A Modification Method of Involute Tooth Profile in Harmonic Drive

An involute tooth, harmonic drive technology, applied in the direction of the transmission device, components with teeth, belt/chain/gear, etc., can solve the problems of unfavorable oil film, cusp contact, poor meshing performance, etc. Performance, increased number of teeth, small meshing backlash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

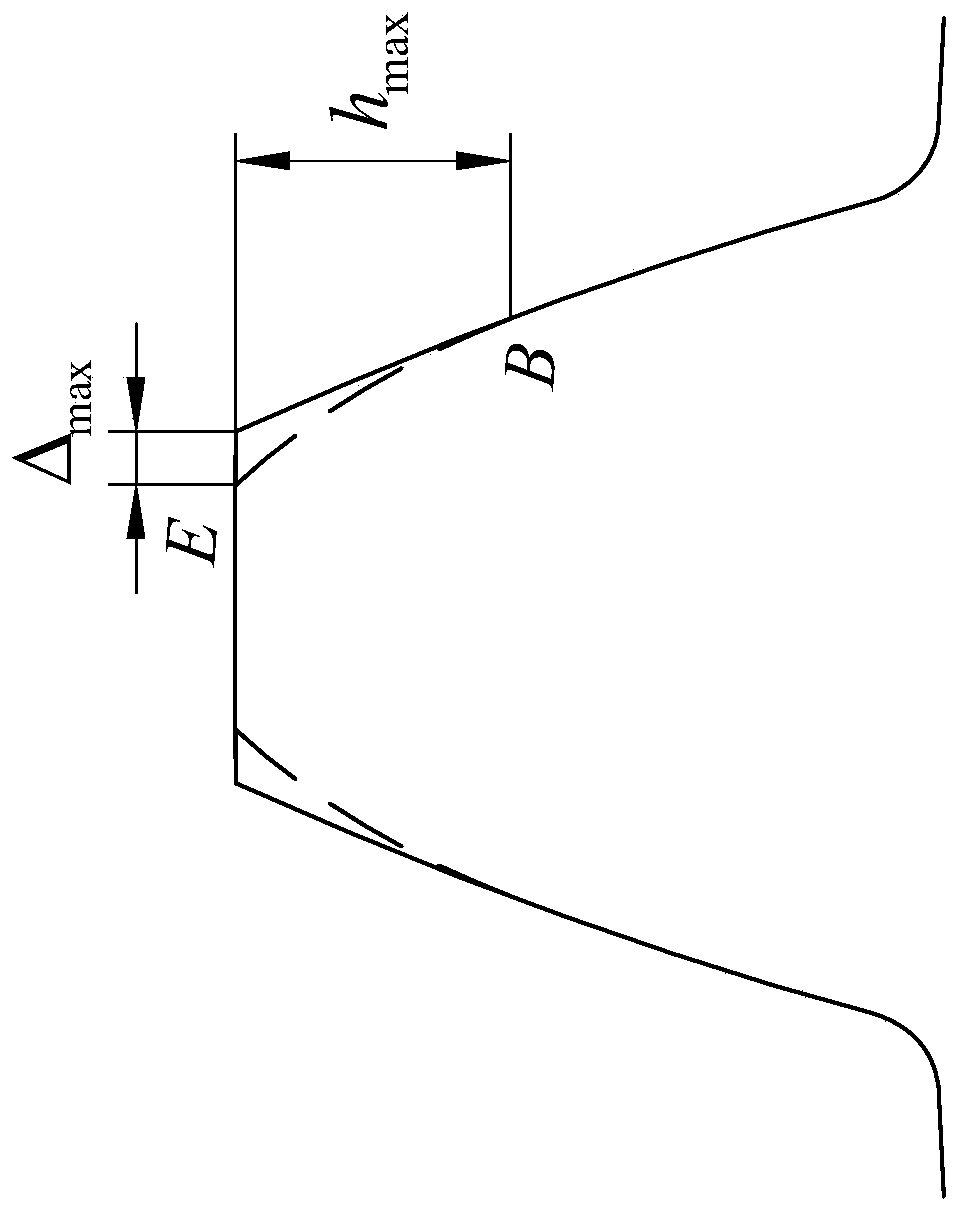

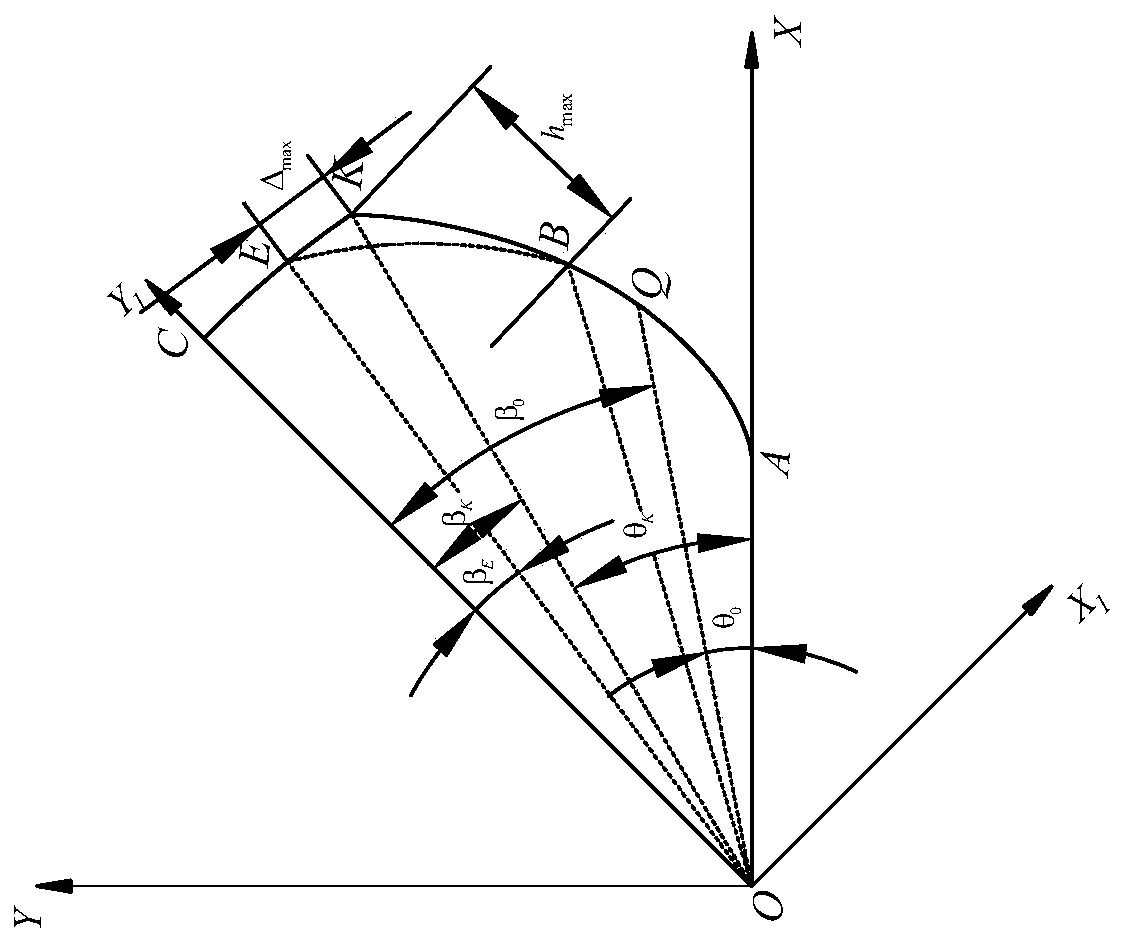

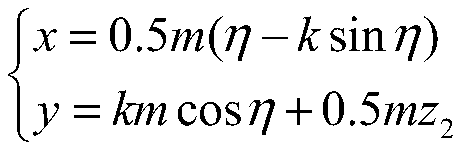

[0113] The following is a specific calculation combined with the modification curve of a specific flexspline gear. The main parameters are selected as follows: the number of flexible gear teeth z=60, the modulus m=1.3, the pressure angle α 0 =20°, addendum height coefficient Then β 0 = π / 2z = 0.0262, θ 0 =tanα 0 -α 0 = 0.0149. Let the maximum modification amount and modification length of the harmonic involute tooth profile modification be Δ max =0.2m=0.26, The parametric equation of the involute in the coordinate system XOY is

[0114]

[0115] Among them, the base circle radius

[0116] The equation in the addendum circle coordinate system XOY is

[0117]

[0118] Among them, the radius of the addendum circle

[0119] Simultaneous involute and addendum circle equations can be obtained

[0120]

[0121] Thus, the rolling angle φ of point K is obtained K for

[0122]

[0123] Therefore, the length of arc KA is

[0124]

[0125] Similarly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com