Disassembling C type arm alignment target

A ring-shaped and template technology is applied in the field of devices in the field of medical engineering technology, which can solve the problems of large influence of navigation precision machining and installation precision, high manufacturing cost, and difficulty in guaranteeing precision, and achieves easy guarantee of machining precision, simple structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

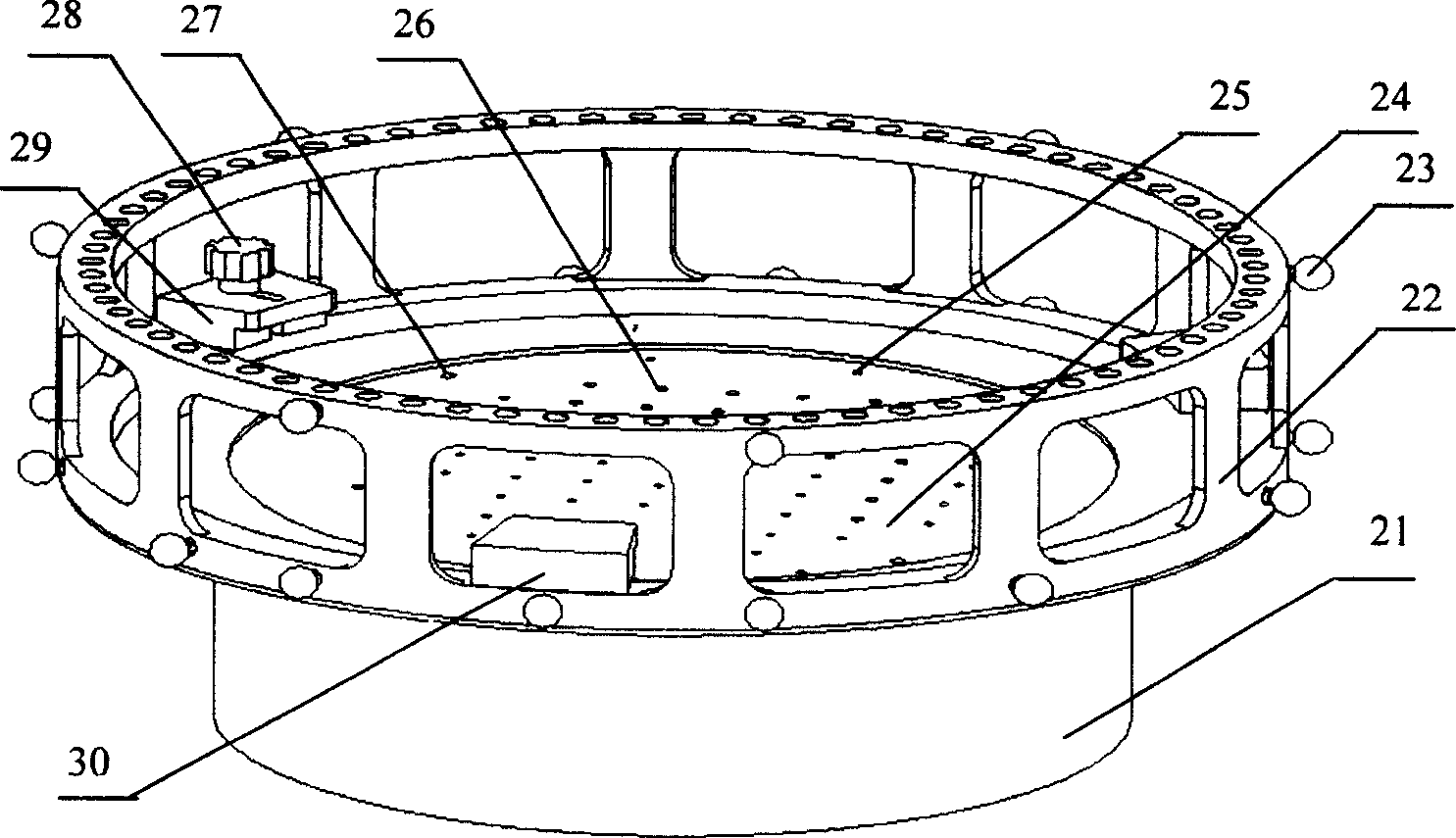

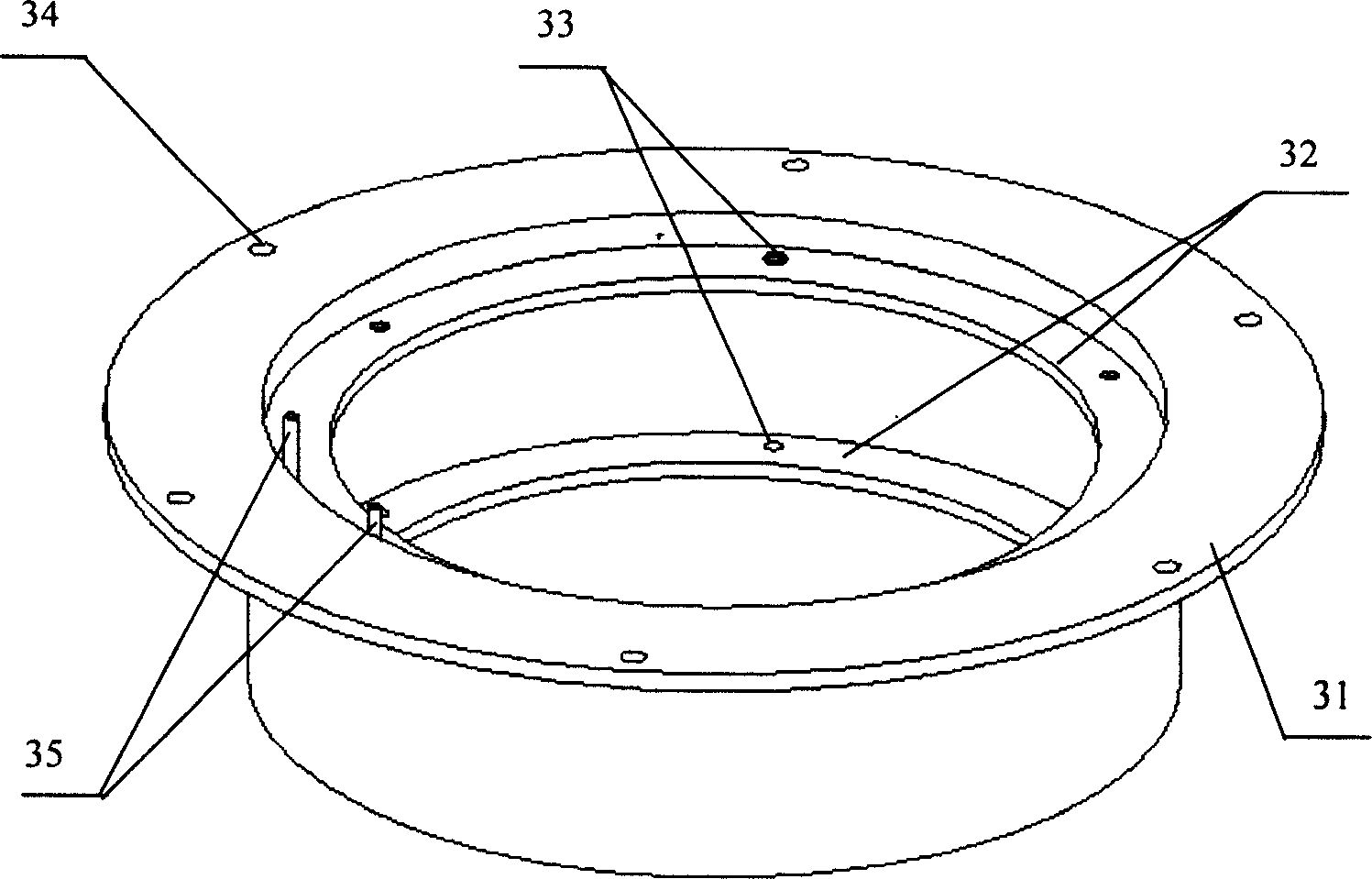

[0021] Such as figure 1 As shown, the calibration target of the present invention is composed of two major parts: a removable main body frame and a calibration template assembly. Calibration template matrix (the lower calibration template matrix is not visible in this figure, see the lower calibration template matrix for details Figure 5 ), positioning pin 25, steel ball 26, set screw 27, locking screw 28, movable positioning claw 29, fixed positioning claw 30.

[0022] Among them, the drum-shaped structure 22, the infrared reflective ball 23, the locking screw 28, the movable positioning claw 29, and the fixed positioning claw 30 belong to the composition of the main body frame, and the fixed positioning claw 30 is fixed on the upper end surface of the lower edge of the drum-shaped structure 22 by screws. Above, the locking screw 28 passes through the groove on the movable positioning claw 29 and is screwed on the upper end surface of the lower edge of the drum-shaped str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com