Automatic winding device

A winding device and automatic technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of unfavorable automatic assembly line production mode and unfavorable operator's own safety, etc., and achieve constant winding tension and reduced The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The objects and effects of the present invention will become more apparent when the present invention is described in detail below with reference to the accompanying drawings.

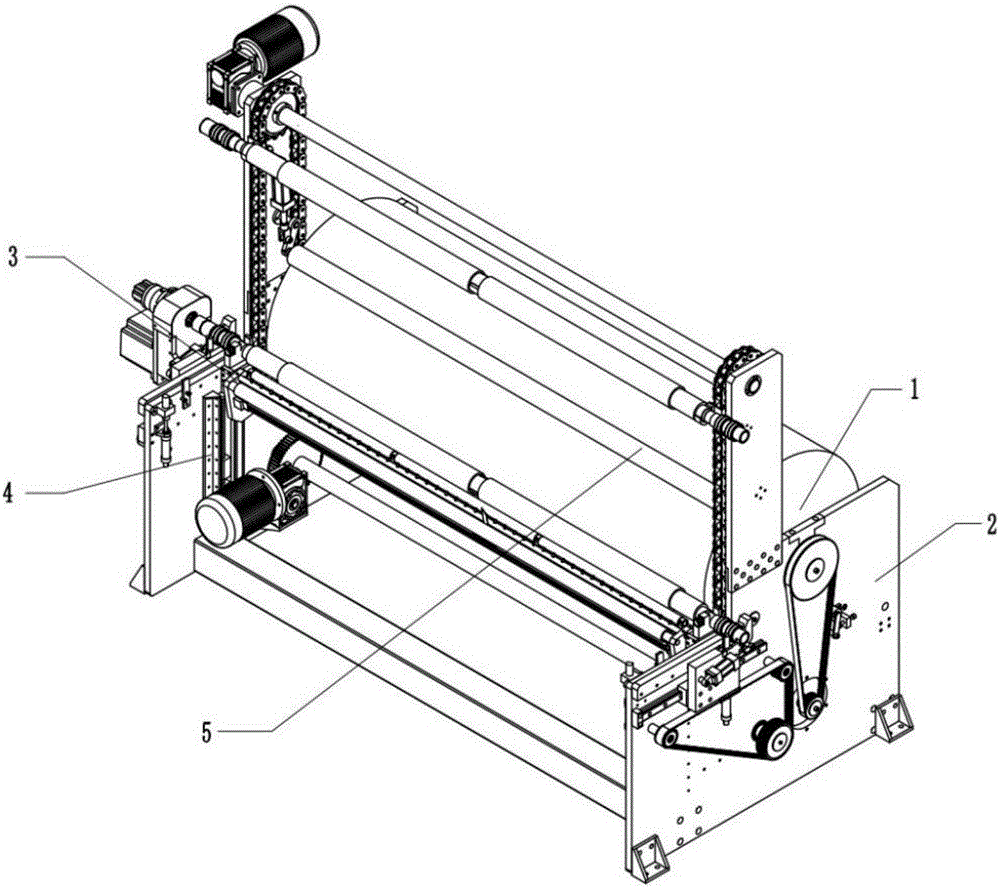

[0022] Such as figure 1 As shown, the automatic winding device provided by the present invention includes a winding mechanism 1, a frame 2, an automatic roll changing mechanism 3, an air shaft transmission mechanism 4 and a tension control system. The winding mechanism 1 , the automatic roll changing mechanism 3 , the air expansion shaft transmission mechanism 4 and the tension control system are all installed on the frame 2 .

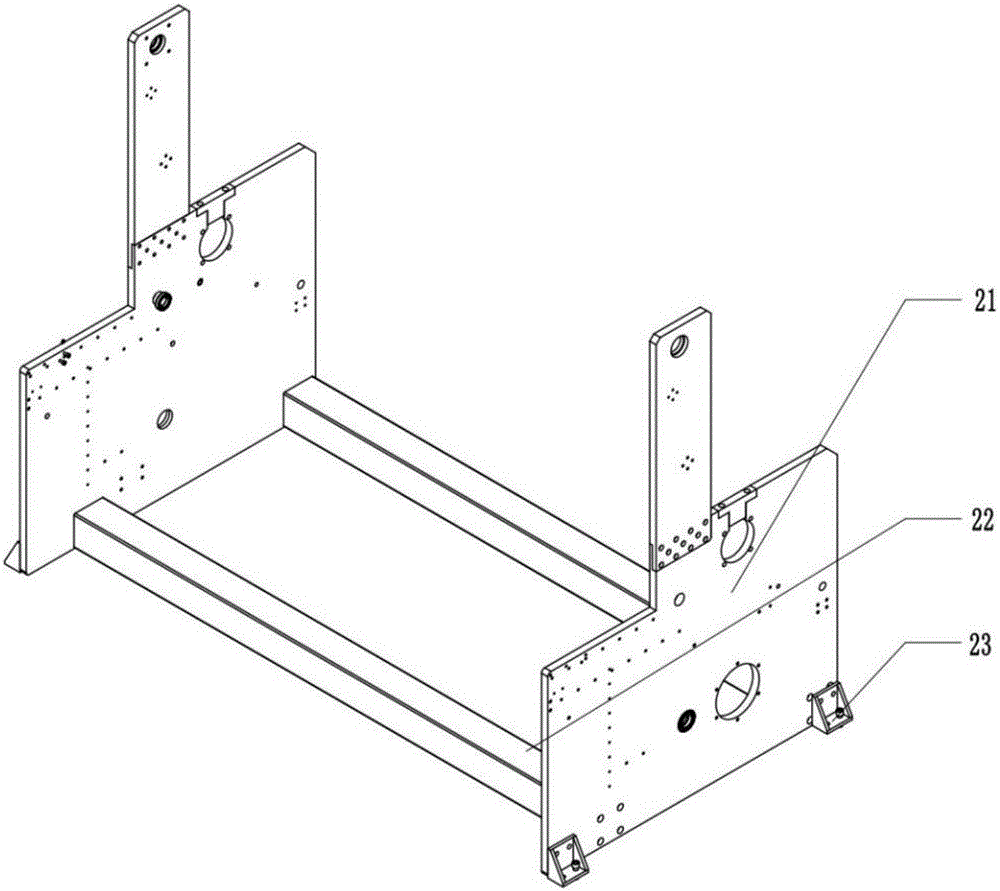

[0023] Such as image 3 As shown, the frame 2 includes two wallboards 21, connecting rods 22, and adjusting feet 23. The two wallboards 21 are fixedly connected through the connecting rods 22, and an adjusting foot is respectively installed on both sides of the bottom of each wallboard 21. 23. The adjustment feet 23 are used to adjust the height and level of the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com