Patents

Literature

1224 results about "Cycloid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

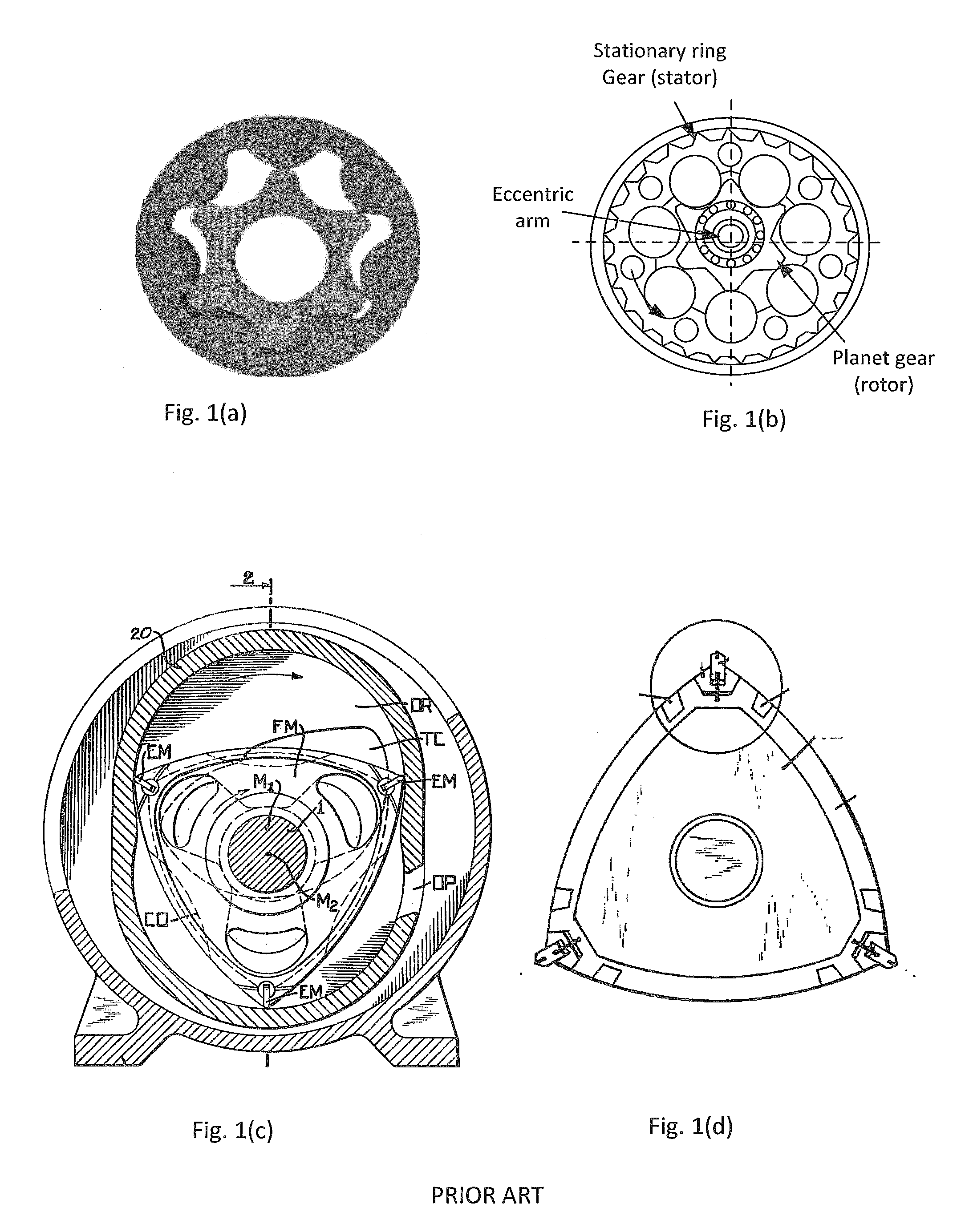

A cycloid is the curve traced by a point on the rim of a circular wheel as the wheel rolls along a straight line without slipping. A cycloid is a specific form of trochoid and is an example of a roulette, a curve generated by a curve rolling on another curve.

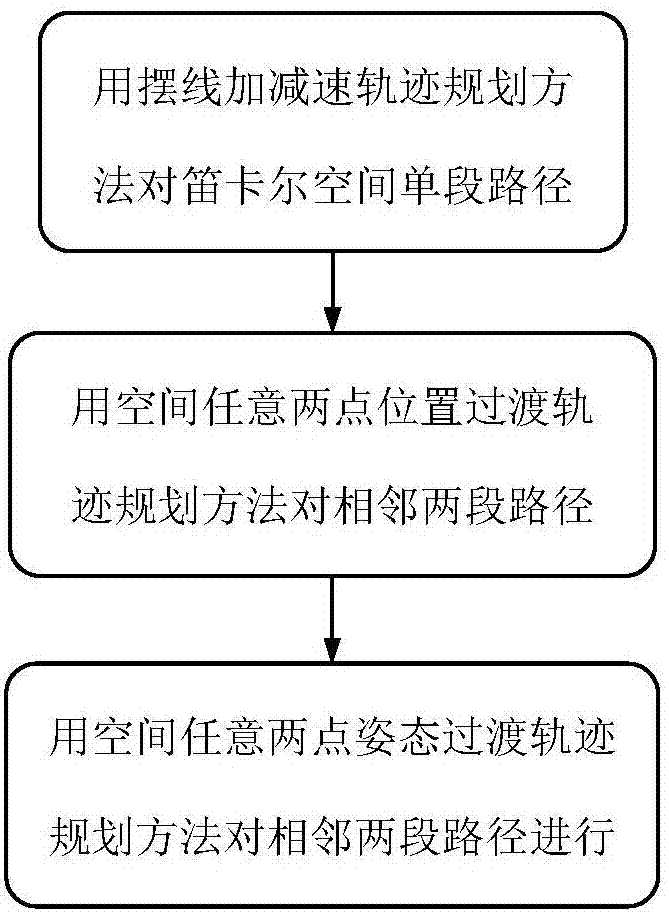

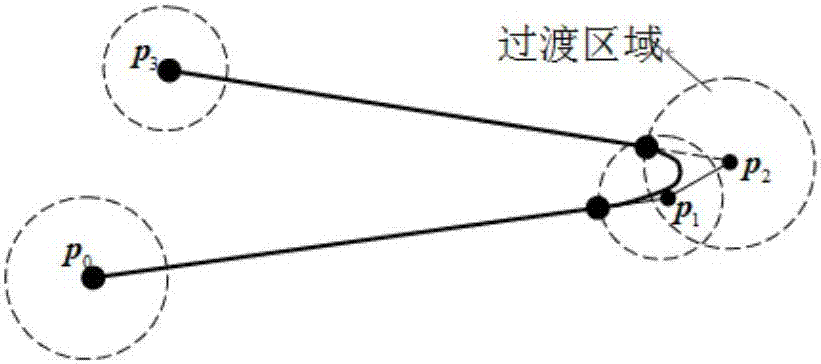

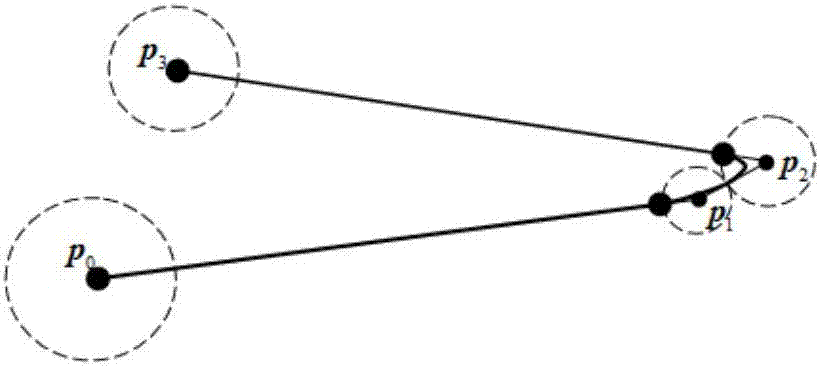

Planning method for smooth trajectory of robot in Cartesian space

ActiveCN107030697AAcceleration continuousSimple calculationProgramme-controlled manipulatorQuaternionEngineering

The invention discloses a planning method for the smooth trajectory of a robot in Cartesian space. The planning method comprises the following process: planning the positions and postures of single-section trajectories, such as a spatial line and an arc; carrying out planning on the smooth transition of a path; controlling the size of the transition region of the path by adopting a transition grade; fitting the path in the transition region by adopting a parabola, and fitting the postures by adopting a quaternion algorithm; and adopting a cycloidal acceleration and deceleration planning method containing acceleration and an acceleration restraint to carry out planning on the spatial trajectory of the path so as to obtain the smooth spatial position and posture trajectory of a robot. The method can effectively solve robot trajectory problems, such as pause, non-smoothness, dithering, path deviation and speed excess and improve the running stability of the robot. The planning method for the smooth trajectory, related to the invention, has certain flexibility, and not only can plan the positions and the postures in the Cartesian space but also can adapt to various robot structures, containing common 6-degree-of-freedom vertical joint mechanical arms, low-degree-of-freedom robots and redundant robots.

Owner:GUANGZHOU UNIVERSITY

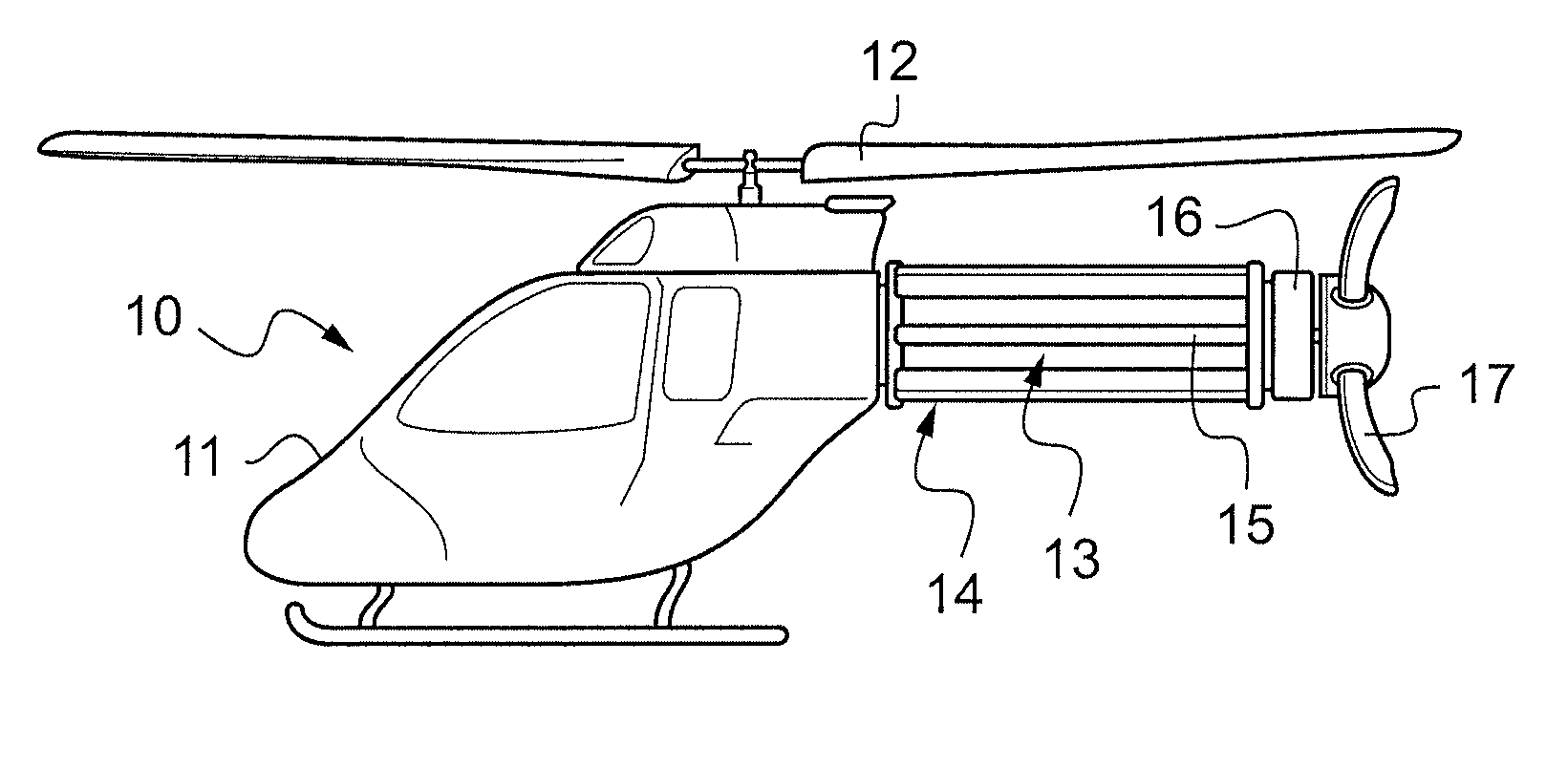

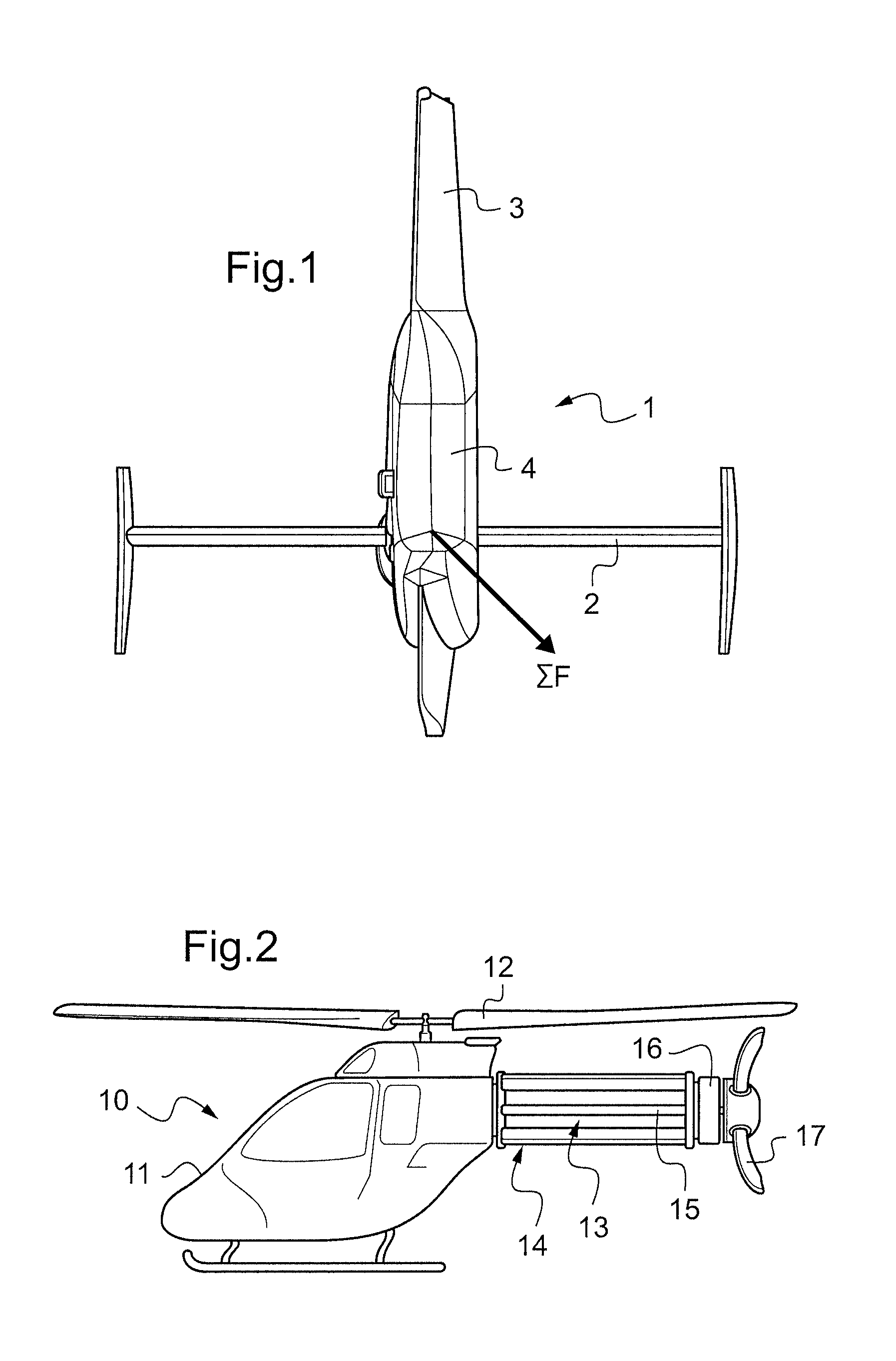

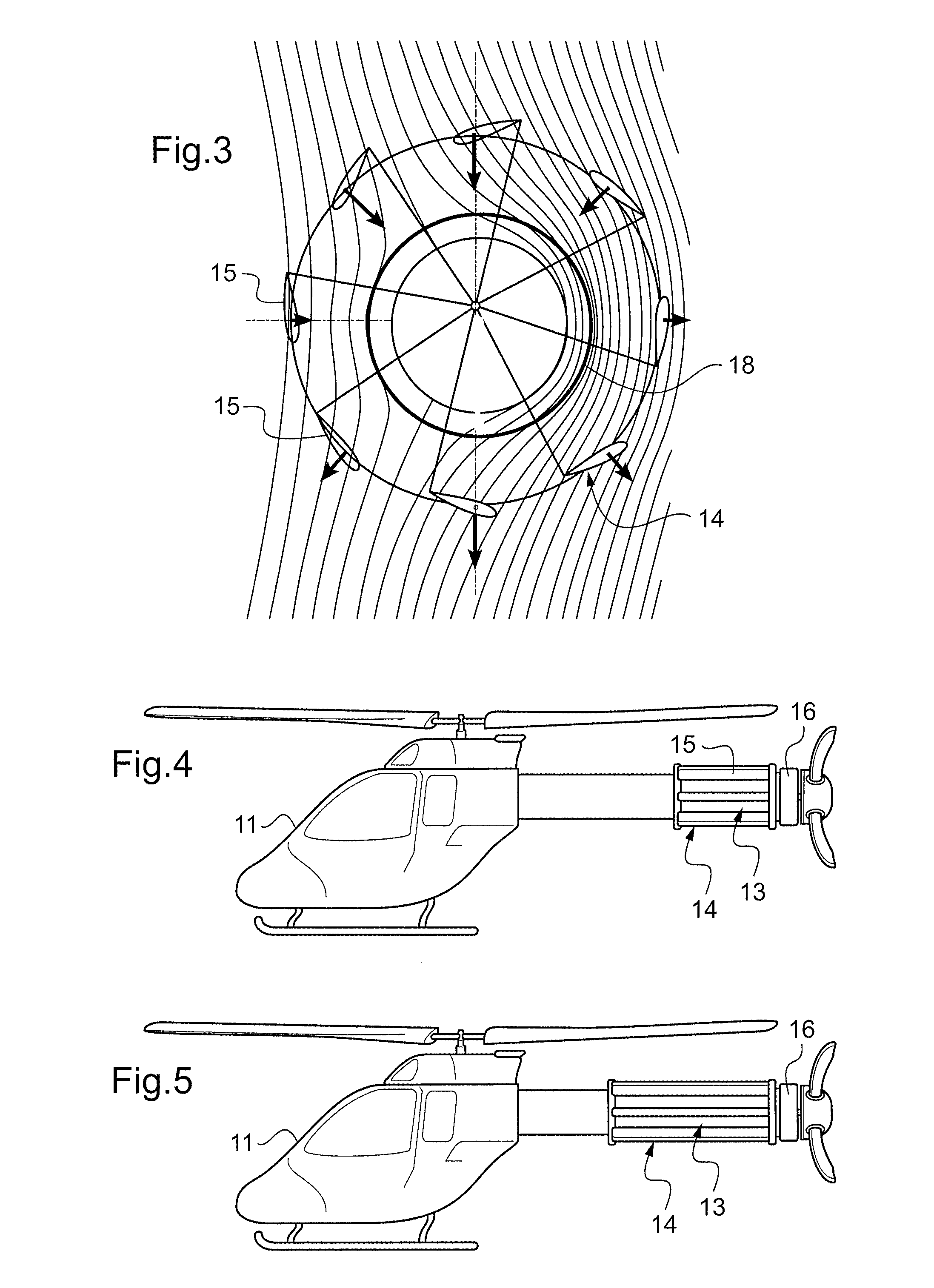

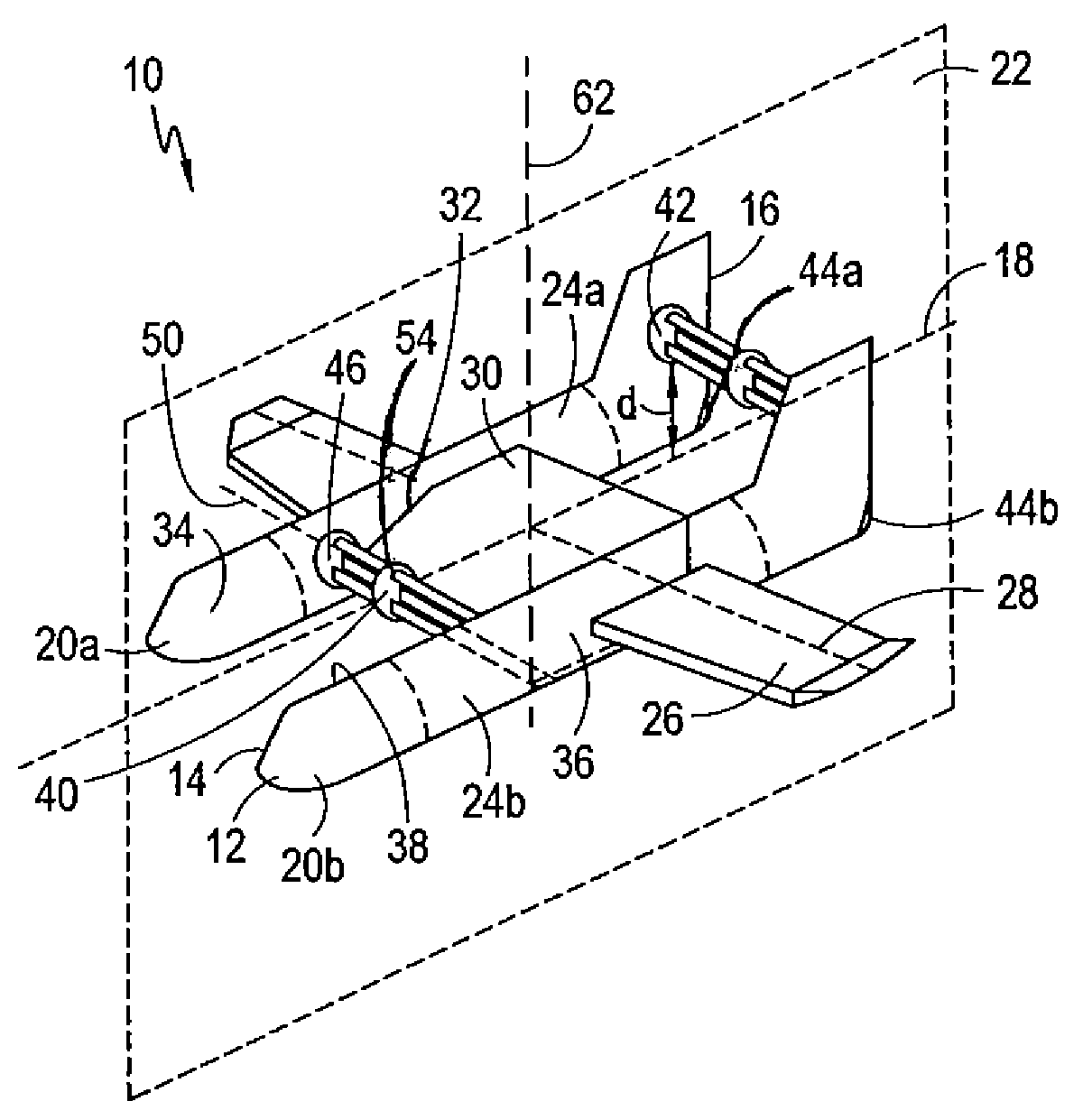

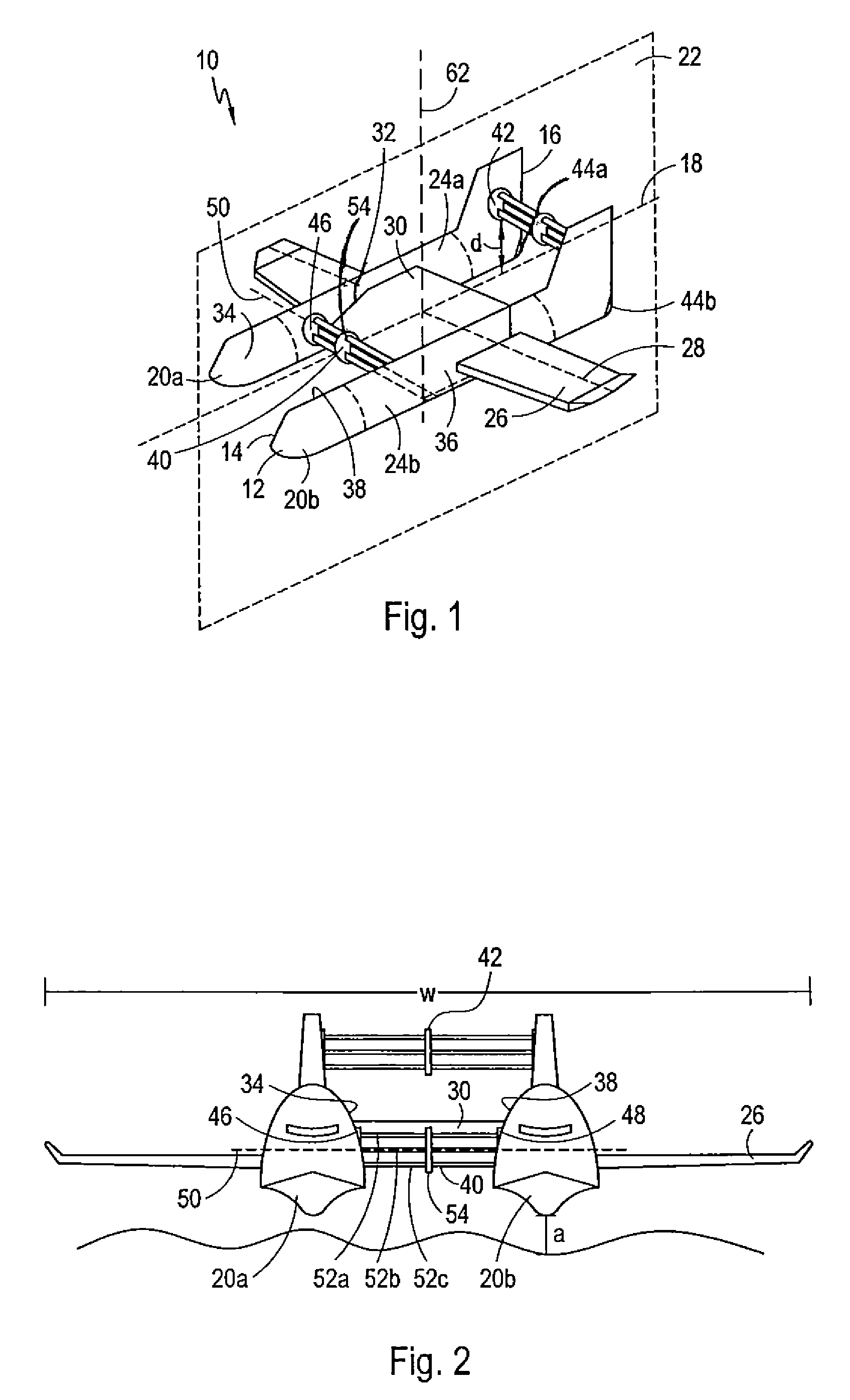

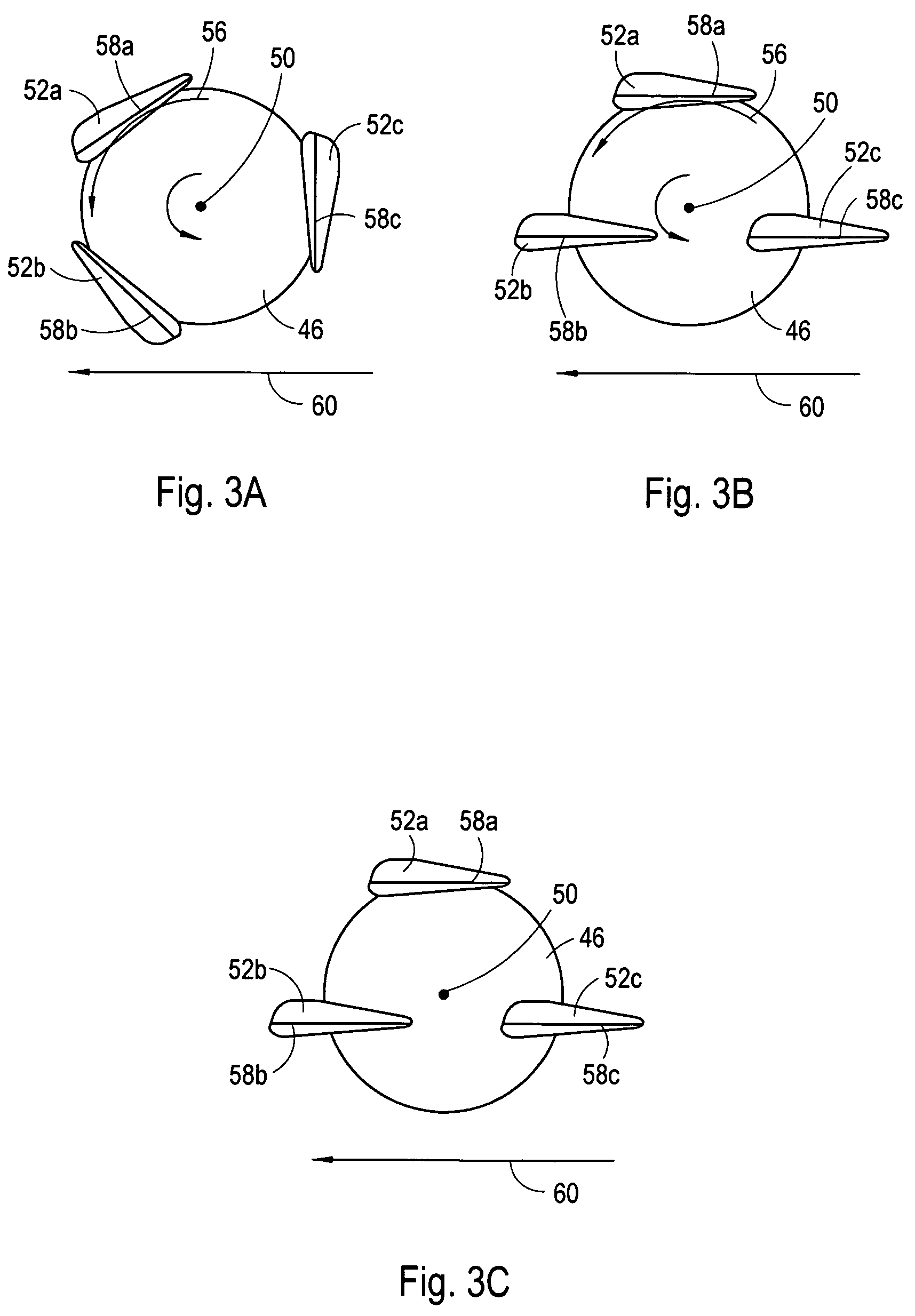

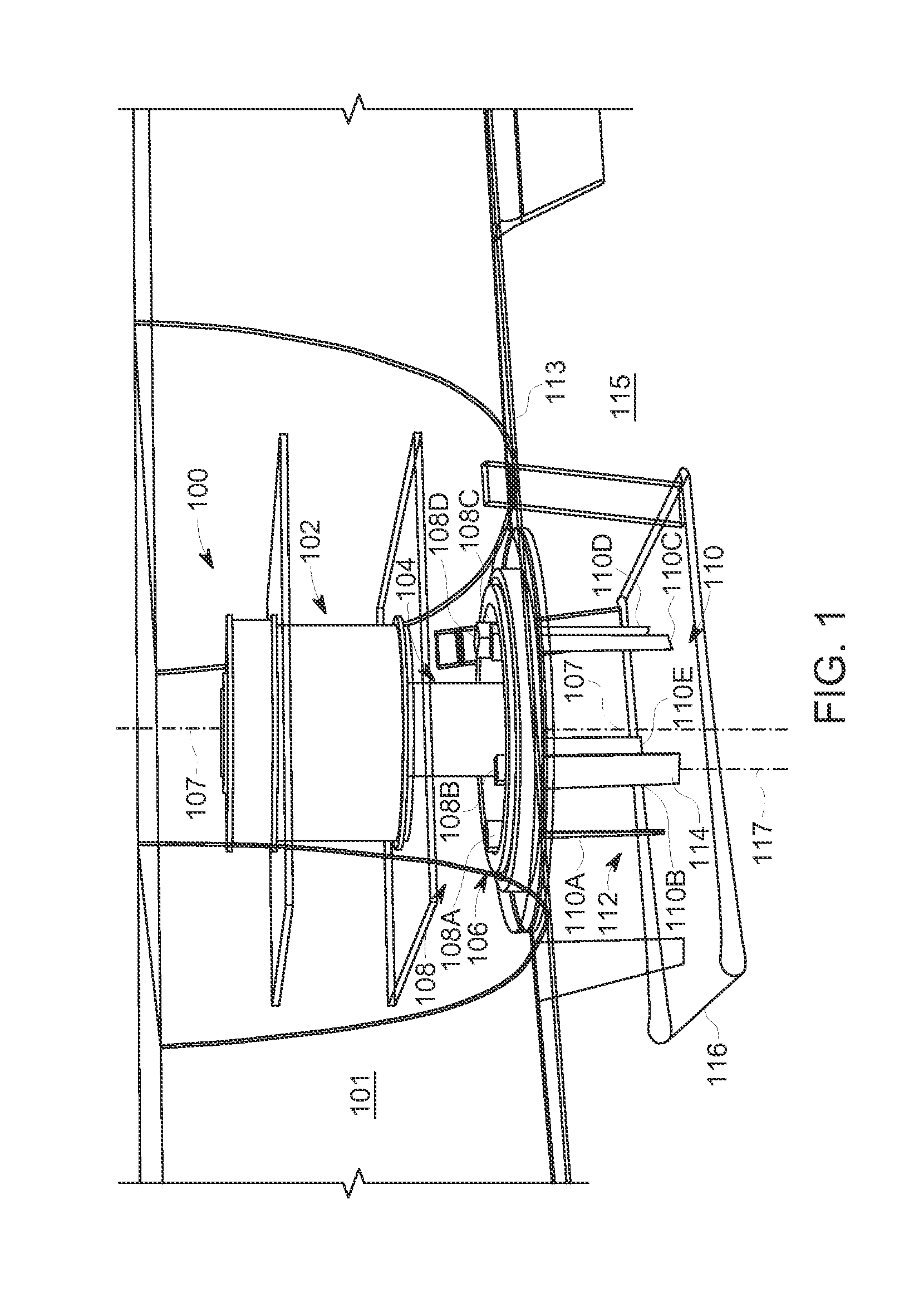

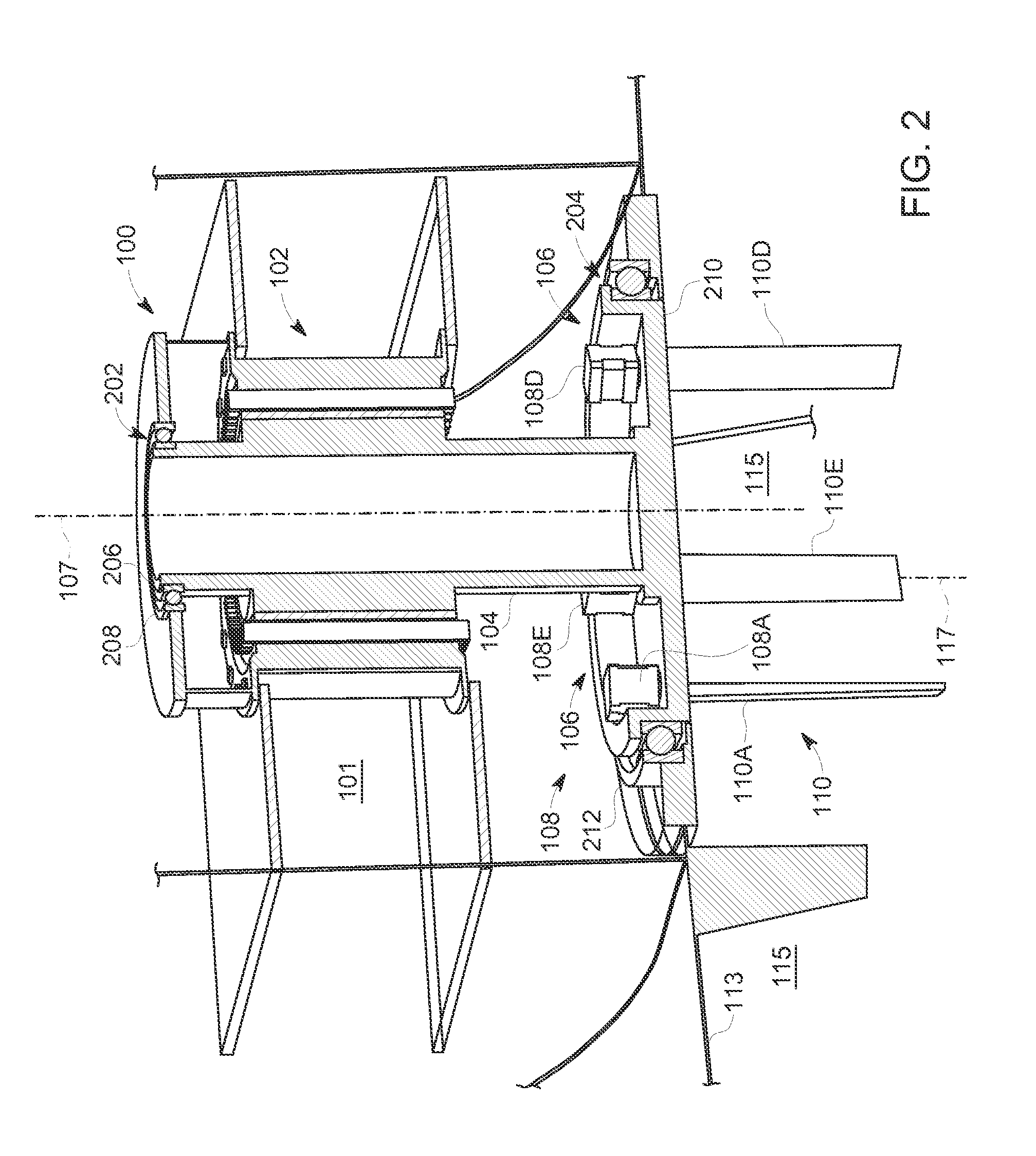

Helicopter with cycloidal rotor system

The invention is related to a helicopter (10) comprising a main rotor (12), a cycloidal rotor (14) and a rotating cylinder (18). The rotating cylinder (18) extends along a longitudinal axis of a tail boom (13). The cycloidal rotor (14) extends at least partly along said same tail boom (13) and rotates outside the rotating cylinder (18).

Owner:AIRBUS HELICOPTERS DEUT GMBH

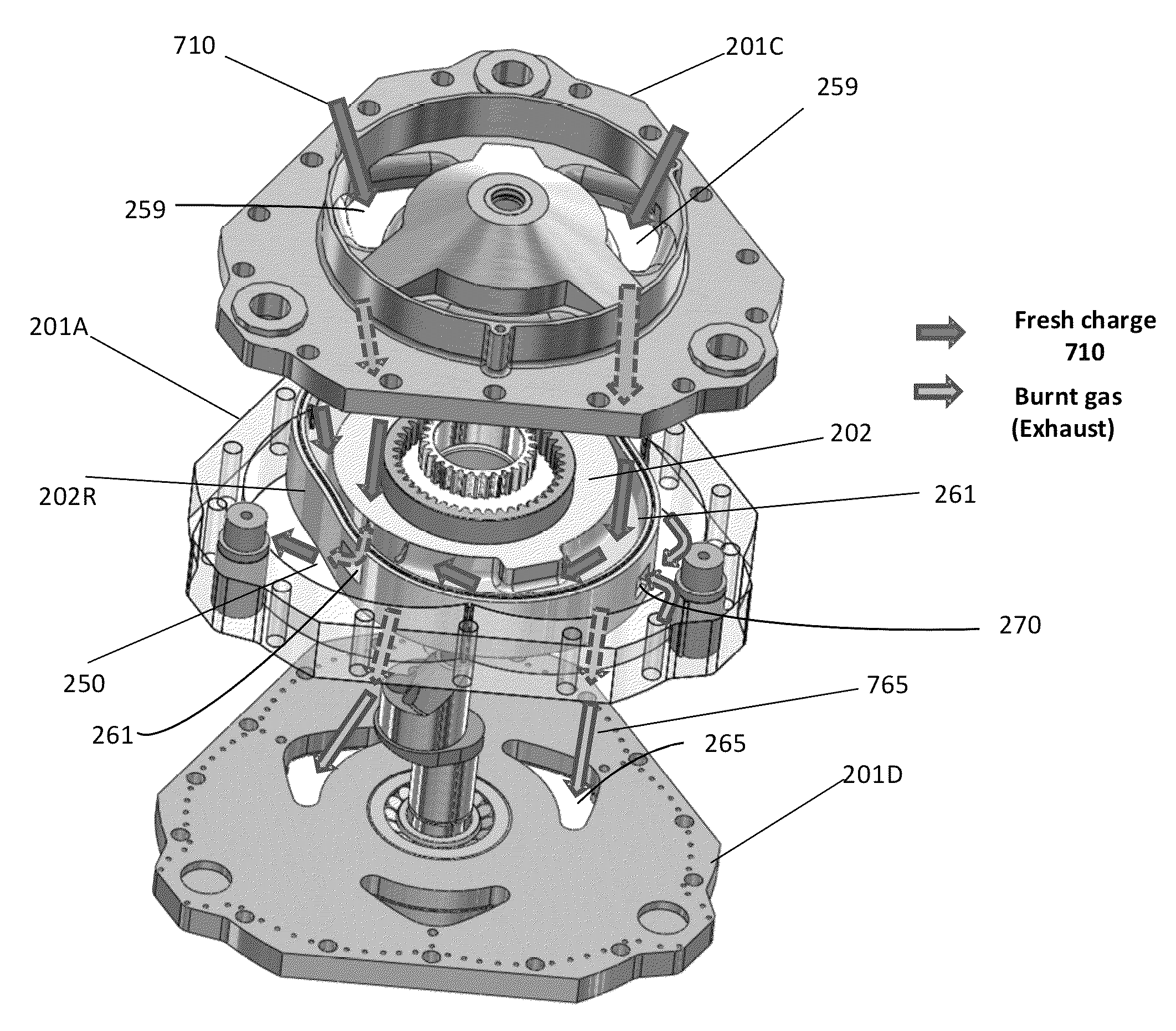

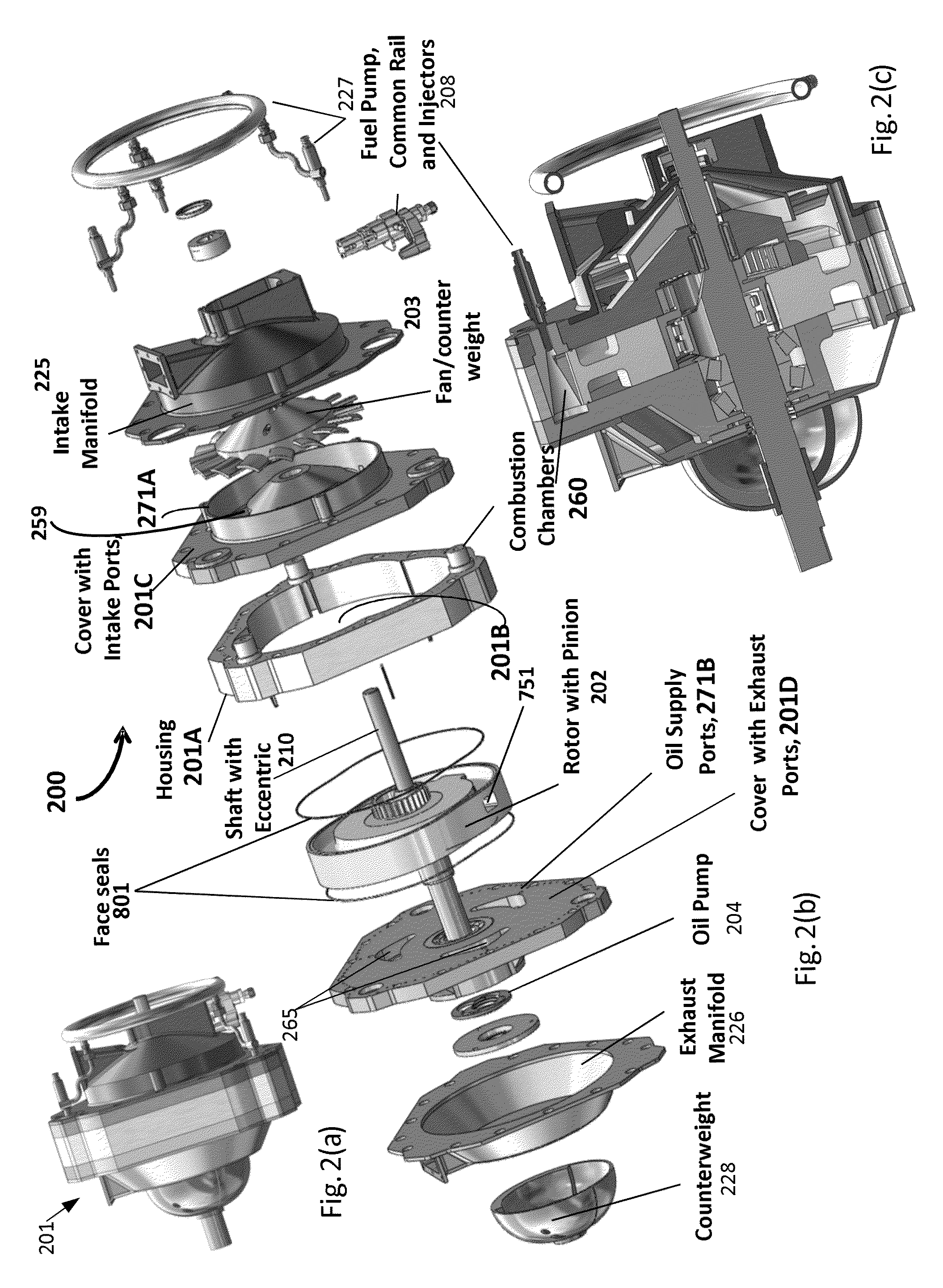

Cycloid rotor engine

ActiveUS8523546B2Internal combustion piston enginesEngine of arcuate-engagement typeRotary engineEngineering

Owner:LIQUIDPISTON INC

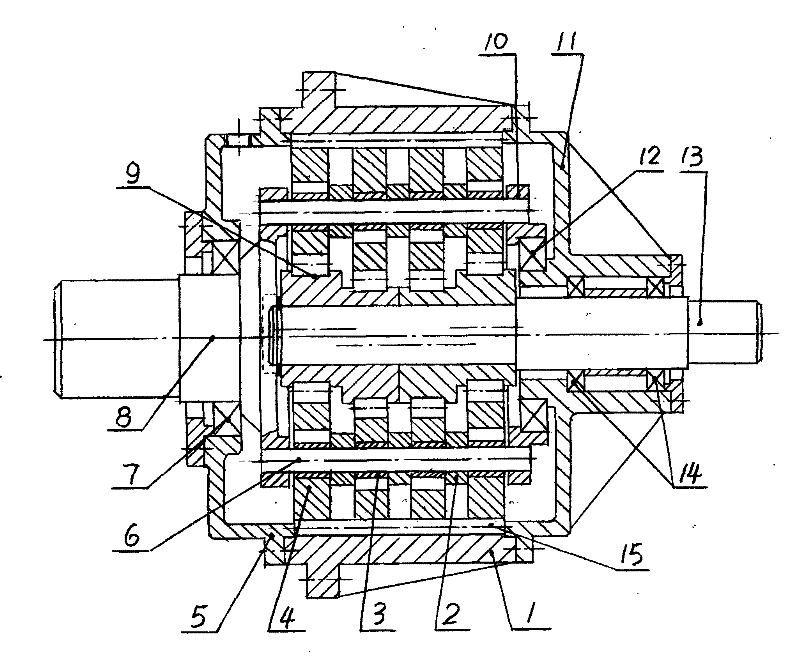

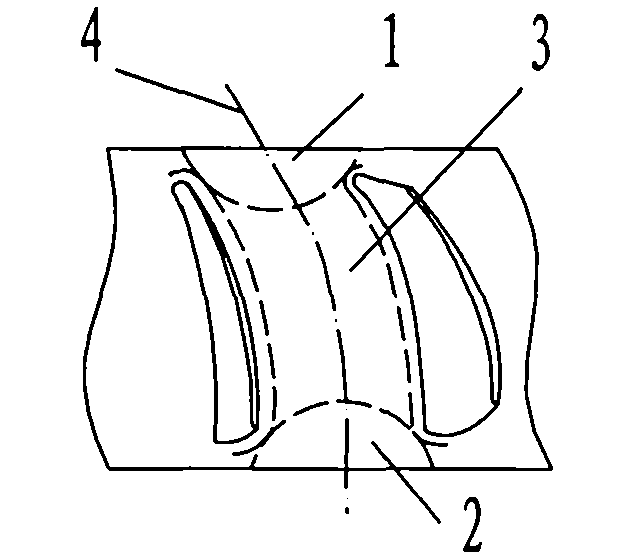

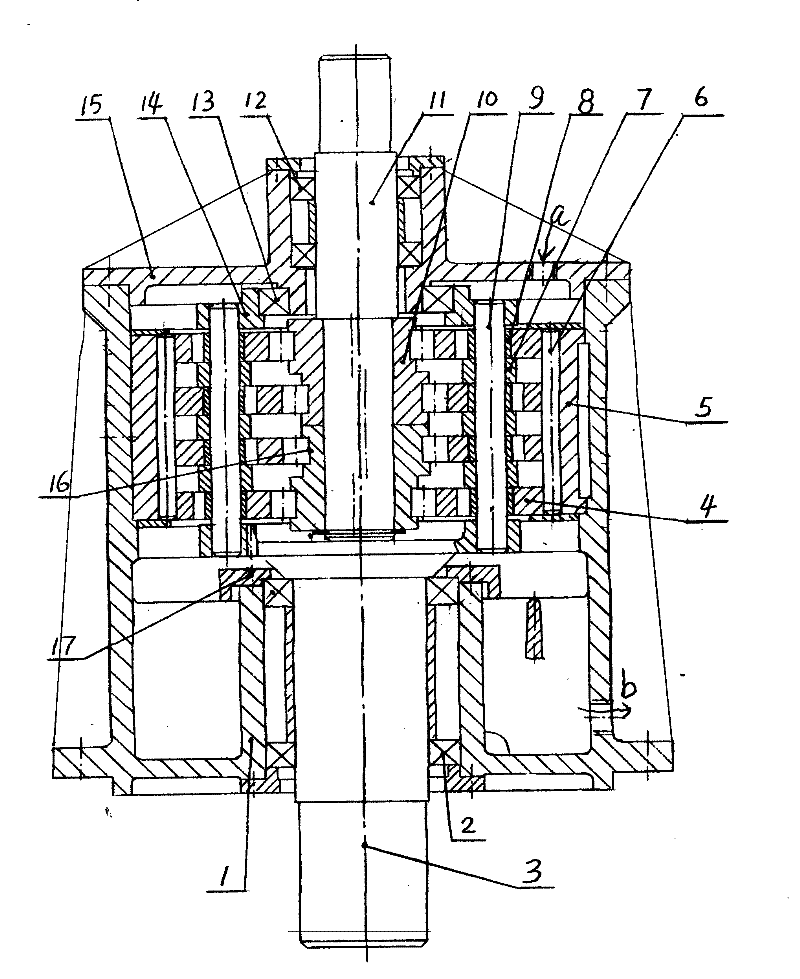

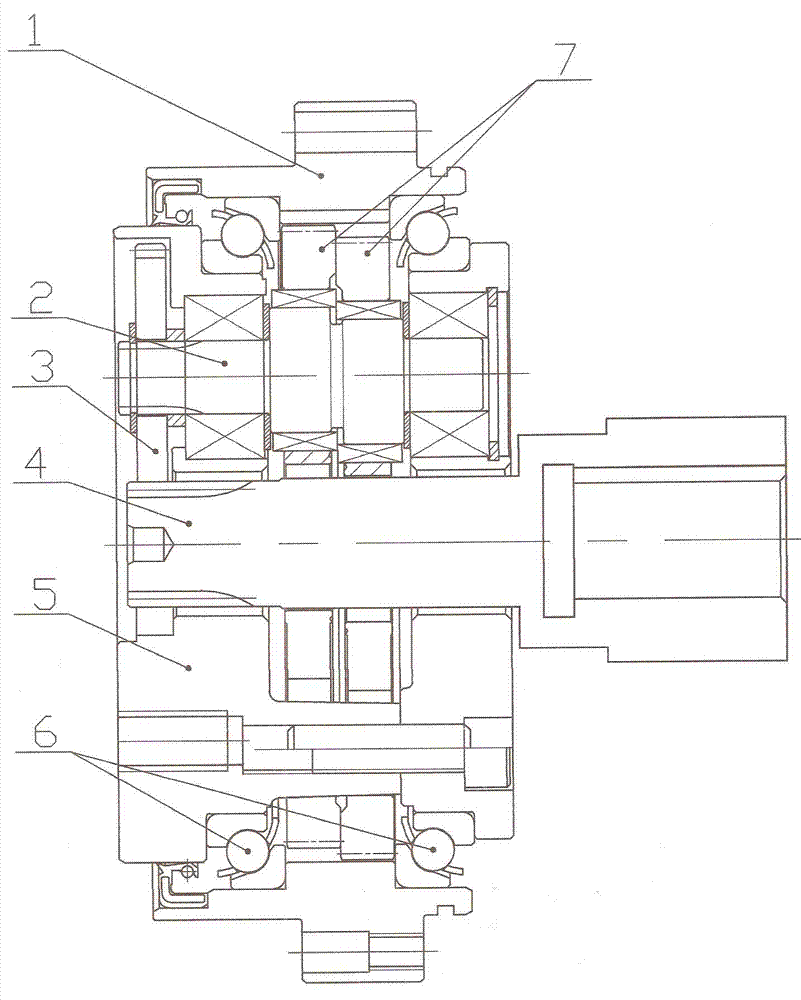

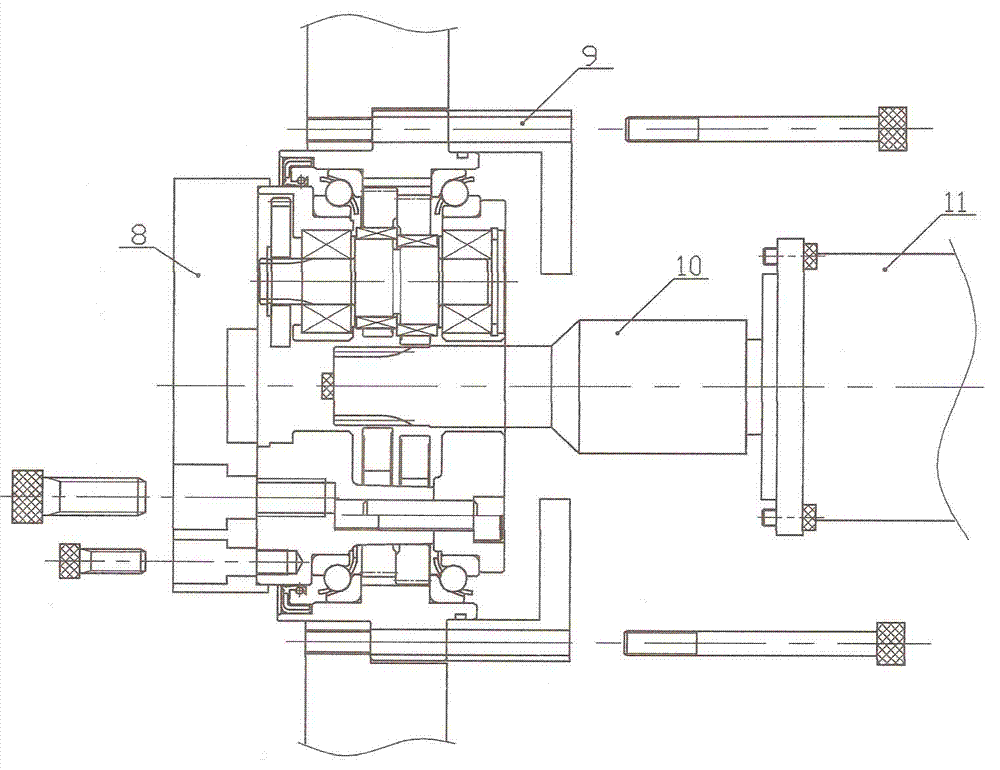

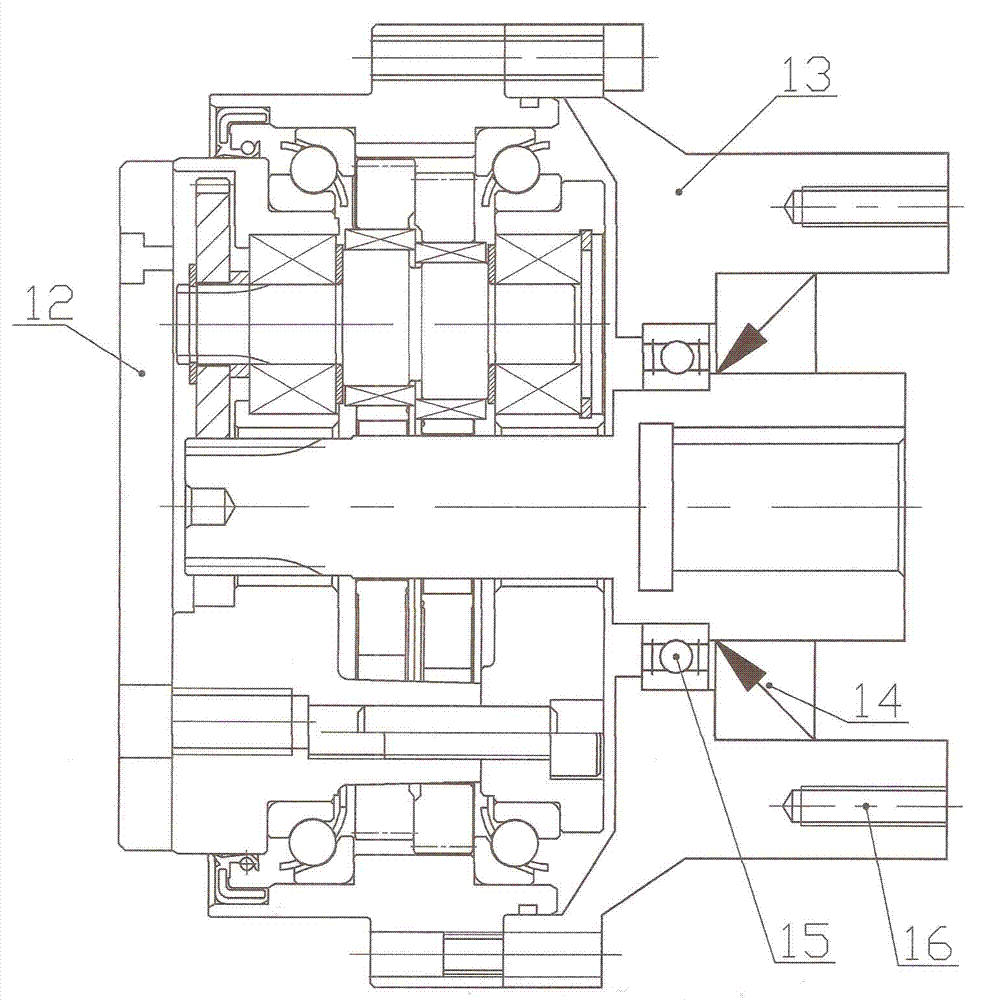

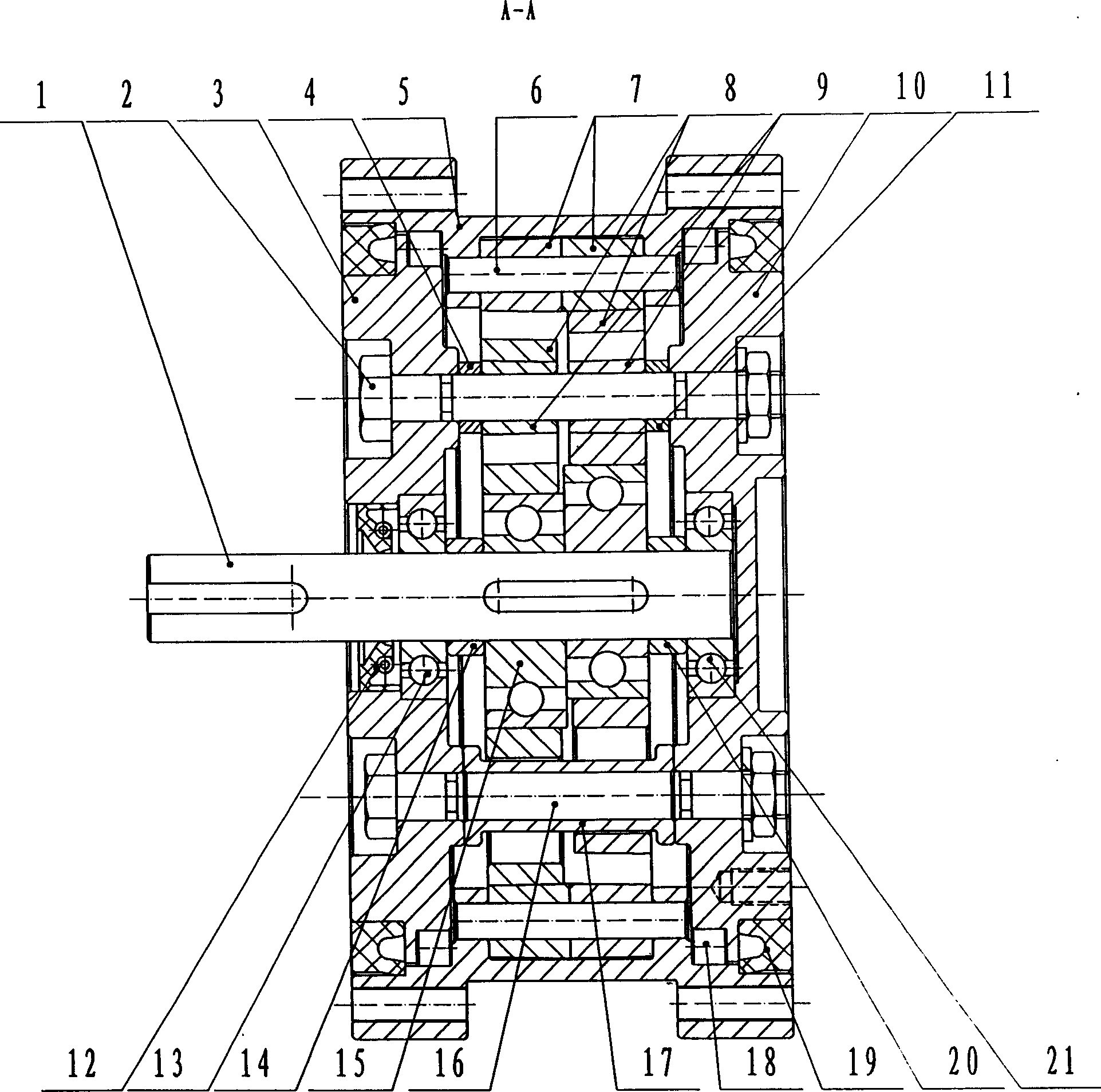

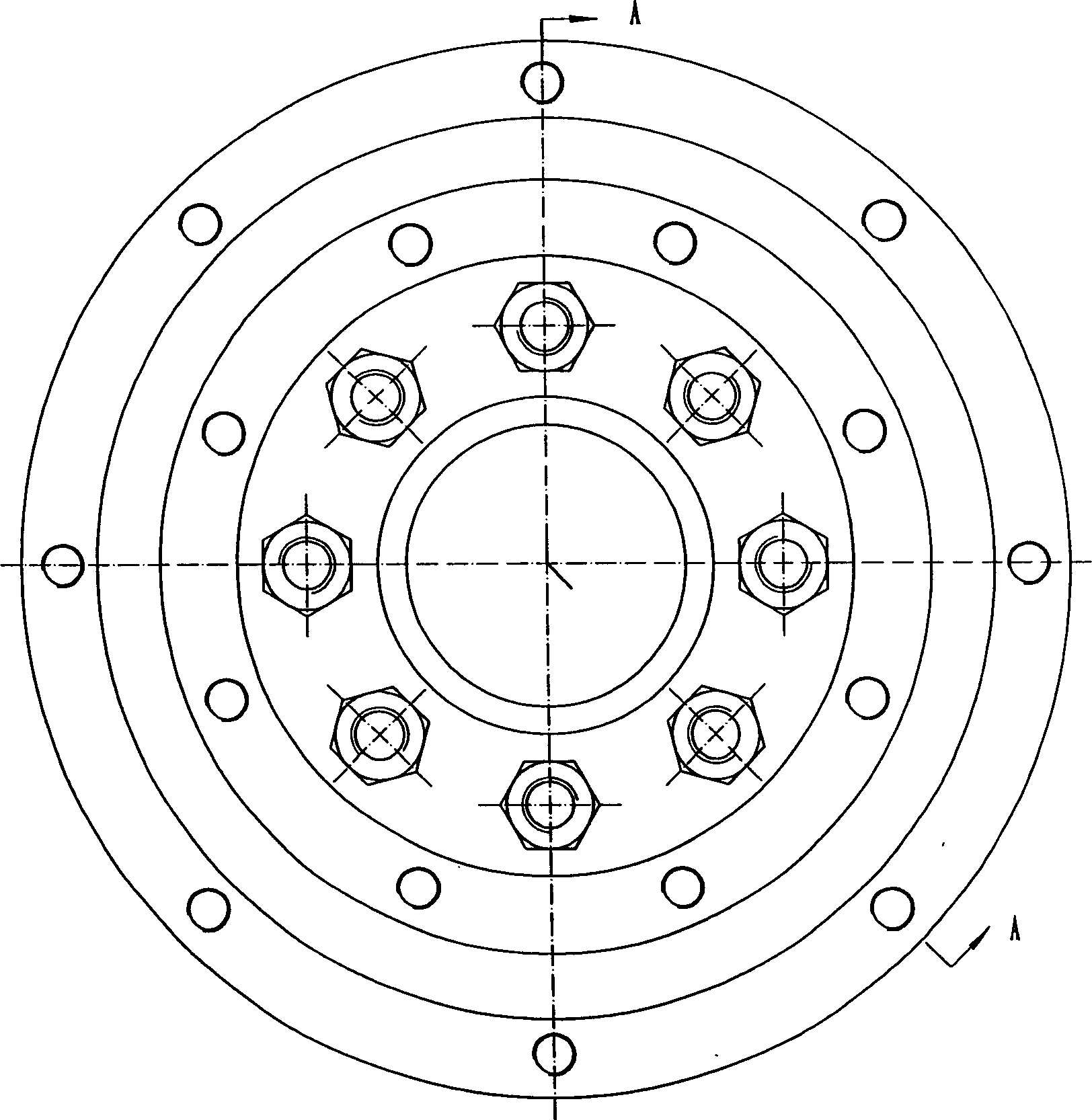

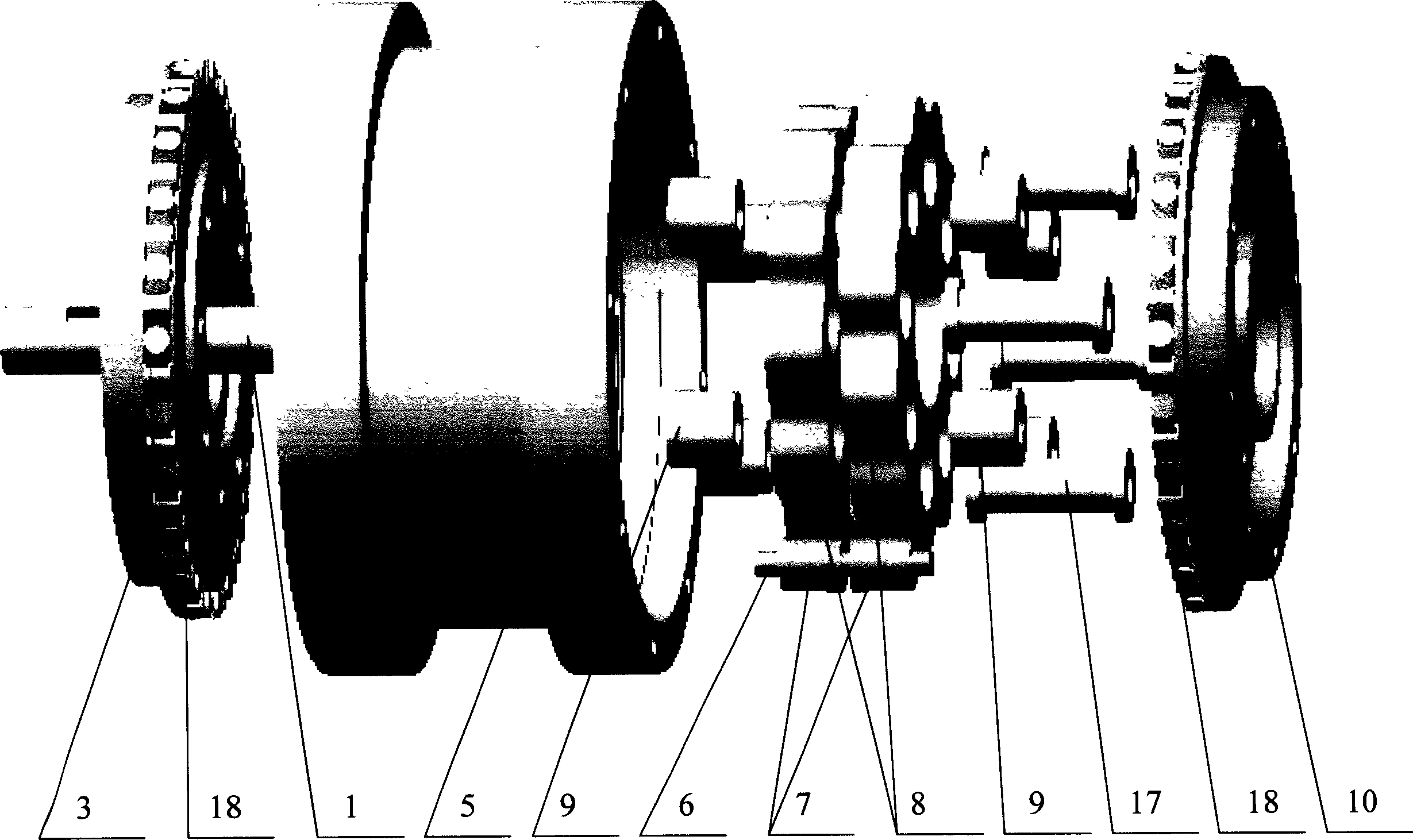

Soil pressure balance shield machine cycloid speed reducer

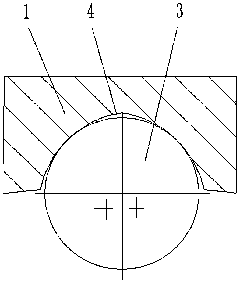

ActiveCN102192279AIncreased bending stressReduce axial sizeToothed gearingsPhase differenceReduction drive

The invention relates to the technical field of shield machine speed reduction, and discloses a soil pressure balance shield machine cycloid speed reducer. The soil pressure balance shield machine cycloid speed reducer is characterized in that: a cycloid driving part is arranged in a cavity formed by connecting a front end cover with a back end cover by using a pin wheel housing, wherein a half-buried hole of the pin wheel housing is in movable fit with a sleeveless needle pin; four cycloidal wheels are arranged on a double-eccentric bearing, wherein the phase difference between a first cycloidal wheel and a second cycloidal wheel and between a third cycloidal wheel and a fourth cycloidal wheel is 180 degrees, and the second cycloidal wheel and the third cycloidal wheel have the same phase; and a W output mechanism consists of an output shaft, a pin and a uniform loading plate, the pin is provided with three circular ring plates to form a four-section freely supported structure, and the W output mechanism is supported in an inner hole of a front end cover and an inner flange outer circle of a back end cover through a bearing respectively. The soil pressure balance shield machine cycloid speed reducer has the following advantages that: (1) the axial size is 45 to 55 percent shorter than that of a third-class planetary reduction gear of the background art; (2) the cycloidal wheels can be assembled in a reversed mode to double the service life; (3) the manufacturing cost is 40 to 50 percent of that of the third-class planetary reduction gear of the background art; and (4) the inertia force and the inertia moment in operation are theoretically completely balanced.

Owner:国茂精密传动(常州)有限公司

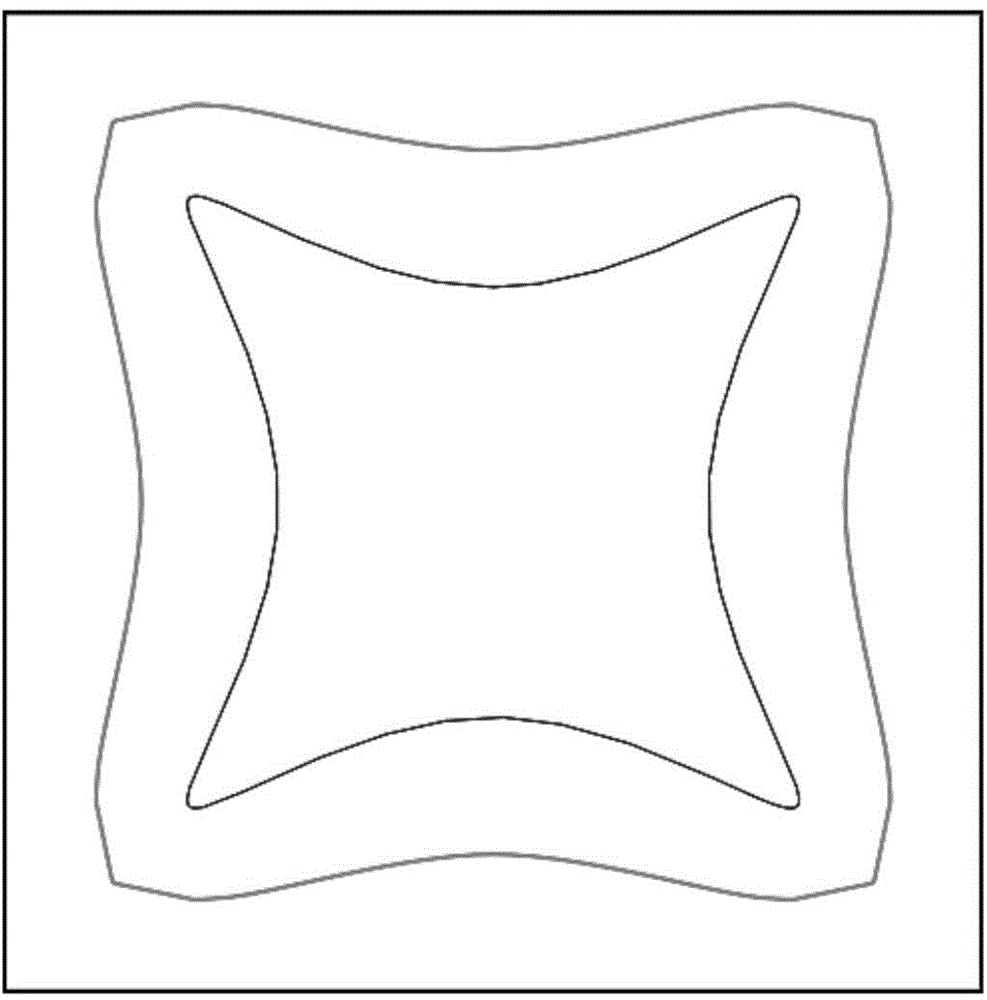

Closed cycloid precision gear reducer

ActiveCN103994184AImprove bending strengthImprove carrying capacityPortable liftingToothed gearingsLeveling effectCarrying capacity

The invention discloses a closed cycloid precision gear reducer. The closed cycloid precision gear reducer comprises an input part, a pin wheel housing, an output part and a small-tooth-difference inside-gear reducing mechanism. Wheel pins used for being meshed with a cycloidal gear of the small-tooth-difference inside-gear reducing mechanism are arranged on the inner ring of the pin wheel housing in the circumferential direction. The inner ring of the pin wheel housing is provided with containing grooves which correspond to the wheel pins in a one-to-one mode and are used for containing the wheel pins. The wheel pins make double-line contact with the inner walls of the corresponding containing grooves. According to the closed cycloid precision gear reducer, the double-line contact characteristic exists between the wheel pins and the containing grooves in the pin wheel housing; as the wheel pins make double-line contact with the corresponding containing grooves in the tooth width direction, the bending strength is enhanced, and carrying capacity is improved; meanwhile, due to the increase of the number of contact lines, the achievement of the error leveling effect is facilitated, transmission accuracy can be improved, and then the requirements for machining errors and assembly errors can be lowered. Compared with an existing RV gear reducer, the return difference of the closed cycloid precision gear reducer is smaller; besides, the closed cycloid precision gear reducer is compact in structure, long in service life, simple in machining process and low in manufacturing cost.

Owner:CHONGQING UNIV

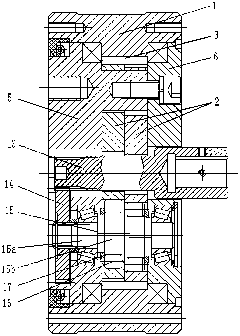

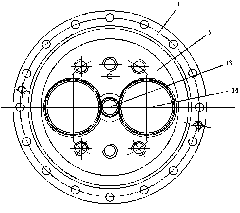

Accurate cycloid pin gear epicyclic transmission apparatus

InactiveCN101280824AEliminate or reduce hysteresisSmall hysteresisToothed gearingsEngineeringCycloid

The invention discloses a precision cycloidal-pin wheel planetary transmission device which comprises a machine base, a power input shaft, an eccentric bushing provided with two off centers, a cycloidal wheel I, a cycloidal wheel II, a dowel pin for cycloidal wheels, a power output shaft, a wheel spider I, a wheel spider II and two sets of pin gears that are respectively arranged on the wheel spider I and the wheel spider II; one end of the dowel pin for cycloidal wheels is fixedly arranged on a flange of the power output shaft and the other end is inserted into an isotonic pin hole of the cycloidal wheel I and the cycloidal wheel II to form a pin type output mechanism; the direction of a tooth outline on which the cycloidal wheel I and a pin gear I are meshed and the direction of a tooth outline on which the cycloidal wheel II and a pin gear II are meshed are reverse. The precision cycloidal-pin wheel planetary transmission device of the invention can eliminate or reduce tooth clearance during the transmission process, thereby improving transmission efficiency, reducing vibration and noise and prolonging service life; the relative position of the two wheel spiders in a circumferential direction is adjustable, so that meshed gap and return difference can be controlled effectively and more options are available when shaping the tooth outline of the teeth of the cycloidal wheels.

Owner:CHONGQING UNIV

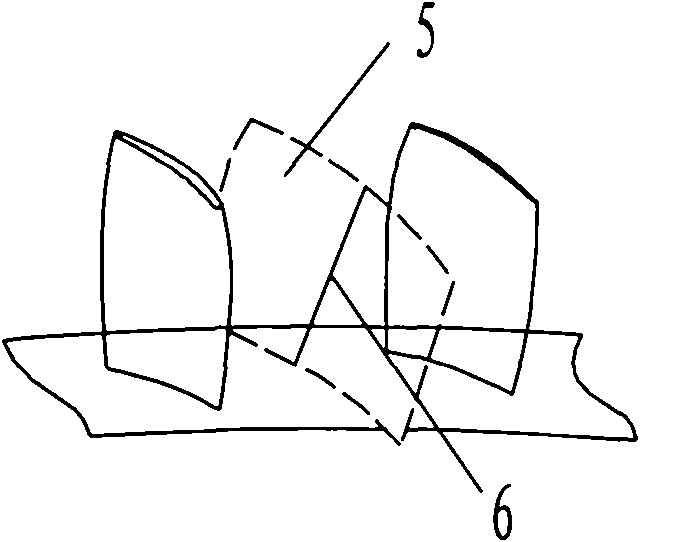

Method for composite machining of blisk flow passage

InactiveCN101966604AImprove rigidityImprove processing stabilityMilling equipment detailsNumerical controlBoundary contour

The invention belongs to the technical field of aircraft engines, and discloses a method for the composite machining of a blisk flow passage. The method is a numerical control machining method of selecting the adaptive machining strategy based on regional characteristics. The method comprises the following steps of: (1) dividing a machining region; and (2) selecting the adaptive numerical control machining strategy based on the regional characteristics. In the method, a rough slotting numerical control machining method of combining milling, drilling milling and slotting milling of a cycloid is adopted, so that a medial cambered surface is approximate to a curved surface of a blade profile, and the boundary contour and the optimal cutter-axis vector of a rough machining region in a channel are determined. The method has the advantages that the machining method of region division and cutting-in changing enhances the rigidity and machining stability of blades; a process method of combining the milling and slotting milling of the cycloid improves the durability of cutters and the removal rate of materials; and the vibration phenomenon in the rough machining process is prevented effectively, the cutting force is reduced, the movement space of the cutters is expanded farthest, and the machining efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

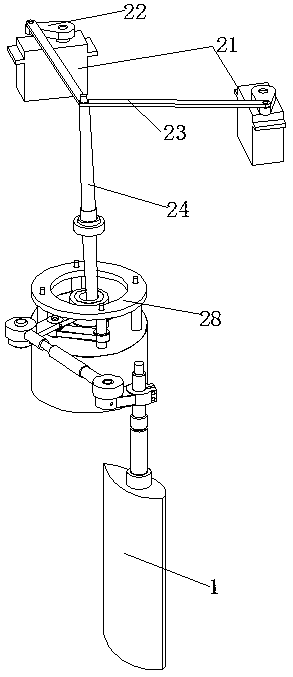

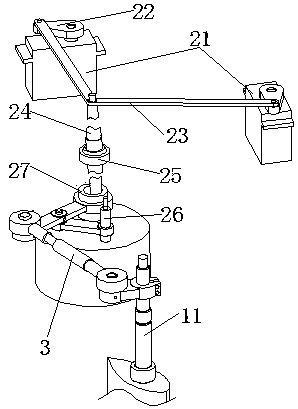

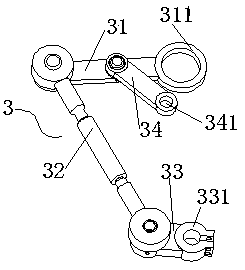

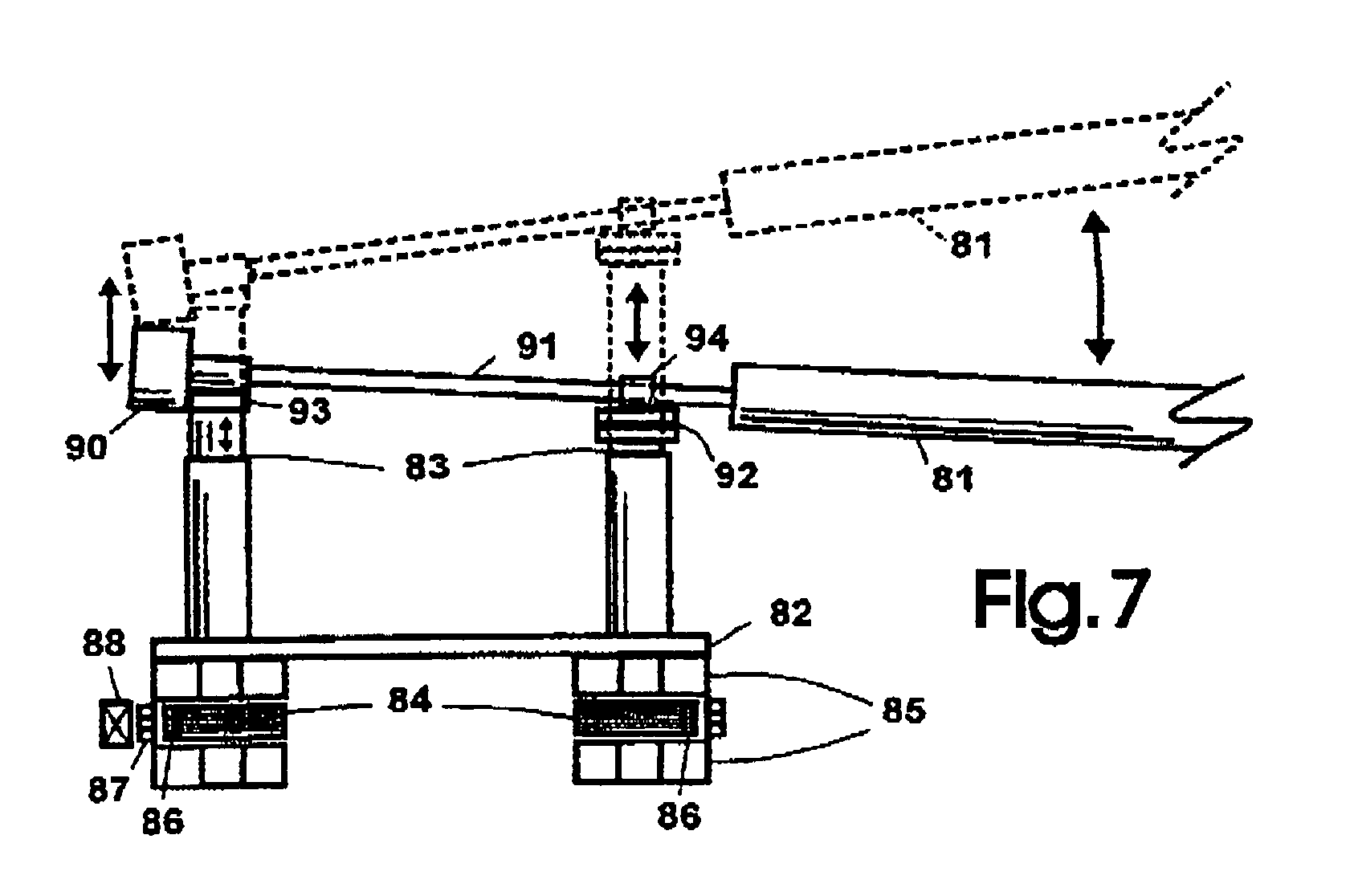

Blade swing mechanism and marine cycloidal propeller comprising blade swing mechanism

ActiveCN103723259ASimple structureGood follow-upSteering ruddersPropulsive elements of rotary typePropellerKnuckle

The invention provides a blade swing mechanism. The blade swing mechanism comprises at least one steering machine, an adjusting rod connected with the steering machine through a driving rod and a driven rod, and connection rod mechanisms used for connecting the adjusting rod and a corresponding blade. One end of the driving rod and one end of the driven rod are arranged together in a rotating mode, the other end of the driving end is fixedly connected to a power output shaft of the steering machine, and the other end of the driven rod and the upper end of the adjusting rod are fixedly arranged together; the middle of the adjusting rod is sleeved with a first knuckle bearing fixed in the axial direction, and the connection rod mechanisms and the lower end of the adjusting rod are connected together. The invention further provides a marine cycloidal propeller. The marine cycloidal propeller comprises a fixed base provided with at least one blade, a motor installed on the fixed base, a transmission mechanism used for transmitting motor power and driving the blades to revolve, and the blade swing mechanism. Each blade corresponds to one connection rod mechanism, and the axis line of the first knuckle bearing and the central line of revolution motion of the blades are coincident. The blade swing mechanism is controlled by the steering machine, so real-time performance is good; the cycloidal propeller utilizing the blade swing mechanism is high in control accuracy, good in real-time performance and high in flexibility.

Owner:ZHEJIANG UNIV

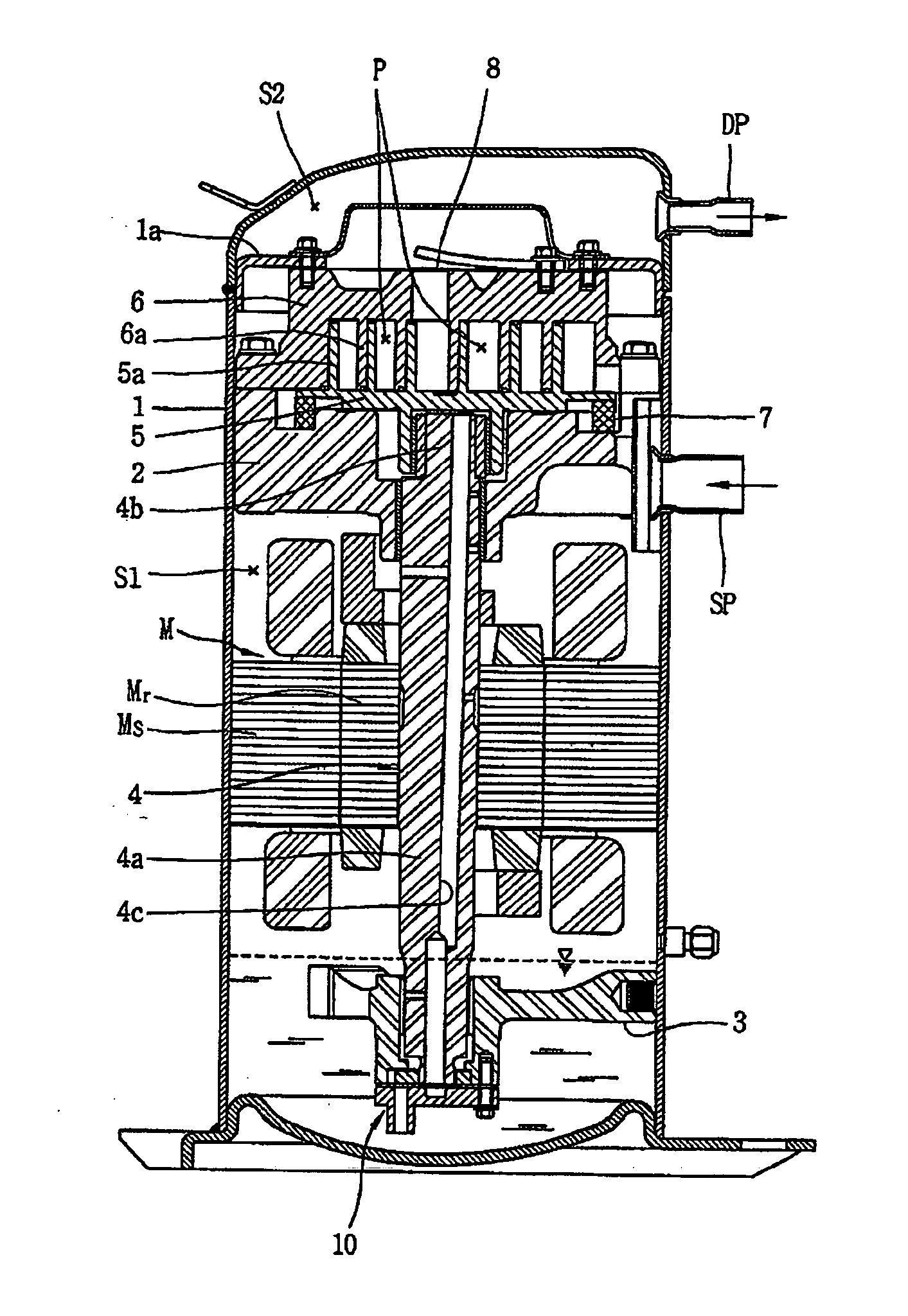

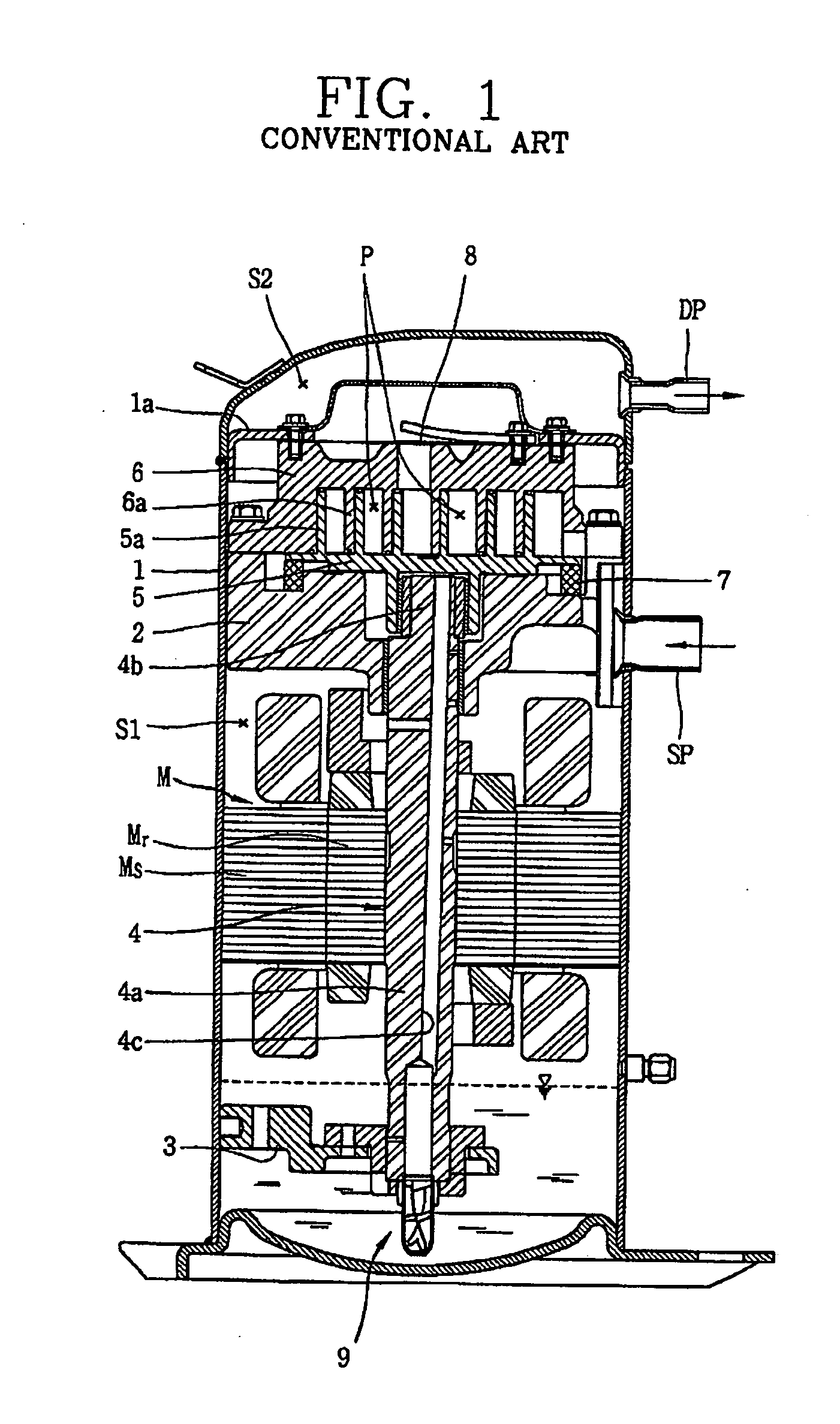

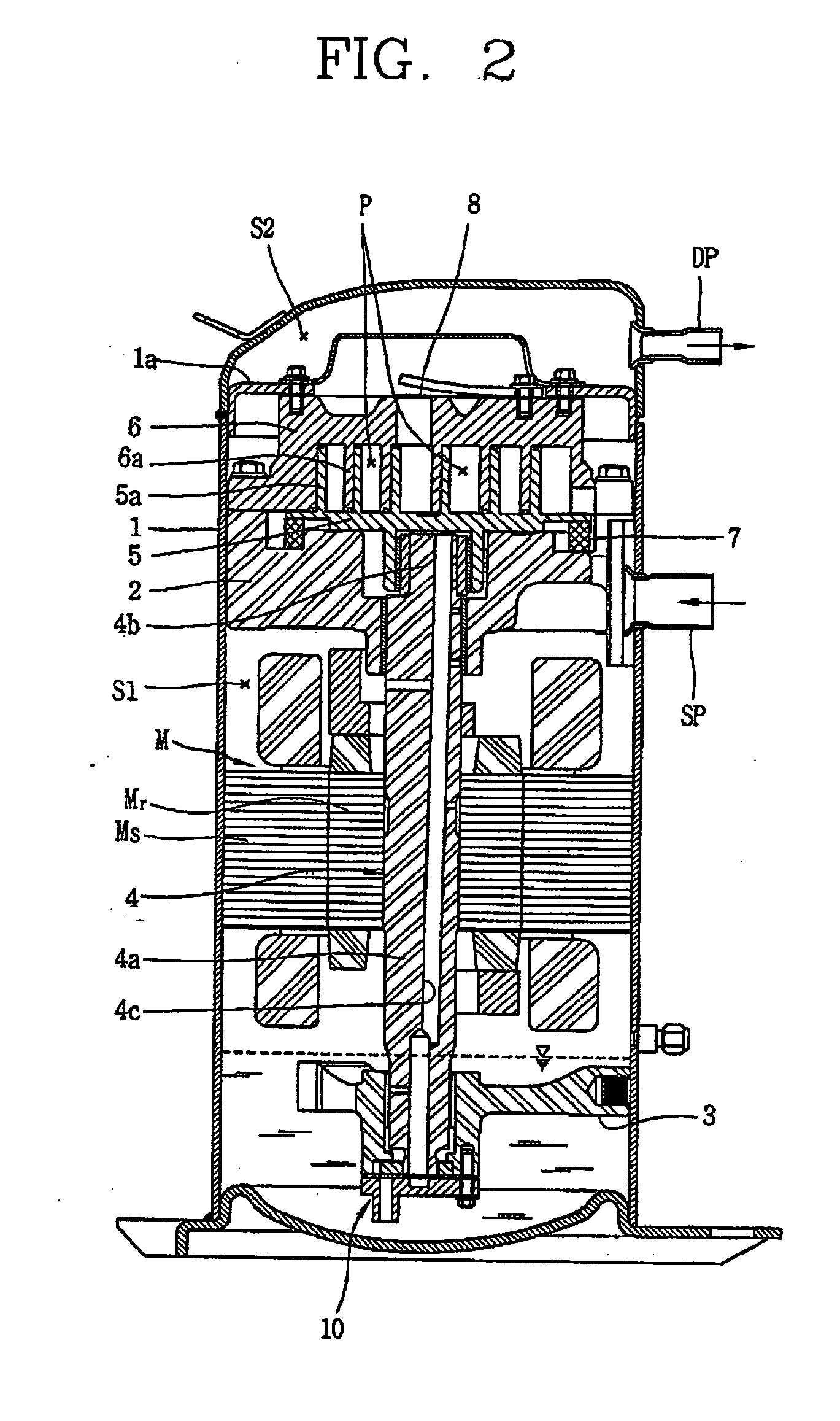

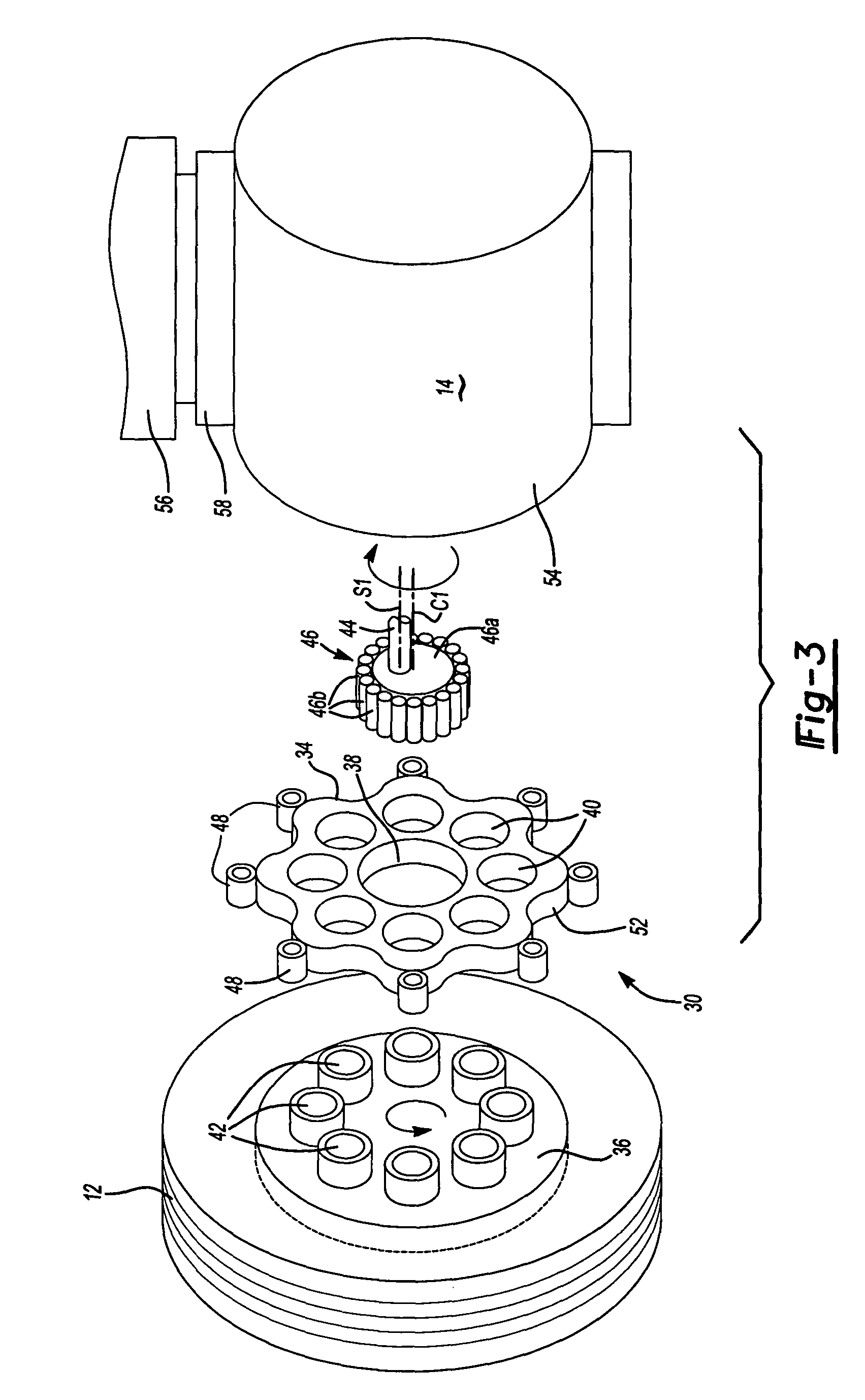

Oil pumping device of hermetic compressor

ActiveUS20070071627A1Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive motorRefrigerant

A hermetic compressor uses an oil pump that includes a trochoid gear. Therefore, regardless of the rotation speed of a driving motor of the compressor, a sufficient amount of oil can always be pumped. The oil pump unit may include a plurality of suction holes with openings at different heights. If the refrigerant and oil separate, at least one of the openings will admit oil into the oil pump unit, to ensure lubricating oil is supplied to the moving parts of the compressor.

Owner:LG ELECTRONICS INC

Cycloidal rotor with non-circular blade orbit

ActiveUS8540485B2Improve efficiencyPowerfulPropellersRotary propellersSpatial OrientationsComputerized system

Owner:OPTIVECTOR LTD

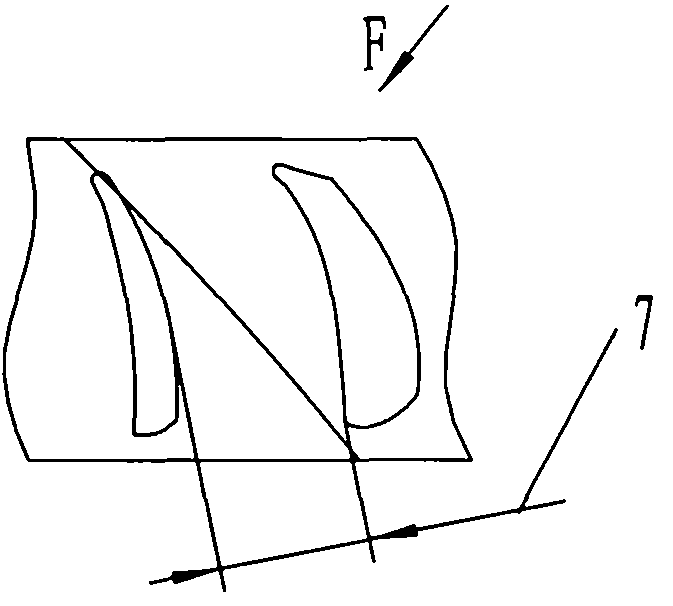

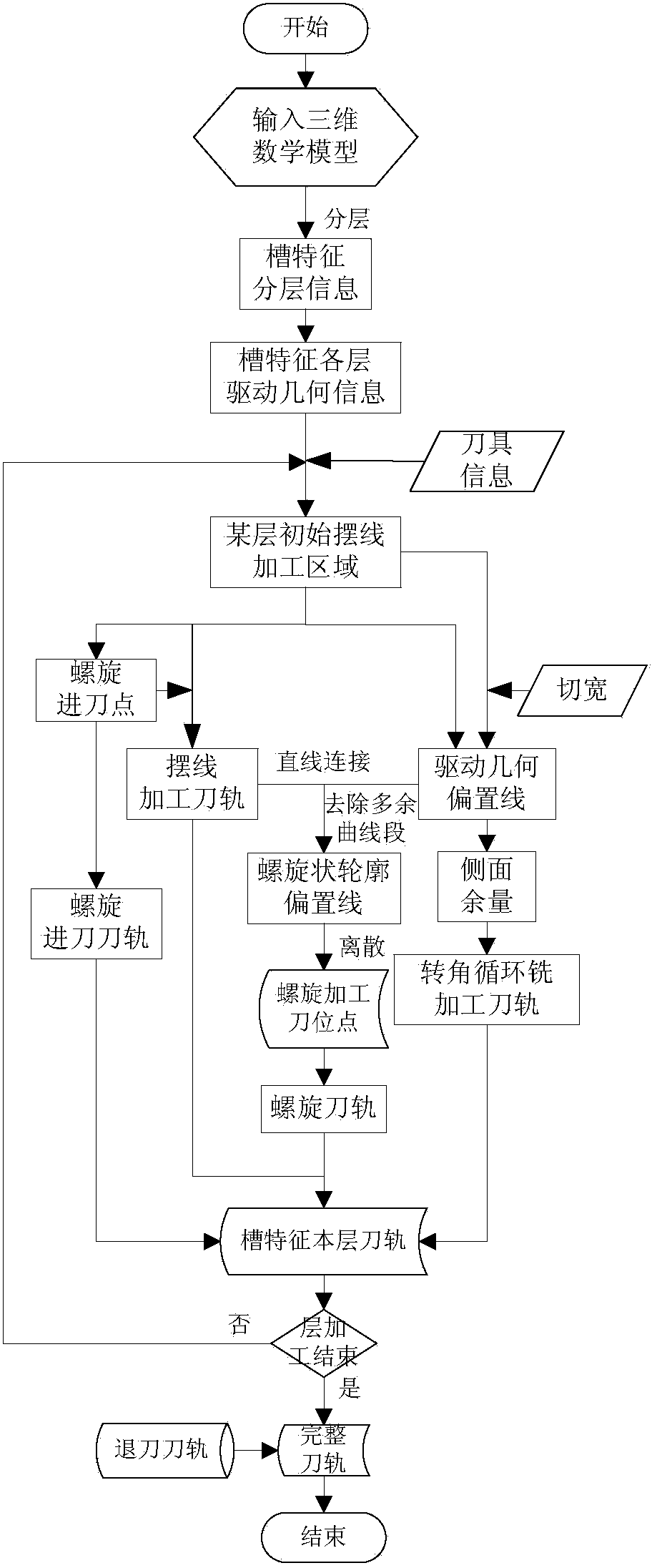

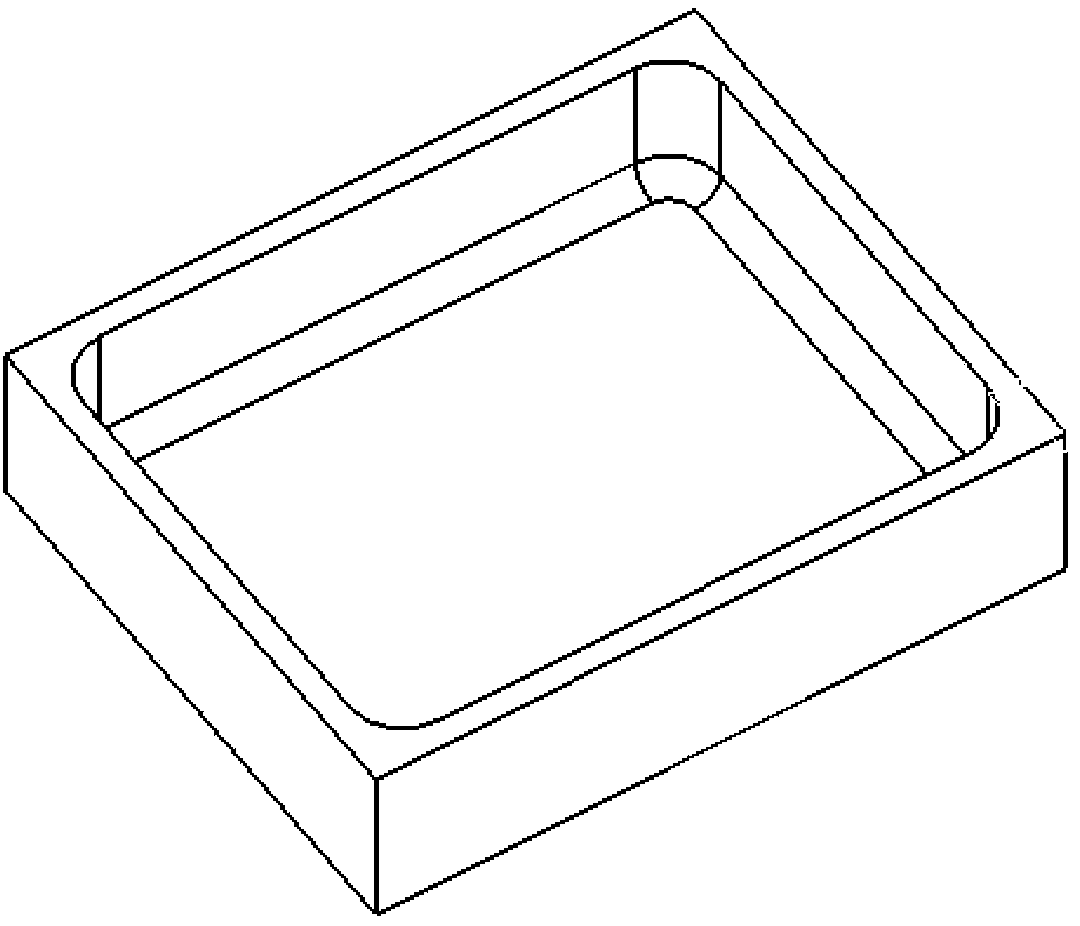

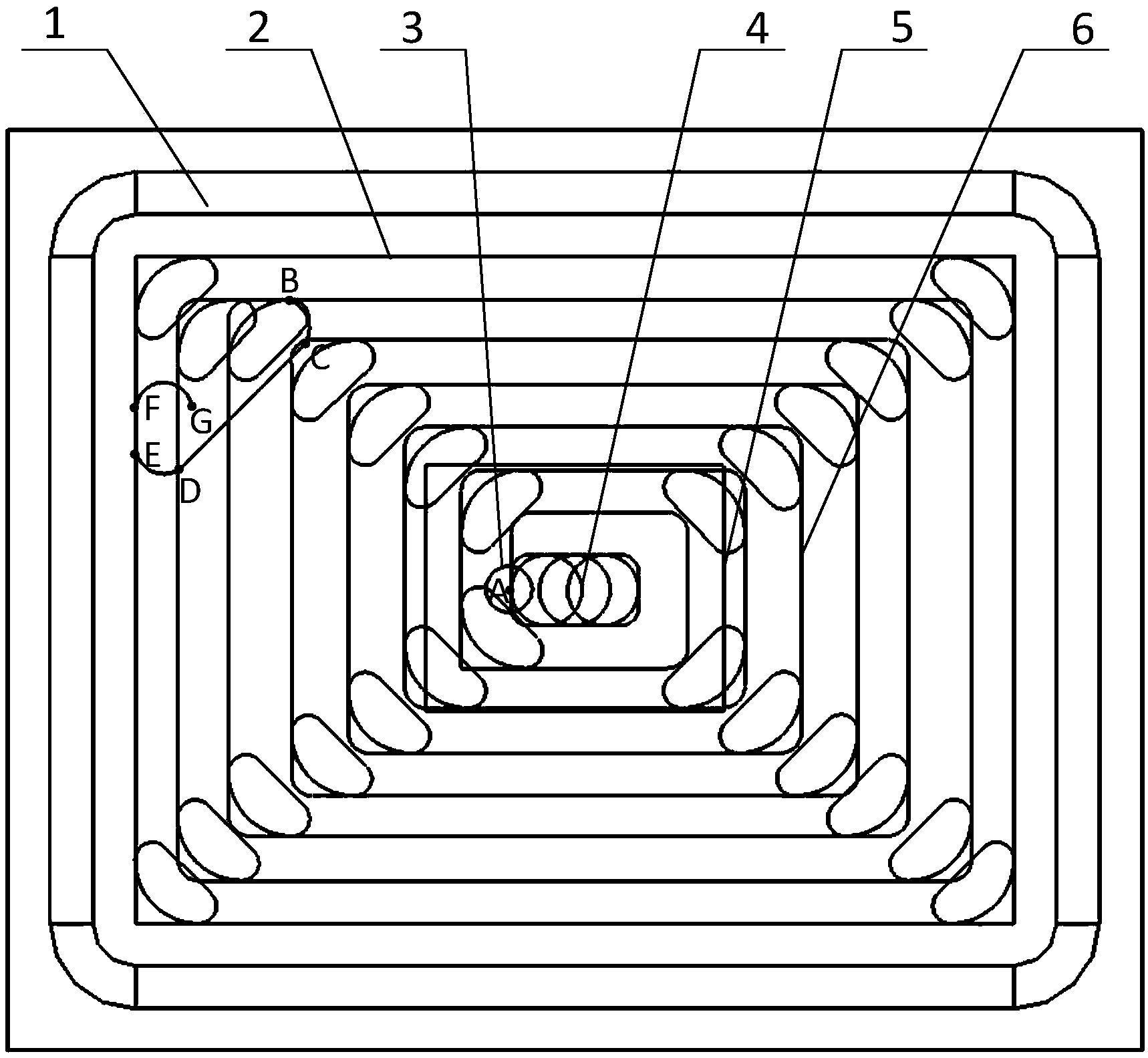

Cycloid and spiral composite milling method for web with slot features

ActiveCN103949705AImprove stabilityReduce cutting forceMilling equipment detailsEngineeringCutting force

The invention discloses a cycloid and spiral composite milling method for a web with slot features. The cycloid and spiral composite milling method is characterized by comprising the following steps: firstly, feeding a tool in a spiral manner; secondly, slotting by adopting cycloid to reduce cutting force of a first tool; thirdly, machining layer by layer by adopting a spiral machining tool path and transiting by adopting variable spiral at a corner, so that the curvature changes continuously, and the cutting force mutation caused by the mutation of a sharp point and a machining direction in the tool path is avoided, the stability of a tool load is guaranteed, and the vibration of the tool is reduced; and finally, machining by adopting a corner loop milling tool path at the corner. The cycloid and spiral composite milling method can be used for machining a material which is difficult to machine; the cutting force of the first tool is reduced by cycloid slotting; the variable spiral curve is adopted at the corner of the tool path; the mutation of the sharp point and the machining direction is avoided, so that the tool path is smooth; the cutting force is reduced; the machining quality of the surface of a workpiece is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

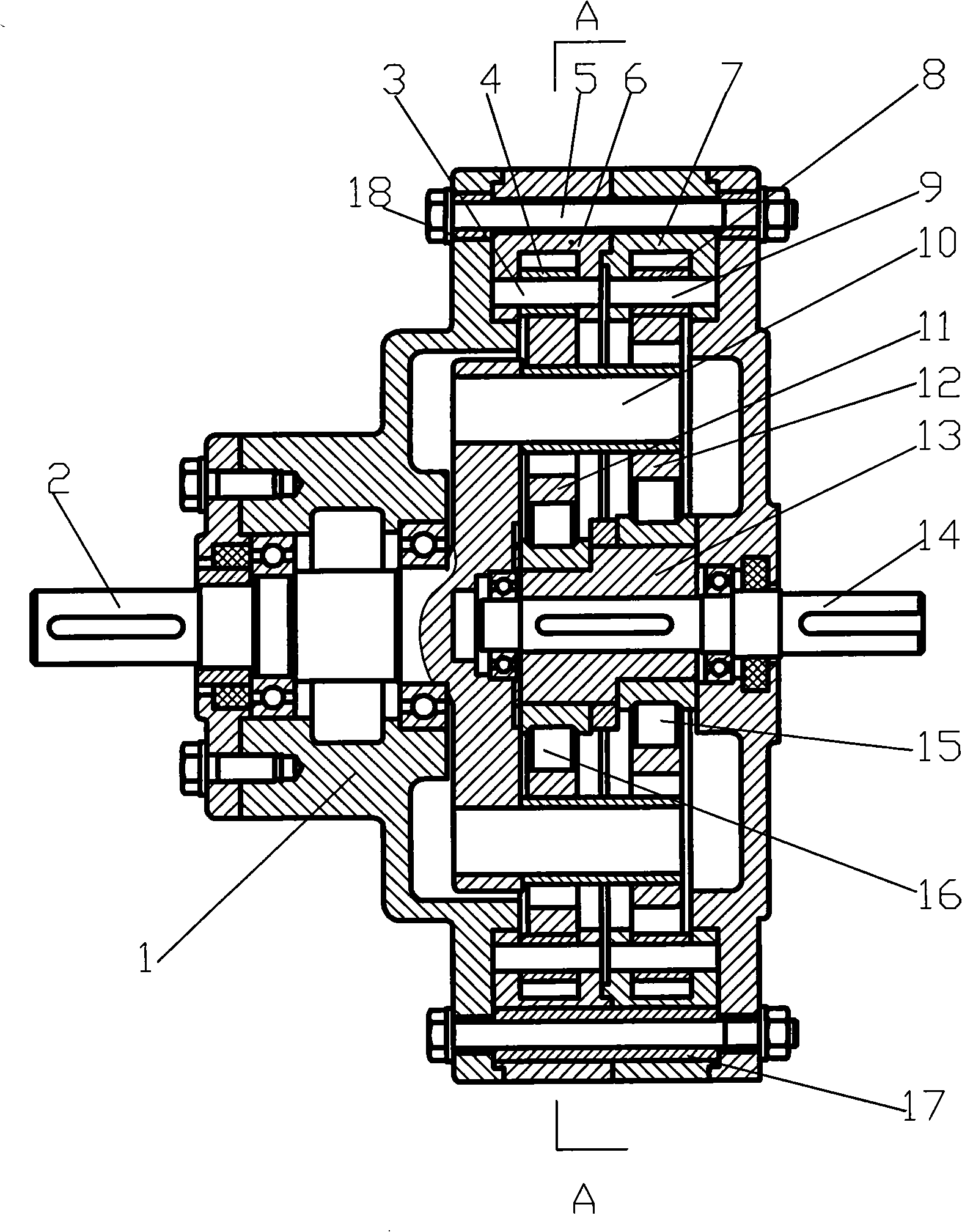

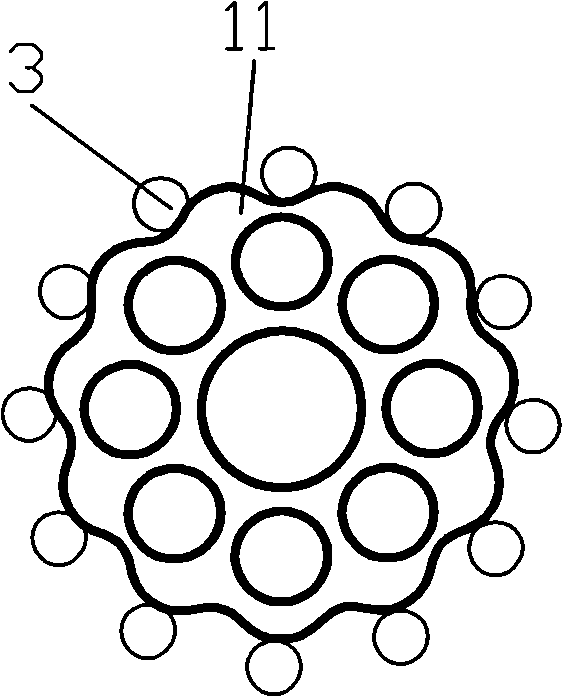

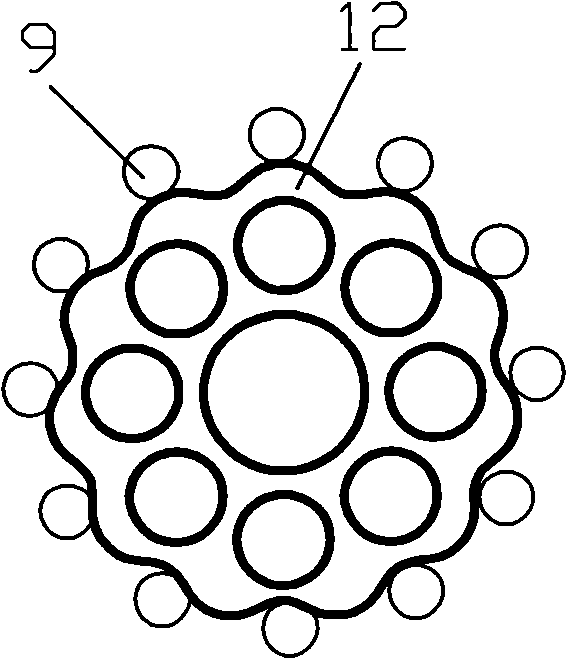

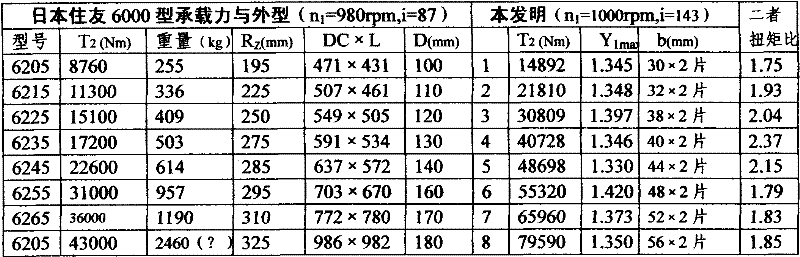

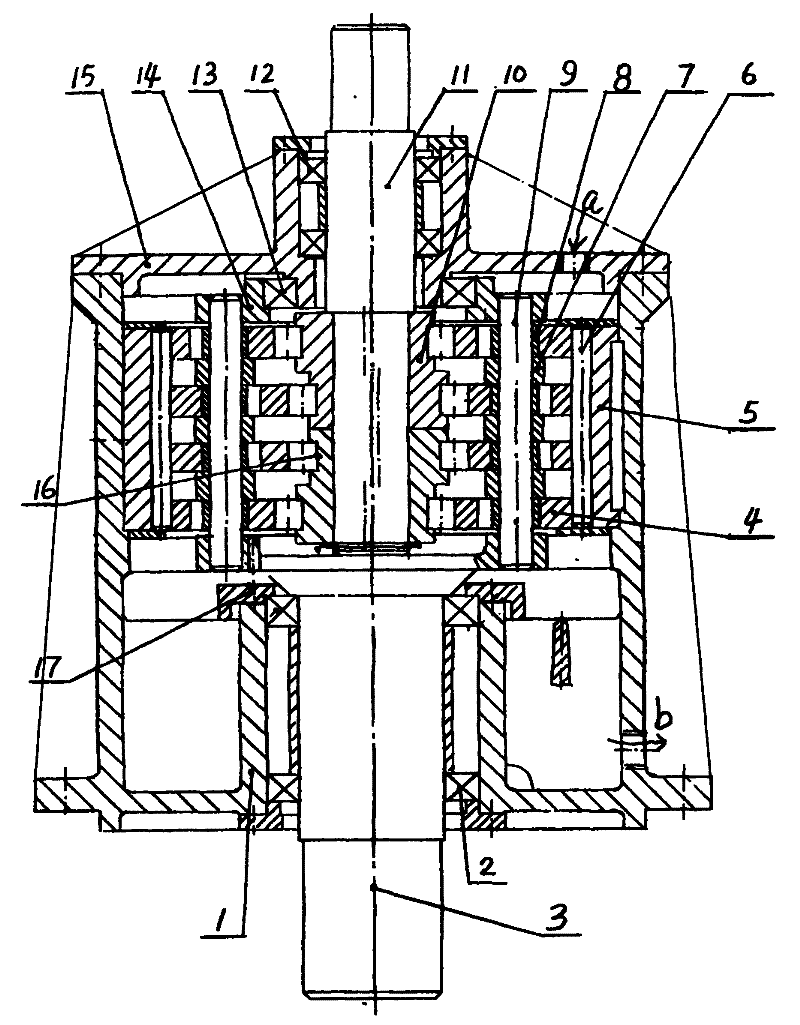

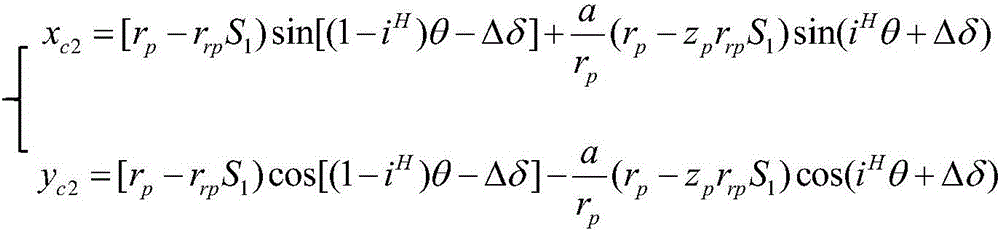

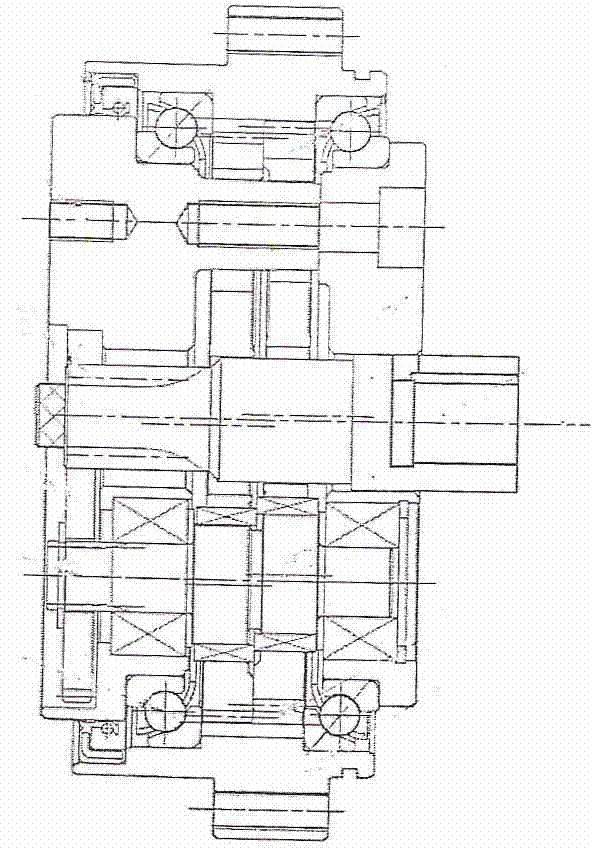

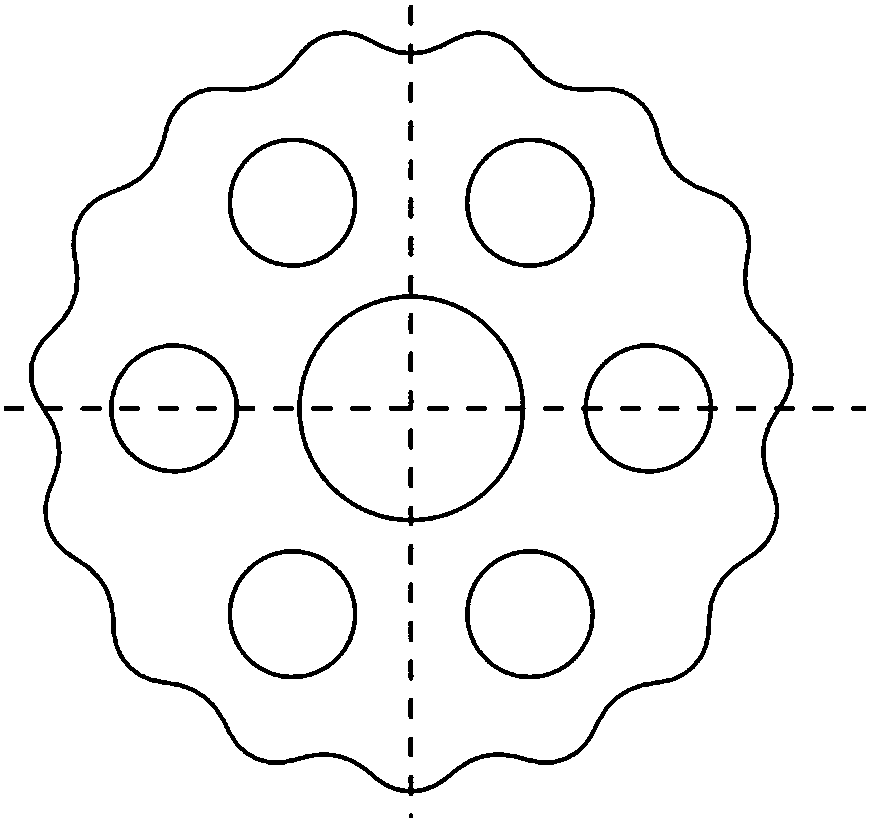

Novel vertical type dynamic balance needle-sleeve-free cycloid reducer

InactiveCN102192278AReduce weightAxial dimension shortGearboxesToothed gearingsDynamic balanceEngineering

The invention relates to the technical field of cycloid speed reduction. A novel vertical type dynamic balance needle-sleeve-free cycloid reducer is composed of a machine body, an input shaft, two double-eccentric bearings, four cycloid wheels, a needle gear shell, needle pins, a column pin, a column sleeve, a W output mechanism and bearings, wherein (A) a vertical type thin-wall cylinder with flange rings on two end faces and a radiating rib at the outer part is utilized; (B) the W output mechanism is composed of an output shaft, the column pin and a uniform loading disc; a simple support structure is formed by the column pin through utilizing an upper annular plate on the column pin; in the W output mechanism, the neck of the output shaft is supported in an inner hole of the machine body through utilizing the bearing and an inner hole of the uniform loading disc is supported on an outer circle of a flange in an end cover through utilizing the other bearing; (C) the needle gear shell with semi-buries holes is installed in the inner hole of the machine body; (D) the needle pins have no sleeves and the needle pins are movably matched with the semi-buries holes. In the invention, the reducer has the beneficial effects as follows: (1) the weight is reduced by 20-30% and the axial size is shortened by 25-35%; (2) the bearing capability is 1.5-2 times as much as that of the 6000 type reducer; and (3) the inertia force and the inertia moment are completely balanced in theory when the reducer is operated.

Owner:陈卫

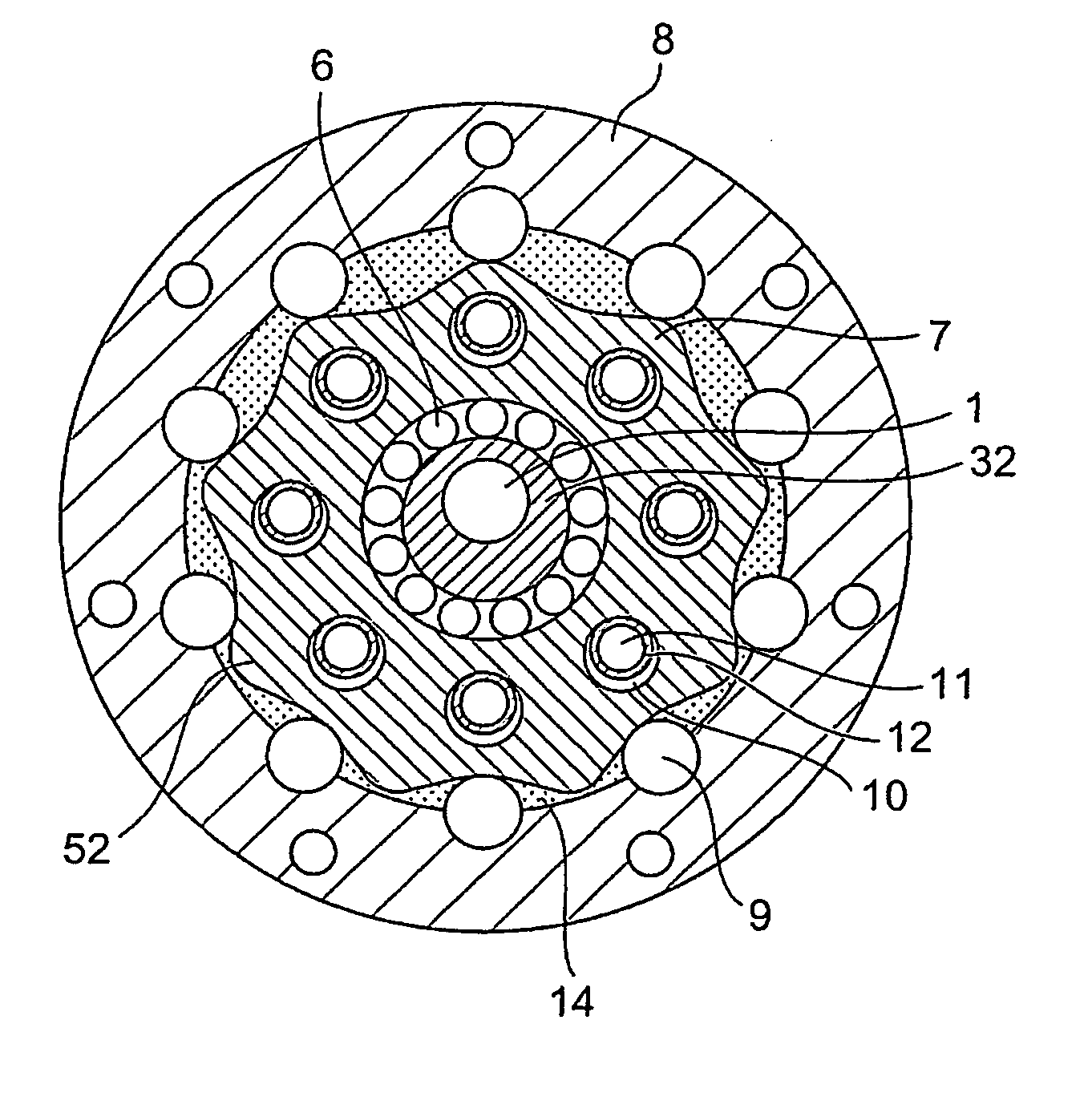

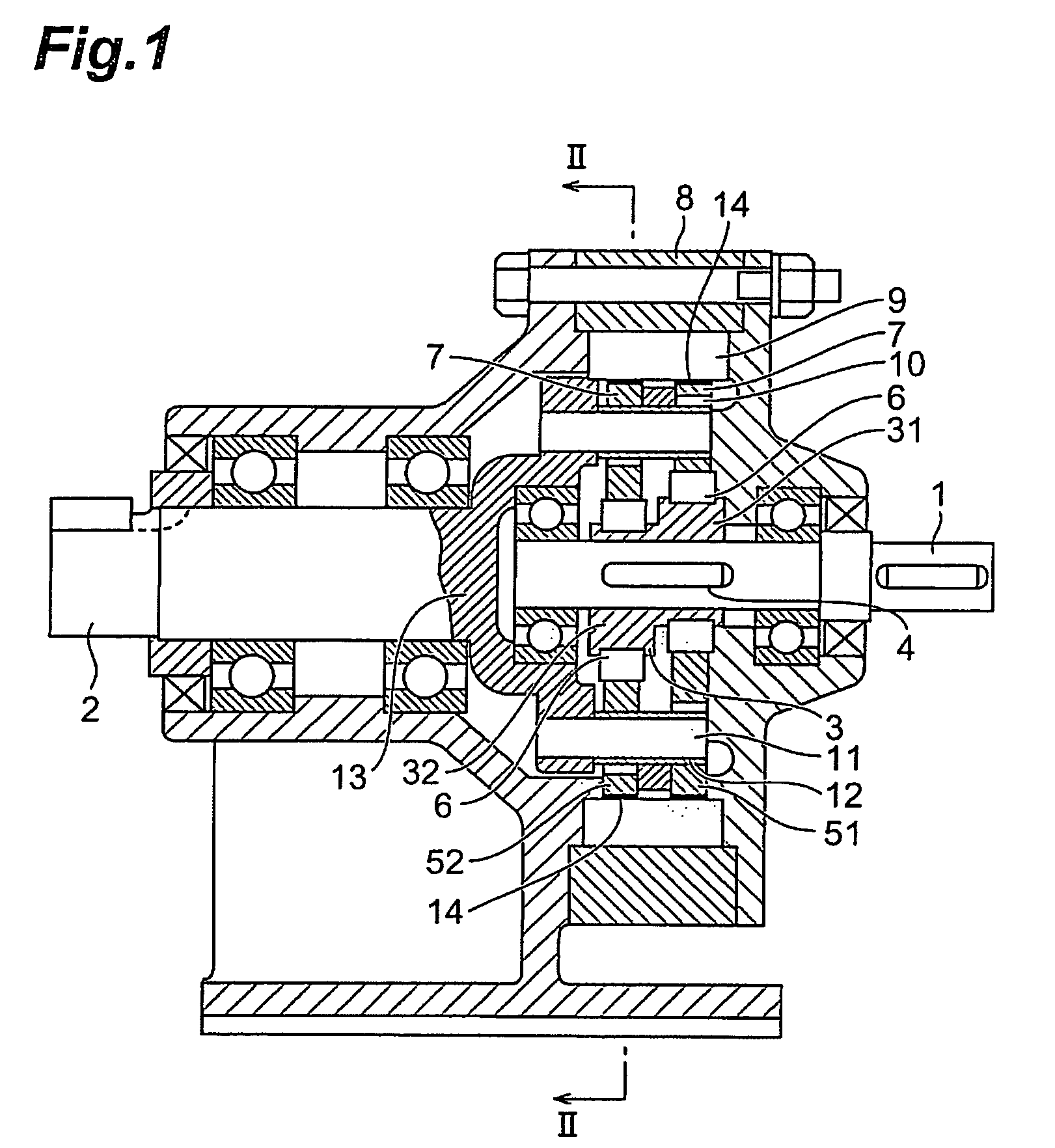

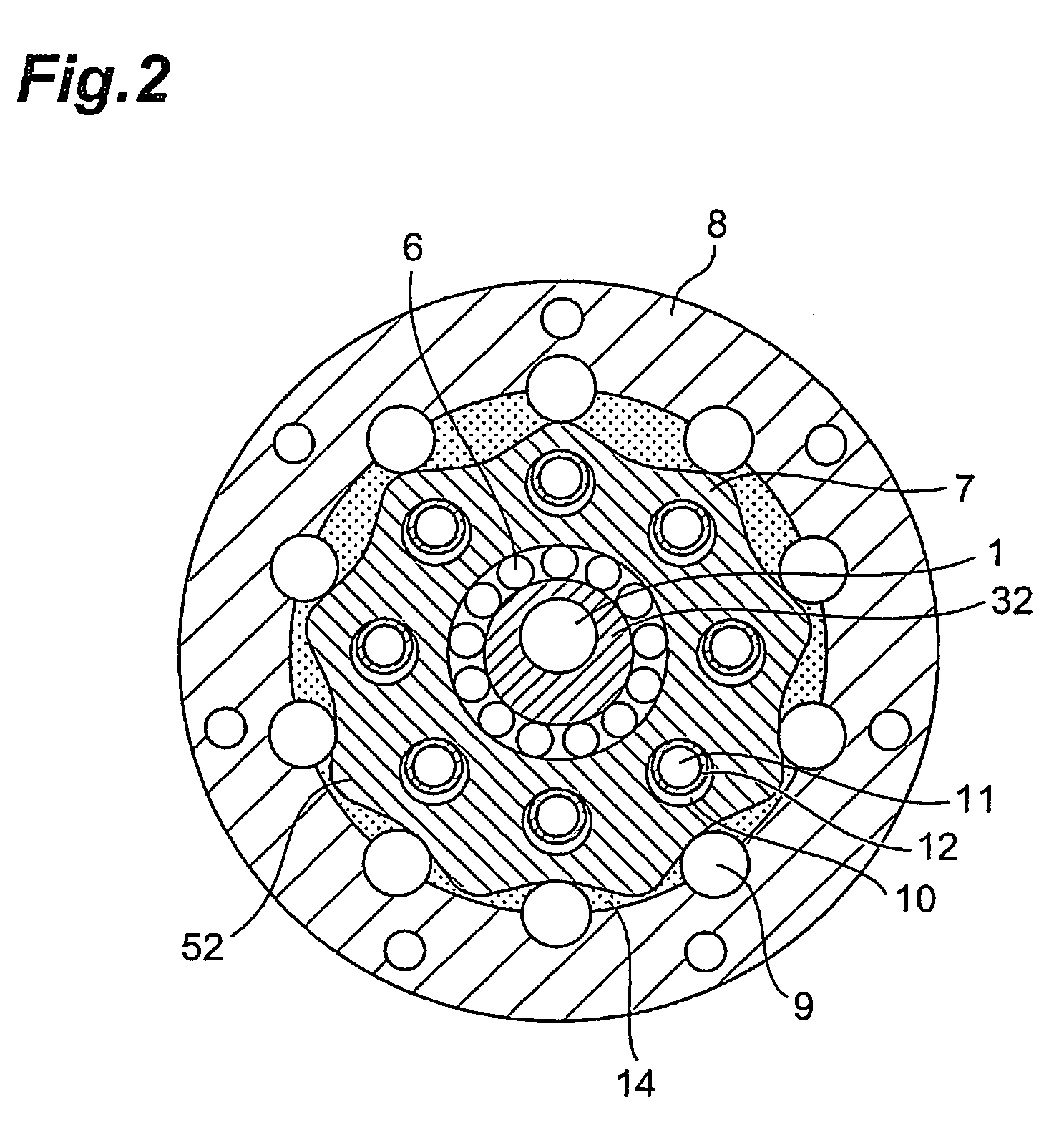

Oscillating internal-meshing planetary gear system and method for improving the durability thereof

InactiveUS20040248688A1Solution to short lifeLong operationToothed gearingsGear lubrication/coolingDrivetrainAdipic acid

In the oscillating internal-meshing planetary gear system of the present invention, a space formed between a external gear (52) and a internal gear (8) is filled up with a grease (14), which contains base oil whose kinetic viscosity is equal to or higher than 10 mm<2> / s at 100° C. and lithium complex thickener synthesized from adipic acid. Such construction of the oscillating internal-meshing planetary gear system of the present invention provides a power transmission system using a trochoidal tooth profile gear and a circular-arc tooth profile gear that enables to realize a long life and keeping a high efficiency, even without applying grease containing sodium nitrite.

Owner:SUMITOMO HEAVY IND LTD

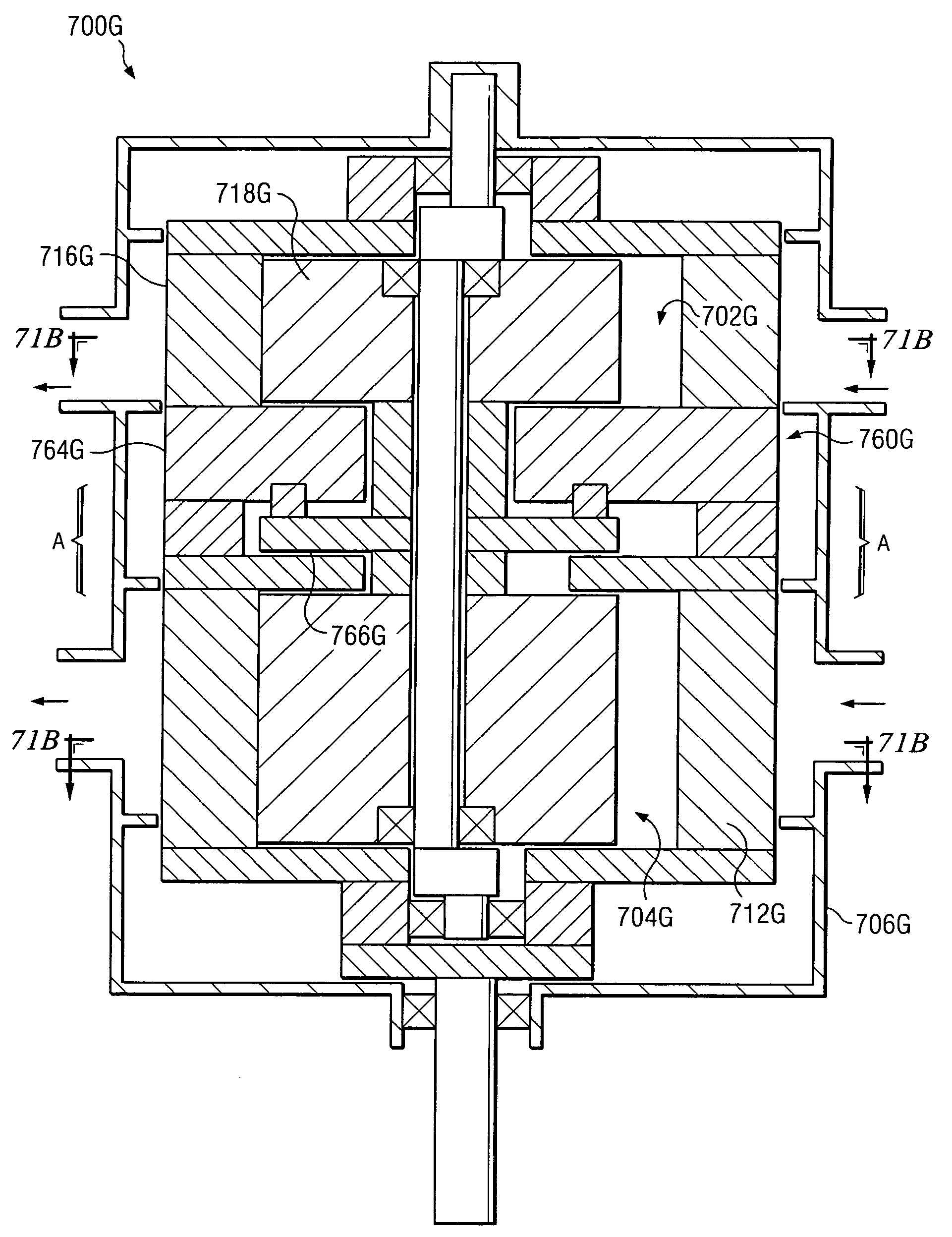

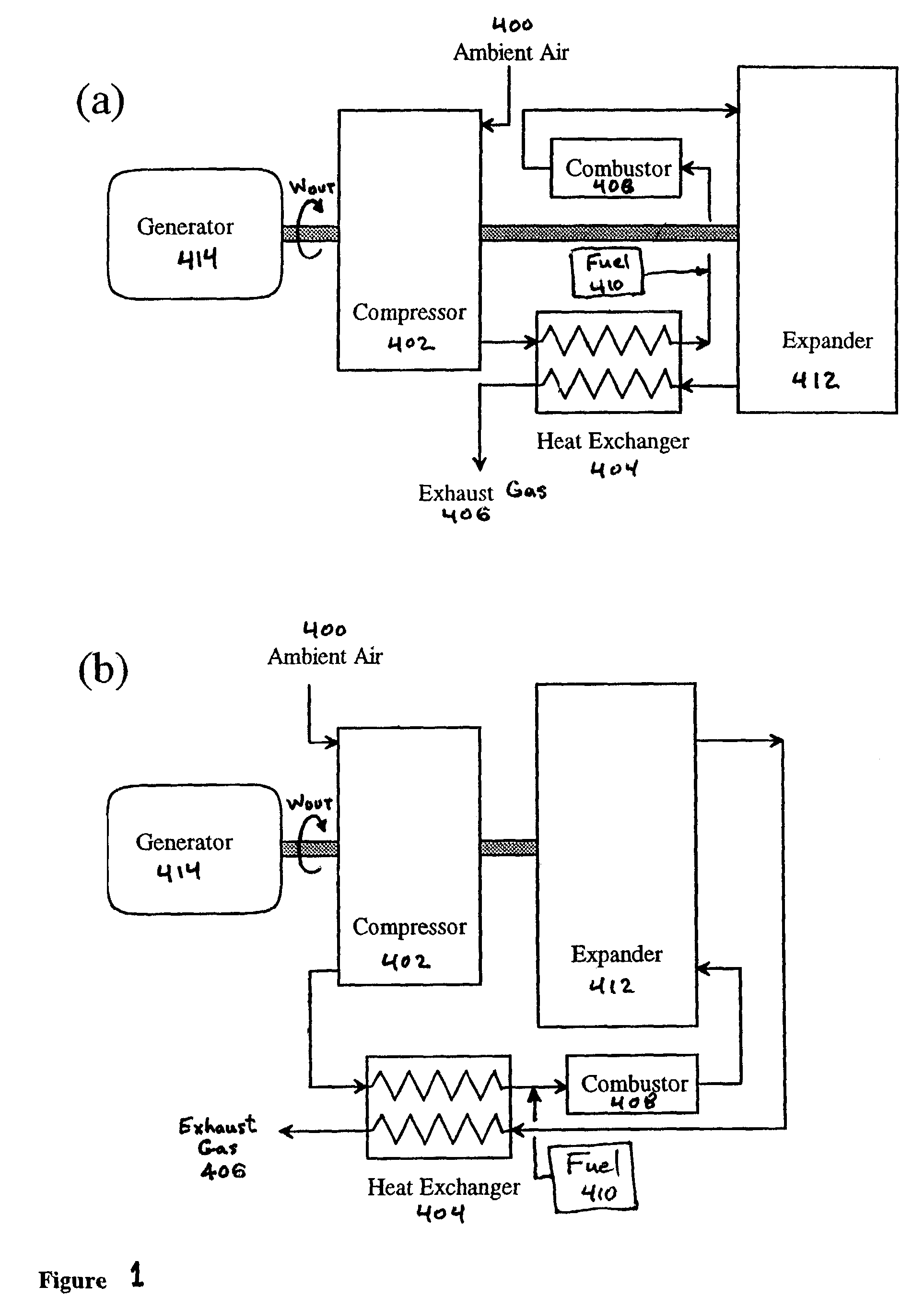

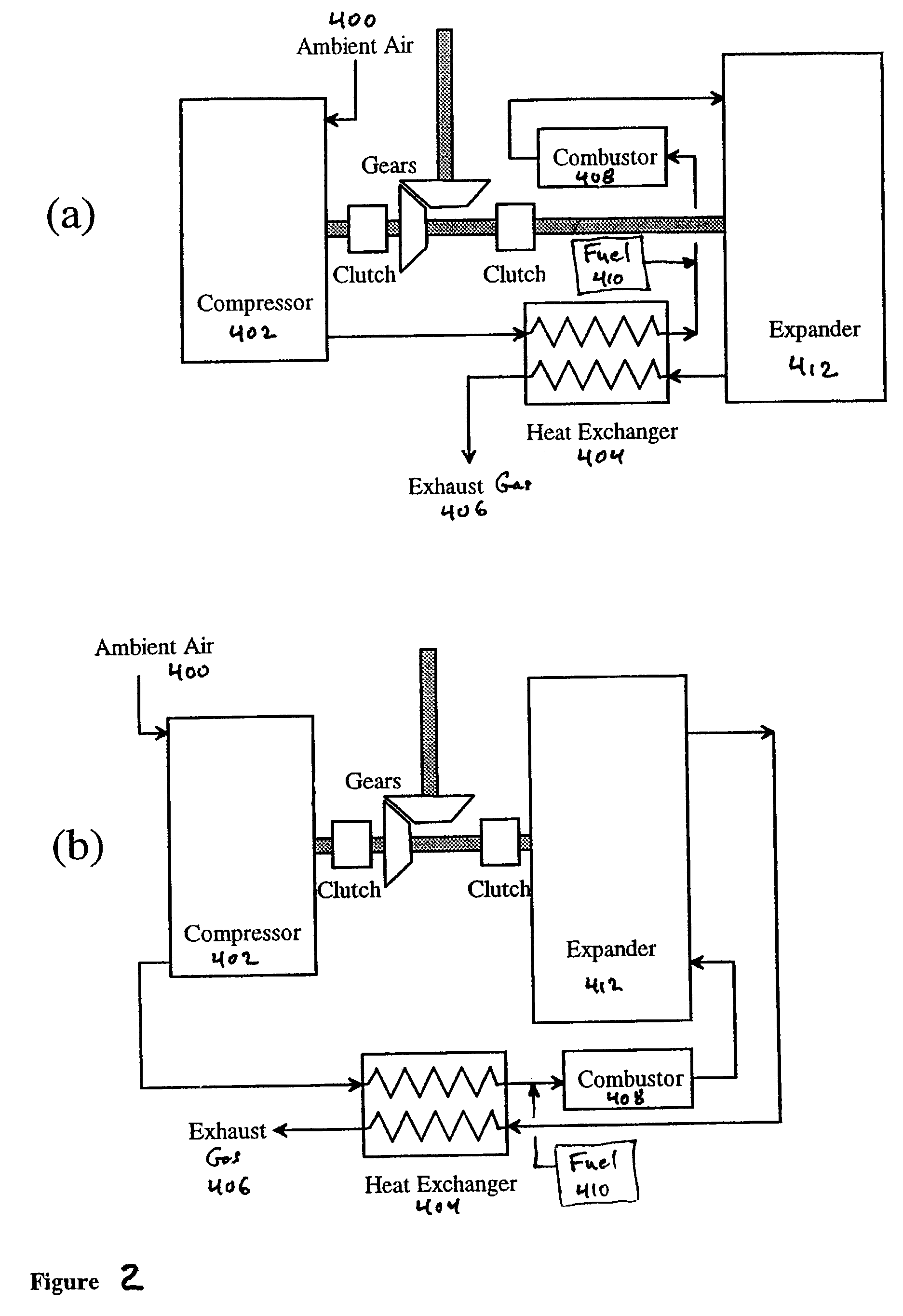

Gerotor apparatus for a quasi-isothermal brayton cycle engine

InactiveUS7008200B2Simpler gas flow pathLess loadRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesBrayton cycleEngineering

According to one embodiment of the invention, a gerotor apparatus includes an outer gerotor having an outer gerotor chamber, an inner gerotor, at least a portion of which is disposed within the outer gerotor chamber, and a synchronizing apparatus operable to control the rotation of the inner gerotor relative to the outer gerotor. The inner gerotor includes one or more entrance passages operable to communicate a lubricant into the outer gerotor chamber.

Owner:STARROTOR CORPORATION +1

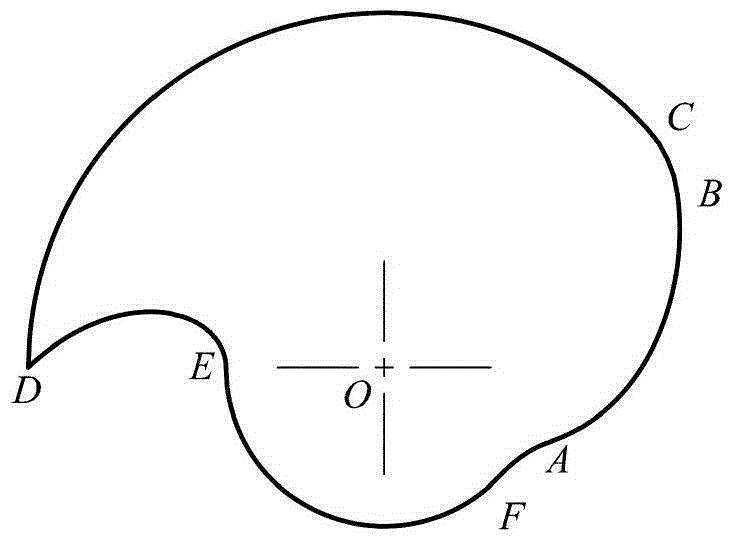

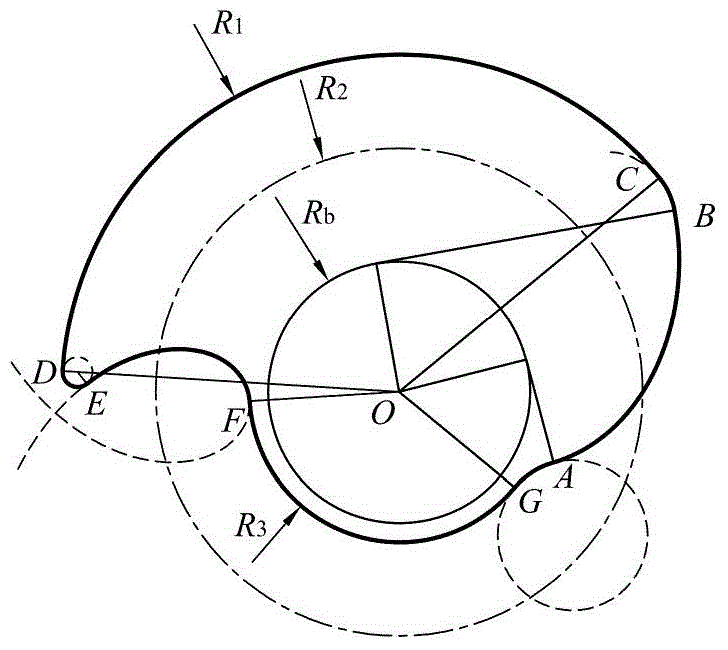

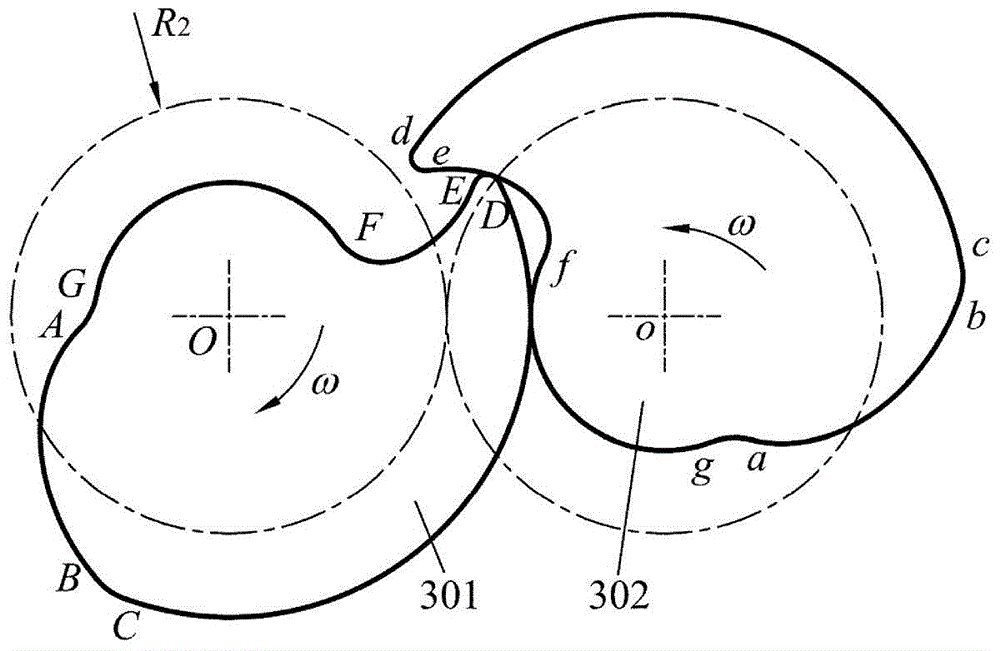

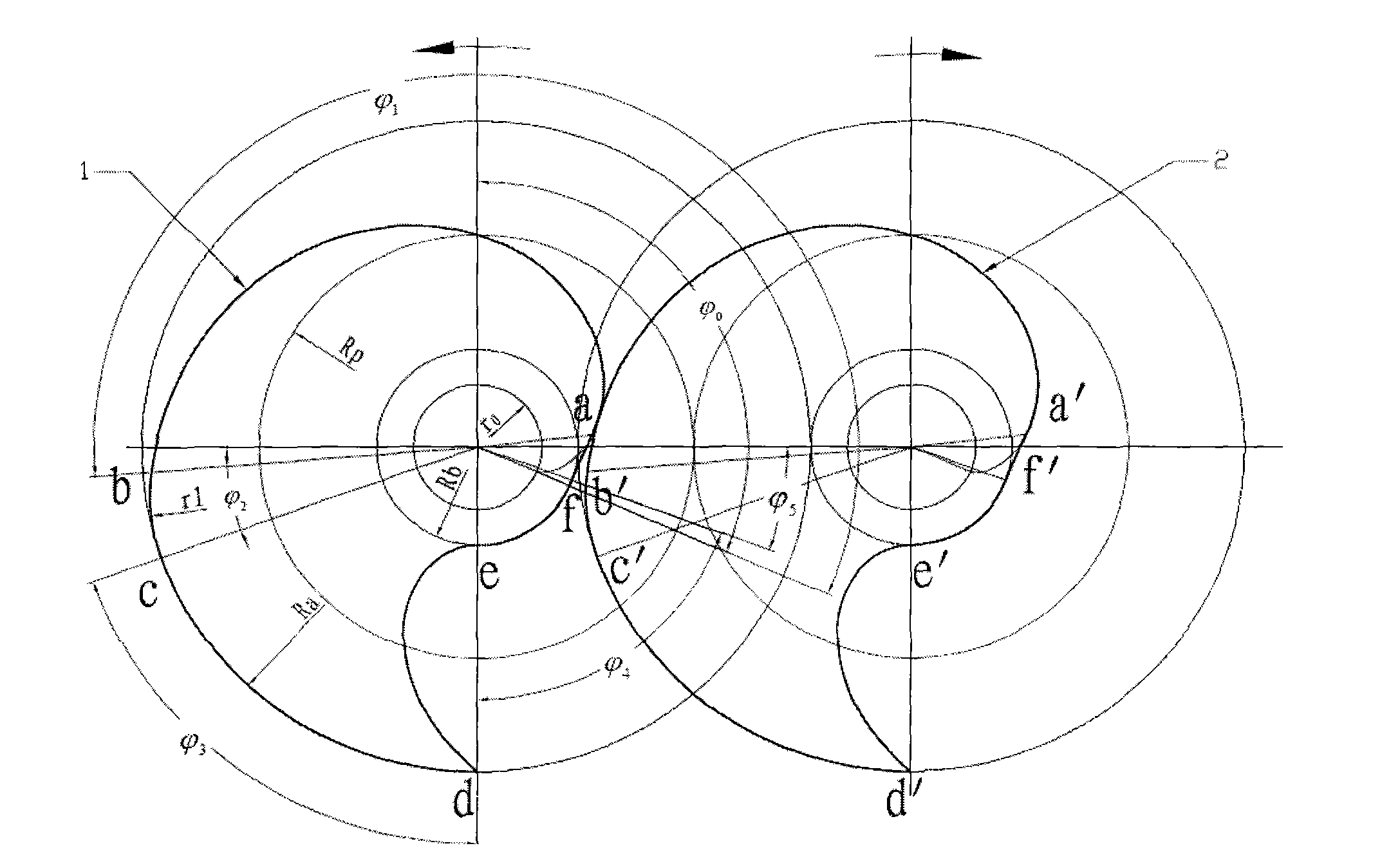

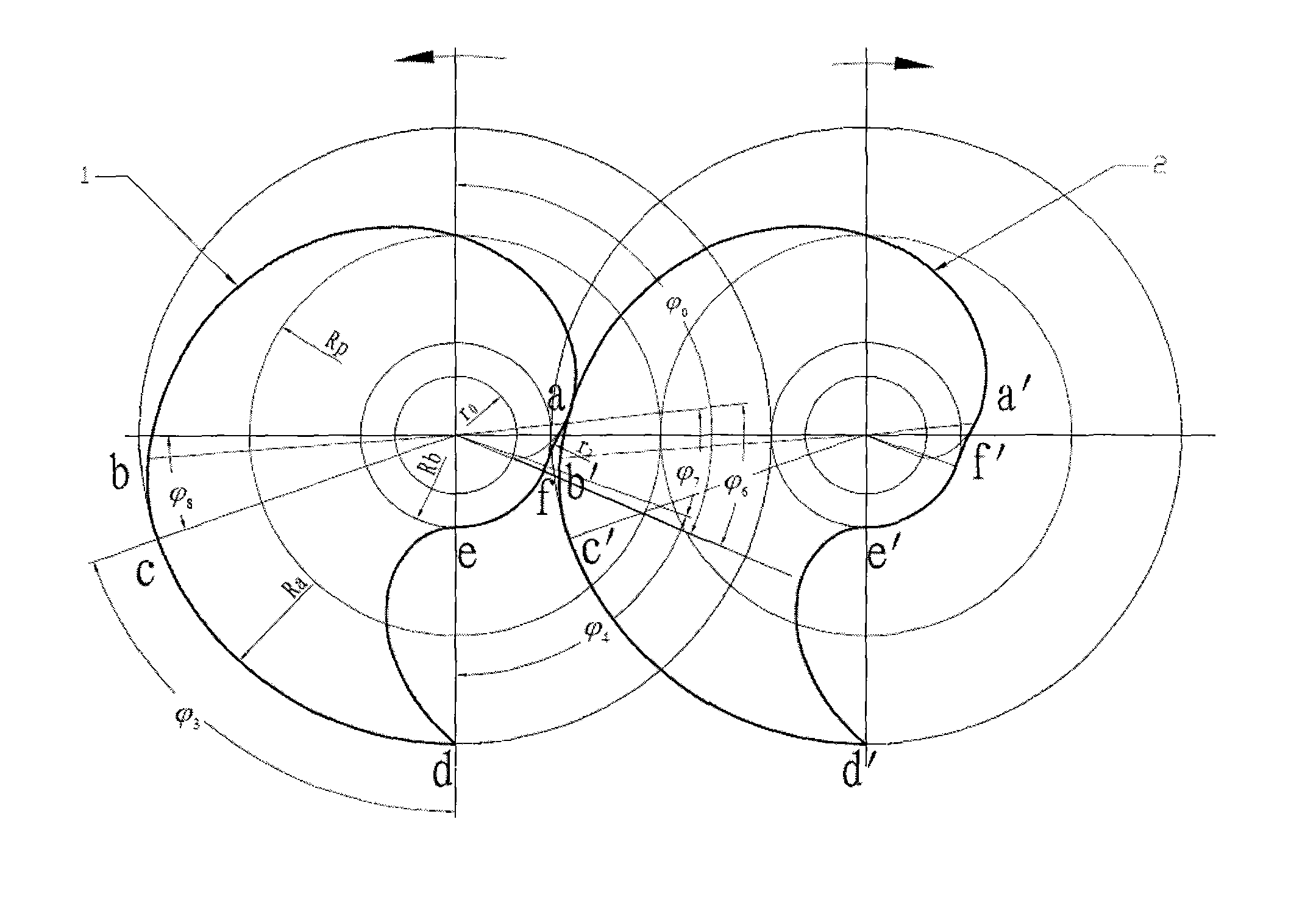

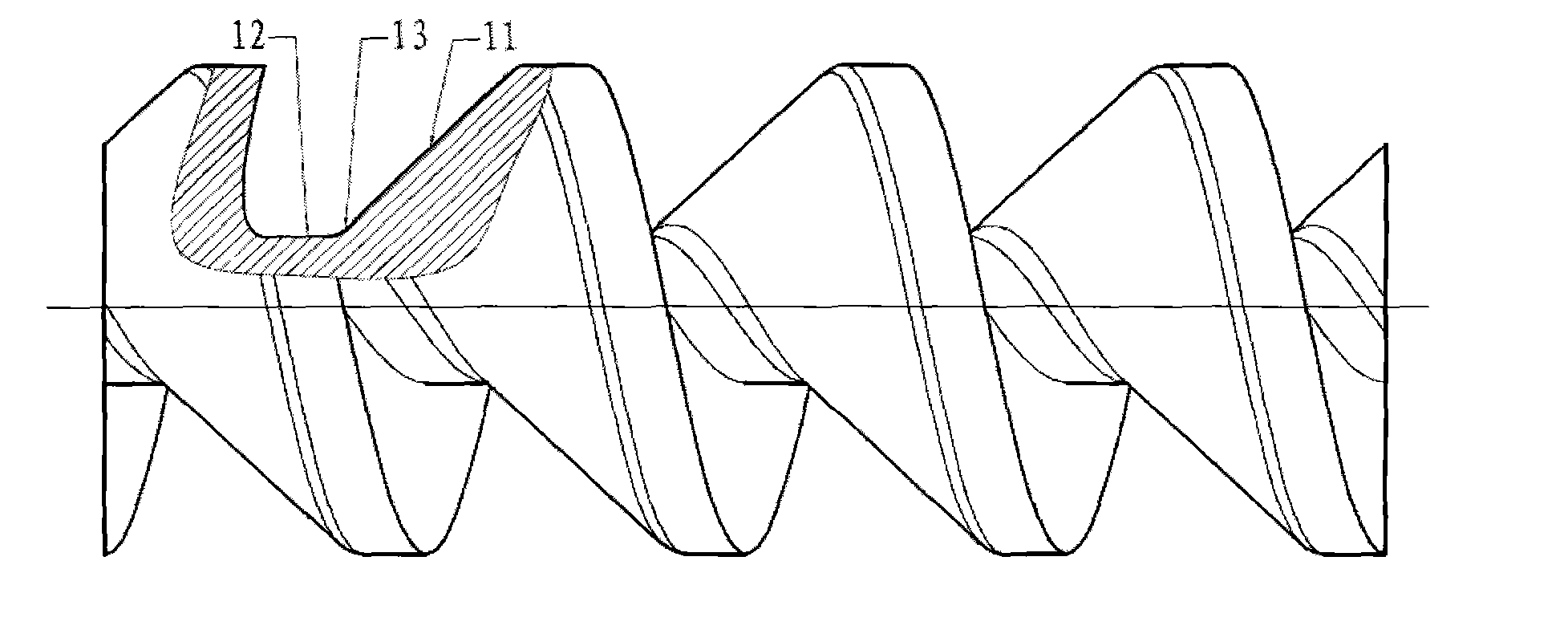

Fully-smooth screw rotor of twin-screw vacuum pump

InactiveCN105240277AImprove sealingImprove mechanical propertiesRotary piston pumpsRotary piston liquid enginesStress concentrationEngineering

The invention discloses a fully-smooth screw rotor of a twin-screw vacuum pump, and belongs to the technical field of dry-process twin-screw vacuum pumps. An end surface molded line of the screw rotor consists of 7 sections of curves which are smoothly connected without cuspidal points; a circular-arc DE and an equidistant curve EF of a cycloid are used for smoothly connecting a tooth-crest circular arc CD with a tooth-root circular arc FG; a circular arc GA is adopted for smoothly connecting the tooth-root circular arc FG with a circle involute AB; an equidistant curve BC of the cycloid is used for smoothly connecting the circle involute AB with the tooth-crest circular arc CD; and two screw rotor end surface molded lines which are conjugated and engaged with each other are the same, so that correct engagement can be realized in work; and the screw rotor generated by the screw rotor end surface molded lines consists of 7 tooth surfaces, and all tooth surfaces of the screw rotor are in smooth transition for eliminating an area which easily generates stress focus. The screw rotor has the advantages of high strength, good tightness, small abrasion and a long service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

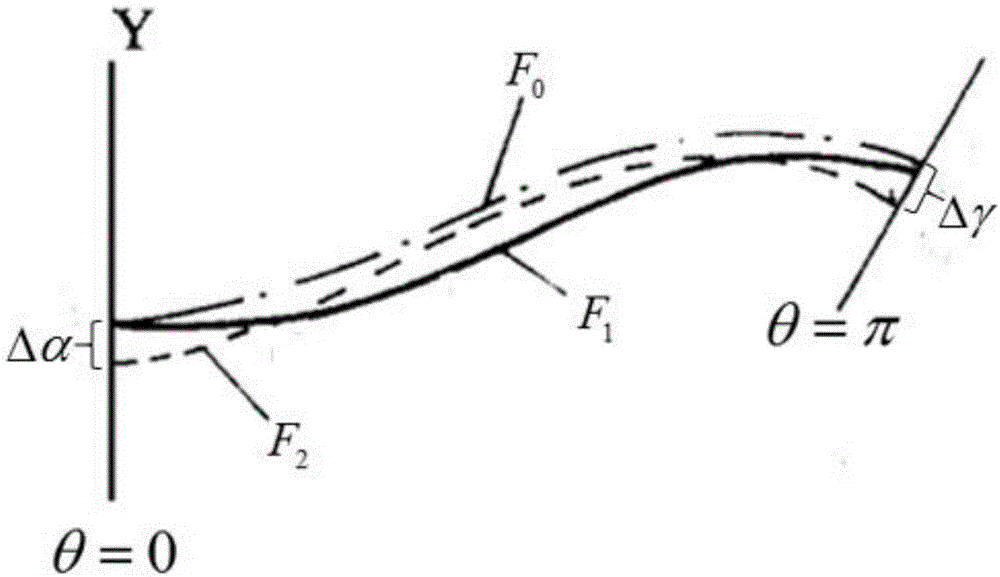

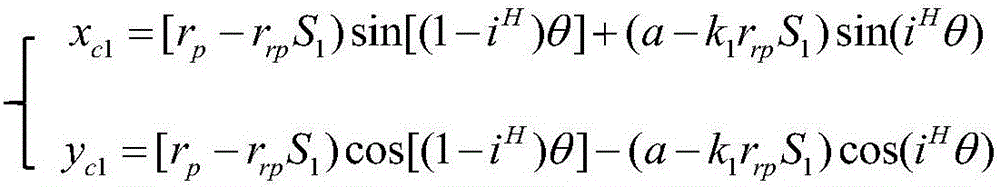

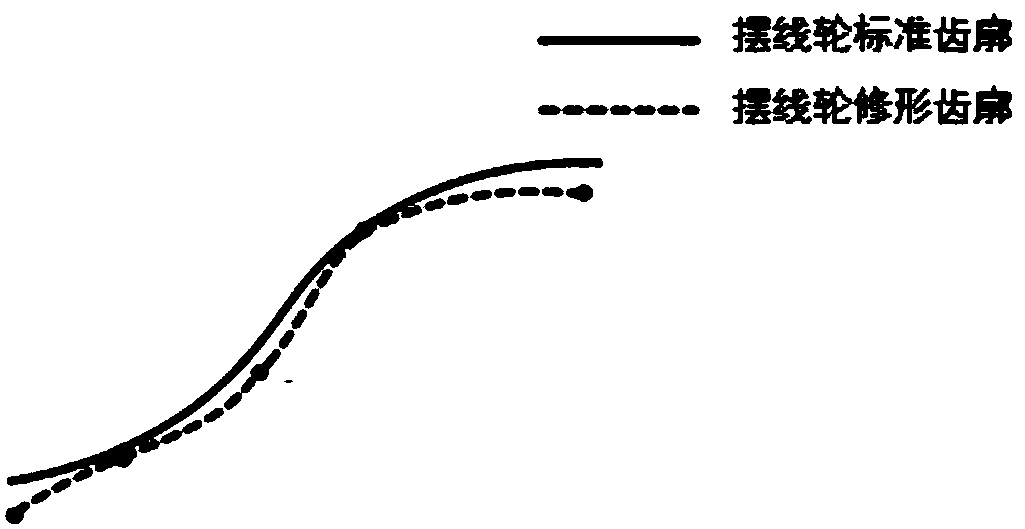

Optimization method of cycloid pin wheel profile modification based on particle swarm algorithm

ActiveCN106227918AShort calculation cycleImprove calculation accuracyGeometric CADArtificial lifeGlobal optimizationShape optimization

The invention discloses an optimization method of cycloid pin wheel profile modification based on particle swarm algorithm, and the method comprises the steps of determining a design variable and an object function according to a basic parameter of a cycloid wheel; re-determining a constrained condition according to a traditional constraint method and constraint requirements to a reshaped cycloid wheel tooth tip gap and a tooth root gap provided by the invention; playing the global optimization ability of particle swarm optimization algorithm in combination with the reshaped characteristics of the cycloid wheel to construct a particle swarm optimization algorithm model after the cycloid wheel shaping optimization; making an optimization object that the reshaped tooth profile can get close to a corner shaping tooth profile maximally and a return difference as small as possible is guaranteed, and further increasing the constraint requirement to the tooth tip gap and the tooth root gap on the basis of the traditional constraint, thereby obtaining a shaping tooth profile with an optimal equidistant and offset. In this way, the invention discloses the optimization method of cycloid needle wheel tooth profile modification based on the particle swarm algorithm with a short calculating period and high calculating precision, and the effect is good.

Owner:BEIJING UNIV OF TECH

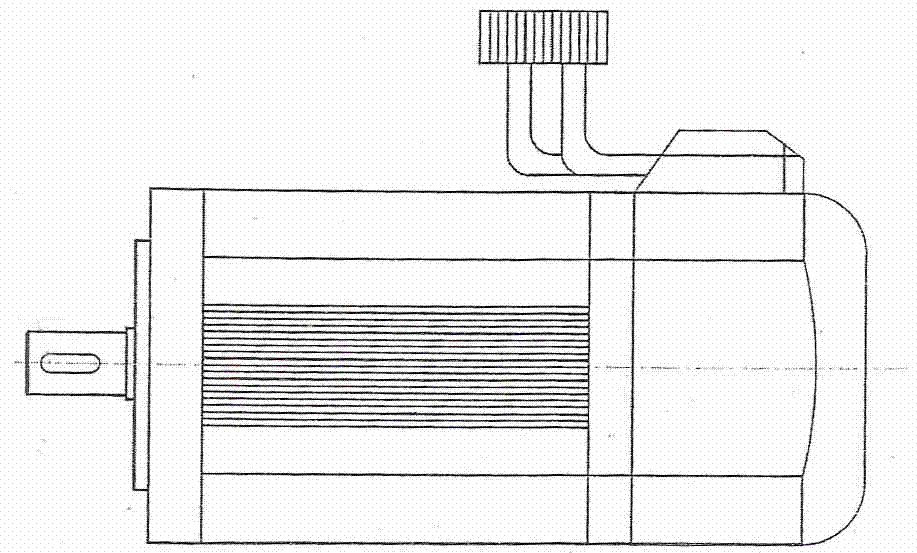

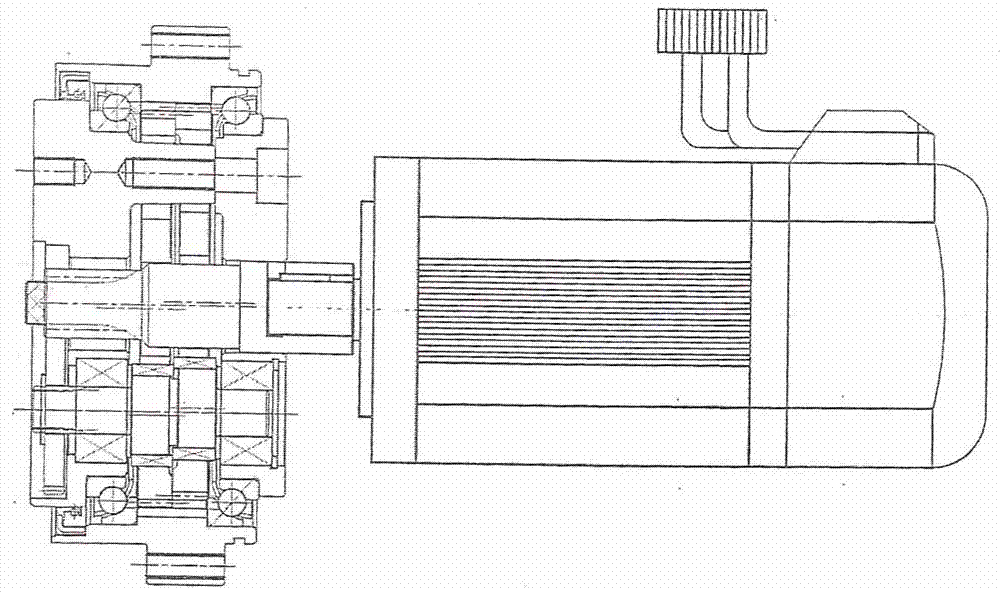

Fully sealed integrated RV speed reducer

ActiveCN104847873AReasonable structureImprove work performanceGear lubrication/coolingToothed gearingsWork performanceEngineering

The invention discloses a fully sealed integrated RV speed reducer which comprises a second grade cycloidal-pin wheel speed reducing structure composed of a pin wheel housing, a cycloid line wheel and a roller pin, a first grade planet speed reducing mechanism composed of an input shaft and a planet wheel, and an output plate rack, wherein an output end cover is arranged at the outer side of the output plate rack and the output end cover is fixed on the output plate rack of the RV speed reducer through a screw; a plurality of through holes being corresponding to the output threaded holes formed in the output plate rack are formed in the output end cover, the pin wheel housing is connected with an input flange, an input shaft support bearing is arranged between an input end flange and the input shaft, and a framework oil seal is arranged between the input end flange and the input shaft; a plurality of threaded holes used for mounting a servo motor are formed in the input end flange. The fully sealed integrated RV speed reducer is reasonable in structure, good in work performance, and has fully sealed structure.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY

RV reducer with novel structure

InactiveCN104712709AReasonable structureManufacturing precision requirements are lowGearboxesToothed gearingsGear wheelControl theory

The invention discloses a RV reducer with a novel structure. The RV reducer with the novel structure comprises a RV reducer shell, a first level planetary reduction mechanism and a second level cycloid reduction mechanism are arranged in the RV reducer shell, a planetary gear of the first level planetary reduction mechanism is meshed with a center gear on one end of an input shaft, the input shaft and an output shaft of a servo motor are the same shaft, and the center gear is manufactured and made at the tail end of the output end of the servo motor; one end of the RV reducer shell is connected with a servo motor shell through a flange, the output shaft of the servo motor and the flange are sealed through a skeleton sealing ring, and an output end cover is arranged on the other end of the RV reducer shell. The RV reducer with the novel structure is reasonable in structure, the precision is high, and the noise is low.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY

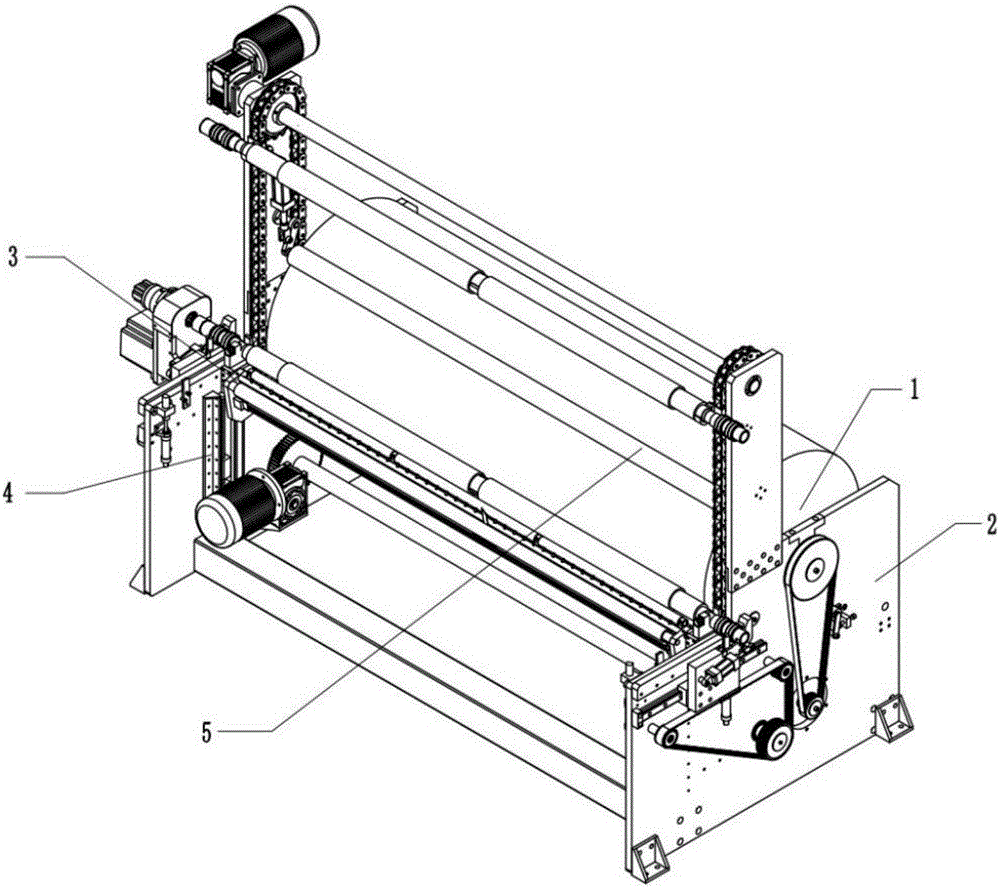

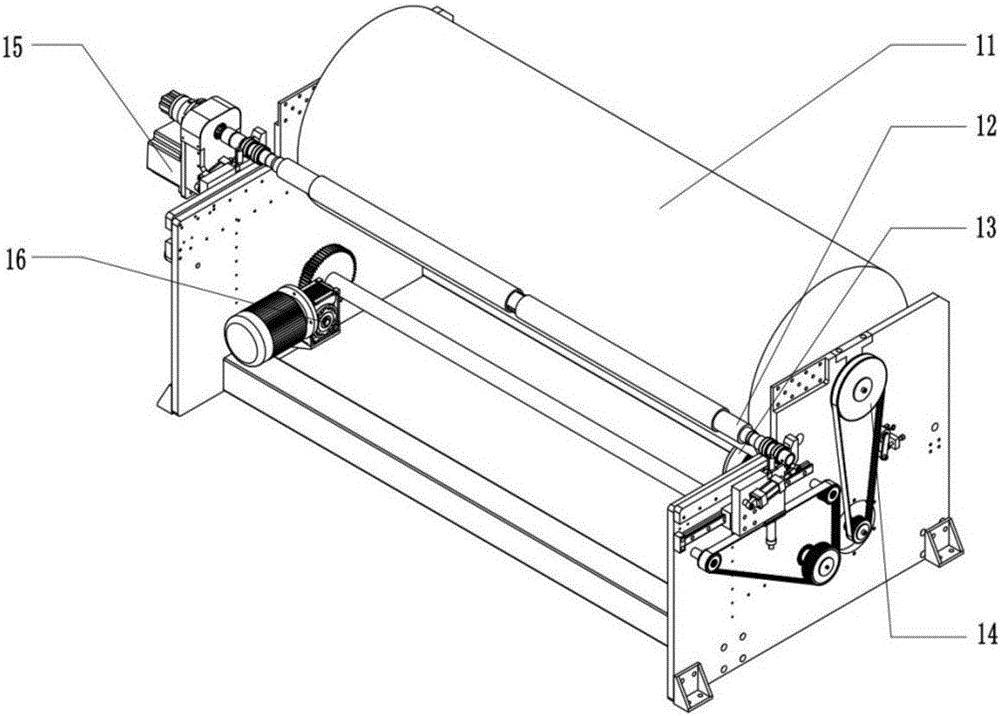

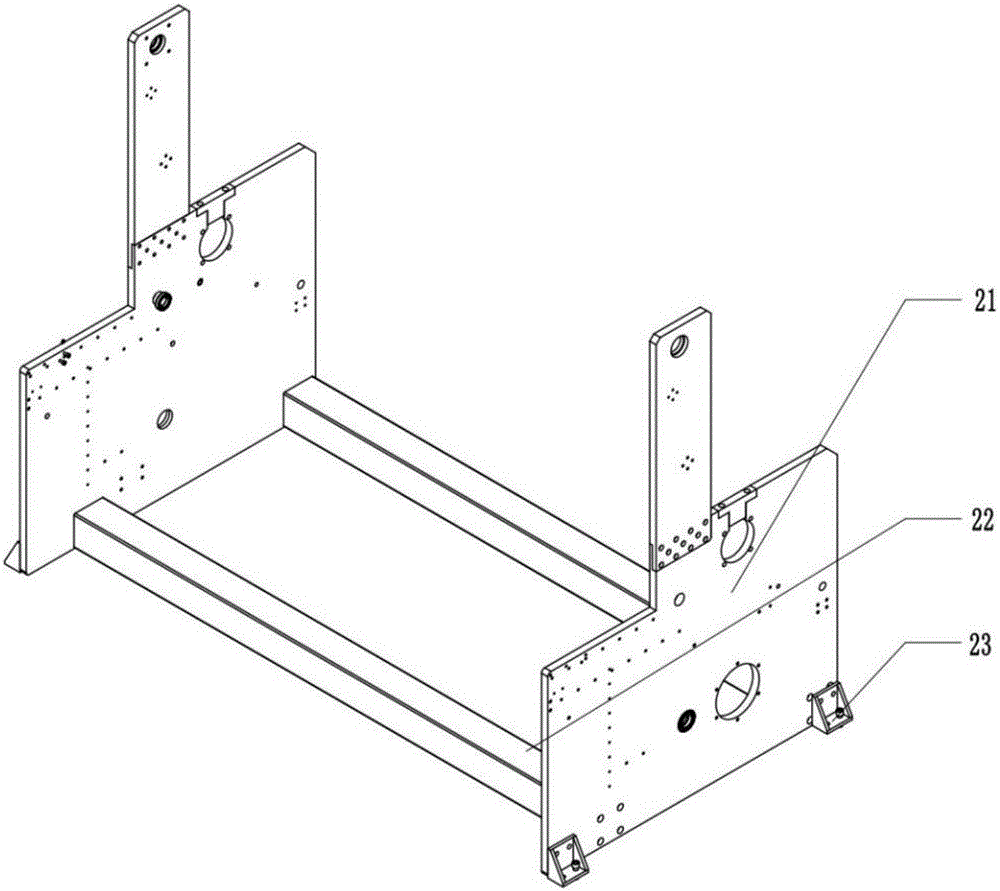

Automatic winding device

The invention relates to an automatic winding device. The automatic winding device mainly comprises a winding mechanism, a rack, an automatic roll changing mechanism, an air swelling shaft transmission mechanism and a tension control system. The winding mechanism is composed of a winding roller, an air swelling shaft, a cycloid motor, synchronous pulleys, an air swelling shaft drive mechanism and an air swelling shaft guide mechanism. The automatic roll changing mechanism is composed of an air pipe, a pull-rod-type cylinder, a carrier roller, a compression roller, a rubber roller, a rodless cylinder and the like. A roll discharging mechanism is composed of a miniature cylinder, a baffle and a spring. The air swelling shaft transmission mechanism is composed of a linear sliding block, a sliding rail, a cylinder, an air swelling shaft transfer rack, a motor, chain wheels and a chain. The tension control system comprises a tension detector, a tension detection roller, a tension controller and the like. The automatic winding device is mainly used for automatically winding plastic films and changing rolls of the plastic films, the effect that winding tension is constant is guaranteed, machines can replace people and thus labor using cost of enterprises can be reduced.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Double-disc cycloid cam planet driving device

The invention relates to a dual round disc cycloid wheel planet transmission device, providing a planetary reducer with fewer teeth differ, which can solve the problems of present cycloid planet reducer which can not bear bigger external axial force and need special frame with worse dynamic balance property and lower N-N transmission efficiency. The invention comprises a main body, an input axle, a roller, needle teeth, and a sleeve, left and right round discs, cycloid planet wheel, teeth sheath, and pin sheath and connection elements. Wherein, the dual-eccentric bearings, the pin sheath, the teeth and the teeth sheath are inside the cylinder hole which is in the middle of main body between the left and right round discs; the needle wheel formed by the needle teeth, the teeth sheath, and the main body can form a cycloid planet meshed pair with the cycloid planet wheel. The invention has better bearing capacity, especially bearing bigger external axial force with better dynamic balance property, easy production, N-type transmission, a meshed pair and a slit adjustable device. It can attain high transmission accuracy and efficiency while it can realize coaxial output since the dual round disc output element has symmetry functions.

Owner:CHONGQING UNIV

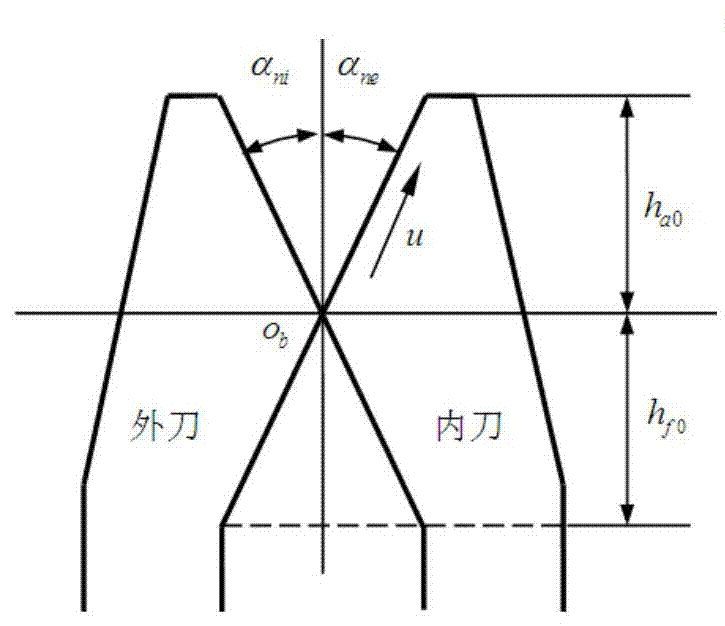

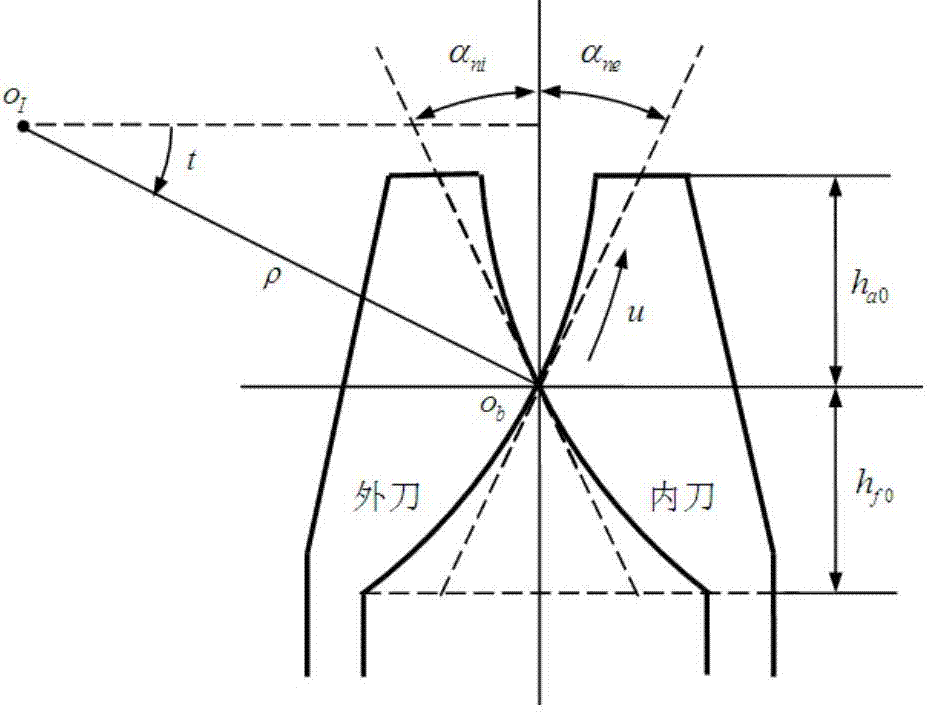

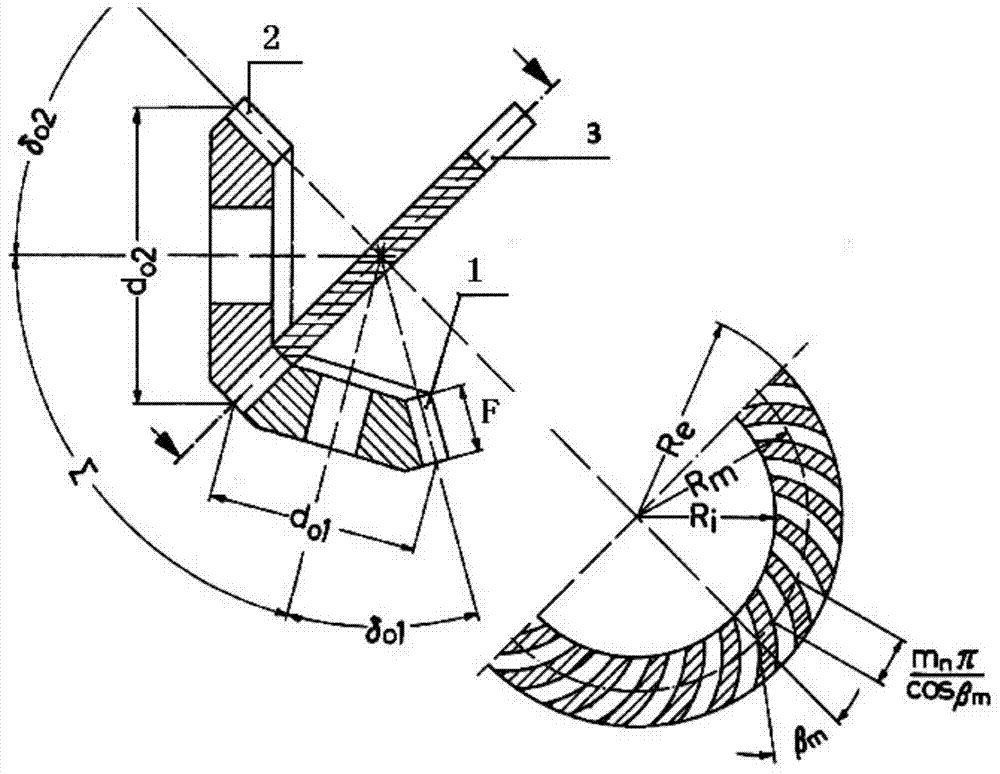

Machining method of cycloidal-tooth bevel gear

The invention discloses a machining method of a cycloidal-tooth bevel gear. The machining method comprises the following steps: (1) determining basic parameters of a generating wheel; (2) determining the movement for forming a tooth surface of the generating wheel; (3) determining the movement for expanding the generating wheel into the gear; (4) correcting the movement for expanding the generating wheel into the gear; and (5) finishing expansion of the machined gear. Compared with the Klingelnberg method, the machining method disclosed by the invention has the advantages that the structure of a tool disc is greatly simplified, a cross-shaped sliding block mechanism is not needed and the rigidity is improved; compared with the Oerlikon method, the machining method disclosed by the invention has the advantages that a tool inclining mechanism is not needed, so that the structure of a machine tool is greatly simplified and the rigidity is improved; the cycloidal-tooth bevel gear and a quasi-hyperbolic gear are processed on a bevel gear milling machine without a tool inclining and swinging disc; the correction of the tooth surface does not cause additional adjustment of the machine tool and the tool; second-order precontrol of the position, the size and the shape of contact spots of the tooth surface can be realized; second-order precontrol of required transfer errors can be realized; and a cycloidal-teeth bevel gear pair conjugate completely on theory also can be machined.

Owner:TIANJIN TEEK TRANSMISSION

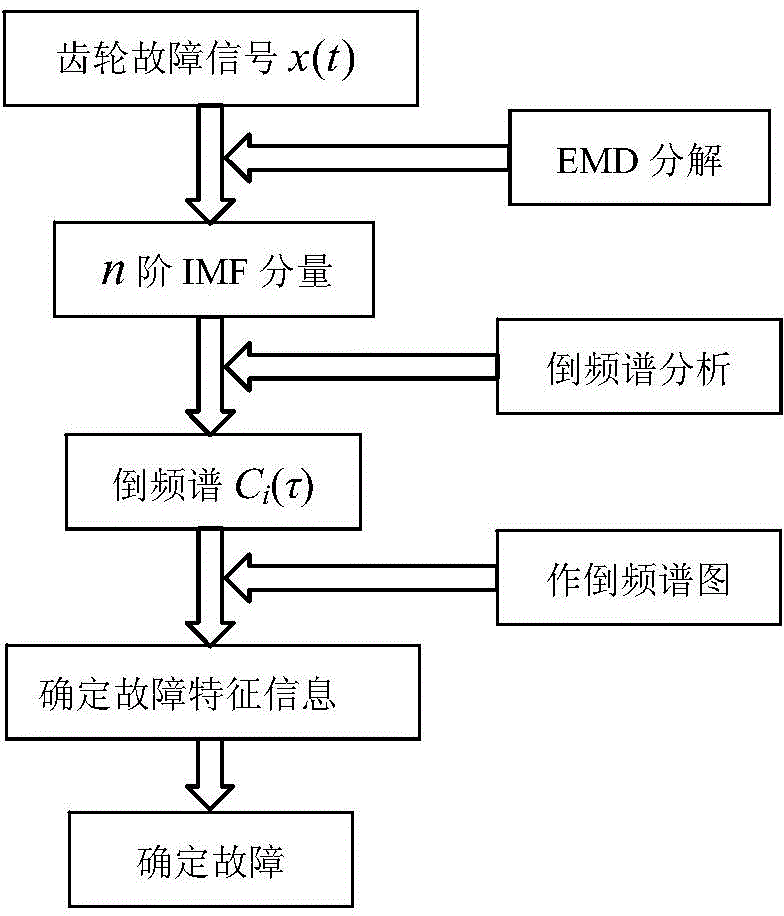

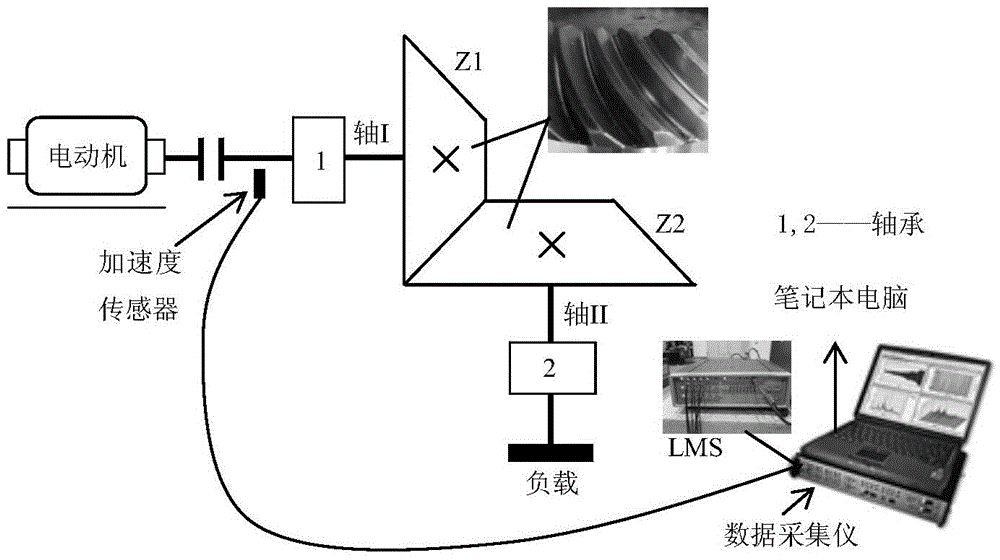

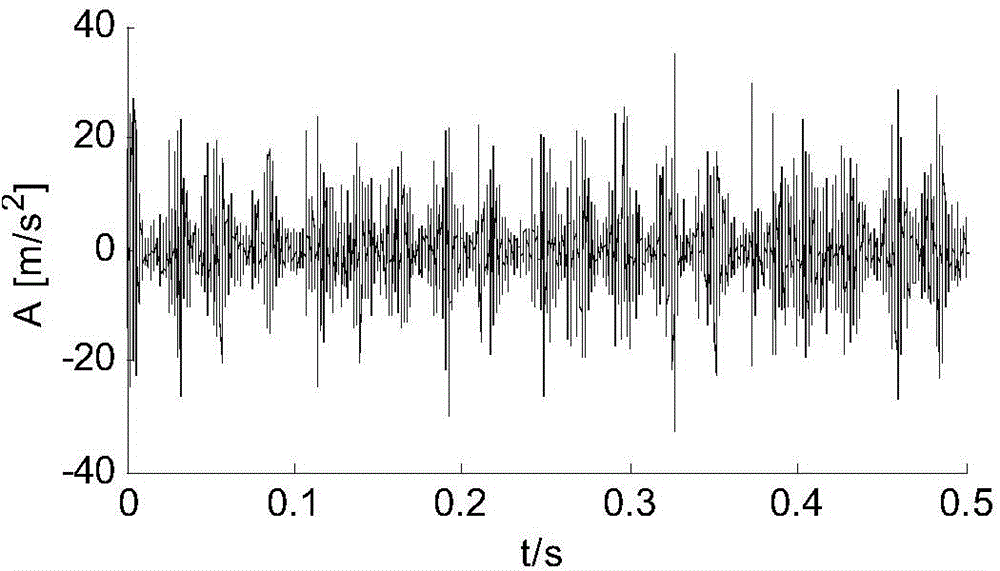

Cycloid bevel gear fault diagnosis method based on empirical mode decomposition and cepstrum

InactiveCN104006961AExtract fault characteristic frequencyExtract fault featuresMachine gearing/transmission testingDecompositionEngineering

The invention relates to a cycloid bevel gear fault diagnosis method based on empirical mode decomposition and cepstrum, and belongs to the technical field of fault diagnosis. The method includes the steps that (1), a cycloid bevel gear pair is measured through an acceleration sensor, and accelerated speed vibration signals are collected and used as signals to be analyzed; (2), the collected signals are guided into Matlab software to obtain original signals, and the original signals are decomposed into a series of intrinsic mode function (IMF) components through an empirical mode decomposition (EMD) method; (3), the IMF components of the previous orders are analyzed in a cepstrum mode to obtain amplitude cepstrum of the IMF components; (4), the amplitude cepstrum is drawn by adopting a drawing tool of the Matlab software, and fault feature information is extracted according to amplitude distribution in the cepstrum. The method can be applied to cycloid bevel gear fault diagnosis and can accurately extract fault feature frequency. A new method is provided for cycloid bevel gear fault diagnosis, and effective reference is provided for other rotating machine fault diagnosis technologies.

Owner:BEIJING UNIV OF TECH

Strictly-sealed screw rotor profile of dry-type screw vacuum pump

ActiveCN103233894AAvoid formingImprove dynamic performanceRotary piston pumpsRotary piston liquid enginesChemical industryManufacturing cost reduction

The invention discloses a strictly-sealed screw rotor profile of a dry-type screw vacuum pump, which belongs to the technical field of dry-type screw vacuum pumps. The rotor profile disclosed by the invention comprises six sections of curves, namely an involute ab, a transition curve bc, a tooth crest arc cd, a prolate cycloid de, a tooth root arc ef and a transition curve fa. The transition curve bc and the transition curve fa are designed to be with conjugate of arcs and cycloids or conjugate of cycloids and arcs. The two transition curves are respectively added between the tooth crest arc cd and the involute ab and between the tooth root arc ef and the involute ab to form smooth connection, so that leakage areas are avoided and strict sealing is formed. The changes of end faces generated from the smooth connection promote the improvement of dynamic properties. Meanwhile, the transition curves enable the tooth root of a rotor to be smoothly connected with a tooth profile part, so that only one cutter is needed to process the tooth root and the tooth profile and the manufacturing cost is effectively lowered. The dry-type screw vacuum pump with the profile disclosed by the invention can be widely applied to the fields of electrons, semiconductors, chemical industry, food, aerospace and the like.

Owner:浙江珂勒曦动力设备股份有限公司

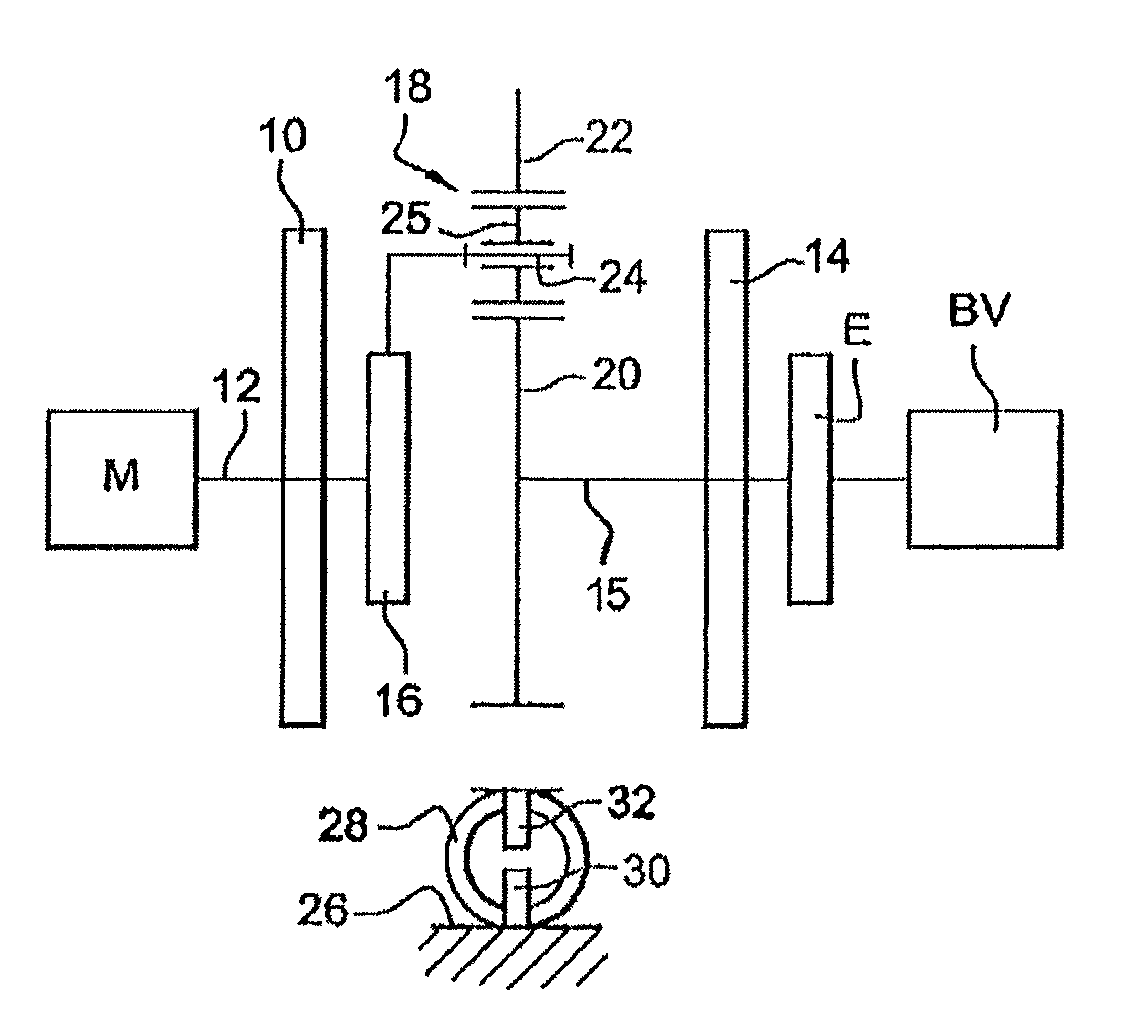

Double-fly wheel damper with epicyclic gear train

ActiveUS8523732B2Absorbs and damp vibrationEliminate the problemRotating vibration suppressionYielding couplingSteering wheelFixed frame

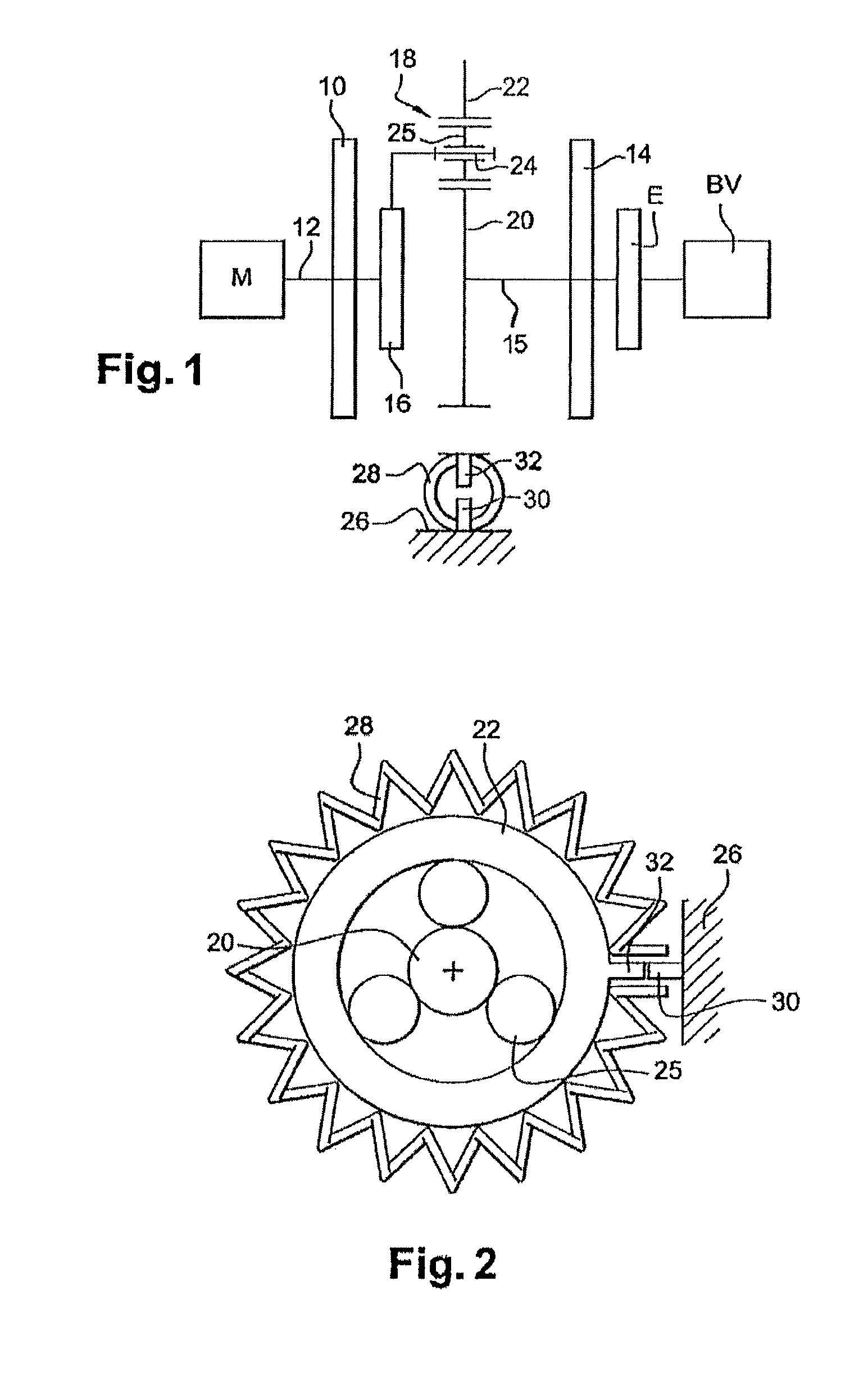

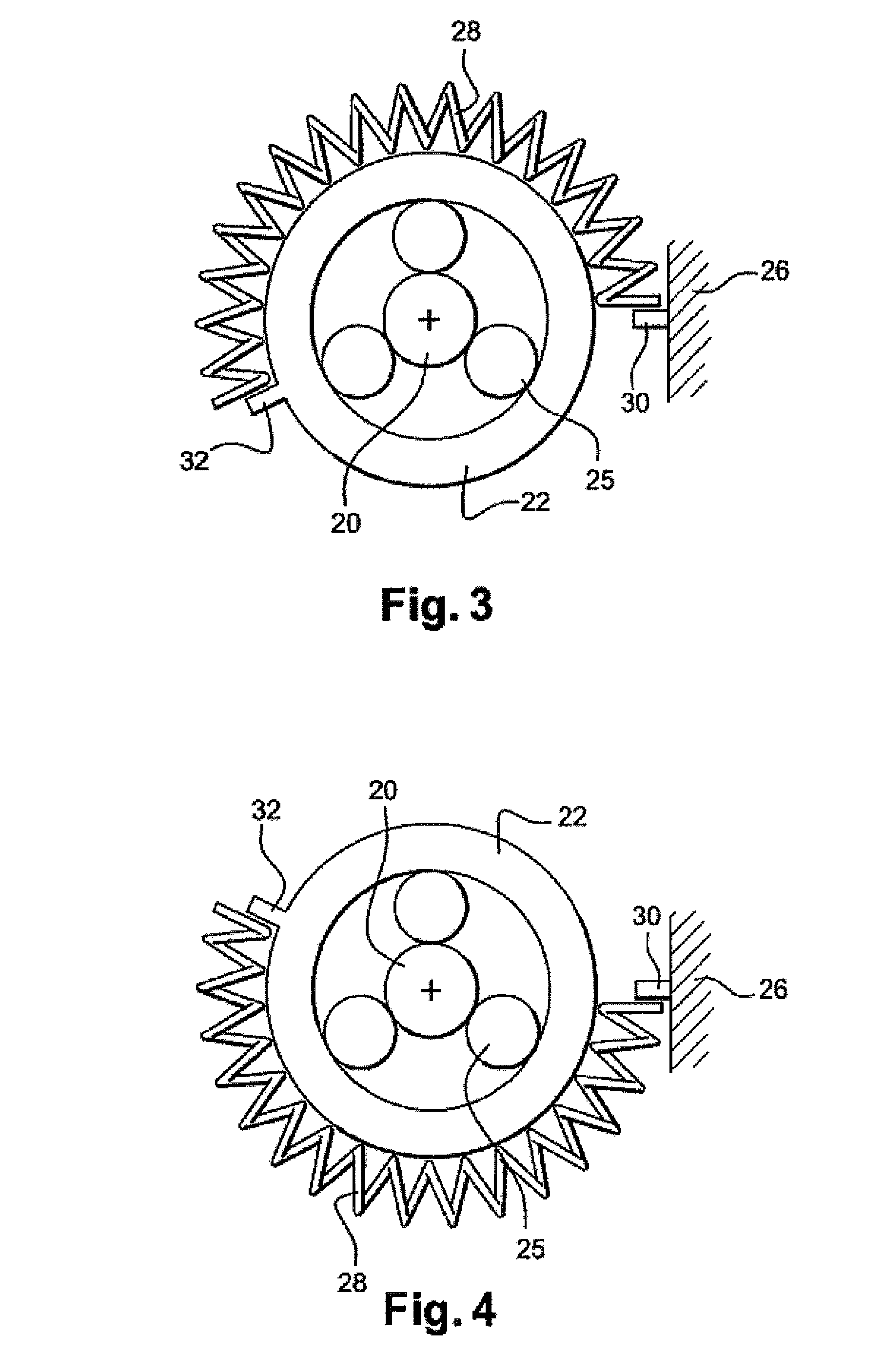

A double shock-absorbing steering wheel, in particular for automobile vehicles, including a primary inertia mass connected to an engine shaft (12), a secondary inertia mass (14) connected by clutch E to a gearbox BV, and a torsion damper (18) rotatably connecting the two inertia masses (10, 14). The torsion damper includes an epicycloidal gear train whose outer crown wheel (22) engages with a spring (28) for absorption of vibrations and rotation acyclisms. The spring is mounted around the crown wheel (22) in a fixed frame (26).

Owner:VALEO EMBRAYAGES SAS

Electric motor and gear drive assembly for driving a vehicle wheel

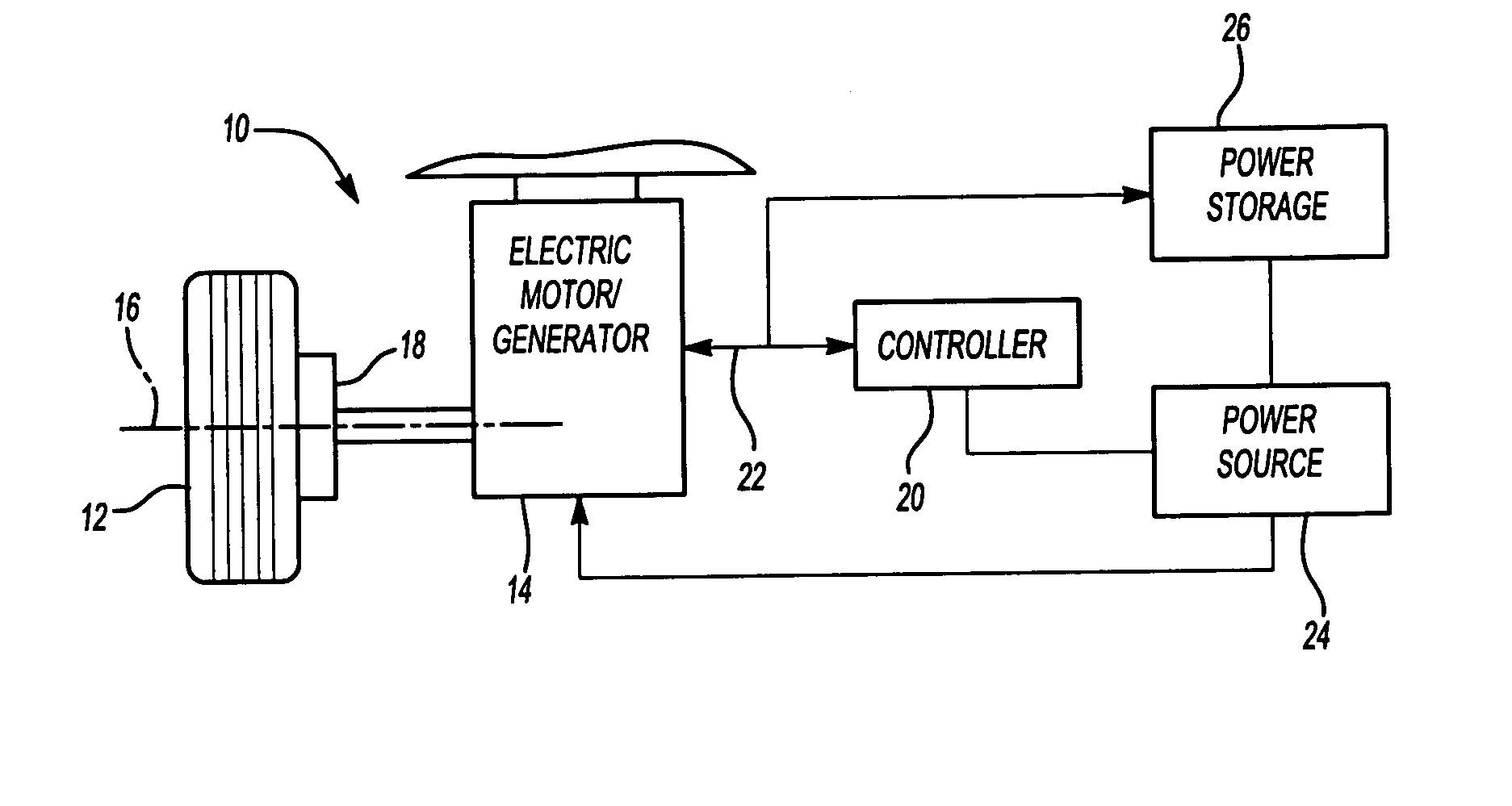

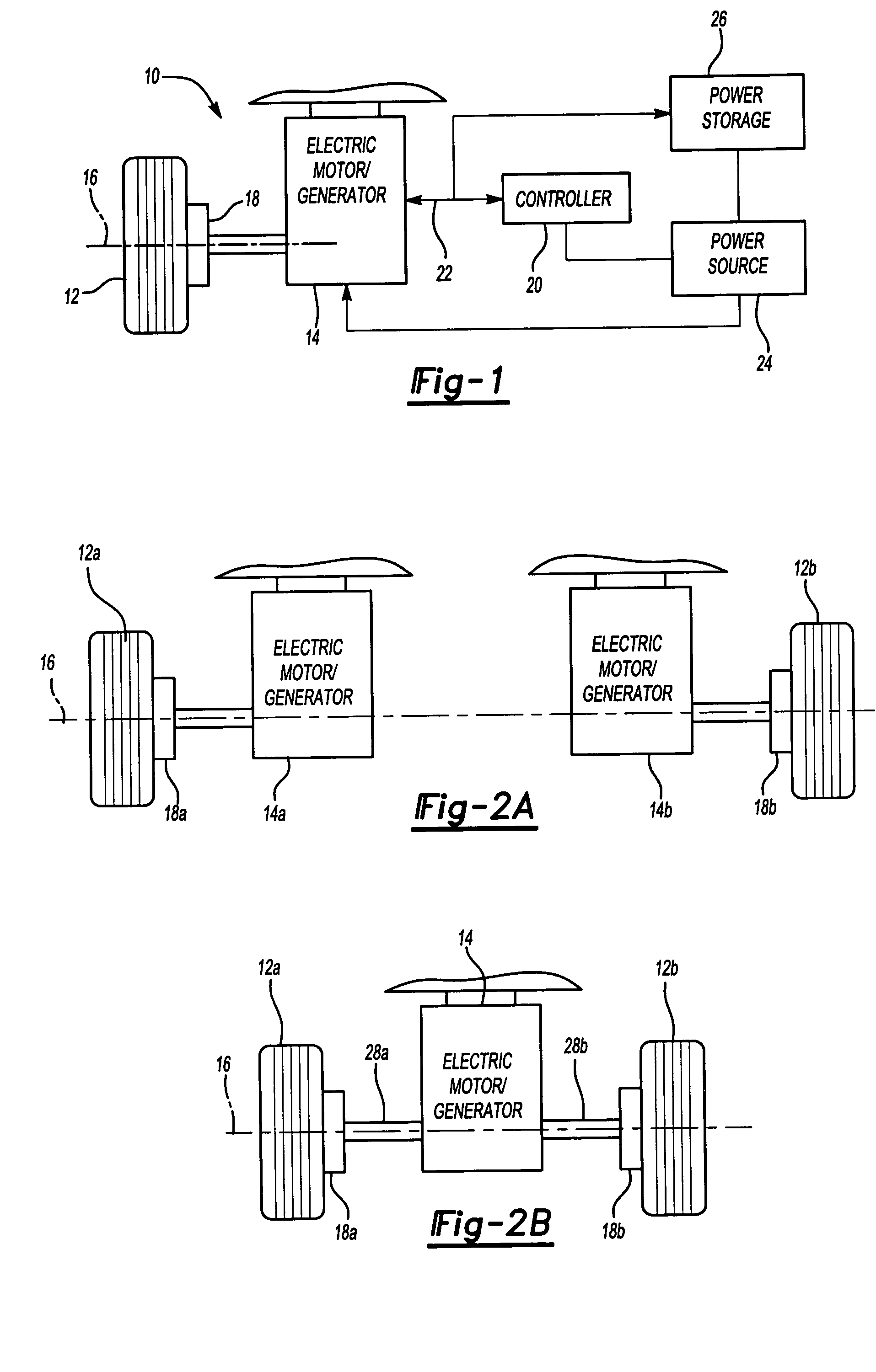

A drive unit assembly for a vehicle wheel includes a rigidly mounted electric motor coupled to the vehicle wheel via a gear drive. The gear drive includes a cycloid or epicycloid gear arrangement that provides significant speed reduction at the wheel.

Owner:ARVINMERITOR TECH

Cycloid drive epicycloid planet gear cam

InactiveUS20140150601A1Efficient and adaptableEasy to controlCam-followersToothed gearingsGear wheelCycloid

An epicycloid planet gear cam that converts rotational movement of a driveshaft into linear movement of an output device is disclosed. An epicycloid planet gear is assembled inside a stationary housing with an internal stationary ring gear. A driveshaft eccentric is connected to a driveshaft. The driveshaft eccentric rotates freely in a mounting hole of the epicycloid planet gear. When the driveshaft rotates, the driveshaft eccentric engages the epicycloid planet gear against the stationary ring gear and causes the epicycloid planet gear to rotate. A cam follower pin attached to an output device is held against a cam track of the epicycloid planet gear. As the epicycloid planet gear rotates, the raised cam track height or the slotted cam track distance from the center of the epicycloid planet gear causes the cam follower pin to move up, down, in, or out thereby moving the output device.

Owner:MCGRATH PATRICK JAMES

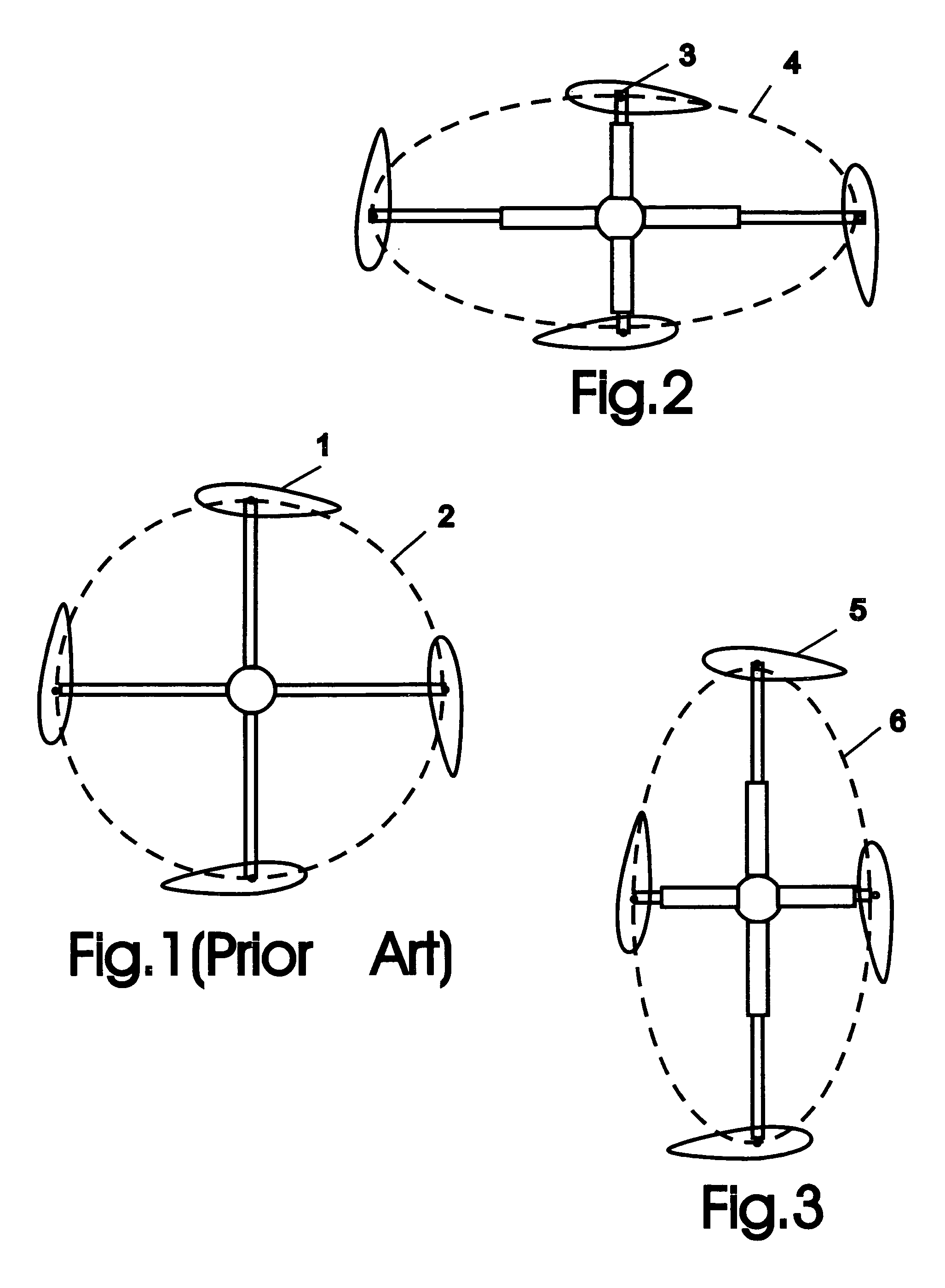

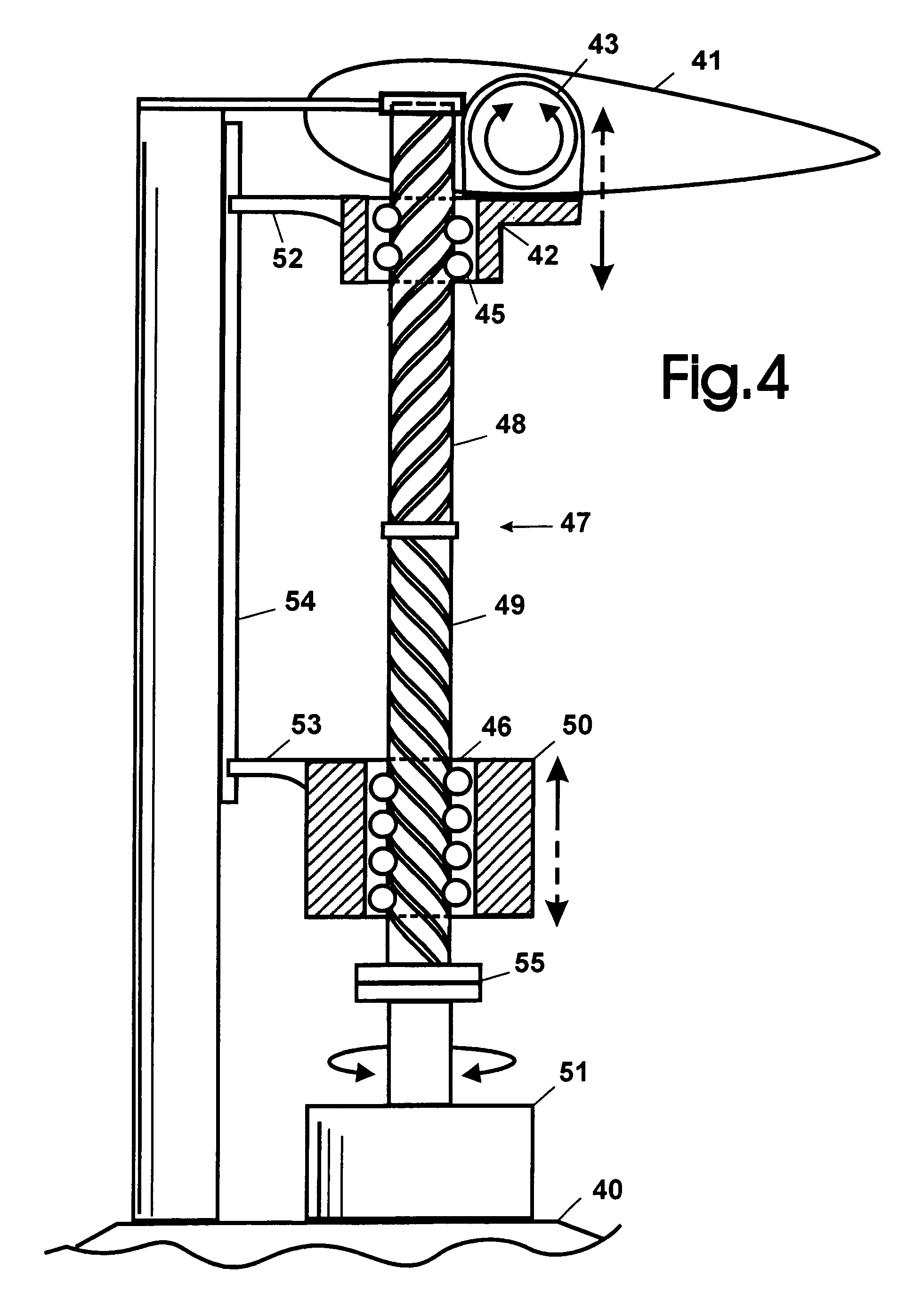

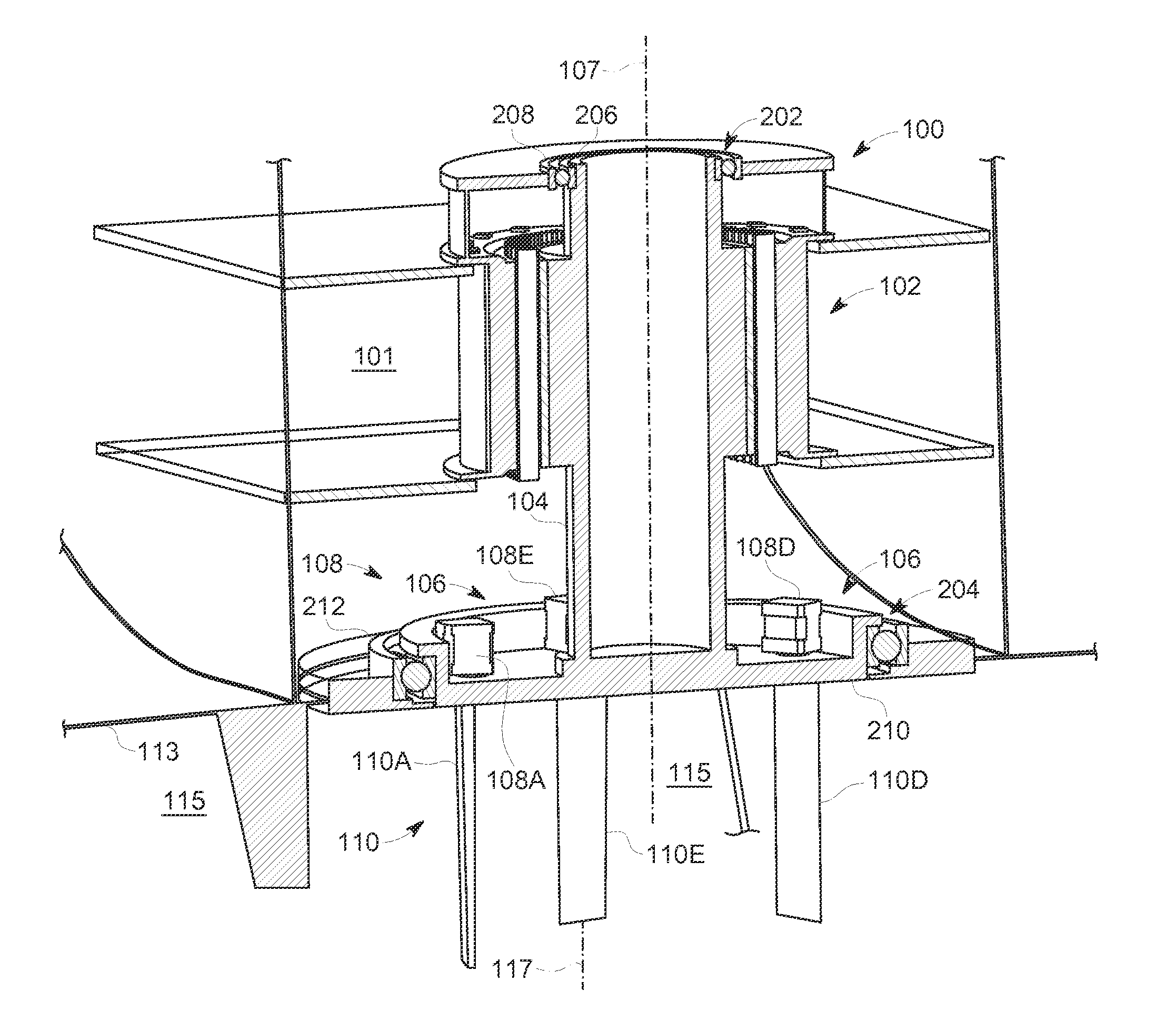

Cycloidal hybrid advanced surface effects vehicle

InactiveUS7219854B2Drag minimizationMaximize vehicle liftPropellersWaterborne vesselsCycloidFixed wing

A “wing in ground effect” aerial vehicle includes a wing mounted on a fuselage, and two cycloidal propulsion units for providing lift, thrust and longitudinal control. Additional lift is provided by a lighter-than-air gas such as helium contained in the fuselage. Operationally, the two cycloidal propulsion units and the volume of lighter-than-air gas are concertedly regulated to achieve “wing in ground effect” flight. Importantly, the two cycloidal propulsion units may operate in one of several modes, to include a curtate mode, a prolate mode, and a fixed-wing mode. Additionally, the vehicle may hover. Also, a thruster unit is mounted on the fuselage for providing forward thrust in combination with, or in lieu of, the two cycloidal propulsion units.

Owner:BOSCHMA RES

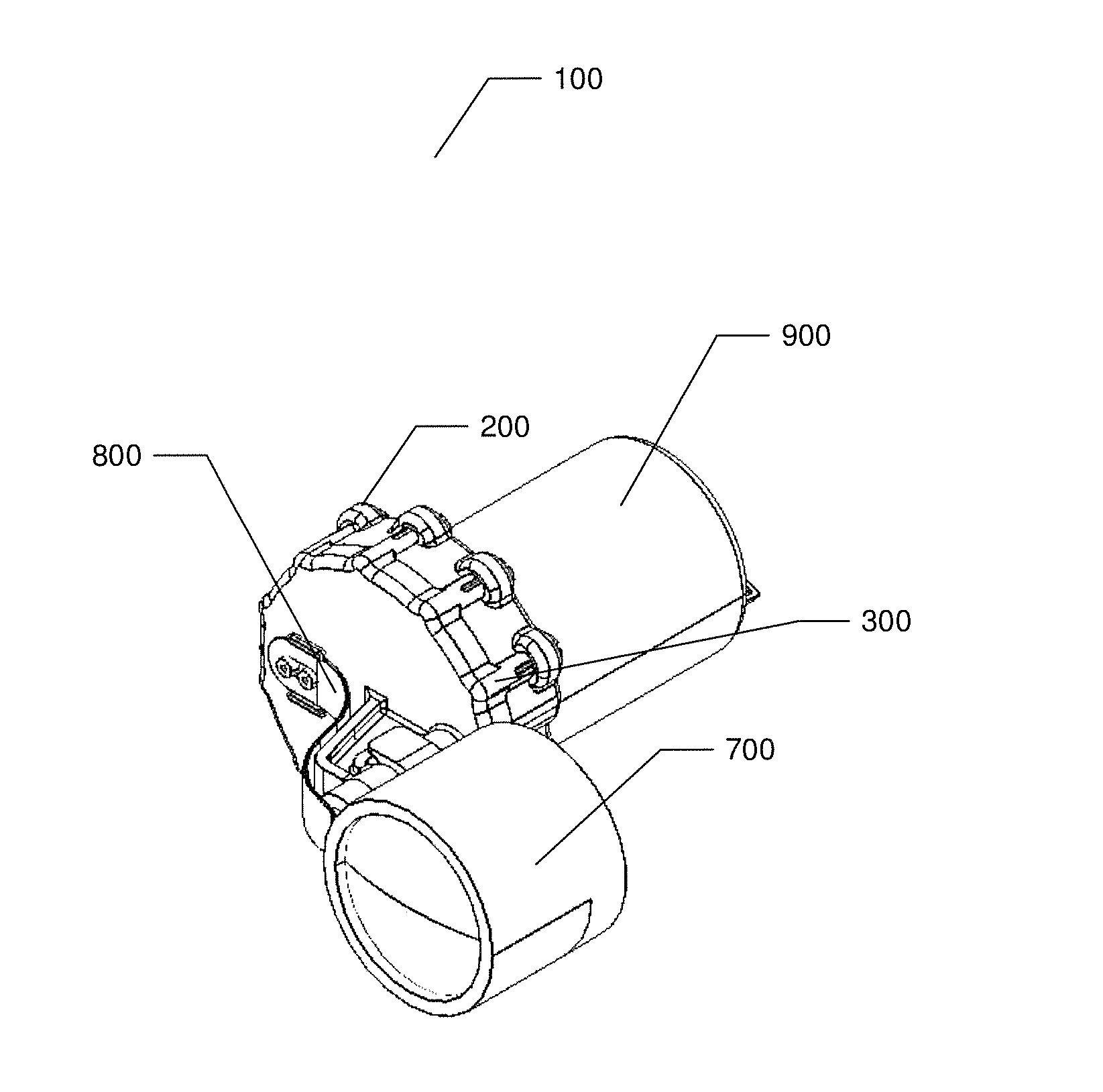

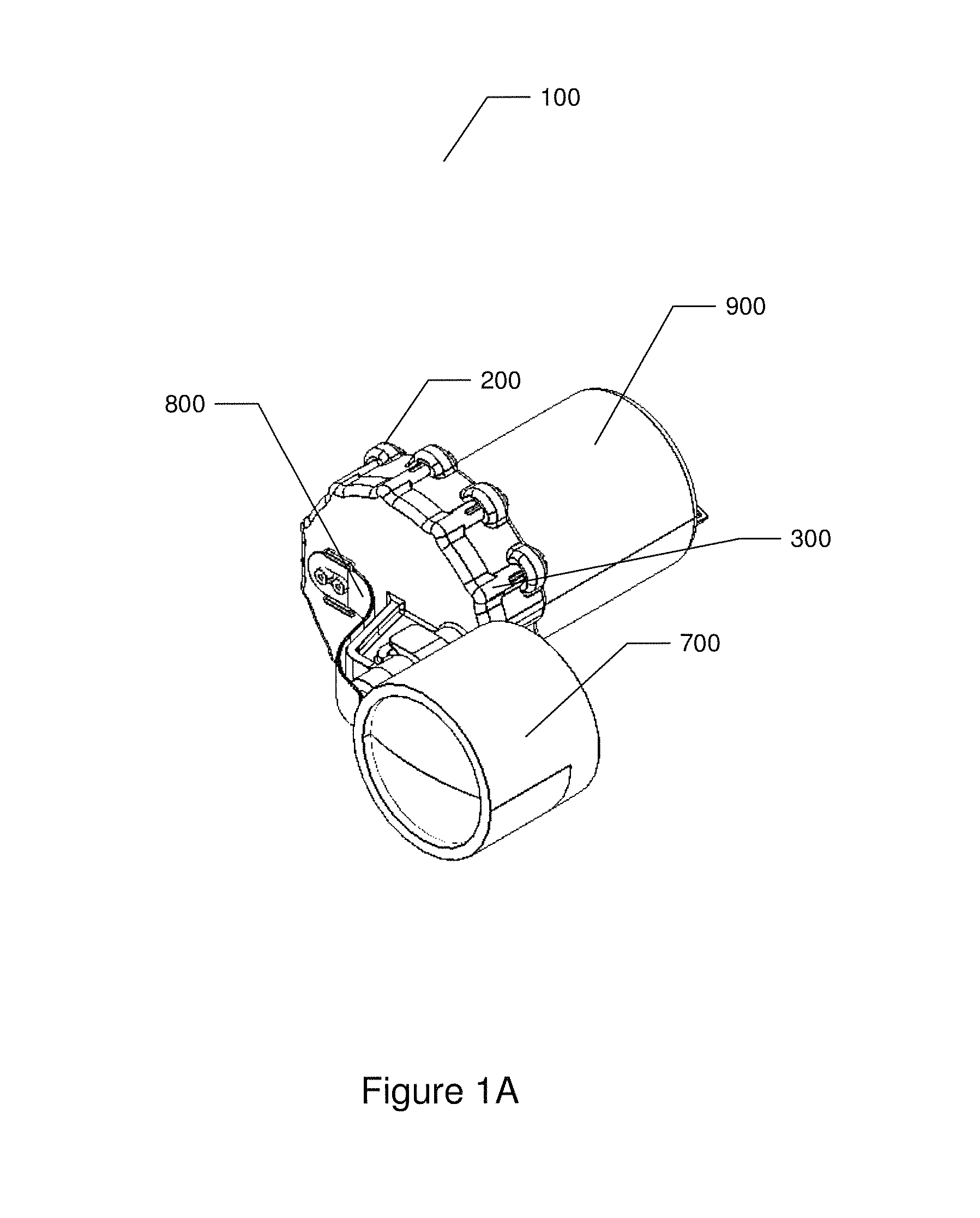

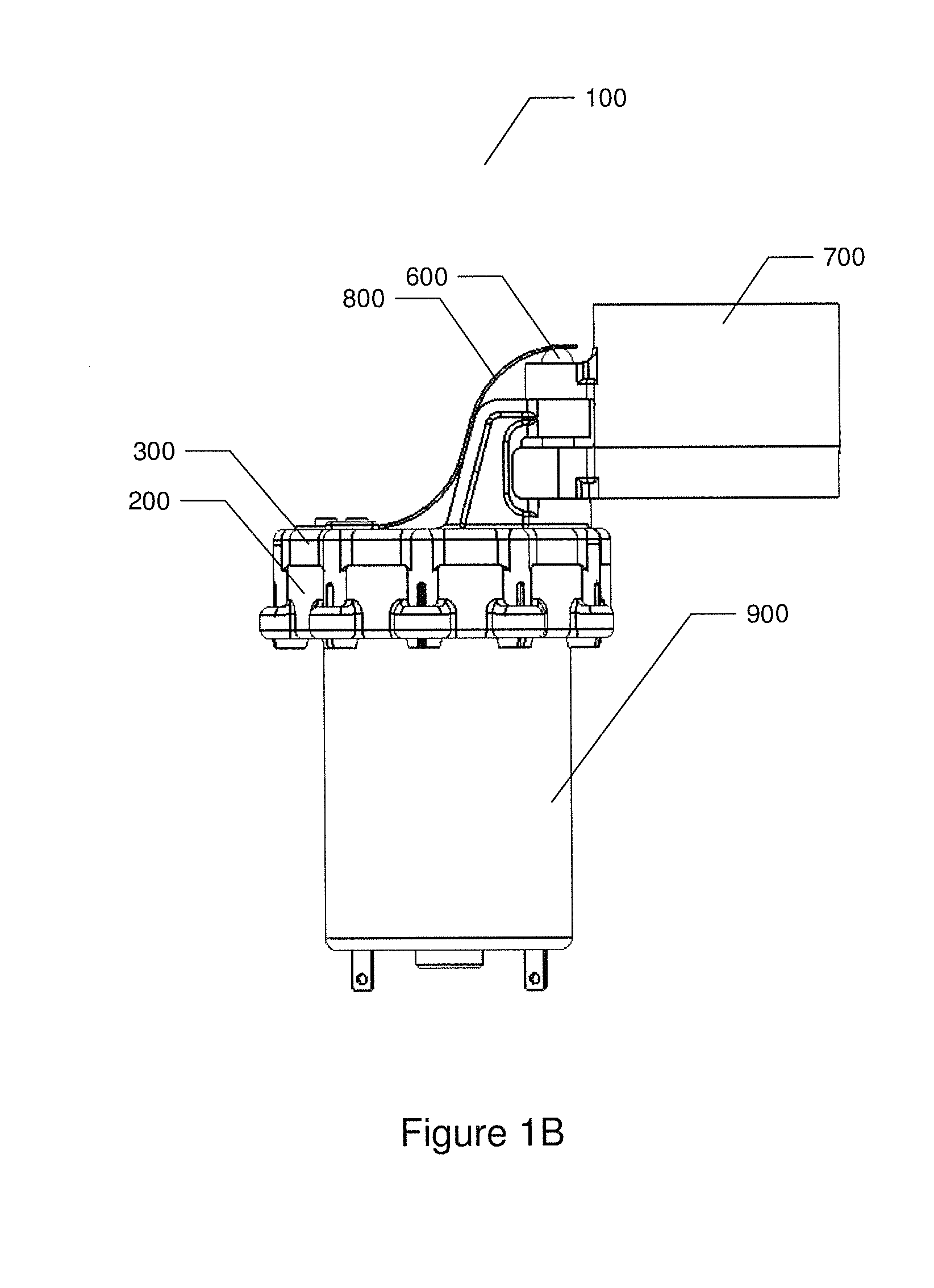

Cycloidal marine-propulsion system

InactiveUS20150321740A1Reduces significantly dragReduce resistancePropellersBlade accessoriesMarine propulsionActuator

A cycloidal marine-propulsion system is disclosed. The system comprises a blade-mounting disc and a plurality of propeller blades. Each of the plurality of propeller blades has a respective primary blade axis and is connected to the disc in a manner allowing the blade to be rotated about its primary blade axis independent of any about-axis rotation of every other one of the propeller blades. The system also includes a plurality of electric actuators, each actuator being connected to a respective one of the propeller blades. The system further includes a controller in communication with the electric actuators for controlling selectively each of the electric actuators.

Owner:GE ENERGY POWER CONVERSION TECH

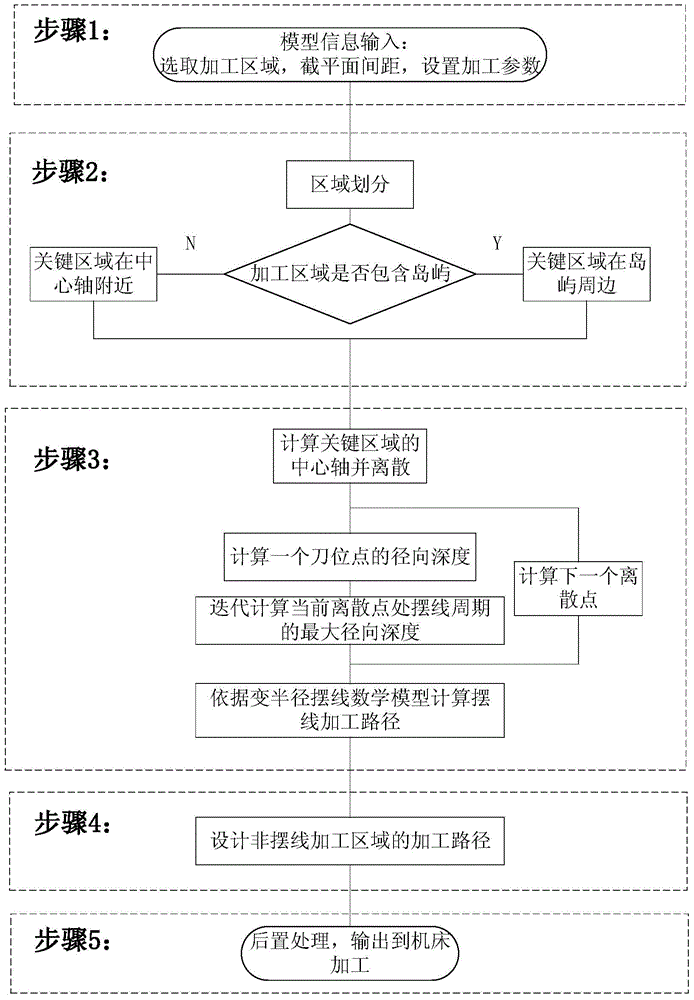

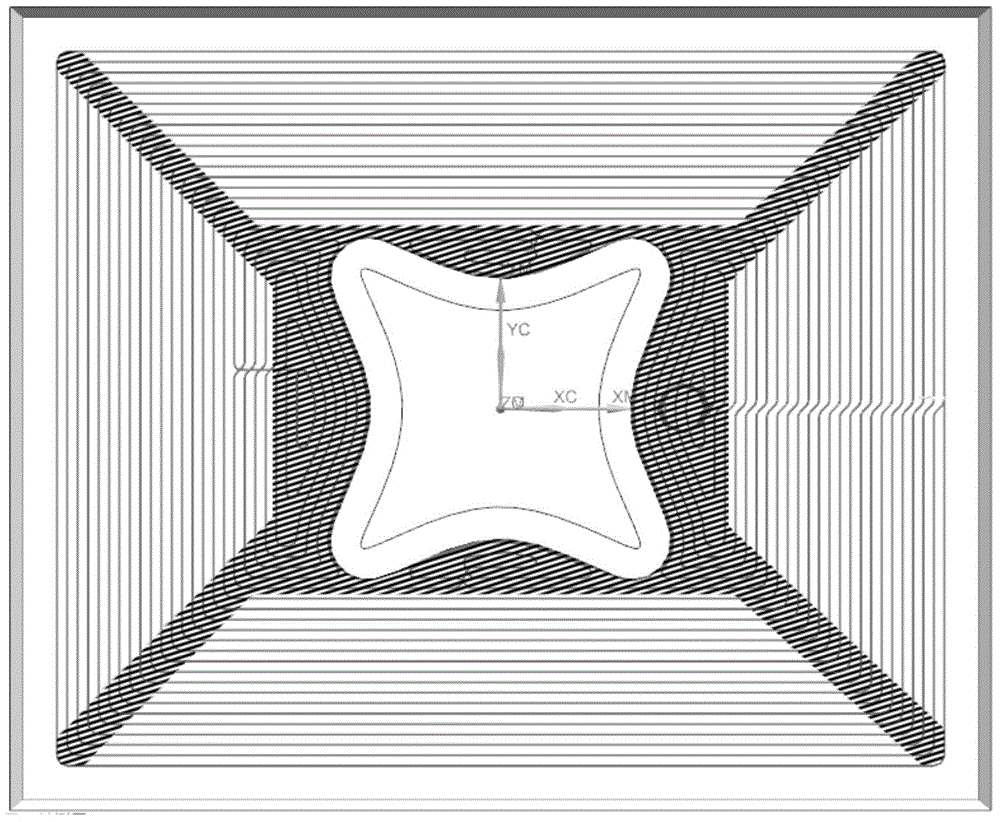

Method suitable for cycloid high-speed milling machining path

ActiveCN104090528AReduce redundancyShorten the lengthProgramme controlComputer controlMathematical modelCutter location

The invention discloses a method suitable for a cycloid high-speed milling machining path. The method includes the steps of firstly inputting part model information and part characteristic information, and automatically dividing a machined area to obtain a key cycloid machined area and a traditional cycloid machined area; according to boundary information of the key area, calculating a cycloid center path, carrying out dispersing, and iteratively calculating the cycloid single-cycle maximum radial depth of each discrete point with the simplex method; then, screening the discrete points of the variable-radius cycloid center axis according to the maximum radial cutting-in depth; after screening is completed, calculating the cycloid machining path of the key area according to a mathematic model of a variable-radius cycloid, and carrying out dispersing on cutter location points; finally, machining left areas with a traditional machining method. By means of the method, the cycloid path is short, the time for passing through an idle-cutting path is short, and the redundancy is low; the cutter contact angle and the radial cutting-in depth can be kept relatively stable, the problems that in the high-speed milling process, the cutter contact angle is prone to sudden change, and the idle-cutting path is long are solved, the machining path is stable, and the milling efficiency is improved.

Owner:ZWCAD SOFTWARE CO LTD

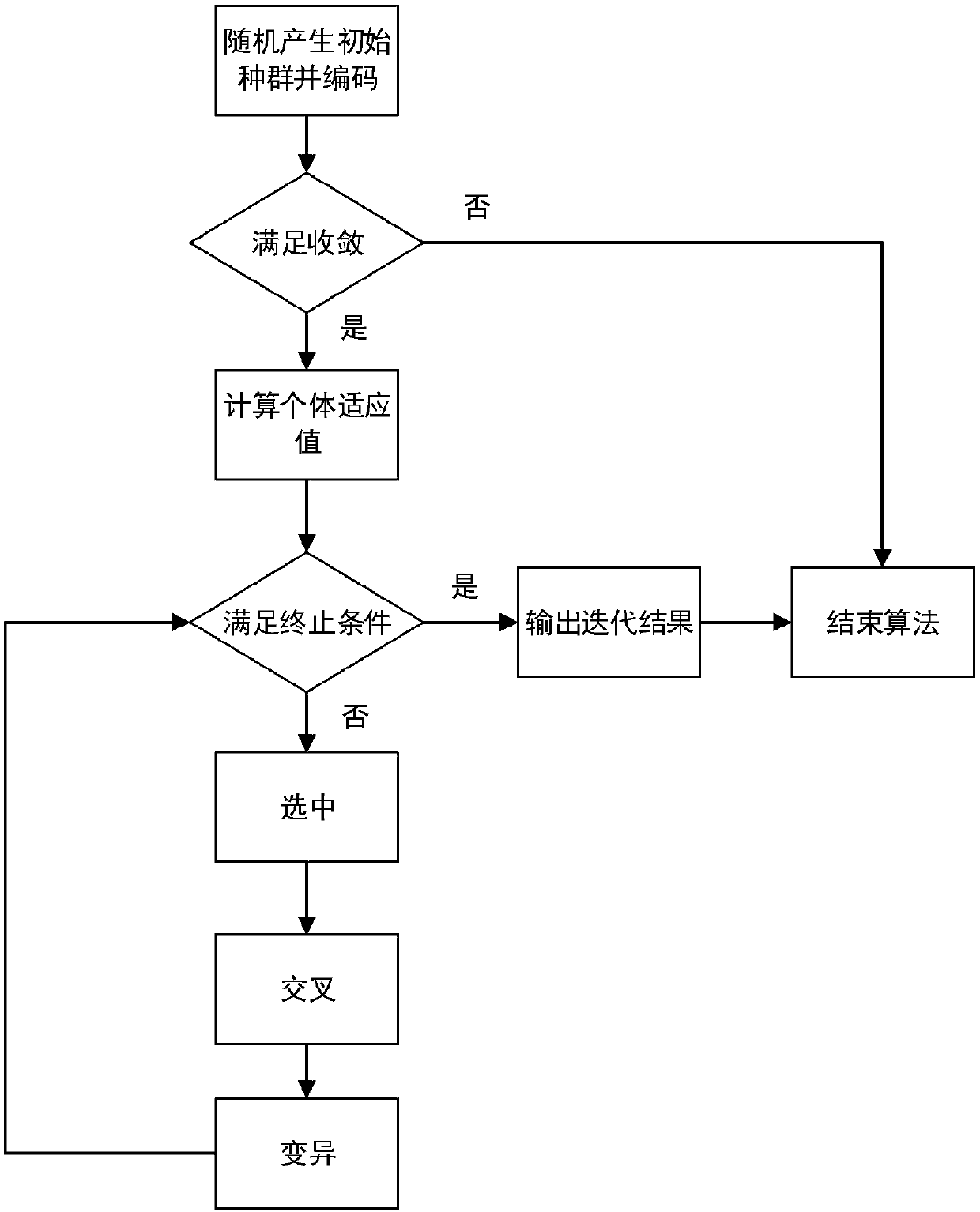

Genetic algorithm-based RV speed reducer tooth profile optimizing and modifying method

InactiveCN107742054ASpeed up iterationEfficient determinationGeometric CADSpecial data processing applicationsEngineeringCycloid

The invention discloses a genetic algorithm-based RV speed reducer tooth profile optimizing and modifying method. The tooth profile equation of a cycloidal gear after modifying and the contact range during actual work are determined according to the traditional three modifying methods of the cycloidal gear; the corresponding target function and the constraint condition are determined by the engaged nominal clearance of the tooth profile after modifying; the optimal modifying quantity is compensated into the tooth profile of the cycloidal gear of an RV speed reducer, so that the genetic algorithm optimization model of the tooth profile of the cycloidal gear is obtained. The optimal equidistant modifying quantity and the shift modifying quantity serve as target variables, the minimal tooth profile clearance after two kinds of optimal modifying serves as the target function, the engaged clearance between the node of the cycloidal gear and the engaged point serves as the constraint condition during optimization, the mixed penalty function of two-point heterodyning is introduced, so that the iteration speed of the optimization algorithm is increased, and finally the optimal equidistantand shift modifying quantity is obtained. By the method, optimal computation parameters can be determined rapidly and effectively, and the computation efficiency and the optimization precision are greatly improved.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com