Speed reducer with planetary gears and cycloidal gear

A technology of gear reducer and planetary gear, which is applied in the direction of gear transmission, belt/chain/gear, components with teeth, etc., can solve the problems of large space occupation, inconvenient use, cumbersome installation, etc., to simplify the structure and reduce the The effect of high manufacturing cost and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

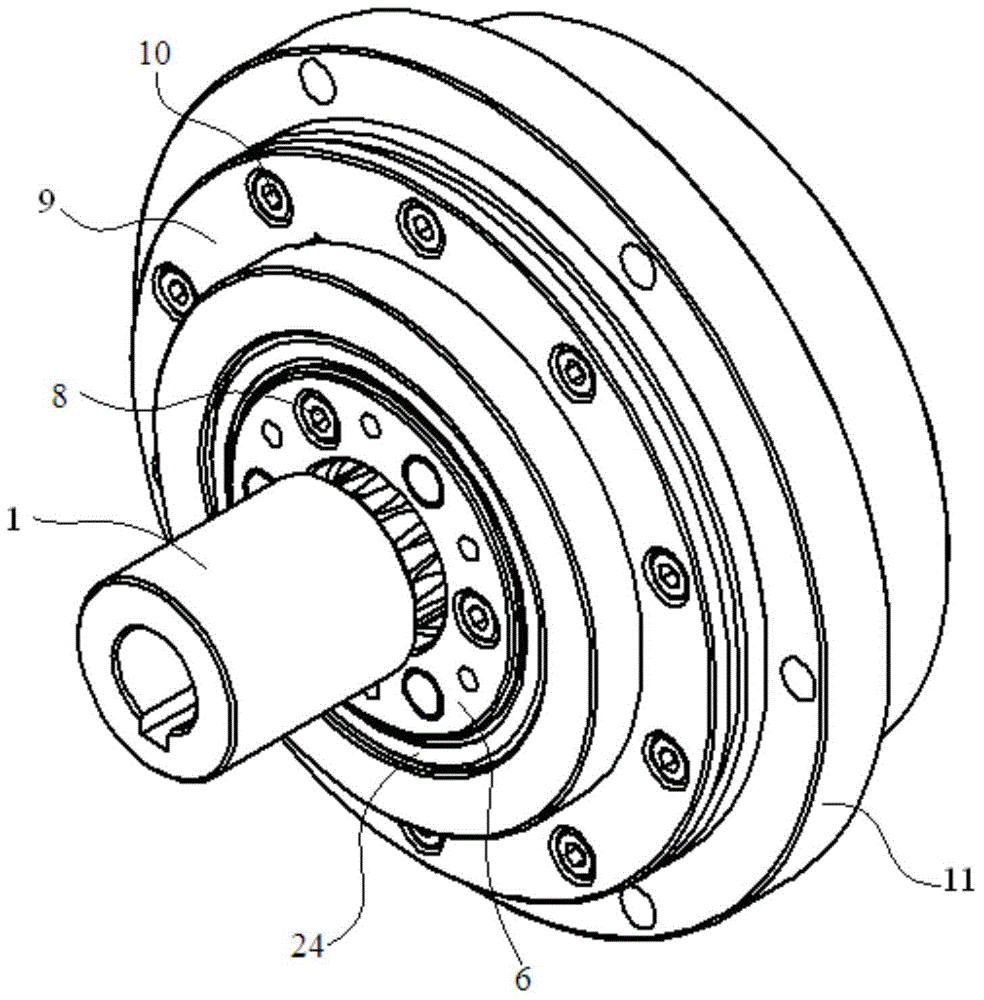

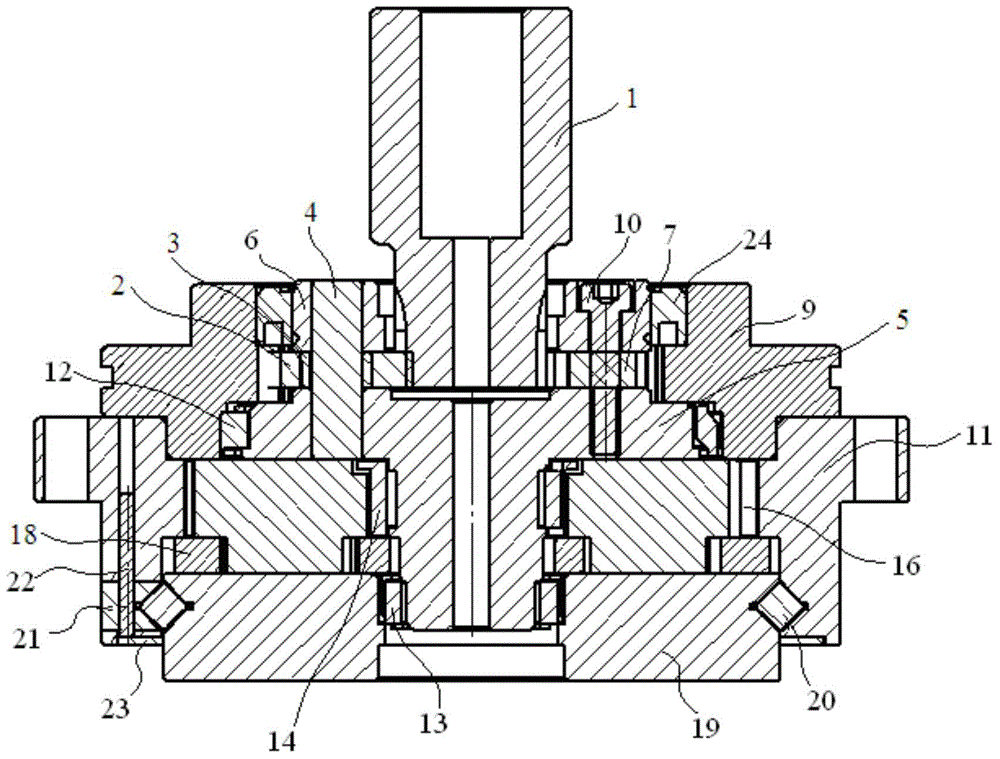

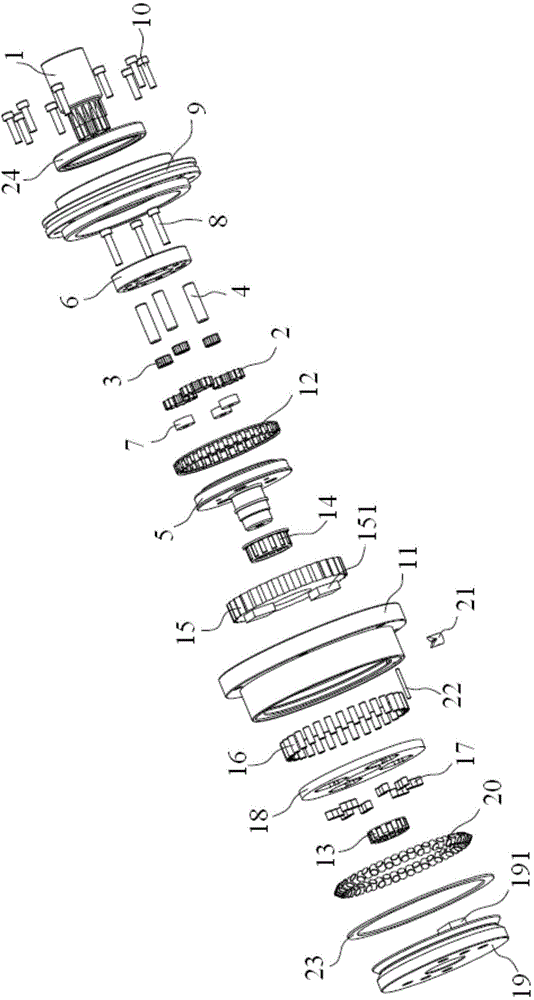

[0023] See Figure 1 to Figure 3 As shown, a planetary cycloid gear reducer includes an input gear shaft 1, a planetary gear 2 meshed with the input gear shaft 1, a pin shaft 4 arranged in the inner hole of the planetary gear 2, and located in the The needle roller 3 between the pin shaft 4 and the planetary gear 2, the crankshaft 5 and the planet carrier end cover 6 respectively connected to the two ends of the pin shaft 4, the crankshaft 5 and the planet carrier end cover 6 The spacer 7 between them, the outer ring gear 9 located on the outer ring of the planetary gear 2 and meshing with it, the housing 11 fixedly connected with the outer ring gear 9, and the cylindrical roller bearing B14 are sleeved on the The cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com