Four-stage driving combined type speed reducer and speed reduction method thereof

A technology of four-stage transmission and reducer, which is applied to transmission devices, gear transmission devices, mechanical equipment, etc., can solve the problems of weak load-bearing capacity, high manufacturing cost, and influence on popularization and application, and achieve strong load-bearing and overload capacity and improved Gear ratio and output torque, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

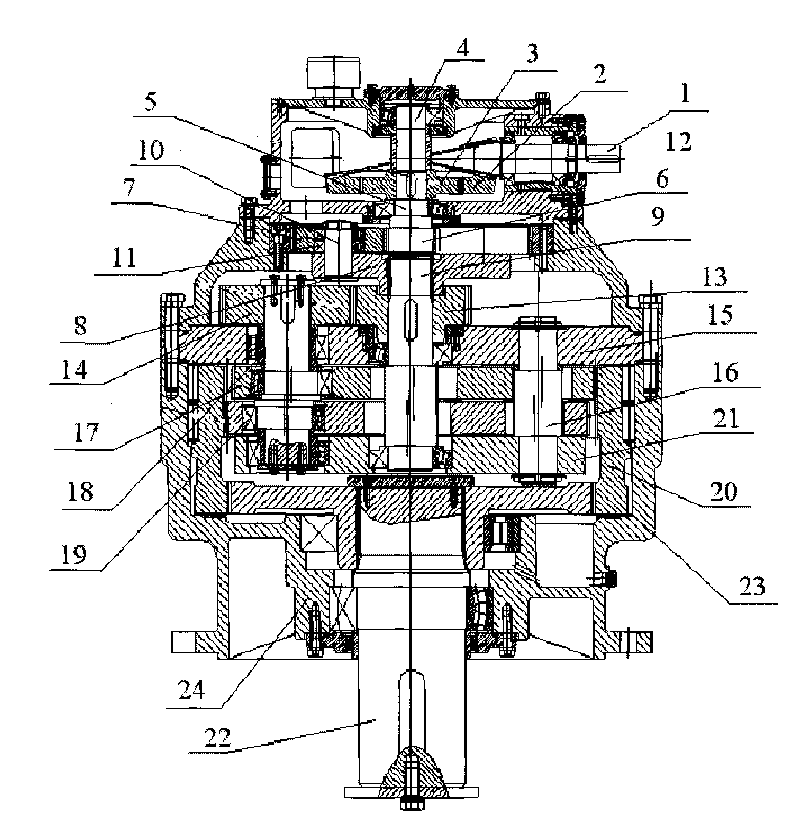

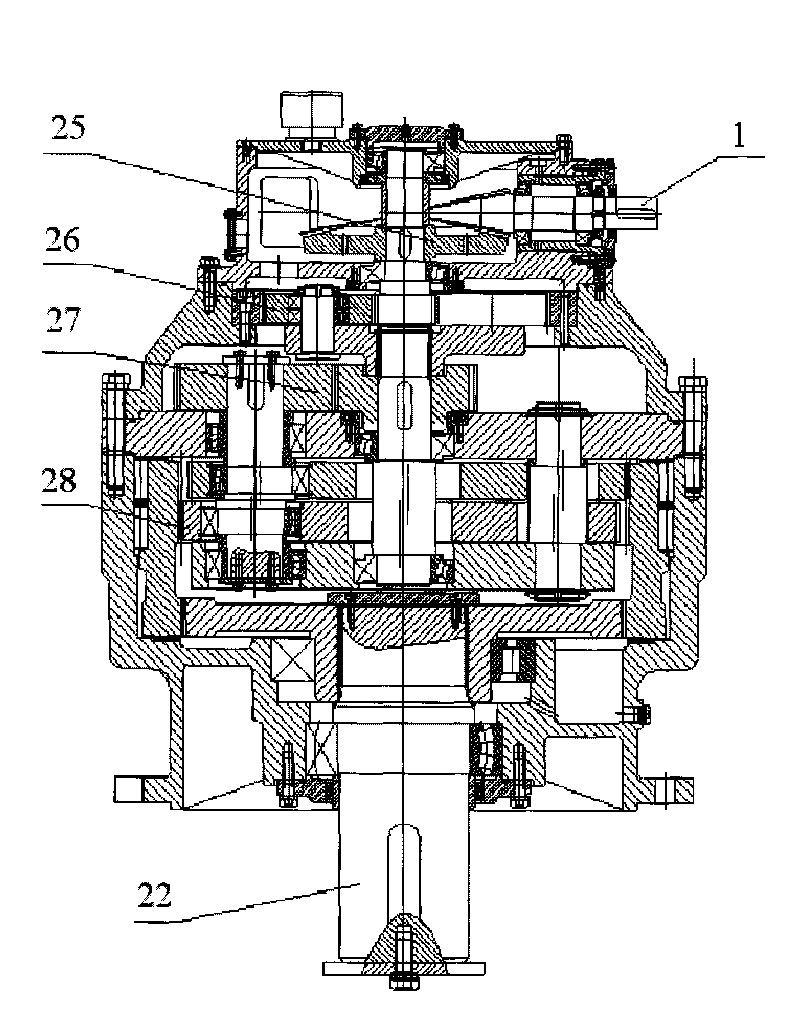

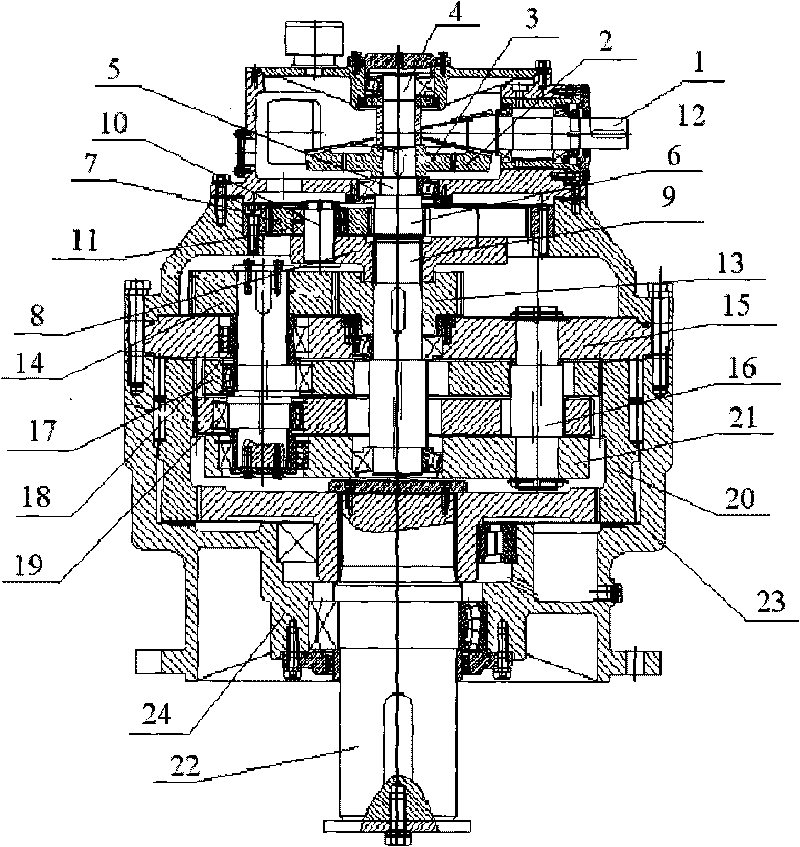

[0044] figure 1 It is a schematic diagram of the overall structure of the four-stage transmission compound type less-difference gear reducer of the present invention.

[0045] Such as figure 1Shown: a bevel gear-planetary-parallel shaft-less tooth difference four-stage transmission compound type reducer with less tooth difference, mainly including input gear pair, intermediate planetary gear pair, parallel shaft gear pair, output gear pair with less tooth difference, Box body 23 and end cap 24. Wherein, the input gear pair includes the input shaft 1, the driving bevel gear 2, the driven bevel gear 3, and the drum gear pinion 4; the intermediate planetary gear pair includes the intermediate sun gear 6, the intermediate planetary gear 7, the intermediate The inner ring gear 8, the intermediate sun gear shaft 9, the intermediate planetary gear shaft 10, the intermediate planetary wheel bearing 11 and the intermediate planetary carrier 12; the described parallel shaft gear pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com