Chain tensioning device with adjustable tensioning force

A chain tensioning device, tensioning force technology, applied in the field of garbage storage devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

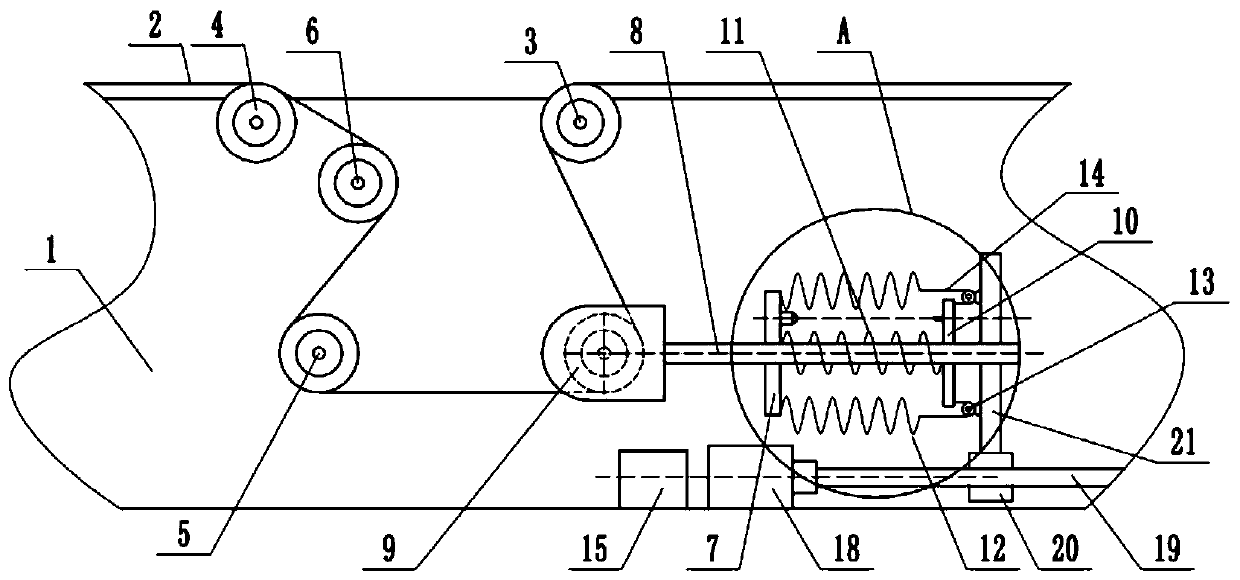

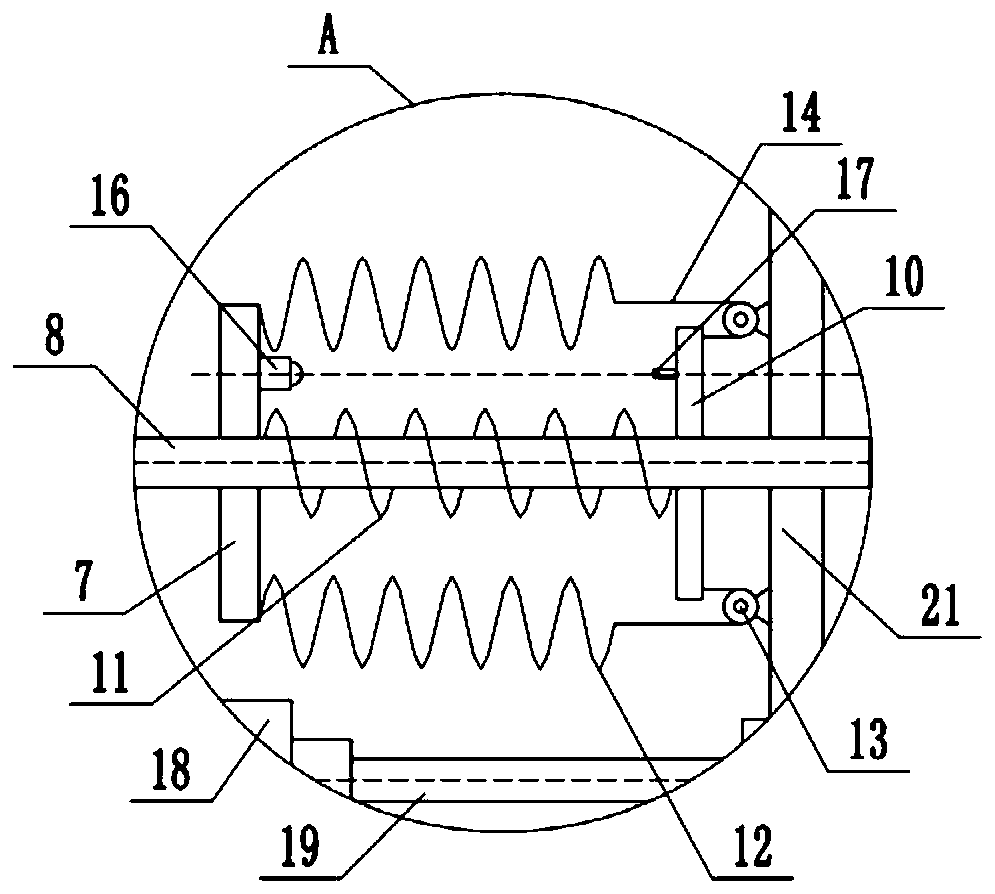

[0036] Embodiment one is basically as figure 1 with figure 2 As shown, a chain tensioning device with adjustable tension force includes a base 1, on which a transmission chain 2 is arranged, and on the base 1, a drive wheel 3 and a driven wheel 4 are fixedly connected by screws. Wheel 5 and buffer wheel 6, chain 2 and drive wheel 3, steering wheel 5, buffer wheel 6 and driven wheel 4 are meshed successively and carry out transmission.

[0037] Such as figure 1 As shown, the base 1 is fixedly connected with a support seat 7 by screws, and the support seat 7 is provided with a guide hole arranged horizontally, and a slide bar 8 is connected to slide horizontally in the guide hole. Tightening pulley 9, the tensioning pulley 9 meshes with the inner side of the chain 2 and the tensioning pulley 9 is located between the driving pulley 3 and the steering wheel 5, the tensioning pulley 9 and the steering pulley 5 are located in the same horizontal plane, and the right end of the sl...

Embodiment 2

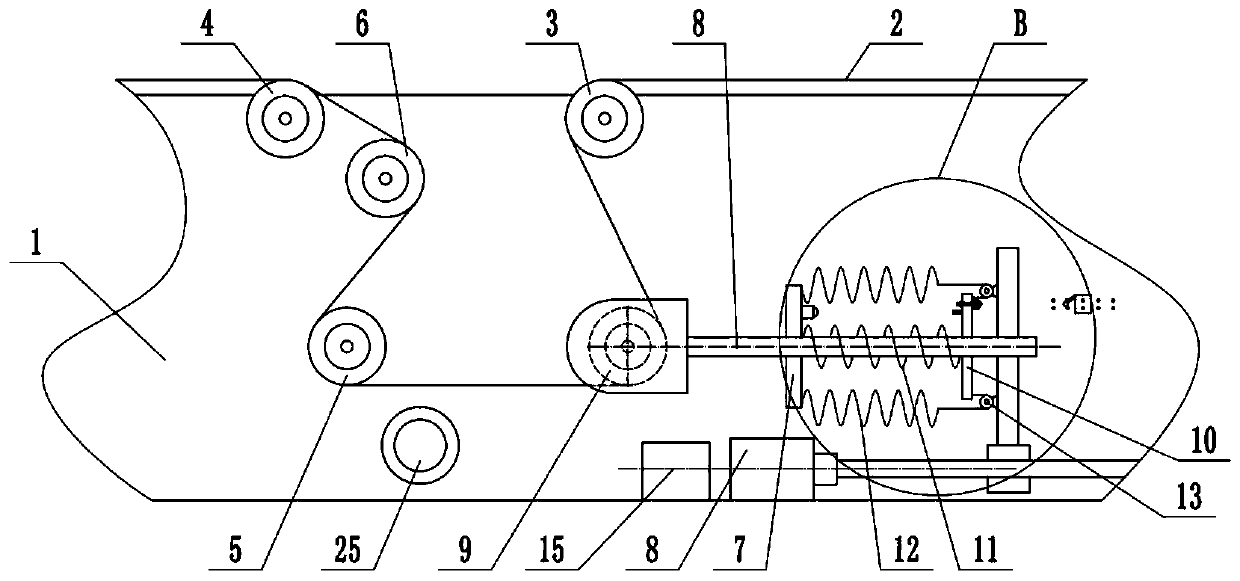

[0045] The difference between embodiment two and embodiment one is: as image 3 with Figure 4As shown, the support base 7 is provided with a detection mechanism for detecting the elongation of the chain 2, and the detection mechanism is provided with an alarm unit. In this embodiment, the detection mechanism includes a travel switch 22 and a trigger lever 23 for triggering the travel switch 22. , the alarm unit includes an alarm 25 and a power supply (not shown in the figure). Two horizontally arranged lockholes can be locked into different lockholes by the travel switch 22, so that the distance between the travel switch 22 and the trigger lever 23 is adjustable; the travel switch 22 is electrically connected with the alarm 25 and the power supply, and the stroke When the switch 22 was closed, the alarm 25 was energized and sent an alarm; the push pedal 10 had a through hole, and the trigger rod 23 was inserted into the through hole, and the left end of the trigger rod 23 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com