Single-piece feeding device, embroidering, sewing or quilting machine comprising the device, and method for embroidering on a single-piece

A feeding device and single-piece technology, applied in sewing machine components, embroidery machine mechanisms, automatically controlled embroidery machines, etc., can solve the problems of constant movement in a specific direction and limited relative movement, and achieve the effect of saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

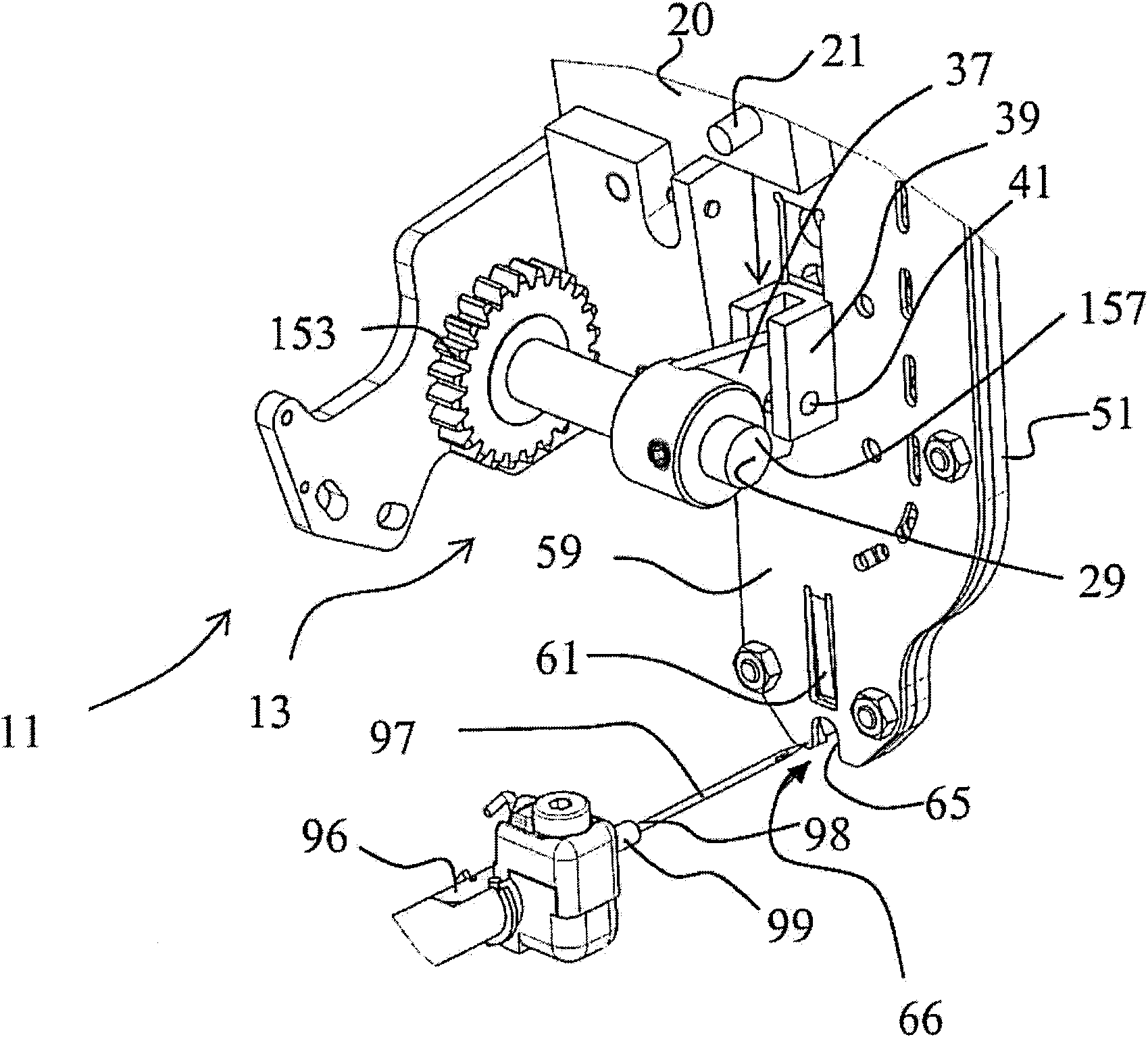

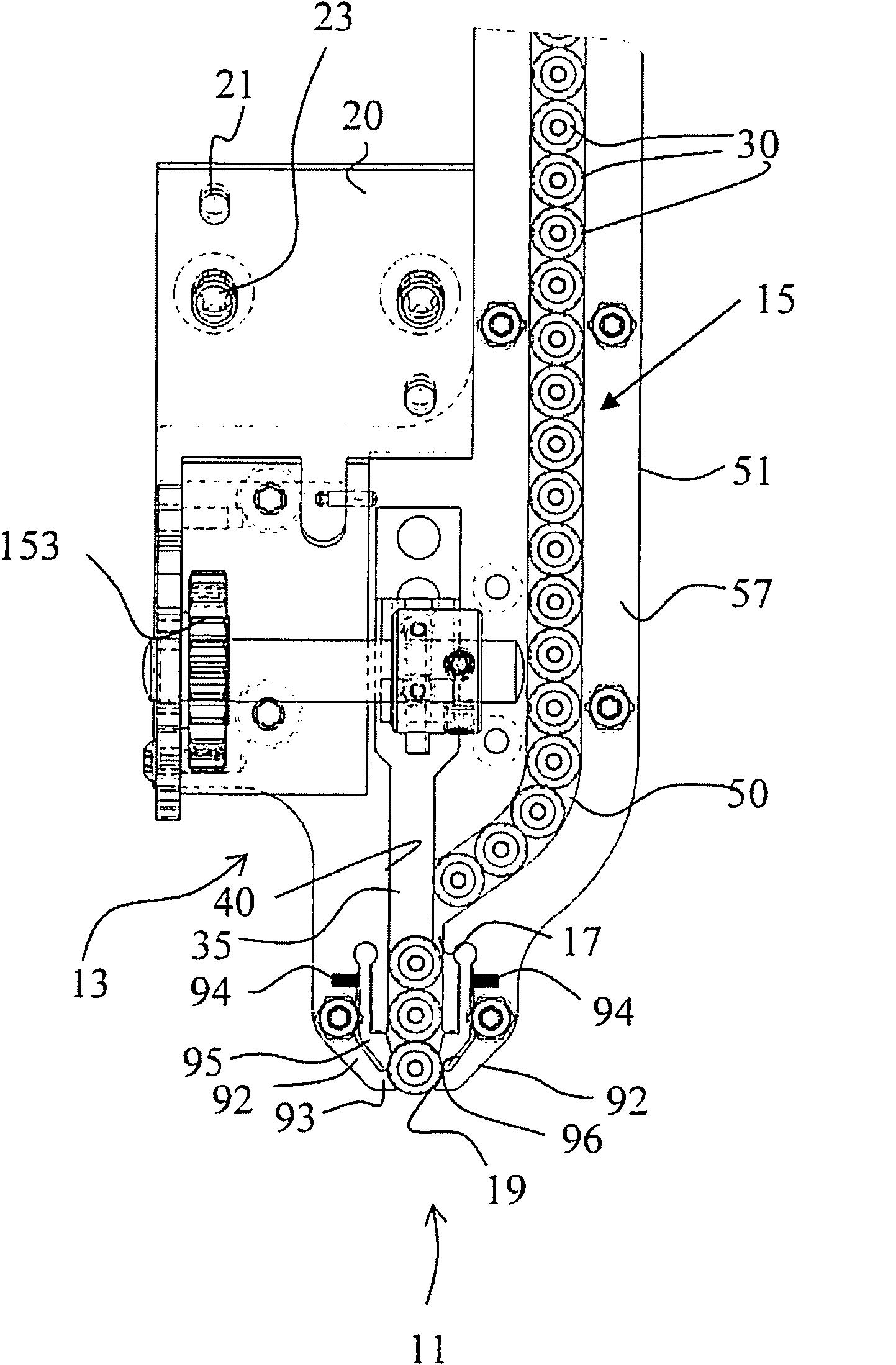

[0054] The exemplary embodiments described below are designed to be driven with the drive of a sewing or embroidery machine. The drive can be driven by a geared shaft 3, or a sprocket shaft ( Figure 4 ). The shaft 3 can extend the entire length or part of the length of the embroidery machine and can be driven to rotate in either direction by a motor (not shown).

[0055] According to the invention, the switching of the drive means can be controlled in a switch arrangement or coupling means in the single-piece feeding device, as disclosed, for example, in patent EP 1 764 434. The content of patent EP1 764 434 has been incorporated into the present specification by reference. This known switch structure, which is not part of the present invention, enables items such as small metal pieces or ribbon guides to be connected by needle tappets.

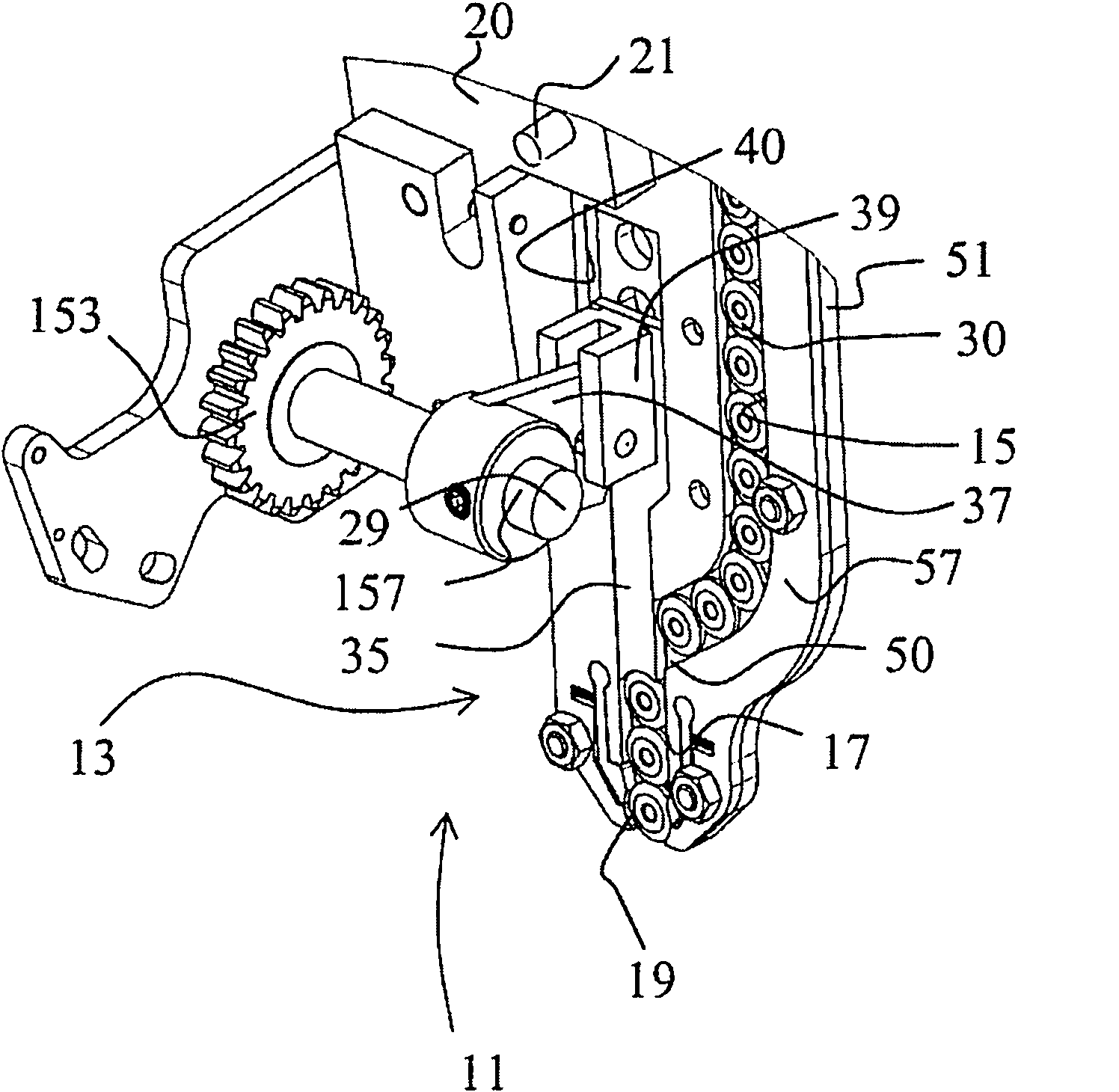

[0056] The main components of the feeding structure 13 of the single-piece feeding device according to the present invention are a feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com