Biomass material conveying mechanism

A material transmission and biomass technology, applied in the field of biomass material transmission mechanism, can solve the problems of material conveying failure, discontinuous material conveying, poor fluidity, etc., to reduce power consumption and facilitate the extraction of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

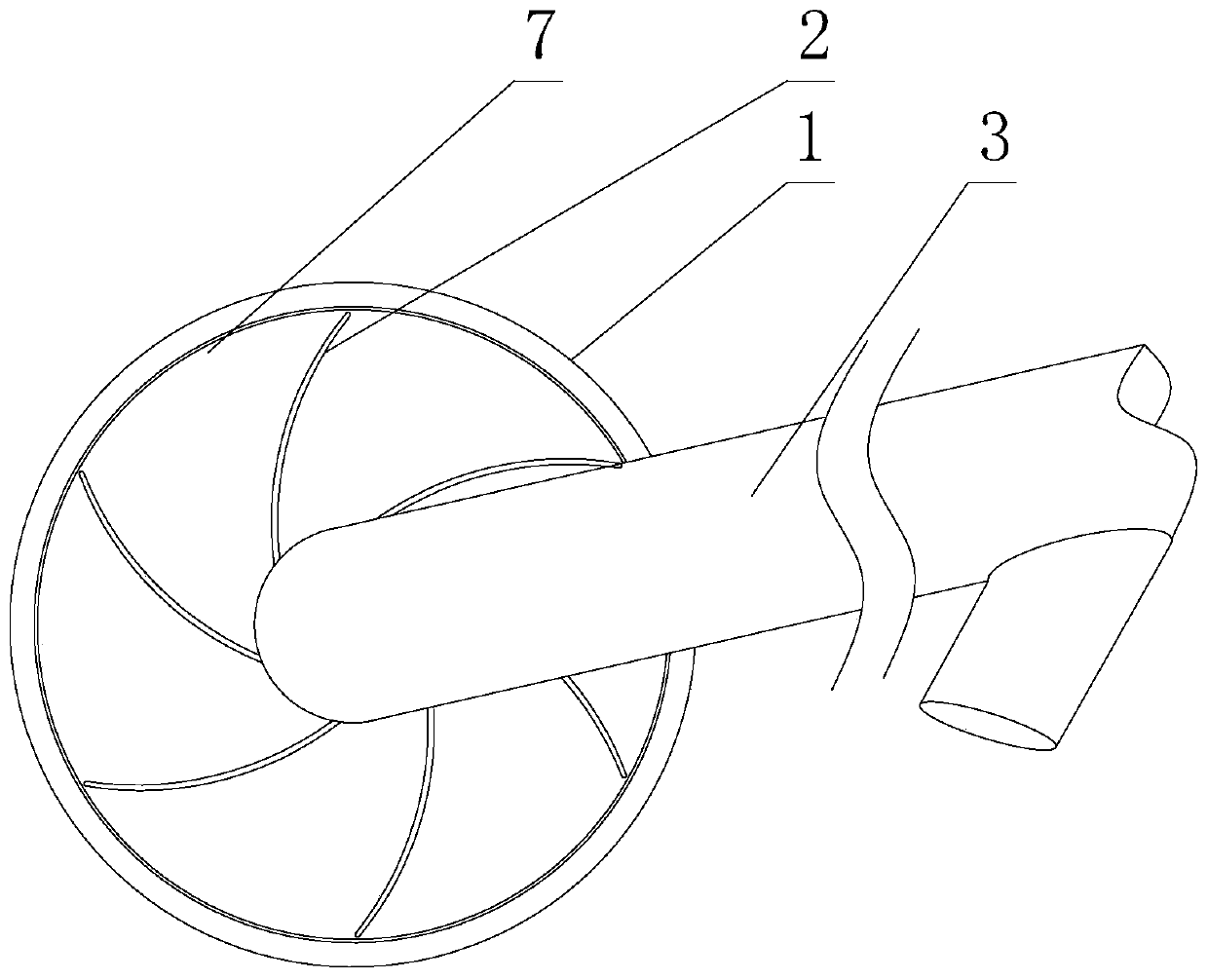

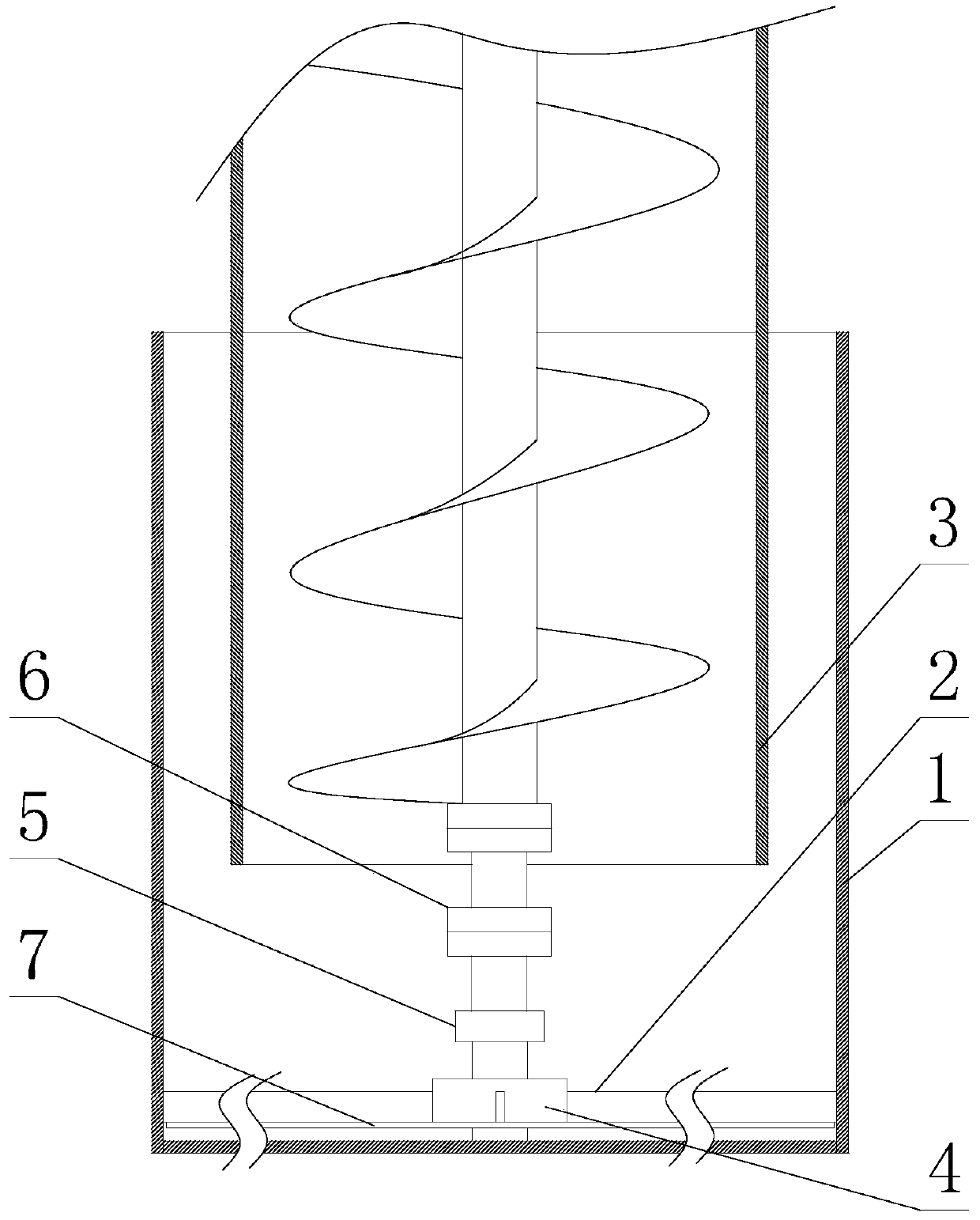

[0027] Such as figure 1 and figure 2 As shown, a biomass material transmission mechanism includes a hopper 1, and also includes a stirring mechanism installed in the hopper 1. The stirring mechanism includes a rotating shaft 4 installed at the bottom of the hopper 1, and a paddle is also installed on the rotating shaft 4. 2. The paddle 2 is an elastic piece made of elastic material, one end of the paddle 2 is fixed on the side of the rotating shaft 4, and when the paddle 2 is in a free state, the free end of the paddle 2 extends to the outside of the rotating shaft 4 In this way, the combination of the plectrum 2 and the rotating shaft 4 is in the shape of an open impeller; during the rotation of the plectrum 2, when the side of the plectrum 2 is resisted, the plectrum 2 can be wound on the rotating shaft 4.

[0028] In the prior art, if biomass materials such as straw and wood are used for gasification or pyrolysis, it is generally necessary to use a conveyor to transport t...

Embodiment 2

[0033] The present embodiment is further limited on the basis of embodiment 1, as figure 1 and figure 2 As shown, as the specific arrangement form of the rotating shaft 4 and the dial 2, it is set as follows: the axis of the rotating shaft 4 is perpendicular to the bottom surface of the hopper 1, the dial 2 is multi-piece, and the dial 2 is circular around the axis of the rotating shaft 4 Evenly distributed. Adopting this solution can effectively increase the frequency that the paddle 2 touches the material, and at the same time make the paddle 2 evenly act on the material, which is beneficial to the uniformity of material transmission.

[0034] As a material of the plectrum 2 that is wear-resistant and easy to obtain a suitable elastic coefficient, it is set that the elastic material is spring steel.

[0035] As a specific arrangement form of the plectrum 2, it is set as follows: when the plectrum 2 is in a free state, the protruding part of the plectrum 2 relative to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com