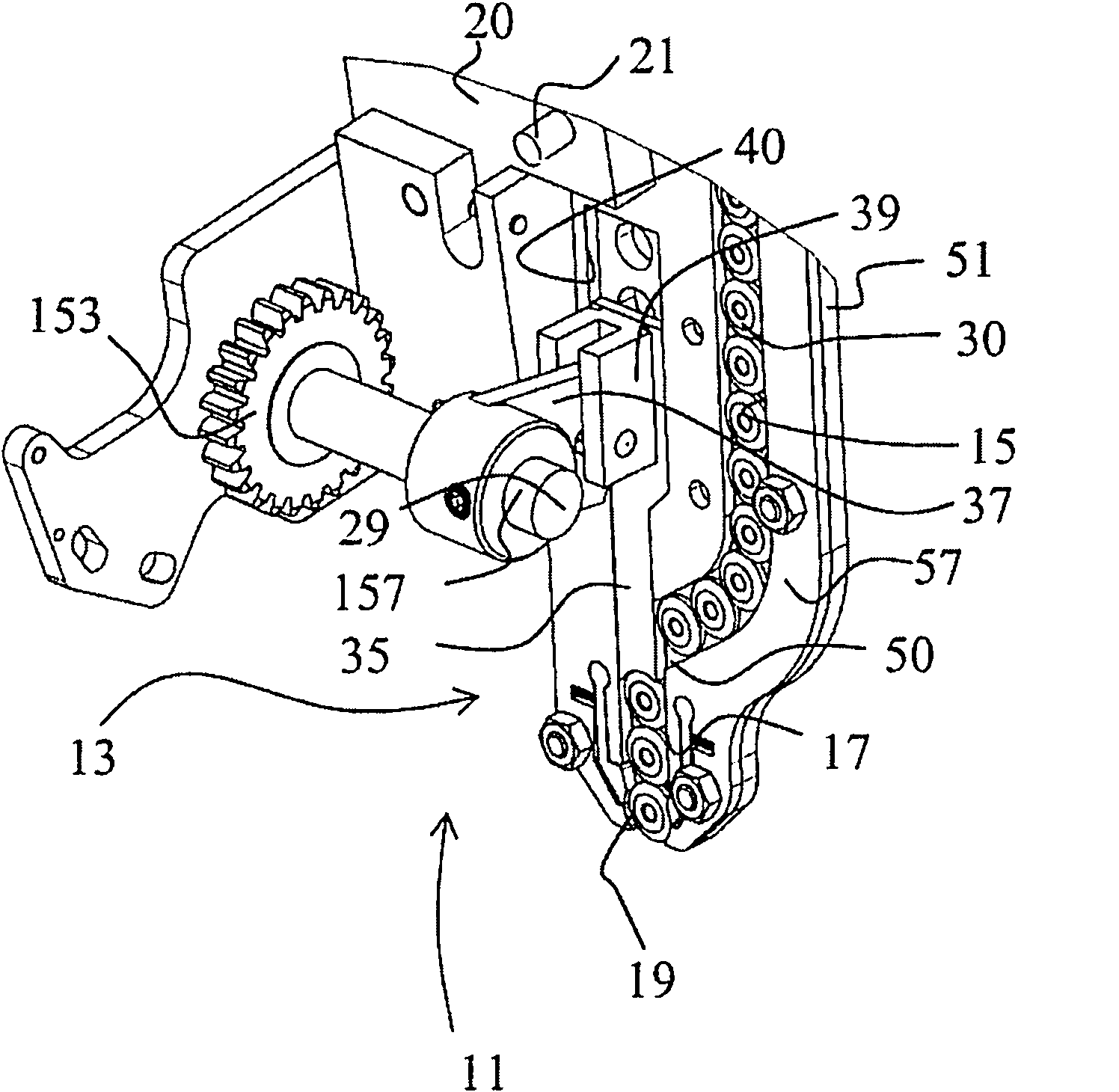

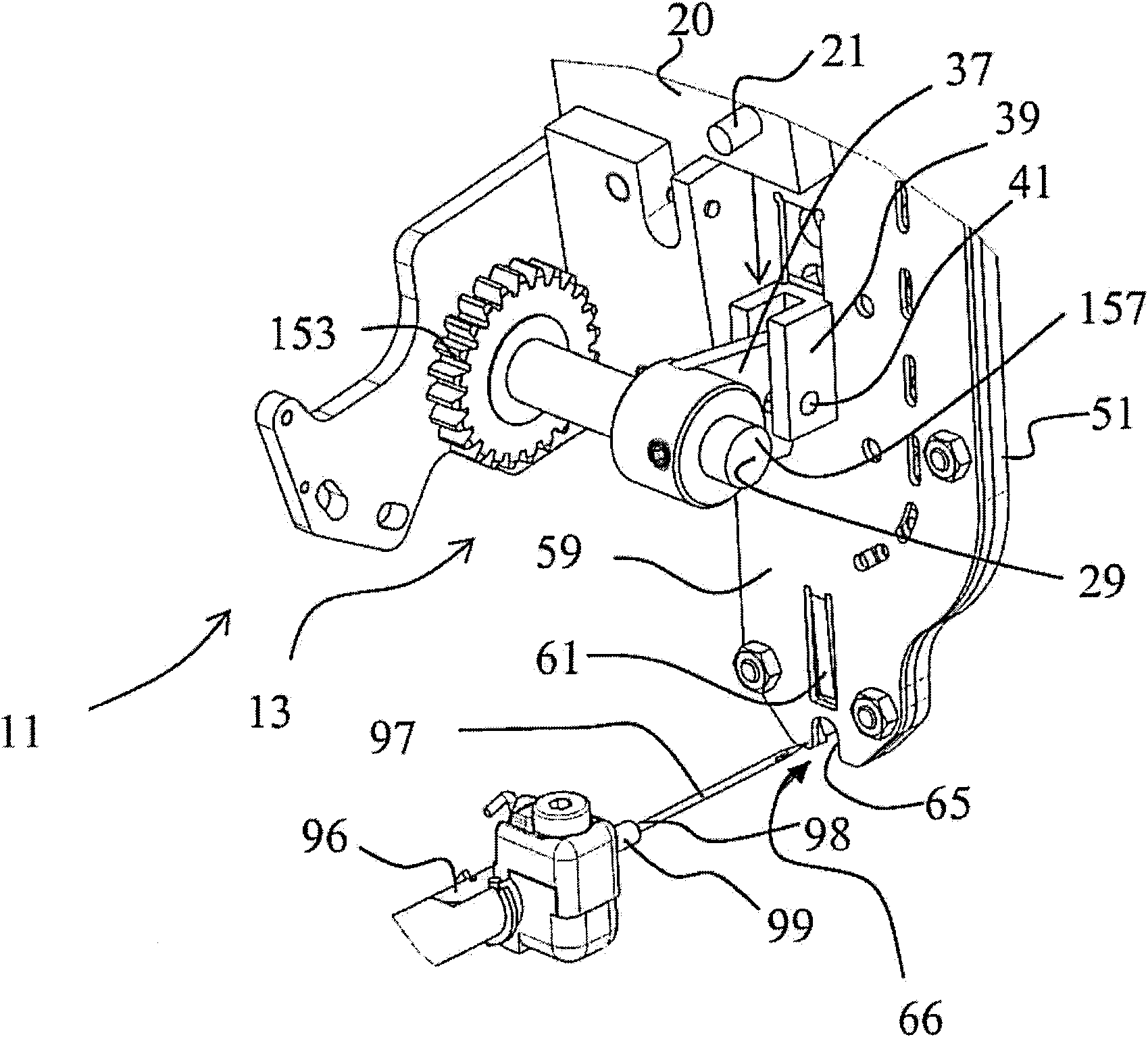

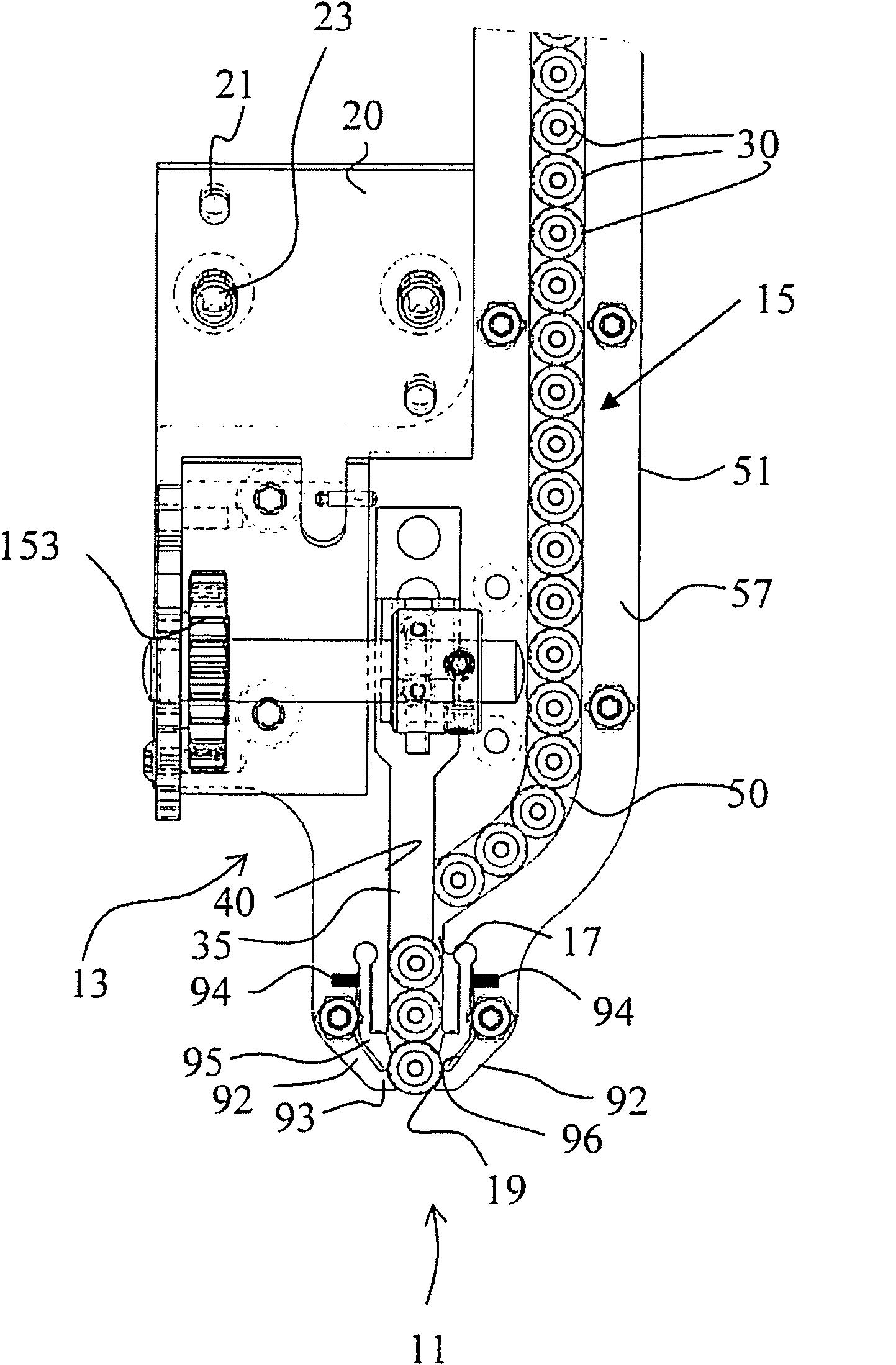

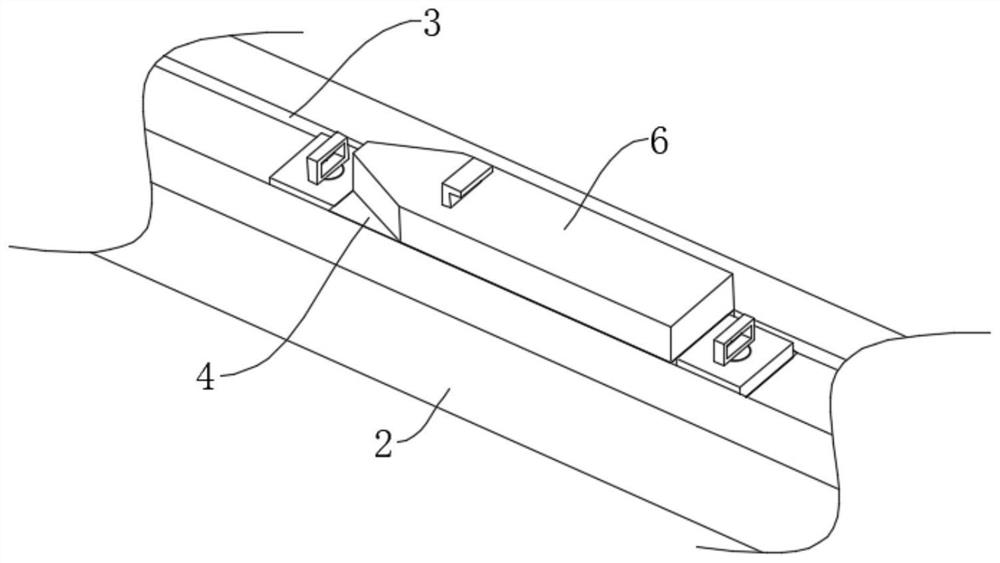

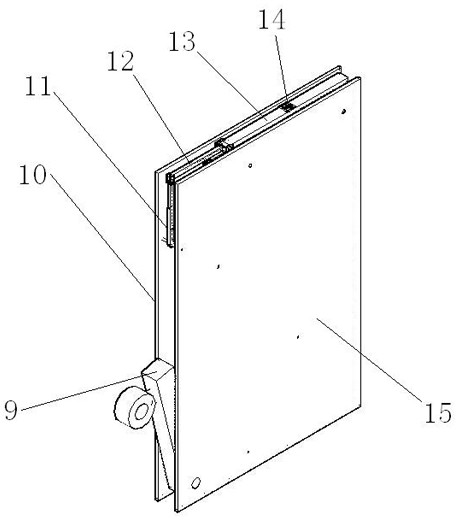

Single-piece feeding device, embroidering, sewing or quilting machine comprising the device, and method for embroidering on a single-piece

InactiveCN101914839AShorten the timeWon't wind upWork-feeding meansAutomatic machinesMechanical engineeringEngineering

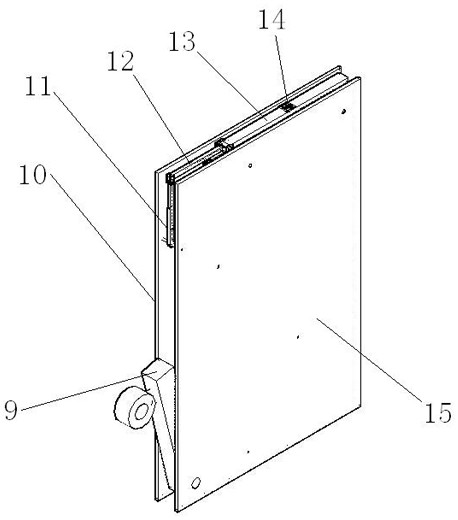

The invention relates to a single-piece feeding device (9) used in embroidering, sewing or quilting machine, which comprises a front part (11) with the back (12) facing the embroidery base cloth (67) to clamping a single-piece (30) at a correct position to embroidering the single-piece on the embroidery base cloth (67); the front part (11) can comprise a box (15), a single-piece clamper (19) and a feeding structure (13); the box (15) has an inner space for containing a plurality of single-piece for embroidery; the single-piece clamper (19) is used for fixing a single-piece (30) at a position; the feeding structure (13) is configured to move one of the single-pieces (30) in the box (15) to the single-piece clamper (19) along a feeding path (17) by a conveying motion by power. The apparatus is characterized in that: the single-piece clamper (19) has an outlet (91) for limiting the single-piece (30) to move to its back side (12) only, thereby the single-piece (30) has no option but to leave the single-piece clamper (19) by the outlet (91) direction. The invention also relates to an embroidering machine comprising the device, especially a shuttle embroidering machine.

Owner:LAESSER AG

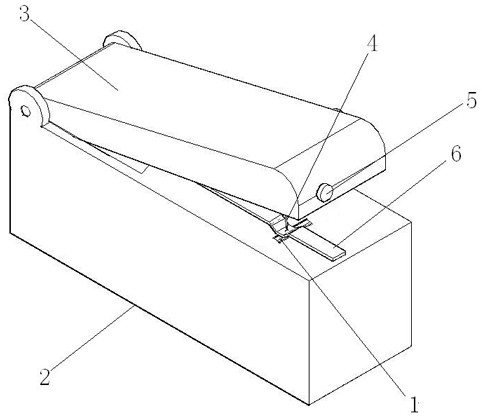

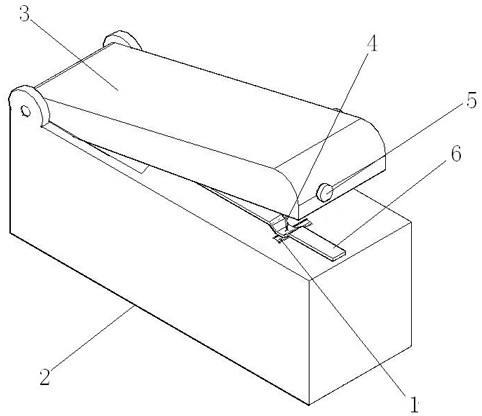

Handheld sewing machine with shuttle bottom threads and movement mode thereof

The invention discloses a handheld sewing machine with shuttle bottom threads and a movement mode thereof. The handheld sewing machine comprises a linkage mechanism, a base and a press beam. One end of the press beam is provided with a sewing machine needle which is fixed by screwing in a needle fixing bolt, the side face of the press beam is provided with a thread adjustment button which is connected with a thread wheel in the press beam, the abdomen part of the press beam is connected with one end of a compression spring, the other end of the compression spring is connected with the base, the press beam is clamped to a base insertion shaft to be hinged, the base is internally provided with the linkage mechanism which is connected with the press beam, and the press beam is fixedly connected with a presser foot. According to the movement mode of the handheld sewing machine, the press beam drives the linkage beam. The handheld sewing machine adopts an up-down double-thread mode and is flexible to operate, good in sewing effect and convenient to carry.

Owner:GUIZHOU NORMAL UNIVERSITY

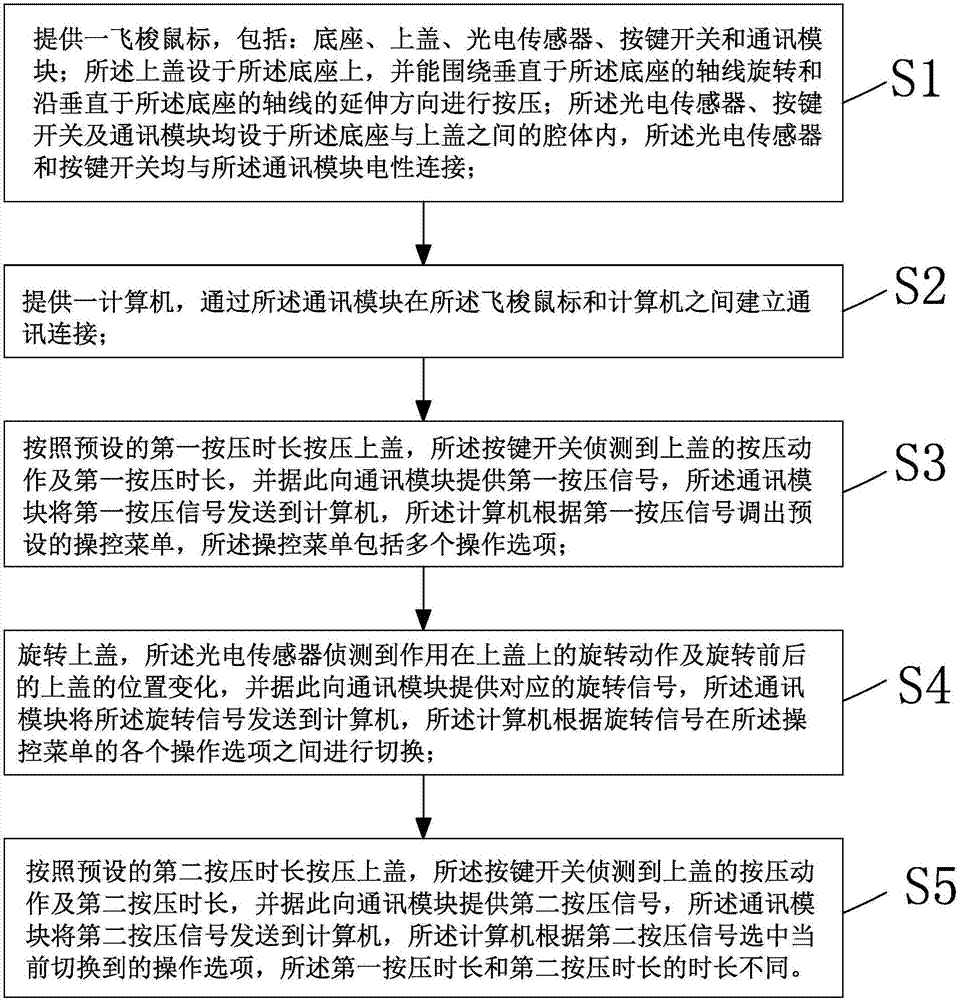

Flying shuttle mouse and input method

ActiveCN107015672AQuick callQuick operabilitySpecial data processing applicationsInput/output processes for data processingComputer Aided DesignFlying shuttle

The invention provides a flying shuttle mouse and an input method. The flying shuttle mouse comprises a base, an upper cover, a photoelectric sensor, a key switch and a communication module, can detect the rotating action acting on the upper cover through the photoelectric sensor, produces a corresponding rotary signal according to the position change before and after rotation of the upper cover, detects a pressing action acting on the upper cover through the key switch, sends a rotating signal, a first pressing signal and a second pressing signal to a computer through the communication module according to the corresponding first pressing signal or the corresponding second pressing signal produced based on different pressing durations, utilizes the first pressing signal to control the computer to call out a preset control menu, utilizes the rotating signal to control the computer to switch operation options of the control menu, and utilizes the second pressing signal to select the operation options in the control menu. The design efficiency of computer aided design can be improved, and user experience can be improved.

Owner:深圳晟光优彩佳实业有限公司

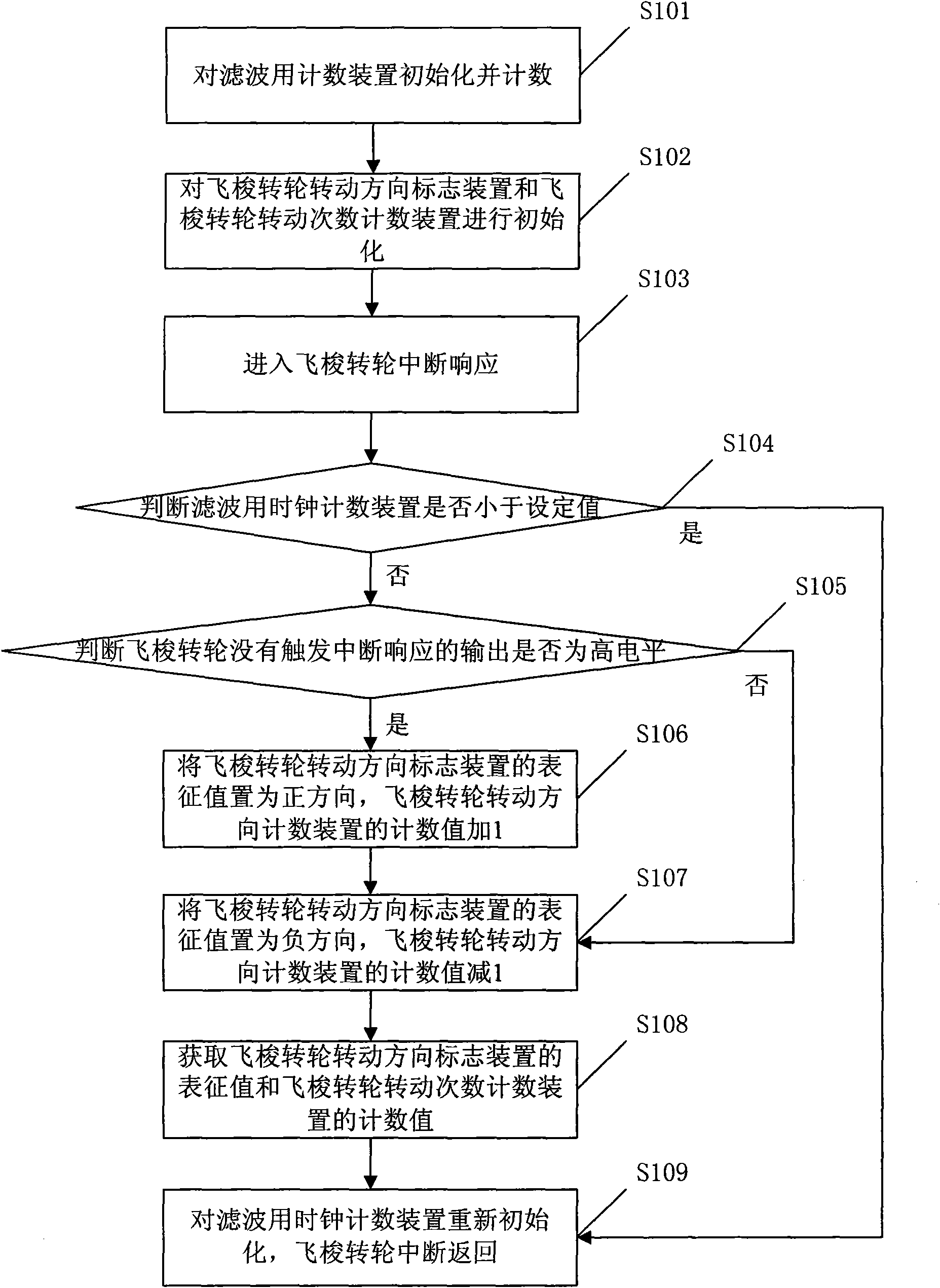

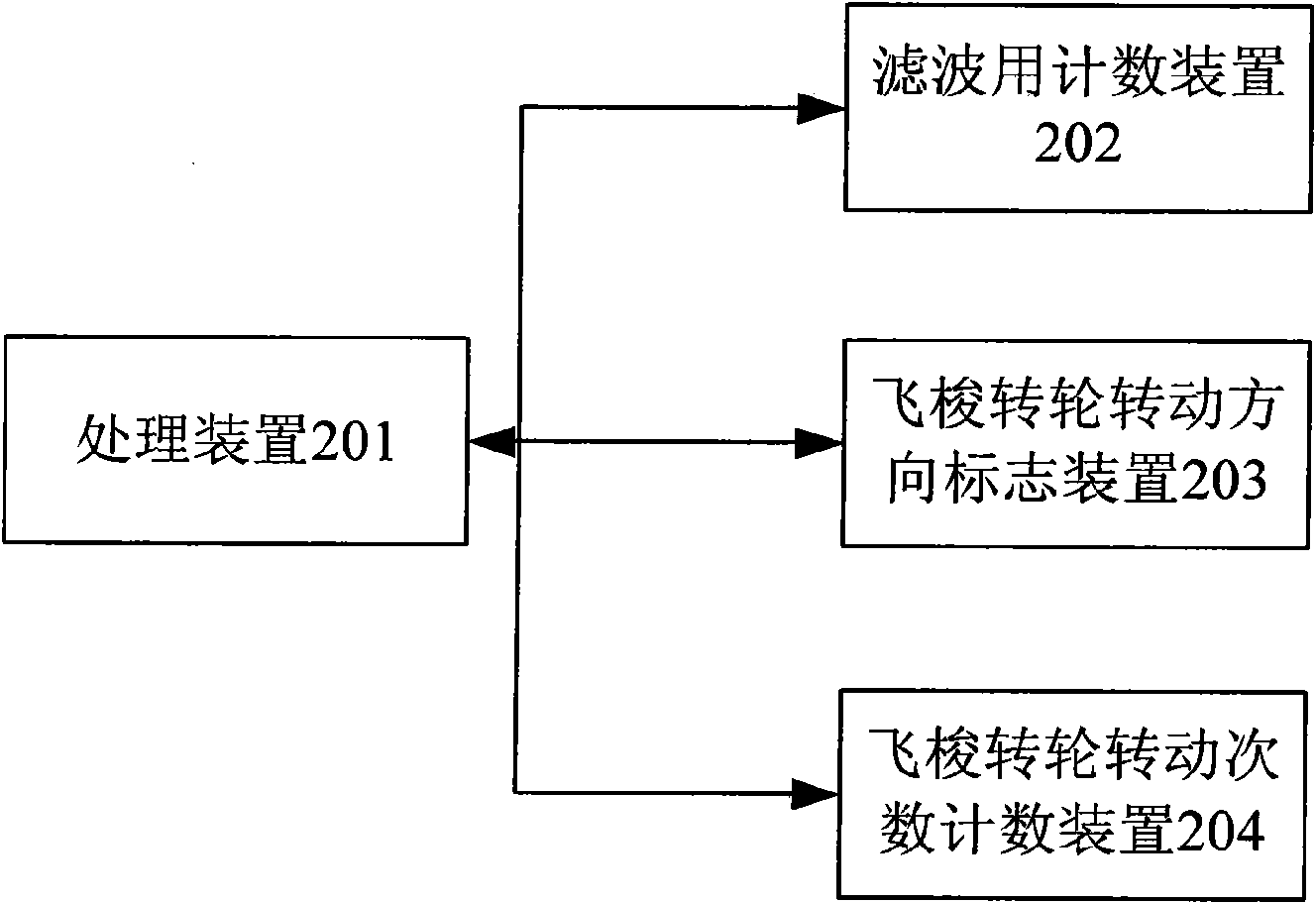

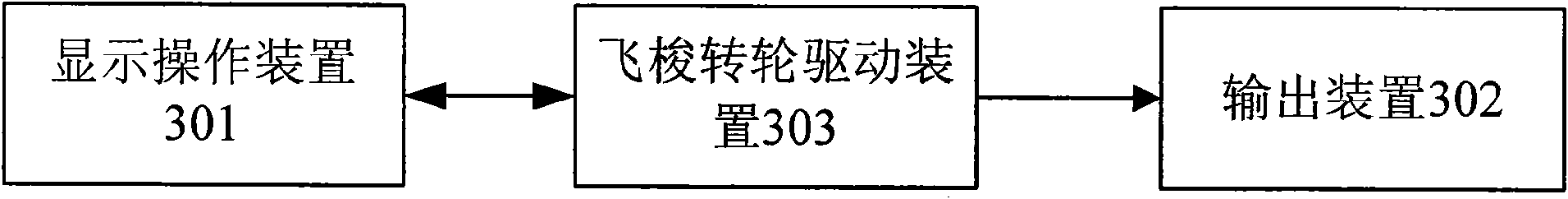

Digital TV test signal generator and method and device for driving flying shuttle rotary wheel thereof

The invention provides a digital TV test signal generator and a method and a device for driving a flying shuttle rotary wheel thereof. The method comprises the following steps: initializing a clock counting device for filtering, and counting; initializing a device for marking a rotation direction of the flying shuttle rotary wheel and a device for counting a rotation number of the flying shuttle rotary wheel; interrupting a response of the flying shuttle rotary wheel; when the clock counting device for filtering is smaller than a set value, re-initializing the clock counting device for filtering, and stopping the flying shuttle rotary wheel and returning; and when the clock counting device for filtering is greater than a set value, acquiring a characterization value of the device for marking the rotation direction of the flying shuttle rotary wheel and a counting value of the device for counting the rotation number of the flying shuttle rotary wheel, re-initializing the clock counting device for filtering, and stopping the flying shuttle rotary wheel and returning. Therefore, a method for using the flying shuttle rotary wheel of the digital TV test signal generator, which has the advantages of accurate response and stability, is provided.

Owner:MUDAN SHIYUAN ELECTRONICS BEIJING

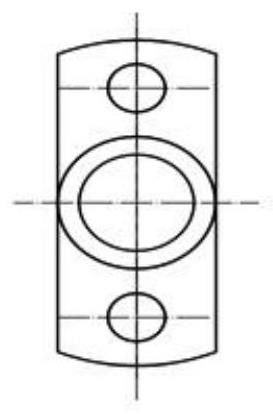

Wire breaking protection mechanism for radiation type fly shuttle on plastic flat wire circular knitting machine

ActiveCN109440268ALess interferenceAvoid interferenceCircular loomsProduction rateProtection mechanism

The invention discloses a wire breaking protection mechanism for a radiation type fly shuttle on a plastic flat wire circular knitting machine. The mechanism includes a fly shuttle main frame, the topof the fly shuttle main frame is fixedly provided with a fixation plate, a ratchet-type wire breaking locking assembly is installed in the fixation plate, and the ratchet-type wire breaking locking assembly is composed of a fixation screw, an upper burner gauze cone, a ratchet wheel, a ratchet wheel pressure plate, a probe arm, a probe-arm wire through hole, a wire breaking locking base, an upperburner gauze cone shaft, an upper burner gauze cone spring, a probe-arm clamp knife and an adjustment screw. The ratchet wheel type mechanism is separated from a bake mechanism and integrated into the burner gauze cone, interference with weft yarn is quite small before the wire breaking standard is reached, and the mechanism can be locked instantaneously at the time of wire breaking. The inverseclamping effect of the ratchet wheel and the probe arm is used for achieve instantaneous locking of a thread spool, the mechanism can completely avoid unnecessary waste of labor and materials causedby weft breaking of all plastic circular looms, and the productivity and the yield are greatly improved.

Owner:东莞市震天实业投资有限公司

Fly shuttle composite embroidery preparation technique

InactiveCN101104990AImprove processing utilizationComposite with multi-fabricAutomatic machinesRough surfaceFlying shuttle

The invention discloses a production process of shuttle complex embroidery, which comprises the steps of programming the production process, cutting and sewing, winding, edge matching and feeding, positioning, and starting the machine embroidery program for shuttle complex embroidery. The invention can embroider various patterns on multilayered composite fabric. The product made by this process integrates the advantages of various fabrics; has good hand-feeling, three-dimensional effect, good heat insulation, softness and elasticity, rich patterns, and beautiful appearance; and can meet the pattern and size requirements of users. The invention overcomes the limitations in pattern and size in the prior art, and avoids the deformation and rough surface of product after washing.

Owner:SHANDONG CHARMING HOMETEXTILES

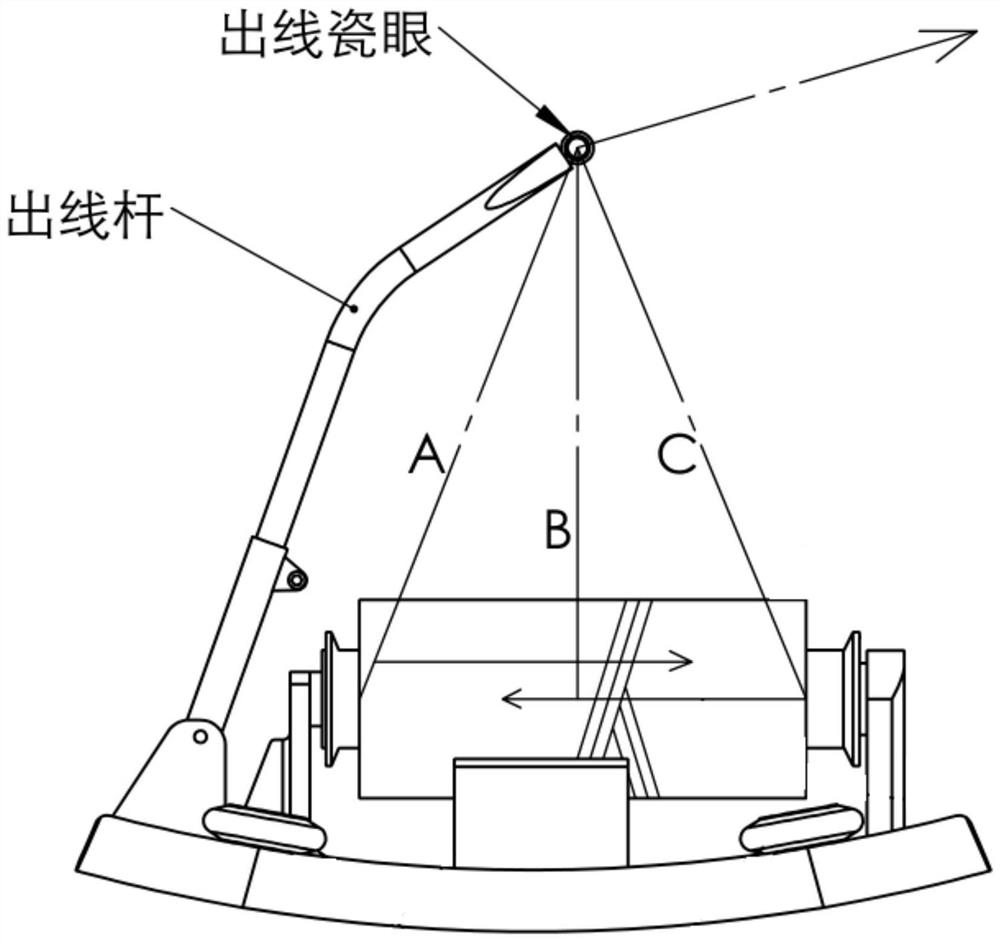

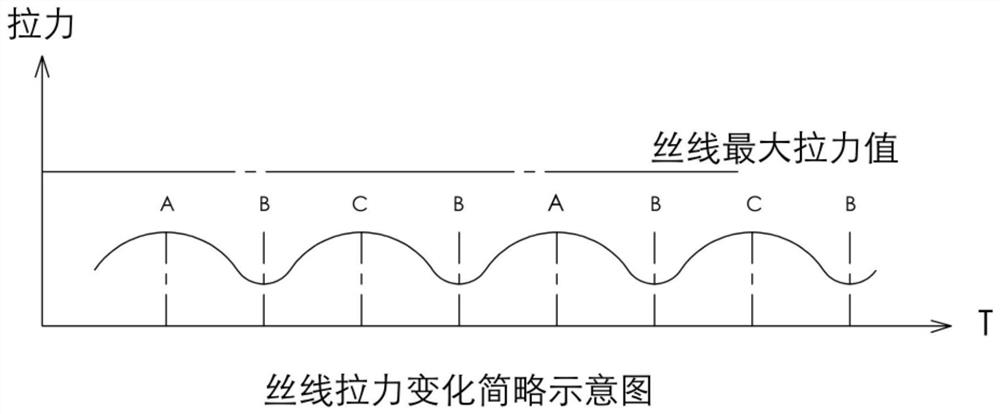

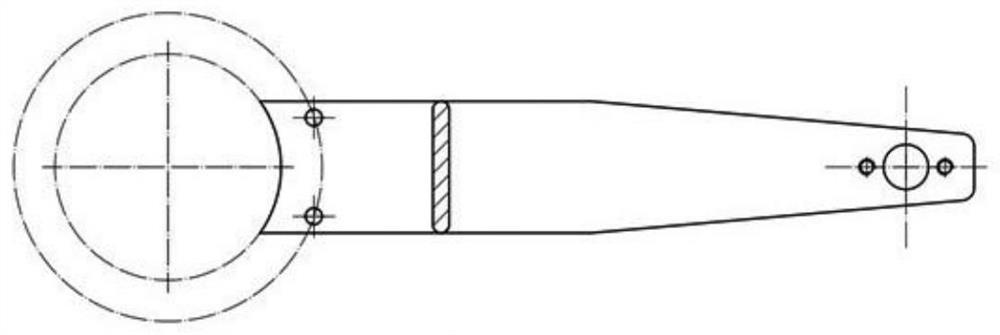

Tension balance type flying shuttle and balance assembly

The invention discloses a tension balance type flying shuttle and a balance assembly. The tension balance type flying shuttle includes a frame body, wherein the frame body is provided with a porcelain eye and a yarn shaft used for mounting a yarn roll, the tension balance type flying shuttle further includes the balance assembly, the balance assembly includes a balance plate, the balance plate is provided with a cambered surface, silk yarn is led out from yarn outlet points of the yarn roll, the silk yarn passes through the cambered surface and then reaches the porcelain eye, and due to the cambered surface, the lengths of the silk yarn from any yarn outlet point of the yarn roll to the porcelain eye are equal. According to the tension balance type flying shuttle and the balance assembly provided by the invention, the tension of the silk yarn can be basically kept unchanged after the yarn outlet point is continuously changed, so that the silk yarn is not easy to break.

Owner:东莞市震天实业投资有限公司

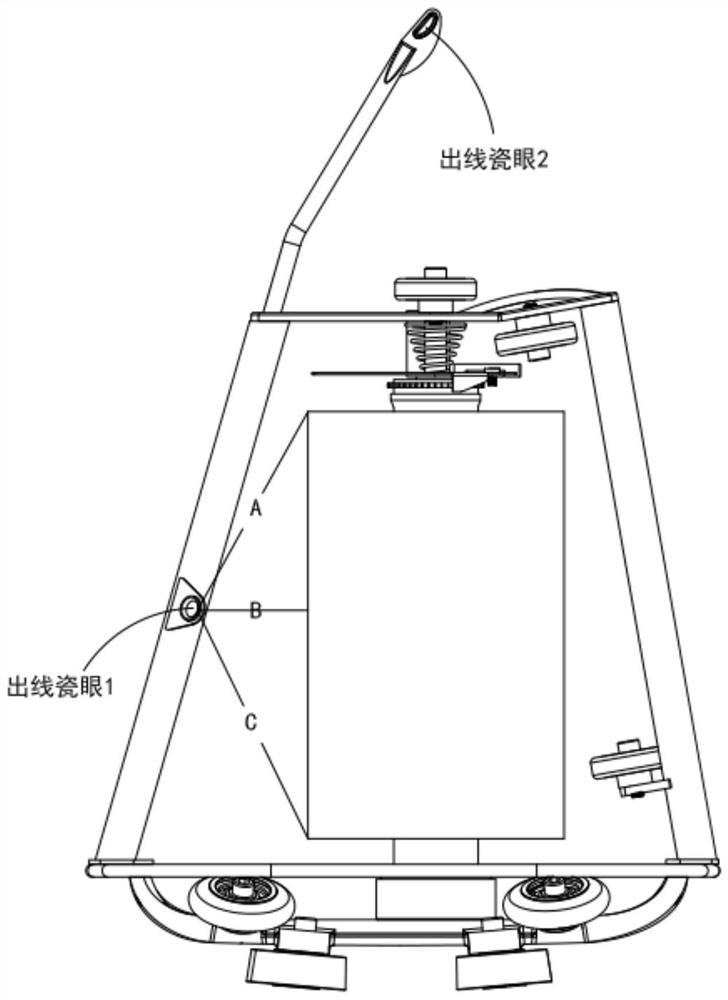

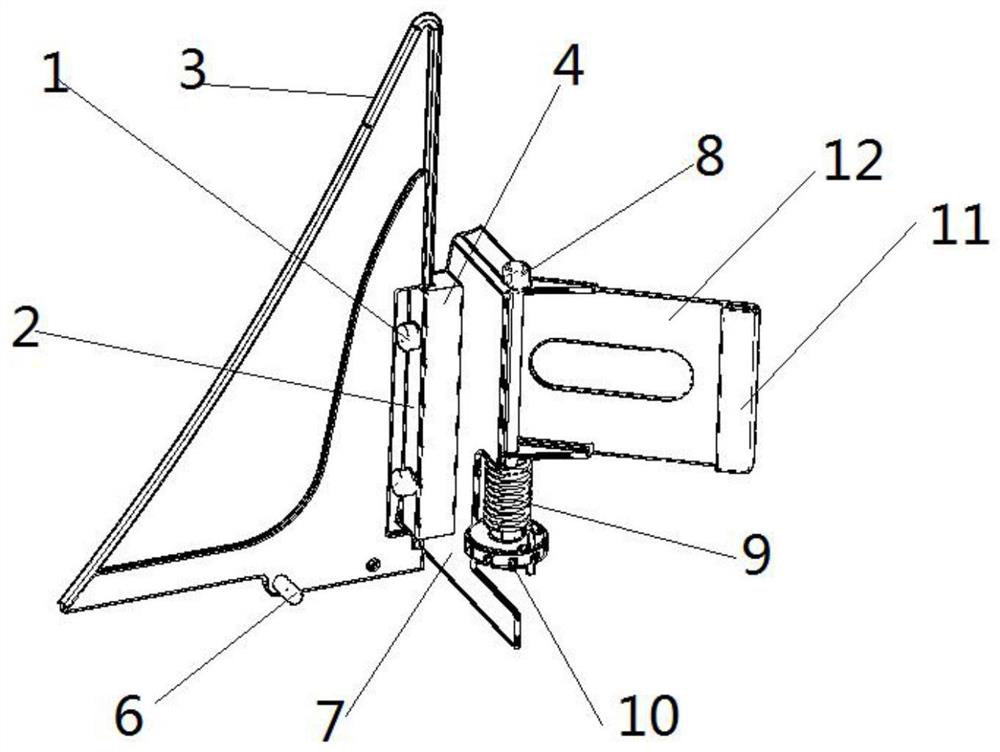

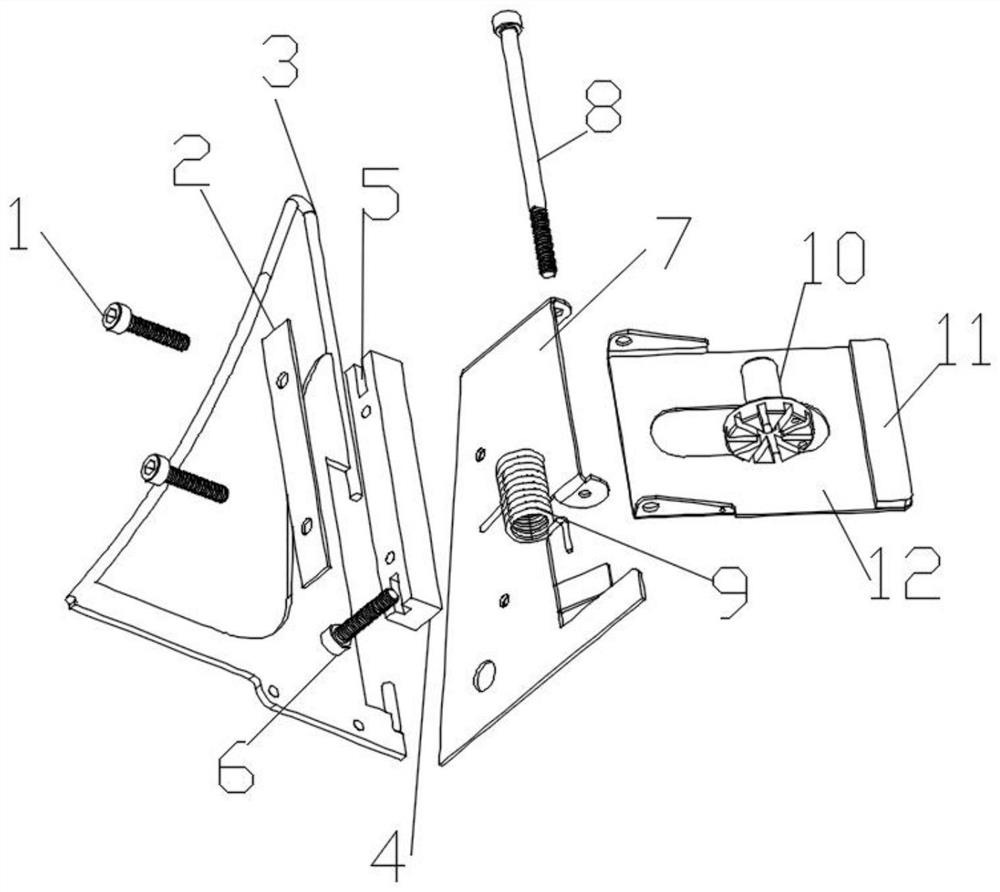

A flying shuttle front sail assembly

The invention discloses a flying shuttle front sail board assembly, comprising: fixing bolts, loose-leaf seat plate cover, folding tripod, loose-leaf seat, groove, adjusting bolts, sail board, brake plate loose-leaf shaft, brake pads, Brake plate, the brake plate is hinged with a sail plate through the brake plate loose-leaf shaft, a brake pad is arranged on one side of the brake plate, a loose-leaf seat is arranged on the sail plate, a groove is arranged on the loose-leaf seat, and a groove is arranged on the groove. A loose-leaf seat plate cover is provided, and the loose-leaf seat is connected with a folding tripod through a groove. The fixing bolts pass through the loose-leaf seat plate cover, the loose-leaf seat and the sail board in sequence to make a fixed connection between them. The folding tripod is in the shape of a right triangle. Among them, the hypotenuse is designed with a certain radian, and there is an adjusting bolt under the folding tripod. The hypotenuse of the folding tripod is designed with a certain radian, so that the tension received by the yarn is even when it is working, and the adjusting bolt can adjust the yarn to stop. Thickness when turned.

Owner:东莞市震天实业投资有限公司

A separate upside-down double-thread lock stitch sewing device

ActiveCN109652922BSmall form factorMeet the actual needs of sewingNeedle-threading devicesTake-up devicesFlying shuttleEngineering

The invention relates to a separated inverted filling double-thread locking stitch sewing device which comprises a needling thread leading module and a thread penetrating and hooking module. The thread penetrating and hooking module and the needling thread leading module are arranged in a separated manner and provided with independent driving mechanisms, the needling thread leading module is arranged below a fabric to be sewn for completing needling thread leading, and the thread penetrating and hooking module is arranged above the fabric to be sewn and used for hooking a thread and shuttle threading. According to the device, by the aid of a separated inverted filling structure, the needling thread leading module is arranged below the fabric to be sewn, the thread penetrating and hooking module is arranged above the fabric to be sewn, the boundary dimension of a sewing module in a conical die is shortened, and a structure with large size is mounted outside the die. The sewing device can be applied to three-dimensional sewing of lager-size cones and solves the problem that a conical groove is provided with small inner space and large in sewing size and has a certain close performance under the condition. Sewn stitches are two equidistant double-thread locking stitches, and sewing strength can be ensured.

Owner:WUHAN TEXTILE UNIV

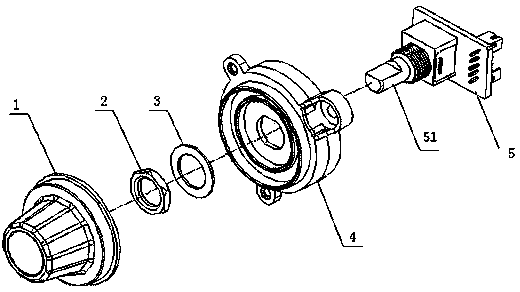

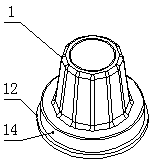

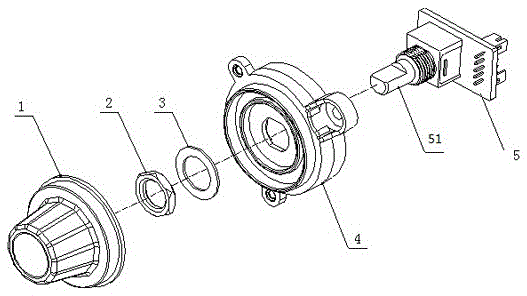

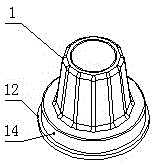

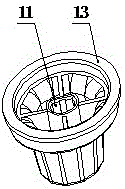

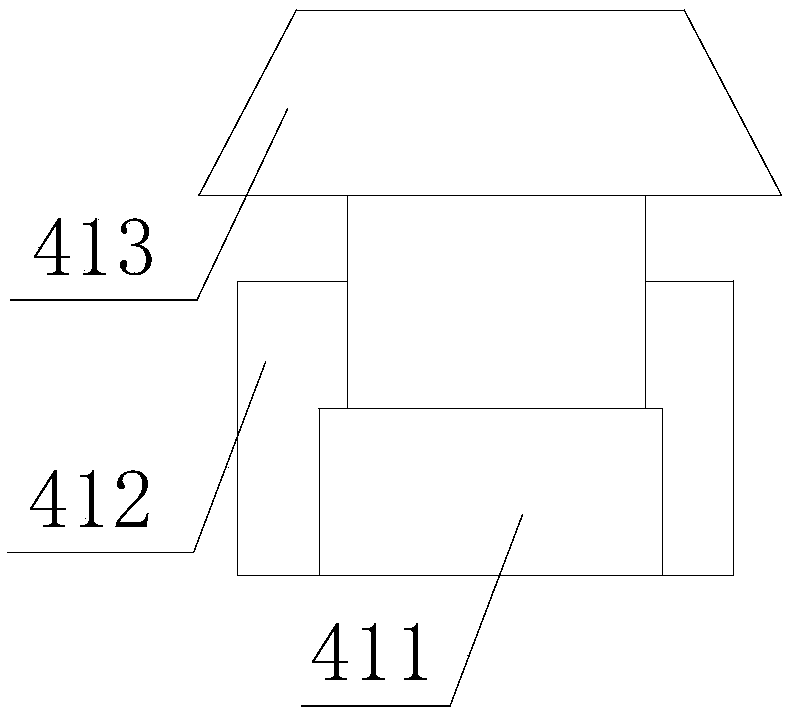

Flying shuttle of medical device and medical device with flying shuttle

ActiveCN104107091APrevent excessive depressionAvoid breakingDiagnosticsSurgeryFlying shuttleMedical device

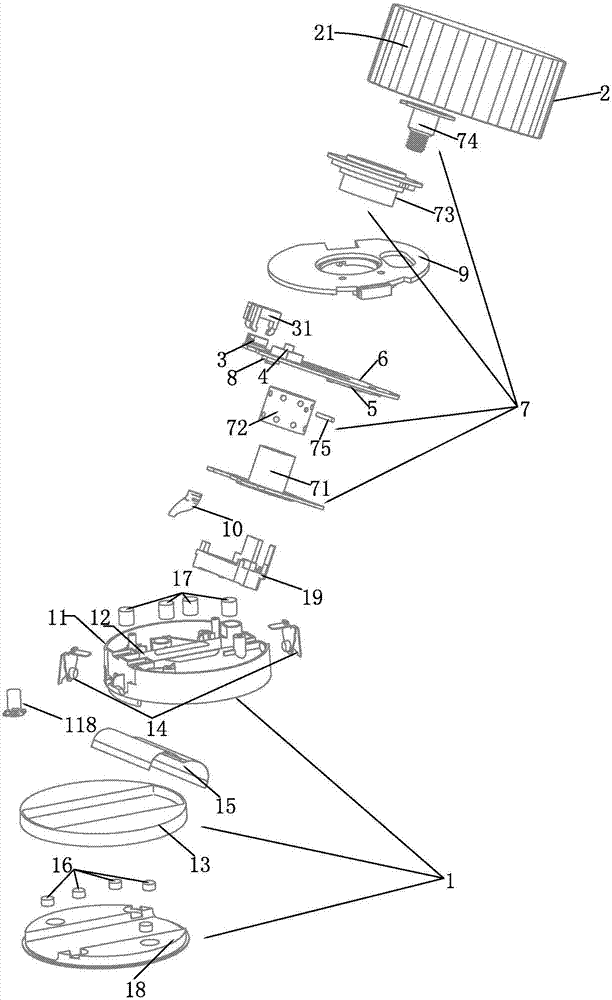

The invention provides a flying shuttle of a medical device. The flying shuttle of the medical device comprises an installation housing and a flying shuttle component, wherein the flying shuttle component comprises a flying shuttle cap, a flying shuttle support and a circuit board, the flying shuttle support is fixed in the installation housing, a flying shuttle rod is installed on the circuit board, the circuit board is arranged on the flying shuttle support, the flying shuttle support is provided with a flying shuttle rod avoiding through hole, a flying shuttle rod installation blind hole is formed in the flying shuttle cap, the flying shuttle rod passes through the flying shuttle rod avoiding through hole and is fixedly inserted into the flying shuttle rod installation blind hole, the flying shuttle support is provided with an abutting portion which limits the downward pressing stroke of the flying shuttle cap, the bottom end face of the flying shuttle cap and the abutting portion are oppositely arranged, and a downward pressing interval is arranged between the bottom end face of the flying shuttle cap and the abutting portion. The flying shuttle of the medical device has the advantages of limiting the downward pressing stroke of the flying shuttle cap through the abutting portion, preventing the flying shuttle cap from being excessively pressed downwards due to downward impact, and then preventing the flying shuttle rod from being broken off due to the fact that the flying shuttle cap is excessively pressed downwards.

Owner:EDAN INSTR

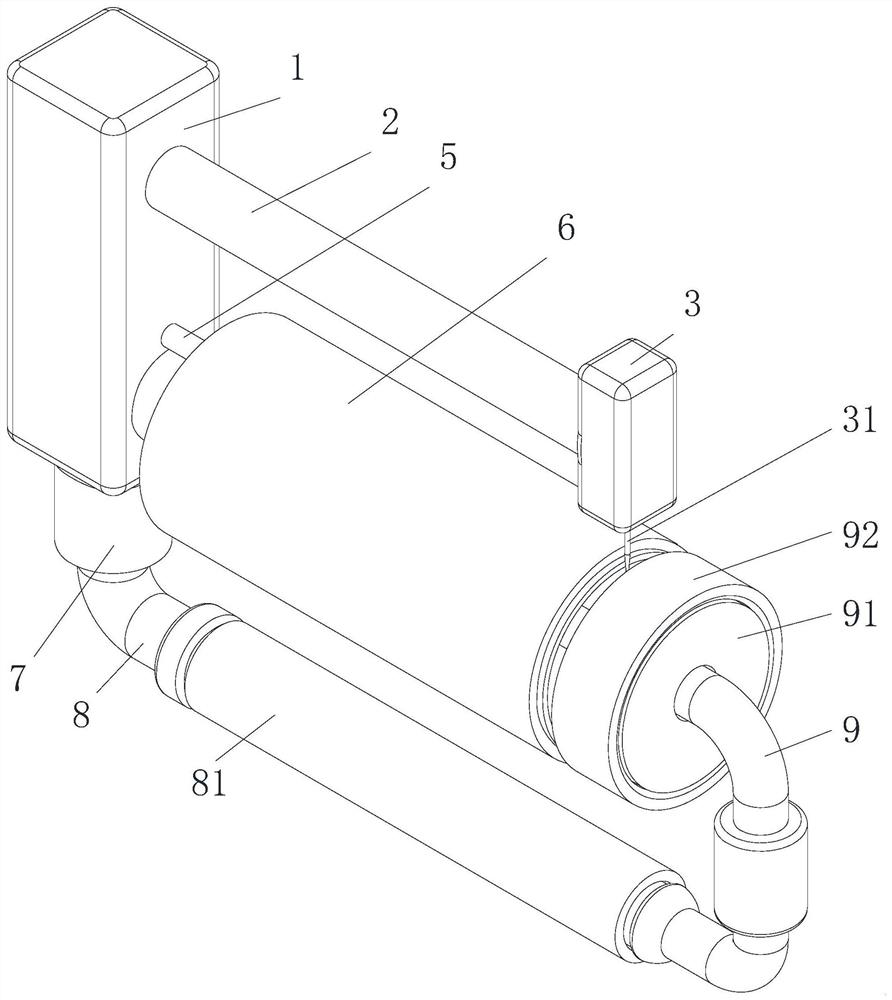

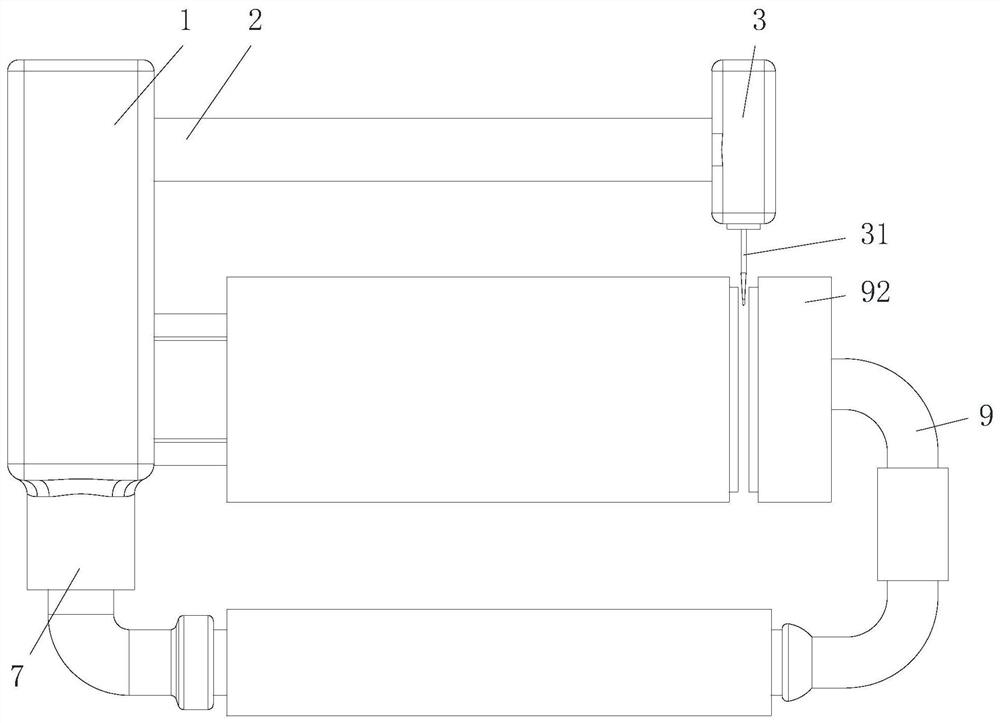

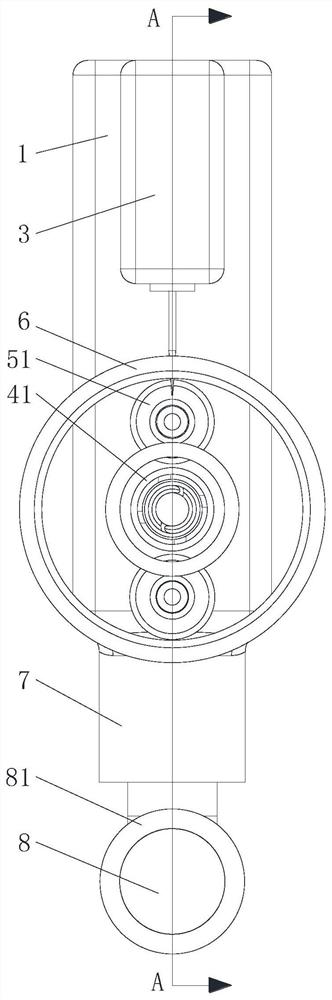

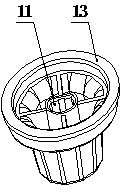

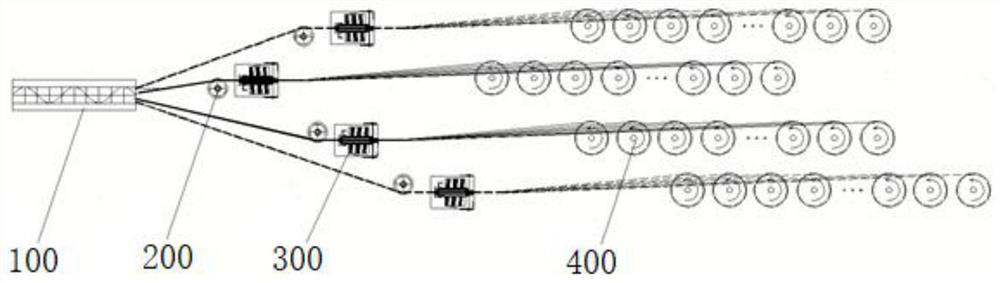

Internal grouping type yarn winding water-blocking system of high-density optical cable

The invention discloses an internal grouping type winding water-blocking system for a high-density optical cable, wherein the system comprises a twisting table and a casing pipe yarn winding unit; the casing pipe yarn winding unit comprises a pay-off head matrix, a yarn winding machine and a guide wheel, and the pay-off head matrix is provided with a plurality of casing pipe wire spools; the yarn winding machine comprises a machine frame, a motor, a main fixed shaft barrel, a flying shuttle rotating barrel, a movable ring mold base, a yarn ball rotating barrel, a flying shuttle and a yarn guide pipe; the flying shuttle rotating barrel is mounted on the inner side of the main fixed shaft barrel through a first bearing, a rotating shaft of the motor is connected with the first end of the flying shuttle rotating barrel, and the movable ring mold base is mounted at the second end of the flying shuttle rotating barrel; and the yarn ball rotating barrel is mounted on the outer side of the main fixed shaft barrel through a second bearing, the flying shuttle is mounted on the movable ring mold base, the yarn guide pipe is mounted on the flying shuttle, and the guide wheel is mounted on a supporting frame. According to the invention, a grouping type winding mode is adopted, and physical yarn winding isolation is completed on grouped casing pipe groups, so that identification is facilitated; and a casing pipe is woven by water-blocking yarns in a winding mode, isolation and water blocking are achieved, tension is small, optical fibers in the casing pipe cannot be damaged, and use is quite reliable.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Fly-shuttle loom harness frame position limiter

InactiveCN101173414BGood for up and down movementReduce distanceAuxillary apparatusHealdsYarnFlying shuttle

The invention discloses a heald frame limit device for shuttle loom, comprising a plurality of heald frames, which is characterized in that: two heald transverse heads are respectively arranged at two ends of a heald frame; an upper row and a lower row of location perforations are arranged on the heald transverse heads of the heald frame for a heald bar to pass through; a plurality of heald yarnspass through the heald bar; the heald bar is fixed on the heald frame via a heald clip; a slider is arranged on each heald transverse head of the heald frame; a limited block is arranged at each end of the heald frame, and a lifting track corresponding to the slider and capability of controlling the sliding of the slider is arranged on the limited block. The invention has the advantages that the shaking of the heald frames in the weaving process is effectively solved and the distance between heald frames is greatly reduced, so that friction between warp and heald yarn or other loom elements in the weaving process is avoided and the end breaking is reduced.

Owner:丁宏利

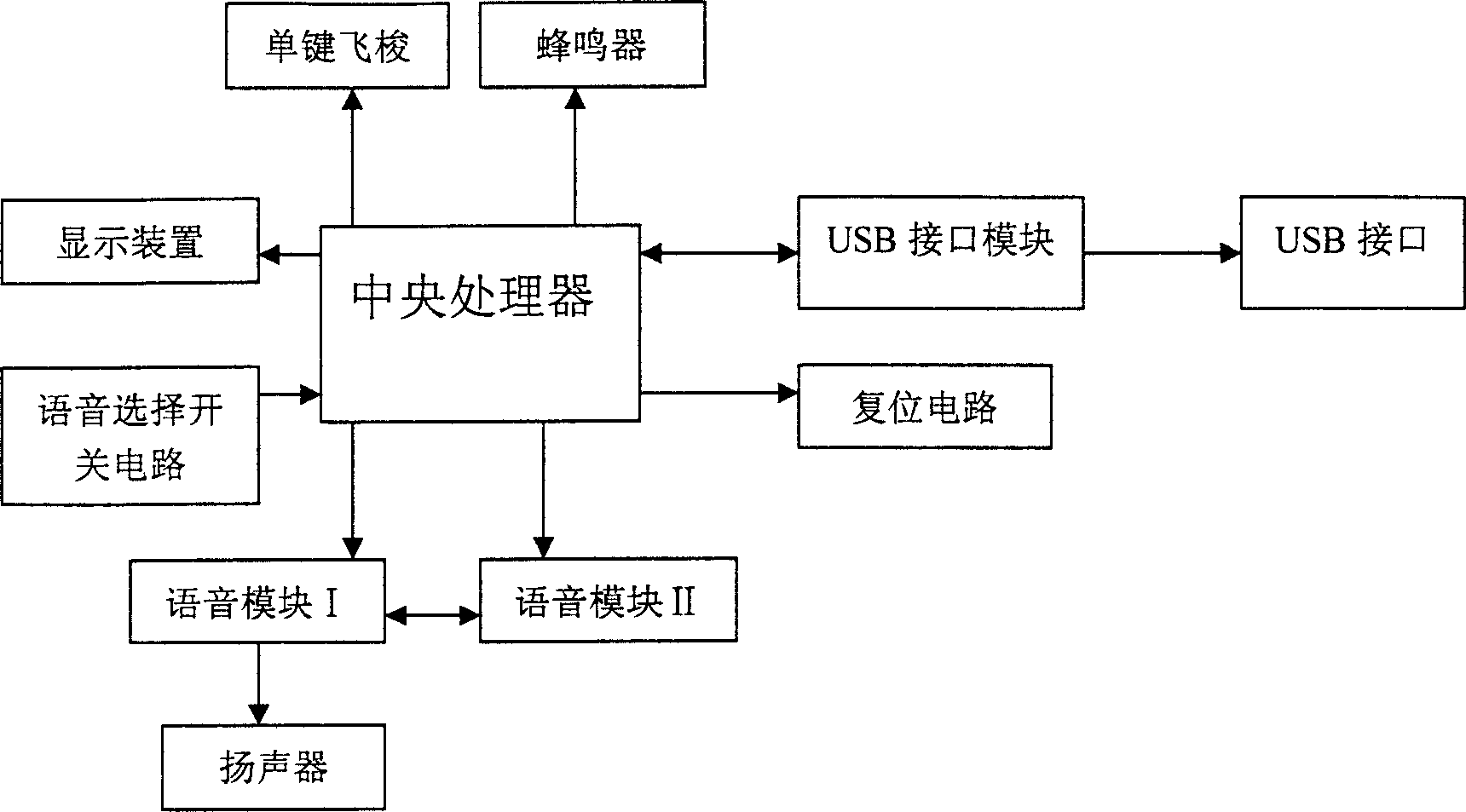

Peep-proof cipher input apparatus and input method thereof

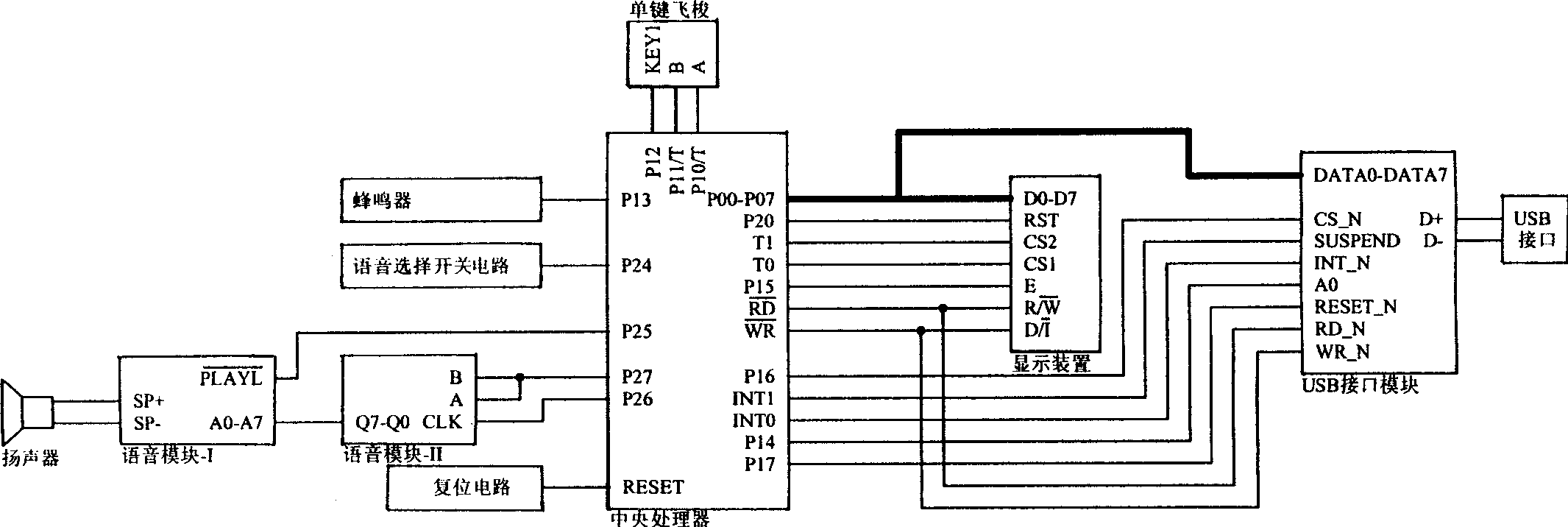

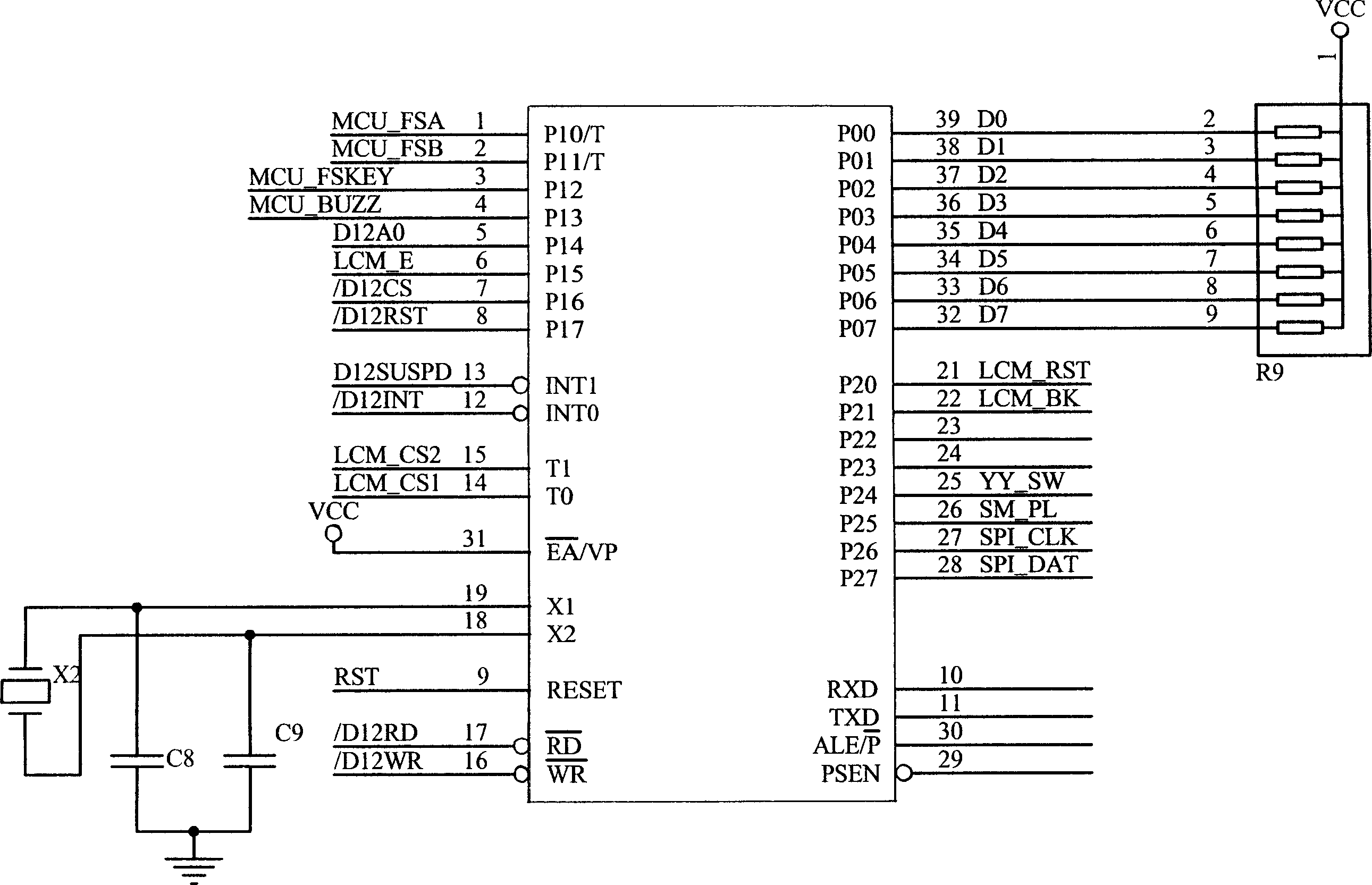

InactiveCN1734409APrevent peepingImprove confidentialityInput/output for user-computer interactionInternal/peripheral component protectionFlying shuttleDisplay device

The invention discloses a peep-proof code input device and method, which comprises the following parts: centre processor, display device, USB interface mode, USB interface element, reset circuit and singly-bound fly-shuttle, wherein the centre processor connects display device; USB interface mode connecting USB interface element; reset circuit and singly-bound fly-shuttle separately. The device controls the program of centre processor by singly bound fly-shuttle, which helps users operate entire course.

Owner:张俊

Composite material textile fabric manufacturing equipment

PendingCN114875556AReduce frictionReduce wearLoomsAuxillary apparatusFlying shuttleStructural engineering

The invention discloses composite textile fabric manufacturing equipment which comprises a rapier loom body, a guide rail plate is fixed to the inner side wall of the rapier loom body, a guide rail sliding groove is formed in the upper end face of the guide rail plate, a movable sliding block is slidably connected into the guide rail sliding groove, and two limiting sliding grooves are symmetrically formed in the inner side wall of the guide rail sliding groove; limiting sliding blocks used in cooperation with the limiting sliding grooves are fixed to the two sides of the movable sliding block, a flying shuttle is fixed to the upper end face of the movable sliding block, and pulling belts are arranged on the two sides of the movable sliding block. Through cooperation of the guide rail plate and the guide rail sliding groove, the movable sliding block and the pulling belt can move in the guide rail sliding groove, friction of the side wall of the guide rail plate to the pulling belt is reduced, and therefore abrasion to the pulling belt is reduced, and the damage rate of the pulling belt is reduced.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

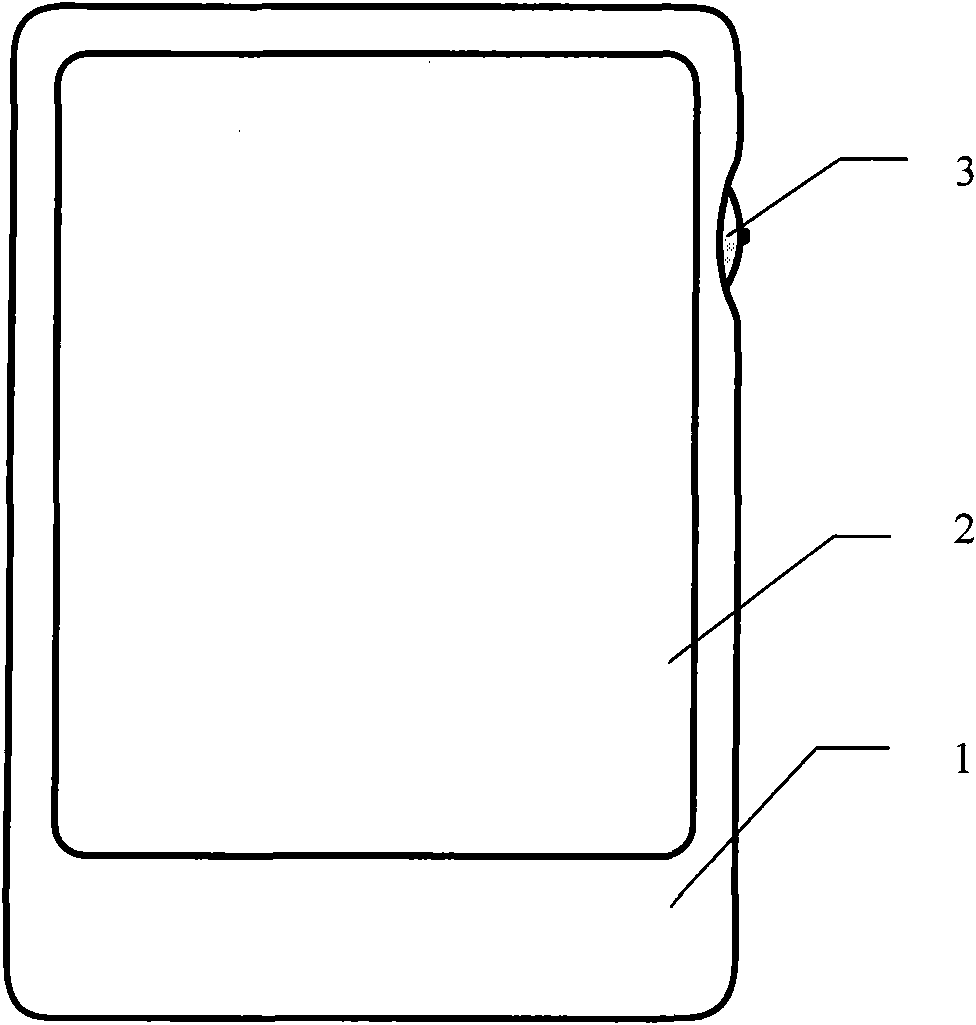

Electronic reader capable of rapidly selecting content and method thereof

InactiveCN102147984AQuick searchRapid positioningElectrical appliancesInput/output processes for data processingKey pressingComputer hardware

The invention relates to an electronic reader capable of rapidly selecting content and a method thereof. The technical scheme is as follows: a rapid selection function key which is a flying shuttle key is arranged, different speeds can be given to the key according the content or data required to be found and different instructions are judged by determining whether the function key is pressed down or not while the flying shuttle key is rotated, namely different key instructions are obtained by different speeds of the flying shuttle key. The electronic reader provided by the invention has the advantages and effects that the content of the electronic reader can be rapidly selected, and especially during page turning, a page can be rapidly found and located according a page number.

Owner:HANVON CORP

A shuttle for medical equipment and medical equipment with the shuttle

ActiveCN104107091BPrevent excessive depressionAvoid breakingDiagnosticsSurgeryFlying shuttleMedical device

The invention provides a flying shuttle of a medical device. The flying shuttle of the medical device comprises an installation housing and a flying shuttle component, wherein the flying shuttle component comprises a flying shuttle cap, a flying shuttle support and a circuit board, the flying shuttle support is fixed in the installation housing, a flying shuttle rod is installed on the circuit board, the circuit board is arranged on the flying shuttle support, the flying shuttle support is provided with a flying shuttle rod avoiding through hole, a flying shuttle rod installation blind hole is formed in the flying shuttle cap, the flying shuttle rod passes through the flying shuttle rod avoiding through hole and is fixedly inserted into the flying shuttle rod installation blind hole, the flying shuttle support is provided with an abutting portion which limits the downward pressing stroke of the flying shuttle cap, the bottom end face of the flying shuttle cap and the abutting portion are oppositely arranged, and a downward pressing interval is arranged between the bottom end face of the flying shuttle cap and the abutting portion. The flying shuttle of the medical device has the advantages of limiting the downward pressing stroke of the flying shuttle cap through the abutting portion, preventing the flying shuttle cap from being excessively pressed downwards due to downward impact, and then preventing the flying shuttle rod from being broken off due to the fact that the flying shuttle cap is excessively pressed downwards.

Owner:EDAN INSTR

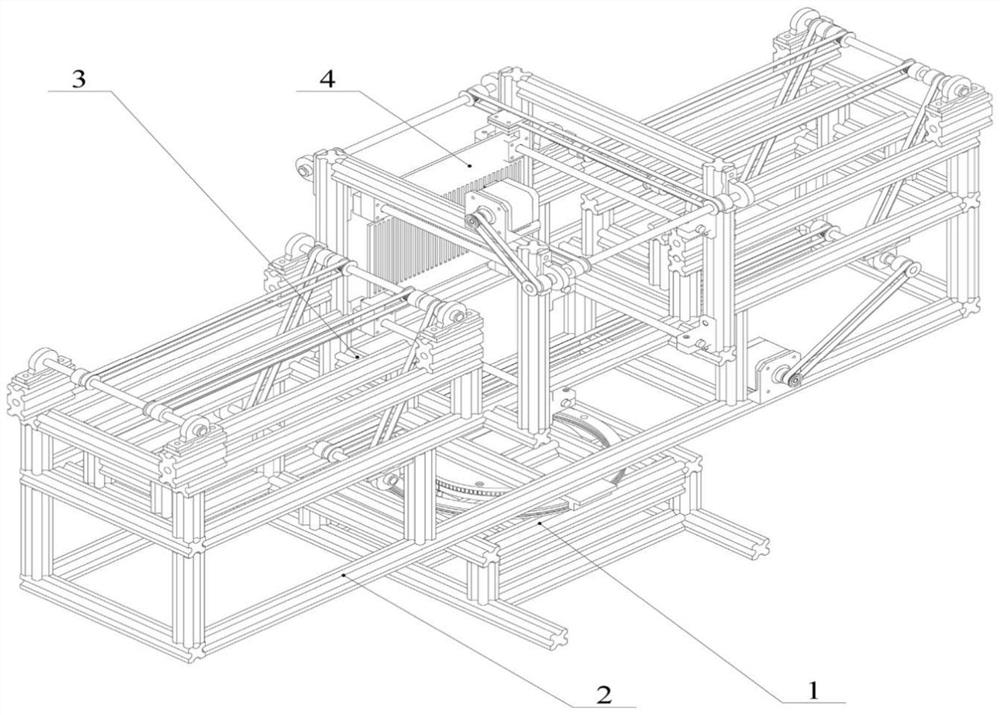

Variable-angle knitting device of knitting machine

ActiveCN114775146ASolve the problem of only weaving fixed-angle fabricsRealization of variable angle weavingLoomsTextile/flexible product manufactureFlying shuttleElectric machinery

The invention discloses a variable-angle knitting device of a knitting machine, and relates to the technical field of textile machinery, a shuttle flying mechanism and a beating-up mechanism are integrated on a rack of a weft insertion device, a rotating mechanism is designed at the bottom of the rack of the weft insertion device, and the rotating mechanism is composed of a planetary gear train, an annular guide rail sliding seat, a limiting mechanism and the like. A weft insertion device rack is connected with a rotating mechanism through an annular guide rail sliding seat, a sun gear in a planetary gear train is connected with a motor output shaft, a circular 3D printing piece is connected with the planetary gear train and the weft insertion device rack, and rotation of a motor is accurately controlled through an angle sensor; when the weft insertion device rotates, the shuttle flying mechanism and the beating-up mechanism which are integrated on the weft insertion device rack are driven to rotate by a set angle, and at the moment, the rotating weft insertion device rack is secondarily fixed by the limiting mechanism, so that the stability is improved, and the variable-angle weaving function of the fabric is realized.

Owner:JILIN UNIV

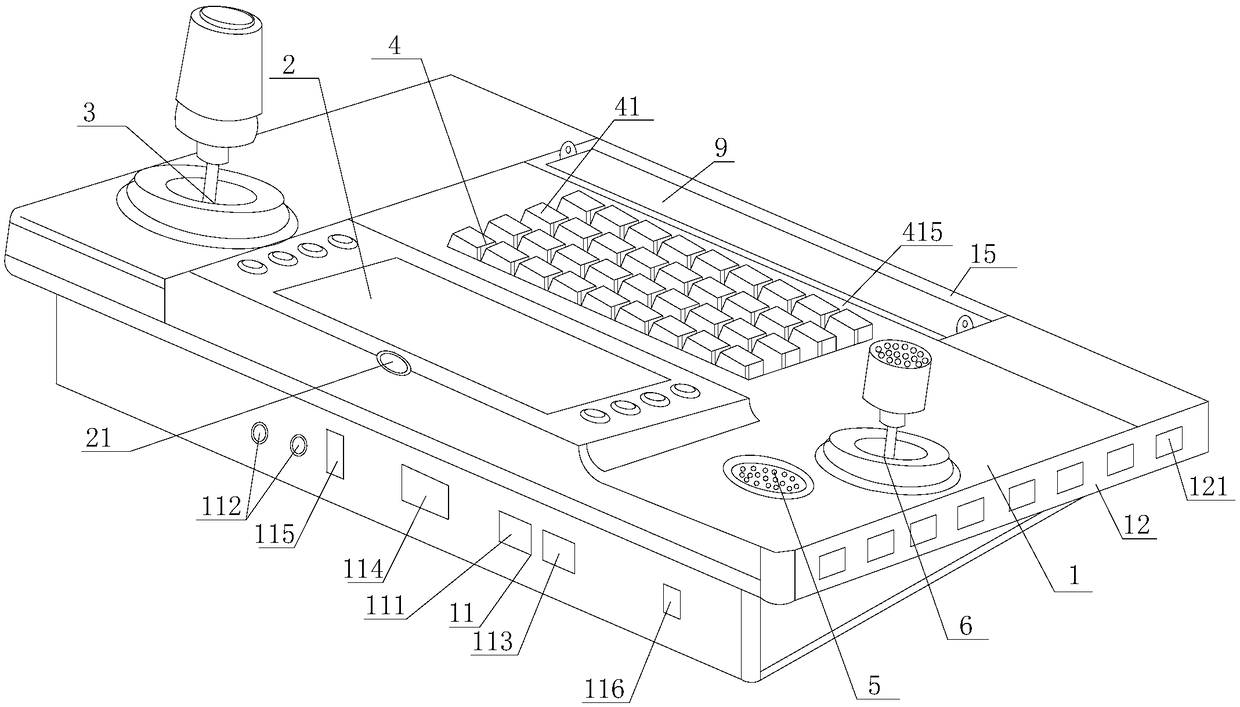

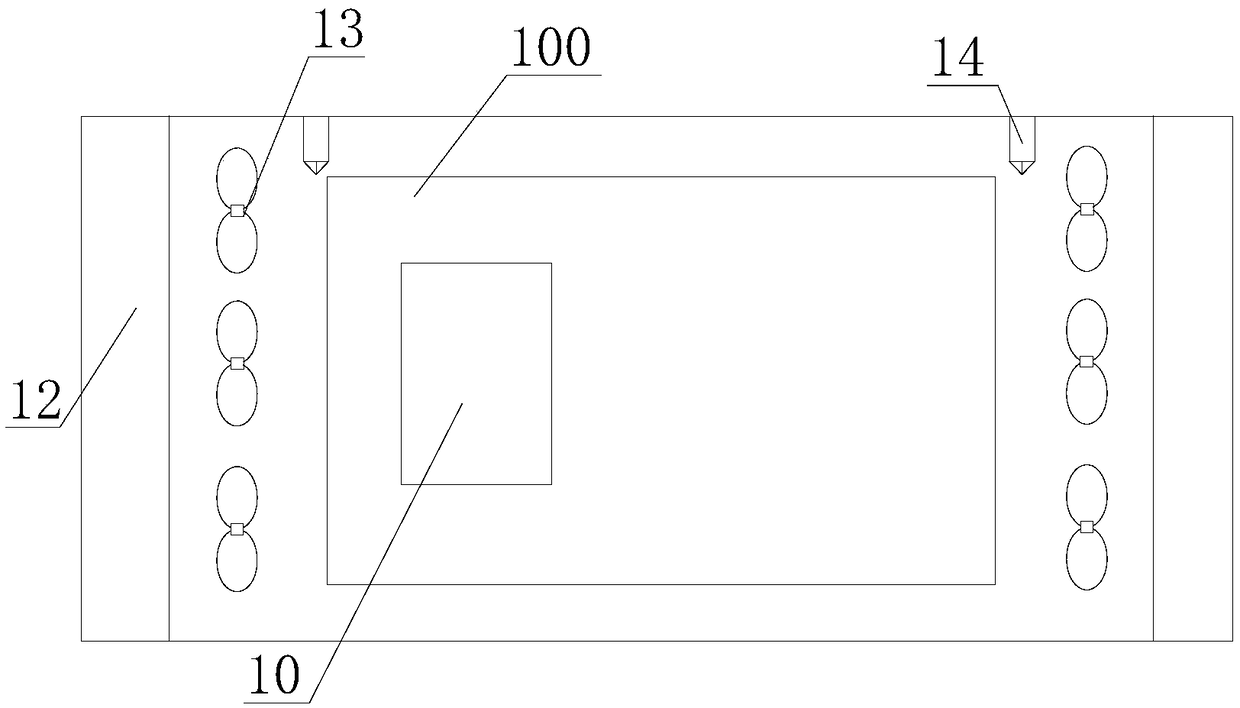

Multifunctional network control keyboard

InactiveCN108874163AIncreased versatilityAffect performanceInput/output for user-computer interactionDigital data processing detailsFlying shuttleDual core

The invention provides a multifunctional network control keyboard. The keyboard comprises a keyboard seat, a display screen, a three-dimensional rocker, a keyboard group, a flying shuttle control module, a microphone, an MCU processing module and a dual-core CPU module; the display screen is arranged on the upper side of the keyboard seat; a camera is arranged at the upper end of the display screen; the three-dimensional rocker is arranged on the right side of the display screen; the keyboard group is arranged on the lower side of the display screen; the keyboard group is provided with a plurality of typewriting key groups; a dust collecting groove is formed in the lower side of each typewriting key group; the flying shuttle control module is arranged on the left side of the display screen; the microphone is arranged below the flying shuttle control module; a plurality of modules are arranged in the keyboard seat; a plurality of data interfaces are formed in the rear side of the keyboard seat; ventilation plates are arranged on the two sides of the keyboard seat; and a plurality of radiators are arranged on the inner sides of the ventilation plates. The multifunctional network control keyboard is easy to clean, simple in structure, rich in function, good in heat dissipation effect and high in processing speed.

Owner:浙江麦知网络科技有限公司

A hand-held sewing machine with shuttle bottom thread and its movement mode

The invention discloses a hand-held sewing machine with a shuttle thread and its movement mode, which includes a linkage mechanism, a base, and a pressure beam, wherein a sewing machine needle is screwed into a fixed needle bolt at one end of the pressure beam to fix it, and an adjusting needle is installed on the side of the pressure beam. The wire button and the wire adjustment button are connected to the wire wheel in the pressure beam. The abdomen of the pressure beam is connected to one end of the compression spring, and the other end of the compression spring is connected to the base. , the pressure beam is fixedly connected to the presser foot. Its motion mode is that the pressure beam drives the linkage mechanism, and the present invention has double upper and lower threads, flexible operation, good sewing effect and easy to carry.

Owner:GUIZHOU NORMAL UNIVERSITY

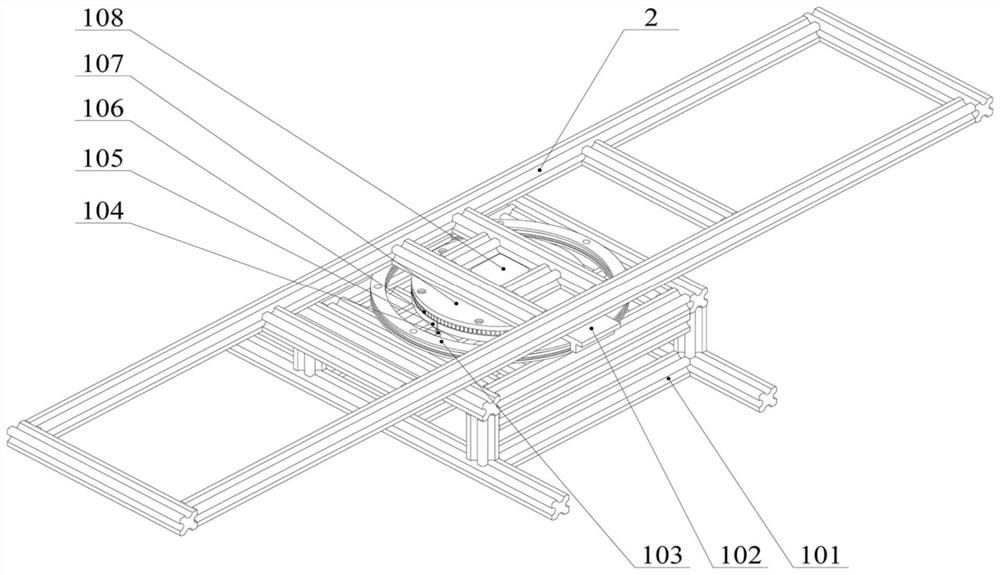

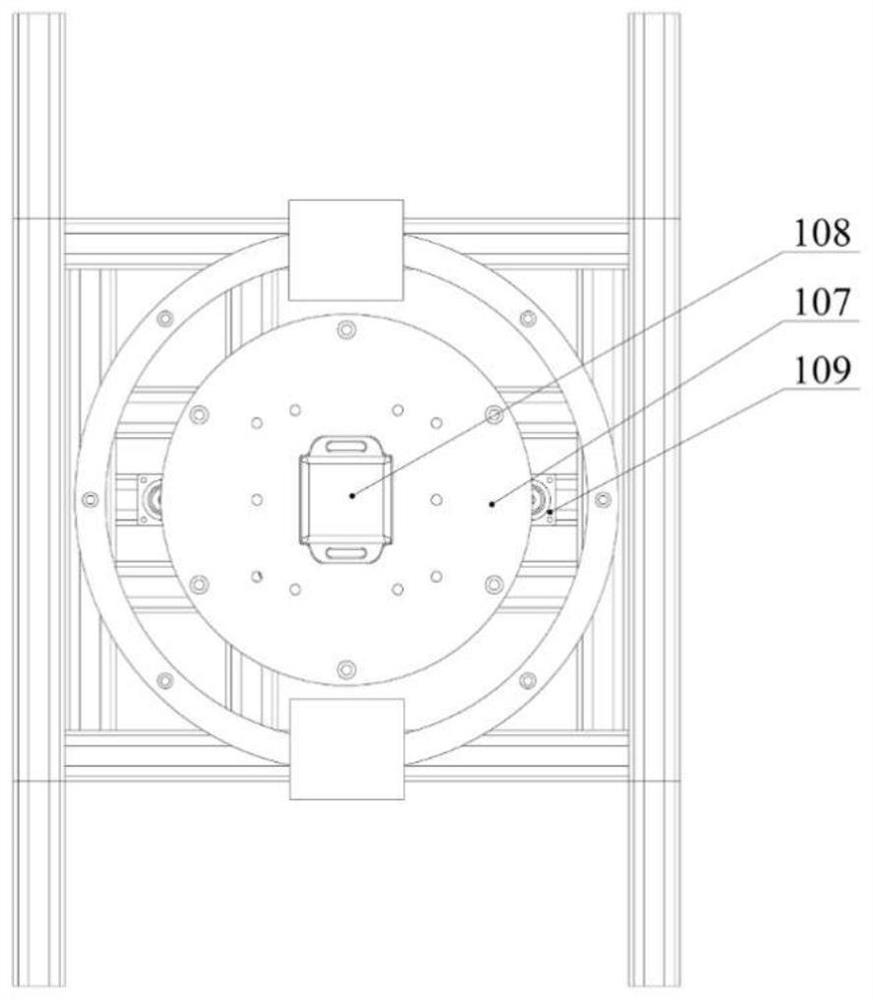

Single-line flying shuttle system

ActiveCN101848320BReduce weightTelevision system detailsColor television detailsLinear motionFlying shuttle

The present invention relates to a special shooting technology in the film and television industry, in particular to a single-line system for air motion shooting. The system realizes motion control of azimuth, rolling and pitching on a shooting holder hung and carried on a vehicle body in motion by adopting a single lead as a guide rail and leading the vehicle body to carry power and run along the guide rail. The present invention adopts a lightweight design and reduces weight as much as possible on the premise of ensuring function; meanwhile, when the linear motion of a flying shuttle is designed, a soft limit is set for enabling a cameraman to concentrate on artistic creation without fearing the safety problem of running of a flying shuttle during creation; and the holder carried by the flying shuttle has the function of stabilizing a camera and enables a shot image to be more stable.

Owner:必威易悠孚(北京)影视技术有限公司

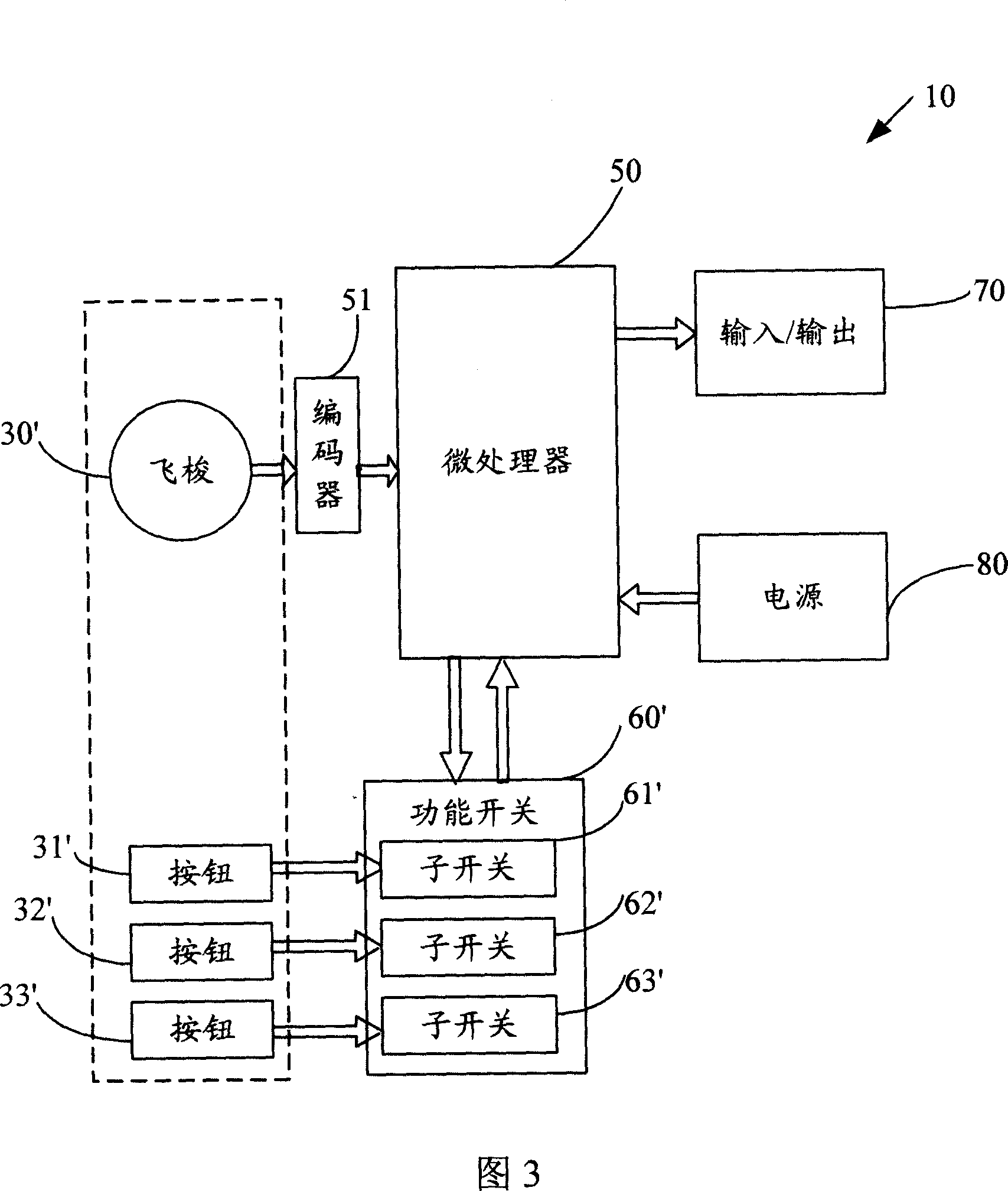

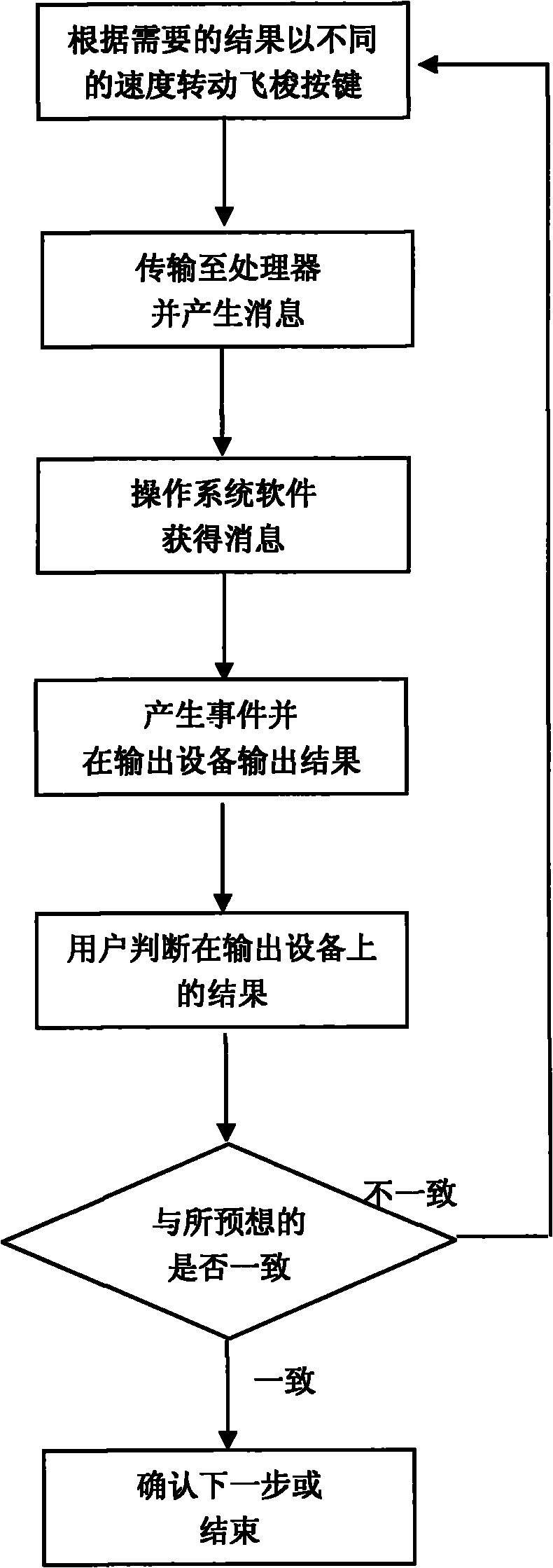

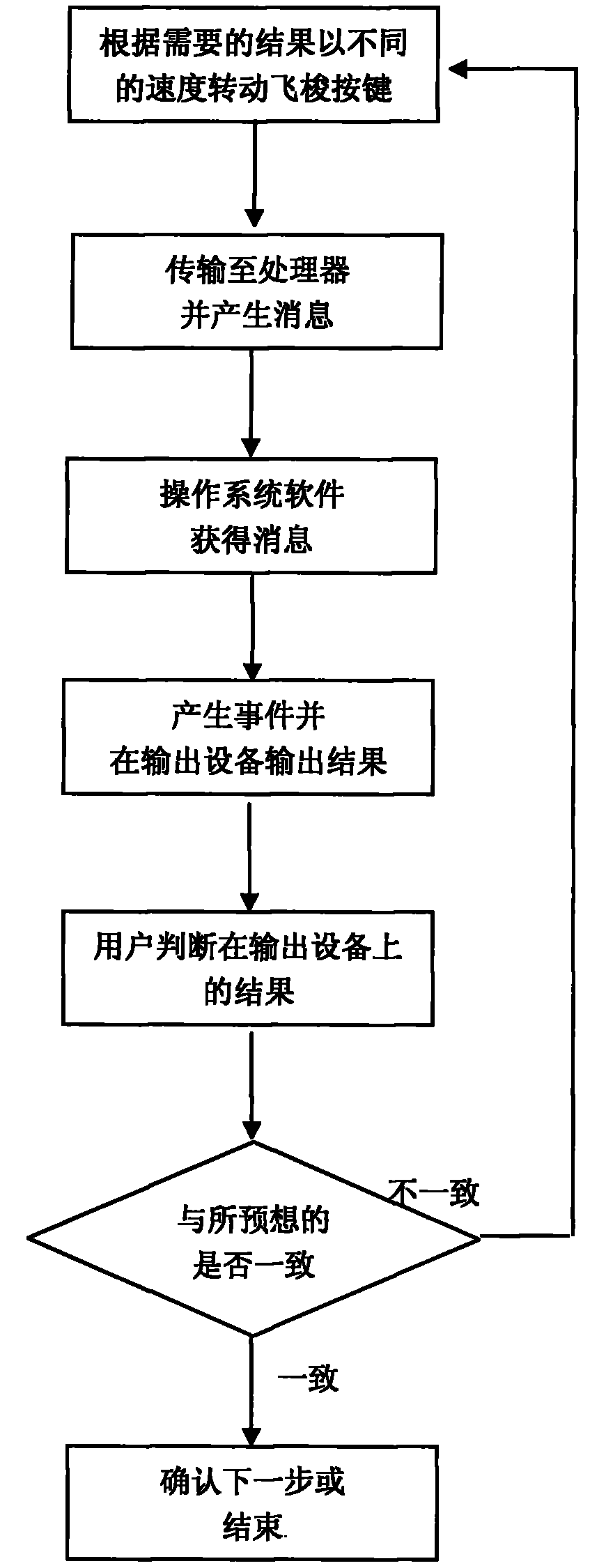

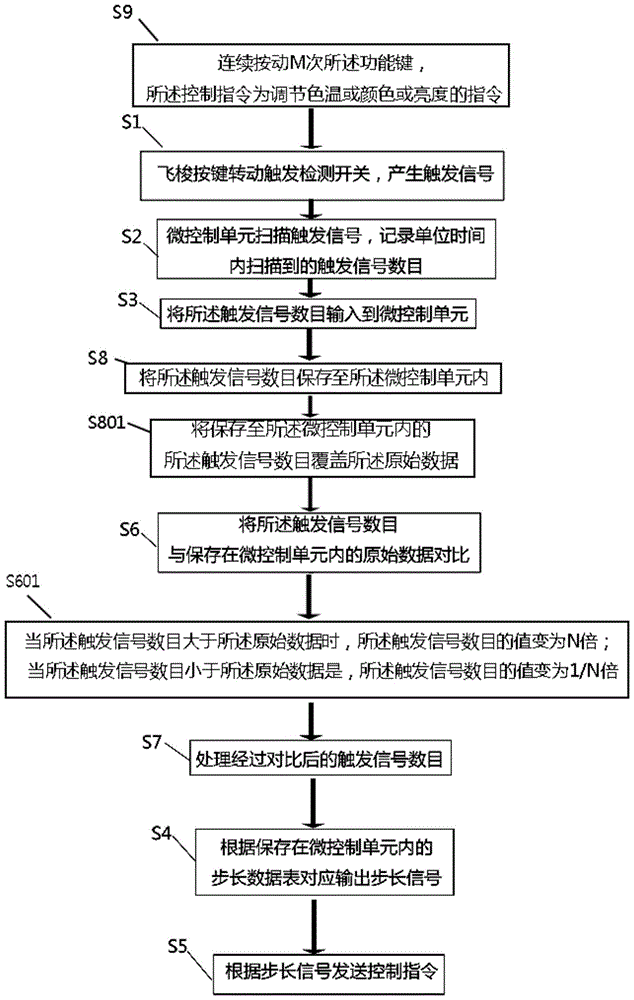

A kind of shuttle device adjustment method

The invention mainly relates to an adjusting method for a flying shuttle device, and aims at automatically adjusting the step size signals of a flying shuttle according to the rotating speed. The method is that a functional key is arranged in the center of the flying shuttle device. The method comprises the steps of S1, rotating the flying shuttle device to trigger a detecting switch to generate triggering signals; S2, scanning the triggering signals through a micro-control unit, and recording the number of the triggering signals canned within the unit time; S3, inputting the number of the triggering signals into the micro-control unit; S4, correspondingly outputting the step size signals according to the step size data stored in the micro-control unit; S5, sending a control instruction according to the step size signals; S6, comparing the number of the triggering signal with the original data stored in the micro-control unit; S7, treating the compared number of triggering signals, wherein the steps S6 is performed after step S3 and before step S4.

Owner:OPPLE LIGHTING

Portable small-tension yarn winding machine for large-core-number high-density micro-cluster optical cable

ActiveCN113900204ADoes not interfere with walking pathImprove convenienceFibre mechanical structuresYarnWinding machine

The invention discloses a portable small-tension yarn winding machine for a large-core-number high-density micro-cluster optical cable, wherein the machine comprises a rack, a motor, a supporting sleeve, a central hollow pipe, a first bearing, a movable ring mold seat, a yarn drum shaft sleeve, a guide mold, a flying shuttle and a yarn guide pipe; the central hollow pipe is rotatably mounted on the inner side of the supporting sleeve through the first bearing; the motor is connected with the first end of the central hollow pipe through a transmission mechanism, the movable ring mold seat is mounted at the second end of the central hollow pipe, and the guide mold is mounted on the movable ring mold seat; the yarn drum shaft sleeve is rotatably mounted on the outer side of the supporting sleeve through a second bearing; the flying shuttle is fixedly mounted on the movable ring mold seat; and the yarn guide tube is fixedly arranged on the flying shuttle. The rotating resistance torque of the second bearing can be converted into the product of yarn winding tension and the force arm from the outer diameter of a yarn roll to the central hollow pipe, the maximum yarn winding tension is small, the maximum value and the minimum value of the yarn winding force value are controllable, control is safe, the situation that a micro-cluster pipe or an optical fiber is damaged by tying cannot occur, and the yarn winding machine is reliable.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com