A conveyor belt winding trolley and winding method

A conveyor belt and trolley technology, applied in the field of conveyor belt winding, can solve the problems of dangerous anti-slip weight, inconspicuous effect, poor winding effect, etc., and achieve the effects of reducing manual labor, improving winding effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

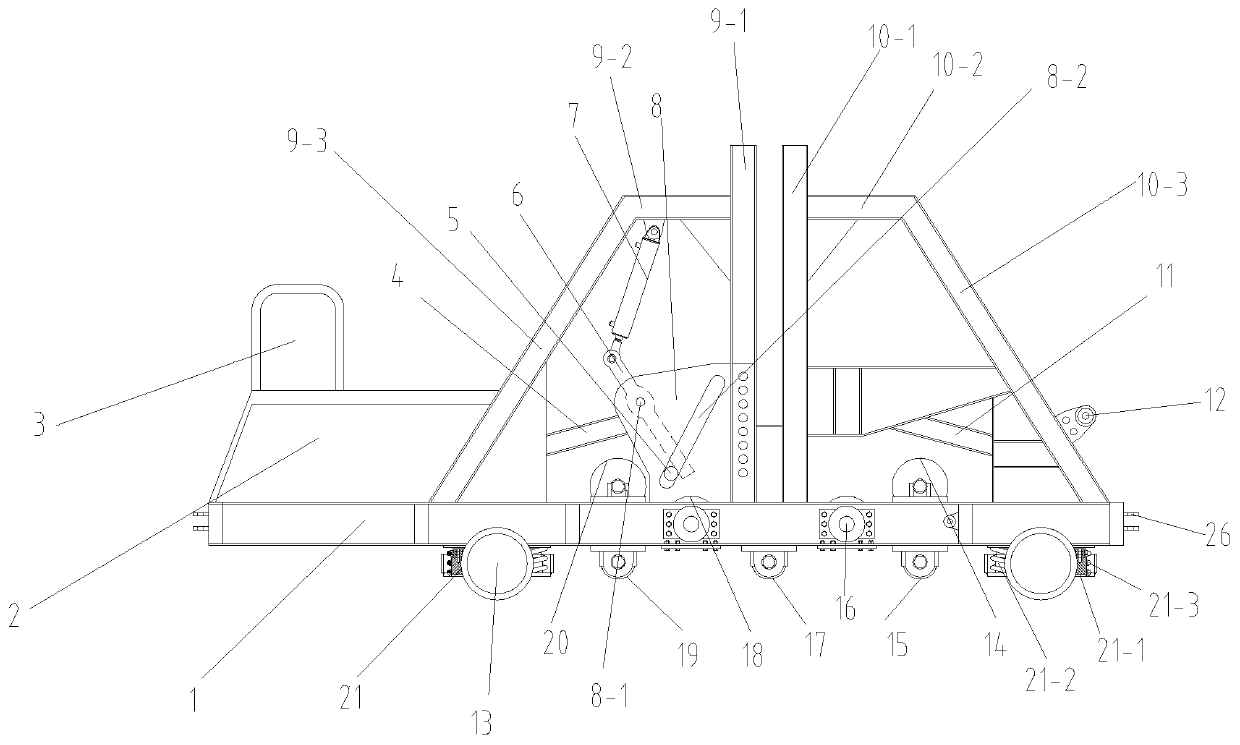

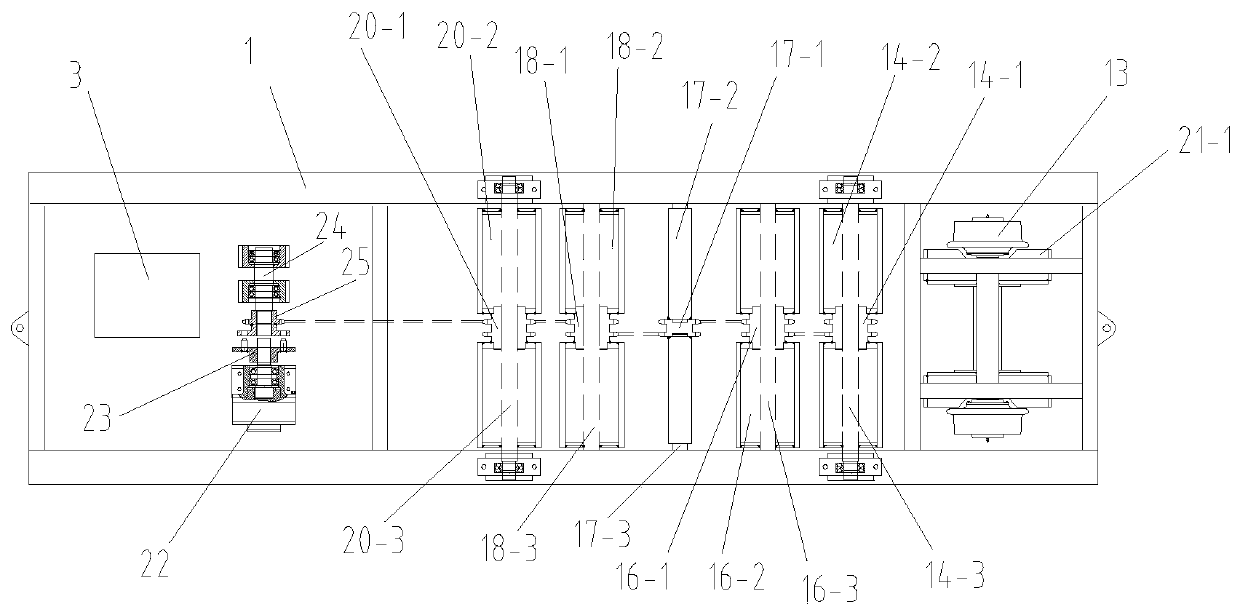

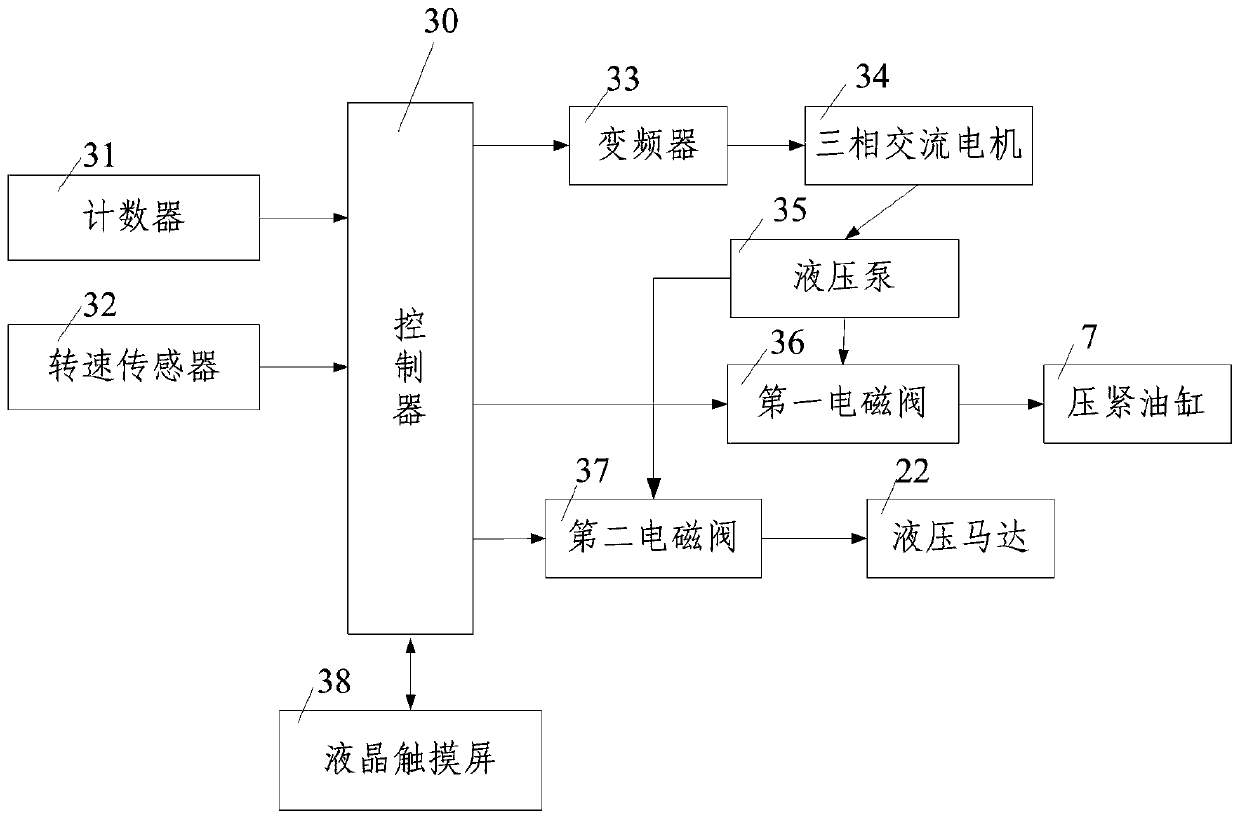

[0065] like figure 1 and image 3 The shown conveyor belt winding trolley includes a frame, a conveyor belt winding device arranged on the frame and winding the conveyor belt, and a winding and pressing device arranged on the frame , and a monitoring device for monitoring the conveyor belt winding device and the winding and pressing device, the conveyor belt winding device includes a reel installed on the frame and used for the conveyor belt to be wound, for the The feeding mechanism that continuously feeds the reel into the conveyor belt and the feeding driving mechanism that drives the rotation of the feeding mechanism, the feeding driving mechanism is installed on the frame, and the winding and pressing device includes two groups of symmetrically arranged and respectively A winding and pressing mechanism for pressing both ends of the reel, and two sets of the winding and pressing mechanisms include a pressing swing arm 6 and a pulling and pressing swing arm 6 for pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com