Gear case for high-power vertical roller mill

A vertical roller mill, high-power technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problem of small transmission torque, poor load transmission capacity, and poor load equalization capacity of vertical roller mill gearboxes and other problems to achieve the effect of improving the ability to transmit power and load and improving the load-sharing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

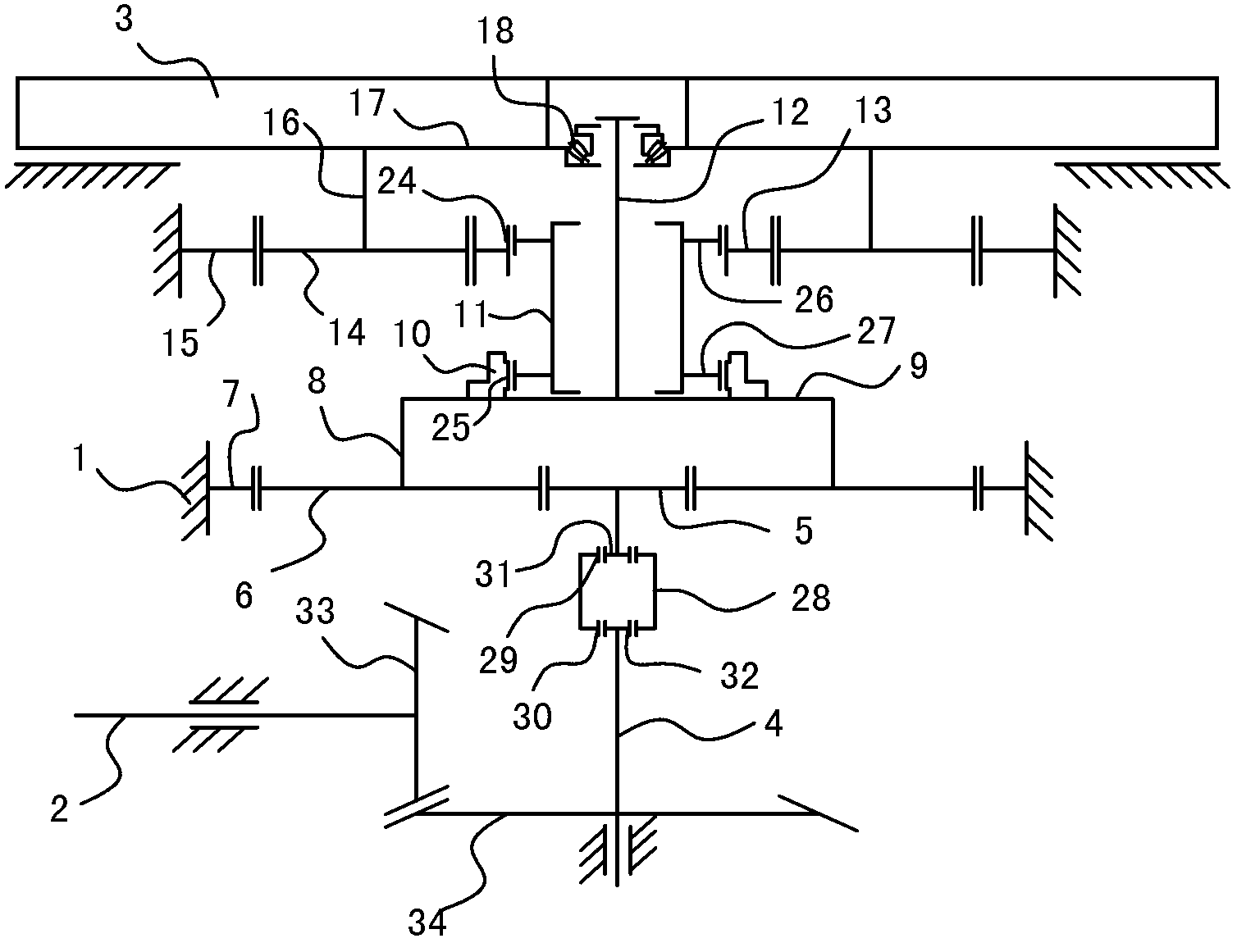

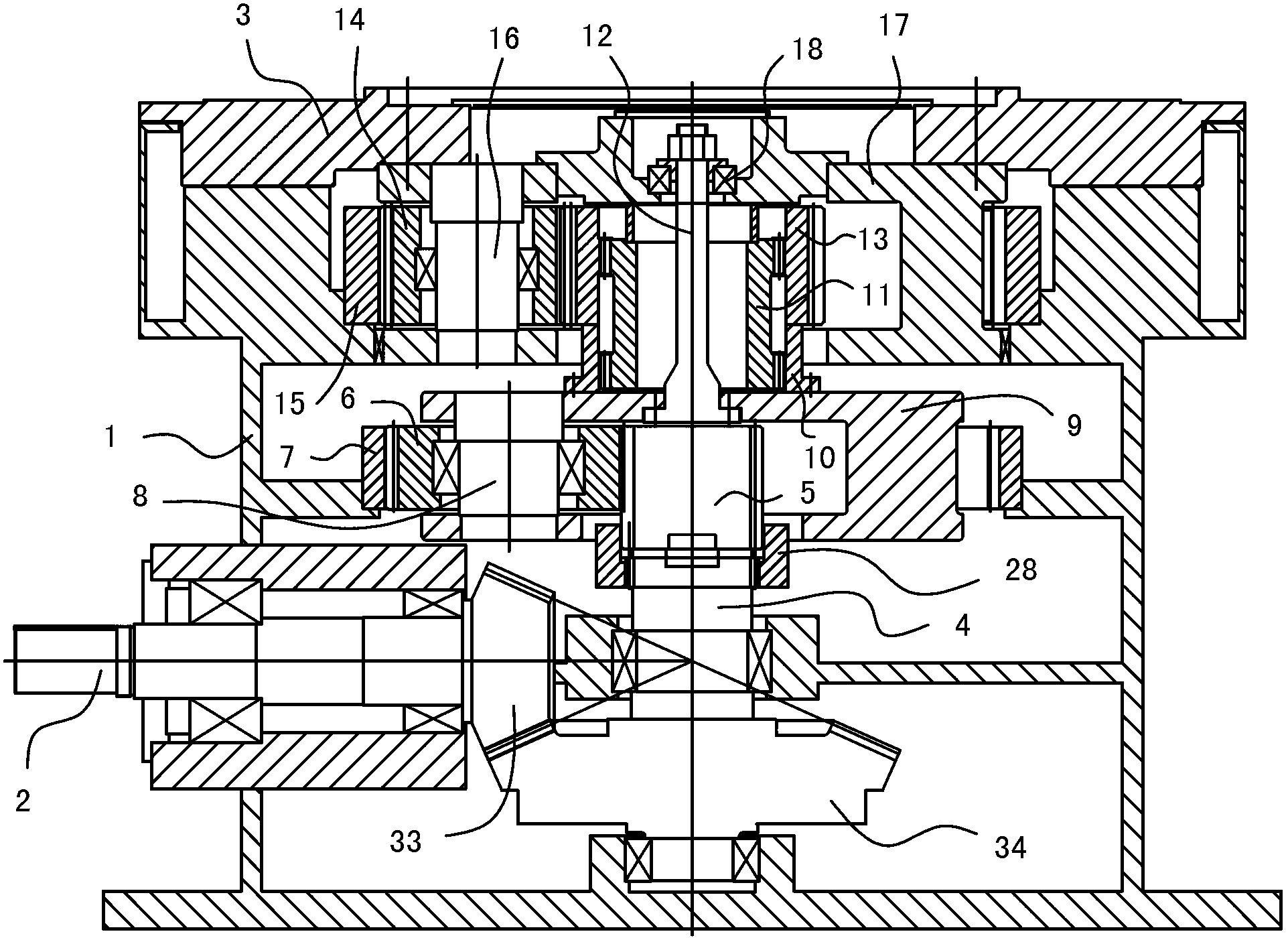

[0027] Example 1: A high-power vertical roller mill gearbox

[0028] like figure 2 and image 3As shown, the gear box of the vertical roller mill is composed of a box body 1, an input shaft 2, an output flange 3 and a three-stage reduction transmission structure arranged in the box body 1. Wherein, the input shaft 2 is arranged at the side of the box body 1 , and the output flange 3 is arranged at the top of the box body 1 . The three-stage deceleration transmission structure is composed of the first-stage transmission mechanism, the second-stage transmission mechanism and the third-stage transmission mechanism. The first-stage transmission mechanism, the second-stage transmission mechanism and the third-stage transmission mechanism are in the box 1 is arranged in order from bottom to top.

[0029] Compare below figure 2 with image 3 Describe the three-stage reduction transmission structure respectively:

[0030] The first-stage transmission mechanism adopts a bevel g...

Embodiment 2

[0033] Example 2: A high-power vertical roller mill gearbox

[0034] The difference from Embodiment 1 is that the first-stage transmission mechanism in Embodiment 1 is changed from a bevel gear mechanism to a pulley mechanism, and the pulley mechanism is composed of a transmission belt and a pair of pulleys connected. Bottom of body 1 (not shown). Other structures are the same as those in Embodiment 1, and will not be described again here. Variations in this embodiment can also achieve the purpose of the present invention and obtain the same or similar technical effects.

Embodiment 3

[0035] Example 3: A high-power vertical roller mill gearbox

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com