Patents

Literature

48results about How to "High gear ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

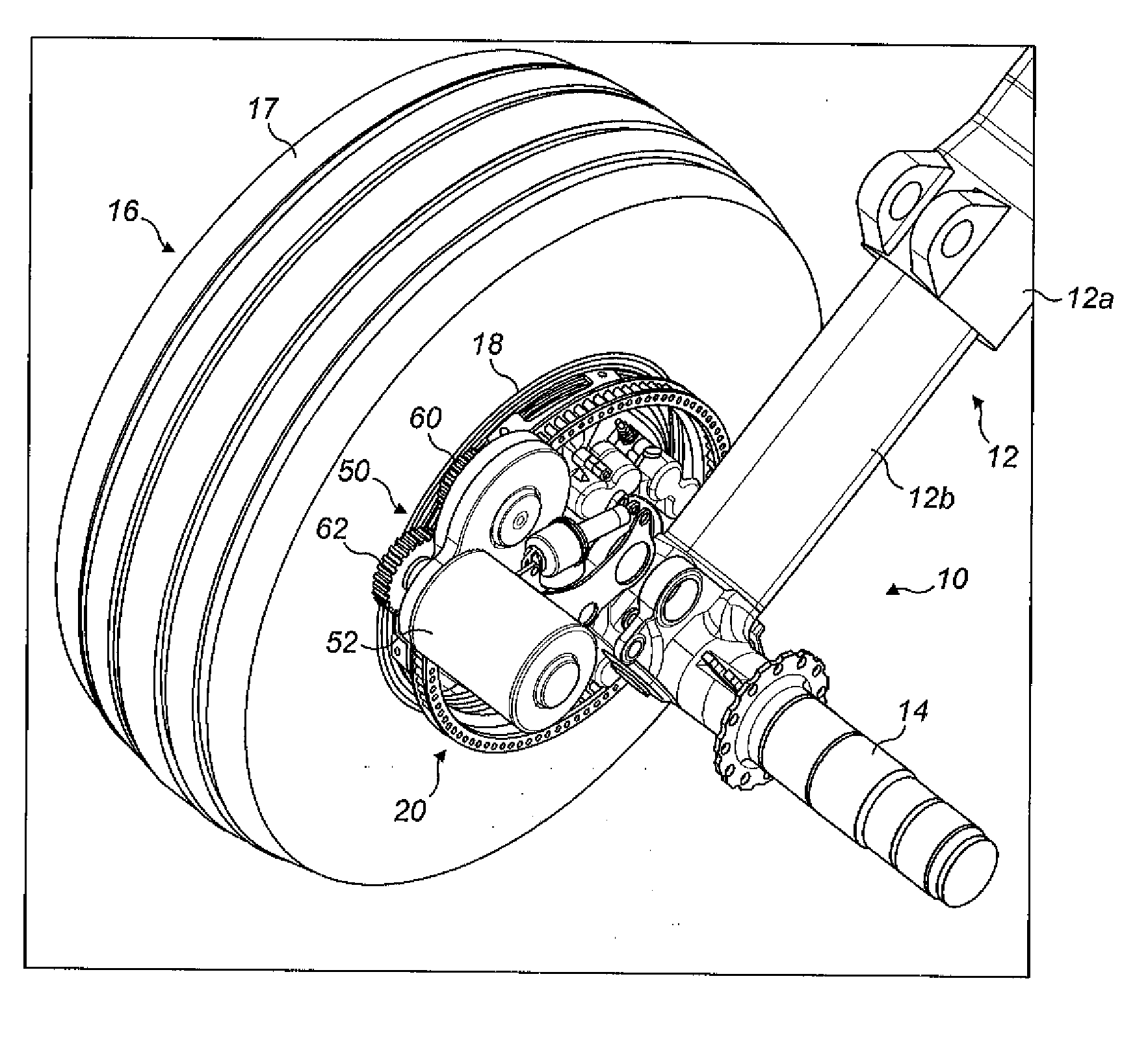

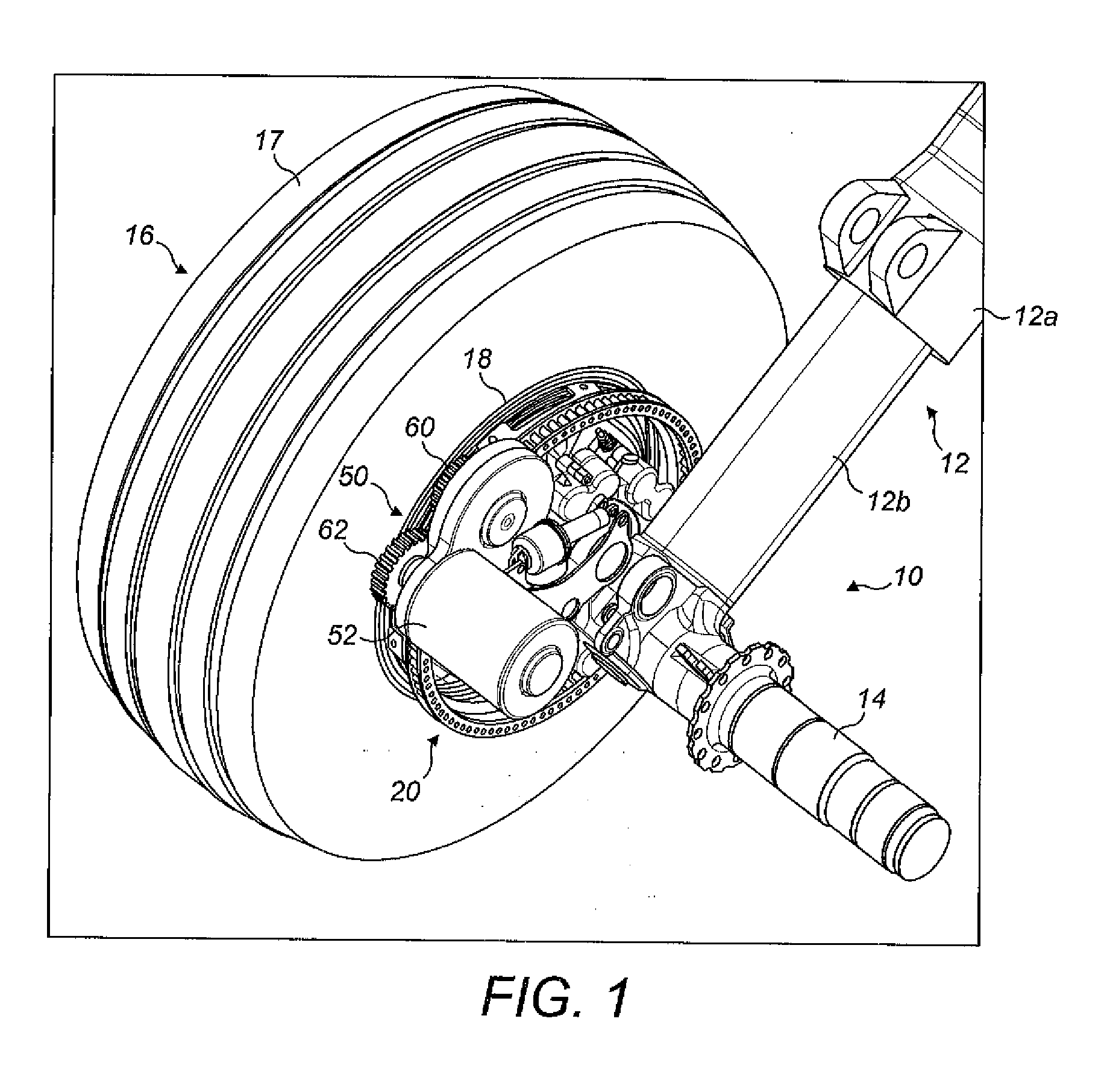

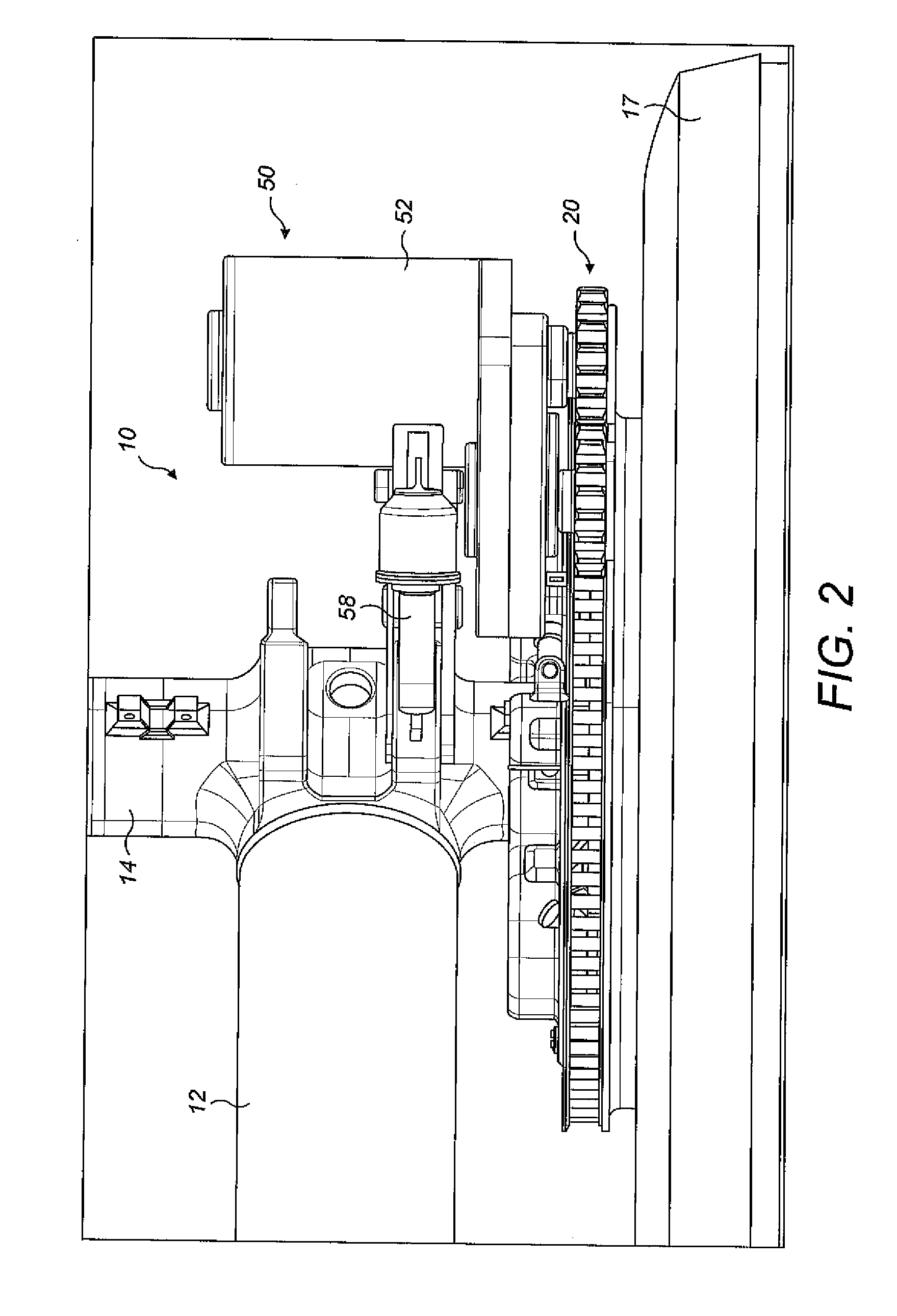

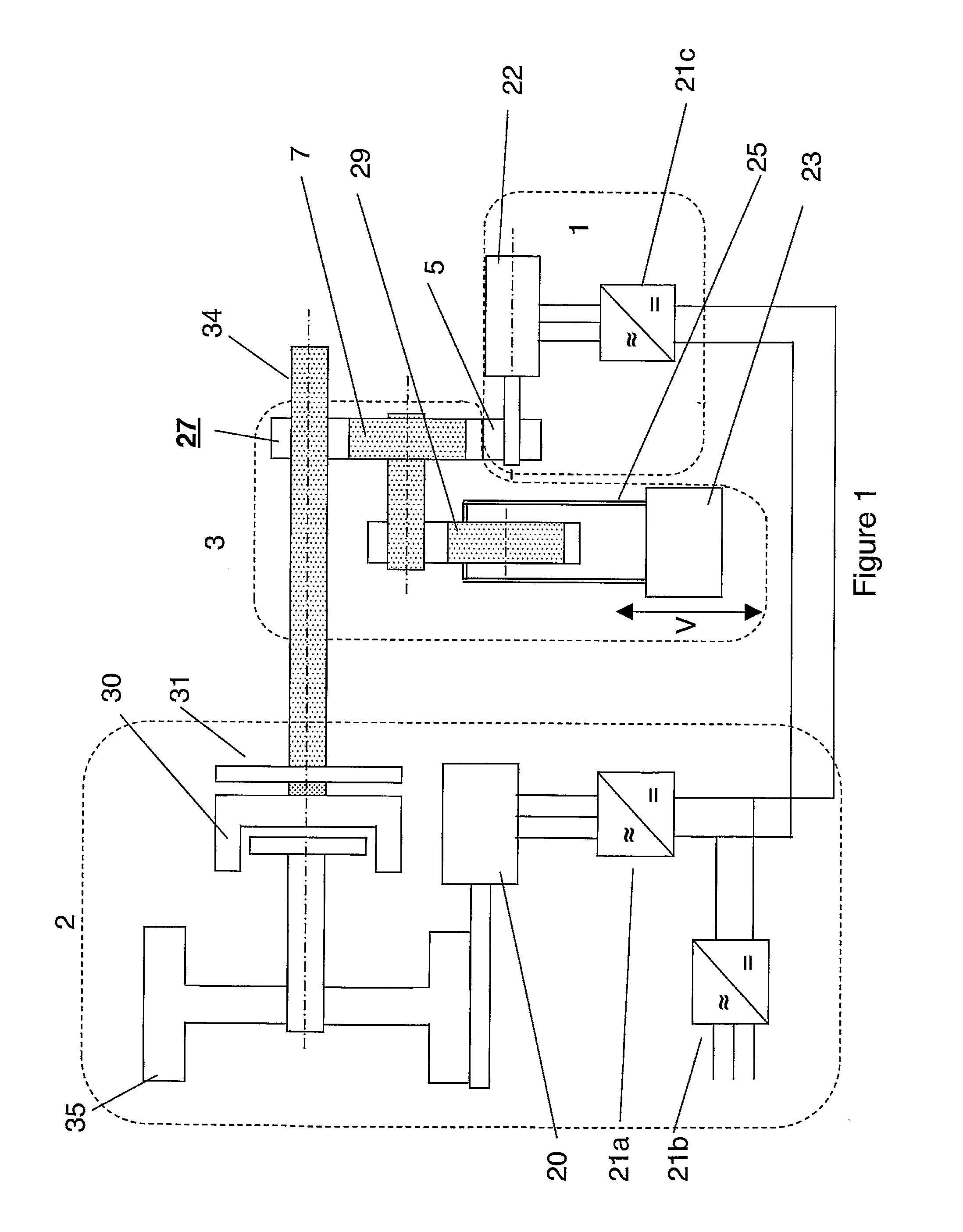

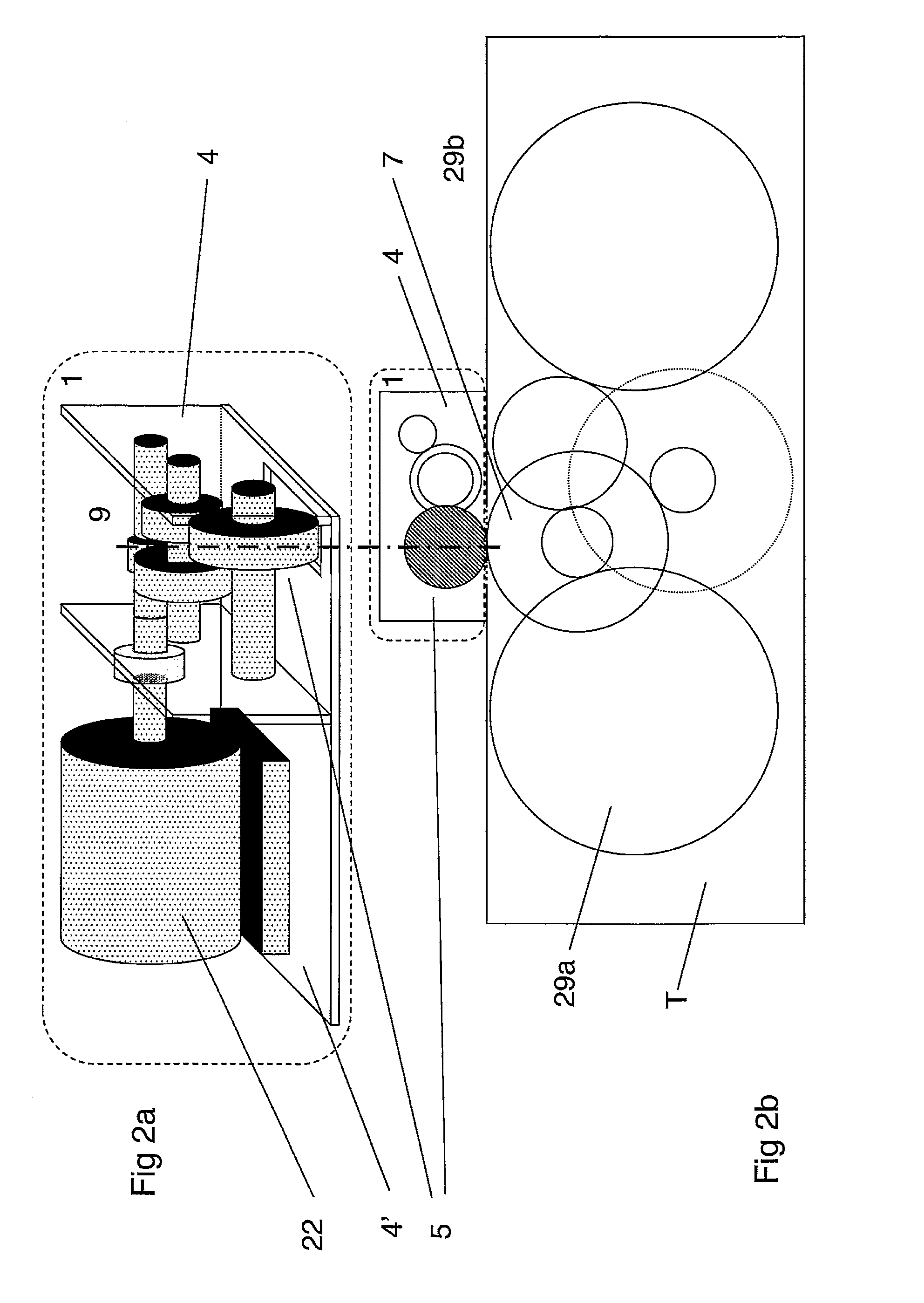

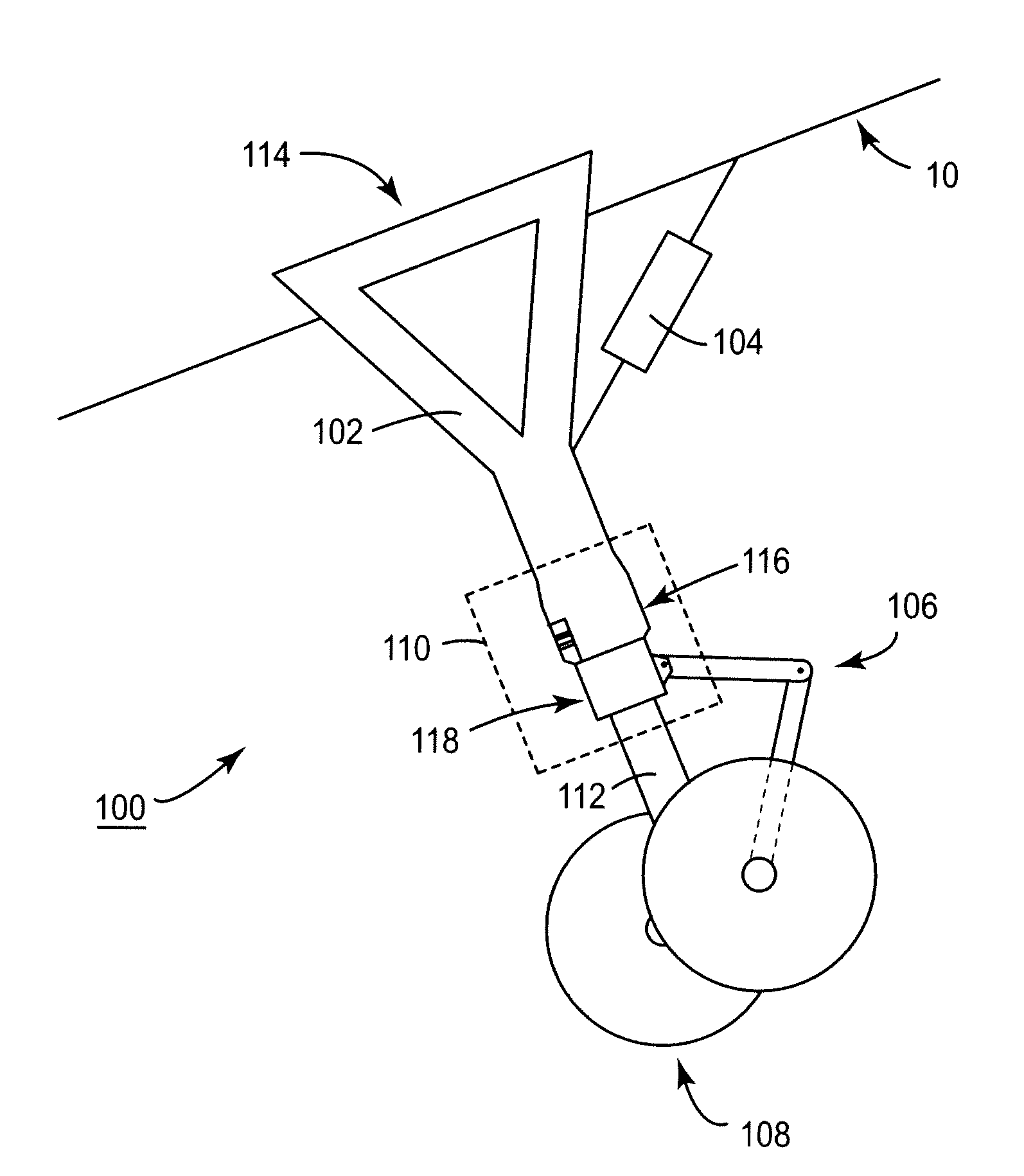

Landing gear drive systems

ActiveUS20150210385A1High gear ratioHigh wheel speedEnergy efficient operational measuresToothed gearingsAirplaneAutomotive engineering

A drive system for rotating one or more wheels of an aircraft landing gear for the purposes of ground taxiing and / or spin-up prior to landing includes a motor operable to rotate a first drive pinion via a first drive path, and a driven gear adapted to be fixed to the wheel. The drive system has a first configuration in which the first drive pinion is capable of meshing with the driven gear to permit the motor to drive the driven gear via the first drive path. One of the first drive pinion and the driven gear includes a first sprocket and the other of the first drive pinion and the driven gear includes a series of rollers arranged in two or more rows, each row of rollers being arranged to form a ring, each roller being rotatable about a roller axis at a fixed distance from an axis of rotation of the first drive pinion or driven gear, respectively.

Owner:AIRBUS OPERATIONS LTD

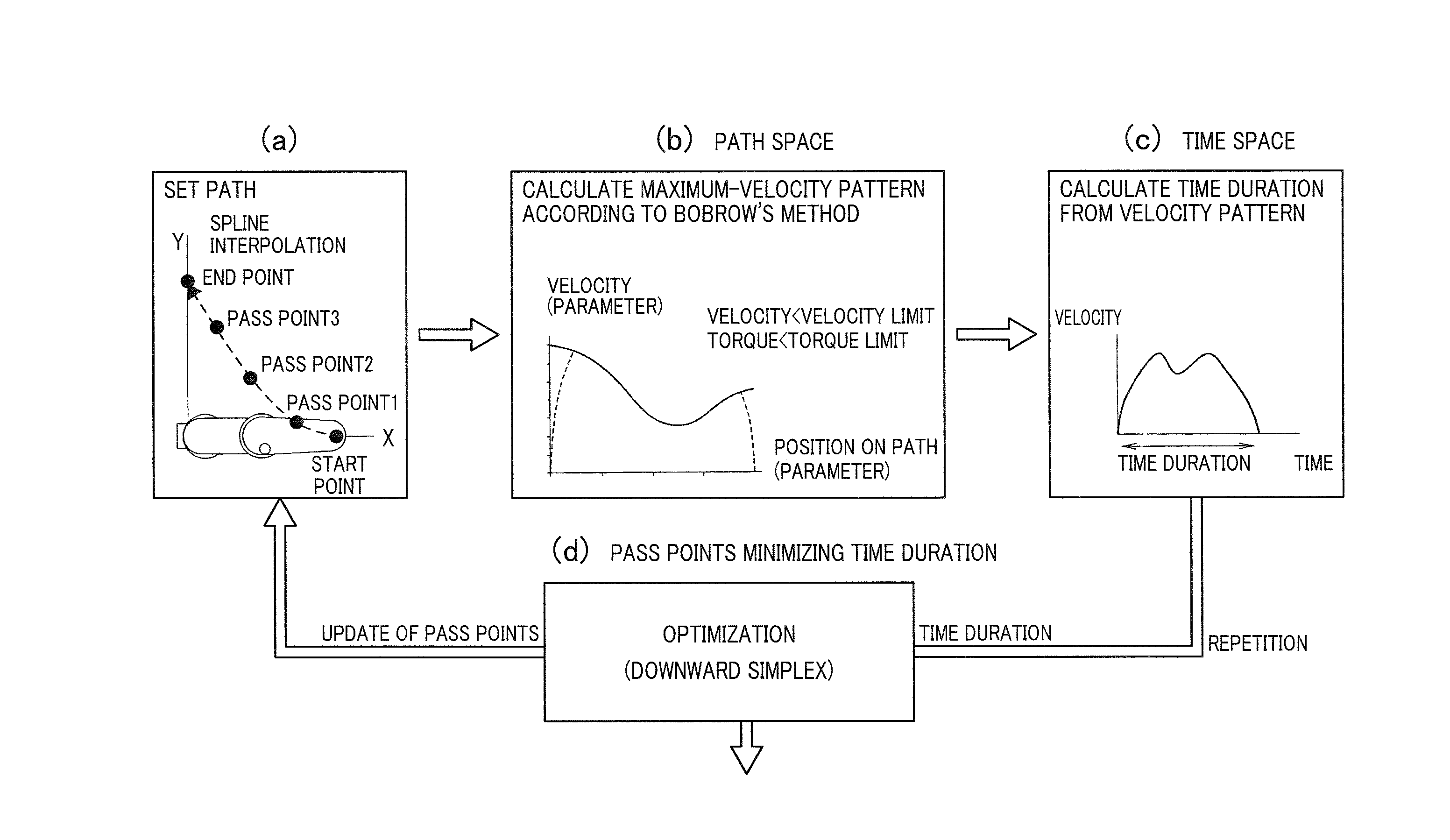

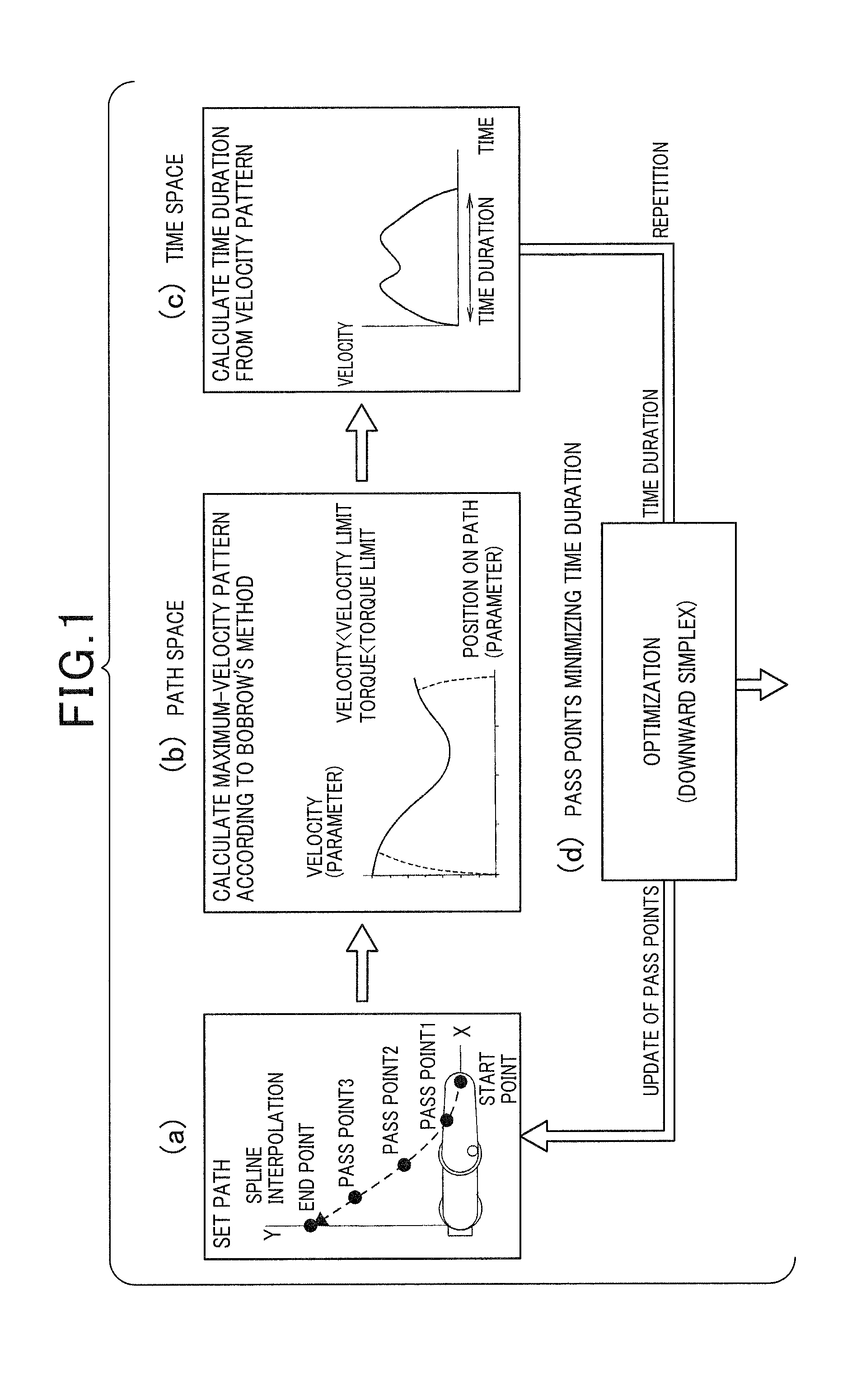

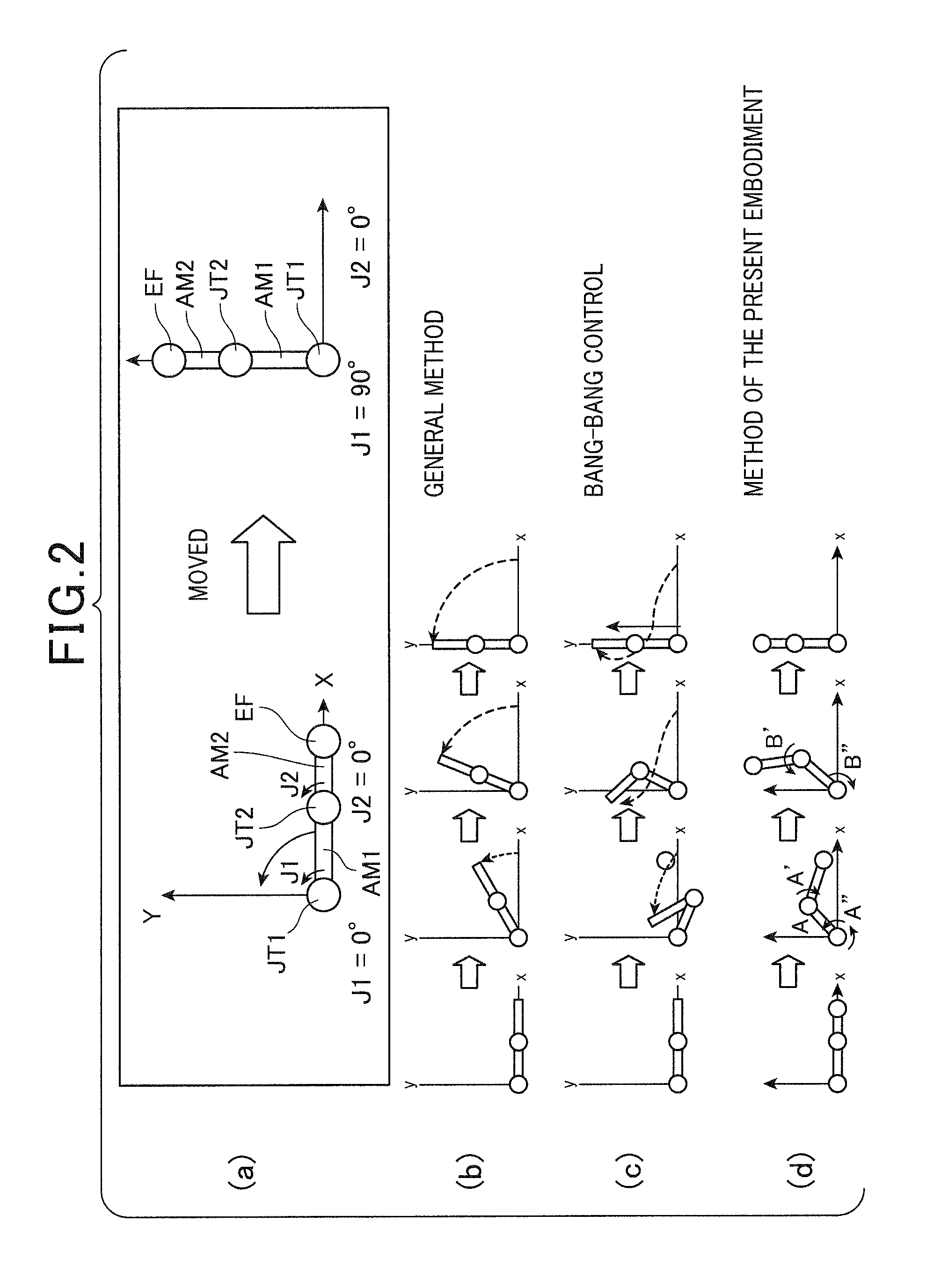

Method of generating path of multiaxial robot and control apparatus for the multiaxial robot

ActiveUS20140297030A1Avoid movement speedShortening duration of timeProgramme-controlled manipulatorSpecial data processing applicationsEngineeringActuator

In a multiaxial robot, a path along which the end effector of the robot moves in the shortest time duration is generated. The robot includes a first link and a second link positioned closer to an end effector than the first link. Start and end points are specified, and velocity patterns are generated for joints driving the first and second links based on the specified start end points. The velocity patterns enable a movement of the second link to cause i) a reaction for increasing an acceleration force generated by the first joint when the end effector is started to be moved from the start point toward the end point, and ii) a reaction for increasing a deceleration force generated by the first joint when the end effector is stopping to the end point.

Owner:DENSO WAVE INC

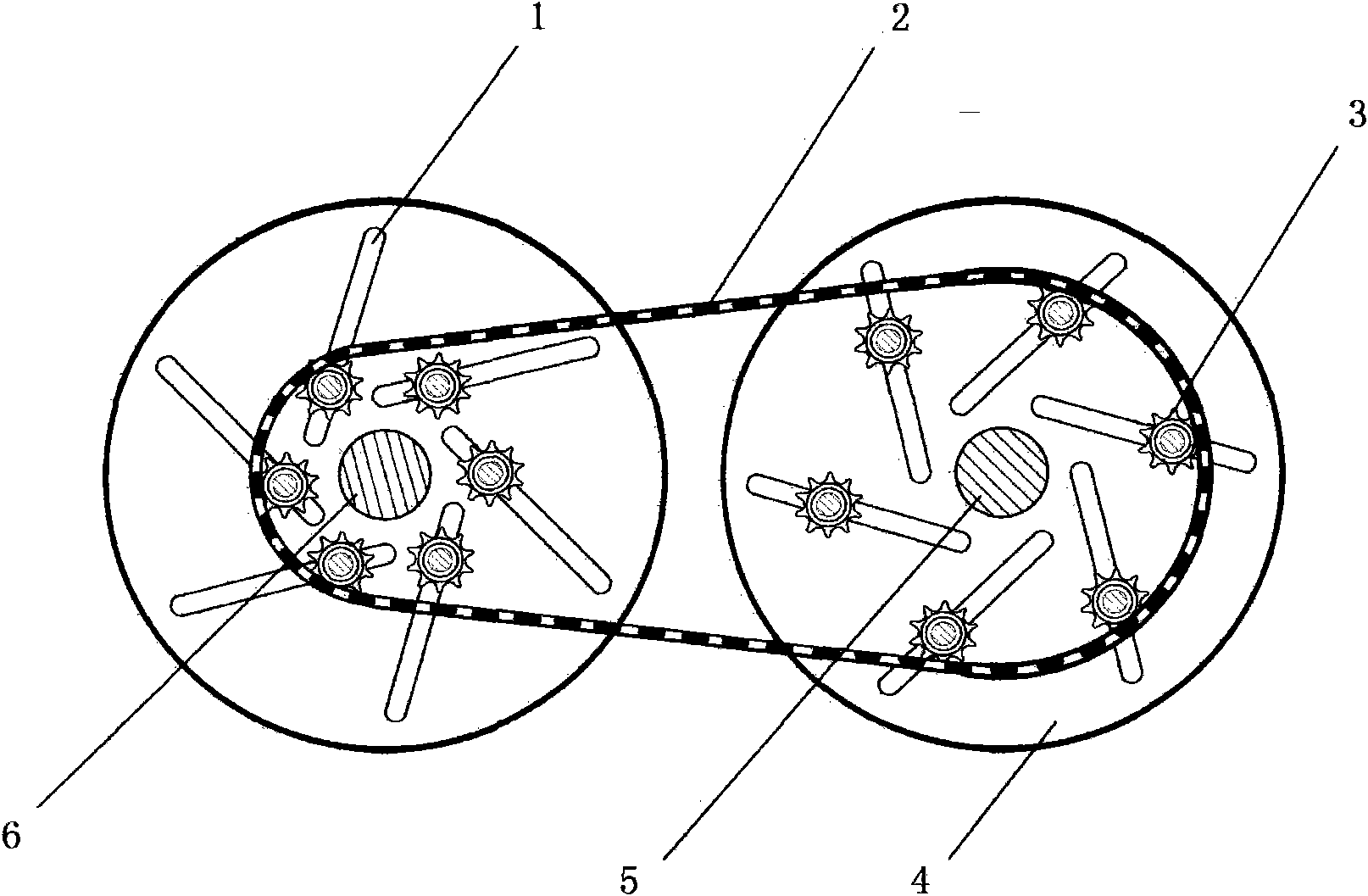

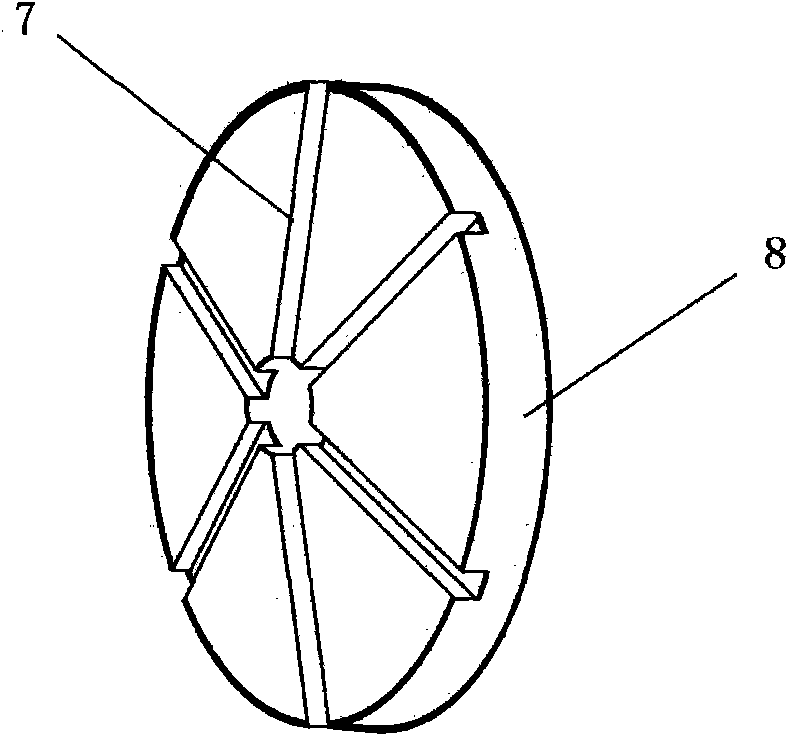

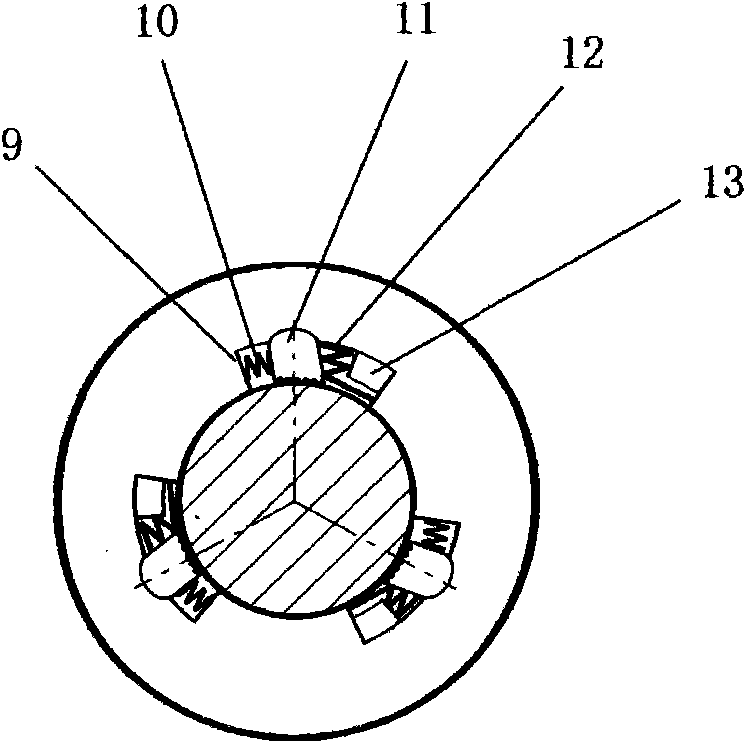

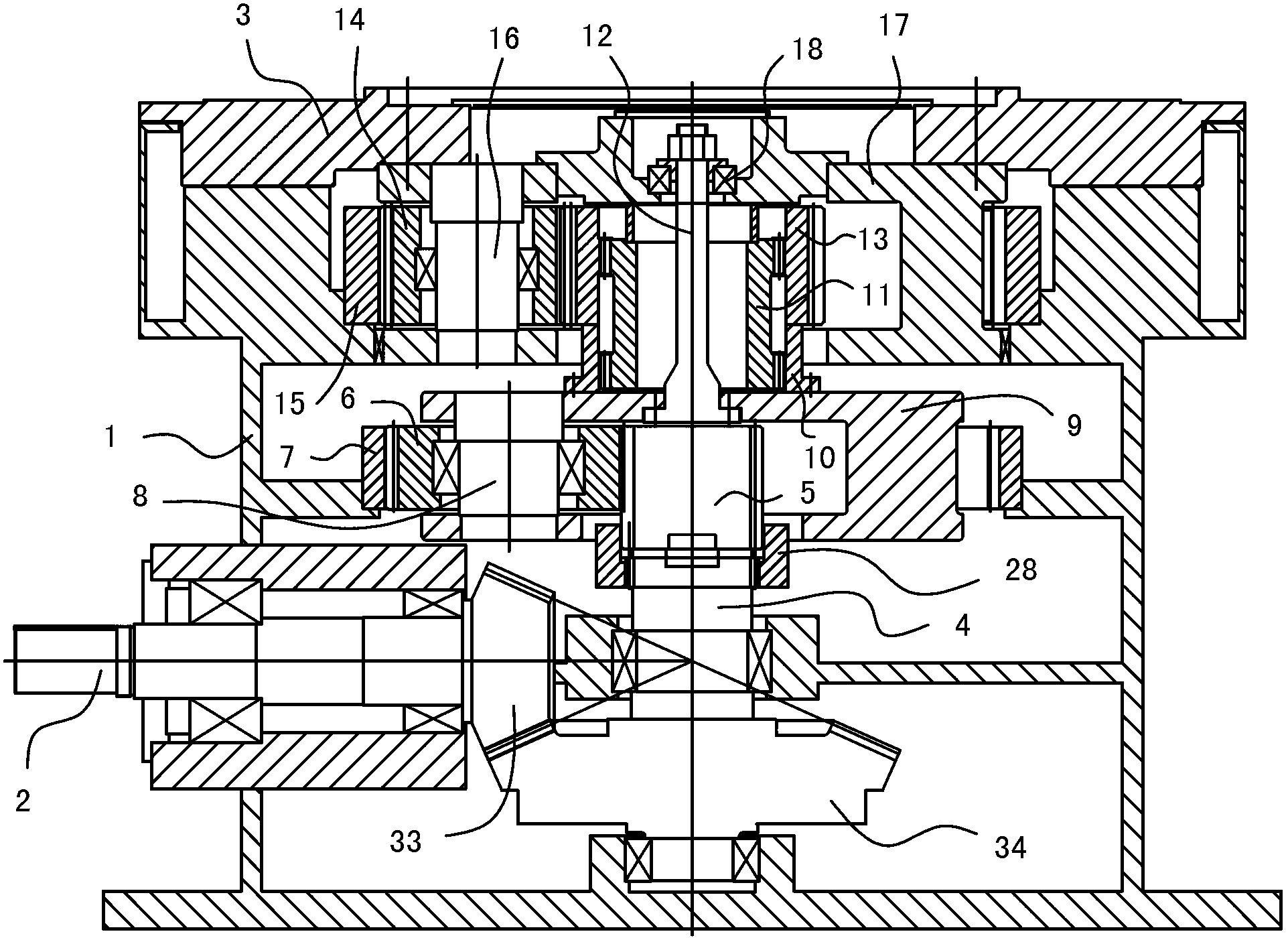

High-power stepless transmission

The invention relates to a tooth chain type stepless transmission for an automobile. A tooth chain is arranged around a plurality of planetary gears which can unidirectionally rotate; all the planetary gears can move in a corresponding radial chute on a drive wheel; and stepless transmission is realized by changing the revolution diameter of the planetary gears. An unlocking key is arranged in a one-way clutch of each planetary gear; and when the tooth chain and the planetary gears are meshed and separated, the unlocking key can be driven so that the clutch is maintained in a one-way locking state or unlocking state. The invention breaks through the traditional theory that the stepless transmission is only friction power transmission, solves the problem of carrying out stepless transmission by utilizing a gear, can effectively improve the transfer power of the stepless transmission and has the advantages of large force transmission, high rotating speed, stable running, reliable work, and the like.

Owner:刘爱诗

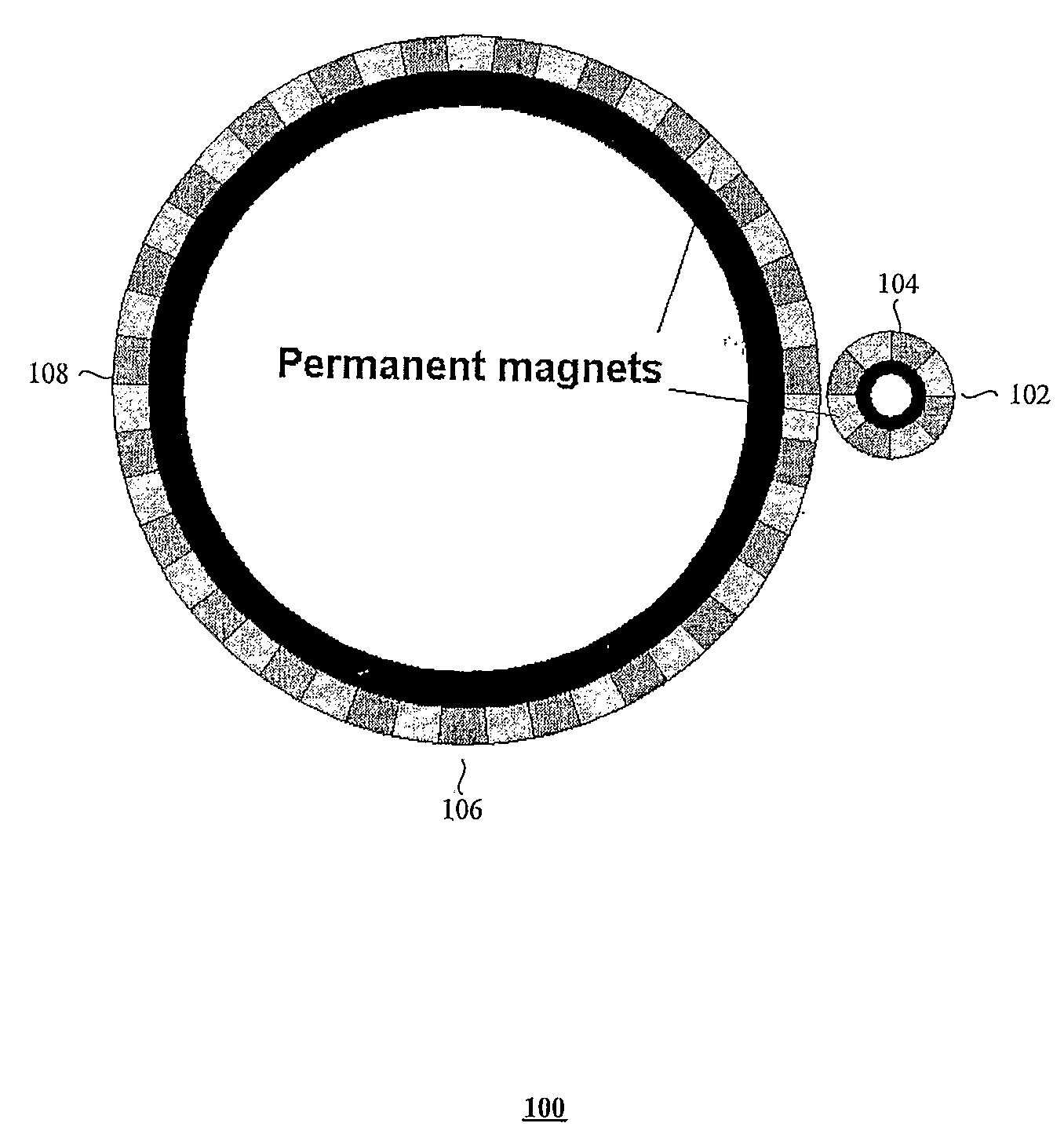

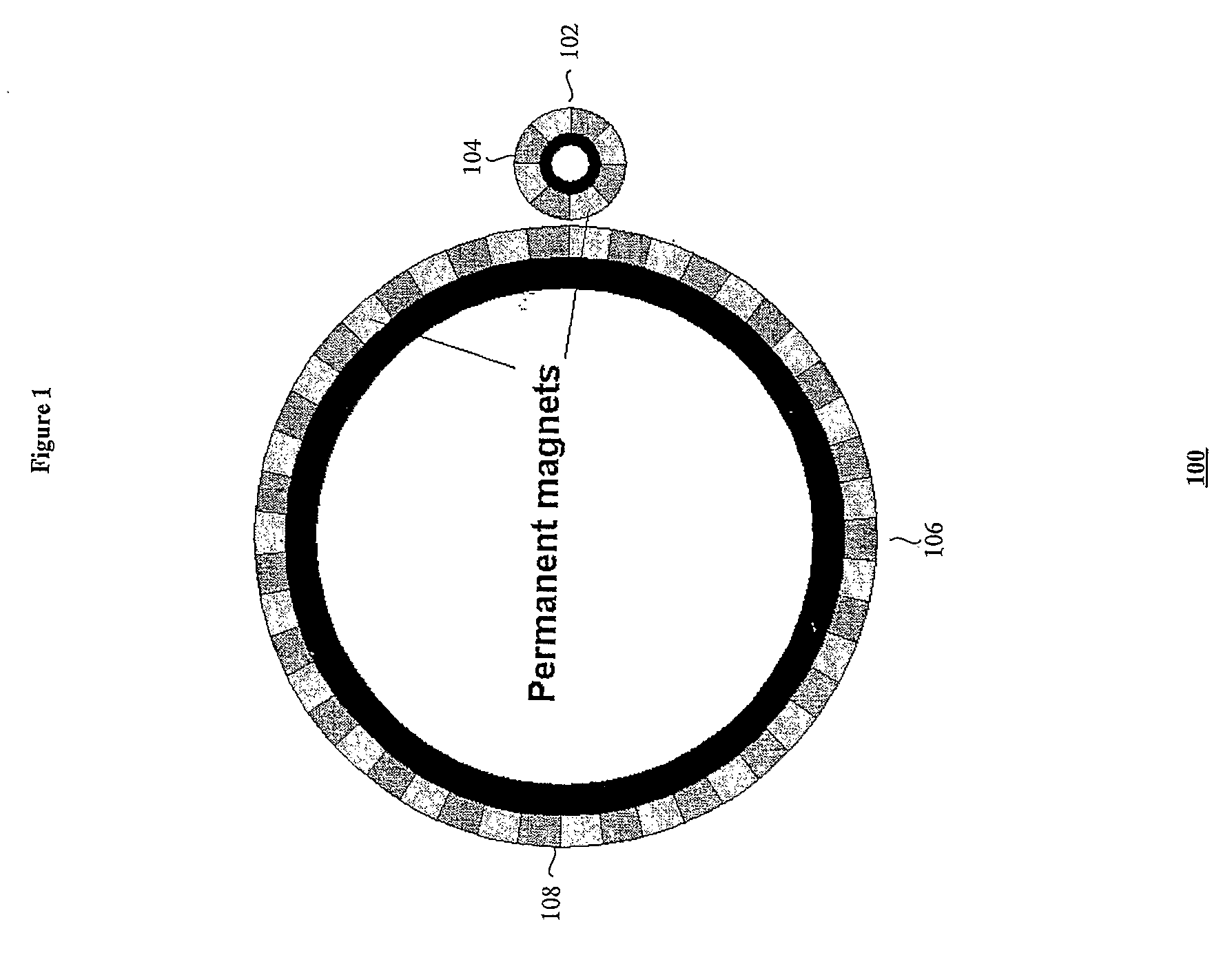

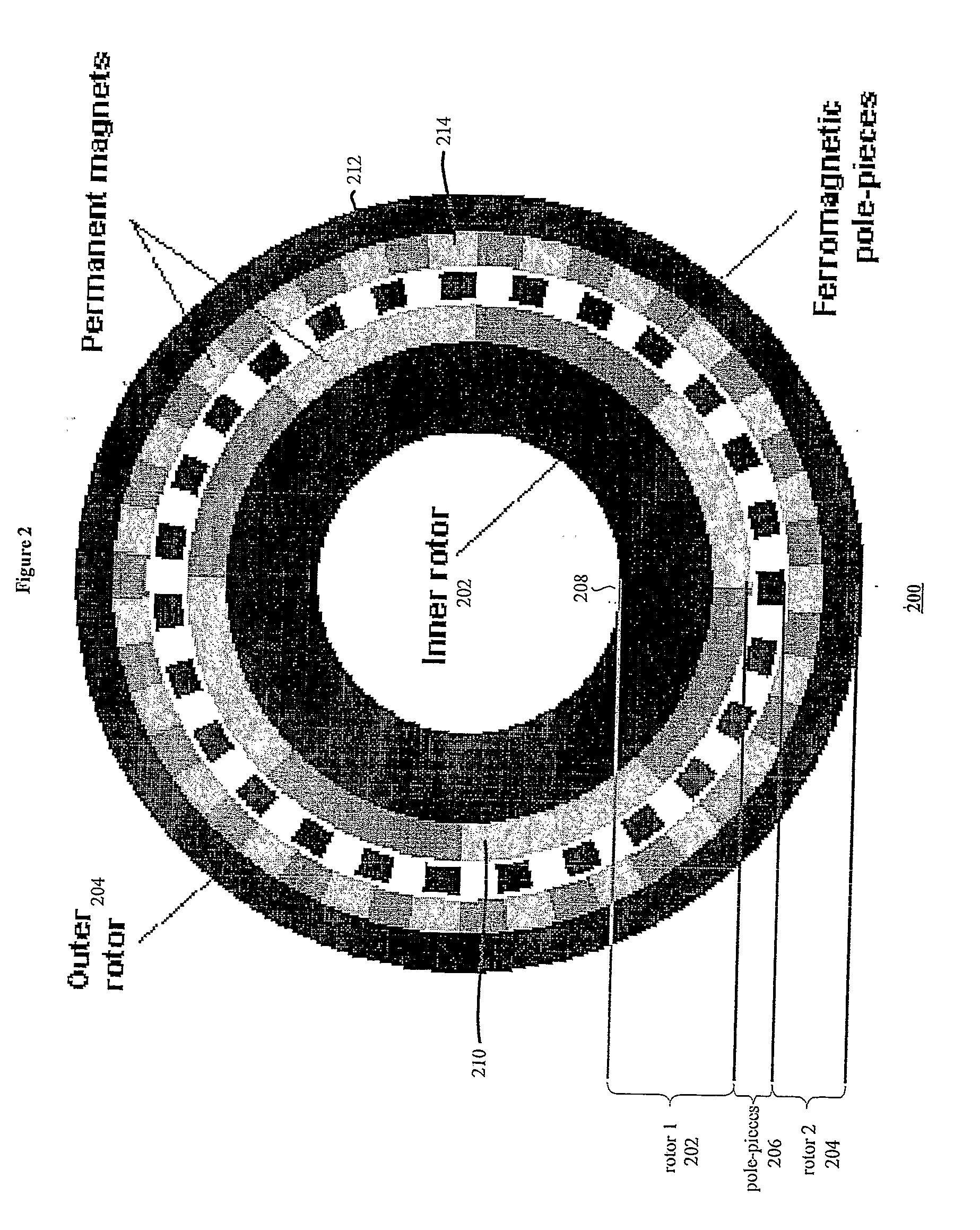

Magnetic gear

Embodiments of the present invention relate to magnetic gears comprising a pair of rotors magnetically coupled in a geared manner via a magnetic space harmonic generated as a consequence of varying an air gap between sets of permanent magnets.

Owner:MAGNOMATICS LTD

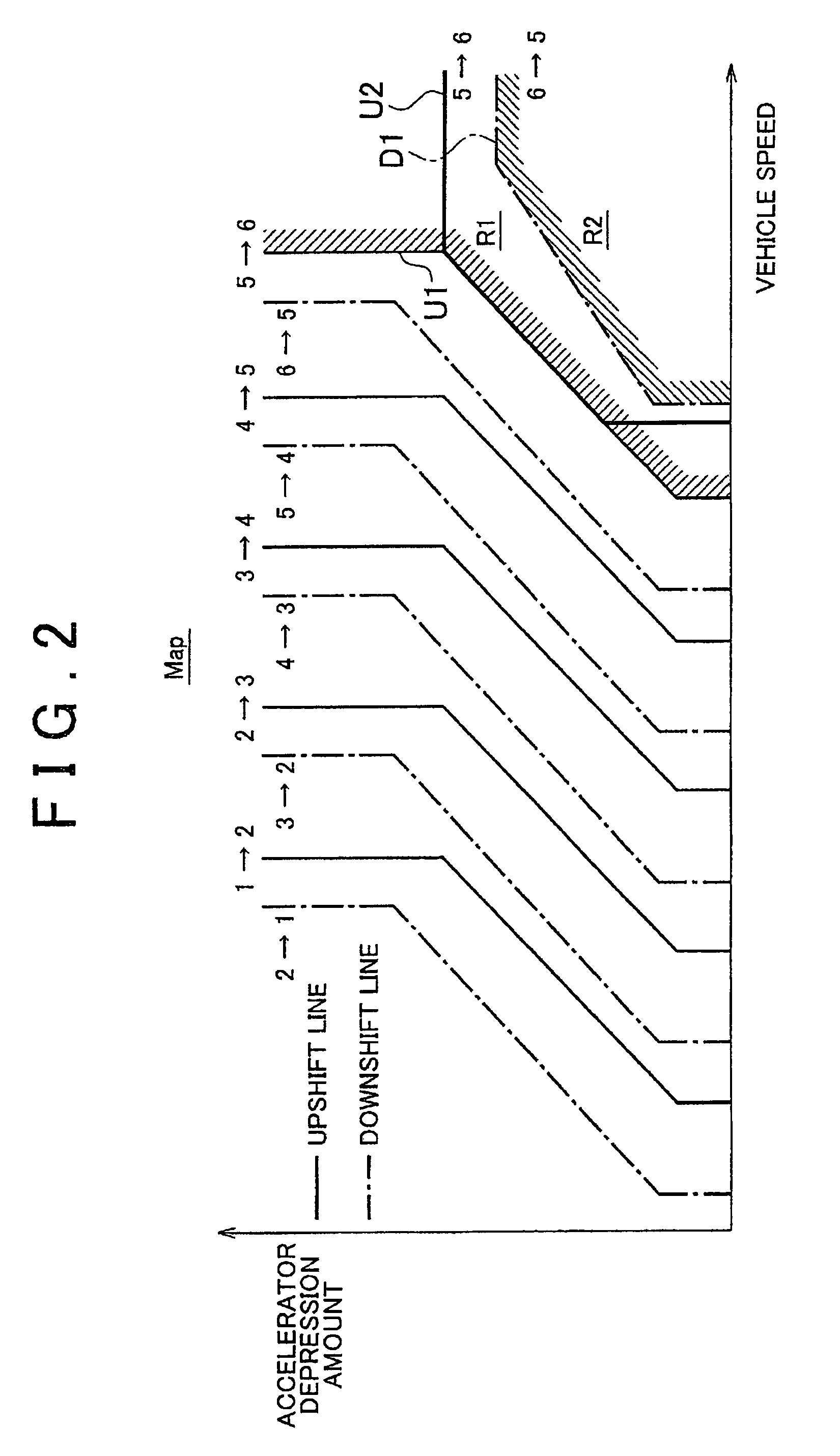

Vehicle transmission

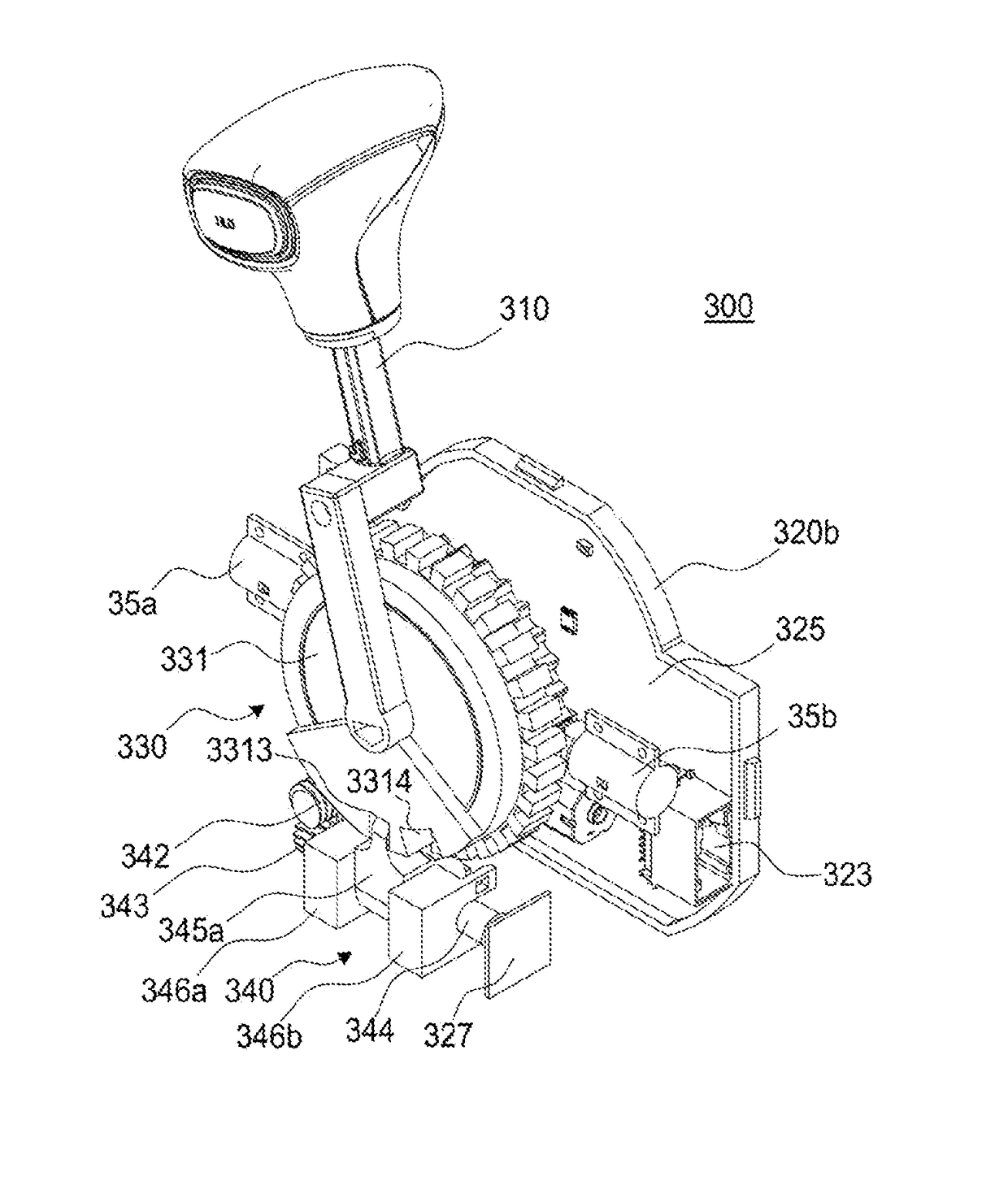

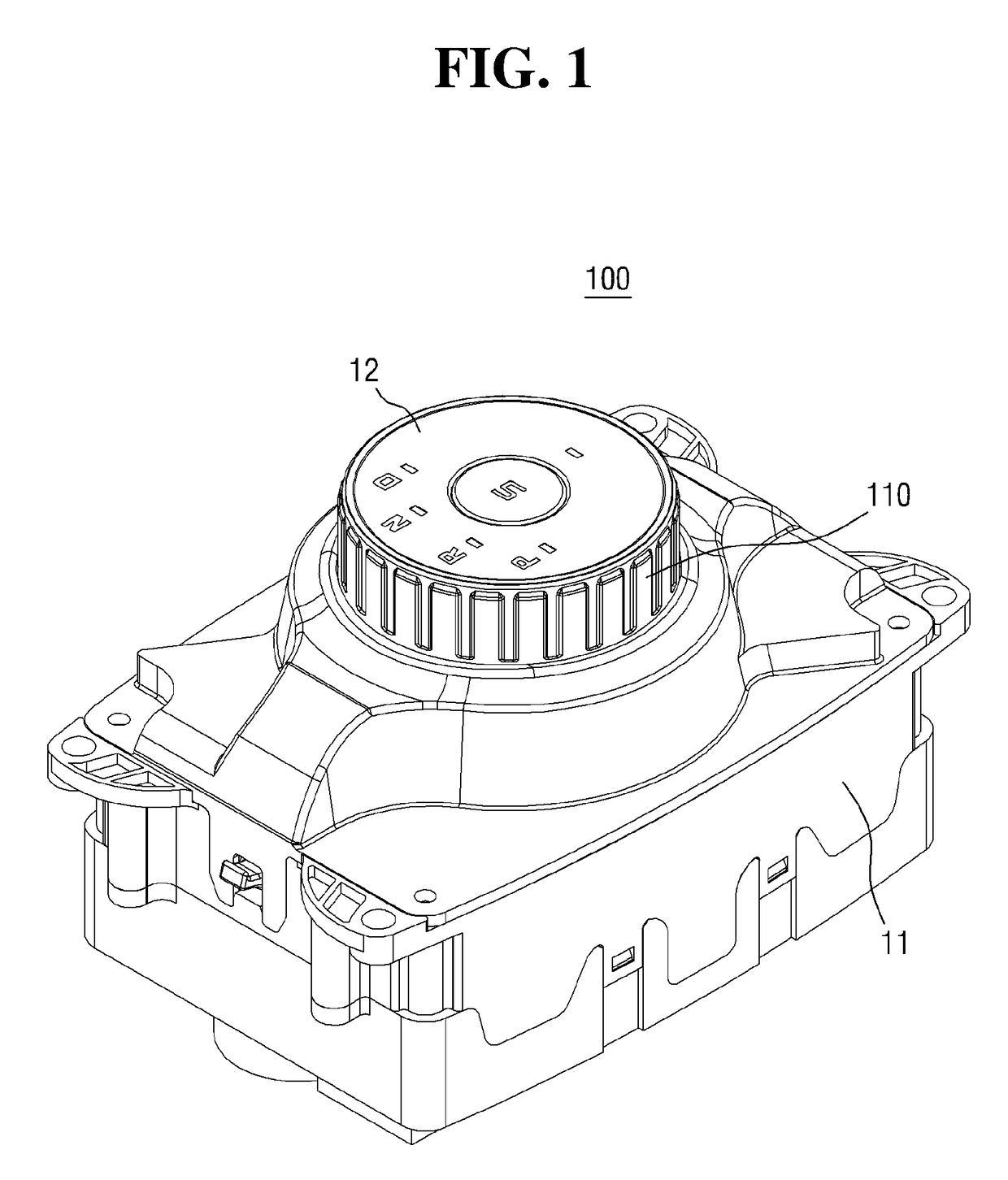

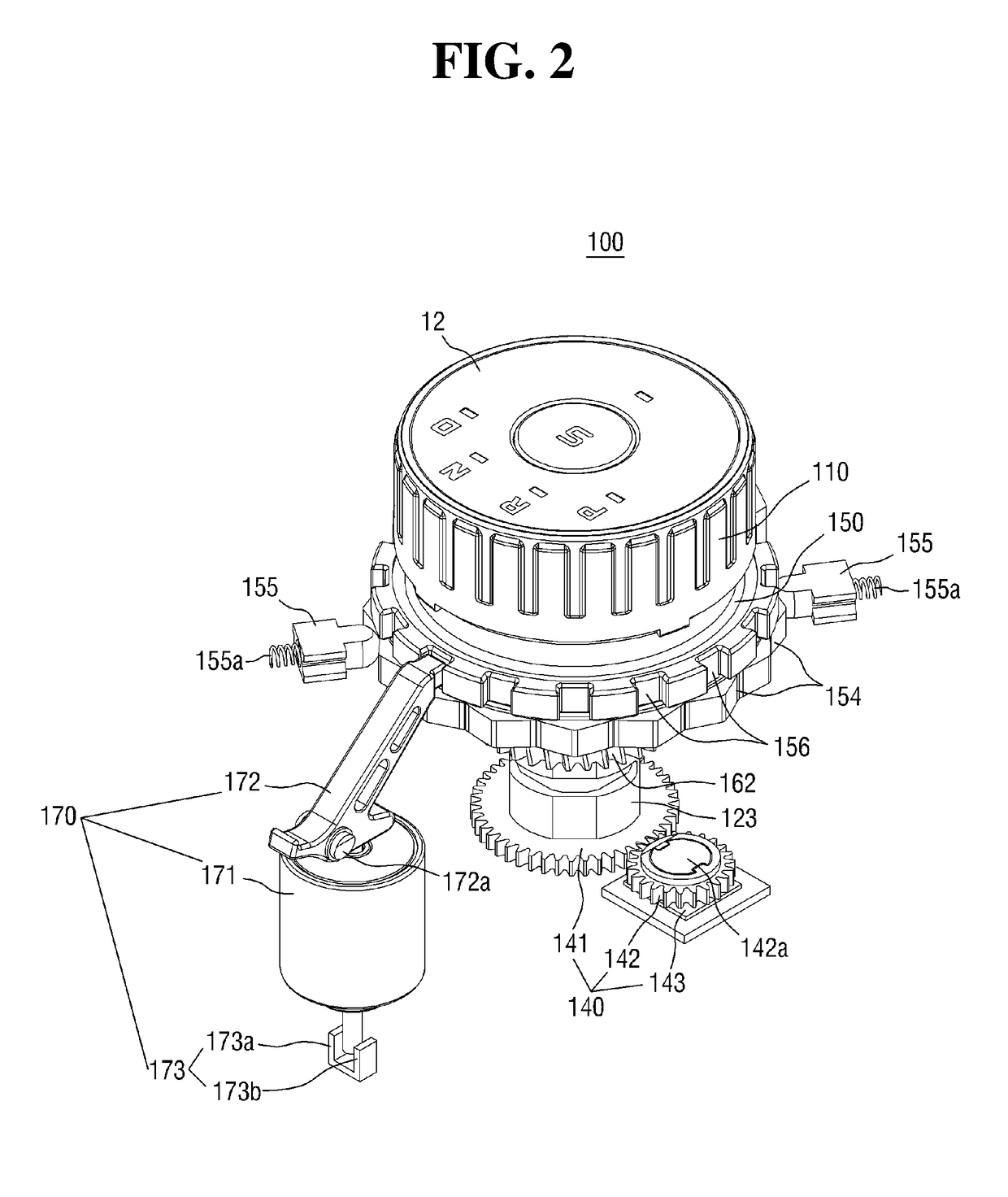

ActiveUS20180320780A1Improve useHigh gear ratioGear vibration/noise dampingGearing controlVariatorMechanical engineering

Provided is a vehicle transmission for a gear shift operation. The vehicle transmission includes: a shift lever which is at least partially displaced toward front or rear directions by a driver to select shift stages; a movable plate which includes an input shaft rotated according to the displacement of the shift lever and an internal gear; an eccentric gear unit which has a first external gear eccentrically engaged with the internal gear and a second external gear moved simultaneously with the first external gear; a rotation unit having a ring gear with which the second external gear is eccentrically engaged; and an insertion unit which includes an eccentric shaft inserted into an aperture formed at a center of the eccentric gear unit and a central shaft formed with the eccentric shaft and inserted into an aperture formed at a center of the rotation unit.

Owner:SL CORP

Motor Upgrade Kit For A Mechanical Press

ActiveUS20100089258A1Increase flexibilitySufficient accuracyOther manufacturing equipments/toolsPress ramGear wheelDrive motor

A press drive motor upgrade kit for adapting a mechanical press of the flywheel-driven type to a servo press including a drive motor and a drive train, and a mechanical press so modified. The kit includes at least one servo motor adapted for driving said mechanical press and a drive transmission apparatus or gear transmission or the like, connected to the servo motor and adapted for engagement with at least one gear or shaft of said drive train of said mechanical press. The kit may also include a baseplate or mounting structure on which the servo motor and transmission are arranged.

Owner:ABB (SCHWEIZ) AG

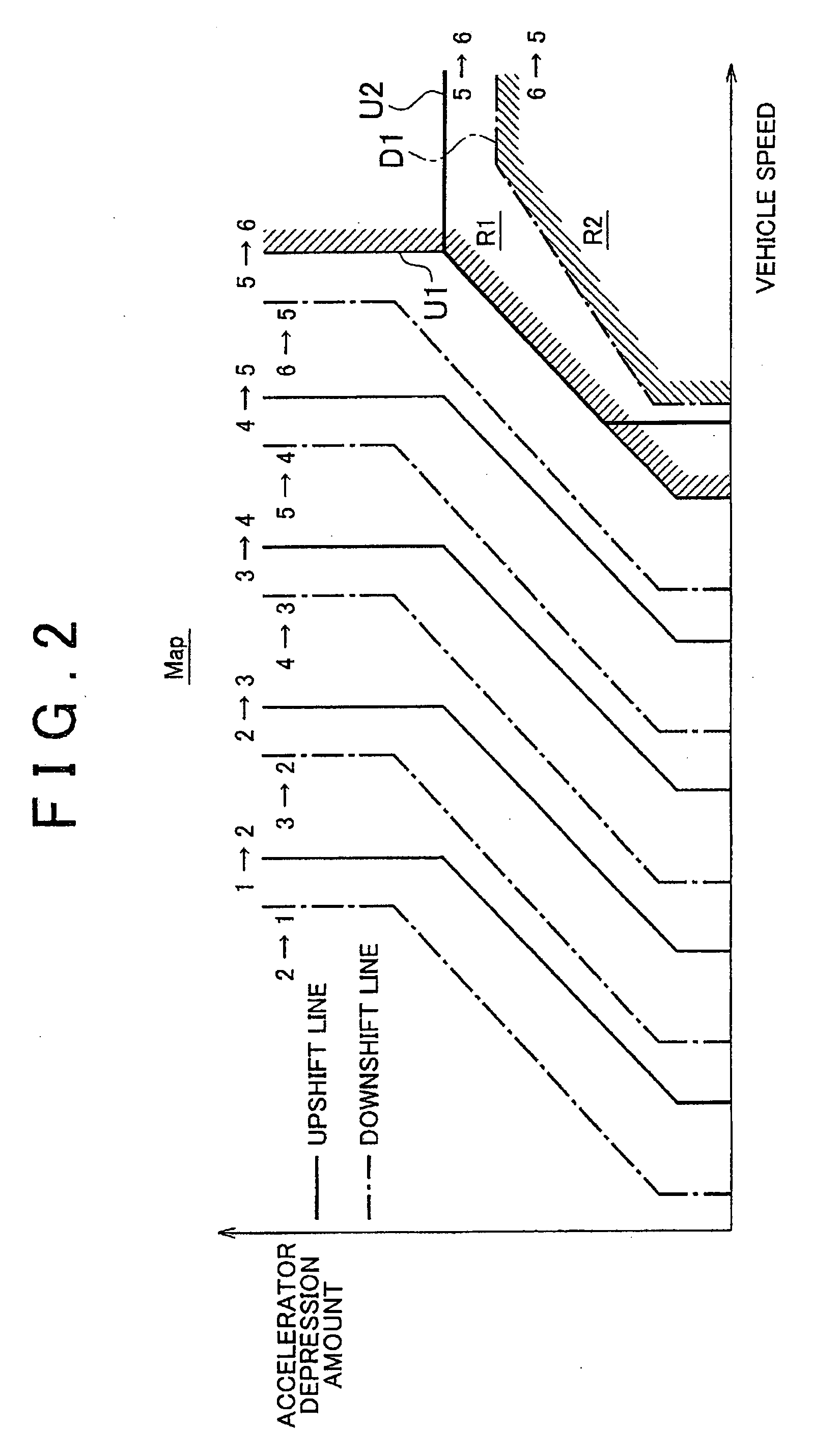

Four-stage driving combined type speed reducer and speed reduction method thereof

InactiveCN101761633AImprove machining accuracyReduce the center distanceToothed gearingsGear wheelControl theory

The invention relates to a four-stage driving combined type speed reducer and a speed reduction method thereof. The four-stage driving combined type speed reducer with small teeth difference is a bevel gear-planetary-parallel shaft-four-stage drive with small teeth difference and structurally comprises an input gear pair, a middle planetary gear pair, a parallel shaft gear pair, an output gear pair with small teeth difference, a box body and an end cover. The principle of the speed reduction method of the four-stage driving combined type speed reducer with small teeth difference is that the speed reduction of the speed reducer is realized through a first-stage driving bevel gear drive, a second-stage planetary gear drive, a third-stage driving parallel shaft drive and a fourth-stage driving drive with small teeth difference. The invention has the advantages that the transmission speed ratio and the output torque of the vertical speed reducer are greatly improved, and the bearing capacity and the overload capacity are strong; and the vibration noise is low, the heat dissipation is rapid, the gear machining precision is improved, the machining precision can be ensured easily, the volume and the weight of the entire speed reducer are reduced, the manufacturing cost of the large-power vertical speed reducer is greatly reduced and the production cycle is shortened.

Owner:TIANJIN GENERAL PRINCIPLE MACHINERY NEW TECH

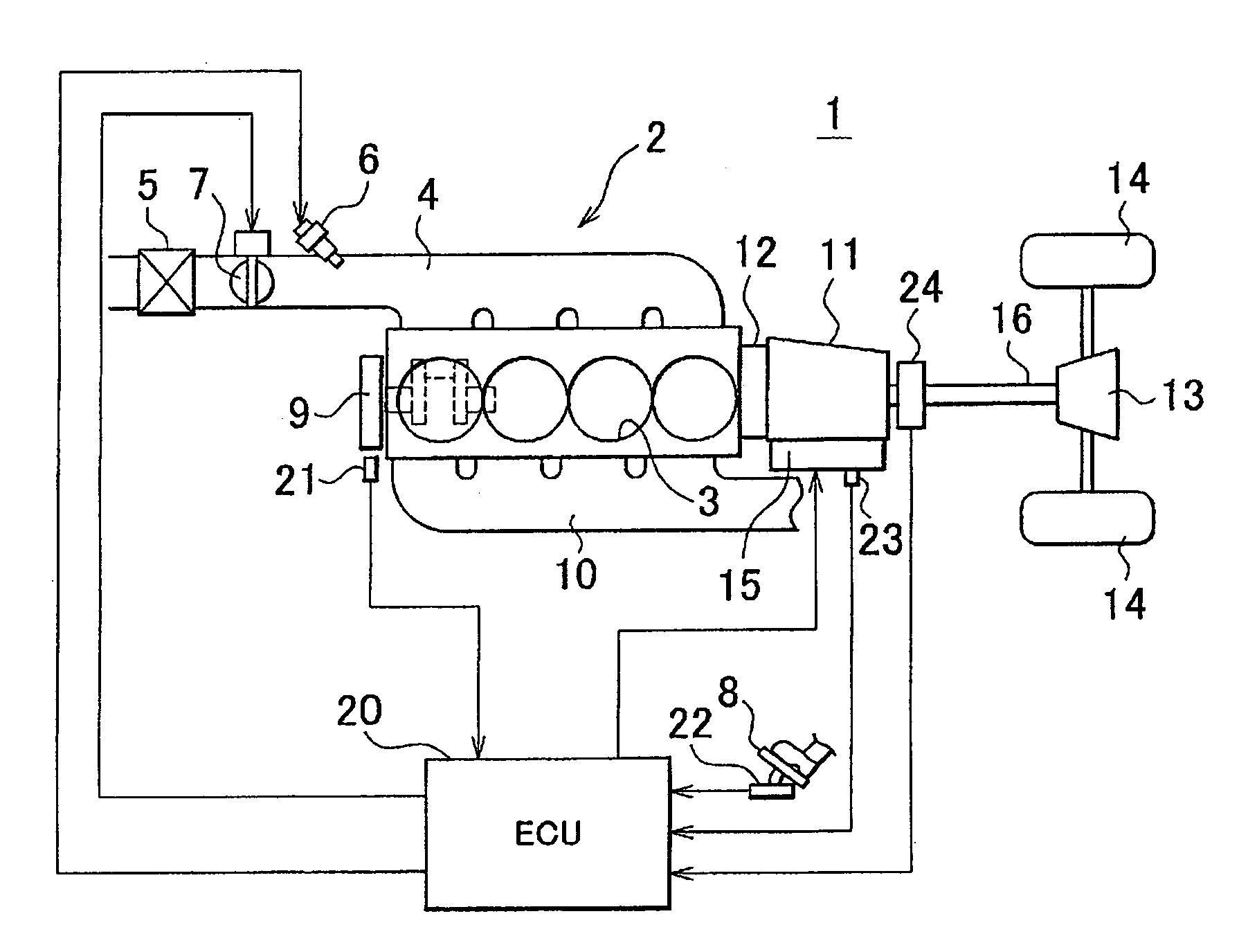

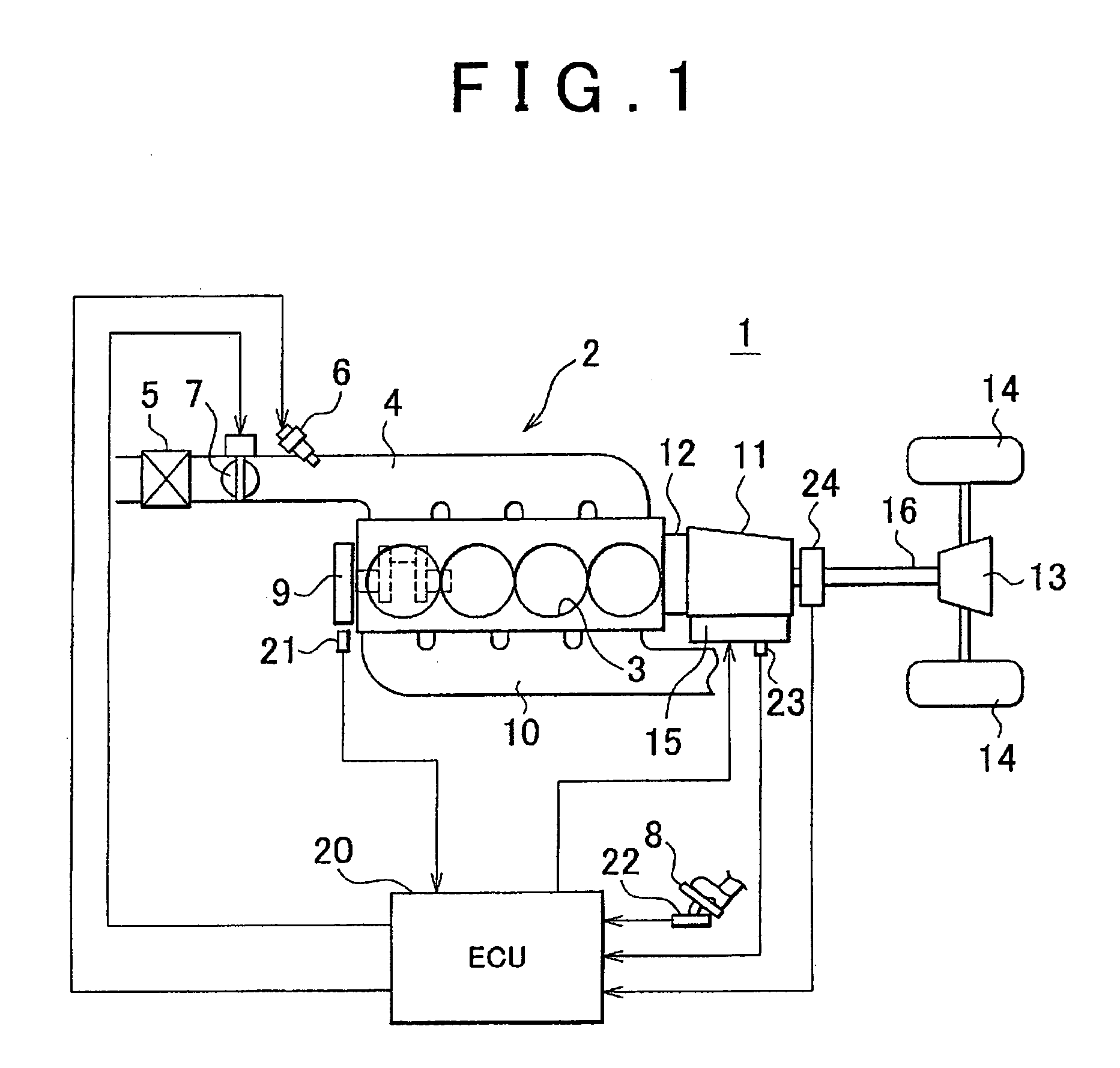

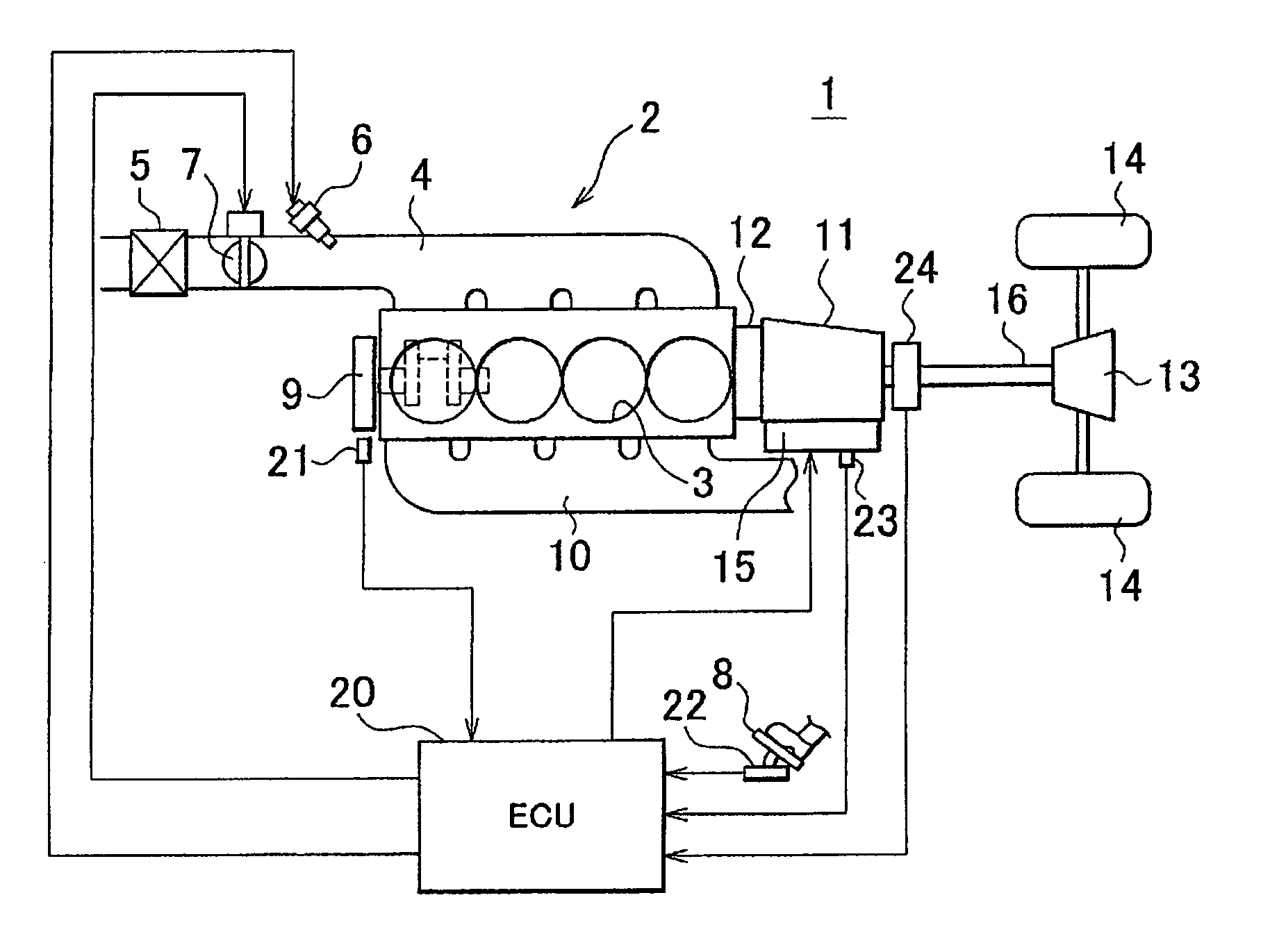

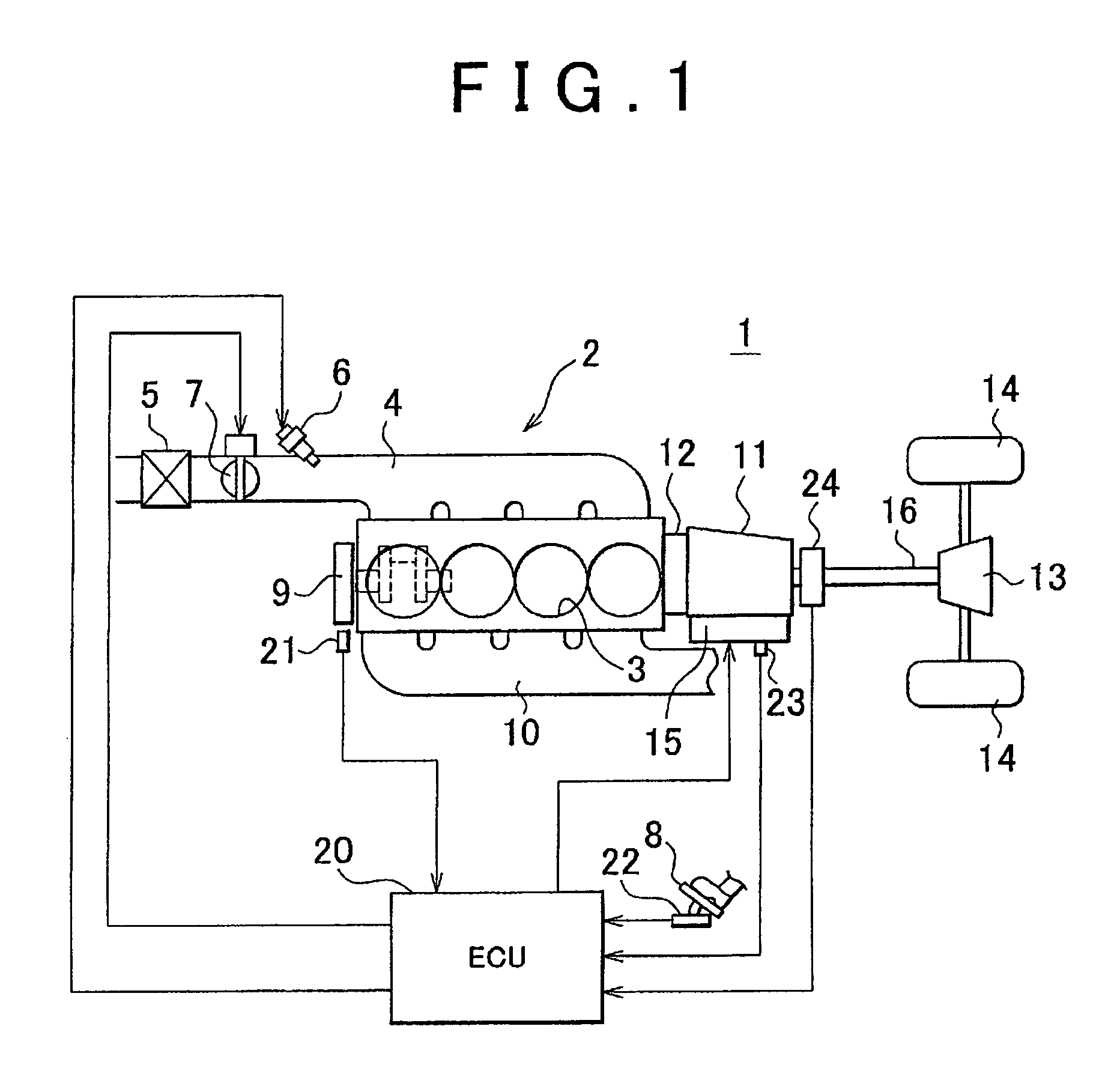

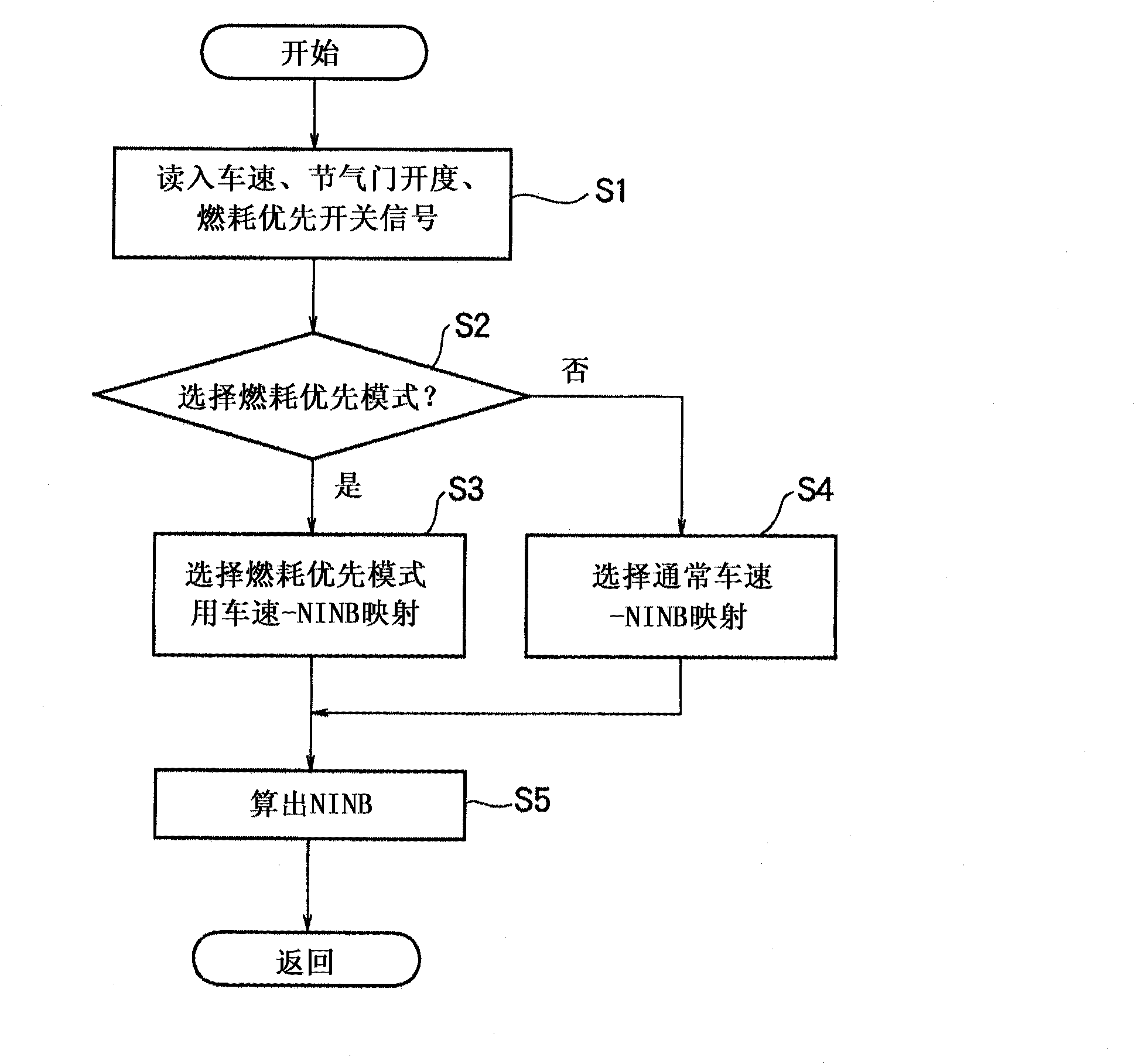

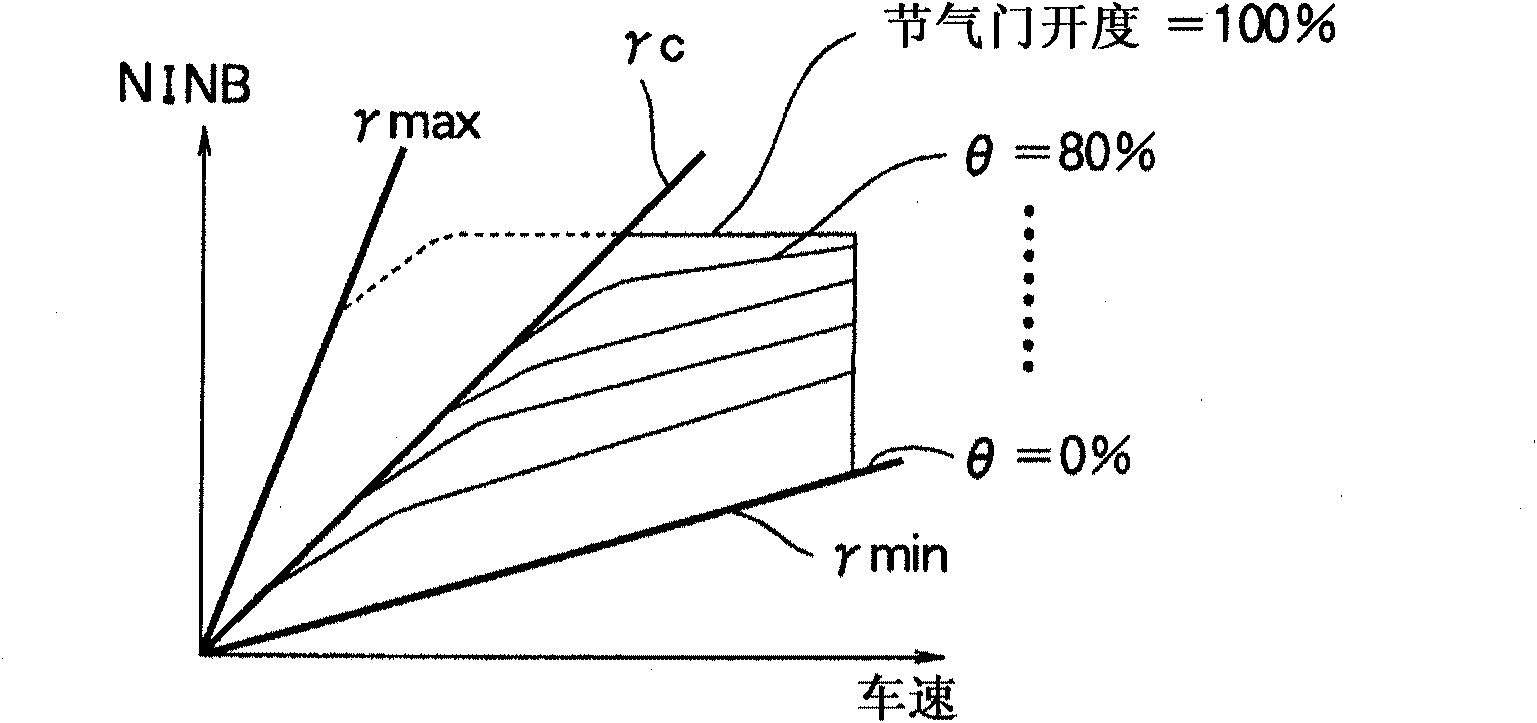

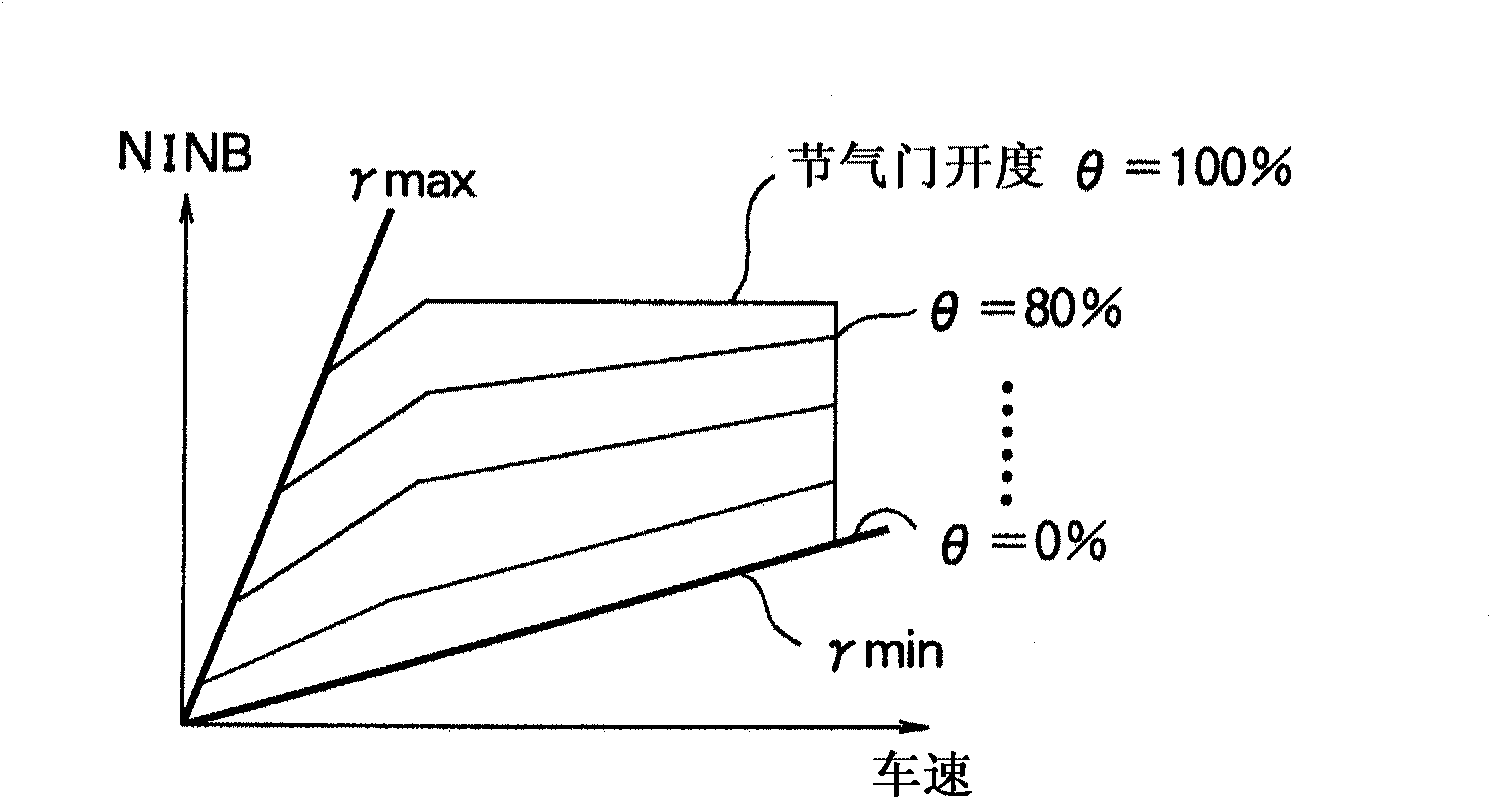

Vehicle gear shift control device and gear shift control method

ActiveUS20110093173A1Inhibit deteriorationHigh gear ratioDigital data processing detailsRoad transportEngineeringGear ratio

In a gear shift control device for a vehicle that shifts a transmission having a plurality of gears based on a shift line set in a shift map, an upshift line for shifting to the highest gear, and a downshift line that is located in a high vehicle speed region on the side of a higher vehicle speed than the upshift line are set in the shift map. The downshift line is used when shifting from the highest gear to a prescribed gear that has a larger gear ratio than the highest gear.

Owner:TOYOTA JIDOSHA KK

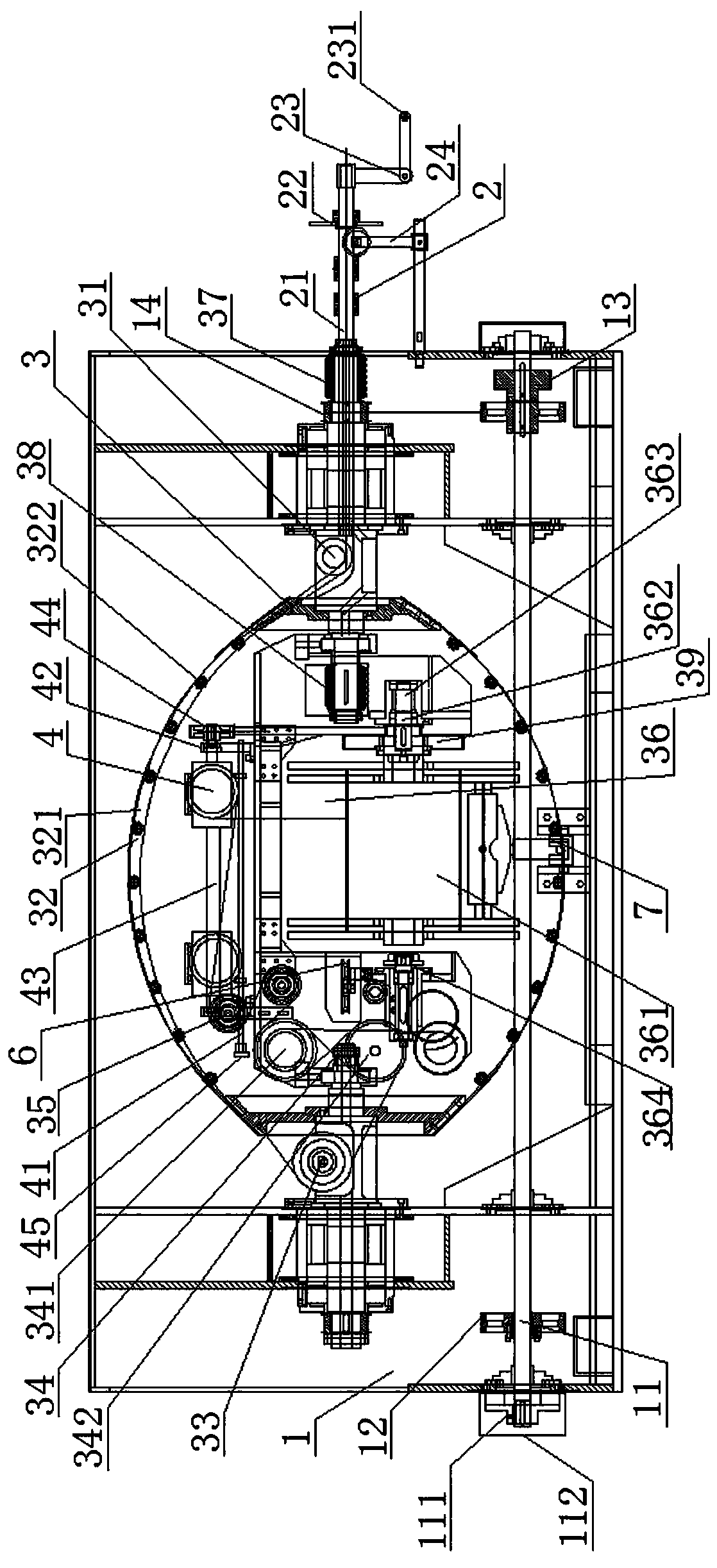

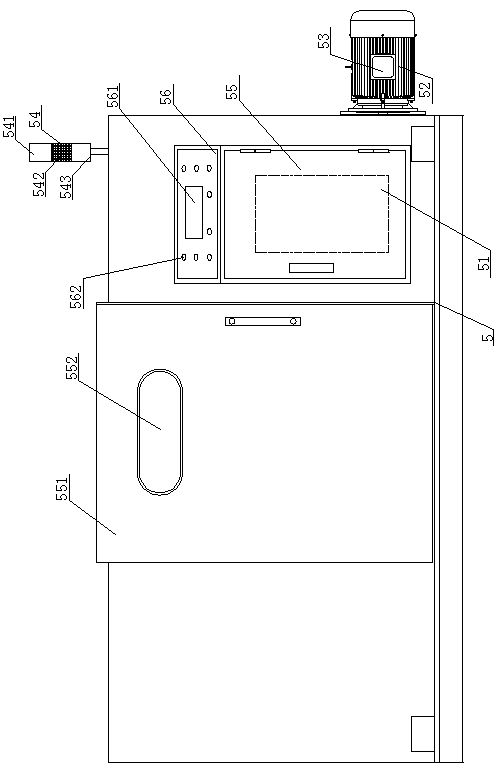

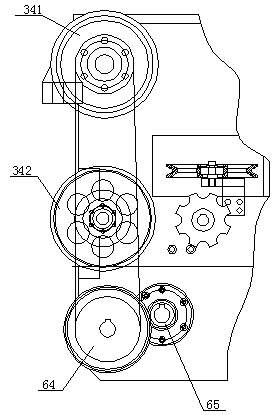

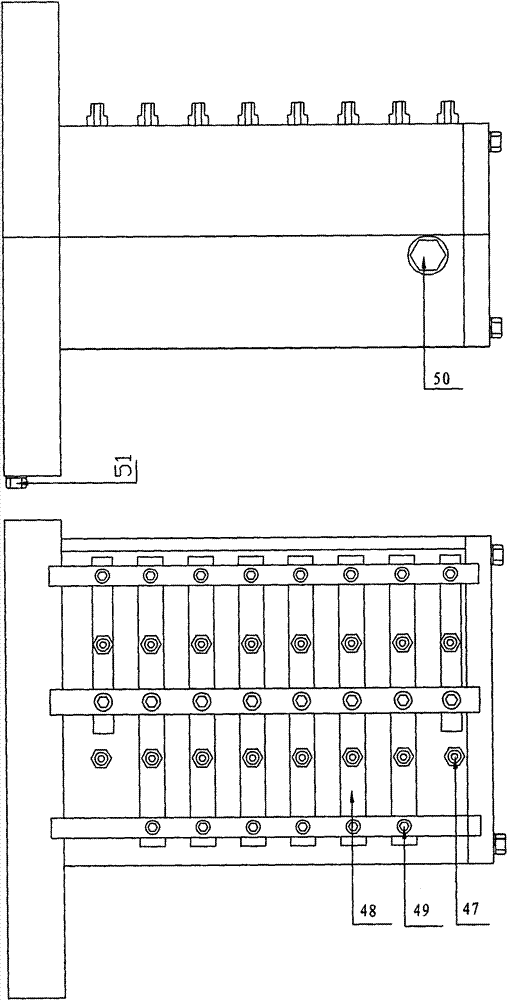

High-speed wire twisting machine with excellent performance

PendingCN109686506AEasy loading and unloadingQuality improvementCable/conductor manufactureCopper wireEngineering

The invention provides a high-speed wire stranding machine with excellent performance. The high-speed wire stranding machine with excellent performance comprises a case, a wire inlet mechanism, a wiretake-up mechanism and a wire arranging device, wherein the wire inlet mechanism comprises a wire inlet main shaft, a wire inlet die holder, a broken wire supporting rod and a meter counting wheel. Acontrol device is arranged outside the case, the wire take-up mechanism sequentially comprises a wire drawing wheel, a winch, a wire passing wheel, a traction wheel, a guide wheel and a wire take-up cradle stand, a drawing part is arranged below the traction wheel and comprises a speed reduction box, a main shaft synchronous wheel, a motor synchronous wheel, driven hanging teeth, active hanging teeth and a connecting shaft, and a lifting device is arranged below a take-up reel and comprises a lifting platform, a connecting rod mechanism and a pushing mechanism. The high-speed wire stranding machine with excellent performance can reduce noise, facilitate wire take-up, is stable in transmission, makes wire threading and winding smoother, ensures set constant tension, makes copper wires or core wires not damaged in the wire stranding process, and ensures that high-quality wires can be machined in the wire industry.

Owner:浙江金莱尔机电设备有限公司

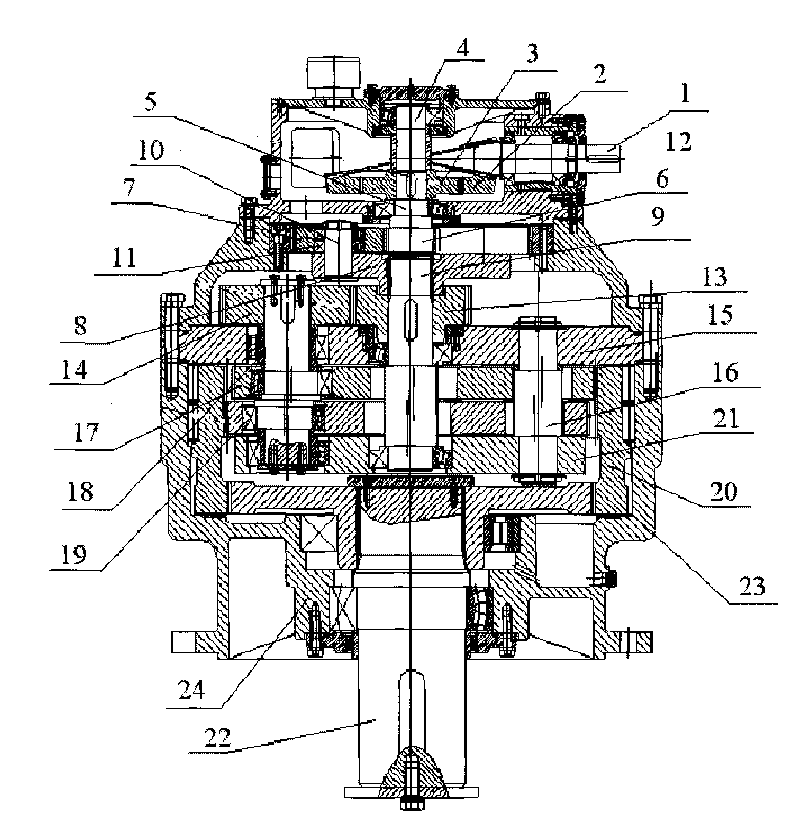

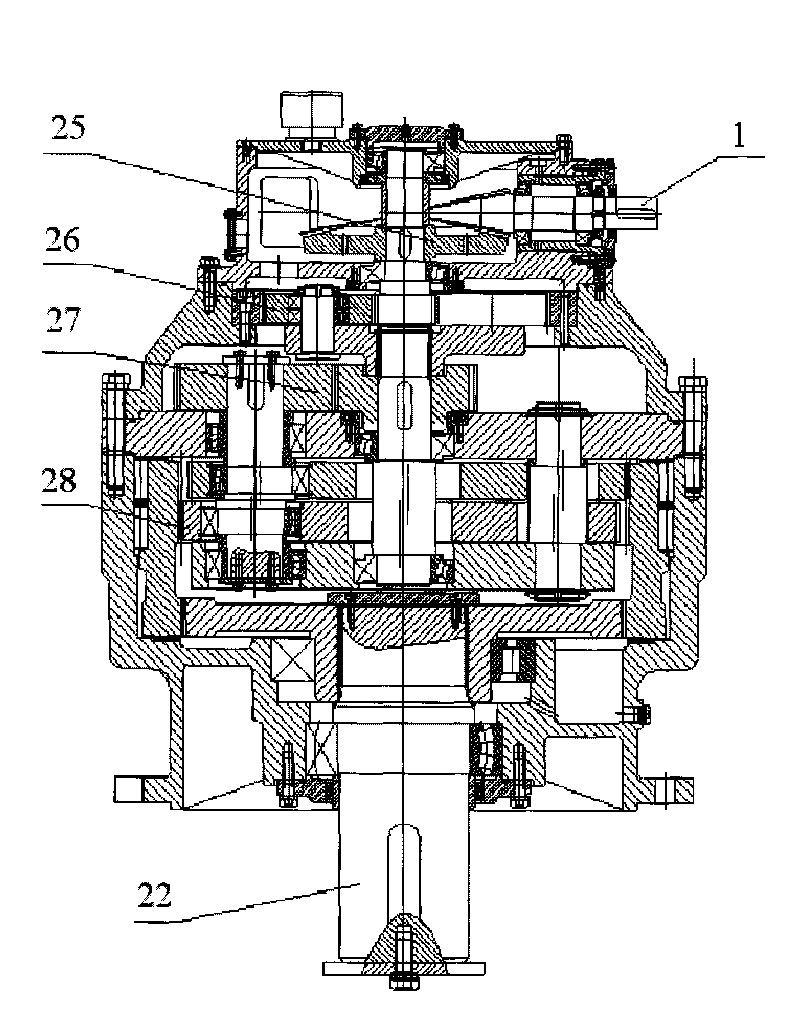

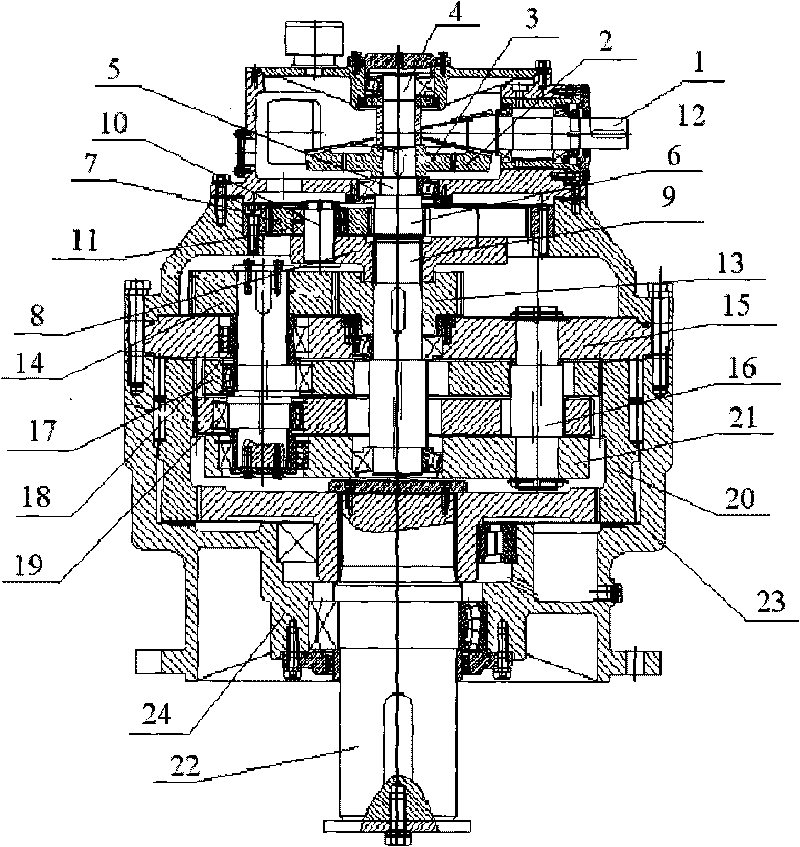

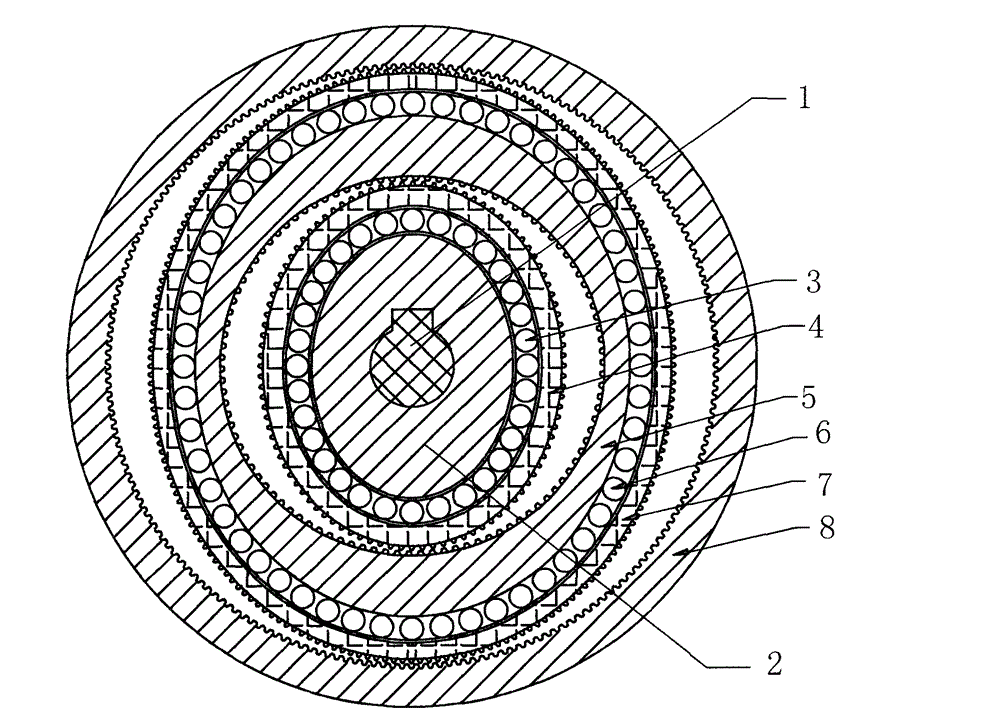

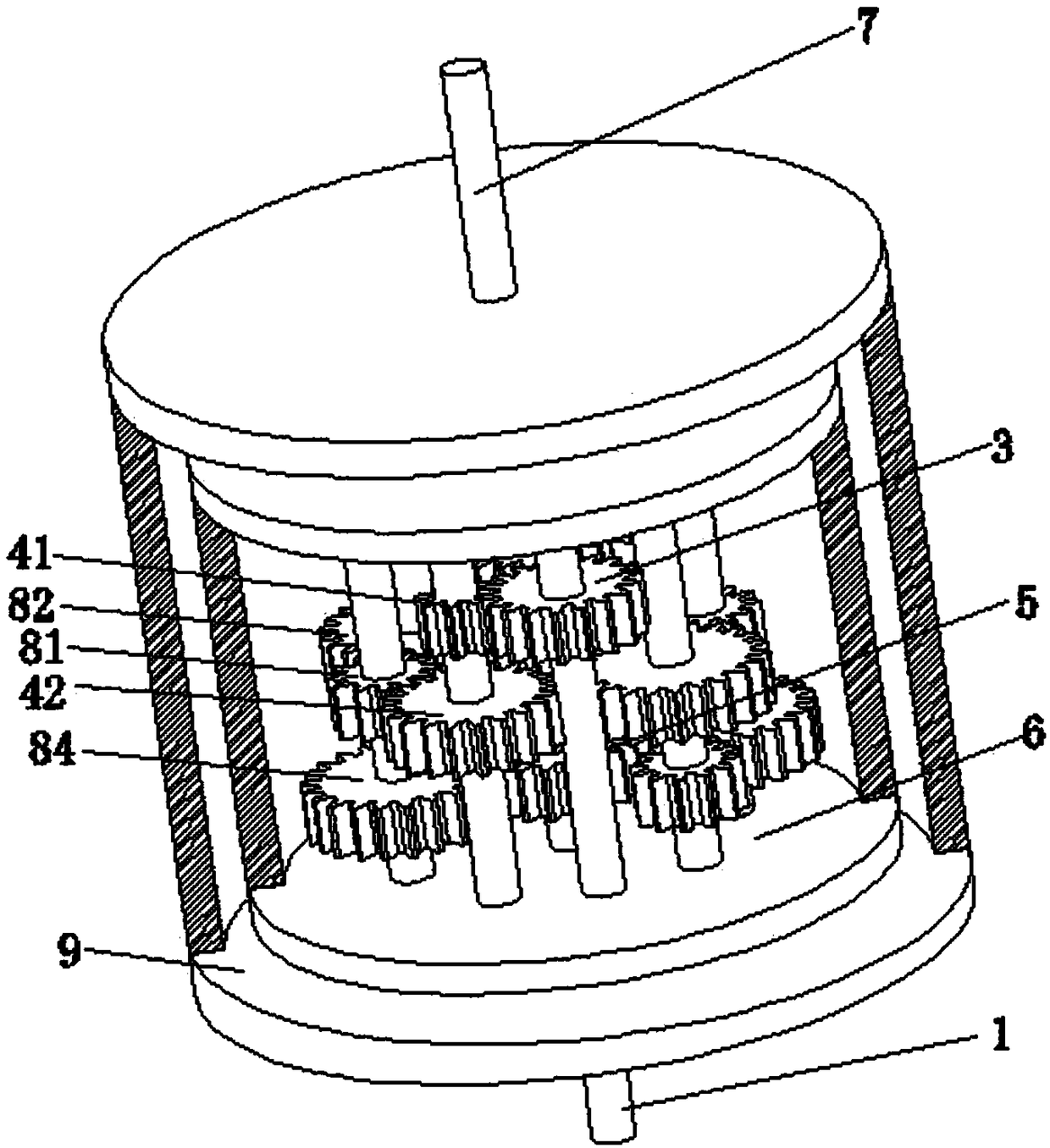

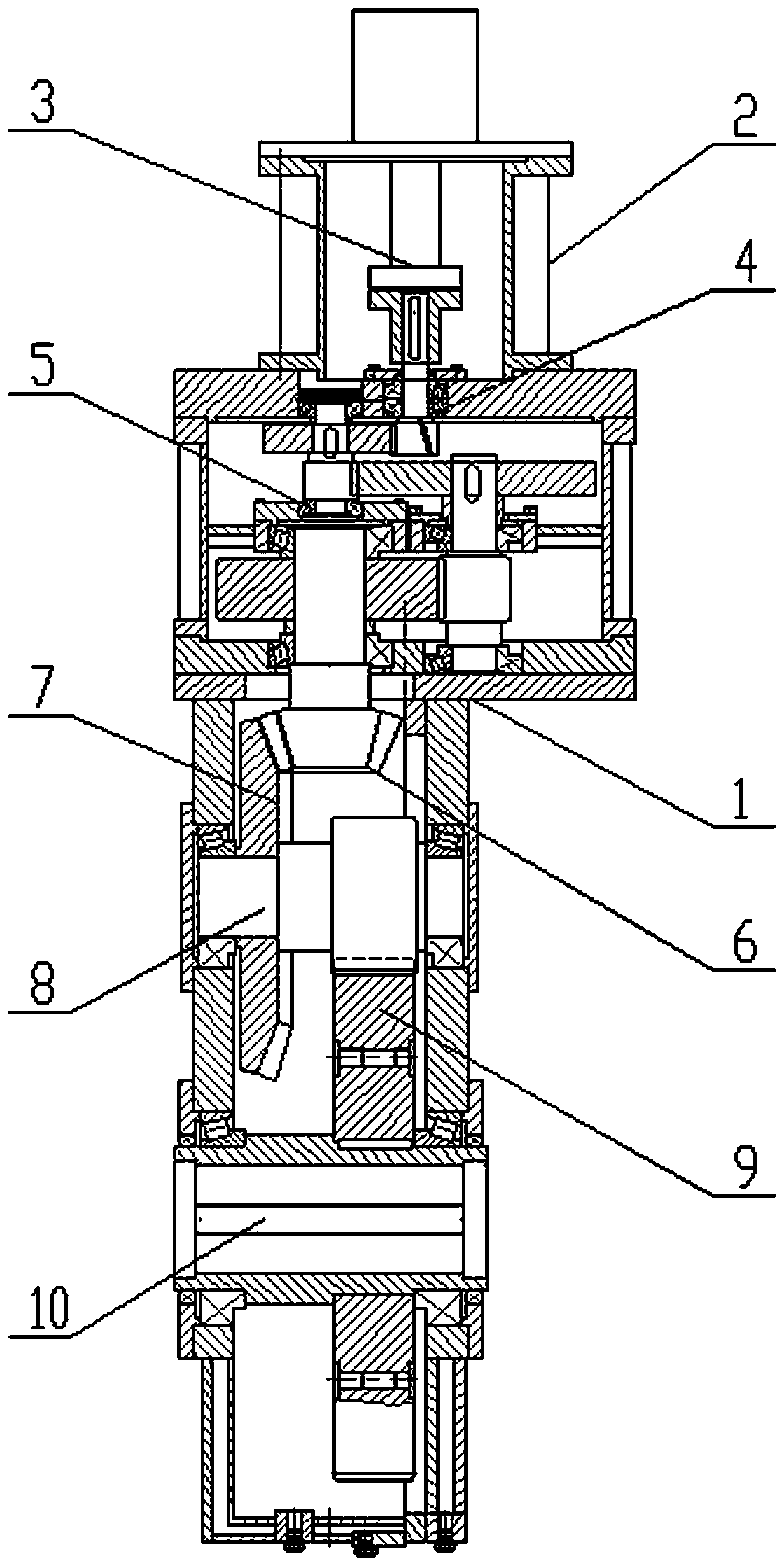

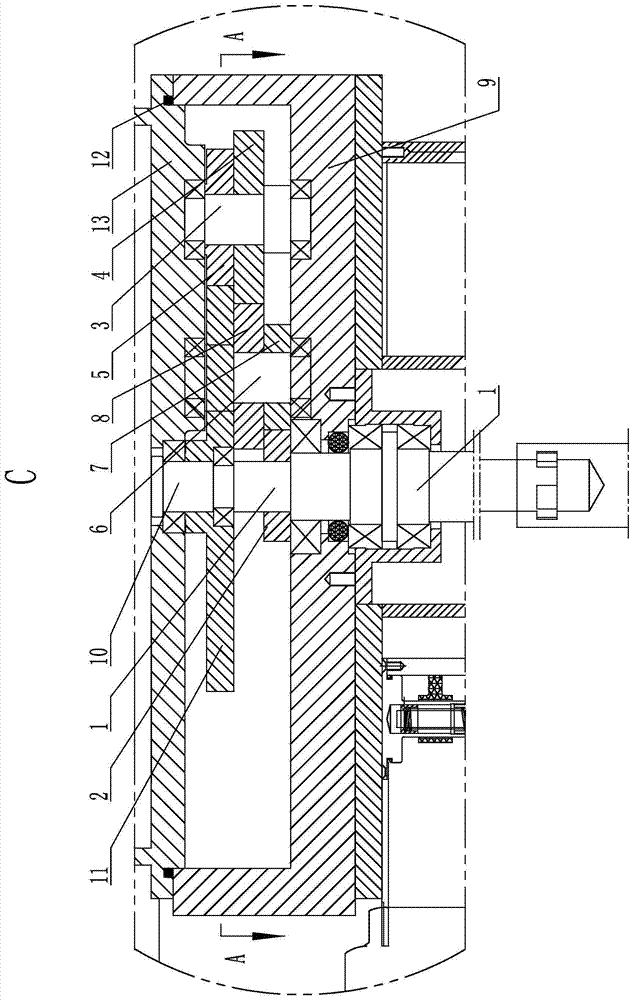

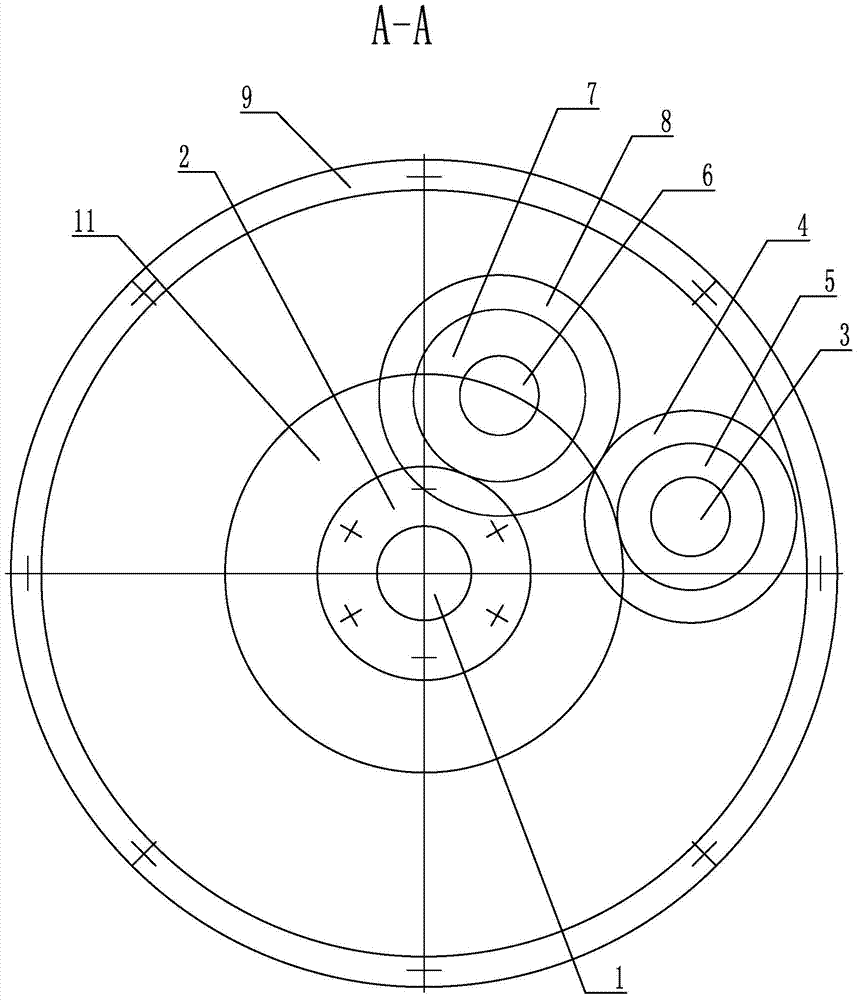

Embedded two-layer harmonic drive reducing gear

InactiveCN102797799AHigh gear ratioImprove accuracy and efficiencyToothed gearingsPortable liftingGear ratioHarmonic drive

The invention relates to an embedded two-layer harmonic drive reducing gear, which comprises a wave generator. The output end of the wave generator is provided with an input shaft, and a cam is arranged outside the input shaft. The embedded two-layer harmonic drive reducing gear is characterized in that inner-layer flexible bearings are distributed outside the cam; and an inner-layer flexible wheel is sleeved outside the inner-layer flexible bearings. Furthermore, an inner-layer steel wheel is sleeved outside the inner-layer flexible wheel, and outer-layer flexible bearings are sleeved outside the inner-layer steel wheel. Meanwhile, an outer-layer flexible wheel is sleeved outside the outer-layer flexible bearings, and an outer-layer steel wheel is sleeved outside the outer-layer flexible wheel. Therefore, double-layer harmonic waves are realized, and can achieve a higher gear ratio than the conventional single-layer harmonic waves. Meanwhile, due to the elliptical fit design, the accuracy and the efficiency are higher than single harmonic waves. The huge torque output can be realized; and in addition, the embedded two-layer harmonic drive reducing gear is precise in structure, small in size and compact in structure, easily adopts to different installation places and deserves promotion and application.

Owner:SUZHOU LEADERDRIVE HARMONIC WAVE TRANSMISSION TECH CO LTD

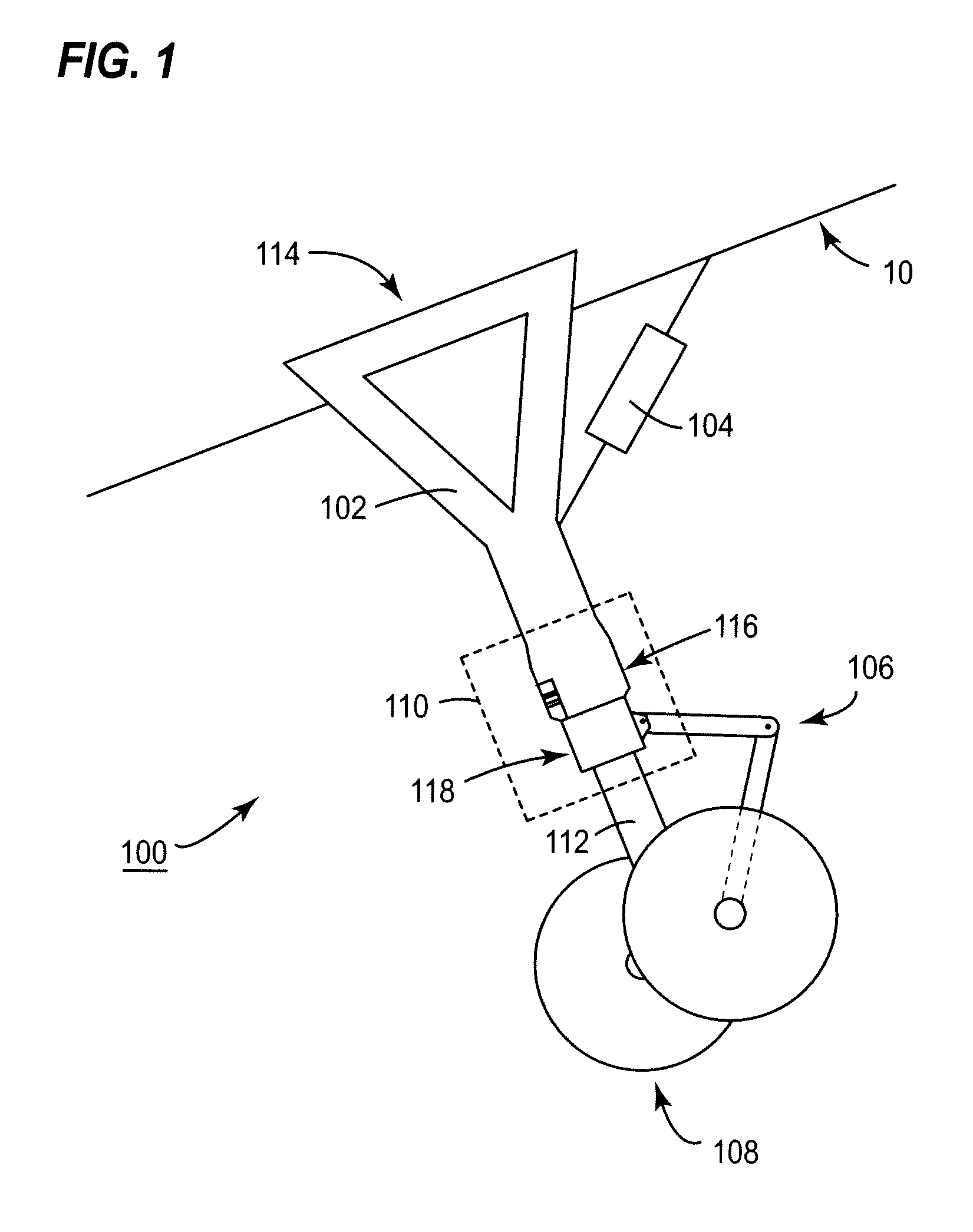

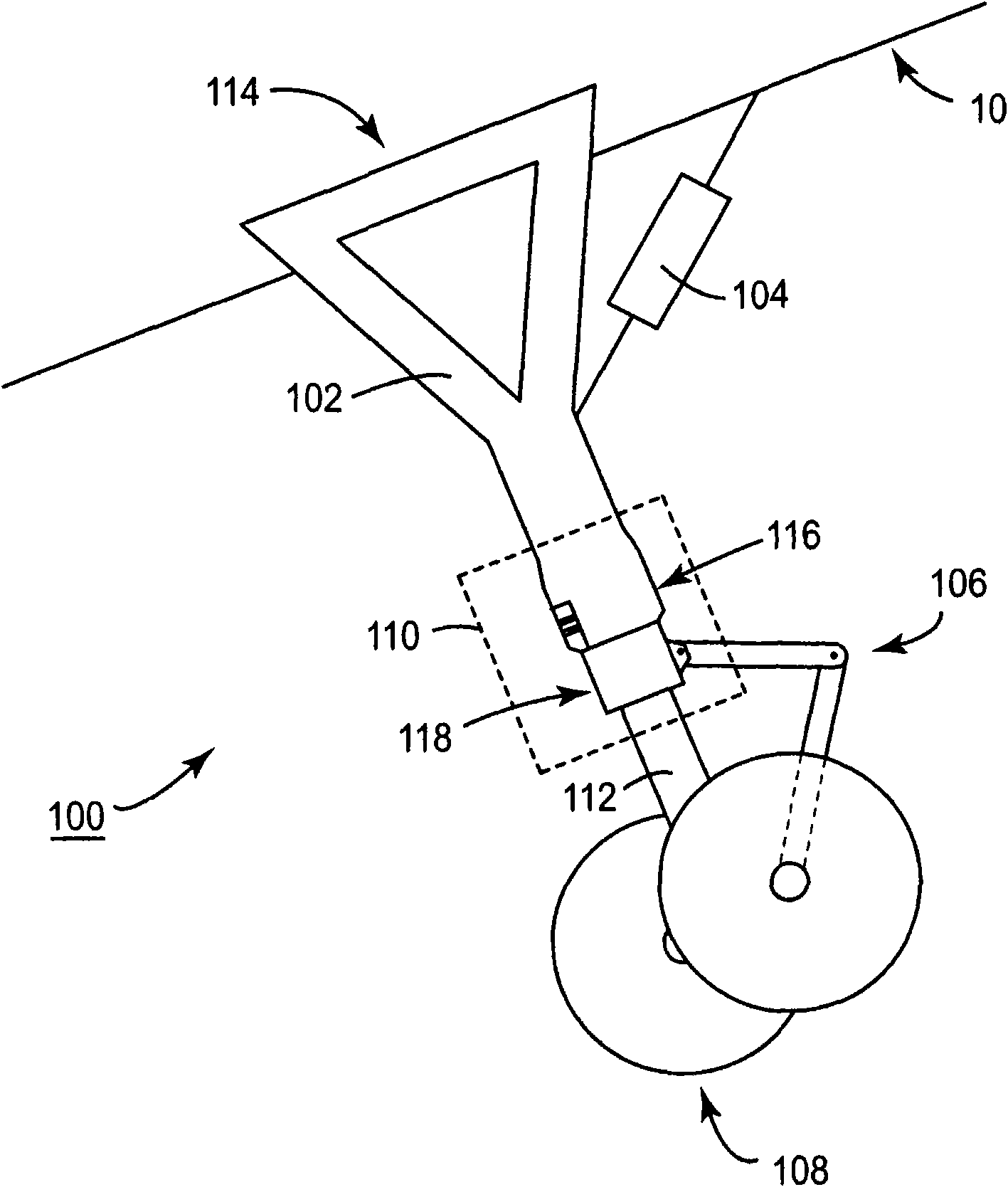

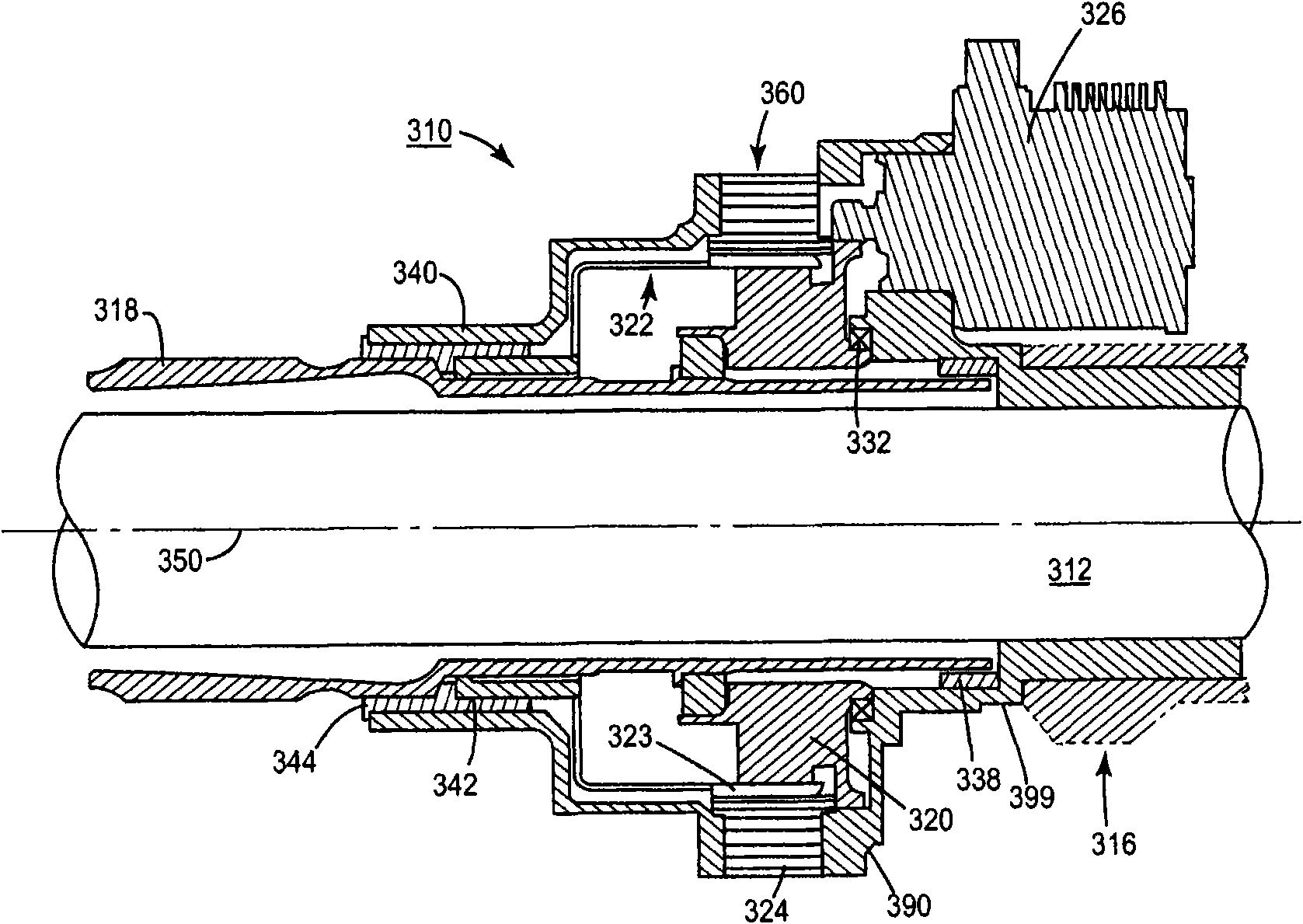

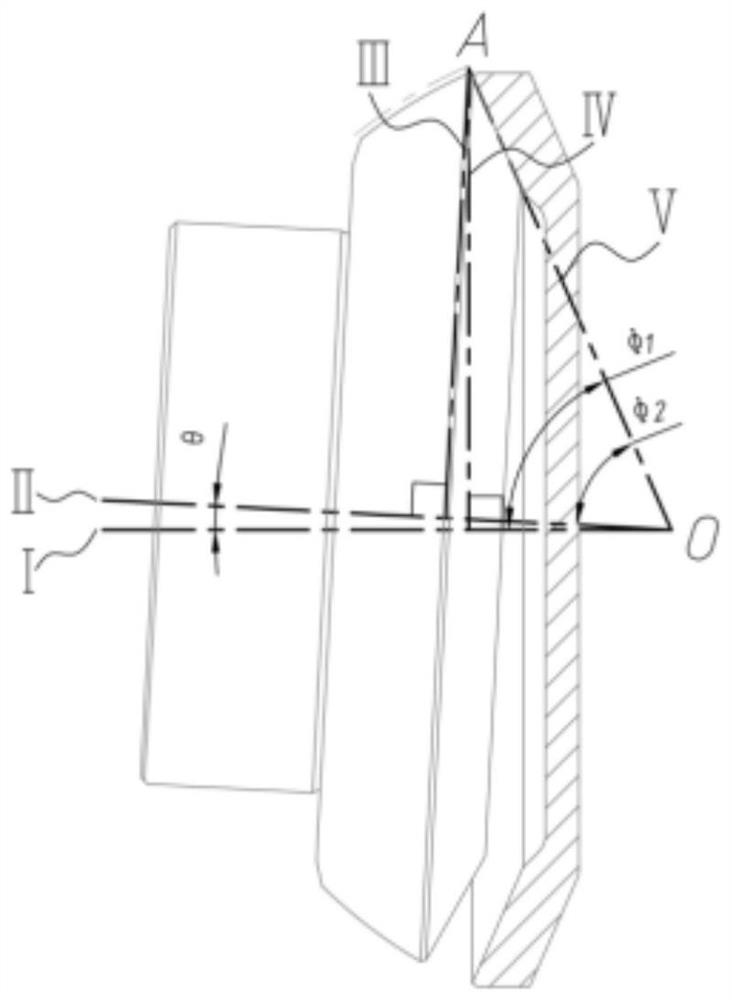

Aircraft landing gear steering system

ActiveUS20090294578A1High gear ratioLow torque actuatorGearingMechanical steering gearsAirplanePower steering

An aircraft landing gear steering system comprising a turning member that is operably coupled to a landing gear leg through a harmonic drive mechanism. The landing gear steering system may be electrically driven. Additionally, the landing gear system has various advantages, including the provision of a safe failure mode should the harmonic drive mechanism fail.

Owner:TRIUMPH ACTUATION SYST UK

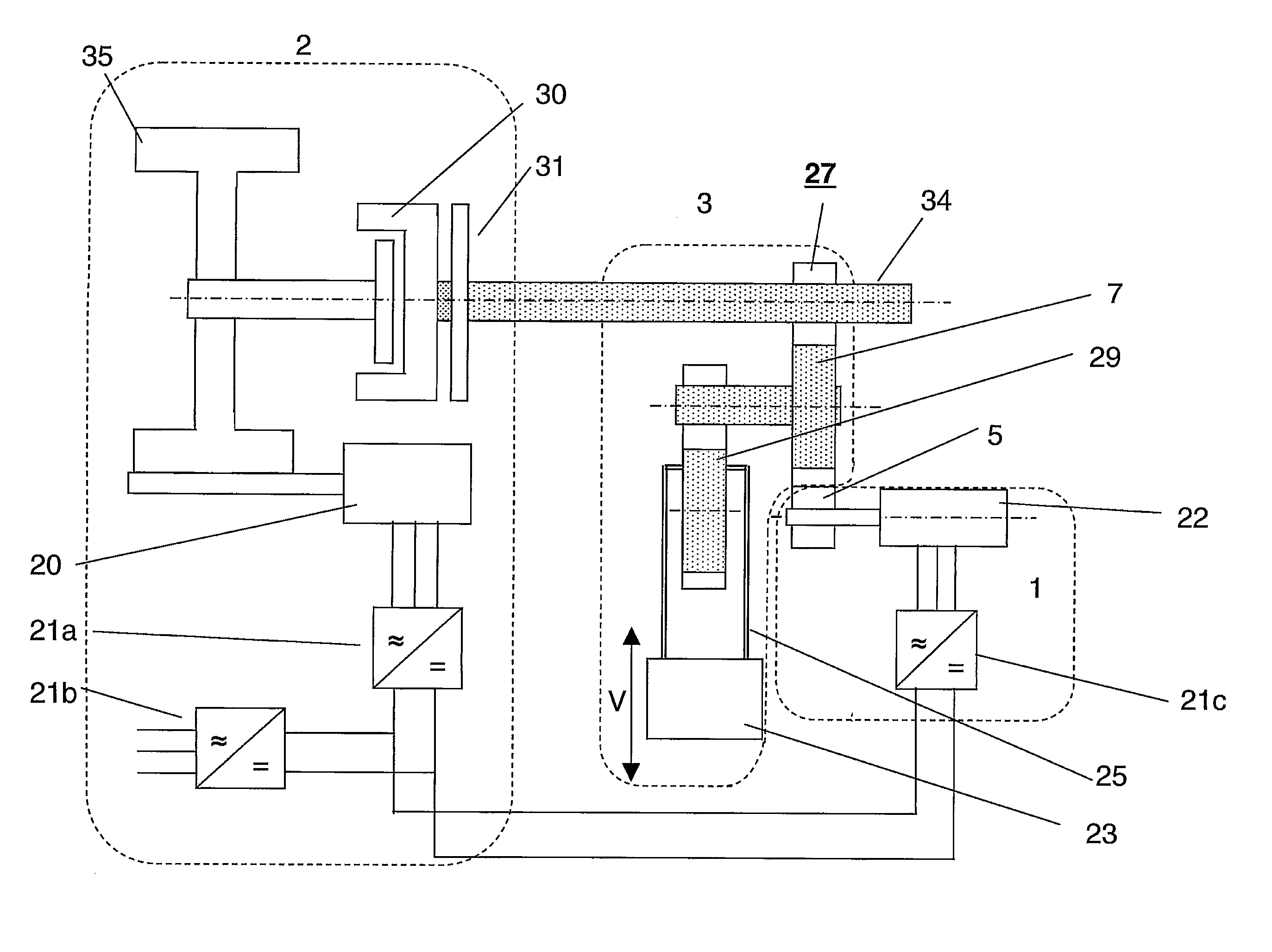

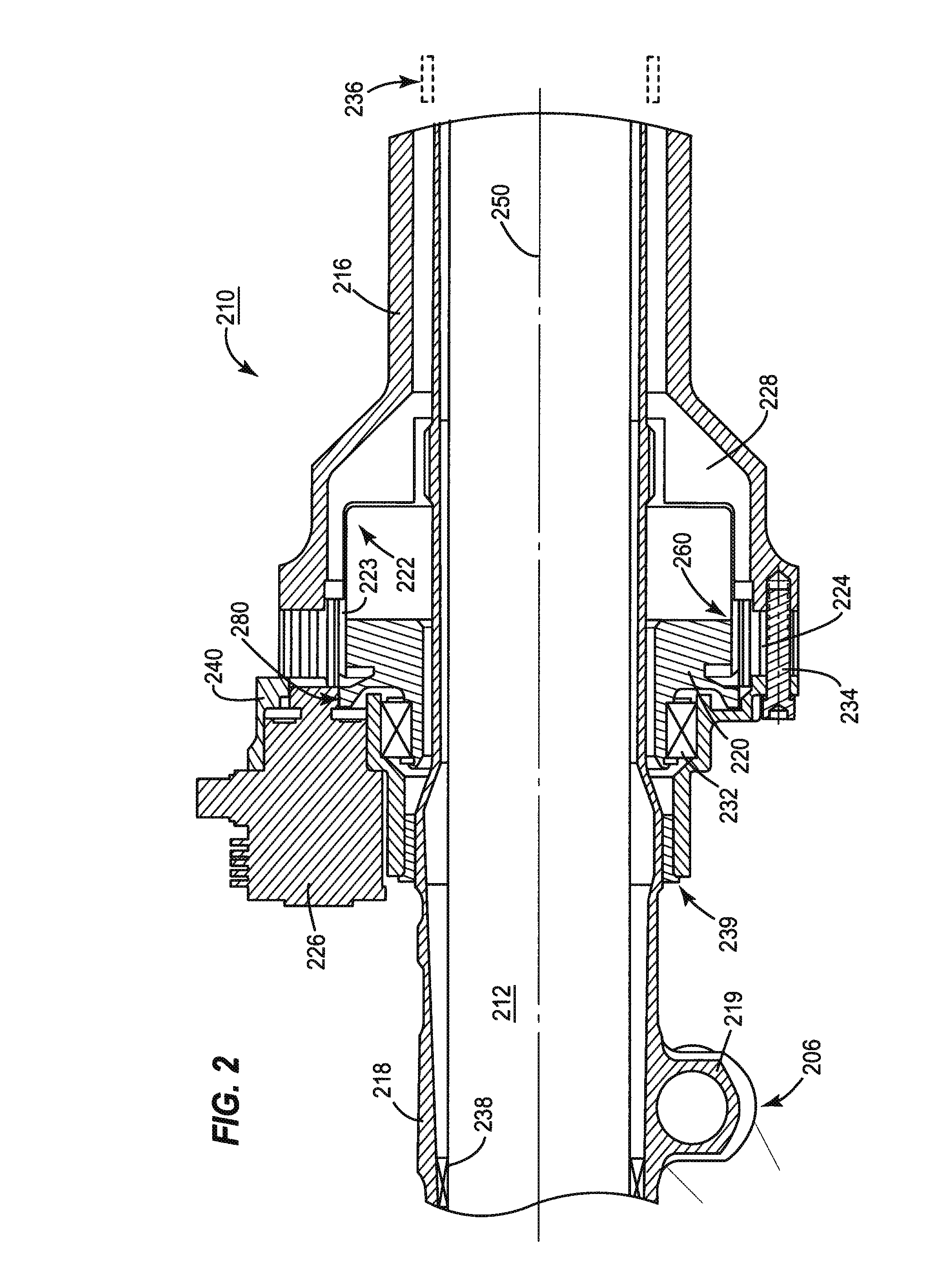

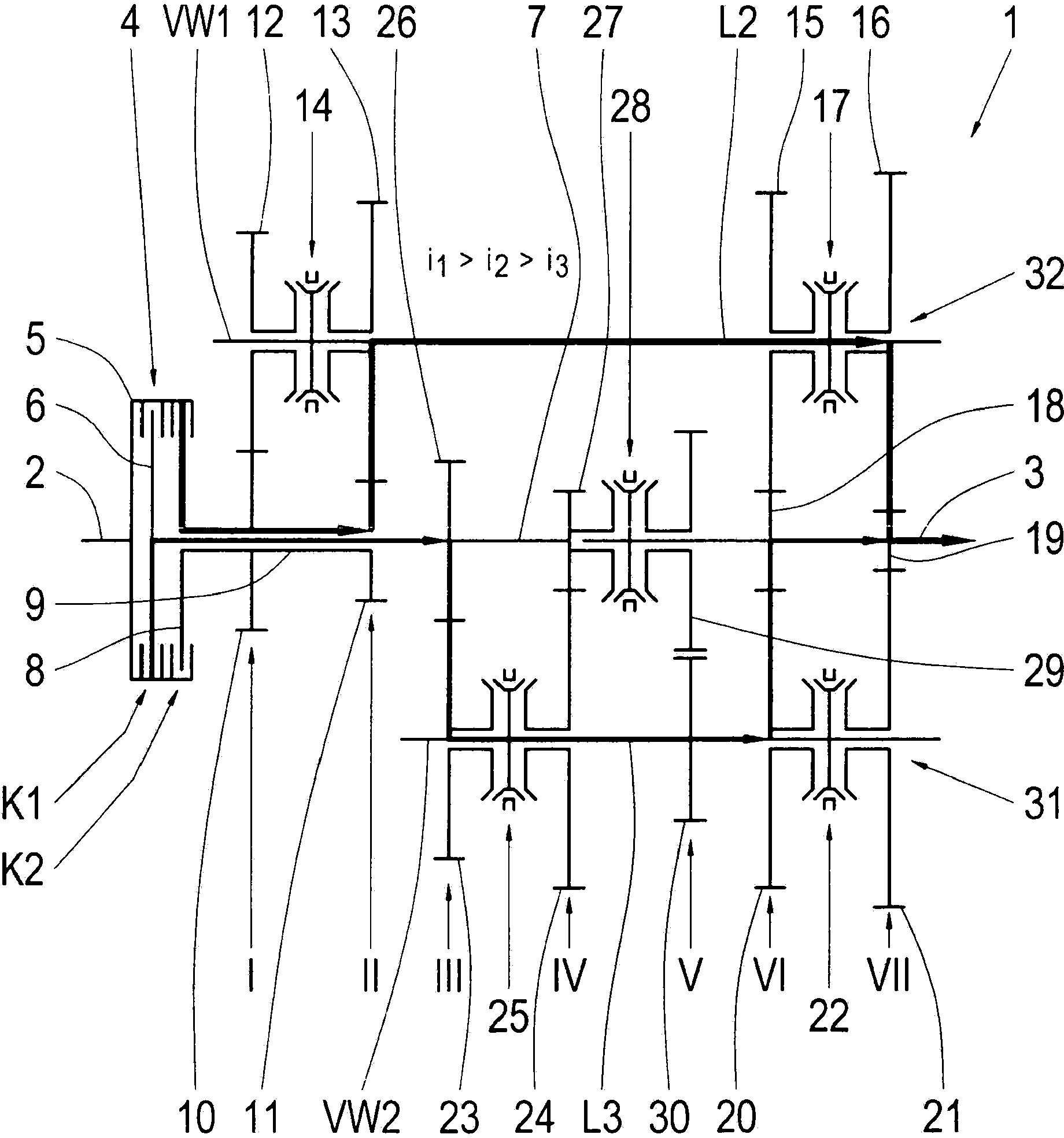

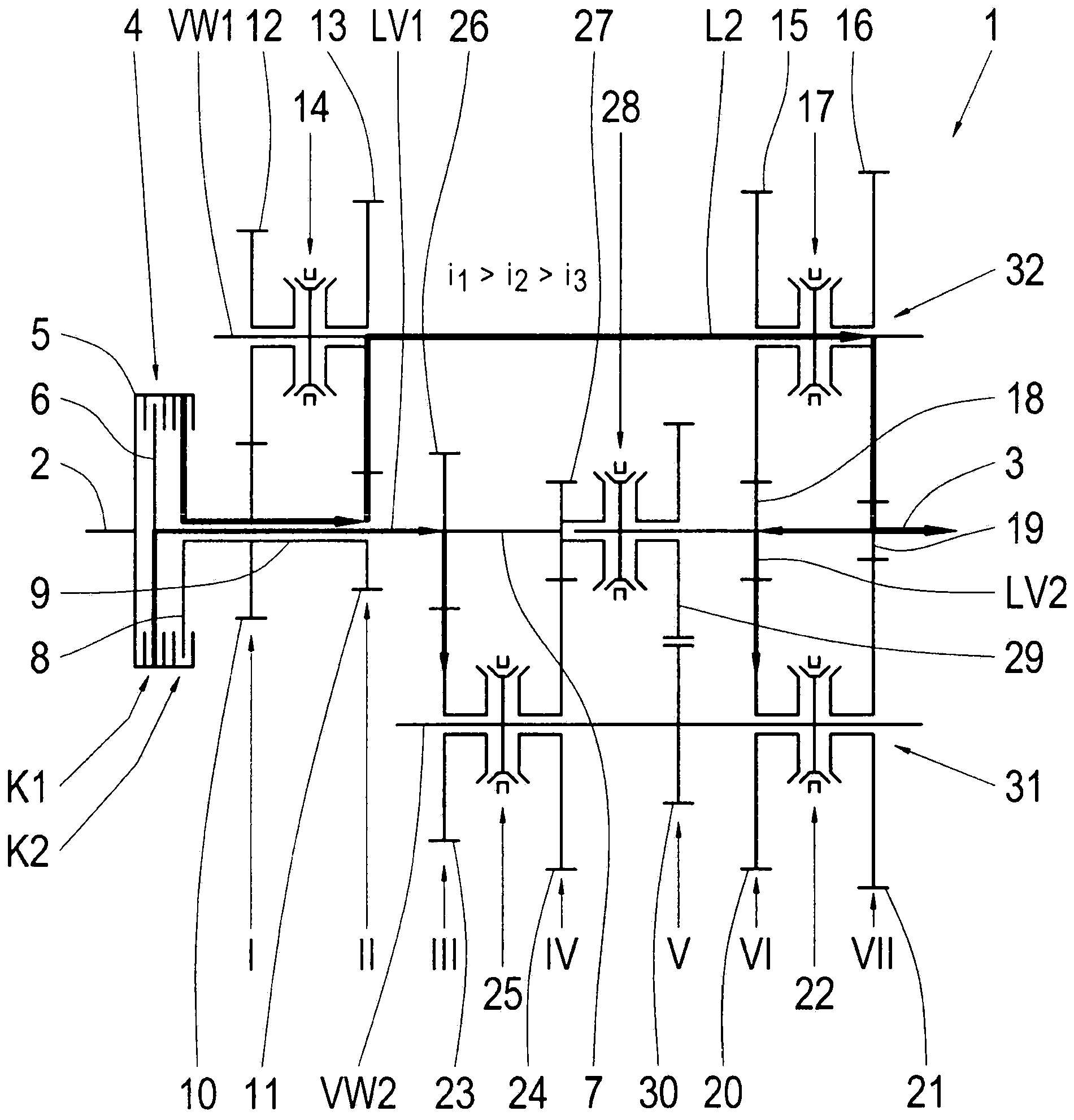

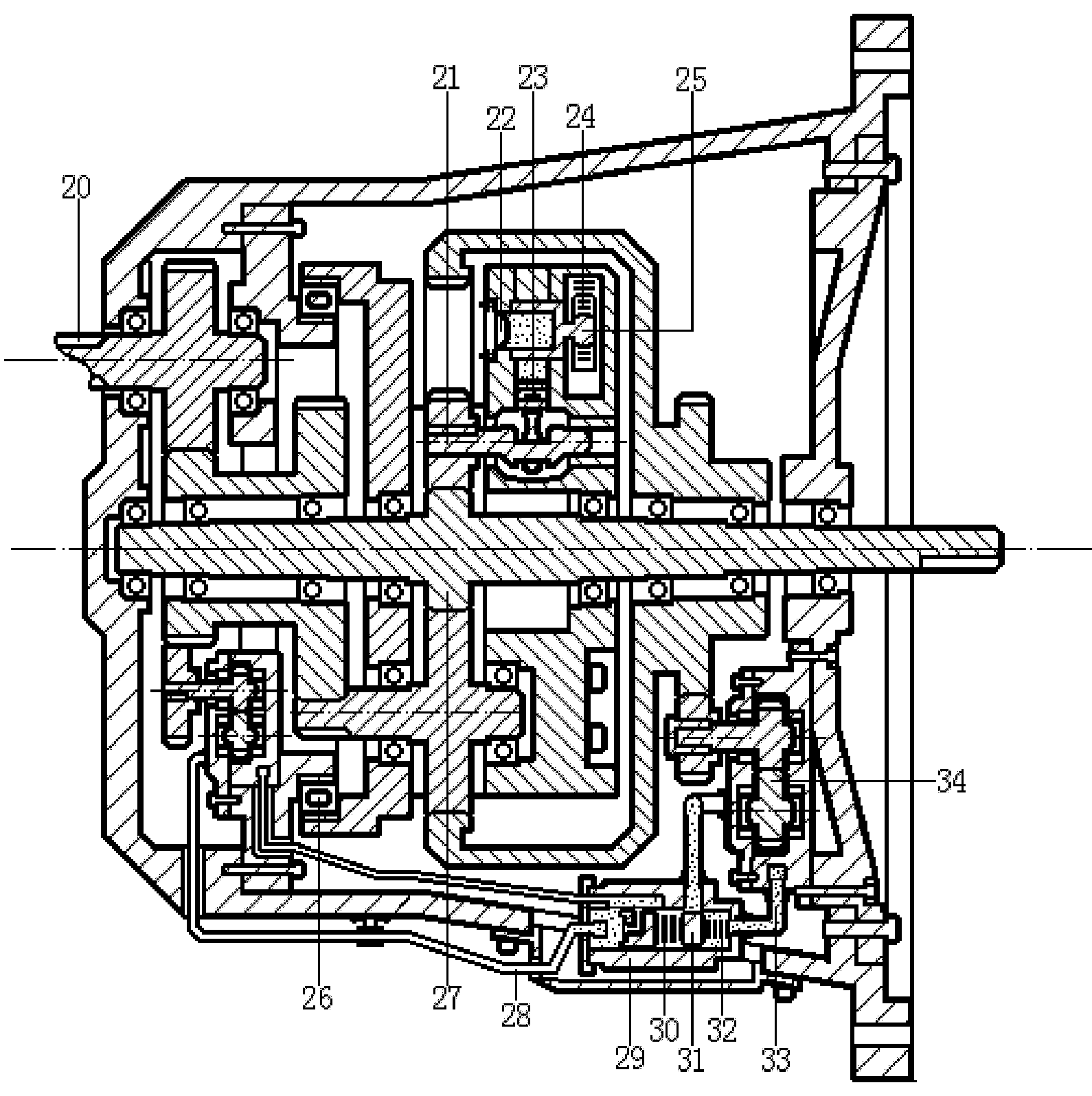

Method for operating a double clutch transmission

The invention relates to a method for the operation of a dual-clutch transmission (1) including sub-transmissions (31, 32) wherein, through a clutch of a dual-clutch device (4), the sub-transmissions are able to be switched on in the power flux of the dual-clutch transmission or are able to be switched off from the power flux. In the sub-transmissions, two different transmission ratios are able to be engaged or disengaged through the actuation of shifting elements. In the operation of the dual-clutch transmission, one of the sub-transmissions (31 / 32) is switched on, while the other sub-transmission (32 / 31) is switched off. If the transmission ratio in the switched-on sub-transmission (31 / 32) is engaged, all transmission ratios in the switched-off sub-transmission are simultaneously disengaged through the shifting elements(14, 17 / 22, 25), as long as there is no request for a change of transmission ratio in the dual-clutch transmission (1).

Owner:ZF FRIEDRICHSHAFEN AG

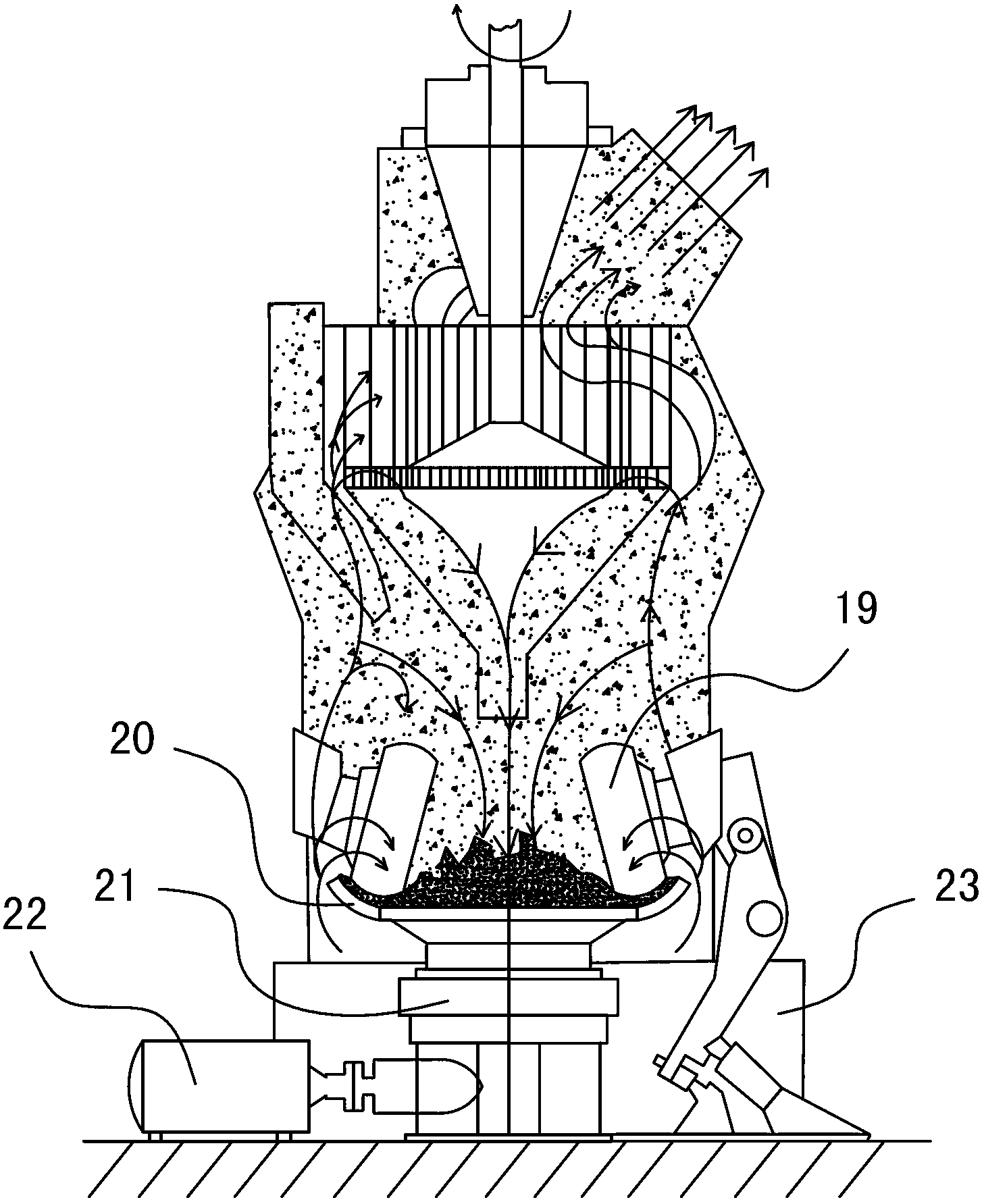

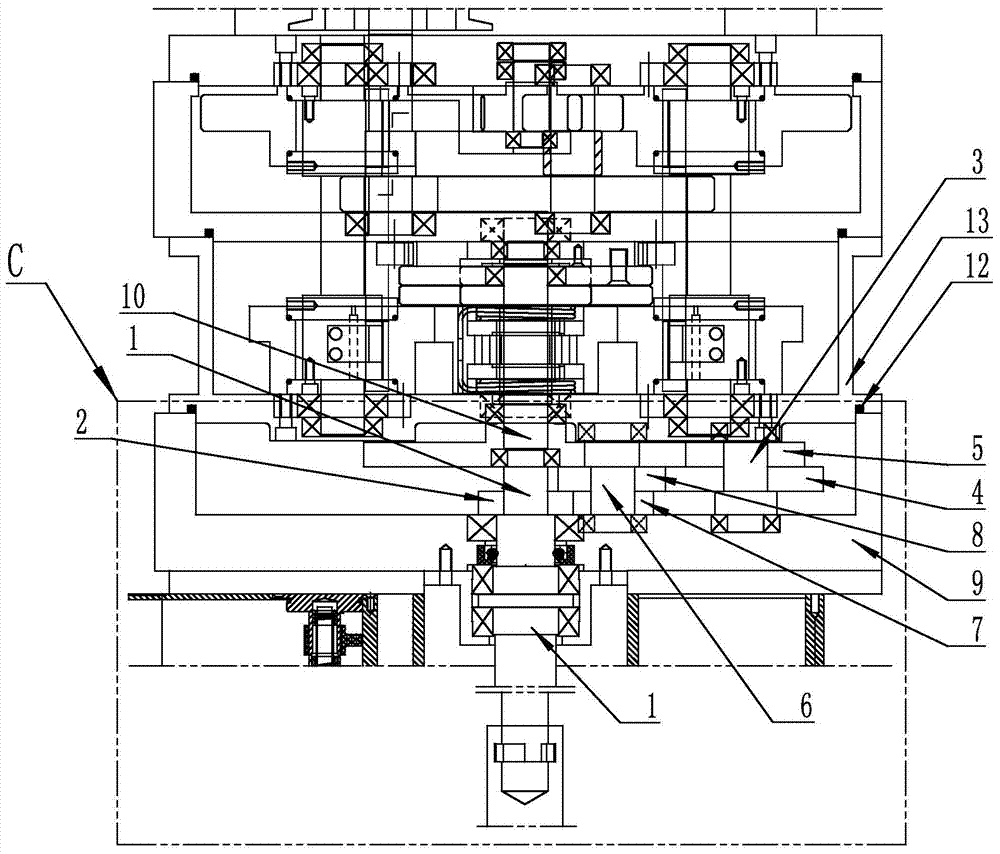

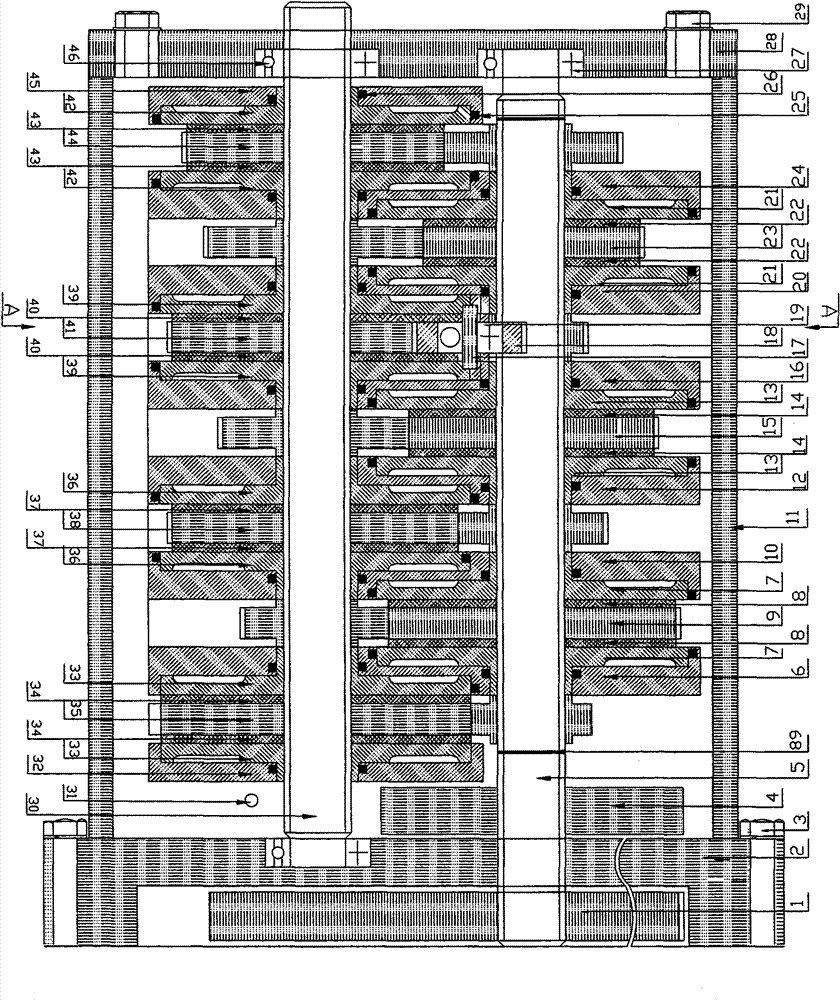

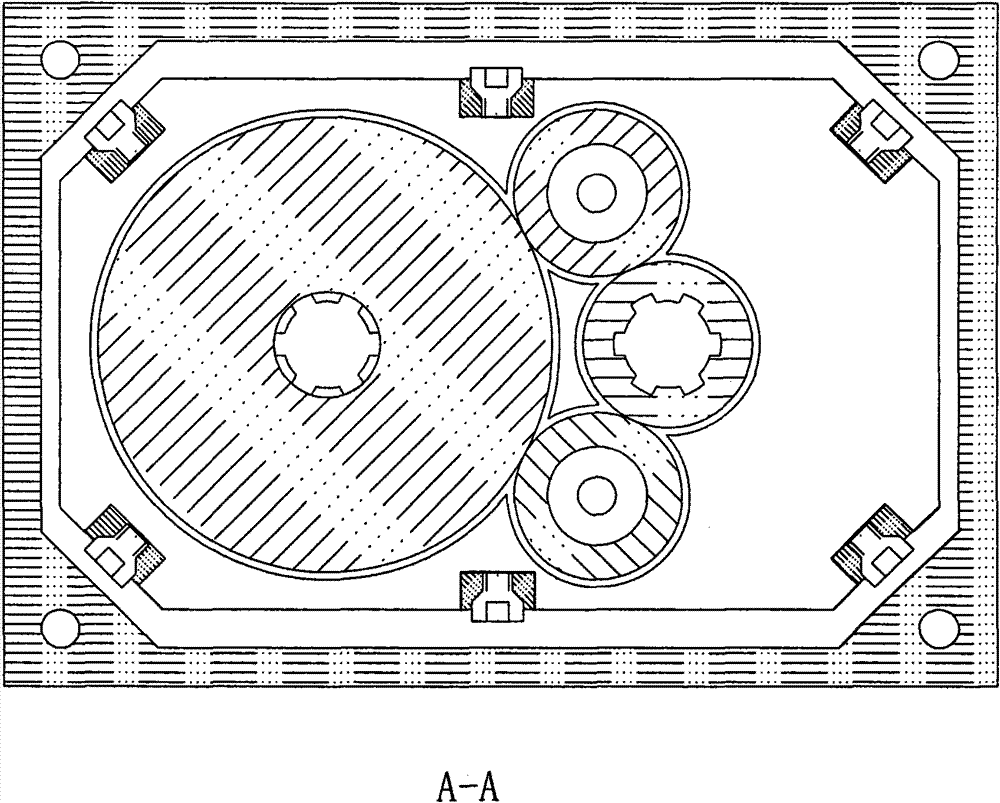

Gear case for high-power vertical roller mill

InactiveCN102705467AImprove load sharing capacityIncreased ability to transmit power and loadsGearingEngineeringRoller mill

The invention discloses a gear case for a high-power vertical roller mill, which is composed of a three-stage reduction transmission structure. The gear case for the high-power vertical roller mill is characterized in that a first stage transmission mechanism adopts a bevel gear or a belt pulley or a worm gear mechanism, and a second stage transmission mechanism and a third stage transmission mechanism adopt a planet gear mechanism. The three stages of transmission mechanisms are sequentially arranged from bottom to top inside a case body; an input shaft of the first stage transmission mechanism is used as an input end; an output shaft of the first stage transmission mechanism is in transmission connection with a sun wheel of the second stage transmission mechanism, and an inner gear of the second stage transmission mechanism is fixed. On one hand, the planet gear of the second stage transmission mechanism is in transmission connection with the sun wheel of the third stage transmission mechanism through an inner gear sleeve and a duplex outer gear sleeve, on the other hand, the planet gear of the second stage transmission mechanism is supported on a planet carrier of the third stage transmission mechanism through a hanger rod and a thrust bearing via floating suspension, and the planet carrier of the third stage transmission mechanism is fixedly connected with an output flange. The invention provides the gear case for the high-property vertical roller mill with high power, large transmission ratio and strong uniform loading capacity.

Owner:宝钢苏冶重工有限公司

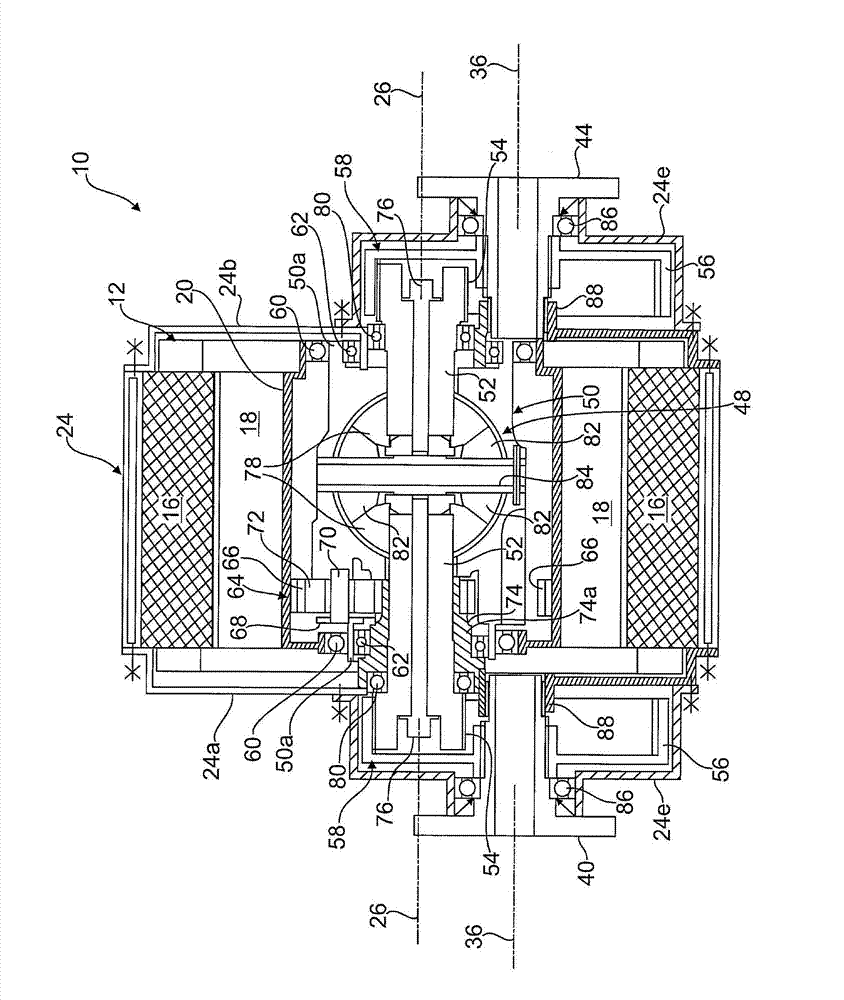

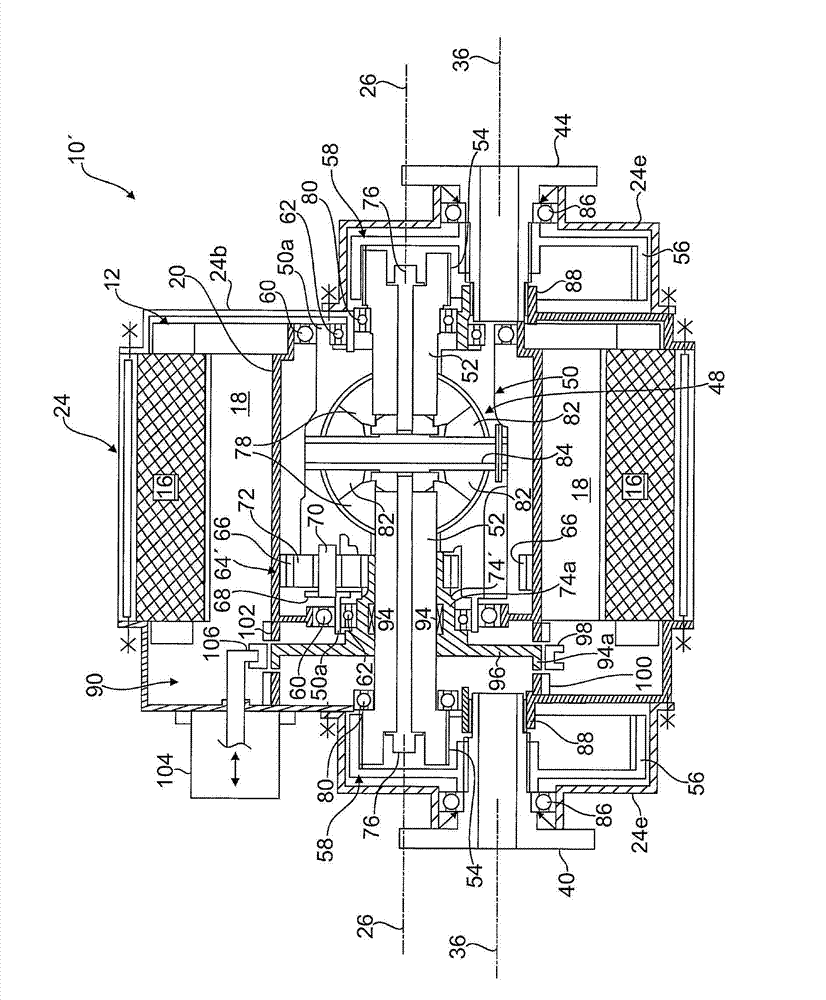

Driving device

ActiveCN102774281AIncrease drive torqueCompact structureDifferential gearingsMotor depositionElectric machineControl theory

The invention relates to a driving device, used for a wheel of a motor vehicle having the aid of a motor and driven by a differential mechanism; wherein the motor possessing rotors and a stator drives the input element of the differential mechanism, and the output element of the differential mechanism is outputted to the wheel of the motor vehicle via an output shaft. In order to realize a structure which is compact in structure and favorable in gear ratio, the driving device is provided. The annular rotors (18) of the motor (12) are outputted to the input element (50) of the differential mechanism (48) via variable-speed control mechanisms (64, 64'), and the variable-speed control mechanisms (64, 64') and the differential mechanism (48) are integrated in the rotors (18, 20).

Owner:AUDI AG

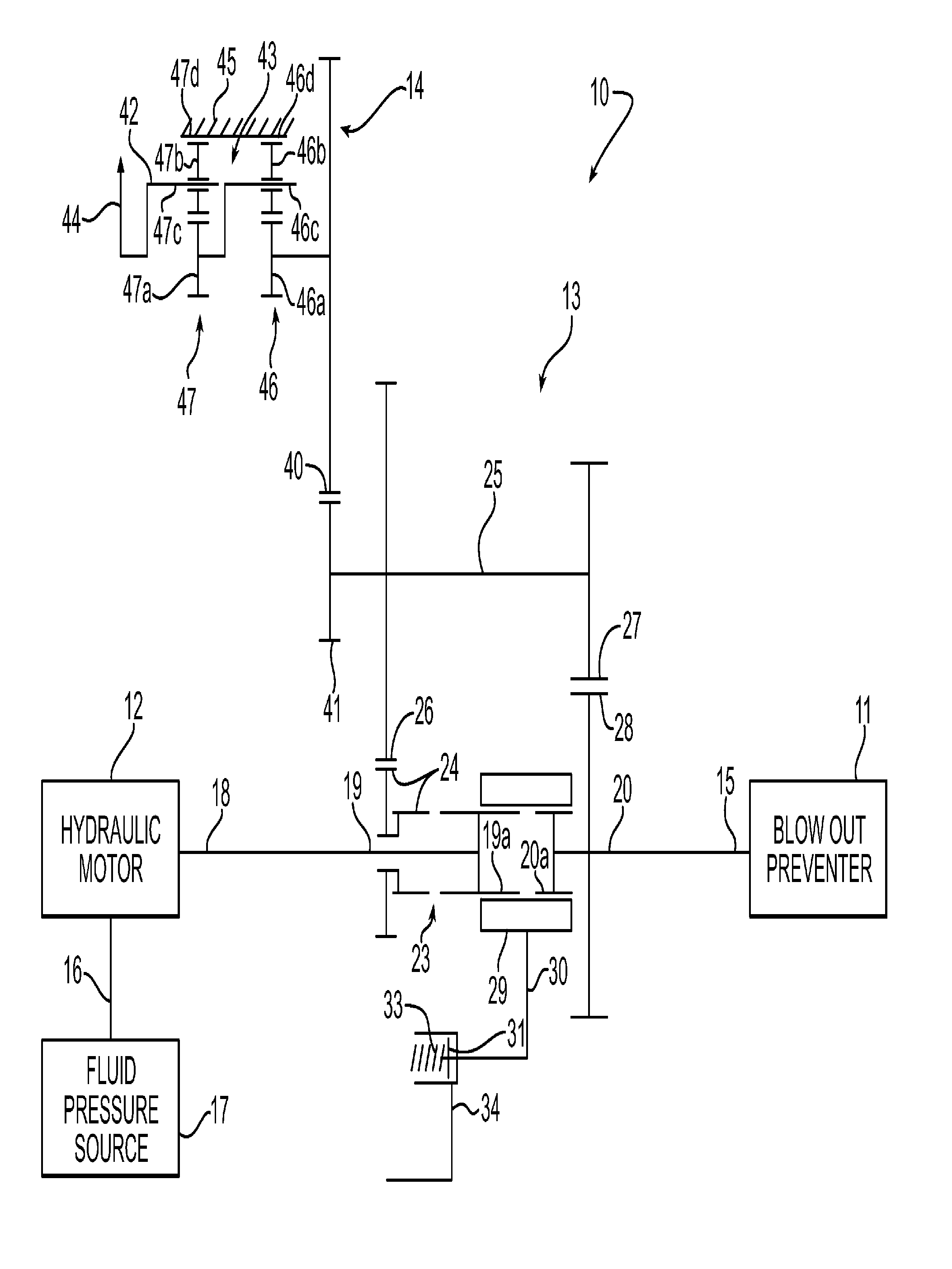

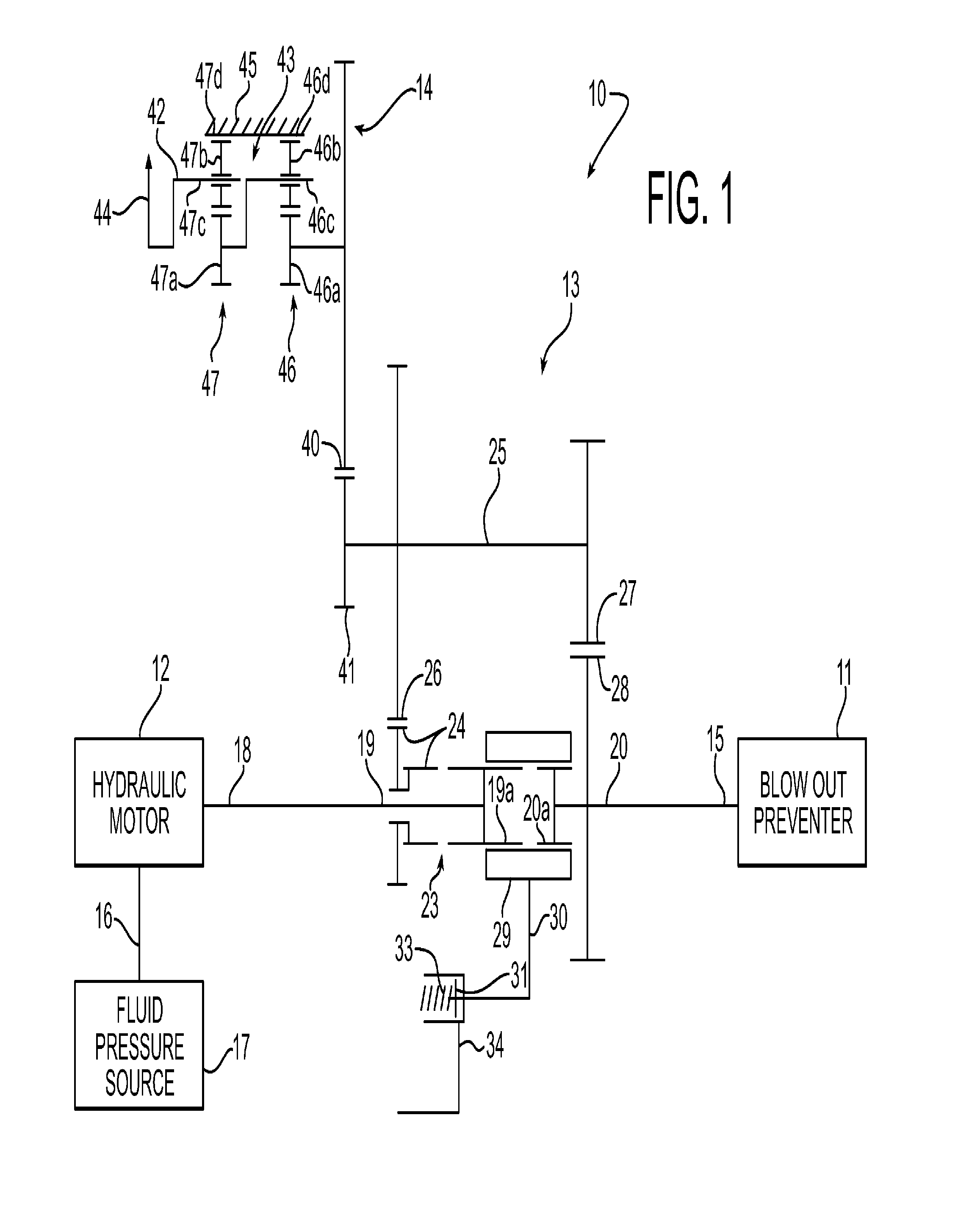

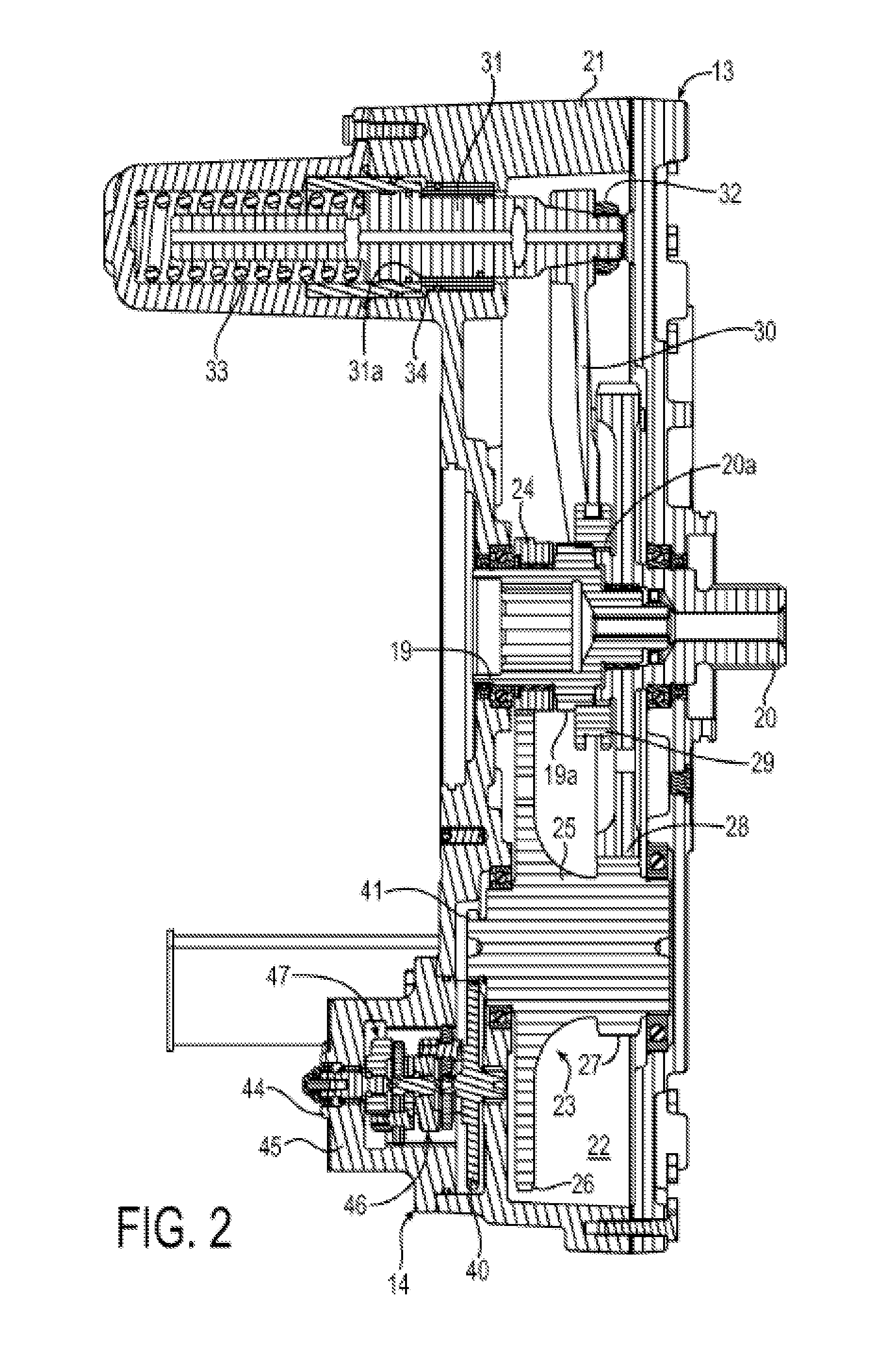

Actuator Provided with a Gear Box, Position Indicator for a Gear Box, and Related Methods

ActiveUS20160131251A1High speedHigh gear ratioManual control with multiple controlled membersDrilling rodsPistonGear ratio

Owner:PARKER INTANGIBLES LLC

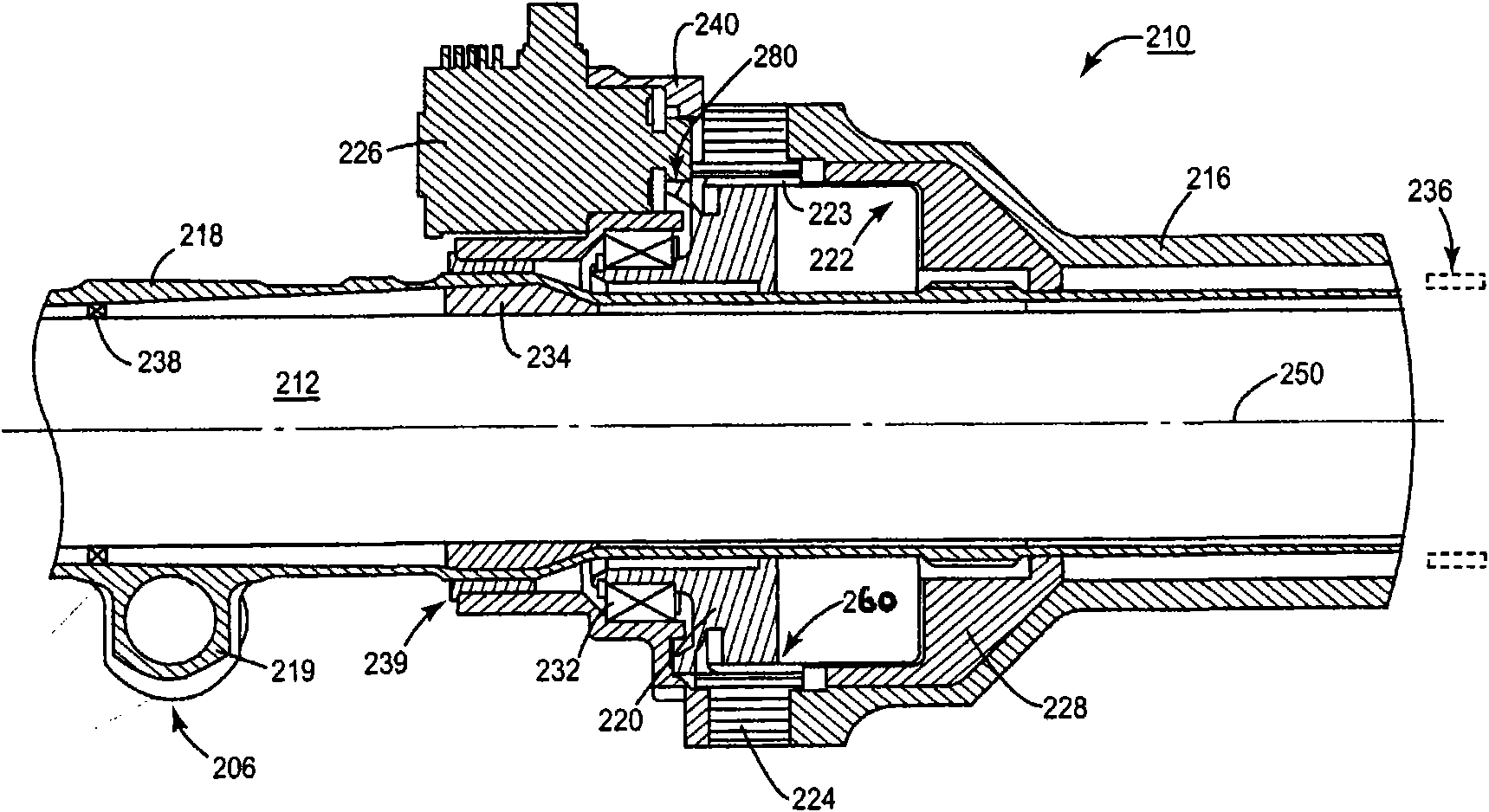

Aircraft landing gear steering system

InactiveCN101665154AReduce torqueHigh gear ratioGearingMechanical steering gearsFlight vehicleAircraft landing

The invention relates generally to an aircraft landing gear steering system (110, 210, 310) comprising a turning member (118, 218, 318) that is operably coupled to a landing gear leg (116, 216, 316) through a harmonic drive mechanism (260, 360). The landing gear steering system 110 may be electrically driven. The system typically comprises a flex spline (239), for providing a low gear ratio. The system may also comprise a steering drive disengagement clutch. Additionally, the landing gear system (110, 210, 310) has various advantages, including the provision of a safe failure mode should the harmonic drive mechanism (260, 360) fail.

Owner:TRIUMPH ACTUATION SYST UK

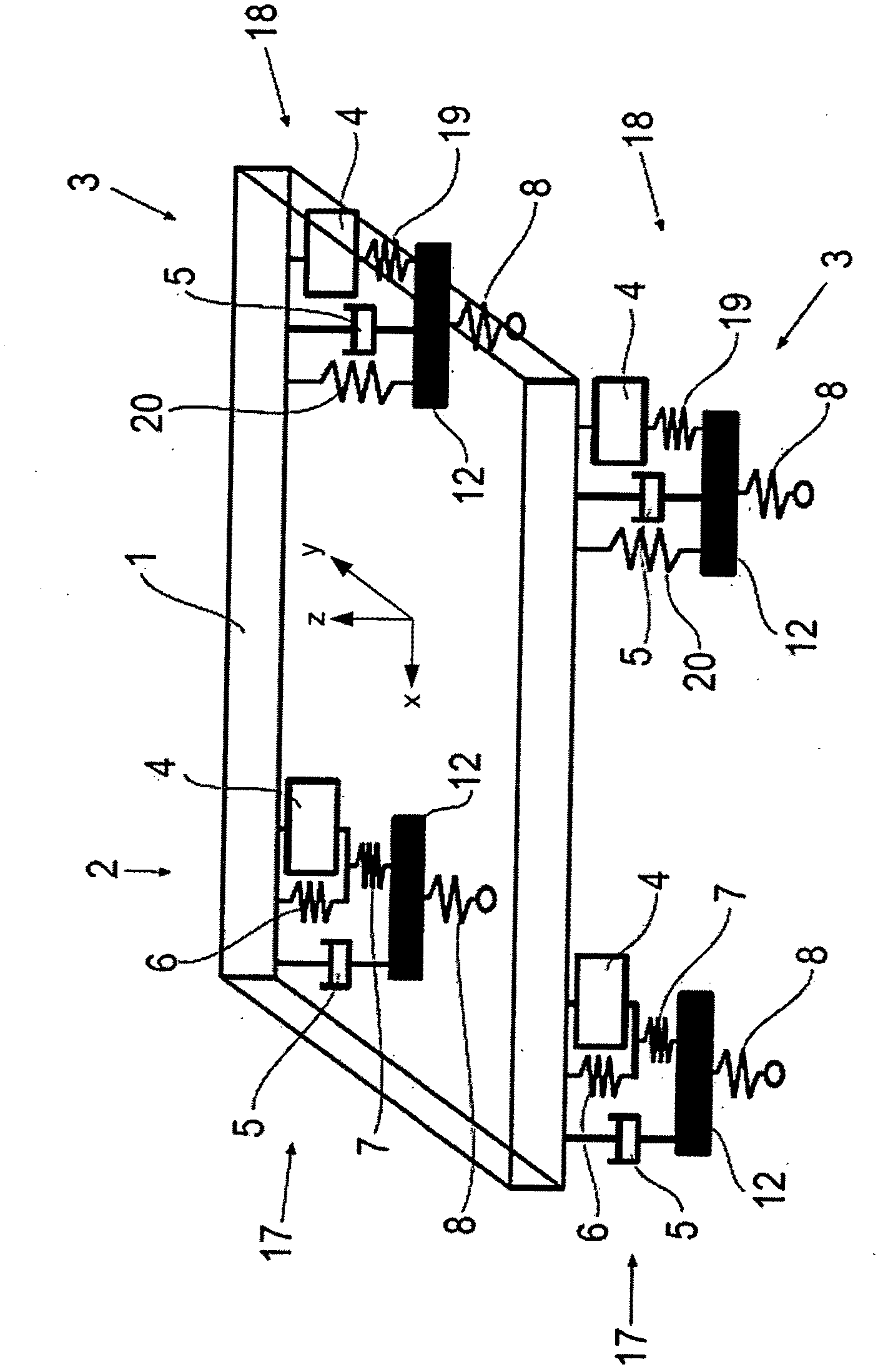

Active electromechanical suspension system for a chassis of a motor vehicle

InactiveCN102361766ALow costHigh gear ratioInterconnection systemsResilient suspensionsControl theoryRolling chassis

The invention relates to an active electromechanical suspension system for a chassis of a motor vehicle, having a first and a second axis for two opposing wheels (9). Struts (17) having strut actuators (2) are assigned to the first axis for the opposing wheels, and strut arrangements (18) having rotation actuators (3) are assigned to the second axis for the opposing wheels.

Owner:AUDI AG +1

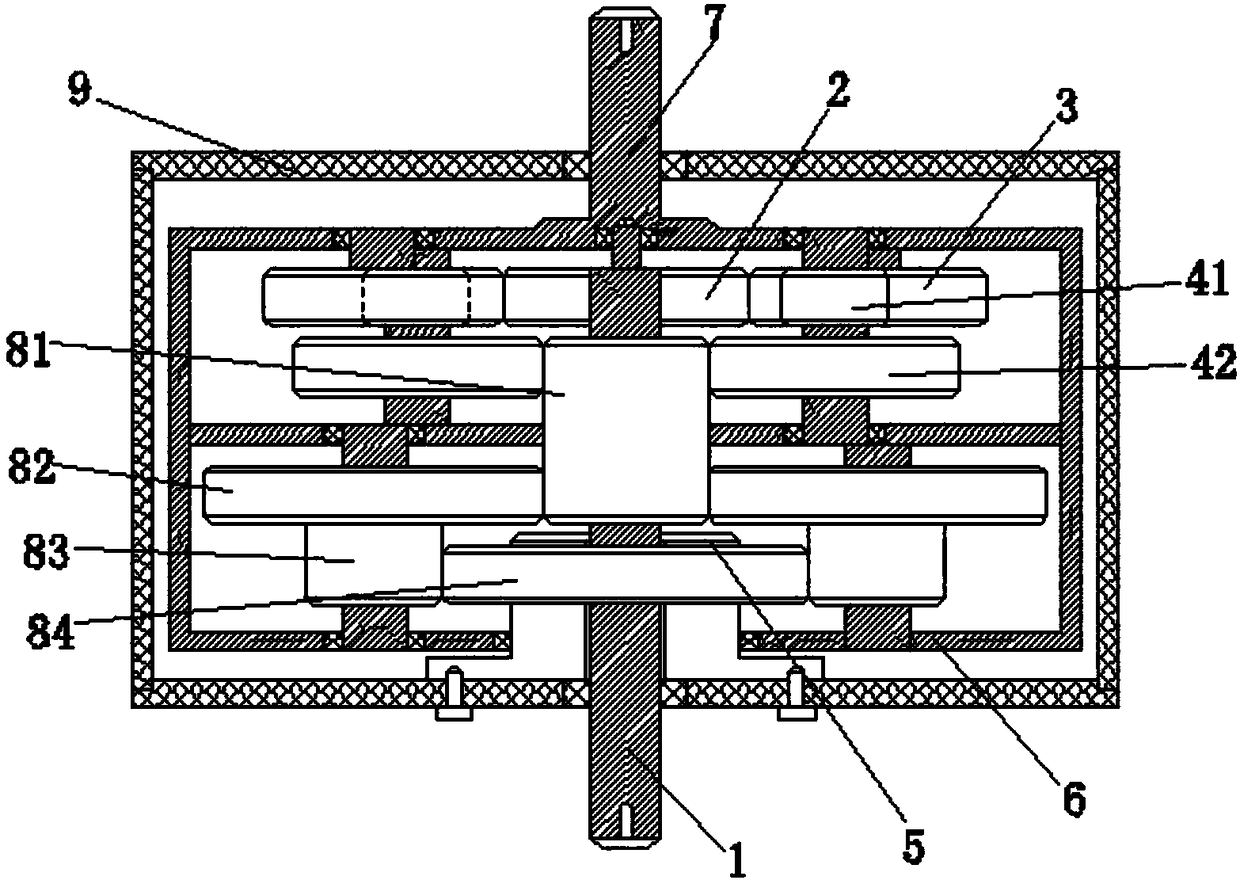

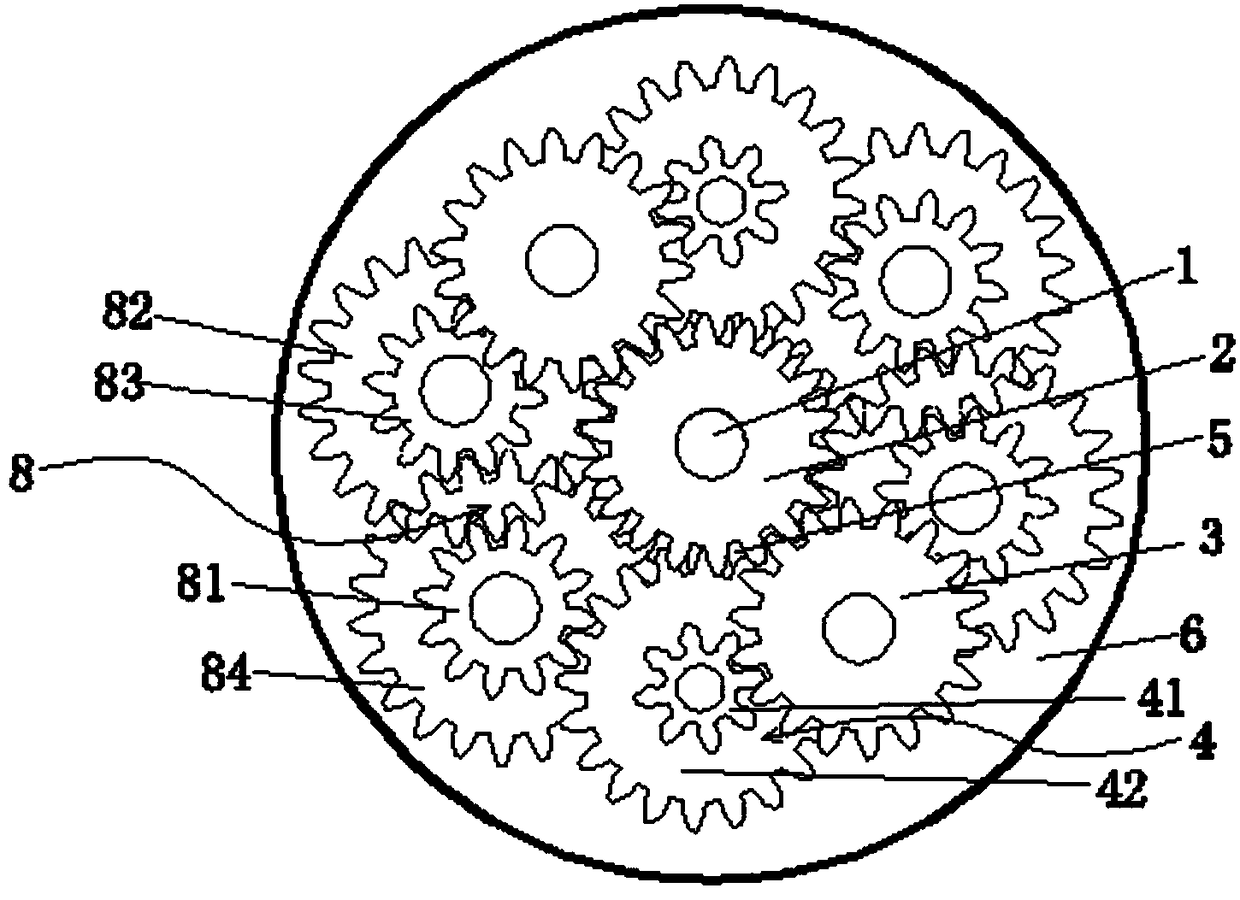

Equidirectional multivariable gear speed differential continuously variable transmission for automobile

InactiveCN102094955AHigh mechanical strengthHigh gear ratioFluid gearingsGear wheelUltimate tensile strength

The invention discloses an equidirectional multivariable gear speed differential continuously variable transmission for an automobile, and relates to a gear continuously variable transmission device for the transmission of a large-power automobile. The speed changing method for the gear continuously variable transmission device is as follows: the planetary equidirectional variable speed difference generated by the rated deceleration and hydraulic damping of a gear enable the gradual changes of rotation speed to be output and generated, and the stepless speed change is generated by the output gear at an uninterrupted meshed state caused by the cyclic variable of the output rotation speed and the hydraulic damping. The continuously variable transmission has the advantages of high transmission power, high variable speed ratio, excellent variable speed performance and high mechanical strength, can be configured to a car of large displacement, an SUV (sports utility vehicle), a bus, a truck and even a heavy type automobile to realize the stepless speed change, has a simple structure, is made of normal materials, has low manufacturing cost, and ensures long service lives of the products.

Owner:罗永

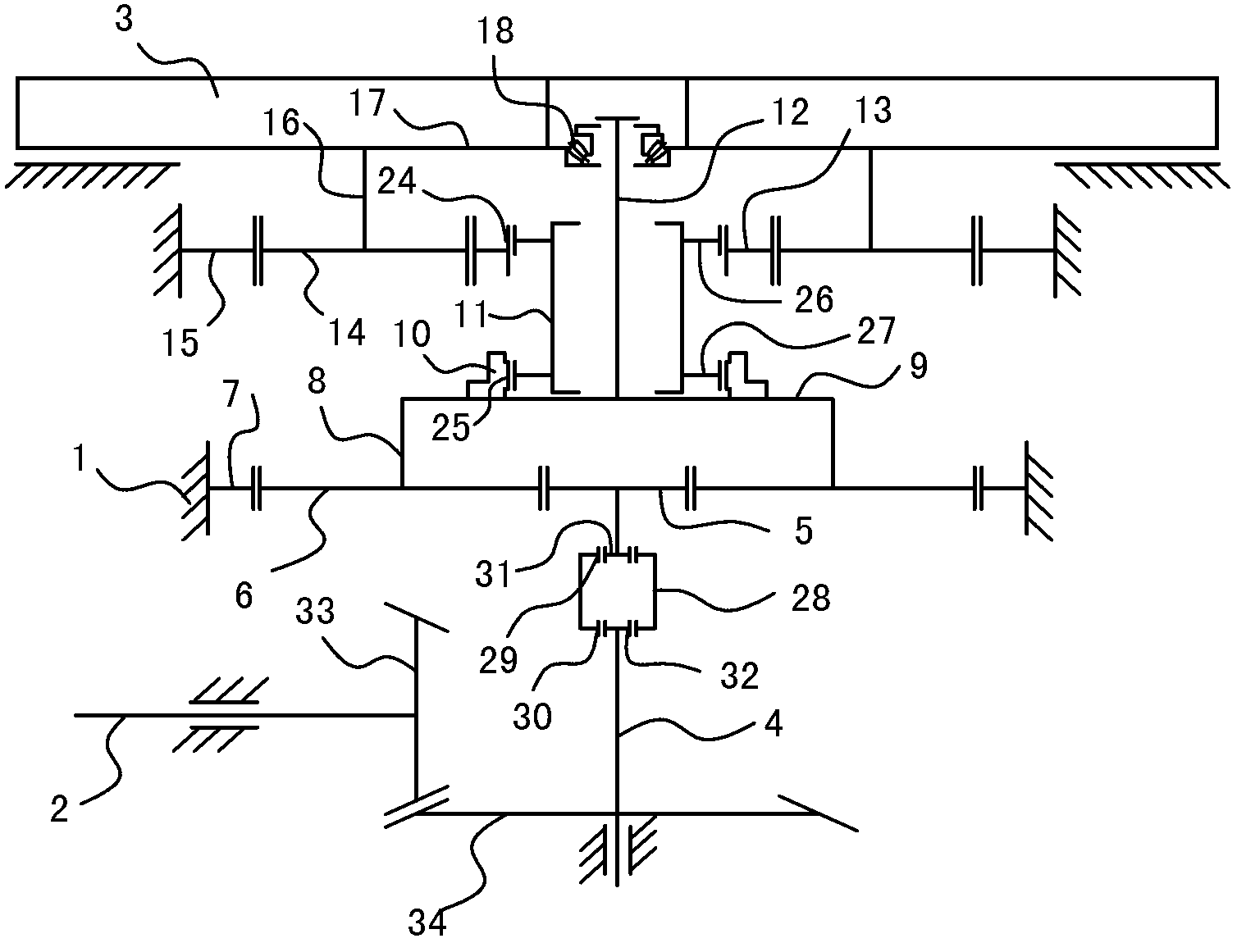

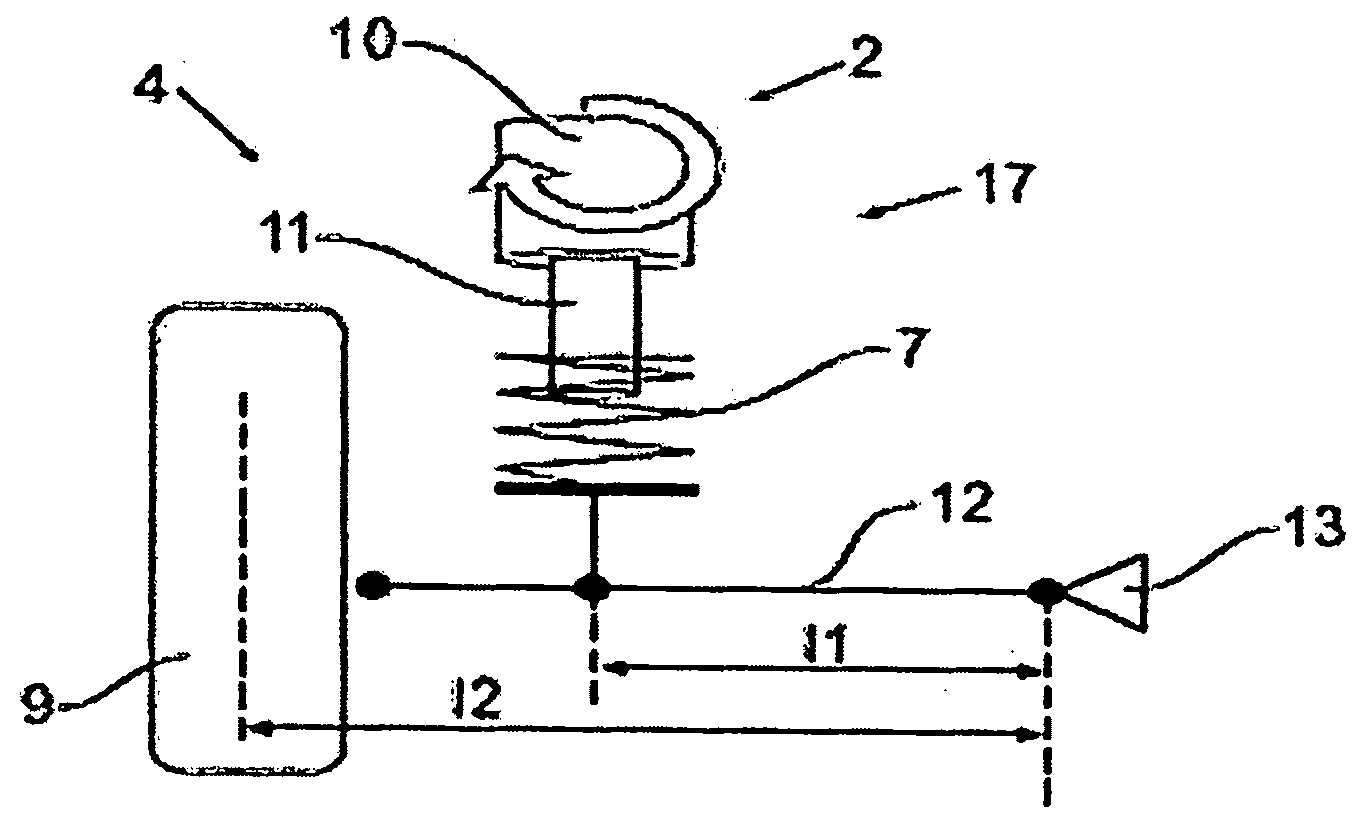

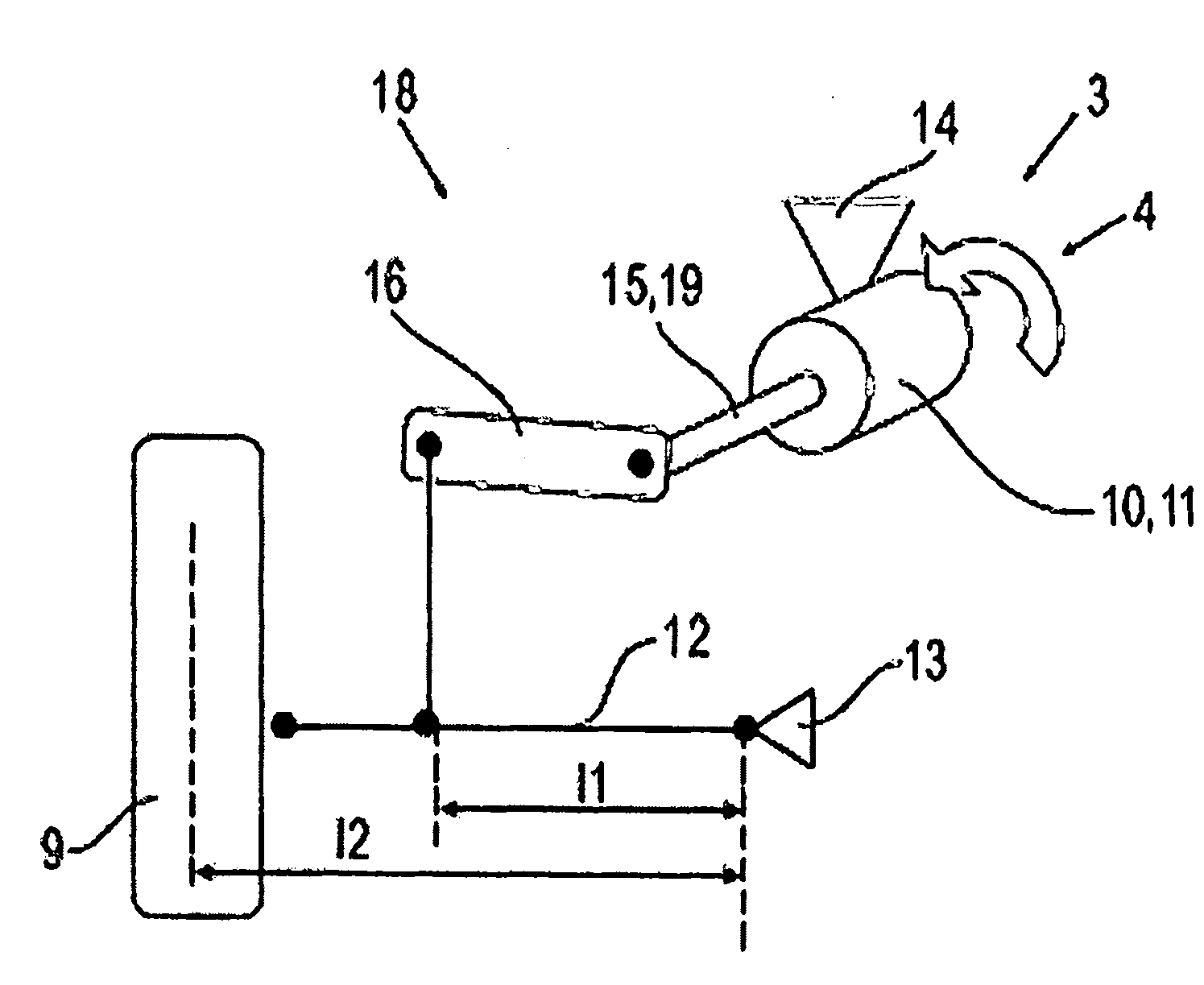

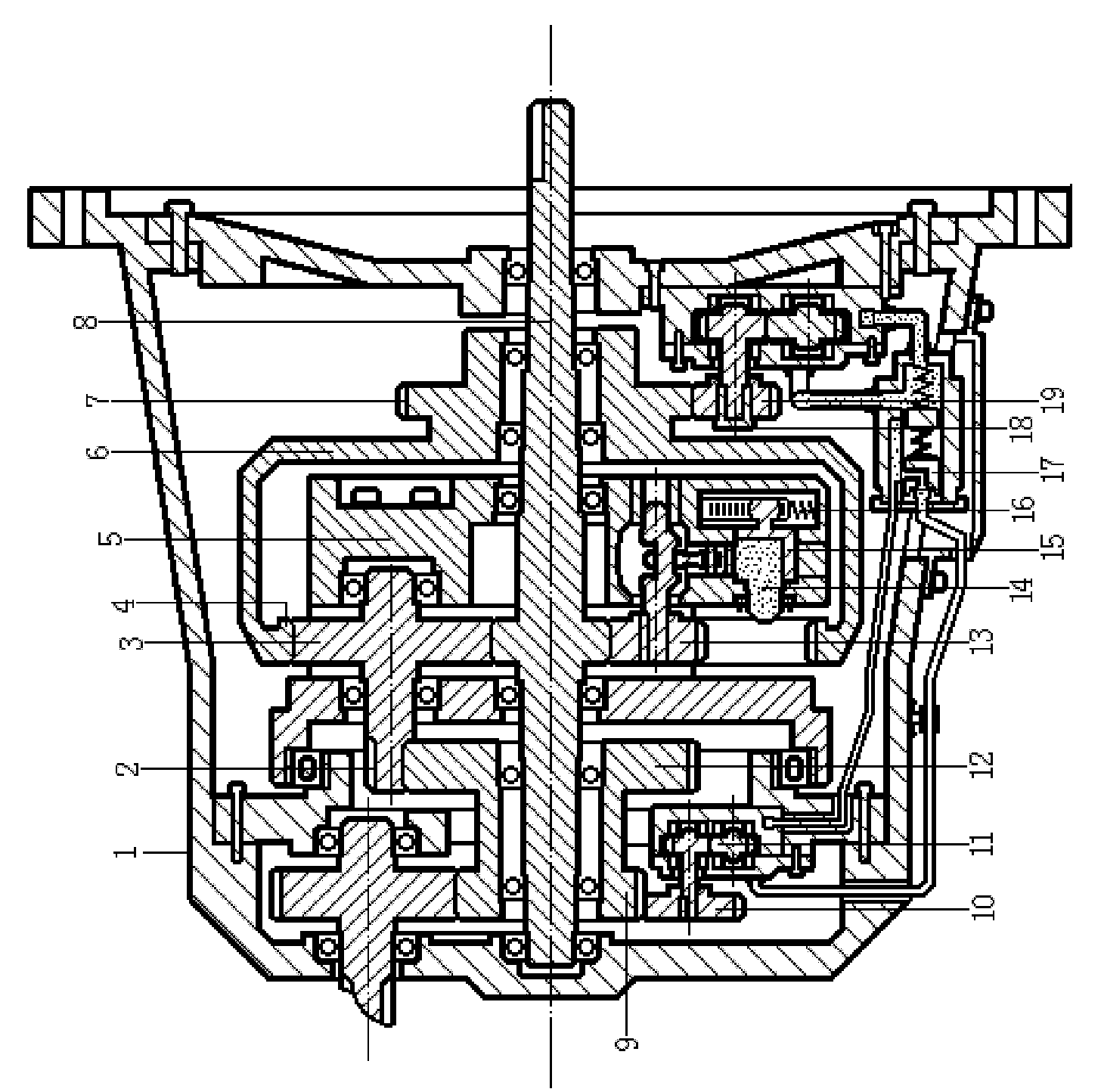

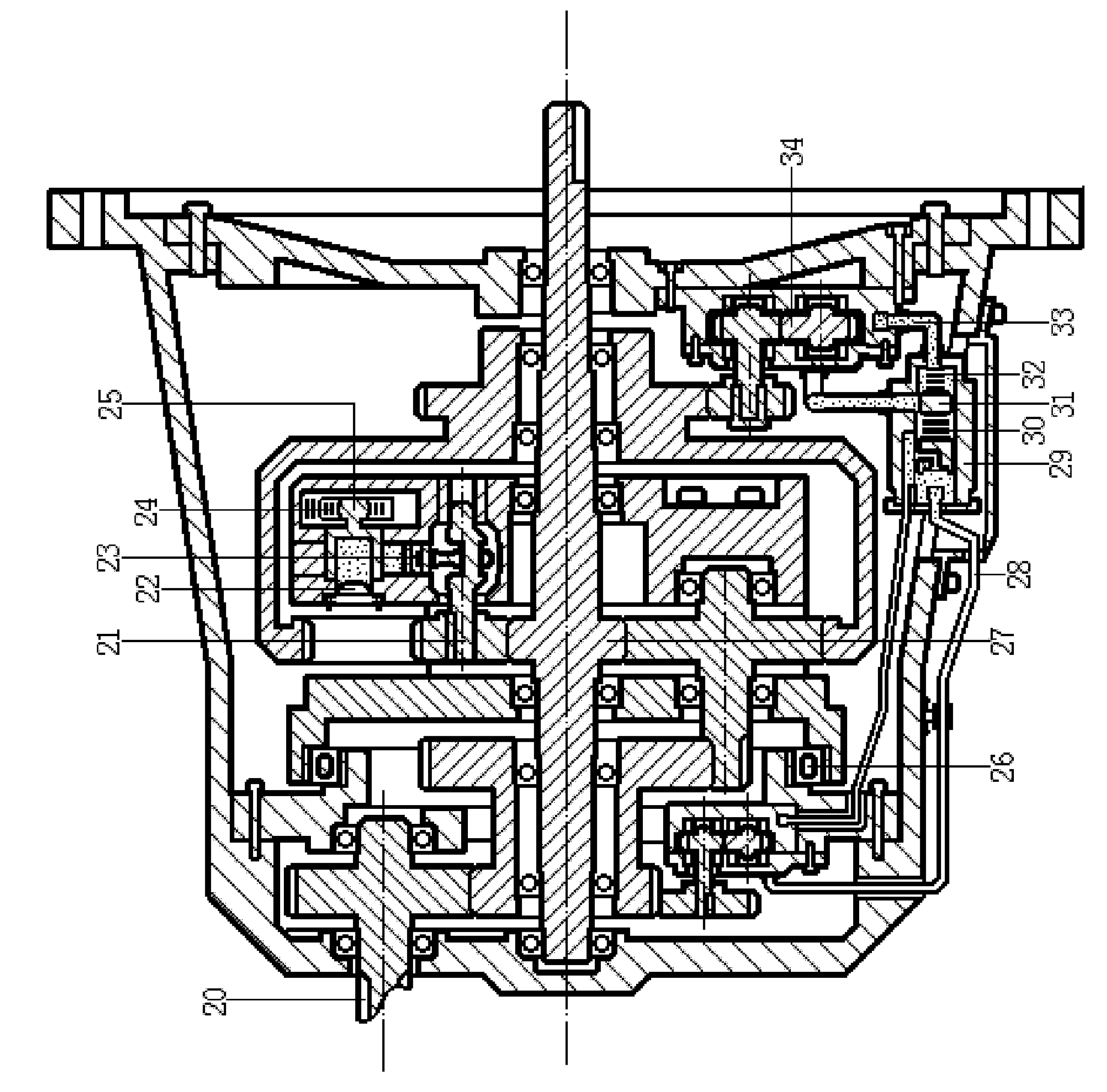

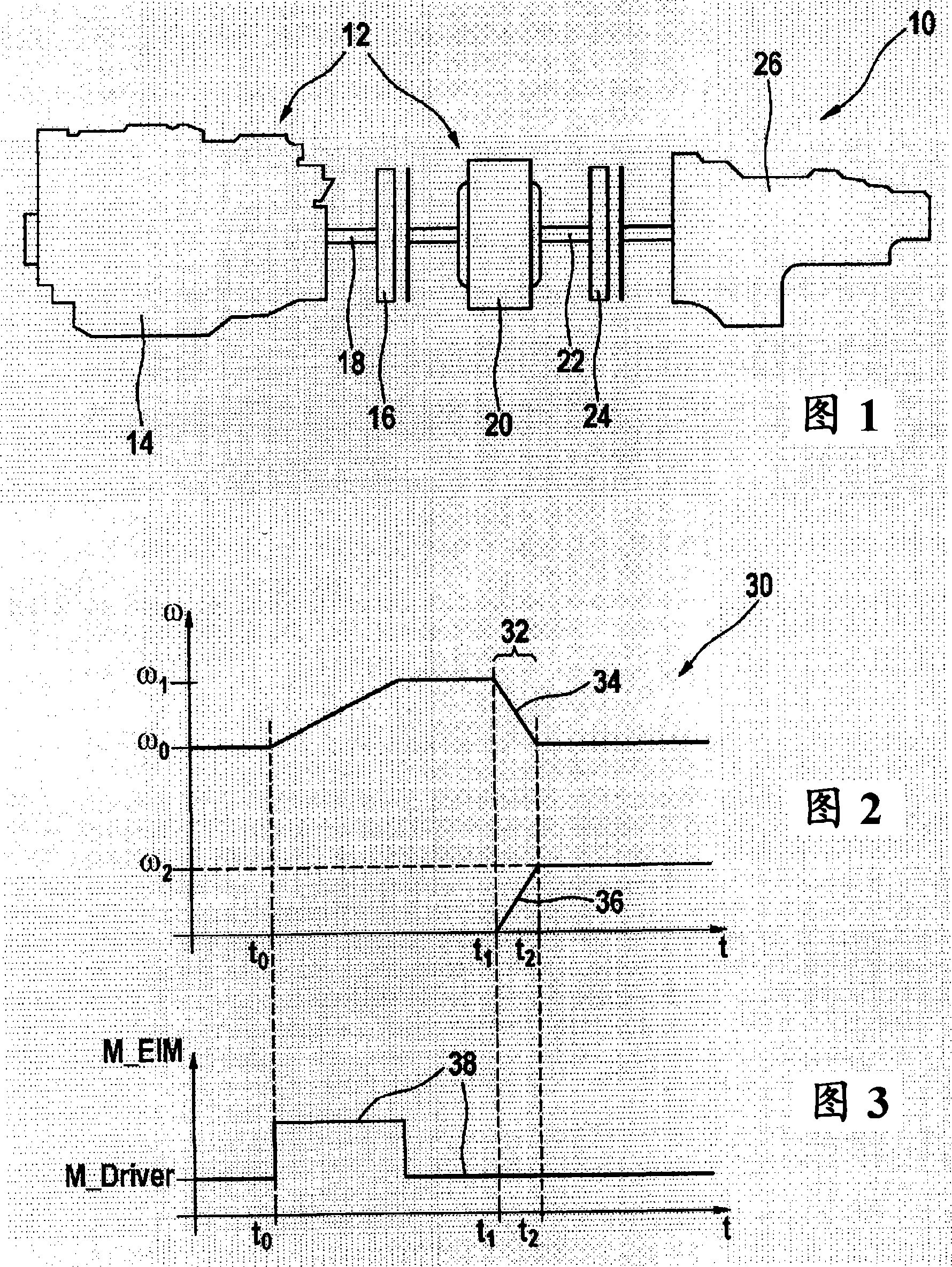

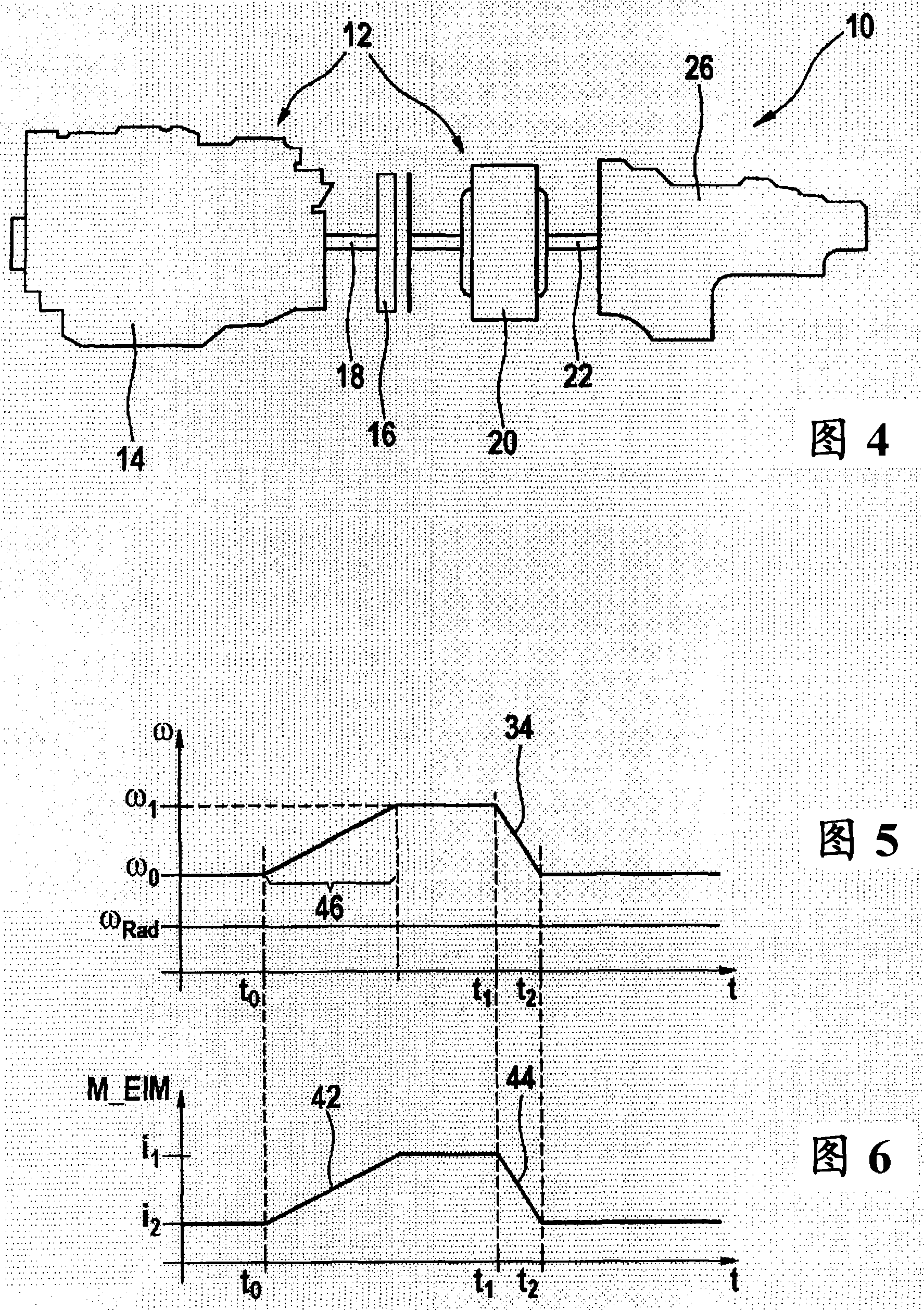

Method for starting an internal combustion engine in a hybrid drive

InactiveCN101443219AHigh gear ratioIncrease speedSpeed controllerGas pressure propulsion mountingElectricityExternal combustion engine

The invention relates to a method for starting an internal combustion engine (14) of a hybrid drive (12) comprising at least one electric drive (20). This can be coupled to the internal combustion engine (14) via a first clutch (16) for pulsed starting of the internal combustion engine. A rotational speed change (34, 36) in the at least one electric drive (20), which change occurs during pulsed starting of the internal combustion engine (14), is compensated for by continuous changes (42, 44) in the transmission ratio in a vehicle gearbox (26).

Owner:ROBERT BOSCH GMBH

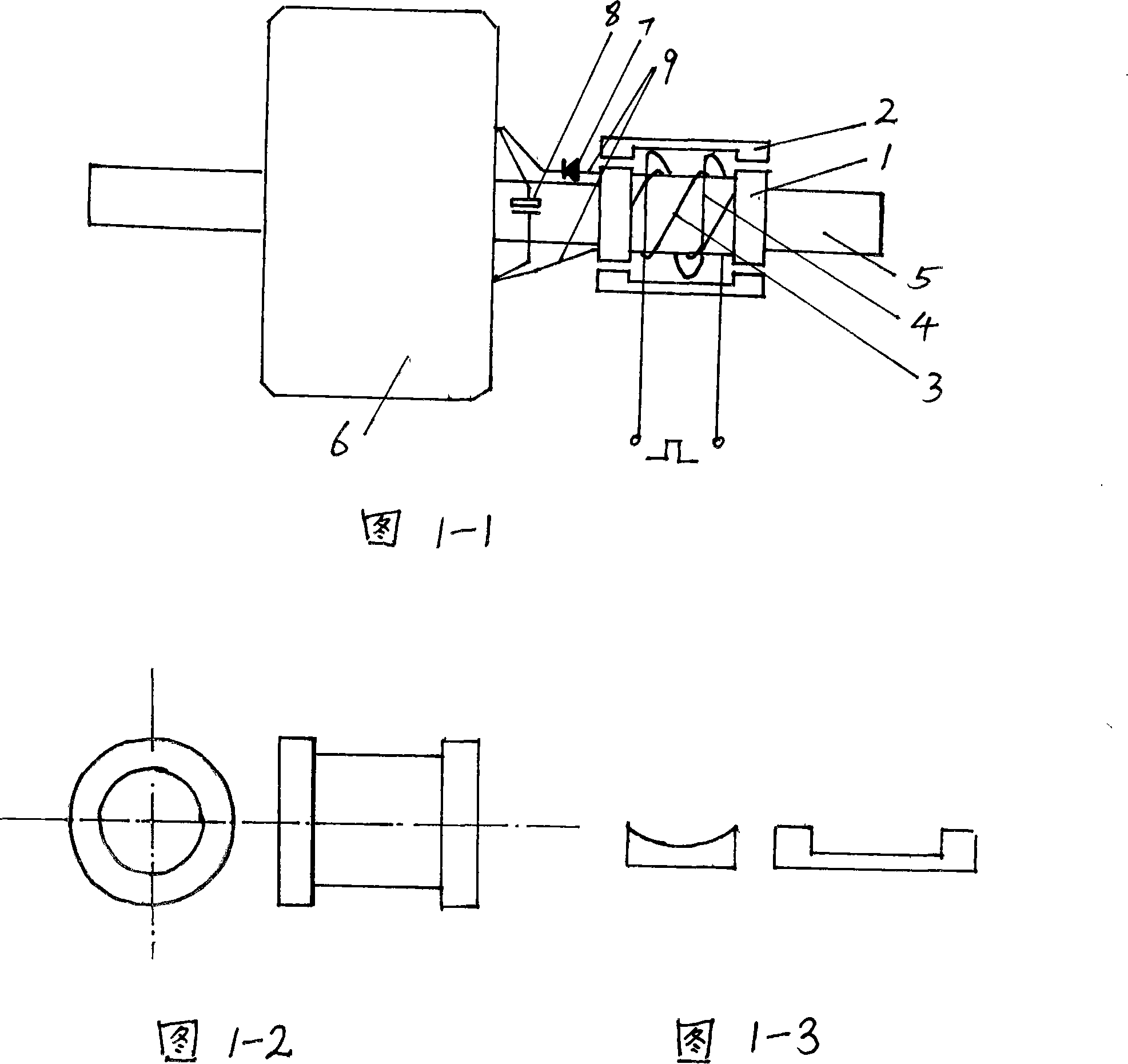

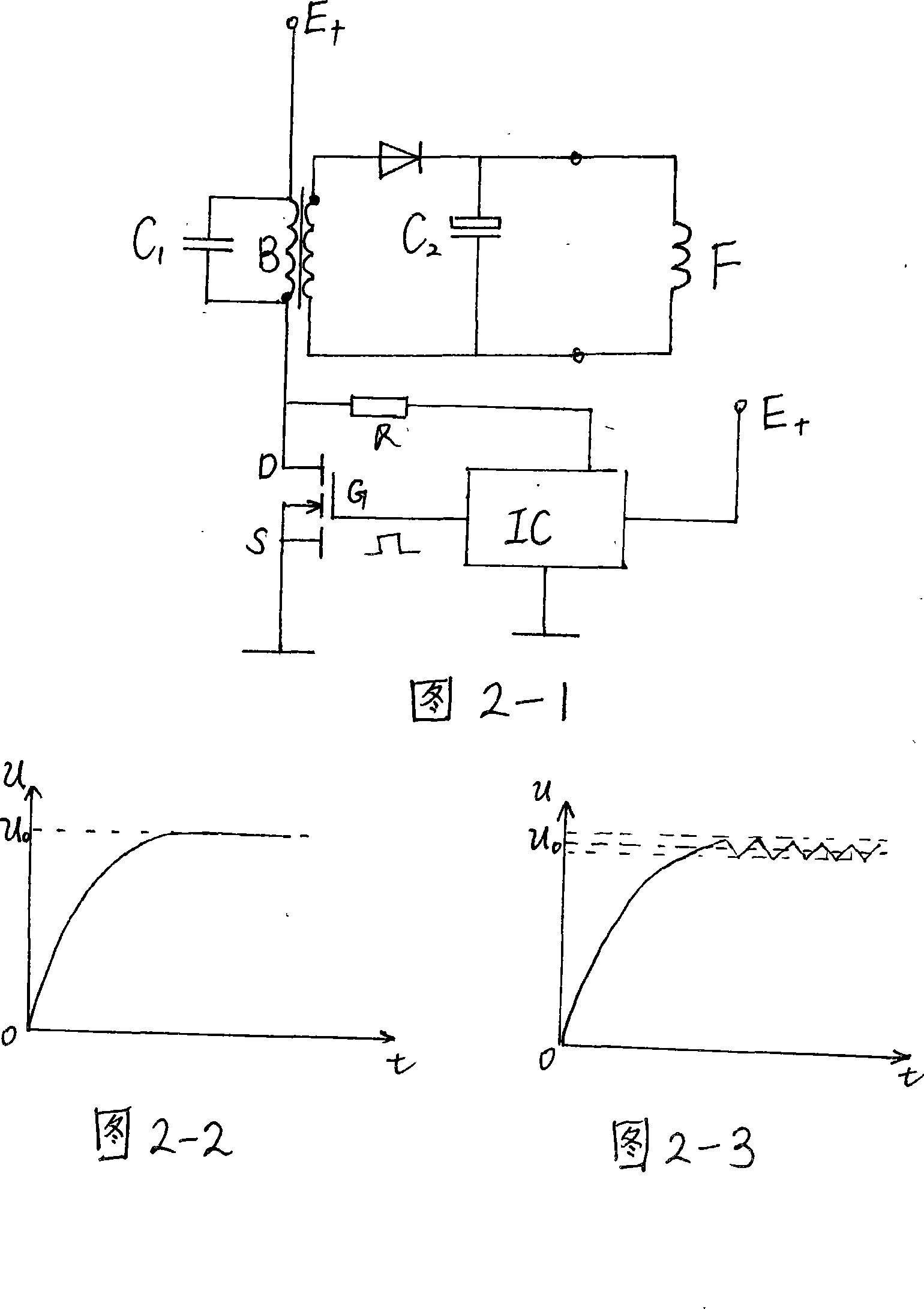

High frequency coupling excitation automobile generator

InactiveCN101232224ASimple preparation processCompact and strong structureSynchronous generatorsStructural associationEngineeringLow speed

The invention relates to an automobile generator which utilizes isolated coupling of a high-frequency transformer to realize brushless excitation, and represents a combination of the modern switch power technology and the motor technology. High-frequency current is coupled to a secondary coil rotating together with a rotor through a fixed primary coil, and the high-frequency current provides power for an exciting coil in the rotor after rectifying and wave-filtering. The simple and efficient excitation not only brings the advantage of a brushless generator to the invention, but also enables the invention to maintain the advantages of low speed, good charging performance and simple structure in a brush generator; in addition, the invention has more stable voltage output. By adopting the technology of the invention, a regular brush automobile generator can be improved into such a brushless generator through simple changes.

Owner:王铁夫

Vehicle gear shift control device and gear shift control method

ActiveUS8401749B2Inhibit deteriorationHigh gear ratioDigital data processing detailsRoad transportGear wheelEngineering

Owner:TOYOTA JIDOSHA KK

Gear transmission structure

InactiveCN108240417AImprove transmission efficiencyHigh gear ratioToothed gearingsGear wheelEngineering

The invention discloses a gear transmission structure. The gear transmission structure comprises an input shaft, a carrier gear, a carrier speed increasing gear set, a speed reduction gear set, a fixed counterpressure gear, a supporting body and a shell, wherein the carrier gear, the carrier speed increasing gear set, the speed reduction gear set and the fixed counterpressure gear are arranged inthe supporting body; the fixed counterpressure gear and the carrier gear are arranged coaxially in a layered mode; the fixed counterpressure gear is fixed to the shell; the supporting body is rotationally connected with the shell; and the carrier speed increasing gear set and the speed reduction gear set are connected between the carrier gear and the fixed counterpressure gear in a transmission mode. According to the gear transmission structure, the speed reduction gear set and the carrier speed increasing gear set are arranged, the gear friction resistance is balanced, output is carried out in cooperation with the fixed counterpressure gear, and the overall operation efficiency of the mechanism is improved.

Owner:何晓明

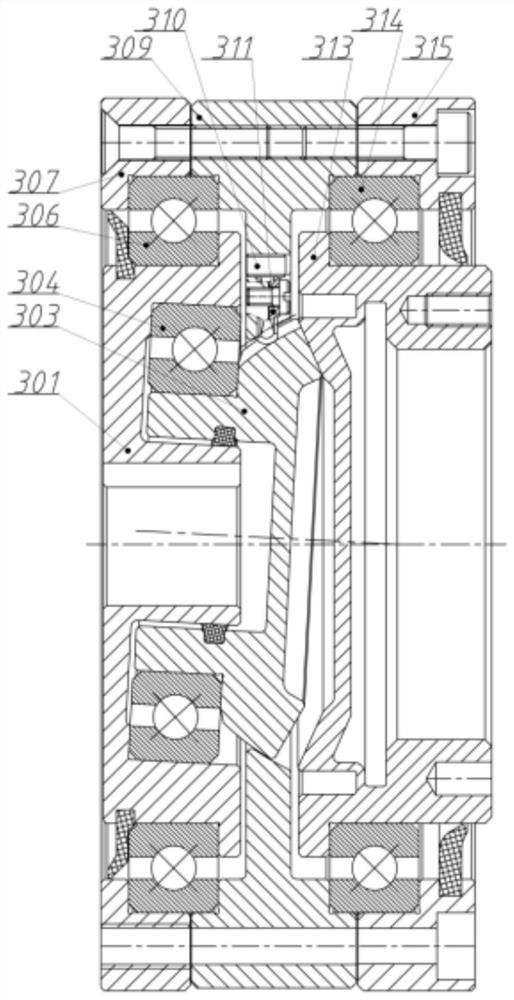

Robot joint speed reducer based on nutation speed reduction and friction transmission and design method

The invention discloses a robot joint speed reducer based on nutation speed reduction and friction transmission and a design method. The robot joint speed reducer comprises a shell jointly composed of a bearing base, an upper positioning ring and a lower positioning ring, a nutation wheel base installed on the lower positioning ring and a nutation wheel installed on the nutation wheel base. The robot joint speed reducer further comprises an output flange, a positioning needle and a small clamping plate. The output flange is installed on the upper positioning ring, and the positioning needle and the small clamping plate are installed on the bearing base. Under the limiting effect of the positioning needle and the driving of the rotary motion of the nutation wheel base, the nutation wheel generates nutation motion, the output flange is pushed to rotate under the effect of friction force, and decelerating motion is generated. The robot joint speed reducer based on nutation speed reduction and friction transmission and the design method have the advantages of reasonable torque load, large transmission speed ratio, high transmission precision, stable transmission, reverse self-locking, simple and compact structure and the like.

Owner:赣州精诚机械制造有限公司

Large torque reduction box for withdrawal and straightening machine

The invention relates to a large torque reduction box for a withdrawal and straightening machine. One or more stages of cylinder gear transmission sets, a tail stage taper gear, a tail stage gear shaft, an output large gear and an output hollow shaft are arranged in a box, a motor flange is arranged on one side of the box, an input gear shaft extends into the box from the motor flange, the part, outside the box, of the input gear shaft is connected with a coupler, a tooth part of the part, inside the box, of the input gear shaft is in transmission connection with the one or more stages of cylinder gear transmission sets, a cylinder gear shaft of the last stage of cylinder gear transmission set in the one or more stages of cylinder gear transmission sets is provided with a small taper gear,the small taper gear is meshed with a tail stage large taper gear connected to the tail stage gear shaft in a sleeving manner, and the tooth part of the tail stage taper gear is meshed with an outputlarge gear connected to the output hollow shaft in a sleeving manner. The large torque reduction box is simple in structure and capable of effectively giving consideration to the high speed ratio andthe large torque.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

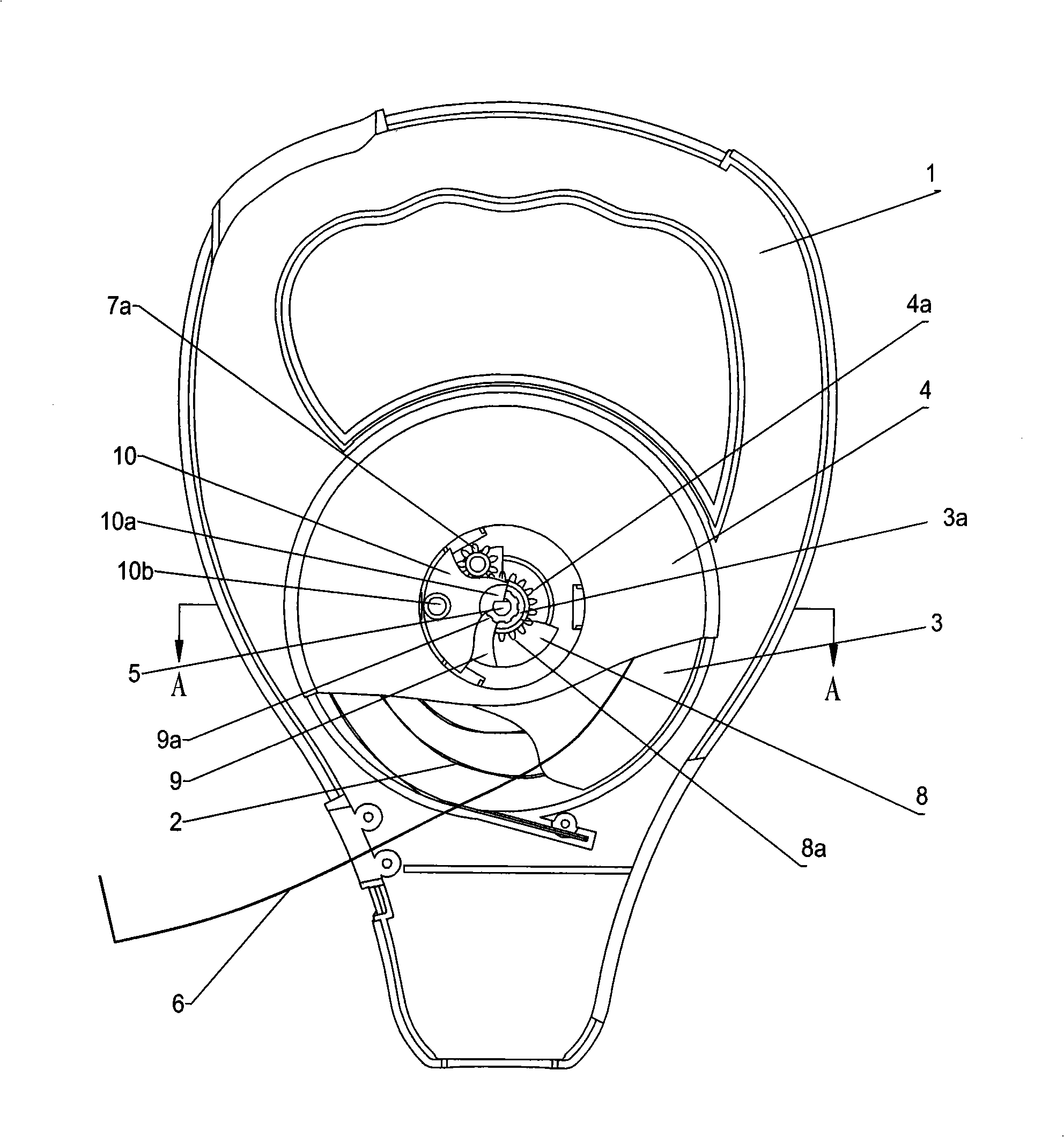

Tape measure and driving mechanism thereof

InactiveCN101644556BReduce volumeHigh gear ratioMeasuring tapesEngineeringElectrical and Electronics engineering

The invention discloses a tape measure. The tape measure comprises a tape shell, a tape core disk, and a driving mechanism, wherein the tape shell is used for accommodating and arranging the tape core disk which can rotate, a tape spring and a tape band; the tape band is wound on the tape core disk, and one end of the tape band extends out of the tape shell; and the tape spring is in driving connection with the tape core disk through the driving mechanism. The tape measure is characterized in that the tape spring is arranged in a cavity on one side of the tape shell; the tape core disk is arranged in a cavity on the other side of the tape shell and is rotatablely arranged on a tape core shaft in the tape shell; the position, which is near the center, of the tape core disk is provided withan accommodation space; and the inside of the accommodation space is provided with a planetary gear speed reduction mechanism which is taken as the driving mechanism to ensure that the tape core diskcan be directly or indirectly connected with the tape spring through the planetary gear speed reduction mechanism. The invention also discloses the driving mechanism which adopts the planetary gear speed reduction mechanism, and the driving mechanism also reduces the volume of the tape measure and the thickness under the condition of improving the variation ratio, and is particularly suitable forlong tape measures.

Owner:NINGBO JUFENG TOOLS IND

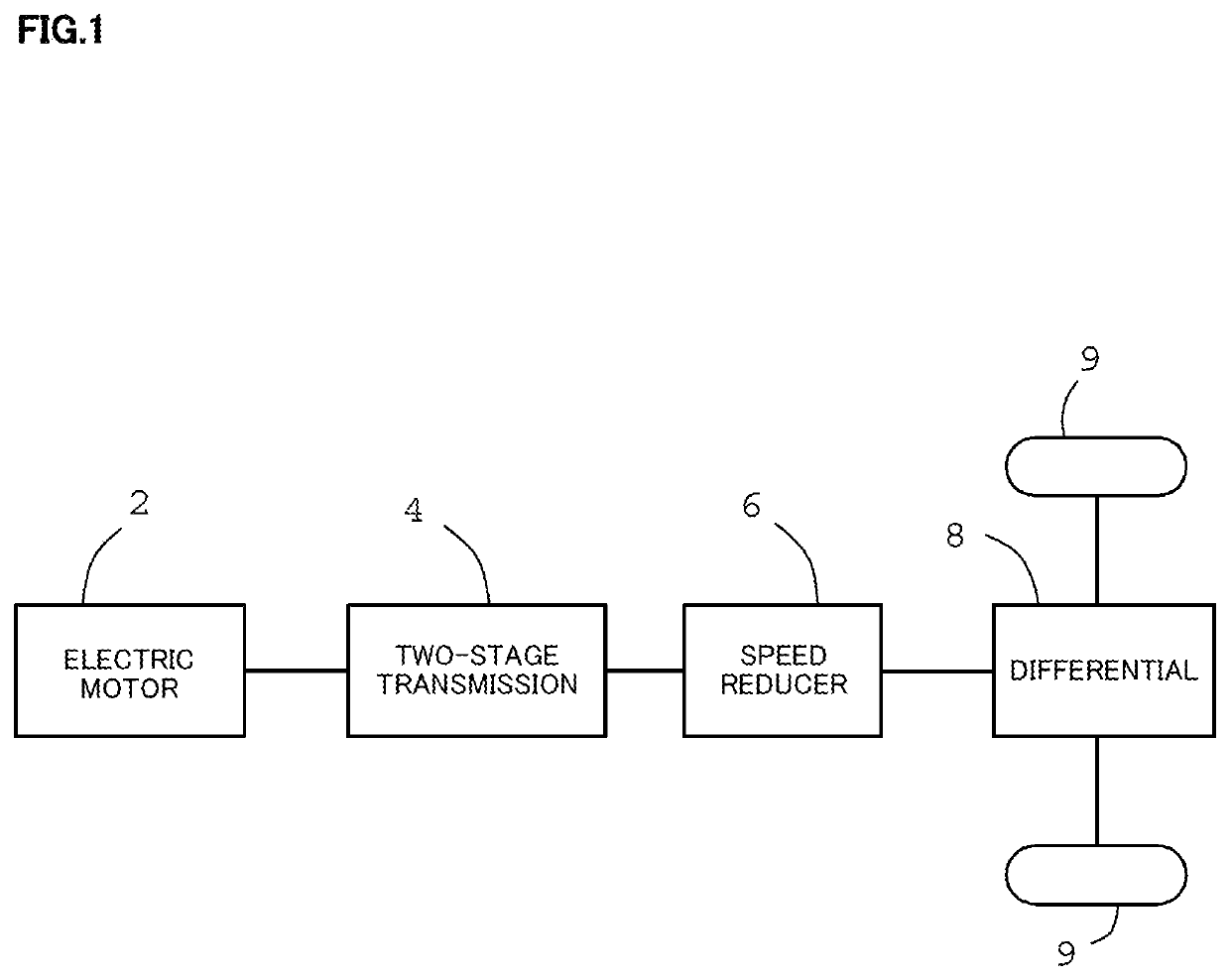

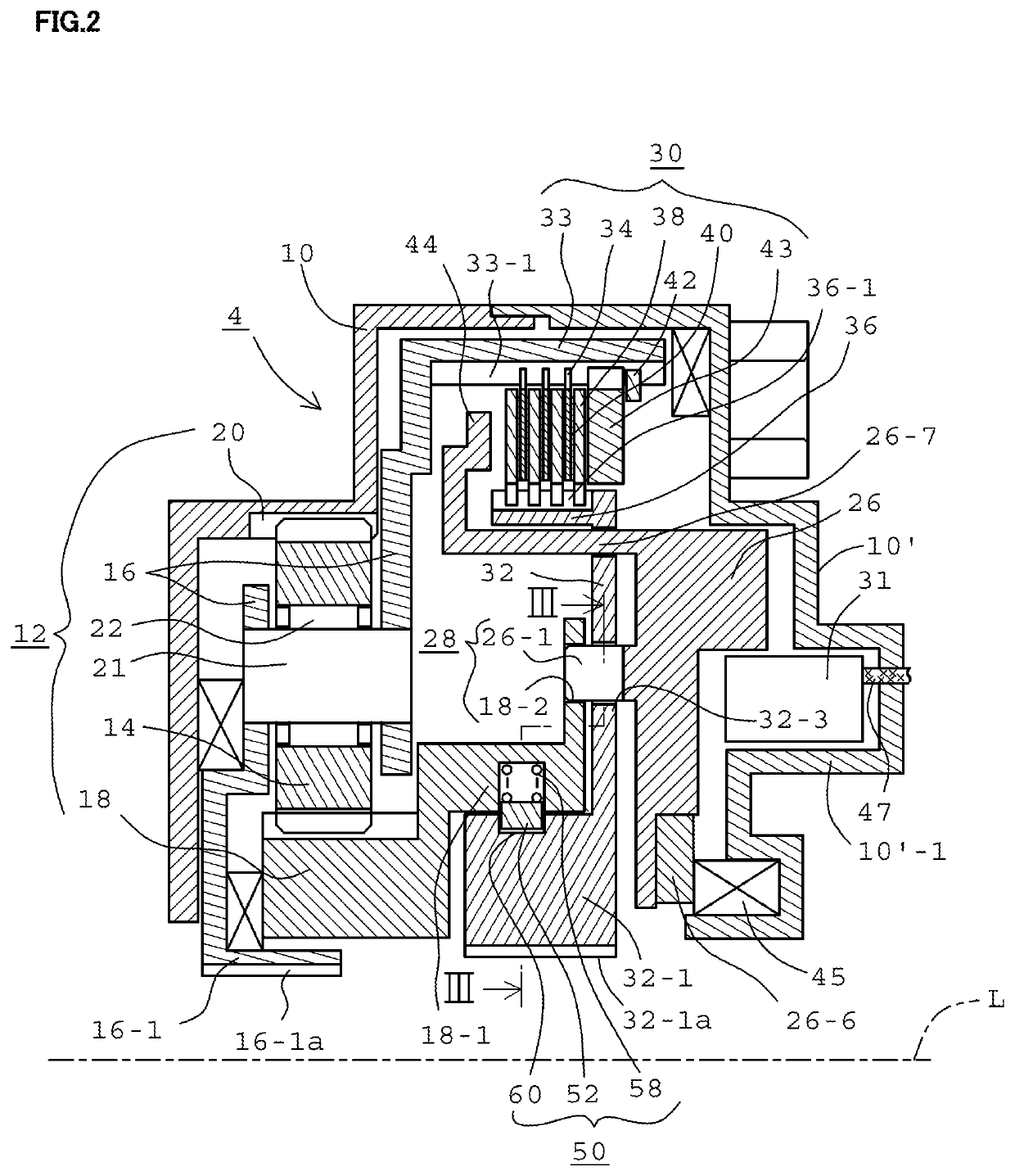

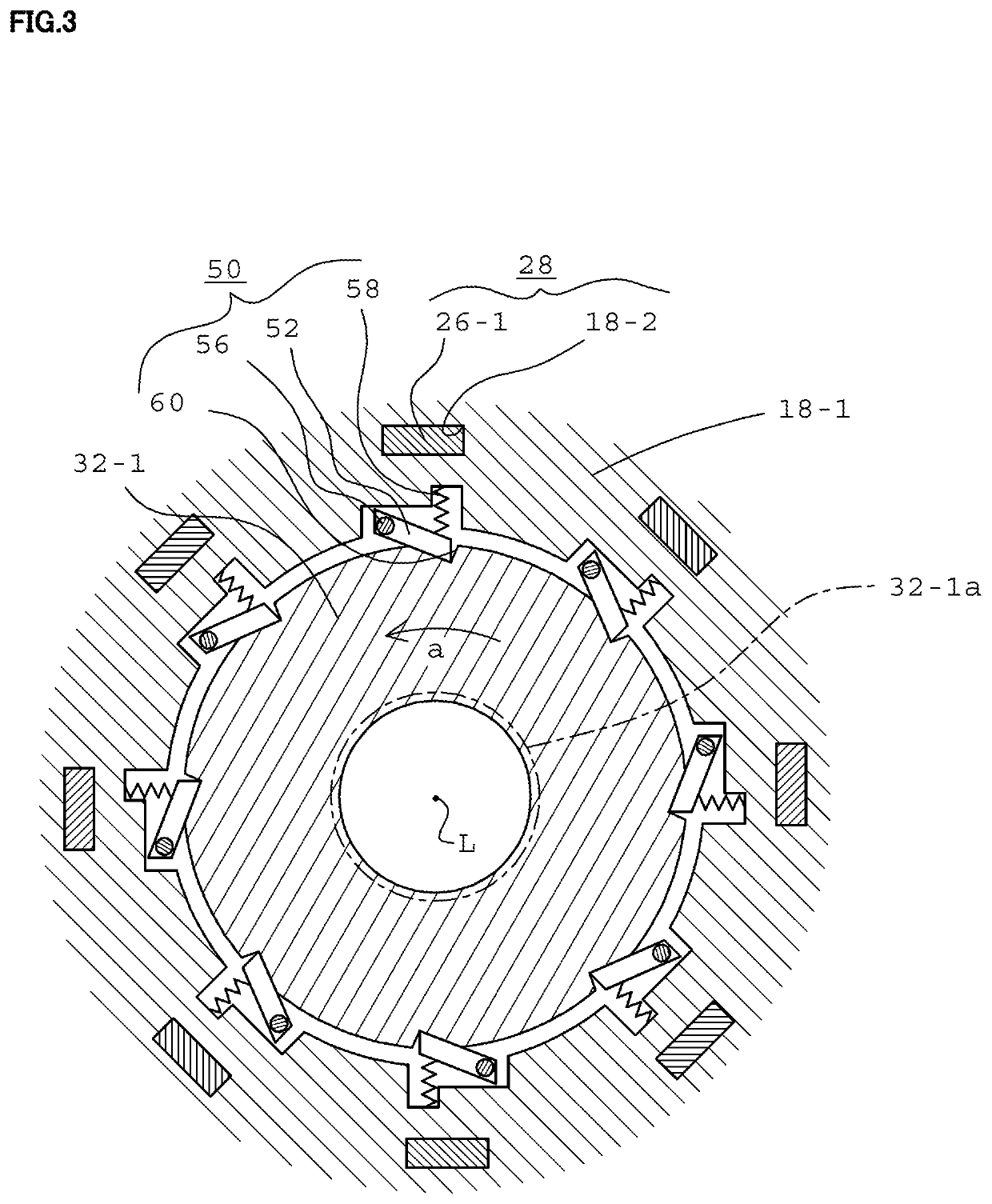

Two-stage transmission for electrically driven vehicle

ActiveUS11408488B2Avoid spreadingReduce transmissionMechanical actuated clutchesToothed gearingsRatchetGear wheel

Owner:UNIPRES CORP

Speed increase gear drive mechanism of speed increase device of circulation type forward and backward turning and variable speed vacuum compressor

InactiveCN103671010AImprove vacuum efficiencyImprove compression efficiencyPiston pumpsPositive-displacement liquid enginesVacuum pumpingVacuum pump

The invention belongs to a vacuum compressor, and particularly relates to a speed increase gear drive mechanism of a speed increase device of a circulation type forward and backward turning and variable speed vacuum compressor. The speed increase gear drive mechanism comprises an output shaft, an output gear, a main turning shaft, a turning gear, a speed increase gearbox and a turning case, and is characterized in that a speed increase gear drive mechanism body is installed on the output gear of the output shaft and composed of a first transition gear shaft, a first transition gear, a second transition gear, a second transition gear shaft, a third transition gear and a fourth transition gear, the first transition gear shaft is provided with the first transition gear and the second transition gear sequentially, the third transition gear and the fourth transition gear are sequentially installed on the second transition gear shaft, the output gear is meshed with the third transition gear, the fourth transition gear is meshed with the first transition gear, and the second transition gear is meshed with the turning gear of the main turning shaft. The speed increase gear drive mechanism is reasonable in design and compact in structure, and has the advantages of being high in speed increase transmission ratio, stable and reliable in transmission performance, capable of improving the vacuum pumping efficiency and compression efficiency of the vacuum compressor, and the like.

Owner:兆盈建筑劳务(大连)有限公司

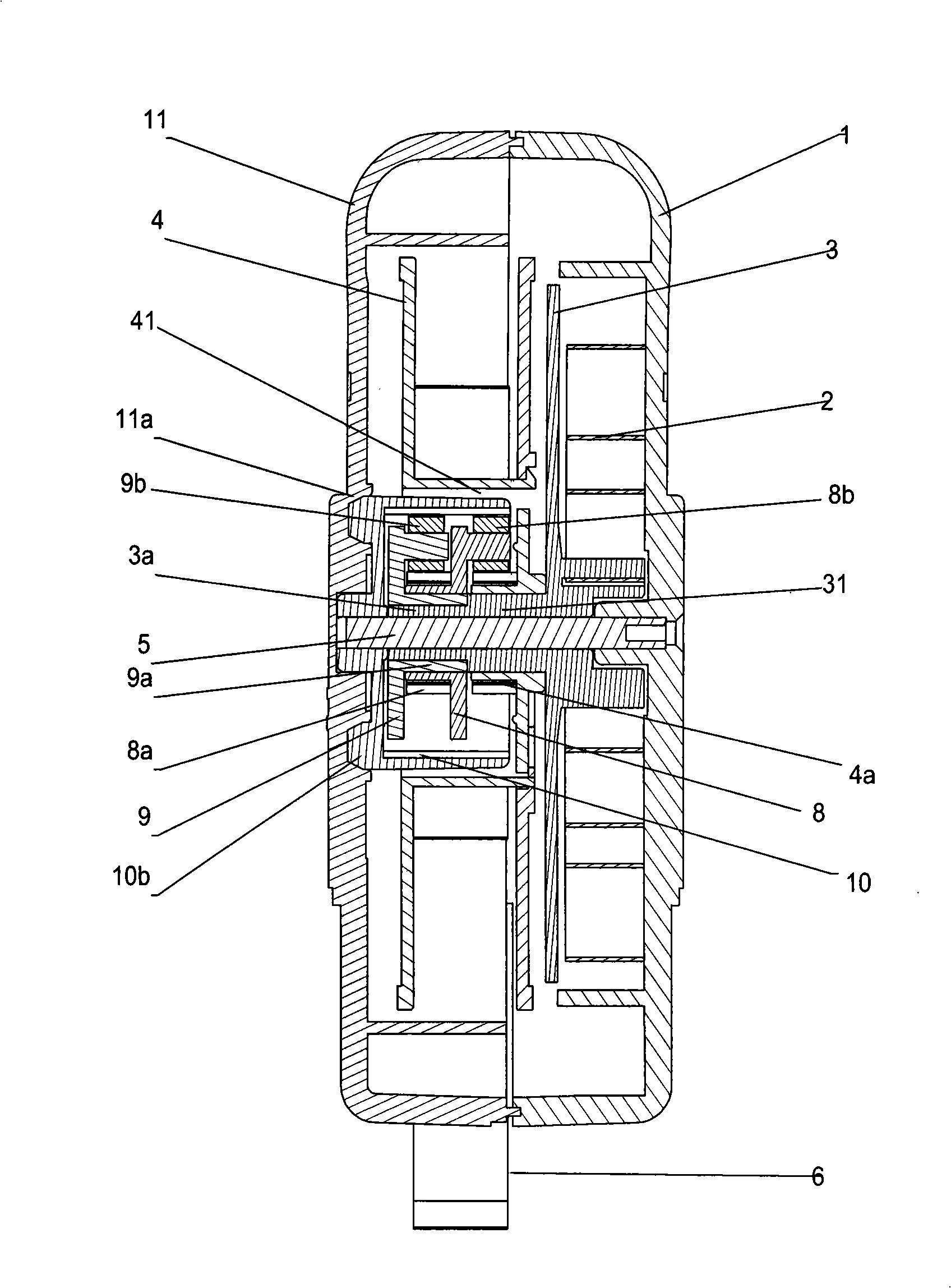

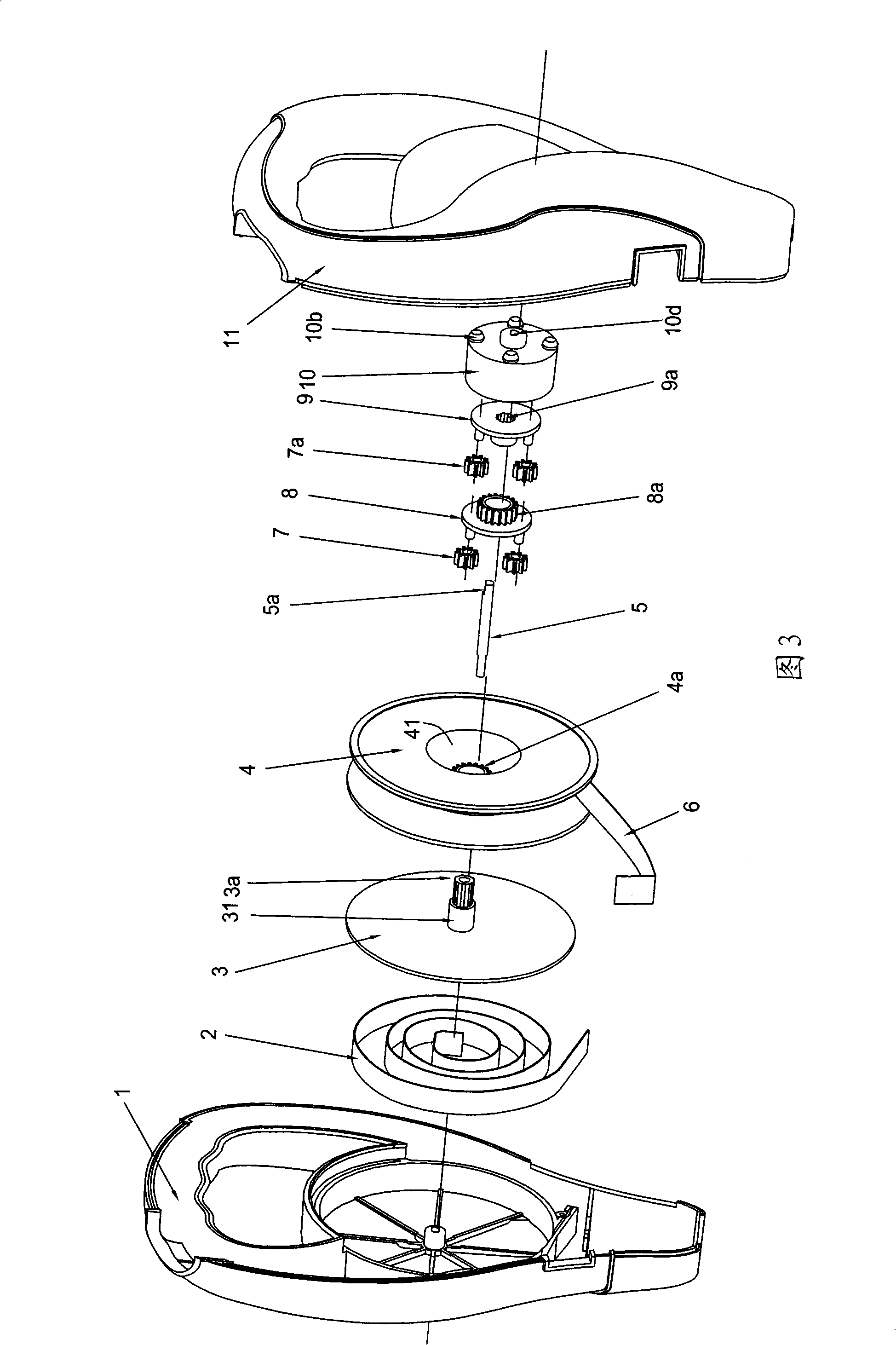

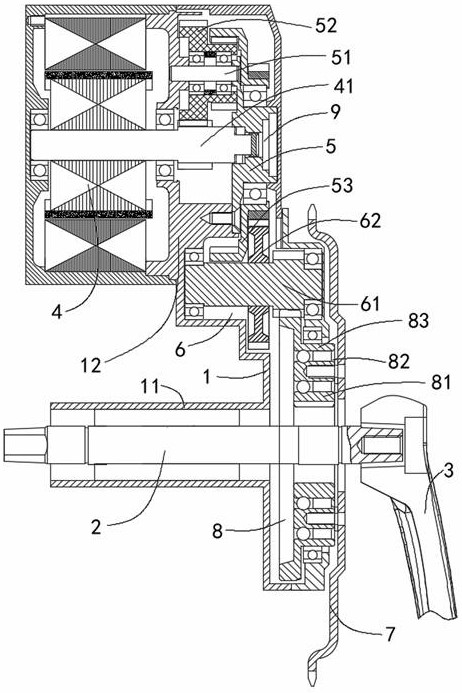

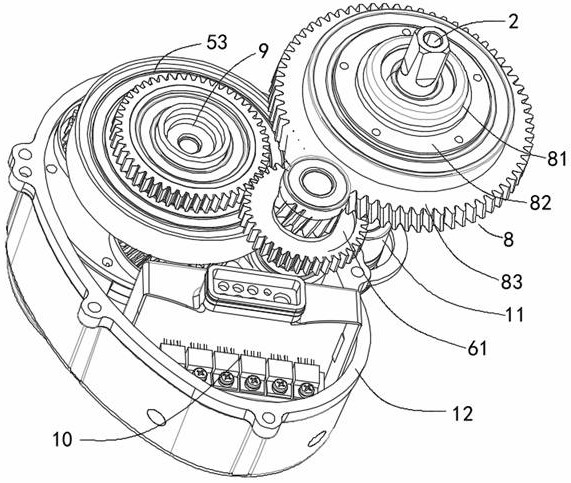

Stable high-power plug-in centrally-mounted motor

PendingCN114132422AIncrease motivationSmooth transmissionMechanical energy handlingRider propulsionElectric machineEngineering

The invention provides a stable high-power plug-in centrally-mounted motor, which comprises a main shell, the main shell comprises a shaft sleeve inserted into a bicycle five-way assembly and an assembly shell fixed on the upper part of the shaft sleeve, and an electric module is assembled on the left side of the assembly shell; a penetrating through hole is machined in the middle of the assembling shell, an output shaft of the electric module extends out of the left side of the assembling shell to the right side of the assembling shell, a fixing frame is fixedly assembled on the right side of the assembling shell, two or more planet shafts evenly distributed relative to the circumferential direction of the output shaft are assembled between the assembling shell and the fixing frame, and planet wheels are assembled on the planet shafts. A sun gear in meshing transmission is assembled outside the planet gear, a transition module is in transmission connection with the sun gear, and the transition module is in transmission connection with the chain wheel. A planetary transmission structure is adopted in the motor, so that transmission is more stable, and the output power of the motor can be greatly improved under the same size.

Owner:苏州同盛电器有限公司

Control device for belt-type continuously variable transmission

InactiveCN102844593AImprove energy consumption efficiencyReduce thrustV-beltsGearingChange controlEngineering

Provided is a control device for a belt-type continuously variable transmission, the control device being capable of suppressing a deterioration in fuel consumption. Compared to the friction coefficient ([mu]1) of an inside portion in the radial direction of each tapered surface of a driven pulley (7), the friction coefficient ([mu]2) of an outside portion is formed smaller, and the present invention is provided with a gear change range setting means for increasing the frequency of changing the change gear ratio using the inside portion when a gear change control mode for improving energy consumption efficiency is selected.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com