Patents

Literature

33results about How to "Unchanged tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

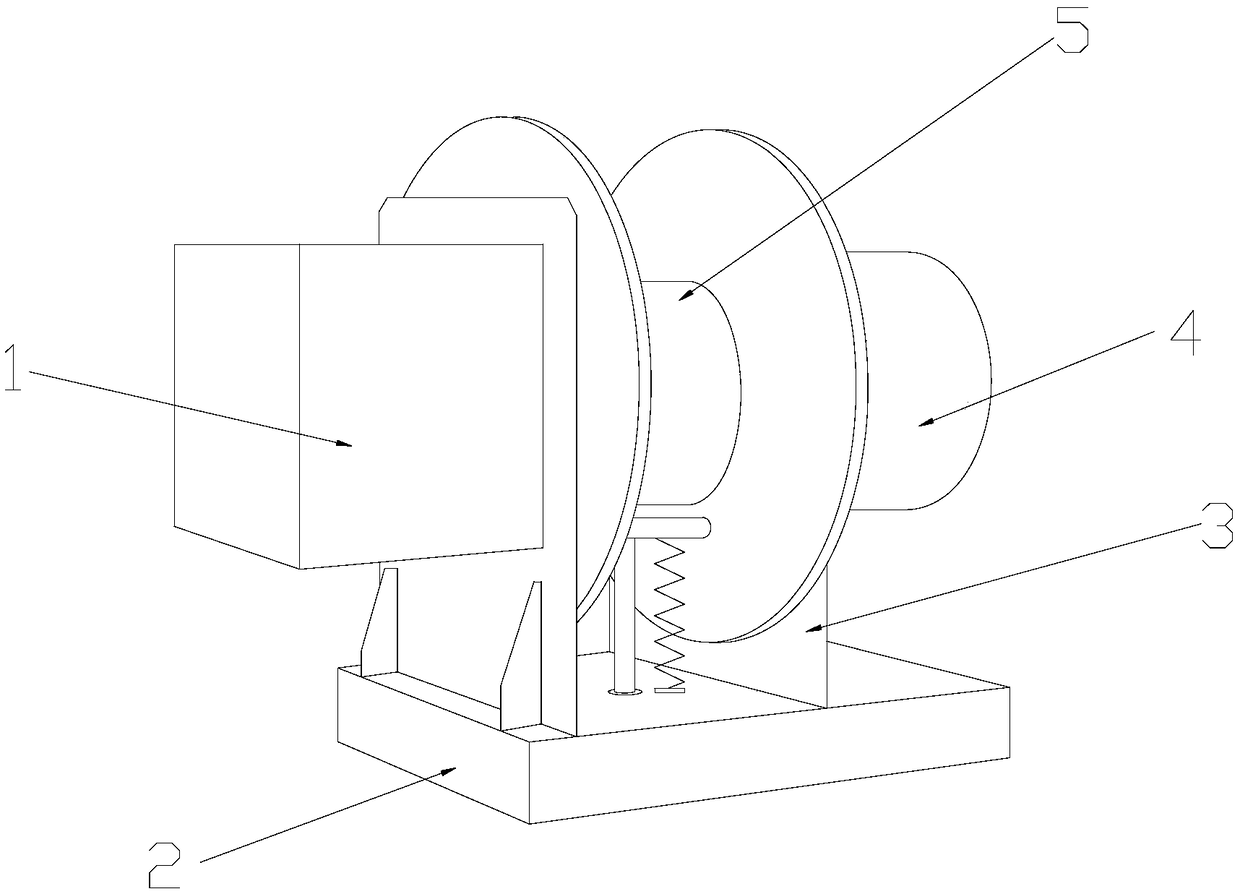

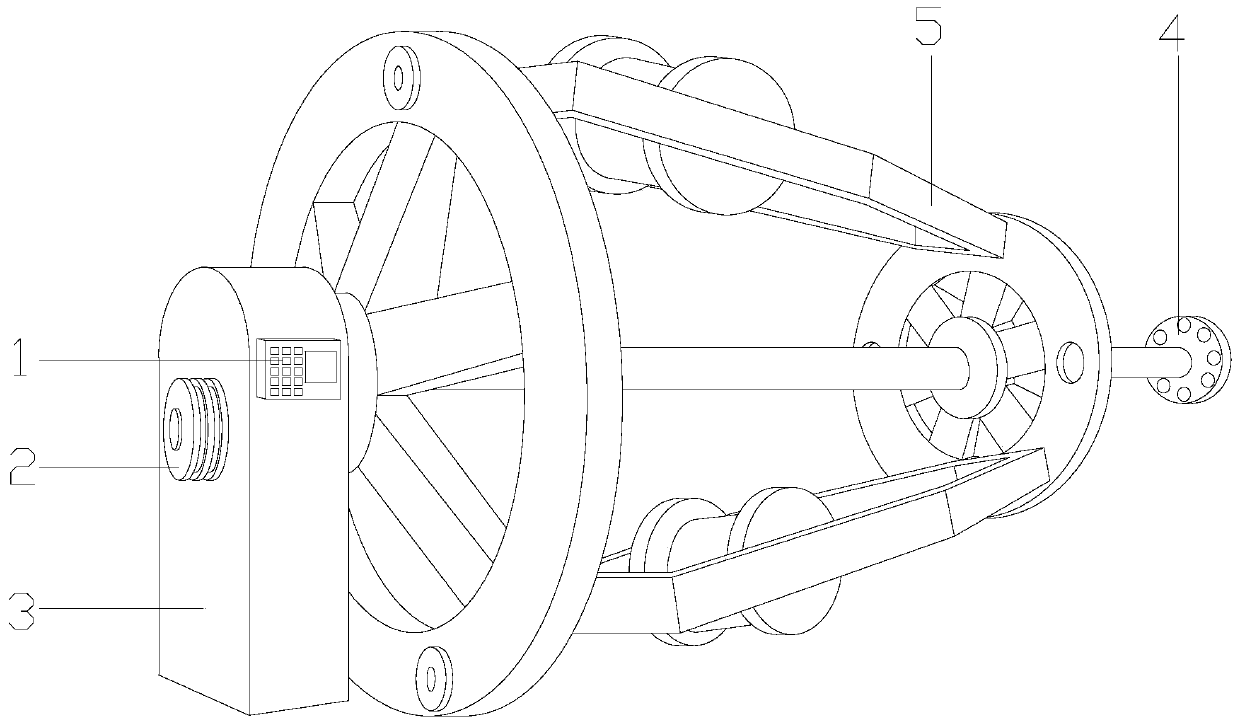

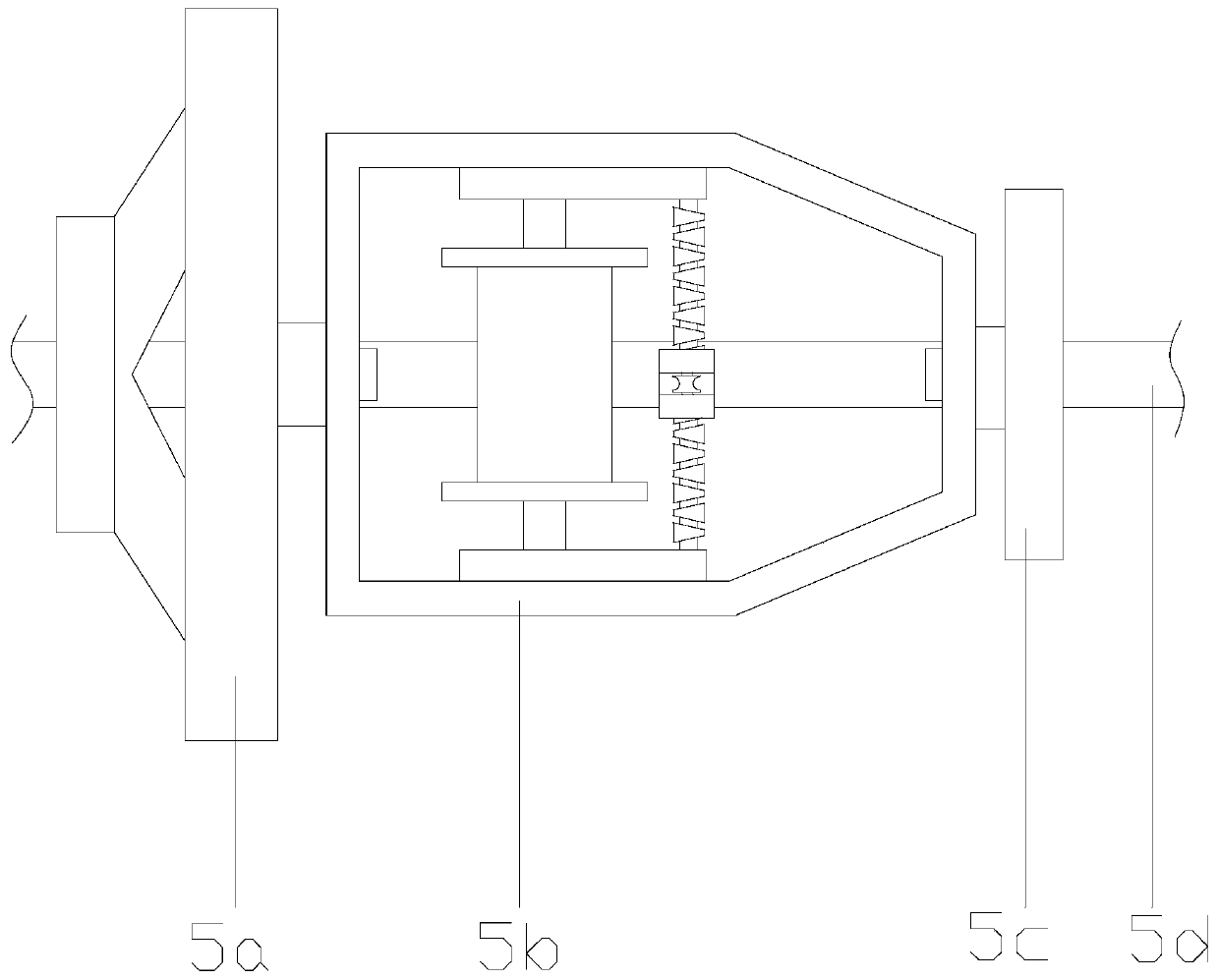

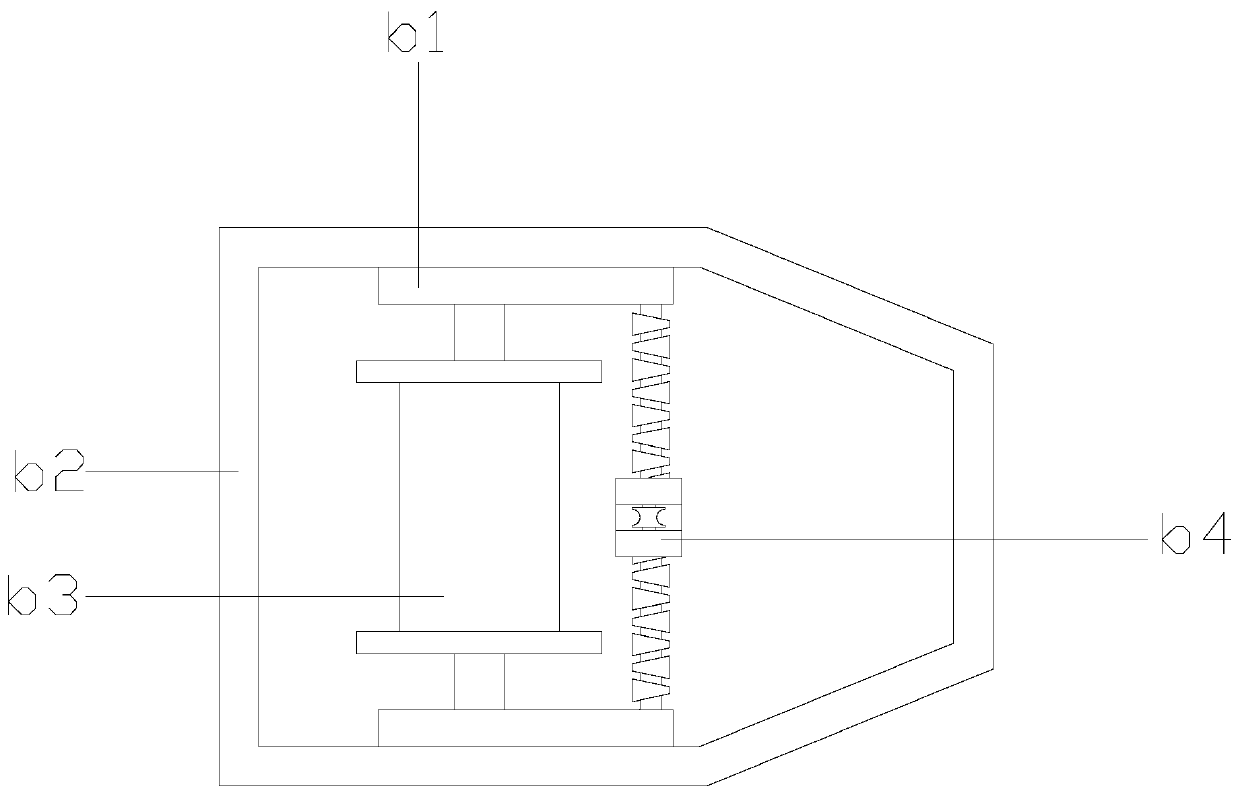

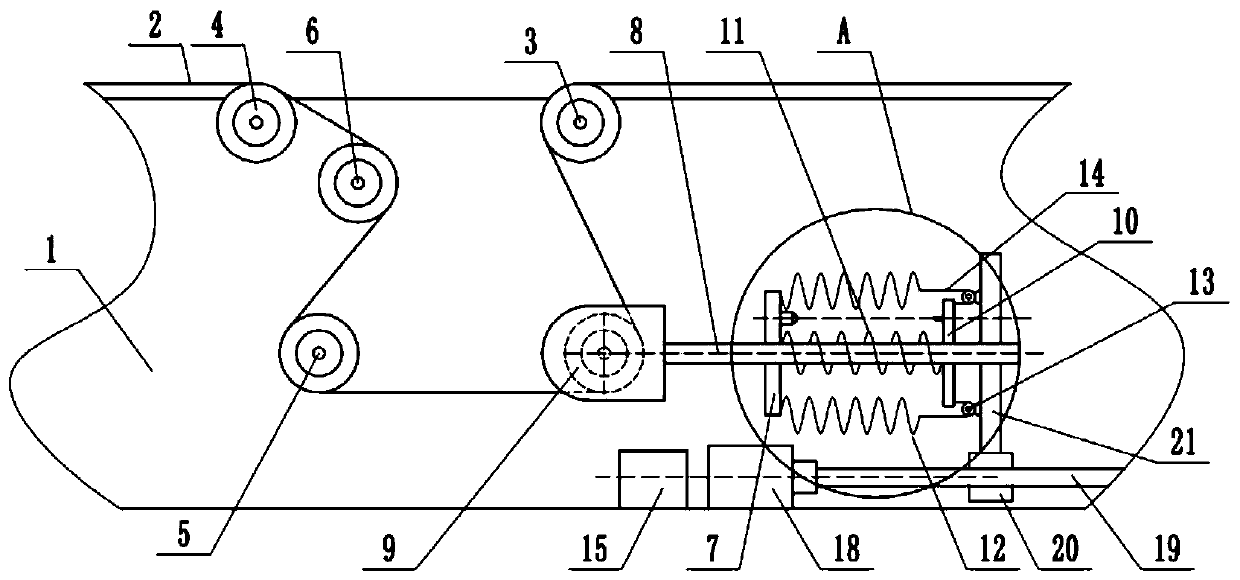

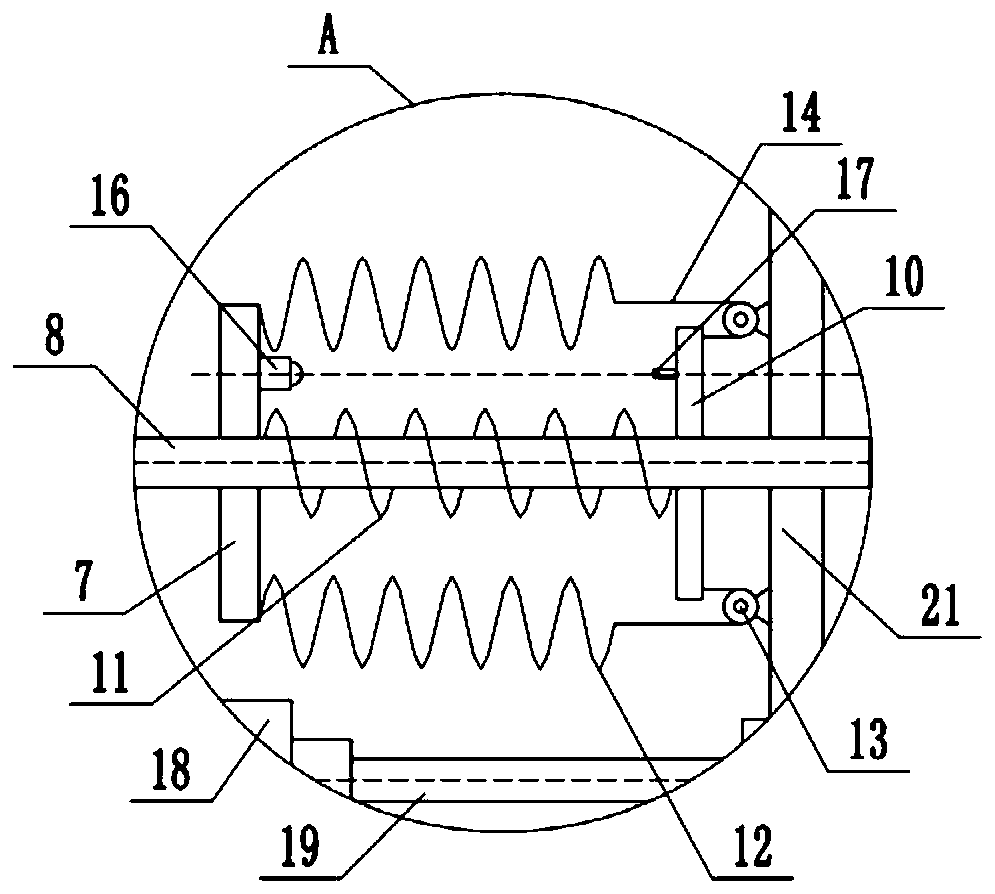

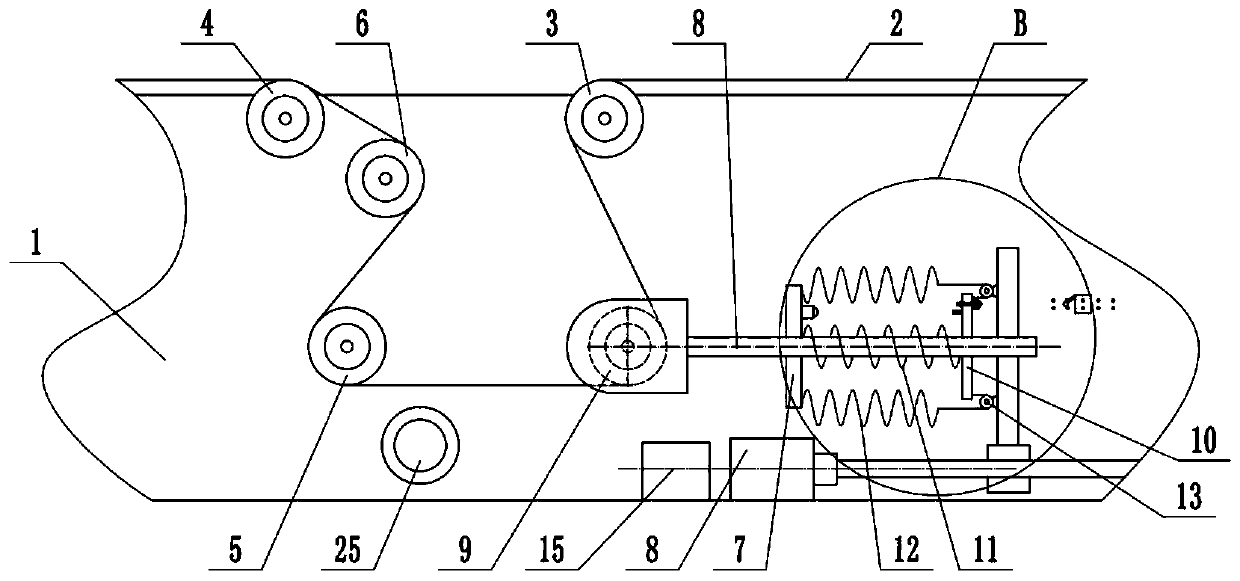

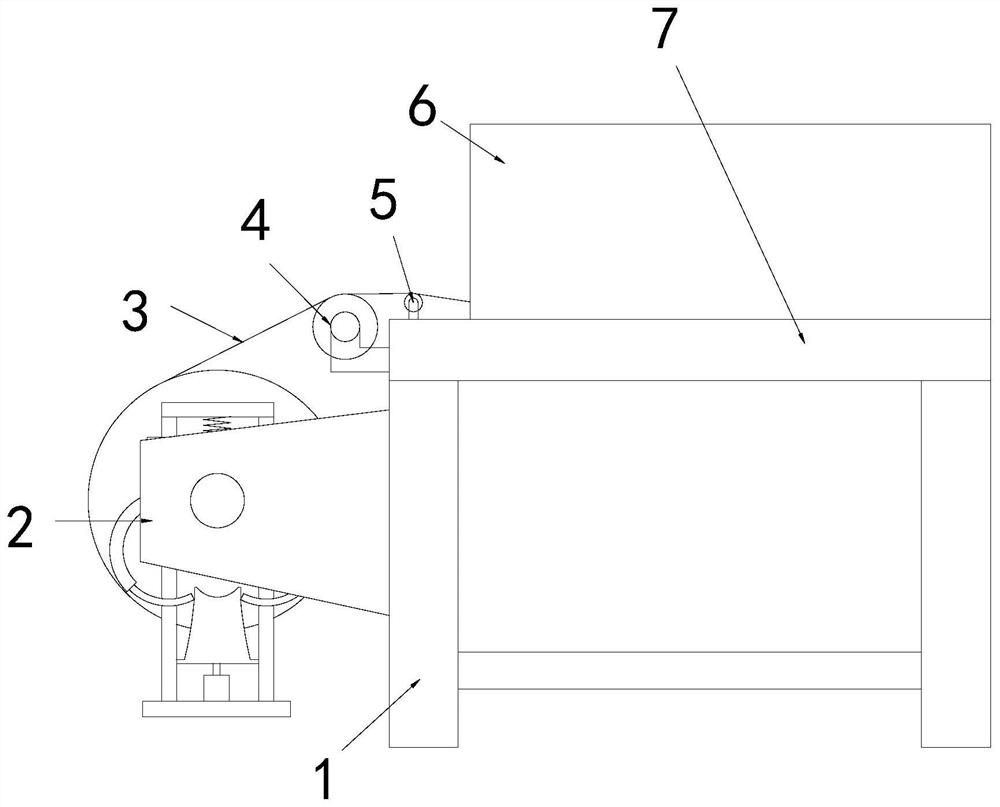

Steel strip uncoiler

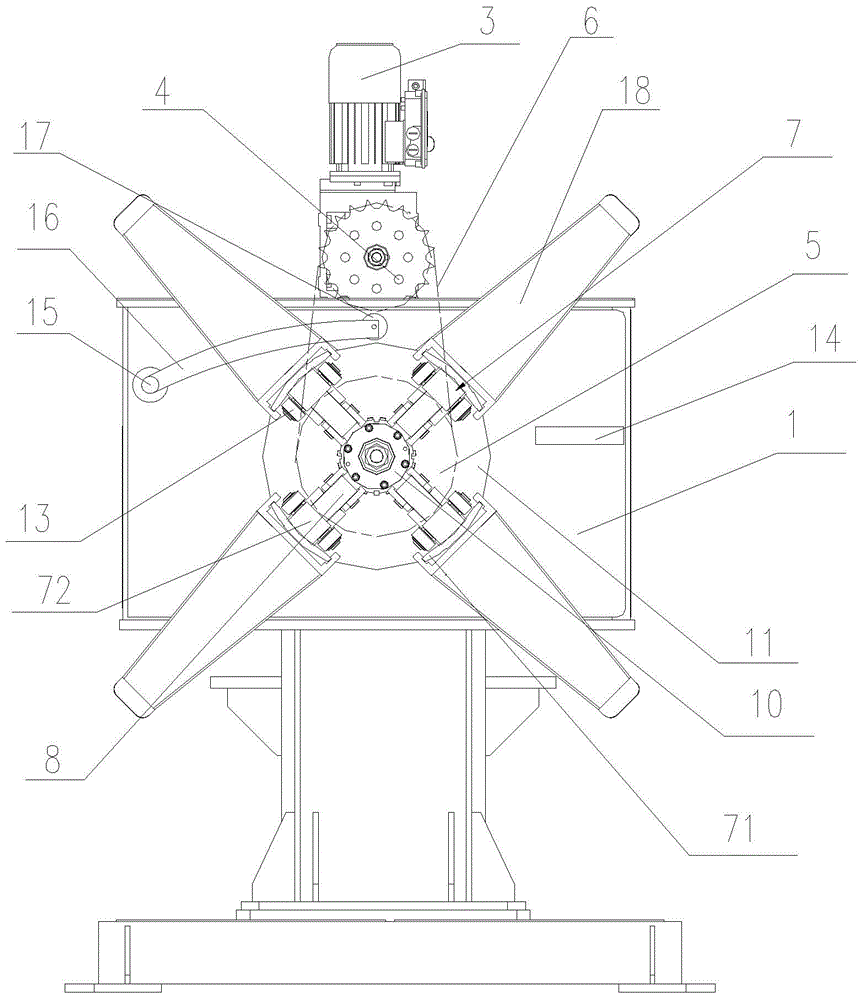

ActiveCN105312355AReduce labor intensityUnchanged tensionShaping safety devicesElectric machinerySteel belt

The invention relates to a steel strip uncoiler. The steel strip uncoiler comprises an uncoiler rack, a center shaft arranged on the uncoiler rack and freely rotating on the uncoiler rack, and a power input device for controlling the center shaft to rotate, and the circumference of one side of the center shaft far from the uncoiler rack is provided with a supporting body. The steel strip uncoiler has the advantages of simple structure, stable and reliable running and no maintenance on the premise of guaranteeing the constant steel strip uncoiling tension; and additionally, when manual traversing of a steel strip is carried out, a motor is controlled to rotate forward or inversely to drive the center shaft to rotate, so the steel strip on the center shaft moves forward or backward, thereby the labor intensity of an operating personnel is greatly reduced through substituting manual pulling of the steel strip.

Owner:NANJING BANKNOTE MINTING +1

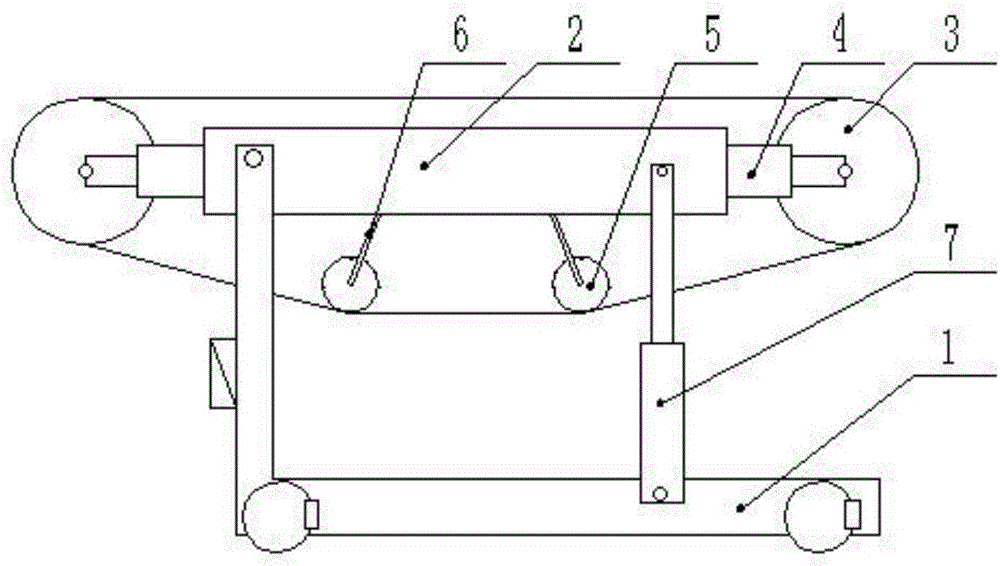

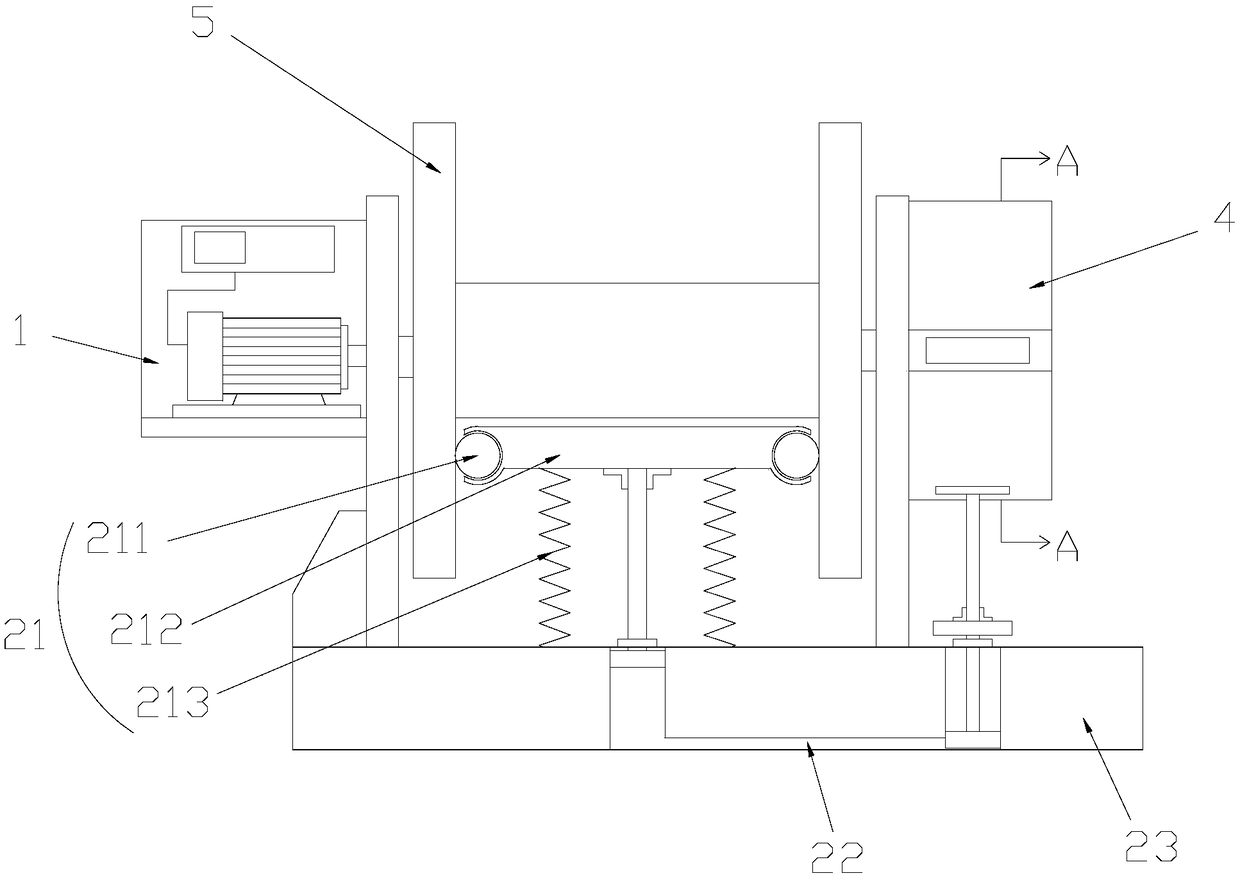

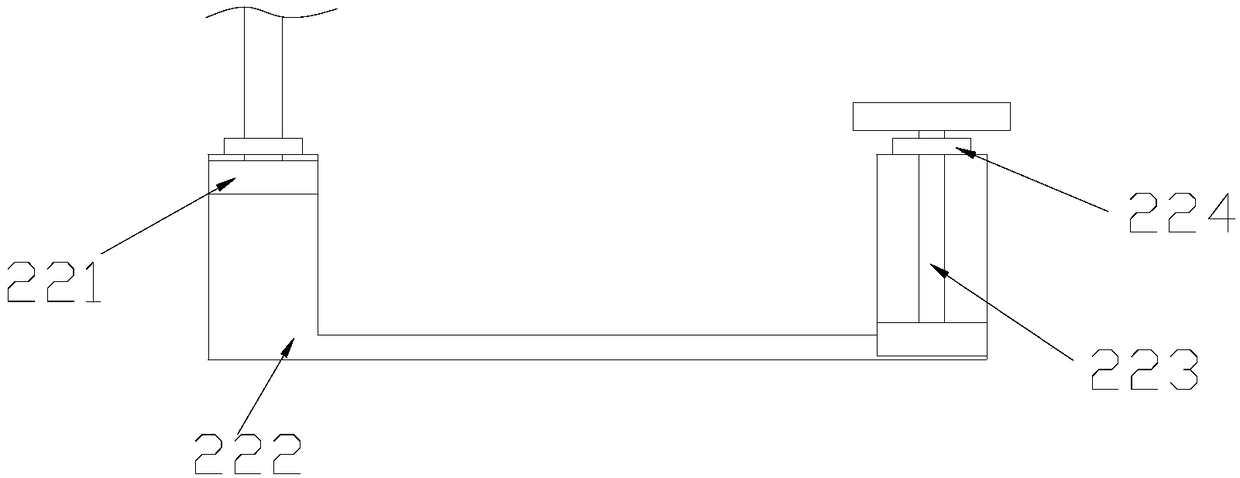

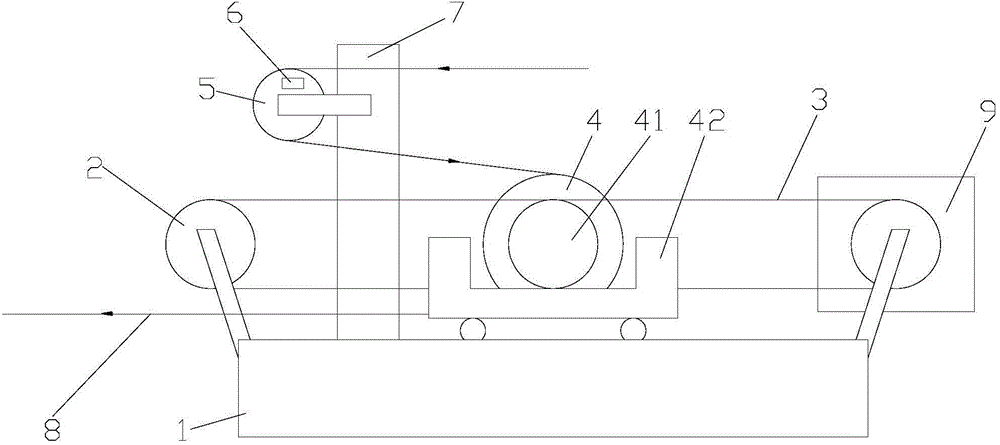

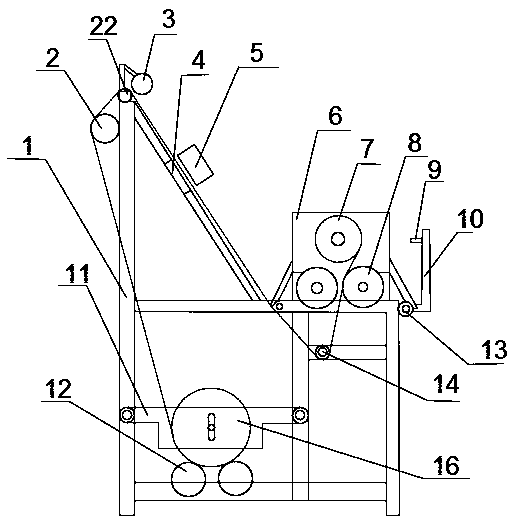

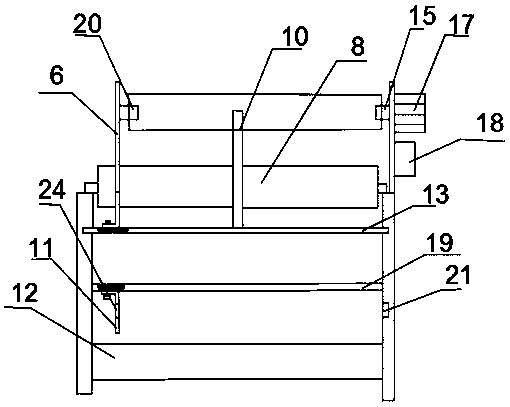

Adjustable conveyor

InactiveCN105836385ASimple structureUnchanged tensionConveyorsSupporting framesWorking environmentEngineering

The invention discloses an adjustable conveyor and belongs to the field of belt conveying. The problems that an existing conveyor cannot stretch or retract and the tension of a conveying belt is changed after stretching or retracting of the existing conveyor are solved. The adjustable conveyor comprises a machine frame, a mounting frame arranged on the machine frame, a telescopic rod arranged on the mounting frame, a roller arranged on the telescopic rod, a carrier belt set arranged on the lower portion of the mounting frame, a conveyor belt arranged on the roller and the carrier belt set, and a height rod arranged on the machine frame and the mounting frame. The upper end of the machine frame and the end of the mounting frame are connected through a hinge. The adjustable conveyor can ascend, descend, stretch and retract freely and can adapt to the working environments of different heights and depths; the working efficiency is improved, the structure of the existing conveyor is simplified, the lifting function and the stretching and retracting functions are integrated, and convenience is provided in the actual use; and besides, in the stretching and retracting process of the conveyor, the tension of the conveying belt basically keeps unchanged.

Owner:ANHI SHENGYUN HEAVY MACHINERY CO LTD

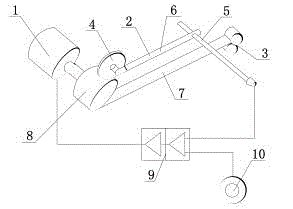

Cable extruder constant tension wire storing device utilizing magnetic effect

The invention discloses a cable extruder constant tension wire storing device utilizing the magnetic effect. The structure of the cable extruder constant tension wire storing device utilizing the magnetic effect comprises an electric driving structure, a cable detecting device, a winding reel fixing frame, a magnetic force adjusting device and a winding reel body. According to the wire storing device, due to the fact that the cable detecting device is matched with the magnetic force adjusting device, after extruding of a cable is completed, the cable is fixed into the winding reel body to be wound, along with slow increasing of the diameter of a cable wound wire coil, the cable detecting device can perform detection in time and resistance is generated through the magnetic force adjusting device so that the rotating speed of a motor is gradually lowered, and it is guaranteed that the cable tension is kept unchanged; and the situation that after the coil diameter becomes large, the angular speed of a winding reel does not change, consequently the tension of the cable is too large, the wire diameter of a wire becomes small in a pulling manner and even the wire is broken in a pulling manner is avoided, and the winding quality of the wire storing device is effectively improved.

Owner:SHANGHAI QINXUAN INFORMATION TECH CO LTD

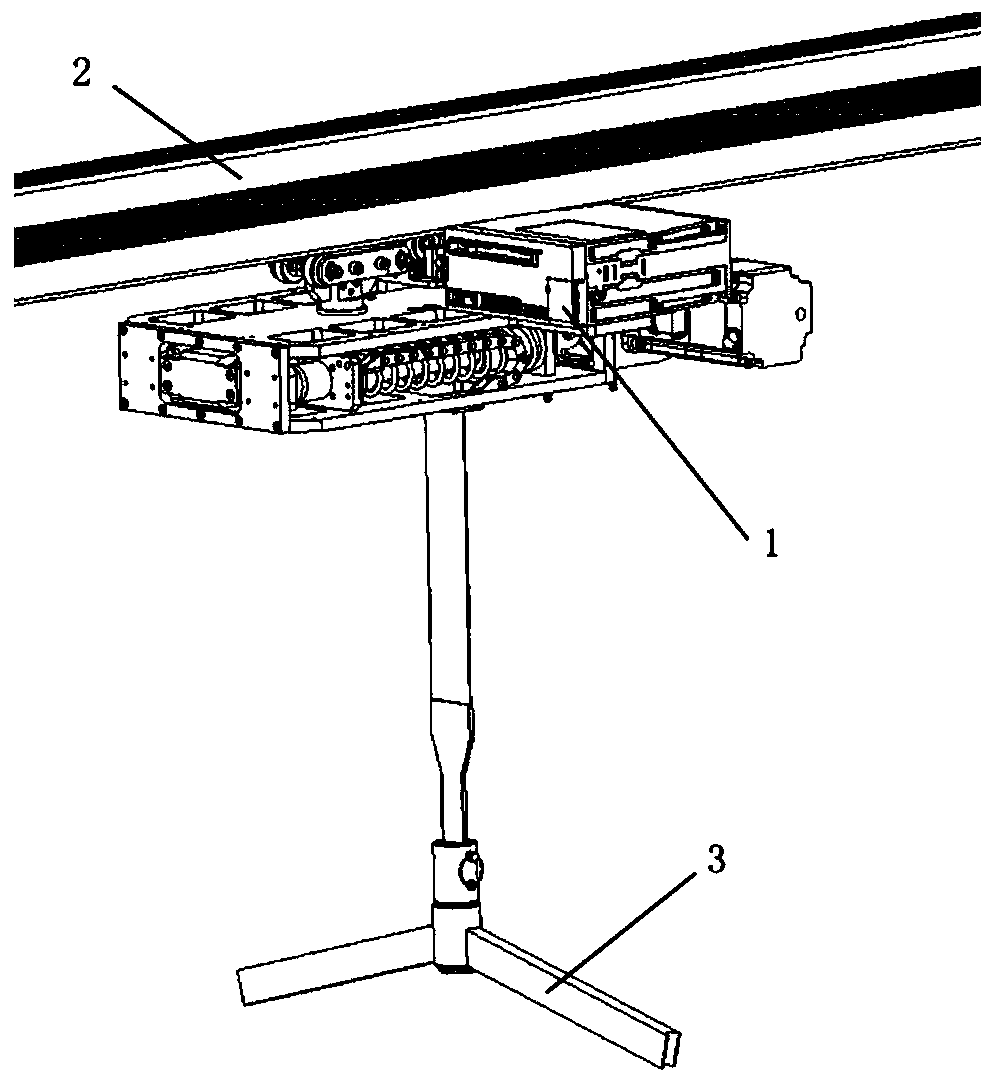

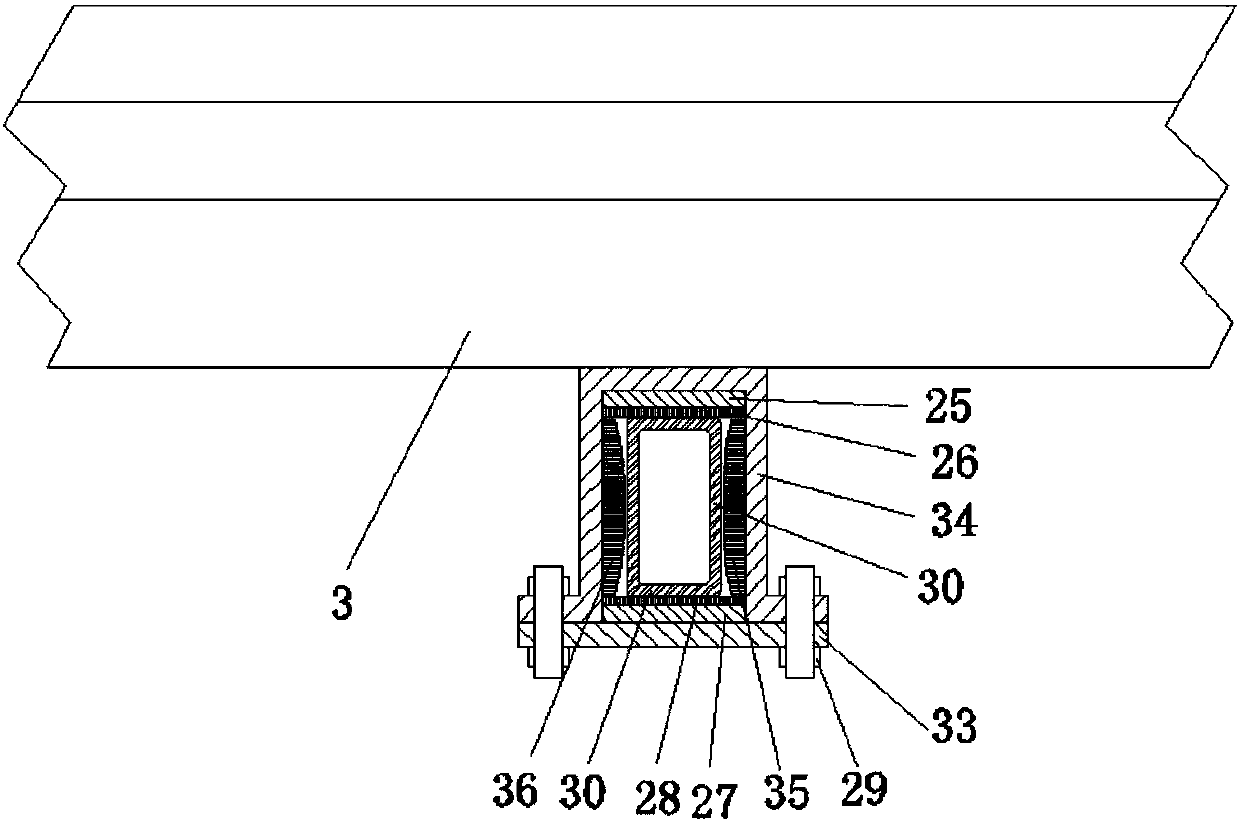

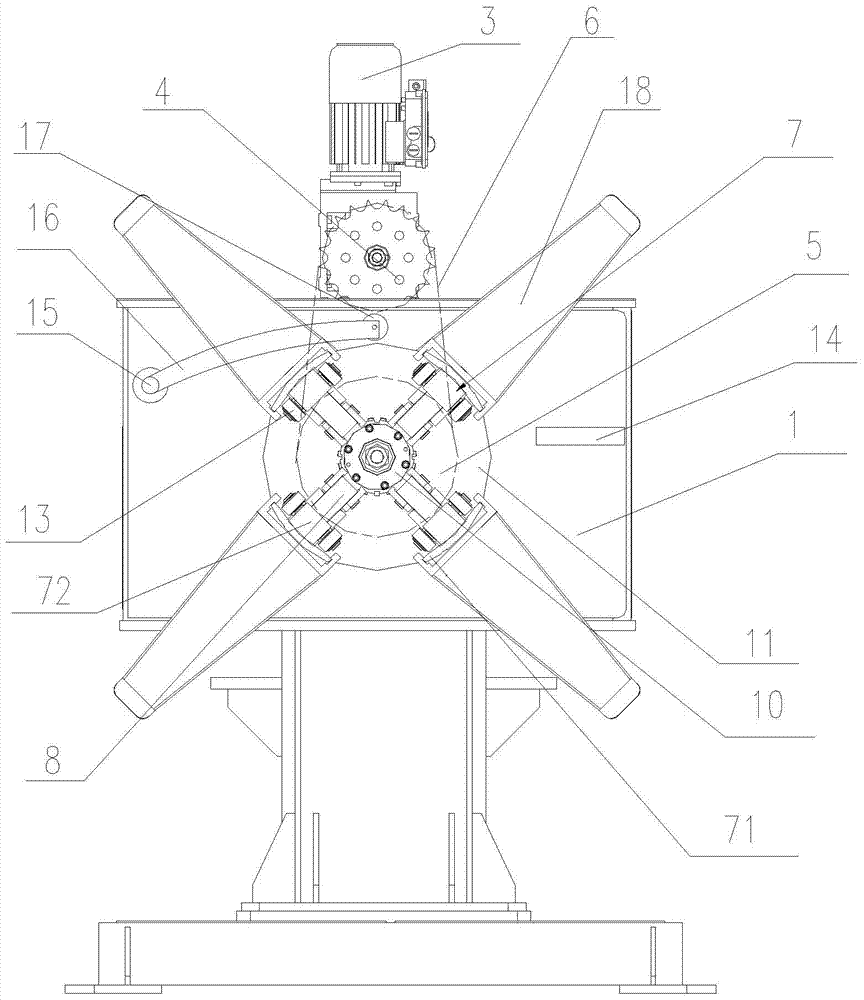

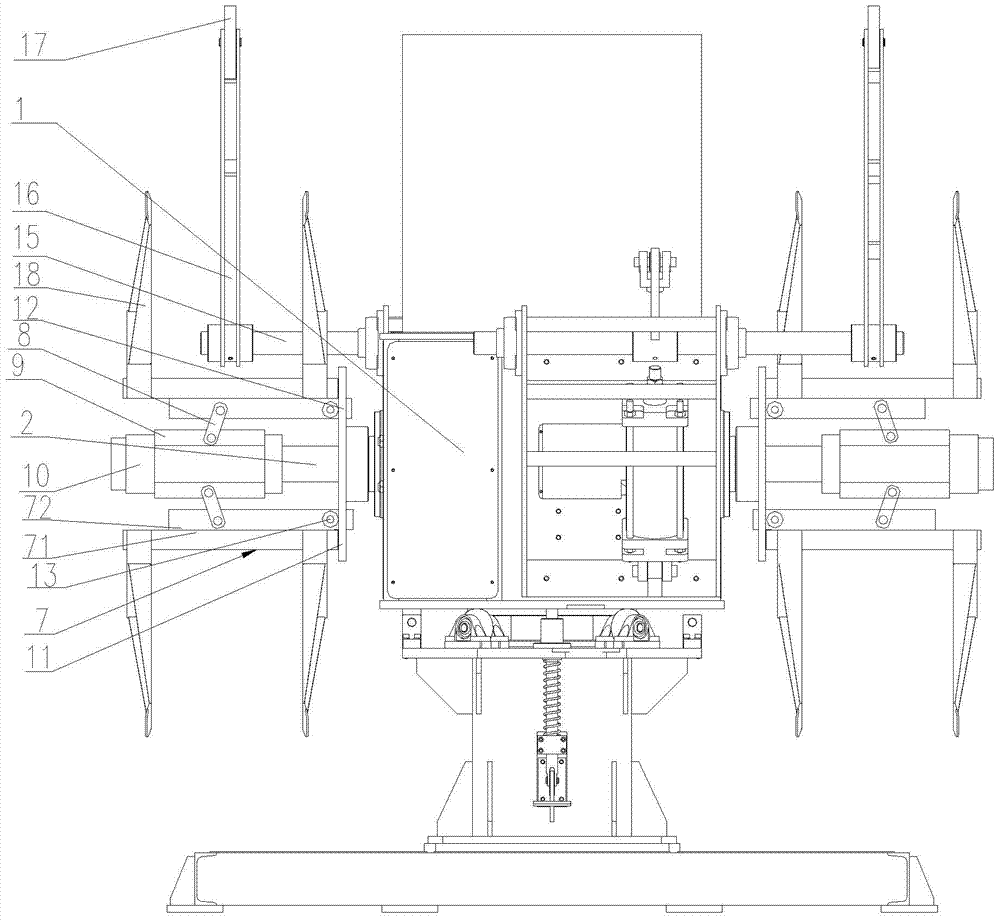

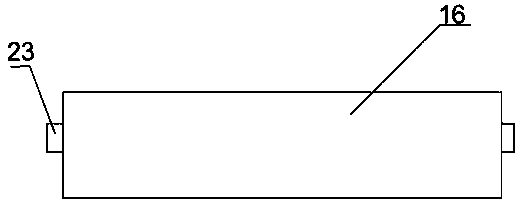

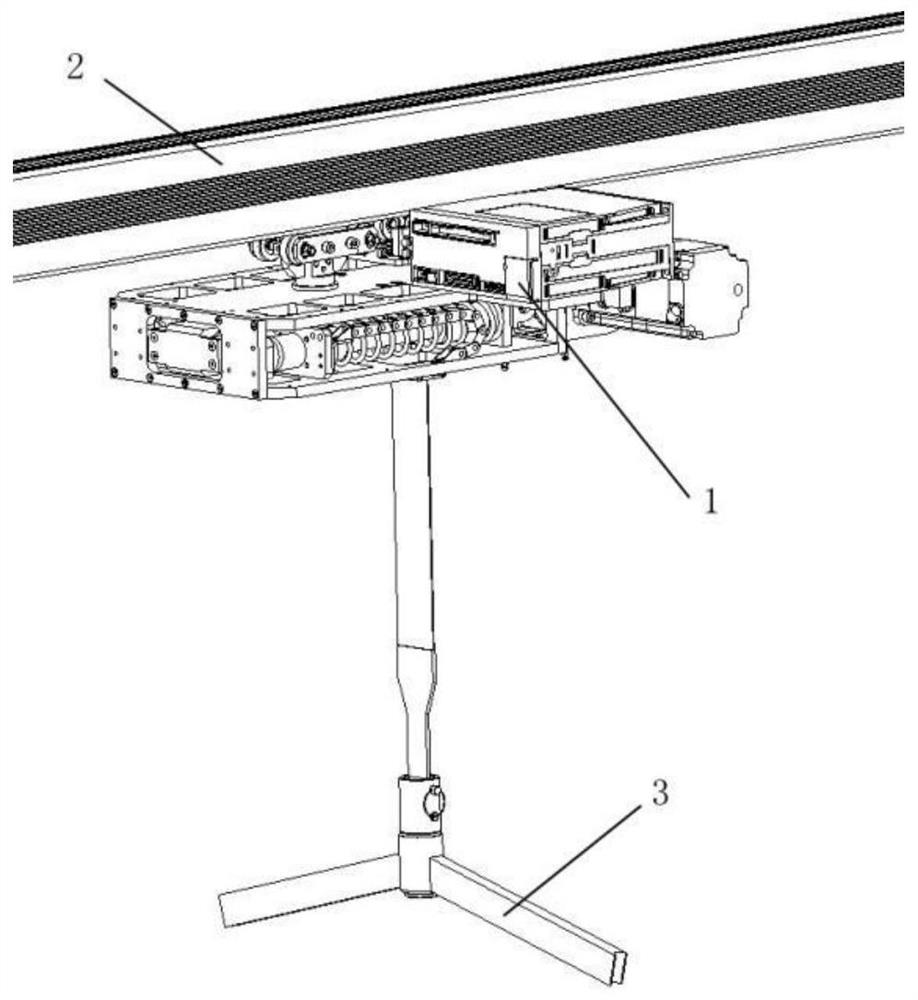

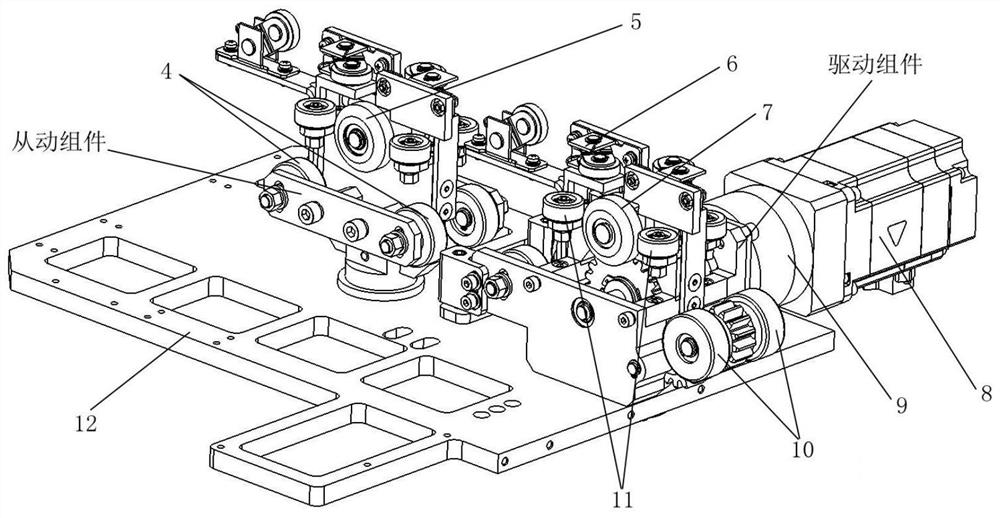

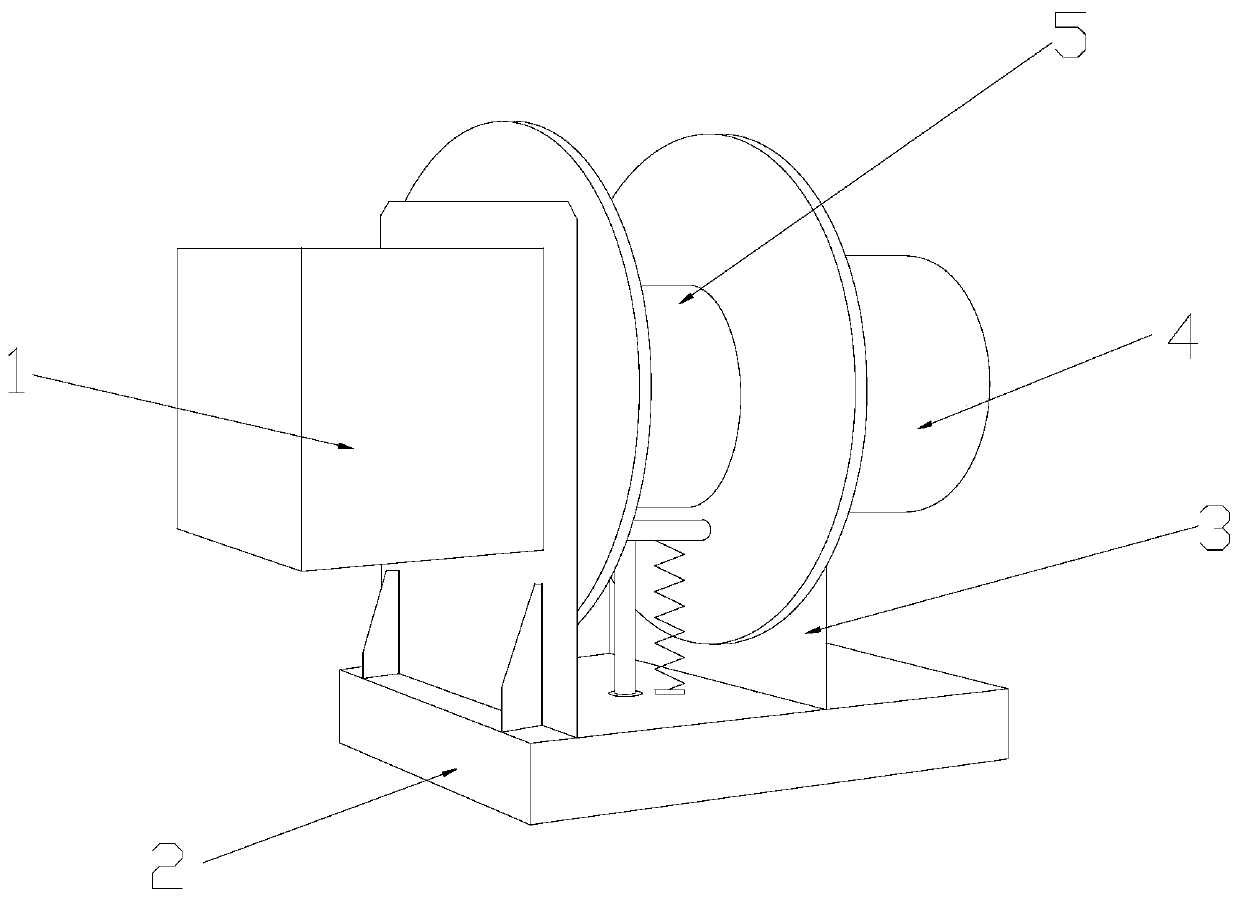

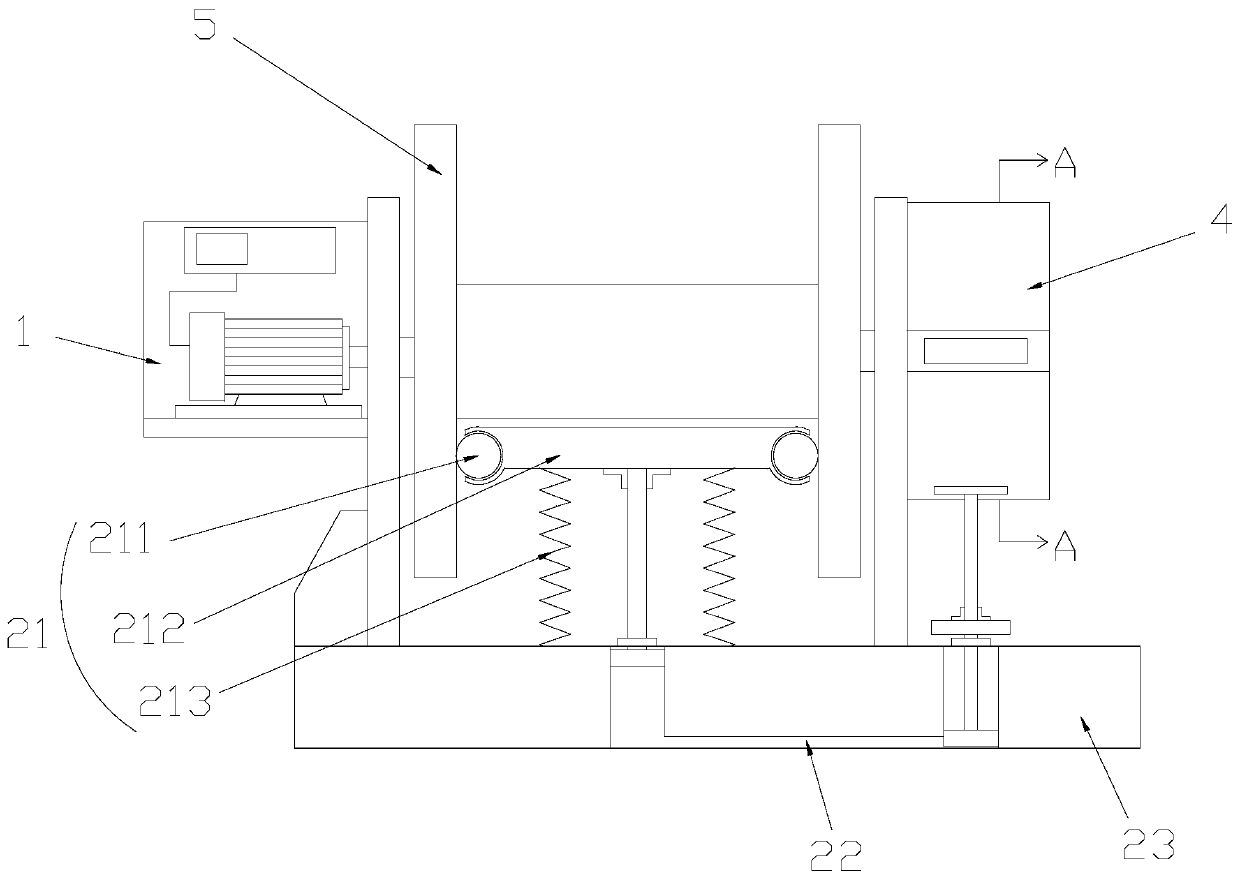

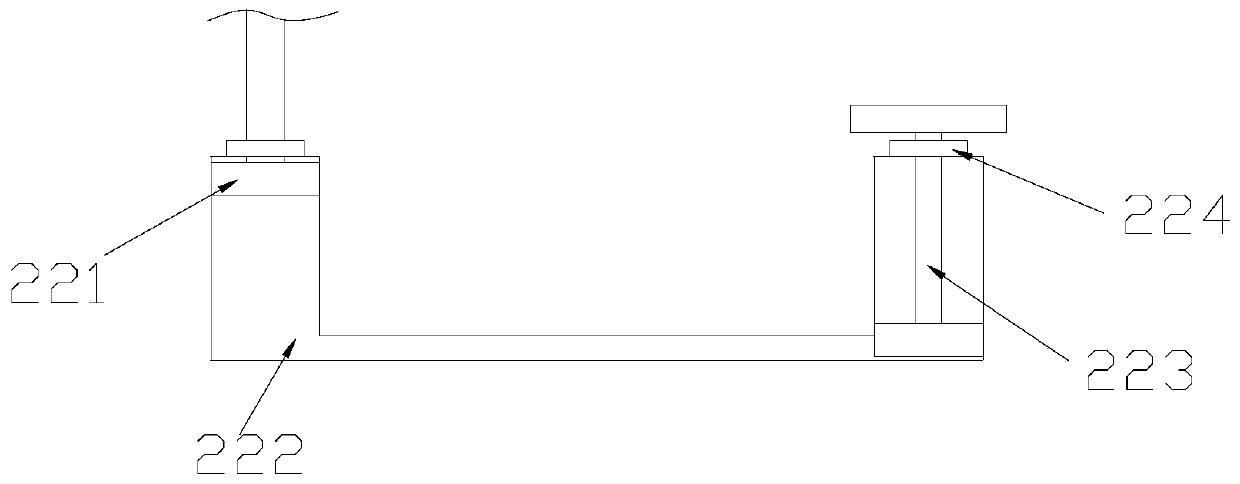

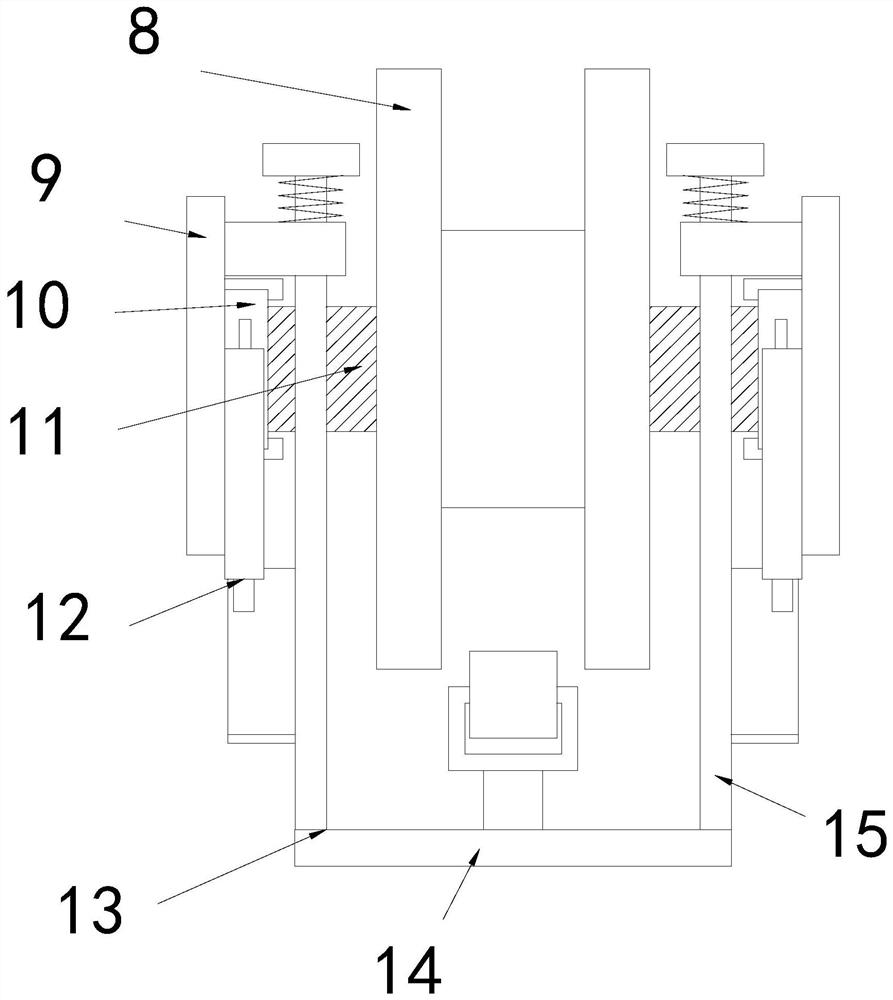

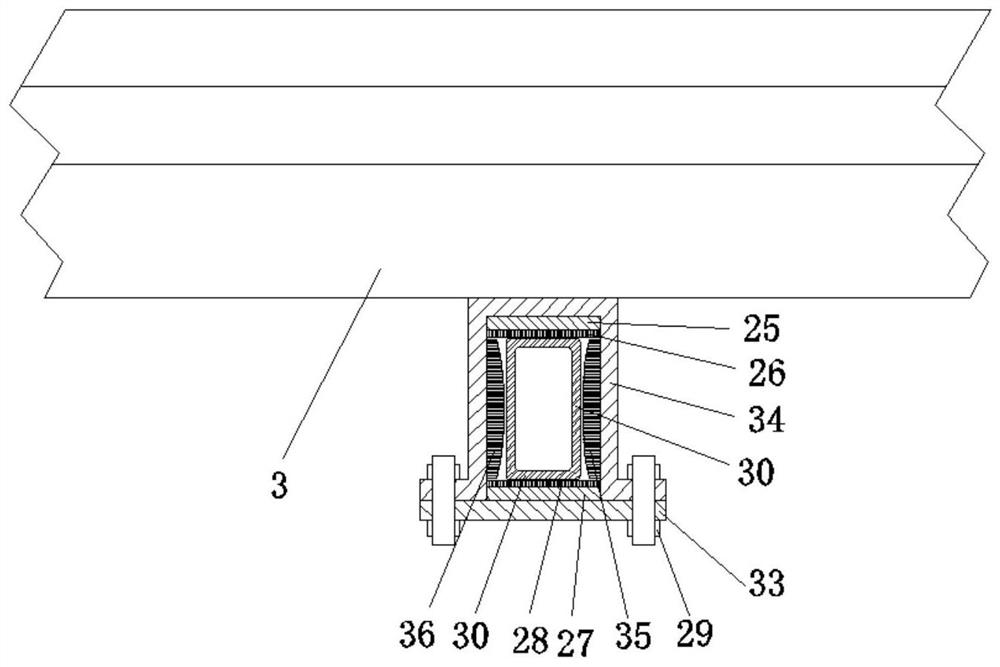

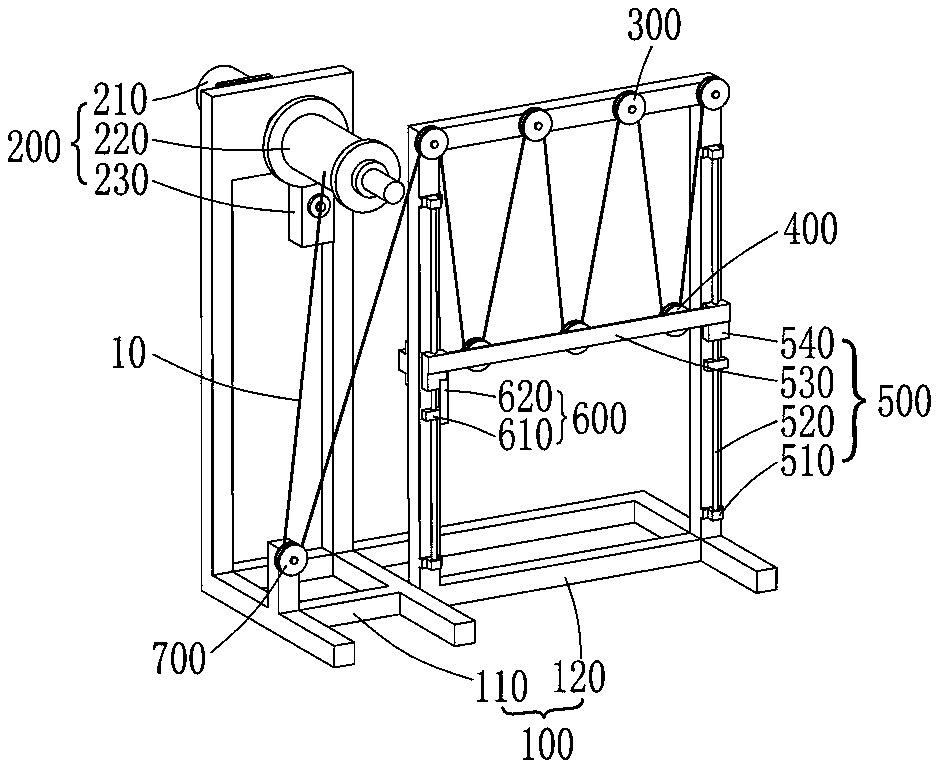

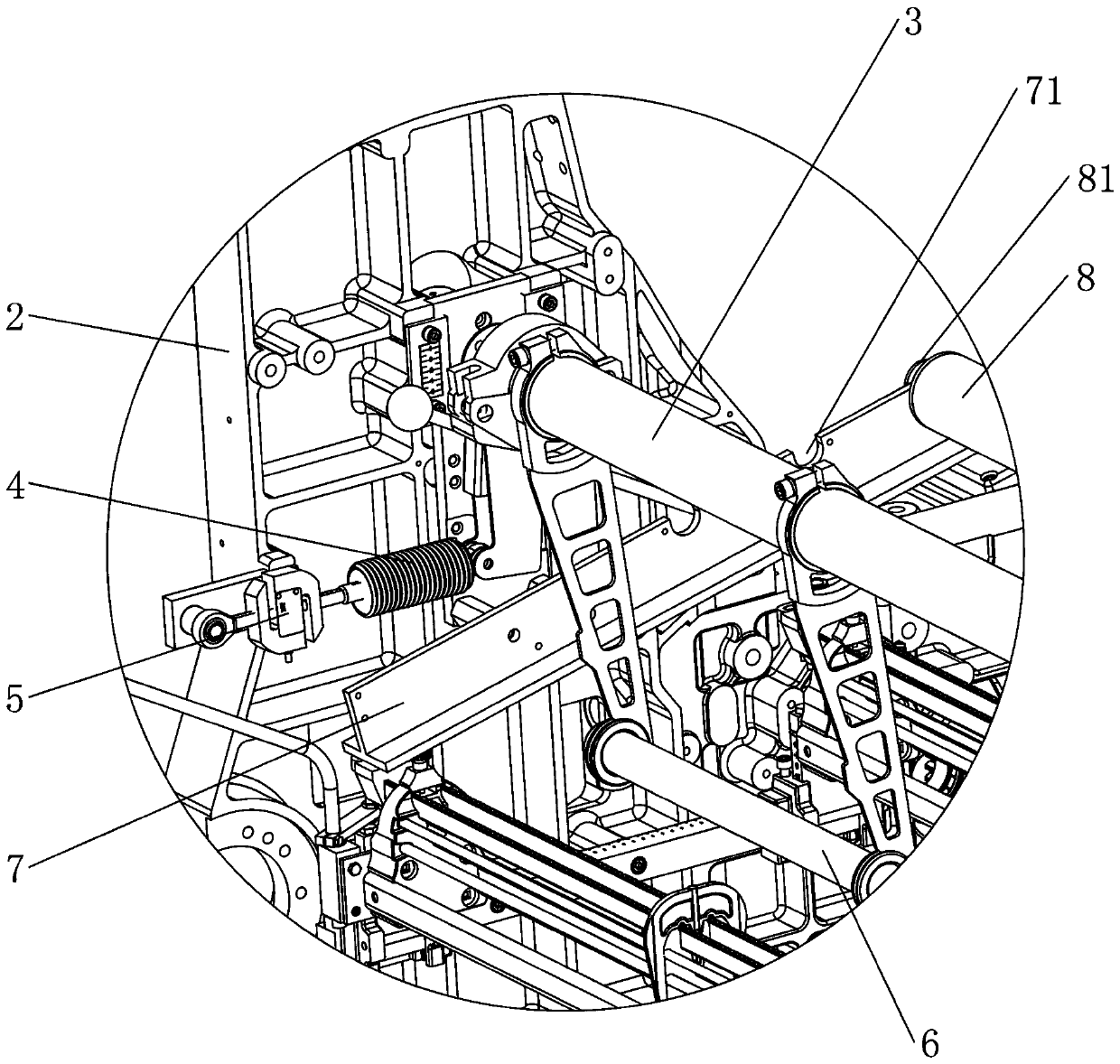

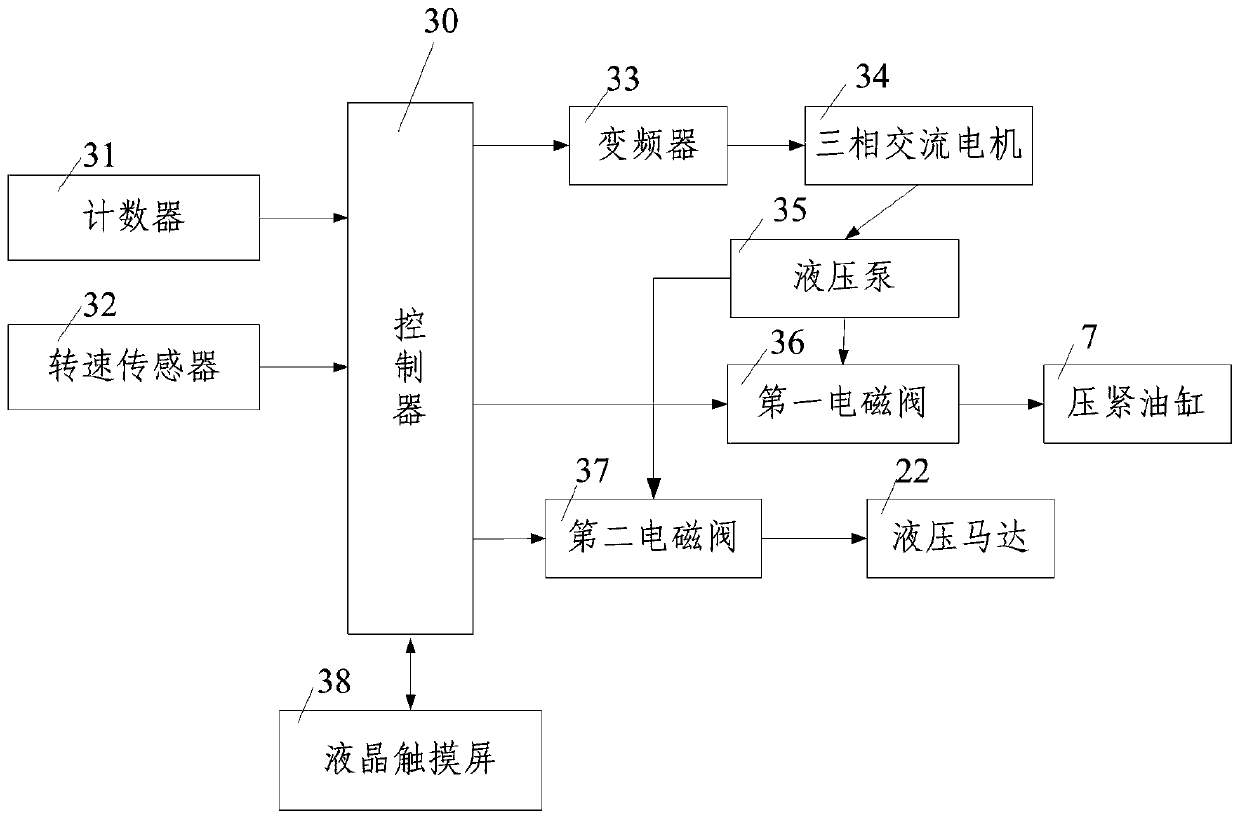

Walking training instrument for dynamic weight reduction

ActiveCN111150615AUnchanged tensionAchieve dynamic weight lossChiropractic devicesWalking aidsPhysical medicine and rehabilitationEngineering

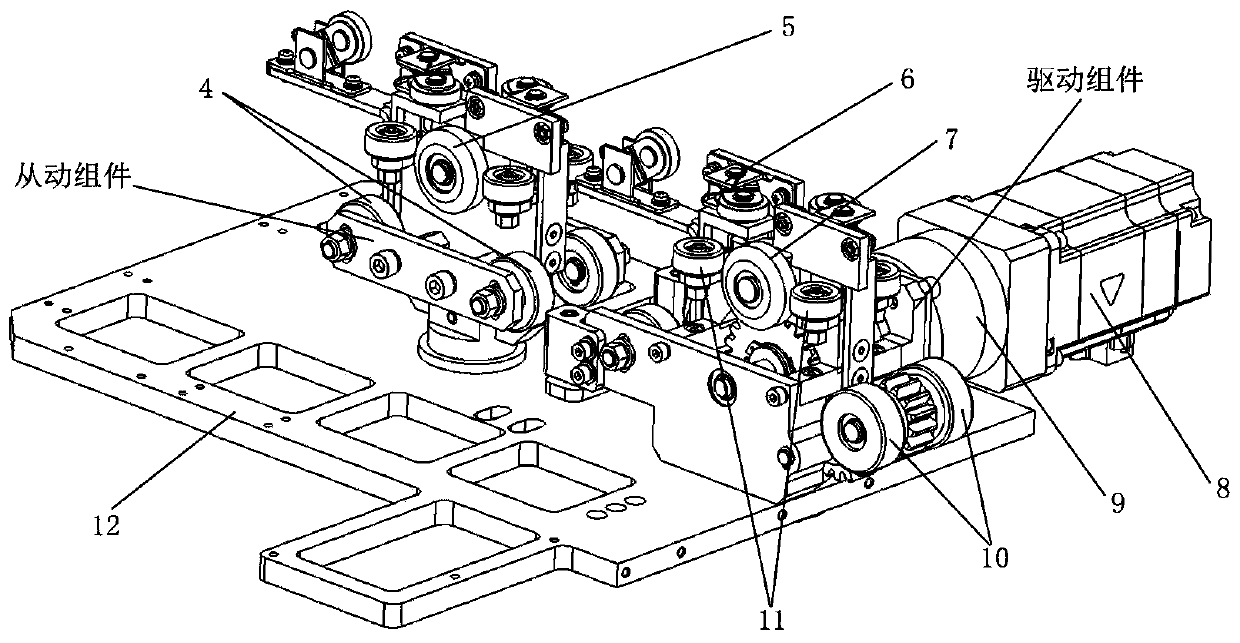

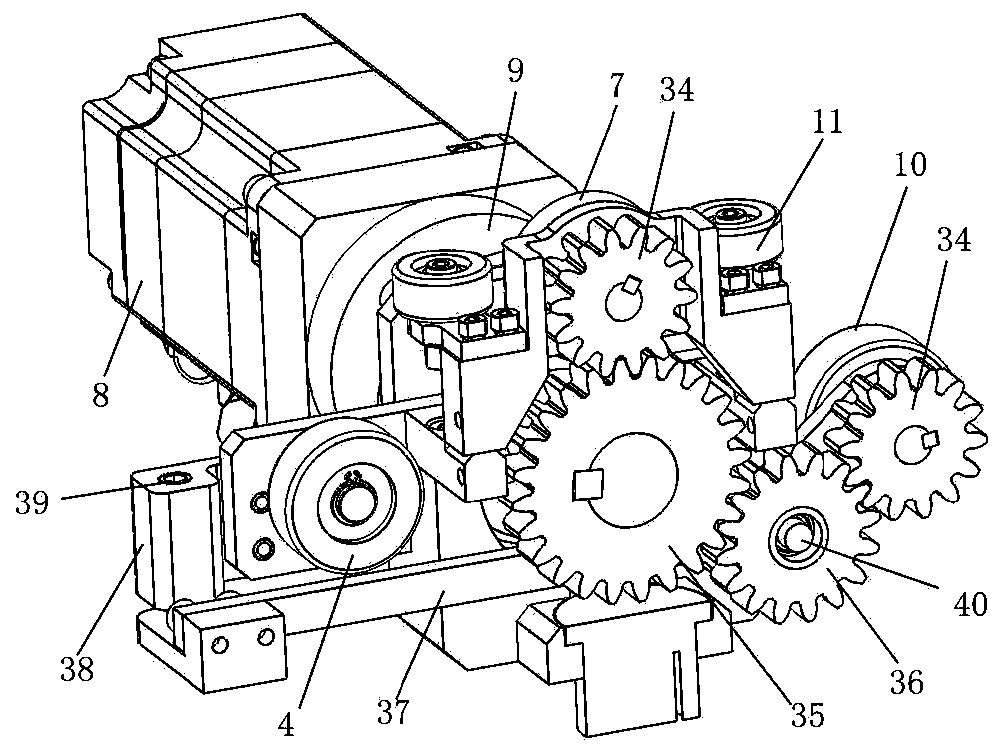

The invention discloses a walking training instrument for dynamic weight reduction. The walking training instrument comprises a machine head, a rail and a hanging stand, wherein the machine head comprises a walking assembly and a lower box body; the walking assembly is used for producing power and is walked along the rail, and a sling is arranged on the lower box body positioned at the bottom of the walking assembly; the other end of the sling is connected with the hanging stand; and the hanging stand is used for being connected with a patient, and a retractable sling can be used for realizingdynamic weight reduction of the patient during walking. According to the walking training instrument for dynamic weight reduction disclosed by the invention, requirements on walking training and transferring for the dynamic weight reduction can be met in a compact space, and quick vertical and horizontal motion in a large scale can be realized; and the walking training instrument has a simple structure, is attractive in appearance, is high in reliability, convenient to maintain, is high in intelligent degree, and can reduce the working pressure of therapists.

Owner:江苏绿柏智能科技有限公司

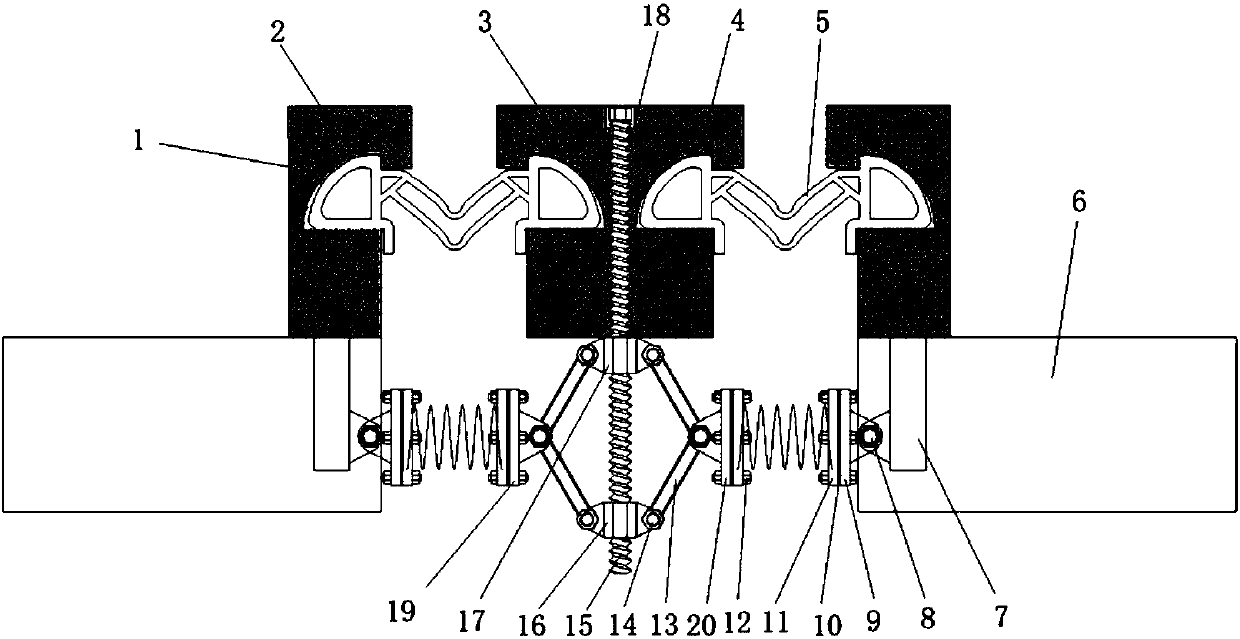

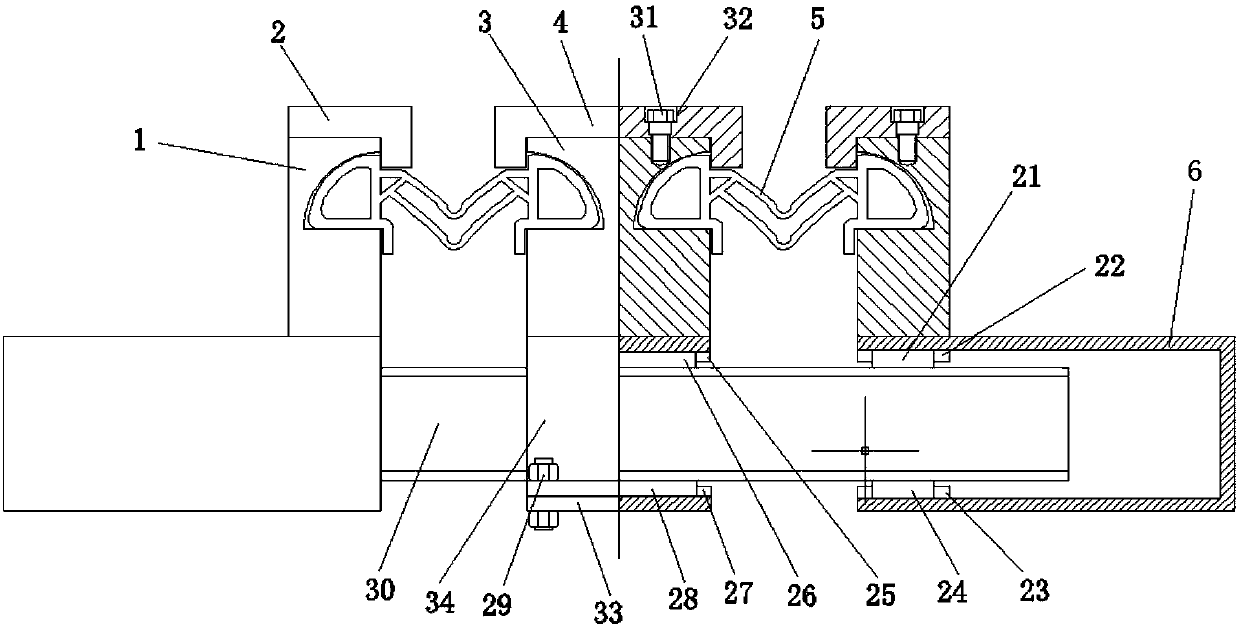

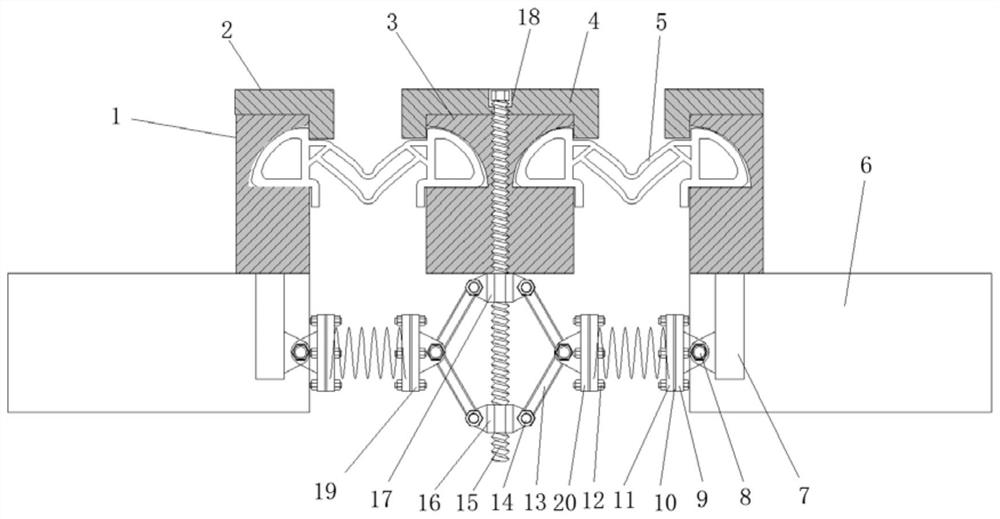

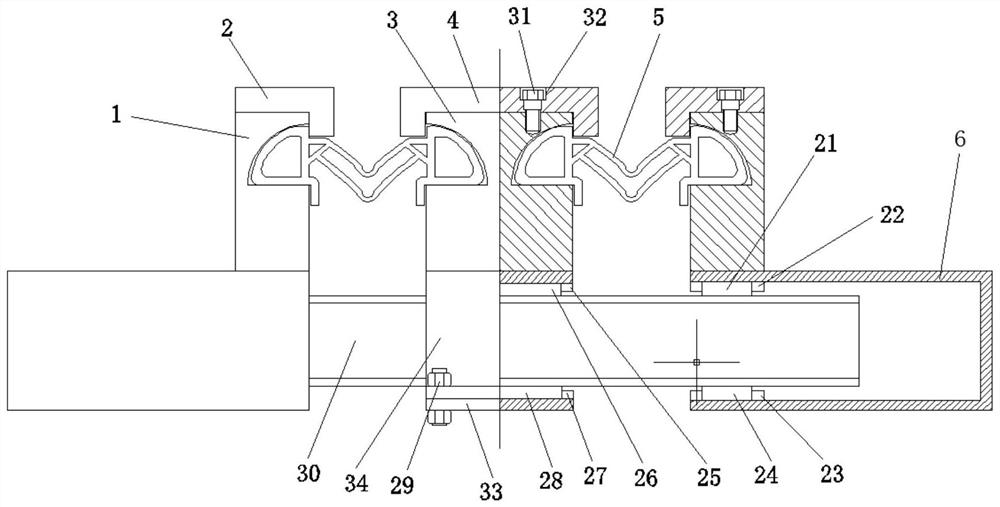

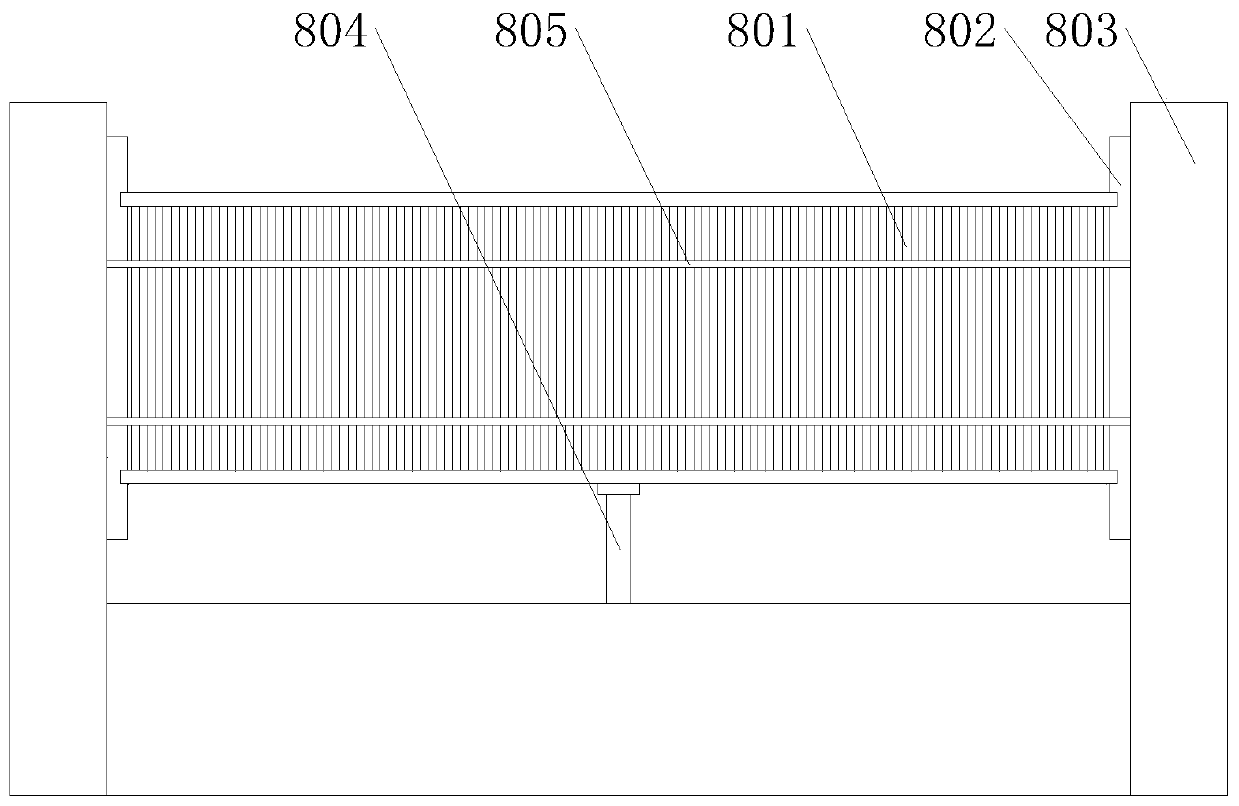

Assembly combination replaceable modular expansion device and preparation process thereof

ActiveCN109778687AEasy to replaceAvoid Structural CorrosionBridge structural detailsBridge materialsIndustrial engineeringBolt connection

The invention belongs to the technical field of bridge expansion devices, and discloses an assembly combination modular expansion device which is convenient to replace and a preparation and maintenance process thereof. The device includes a side beam assembly combination profiled steel and a middle beam assembly combination profiled steel, the bottom of a side beam is provided with a displacementcontrol box with a cross beam, the side beam and a middle beam and an adjacent middle beam are connected by a displacement transmission device, and a waterproof rubber strip is arranged; the displacement transmission device comprises a polyurethane spring and spring tension adjusters, the spring tension adjusters are disposed at the bottoms of each middle beam, the adjusters are provided with screw rods penetrating through the middle beams, the bottoms of the screw rods are provided with two upper and lower separated nuts, the left portions and the right portions of the two nuts are respectively connected by linking rods, one end of the polyurethane spring is hinged to the side beam, and the other end is in bolt connection with the spring tension adjusters. The expansion device can solve the degradation of the tension caused by the long-term use of a spring, and the expansion and deformation of the device are kept uniform at all times. The device can fully assemble all components, provide convenience for replacing partially damaged components and reduce maintenance costs.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

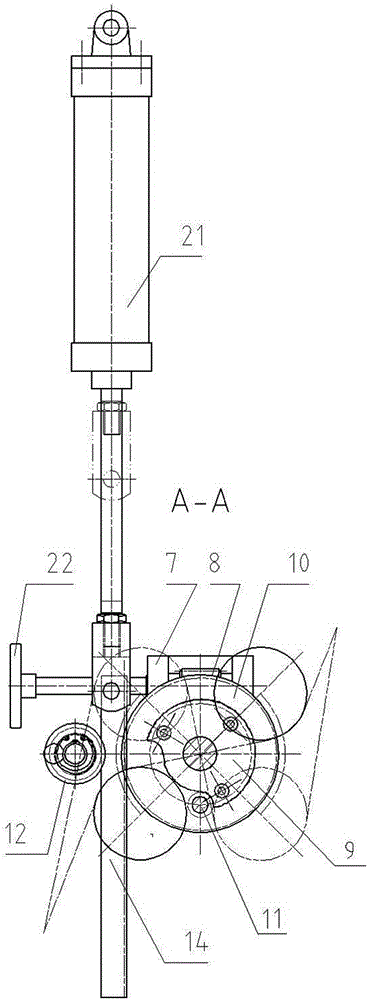

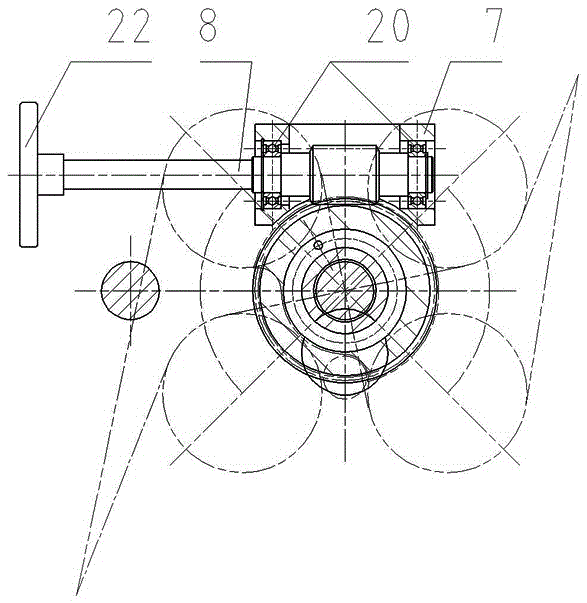

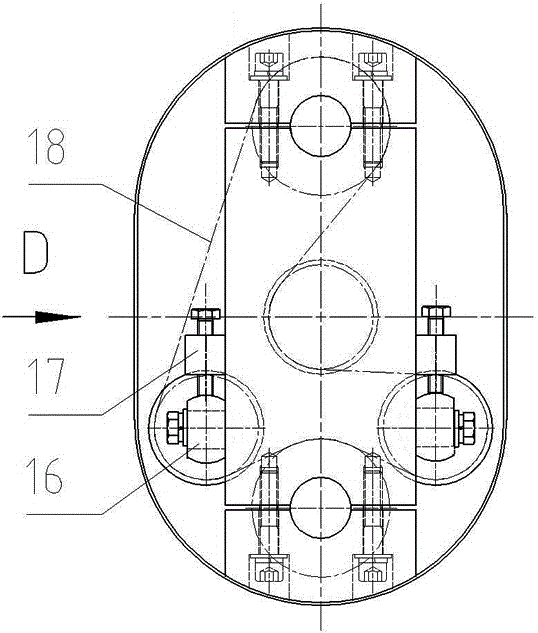

Strip uncoiler

ActiveCN105312355BReduce labor intensityUnchanged tensionShaping safety devicesMotor driveElectric machinery

The invention relates to a steel strip uncoiler, comprising an uncoil frame, a central shaft installed on the uncoil frame and free to rotate on the uncoil frame, and a power input device for controlling the rotation of the mandrel, the central shaft is far away from the coil A supporting body is arranged circumferentially on one side of the frame. On the premise of ensuring constant tension of the uncoiling steel strip, the present invention has simple structure, stable and reliable operation, and maintenance-free. In addition, when threading the steel strip in manual mode, the motor drives the central shaft to rotate by controlling the forward or reverse rotation of the motor, and the central shaft The upper steel belt advances or retreats instead of manually dragging the steel belt, which greatly reduces the labor intensity of the operator.

Owner:NANJING BANKNOTE MINTING +1

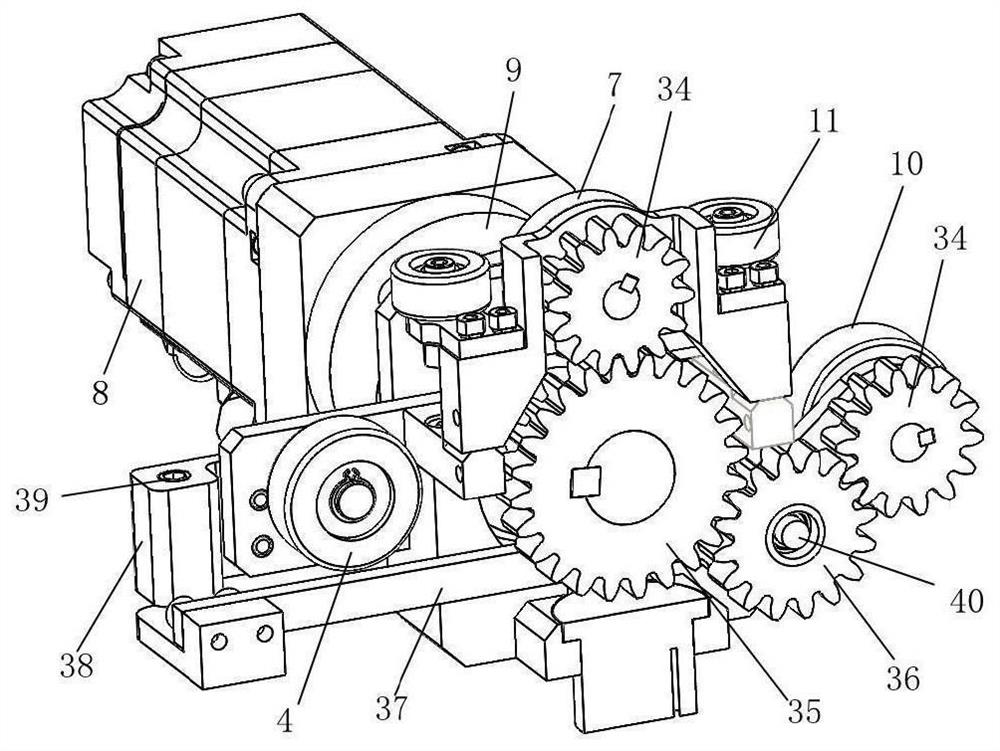

Cable-forming machine by utilizing centrifugal adjustment tension

ActiveCN110391055AAvoid Serpentine SituationsImprove processing qualityCable/conductor manufactureEngineeringLeather belt

The invention discloses a cable-forming machine by utilizing centrifugal adjustment tension. The structure of the cable-forming machine comprises a control panel, a belt drive shaft, a drive gear box,a cable traction disk and a cable cradle frame. Through the combination of a speed regulator and a pre-twist structure, the residual lengths of the cable are different, the cable disks can be outputat different rotation speeds in the cable output twisting process, so that the output lengths of the two cable disks can be ensured to be consistent, the tensions of cable output is unchanged, and thecondition is avoided the cable heights output by the two cable disks are different to cause the hunch-up of the cables in the twisting process and generation of the snake shapes of the cables; and moreover, the pre-twist operation is performed in the cable output process to reduce the condition that the twisting angles are different due to friction in the cable twisting process to generate hunch-up and improve the cable processing quality.

Owner:诸暨市友利针纺织有限公司

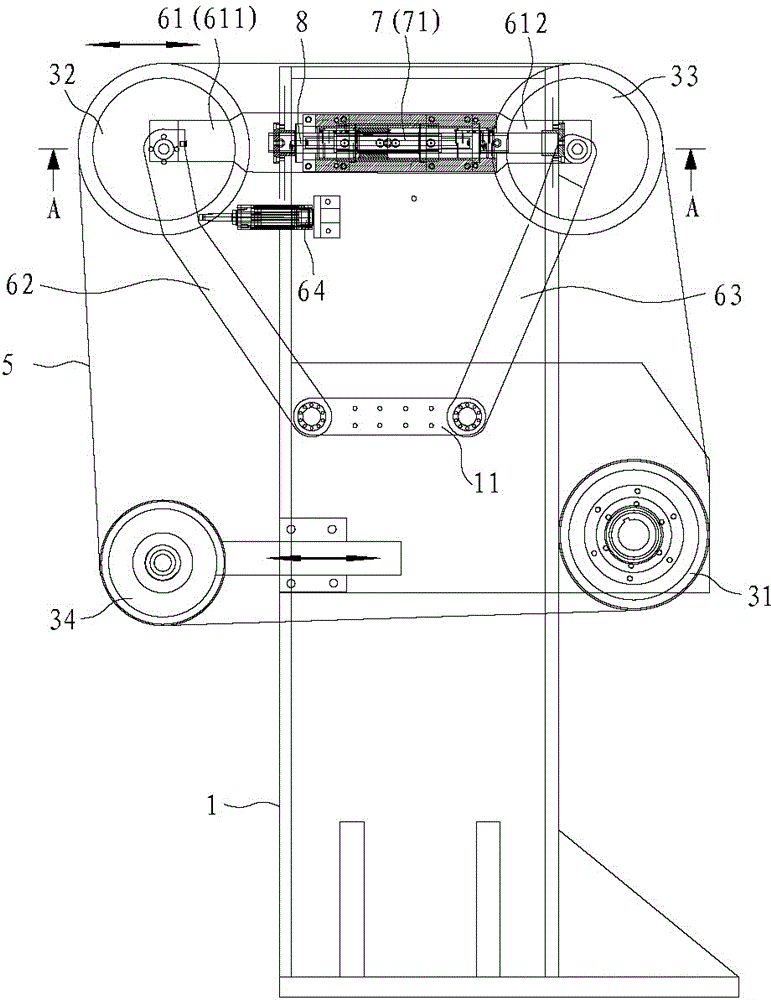

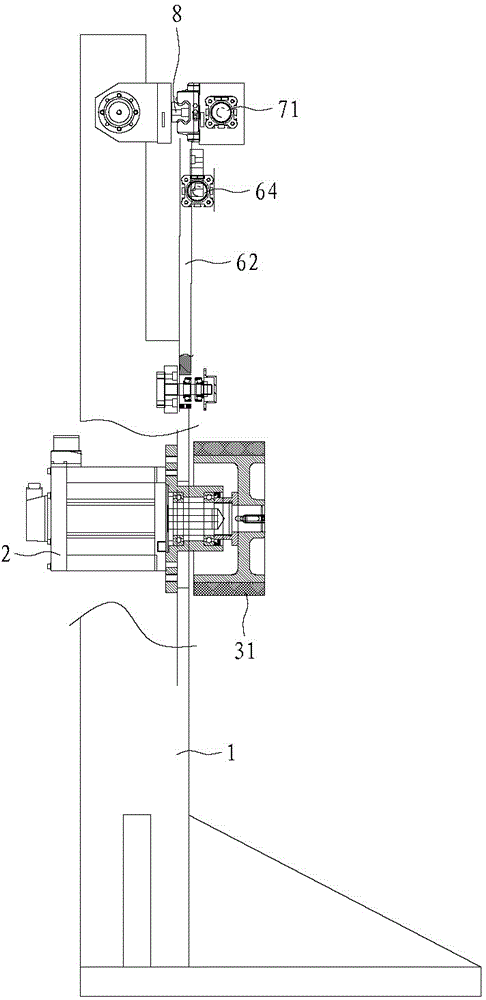

Electric moving type dance roll tension adjusting equipment for cold-rolling strip steel

InactiveCN104438357AKeep strip tension constantImprove production qualityMeasuring devicesTension/compression control deviceSprocketSpeed reduction

Owner:合肥市伟远金属材料有限公司

Chain tensioning device with adjustable tensioning force

Owner:重庆众思创智能科技有限公司

Cloth rolling machine

PendingCN108946260AUnchanged tensionGuaranteed smoothArticle deliveryWebs handlingPulp and paper industryCotton material

The invention discloses a cloth rolling machine. The cloth rolling machine comprises a machine frame, a cloth placing roller, a winding roller and a motor, wherein the cloth placing roller is arrangedon the left side of the bottom of the machine frame, clamping blocks are fixedly connected to the two ends of the cloth placing roller, a first partition plate is arranged on one side of the cloth placing roller, the upper end of the first partition plate is in threaded connection with a first cross rod, the two ends of the first cross rod are fixedly connected to the bottom of the machine frame,a first clamping groove is formed in the first partition plate, a second clamping groove is formed in the joint of the cloth placing roller and the machine frame, and clamping blocks at the two endsof the cloth placing roller sleeve the first clamping groove and the second clamping groove respectively. The cloth rolling machine is simple in structure and can roll cloth with different thicknessesand widths, and the rolled cloth is flat and is free of wrinkles.

Owner:湖州南浔润欣纺织有限责任公司

A dynamic weight loss walking training device

ActiveCN111150615BUnchanged tensionAchieve dynamic weight lossChiropractic devicesWalking aidsPhysical medicine and rehabilitationEngineering

The invention discloses a dynamic weight-reducing walking training instrument, which includes a machine head, a track and a hanger. The machine head includes a walking assembly and a lower box. The walking assembly is used to generate power and walk along the track. The lower box is located at the bottom of the walking assembly. A sling is arranged on the top; the other end of the sling is connected with a hanger, the hanger is used for connecting and using the patient, and the retractable sling is used for realizing dynamic weight loss when the patient walks. The dynamic weight loss walking training device can meet the needs of dynamic weight loss walking training and transfer in a compact space, and can realize a wide range of rapid vertical and horizontal movements. It has a simple structure, beautiful appearance, high reliability, easy maintenance, and intelligence. High degree of automation can reduce the work pressure of the therapist.

Owner:江苏绿柏智能科技有限公司

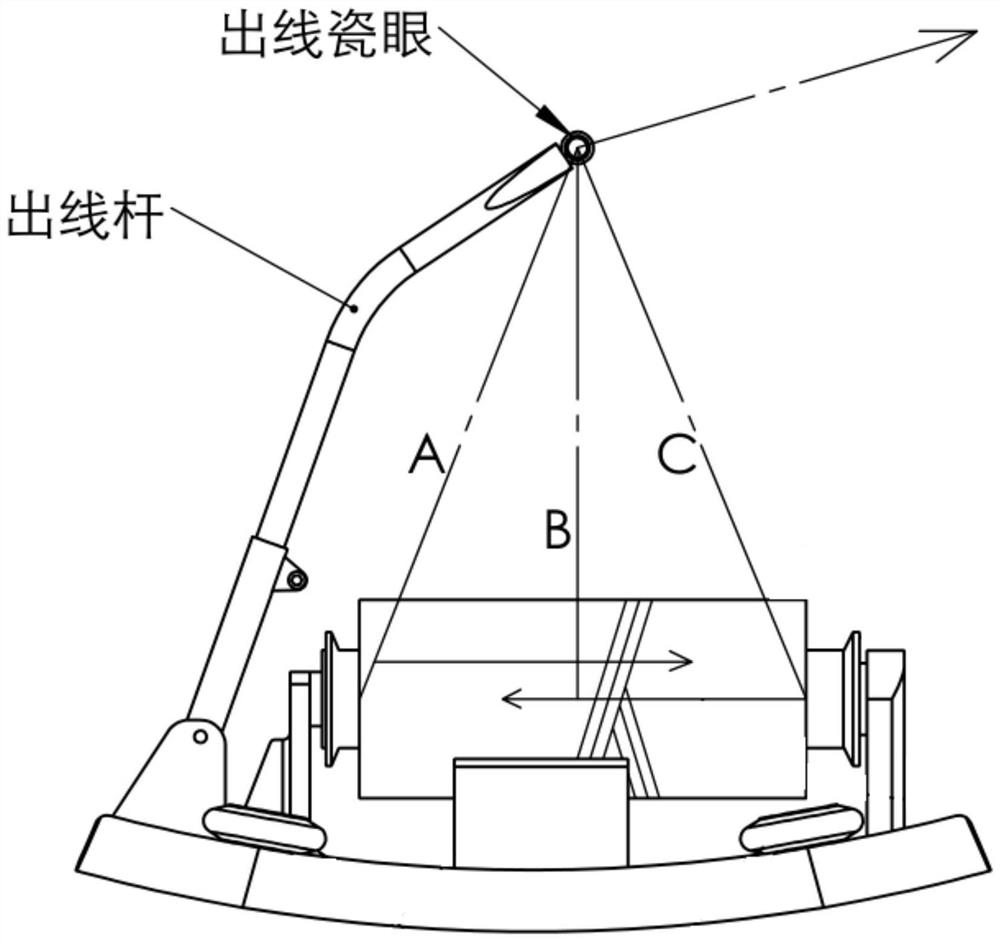

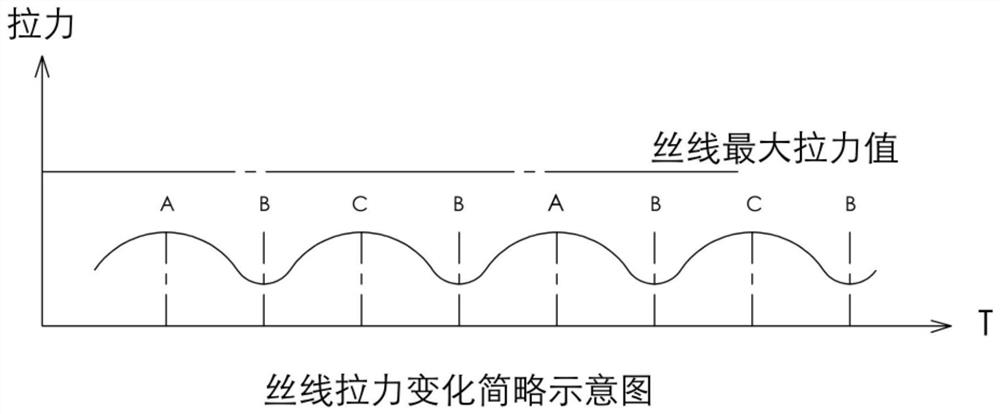

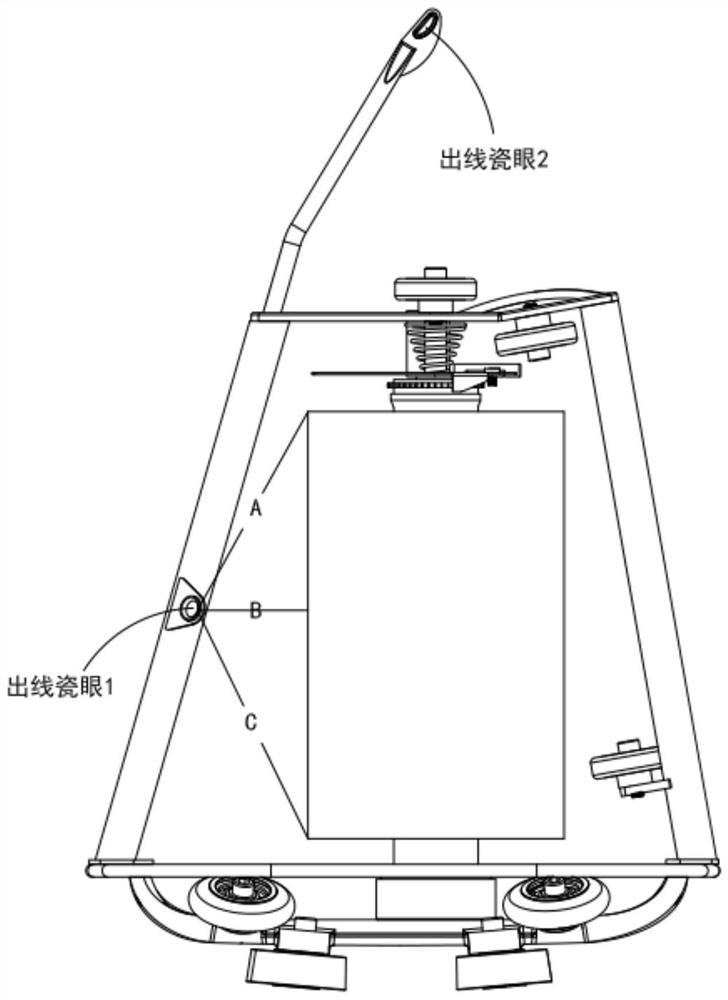

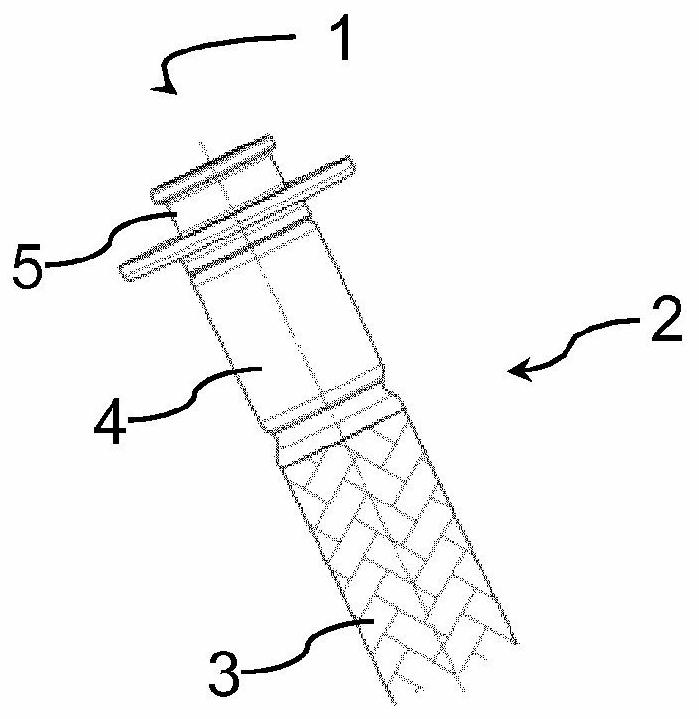

Tension balance type flying shuttle and balance assembly

The invention discloses a tension balance type flying shuttle and a balance assembly. The tension balance type flying shuttle includes a frame body, wherein the frame body is provided with a porcelain eye and a yarn shaft used for mounting a yarn roll, the tension balance type flying shuttle further includes the balance assembly, the balance assembly includes a balance plate, the balance plate is provided with a cambered surface, silk yarn is led out from yarn outlet points of the yarn roll, the silk yarn passes through the cambered surface and then reaches the porcelain eye, and due to the cambered surface, the lengths of the silk yarn from any yarn outlet point of the yarn roll to the porcelain eye are equal. According to the tension balance type flying shuttle and the balance assembly provided by the invention, the tension of the silk yarn can be basically kept unchanged after the yarn outlet point is continuously changed, so that the silk yarn is not easy to break.

Owner:东莞市震天实业投资有限公司

Glass fiber yarn constant-tension pay-off device

The invention discloses a glass fiber yarn constant-tension pay-off device which comprises a feed wheel, a roller and an electronic control unit. The feed wheel is connected with roller through a tension testing belt. A sensor is connected between the roller and the tension testing belt. The roller is connected with a brake. The sensor is connected with the electronic control unit which is connected with the brake and a torque control rotary knob. The glass fiber yarn constant-tension pay-off device is simple in structure and convenient to use; the tension of glass fiber yarn is tested through the tension testing belt, the brake is controlled through the torque control rotary knob according to the pay-off tension of the glass fiber yarn, and the tension is kept unchanged.

Owner:SHANGHAI QISHAN INSTR TECH

A constant tension wire storage device for cable extruder using magnetic effect

The invention discloses a cable extruder constant tension wire storing device utilizing the magnetic effect. The structure of the cable extruder constant tension wire storing device utilizing the magnetic effect comprises an electric driving structure, a cable detecting device, a winding reel fixing frame, a magnetic force adjusting device and a winding reel body. According to the wire storing device, due to the fact that the cable detecting device is matched with the magnetic force adjusting device, after extruding of a cable is completed, the cable is fixed into the winding reel body to be wound, along with slow increasing of the diameter of a cable wound wire coil, the cable detecting device can perform detection in time and resistance is generated through the magnetic force adjusting device so that the rotating speed of a motor is gradually lowered, and it is guaranteed that the cable tension is kept unchanged; and the situation that after the coil diameter becomes large, the angular speed of a winding reel does not change, consequently the tension of the cable is too large, the wire diameter of a wire becomes small in a pulling manner and even the wire is broken in a pulling manner is avoided, and the winding quality of the wire storing device is effectively improved.

Owner:SHANGHAI QINXUAN INFORMATION TECH CO LTD

A Ribbon Processing Fixed Width Unwinding Device

Owner:东莞广上运动用品有限公司

An assembly-combined replaceable modular telescopic device and its preparation process

ActiveCN109778687BUniform expansion and deformationOffset frictionBridge structural detailsBridge materialsClassical mechanicsEngineering

The invention belongs to the technical field of bridge expansion devices, and discloses an assembly combination modular expansion device which is convenient to replace and a preparation and maintenance process thereof. The device includes a side beam assembly combination profiled steel and a middle beam assembly combination profiled steel, the bottom of a side beam is provided with a displacementcontrol box with a cross beam, the side beam and a middle beam and an adjacent middle beam are connected by a displacement transmission device, and a waterproof rubber strip is arranged; the displacement transmission device comprises a polyurethane spring and spring tension adjusters, the spring tension adjusters are disposed at the bottoms of each middle beam, the adjusters are provided with screw rods penetrating through the middle beams, the bottoms of the screw rods are provided with two upper and lower separated nuts, the left portions and the right portions of the two nuts are respectively connected by linking rods, one end of the polyurethane spring is hinged to the side beam, and the other end is in bolt connection with the spring tension adjusters. The expansion device can solve the degradation of the tension caused by the long-term use of a spring, and the expansion and deformation of the device are kept uniform at all times. The device can fully assemble all components, provide convenience for replacing partially damaged components and reduce maintenance costs.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

A floating sanding machine

ActiveCN103240658BRealize floating sanding and polishingOvercome the disadvantage of poor floating effectBelt grinding machinesGrinding wheelPiston rod

Owner:XIAMEN LOTA INT CO LTD

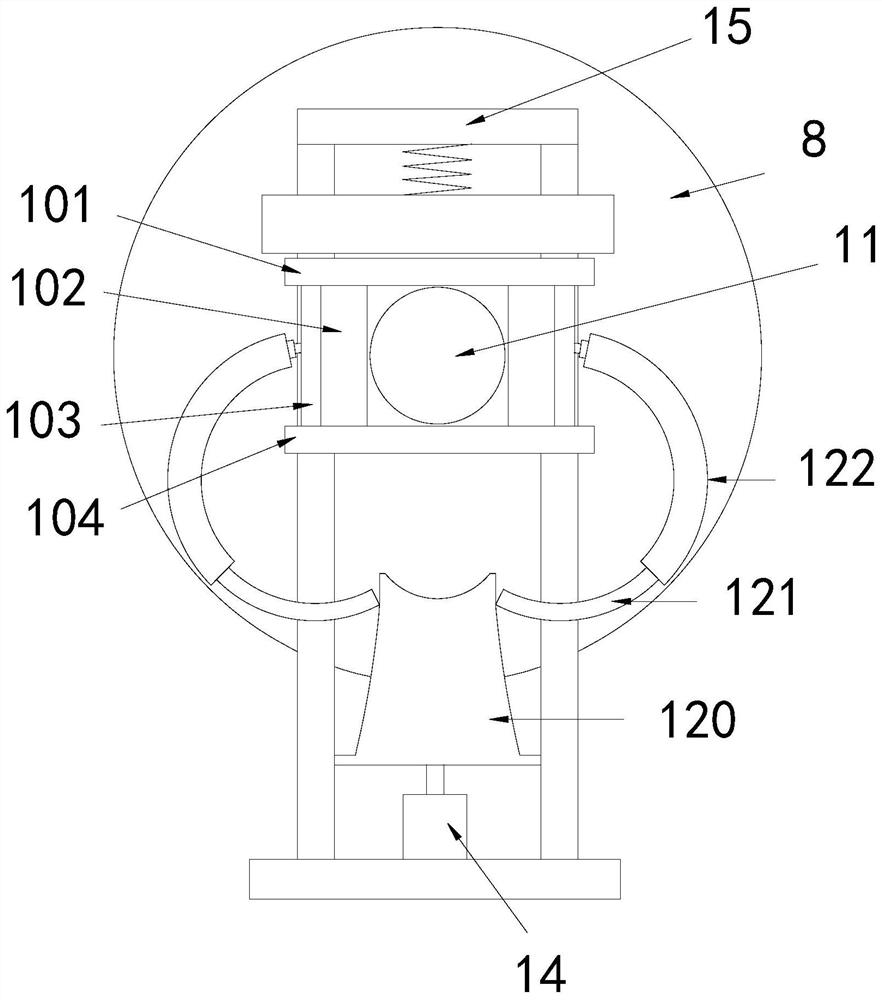

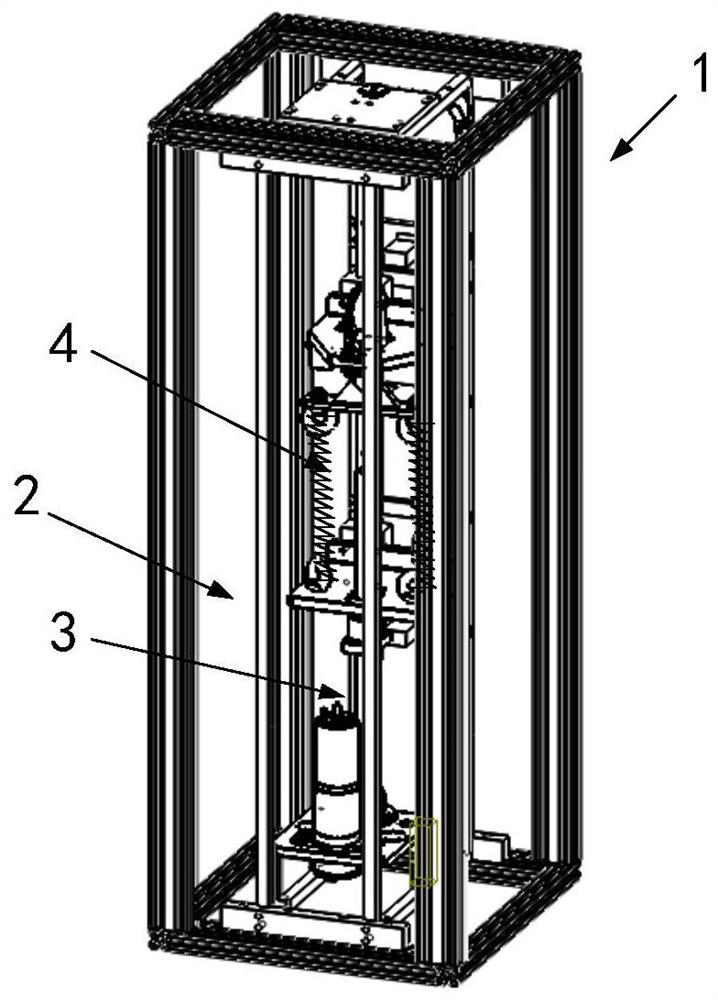

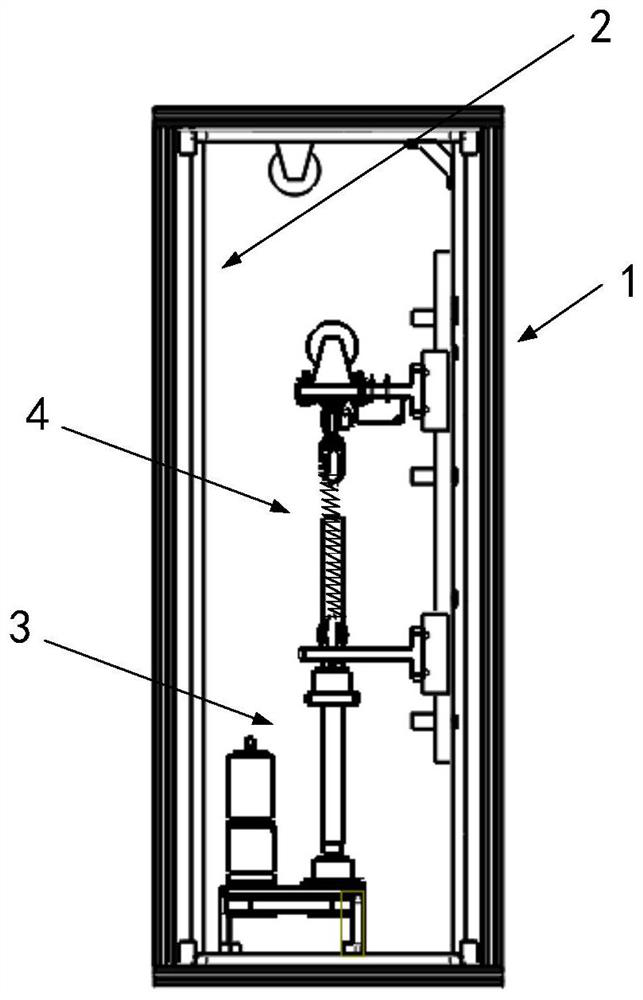

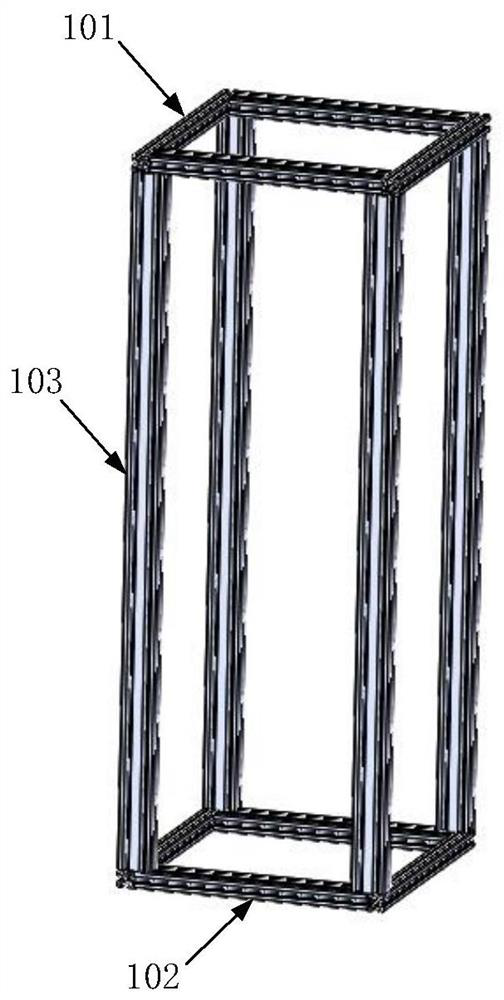

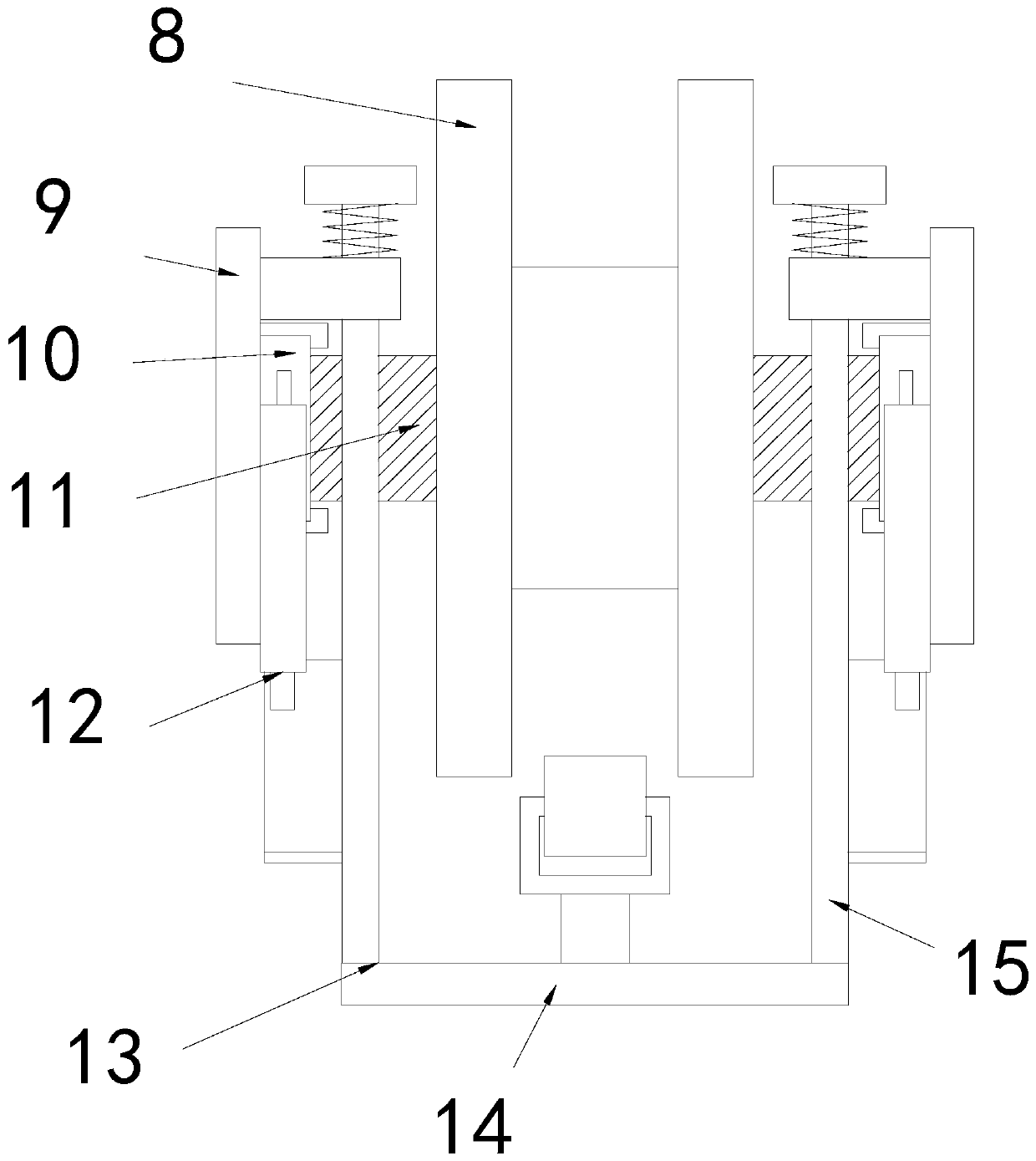

A constant force human body suspension system for rehabilitation training

ActiveCN110507516BReduce measurement error and control complexityEnsure stability and structural reliabilityWalking aidsDistance sensorsPull force

The invention discloses a constant-force human body suspension system for rehabilitation training, a whole system is of a frame structure, a guide rail sliding block is installed in a frame, and upperand lower moving platforms are installed on the guide rail sliding block; and a fixed pulley is mounted at top. The lower moving platform is driven by a driving module and can move up and down. A moving balance module is mounted on the upper and lower moving platforms; wherein a movable pulley and a pull plate of which the middle part is hinged with the upper moving platform are arranged on the upper moving platform; the pulling plate is connected with the lower moving platform through springs. A distance sensor is further installed on the upper moving platform. During use, a suspension steelwire bypasses the fixed pulley and the movable pulley, one end is connected with a human body and the other end is connected with a winch or ground. When the human body moves to drive the suspensionsteel wire to move, the upper moving platform is driven to move, the driving module can drive the lower platform to move, the distance between the upper platform and the lower platform is kept at a constant value, and therefore the elongation of the spring is kept at a constant value, passive movement adapting to height changes in human body movement is achieved, and constant suspension tension can be provided for the human body.

Owner:BEIHANG UNIV

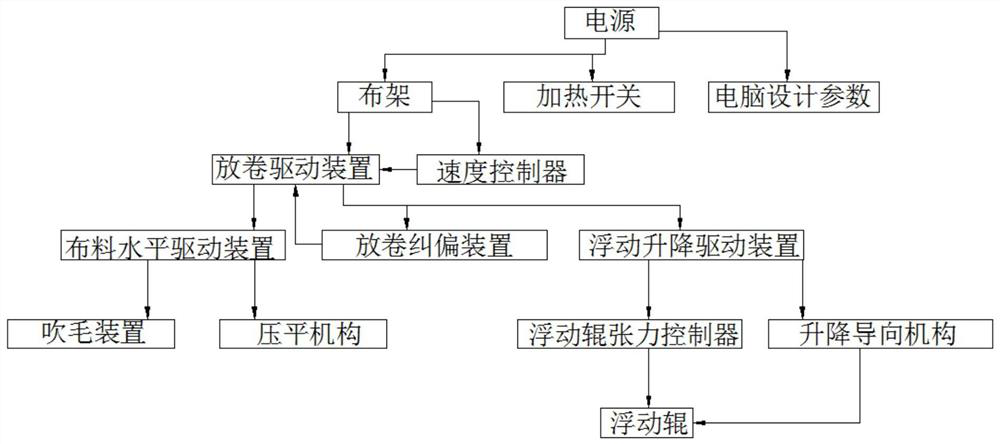

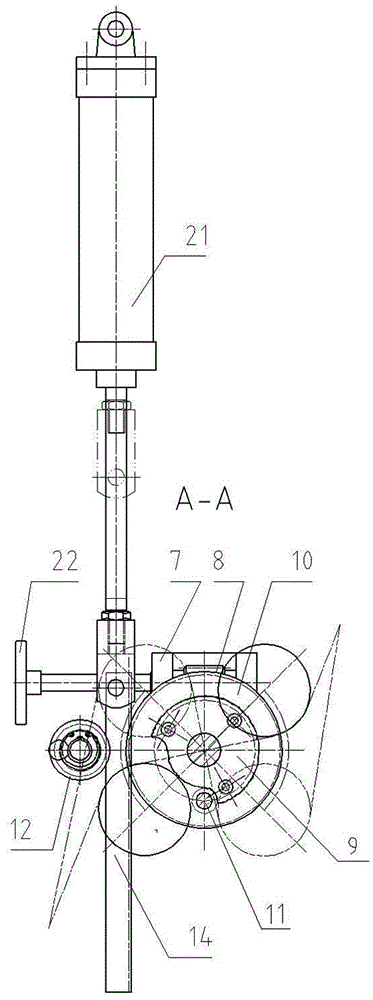

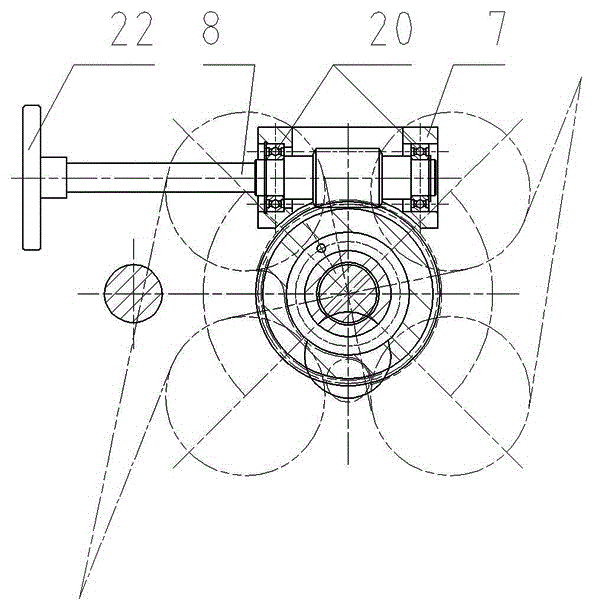

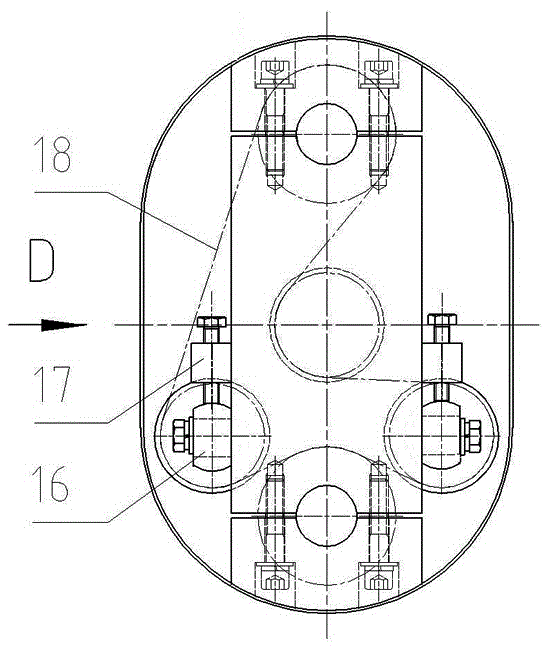

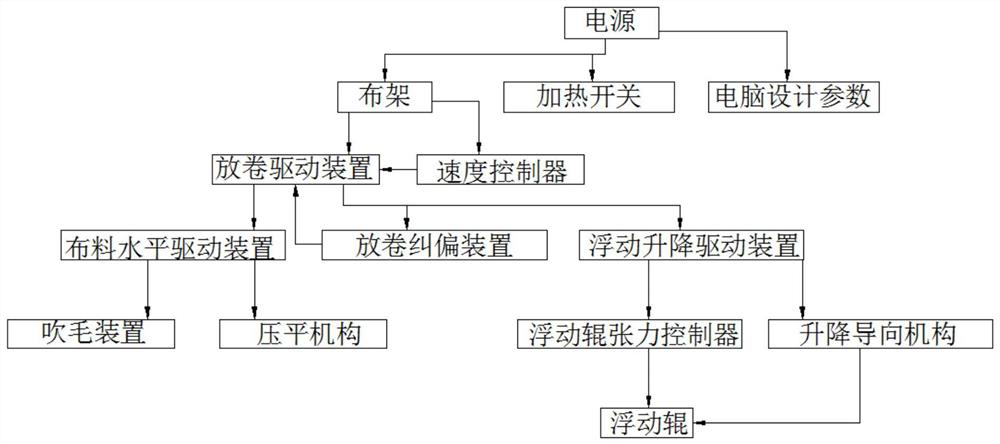

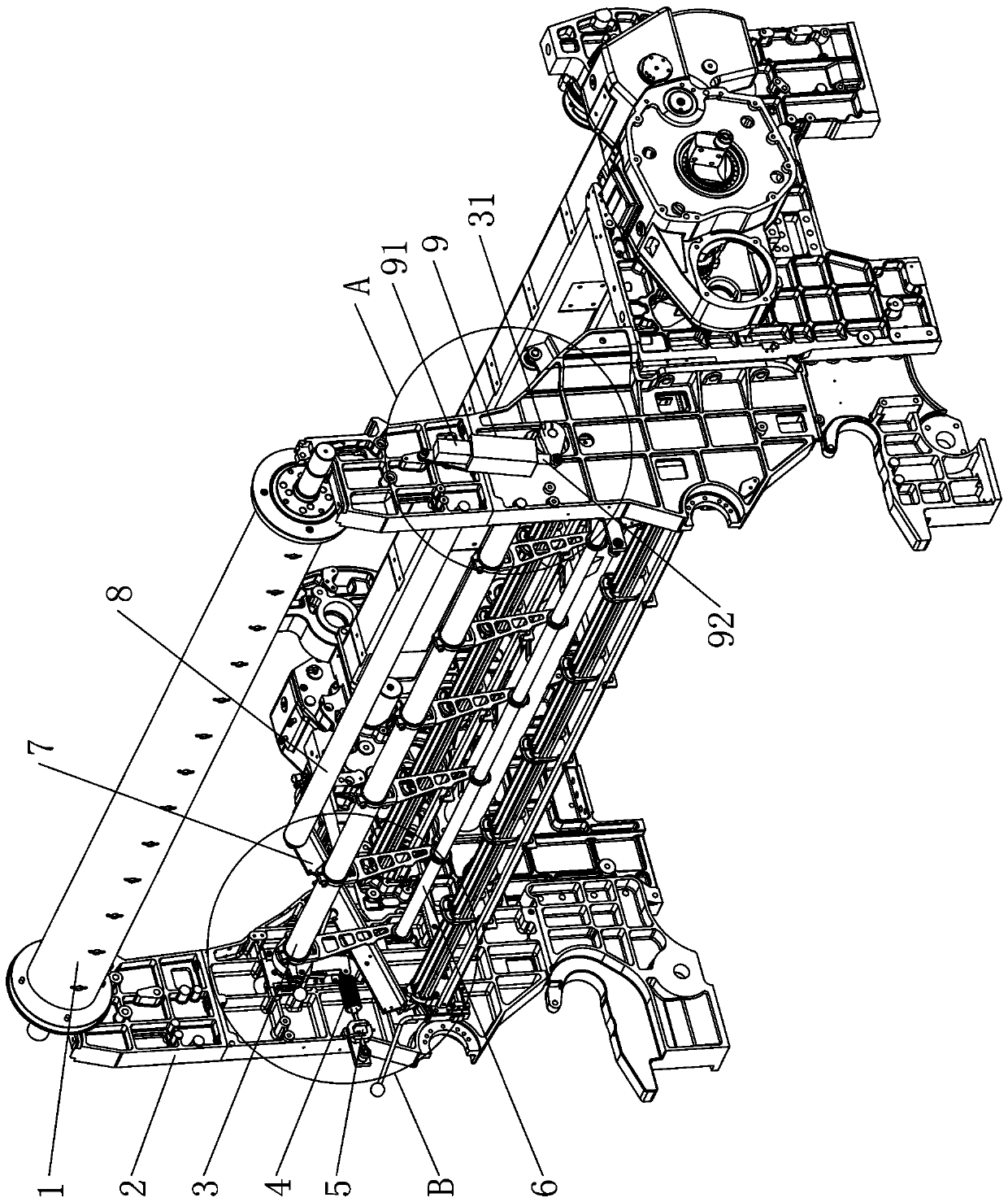

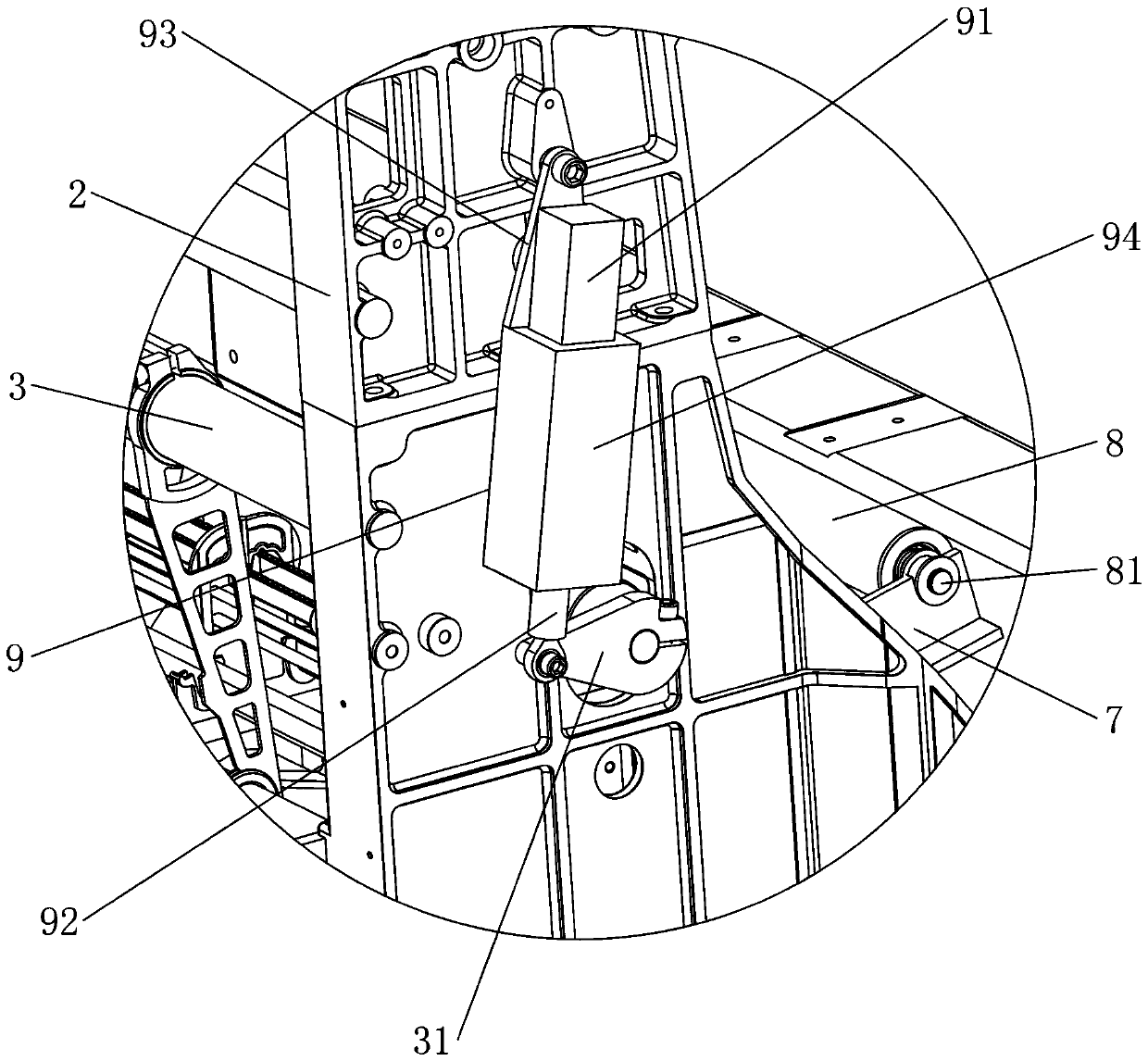

An automatic cloth guide system for thermal transfer printing machine

ActiveCN112249772BIncrease flow rateGuaranteed aestheticsPrinting press partsWebs handlingPleatPhysics

The present invention relates to the technical field of fabric guiding equipment, in particular to an automatic fabric guiding system for a thermal transfer printing machine, which includes an unwinding drive device, and the unwinding drive device includes a cloth horizontal drive device, an unwinding deviation correction device and a floating lifting drive device , the cloth horizontal drive device includes a hair blowing device and a flattening device, the inside of the hair blowing device is fixedly connected with a blowing fan and an air outlet pipe, and the inside of the flattening mechanism is fixedly connected with a pressing plate, and the pressing plate is located directly above the cloth , by accelerating the air velocity on the upper surface of the fabric, the impurities and fabric wool on the fabric move towards the direction of low pressure, and the impurity is processed while ensuring the same orientation of the fabric wool, so that the next step of processing the fabric When it is used, the aesthetics of the fabric surface can be well guaranteed, and the distance between the floating rollers can be controlled to ensure that the tension of the fabric remains constant, so that it can well avoid wrinkles in the fabric during the process of conveying the fabric.

Owner:浙江蓝宇纺织科技有限公司

Wrap angle adjustable fabric expanding device with cloth length compensation function

ActiveCN104988692APrevent getting involvedUnchanged tensionStretchingEngineeringMechanical engineering

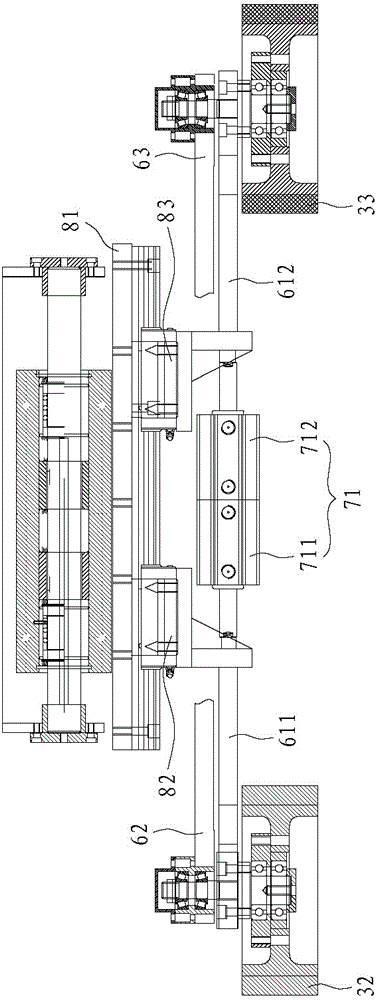

The invention discloses a wrap angle adjustable fabric expanding device with a cloth length compensation function. The device comprises a frame, a spreading roller transmission assembly, a spreading roller assembly, a worm gear-worm assembly for adjusting the wrap angle, and a synchronous belt-pressing wheel assembly; the spreading roller transmission assembly is sleevedly arranged in the center hole in the right end of the spreading roller assembly; the synchronous belt-pressing wheel assembly is fixed on the support plate in the right end of the spreading roller assembly; the support shaft in the left end of the spreading roller assembly is provided with a gear; the worm gear-worm assembly comprises a worm gear, a worm gear seat, a worm, and a hand wheel; the lower side of the gear is provided with a roller; the roller is assembled with a bearing and a core shaft, then the roller, bearing, and core shaft is fixed on the frame as a whole; a rack is arranged between the gear and the roller, the rack is connected to a cylinder, the cylinder is fixedly connected to the frame, the cylinder drives a piston rod to move forward and backward so as to drive the spreading roller assembly to swing in a clockwise direction or a counter-clockwise direction. When the fabric seam goes through the milling roller, the loosen fabric can be tensioned under the assistance of press roller's movement, and the tension force of the fabric is basically not changed.

Owner:HAINING TEXTILE MACHINERY FACTORY

A Wrap Angle Adjustable Expanding Device with Cloth Length Compensation Function

ActiveCN104988692BPrevent getting involvedUnchanged tensionStretchingEngineeringMechanical engineering

The invention discloses a wrap angle adjustable fabric expanding device with a cloth length compensation function. The device comprises a frame, a spreading roller transmission assembly, a spreading roller assembly, a worm gear-worm assembly for adjusting the wrap angle, and a synchronous belt-pressing wheel assembly; the spreading roller transmission assembly is sleevedly arranged in the center hole in the right end of the spreading roller assembly; the synchronous belt-pressing wheel assembly is fixed on the support plate in the right end of the spreading roller assembly; the support shaft in the left end of the spreading roller assembly is provided with a gear; the worm gear-worm assembly comprises a worm gear, a worm gear seat, a worm, and a hand wheel; the lower side of the gear is provided with a roller; the roller is assembled with a bearing and a core shaft, then the roller, bearing, and core shaft is fixed on the frame as a whole; a rack is arranged between the gear and the roller, the rack is connected to a cylinder, the cylinder is fixedly connected to the frame, the cylinder drives a piston rod to move forward and backward so as to drive the spreading roller assembly to swing in a clockwise direction or a counter-clockwise direction. When the fabric seam goes through the milling roller, the loosen fabric can be tensioned under the assistance of press roller's movement, and the tension force of the fabric is basically not changed.

Owner:HAINING TEXTILE MACHINERY FACTORY

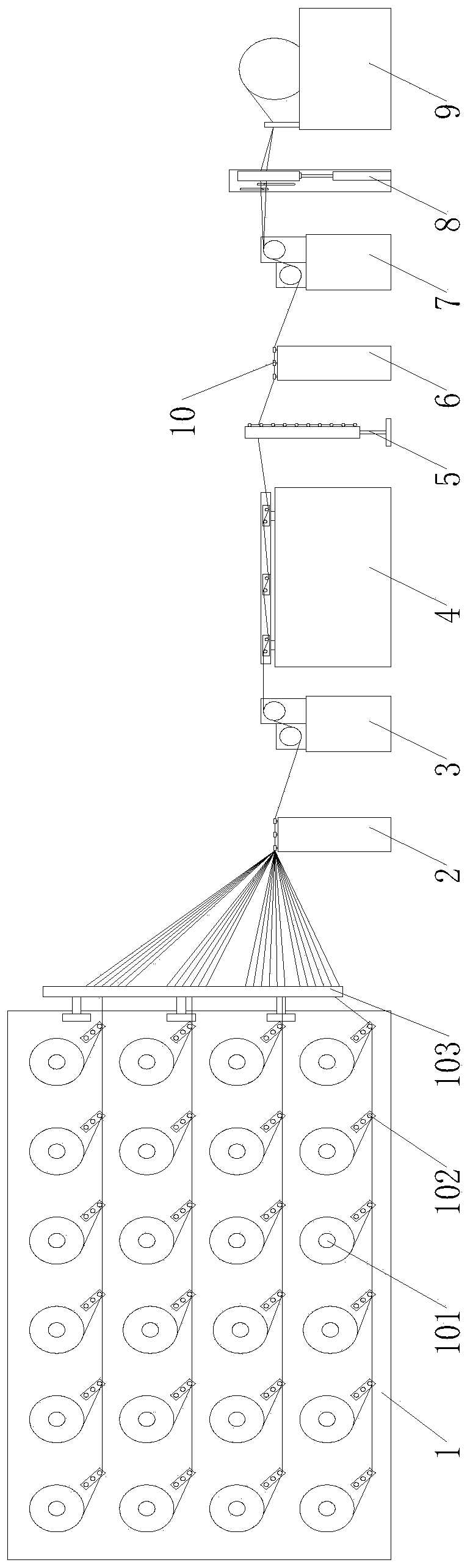

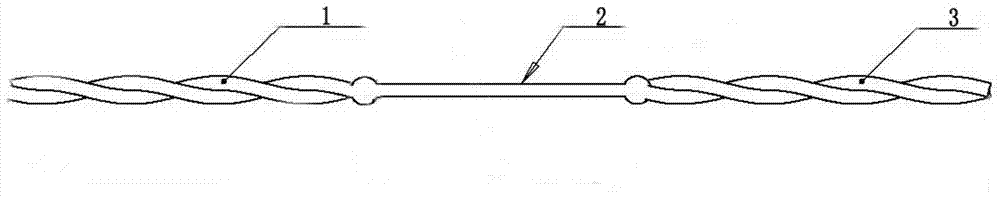

Nylon mother yarn warping method and nylon mother yarn warping device

The invention discloses a chinlon mother yarn warping method and a chinlon mother yarn warping device. The method comprises the steps of firstly, mutually twisting 10 chinlon son yarns to form a mother yarn and then winding the mother yarn on a cylinder to obtain a mother yarn spindle; then respectively arranging the mother yarn spindle on a fixed roller of an electric-control spindle frame, sequentially penetrating one end of each mother yarn through a yarn threading frame, a mother yarn locating frame, a mother yarn tension roller and an adjusting base; then separating the son yarns from the mother yarn and penetrating the son yarns into a yarn dividing frame side by side; then sequentially penetrating the son yarns through a son yarn locating frame and a son yarn tension roller, layering by a leasing rod and then penetrating the son yarns through a reed; finally penetrating the son yarns into a warping machine to finish warping. The chinlon mother yarn warping method disclosed by the invention not only can achieve once forming of spindles, but also achieves whole-process control on yarn tension in a chinlon warping process and has the advantages of high production efficiency and good stability.

Owner:HUZHOU HENGXIN TRADEMARK MAKING BRINGING

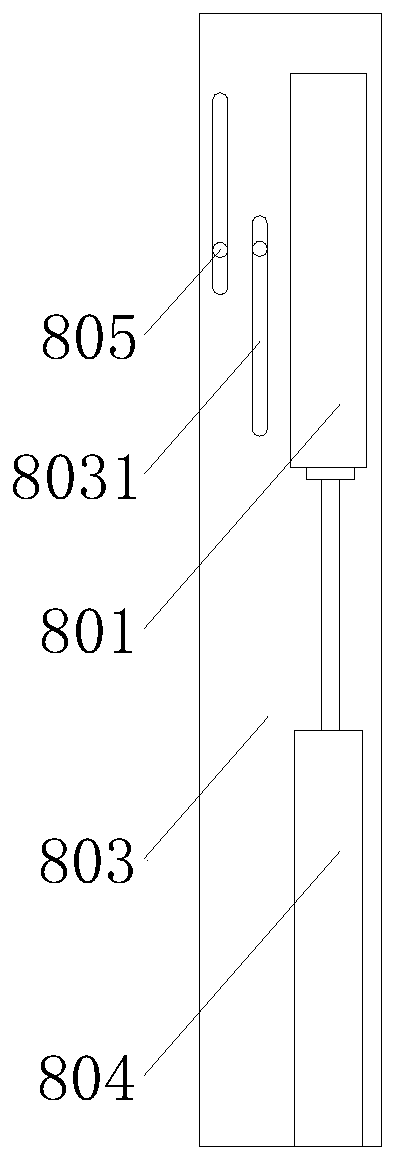

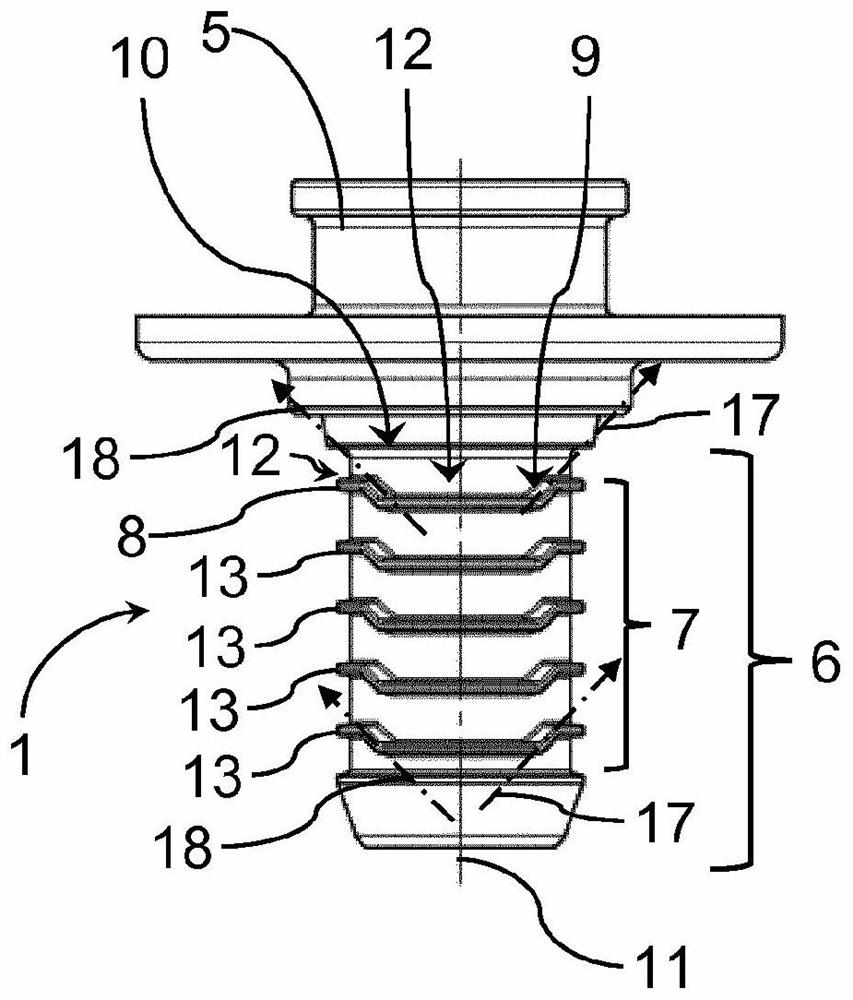

Connection coupling

The invention relates to a connection coupling (1), wherein at least two rib sections (9, 10) are aligned at an angle to each other at at least one rib (8) of a rib structure (7) of a hose nipple (6)such that the course directions (17, 18) in the rib sections (9, 10) are aligned at an angle to each other.

Owner:NEOPERL

Anti-knotting device for stranded wires

The invention discloses an anti-knotting device for stranded wires. The anti-knotting device comprises a fixed bracket, and a stranded wire winding and unwinding assembly, a fixed pulley block, a movable pulley block, a winding and unwinding adjusting assembly and a sensing assembly which are arranged on the fixed bracket, the fixing support comprises a first fixing support body and a second fixing support body. The stranded wire take-up and pay-off assembly is arranged at the top of the first fixed bracket; the fixed pulley block, the movable pulley block, the winding and unwinding adjustingassembly and the sensing assembly are arranged on the second fixed support, and the stranded wire is wound on the stranded wire winding and unwinding assembly through the fixed pulley block and the movable pulley block. The invention provides the anti-knotting device for the stranded wires, which can effectively prevent the occurrence of a stranded wire knotting phenomenon when a transformer and an inductor are wound, so that the winding of coils of the transformer and the inductor is smoother, the winding efficiency is higher, and the problem that the coils of the transformer and the inductorare poor in voltage resistance or too large and are not convenient to assemble is effectively solved.

Owner:深圳市斯比特技术股份有限公司

Webbing processing fixed-width unwinding device

The invention discloses a webbing processing fixed-width unwinding device which structurally includes a machine frame, an unwinding device body, a webbing, a deflection rectify wheel, a tensioning wheel, a work box and a workbench. The workbench is welded to the top of the machine frame, the work box is installed on the workbench, the tensioning wheel is arranged on the side surface of the work box, and the deflection rectify wheel is arranged on the side surface of the tensioning wheel. The unwinding device body is connected to the side surface of the machine frame and is located below the deflection rectify wheel, and the webbing is wound on the unwinding device body. The unwinding device body includes an unwinding wheel, a shaft bracket, a friction device, rotating shafts, a transmission device and a lifting device. The two sides of the unwinding wheel are correspondingly mounted on the shaft bracket through the rotating shafts, and the shaft bracket is connected to the side surfaceof the machine frame. The webbing processing fixed-width unwinding device has the beneficial effects that through the thickness change during webbing unwinding, the friction of a rubber block with the rotating shafts is gradually increased, the reduction in the weight of the webbing can be offset by the increase in the friction, the pulling force of the unwinding wheel on the webbing remains unchanged, the tension of the webbing can be kept constant by cooperating with constant tensile force, and processing is convenient.

Owner:东莞广上运动用品有限公司

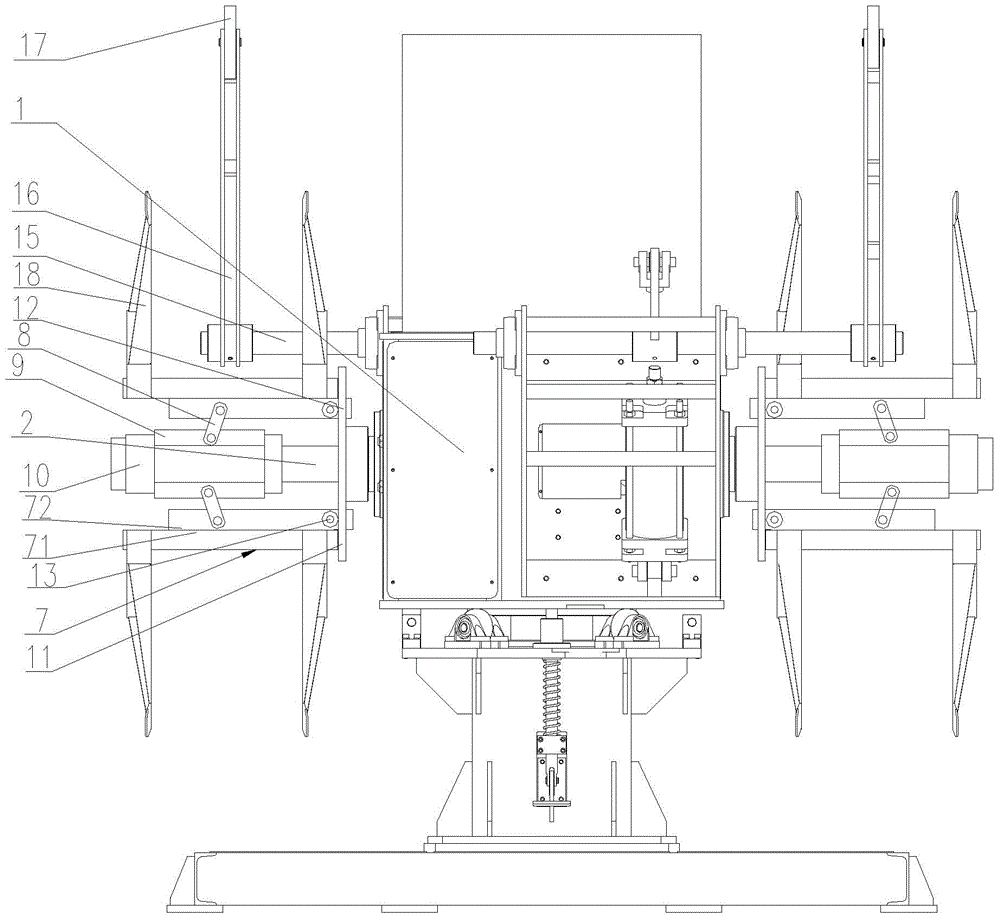

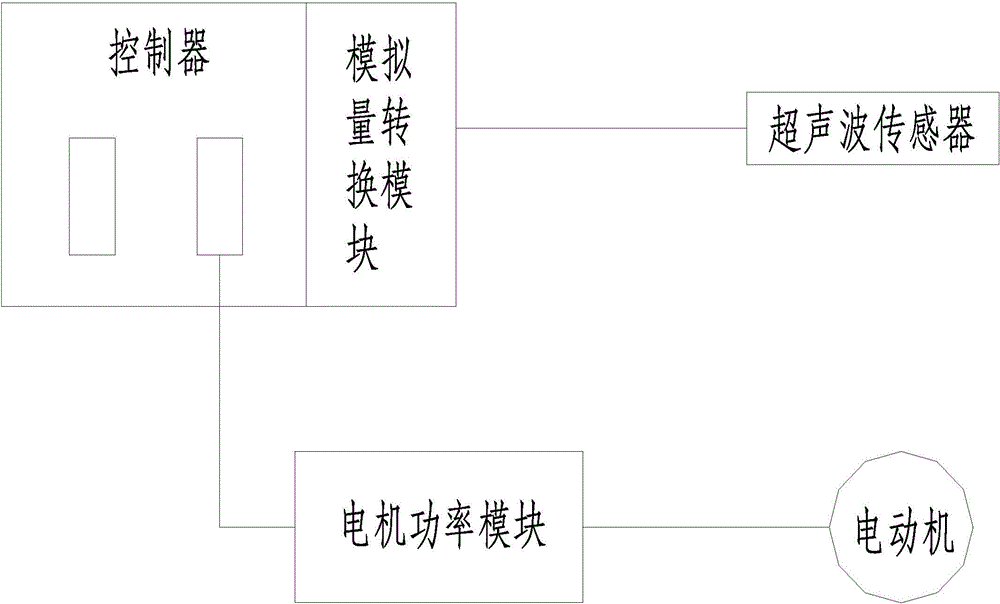

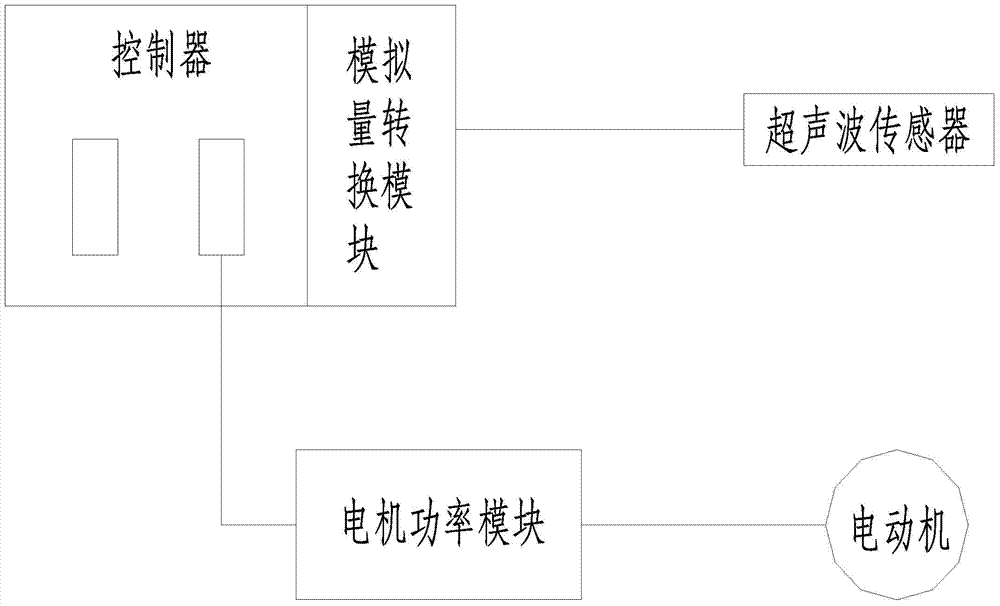

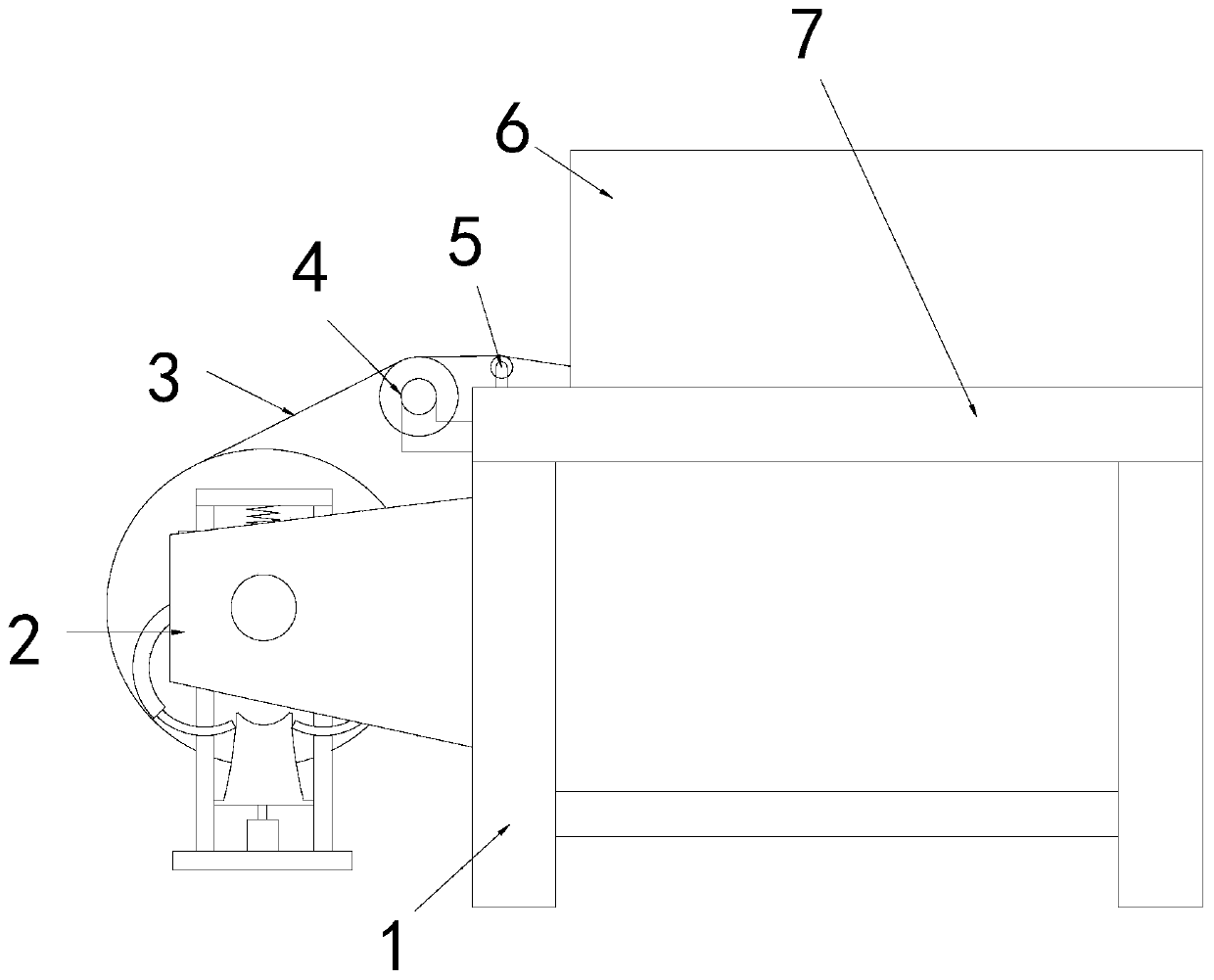

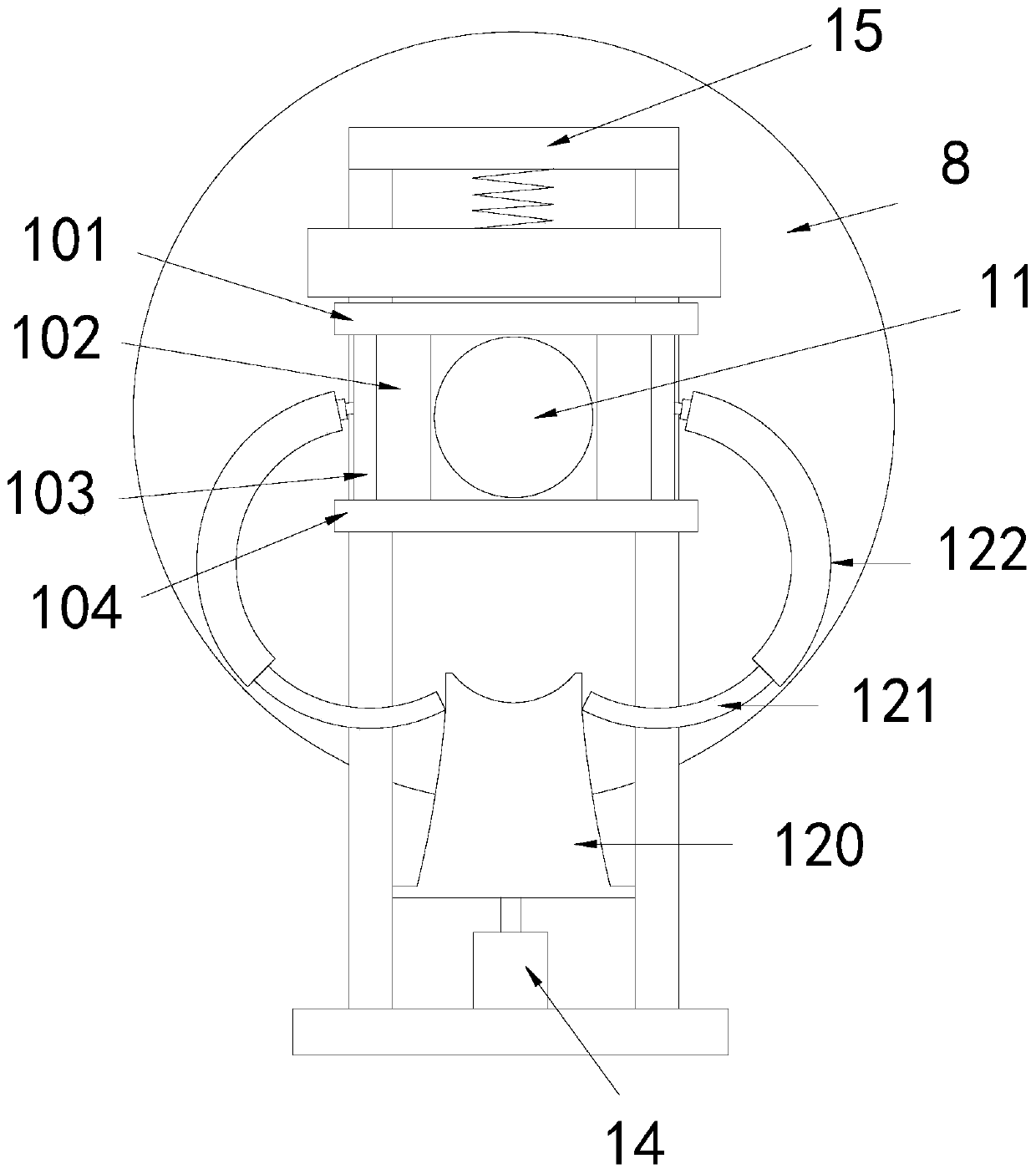

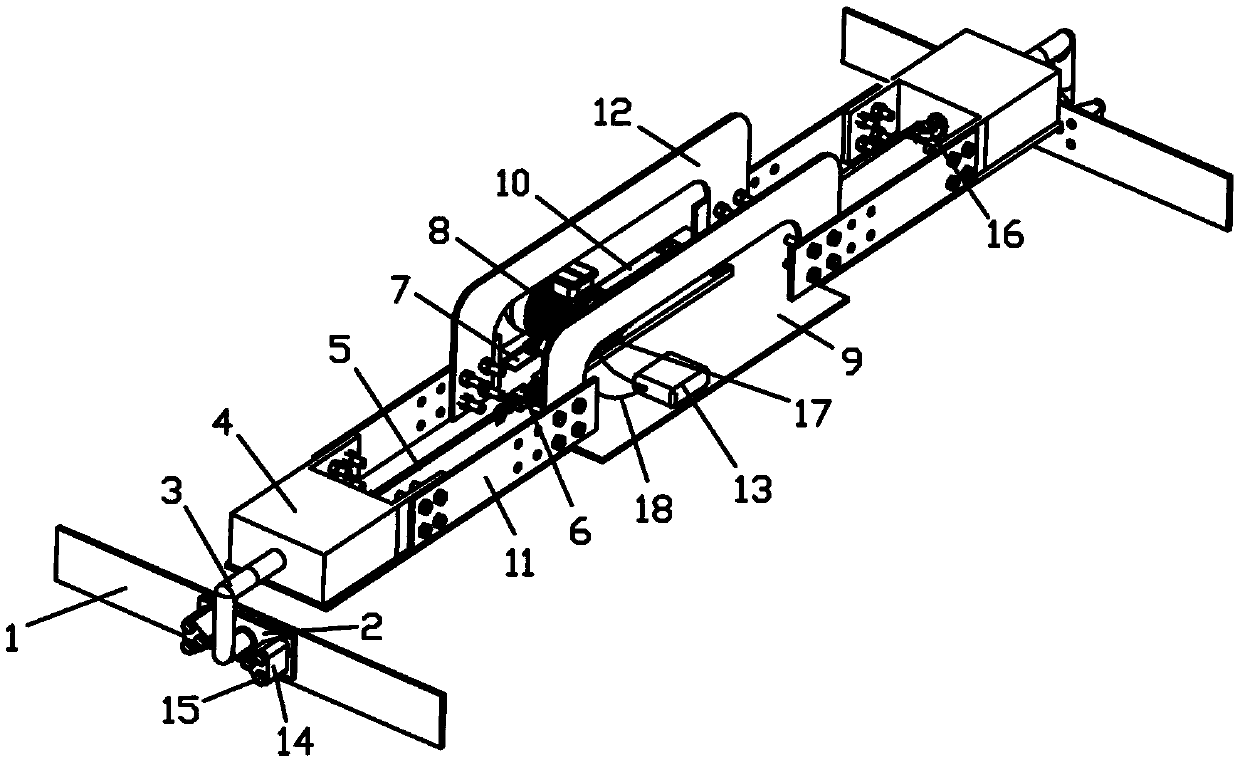

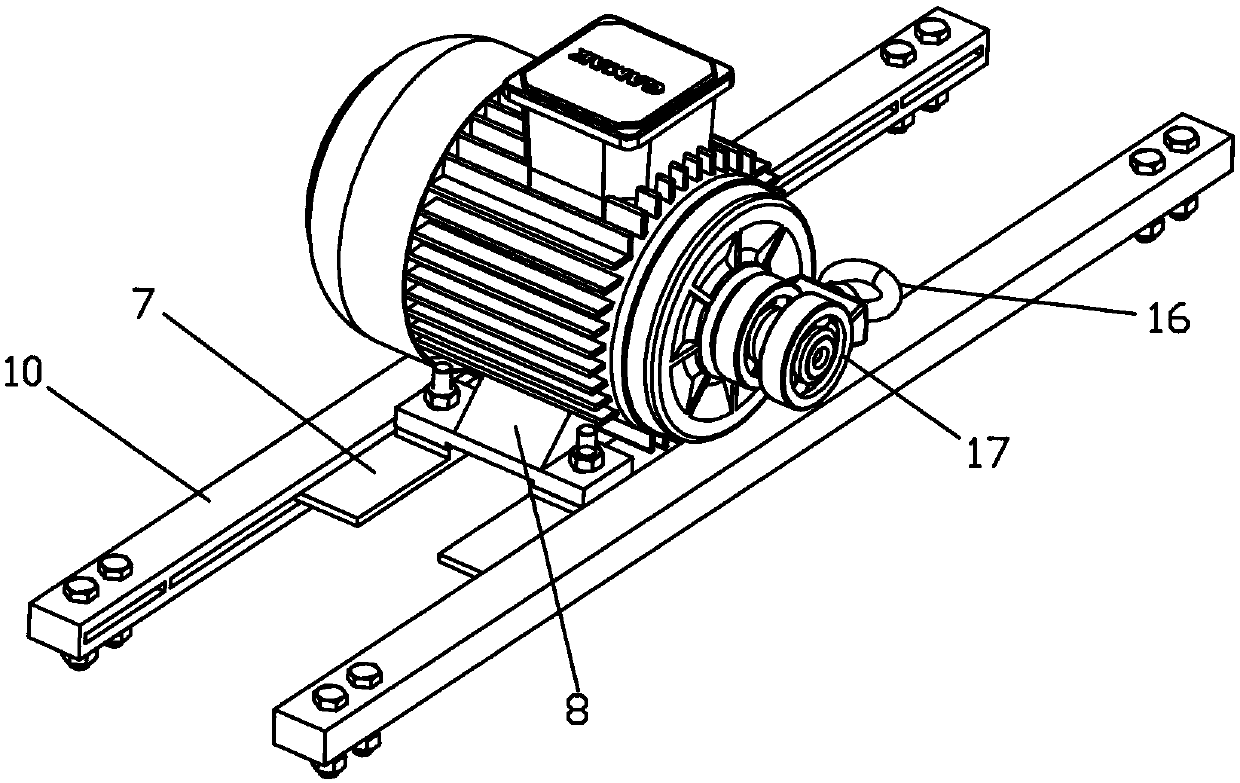

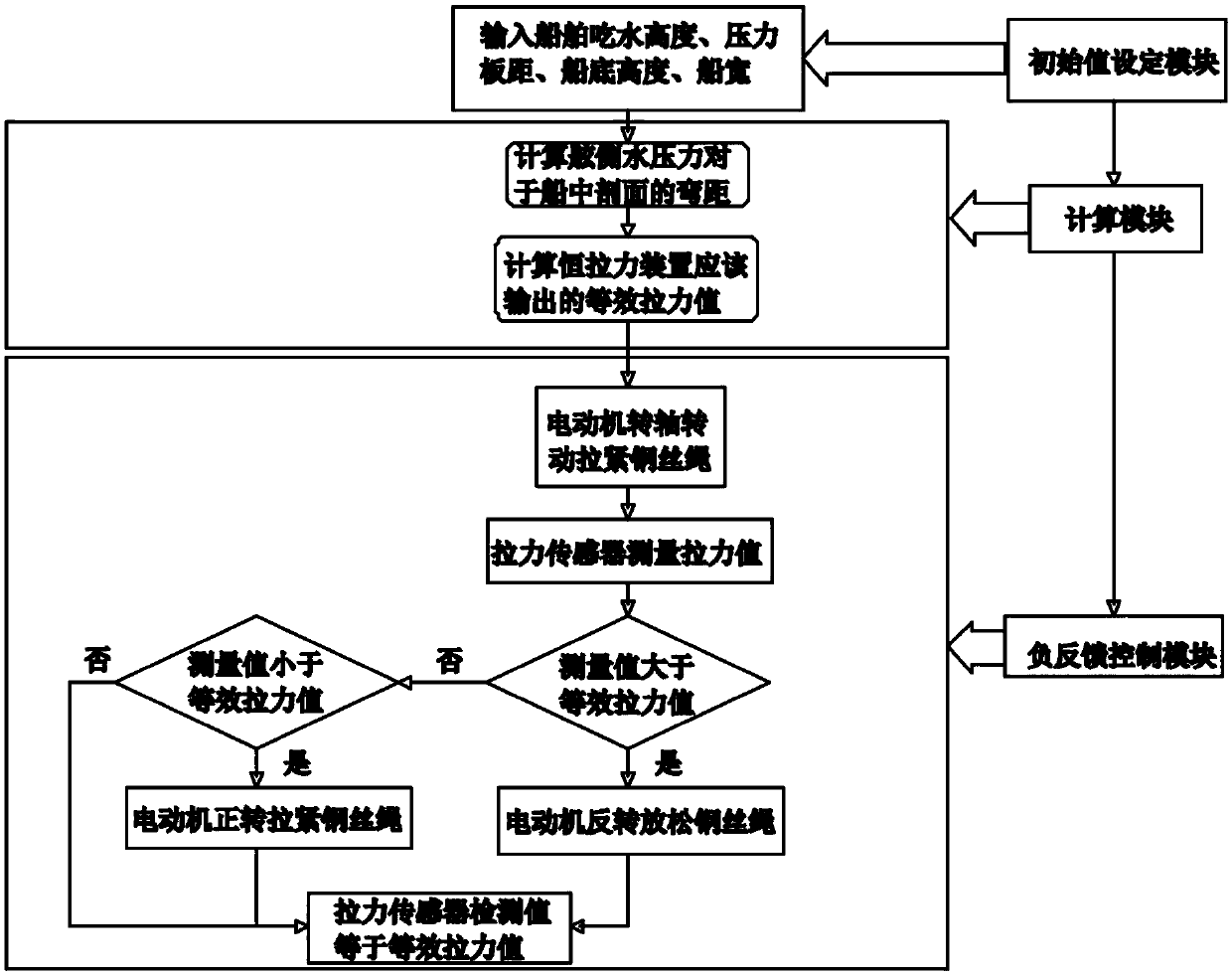

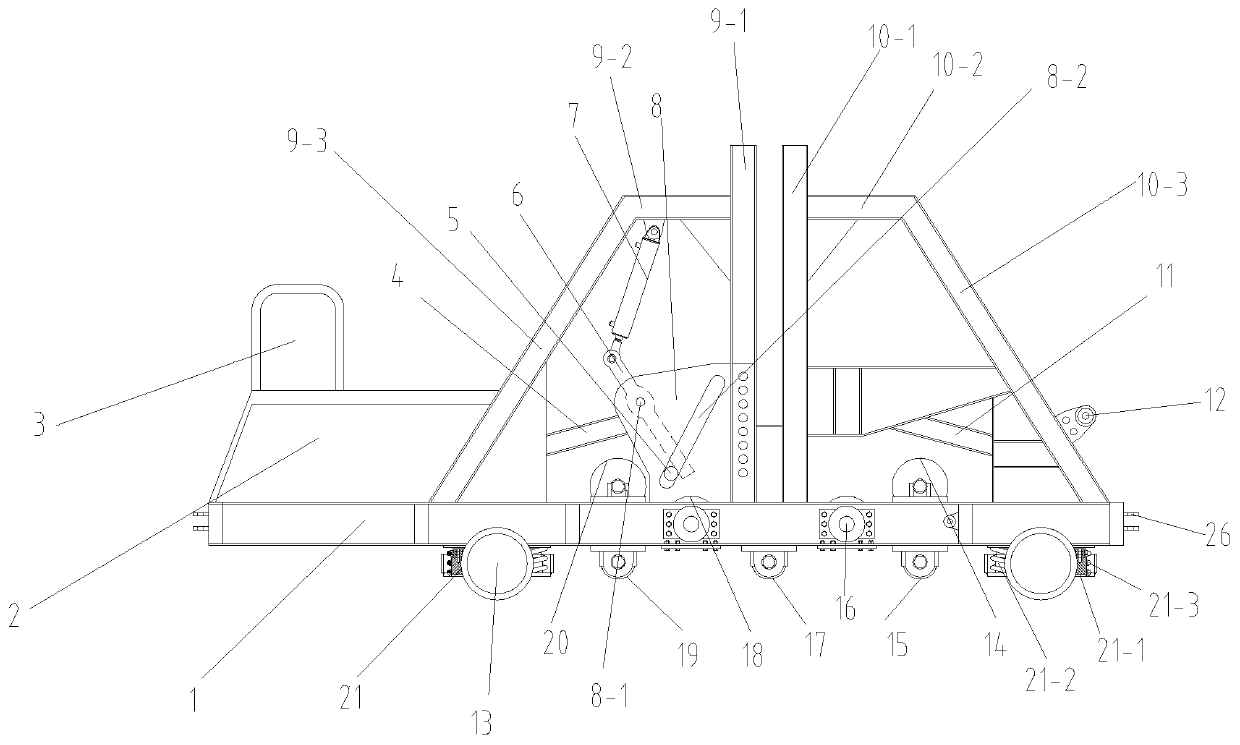

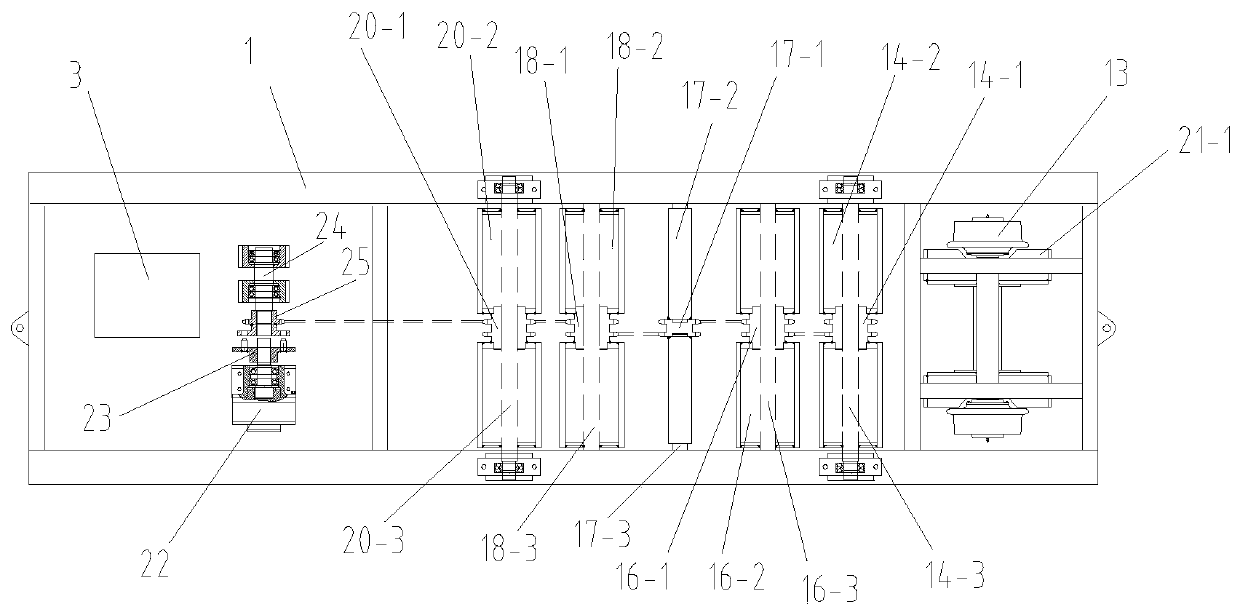

A Constant Tension Device for Large Opening Model Tests of River-sea Direct Ships

ActiveCN107826211BUnchanged tensionImprove accuracyHydrodynamic testingVessel designingData signalSlide plate

The invention relates to the technical field of ship and ocean engineering professional ship models, in particular to a constant tension device for large-opening model test of a river-to-sea ship. Theconstant tension device for large-opening model test of the river-to-sea ship comprises a pressure plate, a transitional panel, a sliding loading shaft, a loading shaft slide groove, a steel wire rope, a tension sensor, an electric motor sliding plate, an electric motor, a supporting platform, an electric motor slide groove, a rectangular connecting plate, a U-shaped connecting plate, a controller and a tension balancing device. According to the constant tension device for the large-opening model test of the river-to-sea ship, the load simulation of outboard water pressure is increased in themodel test by analyzing the characteristic of a wide and flat ship model of the river-to-sea ship and a data signal of the tension sensor is monitored to adjust the torque, output by the motor, in real time by using a control program; therefore, the constancy of the tension applied to a side shell by using the steel wire rope is guaranteed so that the test process is more appropriate for the actual situation and the test result is more persuasive.

Owner:武汉理航智能船舶科技有限责任公司

Automatic cloth guiding system of heat-transfer printing machine

ActiveCN112249772AIncrease flow rateGuaranteed aestheticsPrinting press partsWebs handlingEngineeringPleat

The invention relates to the technical field of cloth guiding equipment, in particular to an automatic cloth guiding system of a heat-transfer printing machine. The automatic cloth guiding system comprises an unwinding driving device; the unwinding driving device comprises a cloth horizontal driving device, an unwinding deviation correcting device and a floating lifting driving device; the cloth horizontal driving device comprises a fluff blowing device and a flattening device; a blowing fan and an air outlet pipe are fixedly connected inside the fluff blowing device; a flattening plate is fixedly connected inside the flattening mechanism; the flattening plate is located above cloth; the air flow speed on the surface of the cloth is increased, so that impurities and cloth fluff on the cloth move towards the low pressure intensity, it is guaranteed that the directions of the cloth fluff are identical while the impurities are treated, and when the cloth is subjected to next-step processing, the attractiveness of the surface of the cloth can be well guaranteed; the distance between the floating rollers is controlled, so that it is guaranteed that the tension of the cloth is kept unchanged, and the cloth can be well prevented from wrinkling in the cloth conveying process.

Owner:浙江蓝宇纺织科技有限公司

Three-section electric connecting guide wire for electric light source and its manufacturing process

ActiveCN104143493BNot easy to produceSolder joints are firmElectric discharge tubesElectric discharge lampsElectricityCopper plating

The invention relates to a three-section electrical connection guide wire for an electric light source and a manufacturing process thereof. The electrical connection guide wire includes an inner guide wire, a sealing wire, and an outer guide wire. The inner guide wire is welded to one end of the sealing wire, and the sealing wire The other end is welded and connected with the outer guide wire, the inner guide wire and the outer guide wire are formed by twisting at least two conductive metal monofilaments along the central axis, the sealing wire is du magnesium wire, and the conductive metal wire of the inner guide wire is Copper-plated nickel wire, the conductive metal wire of the outer guide wire is copper wire, the inner guide wire of the three-section electrical connection guide wire, the sealing wire, and the outer guide wire are all concentric after welding, and can withstand a pressure of 40‑50N and bend at 90 degrees 3 back and forth without breaking, and the tension remains the same. Compared with the prior art, the welding point of the present invention is strong, and when it is sealed with glass, it is not easy to leak air, and it is not easy to generate air bubbles. When making the core column, there is less material jamming, the production efficiency is improved, and the production cost is saved.

Owner:江苏海昱精密合金材料有限公司

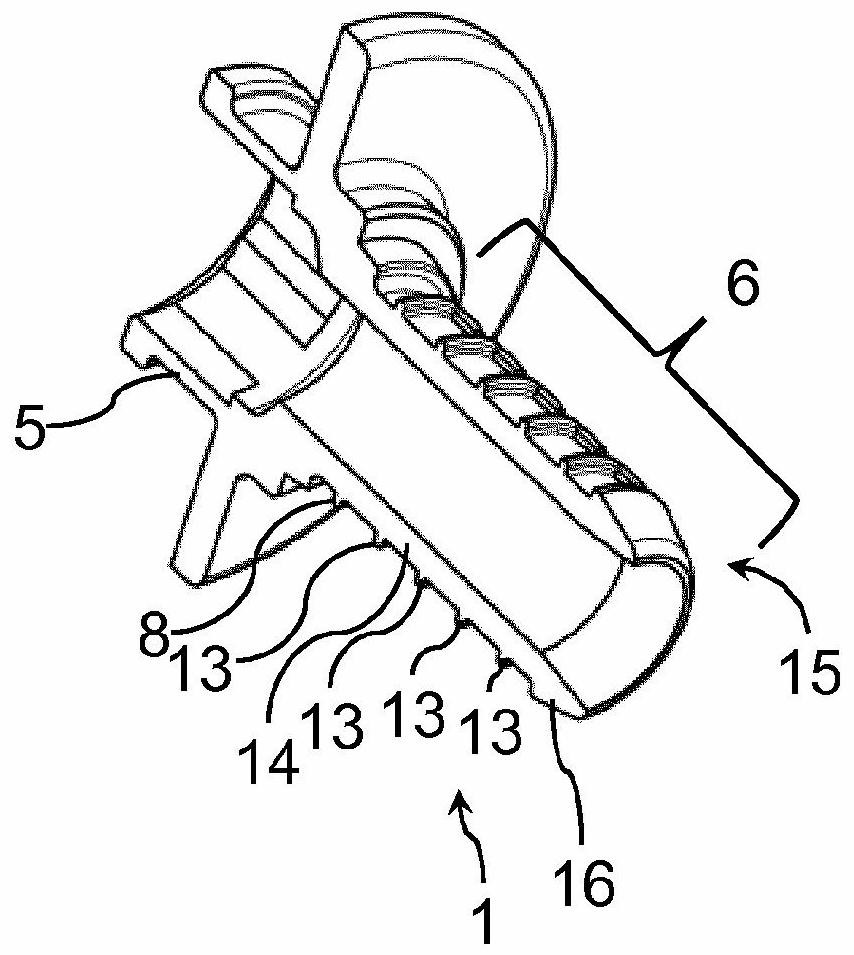

Active type upper let-off structure

The invention relates to an active type upper let-off structure which comprises a left wall plate, a right wall plate, a top beam, a fixed beam, elastic reset mechanisms, a swing rod and a rotating beam. The top beam is arranged at the upper ends of the wall plates. The two ends of the fixed beam are rotationally matched with the left wall plate and the right wall plate respectively. The elastic reset mechanisms are connected between the fixed beam and the wall plates. The fixed beam is connected with the swing rod through a swing arm. The rotating beam is rotationally arranged on the wall plates. The upper let-off structure further comprises a swing rod driving device connected with the fixed beam in a transmission mode. According to the active type upper let-off structure, the fixed beamcan be driven by the swing rod driving device to actively work when and after fluffing, and therefore the swing rod actively relaxes during fluffing, the tension of warp does not change before and after fluffing, and it is avoided that the warp is pulled back after fluffing.

Owner:广东康特斯织造装备有限公司

A conveyor belt winding trolley and winding method

Owner:中电建(广宁)绿色矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com