Patents

Literature

205results about How to "Machining accuracy is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

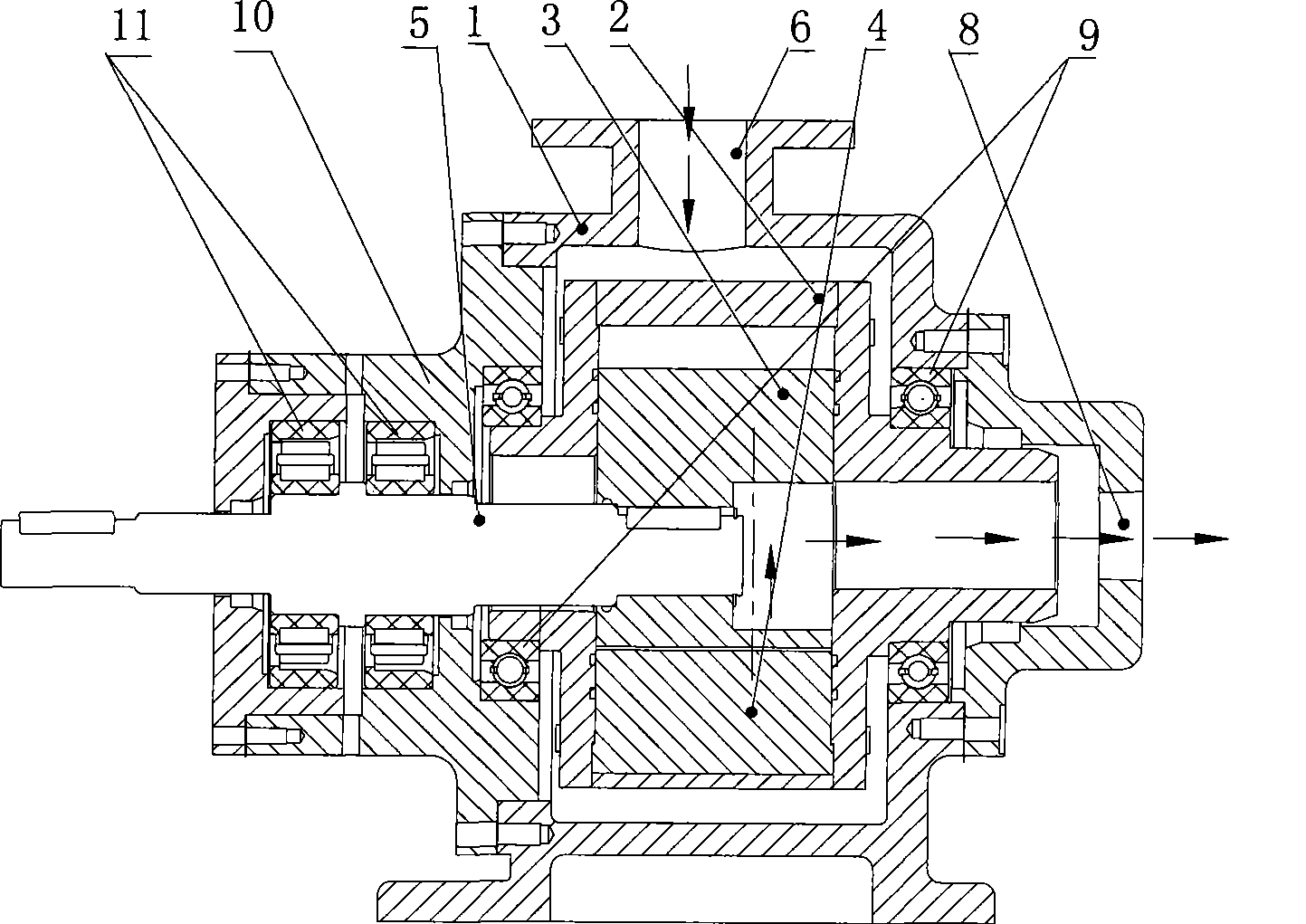

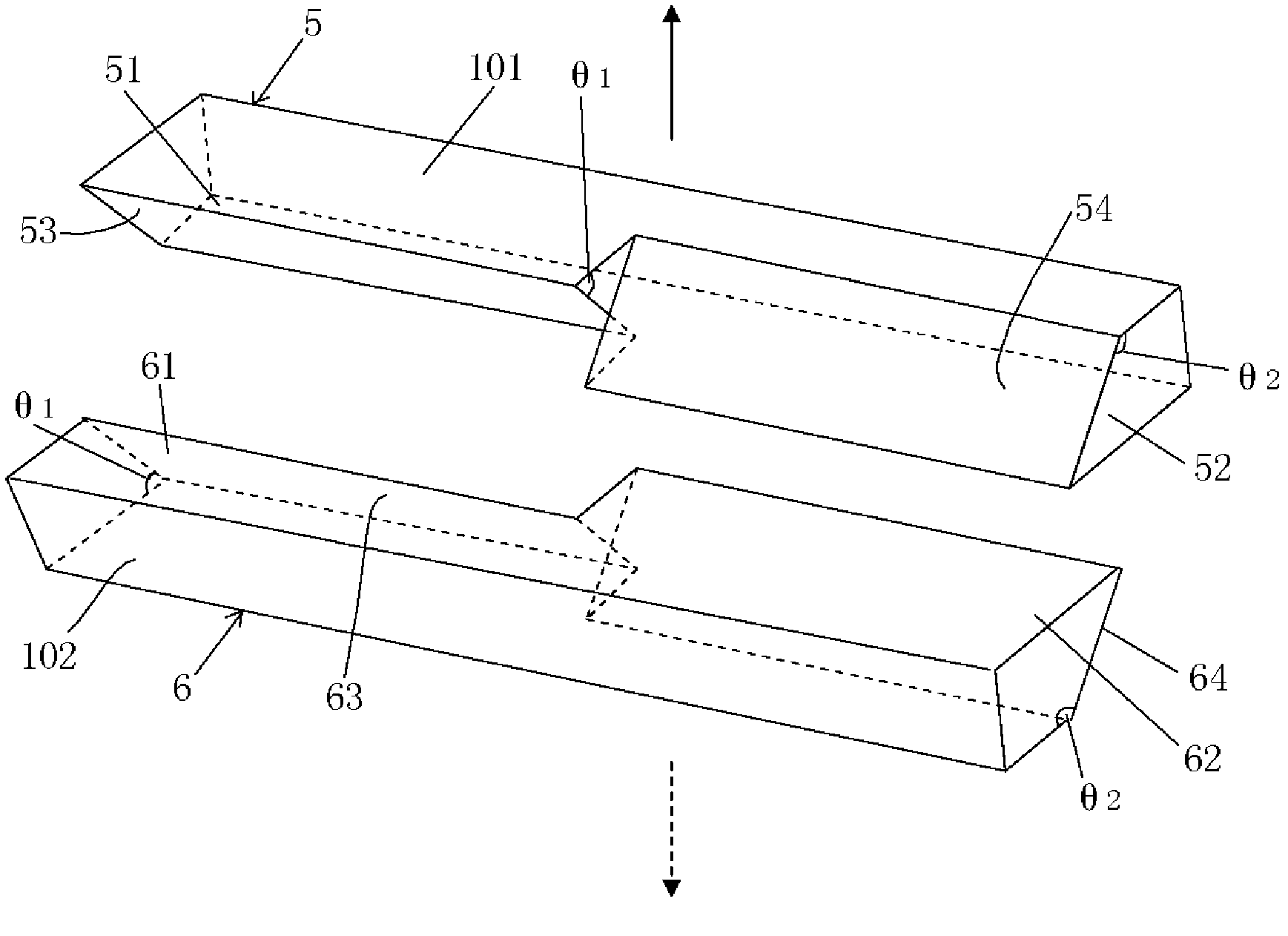

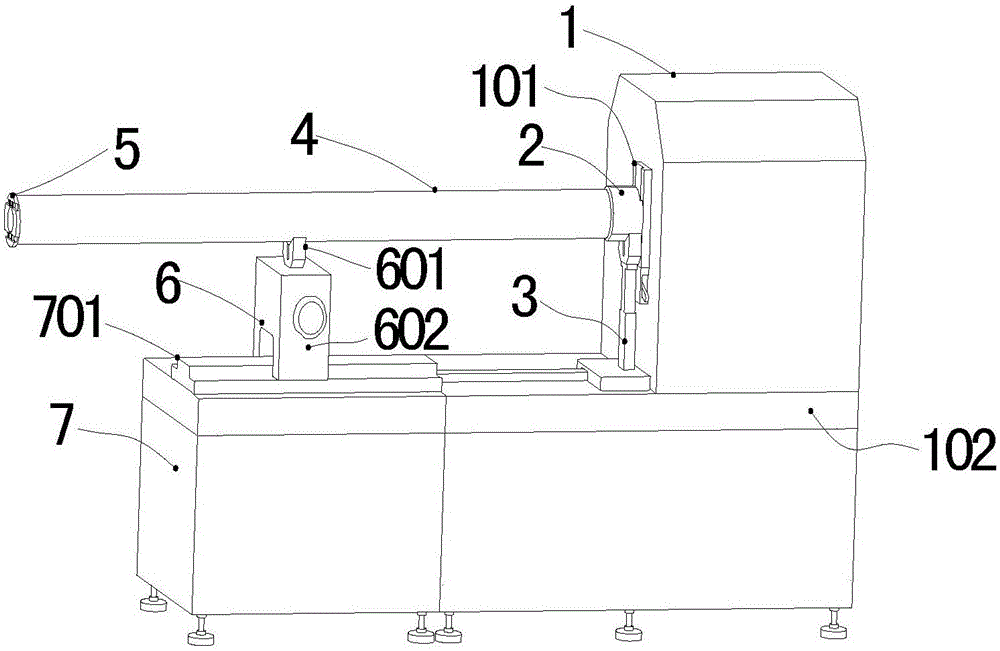

High-power semiconductor fiber-coupled laser and coupling method thereof

ActiveCN104979749AIncrease the number ofIncrease powerSemiconductor laser arrangementsLaser output parameters controlLight beamMaterial consumption

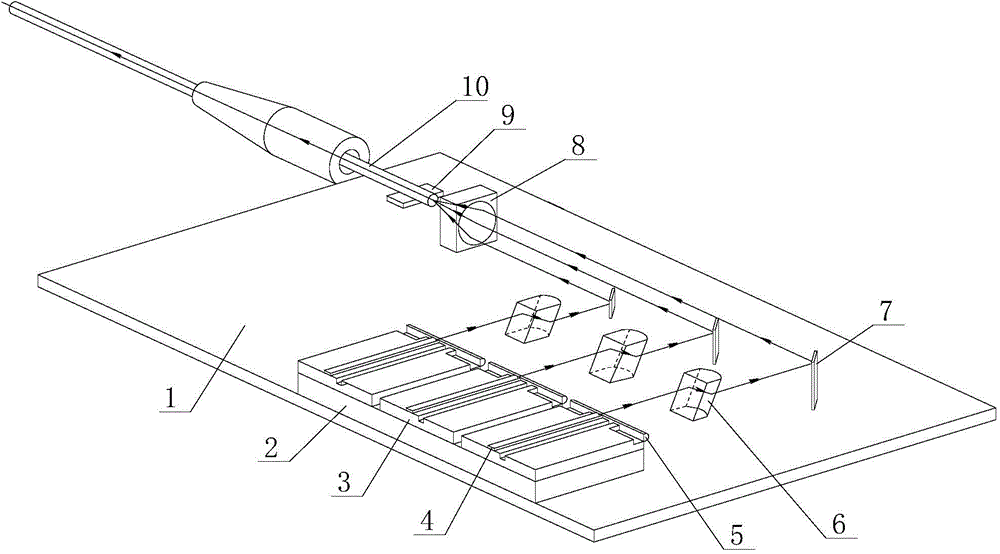

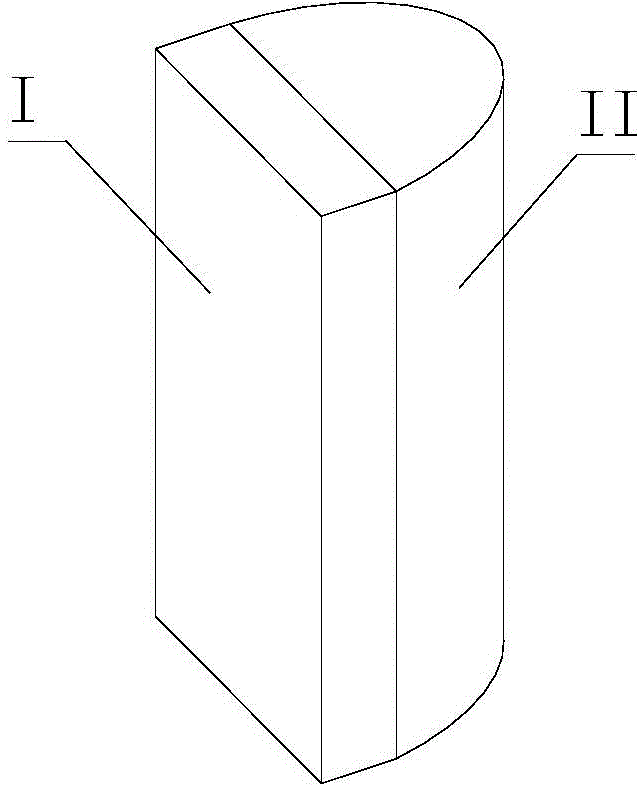

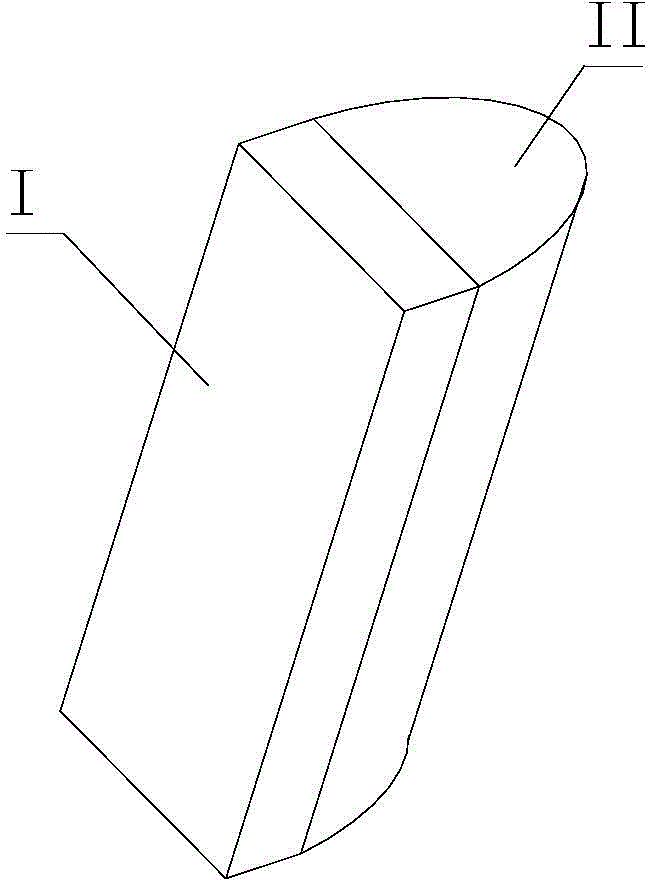

The invention relates to a high-power semiconductor fiber-coupled laser and a coupling method thereof. Laser diodes are arranged at the same height level. Fast axis collimators FAC are arranged on the front ends. Slow axis collimators SAC are directly arranged on a bottom plate and are plano-convex lenses which integrally tilt. As the distance to a focusing lens is further, the thickness of the slow axis collimators SAC descends. The laser diodes produce a number of beams of the same height. Through the fast axis collimators FAC and the slow axis collimators SAC, high and low parallel beams are produced, are reflected to the focusing lens through the respective reflector, and are focused on a fiber. According to the invention, the slow axis collimators which integrally tilt are used to replace ladder heat sink to realize a height difference after beam adjusting; the processing accuracy is easily ensured; package components are reduced; the package difficulty is reduced; all components are horizontally arranged on the bottom plate; the laser has the advantages of simple and lightweight structure, small size, light weight and low material consumption; the number of coupled chips can be increased; and a laser of higher power can be produced.

Owner:ANSHAN WONDER LIGHT LASER TECH CO LTD

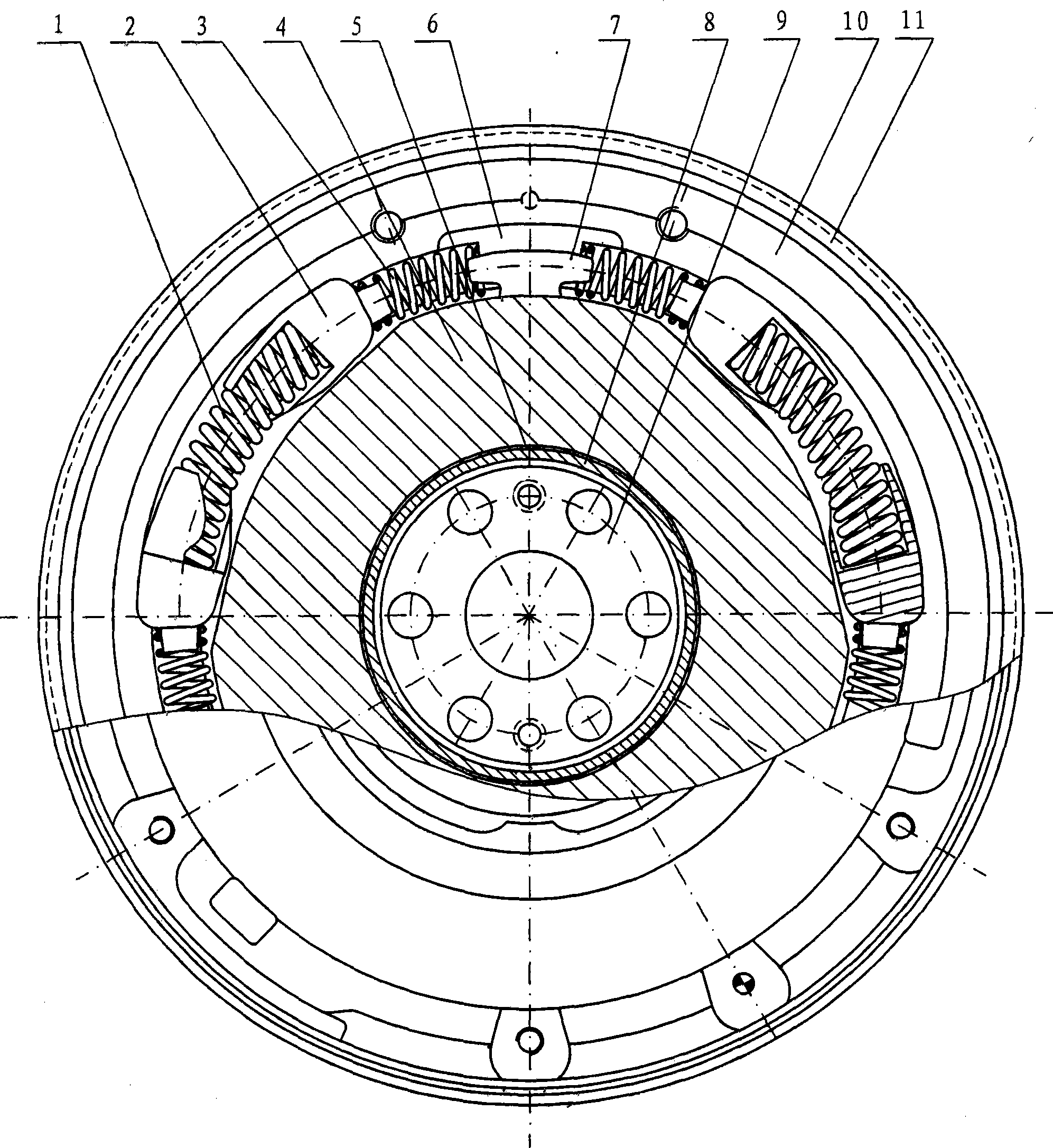

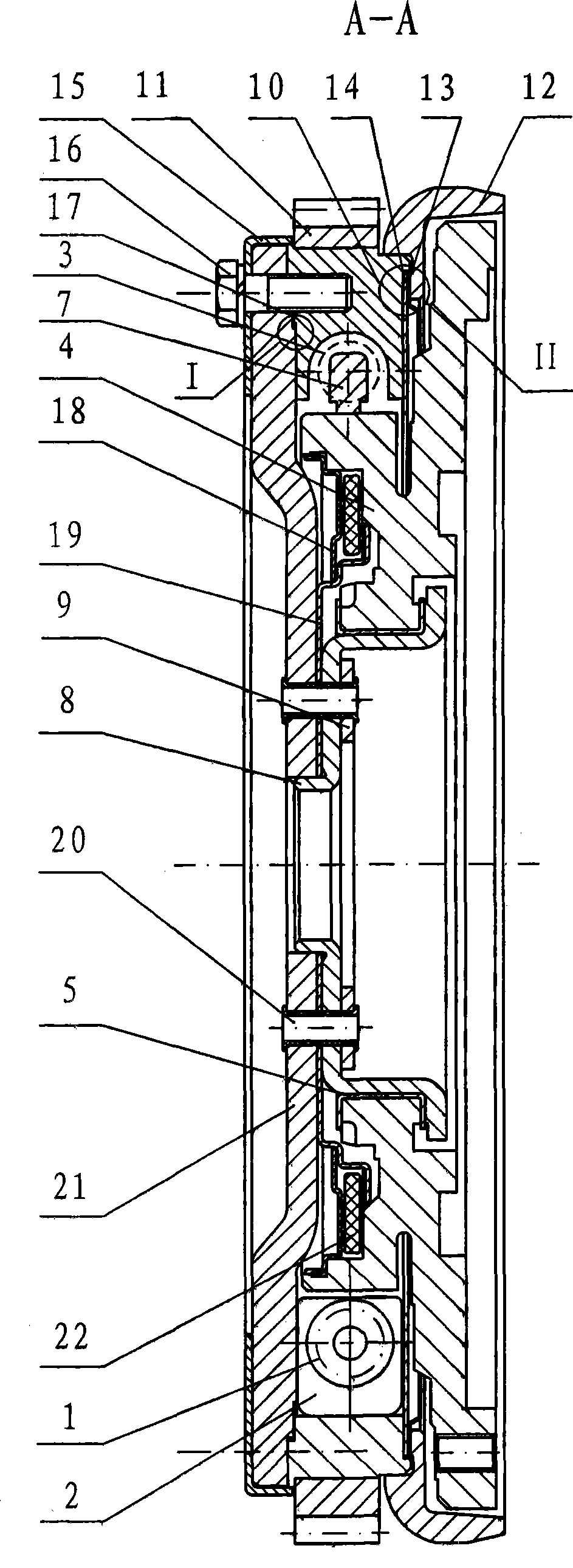

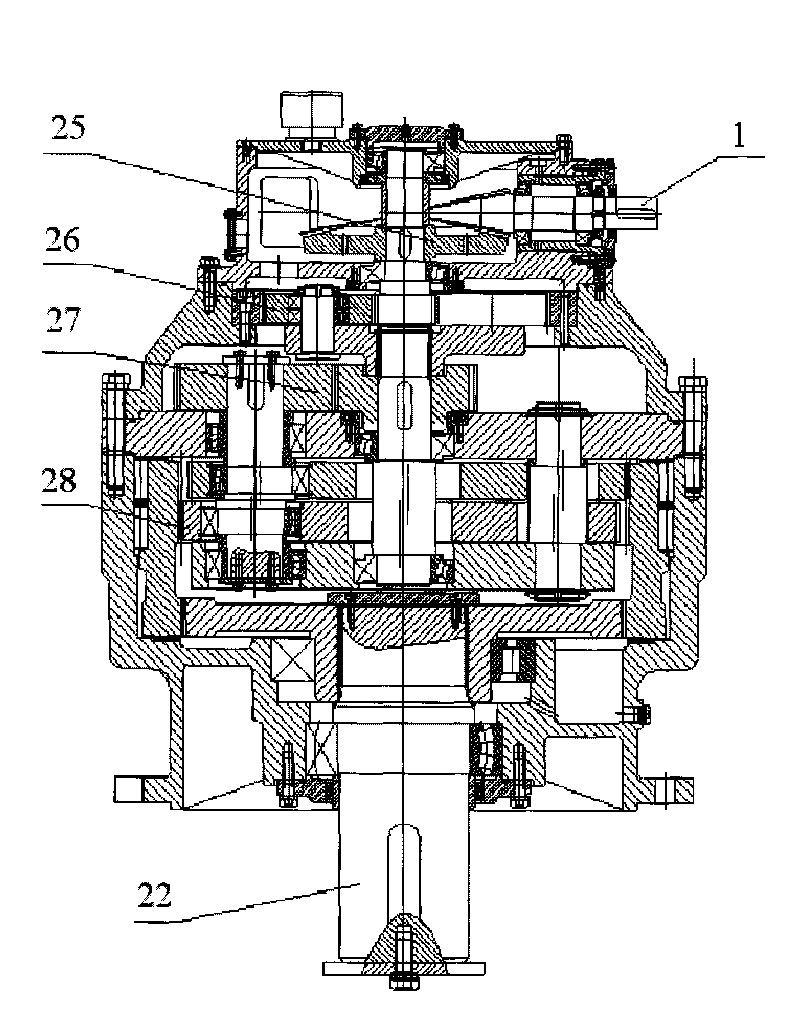

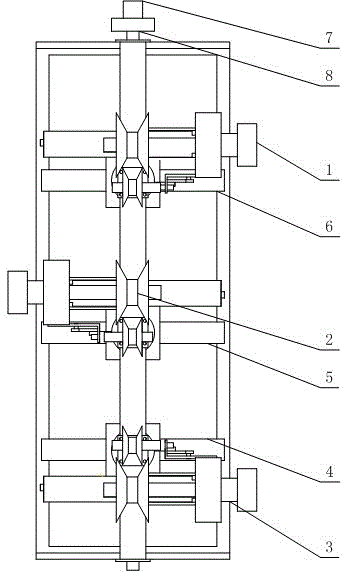

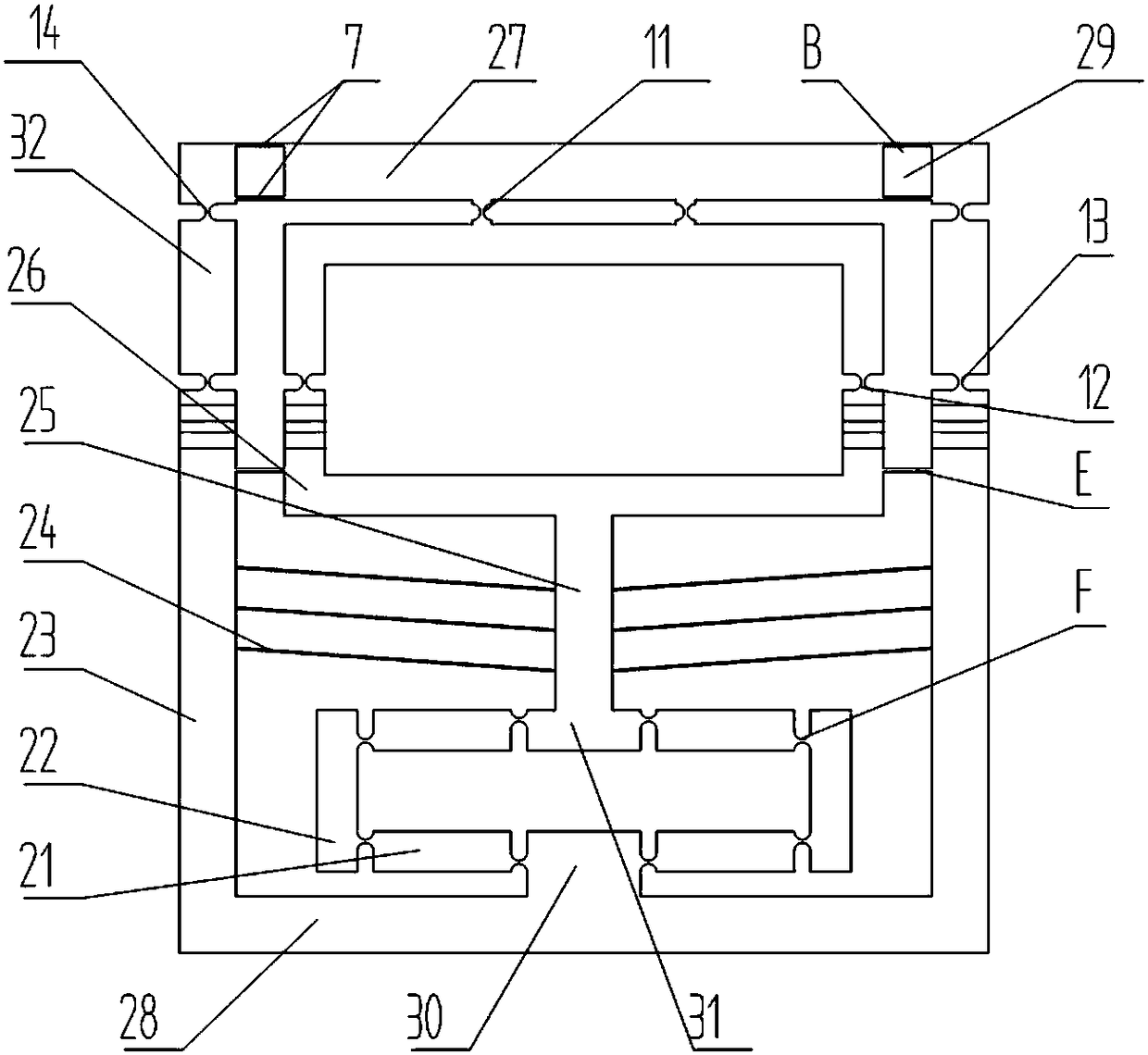

Two-stage friction type dual-mass flywheel

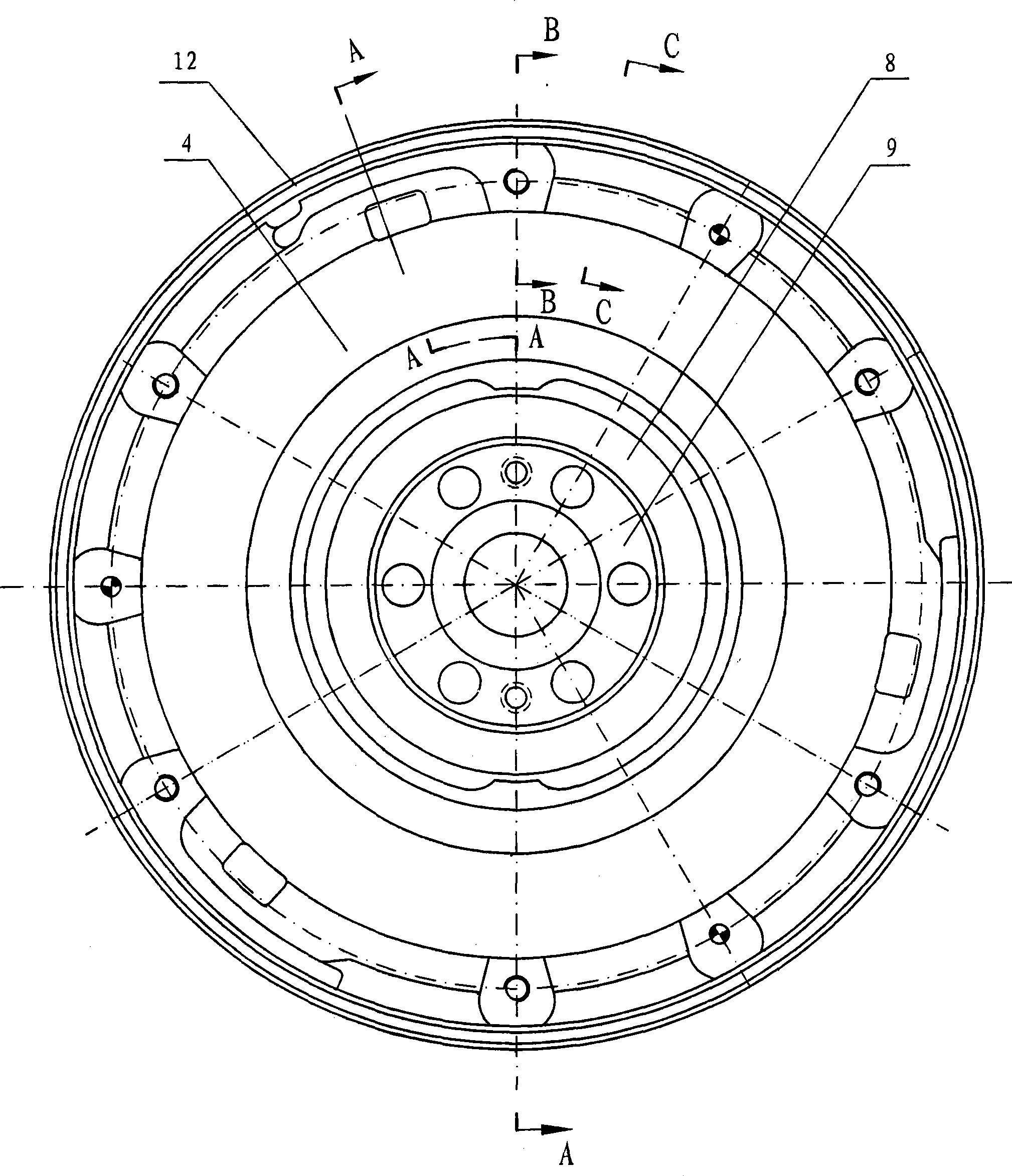

A two-stage friction type dual-mass flywheel between the engine and the clutch gearbox of a car comprises a spring, a spring seat, a secondary flywheel, a washer, an end cover, a cushion block, a primary flywheel, a startup ring gear, a right ring, a left ring, a backing ring, a connecting plate, a pin bush and a circular block. The invention provides a dual-mass flywheel which can achieve two-stage variable stiffness transmission, and aims to overcome defaults that the torsion angle of a single-stage circumferential short spring dual-mass flywheel is small and the variable stiffness transmission can not be achieved. The invention ensures that the torsion angle is increased; the two-stage variable stiffness transmission is realized; the first nature frequency of a transmission system is enabled to be greatly lower than exciting frequency, and the second nature frequency is higher than the exciting frequency of the maximum turning speed of an engine, thereby avoiding resonance; the friction effects among the spring seat, the primary flywheel and the secondary flywheel ensure that various torque characteristics can be produced when the torsion angle is incresed or decresed; the normal pressure on the spring seat is reduced; and the service life of the spring seat is prolonged.

Owner:CHONGQING GUANGDA IND +1

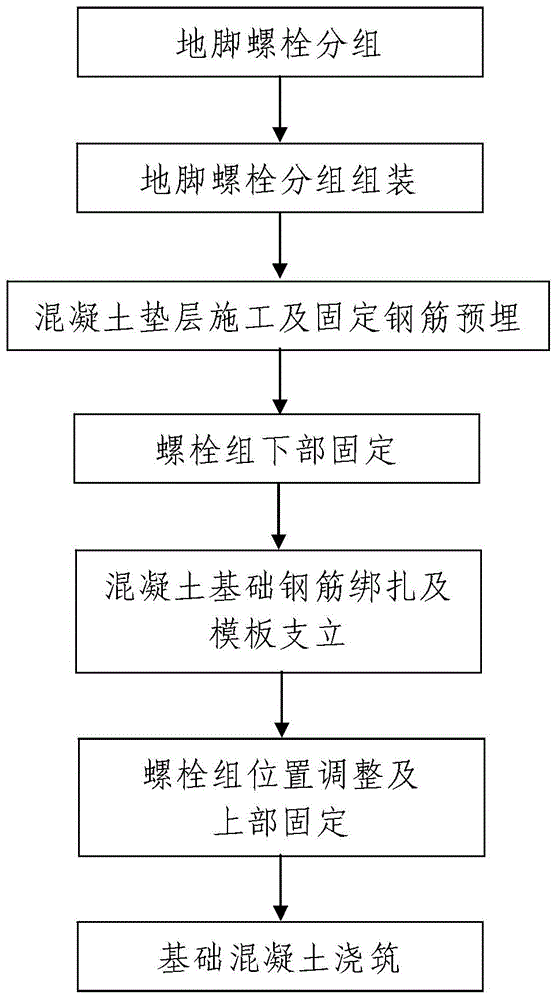

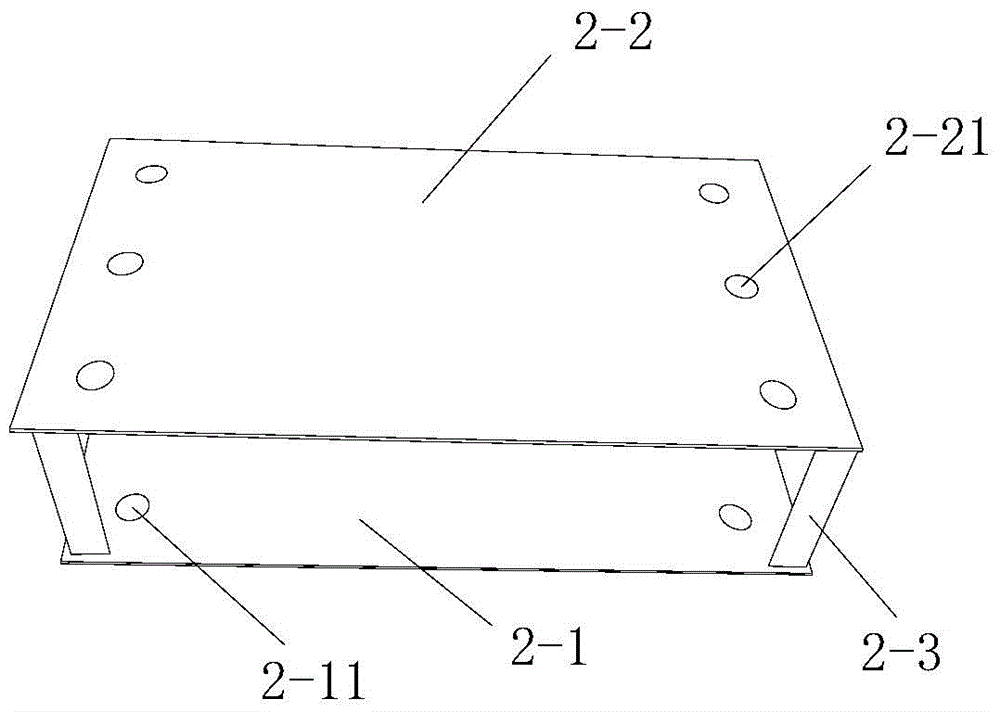

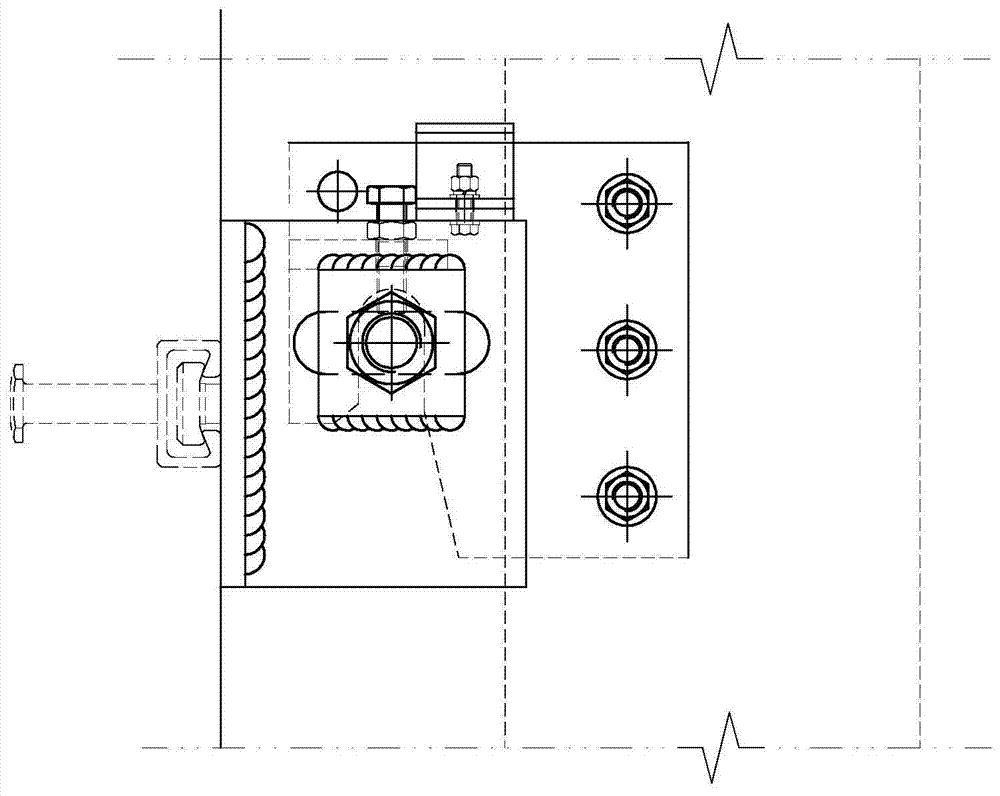

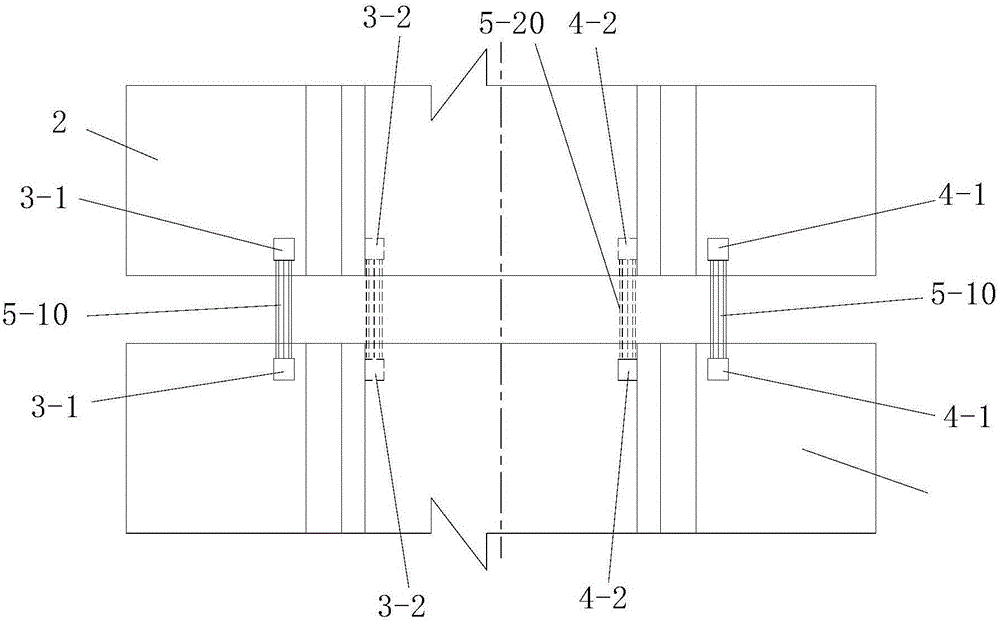

Steel structure building construction method for one-step pre-burying of foundation bolts

The invention discloses a steel structure building construction method for pre-burying of foundation bolts. The steel structure building construction method comprises the following steps: 1. grouping of the foundation bolts: all the foundation bolts to be pre-buried are divided into a plurality of groups, the groups of the foundation bolts are respectively distributed in a plurality of bolt pre-burying areas in a concrete foundation, and the foundation bolts in each group form a bolt group; 2. grouped assembly of the foundation bolts: the bolt groups are respectively assembled, and the assembly procedure comprises manufacturing of a positioning mold, inserting of the foundation bolts, fixing of the foundation bolts, and separating of the bolt groups from positioning mold; 3. concrete cushion construction and pre-burying of fixing steel bars; 4. lower part fixing of the bolt groups; 5. binding of the steel bars and support arrangement of a template erection in the concrete foundation; 6. a position adjustment and upper part fixing of the bolt groups; 7. concrete foundation pouring. The method provided by the invention is simple in procedure, reasonable in design, convenient in implementation, and good in use effects, and has the advantages that the construction process for the high-precision pre-burying of the foundation bolts in the concrete foundation can be simply, conveniently and rapidly completed with high quality.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

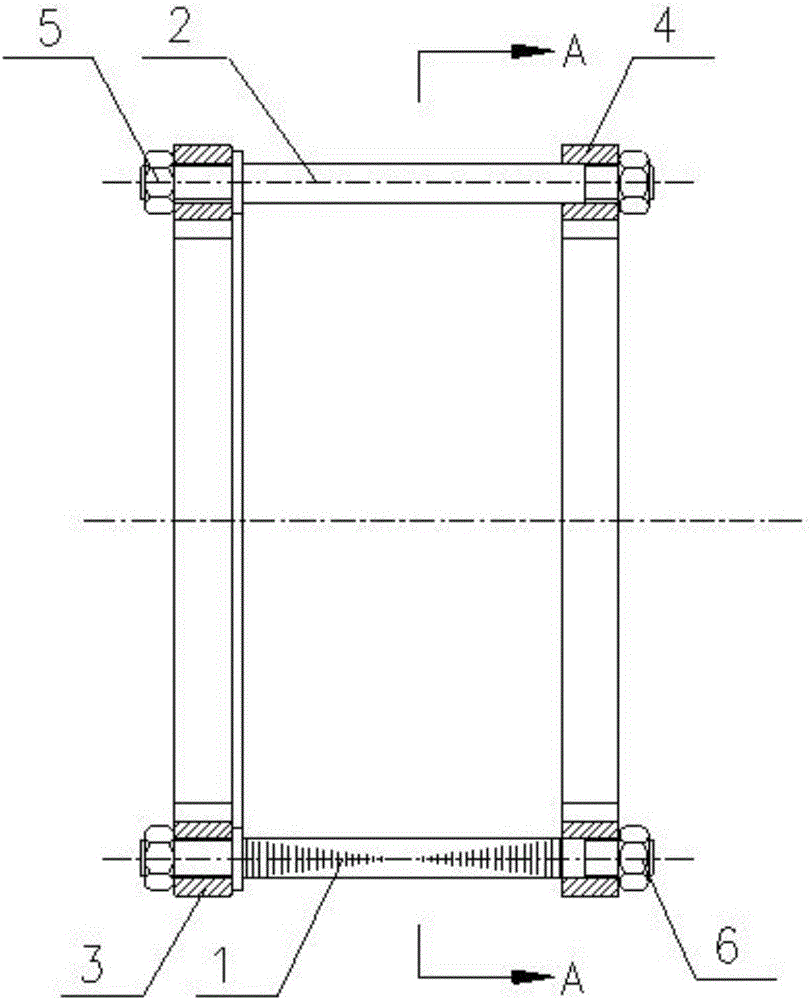

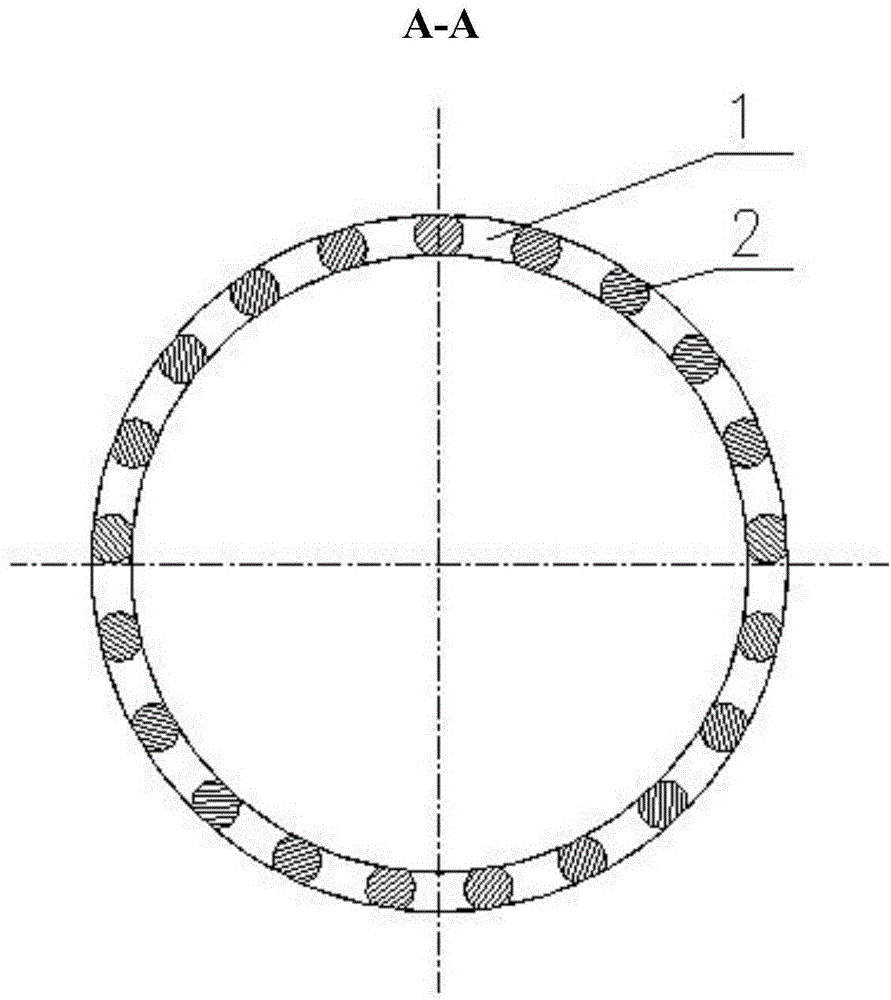

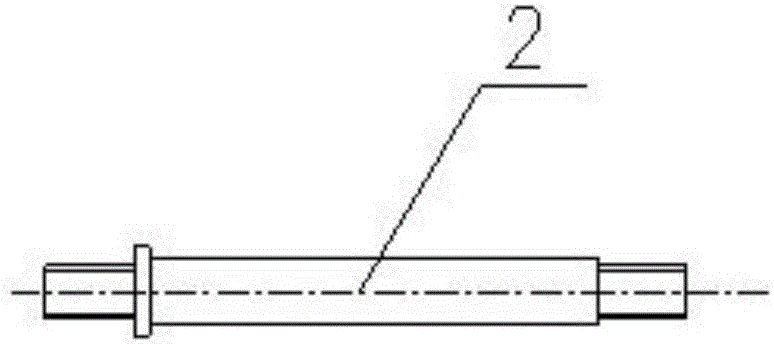

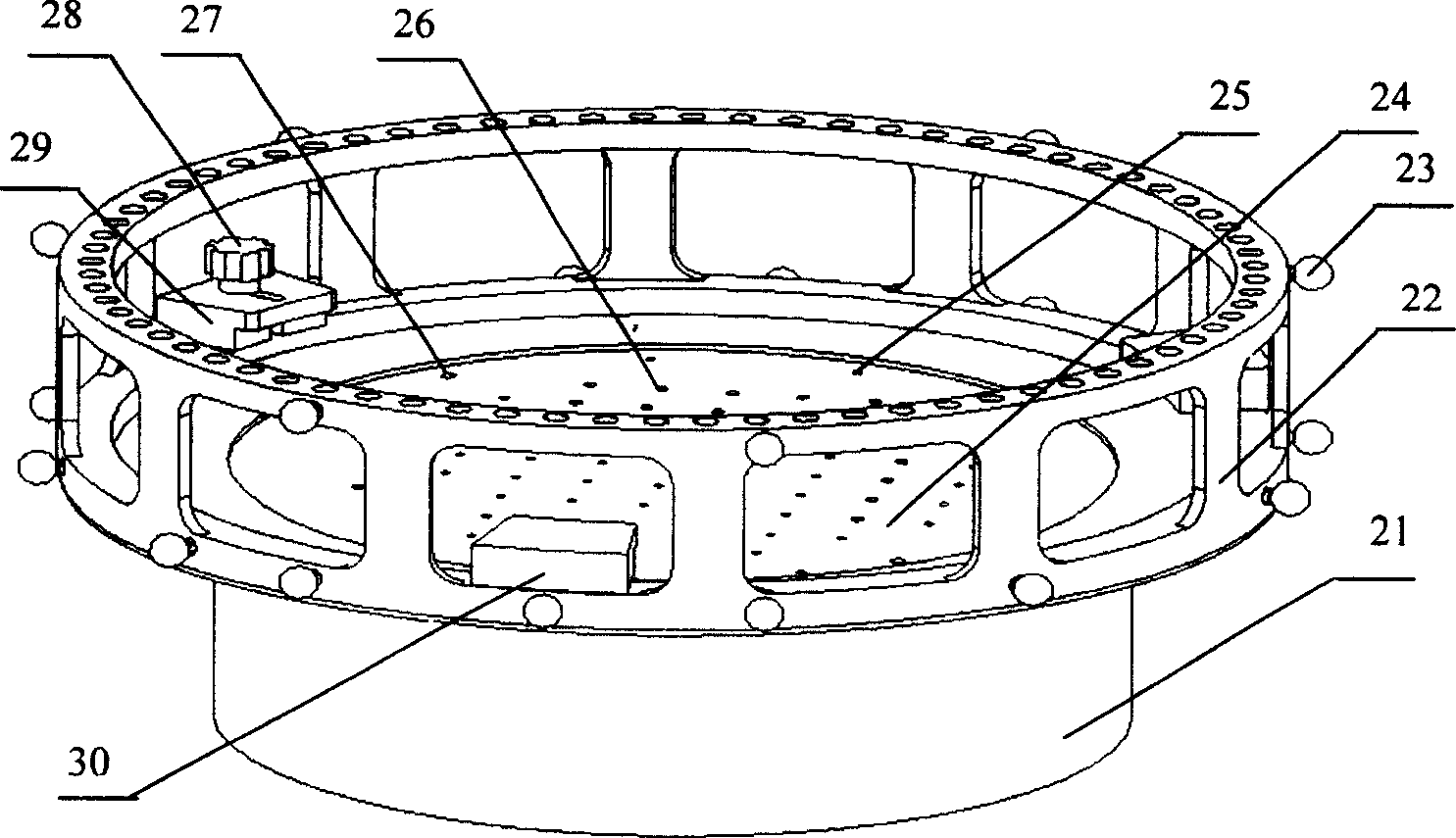

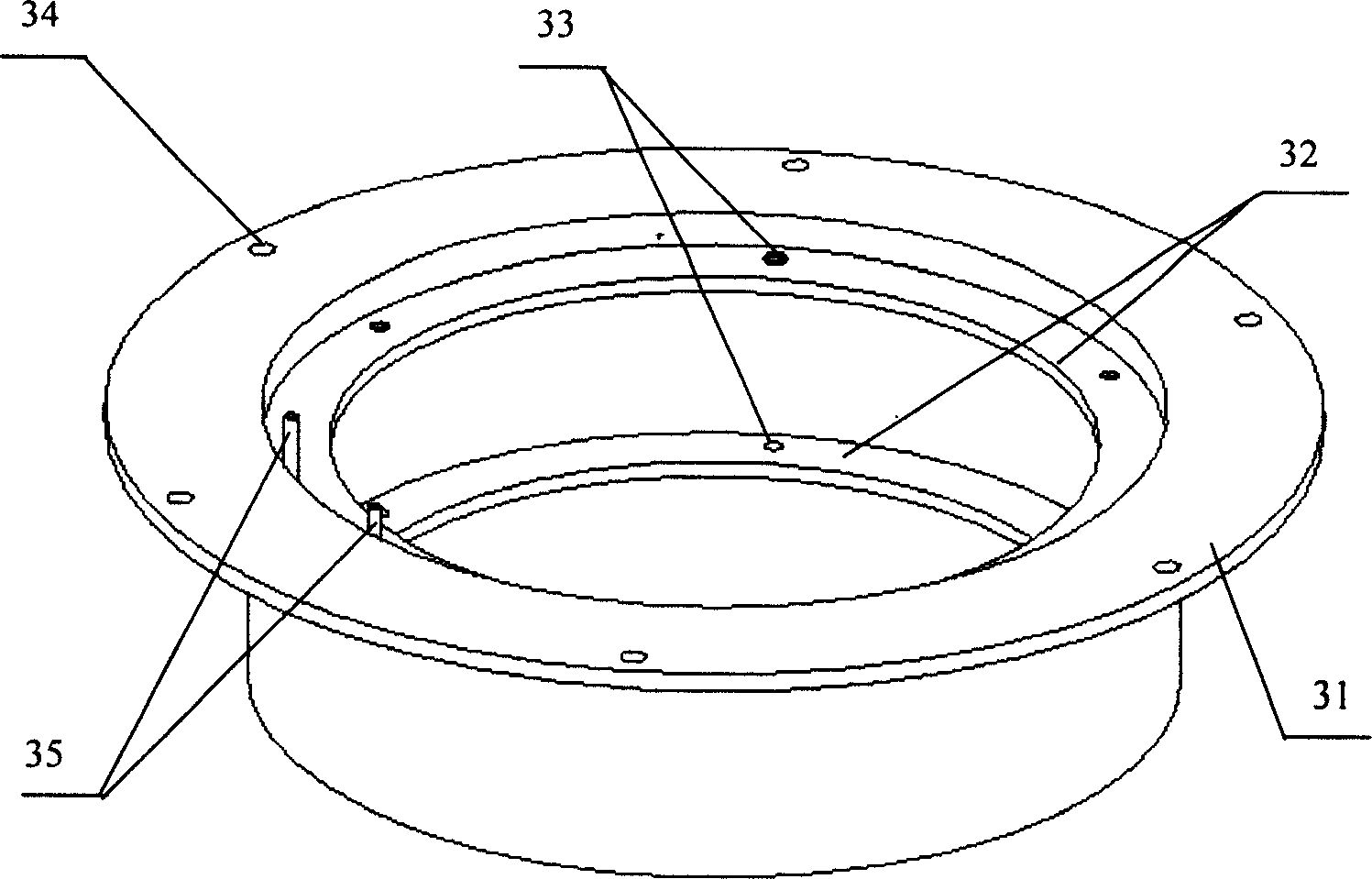

Concentric permanent magnetic gear magnetism regulation ring device and production method thereof

ActiveCN106452002AShorten the production cycleReduce manufacturing costPermanent-magnet clutches/brakesRing devicePole piece

Owner:DALIAN YULIN ELECTRIC MOTOR

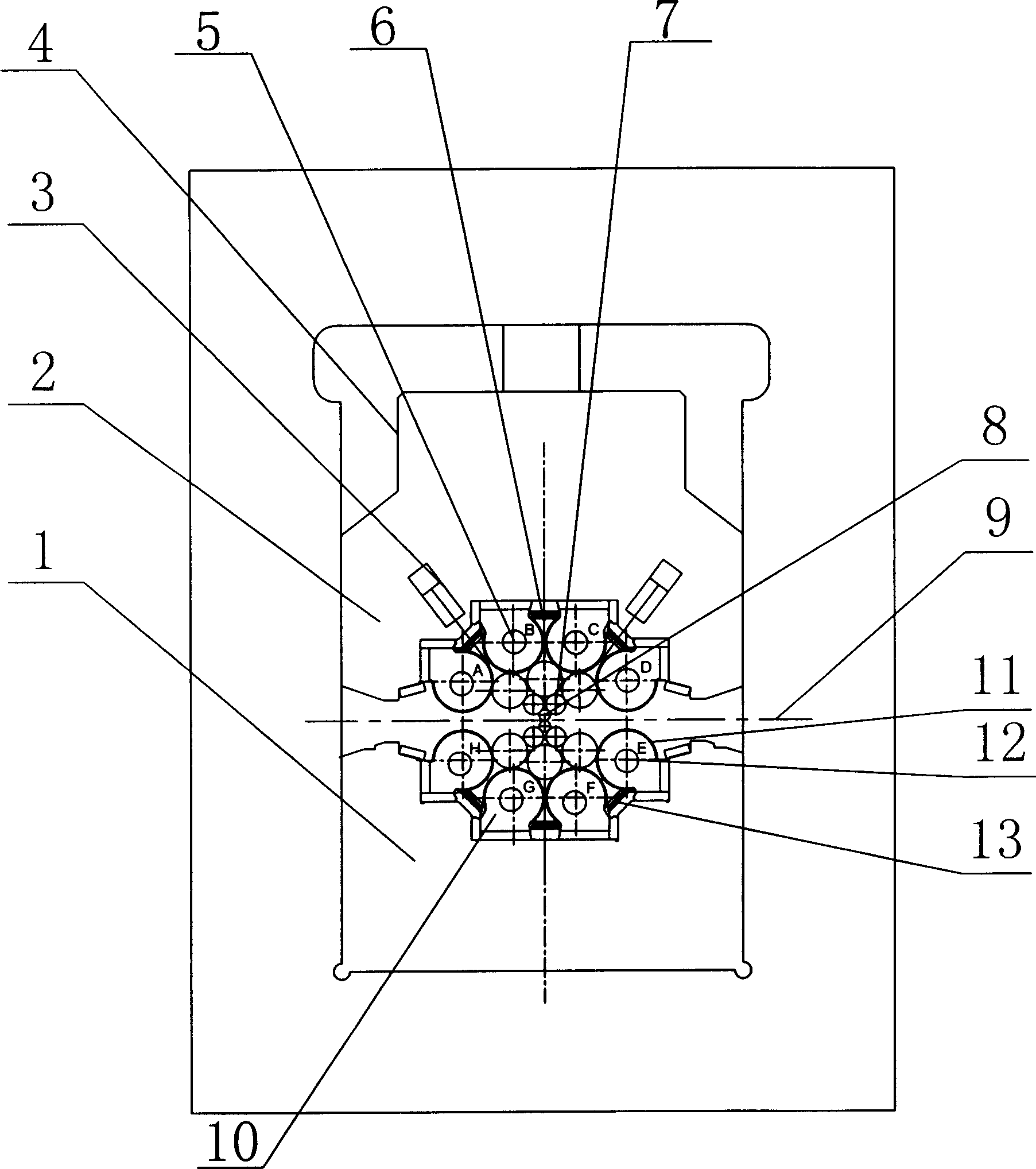

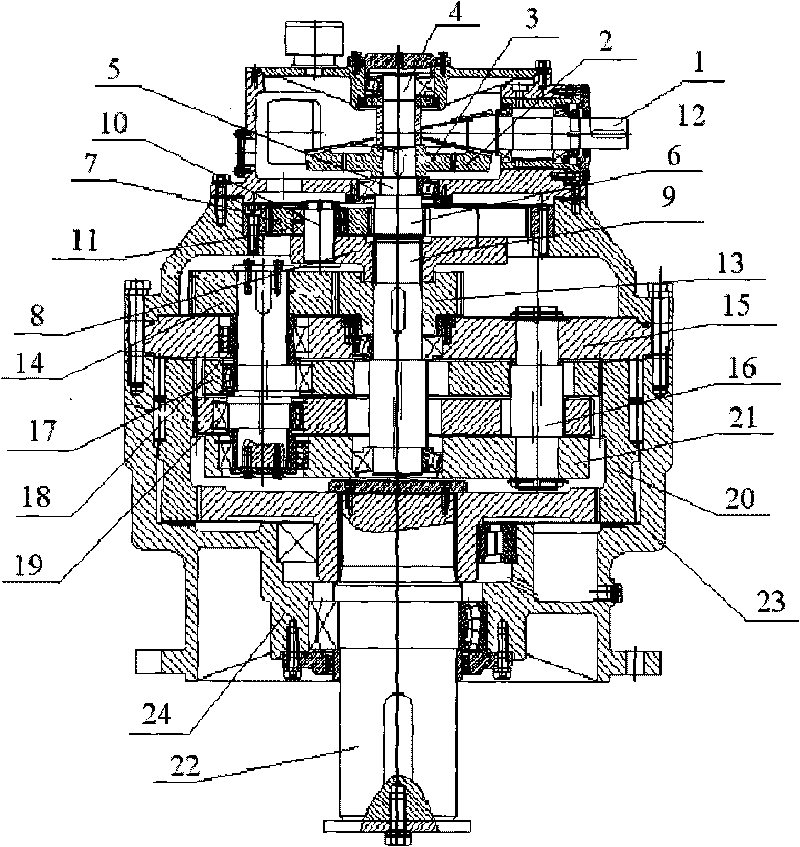

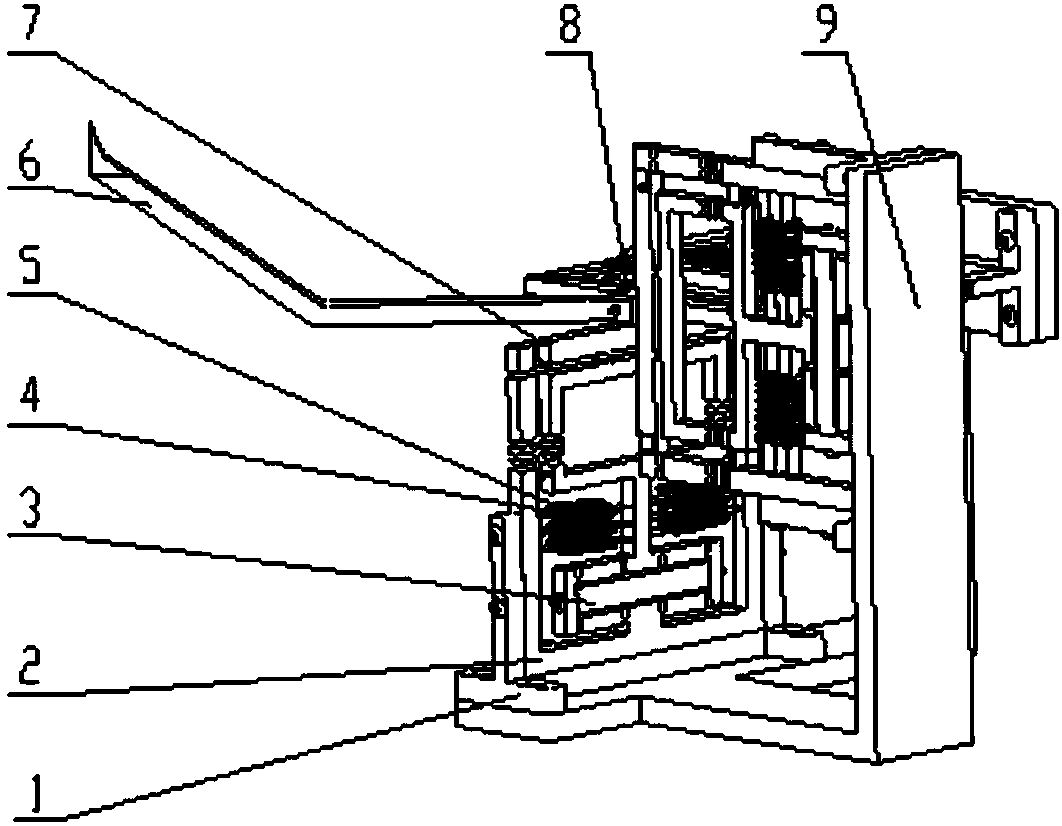

New type 20 roller mill

InactiveCN1872439AMachining accuracy is easy to guaranteeHigh precision of product sizeMetal rolling stand detailsRollsRoller millRolling mill

A novel 20-roller rolling mill is composed of integral rectangular machine frame, a roller box unit consisting of upper and lower roller boxes with rectangular saddle and lock unit, a dual-wedge regulator for said lower roller box and comprising swinging cylinder, swinging arm, connecting rod and wedge blocks, and the convexity controller consisting of hydraulic cylinder, rack bar and sectorial gear.

Owner:曹全有

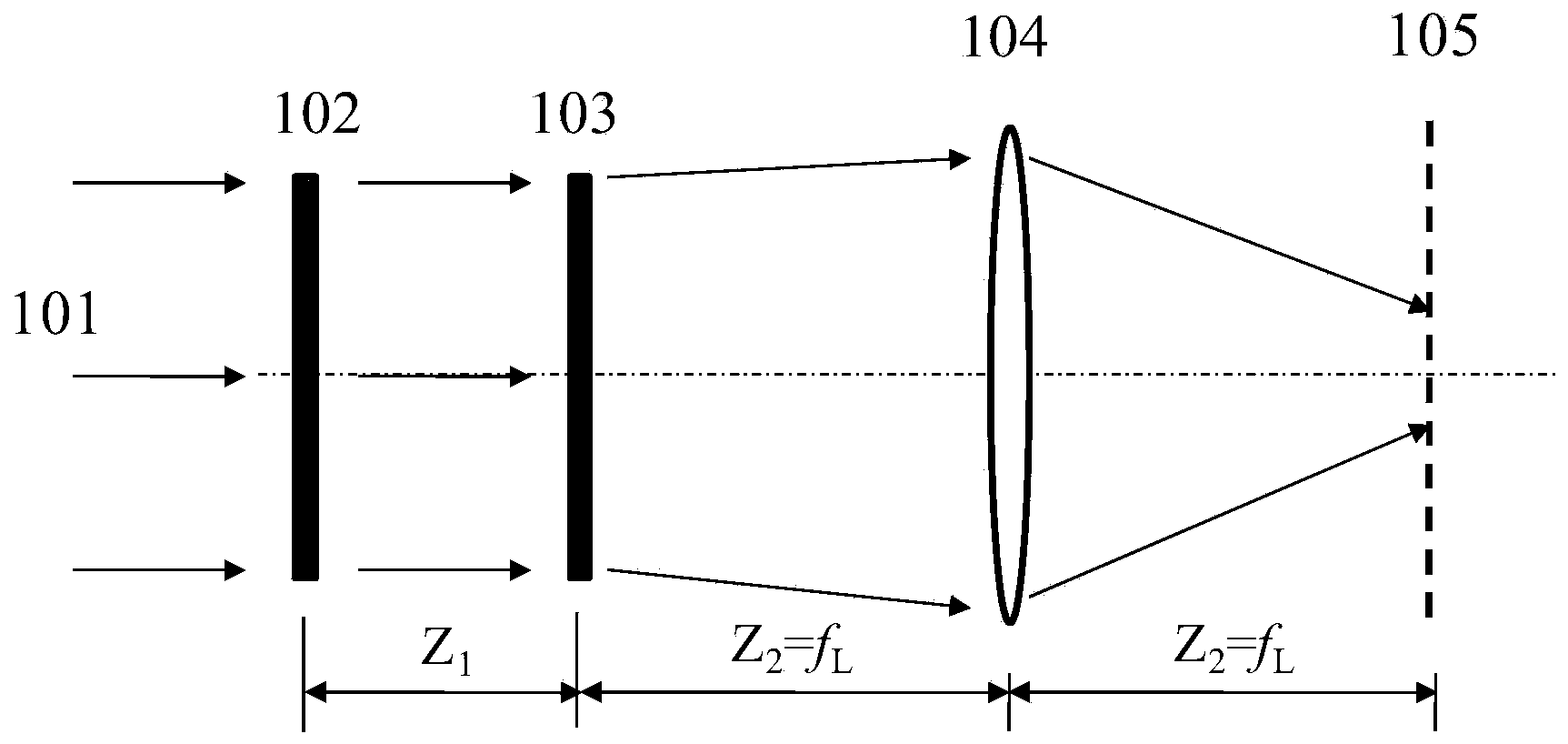

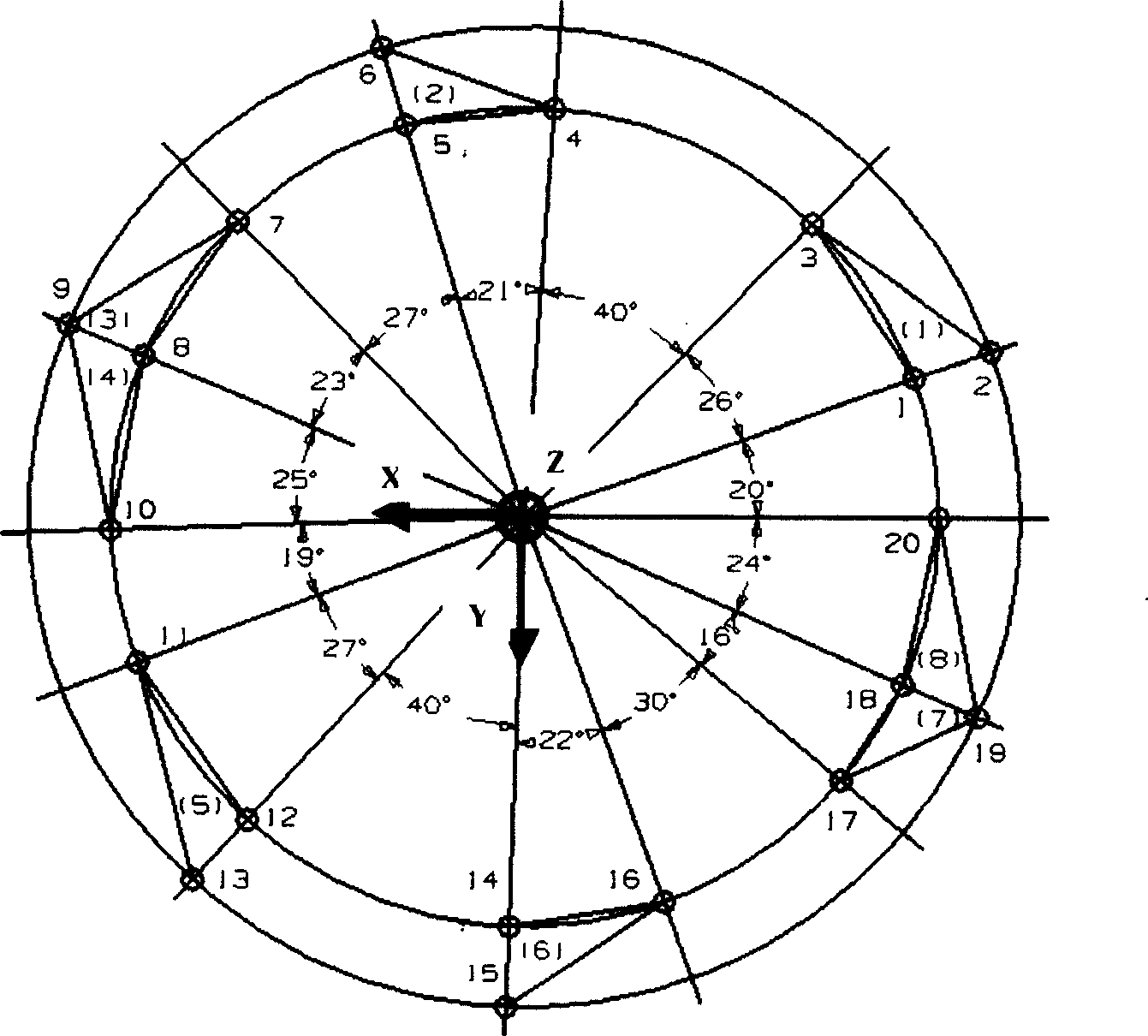

Pupil shaping unit structure of lithography machine and design method for diffraction optical element of pupil shaping unit structure

ActiveCN103676498AMultiple Design FreedomHigh diffraction efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusUnit structureDiscretization

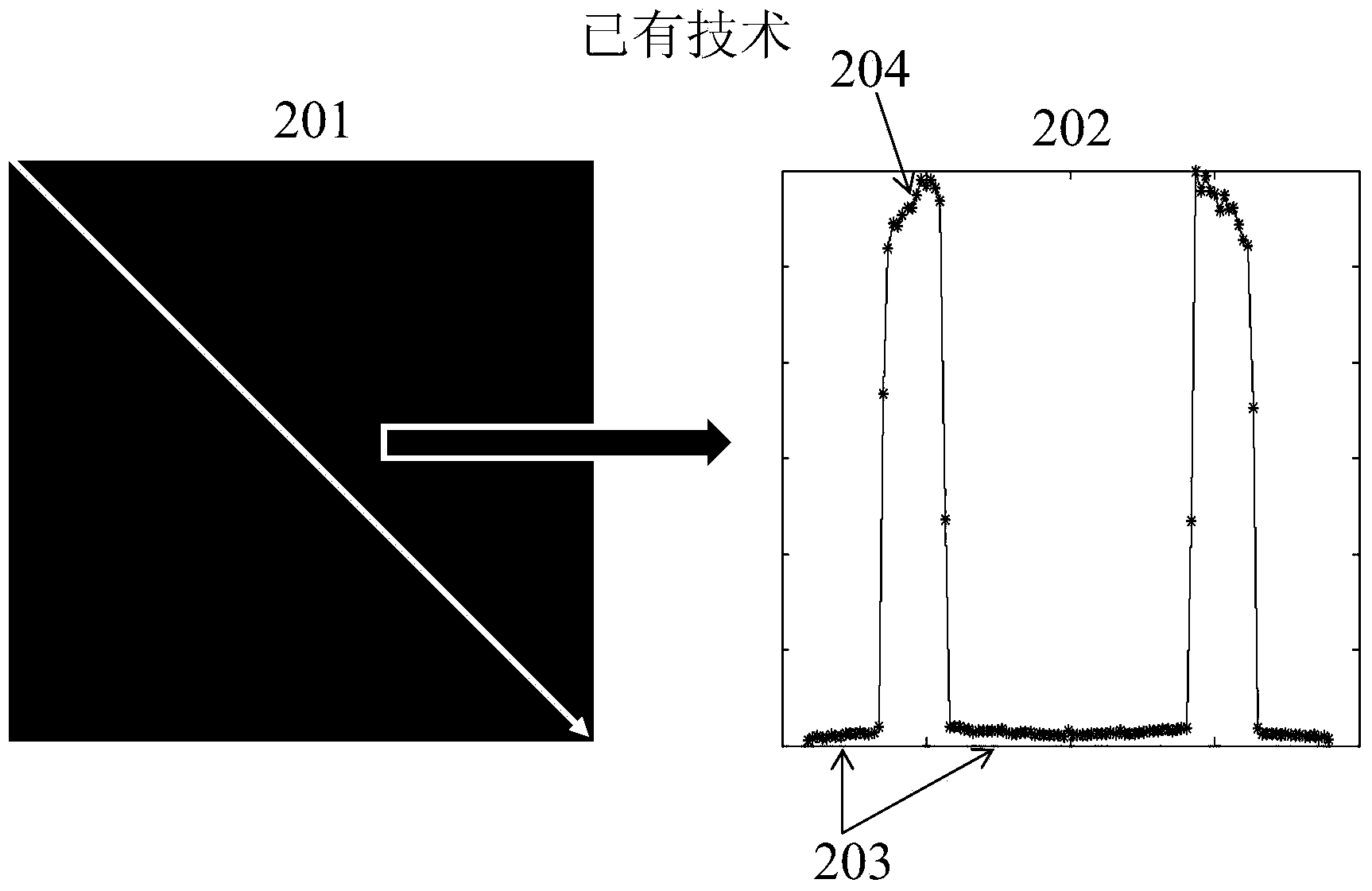

The invention discloses a pupil shaping unit structure of a lithography machine and a design method for a diffraction optical element of the pupil shaping unit structure. The pupil shaping unit structure comprises a cascade diffraction optical element and a varifocal collimating lens group, wherein the cascade diffraction optical element comprises a first diffraction optical element and a second diffraction optical element; the light transmittance surfaces of the two diffraction optical elements are perpendicular to the optical axis of a lighting system; the two diffraction optical elements are pure phase elements. The design method for the cascade diffraction optical element comprises the following steps of calculating a period of a phase unit; enabling a light beam to be incident, determining the light intensity distribution of the required optical beam and performing discretization processing; entitling initial phase matrixes of the first diffraction optical element and the second diffraction optical element; performing quantification processing through an iteration algorithm to obtain quantified phase matrixes of the first diffraction optical element and the second diffraction optical element; evaluating a design result.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

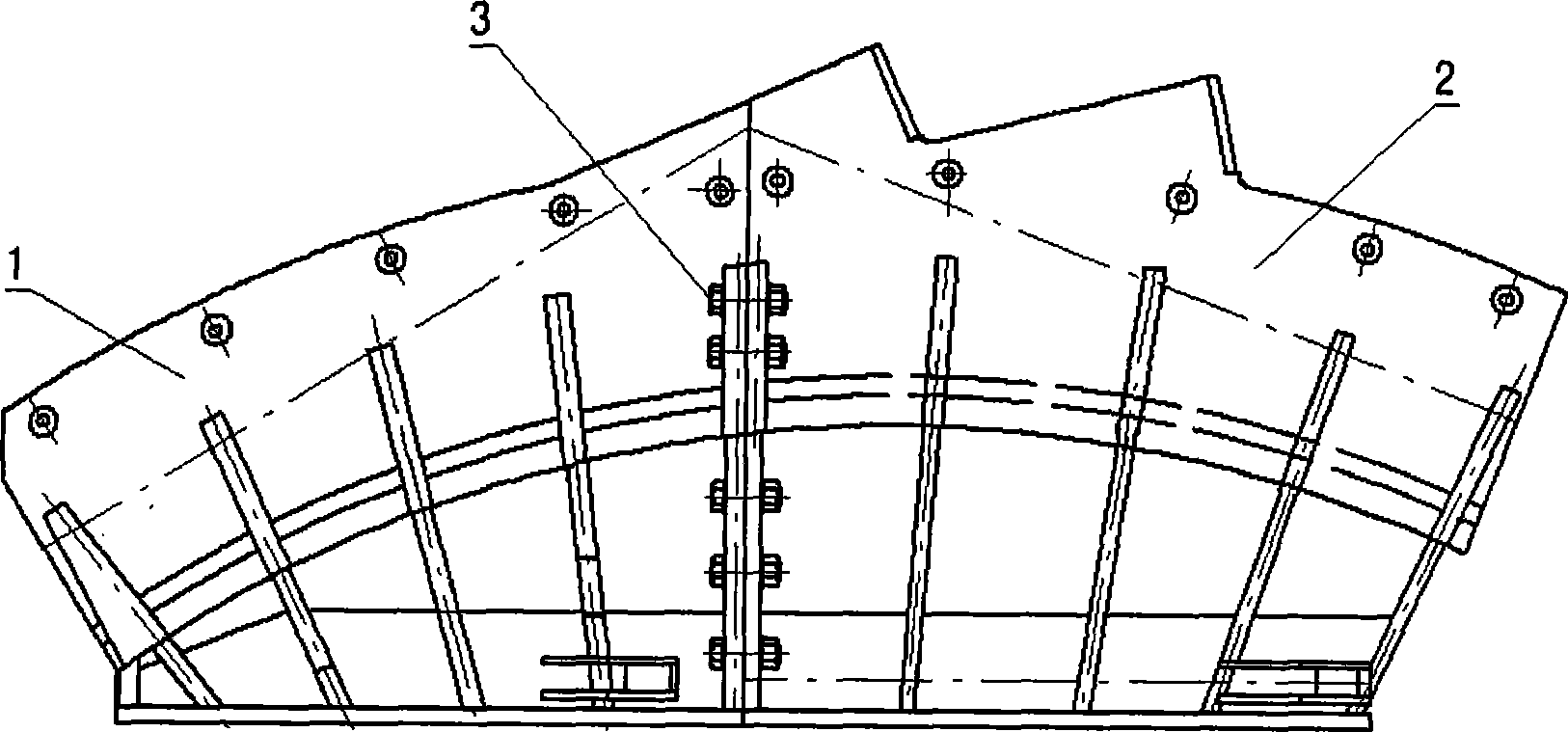

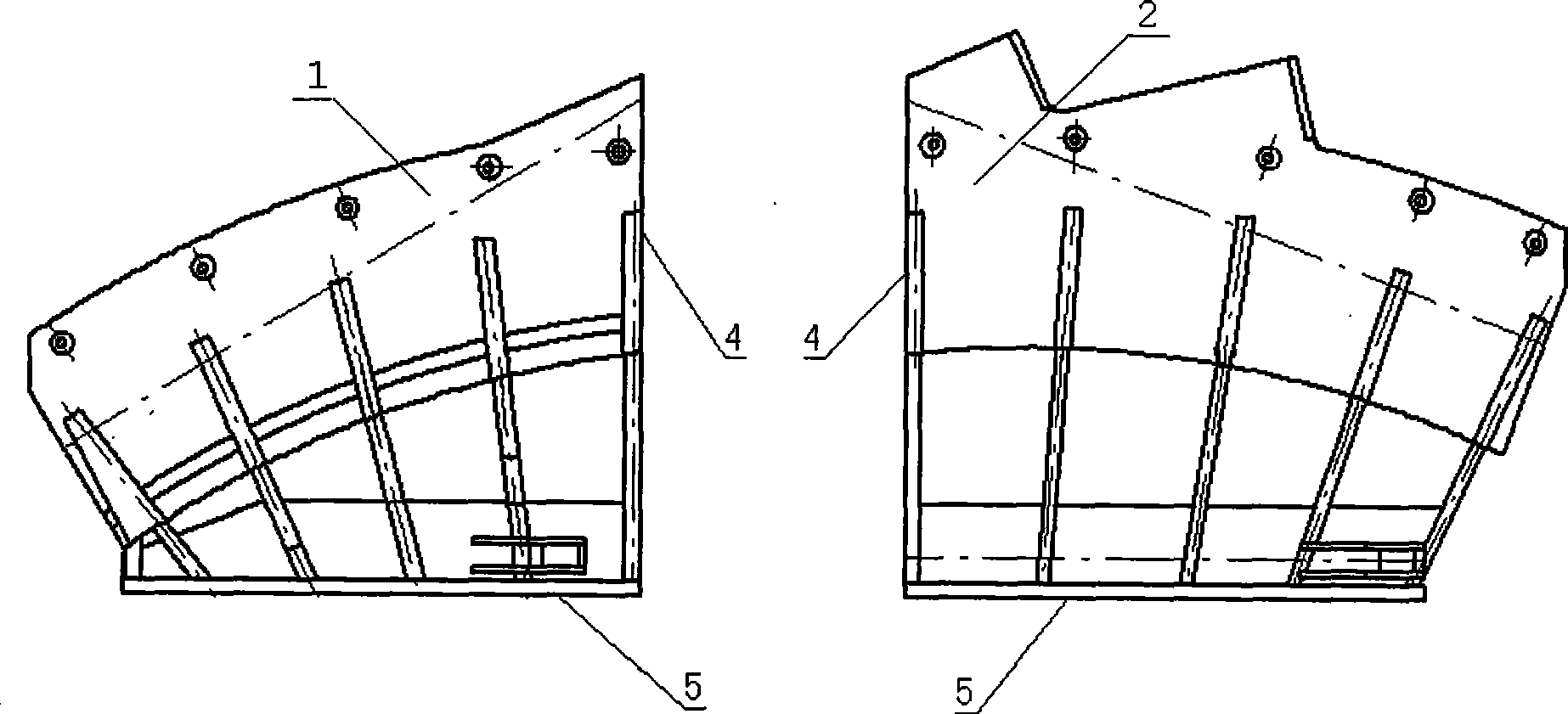

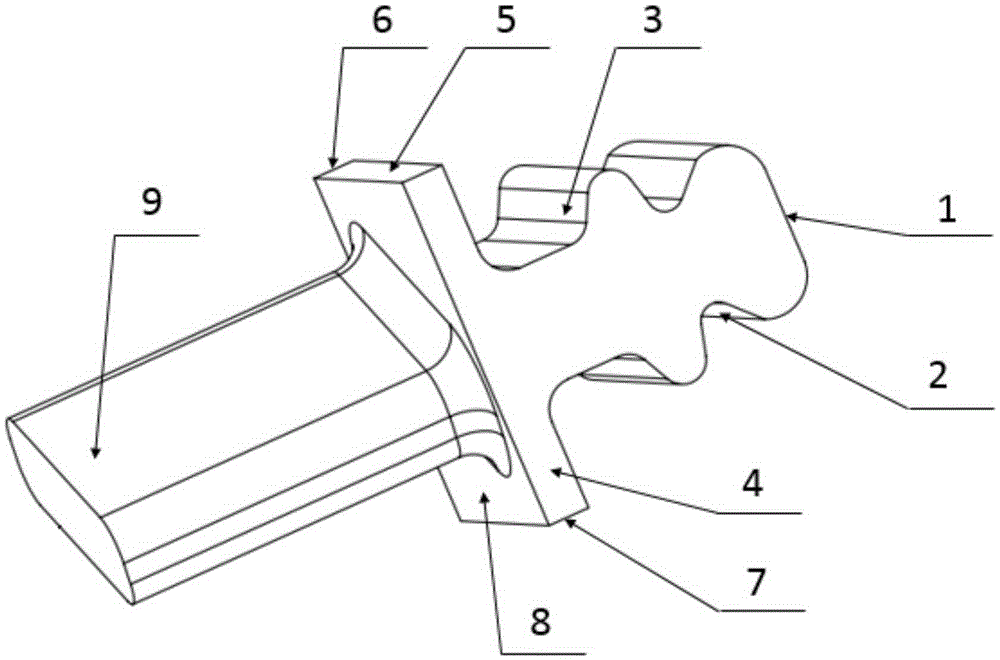

Method for processing main cable saddle of suspension bridge

The invention discloses a method for processing a main cable saddle of a suspension bridge. A side span (1) and a midspan (2) of the main cable saddle are respectively processed, then a bolt (3) is used to connect the side span and the midspan, and a joint surface of the side span (1) and the midspan (2) is provided with a positioning pin hole (6). The method guarantees the consistency of the size of a rope groove after the side span (1) and the midspan (2) are butted, has no alternate edges, high butting accuracy and small error, unifies processing reference, has low requirement on processing equipment, is more convenient for clamping and calibration of workpieces, is easy to guarantee processing accuracy, and improves processing efficiency.

Owner:WUHAN MARINE MACHINERY PLANT

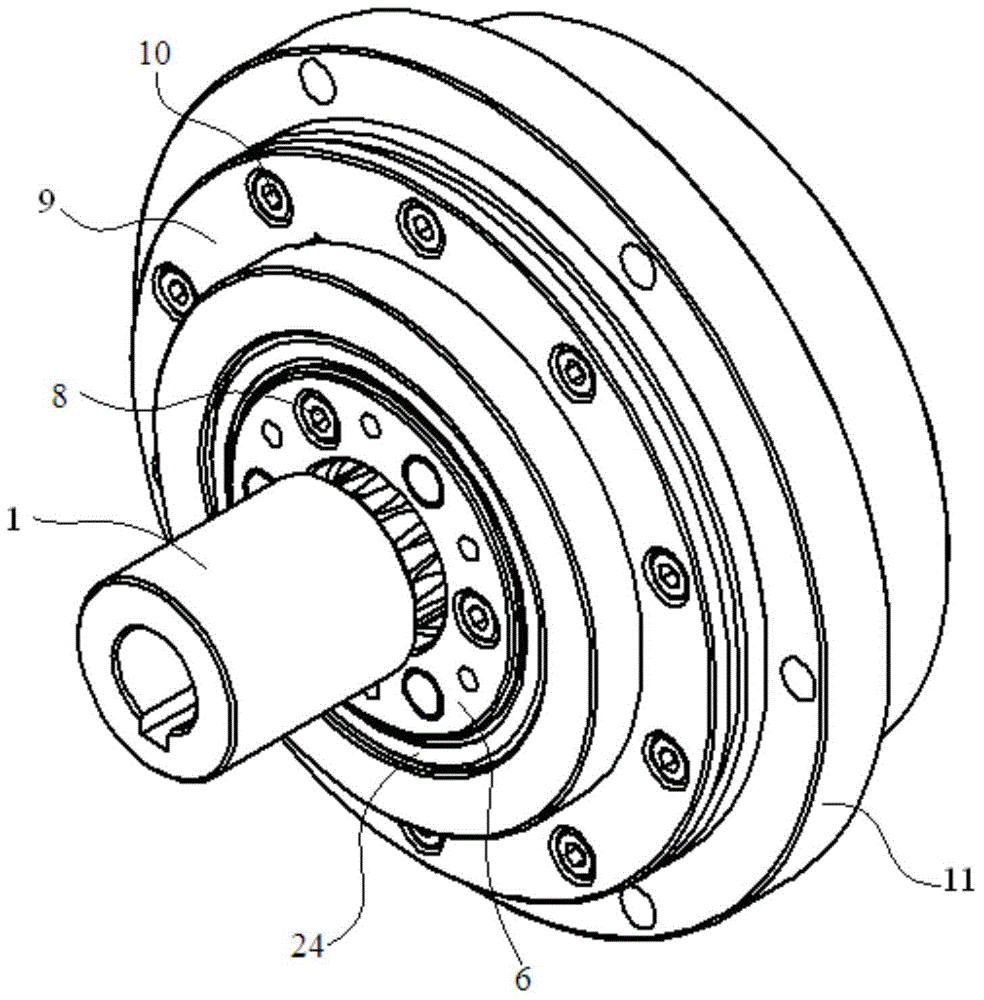

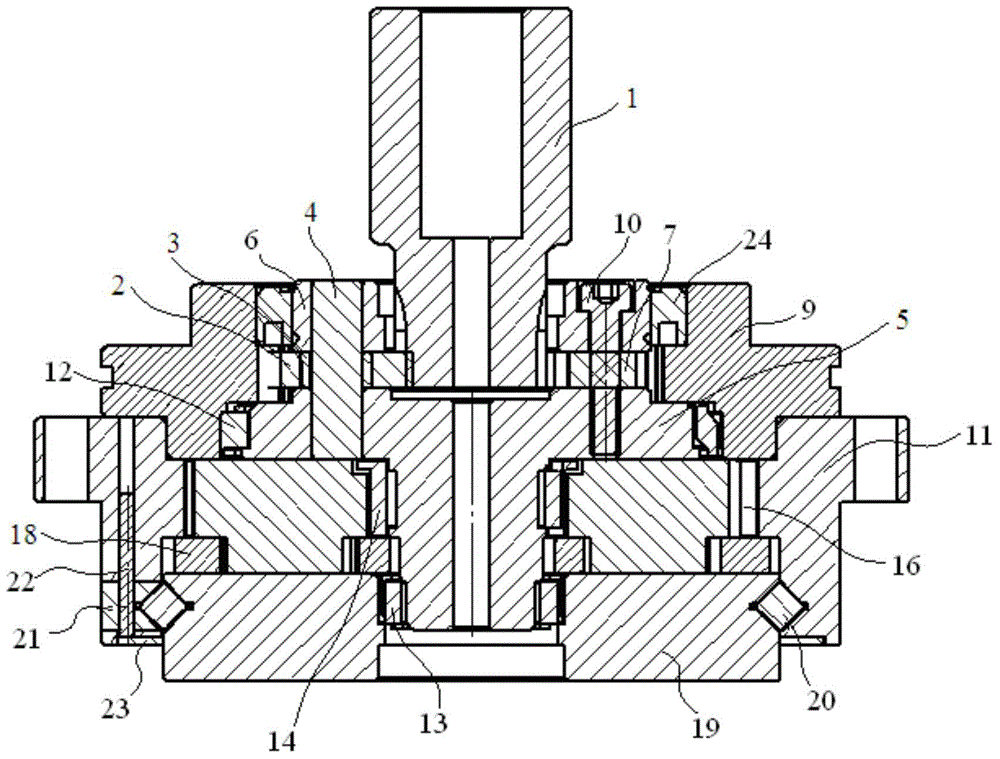

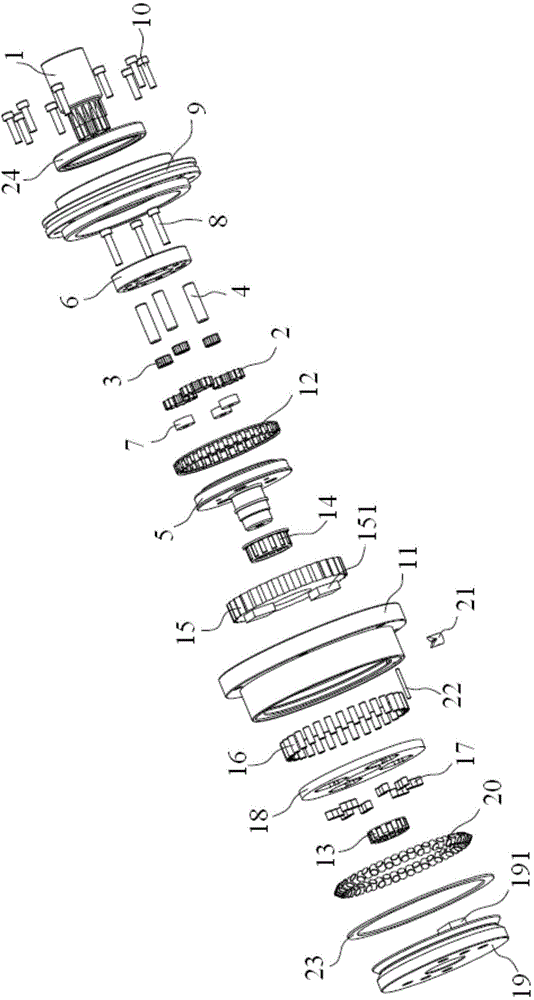

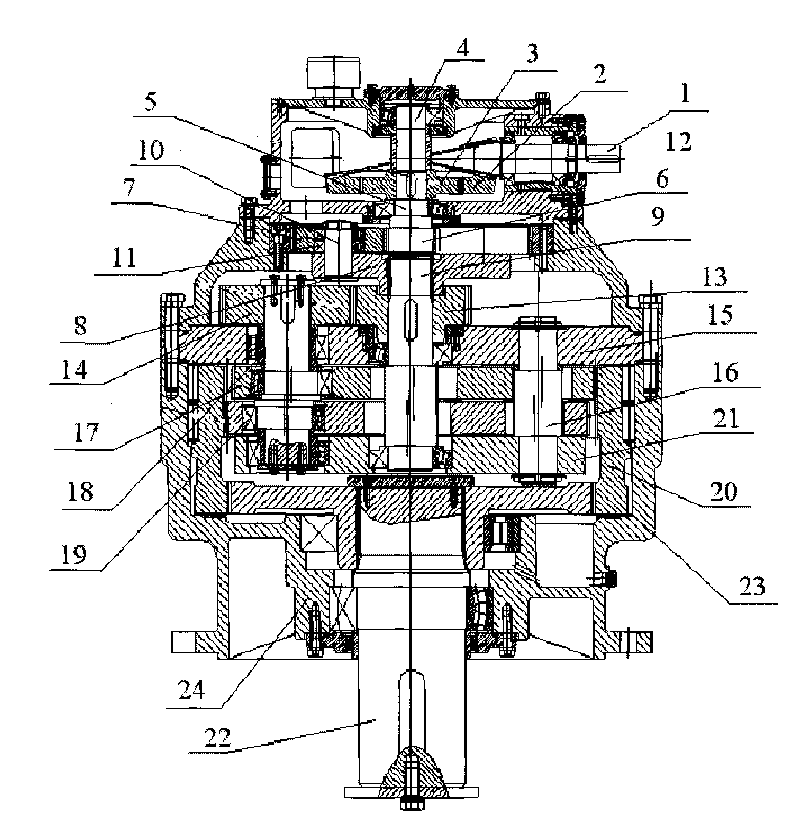

Speed reducer with planetary gears and cycloidal gear

The invention discloses a speed reducer with planetary gears and a cycloidal gear. The speed reducer comprises an input gear shaft, the planetary gears meshed with the input gear shaft, pin shafts arranged inside inner holes of the planetary gears, roller pins positioned between the pin shafts and the planetary gears, a crankshaft, a planetary carrier end cover, cushion columns, an outer gear ring, a casing, the cycloidal gear, a transmission component and an output end, wherein the crankshaft and the planetary carrier end cover are respectively connected with the two ends of the pin shafts; the cushion columns are positioned between the crankshaft and the planetary carrier end cover; the outer gear ring is positioned on the outer rings of the planetary gears and meshed with the planetary gears; the casing is fixedly connected with the outer gear ring; the cycloidal gear sleeves the eccentric circle of the crankshaft through a cylindrical roller bearing B; the transmission component is clamped with the cycloidal gear; the output end is clamped with the transmission component. The speed reducer has the advantages of being high in precision, high in transmission efficiency, simple in structure, small in size, convenient to mount, and low in manufacturing cost.

Owner:江苏哈工联合精密传动有限公司

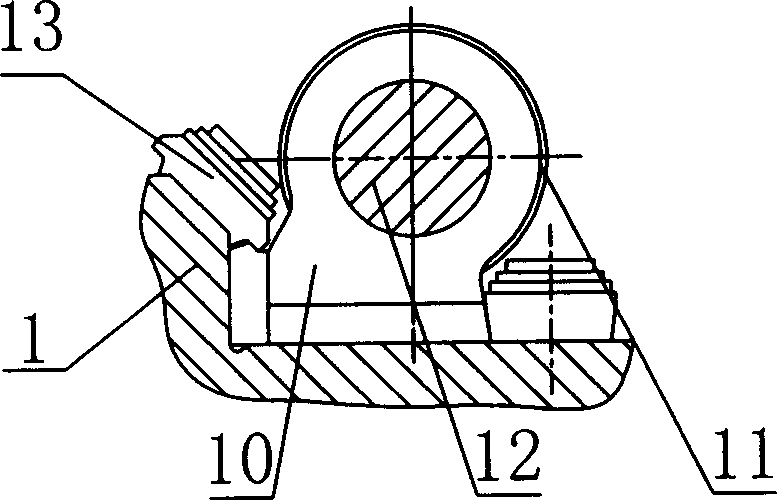

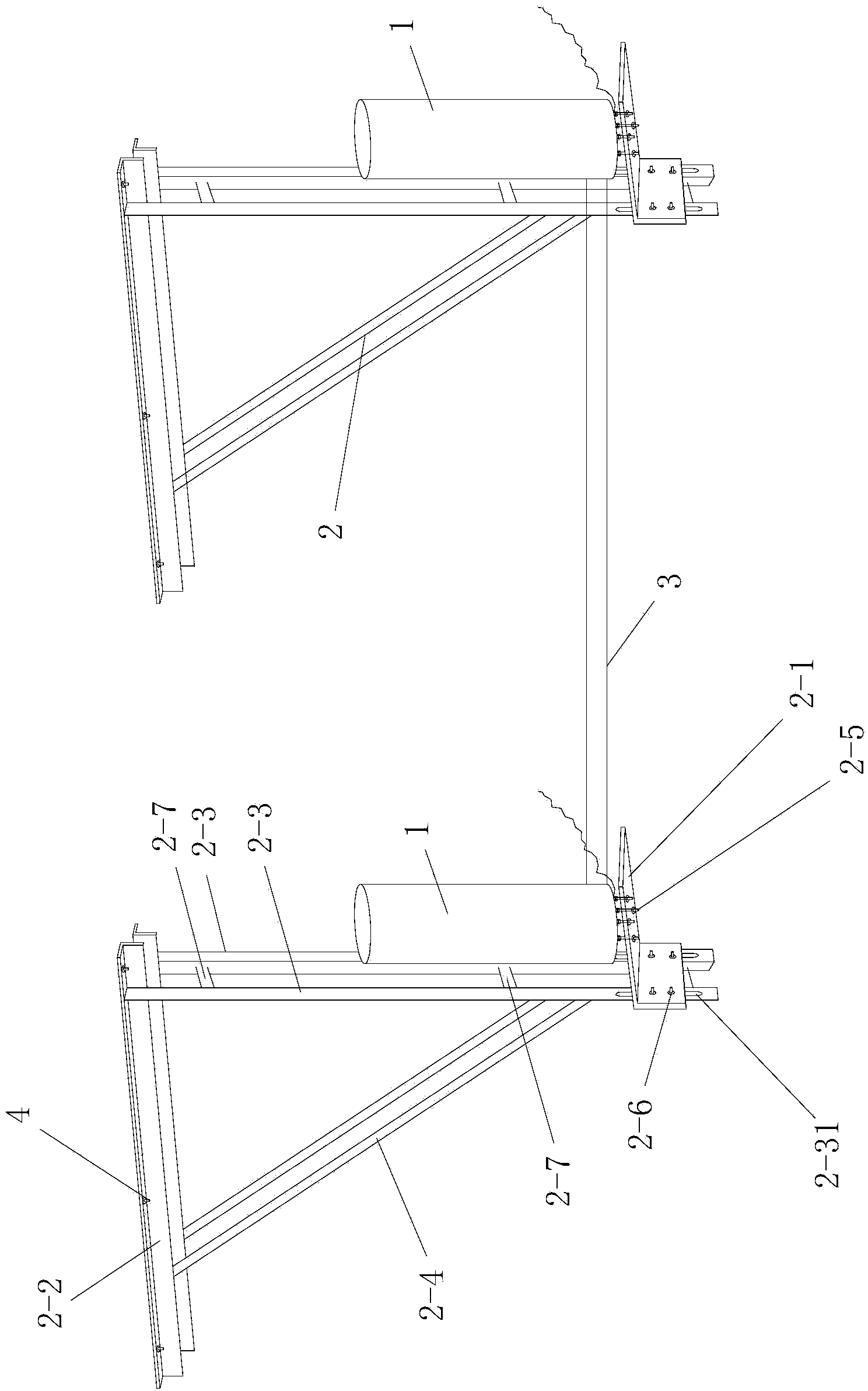

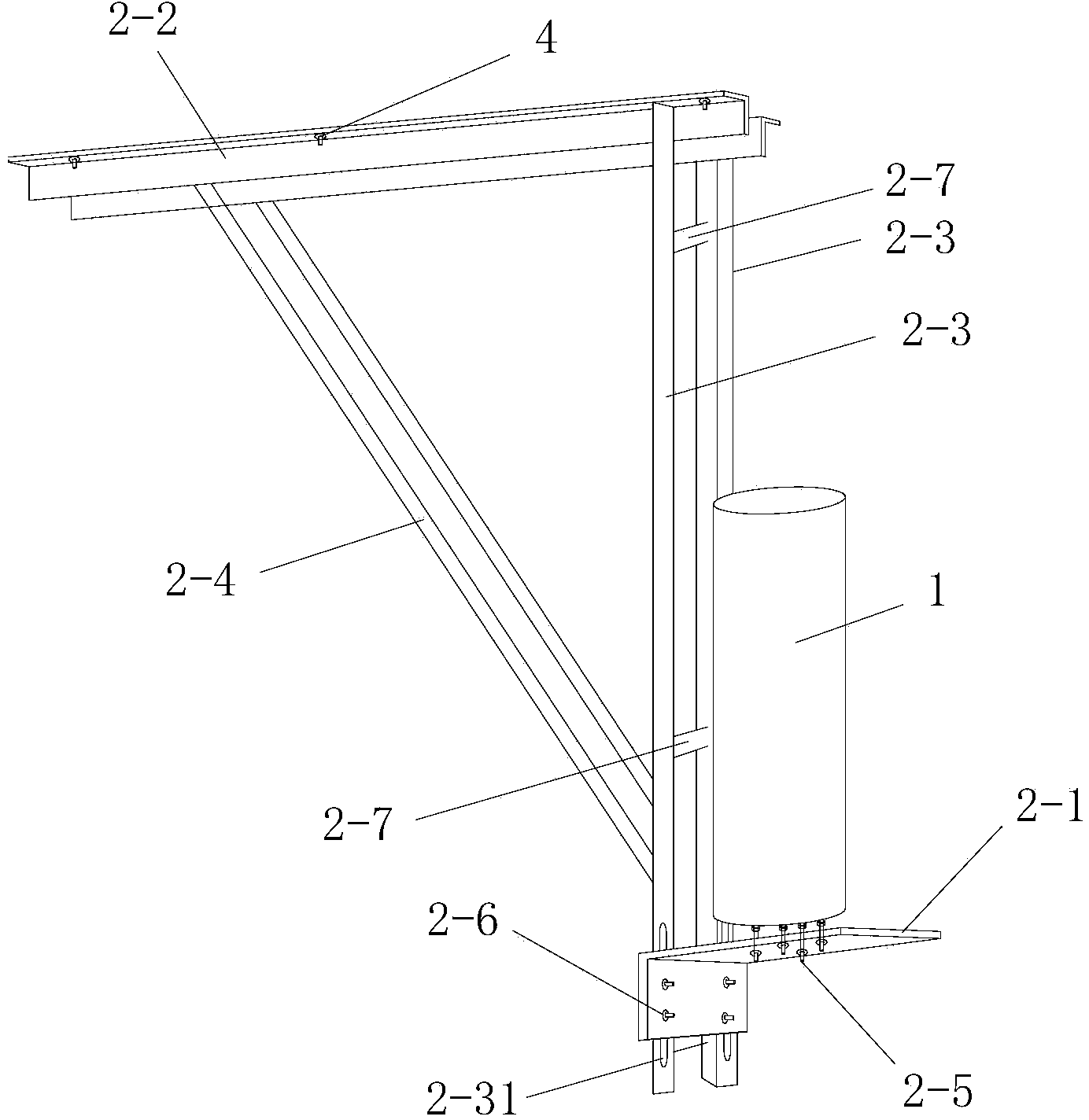

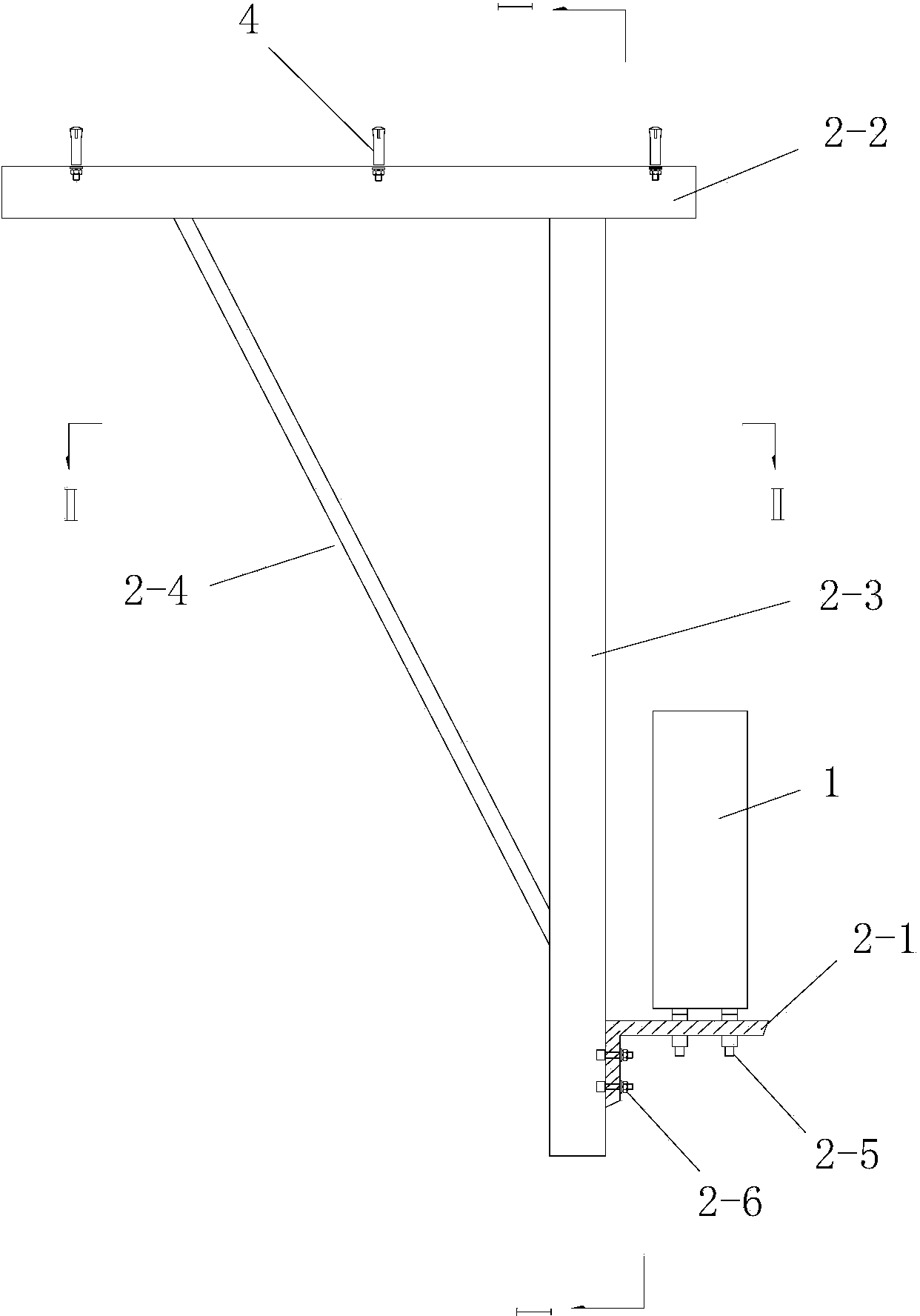

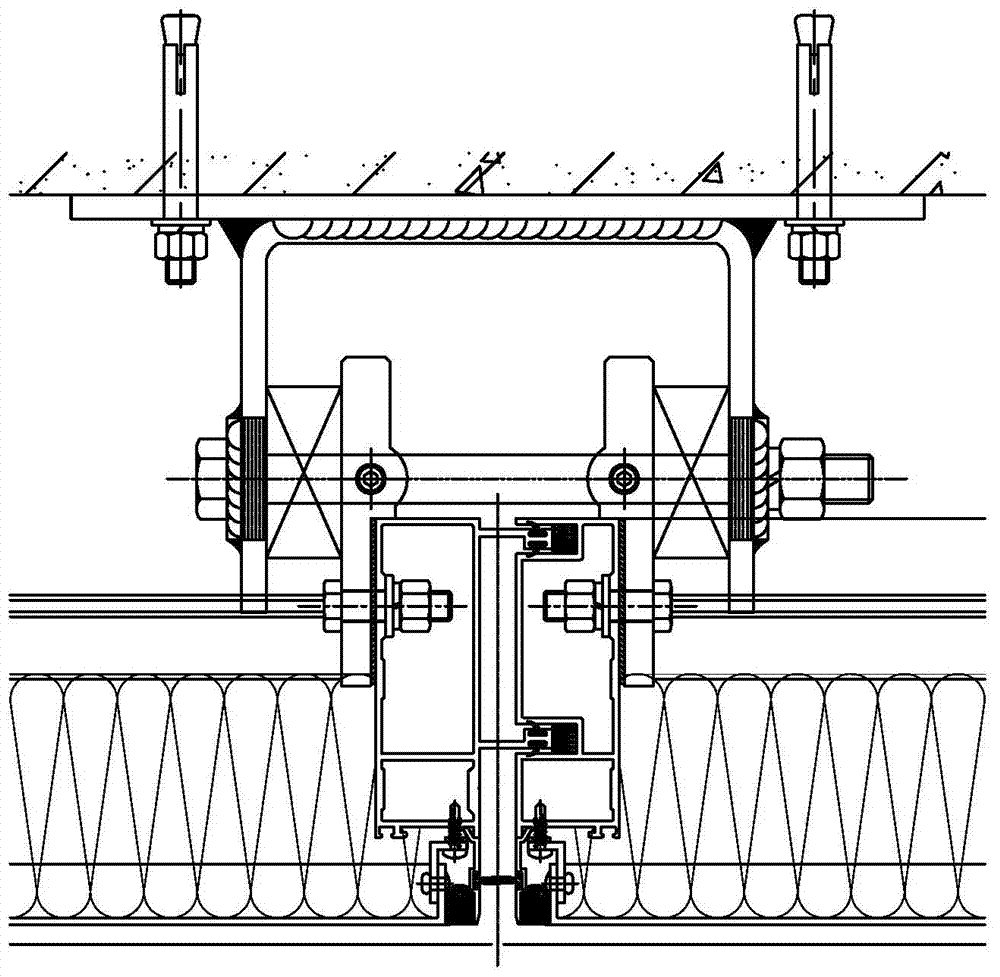

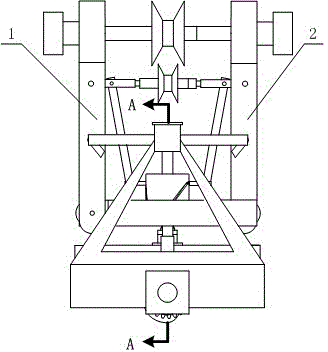

Long-term deflection monitoring system and method for long-span bridge

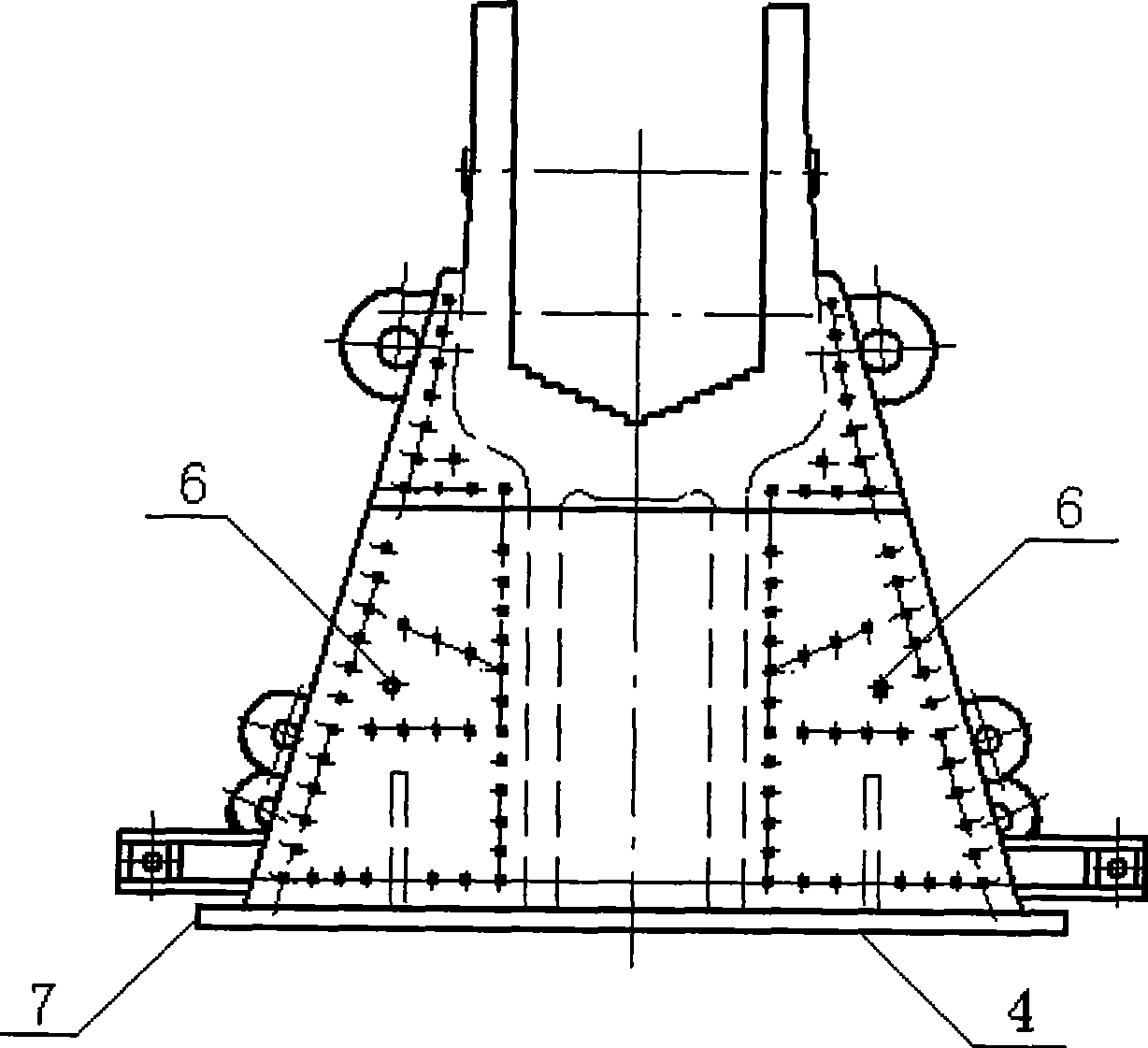

InactiveCN104132630ASimple structureReasonable designHydrostatic levellingUsing fluid meansMonitoring systemEngineering

The invention discloses a long-term deflection monitoring system and method for a long-span bridge. The monitoring system comprises a plurality of static level gages which are installed on a monitored bridge body through multiple installation frames, the monitored bridge body is a box girder, and the installation frames are installed at the bottom of a box girder top board; each installation frame comprises a triangular supporting frame and a supporting board which is installed on the triangular supporting frame and is adjustable in installation height, the triangular supporting frames are transversely arranged in the bridge direction, and the static level gages are installed on the corresponding supporting boards. The monitoring system is easy and convenient to install and arrange, influence from external environment is small, the monitoring precision is high, and the use effect is good. The monitoring method comprises the first step of determining measured points and selecting a datum point, the second step of installing the installation frames, the third step of installing the static level gages, and the fourth step of monitoring the deflection for a long term. The process of monitoring the deflection for a long term comprises the steps of obtaining the initial liquid level height, determining the monitoring time points of the deflection and monitoring the deflection. The monitoring method is simple in step, convenient to implement, good in use effect and capable of effectively monitoring the deflection of the bridge for a long term.

Owner:XIAN HIGHWAY INST

Machining method for aero-engine high-temperature alloy counterweight blade

The invention discloses a machining method for an aero-engine high-temperature alloy counterweight blade. The machining method includes the following steps that (1) a blade root mortise is cut in a wire cutting mode, specifically, most of the margin of a mortise part of a counterweight blade blank is removed through a wire cutting method; (2) the blade root and the blade form are milled, specifically, the blade root of the blank with the mortise margin removed in a wire cutting mode is upwards vertically clamped on a two-rotary-table five-shaft linkage machining center, then the end surface, the inner arc radial surface, the back arc radial surface, the steam inlet lateral surface and the steam outlet lateral surface of the blade root are machined through a face mill cutter in a rough and fine mode, a profile modeling milling cutter is used for machining a mortise in the steam inlet side and a mortise in the steam outlet side, and finally the adaptation surface of the blade root and the blade form and a blade form surface are machined in a rough, semi-fine and fine mode; and (3) the blade crown is cut in a wire cutting mode. According to the machining method for the aero-engine high-temperature alloy counterweight blade, the clamping frequency, the tool number and the varieties of tools are reduced. Meanwhile, the machining procedure is reasonably planned, reliability of machining is guaranteed, the machining accuracy is guaranteed, the machining efficiency is improved, and the production cost is reduced.

Owner:JIANGSU JITRI HUST INTELLIGENT EQUIP TECH CO LTD

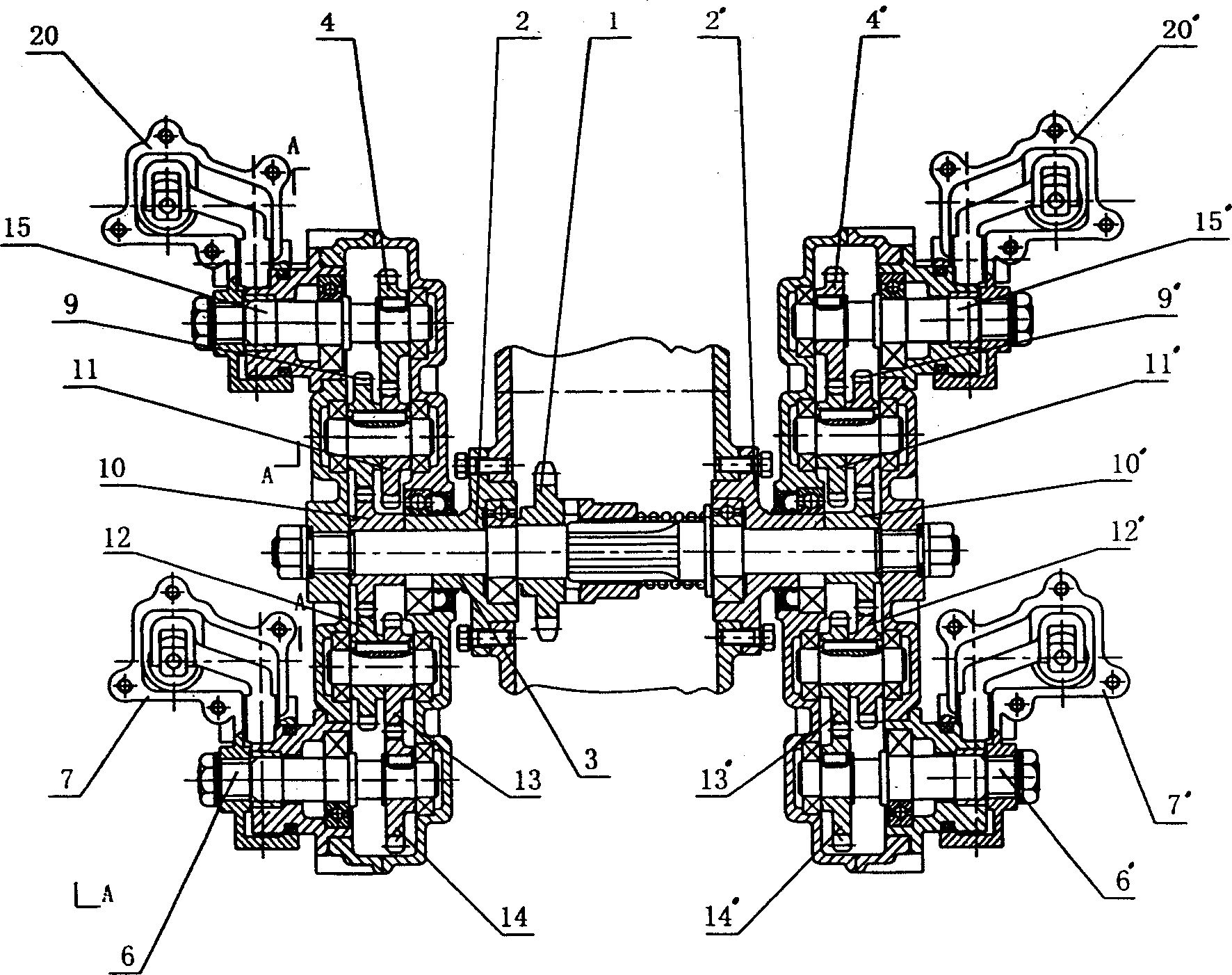

Column gear ellipsoid gear planetary system transplanting mechanism

A planetary gear train type rice seedling transplanter is disclosed. A left and a right gear boxes are driven by a central sprocket in a sprocket case for making them rotate. Two cylindrical planetary gears engaged with the static central cylindrical gear in the said gear box rotate with the gear box to drive the coaxial elliptical gear to rotate, and the said elliptical gear is further engaged with the elliptical planetary gear, so resulting in that the said elliptical gear rotates at non-uniform speed relatively to the gear box. The absolute movement of a transplanting arm pair is the composition of the circumference movement of gear box and the non-uniform movement of elliptical planetary gear. Its advantages are low inertial force, no damage to rice seedlings and reasonable structure.

Owner:ZHEJIANG SCI-TECH UNIV

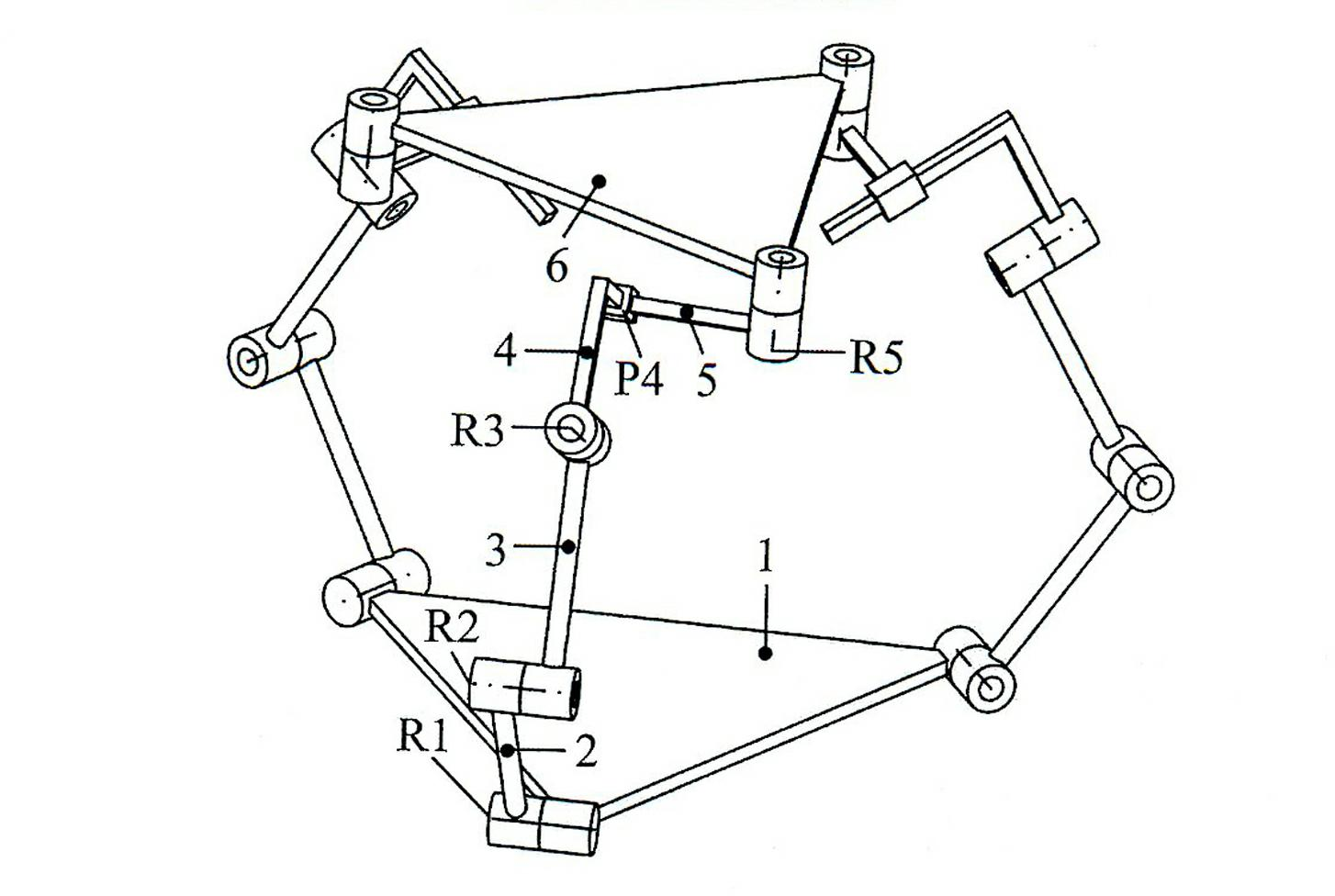

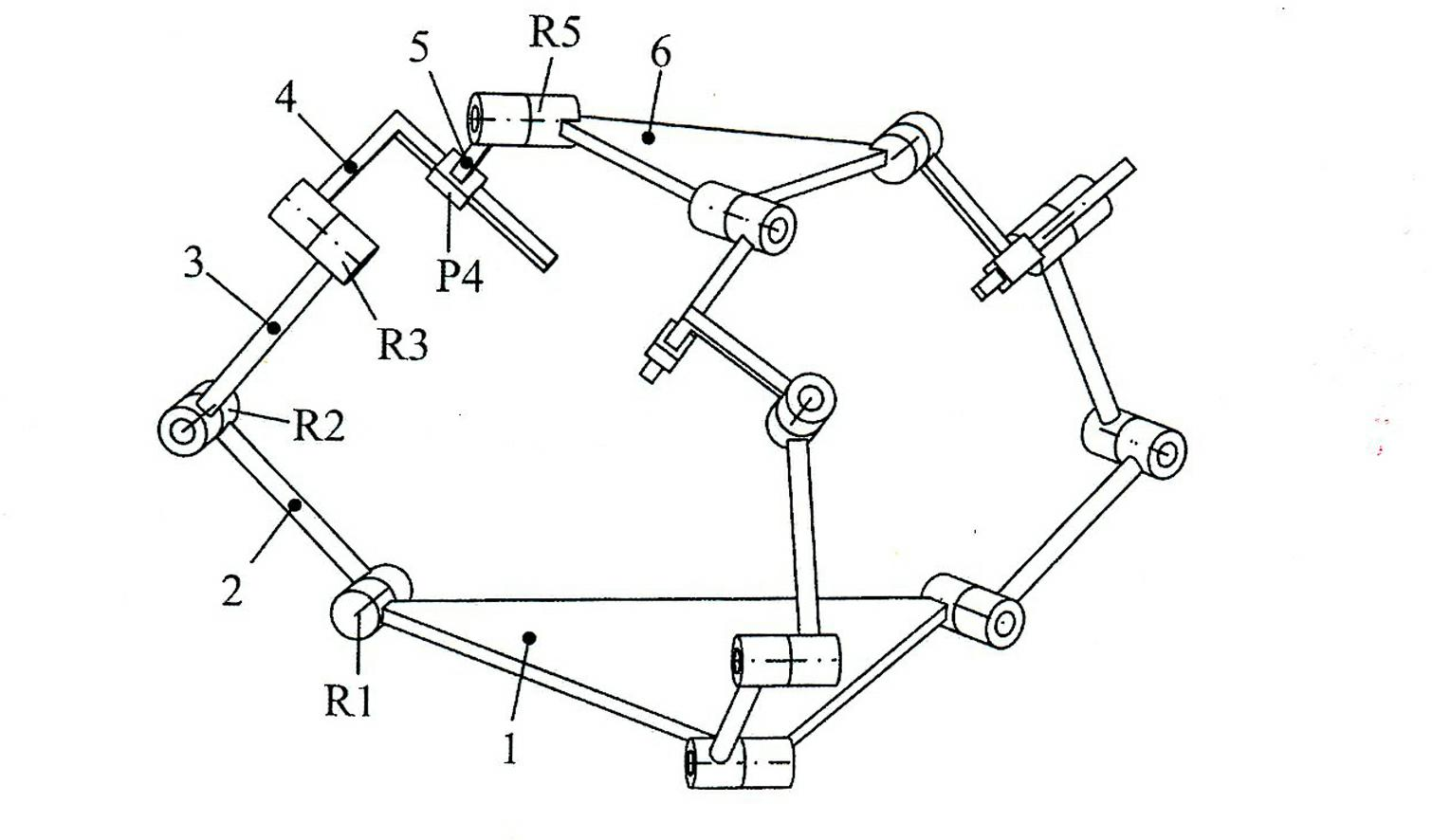

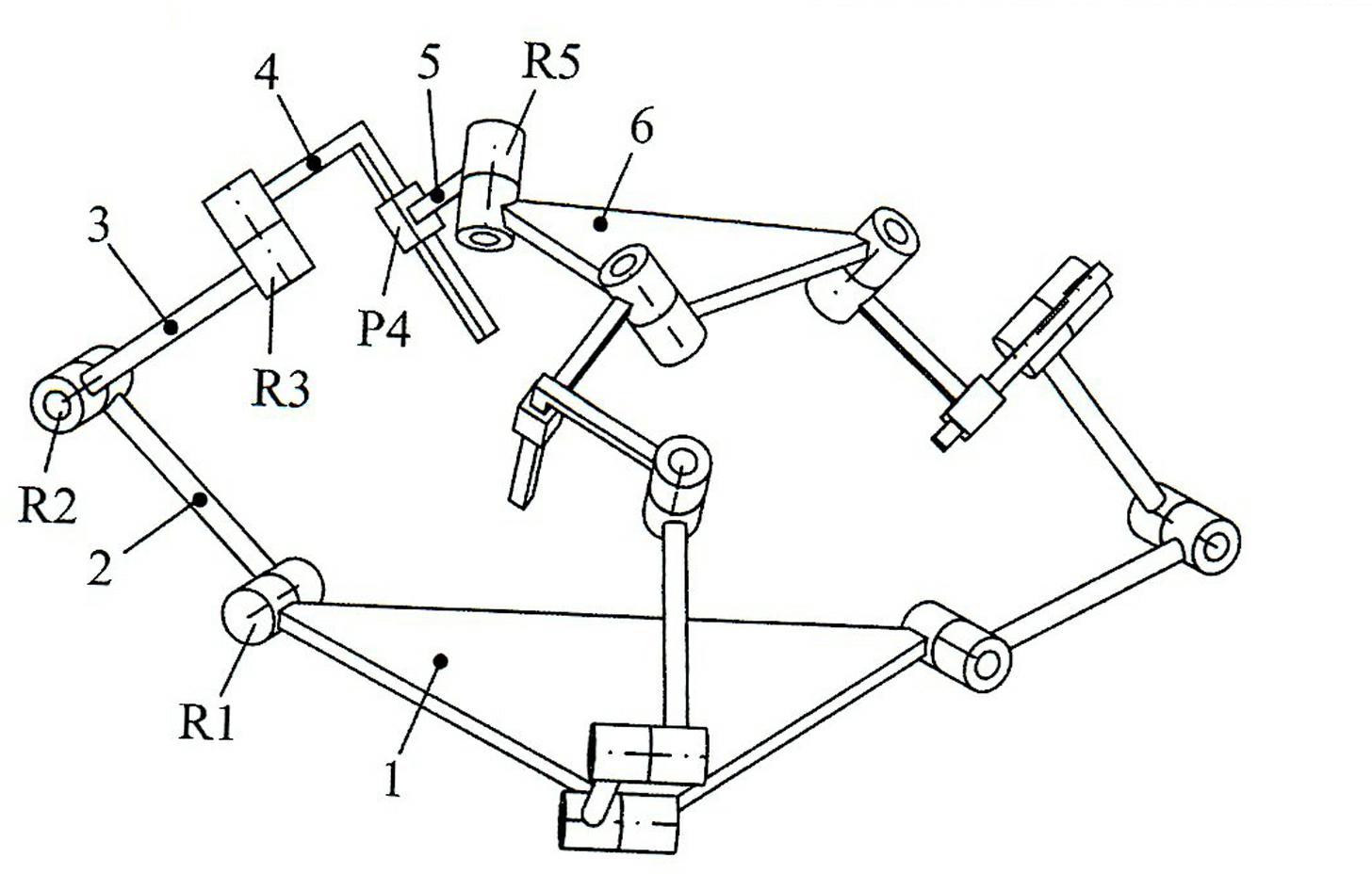

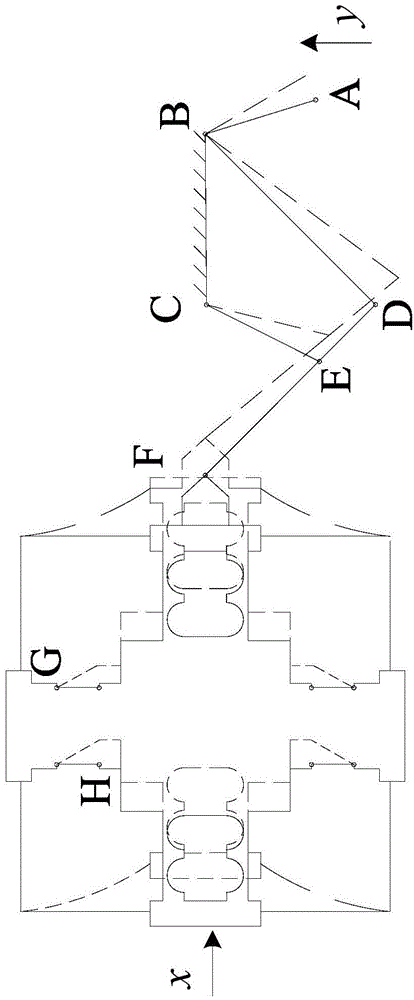

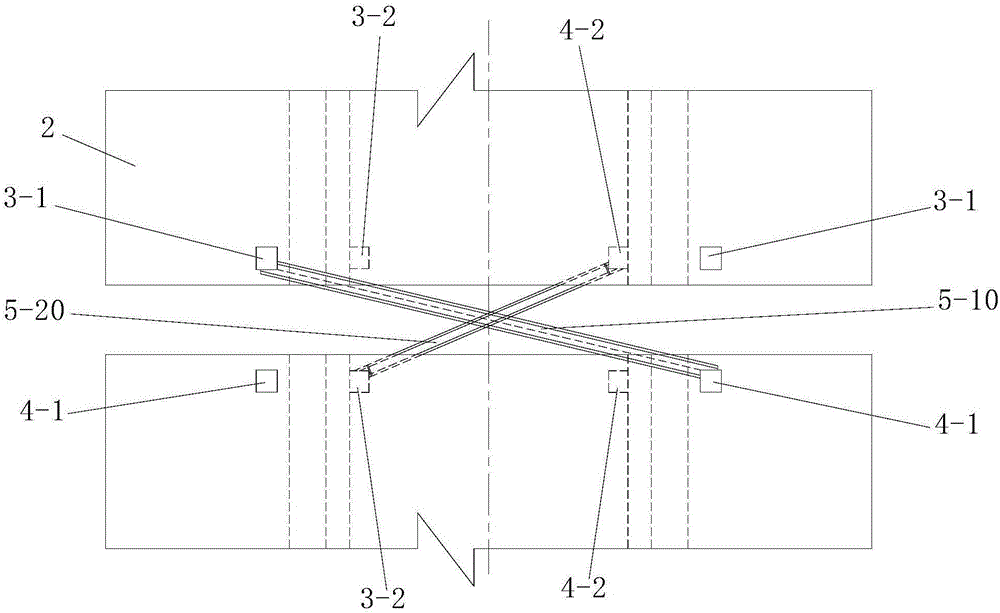

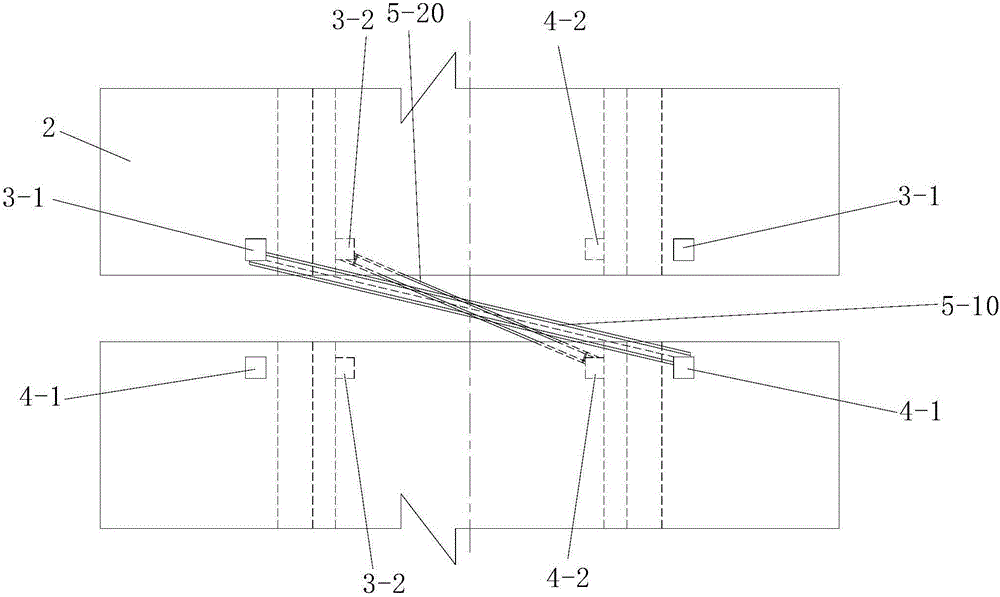

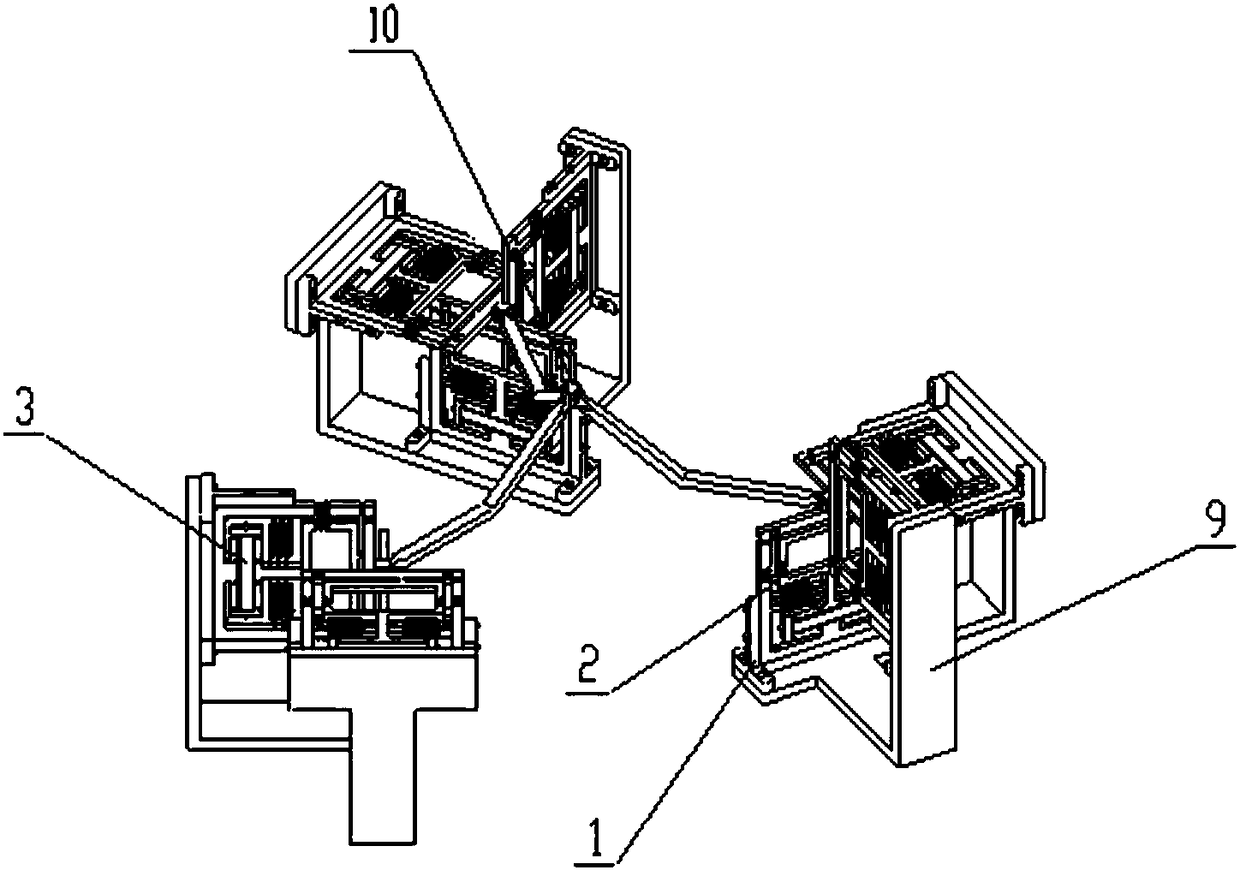

Non-concurrent axis symmetric two-rotation one-movement parallel mechanism with two-degree of freedom planar subchains

InactiveCN102626921ASimple branch structureEasy to processProgramme-controlled manipulatorLarge fixed membersVertical planeMechanical engineering

A non-concurrent axis symmetric two-rotation one-movement parallel mechanism with two-degree of freedom planar subchains comprises a moveable platform, a static platform, and three structurally identical moveable branches for connecting the moveable platform and the static platform, wherein each branch consists of a sliding pair, two revolute pairs and a two-degree of freedom planar subchain; the revolute pairs in the planar subchain are parallel to each other; the sliding pair is vertical to the revolute pairs; and the revolute pairs in the planar subchain are parallel to the static platform and the moveable platform. The non-concurrent axis symmetric two-rotation one-movement parallel mechanism with the two-degree of freedom planar subchains has two rotational degrees of freedom and a movement degree of freedom, and no any concurrent axis exists in the branches and between the branches, so that the non-concurrent axis symmetric two-rotation one-movement parallel mechanism with the two-degree of freedom planar subchains is very simple in structure and relatively convenient to manufacture and has very wide application prospect.

Owner:YANSHAN UNIV

Laser light source collimating device, collimating device array, lighting system and projection equipment

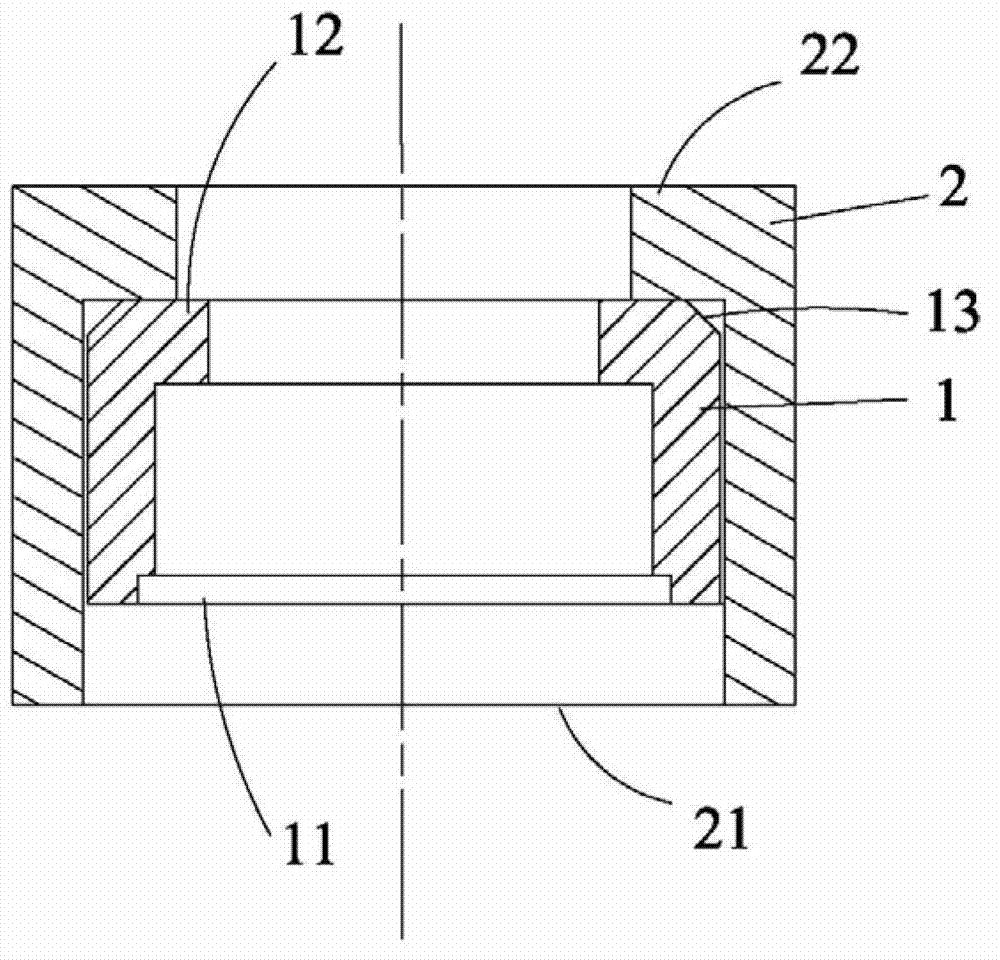

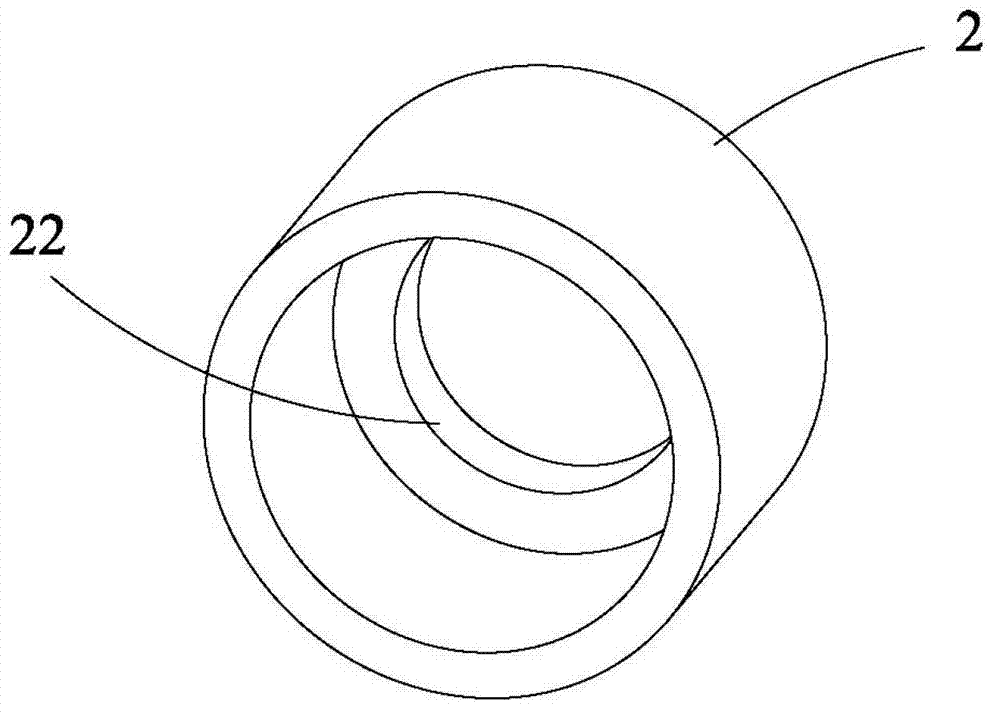

InactiveCN102854632AGood effectGuaranteed concentricityLaser detailsProjectorsEngineeringLaser light

The invention is suitable for the technical filed of optics and provides a laser light source collimating device, a collimating device array, a lighting system and projection equipment. The collimating device comprises an inner sleeve and an outer sleeve, wherein both ends of the inner sleeve are located in the outer sleeve; one end of the outer sleeve is provided with a first opening and the other end of the outer sleeve is provided with a first flange extending inwards; the center axes of the first flange and the first opening are overlapped; one end (close to the first opening) of the inner sleeve is provided with a second opening and the other end of the inner sleeve is provided with a second flange extending inwards; and the upper surface of the second flange presses against the lower surface of the first flange and the second flange is bulged inwards relative to the first flange so as to form a step structure. According to the laser light source collimating device, the collimating device array, the lighting system and the projection equipment, the spacing design and the concentricity design of a laser and a collimating lens are respectively realized through two independent sleeves; the inner and outer sleeves can be individually manufactured thus being convenient to process; and therefore, the collimating device is convenient to process, high in processing accuracy, suitable for batch production and relatively good in laser collimating effect at the same time.

Owner:WUHU AMT MICRO DISPLAY TECH

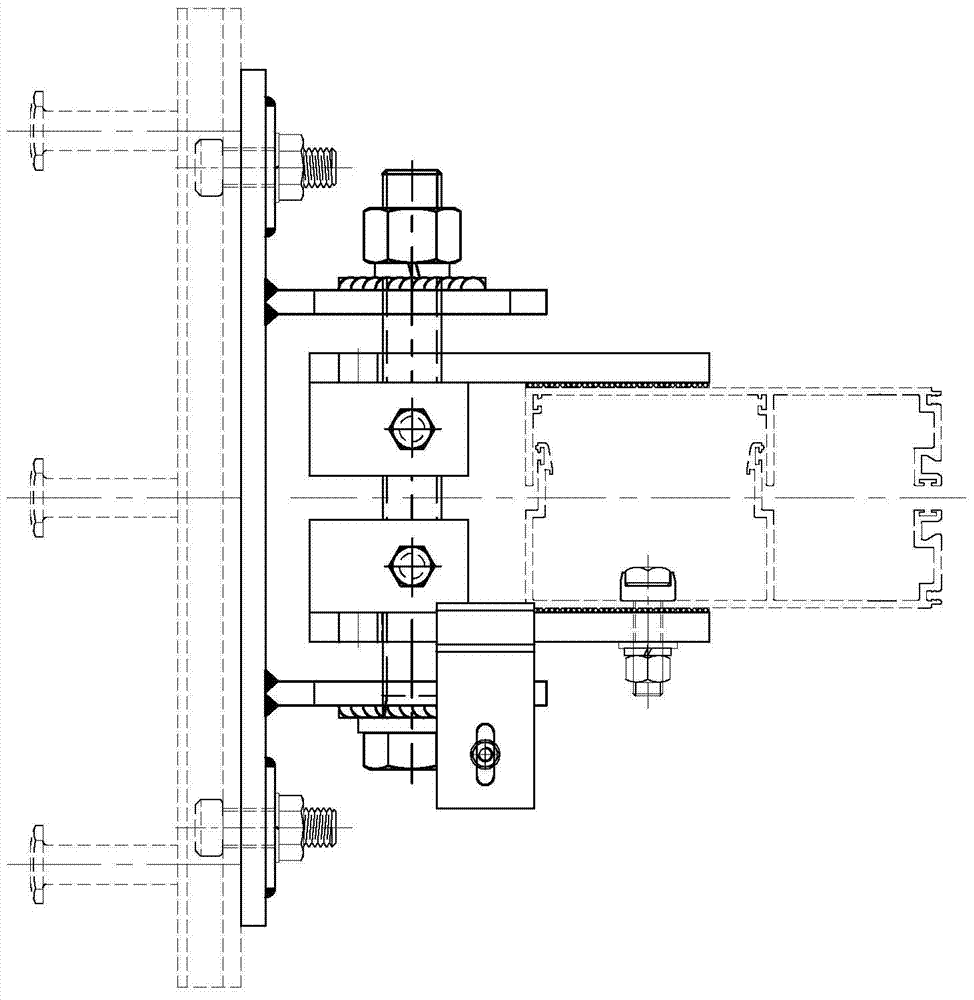

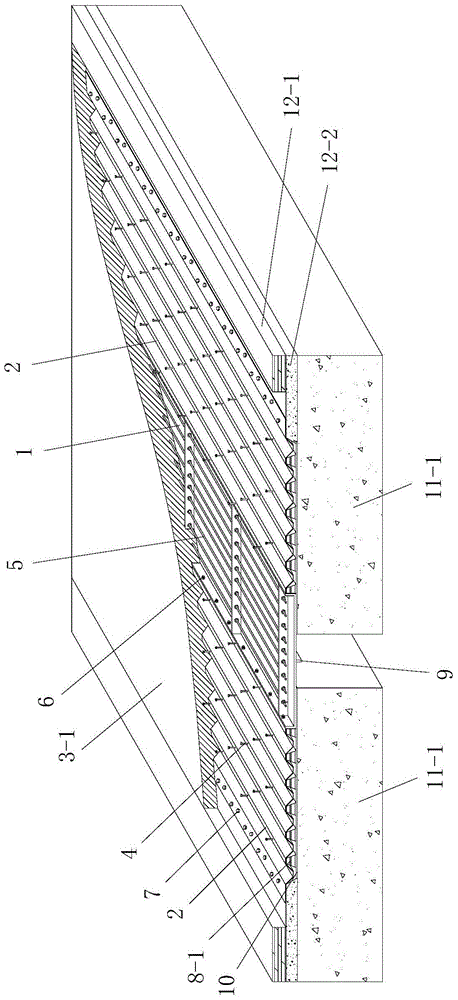

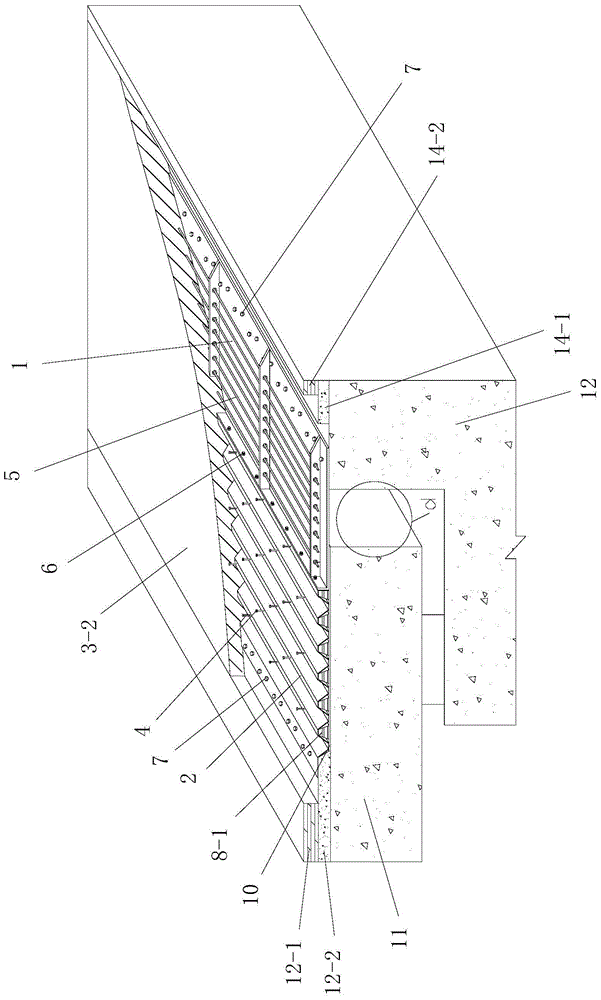

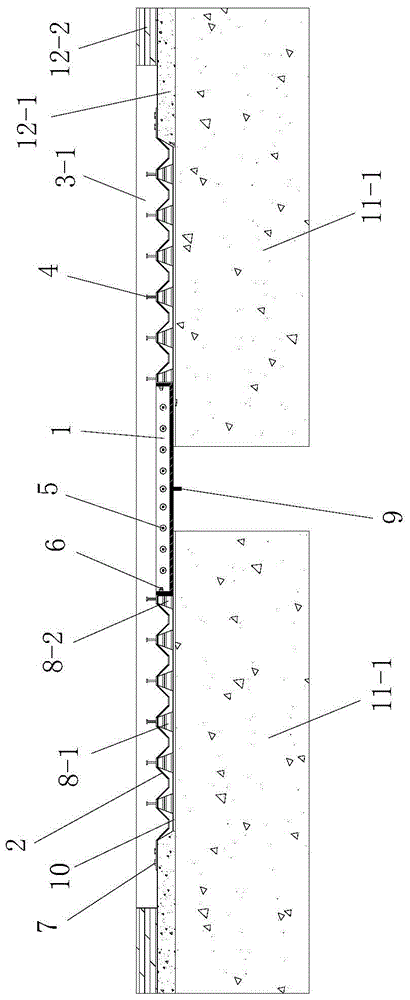

Sideward-hanging connection piece of unit-typed curtain wall stand column

ActiveCN103615060AConvenient force adjustmentChange the state of stressWallsPunchingProcessing accuracy

A sideward-hanging connection piece of a unit-typed curtain wall stand column comprises a backboard, two side plates and a bolt shaft. The backboard and the two side plates are squeezed to be formed in an integrated mode through a compound die made of aluminum, and an aluminum hanging shaft penetrates through the bolt shaft. Vertical teeth are arranged on the outer side faces of horizontal long-strip-shaped holes in the two side plates. Gaskets are correspondingly arranged on the vertical teeth and are provided with vertical teeth matched with the vertical teeth on the outer side faces of the horizontal long-strip-shaped holes. Transverse teeth are arranged on the outer side faces of the vertical holes in the backboard on the outsides of the two side plates. Gaskets are arranged on the corresponding faces of the transverse teeth and provided with transverse teeth matched with the transverse teeth on the outer side faces of the vertical holes, and the transverse teeth on the outer side faces of the vertical holes are made in a punching mode. The hanging shaft is of an asymmetric design. The sideward-hanging connection piece has the advantages that on-site welding can be avoided, the bearing force is higher, the structural safety is better, adjustment is more convenient to achieve, the machining precision is easy to guarantee, a needed space is smaller and the weight is lower.

Owner:JANGHO GRP

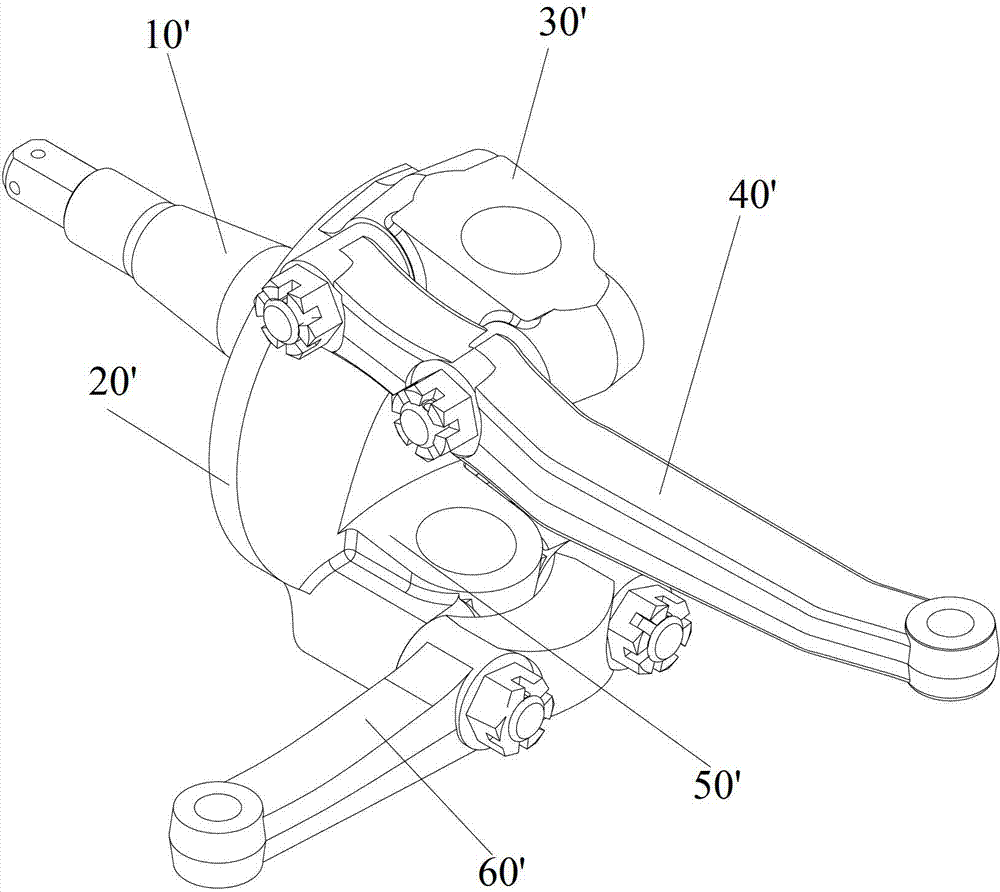

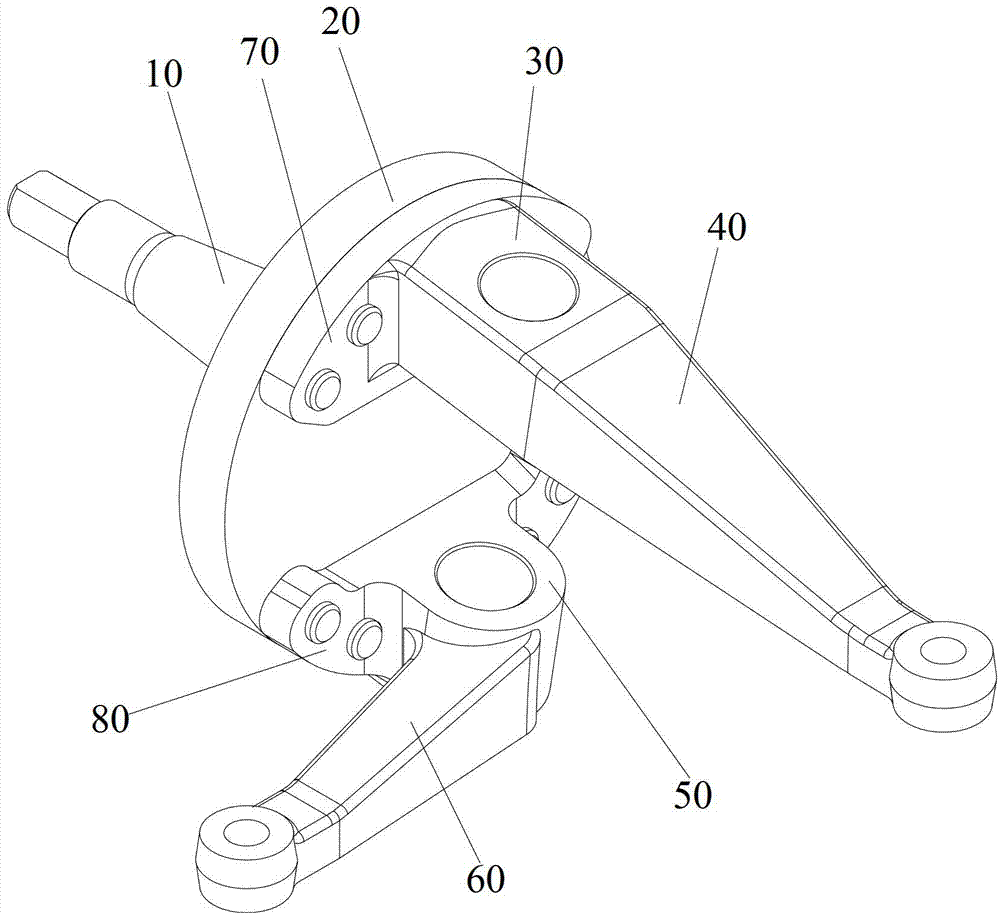

Knuckle assembly, processing method thereof and vehicle comprising knuckle assembly

ActiveCN103042154AWith transition arcSimple process structureSteering linkagesRailway componentsFlangeKnuckle

The invention provides a knuckle assembly, a processing method thereof and a vehicle comprising the knuckle assembly. The processing method of the knuckle assembly includes: integrally processing and forming a finger shaft (10) and a shaft end flange (20); processing a first lug plate (30) and a straight lever arm (40) and fixedly connecting the first lug plate (30) and the straight lever arm (40) to the shaft end flange (20); processing a second lug plate (50) and a tie rod arm (60) and fixedly connecting the second lug plate (50) and the tie rod arm (60) to the shaft end flange (20). The knuckle assembly which is processed by the processing method is simple in structure and easy to process, and thus, work efficiency can be effectively improved.

Owner:湖南中联重科车桥有限公司

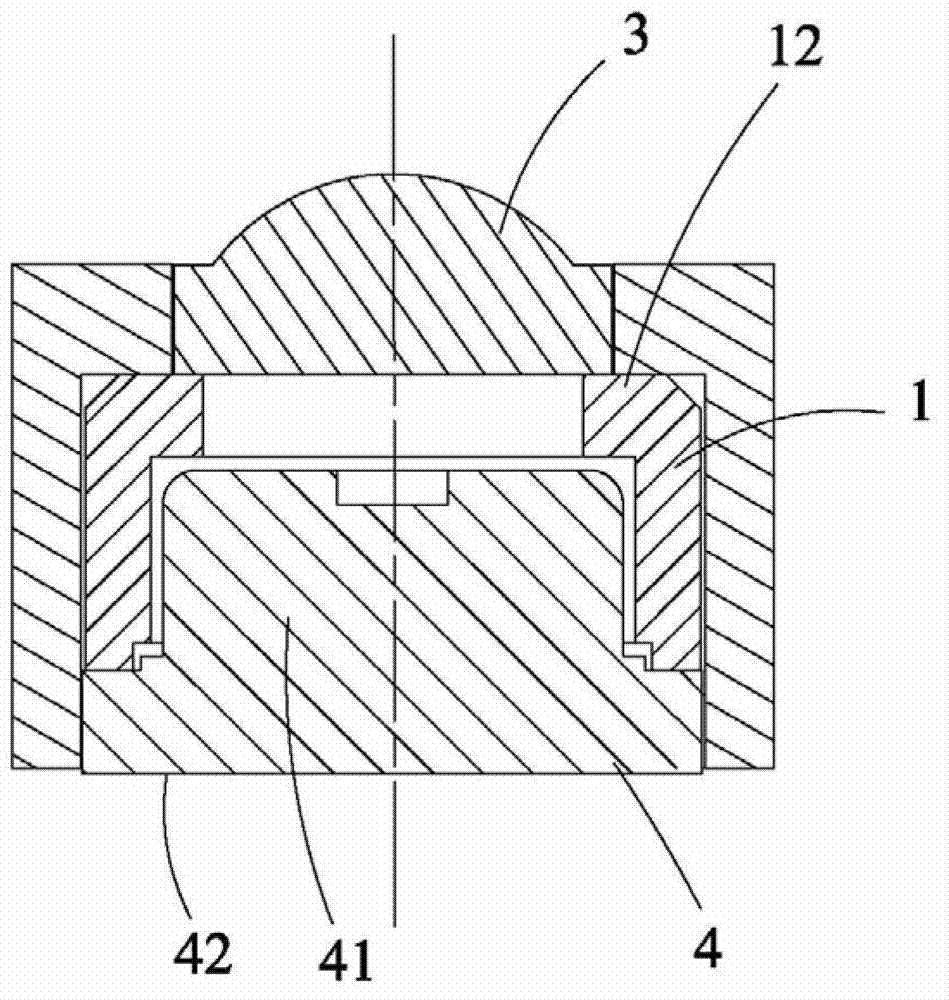

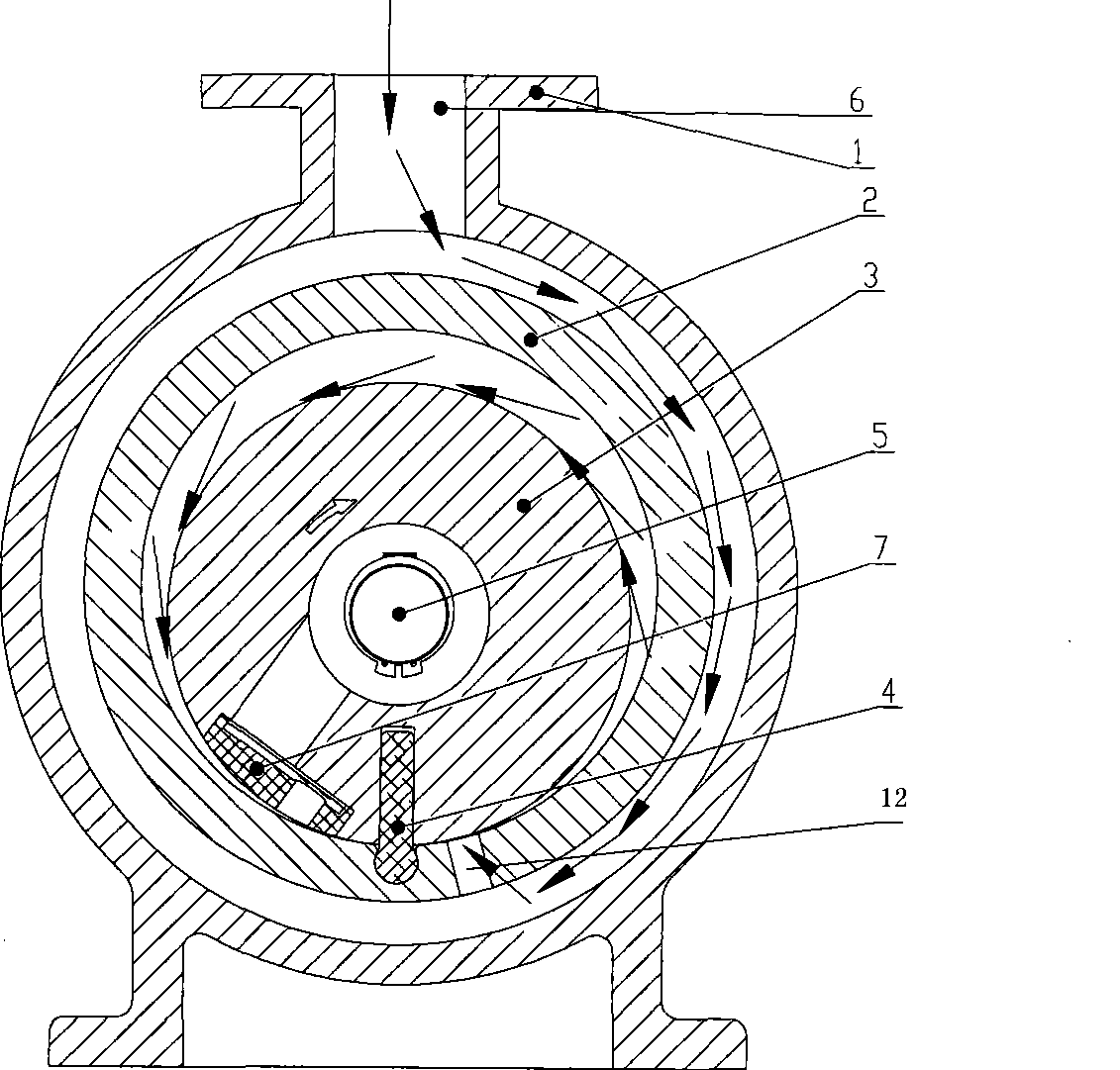

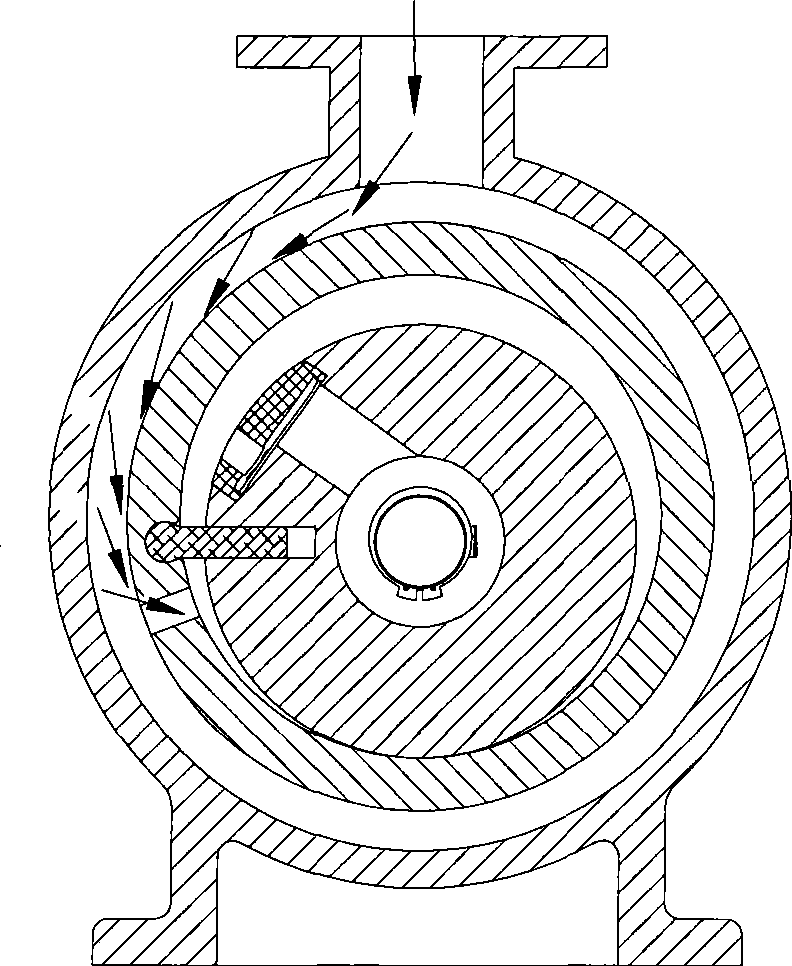

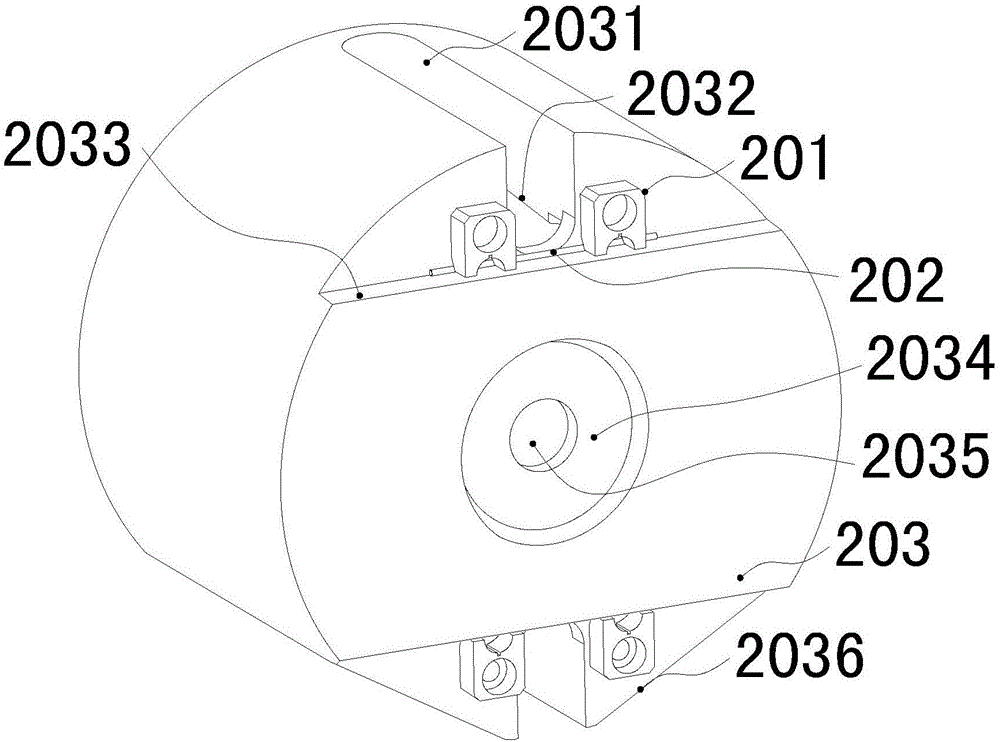

Rotary compressor

ActiveCN101498306AThe machine runs smoothlyReduce flow rateRotary piston pumpsRotary piston liquid enginesCylinder blockEngineering

The invention discloses a rotary type compressor which comprises a shell (1), a cylinder body (2), a rotor (3), a sliding plate (4) and an exhaust valve (7), wherein an air suction hole (6) and an exhaust hole (8) are arranged on the shell (1), rotating central axes of the cylinder body (2) and the rotor (3) are offset into a state that the outer circumferential surface of the rotor (3) is tangential with the inner circumferential surface of the cylinder body (2), the head of the sliding plate (4) is embedded into a cylinder of the cylinder body (2), the main body of the sliding plate (4) extends into a sliding plate groove of the rotor (3), the exhaust valve (7) is arranged on the outer circumference of the rotor (3) and the front of the rotating direction of the sliding plate (4), a cylinder body air inlet (12) which is positioned at the rear of the rotating direction of the sliding plate (4) is arranged on the cylinder body (2), and the sliding plate (4) and an internally tangent point are used for dividing crescent working volume between the inner circumferential surface of the cylinder body (2) and the outer circumferential surface of the rotor (3) into an air inlet cavity and an exhaust cavity.

Owner:DAFENG FENGTAI FLUID MACHINERY TECHNOLOGY CO LTD

Four-stage driving combined type speed reducer and speed reduction method thereof

InactiveCN101761633AImprove machining accuracyReduce the center distanceToothed gearingsGear wheelControl theory

The invention relates to a four-stage driving combined type speed reducer and a speed reduction method thereof. The four-stage driving combined type speed reducer with small teeth difference is a bevel gear-planetary-parallel shaft-four-stage drive with small teeth difference and structurally comprises an input gear pair, a middle planetary gear pair, a parallel shaft gear pair, an output gear pair with small teeth difference, a box body and an end cover. The principle of the speed reduction method of the four-stage driving combined type speed reducer with small teeth difference is that the speed reduction of the speed reducer is realized through a first-stage driving bevel gear drive, a second-stage planetary gear drive, a third-stage driving parallel shaft drive and a fourth-stage driving drive with small teeth difference. The invention has the advantages that the transmission speed ratio and the output torque of the vertical speed reducer are greatly improved, and the bearing capacity and the overload capacity are strong; and the vibration noise is low, the heat dissipation is rapid, the gear machining precision is improved, the machining precision can be ensured easily, the volume and the weight of the entire speed reducer are reduced, the manufacturing cost of the large-power vertical speed reducer is greatly reduced and the production cycle is shortened.

Owner:TIANJIN GENERAL PRINCIPLE MACHINERY NEW TECH

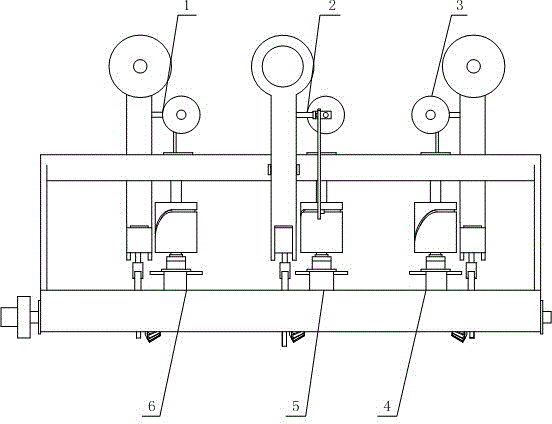

High voltage line patrol robot with single motor to control movement of three arms

ActiveCN104485607AIngenious structureSimple structureApparatus for overhead lines/cablesElectric machineEngineering

The invention relates to a high voltage line patrol robot with a single motor controlling movement of three arms. The high voltage line patrol robot comprises a first mechanical arm fixedly mounted on the left side of the bracket via a left support arm and a right support arm, wherein the first mechanical arm is located right behind a cross beam of the bracket. A second mechanical arm is fixedly mounted in the middle of the bracket via a left support arm and a right support arm and located right ahead the cross beam of the bracket, and a third mechanical arm is fixedly mounted on the right side of the bracket via a left support arm and a right support arm and located right behind the cross beam of the bracket. Disc cams and vertical bevel gears are mounted at the bottom ends of the three mechanical arms, a rotation shaft is fixedly mounted at the bottom of the bracket, a swing motor is mounted at the front end of the rotation shaft, and the disc cams and the vertical bevel gears are concentrically and fixedly mounted on the rotation shaft. The robot has the advantages that the cam move to control the movement of the mechanical arms, the robot can avoid a barrier when encountering the barrier and return to the original position for clamping, and the high voltage line patrol robot is driven by the cams, and has a small number of motors, and good climbing ability.

Owner:武汉科技大学资产经营有限公司

Bridge seamless telescopic device and construction method of device

InactiveCN104594190ASimple structureWell formedBridge structural detailsBridge erection/assemblyWave shapeArchitectural engineering

The invention discloses a bridge seamless telescopic device and a construction method of the device. The bridge seamless telescopic device comprises a main beam span telescopic device and a bridge abutment telescopic device, wherein the main beam span telescopic device comprises a first prefabricated telescopic component and a first telescopic joint filler filling layer; the bridge abutment telescopic device comprises a second prefabricated telescopic component and a second telescopic joint filler filling layer; the first prefabricated telescopic component and the second prefabricated telescopic component are formed by reinforced joint-crossing plates and wave-shaped telescopic plates. A construction method of a telescopic device to be repaired comprises the following steps: cleaning an original bridge telescopic device, constructing a preserved mounting slot, constructing a sliding layer, assembling and mounting prefabricated telescopic components, and constructing telescopic joint filler filling layers. A construction method of a telescopic device to be constructed comprises the following steps: prefabricating and processing prefabricated telescopic components, assembling the prefabricated telescopic components on site, constructing a sliding layer, mounting prefabricated telescopic components, paving a structure and constructing telescopic joint filler filling layers. The bridge seamless telescopic device is reasonable in design, convenient to construct and high in using effect, and can be used for solving various problems of the existing telescopic device.

Owner:XIAN HIGHWAY INST

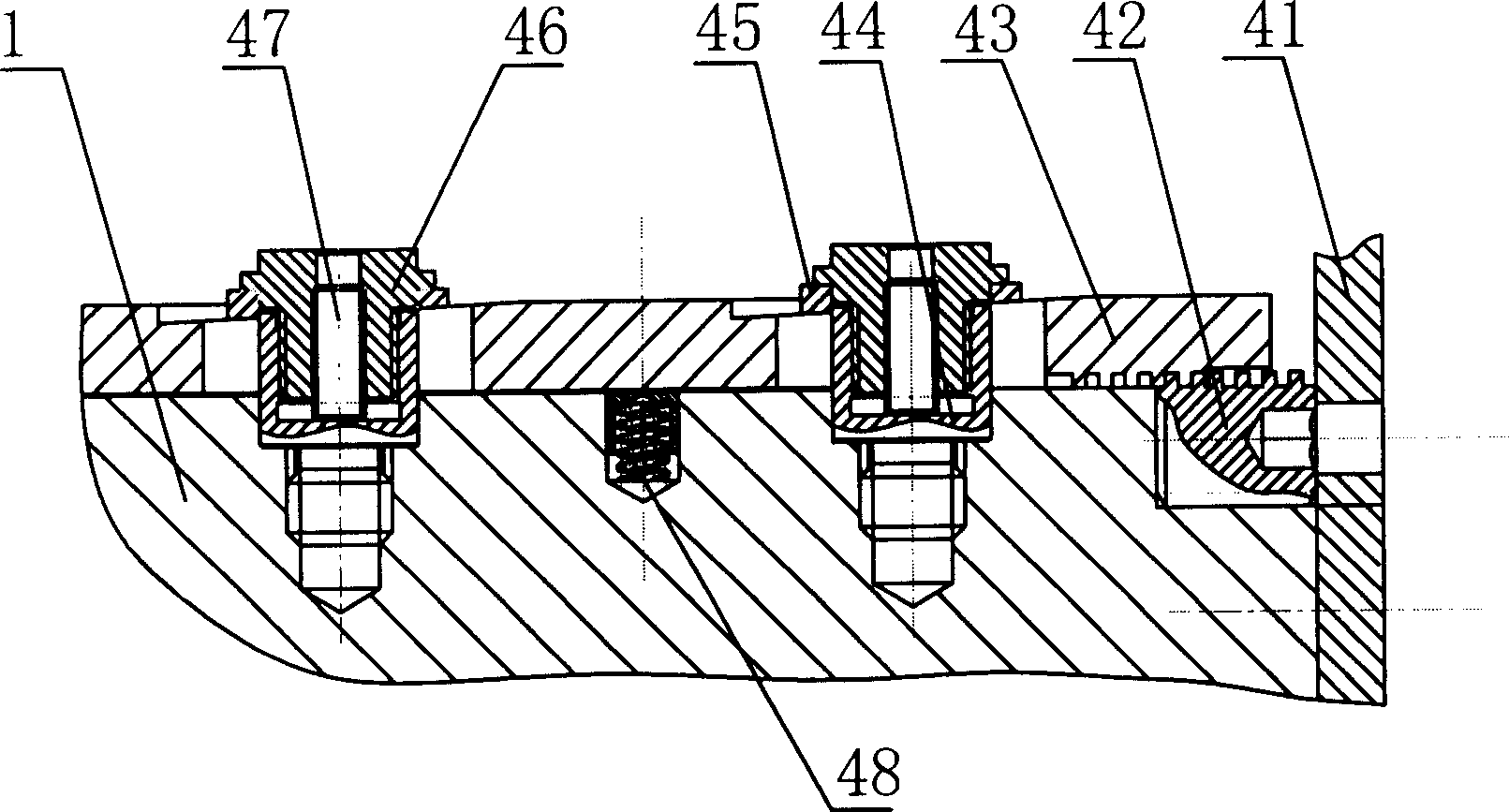

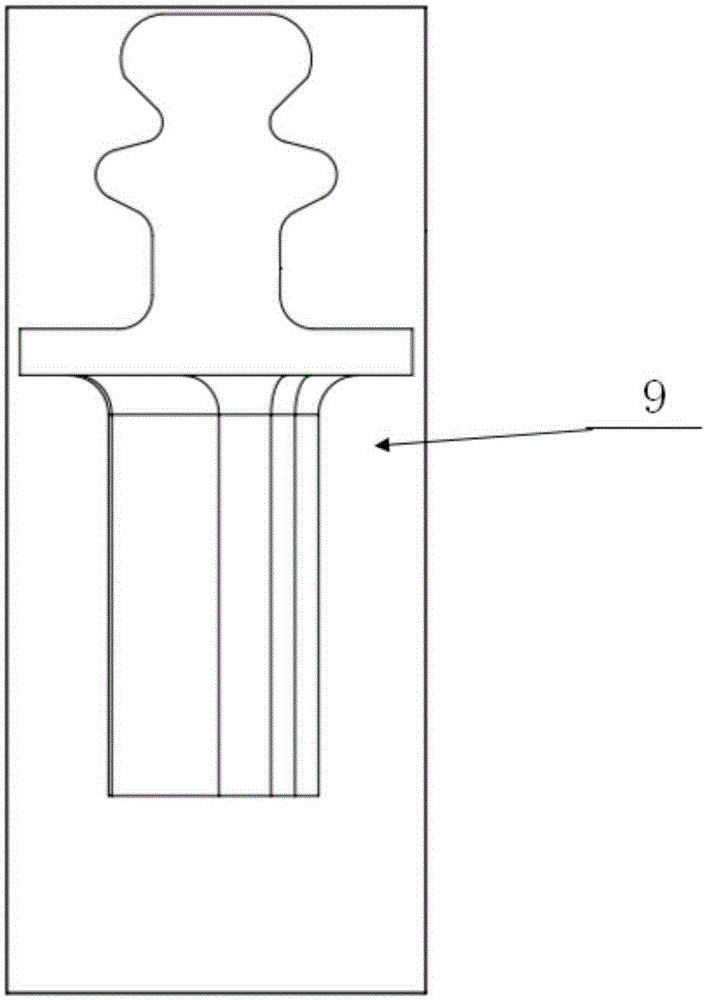

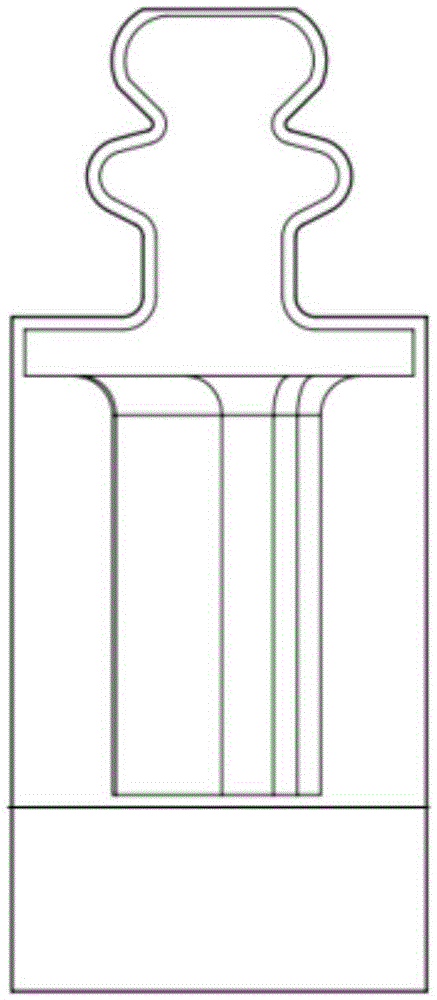

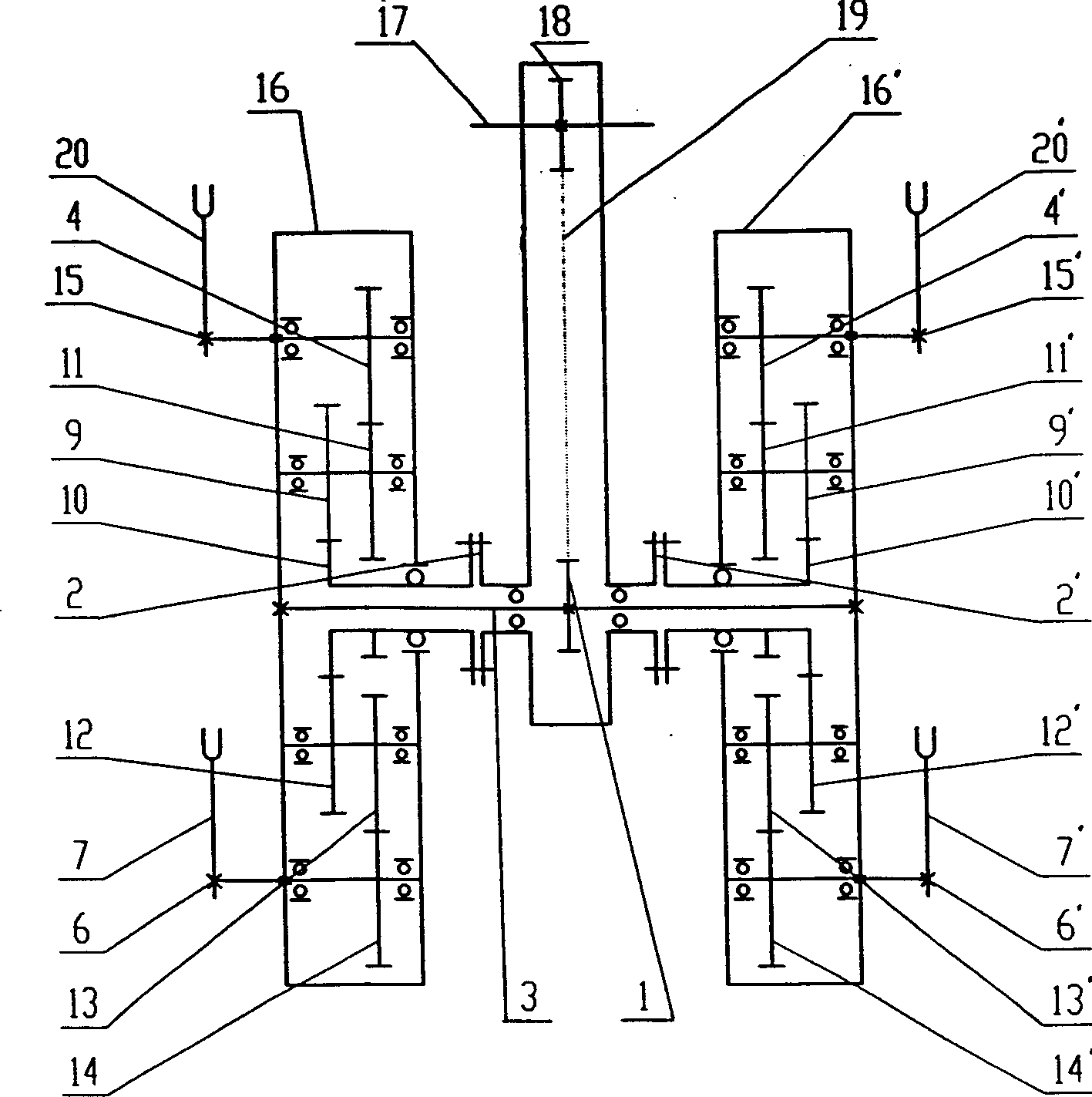

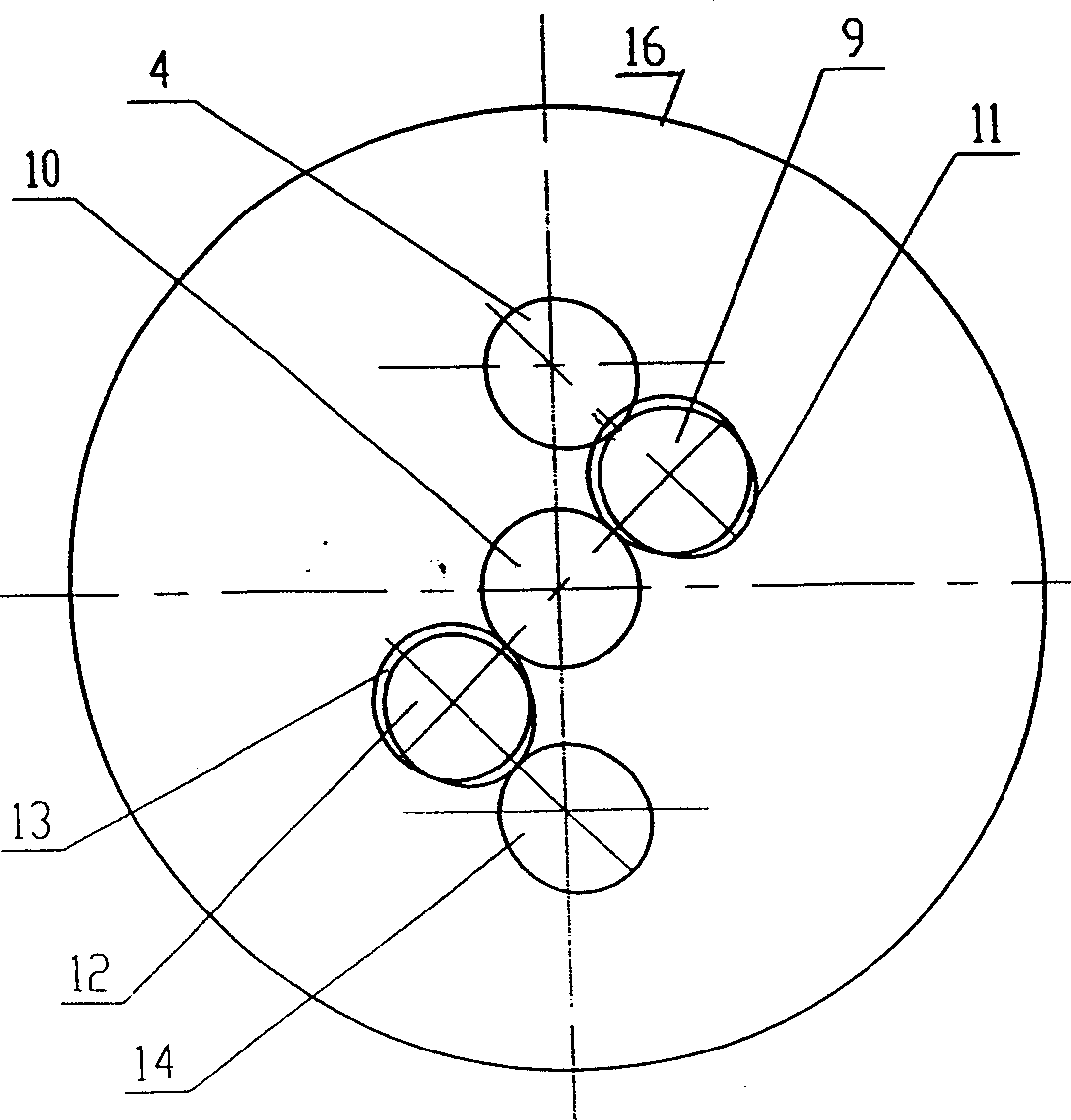

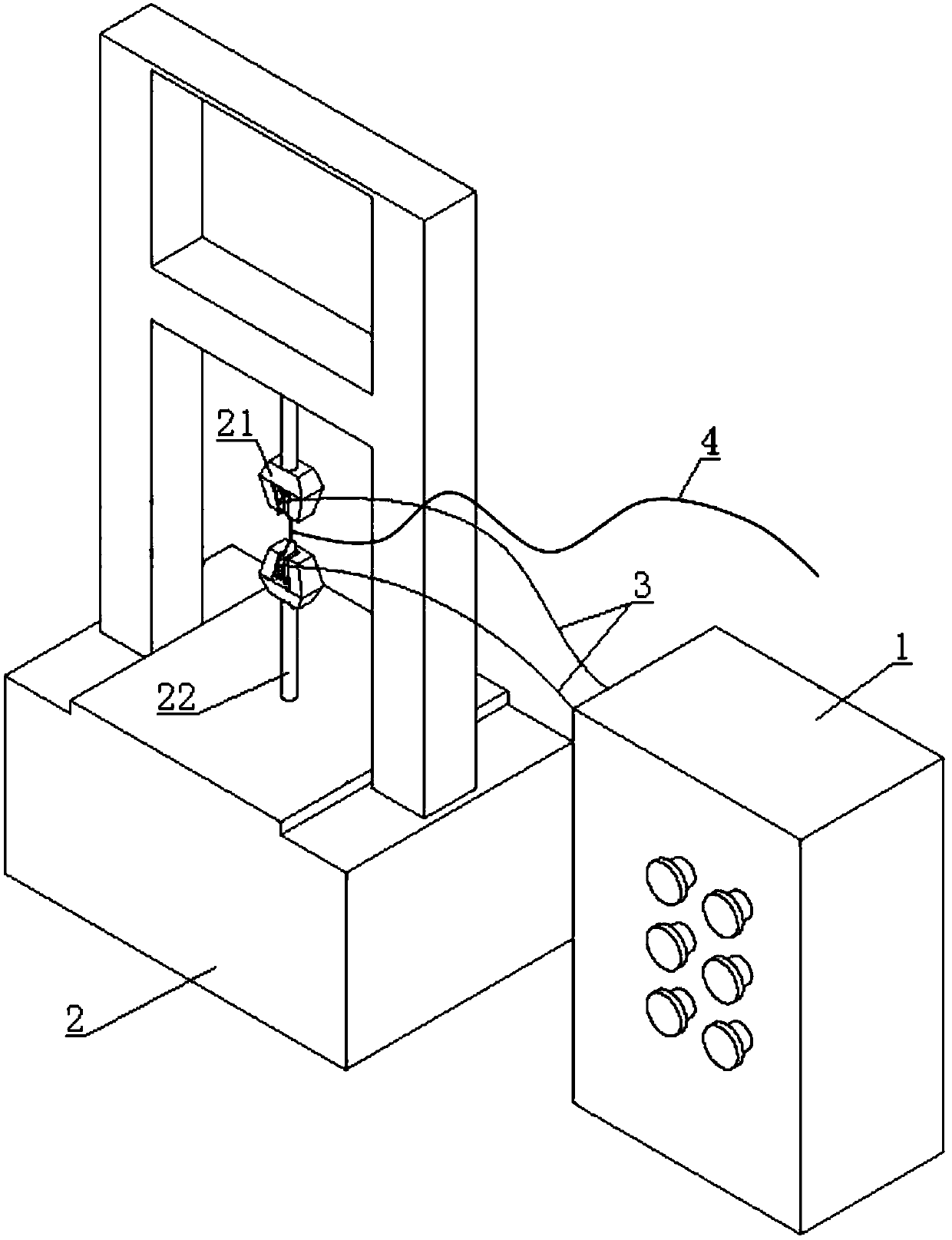

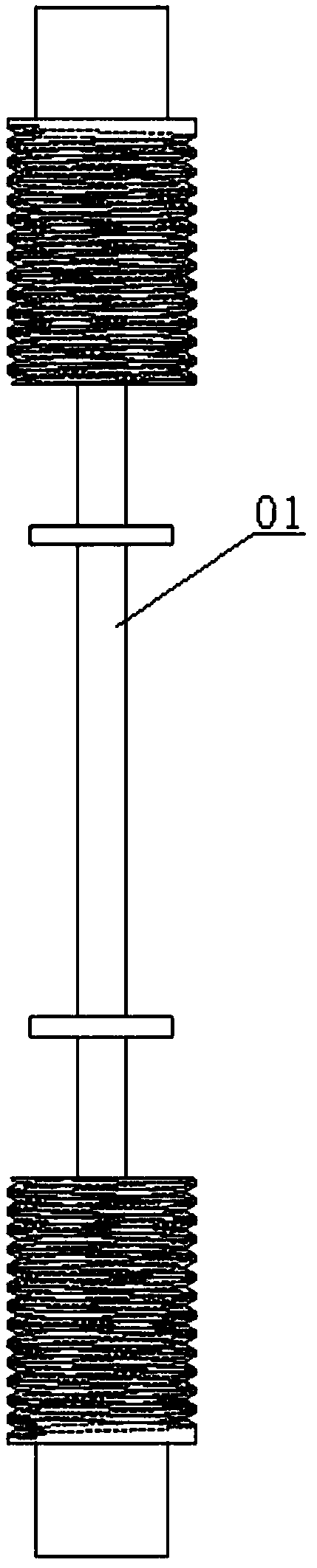

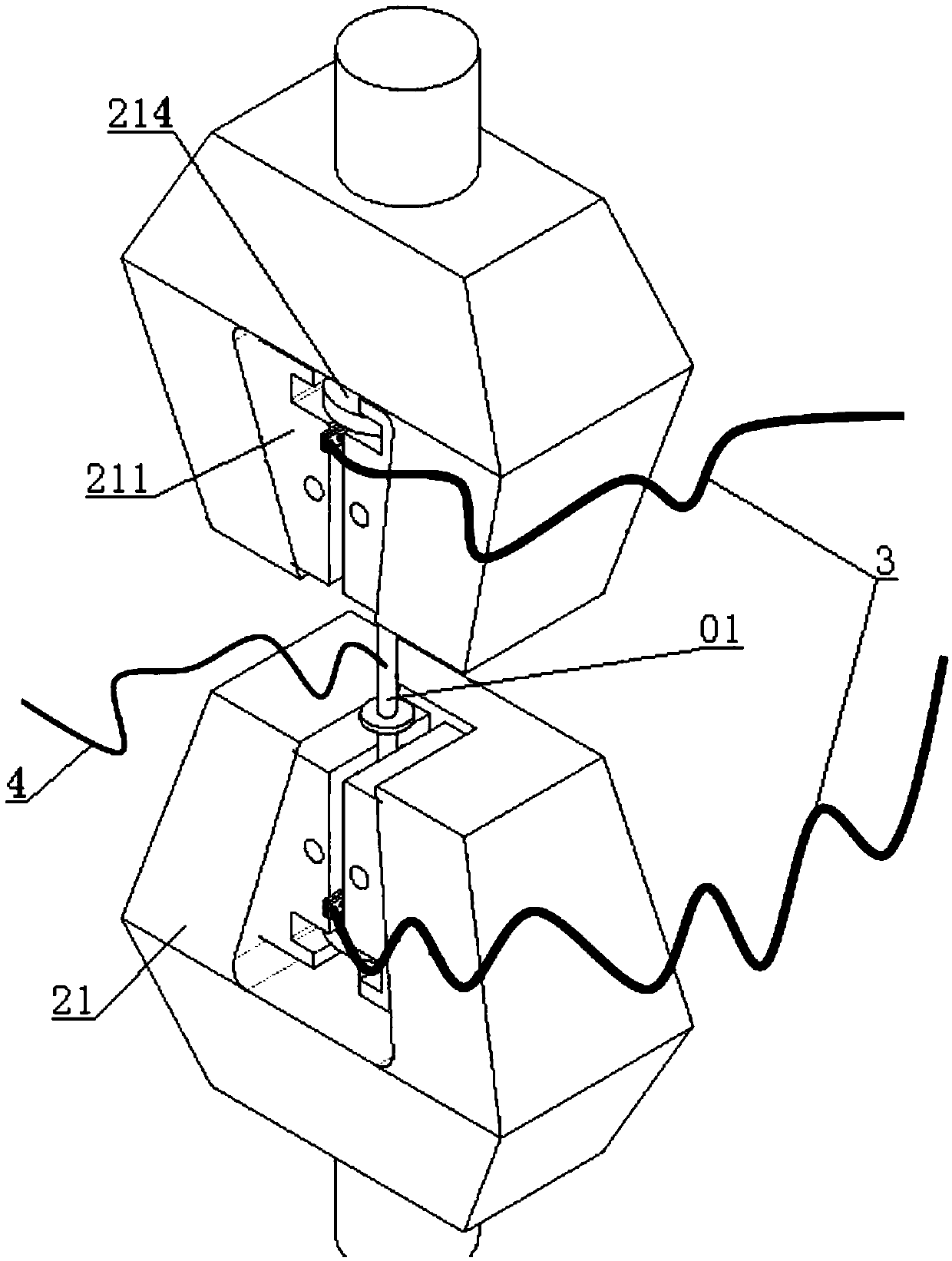

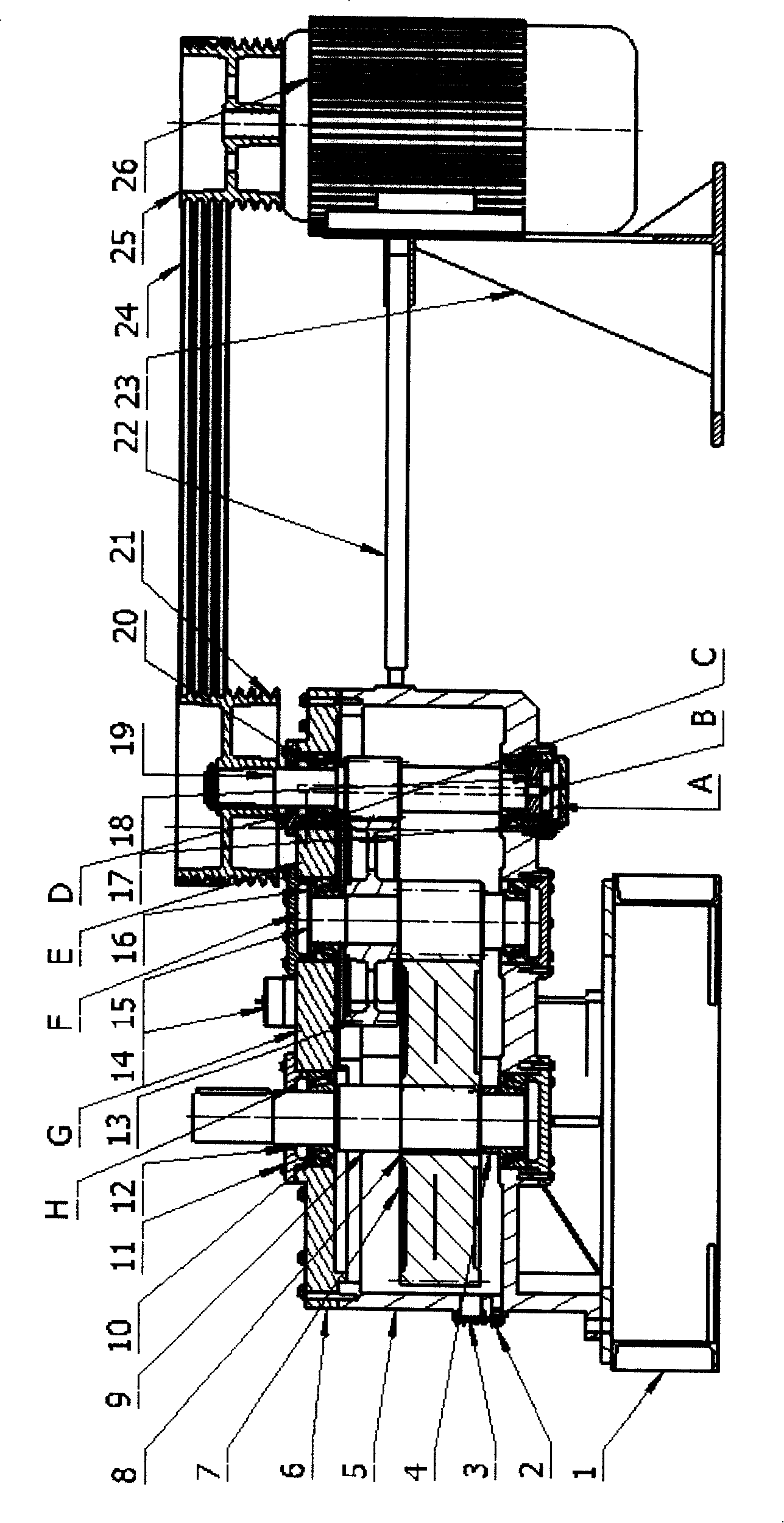

Testing device for assisting rod-shaped sample uniaxial drawing through pulse current

PendingCN107727510ASmall structureReduce joule heatingMaterial strength using tensile/compressive forcesMetallic materialsEngineering

The invention provides a testing device for assisting rod-shaped sample uniaxial drawing through pulse current. The device comprises a pulse power source and a drawing test machine, the drawing test machine comprises drawing clamps and a driving device, the drawing clamps are fixedly connected with the two ends of a rod-shaped sample, the driving device is used for driving the drawing clamps to get close to or away from each other, and the two ends of the rod-shaped sample are provided with conductive rings connected with the positive pole and the negative pole of the pulse power source respectively. Each drawing clamp is provided with a wedged-shaped cavity, wherein the cavity is internally provided with two opposite insulating clamping blocks, the opposite sides of the two insulating clamping blocks are provided with clamping grooves, each clamping groove is internally provided with a positioning clamping block, the opposite sides of the two positioning clamping blocks are provided with positioning grooves used for containing the two ends of the rod-shaped sample and the conductive rings, and knurled anti-skid structures are arranged on the contact surfaces of the positioning grooves and the rod-shaped sample. The device is suitable for research of deformation behaviors of rod-shaped metal materials under the action of the pulse current, processing of the sample is facilitated, material waste is avoided, and joule heat generated at the joints is reduced.

Owner:CENT SOUTH UNIV

Main unit transmission device for ultra-fine pendulum powder mill

InactiveCN101195103ASmooth transmissionReduce manufacturing costGear lubrication/coolingToothed gearingsLow noiseEngineering

The invention discloses a driving device for a host machine, which is used for an ultra-fine pendulum type miller. The invention adopts a vertical shaft type reducing box, and one or two cylinder helical gears of horizontal engaging drives which are used to carry out speed reductions are installed inside the reducing box. The invention has simple structure, low cost, stable driving and low noises.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

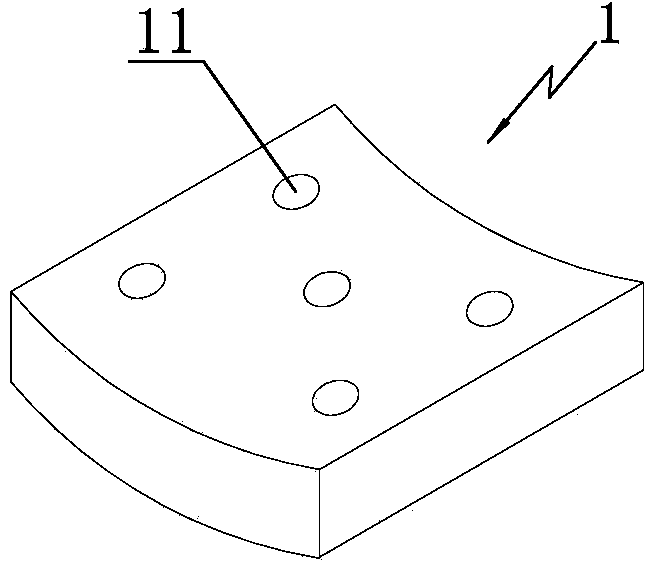

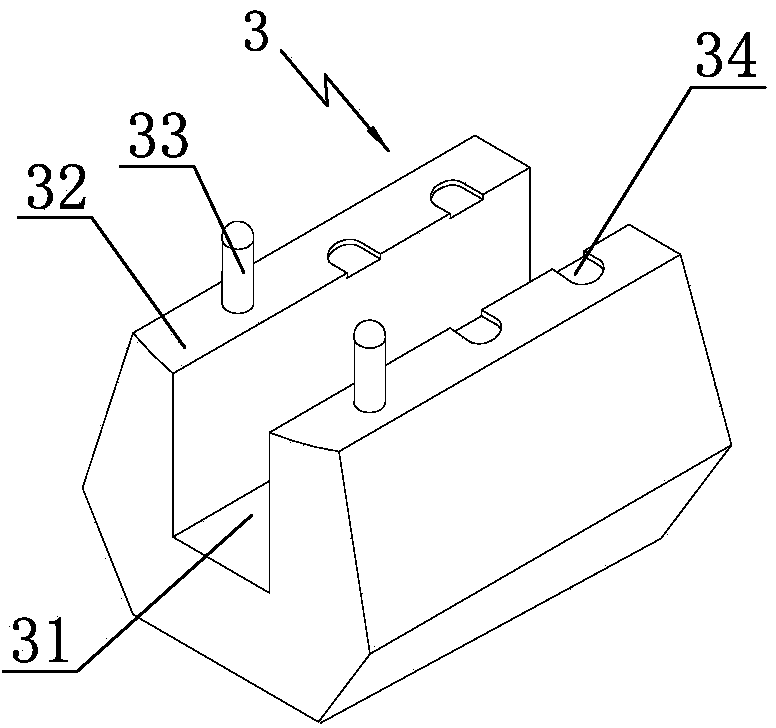

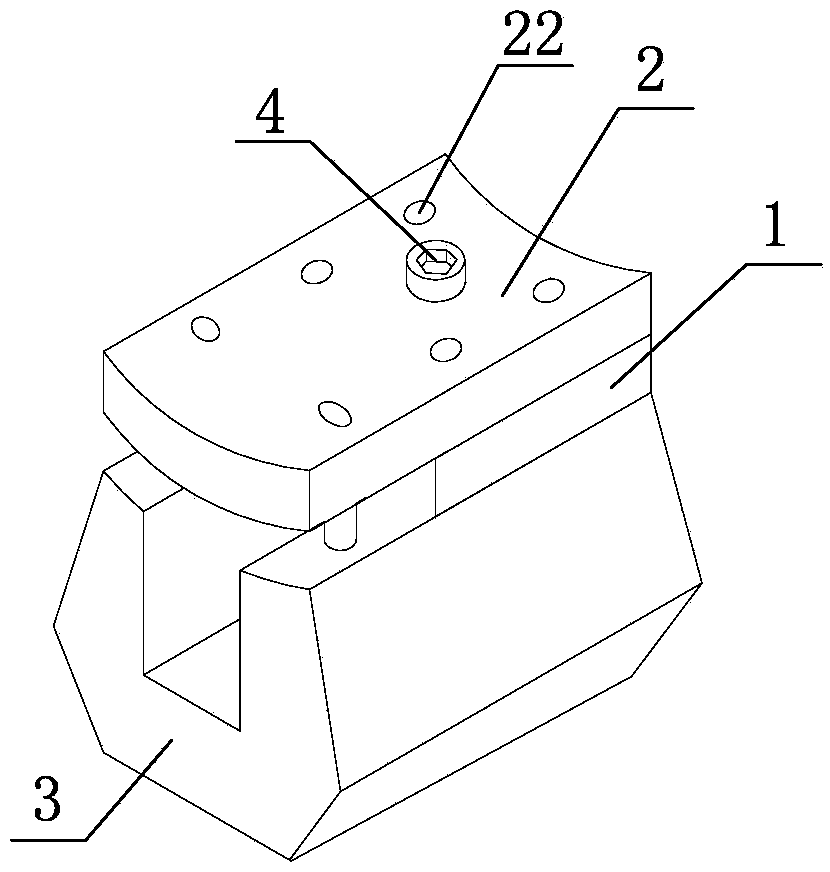

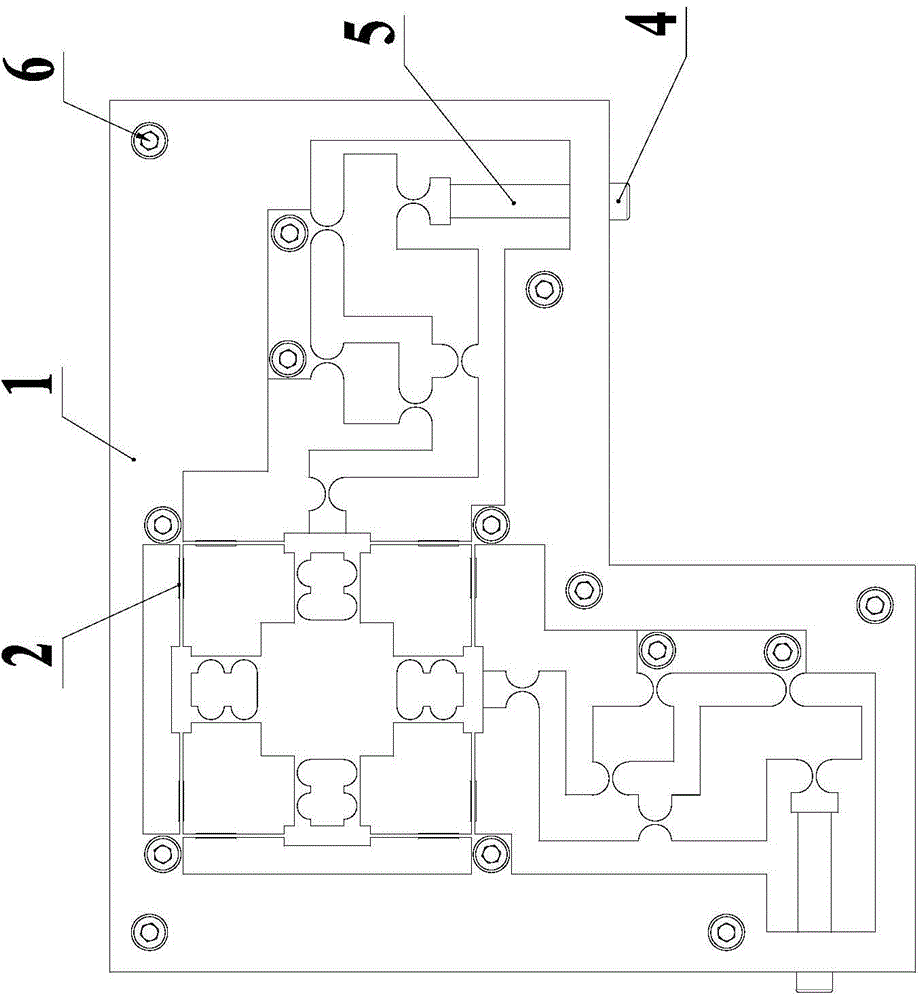

Arc-shaped plate drilling positioning device

The invention relates to an arc-shaped plate drilling positioning device which comprises an upper die and a lower die. The front and back surfaces of the upper die are cambered surfaces. Four drilling holes are evenly formed in the upper die. The positions of the four drilling holes are identical with those of the four holes in a workpiece. A screw hole and positioning holes are formed in the upper die. A U-shaped positioning groove is formed in the lower die. The top surfaces on two sides of the positioning groove are arc-shaped, the radian of the top surfaces is identical with that of the lower cambered surface of the workpiece, and each top surface is provided with a positioning pin and blanking grooves. Threaded holes are formed at the bottom of the positioning groove. The arc-shaped plate drilling positioning device is simple in structure, flexible and convenient to use, simple in clamping, and high in machining precision.

Owner:WUXI HANGHU TECH

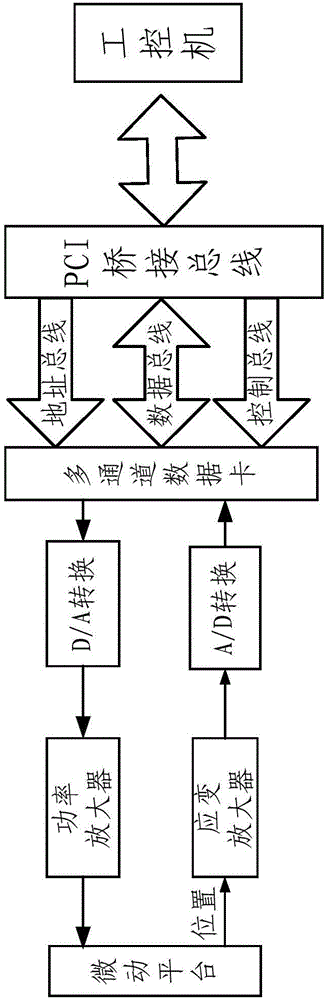

Piezoelectric micro-platform capable of amplifying based on flexible hinge

ActiveCN104925738AReduce volumeNo mechanical frictionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringHinge point

The invention discloses a piezoelectric micro-platform capable of amplifying based on a flexible hinge. The piezoelectric micro-platform comprises a frame and a carrier platform, wherein a micro-driver and an amplifying mechanism are arranged on the frame; the amplifying mechanism is a double-rocker mechanism; an extension section is arranged on one end, which is far away from a connecting rod, of a driving rocker of the double-rocker mechanism, and a free end of the extension section of the driving rocker supports the micro-driver; the driving rocker and the extension section thereof form an amplifying lever with a hinge point of the driving rocker and the frame as a pivot; an extension section is arranged on one end of the connecting rod, which is far away from the driving rocker; the carrier platform is connected to a decoupling mechanism, the decoupling mechanism is formed by at least one pair of decoupling units, and the two decoupling units are symmetrical around the center of the carrier platform; each decoupling unit is formed by a connecting arm and a pair of flexible arms, one end of each flexible arm is hinged to the frame, the other end of each flexible arm is hinged to the connecting arm, and the other end of the connecting arm is hinged to the carrier platform; the extension section of the connecting rod is hinged to any one decoupling unit. The piezoelectric micro-platform has the advantage that the driving displacement of the micro-driver can be amplified.

Owner:NINGBO UNIV

Jacking system for closure section of continuous rigid frame bridge and jacking deviation rectifying method

The invention discloses a jacking system for a closure section of a continuous rigid frame bridge and a jacking deviation rectifying method. The jacking system is composed of a top plate jacking system and a bottom plate jacking system. The top plate jacking system comprises two sets of top plate embedded bases arranged at the ends of two cantilever beam sections of the continuous rigid frame bridge correspondingly, top plate rigid supporting structures supported between the two sets of top plate embedded bases and a top plate jacking mechanism. The bottom plate jacking system comprises two sets of bottom plate embedded bases arranged at the ends of the two cantilever beam sections correspondingly, bottom plate rigid supporting structures supported between the two sets of bottom plate embedded bases and a bottom plate jacking mechanism. The jacking deviation rectifying method comprises the steps of (1) measurement of position deviation of the cantilever beam sections, (2) adjustment of elevation deviation of the cantilever beam sections, (3) deviation rectifying adjustment and (4) longitudinal jacking. The jacking system is simple in structure, reasonable in design, easy and convenient to construct and good in using effect, the jacking deviation rectifying process of the cantilever beam sections on the two sides of the closure section can be completed easily, conveniently and rapidly, and the rectifying requirements of lateral deviation and reverse deviation of the cantilever beam sections can be met.

Owner:XIAN HIGHWAY INST

Disassembling C type arm alignment target

A detachable C shape arm alignment target in medical engineering field comprising a template assembly, a body frame and a weight balance member, wherein the template assembly consists of a template body employing steel balls to occlude the precision blind holes on an organic glass plate and a hoop frame for connecting the template and the main frame, the body frame is designed as a hollow cylinder structure, on the upper, lower and external surface of which infrared reflective beads are arranged according to NDI independent tool design rule. The alignment template assembly and assembled body frame can not only be used for on-line alignment but also for off-line alignment system initialization period, the weight balance member and the assembled body frame may be used in usage period of off-line alignment. The body frame and the hoop frame blank are forged by aluminium material, the body frame, hoop frame refined-machining, template and other parts employs digital control equipment for processing. The novel alignment target has low cost, high accuracy and dual purposes.

Owner:SHANGHAI JIAO TONG UNIV

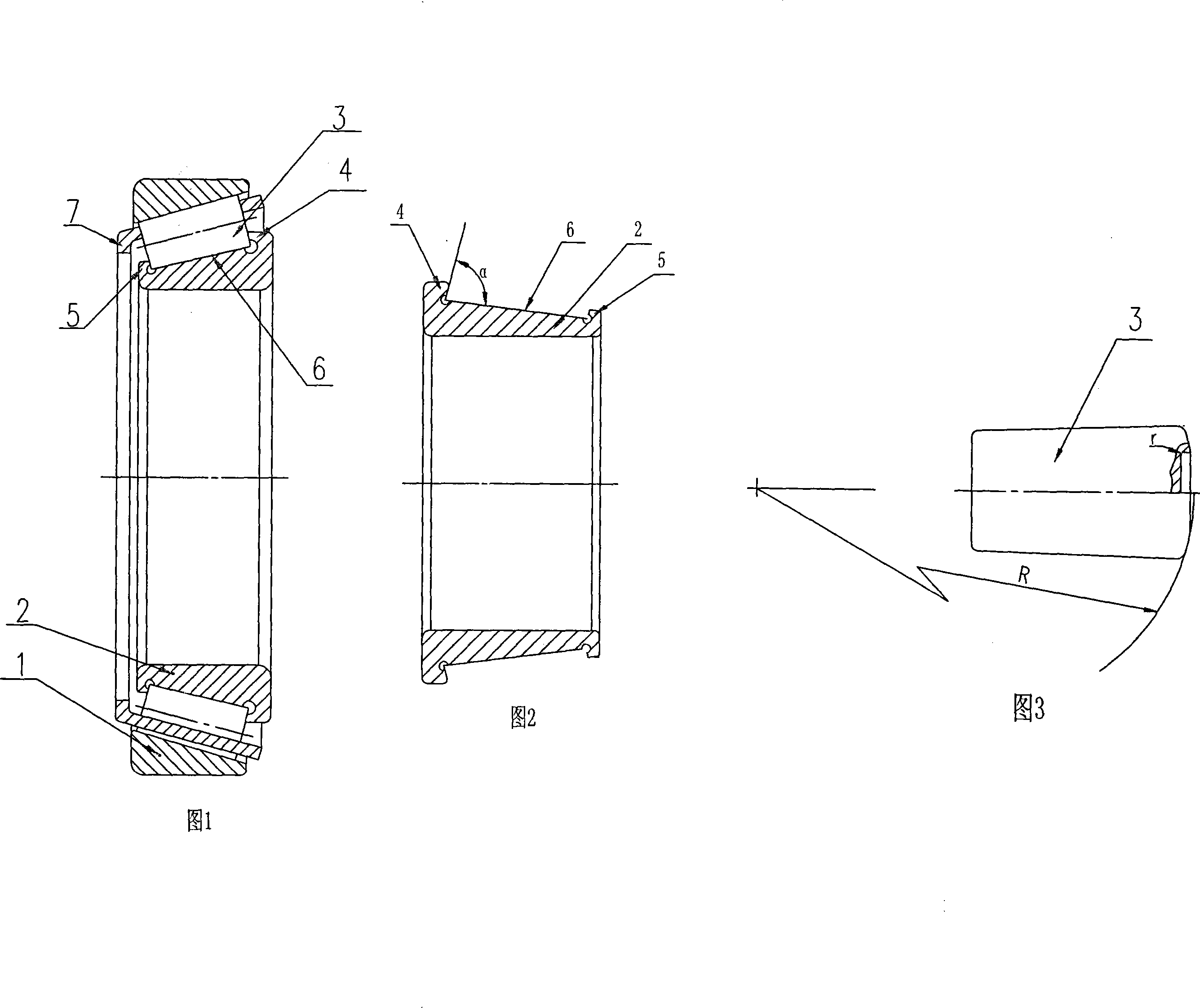

Method for realizing conical roller bearing low friction and structure thereof

InactiveCN101158371AReduce the number of touch pointsImprove contact conditionsRoller bearingsShaftsRetaining ringEngineering

The invention discloses a method and a structure of a taper roller bearing low friction. The invention causes the angle between a large retaining ring of the taper roller bearing and a raceway generatrix more than 90 DEG and reduces the ball diameter of the sphere at one end of the taper roller, meanwhile, the invention implements the object that the contact between the taper roller sphere and the large retaining ring is changed from crossed multi-point contact into slippery one-point contact; meanwhile, the invention presents the angle range is 90 DEG-93 DEG; furthermore, the ball diameter complies with the specific requirement of 40%-80% of the stipulated value of the existing drawing of the products. The invention is beneficial for reducing the friction, reducing the abrasion between the large retaining ring and the sphere and implementing the high-speed heavy loading of the taper roller bearing.

Owner:张荣发

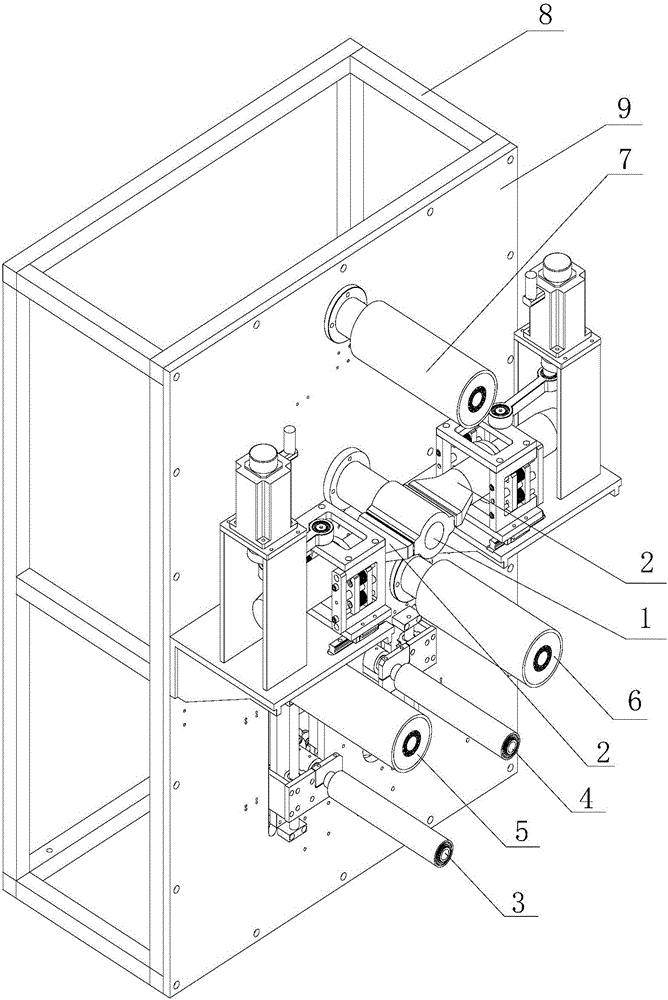

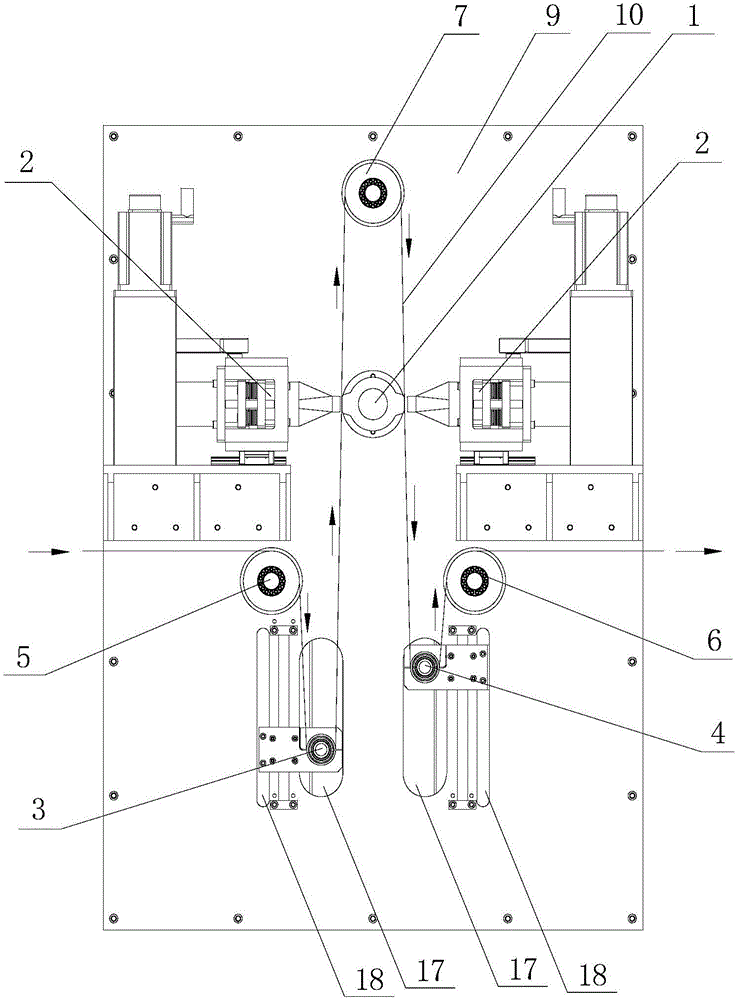

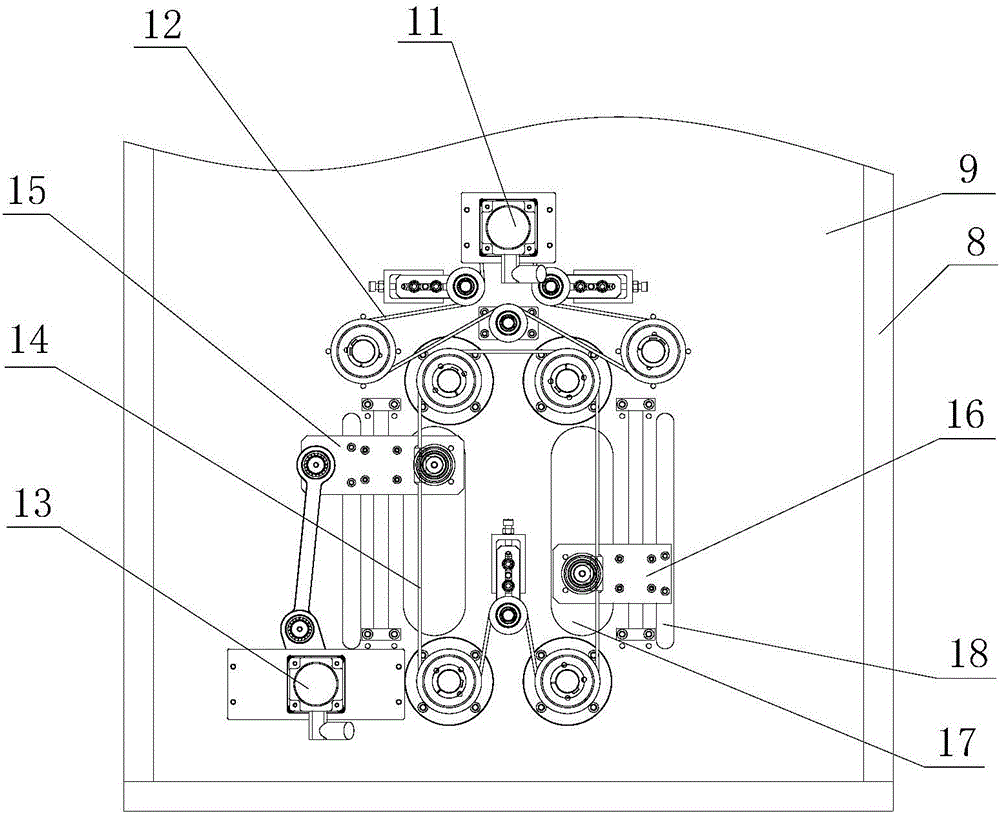

Ultrasonic sealing-pressing device and method

InactiveCN105943248ASimple structureReduce labor intensityAbsorbent padsBaby linensMechanical engineeringUltrasound

The invention discloses an ultrasonic sealing-pressing device and an ultrasonic sealing-pressing method. The ultrasonic sealing-pressing device comprises a support frame, an anvil roller, two groups of ultrasonic devices and one group of material conveying device, wherein the anvil roller, the ultrasonic devices and the material conveying device are respectively arranged on the support frame, the two groups of ultrasonic devices are symmetrically arranged on the two sides of the anvil roller, and a strip material product is placed on the material conveying device. The ultrasonic sealing-pressing method comprises the steps that the material conveying device continuously conveys the strip material product, when the sealing-pressing position of the strip material product reaches the anvil roller, a first floating roller and a second floating roller carry out vertical movement in contrary directions, so that the strip material product positioned above the first floating roller and the second floating roller is in a relatively static state, and the anvil roller and the ultrasonic devices on the two sides of the anvil roller carry out sealing-pressing on the strip material product. The ultrasonic sealing-pressing device is simple in structure, the processing precision for the strip material product can be easily guaranteed, the structure of the device is simplified, and meanwhile, the production and manufacturing costs are effectively reduced.

Owner:GUANGZHOU XINGSHI EQUIPS

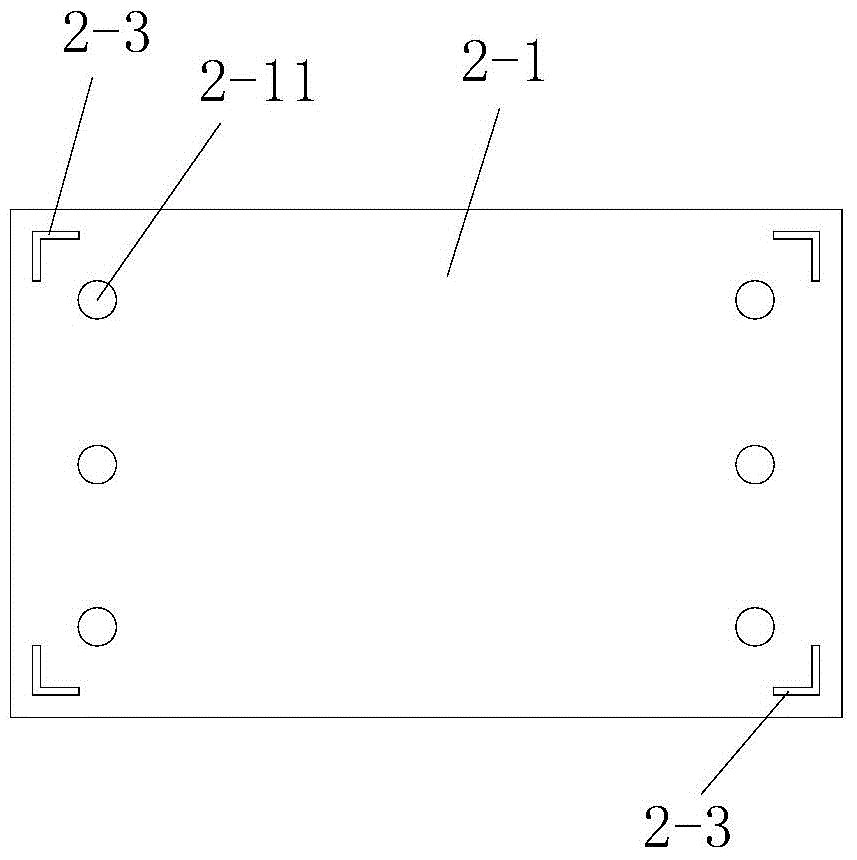

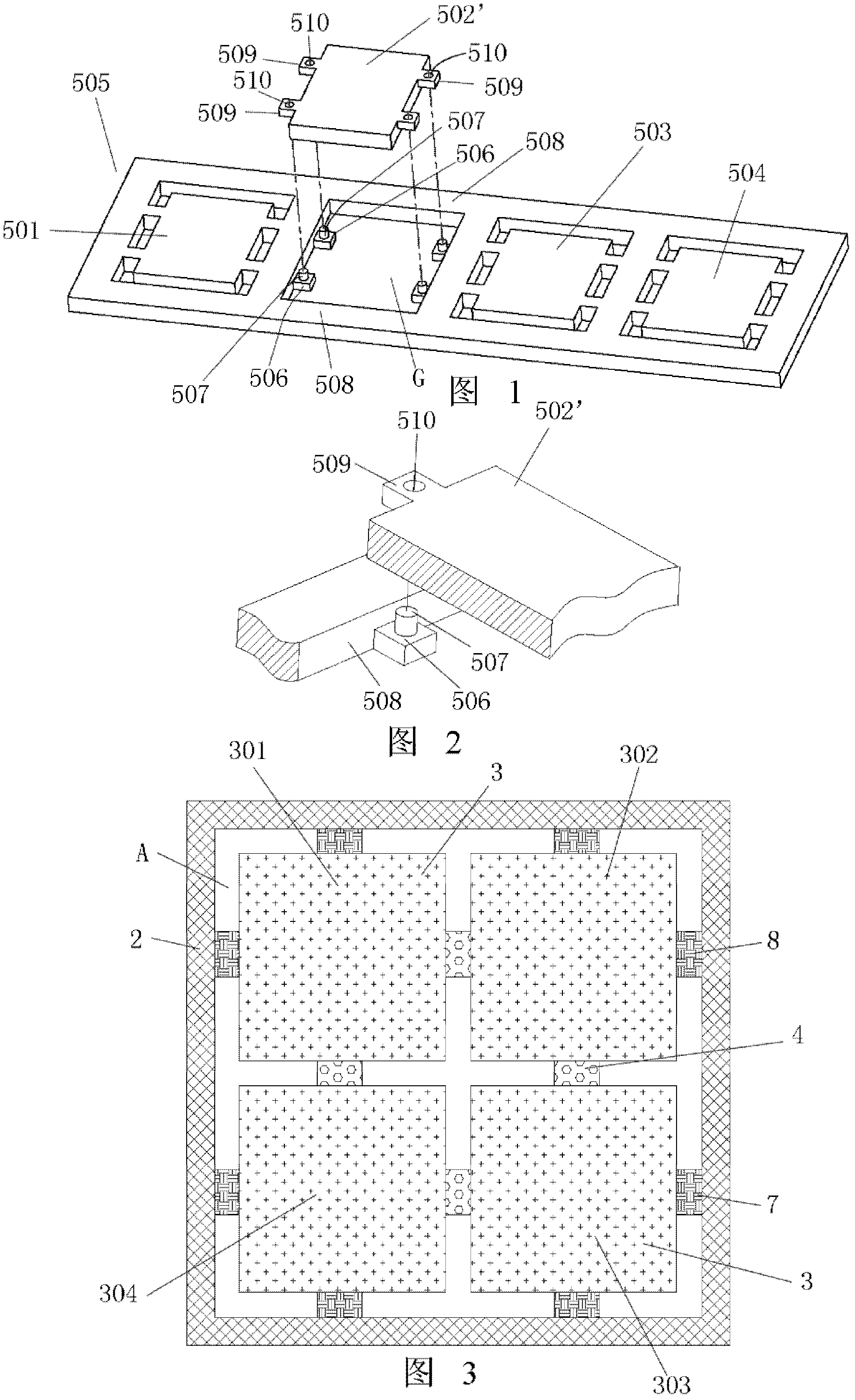

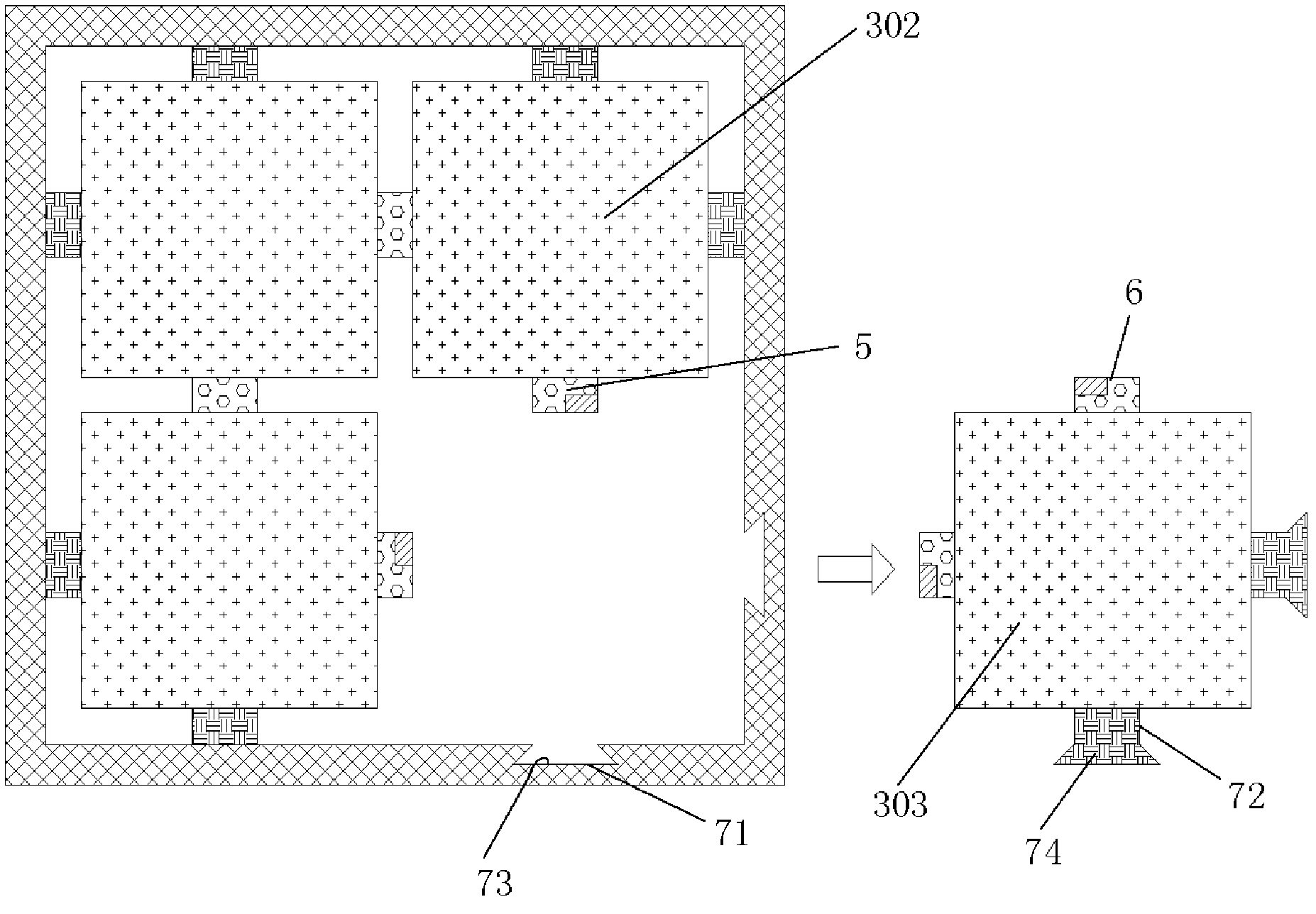

Multichip typesetting substrate and manufacturing method thereof

ActiveCN103025056AImprove connection strengthLimit thicknessPrinted circuit assemblingPrinted circuits structural associationsEngineeringUltimate tensile strength

Owner:IBIDEN ELECTRONICS BEIJING

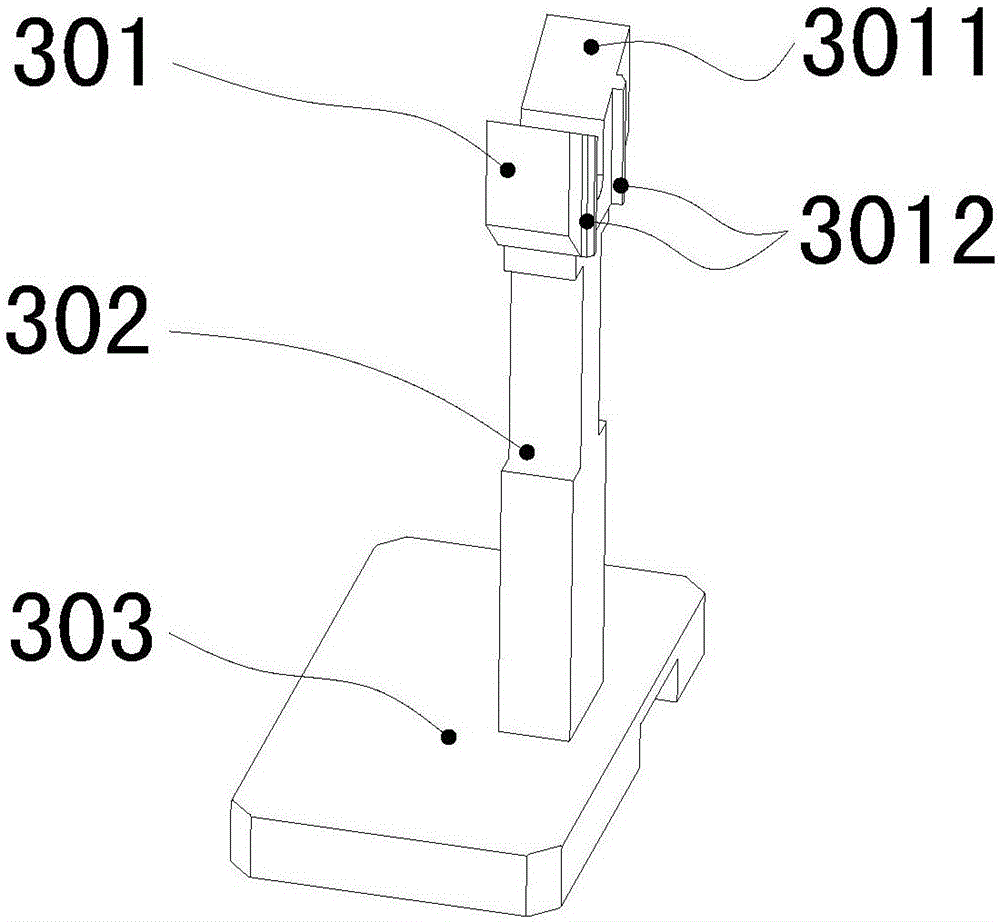

Long-pipe taper thread measurement device, taper plug gauge clamp and taper ring gauge clamp

ActiveCN106403756AHigh measurement accuracyMachining accuracy is easy to guaranteeAngles/taper measurementsMeasurement deviceEngineering

The present invention discloses a long-pipe taper thread measurement device, a taper plug gauge clamp and a taper ring gauge clamp. The measurement device of the long-pipe tape thread comprises a support platform and a measurement mechanism, and also comprises a first support clamp, a second support clamp, a first taper sleeve clamp and a second taper sleeve clamp. A standard is installed on the first taper sleeve clamp and the second tape sleeve clamp, the first taper sleeve clamp is installed on an outer taper thread, and the second taper sleeve clamp is installed on an inner taper thread to allow the standard to fix with the outer taper sleeve thread and the inner taper sleeve thread; and the first support clamp and the second support clamp are installed on the support platform for measurement, and the location of the outer taper thread and the inner taper thread are completed at one time to avoid the installation location error caused by installing the standard at first and then installing the long taper tube. The long-pipe taper thread measurement device can realize measurement through one-time installation, so that the measurement precision of the measurement device is high and the measurement is simple and convenient.

Owner:CHOTEST TECH INC

Constant-force-adjustable multi-freedom-degree flexible micro-gripper

ActiveCN108312086AAchieve constant force outputChange intensityWork holdersMicro-operationConstant force

The invention provides a constant-force-adjustable multi-freedom-degree flexible micro-gripper. The constant-force-adjustable multi-freedom-degree flexible micro-gripper comprises a micro-gripping unit; the micro-gripping unit comprises a gripping component and a freedom degree regulating component; the gripping component is installed on the freedom degree regulating component and can move in theup-down direction, the left-right direction and the front-back direction under the driving of the freedom degree regulating component; the gripping component is connected with the freedom degree regulating component through a connecting block; the freedom degree regulating component is fixed to an abnormal-surface pedestal through a substrate, and thus the freedom degree regulating component moving in different directions is different in installation directions on the abnormal-surface pedestal. The constant-force-adjustable multi-freedom-degree flexible micro-gripper provided by the inventionrealizes constant-force output and constant-force adjustability of the micro-gripping unit, and simultaneously makes the gripper have a plurality of freedom degrees. The constant-force-adjustable multi-freedom-degree flexible micro-gripper provided by the invention is small in structure weight, convenient to operate and applicable to a micro-operation robot system and a micro-electromechanical system.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com