Patents

Literature

63results about How to "Realize continuous transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Angular bevel gear mechanism

ActiveCN101782129AReduced structureSmall geometryPortable liftingToothed gearingsDrive wheelElectric machine

Owner:SOUTH CHINA UNIV OF TECH

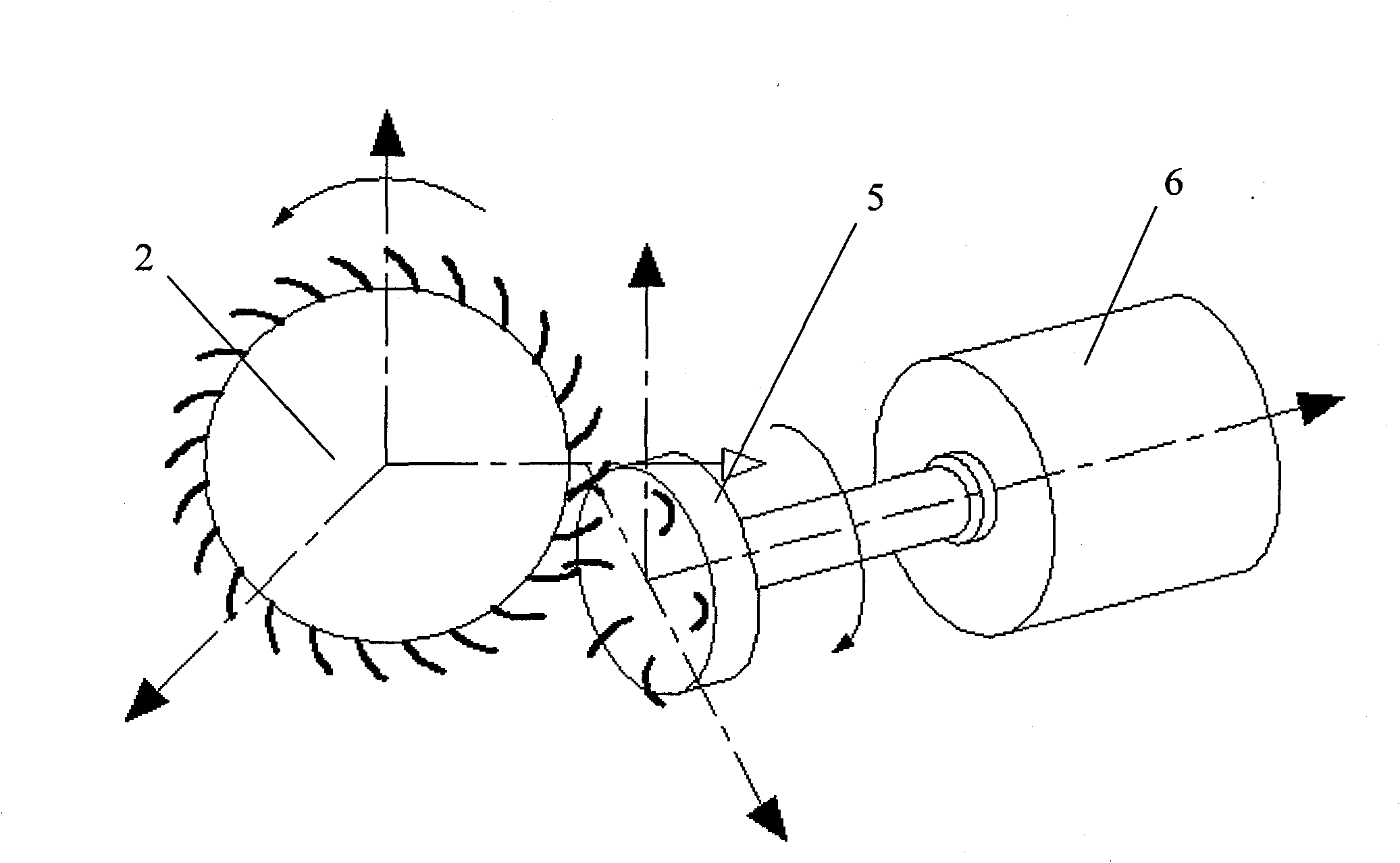

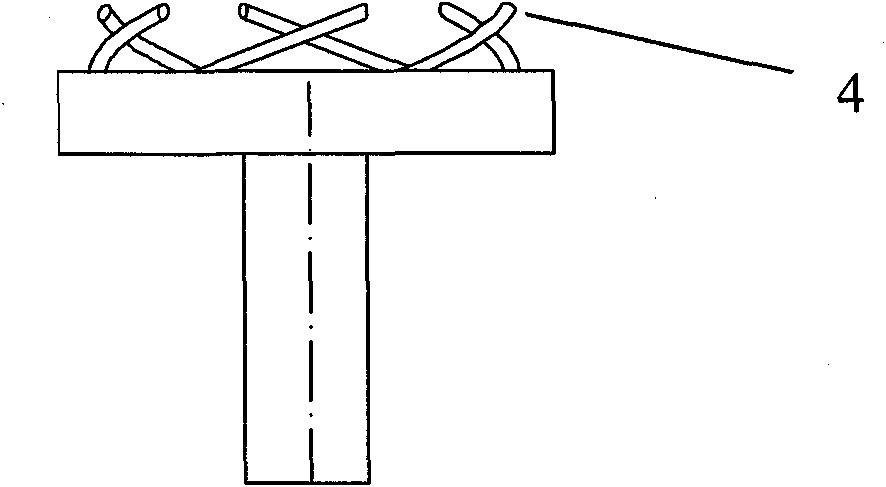

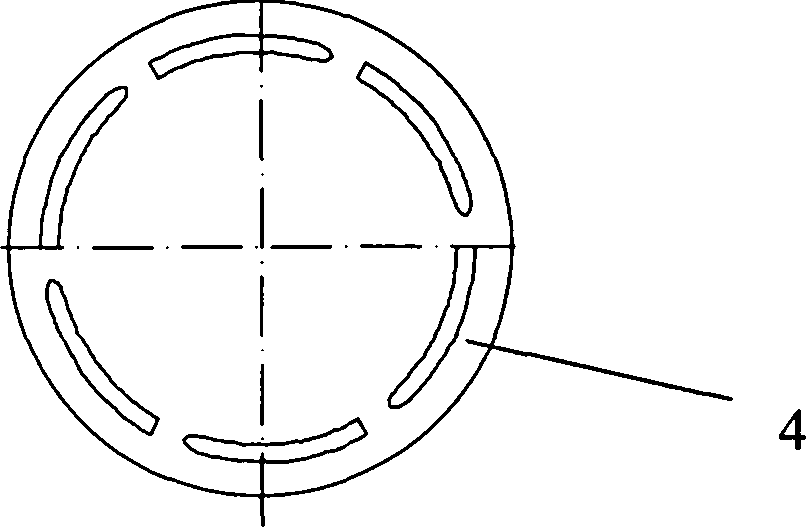

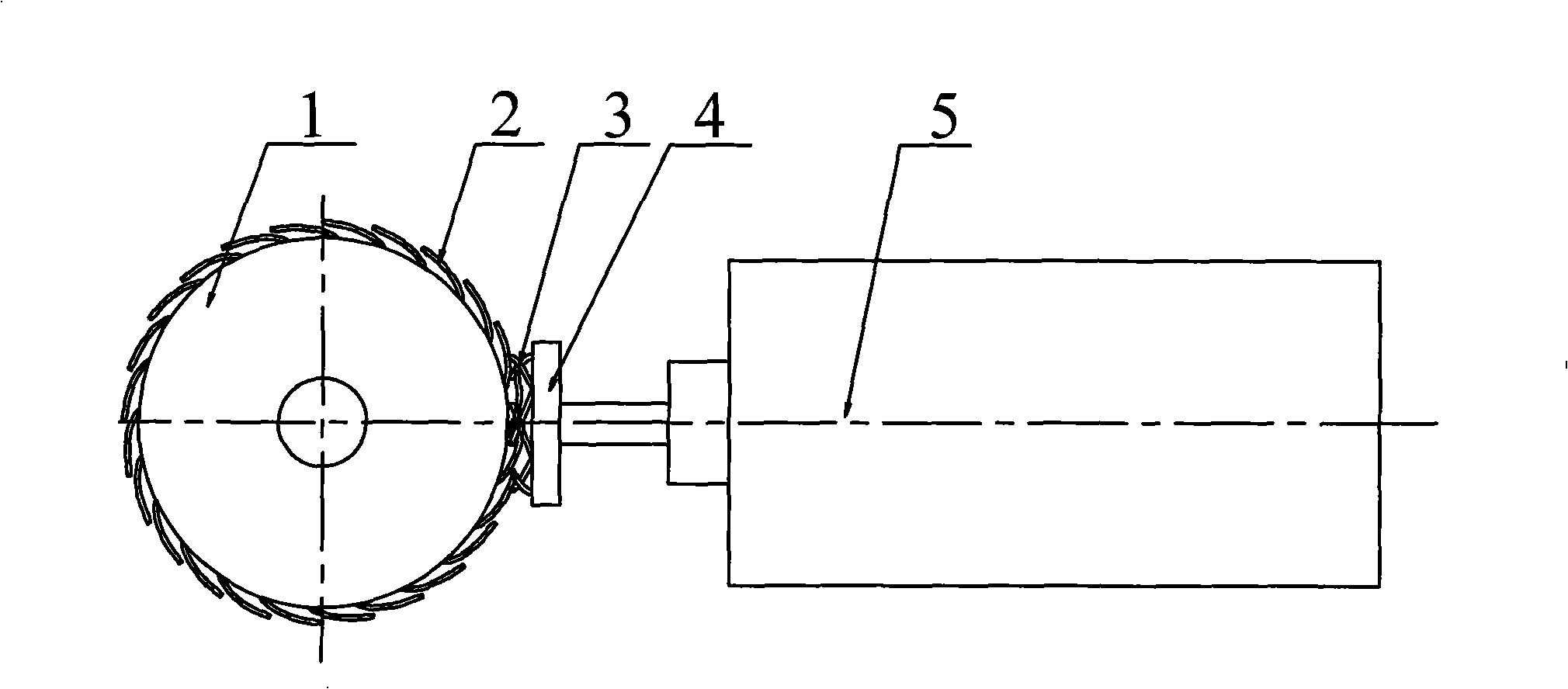

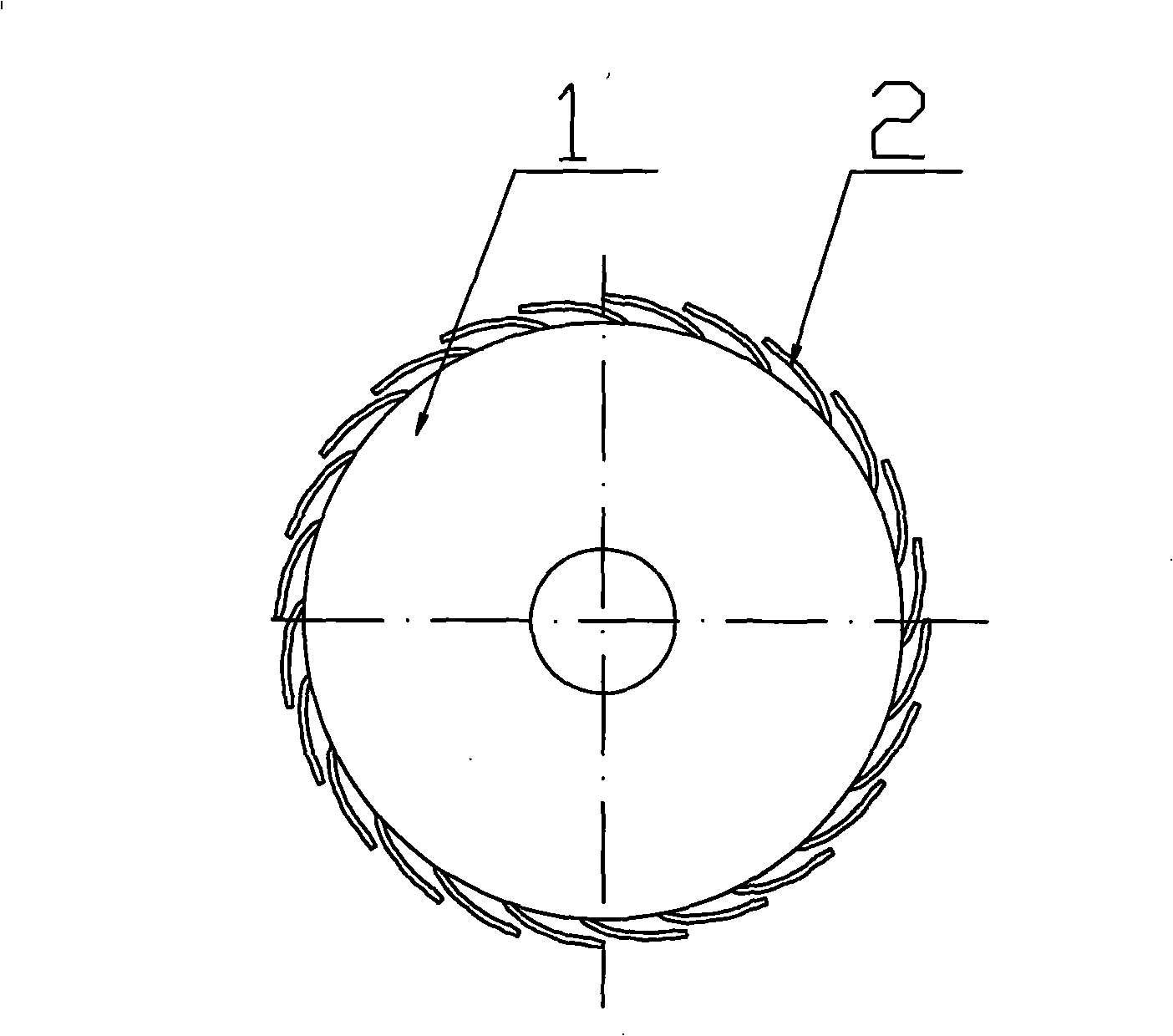

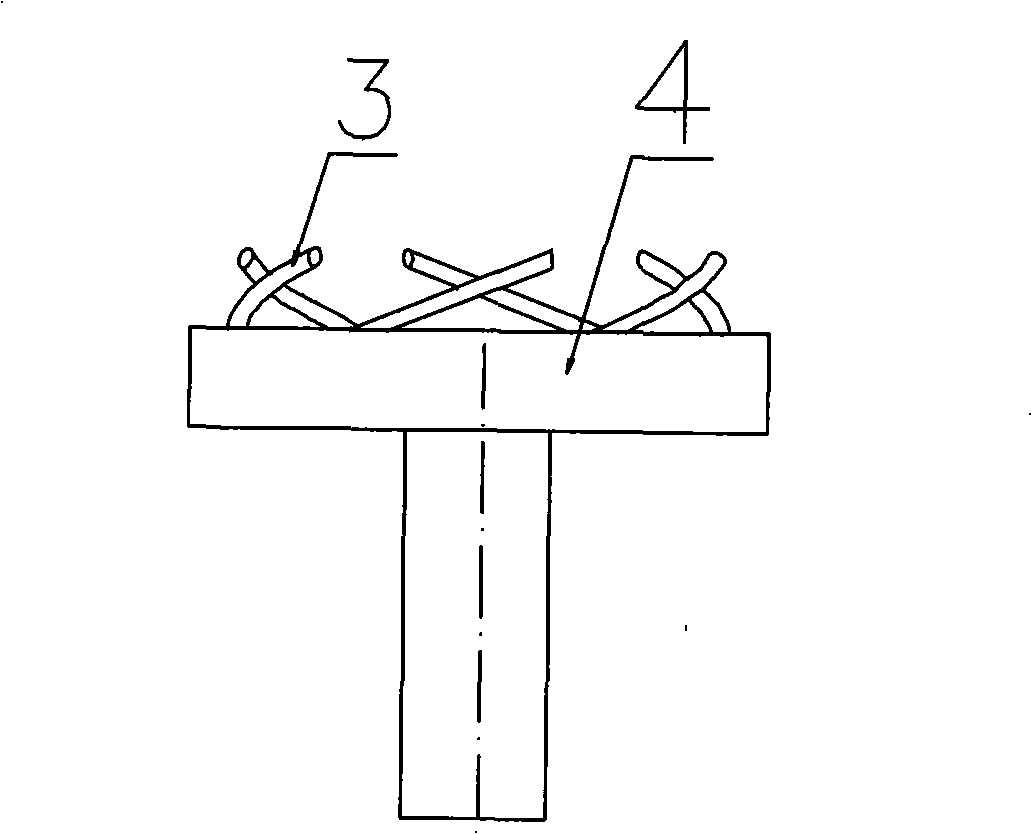

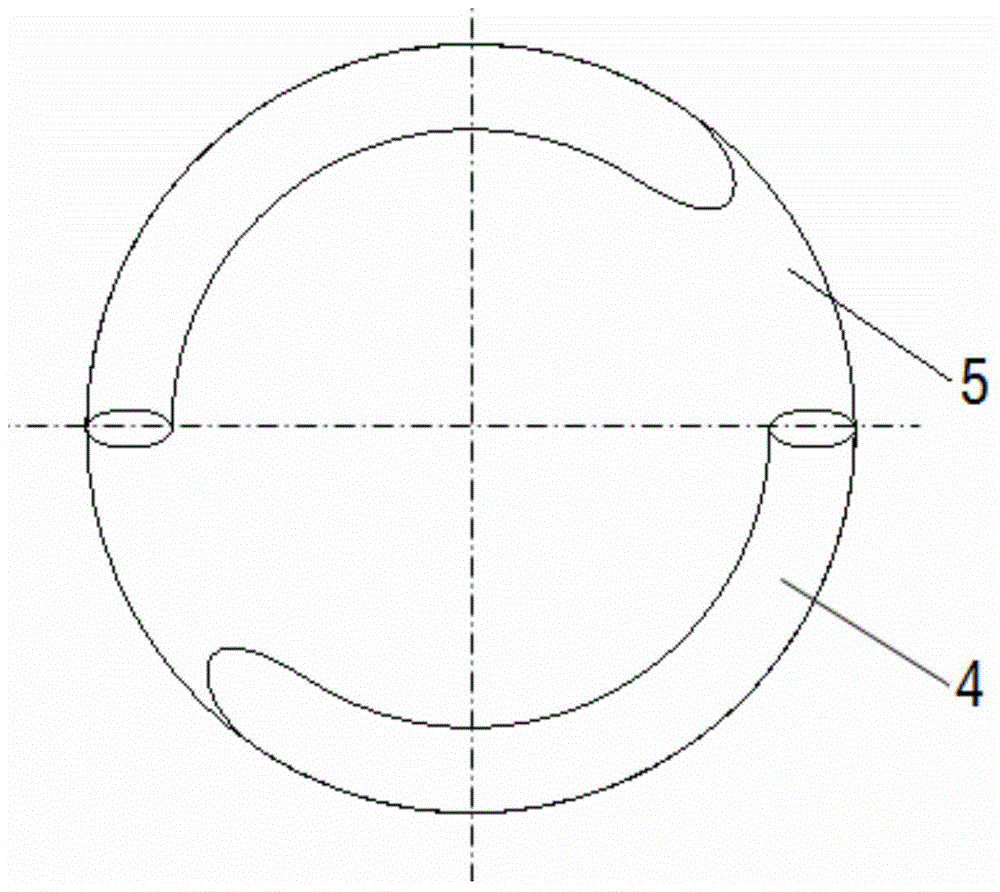

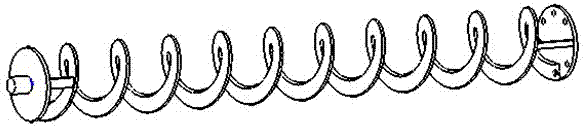

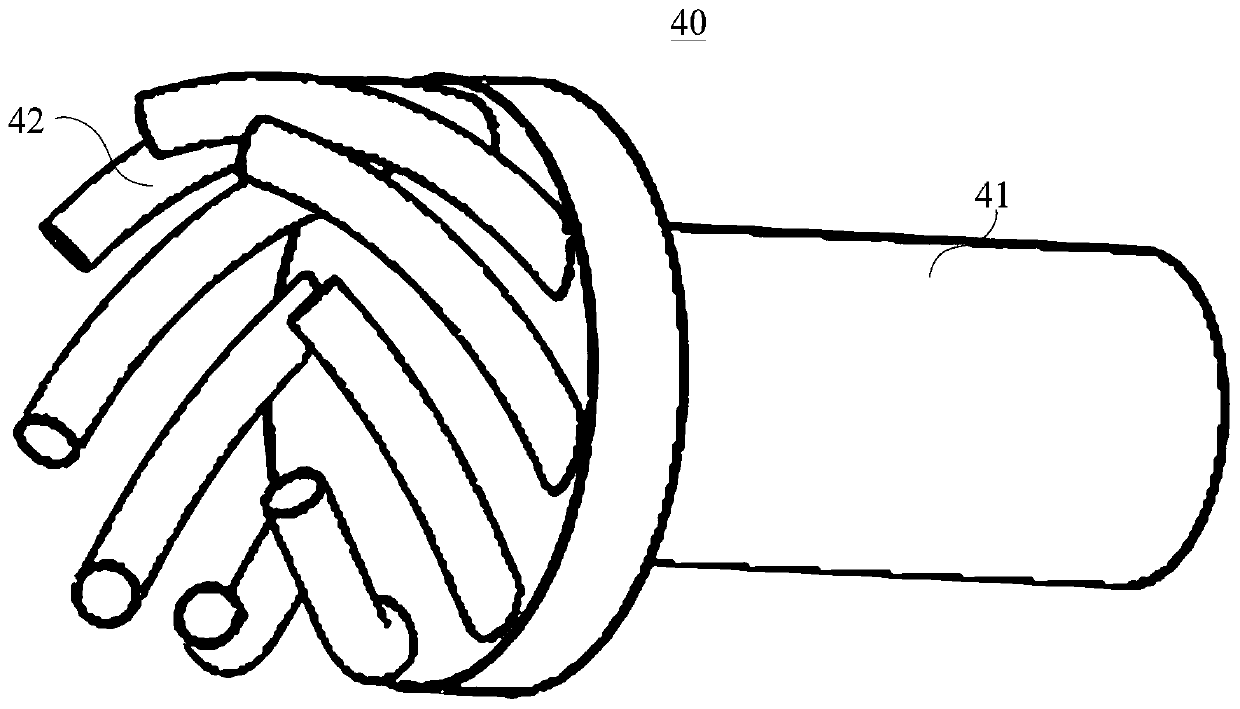

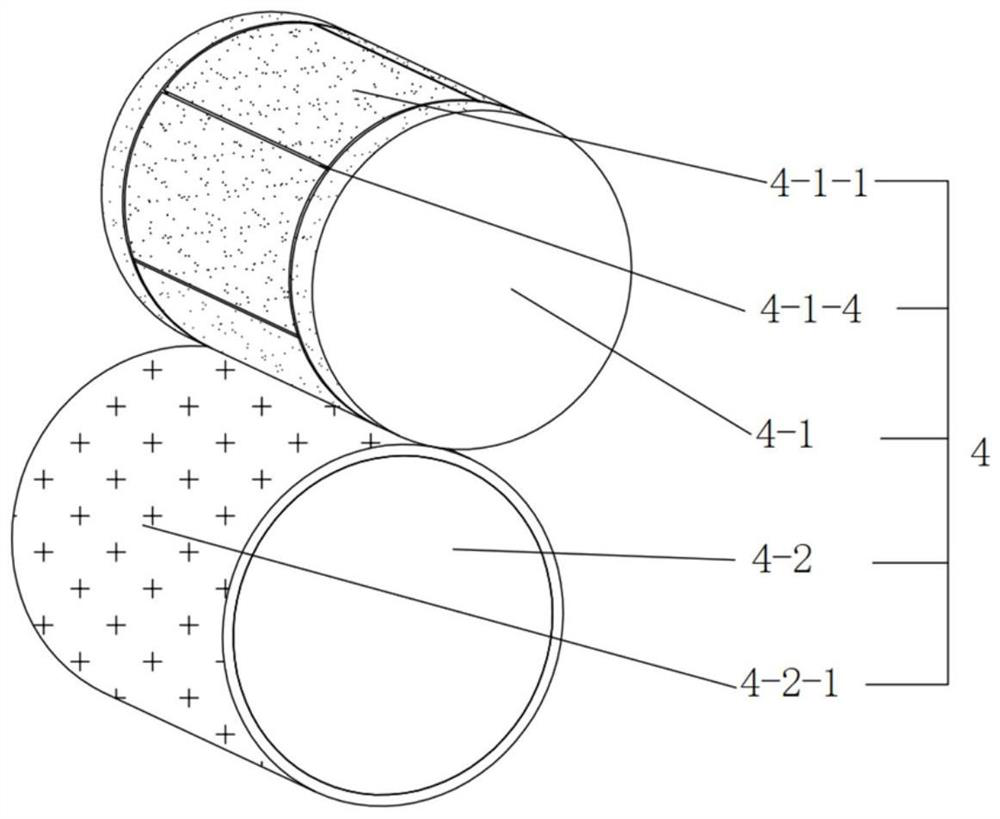

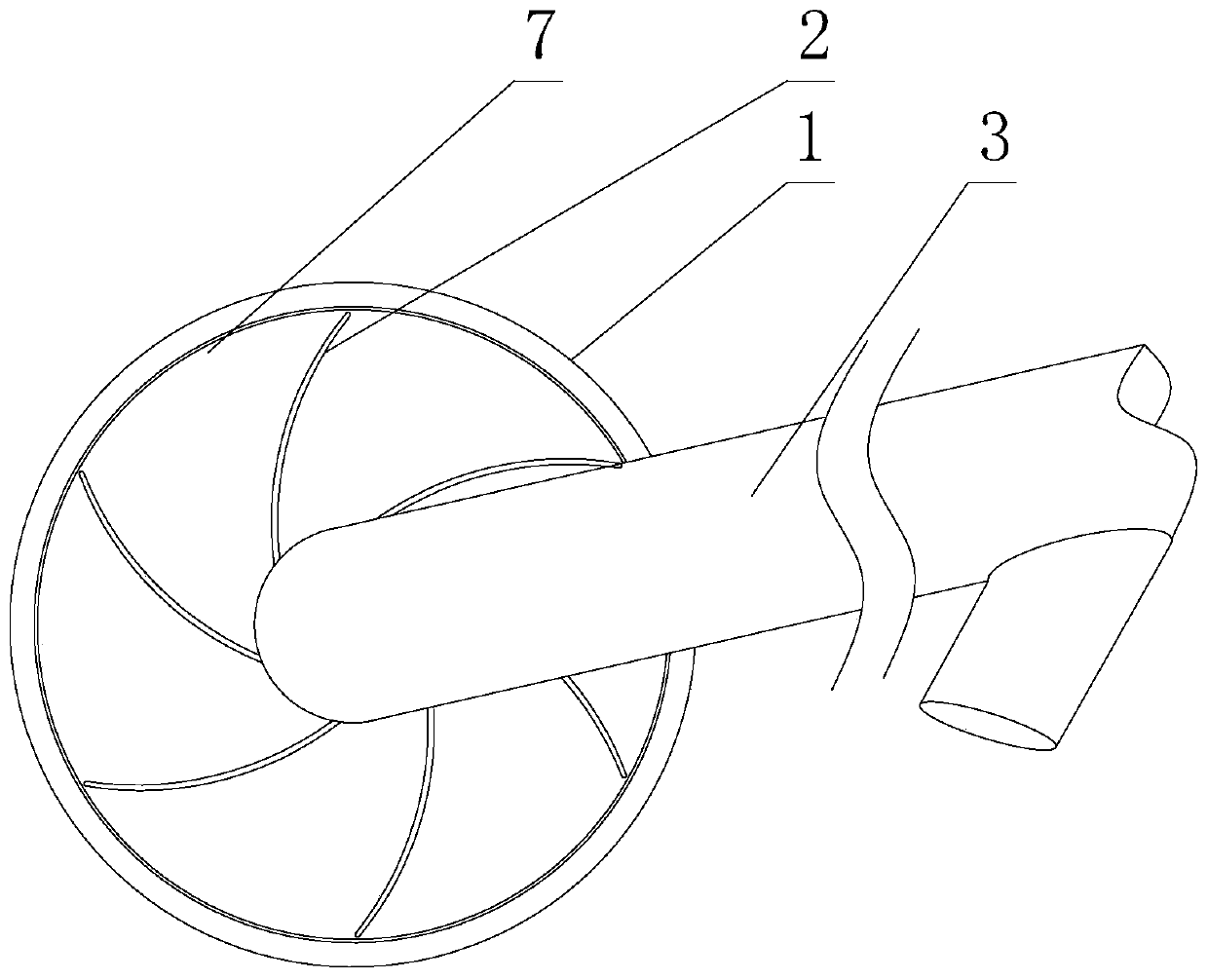

Space curve engagement transmission mechanism

The invention discloses a space curve engagement and transmission mechanism, which is a novel transmission mechanism on the bases of the engagement principle of space curves. The transmission mechanism comprises a driving wheel, a driven wheel, a plurality of driving wheel hook levers and a plurality of driven wheel hook levers, wherein, the driving wheel hook levers are uniformly arranged on the end surface of the driving wheel; the driven wheel hook levers are uniformly arranged on the circumference of the driven wheel in a single row; the driving wheel hook levers and the driven wheel hook levers are in a conjugated spatial engaging curved shape; the driving wheel and the driven wheel which have mutually vertical axes form a transmission pair; and when the driving wheel is rotated, continuous stable engagement transmission is generated between the driving wheel hook levers and the driven wheel hook levers. The transmission mechanism has the advantages as follows: the mechanism is provided with only one transmission pair so that the number of transmission unit parts is minimized and the structure of the transmission unit is quite simple; transmission with high transmission ratio, such as the transmission of worm and gear, is achieved; and since two wheel axles are positioned on the same plane, the space dimension is smaller and the process is easy.

Owner:SOUTH CHINA UNIV OF TECH

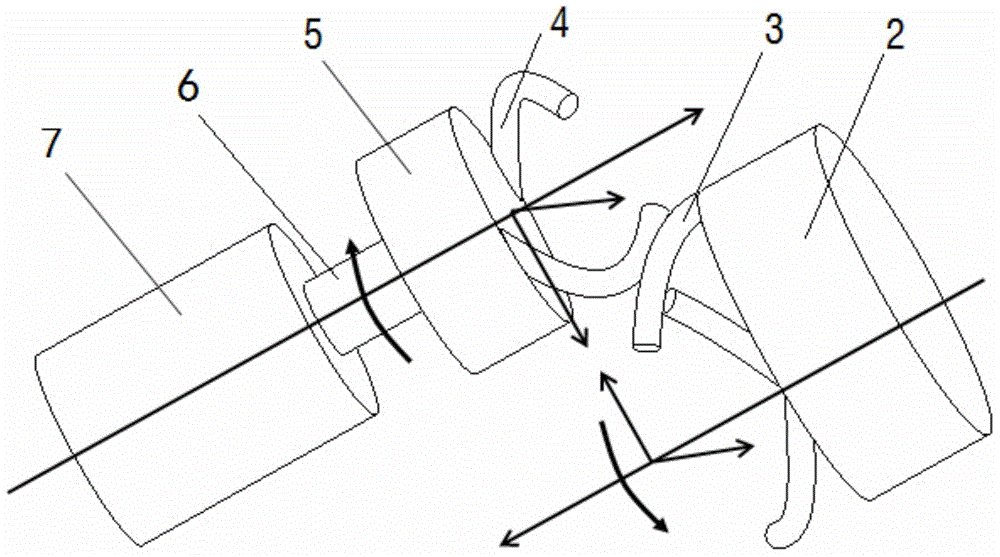

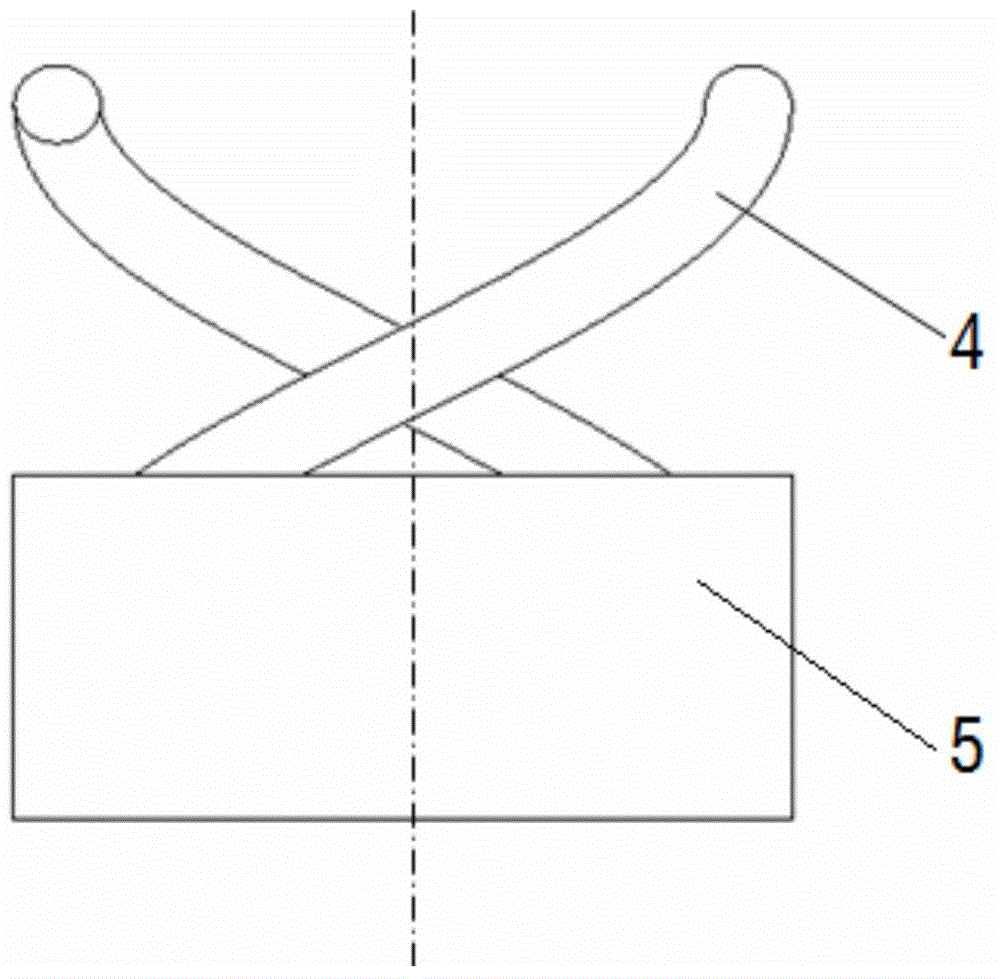

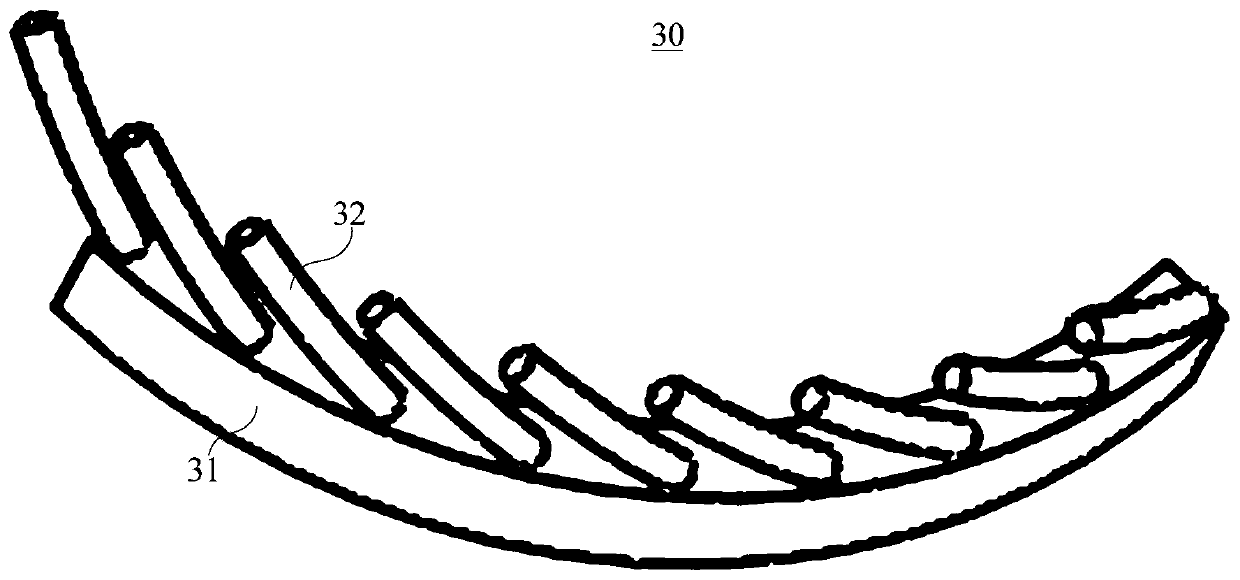

Hook rod gear mechanism for parallel shaft transmission

The invention relates to a hook rod gear mechanism for parallel shaft transmission. The hook rod gear mechanism comprises a transmission pair composed of a driving wheel and a driven wheel. The axis of the driving wheel and the axis of the driven wheel are parallel to each other. The driving wheel is connected with an input shaft. The driven wheel is connected with an output shaft. Driving hook rods on the driving wheel are evenly distributed in the circumference of the cylindrical end face of the driving wheel. Driven hook rods on the driven wheel are also evenly distributed in the circumference of the cylindrical end face of the driven wheel. The driving hook rods and the driven hook rods are each in a cylindrical spiral linear shape. When the driving wheel and the driven wheel are installed, the driving hook rod and the driven hook rod in one pair are meshed, the driving wheel is driven by a driver to rotate, the continuous and stable meshing is completed through the meshed hook rods, and transmission between the two parallel shafts is achieved. The spiral linear shapes of the driving hook rods and the driven hook rods can be determined according to the installation spatial coordinate system, the transmission ratio and other parameters of the driving wheel and the driven wheel and according to the hook rod contact line equation. The hook rod gear mechanism is simple in structure, fewer in transmission mechanism part, small in size, light in weight, large in transmission ratio, stable in transmission and suitable for being applied to the fields of mini machines and micro machines.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

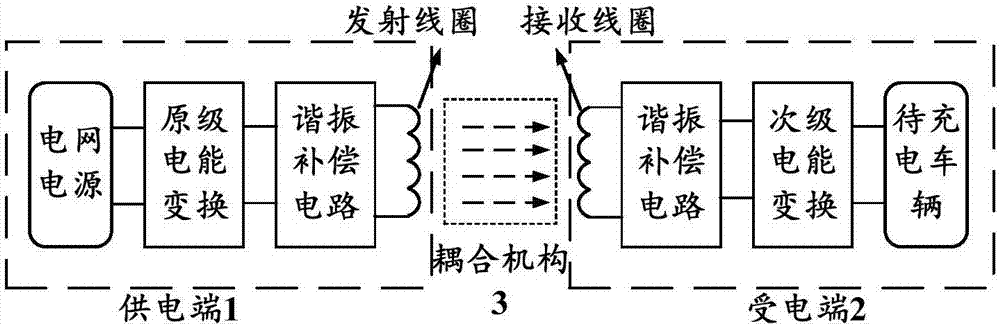

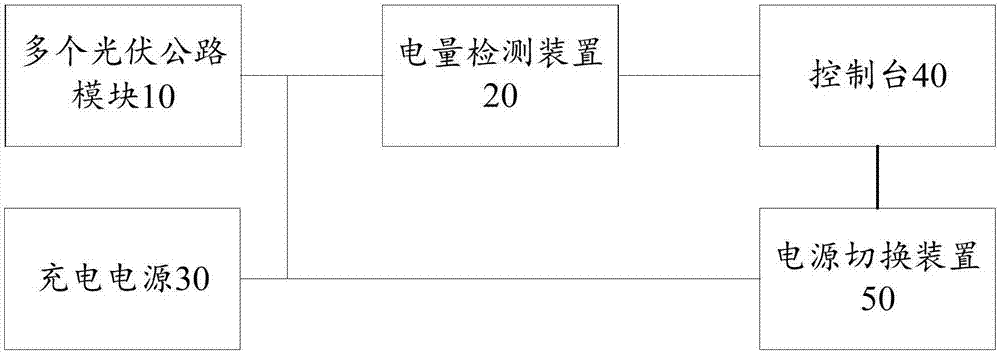

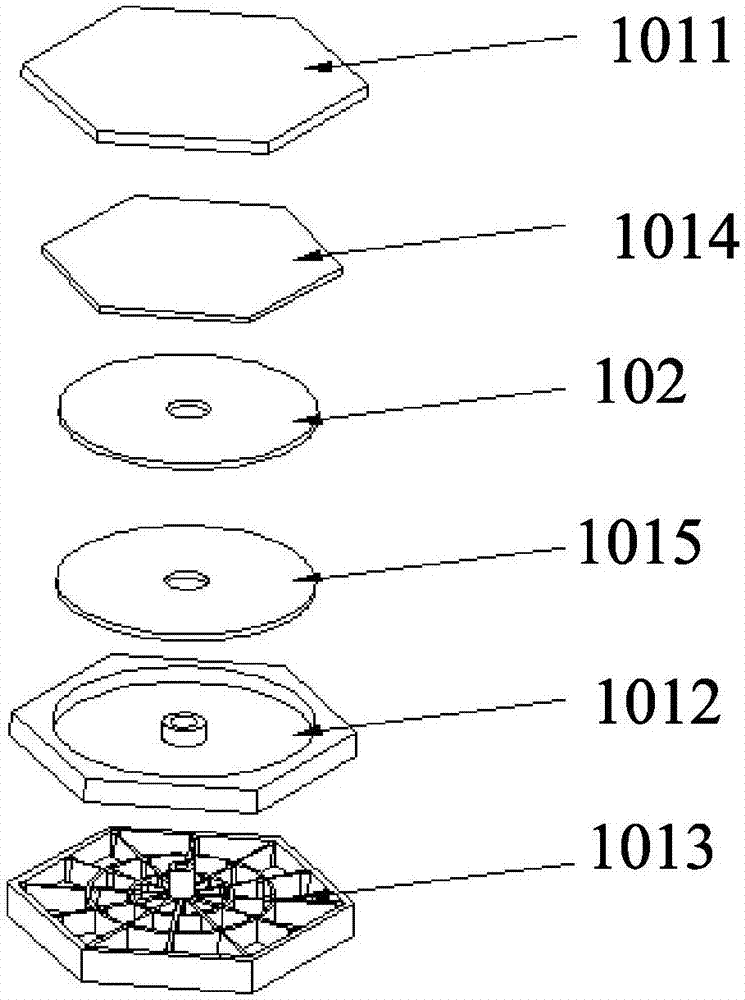

Photovoltaic highway induction wireless charging system and charging system of vehicle

PendingCN107069873AImprove convenienceRealize continuous transmissionBatteries circuit arrangementsCharging stationsEngineeringElectric vehicle

The present invention provides a photovoltaic highway induction wireless charging system and a charging system of a vehicle. The photovoltaic highway induction wireless charging system comprises a plurality of photovoltaic road modules, an electric quantity detection device, a charging power source, a console and a power source switching device; each photovoltaic road module comprises a photovoltaic power generation device and an emission coil; the plurality of photovoltaic road modules are arranged in a rail arrangement mode and / or an array arrangement mode; the photovoltaic power generation devices are used for converting solar energy into electrical energy and storing the electric energy in an energy storage device; the electric quantity detection device is used for detecting an electric quantity value in the energy storage device; the console is used for determining the working state of the charging power source according to the electric quantity value and the control instruction of the console; and the power source switching device is used for controlling the energy storage device and one or more low-frequency alternating-current power sources to supply electric energy for the charging power source according to the working state of the charging power source. With the photovoltaic highway induction wireless charging system and the charging system of the vehicle of the invention adopted, the technical problem of complicated operation caused by a complex installation mode of an existing electric vehicle charging device can be solved.

Owner:ZONECHARGE (SHENZHEN) WIRELESS POWER TECH CO LTD

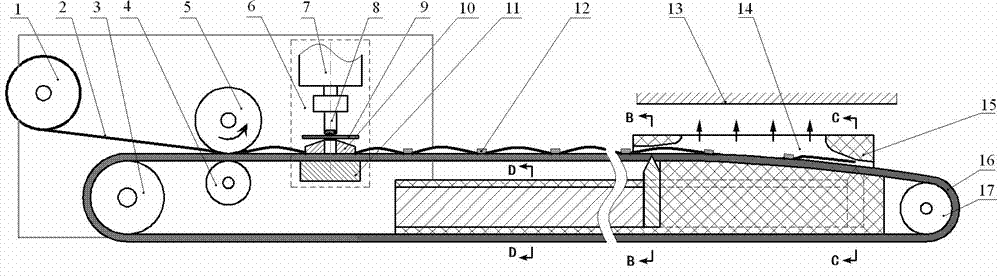

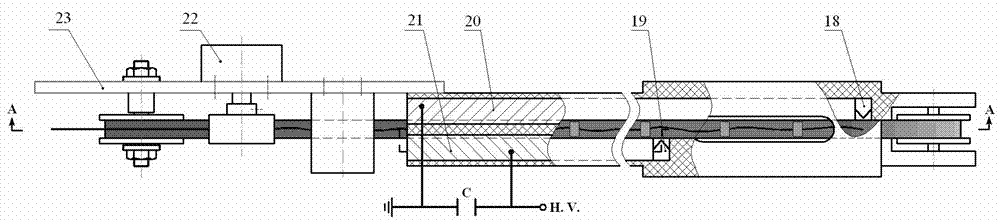

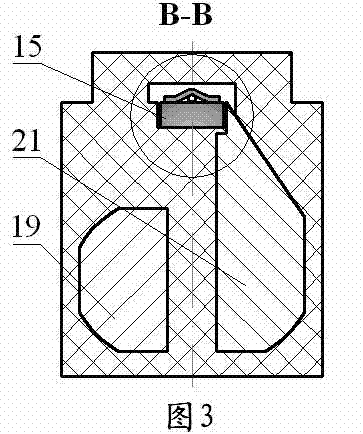

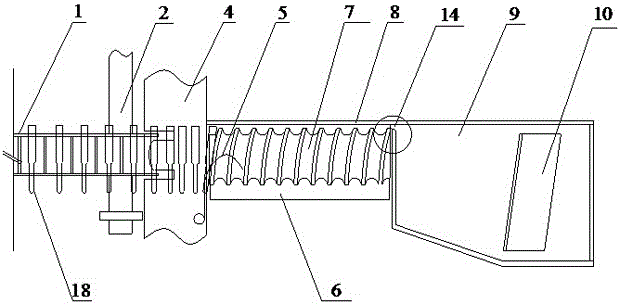

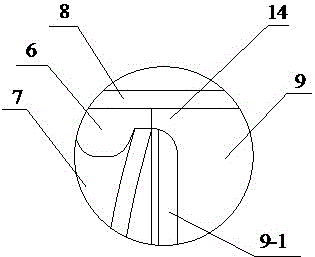

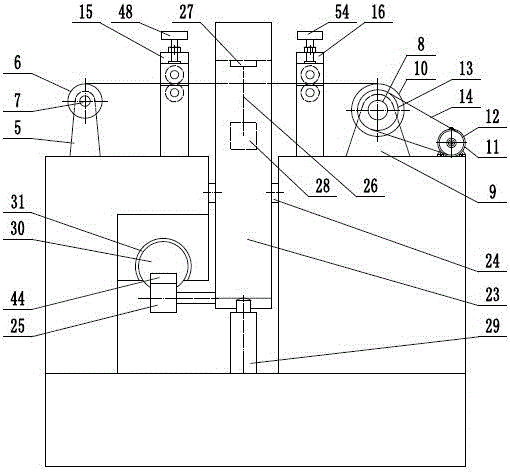

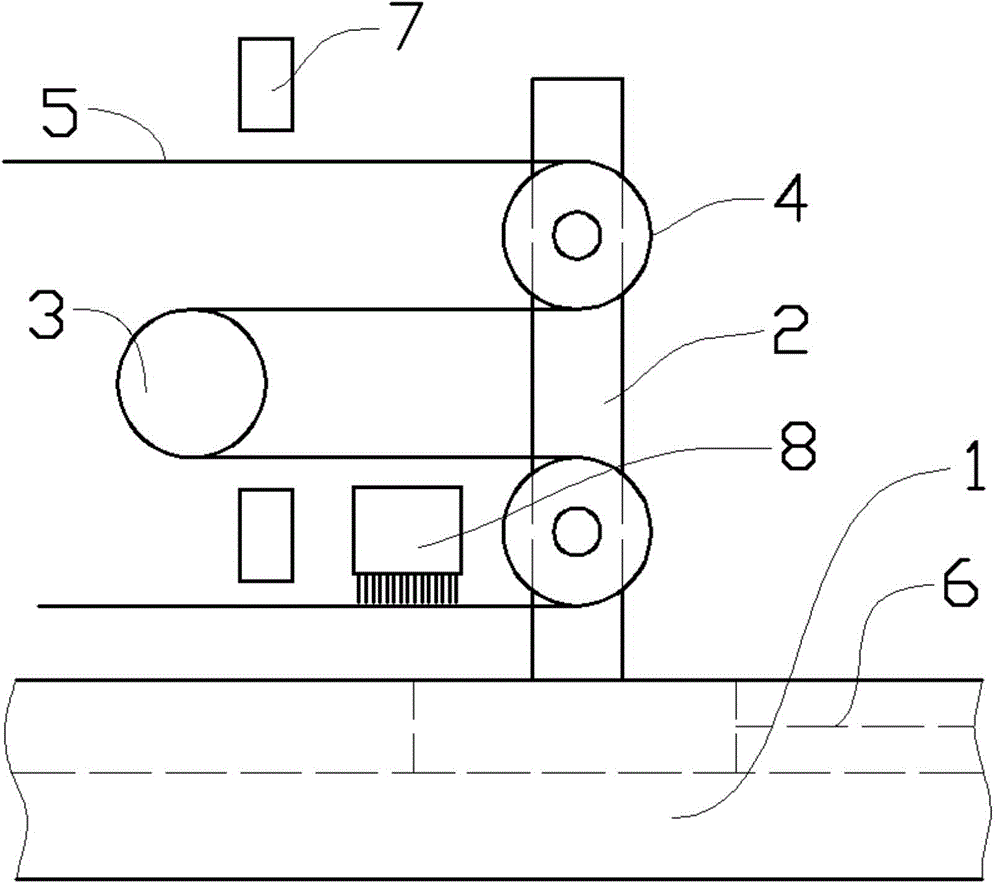

Continuous electric explosive spraying device for hole inner wall wires

InactiveCN102864433ARealize continuous transmissionEnables directional sprayingMolten spray coatingVacuum evaporation coatingEngineeringMechanical engineering

A continuous electric explosive spraying device for hole inner wall wires comprises a long electric-conducting support body, a drive mechanism and an electric explosive chamber. One end of the long electric-conducting support body is connected with two poles of a high-voltage energy accumulator (C), the other end of the long electric-conducting support body is provided with the explosive chamber (15), the explosive chamber (15) extends into a base body tubular cavity (13) along with the long electric-conducting support body, metal wires (2) are continuously transmitted by the drive mechanism into the explosive chamber (15) so as to enable a positive pole (18) and a negative pole (19) to explode in a high-voltage electric field, an explosive product is jetted onto an inner wall of the base body tubular cavity (13) along a jetting window (14) at the ultra-high speed, and continuous electric explosion and directional spraying of the hole part inner wall wires are achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

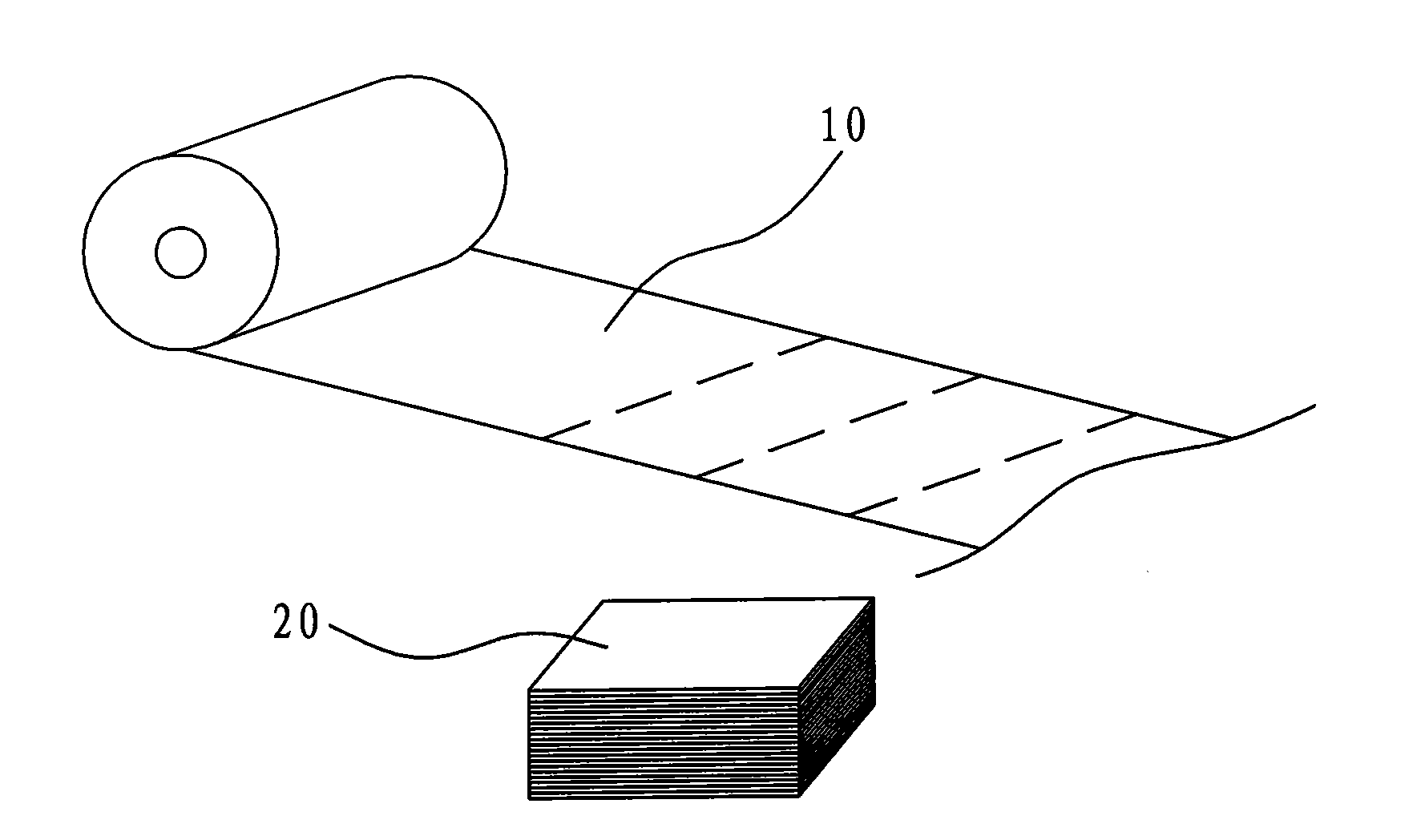

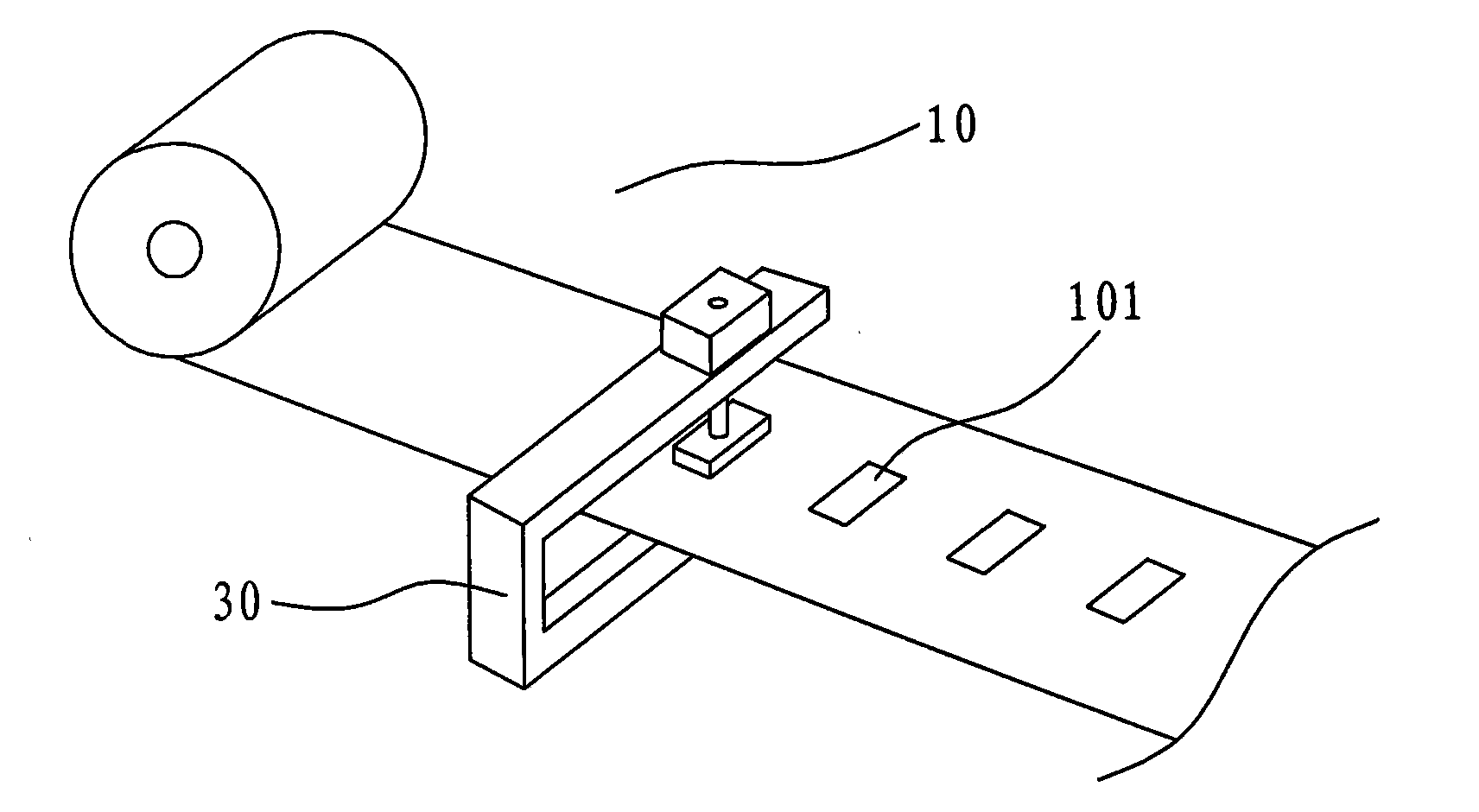

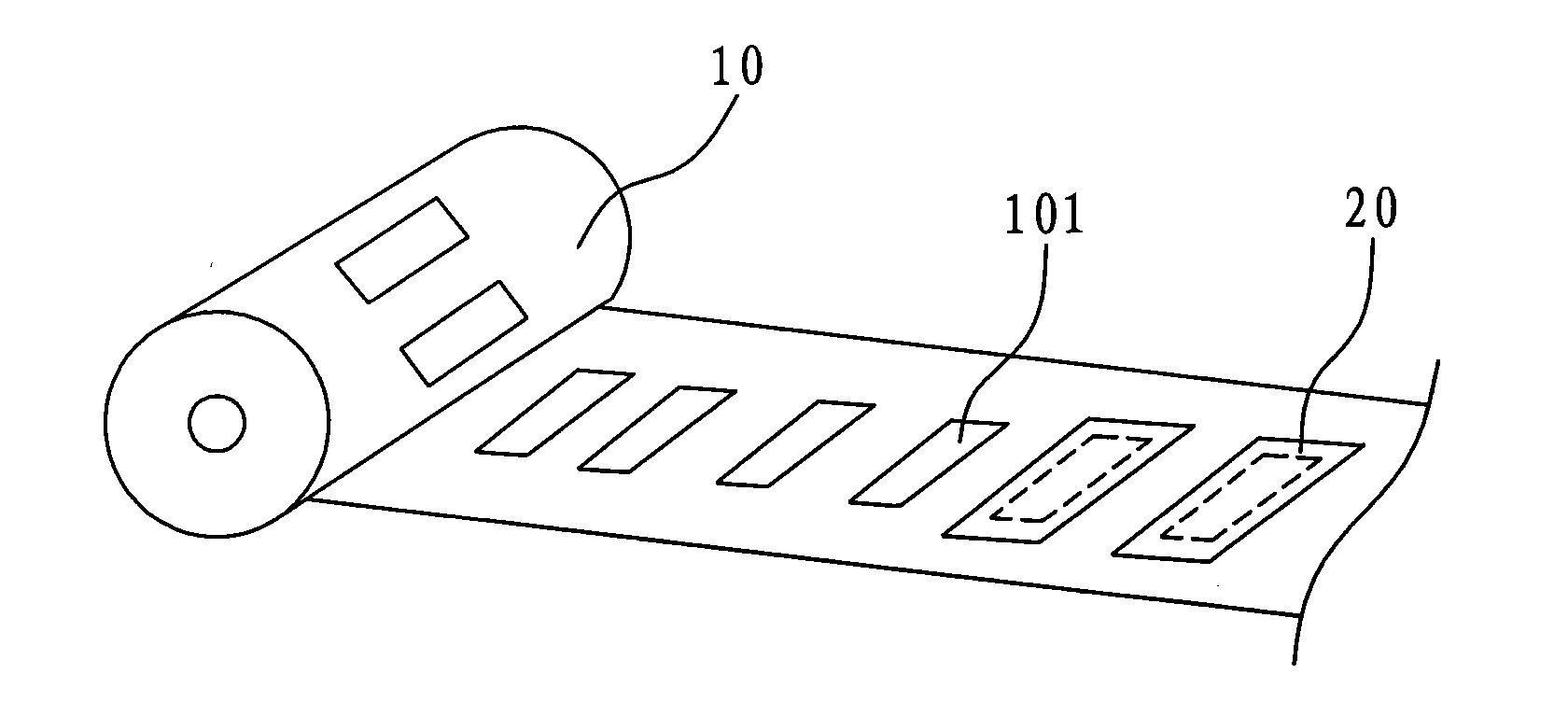

Method for manufacturing paper-plastic composite bag with window

InactiveCN102069602AVolume has little effectProduction costs are not affectedBox making operationsPaper-makingMolded pulpEngineering

The invention discloses a method for manufacturing a paper-plastic composite bag with a window, which comprises the steps of: (1) longitudinally cutting a window with preset width at the needed position of paper; (2) spreading glue on the surface on one side of a plastic film except the area corresponding to the window; (3) oppositely laminating the paper with one surface of the plastic film spreading with the glue to form a composite material; and (4) molding the composite material into the bag with the window which has the needed specification and shape. The manufacturing method is high in continuity of manufacturing procedures and high in production efficiency; and the product has unlimited window size and is low in manufacturing cost.

Owner:崔俊

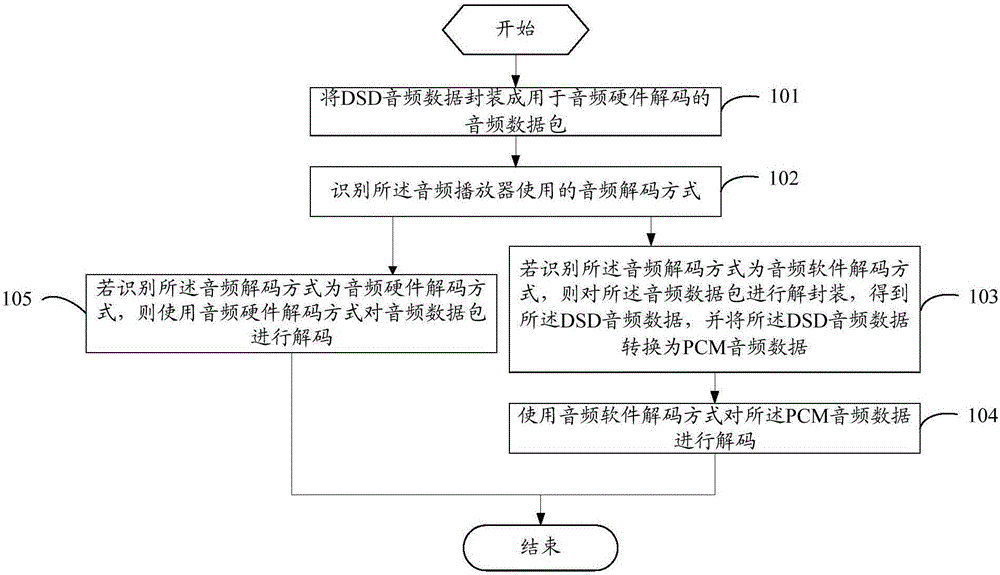

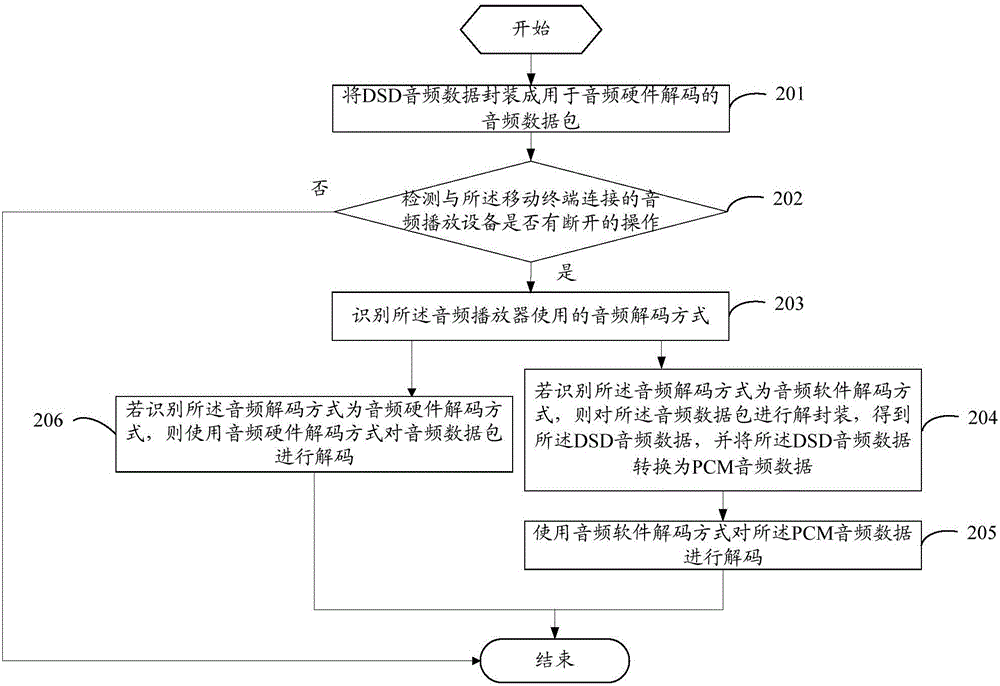

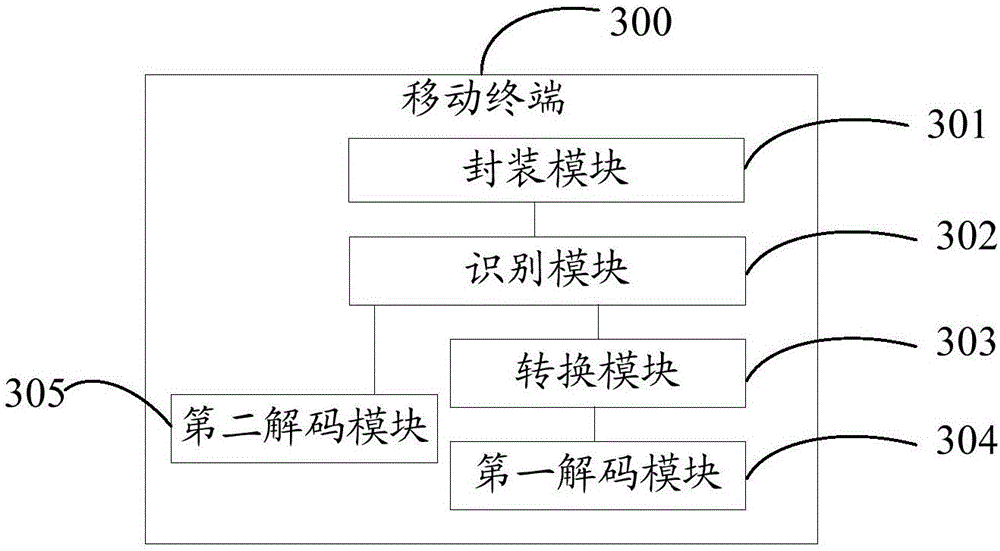

Audio data decoding control method and mobile terminal

ActiveCN106648537AImprove experienceRealize continuous transmissionSound input/outputNetwork packetComputer terminal

The invention provides an audio data decoding control method and a mobile terminal. The method comprises steps of encapsulating DSD audio data into a voice data package capable of being decoded by audio hardware, identifying an audio decoding way used by an audio player, decapsulating the audio data package to achieve DSD audio data if the audio decoding way is an audio software decoding way, converting the DSD audio data into PCM audio data, decoding the PCM audio data via the audio software decoding way, and otherwise decoding the audio data via the audio hardware decoding way. When the audio decoding way used by the player changes, re-transmission of the DSD audio data can be unnecessary; the audio data package can be decoded via the current audio decoding way, so DSD audio data can be continuously transmitted during software and hardware decoding switch, and user experience can be improved.

Owner:VIVO MOBILE COMM CO LTD

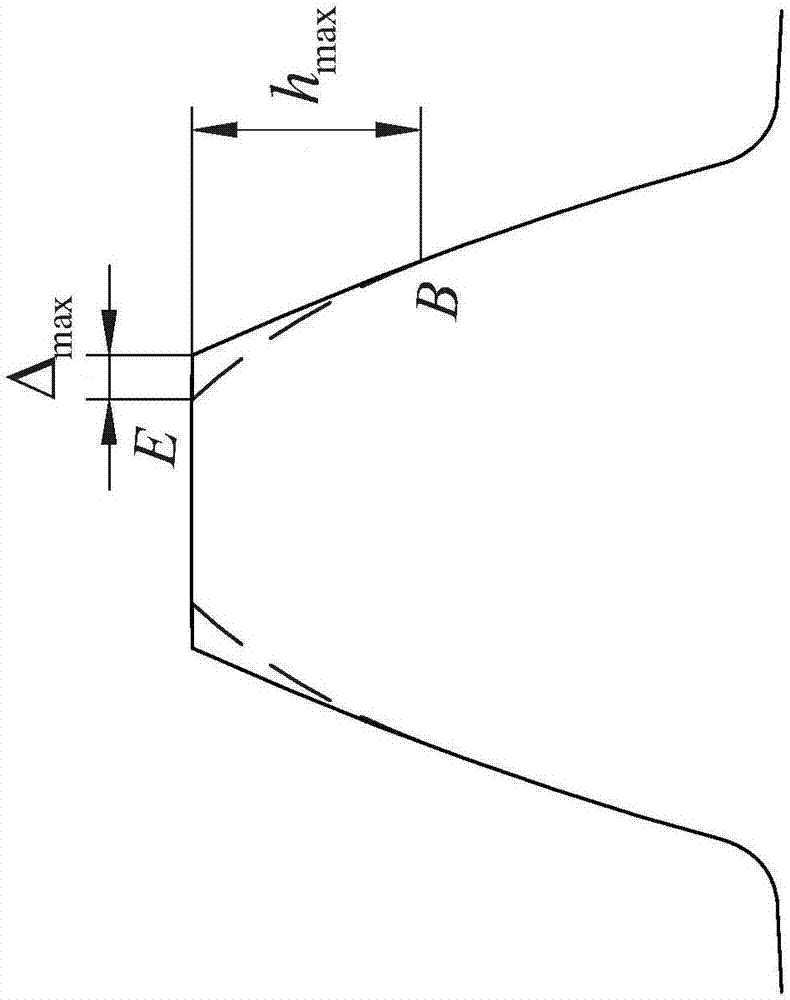

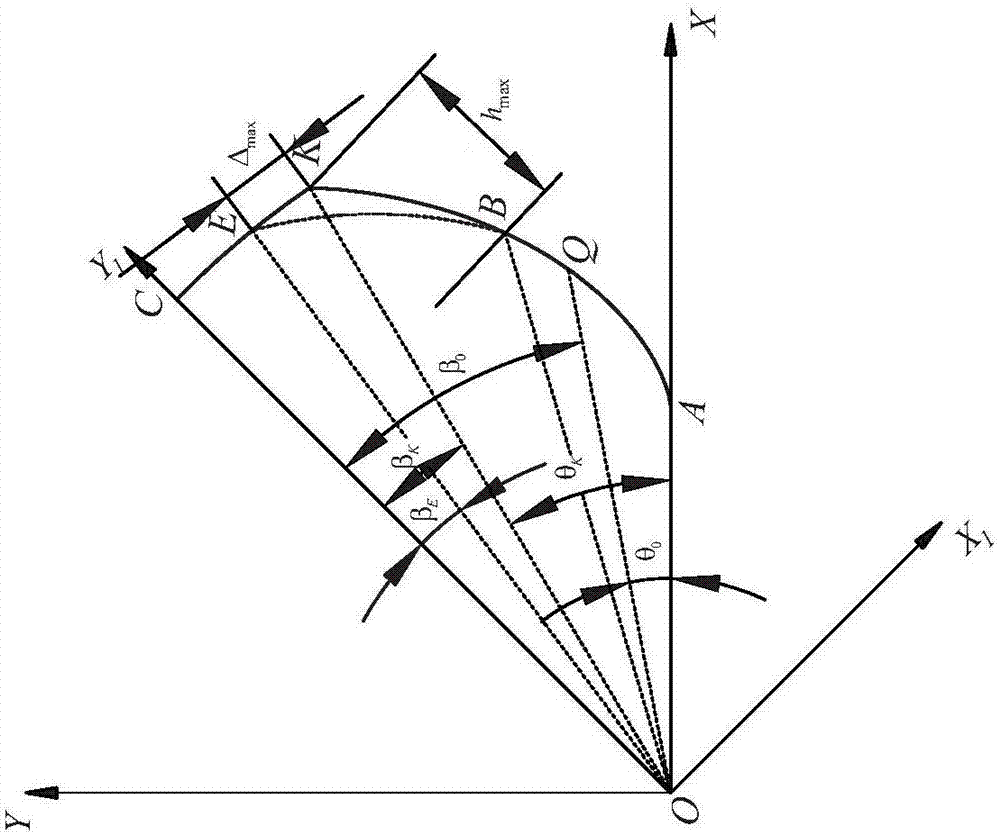

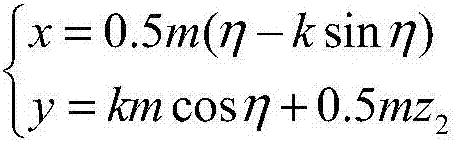

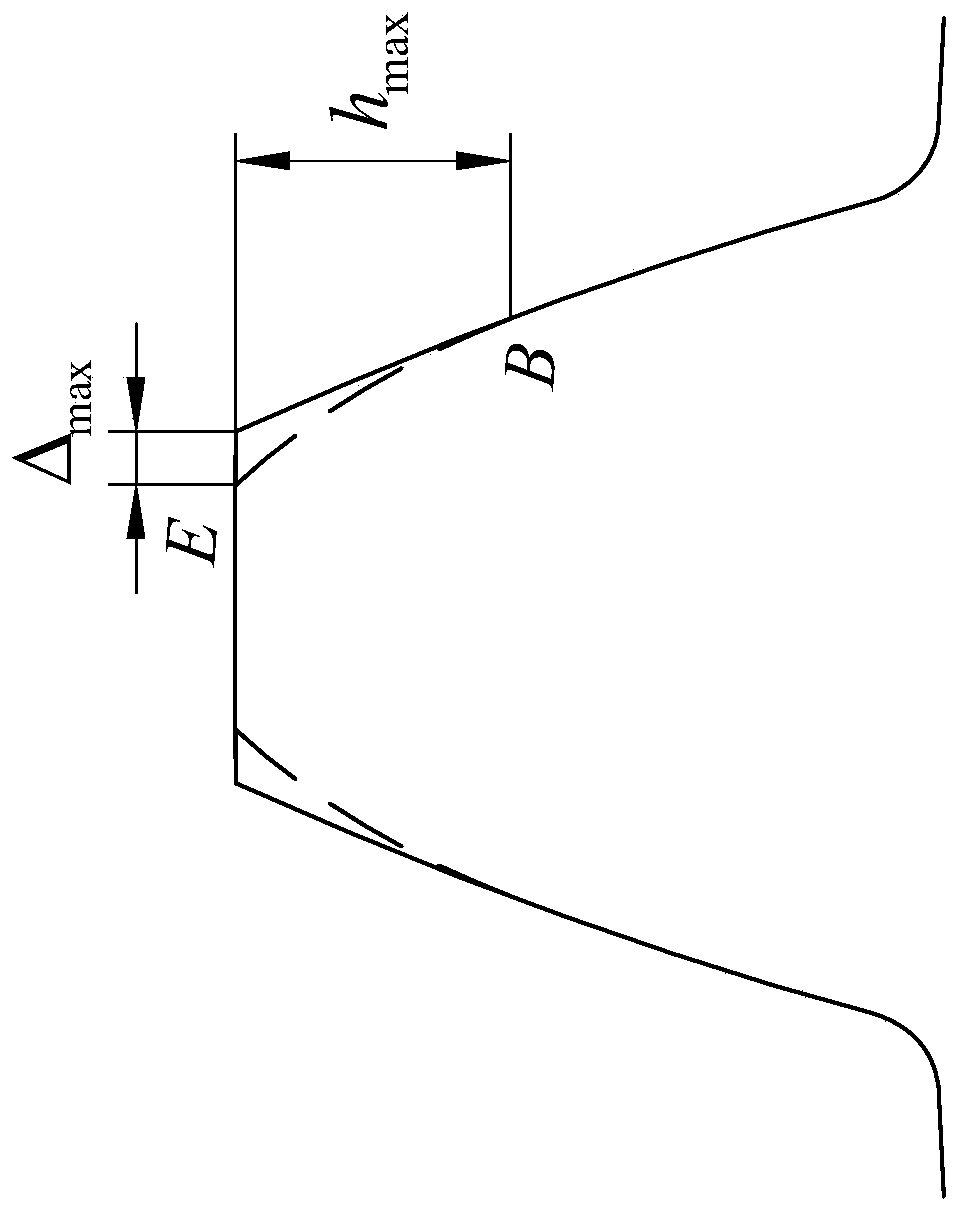

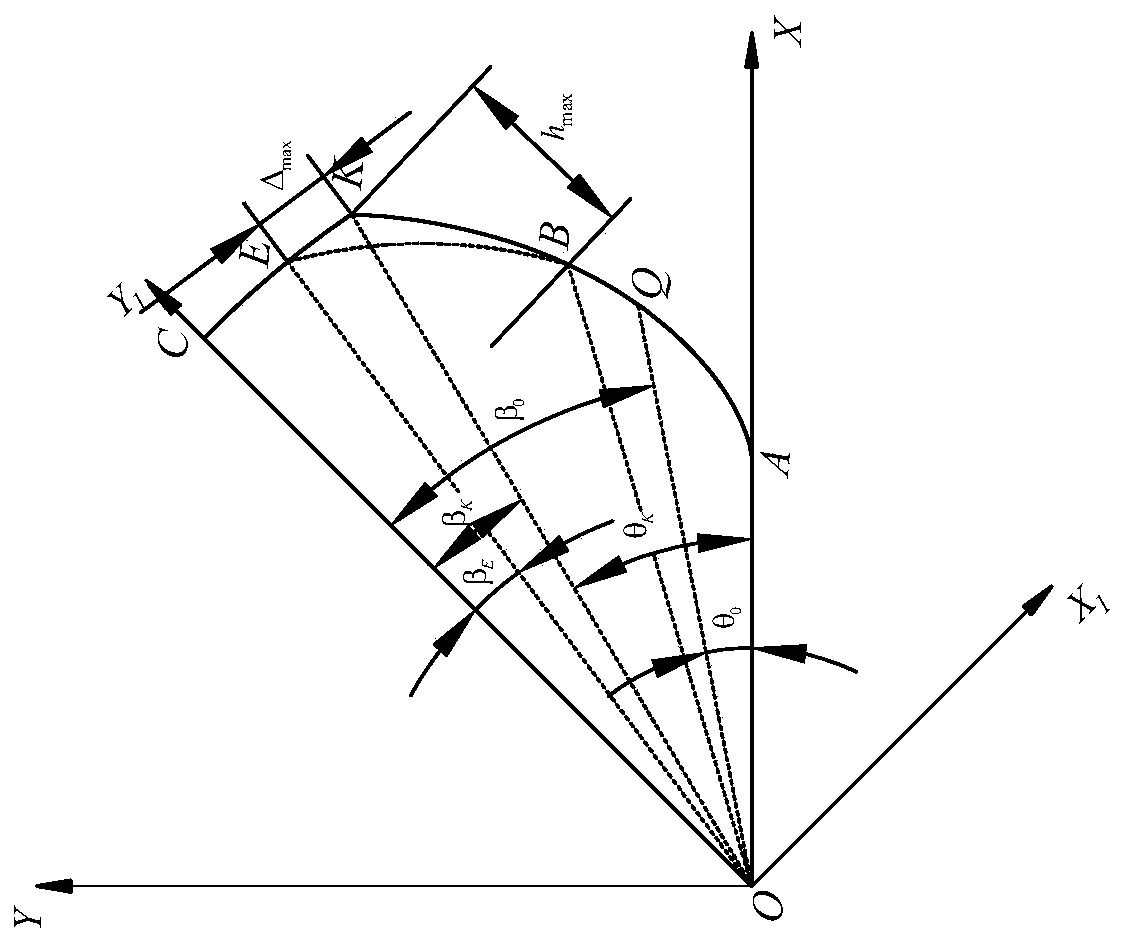

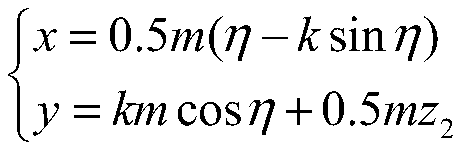

Modification method for harmonic driving involute profile

ActiveCN107882950AIncrease the number of teethSmall engagement backlashGearingPortable liftingKinematic theoryInvolute

The invention discloses a modification method for a harmonic driving involute profile. A point B serves as a point of tangency of a modification curve and a involute tooth surface. A point E serves asa point of intersection of the modification curve and an involute addendum circle. A coordinate system XOY is built with a radial OA as the abscissa axis. A coordinate system X1OY1 is built with a radial OC as the ordinate axis. After the steps of determining the coordinates of the point B and the point E in the coordinate system X1OY1 and the slope of a tangent of the involute at the point B, determining a flexible gear central point approximate movement track curvilinear equation, determining the parameter equation of the modification curve in the coordinate system X1OY1 and the like, a system of simultaneous equations is built and used for solving parameters, and the parameter equation of the modification curve in the coordinate system XOY is obtained through conversion of the coordinate system. According to the modification method, the harmonic driving involute profile is modified based on the harmonic driving kinematics theory, processing manufacturability and economy can be guaranteed, engagement performance is improved, the advantages of various harmonic tooth profiles are integrated, and the modification method can be widely applied to the technical field of harmonic gears.

Owner:国茂精密传动(常州)有限公司

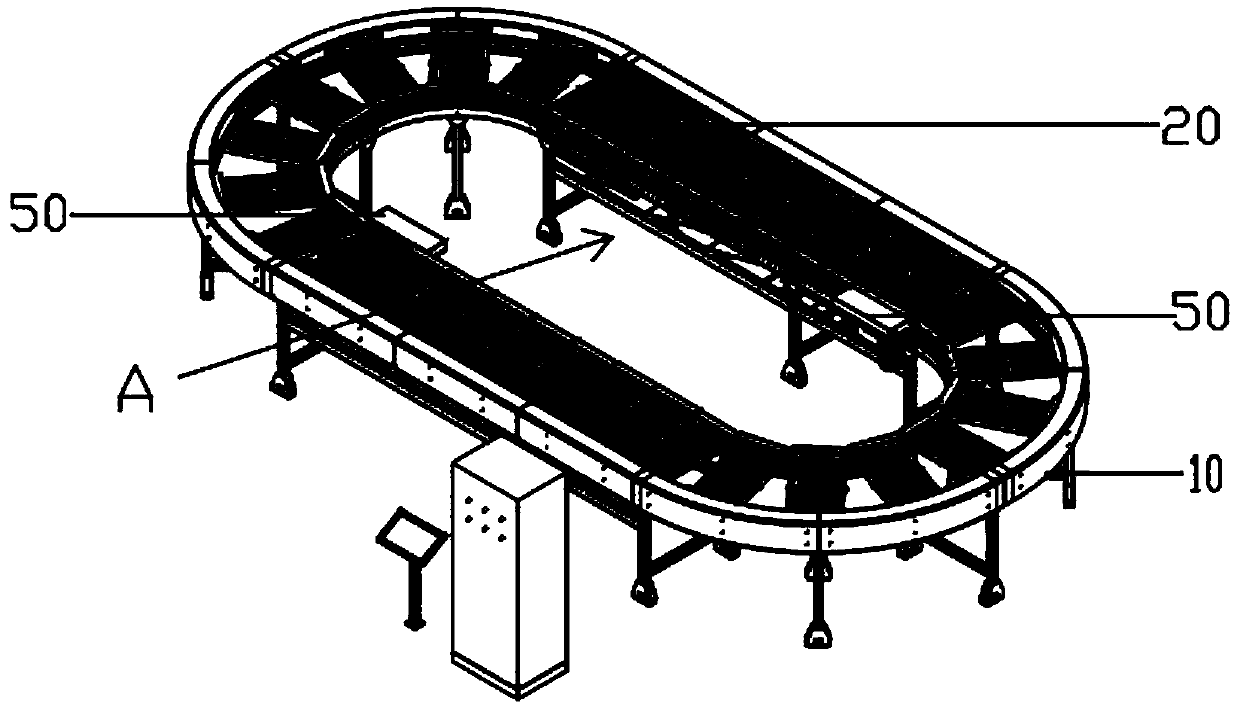

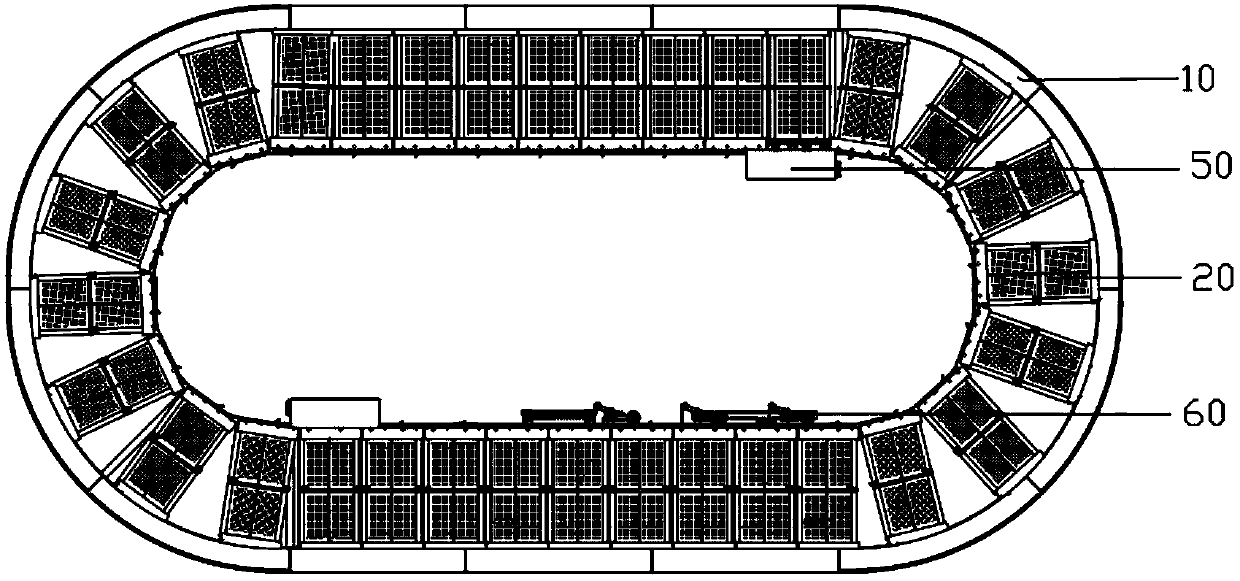

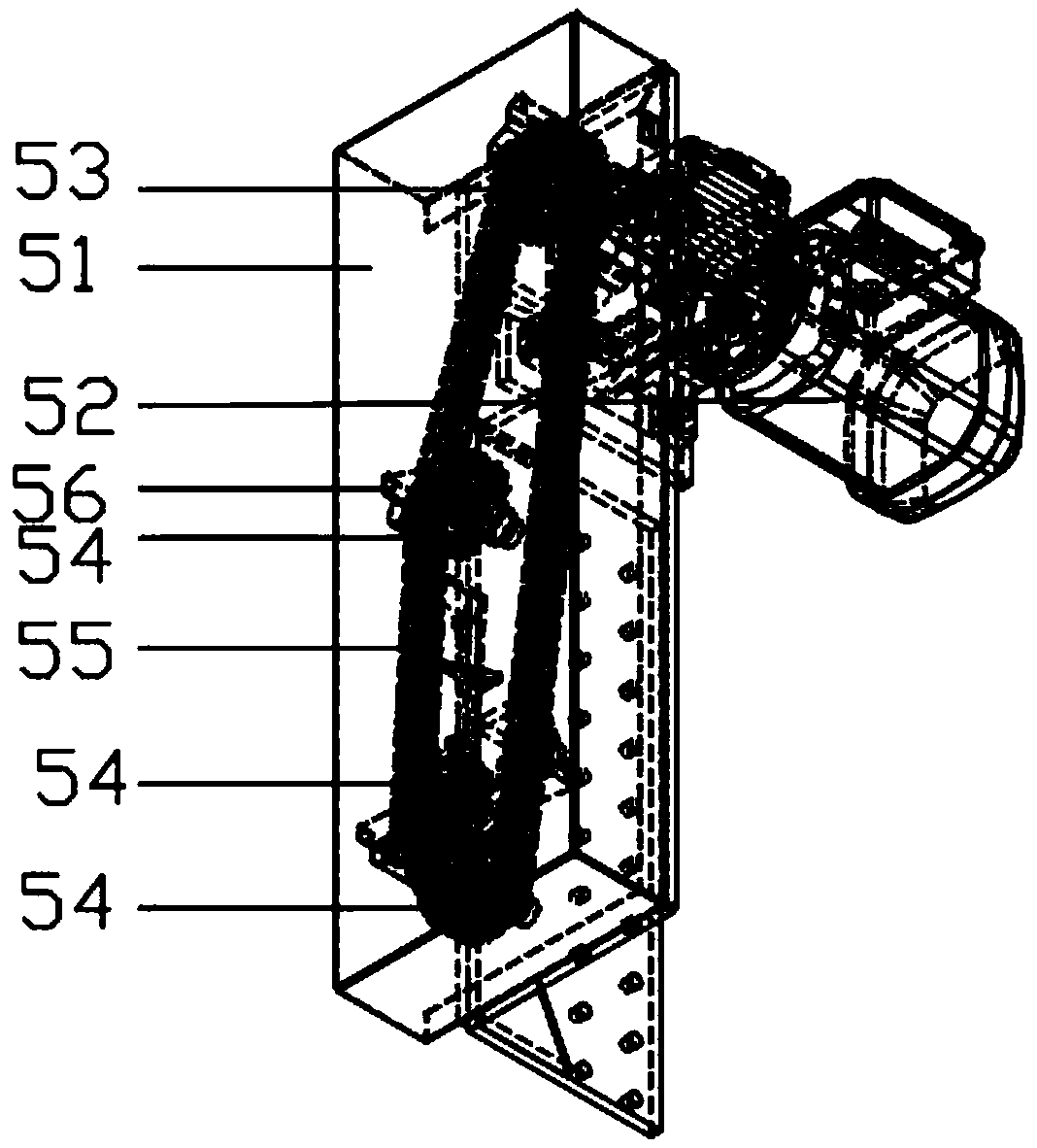

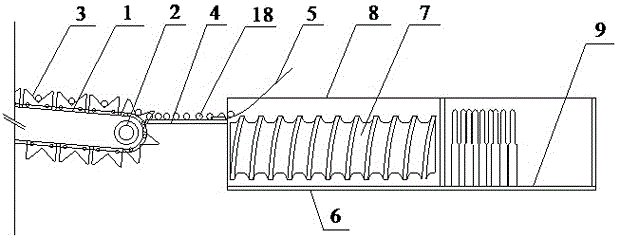

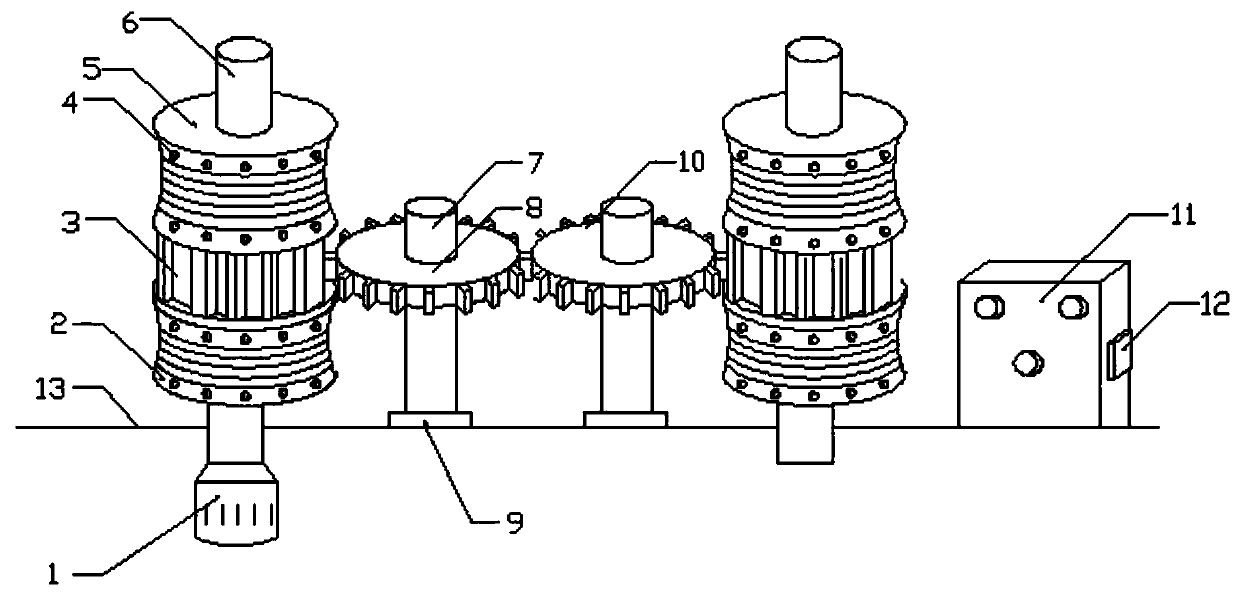

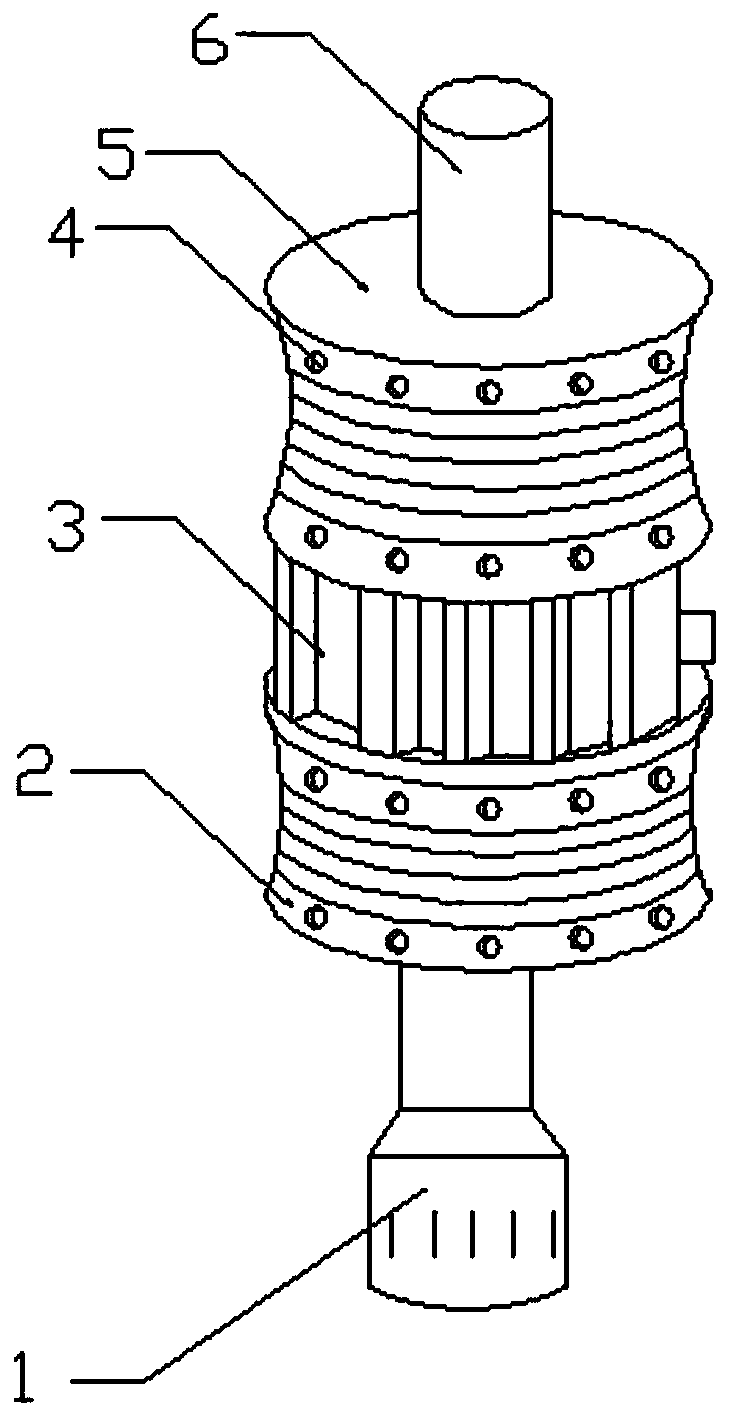

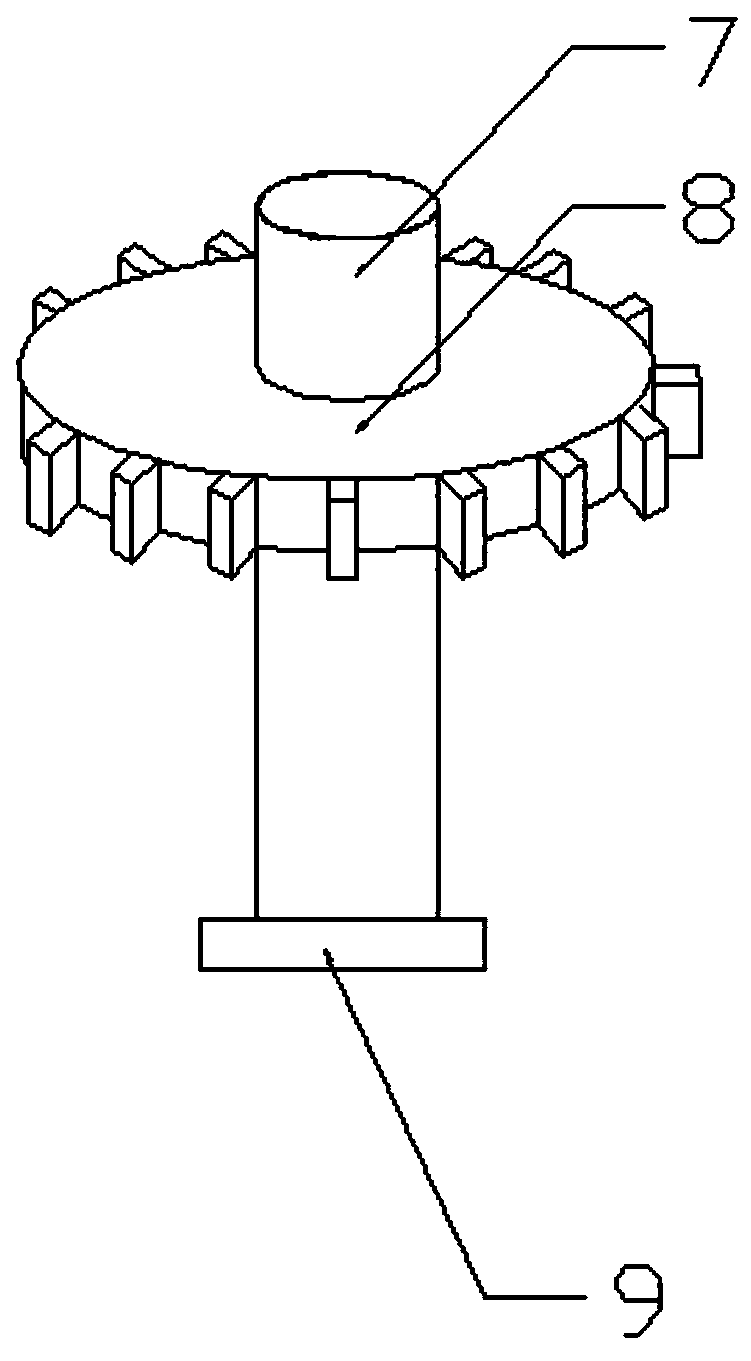

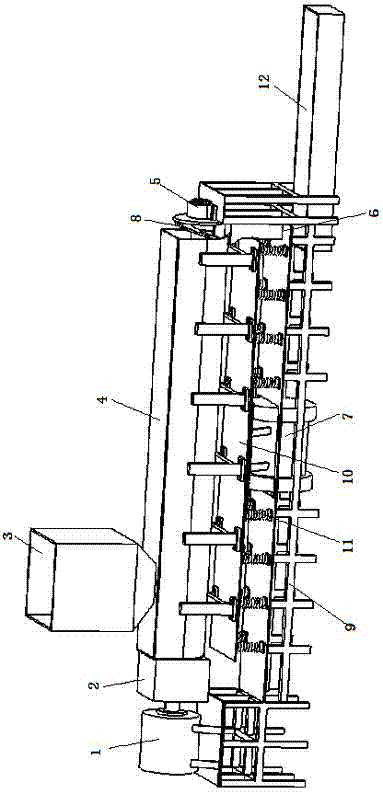

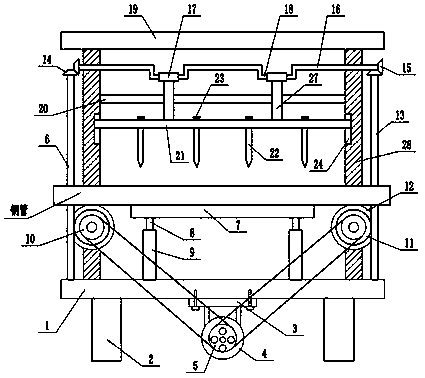

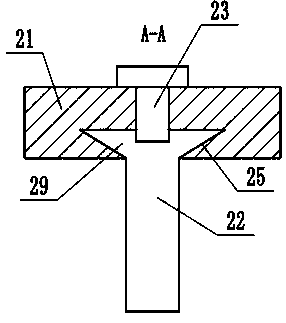

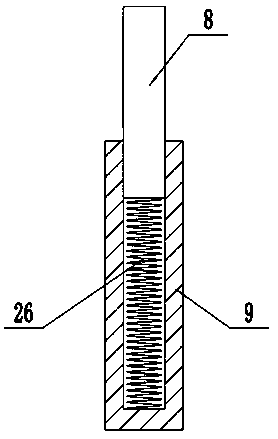

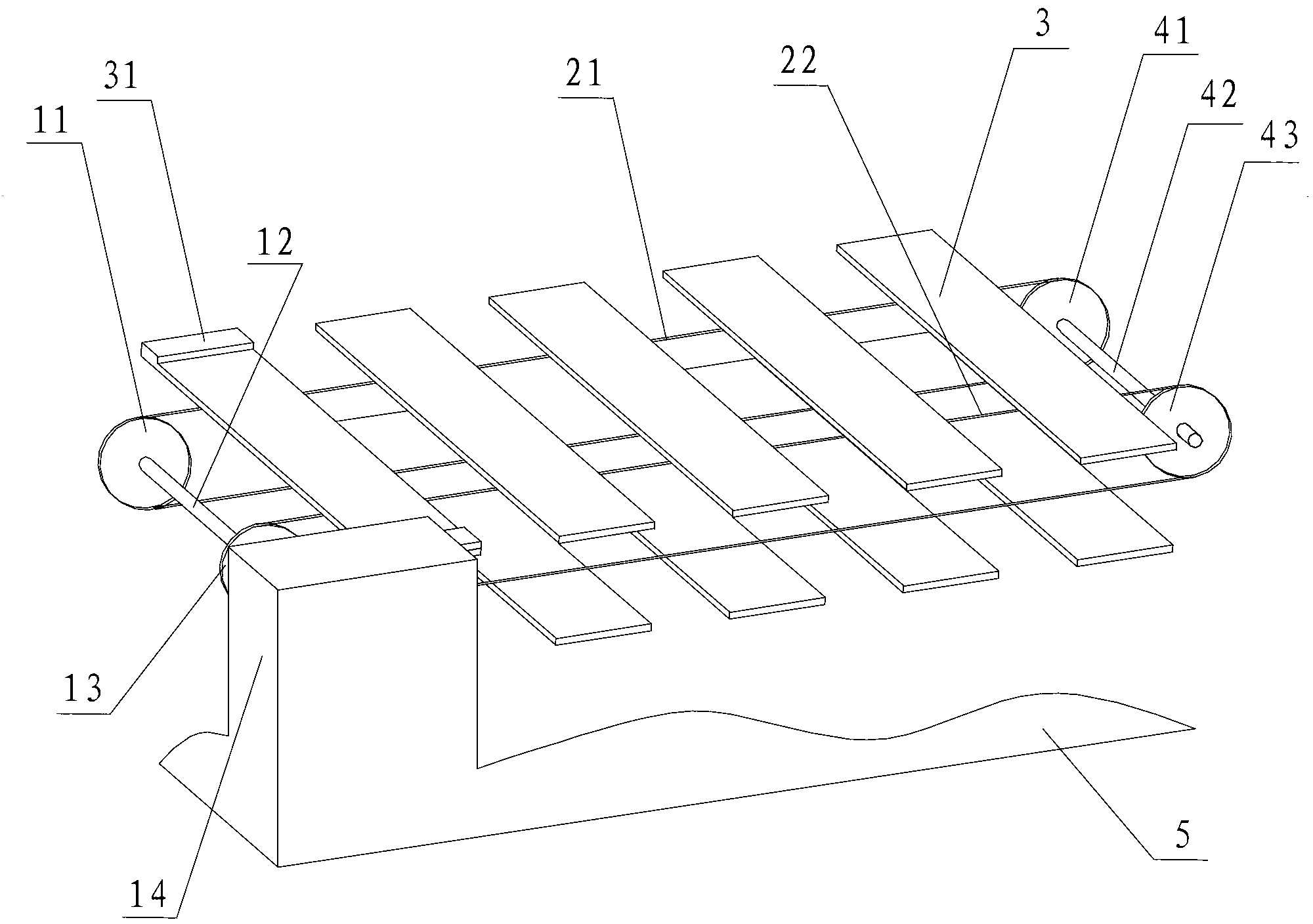

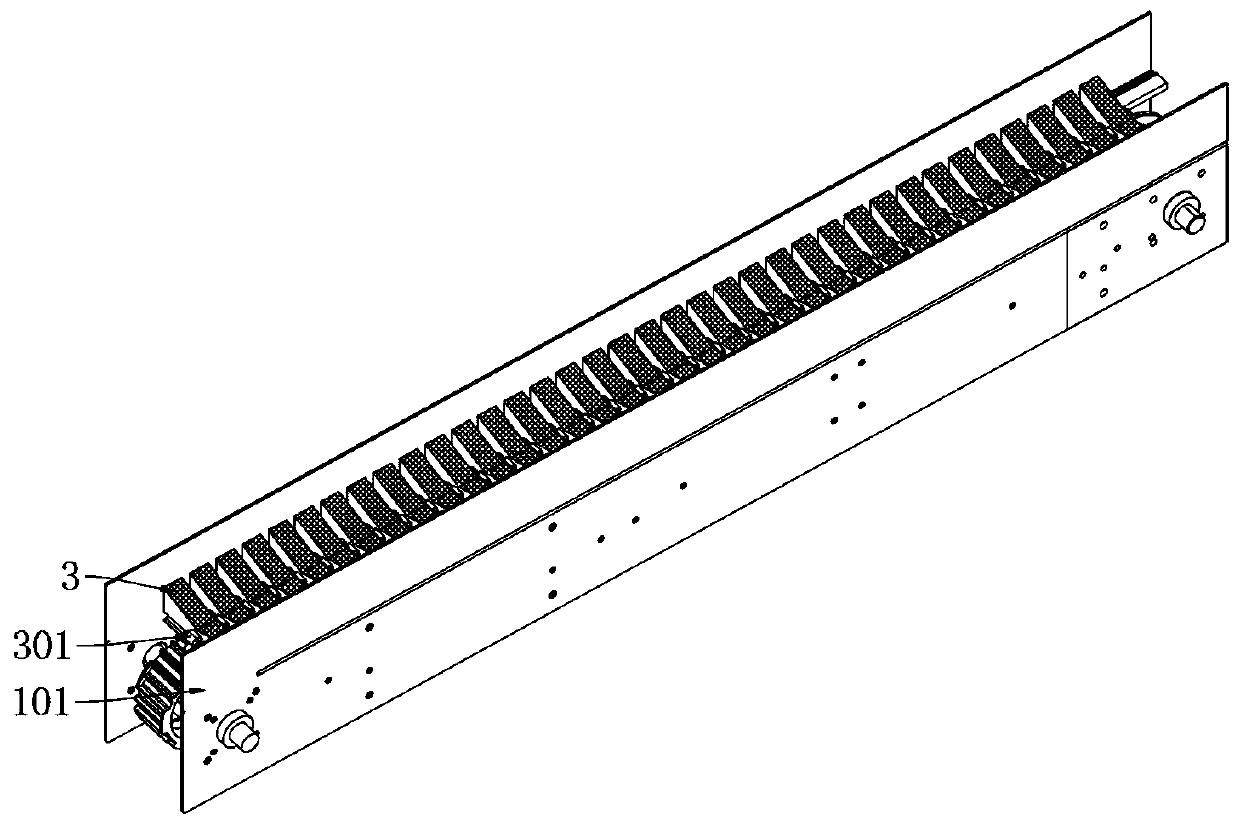

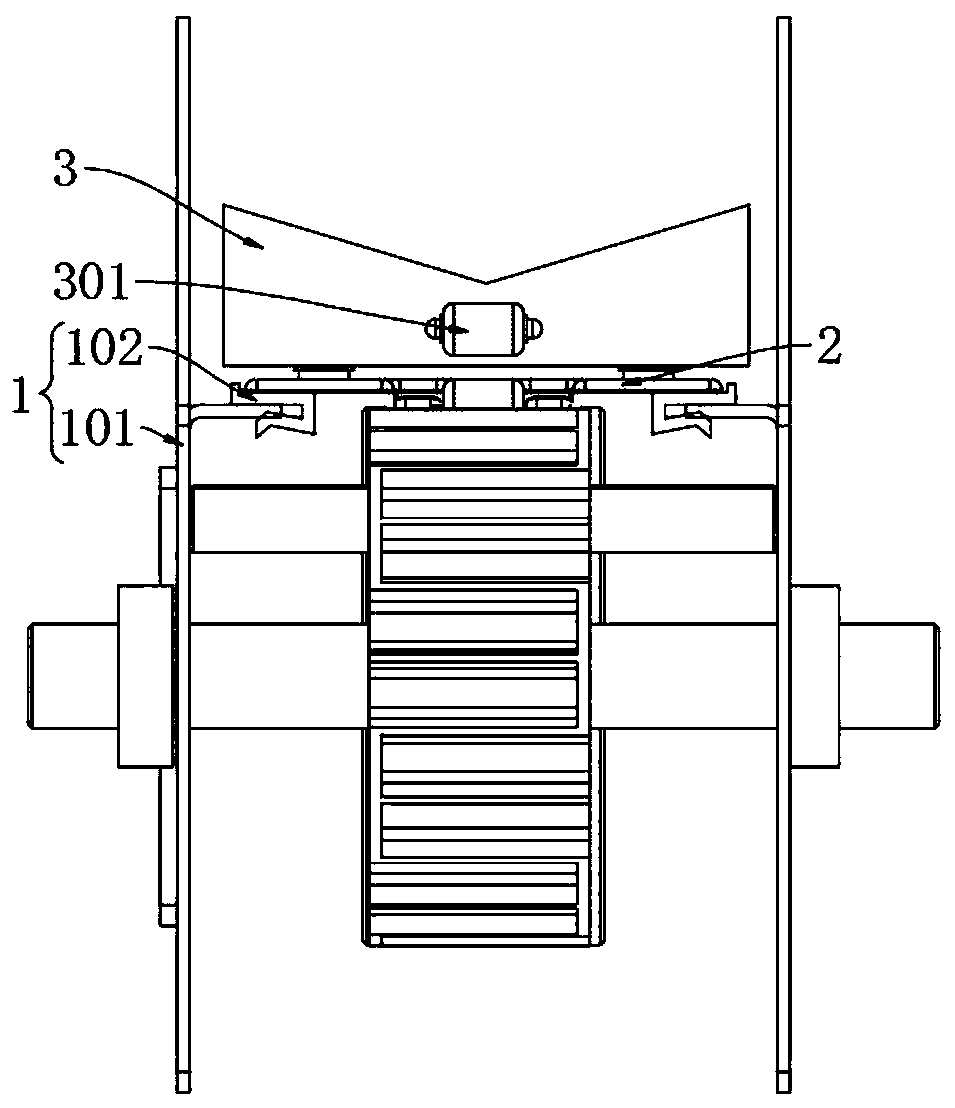

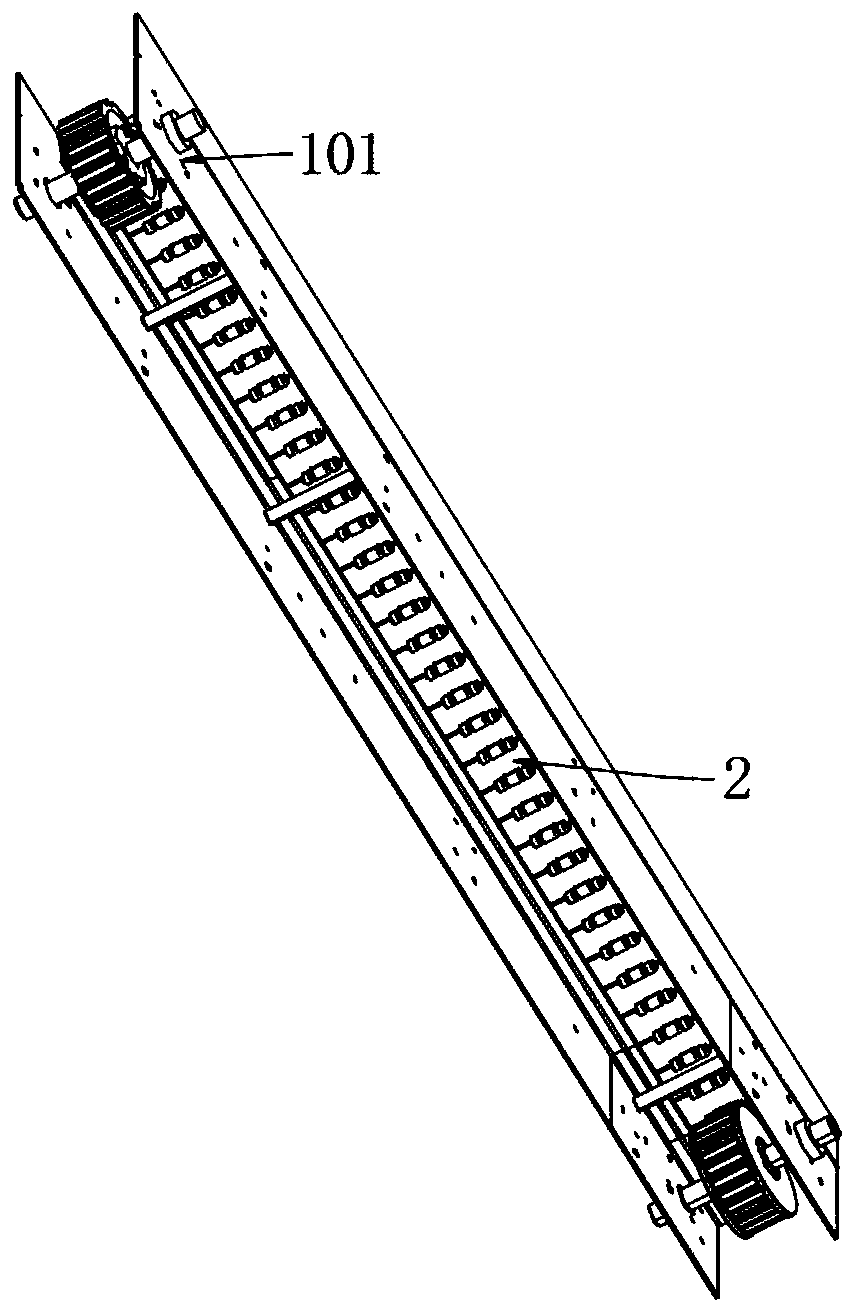

Tray sorting equipment for material sorting and sorting method thereof

PendingCN109516112ARealize continuous transmissionAvoid stuck phenomenonMechanical conveyorsDrive wheelDrive motor

The invention provides tray sorting equipment for material sorting and a sorting method thereof. The tray sorting equipment comprises an annular walking rail and a plurality of gravity type tray trolleys. All the gravity type tray trolleys are connected through rotary connecting shafts. A plurality of rotary shafts are installed on each gravity type tray trolley. At least one poking block drivingassembly is fixedly connected to the annular walking rail and comprises an installing support, a driving motor fixedly connected to the installing support, a driving wheel connected with the driving motor, multiple sets of double-row guide wheels connected in the installing support, double-row chains movably connected with the driving wheel and the multiple sets of double-row guide wheels, and a plurality of poking blocks meshing with the rotary shafts. The poking blocks on the poking block driving assembly and the rotary shafts on the gravity type tray trolleys are in meshing connection, thusthe gravity type tray trolleys conduct a certain distance of displacement, and the next poking block meshes with the next rotary shaft so as to achieve continuous transmission of the tray trolleys before the poking blocks and the rotary shafts are separated.

Owner:上海询愿信息科技中心

Transposition and transferring device for ampuliform containers

ActiveCN105645040ATransposition transfer is convenientTransposition transfer continuousConveyorsPackagingEngineeringMechanical engineering

Owner:河南省淅川伏山药用包材有限责任公司

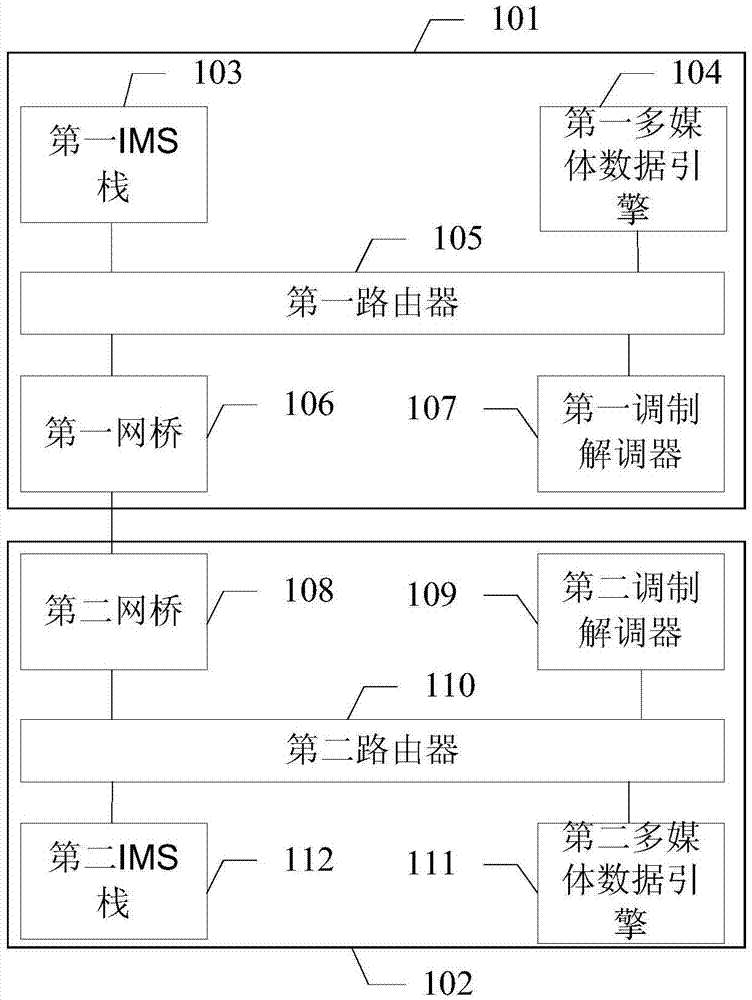

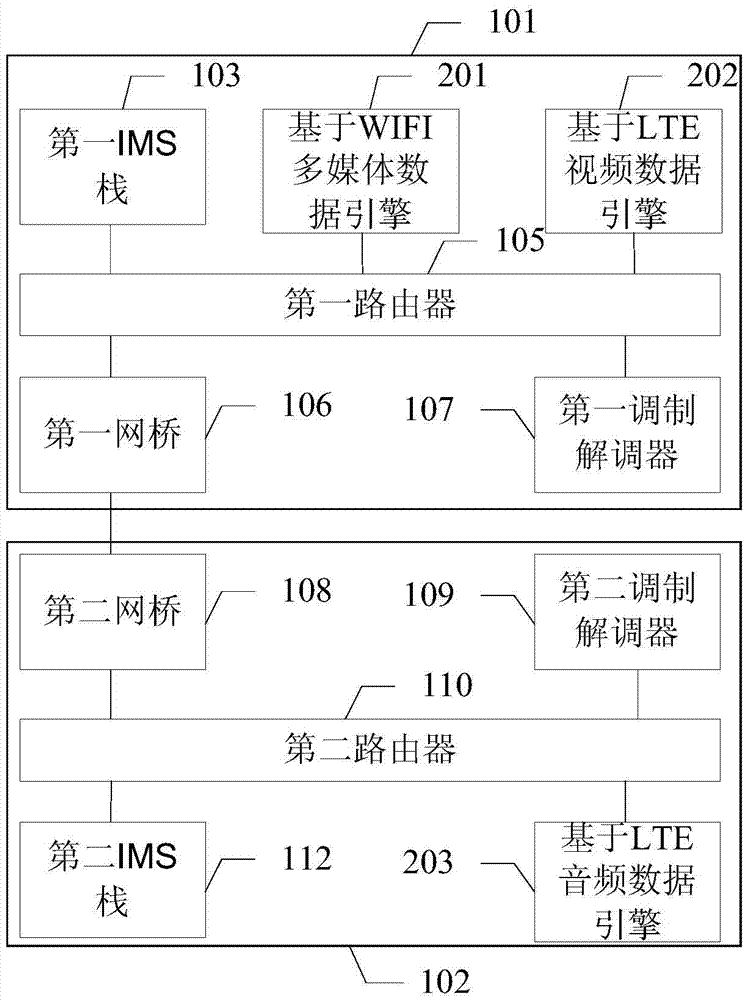

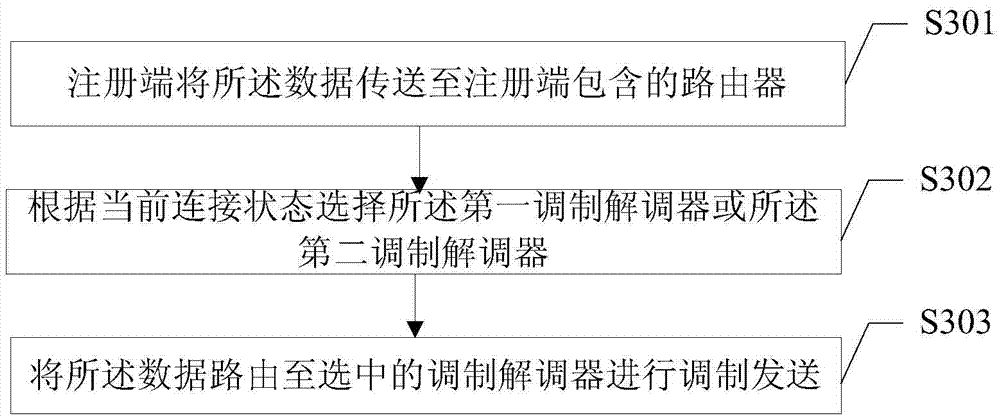

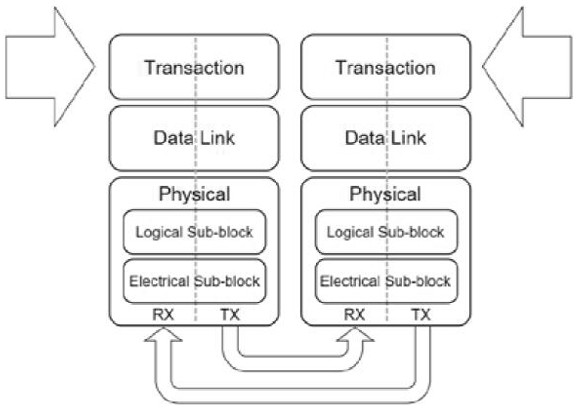

Multimedia service processing system, data sending method, data receiving method and terminal

ActiveCN106921625ARealize continuous transmissionQuality improvementTransmissionWireless communicationModem deviceHandling system

The invention discloses a multimedia service processing system, a data sending method, a data receiving method and a terminal. The multimedia service processing system comprises an application processor side and a processor side. The application processor side comprises a first multimedia data engine, a first IMS (IP Multimedia Subsystem) stack, a first network bridge, a first modem and a first router. The processor side comprises a second multimedia data engine, a second IMS stack, a second network bridge, a second modem and a second router. The application processor side and the processor side forward data through the first network bridge and the second network bridge. One of the application processor side and the processor side is a registration side according to a connection state when a session is established, and the other side is a non-registration side. The registration side finishes registration through adoption of the contained first IMS stack or the second IMS stack. Data and signals of the non-registration side are forwarded to the registration side through the first router and the second router. According to the technical scheme of the invention, the efficiency and flexibility of an IMS system are improved.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

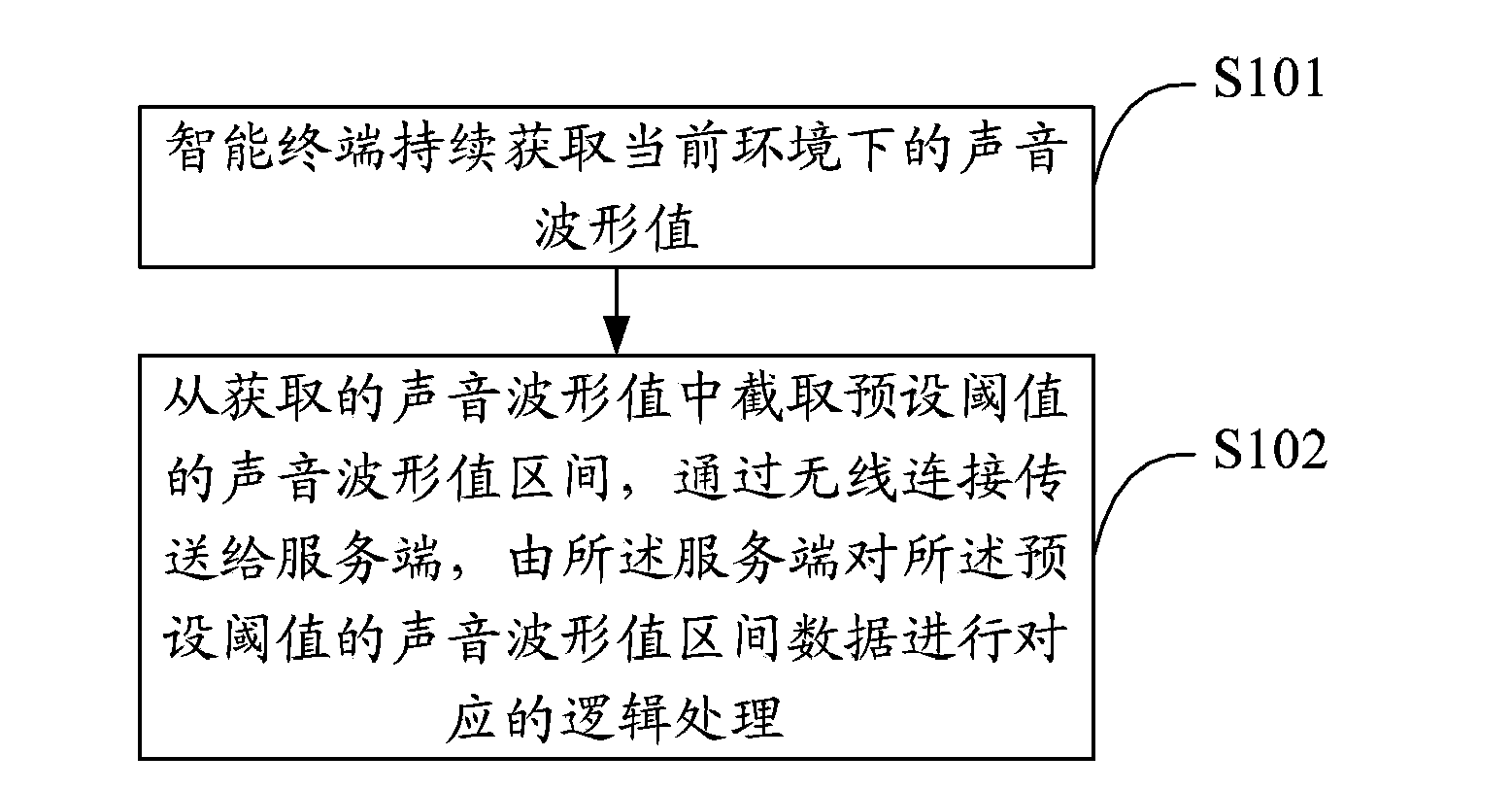

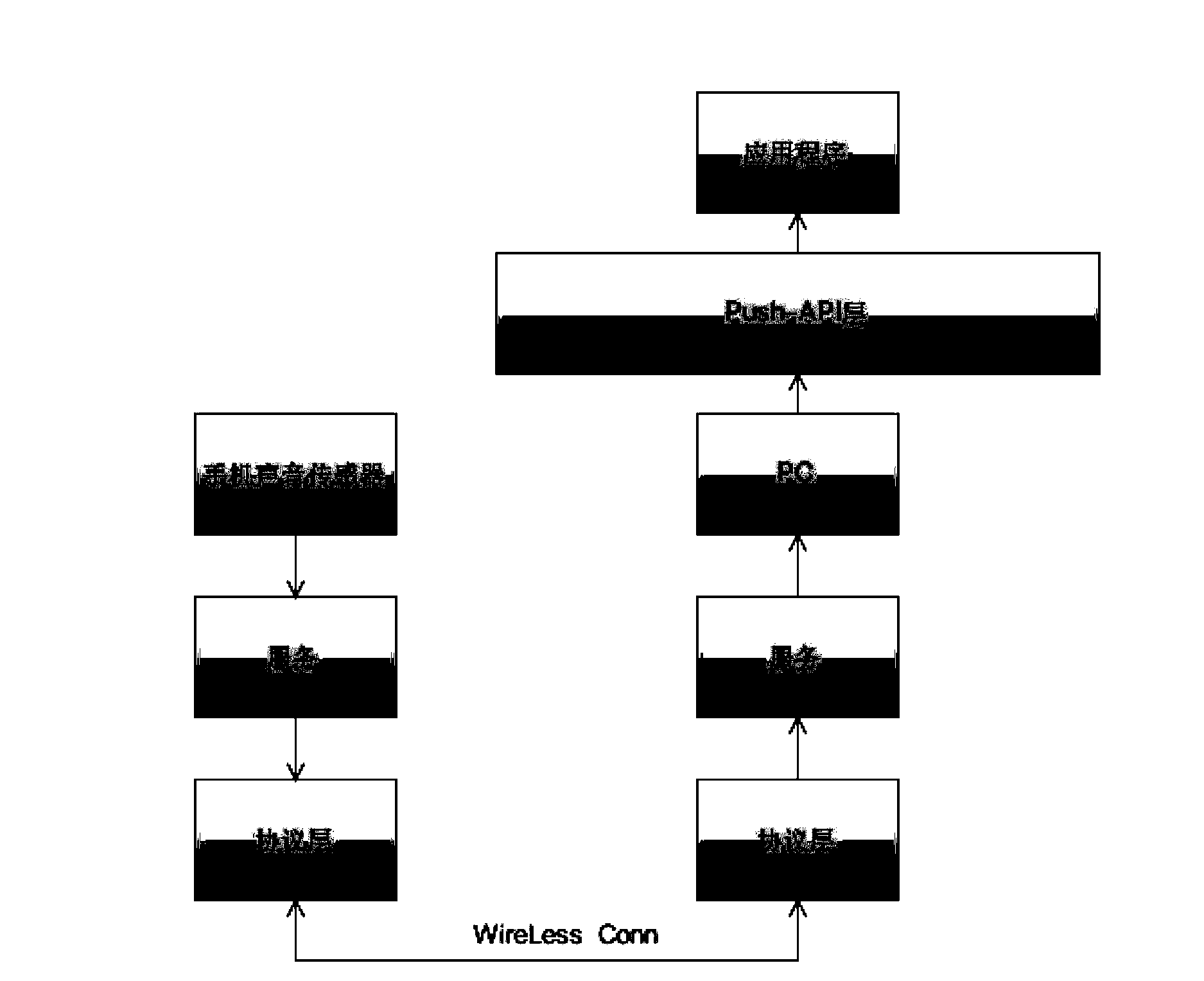

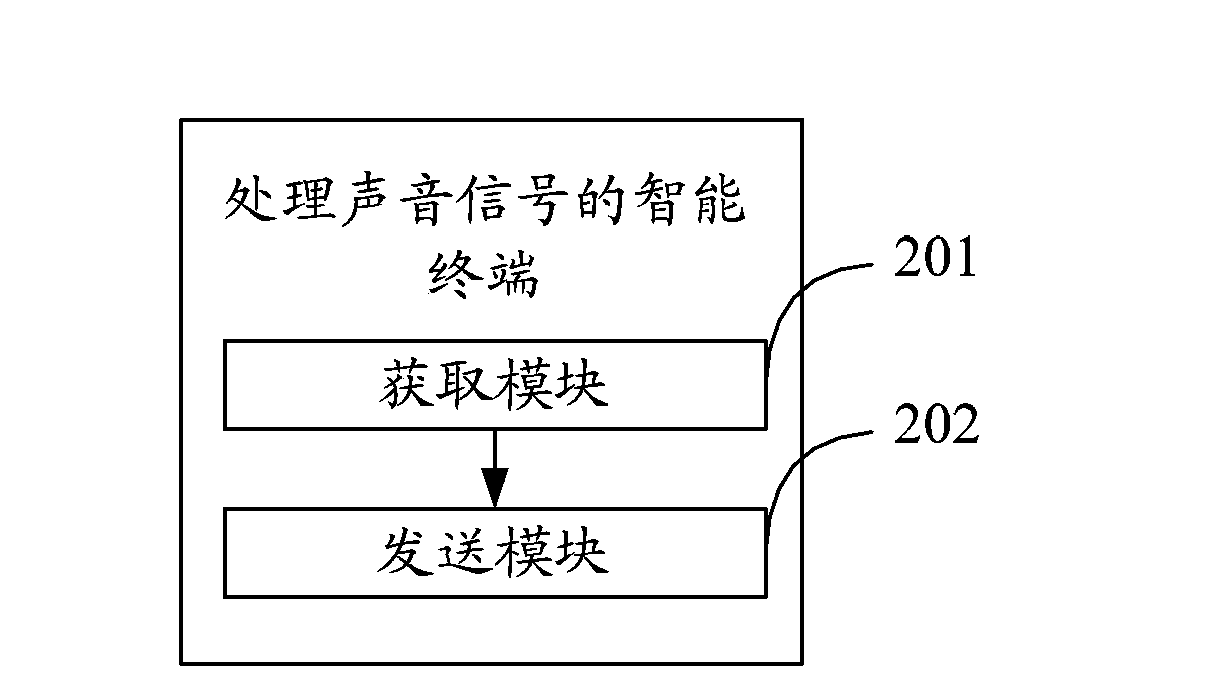

Sound signal processing method, intelligent terminal and system

InactiveCN103841252AImprove performanceRealize continuous transmissionNon-electrical signal transmission systemsSpeech analysisComputer scienceWireless connectivity

The invention discloses a sound signal processing method, intelligent terminal and system. The method comprises: an intelligent terminal continuously obtaining sound waveform values of a current environment, intercepting a sound waveform value range of a preset threshold from the obtained sound waveform values for transmitting to a server end through wireless connection, and the server performing corresponding logic processing on the sound waveform value range data of the preset threshold. According to the invention, the sound waveform values of the current environment are continuously obtained through the sound sensor of the intelligent terminal, the sound waveform value range of the preset threshold is intercepted from the sound waveform values for transmitting to the server end through the wireless connection mode, and then the server end performs the corresponding logic processing on the sound waveform value range data of the preset threshold such that continuous transmission of the sound waveform values from such intelligent terminals as an intelligent mobile phone and the like to such server ends as a PC and the like can be realized, sound can be tested at a place away from a computer, and the overall system performance of the server ends and the intelligent terminal is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

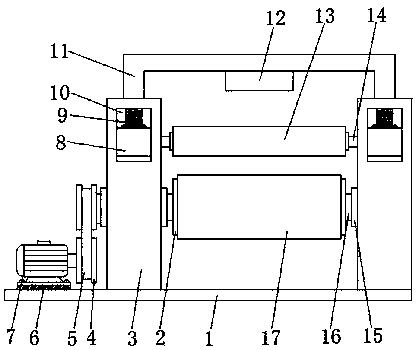

High-efficiency energy-saving textile machine winding reel mechanism

The invention discloses a high-efficiency energy-saving textile machine winding reel mechanism. The mechanism comprises a working platform, wherein two first rotating rods are arranged at the top endof the working platform, first rotating reels are arranged at the lower parts of the first rotating rods in a sleeved mode, driving gears are arranged at the top ends of the first rotating reels, second rotating reels are arranged at the top ends of the driving gears, two second rotating rods are arranged between the two first rotating rods, the upper parts of the two second rotating rods are bothsleeved with a first driven gear and a second driven gear, and two grooves are formed in the surface of the middle of the top end of the working platform. The driving gears, the first driven gear andthe second driven gear are arranges so as to realize continuous transmission, under the condition that one motor is used, a plurality of winding reels can be driven to rotate, so that the output of electric power is saved, energy conservation is realized, the rotating speed of the first rotating rods and the rotating speed of the driving gears are controlled through a control box and a controller, so that the rotating of a winding mechanism is in a controllable range, and yarns are guaranteed to be pulled orderly.

Owner:谢渊

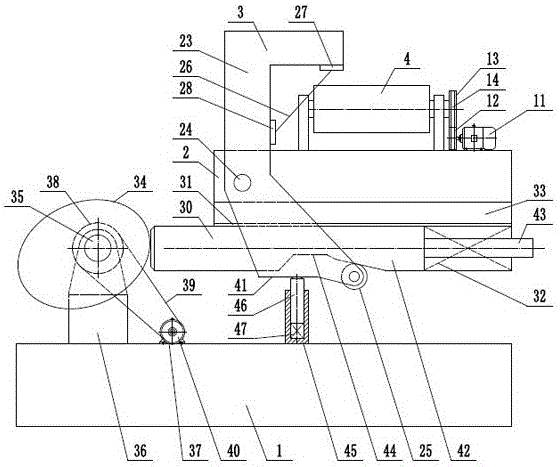

Swinging arm type advertisement paper cutting device

The invention provides a swinging arm type advertisement paper cutting device, and belongs to the technical field of cutting equipment. The swinging arm type advertisement paper cutting device comprises a cutting mechanism and a conveying mechanism, wherein an unrolling roller of the conveying mechanism is rotatablely arranged on an unrolling support frame; a coiling roller is rotatablely arranged on a coiling support frame; a swinging arm of the cutting mechanism is hinged onto the machine frame through a swinging arm pin shaft; the two ends of a cutting pulling wire are respectively arranged on a first wire pulling support seat and a second wire pulling support seat; a slide rod is arranged on a slide rod guide seat in a way capable of leftwards and rightwards sliding; a pressing jacking rod of the pressing assembly is always attached to a pressing platform arranged at the lower end of the swinging arm under the effect of a jacking rod press spring; a support rolling wheel arranged on the swinging arm is always attached to a wedge groove of the slide rod under the effect of the pressing jacking rod; the driving cam is rotatablely arranged on a cam support seat in an eccentric way through a cam shaft; the slide rod is always attached to a driving cam under the effect of a slide rod press spring. The swinging arm type advertisement paper cutting device has the advantages that the fast cutting on advertisement paper is realized; a cut edge is regular; the automation degree is high; the cutting efficiency is high; the reliability is high.

Owner:佛山市顺德区北滘镇千艺制版有限公司

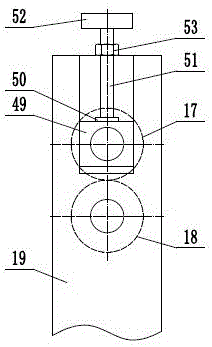

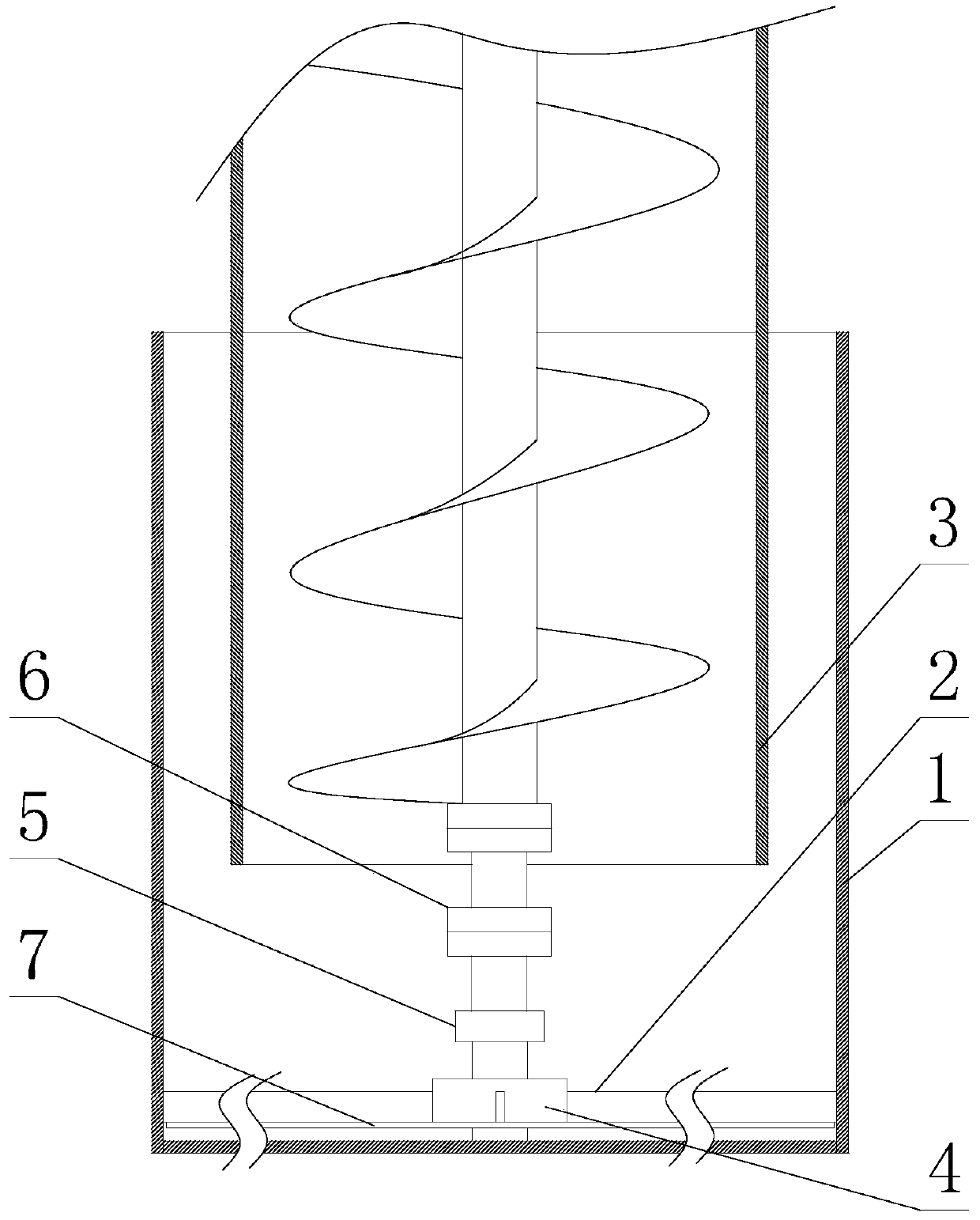

Vibratory spiral polisher

InactiveCN102862116ARealize continuous transmissionReduce time spent on polishingEdge grinding machinesPolishing machinesReducerOperation mode

The invention relates to a vibratory spiral polisher. A vibrating grid is connected on the upper side of a frame through springs, a feed device is connected on the upper side of the vibrating grid, a vibrating machine is fixedly connected on the lower side of the vibrating grid, a feed inlet is arranged on the upper side of the feed device, a screw propulsion device is mounted in the feed device, a part machining space is formed between the feed device and the screw propulsion device, one end of the screw propulsion device is in rigid connection with a speed reducer and a feed motor, the other end of the screw propulsion device is connected with a supporting seat, a left port of the feed device is connected with the speed reducer and the feed motor in a floating manner, and a discharge port is arranged below a right port of the feed device. By the vibratory spiral polisher, time spent on part polishing can be reduced, continuous conveying of parts can be achieved, and production efficiency is improved greatly. By the aid of the continuous conveying process, the vibratory spiral polisher can be connected into an assembly line to achieve an assembly line operation mode of part forming, polishing and finish machining. Besides, a feeding and discharging mode is improved, inertial impact is alleviated, machining steps are decreased, and time spent on polishing is greatly decreased.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

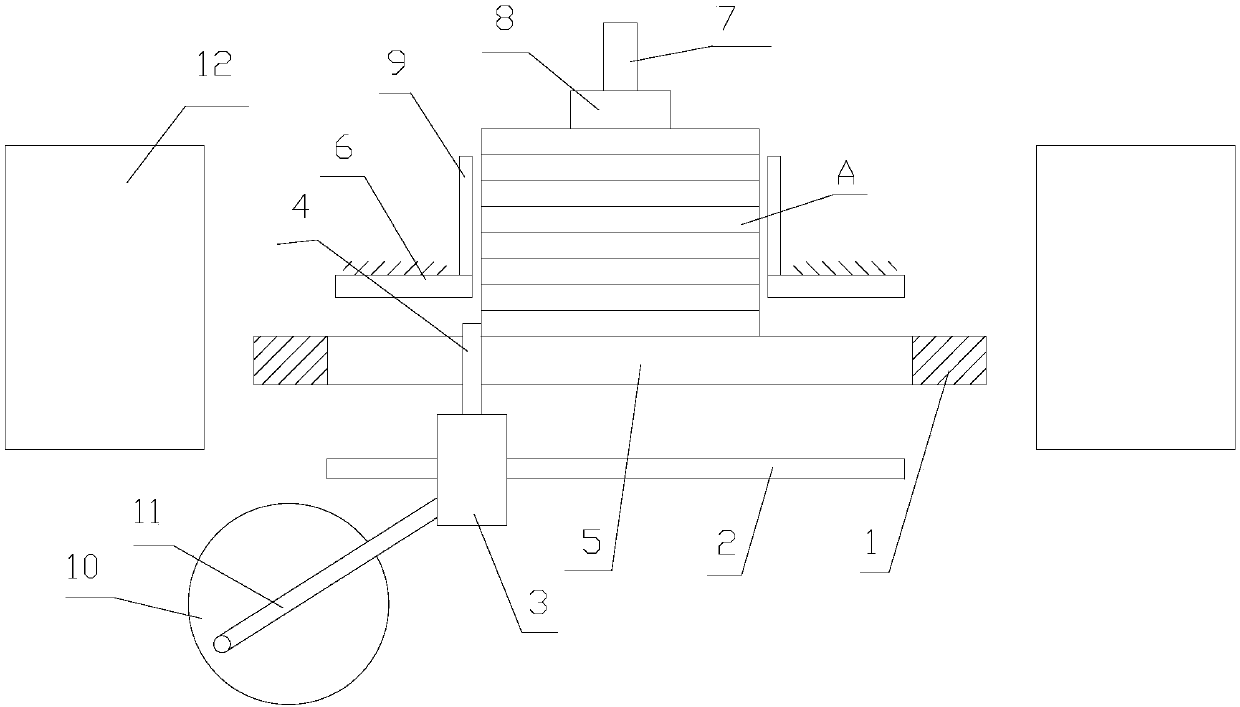

Continuous adjustable small-diameter steel pipe cutting device

InactiveCN109590530AReasonable structureInnovative designTube shearing machinesShearing machine accessoriesSteel tubeEngineering

The invention discloses a continuous adjustable small-diameter steel pipe cutting device, and belongs to the technical field of steel pipe cutting equipment. The continuous adjustable small-diameter steel pipe cutting device includes a fixed base, supporting frames are mounted on both sides of the upper end of the fixed base, a roof is mounted at the top ends of the supporting frames, a motor seatis mounted in the middle of the lower end of the fixed base, a motor is mounted at the lower end of the motor seat, the output shaft of the motor is connected with a driving belt wheel, and the driving belt wheel is connected with driven belt wheels through two belts wheels; and the driven belt wheels are coaxially connected with transmission rollers and worm wheels, the left end of the worm wheel on the left side is meshed with a left worm, the right end of the worm wheel on the right side is meshed with a right worm, driving gears are mounted at the top ends of the left and right worms respectively, the upper ends of the driving gears are meshed with driven gears, a rotating shaft is mounted between the driven gears, and a crank is arranged in the middle of the rotating shaft. The continuous adjustable small-diameter steel pipe cutting device realizes the continuous transmission of the steel pipe, meanwhile, achieves the up and down moving of a moving cutting knife through the cooperation between the crank and a rotating sleeve, ensures the automatic cutting of the steel pipe and reduces the labor strength of the workers.

Owner:青岛瑞吉德精密机械有限公司

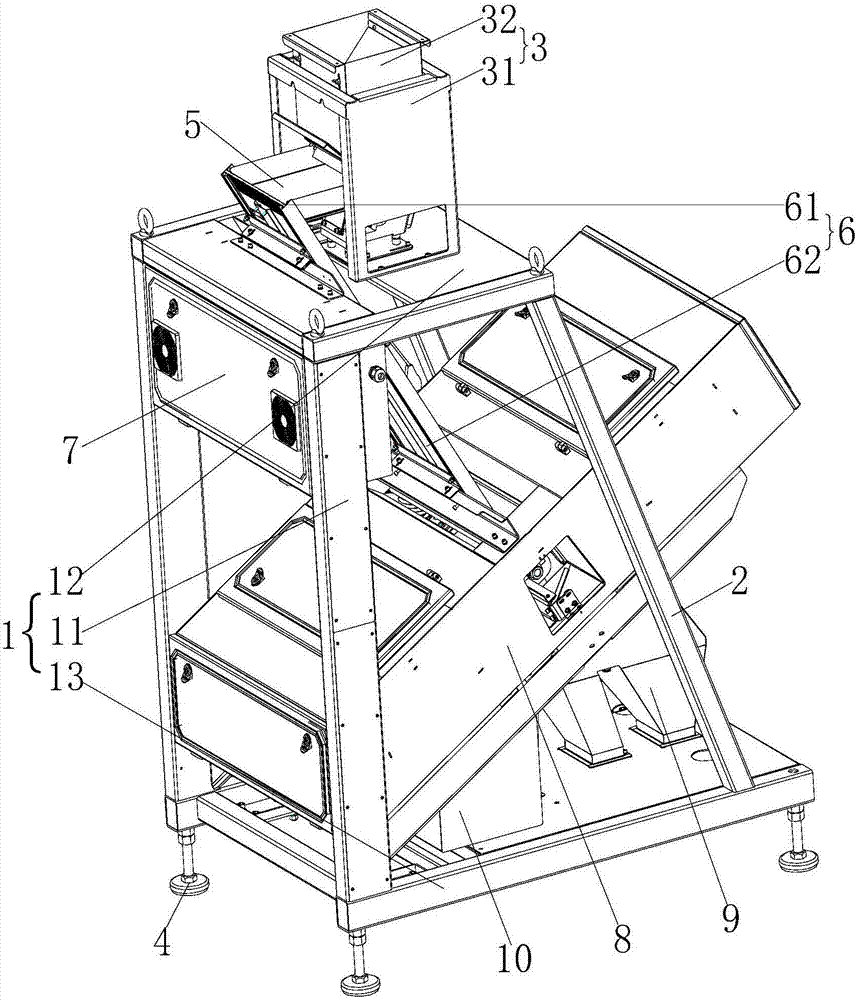

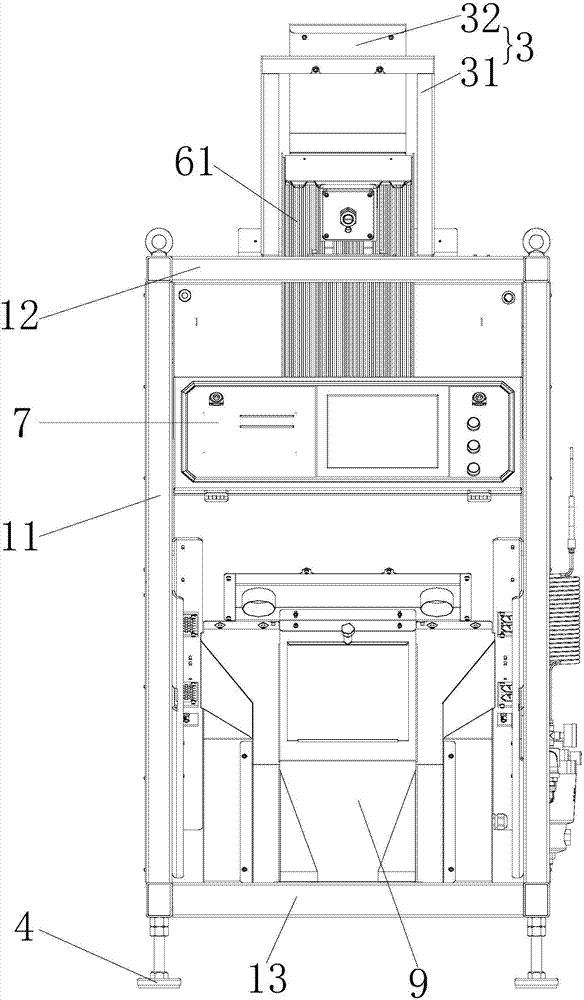

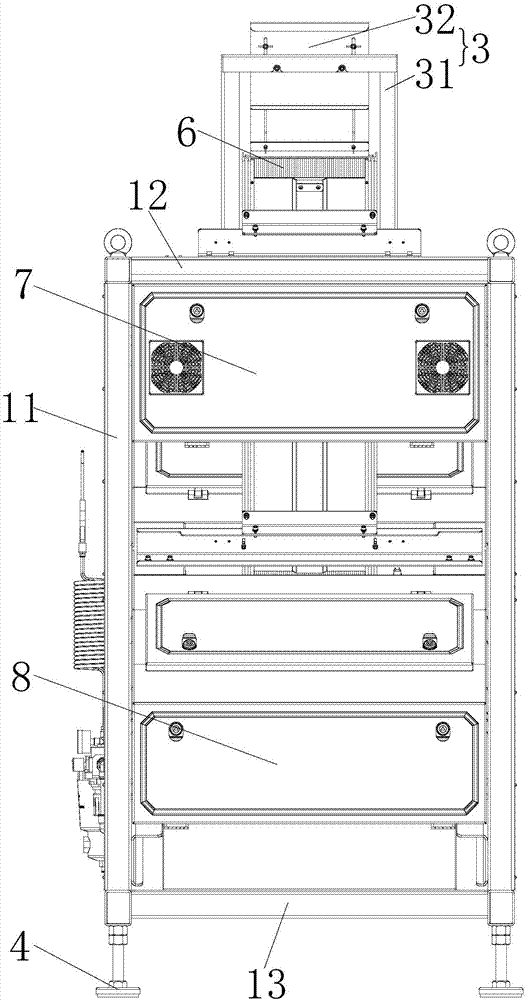

Assembled color sorter

The invention discloses an assembled color sorter. The assembled color sorter comprises a machine frame body, wherein a supporting beam is arranged on one side of the machine frame body, a feeding hopper device is arranged at the top of the machine frame body, and a vibrating hopper assembly and a trough device are arranged on the lower portion of the feeding hopper device; an electric control box and a sorting box are arranged on the upper portion and the lower portion of the inner sides of supporting columns, and a discharging hopper device and a valve seat box are arranged on the lower portion of the sorting box. The supporting beam and a bottom plate are arranged at the angle of 70 degrees, so the stretching-out length of the bottom plate is effectively reduced; meanwhile, the whole color sorter is compact in structure and small in occupied space, the space utilization rate is improved, and the manufacturing cost is reduced; through the feeding hopper device, the trough device, the discharging hopper device and the like which are arranged in sequence, continuous conveying of materials is realized, assembly line type work of the color sorter is facilitated, color sorting is quick, the labor intensity of workers is relieved, the work efficiency of the color sorter is improved, and the color sorting effect is good.

Owner:ANHUI HONGSHI ZIJING PHOTOELECTRIC INST

Transporting device

The invention discloses a transporting device. The transporting device comprises a driving mechanism, a driven mechanism, a base, a first chain, a second chain and at least one working plate; wherein the driving mechanism comprises a first driving gear, a second driving gear, a driving shaft and a power unit, the driving shaft and the first driving gear and the second driving gear are coaxially fixed, and the power unit is connected with the driving shaft in a driving mode; the driven mechanism comprises a first driven gear, a second driven gear and a driven shaft, and the driven shaft and the first driven gear and the second driven gear are coaxially fixed; the base rotatably supports the driving shaft and the driven shaft; the first chain is connected with the first driving gear and the first driven gear in a transmission and chain mode; the second chain is connected with the second driving gear and the second driven gear in a transmission and chain mode; one end of every working plate is fixed onto the first chain and the other end of every working plate is connected with the second chain. The transporting device achieves the continuous transporting of products; meanwhile, compared with a traditional transporting device, the transporting device is low in costs, improves profit margins and greatly improves using space.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

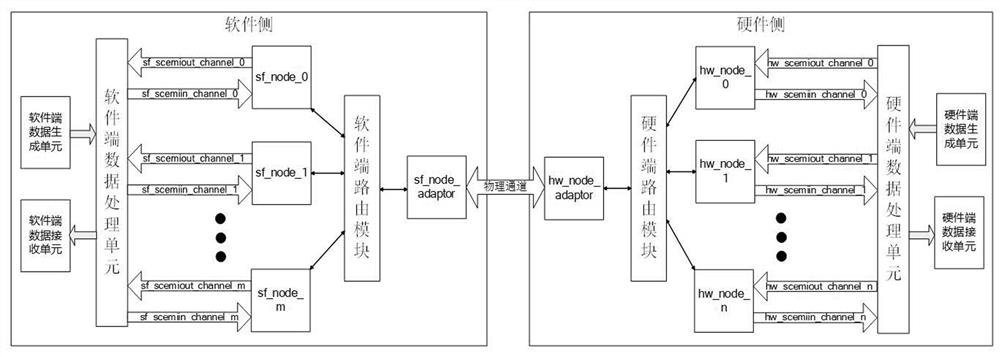

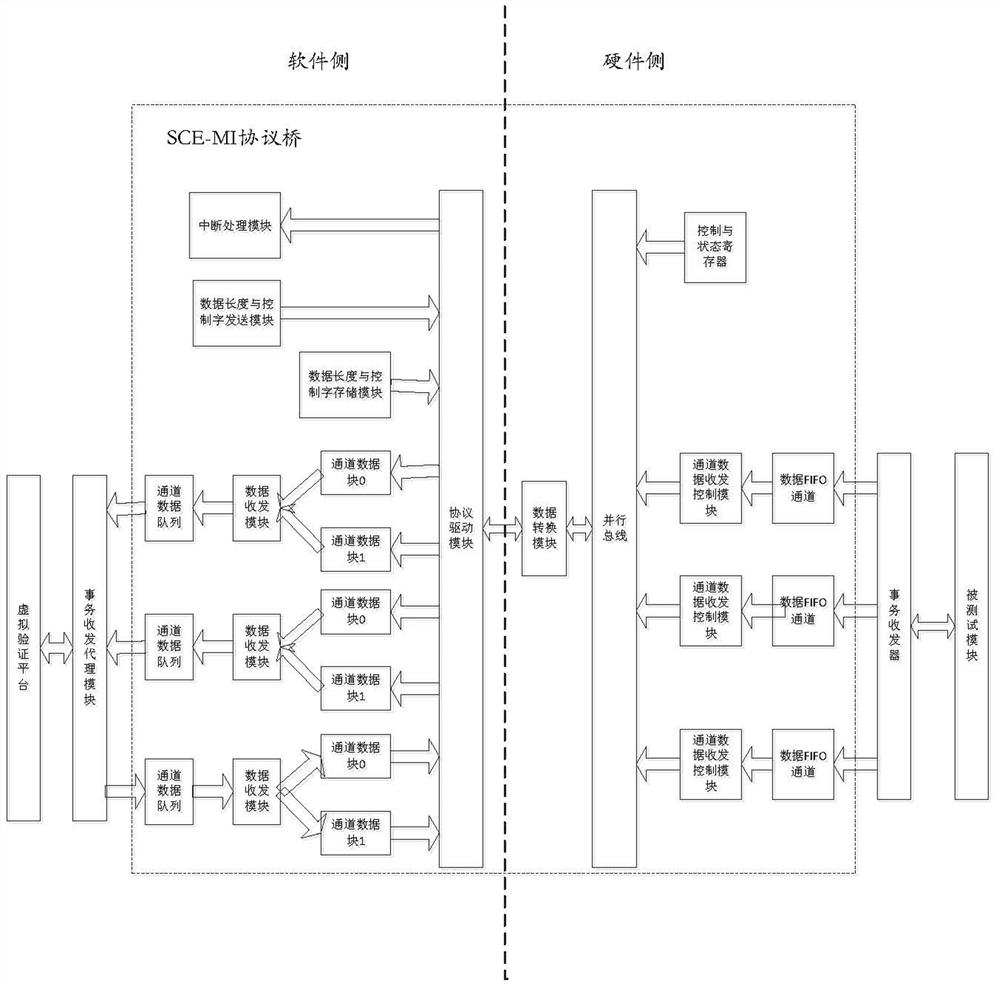

SCE-MI protocol bridge and simulation system

ActiveCN112511537ARealize continuous transmissionHigh bandwidthData switching networksChannel dataData transformation

The invention discloses an SCEMI protocol bridge and system, and the SCEMI protocol bridge comprises a data conversion module, a parallel bus, a plurality of channel data receiving and transmitting control modules, a plurality of data FIFO channels, a protocol drive module, a plurality of channel data blocks, a plurality of data receiving and transmitting modules, and a plurality of channel data queues, and the protocol driving module is connected with the data conversion module. The SCEMI protocol bridge has the advantages of being high in bandwidth, small in delay and capable of dynamicallyconfiguring the number of ports.

Owner:深圳国微晶锐技术有限公司

Envelope printer

InactiveCN107839348ARealize automatic transmissionRealize continuous transmissionTypewritersOther printing apparatusEngineering

Owner:合肥汉闻数字印刷设备有限公司

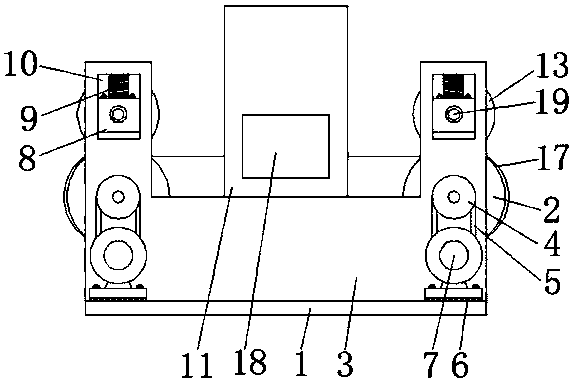

Wire damage degree detection device based on image processing

PendingCN107764845ARealize continuous transmissionRealize press finishingMaterial analysis by transmitting radiationImaging processingImage manipulation

The invention discloses a wire damage degree detection device based on image processing. The wire damage degree detection device comprises a fixed bottom plate, wherein supporting plates are respectively arranged at two ends above the fixed bottom plate; conveying rollers are respectively arranged between two ends of the two supporting plates; pressure rollers are arranged above the conveying rollers; and a detector fixing box is arranged above a space between the middle positions of the two supporting plates. Due to the arrangement of conveyer belts between the two conveying rollers, continuous transfer of produced to-be-detected wires and cables is realized; due to the pressure rollers arranged above the conveying rollers, pressing arrangement of the to-be-detected wires and cables is realized, so that the to-be-detected wires and cables are conveniently detected, and the detection accuracy and reliability are improved; and according to the device disclosed by the invention, the damage degree in the production process of the wires and cables is detected, the yield of the product is increased while the detection efficiency is increased, and the using safety of the wires and cablesby users is ensured.

Owner:FOSHAN ZHIBEIHUI TECH CO LTD

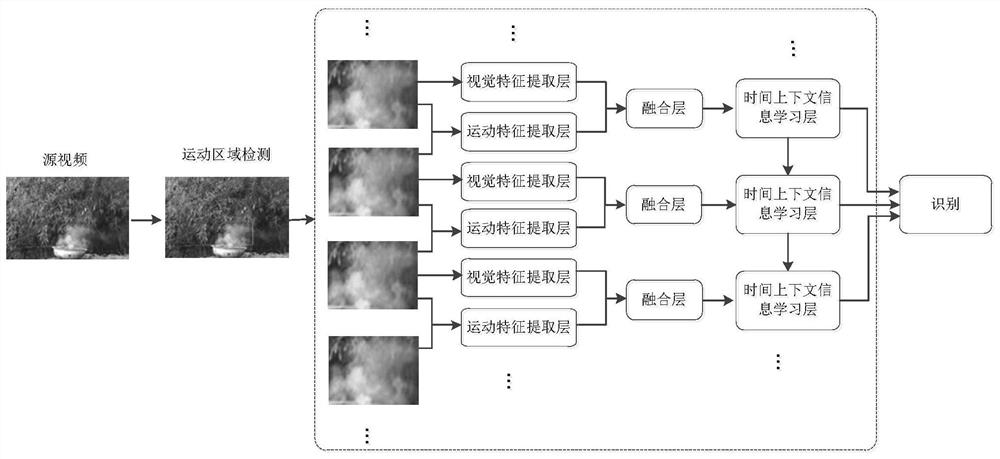

Fire smoke detection method based on motion feature hybrid deep network

PendingCN112766179AImprove accuracyImprove timelinessCharacter and pattern recognitionNeural architecturesNetwork modelVideo streaming

The invention provides a fire smoke detection method based on a motion feature hybrid deep network, which is used for solving the technical problem of low detection precision of video smoke in a complex scene. The method comprises the following steps: firstly, acquiring a data set from a video image library, and dividing the data set into a training set and a test set; secondly, constructing a motion feature hybrid deep network, inputting the training set into the motion feature hybrid deep network for training to obtain a motion feature hybrid deep network model, and testing the motion feature hybrid deep network model by using the test set; then, obtaining a to-be-detected video sequence, and processing a detected video by using a motion area detection algorithm to obtain a video motion image; and finally, inputting the motion image into the motion feature mixed deep network model, outputting a detection result, and completing video smoke detection. According to the invention, continuous transmission of smoke characteristics can be realized on the whole video stream, the timeliness of smoke detection is improved, and the false alarm rate of smoke early warning is reduced.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

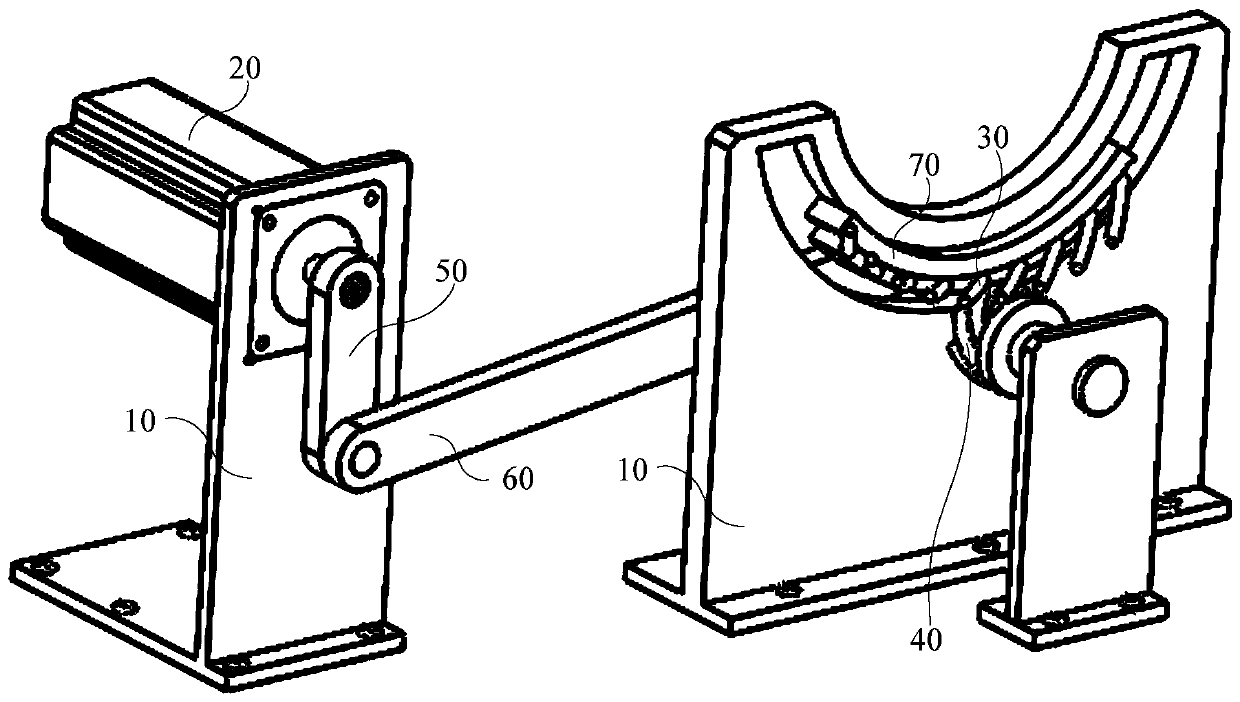

Bidirectional engaged transmission device

InactiveCN110273996ASimple structureGood workmanship and economyGearingGear vibration/noise dampingElectrical and Electronics engineering

The invention provides a bidirectional engaged transmission device. The bidirectional engaged transmission device comprises a base, a driving member, a crank, a driving gear, a connecting rod and a driven gear; the driving member is connected to the base; the crank is connected to the output end of the driving member; the driving gear includes a driving member and a plurality of driving hook levers, and the multiple driving hook levers are arranged on the end surface of the driving member; two opposite ends of the connecting rod are hinged with the crank and the driving member, respectively; the driven gear includes a driven member and a plurality of driven hook rods, and the multiple driven hook rods are arranged on the end surface of the driven member; and when the driving member drives the crank to rotate, the connecting rod drives the driving member to swing, and therefore continuous engaged transmission is formed between the driving hook levers and the driven hook levers. The engaged transmission of the driving gear and the driven gear of the bidirectional engaged transmission device can achieve continuous and stable bidirectional engaged transmission.

Owner:GUANGXI UNIV

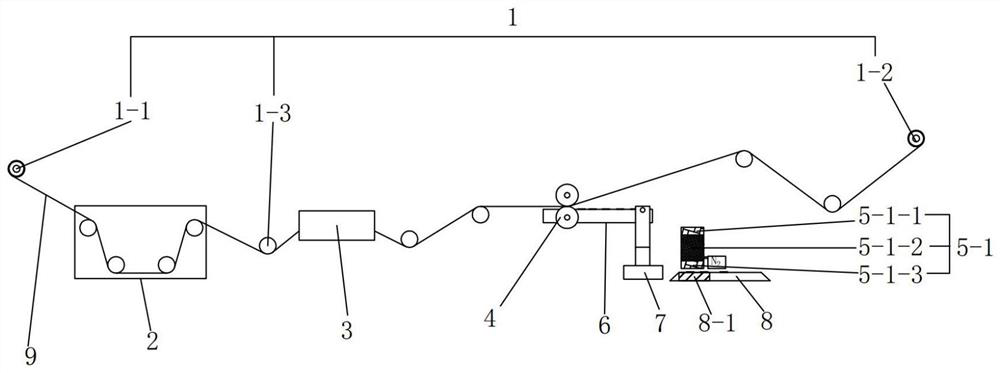

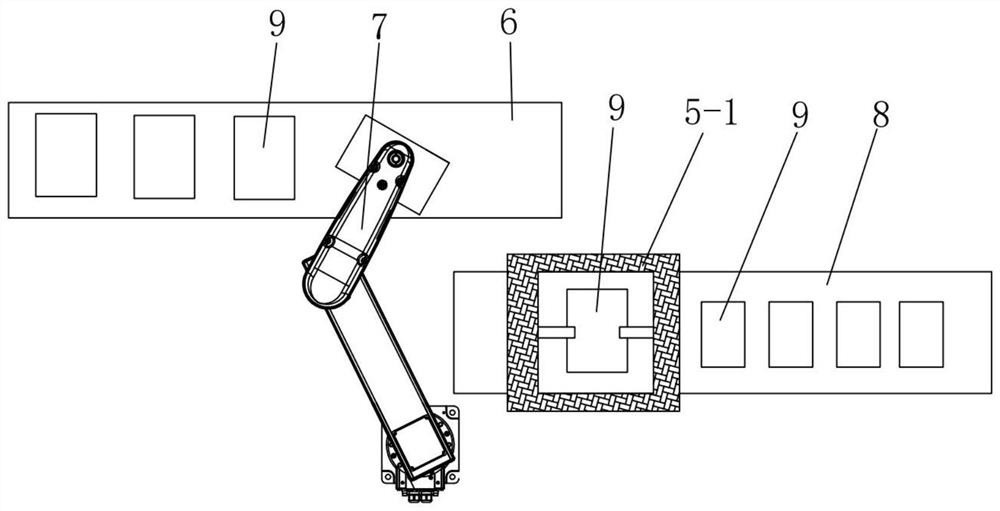

Device and method for continuous hydrophobicity of gas diffusion layer of fuel cell

PendingCN114824310AFlexible feature changesEasy for printing workCell electrodesThermodynamicsFuel cells

The invention discloses equipment for continuous hydrophobicity of a gas diffusion layer and a treatment method, the equipment comprises a conveying roller mechanism, a hydrophobic liquid storage pool, a low-temperature drying oven, a carbon paper cutting mechanism, a carbon paper roasting mechanism and a tail end conveying table, and the conveying roller mechanism sequentially penetrates through the hydrophobic liquid storage pool, the drying oven and the carbon paper cutting mechanism; in the conveying direction of the conveying roller mechanism, the unwinding roller is located at the front station of the hydrophobic liquid storage pool, the winding roller is located at the rear station of the carbon paper cutting mechanism, and a transfer conveying table allowing cut carbon paper to fall down is arranged under a discharging port of the carbon paper cutting mechanism. The carbon paper placed on the transfer conveying table is grabbed by the mechanical arm with the adsorption function in an adsorption mode and then placed in the carbon paper roasting mechanism, and a discharging port of the carbon paper roasting mechanism is communicated with the tail end conveying table. According to the treatment method, two steps of low-temperature treatment and high-temperature roasting treatment are respectively carried out in the hydrophobic treatment process of the carbon paper; continuous hydrophobic treatment of the gas diffusion layer can be achieved for flexible carbon paper, manpower is reduced, and working efficiency is improved.

Owner:上海碳际实业集团有限公司

A Modification Method of Involute Tooth Profile in Harmonic Drive

ActiveCN107882950BIncrease the number of teethSmall engagement backlashGearingPortable liftingKinematic theoryGear wheel

The invention discloses a modification method for a harmonic driving involute profile. A point B serves as a point of tangency of a modification curve and a involute tooth surface. A point E serves asa point of intersection of the modification curve and an involute addendum circle. A coordinate system XOY is built with a radial OA as the abscissa axis. A coordinate system X1OY1 is built with a radial OC as the ordinate axis. After the steps of determining the coordinates of the point B and the point E in the coordinate system X1OY1 and the slope of a tangent of the involute at the point B, determining a flexible gear central point approximate movement track curvilinear equation, determining the parameter equation of the modification curve in the coordinate system X1OY1 and the like, a system of simultaneous equations is built and used for solving parameters, and the parameter equation of the modification curve in the coordinate system XOY is obtained through conversion of the coordinate system. According to the modification method, the harmonic driving involute profile is modified based on the harmonic driving kinematics theory, processing manufacturability and economy can be guaranteed, engagement performance is improved, the advantages of various harmonic tooth profiles are integrated, and the modification method can be widely applied to the technical field of harmonic gears.

Owner:国茂精密传动(常州)有限公司

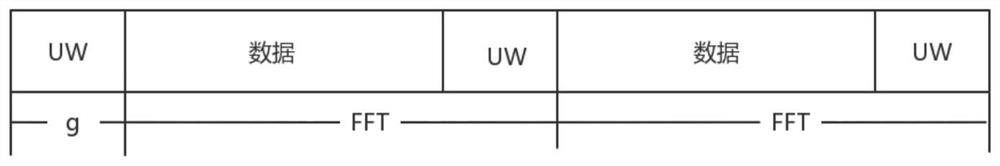

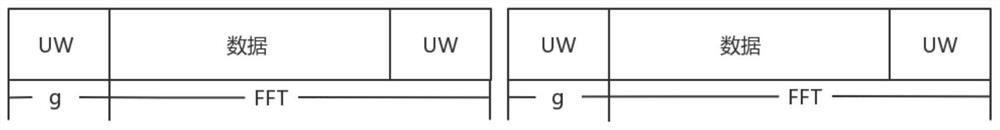

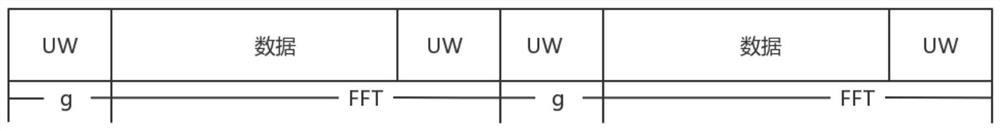

Single carrier frequency domain balanced transmission system for remote unmanned aerial vehicle image transmission

ActiveCN113132276AIncrease the lengthImprove transmission efficiencyChannel estimationMulti-frequency code systemsCarrier signalCyclic prefix

The invention belongs to the field of unmanned aerial vehicle wireless communication, and particularly relates to a single-carrier frequency domain balanced transmission system for remote unmanned aerial vehicle image transmission, and the system comprises a transmitting end disposed on an unmanned aerial vehicle and a receiving end disposed on the ground, wherein the transmitting end is used for coding and modulating a collected binary image transmission signal to obtain a symbol sequence, blocking the symbol sequence, inserting a unique word as a cyclic prefix, packaging the symbol sequence into a data frame in a self-defined format, and transmitting the data frame; and the receiving end is used for receiving the data frame transmitted through the channel, performing time-frequency synchronization and frame decoding processing, performing FFT (Fast Fourier Transform), frequency domain equalization and IFFT (Inverse Fast Fourier Transform) after removing a cyclic prefix, and then performing demodulation and decoding processing to obtain an information sequence transmitted by an image of the unmanned aerial vehicle. According to the data frame structure in the self-defined format, the length of effective data is increased, and the transmission efficiency of the effective data is greatly improved.

Owner:NAT SPACE SCI CENT CAS

Continuous production device for cloth

ActiveCN104085718ARealize continuous transmissionGuaranteed to be continuousWebs handlingMechanical engineeringPower module

The invention provides a continuous production device for cloth. The continuous production device for cloth comprises a bottom rail, sliding stand columns, a fixed roller and following rollers. A sliding groove is formed in the bottom rail. The sliding stand columns are used in pairs, and the sliding stand columns are vertically arranged in the sliding groove and can horizontally slide. The following rollers are horizontally assembled on the sliding stand columns with one above the other. The following rollers can be assembled on the sliding stand columns in the mode that the following rollers can rotate around the axis in the axial direction. The fixed roller can be assembled on the rack in the mode that the fixed roller can rotate around the axis. The fixed roller is parallel to the following rollers. Fabric is wound around the fixed roller and the following rollers and penetrates through the spaces between the fixed roller and the following rollers. The bottoms of the sliding stand columns are connected with a power module through a chain. By the adoption of the continuous production device for cloth, the fabric is continuously conveyed during production, it is guaranteed that the production device can continuously operate, and the production efficiency is improved.

Owner:JIANGSU WEIMIAO TEXTILE TECH CO LTD

Assembly line conveying structure for piston rod of hydraulic oil cylinder

The invention provides an assembly line conveying structure for a piston rod of a hydraulic oil cylinder. The assembly line conveying structure comprises a supporting mechanism. The supporting mechanism is symmetrically provided with two rotatably connected chain wheels, and two rectangular supporting plates are mounted on the supporting mechanism; the chain wheels on the supporting mechanism willbe in clamping transmission to chain plates during rotation and the chain plates are interconnected by hinge pin hinges; the chain plates which are connected form a transmission belt, and the transmission belt is connected to the chain wheels through the hinges. A clamping block in threaded connection is arranged on the chain plate, a slot aligned with the clamping block is formed in a V-shaped fixed block, and the V-shaped fixed block is clamped on the chain plate through a groove directly, so that the V-shaped fixed block can be detached and replaced independently. Compared with detachmentof a conveyor belt, it is convenient, simple to repair and maintain and low in maintenance cost. According to clamping serial connection of the V-shaped fixed block, tension during transmission is increased by means of the hinges, and the service life of the V-shaped fixed block is prolonged.

Owner:湖北统联汽车零部件有限公司

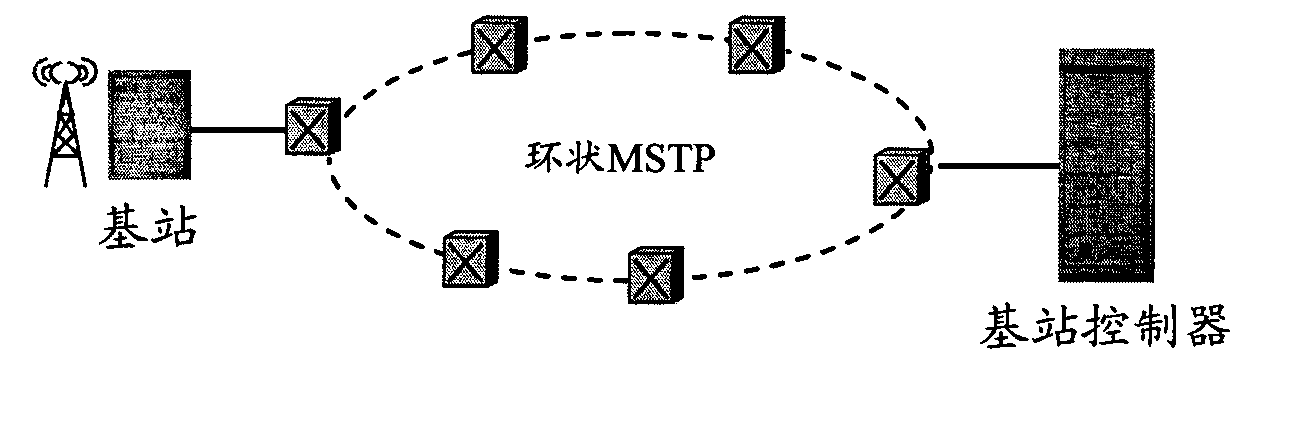

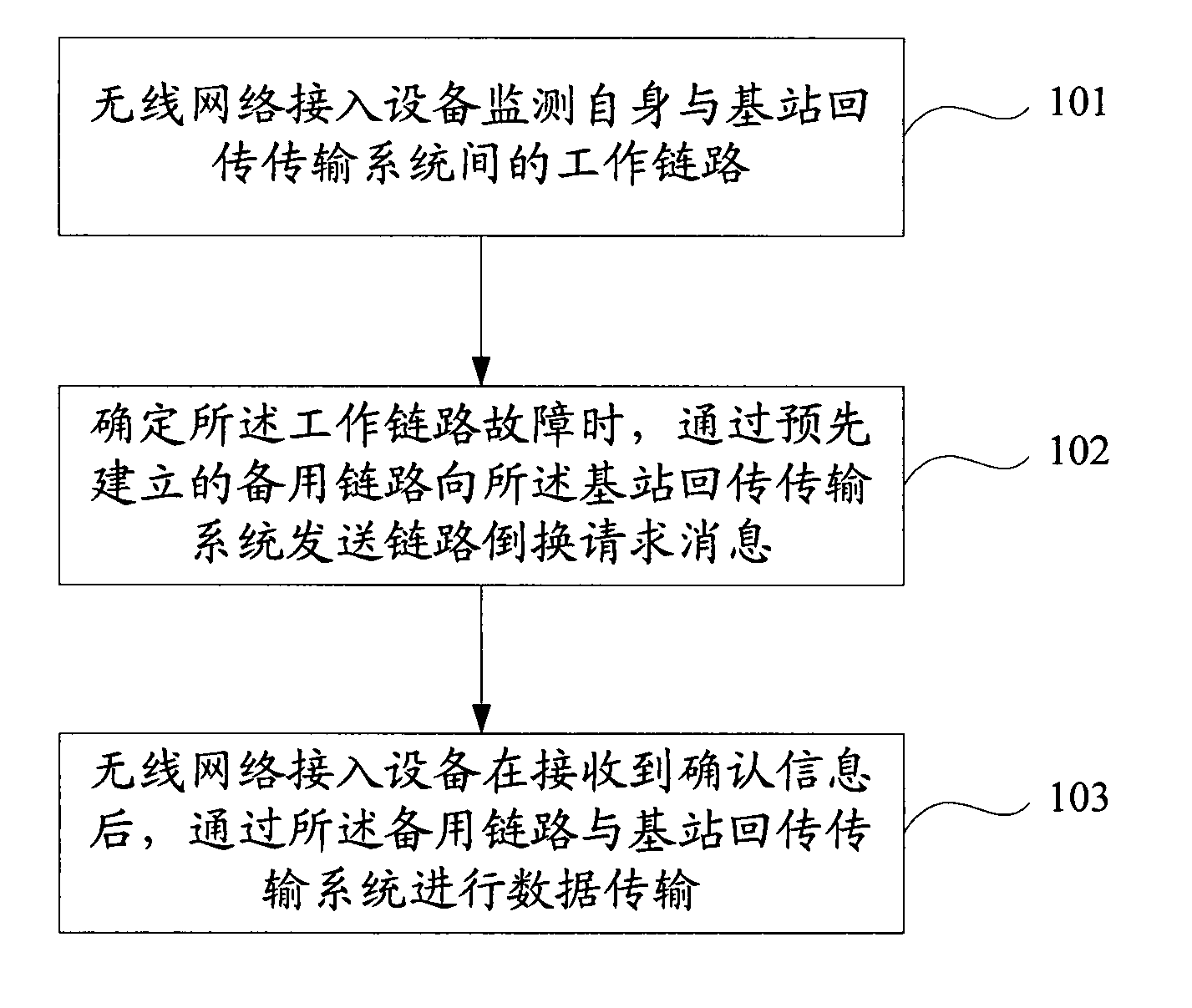

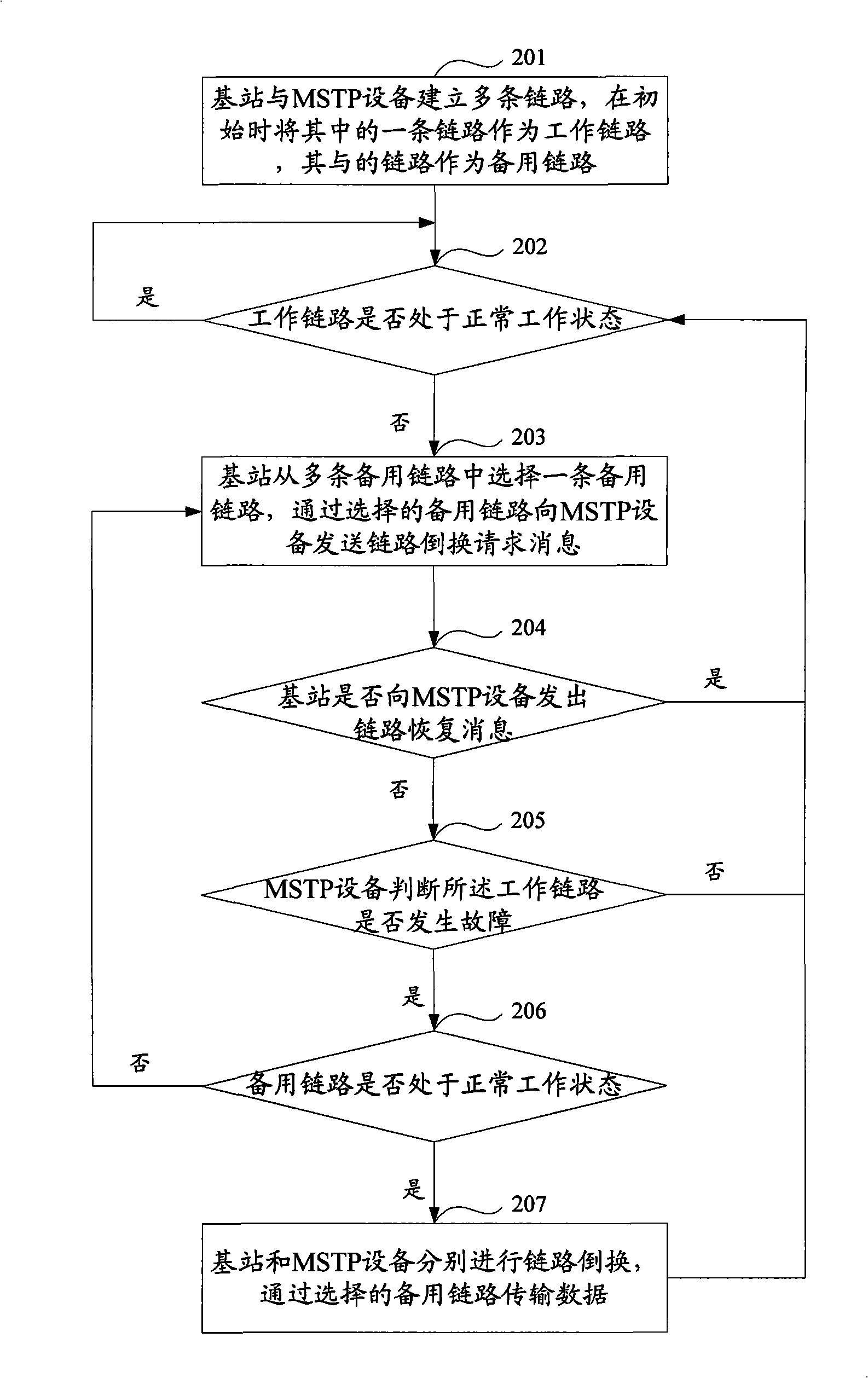

Method, system and equipment for transmitting data by wireless link

ActiveCN101860888BEnsure safetyRealize continuous transmissionTransmissionWireless communicationTransport systemData transmission

The invention discloses a method for transmitting data by a wireless link, which comprises that: wireless network access equipment monitors an active link between the wireless network access equipment and a base station back transmission system; when the active link is determined to fail, the wireless network access equipment transmits a link switching request message to the base station back transmission system by using a pre-established backup link; and after receiving confirmation information returned by the base station back transmission system, the wireless network access equipment performs data transmission with the base station back transmission system by using the backup link. The method has the advantage of ensuring the security of the link between the wireless network access equipment and the base station back transmission system. The embodiment of the invention also provides a system and equipment for transmitting the data by the wireless link.

Owner:CHINA MOBILE COMM GRP CO LTD

Biomass material conveying mechanism

PendingCN110525928ARealize continuous transmissionImprove transmission efficiencyLarge containersConveyor partsImpellerFree state

The invention discloses a biomass material conveying mechanism comprising a hopper, and a stirring mechanism that is mounted in the hopper; the stirring mechanism comprises a rotating shaft mounted atthe bottom of the hopper; a poking piece is further installed on the rotating shaft, the poking piece is an elastic piece made of an elastic material, one end of the poking piece is fixed to the sideface of the rotating shaft, and the free end of the poking piece extends out of the rotating shaft in a free state, so that a combined body composed of the poking piece and the rotating shaft is in an open impeller shape; in the rotating process of the poking piece, when the side face of the poking piece is subjected to resistance, the poking piece can be wound around the rotating shaft. The conveying mechanism can effectively prevent bridge arches or air holes from being formed in materials to be conveyed, and meanwhile the advantage of saving power consumption is realized.

Owner:成都翠威新能源科技中心(有限合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com