Patents

Literature

197results about How to "Axial dimension short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

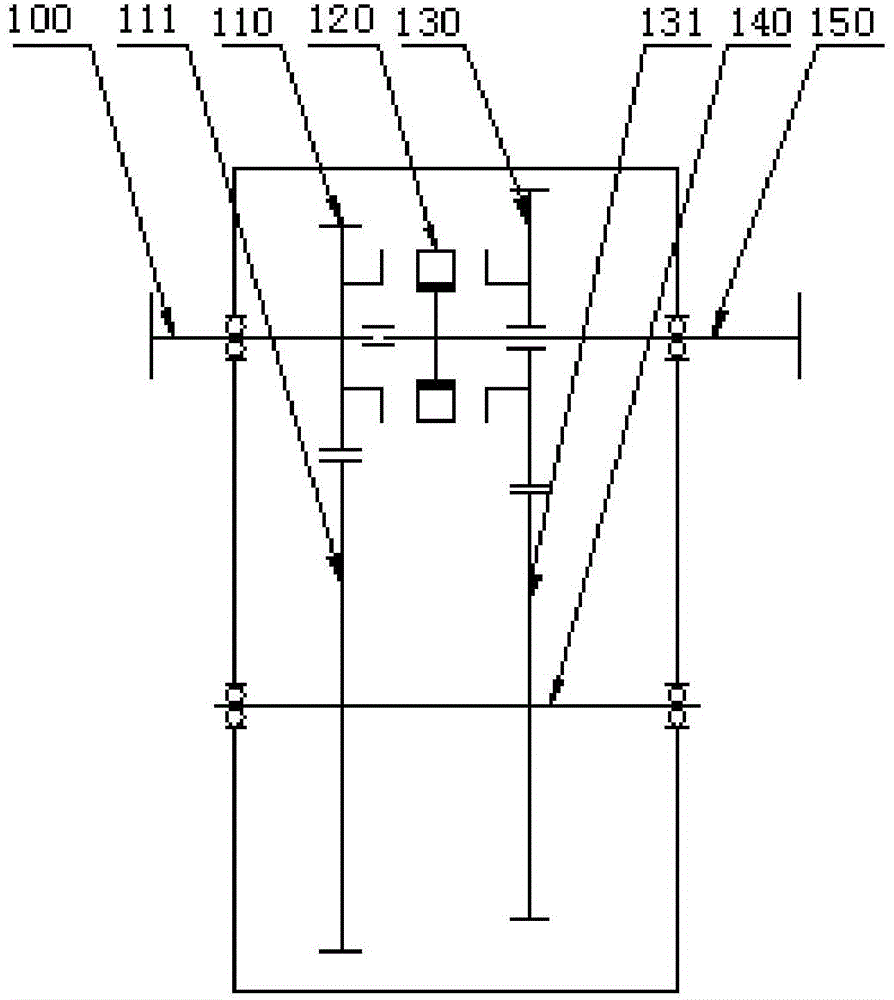

Automatic speed changer

ActiveCN104930137AOptimize layoutImprove reliabilityGearboxesToothed gearingsAutomatic transmissionEngineering

The invention discloses an automatic speed changer. The automatic speed changer comprises a double-end-face tooth combined fluted disc and a two-level speed reduction fixed shaft wheel train. A gear shifting mechanism of the speed changer is the double-end-face tooth combined fluted disc and is provided with double-end-face teeth including the left end face teeth and the right end face teeth. The double-end-face tooth combined fluted disc axially moves on an output shaft of the speed changer, the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are engaged with end face teeth of a one-level speed reduction gear and a two-level speed reduction gear respectively, the two-gear position and the one-gear position are achieved, and when the left end face teeth and the right end face teeth of the double-end-face tooth combined fluted disc are not combined with the end face teeth of the one-level speed reduction gear and the two-level speed reduction gear, the speed changer is at a neutral position. According to the technical scheme, compared with a traditional AMT, a synchronizer is removed, the structure is simple, reliability is high, the gear shifting time is short, the gear shifting impact is small, the production cost is low, and industrialization is easy to achieve. The gear arrangement mode of the speed changer is simple, the axial size is short, the occupied space is small, the weight is low, and the automatic speed changer conforms to the development trend of light weight and energy saving.

Owner:JING JIN ELECTRIC TECH CO LTD +1

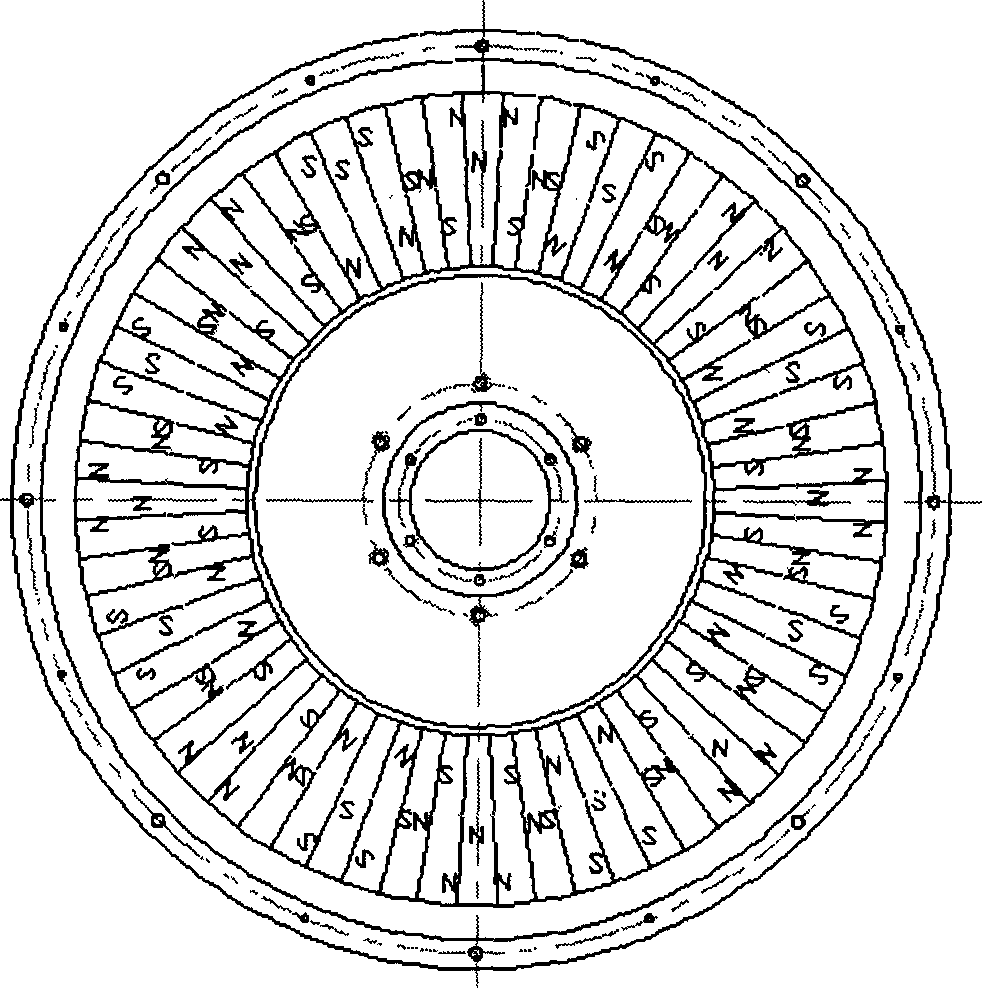

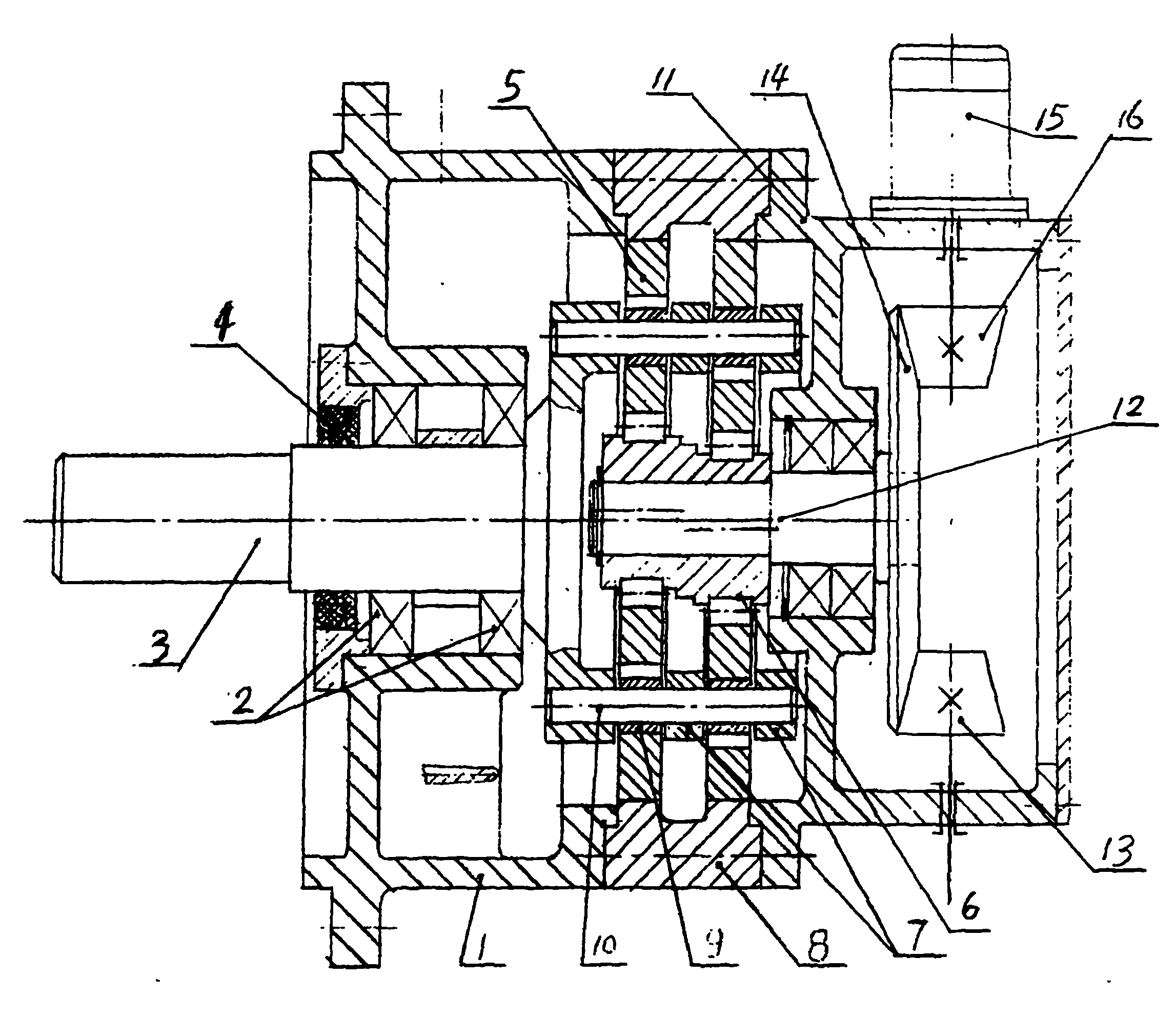

AC plate type non-core permasyn motor based on Halbach array

InactiveCN1773817AAxial dimension shortReduce weightMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSynchronous motorPermanent magnet synchronous motor

An iron core free permanent magnetic and synchronous motor of AC disc type based on Halbach array is prepared as applying double external rotator structure, binding magnetic steel disc at inner wall of external rotator, applying Halbach permanent magnet array structure for magnetic steel disc to generate axial magnetic field, utilizing iron core free structure for stator armature being formed by winding injection directly, using double rotators and stator armature to form air gap at two sides. The prepared motor is suitable to be used at occasion of applying large torque and direct driving.

Owner:SHENYANG POLYTECHNIC UNIV

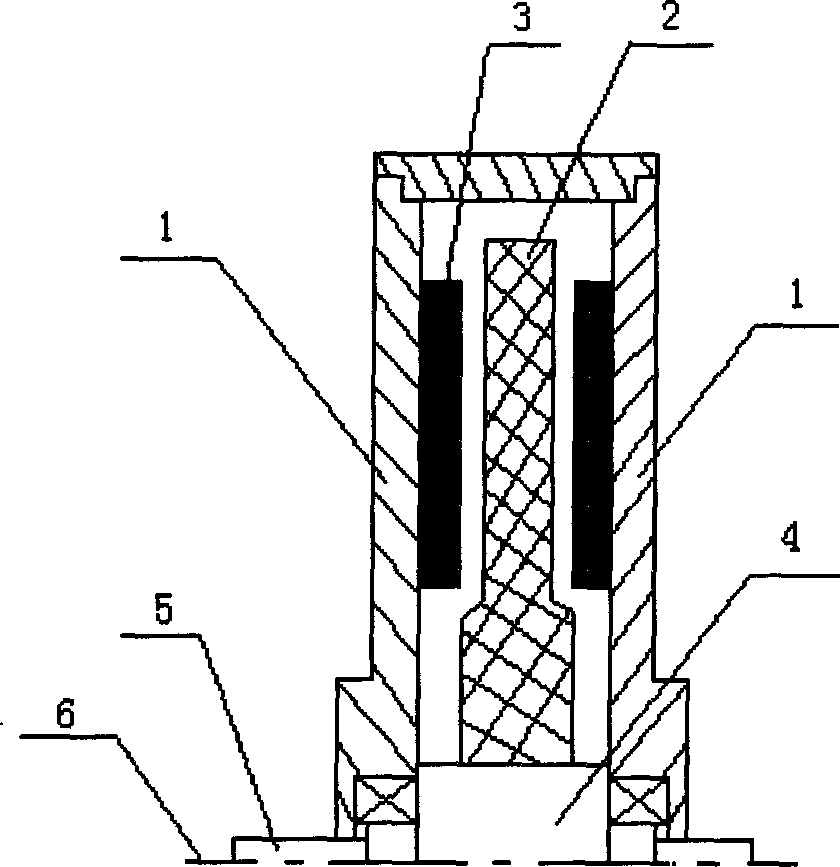

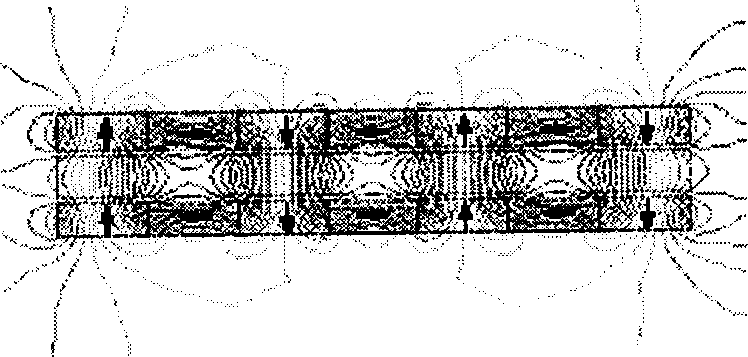

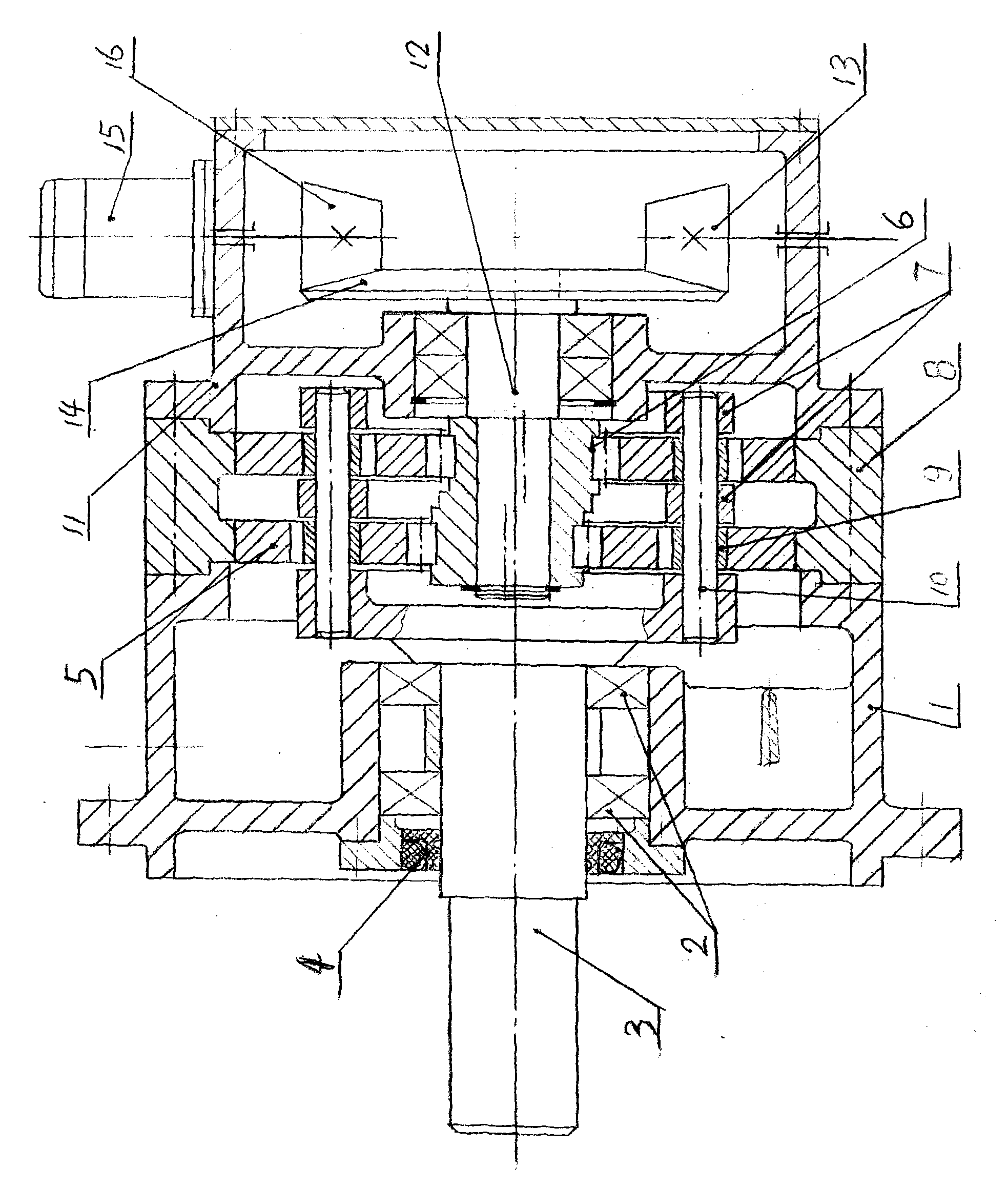

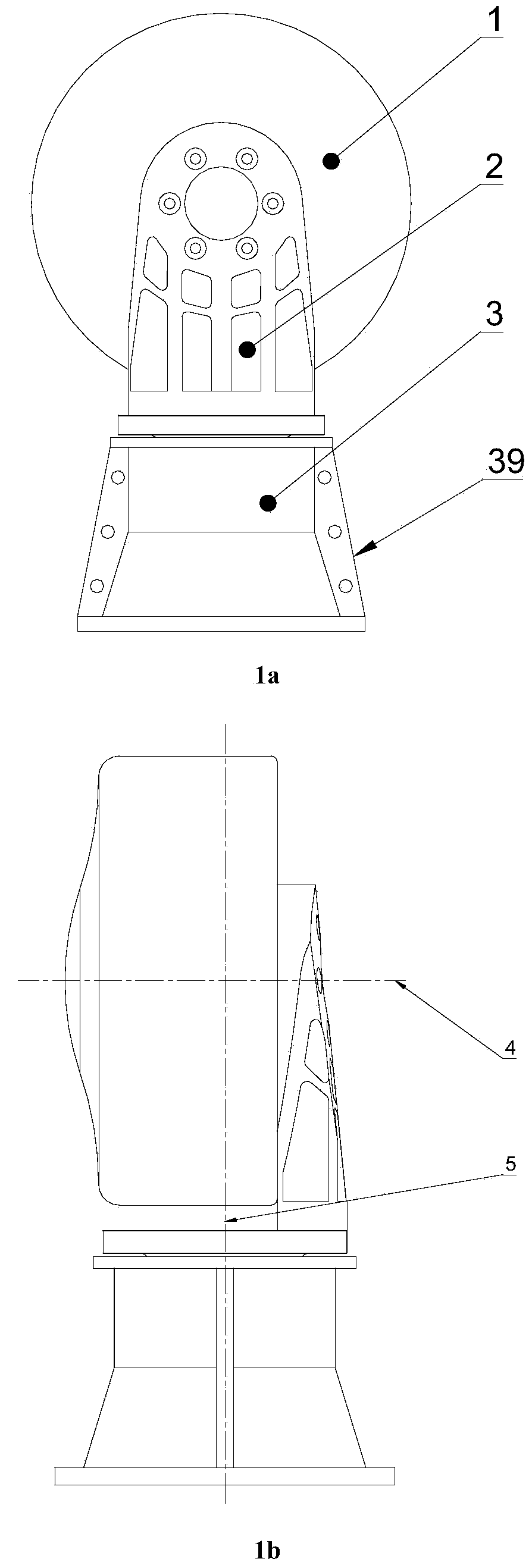

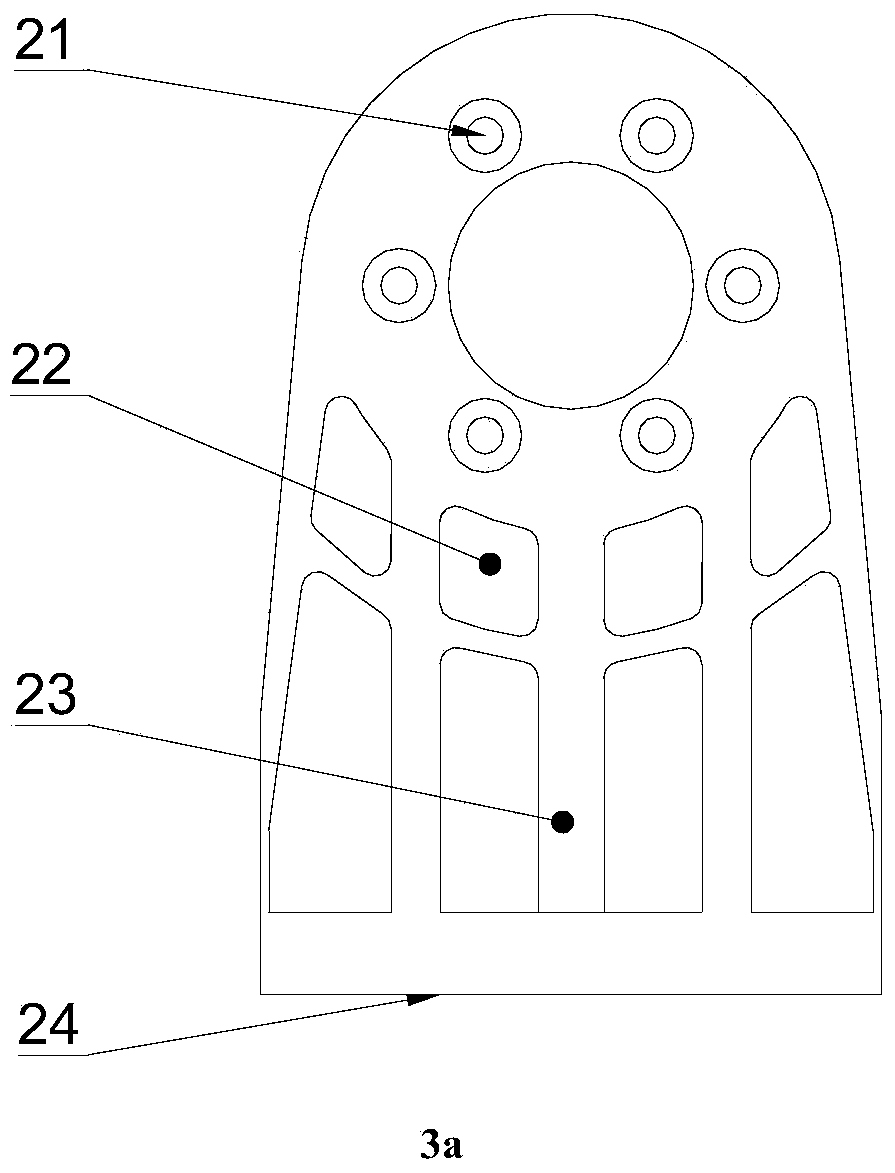

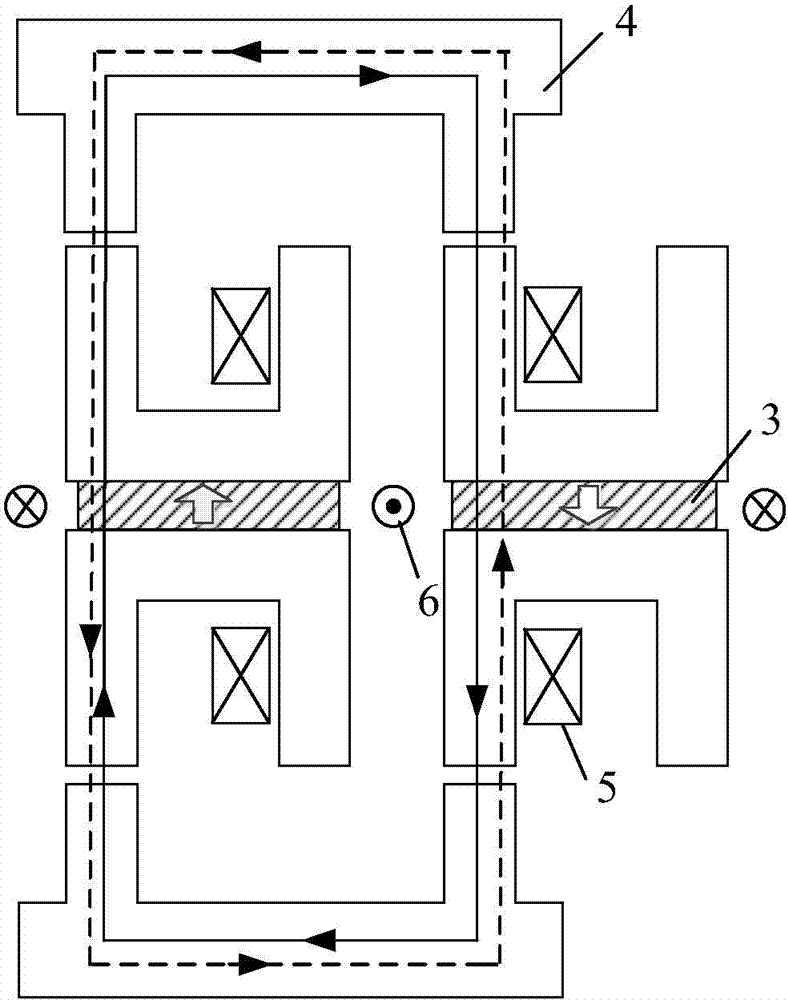

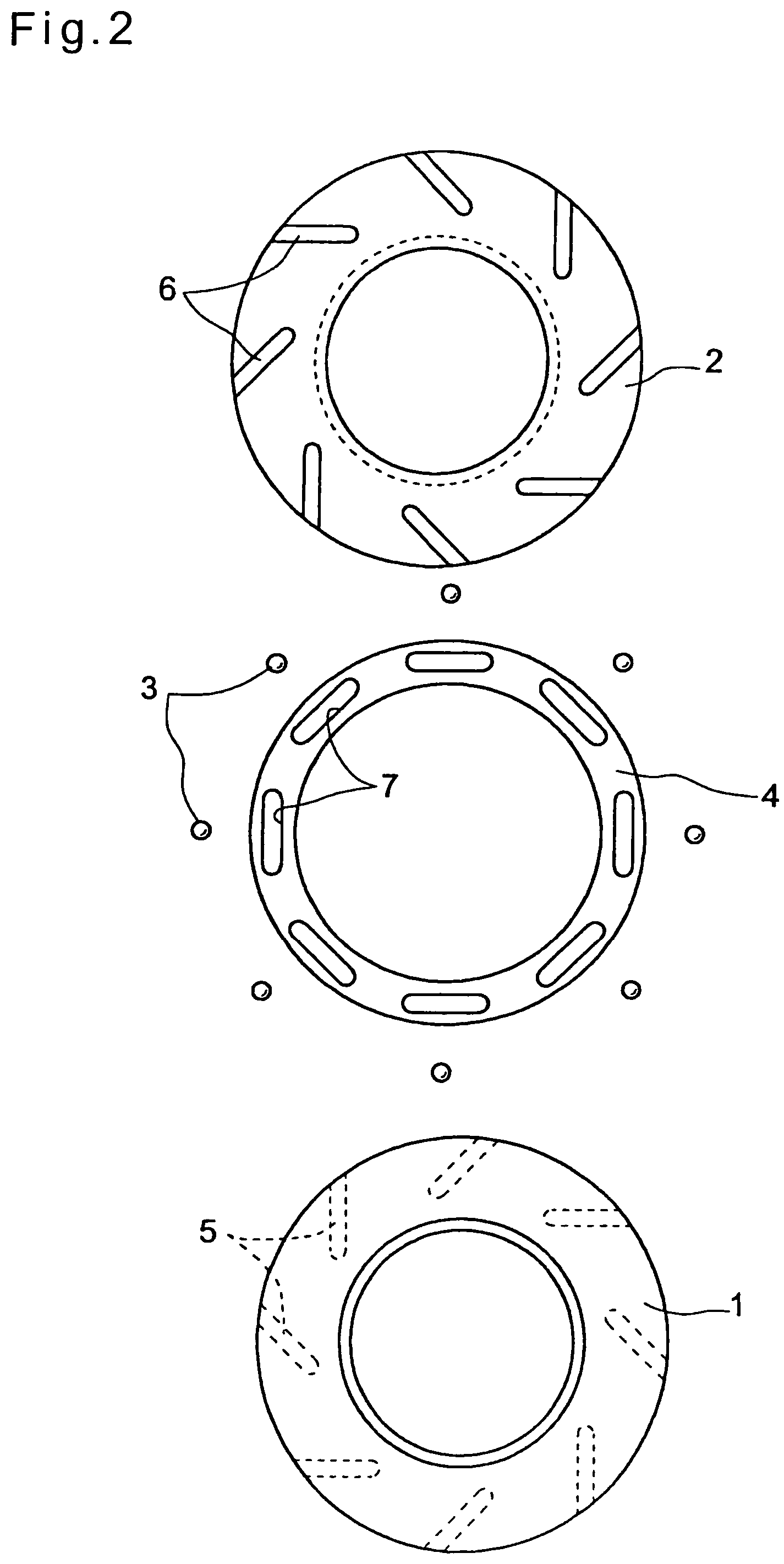

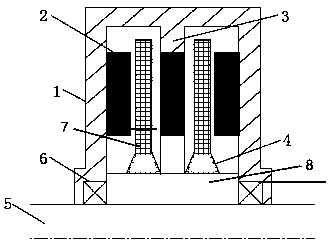

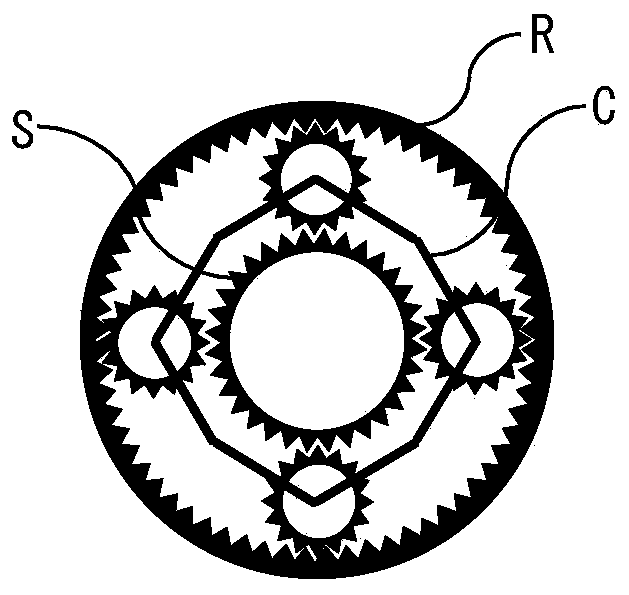

Magnetic flow switching type axial magnetic field magnetoelectric machine with middle stator structure

InactiveCN101621234ARotor structure is simpleAxial dimension shortMagnetic circuit rotating partsMagnetic circuit stationary partsHigh power densityPhysics

The invention relates to a magnetic flow switching type axial magnetic field magnetoelectric machine with a middle stator structure, which is a double-air gap magnetoelectric machine consisting of a stator (1) and two rotors (2). The stator (1) and the rotors (2) are coaxially arranged; the stator (1) is clamped between the two rotors (2); air gaps with a certain thickness are reserved between the rotors (2) and the stator (1); and each stator (1) consists of 12 H-shaped stator iron cores (5), 12 permanent magnets (6) and 12 coils (7), wherein the H-shaped stator iron cores (5) and the permanent magnets (6) are alternately placed to form a disk; the H-shaped stator iron cores (5) and the permanent magnets (6) on the stator (1) correspond to each other, but the permanent magnets in the stator alternately charge magnetism along the circumferential direction; the permanent magnets and concentrated armature windings are all arranged on the stator; and neither permanent magnets nor armature windings are arranged on the rotors. The simple rotor structure can effectively improve the running reliability of the magnetoelectric machine; the axial magnetic field structure enables the axial dimension of the magnetic field to be shortened, and thereby the magnetoelectric machine has higher power density; and an outer rotor structure enables the rotor to play a fan role when the rotor rotates.

Owner:SOUTHEAST UNIV

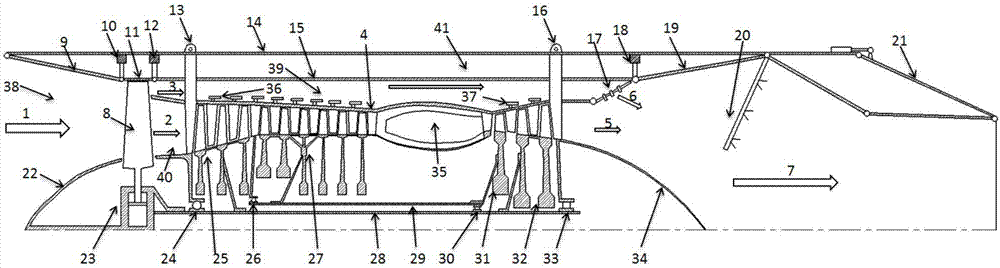

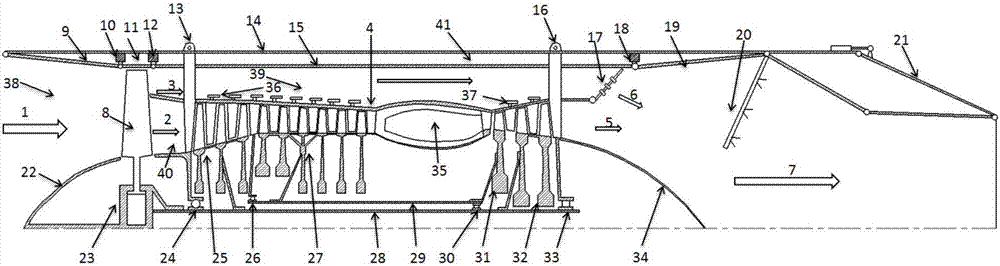

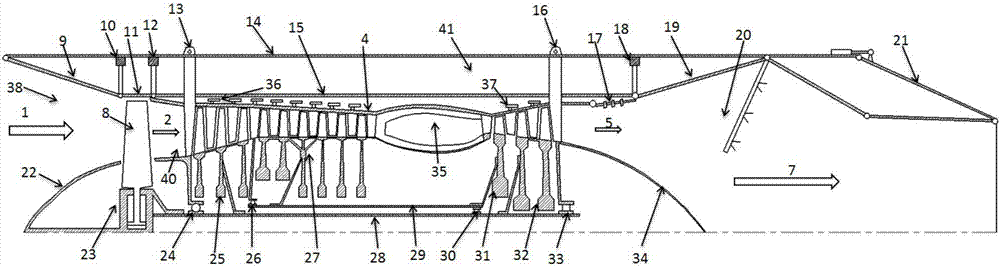

Intelligent engine adopting self-adaptive machine case and self-adaptive fan

ActiveCN108005812ALarge external duct flowAxial dimension shortJet propulsion plantsEngineeringFan blade

The invention provides an engine adopting a self-adaptive machine case and a self-adaptive fan. The engine comprises the self-adaptive machine case, the self-adaptive fan and a fuel gas generator; theself-adaptive machine case comprises a self-adaptive machine case driving execution part, an inlet section self-adaptive machine case, a fan section self-adaptive machine case, an engine middle section self-adaptive machine case and an outlet section self-adaptive machine case, wherein the inlet section self-adaptive machine case, the fan section self-adaptive machine case, the engine middle section self-adaptive machine case and the outlet section self-adaptive machine case are sequentially connected; the self-adaptive fan comprises self-adaptive fan blades and a fan driving execution part;a self-adaptive external duct is formed between the engine middle section self-adaptive machine case and an internal duct machine case of the fuel gas generator; an internal duct is formed in the internal duct machine case; the self-adaptive machine case driving execution part drives the self-adaptive machine case to move to control the cross section area of the external duct; and the fan drivingexecution part drives the self-adaptive fan blades to move in the axial direction to enable the self-adaptive fan blades to be matched with the fan section self-adaptive machine case.

Owner:AERO ENGINE ACAD OF CHINA

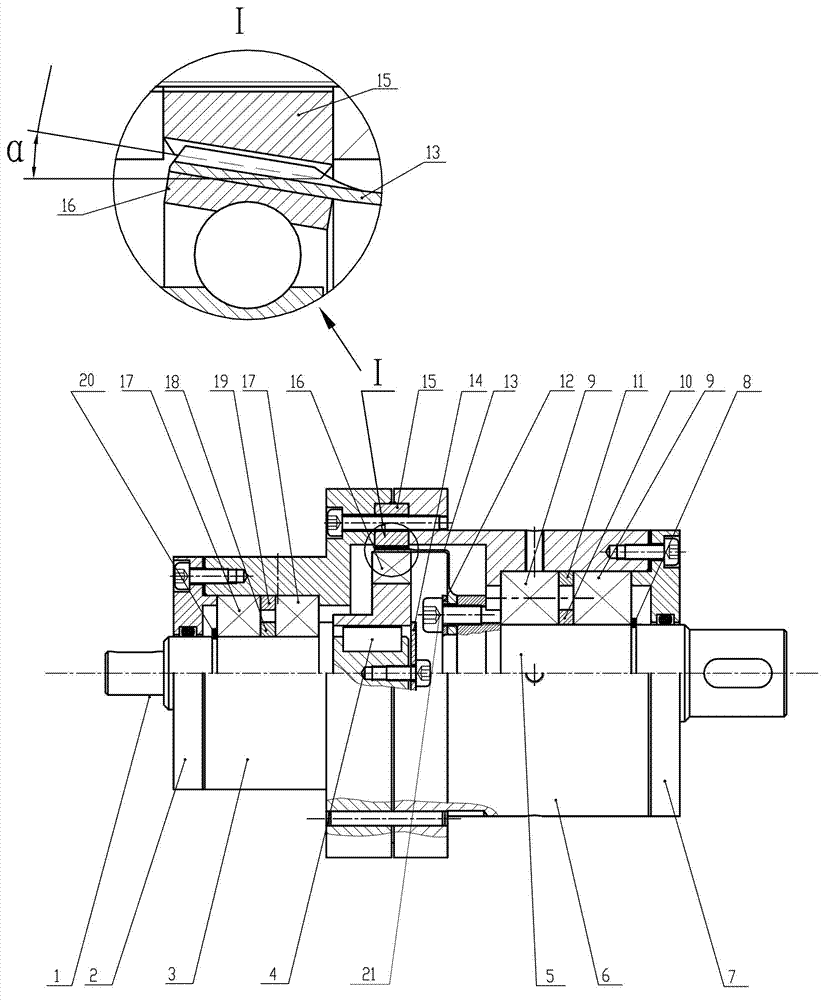

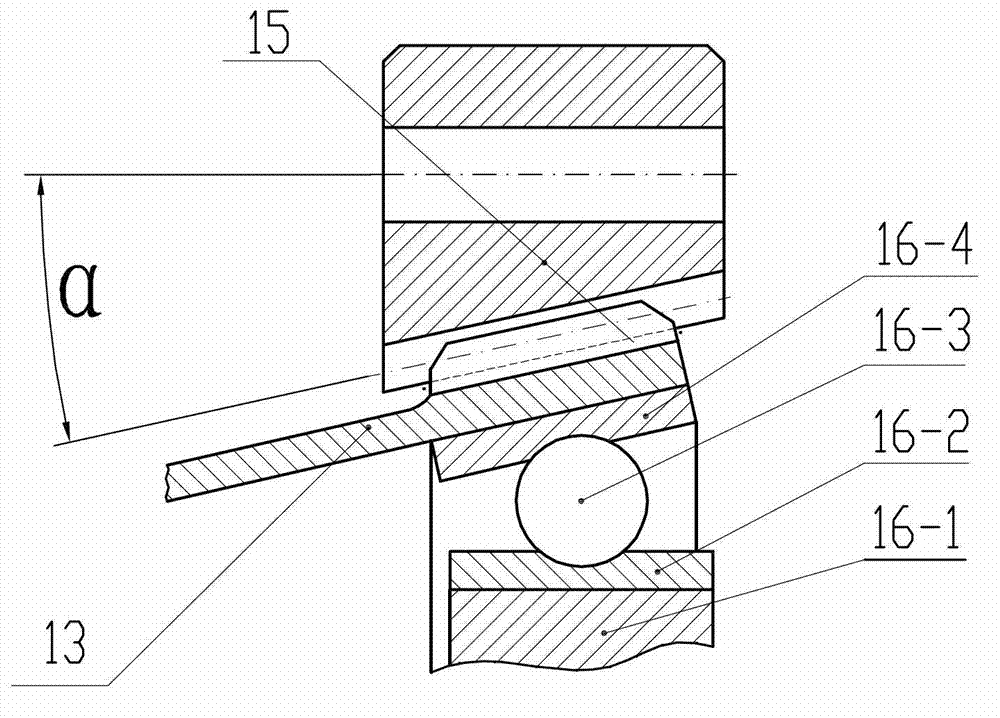

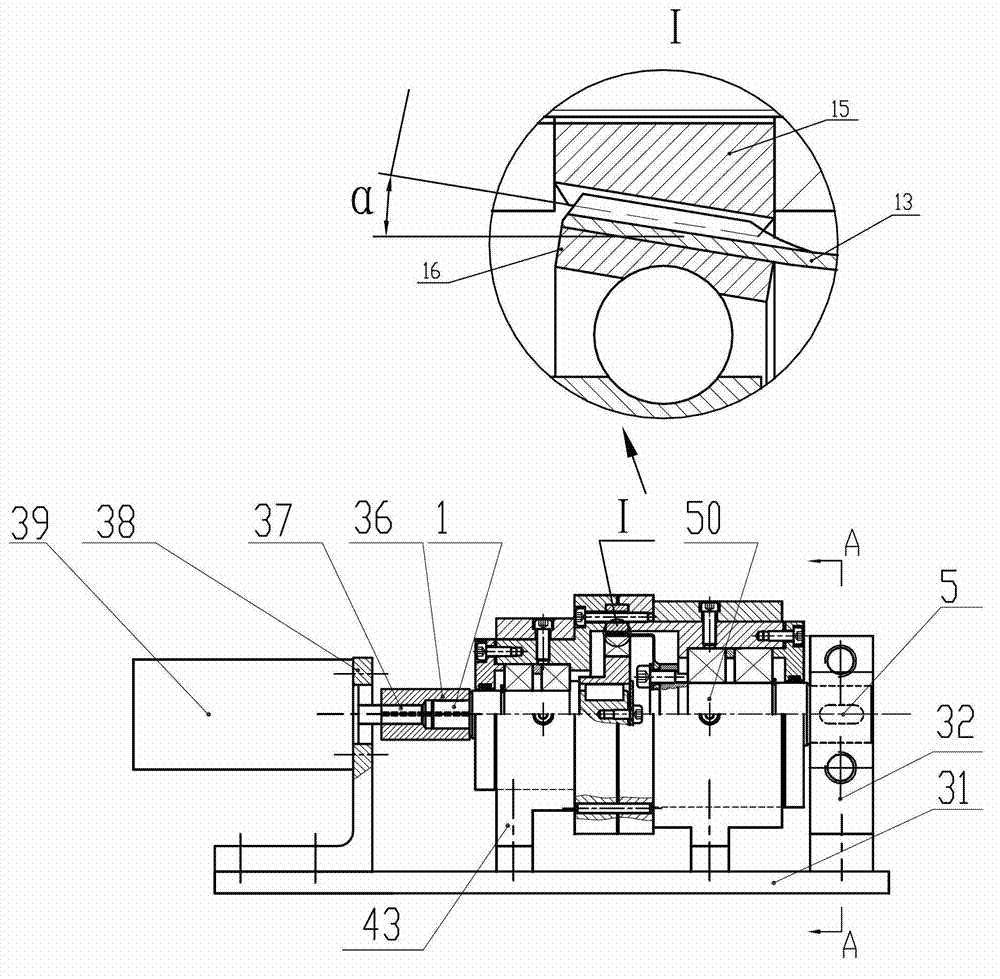

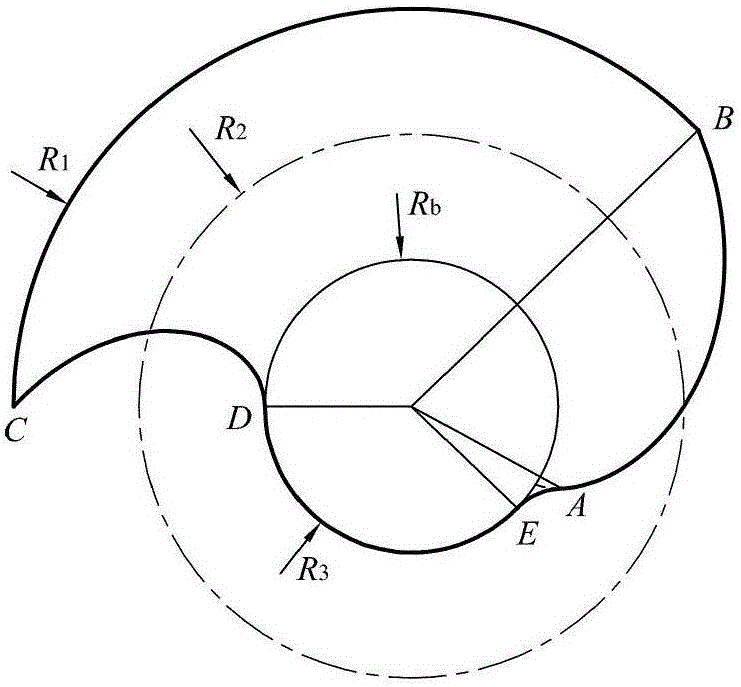

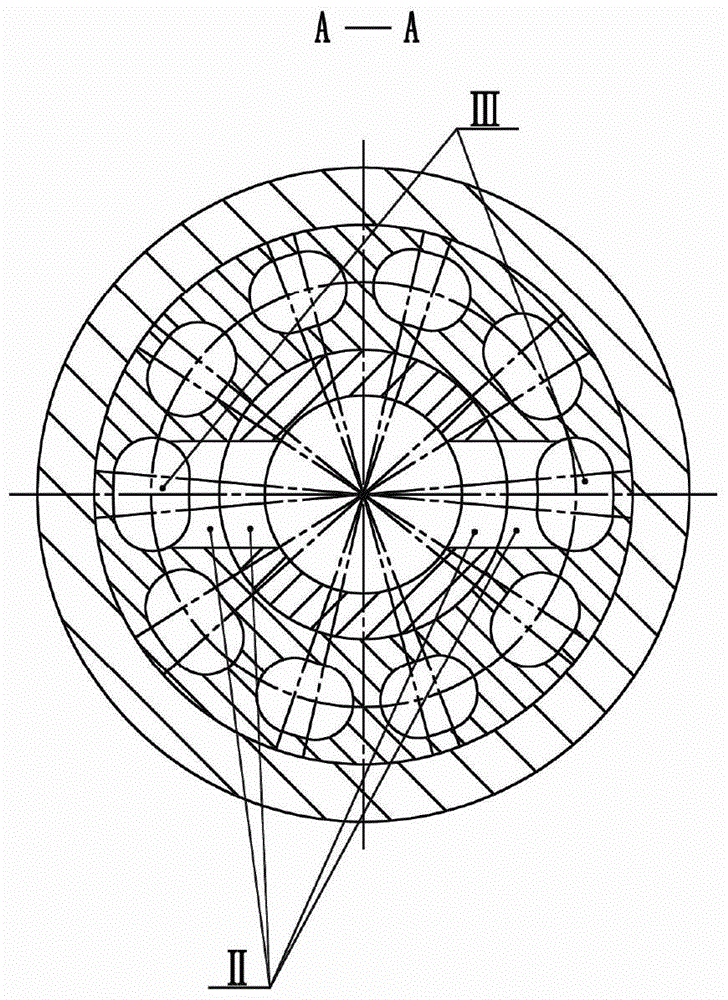

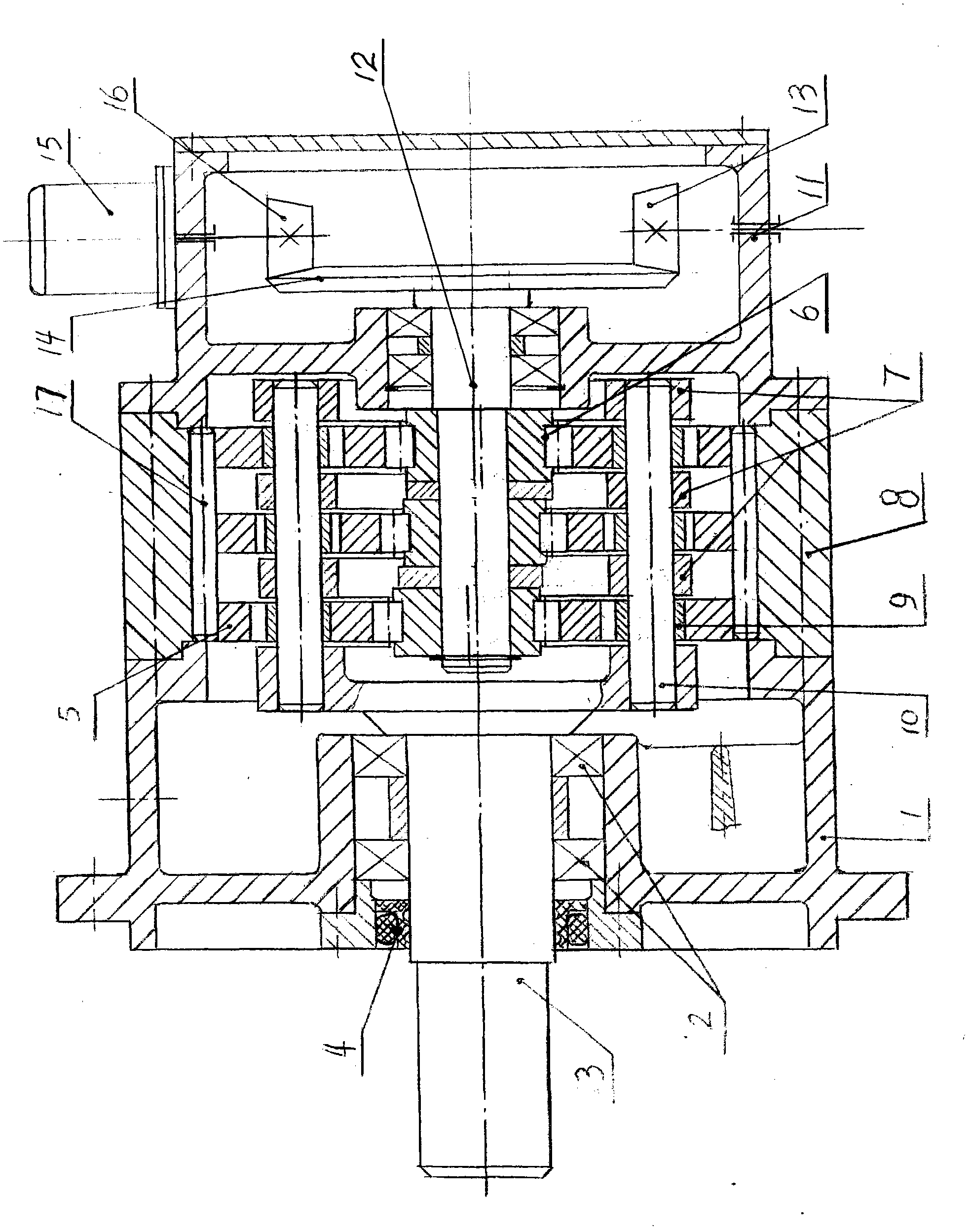

Short tube flexible gear harmonic reducer of rigid wheel tooth dip angle and transmission rigidity testing device thereof

ActiveCN102777546AEasy meshImprove transmission stiffnessMachine gearing/transmission testingToothed gearingsDiameter ratioEngineering

The invention discloses a short tube flexible gear harmonic reducer of a rigid wheel tooth dip angle and a transmission rigidity testing device thereof, and relates to the technical field of harmonic reducers. According to the invention, the deflection of the flexible wheel gear teeth is caused by the reduction of the axial size of the short tube flexible gear harmonic reducer, so as to realize the reduction of the surface area between the rigid wheel gear teeth and the flexible wheel gear teeth, and to realize the lowering of the transmission rigidity; the problem of complicated operating process of the existing harmonic drive rigidity experiment testing device is solved; and the length diameter ratio of a soft wheel is 1 / 4 to 3 / 5 of a short tube wheel, the inner wheel of the rigid wheel with a dip angle is the wheel teeth with the dip angle alpha along the rigid wheel axial direction, and the deflection direction and the field angle direction of the soft wheel on a long shaft are coincident. The transmission rigidity testing device of the short tube flexible gear harmonic reducer implements current control namely torque control through a computer and a servo driver, and the harmonic drive output end realizes continuous loading unloading; and the harmonic drive rigidity of the short tube soft wheel is obtained, and the transmission rigidity is serially, rapidly accurately obtained.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

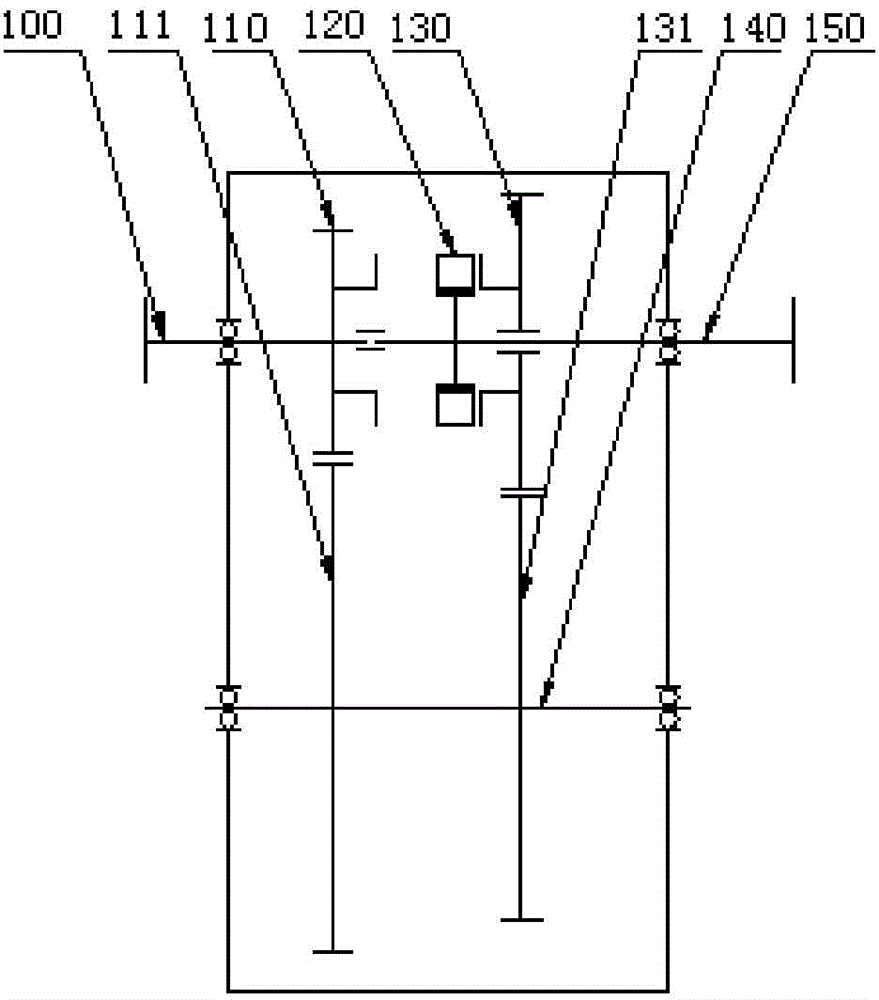

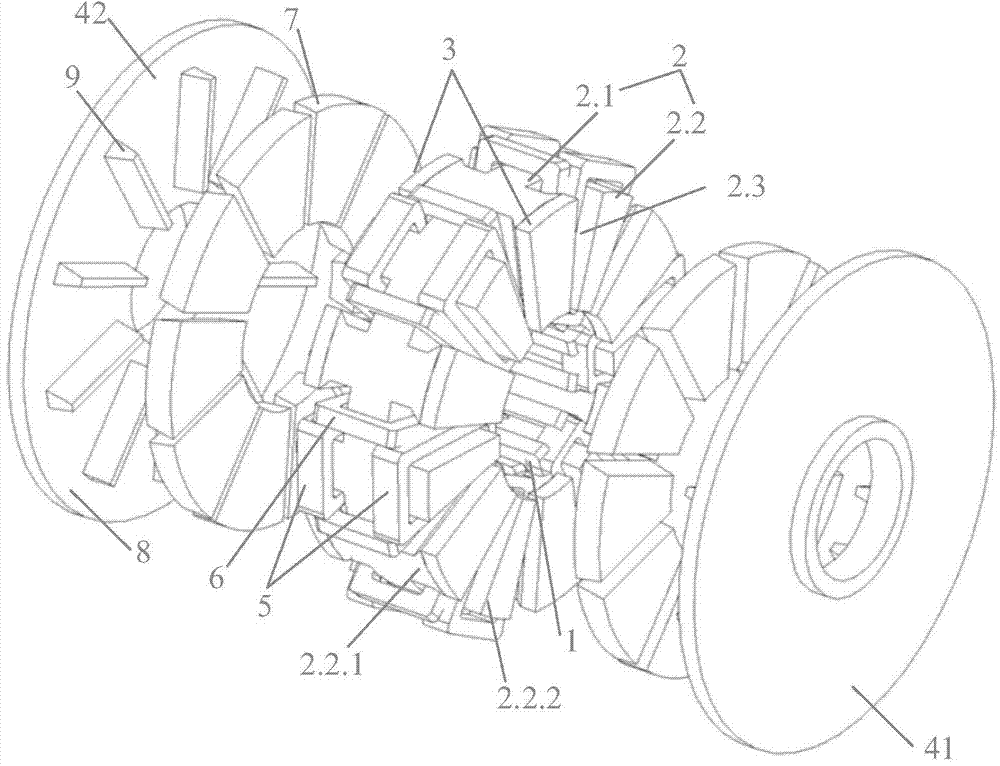

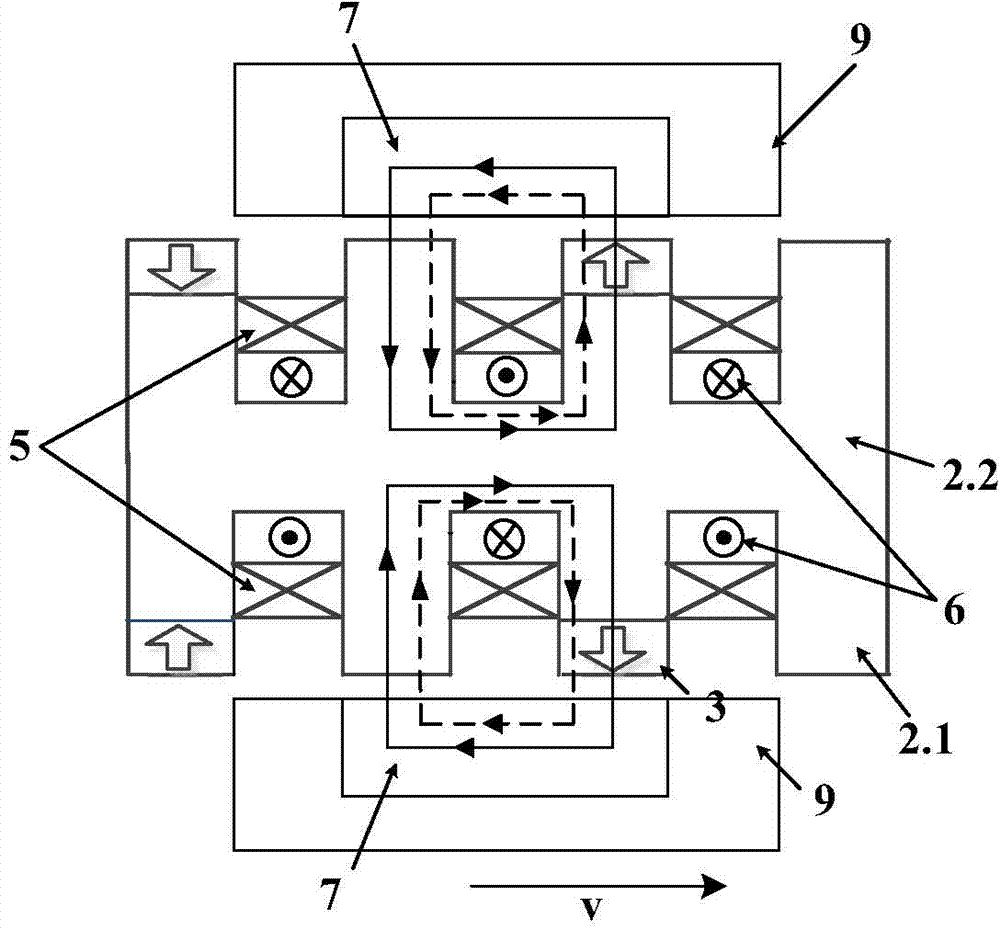

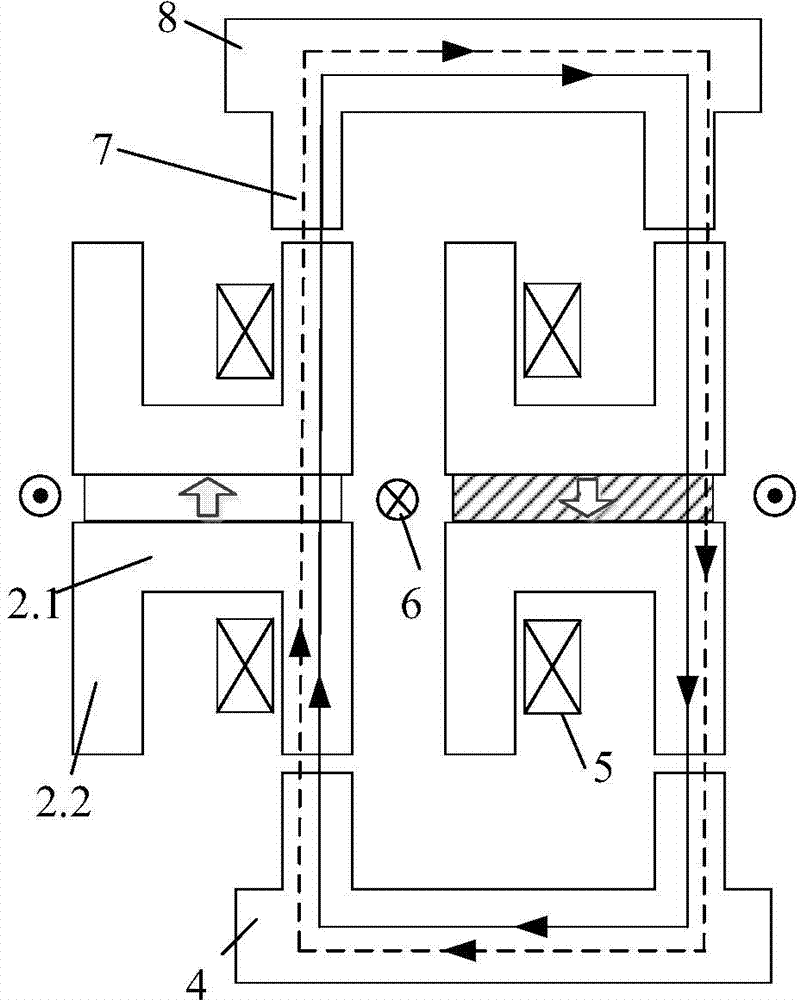

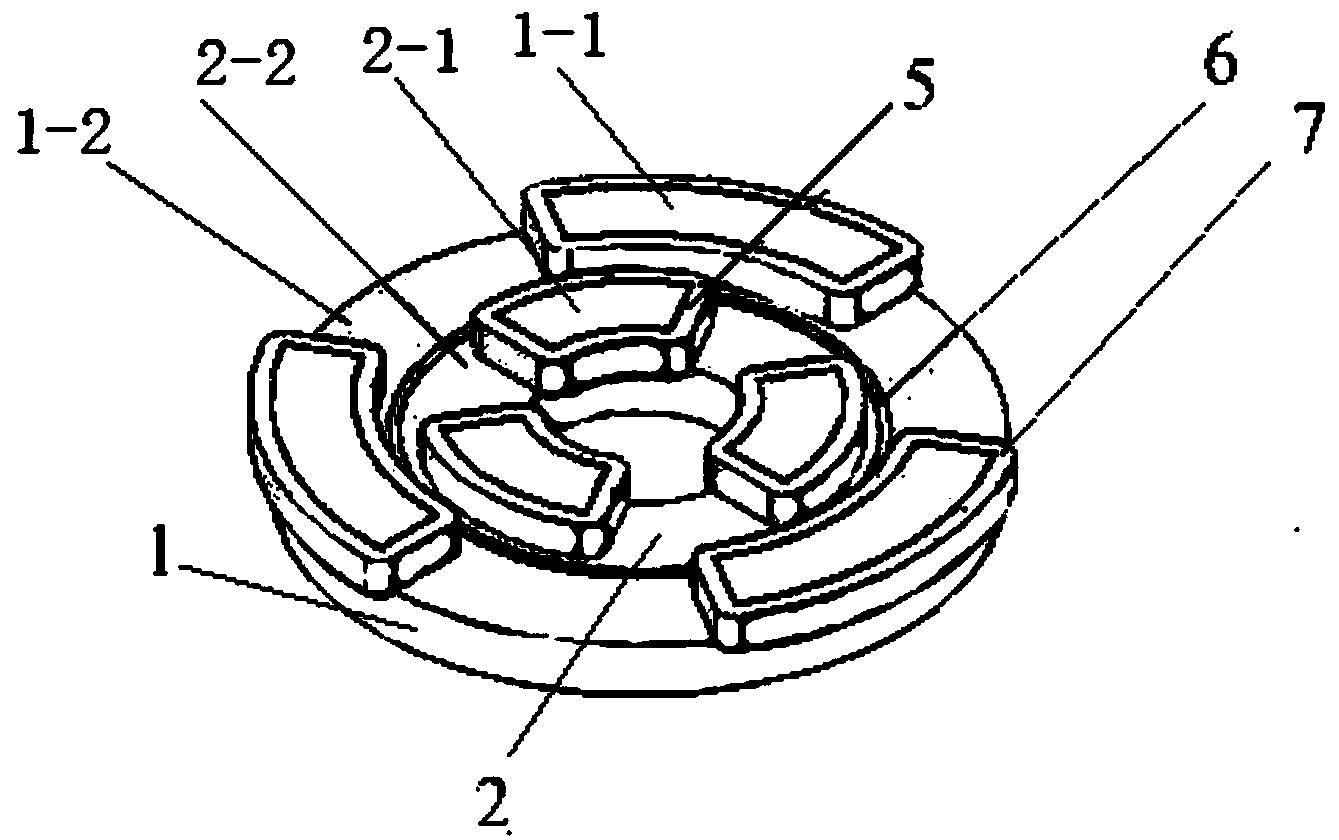

Axial magnetic field magnetic flux switching type surface-mounted permanent magnet memory motor

ActiveCN103490573ASimple structureReduce wind resistanceMagnetic circuit rotating partsMagnetic circuit stationary partsSurface mountingElectric machine

The invention discloses an axial magnetic field magnetic flux switching type surface-mounted permanent magnet memory motor. The permanent magnet memory motor comprises a first rotor (41), a second rotor (42), a stator (1) and an installing shaft, wherein the stator (1) is arranged between the first rotor (41) and the second rotor (42) and of an axial two-side symmetrical structure, the installing shaft is used for coaxially installing the stator (1), the first rotor (41) and the second rotor (42), and the stator is located between the two rotors to form an axial two-air-gap motor. The stator (1) is of the two-side symmetrical salient pole structure and comprises a stator iron core (2), a plurality of permanent magnets (3), a three-phase armature winding (5) and a single-phase pulse winding (6). The stator iron core (2) comprises a stator yoke (2.1) and stator teeth (2.2), wherein the stator teeth (2.2) protrude in the center direction of the first rotor (41) and in the center direction of the second rotor (42) respectively from the stator yoke (2.1). By the adoption of the permanent magnet memory motor, power density of the motor is improved, and the wide rotating speed operation range is possessed.

Owner:SOUTHEAST UNIV

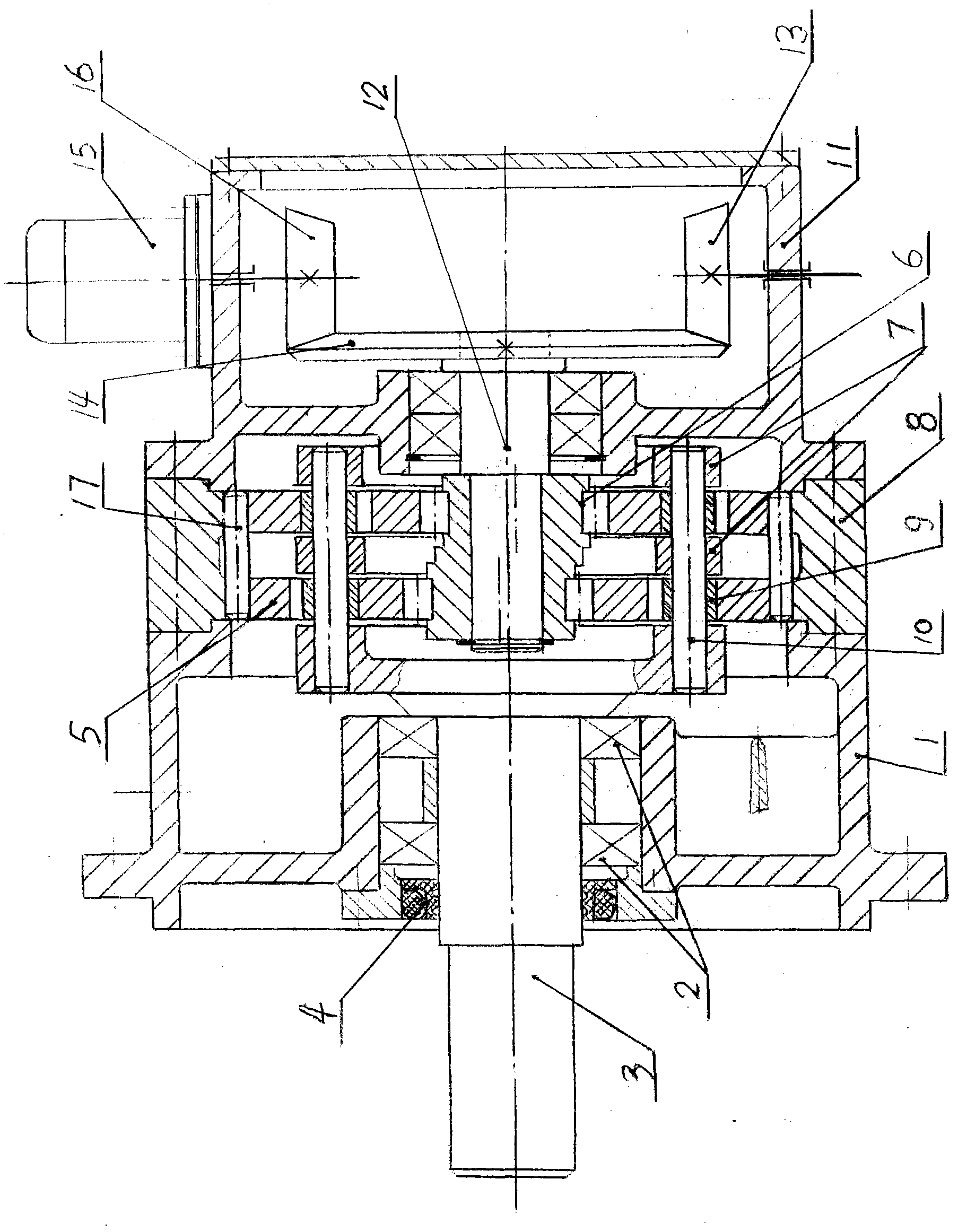

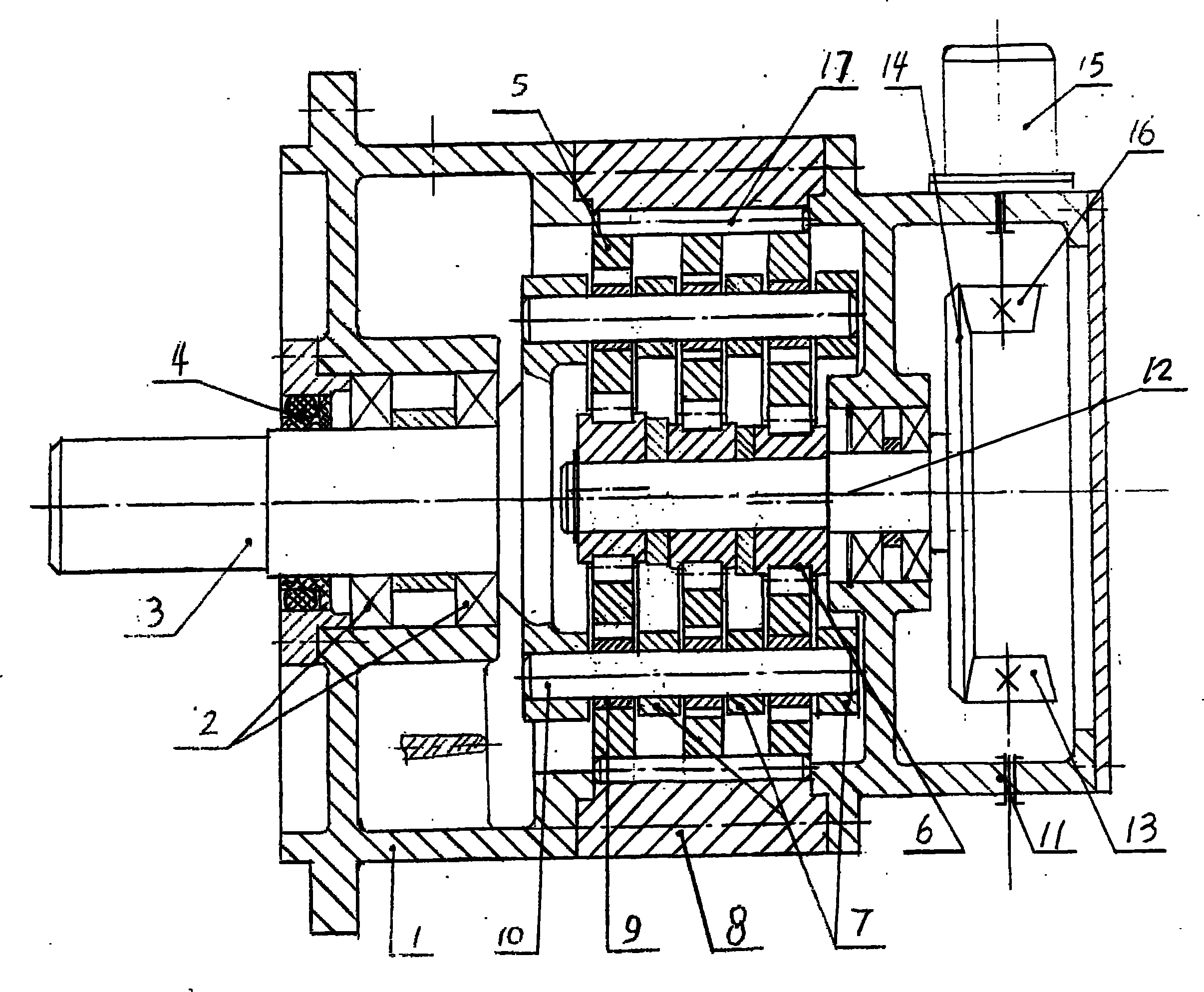

Bevel gear-double cycloid speed reduction device for rocket launching movable platform

InactiveCN101963208AImprove bending resistanceImprove bending performanceGearboxesToothed gearingsReduction driveRocket launch

The invention relates to the technical field of speed reducers, in particular to a bevel gear-double cycloid speed reduction device for a rocket launching movable platform. The device is a two-stage speed reduction device characterized by comprising a bevel gear pair and double-cycloid transmission, wherein (A) the cycloid transmission comprises a base, an output shaft, support bearings, a cycloid wheel, an eccentric bearing, an inner cycloid gear ring, a front base, an input shaft and a W output mechanism, the input shaft is supported in an inner hole of the front base through a bearing, the shaft extension end is connected with the eccentric bearing, and the input end is connected with a big bevel gear; the front base is integrated with the inner cycloid gear ring and the base in sequence; the output shaft is supported in the inner hole of the base through a bearing; and (B) two symmetrically installed small bevel gear shafts engaged with the big bevel gear are supported in wall holes of a front base box through bearings, and the small bevel gear shafts are connected with a motor; and another small bevel gear shaft is connected with a manual handle. The invention has the advantages of two-stage speed reduction, small axial size, light weight and high-degree lightweight; cycloid gear teeth are uninterrupted, so that the bearing capacity is greater than that of planet transmission with only four planet wheels; and the cost is low and is reduced to 40-55%.

Owner:吴声震

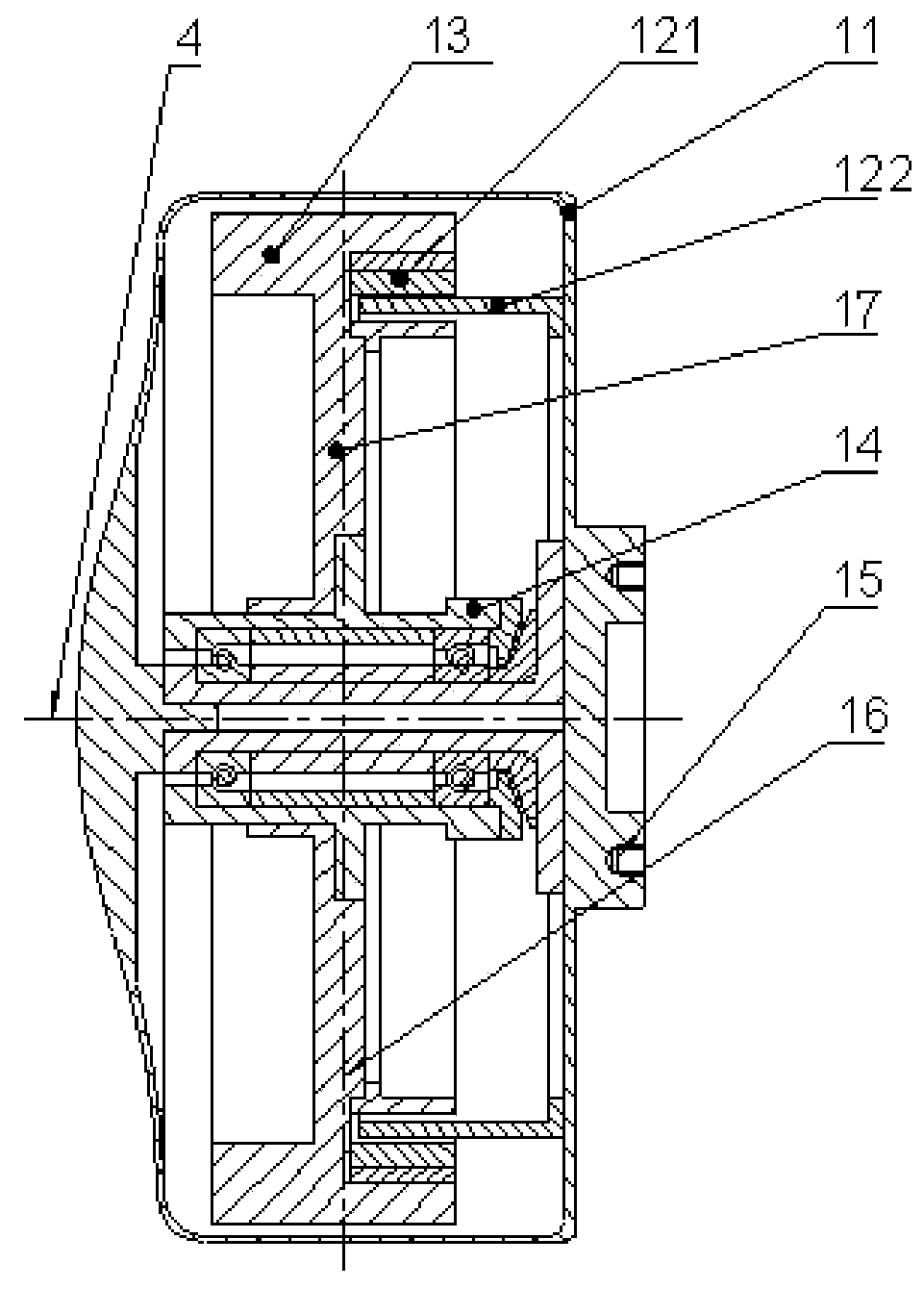

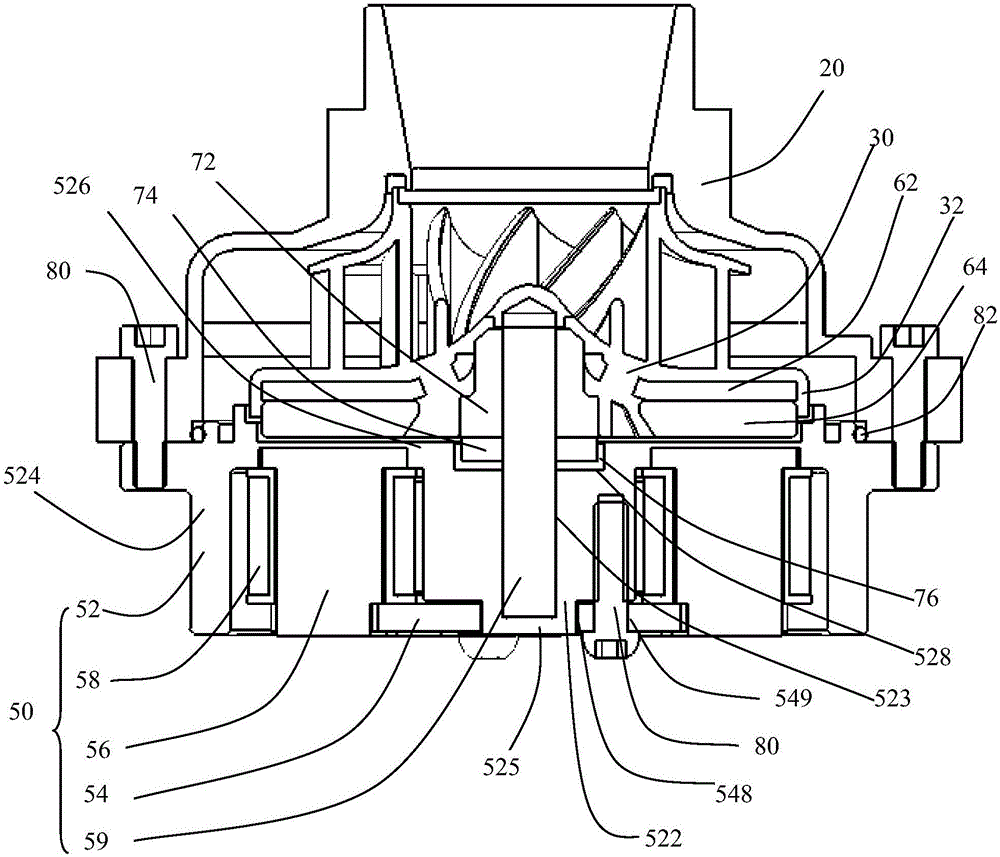

Novel double-braking rim driving device

ActiveCN103032560AAvoid damageImprove work efficiencyAxially engaging brakesBrake actuating mechanismsHydraulic motorRubber ring

The invention discloses a novel double-braking rim driving device, and relates to a double-braking device for tire parking braking and driving braking. The novel double-braking rim driving device comprises a supporting base, a hydraulic motor, a planetary gear speed reducer, a parking brake, a driving brake and the like, wherein a plurality of groups of movable friction sheets of the driving brake are respectively embedded into splines arranged outside an inner gear shell of the planetary gear speed reducer; a plurality of groups of steel sheets are simultaneously connected onto a connecting rod in series; and a rubber ring is arranged between each steel sheet and each movable friction sheet, which are adjacent. The braking on the inner gear shell is directly carried out so that the braking is more reliable and safer; elastic auxiliary steel sheets of the rubber rings and the movable friction sheets are completely separated, so that movement failure is prevented from happening; the driving brake is additionally provided with a cooling circulating system, so that heat generated by the driving braking can be eliminated, parts are prevented from being damaged at a high temperature, and the service life is prolonged; and the improved rim driving device also has the advantages of compact structure, high working efficiency, large transmission torque and the like.

Owner:INI HYDRAULIC

Small-size speed change control moment gyroscope

InactiveCN104075700AIncrease moment of inertia/mass ratioFirmly connectedRotary gyroscopesGyroscopeLow speed

The invention discloses a small-size speed change control moment gyroscope, and belongs to the technical field of control moment gyroscopes. The small-size speed change control moment gyroscope comprises a high-speed component, a connection bracket and a low-speed component, wherein the high-speed component supplies constant angular momentum in a control moment gyroscope mode and outputs fine moment required by whole satellite attitude control in a flywheel mode; the connection bracket is connected with the high-speed component and the low-speed component and guarantees the orthogonal perpendicularity between the angular momentum direction and the axial direction of a framework; the low-speed component supports the high-speed component and the connection bracket and supplies a mounting interface for a whole satellite; in the control moment gyroscope mode, large moment which is required by fastmoving of the whole satellite and is also orthogonal to the angular momentum direction and the axial direction of the framework is generated; in the flywheel mode, the fine moment output by the high-speed component is transmitted to the whole satellite for the attitude control. The speed change control moment gyroscope disclosed by the invention realizes the high-precision framework locking, the minimization, the light weight and the high rigidity, and is suitable for the application to small quick satellites.

Owner:BEIJING INST OF CONTROL ENG

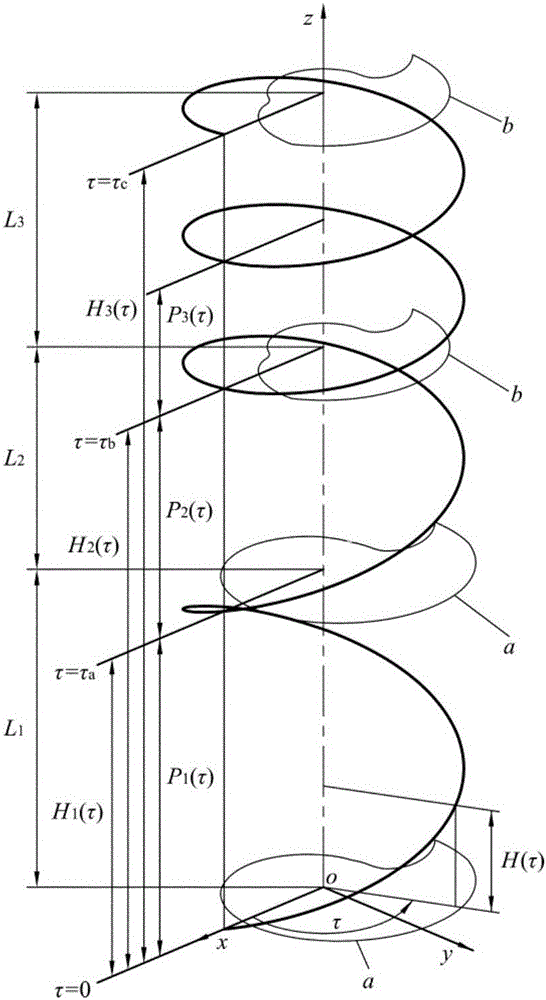

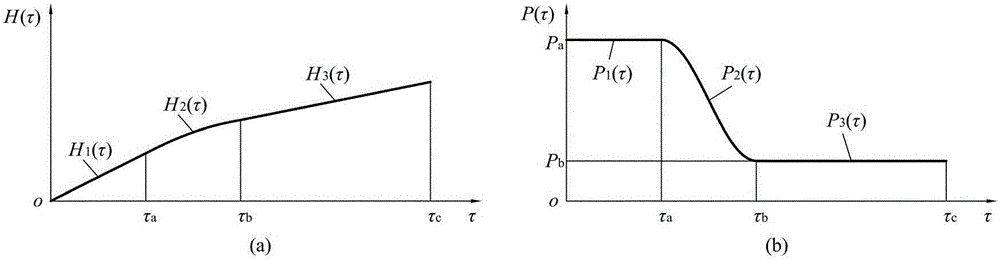

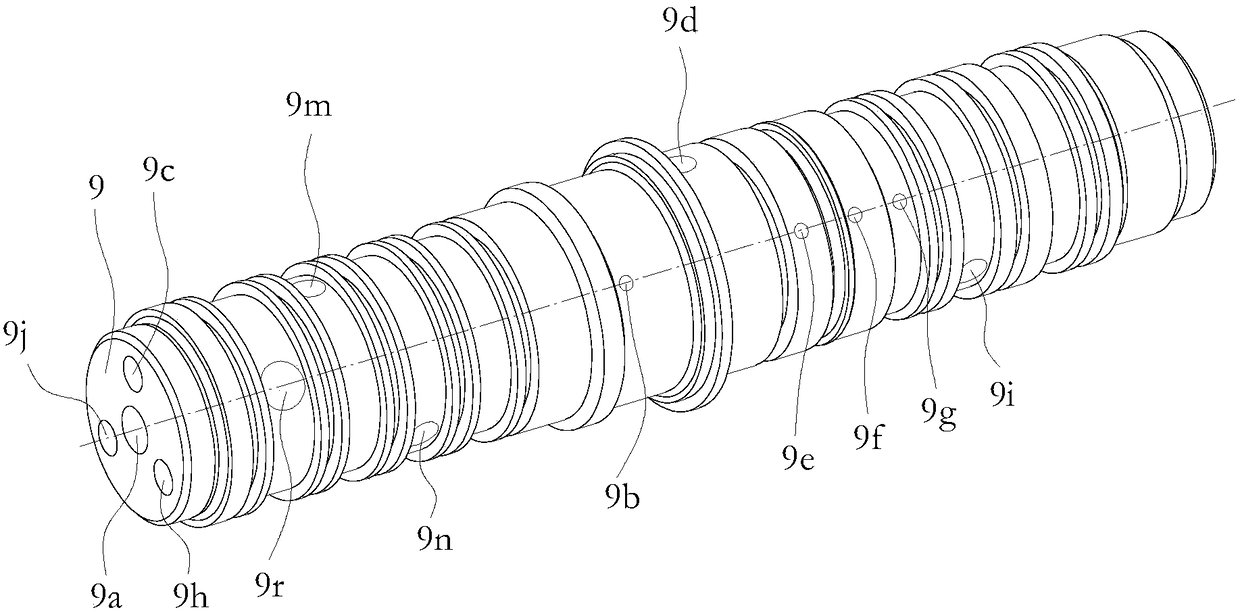

Conical screw rotor and double-screw vacuum pump thereof

InactiveCN105971877AIncrease the internal volume ratioIncrease inspiratory volumePump componentsRotary piston pumpsVacuum pump

The invention discloses a conical screw rotor and a double-screw vacuum pump thereof and belongs to the field of dry double-screw vacuum pumps. The conical screw rotor comprises a suction section, a compression section and an exhaust section, wherein molded lines of cross sections of the suction section, the compression section and the exhaust section change continuously along spiral spread angles; the molded lines with uniform pitches and uniform cross sections are adopted in the suction section and the exhaust section of the conical screw rotor, the molded lines with variable pitches and variable cross sections are adopted in the compression section of the conical screw rotor; spiral spread directions of a main screw rotor I and an auxiliary screw rotor II are opposite; the main screw rotor I and the auxiliary screw rotor II can be meshed correctly at work; the screw rotor can form a big suction volume and a small exhaust volume in a short axial dimension, thus the inner volume ratio of the screw rotor is improved to the maximum degree. The screw rotor has the advantages of high inner volume ratio, compact structure, short axial dimension and low processing difficulty, and improves the limit vacuum degree and the pumping speed of the double-screw vacuum pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

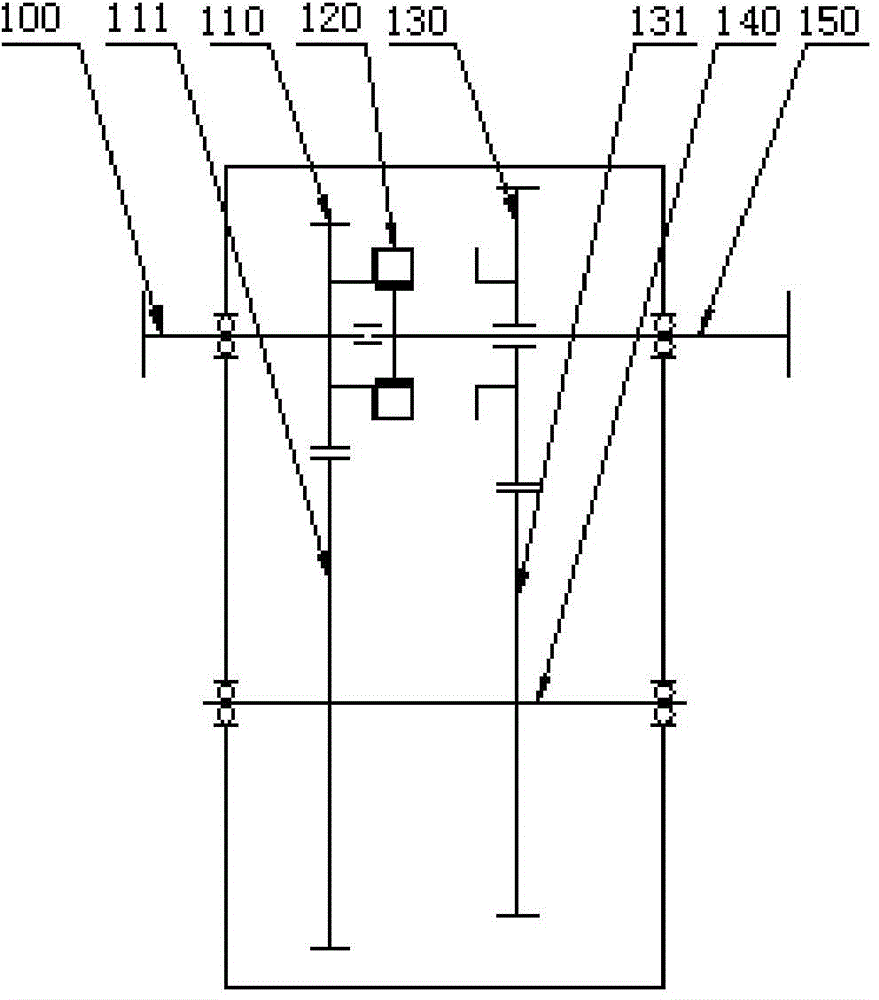

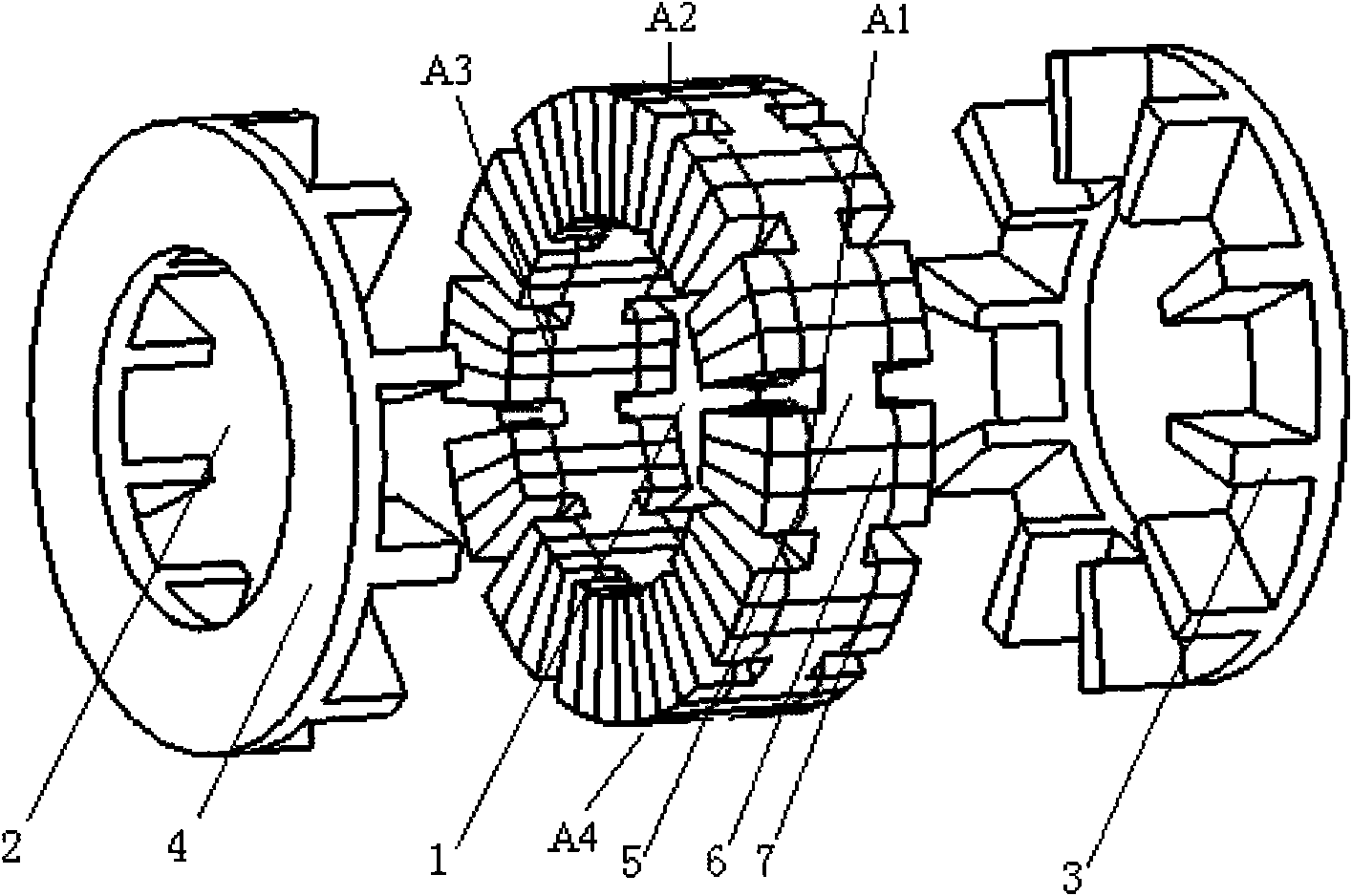

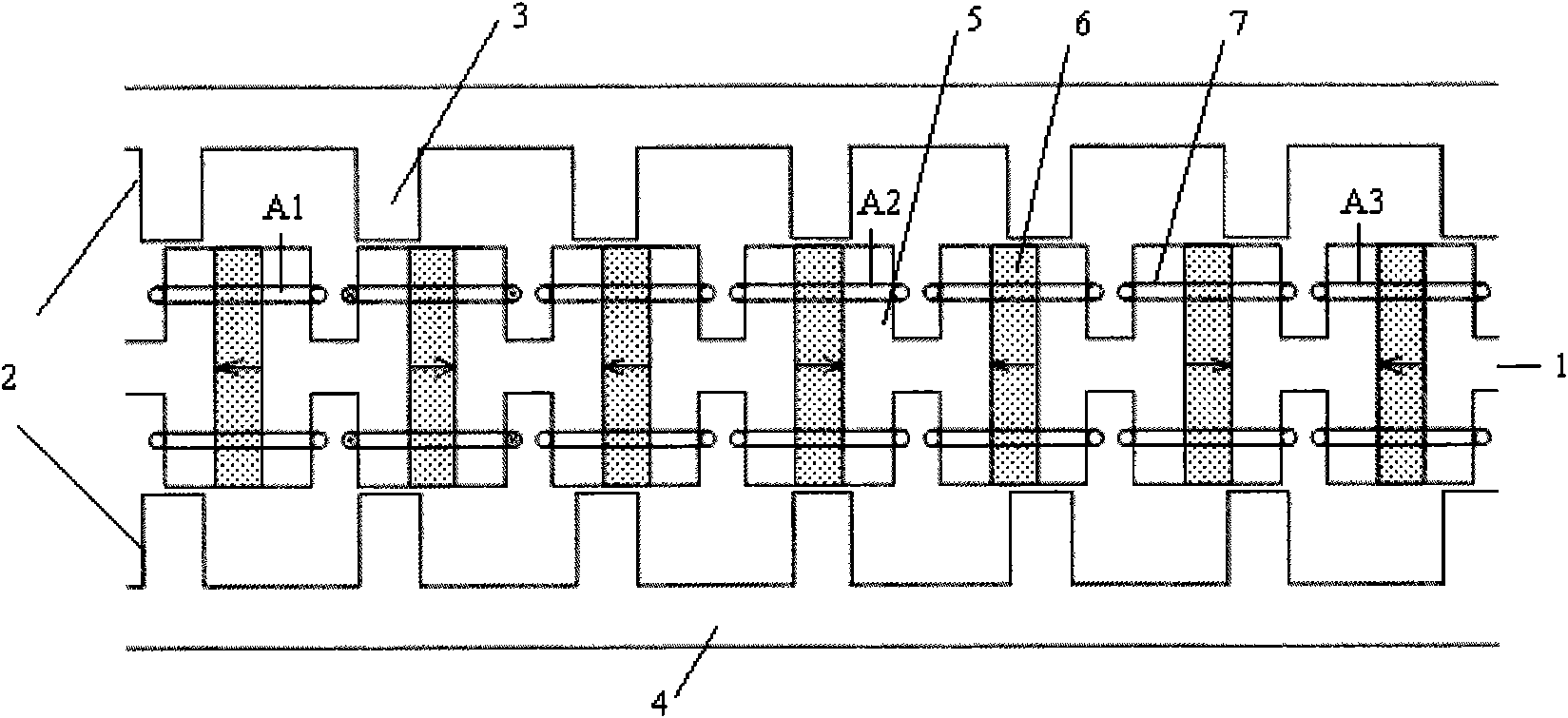

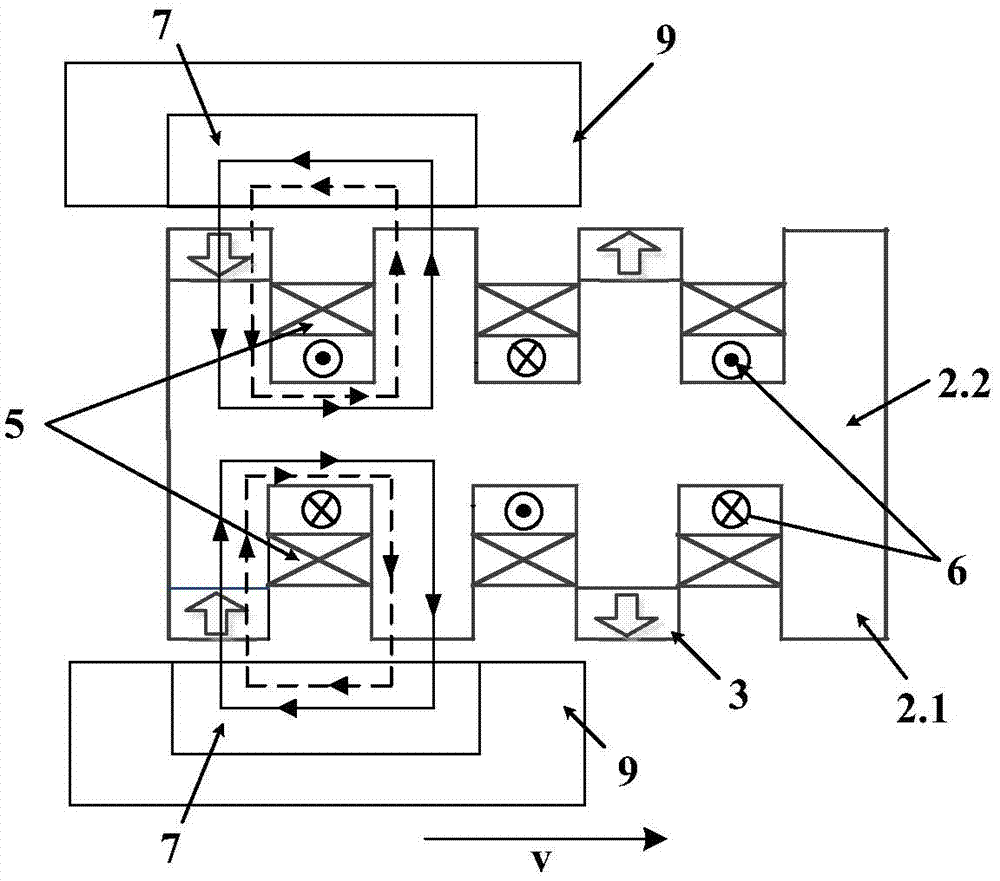

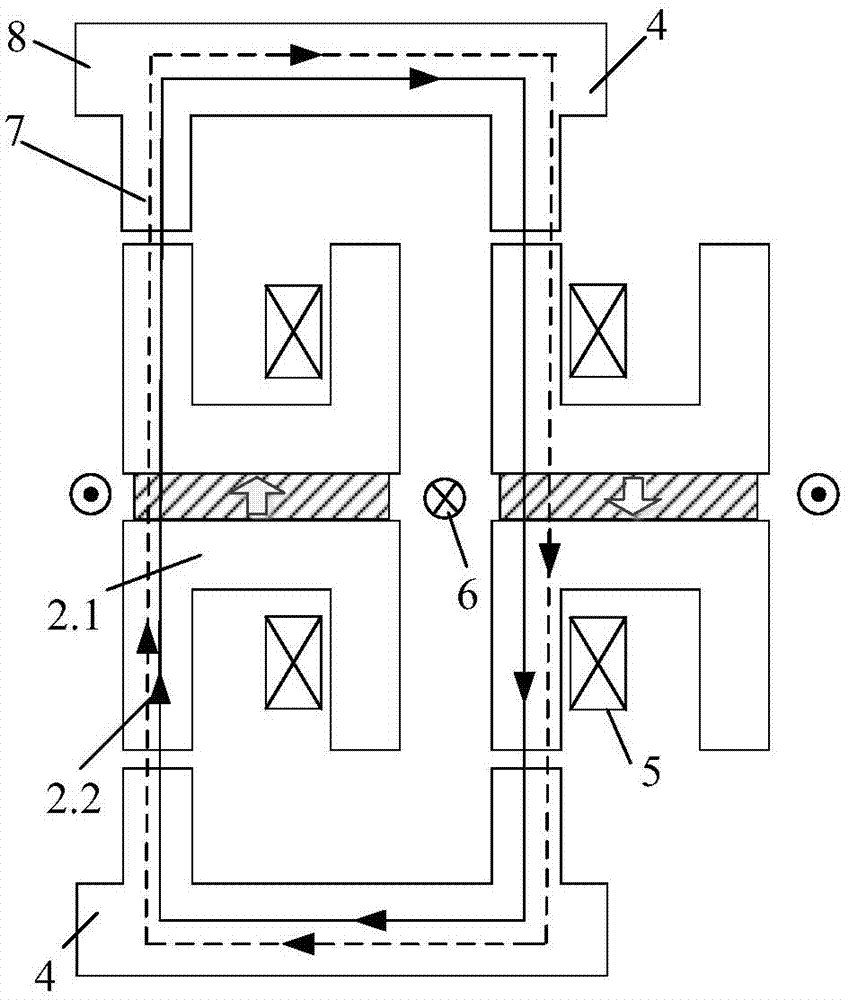

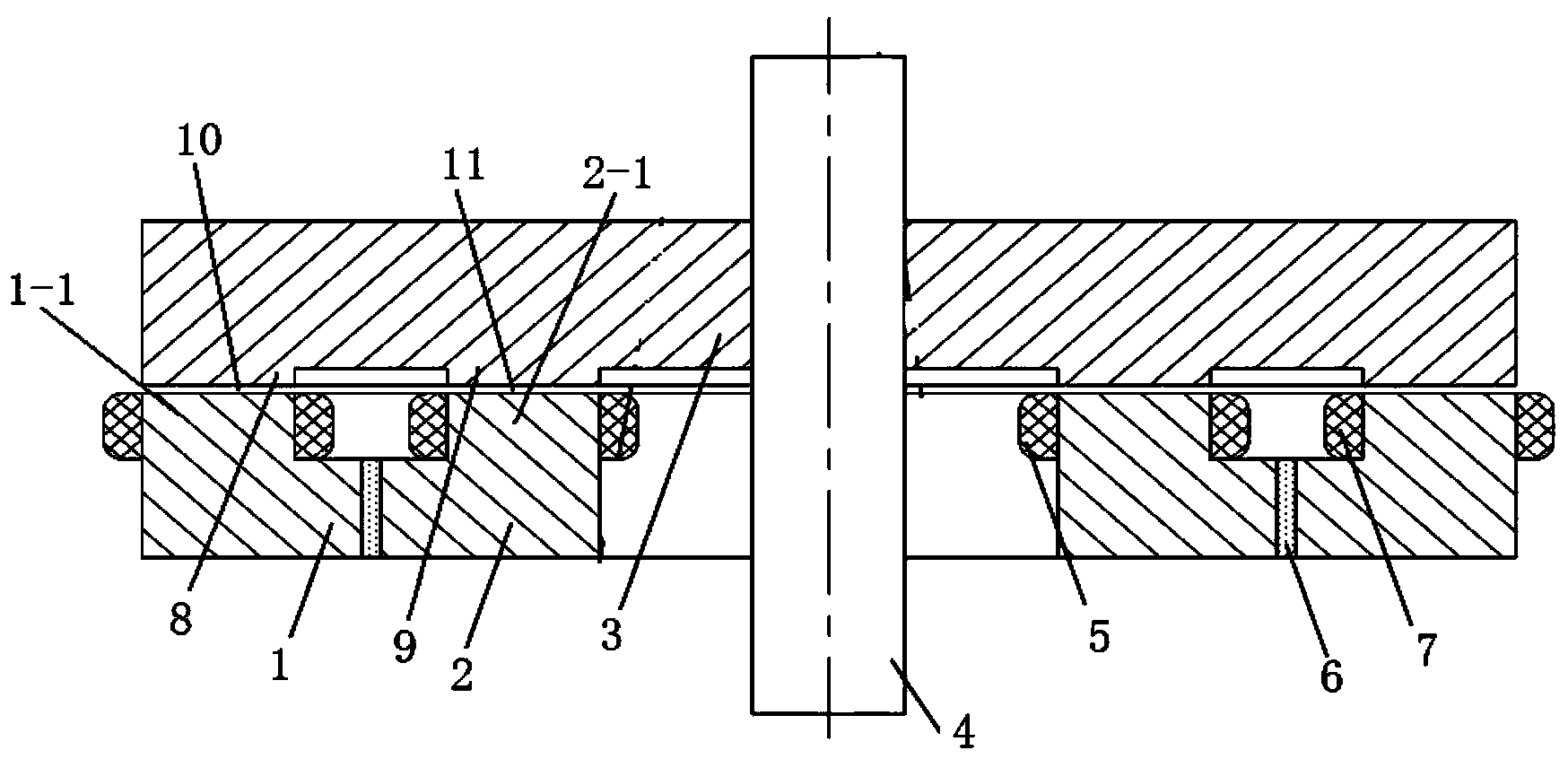

Axial magnetic field stator partitional flux switching memory motor

ActiveCN103715848ASimple structureAxial dimension shortDynamo-electric machinesElectric machineMemory motor

The invention discloses an axial magnetic field stator partitional flux switching memory motor. The memory motor comprises a first rotor (41), a second rotor (42), a stator (1) which is arranged between the first rotor (41) and the second rotor (42), and an installation shaft which is used for coaxially installing the stator (1), the first rotor (41) and the second rotor (42). The stator (1) comprises a stator iron core (2), a number of permanent magnets (3), a three-phase armature winding (5) and a single phase pulse winding (6). The stator iron core (2) comprises a first stator iron core (21) and a second stator iron core (22), wherein the first stator iron core (21) and the second stator iron core (22) have the same structure and are coaxially and oppositely arranged. The stator iron core (2) comprises a stator yoke (2.1) and a stator tooth (2.2). According to the invention, the power density of the motor is improved; the rotation speed operation range is wide; and a no-load air gap magnetic field is adjustable.

Owner:SOUTHEAST UNIV

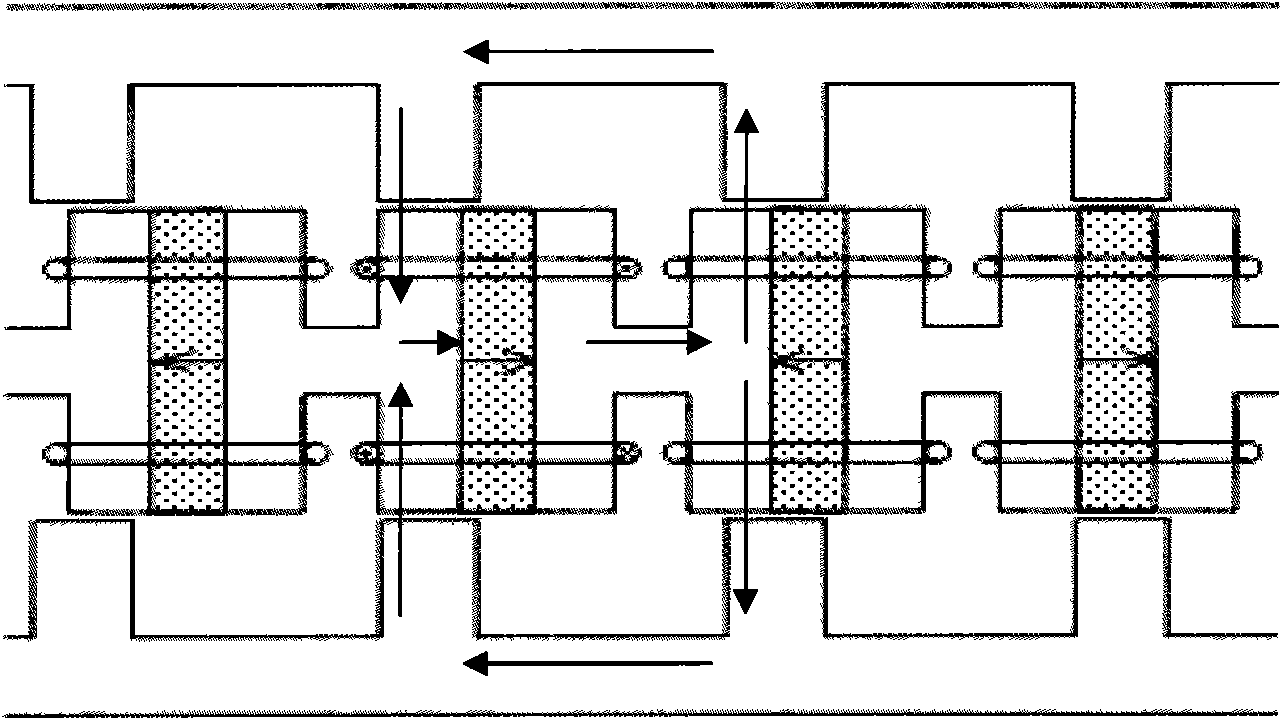

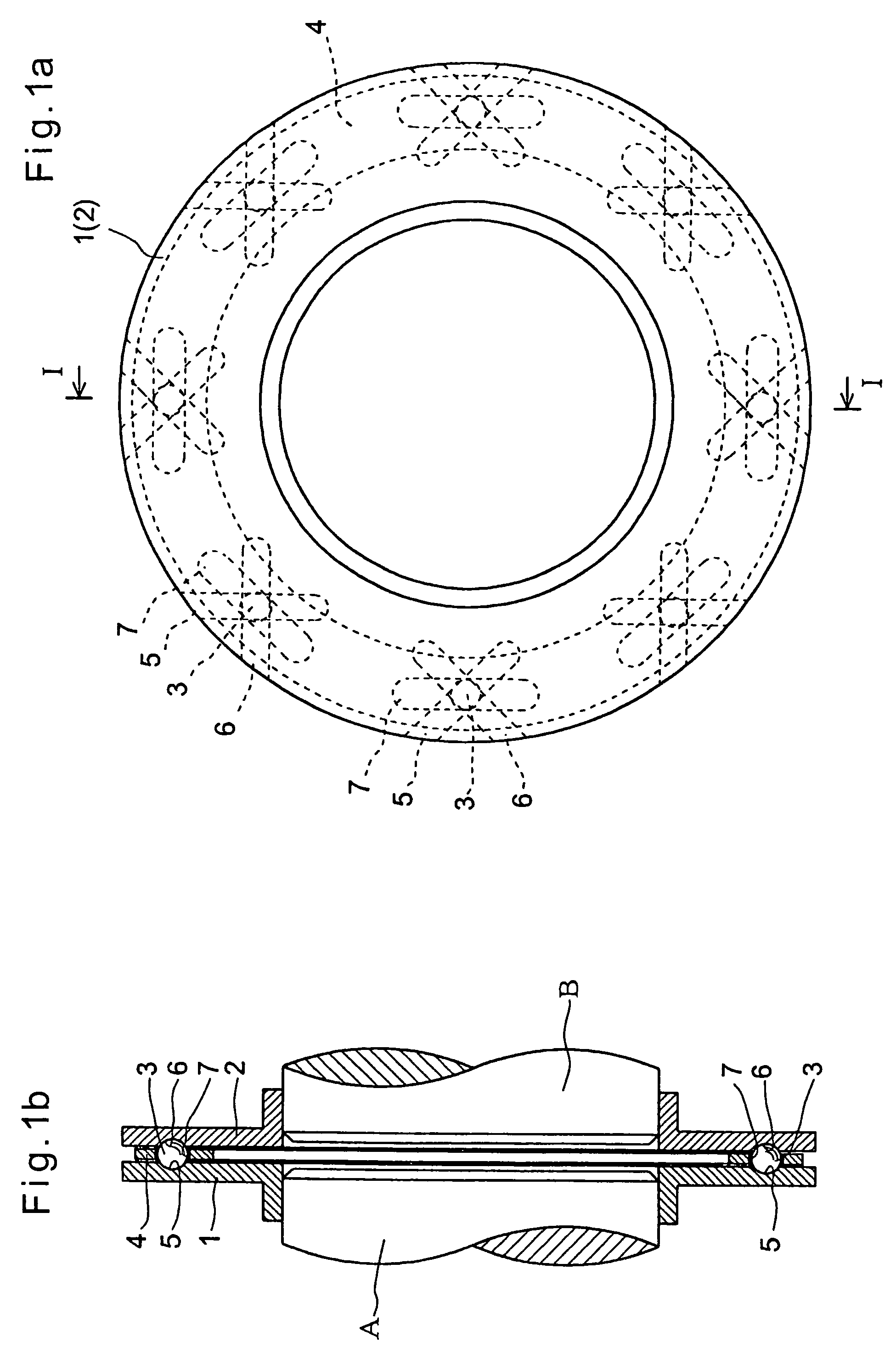

Shaft coupling

A shaft coupling includes plates fitted on ends of input and output shafts, respectively. A plurality of guide grooves are formed in the opposed surfaces of the plates, respectively, so that each of the grooves extends perpendicular to the corresponding groove formed in the other plate. A steel ball is disposed between each pair of guide grooves of the plates at a portion where the pair of grooves cross each other. When the steel balls are pushed by the driving plate, they push the driven plate while rolling in the guide grooves, with their movements restricted by a retainer in the radial direction of the plates. Thus, large power can be smoothly transmitted between the rotary members with less frictional resistance. The offset amount can be changed easily. Between the plates, there are only the steel balls and the retainer.

Owner:NTN CORP +1

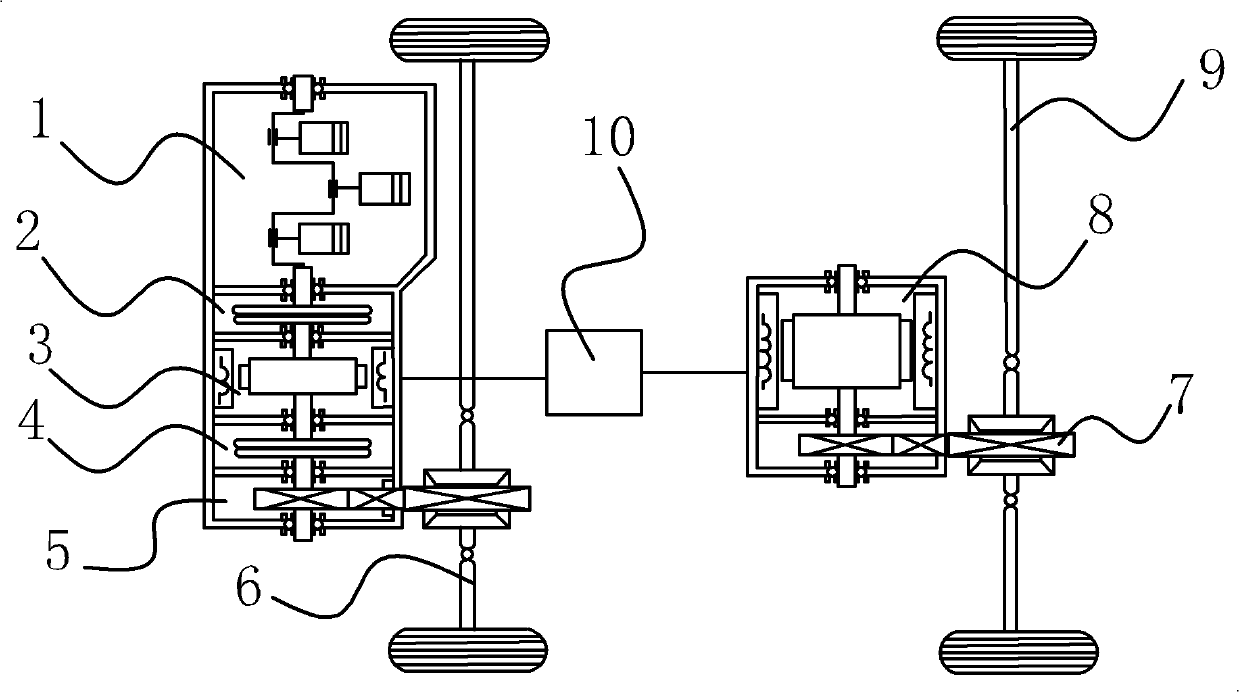

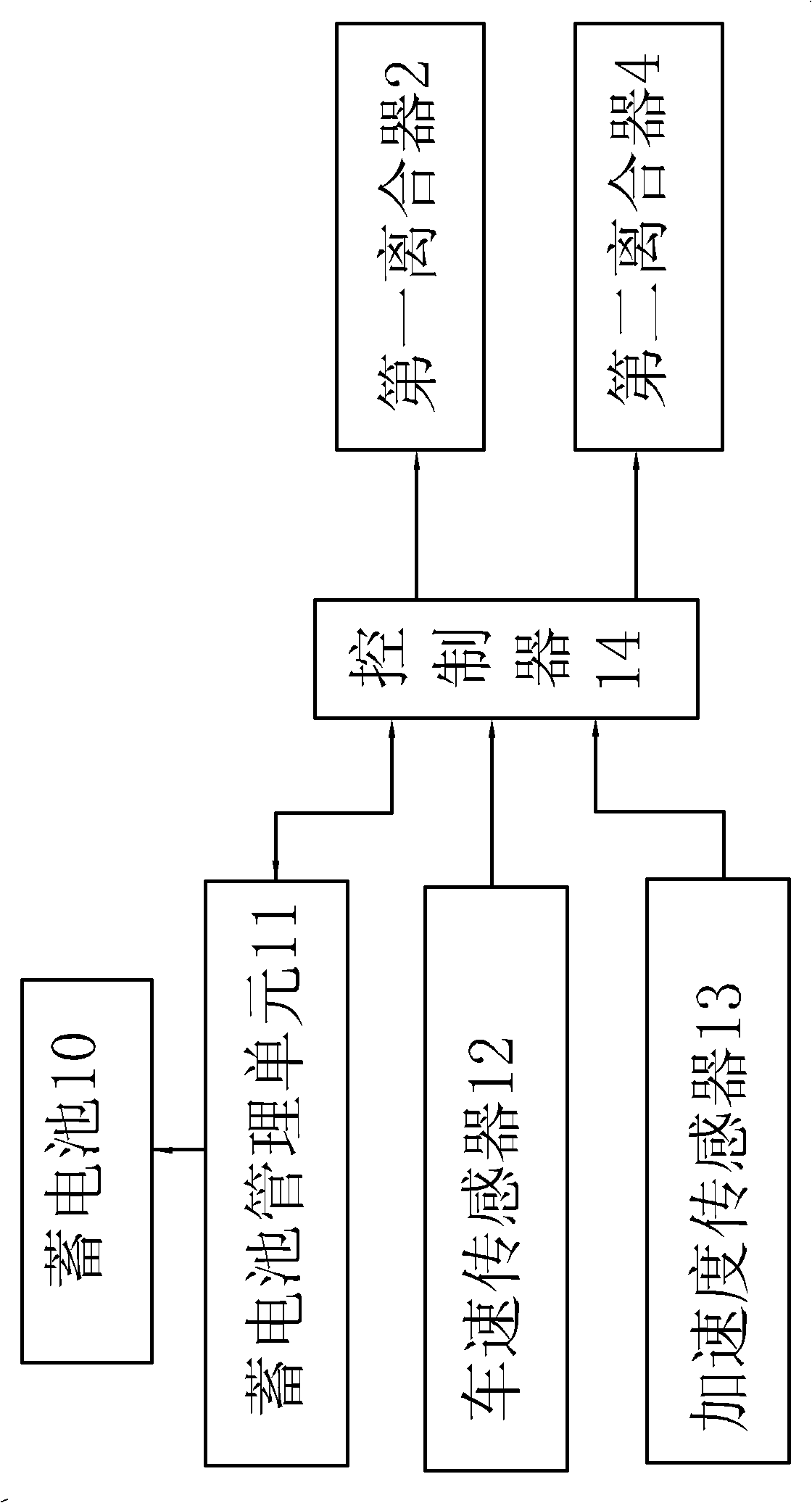

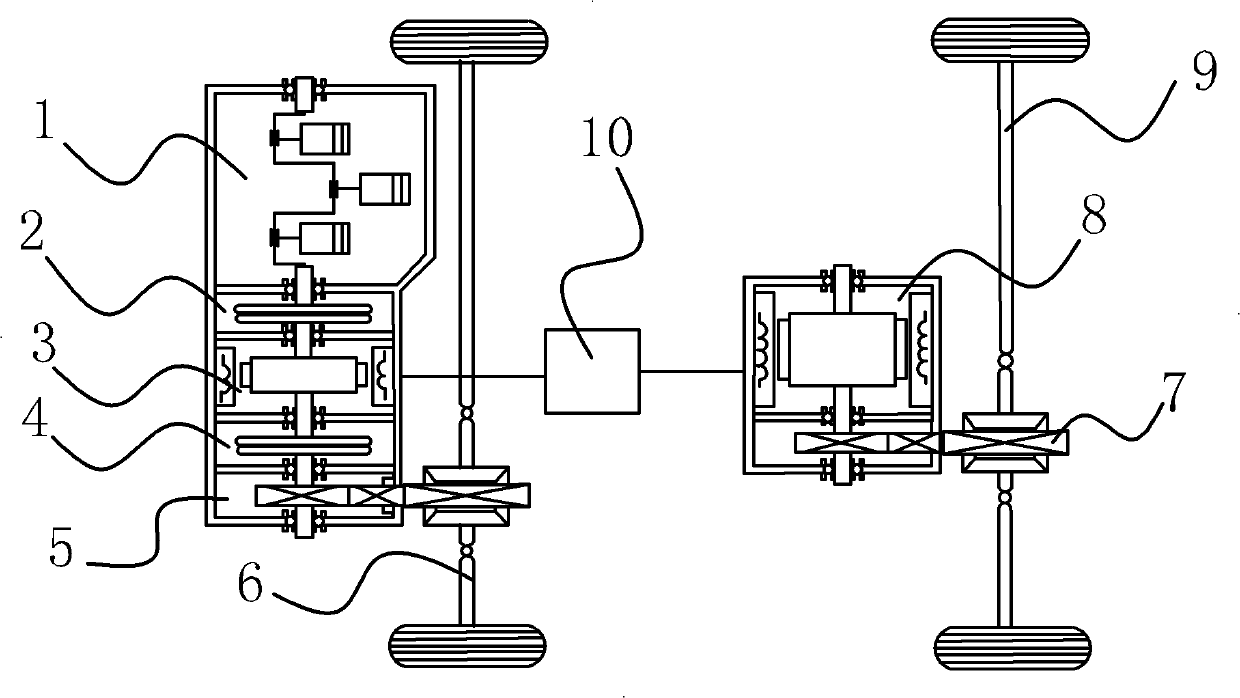

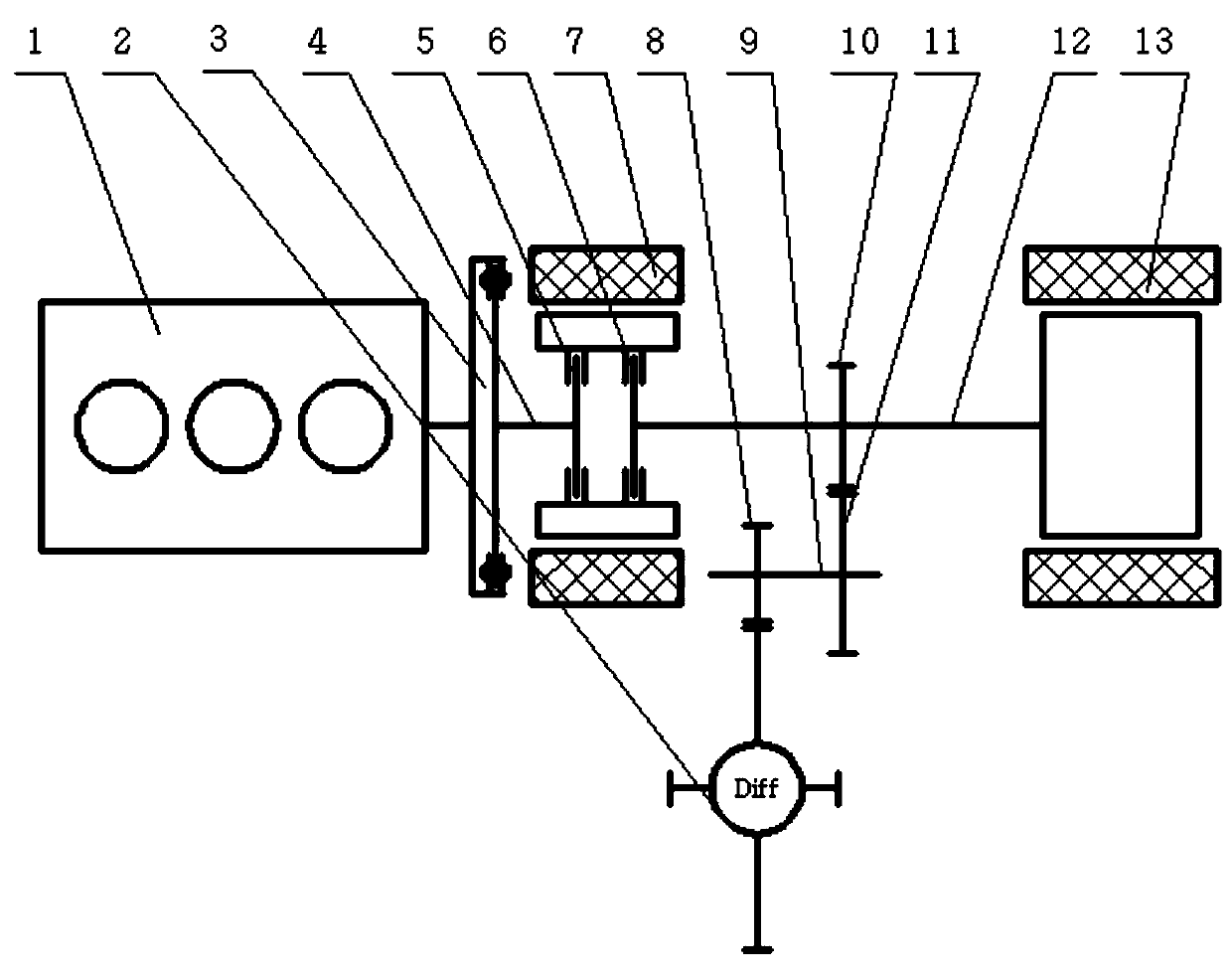

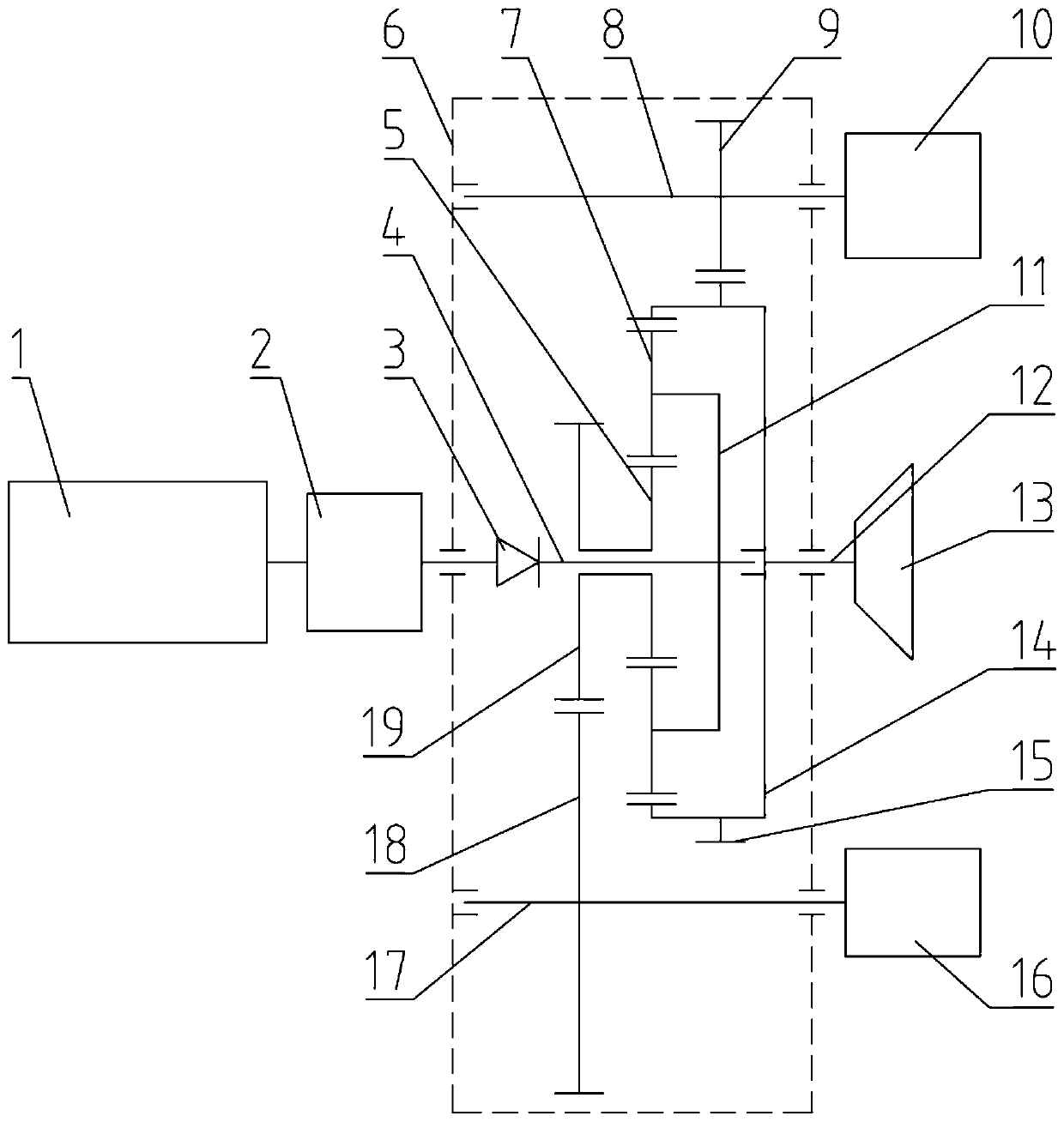

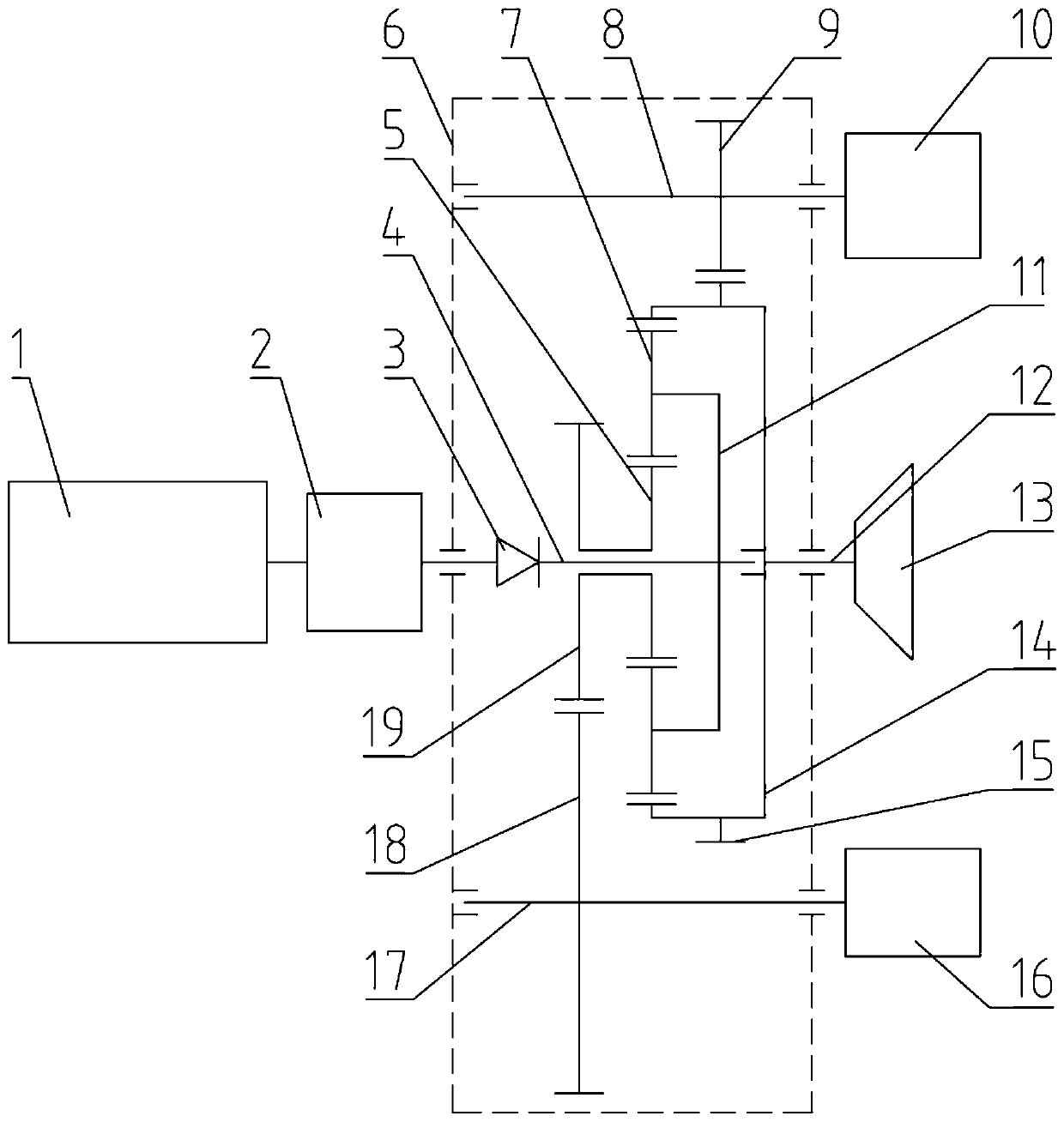

Automobile hybrid driving device and control method thereof

ActiveCN102555762AConducive to installation and layoutIncrease the rate of recyclingElectrodynamic brake systemsElectric propulsion mountingClutchDrive motor

The invention provides an automobile hybrid driving device and a control method thereof, which belong to the technical field of hybrid and solve the problem that the existing hybrid driving device is long in axial length and extremely difficult in layout. The hybrid driving device comprises an engine, a front driving motor, a back driving motor and a storage battery, the engine is connected with the front driving motor through a first clutch, the front driving motor is connected with a front driving shaft through a speed changer, a second clutch is arranged between a front speed changer and the front driving motor, the back driving motor is connected with a back driving shaft through a speed changer, and the front driving motor and the back driving motor are both connected with the storage battery. The control method achieves driving of the whole automobile under different models and recovery of braking energy by judging stored electric quantity of the storage battery, automobile speed signals and acceleration speed signals. The automobile hybrid driving device and the control method are easy to install and lay out, and improve recovery ratio of the braking energy and the whole automobile all-electric range.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

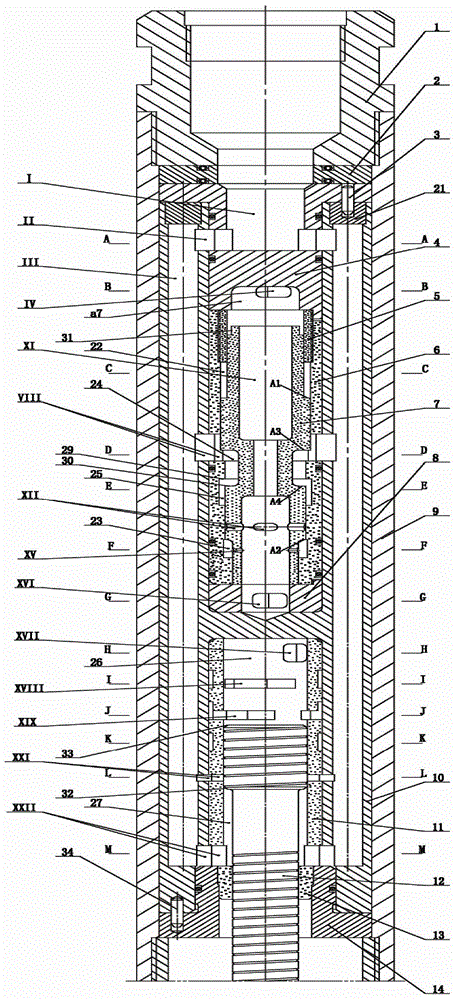

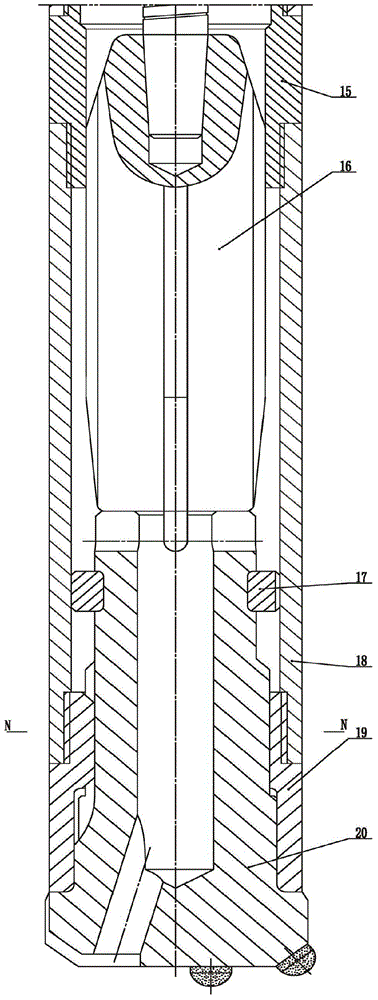

Stroke differential type high-energy hydraulic drive down-hole hammer

The invention relates to a stroke differential type high-energy hydraulic drive down-hole hammer. A spline on a drill bit is in sliding fit with a spline groove, a valve cover sleeve is in interference fit with a valve sleeve to be installed into the upper end of the valve sleeve. A valve cover is inserted into a cylinder body upper end hole and is radially provided with low-pressure emptying channels, hole channels corresponding to the radial channels are radially formed in the radial direction of a cylinder body and are communicated with axial hole channels. The upper portion of the high-energy hydraulic drive down-hole hammer is in threaded connection with an outer cylinder through an upper connector and a middle connector respectively to form a whole through package. The axial size of a piston of the hammer is small, matching surfaces are few, the leakage area is greatly decreased, and the hammer is easy to assemble, not prone to abrasion, long in service life and high in sensitivity. A differential loop is adopted for a stroke, so that the piston quickly obtains large impact end speed within a shorter stroke, and the hard rock drilling efficiency is remarkably improved. The hammer is provided with a novel empty hammering preventing mechanism, high-pressure slurry flows into a cavity through the channels and then flows into the bottom of a hole, the hammer is not driven, it is ensured that the down-hole hammer does not work when a drilling tool is lifted to be away from the down-hole hammer, and accordingly the safety of the drilling tool is ensured.

Owner:JILIN UNIV

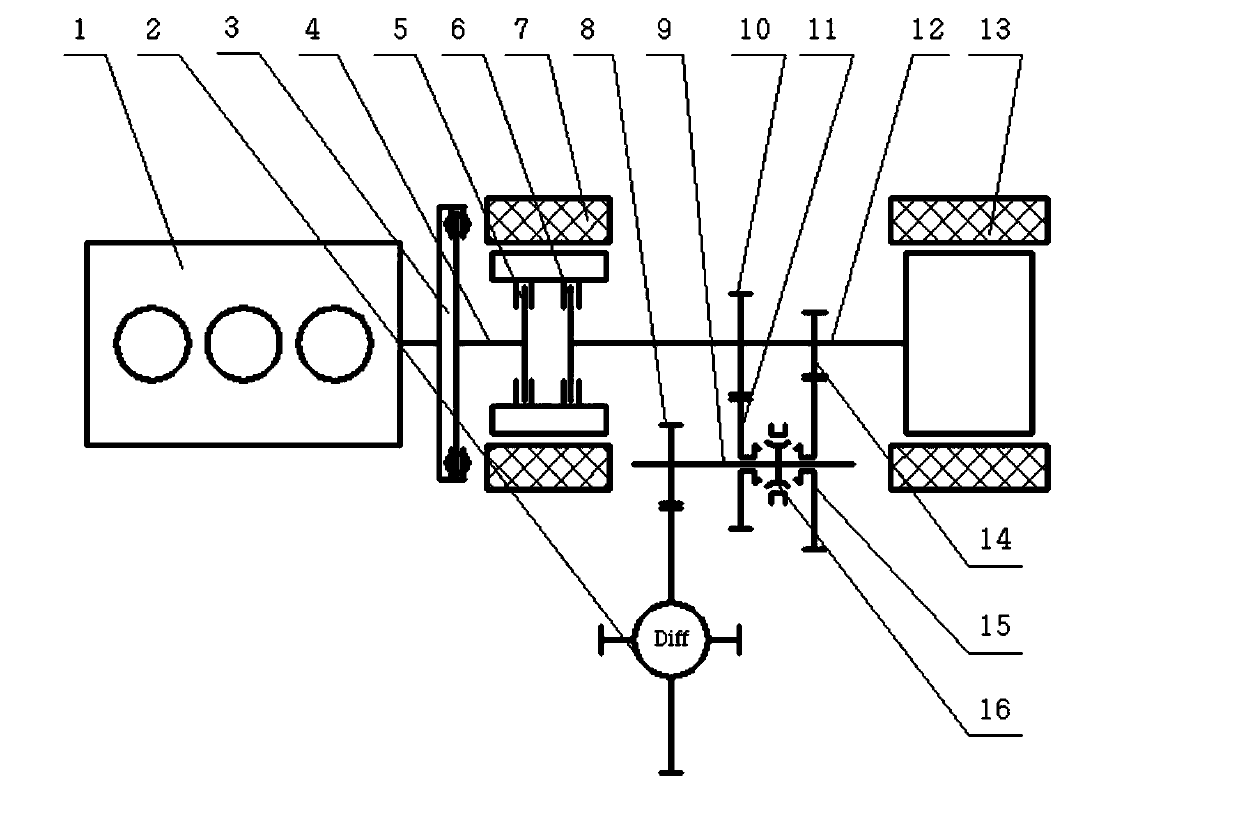

Hybrid power system with double clutches arranged in motor and working method

InactiveCN110103698AShorten the axial lengthSimplify the hybrid structureGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelEngineering

The invention provides a hybrid power system with double clutches arranged in a motor. The hybrid power system comprises an engine, a differential mechanism, a shock absorber, an engine power input shaft, the first clutch, the second clutch, the first motor EM1, a main deceleration driving gear, a power output intermediate shaft, a power output driving gear, a power output driven gear, a power output shaft, a second motor EM2, a low-gear driving gear, a low-gear driven gear and a synchronizer. By the adoption of the provided hybrid power system with the double clutches arranged in the motor, the double clutches are arranged in a rotor of one motor, so that the axial length of a transmission is effectively reduced. Through arrangement of the two clutches, a hybrid power structure is simplified, and a pure electric drive mode, a range extension type drive mode, an engine direct drive mode, a parallel connection drive mode, a series-parallel connection drive mode and the like are achieved; and the structure is simple, multiple functions can be achieved, one integrated double-clutch is used, only two pairs of normally-engaged gears are arranged in a coupling box, no gear shifting is needed in the operation process, and operation is stable.

Owner:CATARC TIANJIN AUTOMOTIVE ENG RES INST CO LTD +1

Reducer with bevel gear and cycloid in large transmission ratio for ore grinding machine

InactiveCN102192274AAxial dimension shortExtended service lifeGearboxesToothed gearingsPhase differenceReduction drive

The invention relates to the technical field of reducing the speed of an ore grinding machine. A reducer with a bevel gear and a cycloid in a large transmission ratio for an ore grinding machine is characterized by comprising a bevel gear pair and a cycloid transmission part; the bevel gear pair comprises driving and driven bevel gears; in the cycloid transmission part, (A) needle pin semi-buried holes are uniformly distributed on a needle gear shell, and the needle pins without sleeves are movably matched with the semi-buried holes; (B) a W output mechanism is composed of an output shaft, a column pin, a uniform loading disc and an annular plate; two sides of the W output mechanism are supported on an inner hole of a machine body and the outer circle of a flange in an end cover through bearings; in four single-eccentric bearings, the phase difference between the first bearing and the second bearing and the phase difference between the third bearing and the fourth bearing are 180 DEG and the phase of the second bearing is same as that of the third bearing. In the invention, the reducer has the beneficial effects as follows: (1) the bearing capability is improved by 2-3 times; (2) the length of the axial direction is reduced by 45-55% and the cost is reduced by 40-50%; (3) the reversed installation service life of a cycloid gear is doubled; and (4) the inertia force and the inertia moment are completely balanced in theory when the reducer is operated.

Owner:吴江科技创业园管理服务有限公司

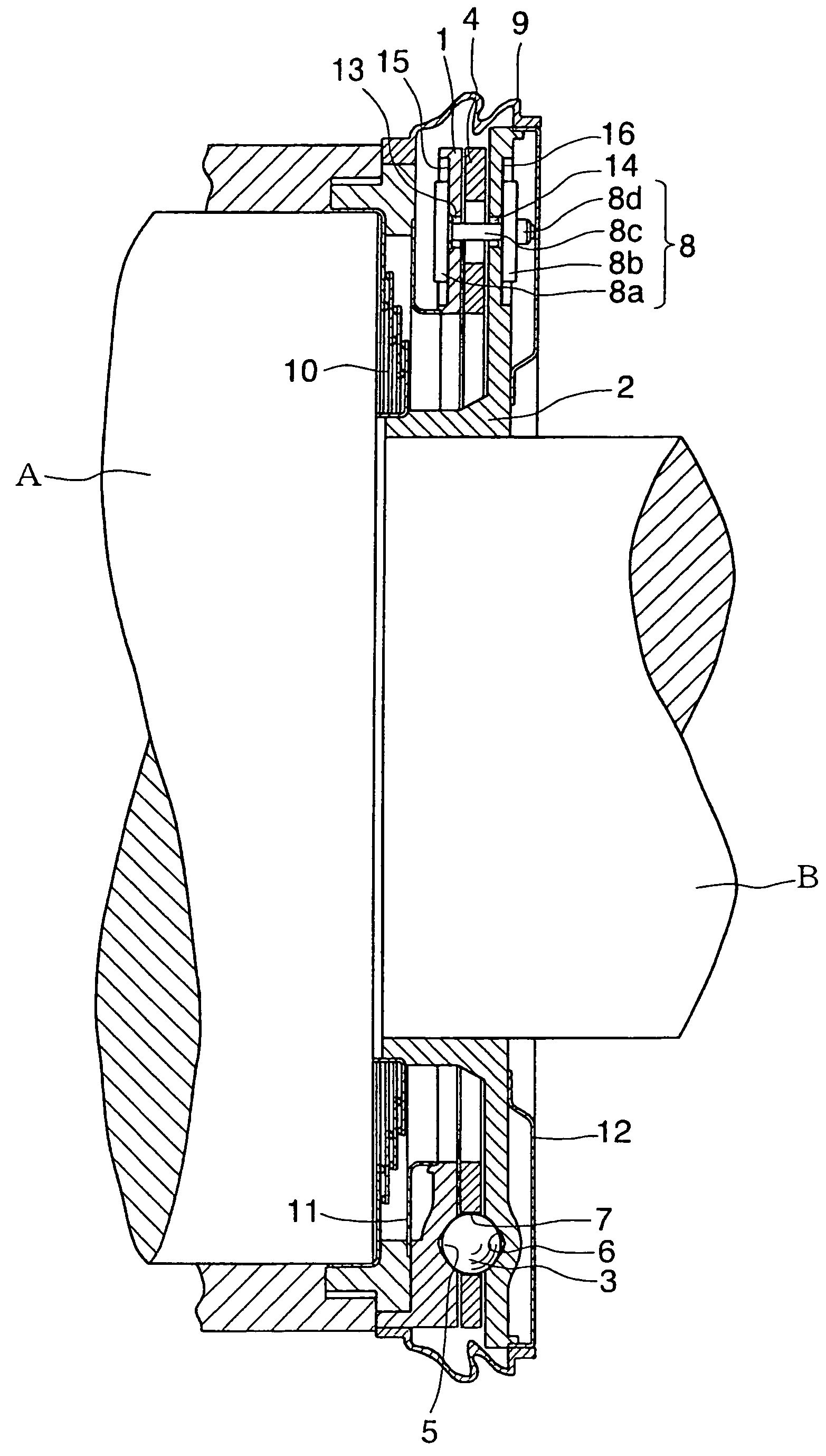

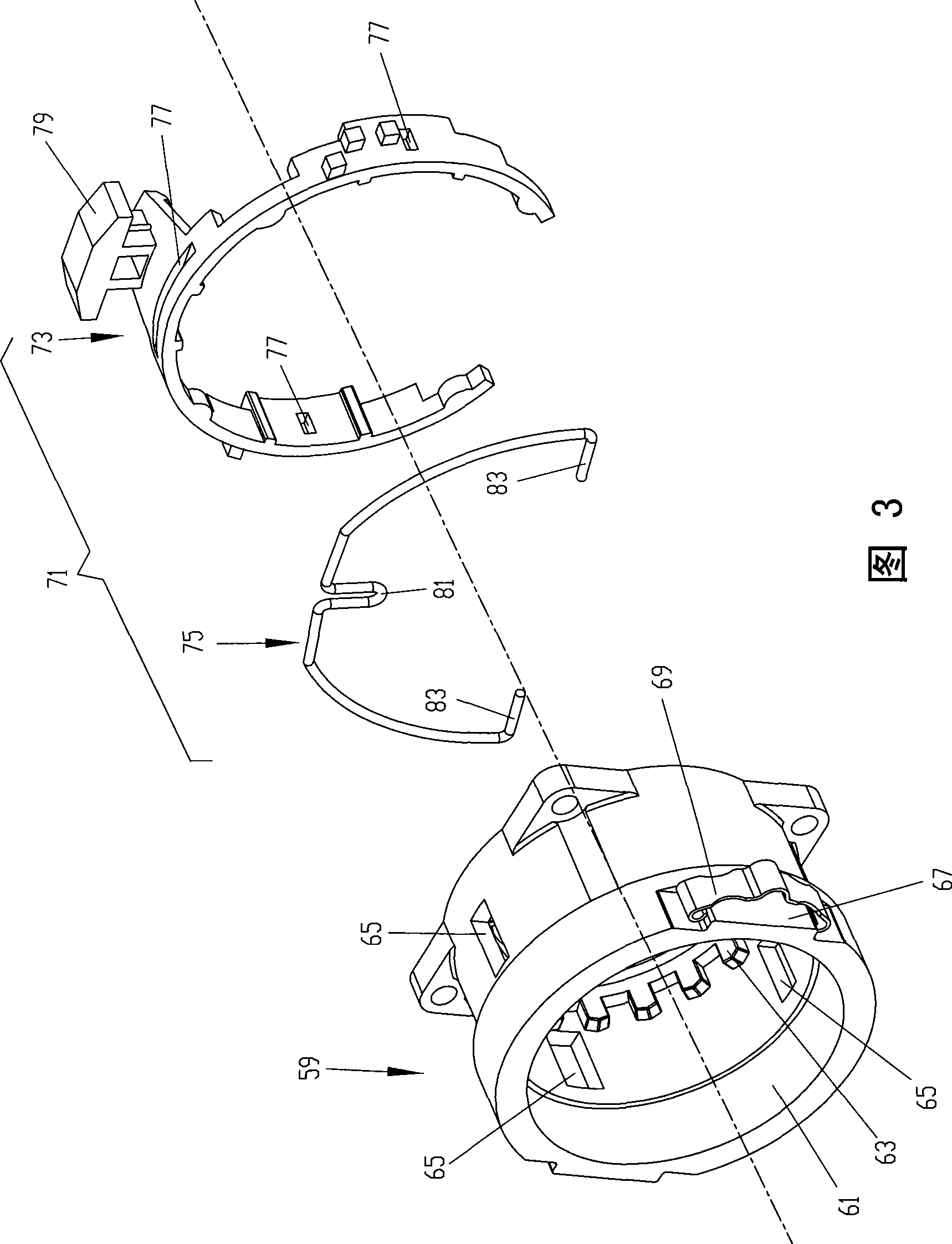

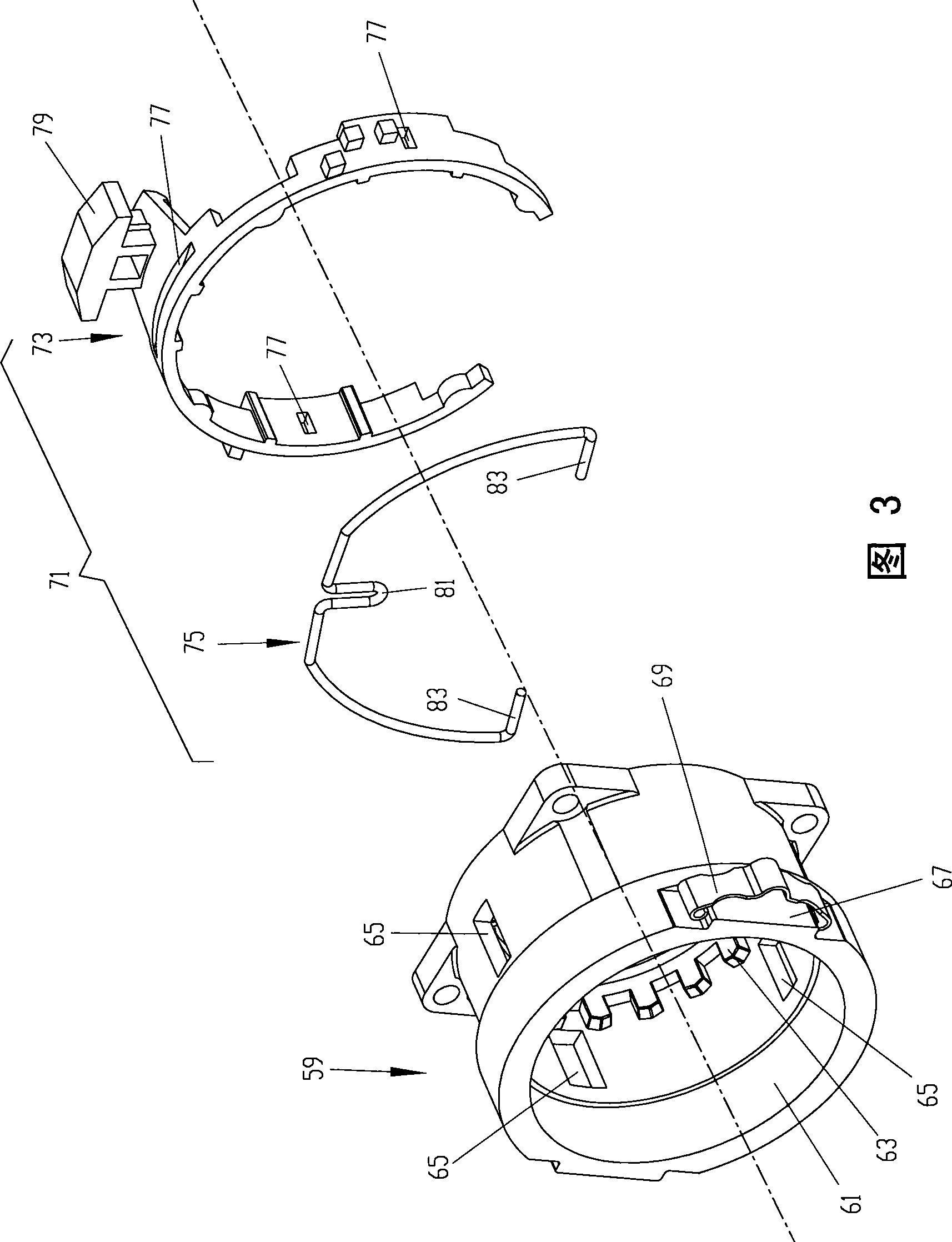

Impact drill

The invention provides a percussion drill which comprises a casing, a main shaft, a still end tooth which is installed inside the casing and can not rotate relatively to the casting, a movable end tooth which is fixedly connected on the main shaft and can move along with the main shaft, and a function shifting mechanism used for leading the movable end tooth and the still end tooth to be engaged optionally. The function shifting mechanism comprises a restraining element which is matched with the movable end tooth movably along the radial direction so as to prevent the movable end tooth from axial movement.

Owner:POSITEC MACHINERY ZHANGJIAGANG +1

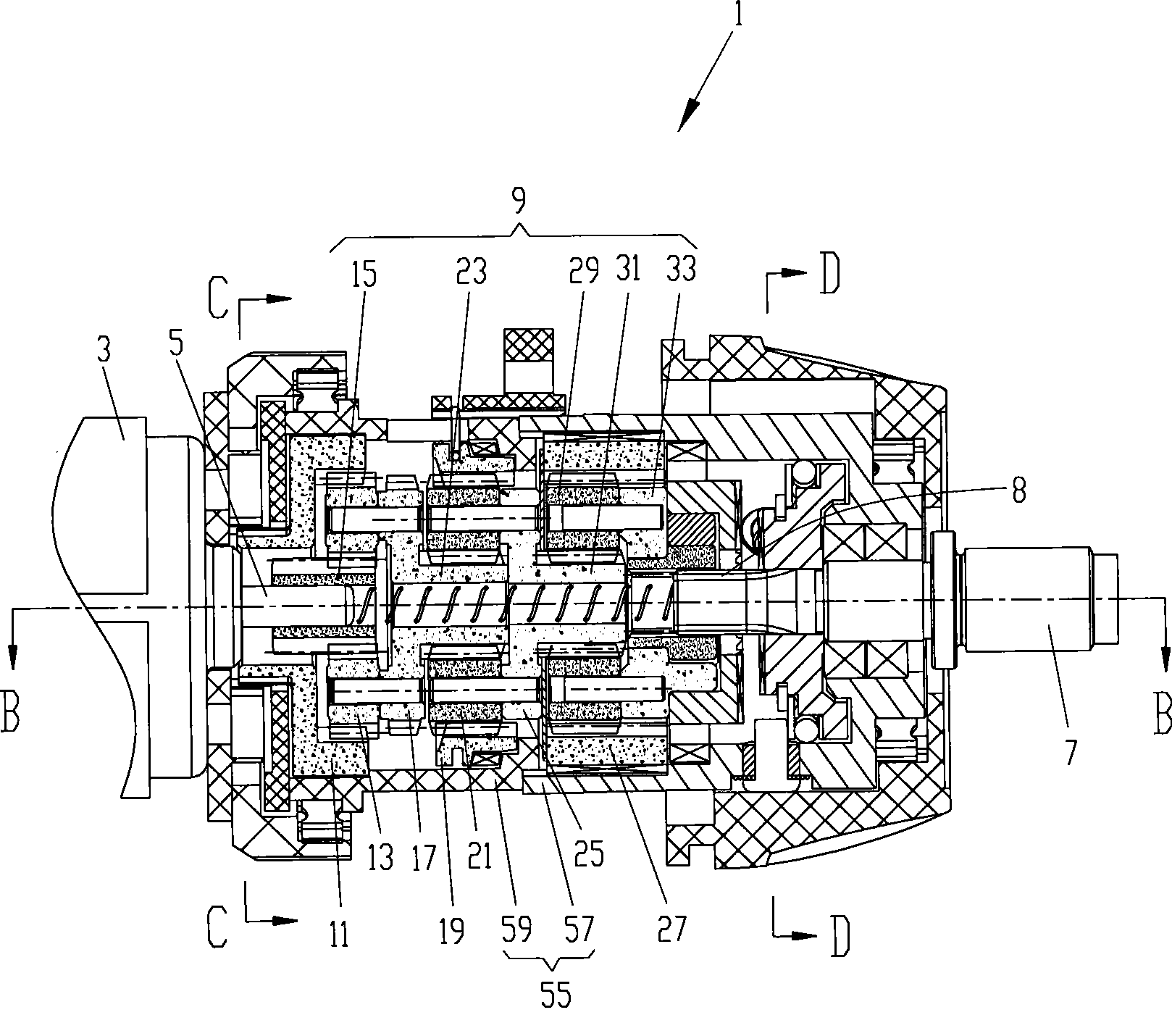

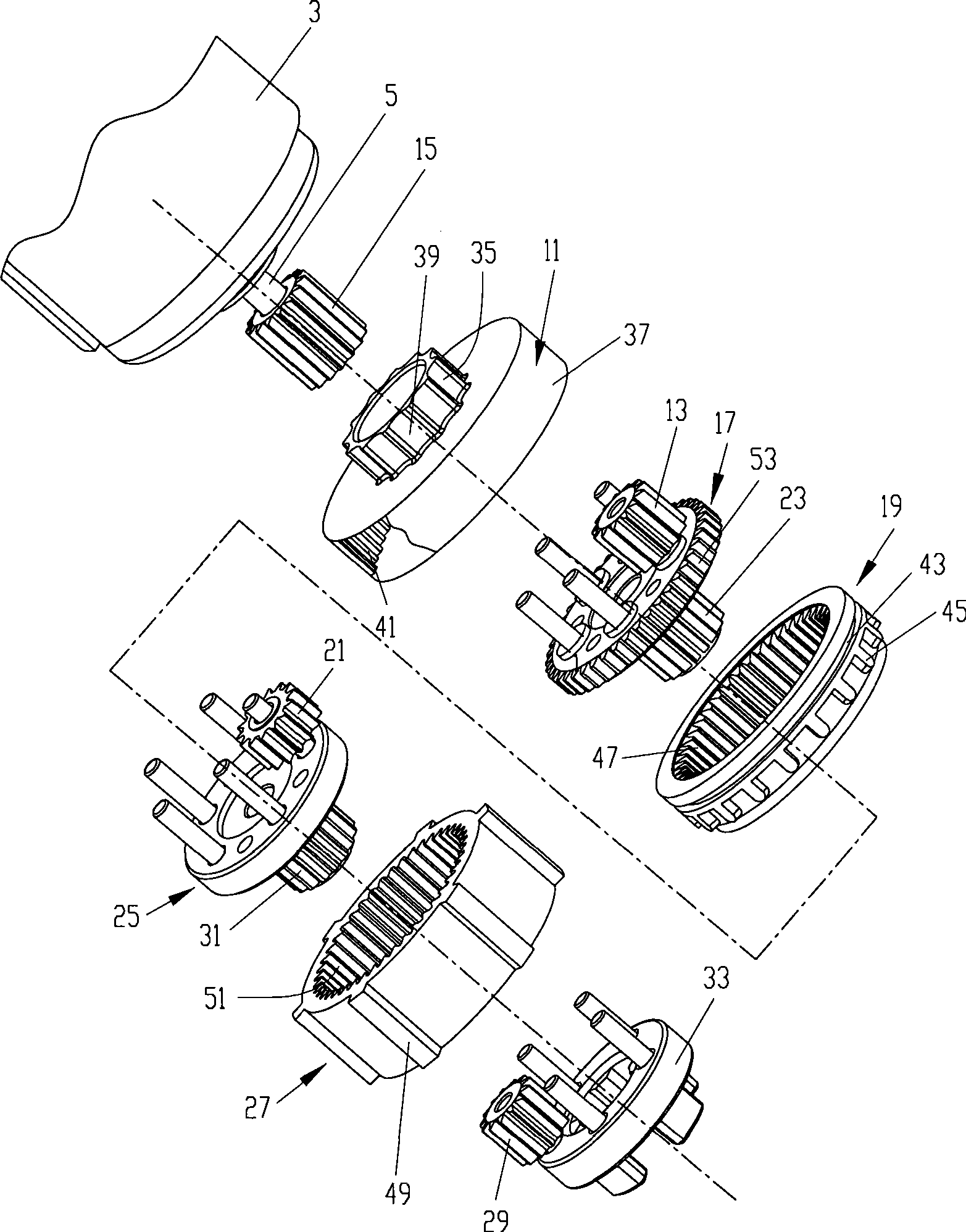

Vehicle hybrid power system achieving multi-power-source coupling

PendingCN110001376AReduce design requirementsLower manufacturing requirementsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingReduction driveCoupling

The invention belongs to a vehicle transmission, and provides a vehicle hybrid power system achieving multi-power-source coupling. The problems that as for an existing hybrid power system, a motor isexcessively large in torque and excessively low in rotating sped, and thus the system is large in size, large in weight and high in cost are solved. The vehicle hybrid power system comprises an engine, a first motor, a second motor, a speed reducer and an output flange disc; the speed reducer comprises a speed reducer box, an input shaft and an output shaft, and further comprises a one-way clutch,a planetary gear train, a first motor gear pair and a second motor gear pair which are arranged in the speed reducer box; the planetary gear train comprises a sun gear, a planetary frame, a gear ringand planetary gears; one end of the input shaft is arranged on the speed reducer box and connected with engine output, and the other end of the input shaft is arranged on the gear ring; one end of the output shaft is fixedly connected with the gear ring, the other end of the output shaft is fixedly connected with the output flange disc, and outer teeth of each planetary gear are engaged with inner teeth of the gear ring and outer teeth of the sun gear correspondingly; and a first motor passive gear is arranged on the outer side face of the gear ring, and a second motor passive gear is coaxially and fixedly connected with the sun gear.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

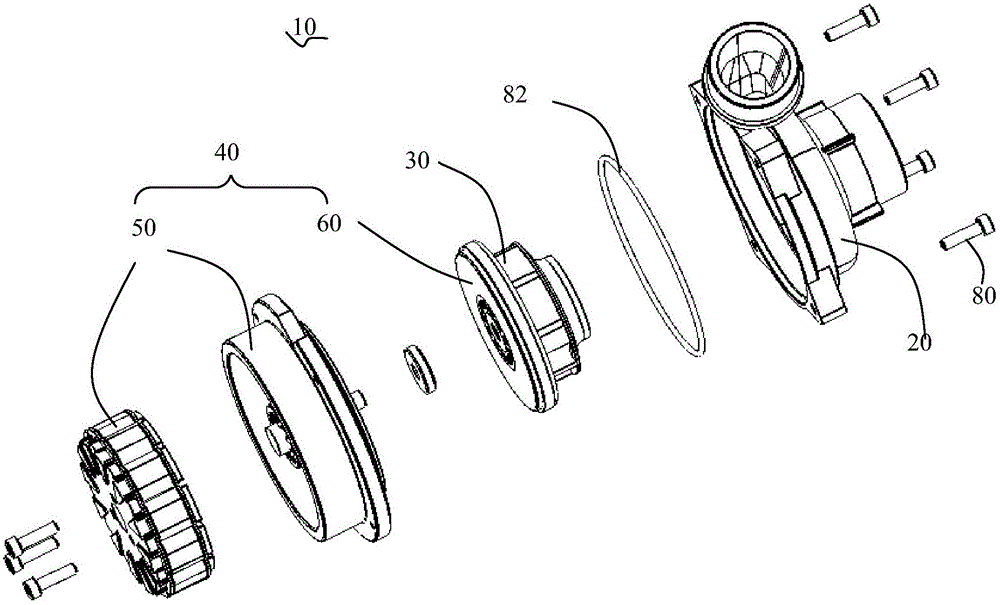

Power tool

The invention provides a power tool, comprising a motor, a shell, and a gear reducing mechanism which is driven by the motor and is arranged in the shell; the gear reducing mechanism comprises an internal tooth ring which can be contained in the shell in a rotatable way; the power tool also comprises a clutch mechanism which comprises a pushing element and an elastic element, and a torque adjusting element; the external surface of the internal tooth ring is provided with at least a concave trough; the pushing element is arranged in any concave trough movably; the elastic element which can be deformable in radial direction is arranged between the pushing element and the torque adjusting mechanism, thus leading the elasticity of the elastic element to be changed by adjusting the torque adjusting element.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

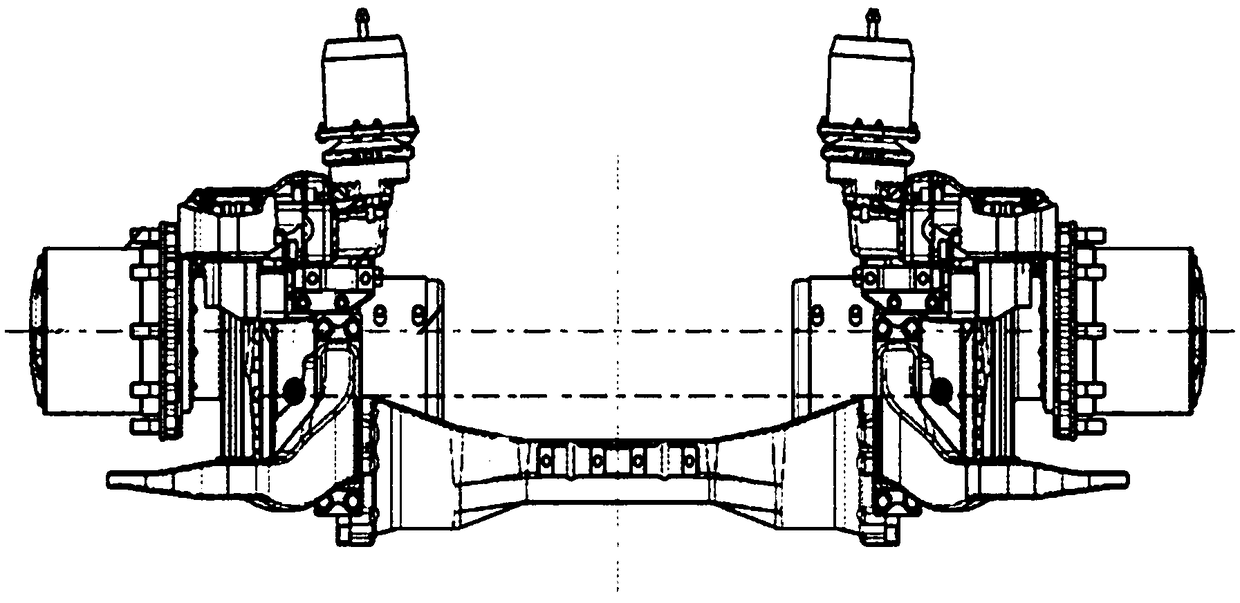

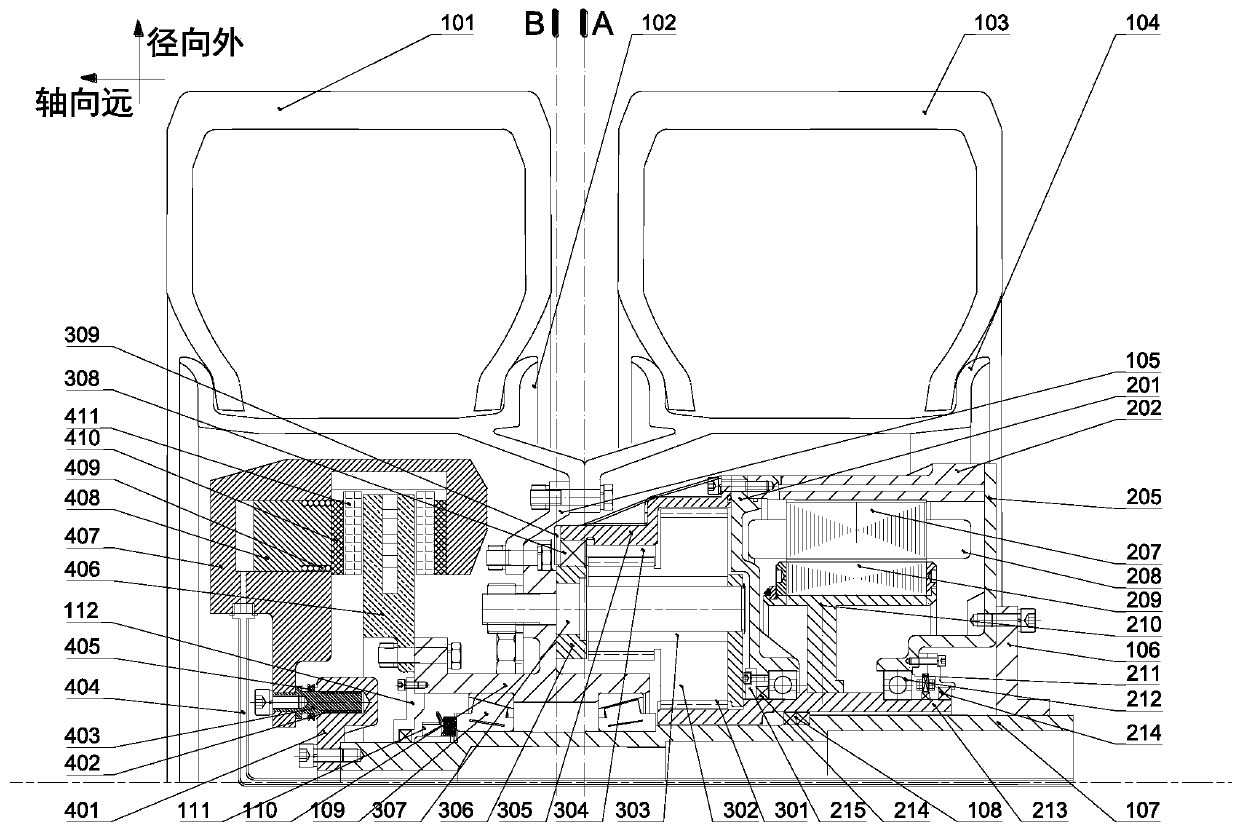

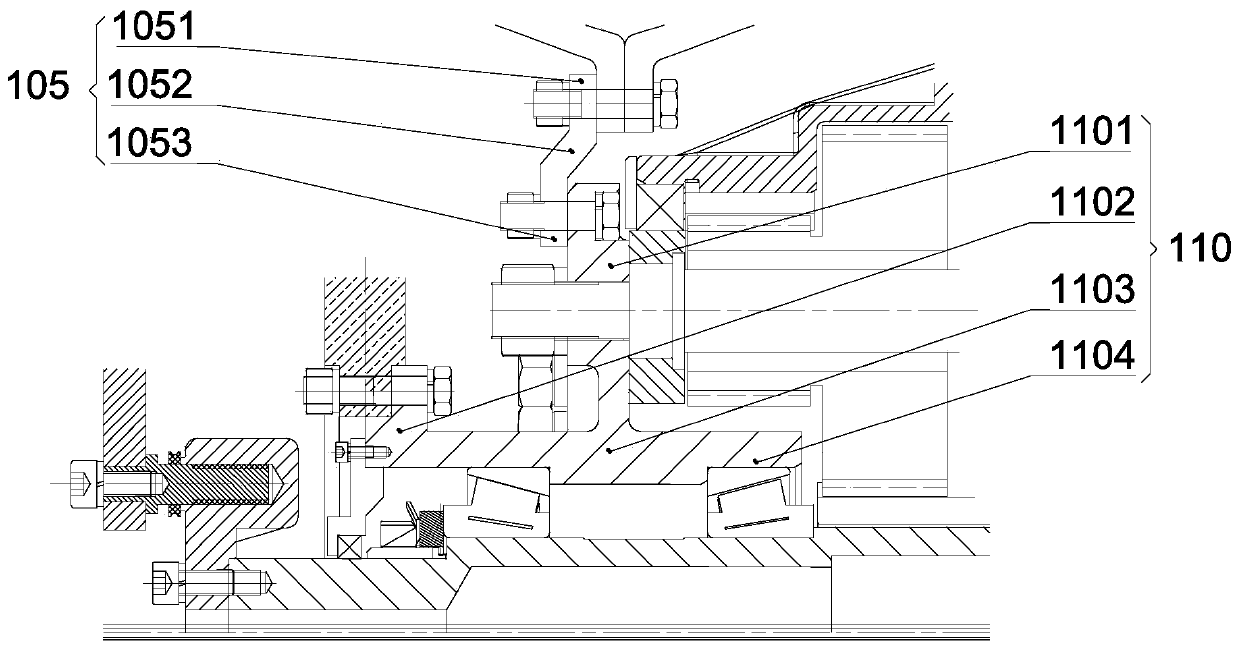

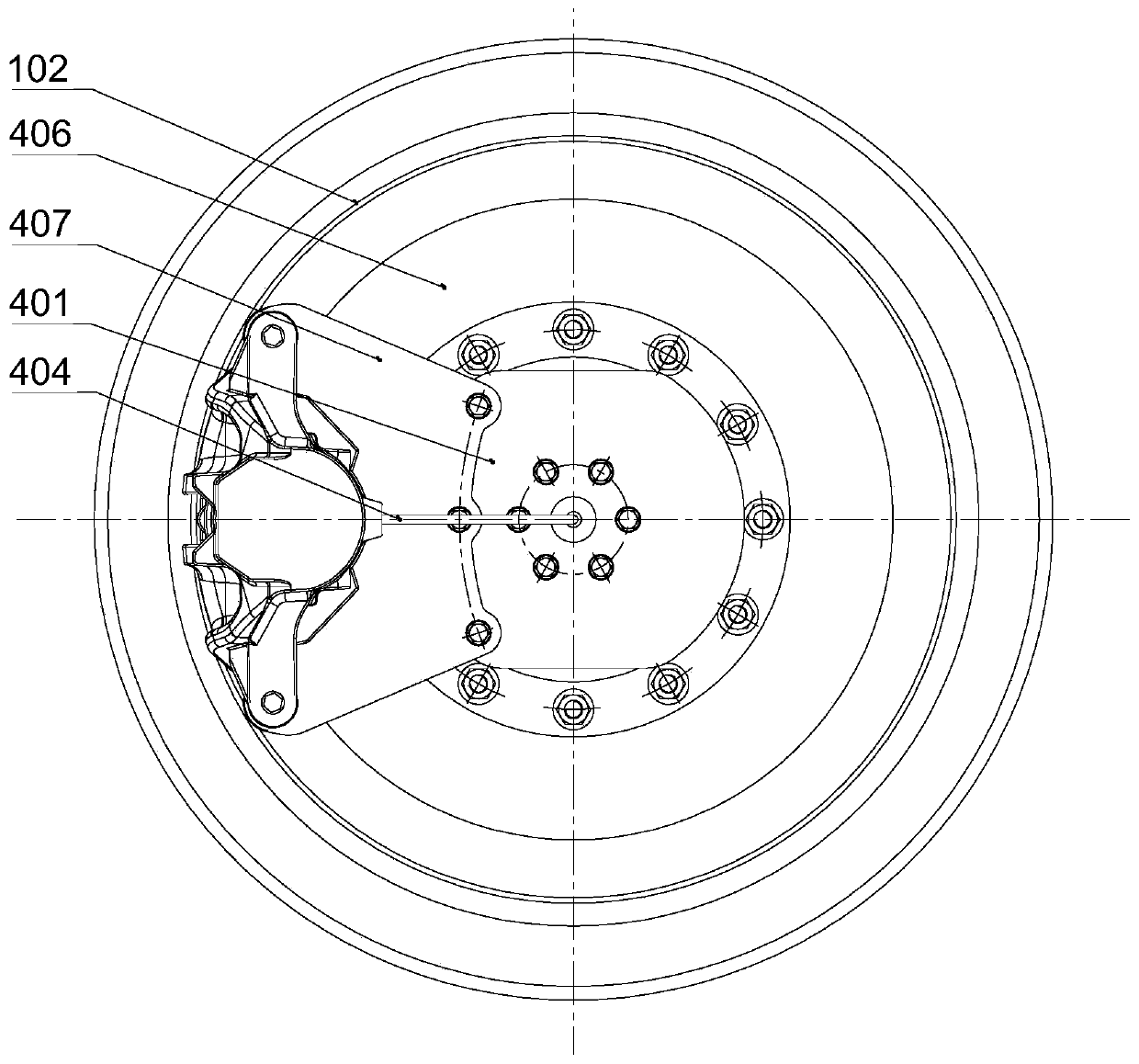

Electric wheel assembly, axle and vehicle suitable for twin tires and loading wheels

ActiveCN109130839AAxial dimension shortCost controlBraking element arrangementsBrake coolingReduction driveGear wheel

The invention discloses an electric wheel assembly, axle and vehicle suitable for twin-tire parallel loading wheels. The electric wheel assembly comprises wheels and a support shaft assembly, an innerrotor hub motor, a planetary gear reducer and a braking system. A planet carrier is connected with a wheel hub, the wheel hub connects a spoke and a wheel rim, a wheel support shaft passes through arotor sleeve, and hub bearings are arranged on the wheel support shaft to support the wheel hub and the whole wheel. The sun gear at one end of the rotor sleeve of the inner rotor hub motor is the power input of the planetary gear reducer, and the planet carrier is the power output. The planetary gear of planetary gear reducer adopts tower gear to realize larger transmission ratio under smaller axial length. The brake system adopts drum brake, the brake drum is connected with the rotor sleeve, and the braking force is amplified through the planetary gear reducer, which can reduce the braking force required by the brake system, and the electric motor can provide the electric braking force when braking. The electric wheel assembly can be used for the non-independent suspension of the commercial vehicle, and the cooling lubrication mode of the integrated cooling lubrication can be adopted to improve the performance.

Owner:南京清研易为新能源动力有限责任公司

Permanent magnet non-iron-core motor used for electric vehicle

InactiveCN110429780AReduce weightAxial dimension shortMagnetic circuit rotating partsElectric machinesElectric vehicleControl theory

The invention provides a permanent magnet non-iron-core outer rotor motor used for an electric vehicle. The permanent magnet non-iron-core outer rotor motor used for the electric vehicle includes twoouter side rotor disks, a motor intermediate rotor disk, two stator armatures, two stator armature disks, a permanent magnet, a bearing, a shaft and a motor shell. A motor rotor consists of the two outer side rotor disks and one intermediate rotor disk. The motor shell and three rotor disks are made of aluminum alloy. An iron core structure of the rotor and a stator is removed, which greatly reduces weight of the motor. The stator and the rotor adopt a non-iron-core structure and are connected in series to ensure performance of the motor. The non-iron-core motor is made without a silicon steelsheet, and the rotor is directly used as a hub of the electric vehicle, which greatly reduces the weight of the motor, and improves efficiency of the motor, and simultaneously motor vibration, noisesand cost are greatly reduced.

Owner:成都署信科技有限公司

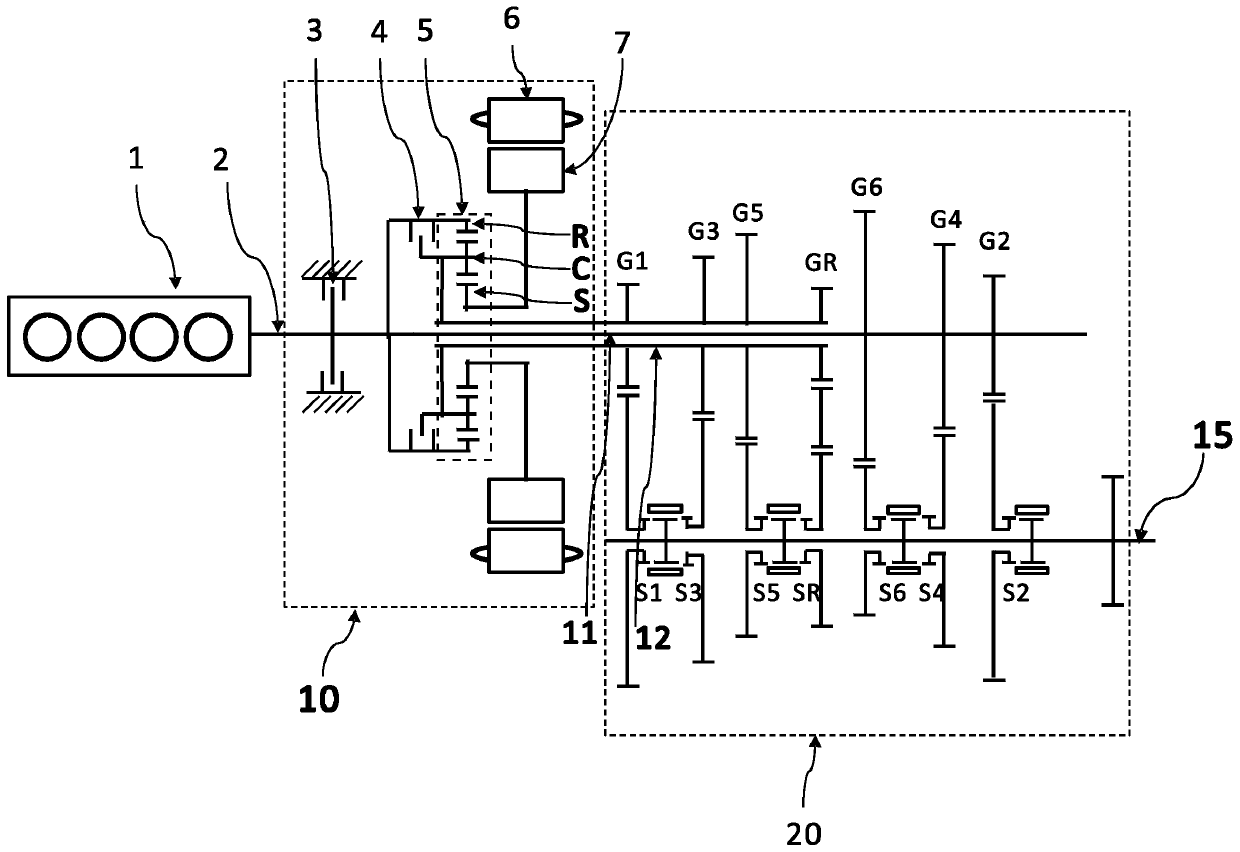

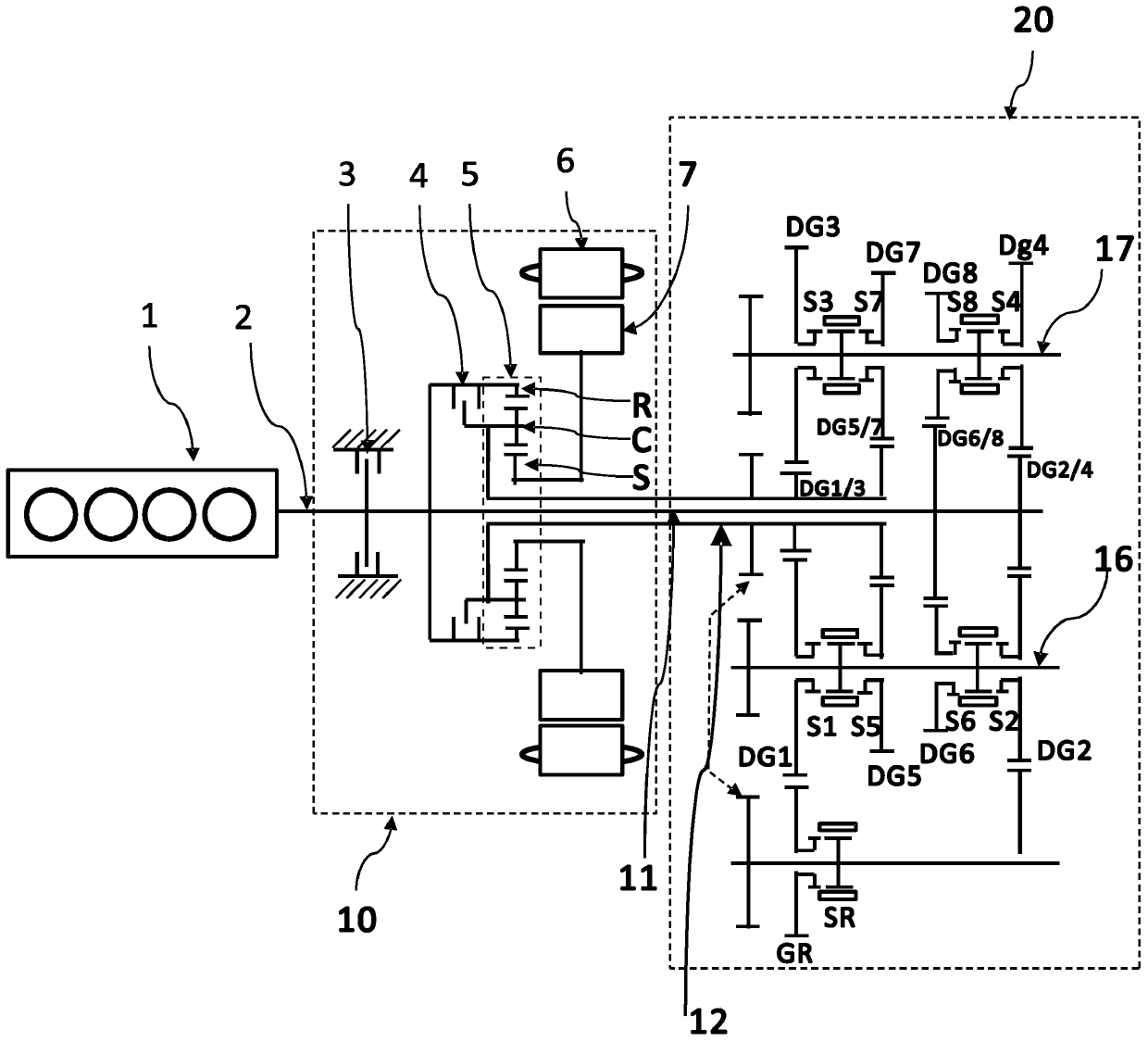

Vehicle hybrid power system and control method thereof

ActiveCN110525191AAdjust torqueTorque balanceHybrid vehiclesGas pressure propulsion mountingElectric machineGear wheel

The invention discloses a vehicle hybrid power system and a control method thereof. The system involves an engine, a hybrid power module and a double-input-shaft speed change mechanism, wherein the hybrid power module is composed of a motor, a planetary gear train and a first clutch, the planetary gear train is provided with at least three rotating shafts, the three rotating shafts comprise a rotating shaft X1, a rotating shaft X2 and a rotating shaft X3, axes of the three rotating shafts are on one straight line, the rotating speed of the rotating shaft X2 is between the rotating speed of therotating shaft X1 and the rotating speed of the rotating shaft X3, a first clutch is arranged between any two of the three rotating shafts, a power output shaft of the engine is connected with the rotating shaft X3 or the rotating shaft X1 of the planetary gear train and a second input shaft of the double-input-shaft speed change mechanism, a rotor of the motor is connected with the rotating shaft X1 or the rotating shaft X3, and the rotating shaft X2 is connected with a first input shaft of a double-input-shaft gearbox. According to the system and the method, the transmission efficiency is high, multiple gears are provided, the three-axis double-freedom-degree planetary gear train is introduced, a vehicle is driven to start by the differential between the engine and the motor, starting of the vehicle is stable, the smoothness of gear shifting is good, and the impact of gear shifting is small.

Owner:段志辉

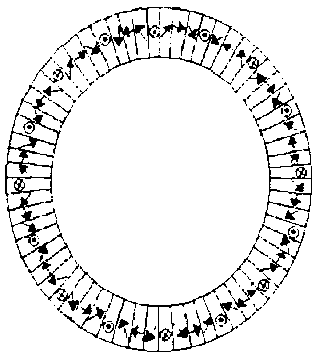

Novel axial magnetic flux double-salient permanent magnet generator

ActiveCN103915961AAxial dimension shortImprove power densityDynamo-electric machinesPermanent magnet motorHigh power density

The invention discloses a novel axial magnetic flux double-salient permanent magnet generator. The technical problem that an existing generator is excessively complex in structure, large in self energy consumption and the like is solved. According to the technical scheme, the novel axial magnetic flux double-salient permanent magnet generator comprises a rotor, a generator outer stator, a generator inner stator, a permanent magnet ring and a rotor shaft. The generator inner stator is embedded in the generator outer stator, and a gap is reserved between the generator inner stator and the generator outer stator, the permanent magnet ring is installed in the gap, the rotor shaft is arranged in the center of the rotor, and the rotor shaft and the rotor are fixed into a whole; the rotor shaft penetrates through the center of the generator inner stator and is not in contact with the generator inner stator; the rotor is located above the generator outer stator and the generator inner stator. By means of the novel axial magnetic flux double-salient permanent magnet generator, a double-salient permanent magnet motor and an axial magnetic flux motor are organically combined; the novel axial magnetic flux double-salient permanent magnet generator has the advantages of being high in efficiency, high in power density, compact in structure, low in noise and low in starting air speed.

Owner:南京轮电动力科技有限公司

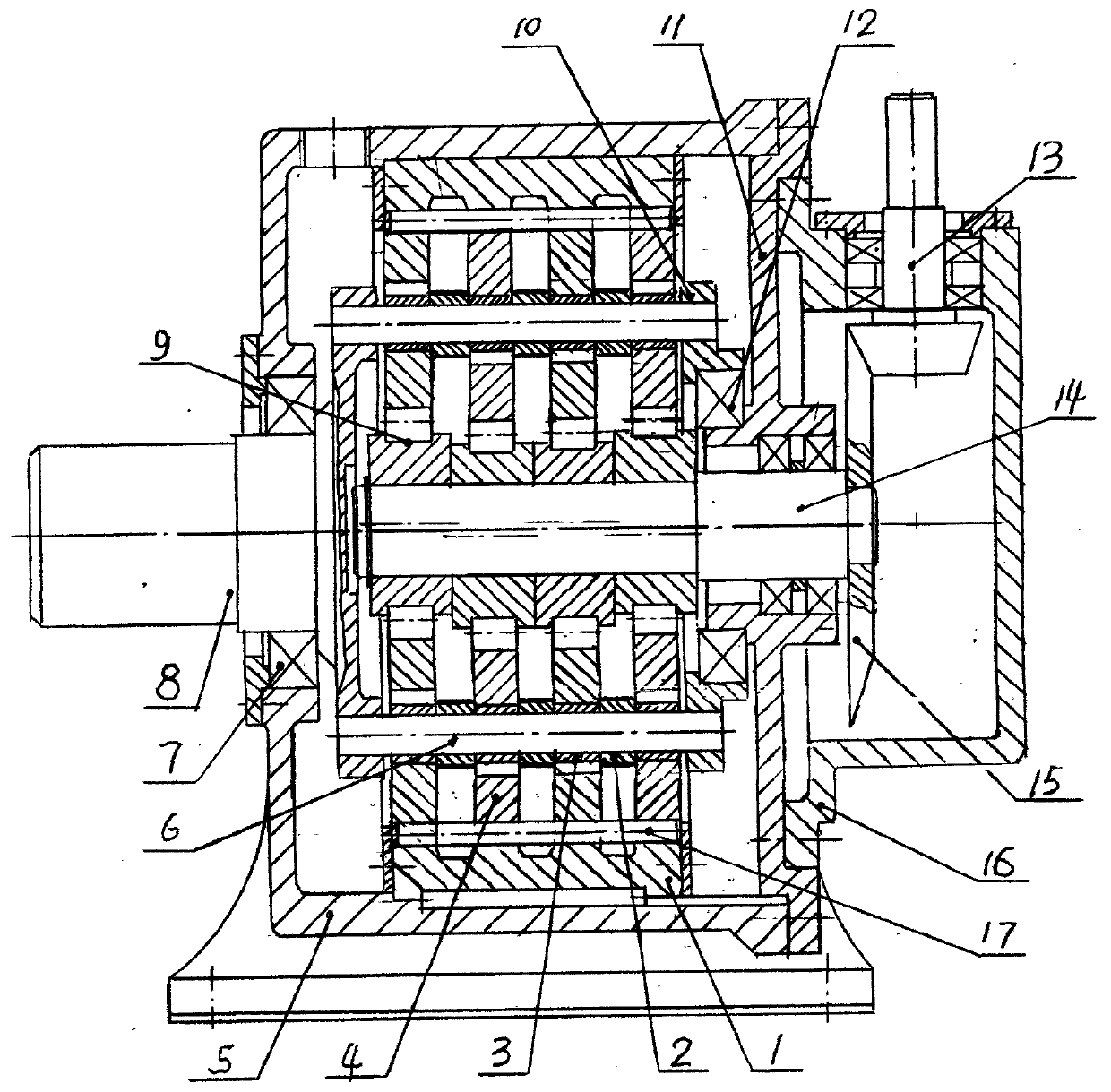

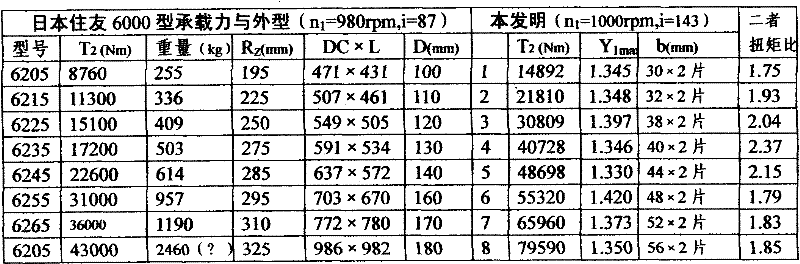

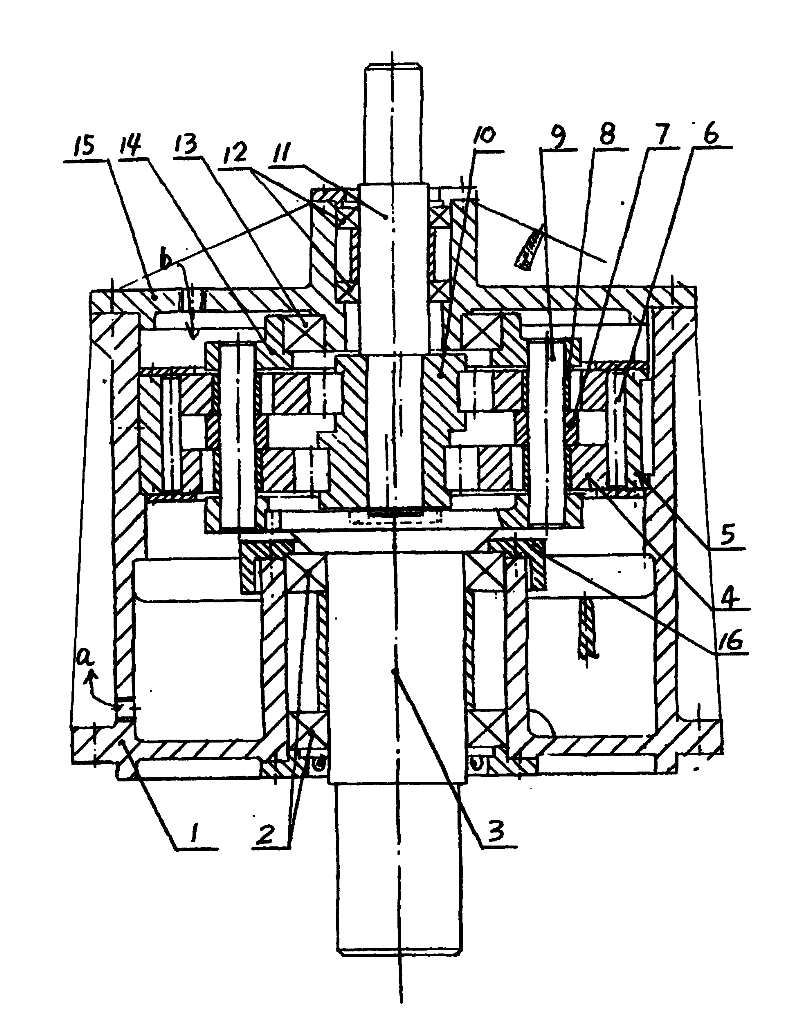

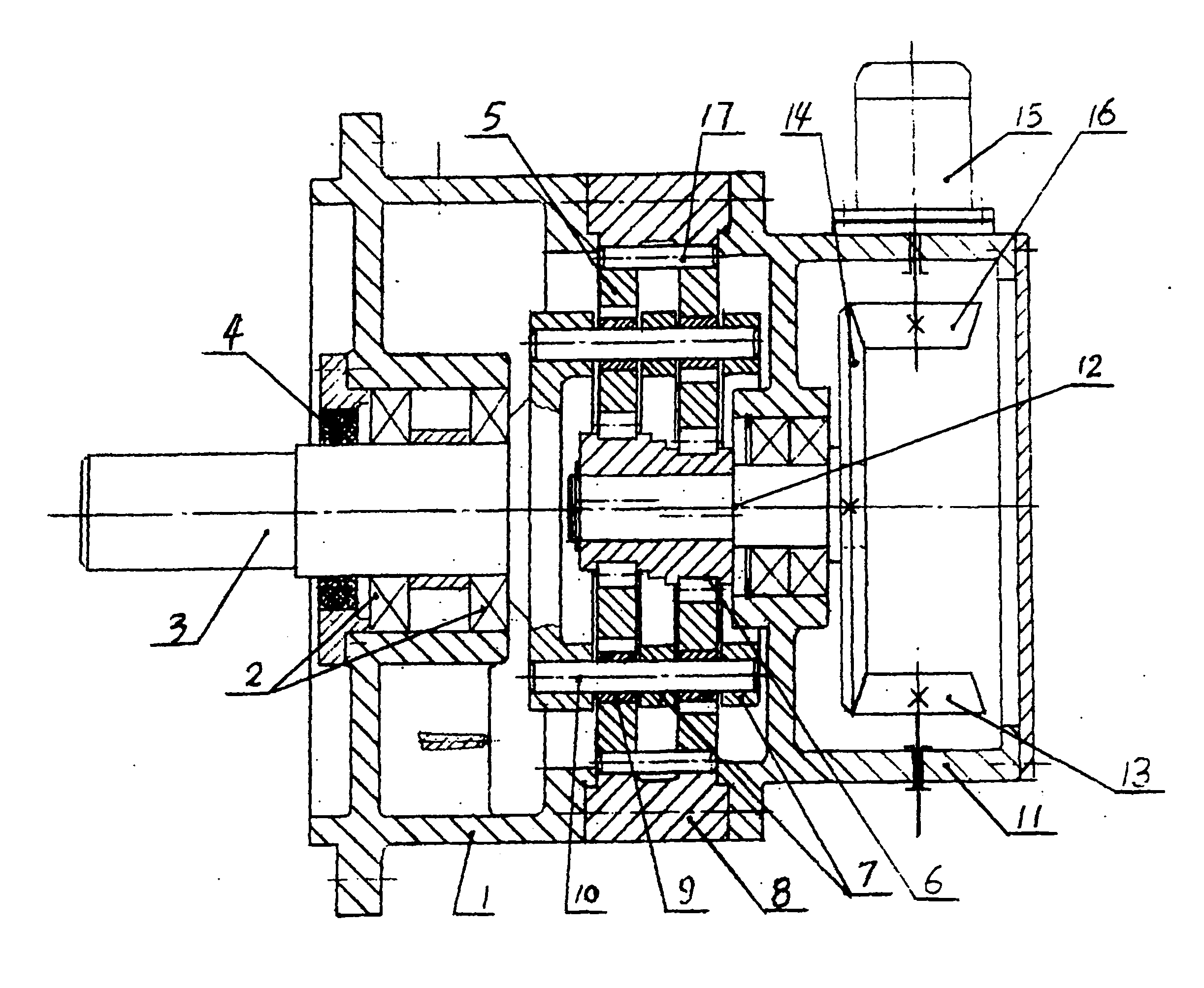

Novel vertical type needle-sleeve-free cycloid reducer

The invention relates to the technical field of cycloid reducers. A novel vertical type needle-sleeve-free cycloid reducer is composed of a machine body, an input shaft, double-eccentric bearings, a cycloid gear, a needle gear shell, needle pins, a column pin, a column sleeve, a W output mechanism and bearings. The novel vertical type needle-sleeve-free cycloid reducer is characterized in that: (A) a vertical type thin-wall cylinder with flange rings on two end faces and a reinforcing rib at the outer part is utilized; (B) the W output mechanism is composed of an output shaft, the column pin and a uniform loading disc; a simple support structure is formed by the column pin through utilizing an upper annular plate on the column pin; in the W output mechanism, the neck of the output shaft is supported in an inner hole of the machine body through utilizing the bearing and an inner hole of the uniform loading disc is supported on the outer circle of a flange in an end cover through the other bearing; (C) the needle gear shell with semi-buried holes is installed in the inner hole of the machine body; (D) the needle pins have no sleeves and the needle pins are movably matched with the semi-buried holes. In the invention, the reducer has the beneficial effects as follows: (1) the reducer has the advanced thin-wall machine body and the W output mechanism, so that the weight is reduced by 20-30% and the axial size is shortened by 25-35%; and (2) the needle pins have no sleeves so that the bearing capability is 1.5-2 times as much as that of a 6000 type reducer.

Owner:吴小杰

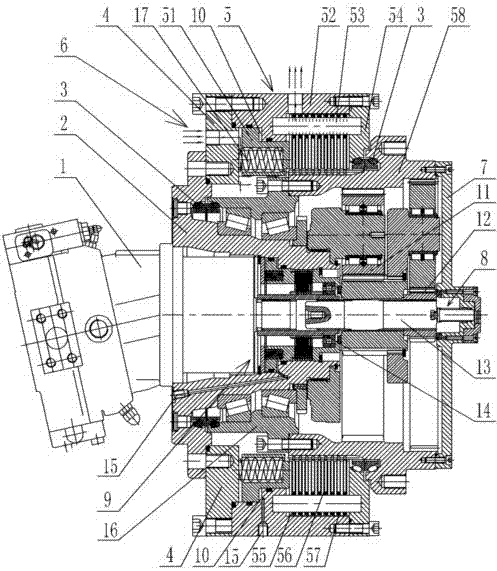

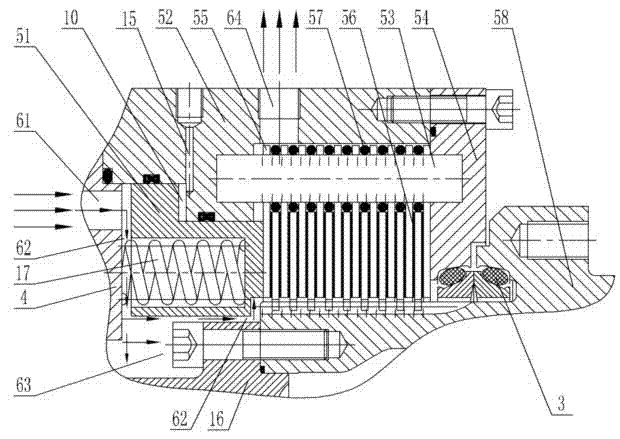

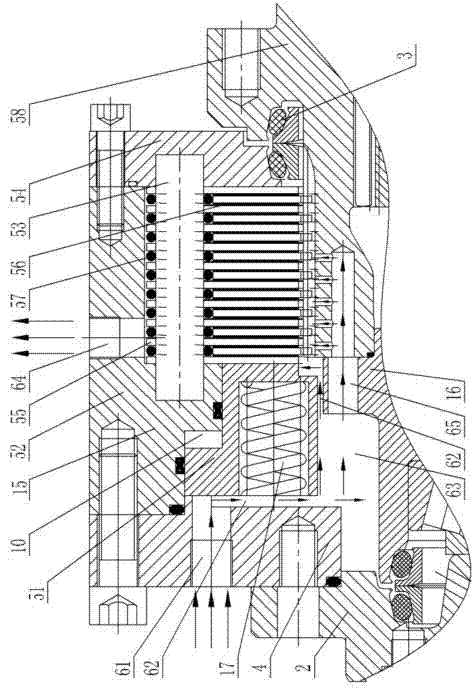

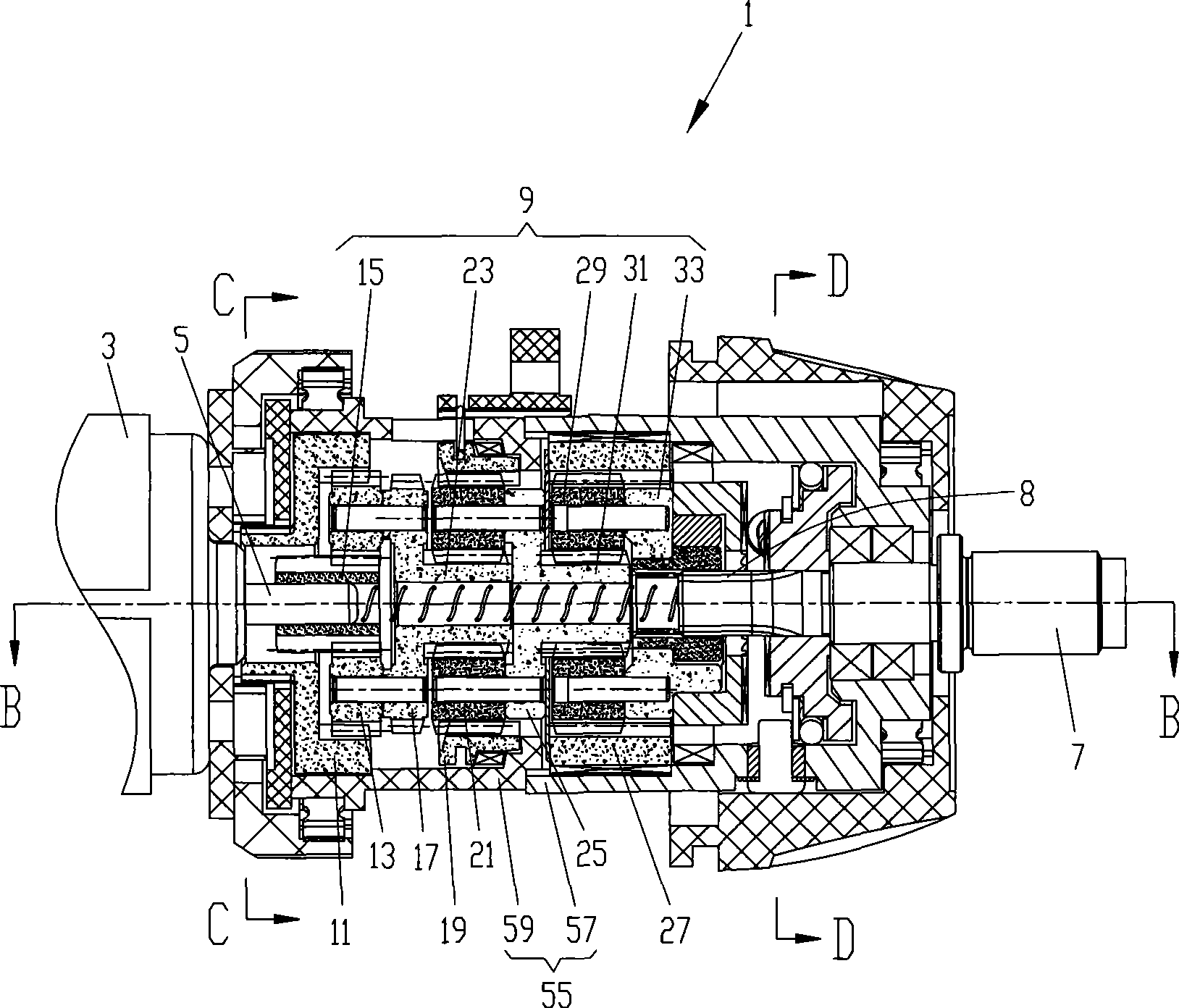

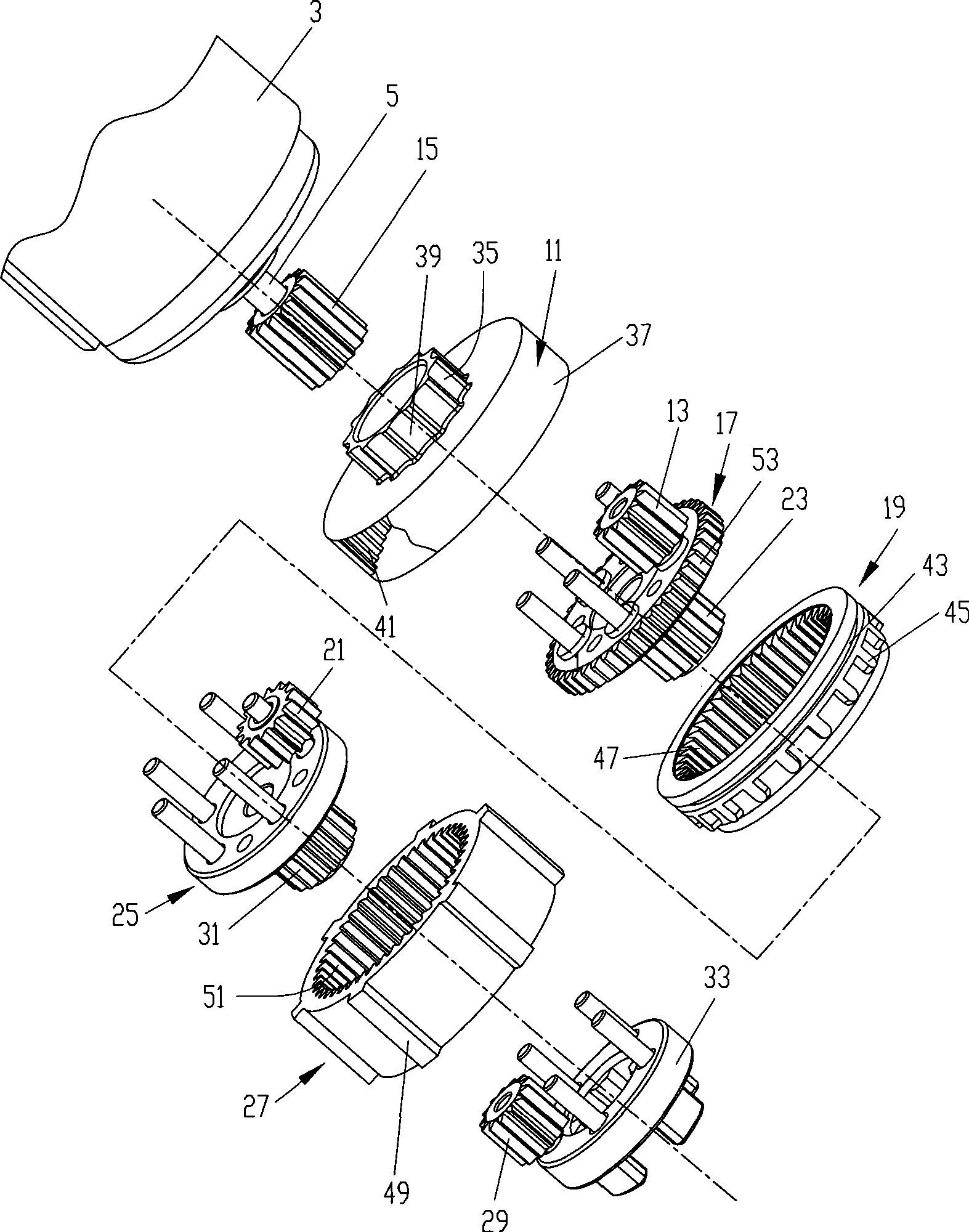

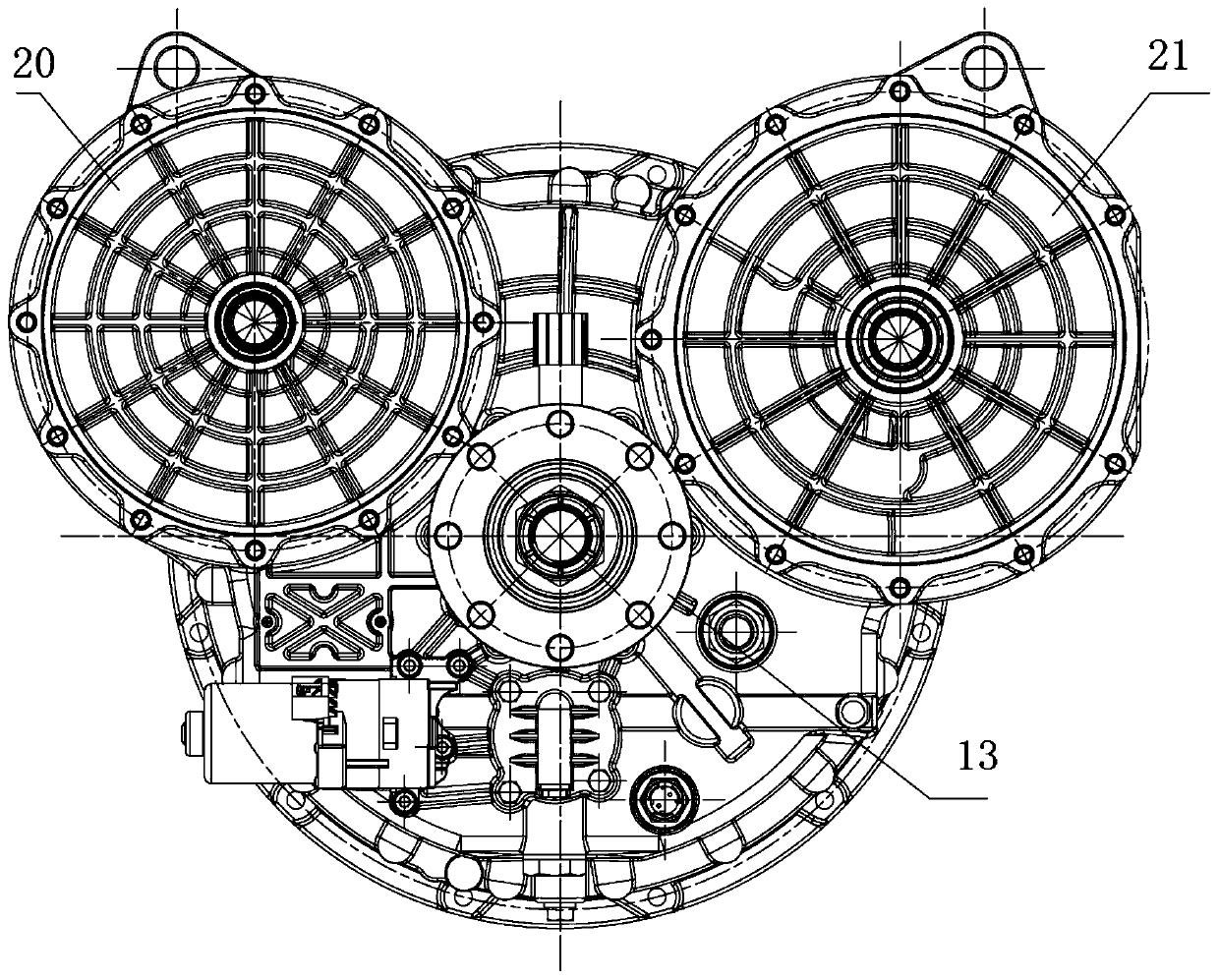

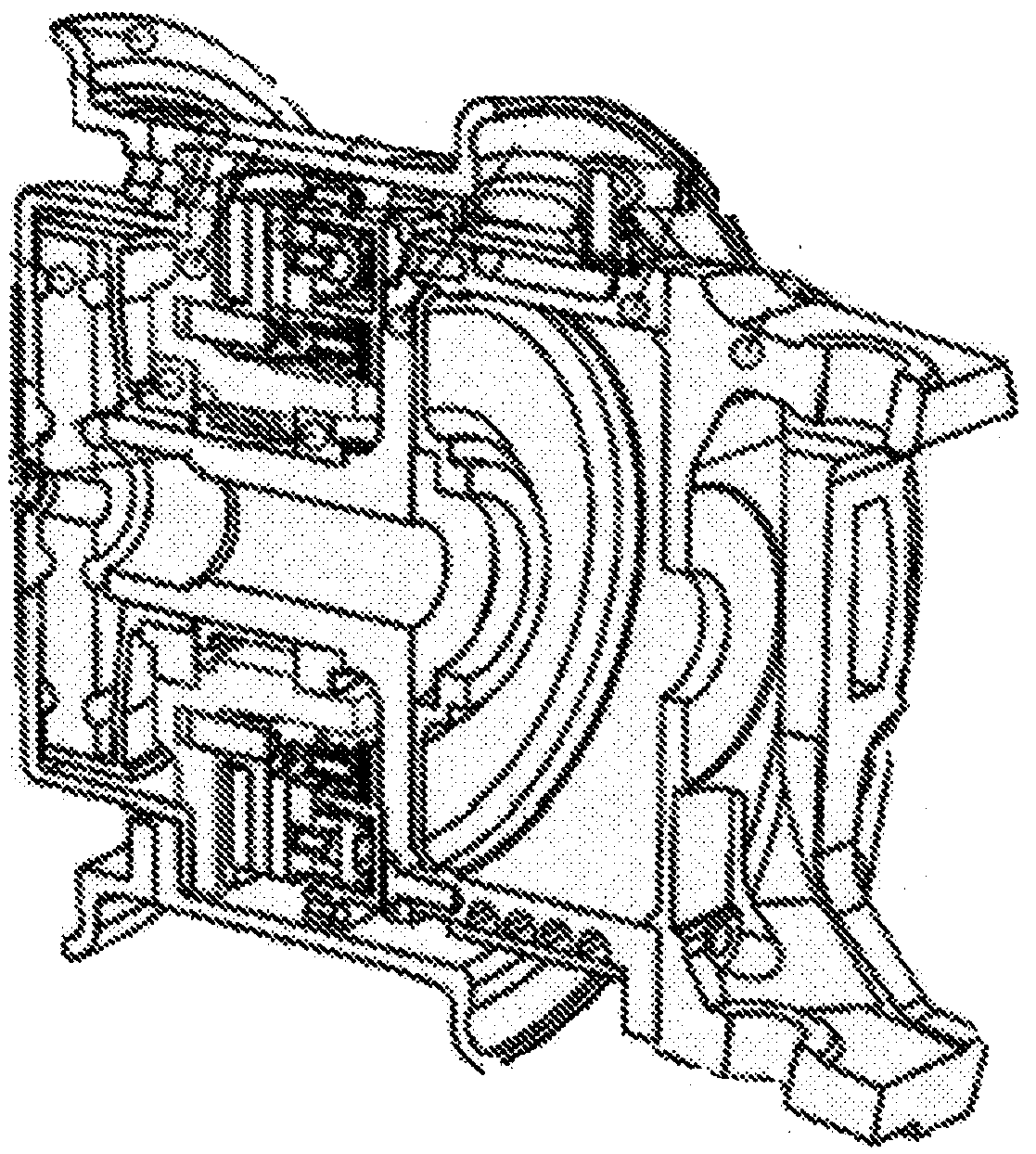

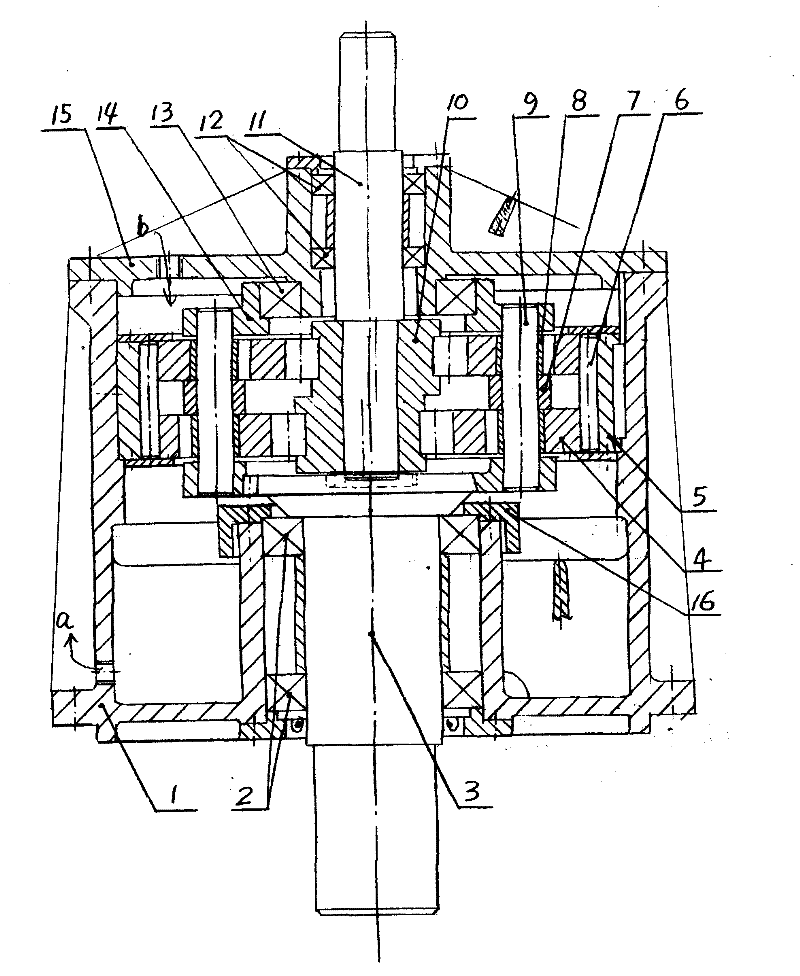

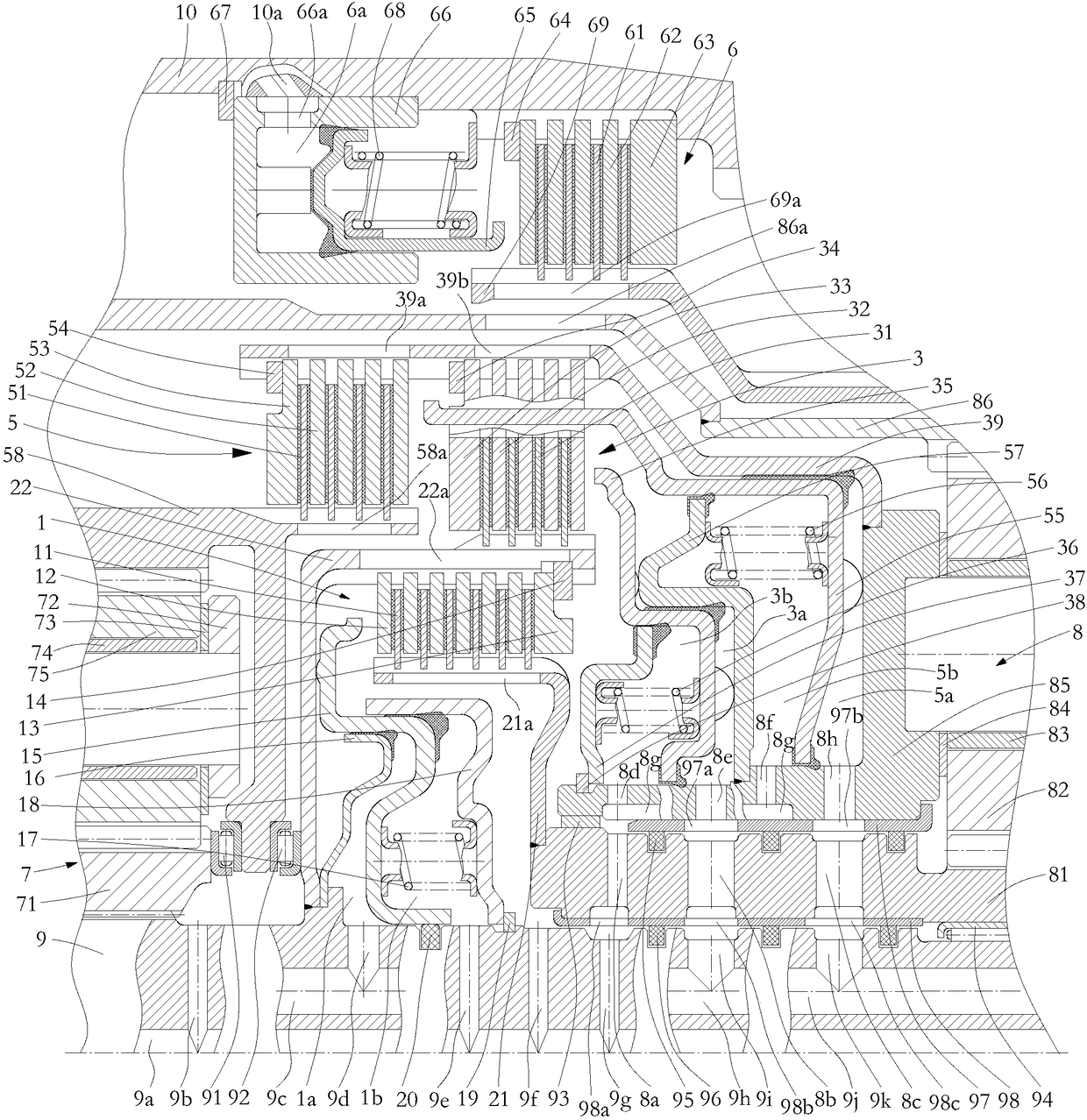

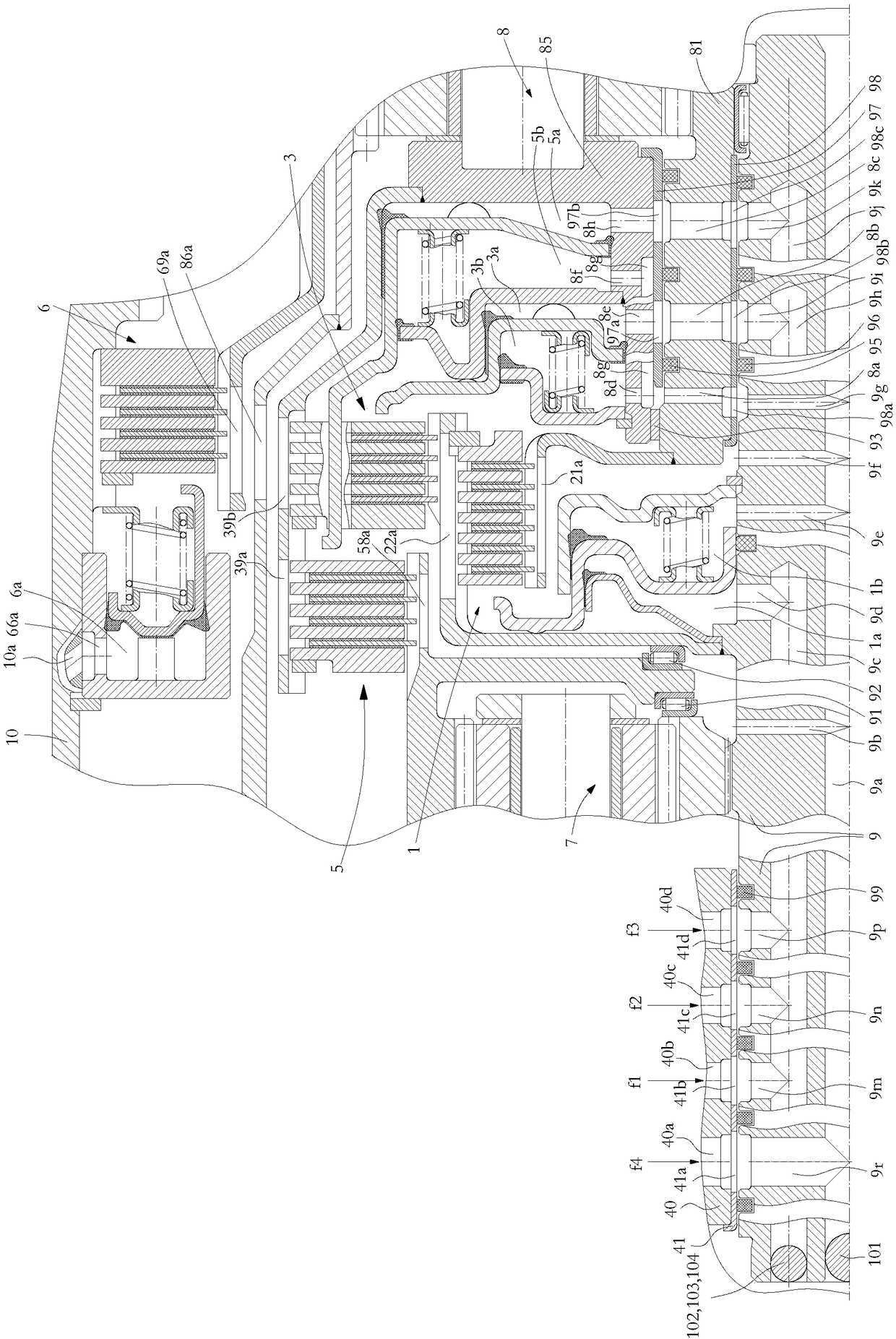

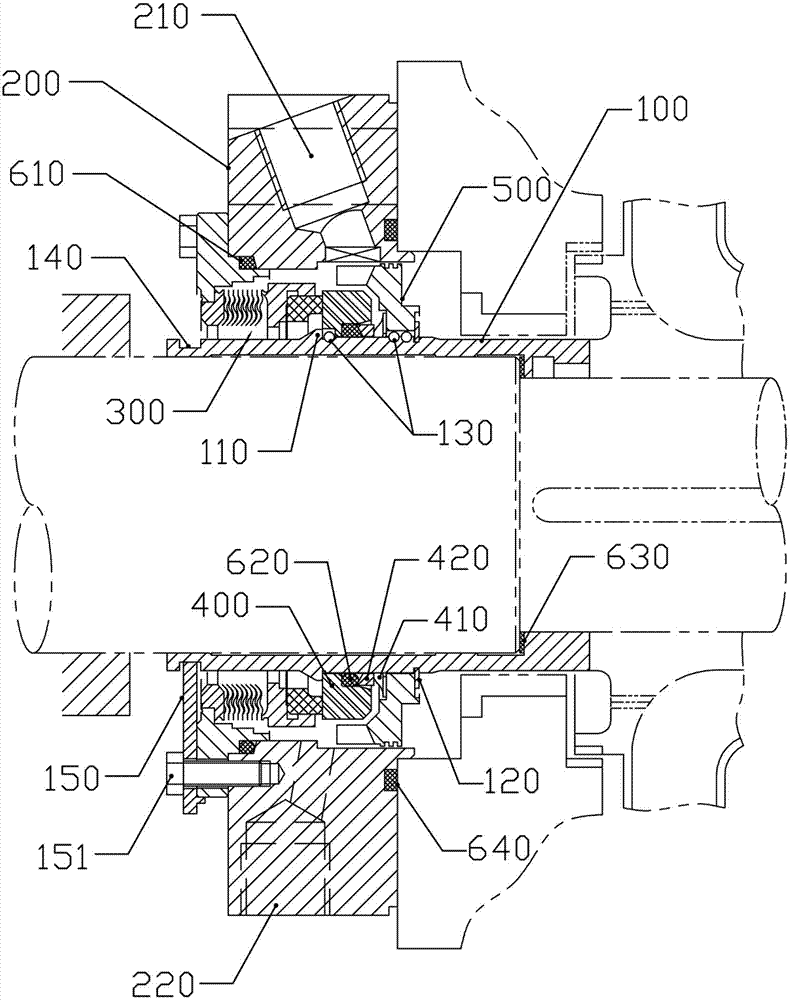

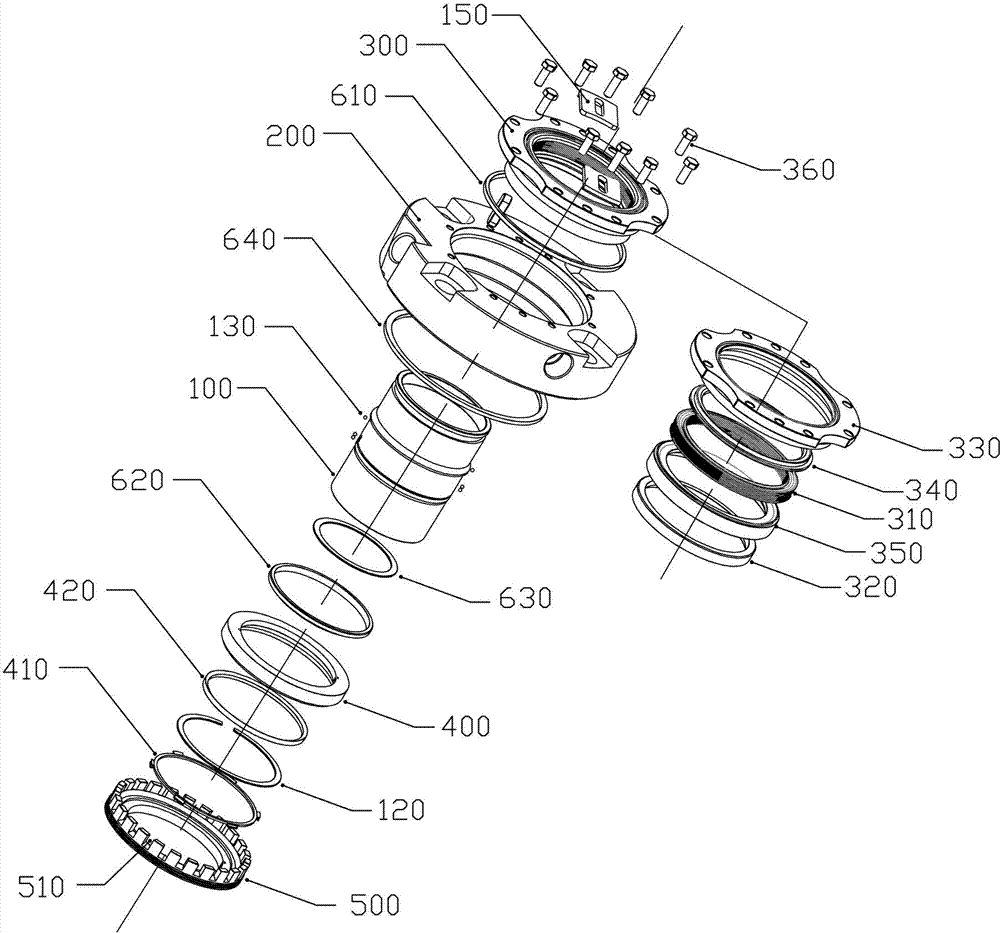

Multi-clutch module, clutch oil supply system and electric control hydraulic automatic transmission

ActiveCN108278335AOptimize layoutAxial dimension shortFluid actuated clutchesToothed gearingsAutomatic transmissionEngineering

The invention provides a multi-clutch module, a clutch oil supply system and an electric control hydraulic automatic transmission. The multi-clutch module comprises a shell structure, and an input shaft, a first planet row structure, a second planet row structure, a first clutch structure, a second clutch structure, a third clutch structure and a brake structure arranged in the shell structure; the first planet row structure and the second planet row structure are arranged at the two ends of the input shaft; the first clutch structure is connected to the second planet row structure and the input shaft; the second clutch structure is connected to the second planet row structure and the input shaft; the third clutch structure is connected to the first planet row structure and the input shaft; the brake structure is connected to the second planet row structure and the shell structure; the first clutch structure is positioned on the radial outer side of the input shaft; the second clutch structure and the third clutch structure are positioned on the outer side of the first clutch structure side by side; and the brake structure is positioned on the outer sides of the second clutch structure and the third clutch structure. The multi-clutch module is more compact in structure, reduces occupied space, simplifies the structure, and reduces the assembly requirements.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Cycloid speed-reducing device of rocket launching movable platform

InactiveCN101963209AImprove bending resistanceAxial dimension shortToothed gearingsReduction driveRocket launch

The invention relates to the technical field of speed reducers, in particular to a cycloid speed-reducing device of a rocket launching movable platform, which is characterized in that the cycloid speed-reducing device is a two-stage speed-reducing device comprising a bevel gear pair and a cycloid transmission, wherein (A) the cycloid transmission comprises a base, an output shaft, a supporting bearing, a cycloid gear, an eccentric bearing, a needle-tooth shell, a needle-tooth pin, a front base, an input shaft and an W output mechanism, wherein an input shaft is supported on an inner hole of the front base by bearings, the shaft-extension end of the input shaft is connected with the eccentric bearing, and the input end is connected with a large bevel gear; the front stand is sequentially connected with the needle-tooth shell and the base; the output shaft is supported on the inner hole of the base by the bearings; and (B) two symmetrical small bevel gear shafts meshed with the large bevel gear are both supported in a box wall hole of the front base by the bearings, wherein one small bevel gear shaft is connected with a motor, and the other small bevel gear shaft is connected with amanually-operated handle. The cycloid speed-reducing device has the advantages of two-stage speed reduction, short axial size, light weight and high quantization; in addition, as cycloid gear teeth and semi-buried teeth are continuous, the cycloid speed-reducing device has larger bearing capacity than that of a planetary transmission with only four planet gears; moreover, the cost of the cycloid speed-reducing device is lowered by 40%-55%.

Owner:郑雪霞

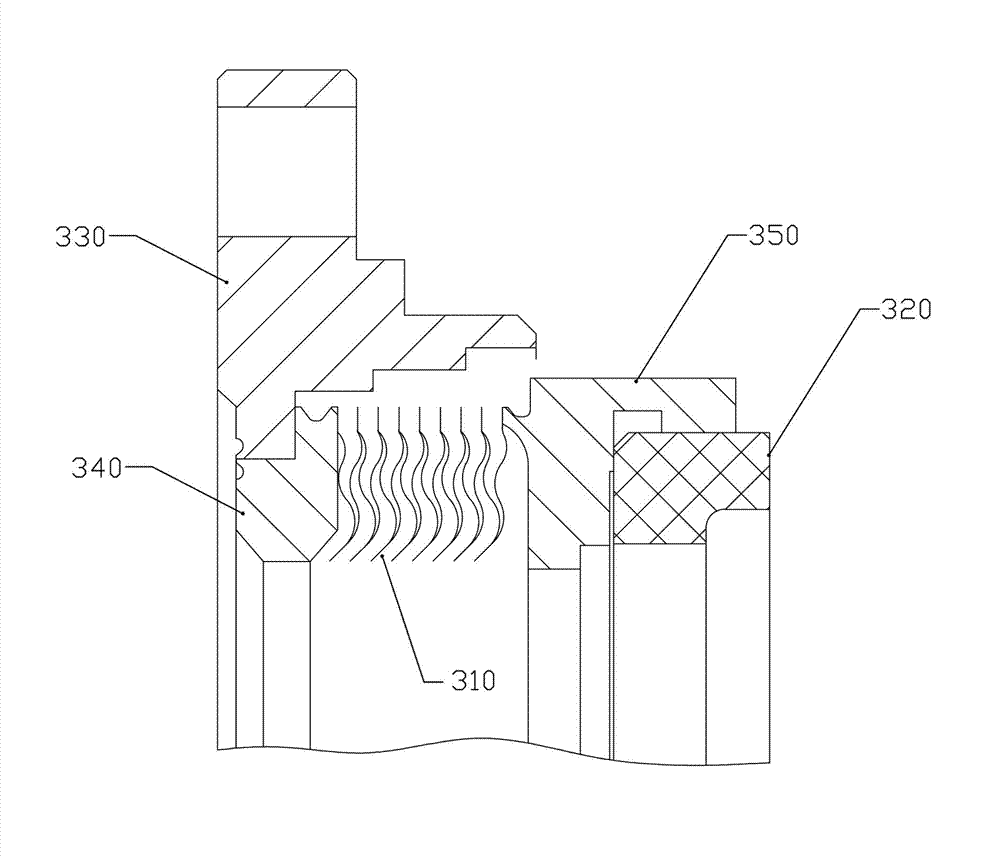

Bellows mechanical sealing device with self-circulation function

The invention discloses a bellows mechanical sealing device with a self-circulation function, which comprises a shaft sleeve, a sealing gland, an elastic compensation component, a moving ring, an auxiliary sealing part and a pump ring. The elastic compensation component comprises a bellows, a static ring and an end cover; the static ring and the end cover are connected to both ends of the bellows in a sealing manner; the end cover is fixed on the sealing gland; the outer wall of the shaft sleeve is provided with a step; one side of the moving ring is abutted against the step; the pump ring is propped against the moving ring by a wave spring; a clamp spring is arranged on the shaft sleeve in a position outside the pump ring; the pump ring and the moving ring are clamped on the shaft sleeve by the clamp spring and the step; anti-rotating parts are respectively between the shaft sleeve and the moving ring and between the shaft sleeve and the pump ring; a ring-shaped clamping groove is formed in the shaft sleeve in a position outside the end cover; and a limiting plate is clamped in the clamping groove and is fixed on the sealing gland. The elastic compensation component is fixed with the sealing gland, the moving ring and the pump ring are clamped on the shaft sleeve by the step and the clamp spring and the sealing gland and the elastic compensation component are limited on the shaft sleeve by the limiting plate, so as to form a cartridge mechanical seal.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

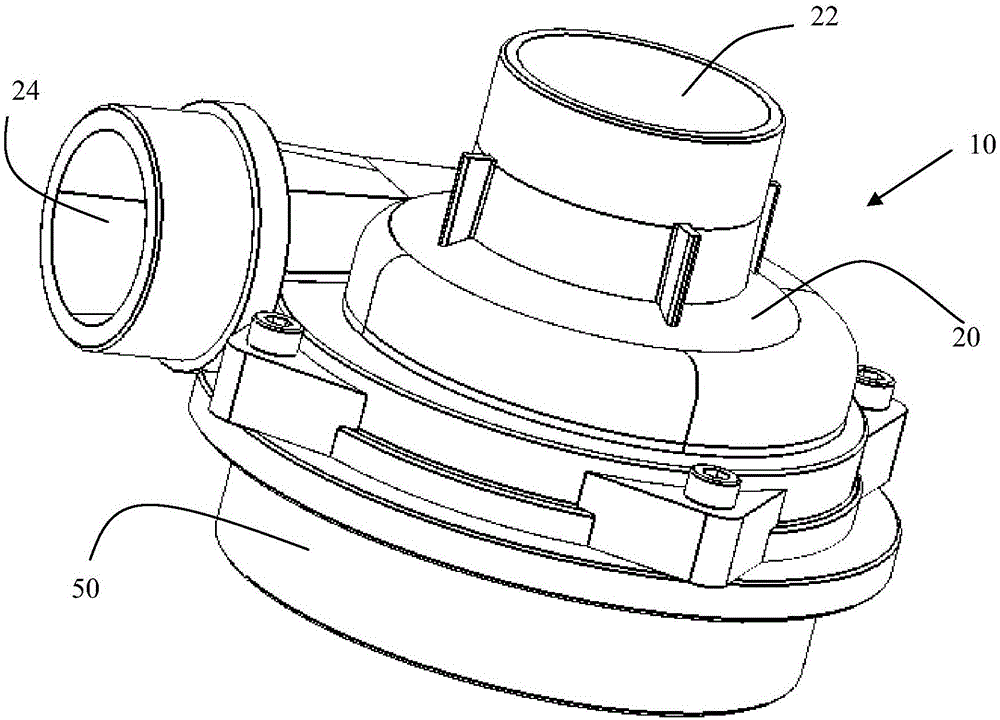

Electric pump

InactiveCN105370584AAxial dimension shortSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsImpellerMagnet

The invention relates to an electric pump. The electric pump comprises a pump body, an impeller contained in the pump body and a motor for driving the impeller to rotate; the motor comprises a stator and a rotor, the rotor comprises a rotor yoke and a permanent magnet which are fixed to the impeller, and the stator comprises a stator yoke, a plurality of stator teeth arranged in the circumferential direction at intervals and a coil wound on the stator teeth; the stator yoke is provided with a containing groove corresponding to each stator tooth, clamping claws are arranged on the two sides of the tail end of the containing groove, and after each stator yoke is inserted into the corresponding containing groove of the stator yoke, the clamping claws on the two sides of the tail end of the containing groove deform towards the stator teeth so as to fix the stator teeth into the containing groove. The electric pump is short in axial size, simple in structure, convenient to assemble and low in machining cost.

Owner:JOHNSON ELECTRIC GUANGDONG CO LTD

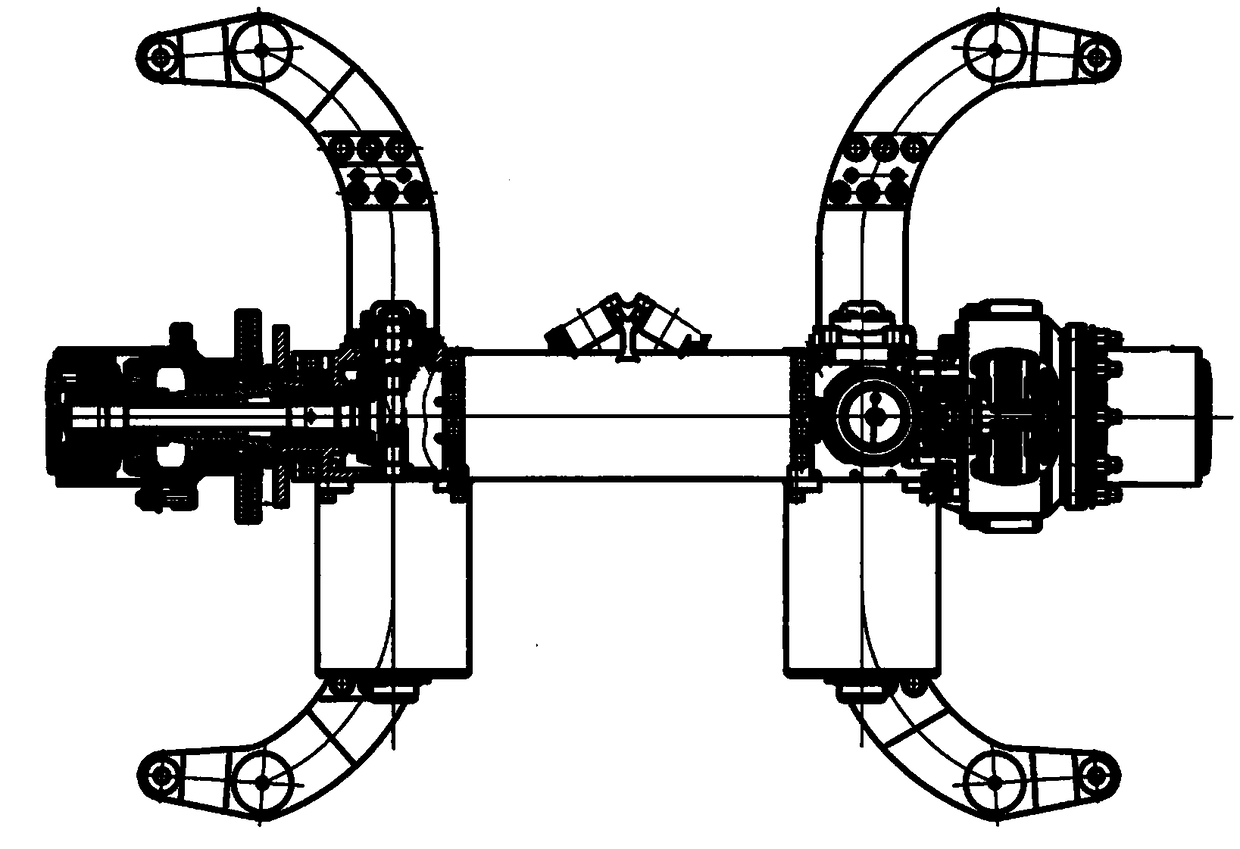

Heavy-load electric wheel

PendingCN111361358AAxial dimension shortCost controlBraking element arrangementsMagnetic circuit rotating partsReduction driveGear wheel

The invention discloses a heavy-load electric wheel, and belongs to the field of electric vehicle power devices. A brake, a planetary gear reducer and a hub motor are sequentially arranged on the outer side of a supporting shaft from the distant to the near; the outer side of a hub is connected with a spoke mounting plane of a rim through a spoke, and the hub is mounted on the outer side of the supporting shaft through a pair of hub bearings; a brake caliper support in the brake is installed outside the distal facet of the wheel supporting shaft through a bolt, and a brake disc is installed ona brake disc installation flange of the hub; a hub part of the hub motor rotor support is sleeved on the rotor shaft; and a sun gear in the planetary gear reducer is disposed outside the distal end side of the rotor shaft. The axial size of the whole electric wheel assembly is short, and the hub motor, the planetary gear reducer and the brake are all arranged in the space defined by the rim on the inner side and the outer side of the electric wheel assembly, so that the electric wheel assembly can be suitable for common commercial vehicle double-tire parallel loading wheels.

Owner:南京清研易为新能源动力有限责任公司

High-torque cycloidal speed-reduction device of rocket launching moving platform

InactiveCN102032321AImprove bending resistanceAxial dimension shortRocket launchersToothed gearingsRocket launchReduction drive

The invention relates to the technical field of a speed reducer, in particular to a high-torque cycloidal speed-reduction device of a rocket launching moving platform. The high-torque cycloidal speed-reduction device of the rocket launching moving platform is characterized in that: a two-stage speed-reduction device is formed through cycloidal transmission of a bevel gear pair and three cycloidal wheels, wherein, (A) the cycloidal transmission is constituted by a base, an output shaft, a supporting bearing, three cycloidal wheels with 120 degrees of phase angles, an eccentric bearing, a pin gear housing, a gear pin, a front base, an input shaft and a W-shaped output mechanism, wherein the input shaft is supported in an inner hole of the front base by a bearing, the shaft extension end of the input shaft is connected with the eccentric bearing, and the input end is connected with a bevel gear wheel; the front base is sequentially integrated with the pin gear housing and the base; and the output shaft is supported in the inner hole of the base by a bearing; and (B) two systematical bevel pinion shafts which are meshed with the bevel gear wheel are supported in a box wall hole of the front base by a bearing, and one bevel pinion shaft is connected with a motor and the other bevel pinion shaft is connected with a manual handle. The high-torque cycloidal speed-reduction device of the rocket launching moving platform has the beneficial effects that: (a) two-stage reduction is adopted, the axial size is short, the weight is small and the height is lightened; (b) cycloidal gear teeth and half-buried teeth are not broken, and three cycloidal wheels are adopted, therefore, the bearing capacity of three cycloidal wheels is higher than that of epicyclic transmission of four planet wheels; and (c) the cost is reduced by 40-55 percent.

Owner:吴声震

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com