Patents

Literature

330 results about "Cycloid gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

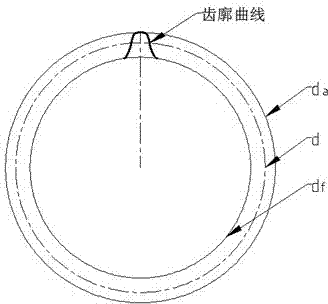

The cycloidal gear profile is a form of toothed gear used in mechanical clocks, rather than the involute gear form used for most other gears. The gear tooth profile is based on the epicycloid and hypocycloid curves, which are the curves generated by a circle rolling around the outside and inside of another circle, respectively.

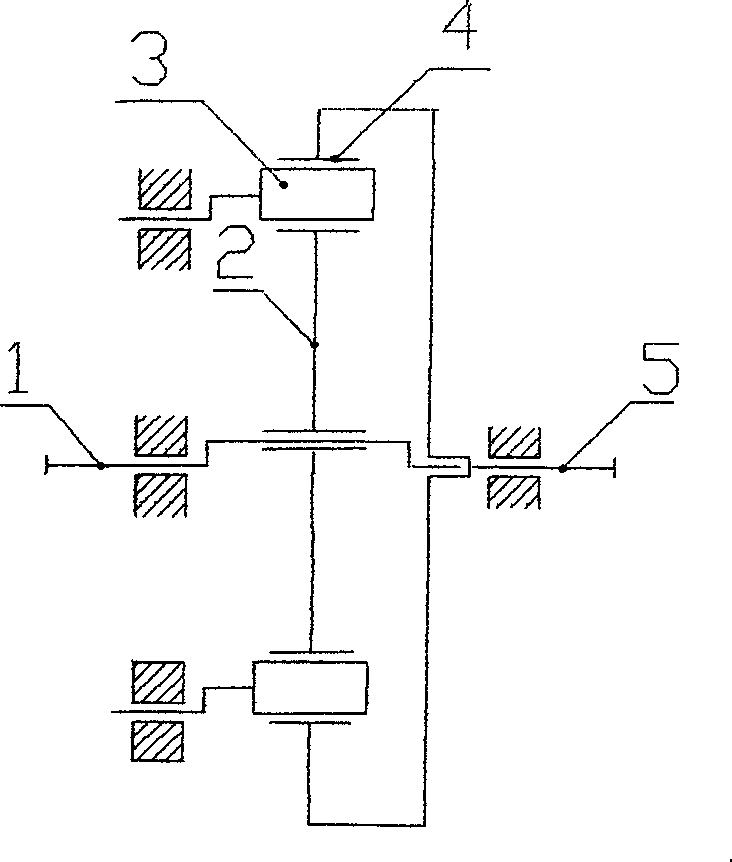

Double-drive coaxial forward and reverse output spiral rock-entering drilling machine

ActiveCN103670264ANo pollution in the processImprove reliabilityConstructionsToothed gearingsGear wheelEngineering

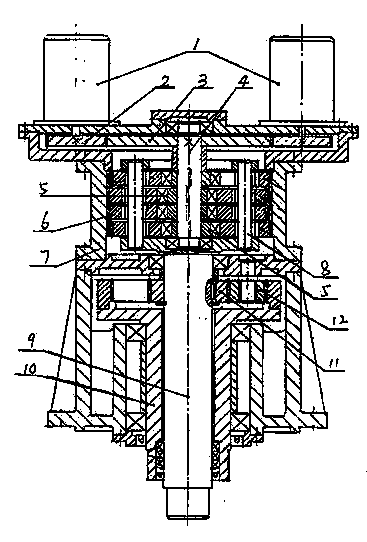

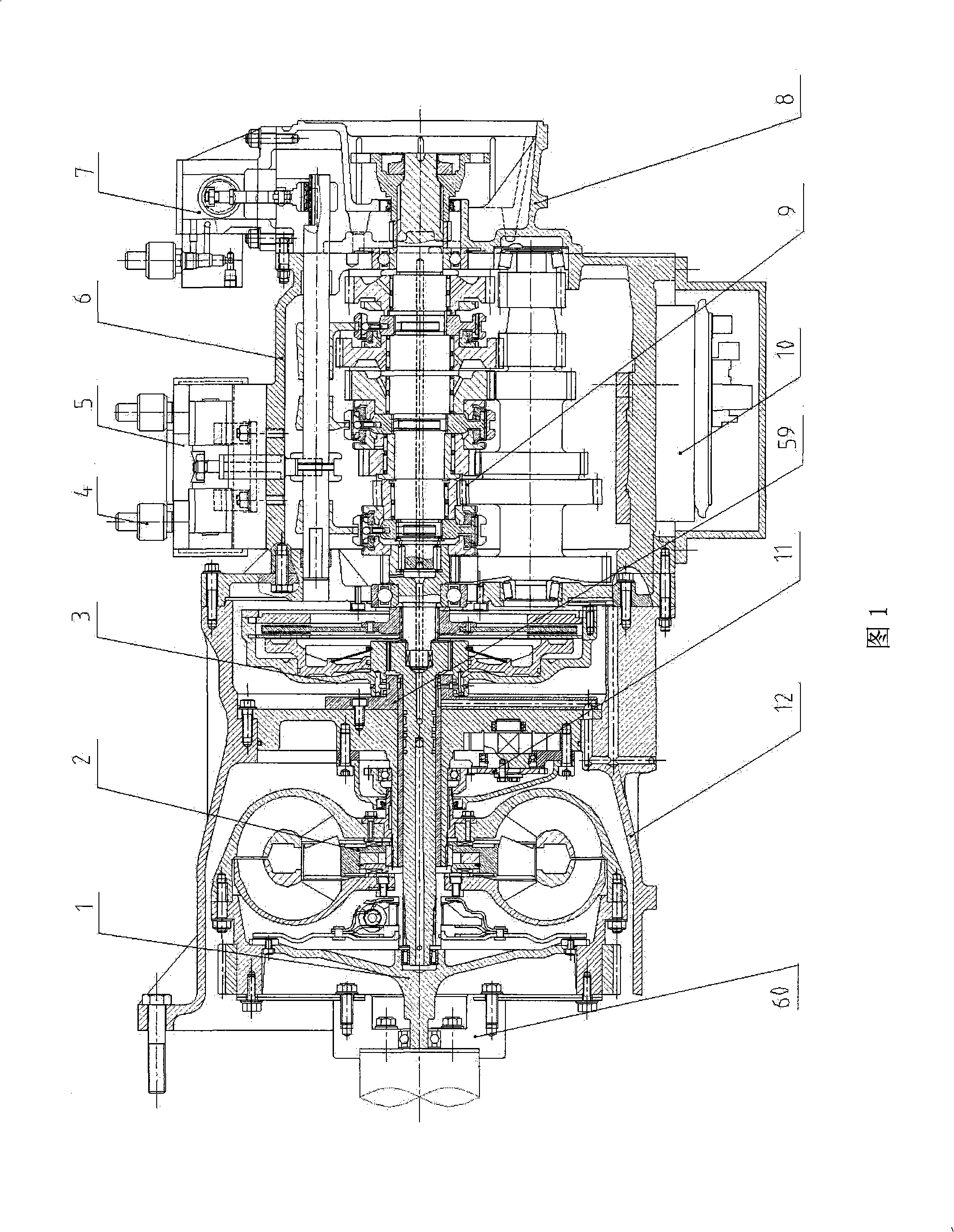

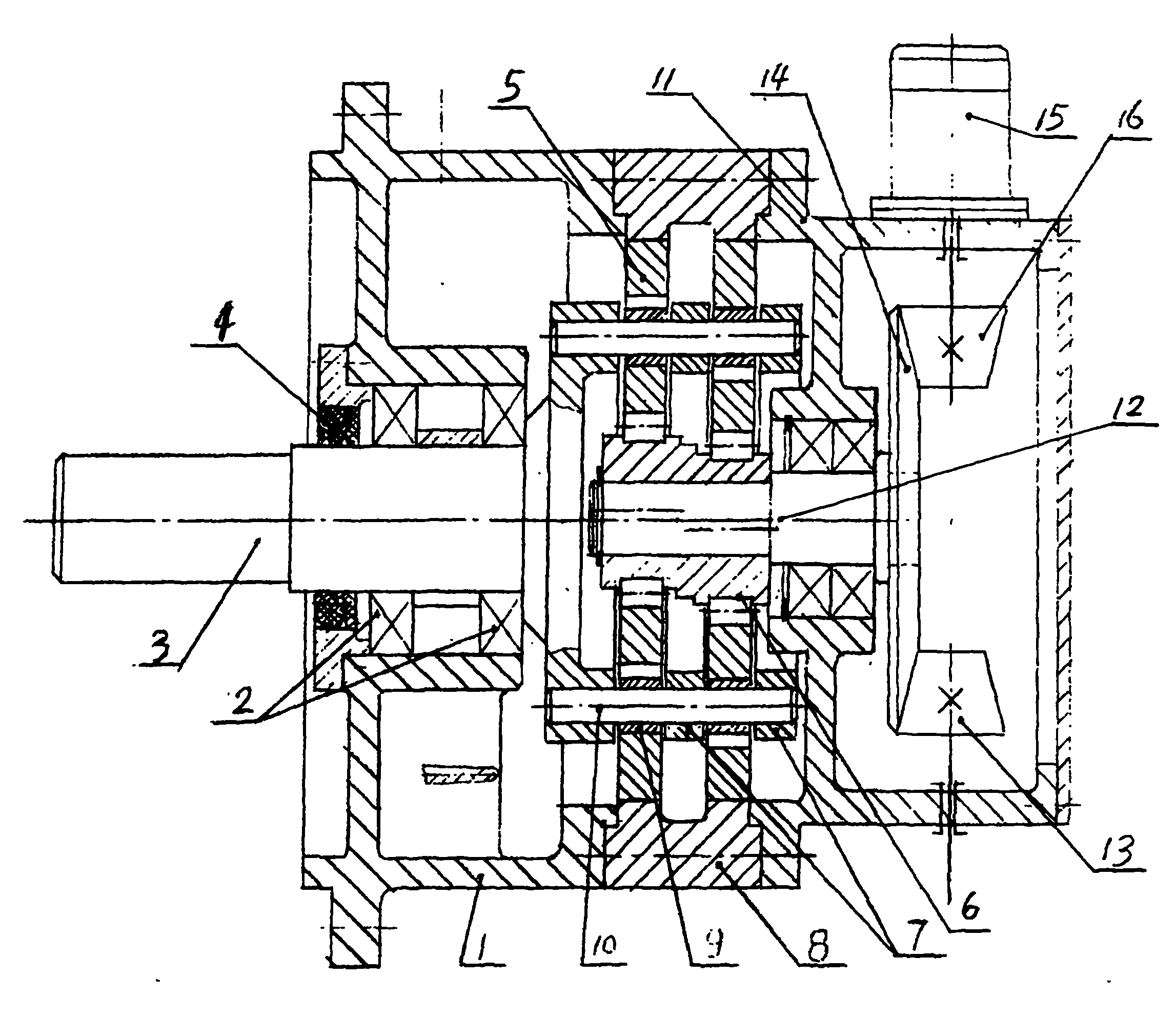

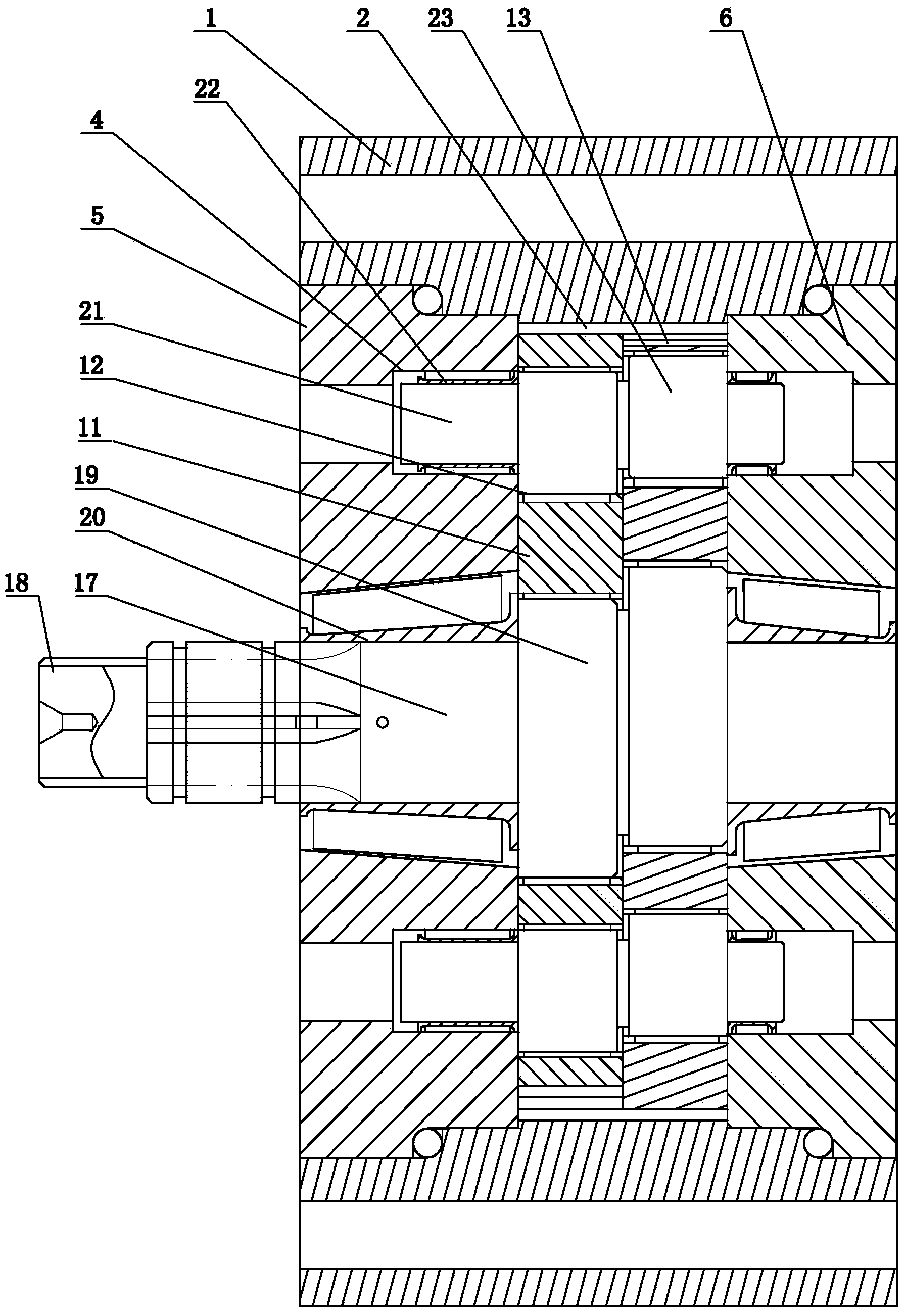

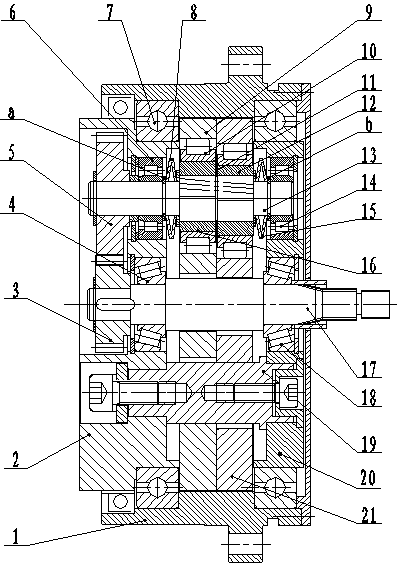

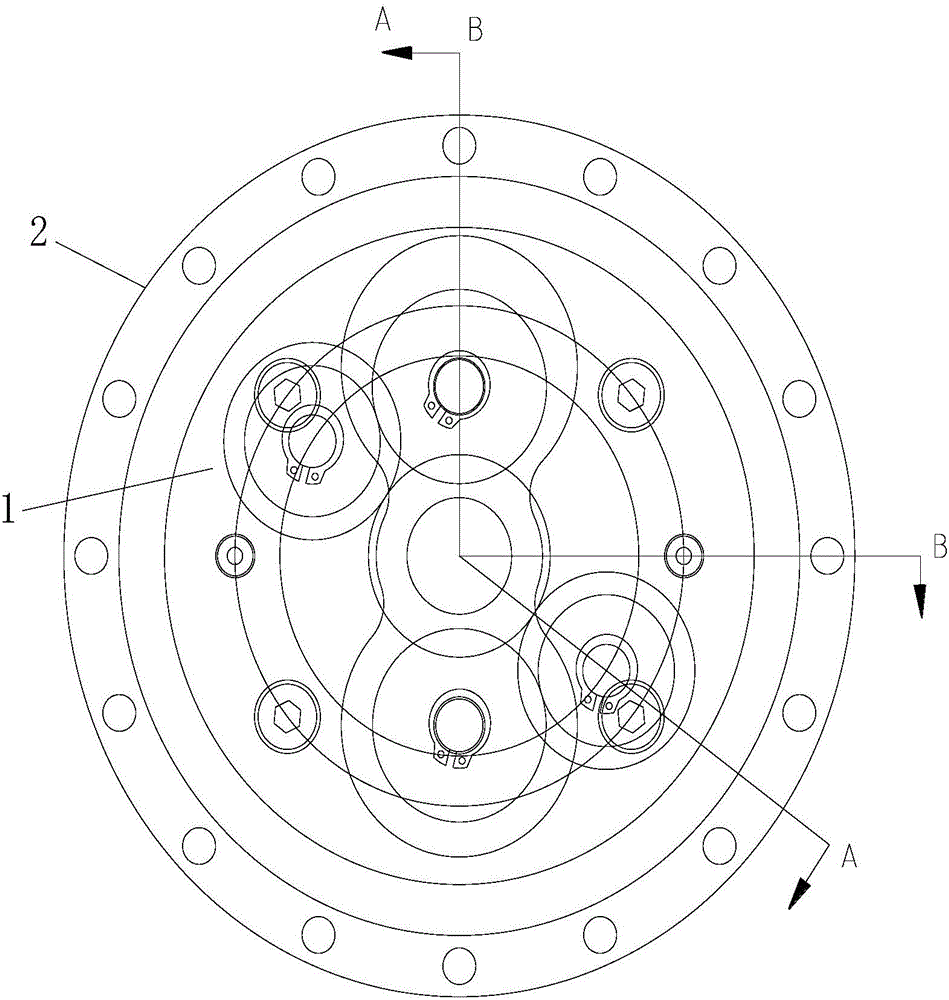

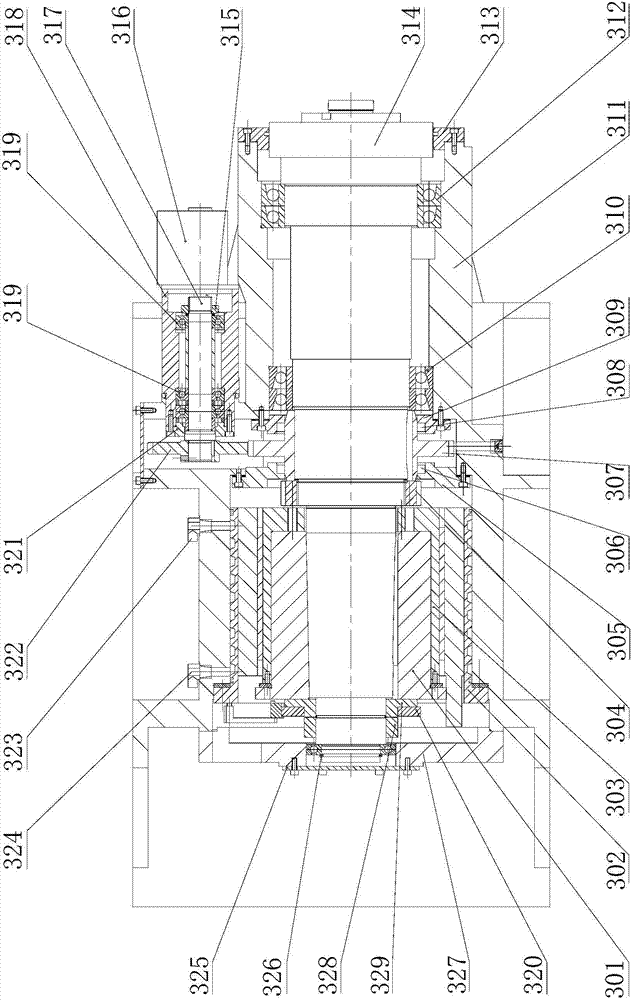

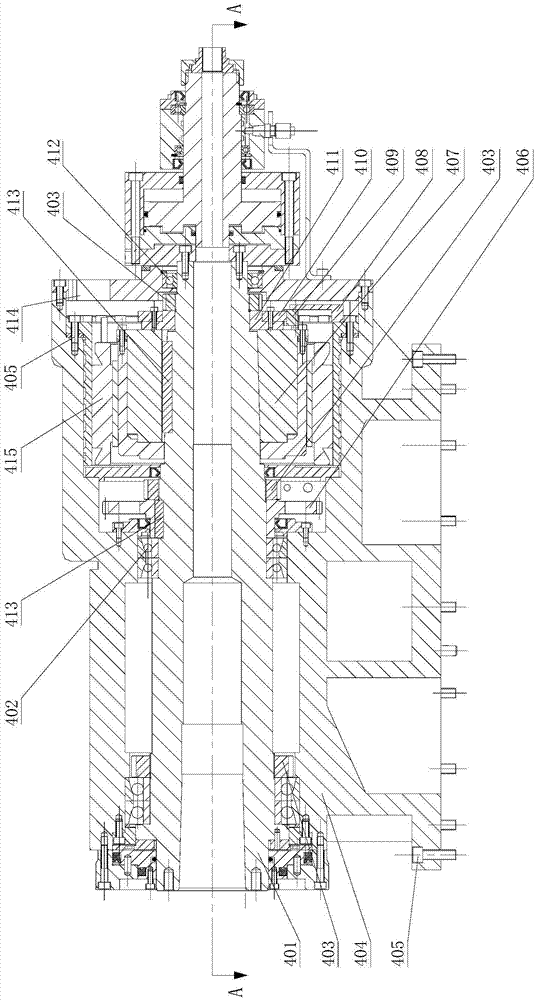

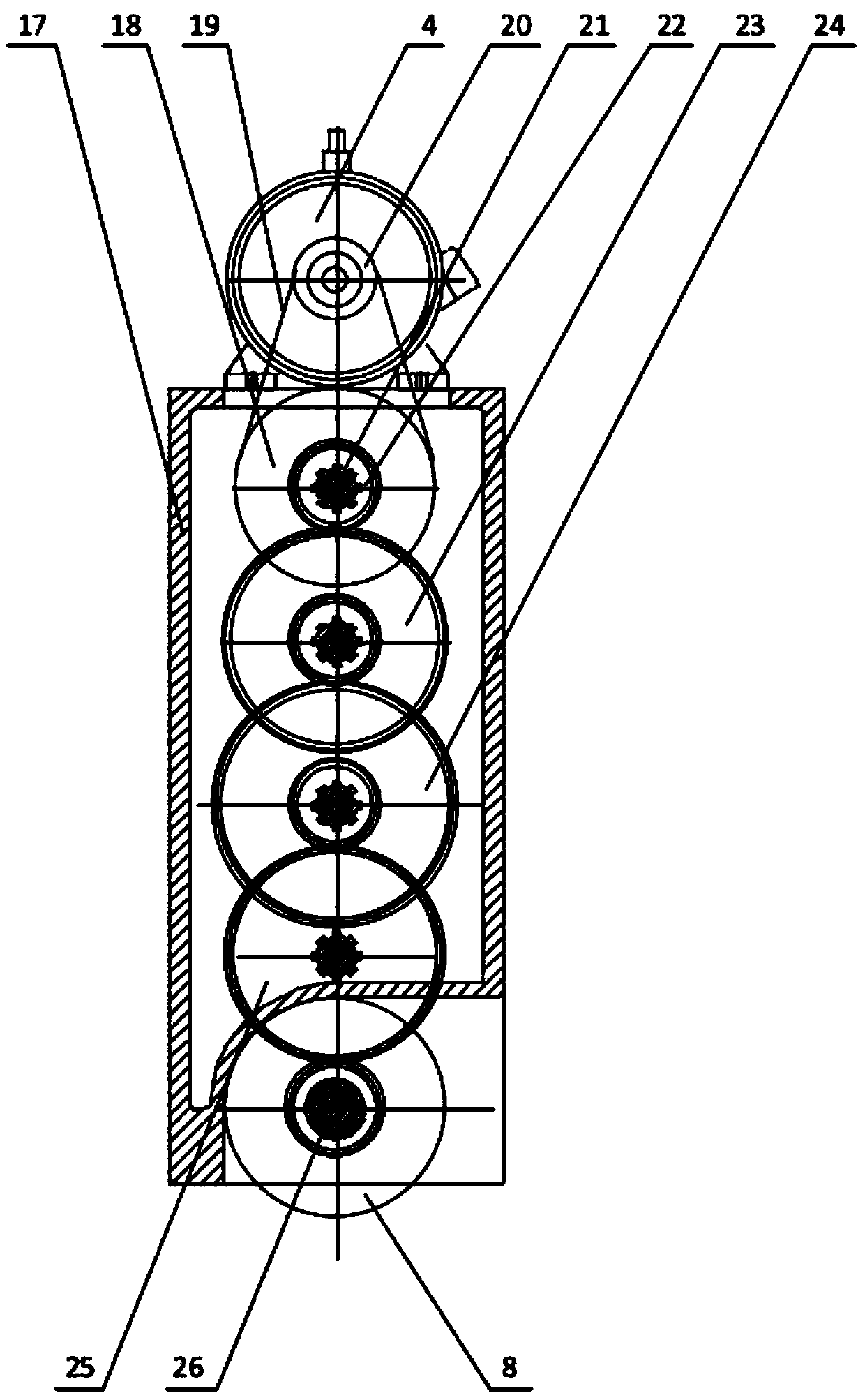

The invention relates to a double-drive coaxial forward and reverse output spiral rock-entering drilling machine which comprises double input motors, an input shaft, an output shaft, an outer sleeve, four cycloid gear mechanisms and four planetary speed reduction mechanisms. The double input motors are respectively meshed with a gear wheel on the input shaft via pinions, the outer sleeve is coaxially sleeved on the output shaft via a bearing, four eccentric bearings are serially connected into the input shaft and are respectively connected into center holes of four cycloid gears, outer gears are arranged on the outer sides of the cycloid gears and are meshed with internal teeth of a housing case, outer holes are respectively formed in the left side and the right side of each cycloid gear, pins are respectively coaxially and movably arranged in the outer holes and are connected with the output shaft, a center wheel is connected onto the output shaft, and planet gears are uniformly distributed at the peripheral edge of the center wheel in a meshed manner and are meshed with an inner gear ring of the outer sleeve.

Owner:山东卓力桩机有限公司

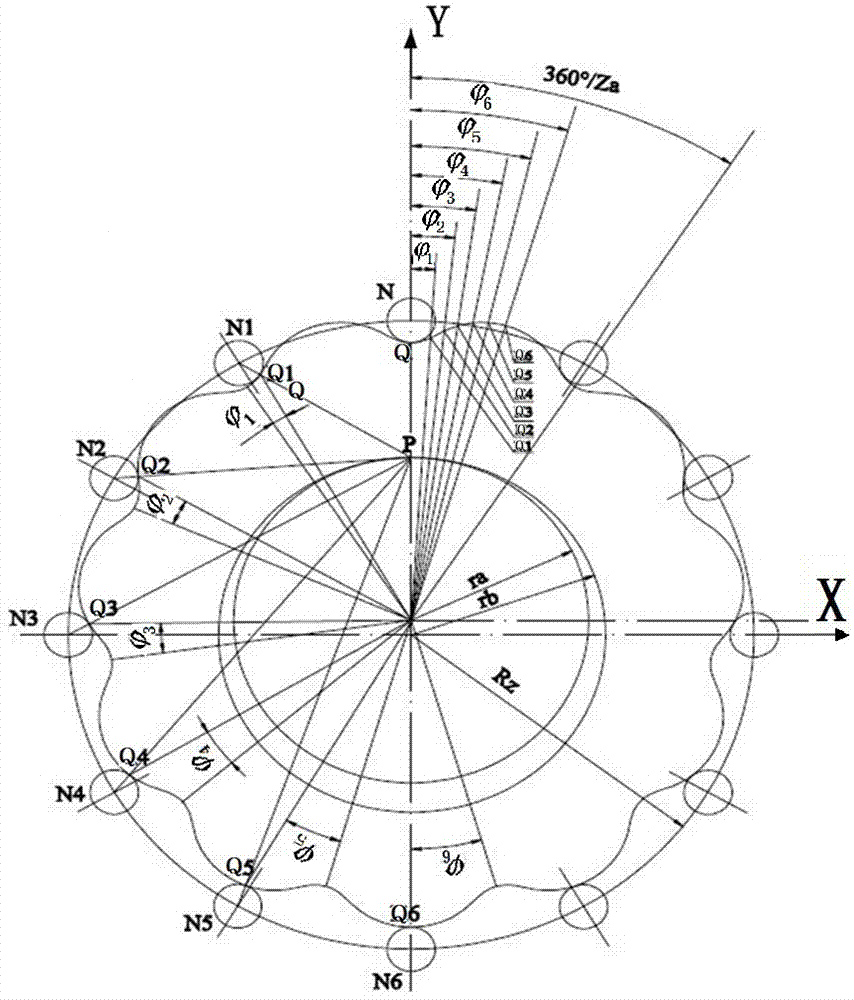

Method for optimizing cycloid gear tooth outline modification amount based on matlab

InactiveCN103886154AShorten calculation cycleOptimum equidistant displacement modified tooth profileSpecial data processing applicationsMathematical modelProcess engineering

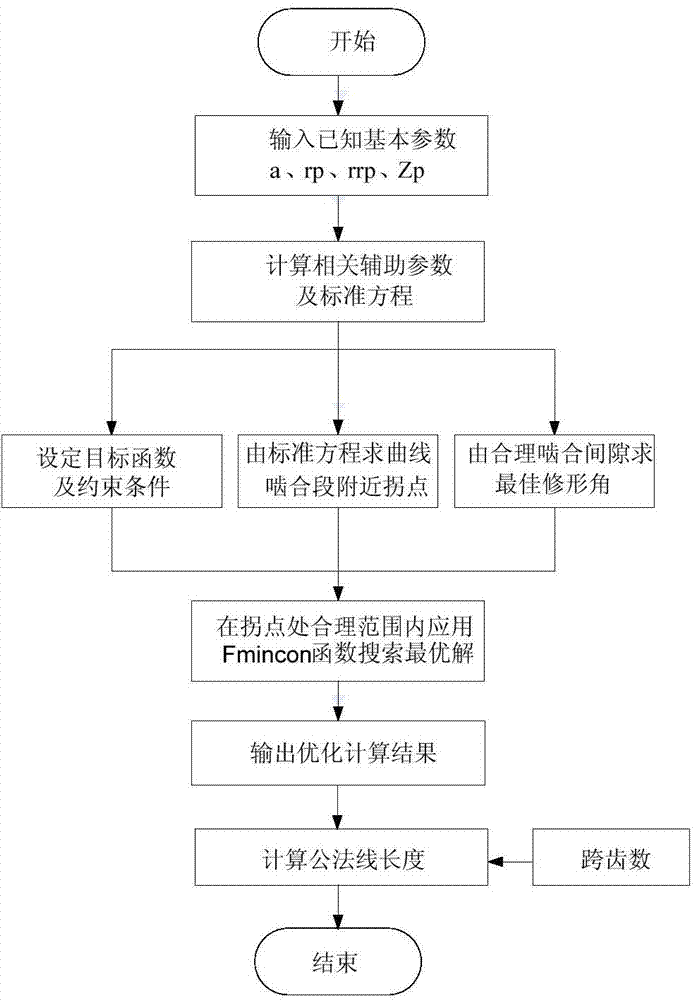

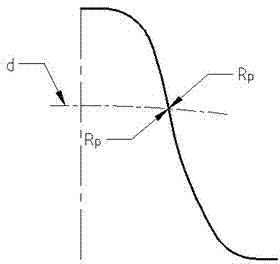

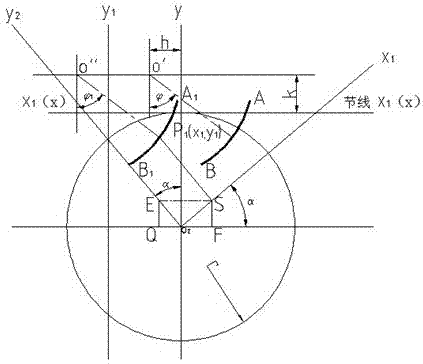

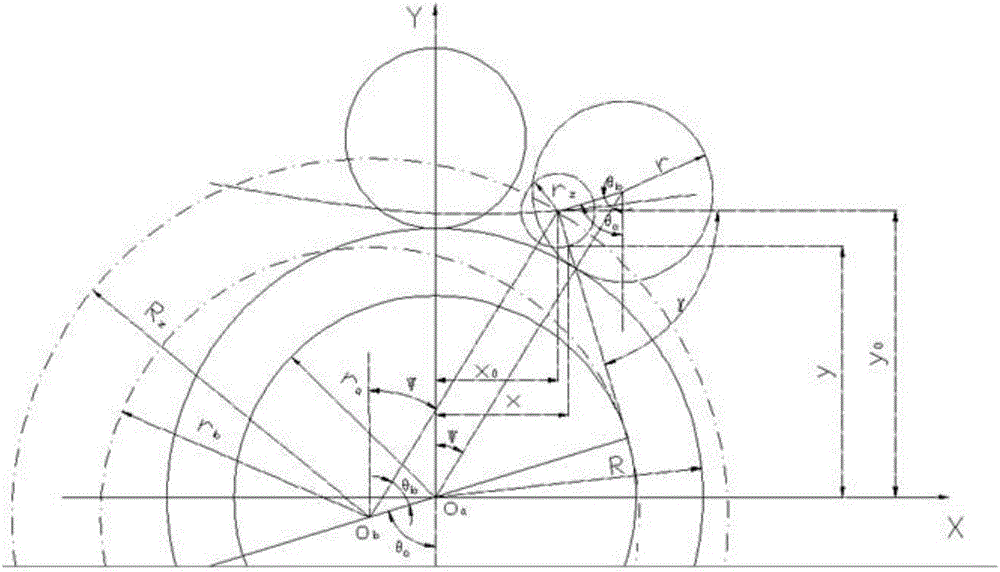

The invention discloses a method for optimizing the cycloid gear tooth outline modification amount based on a matlab. The method comprises the first step of calculating the inflection point position of the cycloidal gear tooth outline according to basic parameters of a cycloidal gear, the second step of calculating the optimal modification angle according to the oil film thickness and the inflection point position, the third step of calculating the optimal isometry and the shifting modification amount according to the optimizing function of the matlab, and the fourth step of acquiring testing parameters tested conveniently. Compared with the prior art, the method has the advantages that the analyzing method for improving and optimizing the cycloid gear tooth outline through a MATLAB optimization toolbox by analyzing a mathematical model of cycloidal gear modification is put forward, the optimal modification angle is obtained according to the oil film thickness, the range of the optimal modification amount is found out according to the inflection point position in a meshing area, and the optimal isometry and shifting modification tooth outline is obtained; the calculation period of the tooth outline modification amount is greatly shortened, the number of teeth meshed at the same time is guaranteed, the stability of transmission is guaranteed, and the transmission efficiency is improved.

Owner:CENT RES INST OF TIANJIN BENEFO MECHANICAL EQUIP GRP CO LTD

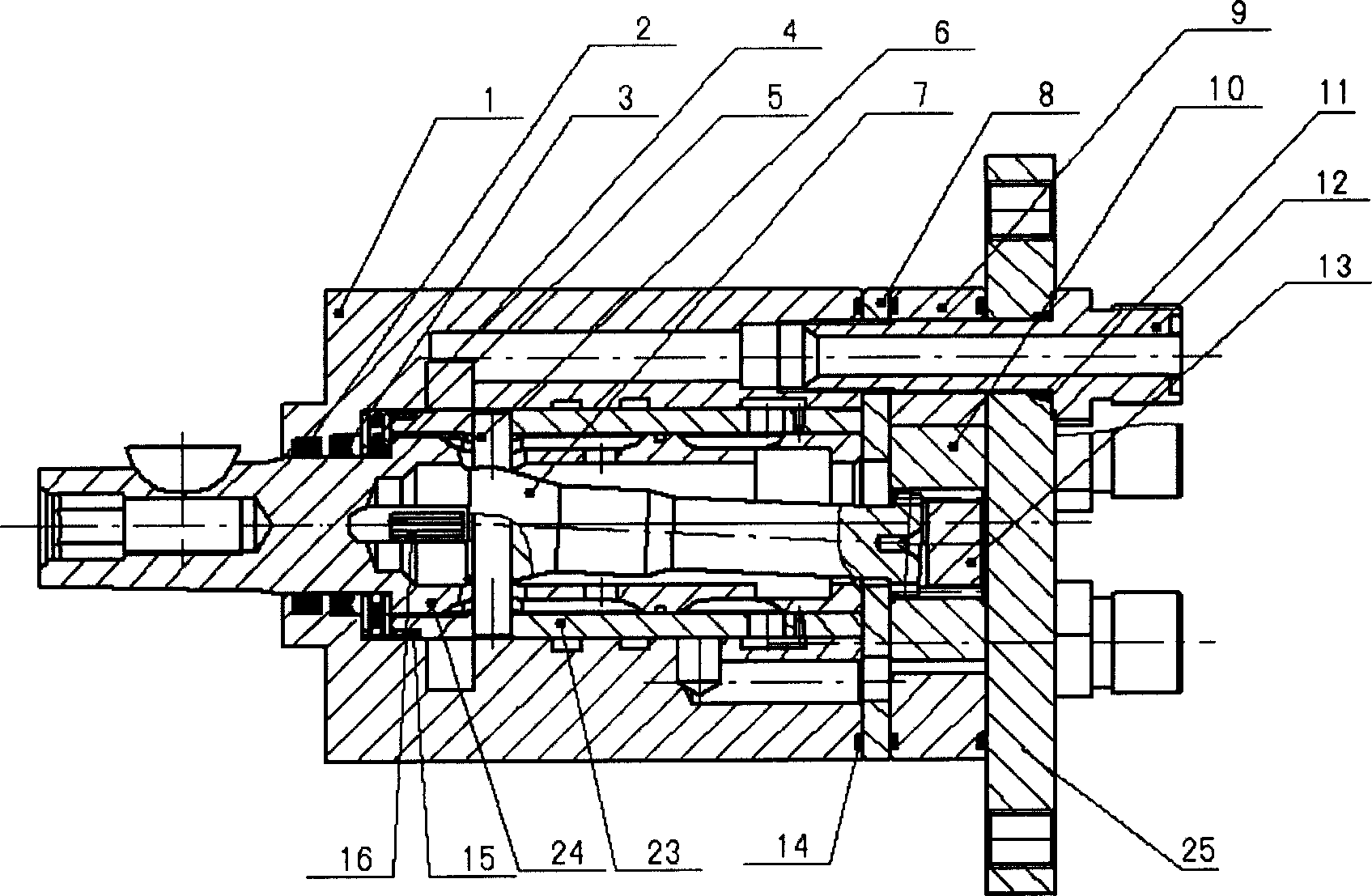

Hydraulic mechanical type automatic gear shifting system

The invention discloses a hydraulic machine type automatic shift system, aiming to solve the problems of complicated planetary drive mechanism and high manufacture cost of AT and the problems of great difficulties of shift impact and launch control of AMT. The invention consists of a machine structure and an automatic control system, wherein the machine structure comprises a hydraulic torque convertor assembly (2), a wet type shift master clutch (3), a shift actuating mechanism assembly (5), a position selecting actuating mechanism assembly (7), a multiple positions parallel shaft type gear box (9) and a front box body (12). The machine structure is connected through a pump wheel cover (1) and a crank shaft (23), the output end of the machine structure is connected with the second shaft (48) of the multiple positions parallel shaft type gear box (9) and an automobile transmission shaft. The automatic control system comprises an electric control system and a hydraulic control system. The hydraulic control system comprises an internal meshing cycloid gear pump (11) providing pressure oil, action elements and control elements. The hydraulic machine type automatic shift system comprises four control circuits. The hydraulic machine type automatic shift system is more applicable to the automobiles such as large off-road vehicles.

Owner:JILIN UNIV

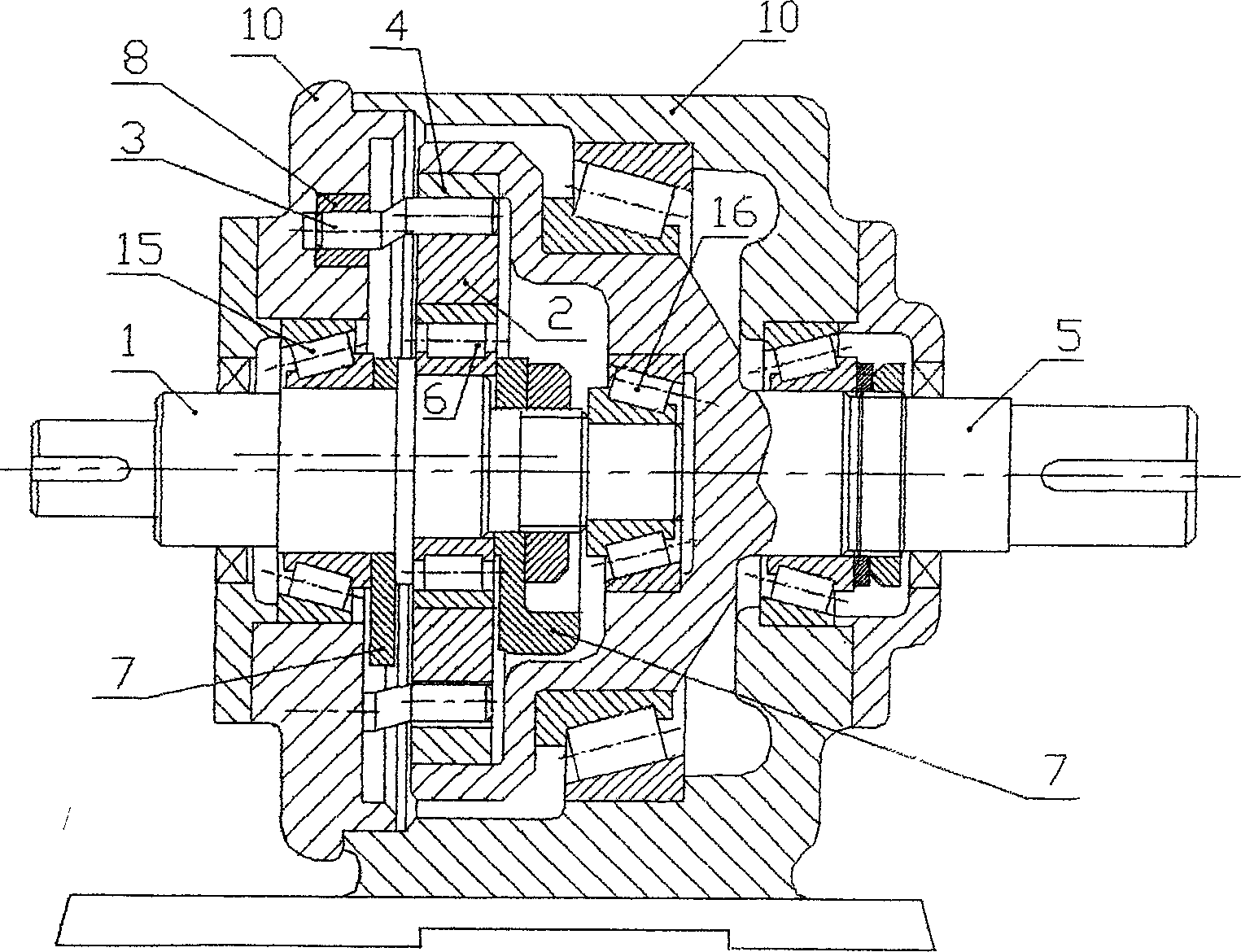

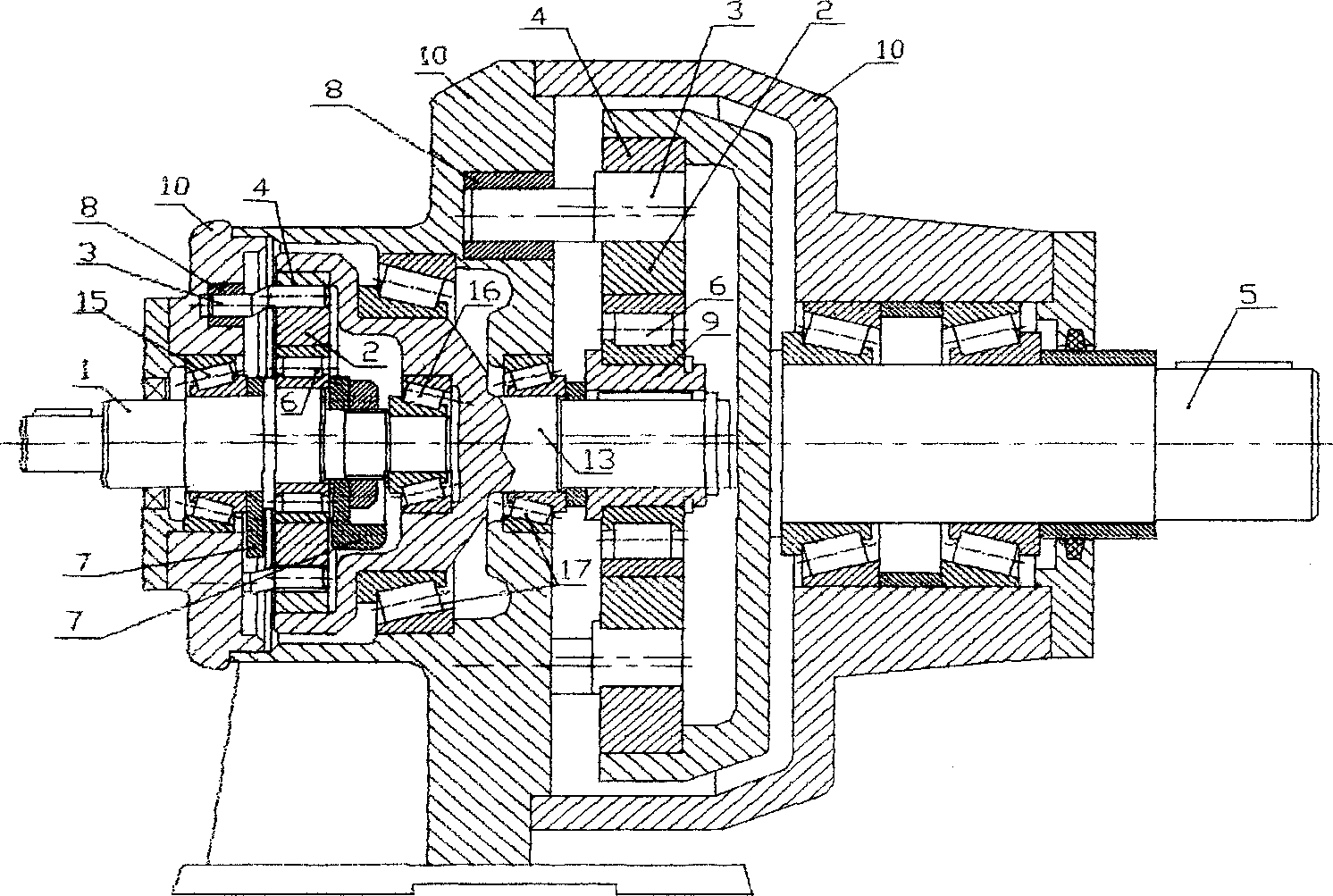

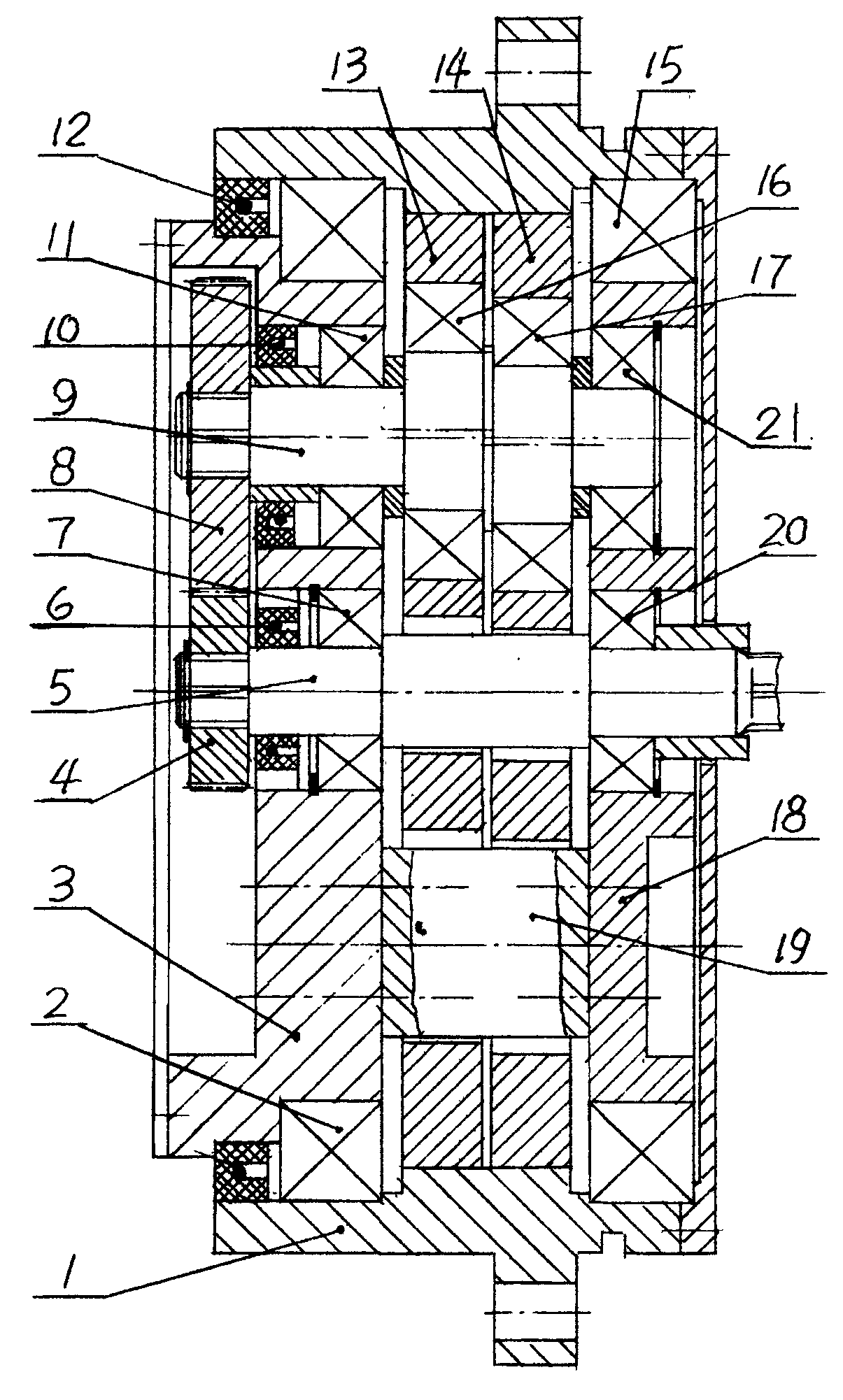

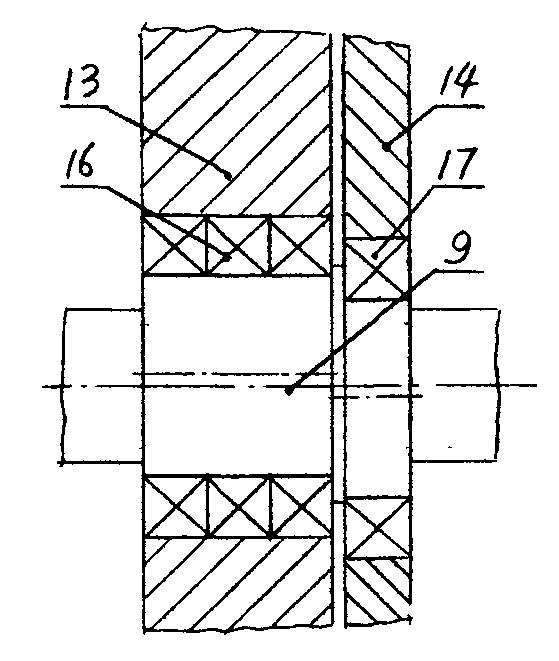

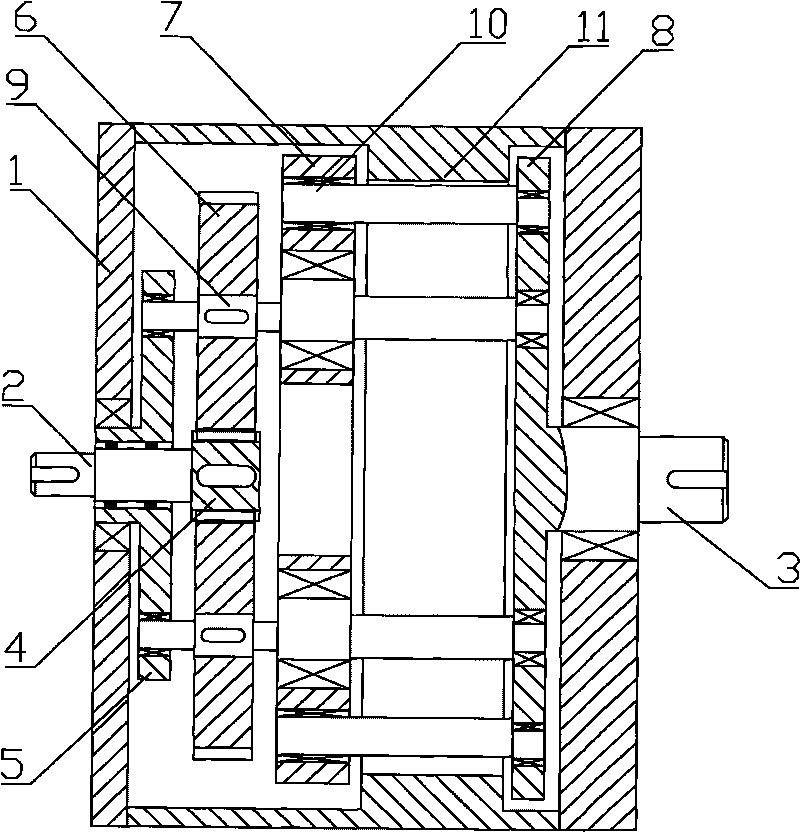

Bevel gear-double cycloid speed reduction device for rocket launching movable platform

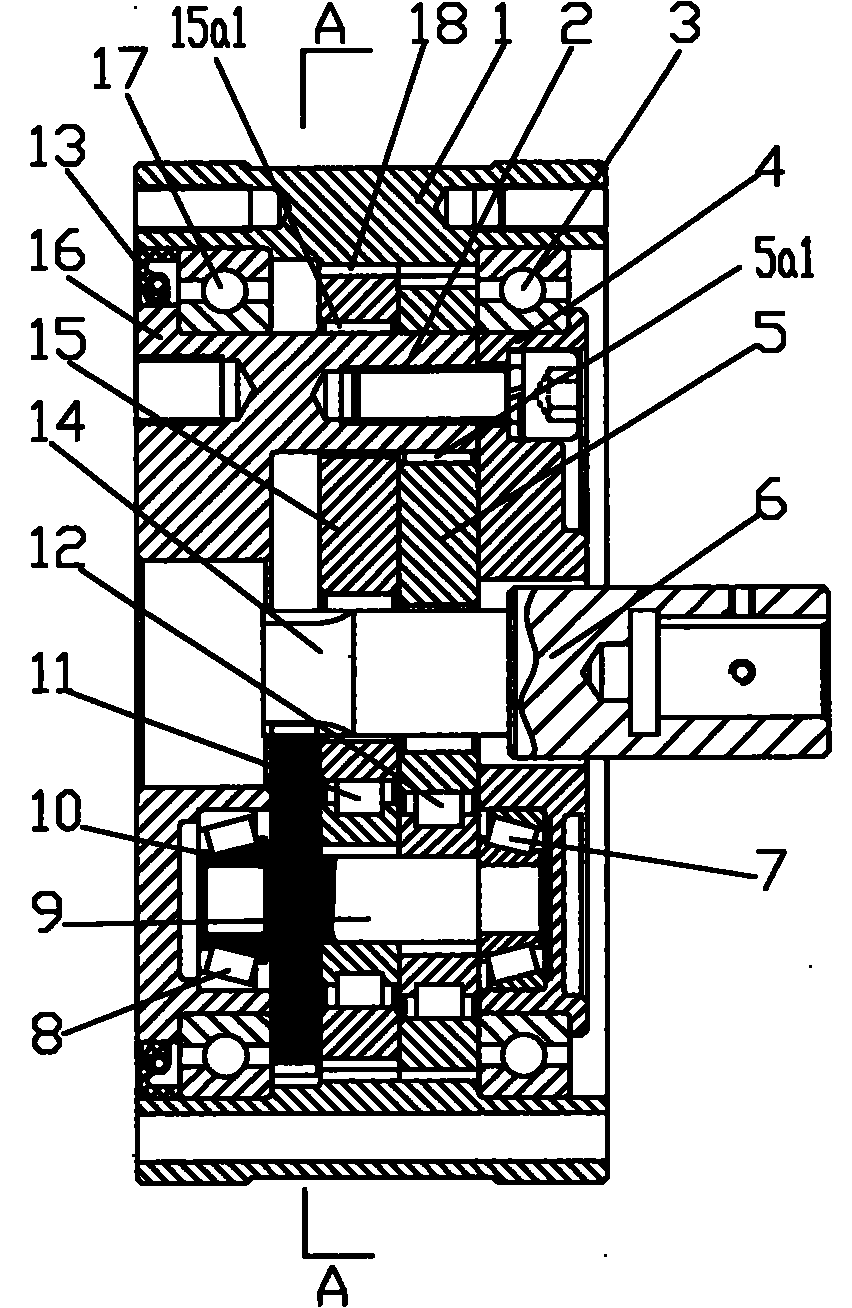

InactiveCN101963208AImprove bending resistanceImprove bending performanceGearboxesToothed gearingsReduction driveRocket launch

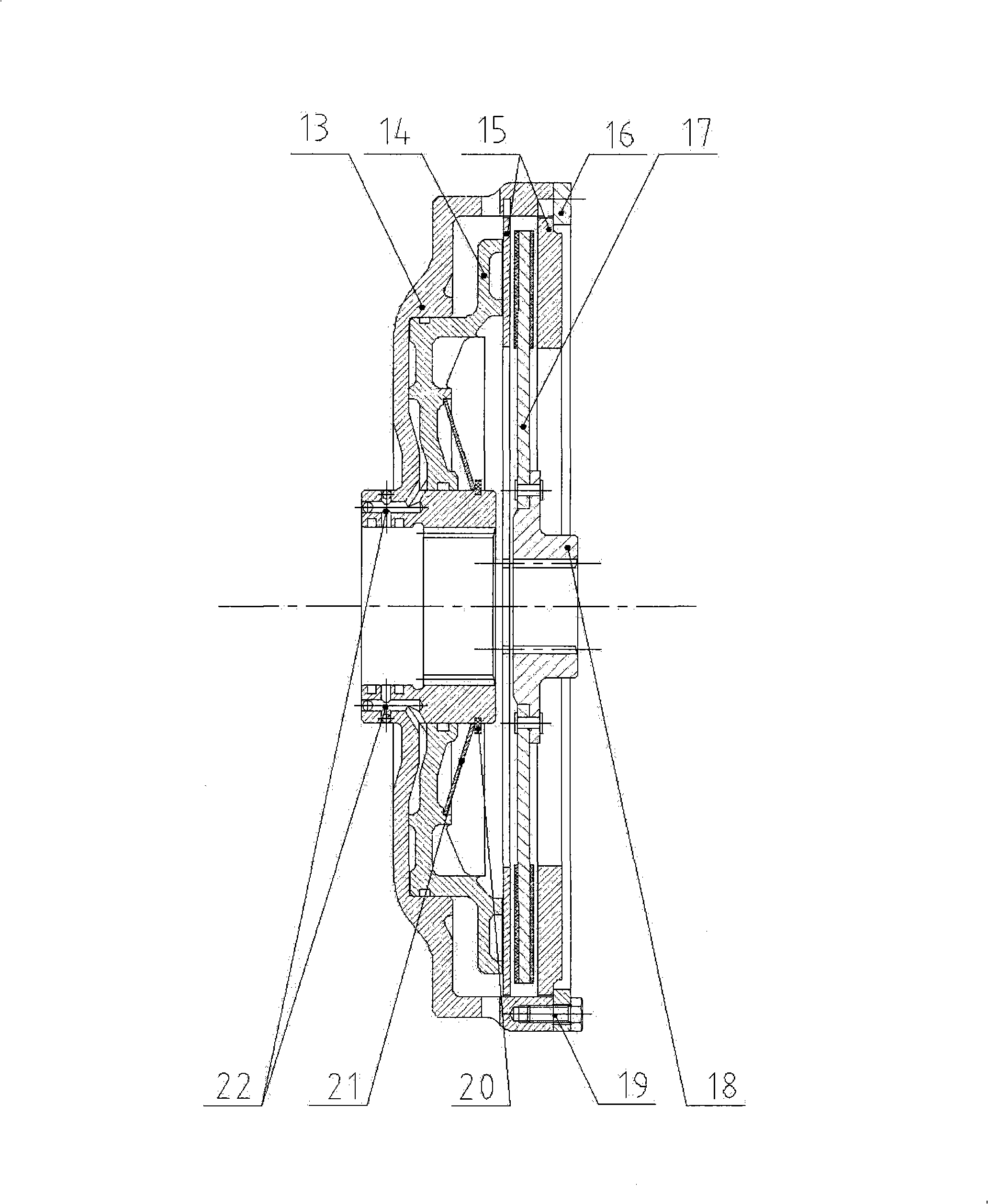

The invention relates to the technical field of speed reducers, in particular to a bevel gear-double cycloid speed reduction device for a rocket launching movable platform. The device is a two-stage speed reduction device characterized by comprising a bevel gear pair and double-cycloid transmission, wherein (A) the cycloid transmission comprises a base, an output shaft, support bearings, a cycloid wheel, an eccentric bearing, an inner cycloid gear ring, a front base, an input shaft and a W output mechanism, the input shaft is supported in an inner hole of the front base through a bearing, the shaft extension end is connected with the eccentric bearing, and the input end is connected with a big bevel gear; the front base is integrated with the inner cycloid gear ring and the base in sequence; the output shaft is supported in the inner hole of the base through a bearing; and (B) two symmetrically installed small bevel gear shafts engaged with the big bevel gear are supported in wall holes of a front base box through bearings, and the small bevel gear shafts are connected with a motor; and another small bevel gear shaft is connected with a manual handle. The invention has the advantages of two-stage speed reduction, small axial size, light weight and high-degree lightweight; cycloid gear teeth are uninterrupted, so that the bearing capacity is greater than that of planet transmission with only four planet wheels; and the cost is low and is reduced to 40-55%.

Owner:吴声震

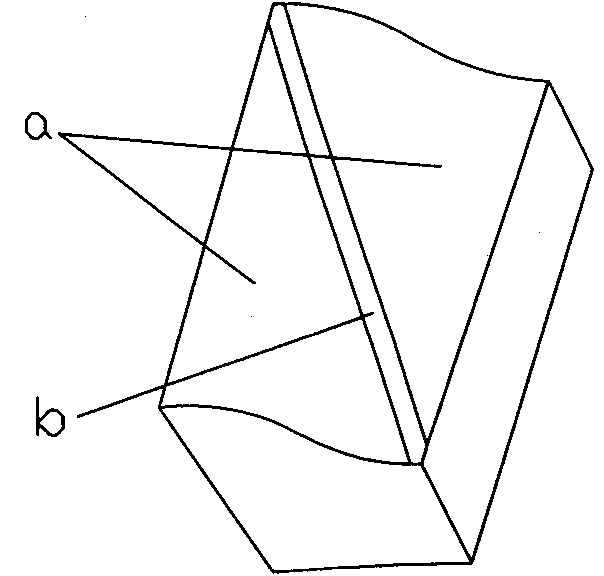

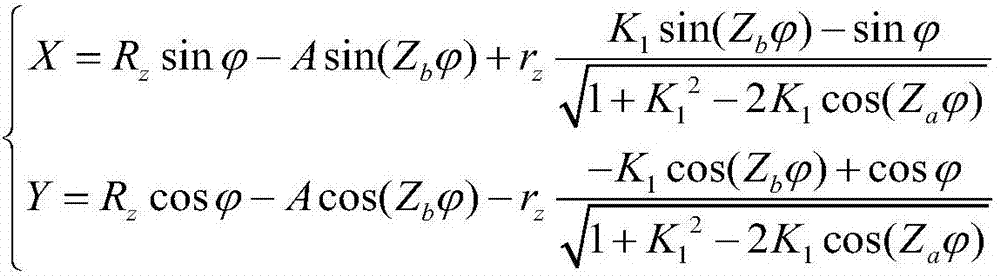

Precise modeling method for biarc correction cycloidal gear

ActiveCN103678818AHigh precisionSave programming calculationsPortable liftingSpecial data processing applicationsGear wheelMachining

The invention relates to a precise modeling method for a biarc correction cycloidal gear and belongs to the technical field of gear modeling. The method concretely includes the steps that basic parameters are determined, the reference circle, the addendum circle and the dedendum circle of the gear are drawn, a biarc correction cycloid is calculated according to the basic parameters in the biarc correction cycloid and interior and exterior tooth profile equations, a single tooth profile and a single tooth blank are established, the single tooth profile and the tooth blank are imported into professional software so that the solid body can be stretched and Boolean operation can be carried out, modeling of the single tooth is completed, and then modeling of the whole gear is completed by applying array. The precise modeling method for the biarc correction cycloidal gear is an important modeling method for actual machining and simulation operation of the biarc correction cycloidal gear and has the advantages of being high in modeling precision and efficiency, and simple and convenient in calculation, design and manufacturing process and ensuring the design precision and the manufacturing precision of the biarc correction cycloidal gear.

Owner:KUNMING UNIV OF SCI & TECH

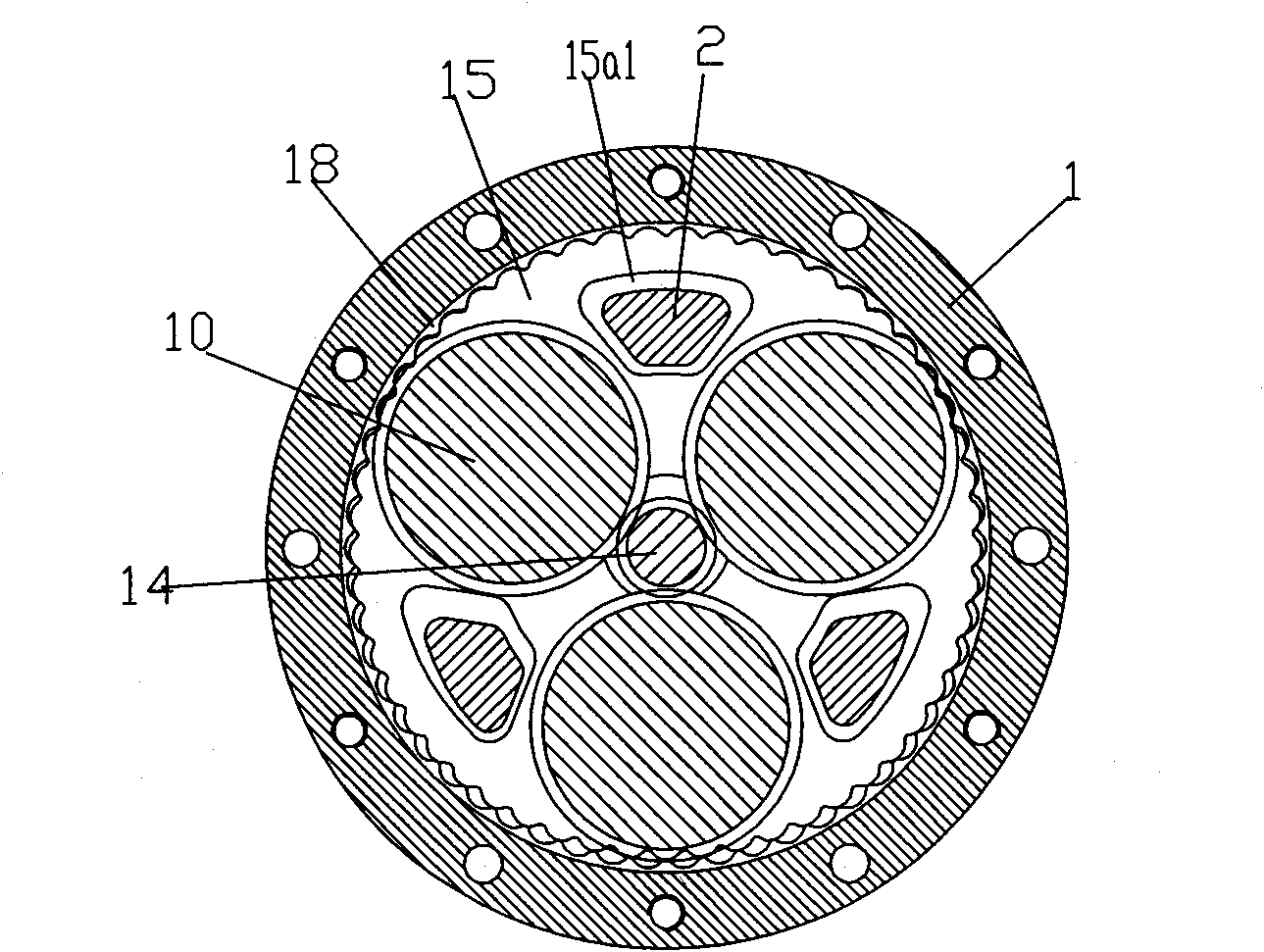

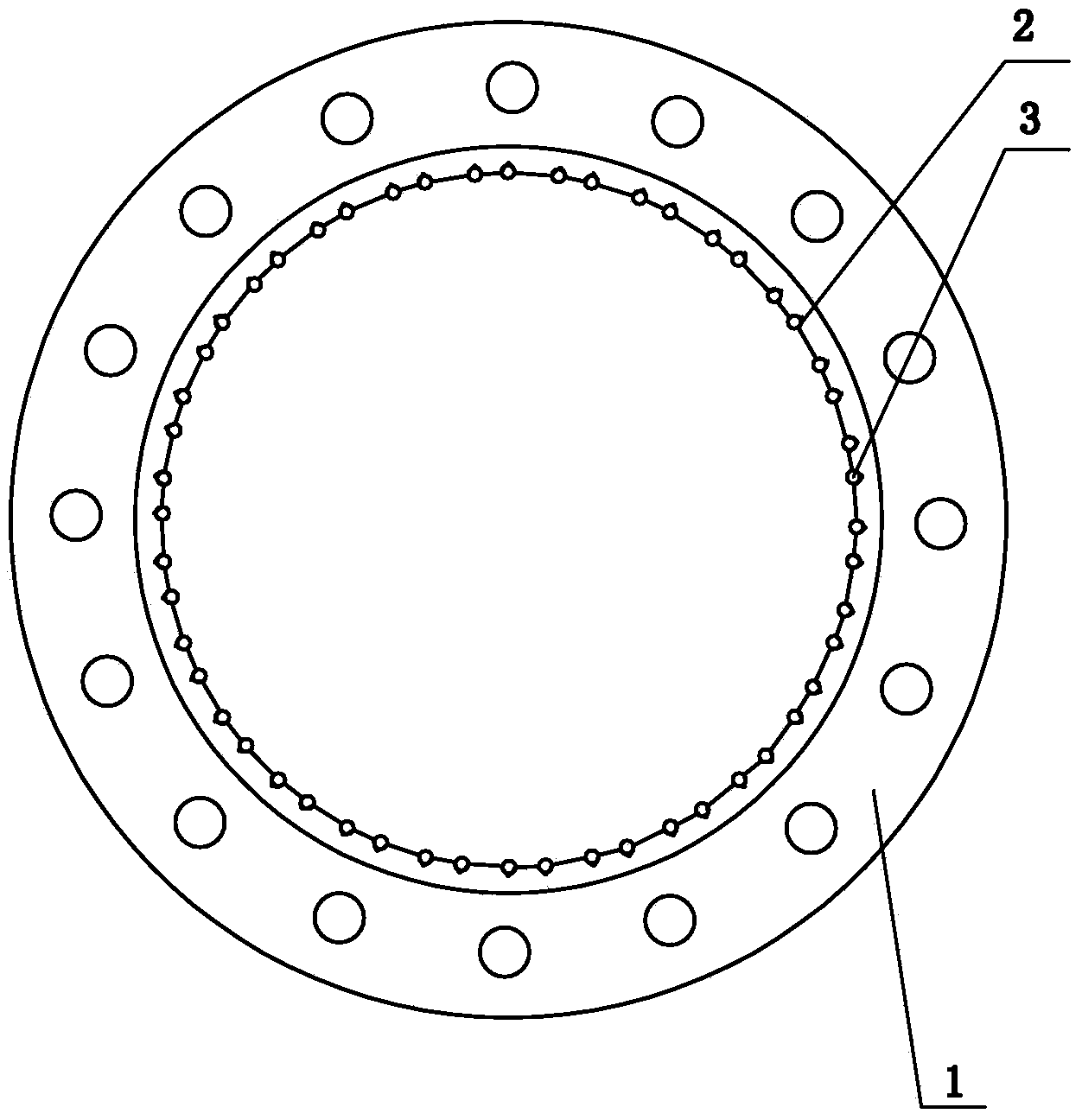

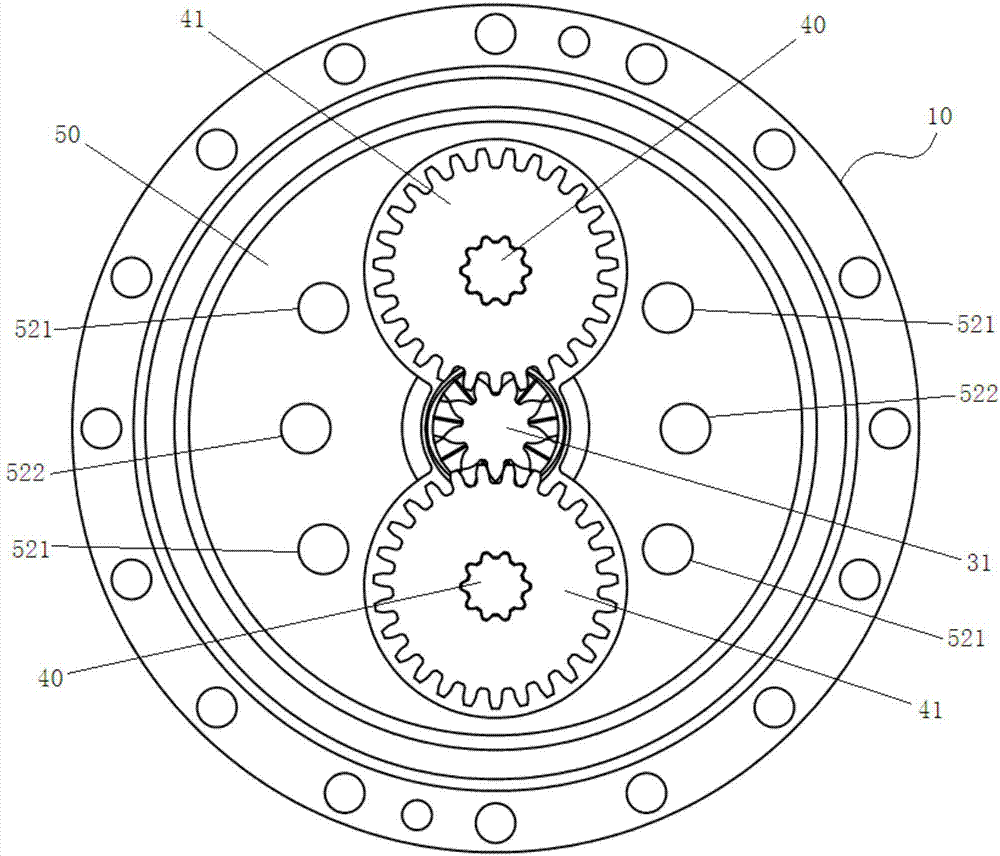

Planetary speed reducer with small tooth number difference

The invention discloses a planetary speed reducer with small tooth number difference, which comprises a housing, a power input shaft matched with the rotation of the housing and a power output tray, wherein a sun wheel is fixedly matched and arranged on the power input shaft in the circumferential direction, at least two planetary wheels are meshed with the sun wheel, and planetary wheel shafts of the planetary wheels are provided with eccentric sleeves; a cycloidal gear is arranged on the housing in a manner of being meshed with a fixed pin gear with small tooth number difference; each eccentric sleeve respectively penetrates the cycloidal gear along the axial direction and is in running fit with the cycloidal gear, the end parts of each planetary wheel shaft penetrates into the power output tray along the axial direction and is in running fit with the power output tray in the circumferential direction, the tooth profile of the cycloidal gear is formed by leading the pin gear to do primary envelope motion, and the tooth profile of an internal gear is formed by leading the cycloidal gear to do secondary envelope motion. The planetary speed reducer with the small tooth number difference not only has the characteristic of multi-tooth meshing of the ordinary cycloidal pin gear planetary transmission, but also has the doublet contact characteristic, and can further fully play the error averaging effect by increasing contact points and improve the transmission precision.

Owner:CHONGQING UNIV

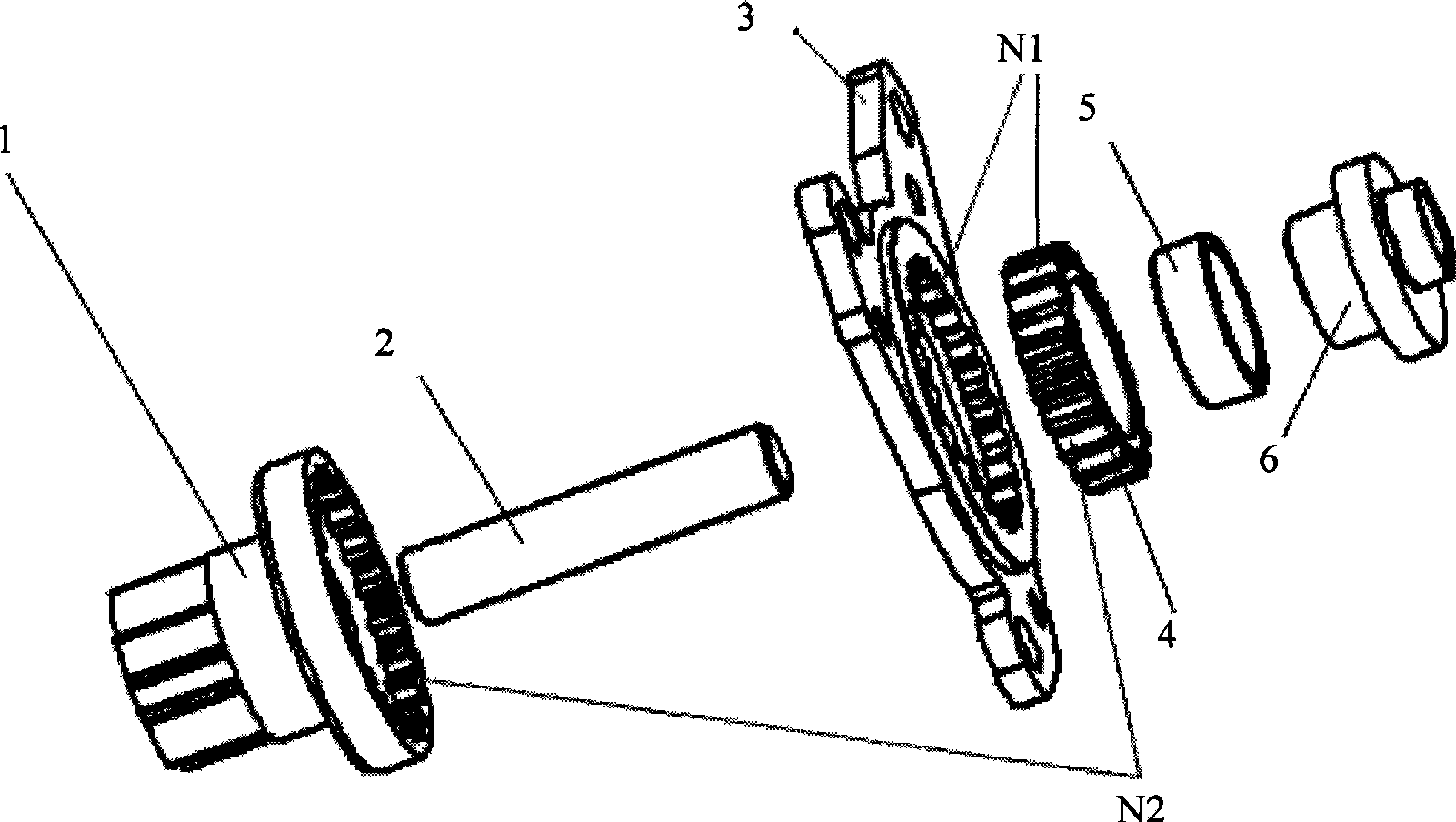

Pin gear cycloid gear driving device and speed reducer thereof

InactiveCN1542310AHigh positioning accuracyImprove stabilityToothed gearingsReduction driveGear wheel

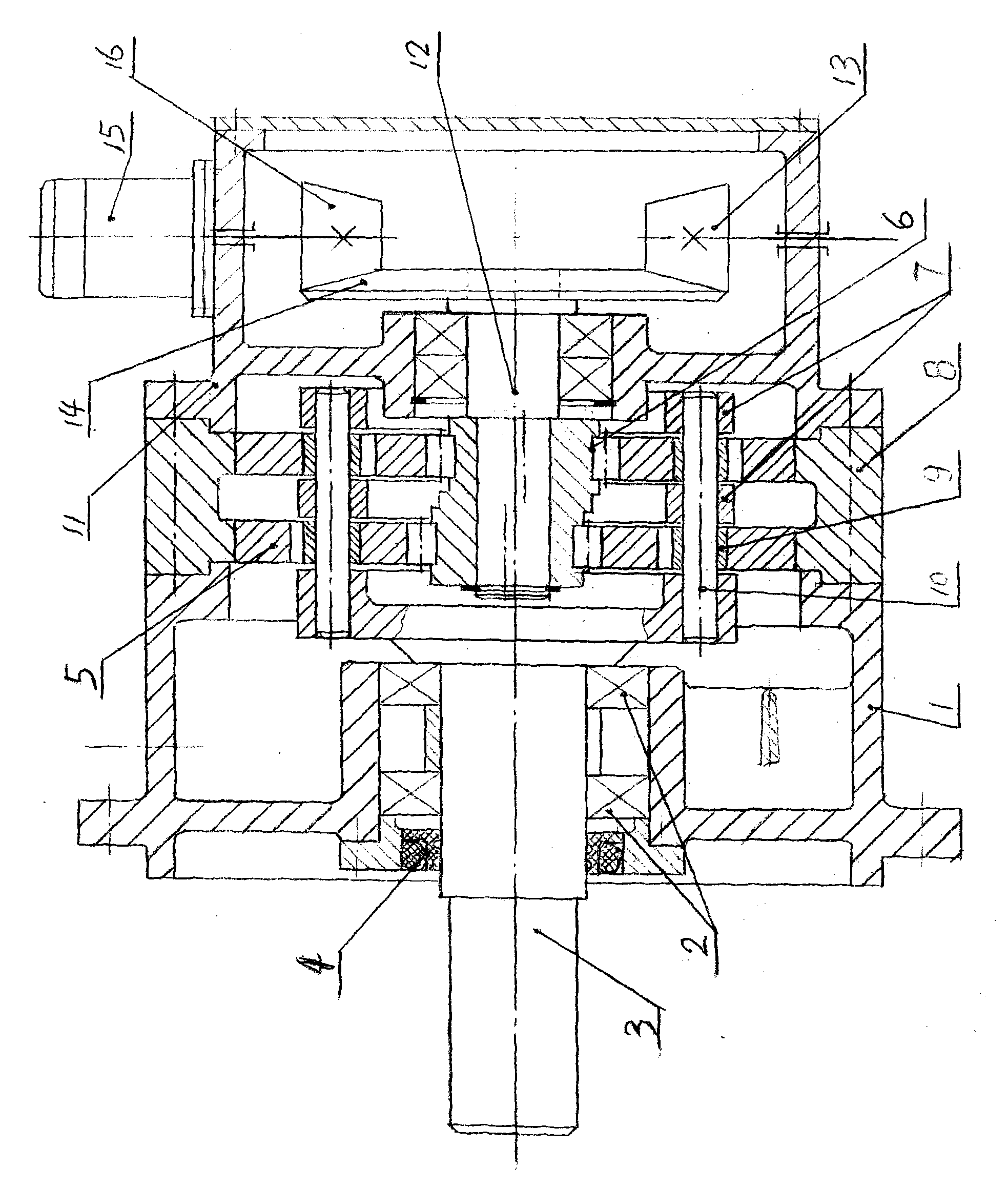

The transmission mechanism consists of inner gear, pin gear and hypocycloidal gear. The inner gear is set eccentrically to the hypocycloidal gear and meshed with the pin gear, and the pin gear is meshed with the hypocycloidal gear. The present invention features that the eccentric pin gear has fixed rotation shaft and its rotation axes are distributed in the cylindrical surface with the rotating axis of the hypocycloidal gear as center. The advantages of the pin gear-hypocycloidal gear mechanism includes raised position precision, raised transmission smoothness and efficiency, raised transmission bearing capacity, compact structure, low cost, etc.

Owner:SHANGHAI NORMAL UNIVERSITY

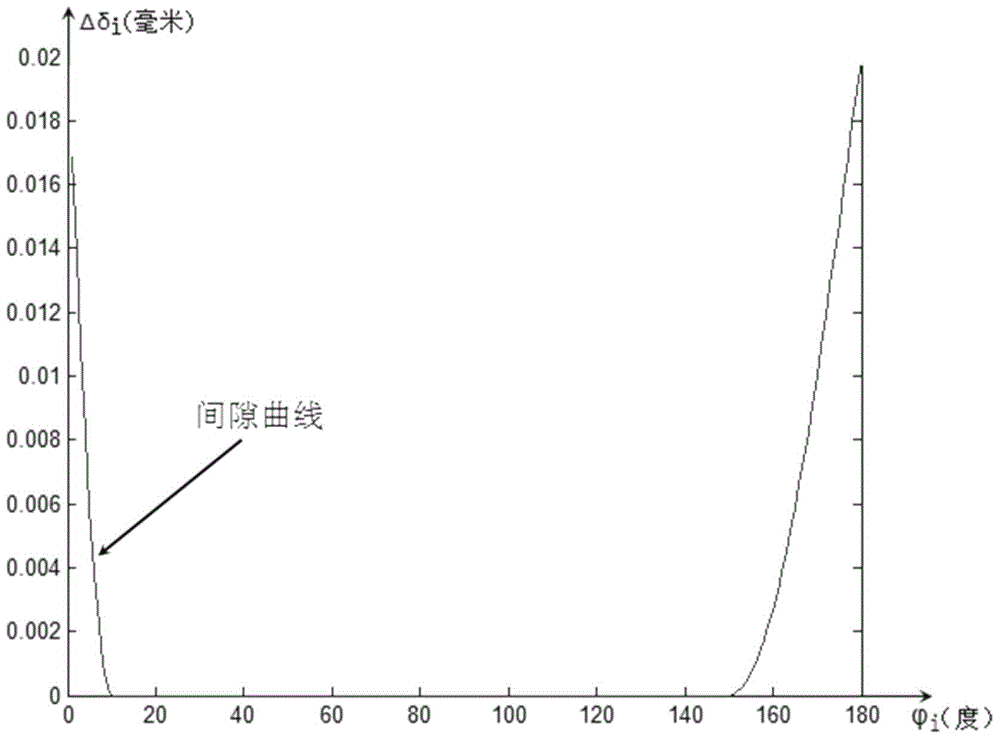

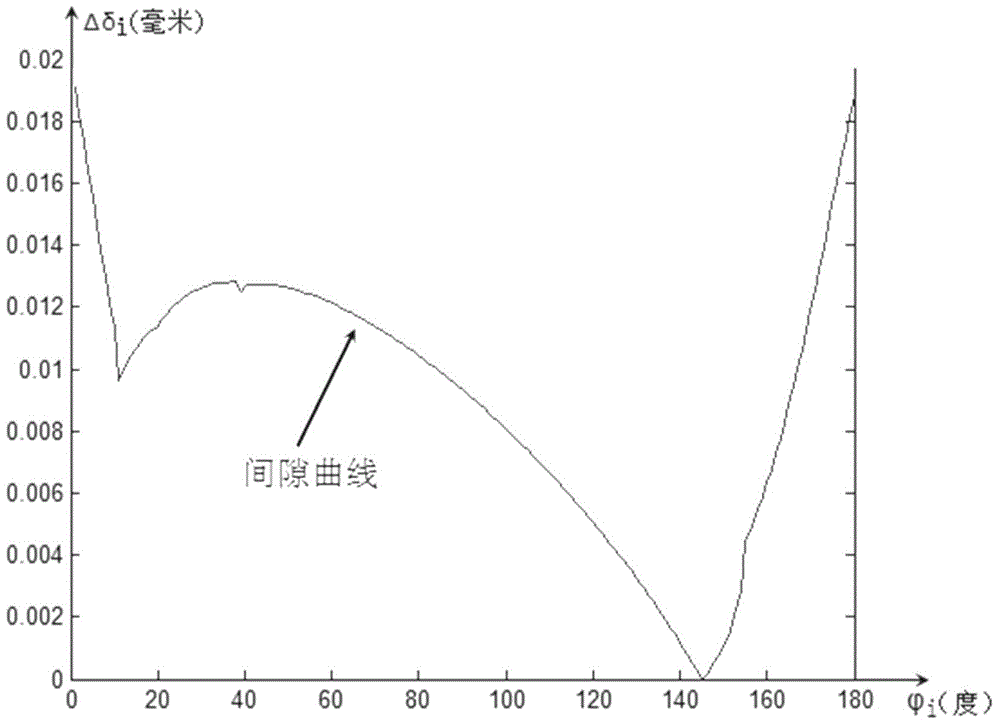

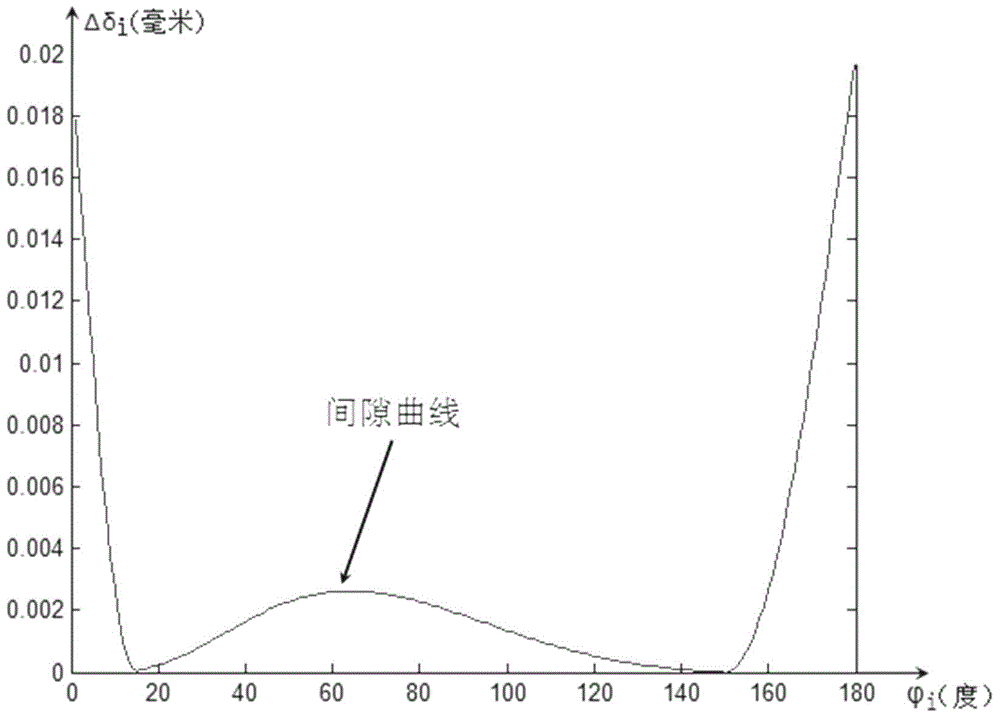

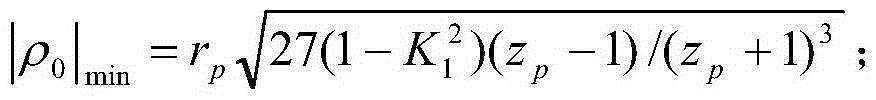

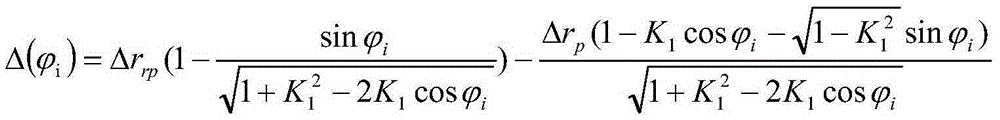

Method for shaping cycloidal gear tooth profile

The invention discloses a method for shaping cycloidal gear tooth profile, which comprises the following steps: 1 a shaping target of a cycloidal gear tooth profile is obtained, a gap curve is obtained according to the shaping target of the cycloidal gear tooth profile, and the shaping target of the is cycloidal gear tooth profile is a shaping which uses the minimum elastic deformation in an engaged point as a target, a shaping which transmits the minimum error as a target and a shaping which uses the minimum contact stress as a target or uses the minimum contact force as a target; and 2 a shaping pin-teeth radius delta value delta residential rental price index (Delta rrpi) is obtained according to the gap curve, a cycloidal gear tooth profile shape after being shaped is obtained according to the shaping pin-teeth radius delta value Delta rrpi, the profile of grinding wheels is obtained according to the cycloidal gear tooth profile shape after being shaped, and a cycloidal gear is processed on a computer numerical control gear profile grinder according to the profile of the grinding wheel. The method for shaping the cycloidal gear tooth profile can shape the cycloidal gear tooth profile according the shaping target, and enables the shaping target to be the best.

Owner:盐城国卓科技有限公司

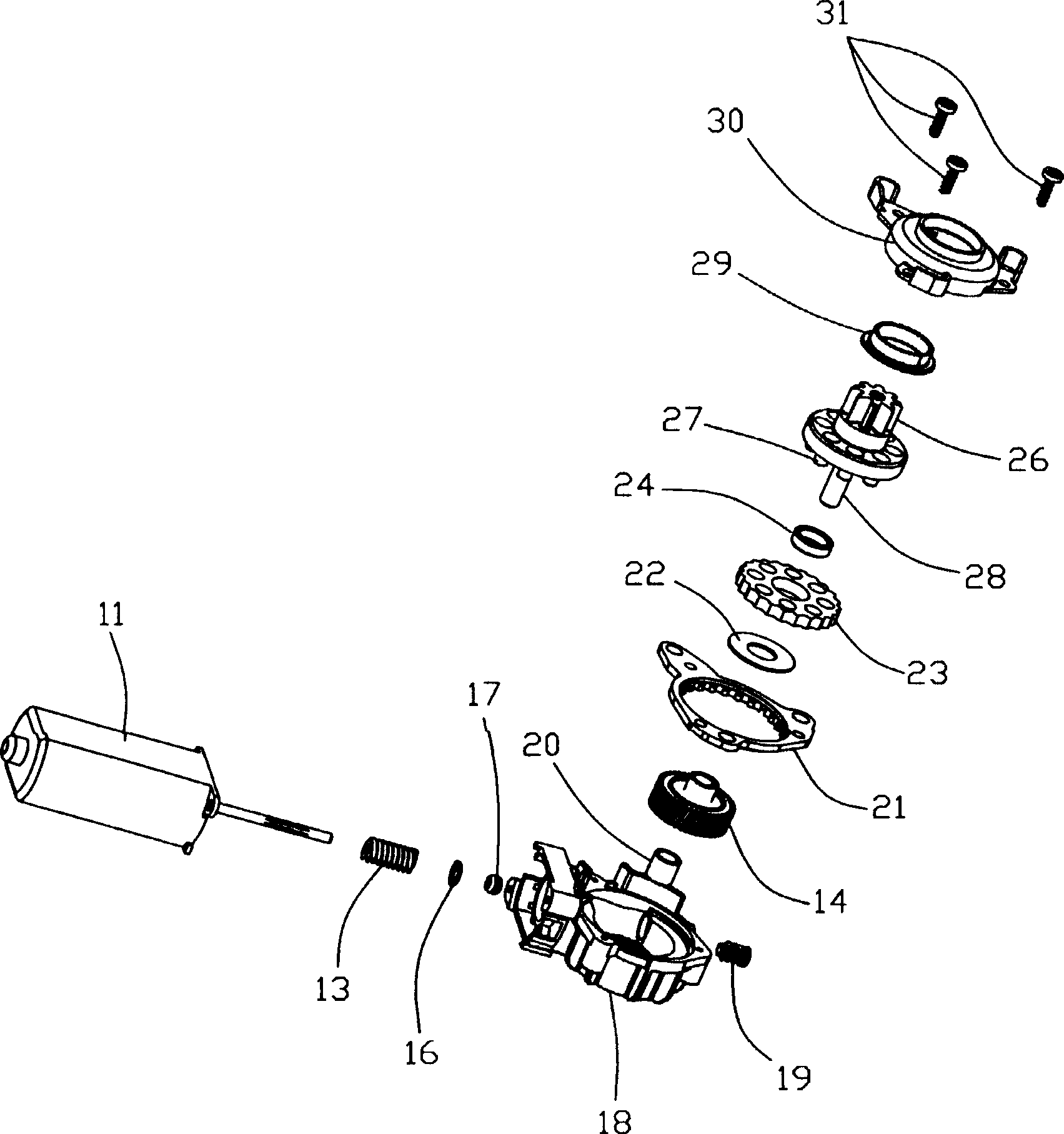

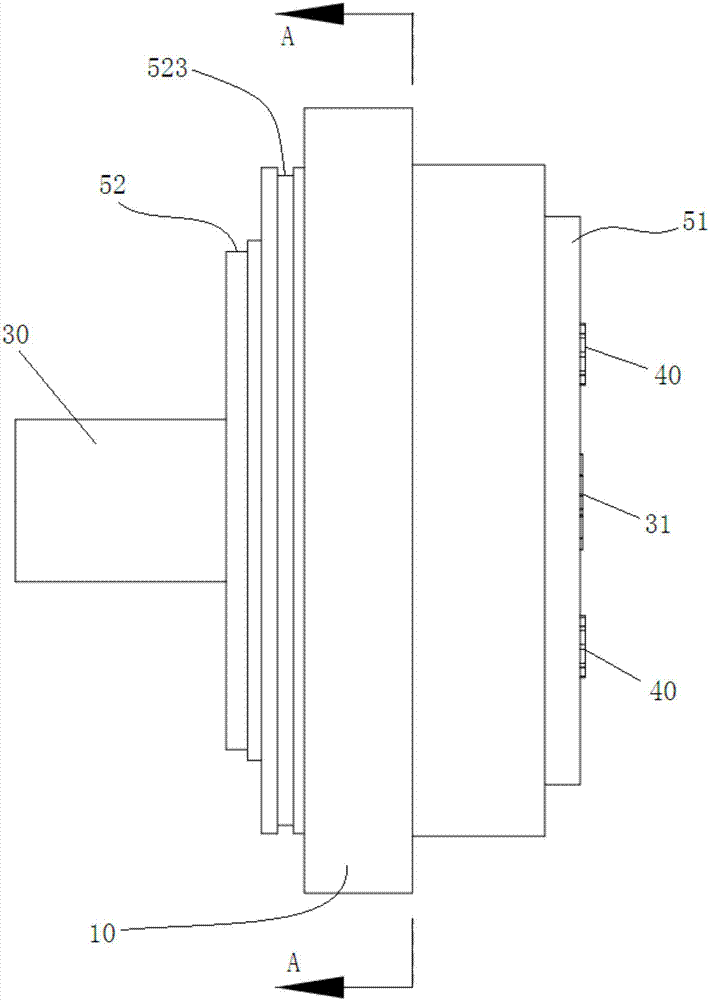

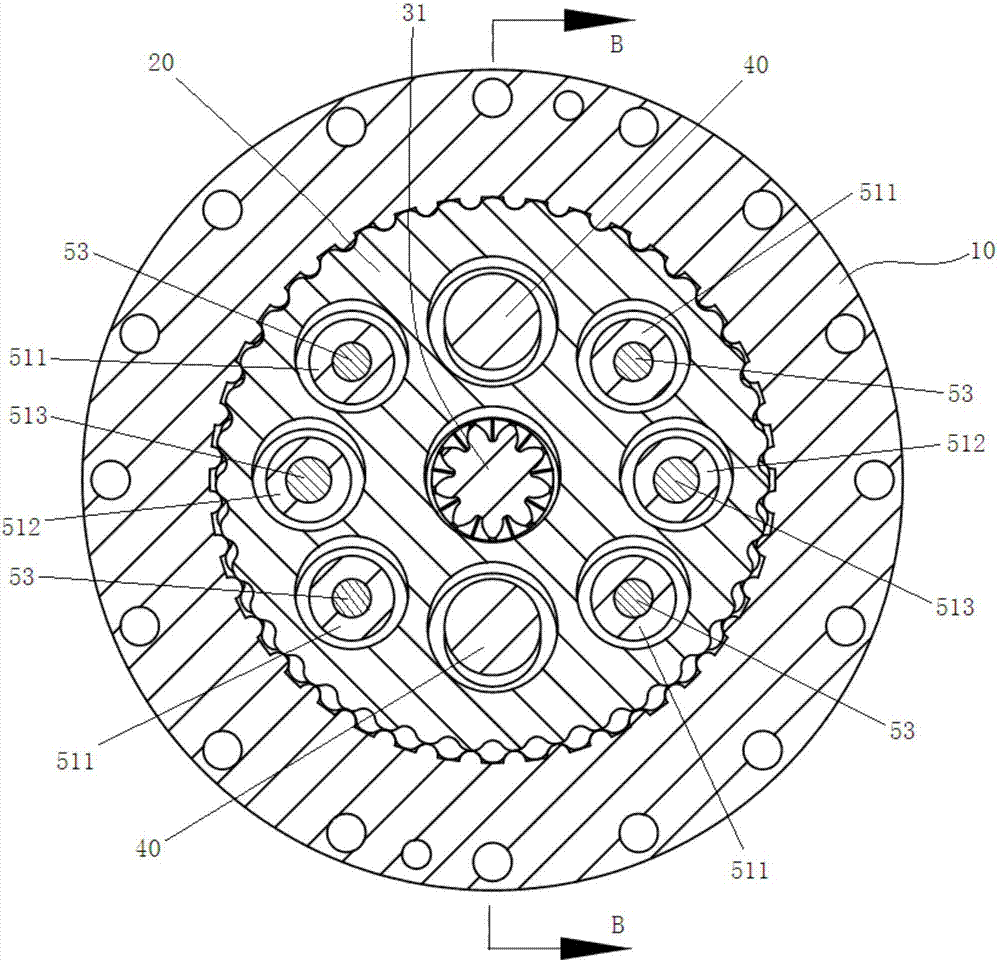

Precise planetary cycloid reducer

InactiveCN103742611AReasonable structureImprove reliabilityToothed gearingsGearing detailsEngineeringLubrication

The invention discloses a precise planetary cycloid reducer which can be used for being connected onto the joint portion of an industrial robot. The precise planetary cycloid reducer comprises a first level planetary gear mechanism and a first level cycloidal-pin wheel mechanism; the planetary gear mechanism is formed by a sun gear and a planetary gear; the cycloidal-pin wheel mechanism is formed by an eccentric shaft, a cycloid gear and a pin tooth housing; the eccentric shaft is fixedly connected with the first level planetary gear to serve as an input shaft of the cycloidal-pin wheel mechanism; the plane movement is performed on the cycloid gear under the combined action of the eccentric shaft and pin teeth, namely that the cycloid gear revolves around the axis of the pin tooth housing and reversely rotates around the self-axis simultaneously and the rotation movement of the cycloid gear is output through a W mechanism. According to the precise planetary cycloid reducer, the modification and optimization is performed on the tooth shape of the cycloid gear and accordingly the bearing capacity can be significantly improved and the lubrication of a side gap can be ensured.

Owner:秦川机床工具集团股份公司

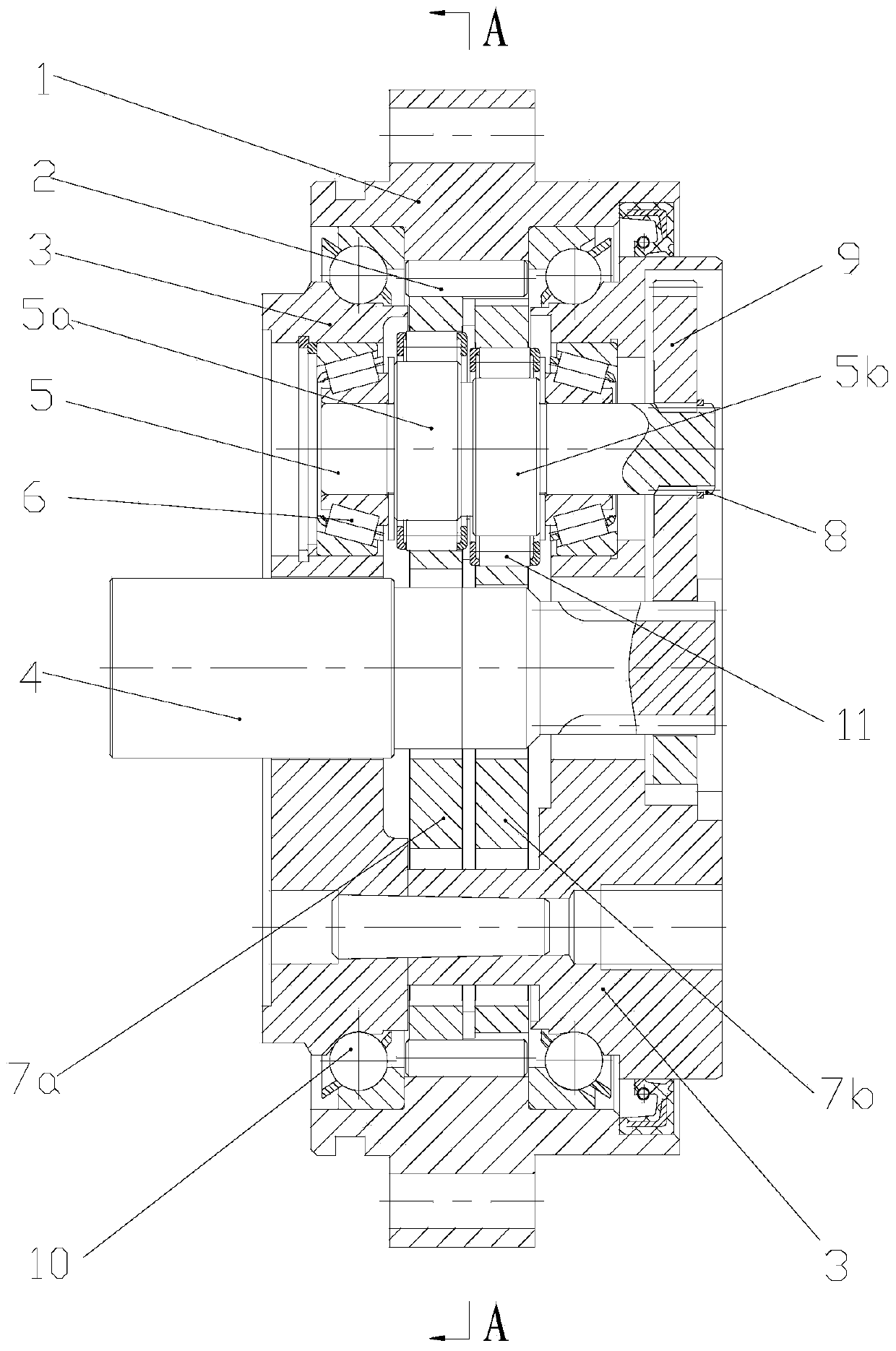

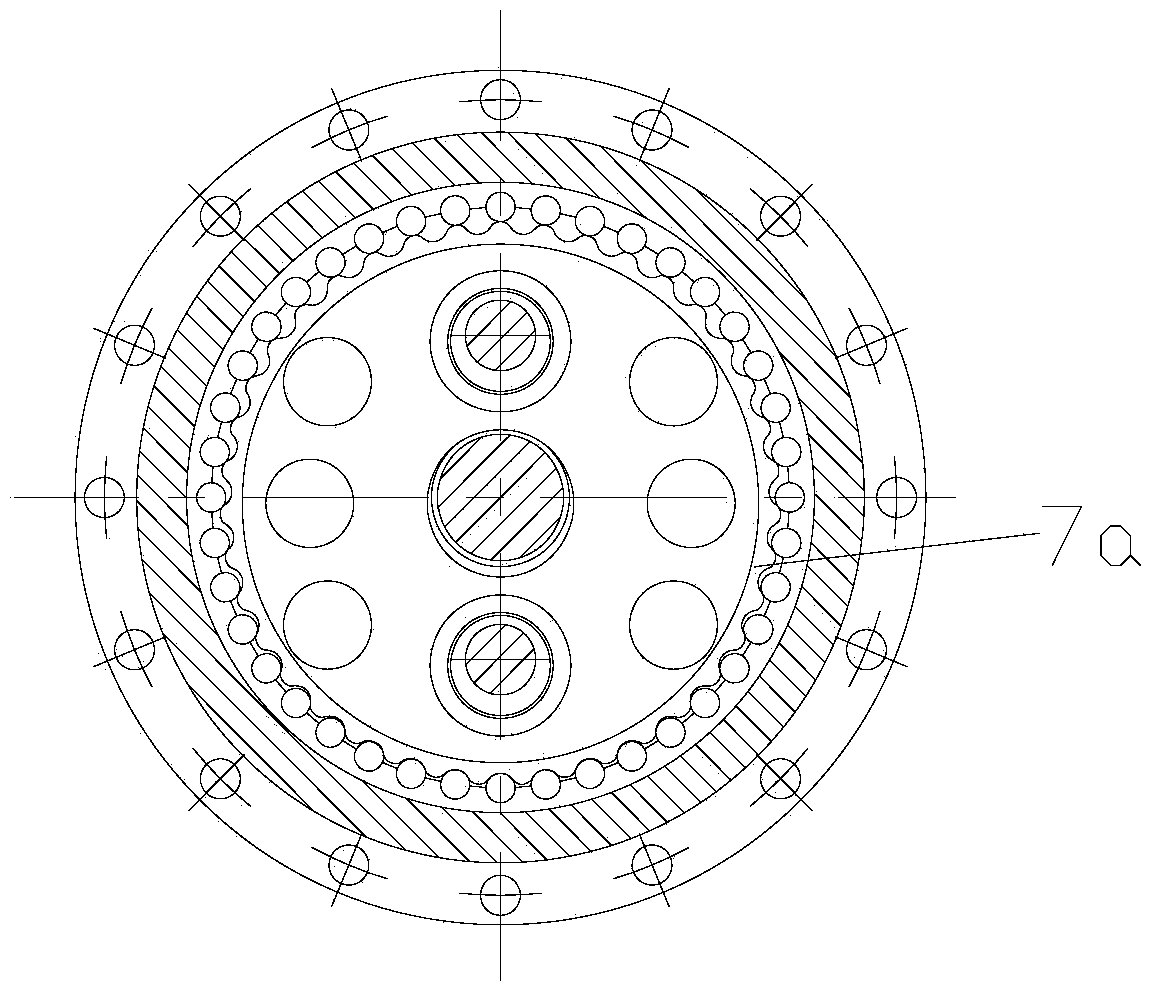

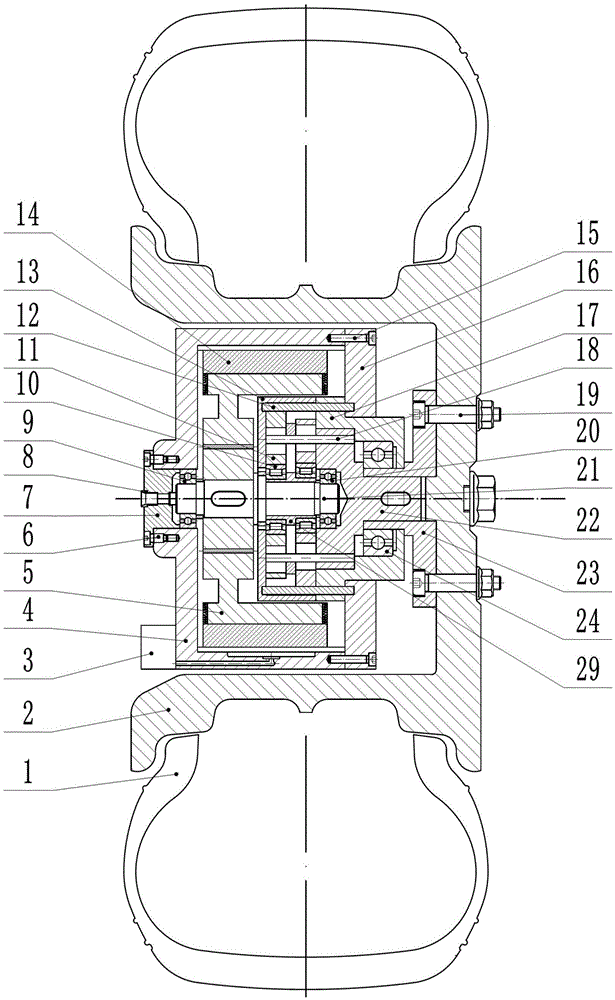

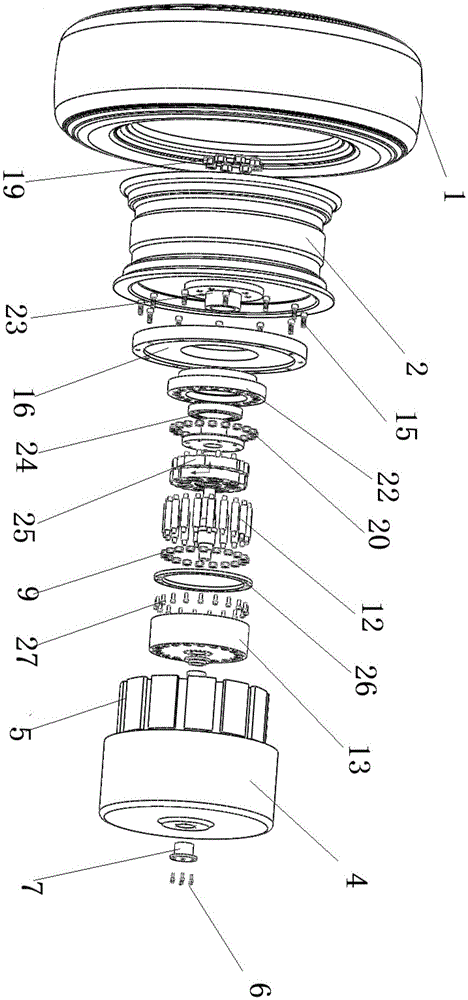

Bearing type RV speed reducer

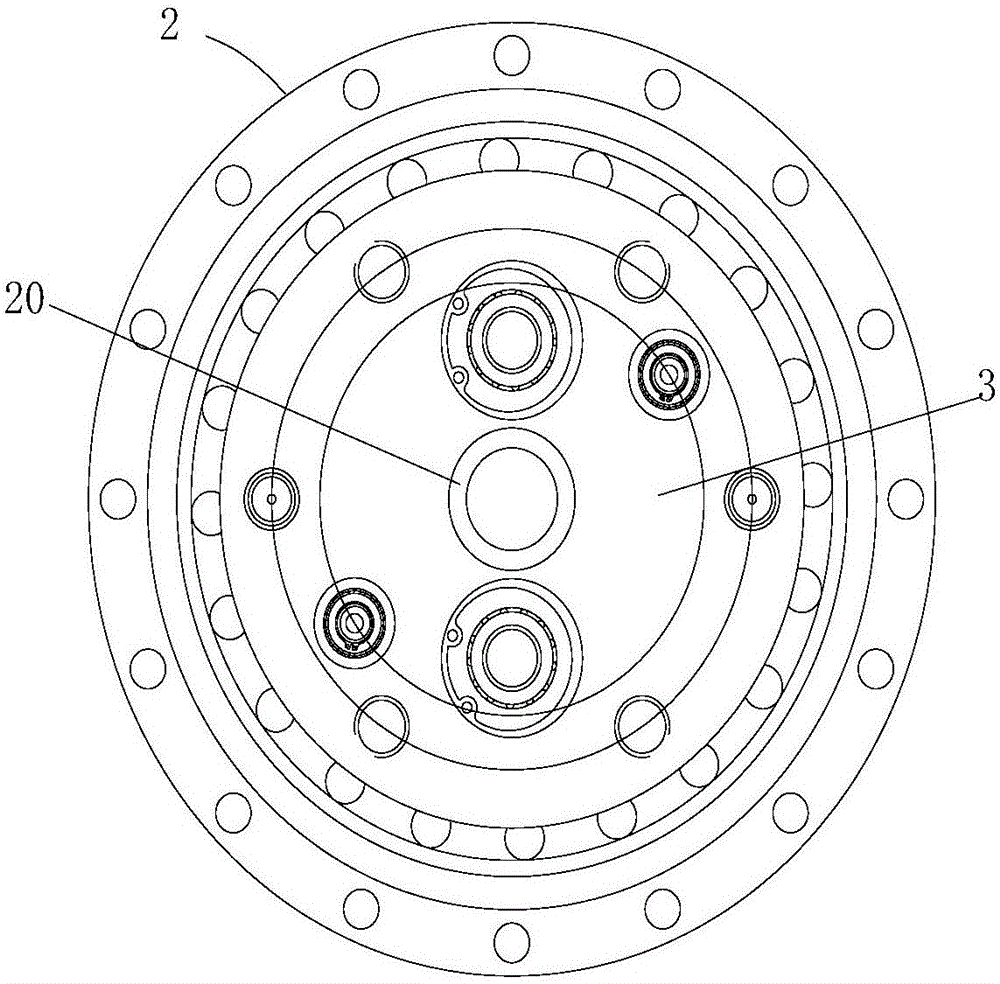

InactiveCN103527719AReduce processing difficultyHigh transmission reliabilityToothed gearingsGearing detailsDrive wheelReduction drive

The invention discloses a bearing type RV speed reducer, and belongs to the technical field of speed reducers. The speed reducer comprises a pin wheel housing, an installation frame is arranged in the pin wheel housing in a rotary mode, the installation frame is provided with two cycloid gears in transmission connection with the pin wheel housing through needle rollers, the installation frame is rotatably provided with a power input shaft, the power input end of the power input shaft extends out of the installation frame, the power input shaft is provided with two eccentric drive wheels which penetrate through the centers of the two cycloid gears respectively and are matched with the corresponding cycloid gears, the installation frame is rotatably provided with at least two positioning shafts which are symmetric to the rotation center of the power input shaft, and each positioning shaft is provided with two eccentric transmission wheels which penetrate through the two cycloid gears respectively and are matched with the cycloid gears. Power center input and first speed reduction are achieved. Compared with the prior art, the bearing type RV speed reducer reduces the number of power input shafts and use of sun gears and planetary gears, manufacturing cost is low, transmission is reliable, machining and installation are convenient to achieve, and service life is prolonged.

Owner:SHANDONG SHKE MACHINERY MFG

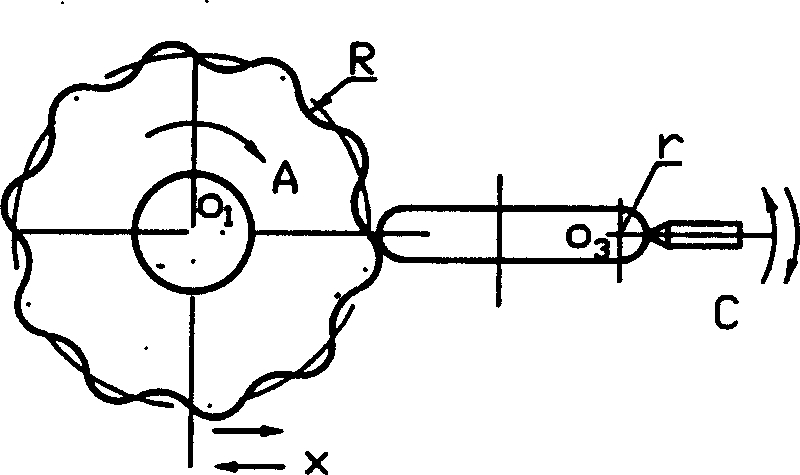

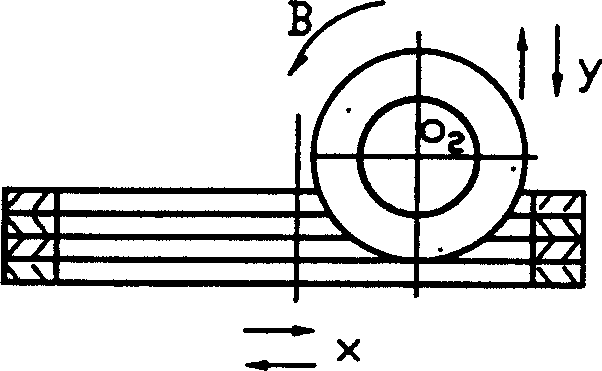

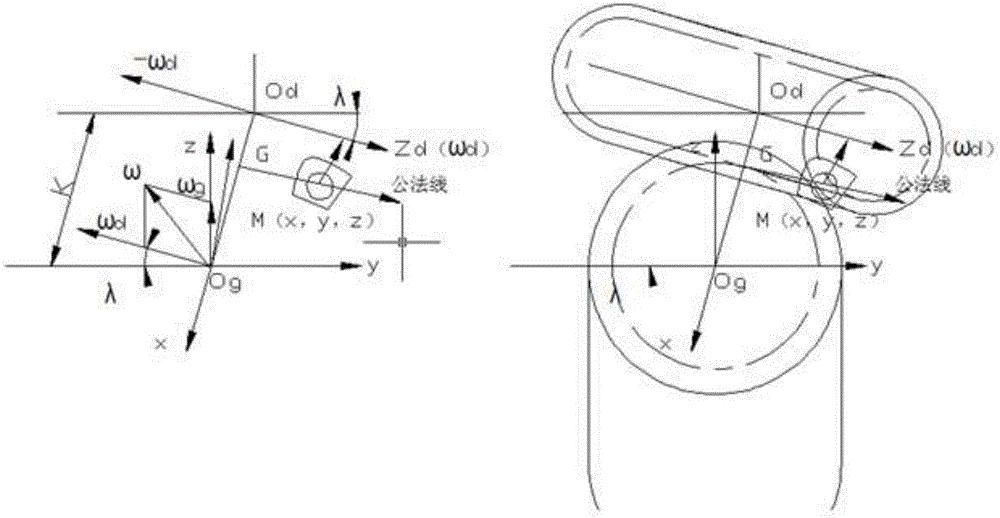

Digital controlled method for grinding teeth of cycloidal gear, and its appts.

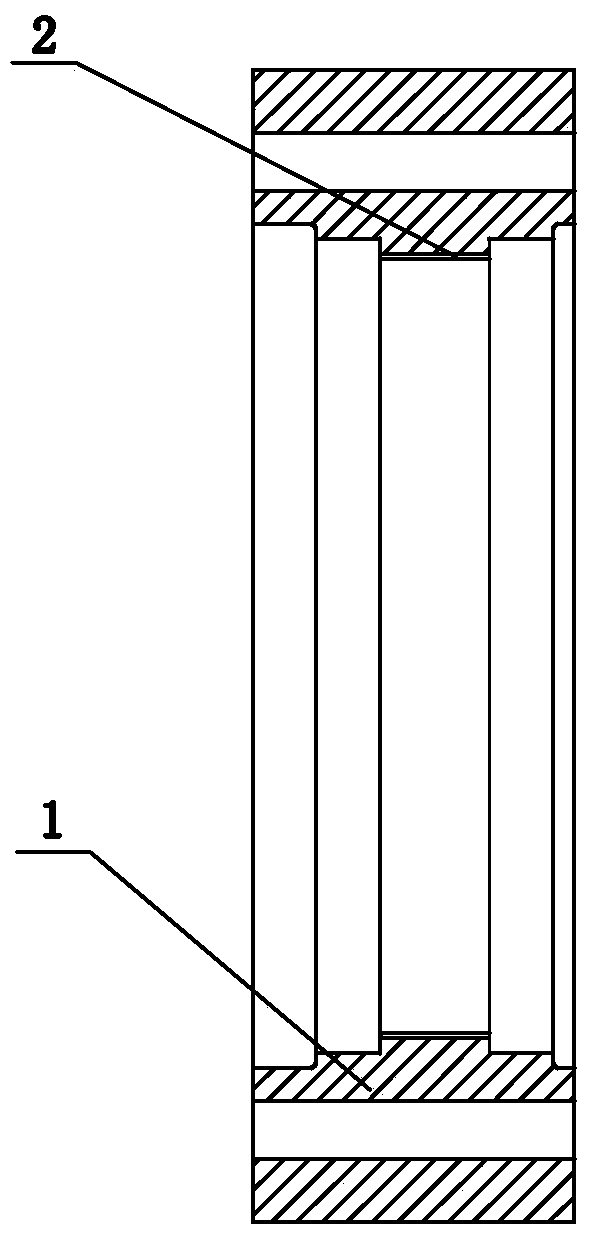

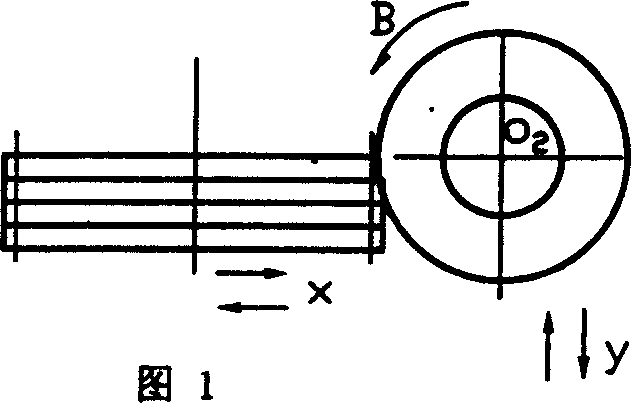

A numerally controlled tooth grinding method for cycloid gear features that an abrasive disk is driven by a cranker-connecting rod mechanism to linearly reciprocate for forming an equivalent cylindrical grinding surface and the cycloid gear to be machined is driven by a dual-coordinate numerally controlling system controlled by microcomputer to shift and rotate, so enveloping whole tooth profile of cycloid gear.

Owner:CHONGQING UNIV

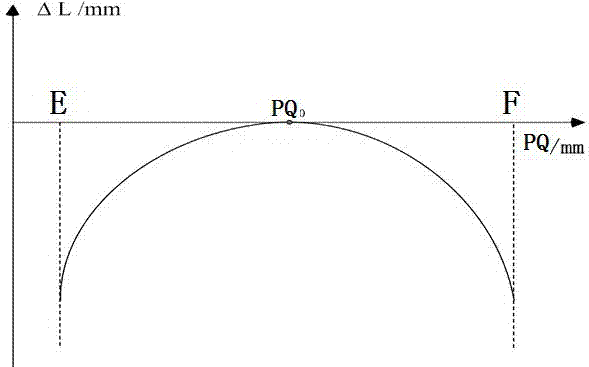

Cycloidal gear tooth profile correction method, cycloidal gear and RV (rotary vector) reducer

InactiveCN107229836ASmall amount of modificationHigh degree of engagementInformaticsSpecial data processing applicationsReducerGear tooth

The invention relates to the field of processing of cycloidal gears, in particular to a cycloidal gear tooth profile correction method, a cycloidal gear and an RV (rotary vector) reducer; a main operating area of each tooth of the cycloidal gear is located mainly between the root and crest of the tooth close to its middle, and the root and crest are non-principal operating areas. The method of the invention imparts a second-order or higher-order parabolic relationship the correction amount of the tooth profile and a normal distance from a standard cycloidal gear node to a meshing point of a standard cycloidal gear and pin wheel, the correction amount decreases gradually from the crest and root to the middle main operating area, a certain meshing clearance is generated in the non-principal operating areas and forms a lubricating clearance, and the main operating area has small correction amount so that it is ensured that the main operating area attaches to the standard cycloidal gear tooth profile to the maximum extent; during transmission in no-load state, only one pair of teeth are involved in meshing transmission; after loading, the cycloidal gear and the pin wheel deform slightly under stress, multiple pairs of teeth are involved in meshing, meshing contact ratio is increased, and the transmission is more stable.

Owner:HENAN UNIV OF SCI & TECH

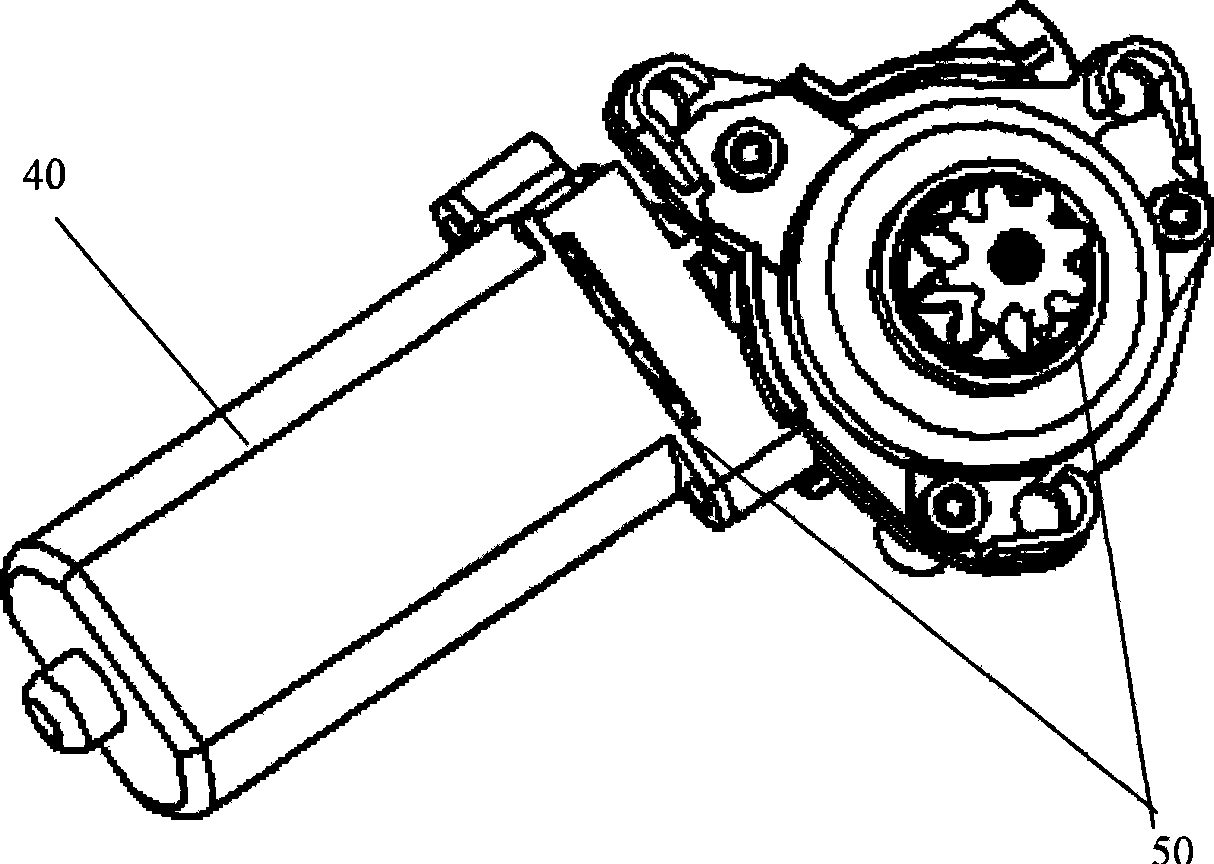

Gear motor for seat regulating means

ActiveCN101499695AReduce bending stressIncrease loading capacityVehicle seatsToothed gearingsGear wheelGear system

The invention provides a gear motor used for a seat adjusting device, comprising a motor and a gearbox; wherein, the gearbox comprises a primary transmission mechanism with a worm rod and a worm wheel which are meshed with each other, a secondary transmission mechanism with an annular gear, a cycloidal gear, an eccentric wheel, a rotation frame and an output gear which is connected with the rotation frame; the worm rod is fixed on a motor shaft and can rotate correspondingly to the motor shaft; the worm wheel is driven by the worm rod and drives the eccentric wheel which is fixed on the worm wheel to rotate; the eccentric wheel and the annular gear lead the cycloidal gear to own autorotation and revolution; and the rotation frame transmits the autorotation of the cycloidal gear to the output gear. The gear motor adopts the cycloidal gear to replace an N-N-typed planetary gear system; and with the same volume, the cycloidal gear has higher bearing capability and higher efficiency. When the cycloidal gear system is used, the load can be shared by a plurality of gear teeth; as multi-pair of wheel teeth are used for mesh, the bending stress exerted on the wheel teeth is reduced. Due to the multi-pair of meshed wheel teeth, the gear motor has higher bearing capability and stronger anti-shock capability.

Owner:JOHNSON ELECTRIC SHENZHEN

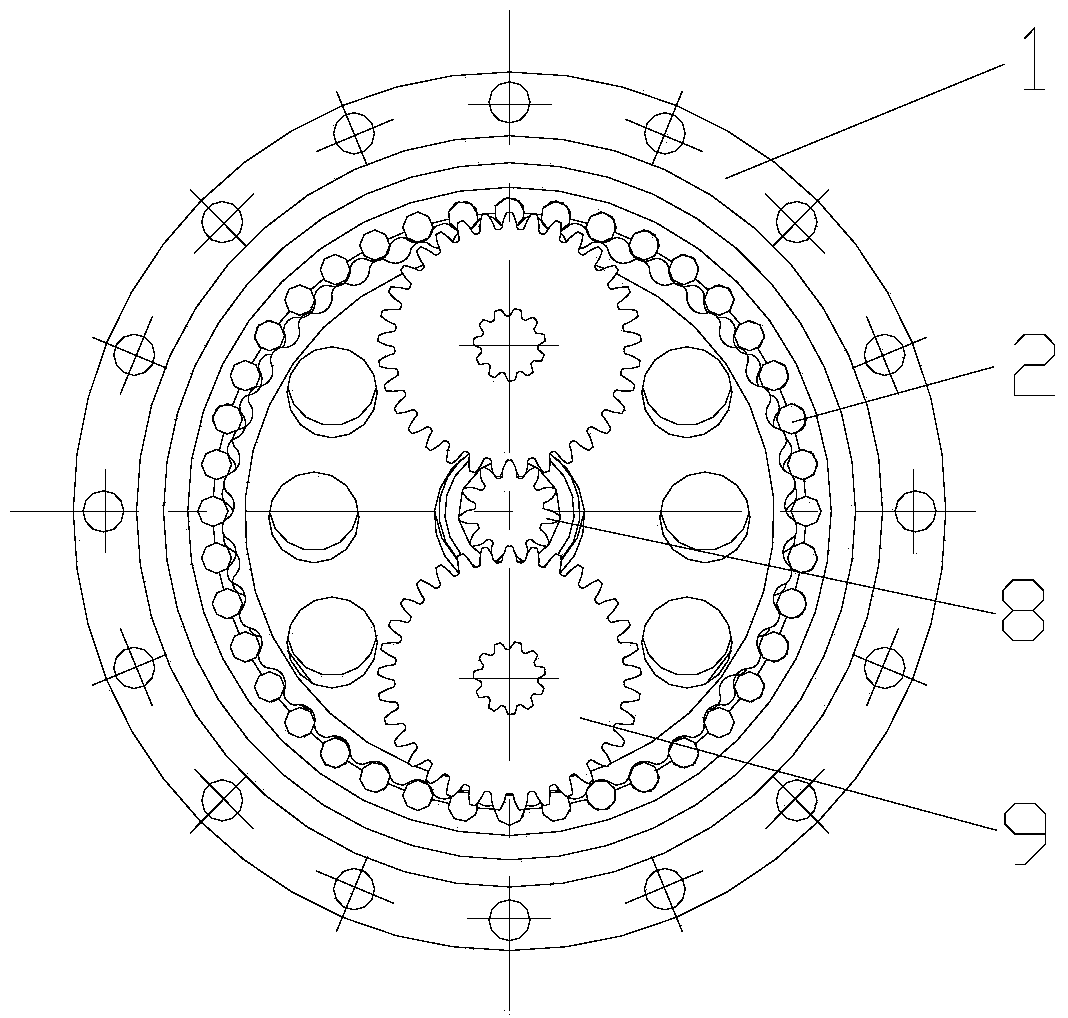

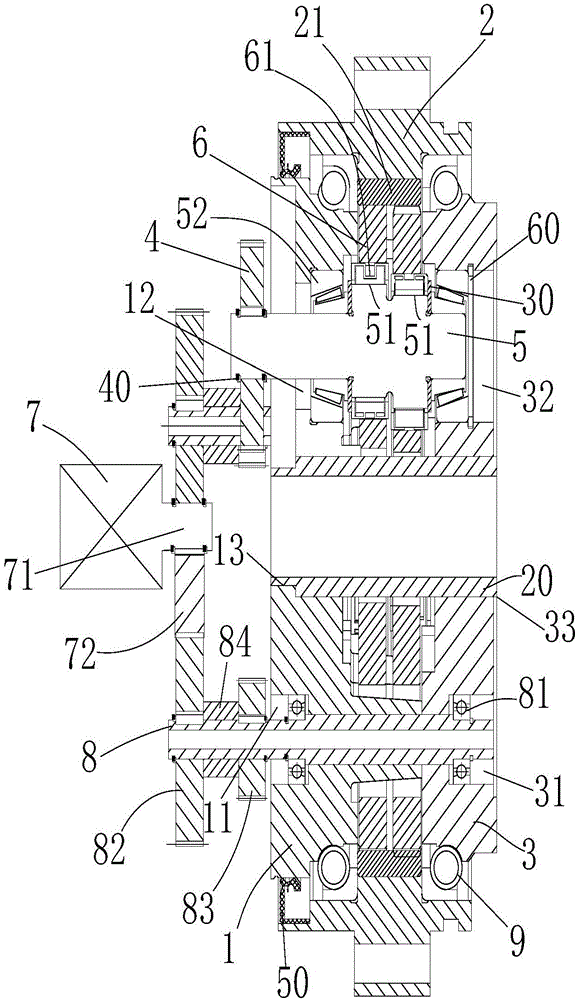

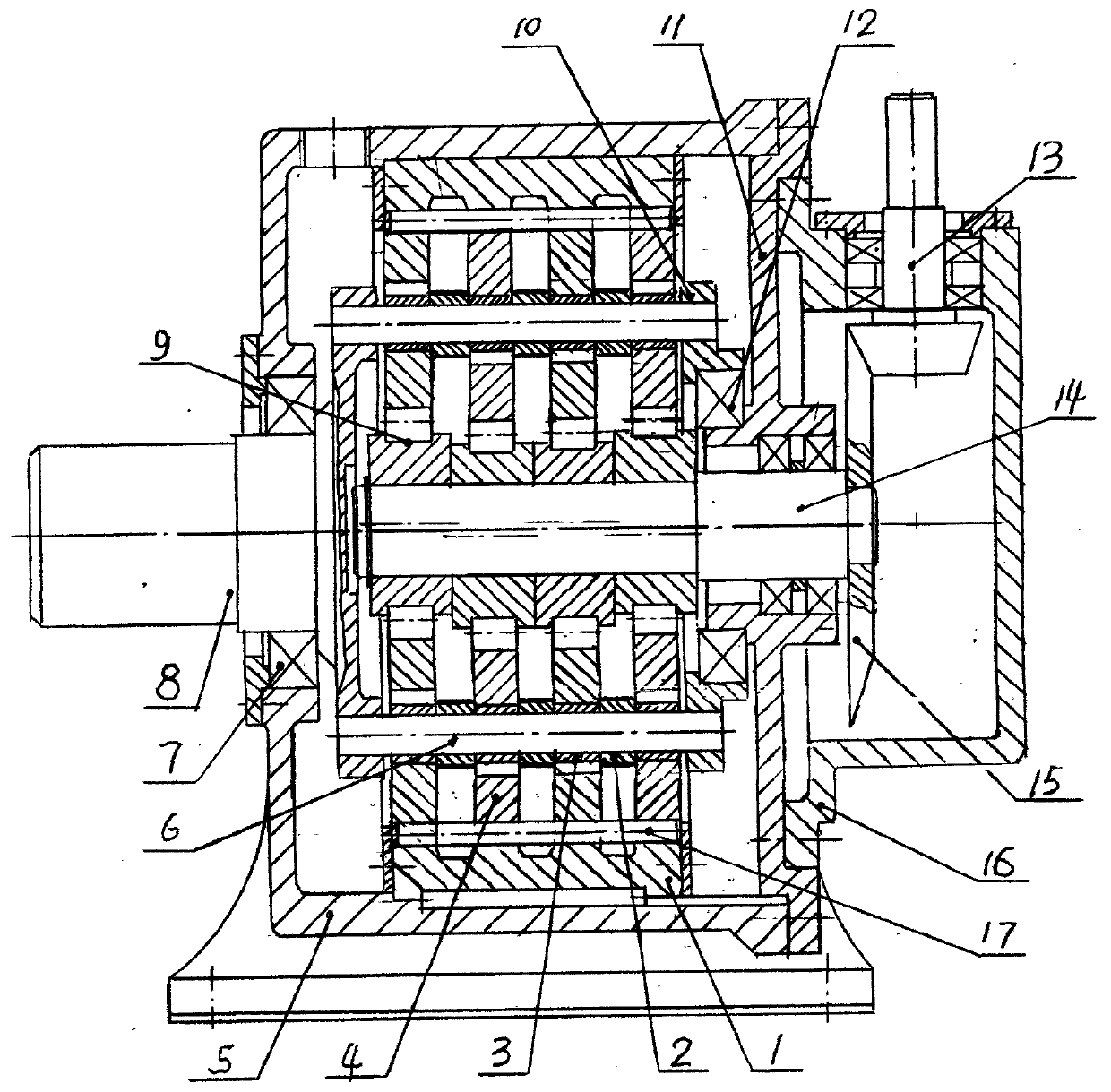

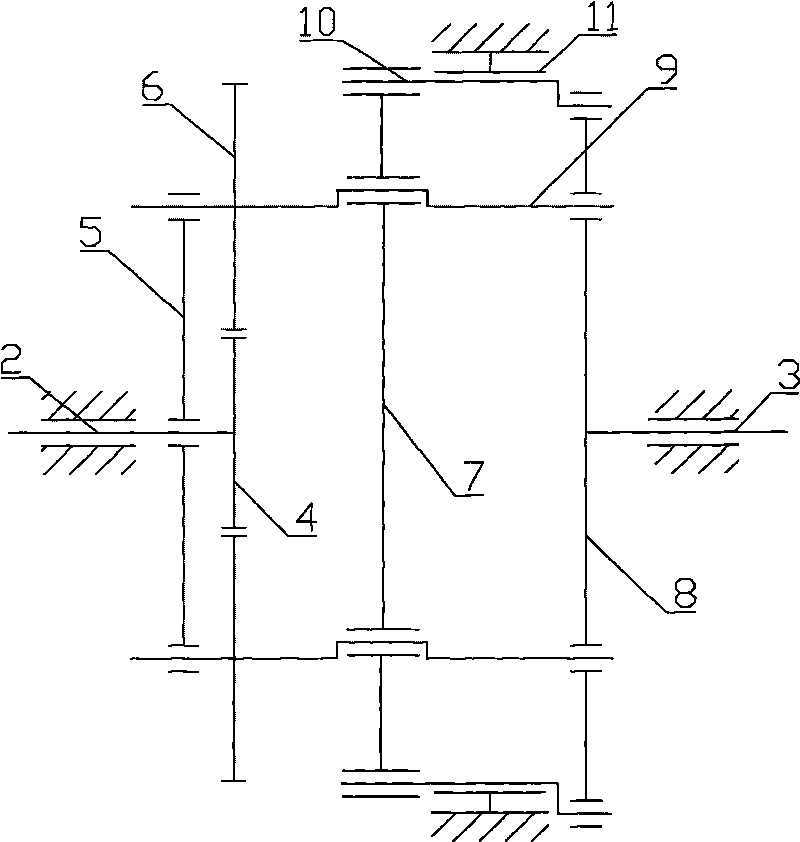

Double-cycloid speed reducer of RV-E type substituted industrial robot

InactiveCN103234007ALow mechanical manufacturing process difficultyReduce manufacturing costToothed gearingsGearing detailsProduction linePhase difference

The invention relates to a double-cycloid speed reducer of an RV-E type substituted industrial robot. The double-cycloid speed reducer of the RV-E type substituted industrial robot comprises a planetary transmission part and a double-cycloid transmission part, wherein the planetary transmission part comprises a central shaft, a sun wheel, a planet wheel and an input shaft, and the double-cycloid transmission part comprises a first cycloid wheel, a second cycloid wheel, a first eccentric bearing, a second eccentric bearing, an inner cycloid gear ring, a left machine frame and a right machine frame. The cycloid wheels are connected through a roller bearing in a penetrating mode, eccentric sleeves are installed in inner holes of the roller bearing, and an inner hole of the eccentric sleeve is an involute oblique inner tooth, and the involute oblique inner tooth is matched with an involute oblique outer tooth in a sliding mode on the input shaft. The oblique inner teeth and the oblique outer teeth are processed by a cutting machine tool with medium-slow production lines, a processing technology is simple, the production efficiency is high, the cost is low, and the matching accuracy of the oblique inner teeth and the oblique outer teeth is high. Elastic retainer rings are respectively arranged on outer sides of disc springs on two sides of the input shaft. The double-cycloid speed reducer aims at enabling phase difference of the two single eccentric sleeves to be 180 degrees-delta psi, wherein a small deflection angle delta psi is that wheel teeth of the first cycloid wheel 9 lean against one anticlockwise side of wheel teeth of an upper half region of the inner cycloid gear ring, and wheel teeth of the second cycloid wheel 21 lean against one clockwise side of wheel teeth of a lower half region of the inner cycloid gear ring. The shortcoming of repeated dismantling in the former invention is improved.

Owner:JIANGSU TAILAI REDUCER

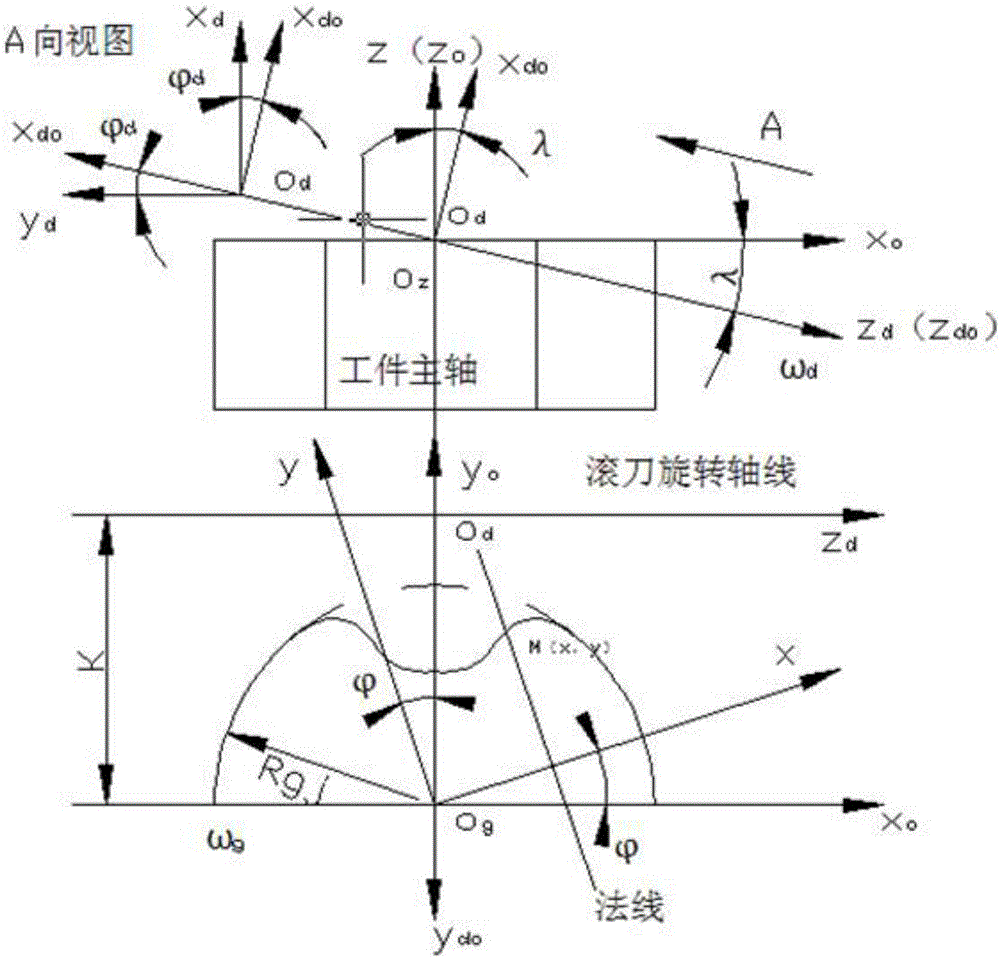

Grinding method for numerical-control worm grinding wheel of cycloid gear

The invention relates to a grinding method for a numerical-control worm grinding wheel of a cycloid gear. The space engagement theory is utilized, the three-dimensional profile equation of the worm grinding wheel of the machined cycloid gear is deduced according to the three-dimensional profile equation of the cycloid gear, and the cycloid gear is subjected to fine polishing through the worm grinding wheel. The grinding method has remarkable advantage compared with a cycloid gear forming and grinding technique, and intermittent machining is replaced by continuous machining. Meanwhile, the generating motion precision stability is higher than the intermittent Intermittent precision, so that the gear polishing precision is remarkably improved, the gear polishing production cost is remarkably reduced, and the gear polishing efficiency is remarkably improved. The grinding method is applied to a machine tool used for grinding the cycloid gear through the worm grinding wheel, a special clamp table for corresponding workpieces is designed, two cycloid gear blanks are positioned and installed at a time, and the spatial positions of the two cycloid gear blanks are determined. An online measuring head is additionally arranged on one side of the worm grinding wheel so as to position the spatial position of the worm grinding wheel. By means of the combination of the two techniques, rapid and accurate tool setting of the cycloid gear blanks and the worm grinding wheel is achieved.

Owner:CHONGQING UNIV

Speed reducer with planetary gears and cycloidal gear

The invention discloses a speed reducer with planetary gears and a cycloidal gear. The speed reducer comprises an input gear shaft, the planetary gears meshed with the input gear shaft, pin shafts arranged inside inner holes of the planetary gears, roller pins positioned between the pin shafts and the planetary gears, a crankshaft, a planetary carrier end cover, cushion columns, an outer gear ring, a casing, the cycloidal gear, a transmission component and an output end, wherein the crankshaft and the planetary carrier end cover are respectively connected with the two ends of the pin shafts; the cushion columns are positioned between the crankshaft and the planetary carrier end cover; the outer gear ring is positioned on the outer rings of the planetary gears and meshed with the planetary gears; the casing is fixedly connected with the outer gear ring; the cycloidal gear sleeves the eccentric circle of the crankshaft through a cylindrical roller bearing B; the transmission component is clamped with the cycloidal gear; the output end is clamped with the transmission component. The speed reducer has the advantages of being high in precision, high in transmission efficiency, simple in structure, small in size, convenient to mount, and low in manufacturing cost.

Owner:江苏哈工联合精密传动有限公司

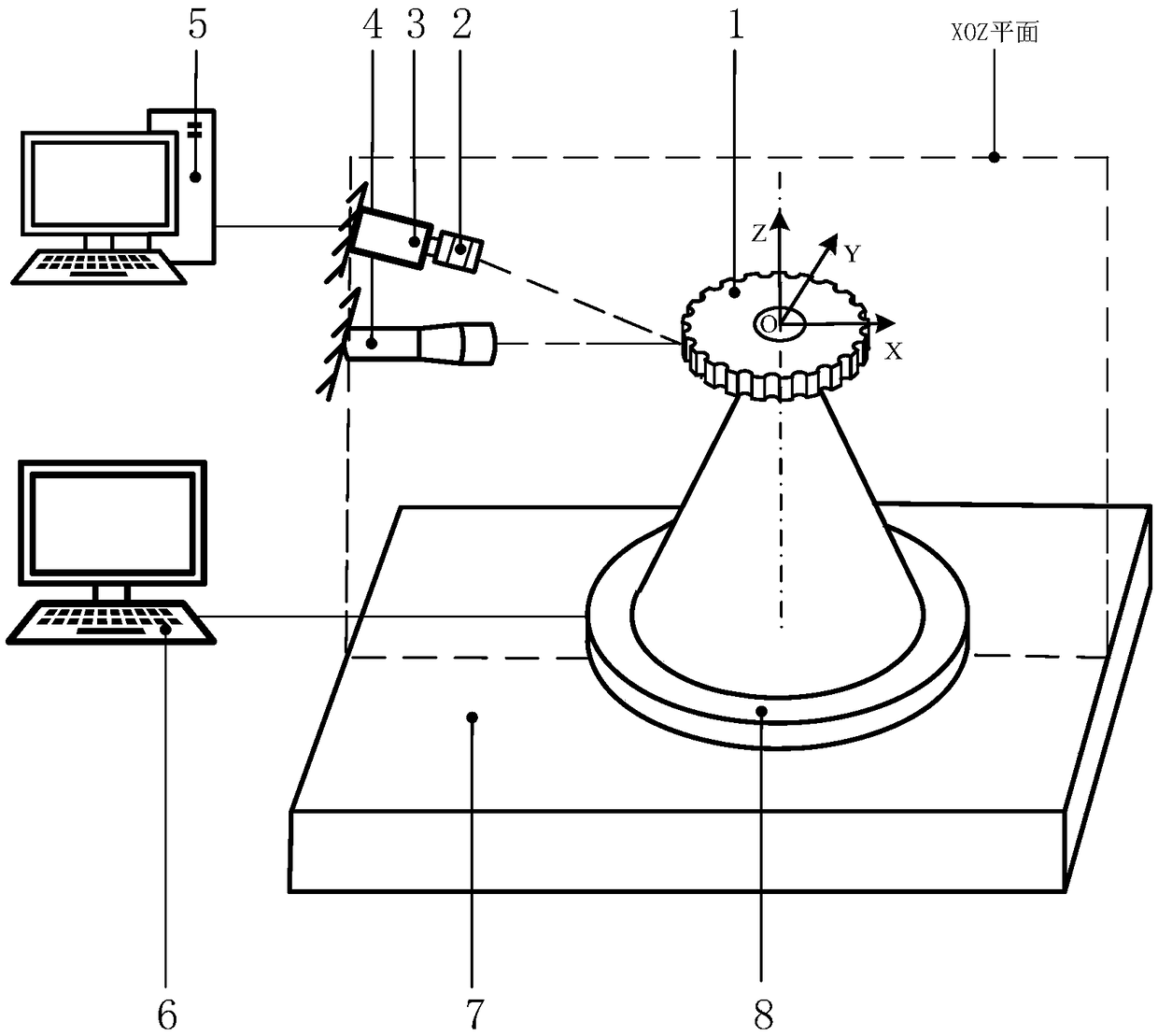

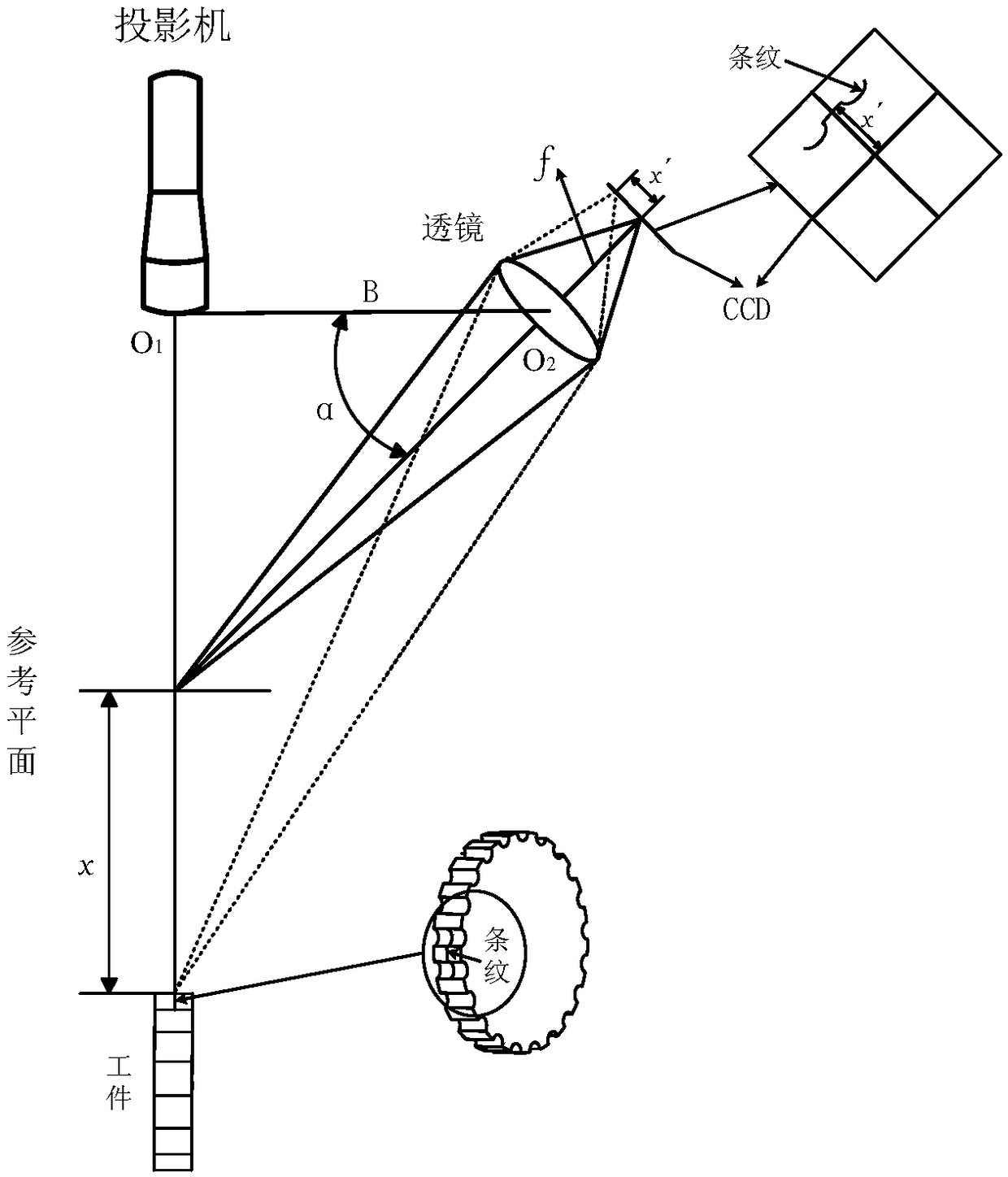

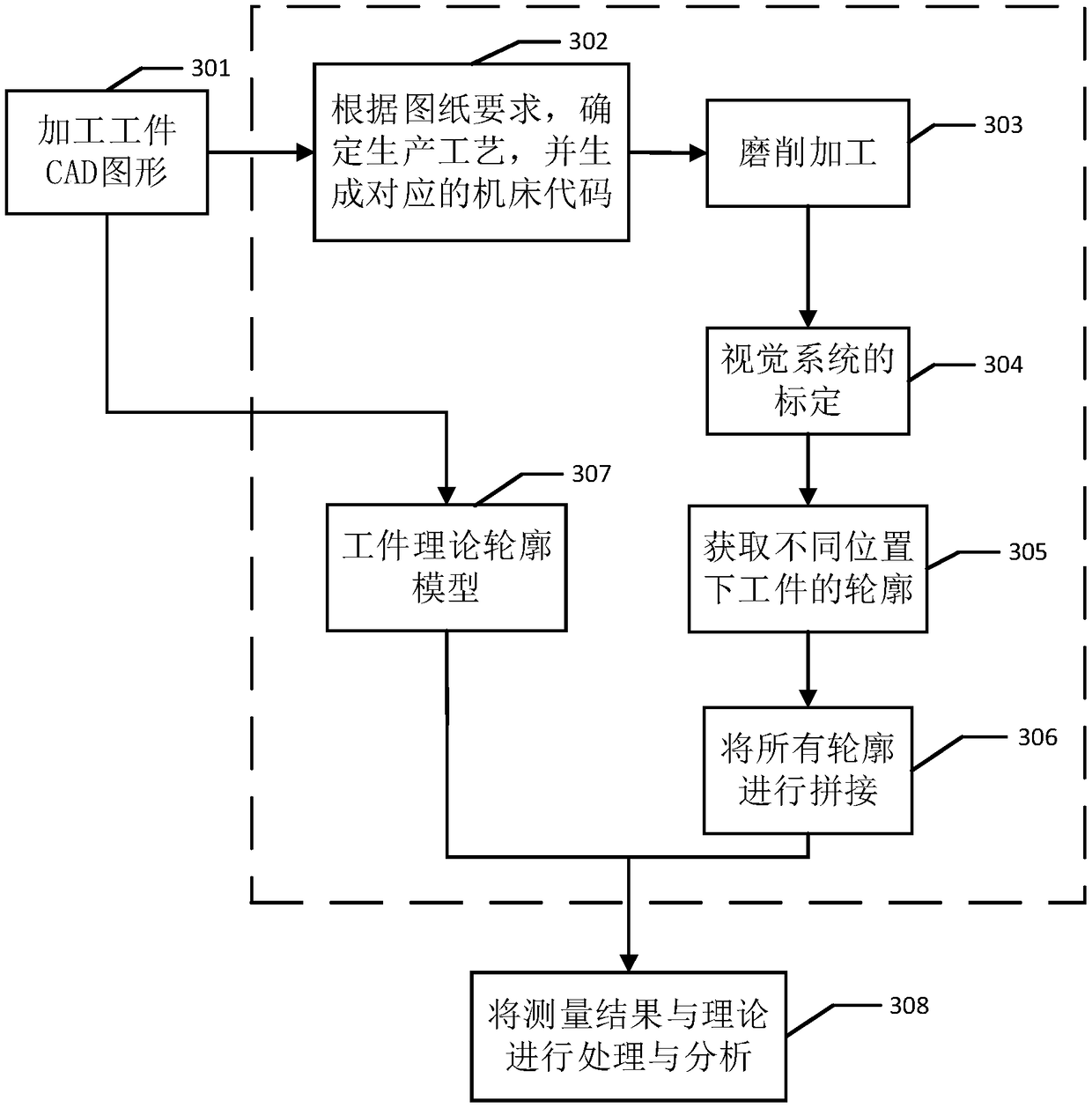

On-machine non-contact workpiece contour detection system and method of cycloid gear grinder

InactiveCN108789155ALow costHigh precisionGrinding feed controlUsing optical meansControl systemMachine tool control

The invention discloses an on-machine non-contact workpiece contour detection system of a cycloid gear grinder. The on-machine non-contact workpiece contour detection system of the cycloid gear grinder comprises a machine tool rotary table, a machine tool bed, a CCD camera, a telecentric lens, a projector, a machine tool control system and an upper computer. The machine tool rotary table is installed on the machine tool bed at the bottom, and workpieces are clamped on the machine tool rotary table through central positioning holes. The CCD camera and the projector are fixed to the machine toolbed on the left side. The machine tool control system is connected with the machine tool rotary table in a circuit mode to be used for controlling the rotary table to rotate so as to measure workpiece contours at different positions. The CCD camera is connected with the upper computer in a circuit mode to be used for transmitting the photographed image to the upper computer for processing. The invention further discloses an on-machine non-contact workpiece contour detection method of the cycloid gear grinder. The on-machine non-contact workpiece contour detection system and method of the cycloid gear grinder have the characteristics of low cost, high efficiency and high precision, can be widely applied to various occasions of on-machine non-contact detection and processing, and have greatpotential.

Owner:SOUTH CHINA UNIV OF TECH +1

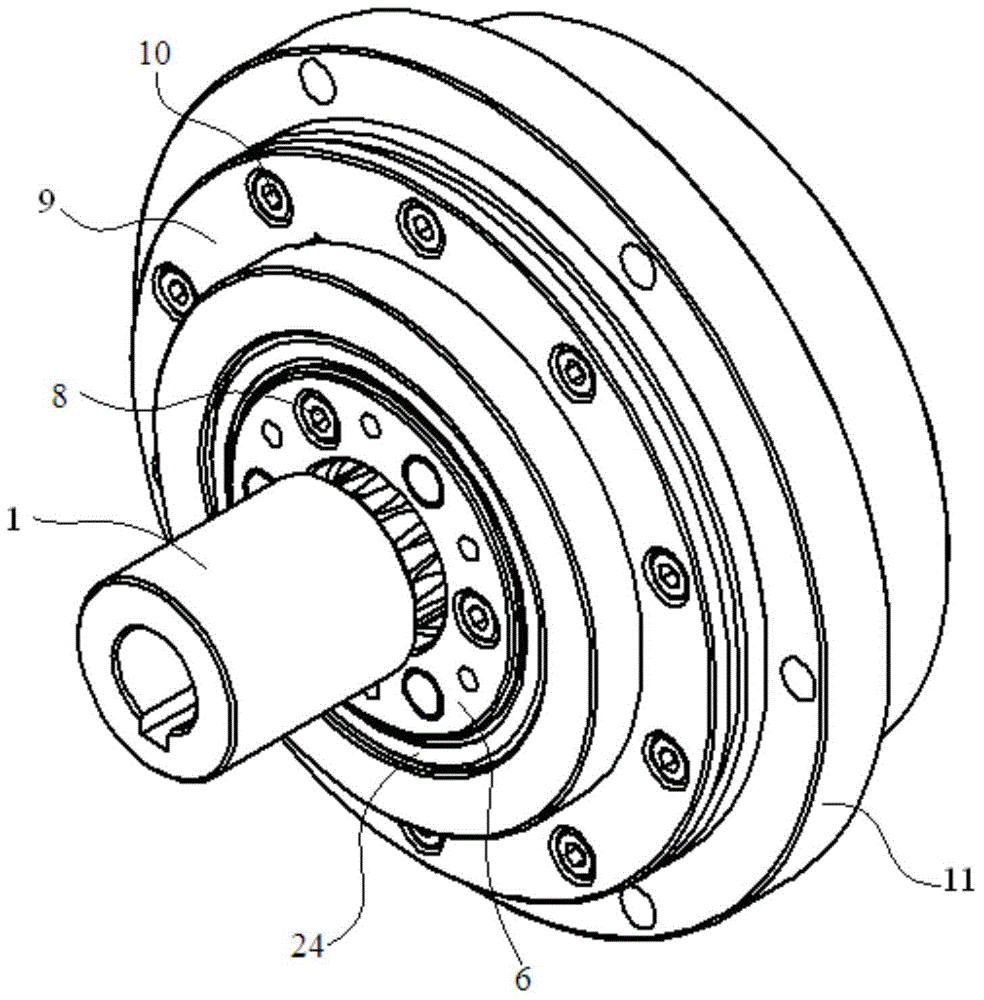

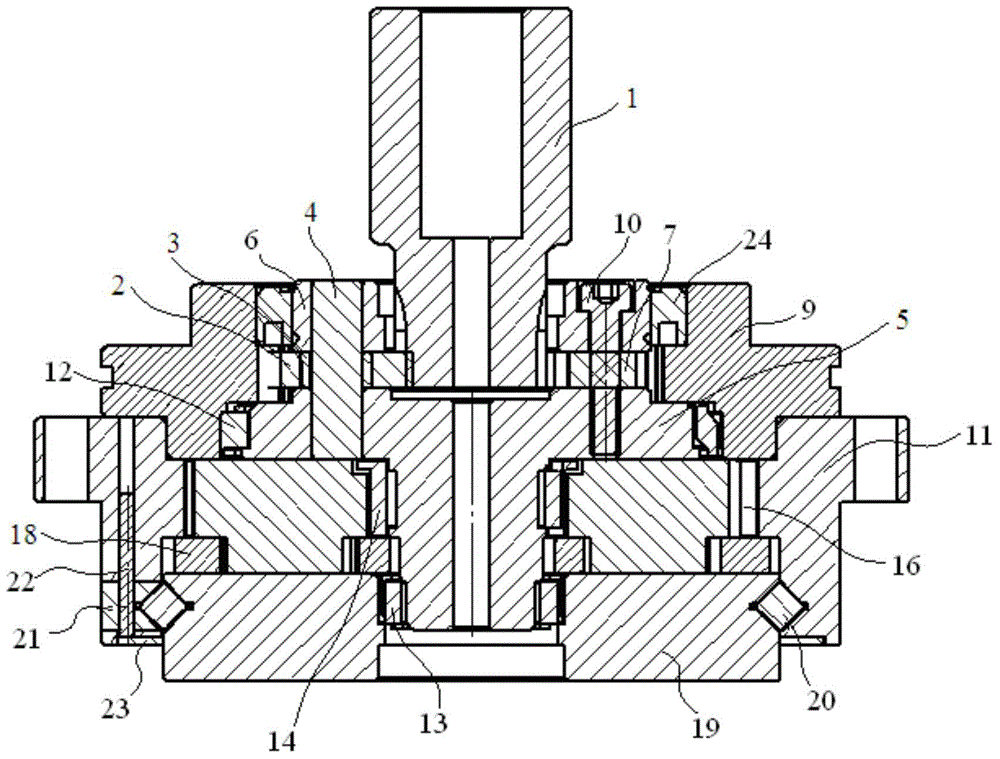

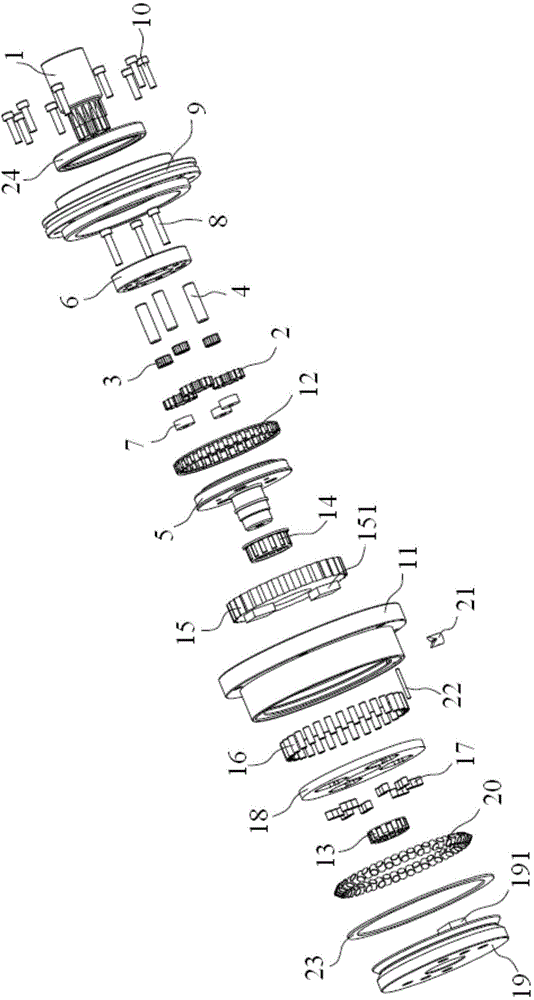

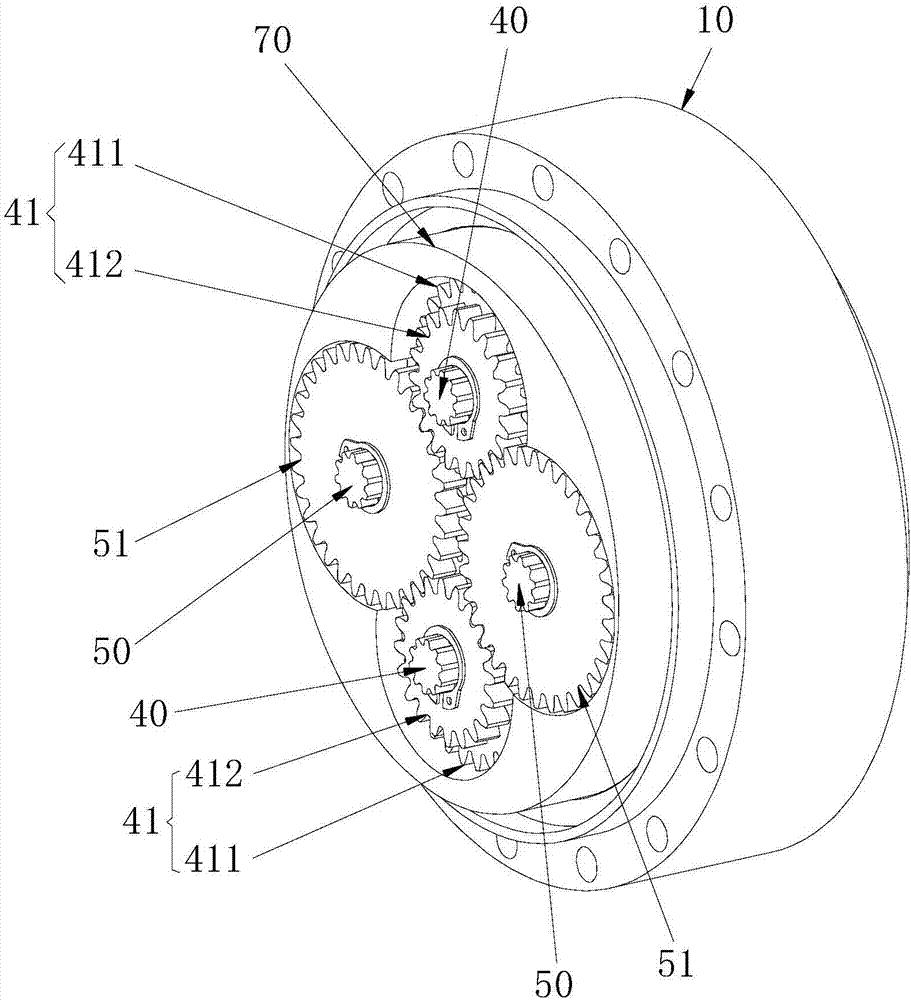

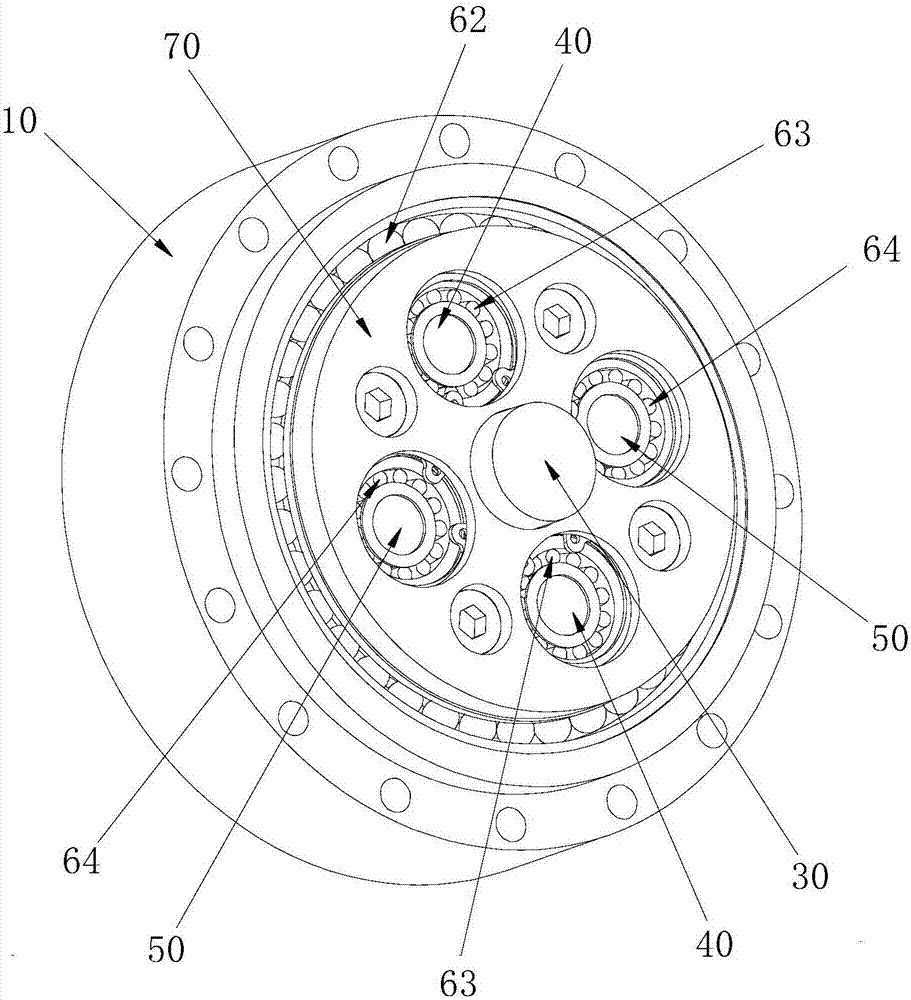

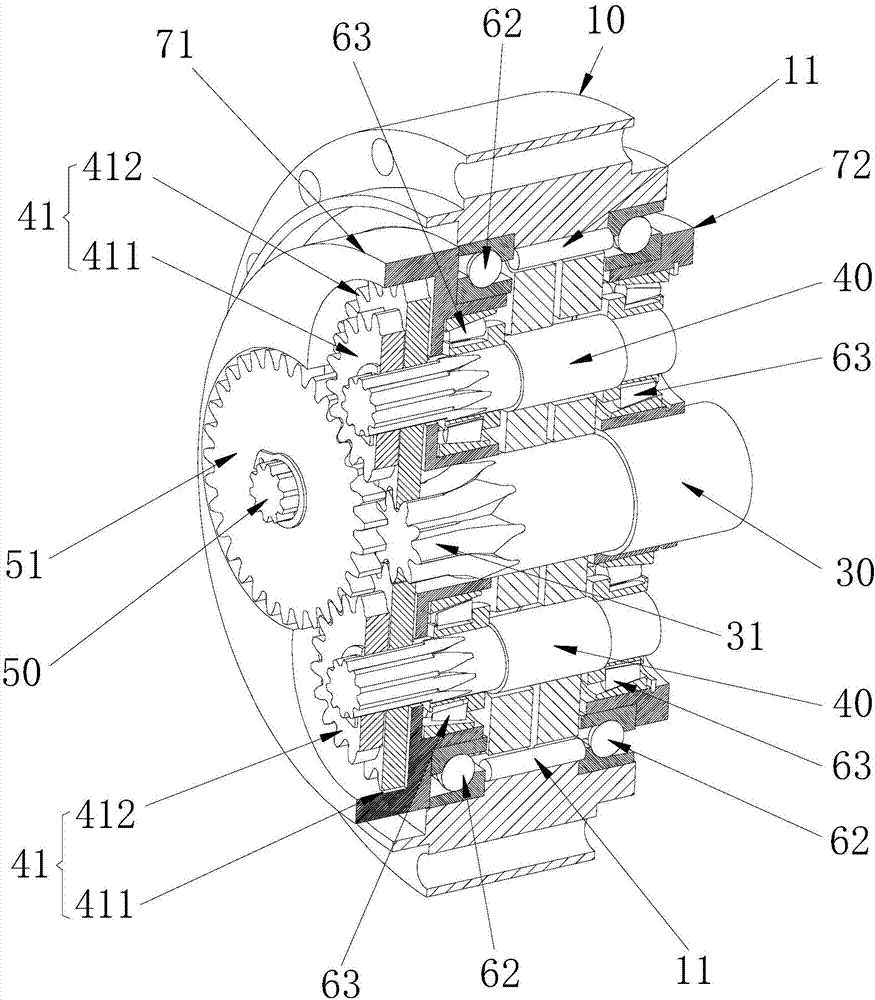

Integrated high-speed cycloidal wheel hub motor

InactiveCN105667296AIncrease powerIncrease speedMotor depositionMechanical energy handlingGear wheelEngineering

The invention discloses an integrated high-speed cycloid hub motor, which includes a hub component, a motor component, a cycloid reducer component, and an output component. The motor component is arranged in the hub, and the motor component includes a motor casing, a motor inner casing, The central shaft, the rotor connected to the central shaft, and the stator matched with the rotor, the rotor is a cantilever structure, and a concave space is formed at one end, and the cycloidal reducer components are installed in the concave space. The central shaft is connected with the cycloidal reducer part as the input end of the cycloidal reducer part, and the other end of the cycloidal reducer part is connected with the output part, and the output shaft of the output part is fixedly connected with the hub part. The invention can provide sufficient torque and rotating speed of the automobile to ensure the adaptability to various complex working conditions; secondly, the integrated design of the cycloidal gear reducer and the motor reduces the excessive size of the gear reducer and makes the structure of the hub motor Compact and able to maintain high efficiency operation.

Owner:WUHAN UNIV OF TECH

Three-grade deceleration planetary reducer and industrial robot

ActiveCN107366716ATaking into account the small size designCompact installationToothed gearingsReduction driveGear tooth

The invention provides a three-grade deceleration planetary reducer and an industrial robot. The three-grade deceleration planetary reducer comprises a pin gear shell, a cycloidal gear, an input shaft, a planet shaft, a crank shaft and an output part; gear teeth of the cycloidal gear can be engaged with pin teeth in the pin gear shell; a first-grade planet gear on the planet shaft is engaged with a driving gear on the input shaft; a second-grade planet gear on the crank shaft is engaged with the first-grade planet gear; the crank shaft is provided with an eccentric cylinder eccentrically arranged relative to the center axis of the crank shaft; a first bearing is arranged between the eccentric cylinder and the hole wall of a bypass hole; the output part is supported and connected into the pin gear shell through a second bearing; the planet shaft is supported and connected to the output part through a third bearing; and the crank shaft is supported and connected to the output part through a fourth bearing. The three-grade deceleration planetary reducer solves the technical problem that a speed reducer in the prior art cannot achieve compatibility of the high deceleration ratio and the smaller designed size.

Owner:SHENZHEN INST OF ADVANCED TECH

Hollow type gear transmission speed reducer

ActiveCN106195137AAvoid wear and tearFacilitate transmissionToothed gearingsMechanical energy handlingReducerCrankshaft

The invention discloses a hollow type gear transmission speed reducer. The hollow type gear transmission speed reducer comprises an output disc, a pin gear housing, a support flange, planet wheels, a crankshaft, a cycloidal gear, a motor and rotary shafts. The output disc and the support flange are installed at openings in the two ends of the pin gear housing correspondingly. The middle of the output disc is provided with a left through hole. The middle of the support flange is provided with a right through hole. The left through hole, an inner cavity of the pin gear housing and the right through hole communicate sequentially to form a first through hole. A first gear is arranged at one end of an input shaft of the motor. Each rotary shaft is provided with a second gear and a third gear. All the second gears mesh with the first gear, and each third gear meshes with the corresponding planet wheel. The hollow type gear transmission speed reducer has the characteristics of being good in transmission performance, small in machining difficulty and low in production cost and is provided with the through holes capable of holding wirings and tubings, abrasion of the wirings and the tubings can be avoided effectively under the circumstance that the transmission performance is not influenced, and thus the whole speed reducer looks neat and attractive.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Geluote energy saving high efficiency hydraulic deflector

ActiveCN1824562ASimple designCompact structureFluid steeringTransmission technologyControl engineering

The present invention relates to a Groth's energy-saving high-effective hydraulic steering equipment, belonging to the field of hydraulic transmission technology. Said steering equipment is composed of the following several portions: external shell, flow channel communicated with fluid inlet and fluid outlet, valve body and valve core, universal driving shaft, spline gear pair, cycloid gear pair, rotor and non-return valve, etc. Said invention also provides the connection mode of all the above-mentioned portion and the working principle and operation method of said steering equipment.

Owner:ZHENJIANG HYDRAULICS

Gear modification method for cycloidal pinwheel transmission device and cycloidal pinwheel transmission device

InactiveCN106523599AImprove carrying capacityHigh transmission precisionPortable liftingToothed gearingsGear wheelEngineering

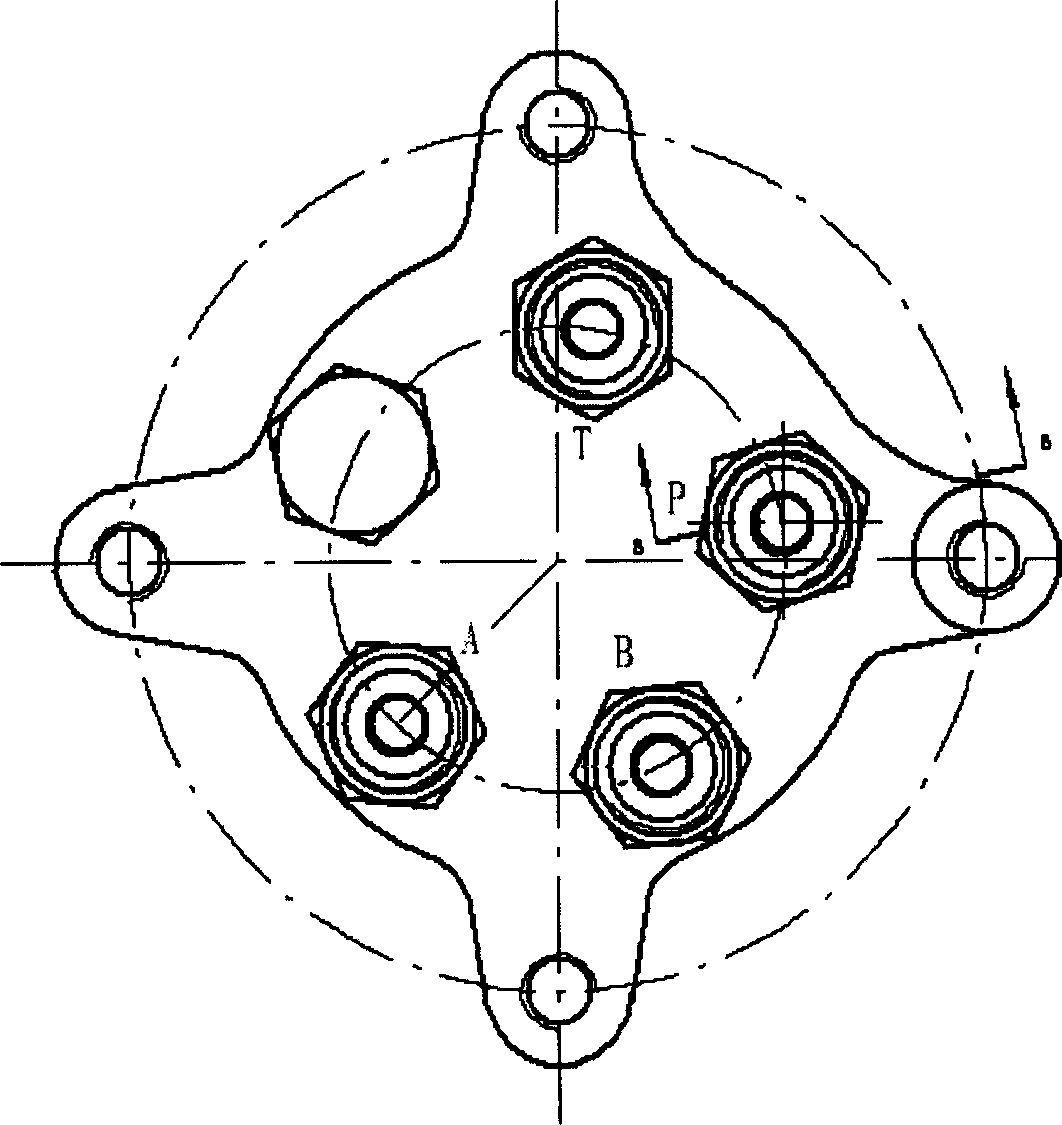

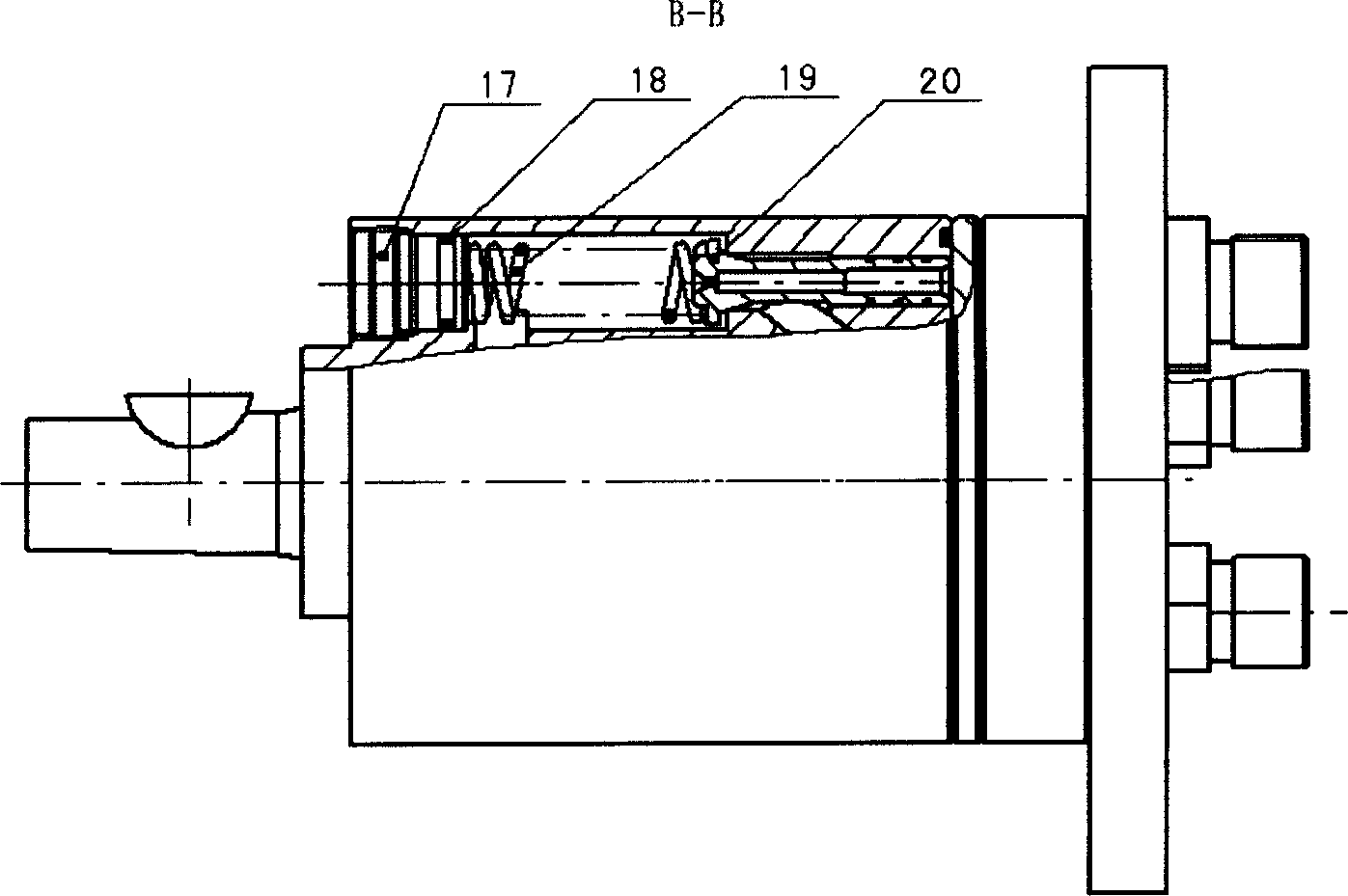

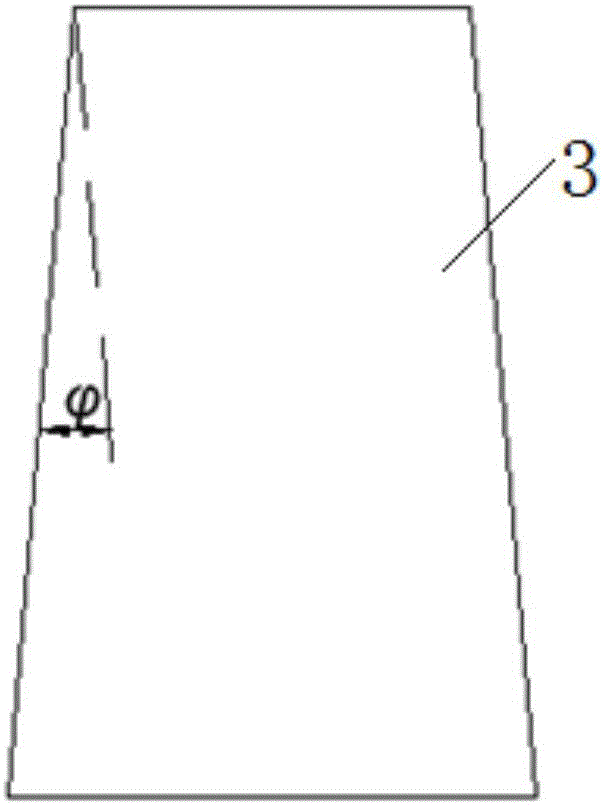

The invention relates to a gear modification method for a cycloidal pinwheel transmission device and the cycloidal pinwheel transmission device. The cycloidal pinwheel transmission device comprises a shell, a cycloidal gear, pin teeth, springs and an end cap. A pin tooth groove for containing the pin teeth is formed in the inner side wall of the shell. The cycloidal gear is arranged at the center of the shell. The pin teeth are arranged in the pin tooth groove. The pin teeth are in contact with the cycloidal gear and the pin tooth groove at the same time. The pin teeth are circular-truncated-cone-shaped pin teeth. The inner surface of the pin tooth groove is an inclined cylindrical face. The end cap is connected to the shell. The springs are arranged between the big end face of each pin tooth and the end cap. The taper angle phi of each pin tooth satisfies the formula (please see the formula in the specification), wherein mu is the friction coefficient of the surface, in contact with the pin teeth, of the pin tooth groove, and the inclination angle theta of the cylindrical face of the pin tooth groove is equal to the taper angle of the pin teeth. Compared with the prior art, by the adoption of the gear modification method and the cycloidal pinwheel transmission device, the gap defect which is generated between the cycloidal gear and the pin teeth and brought by the manufacturing error and working wear can be made up for, all the pin teeth are made to be kept in contact with the cycloidal gear, and thus the transmission bearing capacity and the transmission accuracy of a cycloidal pinwheel are improved remarkably.

Owner:TONGJI UNIV

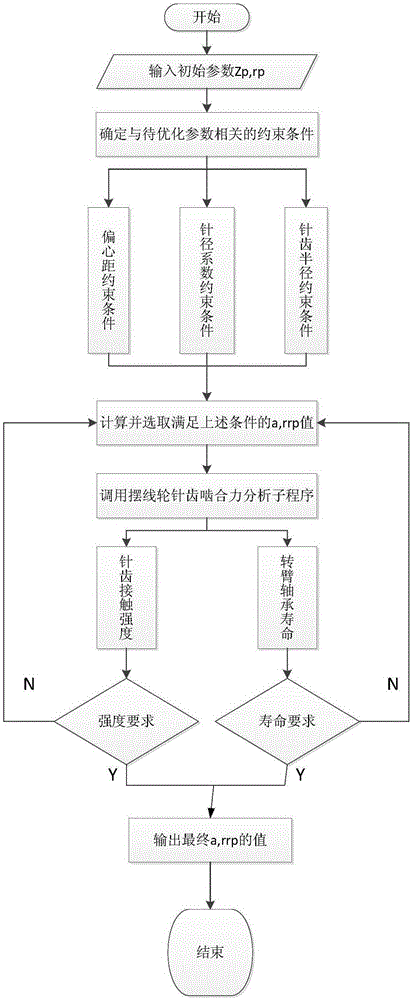

MATLAB based cycloid gear parameter optimization method

InactiveCN105404737AShorten calculation cycleGuarantee the rationality of the designGeometric CADSpecial data processing applicationsCarrying capacityTooth number

The invention discloses an MATLAB based cycloid gear parameter optimization method. The method comprises the following steps: step1. obtaining number ZP of needle teeth and needle teeth central circle radius rp; step2. according to restricting conditions, obtaining an eccentric distance and a needle gear sleeve outer circle radius rrp; step3. determining tooth number range and maximum engagement force involving in engagement simultaneously at the moment when the cycloid gear transmits; and step4. when needle teeth contact stress reaches strength requirement and rotary arm bearing life meets the requirement, outputting the eccentric distance a and the needle gear sleeve outer circle radius rrp, otherwise, executing step 2 until the requirement is met. According to the cycloid gear parameter optimization method, cycloidal gear parameter optimization is completed by analyzing basic principles of cycloid pin gear transmission and a design method of the cycloid gear. In the optimization, main parameters affecting cycloid gear transmission carrying capacity, the eccentic distance and the needle tooth radius rrp, are used as design variables, cycloid pin gear engagement strength and rotary arm bearing life are to-be-solved targets, and certain constraints are met.

Owner:天津市鑫达物业管理有限公司

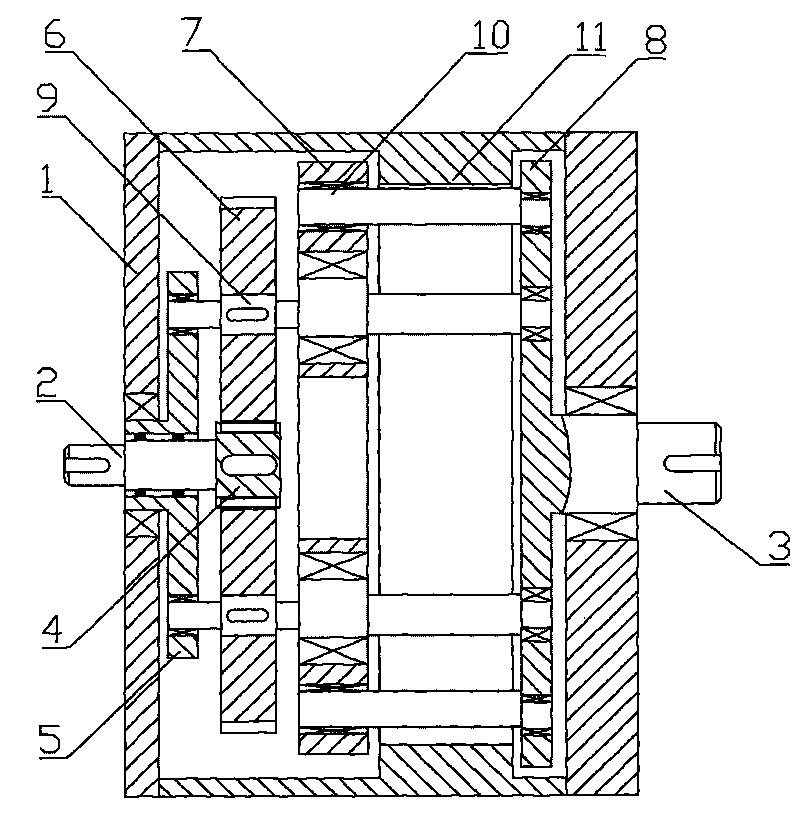

Double-cycloid speed reducer for RV-E simulation carrying welding robot

InactiveCN103016640ASimple structureMechanical manufacturing process is less difficultToothed gearingsGearing detailsReduction drivePhase angle difference

The invention relates to the technical field of precision speed reducers, in particular to a double-cycloid speed reducer for an RV-E simulation carrying welding robot. The double-cycloid speed reducer comprises a planetary driving medium and a double-cycloid driving medium, wherein the planetary driving medium comprises a sun wheel, a planetary wheel and an input shaft; and the double-cycloid driving medium comprises a frame, an inner cycloidal gear ring, a first cycloidal gear, a second cycloidal gear and a double eccentric shaft. The double-cycloid speed reducer is characterized in that: a second sealing element is arranged between the sun wheel and a third bearing; a third sealing element is arranged between the planetary wheel and a fifth bearing; the sealing elements are rotating shaft lip-shaped sealing rings or Che seals; the phase angle difference between two single eccentric sections of the double eccentric shaft is 180 degree-deltapsi, and the minute deflection angle is deltapsi; the gear teeth of the first cycloidal gear cling to one anticlockwise side of the gear pin in an upper half region; the gear teeth of the second cycloidal gear cling to one clockwise side of the gear pin in a lower half region; the return difference of the speed reducer is always kept at zero; and the effective facewidth of the first cycloidal gear is 1-3 times that of the second cycloidal gear. The double-cycloid speed reducer has the beneficial effects of simple structure, low manufacturing process difficulty and no need of any high-accuracy processing machine tool.

Owner:吴小杰

Reducer with bevel gear and cycloid in large transmission ratio for ore grinding machine

InactiveCN102192274AAxial dimension shortExtended service lifeGearboxesToothed gearingsPhase differenceReduction drive

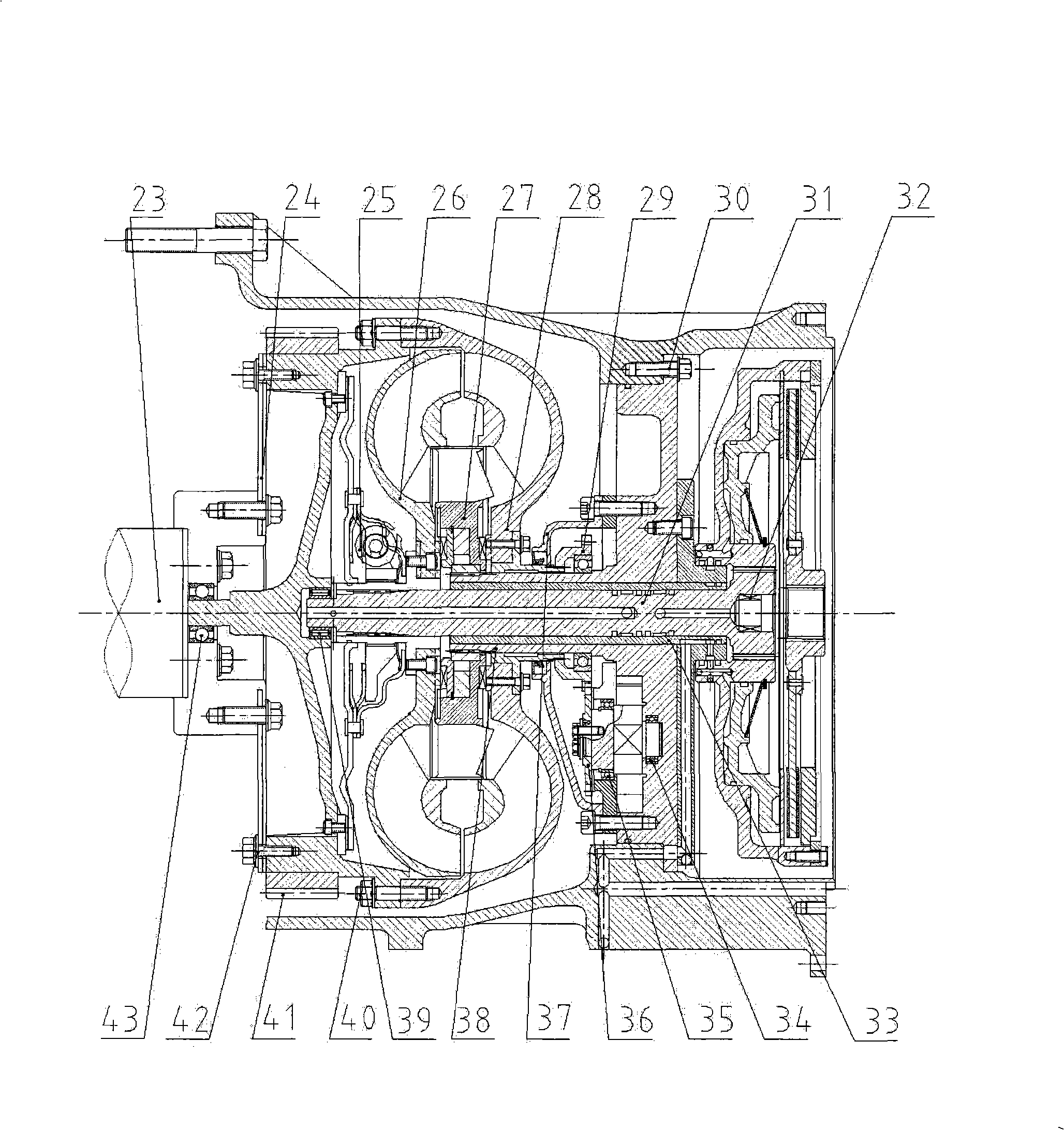

The invention relates to the technical field of reducing the speed of an ore grinding machine. A reducer with a bevel gear and a cycloid in a large transmission ratio for an ore grinding machine is characterized by comprising a bevel gear pair and a cycloid transmission part; the bevel gear pair comprises driving and driven bevel gears; in the cycloid transmission part, (A) needle pin semi-buried holes are uniformly distributed on a needle gear shell, and the needle pins without sleeves are movably matched with the semi-buried holes; (B) a W output mechanism is composed of an output shaft, a column pin, a uniform loading disc and an annular plate; two sides of the W output mechanism are supported on an inner hole of a machine body and the outer circle of a flange in an end cover through bearings; in four single-eccentric bearings, the phase difference between the first bearing and the second bearing and the phase difference between the third bearing and the fourth bearing are 180 DEG and the phase of the second bearing is same as that of the third bearing. In the invention, the reducer has the beneficial effects as follows: (1) the bearing capability is improved by 2-3 times; (2) the length of the axial direction is reduced by 45-55% and the cost is reduced by 40-50%; (3) the reversed installation service life of a cycloid gear is doubled; and (4) the inertia force and the inertia moment are completely balanced in theory when the reducer is operated.

Owner:吴江科技创业园管理服务有限公司

Full-numerical-control spiral bevel gear milling machine

ActiveCN103567550AStable and reliable transmissionMove fastDriving apparatusGear-cutting machinesNumerical controlGear wheel

The invention relates to a full-numerical-control spiral bevel gear milling machine. The full-numerical-control spiral bevel gear milling machine comprises a lathe bed, a stand column, a tool box, a workpiece box, a rotary table transmission device, an electric system, a pneumatic system, a hydraulic system and a cooling system. The full-numerical-control spiral bevel gear milling machine is characterized in that a machine tool spindle torque motor rotor is connected with a machine tool spindle, the machine tool spindle is provided with a spindle damping mechanism, one end of a workpiece spindle is directly fastened with the machine tool spindle torque motor rotor, a workpiece spindle clamping mechanism is arranged at the other end of in a box body of the workpiece box, the workpiece spindle is provided with a workpiece spindle damping mechanism, and the rotary table transmission device comprises a worm wheel bottom sleeve, a worm wheel and worm pair, a rotary table oscillating bar mechanism, a rotary table clamping oil cylinder and a supporting base. The full-numerical-control spiral bevel gear milling machine has the advantages that a torque motor is adopted to serve as power to directly drive the machine tool spindle and the workpiece spindle, the transmission precision and the machining efficiency can be improved greatly, adjustment is convenient, and the rigidity is good; due to driving of the worm wheel and worm pair, the adjustment on the root angle of the workpiece box and the large rotation of feeding and discharging are achieved, and the rotary table oscillating bar mechanism achieves the finish machining of a small gear wheel matched with a forming-method big gear wheel and the machining of a cycloid gear.

Owner:通用技术集团天津第一机床有限公司

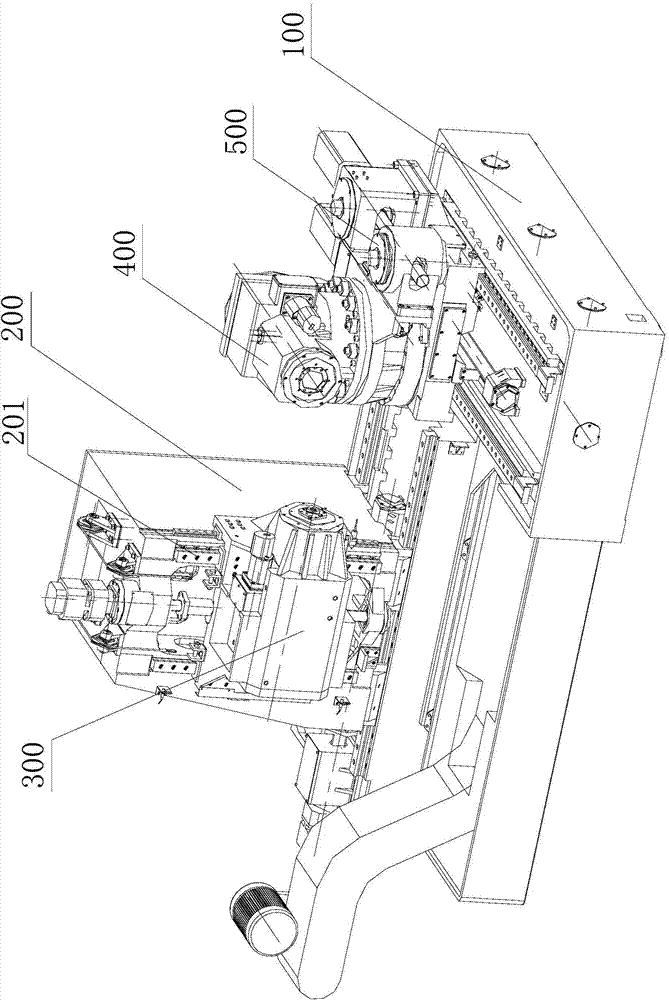

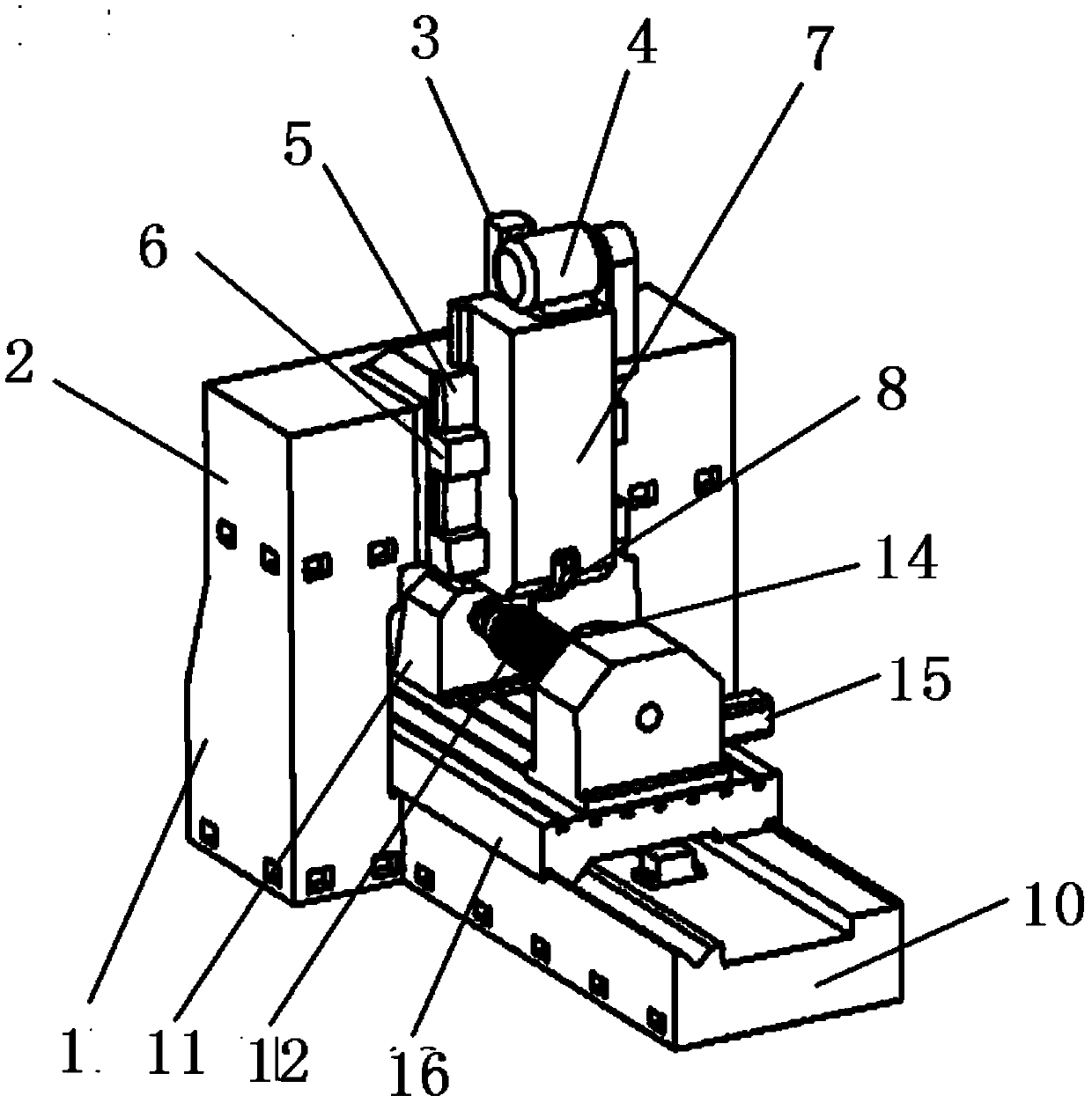

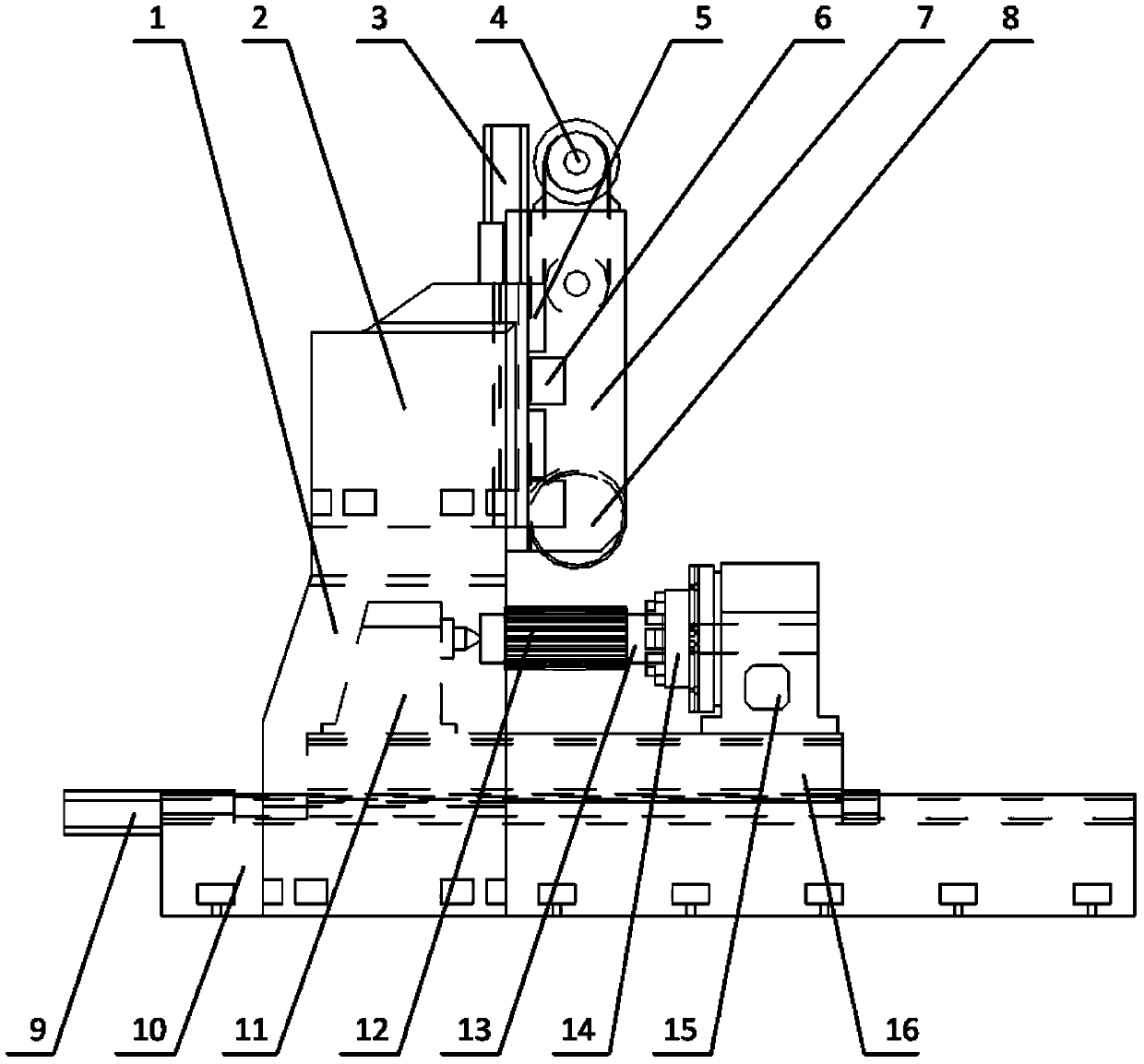

Numerically-controlled horizontal-gantry fixed-girder milling machine for cycloid gears

ActiveCN103722250AImprove processing efficiencyLow costMilling cuttersGear teethMilling cutterGear wheel

A numerically-controlled horizontal-gantry fixed-girder milling machine for cycloid gears is characterized in that the milling machine comprises a machine body (10), a stand column (1), a rectangular workbench (16), a fixed girder (2), a milling spindle box (7), a disc milling cutter (8), a vertical rotary indexing table (15) and a tail-ejector-pin support (11). The numerically-controlled horizontal-gantry fixed-girder milling machine is optimized in structure, convenient to operate, high in processing efficiency, applicable to processing the cycloid gears with few teeth, high in performance-cost ratio and applicable to processing of various batches of the cycloid gears in the cycloid speed reducer industry; when different shaping cutters are replaced, the milling machine is also applicable to other shaft parts, such as splines and motor rotor slots, in need of slotting; on the condition of same input-output ratio, user investment and occupation area are reduced, and equipment application range is widened.

Owner:NANJING UNIV OF TECH +1

Cycloidal planetary reducer and mechanical equipment tool

ActiveCN107420528AImprove transmission efficiencyReduce friction lossToothed gearingsGearing detailsGear wheelEngineering

The invention provides a cycloidal planetary reducer and a mechanical equipment tool. The cycloidal planetary reducer comprises a pin gear housing, a cycloidal gear, an input shaft, a crankshaft and a planetary carrier, wherein gear teeth of the cycloidal gear are engaged with pin teeth in the pin gear housing; the pin teeth are strip-shaped convex teeth which are arranged on the inner wall of the pin gear housing, and the strip-shaped convex teeth and the pin gear housing are formed integrally; a planetary gear on the crankshaft is in engaging transmission with a driving gear on the input shaft; an eccentric shaft is arranged on the crankshaft, and a first bearing is arranged between the eccentric shaft and the wall of a hole of the input shaft; the planetary carrier is connected to the pin gear housing in a supported mode through a second bearing; and the crankshaft is connected to the planetary carrier in a supported mode through a third bearing. By adoption of the technical scheme, the technical problem that in the prior art, gap inevitably exist between pin teeth and a pin gear housing in an ordinary cycloidal planetary reducer due to the assembling structure between the pin teeth and the pin gear housing, the manufacturing precision and other factors, and consequentially vibration and noise are generated in the transmission process is solved.

Owner:SHENZHEN INST OF ADVANCED TECH

Hypocycloid RV transmission device

InactiveCN101718329ARealize large transmission ratio transmissionImprove stress conditionsToothed gearingsStress conditionsGear wheel

The invention discloses a hypocycloid RV transmission device comprising a shell, a power input shaft and a power output shaft. The power input shaft and the power output shaft are coaxially arranged and are in running fit with the shell; a support disc, a driven gear, a pin tooth installation disk and an output disk are axially juxtaposed in the shell in sequence; and the shell is provided with a hypocycloid gear. The hypocycloid RV transmission device retains the advantage of the RV transmission and improves and overcomes the disadvantages of the RV transmission. A pinwheel is adopted by the hypocycloid RV transmission device to do planetary motion, and only one pin tooth installation disk provided with a lightening hole is used by the hypocycloid RV transmission device, thus the weight of the hypocycloid RV transmission device is effectively reduced. Two ends of the pinwheel are respectively arranged on the pin tooth installation disk and the output disk, thus the vibration of the hypocycloid RV transmission device is effectively decreased, and the dynamic performance of the hypocycloid RV transmission device is improved. The hypocycloid RV transmission device adopts a crankshaft and the pinwheel to output simultaneously, thus the stressing condition of a rotating arm bearing is improved, and the bearing capacity of the rotating arm bearing is enhanced. Due to the appropriate tooth choose and pinwheel diameter increase, the bearing capacity of the rotating arm bearing can be further enhanced. The invention has simple and compact structure and low manufacturing cost and is convenient to maintain.

Owner:CHONGQING UNIV

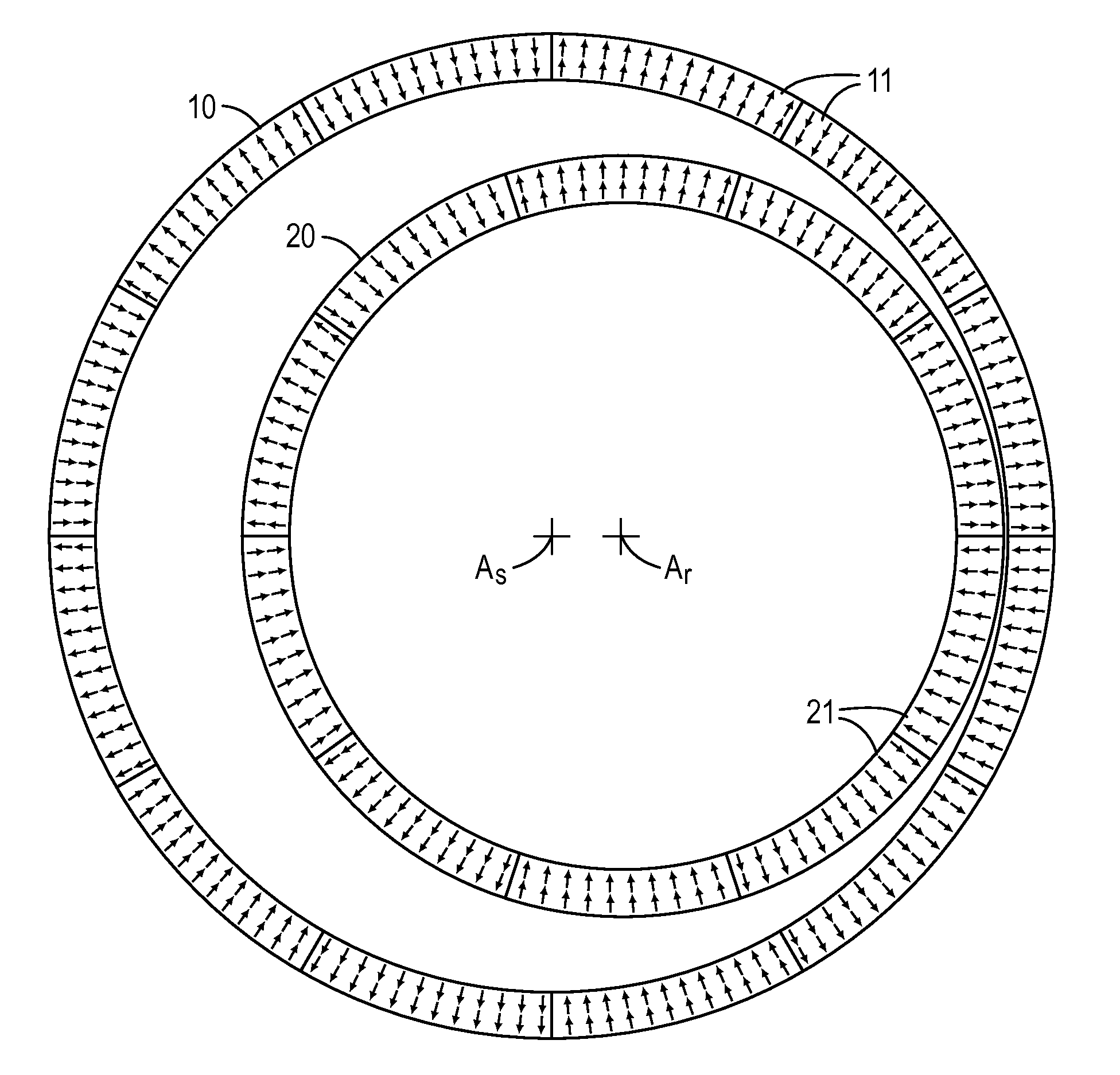

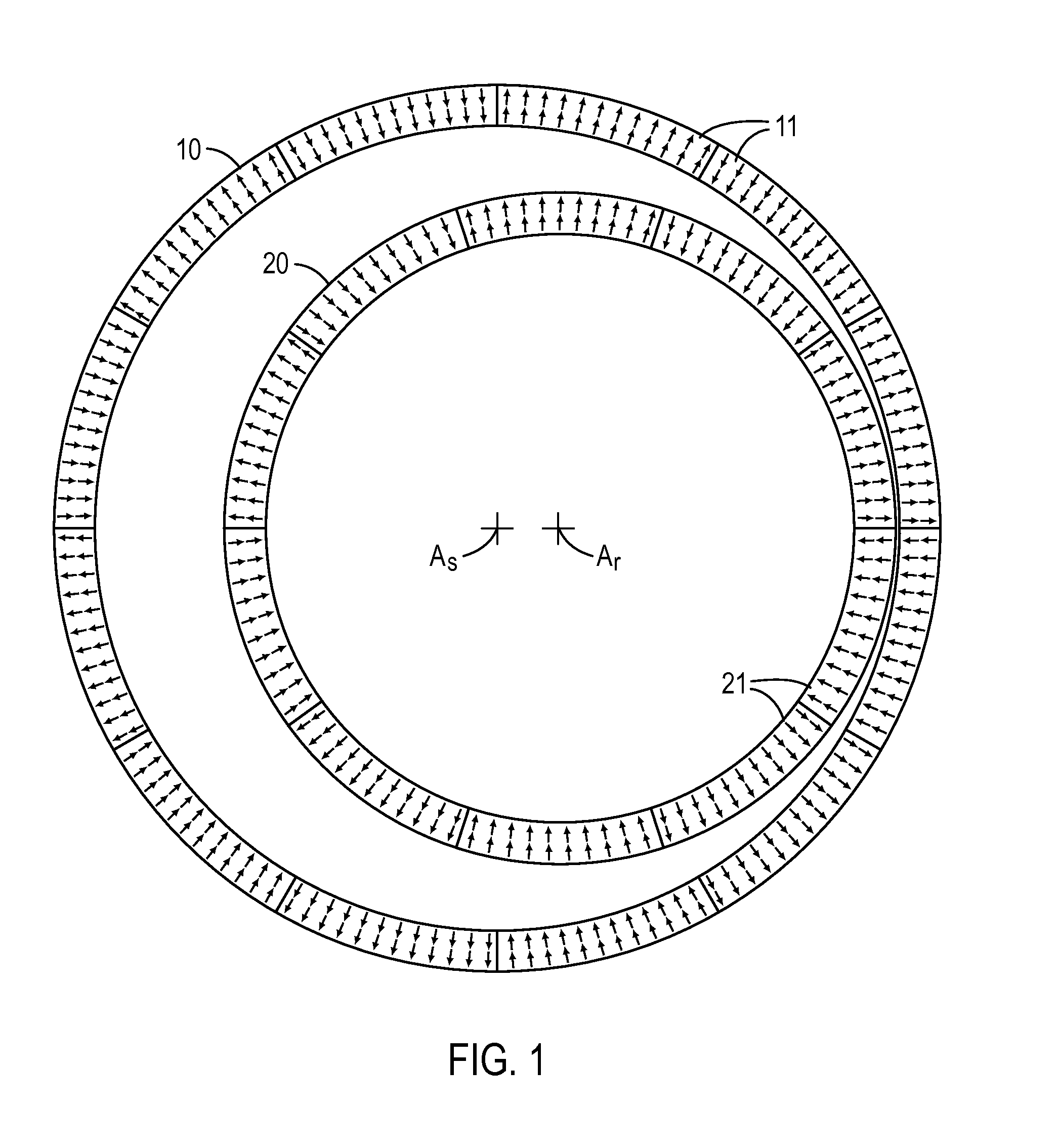

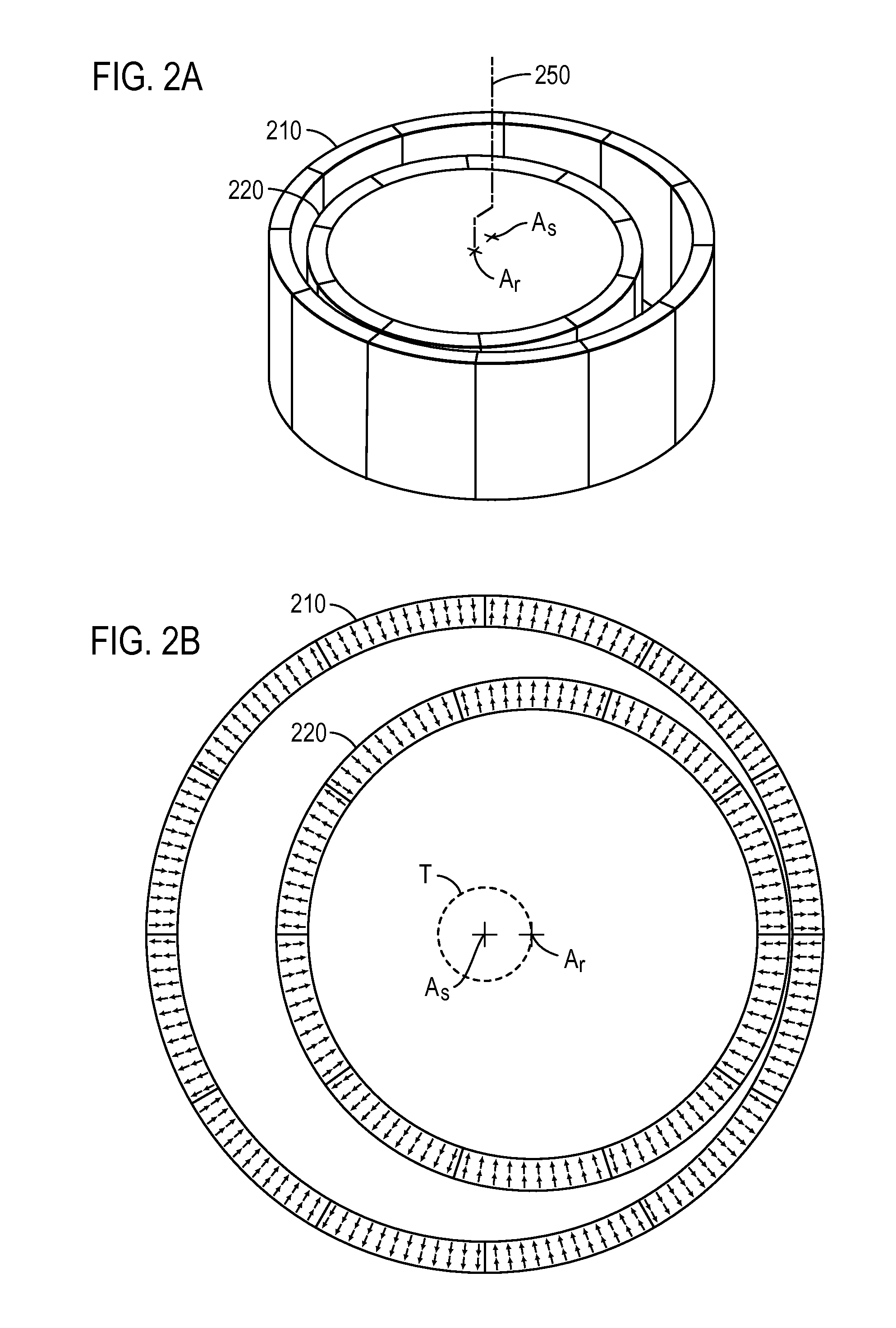

Magnetic cycloid gear

A magnetic cycloid gear includes an outer gear member comprising a first plurality of magnets that provide a first number of magnetic pole pairs, wherein the outer gear member has an outer gear member axis, and an inner gear member comprising a second plurality of magnets that provide a second number of magnetic pole pairs, wherein the inner gear member has an axis that is offset from the outer gear member axis and wherein the second number of magnets differs from the first number of magnets. The gear further includes a drive mechanism operatively coupled to rotate the inner gear member as it revolves in an eccentric manner relative to the outer gear member axis, and a constraint mechanism coupled to the inner gear member to prevent it from rotating bout its own axis as it revolves. The outer gear member rotates in response to the inner gear member revolving.

Owner:NAT OILWELL VARCO LP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com