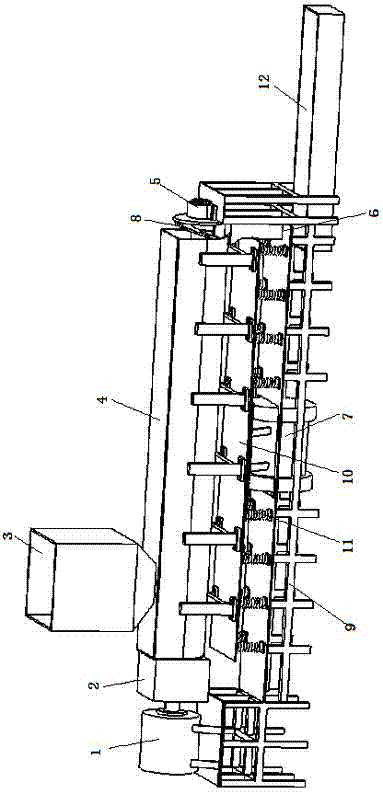

Vibratory spiral polisher

A vibrating screw, polishing machine technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc., can solve problems such as polishing occupation, and achieve the reduction of processing steps and polishing. time, the effect of improving the method of feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

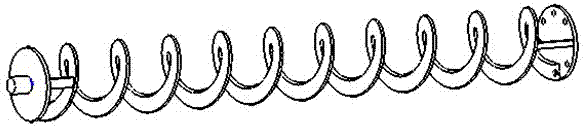

[0021] The feed motor 1 drives the reducer 2 to rotate, the reducer 2 is connected to the screw propulsion device 8 and transmits the power to the screw propulsion device 8 to make the screw propulsion device 8 rotate, the vibration motor 7 drives the material container 4 to perform high-frequency vibration through the vibrating frame 10, The parts enter the material container 4 from the feeding port 3 and pass through the material container 4 under the push of the screw propulsion device 8 shaftless spiral push rod, and the parts arrive at the bottom of the right port of the material container 4 under the push of the screw propulsion device 8 shaftless spiral push rod The discharge port 6 is exported by the discharge port 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com